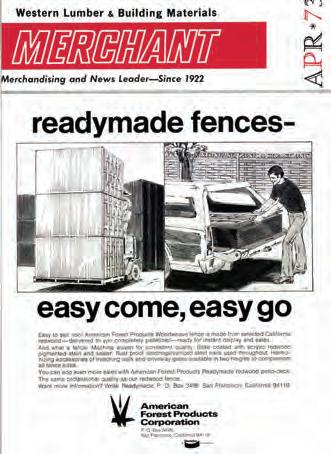

WWPI GUIDE TO PRESSURE TREATED WOOD: HOW TO SOURCE • HOW TO SELL • TOP TREATERS April 2023

WWPI GUIDE TO PRESSURE TREATED WOOD: HOW TO SOURCE • HOW TO SELL • TOP TREATERS April 2023

Digital Edition Sponsored by

THE VOICE OF LUMBER MERCHANTS AND BUILDING MATERIAL DEALERS & DISTRIBUTORS IN THE WEST — SINCE 1922

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Claudia St. John, Dave Kahle

CONTRIBUTORS

Butch Bernhardt, Allison DeFord, Kari Gaviria, Paige McAllister, Kim Merritt, Ryan Pessah, Belinda Remley

ADVERTISING SALES

(714) 486-2735

Chuck Casey ccasey@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

VIRTUAL EVENTS

Alek Olson • aolson@526mediagroup.com

CIRCULATION/SUPPORT info@526mediagroup.com

A PUBLICATION OF 526 MEDIA GROUP, INC.

151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 Phone (714) 486-2735

CHANGE OF ADDRESS Send address label from recent issue, new address, and 9-digit zip to address below.

POSTMASTER Send address changes to The Merchant Magazine, 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626. The Merchant Magazine (ISSN 7399723) (USPS 796-560) is published monthly at 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 by 526 Media Group, Inc. Periodicals Postage paid at Newport Beach, CA, and additional post offices. It is an independently-owned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 western states.

Copyright®2023 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. We reserve the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles are intended for informational purposes only and should not be construed as legal, financial or business management advice.

Volume 102 • Number 4

4 • the merchant magazine • april 2023 building-products.com SUBSCRIBE TODAY OUR MARKET MOVES QUICKLY—SO DON’T GET LEFT BEHIND! The Merchant is available on a qualified requester basis to senior management of U.S.-based dealers and distributors specializing in lumber and building materials, and to others at the rate of $22 per year. Subscribe now at www.building-products.com/subscribe. SUBSCRIBE NOW AT WWW.BUILDING-PRODUCTS.COM/SUBSCRIBE THE MERCHANT MAGAZINE SUBSCRIBE TO RECEIVE PRINT, DIGITAL, ENEWSLETTER & MORE! The LBM supply chain’s leading publication for qualified industry decision makers! • Update your subscription • Sign up key colleagues • Enroll multiple locations

California Cascade Building Materials 800-339-6480 californiacascade.com California Cascade uses Koppers Performance Chemicals to provide the most environmentally friendly, and effective pressure treated lumber available for a multitude of applications. Our most popular treatments are NatureWood for Copper Azole (CA) treatment, Advance Guard for borate and FlamePRO for fire retardant treatment. California Cascade has been offering innovation and quality in the building products industry since 1974.

6 • the merchant magazine • april 2023 building-products.com ------------| CONTENTS April 2023 STAY CONNECTED ON SOCIALS: @BPDMERCH THE OFFICIAL PUBLICATION OF PROUD SUPPORTERS OF VOL. 102 • NO. 4 |-----------DIGITAL EDITION CHECK OUT THE WWW.BUILDING-PRODUCTS.COM FEATURES 34 COMPETITIVE INTELLIGENCE Sealing the deal with Farmer’s Building, Feed & Garden Supply of Oregon 38 OLSEN ON SALES The all-important first call 40 3 QUESTIONS Meet Pelican Bay Forest Products’ Ron Hanson 54 PHOTO RECAP NAWLA holds annual Leadership Conference in Palm Desert EVENT RECAP Do it Best moves spring market to sunny Orlando EVENT RECAP LMC annual meeting kicks into high gear 56 58 TREATED INSIDER 10 GUIDE TO SELLING TREATED WOOD Western Wood Preservers Institute shares everything you need to know to source and sell preserved wood products DEPARTMENTS 08 ACROSS THE BOARD 42 TRANSFORMING TEAMS 48 MOVERS & SHAKERS 50 NEW PRODUCTS 63 DATEBOOK 64 IN MEMORIAM 64 TALKBACK 65 ADVERTISERS INDEX 66 FLASHBACK 56 34 10

ACTIVE LEADERSHIP

BY PATRICK ADAMS

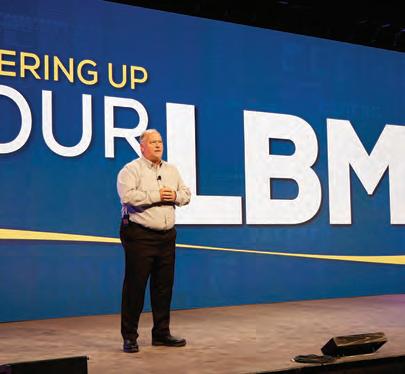

LATELY, “LEADERSHIP” seems to be something that keeps hitting me in the back of the head, but I don’t seem to really notice. Every day, all around me are little reminders of the importance of “leadership” and yet, it didn’t really hit home until I attended a recent event.

There, surrounded by some of the pillars and legends of our great industry, I caught up with friends, and heroes. I listened to several presentations that emphasized the importance of leadership. I spoke with friends who just a few years ago started their business that is now thriving under their unconventional style of leadership in this industry. As I retired for the evening in my hotel room, the nightly news recounted speeches and actions from our nation’s “leaders.”

I used to consider myself a better-than-average leader, who has seen and been led by a few great leaders. I also spent considerable time in my younger years studying great leaders, being inspired by them, and then trying to emulate them in some way that would then bring out greatness in the teams I led. However, as I’ve grown older and I reflect in an honest moment, I think I’ve become a lazy leader. My team is partially to blame for this because they are great in what they do and I know they will get it done. I know the business well and know how to do the tasks that I am accountable for. However, those tasks are now what I’m talking about when discussing leadership.

As I am now studying this, I think to illustrate my point I can describe that there are “leaders,” and there are “drivers.” Drivers go from point A to point B. They make data-driven decisions on purchases, payments, acquisitions and expansion. They make sure the business is solid, sign the checks, and make tough decisions when they need to be made. That is what leaders do, but that is not “leadership.”

When I think of whether or not I am a good leader, I consider our U.S. military Special Forces. I think of my staff as a team and if they were deployed on a mission today, would they operate efficiently, effectively and as a cohesive unit? If one went down, would the others fill that gap of specialized training? As the mission evolved

dynamically, would my team improvise and adapt to still accomplish the mission? This is what true leadership looks like; equipping a team to do this very thing.

At this recent event, I listened to a speaker who is the CEO of a publicly traded company. From his presentation, I concluded that he viewed the majority of his job to be how to bring out the best from every individual in his company. He felt that it was his job as a leader to adapt and improvise solutions for each of his employees’ needs that limited their performance. His job was to motivate, inspire and educate this team, and that if he was successful in this effort, the business would thrive.

This was what I always used to consider my role as a leader to be. To be accessible, predictable, transparent and inspirational. For my team to always know how grateful I was for their efforts, but also to inspire them to grow in their positions and their role within the team. Over time, I’ve gotten lazy. I do what I do, they do what they do, and as a result, we’re a “team”? No, it’s not that easy. Yes, a business can survive on this. Yes, you can make a profit with this approach. But I would argue that you will never be great and, you will leave money and employee retention and productivity on the table.

Regardless of the role you are in, you are a leader. Whether or not anyone looks up to you today, there is an opportunity for them to look up to you tomorrow. At work, at home, or in your community. We need more true leaders who view the majority of their role is to make others around them better. It was a humbling slap in the face of my shortcomings, but one I welcome because I’m still around to do better tomorrow.

So ask yourself: are you a leader or are you an active leader? I now know which I want to be and am reinvesting in becoming it again in all areas of my life. I’ll keep you posted on how that goes and hope you do the same!

Thank you all for the privilege of serving this great industry.

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

8 • the merchant magazine • april 2023 building-products.com ------------| ACROSS THE BOARD

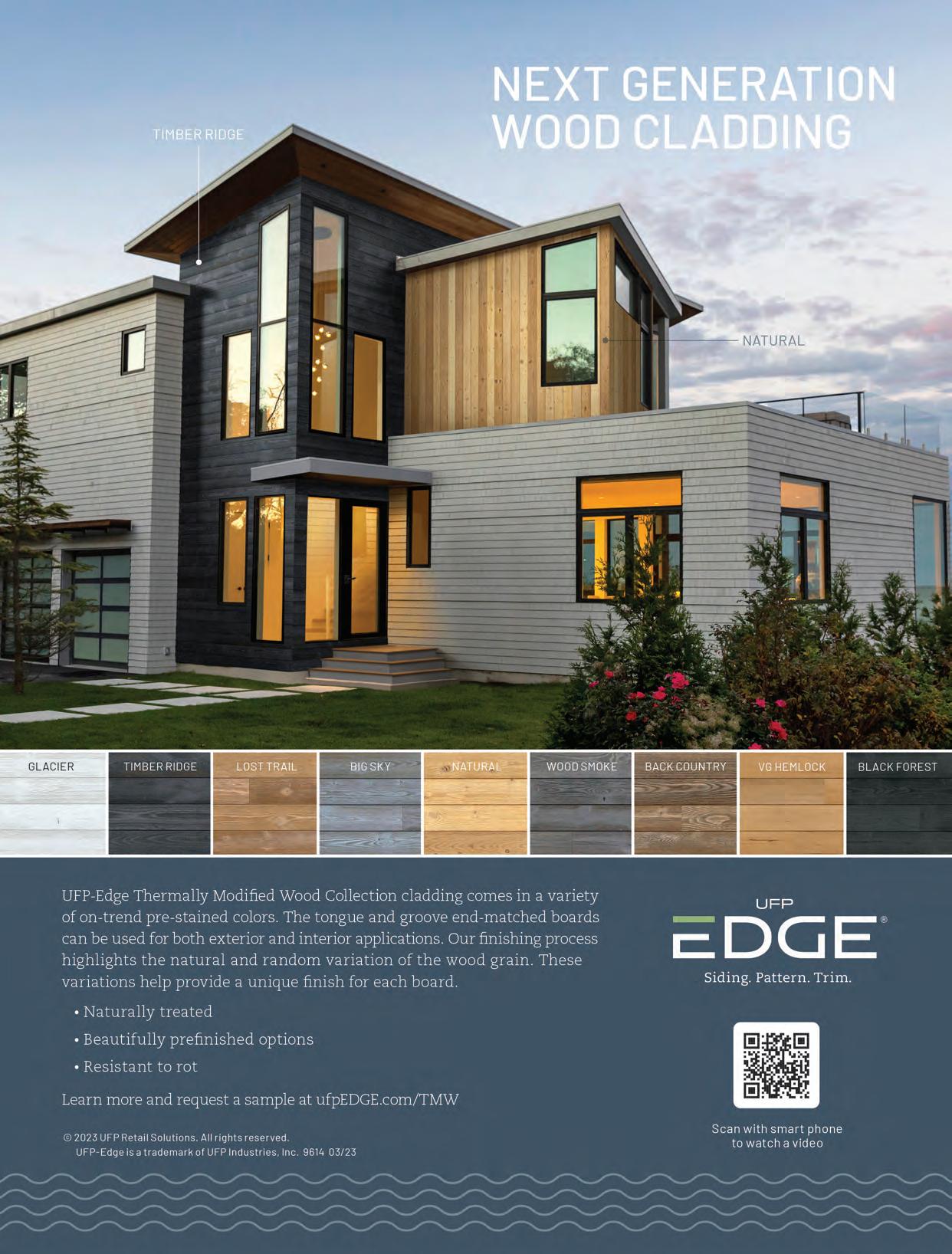

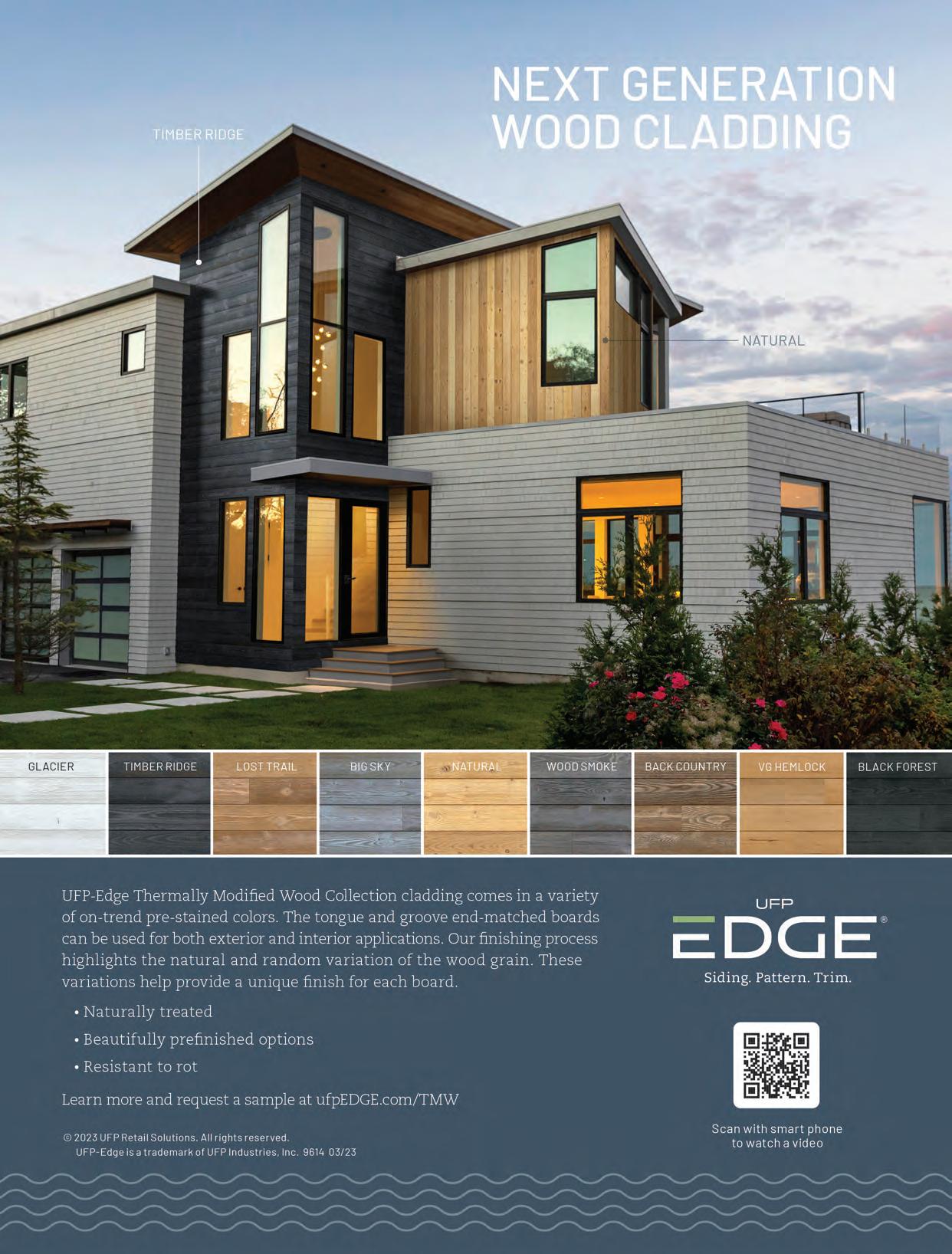

PRESENTED IN PARTNERSHIP WITH THE WESTERN WOOD PRESERVERS INSTITUTE

GUIDE TO SELLING TREATED WOOD

IMAGE BY BB&S TRATED LUMBER OF NEW ENGLAND

IMAGE BY BB&S TRATED LUMBER OF NEW ENGLAND

TREATER UPDATE: CONSOLIDATION QUICKENS 12 TOP TREATERS 12 THE ENGINEERING BEHIND TREATED WOOD 14 SOURCING TREATED LUMBER 18 TREATED WOOD DISPOSAL 20 FRTW 22 INCISING 24 FIELD TREATING 26 QUALITY CONTROL 28 PRESERVED LUMBER & BEES 30 THE INDUSTRY’S FUTURE 32 TREATER UPDATE: CONSOLIDATION QUICKENS 12 TOP TREATERS 12 THE ENGINEERING BEHIND TREATED WOOD 14 SOURCING TREATED LUMBER 18 TREATED WOOD DISPOSAL 20 FRTW 22 INCISING 24 FIELD TREATING 26 QUALITY CONTROL 28 PRESERVED LUMBER & BEES 30 THE INDUSTRY’S FUTURE 32

