Boral TruExterior'Trim Like no other...

Pioneering the poly-ash category of the exterior trim market, Boral TruExterior'Trim is like no other trim product on the market today. lt offers an optimal solution for a wide variety of non-structural applications including fascia boards, soffits, frieze boards, rake boards, garage door casings, window and door surrounds, and others. Uniquely, Boral TruExterior" Trim provides both workability and durability that your customers desire without the limitations facing other exterior trim products.

a a a a a

Proudly Distributed by:

Maintaining dimensional stabilityt

No need to glue joints

No need to prime ends or field cuts

Easily accepts paint of any color

Suitable for ground contact

Build something great'"

t See Boral TruExterior" Trim Wananty and Product Data Sheet for proprietary lest results at vwwv.BoralTruExterior.com

IA@LE

A Amefrart G/APIT:A,L Bciuing elutiow sIne I AJ

timber panels, feature our exclusive ENVIRO = LAM'" technology, a unique process that minimizes waste through fiber optimization.

Nordic Lam" is ideal for residential, commercial, industrial and architectural applications.

.1|00o/o ilISR Black $pruce

.llesign Flexible

.Dirnensionally stable

.Auailable in a uariety of grades and standard depths

.light in weight

QFd easily Installed ,i BOARD

N@BDIC X.

l;,il,l r I' #r Drsuor

Special Features

Online

Bnrnxrlc lNousrny Nrws & lNousrnY Pnoro DowNr-oaos

BurrorNc-PnoDUCTS.coM (Forrow LrNr ron PHoros)

BPD: Drcrrel VrnsloN

Vrrw rHe L,qrrsr lssur nr B u rror Nc-PnoDUCTS.coM

January 20'13 t votume3l r Numberll Buililing Proilucralligcst { e

.3:--ic:-,-, i 1q =.--.-- it -,,-

BPD

REcoveRy

Butorns

Tnrrra PRooucrs

Pnooucr Sporucnr Cronn SHRrrs vs. SHrNcrrs '17 Pnooucr Sporucnr FrerRcrnss SrorNc Loors Up 26 SprcrnL Focus: Wrsrrnx Wooos 4 I Building Products Digest I January 201 3 6 Tornlly Rnruoor'r 1 B Comprrrrrvr lNrrLucENcE 20 OLsrr.r oH Snlrs 24 CnrrN RrrnrLrNc 34 Movrns & SHRxrns 36 Nrw Pnooucrs 40 Fnl.rrr-Y BusrNrss 42 Assocrnrroru Uponrr 44 lN Mrmonrnm 44 Cmssrrrro Mnnrrrpucr 45 Darr Boor 45 BusrNrss Cnno Aos 46 lorn FrLr 46 Aovrnrrsrns lNorx RAY WHITE LUMBER GOMPANY Sparkman, Arkansas Phone: (870) 226-6850 . (870) 678-2277 . Fax: (870) 678-2522 The White Family - Seruing the Lumber lndustry for Four Generations High Quality Arkansas Southern Yellow Pine Boards, Pattern Stock and 5/4 Square Edge, Flooring, Beaded Geiling, 105, I 16, 1171 1 lg, 122,131, 139, 514x12 Nosing. Building-Products.com

1 0 Ftnrunr Srony Tnerrr Co,r,tpurrns AT THE Lu,MerRynno 11 lNousrny Tnrnos SourHEnN PINE BnNxs oN

14 MnncrN

SrrrrNc ALlrnNRrrvr

1 6

Style is in The

When

F

Boulevard

PERFECT@

sash

and

for

or renovation projects,

Boulevard Series

Style

RFECT@

door

to reach for

5KYRENtrH Skyreach L&S Extrusions Corp, Ca nadian Headq uarters: 55 Freshway Dr. Vaughan, ON L4K 1S1 Tel: 4L6-663-1888 Fax: 41.6-663-8899 US Plant: 1814 N. Neville St. Orange, CA 92865 Tel: L-866-903-8800 Fax: L-866-302-8899 WWW.SkyfeaCh lS.COlTt visit often-our product tine is growing!

you purchase the Boulevard Series French Style

pafio door system, you acquire leading-edge innovatjon and distinctive style. This wide

all vinyl sliding patio door combines fine engineering with beauty

simplicity. Perfect

new home construction

the

French

pf

patio

makes it easy

excellence.

By Alan Oakes

Moving forward and upwards

firrnsr. A BELATED but Happy New Year. I hope you had a chance to enjoy the holi.|-' days. recharge the batteries, and prepare for what could be a good year-provided a deal was struck to solve the "fiscal cliff' crisis. I have no doubt a deal of some type will be reached, but I hope it is one that it is reasonable. I already sense during my calls that small business owners are very wary of the outcome. I can already hear that with the impact of the new health care plan really coming to light, we are still in a fragile space and the recovery we are beginning to sense could go back in the other direction. We have all fought hard to keep our businesses operating, we have all cut costs and seen diminished retums, and we have done our very best to keep our people employed-we do not need any additional hits. I hope by my next column the uncertainty will be over, as uncertainty can cause more harm than the outcome.

Once a year, we tend to look back and reflect on the year just passed-the successes and failures, in both our personal and business lives. There is no doubt that in both cases our expectations have been lowered compared to perhaps any time in our lifetimes-especially in this industry. Downturns are normally 18 to 24 months, not six years.

After all that has happened these past years, by all accounts 2012 was a steady year. It was relatively quiet, despite the divisive election. In our industry, we started to sense for the first time that the tide is turning. So, perhaps a B-. Not great, but welcome stability after a horrendous 201 1

As I reported last month and sensed everywhere I traveled, the mood is changing. You can already see some smiling, and hope is hanging in the air. Most stats show improvement. Employment is modestly better. Banks seem to be giving out mortgages and loans a little easier (although maybe not to this industry). The housing numbers are improving, albeit shadows of their former selves. The stock market is hanging in there, despite wony about the cliff. Manufacturing is slighttly improving. Even Apple announced it will start making some Macs here. While the stats show we still have some way to go, improvement is measured in inches and the transition to a growing economy has begun. We are all mostly more efficient out of necessity, and this is perhaps both good and bad for the market to come.

So what can go wrong? External to our industry, bad economies elsewhere could bring a chill. Europe is in duress pretty much everywhere and the Middle East seems under constant stress. The good news is that the U.S. economy has stood tall this year throughout the various crisises abroad.

I think the biggest issue in this industry in a growth scenario will be lack of supply. I am already hearing about sold-out positions and with so much less capacity, production cannot be increased at the flip of a switch. Also, with so much human capital experience having been lost in the downturn, it will be difficult to staff up again. Credit limits and lines that have been lowered in recent years might not be able to change fast enough to keep pace with higher volumes of business. Transportation will be a huge issue at some point again, too. Therefore, it will be hard to meet market demand at some point (with all that means), and it takes very brave senior management to recommend to the board to start expansion ahead of the curve, with always a sense of insecurity about what will hit next. But I am getting ahead of current reality-we are not there yet.

In some ways, it's a nice position to be in after what we've had to deal with in recent years. I suspect, though, that we have learned the hard way and will not succumb to the excesses of 2004 to 2006. If 2013 shows a steady increase over 2012, I will be happy to take that! Again, have a great year and I look forward to seeing you on my travels. Stop me and say hello.

BPII

Bullillng Products 0igest

www. building-products.com

A publication of Cutler Publishing 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

Publisher Alan Oakes ajoakes@aol.com

Publisher Emeritus David Cutler

Director of Editorial & Production

David Koenig dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Carla Waldemar, James Olsen, Jay Tompt

Advertising Sales Manager Chuck Casey ccasey@building-products.com

Administration Director/Secretary Marie Oakes mfpoakes@aol.com

Girculation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www. bu ild ing-products.com

Phone (949) 852-'1990 Fax 949-852-023'l ajoakes@aol.com.

CLASSIFIED MARKETPLACE

David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather Kelly

Phone (949) 852-1990 Fax 949-852-0231 hkelly@building-products.com

or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A.: One year (12 issues), $24 Two years, $39 Three years, $54 F0REIGN (Per year, paid in advance in US funds): Surface-Canada or Mexico, $49 Other countries, $65 Air rates also available.

SINGLE COPIES $4 + shipping

BACK ISSUES $5 + shipping

Alan Oakes, Publisher aioakes@aol.com

BUILDING PRODUCTS DIGEST is oublished monthly at 4500 Campus Dr., Ste.480, Newport Beach, Ca. 92660-1872, (949) 852-1990, Fax 949-852-0231, www.buildingproducts.com, by Cutler Publishing, Inc. (a California Corporalion). lt is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright@2012 by Cutler Publishing, Inc. Cover and entire contenls are fully protected and must not be reproduced in any manner without written oermission. All Riqhts Reserved. BPD reserv'es the right to acceit or reject any editorial or advertising matter, and assumes no liabilitv for materials furnished to it.

6 I Building Products Digest r fanuary 2013 Building-Products.com

Fiber Cement Siding & Roofing

PGRADE

TO MAXITILE'FIBER CEMEIVT PRODUCTS!

