OUTDOOR LIVING SPECIAL ISSUE: DESIGN • MATERIALS • SUPPLY • SALES May 2023 THE VOICE OF LUMBER MERCHANTS AND BUILDING MATERIAL DEALERS & DISTRIBUTORS IN THE WEST — SINCE 1922 Digital Edition Sponsored by SUSTAINABLY SOURCED NATURALLY STRONG WFP COAST TIMBERS - DOUGLAS-FIR For more information about WFP Coast Timbers - Douglas-Fir, visit westernforest.com Your next project deserves sustainably sourced timber from WFP Coast Timbers. Our Douglas-fir timbers are held to the highest manufacturing and quality standards for long-lived durability and elegant charm. Photo Credit: Island Timber Frame

Ltd.

The Most Valuable Player on Your Next Job

Introducing FastenMaster MVP: the ultimate multipurpose wood screw that combines ease of use, durability, and versatility, making it the MVP for all your wood construction projects. MVP’s ProjectLife™ coating offers superior corrosion protection in pressure treated applications and is guaranteed for the life of the project. Visit your local lumberyard to try it for yourself!

SCAN

To learn more about MVP and watch a video

Scan to learn more about MVP and watch a video

Scan to watch a video of MVP in action

FastenMaster.com 800·518·3569

TORX® ttap® Drive

wobble-free

ProjectLife™ Coating superior

SureSink™ Head prevents

SureStart™ Point for

starts

System

drive

protection

spin-out

fast

NEW

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Claudia St. John, Dave Kahle

CONTRIBUTORS

Susan Cho, Paige McAllister, Joe Raboine, Tyler Sharpe

ADVERTISING SALES

(714) 486-2735

Chuck Casey ccasey@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

VIRTUAL EVENTS

Alek Olson • aolson@526mediagroup.com

CIRCULATION/SUPPORT info@526mediagroup.com

A PUBLICATION OF 526 MEDIA GROUP, INC.

151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 Phone (714) 486-2735

CHANGE OF ADDRESS Send address label from recent issue, new address, and 9-digit zip to address below.

POSTMASTER Send address changes to The Merchant Magazine, 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626. The Merchant Magazine (ISSN 7399723) (USPS 796-560) is published monthly at 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 by 526 Media Group, Inc. Periodicals Postage paid at Newport Beach, CA, and additional post offices. It is an independently-owned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 western states.

Copyright®2023 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. We reserve the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles are intended for informational purposes only and should not be construed as legal, financial or business management advice.

Volume 102 • Number 5

4 • the merchant magazine • may 2023 building-products.com SUBSCRIBE TODAY OUR MARKET MOVES QUICKLY—SO DON’T GET LEFT BEHIND! The Merchant is available on a qualified requester basis to senior management of U.S.-based dealers and distributors specializing in lumber and building materials, and to others at the rate of $22 per year. Subscribe now at www.building-products.com/subscribe. SUBSCRIBE NOW AT WWW.BUILDING-PRODUCTS.COM/SUBSCRIBE THE MERCHANT MAGAZINE SUBSCRIBE TO RECEIVE PRINT, DIGITAL, ENEWSLETTER & MORE! The LBM supply chain’s leading publication for qualified industry decision makers! • Update your subscription • Sign up key colleagues • Enroll multiple locations

6 • the merchant magazine • may 2023 building-products.com ------------| CONTENTS May 2023 STAY CONNECTED ON SOCIALS: @BPDMERCH THE OFFICIAL PUBLICATION OF PROUD SUPPORTERS OF VOL. 102 • NO. 5 |-----------DIGITAL EDITION CHECK OUT THE WWW.BUILDING-PRODUCTS.COM FEATURES 10 FEATURE STORY 2023 outdoor living forecast eyes privacy, sustainability 12 INDUSTRY TRENDS New rules could eventually tighten imports of hardwood decking 14 PRODUCT SPOTLIGHT What’s hot in pavers and patios 16 INDUSTRY TRENDS State of supply for the millwork industry OUTDOOR LIVING SPECIAL ISSUE: May 2023 SUSTAINABLY SOURCED NATURALLY STRONG WFP COAST TIMBERS - DOUGLAS-FIR For more information about WFP Coast Timbers Douglas-Fir, Your next project deserves sustainably sourced timber from WFP Coast Timbers. Our Douglas-fir timbers are held to the highest manufacturing and quality standards for long-lived durability and elegant charm. COMPETITIVE INTELLIGENCE At home with Indiana’s Tweedy Lumber 3 QUESTIONS Meet PLM’s John K. Smith EVENT RECAP West Coast Lumber & Building Material Association finds new site for Southern California golf tournament 18 24 60 SPECIAL REPORT 38 NAWLA INSIDER Special section from the North American Wholesale Lumber Association spotlights members and previews upcoming events DEPARTMENTS 08 ACROSS THE BOARD 22 OLSEN ON SALES 26 TRANSFORMING TEAMS 28 SELLING WITH KAHLE 34 NEWS BRIEFS 36 MOVERS & SHAKERS 53 NEW PRODUCTS 59 DATEBOOK 65 ADVERTISERS INDEX 64 IN MEMORIAM 66 FLASHBACK 16 12 10

FINDING YOURSELF

BY PATRICK ADAMS

A“MILESTONE BIRTHDAY” was coming up, so I was excited to plan something special for the most important person in my life. Since we met when she was 19, she has mentioned her “bucket list” included staying in “one of those island places where the bungalows were right over the ocean.” Since she doesn’t like surprises, I gave her some notice of my intentions and her “mother reaction” was not what I expected. Instead, she shared that she would prefer something a bit closer to home. To my surprise, she ended up picking a ranch in western Montana… in March.

Now, for me this is heaven! Not unlike my favored elk hunting locations, I knew the area—high mountain country—cold, pure, unspoiled and, in winter, not many people (i.e., tourists). I sat puzzled for many weeks at her selection wondering if I should attempt to save her from herself. Whether it was my trust in her, or my own selfishness, away we went to Montana for some time at a ranch without the kids in tow (a rare treat these days).

During the flights, my mind was racing back over all of the packing advice I gave her in hopes that I could make what she was about to land in at least bearable. Thermals, wool socks, good boots, head covering… the list went on, then back through again. As we flew east from Seattle, the scenery out of the plane started to reveal the landscape that I have found must have been my home in past lives. Have you ever been somewhere that almost instantly you feel yourself change inside? Your mind stops racing, your pulse rate drops and that huge smile that’s inside starts to creep to the outside. As we landed and made the drive to Phillipsburg, she marveled at the raw beauty of the landscape.

Together, we explored and did things that normally I wouldn’t have imagined her wanting to sign up for. We went fly fishing—in 28° weather and she caught a rainbow trout! We went horseback riding in untouched snow and she tried her hand with both clays and long rifle. Each night for dinner, we walked about a half-mile from our cabin to the lodge. Half the time it was snowing and every time it was cold. There was a small river directly behind our cabin that each early evening, wildlife would wander down to for their evening’s hydration and grazing.

The entire time we were on the move, mostly on foot and always in the cold. There were many times I considered how far away from her “bucket list” this trip was. But each time I looked over at her, she wasn’t shivering or grimacing about trudging through the muck. Her eyes were up and constantly scanning like a bright-eyed kid. When she hooked the trout in that river, she immediately looked over to me beaming with pride and a smile that took me back to when she was 19. When we rode horseback side by side, without another human in sight, it reminded me of those walks we used to take on the beach as kids because I didn’t really have the funds for much more on date nights back then.

Almost the minute we got home, we fell back into our routines and managing the chaos of our wonderful, blessed life—business, kids, dogs, laundry. Since we’ve been home, I’ve thought about that trip so many times I can’t begin to count. Yes, I’ve thought, “Why can’t every day be like that? Maybe we should just move somewhere like that.” But I know that’s not realistic on countless levels. I’ve thought of how I can be more of that person I was during our trip in Montana every day, regardless of where I am. But more than anything, I keep thinking about whether she chose that trip for her, or for me? Did she really give up the island bucket list trip because she was curious about Montana, because she didn’t want to be that far from the kids, or because what was on her bucket list was finding ways to find ourselves again? I’ll probably never know.

In this frantic life of goals that we pursue, it is easy to lose yourself. It’s easy to blame it on stress or other demands in life and after long enough, it’s easy to lose sight of the person you really are. It sometimes feels even more stressful planning a trip away from your responsibilities when what you should be doing is working. But, do it anyway! Find yourself… and then fight to hold on to that person regardless of where you are.

Thank you for the privilege of serving you and this great industry. Enjoy your spring and get out there!

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

8 • the merchant magazine • may 2023 building-products.com ------------| ACROSS THE BOARD

GET OUTSIDE THE EVERYDAY

Everyday living doesn’t have to mean having an everyday life. MoistureShield is the only high-performance composite decking engineered to deliver 360-degree protection, 365 days a year. So you can enjoy the outdoors to the fullest, no matter where you call home.

