RESETTING YOUR LUMBERYARD: NEW LAYOUT • NEW RACKING • NEW TECHNOLOGY THE VOICE OF THE LBM SUPPLY CHAIN June 2023 Digital Edition Sponsored by Introduce your customers to the GOLD STANDARD of exterior adhesive protection. Scan the QR code on the left and get your free sample today. with premium, high-performance acrylic adhesive products: water resistant barriers, flashing tapes, and many more air tightness removes bulk water uv protection vapor permeable maxiumum protection BPD-FrontCover_2023.pdf 1 5/15/2023 1:49:56 PM

Help

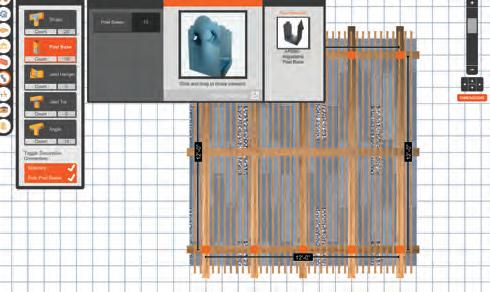

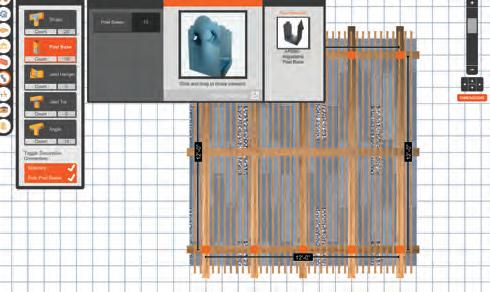

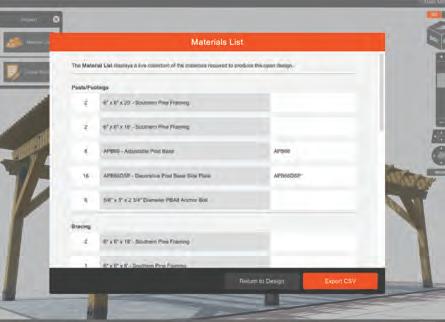

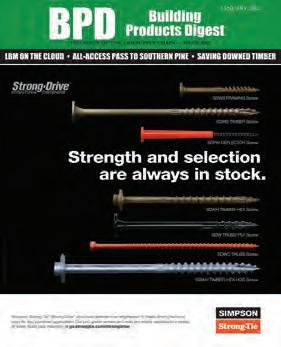

To learn more about our free downloadable software, visit our website at go.strongtie.com/pergolaplannersoftware or call ( 800) 999-5099.

your customers build their dream backyard with Deck Planner Software™ and Pergola Planner Software™ from Simpson Strong-Tie. Easily

a strong and beautiful deck, pergola or other popular structure in

minutes using prebuilt templates or custom dimensions.

in 2D or 3D environments and select wood species or additional features from

library of options.

plan

design

just

Work

a full

Then just print out the

view and materials list. Your clients, and your business, will thank you.

DPS Deck Planner Software™ PPS Pergola Planner Software™ ©2023 Simpson Strong-Tie Company Inc. PERGDECKPLAN20-D Great software for building great outdoor structures. Outdoor Living Solutions | Products, Software and Service for Smarter Building

4 • building products digest • June 2023 building-products.com ------------| CONTENTS June 2023 STAY CONNECTED ON SOCIALS: @BPDMERCH THE OFFICIAL PUBLICATION OF PROUD SUPPORTERS OF VOL. 42 • NO. 6 |-----------WWW.BUILDING-PRODUCTS.COM 16 32 DIGITAL EDITION CHECK OUT THE June 2023 Introduce your customers to the GOLD STANDARD of exterior adhesive protection. Scan the QR code on the left and get your free sample today. with premium, high-performance acrylic adhesive products: water resistant barriers, flashing tapes, and many more 10 SOUTHERN PINE 10 FEATURE STORY Is your family lumberyard a legacy facility or an operational win? 14 INDUSTRY TRENDS Lumberyard racking in a postCOVID era 16 MANAGEMENT TIPS Technology Lifesavers: 6 ways to improve your bottom line 18 PRODUCT SPOTLIGHT Investing in digital tools to better manage market challenges 20 OLSEN ON SALES Master Sellers stay nimble by using pivot points 22 3 QUESTIONS Meet Reclaimed Woods of the World’s Tom Flynn 42 COMPANY SPOTLIGHT Maze Nails hits 175-year milestone 08 ACROSS THE BOARD 24 TRANSFORMING TEAMS 38 MOVERS & SHAKERS 44 NEW PRODUCTS 48 IN MEMORIAM 48 CLASSIFIED MARKETPLACE 49 DATEBOOK 49 ADVERTISERS INDEX 50 FLASHBACK 26 LUMBER 411 32 SFPA PREVIEW Southern Forest Products Association previews this summer’s Forest Products Machinery & Equipment EXPO in Nashville, as it comes off a record year in SYP production. FEATURES DEPARTMENTS

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig • dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves • sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Kim Drew, Claudia St. John, Dave Kahle

CONTRIBUTORS

Clint Darnell, Jeff Easterling, Tom Flynn, Eric Gee, Chris Krauter, John Maiuri, Paige McAllister, Christian Moises, Kevin Stanton

ADVERTISING SALES (714) 486-2735

Chuck Casey ccasey@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

DIGITAL SUPPORT

Alek Olson • aolson@526mediagroup.com Mik Olson • molson@526mediagroup.com

CIRCULATION/SUPPORT

info@526mediagroup.com

A PUBLICATION OF

526 MEDIA GROUP, INC.

151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 Phone (714) 486-2735

BUILDING PRODUCTS DIGEST is published monthly at 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626, (714) 4862735, www.building-products.com, by 526 Media Group, Inc. (a California Corporation). It is an independently owned publication for building products retailers and wholesale distributors in 37 states East of the Rockies.

Copyright®2023 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. BPD reserves the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles in this magazine are intended for informational purposes only and should not be construed as legal, financial, or business management advice.

6 • building products digest • June 2023 building-products.com BPD SUBSCRIBE TODAY OUR MARKET MOVES QUICKLY—SO DON’T GET LEFT BEHIND! BPD is available on a qualified requester basis to senior management of U.S.-based dealers and distributors specializing in lumber and building materials, and to others at the rate of $22 per year. Subscribe now at www.building-products.com/subscribe. SUBSCRIBE NOW AT WWW.BUILDING-PRODUCTS.COM/SUBSCRIBE BPD - BUILDING PRODUCTS DIGEST SUBSCRIBE TO RECEIVE PRINT, DIGITAL, ENEWSLETTER & MORE! The LBM supply chain’s leading publication for qualified industry decision makers! • Update your subscription • Sign up key colleagues • Enroll multiple locations

YellaWood® brand pressure treated products are treated with preservatives (the “Preservatives”) and preservative methods, and technologies of unrelated third parties. For details regarding the Preservatives, methods, and technologies used by Great Southern Wood Preserving, Incorporated, see www.yellawood.com/preservative or write us at P.O. Box 610, Abbeville, AL 36310. Ask dealer for warranty details. For warranty or for important handling and other information concerning our products including the appropriate Safety Data Sheet (SDS), please visit us at www.yellawood.com/warranties or write us at P.O. Box 610, Abbeville, AL 36310. YellaWood and the yellow tag are federally registered trademarks of Great Southern Wood Preserving, Incorporated. All other marks are trademarks of their respective owners and are used with their permission. HAS YOUR BACK QUITE LIKE YELLAWOOD.® NOBODY That includes not going behind it. The YellaWood® brand not only prioritizes our dealer relationships, but we prove it through our actions. We take great pride in our fifty-plus year history of only selling to dealers and not directly to their customers. See all the other ways the YellaWood® brand has your back. Visit yellawood.com/for-dealers.

PASS IT ALONG

BY PATRICK ADAMS

IT’S BEEN A LONG TIME since I received an email that caused me as much thought as this one. It landed in my inbox the same as any other, except that it was from a man that I put among the top of my list of those whom I respect and admire. In it, he was asking for a “favor,” but in my eyes this was not something that he needed, or should even want from me.

I have shared plenty of vague references about my upbringing and past. To say I grew up poor was a bit like saying that you’re hungry; it’s a matter of perspective. It wasn’t a nice place to grow up, nor was it surrounded by nice people, and in this environment, my dreams were somewhat limited in most cases to simply escaping. Luxuries like going to college were never discussed and, therefore, never a part of my plan until much later in my adult life. I was simply happy to get out just before I turned 17, and I never looked back.

Of course, the life I have now is blessed beyond measure and something that in my wildest childhood dreams never would have entered my mind. I have lived a very full, interesting and exciting life so far. So when I read this email again for about the 12th time, my head just continued to spin. I was being asked to travel north to a university to be a guest lecturer for the day in the class taught by this man whom I am honored to call a friend. He is known and respected by the entire industry, not for his titles or his bank account, but because of the man that he has always been. The type of man I have always aspired to be, but for countless reasons I do not have the ability to see myself that way. But, of course, I couldn’t say no to a friend.

