Know what builders need before they do.

As a partner to the construction industry for more than 65 years, Simpson Strong-Tie knows the needs of builders before the workday even begins. Our innovative products, software and services are widely available and backed by expert support. So you can keep customers fully stocked and continue building your business. Learn more at go.strongtie.com/buildersolutions or call (800) 999-5099.

LBM DEALERS’ BEST NEW PRACTICES • SIDING TRENDS • TREATED WOOD 101 THE VOICE OF THE LBM SUPPLY CHAIN January 2023 Digital Edition Sponsored by

Inc. PROSUPPCOV22

© 2023 Simpson Strong-Tie Company

Celebrating

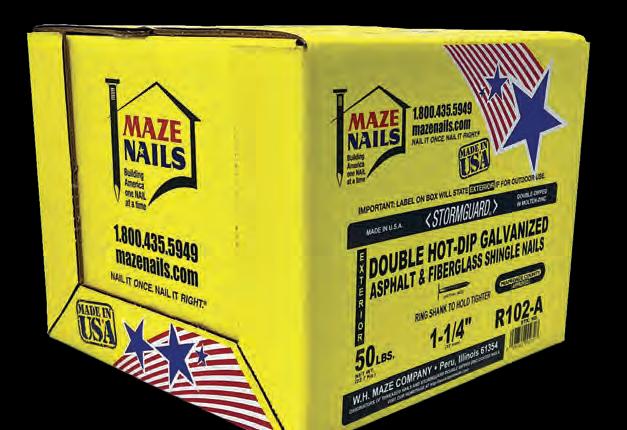

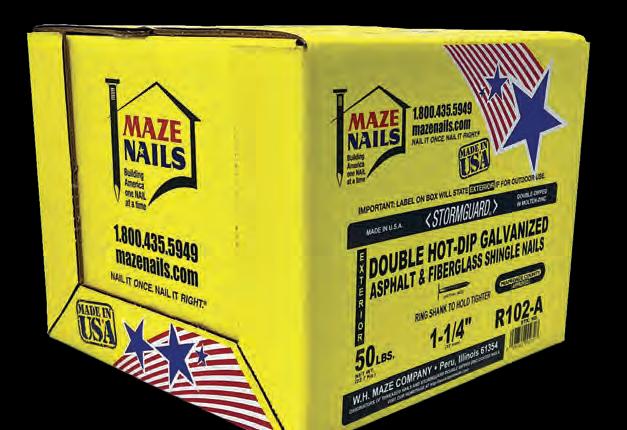

MAZE LUMBER

1848 Founded by Samuel Maze in Peru, Illinois 1886 Purchases First Nail Machine to Produce Nails from Pure Zinc 2023 Maze Lumber is the Oldest Lumberyard in Illinois

MAZE NAILS

1900 First Manufacturer to Pack Nails in 50 Lb. Boxes 1905 First Manufacturer to Pack Nails in 5 Lb. Boxes 1914 Produces the First Hot-Dipped Nails by Hand 1930 Designs and Launches Spiral Shank Nail Product Line 1934 Designs and Launches Ring Shank Nail Product Line 1955 Develops Exclusive Stormguard Double Hot-Dip Galvanizing 1996 Founded S.S.E., our Collating Division 2006 Earns Miami-Dade County Approval on Selected Roofing Nails 2008 Certified by Scientific Certification Systems for Recycled Content 2011 Fifth Hot-Dip Galvanizing Production Line Installed 2011 Highlighted on ABC News, Diane Sawyer’s Made In America 2016 Installs Second Paint Production Line for Trim Nails 2023 EVERY Maze Nail still 100% Made in the USA

AMERICA S PREMIER SPECIALTY NAIL MANUFACTURER

4 • building products digest • January 2023 building-products.com ------------| CONTENTS January 2023 STAY CONNECTED ON SOCIALS: @BPDMERCH THE OFFICIAL PUBLICATION OF PROUD SUPPORTERS OF VOL. 42 • NO. 1 |-----------SFPA SPECIAL REPORT WWW.BUILDING-PRODUCTS.COM FEATURES DEPARTMENTS 14 31 10 FEATURE STORY LBM dealers retain valuable changes from COVID 12 INDUSTRY TRENDS Expect more fiber cement, energy efficiency in siding 14 COMPETITIVE INTELLIGENCE Washington State dealer makes sure relationships with employees and customers aren’t just transactional 22 TRANSFORMING TEAMS Preparing for the new year in HR 38 MARGIN BUILDERS The importance of market diversification for forest products suppliers 08 ACROSS THE BOARD 18 OLSEN ON SALES 20 SELLING WITH KAHLE 24 LUMBER 411 29 MOVERS & SHAKERS 44 NEW PRODUCTS 48 CLASSIFIED MARKETPLACE 48 IN MEMORIAM 49 DATEBOOK 49 ADVERTISERS INDEX 50 FLASHBACK 31 TREATED WOOD 101 The skinny on code acceptance, identification and preservatives for lifelong performance DIGITAL EDITION CHECK OUT THE January 2023 Know what builders need before they do. keep customers fully stocked and continue building your business. Learn more at go.strongtie.com/buildersolutions or call (800) 999-5099. 10

Patrick Adams padams@526mediagroup.com

Shelly Smith Adams sadams@526mediagroup.com

David Koenig dkoenig@526mediagroup.com

Rose Braden, Jeff Easterling, Paige McAllister, Christian Moises ADVERTISING

(714) 486-2735 Chuck Casey ccasey@526mediagroup.com Nick Kosan nkosan@526mediagroup.com

VIRTUAL EVENTS

Alek Olson • aolson@526mediagroup.com

CIRCULATION/SUPPORT info@526mediagroup.com

A PUBLICATION OF 526 MEDIA GROUP, INC.

151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 Phone (714) 486-2735

BUILDING PRODUCTS DIGEST is published monthly at 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626, (714) 4862735, www.building-products.com, by 526 Media Group, Inc. (a California Corporation). It is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright®2023 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles in this magazine are intended for informational purposes only and should not be construed as legal, financial, or business management advice.

6 • building products digest • January 2023 building-products.com BPD SUBSCRIBE TODAY OUR MARKET MOVES QUICKLY—SO DON’T GET LEFT BEHIND! BPD is available on a qualified requester basis to senior management of U.S.-based dealers and distributors specializing in lumber and building materials, and to others at the rate of $22 per year. Subscribe now at www.building-products.com/subscribe. SUBSCRIBE NOW AT WWW.BUILDING-PRODUCTS.COM/SUBSCRIBE BPD - BUILDING PRODUCTS DIGEST SUBSCRIBE TO RECEIVE PRINT, DIGITAL, ENEWSLETTER & MORE! The LBM supply chain’s leading publication for qualified industry decision makers! • Update your subscription • Sign up key colleagues • Enroll multiple locations

PRESIDENT/PUBLISHER

PUBLISHER EMERITUS

EDITOR

VICE PRESIDENT

Alan Oakes MANAGING

EDITOR

SENIOR

Sara Graves sgraves@526mediagroup.com COLUMNISTS James Olsen, Kim Drew, Claudia St. John, Dave Kahle CONTRIBUTORS

SALES

THE CURSE

BY PATRICK ADAMS

I LOOKED AT MYSELF in the mirror this morning and wondered what happened. I’m not talking about this face and body that continue to age, but more about who is inside. I’ve spent the past few weeks pondering, worrying, stressing about making the right decision about an acquisition opportunity that was presented to us, about the changing business landscape, about a new magazine that I dreamed about for over a decade that isn’t working out.

It’s not that these are new things to consider. The acquisition, for example, should not be an impulse decision, but after years in business and a track record of having made several other successful acquisitions, does it warrant the level of stress that I’m putting on myself? For perspective, this “stress-inducing opportunity” is about 20 times smaller and about 100 times less risky than my first acquisition.

In past lives, I was called “fearless.” Inside I wasn’t, but I will say I was “quick to calculate.” Evaluate the landscape, the task, the risk, formulate a plan, and then move. Adapt and improvise while I moved and, needless to say, they all must have worked out because here I am today writing this article. That success time and time again fed the next success and over time, you develop a confidence that is based in your abilities to adapt and overcome obstacles.

But for me, time has continued on and my life is different. The risks are different now, and having a family, kids and a team who rely on your decisions makes it feel different. It also feels like as time goes on, you have less time to recover if you make a wrong call.

