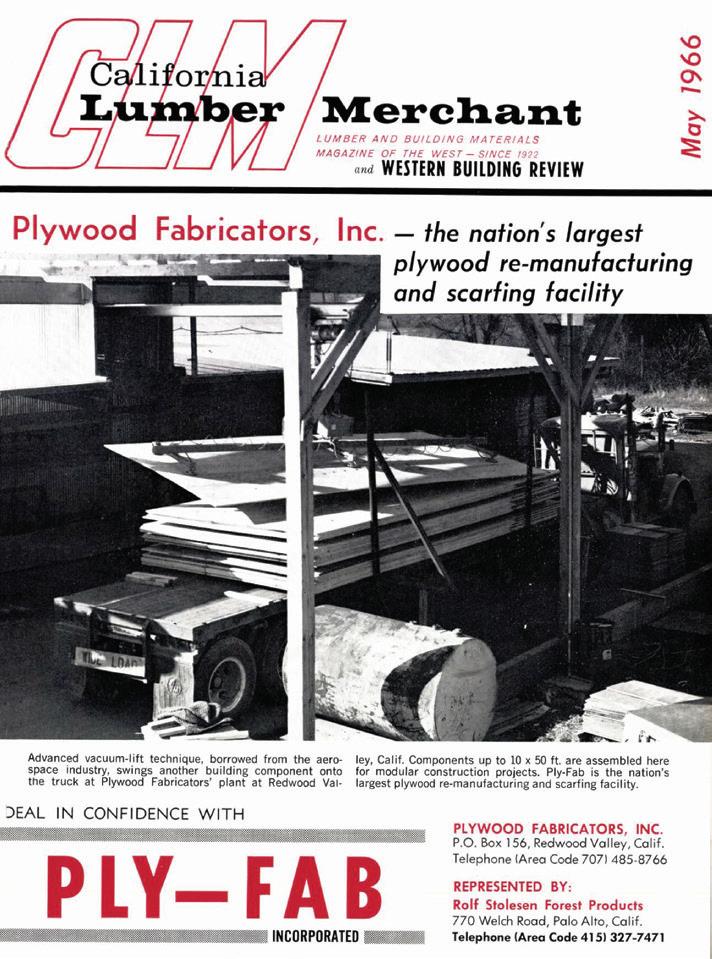

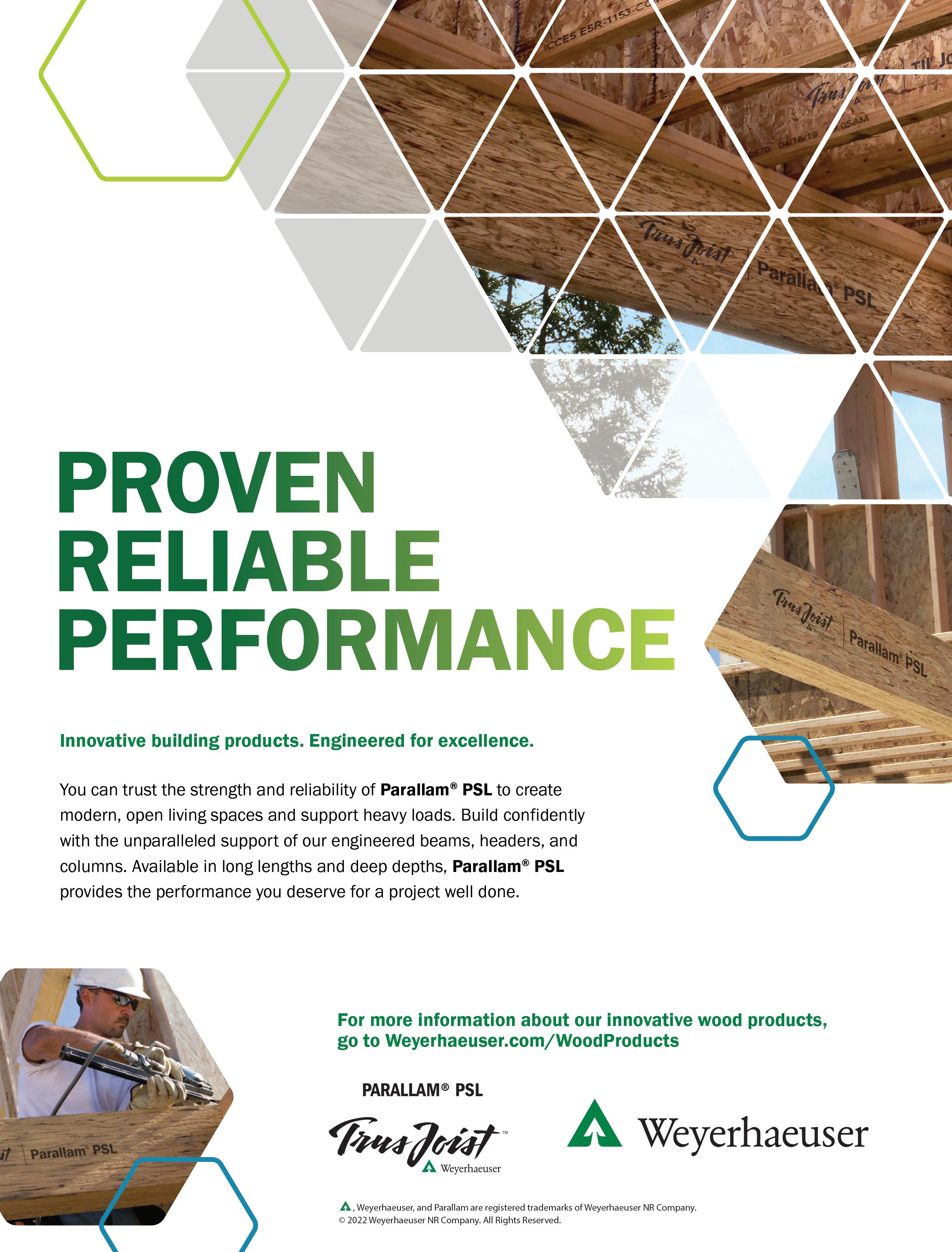

Like the foods we buy, when it comes to decking, we want natural and real. Redwood is always available in abundance of options. So stock the shelves! Unlike mass-produced and inferior products, Redwood is strong, reliable and possesses many qualities not found in artificial products. They maintain temperatures that are comfortable in all climates.

Redwood Empire stocks several grades and sizing options of Redwood.

NAWLA SPECIAL ISSUE • SYSTEM SELLING OUTDOOR LIVING PROJECTS • DO IT BEST MARKET RECAP THE VOICE OF THE LBM SUPPLY CHAIN May 2024 Digital Edition Sponsored by Call us at 707.894.4241 Visit us at buyRedwood.com DECKING Composite can’t compare.