WOOD

TREATER

UPDATE CONSOLIDATION QUICKENS

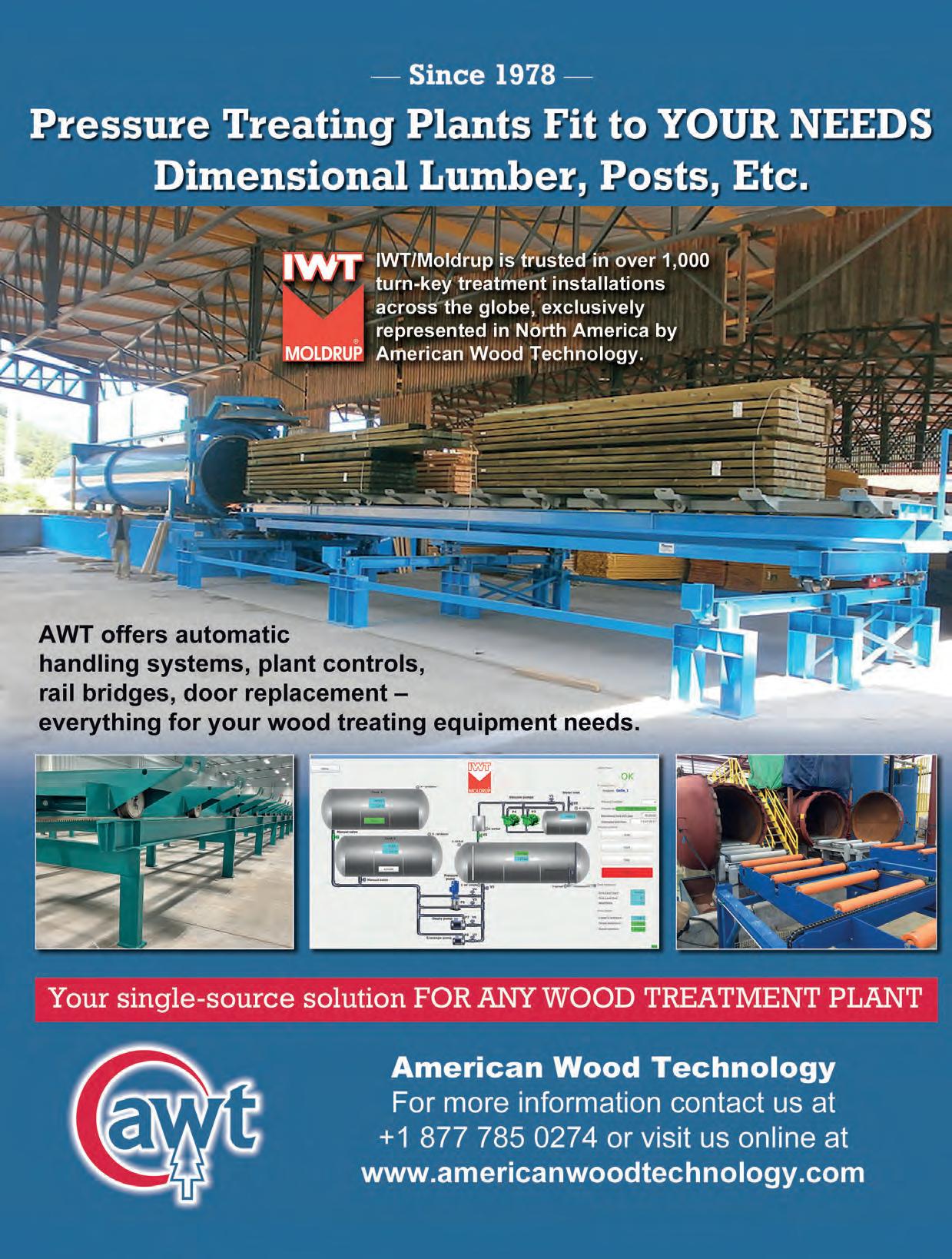

IT MAY BE hard to believe, but over the past year, somehow the pace of consolidation got even more frenzied in the wood treating industry.

Stella-Jones, Allweather Wood, Great Southern Wood Preserving, Koppers and Culpeper Wood Preservers were among those that increased their holdings.

No one was more active than Culpeper, which last year purchased four other treaters—all located in regions they had already been supplying.

“As we continue to grow, the goal is to get closer to the customers and regions we want to service,” said director of business development Chris Brown. “We have been looking at our footprint and really filling in the gaps strategically

where it makes sense. We are not trying to just get bigger. But as the consolidation trend has ramped up the past few years, we have been presented with opportunities. Some of those have made sense and some, of course, have not.”

Brown added, “When you have this ‘consolidation movement’ as we have seen, it really starts to narrow the field down. This creates opportunities to expand your product mix, but also to gain more market share due to competition. The gain of market share equates to needing additional production capacity or product offerings in order to serve your customer.”

That pursuit among treaters of greater market share is a business reality sure to continue. MM

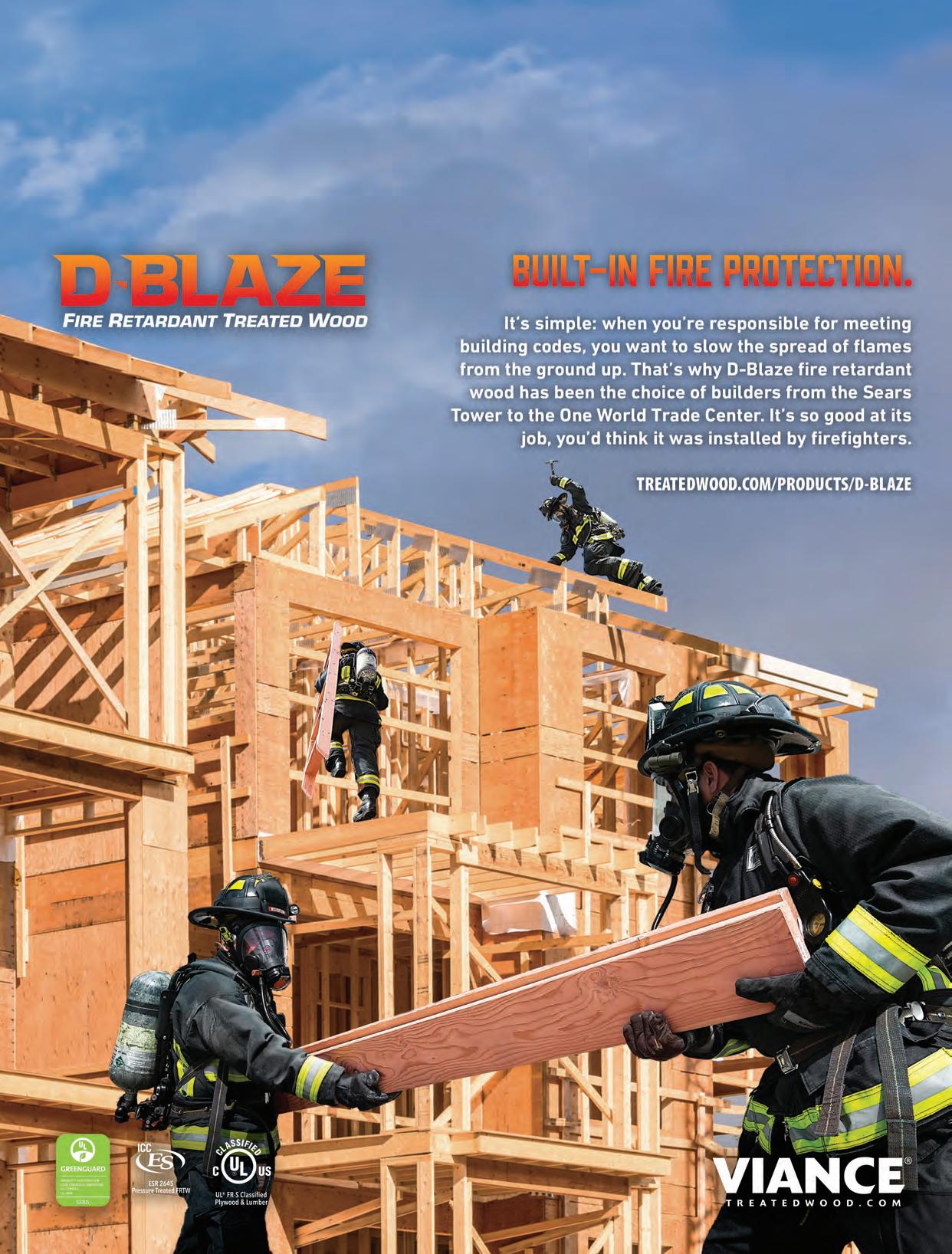

2023 Top Treaters

Stella-Jones has 12 pole-peeling plants and 43 treating facilities (27 of them in the U.S.) following its purchase last year of Texas Electric Cooperatives’ wood utility pole plant in Jasper, Tx. Treatments include CCA, creosote, CuNap, borates, MCA, CA and ACQ.

UFP Industries has 221 affilted operations in nine countries, including 22 treating plants from Colorado eastward, primarily along the East Coast, Midwest and Texas. Treatments include ProWood brand MCA, CA-C, borates and FRTW. UFP also owns Sunbelt Forest Products, Bartow, Fl., which operates 11 plants in the Southeast and mid-Atlantic regions, utilizing Ecolife, TimberSaver borates, Preserve CA, Preserve Plus CA with water repellent, Wolman E MCA with BARamine technology.

Doman Building Materials, Vancouver, B.C., in addition to its seven CanWel treating plants in Canada and vast distribution operations throughout North America, has 23 treating facilities in the U.S. under its Hixson Lumber Sales, Honsador, and California Cascade divisions.

Culpeper Wood Preservers, Culpeper, Va., has quickly grown to 17 facilities that extend from the Southeast to the Northeast through the Midwest. Over the last year, it acquired four plants—formerly H.M. Stauffer & Sons, eola, Pa.; Northeast Treaters, Belchertown, Ma., and Athens, N.Y.; and Koppers Utility & Industrial Products, Sweetwater, Tn. Treatments include MicroPro MCA, Advance Guard borates, CCA, FlamePro interior FRTW, and CAC.

Great Southern Wood Preserving, Abbeville, Al., is among the nation’s highest volume treaters from its 15 facilities throughout the South, Midwest and Eastern Seaboard—the latest acquired last year from Escue Wood Preserving, Millwood, Ky. Its YellaWood brand family of products includes YellaWood Select and SuperSelect KDAT products, YellaWood Columns, MasterDeck decking, and Rainwood with water repellent, plus fencing, railing, specialty products, fasteners, joist tape, stains and sealants. Treatments are MCA, borates, FRTW, CCA and CA-C.

Koppers Utility & Industrial Products, a division of Koppers Holdings, operates 11 industrial plants, concentrated in the Southeast plus Arbuckle, Ca., treating with CCA, penta, CuNap, and creosote. It just purchased Swanson Group’s 70-acre former mill site in Glendale, Or., which it is currently converting to its own uses.

Hoover Treated Wood Products, Thomson, Ga., is best known as an originator of fieretardant treatments, but also has 10 of its own treating plants, from coast to coast, offering Pyro-Guard interior FRTW, Exterior Fire-X exterior FRTW, CCA, permethrin/IPBC-based Clear-Guard, Cop-Guard CuNap, Micro-Guard MCA, and Dura-Guard ACQ.