There are a lot of sayings about “success” that are relevant at this point, but this one feels appropriate: “The true enemy of success is success.” Whether it is being afraid (another enemy of success), or getting comfortable, or getting big enough that you shift your focus from offense to defense, it is a curse. And this curse not only affects your business, but your entire life. There is a great quote from a show I have grown to love: “There’s sharks and minnows in this world, and if you don’t know which one you are, then you aren’t a shark.”

During a recent meeting with one of the contributors

for one of our publications, this leadership and development expert gave me one sentence of advice that has lingered with me ever since. He said, “Patrick, your problem is that you don’t have any mentors, nobody to look up to, to compete with, or to bounce ideas off of. How can you be your best self when you surround yourself only with people whom you serve that role for?”

Many of you reading this will shake your head knowingly only because I have had the privilege of talking to you about your own business, your decision-making process, and your fearlessness. I am inspired by you and the industries we serve. You have shared your stories with me that I feel are among the greatest American Dream-Hero stories that I’ve ever heard.

And so, as we get the opportunity to set new goals, reinvent ourselves, and start anew simply because a calendar switches over a 24-hour period, I am going to look into the mirror looking for who I should be, or perhaps always have been. We have several new products, services and ventures launching this year to better serve you and your business needs. There are a few acquisitions on our doorstep that I aspire to look at through the same objective, fearless lens that has extended my life this long. But most of all, I aspire to do something new this year. I will begin reaching out to some of you—my fearless heroes—to simply have a talk. To bounce things off of and to gain from your wisdom and perspective.

I don’t know what led us to this state where we have shrunk into ourselves with our only exposure to the “outside” is through the lens of social media. But, I aspire this year to harken back to the days of barber shops and BBQ’s where we would “talk,” and gain wisdom from each other as we all fight to be our best selves and achieve our American dream.

I’m eternally grateful to serve this industry and each of you and look forward to another year of excitement, adventure, perseverance and achieving our goals. Happy New Year.

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

8 • building products digest • January 2023 building-products.com

------------| ACROSS THE BOARD ------------

DEALERS RETAIN VALUABLE CHANGES FROM COVID

BY DAVID KOENIG

FOR THE MAJORITY of communities, the sudden changes made necessary to function on a daily basis amid a pandemic are becoming a thing of the past. Most of the hassles and true hardships—wildly fluctuating prices, product shortages, the constant gloom of exposure to illness, mandatory masking, and countless other emergency procedures—have mostly worked themselves out of the system.

Yet suddenly having to confront COVID taught many dealers how to run their business better. New procedures, initially thought temporarily, have become permanent.

Inventory & Purchasing

“The primary sticking point during COVID which remains the same today is the acute attention to inventory,” William Crosby, manager of County Building Center, Madill, Ok. “Whether being proactive on particular items and their sensitivity to supply chain disruptions or the extreme price volatility. Everyone in our industry became well aware in knowing where the markets were and where they could go in the future. You have no desire to find yourself with too much product on a high market, being there is little chance to ‘average down’ and remain competitive. However, it is also costly to be without product. Finding the balance is a subject everyone has on the forefront of the thought process.”

Lummus Supply, Atlanta, Ga., similarly shook up how it bought product. “We are doing a better job with our purchasing by not becoming so dependent on one source for certain products,” said president/CEO Will Lummus. “We have learned to start using multiple sources to help us with supply chain and allocation issues in the future.”

As a result of supply bottlenecks and elongated re-supply times, Lumbery, Cape Elizabeth, Me., has been forced to order in bulk six to eight months in advance. That’s necessitated renting a separate warehouse to store the bulk orders, purchasing an additional forklift, and preparing to upgrade its small yard to accommodate a larger inventory.

“Our capital and operational costs have increased while our liquidity has decreased, forcing us to decrease staffing and increase prices,” lamented Mike Friedland. “The one benefit is that contractors are finding it difficult to find the specialty items that we stock in bulk due to the pronounced lag times, most notably white cedar, therefore we, at times, are the only option.”

Communication

Retailers were forced to communicate more directly and more frequently with staff and the public—and saw lasting benefits. “COVID taught us to communicate better not only with our customers, but also within our orga-

10 • building products digest • January 2023 building-products.com

------------

------------| FEATURE STORY

nization,” Lummus said. “We have implemented many new policies that are based on communication which has made us a better company today. It has also become one of our five core values.”

Likewise, noted Jonathan Ramsey, general manager for Beatty Lumber & Millwork, Upper Darby, Pa.: “With customer interaction limited during COVID, we called all those customers that had a delivery of material the very next day to check up and make sure everything went smoothly. We have continued that practice. It allows us to identify any issues that need to be addressed. Ninetynine percent of the feedback from these calls is positive, so I find myself giving those team members involved in the delivery a “pat on the back,” which goes a long way in building a positive environment.”

Companies hesitant to adopt new tools, like Zoom, received a crash course that continues to pay benefits. Katherine Cornelius, marketing director for TAL Holdings, Vancouver, Wa., noted, “The only thing that has had a lasting impact is our adoption of, and now standard-practice use of, Microsoft Teams as a collaboration and information sharing platform. Prior to the pandemic, we had done virtually no video conferencing and had a poor information sharing network beyond email. Through the pandemic, we were forced to adopt the software platform to continue to communicate and function. The forced adoption spurred our embrace of Teams so that it is now woven through the fabric of almost everything we do these days.”

Staff from Big Creek Lumber’s main office in Davenport, Ca., physically travels less to its branches throughout Northern California. A growing percentage of interactions with staff, customers and vendors is no longer in-person. There are more remote/virtual meetings, more webinars, and more virtual conferences, reducing travel expenses and increasing frequency. Virtual meeting check-ins are now held regularly, companywide.

Health & Safety

Stine Lumber, Sulphur, La., decided to keep up the Plexiglass partitions that protect clerks at all of its checkout stations. The dealer has also stepped up cleaning with antibacterial products beyond what it had preCOVID, according to Tim Stine.

Meanwhile, at Beatty Lumber, said Ramsey, “we have installed automatic soap dispensers and automatic antibacterial stations in the restrooms and strategically located throughout the office/retail store area. We have also displayed framed documents that tell the person reading how and why washing your hands, and using antibacterial lotion is important.”

At Big Creek’s administration office and wholesale/ sawmill, according to Michelle Webb, “Aside from the various health/social distancing protocols that are still in place, one outcome is that in attempting to socially distance as many office personnel as possible, we had to come up with systems and the technology that allowed employees to work effectively from home. We also started using and continue to use scanned and/or text messaged photos of various types of paperwork/information between our shipping yard and admin or home offices.”

Not every dealer, however, was faced with rolling back a ton of temporary changes. Joel Jumper, owner of Coshocton Lumber Co., Coshocton, Oh., tried to keep changes minor and few. “When the pandemic started, I wanted to try and not make changes in the business,” he said. “We worked to keep things ‘normal’ like the pre-pandemic days. We worked hard to provide the same service and products to our customers. So as the situation eased, we just fell back into our normal world. I honestly thought I would be changing procedures, product, etc. We had enough going on during those times. We didn’t need me reinventing the wheel.” BP

building-products.com January 2023 • building products digest • 11

LUMBER and hardware retailers instituted numerous changes to operate during the pandemic, some of which have outlasted the pandemic.

EXPECT MORE FIBER CEMENT, ENERGY EFFICIENCY IN SIDING

BY DAVID KOENIG

GOOD NEWS for lumber dealers, as fiber cement—the type of siding most commonly distributed by traditional lumberyards—is forecast to exhibit the fastest growth among all types of siding, according to a new Lucintel report, “Siding Market: Trends, Opportunities and Competitive Analysis.”

The global siding market is expected to reach an estimated $126.1 billion by 2027 with a compounded annual growth rate of 4.9% from 2022 to 2027. The

major growth drivers for this market are increasing construction activities, growing repair and maintenance of building exteriors, and a rise in the hospitality industry.

The sharpest increase lies with fiber cement. “Fiber cement siding continues to pick up steam for several reasons,” explained Jamal Saghir, director of products at James Hardie. “First, we’ve seen that traditional construction practices using brick and stucco are becoming increasingly more expensive and difficult to achieve, leading consumers to evaluate alternative siding options. Another trend we’ve seen is an increase in modern styles and the growing desire for customization. Fiber cement panels are well aligned to this trend of modern styles as they deliver a clean and simple aesthetic.