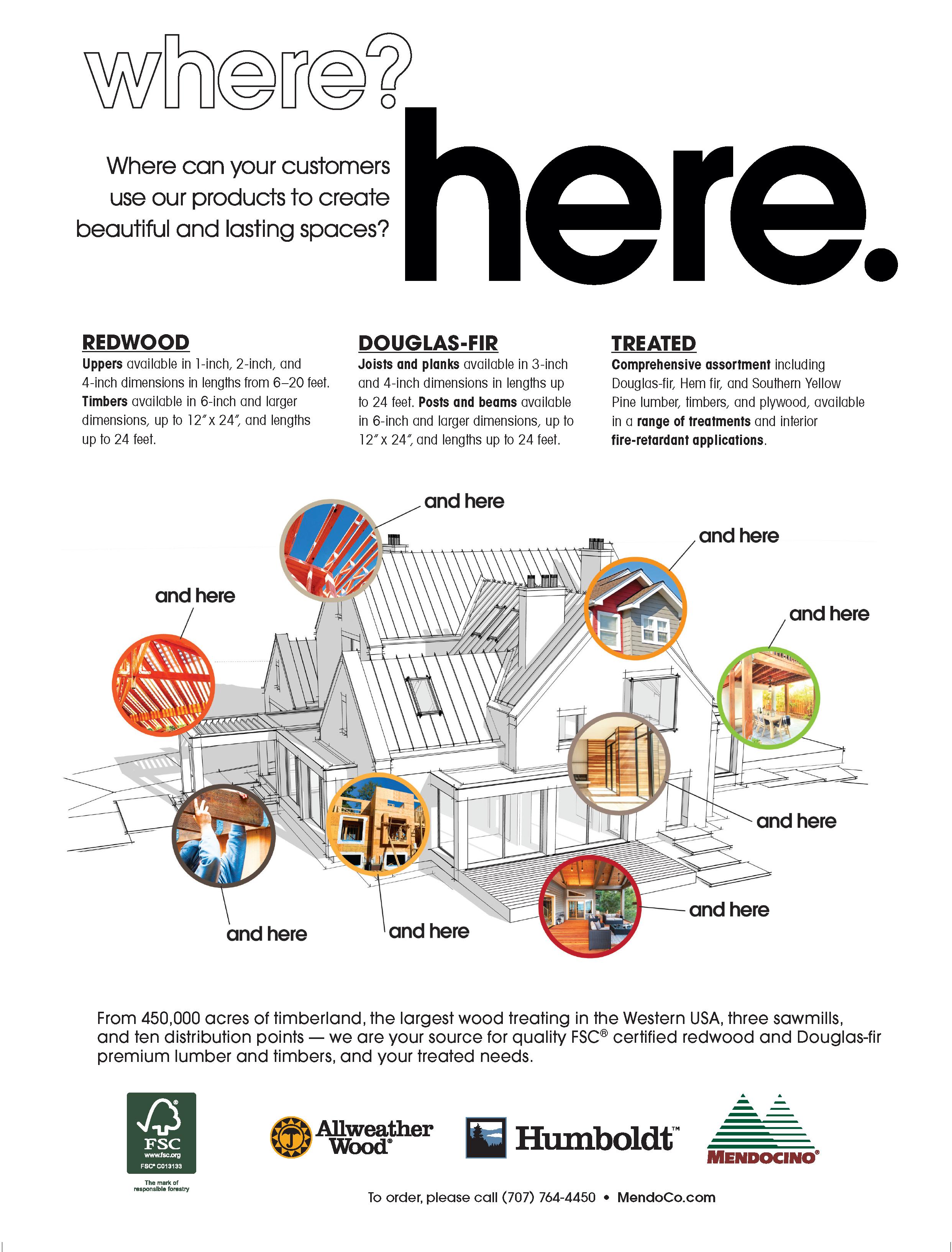

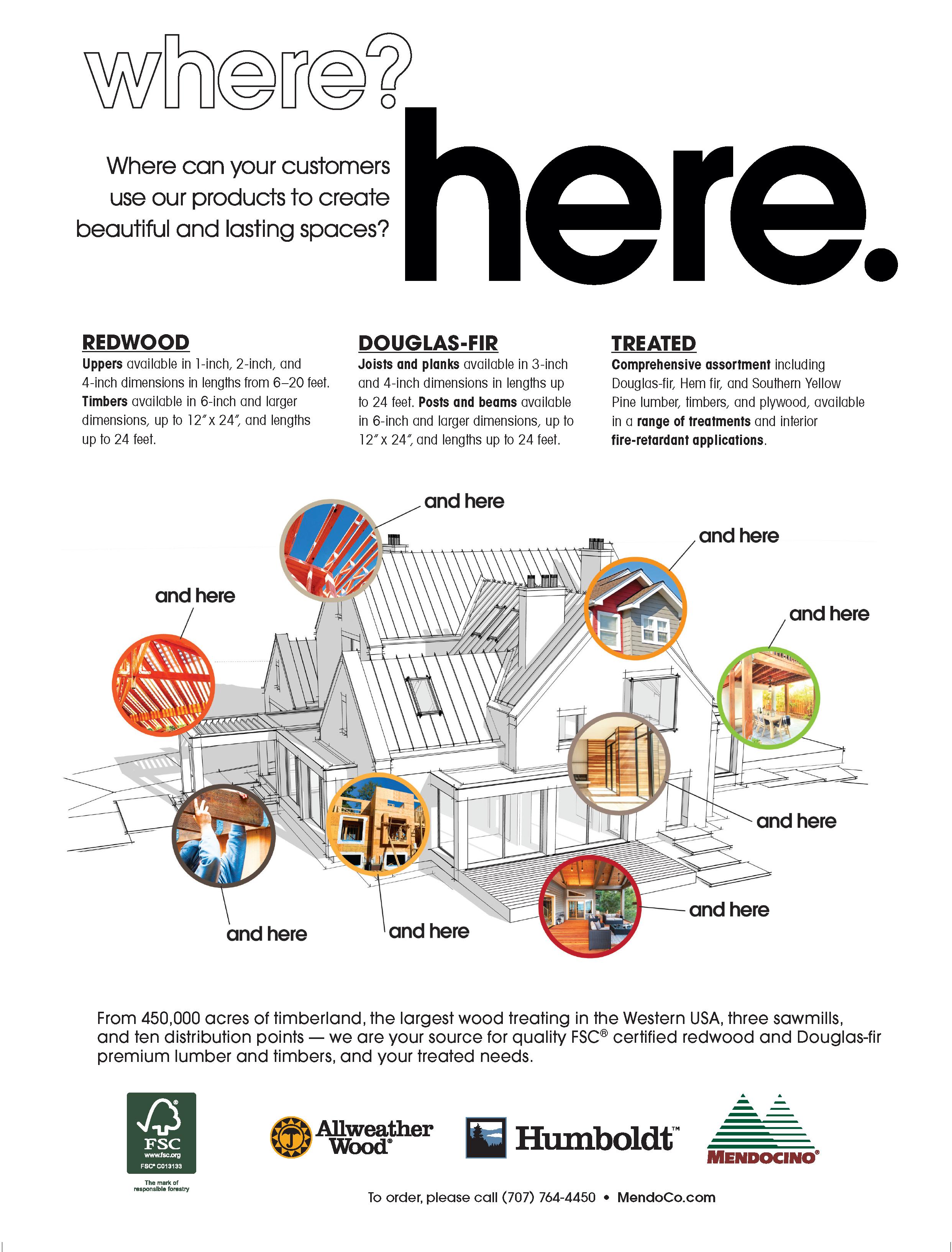

REDWOOD

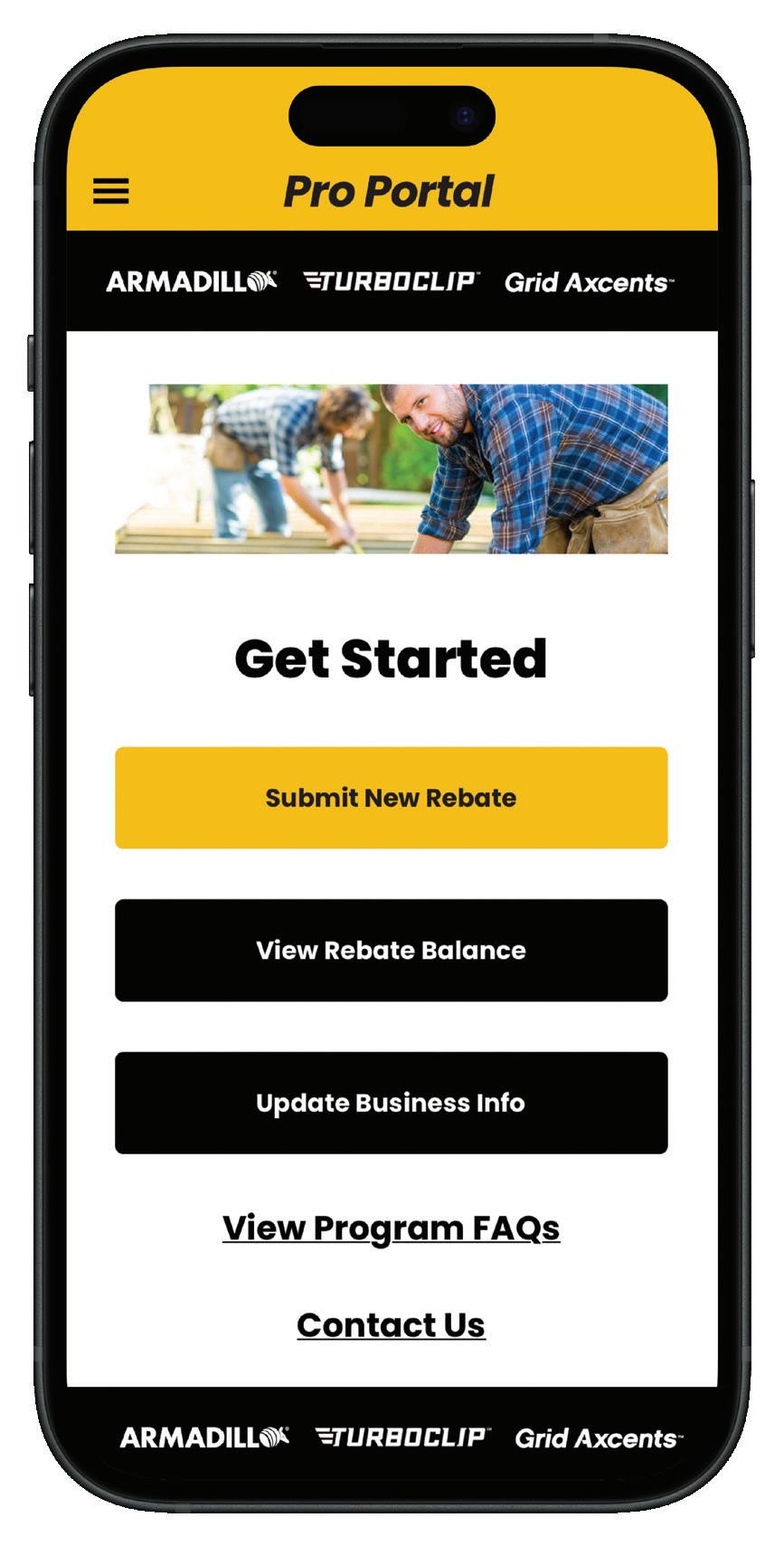

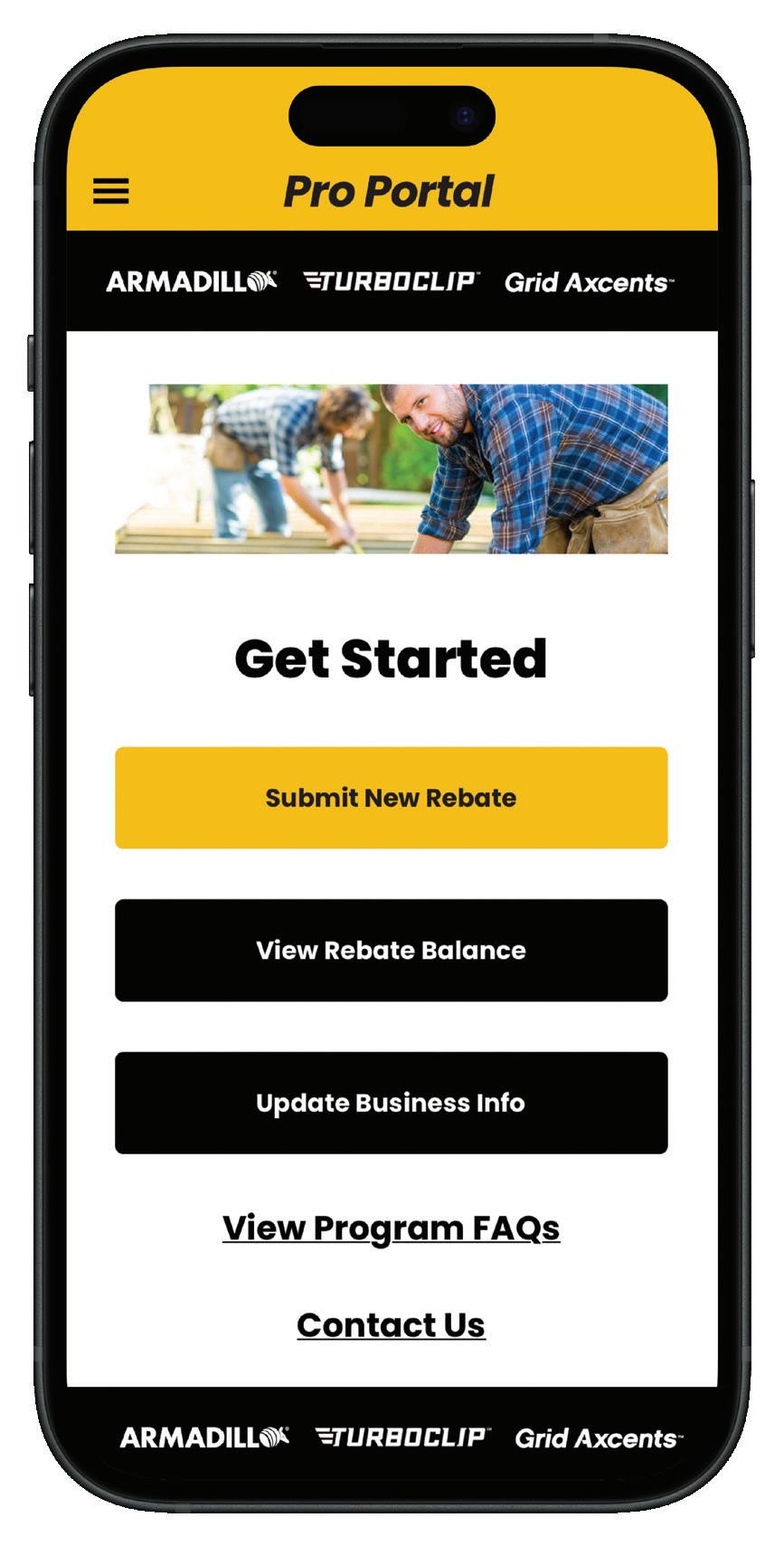

3 STEPS TO REBATE! 1. UPLOAD RECEIPT & DECK PHOTO 2. ENTER JOB SITE ADDRESS 3. CLICK SUBMIT IT’S EASY! Use it at the job site, on the go, at home or anywhere! BUILDER REBATE APP TODAY! DOWNLOAD THE SCAN THE CODE! WILL BE FEATURED ON AIRING THIS FALL ON FAST SUBMIT REBATES BACK GET CASH SELL MORE. BUILD MORE. EARN MORE. PARTNER WITH ARMADILLO

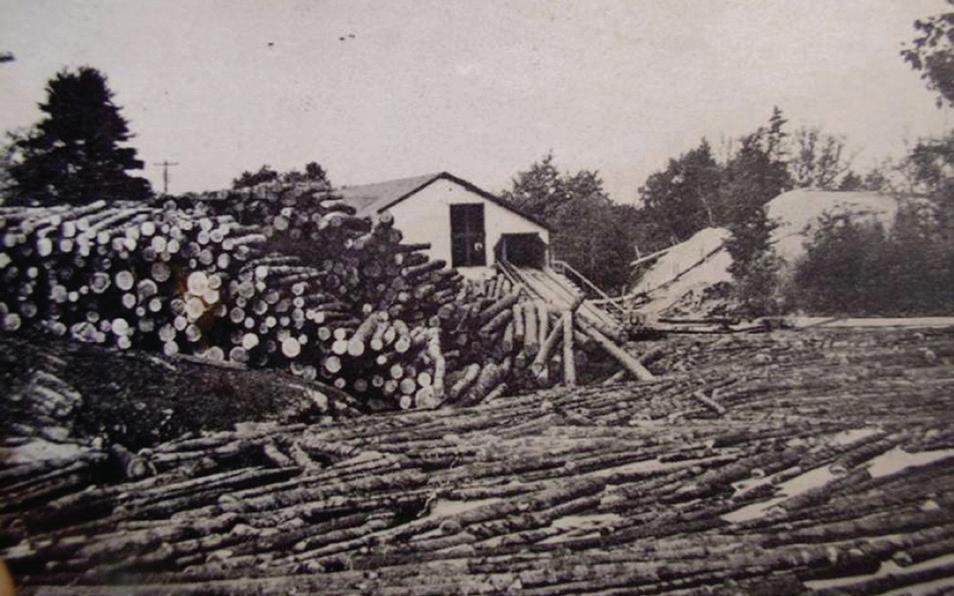

4 • building products digest • May 2024 building-products.coM ------------| CONTENTS May 2024 STAY CONNECTED ON SOCIALS: @BPDMERCH THE OFFICIAL PUBLICATION OF PROUD SUPPORTERS OF VOL. 43 • NO. 5 |-----------WWW.BUILDING-PRODUCTS.COM 12 14 DIGITAL EDITION CHECK OUT THE THE VOICE OF THE LBM SUPPLY CHAIN buyRedwood.com DECKING Composite can’t compare. Like the foods we buy, when it comes to decking, we want natural and real. Redwood is always available in abundance of options. So stock the shelves! Unlike many qualities not found in artificial products. They maintain temperatures that Redwood Empire stocks several grades and sizing options of Redwood. REDWOOD 10 SPECIAL SECTION FEATURES DEPARTMENTS 30 NAWLA SPECIAL REPORT Get up to date on the latest happenings of the North American Wholesale Lumber Association. 08 ACROSS THE BOARD 18 OLSEN ON SALES 54 NEW PRODUCTS 28 MOVERS & SHAKERS 22 LUMBER 411 62 DATE BOOK 64 CLASSIFIED MARKETPLACE 64 IN MEMORIAM 64 TALK BACK 65 ADVERTISERS INDEX 66 FLASHBACK 20 TRANSFORMING TEAMS 12 INDUSTRY TRENDS 9 outdoor living trends in time for the spring deck season 52 ANOTHER PERSPECTIVE The dismantling of the American timber industry 14 MARGIN BUILDERS High-tech add-ons for your deck builder customers 16 COMPETITIVE INTELLIGENCE Home cooking with Michigan’s Barden Lumber 60 EVENT RECAP Do it Best unveils new tech-based tools at spring market 10 FEATURE STORY 5 benefits of system selling outdoor living projects

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig • dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves • sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Kim Drew, Claudia St. John, Dave Kahle

CONTRIBUTORS

Jim Bouchard, Jeff Easterling, Michelle Hendricks, Jeff Price, Liz Whisler

ADVERTISING SALES

(714) 486-2735

Chuck Casey ccasey@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

John Haugh jhaugh@526mediagroup.com

DIGITAL SUPPORT

Alek Olson • aolson@526mediagroup.com

Josh Sokovich jsokovich@526mediagroup.com

CIRCULATION/SUPPORT info@526mediagroup.com

A PUBLICATION

OF 526 MEDIA GROUP, INC.

151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 Phone (714) 486-2735

BUILDING PRODUCTS DIGEST is published monthly at 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626, (714) 4862735, www.building-products.com, by 526 Media Group, Inc. (a California Corporation). It is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies. Copyright®2024 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles in this magazine are intended for informational purposes only and should not be construed as legal, financial, or business management advice.

Update your subscription

6 • building products digest • May 2024 building-products.coM BPD SUBSCRIBE TODAY OUR MARKET MOVES QUICKLY—SO DON’T GET LEFT BEHIND! BPD is available on a qualified requester basis to senior management of U.S.-based dealers and distributors specializing in lumber and building materials, and to others at the rate of $22 per year. Subscribe now at www.building-products.com/subscribe. SUBSCRIBE NOW AT WWW.BUILDING-PRODUCTS.COM/SUBSCRIBE BPD - BUILDING PRODUCTS DIGEST SUBSCRIBE TO RECEIVE PRINT, DIGITAL, ENEWSLETTER & MORE! The LBM supply chain’s leading publication for qualified industry decision makers! •

• Sign up key colleagues • Enroll multiple locations

CLOSING A CHAPTER

------------

BY PATRICK ADAMS

I LIKE TO EXPLAIN life as if it were a book, and each phase is a “chapter.” Some are good, some are boring, some are bad. But this ends up being the story of your life that hopefully, when you get to the end of the book, everyone says, “That was a pretty good story.”

I’ve had many interesting chapters in my life so far. Some good, some bad, and very few that were boring. My best chapters have been since I found my wife 32 years ago and, certainly, the chapters that include our kids. If only we could capture the video reels that go on in my head struggling to figure out how best to raise these kids, to be a “role model” (whatever that is), and to build a foundation with them that serves them well into their adult lives!

So far, I think we’ve done pretty well. No visits from Child Protective Services. No calls to 911 (well, there was one when my wife thought our then-2-year-old daughter was choking on an apple slice). They are good kids, who love each other (most of the time), and get along with others without a ton of drama.

As you know from past stories, we try to surround them with “real” people, take them out of the “bubble” to see the real world, and get them out of their city life and into nature on our many camping trips. Past summers have been full of these activities and, honestly, my favorite is our extended camping trips. My soul is at home in the woods, in unspoiled nature where you must build a relationship with nature to survive. Granted, our camping trips now include a 32-ft. fifth wheel that is about the same size as the home I grew up in and far more luxurious. But each time we go, it only takes about an hour for the kids to adjust to their surroundings and suddenly, they become “kids.” Not afraid to get dirty, not afraid to wander off and explore, and highly observant of their surroundings. For me, they are their best selves when we are in the woods.