OutsideTheEveryday.com

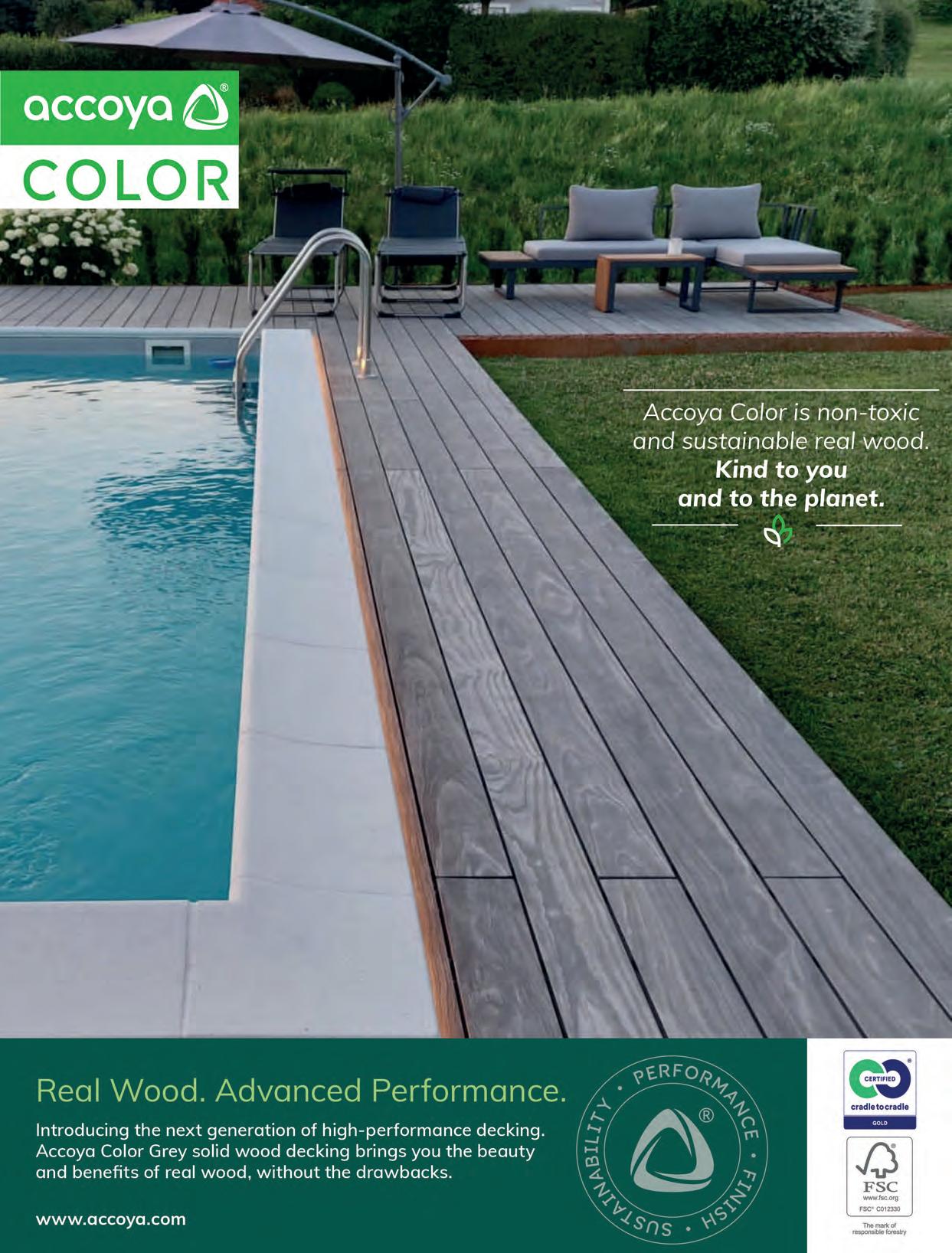

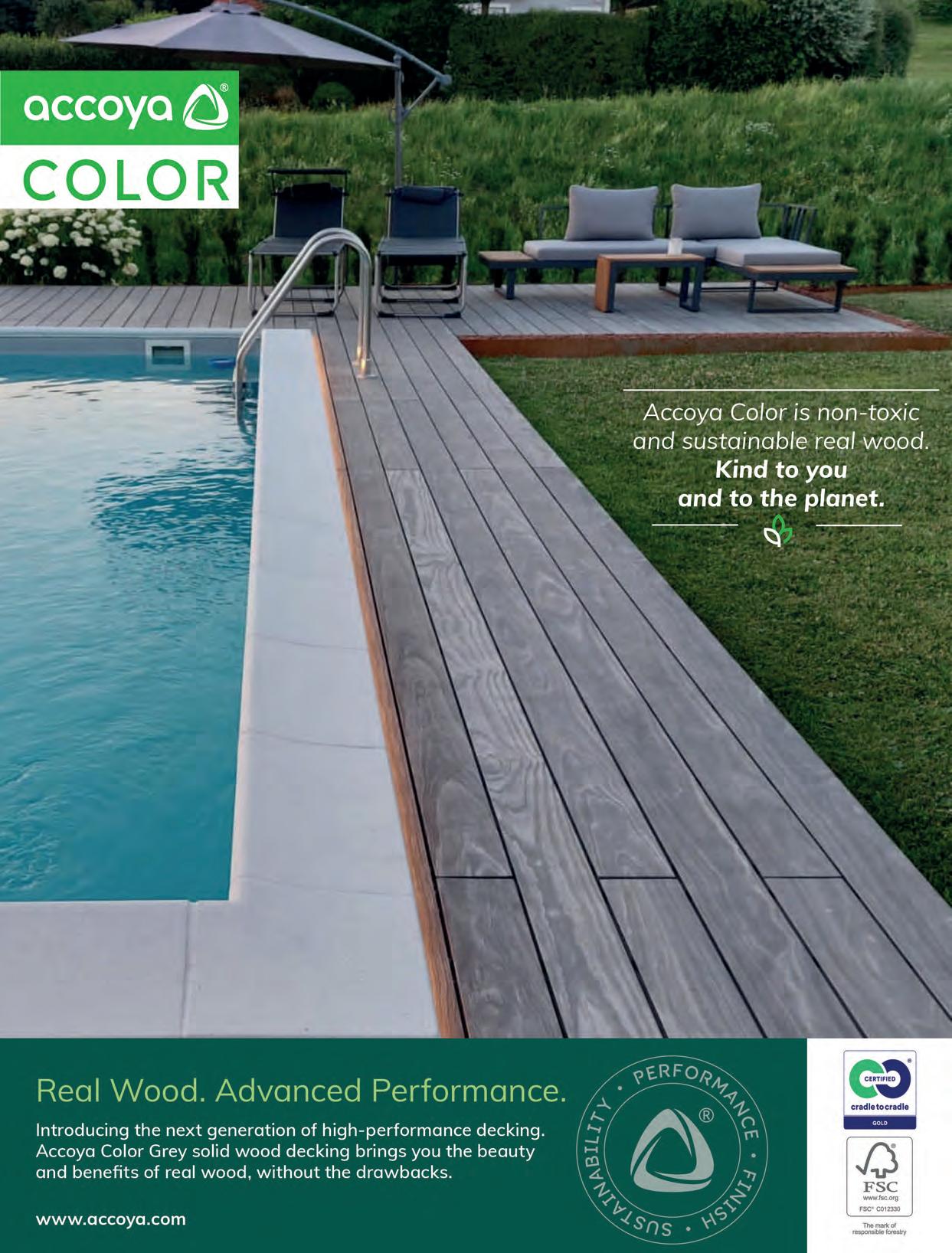

2023 OUTDOOR LIVING FORECAST

ACCORDING TO to leading real estate website Zillow, a functional outdoor space is the most soughtafter amenity among today’s homebuyers. For homeowners looking to make the most of their outdoor spaces this year, Trex Co. has just released its 2023 Outdoor Living Trends Forecast. Based on input from consumers, contractors, retailers and industry insiders, along with its own expertise, this annual report projects backyard and outdoor trends for the year ahead.

“Spending time with friends and family has never been more valued and backyards are often the epicenter for home entertaining,” said Leslie Adkins, vice president of marketing and ESG development for Trex.

BIOPHILIC DESIGN, PRIVACY, SUSTAINABILITY LEAD TOP TRENDS

“Based on what we are seeing and hearing from our consumers, trade and retail partners, the focus on outdoor living shows no signs of slowing. As we head into peak outdoor living season for 2023, we already feel the momentum and demand building as homeowners continue to invest in optimizing their outdoor spaces as functional and stylish extensions of their homes.”

Following are six trends that Trex expects to shape backyards in 2023:

1. Light Neutrals

The biophilic influence of nature on home design—both indoors and out—will be evident in everything from material choices to colors. According to this recent online poll,

light neutral hues are expected to permeate home exteriors in 2023 due to their ability to create a sense of calm and serenity.

2. Mixed Materials

Gone are the days of matchymatchy monotony. Today’s homeowners are embracing eclectic design schemes with lots of visual interest created by juxtaposing materials like concrete and composite, wicker and aluminum, copper and stone—as well as mixing colors and patterns for added personality and visual intrigue.

Integrating nature-inspired materials can complement a home’s natural surroundings and infuse creative contrast with pillows, cushions, furnishings and decorative accents.

10 • the merchant magazine • may 2023 building-products.com ------------| FEATURE STORY

SOFT NEUTRALS are in demand for home exteriors. Trex Transcend Lineage decking features four nature-inspired hues, including a creamy taupe, deep mocha, light coastal brown, and airy mountain gray. (Photos by Trex)

3. Sustainable Selections

Sustainability is no longer a “nice to have,” but a meaningful requirement among increasingly eco-conscious consumers. Purchases made with sustainability in mind will remain a priority in 2023—and beyond—as more and more homeowners purposefully consider how to reduce their own environmental impact.

