being green

I\lnd'lc Engineered,Wood was built on the id@ of providin$ the best ssstainahle solutions to the building industry

ourwooo rrDer. vvnrle rt's not easy to process underuullzecl fiber, Nordic transforms treetips into the key component of its glued laminated product line. envtno = LAM'" is featured in Nordic Lam'" Beams, Columns, TallWallStuds, the Nl-90x l-Joist Series, and Nordic's X-Lam cross-laminated timber panels-our latest innovation.

It means investing in the future

In addition to our ongoing commitment to sustainable forestry, Nordic continues to invest in advanced manufacturing processes to keep on the cutting edge of technology and product development.

Kiln-dried upper-grade siding

tuxury interior moldings, fascia and trim

B, Heart B, Clear and Clear All Heart grades

Vertical grain available in all upper grrades

r lxZ tluu lxl2; ZxZ ttuu 2xl2

I Green and air seasoned decking up to 20'lengths

I Timbers up to 12" x L2" x 24'

x Rail-car service and fleet trucking available

We can match virtually any pattern ever made - call us today!

BPD

BuililinA Prnducls lligest

Special Features

9 MlNncrmrnr Trps Crvr Youn Luvarn Rncrs RrcurRn CHrcr-Ups

10 Frnrum Srony

ls NnNorrcHNoLocY rHr Nrxr FnoNt rN Wooo PnrsenvrNc?

1 2 Comprnnvr lNrrrLrcENcE Groncrn Drnrrns Rrvs Up ExpRNsroN PraNs

1 6 Mnsrrnrnc LeAornsnrp CHecrrrsr ro ENsunr You'nr REcervrNc CnrRr CoRcHrNc

22 Sprcral Focus

APA oN ENctNrrrco Wooo-

1 4-Pncr Sprcr,qr SecrroN, lNcr-uorNc EWP Fonrcnsr, APA Uponru, AovnNcro FnnulNc TrcHNrqurs, Cunveo Cruuus, Snrsry LrRoens

In Every lssue

6 Tonlly Rnroor'r

14 OLsrN oN Snlrs

15 Cnrrru Rrretrr.rc

20 Movrns & Sunxrns

36 Nrw Pnooucrs

40 Fnl,rLv BusrNrss

Bnrnxrnc lNousrnv Nrws & Inousrny PHoro Downlolos

B urr-orNc-PnoDUCTS.coM (FoLLow LrNr roR PHoros)

BPD: Drcrrnl Vrnsrolr

The (guilty) pleasures of traveling

f, s I wrs JUSr ABour to leave for vacation, I read an ad we have running in our classi.Cl,fied section about a "Road Warrior" and realized just how much I, too, enjoy traveling, and how much I could not do without it as part of my life. Whether for business or pleasure, I love to travel.I love the stimulation, the new sites and sounds, hotel rooms (sans cockroaches), different food, and seeing how other people live. I love meeting customers and hearing what they think and how they think.

The thought of landing in a far-off place where I do not understand a word, where there are no signs in English, roads with no lanes, and general chaos doesn't scare me, it stimulates me. The excitement of packing my bag and the expectation as I leave the house is still there after all these years. The one rule I created for myself many years ago was that if you have to do it, you better enjoy it!

In my prior business life, I would spend 4O7o to 5OVo of my days traveling, and it became a way of life. A different day, a different city is an opportunity to leam something new. It may be in the U.S. or Canada, India, Hong Kong, or... This tifestyle is not for everyone, but it has helped to define me. Yes, we've seen Willy Loman in Death of a Salesman and, more recently, George Clooney in Up in the Air, both sad in many ways (although I would not mind being more like George...). When I share my upcoming travel plans, many tell me that they don't know how I do it, or that they would not want to do it. But I enjoy nothing more than heading off with my suitcase, even when it is a 4 a.m. start.

From my first international travel as part of a school trip at the age of 12 to France and Switzerland, I became fascinated with local life domestic and international. When I left school, I went into sales because I knew it would get me traveling, enjoying new experiences, and unchaining me from a desk. In those days, I thought nothing of driving 300 miles a day, day after day. Since 1968, my life has been constantly on the road both for business and pleasure. Those off-site sales meetings and management meetings were my guilty pleasure-having fun and enjoying the camaraderie. I even count much of my business travel as personal travel as I enjoy one as much as the other. I may have worked hard all day, but I love to walk and enjoy a new city at night by visiting galleries, cafes, and finding ways to blend in with locals.

Sure, I've had catastrophes (my business trip to India in the 1990s is worth a movie in its own right), but I love to land somewhere and try to find my way and start a new adventure. I have been sick, landed in a hospital, had my money stolen, lost my luggage, and at times have been desperate to retum to my own bed, but I still have the travel bug. Whether here in the U.S. or abroad, I have gathered experiences I would not trade for anything: watching the sun rise and set in distant cities, eating in a cafe overlooking an illuminated monument, turning the corner and seeing a piece of history thousands of years old and wondering how they could possibly build those small hilltop villages or giant pyramids. I have met the most fascinating people at all ends of the spectrum, from business celebrities to film stars to politicians (okay, that part I'm stretching) to simple folk on their pilgrimage or trying to eke out a living. I have stayed in some crummy hotels and in some of the best. I have eaten poorly and have eaten well. My planes has been hit by lightning and wind shear, and I have had one or two scary moments, but still give me a ticket and I am off.

And, yes, I love those frequent flier miles and the perks that go with them. I find great pleasure in trying to find ways to buck the system, finding the best deals, getting an upgrade or a free breakfast. And, yes, I don't enjoy being scrunched up on a commuterjet, or being stranded for hours or days in an airport, but these types of stories give me memories to talk about for years.

In business I learn far more getting out of the office than I ever could sitting in the office. While I like hearing how good our publications are, I also appreciate learning from disappointed customers and field reps what we could do better. Face to face gives no one a place to hide. I use my travels to probably meet 50Vo of my future customers and to save a few customers, too!

So as I head out-only to return by the time you read this-I hope you will get a chance to travel over the summer with your families and enjoy travel the way my family does. I have learned that travel lets me escape from the normal crazy. And nothing can be better. Bon voyage!

BPII

Bullding Ploducts lligesr

www.bu ilding-products.com

A publication of Cutler Publishing 4500 Campus Dr., Ste.480, Newport Beach, CA 92660

Publisher Alan 0akes ajoakes@aol.com

Publisher Emeritus David Cutler

Director of Editorial & Production

David Koenig dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Gontributing Editors

Carla Waldemar, James Olsen, Jay Tompt

Advertising Sales Manager Chuck Casey ccasey@building-products.com

Administration Director/Secretary Marie Oakes mfpoakes@aol.com

Circulation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www. building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com.

CLASSIFIED MARKETPLACE

David Koenig

Phone (949) 852-1 990 F ax 949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather Kellv

Phone (949) 852-1990 Fax 949-852:0231 hkelly@building-products.com

or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A.: One yeat (12 issues), $24 Two years, $39 Three years, $54 FOREIGN (Per year, paid in advance in US funds): Surface-Canada or Mexico, $49 Other countries, $65 Air rates also available.

SINGLE COPIES $4 + s5;Op,nn BACK TSSUES $5 + shipping

Alan Oakes, Publisher ajoakes@aol.comBUlLDll'lG PRODUCTS DIGEST is published monthly at 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-1872, (949) 852-1990, Fax 949-852-0231, www.buildingproducts.com, by Cutler Publishing, Inc. (a California Corporation). lt is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright@2O12 by Cutler Publishing, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permisslon. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it.

'From Tree to Finished Product

Give your lumber racks regular check-ups

f) ecx sAFEry should be a primary concern at all lum-llbervards and home center warehouses.

FBS Group, Chicago, Il., which provides rack protection products and conducts rack safety inspections, suggests regularly reviewing your racking for signs of damage or deterioration.

Inspections should include:

Look for signs that the rack's structural integrity has been compromised. Lumber racks, like any other structures, depend on their form for their structural integrity. Once their form is compromised, their load-carrying capacity decreases. And once a rack member deteriorates, it may no longer carry its rated load.

Most rack damage occurs gradually. It's easy to spot and recognize the need to repair, say, a frame leg that has been struck so forcefully that it's now bent to the point it's no longer touching the ground.

Less obvious, but perhaps equally in need of repair, is the frame or beam that has been banged into repeatedly for months or years and appears "merely" dented. It may still support some loads, but possibly not the maximum design load.

. Make sure the racks are being used as intended. Are loads properly positioned? Are loads exceeding the designed weight? Is the rack designed to accommodate that type of product?

