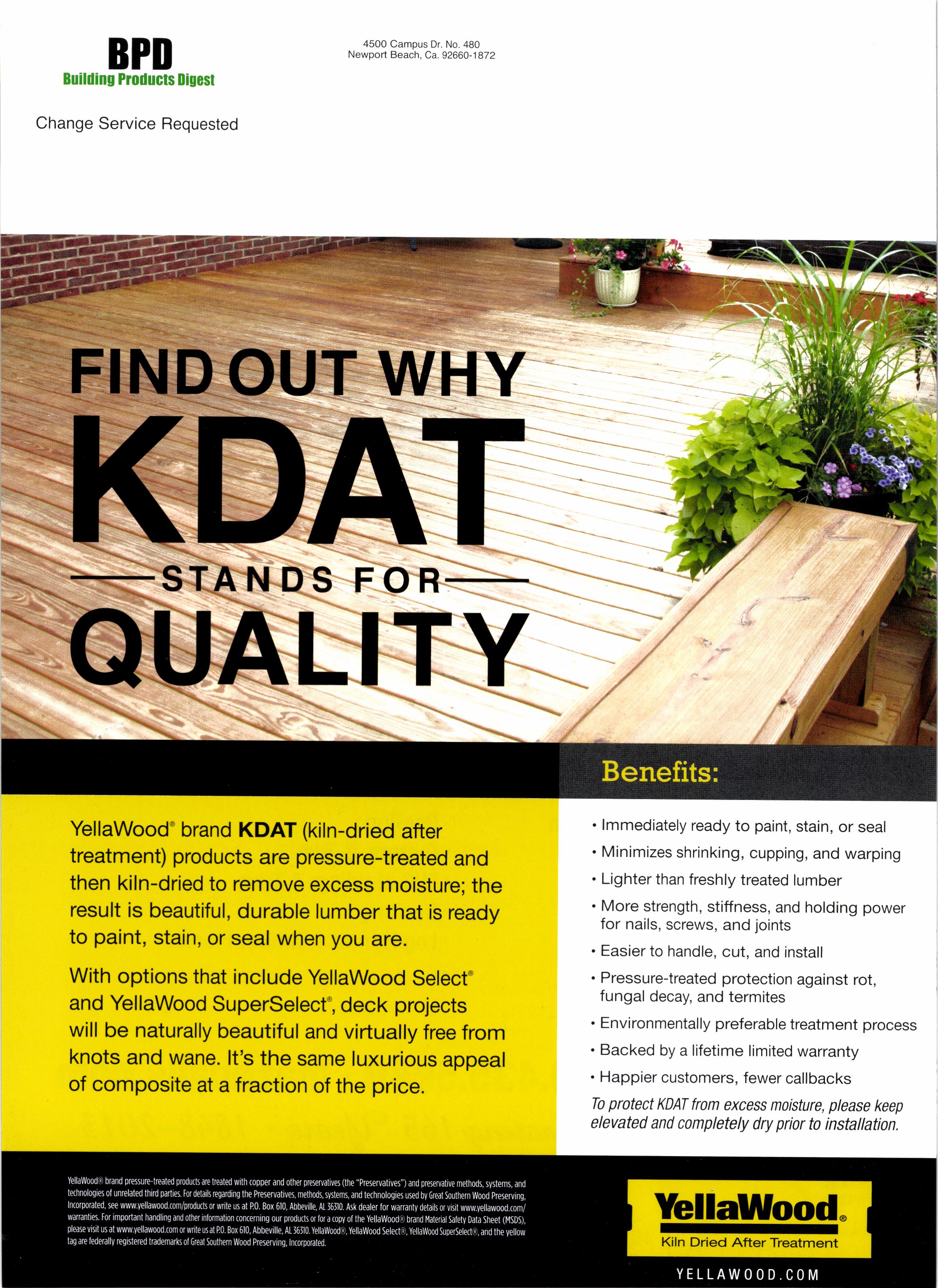

The Best Choice for Wood Decking

Better "Yarding" and Job Site Performance.

. Ecolife significantly reduces cracking, checking, customer complaints and CALLBACKS.

Meets Strict Industry Standards

. IBC & IRC Building Code compliant

. AWPA Standardized for Above Ground Exposed Use.

Lasting Beauty with Less Maintenance. Built-in water repellency reduces homeowners need to apply an additional brush-on water repellent for up to three years. Lighter color is easy to paint and stain.

Scan

NAHB I RESEARCH I cENTER IGREEN APPROVED Ecolife is a Green Approved Product by the NAHB Research Center and is eligible to earn '^' points toward Green Certification under the National Green Building StandardTM.

@ Proud Sponsor I

Ecolife

to

E

this QR code to watch the

performance video or go

treatedwood.com

E tr I .s I I 'E o f

BPD

Buililing Prnilac$ nigesl

Special Features

B Pnooucr Sporucnr

WrsrlnN Rto Cronn Mercprs Srrrr & Buocrr

1 0 Frnsr PrnsoN

lN Dlr,rssr or Croan Sl,rrrs & SHtN<;r rs

1 2 Frnrunr Sronv Rt utvrlon ,\ N,ltL.R,lL ron "But Arrtt ntr',tr" C.t,rtt,,\t(, xs

1.t 30

Inousrny TnrNos

SoL Tl lt,rrx (,t'r,r<rss E,.tt<^-rNc Pil r': rtttt I Ati' lil|lr l\

MeNncrrr,rrNr Trps

LrssoNs FR()r\4 Tt t Snrtrv FLoc,rtt: l]ox'r St r II t: I()lt VtsrgrLttv

PHoro Rrcnp: IBS rN Vrcns

PHoro RrcRp: NRLA Expo

In fivery lssue

{r Torarry RRNool.r

'l {* Co,uprrrrrvs lNrrrrrcENCE

,I I OLsrN oN Snlrs

2{} Gnrrr RrrarrrNc

2fJ Movrns & SHRrrns

29 tN Mr,monrnm

.l? Nrw Pnooucrs

-l.J AssocrnrroN UpoRrr

-l-[ CLnssrrrro MnRrrrpLncr

.l.i Dnre Boox

46 loen Frrr

4fu Aovrnrrsrns lNorx

Online

BnrRrrNc lNousrny Nrws & lNoustny PHoro DowNroRos

Bu tror,c-PHc)DLrc rs.(-( )N1 rFoLrorl Ltr.x ron Pr rorcts)