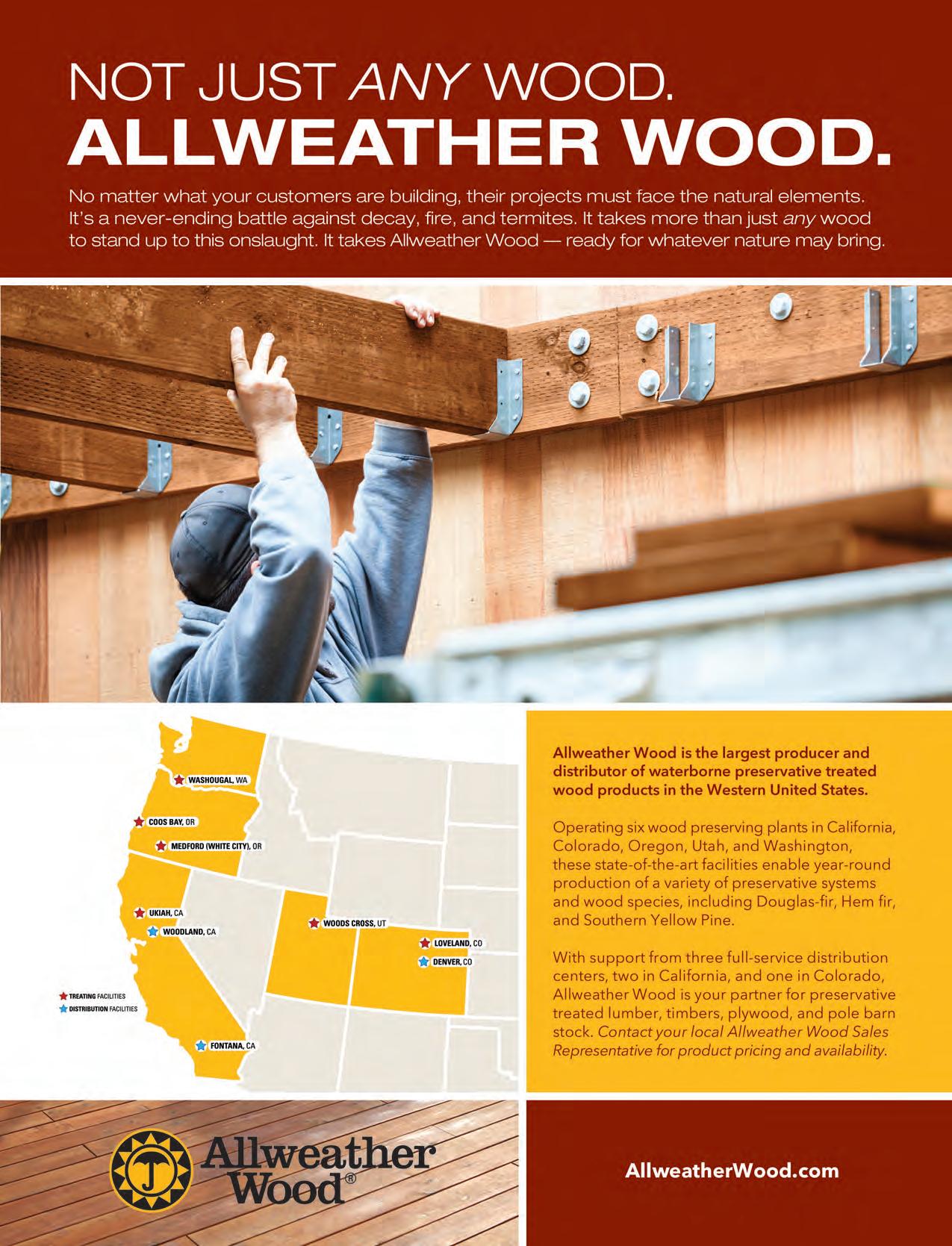

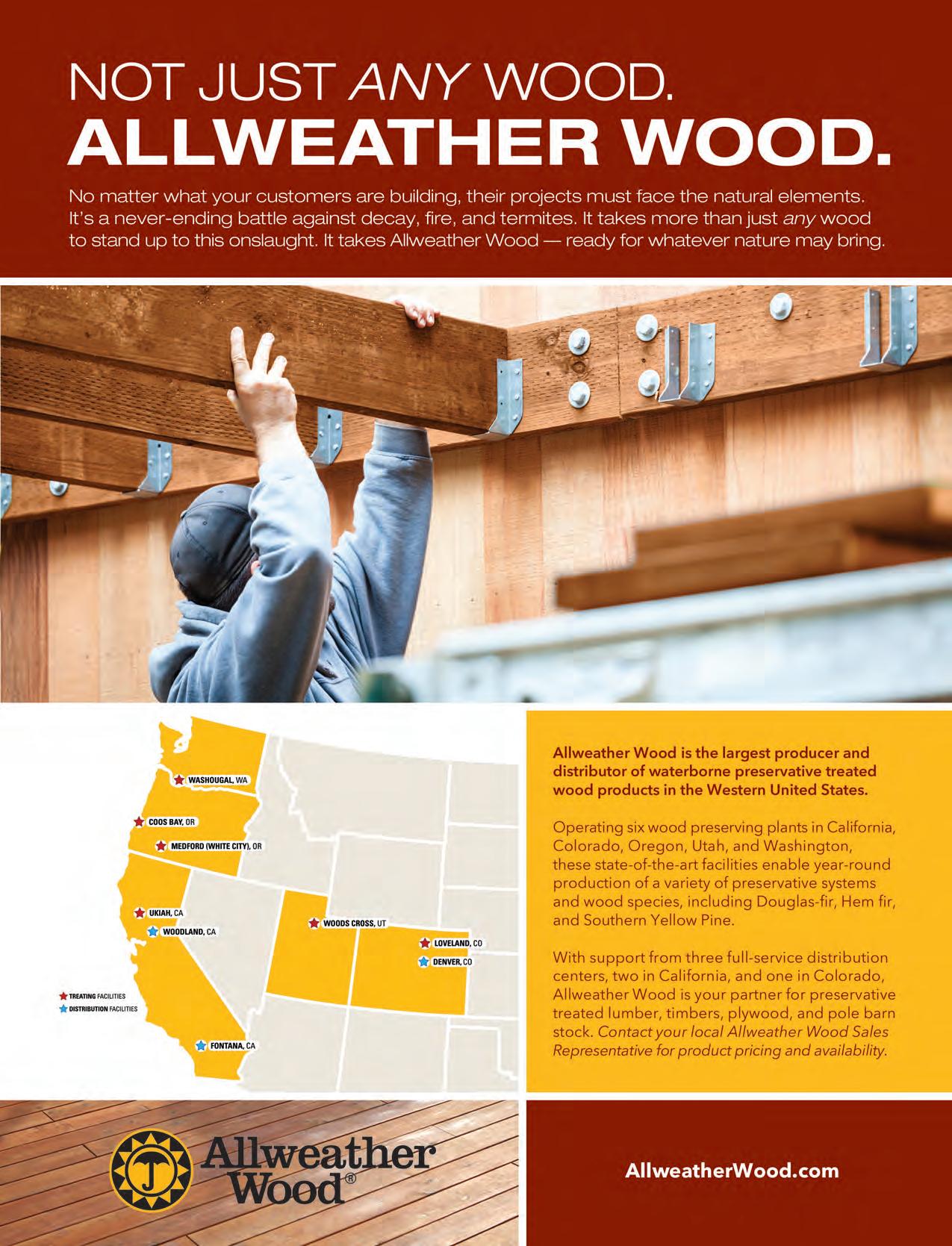

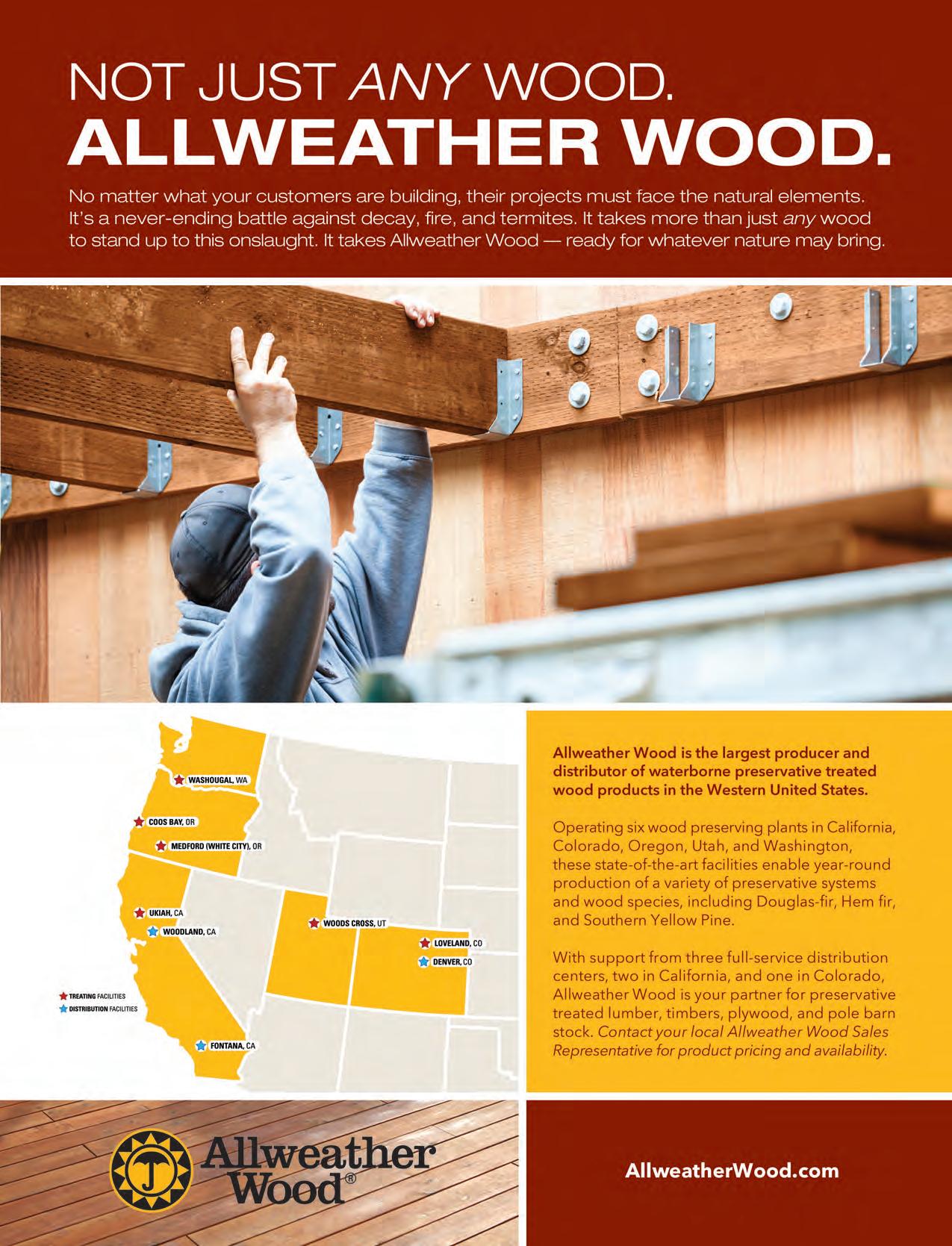

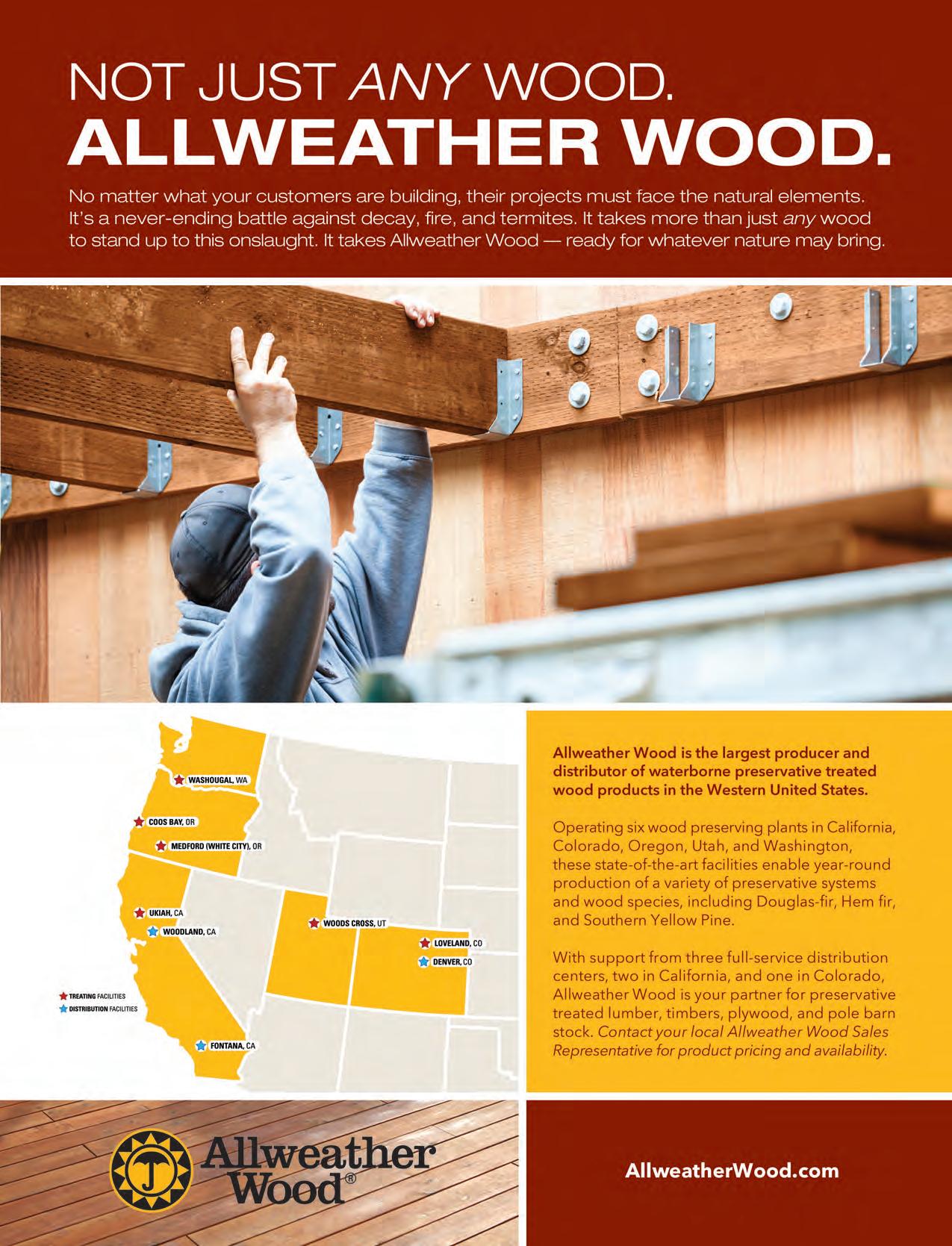

Allweather Wood is the largest waterborne preservative-treated lumber manufacturer and distributor in the western U.S., with six treating plants in California, Colorado, Oregon, Washington and Utah, having just acquired Utah Wood Treating, Woods Cross, Ut. Treatments include borates, CA-C, CCA, MCA and interior FRTW.

Bestway, Cortland, N.Y., has four treating plants (in New York, Pennsylvania and North Carolina) that offer olmanized Outdoor Wood, Wolmanized Heavy Duty CCA, and D-Blaze interior FRTW.

Fortress Wood Products’ three plants in North Carolina produce MicroPro MCA and CCA, including KDAT.

Biewer Lumber’s three treating plants (in Lansing, Mi.; Seneca, Il.; and Prentice, Wi.) have a combined annual capacity of 350 million bd. ft. of CA-C, MCA and FlamePro FRTW. The company is currently investing in facility upgrades to increase production capacity.

Southeast Forest Products, Montgomery, Al., operates three treating plants in Louisville and Nauvoo, Al., and Richmond, In., utilizing CA-C, Ecolife, MCA and borates.

C.M. Tucker Lumber, Pageland, S.C., runs three plants in the Carolinas, treating fencing, decking, lumber and plywood with Ecolife, Preserve CA, Wolmanized MCA, and FlamePro interior fie retardant.

Conrad Forest Products treats in North Bend and Rainier, Or., and Arbuckle, Ca., using Wolmanized Heavy Duty CCA, Chemonite ACZA, Wolmanized Outdoor Wood CA-C, Sillbor/ FrameGuard borates, interior and exterior FRTW, and QNap.

12 • the merchant magazine • april 2023 building-products.com

THE WWPI GUIDE TO SELLING TREATED WOOD

The following 14 companies are those that operate at least three treating plants in the U.S. They are ordered by number of facilities, not by production volumes.

THE ENGINEERING BEHIND TREATED WOOD

BY BELINDA REMLEY

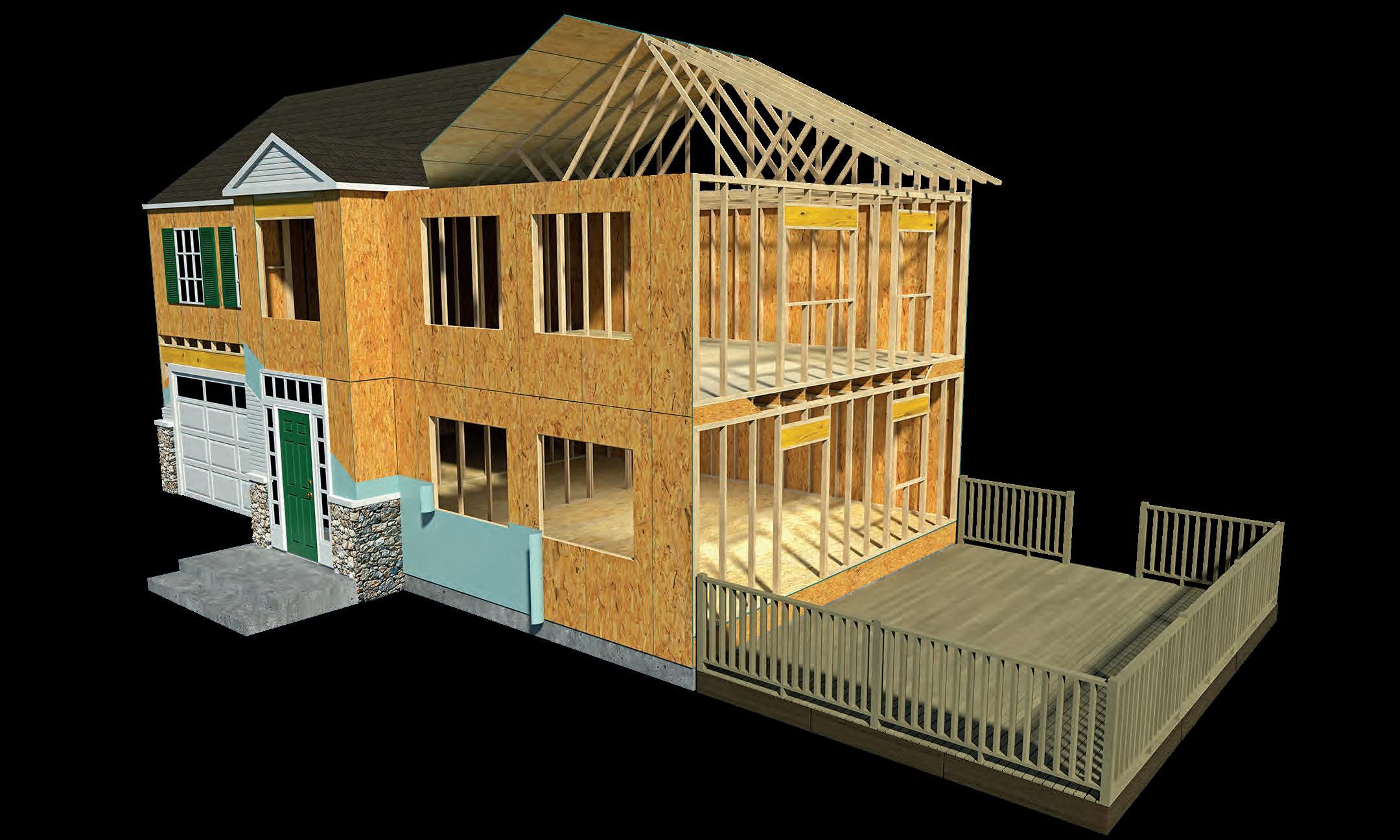

TECHNOLOGY AROUND the world both in industry and in everyday life has changed greatly over the past century. We have moved from horse drawn wagons, cars that crank, and party line telephones to supersonic jets, cars that drive themselves, and phones that we carry in our pockets, giving us access to family and friends and the world. Of course, we cannot talk about the innovative leaps made in engineering, design, and technology without talking about those successes within the wood

INNOVATIONS IN THE TREATING PROCESS HAVE LED TO BENEFITS TO THE SUPPLY CHAIN

products industry as well.