In a lumberyard or warehouse, information as to how much a load weighs is not always immediately available. One way to detect overloading is by measuring the amount of beam deflection present. All load beams will and are allowed to deflect, or sag, a certain amount. According to the Rack Manufacturers Institute, a roll-formed beam has an allowable deflection of the length of the beam divided by 180 (i.e., a 10-ft. beam would have an allowable deflection of two-thirds of an inch). If the deflection is greater, the beam has been overloaded.

. Identify any loose, missing or damaged fasteners. Forklift impact can shear off anchor bolts or disengage load locks, snap locks, and other locking devices designed to prevent beam end plates from being lifted up and sepa-

rating from the slots in the column.

. Ensure accessories are not missing or damaged. Accessories such as wall ties. cross bars. wire mesh decks. pallet stops, corner guards, and other impact protectors are usually installed to protect the rack structure or enhance safety.

Pay special attention to any modifications to the original rack structure. The primary areas of concern are non-engineered additions that introduce loads to or change the original structural design of the rack system. In particular, welding anything to a rack, even if the addition seems to be of inconsequential weight, can drastically affect the member it is welded to. And, the weld itself can also be a problem.

If columns have been repaired, make sure the kits were installed properly. FBS inspectors have observed column repair kits installed without a splice cuff, with all or parts of the backer column removed, and lacking the specified weld per the manufacturers specifications.

ls nanotechnologythe next front in wood preserving?

L.TorrNc rHE PoPULARTTy of wood I \ pressure treated with micronized wood preservatives, researchers are experimenting with even smaller "nanotech" particles, to further prevent leaching.

A team of Michigan Technological University scientists is preparing to reveal their findings, following a fiveyear study of nanotechnology in wood preservation.

"It's a new method that uses nanoparticles to deliver preservatives

into the lumber," said chemistry professor Patricia Heiden. "In our experiments, it reduced the leaching of biocidesby 90Vo;'

The nanoparticles are tiny spheres of gelatin or chitosan (a material found in the shells of shrimp and other shellfish) chemically modified to surround the fungicide tebuconazole. The little spheres require no special handling.

"You just pressure-treat the wood in the usual wav." Heiden said. "We

used tebuconazole as an organic preservative-donated by Lanxess Corp., Pittsburgh, Pa.-and copper oxide nanoparticles we made ourselves as an inorganic preservative. Our main goal was to study how we could reduce the leaching."

The initial tests show that nanoparticle-treated wood is just as resistant to rot and insects as conventionally treated lumber. The researchers have now moved their tests from the confines of MTU to the warm, wet weather of Hawaii. "Most of the work is already done, but we are testing a few other things out of curiosity," Heiden said.

The research is funded by the U.S. Environmental Protection Agency, under the program name

"Environmentally Benign

Manufacturing & Processing 2005GO-AI." The preliminary study was completed last year and one group of findings has been published so far, with several more in the offing.

The researchers had completed similar studies before, using petroleum-based components and dilute conditions. "We used gelatin and chitosan (biopolymers) and methyl methacrylate (MMA, which is petroleum based and is used to make plexiglass),"

Heiden explained. "We made the nanoparticle in water by a simple combination of gelatin or chitosan with methyl methacrylate, an initiator,

and the tebuconazole biocide and heated for a few hours. We then isolated the nanoparticles or diluted to the appropriate volume to treat the wood. We found that these nanoparticles reduced the leaching by 90Vo or so, and were effective in soil jar studies. We have treated field stakes to make sure we could penetrate wood completely, but did not do field studres.

MTU scientists initially tried to use some commercial copper-based preservative systems, according to Heiden, "but they were highly formulated and we did not always know with what, so we made a simple 'inhouse' ACQ system and also a simple copper oxide nanoparticle, made in a solution method rather than by any sort of a mechanical reduction system of copper carbonate." She found the results "rather surprising," saying that the nature of the copper oxide surfaces influenced how much the nanoparticles leached and promising to share further information in the coming months.

Here's what she can divulge: "The organic nanoparticles definitely reduce leaching of organic biocide, and the reduction is substantial compared to a straight solution or emulsion treatment of organic biocide, even without the use of a surfactant. In our work, we found that the use of a chitosan shell did not reduce the leaching of copper oxide nanoparticles."

John Lounsbury, managing editor and co-founder of Global Economic Intersection, speculates that the new technology could result in preservatives that are both more effective and more affordable. Current preservatives for residential use, says Lounsbury, "are much more expensive than the older most common compound used before 2004 (CCA), so manufacturers try to use less of it. That leads to at least 12 different grades of treated wood product today and makes choosing the correct wood for each application a process that requires greater care."

So while he optimistically has his "fingers crossed" about the viability of nanotechnology, questions remain: "How expensive is the nanotech process?" he asks. "Does the reduced leaching mean that much less of the expensive treatment chemicals can be used? And, can nanotech processing mean that more toxic chemicals that have been phased out-or never

Downsize? Heck, llo. Expand!

fnv SHonr is making lemonade. j When the economy turned sour a few years back, the president/c.e.o. of Tifton, Ga.-based Short & Paulk Supply Co. didn't waste time in wringing hands.

"Sure, it's bad," he acknowledged, then moved on. "Focus on things you can cor,trol. Find something that works. We're aggressively trying to grow, looking for opportunities."

He professes: "When things slow down, you've got two choices. You can considerably downsize your business or you can find sales to keep it going. Study the numbers, the demographics..."

And then, open a new store.

May 4 was the grand opening of the new Dawson. Ga.. location, after

S&P purchased and remodeled a former hardware store as its fourth location. It joins Albany (where Jay picked up a closed yard in 2010), Sylvester (launched by his father in 1985), and headquarters in Tifton, as well as a truss plant and door manufacturing plant.

Now well into its third generation-Jay joined his dad and grandfather in 1989 after graduating from the U. of Georgia and bought his dad out in 2008-the operation originated in l94l with three employees. Back then, its phone number was 97. Today Jay Short V signs paychecks for 55 coworkers and the phone line (10 digits) takes a back seat to the Internet.

But what hasn't changed is the philosophy instilled by Jay's grandfather,

which Jay recites: "Sell good products, unite with good, accountable suppliers, and treat folks right. If you do that, they'll come back. We focus on imparting that to our employeesto do what we say we'll do, at a competitive price and with top-notch staff. If there's a problem, it's an opportunity for us to solve it."

Each location serves a slightly different market. Dawson, set amid farmers' fields, is unique in canying feed and seed. Albany's larger footprint of rental units sends S&P a hunk of commercial repair business. Sylvester, a small, rural town, carries 'Just about everything, including coffeemakers," laughs Jay, while Tipton focuses on the new home and remodelins slice of the pie.

Meanwhile, the truss plant, established in the early '70s in Tifton, supplies all four stores, plus other independent dealers beyond a radius that deflects competition. The door operation, relaunched with new equipment in 2008, "is mainly for our customers," Jay explains-"a low-volume shop that gives us control over the quality of the work and a quicker turn-around time. Before, when we dealt with special orders, a six-panel door, with one available hardware style and one style of moulding, took two to five days to reach us. Now, it's a day-and-a-half turnaround, with six different frames, four or five different hardware options, and 10 to 15 door panels. There are some cost savings, too. And, with the trusses, we can offer one-stop shopping.

"We've always concentrated on new construction, and, 10 years ago, it was going at a really good clip. Now, we're going after other avenues: institutions - schools, hospitals; commercial, like the apartment market; the remodeler, and the d-i-y folks. And each of our locations has something a little different to offer."

Add it all up, and you arrive at S&P's potential customer base, which Jay defines as "anyone alive and breathing with a good credit record."

To go after the remodeler, S&P has reset its inventories

and showrooms. (They've recently changed to affiliate with Orgill.) "To keep moving positively, we market to new homeowners, not only builders," Jay says. "We want to get our name out to young couples, to have them think of our store first-have an opportunity to show them new products and prove we have quality people. If we get the opportunity to take on a little project, do that little repair-if we take care of that now, do the job right, then we'll build a customer. And five years down the road, when things have turned around and they build a house, they'll think of us."

And how to reach these 20-somethings? Social media, duh! Sure, TV and print ads, but more to the point, YouTube videos, Facebook and Twitter messages, blogs, web offers and instruction. "I do a lot of the marketing myself," says Jay, who appears on talk shows and You Tube features, "but I've got a l4-year-old marketing manager who's very good with computers." Happens to be his son, Jackson.

"Our philosophy hasn't changed, but technology helps us do it better-for instance, inventory control and dispatching," Jay continues. "It makes us more efficient, but still in tune with my grandfather's ideals: Make sure you greet people, stay on top of them. We have a crew in the front of the store for the retail trade, and salesmen in the back office to assist builders. We sell the same commodities as everybody else, but the difference is, we do what we say we'Il do. We really, really focus on service. Plus, we just joined LMC, whose buying power allows us to offer better pricing."