Better High-Definition Texture . Better Full Coverage Primer

LE@ provides you with:

. The best "Quolity-to-Cost" rofio in lhe building indusfry

Over 75 yeors of fiber cement technologicol experlise

. A complele line of fiber cement siding & roofing products

. The preferred poinfing surfoce for o greof finish

. Inverfible lop siding for less wosfe

. Non-combustible products resistont to termites, hoil & rot

. Reodily occepted products thot ore ovoiloble now!

MAXITILE-

Wa

Better 5 0-Ye a r Tra n sfer r a bl e

r ra nty

MAXITILE@, Inc. . 15055 Woodhom Dr., Houston, Texos 77073 . Focsimile: 888-308-2214 Cusfomer Service: 800-451-2003 cuslomer.service@moxilile.com . www.fllo)dtlle.com Reference Code # Upgrods l30l BPD

; ,. ;'r ;:* w lJ lr, t\ lt ,*. .j i'I ,. $ 'j ' ii l, ! l, ..1 :il , ii ; i. 5 c t It t i I t l t I B

lP Sells LBM Division to G-P

To better focus on its packaging business, International Paper, Memphis, Tn., has agreed to sell its Temple-Inland Building Products division to Georgia-Pacific, Atlanta, Ga., for $750 million cash.

The unit includes 16 manufacturing plants-five sawmills, four particleboard plants, two MDF facilities, one fiberboard mill, and four gypsum wallboard plants in eight states, primarily in the South and East-that IP acquired last year as part of its $3.7billion takeover of Temple-Inland, Diboll, Tx.

"While not core to IP's strategy, Temple-Inland Building Products is an industry leader," said John Faraci, IP chairman and c.e.o. "I am pleased to have reached a deal that recognizes the strength of the business and provides excellent value for IP shareowners."

The deal is expected to close in the first quarter.

Harvey Files Chapter 11

Harvey Lumber Co., Columbus, Ga., has filed for Chapter I I bankruptcy protection, listing $2 million in assets and over $5 million in debt.

Founded in 1863, the chain operates yards in Columbus and Phenix City, Al. It had as many as six locations at the height of the housing market.

At the time, Harvey employed 165. It was down to 57 at the time of the bankruptcy filing, before temporarily furloughing | 7 workers.

"The remaining employees, from top management down, have agreed to significant reductions in compensation to aid in the process," said president and c.e.o. Bailey Gross. "Harvey's hope is that the furloughed employees can be returned to regular employment, sooner rather than later."

Maine's Pleasant River Buys Former Lavalley Mill

Pleasant River Lumber, DoverFoxcroft, Me., has purchased New England Building Materials' sawmill in Sanford, Me., and will market production under the trade name Pleasant River Pine.

The Sanford mill has an annual capacity of 20 million bd. ft. of eastern white pine, joining the l5 million ft. of eastern pine Pleasant River produces annually in Hancock, Me., and 100 million ft. of SPF in Dover-Foxcroft.

The sawmill had operated as

Lavalley Lumber until 2009, when the company changed its name to NEBM after purchasing three former Stock Building Supply yards. One year ago, NEBM filed for Chapter 1l bankruptcy and sold its last retail operation-in Sanford-to Deering Lumber, Biddeford, Me.

New York Dealer Regroups

Martha Rezin is winding down 75year-old Schwalbach Building Supplies, Marspeth, N.Y., and "regrouping" as a new company with new paftner Scott Rogener.

The facility is being remodeled and

restocked to allow the newly named Village Lumber & Masonry Supplies to offer more masonry products and a wider selection of lumber and panel products.

Sherwood Grows in Florida

Sherwood Lumber is expanding operations at its Tampa, Fl., office as its adds new products and recruits new salespeople.

Relocating to Tampa to head the expansion are East Coast regional sales mgr. Bob Kruse, from the Islandia, N.Y., office, and plywood mgr. Dean Harnell, from the Chicago, Il., office.

-t

Build ing-Products.com

--l f anuary 2013 I Building Products Digest t 9

Dealersr distributors latch onto tablet computers

f, s LBM DEALERS and distributors retool and recharge, la.many are bringing tablet computers into their businesses-often starting with the "road warriors" in outside sales.

The top choice in the LBM industry appears to be the leading option for consumers, Apple's iPad, first released in April 2010. The mobile devices are gradually making inroads into the business world-especially among smalland medium-sized companies-because owners and employees want to bring the convenience of a tablet to work.

At Boston Cedar, Mansfield, Ma., the first step was to begin replacing aging Blackberrys with iPhones. Then, in Aprll2Ol2,laptops were gradually replaced with iPads.

"One of our owners got an iPad and he was sold," says Angie Wallert, director of information technology, who oversaw implementation for l2 employees who mostly work outside the office: eight outside salespeople, plus four more in education and training.

"They tended to take notes during the day and use their laptops at night, because they were hard to use in the car and took time to boot at customers' offices," she notes. "Tablets are lighter, easier to use and carry, no booting, so they are easier and faster to use reactively with customers."

Best of all, the employees have a host of documents and information at their fingertips, on the tablet, instead of reams of paper in their briefcases. In less time than making a phone call to the office-for sales information, deliveries, etc.-they can quickly get all the answers they need and keep customers engaged in the process.

At Parr Lumber, Hillsboro, Or., iPads were implemented last summer, at the company's Cascade Wholesale Hardware division. Ten outside salespeople, mostly older employees with little or no experience with tablets, quickly embraced the ease and efficiency of the devices. The experiment went so well that the company wants to implement tablets throughout the company.

"Obviously, we believe there's a real case to be made for iPads and tablets, which are lighter and more mobile than laptops," says Ken Munson, who handles IT for Parr's 23 retail locations, cabinet design center, a structural components plant and installer, and its marketing group. "Price-wise, it's $600 to $700 for an iPad versus $2,000 for a new laptop."

Outside salespeople at Ridgefield Supply, Ridgefield, Ct., also received iPads this past summer, joining the iPhones they already had. Now, owner Margaret Price Sims wants to bring the devices into other parls of the business.

"The new technology allows our sales team to go out and have instant information," she says. "It's important to wrap up business quickly. They can check pricing, create quotes, place orders, and check on delivery status."

Mike Sonderman, an outside salesperson who works with Sims on technology issues, says that Ridgefield's enterprise software is on a desktop service so it can be accessed with mobile devices. The company's quoting software doesn't work on the desktop, but salespeople can access a manufacturer's quoting software if it is websitebased. He believes that "being able to change and work in any environment" is what's most important.

When queried by other dealers, Sonderman advises them to keep mobile devices and company information secure. "lt's like locking the door to your house at night," he says. "You have to keep your website safe." He advises the use of a mobile device management system that allows a remote lock or complete data wipe if a device is lost or stolen.

Sims says that the increased efficiencies of new technology help offset lost margins. "Consumers, even those who may have contractors, do research to get the cheapest price," she says. "Dealers have to fight for the business, and new technologv helos."

FEATURE S the Lumberyard iPads at

1 0 r Building Products Digest I lanuary 2013

OUTSIDE SALESMEN in the lumber industry have begun toting iPads in olace of overstuffed briefcases (Photo by Entree)

Building-Products.com

Southern pine industry banks on housing recovery

T"u couNTRY's RECENT economic I recession may be tading into history, but the nation's roughest downturn for construction markets is keeping many a lumber dealer struggling to record solid sales on a monthly basis. Resourceful yards are finding the means to stay ahead in a lagging building market that's showing some faint glimmers of recovery.

The Southern Forest Products Association delivers the tools and information lumber dealers need to sell more southern pine:

. span tables and design values

o construction guides

specification guidelines

. d-i-y outdoor project plans

For nearly 100 years, SFPA has conducted a wide range of promotional programs and weathered every market downturn.

The inherent features that made southern pine a preferred material of this country's founding fathers continue to make it a wise choice today. Southern pine is plentiful, durable and renewable, making it one of the most sensible, environmentally friendly building products available. Customers want what southern oine lumber has to offer: strength. treatibility, and beauty-not to mention outstanding value.

Some 66 billion bd. ft. of southern pine lumber was produced over the last five years. Nearly half of that volume goes to treated lumber markets for residential applications like decks, fences. gazebos and marine structures. Lumber used in structural applications-framing and trusses-calls for another third of total annual production. What remains is used for flooring, siding, specialty patterns, and industrial applications, including pallets and crates.

As residential buildins markets

slowly recover, southern pine manufacturers are reacting, producing framing lumber in a wide range of grades and sizes and offering the latest preservative treatments, plus the most popular items in flooring, siding, ceiling and paneling patterns. With mill operations in close proximity to major markets, special-order items can be processed quickly.

All Grades, All Sizes

Versatile southern pine materials can be used for everything from building concrete forms to creating beautiful interior floors and ceilings. Lower grades may be the economic choice for certain applications where appearance is not a priority. But when a customer's home is involved, both the contractor and the homeowner may prefer higher-grade lumber for many USCS.

The proper grade counts when using southern pine in any application.

The Southern Forest Products Association offers a number of tools to help dealers, architects, specifiers, contractors and other professionals make sure they have the right grade for the job.

The place to start is the Southern Pine Use Guide, which includes grade descriptions, standard sizes, seasoning requirements, design values, and span tables. Other publications are available listing maximum spans for joists & rafters, plus size selection and allowable load tables for headers and beams. All titles are provided as free PDF downloads from the publications page of SouthernPine.com.

