Special Features ln Every lssue

PROUD DISTRIBUTOR OF AMWESTERN FOREST PRODUCTS INC

)UALITY. SUSTAINABLE. CERTI FI ED.WESTERN RED CEDAR

)UALITY. SUSTAINABLE. CERTI FI ED.WESTERN RED CEDAR

www.building-products.com

A publication of Cutler Publishing 4500 Campus Dr., Ste.480, Newpo( Beach, CA 92660

f, rrer I puslIsFleo my February column ("What Is Your New Growth

I received calls from a number of friends and readers in the industry saying that although things were better for sure, they did not entirely share my optrmism of how strong things are. I understand those comments with a few caveats.

As I wrote this column, the stock market hit a new record at 14,253 compared to 14,164 on Oct. 9, 2007. Yes, it took five-and-a-half years to get back to this point and a lot of pain along the way! Of course, it is possible that by the time you read this, it may have dropped lOTo.But I think, with some twists and turns, we are heading for some good times.

The truth is that we caused much of the pain of the last several years by panicking in 2008. That panic caused the market to drop in three months to a low of 6,547. For those who panicked and sold off everything, the toll has been heavy. For those of us who didn't, the cost has been a lot more bearable. More importantly, among those who got out, many stayed out and now find it difficult to get back in. Unfortunately, come the next down market, many who got back in will sell off all over again. Panic causes everything around us to crumble.

But the sun is rising again. On our side of the economy, the facts are clear. Our industry driver-housing starts-was nicely up in 2012 vs. 2011. In 2013, starts (single and multifamily) are expected to be 960,000 compared to 780,000 in 2012-a 23Vo increase. So the question is, who is getting the business and, ifyou are not seeing it, why not? Some of the industry heavyweights are enjoying great results right now, but I think the turnaround is more slowly impacting the smaller of us.

While the big corporations are starting to rake in high profits (and why not?), many small companies are still not enjoying the same success. Betterresults are on the way, as the housing market comes to life with home prices rising, the number of underwater homes is falling, and foreclosures are down. Yet, many small companies continue painting a picture of stagnant sales. Might uncertainty be the key factor preventing them from participating in this turnaround? So I stand by my February column: what is your growth plan?

Small business typically leads the way out of recession, but that is certainly not what has happened with this economy. And I can see whyl Most small companies do not have the reserves and financial cushion that larger companies have had through the recession, so making a decision to start investing again and employing more people is a VERY tough decision. In the U.S. since February 2010, at companies with 1,000 or more workers, the number of employees has grown by more thanSVo, according to ADP. But for firms of less than 20 , the same number is 3 .4Vo

No doubt all of us small business owners have had anxiety of how the new medical plans will impact us in 2014. The payroll tax increase in January did not help matters, and the sequestration brought us hiccups and a wait-and-see attitude. Government threats for even higher taxes continue to make us reluctant to invest. But as the confidence index starts to increase, we have to have a plan to grow again, lest our businesses further decline as we get beat out by the big boys. They are not standing still.

In our industry, we need to start seeing some of the shuttered mills being reopened, shifts being added, trucks getting back on the road, and people heading back into the field. We need to see new product innovation. We need to see investments in trainins and marketing (naturally). Granted, small business is finding credit tight as banks large and small, who are with us in good and bad times (yes, I jest), are still missing in action.

However, the reality is that although for most of us time has stood still for the last five years, it is now time to wake up or be left behind. Good sellinel

Alan Oakes, Publisher aioakes@aol.com

Publisher Alan 0akes ajoakes@aol.com

Publisher Emeritus David Cutler

Director of Editorial & Production David Koenig dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Carla Waldemar, James Olsen, Jay Tompt

Advertising Sales Manager Chuck Casey ccasey@building-products.com

Administration Director/Secretary

Marie Oakes mfpoakes@ad.com

Circulation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Ghuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www.building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com.

CLASSIFIED MARKETPLACE

David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather Kelly

Phone (949) 852-1990 Fax 949-852-0231 h kelly@building-products,com

or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A.: One yeat (12 issues), $24 Two years, $39 Three years, $54

FOREIGN (Per year, paid in advance in US funds): Surface-Canada or Mexico, $49 Other countries, $65 Air rates also alailable.

SINGLE COPIES $4 + shipping

BACK ISSUES $5 + shipping

BUILDING PRODUCTS DIGEST is oublished monthly at 4500 Campus Dr., Ste.480, Newport Beach, Ca. 92660-1872, (949) 852-1990, Fax 949-852-0231, www.buildingproducts.com, by Cutler Publishing, Inc. (a California Corporation). lt is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright@20'13 by Cutler Publishing, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner wilhout written permission. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it.

concept of thermal modification, but don't intend to continue with the product."

He says thermally modified products are having a tough time cracking the crowded decking market due to limited marketing budgets. "There are so darned many competitive products," Bischel said. "People have so many choices. Dealers will put the sample on the counter alongside the other 53 deck samples and leave it up to the consumer. And it's difficult to get their attention, unless you're a Trex, who's in every magazine everywhere. There's just not the promotion for (thermally modified wood)."

Bischel, however, is convinced there is a place in the market for modified wood. "I got an email yesterday looking for some," he said. "They installed a job three or four years ago. Hurricane Sandy wiped out the area, but the project still looked gorgeous. He wanted some more."

NEW PRODUCTS such as Thermory decking are bringing renewed attention to thermally treated wood.

f, nour FIvE vEARS ago, modified wood arrived in the IA.U.S., touted as the Next Big Thing in decking. In the interim, several high-profile brands, like PureWood and Radiance, have disappeared, and the category as a whole has yet to make a dent in the overall decking market.

But now, thanks to a crop of new products, brands and distribution deals, modified wood appears ready for a second stab at success.

The category currently consists of two similar yet distinct processes. The first, thermal modification, basically cooks the wood in 4O0-plus-degree heat and steam to remove organic compounds from the wood cells, so it will not absorb water, expand, contract, or provide nourishment for insects or fungi.

The second process, acetylation, achieves similar benefits through heat, pressure and introduction of a vinegarbased acid to transform the wood's cells.

Although acetylation has been around for decades and thermal modification has been popular in Europe since the early 1990s, both have yet to enjoy widespread use in the states. Northern Crossarm, Chippewa Falls, Wi., and sister company Rocky Mountain Bluwood, Denver, Co., were early adopters of Radiance brand thermally modified wood, but are currently liquidating their inventories of the product. "We have only a small quantity left, and then the line will be gone," said president Pat Bischel. "We still like the

He doesn't see the price tag-notably higher than pressure treated lumber-as a barrier, since it's "comparable to an inexpensive composite."

Over the last five years, Lake States Lumber, Aitkin, Mn., has seen competitors to its Evolutions thermally modified wood come and go. "Other companies have made mistakes in the species they used, mostly using yellow pine," said manager Jerry Lipovetz. "We're using a different type of wood, with a different knot structure. When you cook wood, it's important which species you use and how you mill it."

Kustom Kilns, Terre Haute, In., spent five years manufacturing thermally modified wood products for several different private label resellers before launching its own brand, DuraHolz, in January 2012. The products are currently sold throughout North America, with plans to expand distribution into parts of Asia, Australia and Europe by the end of the year.

Kustom Kilns is capable of processing a large variety of wood species for a range of applications, but currently is focusing on decking, framing and fencing products made from Select Structural grade southern yellow pine.

For the future, said sales manager Kersten Russell, the company is eyeing the commercial roofing industry and "is currently working on a laminated product that will provide the durability of our hardwood products and the structural strength of our softwood products all at a extremely competitive price."

At the same time Kustom Kilns introduced DuraHolz,

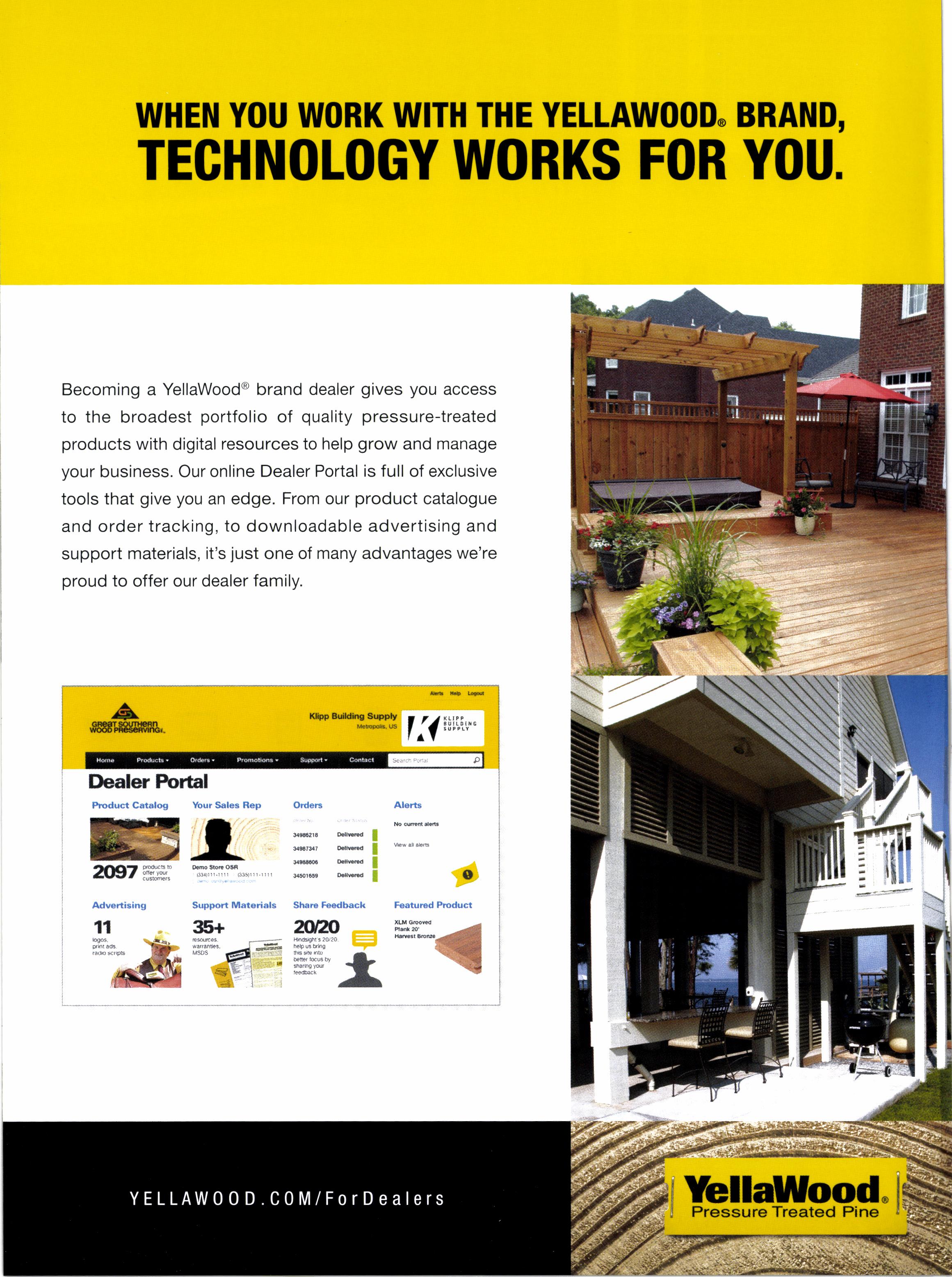

Build traffic in your store with the YellaWood@ brand.

With over 40 years of experience working with building supply dealers, we've gained the know-how to help busy retail and prooriented lumberyards succeed. Not only does our industry-leading advertising reach millions, we're also firmly committed to dealer support that's second to none. And when you carry YellaWood'o brand products you'll immediately start benefitting from our quality lumber and unmatched customer service.

People who care about your business as mucn as you oo.

When you work with the YellaWood brand, you can expect:

.We go above and beyond to provide true customer service when you call

.Regular dealer visits to assure quality and service

'Knowledgeable sales reps that go beyond product advice by responding to issues promptly and professionally

Becoming a YellaWood@ brand dealer gives you access to the broadest portfolio of quality pressure-treated products with digital resources to help grow and manage your business. Our online Dealer Portal is full of exclusive tools that give you an edge. From our product catalogue and order tracking, to downloadable advertising and support materials, it's just one of many advantages we're oroud to offer our dealer familv.

Eastman Chemical launched its own brand of acetylated southern pine decking, Perennial Wood. It has since expanded to porch flooring, deck posts, and solid (non-grooved) deck boards. Products are currently distributed in the Northeast by Boston Cedar and in the South Atlantic by Snavely Forest Products.

Royal Plywood, Cerritos, Ca., began distributing an established acetylated product-Accoya-as the commercial/industrial specialist's first step into the outdoor wood market. Thermally modified wood also caught v.p. Cliff Duernberger's eye, but he was skeptical. "I'd had it introduced to me five, six, seven years ago and samples sent," he recalled. "It was all so dark. The white oak looked like a diff'erent species. The poplar looked like maple. It was all random width lumber. Where would you use it? I never saw anywhere it fit."

Then, last summer, he was paid a visit but Thermory USA, which was looking for distributors for its new thermally modified wood. "They really figured out the process," said Duernberger. "The decking is beautiful; they have lx6, 514x6, grooved and non-grooved. It's a lot easier than working with ip6, and the price is

about the same."

Royal Plywood now distributes Accoya and Thermory throughout Southern Cal ifornia. Customers choose between the two based on the look and the application. "Accoya is radiata pine from New Zealand, treated in the Netherlands, and it's a pinelooking product," Duernberger explained. "Thermory is North American ash, treated in Estonia, and it looks like chocolate-colored ash. It comes to us with a smoky, campfirewood odor that dissipates over Lime. Accoya would be fine for a residential deck, but fbr a lar-ee commercial project, like a restaurant, the hardwood is better suited to moving around tables and chairs, high heels. and the heavicr fbot trafTic."

Shelter Products, New Ulm, Mn.. recently began distributing EcoDeck thermally modified decking in Minnesota. Iowa. Wisconsin and the Dakotas. "All of our market research has shown there are great opportunities fbr a product like this," said v.p. Aaron Lambrecht. "There is a segment of the market looking to use real wood, but with a significantly reduced environmental impact. There are also specialty applications where raw and chemical treated lumber cannot be

used. Ultimately, wood still remains the predominate product in the decking and railing category, even after the gains composite decking and railing has made in recent years."

tTt"u MULTtFAMTLT industry is |. expected to remain strong through 2013 and into 2014, according to the National Association of Home Builders. The organization has forecast 299,000 multifamily housing starts for 2O13, a 22Vo improvement over the previous year.

As builders and developers seek cost-effective ways to meet the demand, many are turning to wood framing for four- and five-story buildings-and even up to six stories in Canada. However, wood shrinkage can be an issue. Laminated strand

lumber (LSL) provides an effective means of dealing with shrinkage in wall plates.

Wood framing in taller buildings offers a number of benefits, from product availability to strength and durability. Plus, the reduced material and labor cost of building with wood, when compared to steel or concrete, means a cost-competitive option.

But wood framing isn't without its challenges, especially when it comes to shrinkage. Shrinkage occurs in solid-sawn lumber as the wood's moisture content dries from manufac-

turing conditions to equilibrium. The percent of shrinkage across the grain of lumber is roughly 40 times greater than along the length. Because of this, the shrinkage in a building caused by wall plates will be significantly greater than that caused by the studs.

With moisture content of up to 197o, traditional surfaced-dry lumber will shrink as it reaches its moisture equilibrium in the finished buildingtypically somewhere between 8Vo and 127o. As the lumber dries, it's not uncommon to see a quarter of an inch of shrinkage per story in a typical multifamily building. For a four- or fivestory building, that's more than an inch of shrinkage, with the wall plates alone accounting for nearly a third of the total, according to a technical report from Western Wood Products Association.

Wall shrinkage in multifamily developments can affect both the shear wall performance and structural capability of the building. Additionally, shrinkage can lead to moisture infiltration. Window seals can break as framing misaligns with brick and stucco veneer. Plumbing components running through the building's framing members can also be damaged if those members shrink.

Precise compensation for building movement with flashing and detailing is difficult and expensive because of lumber's natural variability in moisture content and other properties. Little can be done to fix building shrinkage retroactively, so builders and developers planning to construct tall wood buildinss need a solution for

mitigating shrinkage on the front end. Using LSL for horizontal framing members in the wall plate system can help.

LSL is created from a mixture of hardwoods. The raw logs are debarked, cut into strands, blended with waterproof adhesives that contain no formaldehyde, and formed into dense mats. A massive steam injection press then uses steam and pressure to convert the mats into billets.

The final product typically has moisture content around Jo/o to 8Vo, less than the equalized framing in most enclosed structures. Wall plate shrinkage is then minimal or nonexistent because the moisture content of LSL is so close to the moisture equilibrium of the building.

Further mitigation of wall shrinkage along the length of the grain can be obtained with LSL in stud and rim board applications. Plus, LSL studs are strong, straight and true, helping reduce product waste and labor time when used instead of traditional studs. Due to its strength and consistency, LSL rim board is ideal for supporling both high vertical and lateral loads in multi-story construction and is more dimensional stable than lumber.

The benefits of LSL don't end there. The manufacturing process for LSL provides a uniform cure and even density gradient across the thickness of the product, adding to its strength and making it more resistant to warping, shrinking and twisting.

The strongest LSL on the market is rated up to 1.75E, making it an ideal alternative to traditional lumber for beams, headers and tall wall stud

applications. LSL products can be a direct replacement for 2x4, 2x6, 2x8, and 2xl0 lumber products. LSL can also serve as a cost-competitive alternative to LVL and glulam beams.