Everything from the preservative formulation to the treatment process has been innovated to improve the way wood is preserved, making the process more streamlined, cost efficient, and precise. While the treatment of wood has been around since even before the 1920s when Dr. Wolman improved the process, engineers since have made the process even better.

“The industry as a whole has made huge leaps surrounding the way wood is treated,” says Justin Mackender, senior engineering manager for Arxada’s Wood Protection Business Unit. Arxada, along with other preservative manufacturers, has worked closely with treaters to innovate plant upgrades that make preserving wood safer, more reliable and more efficient.

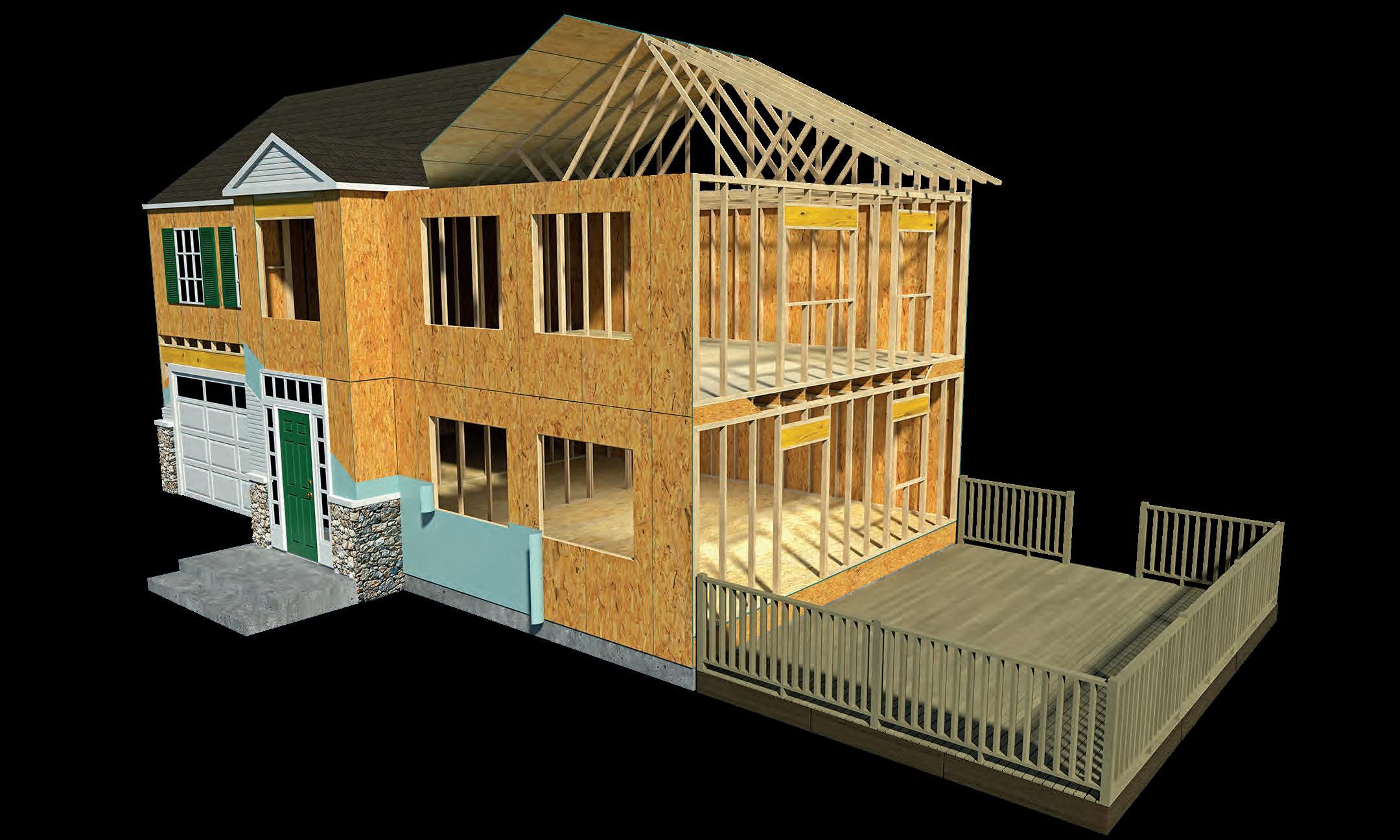

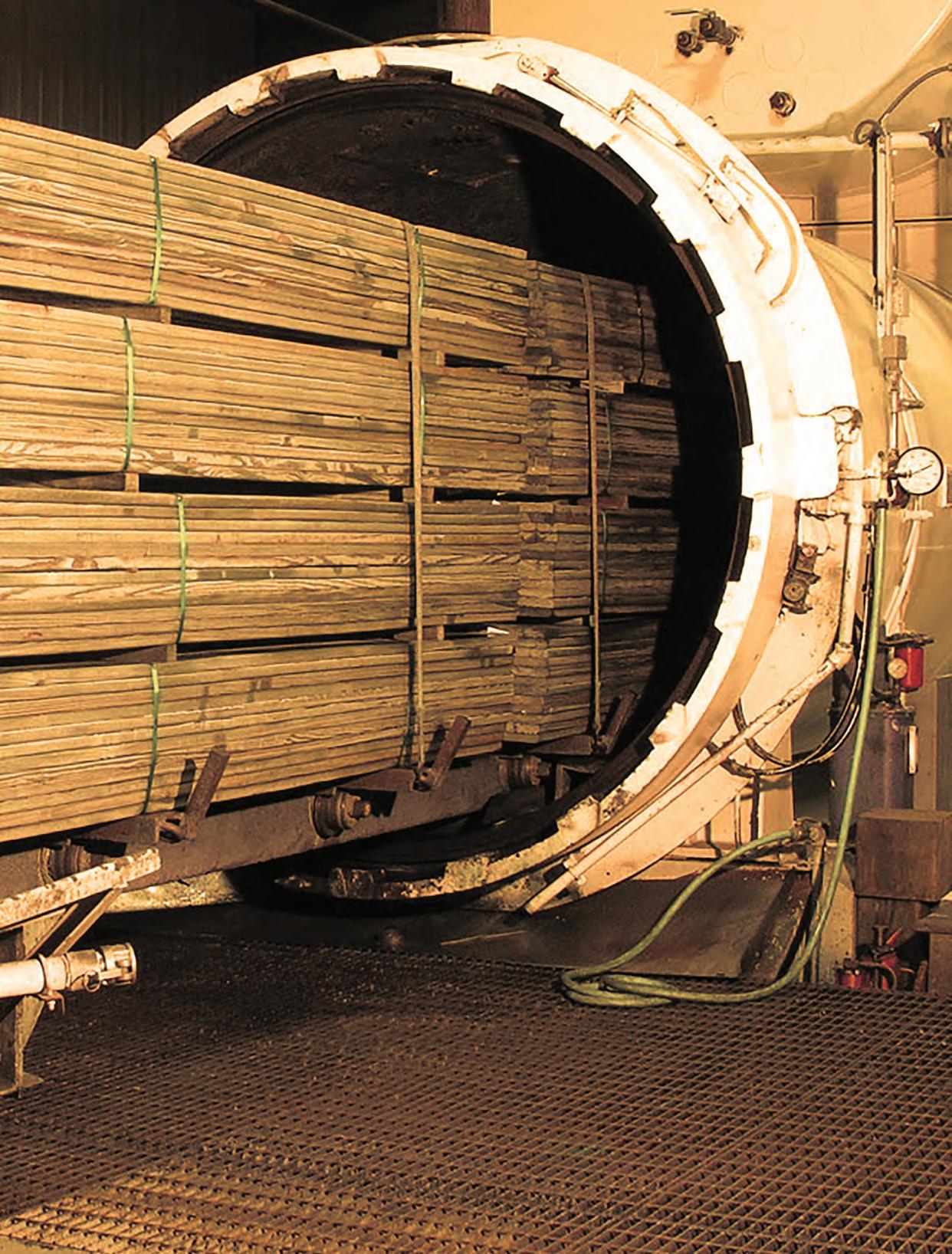

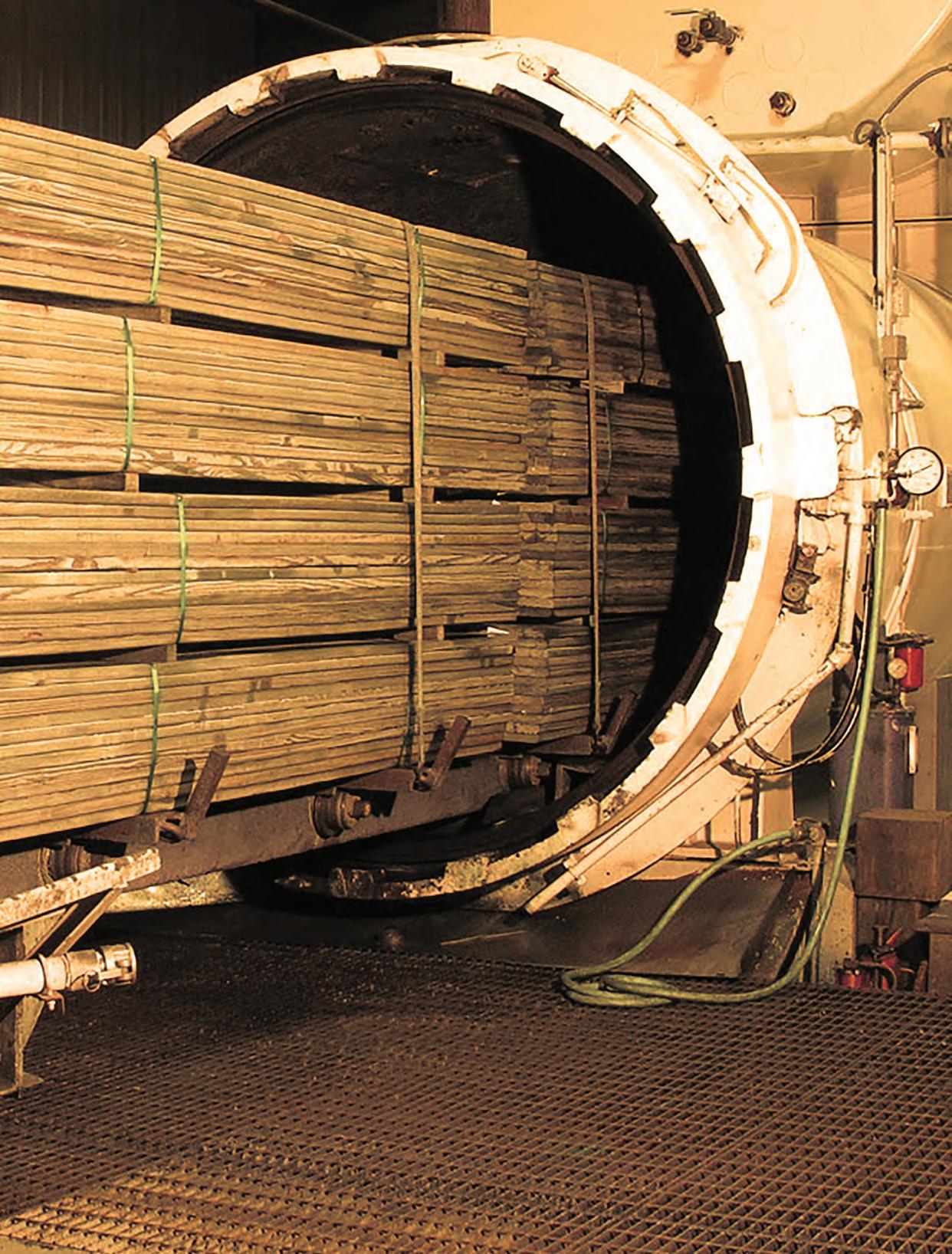

The actual process of treating timbers, lumber, etc., so that those building materials will last longer, began centuries ago when builders used pitch and tar to coat wood. In the last century, the coating (dipping and spraying) processes have been improved and pressure treating was developed. Pressure treatment is a simple concept that is executed in an ever-advancing process by which wood is pushed into a pressure vessel that is closed off and sealed. The preservative is pulled into the vessel by vacuum, where it is then forced into the wood by pressures up to 190 psi. The pressure time is scientifically determined and monitored carefully to ensure the correct amount of wood preservatives are pressed into the wood. Once the wood is impregnated, a final vacuum reclaims the excess preservative to be used for the next batch of wood to be preserved.

14 • the merchant magazine • april 2023 building-products.com

------------

MANY TREATERS use double-door pressure vessels to improve efficiency within their treatment process. (Photos by Arxada)

THE WWPI GUIDE TO SELLING TREATED WOOD

“THE INDUSTRY AS A WHOLE HAS MADE HUGE LEAPS SURROUNDING THE WAY WOOD IS TREATED.”

“The system has been effective for decades,” explains Justin. “However, we have worked to improve it through physical plant upgrades and through the use of computer systems.”

One major improvement is the use of quick opening doors. In the past, the doors on the pressure treatment cylinder were bolted closed. This caused the treater to have to tighten and loosen the bolts by hand both before and after the treating cycle. With hydraulically operated, quick opening doors, the doors can be remotely closed and opened, allowing the treater to be safely away from the vessel when it is first opened.

“This equipment improvement was innovated originally for the safety of plant team members,” Justin says. “However it also reduces the time it takes to treat wood because opening and closing the 8’ (or larger) doors by hand with a wrench takes time and lessens efficiency between treating cycles.”