First Choice: Treated SP

It's no wonder that some 9OVo of all pressure-treated lumber produced in the U.S. is southern pine. The unique cellular structure of southern pine permits deep, uniform penetration of preservatives without incising, making

Southern Pine

SFPA delivers the tools dealers need-span tables, design values, and conshuction guides-to successfully sell southern pine lumber.

Building-Products.com lanuary 2013 t Building Products Digest I 1 1

it the preferred species for pressure treatment. This material remains popular for decks and gazebos, plus marine applications such as fishing piers, bridges and walkways. And, of course, it's perfect for framing homes and other structures in areas of the country where decay and termites can create problems.

Thanks to progress in wood preservation technology, new earth-friendly formulations are now widely available to address green building concerns. New code-approved preservatives include several micronized (or dispersed) copper formulations, which reduce impact on aquatic or terrestrial environments and are less corrosive to fasteners. For the end-user, paints and stains also look better when applied to these materials. Borates are finding popularity for wall plates and interior applications not exposed to continual moisture.

SFPA offers a number of technical guides about choosing and using pressure treated southern pine. Available as a free PDF download at SouthernPine.com, these helpful booklets include a pair of comprehensive specification guidesP r e s s ur e -Tr e at e d Southern Pine and Aquatic and Wetland Structures. The treated booklet features a table listing the commercial trade name under which each preservative is marketed and a corresponding product website for those wanting additional information.

Following an explanation of available southern pine grades and sizes, the aquatic guide provides detailed specifications for treated lumber used in

saltwater and fresh water. Decking specifications, fastener recommendations, and special grades for marine service are also included.

These publications are proving to be especially helpful as regions of the country rebuild waterfront and other outdoor structures in the wake of 2012 hurricanes Isaac and Sandy.

Dealers wanting to inspire handy do-it-yourselfers with weekend projects can turn to SFPA's online collection of l0 outdoor project plans. Each plan listed on the D-I-Y Project Plans page of SouthernPine.com is now formatted to standard 8.5x11 sheets, making it quick and easy for dealers or their customers to download and print. Plans include lists of pressure treated southern pine materials and tools required plus detailed construction steps. Illustrations cover every phase of assembly. The collection features three deck plans, backyard storage units, a playhouse, a doghouse and a kiddy picnic table, among others. The projects appeal to all levels of skill, from very basic to more advanced. Year after year, these plans are among the most popular downloads from the site.

Decks & Porches

This year, nearly one million U.S. homeowners will build a deck or add on to the one they already have. The porch remains an icon of American architecture, as well. Both projects are ideal candidates for using more pressure treated southern pine lumber. SFPA offers a helpful construction guide that dealers can use with profes-

sional deck builders and advanced doit-yourselfers. Southern Pine Decks and Porches highlights the beauty, durability, comfort and value that pressure-treated southern pine materials bring to outdoor structures. The I2-page, full-color booklet covers the deck and porch building process from start to finish, compiling the latest information for the proper specification and use of treated southern pine materials for code-accepted decks and porches. Product selection and construction steps for building both freestanding decks and decks attached to a house are illustrated, along with helpful tables listing joist and beam spans. Porch construction details are provided as well, with tips on fasteners, finishes and proper maintenance. Handy tips are included to enhance the building process. Impressive deck and porch projects are pictured throughout the booklet.

Dealers and professionals already familiar with treated lumber can use this booklet as a refresher course in building techniques, or to acquaint a customer with the versatility and value of using real wood products for their new deck or porch. A free PDF download is available at SouthernPine.com.

Dealers can use another SFPA websiteSouthernPineDecks.comas a ready reference to answer questions about outdoor construction. The site includes much of the information contained in the new construction guide.

Raised Floors Excel

Educating professionals and consumers about the merits of building a home on a raised wood floor foundation rather than a concrete slab has been a long-term focus of SFPA promotions. Over the last dozen years, the campaign has included demonstration homes, training seminars, and research. Focus groups conducted by SFPA have confirmed that homeowners appreciate the enhanced curb appeal and other benefits of a raised floor home.

Obviously, a raised wood floor foundation makes sense in flood-prone areas, due to its inherent elevation advantage. A raised floor system may also be the cost-effective approach in areas with poor soils. This type of foundation is easier and less expensive to level than a concrete slab if any shifting or subsidence does occur.

Developers are finding that a raised wood floor foundation is also the cost-

12 r Building Products Digest r

lanuary 201 3

Bui lding-Products.com

RAISED WOOD floor foundations provide homebuilders with many selling points to offer clients.

effective solution for sloping lots that would otherwise require expensive fill. Remodeling projects and underfloor repairs are simplified with a raised floor foundation.

Lumber dealers are winners, too, as raised floor systems can add up to a third more lumber to the typical framing package for a new home.

SFPA provides the resources dealers need to maximize a customer's satisfaction with a raised wood floor foundation. The basic facts and features are outlined in a sixchapter video series accessed from the home page of RaisedFloorliving.com. Helpful construction guides and promotional brochures can also be downloaded from the publications page at SouthernPine.com.

If a customer is looking for an experienced raised floor builder, chances are good they can find one nearby, within listings of the online building pro locator.

Best for Remodels

While new homebuilding activity attempts to rebound, repair and remodeling projects are keeping dealers' customers busy. And southern pine products are ideally suited for projects all around the home.

Homeowners have discovered that a wood floor adds comfort and value, not to mention being a healthier, allergy-free alternative to carpeting. No matter the d6cor, southern pine flooring, available in a range of widths, grades and finishes, can enhance the look of any indoor space.

Wall paneling and ceilings add a dramatic flair to all rooms of the home while contributing to energy efficiency, another opportunity for a dealer to boost southern pine sales. Using the long lengths available, a customer can reduce splicing. Eye-catching clear or semi-transparent finishes draw attention to southern pine's distinctive grain. And best of all, wood is a natural insulator, contributing to the energy efficiency of the home.

When it comes to proper installation and maintenance tips, SFPA offers comprehensive guides for using both interior flooring and exterior porch flooring. Copies of Southern Pine Flooring and Southern Pine Patterns are available as free PDF downloads from SouthernPine.com.

A two-part video program covers installation of both materials from start to finish in a case study format. With a visit to SFPA's online video gallery inside the media center of SouthernPine.com, dealers and their customers can view both instructional programs on the site, too, right at their desktop.

Services for Dealers

Until construction markets experience a more robust recovery, lumber dealers can invest in their future success by visiting SouthernPine.com to see what's available to help themselves and their customers learn more about versatile, durable southern pine. Copies of SFPA's technical and reference publications can also be downloaded at no charge from the site.

Today, SouthernPine.com is a dealer's top resource for answers to customers' questions, training salespeople, and locating product suppliers. Sourcing hard-to-find items can be just a few mouse clicks away.

Complete information about SFPA, its programs, and services to the industry are presented online at SFPA.org. Here, dealers can access SFPA's family of websites, review the latest updates on industry issues, and explore details of SFPA marketing efforts. The site now has

numerous links to existing services offered at SouthernPine.com, including product locator and media center.

SFPA continues to expand its social media reach, too. Dealers can follow SFPA on Twitter (@Southern_Pine), receiving news updates and immediate access to information. There's also an RSS feed on SouthernPine.com, delivering the latest content posted to the site to interested subscribers. And dealers are reminded to visit SFPA's YouTube channel-southernpinelumber-review more product features and updates.

Goming Soon: New SP Design Values

Effective June 1, 2012, new design values became effective for visually graded Southern Pine and Mixed Southern Pine 2" to 4" wide and 2" to 4" thick (2x2s through 4x4s) in No.2 Dense and lower grades (No.2, No.3, Stud, Construction, Standard and Utility) only.

Since then, the Southern Pine Inspection Bureau completed the full in-grade design value matrix of other visual grades and sizes of dimension lumber. SPIB worked with the USDA Forest Products Laboratory to verify all data to develop proposed design values, for final consideration by the American Lumber Standard Committee board of review, scheduled to take place at their next meeting Jan. 30. SFPA continues to monitor the process and keep all stakeholders informed of the latest developments. SFPA and key customer groups support an orderly transition to new design values and have recommended a six-month transition period following certification of new design values for all grades and sizes of visually graded dimension lumber.

As a service to the industry, SFPA has provided SPIB's proposed design values on SouthernPine.com, under the dedicated section New Design Values. Also from this landing page, dealers can review a collection of news releases with comprehensive background information and the latest updates, plus answers to the most frequently asked questions explaining the process and impacts of the SPIB proposal. Current design values will also remain on this site until the new design values become effective.

"As a service to our customers, SFPA is providing this information to all levels of the southern pine lumber manufacturing and supply chain," said Cathy Kaake, SFPA's vice president of technical marketing. "These proposed design values from SPIB will help the dialogue progress to a better understanding of the process, the data and the impacts on our industry."

Southern pine's strength and stiffness remain comparable to other softwood species used in residential and commercial construction. Southern pine users have many available product options including visually graded dimension lumber and an increasing supply of mechanically graded lumber. From framing a house to building a deck, southern pine continues to be a dependable product with superior treatability against decay and termites.

The last major change for visually graded dimension lumber occurred in 1991 when design values for southern pine and other North American species were published based on in-grade testing of full-size samples of commercially produced lumber.