“Lastly, the impact of severe weather on home design is something we’ve been watching closely for several years now, as homeowners are looking to protect their homes and their families inside those homes.”

Nonetheless, vinyl will remain the largest material type segment over the forecast period, due to low material and maintenance costs, and availability of a wide variety of colors.

Also becoming increasingly popular are sidings that offer good insulation to reduce energy consumption generated by air conditioners and heaters. The most energy-efficient type of siding—insulated vinyl—is laminated with a solid foam-core backing. Once installed, it looks similar to regular vinyl siding with a stepped profile, but provides significantly higher R-values. However, it does cost more and is more labor intensive to install.

Globally, non-residential will remain the largest end use segment for siding during the forecast period due to growth in retail and office buildings. Yet residential construction is expected to witness the highest growth due to increasing adoption of energy efficient homes.

Asia Pacific is expected to remain the largest market and witness the highest growth over the forecast period, supported by increasing urbanization and building construction activities. BP

12 • building products digest • January 2023 building-products.com

------------| INDUSTRY TRENDS

FIBER CEMENT may hold a fraction of the siding market, but it remains the fastest-growing type. (Photo by James Hardie)

------------

® Real Stone Aesthetics Easy Installation Moisture Protection Help your customers and your sales by introducing them to SILVERMINE STONE that protects the house from moisture with a patented flashing system. To learn more visit silverminestone.com The ONLY BRAND of Mortarless Stone Learn more about how Silvermine Stone protects the house from water

RELATIONSHIPS AREN’T JUST TRANSACTIONAL

BY SARA GRAVES

IT WAS THE SPRING of 2019 and the country was on the brink of a global pandemic when the Lumber Traders board approached Danny Steiger to ask him to step in as interim CEO. The existing CEO, who took over the reigns in 2014, announced that he was moving on. Steiger, a store manager who had been with the company just shy of three years, had some big shoes to fill.

And as it turned out, the board was correct to ask him. Steiger not long after became the official CEO/ president of Lumber Traders, Inc., parent company to Angeles Millwork & Lumber Co. and Hartnagel Building Supply, Port Angeles, Wa. “All the stars aligned with my past experiences and what I had learned and what I had been through.”

Ironically, he was able to draw upon his past experiences to be successful. He reflected on his time working at his parent’s pet and feed store, where he learned bookkeeping, customer service and basic business practices, and on his experience at Westside Building Supply, Lynden, Wa., where at 18, he began learning pro and contractor sales, and later cabinetry.

And although he originally had no intention of working in the industry out of college, he says it was the customers that caused him to fall in love with the industry. “It’s a relational industry. We’re seeing the same builders in here every single day. We’re getting to know them—working on their projects—really partnering in

their success. It’s not just a transactional relationship.” He is still in love with the industry 21 years later.

He looked to customers like Scott Schwagler of J&J Construction, returning board member for the North Peninsula Building Association (NPBA), who supports many of the area’s youth programs, and Kevin Russell of Kevin Russell Construction, a builder who builds custom homes on the Olympic Peninsula, who remains very active in local politics and lobbying for the industry and community.

“These are the salt-of-the-earth people who really dig in and give

back to their community and want to make it a better place,” Steiger says.

He adds although it was a weird time for the industry through the global pandemic, the company has, nevertheless, flourished. “We’re on target to be up, since 2019, 36% in our revenues.” And as an ESOP (Employee Stock Ownership Plan), the share value has increased 66% during the same time period. Through 2021, the ESOP value was nearly $6 million, and on target to grow as 2022 came to an end.

A big part of that success, he says, is being pragmatic and flexible. “The things that worked for us

14 • building products digest • January 2023 building-products.com

------------| COMPETITIVE INTELLIGENCE ------------

EACH YEAR, Washington sister companies Angeles Millwork and Hartnagel Building Supply distribute new branded hats and hoodies to customers and contractors.

previously—some of those things worked great, and some things were completely turned on their head. We had to get flexible for where we were sourcing product, the supply chain being in a state of shambles, and trying to be proactive about those things.”

In addition, the company’s ability to retain longtime staff and acquire

highly skilled staff from outside of the industry have helped the company grow in the years since the pandemic began.

Yet, finding new employees has been hard, Steiger acknowledges, so the company began looking outside of the industry to find potential employees who had the right talent and skills to learn the industry,

but also had the right business fundamentals to expand on their knowledge and experience in other areas as well. “There’s not a lot of people coming into the industry, so we really need to look outside of the industry and find the people to bring in who have the skills who can grow the company.”

Thankfully, being an employeeowned company has aided in their search and has been highly attractive to the new talent the company has been looking to bring into the industry. For instance, one store manager hired by the company for his exceptional skills in managing operations, Steiger says, was previously a manager at a Big 5 Sporting Goods store who had no building industry experience. “He’s actually going to be promoted to our operations manager here very shortly (once a replacement is found for his position).”

“So, absolutely, we plan to keep recruiting from out of the industry and bring people who have these skills,” Steiger exclaims, so the company can capitalize on “great ideas that maybe didn’t come from our industry.”

Interestingly, the company has found employee recruiting success in having its employees hand out little cards to people in their community doing an exceptional job. The cards essentially say, “Hey you’re awesome,” and feature a QR code to the company website that asks the person if they would be interested in applying a job. So far, two employees have joined the company using this recruitment method once they learned more about the ESOP.

“It is kind of the ethos of the company—being employee owned. It has changed how the employees view company profits, Steiger says. For instance, “if we wrecked a few boards in the yard, we start thinking, ‘Ok, these boards that we wrecked— let’s say $15,000 last year in damage—that’s half a penny on the share price.’ It doesn’t sound like much, but when you start multiplying that out by how many shares, that’s a lot of money.”

As the company grows its personnel, it also has been eying its expansion in the Port Angeles community.

building-products.com January 2023 • building products digest • 15

CEO Danny Steiger stands in front of one of the two Hartnagel Glassworks trucks purchased last year.

PARTNERING with Do it Best, Hartnagel Building Supply has been extensively remodeled, adding $250,000 in additional in-store inventory and categories.

In fact, Angeles Millwork grew its rental department from $105,000 in revenue three years ago, to $250,000 in 2022. And, after looking at the needs of the local community, it closed on a new 11,000-sq. ft. location (in downtown Port Angeles in the Sears building) on December 13, 2022, that will house its rental center so the company can “get a lot more equipment and some different product lines,” Steiger adds. “We don’t have any other rental centers in Port Angeles. Everybody had to drive 20-30 minutes to Sequim (Washington), for those services.”

In addition, the company identified that the Port Angeles area lacked good sources of glass, namely window installation, mirrors, and shower doors. Stepping into that underserved market has proven highly successful for the company.

In fact, the demand on the Hartnagel Glassworks team has been so high that at the end of 2022, the company was booking out about three months just for a measurement and has hired another apprentice for the department.

As the company looks to expand its presence in Port Angeles and the Olympic Peninsula area in the future, Steiger says it is busy launching a new e-commerce platform so it can run its businesses as efficiently and nimbly as possible, and to “adjust and pivot as we need to in the face of changing market conditions. We can’t be stagnant.”

It’s this constant forward momentum that has enabled this company to grow, adapt and faithfully serve its customers and community for nearly 120 years. “The better the community does, the better the business does. And the better the business does, the more we can give back to the community so it can really keep building on each other,” Steiger concludes. BP

SARA GRAVES

16 • building products digest • January 2023 building-products.com

Sara Graves, senior editor, is interested in your story. Contact her at sgraves@526mediagroup.com.

CUSTOMER SERVICE is at the heart of Lumber Traders.

A GOOD OMEN ascends over the corner of Hartnagel Building Supply—as the company likes to say, “The sun is always shining in the Pacific Northwest, even if we can’t always see it.”

SALES EFFORT

BY JAMES OLSEN

SALES IS AN “effort out—money back” business. Our industry is competitive and going to be more so in 2023.

I have worked with and trained salespeople in the lumber industry for 40 years. I have only seen one seller who worked hard enough not be able to make a career of sales. This person worked hard but just couldn’t connect with people on the phone. He was stiff and unnatural. Sales is a transfer of emotion, so if we cannot relax and act natural, customers will be uncomfortable and will want to get off the phone or out of the meeting as soon as possible and definitely will not be in a “buying” mood.

But the biggest reason people fail in sales is lack of effort. Sales, especially in the early stages of our career, takes a lot of work. We are often building our account base from scratch. Some are fortunate to be given accounts to work, but these are not usually strong accounts; they need to be worked and developed. These salespeople will also be expected to bring on new business.