LSL has a number of additional application benefits, including:

Roof Framing: LSL is ideal for complex and contemporary roofs or vaulted ceilings because it stays straight.

Door & Window Headers: Due to its resistance to twisting and warping, LSL can reduce the likelihood of drywall cracking around windows or framing, especially in sliding glass door and specialty window applications, and shallow headers allow for transoms and arched windows.

Talt Wall Framing: LSL is excellent for framing in walls over l0 ft. high, as it reduces movement that could lead to stress cracks and leaking seals.

Columns: LSL provides a solid, continuous load path for hold-downs in high-wind areas.

Truss Chords: Well suited for attic or girder applications, LSL has excellent plate and nail-holding capabilities.

Stair Stringers: Because LSL resists shrinking and twisting, it reduces the likelihood of squeaks.

- Ben Midgette is technical services manager in the engineered wood proclucts division o.f LP Building Products, Nashville, Tn. Reach him via www.lpcorp.com.

Take ownership of your design department now. Increase productiviV without giving up your freedom of choice and never worry about changing design software again. iStruct" delivers a brand agnostic solution that develops and transfers loads through the structure and then designs all the structural elements in one stateof-the-art package. The iStruct" suite includes our full 3D design studio along wrth single member deisgn and material optimization applications.

Call today and find out how iStruct'" can set you free.

WALL SHRINKAGE in multifamily developments can affect both the shear wall performance and structural capability of the building. Using LSL provides an effective means of dealng with both.

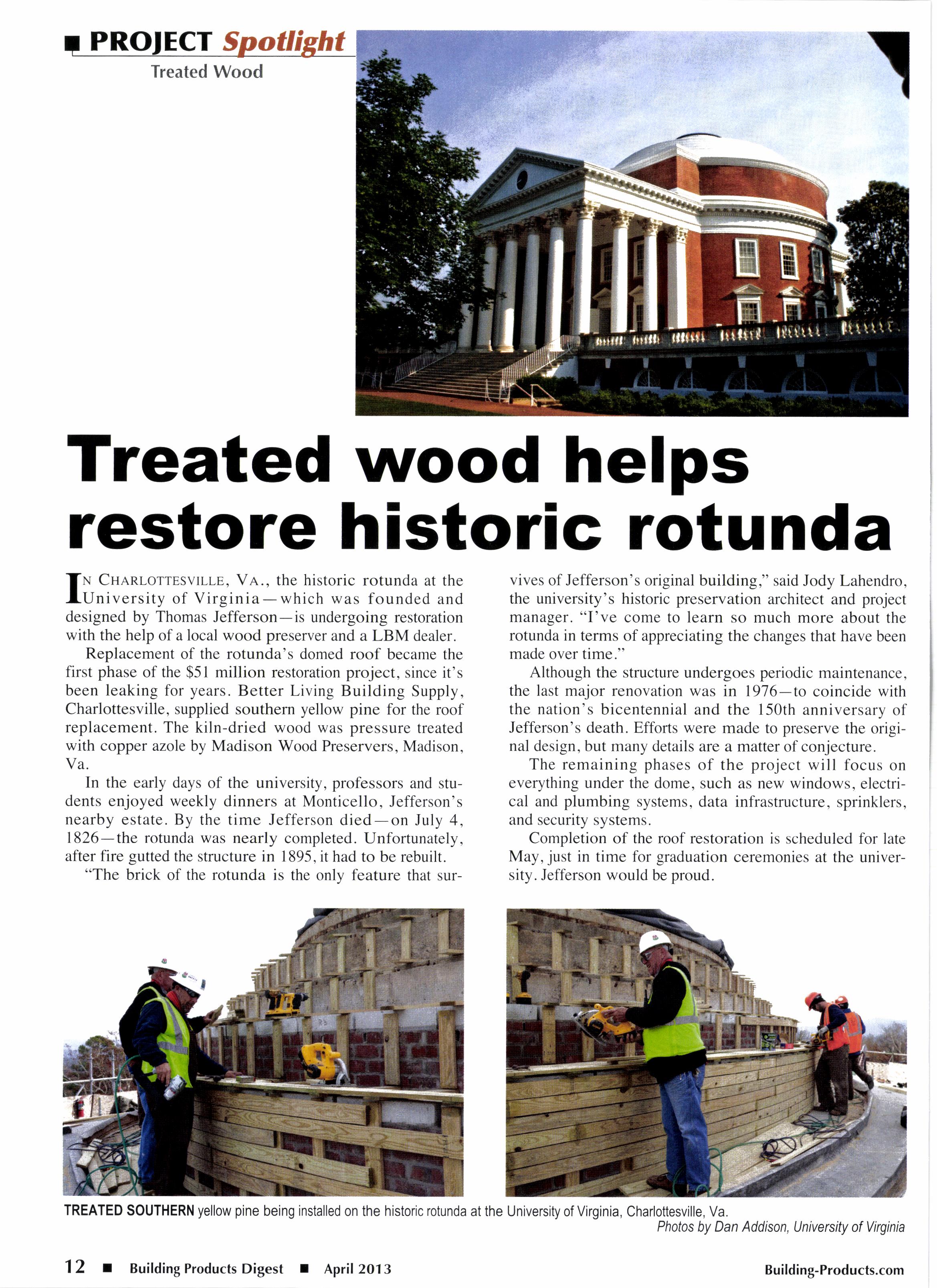

fN CHnnr-orrEsvlLLE, V,e.., the historic rotunda at the lUniversitv of Vireinia-which was founded and designed by ihomas JEfferson-is undergoing restoration with the help of a local wood preserver and a LBM dealer.

Replacement of the rotunda's domed roof became the first phase of the $51 million restoration project, since it's been leaking for years. Better Living Building Supply, Charlottesville, supplied southern yellow pine for the roof replacement. The kiln-dried wood was pressure treated with copper azole by Madison Wood Preservers, Madison, Va.

In the early days of the university, professors and students enjoyed weekly dinners at Monticello, Jefferson's nearby estate. By the time Jefferson died-on July 4, 1826-the rotunda was nearly completed. Unfortunately, after fire gutted the structure in 1895, it had to be rebuilt.

"The brick of the rotunda is the onlv feature that sur-

vives of Jefferson's original building," said Jody Lahendro, the university's historic preservation architect and project manager. "I've come to learn so much more about the rotunda in terms of appreciating the changes that have been made over time."

Although the structure undergoes periodic maintenance, the last major renovation was in 1976-to coincide with the nation's bicentennial and the l50th anniversary of Jefferson's death. Efforts were made to preserve the original design, but many details are a matter of conjecture.

The remaining phases of the project will focus on everything under the dome, such as new windows, electrical and plumbing systems, data infrastructure, sprinklers, and security systems.

Completion of the roof restoration is scheduled for late May, just in time for graduation ceremonies at the university. Jefferson would be proud.