Building-Products.com

fanuary 2013 r Building Products Digest I 1 3

business with alternative Growing your

trim products

urethane pieces installed showed consistency of product appearance.

. Repetitive use of built-up systems (for example, in town homes) will have more continuity and accuracy when using standardized urethane pieces.

Jobsite waste was significantly less for the urethane products than the wood pieces.

f ooxlNc FoR cRowrH opportunities for your business in L-12013? Search no further than your trim product offerings. During the past decade, alternative trim products such as PVC, polyurethane and composite products have become favorites with builders and remodelers, and for good reason.

Dollar for dollar, it's more cost effective to install alternative products on a home than wood. That's what experls at Market Resource Associates discovered when doing a hands-on comparison field study of professional contractors.

"Our research shows that contractors save on time and labor by installing urethane products versus using builrup traditional wood pine pieces," says John Cashmore, thenpresident of MRA. "Overall, using urethane products saved our research participants up to l97o on labor over a similar project that required wood product. We observed that using urethane products required less skill on the part of the professional installer and ensured a higher, repeatable quality element than when wood was installed."

For the research project, a small group of trade contractor participants were asked to create two entryway surrounds-one from builrup wood pieces and the other from a Fypon urethane door surround kit. MRA findings in the study include:

. Built-up wood systems require substantially more time and dedication toward measuring, re-measuring and checking than the urethane system pieces.

The quality of work supplied by different contractors tremendously affects the look of the finished product. Those home exteriors in the study with wood built-up pieces showed dramatic inconsistency. Home exteriors with

. Installation skill level needed for installing urethane products was far less than for piecing together a built-up wood system. Thus, subcontractors may be able to more successfully work with the urethane pieces than the wood products.

Exterior Door Surrounds

According to the independent research done by MRA, when analyzing an exterior enhancement project, urethane tops wood for savings. Installing a set of urethane plain fluted pilasters flanking an entry door and topping the door off with a crosshead costs an average of just $44 for labor and takes under an hour. To create the same door surround out of built-up wood is estimated to cost an average of $181 in labor and can take up to four hours for the same project.

By offering fast "out-of-the-box and onto the house" urethane products, building product dealers can provide their customers with products that speed up installation times and save on jobsite labor. The additional benefits of urethane products-which can include shutters, window surrounds, soffit systems, and mouldings-include resistance to decay, water damage, weather and insect infestations. The high-performing products are available in hundreds of styles from various manufacturers nationwide.

Many contractors already understand that urethane products are best for replacing built-up wood assemblies like crossheads, dentil moulding, window and door trim-anything with a three-dimensional profile. With urethane products there is also the ability to get one-of-a-kind custom pieces created that can set proJects apart.

PVG on the Rise

For builders and remodelers looking for an alternative to wood, PVC is a strong fit for replacing flat wood stock or

MARGIN Builders

PVC & Urethane Exterior Trim

14 I Building Products Digest r fanuary 2013

Building-Products.com

similar profiles. Long-term performance and appearance of PVC trim and board sheets are two of the most lmportant attributes dealers can promote for these products. Since PVC products come with the option of smooth or woodgrain surfaces, these products are widely accepted by contractors needing products that are easy to work with, and won't warp, split or check.

Some PVC manufacturers offer conveniently packaged PVC trim products that make it easy for dealers to offer the product to their customers. Manufacturers offer PVC trim profiles in a variety of popular styles. The smooth profiles-including crown, base cap, brick mould, drip cap, historic sill, quarter round, rake moulding, rams crown, and Scotia cove mouldings-often come ready to use and easy to install.

Dealers can also offer millworkgrade PVC board products, including bead board, corners, sheets and boards, that come in easy-to-stock carton packaging. Each piece of PVC is individually shrink-wrapped and placed inside the carton to protect it from dirt and blemishes once the carton is opened. These pieces can be used for corner trim, fascia and soffit system applications, window and door

casing, wainscoting and flat panel applications.

PVC products are impact- and moisture-resistant and do not have the potential to absorb water, making them an ideal long-term product for the interior or exterior of any project. The density and cell structure of the PVC allows the product to cut smoothly without chipping, making ir the perfect material for routing and

milling. Dealers looking to stock PVC trim and board products should seek those offered by manufacturers that provide a limited lifetime warranty on the product.

A large advantage of PVC products is that they may be placed directly against masonry without fear of decay or water absorption. They have no above-grade distance requirement and they will never rot.

1

Building-Products.com

All photos couftesy Fypon

REDWOOD DECKIIIG THT IIATURAI. AlfiRlIATIUE Full Range & Iarge Inventory Reman to Specific Patterns . Clear AII Heart Clear Mlxed 0raln . Constructlon Heart o llecking Pattern Stock o Bevel Sldlng . Beaded Celllng We Shlp by the Unlt or by the Piece Famlly 0wned & 0perated for Over 60 Years CHI(ACO SUBURBAII 1UITIBER SA1ES 800-341.6485 7459 Franklln St., Forest Park, I[ 60130 Fax 708.771-7391 Emall: Joe@cnlcagosuburbanlumber.com www.chicagosuburbanlumber.eom fanuary 2013 r Building Products Digest I 15

cONTRAcroR tops off a door sunound with urethane millwork pieces that look like wooo.

By Brian Kirkey, Ecoshel

between cedar shingles and shakes

tTtHg DIFFERENCE between cedar |. shakes and shinsles is less clear now than it was i0 y"utt ugo. Initially, cedar shingles were sawn from a block, while cedar shakes were split off using a mallet and froe.

Cedar shingles are more preciselY milled than shakes, and provide a more refined classic appearance, which is well suited to a wide range of styles. Shingles were the siding of choice for the post-Victorian "shingle style" of the late 19th century, as well as for the many styles of the Arts and Crafts period. Cedar shingles were very prevalent in the hundreds of Craftsman-style bungalows designed by Gustav Stickley, and were frequently specified for both roofing and siding installations.

Cedar shake installations provide a more irregular, rustic appearance. They make a less sophisticated, more charming statement that works well for some smaller cottage styles.

Most cedar shakes today are made by machines, and are sawn on at least one side. Shakes are sometimes machine-grooved to appear more like

authentic hand-split shakes. Although cedar shakes today are seldom hand split, they still follow the dimensional rules of their predecessors, which vary by grade.

Shakes are thicker than shingles, ranging from ll2" to 314" or greater at the butt end, while shingles range from about 3/8' to ll2'

Functionally, the most imPortant difference between cedar shakes and shingles is that shingles are milled more precisely than shakes. Cedar shakes are more irregular and don't lay as flat when installed. This creates gaps that can be penetrated bY wind blown precipitation.

Because shakes can be Penetrated by wind-blown rain or snow, a laYer of felt paper is required between courses for roofing installations. Interleaving felt paper helps blocks wind-blown precipitation, and also allows shakes to be installed with two layers of shakes and one layer of felt paper-rather than three laYers of shakes, which would be quite thick.

Unfortunately, when installing cedar shakes, many roofers take

advantage of this felt interlayer as a license to ignore the code requirements. Joints between cedar shakes must still be offset by at least l-ll2" from course to course.

When joints in adjacent courses are aligned, or nearly so, the only protection from the elements is the felt paper, which has already been riddled with nail holes, and is easily tom. The felt underlayment was designed for temporary protection and as a secondary barrier for sparse and intermittent leaks, not as a primary weather barrier.

Cedar shingle installations are more precise, lay flat, and are never installed with felt interleaving. For roofing, shingles are always installed so there are three layers of shingles at any point. Cedar shingles, properly installed as three overlapping layers, provide a highly weatherproof system, even in extreme weather.

lnc.

16 r Building Products Digest I

lanuary 201 3

Building-Products.com

- Bryan Kirkey is president of Ecoshel Inc., Atlanta, Ga., manufacturer of a patented cedar shingle system for siding and roofing. Reach him via www .ecoshel .com.

Fiberglass siding looks up

f ooxrNc rowARD increased remodeling activity and I-lnew-home construction, Marvin is spreading the word about its newest product: fiberglass siding with the look of wood, without the maintenance.

Named Apex, the siding is made of Ultrex, a fiberglass material developed and patented 20 years ago for Marvin's Integrity- and Infinity-brand windows and doors. Produced in Marvin's 110,000-sq. ft. manufacturing plant in Fargo, N.D., the fiberglass siding represents the company's first expansion into other building products.

"Innovation is the key to growth in today's business world," says president Susan Marvin. "Apex represents an innovative use of a proprietary technology that's already been proved in tens of thousands of homes across the U.S."

Apex's story began in 1990, when Marvin partnered with John Jambois to form Tecton Products in Fargo. Once Ultrex proved itself in Marvin's windows and doors, it was time to look toward other product categories. In 2006, Tecton launched its structural siding line.

Three years later, Tecton became a wholly-owned subsidiary of Marvin and the new product-now named Apex-was formally introduced. Despite the economic downturn, the product received notice as a good-looking alternative to traditional wood siding or other alternative siding materials.