What about the touted green market? Jay Short prefers to take a practical approach. Rather than jumping on the bandwagon of hype, he opts to offer selected services S&P calls Living Smart. "I find so much conflicting information, so much uncertainty and 'greenwashing."'Thus, he's chosen the middle road, aka "helping the customer live better"-light bulbs, air filters. "You might not replace all your windows, but there's weatherstripping, insulation" and the 40-gallon challenge he spotlights on talk shows.

The new Dawson store fits the conservation mode. "The existing store had a lot of opportunity to it. It's in a growing area we already serve, 20 miles from Albany. It could be the feeder store down the road-location, size, everything. What we did is, open it as a pick-up yard, with a pick-up truck. If it sells a roofing job, they'll get a delivery from Albany. But it can also save builders from running 20 miles for a couple of 2x4s. At our grand opening," he chuckles, "we didn't cut a ribbon. That's for jewelry stores. We cut through a l1-7l8-in. joist with a chainsaw!"

In these trying times, efficiencies have kicked in all across the board. "We're working at I 10, l20Vo, and we all change hats every 30 minutes," he laughs (sort o0. "You learn how to do with a lot less."

The results from the new marketing push are in: "One-third of last year's business came from clients we didn't even have three years ago. You try to grow, but very carefully. And," he underscores," we're growing!"

Carla Waldemar THIRD-GENEMTION owner Jay Short V is flanked by sons J.P. Vl (/efr), a high school senior, and Jackson fight),his 14-year-old marketing guru.Proper care and feeding of your sales force

,, W il:"""x'JiJ xyi ;:f :::xl""lJi." f ?l:,}Kffi I sell."

I've heard a version of this statement from many managers. These same managers are disappointed in their team's results. There's an Egyptian saying: "Giving friendship to a man who is looking for love is like giving a loaf of bread to a man who is dying of thirst." Giving merely "tools" to your team is the same thing.

Salespeople need tools, yes, but what they need more than tools is attention. Your sales team cannot pay attention to itself. That's your job. Telling them what to do and walking away is not management and will not deliver the kind of results you want.

If you want extraordinary results from your team, you will have to give them extraordinary attention (and caring).

Respect or Cogs?

Some managers have the attitude (sometimes even voiced aloud): "You're lucky to have a job." If you say this to any good salesperson, you are saying "#x@Vo you" in their head and they will start to look somewhere else immediately, if not sooner. They definitely will underperform and passively or actively resist all company (and specifically your) initiatives.

"They want us to be smart enough to find new business, negotiate with crafty customers, solve claims without giving away the farm or losing the customer, and make a profit, but they don't want us to be smart enough to know when they are trying to slip one by us." This is a quote from a disgruntled salesperson who was getting jerked around on her commissions.

Salespeople are not factory workers. They are profitmaking partners in your business. If you treat them like

cogs in your wheel, you will self-select for low-performing cogs in the wheel because all self-loving salespeople (who are always the best) will leave your organization.

Treat your sales team the way you want them to treat their customers. If you want them to give their customers their all, you will have to give them your all.

Spouses & Children. Do you know anything about your team members' families? What kind of support do they get at home? Show a genuine interest. If you have a good relationship with your team member's family, you will have more (positive) influence on that salesperson.

Making your team's families feel like "part of it" will also create more loyalty. Company bowling nights, picnics, holiday parties are all easy and effective ways to bring your team together-but you must be present and active at these events. You are not an "event planner." You are a leader who makes individuals feel your presence.

Lunch. There are approximately 22 working days in each month. That's 22 lunches you can have with individual salespeople. These are not "business" lunches. This is not a review of their progress at work. Talk about everything but work-make a point of it. And talk about what your salesperson wants to talk about-just like we would with a customer. Weird, huh?

Contests. Salespeople love to compete. Go as heavy on contests as you can. Salesman of the morning, day, month, year, department. Top new salesman. Make sales teams for contests. Make teams matching your top guy with your bottom guy and on down the line to create camaraderie.

Love & Favoritism. UCLA's John Wooden struggled for years with the fact that he liked some players more than others. He didn't want to play favorites, but knew in his heart how he felt. His initial philosophy was, "I may not like them all the same, but I treat them all the same." He was still uneasy. Years later, he hit on a better philosophy: "l don't like them all the same, but I love " them all the same."

Great managers have this attitude. Who they like has nothing to do with it. They give attention, caring and love to all team members and get world-class results in return.

James Olsen Reality Sales Training (503\ 544-3572Gompl iance or leadershi p?

C'lrer.rtNc FRoM A cLsaN slate confers all sorts of bene\Jfits. For new merchants, those just starting up (a rare breed, I know), it's relatively easy to develop a green business model and brand, stock only greenest-in-class products, and forge winning customer relationships with green builders and remodelers.

For those saddled with the baggage of history, existing customer and supplier relationships, and predictable revenue streams. it's a different story. How do you green your product lines and bring your existing customers with you, while appealing to a new breed with rising green expectations?

We've been dealing with these questions in this column for the last several years. Based on personal experience, as well as observations of what has worked for others, we've drawn the conclusion that any merchant can become a green merchant and, inevitably, every merchant must. But it is a difficult journey fraught with many compromises. The recent kerfuffle over a new credit category proposed for the latest incarnation ofLEED 4 highlights one of the trickiest.

First, the kerfuffle. Without getting too bogged down in technical detail, the main issue is the proposed "Avoidance of Chemicals of Concern" credit, which aims to raise the bar on indoor air quality by eliminating certain chemicals in emitting products and that certain products include disclosure of chemicals used. In one part of the proposal it references REACH, an European Union program that monitors chemicals.

The American Coatings Association took exception in widely publicized comments it submitted to U.S. Green Building Council, arguing that compliance would hurt the market. They suggested an alternative, compliance with 2007 California Air Resources Board Suggested Control Measure. Even 61 members of Congress got involved.

There are two points to be made here. First, let's recall some recent compliance history. There were a few industry leaders who saw new CARB regulations coming in 2007, did nothing, and were forced to take back their non-compliant product from retailers' shelves and distributors' warehouses. Second, LEED does not require compliance. On the contrary, it aims to identify leadership-that's what the "L" in LEED stands for-and more to the point, it is voluntary. No manufacturer is required to make, test, or certify

products that meet LEED credits. This is an all important difference that separates compliers from leaders.

For merchants trying to create a winning, green formula, being able to identify the difference between products and manufacturers aiming for compliance, and those focused on leadership, is crucially important. Who would hire a builder or an employee whose main selling point is compliance with minimum regulated standards? Don't we all want to work with leaders who go beyond the minimum and set their own standard? Don't we want to be leaders? But the unfortunate reality is that because of longstanding channel marketing practices, with manufacturer spiffs, promotional deals, brand or industry dominance, and so on, this is also an area where compromises are inevitable. And probably, there are long-term relationships involved, too, which can make it tricky.

So, what to do? First, develop an understanding of current vendor relationships and identify the manufacturers with a commitment to continuous product improvement, innovation, and leadership. Second, start strengthening relationships with the leaders and collaborate on new programs wherever possible. Third, identify gaps and seek new greenest-in-class alternatives in every category. Fourth, engage those manufacturers in the compliance camp and encourage a change in their product development philosophy. You never know, they just might listen. Finally, develop a long term trend toward greenest-inclass products. It may be tricky to manage existing relationships and the short-term benefits they confer. but in the end. working with leaders delivers its own rewards.

Jay Tompt Managing Panner William Verde & Associates (4rs) 32t-0848 info@ williamverde.com www.williamverde.comAre you receiving great leadership coaching?

Vou KNow you ARE getting great leadership coaching

when...

l. you are in the pit of despair. Many of your basic beliefs and assumptions about your role as a leader have been challenged, and you feel like you are losing your footing. You are seriously questioning your career to date and your personal aspirations.

2.... you are really excited about the future. You don't know what the next chapter of your leadership career is going to look like, but you do know that there is no going back now. Something new and fresh awaits you.

3, you are angry, frustrated and ready to fire your coach. None ofyour expectations for great pieces of advice and insights have been met. All you get are annoying ques-

between the leader you are and the leader you can be. You've taken stock of your talents and strengths, and realized that you can have an enormous,lasting impact on your organization and the people in it. Very cool!

6. ... you are shaken by some sharp, gut-wrenching feedback. It's getting tougher to dismiss this feedback as the product of people who simply don't understand you or who have ulterior motives. What if this is actually true? What if I am wrong?

7. you are feeling energized and powerful. No longer a victim of organizational circumstances, you now have options and alternatives. You are committed to making your own choices and crafting your own leadership story. Wow!

8. ... you. personal life has become brighter. You now show up to your friends and family as a kind, caring and patient person who sees the very best in them and continually seeks out ways to serve them. You have realized that you can only be the best possible leader at work by being the best possible person at home.