My trip up was full of racing thoughts. Don’t sound stupid. Don’t embarrass yourself, or especially this amazing man who clearly was at the bottom of his guest list. Try to relate to these kids… Relate to these kids… this generation that is more of a punchline to a joke than something I look at with hope? I sat in the front of the class with notes in front of me—not that I needed them, because I have spent weeks trying to package 45 minutes of valuable content from a lifetime that most can’t understand.

As I began recounting a few nuggets that I thought might be considered “wisdom,” a strange comfort came over me. It took me back to early days where I would sit entranced at the older generation sharing stories of advice, which I soaked up in my eagerness to forge a different life for myself. To my surprise as I looked around the room, I did not see a generation doing God knows what on their phones or fading off into a daydream wishing they were somewhere else. Instead, eyes were up and attention was focused. Notes were actually being taken and heads nodded or smiles emerged at all of the appropriate moments. In a flash, my 45 minutes were up and I made the closing statement I dreaded most: “And now, if anyone has any questions

I would be honored to answer them.” I had thought long and hard about closing this way because I expected the dread of any speaker—crickets. Instead, hands shot up and we spent another 30 minutes in lively discussion answering extremely thoughtful and wise questions that demonstrated a generation eager to accomplish the same things that I had at that age.

Several asked for my business card and more still came up, shook my hand, and simply said, “Thank you.” I walked away humbled, amazed, inspired and eternally grateful for this honor. I have thought a lot about this couple of hours since then and why it made an impact and memory that I will remember for the rest of my life. Was it ego? Was it surprise? Was it that this man I respect so much thought to ask me instead of the countless amazing people he must call friend?

Yes, perhaps all of that. But more than that, what he provided to me was a bit of redemption that just maybe that poor kid actually turned into someone who has led a life that has collected a bit of wisdom worth sharing. That maybe, while the stereotype of the next generation is well earned, that there are also countless amazing young people ready to take up the torch and do things even more amazing than we did for this industry, and this nation. But even more than that, it made me realize that mentoring and sharing is not just a gift for us, but an obligation on all of us to assure the next generation has the opportunity to do better than us.

In the rush of our daily leadership, do we ever pause to simply have a conversation with those who will succeed us? Do we view mentorship as a responsibility of good leadership? Perhaps I’m making more out of this than it really was. Maybe this generation is so skilled at technology and multitasking that they were indeed ordering lunch and setting up their next online date while playing a video game all the while being able to act like they were engaged. But maybe, just maybe, they weren’t.

So, just in case, take a minute, grab one of those youngsters and take them out to lunch. Tell them stories and let them ask questions, and just maybe someday they will tell stories about the day that this “old guy” took the time to share some wisdom with them that they carried through their career.

I am eternally grateful that I found this industry full of amazing individuals from several generations that all share the common bond of serving something greater than themselves. I hope as spring blooms, so does your family, your business, and your hope for the future.

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

8 • building products digest • June 2023 building-products.com

------------| ACROSS THE BOARD

------------

Call us at 707.894.4241 Visit us at buyRedwood.com DECKING Composite can’t compare. Like the foods we buy, when it comes to decking, we want natural and real. Redwood is always available in abundance of options. So stock the shelves! Unlike mass-produced and inferior products, Redwood is strong, reliable and possesses many qualities not found in artificial products. They maintain temperatures that are comfortable in all climates. Redwood Empire stocks several grades and sizing options of Redwood. REDWOOD

YEARS IN THE REMAKING

------------ BY CLINT DARNELL

THE FAMILY-OWNED lumberyard is a winner when it comes to longevity. In the U.S., the average lifespan of a family business is 24 years, with 60% never making it past the first generation, according to Cornell University. Yet, it’s not hard to find multi-generation, family-owned yards that have been around 75 to 100 years, or more.

Keeping the enterprise going from one generation to the next is no small feat, but it often comes with the pitfalls of a legacy yard design. Conducting business today in a facility built for yesterday, undercuts operational efficiency and limits the ability to grow.

What Operational Wins Look Like

When a lumberyard is designed well and outfitted with the right buildings and racking systems, the operational gains, or wins, are built-in and permanent: increased storage capacity, better traffic flow, reduced material

IS YOUR FAMILY YARD A LEGACY FACILITY OR AN OPERATIONAL WIN?

handling, safer operations, and a nicer customer experience, along with reduced cull and labor costs.

Yet, many owners don’t realize how much more efficient their yards could be, or assume improvements would be cost-prohibitive. Often, it’s not until circumstances force them to make changes, or they build a yard at a new location, that they appreciate the limitations of their legacy facility.

Overcoming Resistance

Dick Jennings, the owner of Jennings Builders Supply & Hardware, Cashiers, N.C., knew the wooden pole barns he used for storing lumber were inefficient, but he felt they did the job well enough. For him, cantilever rack T-sheds were a “nice-to-have” and he didn’t think their cost could be justified.

10 • building products digest • June 2023 building-products.com ------------| FEATURE STORY

TOWNSEND Building Supply’s nine-acre location in Panama City, Fl., is thriving, aided by an optimized layout featuring three pre-engineered metal buildings, a user-friendly retail operation, convenient drive-thru building, busy lumberyard, and modern racking systems. (Photos by CT Darnell/Sunbelt Rack)

Nevertheless, when he was building a new location, he decided to “go out on a limb” and try T-sheds. “Boy, was I wrong,” says Jennings, commenting on his initial resistance. “Not only do [the T-sheds] get our lumber off the ground and out of the weather, they are easy for our employees to load and unload.”

Now, all his locations have steel sheds and drive-thru buildings. “The efficiencies are remarkable,” says Jennings. “In the first year, our labor went down 35%, while sales went up 20%. It proved to be a good move.”

Doing More with Less

Southern Lumber & Millwork has operated from its original location in Mount Pleasant, S.C., since 1945. So, when they learned they were losing two of their seven acres to a highway expansion, pulling up roots was not an option. Neither was scaling back inventory.

Based on an in-depth study of Southern Lumber’s SKUs, a new site master plan with a lineup of drive-thru buildings, sheds, and

racking systems enabled Southern Lumber to utilize vertical space and retain all its inventory. What’s more, before the project had even wrapped up, the company had successfully managed through its greatest year of increased sales.

Centralizing Specialty Products

For Zuern Building Products, it wasn’t about losing almost a third of its acreage. Instead, it was about turning a vacant warehouse in Slinger, Wi., into a dedicated distribution center for their specialty millwork, paying for the project by maximizing internal efficiencies. Having already experienced the benefits of improving some of their other facilities, they knew the project’s ROI goal was realistic.

“Our sales have grown tremendously,” says Thad Schuler, CEO of inventory operations. “The new layout of the facility has an easy flow. We feel the gains in efficiency and effectiveness now have us geared-up for our next 75 years.”

The labor savings and reduced product damage achieved with millwork stack racks and PowerBin systems got them part of the way there. But one of the biggest gains was in fleet reduction. In the first year, Zuern shipped an additional $8.4 million in product with an average of two fewer trips per day, and was able to cut its fleet by almost a third.

Good Flow Is Key

Along with efficient storage of material, optimizing flow is one of the most important aspects of facility design. Traffic, materials,

building-products.com June 2023 • building products digest • 11

CT DARNELL/Sunbelt Rack remade the main building at Griffin Lumber, Warner Robins, Ga., which contains a warehouse, retail showroom, offices and a door manufacturing facility. Space-saving additions included the two T-sheds and two umbrella sheds seen above.

MANY OWNERS DON’T REALIZE HOW MUCH MORE EFFICIENT THEIR YARDS COULD BE, OR ASSUME IMPROVEMENTS WOULD BE COST-PROHIBITIVE.

and people need to be able to move through the facility without hindering each other, and with the fewest possible touches.

This was especially important for Griffin Lumber & Hardware’s new location in Warner Robins, Ga. The site wasn’t very large, yet still needed to function as a lumberyard, retail store, and door manufacturing shop.

Millwork stack racks minimized the footprint of the door shop, enabling Griffin to triple the amount of raw materials that could be stored, and preventing the door shop from impinging on the rest of the operation. The racks also provided efficient handling of the finished products. “You manually handle the material just one time (to load the rack) and then everything else is done with a forklift,” says Jason Settles, Griffin’s president.

The layout of the yard, including wide aisles between lumber sheds, keeps materials and shipments moving efficiently. At other yards, explains branch manager Chris Baroni, “it might take two men over three hours to pull a 2,000-sq. ft. house framing package. The way this yard is laid out, one guy can do it in about an hour.” What’s more, material can be loaded on both sides of the truck, keeping traffic moving and never blocking the aisle.

The Next Generation

Of the 40% of family businesses that make it to the second generation, only 13% are passed down to the third. After that, the succession rate falls to 3%.

While the statistics might be better for lumberyards, moving beyond the legacy facility with an updated design, new sheds, and new rack systems, creates operational wins every day that will help to preserve the family legacy for the future. BP

CLINT DARNELL

12 • building products digest • June 2023 building-products.com

POWER BIN storage systems employ a battery-operated loader deck that automatically places building materials into pigeonhole bins equipped with heavy-duty rollers.