Right Place(s) Right Time(s)

One of the ways we break into accounts is to be in the right place at the right time when our customer’s preferred supplier makes a mistake. Some sellers seem to have a knack for it. This “knack” comes from being in the right place at the right time with many accounts, not just a few. These sellers simply give themselves more opportunity for “luck” to come their way.

In sales, we only count the makes not the missus, so if we take more shots we have a better and faster chance to opening new accounts.

Minimum Effort

Our minimums when I traded were 50 outbound phone calls and 200 minutes a day. To be successful we must hit those numbers or very close. Several colleagues did more than that on a consistent basis and guess what? They made the most money. One call every 10 minutes is 48 outbound calls in an eighthour day.

I know and have trained many wildly successful salespeople. The grand majority work their tails off. Many of them make great incomes. But... the top producers don’t talk, think or, most importantly, work like the bottom 90%. The math just doesn’t work.

Two Most Important Hours

The two most important time and effort hours of the day are the last and the first.

Last hour of the day: We make a call list of minimum 20 customers that we are going to contact with delivered prices worked up on multiple items before we go home. If we are going to send offerings to our customers by email, we send them night before and use the “delayed email” option in Outlook, so they arrive at our customers desk in the morning.

Many sellers spend the first hour of the day “getting ready.” They come in, fix themselves some breakfast (eat breakfast at home!), surf the net a bit, then start. That does not and never will work.

First hour of the day: When our behinds hit our chair our finger should hit the phone. I also encourage you to

prospect the first hour of every day, unless the market is running.

Excuses

Excuse #1: “My customers all buy by email.” Okay, send out your offerings the night before. In addition, if this is true, you should be able to make more phone calls.

Excuse # 2: “I make and take a lot of calls on my cell phone.” Okay, document the number of these calls so your effort is recognized.

Ms. or Mrs. Charisma

If you have an established customer base or you are Mr. or Ms. “Charisma,” you can probably get away with less effort. I find charismatic sellers are about one in 50, so statistically speaking most of us are not that person. If you are new, the chances of you becoming top producer are infinitesimally small without effort. If you are Mr. or Ms. Charisma, it will happen bigger and faster with more work.

The Hard Way IS the Easy Way

“The hard way is the easy way; the easy way is the hard way.” It’s not about working more hours; it’s about the intensity of the hours we put in.

544-3572

18 • building products digest • January 2023 building-products.com

------------| OLSEN ON SALES ------------

JAMES OLSEN

James Olsen is principal of Reality Sales Training, Portland, Or. Call him at (503)

or email james@realitysalestraining.com.

DO UNTO OTHERS AS YOU WOULD HAVE THEM DO UNTO YOU

BY DAVE KAHLE

ONE OF THE principles that I have discovered in my 35 years as a consultant and sales guru is this: Biblical business principles are also those principles that enable a company to achieve more of its potential. In other words, you can take the Biblical sourcing away from a business principle, and the principle still works.

I’ve stumbled across this truth as it specifically relates to B2B salespeople. Assemble a system and a set of practices that enable a salesperson to leap to the top of his/her profession, and, coincidentally, those principles arrived at through a study of the best practices of successful salespeople, are the very same principles discerned through a study of the Bible.

As a consultant, I’ve discovered the same truth applied to businesses and professional careers. Adhere to certain Biblical principles, whether or not you know they are Biblical, and your career will blossom, and your business will reach more of its potential. You don’t need to be a Bible student to discover the principles upon which you can build a successful career, you just need to study the best practices of the best in your business and the two will coincide.

In this article, I’m going to unpack one such principle: Do unto others as

you would have them do unto you. Biblically, Jesus said this in Matthew 7:12. Practically, it’s incredibly good advice upon which you can build a personal character and a corporate culture.

You can apply it in multiple contexts and situations.

• Think of prospecting for new customers, for example. If you were guided by this principle, you’ll sharpen your definition of who is a potential customer to a highlyrefined set of specific criteria. You’d want to reach out to only that set of people/organizations that were most likely to have an interest or a need for your products/service. You wouldn’t want to solicit someone who was less likely to need what you offer. Why? Because you wouldn’t want to be approached by someone with a product or service that you were only marginally interested in. It would be a waste of your time. Do unto others….

• Your pricing would be fair and market based. Why? Because you want to have some trust in the fairness of the price you were quoted, if you were on the other side of that issue.

• You’d treat all your customers with courtesy and respect, because that’s how you would want to be treated. You’d listen carefully to

any complaints, and do your best to resolve them.

• You’d strive to be a great customer to your vendors. Respect their time, listen to their conversations and presentations, and strive to pay all your bills within their terms. After all, that’s how you would want to be treated.

• You’d pick up your messes and tidy up a bit before you left a hotel room. You’d tip generously. You’d praise and compliment regularly.

As a result of consistently applying this principle, your employees would enjoy working for you, your customers would grow in their loyalty to you, your vendors would favor you, and your community would respect and support you.

Not a bad outcome.

DAVE KAHLE

20 • building products digest • January 2023 building-products.com

------------| SELLING WITH KAHLE ------------

Dave Kahle is a leading sales authority, having written 12 books and presented in 47 states and 11 countries. For more information, visit davekahle.com.

Reach more customers by getting listed on NELMA’s Retailer Directory.

Read grade rules, span details, and get new promotional ideas for your business.

Listen to and watch product installation and comparison videos, plus grade representations.

Sample the variety and versatility of eastern white pine.

.ORG

@NortheasternLumberMfg @WoodInspiration @wood_inspiration1933

Use all your senses. Visit for all things eastern white pine, spruce-pine-fi r and other softwood species grown in the Northeast and Great Lakes region.

Plastic, concrete or pine? Learn why consumers prefer natural over fabricated.

PREPARING FOR 2023

BY PAIGE McALLISTER

WE HAVE ALL been on a roller coaster for the past two years and all signs look to that continuing into 2023. Here are some of the things we are watching heading into the new year.

Impacts from Election Day 2022

Ballot Initiatives: Along with the much-publicized control of Congress, several ballot initiatives were on the ballot across the country this election. While we do not know some requirements yet, here are some things considered to have big impacts on employers and employees:

Q. How often do we need to update our handbook?

A. In general, handbooks should be reviewed every year to ensure the language still matches your actual practices. During a review, you should make sure the correct people, contact information, forms, etc. are referenced. You should also make sure it matches your current work structure (i.e., remote, in-person, or hybrid) and expectations (i.e., work hours, availability, security, dress code, restrictive covenants, etc.).

However, reviews may need to be done more often if any federal or state employment laws change or are passed. This could include time off laws, paid leave, updated protected groups, and marijuana legalization. Current guidelines from the National Labor Relations Board about handbook language need to be considered as well.

You also need to update it when you hire employees working in a different state as each state’s laws impact several policies throughout the handbook, not just the obvious ones such as paid time off.

Consider having an HR consultant or employment attorney complete a thorough review every year or two, revising as needed, to ensure the legal language is current and correct, minimizing your obligations and exposure.

• Minimum wage: Nebraska voters passed a measure to increase the state’s minimum wage incrementally until it reaches $15 per hour by 2026 and then annually thereafter based on the increase in cost of living. Nevada’s minimum wage measure that passed will increase the minimum wage to $12 an hour and remove the differences based on if the employer is offering health care benefits.

• Legalized marijuana: Maryland and Missouri passed measures to legalize the recreational use of marijuana for adults over 21. This would not impact an employer’s right to prohibit the use, possession, or being under the influence; however, it could change how employers can use positive marijuana drug test results in making employment decisions. Similar measures did not pass in Arkansas, North Dakota, and South Dakota.

Legislatures: For the next two years, we do not expect to see much legislation from the divided U.S. Congress. In fact, the division could create more issues if needed legislation is obstructed, budgets are not passed, and the government is shut down.

However, on the state level, we expect legislation on sick pay, legalized marijuana, paid leave, weapon restrictions or permissions, pay equity or transparency, anti-discrimination, and restrictive covenants depending on the philosophy and needs in different states. The shifting control in some state governments from one party to another or from a split to one party being in control often means a change in legislative agenda with topics often dictated by the party in charge.

Employers need to stay aware of legislation moving through all levels of government, updating policies and procedures as new regulations are implemented and educating employees on their rights and responsibilities.