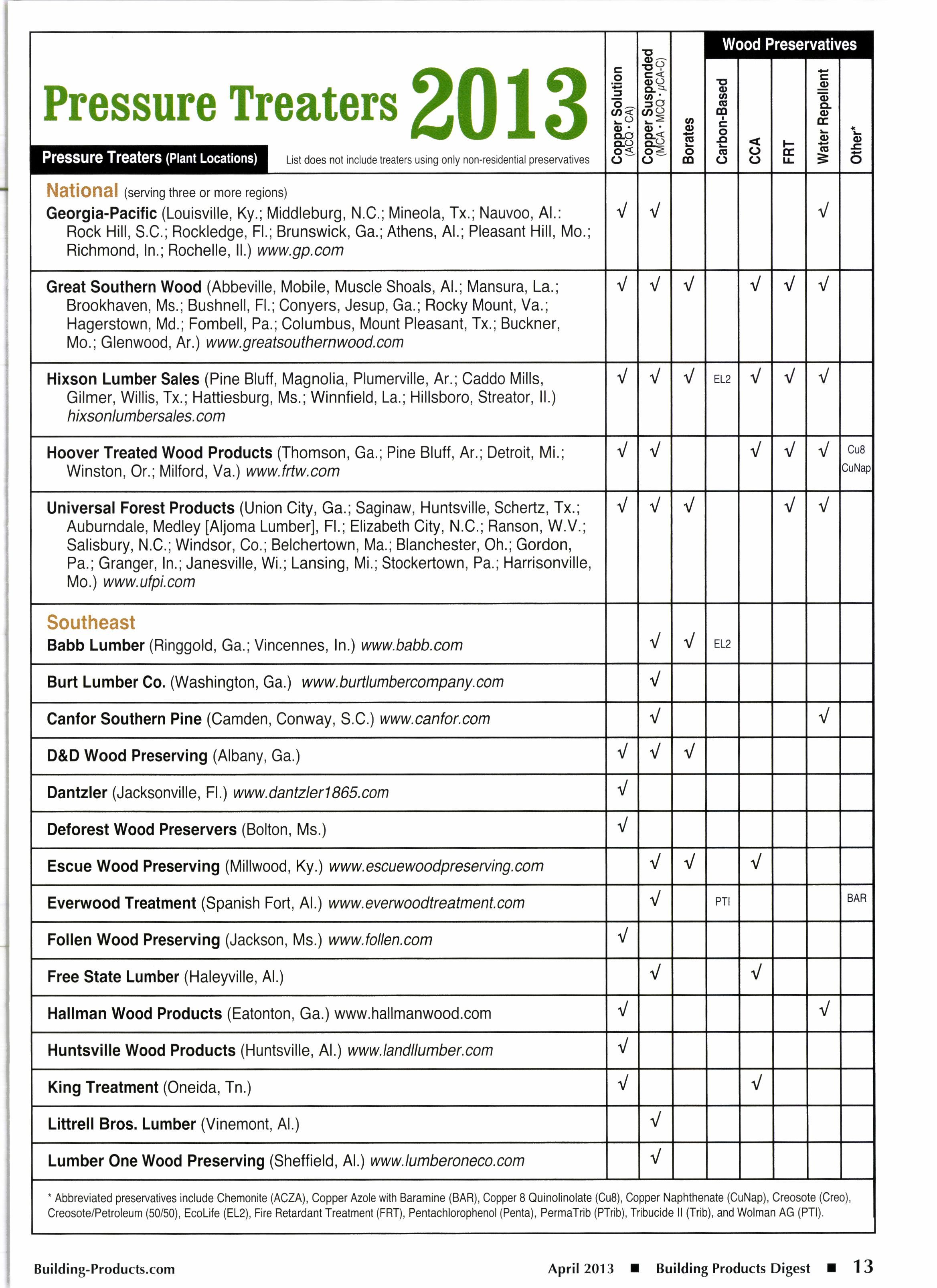

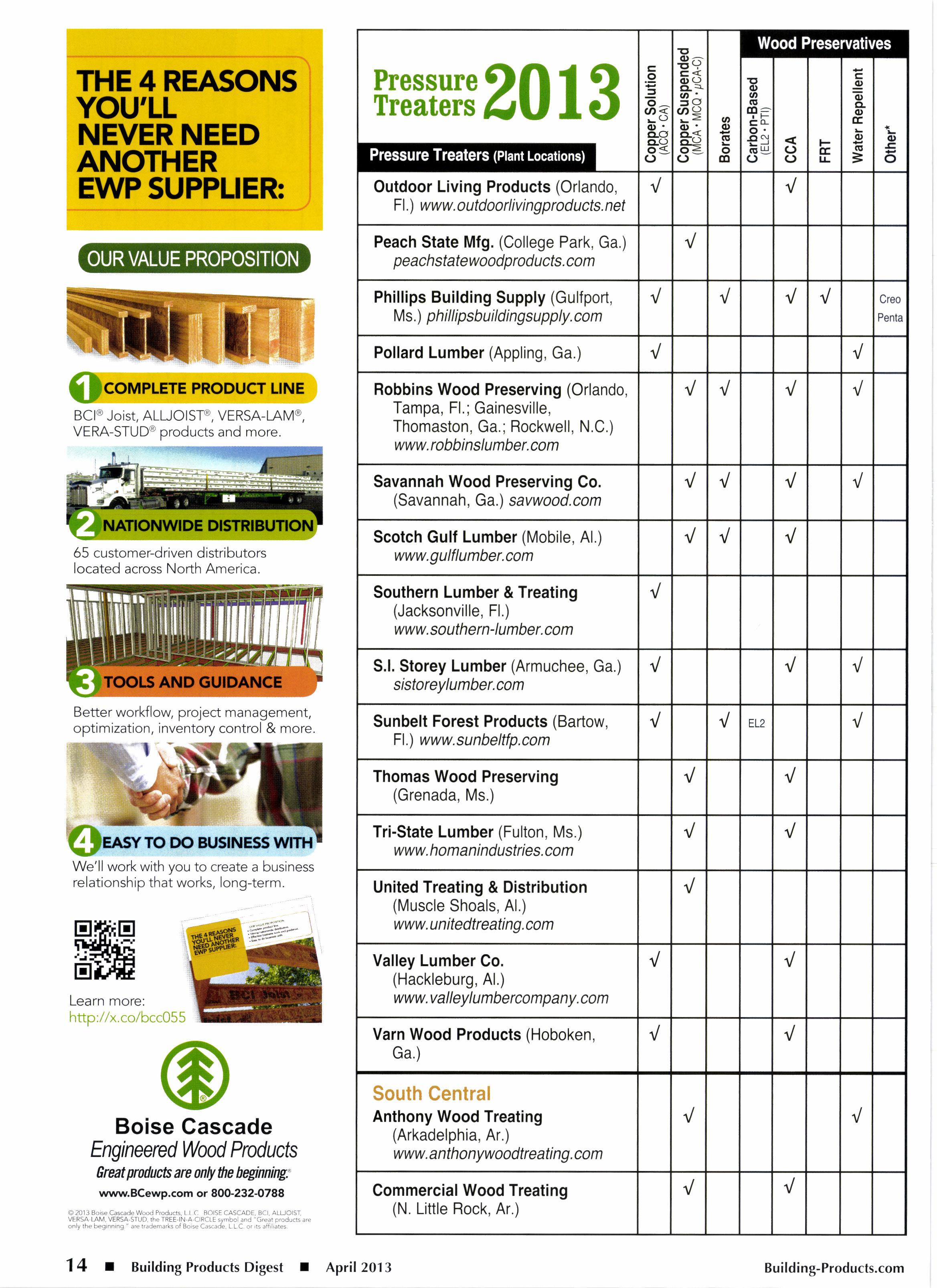

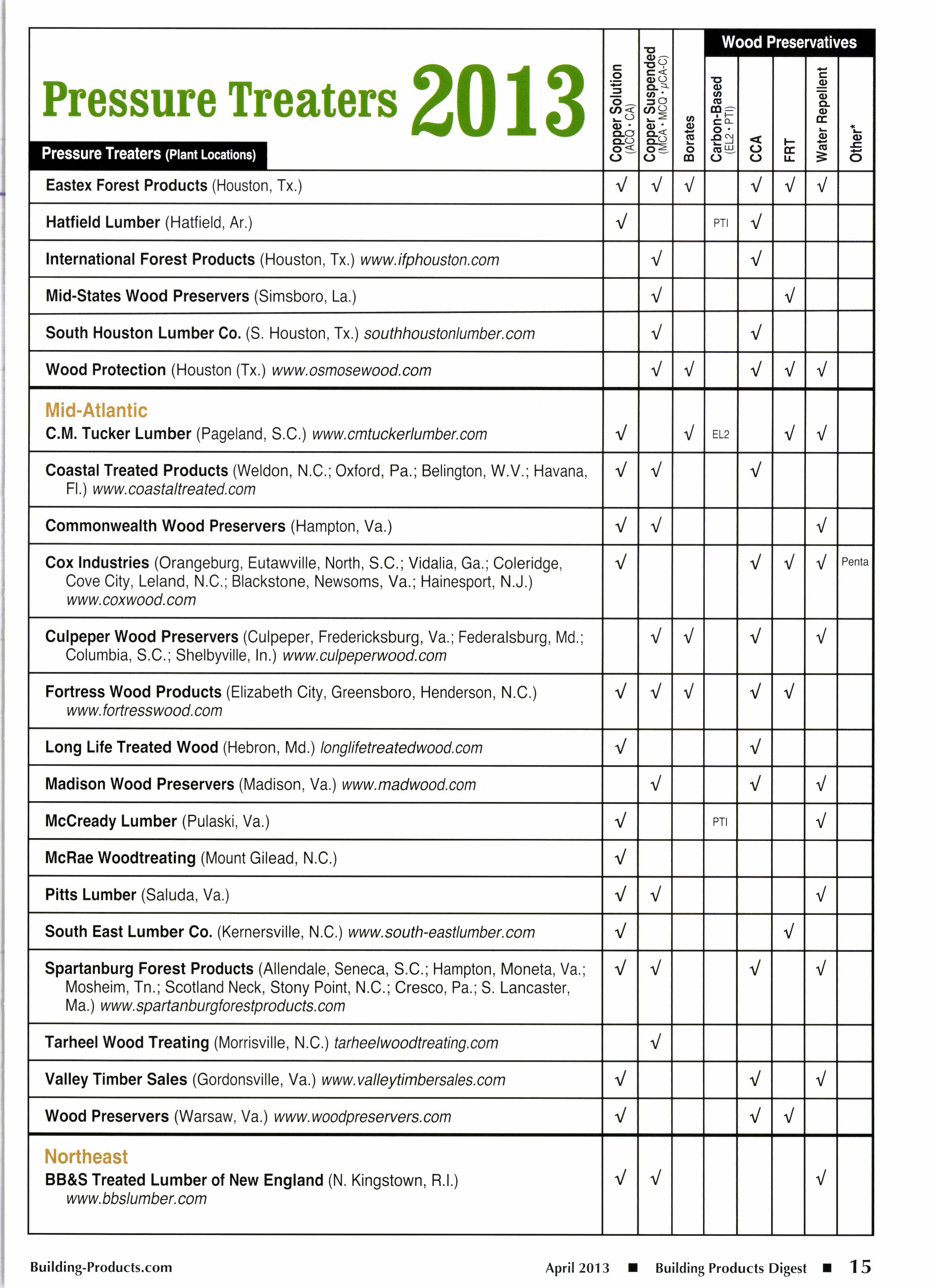

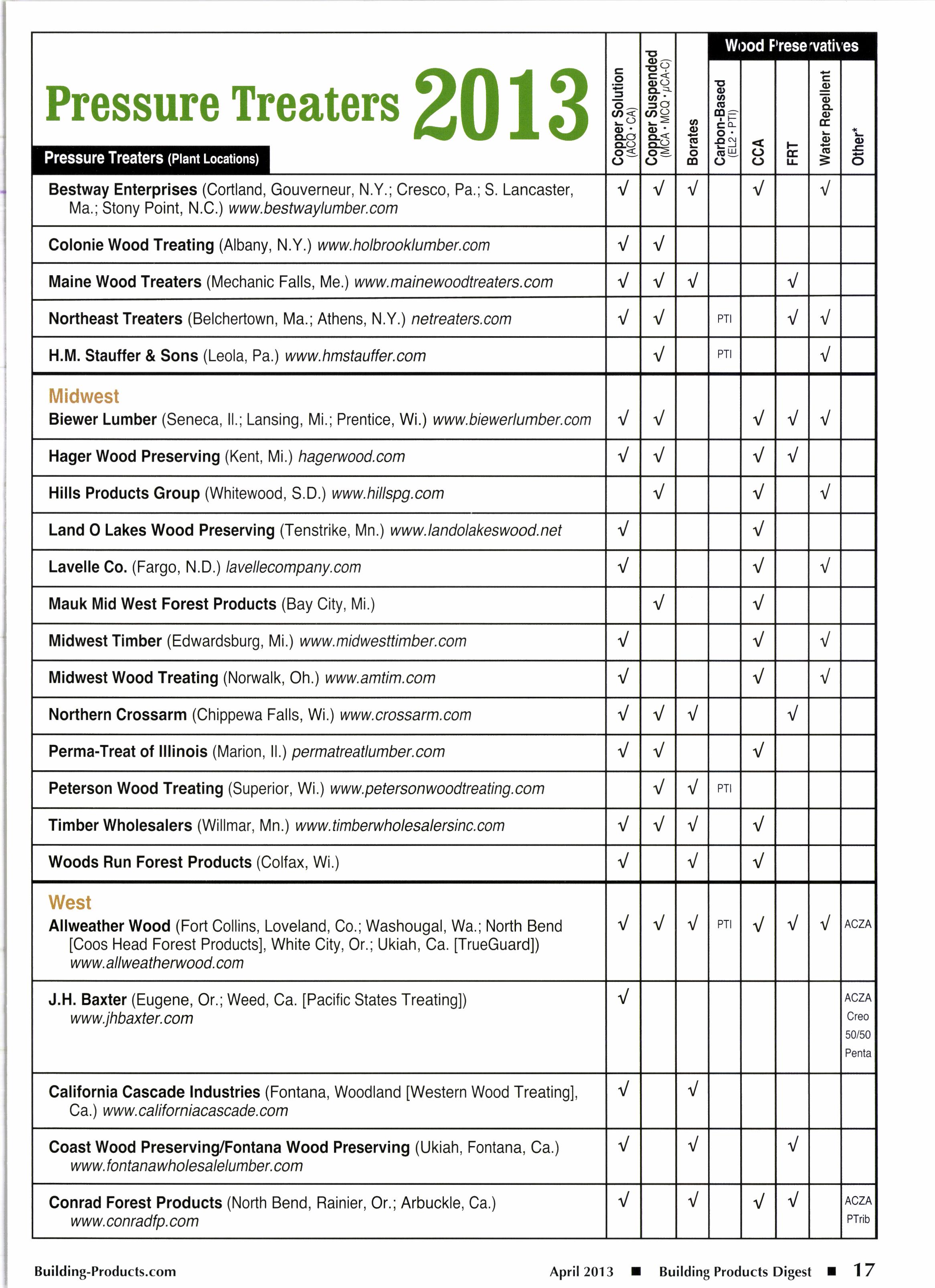

ffiListdoesnotinc|udetreatersusingon|ynon.residentia|preservaIVes

NatiOnal (serving three or more regions)

Georgia-Pacific (Louisville, Ky.;Middleburg, N.C.;Mineola, Tx.;Nauvoo, Al.: Rock Hill, S.C.;Rockledge, Fl.; Brunswick, Ga.;Athens, Al.; Pleasant Hill, Mo.; Richmond, ln.; Rochelle, ll.) www.gp.com

Great Southern Wood (Abbeville, Mobile, Muscle Shoals, Al.; Mansura, La. Brookhaven, Ms.; Bushnell, Fl.; Conyers, Jesup, Ga.; Rocky Mount, Va.; Hagerstown, Md.; Fombell, Pa.;Columbus, Mount Pleasant, Tx.; Buckner Mo. ; G f enwoo d, Ar .l www. gre atsouth e rnwoo d. co m

Hixson Lumber Sales (Pine Bluff, Magnolia, Plumerville, Ar.; Caddo Mills, Gilmer, Willis, Tx.; Hattiesburg, Ms.;Winnfield, La.; Hillsboro, Streator, ll.) h i xson Iu mbe rsal e s. co m

Hoover Treated Wood Products (Thomson, Ga.; Pine Bluff, Ar.; Detroit, Mi.; Winston, Or.; Milford, Y a.) www.frtw.com

Co. (Washington, Ga.) www.burtlumbercompany.com

Canfor Southern Pine (Camden, Conway, S.C.) www.canfor.com

D&D Wood Preserving (Albany, Ga.)

Dantzler (Jacksonville, Fl.\ www.d antzl e r 1 865.com

Deforest Wood Preservers (Bolton, Ms.)

Escue Wood Preserving (Millwood, Ky.) www.escuewoodpreserving.com

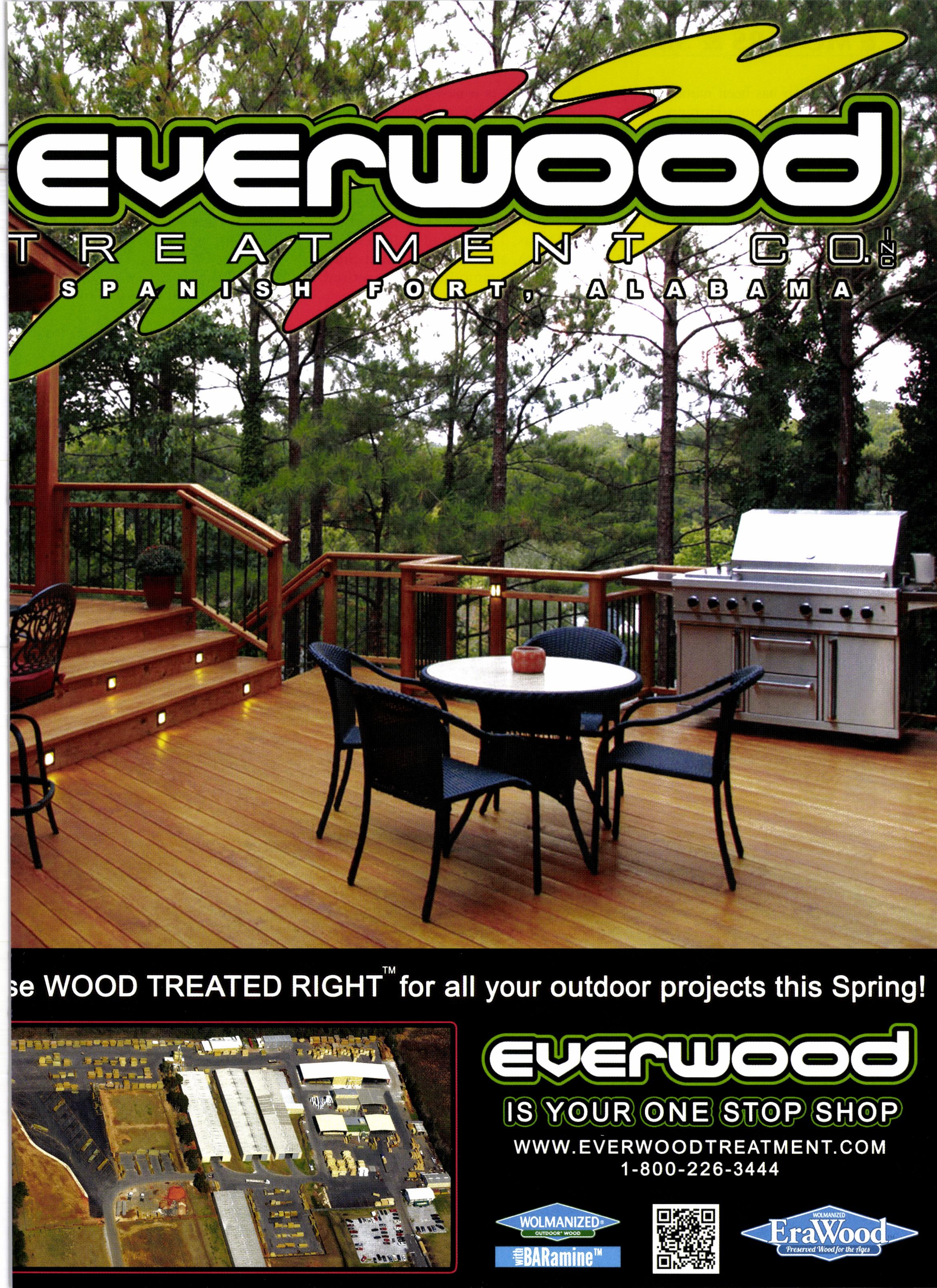

Everwood Treatment (Spanish Fort, Al.) www.evewoodtreatment.com

Follen Wood Preserving (Jackson, Ms.) www.follen.com

Free State Lumber (Haleyville, Al.)

Hallman Wood Products (Eatonton, Ga.) www.hallmanwood.com

Huntsvi lf e Wood Products (Huntsvi ll e, Al.) www.landll u mber.com

King Treatment (Oneida, Tn.)

Littrell Bros. Lumber (Vinemont, Al.)

Lumber One Wood Preserving (Sheffield, Al.) www.lumberoneco.com

- Abbreviated preservatives include Chemonite (ACZA), Copper Azole with Baramine (BAR), Copper 8 Quinolinolate (Cu8), Copper Naphthenate (CuNap), Creosote (Creo), Creosote/Petroleum (50/5,0), EcoLife (EL2), Fire Retardant Treatment (FRT), Pentachlorophenol (Penta), PermaTrib (PTrib), Tribucide ll (Trib), and Wolman AG (PTl).

Industries (Orangeburg, Eutawville, North, S.C.; Vidalia, Ga.;Coleridge, Cove City, Leland, N.C.;Blackstone, Newsoms, Va.; Hainesport, N.J.) www.coxwood.com

Fortress Wood Products (Elizabeth City, Greensboro, Henderson, N.C.) www.fortresswood.com

Long Life Treated Wood (Hebron, Md.) longlifetreatedwood.com

Lumber (Pulaski, Va.)

McRae Woodtreating (Mount Gilead, N.C.)

Pitts Lumber (Saluda, Va.)

South East Lumber Co. (Kernersville, N.C.) www.south-eastlumber.com

Spartanburg Forest Products (Allendale, Seneca, S.C.; Hampton, Moneta, Va.; Mosheim, Tn.;Scotland Neck, Stony Point, N.C.; Cresco, Pa.;S. Lancaster, Ma.) www. spartanburgforestp roducts.com

Tarheef Wood Treating (Monisvil le, N. C.) farhee lwoodtreati ng. com

Valf ey Timber Sales (Gordonsvil le, V a.) www.val leytimbe rsales, com

Wood Preservers (Warsaw, Va.) www.woodpreservers.com

Northeast

BB&S Treated Lumber of New England (N. Kingstown, R.l.) www.bbslumber.com

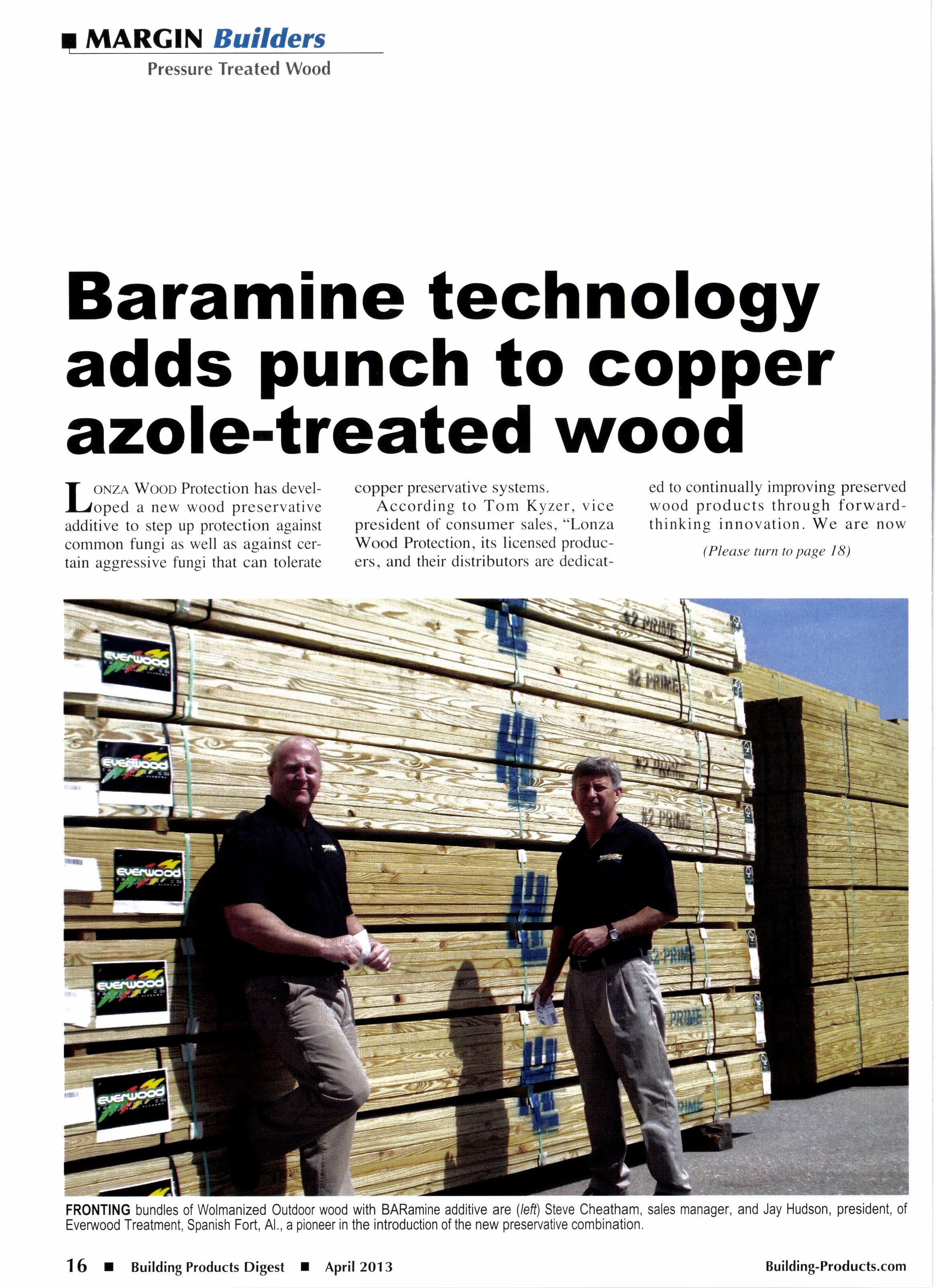

T | )\2.\ \\'on1r p;irlgqtitrtt lttts tle t cl- I I '0Pe tl lt tlL' \\ \\ ilrrrl Pte :r'lr lllit c lrdclitii e ltr sllp 1t1r p1it1q'1'1i1r1t ltlltitlsl (()rlr'n()n l'uttSi rrr r'rt'll lrr lrslrirtsl eettain lggrcssivc lirngi thut cun tolcrltc

coppcr plcscrvatlVc sVstcnrs.