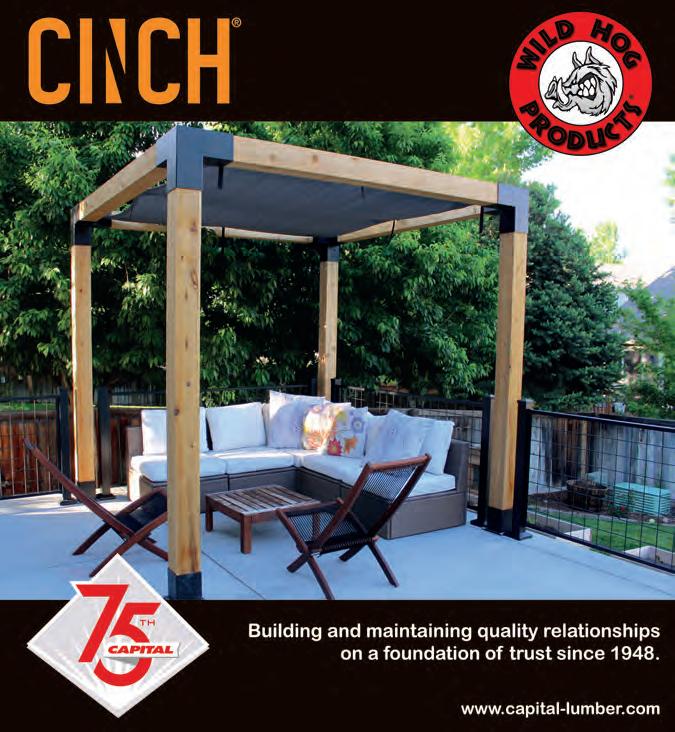

4. Stylish Seclusion

Privacy remains a priority with more than a quarter of all Zillow listings now highlighting this as a selling point. This penchant for stylish seclusion is driving demand for products like fencing, pergolas, privacy panels, and lattice, which allow contractors and homeowners to enhance the sense of sanctuary with products that are visually appealing, durable and easy to maintain.

Incorporating plants and greenery is another clever way to enhance privacy while tapping into the design and wellbeing benefits of biophilic design. Add color and creativity with hanging baskets, planter boxes, pouches or a trellis dripping with flowers or ivy.

5. Mood Lighting

Faced with rising inflation, homeowners will be looking for small home investments that make a big impact. Lighting has the ability to completely change the look and feel of an outdoor space without breaking the bank. Candles, tiki torches, string lights, and fire features add warmth and ambiance to an outdoor space and can help to extend the time you are able to spend outdoors—both in hours and weeks.

For even greater impact, deck lighting can take your outdoor space to a whole new level, enhancing style and sophistication as well as safety. Trex offers a plug-and-play system that is easy to install on a new or existing deck. It even comes with a new Wi-Fi lighting controller for optimal convenience and control.

6. Added Function and Value

Homeowners also will be looking for improvements that add both function and value to their homes. One such investment for those with elevated decks is adding an under-

deck drainage system. Designed to divert water away from the foundation, these systems protect a deck’s substructure from moisture damage while also creating dry space beneath the deck surface that can be used for any number of purposes, from storing seasonal items to serving as bonus living area.

Some systems, such as Trex RainEscape, install above the joists of a deck’s foundation, allowing for the addition of electrical and gas lines to power ceiling fans and lighting, as well as outdoor kitchen and entertainment components, creating outdoor spaces with the function and finished look of an interior room. MM

building-products.com may 2023 • the merchant magazine • 11

MIXED MATERIALS that result in eclectic design schemes are all the rage.

MOOD LIGHTING can be achieved through candles, tiki torches, string lights, fire features, and—most impactfully—deck lights.