Labor Market

At the end of 2022, the labor market was still competitive and tight. Recent job growth was higher than

22 • building products digest • January 2023 building-products.com

------------| TRANSFORMING TEAMS

------------

projected, with 263,000 jobs added in November and the unemployment rate holding steady at 3.7%. Wages are increasing with the average hourly earnings increasing 0.6% in November, increasing the annual increase to 5.1%.

It appears “the Great Resignation” is slowing down, but approximately 4 million people are still quitting their jobs each month.

Employees are quitting due to personal reasons (such as illness, to care for family, or to pursue other career or educational opportunities),

While the layoffs at large tech companies like Amazon, Twitter and Meta made headlines, many companies are not expecting to lay off employees given their need to meet continuing demand and their need for qualified workers. Instead, we may see fewer job openings as companies reduce their hiring efforts while waiting out the threat of recession.

Employers need to prepare their companies to adjust and withstand the fluctuating and uncertain conditions of the economy and job market as well as the impacts felt within their industry, city and state. They should also be attuned to the financial, flexibility, and developmental needs of their employees to retain them.

COVID, RSV, Flu...

With approximately 300,000 new cases per day in the U.S. and almost 2,000 people dying each day, COVID-19 is evolving into an endemic but, with highly-contagious emerging variants, is still considered a public health emergency in some areas. An estimated 16 million employees have long COVID with an estimated 2–4 million people needing to leave the workforce due to long COVID which accounts for 20-40% of the labor shortage.

work options and prepare for coverage if someone needs to miss time out of the workplace.

• Offer cleaning and sanitizing products and create more open spaces to reduce exposure in the workplace.

• Support and encourage employees and their families to get vaccinated against COVID-19 and the flu, both of which have been shown to reduce the number of cases and severity of illness.

for better compensation (such as higher wages, more paid time off, or better insurance options), greater flexibility (such as remote work or flexible scheduling), or to escape a poor corporate culture (including long hours, poor management, or blatant discrimination or harassment).

With over 10 million job openings (equivalent to 1.7 openings for each person looking for a job), employees still greatly control the job market… for now.

The state of the economy will impact the job market in 2023. Financial experts have been warning about a recession, but with a currently strong economy and the rate of inflation slowing, they now think it may be weaker and shorter than originally feared.

With the predicted inflation, many expected massive layoffs in 2023.

Additionally, many officials are declaring pediatric RSV a public health emergency given the rising numbers of children becoming sick, being hospitalized, and dying due to the infection. Added to that, we are seeing the annual winter impact of influenza with millions of people already infected and hundreds of thousands hospitalized.

Employers need to know their legal and practical responsibilities to prepare for employees who become sick or have to care for a family member who becomes ill:

• Several states still have COVID-19-related pay, disability pay, and/or protections for time off due to covered purposes, some of which have been extended to cover RSV and the flu.

• Review the possibilities of remote

Look Out For Diversity, Equity, and Inclusion (DEI): Diversity in cultures, races, genders, religions, etc. as well as of thought is often considered a factor for the success of an organization. Employees want to feel included and clients want to work with people that look like them.

Other Trends to

Differing perspectives and backgrounds can lead to better ideas to weather uncertainties. While discrimination is prohibited under law, incorporating true equity and inclusion can help companies thrive. Employers should learn to embrace and support differences and require that support from everyone in their organizations.

NLRB: The National Labor Relations Board is continuing to strengthen employee and union rights. This includes measures that impact non-unionized companies, such as handbook language and restricting protected activity in the pursuit of better working conditions. Employers need to ensure they know the legal requirements and are not impeding those rights.

PAIGE McALLISTER

building-products.com January 2023 • building products digest • 23

EMPLOYERS NEED TO PREPARE THEIR COMPANIES TO ADJUST AND WITHSTAND THE FLUCTUATING AND UNCERTAIN CONDITIONS OF THE ECONOMY.

Paige McAllister, SPHR, SHRM-SCP, is vice president for compliance with Affinity HR Group. Reach her at (877) 660-6400 or contact@affinityhrgroup.com.

THE NATIONAL GRADING RULE AND WHY IT MATTTERS

A SPECIAL SERIES FROM

BY JEFF EASTERLING

IF YOU’VE EVER wondered how the lumber grading industry works, read on. This is some fascinating “behind the curtain” information.

The U.S. and Canadian lumber industries are driven and defined by a finite set of rules and interpretations set forth by the American Lumber Standard Committee. For lumber used in construction, this information is called the National Grading Rule, and without it, consumers would lose the consistency and confidence it provides when building with today’s most environmentally friendly and user-friendly material.

Let’s dig a little deeper.

What Is the National Grading Rule?

The National Grading Rules Committee, composed of members knowledgeable in the field of lumber technology, is called upon to “establish, maintain and make fully and fairly available nomenclature and descriptions of grades for dimension lumber.” Further, “grading rules of an agency shall not be certified as conforming to the American Softwood Lumber Standard if the Board of Review determines that the dimension lumber rules therein fail to conform to the provisions of the National Grading Rule for dimension lumber.”

In a nutshell: A group of lumber experts representing the five U.S. grade rules writing agencies and the one Canadian rules writer meet regularly to ensure that the lumber you sell, and your customers buy, will perform exactly as expected. What this group publishes, watches over, and updates

as necessary is like a cookbook that dictates what goes into a properly graded piece of lumber.

Dimension Lumber, Classifications

Dimension lumber is defined in the National Grading Rule as surfaced softwood lumber of nominal thicknesses from 2” through 4” and nominal widths of 2” and wider which is designed for framing (joists, planks, rafters, studs). Not included in this grouping: special products such as crossarms, foundation lumber, laminating stock, rough lumber, railroad stock, ship decking, and more.

As part of the National Grading Rule for Dimension Lumber, the wood is divided into three width categories and four use categories. Dimension up to 4” wide is “structural light framing” and “light framing.” Dimension lumber 2” and wider is “studs.”

If the pieces of dimension lumber are five inches and wider, this is classified as “structural joists and planks.”

Additional interpretations of the lumber grading procedures include definitions and parameters for knots and the like, how they should be measured, and how they should be applied to determine the grade.

It’s interesting to note that the exact language used in the National Grading Rule is echoed in the grade rule books of all six grading agencies—NELMA, WWPA, SPIB, Redwood Inspection Service, PLIB, and NLGA.

The use of the same language and the same interpretations ensures the proper grade is applied consistently to each and every piece of lumber

produced, whether it’s southern pine or Douglas fir.

Let’s Take a Field Trip

To explain in greater detail, let’s follow an SPFs 2x6 as it goes through the process: A log is harvested and sent to a mill, where it’s cut into a piece of dimension lumber, in this case, a 2x6. It’s then dried and planed before it is graded by either a human or a machine. Using the criteria set forth within the National Grade Rule and its interpretations, the 2x6 is assigned an official grade The lumber is then sold to a customer that will then apply the appropriate published strength properties based on the grade of the piece that will determine how it may be used in construction.

Grading is a critical component within the manufacturing process, and the National Grading Rule is the backbone. It provides the basis on how important end-use decisions are made for building with confidence.

For more information on the National Grading Rule, please open the camera on your phone, hold it over the QR code at the top of the page, and click on the link that appears.

JEFF EASTERLING

JEFF EASTERLING

24 • building products digest • January 2023 building-products.com

------------| LUMBER 411 ------------

Jeff Easterling is president of the Northeastern Lumber Manufacturers Association, Cumberland Center, Me. Reach him at info@nelma.org.

s g sooffttwwood spe ood specciieess. . It thrives in some of the most productive timberlands in the world. Redwood is known for its timeless durability without the use of chemicals. Due to its flawless formation, there has never been a Redwood recall. There is a grade of Redwood for every application, every budget, and every customer. “Growing beyond measure.” Call or visit us today. Our family of Redwood timberland owners will continue to be your reputable and reliable source of Redwood.

REDWOOD THE POSSIBILITIES KEEP GROWING: Call us at 707.894.4241 Visit us at buyRedwood.com Nature’s majestic pilla rs.

Reddwwood i ood is o s onne o e of t f thhe s e sttrroonnggeesst a t annd f d faasstteesst g t grroow

Re

wiinng

BOISE CASCADE DISTRIBUTION

EXPANDING IN SC, TEXAS

Boise Cascade’s Building Materials Distribution is adding new distribution centers in South Carolina and Texas.