According to Tonr K1zcr. r icc prcsiclcnt ol' corrsurrrcr sitlcs. "I-onza Wood Protcction. its liccnscd procluccrs. uncl thcil clistribu(ors arc dcrliclt-

cd to continuallf inrproving prescrvcd u ood ploclncts thlough forwardthinking innovatiorr. Wc arc ttou ( I'ltu.st' tLu'tr t() !)e.q( lE)

Allweather Wood (Fort Collins, Loveland, Co.; Washougal, Wa.; North Bend [Coos Head Forest Products], White City, Or.; Ukiah, Ca. [TrueGuard]) www. allwe ath e rwood. co

J.H. Baxter (Eugene, Or.; Weed, Ca, [Pacific States Treating]) www.jhbaxter.com

California Cascade Industries (Fontana, Woodland [Western Wood Treating], Ca.) www.californ iacascade.com

Coast Wood Preserving/Fontana Wood Preserving (Ukiah, Fontana, Ca.) www. fo ntan aw h o Ie sale Iu mbe r. co m

Conrad Forest Products (North Bend, Rainier, Or.;Arbuckle, Ca.) www.conradfp.com

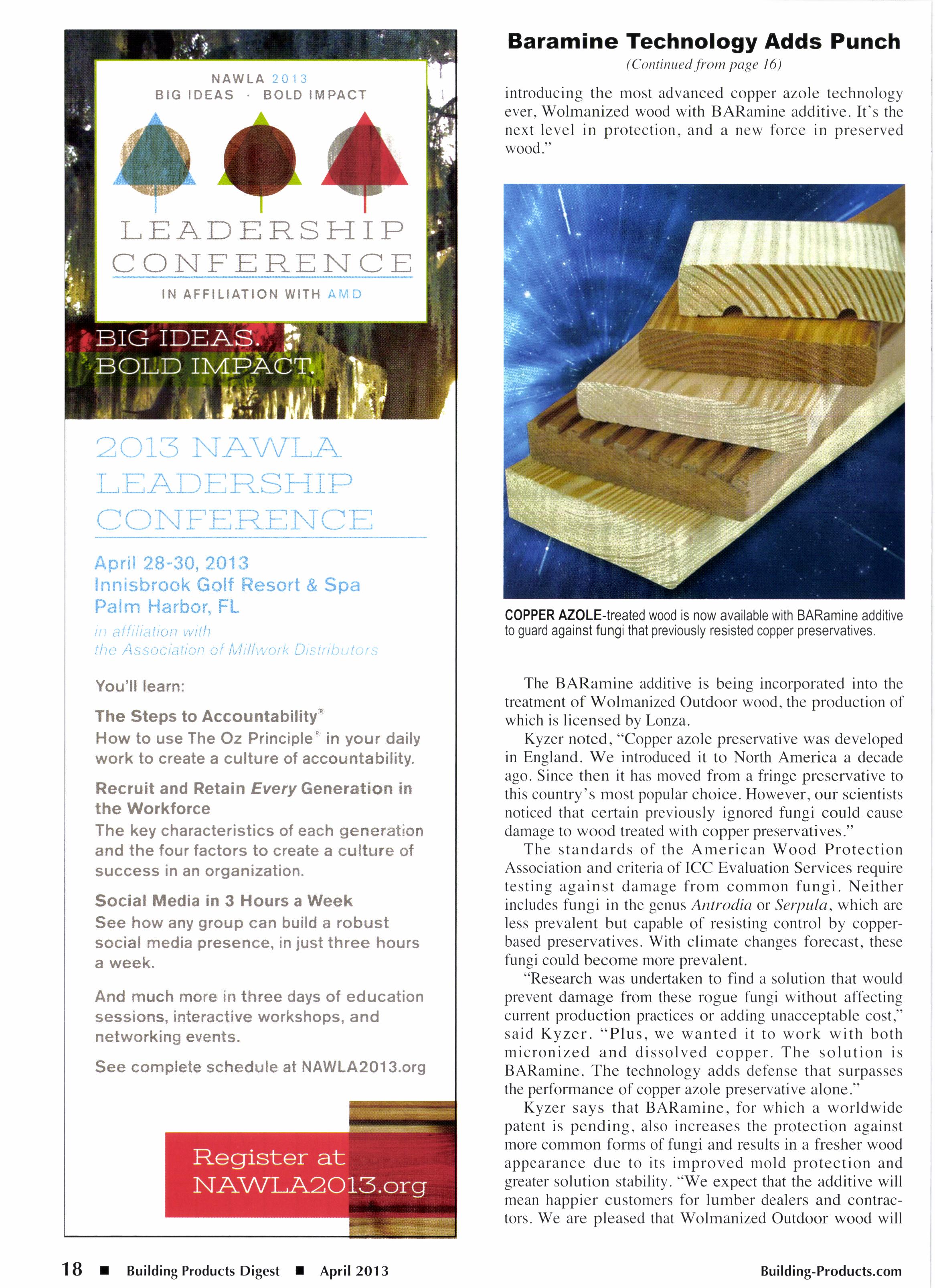

(Continued .from page l6) introducing the most advanced copper azole technology ever, Wolmanized wood with BARamine additive. It's the next level in protection, and a new force in preserved wood."

tril1#

lnr:is*rc*k fi*if {Qesmrt & $pa

Fairy: H*ri:*r, FL

i:i ,',, i irr.,;t :'i lli:

li':r' ..'iri:rlr.l,i'l: ii) t)i i'"!'::.' '1;:. i.'); ; '

You'll learn:

The Steps to Accountability"

How to use The Oz Principle' in your daily work to create a culture of accountability.

Recruit and Retain Every Generaticn in the Workforce

The key characteristics of each generation and the four factors to create a culture of success in an organization.

Social Media in 3 Hours a Week

See how any group can build a robust social media presence, in just three hours a week.

And much more in three days of education sessions, interactive workshops, and networking events.

See complete schedule at NAWLA2013.org

The BARamine additive is being incorporated into the treatment of Wolmanized Outdoor wood, the production of which is licensed by Lonza.

Kyzer noted, "Copper azole preservative was developed in England. We introduced it to North America a decade ago. Since then it has moved from a fringe preservative to this country's most popular choice. However, our scientists noticed that certain previously ignored fungi could cause damage to wood treated with copper preservatives."

The standards of the American Wood Protection Association and criteria of ICC Evaluation Services require testing against damage from common fungi. Neither incfudes fungi in the genus Antrodia or Serpula, which are less prevalent but capable of resisting control by copperbased preservatives. With climate changes forecast, these fungi could become more prevalent.

"Research was underlaken to find a solution that would prevent damage from these rogue fungi without affecting current production practices or adding unacceptable cost," said Kyzer. "Plus, we wanted it to work with both micronized and dissolved copper. The solution is BARamine. The technology adds defense that surpasses the performance of copper azole preservative alone."

Kyzer says that BARamine, for which a worldwide patent is pending, also increases the protection against more common forms of fungi and results in a fresher wood appearance due to its improved mold protection and greater solution stability. "We expect that the additive will mean happier customers for lumber dealers and contractors. We are pleased that Wolmanized Outdoor wood will

COPPER AZOLE-treated wood is now available with BARamine additive to guard against fungi that previously resisted copper preservatives.

COPPER AZOLE-treated wood is now available with BARamine additive to guard against fungi that previously resisted copper preservatives.

We know how a beautiful deck order can become a nightmare in no time. We'll make it easy to iump at each and every order this decking season with:

Product experts right in your back yard

Weyerhaeuser Distribution - it's all in the delivery. Gall us today to lighten your load or learn more at woodbywy.com,/distribution. Baltimore800.368.6226 Gharlottel.800.645.93?0

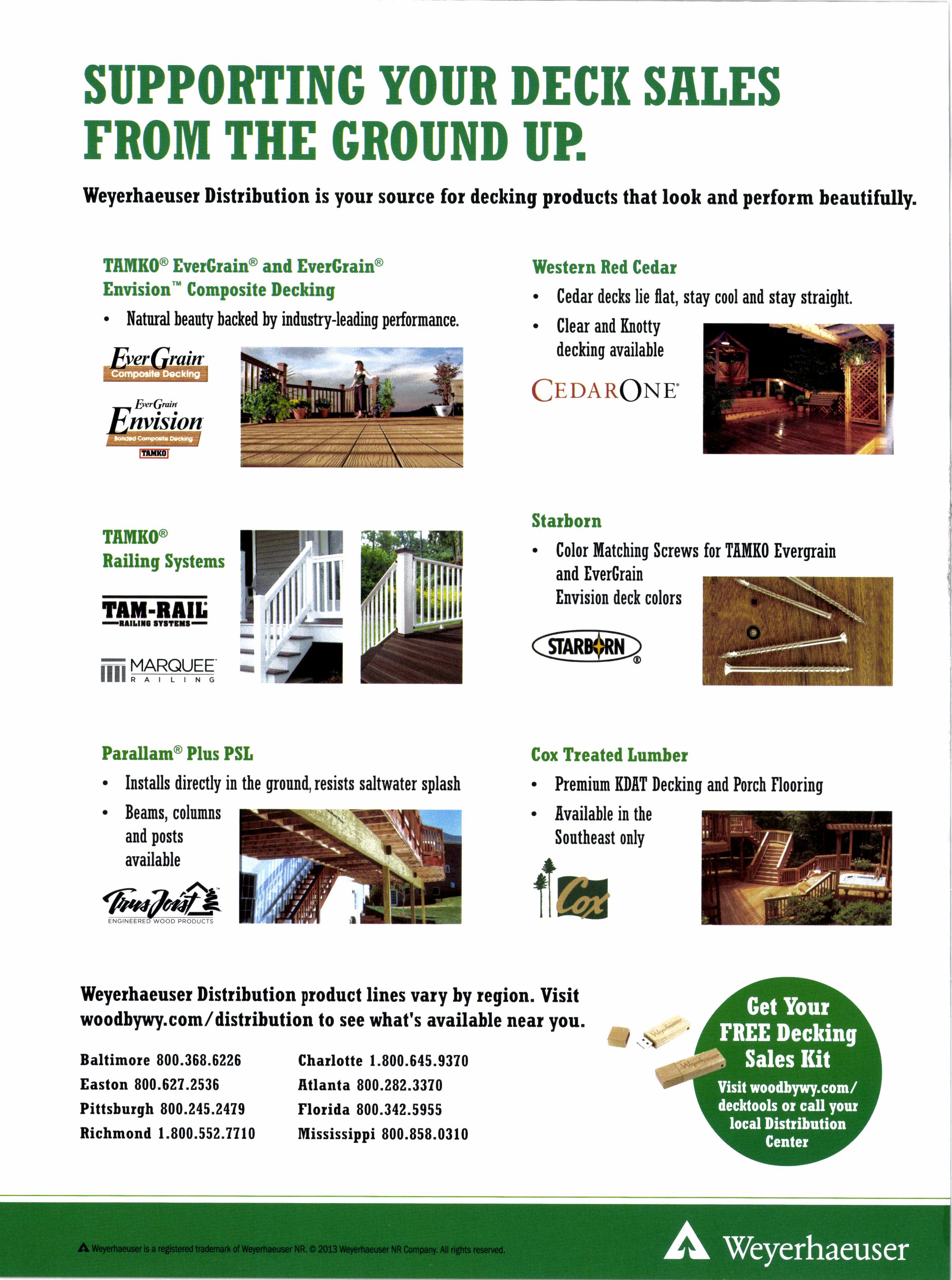

Weyerhaeuser Distribution is your source for deching products that look and perform beautifutly.

Tllllf,0@ EverGraino and EverGrain@ Envision" Gomposite llecking

. l{atunl bearty backed by industry-leadiry performance.

nfuG.*. ,<.tnnsnfi E@lml TIMIIO@ Bailing Systems !$il[.mu ffi y+FgyFE

Parallam@ Plus PSL

. Instdls directly

. Beans, columns and posts available

in the ground,resists saltwater splash

Western Red Gedar

. Cedu dech lie lat, stay cool and stay straight.

. Cleu and llotty decking available

Starborn

. Color tatchilg $crews and fver0rain

lnvision deck colors

for Tllffi0 [verqrain

Gox Treaterl Lumber

. Preniun [I)lT llecking and hrch flooring

. lvailable in the $outtreast olly

Weyerhaeuser Distribution product lines vary by region. Visit woodbywy.com/distribution to see what's available near you.

Baltimore 800.368.6226 Gharlotte 1.800.645.93U0

Easton 800.62?.2536 trtlanta 800.282.33I0

Pittsburgh 800.245.2419 florirla 800.3{2.5955 Richmonrl 1.800.552.??10 Mississippi 800.858.0310

be the first brand to have this protection."

A pioneer in the commercialization of BARamine additive was Everwood Treatment, Spanish Fort, Al. They first used it in late 2Ol2. "We were willing to be a trial plant because we wanted to be ahead of the curve," said Everwood president Jay Hudson. "I would not be surprised if, in the near future, many treating plants provide treatments with BARamine, or something like it.

"Fungi, like other forms of life, will adapt to their conditions. To control decay, preservatives must stay in front of the adapting fungi. The data show that this new combination does that."

Hudson explained that the addition of BARamine does not change the natural color of copper azole-treated wood, nor does it make the wood more corrosive. "It adds some moldicide value, which is welcome, and helps our finished product look cleaner and brighter. Our customers have

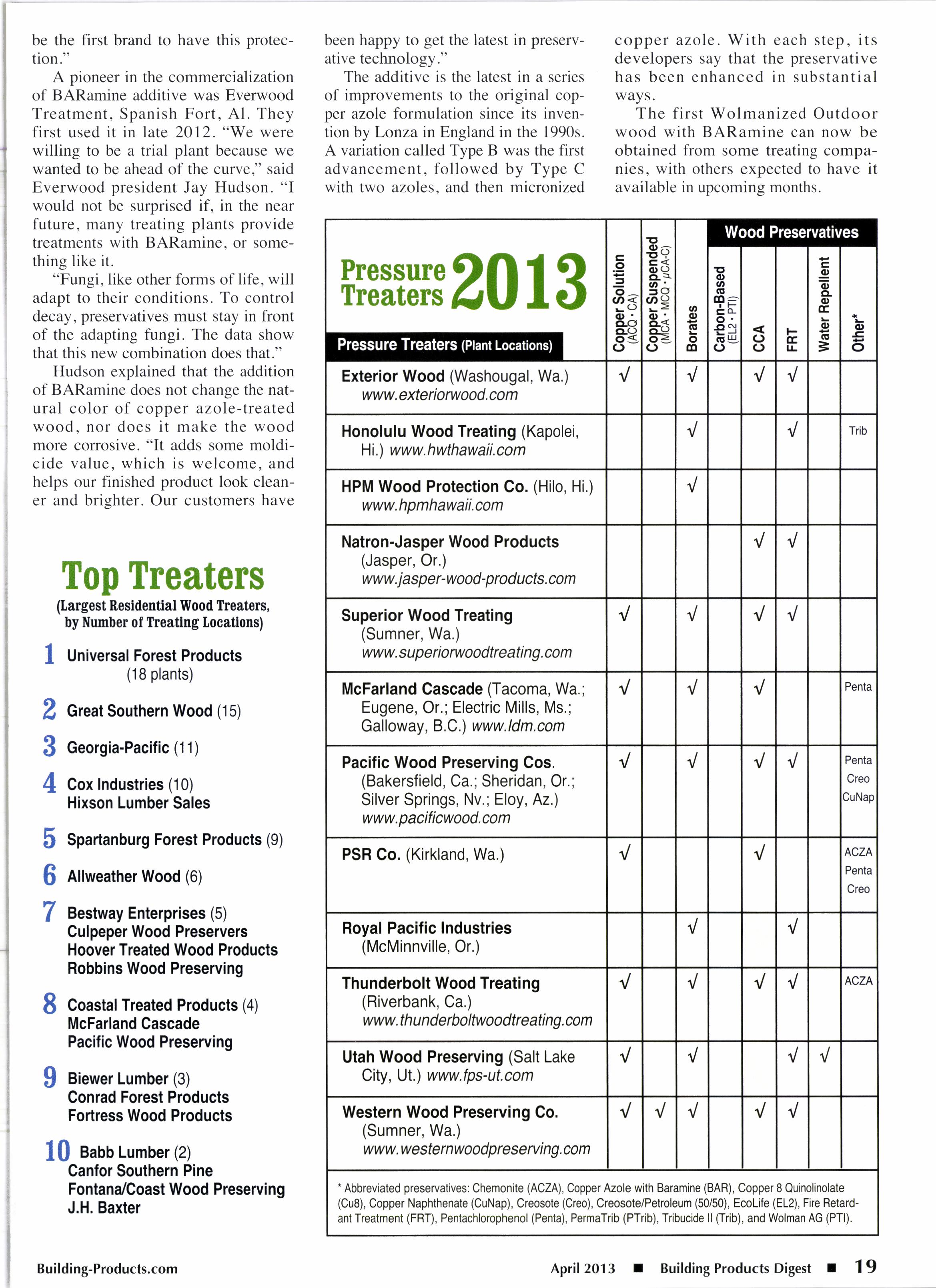

(larEest Besldentlal Wood Treaters, by Number of Treating locatlons)

I Universal ForestProducts (18 plants)

f ereatsouthern Wood (15)

$ Georgia-Pacific (11)

4 Coxlndustries (10)

Hixson Lumber Sales

$ SpartanOurg Forest Products (9)

$ rutweather Wood (6)

/ eesmay Enterprises (5)

Culpeper Wood Preservers

Hoover Treated Wood Products

Robbins Wood Preserving

$ CoastatTreated Products (4)

McFarland Cascade

Pacific Wood Preserving

$ eiewer Lumber (3)

Conrad Forest Products

Fortress Wood Products

eauo Lumber (2)

Canfor Southern Pine

Fontana/Coast Wood Preserving

J.H. Baxter

been happy to get the latest in preservative technology."

The additive is the latest in a series of improvements to the original copper azole formulation since its invention by Lonza in England in the 1990s. A variation called Type B was the first advancement, followed by Type C with two azoles, and then micronized

copper azole. With each step, its developers say that the preservative has been enhanced in substantial ways.

The first Wolmanized Outdoor wood with BARamine can now be obtained from some treating companies, with others expected to have it available in upcoming months.

e ri o rwo odtre ating. co m

McFarland Gascade (Tacoma, Wa.; Eugene, Or.; Electric Mills, Ms.; Galloway, B.C.) www.ldm.com

Pacific Wood Preserving Gos. (Bakersfield, Ca.; Sheridan, Or.; Silver Springs, Nv.; Eloy, Az.)