Justin, whose team builds one to two plants per year, explains that

research and implementation of new treating processes are key steps when designing new facilities or when retrofitting current plants with better equipment. “We know how to make a plant hum. By considering

Wood Treating Service with a Superior Preservative Selection

important design decisions, such as process flow, equipment, production requirements, and the commodity (utility poles, piling, lumber, timbers) that will be treated, we can optimize the production process.” His team

building-products.com april 2023 • the merchant magazine • 15

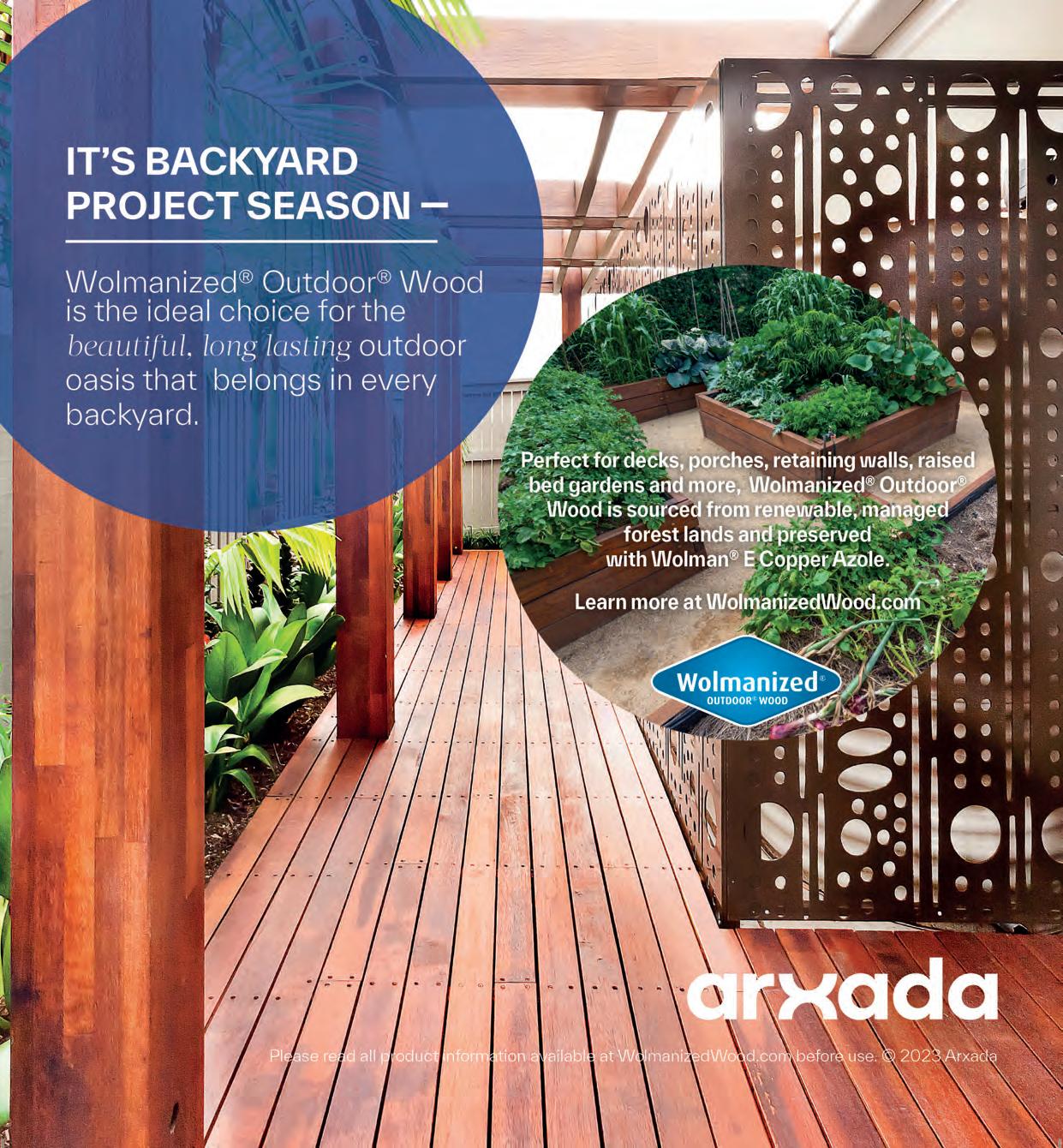

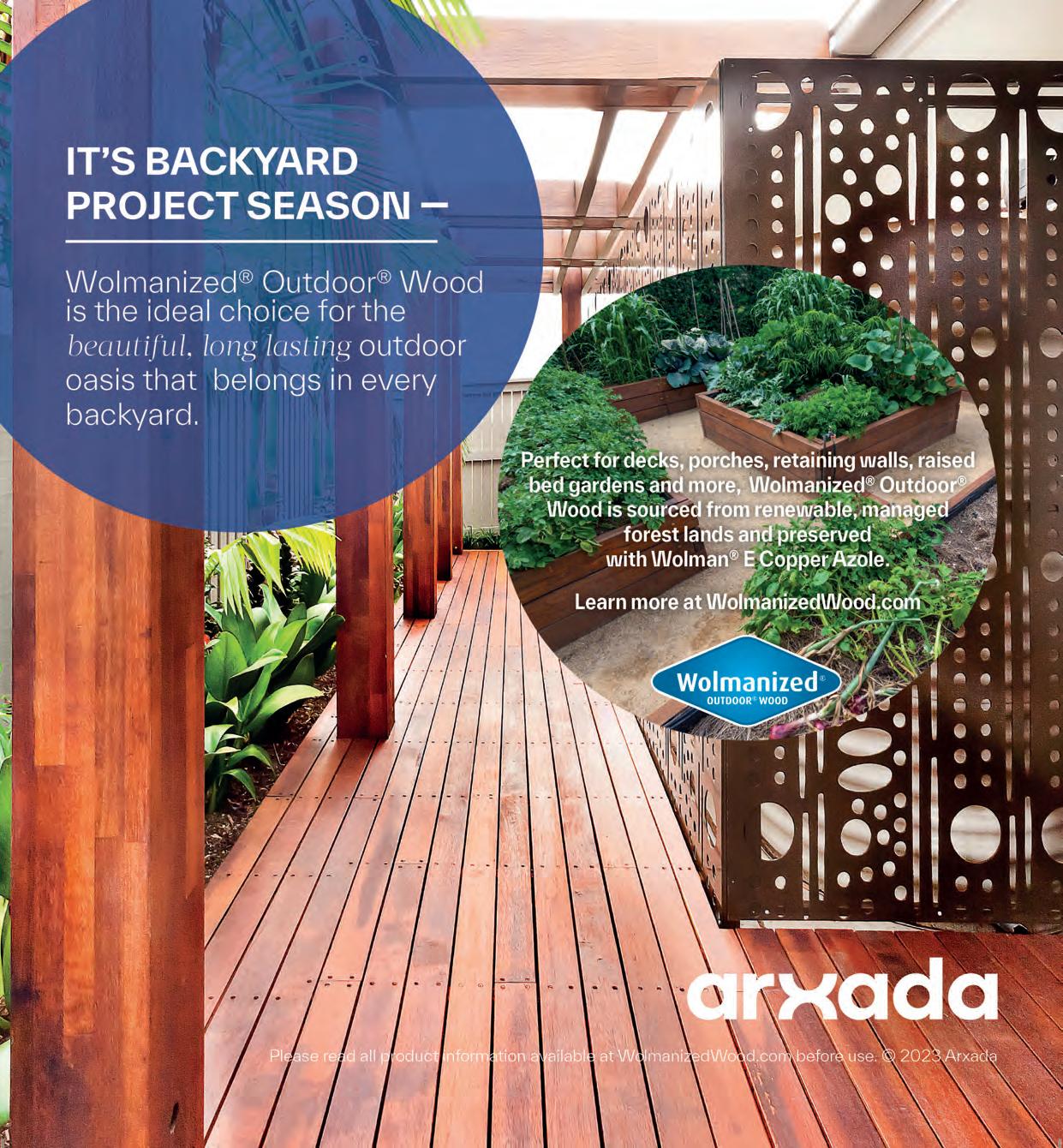

JUST AS WHEN the outdoor living revolution began in the ’70s, decks today are built with long-lasting, beautiful, natural wood preserved in an industry motivated to push improvements in product and process.

Also availalable through Thunderbolt We can pressure treat your wood products for any residential application www.thunderboltwoodtreating.com Danny Sosa 209-747-7773 dannys@thunderboltwt.com Riverbank, California

CCA Our family owned business has served the Western US for over 40 years T-BOR COPPER AZOLE

thinks about what would make a plant both efficient and fast, yet also a safe environment in which to work.

“Most plants today are designed with a double door vessel,” says Justin. “Wood to be treated is loaded

onto the tram into one end of the cylinder then pushed out the other end of the pressure vessel when the treating process is completed. This reduces the change over time and increases the number of charges a plant can do in one day.”

Recently, United Treating & Distribution (UTD) in Muscle Shoals, Al., retrofitted their cylinder to include a door at both ends. “Our efficiency has improved by about 27%,” says Casey Epperson, UTD’s vice president of operations. “That means a couple of important things for us. We can treat more wood in the same amount of time. Also, we can offer a better work/life balance to our team members. This new efficiency has allowed us to work fewer weekends and extended shifts; yet, we are able to get the same quality treated wood to our retailers and dealers in a timely manner.”

Other treating plant improvements include maximizing equipment capabilities to speed the treating process. “Our design specs always include blowback to empty a cylinder instead of a transfer pump, which is

16 • the merchant magazine • april 2023 building-products.com

TREATING OPERATOR Ryan Gann with United Treating & Distribution, uses Arxada’s Treat Right computer system to ensure that the preservation of lumber is accurate and timely.

much quicker,” adds Justin.

Another innovation in the treating process involves using a speed-controlled pressure pump and eductor to empty pressure vessel during final vacuum. This eliminates the final drain step and decreases charge time. Additionally, automated preservative mixing systems blend multiple chemistries into a single work tank for the next batch of wood to be preserved.

“The list of treating plant improvements goes on,” says Justin. “Tank agitation provides uniform treating solution concentrations and reduces fallout, yielding a cleaner, more consistent treating. We also recommend, in some cases, chiller systems to reduce the impact that high temperatures can have on some preservative systems.”

“Of course, the treating process could not be nearly as effective as it is,” says Casey, “without the use of a good control system.” UTD uses the Treat Right system designed by Arxada. In addition to ensuring the wood is treated properly, the system has an additional component called

Treat Right BI, a data driven dashboard. “With Treat Right BI we are able to monitor our entire treating process. We can tell when our cycles are most efficient. We study each step of treatment to determine if we need to adjust our system or if we need to fix a piece of equipment. Using a computerized system has saved us time and money by allowing us to analyze data on our treating history and identify trends that can help us treat better.”

Justin says that equipment is not the only concern and is not the only place where plants have benefitted from innovations. Treaters have made improvements in protecting their employees by providing better air quality and ventilation systems. Because worker safety is paramount,

treat better in less time ensuring retailers and dealers receive the treated wood they need to keep their shelves stocked,” says Justin.

Due in great part to the innovations in the treating process, preserved wood is still the most widely used building material for backyard projects. It is widely available, created from nature’s sustainable building block, and enhanced to be long lasting at efficient plants. Justin concludes, “Outdoor living is always in style and modern treating plants make sure that lumber aisles will have what the consumer needs to build backyard projects.” MM

building-products.com april 2023 • the merchant magazine • 17

BELINDA

• Full Service Pressure Treated Lumber & Plywood • Cedar Deck Accessories • Specialty Decking Products Tacoma, WA 800-426-8430

SOURCING PTW

------------ BY KARI GAVIRIA

IF YOU AREN’T asking your customer, “What are you using it for?” on a regular basis, you’re doing it wrong. It’s highlighted and underlined in the second paragraph on the first page of the Treated Lumber for Dummies handbook.

Okay. There isn’t actually a Treated Lumber for Dummies handbook. But, if we are being honest, there probably should be. Treated lumber isn’t a flashy new product, and consumers aren’t chomping at the bit to discuss something that’s been in play since the 1940s. Regardless, regulations, best practice standards, and applications continue to evolve. Education is not only relevant but critical to the health of our industry. For treated lumber, the use category needs to match the application for project success.

“Creating an outdoor living space” used to mean building the same cookie cutter, 10x10 deck to grill a few burgers. These days, decks have been rebranded as extensions of million-dollar homes. Some of these folks have nicer decks than they have living rooms. Amenities and aesthetics play a crucial role in the overall vibe consumers are aiming to achieve. Yes, that’s right, decks are a vibe.

Do you know what decks, docks and fences all have in common? They are expensive to build for a homeowner, and it can be a real ego bruiser the second go round when products are improperly installed–not to mention a liability and a safety hazard. That’s why something as easy as asking “What are you using it for?” should be a mandatory value proposition sown into your business model. Not to men-

tion all the additional items your customer will purchase that they did not know they needed before they started the project–joist tape or end coat solution anyone?

Why aren’t your employees asking the right questions during the sale? Two reasons: (1) Either they are intrinsically lazy and their shift ends in 15 minutes, or (2) they truly don’t comprehend the importance of the questions. To best explain this, consider fitting every industry professional into one of three categories: The Greats, The Goods, and The Ordinaries. I purposefully avoided using the word “bad” because the knowledge void isn’t intentional.

Ordinary folks: Take orders.

Good folks: Ask questions.

Great folks: Know the answers.

See it in action:

Contractor: “I need 8x8x12’s”

Ordinary Sales Rep: “We don’t have that in stock.”

Good Sales Rep: “I’ll call and ask what’s available.”

Great Sales Rep: “We can special order it. What are you using it for?”

Contractor: “A dock.”

That changes the game now, doesn’t it? You now have the opportunity to follow up—fresh, salt or brackish water? These things matter. Chapter two of the Treated Lumber for Dummies handbook should be titled, “Treaters Don’t Put Tags on Lumber for Fun.” Each tag lists, in tiny print, a retention standard and a use category. These categories uniquely define where you can use the product. In this scenario, The Goods aren’t afraid to

ask but, The Greats already know what options exist.

Apply the same logic to the contractors:

Ordinary Contractor: “I need 8x8x12’s.”

Good Contractor: “I need 8x8x12’s for a dock.”

Great Contractor: “I need 8x8x12’s for a dock, and the job requires UC4C.”

Sales Rep: “Let me call my treater and get you a quote.”

More often than not, you’ll witness one of The Greats asking for a specific use category, for example UC4C. Retailers, read this next line carefully. Stop losing out on sales because you don’t have the material on the ground. I promise that your on-ground inventory doesn’t account for even half of what treaters have to offer. It is your duty to pick up the phone and ask someone. Make sure you are prepared to tell them, for the love of all things lumber, what it is being used for. Treaters are the industry experts on the application of their product. They know how to get what you need, or at the very least, can provide an alternative solution.

No matter which side of the counter you are on, it is important that you recognize the sheer magnitude of these interactions. Pinpoint if you are speaking to one of The Ordinaries, The Goods, or The Greats. Take a moment to self-reflect. Which one are you?

Ordinary, Good or Great? Then the next time you find yourself standing across from someone who says, “We don’t stock that,” without ever asking any questions or offering to make a phone call, put your items down on the counter and run. Run for your life.

Want the cold hard truth? Stop wasting your time with Ordinary folks expecting extraordinary results. The Greats are plentiful in our industry. It’s your job to find them MM

18 • the merchant magazine • april 2023 building-products.com

KARI GAVIRIA

Kari Gaviria is president of Madison Wood Preservers, Madison, Va. (www.madwood.com).

THE WWPI GUIDE TO SELLING TREATED WOOD

Whhen Wood is Made to be Se en ™

SaferWood™ treated with Thermex-FR™ by Chemco is compliant per 2303.2 of the IBC and ignition-resistant per 2018 IWUIC Section 503.2, Item 3, FRTW, and may be used in the exterior design and construction of buildings under the IWUIC where an ignition-resistant material is required.

ICC ESR-1159 USA

ICC ESL-1021 Canada

Cal-Fire #2520-1450:0502

U.S. Navy QPL MIL-L-19140E

QUALITY PEACE OF MIND IGNITION-RESISTANT NON-TOXIC THE

DEMANDS Scan for Report

WILDLAND URBAN INTERFACE

Since 1981 Chemco, Inc. Ferndale, WA 98248 360-366-3500 www.saferwood.com

PREMIER EXTERIOR FRTW • INTERNATIONAL WUI CODE COMPLIANT

EVALUATED COMPLIANCE

IWUIC

Private Residence | FRT Redwood Decking | Harrison Lake BC, Canada

OUTREACH FOR TREATED WOOD DISPOSAL

------------ BY RYAN PESSAH

EFFORTS TO EDUCATE California businesses and consumers on how to properly dispose and handle treated wood waste, or TWW, are succeeding and earning high marks from state regulators.

California is the only state with specific regulations regarding TWW disposal. While the state has maintained alternative management standards for TWW disposal for more than three decades, lawmakers readopted regulations in 2021, after the previous regulations expired in December 2020. Under the legislation, the preserved wood industry is required to work with state regulators to conduct educational outreach efforts on the disposal requirements.