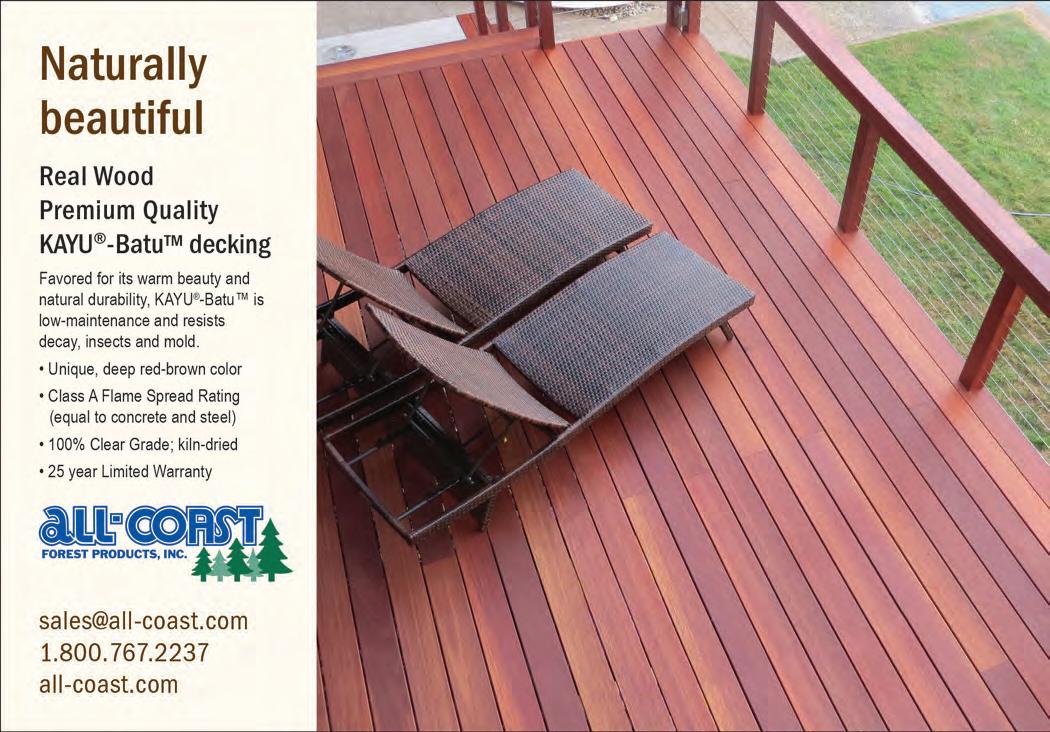

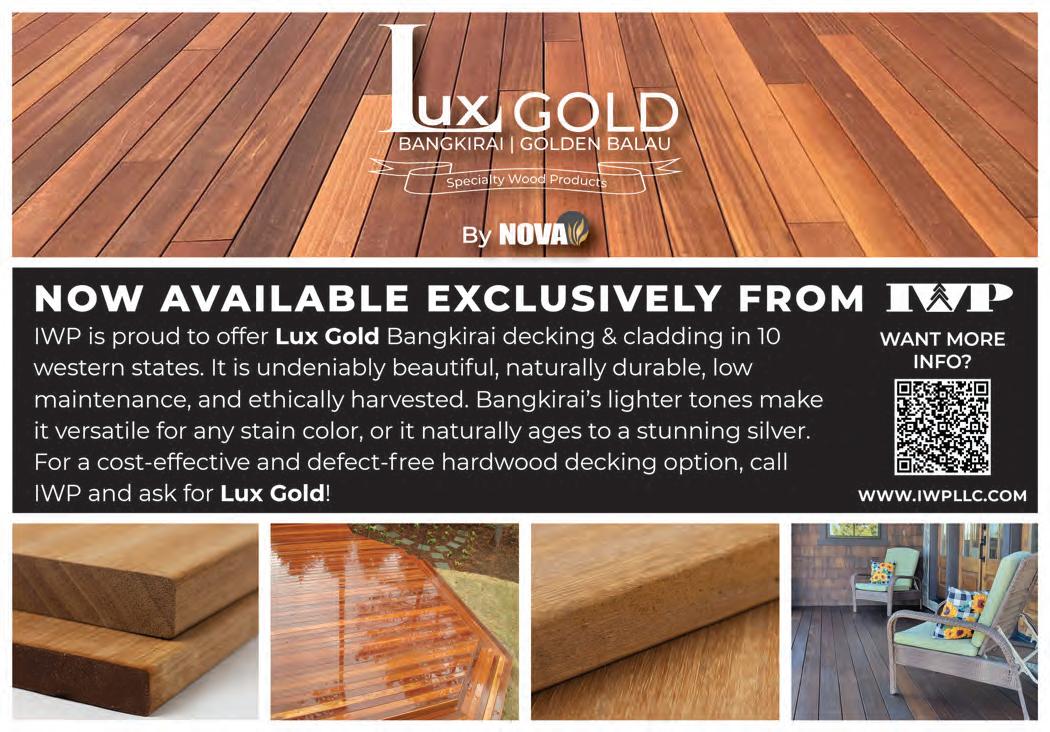

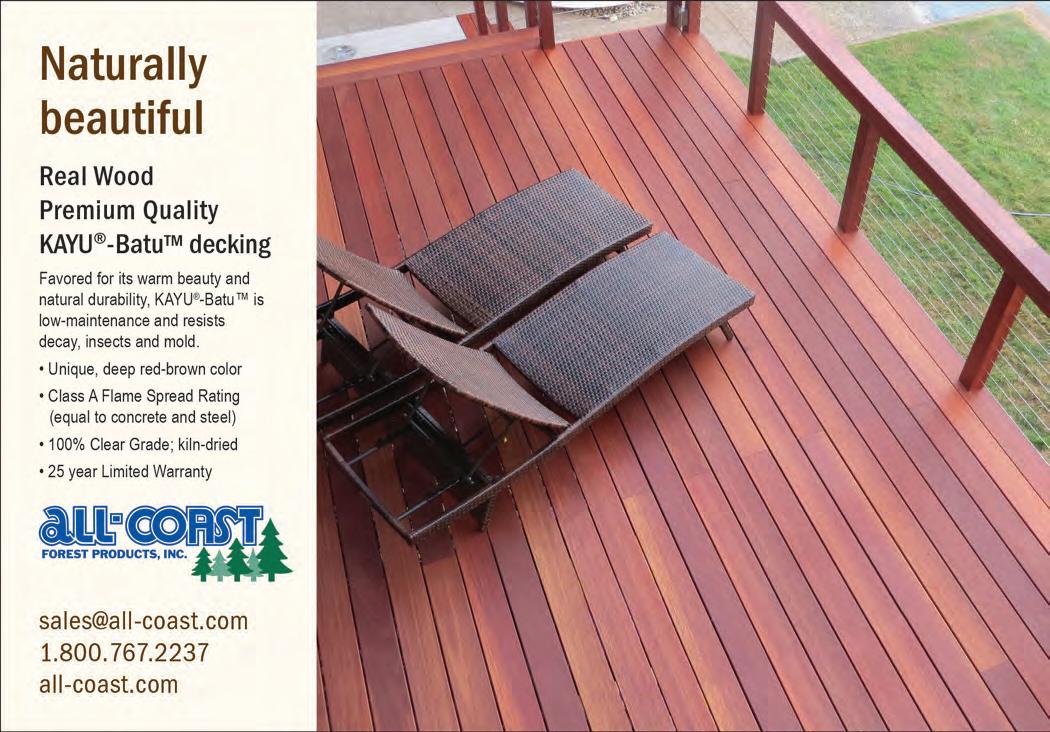

IPÉ IN STOCK... FOR NOW

------------ BY DAVID KOENIG

SIX MONTHS ago, CITES (the Convention on International Trade in Endangered Species of Wild Fauna & Flora) voted to add the South American hardwoods ipé and cumaru to its list of protected species. Some suppliers are warning that the ruling will tighten supply and increase prices of imports made with the tropical species.

So far, there appears to have been little immediate change. Several of the leading suppliers of ipé—including Redwood Empire, J. Gibson McIlvain, and Tropical Forest Products—say the new CITES requirements should integrate seamlessly into their current third-party certification systems.

Ipé and cumaru were added to CITES’ Appendix II list of potentially

RECENT CITES RULING MAY IMPACT SUPPLY, PRICE IN THE FUTURE

threatened species, not its Appendix I list of critically endangered species. Appendix II species are not considered endangered, but rather “in danger of becoming endangered,” and can continue to be harvested, exported and sold under certain conditions.

The idea is to place controls over their trade so they don’t become over-utilized to the point that they one day do become endangered.

Most noticeably, the ruling will result in an extra layer of paperwork: an export permit. This is in addition to current requirements to meet the Lacey Act.

“We do expect that this additional documentation could cause some delays in export,” notes Shannon Rogers, J. Gibson McIlvain. “Expect

this to cause shortages in supply here in North America. Ultimately, it is a question of whether or not a bottleneck will slow things down. Brazil has stated they will be requiring on-site inspections of export material in order for the permit to be issued. Depending on the size of that inspection team, this could cause a significant delay.”

CITES’ implementation deadline is 24 months—the requirements don’t take effect until the end of next year. However, Brazil—the leading source of ipé—intended to start requiring CITES permits by July 1, 2023.

Redwood Empire’s buyer in Brazil was doubtful the Brazilian Forestry Ministry had the ability to speed up issuing of certificates that quickly. Currently, Brazil requires CITES permits for only two species—cedar and mahogany—and issuing them can take months.

“The concern is the processing time,” says Redwood Empire’s Sean Burch. “I think there is a enough ipé stateside to handle this season’s demand and to stay ahead of delays.”

If this were a decade earlier, when ipé burst onto the American decking scene, the new requirements may have had a bigger effect. But sales volumes are now such that suppliers like Redwood Empire have been able to maintain sufficient inventories. “The footprint is smaller, due to its price and alternative species,” Burch explains.

The reality is that neither ipé nor cumaru are scarce—a state the new regulations were intended to make sure continue. MM

12 • the merchant magazine • may 2023 building-products.com

------------| INDUSTRY TRENDS

IPÉ DECKING remains in plentiful supply, but coming regulations could slow availability and increase prices in future years. (Photo by Nova USA)

Fresh ideas for home improvement.

Strength and selection go together with Outdoor Accents® decorative hardware from Simpson Strong-Tie. We’re always expanding our Mission Collection ® and Avant Collection™ lines with new products and accessories, making it easy to enhance outdoor structures and living spaces. Both feature an innovative hex-head washer and fastener combo that looks like a bolted connection but installs as simply as a screw. It’s the only approved fastening solution for Outdoor Accents connectors. Plus, our code-listed connectors and fasteners are rigorously tested for performance. So whether your customers are building a planter box or a pavilion, it will be strong, safe and beautiful for years to come.

To see our complete lines of Outdoor Accents decorative hardware, visit go.strongtie.com/outdooraccents or call (800) 999-5099.

©2023 Simpson Strong-Tie Company Inc. OA23-D Mission Avant Outdoor Living Solutions | Products, Software and Service for Smarter Building

own contractors

Having

Prioritizing Sustainable Products

Environmental concerns will remain an important conversation around the world, making it essential

March/April 2023 | Deck Specialist | 13

12 | Deck Specialist | March/April 2023

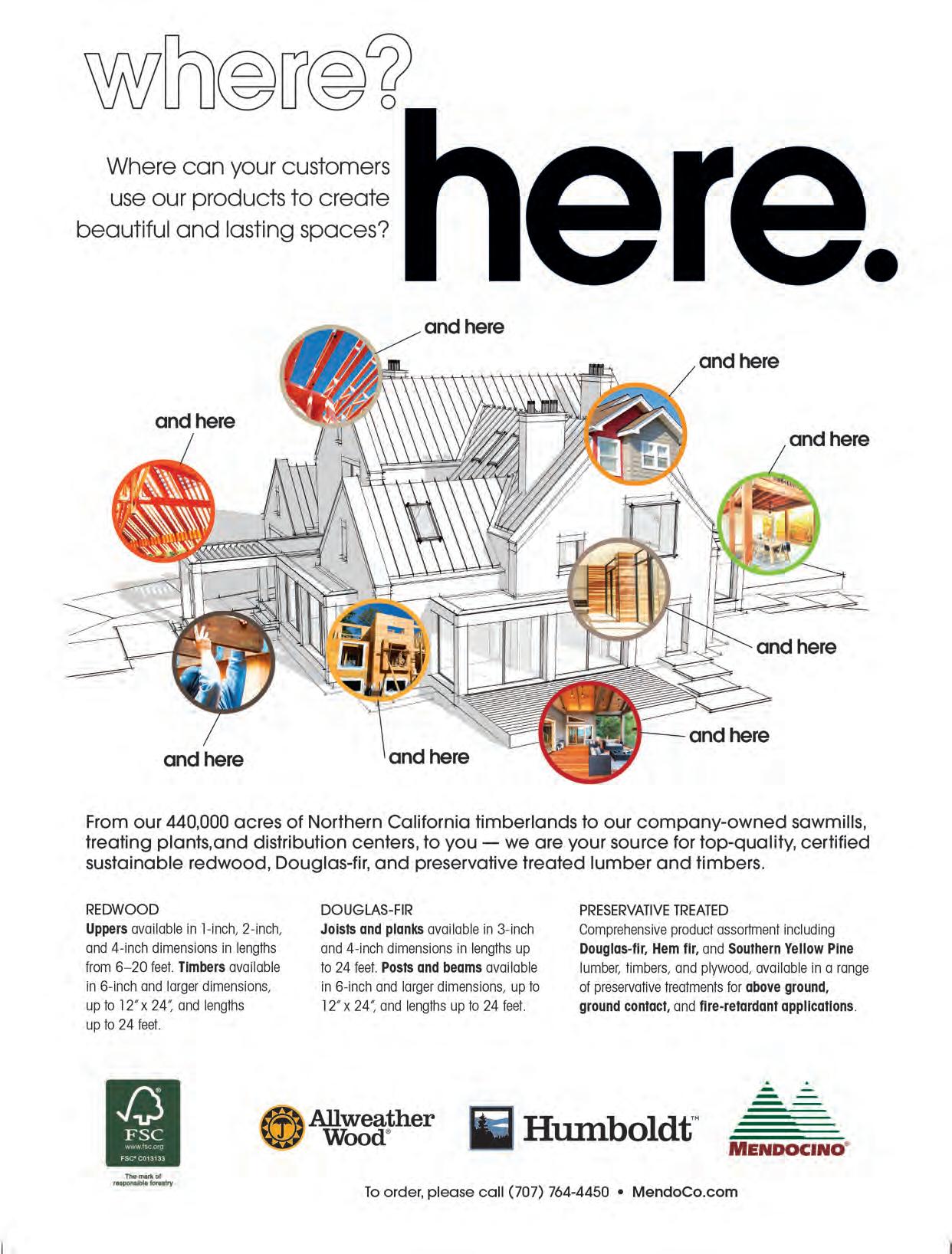

WHAT’S HOT IN PAVERS AND PATIOS

------------ BY JOE RABOINE

While for many are more door we perform working—meaning on their al for

Updating, spaces off their ing design opportunity create textures There popular you ule this Adding Clients est to choosing their of

OUTDOOR LIVING remains a high priority for homeowner investment. According to a study published by Angi, 19% of all home improvement spending by 2027 is expected to go toward outdoor improvements— specifically what they call “outdoor leisure.”

While outdoor leisure certainly is a catch-all term for many of these renovations, outdoor living spaces are more than just areas to lounge and relax. Outdoor living encompasses many of the same activities we perform indoors—like cooking, exercising and even working—meaning homeowners are looking to expand on their outdoor spaces to make them more functional for everyday life.