I sat down with my wife this weekend to begin planning our traditional summer fun. In my mind, I already had several trips and options on the plate to consider. But, as we started looking at the calendar that already had many summer entries, my hopes started fading. School lets out in

mid-June. Swimming lessons for my 7-year-old son, followed by a volleyball camp that is a byproduct of following his big sister around. Club volleyball doesn’t end until late June for my 13-year-old daughter, which goes into a church camp, two volleyball summer clinics, a clinic at a high school that is trying to recruit her, and a couple of business trips of mine.

Basically, there is one week available for camping this year. My daughter came down at the tail end of this discussion and, after listening, I could see she wanted to say something. My heart was hopeful that her desire for our camping traditions would outweigh a volleyball clinic or two. Her contribution was, “Do you think I can bring a friend camping, because it is getting kind of boring otherwise?”

And so there it was. With the thud of a large book full of interesting chapters, this one is coming to a close. She is a teenager now and her life is full of teenage things. She is a student, an athlete, and a friend. She is now interested in her wardrobe, and how her hair looks. Instead of tucking her into bed, she now says good night and goes upstairs herself. Indeed, the chapter of my “little girl” who was a tomboy and my little partner in crime has come to an end. In less than five years, she will be 18 and all that goes along with it. It’s hard to believe this chapter went so quickly, but like all good chapters, you wish there was just a little more.

So, we will camp for one week this summer while we experiment with new traditions that give my little guy all he needs, while not “boring” my young grown-up daughter! I guess it’s only the good things that you wish went on forever, so I know how blessed I am to be “complaining” about this. As many of you know already, it’s hard to let go, but also a source of pride that you gave them the tools to be independent and fearless.

I hope as we start summer that your chapter includes some amazing adventures that will add to your story. As always, I am humbled and grateful to be serving such an amazing industry.

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

8 • building products digest • May 2024 building-products.coM

------------| ACROSS THE BOARD

Cortex® #PerfectPlug

Perfect Match

Plugs are fabricated using actual deck boards for a virtually invisible finished look.

Perfect Install

Plugs come on collated strips with pre-aligned grain, making that perfect fit 50% faster.

Perfect Plug

Cortex is guaranteed to last for the life of the project and matches major board brands including Trex, TimberTech and more.

Scan to watch the #PerfectPlugInstall

5 BENEFITS OF SYSTEM SELLING DECK PROJECTS

YOU WOULDN’T BUY a Chevy truck and then put Ford bumpers on it, would you? The same philosophy applies to decking projects. Commonly referred to in the field as “system selling,” the concept of working with a single brand for multiple components offers a number of benefits to both your contractor and homeowner customers.

Based on conversations with Platinum-level TrexPro contractors, following are five reasons to embrace a monogamous relationship with your materials supplier.

1. Product Compability

Customers want their decks to look cohesive. They also don’t want to be overwhelmed with too many choices. Selling products from multiple brands for the same job may lead to confusion and compatibility issues that can negatively impact efficiency, productivity and customer satisfaction.

Conversely, partnering with a single brand that offers a full range of complementary products reduces risk and worry. By working within a strategically engineered product eco-system, contractors can alleviate concerns about component sizing and color matching and outfit entire outdoor spaces with components that are intentionally designed to be compatible.

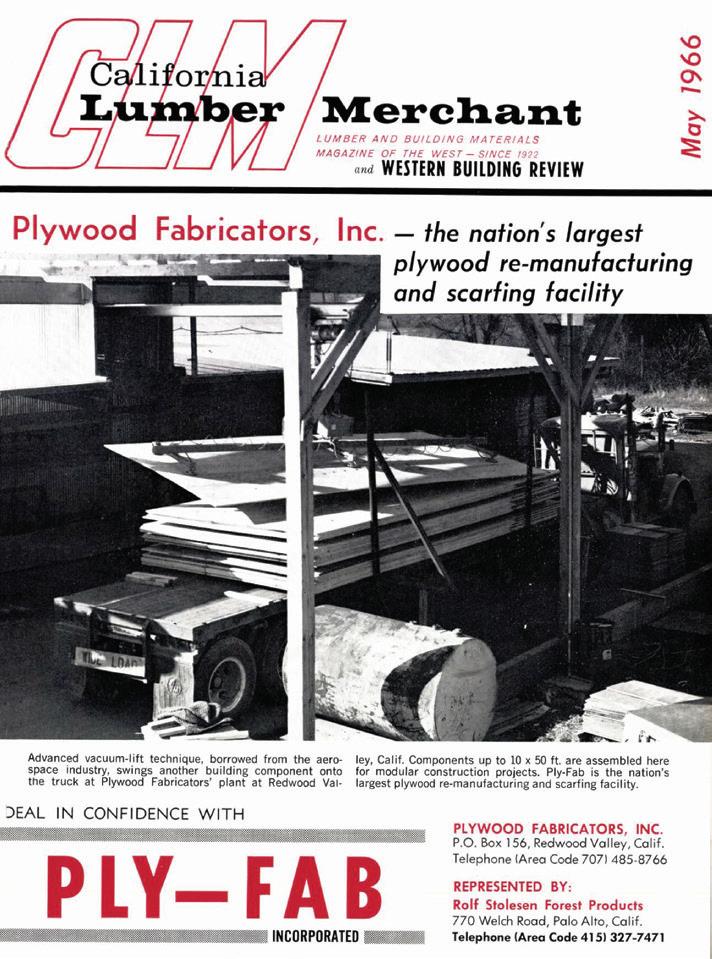

“It’s natural to talk to customers about Trex railing and lighting when you’re already selling them Trex decking,” said Bruce Verblaauw, owner of NJ Decks and Railing in Mahwah, N.J. “Working with a brand that offers a comprehensive portfolio instills confidence with homeowners and our installers because they know the products will work well together.”

2. Time Savings

Efficiency is at the heart of any successful project. At the end of the day, time is money. Working with a mix

10 • building products digest • May 2024 building-products.coM

------------| FEATURE STORY

MYRIAD ADVANTAGES are in store for contractors who utilize multiple decking components from the same brand. (Photos by Trex)

of brands and suppliers means going through multiple distributors. It also means dealing with different warranties which can lead to major headaches. Having a single point of purchase allows less room for error. Products are easier to source and easier to replace if needed.

Working with a branded system also affords greater quality control for contractors and streamlines the installation process because components are purposefully designed to integrate. Case in point, the new Trex Hideaway Fastener Collection works seamlessly with Trex decking and railing to make the assembly process more efficient while delivering a clean, cohesive aesthetic. This gives channel partners a competitive advantage by allowing them to deliver end-to-end solutions from one supplier for a smooth, worry-free deck-building experience from the joists up.

“Working with one brand simplifies the entire process,” noted Verblaauw. “You have one supplier, one distributor, and one warranty provider. It just makes things easier.”

3. Warranty Coverage & Rewards

Speaking of warranties, this is an area where brand loyalty pays off—literally. Beyond backing their products, some brands also offer labor warranties that stand behind the installation and the installers. Trex offers a labor warranty on certain products that increases with a contractor’s status in the company’s TrexPro program as well as with the number of Trex projects and the number of Trex products used on each project. For instance, if a contractor uses both qualifying decking and railing for a project, the labor warranty automatically doubles.

Another way suppliers reward contractor loyalty is with marketing support, be it co-op funds, point-of-sale displays, branded merchandise or access to customizable advertising and public relations materials.

“Trex has a pretty robust loyalty program,” said Tim Kidd, owner of Decks by DAK in Charlottesville, Va. “If you do a good job of registering your decks, it’s good for you and for your customers as well. We’ve earned enough reward points to outfit our entire crew in branded gear. We also give branded gifts to all of our clients. If you play your cards right, you can cover your entire marketing budget with warranty registration-based reward funds. This is added incentive for me to use as many Trex products as possible.”

4. Service & Support

Building a relationship with a supplier offers more than just convenience and financial rewards. It nurtures trust and leads to shared success. Brands and distributors are likely to take care of contractors with more skin in the game, make them a priority when issues arise and support their business objectives.

“I have a strong relationship with Trex and also a good relationship with our distributor (U.S. Lumber). I know all the players personally and they know me and my team,” explained Kidd, whose crews build more than 100 decks each year, mostly in the $20,000-$30,000 range. “By working with one supplier, we are able to leverage our position and volume to get distributors

to stock the products we want. We also get a good percentage of our leads from Trex due to our status in the TrexPro program, which ranks us high in the dealer locator on the Trex website. It’s a true partnership where everyone has everyone’s back!”

5. Increased Profit Potential

A beautiful backyard consists of more than just a deck. In fact, it’s accessories like railing and lighting that truly bring a client’s vision to life. A comprehensive outdoor living brand allows contractors to optimize profit potential by providing a one-stop showroom and shopping resource. Additionally, resources like the Trex AR Deck Visualizer, Color Selector, Deck & Railing Duos and Online Deck Designer allow builders and homeowners to experiment with different decking materials, profiles and configurations in an organic way that highlights extras without coming across like a hard sell.

“We know we are not just building a deck, we are building the deck for our customers,” said Kidd. “We bid the system based on their total vision. That means decking, railing, lighting, drainage, pergola, outdoor kitchens, fencing, you name it. It’s important to discuss the full scope of a project from the outset so expectations are aligned and there are no costly surprises along the way that might impact customer satisfaction.”

“If you’re not system selling with your customers, you’re missing out on a critical opportunity to maximize profit, grow your business and better serve your clients,” Verblaauw added. “With the tiered decking offerings and the robust line of complementary products and tools offered, it’s easy to upsell based on customer preferences and budgets and offer clients complete outdoor living solutions.”

As with any good relationship, commitment can be incredibly rewarding. Look for companies that share your values and truly care about your success. By partnering with a full-service supplier and mastering the art of selling the system, your contractor customers can enhance efficiencies, leverage their loyalty, and drive incremental business. BPD

building-products.coM May 2024 • building products digest • 11

MANY COMPOSITE decking lines have complementary fastening systems specially made to coordinate with their sizes, shapes and colors.

9 OUTDOOR LIVING TRENDS FOR SPRING DECKING SEASON

SPRING SELLING season is underway, bringing with it growing demand for decking and other materials that help homeowners embrace the outdoors. To help dealers prepare, Envision Outdoor Living Products offers a look at some of the hottest trends this year, including a few familiar favorites and some emerging must-haves.

1. Outdoor Living Remains Strong

It’s no secret that outdoor living has been one of the hottest trends in home design since the pandemic, and the demand continues as homeowners seek more space to gather, relax, and entertain. This is particularly true for homeowners who aren’t able to buy a larger home due to interest rates and therefore are looking to enhance and/or expand their existing footprint. We don’t anticipate this trend stopping anytime soon, especially when there are so many versatile ways for homeowners to create outdoor living experiences that meet their needs, their space, and their budget.

2. Bringing the Indoors Out

Seamless connections from indoors to out has been an ongoing trend for a number of years, particularly with the rise of larger doors, multi-panel sliders, and opening glass walls. The demand continues with colorand texture-coordinated flooring and decking that make

the transition even smoother. In addition, homeowners want their outdoor spaces to reflect their interior life and style, including furniture that looks like indoor models yet withstands the exterior elements as well as décor elements, lighting, and entertainment.

3. Ready-for-Anything Modular Furniture

Speaking of furniture, expect more modular options that can be rearranged to accommodate almost any outdoor living space—furniture that contours to the other features on the deck instead of the other way around. Not only does this provide more flexibility, it can save homeowners money as their tastes and activities shift or as they make changes to the size or scope of their outdoor living space.

4. Designated Spaces

As the outdoors continue to emulate the interior, that includes designing for everyone and every task—areas for group gathering around a fire pit, a relaxing space to read or nap, an outdoor dining space and kitchen, etc. This can be accomplished in a variety of ways, including designing composite decks with different-color inlays, picture framing, and borders to visually separate spaces. Large planters, fire features, rugs, and furniture placement can also serve that function.

12 • building products digest • May 2024 building-products.coM

------------| INDUSTRY TRENDS

5. Edible Gardens

While gardening has always been popular, this year green thumbs are turning toward growing more of their own food. Even with one planter box, homeowners can grow enough vegetables, fruit, and herbs to use in cooking at least once a week. Along with pre-made metal structures, pros and DIYers can craft raised beds or planters using Envision composite deck boards that will absorb little to no moisture while matching the rest of their deck.

6. LED Lighting

The importance of creating the right atmosphere continues this year, and we expect adjustable LED lights to be quite popular. LEDs allow homeowners to easily change (and sometimes pre-program) the brightness and/or color of outdoor lights, so they can set the right mood for almost any outdoor living activity while extending the usability of the space well into the evening hours.

7. Low-Maintenance Materials

Every outdoor living space comes with some degree of maintenance, thanks to weather and debris. But as homeowners clamor for low-maintenance options, manufacturers continue to deliver. Two options to consider are composite deck boards, which require far less maintenance than traditional wood, eliminating the need for regular staining or replacing rotted boards, and aluminum deck railing, which is known for its durability and low-maintenance qualities. There also has been a recent increase in demand for outdoor furniture without cushions.

8. Entertaining Details

With outdoor spaces a prime spot to host friends and gatherings, small touches that enhance the experience for partygoers are a must. This includes a drink rail that provides a convenient place for beverages and small plates. Other growing musthaves include outdoor heaters, for which we’re seeing a growing number of options with sleeker designs, as well as built-in speaker systems and programmable mood lighting.

9. Quality Over Price

Whether fashion, housing or anywhere in between, Americans are realizing that investing in higher-quality materials can save them money in the long run and are “deinfluencing” from the trend of always buying the cheapest option. For the outdoors,

this not only includes choosing a low-maintenance alternative to wood decking, but also choosing a manmade material that is more durable than cheaper options. Capped composite decking, for example, is more durable and less likely to fade compared to traditional, less-expensive composites. BPD

Hydro-Thermo Modification

building-products.coM May 2024 • building products digest • 13

Wood treatment plant manufacturing, worldwide since 1983. The most environmentally friendly wood treatment ever known!

CONSUMERS increasingly demand low-maintenance materials such as composite decking aluminum railing. Show here: Envision Distinction Decking in Spiced Teak with Fairway A210 black railing.