MILLWORK STACK racks for doors and windows can be placed three high, making the best use of space.

Clint Darnell is the vice president and owner of CT Darnell Construction/ Sunbelt Rack. Learn more by visiting sunbelt-rack.com or ct-darnell.com.

LUMBERYARD RACKING IN A POST-COVID ERA

------------ BY CHRIS KRAUTER

THE LUMBERYARD INDUSTRY has certainly enjoyed robust activity since the onset of COVID in 2020. From our perspective as a material handling dealer and looking at the post-COVID product category sales revenue, certain trends can be identified.

The industry was faced with increasing commodity costs, longer lead times, and, most importantly, a shortage of labor. Lumber quickly became a high value commodity. Cull lumber, for example, previously addressed

as normal inventory shrinkage, suddenly became a focal point of preservation. Lumberyards were facing increasing sales volume and product throughput, all without the benefit of readily available labor. They had to do more with the same staffing.

Expanded product offerings increased the storage requirements. Dealers were faced with the need to extend their facilities and/or look at ways of increasing current storage capability while concurrently maintaining organization and a smooth order-fulfillment process.

To meet that challenge, many dealers converted their current warehouse cantilever and/or pallet rack storage systems to that of a semi-automated roller rack system. Studies have shown that SKU density can be increased by 30-40% in the same available warehouse space, plus all SKU locations are accessible on grade or via a catwalk. The reason is the simple elimination of access aisles. Where vertical space allows, a system can have a top mezzanine platform, which to an extent, captures back the square footage for bulk storage of hardware, insulation, archives, and other items. The result has been an increased SKU count, and more efficient order fulfillment by employees. The demand for this product category is up significantly versus the pre-COVID years.

Looking to the exterior lumberyard, covered cantilever rack canopies effectively organize and protect product.

14 • building products digest • June 2023 building-products.com ------------| INDUSTRY TRENDS

COVERED drive-thru systems permit order fulfillment in any weather and can accommodate a semi-automated roller rack system inside the canopy.

COVID-INDUCED labor shortages forced lumberyards to look for labor-saving ways to store and handle their merchandise. (Photos by Krauter Auto-Stak)

Trends have shown a similar doubling of demand versus the pre-COVID years. Perimeter single-face cantilever canopies are a good solution, as they offer selectivity, weather protection, and security.

Covered drive-thru systems enable order fulfillment in any weather and have the capability of adding a semi-automated roller rack system inside the canopy, with cantilever on the exterior facings.

The biggest trend, however, has been the explosion of the stacking frame concept for windows, doors and cabinets. This essentially has been an acceptance of the “containerization” of product, which significantly cuts down on handling while maintaining organization of orders. The fact that these stacking frames can be stored in a very tight pattern with minimal aisle space increases inventory density without losing accessibility. Many dealers have abandoned pallet racks used for their normal in-stock SKUs and converted to these stackers, which are essentially a “modular” pallet rack.

The use of these stacking frames for custom orders along with a

flatbed trailer equipped with a tail mounted forklift enables a single employee to deliver orders efficiently and quickly. The orders are handled only one time by hand when loading into the stacking frame. From there the items are secured via ratchet straps or similar, awaiting final delivery. The driver unloads the stackers and sets them on the jobsite in the

garage. The contractor then unloads the merchandise, signs off the bill of lading, and the stacker is set back into the next cycle.

The trend in this type of material handling has exploded over four-fold vs. pre-COVID. BP

building-products.com June 2023 • building products digest • 15

BIGGEST TREND in lumberyard storage has been the proliferation of portable millwork stacking racks, which “containerize” the movement and housing of doors, windows, millwork and more.

– Chris Krauter is president of Krauter Auto-Stak, Brookville, In. (www.ks-ka.com).

Ask about our Saberis integration

TECH SAVERS

6 WAYS TO IMPROVE YOUR BOTTOM LINE

BY KEVIN STANTON

THE LUMBER INDUSTRY has undergone significant changes over the years, with technology playing an increasingly important role in managing lumber businesses across the nation.

The most successful leaders and businesses understand that the right enterprise resource planning (ERP) system saves time and money, leads to better customer service, and helps keep things organized and running smoothly.

What is ERP? Enterprise resource planning is a software system that helps you run your entire business, supporting automation and processes in finance, human resources, manufacturing, supply chain, services, procurement and more.

Gone are the days of manual processes and disparate systems that don’t interoperate well with one another. These unproductive prac-

tices are quickly becoming a thing of the past replaced with time-efficient, easy-to-use software solutions.

1. Inventory Management

One of the primary uses of ERP in the lumber industry is inventory management. Companies rely heavily on accurate inventory data to ensure that they have enough raw materials on hand to meet production demands and that wholesalers have visibility of inventory.

By using reliable software programs, lumber companies can keep track of inventory levels in real-time, allowing them to quickly identify when supplies are running low and reorder as necessary.

Inventory management software can also be used to monitor customer orders ensuring that each stage in the fulfillment cycle is completed accurately and on time. Reliable data

helps lumber companies avoid stockouts and delays in delivery, which can have a significant impact on customer satisfaction.

2. Project Management

Project planning and management is the foundation to running efficient workstreams. With the right software system, wholesalers can develop projects that manage workflows and organize multiple documents such as RFPs, contracts, business communications, and more. It can also help manage materials for projects and incremental billing which helps lower management costs, and increases throughput and profitability.

3. Treatment Processes

Timely management of wood treatment is another area where technology is beneficial in the lumber industry. By using specialized

16 • building products digest • June 2023 building-products.com ------------| MANAGEMENT TIPS

------------

software, companies can monitor the quality of each step of the treatment process and accurately track every stage.

For example, utilizing barcode scanning applications that provide instant updates keeps track of bundles through various treatment processes. This provides immediate status of services on any given bundle. Managers are immediately notified when all services are completed and ready to ship.

4. Accurate Accounting

Rather than using a third party service or program, the right integrated software solution can run your accounting within the same system it uses to run other services that manage your business. Streamlining your accounting within one easy-touse system cuts back on time—and it cuts back on errors.

As an example, accounting that is integrated with your current setup can auto-generate and send invoices in one easy step, keeping your books up to date, controlling checks and balances, and managing timely payments.

5. Performance Monitoring

Equipment maintenance can slow things down unless proactively managed. Specialized software allows companies to monitor the performance of their equipment and identify potential issues before they become major problems. This prevents costly downtime and repairs, which can have a significant impact on production and profitability.

For instance, predictive maintenance software can be used to monitor the performance of saw blades. By analyzing data on blade wear and tear, companies can identify when blades need to be sharpened or replaced. This helps extend the life of the blades, ensuring that they are always operating at peak performance.

6. Data Analysis

Accurate data and ongoing analysis is essential to a well-run organization. By collecting and analyzing data on production times, costs, and quality, companies can identify trends

leads to better efficiency, reduced waste, and increased profitability.

Additionally, by analyzing data on production times and costs, companies can identify which products are the most profitable to produce. This will inform production planning and ensure that the company is focusing its efforts on the most profitable areas of the business.

Technology will continue to serve a significant role in the lumber industry, revolutionizing the way lumber is processed, managed, and sold. Year-over-year, we expect to see the release of more innovative software programs built specifically to meet custom needs across the industry. BP

Amazing performance, extensive battery life and unrivalled ergonomics combined with all the advantages of the Combi-CB range make the CB70E the most powerful, compact multidirectional forklift yet.

The new COMBi-CB70E electric multidirectional forklift is the most compact 15,5000 lbs counterbalance truck on the market. Multidirectional ability enables the handling of both long and bulky loads, maximizing the safety, storage & efficiency of your logistics.

The CB70E is loaded with a host of ergonomic features that greatly enhance operator comfort, including excellent all-round visibility, a spacious gas-strut suspension cab, independent electric traction and our newly developed Auto Swivel Seat which intelligently swivels 15O in the direction travel.

To find out how Combilift can help you unlock every inch of your storage space.

building-products

KEVIN STANTON

Kevin Stanton is founder and software architect for RDB Solutions, Bend, Or.

combilift.com 1 877 2662456 Introducing

2 5

Contact Us Today

Builders merchant amanda 7x4.875 rev 1.3.indd 1 16/05/2023 14:35:51

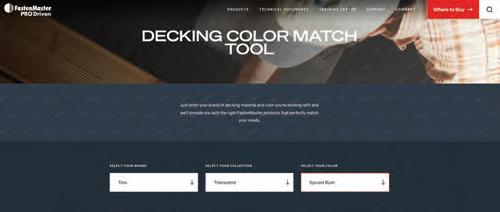

INVESTING IN DIGITAL TOOLS TO BETTER MANAGE MARKET CHALLENGES

BY JOHN MAIURI

BY JOHN MAIURI

WHILE THE LAST three years can be characterized by themes of uncertainty and turmoil, there has also been an undeniable acceleration in the rate of digital transformation and innovation—even across industries that have been historically slower to embrace change. The lumber and building material industry is a prime example of an industry that’s put a spotlight on digital transformation to better manage market challenges.