Updating, renovating and building

these outdoor spaces provides a space where contractors can show off their creative prowess. With new trends influencing design and construction, you have the opportunity to work together with your clients to create a stunning space using different materials, textures and more.

There are a few key trends we expect to be heavily popular in 2023 in terms of hardscape design.

Adding Color and Texture

Clients today are looking to add more visual interest to make their spaces truly unique. As opposed to choosing just one product to cover the majority of their outdoor surface area, they are looking for a mix of different colors, patterns and textures.

Combining materials such as wood, composite decking, textured pavers, and even metal or glass elevates and adds more depth to spaces that may otherwise feel flat and too linear. Integrating more color and texture is a natural extension of the popular modular design trend, as it layers in even more dimension.

Hardscape manufacturers are capitalizing on this trend, developing new textured pavers that mesh with any design style. They can be used on their own or paired with other paver colors and textures to create one-ofa-kind designs and patterns.

With color and texture being the top deciding factor for homeowners selecting pavers, you can step into the role of an interior designer.

14 • the merchant magazine • may 2023 building-products.com ------------| PRODUCT SPOTLIGHT

more popmore this

contractors around to for checker and includthat projsurvey,

GEOMETRIC pavers in related tints of the same color family create a one-of-a-kind pattern.

2/10/23 10:56 AM all home ed to what

different

COLOR and texture will be the top deciding factors when homeowners are choosing pavers this year.

DS Mar Apr 2023 FINAL.indd 12

GEOMETRIC pavers in related tints of the same color family create a oneof-a-kind pattern. (Photos by Belgard)

COLOR and texture will be the top deciding factors when homeowners are choosing pavers this year.

2023 Paver & Patio Designs

you look at popular design choices and elements that the exterior.

Combining materials such as wood, composite decking, textured pavers, and even metal or glass elevates and adds more depth to spaces that may otherwise feel flat and too linear. Integrating more color and texture is a natural extension of the popular modular design trend, as it layers in even more dimension.

Contractors can also use the excitement around colored and textured pavers to elevate projects to the next level. One option is incorporating colors and designs that can double as an outdoor game for families to enjoy, such as a chess board or checker pattern. Homeowners are looking to create fun and entertaining spaces for children and guests by including games like bocce ball, checkers or Scrabble, that are integrated into their outdoor living area.

By Joe Raboine Photos by Belgard

Overall, hybrid spaces combining multiple features make outdoor living areas feel more cohesive. For example, a beautiful lounge area can also include outdoor kitchen or gardening elements that are a source of food for the family. Homeowners want to expand their space to prioritize functionality to best suit their family’s needs.

the variety of paver materials available to build both the patio and base of the planters. Products, such as concrete panel systems, which align well with popular modern design styles, are perfect for creating raised patio garden beds.

Hardscape manufacturers are capitalizing on this trend, developing new textured pavers that mesh with any design style. They can be used on their own or paired with other paver colors and textures to create one-of-a-kind designs and patterns.

With color and texture being the top deciding factor for homeowners selecting pavers, contractors must step into the role of an interior designer. Having that extra knowledge to consult homeowners on more complex design decisions can give contractors an edge and create an additional selling point for your business.

Gardening for Functional Living

Functionality is a top priority in outdoor living projects. According to the same Angi survey, 26% of projects in the last year were focused on creating spaces that better met lifestyle needs. This now includes outdoor spaces so homeowners can spend more time in nature.

Contractors can also use the excitement around colored and textured pavers to elevate projects to the next level. One option is incorporating colors and designs that can double as an outdoor game for families to enjoy, such as a chess board or checker pattern. Homeowners are looking to create fun and entertaining spaces for children and guests by including games like bocce ball, checkers or Scrabble, that are integrated into their outdoor living area.

With this continued interest in connecting with nature, gardening is seeing a resurgence. More people aim to grow their own produce at home, as well as add decorative plants around patios, decks and walkways.

Raised and vertical gardens are well suited for patios, especially with

Gardening for Functional Living

OUTDOOR

Prioritizing Sustainable Products

ing energy and waste. New products continue coming to market that prove homeowners are understanding the value of taking care of their outdoor spaces, and contractors are prioritizing high quality products that have longer lifecycles.

LIVING remains a high priority for homeowner investment. According to a study from Grand View Research published by Angi, 19% of all home improvement spending by 2027 is expected to go toward outdoor improvements—specifically what they call “outdoor leisure.”

Environmental concerns will remain an important conversation around the world, making it essential

Functional and biophilic design trends have encouraged homeowners to consider patios and porches as true extensions of their home, blending the indoor and outdoor spaces to create one cohesive unit. This shift in perspective can be observed when you look at popular design choices and elements that homeowners are integrating into their spaces, like mixed materials or folding glass walls that connect to the exterior.

While outdoor leisure certainly is a catch-all term for many of these renovations, outdoor living spaces are more than just areas to lounge and relax. Outdoor living encompasses many of the same activities we perform indoors—like cooking, exercising and even working—meaning homeowners are looking to expand on their outdoor spaces to make them more functional for everyday life

If you are looking for ways to integrate sustainability practices into your business, start by recommending products that prioritize durability and have a long life cycle. Also, local requirements regarding permeable pavers have become more common as communities realize the importance of water runoff and planning for city expansions, so stay up to date with local legislation and community guideline updates.

Updating, renovating and building these outdoor spaces provides a space where contractors can show off their creative prowess. With new trends influencing design and construction, contractors have the opportunity to work together with their clients to create a stunning space using different materials, textures and more.

Overall, hybrid spaces combining multiple features make outdoor living areas feel more cohesive. For example, a beautiful lounge area can also include outdoor kitchen or gardening elements that are a source of food.

Prioritizing Sustainable Products

Environmental concerns will remain an important conversation around the world, making it essential that the outdoor living industry adapts to meeting new goals regard-

COLOR and texture will be the top deciding factors when homeowners are choosing pavers this year.

Functionality is a top priority in outdoor living projects. According to the same Angi-published survey,

There are a few key trends we expect to be heavily popular in 2023 in terms of hardscape design, which you can incorporate into the projects on your schedule this year.

Adding Color and Texture

Overall, outdoor living investments will remain a high priority for homeowners in 2023, especially in terms of hardscape products like pavers and other patio elements. Continued interest in outdoor living opens the door to more creative design ability and unique challenges pushing dealers to think outside the box to meet all the homeowner wants and needs. MM

– Joe Raboine is director of residential hardscapes at Belgard (belgard.com).

Clients today are looking to add more visual interest to make their spaces truly unique. As opposed to choosing just one product to cover the majority of their outdoor surface area, they are looking for a mix of different colors, patterns and textures.

building-products.com may 2023 • the merchant magazine • 15

INTEGRATING a functional outdoor fire pit with stylish geometric pavers completes this year-round space.

March/April 2023 | Deck Specialist | 13

GEOMETRIC pavers in related tints of the same color family create a one-of-a-kind pattern.

COMBINING different colored pavers the perfect board for an outdoor game of chess.

12 | Deck Specialist | March/April 2023

INTEGRATING a functional outdoor fire pit with stylish geometric pavers completes this year-round space.

COMBINING different colored pavers can create the perfect board for an outdoor game of chess.

STATE OF SUPPLY FOR THE MILLWORK INDUSTRY

------------ BY TYLER SHARPE

THE MILLWORK industry has been rocked by significant changes these past few years with supply chain breakdowns, product import duties, COVID-fueled growth and a sharp decline in demand.

Ocean freight and raw material pricing experienced a cost multiplier leading to high inflation, widespread disruption and continued uncertainty before falling back to pre-pandemic levels. Millwork product manufacturers, suppliers and installers were forced to adapt quickly while many struggled to navigate an unpredictable landscape brought on by external forces.

After years of volatility, the industry expectation in 2023 is that we should be able to deliver our products and services with pre-pandemic reliability, even in the face of continued uncertainty. Raw material pricing is still fluctuating, supply chains are distressed with strikes, blank sailings and GRIs, unexpected outcomes of annual CVD/AD duty reviews and a cloudy demand pipeline one to two

quarters down the road.

In this article, we will explore strategies to help millwork businesses navigate ongoing instability and change. We will examine strategic supply considerations and offer practical advice to increase product reliability while remaining competitive and situated for growth in this rapidly evolving landscape.

Following an unpredictable 202022, I wholeheartedly embrace that we’re at the mercy of market forces. We operate in a world of fragile supply chains, inflation, challenges in employee recruitment/retention and a daunting geopolitical atmosphere. It’s not all doom and gloom, it’s far from it. The path forward acknowledges that continued uncertainty should be embedded into long-term sourcing strategies.

Logically, continued uncertainty in the market implies the likelihood of change. We all faced considerable disruption these past few years. How do we take stock of recent lessons learned? One of the biggest chal-

lenges experienced revolved around our supply chains, whether it be stock outs, delays, price increases, or quality issues. We are only as strong as our weakest link and should be evaluating the SWOT (strengths, weaknesses, opportunities, threats) of our supply chain. Knowing that many product costs peaked almost a year ago and will eventually bottom out, is there an effective strategy to balance short-term cost savings with long-term strategic planning? It is mission critical for all millwork businesses that supply partners ensure you are well positioned to deliver on your value proposition.

For sourcing directors, key considerations include a supplier’s ability to deliver:

• High service level commitments

• Quality control and assurance procedures

• Diversified supply sources

• Local warehousing, buffer stock and last mile logistics services

• Overall reliability

16 • the merchant magazine • may 2023 building-products.com ------------| INDUSTRY TRENDS

Although cost was not on the list of considerations, we all know it’s essential. The reason it doesn’t make the list is price needs to be competitive, but the lowest price is not a key indicator of the best supply choice.