1-877-785-0274 www.americanwoodtechnology.com American Wood Technology Options may include design, fabrication, layouts & accessories •Smallest footprint & simplest installation •Most gentle process available • Most effective heat transfer • Fastest process time & better product quality • Lowest processing cost per board foot From IWT-Moldrup we are proud to offer:

HIGH-TECH ADD-ONS FOR YOUR DECK BUILDERS

SAVVY DEALERS that keep up with the latest hightech add ons that customers are looking for should be aware of the type of products builders are turning to. This includes outdoor lighting, privacy glass, video and sound, all of which can be controlled remotely.

Outdoor Lighting

When it comes to elevating the outdoor space, homeowners are using lighting to create ambiance and to express their personalities.

One type of lighting that customers are turning to is Tru-Scapes deck lighting system because it offers everything from the transformer and wiring to a wide array of lighting options for all areas of the railing deck, stairs and landscape space. Clint Webb, Webb Decks, Godfrey, Il., says his favorite Tru-Scapes product is the array of post cap lights that fit a wide variety of railing brands that he most commonly installs. While Webb says he’s been working on getting Tru-Scapes products stocked through his local supplier, he relies on his local lumberyard, R.P. Lumber, and online retailers, such as D.I.Y Home Center and Decks Direct, for other products and materials he uses in his deck projects.

Another brand growing in popularity is DEKOR. The RGBW color-changing lighting system is a customer favorite. The system’s tiny, waterproof dots install flush with the installation surface, and can be controlled with DEKOR’s WiFi controller. Customers also turn to their L’Accents line of premium, eco-friendly lighting that is designed for aluminum or metal railing.

Privacy Glass

A high-tech product that might find itself in more stores in the next few years is smart glass. Smart glass allows transparent glass to be switched to an opaque

film. It is currently being used in residential applications as a privacy film when window coverings won’t work, and in commercial applications as a rear projection screen for marketing purposes.

“Smart glass and smart film are becoming more and more common in residential settings,” says Klara Johanna, marketing director, Smart Glass Country, which develops smart glass and film for both interior and exterior usage.

As a rear-projection screen in a residential setting, this typically involves a smart glass home window or smart glass room divider being used as a projection screen under dark light conditions. In cases where the home window faces the back patio, the glass window or glass staircase railing could be used as a projection screen from both the patio and outdoor space as well as inside the home.

Sights and Sounds

Another growth area is outdoor entertainment. Whether it be an outdoor TV, projection screen, or surround sound, homeowners have made it clear they want their high-tech extras to blend seamlessly with the rest of their outdoor living space. That’s why some builders are purchasing matching materials to tie their decking and other building materials with the materials needed to disguise these extra features.

“Our team recognizes the importance of proximity to hot tubs, pools or general outdoor living areas, ensuring that viewers will have an immersive experience no matter where they are within the space,” says Ted Tidmore, owner of Holloway Co., Dulles, Va.

By seamlessly incorporating outdoor TVs beneath elevated decks, they create visual focal points without obstructing views. BPD

14 • building products digest • May 2024 building-products.coM

------------| MARGIN BUILDERS

HELP DECK builders take projects to the next level with high-tech upgrades like programmable lighting (left, photo courtesy Webb Decks) and retractable TVs (right, photo courtesy Renovation Station LLC).

THE BEST IS ALWAYS IN DEMA ND.

YellaWood® brand pressure treated pine stands unrivaled in providing the best available protection against rot, fungal decay and termite attack. Enjoy the uncompromising beauty of a backyard made with high quality natural wood products from YellaWood ® brand pressure treated pine. Visit yellawood.com for more information.

YellaWood® brand pressure treated products are treated with preservatives (the “Preservatives”) and preservative methods, and technologies of unrelated third parties. For details regarding the Preservatives, methods, and technologies used by Great Southern Wood Preserving, Incorporated, see www.yellawood.com/preservative or write us at P.O. Box 610, Abbeville, AL 36310. Ask dealer for warranty details. For warranty or for important handling and other information concerning our products including the appropriate Safety Data Sheet (SDS), please visit us at www.yellawood.com/ warranties or write us at P.O. Box 610, Abbeville, AL 36310. YellaWood® and the yellow tag are federally registered trademarks of Great Southern Wood Preserving, Incorporated. All other marks are trademarks of their respective owners and are used with their permission.

RECIPE FOR LASTING SUCCESS HOME COOKING WITH

------------ BY SARA GRAVES

AT 102, northern Michigan’s Barden Lumber has learned a thing or two about what it takes to stay current, without losing sight of the principles that has made it a success for over a century.

“We stay current from listening to our customers,” explains president Paul Barden. “I always tell everybody here that means if somebody comes walking through that door with products that we’re not familiar with, then write it

MICHIGAN’S BARDEN LUMBER

down, and let’s get familiar with (those products). A lot of times, people, when they come in the door, they are more familiar with what they want than we are because of the Internet. They’ve done their research.”

It’s this open mindedness that has allowed the fourth-generation, Boyne City, Mi., drive-thru lumberyard to remain competitive despite being surrounded by box stores within 20 minutes of it.

When asked how his yard stays competitive, Paul replies, “I stopped trying to compete (with big box stores) because when I did, I lost track of what it took to run this business and live in this community.”

He adds that although he competes with other independent yards north of them, it remains friendly competition. Ultimately, he said, there’s always going to be a certain number of customers “that are going to spend a dollar’s worth of gas to go north to save a dime on materials. That’s just their nature.”

But it’s the customers that are on a first-name basis with the Barden staff, who have remained loyal to the yard, that have made it all worthwhile, Paul says. Customers like Jim Kuhn, who has since passed, who always walked in with a smile on his face. “I have a special place for the ones that after we service them or did business with them for years...they would come up to us later in life and say, ‘It’s because of what your Dad did, which allowed me an extra month or two when things were tight.’ It’s stuff like that that really resonates and keeps you going. That happens quite often in a small community.”

16 • building products digest • May 2024 building-products.coM ------------| COMPETITIVE INTELLIGENCE

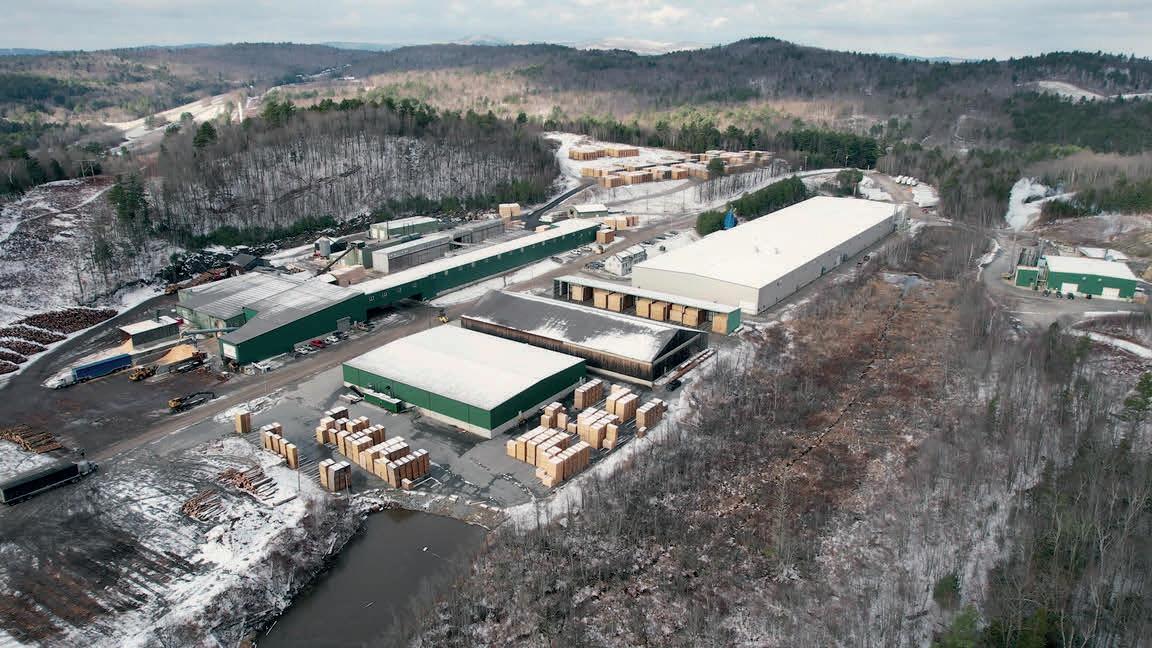

FOURTH-GENERATION Barden Lumber in Boyne City, Mi., was founded in 1922 by F.O. Barden and is currently run by Paul Barden.

It’s the same commitment to his customers that causes Paul to go the extra mile, often opening the yard on the weekends when it’s closed. “We know all their names when they come in the front door.”

It’s also why Barden Lumber will open its doors this month to celebrate

nearly 500 of its customers. The company will once again host its annual customer appreciation event in which vendors are brought in to showcase their latest products to Barden Lumber’s customers. “It’s not like we’re stagnant doing the same thing,” says Paul. “We’re trying to evolve and show

our customers new products so they can share those with their customers.”

That same commitment to offering the latest products to its customers is why the company offers a wide selection of lumber and building products for its customers, including Milwaukee tools, Deckorators decking, RDI Railing, Versatex PVC trim, and CAMO fastening systems.

Paul says they carry roughly 20% different products than what the local box stores carry. “The goal is not to send people anywhere else. Give them what they can’t get anywhere else,” he adds. ”We just try to keep it like an old-fashioned hardware store.”

Barden Lumber’s recipe for success is still working. “We’ve got a very good customer base. We’ve been doing a great job of servicing them, and we can relate to them. We just need to keep taking care of what we’re doing here because the customer base seems to increase every year,” Paul asserts.

“We know our customer service is second to none, and we know most of our customers by name,” he emphasizes. “We’re just a good old-fashioned yard.” BPD

building-products.coM May 2024 • building products digest • 17

BOYNE CITY, located on the eastern end of Lake Charlevoix, Michigan’s largest inland lake, has a population of more than 3,800 people, which more than doubles during summer months.

CABLE RAILING SPECIALISTS Available Nationally Through Our Network of Dealers 1.800.541.6829 | info@atlantisrail.com | www.atlantisrail.com Spectrum Railing System AUTHO RIZED DE A L ER A ER ®

SAY WHAT YOU MEAN AND MEAN WHAT YOU SAY

------------ BY JAMES OLSEN

SPEAKING SHOULD COME naturally. Most of us start talking between 12 and 18 months and keep talking every day after. There are some silent monk types who don’t speak much, but on average most people speak 15,000 to 16,000 words a day. That’s a lot of words by the time we start working.

Why Sales Speak Is Different

The fundamental difference between sales speak and talking about the weather or last night’s ball game is in sales we are moving people to action. Pericles, a Greek orator speaking of another orator, said, “When Pericles speaks they say, ‘How well he speaks.’ When Demosthenes speaks they say, “Let’s march!” In sales we are in the “Let’s march” business.

It’s not merely the words we use, but how we use them. Tone, pace, volume and demeanor of the salesperson all matter. And all of these need to be calibrated to our audience. When in Rome, speak Italian. In Paris, speak French. If a customer is the jovial type, we will want to keep our demeanor light. If they’re the serious type, we’ll keep our conversation a bit more serious. If we’re selling to a highly educated person, we can let our vocabulary flow, but most newspapers are written at the tenth-grade reading level, so in most cases when selling we don’t have to “dumb down” our speech, but we don’t want it to be too highfalutin!

Uncomfortableness & Pressure

Create Garbled Speech

Between expectations (our own

and our boss’), competition (inside and outside our company), and dealing with new customers, there’s a lot of pressure in sales. Pressure makes the simplest things (talking, for example) difficult. Below are some of the verbal hiccups I spend a lot of time unteaching my students:

Ums and Uhs. When we are trying to convince someone to do something, we must sound confident. Sales is a transfer of emotion. If we sound unsure or nervous our customer will be reluctant to go with our proposal. Many salespeople “um” and “uh” after every sentence. Customers may not even consciously hear it, but subconsciously they do, and it breaks rapport and does not inspire trust.

Beat-Around-The-Bush-Itis. “Good day, my name is John from, uh, ABC Lumber Co., and I was just wondering, I don’t want to bother you and this will just take a moment, if you have the time, I was just wondering if it would be possible to talk to the person who does, if they’re in, to talk to the person who does the lumber buying, possibly.”

You may think the above example is an exaggeration, but I assure you it is not. Simple is professional: “Good day, this is Rebecca Johnston from ABC Lumber out of Spokane, Wa. Could you tell me who does your lumber buying, please?”

Filler Words are any that are unnecessary. “Kinda,” “you know,” “maybe,” “might,” “possibly,” “like” and “literally” are some of the most common.

Repetitions. “One coat of paint

and ask for the order” is what I tell my students. “We see this market moving. It really looks strong, and inventories are very thin. In our morning meeting we all agreed that the market is going to move up and we see it staying strong. Inventories are thin and it doesn’t look like there will be a slowdown anytime soon. We are selling really well, and customers are buying. So is there anything you need today?” Happens more than you think.

Simply and Directly Ask for the Order. Eighty percent of salespeople do not ask for the order. They present products and wait for the customer to buy. Unfortunately, this works. It just doesn’t work as well as asking for the order. Short term we will get more business if we ask for it. Long term, and for me more importantly, we will create relationships with customers so that they know we are going to present them with products and solutions and ask for the order and they will begin to expect it.

Talk To Them Like a Brother. My first boss, Terry Lane, said, “James, relax and talk to them like a brother.” The more relaxed and natural our speech is, the more we will sell. BPD

JAMES OLSEN

JAMES OLSEN

18 • building products digest • May 2024 building-products.coM

------------| OLSEN ON SALES

Olsen is principal of Reality Sales Training, Portland, Or., and creator of SellingLumber.com. Call him at (503) 5443572 or email james@realitysalestraining.com.