9. you have stopped wasting your precious time and energy. You have embraced your emotions and become their master, not their slave. You have ceased to bum emotional energy reacting to organizational issues that you cannot influence and t people you cannot control. You have developed an inner muscle that gives you the strength to choose your own best leadership actions and reactions.

tions like, "What will happen if your performance as a leader does not change?" and even more annoying statements such as, "I think you are much better than this."

4. ... you are feeling a little sheepish. Your coach has called you on the many ways you sell yourself short or get in your own way, and you have just realized you have been blaming others in the organization for holding you back when, in reality, most of your limitations have been selfimposed.

5. you have a renewed excitement about yourself as a leader. You have just realized that there is a huge gap

I 0. ... remarkably, the people around you have changed for the betbe ever-present are now gone and have been replaced with wonderfully creative and highlyengaged teammates. Interesting !

i?1, lffi '"xx ;i:#H;nT;T

Jeld-Wen Acquiring GMI

Jeld-Wen, Klamath Falls, Or., agreed to acquire Craftmaster Manufacturing Inc., Chicago, Il. The deal is expected to close in third quarrer 2012.

CMI manufactures CraftMaster molded door facings and doors, MiraTEC exterior composite trim, and Extira exterior composite panels, with its primary production plant in Towanda, Pa.

Kuiken Expands in Gommercial

Kuiken Brothers Co., Fair Lawn, N.J., has doubled the size of its commercial division, by opening a l2-acre branch in Succasunna, N.J.

Its existing commercial subsidiary-Elmwood Supply, Garfield, N.J., acquired in 2003-is also changing its name to Kuiken Brothers.

New England Dealer Adds Location

Timberline Enterprises, Gloucester, Ma., has received planning permission to open a second location on a fouracre parcel in Newburyport, Ma.

The company serves professional builders and will operate as "a wholesale lumber business there, accompanied by incidental retail," said president Chris Costello. "We have customers in Newburyport now, and we'll be able to serve them better."

Timberline paid $1.4 million for the parcel and plans to tear down one building, preserve two others, and construct four new structures: two drive-through storage buildings, one three-sided materials storage building, and one threesided storage building that will include enclosed storage.

Falling Materials Kill Gustomer

Police have determined that the May 18 death of a 56year-old customer at East Texas Lumber, Kilgore, Tx., was accidental.

"We've been in business since 1934, and we have never had an accident of this magnitude occur," said Stacy Hartsell, the company's safety director. "Our deepest sympathies and prayers go out to the family."

Joseph Barber, 56, was killed when building materials being moved by forklift fell from a rack and onto him. The employee who was driving the lift told coworkers he did not see the customer move behind the rack. "This is the worst thing I've ever seen," said owner Ronnie Spradlin.

Cape Cod Lumber has broken ground on a new 1 36,000-sq. ft retail facility, drive-thru-lumberyard, warehouse and office near its current base in Abington, Ma.

The new complex, set to open in late January 2013, will serve as Cape Cod's headquarters and operations center.

Arrowhead Building Supply, St. Peters, Mo., is investing $3 million to add equipment, 10 jobs, and a 30,000sq. ft. warehouse at its 4-year-old slore in Stafford, Mo.

Central Network Retail Group opened a new NFL Home Center in Gautier, Ms., at the former home of Coast Building Supply.

Alpine Building & Post Supply, Reedsville, Pa., has reopened as Alp'tne Building'Supply, five months after a fire that caused $200,000 in damages.

The name change and upgrade from an 800-sq. ft. to a 2,500-sq. ft. facility allows the business to expand into a "fullblown hardware store, conhactor supply outlet."

J.M. Parker & Sons, Supply, N.C., is closing after 67 years. Owner John Morton Parker has sold the propefi to a relative, who will redevelop it as a grocery store, pharmacy and smaller hardware store.

Ace Hardw?te is opening an 11,000-sq. ft. store this summer in Canton, Md.-the 8th in the D.C. area for owners Gina Schaefer and Marc Friedman.

Haruinton True Value, Haruvinton, Ct., closed May 28 after 31. with the retirement of Jim Keith. owner since 1992.

Hahn Hardw?r€, Hartford, wi., and Harry's Hardware, Franklin, Wi., have converted from True Value to Ace.

Rocky's Ace Hardware is building 12,500-sq. ft. store #34 in Fairhaven, Ma., for a Seplember opening.

Sears Hometown Hardware, overland, Mo., has been opened by Jim Cohen, ex-Central Hardware.

Cedar Lake True Value Hardware. Cedar Lake, In., reopened following a major remodel.

Milford Lumber has reopened its newly remodeled Muir Kitchen & Bath showroom in Bedford. N.H.

Horizon Forest Products and Long Floor have opened their ninth location, a 14,000-sq. ft. wood flooring showroom in Sterling, Va. (PaulWilmer, mgr.).

Lowe's has backed out of olans to build a new store in Tarpon Springs, Fl.

Menards next year will add four stores in the Detroit market-Warren, Livonia, Belleville and Chesterfield, Mi.

The chain has also broken ground for a new 162,000-sq. ft. store on 28 acres in Garden City, Ks.

Ace Hardware Corp. this month opens a new 336,000-sq. ft. import redistribution center in Suffolk, Va.

Stock Building Supply division Bison, Houston, Tx., has launched a new website at www.bisonbuilding.com.

Conex Forest Products, Jacksonville, Fl., has closed after 23 years, with the retirement of owners Steve and Kathy Conowall.

Krumenacker Lumber Co., Carrolltown, Pa., auctioned off its assets June 23, six months after the 110-year-old mill closed due to the poor econ0my.

Keener Lumber Co., ctinton, N.C., is set to resume production in the near future after being purchased "as a going concern" by an unnamed buyer, two weeks before it was to be sold in pieces at auction.

Lewisville Wood Products' plywood mill in Lewisville, Ar., was damaged by an early morning fire June 3.

J. Bruce Barnes Lumber Co., Crozet, Va., was auctioned off June 27, after shutting down due to foreclosure.

Georgia-Pacific is reducing hours and cutting 40 of 218 jobs at its EWP plant in Thorsby, Ar., due to market conditions.

Warren Trask, Stoughton, Ma., now distributes treated olulams from Boozer Beam, Rnnistoi, At.

WoLF, York, Pa., has expanded distribution of its kitchen and bath products in Ohio and parts of Tennessee.

Metal Sales Manufacturing Corp., Louisville, Ky., is opening iti 21st metal roof/wall panel plant this summer in Sioux Falls, SD.

Nichiha USA, Rttanta, Ga., has consolidated all of its shake oroducts into the Nichiha Shake Collection.

Public Lumber Co., Detroit, tr,ti., is now distributino Hiquera Hardwoods' FSC-ceilifieo-bamboo oroducts in Michigan.

Material Handlinq Products Corp., E. Syracuse, ru.Y., is Nissan Forklift's new authorized distributor in uostate New York.

Matthews Marking Products, Pittsburgh, Pa., redesigned its website, www.matthewsmarking.com, with new branding and quicker, easier navigation.

Koopman Adding 2 Stores

Massachusetts' Koopman Lumber Co. has opened its fifth location and is readying its sixth.

The chain has acquired Westboro Paint & Decorating, Westborough, Ma., and rechristened it as its second Koopman Paint branch, under the management of Westboro Paint founder Doug Curving.

Koopman also purchased the former Village Lumber property in Westborough, to reopen later this year as a full hardware and lumber operation. under Curving's supervision. Village Lumber closed in March after 51 years.

Anauco To Buy Flakeboard

Chile-based Anauco has agreed to purchase panel producer Flakeboard, Markham, Ont. The deal is set to close in the second half of 2012.

Flakeboard operates seven production facilities in the U.S. and Canada, producing MDF, particleboard and thermally fused melamine panels. Locations include Bennettsville, S.C.; Malvern, Ar., and Albany and Eugene, Or.

In January, AnRuco also acquired an MDF and particleboard facility

located in Moncure, N.C., which will be combined with Flakeboard's existing mills and operate under the Flakeboard name. Kelly Shotbolt, president and c.e.o. of Flakeboard, and his senior management team will combine and lead this company.

Progressive Solutions Okays Buyout by Solarsoft

Solarsoft Business Systems agreed to acquire Progressive Solutions Inc., Vancouver, B.C.

Founded in 1989 by c.e.o. Len Williams, PSI provides bisTrack, lumberTrack, and other software to sawmills, lumberyards, and suppliers of construction materials in North America and the U.K.

"We believe that the combination with Solarsoft will provide fresh momentum to the ongoing development of PSI's products and services for the benefit of customers, suppliers and employees," Williams said.

Solarsoft c.e.o. Shawn McMorran added, "This acquisition will add significant strength to our offering for distribution and wholesale customers. PSI's customers will benefit too from being supported by a larger organization with international operations."