Last spring, Western Wood Preservers Institute (WWPI) created a new website TWWDisposal.org to provide key information on disposal, including links to a current list of more than 50 state landfills accepting TWW. Thousands have accessed the site to learn how to identify TWW and understand the requirements for handling, storage, labeling and transportation of TWW.

The site details requirements for those who may be disposing of TWW, from households to contractors, businesses, haulers and even landfills. To enhance under-

standing of the regulations, a Spanish-language translation of the website was added.

One positive sign of the educational outreach is that the City of Sacramento now offers TWW pickup for households upon request. While the city is the only one in the state to offer this service, there is optimism that other municipalities will follow.

The preserved wood industry, working with the Contractors State License Board and other associations, contacted more than 17,000 individuals and entities with educational information on TWW disposal. Wood treaters also include notifications of the TWW disposal information in shipping documents for preserved wood sold in the state.

DTSC officials have offered positive comments on the treating industry’s outreach efforts. This year, WWPI is working to drive more visitors to TWWDisposal.org by increasing the website’s visibility on internet search engines. For a full report on the outreach, go to the Other Resources section on the website. MM

– Ryan Pessah is government relations director for the Western Wood Preservers Institute (www.wwpinstitute.org).

THE WWPI GUIDE TO SELLING TREATED WOOD

20 • the merchant magazine • april 2023 building-products.com

CALIFORNIA officials have been pleased with industry outreach efforts on treated wood waste disposal, such as a new, dual-language website and materials detailing proper disposal sent to more than 17,000 in the state.

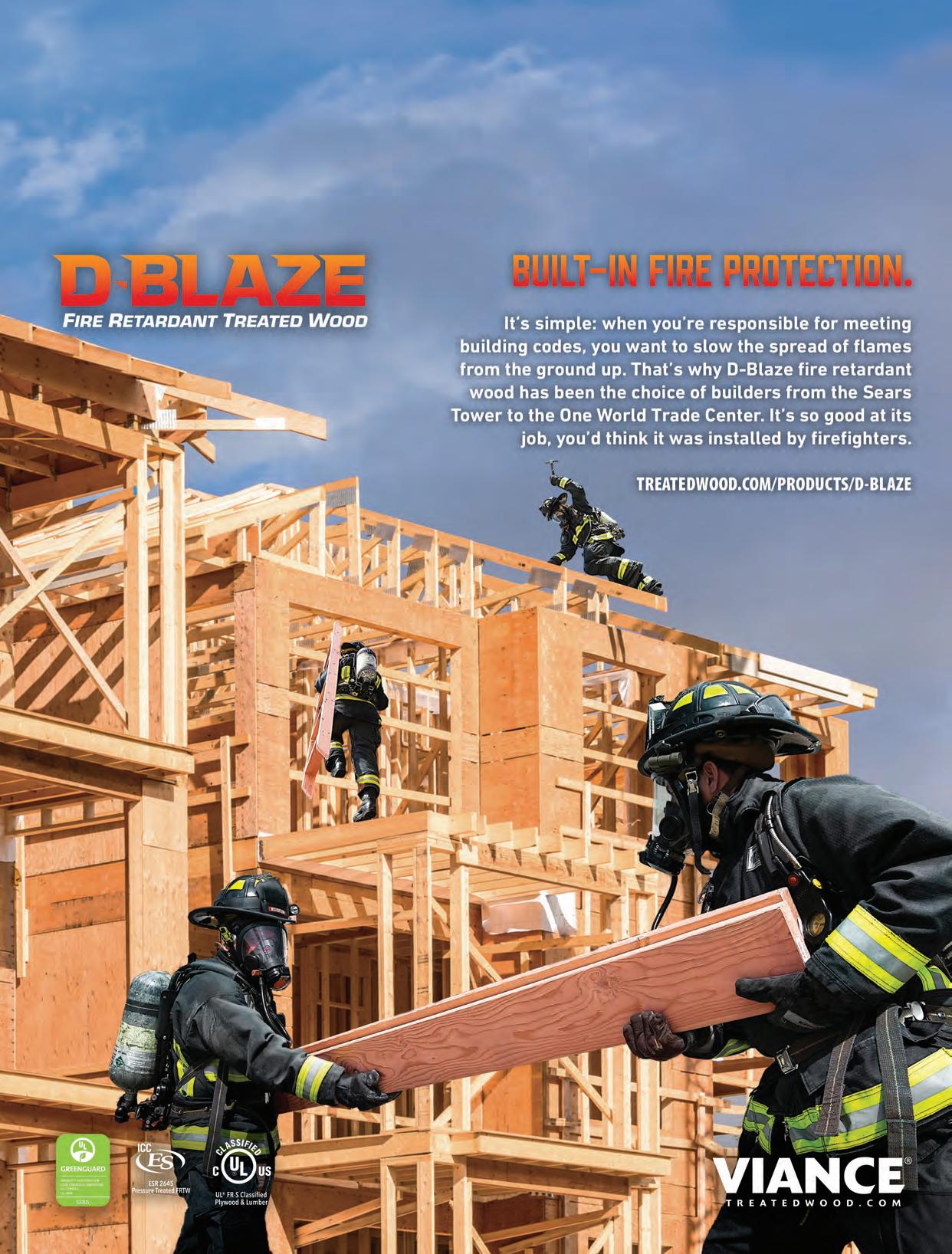

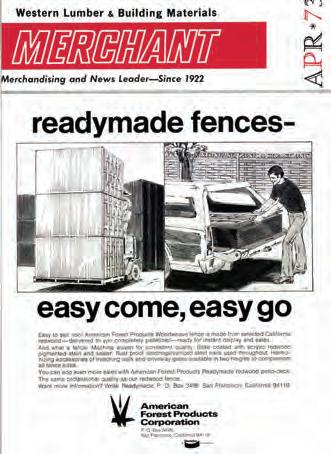

FLURRY OF INTEREST IN FRTW

PARDON THE PUN, but interest in learning about fire-retardanttreated wood products continues to run hot.

For decades, fire retardant wood has been used in commercial and multifamily construction, most often as a substitute for non-combustible materials as allowed by building codes. Destructive wildfires in the West in recent years have prompted homeowners and others to look into pressure-treated fire retardant wood, particularly in areas with wildlandurban interface (WUI) regulations.

Visits to the website FireResistantWood.org, administered by Western Wood Preservers Institute (WWPI), increased by some 30 percent in 2022. The number of people viewing the site has increased by double-digit percentages since it debuted in 2018.

Many of those coming to the site were seeking information on fire-rated assemblies. These include pre-designed wall, floor and ceiling assemblies that have been tested for their fire resistance. Fire retardant manufacturers conduct the tests on such assemblies constructed from wood treated with their formulations.

Typically the assemblies are rated as one or two hours, which describes how long the assembly will maintain its structural capabilities when exposed to fire. During testing by an independent laboratory, an assembly is loaded to 100% of its design load and then exposed to flames

MORE SEEKING INFO ON FIRE RETARDANT WOOD PRODUCTS, ASSEMBLIES

to determine its endurance performance. Each assembly prescribes the list of materials used, including the insulation, gypsum board and even fasteners.

WWPI has seen a growing number of requests for wood that is both preservative- and fire-retardanttreated, most often for outdoor applications. However, there is no way to pressure treat for the vastly different protections.

Fire retardants for interior applications may contain components such as borates, which are used as preservatives. Check with the specific fire retardant manufacturer for more

information on the formulation’s preservative properties.

While there are exterior fire retardants available, they are formulated to maintain the fire protection performance when exposed to the elements. As such, they don’t offer the same protections against insects and decay fungi found in preservatives.

Architects, designers and specifiers also are seeking more in-depth information on fire retardant wood. Online courses developed by WWPI set new records for downloads in 2022.

(Continued on page 64)

22 • the merchant magazine • april 2023 building-products.com

------------ BUTCH BERNHARDT

THE WWPI GUIDE TO SELLING TREATED WOOD

DEMAND for fire-retardant-treated wood is growing in the West for use beyond traditional projects like commercial and multifamily structures. A record number of visitors have visited fire-retardant-treated websites and online education resources.

building-products.com april 2023 • the merchant magazine • 23

WHY THERE ARE CUTS IN SOME TREATED WOOD

BY BUTCH BERNHARDT

ONE COMMON QUESTION heard from those buying preserved wood in the West: Why does this wood have all these cuts in it?

The slices made in preserved wood products are called incisions and it serves a very important purpose in making the wood last in service. The reasons behind the need for incising start with the wood itself.

Douglas fir and Hem-Fir are the most commonly pressure treated Western species. These species are considered refractory species, which means they are more difficult to treat. There are two kinds of wood in a tree: sapwood, or the outer portion, and heartwood, which is deeper

inside. Sapwood accepts pressure treating more readily than heartwood, which is difficult to penetrate with preservatives.

Western species have a thinner sapwood layer and, in some pieces, there may be a higher percentage of heartwood. Incising helps overcome the difficulties in treating to get preservatives into the wood. By comparison, southern pine has a thicker sapwood layer and typically doesn’t need incisions to achieve treating standards.

Decades ago, treaters discovered that putting incisions in thin sapwood species helps create pathways to achieve the required preserva-

tive penetration. This is done prior to treating, with the sawn wood moved through rollers with teeth that make incisions on all four sides of the wood. The American Wood Protection Association defines the standards for the amount and depth of the incisions for the wood.

Traditionally, western wood products that were treated for Ground Contact had to be incised to receive enough treatment. Products produced under Above Ground standards usually do not need incising. If the wood is incised, however, it doesn’t always mean it is treated for Ground Contact.

In recent years, treaters have incised other wood products used in Above Ground conditions. For example, sill plates may be incised as well as colored with red, blue or green stains. This can help construction labor identify the right wood for use as sills. Since sill plates are typically treated with borates, the incising improves penetration to protect the wood from termites and other insects.

While incising helps in protecting the wood, it also impacts the strength of the wood. In most applications, the lower strength has little impact in how the product is used, such as framing for deck structures. However, when used in engineered applications, some strength values must be adjusted. MM

– Butch Bernhardt is deputy director of the Western Wood Preservers Institute. For more info on incising, visit PreservedWood. org online library to download the publication PreserveTech - Incising

24 • the merchant magazine • april 2023 building-products.com

------------

THE WWPI GUIDE TO SELLING TREATED WOOD

TREATED Douglas fir and Hem-Fir for Ground Contact uses is incised to allow preservative to penetrate deep enough to provide protection and meet industry standards. Western treaters perform the incising by running the wood through rollers with teeth for a uniform pattern of incisions.

A squeak-free fastener from the brand your customers trust.

Introducing the Strong-Drive ® SDPW DEFLECTOR screw from Simpson Strong-Tie — a premium structural fastening solution that provides support for non-load-bearing, full-height partition walls and helps minimize squeaks and wall separation. Keep your shelves stocked with the high-performance fasteners your customers demand. Pair it with our Strong-Drive SDWC Truss screw for load-bearing walls to offer a complete wall-to-truss fastening solution.

For more on the Strong-Drive SDPW DEFLECTOR screw, visit our website at go.strongtie.com/sdpw or call (800) 999-5099.

Available in 6", 5" and 3 ½" lengths © 2023 Simpson Strong-Tie Company Inc. SDPW20D Framing Solutions | Products, Software and Service for Smarter Building

FIELD TREATING ENHANCES PTW’S LONGEVITY

BY BUTCH BERNHARDT

HELP YOUR PRESERVED wood buyers get the maximum service life for their wood by showing customers how to field treat cuts and holes made in the wood during construction.

During treating, wood deep in the lumber may not receive preservatives. Pressure treating integrates the preservatives far enough to create a protective shell on the outside area of the piece.

Cutting and drilling holes often exposes wood that did not receive treatment. Protecting this wood by field treating during construction keeps the protective enve-

lope intact and extends the time the wood can remain in service.

Building codes and the American Wood Protection Association (AWPA) require field treating for preserved wood used in construction. Copper naphthenate is the most commonly available preservative recommended for field treating. Preservatives with oxine copper and micronized copper quaternary also can be used.

Field treatments should contain between with 1% to 2% copper, per AWPA standards. A higher level of copper in the field treatment can enhance the protection.

Field treating is done using a brush to apply the preservative to the cut area or hole. Follow the preservative’s label for application instructions. When field treating wood placed over water, take care to avoid dripping the preservative into the water.

The surface of the area treated should be cleaned before application, then coated liberally so the treatment can penetrate into the fiber. A standard paint brush can be used for most field treating. Be sure to coat all cuts, including the ends, and apply the preservative deep into the holes. MM

– Butch Bernhardt is deputy director of the Western Wood Preservers Institute. For more info and links to the most common field treatment products, download the publication PreserveTech –Field Treating from the online library at PreservedWood.org.

26 • the merchant magazine • april 2023 building-products.com

------------

THE WWPI GUIDE TO SELLING TREATED WOOD 888-807-2580 Bend, OR www.pelicanbayfp.com DISTRIBUTION LOCATIONS Colton / Fontana / Modesto / Salinas / Stockton, CA PRODUCTS & SERVICES Framing Lumber / Pallet Stock / Industrial Lumber / Softwoods Hardwoods / Cedar / Fencing / Decking / Redwood Custom Cut Stock / Treated Lumber / Tile Battens 3-Hole & Slotted Vents / Custom Cutting / Remanufacturing Heat Treating / Fire & CCA Treating “Focused on the future with respect for tradition”

A PAINT BRUSH and copper-based field treatment can go a long way in protecting preserved wood that is cut and drilled on worksites.

QUALITY CONTROL FREAKS!

------------ KIM MERRITT

TO SAY THAT the treated wood industry is obsessed with quality control is likely not an overstatement. From a widespread, concerted effort in the ongoing improvement of standards-writing to the rigorous in-plant quality control work performed daily by treated wood producers to the exacting audits performed routinely by third-party inspection agencies, the industry spends a lot of time focusing, yes, even obsessing over quality control!

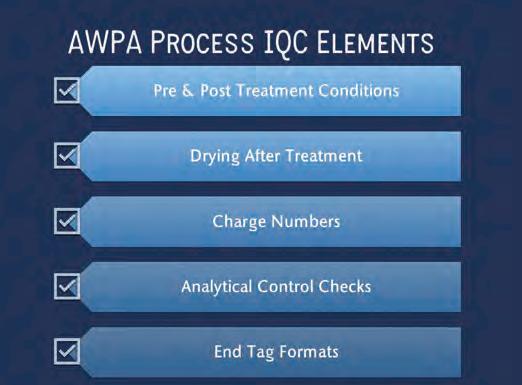

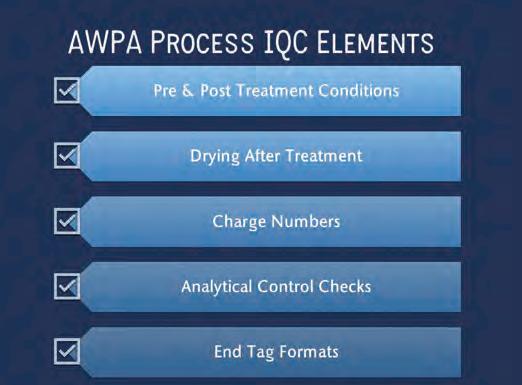

For starters, The American Wood Protection Association (AWPA) serves as the standards-writing organization for treated wood. The AWPA maintains active task groups and committees to continuously review standardized methods to define required elements of in-plant quality control (IQC) and the mechanisms third-party agencies use to evaluate audit findings.

As noted above, AWPA Standards, while voluntary, establish minimum requirements for manufacturers of treated wood to

QUALITY CONTROL REQUIREMENTS FOR TREATED WOOD PRODUCERS

maintain strict in-plant quality control procedures. These procedures ensure that pressure treated wood products are manufactured in a controlled process to help prevent material damage and provide valuable data for the plant quality control team to determine if their treated products meet required quality specifications.