BPD: Dlcrrlr Vrnsrolr

Vrrrl rHr L,lrrsr lssul ,qr

B ur rotrc- PnoDUCTS.(.oN4

March 2013 t votume 32 r Number 1

4 I Building Products Digest I March 2013 Building-Products.com

2a ;t {J

J$ru TJlI t

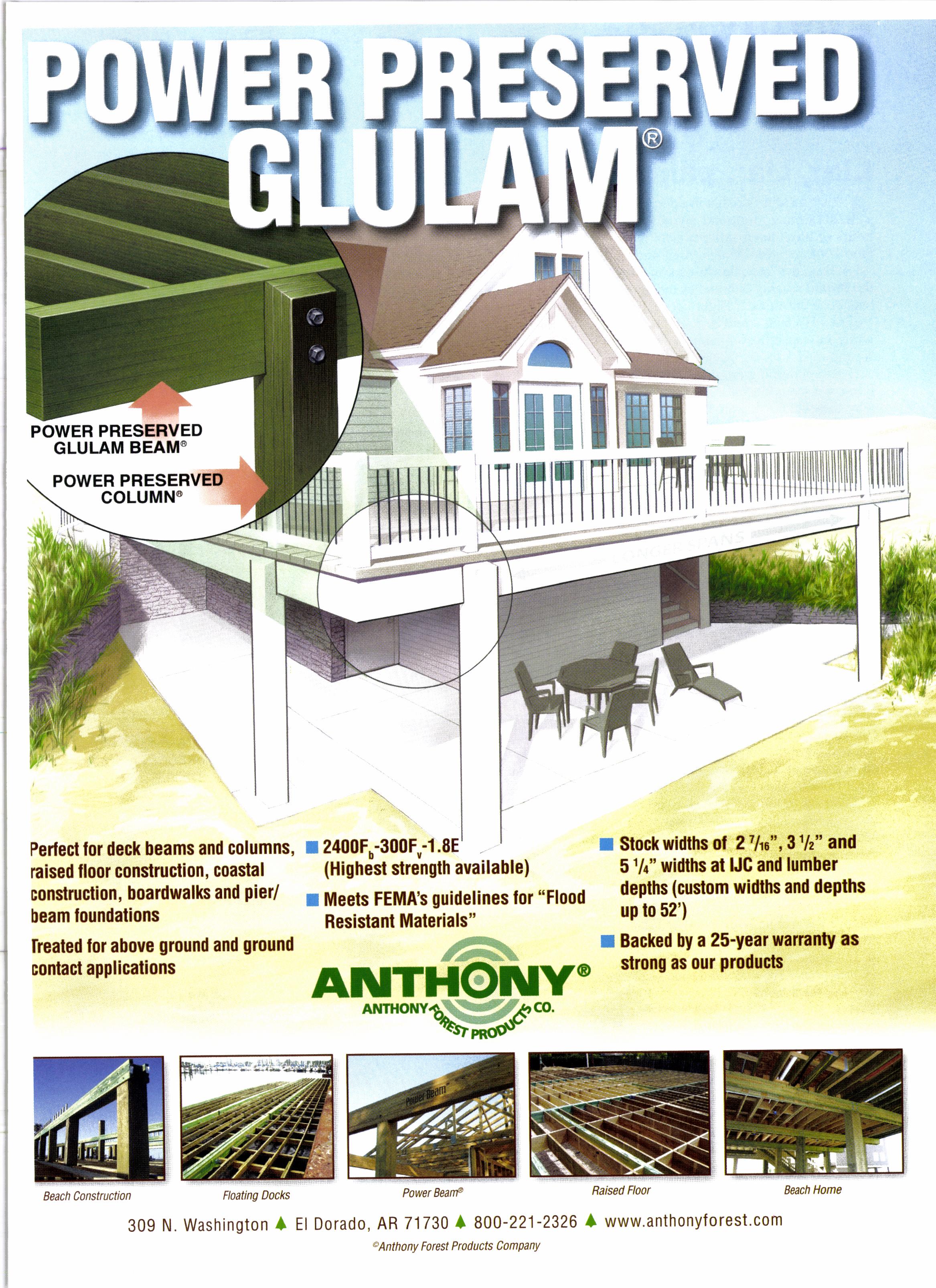

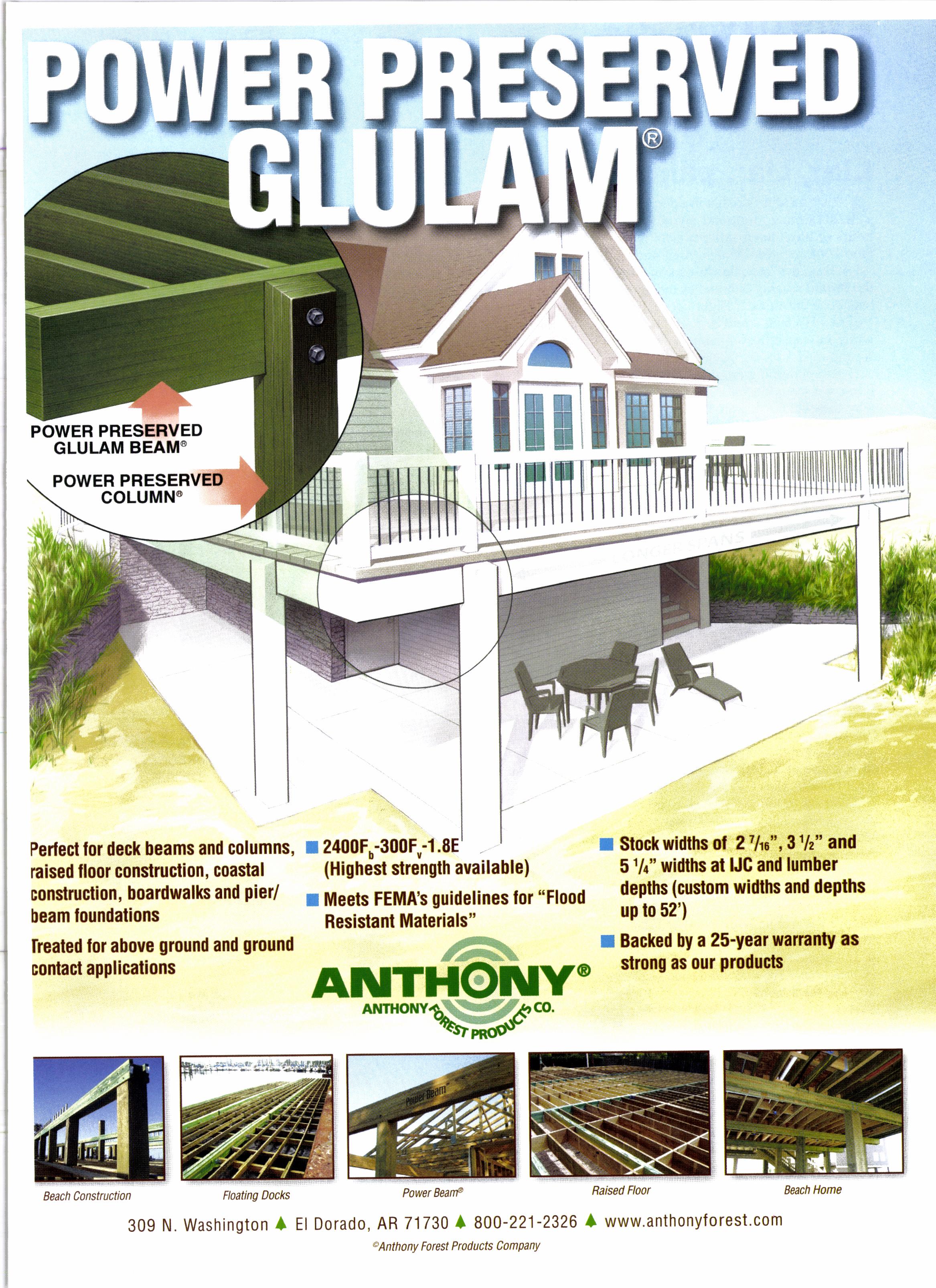

POWER PRESMVED GLULAM BEAM@

POWER COLUMNO

Perlect lor deck beams and columns, raised floor con$ruction, coastal constnrction, boardwalks and pier/ beam foundations

Ireated lor aboye gtound and gtound contact applications

r 2400Fb-300F,-1.8E' (Highesf strength available)

IMeets FEMA's guidelines lor'-Flood Resistant Maleilals"

IStockwidlltsof 271t",3112" and 514" widths at UG and lumber depths (cuslom widths and dePths up to 52')

r Backed by a 25-year wananU as strong a8 our produtb

HHI

Eeach Construction 309 N.

mffiltTifillm ,

Floating Docl(s Power BunP Raised Floor Beach Home Washington I El Dorado, AR 71730 | 800-221-2326 I www.anthonyforest.com oAnthany Forest Products ConPanY

By Alan Oakes

Liar, Liar, pants on fire

s EVERYTHING corr,les in threes, my hope is that my first three travel adventures of -cl'2013 bring to an end my mishaps for the year. My first event cost $g00 and 17 hours of travel time-after which I never arrived in Eureka, Ca., for the Humboldt Hoo-

Hoo club crab feed. unlike Archimedes, the pilot could not find his way in the fog.

A few days later, heading for the Intemational Builders show, I placed my shoes on the airport security belt and by the time they emerged from the ,cannir, one oi my shoes had been cut in half. Eighty dollars in taxi fares later, I found the only store open in Vegas -Walmart-and a new shiny pair of 930 shoes. And, the following weekend, while I escaped Boston hours before the blizzafi,, I endured a great bout of seafood ooisoning to kick off the NRLA show. Happy days!

I had something happen to me the other day that made me think about how much lying we see in business. Sometimes people just cannot face you and tell you outright why they did not do something you were expecting. The trouble is so many of these fies are so transparent it creates a pattern of distrust that is difficult to overcome in future negotiations or contact. In a recent survey,257o of executives admitted to lying at work and 39Vo confessed to exaggeration.

Sometimes, it is not the actual lying itself but _ ala' Lance Armstrong-the cover-up that can be more difficult to forgive. Now, I think it true that we all fib a bit. Studies suegest we all bend the truth one to two times a day, mostly at work. some of the lies at work are really a covering up to protect a mistake or something forgotten, but in most cases they create no real harm, unless there is a consistent pattern oi incompetence. In some cases, it may be to give a positive yet unearned affirmation to try to motivate a colleague or employee. But what about those sick days when not really iick? The trouble is that human nature creates a snowball. once you get away with one, then two fabrications,lying can become a habit and those around you must decide when to believe youand at what point to pretty much discount everything you say.

As an employee, while we may not actually think we are lying, a simple act of omission is no different. For example, if we see an employee stealing stationeiy, we are faced with a difficult dilemma: do we do nothing or do we blow the whistle and suffer all the negatives that accompany that decison? How about not announcing a pregnancy at work because of fear of what it might mean? I think most of us would underitand the latter due to corporate behavior. I think the biggest lies I have observed in my career came when state-of-the-art practitioners of sucking up got away with it and were even promoted because of it. Inflation of truth, whether on your resume or telling your boss how great (s)he is when (s)he is not, is in fact a lie.

Over the years, we have all heard of severe fraud within corporations. such as Enron. Even in this industry, BPD's news columns have reported on bookkeepers who have been ripping off their employers for years. But more often it is that above- and belowthe-line stretching of the truth we encounter in dealing with customers and suppliers. While most business actions are transparent, there are a number of occasions where negotiations may not be quite truthful if it means getting the order or not getting it. To be able to negotiate effectively, you need to be able to trust who

you are negotiating with. I always try to establish this honesty by asking questions that I already know the answer to. If I come to the conclusion that I cannot trust them, I try to let them know in subtle and sometimes not-so-subtle ways that I know.

But, just as at Enron, if you create a culture from the top down that says nothing stands in the way of business

results and personal gain, that everything and anything is okay, and that cheating and lying, both intemally and externally, are acceptable methods of conducting business, be careful. Just ask old Bemie Madoff!

I look forward to being in the safety of my office for the next two weeks, but happy trails to you.

Alan Oakes. Publisher ajoakes@aol.com

BPII

Buildlng ProducF Dige$t

www.bu ilding-products.com

A publication of Cutler Publishing 4500 Campus Dr., Ste.480, Newport Beach, CA g2660

Publisher Alan Oakes ajoakes@aol.com

Publisher Emeritus David Cutler Director of Editorial & Production David Koenio dkoenig@building-proiucts.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Carla Waldemar, James Olsen, Jay Tompt

Advertising Sales Manager Chuck Casey ccasey@building-products.com

Administration Director/Secretary Marie 0akes mfpoakes@aol.com

Girculation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www. building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com.

CLASSIFIED MARKETPLACE

David Koenig

Phone (949) 852-1 990 Fai949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather Kettv

Phone (949) 852-1990 Fax 949-852:0231 hkelly@building-products.com

or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S,A.: One year (12 issues), 924 Two years, 939 Three years, 954

FOREIGN (Per year, paid in advance in US tunds):

Surface-Canada or Mexico, $49 0ther countries, $65 Air rates also available.

STNGLE COptES $4 + shipping BACK TSSUES $5 + shipping

BUILDING PRODUCTS DIGEST is pubtished monthly at 4500 Campus Dr., Ste.480, Newport Beach, Ca. 92660-1872, (949) 852-1990, Fax 949-852-0231, www.buildingproducts.com, by Cutler Publishing, Inc. (a California Corporation). lt is an independently owned publication for building producls retailers and wholesale distributors in 37 slates East of the Rockies. Copyright@2013 by Cuiler Publishing, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. BPD reserves the right to acceft or reject any editorial or advertising matter, and assumes no liability for materials furnished to it.