Mike Curda, ex-Snavely Forest Products, has joined the sales team at Dixie Plywood & Lumber Co., Tampa, Fl.

Chad Hammonds, ex-Westervelt Lumber, now handles international sales at Klumb Lumber, Daphne, Al.

Mike Yazwinski, ex-Russin Lumber, is new to sales in the Portland. Me.. area for Coastal Forest Products, Bedford, N.H.

Tim Roush, ex-Conex Forest Products, has joined the sales team at Wholesale Building Products, Jacksonville, Fl.

Mike Pierson, ex-Bent River Lumber, has rejoined Weyerhaeuser, handling inside sales for the Dallas, Tx., DC to the Oklahoma City, Ok., area.

Corey Welsh is the new lumberyard foreman at NFL Home Center, Gautier, Ms.

Lorraine Fincher, ex-GeorgiaPacific, is new to sales at Tolleson Lumber, Perry, Ga.

Martin Wojick has been named v.p. at Atlantic Plywood, Woburn, Ma.

Tim Schrader, ex-Lowe's, has joined Viance LLC, Charlotte, N.C., as director of sales & marketing. Dr. Kevin Archer has been promoted to director of development. Dr. Lehong Jin is now director of research, and Steve Furr is director of engineering & technical services. Todd Schoffstoll, ex-Pacific States Treating, is new as West Coast treating services mgr., based in Weed, Ca.

Robert McManus, ex-Stringfellow Lumber, is now part of the trading staff at Birmingham International, Birmingham, Al.

Ryan Unick, ex-Starborn Industries, is now market development mgr. at Manasquan Premium Fasteners, Brick. N.J.

David Bloodgood is new to counter sales at Somerville Lumber, Bridgewater, N.J.

Mike Dykstra has been promoted to c.e.o. at Zeeland Lumber, Zeeland, Mi., succeeding Herk VandenBosch, who continues as a director and executive v.p.-business development.

Fran Seymour has been promoted to president and chief operating officer at Brown Lumber Co., Traverse City, Mi.

Stephen Caligiuri is new to outside sales at Carter Lumber. Macomb. Mi.

Nick Fitzgerald, ex-Universal Forest Products, is now branch mgr. for Building Products Inc., Council Bluffs.Ia.

Jason Hipskind, Do it Best Corp., Fort Wayne, In., has been promoted to regional sales & business development mgr. for the Southeast. Jean Fahy is new as regional sales & business development mgr. for the West.

Brad Southern has been promoted to senior v.p. & gen. mgr.-siding at Louisiana-Pacific, Nashville, Tn. Brian Luoma was promoted to senior v.p. & gen. mgr.-engineered wood products.

Dan Chaney, ex-Universal Forest Products, has joined Stock Building Supply, Rock Hill, S.C., as installed sales mgr.for the Charlotte market.

Rick Hunter, ex-Boise Cascade, has been appointed branch mgr. at Marjam Supply, Orlando, Fl.

John Fekete, ex-Dougherty Lumber, is now in lumber sales at Mentor Lumber. Mentor. Oh.

John Shattuck is now in commercial division sales & estimating at Foxworth Galbraith Lumber, Van Alstyne, Tx.

Emily Bonilla, ex-Boise Cascade, is now area sales mgr. for the Rocky Mountain region at Boral Stone Products. Roswell. Ga.

Coy Green, ex-31-W Insulation, is now account mgr. for the Southeast at Heritage Stone by ProVia. Charlotte. N.C.

Bob Merritt has been named c.e.o. of Benjamin Moore, Montvale, N.J., replacing Denis Abrams, who has left the company after five years.

Tonya Taylor is a new marketing specialist at Bluelinx, Atlanta, Ga.

Kenny Collins has been promoted to sales director-residential division for Nichiha USA, Atlanta, Ga.

Garth Gray, ex-Carolina Green Building, is new to sales at Builders FirstSource, Wilmington, N.C.

Paul Buscemi has been promoted to v.p. of professional sales at Empire Level Mfg. Corp., Mukwonago, wi.

Michael Joyce, ex-GAF, has been named sales director for Richards Building Supply, Chicago, Il.

Raymond Jandura is a new kitchen designer at Blue Ridge Lumber Co.. Hackettstown. N.J.

Lori Platts, 84 Lumber, Manassas, Va., has been promoted to outside sales.

Coy Green has joined ProVia, Sugarcreek, Oh., as Heritage Stone account mgr. for the Southeast.

Doyle Simons, ex-Temple-Inland, has been named to the board of Weyerhaeuser Co., Federal Way, Wa.

Jai Shah has been promoted to v.p.human resources at Masco Corp., Taylor, Mi., replacing Charles Greenwood, who retires in 2013.

Dana Lee Cole, ex-National Association of Manufacturers, has been named executive director of the Hardwood Federation, Washington, D.C., succeeding Deb Hawkinson, now president of the Forest Resources Association.

Walter Melon is organizing the annual summer picnic for MungusFungus Forest Products, Climax, Nv., report co-owners Hugh Mungus and Freddy Fungus.

New Owner for Flooring Firm

Kelly Lumber Sales, Ashland, Me., has sold its MooseWood premium hardwood flooring division to forest management company Seven Islands Land Co., Bangor, Me.

Seven Islands plans to retain MooseWood's l6 employees, upgrade operations, and expand distribution of the product.

"This brings a value-added component to our timber resources and supports jobs in the heart of Maine's northern forest," said Seven Islands president John McNulty. His company was already harvesting the lumber used for MooseWood flooring and milling it at its Maine Woods Co. sawmill in Portage, Me.

Trex Teams Up on Composite Decking Blade

Trex Co., Winchester, Va., has cut a licensing deal with Diablo tool manufacturer Freud America, High Point, N.C., to introduce the first saw blade specifically designed for cutting composite decking materials.

The Diablo/Trex co-branded blade will be offered in three sizes-12", 10" and 7V+"-for use on hand-held, miter and table saws.

tosh Meschi, Meschi Construction

ln Santa Cruz, California, Josh Meschi helps his framers and subs work more efficiently by putting color-coded information on the subfloor. (And not just any floor: pointSlX Durastrand Flooring with its innovative tapered edge.) See his system and learn more in "Three Thlngs Itve Learned: Tips from Searoned Pfosr" one in a series of short high-value videos from pointSlX and Ainsworth Engineered.

Structural panel and EWP demand to grow

tTt"t sLow-BUT-sreaov improveI ment in the housing market is expected to boost demand for engineered wood products throughout 2072, according to estimates by APAThe Engineered Wood Association.

U.S. housing starts are forecast to increase l5Vo in 2012 to 700,000 units. As a result, and for the first time in several years, all of the major end-use markets for wood products are expected to move in concert and increase this year. In addition to growth in housing, demand is expected to grow in repair and remodeling, nonresidential building construction and industrial uses, as well as exports to Asia, Mexico and the Caribbean.

"There is a little more life to engineered wood demand this year. Last year, we were just treading water," said Craig Adair, APA's market

research director. "This year, we're expecting demand to pick up ftom 47o to IIVo, depending on the product."

Although the Great Recession in the U.S. ended in mid-2009, the recovery has been uneven and only now is the U.S. economy showing signs of sustainable growth. Adair noted that single-family housing is still plagued with several obstacles, including banks that are reluctant to lend and more foreclosures on the way. Single-family construction is expected to improve in 2012,but it should have a more meaningful recovery in2013.

"It may not be a lack of consumer demand that's holding housing back; it's more likely a financial system that currently doesn't freely accommodate residential mortgages, and it could take years to repair and reorganize the

system," Adair said. Meanwhile, the demand for rental housing is so great that apartment construction has picked up, along with a wave of investment in existing single-family rental housing.

EWP, Panel Output Grows

Demand and production of North American structural panels and engineered wood products are expected to grow in 20 12. Structural panels are forecast to increase 1Vo in 2Ol2 as all end-use markets demand more volume. Overall, structural panel production is forecast at 28.0 billion sq. ft. in 2012.

The outlook for glulam timber is better in 2Ol2 than in 2011 because both residential and nonresidential construction are forecast to increase. North American production is forecast at 213 million bd. ft. in 2012, a 5Toincrease from 2011.

I-joist market share is forecast to increase modestly in 2012 to 53Vo of raised floors. As the housing market improves, I-joist market share is expected to grow steadily. The forecast for 2Ol2 is an ll%o increase to 509 million linear ft.

In the structural composite lumber family, laminated veneer lumber production is expected to follow the demand for beams and headers, rim boards and I-joist flanges. Production is forecast to increase 4Vo in 2Ol2 to 43.4 million cu. ft.

Additional market details and historical data are contained in APA's 2012 Structural Panel & Engineered Wood Yearbook, availabTe for $250 at www.apawood.org.