The company has acquired 45 acres in Walterboro, S.C., about 45 miles west of Charleston. The rail-served facility, its first DC in the state, will help better serve Myrtle Beach, Charleston and Columbia, S.C., as well as Savannah, Ga. The BMD division currently services these markets through its facilities in Greensboro, N.C., and Atlanta.

Boise Cascade also closed on the purchase of a 34-acre land parcel in Hondo, Tx., located 40 miles west of San Antonio. It will be the third Boise Cascade DC in the state, along with two door shops. The property is rail-served and will help serve Austin, San Antonio, Corpus Christi, and the Rio Grande Valley.

Construction should begin soon.

GREAT SOUTHERN EXPANDS IN AL.

Great Southern Wood will invest $13.7 million to expand its treating facility in Mobile, Al.

The expansion will create 12 new jobs, improve the plant’s traffic flow, add storage space, and better its ability to process imports and exports through the Port of Mobile.

The company will break ground on the expansion project this month and expects it to be completed by the end of February 2024.

WESTLAKE BUYS PALIGHT TRIMBOARD

Westlake Royal Building Products, Houston, Tx., has purchased the Palight Trimboard business from Palram Americas, Kutztown, Pa.

Palight Trimboard product lines will be incorporated into the Westlake Royal Trim & Mouldings Solutions portfolio.

The transaction builds upon a long-standing manufacturing relationship between Westlake Royal and Palram. Manufacturing will continue to occur in Kutztown, as Westlake Royal will assume responsibility for an existing manufacturing facility on the Palram campus.

ACCOYA BUILDING PLANT IN US

Early in 2024, Accoya will begin modified wood product production at a new plant currently under con-

struction in Kingsport, Tn.

The plant, to be known as Accoya USA LLC, is a joint venture between Accsys, the world’s only acetylated wood producer, and Eastman, a global specialty materials company.

Once operational, the facility will supply the North American market and Accoya’s Netherlands plant will supply the rest of the world. The U.S. reactors are currently being transported from Europe and will arrive in Kingsport this month.

HDI REBRANDS AS ADENTRA

Hardwoods Distribution Inc. has rebranded as Adentra, Inc.

Deriving from the Spanish word “dentro” meaning “within,” Adentra represents the company’s modern identity as a distributor of architectural design products used to create beautiful spaces where we live, work and play.

“We believe the new name captures the overall value we have built—our extensive product portfolio, our critical role in providing supply chain expertise, and the benefits of scale we deliver across our vast network of customers,” said president and CEO Rob Brown. “While our corporate name undergoes a rebrand, our work with customers and vendors continues through our five flagship brands: Novo Building Products, Mid-Am Building Supply, Rugby Architectural Building Products, Paxton Lumber, and Hardwoods Specialty Products.”

The rollout includes a new logo, tagline (“Creating beautiful spaces where we live, work and play”), and website (adentragroup.com).

The rebranding initiative comes just over a year after HDI acquired Novo and Mid-Am, which expanded its markets beyond industrial distribution, architects and designers to pro dealers and home centers.

Effective Dec. 8, 2022, Adentra’s common shares began trading on the Toronto Stock Exchange under the symbol “ADEN.”

WORKER DIES AT GEORGIA MILL

OSHA is investigating an apparent industrial accident at Battle Lumber Co., Wadley, Ga., that resulted in the death of an employee.

On Dec. 7, Trenton Lewis, 31, suffered blunt force trauma to the torso.

Nation’s Best has acquired 72-year-old Forslund Building Supply, with yards in Ironwood, Caspian and Norway, Mi.

Randy’s Do it Best Hardware hosted a grand reopening on Nov. 26 at its new store location in Mt. Jackson, Va., replacing its home of 70 years, which was destroyed by fire last February.

Builders Supply of Delmarva, De., held a grand opening Nov. 3 for its new 4,400-sq. ft. showroom in Rehoboth Beach, De., showcasing windows, doors, trim, siding, cabinetry, stairs, decking, railing, hurricane shutters, and more.

Sully’s Ace Hardware, Sullivan, Mo., has been purchased by R&R Center, St. Clair, Mo.

Curt’s Ace Hardware opened its newest location Nov. 29 in Elizabethton, Tn.

ABC Supply Co. opened a new location in Havre de Grace, Md., managed by Ethan Lear.

Westlake Ace Hardware signed a lease agreement to open a 20,000-sq. ft. store in High Point, N.C., by the end of July. Westlake also plans to open two additional locations in the Raleigh area during the first quarter of 2023.

Spring Glen Hardware & Appliance, Hamden, Ct., is closing after 60 years in business.

Damascus Hardware, Damascus, Oh., owners Justin and Allison Biery have purchased 123-year-old Leonard Hardware, Sebring, Oh., from Sue Risbeck Sanor, who has retired. They will remodel then reopen the store in mid-April as Sebring Hardware.

Revell Ace Hardware acquired Madison Ace Hardware, Madison, Ms., as its 8th location.

Lumbermen’s Association of Texas is partnering with UFP Industries to advocate for the industry during its 2023 LAT Action Day Feb. 15 at the Texas Capitol in Austin, Tx.

Home Depot presented 2022 Innovation Awards to FastenMaster’s Cortex Hidden Fastening System, Hubspace String Lighting, and Glidden Max Flex spray paint.

26 • building products digest • January 2023 building-products.com

------------| DEALER BRIEFS

Join Us at these NAWLA Events in 2023

Summit

Executive Management Institute

with

Spring Wood Basics

May

Fall Wood Basics Peachtree, GA September

NAWLA Traders Market Columbus, OH November

Join Us at these NAWLA Events in 2023 Find more details and register at nawla.org North American Wholesale Lumber Association Find more details and register at nawla.org North American Wholesale Lumber Association

Summit

Executive Management

Spring Wood Basics

May

Fall Wood Basics Peachtree, GA September

NAWLA Traders Market Columbus, OH November

Regional Event Locations Arlington, TX Birmingham, AL Minneapolis, MN Montreal, QC Portland, OR Rockland, ME Vancouver, BC Regional Event Locations Arlington, TX Birmingham, AL Minneapolis, MN Montreal, QC Portland, OR Rockland, ME Vancouver, BC

Leadership

Palm Desert, CA March 12-14

(EMI) In conjunction

Northwestern University Chicago, IL April 23-28

Vancouver, Canada

8-11

11-14

8-10

Leadership

Palm Desert, CA March 12-14

Institute (EMI) In conjunction with Northwestern University Chicago, IL April 23-28

Vancouver, Canada

8-11

11-14

8-10

MFM FINISHES MAJOR EXPANSION

MFM Building Products has completed a near-twoyear-long expansion project in Coshocton, Oh., adding 48,000 sq. ft. to the production area and installing new production equipment to meet rising demand for its exterior waterproofing membranes.

The project also included constructing new offices in the main headquarters building, adding a state-of-theart research & development laboratory for increased quality control and new product development.

“We definitely had some setbacks with the current state of the supply chain, which caused some delays in the completion date,” said president Tony Reis. “Now that we are finished, we are focused on meeting the needs of our customers and hope to be introducing several new waterproofing products to our portfolio.”

SNAVELY

ACQUIRING MID-STATES

WHOLESALE

Snavely Forest Products, Pittsburgh, Pa., has agreed to purchase Mid-States Wholesale Lumber Co., Oklahoma City, Ok. The deal was expected to close on or before December 30, 2022.

As a subsidiary of Snavely, Mid-States will continue to operate seamlessly and consistently. They will preserve the Mid-States name, management team, and employees.

Mid-States Wholesale has been serving the Oklahoma City, Tulsa, and Wichita regions since 1986.

BLIFFERT ACQUIRES MILWAUKEE HARDWOOD MILLWORK MANUFACTURER

FILLINGER

Ten-unit Bliffert Lumber & Hardware, Milwaukee, Wi., has acquired Milwaukee hardwood moulding and custom millwork manufacturer Fillinger Millwork.

“My brother and I managed A. Fillinger, Inc. through its fourth generation, and we’re proud of securing a long-term future for our staff and product lines,” said Justin Fillinger, co-owner of A. Fillinger, Inc. “By joining the Bliffert team, we align our mutually beneficial goals of building a sustainable and high-efficiency production environment in the moulding and cabinetry industry.”

VP Eli Bliffert said, “The Fillinger family has been an institution in Wisconsin for generations. Their reputation for innovation and old-world craftsmanship is unparalleled. Adding the Fillinger manufacturing and custom cabinet lines gives our customers more options.”