6 I Building Products Digest r March 2013 Building-Products.com

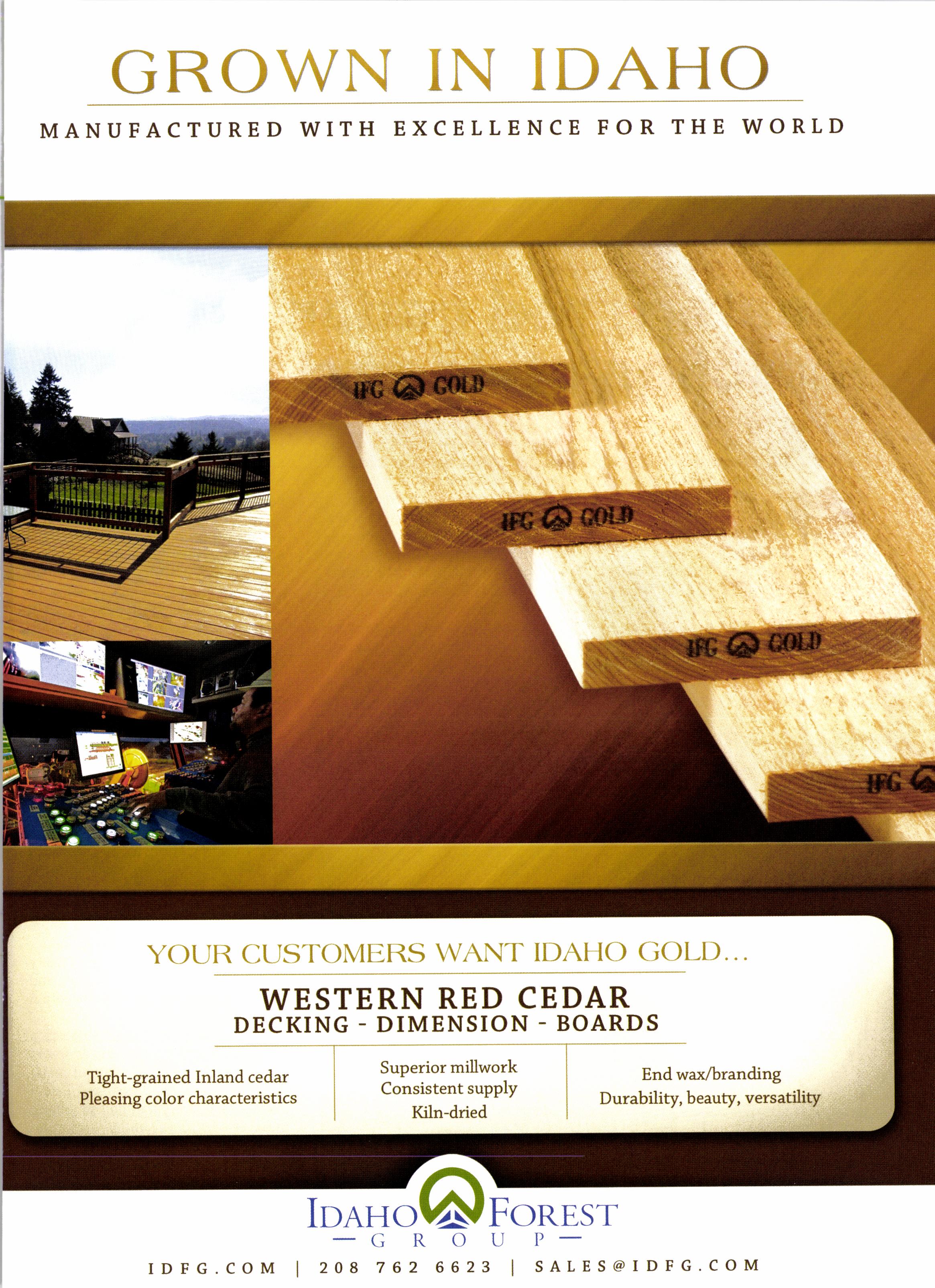

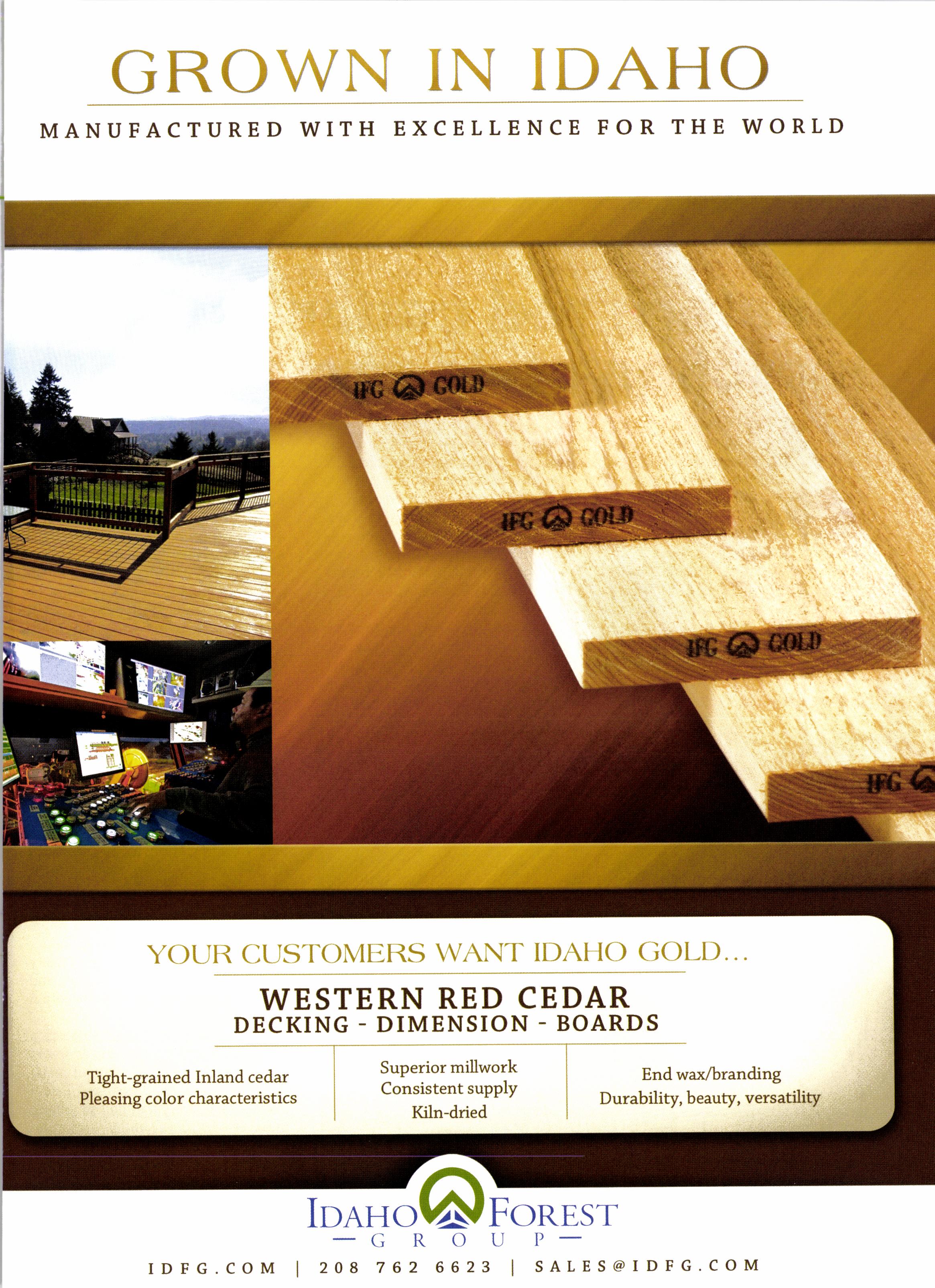

MANUFACTURED WITH EXCELLENCE ir .it FOR THE WORLD F"-'i1 '{r! s-" -,,;'ii:l'o"ililil|. ItItlt() /a lrtllil\I t, ]i r) | l,-I 208 762 6623 i SALESiq')IDFG.COM WESTERN RED CEDAR DECKING - DIMENSION - BOARDS Tight-grainecl lnland cedar Pleasing color: charactcrlstics StLperior nrillwork Consistent supply Kiln-dried End rnraxlbranding Durability, beauty, versatility IDFG.COI\4

Western red cedar matches style and budget

AsrcNrFrcANT MARKET reset over .I-Lthe past several years has redefined the way consumers live and spend, and created a need for distributors to shift the way they specify and supply materials.

Today's selective marketplace casts more scrutiny on building products than ever before. Materials have to stand up to demanding construction and environmental expectations, all while returning value from source to supplier to end user.

Materials must meet the demand for inspired design that is durable and timeless. Building products have to

look good, be environmentally conscious, and deliver a retum on investment. Identifying materials that deliver well-rounded value is where the distributor plays an important role.

Once a nice-to-have. green is now a given. Materials that combine independently verified environmental qualities with unquestioned beauty, durability and functionality achieve the greatest return.

For those reasons, western red cedar is a desirable choice, especially for siding and decking projects. Renewable and readily available, western red cedar infuses natural

beauty, warmth and a uniquely real aesthetic appeal into projects large and small. Ideas, tips and how-to information can be found at wrcla.org.

Rising consumer conf idence among upper-income households has driven increased home-related spending and created a surge in home repair and remodeling. Remodel projects are still carrying the load in residential construction, even as the new construction housing market has shown some encouraging signs.

An evolving family dynamic has put added pressure on homeowners to accommodate multi-generational households. As a result, motivated homeowners are turning to professional contractors and tackling projects themselves to transform need into reality.

Spring is the most popular time of year for renovation. Room additions or enhancing decks and outdoor spaces are at the top of many to-do lists-but far from the only home improvement pursuits. Projects range from the practicality of adding indoor or outdoor living space to the beauty ofenhancing curb appeal. Some blend the two to create a seamless transition from indoor to outdoor.

Western red cedar adds value to a home, deck and outdoor living space. The wood's deep hues, natural resistance to moisture, decay and insect damage, and straight grain and texture make it one of the most workable, rewarding and versatile woods. Its dimensional stability, the result of low density and shrinkage factors, allows the wood to lie flat, stay straight, and hold fastenings tightly.

Product Western Red Cedar

8 t Building Products Digest I March 2013 Building-Products.com

WESTERN RED CEDAR adds value to a home or outdoor livino area. Alt photos couftesy We\tern Red Cedar Lumber Association

Hailed by both contractors and doit-yourself experts alike, wood's ability to lend warmth to modern and monolithic designs and to the surrounding environment is unquestioned. The stylish texture and rusticcolored warmth of western red cedar

defines a mood and character, especially when building a stylish deck.

Wood's return on investment is also an important consideration. Woods like western red cedar typically recoup between 697o and 787o of their initial costs when a home is

resold, according to industry experts.

Materials that combine timeless appeal, durability and a reputation for being easy to maintain are popular choices for a lasting impression. They deliver the value today's consumer is looking for and look good doing it.

Gladding for Greative Tastes & Gustomized Needs

A building's exterior is its first and lasting impression on visitors and passersby. It also serves as a first line of defense against the elements. Done well and utilizing timeless materials, its cladding can create a classic look that stands out while adding value.

Western red cedar is one such material. Its ageless sophistication and elegance perfectly infuse natural beauty, warmth and inspired design that complements any architectural style.

Although modern science has given us many synthetic Products that try to mimic the look of wood, solid woods like western red cedar still remain a favorite choice. With routine care, wood siding will our last synthetic siding materials while radiating the real wood warmth and appearance.

Many resources are available at wrcla.org to help generate ideas and inform the materials selection process for the professional and doit-yourself homeowner. But there are several key factors to consider when choosing cedar as a siding material.

Beauty. Above all, western red cedar has an enduring beautY that enhances the style of any building. Many cedar-sided houses built centuries ago still look beautiful today and have been prized because of their innate resistance to both moisture and insects.

Wood siding is available in many options and finishes to fit the lifestyle of any building and effortlessly add warmth to both monolithic and modern structures.

Durability. As is true with most materials, the most sustainable siding products are those that last the longest. Choosing a material that is both durable and suitable for your region's climate will help reduce maintenance and repair costs, extend

the life of a home, and keep old materials from filling up the local landfill.

Westem red cedar is a wood with great dimensional stability and natural decay resistance. Free of pitch and resin, it provides an excellent base for a wide range of finishes. Paired with vapor barriers and building paper, and installed on the outside face of the wall sheathing, cedar provides a tight, natural barrier that prevents outside moisture from getting into the wall cavity while allowing moisture vapor to escape.

Usability. To add to the ease of cedar siding installation, wood clapboards can also be stained rather than painted to minimize peeling. Western red cedar siding comes in many different patterns and grades-such as bevel, board and batten, channel, and tongue-andgroove-to match style and budget and accommodate creative tastes

and customized needs.

Sustainability. while some siding products are still being manufactured from trees harvested from old-growth forests, Western red cedar is the only Forest Stewardship Council-certified siding. Cedar is also made from a renewable resource, uses less energy to manufacture than more highly processed synthetic materials, and results in very little waste because various industries make use of all the scrap wood.

Choosing a material that combines aesthetic appeal, versatility and durability delivers the greatest value, especially when care is taken for proper application.

Installation and maintenance of western red cedar siding is easy and the finished product produces a great result. The wood's durability wanns up a building with a clean, rich look and ageless style.

Bui lding-Products.com

March 201 3 r Building Products Digest t 9

By Randy Engh, B.C. Shake & Shingle Association

ln defense of cedar shakes and shingles

If you've bought into any of these statements, remember, they didn't come from our industry! While it is said that imitation may be the sincerest form of flattery, the shake and shingle industry is not impressed with the ongoing negative smear campaign. We appreciate the opportunity to set the record straight and speak for ourselves about our own product.