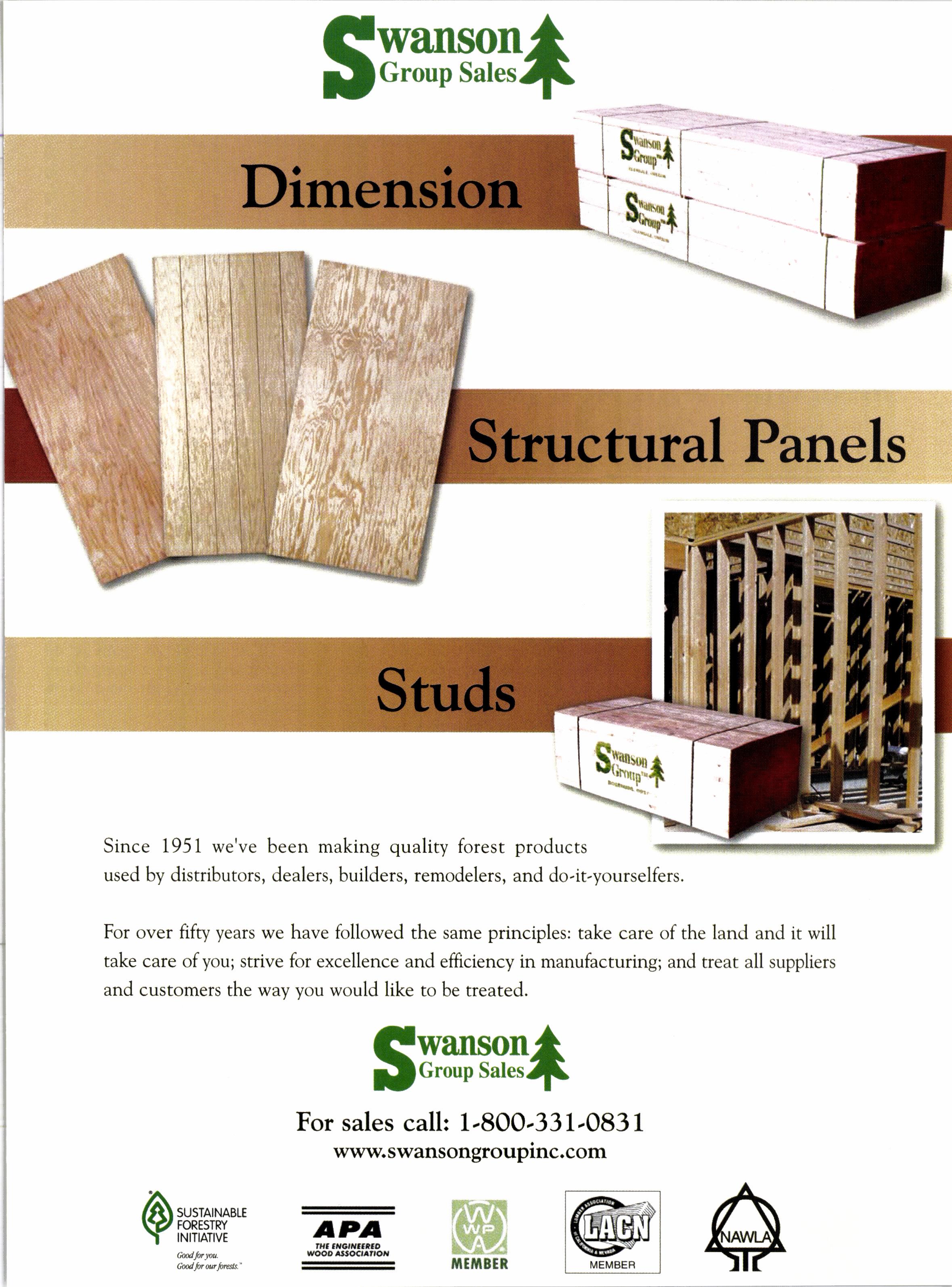

Sincc 1951 lve'r,'e l-,ccn mirkir-ig qr-raliry forest products

r:sec{ l',y c{istributors, ,,lcalers, builtlcrs, remclclelers, :lntl rlo-it-1',.rrrrsclfe rs.

For ttvcr fift1, 1,c11. w. take c:rre rlf you; strivc and cusf()lrers the wiry

havc lirllowctl thc same principles: tirkc crrrc of rhc lantl irnrl it u,ill ftrr cxccllcr-rcc rrnrl efticiency iu manufacturitrg; unrl frcrrt irll supphcrs yorr rvoultl likc tt, bc treatecl.

For sales call: 1.800,331,0831 www. swansongroupinc.com

State of Affairs

Interview with APA president Dennis Hardman

f, PA-THe Encrxeeneo Wood lll,Association president Dennis Hardman recently shared his views on the state of the industry and the association:

Q: It's been a tough few years for the structural wood panel and engineered wood products industry. What's your assessment of the challenges facing the industry at this point?

Hardman: Where do I start?

Market demand, of course, is still the primary problem. North American structural wood panel production last year was 26.07 billion sq. ft. on a 3/8" basis. That was almost identical to 2010, and we're still way below the 43 billion ft. at the peak of the housing market in 2005. So we have a long road of recovery ahead of us.

There is also the ongoing challenge of safeguarding industry interests in codes and standards. Recently, for example, we've been working to gain fairer treatment of wood products in the International Energy Conservation Code. In addition, the industry faces numerous regulatory challenges, such as the Boiler MACT issue, ever more stringent formaldehyde emissions limits, growing green building requirements, among others.

And there is the continuing federal timber supply problem in much of the West. So there's no shortase of challenges.

Q: What's the industry production forecast for this year and beyond? Are things looking up?

Hardman: We're now forecasting U.S. and Canadian plywood and OSB

production to rise this year by about 1.9 billion sq. ft., and to continue to increase next year and beyond. By 2016, we expect U.S. and Canadian structural wood panel production to be back at around 37 billion sq. ft., or about a 4OVo increase from 201 L

Q: What about the other engineered wood products that APA represents?

Hardman: Same thing. Glulam, wood I-joists, and laminated veneer lumber should all experience strengthening demand as the economy in general and the housing market in particular improve. Production of I-joists looks especially promising, almost doubling by 2016 from the 2011 volume.

Q: So, you're expecting some improvement now in the housing market?

Hardman: Yes. we believe we have hit or are very close to hitting the bottom of the market. We're forecasting a l5%o increase in U.S. housing starts this year compared with 2011. Looking farther ahead, we think U.S. single-family and multifamily starts could reach 1.4 million by 2016.

The problem right now is the continuing high inventory of unsold existing homes, including the millions that are in foreclosure. We also need to see stabilization and then increases in home values in order to renew consumer confidence and investment.

Q: What about exports? Those have been strong, correct?

Hardman: Yes. North American plywood and OSB exports, excluding

shipments between the two countries, totaled 1.23 billion sq. ft. last year, the highest volume in 12 years. That's been fueled by the weak domestic markets, which have made manufacturers here more aggressive in selling overseas.

As domestic demand improves, more of that product is likely to remain in North America, so exports are expected to slow. Conversely, imports have declined recently, but are likely to pick up again as the North American market improves and becomes more attractive to offshore producers.

Q: The industrial market is especially important to plywood manufacturers. Howts that market looking?

Hardman: Solid. Demand in industrial markets declined by about 7Vo and 87o, respectively, in 2008 and 2009, but rose by 6Vo in 2OIO and another 3Vo or so last year. We expect the rate of growth to remain at about 3Vo per year over the next several years.

Q: You cited regulatory matters as among other industry challenges, including energy codes. What's the issue there?

Hardman: That has to do with the International Energy Conservation Code, or IECC, which in late 2OlO approved changes that in effect unfairly favor foam sheathing over structural wood panels. We did a study that indicated those changes could represent a potential U.S. market demand loss of approximately 905 million sq. ft. of structural wood pan-

els. That's almost 20% of the structural wood panel wall sheathing market. So it's a big deal.

Q: How are you addressing that challenge?

Hardman: We helped last year tit establish an inclepcnclent coalition o1' wood products industry manufacturcrs and associations. called thc Coalition for Fair E,nergy Codes. lt has a twofold purpose: first. to ensurc that identified priority statcs adopt energy codes that allow fbr thc continued use of cost-eff'ective building envelope design options that include oriented strand board. plywood and lumber framing. and. second, to influence development of future energy codes. includine the 2015 IECC. to

ensure structural wood products and systems are appropriately re-tulated and not disadvantaged in their acceptance and use in the marketplace.

Q: What does the coalition do exactly?