James

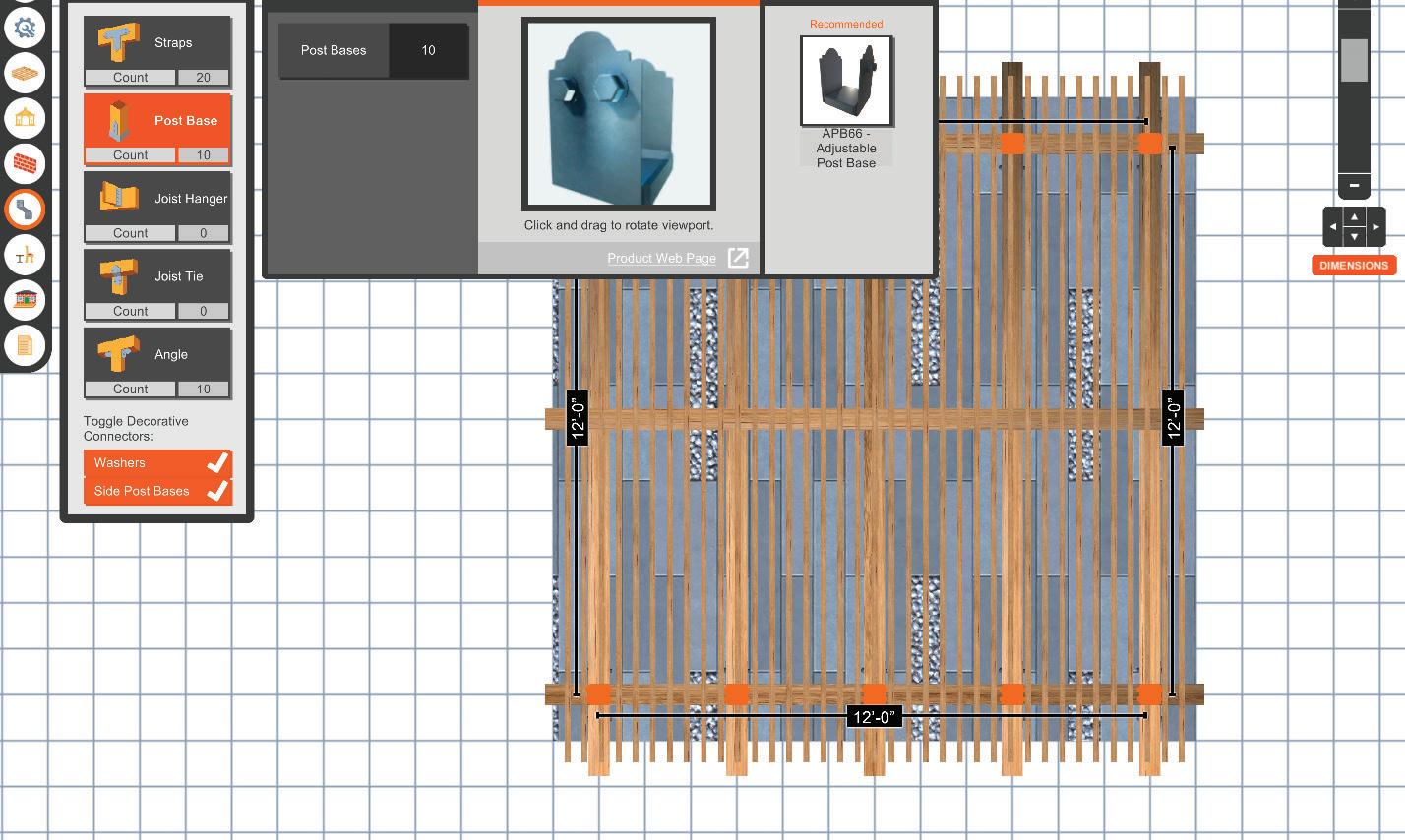

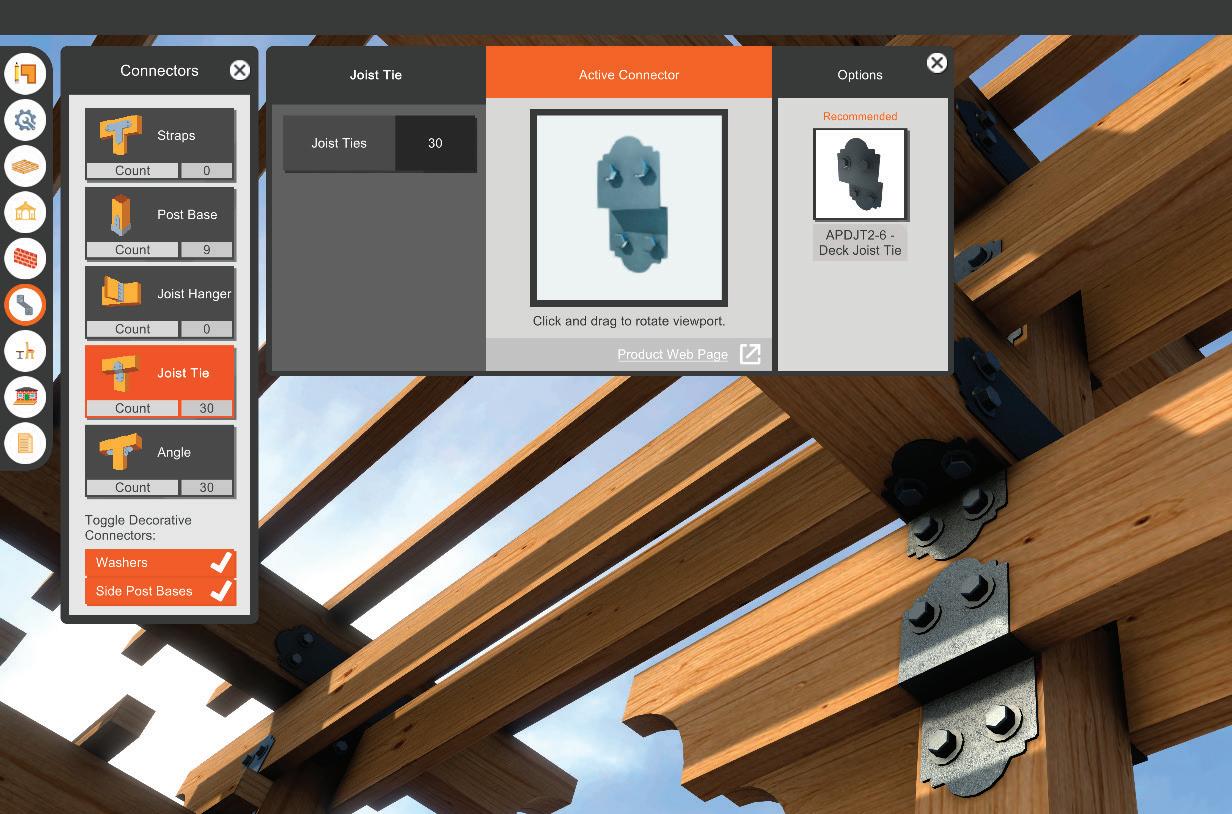

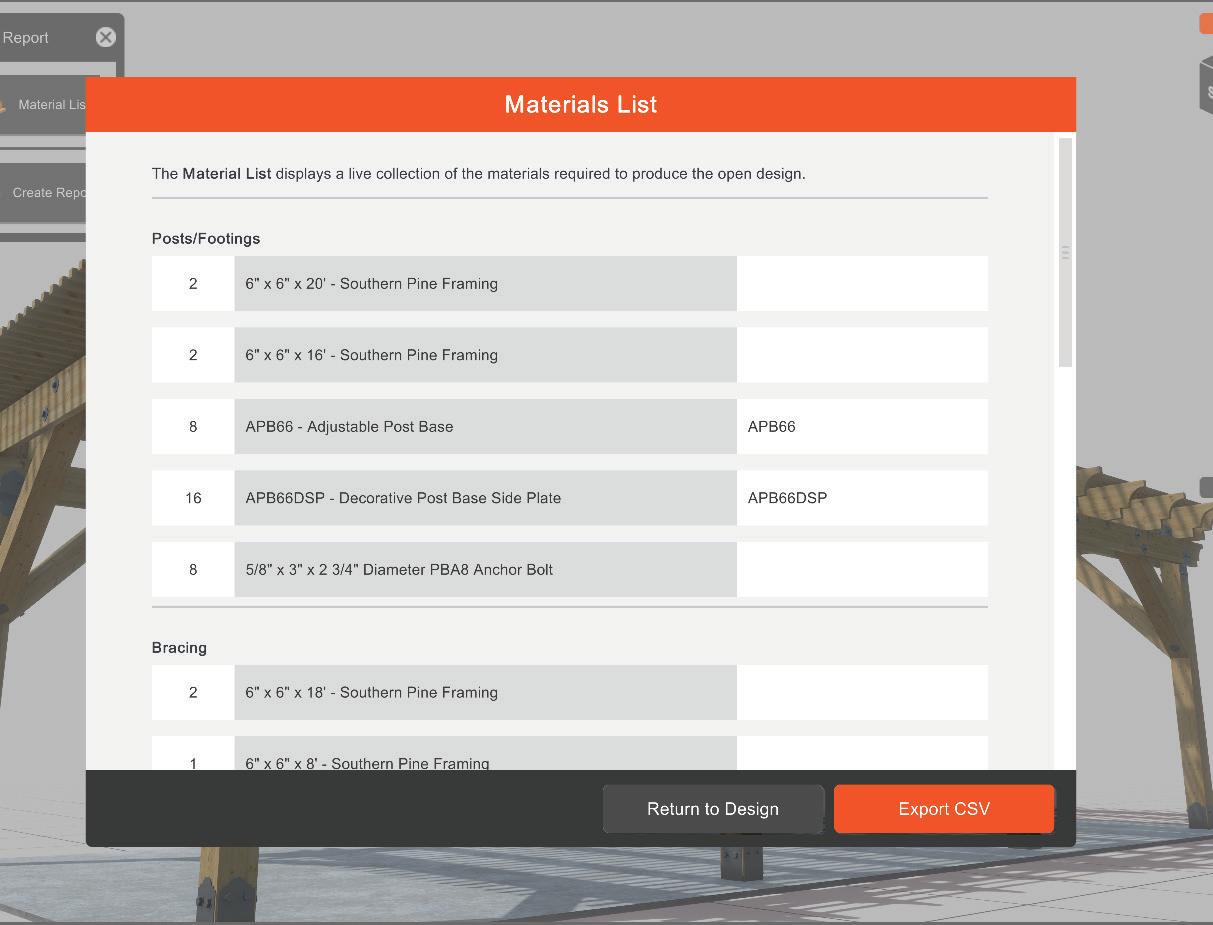

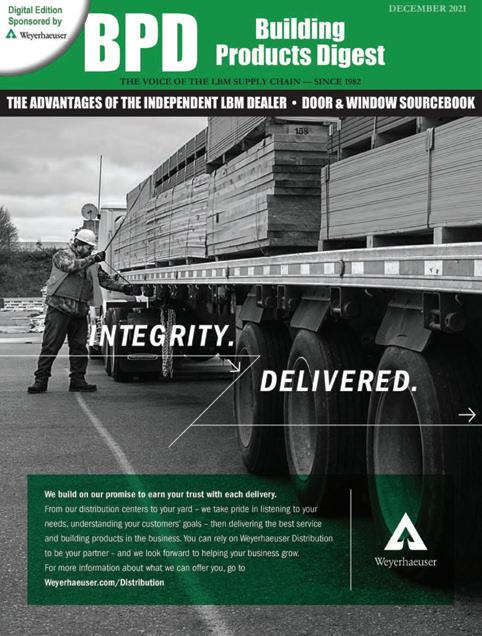

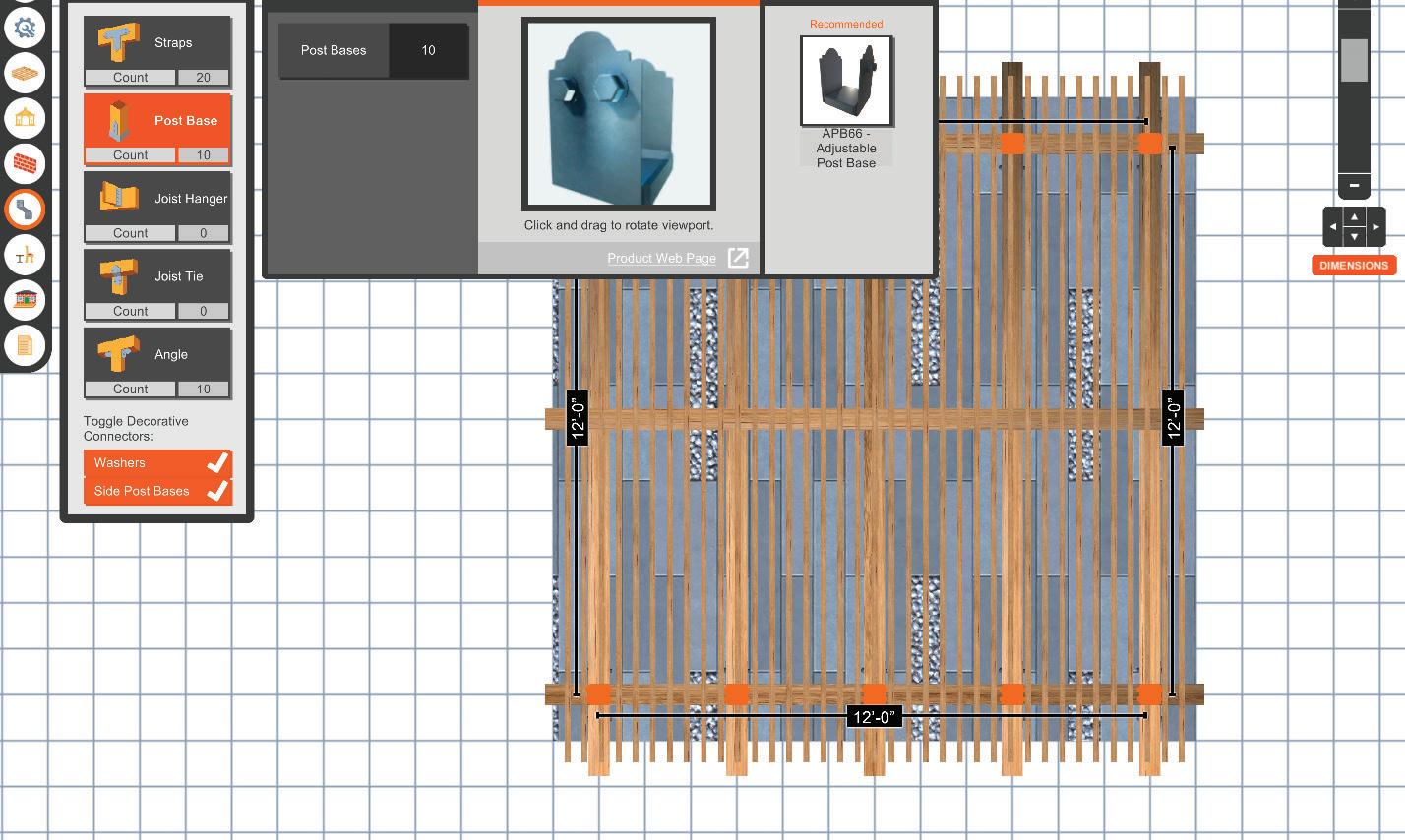

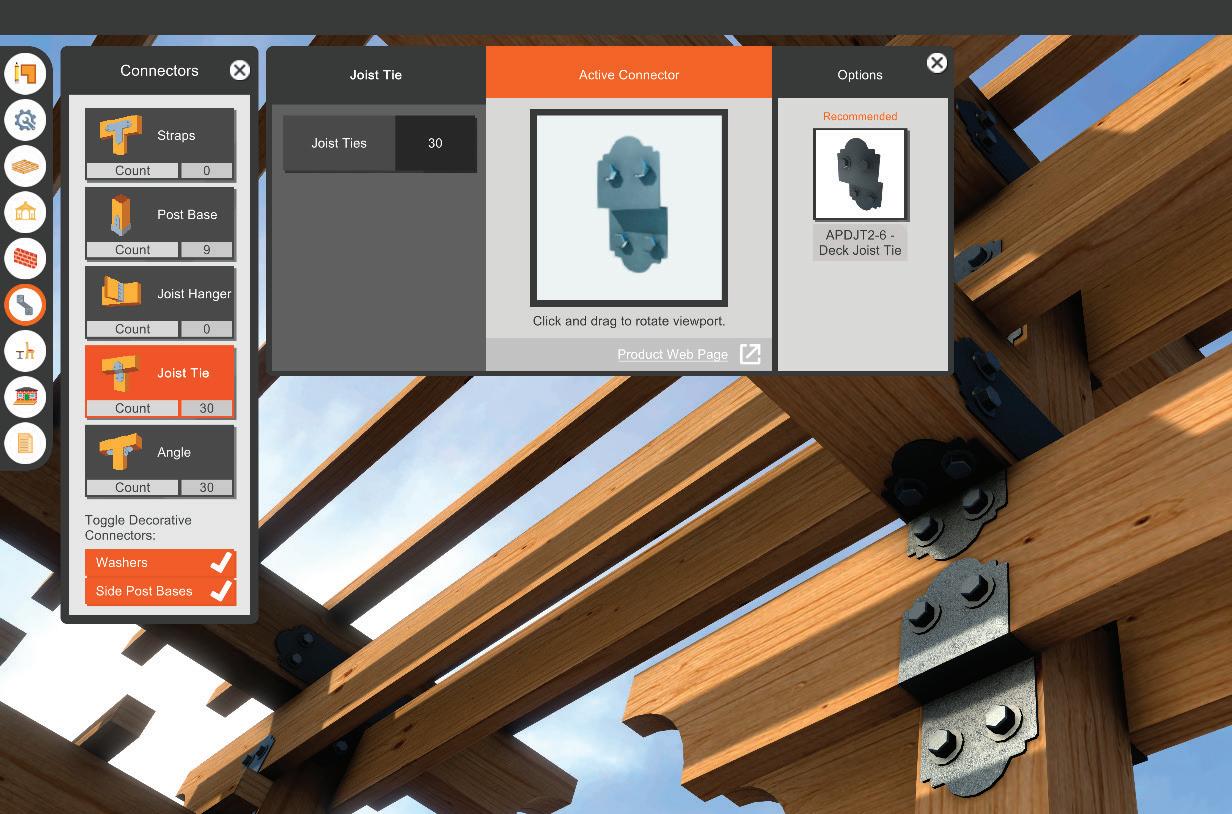

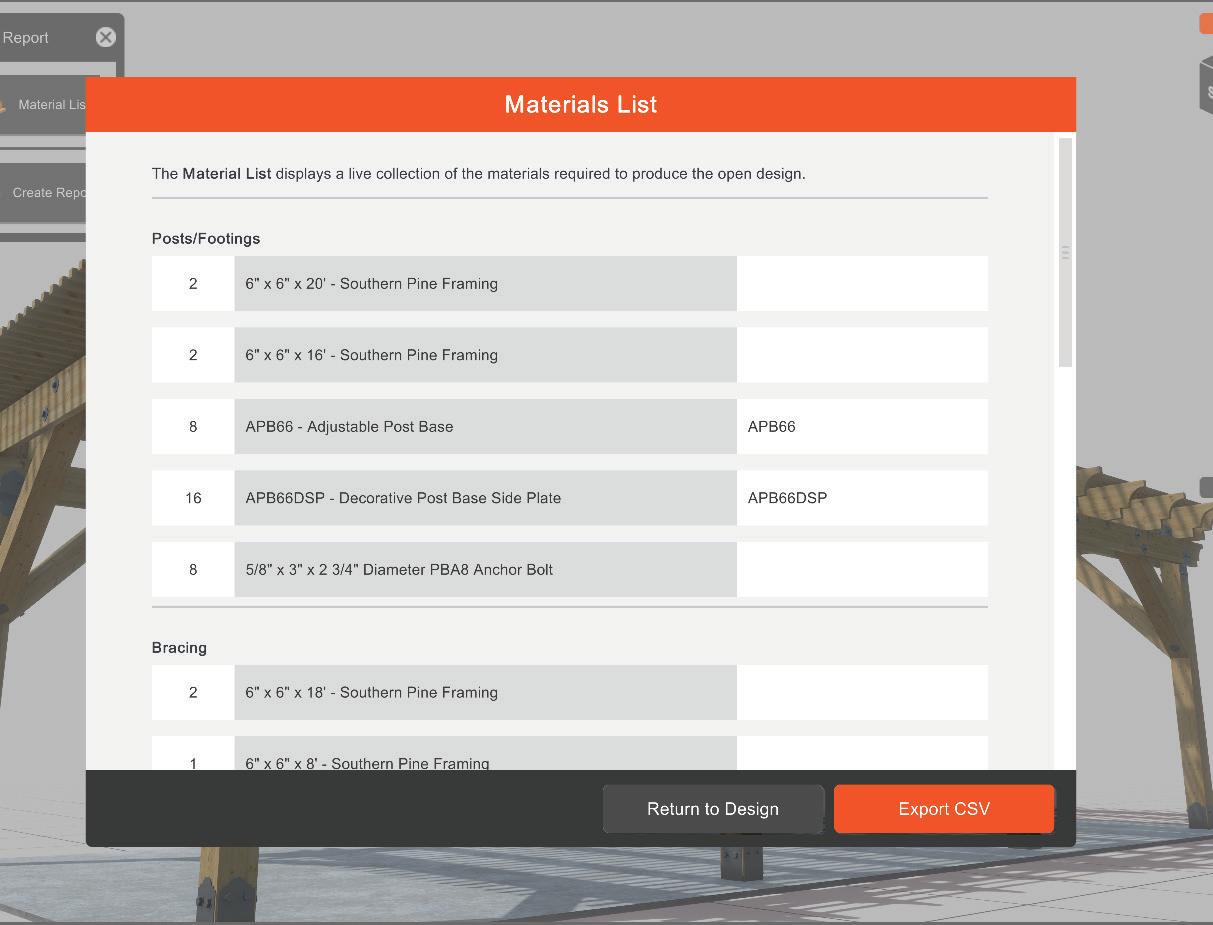

Great software for building great outdoor structures.

Help your customers build their dream backyard with Deck Planner Software™ and Pergola Planner Software™ from Simpson Strong-Tie. Easily design a strong and beautiful deck, pergola or other popular structure in just minutes using prebuilt templates or custom dimensions. Work in 2D or 3D environments and select wood species or additional features from a full library of options. Then just print out the plan view and materials list. Your clients, and your business, will thank you.

To learn more about our free downloadable software, visit our website at go.strongtie.com/pergolaplannersoftware or call ( 800) 999-5099.

DPS Deck Planner Software™ PPS Pergola Planner Software™

Outdoor Living Solutions | Products, Software and Service for Smarter Building © 2024 Simpson Strong-Tie Company Inc. PERGDECKPLAN20-D

THE POWER OF LEADERSHIP COACHING

------------ BY LIZ WHISLER

EFFECTIVE LEADERSHIP is essential for organizational success in today’s dynamic and fast-paced business environment. However, even the most experienced leaders can encounter challenges and areas for improvement in their leadership skills. This is where leadership coaching comes into play, offering a personalized and transformative approach to leadership development.

What’s leadership coaching and how does it work?

At its core, leadership coaching is a collaborative process and partnership between a leader and a trained coach, where both parties work to reach shared destinations and goals. It aims to unlock the leader’s full potential, enhance performance, and achieve professional and personal goals. Unlike traditional training programs, which often focus on imparting knowledge and skills in a one-size-fits-all manner, leadership coaching is highly individualized and tailored to each leader’s specific needs, strengths, and aspirations.

The benefits of leadership coaching

Deepen your understanding. One of the essential benefits of leadership coaching is its ability to provide leaders with valuable insights into their strengths and growth areas. Through reflective questioning, active listening, and constructive feedback, coaches help leaders gain a deeper understanding of their leadership style, behaviors, and impact on others. This self-awareness is the foundation for meaningful growth and development as a leader.

Practical tools. Moreover, leadership coaching equips leaders with practical strategies and tools to enhance their effectiveness in areas of leadership, such as communication, decision-making, performance, and team building. By identifying and addressing specific challenges and opportunities, coaches empower leaders to implement positive changes and achieve better outcomes.

Continuous learning. Another significant advantage of leadership coaching is its focus on continuous learning and improvement. In today’s ever-evolving business landscape, leaders must adapt and grow to meet new challenges and seize emerging opportunities. Through ongoing coaching sessions, leaders can refine their skills, experiment with new approaches, and stay ahead of the curve.

Open communication and support. Furthermore, leadership coaching fosters a supportive and confidential environment where leaders can openly discuss their concerns, explore innovative ideas, and seek guidance without fear of judgment or repercussion. This safe space encourages leaders to step out of their comfort zones, take calculated risks, and confidently pursue ambitious goals.

Group benefits. In addition to individual leadership coaching, organizations can benefit from implementing coaching programs at the team or group level. Team coaching focuses on improving collective performance, fostering collaboration, and aligning team members around shared goals and values. Team coaching can drive greater productivity, innovation, and employee engagement by enhancing team dynamics and communication.

Leadership coaching can have a ripple effect throughout the organization. As leaders develop and refine their skills through coaching, they become role models and inspire others to continue learning and growing. This cascading effect can improve employee morale, higher retention rates, and, ultimately, better business results.

A Fortune 1000 Survey found that 1:1 coaching:

• 77% of supervisors reported a more effective working relationship with direct reports

• 61% felt increased job satisfaction

• 81% reported they had better time management and more work/life balance

20 • building products digest • May 2024 building-products.coM

------------| TRANSFORMING TEAMS