Vou DoN'r HAVE ro go very far

I these days to be exposed to manrnade roofing materials, all claiming to emulate, replicate, duplicate and imitate real western red cedar shakes and shingles. Many imitators even use the long-standing trade names associatcd with real cedar shakes and shingles, such as split shakes and sawn shingles.

Take, for example, the recent International Builders Show in Las Vegas. Literally dozens of shake and shingle producers clamored for attention with their sample roof and wall panels of fakes, attempting to copy real cedar while at the same time denigrating the very product they tried to copy. We even had one shake producer come to our cedar shake and shingle stand at the show asking for a special selection of cedar shakes they could use for their copy moulds!

Advertising with negative messaging about real cedar shakes and shingles feeds off the principal of "If you say something enough times, sooner or later people will believe you."

When they believe your message, they will pass it on. By the time the third or fourth person hears and repeats the false message, presto, it becomes accepted as fact by the general population.

Just consider the following false statements now thought of as accepted facts :

"You can't get old growth anymore and there are no forests left."

"Cedar shakes need constant maintenance and don't last."

"Cedar shakes burn."

"Quality cedar is not available or is too expensive."

"Cedar shakes are too hard to install."

Cedar shake and shingles are, of course, made from old growth raw material. They are salvaged in ecologically responsible helicopter airlifts from downed trees left in the forest from multiple decades ago, as well as supplied from the world's leaders in forestry stewardship in log form that big-lumber sawmills can't utilize. Produced in factories with complete waste utilization and the lowest energy consumption of any roofing product, real old growth western red cedar shakes are truly the most ecological, green, renewable roofing choice.

Cedar is classed in the scientific category of "most durable"-that's why natural cedar shakes have been used and proven for three centuries of human habitation protection. Today's added factory pressure preservalive treatments increase cedar's oerformance in damp climates wheie roof debris and moisture accumulate. The products even carry a 3O-year transferable, 50-year non-transferable, non-pro-rated warranty to back it up.

Pat Skwarok, Western Wood Preservers, Aldergrove, B.C., says that in over 30 years of treating real cedar for the industry, his company has never had a claim due to decay.

Factory-applied pressure preserva-

1 0 I Building Products Digest r March 201 3 Building-Products.com

tives greatly reduce the need for roof cleaning and maintenance. In fact, just like every other roofing product on the market today, cleaning of excess debris for appearance and fire protection is all that is required with factory preserved shakes and shingles.

Fire protection for cedar shakes and shingles in areas that require Class C, B, and even Class A roofing has been available for decades and also carries a 30/50 year, code-performing warranty.

Quality of shakes and shingles is never an issue when purchasing products with ICC-ES report numbers on the label Each member mill of the B.C. Shake & Shingle Association adheres to grading and packing requirements of 288 lineal inches of on-grade shakes per bundle of 24-inch shakes and tapersawns, and 635 lineal inches of on-grade shingles per bundle of l8-inch perfections. Simply demand ICC-ES-accredited. BCSSA member mill production, for assurance of quality from mills that conform to grade.

While the cost of all roofing products fluctuates, real cedar is very competitive with, if not less expensive than, many of the current manmade imitations. A quick price comparison will show that all the benefits of using real cedar, with its centuries of proven performance, are available at favorable price points.

Installation methods of real cedar shakes and shingles have changed very little over the decades. BCSSA has produced a helpful installation instruction DVD in English and Spanish. It's posted on our website along with our "Authentic Choice," "Care & Maintenance," and "Facts & Myths about Real Cedar" video collection.

There are regional and preference differences for cedar shakes and shingles. Shakes have the natural split face and appeal, tapersawn shakes the thick smooth profile, and shingles the flat refined appearance. It's understandable that suppliers promote the products that are easiest to market. Just bear in mind that cedar shakes, with their two-ply and felt paper installation. have been proven since their inception; cedar tapersawn shakes are a beautiful choice for a shake-style, flat-laying roof, and shingles, with their three-ply system, are refined and elegant. All three choices are perfectly adaptable and acceptable, depending on your customer's

Building-Products.com

lnterests.

There has never been more information available that is so easY to access. Just check out our site at www.bcshakeshingle.com for all the facts, as well as our member mill list.

So the next time you hear or see negative advertising or misinforma-

tion about real cedar shakes and shingles, just consider where it's coming from. Real cedar may be often imitated, but simply cannot be duplicated.

- Randy Engh is mandger oJ' the B.C. Shake & Shingle Association. Reach him at randyent!h@ shaw.ca.

REAL CEDAR roofing has distinct advantages over the manmade imitators.

- Randy Engh is mandger oJ' the B.C. Shake & Shingle Association. Reach him at randyent!h@ shaw.ca.

REAL CEDAR roofing has distinct advantages over the manmade imitators.

Direct lmporters of Hardwood Decking, lumber, & Flooring 'dN "I'4t* BraziliarrHardwoodSpecialisrc Your direct source for lpe, Tigerwood, Garapa, and Cumaru decking Many OpdonsTo Choose From: l) Shipping from ov Brazilian Milb dkrr to your job site or lumberyard '' i\ C*n- Milhngavulable from our U.S. Facilities .{r\ab\e 3)Brindshippinsisarsoavailabre a"fl Wholesale Division L-! Telephone: (941)-388-9299 S, w"rw.ldtantagelumb er. com/wholes de March 201 3 r Building Products Digest I 1 1

(All photos courtesy B.C. Shake & Shingle Association)

Redwood 'iBuy America n" cam paig-s

(-\or.rsuve R pRIDE rN American-made products has \-zreturned, with a lesson for manufacturers: quality, quality, quality. In an age where brand loyalty can shift with the perceived best price for the product, we have our work cut out for us to not only help consumers give themselves permission to invest in American-made products, but to applaud their faith in the quality of the products that cannot be grown anywhere else in the world.

Today's consumer is used to abundant selection when purchasing just about anything-even building products for their home improvement projects. Thanks to eye-opening reports, like the ABC News "Made in America" series from 2011, the trend is shifting to more awareness of the product's origins and a preference for items original to America. For example, Walmart has a $50 billion "Buy American" campaign for things made and grown in the

U.S. that boost our economy and quality of life

One example of quality ttrat'. uniqu"ly American: redwood. This entire species, Sequoia sempervirens, is grown, harvested and manufactured along a strip of Northern California coast. Redwoods have grown here since before the first settlers set foot on this land. Thanks to the strictest forest management standards, our member companies proudly nurture and grow the most protected commercial timber species in the world. Moreover, they plant more trees than they harvest, ensuring there will be redwood trees both to enjoy and harvest for future generations.

Indeed, the names of the member mills of the California Redwood Association read like a map of our beautiful state: Big Creek Lumber Co., Humboldt Redwood Co., The California Redwood Co., Mad River Lumber, Mendocino Forest Products, Schmidbauer Lumber Co. Each business, like their products, is proudly Californiagrown and connects its corporate identity with the state, county,local watercourse, or well-known local family.

The people who grow redwood are not only proud of where it's grown, but its quality and eco-friendliness. The hardiness and natural benefits of redwood make it an ideal material for outdoor living. Other manmade products market themselves as equal to the task, but is it really true, or just marketing?

That's the question we found ourselves asking as some composite/plastic decking alternatives came to market promoting their supposed environmental qualities. So we commissioned a Life Cycle Analysis study comparing redwood decking to composite decking. To read an executive summary of the LCA study, visit www.rootedintruth.org.

The results clearly show that the energy needed to manufacture and transport composite decking has a huge environmental cost in terms of carbon footprint or global warming potential when compared to naturally grown and American-made redwood decking.

When a customer asks what the differences are. what sort of return they will see on their investment of a new

By Charlie f ourdain, California Redwood Association

12 I Building Products Digest I March 2013

HOMEGROWN California redwood deckino can be the oerfect centerpiece of "Buy American" sales efforts. - (All photos'couftesy CRA)

Building-Products.com

deck when choosing a naturally grown product over something man-made, I'd humbly argue that redwood has a huge edge on new, relatively-untested products. Grown in one of the world's healthiest forest systems, redwood is decay-resistant and easy to work with. A renewable resource, recyclable (unlike composite decking), redwood absorbs and traps carbon dioxide even after harvesting and milling. It's also naturally resistant to warping and shrinking, meets strict California fire codes, and is easy to maintain and restore. Redwood enhances the natural beauty so many people love about their own surroundings. And the cherry on top: originally American.

American-made redwood is also superior to natural wood that is shipped in from long distances. Though some consumers might feel the pull of exotic or imported hardwoods, redwood is the natural choice. Species such as ipd or other tropical hardwoods travel thousands of miles to be installed in an American backyard. Even species of cedar from Canada or China, or radiata pine from

Lyle Lee hos been building custom homes for over 20 yeors. Here is whot he hos to sqy obout Roseburg's Engineered Wood Products.

"When building o quolity home, it's importont for oll the froming rnoleriols to malch. ln other words come together os specified in the design plons. lf the froming is off by even o t/t of on inch, it con cosl me fhousonds of dollars in time ond moteriols.

I find Roseburg's RFPI@-Joist ond Rigidlom@ LVI io be very consislent in width ond depth. When luse Roseburg's RFPI@-Joisf, my {loors ore more level, stiffer ond truer, moking my iob much eosier.

New Zealand, take a backseat to redwood in quality and eco-friendliness. There is simply no excuse for someone not to buy redwood. The economic and environmental benefits make a beautiful product all the more attractive to anyone who embraces a "Buy American" mentality.

- Charlie Jourdain is president of the California Redwood Association. Reach him at charlie@calredwood.org or (888) CAL-REDWOOD.

fhis home is 6,000squore feeiso lused lJoistandLVL {rom several difierent units ond the monufacluring consislency wos exoclly lhe some. l{ you wont lo moximize your profit, I would recommend using Roseburg's Engineered Wood Products"

Lyle Lee

L. Lee Euilding Compony

TF 800-245-l I l5

Building-Products.com March 201 3 r Building Products Digest I 1 3

-/ ./ ROSEBURG

m

Engineered Wood

RFPI',

lFSci t i!:l9r:J -"Hsir., w

Producls I Reol Wood S;ding I Softwood Plywood I Lumber

RigidLom', RigidRim' ond Quolity Engineered Wood Products for lodoy's builder' ore registered trodemorks of Roseburg Forest Producls, Roseburg, Oregon

Gypress is earning points with architects

f ocnrso AT A BUSv intersection in I-ldowntown Raleigh, the North Carolina Chapter of the American Institute of Architects' new Center for Architecture and Design is the firstever AIA chapter headquarters built from the ground up.

Clad in cypress and other locally available materials, the 12,000-sq. ft. building also is a flagship for the future of sustainable design. It meets design standards set by AIA's Committee on the Environment

(COTE), as well as the U.S. Green Building Council's Leadership in Energy and Environmental Design (LEED) program at the Plarinum level-the highest level of recognition.

Architect Frank Harmon said he deliberately emphasized building materials that are sustainable and that reflect the history and heritage of the Tarheel State. Included in that mix is locally sourced cypress-used on the center's southern and northern

facades-as well as native zinc and stone.

"Cypress is readily available in North Carolina. and its appearance is warm, friendly, and familiar," said Harmon. "The cypress on this new, modern building's exterior is the same species of wood that's been used for generations to build shrimp boats on the Carolina coast."