Hardman: It has scveral functions, including f'ecleral governmcntlevcl education. mttnitoring and attcmpting to influencc state encrgy codcs and lcgislation. assentbling technir'al dir(ir und inlirrma(ion in support of crcdible encrgy code policy positions, establishing alliances with othcr industry partners and supports. and communicating key messages to stakeholder groups. I'm happy to report that our state efforts have been largely successful to date, but we still

have a lot of work to do.

Q: What are APA's strategic priorities this year?

Hardman: Our priorities are based on a strategic plan that has fbur chief soals as established by ttur board of lru\lce\. The first is maintuining an independent certificaticln program that assLlres member cclmpliance with product and perfbrmancc standards. and that also perfbrms a lcading rolc in sctting industry standards.

The second is protccting and growing wood product market share. The third is strengthening the voice of the industry through APA membership expansion and strategic partners. And finally, the fourth goal is exercising fiscal responsibility and maintaining organizational effectiveness.

Q: You mentioned membership expansion. Has APA's membershiP been affected by the recession?

Hardman: Actually, we've increased our membership quite substantially, with approximately 20 new member mills added to the ranks since 2009. Those are fairly cvenly split between the U.S. and Canada, and represent most of the products for which APA provides serviccs. During that same period, we have ttot lost a single mill other than through closure. So we're quite proud of that record.

We consider it a remarkable statement of laith in the stratcgic direction and value proposition of APA during a period of extreme financial pressure on most wood product manufacturing companies. Our strong membershiP base positions APA very well for the eventual climb out of this down market.

Q: You also mentioned strategic partnerships. What are some of those and what are their purposes?

Hardman: One of the longest standing examples is our purticipation in the USDA Foreign Agricultural Se rvice cooperator program, which eir( h providcs sizeahlc grrnts in support of our international markct development efforts.

Anothcr example is thc Wood Products Council. of which APA is a charter member. Thc council administcrs l nonresidcntial construction market plogram, called WoodWorks, that is designed to increase wood product demand in that market.

Still another example is the Canada Wood Group, an alliance of mostly

Canadian wood products industry associations that coordinates funding for international market deveiopment projects sponsored by the Canadian and British Columbian governments.

APA is a member of the Coalition for Advanced Wood Structures. a university, industry and government partnership whose mission is to identify and execute cooperative research and technology leading to improvement of wood structures.

We also have a close relationship with industry suppliers through the Engineered Wood Technology Association, which is a related APA organization that serves as a networking and infbrmation exchange vehicle for manufacturers and suppliers.

And also, as I mentioned, we participate in the Coalition for Fair Energy Codes in partnership with the American Wood Council. In fact. the day-to-day operations of CFEC are managed by an APA staff member, and APA provides program budget accounting and financial reporting services for the group.

We also have longstanding relationships with the U.S. Forest Products Laboratory, American Wood Council, Green Building Strategy Group, Institute for Business and Home Safety, National Association of Home Builders. Canadian Wood Council, American Forest & Paper Association. and FPlnnovations in Canada, to name a few.

Q: With regard to organizational effectiveness, how has APA adjusted or responded to the budget constraints that you must have faced when the economy collapsed?

Hardman: Well, like almost everyone else in this industry and throughout the country, we had to go through some painful staff and budget cuts, and then adjust our priorities in accordance with the most important needs of our members. That gave rise to the fbur-point strategic plan that I mentioned earlier.

Obviously, quality certification is among the most important of those member needs, so we've devoted a lot of resources to making sure that we continue to operate the best quality certification program in the industry.

I would add that the APA board continues to review incremental investment that would be necessary to restore APA functions and activities to some pre-recession baseline level, once conditions permit. That's impor-

tant to our being as prepared as possible to capitalize on market development irnd other striltegic opportunities as the economy and market improve.

Q: Speaking of the APA board of trustees, who serves on it?

Hardman: The board is comprised of l5 executive-level members who reflec( the broad product mix. geographic range, and diverse size of APA member companies. We also have an APA member advisory committee system that is actively involved in formulating recommendations and developing program plans related to market development, technical services, quality services, glulam and Ijoist/LVL, mill safety, etc.

Q: Given the very difficult business conditions over the past few years, what APA accomplishments are you most proud of?

Hardman: I'd have to say the strong member support that we've had during this period is certainly high on the list. That speaks, I think, to the dcdication and expertise of the APA staff. and also to the excellent strategic guidance we've received from thc APA board and advisory

commrttees.

I'm also proud that despite budget constraints. we have continued to refine and improve our quality certification services. and have remained a globally recognized leader in the standards promulgation arena. I think we have done a good job of protecting market share through a variety of highly targeted promotional programs.

And I'm proud of the increased recognition within APA and among APA's members of the importance of safety, although I really need to give credit there to former APA chairman and current APA trustee Jeff Wagner of LP, who is passionate on that subject. Jeff was the leading force in reorganizing the annual APA mill safety awards competition and in forming a new APA mill safety advisory committee.

Q: Finally, what's the biggest lesson from the last few years of depressed markets?

Hardman: Clearly, within APA, we've learned a lot about efficiencies and essential member values. As market demand improves, we will definitely apply those lessons to rebuilding.

PLYWOOD, a tied and true product

When it comes to quality southern pine plywood, Coastal Plywood has been a leading provider throughout the eastern US since 1981. Wholesale distributors rely on Coastal Plywood for a wide variety of products milled to exacting standards and consistency. Depend on Coastal Plywood for superior customer service and reliable delivery.

Appearance, consistency, and performance. You'll get allthree from Coastal Plywood. And we have decades of history to prove it.

Made from the bounty of the world's best managed forests here in the southeastern USA, we bring you...

that actually does "grow on tr€es".

Advanced Framing

New techniques boost efficiencies, conserve resources

f, ovnNcen FRAMTNc with 2x6 ll,wood studs spaced 24 inches on center is one of the most cost-effective solutions for builders and installing dealers trying to balance energy and structural building code requirements. Installers who utilize advanced framing techniques optimize framing material usage, reduce wood waste and, with effective insulation detailing, boost the building's efficiency.

When properly designed and constructed, advanced framed walls that are fully sheathed with wood structur-

al panels, such as plywood or oriented strand board, provide the structural strength necessary to safely withstand the forces ofnature.

What's Advanced Framing?

Advanced framing is a system of construction framing techniques designed to optimize material usage and increase energy efficiency.

Structures built with advanced framing techniques are more resource efficient and offer more space for cavity insulation than similar structures built with conventional framins.

Conventional framing, the industry standard for framing residential construction, typically consists of 2x4 or 2x6 wood framing spaced 16 inches on center, three-stud corners, multiple jack studs, double or triple headers, unnecessary cripple studs, and other redundant members.

Advanced framing reduces the unnecessary structural redundancies inherent in conventional framing by placing framing members only where they're needed. The most commonly adopted advanced framing technique is 2x6 wood framing spaced 24 inches on center.

Other commonly used techniques include insulated three-stud corners or two-stud corners with ladder blocking, multiple wall intersection options, single headers and insulated headers, minimal use of jack studs and cripples, and the elimination of redundant studs and unnecessary blocking and bridging.

Although some advanced framing techniques can be adopted independently, the greatest savings-in both cost of construction and energy-will be realized when the system is applied holistically.

Advanced framing-also known as optimum value engineering (OVE)was developed by NAHB Research Center in the 1970s for the purpose of optimizing material usage while maintaining structural integrity. Today, growing interest in energy conservation is leading more and more builders and installers to adopt advanced framing techniques.

APA recommends installers consult their local building official early

in the design phase to verify and obtain acceptance of 24-inch framing techniques in their jurisdiction.

Advantages of Advanced Framrng

The key advantages of advanced framing include:

L. Energy Efficiency

Advanced framing is a proven method for cost-effectively meeting energy code requirements. By maximizing space for cavity insulation and minimizing the potential for insulation voids, advanced framing delivers significant energy performance and cost savings for the builder.

Walls built with 2x6 wood framing spaced 24 inches on center have deeper, wider insulation cavities than conventional 2x4 framing spaced l6 inches on center. Increasing the amount of insulation inside the wall improves the

whole wall R-value (see Figure I ).

In addition to maximizing space for cavity insulation, advanced framing simplifies the installation of insulation and air sealing. Conventional framing can leave voids and small cavities in the framing at wall intersections and corners that can be difficult to insulate and seal effectively. By installing fewer framing members, it is easier for the builder to apply complete insulation coverage and achieve a tighter building envelope.

As energy codes have become increasingly stringent, advanced framing has grown more popular in climate zones where high prescriptive wall Rvalues are mandated or desired. While framing with 2x6 studs spaced l6 inches on center is already common in many northern states with more restrictive energy demands, increasing stud spacing to 24 inches on center,

insulating effectively and fully sheathing with wood structural panels, such as plywood or OSB, allows installers to cost-effectively balance energy and structural code requirements.