Fillinger Millwork is a fourth-generation, familyowned business founded in 1938 as a cabinet shop, evolving to a lumber mill, retail hardware store, lumberyard, and now millwork producer.

IOWA’S OGDEN & ADAMS BUYS DELHI LUMBER

Ogden & Adams Building Solutions, Hiawatha, Ia., is purchasing the assets of Delhi Lumber Co., Delhi, Ia. Delhi Lumber co-owners Mike and Vivian Cairney will retire after assisting with the transition.

“I am proud of our staff and the business we built. The merging of these two companies will be good for our employees and customers and I think it is very exciting opportunity,” Mike Cairney said.

Ogden & Adams plans to retain all staff and the Delhi Lumber name. Ogden & Adams recently relocated into the 20,000-sq. ft. facility in Hiawatha, which now serves as its headquarters, design center and warehouse.

SUPPLIER BRIEFS

Wahoo Decks, Dahlonega, Ga., has rebranded as Wahoo Building Products, reflecting its broadening product offerings and customer base.

Mission Forest Products has started up its $160-million, state-of-the-art sawmill in Corinth, Ms. Woodgrain will invest $7.5 million to expand its door-hanging operation in Rocky Mount, N.C., relocating its existing operation to a larger 225,000sq. ft. facility.

Lumberman’s Wholesale, Inc., Montgomery, Il., is adding a branch in St. Louis, Mo., to supply dealers in southern Illinois and eastern Missouri with products from Westlake Royal Building Products (TruExterior, Versetta Stone, Celect, Royal Trim, Zuri), Titebond, Quality Edge, Henry, and AFCO Columns & Railings.

Holbrook Lumber Co., Guilderland Center, N.Y., and J. Gibson McIlvain, White Marsh, Md., are now distributing Tantimber’s ThermoWood products.

Weekes Forest Products’ seven distribution centers are now supplying Typar products throughout the upper Midwest and Southeast. Weekes’ sister company, Snavely Forest Products, is Typar’s largest distributor.

Fi-Foil Co., Auburndale, Fl., acquired Kennedy Insulation Group, Carthage, Mo., manufacturer of VerSola multi-layer reflective bubble insulation.

Oldcastle APG, Atlanta, Ga., has purchased the packaging operations of Sterling Sand, West Columbia, S.C., and the soil business of Soil Mender Products, Tulia, Tx.

TruStile is incorporating Accsys’ Tricoya wood products into its new Resilient Wood Entry System.

Regal ideas’ Crystal Rail aluminum railing system was awarded Best in Show in the Outdoor Living category at the recent Deck Expo in Las Vegas.

ECMD, North Wilkesboro, N.C., is celebrating its 40th anniversary.

28 • building products digest • January 2023 building-products.com

------------|

MFM EXPANSION will allow a significant increase in production of MFM Building Products’ exterior waterproofing membranes.

Dennis Ramey, regional sales mgr., Smith Millwork, Lexington, N.C., has retired after 28 years with the firm.

Mike Olosky has been named CEO of Simpson Strong-Tie, Pleasanton, Ca. He succeeds Karen Colonias, who will continue as an executive advisor until officially retiring on June 30.

Christopher Culver, ex-Builders FirstSource, is now EWP production mgr. at Carter Lumber, Charlotte, N.C.

Michael Ransom, ex-Kight Home Center, is now Columbia, Tn.-based regional design mgr. for 84 Lumber. Sean DeSmet has been promoted to outside sales coordinator in Douglassville, Pa., and James Rodriguez to sales coordinator in Myrtle Beach, S.C. Dylan Miller is a new management trainee in Painesville, Oh. Gene Haddock, ex-Interfab, is now commercial operations mgr. with 84 in Mt. Airy, Md.

Chris Freader has been promoted to senior VP of retail services for Orgill, Collierville, Tn. Geoff McCaslin is now director, replenishment; Andrew Yount, director, vendor support; Jim Rivas, director, retail technology; and Peter Kim, director, cybersecurity. Myron Boswell, VP of dealer sales, Northeast, has retired after 33 years with Orgill. Todd Nowels succeeds him, and Paul Dupont replaces Nowels as VP of dealer sales, Southeast. Laura Freeman is new as executive VP of human resources and chief human resources officer.

Vince Bassalone was promoted to branch mgr. at Boise Cascade, Nashville, Tn.

Sharon Woodbury is now an inside sales rep with PrimeSource Building Products, West Bridgewater, Ma.

Dionne Vernon has been appointed VP, talent management and Gui Nebel VP, finance & treasury for BlueLinx, Atlanta, Ga. Shree Iyer is now senior director, enterprise applications.

Michael Morris has been promoted to senior VP of sales for Derby Building Products, parent of Tando and Novik.

Tony Buroker has launched Buroker Pallet & Lumber Consulting, Carrollton, Ga.

Nick Nelson has joined Jeske Hardware Distributors, as Aylett, Va.-based account mgr. for the mid-Atlantic.

Jenny Chambless joined Do it Best Corp., Fort Wayne, In., as merchandise coordinator. Dylan Hopper is a new sales support coordinator. Recently promoted were Lori Cardelli to associate building materials trader; Joe Hutt, merchandise mgr. for building materials; and Brittany Peavler, associate merchandise mgr. for hardware.

John Williams will retire June 30 after 14 years as president and CEO of Domtar Corp., Fort Mill, S.C. He will be succeeded by Steve Henry, who in the interim will serve as executive VP and chief operating officer.

June Yang has been appointed to the board of SRS Distribution, McKinney, Tx.

Dr. Healy Hamilton has been appointed chief scientist for the Sustainable Forestry Initiative, effective April 4.

Bella d’Ball is the new social director at Mungus-Fungus Forest Products, Climax, Nv., according to owners Hugh Mungus and Freddy Fungus.

building-products.com January 2023 • building products digest • 29

------------| MOVERS & SHAKERS

SOUTHERN FOREST Products Association elected new officers during its annual meeting Oct. 21 in Nashville, Tn., including (left to right) treasurer Pino Pucci, LaSalle Lumber Co.; chairman of the board Mark Richardson, Westervelt Co.; vice chair Rich Mills, Hood Industries; immediate past chair Will Lampe, Lampe & Malphrus Lumber Co.; and executive director Eric Gee.

PRESSURE TREATED WOOD 101

BY CHRISTIAN MOISES

WOOD CAN BE subject to attack by insects, microorganisms and decay fungi, especially in high-moisture conditions. That’s why many builders opt for pressure-treated wood with preservatives to help ensure long-term structural performance by protecting lumber used in a wide range of service conditions. Pressure treated southern pine wood products are an economical and renewable building material.

There is a variety of processes used to protect wood products, including pressure, non-pressure, thermal, nonbiocidal, and fire-retardant treatments. There is also a variety of preservatives used for each treatment process. The best preservative for any project largely depends upon the product, species, and end-use application.

Pressure treatment with preservatives protects wood exposed to high-moisture conditions and potential deterioration. Treated wood must meet minimum requirements for preservative penetration and retention for use in a particular service condition.

But not all wood treats the same. Most wood species do not easily accept preservatives and must first be “incised,” or perforated along the surface, reducing the wood’s strength and stiffness.

Southern pine’s unique cellular structure, meanwhile, easily permits the deep penetration of preservatives, rendering the wood useless as

CODE ACCEPTANCE, IDENTIFICATION, AND PRESERVATIVES FOR LIFELONG PERFORMANCE

a food source for fungi, termites, and micro-organisms without the need to incise. Its superior treatability has made it the preferred species when pressure treatment with wood preservatives is required.

Code Acceptance

The American Wood Protection Association (AWPA) is the standards-writing organization for the U.S. wood-treating industry. AWPA’s Book of Standards provides consensus-based guidance on methods, preservatives, and other technologies that protect wood products.

Wood preservatives are accepted for model building code compliance by referring to the AWPA Book of Standards, or by Evaluation Reports issued by the ICC-Evaluation Service. Model building codes have specific requirements for wood protection by use of approved naturally durable wood, or wood that is preservative treated in accordance with AWPA Standard U1 for the species, product, preservative, and end-use.

The codes acknowledge not all preservative-treated wood is pressure treated. Non-pressure treatments typically involve borate-based

building-products.com January 2023 • building products digest • 31

------------| SFPA SPECIAL REPORT ------------

SOUTHERN PINE is one of the few decking-friendly softwoods that don’t have to be incised to allow deep penetration of wood preservatives. (All images courtesy Southern Forest Products Association)

preservatives that are sprayed on untreated lumber to provide a surface barrier coating.