PSR Co. (Kirkland, Wa.)

Royal Pacific Industries (McMinnville, Or.)

Thunderbolt Wood Treating (Riverbank, Ca.)

www. th un de rboltwoo dtre atin a. co m

Utah Wood Preservlng (Salt Lake City, Ut.) www.fps-ut.com

Western Wood Preserving Co. (Sumner, Wa.)

www. w e sternw oodp re se rv in g. co m

'Abbreviated preservatives: Chemonile (ACZA), Copper Azole with Baramine (BAR), Copper I Quinolinolate (CuB), Copper Naphthenate (CuNap), Creosote (Creo), Creosote/Petroleum (50/50), EcoLife (EL2), Fire Retardant Treatment (FRT), Peniachlorophenol (Penta), PermaTrib (PTrib), Tribucide ll (Trib), and Wolman AG (PTl).

Du Houcs Sn. is like those oldI-ltime preachers testifying that the End is Near. But instead of "Repent!" he preaches: "Diversify or Perish!" And, sadly, that's become the fate, he notes, of many an independent dealer who didn't heed his message.

He's c.e.o.-cum-cheerleader (and, at 70, by no means emeritus) of Phillips Building Supply, with three operations in Mississippiheadquartered in Gulfport-and a new launch across the state line in Picayune, La. The outfit began life in the 1950s as a sawmill and timber company that, from the outset, saw change coming and stared it squarely in the face. "When the big boys took over logging, the company sold off land and tumed to retail," says Bill.

"But you can't make a living selling lumber and plywood," he quickly learned. "There's no mark-up on them; you can't make any money."

That insight was the first clue that it was high time to diversify. But how

do you begin? "You look at the bottom line. It took me awhile to struggle through it, figure out what makes money-but you evaluate and then aim at how you can." Becoming a hardware store was not the answer, he says: "Chain stores have that niche all figured out."

Well... perhaps metal? Hurricane Katrina was a pretty good convincer. "Metal roofs held up better," he says. "We started buying metal roofing, but it's difficult to order up: the time frame," which involves cooling your (or- worse-your customer's) heels with a lengthy wait, and buying pieces and patches. "If you're short, or they're defective, it's your fault."

So, Phillips decided to fabricate its own. "We rented at first, but the operation did so well that, three years ago, we built a multi-million dollar facility, invested in equipment and materials (and it took a huge investment in order to be competitive). It took us from a three-step to a two-step operation,"

eliminating the middle-man mark-up. About 60% of Phillips' business is commercial, and those clients love this new roofing option. Plus, diversification into specialty arenas, such as this, keeps Phillips in the black. Bill says, "After Katrina, people moved in with their special businesses -cabinets, rebar, sheeting-hoping to make money. So, if you didn't diversify, that would leave a dealer only with lumber and plywood"-and a room in the poorhouse.

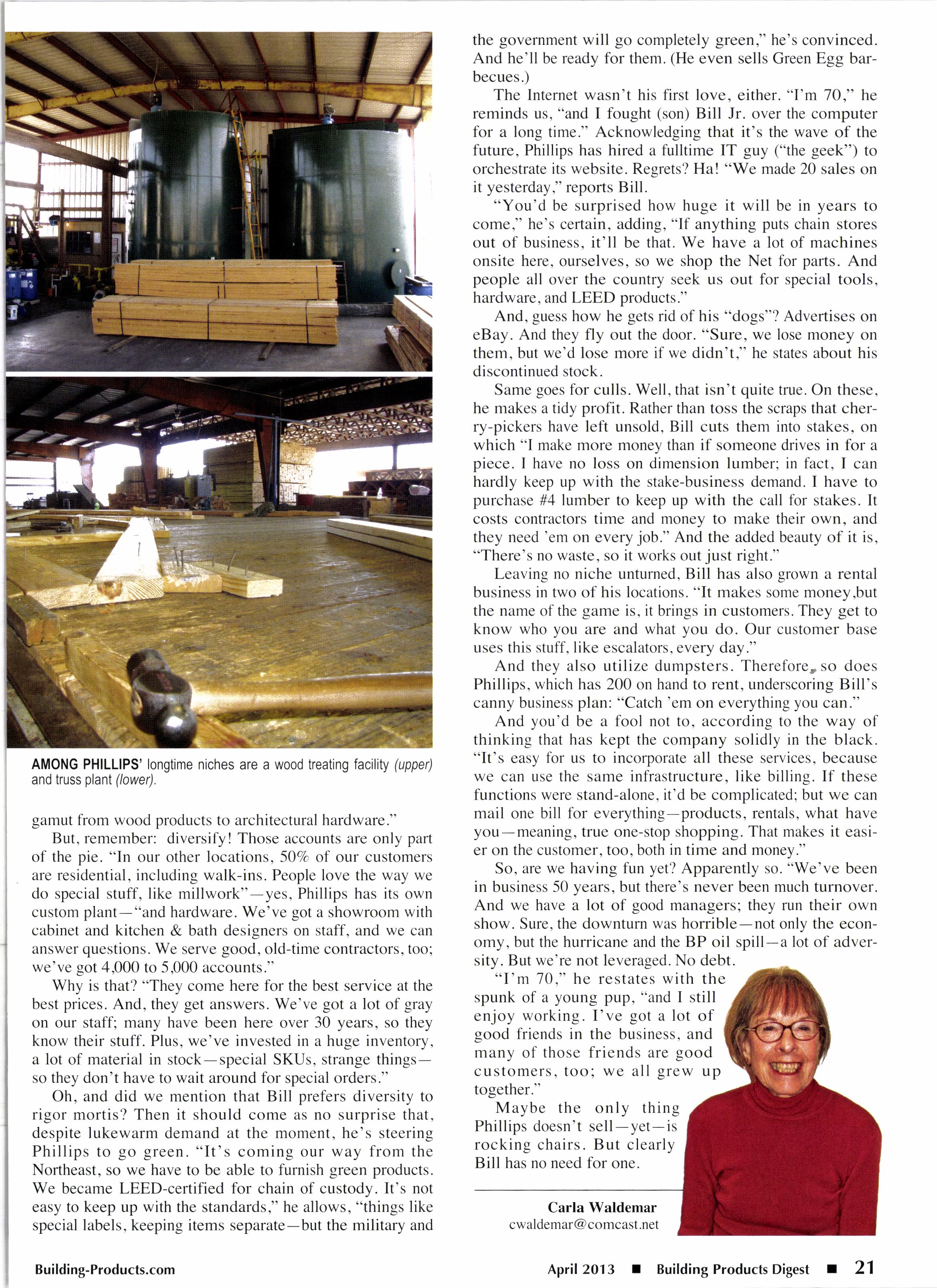

"So," adds Bill in the understatement of the month, "we decided to sell a lot of stuff." Phillips already had been making trusses for over 15 years and continued to push that niche. ("We sell 30 to 40 a year, both residential and commercial"). The next move was to add a wood treatment plant to capture the market for outdoor lumber, either for decks or-even bigger-"huge offshore stuff, like poles."

Architectural hardware seemed a logical further diversification, and has proved a lucrative one. On its lS-acre campus, Phillips also sports a an interior door plant, exterior door plant, and commercial steel door operation, as well as a commercial hardware outlet-think fire-rated doors, washroom equipment. The company also welds metal frames and bends rebar.

The government loves it, and Phillips loves them right back: "We've got l0 people on staff involved in bidding. The government bids on specs, and the specs are huge. You've got to be compliant, label the doors. We handle all that. We saw a need, and we graduated. We'd had one guy working on specs; now, it's mushroomed. We have three," accounting for such projects as the new airport's bathrooms, a $l million account-and work for DuPont. With the Navel Construction Battalion located nearby, "There's a lot of sovernment work-the whole

gamut from wood products to architectural hardware."

But, remember: diversify! Those accounts are only paft of the pie. "In our other locations,50To of our customers are residential, including walk-ins. People love the way we do special stuff, like millwork"-yes, Phillips has its own custom plant-"and hardware. We've got a showroom with cabinet and kitchen & bath designers on staff, and we can answer questions. We serve good, old-time contractors, too, we've got 4,000 to 5,000 accounts."

Why is that? "They come here for the best service at the best prices. And, they get answers. We've got a lot of gray on our staff; many have been here over 30 years, so they know their stuff. Plus, we've invested in a huge inventory, a lot of material in stock-special SKUs, strange thingsso they don't have to wait around for special orders."

Oh, and did we mention that Bill prefers diversity to rigor mortis? Then it should come as no surprise that, despite lukewarm demand at the moment, he's steering Phillips to go green. "It's coming our way from the Northeast, so we have to be able to furnish green products. We became LEED-certified for chain of custody. It's not easy to keep up with the standards," he allows, "things like special labels, keeping items separate-but the military and

the govemment will go completely green," he's convinced. And he'll be ready for them. (He even sells Green Egg barbecues.)

The lnternet wasn't his first love, either. "I'm 70," he reminds us, "and I fought (son) Bill Jr. over the computer for a long time." Acknowledging that it's the wave of the future, Phillips has hired a fulltime IT guy ("the geek") to orchestrate its website. Regrets? Ha! "We made 20 sales on it yesterday," reports Bill.

"You'd be surprised how huge it will be in years to come," he's certain, adding, "If anything puts chain stores out of business, it'll be that. We have a lot of machines onsite here, ourselves, so we shop the Net for parts. And people all over the country seek us out for special tools, hardware, and LEED products."

And, guess how he gets rid of his "dogs"? Advertises on eBay. And they fly out the door. "Sure, we lose money on them, but we'd lose more if we didn't," he states about his discontinued stock.

Same goes for culls. Well, that isn't quite true. On these, he makes a tidy profit. Rather than toss the scraps that cherry-pickers have left unsold, Bill cuts them into stakes, on which "I make more money than if someone drives in for a piece. I have no loss on dimension lumber; in fact, I can hardly keep up with the stake-business demand. I have to purchase #4 lumber to keep up with the call for stakes. It costs contractors time and money to make their own, and they need 'em on every job." And the added beauty of it is, "There's no waste, so it works out just right."

Leaving no niche unturned, Bill has also grown a rental business in two of his locations. "It makes some money,but the name of the game is, it brings in customers. They get to know who you are and what you do. Our customer base uses this stuff, like escalators, every day."

And they also utilize dumpsters. Therefore,so does Phillips, which has 200 on hand to rent, underscoring Bill's canny business plan: "Catch 'em on everything you can."

And you'd be a fool not to, according to the way of thinking that has kept the company solidly in the black. "It's easy for us to incolporate all these services, because we can use the same infrastructure, like billing. If these functions were stand-alone, it'd be complicated; but we can mail one bill for everything-products, rentals, what have you-meaning, true one-stop shopping. That makes it easier on the customer, too, both in time and money."

So, are we having fun yet? Apparently so. "We've been in business 50 years, but there's never been much turnover. And we have a lot of good managers; they run their own show. Sure, the downturn was horrible-not only the economy, but the hurricane and the BP oil spill-a lot of adversity. But we're not leveraged. No debt.

"I'm 70," he restates with the spunk of a young pup, "and I still enjoy working. I've got a lot of good friends in the business, and many of those friends are good customers, too; we all grew up together."

Maybe the only thing Phillips doesn't sell-yet-is rocking chairs. But clearly Bill has no need for one

Carla Waldemar cwaldemar@comcast.net AMONG PHfLLIPS' longtime niches are a wood treating facility (upper) and truss planl (lower).

f, ncurveoes (Greek mathematician,2ST B.C.-212 B.C.) la,said. "Give me a place to stand and a lever and I can move the world."

Why do two salespeople working in identical markets, with identical inventories, and identical customers, have different results? If it is a question of talent, desire or hard work, the answer is obvious.

I refer to a sales mystery. I am talking about the seller who is talented, does work hard, and ftas sales skills. Sometimes the salesperson performing at a lower level actually works harder. What explains his lower production?

Why does he consistently perform at a lower pace than his partner who is not more personable, smarter and does not work harder? What is the differentiator? Archimedes may have the answer.

We were raised on hard work. We were taught that hard work and education overcome all. True to a point. Education and hard work will give us an opportuni4r to live well. But hard work and education alone will not put us in the league with the master sellers and big{ime producers. Hard work and product knowledge alone are not the answer. Salespeople know this. Many "hard workers" fail in the sales business, while some (to the naked eye) easygoing salespeople are massive producers.

Often the difference is our use of leverage.

We must hustle and work hard for business. We must have a sense of urgency. A "nose for the money" is key, but hustle alone is a singular strategy and not the way of the master seller. Many salespeople chase orders instead of building a business. They chase the hottest markets and products. This is an energy game. Nothing is built. We can make a living with this strategy if we are talented, but we are not building a base business (fulcrum). Five years in the future we will still be "hustling" for orders, while our partner who stayed with a certain customer group or product, while they hustled, built a base business (fulcrum) which they can now leverage to produce twice as much with (seemingly) the same or less effort.

Relationships/Customers. We are making 807o of our income from fewer than 10 relationships. Take a long, hard, analytical look at your top 10 relationships and begin to build your leverage with them.

Simple yet profound analysis: Time Spent vs. Income Received. Measure exactly how much time you spend with each customer and how much income you receive from that relationship. It seems simple, but it will reveal where we are most leveraging our time and skills.

You are in a competitive market. Customers are doing business with you because you are doing something right; you are bringing them a competitive advantage. Now sell/ leverage that advantage to others.

When we prospect we will look for similar customers. We will start stronger/faster with them because we know we can help them. We have proof. We are already helping others just like them. This creates positive momentum while adding to our fulcrum. Sales is a competitive business. We will always have to hustle, so let's build a leverage base for ourselves as we compete!

Products/Services. What am I currently selling? Who else can I sell it to? Which other industries will use this product? Our expertise in this product will create the same positive momentum our relationship leverage does for us with the same long-term benefits of building our lever.

Geography. "Better a fool in his own town than a wise man away from home" goes the Spanish proverb. Freight, logistics and just knowing a guy who can get that done is a leverage advantage built by the seller who learns his territory like the cracks on his fingers.

Market Position. A friend to everyone is a friend to no one. We cannot be the best at everything. Figure out your position and be the best at that. The producer, retailer, re-manner, distributor and office wholesaler all have positions (fulcrum points) in the market. The master seller in any organiza- , tion understands their individual as well as their company's strengths and sells to and builds on them.

Hard work and leverage.

When we combine our daily sales energy with Archimedes' principle of leverage, we will move the world!

James Olsen Reality Sales Training (so3\ 544-3572 james @ realitysalestraining .com"l prefer the decking, but it's

decks more so ihon ortificiol motdiiEls; Peop$ hove on inherent conneclion wilh wood.I build decks thot ore used, not iusl n ,. odmired thr.pugh o window.

"l use Wol Outdooro wood. frmibs 6; decoy; my

I don't worry clients ond I 'ion of 'ood."

PEglin r Decks tm. cA ffi.*,, Winner of including Norlh Americon Deck

Willow River Lumber & Hardware, Moose Lake, Mn., has been acquired by employee Joel Ribich and his wife, Tori, from Art and Shelly Underhill, owners for the last 22 years.

Causeway Lumber Go. witt relocate its S.7-acre showroom in Fort Lauderdale, Fl., after selling the site to an auto dealership.

Wickford Lumber, N. Kingston, N.H., closed Feb. 25 after 37 years.

Koopman Lumber paid $1.62 million for a former auto dealership in Sharon, Ma., to open its 6th retail store.

Al Lorenzi Building Products shuttered its Bridgeport, Pa., facility Feb. 15, but will continue serving the area from its Washington, Pa., yard.

Marvin's Building Materials & Home Centers olans a June opening for a new 30,000-sq. ft. store with attached garden center and drivethru lumberyard in Lewisburg, Tn.

Carroll Construction Supply, Council Bluffs, la., was damaged by a March 3 electrical fire, but was saved from destruction by the warehouse's sprinkler system.

Gillard's True Value Hardware & Rental, Carmi, ll., held a grand opening celebration March 15-16 (Jeff and Melissa Gillard, owners).

Middleton Lumber Supply, Middleton, N.H., suffered $250,000 in damage to its machinery building and sawdust facility in an early-morning fire March 19.

C&L Hardw?I€ has been opened by Dean and Mila Curtis in Mead Lumber's former facility in Ashland, Ne. (Larry Lemon, store mgr.).

Chandler Ace Hardw?r€ witl open a 10,000-sq, ft. store with 5,000sq. ft. warehouse in Chandler, Tx.

United Supply True Value, Lakefield, Mn., is adding a sister store in Fairmont, Mn.

Ace Hardw?Io, Wimberley, Tx., was destroyed by a Feb. 22 fire. Losses are estimated at $3 million.

Deltic Timber, El Dorado, Ar., is making improvements to the auto-grading and planer line at its mill in Waldo, Ar.

Advanced Building Products, Cincinnati, Oh., was renamed SMART Building Supply.

Mid-Am Building Supply's s DCs are now distributing Integrity Composites' Duralife deckin! ani railing in Arkansas, lllinois, Indiana, lowa, Kansas, Kentucky, Missouri, Nebraska and Oklahoma.

Parksite, Batavia, ll., now distributes 316 stainless steel color-matched decking screws from Camo Fasteners and Abaco Decking from its branch in Connecticut.

Parksite also has exoanded distribution of Apex sidlng to its branches in 0hio, New York, New Jersey, and lllinois; RDI railings to branches in Maryland, New York, and lllinois, and Progressive Foam products to Maryland and North Carolina.