As a third-party inspection agency, one of the first things we must do when auditing the success of a treated wood producer’s quality management system is to evaluate a plant’s conformance to these industry-approved IQC requirements. The AWPA Standards define this in-plant quality system as “Process” and “Product” IQC elements. Each required Process and Product element plays a significant role in the overall in-plant quality system.

Finally, third-party audits also include the inspection of treated wood products to determine if a plant is meeting minimum treat-

ment specifications. Procedures are also in place to provide a means for third-party agencies to assist the plant in developing corrective action when IQC or treatment deficiencies are identified.

While we constantly strive to advance our evaluation methods, this system provides a level playing field among all participating producers and gives quality assurance to the consumers of our products! In the meantime, we will continue to focus, OK, maybe even obsess a little bit, on how to continue to improve! MM

KIM MERRITT

28 • the merchant magazine • april 2023 building-products.com

THE WWPI GUIDE TO SELLING TREATED WOOD

Kim Merritt is director of the Southern Pine Inspection Bureau Treated Division and its Western Division, Western Wood Services (www.spib.org).

WHERE VALUE MEETS VERSATILITY.

BUILD SMARTER. BUILD BETTER. You will do just that with Western Woods ENDURAWOOD™

Premium Patterns + Trim. Available in White Fir and Pine, ENDURAWOOD™ offers exceptional value for money, unrivaled versatility, and long product life. From siding to trim, decking to fencing, ENDURAWOOD™ does it all. It effortlessly takes stains and paints due to its fine, smooth grain: no grain raising or deformations. Better still, ENDURAWOOD™ is WUI-certified, offering the most essential value of all - peace of mind.

Excellent products. Unrivaled service. It’s what we do.

» Le arn more at westernwoodsinc.com.

+ + + + + + + + +

ENDURAWOOD™ is a Wildland Urban Interface certified product.

+ + + + + + + + + + +

PREMIUM

TM

SIDING, TRIM, & SOFFIT. WESTERN WOODS PREMIUM FIR AND PINE PATTERNS + TRIM

LET’S GET SOCIAL CALL US 800-822-8157 VISIT US westernwoodsinc.com

NO, PRESERVED WOOD IS NOT KILLING THE BEES

------------ BY BUTCH BERNHARDT

------------ BY BUTCH BERNHARDT

The problem is the neonic that’s in the formulation for some wood preservatives has little or no chance to impact bees. Through treating, the preservative is integrated into the wood fiber. As there is a very small amount of the neonic present within the wood product, there is virtually no chance it could affect bees, even if they land on the wood after it’s installed.

Most of the proposed measures are so broad they fail to make any distinction in the many ways neonics are used. That has forced the treating industry to seek exemptions for the preserved wood industry.

“In some ways, it’s like playing whack-a-mole... once you get an exemption in one state, another neonic ban pops up in the neighboring state,” said Ryan Pessah, government relations director for Western Wood Preservers Institute. WWPI is working with the national Treated Wood Council to monitor and respond to the legislation before it becomes law, working with bill authors to include exemptions for preserved wood.

IT’S TOUGH to be named Karen when your name has become an internet meme about demanding, entitled people. Preserved wood makers are learning that such ‘guilt by association’ is not exclusive to the Karens of the world.

In the past few years, politicians in states across the country have introduced legislation to ban or restrict the use of neonicotinoids, also known as neonics. These are a class of insecticides used in farms and other agricultural areas that are believed to be one of the main causes in the death of pollinators, including bees. Since January 2020, there have been more than 100 bills introduced in state legislatures across the country that restrict the use of neonics.

For preserved wood, one ingredient in some preservatives, imidacloprid, is classified as a neonic. Given the broad restrictions detailed in many of the bills, the legislation could eliminate the production and use of preservatives that contain neonics.

While many of these bills fail to get passed, Pessah says it’s important to be proactive and advocate changes earlier rather than later should they become law. He said in most cases, lawmakers who sponsor the bills have been receptive.

“Once they hear the facts when it comes to neonics and wood preserving, almost all of the bill sponsors agree to make changes that exempt the application of wood preservatives and preserved wood products from their bill,” Pessah remarked.

WWPI has responded to 20 bills introduced in western states to restrict the use of neonics. Nearly all of these bills failed to pass, but they show up again in the next legislative session.

For those selling preservative-treated wood products, you can assure your customers the only way that wood can kill bees is if it falls on them. MM

– Butch Bernhardt is deputy director of the Western Wood Preservers Institute (wwpinstitute.org).

30 • the merchant magazine • april 2023 building-products.com

THE WWPI GUIDE TO SELLING TREATED WOOD

EFFORTS to protect bees by banning certain insecticides can have unintended consequences. Wood treaters are responding to more than 100 bills in state legislatures that could impact some wood preservatives, even those that don’t impact bees.

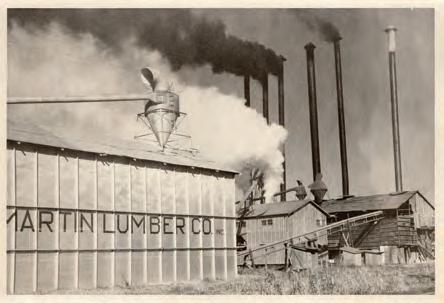

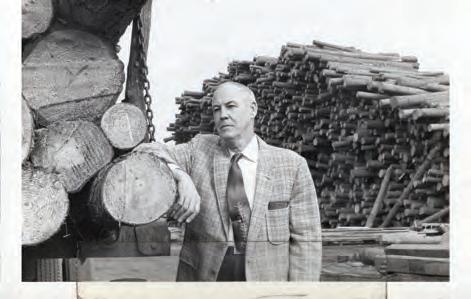

RoyOMartin sincerely thanks our customers, distributors and industry colleagues who have joined us on this journey for the last 100 years.

Since our humble beginnings when our founder Roy Otis Martin purchased the Creston Lumber Mill in Alexandria, Louisiana, (for a whopping $32,000), we have lived our mission to provide the highest quality wood products on building projects across the country. We’ve done it ethically and sustainably, and look forward to continuing our service into the next century.

PLANTING SEEDS FOR THE WOOD INDUSTRY’S FUTURE

------------ BY ALLISON DeFORD

AS SOMEONE whose business is driven by wood— buying, selling, or processing—you understand the growth cycles involved in maintaining a supply of product and the life cycle of forestry. Trees must be planted, nurtured, then harvested.

At the North American Forest Foundation, a similar philosophy drives our mission to change hearts and minds about sustainable forestry and wood products, for good.

Education, promotion and advocacy are the primary ways the non-profit NAFF supports the forest products industry. Dispelling the myths and false messaging, and teaching science-based facts about sustainable forestry and the value of wood products are our main activities to help the next generation understand the benefits.

Today’s kids—the consumers, industry leaders and talent of the future—need a generous dose of truth about wood, trees and forest products. That’s where NAFF comes in. We meet the kids where they are, bringing engaging curriculum and lessons into the classroom to help kids become #exTREEemelysmart.

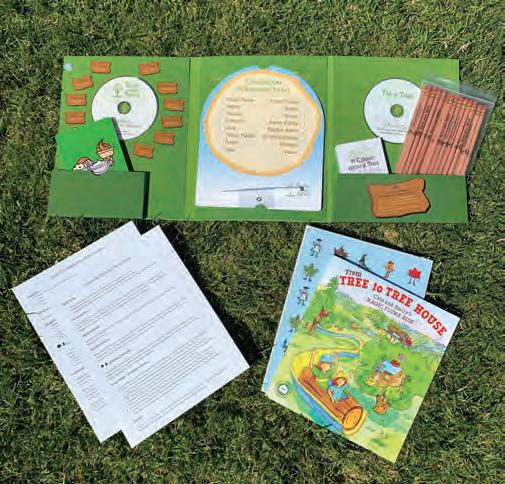

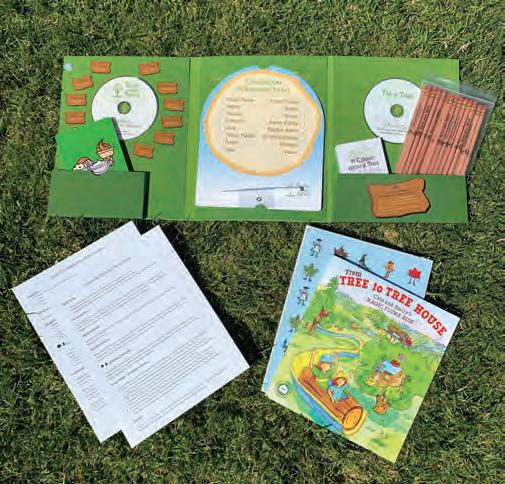

Our Truth About Trees kits are designed to be age-appropriate and are provided free to classroom teachers of grades K-3. Teachers can use the program with more than one classroom and do so over multiple years. The lessons work together with the traveling Forever Forest children’s museum exhibit, in partnership with the Omaha Children’s Museum.

We have a goal to educate 1 million kids by 2030. Plans are in place and we are well on the way to accomplishing our goal. The Forever Forest exhibit saw 148,000 visitors in 2021 alone, with a cumulative attendance of over 630,000 people.

Teachers are thrilled with the kits. Bryan Haecker, a teacher from Texas, says: “Your amazing kit helps me teach my at-risk students all about hardwoods, softwoods, properties of wood, deforestation, reforestation, sustainable materials for constructing projects and buildings in a way that makes the learning more enjoyable and understandable.”

Building on the success of the elementary school program, we’re currently seeking corporate sponsorship for development of an interactive junior high smartphone/ tablet app, scheduled to launch in 2024.

This critical age, grades 6-8, is a period when kids are often beginning to explore career and continuing education paths. The program’s curriculum, with an engaging game format, is intended to increase their awareness of the possibilities in the forest products industry and provide learning opportunities designed for their level.

Helping kids learn the truth about trees is a task that takes many hands and minds to accomplish. NAFF has more than 600 supporters and there are plenty of

32 • the merchant magazine • april 2023 building-products.com

TRUTH ABOUT About Trees kits are available for free to teachers of grades K-3. The kits contain lessons and materials that underscore the importance of trees and wood products in everyday life.

THE WWPI GUIDE TO SELLING TREATED WOOD

EDUCATION initiatives by the North American Forest Foundation have a goal of reaching 1 million children by 2030 with important information about sustainable forestry and the value of wood products.

opportunities for you or your company to get involved:

• Volunteer to help teach the kit in the classroom—a worthwhile experience, highly recommended by members of our board who have taken that opportunity.

• Become a corporate sponsor of the Junior High App and reach potentially 12 million students with the truth about trees

• Help us reach 50,000 students through our Earth Month Kit Drive in April and Back to School Kit drive in August by making a donation today:

o $100 = educates 200 students

o $500 = educates 1,000 students

o $1,000 = educates 2,000 students

o $10,000 = Junior High App Sponsor (12 million students) MM

ALLISON DeFORD

Hi-bor® brand treated wood is a borate treated wood product designed for interior house framing in Hawaii. Hi-bor treated wood resists attack by Formosan and subterranean termites and numerous household insects and pests, as well as fungal decay. Hi-bor borate treated wood is also backed by a 20 year limited warranty*.

FirePro® brand re retardant treated wood is treated with a patented formulation that contains no phosphates and has been shown to exhibit exceptional re performance properties without compromising other critical engineering properties such as strength, durability, corrosivity, and hygroscopicity. FirePro treated wood is also backed by a 50 year limited warranty*.

Advance Guard® borate pressure treated lumber is recommended for sill plate, furring strips, joists, studs, roof trusses, blocking, rafters, beams, and other framing applications. Advance Guard is also recommended for fascia, trim, wall sheathing, roof sheathing, and sub- oors. Advance Guard borate pressure treated lumber is also backed by a lifetime limited warranty*.

building-products.com april 2023 • the merchant magazine • 33

Allison DeFord is the executive director of the North American Forest Foundation. For more info on NAFF and its education initiatives, go to www.northamericanforestfoundation.org.

* See product warranty for details. Hi-bor®, FirePro® and Advance Guard® treated wood products are produced by independently owned and operated wood treating facilities. Hi-bor®, FirePro® and Advance Guard® are registered trademarks of Koppers, Inc. ©10/2014 Providing Customer Satisfaction in All We Do At Royal Paci c you’ll pay no more, but get extra. We guarantee it. P.O. Box 75 • McMinnville, OR 97128 503-434-5450 • FAX: 888-TSO-WOOD (888-876-9663) 28770 Dike Road • Rainier OR 97048 503-556-1297 • Fax: 503-556-1709 Royal Pacific Merchant ad 9_14.indd 1 10/27/14 4:14:53 PM

SEALING THE DEAL

BY SARA GRAVES

IT WASN’T TOO long ago when a farmer’s word and his handshake were as binding as any signed contract. And though business is conducted differently today, for some companies, such as Farmer’s Building, Feed & Garden Supply, doing business honestly with others in mind is still how you seal the deal.

“My dad had many connections in the community… when he gave his word on something, he did it and he completed it and I think that there was a lot of respect in that sense,” said Mark Stutzman, second-generation owner of Grants Pass, Or.,-based Farmer’s. “My dad taught me that you’re only as good as your word, and if you can’t live on what you say that you’re going to do then you won’t be as successful as what you would be if you continue down that road.”

Having been raised in Grants Pass watching his father and mother, Leon and Luella Stutzman, run the company in the early 1960s, Mark knows what it takes to build a successful company.

“I have put sweat equity into it. There was no job that could not be handled by us boys. We would separate the lumber out because at the time when I was a young boy, it would come in multiple stacks of 8s-14s in one stack and you would have to divide it out, and then it would come in 16s-20s and you would have to measure that all out. Then, of course, the mills started doing that themselves when they had the green chains, but those were

part of the jobs that we did.”

Sixty years later, the Stutzman family has been involved with the company all but two years since it was founded. Leon and the pastor of the family’s church originally coowned the hardware store until the pastor sold his shares of the company to Leon.

The Stutzman family currently owns 100% of the business. Leon and Luella own a little over 50%, while Mark owns just under 50% of the business. “I have been managing the store full time since my oldest brother passed away in 2016. I run this business and I run the other two (sister companies) as well—Illinois

Valley Building Supply (Cave Junction, Or.) and Rogue Truss Systems (Grants Pass). I have all three of them now under me.”

Mark’s children are also involved in the business. His son, Grant, manages the marketing and advertising for the company, his eldest son is currently working at the truss plant along with his son-in-law, and his daughter, Mollie, who recently graduated from high school, is helping with advertising and social media.

Although the company has traditionally been stronger on the contractor side, it has more recently focused on the retail end. “We’ve switched more to a retail side now

34 • the merchant magazine • april 2023 building-products.com

------------| COMPETITIVE INTELLIGENCE ------------

ALTHOUGH it’s traditionally been stronger with pros, Farmer’s Building Supply has been increasing its focus on consumers of late. (Photo by Mollie Stutzman)

and have opened a garden center. We have added a door shop and rental, and repair different things in order to continue to drive people to the store,” Mark said.

All along, however, there’s been one large obstacle standing in their way to attract more customers—the Rogue River—which bisects Grants Pass.

“One thing about our store has been that we have been separated from downtown Grants Pass for our entire existence,” Mark explained. “The community of Grants Pass is separated by the Rogue River, which runs right in the middle of it. The city has worked to keep the businesses downtown vibrant and that’s been good, but I think they have missed a lot of us who have been on the other side of the river who have been a part of the community.”

Thankfully, things are looking up. “The town is starting to grow our way and so we’ve been in the heart of a lot of the uptake on the building and stuff… but as those people have gotten a little older, we’re having to work much harder in order to contin-

ue to attract people to come to the store.”

Yet, it’s the company’s honest approach to business and how they treat their customers, going above and beyond as much as possible to make others feel good, that has enabled Farmer’s to continue to attract new customers and retain its existing clientele.

“I almost always try to say good morning to somebody just to initiate a conversation or to talk to them and let them know that they are valuable,” Mark said. “Our customers are not just a number—they’re a valuable piece of the community and we want to serve them.”