Harmon became familiar with cypress as a teenager, when he began studying Frank Lloyd Wright's archi-

Creen Building with Cypress

AMERICAN INSTITUTE of Architects' new regional center in Raleigh, N.C., demonstrates a sustainable way to bui6, with local materials All photos couftesy Southern Cypress Manufacturers Assocnlion 14 r Building Products Digest I March 201 3 Building-Products.com

lecture. "Wright was a master at using natural, unfinished cypress in his iconic houses-inside and out," he said. "He used cypress like Rembrandt used oils, except Wright's canvas was architecture."

By specifying cypress, Harmon did more than honor a native building product. He also equipped the center with a durable cladding that will provide decades of service and good looks. "Used in siding applications, cypress will easily last 100 years with proper care and maintenance," he noted.

Unlike composite materials or pressure-treated wood, cypress is naturally durable thanks to cypressene, a oreservative oil in the wood that makes it naturally resistant to decay, insects, and other damaging elements. "Cypress will weather beautifully over the years, even in a harsh, salty coastal climate." said Harmon.

With abundant and readily available materials such as cypress at their disposal, Harmon believes that architects are moving towards more environmentally responsible designs. And as the country continues to recover from the recession, Harmon saYs design and construction methods are changing.

"We won't be building in the same wasteful ways," he explained. "With new emphasis on alternative energy and sustainable design, the AIANC center demonstrates a new way to build. It is a flagship for green architecture in North Carolina, and a blue-

print that can be adapted across the country."

Other green features of the impressive facility include a geothermal heating and cooling syslem. a rainwater collection system, and efficient water and light fixtures. The building is also oriented to take advantage of

passive ventilation and daylighting, while an overhanging roof provides shade in the summer.

Harmon views the facility as a monument to his profession's commitment to sustainability and to the perseverance of his colleagues throughout the building industry. "This was a really bold gesturemaybe the boldest in the country. It was built during the recession. as a gesture of faith and belief in what we do."

The new facility transformed what was formerly an unused and awkward piece of land in downtown Raleigh into a people center that is encouraging business and residential development. It also hosts events for the public, ranging from art classes for youth to lectures on energy-efficient home lmprovements.

"The center is a compelling example for responsible revitalization of the cores of towns and cities across our state," said Harmon. "It demonstrates sustainable urban development and puts Raleigh on the map as a leader in this endeavor."

For more information on the many uses of cypress, visit the Southern Cypress Manufacturers Association at www.cypressinfo.org.

NEW CENTER hosts events for the public, ranging from art classes for youth to lectures on energy' efficient home imDrovements.

Building-Products.com

March 201 3 I Building Products Digest I 1 5

CYPRESS is readily available in North Carolina and its appearance is warm, friendly and familiar.

By Carla Waldemar

hits refresh button lndiana dealer

acre site across the road from a Super WalMart, swapping what he looks back on as a "poor location, stuck in a residential district that had grown up around it" to prime time on a U.S. highway.

Smart move. But that was then. and this is ten years later. "Time to freshen up and look at our inventory and product mix," he resolved, and with a little prod from his man at Do it Best, who stepped in to study the surrounding market and advise on product mix, the 10,000-sq. fr. store received a makeover worthv of a TV show.

tTt"u

vERDrcr's xor in yet. Debate

I. is still raging among social scientists over the power of heredity vs. environment in forming one's life. Why do we do what we do? Is it in the genes or in the training?

Either way, Art Dragoo's future was pre-determined from the get-go. His great-grandfather owned a lumberyard. The one that Art grew up in the Indiana countryside-Dye Home Lumber, a yard since 1880-was purchased by his grandfather in 1924, from an owner on the other side of Art's family tree. Art, himself, put in plenty of face time with a broom and sawdust before heading out into the future to work in banking and sales.

Bet you can guess what's coming. In 1998, after 12 years in the big city

(well, Fort Wayne), a longstanding general manager of the lumber operation retired, and the call of heredity (or was it, early environment?) proved too strong to resist. Art stepped back in. "It was a good fit; I like to work in a small business and was looking for an opportunity to take charge of one of my own," he confesses.

Not so small by then, however. In 1930 a second yard had been added in Royal Center, then a third in 1946 when his grandfather (who died in 1961 ) broke ground for the Monticello store, today headquarters of the three-yard operation, all about 20 to 30 minutes apart.

Art wasn't a man to march in place. In 2001, he relocated the Monticello operation to a new, 12March 2013

He added 5,000 new products, such as home-d6cor must-haves like vanity tops and kitchen countertops. He expanded the plumbing, electrical and paint lines. He launched a toolrental service, aimed at offering convenience to his roster of pros and save them a time-consuming drive. "Plus, there are two lakes nearby, and the owners of those summer homes come in here. too." Art adds.

Contractors have always been the mainstay of Dye's accounts, but, especially in these wizened times, maybe eggs belong in other baskets, too-like, those on the arms of women. "I heard. 'Women don't like lumberyards"'-think, dark and dusty, a maze of crowded aisles with no roadmap-a frat house for the good ol' boys who knew the secret handshake. So goodbye, lumberyard; hello, home center.

Art changed-okay, dramatically redesigned-his storefront and, especially, its signage, so that now folks bombing along the highway can spot

DEALERS' staff was supportive of-and flexible during-Dye Lumbe/s makeover into a full-service home cenler, including (l-r, front row) Lori clark, Becky Myers, Kathy Polak; (back row) Dexter Knoll, inventory mgr. Matt Kiser, store mgr. Denny Tyler, and owner Art Dr-agoo.

16 r Building Products Digest r

Building-Products.com

cues that spur them to swerve into the parking lot.

"We also moved the contractor sales counter from the front to the back of the store, so the entrance is less intimidating for retail shoppers," staffed with friendly people ready to talk a lady through her project. Paint's up front, now, too, paired with other home-improvement vignettes to motivate a re-do. "We re-lit the store so that it's noticeably brighter. And we actually reduced shelving by 25Vo, creating room for displays and taller fixtures, laid out more efficiently. The staff is ready to spot someone needing help. We didn't have to retrain them, but we did add two more people, one from another store plus a plumbing-supply guy."

But the question is, is it working?

"Cash sales are now a larger percent (not larger gross, of course) than contractors' accounts," Art says. "We had a good holiday season. But since Christmas, with the additions in kitchen and bath and countertops, that business has just ignited! People are coming in, getting quotes. There's not a lot of new construction in this recession, but home-

owners are sprucing up, replacing a roof, adding a deck, creating a new look without destroying the budget."

Contractors are on hand, happy to inhale the work. And in turn, they appreciate the new tool rental service, the free delivery. ("A rarity!" Art notes, adding, "We found a lot of resistance to a $10 fee for delivering a handful ofboards.") Free estimates and design service, too. Hours have not been expanded, but then, they probably don't need to be because Dye keeps the lights on until 4 p.m. on Saturdays.

Dye's l2 employees surprised their boss by cheerleading the project, just when he'd been clenching his teeth in anticipation of grumbles over the chaos. "They weren't afraid of the inconvenience of the store being torn apartl in fact, they thought it was a lot of fun. They stepped up to the plate and appreciated that the remodel offered a lot more stability for all of us."

Even Mike, a gentlemen hired by Art's grandfather back in the 1940s. He'd retired after 54 years, but, Art says, "I called him back to help with screen and glass repairs, and he's here five days a week. He's the first one to offer suggestions and new ideas."

Art's two other stores are benefiting, too. They can send customers to Monticello's showroom or to pick up items that are out of inventory. And Dye's increased advertising and marketing campaigns benefit them, too.

Art uses circulars, newspaper and radio ads to draw newcomers. He used direct mail to send out a 100-page catalog-"an expensive piece, but so good for us-lots of feedback from new customers, who come in saying, 'I had no idea....."' he testifies.

A grand opening drew hordes of first-timers, too. "We got great response. We also did a promotion that gave away a $1,000 shopping spree, for which anyone in all three locations could register. Got a free newspaper article and a photographer out for that one, too.

"We also sponsor events, like our contractor appreciation lunch in December. We offer training sessions, too, such as seminars on building-code changes or vendors' demos of new products.

Although a website is still in the making, Dye is already active on Facebook. "Those users are not my contractors," Art has to laugh. But they're the customers of the future"a whole, new market, that's for sure"-and the outreach is free. "We post employees' photos and promotions, such as on April 1, "April Fool April Tool," offering 2OVo off with the mention of the announcement (507o discount for anyone wearing a propeller beanie!).

Another unconventional promo again cost nearly nothing. Art has stationed a giant, l2-ft. Adirondack chair in front of the building, right across the road from WalMart. "People stop to take their pictures in it" and then, of course, proceed to wander through the aisles.

The moral of the story is pretty clear: When times are slow, use those moments to spruce uP Your offerings, refresh your image, and call on creative, rather than costly, new ways to spread the word. Then, you're ready for take-off: 2013, here we come!

Carla Waldemar cwaldemar@ comcast.net

,,Fl'"

ONE-THIRD of the Monticello store's floor space was converted to kitchen, bath and home decor displays to appeal to consumers.

Bui lding-Products.com

March 2013 I Building Products Digest I 17

By fames Olsen

Rapport is king

fo ser-r- soMETHrNc to someone, anything-a car, a load I of lumber, an idea-the buyer must trust and like us. As salespeople, we are asking for customers' trust. We are asking for their money. Their job performance and their business's performance are influenced by the strength of their relationship with us. Sales demands that we become experts at rapport building.

On the phone or in person, we must have a smile on our face. I'm not talking about a Bozo-the-Clown type of sn-rile. Use your natural smile. If you are a smile-once-a-year rype of person, use that one. If you find it difficult to smile, buy a mirror and put it in front of you (phone sellers only).

It is important that we act as if we are enjoying ourselves. Many sellers sound as if they are pushing a bag of rocks up a hill and can't figure out why the customer doesn't want to join (have rapport with) them.

We can pick up a running chainsaw from one end or the other. The handle is better. The same with humans-use their name. Don't overdo it, but do it. It's simple, but it's magic. Very powerful at introduction and closing.

Use the "throw-awaytt comment

Customers often say things that have nothing to do with the business at hand. This is a rapport opportunity. They may not know it, but they want us to follow up. Example:

Grumpy customer: "You again. What do you want? I'm busy, tired-slept horribly last night. We got 10 trucks going out this morning and I can't be messin' with another salesperson. So, WHAT DO YOU WANT?"

Us: "I've got some deals that are going to fit your inventory like a gfove. Before we get to that, why didn't you sleep well last night?"

Grumpy: "My granddaughter, Isabel, went into the hospital last night with pneumonia. She'll be okay, but... anyway, what about those deals? They're probably not worth anything, but what are they?"

Mix and match

Our customers have a rhythm to their speech. We must match them. Volume, speed and tone-serious or light-all matter. When we are in sync with our customers, they will relax. If not, it is impossible to build rapport. They might buy our deal because it is the cheapest, but we are not building a business partnership with this customer. In competitive situations, we will always lose to our rappol-t-building opponent.

Interruptions kill rapport

Why do salespeople interrupt customers? They are nervous-usually afraid of the no.

They think they know what the customer is going to say. If we know what the customer is going to say, even better, relax and make them feel listened to. (People won't listen until they have "emptied their basket." Sometimes they will even exhaust themselves to the point where they say something like, "Okay,I'm done. What have you got for me?")

Other hints on interrupting:

. Leave a space at the end of the customer's sentence. Many will restart if we give them a chance.

When the customer interrupts us, stop talking. If they are excited enough to interrupt us, let's hear them out.