Each of the considerations above could have a 10 times greater impact on the total cost of ownership as opposed to a small variance in delivered prices. Supply needs to be competitive, but this might be the time to caution that pricing that seems too good to be true, may in fact cost considerably more in the end. Access to reliable supply with the ability to ramp up quickly, increase volumes and deliver on new requirements is valuable for companies looking to grow.

From another perspective, late shipments or poor product quality result in stock outs, missed opportunities or shift reductions for manufacturing businesses. Knowing that economies are cyclical and a bear market will eventually be followed by the bull, there is no better time to focus on assembling the right team of supply partners who can play critical roles by delivering product as demand fluctuates or new opportunities emerge.

When considering suppliers, who do you want on your side to endure the next unexpected market shift?

Evaluating your suppliers’ capabilities directly correlates with the understanding of the quality and limitations of the products that you source. The demand experienced over these past few years presented a gold rush opportunity to new suppliers in our industry to gain market

share with limited due diligence when it came to product composition or properties. Should this be the year where we learn about the intricacies of the products that we use?

It’s easy to decipher at a high level the reliability of your products. We can start with basic documentation and processes:

• Does your supplier have a brochure or a technical data sheet for each product?

• Can they answer questions about dimensional tolerances, MoE, MoR, screw holding, etc.?

fluctuations and emerging government policies?

• Continuity of a trained local workforce, infrastructure to transport materials, stable energy, wages and other operational costs?

Unfortunately, market forces, pandemics, natural disasters and continued geopolitical conflicts all have the ability to drive considerable delays, shutdowns and costs. 2023 is a year to embrace geographical diversification of supply. This could be a daunting challenge on your own but the right partner can provide transparency and support to quickly implement a diversification strategy while maintaining the consistency your business depends on.

To recap, our industry is well positioned to deliver low market pricing to combat inflation, quality control assurances that products meet required specifications, additional value added services to improve your business, and a geographically diversified supply chain. Your landed pricing or COGS is exceptionally important, but the savings opportunities are minimal when compared to an overall reduction in the total cost of ownership of your products.

• Does your MSDS spell out the composition of the product including species, raw material sources, glue types, etc.?

• Is there a series of QC processes and destructive testing performed to ensure each batch meets long-term expectations?

• Do your products come with a transferable warranty?

• Are you comfortable with your supplier’s compliance (social, regulatory, environmental)?

We may be at the mercy of unpredictable market forces but you can avoid the subpar “pandemic quality” by conducting a simple evaluation of product performance.

Our products are further defined by the country of origin as the supply map is changing rapidly. The primary driver of this massive change is the geopolitical climate and the implications are enormous. What is the outlook of your country of origin in terms of:

• Import/export duties, currency

2023 is the year to build reliability protocols, understand your products supply chain, and identify the key partners that can propel your business through the next economic cycle. The millwork industry has experienced significant disruption these past few years; by evaluating the capabilities of our supply chain, we build resilience into our businesses and stand better prepared for future disruptions. MM

building-products.com may 2023 • the merchant magazine • 17

BY EVALUATING THE CAPABILITIES OF OUR SUPPLY CHAIN, WE BUILD RESILIENCE INTO OUR BUSINESSES AND STAND BETTER PREPARED FOR FUTURE DISRUPTIONS.

TYLER SHARPE

Tyler Sharpe is the director of global sourcing and supply for Weston Wood Solutions, an innovative manufacturer, importer and value-added supplier of lumber, engineered wood and composite products for the millwork and building industry (www.westonwoodsolutions.com).

FEELS LIKE HOME

------------

BY SARA GRAVES

WHEN LONGTIME customer

Tom McManus drives up to Tweedy Lumber & Hardware (Tweedy) in his motorcycle with his long beard blowing in the wind, his three dogs in their custom-made side car, and his booming voice announcing that he’s arrived, it’s hard to miss him.

“When he’s in the store everyone in the store knows he’s in the building; there is no mistaking that he is here,” says Tweedy partner, Dustin Reynolds. “He’s just an all-around joy in the store.

A witty, talented, rustic timber craftsman who loves animals, Tom has been coming to the Rushville, IN., store for years. The staff doesn’t know exactly how long, but they know he was there in August of 2019 when the business was sold to the present owners, the Davis Family and Dustin Reynolds.

Tom, the owner of One Off Woodworking, is as good as they come. Recently, after he had overpaid his bill at the store by $1,500, the Tweedy staff returned the money to him. Tom handed them back a $100 bill and told them to buy pizza with it. “You couldn’t ask for a bigger-hearted gentleman,” Dustin exclaims.

Tom and Tweedy’s other customers have learned that it is more than just a store—it’s a comfortable place that feels like home. “I say we know probably 90% of our customers by name and they know us too,” says Dustin, an earning owner whose percentage of ownership increases

yearly. “They know what they’re working on and who to ask about their project as well—who’s good in tools and stuff like that—and they’re able to come and talk to (the person) who knows what they’re talking about.”

It’s the staff’s personal attention that draws the store’s repeat customers back regularly, sometimes up to 10 times a day. “We open from 7:00 in the morning to 7:00 at night,” Dustin says. “We’ll see the same people in and out, so we really get to build that rapport with those guys.”

Listening to their customers and having the products they need in stock has firmly connected Tweedy with its clientele. “Our staff is genuinely interested in the projects our customers are (building),” Dustin says. “Our customers will come back in and show pictures of what they’re doing.”

Since the store is located 18 miles away from the nearest interstate, big box stores have stayed out of town. To set themselves apart from their local, smaller-store competition, Tweedy offers the only

18 • the merchant magazine • may 2023 building-products.com

------------| COMPETITIVE INTELLIGENCE

on page 20)

INDIANA DEALER Tweedy Lumber & Hardware trusts in its staff to provide personal attention that draws repeat customers back regularly—sometimes up to 10 times a day.

(Continued

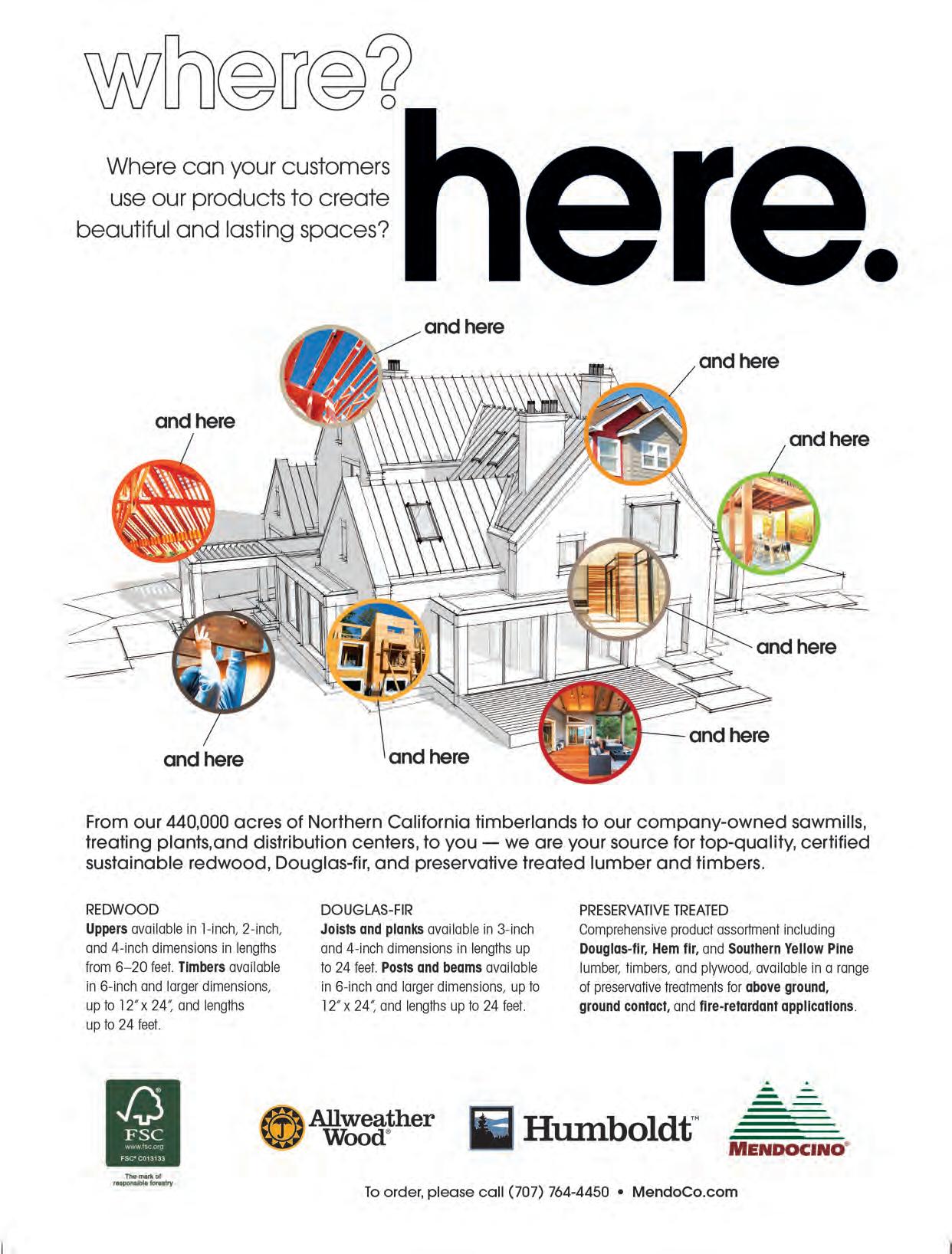

Call us at 707.894.4241 Visit us at buyRedwood.com DECKING Composite can’t compare. Like the foods we buy, when it comes to decking, we want natural and real. Redwood is always available in abundance of options. So stock the shelves! Unlike mass-produced and inferior products, Redwood is strong, reliable and possesses many qualities not found in artificial products. They maintain temperatures that are comfortable in all climates. Redwood Empire stocks several grades and sizing options of Redwood. REDWOOD

lumberyard in town, and the only rental department in 18 miles.