For example, with the pandemic, we witnessed digital commerce and trends like buy online, pickup in-store (BOPIS) take off, spurring an “ecommerce explosion” out of necessity. Now, as the future of the LBM market continues to be unclear as threats of a recession loom, more LBM leaders

are turning to digital technologies, further adapting to the market and evolving customer expectations. These are trends within trends, in an industry known for resiliency despite the challenging macroenvironment of the day. However, as LBM leaders lay the groundwork for their digital transformation strategies, they need to truly understand what digital transformation means for them—in the context of their individual business, in addition to the market and customers they serve.

What digital transformation means for the LBM industry

Depending on who you ask, the LBM industry is at different stages when it comes to digital transfor-

mation and the transition to digital commerce. Some have only recently begun to use this technology, spurred by the pandemic and tech advancements in this space that have made these solutions more readily available. Others may even debate that the LBM industry is decades behind the curve when it comes to adopting new innovations. However, with nonstop disruption and economic challenges, the rewards have been fruitful for LBM leaders that have leaned into digital technology solutions.

At its core, digital transformation is about adopting technology that can inform better decision making, smarter investments and operational efficiencies key to a streamlined

18 • building products digest • June 2023 building-products.com

------------| PRODUCT SPOTLIGHT

------------

customer experience. According to ECI’s 2022 Lumber, Building Material and Hardlines industry survey, more than half of LBM businesses (55%) have increased investment in technology infrastructure to address some of these market concerns, monitor operations and keep an eye on the broader industry’s health.

Business management solutions are one example of a tech investment that’s gaining attention in the LBM industry. The benefits of a reliable business management solution are indisputable as this technology plays a key role in nearly every critical department across an LBM dealer’s business.

For innovative LBM dealers looking to take this investment to the next level, having a solution with an integrated point of sale (POS) system and ecommerce capabilities provides owners and managers with even deeper insight into managing inventory and tracking key performance indicators (KPIs) that let LBM dealers make smarter business decisions. In today’s market and evolving customer landscape, having a digitally led strategy and the tools to support it

can be a major competitive difference and key to meeting emerging customer expectations.

The ecommerce explosion

Convenience is the new loyalty when it comes to today’s consumer, even in the LBM industry. Typically, LBM dealers cater to a range of customers, from the DIYers to the professional contractor pros. With these varying audiences, LBM dealers face an added layer of complexity by having to accommodate different sets of shopping preferences. However, tech tools can help address customers in different ways so they can shop when and how they please. Part of this is having an easy-to-navigate online presence, which is critical for capturing shoppers across this space, especially if LBM dealers are looking to stay competitive against national chains. Delaying or refusing to adopt ecommerce solutions not only means missed sales opportunities, but also missed opportunities to improve operations internally and become a stronger business.

At the center of every successful ecommerce strategy is data and

leveraging these insights to locate potential areas of improvement or identify any weak links. For example, are you missing margin opportunities? Capturing lost sale information by evaluating what customers search for? Real-time data dashboards and reports can provide LBM leaders with a clearer picture for these exact questions. Additionally, LBM dealers can track purchasing behavior to predict customer demand, which can benefit overall organizational health by furthering price stability and compensating for supply chain constraints.

Adopting an innovative culture

Overall, the LBM industry needs to embrace digital tools into their culture if they want to remain resilient amidst the current turbulent marketplace. The strongest digital transformation strategy will not stick if a company’s culture does not value innovation. Understanding what’s at stake and the tools available that can help with this journey, is the first step towards future proofing your business. BP

–

John Maiuri is president of ECI Software Solution’s LBM & Hardlines Group

(www.ecisolutions.com).

building-products.com June 2023 • building products digest • 19

PIVOT POINTS

------------ BY JAMES OLSEN

DURING THE SALES process there will be points in the conversation where we can turn the talk in the direction we would like it to go. We will be able to pivot off a remark from the customer and turn our exchange into something positive for us and the customer.

Many sellers have no idea how they want the conversation to go; they just float along. The strange thing is that when the seller doesn’t control the conversation, many customers become frustrated with the process and treat sellers poorly because of this frustration. They don’t really know why, but it is the feeling of “Why did you call me?” They feel the salesperson is wasting their time—and rightfully so.

So, as simple as it seems, we need to know exactly what we want our customers to do and how to get them there. This is what Master Sellers do.

Often when customers bring up negative things, we can pivot off of these comments to something positive:

I Don’t Like Prices

“I agree with you. I wouldn’t touch 2x4 or 2x6 right now, but 2x8 is within 5% of a five-year low, so we are at investment levels on 2x8. I have three trucks I can pick up for us at $573/MBF, which is a fantastic deal. How many would you like to take?”

The Market Is Coming Off

“Yes, it is, which creates a lot of opportunity for us. We are always looking for straight 16’s out of ABC Sawmill and can never get them,

especially at a price we like, but now they are listening, and we can pick 16’s up for a great price. We have been putting together a lot of great deals. Let’s give them an offer at 50 below print and see what happens. How many can you use if the price is right?”

“Yes, the market is coming off. The only way to buy at the bottom is buy on the way down. We’ve been coming off for 45 days. This thing is getting ready to turn, but the mills are still listening. Let’s give them an aggressive number today. If we wait for it to bounce, which is what everyone is doing, it will be up $50/MBF in two seconds and we will miss it. Let’s make them an offer at $459/MBF and see what happens.”

It’s Winter and My Business Is Slow

We are going to hear a version of this every year from Thanksgiving to April 1. “Yes, it is a bit slower right now but spring is coming. Now is the time to hit the mills with a program for spring. They are flexible and listening. Let’s propose something for delayed shipment on the items we know we are going to need in 60 days.”

I Just Bought

Many sellers shut down or say, “Well what else are you looking for?” We can ask this question, but before we do, get curious. “OK, what did you pick up? When is it going to ship? Whose stock was it? What did you pay? How many did you pick up?” If we ask these questions in a casual curious way most customers

will share the information. Some won’t, but we are not intimidated into not asking these questions again, because most customers will.

When we find out the information about what they purchased, we say, “If I could get us a couple more for extended shipment, would you want to put them on?” One out of 10 customers will say yes. One out of 10 may seem like a low number, but if we are working hard enough that is a lot of extra orders at the end of the month.

I’ve Got Enough

Instead of saying, “Well what do you need?” we say, “I don’t want to sell you something you don’t need, but how long can you wait before you have to buy? Mills are listening, and prices are advantageous right now. Let’s hit them firm with some great numbers for extended shipment and see what they will do.”

Objections and negative statements shut down many sellers but are pivot points for the Master Seller. They turn a supposed negative statement into opportunity for their customers and themselves. Start using pivots today.

20 • building products digest • June 2023 building-products.com

------------| OLSEN ON SALES

JAMES OLSEN

James Olsen is principal of Reality Sales Training, Portland, Or. Call him at (503) 544-3572 or email james@ realitysalestraining.com.

3 QUESTIONS: RECLAIMED WOODS OF THE WORLD’S TOM FLYNN

TOM FLYNN, president of distributor/importer Reclaimed Woods of the World, Costa Mesa, Ca., has seen more than most over his near-50 years in the industry:

1How did Reclaimed Woods of the World gets its start?

Flynn: We started off as a traditional veneer/lumber company in the Midwest, when one of the sons from the original British company opened an office in Los Angeles in 1920, as the Robert S. Osgood Co.

Mr. Osgood supplied the wood to build the Spruce Goose through his friend Howard Hughes. He and Howie met when they were both 15, and remained friends until the end. I had the honor of taking over the valuable Hughes account, which was building custom jets for the wealthy.

The company was also led by his partner, Lt. General James Forgie, a war hero from Pearl Harbor; John R. Osgood, veteran of the Battle of the Bulge; Kurt Gelbard, furniture parts specialist; and Wolf Gordon, one the world’s top veneer specialists.

In 1975, I was asked to join this prestigious group of distinguished international hardwood traders, and I was certainly feeling overwhelmed by all the knowledge flying around. Noticing my bewilderment, John Osgood (Robert’s son) took me aside and said, “Don’t worry, after a decade or two, you’ll figure this out.” At the time, I thought he was joking. Twenty years later, he asked if I recognized this as true. I said, “I do now!”

Mr. Osgood Sr. was still very much in control, as they were navigating a merger with MacMillian-Bloedel of Canada and Jardine Davies of Hong Kong, which took place shortly after my arrival. It was an exciting time to

be involved in the international wood trade, and our office drew wood folks in from around the world.

2What did you learn working under such an eclectic group?

Flynn: Mr. Osgood pointed out that every decade brought major changes, so it was critical to listen to the market to anticipate the coming transitions into whatever new products would appear.

In 1975, he said something that so impressed me, I wrote it down: “Learn all you can, then do your best, and don’t worry—especially about things over which you have no control.” And one more I’ll always cherish: “Work hard—have a worthwhile goal—and be well adjusted (to all things).”

