Digital Edition Sponsored by

DECK

Spring 2020

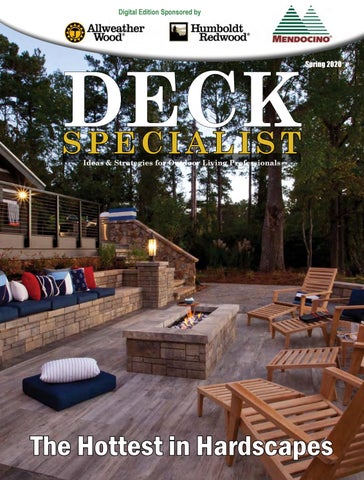

SPECIALIST Ideas & Strategies for Outdoor Living Professionals

The Hottest in Hardscapes

Digital Edition Sponsored by

DECK

Spring 2020

SPECIALIST Ideas & Strategies for Outdoor Living Professionals

The Hottest in Hardscapes