He added, “We want to treat everyone the same way that we would like to be treated. Dad would go above and beyond. We live to serve and that’s been something that has been pounded into me since I was very small.”

The focus on serving and treating others well is not only a core foundation of the company, but of the Stutzman family as well. “I will tell you that we are a faith-based company.

We’ve been a faith-based company… I think a lot of it is the strength of our faith and we believe in prayer and the power of prayer.”

In response, Farmer’s staff and customers have helped the company grow by suggesting new avenues of

building-products.com april 2023 • the merchant magazine • 35

SECOND-GENERATION owner Mark Stutzman “lives to serve.” (Photo by Jillian Anderson)

business for the company to pursue.

One successful addition has been the horse tack and equine supplies. Farmer’s staffer Danielle Sandgren loves horses and knows a lot about them. She encouraged the company to market to that specialized clientele. Today, the tack section is the most popular tack section in the area, according to Grant. “People come and seek it out specifically from all around. (Danielle), who works it, does a phenomenal job. We get a number of customers because we add in some of those niche markets.”

“I think sometimes finding those key individuals to put into those departments to run them helps us grow ourselves as to who we are,” Mark added.

Another way the company has grown is by responding to the needs of the surrounding communities.

Illinois Valley Building Supply, for instance, in the city of Cave Junction, is approximately 30 miles from Grants Pass. Illinois Valley only has two hardware stores, but one full lumberyard. The building supply store is the only full lumberyard dealer in the city. A transfer truck services the location every day.

Similarly, the Rogue Truss Systems plant was started after the local residents complained to Leon that they weren’t satisfied with the existing truss business owner in their community. Those customers asked

Leon, “Why don’t you put up a truss plant? Let us buy trusses from you.”

Today, the truss plant services as far north as Roseburg, Or., nearly 70 miles away, and can accommodate trusses as large as 80 ft. “We’re about the only facility in the Southern Oregon area that can make something that big,” Mark added.

It was the company’s adaptability that helped Farmer’s succeed even when the competition entered the Grants Pass area. For instance, when Home Depot moved into town, people said Farmer’s was going to have a tough time competing. But Farmer’s knew differently.

“They’re on the other side of the river and their location is not very good. It’s tough to get into where things are at, and people do not like to cross the bridge because they know in town, it’s a headache. That’s why more stuff is coming to this side,” Mark explained.

Similarly, when the Grange Co-op moved right across the street, Leon asked Mark, “What are we going to do to fight those guys?” Mark’s reply was: “We’re going to let (them) bring the customers to us.”

And they did. When the Grange Co-op customers heard there was a feed store across the street, they began coming to Farmer’s. “We worked those customers as they stopped in, and we began to make lifelong friends that way and to service them

the way that we do it out of what we’ve learned here at Farmer’s,” Mark added.

Yet, the Stutzmans never failed to show their competition respect.

“I went to school with one of the guys that’s a competitor in my town,” Mark explained. “He and I have never sparred words (with) each other. We know what it is to take one another’s customers away and we do it by the old fashioned way—the hard work of going after them and trying to service them and not bashing one another.”

Looking ahead, Mark said the company would like to grow the truss and the retail side of the business. In addition, it is looking to modernize its store, and improve its security systems. And although the company is taking notes from big box stores, Grant said, “We are trying not to adopt a big box store look because that would really play with who we are as an entity—it would really affect our soul and what people have known us to be—but we’re certainly taking some big box ideas and adapting them and making them Farmer’s appropriate.”

The company is also getting ready for its 50th anniversary on June 17 in Illinois Valley. “We made our (Farmer’s) anniversary about the community because the community has supported us for 60 years,” Grant said. “We’re going to do the same thing out in the Illinois Valley for the 50th anniversary. It’s going to be Illinois Valley Building Supply’s 50th, but it’s also going to be 50 years in the Illinois Valley—and here’s how the Illinois Valley has grown.”

It should be quite the anniversary celebration if the Stutzman family has anything to say about it. As the Stutzmans would tell you, “We’ll get ’er done because you only have what your word is.” MM

36 • the merchant magazine • april 2023 building-products.com

OREGON DEALER tries to be a light to its community. (Photo by Mollie Stutzman)

SARA GRAVES

Sara Graves, senior editor, is interested in your story. Contact her at sgraves@526mediagroup.com.

800-562-8550

living doesn’t have to mean having an everyday life. MoistureShield is the only high-performance composite decking engineered to deliver 360-degree protection, 365 days a year. So you can enjoy the outdoors to the fullest, no matter where you call home. OutsideTheEveryday.com

GET OUTSIDE THE EVERYDAY Everyday

THE IMPORTANT FIRST CALL

------------ BY JAMES OLSEN

OUR FIRST CALL to a potential customer has more to do with how much business we will do with them than any other call. Can we dig out of the hole of a poor first call? Yes. I did it for years. But it takes a lot more time to overcome a bad first call. This is why when Master Sellers lose a big account they still have great years. Master Sellers know how to make a great first call that impresses potential customers.

Many sellers are so nervous and disorganized on their first call that they do the opposite. They turn off potential new customers. In addition, because the first call goes poorly and the proper information is not gathered, the second call is usually a re-prospect call, aggravating the buyer, or the seller offers something on the second call that the customer doesn’t use, which also leaves a negative impression.

Qualification — Not a Sales Call

Prospect calls are not sales calls. Most customers aren’t going to buy from us on a first call. It is a bit more common for distribution sellers because they can sell smaller quantities to local customers, but for sellers of truckload quantities to customers in regions all over the country, it is highly unlikely. The purpose of our first call is to qualify the account. Do they buy what we sell, do they buy it the way we sell it and do they buy enough?

We need to find out:

(1) What are the main three items you bring in?

(2) What grade(s) do you buy that in?

(3) What species?

(4) Mill preference: Are there any

mills you can’t use/prefer?

(5) Quantity per month?

This is 13 questions if we only find out their main three items. This is the minimum number of questions because there will often be follow up/ nuances to the answers—for example, if they use SPF: “Can they use Eastern/ Western/Euro/SPF-S?”

This is why it is important to ask a narrowing question (“What are your main three items you buy in truckload quantities?”). Most customers will give us three to five minutes, so we must be clear and concise with our questions.

If, after we have qualified the customer thoroughly we want to ask, “Is there anything you are looking for today?,” it is OK but only after having qualified the customer.

What’s Your Price On...?

If the customer asks this question before we’ve qualified them, we say, “Susan, I’d love to sell you something today, but that really isn’t the purpose of my call. I’m calling to find out a little bit more about you and your company to see if we will be a good fit going forward. After we find out the main items you’re bringing in, if you want to give me an inquiry, I’ll be glad to work up a professional quote for you.” Then continue qualifying the account.

WSIBFU? Moments

On every prospect call there will be a “Why Should I Buy From You?” moment. Customers will rarely ask this question directly, but in other ways:

• “Where are you calling me from?”

• “I buy direct.”

• “I’m happy with my current supplier.”

• “Your company burned me in the past.”

This is where we need to be prepared to tell our potential customer why they should do business with us. Most sellers wing it. And it sounds like it. I tell my students, “You’re smart enough to wing it and your customers are smart enough to know you are winging it!”

Many students will say, “I don’t want to sound scripted.” I tell them, “Your favorite singer, actor, comedian and athlete are all scripted. It’s called professional preparation.”

Master Sellers have planned for and are ready to impress their potential customers with their answer.

“We are a 35-person sales team. We move 50 million bd. ft. of lumber every month to the most competitive accounts in the nation. In addition, we are the largest importer of XYZ product. Because we move so much volume and because of the contracts we have in place, we get highly competitive pricing that we pass on to customers just like you.”

38 • the merchant magazine • april 2023 building-products.com

at (503) 544-3572 or email james@ realitysalestraining.com.

JAMES OLSEN James Olsen is principal of Reality Sales Training, Portland, Or. Call him

------------| OLSEN ON SALES

Distributed in Northern California and Nevada by Atlantic Forest Products • 1-1/2” RigidRim LVL 1.4E • 1-3/4” RigidLam LVL 2.1E • 1-1/2” RigidLam LVL studs • 3-1/2”, 5-1/4” and 7” RigidLam 2.3E beams Atlantic Forest Product-Stockton, CA inventories Roseburg RFPI-joist series 40, 70, 90. PinkWood I-Joist: PKI 23 Series. Rosboro X-Beam® glulams and Rim, Fire-Treated X-Beam. When you need creative solutions, call on Atlantic’s deep knowledge of Engineered Wood Product Lines to find the most effectie design for your project. Call our Engineered Lumber team at (888) 498-0756 afpcasales@atlanticforest.com One-Stop Shop for Engineered Lumber

Wholesale Distributor of Engineered Wood Products Northern California and Northern Nevada Roseburg I-joist and LVL • PinkWood I-joists Stock Architectural Glulams • Custom Glulams

Atlantic Forest Products

3 QUESTIONS: PELICAN BAY FOREST PRODUCTS’ RON HANSON

RON HANSON, president of wholesaler Pelican Bay Forest Products, Bend, Or., has seen the lumber industry at its highest highs and lowest lows and, after 52 years, continues to appreciate it all.

1 How did you get started in the industry?

Hanson: I started in 1971 working in sawmills during summer breaks while attending Oregon State University. My dad, Walt, managed mills and was a lumberman his entire career. My brother Doug and I are fourth-generation lumbermen and my daughter, Angie, whom I work with, is a fifth-generation lumberperson. I majored in history, but I knew I wanted to be in lumber sales. It took me seven long years to complete my education, as I continued to work in the lumber industry while pursuing my degree. My dad bragged to all his friends that I graduated from OSU in three terms: Nixon, Ford and Carter!

I started wholesaling lumber in 1979 at Forest City. What a great company to work for. I loved selling lumber and knew it would be my career. I’ve never had a day I didn’t want to go to work. I have no retirement plans to date and hope to never completely retire as I get paid to talk with my friends every day.

2 What have been the greatest challenges over the years?

Hanson: I’ve been very fortunate to start two wholesale companies. Our first was Pan Pacific Forest Products, which we started in 1987 and grew to over 50 traders. We were young, and it was exciting to build the company—great memories! I did not own that company and left in 1999 to start Pelican Bay Forest Products, which I do own. It’s been an awesome privilege to work with great traders and phenomenal administrative personnel, including my wife, Joni. We have also built terrific relationships with suppliers, customers and our bankers.

Both companies grew faster than our money supply. Until the last few years, cash flow has always been our biggest challenge. There have been a lot of sleepless nights over the years worrying about paying our suppliers on time, but we persevered and got it done. Electronic transfer of funds will create a challenge when cash flow tightens again. At this time, we have a $15-million credit line, which allows us to be competitive with larger trading floors. We have not borrowed any money for the last six months. Our industry is in the best financial shape I can ever remember. Business has been much easier the last few years, but it looks like we will have some challenges over the next couple years with a possible recession.

Another challenge our industry has is recruiting younger people.

Looking at trading floors a few years ago, we were an aging industry. Luckily we have reversed that trend and we now have the youngest group that we’ve had in 20 years. I continue to see that same trend at industry functions as well. It’s a great business for younger people with unlimited potential for careers.

3 What’s the story behind Pelican Bay?

Hanson: Pelican Bay was a lumber company in Klamath Falls, Or. I was born there and had family that worked at the mill. I just liked the name and decided to use it when we started in 2000. We’ve been able to grow to over 20 traders selling lumber across the U.S. and Canada. We have a great group of senior traders and young traders. Everybody’s different, with all types of personalities, and we all get along—this helps breed success.

As our wholesale industry has morphed, we have become a more valuable partner to the suppliers and customers. We, as wholesalers, provide an important function in the distribution of forest products. What a great Industry to be a part of for 52 years.

– Send suggestions for future interviews to David Koenig at dkoenig@526mediagroup.com.

40 • the merchant magazine • april 2023 building-products.com

------------| 3 QUESTIONS

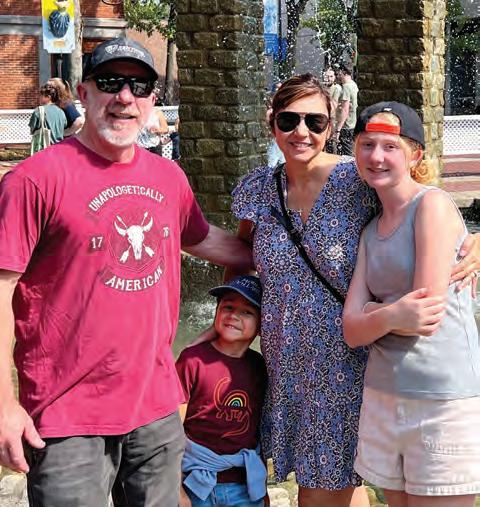

Pelican Bay Forest Products’ Ron Hanson and Joni, his wife of 47 years

Call us at 707.894.4241 Visit us at buyRedwood.com DECKING Composite can’t compare. Like the foods we buy, when it comes to decking, we want natural and real. Redwood is always available in abundance of options. So stock the shelves! Unlike mass-produced and inferior products, Redwood is strong, reliable and possesses many qualities not found in artificial products. They maintain temperatures that are comfortable in all climates. Redwood Empire stocks several grades and sizing options of Redwood. REDWOOD

EMPLOYEE RETENTION

------------ BY PAIGE McALLISTER

MOST EMPLOYERS have felt the impacts of the tight labor market. Employees have been resigning at a rate of over 4 million per month for over a year. Low unemployment rates continue across the country. The labor market participation rates are reduced by 8 million employees due to factors like COVID, immigration, and employees who have left the workforce.

Adding to this, the impacts of replacing an existing employee can run up to two times that position’s salary and result in lost productivity as well as lower morale from other employees while that position remains open.

All of these factors make retaining current employees a proactive measure employers should prioritize in 2023 and beyond.

While the possibilities are unlimited as to what you can offer and what your employees will find valuable, here are some ideas to consider depending on your workforce, goals, and budget:

Compensation

• Increase wages or salaries

• Offer bonuses (“just because,” performance, retention, referral)

• Offer commission opportunities

• Restructure compensation

Considerations: While there may be a positive impact to increased wages or salaries at first, the impact may be short-lived once the increase is divided per paycheck or has been long-spent. This is especially pronounced given the increasing costs of living that many employees face.

Benefits

• Offer additional traditional plans (medical, dental, vision, life, STD, LTD)

• Add creative benefits (pet insurance, cancer coverage, long-term care insurance, college savings program, health advocate, HSA/FSA)

• Offer an employee assistance program (EAP)

• Offer a retirement savings plan or profit-sharing program

• Increase employer-paid portion toward premiums or 401(k)-matching

Considerations: Employees value protections that fit their life; however, different employees have different needs so it will be harder to find a one-size-fits-all solution. Better coverage often means more cost to the company and the employees, which may limit options and participation. Also, new or changing benefit plans usually require more time and effort to research and implement.

Time Off

• Give more paid time off (vacation, sick, personal days, holidays, “unlimited”)

• Make current paid time off more flexible (allow carry-over, require less notice)

• Add “personal holidays” so employees can recognize holidays or events that are important to their religion, culture or lifestyle without using vacation

• Offer creative time off (pet bereavement, school activities, volunteering, blood, organ or bone marrow donation)

Considerations: Small time-off policies can be easier and quicker to implement and may give more impact throughout the year as they help employees with their work-life balance. However, different employees will value different time off. And, you need to make sure that this time off can be balanced with meeting operational demands.

Perks

• Offer healthy-at-work options (healthy snacks, vending machines, desk or office exercise equipment, scheduled walk breaks)

• Implement socially-conscious programs (recycling, community service days, fundraiser walk teams)

• Offer cost- or time-savings programs (free or discounted parking or public transportation, warehouse store memberships, on-site car detailing, errand-runner services, vendor/supplier partner discounts)

• Offer life-balance perks (gym memberships, daycare

42 • the merchant magazine • april 2023 building-products.com