3

Any memorable adventures as you traveled the world?

Flynn: We survived two weeks of head-hunting in Borneo in 2002— 10,000 heads were removed over 10 days, driving natives back to the island from where they came.

We’ve been through coups in Asia and Africa, being once held as “hostages” in Africa before our captors realized no one was coming to save us. They got tired of feeding us, and released us in the Spanish Sahara.

We were arrested in the terrorist attack in Jakarta when terrorists blew up the Hyatt. I was having lunch next door when the deadly bomb went off.

On my first trip overseas to visit suppliers and customers in the 1960s, we visited a sawmill in Papua New Guinea. On our second evening, in the middle of the night, we were awakened by banging on our doors. We were ordered to get dressed immediately and leave our so-called “hotel” without explanation. A convoy of

old jeep-like vehicles awaited, along with a bunch of soldiers waving large guns—the soldiers looked like they were maybe 15 years old.

Off we dashed into the heart of the jungle. We arrived at an old WWII runway. An old DC3 was already fired up as we pulled in to this old airfield (one of the motors was blowing large amounts of smoke from an obvious oil leak). We were ordered on the plane. It was coughing and wheezing, offering little confidence. When we objected, the soldiers waved their guns more vigorously. No one spoke English (well) and a bunch of yelling—and a rifle shot into the air—took place before we were convinced to board. Inside, we noticed no seat belts, just old jump straps. As the pilot gave the engine full throttle to clear the tall trees, we rumbled down the airway. The engines were screaming for altitude. We could hear the branches, as fuselage skimmed the treetops. We barely made it.

And then the oil seal blew. The pilot screamed. We circled back, billowing smoke and fire. The pilot landed hard, blowing out the tires, sending us off the runway into a ditch. Scratch one DC3 for the night.

While we were waiting for the second rickety wreck, we learned what was going on. Some missionaries had been invited for dinner, and they were the dinner. They were eaten by cannibals. This is why we were bounced. When I returned, the Osgood team said they were used to adventures like this—it was a fine way to break in to the Southeast Asian wood business.

– Send suggestions for future interviews to David at dkoenig@526mediagroup.com.

22 • building products digest • June 2023 building-products.com

------------| 3 QUESTIONS

RWOW’s Tom Flynn

MENTAL HEALTH IN THE WORKPLACE

------------

BY PAIGE McALLISTER

SINCE 1949, May has been recognized as “Mental Health Awareness Month” in the U.S. The goals of this campaign include destigmatizing mental health problems, increasing public awareness, and creating support for the millions who suffer from mental health conditions.

According to the National Alliance on Mental Illness (NAMI), mental illness is “a condition that affects a person’s thinking, feeling, behavior, or mood” which “deeply impacts day-today living and may affect the ability to relate to others.” It is estimated that:

• 1 in 5 adults in the U.S. experiences mental illness each year;

• 1 in 20 adults in the U.S. experiences serious mental illness each year; and

• 1 in 6 youths (6–17 years of age) in the U.S. experiences a mental health disorder each year.

Mental health conditions include disorders such as anxiety, ADHD, depression, bipolar, eating disorders, obsessive-compulsive, psychosis, and PTSD, with many people experiencing multiple of these disorders at the same time.

With so many people impacted by mental health conditions, it is no surprise that impacts are felt in the workplace, whether the employee is experiencing the mental health issues

themselves or if they are struggling to help someone else. And, given the countless variations of symptoms, side effects, severity, duration, etc. for not only these conditions but also some of their treatments, mental health is a nebulous situation that takes time, patience, and understanding.

Whether employees are suffering mental health conditions themselves or they are dealing with those of a loved one, it can impact their work. Since each person will be different, it is critical to understand that what may appear as lack of dedication or inability to do the job may actually be an employee’s uncontrollable or unrecognized reaction to a mental health issue. Some common symptoms and side effects that may be exhibited at work are:

• Poor attendance and/or punctuality

• Changes in mood, temper, or appearance

• Performance issues

• Disconnecting from others

• Outside distractions

To help employees manage their mental health, employers can make general changes such as offering flexible scheduling, requiring employees to take regular breaks, providing opportunities for personal contact such as meetings or events,

promoting open communication with management and HR, and offering benefits such as health care with mental health benefits and/or an Employee Assistance Program (EAP).

On a practical level, if an employee is exhibiting concerning behaviors, how you handle them will depend on various factors and circumstances.

If the employee has not informed you or management of an ongoing issue: If an employee has begun to exhibit signs of concern, such as poor performance or attendance but has not notified the company of any medical reason for the unacceptable behavior, do not assume something is wrong. You cannot treat an employee like they have a disability (mental health or otherwise) if they have not disclosed this as a fact to you, even if you “know” something is going on.

Instead, document the performance or attendance issues consistent with your practice. Do not be stricter than you are with others. Use the discussions to allow the employee to freely and voluntarily disclose if something is going on. Otherwise, advise them that their performance or attendance must improve or it will result in further disciplinary action.

If the employee notifies you or management that they have a mental health condition: Once you are notified by an employee (whether

24 • building products digest • June 2023 building-products.com

------------| TRANSFORMING TEAMS

in writing or verbally) that they are experiencing a mental health illness, different laws and regulations along with your company policies will kick in, including:

• Family and Medical Leave Act (FMLA) and/or state leaves: If the employee and the company meet the eligibility criteria for FMLA or related state family and medical leave, then you must send the employee notice. Under FMLA, this is required to be given within five business days of knowing they need at least three days

Q. We have an employee who matched as a living donor. What do we need to offer them?

A. First of all, it’s wonderful that your employee is considering being a living donor! As an employer, it’s important to support your employees in their personal endeavors whenever possible.

You should treat this situation like any other leave request. Request doctors’ notes to clarify the expected duration of the absence, when your employee will be able to return to work, and if there are any restrictions they should adhere to. Depending on your state’s laws, you may be required to offer paid or unpaid time off for living organ donations. If not, your employee may be eligible for other medical leave protections since this is a medical procedure.

Keep in mind that your employee may need to attend pre- and post-operative appointments, and try to be flexible with scheduling. Ask them to provide as much notice as possible so you can plan accordingly.

You should also decide in advance whether you’ll allow your employee to work from home during their absence, if that’s feasible.

Respect your employee’s privacy and do not share any medical information with other employees unless given permission. Your employee should have the right to decide who they want to share this information with.

Finally, make sure to receive a release from your employee’s doctor before they return to work. This will help you understand any limitations they may have and will help reduce your Workers’ Comp liability.

of time off (consecutively or intermittently). The employee will need to provide you with a certification from their health care provider which will give you the information to handle their restrictions and limitations. Often with mental health conditions, absences or tardies may be unplanned but, if stated by the health care provider, then you must allow employees that protected time off.

• Americans with Disabilities Act (ADA) and/or state disability laws: Many employees are protected from discrimination in the workplace due to their disability, including mental health.

In addition, employers covered by ADA and Americans with Disabilities Act Amendments Act (ADAAA) or applicable state laws must engage in a dialogue with the employee to determine possible accommodations such as time off or flexible scheduling. As with FMLA and similar leaves, you should require documentation from the employee’s health care provider which will state the limitations and restrictions such as unexpected tardies or absences. Unlike FMLA, ADA requires that any accommodation be “reasonable,” meaning that it does not cause an undue hardship on the company. If an accommodation would cause hardship, it does not need to be offered but an acceptable compromise may need to be made.

• Paid time off and leaves: Employees may have access to paid time off or paid leave whether under company policies, a short-term disability benefit, or required under state or local law. Employees should be advised of this time off and how to apply for state benefits, if applicable.

General guidelines:

• Application of these procedures should be followed consistently whether it is for the employee’s own mental health condition or because they are dealing with that of a close family member.

• Defer to the guidance of the health care provider; do not modify it based on what the employee, a manager, or anyone else “thinks.” If there is confusion, ask the health care provider for clarity.

• Keep all information confidential. It must be shared only on a “need to

know” basis. For example, if a manager does not know the exact circumstances of an employee’s situation, then they should only be informed that the employee’s accommodation or time off is approved but not why they need it.

Information cannot be shared with others even if they mean well.

• There can be no retaliation for time off or any accommodation needed due to a mental health condition. This includes from managers or other employees and can be in regards to any employment decision.

• Time off taken under multiple laws, regulations, or policies usually runs concurrently unless otherwise dictated by law. For example, FMLA will run concurrently with any paid time off, disability pay, or unpaid leaves under ADA.

• Continue to consistently document performance or attendance issues, making allowances for what is covered by the health care provider. Coach them to improve their performance but be reasonable in your expectations.

Final note! Yes, everyone has “bad days,” but not everyone reacts the same way. How one person experiences anxiety, for example, is not the same way another person will, so each situation is as unique and different as the person involved. Employers must be consistent and adaptable to ensure employees get the support they need and deserve.

If you or anyone you know is experiencing mental health issues, NAMI has a helpline at (800) 950-6264 or text “HelpLine” to 62640.

If you or anyone you know is struggling with thoughts of suicide or are experiencing a crisis, they can call or text the Suicide and Crisis Lifeline at 988 or reach out at 988lifeline.org.