According to Marvin, Apex is the first fiberglass siding

that can be installed in overlapping boards, like traditional wood siding. The product is available in 10 colors, two widths-4" and 7"-and in either a smooth or woodgrain finish. Other pluses:

fiberglass doesn't expand, so pieces can be butted tightly together for a pencil-thin joint

the durable, acrylic finish is four times thicker than paint, for increased resistance to fading and chipping

. a built-in water management system lessens susceptibility to mold and rot

it is lighter than other siding materials, which makes it easier to work with and install

"It truly looks like a mill-finished piece of wood," says Bruce Peter, owner of Just Exteriors Plus, Wappingers Falls, N.Y. "It captures the appeal of wood, without having the maintenance."

Peter also appreciates that Apex is environmentally friendly. "Fiberglass is made of sand, just like glass is made of sand," he notes. And unlike vinyl, it's not petroleumbased so VOC gases aren't released during manufacture and all leftover materials are ground up and reused. "With fiberglass, there's nothing but advantages."

Currently, Apex is distributed by United Products Corp., St. Paul, Mn. (in Mn., N.D., western S.D., and Wi.); Parksite, Batavia,Il. (in Me., N.H., Vt., Ma., Ct., R.I., and eastern N.Y.), and Universal Supply, Hammonton, N.J. (N.J., southeastem Pa., and northern De.).

PRODUCT

Siding

Fiberglass

Building-Products.com

NEW PRODUCT has received notice as a good-looking alternative to traditional wood siding-or siding materials. Photos courtesy Apex

FIBERGLASS doesn't expand, so individual pieces can be butted tighfly together for a pencil-thin joint.

fanuary 2013 I Building Products Digest I 17

By Carla Waldemar

Hunting tons of

business down South

looned it to 15,000 sq. ft.-five times its former footprint. The year-to-year sales skyrocketed 82Vo, and margins mushroomed by six and a half points. Oh, and John doesn't hide from his Do it Best rep anymore. "Now I love him to death."

And customers, needless to say, are thrilled. Contractors now encounter expanded lines of plumbing, electric, hard-

Don vEARS, John Huntington and his brother, David, -[ tnira generation in th-e family business, ran the Huntington Lumber Co. the way their dad-and granddad before him-had. No need to rock the boat in sleepy, little Hazelhurst, pop.4,500, smack in the land-locked middle of Mississippi.

They did a pretty good contractor trade out of the puny, 3000-sq. ft. space. (Okay, it was cramped beyond belief, but the help could locate most of the SKUs even if their customers couldn't.)

But Roy, their regional services rep from Do it Best, kept up his tirade-"Man, you really need to build!"-until whenever John saw the guy coming, he cringed, then hung his head and tried to look busy.

"But he made a strong case," John had to admit, when cornered. "We had to do it; we'd outgrown our space."

So two years ago, lured in part by attractively low interest rates, and the detailed planning help Do it Best provided, the brothers caved. They set about building a brandnew store which not only doubled the size, oh no, it bal-

COMPETTTM Inte

NEWLY BUILT store came just at the right time for Mississippi dealer.

1 B r Building Products Digest r f anuary 2013

Buildi ng-Products.com

EXPANDED PAINT and other departments has boosted Huntington Lumber's business to consumers to 70% of sales compared t0...

ware and paint, to name a few. Brand-new departments include tools, lawn & garden, and housewares. And a whole new customer base has darkened the doors-the walk-in warriors of town, reversing the lOl3O pro-to-retail ratio to 3OVo pro and TOVo retail, which, in this age of rigor mortis in home construction. has saved the dav.

"I wonder what our last year would have blen like if we had not done the expansion," says John with a mix of awe and horror. "Now, anybody who walks in can find anything they want."

The expansion goes beyond mere floor space. It was time to part with the easier, traditional ways of doing business, too ("We were old-school"), so (initially unwillingly, it's true) they decided to open on Saturdays for the first time ever. Not that the brothers were all that eager to jump out of bed on a weekend, but apparently their customers were.

"I was amazedl" John reports. "People kept coming up to me and saying, 'Thank you!'-the walk-ins, the pros, even other business owners. It was a rewarding and a humbling, experience."

Staff has nearly doubled, to 20, too. "Experienced people would be best, but they're hard to find," he allows, so Huntington's able old-timers trained the new crew, with a bit of help from vendors. "We didn't know a lot about retailing, so it's been a learning experience."

Yet the launch went well, indeed. "We did a contractors' night before we opened, then held a huge grand open- ing-very successful," he reports. For several weeks, Huntington held a Saturday sale for which they used 750 five-gallon buckets and invited customers to fill them up and receive a20Vo discount on everything those pails could

hold.

Did the promotion generate new business? "Very much so!" John is happy to report. "I was surprised at the number of new faces. We'd mailed circulars to towns 20 miles away, and folks drove in for the bargains. Will they come back? Well, we'll be top-of-mind."

A showroom was on the books for the original, now vacated, store, but times have been just too busy to get to it (a happy problem). Next yearl Nor does the outfit retain a dedicated outside salesperson yet. "But we have a real good construction salesman, a l9-year veteran. Still," John ponders, "we need to look into that...."

Meanwhile, Huntington installs the flooring it sells, thanks to a manager who's a longtime flooring guy. For other projects, the outfit recommends its trusted contractor customers-a win/win that keeps all three parties satisfied.

Huntington also operates a construction business of its own, run by both brothers, who each take on projects in turn as they roll in, making it a point to decline those upon which their own contractor customers have bid.

"We step away from that," John makes it clear. "But the construction business takes a lot of our time. With our new investment in the store, we'll need to balance it more. It helps in overhead-definitely-but we definitely need to focus attention on the store. In the past, the two businesses were split 50/50, but these days it's a little different. We did the addition at the right time. If we'd stayed where we were..." he shudders at the very thought. "There's very lif tle construction business going on around here, so without the (new) walk-ins, where would we be?

"This year, we're seeing a few more higher-end houses-around here, that means over $200,000-but in general, it's repairs and additions. Contractors who, if you asked them to do decks a couple of years ago, would laugh-now they're eager for the business."

And these days, the Huntington brothers are wellequipped to serve them. The addition has made them virtually the only act in town-a one-stop shopping experience other local stores can't equal. And John loves every minute of it.

Who knew? Not he. Not brother David. Not even their dad. He sent the two boys away to medical school (which, yes, they completed) but just when John was wondering what direction his life would then take, Dad made an offer. "Come home and work here while you figure it out." That was in 1985, and he's still figuring.

"If I hadn't come back after finishing college, I wouldn't have had the relationship I have with my dad. Growing up, he was always busy, so Dad and I weren't close. Now, we've travelled to Europe together and have a really good relationship. I would have missed out on that," he muses.

"I like the quality of life here in Hazelhurst-lots of timber around here, too. I like helping the little old lady looking for an air filter, and I like building a home for somebody. You're always helping people figure out a problem. Plus, I get to work with family, and it doesn't get much better than that."

Carla Waldemar cwaldemar@comcast.net

Building-Products.com

PREVIOUS customer mix had been 700/o professionals, before the construction slumD.

fanuary 201 3 I Building Products Digest I 19

Finding Mr. Right

D

ustNsss owNERS, sales managers, I)and G.M.'s tell me, "James, we are looking to hire a salesperson. What we want is a guylgal in his mid-thirties, preferably with a family (we like a guy who has responsibilities-married guys and gals with kids and a mortgage are ersier to motivzte. We all know what single guys are thinking about, and none of us has any idea what single women are thinking about! ).

"We want him to have a book of business that doesn't conflict with any of our current account assignments. We want him to be a guy who doesn't rock the boat. We want him to be able to fit into our culture. And, please, no baggage, drugs, alcohol,family problems, personal emotional issues, etc.

own personal leadership filter (I only want the emotionally stable) on top of this natural selection, it will narrow the field of candidates even more.

Growing a sales force will be challenging enough. Your company culture and values are important. But don't confuse them with your personal preferences. Make sure that your requirements are based on performance and results and less on your personal desires or prejudices. (And give them a hug for crying in the sink!)

Budget for Growth

Companies that are unrealistic in terms of hire date, speed to profitability, and that do not budget accordingly will have inconsistent growth. Companies that are great at sales growth:

. Budget statistically. They budget realistically for the success/failure rate for sales hires.

. Are realistic in time to profitability forecasting. Have great training programs.

"Signing bonus? We don't wont to pay him a signing bonus-I told you no prima donnas-sheesh, are you listening? We've got guys that are currently working for us who do his numbers. We didn't pay them signing bonuses. That's a big riskfor us. What if he doesn't work out? Besides, what does he need a signing bonus for? If he is that good, he'll make that money when he comes to work for us. Because we do -

better than where he is now, when he starts to sell -,

his commissions will pay for his move, right? "

The above expectations are restrictive. I know hundreds of salespeople and 95Vo of them don't fit the above description. How we are going to grow their business based on finding an almost perfect candidate? This is as untenable as the salesperson who will only open "perfect" accounts; l/ just does not work as a sales growth strateqy.

It is one-sided. Salespeople who have built a following at one company take a big risk when they move. They leave behind a competitor with intimate knowledge of-and an established relationship with-their clients. No matter their talent, they will be in for the fight of their sales lives when they move.

Is Mr. Right out there? Yes. In fact, one of the main responsibilities of sales management is to be on the lookout for talented salespeople who want to change companies for any reason. But this cannot be the only part of the strategy. It is too inconsistent.