Perennial Wood, Binghamton, N.Y., now offers its 1x4 deck boards with a mahogany finish.

Kemper System America, West Seneca, N.Y., has named Allied Building Products, East Rutherford, N.J., ils 2012 Distributor of the Year for its commitment to specifiers of roofing, surfacing and waterproofing systems.

ClarkDietrick Building Systems, West Chester, Oh., now offers its interior steel framing products through On Genter Software's Quick Bid estimating software.

Osmose comoleted its acouisition of the wood oreservatives business of New ZealanO's Mattersmiths Holdinqs Ltd. and Mattersmiths Technologies Ltd.

Boral Roofing, lrvine, Ca., secured exclusive rights to promote Nansulate Crystal roof coating.

Anniversaries: Kroner's True Value Hardware, LaCrosse, wi., 145th Southern Lumber & Treating, Jacksonville, Fl., 25th

Associated Lumber has closed its two locations in Wichita and Neodesha, Ks., and gone out of business. Contents were to be sold at auction and the buildings were leased.

"It's just the economy and bad fortunes," said Ron Hill, who had owned the business with his wife. Doris. for 25 years.

A March 3 fire damaged one building and destroyed thousands of board feet of lumber at Burt Lumber. Washington, Ga.

"It may knock us back a day or two, and we're going to have to do some drying off-site, but we can have it all repaired in a few weeks," coowner Barry Golsby said after the fire. "It'll be a challenge, but we'll be back up to full production soon."

The fire started in a kiln building where l2-ft.-high stacks of cut pine lumber had been drying for about 33 hours of a 36-hour cycle. The building's sprinkler system went off, but it couldn't stop the fire.

Goolsby said that half of the 105,000 bd. ft. of lumber in the kiln was destroyed.

Odor-free fl eece+infued -l 0'xl I' pat& kit ldealftr trinsnen sfr$S

sffied ard rrEftal. rbt putdr kit indudrs Ehe$ stepby-step insilrrctimr Rainproof in ahryt

I-encxu. Ks.-bascd Wcstlakc Harclwllrc's nc\\'cst locution. in Bolii ar. Mo.. is thc I'irst o1'thc chlin's 8(r storcs to lclrturc a nc\\' l)fototr'1tc layout ancl clcsign.

..Wc'lc spcnt thc 1'ritst vcur stutll-'-

ing and analyzing cvcrvtl.rius \\ c know ahou( olll cLlstonrcrs: thc ltrod tucts thcy ncccl . thcil nrinclsct u hcn thcy shop. ancl thc hclp thcl''rc look ing lirr." saicl c.c.o. Ccorgc Srnith. "Thc Bolivar storc is thc cr,rlnrinaliort

of that effbrt."

The nen l7.8:15-sq. ft. building. opened March I has garage-st1'lc doors and skylights lirr rnorc nalullrl light. a woocl uncl nrctal l'acadc. polishccl concrctc I'loors, urrd an attachctl gu'clcn ccntcr - a l'irst lirr Wcstlukc.

Tu o longtinrc Michigun lunrbcr'ralcls Willianrs [-unrbcr. Nilcs. lrrtl \'lcckhol' l-unrbcr. Cascaclc. Mi. urc u incling clovn n opcrati<lns.

Willianrs Lunrbcr is shutting dor.r'rr after I 30 )'ears. C)wner Brucc Willianrs saicl he solcl four tinrcs us nruch ;lrocluct before the recession. but nou' the stclre had been strugglirrg fbr eight 1'ears.

"We have to sell everything. includin-e the real estate, the builclin-e." he saicl. "lt's .just sad when vou havc a homctown busincss closc."

Mcckhof will closc at thc cncl ol' Junc. Tl.rc l-ivc acrcs it sits on havc lullcucly bccn sold.

Gcrritt Mcckhol' bought thc busincss. lornrcrly known ns Marsnran Lurnbcr'. in l9-57. (lurrcnt owncrs lrc his sons. Ecl and (ialy. who run it with thc hclp ol'Ed's two s()ns.

Thc varcl- onc ol'thc l'cw rcrraining l'arnily-owncd lunrbcr- conrpanics in Wcst Michigan not al'l'iliatcd with l nltional ll'anchisc or chain spccial izccl in supplying ccclar, I'ir, and lcdr',ood lumbc| to local contractors.

Ecl Mee khof said thc cornpanv lost busincss in rcccnt ycars as loyal cLrs tomcrs wcnt out of business and ncw' contractors wcrc lurcd to big-box .ompelilrrrs. "Tht'1 'r'c loo pricc cottscic'rus." hc said. "Now, wc'rc thcir trim store instead of their lurnbcr' storc. and there's.just not enough Volume to keep open."

Thc storc is closing at the bcginning ol- sumrncr so Ed's sons can l'incl uolk dttlittl thr' eottstlueli()rt \el\()r'1.

A tractor-tnrilcr I'illccl with synlhct rc clccking nratcrial and parkcd insirlc a largc lurnbcr warchousc at MiclStutc Lunrbcr. BrlnchbLrrg. N..1 caught l'irc March | |

Thc tluck was dcs(roycd ancl a ncurbv of'f icc sul'lcrcd watcr clantagc 1'ronr sprinklcrs.

Al'tcr cuttin-c a lock on the back gatc and forcin-c. thcir way into thc uarchousc. fircfightcrs faced srloky. blackout conditions. yct doused thc blaze quickll' with fbam.

ls your existing wood treating facitity reaching its output capacity? ls the existing equipment in need of reptacement? Are you tooking to buitd a new wood treating facitity?

We work with peopte that have THIS KIND OF PROBLEi ls this you?

We provide busy companies one source to handle any of these issues.

Acompany who wanted to buitd a new cross-tie treating facitiU to irrcrease their ouput capacity came to us.

Wb worked with

A new company, The Pau Lope Canaveral, Fl., has been formed to Lope brand of ip6 decking.

Company LLC, Cape re-introduce the Pau

Pau Lope was among the first hardwood decking imported into the U.S., trademarked in 1984 and active into the early 2000s, but dormant for the last several years. The Pau Lope Company aims to return the Pau Lope brand "better and stronger than ever." Some regional distributution has already been established, with some geographies remaining available.

The Pau Lope Company has aligned with selected Brazilian sawmill producers, secured a long-term direct importer, and refreshed the grade and quality to be consistent with the Pau Lope's heritage of excellence.

Starting May l, Sherwood Lumber's North Bergen, N.J., distribution facility will join Holtsville, N.Y., and Palmer, Ma., in exclusively supplying Georgia-Pacific engineered lumber products to the Noftheast.

"Previously, we were shipping our GP ELP across the Northeast from the New England-based Prime facility and then we added it to our offerings in Long Island, which still left us lacking proximity to Pennsylvania and New Jersey," said sales manager Jason Rastad. "Now, with North Bergen, we will have the Northeast completely covered, which will improve delivery times for all of our customers."

The delivery times for GP ELP will be improved, especially for Pennsylvania and the Hudson River Valley. The New York metro area will also benefit from being supplied from the North Bergen facility, freeing up the Holtsville and Prime facilities to more efficiently cover New England.

"It's really a sort of domino effect," said Rastad. "The New Jersey facility's growth will not only affect the customers it directly serves, but also those that the other facilities serve."

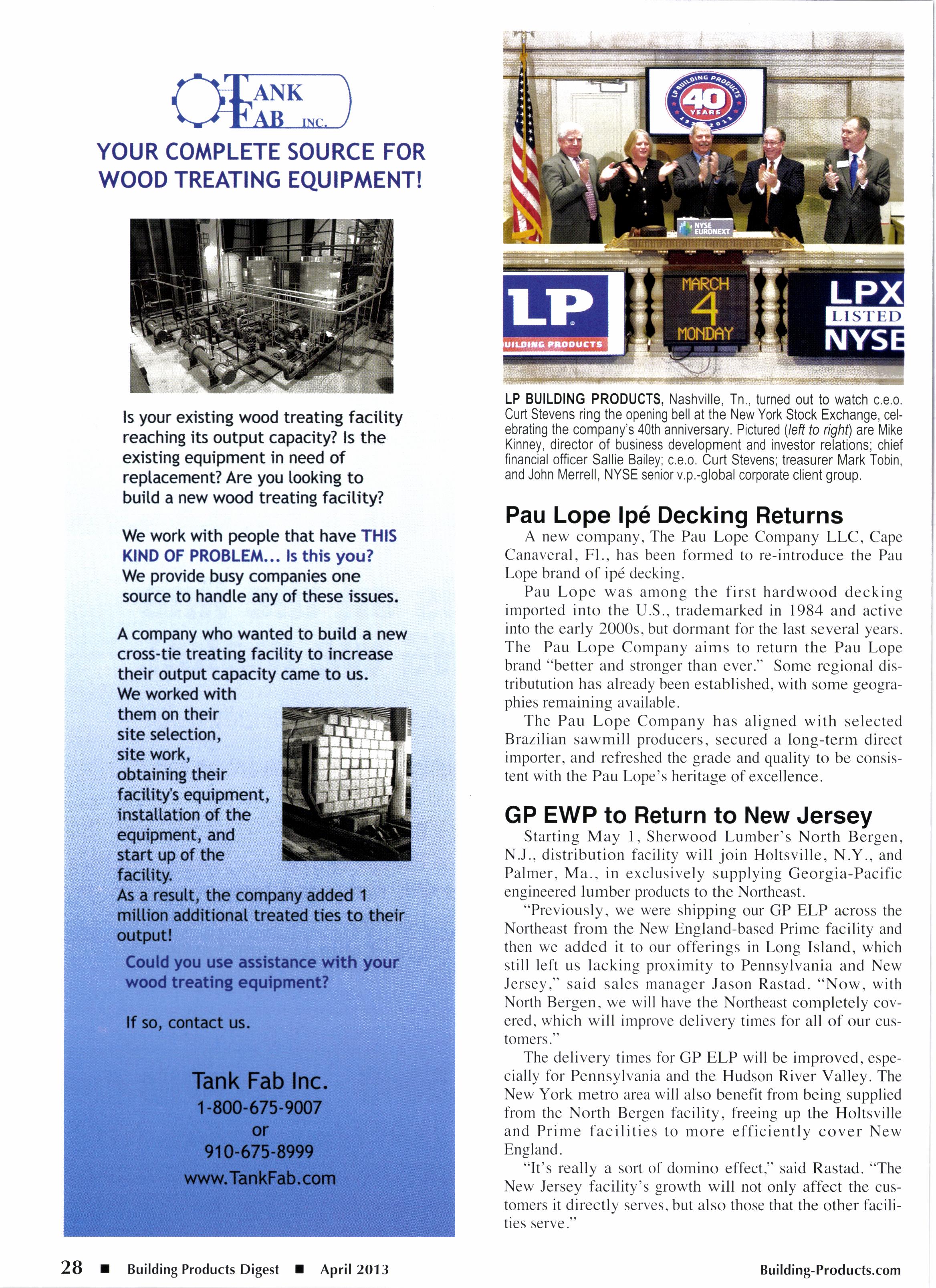

LP BUILDING PRODUCTS, Nashville, Tn., turned out to watch c.e.o. Curt Stevens ring the opening bell at the New York Stock Exchange, celebrating the company's 40th anniversary. Pictured (left to right) are Mike Kinney, director of business development and investor relations; chief financial officer Sallie Bailey; c.e.o. Curt Stevens; treasurer Mark Tobin, and John Menell, NYSE senior v.p.-global corporate client group.VnLur s Pi'liron^^aNcgt

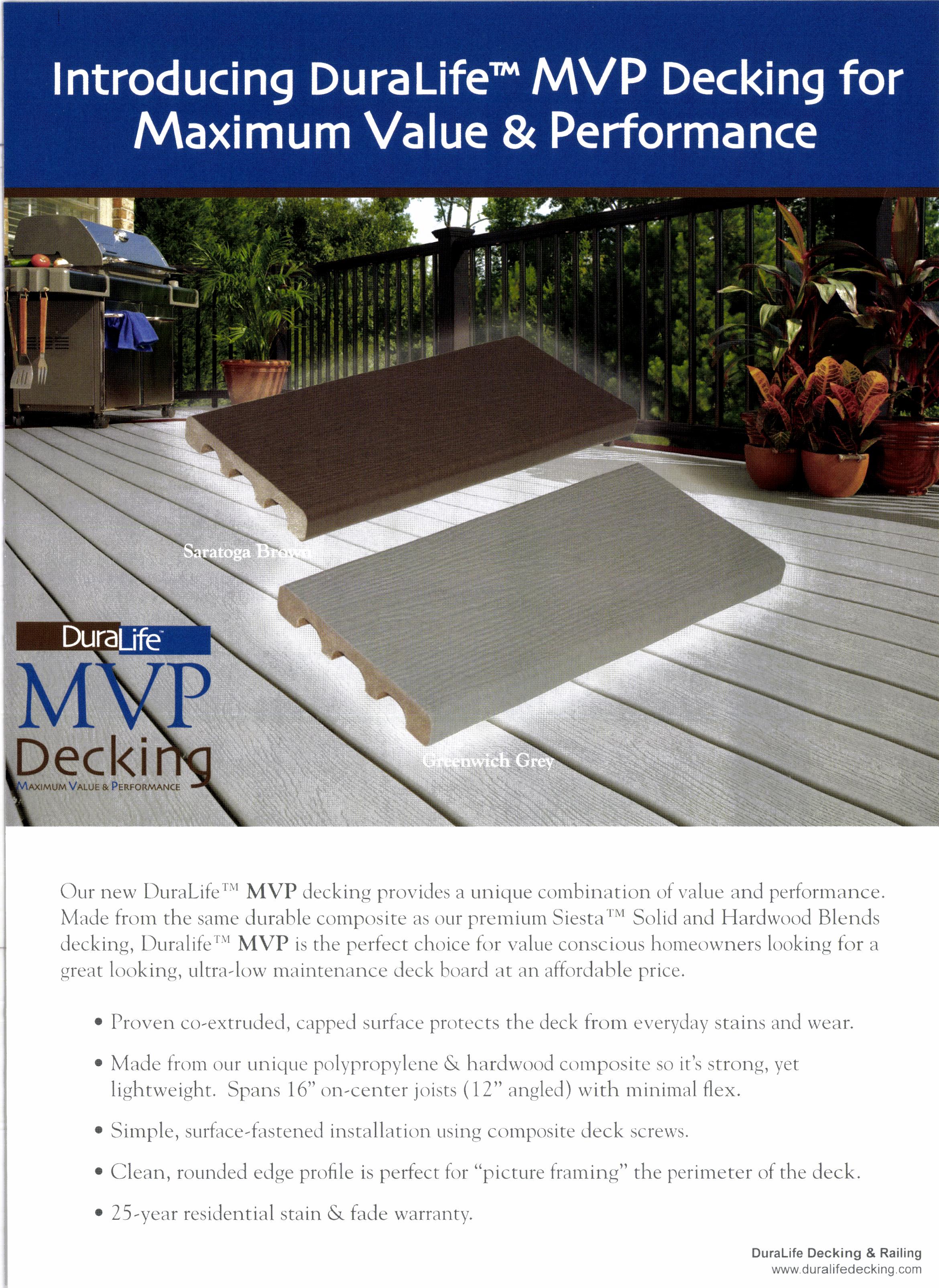

( ')L r t' r t','ii \1,r.1., ll.r)nt llr.'.;ltnl:.lLlt'lll,l.'rr)lnir(r\ni ,l\,rt.l l,t(,lulLtlr :ir:1 trr"r 3,,lr,ilrn,l Il:rr.lrr,,,rti i:lli n.i. '1r.'r.k!tr:, l)Lt:-,r]rir' 'L \lVl) I'tltt'1"'t'll'i'l i ltlir,:r,'l,,t-r,tltir'lr'ir'r;i;ti'. lt,'iit.',r\\lttl-. l,',rli11,' 1,11:'rL';ll l,,irkitt!, ltlt;tr'lti\\'illiririli'lr,nri.r.'.it,. j, l',,'ri', 1 .tf ,rl: rrlilr, l:rl-"ir"'1,rtrr'.

e I)t'.r\'r"tlt rr)-r'\1ttt,lrri,,.,tl.i'.,. I :.rii-l,ir.t. |'i-i;lr'i-1lltt ,ltr:L it-r:t:il ,.',r't-\,,i;t,, .l;tltr.,itt.] \i.r',rl'.

* \1tt,,1t il{rltt1)lti illit,. 1Lr, 1..,lr, 1't'|1:r, 1,'tl'' & lt;tlt'l tr,rrrrl i,,t}}'r'\,-itr.'-,,rl. '11'r)t}!,t. \'L'1 lt:lltrlt'iCil1. )p;i11. l(-r"L,1r-rr'ttlL't.;.,t'.r 'll..: "''tt,':1,'.1) irlfil tttilliltlitl t1.::.

* !tlttrli',:lti'i,rr.r,''ilt.tr'ltl,l iri.i,rli ,i , , :r\i':, r. Irrl .r:iir ,lr'rL rr l'r\\..

t (-lr':rtl, 1',rttlr,],',..1 .'.'li:,'1.t',ilrlc il 1','1..i i,,t I ,.1,t:.'1i;ritiitr:" lltr'1'',t'tttl,-'tt't r,ltlti'tir:tk.

e ] J'r.i'.rr r.'.iLli,r'rlirrI rl;riri ii trrrl.' \\,ln,iru\.