. When the customer makes a noise, stop talking. Many people make noises (grumbles, harrumphs, mumbles, etc.) before they begin to speak.

. If we interrupt an objection, it is still there, but now we cannot overcome it. The interrupted objection cannot be overcome.

Do not waste rapport-close

When our customers use our name, laugh or smile with us, directly or indirectly tell us something personal. ask questions. or interrupt us (strange but true), rapport is built. And. it is time to start closins.

Rapport building and closing is the one-two power combo of the master seller. When customers feel trust, they want to do business with us. Once we have built rapport, ask them to ond thcv will.

James Olsen Reality Sales Training

James Olsen Reality Sales Training

@Sales

(so3)

james@realitysalestraining.com ,&, ,r1 qn.; 1 I r Building Products Digest r March 2013 Building-Products.com

544-3572

By f ay Tompt

By f ay Tompt

Networking yond the green ers

fHene \\'AS A ner when being a I green products dealer marked you as being special, idealistic, a pioneer. Whatever your size, you were likely a relatively huge fish in an infinitesimal pond.

Today, green, if still a small fraction of GDP, is basically mainstream. It's a multi-billion dollar industry and enjoys support from national, state and local government policy. Big-box retailers, national chains, multi-generational independents-all but the last-to-change lag-

gards-are stocking at least some green products and are beginning to integrate "green thinking" into their organization's DNA.

So you stock a few green products? Who cares? So does everyone. What makes the difference these days are relationships. Dealers who are well networked in their local green building communities do best. They belong to their local green building association and know the local contractors, architects, remodelers, etc. For dealers not yet so well connected, it's never too late to get started.

Good relationships with the local green building pros are important, but there are other important networks for the well-intentioned dealer. For some major players, relationships with production builders and government procurement may be what's driving green product sales. For independents, close relationships with their local communities can also confer competitive advantage.

Call me idealistic, but I actually think the independent branch of the green home and shelter supply chain can play a leading role in making their local communities greener and more prosperous. Most importantly, dealers and distributors who understand the needs of their local communities-especially in an era of economic instability, rising energy prices, and extreme weather-can help make their local communities more resilient, too. How? By responding with products, materials, education, and support for projects that meet green building guidelines, yes. But also for other kinds of projects that lead to reduction in energy, water and other non-renewable resource use; anticipates, mitigates, and adapts to the effects of extreme weather; supports and strengthens local economic relationships, and contributes to a general increase in local well being. Dealers could be contributing to all of these positives for

their local community, and make a fair profit, too.

Again, you may ask, "How?"

That's for you and your local community to work out. Start building

/ relationships with local community

E groups. perhaps even local govern- I t..

ment agencies. whose goals are also aligned with green building, renewable energy, sustainability, and community resilience. The answers will soon become clear.

Many such local groups are affiliated with two national networks worthy of mention here. One is BALLE, the Business Alliance for Local Living Economies (www.livingeconomies.org). Their focus is on making local economies strong, sustainable, and resilient through the efforts of networked locally owned businesses working cooperatively to achieve common goals.

The second is Transition US (www.transitionus.org), which seeks to mobilize communities to work collectively to promote green and natural building, energy retrofitting, clean energy, and food security, as well as local economic resilience. Wherever you find a Transition group, you're likely to find loads of practical, "green-it-yourself' projects needing tools and supplies.

These groups embrace green building, but in many respects represent the next phase of green thinking, locating green building within a new economics of de-globalization and re-localization. Recent "Made in the USA" campaigns in this industry are a step in that direction. too. And while connecting with green builders in your community will always be good, building relationships with community groups in related movements will set you apart.

Jay Tompt Managing Partner Wm. Verde & Associates (415) 321-0848 info@ williamverde.com

20 r Building Products Digest r March 201 3

E

|J

Building-Products.com

www.williamverde.com

CNRG Picks Up Harvey

Central Network Retail Group, Natchez, Ms., has acquired out of bankruptcy W.T. Harvey Lumber, with stores in Columbus, Ga., and Phenix City, Al.

Opened in 1863, Harvey will continue to be managed by the founder's great-great grandson, Bailey Gross.

Hines Reopens Wheaton Yard

US LBM Holdings division Edward Hines Lumber, Buffalo Grove, I1., inked a lease on the former site of F.E. Wheaton Lumber, Wheaton, Il., to open a full-service building supply center and showroom by May.

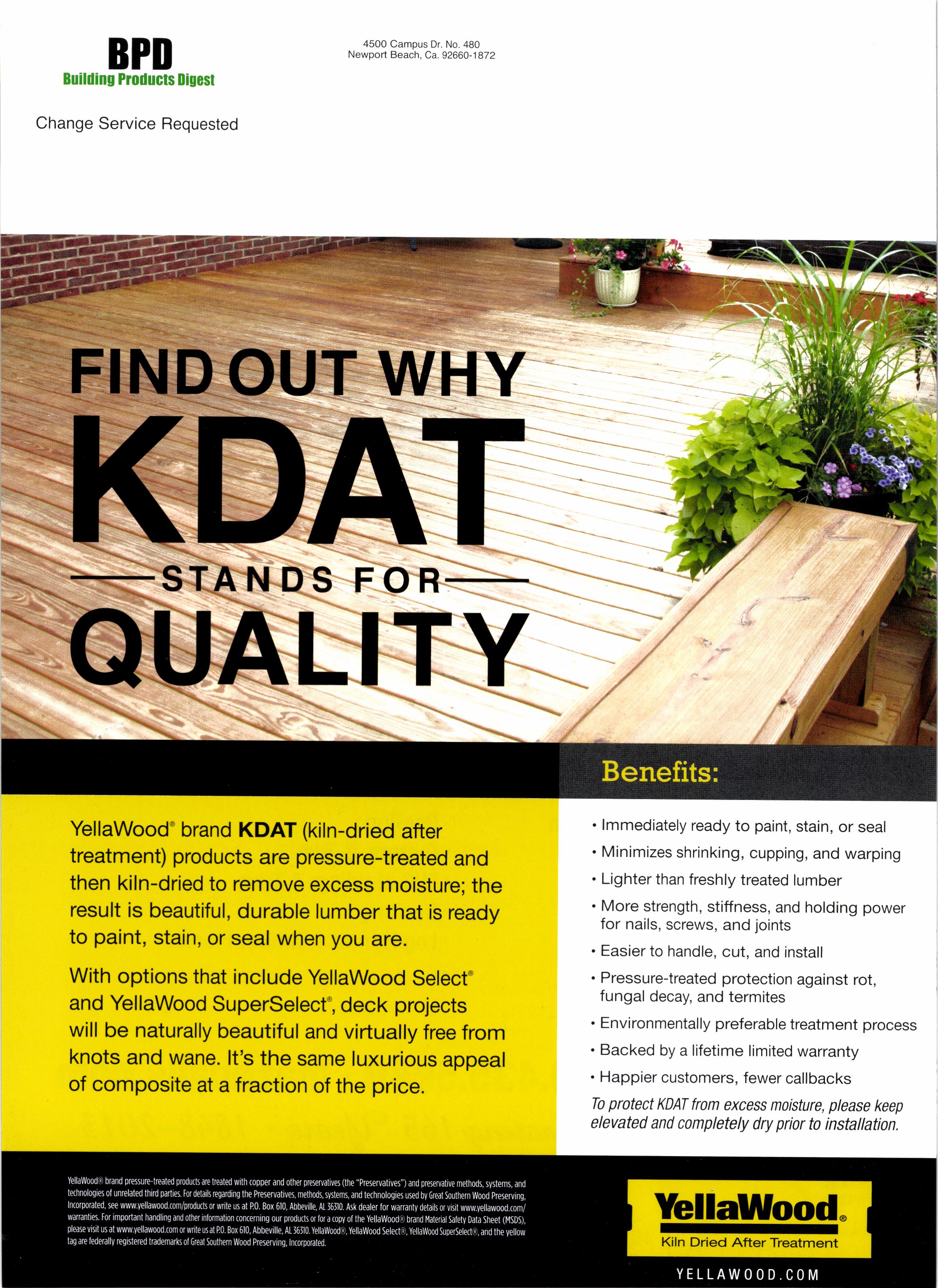

UltraShield

The property has sat vacant since F.E. Wheaton closed in 2010. The new lumberyard will be managed by Pat Briody, who served as F.E. Wheaton general manager for 28 years.

Wisconsin Dealer Rebrands

Effective April l. four sister companies-Kiel Building Supply, Kiel; Campbellsport Building Supply, Campbellsport; Berlin Building Supply, Berlin, and Drexel Inc., Brookfield, Wi.-will change their names to Drexel Building Supply.

Owner Joel Fleischman said the change will help increase brand awareness throughout the region.

Decking

McCoy's Building Supply has broken ground on a new 18,000sq. ft. retail store with 22,000-sq. ft. drive-thru lumberyard in Floresville, Tx., for a July opening.

Lynn Lumbor, Lynn, Ma., has closed after 67 years and three generations of Kessel family ownership.

Rittenhouse Lumber & Mill. work, Erdenheim, Pa., lost its cutting shed in a Feb. 9 fire.

The storage structure was originally built in the early 1900s as a trolley stop for an old amusement park.

Aubuchon Hardware shuttered its branch in Bangor, Me. The location had been a haidware store since 1914.

SouthEastern Builder's Supply, Covington, Ga., has been renamed southEastern Appliances & More, to encourage more c0nsumer business.

True Value Hardware, takefield, Mn., owner Chad Koep is adding a 13,600-sq. ft. branch in Fairmont, Mn.

Habitat for Humanitv is remodeling H.A. Smith Lumb-er's former Farmington Hills, Mi., yard into a ReStore discount LBM ouilet.

Schreiner Ace Hardware added a fourth branch Feb. 1 in Worthington, 0h. (Michael Lynch, store mgr.).

True Value Hardware, Gloversville, N.Y., received planning board approval to add a new sign, a 720-sq. ft. display area, and a 1,036sq. ft. storage facility,

Lowe's submitted olans to build a roughly 99,000-sq. ft. store with 28,000-sq. ft. garden center in Dennis, Ma.

True Value Hardware & Appliances, Aiken, S.C., received a Preservation Award from the Historic Aiken Foundation for the recent restoration of its 12S-year-old buibing.

Bayou Gity Lumber, Houston, Tx., now sells rough cedar lumber to commercial and residential customers.

22 I Building Products Digest I March 201 3 Building-Products.com

Composite

llfs Too Good To Be Wood"

Southern Parallel Forest Products, formed bv Richard and Pahick Glazier, will restart the former Bowatei Lumber sawmill in Albertuilte, Al., in May.

Deltic Timber Co1p. agreed to buy the remaining 50% share in MDF plant Del-Tin Fiber, Et Dorado, Ar.

Anthony Timberlands is added a second shift at its southern pine sawmill in Bearden, Ar., starting Feb. 4.

RoyOMartin has purchased a fourth Coe dryer and second six-deck veneer dryer for its plant in Chopin, La., replacing the last of the facility's original dryers.

Simpson Strong.Tie acquired the TJ Shear Brace tine from Weyerhaeusei, to complement its Strong-Wall shear wall. SST will now handle all shear brace sales, while Weyco continues to dishibute the line in its 22 U.S. markets.

ProVia, Sugarcreek, Oh., now offers Heritage manufactured stone from its Heartland siding warehouse in Boone, Ms.