Your Foibles # Gompany Values

I have a client who does not like serving the emotional needs of his sales team. Heck, he thinks it's unprofessional to even bring such things up at work. I tell him that sales has its own brutal natural selection and that if he puts his

. Hire slowly-multiple interviews with multiple levels in the organization. Potential hires speak with different salespeople and leaders within the organization. Fire quickly. They have a plan and patience, but if the salesperson just can't do it,then they cut the cord quickly.

. Fire the unproductive. If unproductive salespeople are not fired, there is no budget for new blood.

Look for and Hire Attitude

The two most important ingredients of the successful salesperson are empathy and the will to conquer/win (Mayer and Herbert Harvard Business Journal 2006). Do not confuse empathy with likability or you will end up with a sales force that wants to be liked more than it wants to win.

Business experience is helpful, " but more important than product knowledge is people knowledge. Knowledgeable information dispensers will be overwhelmingly outsold by empathetic sellers with a killer instinct.

James Olsen Reality Sales Training (503) s44-3s72 james @realitysalestraining.com

By fames Olsen

20 r Building Products Digest r f anuary 2013

Building-Products.com

sBlRaminen

Dennis Connelly

Dennis Connelly

Recruiting in the new sales environment

t[uenr's A st-ow, suBrLE shift underway in how building |- materials companies are recruiting salespeople. In my recent conversations with distributors, I found it interesting to learn just how surprised they were by this major change, since it goes against years of conventional wisdom.

After three decades of selling to and for LBM distributors and retailers, and training hundreds of sales staff, I am excited about finally being able to help companies navigate through these trying times.

Why are these changes occurring? Selling has undergone a massive shift in the past l0 years. If your salespeople are still selling transactionally-presenting features and benefits-or they selling only on the strength of their great long-term relationships, then they are having difficulty generating business from new accounts, as well as growing their existing accounts.

Customers are more educated and in some cases, they know more than the typical salesperson of l0 years ago. Back then, the salesperson educated the customer, who often welcomed the information. Today, customers usually know what they want and are looking for the best value or worse, the best price. Salespeople are learning that the relationship is not enough to overcome resistance and objections.

Today, a consultative approach that uncovers problems and opportunities and leads to discussions about issues that your customers hadn't considered works best to differentiate your company and move your salespeople away from commodities and prices. That approach just won't work unless they develop the ability to ask a lot of good, tough, timely questions while using an effective sales process.

Customers must notice your salespeople. They need to recognize that you are different and your salespeople must get their undivided attention above all the noise of competing people and products. That's your point of differentiation. When you call, they take the call, not because they like you, but because they rely on you!

And that brings us to the shift we are seeing in how sales staffs are recruited today. If you agree that there are vast differences in selling skill requirements today, then where do you find the talent to meet the challenge? One distributor recently hired someone away from a call center in an unrelated industry. He said, "This guy comes in with

tdno call reluctance whatsoever. He's just used to it. He knows how to sell and he's making inroads where we hadn't performed well in the past."

None of this implies that there isn't tremendous value in industry knowledge. The question is can veterans in our industry make the shift to a new way of selling and maximize growth? If not, can you grow your company more effectively by bringing in talented selling superstars, regardless of their industry background?

Has your company returned to double-digit annual growth? If not, why? Are your people saying, "We can't do this, because...?" You can't use the economy as an excuse. You need to be thinking very hard about two things:

. Can my existing salespeople make the required changes in order to return us to double-digit growth?

Can we succeed by hiring the same kinds of salespeople that we have always hired?

The shift from traditional industry professionals toward salespeople with consultative selling skills is an important and timely change. Are you ready to make this change?

MANAGEMENT

22 r Building Products Digest I January 201 3 \c

Bui lding-Products.com

- Dennis Connelly is an experienced lumber industry executive who also served on the Joint Coatings Forest Products Committee. He is now v.p. of business deveLopment at international sales consubing firm Kurlan & Associates. Reach him at (508) 320-4900 or dconnelly@kurlanassociates.com.

UFPI Rolls Out Pro-Grade Brand

Universal Forest Products, Grand Rapids, Mi., has taken its ProWood brand to a new level, offering pro-grade products to both contractors and serious do-it-yourselfers.

"For years, we used the ProWood name to identify a number of high-quality Universal products," said president and c.e.o. Pat Webster. "Today. ProWood is the exclusive

Bulls Bay Supply, McCteltanvilte, S.C., has been placed up for sale.

Ace Hardware Corp. acquired 8s-unit Westlake Ace Hardware, Lenexa, Ks., for $88 mifiion.

Rand Lumber Co., Rye, N.H., ctosed Dec. 7 after i07 years. Third-generation owners Jim, Ken and Kathy Rand are liquidating all assets, including the 18-acre lumberyard and 65acre tree farm.

SRS Distribution, McKinney, Tx., agreed to buy Gary-Hobart Roofing & Siipply,-Hobart and Valparaiso, In.

SRS is expected to retain current management, including president Jack Ronneau and v.p. Rod Ruess, who will serve as dishict mgr. for Indiana.

Mayfair Lumber, Jefferson Park, ll., is ctosing after more than 80 years due to the poor economy.

Crane Johnson Lumber Co., Fargo, N.D., opened yard #5 in Suney, N.D. (Tony Watterud, v.p. and mgr.).

Pinckney True Value Hardware, pinckney, Mi., has been acquired by longtime employees Mary Banister and Wendy Robertson.

Arrow Ace Hardware lost its lease and closed its 14year-old store in SE Rochester, Mn., Dec. 22. Three of the chain's othelt0 stores are in other parts of Rochester. but owner Dave Neiman is hunting for a new location in the southeast portion of town.

Monahan's Hardware, Etbow Lake, Mn., has been opened by Sue and Bob Kulbeik, their 4th location.

Ace Hardware, Barrington, ll., has been opened by John Brown.

True Value Hardware, Bay Viilage, Oh., ctosed at the end of December after 24 years due to big box competition.

Ace Hardware next year will open a 10,000-sq. ft. store in Champaign, ll., owned by Niemann Foods.

Lowe's opened a g4,000-sq. ft. store with 26,500-sq. ft. garden center Dec. 21 in Dayton, Tn., and applied to build a 134,815-sq. ft. store with 24,390-sq. ft. garden center on 10 acres in Norwalk. Ct.

Menards has shelved plans to open a store in O'Fallon, Mo., citing President Obama's economic policies.

Gomanche Home Center, Lawton, Ok., became the first dealer to utilize BlueTarp's new eMarketing services.

brand for our treated lumber and outdoor products that are backed with a lifetime limited warranty, from dimensional lumber and decking to finished products, like fencing. It's the all-in-one solution for pro-level performance from pressure treated wood."

According to brand manager Chris Fox, another upgrade is the availability of Dura Color infused-color technology for dimensional lumber. "If it comes with a ProWood endtag," he said, "you can be sure the product will perform."

Jason Cameron, licensed contractor and host of DIY Network's Desperate Landscape and Man Ccves shows, was recruited to introduce the products through a new website, social media, print ads, point-of-purchase programs, videos, a deck contest, and much more.

"He's an engaging and well-known television personality who isn't just an entertainer, but also an expert," said Mark Deremo, director of marketing communications.

Building-Products.com

TV HOST Jason Cameron is now spokesperson for ProWood professional grade lumber products from Universal Forest Products.

-3 --tl :r a TFrI-ATATE LUMBE;I Ccl. Fulton, Mississippi www.homanindustries.com [662J 862-?L25. Fax 652.862-4eoo True 2&Btr. with # 1 Stamped Lumber Protected against Sapstain, Mold, Fungi with AntiBlu Treatments r Wolmanized CA-C Good Housekeeping Seal SCS Certified Environmentallg Preferable NAHB Research Center Green Approved . ccA ;!i[$i$t" sourced from tNrTrATrvE SFI Certified Forests Your Southern Pine Specia ltg Rema nufactu rer What Do You Need? Superior Service at Competitive Rates Made the WaU You Want lt Specializing in 6x5, 6x8, 8x8, 10x10 f anuary 201 3 I Building Products Digest I 23

the lesson of resilience Green retailing and

furs rs rHE rtue of I year when we get to take a step back from the day-to day grind of running the business and reflect on the year that was. Why? To learn, so we can do what's necessary to improve in the coming year and into the future.

The first step is looking at the business metrics, comparing performance against plan, and so forth. Diving into the numbers is necessary, informative, and boring as hell. You've got to do it and in times of certainty and little change, it's sufficient. But that's not the world we live in.

More enlightening is taking the time for deep reflection on strategy. If you're a lone wolf who does best keeping your own counsel, head off by yourself to some place that inspires you. Take the time to consider what you know, and don't know, about the changing world you live and do business in. If you lead a management team, take them on a "visioning" retreat that will afford the space and time to adequately consider the new context within which your business operates. What lessons have you leamed?

This past year-with shifting climatic patterns, extreme weather events, unstable macro and regional economic conditions, and rising energy prices-gave a taste of what's in store in coming years. Against this background, construction activity is trending up, especially green building, so that's a somewhat predictable constant, but being prepared for an uptick in green building isn't the same as being prepared for Hurricane Sandy.