• 52% have an increase in self-confidence

It’s worth noting that leadership coaching benefits extend beyond the professional realm and can positively impact leaders’ personal lives as well. By enhancing their self-awareness, resilience, and emotional intelligence, leaders can cultivate more fulfilling relationships, achieve a more excellent work-life balance, and experience overall well-being.

Leadership coaching mindset requirements

Leaders must be interested in growth. It is only possible to successfully coach people who are willing to be coached. Often, those who are assigned coaches are the very individuals who have little interest in improving themselves, which may explain the need for coaching in the first place. You cannot desire more for someone than they have for themselves. Regardless of your efforts, if they are not interested in self-improvement, it will not matter. Therefore, it is important to invest in leaders who have expressed a desire to continue learning and growing.

Leaders must be open to change. Leaders who lack self-awareness and are not open to change can be challenging to work with. Even if they are given feedback, they may refuse to consider it. Self-awareness is a crucial quality that cannot be taught by a coach. No matter how much time or effort is invested in helping a client become more self-aware, there may still be significant barriers.

The boss must be engaged. The leader of the client plays a vital role in the coaching process. It has been observed that when the boss is actively involved in coaching, the likelihood of success increases significantly. On the other hand, when the boss is not involved, the person being coached tends to struggle. Therefore, before investing in coaching, it is essential to ensure that the boss of the individual to be coached is fully committed and supportive of the coaching process.

Although some individuals are likely to not get anything out of coaching, when someone in your organization asks for coaching, it indi-

cates their readiness for a successful coaching engagement that can yield long-term benefits.

In short, leadership coaching is a powerful and transformative tool for unlocking leaders’ full potential and driving organizational success. By providing personalized support, practical guidance, and a safe space for reflection and growth, coaching empowers leaders to become more effective, confident, and inspiring agents of change. As businesses continue to navigate the current complex

and competitive landscape, investing in leadership coaching can yield significant performance, innovation, and employee satisfaction returns. BPD

building-products.coM May 2024 • building products digest • 21

Liz Whisler is VP of leadership develoment for The Workplace Advisors, Inc.; (877) 660-6400, theworkplaceadvisors.com.

LIZ WHISLER

ARE YOU A WOOD GEEK?

------------ BY JEFF EASTERLING

“I LOVE WOOD because I can shape it to almost any purpose. Wood makes sense for the vast majority of home building. Sustainable forestry practices mean we’re no longer using lumber faster than it can be replaced, so lumber will be the go-to structural material for the foreseeable future. In terms of finish materials, although there’s competition from a variety of sources today, nothing else looks like wood.”

CLT Press

Breakdown hoist and chains for transverse boards

Assembly plate 10’ x 42’ USNR Pneumatic press

“(Wood) is just natural. It’s an appreciation for American history and the lasting quality of wood. All you have to do is look at old public buildings, or look at a piece of furniture that’s been passed from one generation to the next to see the value. New England has fabulous architecture

Roll cases to hold panels at infeed and outfeed

Hydraulic pump & jacks for side pressure

Electrical components for press

Various spare parts – chain, bags, gears, etc

FOR SALE

that dates back from the early days of our country; it’s all wood, and it’s still here.”

“The great thing about wood is that every part of it can be used. Cuts and scraps can be bagged up and used as kindling for a wood stove. As building products move to more composites and chemically engineered materials, the byproducts and waste are not easily disposed of and most end up in landfills. There is a noticeable difference at the end of the workday between cutting vinyl siding and pine clapboard siding.”

CNC CLT Press

• Breakdown hoist/chains

• Assembly plate

CNC

• 10”x42’ USNR pneumatic press, and much more!

Utilizes circular

Hundegger PBA D-Machine #7091

• Large format/sawdust pusher/

• Multiple saws & bits

“… being around natural products makes you feel better and healthier. Wood does that for me. Recently I’ve been intrigued that we can help mitigate climate change by using, and then regrowing, a lot more wood. Fancy term: carbon sequestration. Sequester comes from the Latin word to kidnap. Kidnapping carbon… I like the concept.”