Iowa Lumber, Marshalltown, Ia., will close this month due to the economy. after I 4 years of business

"It has been a general slowdown the last three-to-four years, and we noticed it getting worse last November and it hasn't changed," said Bob Jacobson. who has owned the store

with his wife, Ruth, since 1999.

Jacobson joined the company in 1992, after he was laid-off by another yard. He was hired to help run the business because then-owner Scott Pfaltzgraff was undergoing cancer treatment.

"He didn't make it through the cancer treatments. and his wife didn't

want the business. so she offered it to us." he said.

Global power tool demand is forecast to increase 4.67o annually through 2016 to $28.1 billion, bolstered by the rebound in U.S. home construction, reports a new Freedonia Group study.

China has become increasingly important over the last decade, as both the dominant producer and a big user of power tools. From 200 I to 20 I l, production in the country more than doubled, while demand quadrupled.

India will increase at the fastest rate of any country, growing more than l07o per year through 2016.

Cordless electric tools will enjoy the most robust growth, rising 8.37o annually to 2016. Cordless tools will continue to replace plug-in models, as technological improvements have shortened the power advantage that corded tools once held.

Electric power tools account for most power tool demand, since they are used by both professionals and consumers in most applications. Pro demand, which led to 70Vo of 2011's worldwide power tool sales, will outpace consumer demand through 2016.

Regional builders and remodelers in 2013 are looking tor 24/7 access to their LBM dealers. Respond with BuilderLink.

r Online Estimating and Ordering. Customers can build their own estimates with current pricing, locate product information and place orders.

r Build Loyalty and Relationships. BuilderLink's Relationship tool allows salespeople to collaborate and stay connected with customers who are working onlrne.

I Demonstrate Leadership. Over 30,000 contractors currently use BuilderLink. Show you're listening to your customers and be the f irsl rn your market lo deliver. Get

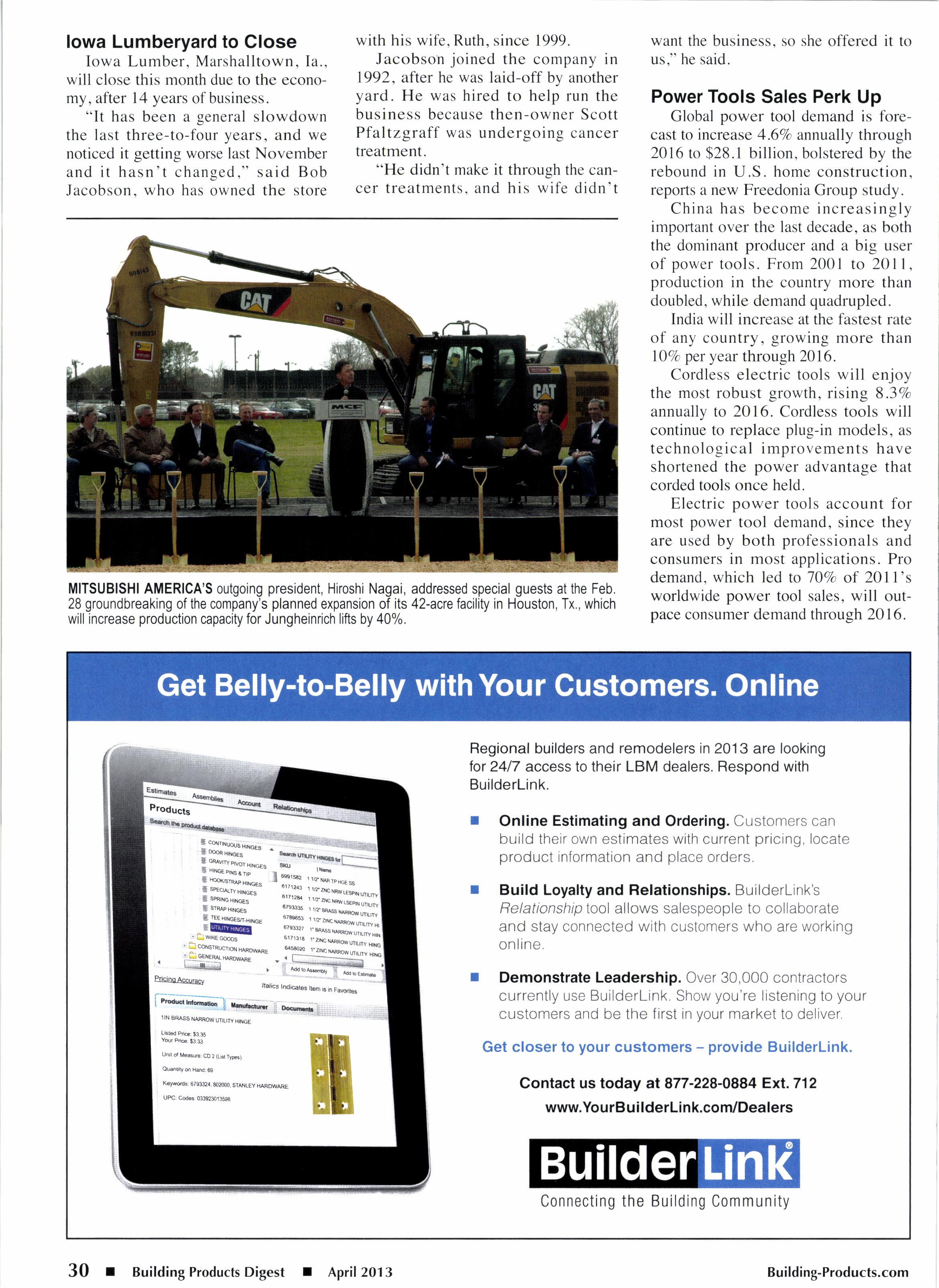

MITSUBISHI AMERICA'S outgoing president, Hiroshi Nagai, addressed special guests at the Feb. 28 groundbreaking of the company's planned expansion of its 42-acre facility in Houston, Tx., which will increase production capacity for Jungheinrich lifts by 40%.

The U.S. Lumber Coalition has expressed concern about log export policy changes in British Columbia, which took effect on March 1. Of particular concern is an increase in the "fee in lieu of domestic manufacture" applied to many log exports, which would be increased to20Vo.

According to the coalition, tightening log export restrictions will allow coastal B.C. mills to pay even further below-market prices for logs.

"In effect. B.C. has increased the implicit subsidy from log export restrictions for B.C. Coast lumber mills," said Luke Brochu, chairman of

the coalition and president of Pleasant River Lumber, Dover-Foxcroft, Me. "This gives B.C. Coast lumber mills a greater advantage in the U.S. market, at the expense of U.S. mills that pay full market price for their inputs."

Logs harvested from public or private lands in B.C. must be advertised to local mills before they can be exported. If a local mill offers to pay the prevailing domestic log pricewhich can be much lower than the export price-export is prohibited. Even when export is permitted, a "fee in lieu of domestic manufacture" is assessed on logs harvested from public and some private land. This fee can be

much greater than the price B.C. charges to log on public land.

The U.S. coalition contends the increase in the "fee in lieu" is inconsistent with the 2006 U.S.-Canada Softwood Lumber Agreement, in which the U.S. forfeited its right to invoke U.S. unfair trade laws on Canadian softwoods, in return for Canada imposing taxes and quotas on Canadian exports when lumber prices fall below certain levels.

Larsen Ace Hardware, Canton. Ct.. submitted plans to remodel and expand to nearly 10,000 sq. ft. Changes include updating the exterior, doubling the number of cash registers to four, installing a single-line system, andmost importantlymoving the customer service desk front and center. "When you walk in the door, you're going to get service," said Fred Larsen Sr. "We're not sreeting; we're helping."

Application: DBsrATroN

Produced by: CertainTeed Gypsum

Price:Free

Platforms: iPad, Android

A new mobile app simulates the acoustical performance of SilentFX noise-reducing gypsum board, allowing architects and builders to actually hear the acoustical differences of wall systems in real-world applications.

The dBstation acoustic simulator features a catalogue where residential and commercial systems can be compared under equivalent settings and a scenario app to demonstrate how specific noises (ringing telephones in an office, watching TV at home, etc.) can impact interior spaces.

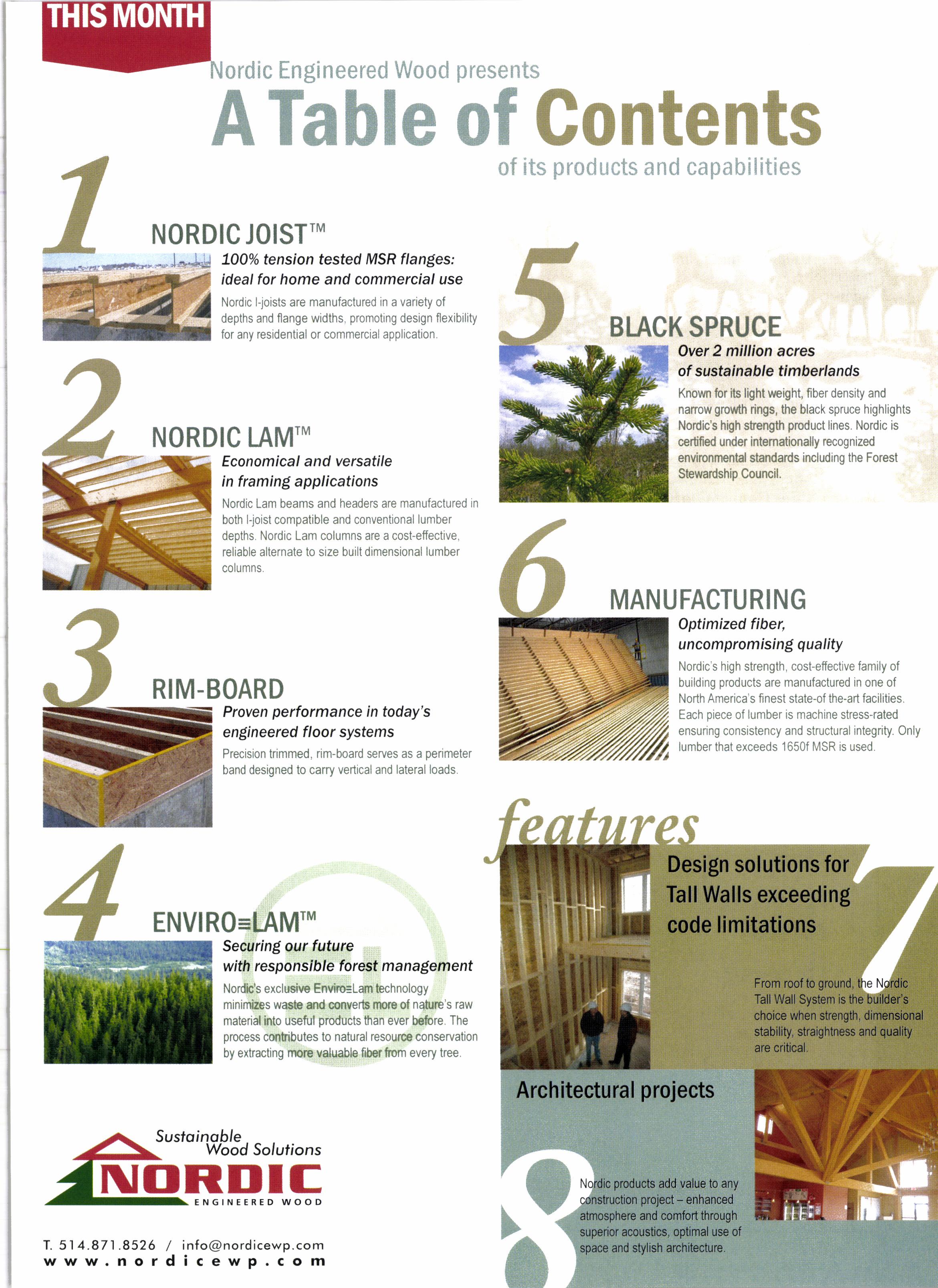

700%o tension tested MSR flanges: ideal for home and commercial use

Nordic l-joists are manufactured in a variety of depths and flange widths, promoting design flexibility for anv residential or commercaal aoolication.

Nordic Lam beams and headers are manufactured in both l-joist compatible and conventional lumber depths. Nordic Lam columns are a cosfeffective. reliable alternate to size built dimensional lumber columns.

Proven performance in today's engineered floor systems

Precrsion trimmed, rim-board serves as a perimeter band designed to carry vertical and lateral loads.

Sewrin(,our future

with responslbl e forest m a n a geme nt Nordds excluefir Endmila$bchnology

minirnbes wasb grd eonverb tmrc ol nafi€'s raw materid into uselirl products han ever bobre The process ccltibutes to natural resour0o conservalion by extracting ffie},.4$S,$hiom every tree.

Ovar2mllllon acres of 9{,,st6rnabre tl mberta nds

Known br ils light weight, fiber density and nanow gmwth rings, he black spruce highlights Nordic's high shength product lines. Nordic is cedified under intemationally recognized environmental standards includino the Forest $bwadship Council.

Nordic s high strength, costefiective family of building products are manutactured in one of North America's finest state-of the-ad tacilities. Each piece of lumber is machine stress+ated ensunng consistency and structural integrity. Only lumber that exceeds 1 650f MSR is used.

Lumberman's Association of Texas booked Danielle DiMartino, a financial analyst at the Federal Reserve Bank of Dallas, to present a lunchtime talk during its April 18-20 annual convention at Westin La Cantera. San Antonio. Tx.

The association's President's Gala will honor outgoing president Matt Mullin, Alamo Lumber, and president-elect John Jones, Cassity Jones Lumber, Longview, Tx.

A Run for the Troops to the Wounded Warrior Project begins the last day. Participants will be treated to a complimentary breakfast afterwards.

The first day will be a bass fishing tournament and a trap shoot, followed by a steak and chop fry at Holiday Shores Resort. A golf tournament at Bear Valley Golf Course is the next day, followed by an awards luncheon.

June l4 will be the Kansas Sunflower Shootout at Highlands Golf & Country Club, Hutchison, Ks.

Ohio Construction Suppliers Association will host an April 9-11 Safety Congress & Expo at Greater Columbus Convention Center, Columbus, Oh.

Squires had served since 2003 as the chief counsel for public affairs and director of regulatory affairs for the National Marine Manufacturers Association, where she directed its regulatory, legal and trade programs.

Northeastern Retail Lumber Association associates will gather at the association's headquarters in Rensselear, N.Y., for the annual spring leadership meeting.

Southern Forest Products Association will host its annual meeting & expo June 3-7 at Omni Hotel at CNN Center. Atlanta. Ga.

Material Dealers Association is sponsoring a Mid-Atlantic Young Dealers roundtable May l-2, leading into the annual Mid-Atlantic Trade Show May 2 at Garden State Convention Center. Somerset, N.J.

Mid-America Lumbermens Association will host its annual Swing-into-Spring May 2-3 in Lake of the Ozarks. Mo.

April l7-18 will be an installed sales roundtable in Lavonia, Ga., while an April 18 webinar will cover scams and how to avoid them.

A tour of Boise Cascade's distribution center in Marion, Oh., has been scheduled for May 2.

A management roundtable will be held on May 15-17 in Peoria,Il.

International Wood Products Association has hired Cindy Squires as its new executive v.p., succeeding Brent McClendon.

The event will open with a wood industry night at Turner Field, viewing a game between the Atlanta Braves and the Pittsburgh Pirates.

The next day will conclude with a reception at the Georgia Aquarium, with cocktails and hors d'oeuvres from Wolfgang Puck, a behind-thescenes tour of aquarium operations, and free admission to the aquarium.

American Architectural Manufacturers Association hosts its national summer conference June 912 in Rosemont, Il.