In addition, advanced framing can help builders meet the requirements necessary to earn the Energy Star label for new homes.

2. Cost Effectiveness

Advanced framing is less expensive because it is more resource efficient than conventional framing. By framing with 2x6 wood studs spaced 24 inches on center, builders optimize framing material use and reduce framing installation labor.

Advanced framing can help to increase the efficiency of other trades as well. More space between framing members means fewer studs for plumbers and electricians to drill through and fewer cavities for insulators to fill. Additional savings may result from a reduction in construction waste and Dumpster costs.

3.

Structural Integrity

The advanced framing method combined with continuous wood structural panel sheathing delivers an optimal solution: a cost-effective framing system that will produce more energy-efficient homes without compromising the strength or durability of the structure.

Where builders align the vertical framing members under the roof trusses or rafters, a direct load path is created in which compression and tension loads are directly transferred through the vertical framing members. The result is a stronger structure with fewer framing members subject to stresses.

When properly constructed, advanced framed walls that are fully sheathed with wood structural panels provide the structure with the strength to safely withstand design loads. Of all the available wall sheathing products, wood structural panels are afforded the most flexibility within the building code for 24-inch on center wall framing, providing solutions to code limitations that restrict most other wall bracing materials and popular siding products.

4. Sustainability

Wood construction systems such as advanced framing techniques fit well with green building strategies. Wood is a renewable resource that is manufactured in efficient processes that require less energy than is required for

COMPONENTS OF ADVANCED FRAMING: Houses constructed with advanced framing techniques may include some or all of the following details: Single heoders (vs. double heoders ond cripples in conventionol rom;ng). lnsuloted lhree-slud corners or lwo-s10d corner with lodder blockins. 2x6 wood slods spoced 24 inches on cenier (vs. 2x4 wod studs spoced l6 inches on center).other building materials, such as steel and concrete. Wood-frame construction that utilizes advanced framing techniques delivers even greater environmental dividends by optimizing material usage and reducing construction waste. Many advanced framing construction techniques may be eligible for points under the leading green building standards and guidelines, such as the National Green Building Standard (ICC 700-2008) and the U.S. Green Building Council LEED for Homes Rating System.

Getting Started

To ease the transition to new methods, some advanced framing techniques can be adopted independently. "Builders can incorporate the tech-

niques in stages rather than all at once," said Mark Halverson, field services manager for APA-The Engineered Wood Association. "For example, if meeting cold climate energy code requirements is the priority, adopting 2x6 framing at 24 inches on center while continuing to use double top plates will increase wall R-values without requiring roof, floor and wall framing to be aligned. The builder can add additional advanced framing techniques later to further reduce costs and increase energy efficiency."

APA details several advanced framing techniques in Ihe Advanced Framing Construction Guide, Form M400. The 24-page guide (shown at right) is available for free download or print purchase at www.apawood.org.

Case Study Gurved glulam beams bring sense of grandeur to LeMay Museum

floor, almost warehouse-like, but aesthetically enhanced with its wood structure and thoughtful display details. Engineered by Western Wood Structures, the curved roof system was created with 19 glulam frames with S-ll8-in. glulam purlins spaced 4 ft. on center as secondary framing. The glulam beams, crafted by American Laminators, Drain, Or., measure 8-3/4 inches bv 52-1/2 inches and arc

ff,/Heu

ENTERTNG rss exhibit hall at the new LeMay

Y Y Museum in Tacoma, Wa., visitors may find themselves gazing up at the ceiling as well as taking in the lines of gleaming classic cars. A soaring roof system made with curved glulam beams offers a striking sense of grandeur while simultaneously lending a warrn, grounded aesthetic to the vast space.

Nicknamed "America's Car Museum," the 165,000-sq. ft. facility was created to celebrate America's love affair with the automobile. Across its four-story, nine-acre campus, the museum will house up to 350 cars, trucks, and motorcycles from private owners, corporations, and the expansive Harold LeMay collection, from a 1906 Cadillac Model M to a 1965 Lotus racecar to a 1983 Delorean DMC 12. Rotating exhibits, such as a collection of glass hood ornaments, also will be showcased.

Along with displaying some of the world's most aweinspiring vehicles, the museum will also serve as a gathering place for automobile enthusiasts, with meeting spaces, a membership club, a show field, and a planned educational center.

Curve Appeal

The museum's main hall is essentiallv a lons exhibit

over the displays below.

Because the roof curves in two directions, each of the 757 roof purlins is unique, with varying compound miter cuts and varying lengths. Each purlin hanger has a different skew and slope.

One-and-one-eighth-inch fully sanded plywood sheathing from Swanson Group Mfg. LLC covers the roof, with l/2-in. and 5/8-in. sheets used around corners to meet the l1/8-in. thickness requirement while bending around the 17-ft. radius of curvature. Waterproof rigid insulation and a metal roof complete the structure.

The arch design-one of the largest wood moment frames in the world-has a one-hour fire-resistive rating and follows the "Special Requirements for Seismic Design of Structural Glued Laminated Timber Arch Members and Their Connections in Three-Hinged Arch Systems" from

Project Details

Project: LeMay-America's Car Museum

Location:Tacoma, Wa.

Gompleted: Spring 2012

Architect: Grant Price Architects

Contractor: JTM Construction

Engineer: Western Wood Structures

the 2009 National Earthquake Hazards Reduction Program provisions. The provisions are intended to produce ductility in the arch systems by allowing the steel connections to yield plastically during a seismic event and prevent glulam members from failing in a brittle fashion.

At the south end of the structure, the roof system cantilevers over the last glulam arch, supporting the curved fascia and creating a covered outdoor gathering space.

The decision to use glulam beams wasn't purely aesthetic, as it also was one of several features that allowed some of the cost savings necessary to meet a tight budget, says Alan Grant, co-director of Grant Price Architects, Los Angeles, Ca. Grant says that construction of the LeMay museum cost about $104 per sq. ft., whereas typical museums can range from $400 to $800 per sq. ft.

Auto-lnspired

From the outside, the effect of the Buildirry.hoduclscom

Lyle Lee hos been building custom homes for over 20 yeors. Here is whot he hos to soy obout Roseburg's Engineered Wood Producls.

"When building o quolity home, if's imporlont for oll the froming moleriols lo mofch. ln olher words come logefher os specified in the design plons. lf the framing is off by even o 1/t of on inch, it con cosf me lhousonds of dollors in time ond moteriols.

I find Roseburg's RFPI@-Joist ond Rigidlom@ LVL to be very consisfenl in width ond depth. When I use Roseburg's RFPI@-Joisf my floors ore more level, stiffer ond truer, moking my job much eosier.

fhis home is 6,000squorefeef so I used lJoist ondLVL from severol dif{erent unifs ond the monufocluring consisfency wos exoctly lhe some. lf you wont to moximize your profit, I would recommend using Roseburg's Engineered Wood Products".

Lyle Lee L. Lee Building Componycurved, metal-topped roof is gleaming The architects took great care to and streamlined-much like the aero- ensure the modern form and size still dynamic surfaces of an automobile. respected Tacoma's largely historic

architecture, standing out from the surrounding buildings, including the adjacent Tacoma Dome, without overpowering them.

Inside, Grant remained conscious of the structure's primary functionshowcasing shiny automobileswhen considering materials. Flooring, for example, is dark stained concrete, much like the roadways automakers consider when designing a car's shell for optimal visual effect. Grant also paid close attention to lighting selection, noting how spot or strip fixtures at auto shows often leave bright spots and glare in photographs. The solution turned out to be simple and inexpensive: hanging fixtures that disperse 407o of the light up and 60Vo down, with a glowing fuse across the front, creating a strong, bright light that sets the space aglow.

The June 2 grand opening of the LeMay Museum capped off nearly a decade of effort by its founders, benefactors and construction teams. The resulting space is not only one to be aesthetically and structurally admired, but one that succeeds in providing a place for car lovers to witness history, share passions, and preserve an American legacy.

Builders Meet lhe New Codes 2x6 Consfruction

GLULAM BEAMS create a sense of warmth inside the exhibit hall, a suitable contrast to the gleaming classic cars below.

GLULAM BEAMS create a sense of warmth inside the exhibit hall, a suitable contrast to the gleaming classic cars below.

Safety by the numbers

APA honors producers for safety strides

A PA-TuE ErucrxEr,neo Wood AAssociation recently announced the winners of its 20 l1 Safety and Health Awards, a program that encourages and recognizes safety and operational excellence in the North American structural panel and engineered wood industry.

Nashville, Tn.-based LP and Canfor-LP OSB Limited Partnership, Fort St. John, B.C., won Safest Company Awards in their respective categories while Roseburg Forest Products Co., Riddle, Or., eamed the coveted Innovation in Safety Award.