If there's one lesson I've learned from this past year, it's that we need to think hard about how we can build resilience into our communities and businesses, and into the built environment, generally. Resilience is loosely defined as the ability of a system to absorb a disturbance and continue functioning without collapsing-in other words, "bounce-back-ability." This is critically important as we enter a new era of super storms, volatile energy prices, and shifting economic priorities. How can we continue to function even when lights go out for days, supply

chains are cut, or fuel prices suddenly skyrocket?

In practical terms, we can begin to outline what this might mean for the home and shelter supply chain, generally, and for individual dealers. More green building products and materials, yes, but what else? Robustness, redundancy, and diversity are three key attributes of resilient systems and are concepts that might inform new product development, categories, and services. Can we retrofit homes to withstand 150-mph winds? Can we build backup energy systems that don't rely on gas or diesel? Can we develop multiple sources of supply for essential goods, multiple sources of income, and multiple sources of finance?

These kinds of questions will undoubtedly gain in importance over the next few years. Obviously, last year was crazy, but we can learn some good lessons from it. More importantly, this industry is already in a good position to begin developing resilience within, as well as helping our customers, stakeholders, and wider communities do the same. What that looks like will differ depending on local conditions. Maybe one day, home centers will include a "resilience department" wedged in between plumbing and electrical. Whatever the future we'll be better prepared thinking deeply about the lessons we learned this past year.

JaY TomPt Managing Partner Wm. Verde & Associates

info

(41s)

321-0848

@ williamverde.com

www.williamverde.com

holds, by

GREEN By f ay Tompt

24 I Building Products Digest r January 2013

Building-Products.com

Wood Products Attend Inauguration

When President Obama takes the oath of office on Jan. 21, he will be standing on a platform made of Douglas fir supplied by Grasmick Lumber, Baltimore, Md., distributed by Sherwood Lumber, Islandia, N.Y., and manufactured by Sierra Pacific Industries' sawmills in Aberdeen and Burlington, Wa.

"SPI is the largest producer of these types of long/wide

Warren Trask Co, relocated its operations and office headquarters Jan. 1 from Stoughton, Ma., to a larger, recently acquired complex in Lakeville, Ma.

Located just south of l-495, the facility has roughly 75,000 sq. ft. of protected storage and office space over 9+ acres.

'The layout and location of the facility will enable us to continue on our current growth path," said v.p. Bernie Nugent.

Jordan Lumber & Supply, Mt. Gitead, N.C., is considering investing $1.5 million and adding 50 jobs to expand to solid wood production at its fencing plant in Biscoe, N.C. Operations could begin as early as this year.

Kleer Lumber, Westfield, Ma., agreed to sell its assets to Tapco parent Headwaters Inc.,-South Jordan, Ut.

Jerith Mfg., enitacetphia, pa., acquired Delgard Premier Alufiinum Fen'cing trom Deiair, Detair,it.J.

Delgard's 300,000-sq. ft. plant will be consolidated into Jerith's 444,000-sq. ft. facility.

Masonite next month is shuttering its door plant in Kirkwood. N.Y.

Wurth Wood Group, Charlotte, N.C., is now distributing Flakeboard particleboard, MDF and TFL products at its 12 branches in the Southeast,

PPG Induslries,Pittsburgh, Pa., agreed to pay $1.05 billion for AkzoNobel's Nortfr American architectural coatings business.

The deal includes its North American architectural coatings production and distribution facilities, paint stores, and product lines, including Glidden, Flood, Liquid Nails, SICO, and ClL.

Weyerhaeuser has added Versatex products at its DCs in Minneapolis, Mn., and Chicago, ll.

In addition, Weyco's DCs in Baltimore, Md.; Pittsburgh, and Easton, Pa., have added Tlmxo decking and railings, extending its Tnuxo dishibution to 21 of its 22 markets.

Guaranteed Supply Co. is now distributing Sto E|FS and stucco products at its 12 branches in the Carolinas and Norfolk. Va.

Horizon Forest Products added a 2s,000-sq. ft. branch in Charlotte, N.C. (J.D. Ziegelhofer, mgr.).

NyloBoard, Covington, Ga., received Code Compliance Research Report 0183 from Architectural Testing Inc. for its NyloDeck products.

Boral Composites, Roswell, Ga., won LEED silver certification for its Boral TruExterior Trim olant in East Spencer, N.C., which was completed in2011.

boards in the U.S., which explains why the supplier back East continues to make purchases of our Washington lumber-quality counts," said Sheri Nelson, SPI spokesperson. Sherwood is one of SPI's largest distributors.

This is the fourth consecutive presidential inauguration in which the platform was built using Sierra Pacific lumber. About 200,000 bd. ft. was used, enough to build about 13 average-size homes. Much of it was 2x4s, but wider 2xl2 and 2xl6 planks-up to 26 ft. long-were also used. On the big day, the more than 10,000-sq. ft. platform will hold more than 1,600 guests.

3tt to 48tt

. Airport Runway/Parking Lot Golf Course Storm Drains

Industrial Waste Water Applications

. Constructed Wetlands Landfill Drainage

Sewer Sludge Compost Pipe 3'to 48"

Crumpler Plastic Pipe, Inc.

Post Otfice Box 2068

Roseboro, NC 28382

Phone: 910-525-4046

FAX 91 0-525-5801

For the Best Quality and Service Call WEB SITE: www.cpp-pipe.com

Building-Products.com

fanuary 2013 I Building Products Digest I 25

DOUGLAS FIR produced by two of Siena Pacific's mills-distributed by Shenvood Lumber and sold'bv Grasmick Lumber-was used to build thir inauguration platform in Washington, D.C.

Douglas Fir-Larch design values confirmed

IIJesrenN Wooo Products Association has completed Y Y testing of Douglas Fir-Larch lumber in cooperation with other western lumber agencies.

Analysis of the 2012 test data indicates higher (+5.5Vo) bending strength, (+5.07a) tensile strength, and (+8.17o) stiffness properties than those established in the 1980s' North American in-grade lumber testing program. The data has been submitted to the USDA Forest Products Laboratory for review. The analysis will be completed prior to consideration of the test report by the board of review of the American Lumber Standard Committee for confirmation at its January meeting.

The comparison to the properties established in the original in-grade testing program indicates no needed change to the published design values for Douglas FirLarch lumber. The monitoring program affirms current uses, building code recognition, and recognized span data for the species group will remain the same. Had the data indicated a shift in properlies, the test findings would have to be reviewed by the cooperating agencies' memberships and appropriate actions taken.

The coordinating western lumber agencies-including Pacific Lumber Inspection Bureau (PLIB), Redwood Inspection Service (RIS), Timber Products Inspection

(TP), West Coast Lumber Inspection Bureau (WCLIB), and Western Wood Products Association (WWPA)-have been working together since early 2011 on the testing program to monitor western lumber design values. This has resulted in the joint effort of these agencies on the sampling and testing of western lumber.

The published lumber design values are based on the ingrade lumber testing program. The testing plan was approved by the board of review of the American Lumber Standard Committee in 201 1 The plan required destructive testing of 360 pieces in bending and 360 pieces in tension of Douglas Fir-Larch No. 2 2x4 lumber.

Professor Robert Fountain of Portland State University provided statistical support for the testing program. A total of 36 representative mills were selected for lumber sample collection from the Douglas fir and western larch production region. The test lumber samples were representative of the lumber volume destined for the marketplace.

Following Douglas Fir-Larch, other western species including Spruce-Pine-Fir (South) and Hem-Fir will be sampled and tested. The testing of western species lumber is conducted periodically to monitor for changes, to allow for timely actions to be taken, if needed, to support western lumber products.

Western Woods

DQUGLAS FIR 2x4

no

to published design values. 26 r Building Products Digest I January 2013 Bu ilding-Products.com