Kleer Lumber, Westsfield, Ma., received National Green Building Certification from the NAHB Research Center for itsiellular PVC him products.

Deceuninck North America, Monroe, Oh,, received code compliance research reports for its Clubhouse decking, Clubhouse Elite railing, and Clubhouse Plus railing.

Portico Has You Covered

The PERFECT@ patio door system is ideal for home renovation and replacement, as well as new home construction. Choose from the traditional Single Slider IX/XA or the fully flexible XX Double Slider in All Vinyl or Woodbuck. Customize with add-on options like blinds between the glass and multi-panel units. Energy efficient and stylish, Portico endures life's little durability tests with ease.

Skyreach L&S Extrusions Corp.

Venerable Indiana Dealer Closing

Williams Do It Best Lumber & Hardware, Nilei In.. began a liquidation sale on Valentine's Day and will close permanently at the end of March.

The six-generation business was founded in the late 1800s. According to president Bruce Williams, the store was a victim of the struggling economy and competition from a nearby Lowe's. "I could have survived one or the other, but not both," he said. "I don't see it settins better."

Everything is for sale during the liiuidalion sale, including inventory, fixtures, equipment, trucks, and the location itself. Former locations in South Bend and Edwardsburg, In., had already been sold, as the company downsized.

Firefighters Hurt in Lumberyard Fire

Five firefighters escaped with minor inJuries from a building at Penn Lumber, Baltimore, Md., that collapsed in a Feb.4 fire.

The blaze apparently started on the ground floor of the three-story structure about 6 p.m.-three hours after the employees had gone home for the day. About 100 firefighters battled the inferno, but were forced to retreat when the structure was deemed unsafe. Several were unable to evacuate as the upper stories began to fall and had to be rescued.

"There were five firefighters that did suffer some injuries who were actually trapped beneath the lumber, the bricks from this building that actually came down from the second and third floor on top of them," said Baltimore Fire Department's Kevin Cartwright.

SKYRENtrH

#' PATIO';ffii*r,.rnl.S Canadian Headquarters: 55 Freshway Drive Vaughan, ON L4K 1S1

416-663-1888

416-663-8899 USA Headquarters: 1814 N. Neville Street Orange, CA 92865 fel: 714-244-4288 Fax: 71"4-244-4290 General: Tel: 1-866-903-8800 Fax: 1-856-302-8899 Visit often-our product line is growing: www.skyreachls.com 24 r Building Products Digest I March 2013 Bu ilding-Products.com

Tel:

Fax:

amd ffi a Bu0ffiflmg AZOLE ERAWOOD LUMBER TRIM SAW SHRINK WRAP CONTAINER STUFFING Lffiffiraroum@@ Srer@ry@rWuB REMANUFACTURING CENTER MATCH V.JOINT CENTER MATCH FLOORING DOUBTE BEADED CEILING CUSTOM PROFILES KILN DRY AFTER TREAT E RWOODT REATM E NT. CO WElNlG,,. 1 -80 0-226-3444

ALSC OK's SP Design Values

Effective June 1, the American Lumber Standard Committee Board of Review has approved the Southern Pine Inspection Bureau's design value changes for all sizes and grades of visually graded southern pine dimension lumber.

"Southern pine producers and their customers are pleased with the ALSC Board of Review's decision on new design values," said Cathy Kaake, v.p. of technical marketing for the Southern Forest Products Association, who testified at the ALSC hearing on Jan. 30. "A June I effective date provides time for an orderly transition to the new design values."

The intent of a transition period is to minimize project delays and supply chain disruptions by providing time to manage design value changes. Producers and key customer groups should use this period to evaluate and prepare for the potential impact on their businesses.

"Throughout this transition period, SFPA will provide both the current design values as well as the ALSCapproved new design values," Kaake added. Detailed Q&As, as well as span tables based on both curent and

the new design values, will be available at SFPA's www.southernpine.com during the transition period. Following publication of SPIB's Supplement l3 to the Standard Grading Rules for Southern Pine Lumber, 2002 Edition, the American Wood Council will work with the International Code Council to incorporate the new design values into span tables in the 2015 International Building Code and 2015 International Residential Code. AWC will also develop addenda and other updates to use with new construction designed in accordance with its standards and design tools, as well as recommended revisions to previous code editions.

Employee Suspected in Thefts at Missouri Dealer

A 34-year-old man is facing two felony counts for stealing from his employer, Tanco Lumber, Forsyth, Mo.

According to police, Joseph Sanpaolo changed purchase orders and invoice numbers to conceal the thefts. He took business checks from customers for projects, then gave Tanco money orders for several thou-

sand dollars less.

The first theft involved $10,500 for doors and windows, but Sanpaolo brought his employer a money order for just $7,500. When a third-party company performing framing work on the project called Tanco, asking why they were paid $2,200 in cash, Sanpaolo reportedly said the client paid the framers directly. The client, meanwhile, reportedly gave a check for $l 1,500 to Sanpaolo, based on invoices he submitted.

After Sanpaolo was fired and the alleged theft was reported to police, he reportedly attempted to collect more than $66000 from other Tanco customers. According to police, the invoices Sanpaolo attempted to collect on had all of the appropriate information, including costs and items sold, but did not have Tanco Lumber's name on them.

Sanpaolo has been charged with felony theft of greater than $500, but less than $25,000, a Class C felony, and attempted theft of greater than $25,000, also a Class C felony. A criminal summons was issued for Sanpaolo last month, but he was not arrested because of the "white-collar" nature of the crime.

creates ofution for the r-ffi ut€J. portion shimsl ier for the Be UberGrade 26 r Building Products Digest I March 2013 Building-Products.com

Sxms$$ Your Market Demands... Swanson Responds. lntr

A customer approached us with a problem... he needed a radiant barrier panel... but the job spec called for veneer plywood and not OSB. After consulting with mill management and our overlay supplier - sales had an answer. Yes, we can do this.

The result is TruBlock, a radiant barrier veneer panel that reduces attic temperatures and saves on energy costs. lt also has the superior strength, stiffness and performance of Douglas-fir plywood. Our customers ask - and Swanson responds.

Swanson Group Sales is now producing 2x4 and 2xO Premium at their Glendale OR sawmill. The grade follows the light to no wane spec that is favored by discriminating buyers everywhere. When appearance is criticaltry Swanson Group's 2x4 and 2x6 Premium.

When the market calls for a better product... Swanson delivers.

Sr'.m"",*i For sales call: 1-800-331-0831 www.swansongroupinc.com SUSTAINABLE FORESTRY INITIATIVE GqNlfLv Jau. etuIftr urIMtf APA tHt rrcrtflnlo wo aJsocatro| ffi. tvttftl8f R

@akers

Dave Adams, ex-Marvin Concepts, has been named general mgr. of Snavely Forest Products, Dallas, Tx. James Gregory "Gregtt Fookes is a new product line specialist and Christine Zizzamia and Christopher Keller new customer service reps in Baltimore, Md.

Chad Byrum, ex-ProBuild, is now general mgr. for Carter Lumber, Meadowlands. Pa.

David Cox has been named president of Richmond International Forest Products, Richmond, Va.

Joe Brown is the new president of Tampa International Forest Products. Tampa. Fl.

Mark Fisher, ex-Builders FirstSource, has joined the sales team at Jones Lumber, Fort Pierce, Fl.

Bill Whitener, ex-Mid-South Lumber, is a new account rep for Universal Forest Products, Tampa, Fl. Sean Hastings is now an estimator in Braintree, Ma.

Don Camp, ex-Branford Building Supplies, has joined ENAP, New Windsor, N.Y., as a Northford, Ct.based lumber trader.

Steve Siemieniewski, ex-McCray Lumber & Millwork, has been named mgr. of Crane Johnson Lumber, Surrey, N.D.

Dennis Lentz, ex-Weyerhaeuser, is now general mgr. of the Milwaukee, Wi., sales office of Weekes Forest Products, St. Paul, Mn.

Micah Chaney is new to sales at Olympic Forest Products, Charlotte. N.C.

Kyle Williams has been appointed mgr.-business development for Holland Southwest, Houston, Tx.

Travis Ross is new to Stock Building Supply, Austin, Tx., as millwork manufacturing mgr.

Mark Dale has been named general mgr.-log supply & business development for International Forest Products, Foxborough, Ma.

Debbie Cain has been named director of business development for Tart Lumber Co., Sterling, Va.

Wilson "Chadtt Shaver has been appointed executive v.p. of Shaver Wood Products, Cleveland, N.C.

Andie Boyd, ex-Brand Vaughan Lumber, is now inside sales coordinator for Nichiha USA, Norcross, Ga.

Mike Baker has joined the outside sales force at Zeeland Lumber & Supply, Kalamazoo, Mi.

Michael Tyson, ex-D.R. Horton, is new to EWP sales at 84 Lumber, Mount Pleasant. S.C. Brian Patterson is a new mgr. trainee in Fairless Hills, Pa.

Rick Brignac is now in lumber sales at Westervelt Co., Tuscaloosa, Al.

John Schincariol, ex-Central Michigan Hardwoods, has been named director of lumber sales & marketing for Besse Forest Products Group, Gladstone, Mi.

Stephen Szilagyi has been promoted to supply chain executive for Lowe's Cos., Mooresville, N.C. Michael Jones is new as chief merchandising officer.

Dave Treinen, ex-Timber Roots, is new to outside sales at Silver Line Windows. He is based in Menahga, Mn.

Kirk Yoggy. ex-BlueLinx. is new ro Oldcastle, Atlanta, Ga., as sales development mgr.

Glenn Knowlton has been named president and c.e.o. of Norandex Building Materials Distribution, Hudson, Oh.

Paul Giggey, ex-Harvey Building Products, has been appointed v.p. of operations for A&A Window Products. Malden. Ma.

Todd Harkness has been promoted to president of the LBM and hardlines division of ECi Software Solutions. Fort Worth, Tx., replacing Scott Stanford, who left after 2l years to pursue other interests.

Thomas Lane has been named regional sales mgr. of Mid-Atlantic commercial products at Cox Industries, Newsoms, Va.

Beverly Richards was named marketing mgr. for North American sales operations at Knrpex Tools, Arlington Heights,Il.

Stanley Bastek has been promoted to Northeast region mgr. for Atlas Roofing Corp., Atlanta, Ga. Jay Linley replaces him as district mgr. for Georgia. Clay Pruitt is now district mgr. for Ms. and La.

Scott Jeffreys was appointed v.p. of sales for Thermal Industries, Pittsburgh, Pa.

Zachary Dominique is a new product mgr. at Therma-Tru Doors, Maumee. Oh.

William Rice, ex-HW Flooring, is now Northeast territory sales mgr. for Custom Building Products, covering N.Y., N.J., and Ct.

28 r Building Products Digest t March 201 3 Bui lding-Products.com

Ed Mullett has retired as v.p.-operations at ProVia, Sugarcreek, Oh., but will continue part-time spearheading ongoing expansion activities. Keith Yutzy is now v.p.-operations; Craig Mullet, v.p.-corporate care; Brent Mullet, v.p.-information technologies, and Freddie Miller, v.p.-supply chain.

Rich Maurer has joined Versatex, as Greenville, S.C.-based Southeastern regional sales mgr. Darren Kennedy is new in Rochester, N.Y., as market development specialist for western N.Y. and Ontario.