PAIGE McALLISTER

building-products.com June 2023 • building products digest • 25

Paige McAllister, SPHR, SHRM-SCP, is vice president for compliance with Affinity HR Group. Reach her at (877) 660-6400 or contact@affinityhrgroup.com.

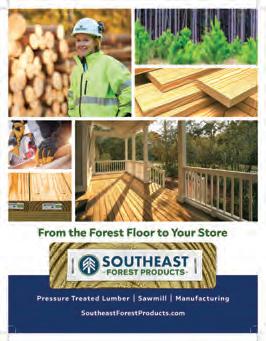

WHERE THE FORESTS ARE

------------ BY JEFF EASTERLING

WE’VE TALKED BEFORE about the mistaken impression that American forests are in danger, that deforestation is taking over, and that all harvesting of trees is bad (it’s not). As lumber retailers, how’s your forestry knowledge? Do you know which states are among the most forested? What about a few basic forestry facts? Read on!

The U.S. Forestry Industry

Here’s a Fun Forest Fact (#FFF) for you: Forested land in the U.S. is increasing or maintaining, while the lumber industry is still going strong. What’s the secret? Strong replanting programs and well-managed forests. How about a few more FFFs?

• Are forests shrinking? No. On average, the forest industry plants three-to-five trees annually for each one harvested. In fact, there are more forests in the U.S. today than there were when Thomas Jefferson drank tea at Monticello.

• Will we ever run out of wood? Not in this lifetime, or that of our children, or even their children’s children. Wood is naturally renewable: it’s not a finite product, and it’s not even close to disappearing. It is the only renewable building material.

• Are our forests in danger? No! Our forests are growing, expanding, and healthy—which is good news to those of us who live among them. It’s okay to print those emails; our NELMA members will keep growing even more trees.

The Most Forested States

There are a few ways to approach these statistics: if we’re comparing actual forested acres of land, then the clear winners are Alaska and Texas, with California coming in a distant third, followed by Oregon, Montana, New Mexico, Georgia, Alabama, Colorado and Washington rounding out the top 10.

But let’s shift the lens and look at states with the highest percentage of land covered by forests: then we’re looking at Maine in the number one spot (it’s not called the Pine Tree State for nothing!), with approximately 90% of the state covered by beautiful eastern white pine, the eastern spruces, balsam fir, among other species.

Following Maine is its neighbor New Hampshire (84%), then West Virginia (79%), Vermont (78%), Alabama (71%), South Carolina (68%), Georgia (67%), Mississippi (65%), Virginia (63%), and New York (63%).

What’s noteworthy here is that forested land in the U.S. is still going strong… and so is the lumber industry. Aggressive replanting programs and well-managed forests east of the Mississippi get the credit for the robust forest industry. Let’s close with a few more valuable facts from our friends at the USDA:

• The U.S. is home to approximately 823 million acres of forests and woodlands, and these areas has been stable-to-increasing for decades.

• Forests and woodlands have becoming more and more accessible and available to Americans. Our infrastructure and network of roads is such that any person in the country can now travel to within one mile of over 88% of our forested land.

• Urban trees are a thing, and their value continues to grow! Not only do city trees reduce the energy needed for heating and cooling by a significant amount annually, but they also give back to us by producing about 67 million tons of oxygen.

Forestry is a huge business in the United States and will be for a long time. The more you know, the more you understand that this is a very, very good thing.

JEFF EASTERLING

26 • building products digest • June 2023 building-products.com A SPECIAL SERIES FROM

------------| LUMBER 411

Jeff Easterling is president of the Northeastern Lumber Manufacturers Association, Cumberland Center, Me. Reach him at info@nelma.org.

BOISE CASCADE ENLARGING BIRMINGHAM DISTRIBUTION CENTER

Boise Cascade’s Building Materials Distribution (BMD) division has finalized the purchase of a five-acre site in Birmingham, Al.

The property is adjacent to its existing rail-served location, which was acquired in 2019.

“Since its integration into the Boise Cascade nationwide network, the Birmingham branch has grown to serve the increasing demand of engineered wood, specialty building products, and commodities in the marketplace,” said Southeast region manager Brian Cullen. “Our customers can continue to expect the very highest level of service and availability with the expanded site.”

STRUCTURLAM SELLING MASS TIMBER PLANTS

Structurlam Mass Timber Corp, has filed for bankruptcy protection and agreed to sell its facilities in Conway, Ar., and Canada to Mercer International for $60 million.

The Conway plant opened in 2021, its success hinging on 1.7 million cu. ft. of timber intended for Walmart’s new corporate headquarters in Bentonville, Ar. When Walmart canceled its contract in January, Structurlam shuttered the plant and laid off 144 workers.

Mercer already has mass timber operations in Canada, Germany and Seattle, Wa.

PELLA CLOSING ON LAWSON

Pella Corp. has agreed to buy South Florida window and door manufacturer Lawson Industries.

Located near Miami, Lawson specializes in impact-resistant aluminum windows and doors as well as installation for the growing South Florida region.

Having served the market for more than 60 years, Lawson will continue operating under the Lawson Industries brand name. President Harold Bailey and VP Ron Bailey will remain with the company to lead business integration efforts.

RUGBY EXPANDS IN NEW YORK

Rugby Architectural Building Products has opened a new Metro New York customer service center

in Greenvale, N.Y., to better serve all of its New York customers.

The new 79,000-sq. ft. warehouse and customer service center is strategically located less than three miles from the Long Island Expressway. It carries a large and diverse inventory of decorative and raw panels, hardware, mouldings, and other products for quick delivery to manufacturers of kitchen cabinets, furniture, store fixtures and specialty wood products.

ALSIDE ADDS 3 SUPPLY CENTERS

Associated Materials has opened three new Alside Supply Centers—in Conway, S.C.; Greensboro, N.C.; and San Antonio, Tx.

Located in the Myrtle Beach area, the Conway location is a 20,000-sq. ft. palletized warehouse offering Alside siding and windows along with a variety of other products, including fiber cement siding, doors and decking.

San Antonio is also a 20,000-sq. ft. facility, while Greensboro measures 63,200 sq. ft.

“We are excited to expand our distribution in these three cities to provide greater convenience, material offerings and better customer service to remodelers and builders in these markets,” said Dan Watkoske, Alside division president. “Alside continues to see increased demand for our best-in-class products, including Ascend composite siding and Mezzo windows, and the supply center openings will allow us to continue to support our customer’s needs.”

GENESIS PRODUCTS REORGANIZES

Now that the ink is dry on its recent acquisition of Funder America, laminated panel and component manufacturer Genesis Products, Goshen, In., has reorganized its divisions and leadership structure.

Formerly structured in four divisions based on operating facilities, the company will now shift to two industry-focused business groups: RV & Vehicles and Industrial Wood Products. “This gives us the opportunity to truly focus on the unique needs of customers in these industry verticals,” said president and CEO Jon Wenger. “Our product, engineering and materials teams

will no longer divide their time between RV and industrial demands. This streamlines efforts and accelerates our ability to serve our OEM partners.”

All RV & Vehicles product and operations teams will be centralized under the leadership of Dave Stace, Business Group VP. David Moser takes on the Industrial Wood Products Business Group VP role. The restructuring is opportune, as Matt Hazelbaker, VP-panels & mouldings, announced plans to retire last year.

DEALER BRIEFS

Gillman Do it Best Home Center held a grand opening celebration May 12-13 at its newest location in Muncie, In. The 17,500sq. ft. home center with expansive outdoor lumberyard is the chain’s 15th.

R.P. Lumber, Edwardsville, Il., agreed to sell R.P. Home & Harvest, with 22 locations and one distribution facility across Illinois, Indiana, Ohio, and Wisconsin, to Minnesota-based retailer Runnings. The deal is set to close in June.

Nittany Valley True Value Hardware, Zion, Pa., held a grand reopening on May 13 after six weeks of renovation.

Mid-Atlantic Roofing Supply has opened a branch in Orlando, Fl.

Westlake Ace Hardware is opening a new store this summer in Liberty, Mo., and will build a new 15,000-sq. ft. store in south Lee’s Summit, Mo., scheduled to be completed in late 2023. A soft opening is tentatively planned for early 2024.

Brinkmann’s Hardware, Holbrook, N.Y., added a location in Glen Cove, N.Y.

Feldco Windows, Siding, Doors & Roofing is moving its corporate offices from Des Plaines to a larger, 40,000-sq. ft. space in Rosemont, Il.

Riverhead Building Supply has become the latest flagship dealer for Tando Composites’ Beach House Shake and TandoStone from its 13 Long Island locations.

Anniversaries: Pierce & Co., Hallsboro, N.C., 125th ... DavisHawn Lumber, Dallas, Tx., 100th.