lumber underwent bending tests at WWPA's testing facility to ensure

changes were required

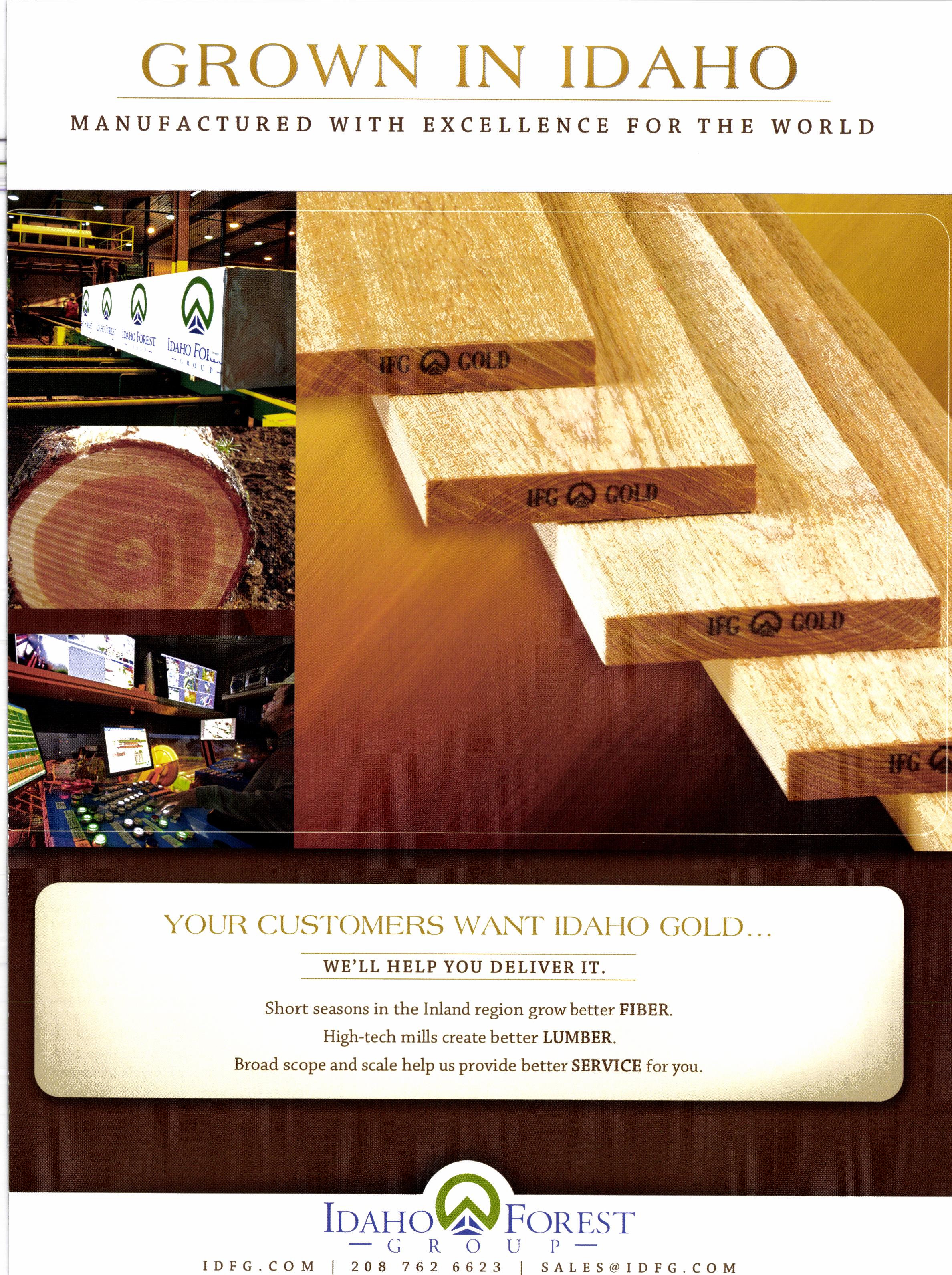

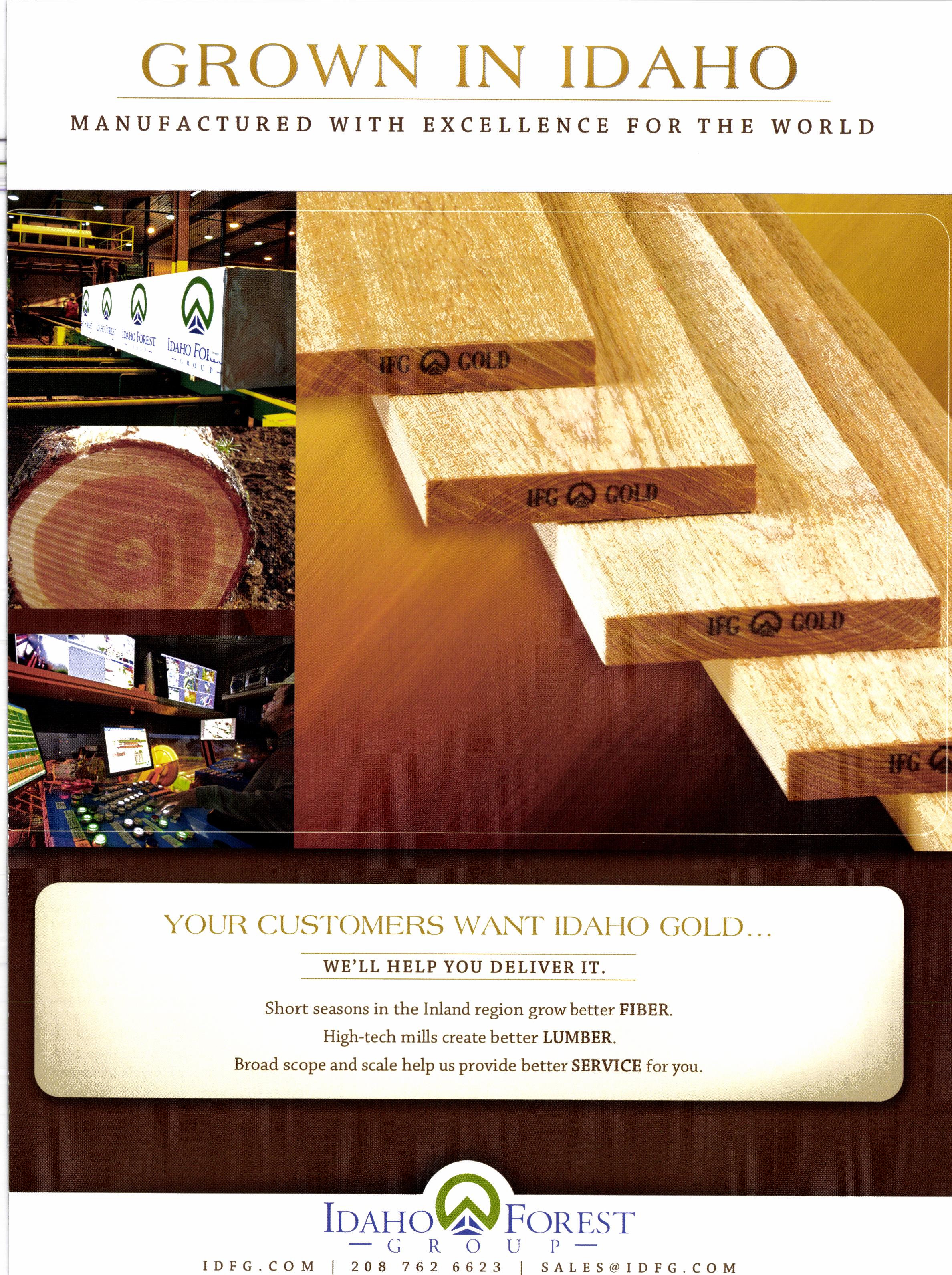

MANUFACTURED WITH EXCELLENCE FOR THE

WE'LL HELP YOU DELIVER IT.

Short seasons in the Inland region grow better FIBER. High-tech mills create better LUMBER. Broad scope and scale help us provide better SERVICE for you. Z*".I

.,l i "'E

rDFG.coM t ,o*tlnr'rt u:"rti ,lo;.rDFG.coM j WORLD i.-n n ,\ ill tAl 6 il,mfol*

It l,{ H ( )q/^t , Fc )l{ I .s I'

By Hakan Ekstrom, Wood Resources International

Sawlog prices rise as western mills up output to meet higher demand

f occens AND TTMBERLAND owners IJin the Pacific Northwest have good reasons to be more optimistic about the new year since there are signs that demand for timber will increase in 2O13.

Housing starts in the U.S. jumped to 894,000 units in October. This was l97o higher than in August, and as much as 42 percent more than in October of last year. For the year, housing starts were at their highest levels since 2008, and market analysts expect the next l2 months to be bumpy but still upward-trending.

The improved housing market has been good news for many sawmills in North America, including the U.S. Northwest. Lumber production in 2012 was higher throughout the continent as compared to 2011, with an increase of 5 .9Vo in the first nine months year-over-year in the U.S., and of 4.6 7o in Canada over the same time period, according to WWPA.

The U.S. Northwest is the region that has experienced the biggest increase in the production of lumber this year, with a 9.1Vo jump yearover-year. It is also interesting to note that for the first time in two years, sawmills in the western U.S. produced as much lumber as the mills in the U.S. South in September. Typically production levels are higher in the U.S. South than in the West. Sawmills in West benefited not only from improved domestic sales, but also from a continued healthy overseas market in Asia to which the western sawmills export between ll%o

(Continued on page 30)

l0 -Log exports - - Log imports 9 8: O aEo .9 €s, a Eq = E"i 2: Western Woods

LOG EXPORTS and imports to

q o o (h 3 140 120 100 80 60 40 20 -Douglas-fir -

Hemlock Source: North American Wood Fiber Review \-/a*1r,-t' SAWLOG PRICES in Western U.S. (Source: North

the U.S. Northwest. (Sources; Cusfoms data and WRI LLC)

*

American Wood Fiber Review)

28 r Building Products Digest r lanuary 201 3 Building-Products.com

Ssw$

Your Market Demands... Swanson Responds.

A customer approached us with a problem...he needed a radiant barrier panel... but the job spec called for veneer plywood and not OSB. After consulting with mill management and our overlay supplier - sales had an answer. Yes, we can do this.

The result is TruBlock, a radiant barrier veneer panel that reduces attic temperatures and saves on energy costs. lt also has the superior strength, stiffness and performance of Douglas-fir plywood. Our customers ask - and Swanson responds.

Swanson Group Sales is now producing 2x4 and 2x6 Premium at their Glendale OR sawmill. The grade follows the light to no wane spec that is favored by discriminatin g buyers everywhere. When appearance is criticaltry Swanson Group's 2x4 and 2x6 Premium.

When the market calls for a better product... Swanson delivers.

1