If a customer has an urgent need, such as when a well pump goes out, Dustin, with his background in the mechanical and contracting side, will visit job sites to help a customer. Or, if a customer urgently needs a part, Dustin or the store’s business manager, Shannon Davis, will open the store even after the store is closed.

“I was born and raised here—most people know how to get a hold of me—so I get phone calls at night—as Shannon does,” Dustin shares. “and if at all possible, we will come in and get them the product. There are times when we both will deliver the product to the site if for some reason they can’t get in or they just need a little help with the loading or unloading.

“I’ve had some rental tools that have failed after hours, and I will trade those machines out. Or, we can facilitate getting the building

opened up where we can make sure they get the replacement tool so they can complete their job. We are very much a small town store.”

“That’s not something that other companies do, or big-buck stores do either,” adds Shannon, who is in charge of the day-to-day operations along with Dustin and R.D. Browning, the store manager who has been with the company for 45 years. In addition, the company is owned by Bruce Davis, who is not involved in the day-to-day operations.

As Dustin explains, “We’re able to see things differently. (Shannon) does a great job on the things that my background doesn’t. We have two different perspectives. I’m more on the mechanical side—I’m looking at what kind of valves we need to bring in—or the electrical wire or water heaters—and building up the rental department... and Shannon does a really good job with the aesthetics, the home and gardens—

all of the stuff that I wouldn’t think about.”

Shannon adds that she has been focusing on drawing more women and younger customers into the store. “We have a lot of women who come in and get paint and they see what we have to offer and become a lifelong customer. I hope to grow that—getting more women—and for more young people, to give them the encouragement that they’re able to do things on their own so they don’t have to hire a contractor. We’re here to help them with whatever projects they have.”

It’s the owners’ differing strengths and flexibility that has enabled the company to succeed. And despite taking over the business and starting a full-store renovation just as the pandemic hit, they have since doubled the company’s sales in the past 3-1/2 years.

“I remember walking out at 4 a.m. that night thinking, ‘Oh my gosh! I don’t know which direction to go right now. We’ve got product everywhere—we’ve got no help—we don’t know (if) we’re going to get shut down.’ Then they tell us, ‘Oh, you can’t get this product,’” Dustin recalls. “We took it day by day—just pushed through and tried sourcing from other areas, other companies. (We) existed the best we could given the circumstances. We had a really good 2020 and 2021.”

“We learned a lot too. I think getting kind of thrown into it and then losing all of our help, we definitely learned a lot for sure,” he adds.

Clearly, one thing they learned is how to treat their customers. And if you are lucky enough to shop at Tweedy’s, keep your ears open; you just might hear Tom’s booming laughter from the next aisle over. MM

SARA GRAVES

20 • the merchant magazine • may 2023 building-products.com

Sara Graves, senior editor for The Merchant Magazine, is interested in your story. Contact her at sgraves@526mediagroup.com.

LEADING THE WAY at Tweedy Lumber: (left to right) Dustin Reynolds, Andy Ralstin, R.D. Browning, Cheryl Cole, Chloe Reynolds, and Rachel Cameron.

LET’S GET GROWING

Our bold new store design transforms any store into a shopping destination that drives traffic and ignites sales growth.

Join a company that’s committed to taking your business as far as you can dream it.

Read how Mike and Brenda MacKay built for growth at doitbestonline.com/Vassar.

Our Do it Best

GETTING AND MISSING ORDERS

------------

BY JAMES OLSEN

THE BEST TIME to ask for an order is right after we have gotten one. When I first started trading, they taught us to hang up as soon as possible after getting the order number for fear of talking the customer out of it.

But there is a partnership approach after getting an order that is better for the customer and better for us.

After We’re Given an Order

1. Thank them. “Julie, I really appreciate these orders.”

2. Go over the details. “John let’s go over the details one more time just for fun. These are three trucks of 2x4 16’s SPF coming out of ABC Sawmill. They are paper-wrapped, shipping the week of 5-15, getting into us at $665/ MBF. Is that what you have?” Better to have a misunderstanding at the time of purchase (that can be fixed before delivery) than to have a claim on three loads a thousand miles from home that we have to clean up.

3. Thank them again. “Julie, I really appreciate these orders.”

4. Congratulate them. “John, these really are a good deal at $665/MBF. Well, we know it’s a good deal because you only buy good deals.”

5. Ask for three more. “John, I don’t know if we can, but if we can get three more of these for the week of 6-5, do you want to put on three more?”

One out of 10 customers will say yes. In addition to getting three more orders, this is a great way to block out our competition. Customers do spread their business around so often they do have more orders to give out.

After We Miss an Order

Get curious.

Customer: “That sounds like a decent deal, but I just bought three of those.”

This is where most sellers say, “Okay, what else are you buying?” Not wrong, just too soon.

Master Seller: “Great, when did you pick those up? When are they shipping? What are they coming in at? What was the tally? Whose stock?”

Our tone is caring and curious. We don’t want to sound too aggressive or defeated. Often we get beat by a lower number, but customers leave out important details of how we are getting beat. In up markets, if they bought this “better deal” three weeks ago, that would make a big difference. Sometimes the tally or the stock isn’t as good as what we are offering. We need to dig in on the details to make sure we are comparing apples to apples. Sometimes our competitors just have a better deal, but it is important for us to understand how we are getting beat. We might be missing supply out of a certain supplier that we should be working harder.

Another good question to ask when we get beat is, “Did you give them a firm offer to get to that price?” Do not whine and say, “Well gosh, if you had given me that firm offer I could have done that number also.” By asking the question we let the customer know that we know. That’s enough for now, but we definitely will be asking for more firm offers in the future with this customer.

When we do get the details of what the customer bought:

Master Seller: “Susan, that’s a great deal. If I could get you three more trucks like that for further out shipment could we put those on?”

One out of 10 will say yes. Some customers won’t share information. But 60-75% will. We are not intimidated by customers who say, “I don’t share that information; just give me your best number up front.” We continue to probe.

Give Me Your Best Number Up Front—I Don’t Play That Game

Master Seller: “John, there are and always have been two prices: the ‘quote’ price and the ‘firm offer’ price. I am giving you the best quote price, but to get the best price we are going to have to work together. Why don’t you give me a firm offer at $550/MBF and let’s see if we can get that done.”

Or...

Master Seller: “Susan, the market into you today is $550/MBF, but with a firm offer I think we can get it done at $500/MBF. Can I have that firm at $500/MBF?”

22 • the merchant magazine • may 2023 building-products.com

------------| OLSEN ON SALES

JAMES OLSEN

James Olsen is principal of Reality Sales Training, Portland, Or. Call him at (503) 544-3572 or email james@ realitysalestraining.com.

3 QUESTIONS: PENNSYLVANIA LUMBERMENS’ JOHN K. SMITH

JOHN K. SMITH, president and CEO of Pennsylvania Lumbermens Mutual Insurance Co., has learned a lot over 40+ years in insurance:

1Tell us about your first experiences with the lumber industry, and how you got involved with it.

Smith: I had been in insurance for more than 20 years when Pennsylvania Lumbermens Mutual Insurance Co. first reached out to me. My experience ranged in positions of ever-increasing responsibilities running large profit centers for national and multi-national insurance companies. But I always wanted to run an entire insurance company, not just a division or region. At that time, PLM was a tertiary insurance player in the lumber and forestry niche. While I had never envisioned leading a small company, I was intrigued. Joining PLM was truly a great decision. My wife, Julie, and I have met tremendous people, from PLM employees to industry clients, who welcomed us into the company and the industry.

One of my first interactions with the lumber industry was at an association dinner where I was clearly the youngest person at the table. The dinner conversation revolved mostly around business operations and new technologies. I was taken aback by the transparency and willingness to share opinions among competitors. At one point, a business owner asked me why he should insure his business with PLM. I launched into the benefits of a PLM relationship and the rest of the table took note. Others joined the discussion and asked deep, pertinent questions. When I finished my pitch, the gentleman who opened the dis-

cussion doubled down, making me repeat myself. Then he informed me he had been PLM insured for decades. In fact, most of the people at the table were PLM customers. The joke may have been on me, but I learned if I spoke my mind, told the truth, treated people fairly, and lived and breathed the promise we make as an insurance carrier to be there at the time of a claim, we would thrive.

The challenges PLM faced 20 years ago have changed, and we have changed to meet them. I firmly believe the day you realize you don’t love what you’re doing, that should be the day you move on and try something else. I love what I’m doing. There has never been a day I regretted choosing to lead PLM.

2What have been the greatest challenges over the years?

Smith: Recognizing all the challenges that need to be handled to develop effective plans and procedures, and ensuring we have right people to manage them, has been our greatest challenge. We call this the Enterprise Risk Management (ERM) process. PLM’s ERM process is deep and broad-based. It gives us a framework to not only address those risks we know about, but also to help us identify developing risks and prepare for those we do not yet know about.