Dave Bristow is now eastern region sales mgr. at Sellick Equipment, Detroit, Mi., succeeding Colin Sellick, who was appointed process systems mgr. Dan Denny is now a product specialist.

Lutha Leahy-Miller is new to sales at Watermill Building Supply, Watermill, N.Y.

Michael Golden has been elected to the board of Trex Co., Winchester, Va.

Abigail Walls has been named director of communiations for the Michigan Forest Products Council, Lansing, Mi.

Rex Easley is the new transportation safety director at Mungus-Fungus Forest Products, Climax, Nv., according to co-owners Hugh Mungus and Freddy Fungus.

Dealers to Help Iniured Vets

The National Lumber & Building Material Dealers Association has launched a "Dealers Helping Heroes" program to assist injured military veterans in renovating old homes or building new homes.

As severly wounded veterans return to civilian life, they often need help creating a home that will accommodate their particular disability. The federal government provides just $7,000 for a remodel or $64,960 for building a new home.

"Servicemen and women suffering with severe injuries deserve homes that will accommodate their new way of life, and I call on lumber dealers to consider adopting a wounded warrior." said NLBMDA chairman Chuck Bankston, Bankston Lumber, Barnesville, Ga. "Construction supply businesses can make an impact in the lives of military families, and we look forward to working with them."

When veterans are ready to transition home, their names are added to a master list maintained by Helping a Hero (helpingahero.org). Every other week, participating state and regional LBM associations receive a list of veterans and where they are transitioning to. The groups then identify a local dealer willing to "adopt" the veteran and furnish whatever assistance they can to help their building project.

Not All Suppliers Are Creoted Equol

Buy your Western Red Cedar from these quality producers.

gJRr-iA M[:MBt RS

Inyeart Cedar Products

Gilbert Smilh Forcs{ Produc{s

Haida Forest Products

ldaho Forerst Group

ntertor

Mrlry's fliver LLrnrber Conrpany

lVid Valley Lrrnber Specialties Lld

Norrh Enderby Tirnbcr

0rePac Building Producls

Powr:r Wootl Corp.

0uadra Wood Products

Edward Wayne Metz,l4, former president of Westall-Chandley Lumber Co., Asheville, N.C., died Feb.3.

In 1986, he teamed with local businessmen Bob Adams, Mal Hopkins, and Perry Bartsch to purchase J.M. Westall Lumber Co., Asheville. He served as president over the next 2O years as the companY acquired Johnson-Chandley Lumber, Asheville, and Brevard Lumber, Brevard, N.C. In 2005, he retired and the partners sold the yards to Frank Taylor, who consolidated them into WestallChandley Building Supplies.

Luther William Brady Sr., 97, longtime owner of Luther Brady Lumber Co., Crosby, Tx., died Jan. 21.

Stanley Louis Buck II, 73, retired former president and owner of Building-Products.com

Crossland Forest Products, Raleigh, N.C., and Allegheny Wood Sales, Willow Grove. Pa., died Feb. 5 from injuries suffered in a fall at his home.

William Earl Nelson. 94. former owner of Nelson Lumber Co., Gurnee. I1.. died Feb. 4.

He served in the the U.S. Army during World War II.

Lloyd Domingue, 92, retired owner and operator of Domingue Lumber Co., Scott, La., died Feb. l3 in Scott.

He served in the U.S. Army Air Corps during World War II.

Charles William Hamilton, 83, former owner of Standard Forest Products, Pancake, Pa., died Feb. 2 in Canonsburg, Pa.

A U.S. Army veteran, he operated Standard Forest Products for 28 years.

Sa'warne Lumber

Sliakerlown

Si:^kiyou Forcst Pruducls

Skana Forrsl Prcducts

Wesi Bay [orest Producls & MattLtlacturing

Westef n f orest Products

AFFl LIATT MAN I.JFACTUR FRS

IJW Creative Woorl Industries

Lledarshed lrdustnes

0utdoor Livrng Today

Syncrgy Par;iiri; Frrgineeted lintbctt

Worrriway & Arboria / I W0

www reolcedor org

March 201 3 I Building Products Digest r 29

1.866.778.9096

By Dennis Connelly

Lessons from the tradeshow floor Are you just riding on visbility?

II Jnlr<tNG rHE tradeshow floor at the recent V V International Builders Show in Las Vegas, I was excited and stunned. While much of the business world thinks of 2008 as the year that started the big economic downturn, many of us know it started in January 2006, because that's when we started feeling the effects. But the story's been changing, and this year brought new excitement to the show.

Companies are leaner now-whether it's operations, administration or sales-but they're finally growing. And what stunned me about this new growth is that there's still much anxiety just beneath the veneer of excitement (excuse the pun.) Just past "Everything's great" and "We've got it all figured out now," not to mention "We're doing better than last year," there's a growing concem and shift in the way that c.e.o.'s are thinking about 2013.

I heard these two questions most often: (l) Is our company capable of adding enough new growth to meet corporate objectives? and (2) Can our current sales staff grow and keep pace with the changing market demands?

I spoke with a company founder who was genuinely concemed that while his business was growing, so was the market in his space. He had a sinking feeling that he wouldn't be able to take business from the competition without lowering price. Yes, all boats are being lifted by the new tide, but, he admitted, it's ultimately not a success formula.

In my last article ("Recruiting in the New Sales Environment," Jan., p. 22),1Ialked about the shifting sands under

salespeople and the new, standard skill sets which must come with every hire, including thc ability to stand apart from the crowd. With those observations. combined with many executives' concerns in the building materials industry about growth and people, I spent the second day at the Builders Show talking to the sales staff and management. There were five questions worth sharing with those who will make a living in 2013 selling building materials:

How do we know whether sales force improvement is fantasy or reality?

Yes, sales are up. But are sales increasing due to organic growth caused by better selling skills, stronger prospecting, perfect positioning statements, insightful problem-solving, needs analysis, thorough qualifying, well-timed proposals, and excellent closing skills? If you aren't sure, you may be going along for the ride or even being taken for a ride.

How do we take business from the compe- tition without lowering price?

This is the true test of our ability to stand apart from the competition. To have the customer pay more attention to us than anyone else requires the ability to have a conversation that is more than just "What do you need?" and "How much is your budget?" To gain the full attention of your customer, above all competition, you must have a business discussion where you can drill down to find a hidden or indirect problem which your product will solve.

For example, you could think about the price of your decking vs. the lower price of the competitor's decking. We're probably good at calculating the cost of their decking problems and tacking it onto their price. But who's the person dealing with those problems at your customer's company? What is that person's regular job? And what is he or she not doing when distracted by and/or dealing with those problems? And, how important is the job that they're supposed to be doing'? And what is rftar costing you? Now you're onto a different discussion, which will help you stand out from the crowd. And now your higher price is less important.

How can we fend off the competition's full court press on our existing accounts without meeting their price?

30 r Building Products Digest r March 201 3 Bui lding-Products.com

This is an account management problem. Having long-standing accounts can lead to complacency. If you're like most LBM salespeople, you have hundreds of potential customers in your territory, but maybe l0 of them account for most of your sales.

Ever seen a basketball team up by 30 points and still lose the game? The Celtics lost to the Knicks that way in a 1986 game. You could see the Celtics' meltdown and if you're a fan, it Put a pit in your stomach. They stopPed having fun. They stopped taking chances. They stopped playing to win and starting playing not to lose. Don't do that with your customers. Once each quarter, act like you're competing for their business all over again.

Can

our salespeople leverage relationshiPs with existing customers to sell the entire product line?

The answer is that some can, but most cannot. The follow-up questions are: (a) Can those who cannot do that, learn to do it? (b) Are there hidden issues causing them to get in their own way? (c) Is the little voice in their head telling them that their customer needs to diversify, that we can't be all things to all people, that we're good at some things and not others, or is there another excuse you're hearing?

If the products you're carrying are right for the market, then selling skills are standing in the way of growing sales within your customer base.

What are we getting out of this show?

That's a great question. Some are gleaning much from it; others see little result. The difference was in the staff's mindset and understanding as to why they were there. If the purpose was merely to be visible and support for the industry, then there was commonly disappointment with the show.

When people with whom I spoke were actively looking for new qualified oppoftunities, they had a different experience. Without an active. thoughtful show strategy, the default of using it as "visibility" results in just the opposite effect. Call it the Denial = Visibility model. The denial comes from the preconceived notion that you cannot really sell at the Show. But you could have, and that's a toPic for another arlicle.

- Dennis Connelly is a building materials veteran and sales development cctnsultant with Kurlan & Associates. Reach him ut dconne I Iy@ kur I una sst r iate s.com.

Building-Products.com March 201 3 I Building Products Digest I 31

Thermo-Ash Decking

Thermally modified hardwood decking from Thermory USA uses no chemicals, glues or rainforest matcrials. Sizes are 1x6 and 514x6. Its hidden-clip system requires no drilling and ensures perfect spacing, using stainless steel hardware and machined side grooves. The wood ages naturally to silver/gray, or a UV deck oil can be used to maintain its rich brown tones.

(847) 2s6-8828

Versatile PVG Trim

Versatex WP4 is a PVC alternative to conventional pine trim. Sold in l8' lengths, it's ideal for wainscoting, soffits, porch ceilings, and a score of other interior and exterior applications. The product features an authentic V-groove center match, with a 314"x5-7n6" profile. Installation requires ordinary carpentry skills, tools and fasteners.

PI VERSATEX.CoM

02q 851-ttrr

WESTERN RED CEDAR

Easy-Gare Gutters

The Boston Gutter System from Intex Millwork offers the appearance of wood, but not the maintenance.

The extruded PVC gutters come in l0- and 20-ft. lengths, with a bracket system to hang and float.

Splice kits for inside and outside corners, end caps, and copper downspouts are also available.

T INTEXMILLWORK.COM

(866\ 293-4rOO

I THERMORYUSA.COM

LUMBERSALES@I^/ESIERNFOREST.COM [I$:@ www.wEsrERN FoREsr. co M !|iiffi P: 604-648-4500 F: 604.899-3737 EiHi[a

Q UAL|TY. SUSTAT NAB LE . CERTT Ft ED

32 r Building Products Digest I March 2013 Building-Products.com

Wholesale Wooil PtoduGts lfotlan, [1 800-033-0s00 Biminuham,[[ 800-421-0010 www.wholesalewoodonlinc.Gom Need gpecialty Lumber? A Redwood rlEmpltg_ ^4nn Plantation GyItess-' ry ffi awc["g*gg "gSS H OUSES,n.o GR=AT F-] OMES March 2013 r Building Products Digest I 33

YOUR COMPLETE WOOD TREATING SOURCE FOR EQUIPMENT!

ls your existing wood treating facitity reaching its output capacity? ls the existing equipment in need of reptacement? Are you looking to buitd a new wood treating facitity?

We work with people that have THIS KIND OF PROBLEM... ls this you? We provide busy companies one source to handle any of these issues.

A company who wanted to buitd a new cross-tie treating facitity to incr€ase their output capacity came to us. We worked with

Water Diversion for Decking

CertainTeed's new water-diversion system creates dry areas under decks for entertaining or storage.

UnderShield features 6'x16" vinyl panels with that can be installed to deck joists with stainless steel hardware. A concealed clip and grid system diverts water to the edge of the deck.

Panels come in two styles-chamfer or beadedand three colors: colonial white, sterling gray, and savannah wicker.

I cERTAINTEED.COM

(800) 233-8990

Patio Doors with Style