These non-pressure treatments are marketed as a defense against mold, fungal decay, and/or termite attack, and are intended only for enclosed, interior framing. Non-pressure treatments cannot be substituted for approved naturally durable or pressure-preservative-treated wood in exterior applications.

International Residential Code (IRC) Sections R317 and R318 provide specific requirements for protection against decay and subterranean termites. Common applications to check for building code requirements regarding wood protection include:

• Wood in contact with the ground or water.

• Sills and sleepers on a concrete or masonry slab.

• Wood used above ground where specified distances from the exposed ground are not met, such as wood joists closer than 18” or wood girders closer than 12”.

• Structural members exposed to the weather without adequate protection.

Whenever practical, boring, machining, trimming or surfacing should be done before treatment. Field-cut ends, notches, and drilled holes in preservative-treated wood should be treated in accordance with AWPA Standard M4.

Identification:

Grade & Quality Marks

Building codes and regulatory agencies recognize southern pine for use in construction and must be properly identified. Each piece of lumber must be grade marked by an agency accredited by the American Lumber Standard Committee (ALSC) and manufactured in accordance with Product Standard PS 20 published by the U.S. Department of Commerce.

Southern pine lumber is graded in accordance with the Grading Rules published by the Southern Pine Inspection Bureau (SPIB). SPIB, Timber Products Inspection Inc. (TP), and

other organizations are accredited to inspect and grade mark southern pine lumber in accordance with SPIB Grading Rules.

Southern pine treated with preservatives standardized by AWPA or evaluated by ICC-ES must be monitored by an accredited third-party inspection agency. All treated southern pine must be identified with a treated quality mark—either plastic end tag or ink stamp—conforming to building code standards.

Treated wood quality marks identify wood products treated with preservatives standardized by AWPA or evaluated by ICC-ES. Use of such marks ensures:

• The preservative is EPA-approved for end-use application.

• The wood product is treated in compliance with federal law.

• The preservative retention and penetration meet the manufacturing specifications.

• An accredited third-party quality-audit program has inspected the pressure-treated wood product.

AWPA-standardized preservatives and ICC-ES-evaluated preservatives are accredited by the ALSC and the International Accreditation Service (IAS), respectively.

Wood Preservative Systems

There are three broad classifications of preservatives used to pressure treat wood products:

• Waterborne preservatives serve a variety of uses including residential, commercial, marine, agricultural, recreational, and industrial applications. They are most often specified because they are clean in appearance, odorless, paintable, and registered with the Environmental Protection Agency (EPA) for interior and exterior use without a sealer.

• Creosote preservatives, including creosote/coal tar mixtures, protect railroad ties, marine pilings, and utility poles.

• Oilborne preservatives are used primarily for utility crossarms and poles, piling, posts, and glulam.

ALL TREATED southern pine should be identified with an inspection agency quality mark (either plastic end tag or ink stamp) conforming to building code standards.

Wood preservatives are registered with the EPA for their safe use. There are numerous preservatives available in the marketplace today,

32 • building products digest • January 2023 building-products.com

many approved by the American Wood Protection Association (AWPA) while others have ICC-ES Evaluation Reports (ESR). These preservatives can be expected to provide excellent protection for wood products when appropriate preservative retention levels are applied.

Waterborne Preservatives, CopperBased

Copper has been used for centuries to control fungi. Copper-based preservatives rely on the well-established effectiveness of copper to provide most of the protection to the wood; co-biocides complete the formulations by adding protection against copper-tolerant fungi. Copper-based preservatives generally can be used in interior and exterior applications, even in the most severe conditions.

There are two main methods to prepare copper-based preservatives for pressure treatment:

• Dissolved copper-based preservative solutions are effective in penetrating the cells in the wood fiber during the pressure-treatment process and provide long-term protection from fungal decay and

termite attack. They were developed to protect wood products exposed to exterior conditions.

o Copper azole (CA) and alkaline copper quat (ACQ) commonly are used to treat southern pine wood products in a variety of exterior residential, commercial, and agricultural construction applications.

o Chromated copper arsenate (CCA) is no longer used in consumer applications, but it remains an EPA-approved preservative for use in non-consumer industrial, commercial, marine, and agricultural applications.

o Typical applications for CCA-treated southern pine include:

* Agricultural timbers and poles

* Foundation pilings

* Highway construction

* Marine (brackish and saltwater)

* Permanent wood foundations

* Utility poles

• Micronized copper-based preservatives are formulated with micron-sized particles of copper suspended in water. They were developed to reduce the impact on aquatic and terrestrial environments

and are less corrosive to fasteners.

Micronized copper azole is commonly used to treat southern pine wood products in interior and exterior applications.

Waterborne Preservatives, NonCopper-Based

Preservatives without copper, which were developed for use in less-severe service conditions, provide a lower environmental impact, a natural appearance, and are not corrosive.

Carbon-based preservatives (PTI and EL2) are approved for interior and exterior above-ground uses. This includes the bulk of exterior wood products used in residential construction—everything except ground-contact applications.

The most common borate preservative is inorganic boron (SBX). SBX is standardized by AWPA for interior uses, such as sill plates, furring strips, joists, studs, roof trusses, blocking, rafters, beams, and other framing applications. ESR-2667 provides acceptance for exterior construction, above-ground, coated, and rapid water runoff uses, such as fascia, siding, and trim, when contin-

building-products.com January 2023 • building products digest • 33

promotion programs, despite travel disruptions. A successful pivot toward virtual events ensured that the association was able to reach a record number of timber traders and construction professionals worldwide and to safely meet their needs effectively.

Let’s break down the activities and successes and take a closer look at each.

FEA Strategic Planning Webinar

As a gold sponsor of this online or virtual event, SFPA was able to provide member access to information, which helped each better define their international goals moving forward.

Worldwide Conference on Timber Engineering

SFPA’s participation bolstered the Association’s seminar programs across the globe to enrich international outreach and education. With international advertising and messaging support in multiple global markets, southern pine information was showcased internationally through a variety of channels.

Japan Technical Committee (JTC)

In partnership with American Softwoods, SFPA and the Southern Pine Inspection Bureau banded together to jointly present information on the southern pine resource and clarify the grading procedures for dense vs. non-dense grades.

Oxine copper is low in toxicity and approved for above-ground end uses, including glulam beams (after gluing) and certain applications where food is harvested, transported, or stored. Oxine copper can also be used to treat field cuts and holes per AWPA Standard M4.

Long-Term Performance

Wood products are preservative treated to provide the required longevity for their intended use. This includes consideration of the following:

Outreach: International Trade Shows

• Using the right fasteners and connectors for corrosion protection

While many lumber industry trade shows across Europe, India, the Middle East, and Asia were cancelled or postponed in 2021, plans are well underway for a full slate of in-person trade shows in 2022. Members are keen to take advantage of these face-to-face opportunities, and SFPA stands ready to serve member needs.

• Re-drying after treatment with waterborne preservatives for dimensional stability

uously protected from direct wetting with a minimum of one coat of primer and two coats of finish paint.

Outreach: Caribbean

include Creosote Preservative (CR), Creosote Solution (CR-S) and Creosote-Petroleum Solution (CR-PS).

• Structural design, including using the latest design values and appropriate adjustment factors

Southern Pine Exports

• Onsite job storage for moisture protection

Creosote-Based Preservatives

Throughout the southern pine-loving Caribbean, virtual seminars targeted hundreds of key buyers in both traditional markets and new markets—some of which SFPA reached for the first time.

Oilborne Preservatives

Export numbers calculated throughout the majority of 2021 are roaring back to pre-pandemic levels, an encouraging sign as plans are underway for 2022.

Outreach: Central America

Multiple southern pine lumber events were held in Guatemala, with brand-new outreach activities expanding into the Panamanian building market.

Outreach: South America

Targeting potential southern pine lumber buyers across the continent, a first-ever virtual education seminar was held and pulled in excellent results.

Outreach: Latin America

Creosote is a tar oil distillate and one of the oldest wood preservatives. Creosote is an effective preservative for severe exposure conditions in commercial, industrial and marine applications, including marine borers in salt water. It is also commonly used by the railroad industry to treat crossties and switchties. Creosote is not generally used in consumer applications due to its odor and oily surface appearance. Creosote-based preservatives