Hundegger PBA D – Machine #7091

Large format gantry CNC

Utilizes circular saw, chainsaw, two milling heads two drill bits

Sawdust pusher to move sawdust to one end of CNC

Safety Photo eyes

Does come with blowpipe for dust ventilation Can be plumbed to baghouse Software is Cambium We created machine files in Cadwork to upload into Cambium

There is a rollcase on the CNC bed, although it was never activated at DRJ This piece of equipment is complete and does come with some spare parts, mills, blades, chain, etc

Above are a small selection of quotes about the power and beauty of wood as shared with us by a few people we like to call Wood Geeks. Check out our website at www. nelma.org/wood-geeks and you can meet each of our Wood Geeks and learn from them what they value most about working with real wood. From the authenticity to the historical nature of wood, each of them come at wood from various angles, but they all love the product, and love working with it.

• Cambium software/CADwork

A Y

chainsaw, two milling heads, two drill bits

Sawdust pusher to move sawdust to one end of CNC

Safety Photo eyes

• 32,000 acfm

Does come with blowpipe for dust ventilation Can be plumbed to baghouse Software is Cambium. We created machine files in Cadwork to upload into Cambium.

• Blow-pipe/motors/dust collection bags/fire-suppression system

• SATOS-32K Dual Head

There is a rollcase on the CNC bed, although it was never activated at DRJ. Th t is complete and do spare parts, mills, bl

541 643 8924

jodiw@drjlumber com drjwoodinnovations com

Are YOU a Wood Geek? We’d love to feature you and your story in the coming months. Is wood your favorite building product? Do you experience the biophilia (look at our March column for more on that big word) of being around a natural building product? We’d love to hear from you and share your thoughts and ideas.

Reach out to us at info@nelma.org and use the email subject “Wood Geek.” We’ll get back to you ASAP and pass along a few questions to get the ball rolling. Hope to hear from you soon! BPD

• Top & bottom sanding/oscillating heads/auto feed/spare sandpaper

22 • building products digest • May 2024 building-products.coM

JEFF EASTERLING Jeff Easterling is president of Northeastern Lumber Manufacturers Association. Reach him at info@nelma.org. A SPECIAL SERIES FROM ------------| LUMBER 411 CALL (541) 874-2231 drjoffice@drjlumber.com drjwoodinnovations.com CLT MACHINERY FOR SALE Top-of-the-line Business Opportunity FOR SALE USE use icant blow-pipe, on bags, etc have a firewhich will likely by a certified fire installer der e bottom e back and forth to prevent clogging of the sandpaper Automatically feed Automatic sanding thickness settings Sandpaper removal/installation tool Blowpipe for dust collection Approximately 45 of Infeed and outfeed S C A L L T O D A Y FOR SALE B SATOS-32K Dual head sander Sands both the top and the bottom Sanding heads do oscillate back and forth to prevent “clogging” of the sandpaper Automatically feed Automatic sanding thickness settings Sandpaper removal/installation tool Blowpipe for dust collection Approximately 45 of Infeed and outfeed roll cases

piece of equipment is complete and does come with spare sandpaper of various grits SANDER 541 643 8924

com drjwoodinnovations com

diw@drjlumber com woodinnovations com FOR SALE s s for ess t infeed and side pressure press n, bags, gears, Hundegger

This

jodiw@drjlumber

541.643.8924

PBA D – Machine #7091

Large format gantry CNC

saw,

O D

C A L L T

CNC

Baghouse

Sander

Watkins Sawmills is one of the largest manufacturers of cedar siding and roofing in North America. Family owned and operated since 1947 the Watkins Group employs over 100 people across their operations including Fire Smart Roofing [FSR] in Maple Ridge BC, Canada and SaferWood with Thermex-FR by Chemco in Ferndale WA, USA.

Watkins Group?

Since 1947 You don’t know the

That ’s bananas.

Photo by Karsten Winegeart on Unsplash

Cedar Shakes | Shingles | Sidewall | ASTM E108 | FRTW | IWUIC

REAL WOOD. MADE SAFER.

Since 1981

CORNERSTONE BUYING HARVEY

Cornerstone Building Brands, Cary, N.C., reached an agreement to acquire Harvey Building Products, a manufacturer of windows and doors, and its portfolio of brands: Harvey, SoftLite and Thermo-Tech.

Based in Waltham, Ma., Harvey has approximately 1,200 employees at four manufacturing facilities in the Northeast and Midwest. Harvey specializes in premium, custom windows and doors primarily serving the Eastern United States.

“Harvey Building Products has a strong reputation as a premium R&R manufacturer and is an ideal addition to Cornerstone Building Brands as we forge ahead in our journey to be a premier exterior building products company,” said Rose Lee, president and CEO of Cornerstone. “This transaction will strengthen our presence across the Northeast and the Midwest with key leading brands. It will also enable us to be a stronger partner of choice for our customers and to better serve them.”

Justin St. Hilaire, president of Harvey Building Products, added, “We are thrilled to be joining Cornerstone Building Brands as this new partnership will mark an exciting chapter in Harvey’s growth journey. The company’s strong customer focus, deep channel relationships and extensive product breadth make it a perfect partner to accelerate our future growth while continuing our mission of delivering a quality experience to our internal and external stakeholders. We are immensely thankful to our previous owner, Dunes Point Capital, for helping us reach this stage of development.”

The deal, is expected to close in the second quarter of 2024.

HOOVER REBRANDS WITH NEW LOGO

Hoover Treated Wood Products has rebranded with a new logo and an updated website.

The updated website at www. frtw.com showcases the company’s new branding and serves as a one-stop shop for information on fire-retardant-treated wood.

Replacing its ages-old “dragon logo” was a trickier matter. The branding team had to decide

whether to retain the iconic dragon or adopt something new altogether. After much feedback, both internally and externally, they were convinced the dragon had to stay, albeit with a modern look.

According to Hoover, “It’s not just another logo. The new dragon represents a deeper meaning, including the direction it faces. It embodies protection, strength, authority and good fortune. These qualities all come together to make it a strong and meaningful choice for representing our brand, aligning seamlessly with what Hoover stands for and aims to achieve.”

RP LUMBER BUYS GOLDEN RULE LUMBER OF ILLINOIS

R.P. Lumber Co. has acquired 33-year-old, family-owned Golden Rule Lumber, Ottawa, Il.

Already operating a retail location in Ottawa, R.P. Lumber aims to extend its service across a wider swath of LaSalle County and its neighboring communities by merging the two locations.

“Paul Pike isn’t just the owner of Golden Rule Lumber,” said Robert L. Plummer, president & CEO of R.P. Lumber. “He’s been an advocate for Ottawa’s growth and development, deeply ingrained in the fabric of LaSalle County as a community pillar.”

According to the Pike Family, “Since opening in 1991, Golden Rule Lumber has proudly served the Ottawa area and beyond. After 33 years of service, we would like to announce the sale of the business to R.P. Lumber. We are confident that R.P. will provide the same level of professional care and service to our customers.”

Plummer added, “We’ve had a location in Ottawa since 2014, so we’ve always considered Golden Rule Lumber a friendly competitor. Their family values and sun-up-tosun-down work ethic are identical to ours, and we’re excited to expand our team and services.”

------------| DEALER BRIEFS

Fence & Deck Direct, Baltimore, Md., is now a Decks & Docks Lumber branch.

GR Mitchell Inc., Willow Street, Pa., acquired Ironstone Building Supply, Lancaster, Pa., from Dave O’Connor, who is retiring.

Wharton Feed & Ace Hardware, Wharton, Tx., held a grand opening event April 5-6 (Richard Lockley, owner).

Lumber Plus, Miami, Fl., has opened a branch in Ronkonkoma (Long Island), N.Y., headed by Carlos Kuhl Nogueira.

Associated Buyers True Value, Fremont, Oh., is closing after 75 years, with the retirement of owner Ed Schultz.

Curt’s Ace Value opened store #9 in Marion, Va.

Maximus Building Supply has renovated its Olive Branch, Ms., location.

Great Lakes Ace Hardware, Shelby, Mi., showed off its recent remodel during an April 19-21 grand reopening celebration.

Costello’s Ace Hardware is up to 49 locations after acquiring Warrenville Paint & Hardware, Warren, N.J., from Bill and Michele MacDonald. Bill will remain on staff, serving commercial accounts.

Northfield Ace Hardware, Northfield, Mn., reopened March 18 under new owners Joe and Kathryn Donahue, following an 11-week remodel. Dave Neiman, who owned Arrow Ace Northfield for 20+ years, is retiring.

Aubuchon Co. is buying sevenunit Bibens Ace Hardware from Rick Bibens, with stores in South Burlington, Burlington, Springfield, Colchester, Essex, Brattleboro (Brown & Roberts), and Woodstock (Woodstock Home & Hardware), Vt. All will retain their current names.

24 • building products digest • May 2024 building-products.coM

HOOVER TREATED Wood Products’ new logo.

www.versatex.com 724.857.1111 | Discover The smarter way forward. VERSATEX manufactures state-of-the-art cellular PVC building products that install like real wood and are completely impervious to moisture or any environmental impact. When you Discover VERSATEX, you find there is a way to blend architectural beauty with long-lasting, low-maintenance performance. Learn how VERSATEX was discovered by this builder at www.versatex.com/discover.VanDuyne Van

NJ

Duyne Builders, Longport,

HOUSE-HASSON ACQUIRING BOSTWICK-BRAUN

Wholesaler House-Hasson Hardware, Knoxville, Tn., agreed to purchase Bostwick-Braun Hardware, Toledo, Oh. The deal will include warehouses and inventory.

“When completed, this acquisition doubles the number of our distribution centers, grows our inventory, and puts us in an even stronger position to provide everything our dealers need,” said Steve Henry, president and CEO of House-Hasson.

House-Hasson’s main warehouse is at its Knoxville corporate headquarters, with a second warehouse in Prichard, W.V. With the addition of Bostwick-Braun’s West Helena, Ar., and Ashley, In., warehouses, House-Hasson will have more than 1.1 million sq. ft. of warehouse, receiving and shipping space.

“Bostwick-Braun has a remarkable history, and, to its leadership’s credit, they recognized that now is a good time to partner together to better serve our combined customers,” Henry said.

CEO Pete Richichi said that Bostwick-Braun has a nearly 170-year history of working for customers throughout the U.S. Midwest.

There are 110 employees working in Bostwick-Braun’s two warehouses; House-Hasson plans to try to retain as many employees as possible. House-Hasson’s staff currently numbers 465 employees in Knoxville and Prichard.

The 56,000 SKUs in BostwickBraun’s warehouses will be incorporated into House-Hasson’s system. House-Hasson presently has 55,000 SKUs in its two warehouses.

HOME DEPOT PURCHASING SRS DISTRIBUTION

The Home Depot has agreed to acquire SRS Distribution, McKinney, Tx., for $18.25 billion

Under the terms of the deal, SRS Distribution will operate as an independent business unit within The Home Depot, focused on accelerating growth in the pro market.

Over the past 16 years, the SRS family has become one of the fastest-growing building products distributors in the U.S.

The proposed acquisition will clear a pathway for accelerated growth with the residential and commercial professional customer by expanding Home Depot’s pro capabilities, combining online, retail, and wholesale. The combined platform will open new opportunities for existing suppliers and partners by providing access to SRS’ expert workforce focused on specialty verticals, as well as Home Depot’s cross-project expertise, product mix, network, and digital assets.

Under the deal, the SRS senior leadership team will remain with the company to guide its ambitious growth plans. Dan Tinker, president and CEO of SRS, will continue to lead SRS operations under this new structure.

“SRS’ ability to build leadership

positions in each of its trade verticals while generating significant revenue growth is a testament to its strong vision, leadership, culture, and execution,” said Ted Decker, chair, president and CEO of Home Depot. “SRS’s branch network, coupled with The Home Depot’s 2,000+ U.S. stores and distribution centers and comprehensive product offering provides the residential and commercial pro customer with more fulfillment and service options than ever before.”

The transaction is expected to close by the end of fiscal 2024.

Founded in 2008, SRS currently operates under 46 local brands encompassing over 760 locations across 47 states, including Acorn Roofing Supply, Advanced Building Products, American Roofing Supply, BL, Kohl Building Products, Marsh Building Products, Metro Roofing & Metal Supply, Midwest Roofing Supply, River City Wholesale, Suncoast Roofers Supply, and Wimsatt Building Materials.

With the purchase, Home Depot estimates its total addressable market is approximately $1 trillion, an increase of approximately $50 billion.

Do it Best/United Hardware merger has been approved.

Do it Best has begun stocking Paslode nailers, staplers and fasteners in its warehouses.

U.S. Lumber lost its Claysburg, Pa., distribution center in a massive blaze on March 18. Investigators are seeking the cause.

Neiman Enterprises is instituting layoffs and production cutbacks at its Spearfish Forest Products mill in Spearfish, S.D., due to reductions to the Black Hills National Forest timber sale program.

White Cap acquired Crimson Steel Supply, with distribution/ steel fabrication yards in Tulsa, Oklahoma City, and Muskogee, Ok.

Jeld-Wen is closing its wood window plant in Hawkins, Wi., and will consolidate production at its facility in Rantoul, Il.

Lansing Building Products added a branch in Greenville, S.C.

Beacon opened branches in Fort Myers and Milton, Fl.; Spring Lake Park, Mn.; and Saginaw, Mi.

Sterling Lumber has consolidated operations from three plants at a single 60-acre complex in Phoenix, Il.

MITER Brands completed the acquisition of PGT Innovations.

Carolina Atlantic is now distributing Vista Railing Systems from Greenville, S.C., in addition to Calhoun, Ga., making the aluminum, glass and cable railings available in South Carolina, eastern Tennessee, western Alabama, and northern Georgia.

K+R Building Materials, Jefferson City, Mo., has begun distributing New Castle Steel framing products in the Midwest.

Keim, Charm, Oh., is now distributing Accsys’ Accoya, Tricoya and Accoya Color modified wood products across Ohio, Pennsylvania, Kentucky and West Virginia.

Bluegrass Wood Products, Gamaleil, Ky., is the latest company to earn NWFA/NOFMA mill certification from the National Wood Flooring Association.

MidSouth Tag & Label, Birmingham, Al., reached a milestone by producing over 1 billion tags and labels for the fourth consecutive year.

26 • building products digest • May 2024 building-products.coM

------------|

SUPPLIER BRIEFS

LET’S GET GROWING

With Do it Best, we can expand our vision without limits.

Do it Best gives Kenny Trujillo and Richie Tabet the power to quickly and efficiently deliver building materials to customers across a vast 122,000-square-mile service area.