28 • building products digest • June 2023 building-products.com

------------|

#1 Inventory Management Profit Strategy:

Stock No More Than Needed to Properly Service Demand

This practice is crucial to profitability. Here’s why:

n Every day that excess inventory is owned, it is either costing interest on borrowed money, which increases expense, or it is preventing the earning of interest on owned money, which decreases income. Whether capital is borrowed or owned, excess inventory is always eroding profitability.

n Let’s say a yard has sales volume of 110,000 BF/month. If brought in all at once by car, the inventory can turn once a month if needs are correctly projected. But if metered in by truck in 27,500 BF increments at one load per week as actually needed, that inventory will turn 4 times per month – and tie up only 1/4 as much cash.

n Now suppose this yard pays for the car 10 days after shipment and delivery takes 3 weeks. It paid for 4 times the inventory it needed, and won’t see any of it for 11 more days. But if it buys by truck with quick delivery, every stick could be sold before the invoice even comes due. In fact, three truckloads could be sold this way before the car could even have arrived, again using only 1/4 the capital.

n This strategy dependably multiplies turns and GMROI, dramatically improves cashflow, cuts carrying costs and frees up both capital and space for more profitable use. Margins are maintained through market moves and downside risk is significantly reduced because the inventory is turning faster than price changes can affect its value. There’s less inventory to count, and stock stays fresher, too.

building-products.com June 2023 • building products digest • 29 (800) 654-8110

Maximize your profit with this safe and efficient strategy. Call Idaho Timber for highly-mixed trucks and just-in-time delivery.

MADISON’S CHASE MERGES INTO BLIFFERT

Thirteen-unit Bliffert Lumber & Hardware, Milwaukee, Wi., acquired Madison-area Chase Lumber and its three locations in Sun Prairie, DeForest and McFarland, Wi.

Chase Lumber has been serving South Central Wisconsin and the surrounding area since 1897, specializing in lumber, millwork, windows, cabinets, decking, kitchens and baths.

“Joining forces with Bliffert and combining nearly two-and-a-half centuries of serving the building industry in Wisconsin is a giant step forward for Chase Lumber’s customers and employees,” said Chase president Valerie Stiener. “We know that Bliffert is a company that shares our values, especially concerning employees, customers and community. We believe

------------| SUPPLIER BRIEFS

Beacon opened greenfield locations in Gulfport, Ms., and Longview, Tx.

ABC Supply added a branch in Pearl, Ms., managed by Kacy Kemmer.

L&W Supply has acquired Old Fort Building Supply, South Bend, In.

Four Corners Building Supply, Charleston, S.C., is now distributing Tropical Forest Products’ Black Label tropical hardwoods.

BlueLinx has expanded its distribution of Allura fiber cement siding and trim to St. Louis, Springfield and Kansas City, Mo.; Little Rock, Ar.; and Tulsa and Oklahoma City, Ok. Snavely Forest Products subsidiary Mid-States Wholesale Lumber is now distributing Typar building wrap, construction tape, flashing and accessories into Oklahoma City, Tulsa, Ok.; Wichita, Ks.; and northwest Arkansas.

Manufacturers Reserve Supply, Irvington, N.J., is a new distributor of Tamlyn’s new TamlynWrap Drainable WRB and Advanced Building Products’ weatherization products, including CedAir-Mat and Mortairvent Rainscreen.

Bliffert Lumber does that and more. A large firm that operates as a family-run business, Bliffert brings buying power and expertise that should allow Chase Lumber to operate as a premier supplier of building materials for many years to come.”

“At Bliffert Lumber & Hardware, we are continually improving on the construction and home improvement experience for our customers across Wisconsin,” said VP Eli Bliffert. “Chase Lumber shares our focus on excellent service and commitment to staff and community. Adding these locations will provide our Madison-area customers with an improved range of services, products and support. Being able to combine two fifth-generation, family-owned lumber companies is not something you get to do every day, if ever. It is the coolest thing since cold beer. We are absolutely stronger together.”

U-C COATINGS PURCHASES COLOR PUTTY

U-C Coatings, Buffalo, N.Y., has acquired Color Putty, Monroe, Wi., maker of putties for filling nail holes or imperfections in wood paneling, furniture and cabinetry.

Toney Priewe, president of Color Putty, said, “We are happy to partner with U-C Coatings. Color Putty is considered ‘The Original’ wood filler by generations of professionals. We are confident U-C Coatings will continue to provide the highest standards that our customers have come to recognize with Color Putty.”

Eric Degenfelder, CEO of U-C Coatings, added, “Color Putty is a great addition to U-C Coatings that will expand our specialty offerings, especially to the contractor and DIY markets. The acquisition continues our emphasis on environmentally friendly, easy-touse, high-performance products. We look forward to continuing and strengthening the support to the Color Putty distributors and customers.”

Zee Water & Energy, Hattiesburg, Ms., is now distributing Arxada’s AntiBlu and Mycostat in the eastern half of the U.S.

Sierra Pacific Windows will build a 610,000-sq. ft. window and door manufacturing facility and warehouse on 113 acres in Phenix City, Al.

IKO Industries paid $5.26 million for 80 acres in Clay County, Fl., to build a $270-million roofing products manufacturing complex. Consisting of three buildings totaling 650,000 sq. ft., the operation is expected to be completed by mid-2026.

Atlas Roofing Corp. will build a new $200-million asphalt shingle manufacturing facility in Clinton, Ia.

M S International has opened a 680,000-sq. ft. showroom and distribution center in Pooler, Ga.

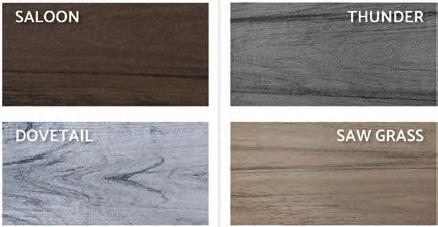

TimberTech by AZEK was named a winner in Good Housekeeping’s 2023 Sustainable Innovation Awards.

Trex has extended the warranty to 25 years on Trexbranded moisture protection products, including Trex RainEscape, Trex Protect and Trex Seal, which are manufactured and sold by IBP, LLC

J.M. Huber Corp., Atlanta, Ga., was selected as a 2023 U.S. Best Managed Company Gold Standard honoree.

Wolf Home Products is now distributing Key-Link Fencing & Railing in Indiana, Illinois, Iowa, Wisconsin and Minnesota.

HDG Engineered Products’ HDG Deck Bracket System was recently issued ICC-ES Evaluation Report ESR5056, confirming the wood framing structural connectors’ code compliance and requirements for proper installation.

MFM Building Products, Coshocton, Oh., won the 2023 Eastern Ohio Development Alliance Small Manufacturer Excellence Award.

MI Windows & Doors’ facilities were awarded the Northeastern Pennsylvania Manufacturers & Employers Association’s 2023 Manufacturers & Employers Commitment Award.

30 • building products digest • June 2023 building-products.com

“Growing beyond measure.”

REDWOOD THE POSSIBILITIES KEEP GROWING: Call us at 707.894.4241 Visit us at buyRedwood.com Nature’s majestic pilla rs. Re Reddwwood i ood is o s onne o e of t f thhe s e sttrroonnggeesst a t annd f d faasstteesst g t grroowwiinng s g sooffttwwood spe ood specciieess. . It thrives in some of the most productive timberlands in the world. Redwood is known for its timeless durability without the use of chemicals. Due to its flawless formation, there has never been a Redwood recall. There is a grade of Redwood for every application, every budget, and every customer.

Call or visit us today. Our family of Redwood timberland owners will continue to be your reputable and reliable source of Redwood.

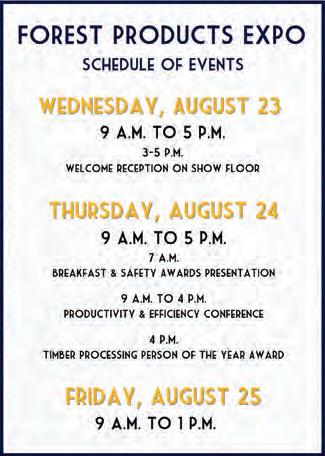

MACHINERY ON DISPLAY PREVIEW OF FOREST PRODUCTS EXPO 2023

DO YOU WANT to be at the center of the forest products community? Are you ready to see how adaptive technology is influencing

manufacturing decisions? Is your company part of the new manufacturing age at this critical moment for the industry?