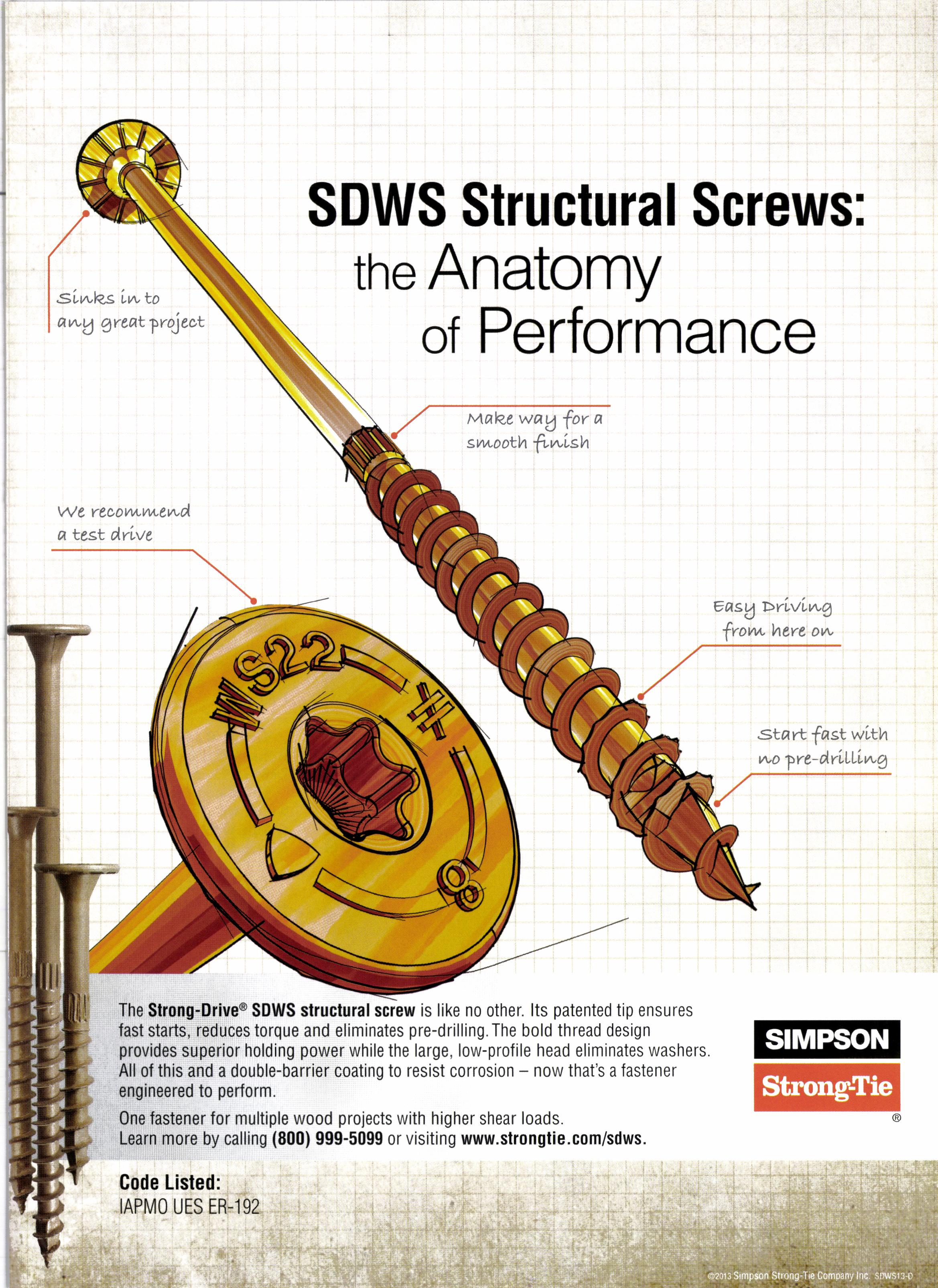

The $[ong-Drlveo SDWS structural sciew is like no other. lts patented tip ensures fast starts, reduces torque and eliminates pre-drilling.The bold thread design ,.provld0sl:$tlpefior'h0lding pourer while the large, low-profile head eliminates washers, -,Alt ol tfris,tnd a double-barrier coating to resist corrosion - now that's a fastener grnineered to oerform.

for multiple wood projects with higher shear loads. q:by calling (800) 999-5099 or visiting www.strongtie.con/sdws.

John Byard Swift Jr., 90, coowner of Swift Lumber, Atmore, Al., died Feb. 23 in Atmore.

During World War II, he intemrpted his studies at Georgia Tech to serve in the Navy as a ship commander in the Asia Theater.

Upon completion of a degree in electrical engineering, he worked briefly for Louisville Power & Light. In 1949, he began managing Swift Hunter Lumber, Atmore, and in 1954 formed Swift Lumber with his cousin.

Robin Swift. He also served as chairman of the board of governors for the Southern Pine Inspection Bureau.

Rodman Austin (6Rodtt Mcleod. 69, president, c.e.o. and owner of Espy Lumber Co., Hilton Head Island, S.C., died of cancer March 14 in Savannah, Ga.

After receiving a degree in electrical engineering from Massachusetts Institute of Technology and an MBA

from Harvard Business School, he purchased Espy Lumber from the estate of founder Wesley Espy in t9t9.

He also served as a director and chairman of Southern Building Materials Association and board member of Roper Brothers Lumber, Petersburg, Va.

Lewis Albert Canter, 87, owner of several LBM businesses in North Carolina, died Feb. l4 in Greensboro, N.C.

Mr. Canter opened Laminated Plastics, Greensboro, in 1963 and Canterboard, Thomasville, in 1980, before launching Canter Sales, Greensboro.

William "Willie" Gelman, 9l, founder of Gelman Lumber Co.. Trenton. N.J.. died March 10.

A highly decorated military colonel, he served in World War II and the Korean War.

Thomas R. "Tom" Black.71. retired c.e.o. and president of Black Lumber, Bloomington, In., died March 2 in Bloomington.

He joined the family business in 1963, after graduating from Indiana University.

Grant R. Benson, 84, owner of Benson's Lumber & Hardware, Derry, N.H., died Feb.23 in Deny. He joined the family businesswhich was founded in 1913-after serving with the Air Force during the Korean War.

Lanny Fulford, 61, former owner and operator of Edwardsport Lumber Co., Edwardsport, In., died March l2 in Ten Mile, Tn.

Lloyd M. Hendrix, 87, longtime manager of L.L. Hendrix Lumber Co., Lubbock, Tx., died March 14 in Lubbock.

After serving with the U.S. Army in Europe during World War II, he obtained a degree in agricultural economics from Texas Tech in 1949.

John Harvey "J.H." Gass, 85, retired foreman for J.B. Cassetty Lumber Co., Red Boiling Springs, Tn., died March 13 in Celina, Tn.

j-'t unnrNr FoRECASTs for 20 | 3 show continued growth in \-rthe housins market. Last vear. new home sales hit a two-year trign while builder .onfid.n.. ratings rose to prerecession levels on the National Home Builders/ Wells Fargo Housing Market Index.

As the economy continues to improve, merchants should prepare for greater stress on recession-tightened inventory, staff, operations and resources. Credit screenings, approvals and reactive extensions, as well as billing, collections and providing quality customer service, can significantly and swiftly drain working capital. By outsourcing your trade credit needs to a trusted financial services company, you can shore up your cash flow and unintentional risk and focus on expanding your business for success.

As a building supply dealer amidst a housing market upswing, you are going to need cash flow to invest in your top-line drivers-things like additional outside sales reps and value-added services. Attempting to go it alone could potentially stunt growth. By selecting a trade credit supplier that specializes in the building supply industry, and shares the same values, you will gain a partner with valuable experience, expertise, tools and intuition.

Most importantly, a trade credit supplier can offer an attractive alternative to the kind of financing that increases your risk portfolio and incurs unnecessary debt (e.g., pursuing the increasingly elusive bank loan). Unlike banks, which make money from interest and hidden fees, the right

financial partner will align incentives completely with your business and develop a customized program to suit your and your customers' specific needs.

Third-party trade credit professionals are risk-reducers. They understand the importance of reliable cash flow, and their objective is to provide it on your terms-guaranteed when you want it and need it the most. With the ability to offer higher approval rates, access to larger credit lines, and flexible terms, credit providers increase sales while minimizing dealer risks.

A quality credit provider will treat your customers the way you do, and replace the headaches of unguaranteed accounts receivable with consistent, predictable payments for all customer purchases. As a result, you are free to invest in rebuilding your services, stock and personnel in preparation for growth.

If cash flow is like water, you shouldn't wait until you're thirsty to drink. Think ahead. Cash flow supports several key components to expansion and growth, such as your sales team and the additional inventory you'll need to keep pace with larger orders and greater demand. Take advantage of early payment discounts, and be wary of the self-funded cash gap. On average, dealers are expected to pay suppliers every 30 days, but receive payment from clients every 48 days. Over the course of a five-month period, you could end up funding your own expenses 5OVo of the time. These gaps are unnecessary and dangerous to your business.

Of course, the thought of letting someone else manage a financial program that you have controlled for so long can be a frightening one, particularly after an extended period of downsizing efforts and looming economic uncertainty. But it doesn't have to be. In fact, outsourcing trade credit should have the opposite etfbct. Pick a partner with the same incentive to treat your customers the way you doone that grows when your customers spend more.

Take comfort in the knowledge that you are not alone. Ask your associations and trusted partners who they use. The sooner you alleviate the burden of an in-house trade credit program, the sooner you will gain greater control to move forward with financial confidence and peace of mind.

Tim Weston has been named v.p. at Tri-State Lumber/Homan Industries, Fulton, Ms.

Brad Wanzenberg, ex-Deerfield Builders Supply, is now dealer territory mgr. for North Florida at Dixie Plywood & Lumber, Orlando, Fl. Kristin Russell, exSnavely Forest Products, is now inside sales/product mgr. at DixiePly's Tampa, Fl., DC.

Rod Shipton, ex-84 Lumber, is new to builder sales at Carter Lumber, Frederick, Md.

Chance Murphy, ex-Allied Building Products, is new to inside sales at Feldman Lumber Co., Brooklyn, N.Y.

Dave Hadden, ex-Nisbet Brower, is now general mgr. at Carter Lumber. Cincinnati. Oh.

Stephen Rykard, ex-Great Southern Wood Preserving. is new to Trussway, Moultrie, Ga., as director of strategic sourcing.

Jeff Conway, ex-Idaho Timber, has been named regional purchasing & sales mgr. for Sterling Lumber, Conway, Ar.

Brett Kerr is a new mass merchant representative at Snavely Forest Products, Pittsburgh, Pa.

Patrick Kenney is new to inside sales at Botello Lumber Co., Mashpee, Ma.

Larry Toney, senior v.p.-purchasing, Foxworth-Galbraith Lumber, Dallas. Tx.. retired at the end of March, after 48 years. Burt Solt, senior commodity buyer, retired after 43 years.

Ken Klimek. ex-Builders FirstSource, has been named general mgr. of Capitol Components & Millwork. Elkwood. Va.

Bob Mistick is new to sales at American Lumber, Walden, N.Y.

Chip Penny, ex-Marjam Supply, has joined Coastal Forest Products, Bedford. N.H.. in outside sales in Long Island, N.Y.

Rich Kniatt, ex-Builders FirstSource, has rejoined the outside sales team at Tart Lumber Co., Sterling, Va.

J.R. Ferguson has joined Handy Hardware Wholesale. Houston. Tx., as director of operations.

Casimiro Rangel has been promoted

to chief information officer for Building Products Inc., Watertown, S.D.

Jon Ingersoll, ex-Crawford Hardwoods, has opened a Cambridge Springs, Pa., sales & purchasing office for Peladeau Lumber Co., Laval, P.Q.

Wayne Lee, ex-Cardinal Hardwood & Tile, is a new business development representative and technical advisor at Middle Tennessee Lumber Co.. Burns. Tn.

Mark Gluhosky is now general mgr. of Huttig Building Products, Newington, Ct.

Dina Fuller has joined the sales team at McShan Lumber, McShan, Al.

Phil Catalano is a new outsidc sales rep at Home Acres Building Supply, Grand Rapids, Mi.

Corey McKinney has joined Do it Best Corp., Fort Wayne, In., as project leader-lumber & building materials.

Bill Hunt is now production supervisor at Jeld-Wen's door plant in Temple, Tx.

Minas Apelian, ex-J.M. Huber, has been appointed v.p. of research & development for CertainTeed Co.p., Valley Forge, Pa.

Lara Lee has been appointed senior v.p.-customer experience design for Lowe's Cos., Mooresville, N.C.

Rich Mauer is new to Versatex Trimboard, Pittsburgh, Pa., as sales mgr. for the Southeast, based in Greenville, S.C. Darren Kennedy, ex-Kennedy Home Center, is a market development specialist for western N.Y. and Ont., based in Rochester, N.Y.

Kevin Washall, ex-Jim Waters Corp., has joined Manufacturers Reserve Supply,Irvington, N.J., as sales territory mgr. for Hudson Valley, N.Y.

Jim Lake has been promoted to c.e.o. and president at Ainsworth Lumber. Vancouver. B.C.

Greg Palese has been named v.p. of marketing for Klein Tool, Lincolnshire, Il

Ken Barina has been promoted to president of Mitsubishi Caterpillar Forklift America, Houston, Tx., succeeding Hiroshi Nagai, who returns to the parent company in Japan. Kent Eudy is now executive v.p. of sales & marketing.

Sandy Johnson, Stanley Security Solutions, was elected president of the Builders Hardware Manufacturers Association. New lst v.p. is Scott James, CompX; 2nd v.p. Dan Picard, Sargent Mfg., and 3rd v.p. Ed Pruitt, Bommer Industries.

Rod N. Reel is organizing the annual fishing outing for Mungus-Fungus Forest Products, Climax, Nv., report co-owners Hugh Mungus and Freddy Fungus.

owner Josh Hicks is negotiating to build a two-story, 6,000-sq. ft. hardware store in Hickman, Ne.

?lS relocated its Auburn, Ma., showroom to a larger site in Worcester, Ma.

Hartje Lumber, LaValle, Wi., was named Small Business of the Year by the Sauk County Development Corp.

Baum Lumber, Chester, 0h., won Stihl's 2012Top Gun award for store performance, was recognized as a Gold-certified servicing dealer, and reached Elite dealership status.

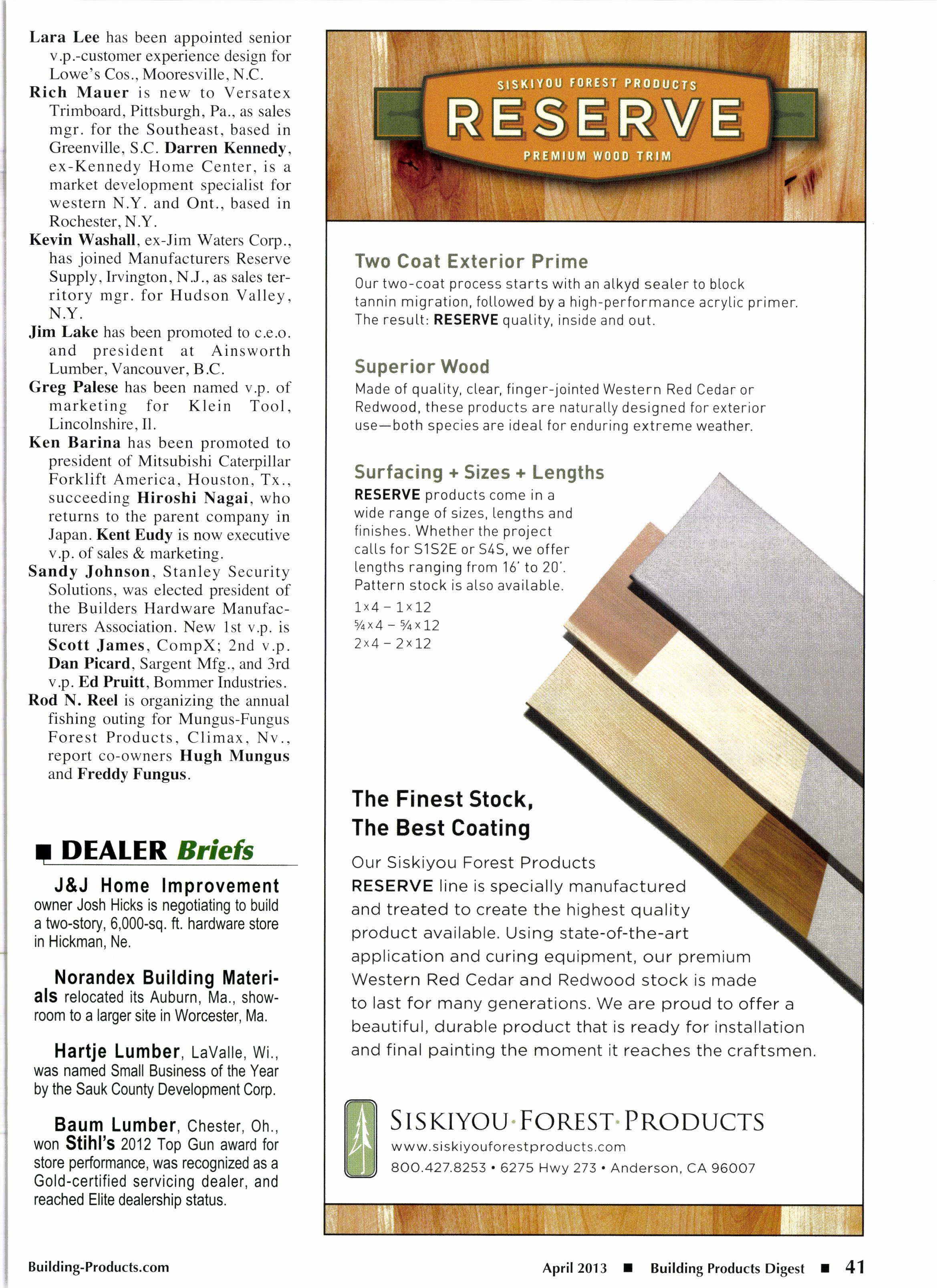

Two Coat Exterior Prime

0ur two-coat process starts with an atkyd seater to block tannin migration, followed by a high-performance acrylic primer. The result: RESERVE qual.ity, inside and out.

Made of quatity, ctear, finger-jointed Western Red Cedar or Redwood, these products are naturatl.y designed for exterior use*both species are ideaI for enduring extreme weather.

RESERVE oroducts come in a wide range of sizes, [engths and finishes. Whether the project catls for S1S2E or 54S. we offer tengths ranging from 16' to 20'. Pattern stock is atso avaitabte, 1x4 - 1x]-,2 s/ax4 - s/ax12 2x4 - 2x12

Our Siskiyou Forest Products RESERVE line is specially manufactured and treated to create the highest quality product available. Using state-of-the-art application and curing equipment, our premium Western Red Cedar and Redwood stock is made to last for many generations. We are proud to offer a beautiful, durable product that is ready for installation and final painting the moment it reaches the craftsmen.

\Zoun sUPPLIER just informed you |. that your shipment is going to be two weeks late. You've just had a call from your son, who's going to take the day off for the fifth time this month. You've just found out that the computer system in the office has broken down again.

Are you stressed yet? What do you do? How do you react? Do you know that how you respond to these circumstances could either shorten or lengthen your life? Do you know that you have a choice about how you react? Do you know what to do for stress management?