Our incredible buying power and logistical strengths have transformed RAKS Building Supply into New Mexico’s best and largest independent building materials dealer.

Join the company with a team of industry experts who are committed to take your business beyond your vision.

Read Kenny and Richie’s success story at doitbestonline.com/RAKS.

MOVERS & SHAKERS

Eric Dolloff has been promoted to regional general mgr. for Hancock Lumber, Casco, Me., covering the greater Portland, Midcoast and Capital area regions. Mike Boulet is now general mgr.-retail manufacturing. He will continue to oversee Mainely Trusses, Fairfield, Me., along with adding wall panel manufacturing in Windham, Me.

Jesse Levin is new to contractor sales at Hingham Lumber Co., Cohasset, Ma.

Drew Wilson has joined Outdoor Living Supply, Charlotte, N.C., as a territory sales specialist.

Mike Ocker, ex-Do it Best, has joined Eastern Engineered Wood Products, Bethlehem, Pa., as outside sales representative in the Carolinas. Marcus Dixon has been promoted to operations mgr. for EEWP’s new distribution center in Pelzer, S.C. Controller Nancy Dixon is taking on a newly defined role as director of administration and will also be relocating to South Carolina.

Marcus Erickson, ex-Midland Garage Door, has moved to the inside sales team at Lyman Lumber/US LBM, Chanhassen, Mn.

Mike Wilson has been promoted to chief commercial officer for BlueLinx, Atlanta, Ga. Leo Oei succeeds him as VP of product management. David Sherwood is now regional VP-North Region, Minneapolis, Mn.

Sam Lakey is now with Barrette Outdoor Living as territory sales rep for St. Louis, Mo.

Bryan Baker has joined LBM Advantage, as member sales mgr. for the Southwest region, covering Texas, New Mexico, Oklahoma and Kansas. He takes over for Barry Brooks, who will now serve Louisiana, Mississippi, Alabama, Arkansas and Tennessee.

Cody Grein has joined the inside sales team at Snavely Forest Products, Oklahoma City, Ok.

Gyorgy Fulop is now mgr. of Contract Lumber, Houston, Tx.

Shane Green has been appointed president of Sterling Lumber, Phoenix, Il.

Matt Rudy has been named incoming general mgr. of Erie Materials’ Auburn, N.Y., branch, to succeed Randy Moore later this year. Brian Moran is a new territory mgr. in Scranton, Pa. New to inside sales are: Jose Cartagena, Scranton; Josh Cady, Binghamton, N.Y.; Mitch DeVito, Watertown, N.Y.; and Tony DiMassimo, Williamsport, Pa. Justin Walker was named warehouse mgr. in Syracuse.

Jeremy Napolitano has been named mgr. of Riverhead Building Supply, Riverhead, N.Y.

Branden Shuler, ex-Guy C. Lee Building Materials, is now plant mgr. for Fortress Wood Products, Elizabeth City, N.C.

Jason LeBright is new to BOLD–Best Outdoor Living Design as N.Y.-based business develoment mgr. for the Northeastern U.S.

John McKinnon is now in outside sales with ABC Supply, Pooler, Ga. Seth Monty is new to outside sales in Richardson, Tx.

Steven Kukulka, Decks & Docks Lumber Co., has been promoted to Charleston, S.C.-based VP for the mid-Atlantic. Alan Butterfield, ex-The Deck Store, is new as VP for the Northeast.

Doug Johnson, COO, Classic American Hardwoods, Memphis, Tn., has retired after 30+ years in the industry.

Thomas Ashley was promoted to outside sales at Carter Lumber, Charlotte, N.C.

Evan Ippolito was appointed co-mgr. of 84 Lumber, Allentown, Pa.

Tyler Bryant, Ace Hardware Corp., has been promoted to Greenville, S.C.based district mgr. over Virginia, West Virginia, and the Carolinas.

Nathan Harmon is now San Antonio, Tx., territory mgr. with Anlin Windows & Doors.

Rob Williams was promoted to forest products divisional purchasing mgr. for Do it Best Corp., Fort Wayne, In. Also promoted were: LBM product sales mgrs. Jim Knepper, Steve May, Kevin Riley, John Trowbridge (SYP), and Zach Vanlandingham (western species); Ronnie Thomas, associate merchandising mgr.-hardware; Brittany Peavler, associate merchandising mgr.; Arron Enyart, merchandising supply planner; and Bill Habegger, IT divisional mgr. of operations. Abeer Saeed is new as home décor, lumber & building materials merchandise mgr., and Craig Thacker, merchandising category management planner.

Jeff Dyer is new to B2B sales at Horizon Forest Products, Houston, Tx.

Raphael Watson is the new distribution mgr. at PrimeSource Building Products, Kansas City, Mo.

Truss Beasley, Beasley Forest Products, Hazlehurst, Ga., was elected Southern Cypress Manufacturers Association president during the group’s recent

annual meeting in Charleston, S.C.

Mike Shook, Norcross Supply Co., Peachtree Corners, Ga., is the new VP.

Rebecca Massey has joined the Building Material Suppliers Association staff as director of conferences & events. Kelly Franklin was promoted to VP and secretary.

Dave Fisher, Pittsburgh area mgr., 84 Lumber, was named the chain’s 2023 Area Manager of the Year. Dan Jones, north Charlotte, N.C., was honored as Manager of the Year; Brennen Byers, Dallas Door Shop, as Manufacturing Manager of the Year; and Andrew Boyd, operations mgr. in Charlotte, as Rookie of the Year.

Matthew Netterville, Fred Netterville Lumber, Woodville, Ms., was elected Hardwood Manufacturers Association president during the group’s national conference in Charleston, S.C. He succeeds Tommy Petzoldt, East Perry Lumber, Frohna, Mo. New VP is Brian Schilling, Pike Lumber, Akron, In. They are joined on the executive committee by Scott Cummings, Cummings Lumber, Troy, Pa.; Tripp Josey, Josey Lumber, Scotland Neck, N.C.; Wayne Law, New River Hardwoods, Beckley, W.V.; Geoff Henderson, Anderson-Tully Co., Vicksburg, Ms.; and Jason Dallas, Stella-Jones, Pittsburgh, Pa. Elected to the HMA board were: Nancy Tuck, Gates Milling, Gatesville, N.C.; Thomas Battle, Battle Lumber, Wadley, Ga.; Scott Ferland, Maine Woods, Portage, Me.; Kirby Kendrick, Kendrick, Inc., Edgewood, Ia.; Steve James, Frank Miller Lumber, Union City, In.; and Jeff Lisk, Wagner Millwork, Owego, N.Y.

Sarah Billig, ex-Mendocino Cos., is the new president of Forest Stewardship Council U.S. She succeeds Stuart Hale, forestry program mgr. for the U.S. and Canada carbon markets team at the Nature Conservancy, who was serving as interim president while co-chairing the board of directors.

Aaron Cox, mgr., Higginbotham Bros., Midlothian, Tx., was honored with US LBM’s Humanitarian Award, earning a $10,000 grant to the Midlothian Independent School District Education Foundation.

Isabelita “Lita” Abele, president and CEO, U.S. Lumber, Woodbury Heights, N.J., was honored as 2024 Small Business Person of the Year for New Jersey by the U.S. Small Business Administration.

Lisa Kwipment has joined the rental department at Mungus-Fungus Forest Products, Climax, Nv., report owners Hugh Mungus and Freddy Fungus

28 • building products digest • May 2024 building-products.coM

------------|

GET TO KNOW THE NEXT GENERATION OF NAWLA

GET TO KNOW the individuals behind NAWLA by getting to know our Young Emerging Lumber Professionals (YELP) members. NAWLA’s YELP program seeks to identify opportunities to strengthen the future of our industry and recognize the achievements of young professionals in the workforce. YELP emerged in 2021 with the mission of creating opportunities for the next generation to learn about NAWLA and to help them grow their professional networks.

Tiffany Richardson Empire Building Materials, Bozeman, Mt.

Currently, a co-leader of the CFO 10 Group and a member of YELP, Tiffany Richardson has become fully immersed in NAWLA programs after joining the lumber industry four years ago.

Tell us about yourself. What is your background and how did you get involved with wholesale lumber?

I was born and raised in Helena, Mt., and eventually made my way back so that I could raise my three kids surrounded by family. I got my degree in Business Management from MSU Bozeman, an MBA from the University of Montana, Missoula, and a master’s degree in accounting from DePaul University in Chicago. I am a CPA, but I never wanted to work in public accounting. I love helping private businesses understand their financial statements and how to use them to continue to grow.

I fell into the lumber industry when I applied to an ad for a corporate controller posted by Empire Building Materials in Bozeman, Mt. It has been a whirlwind learning everything that this industry encompasses, but I have never loved what I do more than now.

What motivates you to continue on this career path and be a part of the wholesale lumber industry?

The lumber industry is an old one with mounds of amazing history. I love the authenticity of this industry as well as the vendors and customers I get to work with. My motivation to continue in my career path lies in my desire to continue to push the industry forward. My passion combines finance and technology which allows my incredible staff to improve processes, create efficiencies, drive sales, and provide killer customer service. To continue to grow in all facets, we can’t stand still.

In what ways have you seen the lumber industry evolve over the years?

My time in the lumber industry has been a wild ride! I was hired in 2020 shortly after COVID ravaged our country, but surprisingly not our industry. So far, I haven’t known anything but gangbuster sales, solid growth, and a future that is almost impossible to predict. I don’t have enough years under my belt, but I see very exciting things evolving in the industry moving forward.

What has been the most rewarding part of your career so far? Are there any “wow” moments that particularly stand out to you?

The people and the endless opportunities are by far the greatest part of my job. Not only do I get to work with an incredibly talented pool of coworkers, but I have never met harder-working and more passionate people than those who work in and own the lumber yards we service.

I think the biggest “wow” moment I have had was seeing the price that OSB hit during COVID!

Tell us about your involvement with NAWLA. How long have you been a member and what made you want to join?

I joined NAWLA on the advice of my boss, Anthony Tangaro, when I first joined Empire in 2020. I was hooked after attending my first Traders Market in Louisville in November of 2021. I am a co-leader of the CFO 10 Group and was nominated as a YELP-er last year. I have attended every Traders Market and Leadership Summit since Louisville and wouldn’t want to miss one.

30 • building products digest • May 2024 building-products.coM

------------| NAWLA SPECIAL ISSUE

What advice would you give to a new NAWLA member?

I think I have heard it a million times, and for good reason, “get involved!” As a member, you only get out of NAWLA what you put in. Get involved, meet new people, push yourself out of your comfort zone, attend events, and show up to every event ready for something new.

What’s been your favorite NAWLA moment?

I don’t have just one since my favorite NAWLA moments stem back to meeting a handful of people that I now consider close and lifelong friends. I am grateful, daily, for these relationships.

Anything else you would like to share?

I am super excited to be assigned a mentor through the Young Emerging Lumber Professional program! I look forward to having an expert in the industry that can guide me to be better and do better in my current position and help prepare me for all this industry has in store!

Mike Andrew Nicholson and Cates, Burlington, Ontario, Canada

After shifting from a career in real estate, Mike Andrew found his home in the wholesale lumber industry. Now working at Nicholson and Cates, he is an active member of NAWLA and a member of the 2023 Young Emerging Lumber Professional class.

Tell me about yourself. What is your background and how did you get involved with wholesale lumber?

I have been in sales for over a decade but completely pivoted my career when my wife and I started growing our family. I was a full-time real estate agent running a successful practice but started to tire of the evening and weekend hours. I was always on call and missed so many planned classes and events with my oldest son to run out on showings, take a listing appointment, or

building-products.coM May 2024 • building products digest • 31

Free & Clear 1-800-547-9520 | timberproducts.com KodiakPly Shasta Series Siding Panels Sizes: 4' x 8', 4' x 9', 4' x 10' Thickness: 11/32", 15/32", 19/32" Groove patterns: Plain, 4", 8", RBB 12" Patch-free face Cedar-like appearance Timber Products’ KodiakPly™ Shasta Series siding is the same KodiakPly panel you know and trust, but with a patch-free, Okoume face. The answer to your exterior needs, KodiakPly Shasta Series is made with a Douglas fir core and holds a timeless look with durable properties to meet the demands of the environment. Contact us today to learn more! Come see us at NAWLA! Booth #934

write up offer paperwork. This really wasn’t the kind of father I wanted to be. My wife and I had been discussing a career change for a while when a family friend that worked for Nicholson and Cates reached out and mentioned an opportunity in the lumber wholesale industry. I made the switch a few months before my wife and I had our second boy, and haven’t looked back since!

What motivates you to continue on this career path and be a part of the wholesale lumber industry?

This is an easy one, the people in the industry. I work on an amazing team at Nicholson and Cates, and the people I get to work with every day have become some of my closest friends. Many of the people I meet and get to do business with on a regular basis have become more like friends than customers.

In what ways have you seen the lumber industry evolve over the years?

I am still relatively new in the industry—having started in 2020—so

I haven’t experienced as much evolution as other seasoned vets, but I am always amazed when I go into a new shop or factory and see the levels of automation in a company’s production process. On a social level, I have definitely seen an influx of young, talented people come into the industry. I am excited to see how the industry evolves and becomes more diverse from where it is today.

What has been the most rewarding part of your career so far? Are there any “wow” moments that particularly stand out to you?

There are many rewarding aspects to this career. On a business level, being able to work together with my customers and help one another grow our respective businesses makes every day rewarding. On a personal level, I love the work/ life balance I have now. My office is seven minutes from my house and the time I get with my three kids is absolutely priceless.

One big “wow” moment was when I had the honor to speak and introduce a panel at the 2023 Montreal Wood Convention/NAWLA Montreal regional meeting. I was introducing Fred Lebel (Groupe Lebel), Bart Bender (Interfor), and Khara Julien (Specialty Building Products), and was blown away by how friendly all of them were and how these high-level industry executives made themselves so available for the benefit of others in our industry. I felt that it really spoke to the character of the people in the industry and how willing most people are to help teach and advance other’s careers.

How long have you been a NAWLA member and what made you want to join?

I have been a NAWLA member since I joined Nicholson and Cates in 2020. I attended a Wood Basics event in 2021 and made some very strong connections with others in the industry that I still keep in touch with today. The knowledge and connections I gained from that made me want to get more involved with the organization.

Patrick Lumber Company

Over 100 Years in Business

What advice would you give to a new NAWLA member?

Get involved and be a sponge! There are so many people that are

32 • building products digest • May 2024 building-products.coM

Est 1915

willing to teach you things about this industry and the connections and friendships you can make through NAWLA are invaluable.

What’s been your favorite NAWLA moment?