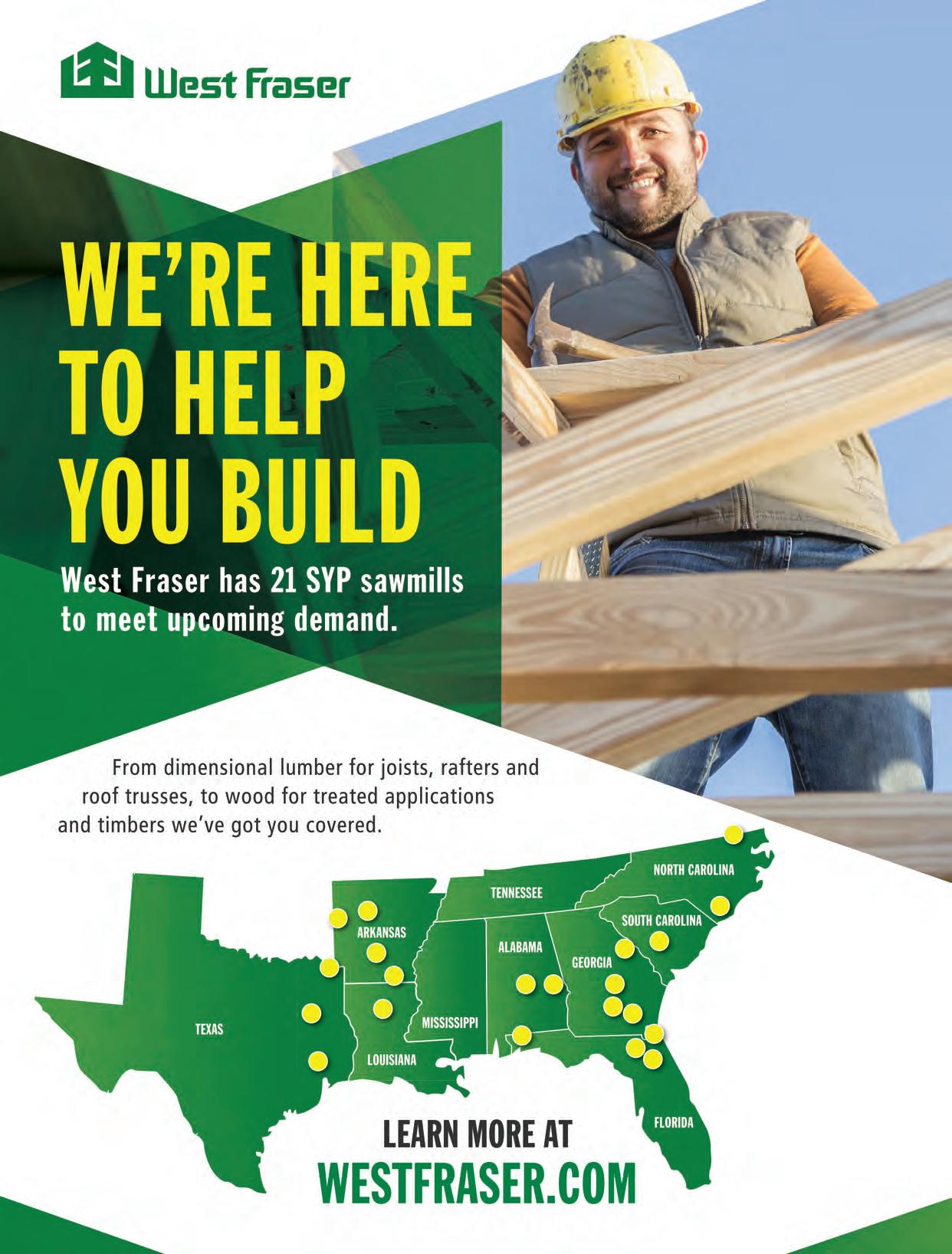

If you answered yes to any of the above questions, don’t second-guess attending the 37th Forest Products Machinery & Equipment Exposition. It’s the place to network with leading equipment manufacturing companies and industry professionals as they develop and share technologies, which adapt to new markets, adjust quickly to increased demand, and bolster operations for the future.

EXPO 2023, set for Aug. 23-25 in Nashville, Tn., will provide you with solutions for nearly every stage of manufacturing. From raw material handling to crane operations; metal detection and scanning technologies; log optimization, drying, grading, sorting, packaging and distribution,

there’s an exhibiting company representative on site to explore these solutions with you face to face.

Make no mistake, this new era of work has arrived. An era of connected systems, responsive manufacturing, and innovative technologies, it will all be under a single roof at EXPO 2023.

A Connected Community

The Southern Forest Products Association established EXPO to help advance the southern pine and greater lumber industry and provide a forum for the exchange of ideas contributing to improved sawmill efficiency. As the industry has become more efficient, typical EXPO attendees have evolved to include:

• key decision makers who control major purchasing budgets,

• mill supervisors looking to

32 • building products digest • June 2023 building-products.com

------------| SFPA ALERT

improve efficiency,

• marketing experts seeking promotional vision, and

• young professionals making tomorrow’s decisions.

The three-day show provides a place to connect and reconnect with colleagues, discover new trends, and explore opportunities. Both first-time and returning attendees alike play a vital role in the continued progress of the lumber industry.

Each exhibiting company has contributed to the industry’s success throughout the years, and attendees will find the EXPO 2023 halls decked out with dynamic displays showcasing the latest in wood processing technology

More importantly, EXPO provides a place where in-person meetings are valued over emails and phone calls; where a handshake and a smile between colleagues communicate genuine respect; and where sharing ideas is best accomplished face-to-face.

EXPO: A History of Innovation

On April 19, 1950, leaders from across the southern lumber

manufacturing region gathered in New Orleans, La., to open the first North American equipment trade event dedicated to improving lumber manufacturing.

More than 500 lumbermen attended and witnessed $1 million of

equipment on display at the inaugural Logging & Sawmill Machinery Exposition (EXPO) held at the Municipal Auditorium in New Orleans.

After a devastating fire in 1939 destroyed the Southern Lumber sawmill in Warren, Ar., general

building-products.com June 2023 • building products digest • 33

FOREST PRODUCTS EXPO provides an up-close look at the latest in forest products machinery.

promotion programs, despite travel disruptions. A successful pivot toward virtual events ensured that the association was able to reach a record number of timber traders and construction professionals worldwide and to safely meet their needs effectively.

manager W.R. Warner set out to build a state-of-the-art sawmill that would stand as the new model of sawmilling for the southern pine lumber industry.

Andersson debarkers had been installed in southern sawmill operations, ushering in a widespread investment in sawmill operational efficiency.

A Place for Softwoods and Hardwoods

Let’s break down the activities and successes and take a closer look at each.

FEA Strategic Planning Webinar

On Feb. 26, 1952, almost two years after viewing debarking technology at EXPO, Southern Lumber installed the first stationary pneumatic debarker. The Andersson Log Barker proved to be a valuable investment at $28,700 and could debark logs up to 30 inches in diameter.

As a gold sponsor of this online or virtual event, SFPA was able to provide member access to information, which helped each better define their international goals moving forward.

While the sawmill machinery show originated from leaders looking for a way to improve softwood lumber production, today’s EXPO showcases machinery and equipment for hardwood and softwood sawmills.

“Without a doubt, the hardwood lumber industry has long been represented at this show,” said SFPA execu-

Worldwide Conference on Timber Engineering

Two weeks after the installation, Southern Lumber hosted Southern Pine Association members so other lumbermen could study the machinery. By 1962, 16

SFPA’s participation bolstered the Association’s seminar programs across the globe to enrich international outreach and education. With international advertising and messaging support in multiple global markets, southern pine information was showcased internationally through a variety of channels.

Japan Technical Committee (JTC)

In partnership with American Softwoods, SFPA and the Southern Pine Inspection Bureau banded together to jointly present information on the southern pine resource and clarify the grading procedures for dense vs. non-dense grades.

Outreach: Caribbean

Throughout the southern pine-loving Caribbean, virtual seminars targeted hundreds of key buyers in both traditional markets and new markets—some of which SFPA reached for the first time.

Outreach: Central America

SOUTHERN PINE SHIPMENTS HIT CENTURY HIGH

(Continued on page 36)

INTERNATIONAL MARKETS have become an important focus for the southern pine industry.

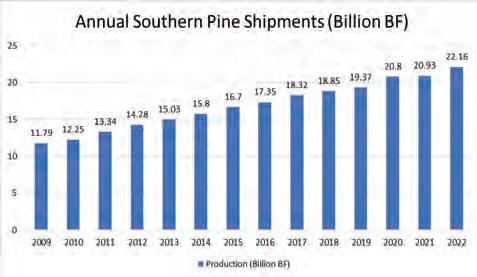

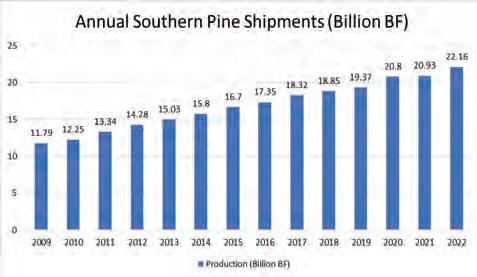

crease over the volume shipped in 2021 (20.93 BBF). They have been on an increase since 2009, when shipments totaled 11.79 BBF, down from 14.57 BBF in 2008.

Outreach: International Trade Shows

While many lumber industry trade shows across Europe, India, the Middle East, and Asia were cancelled or postponed in 2021, plans are well underway for a full slate of in-person trade shows in 2022. Members are keen to take advantage of these face-to-face opportunities, and SFPA stands ready to serve member needs.

Southern Pine Exports

Export numbers calculated throughout the majority of 2021 are roaring back to pre-pandemic levels, an encouraging sign as plans are underway for 2022.

Multiple southern pine lumber events were held in Guatemala, with brand-new outreach activities expanding into the Panamanian building market.

Outreach: South America