For example, consider the winter freeze of 2021 in Texas and the Midwest. Texas is not known for winter freeze losses. Regardless, we were not significantly impacted because we have a strong plan in place to handle multiple types of weather-related property losses. We executed our plan efficiently and effectively to operate

as normal, focusing on helping our customers get their businesses back up and running after a loss.

This challenge was different from COVID-19. The pandemic forced us to send our employees home, where they remain to this day. Yet despite the initial uncertainty, we had a plan to deal with dispersing our workforce if the office became inaccessible due to a fire or a significant cyber event. So, we adjusted our plan to fit COVID-19. Within 48 hours, we established a fully remote workforce and did not miss a beat.

The point being is that when asked about challenges, all I hear is “how do I manage risk?”

3 What have been the most significant changes?

Smith: Two decades ago, PLM was operating at $45 million of premium volume and $60 million of policyholder surplus. There were four or five mutual companies focused on the lumber and forestry segment. PLM’s footprint was primarily on the East Coast.

Today, we are arguably the market leader in our niche with a national footprint. Our premium last year was at $375 million. Our policyholder surplus was just under $200 million, and our profitability has improved dramatically. We are the only mutual insurance company left focused exclusively on lumber and forestry.

What has not changed and will not change is my love of the business, and the commitment and dedication of the PLM team in our pursuit of demonstrating the value of the PLM relationship.

– Send suggestions for future interviews to David at dkoenig@526mediagroup.com.

24 • the merchant magazine • may 2023 building-products.com

------------| 3 QUESTIONS

PLM’s John K. Smith

38% Faster Install OneTen™ Centralized Tensioning THE TECH RDI® Elevation™ Rail with exclusive OneTen™ technology eliminates the need to tension cables individually. Which means it installs 38% faster.* See how it works at RDIElevationRail.com Tensions faster than politics at the dinner table. * Claim based on a 12'x18' deck with 8 posts and 7 panels (RDI Elevation Rail installed 49 minutes faster than competitive cable railing install of 129 minutes)

IMPROVING EMPLOYEE ENGAGEMENT AND RETENTION

------------ BY PAIGE McALLISTER

EMPLOYEES STAY at companies where they feel valued and safe. Employees leave companies where they feel discounted, taken advantage of, or disconnected from managers and co-workers. Increasing the engagement and retention of good employees can propel a company’s success, allowing leaders to focus on proactive strategies instead of reactively putting out fires.

While some more immediate actions can create shortterm engagement, long-term commitment requires leaders to examine and redefine how things are done by the company as a whole and how employees are developed and nurtured.

Organizational Culture: To help employees connect with the company, ensure that every aspect reflects the goals, vision, and philosophy of its leadership. Policies, practices, communication, decisions, clients, etc., all need to connect back to the same message so employees know who the company is and can gauge their actions accordingly. Stating one thing but letting managers and employees do something different sends mixed messages and makes employees doubt the integrity of the company they work for.

• Create purpose and commitment by fostering formal and informal connections between leadership and employees, between departments, and between co-workers. Institute ways for employees to interact with leadership, such as panels, lunches and “meet-and-greets,” and reasons for employees to work with others across the company such as initiatives, committees, and affinity groups.

• Improve communication and transparency to offer regular insights into the company’s goals, financials, wins, and challenges. Schedule quarterly or monthly meetings and/or send regular newsletters or impromptu communication so employees hear what is going on directly from leadership. Hold managers accountable to timely pass along important information to all of their employees.

• Review your organization as a whole, starting at the top and extending through every level and job. Update

your policies, practices, and culture to eliminate any toxicity, harassment, or discrimination and to create the consistency of acceptance and equality throughout. Engage an outside consultant to assess your practices and recommend initiatives from an objective perspective.

• Make all employees feel welcome and valued regardless of their background. Prioritize Diversity, Equity, and Inclusion (DEI) initiatives (including race, gender, LGBTQ+, religion, national origin, age, education, etc.) to benefit from the diversity in thought and experiences that comes from a varied group of people.

• Update your technology, infrastructure, and resourc-

Q. We allow employees to personalize their work areas. However, we have one employee who has so many pictures, plaques, sayings and other trinkets on their desk that there is little space left to work. Can we make them take some of it down?

A. Allowing an employee to make their workspace “their own” is a good idea. It helps them connect to the workplace and feel more comfortable where they spend several hours each day.

However, you should make it clear in policy and practice that the workspace is the property of the company and therefore employees are not entitled to full control or privacy over it.

• Consider creating guidelines for what is acceptable

• Restrict what or how much can be hung on walls or in cubicles

• Limit the number of pictures or plaques that can be displayed, focusing on mostly professional or company-related items such as diplomas or recognition awards

• Require a certain amount of workspace be available for actual work

• Prohibit anything that is unacceptable or could be offensive to other employees

Be consistent in enforcing these policies regardless of who they are or where their workspace is located. Hopefully you can find a balance between completely impersonal and excessive work areas.

26 • the merchant magazine • may 2023 building-products.com

------------| TRANSFORMING TEAMS

es to give your employees the best tools to do their jobs. Find ways to make employees’ jobs easier.

• Stop making decisions “because that’s how we’ve always done it” and allow employees to feel comfortable and empowered enough to offer their thoughts and insights. Welcome brainstorming new ideas and teamwork to improve results.

• Extend your focus on excellent customer service to include your internal client—your employees. Make sure your employees feel valued and respected and ensure you are meeting their needs just as you expect them to do with your external customers.

Employee Development: Recognize that most employees do not “live to work,” but they do want to dedicate their time and talent to a company that appreciates them. Today’s workforce is not composed entirely of people on the “traditional” career path. Employees have different needs, priorities, goals, lifestyles, backgrounds, and challenges, often changing many times during their tenure. By helping employees

succeed with their personal and professional goals, you will enhance their commitment to the company, increase their productivity and inspire their innovation. Meeting employees where they are in life may require individualized, out-of-the-box thinking, and implementing new policies and procedures can produce remarkable results.

• Instead of the necessitating “promotion by changing jobs,” work with employees to determine how they can follow their desired career paths while staying at the company and keeping their institutional knowledge in-house. Are they looking to be promoted? Explain those expectations and give them the chance to learn those skills. Do they want to keep doing what they are doing? Help them refine and improve those skills so they can do them even better. Do they want to try a different job? Find opportunities for employees to work in different departments to find their best fit. Do they want or need to take a step back? Work with them to find schedules and job duties that allow them to balance their demands.

• Change your focus from attendance and punctuality to availability and performance. Recognize that working in the office 8:00 a.m. to 5:00 p.m. Monday through Friday does not work for a significant portion of the workforce, including employees who still have a lot to offer. Instead, explore flexible work arrangements, such as remote work, reduced schedules, partial year, hybrid arrangements, and job sharing, to allow good employees to better integrate their work responsibilities into the rest of their lives.

• Expand employees’ responsibilities to allow them to develop new skills such as supervising others, controlling an aspect of finances, or understanding how their role coordinates with another through cross-training. Don’t require employees to take on more work or stress with no benefit, but rather give them opportunities they value and compensate them appropriately for their added effort.

• Demonstrate your trust in experienced employees by giving them

(Continued on page 64)

Style and Simplicity

building-products.com may 2023 • the merchant magazine • 27

vistarailings.com

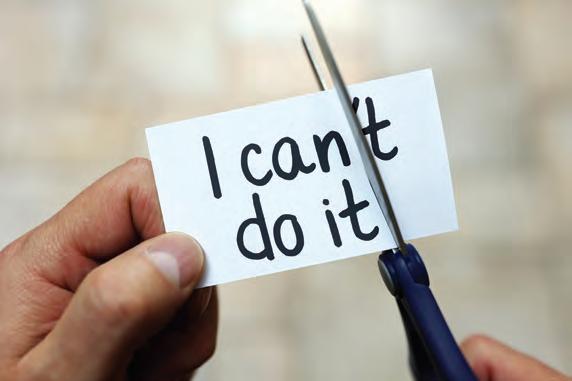

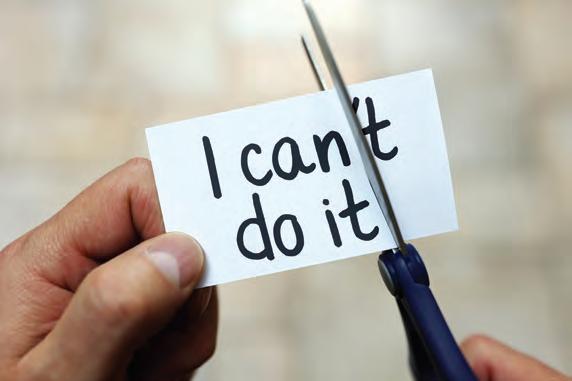

ARE LIMITING BELIEFS HOLDING YOU DOWN?

------------ BY DAVE KAHLE

“IN YOUR TRAINING, do you focus on instilling new skills, or do you try to remove the hindrances to people using their existing skills?”

It’s one of the best questions I’ve ever been asked. I recall it clearly. I was having lunch with the CEO of a large non-profit, for whom I was training their social workers in sales skills. As a professional trainer, it is a question I have considered for decades. It really speaks to the heart of the task of helping someone improve and develop. And, while it is a deep question that I’ve considered, I never expected to hear it from a client.

The answer is that we (the teachers and trainers in the world) do both. We teach the practices and competencies that are proven and fundamental for success in sales and leadership. In many cases, these are new skills, new ideas and new practices for the learner.

At some point in the process, though, a very predictable phenomenon occurs. While the learner accepts, intellectually, the value of what was been taught, he/she makes no—or a very limited—attempt to actually put it into practice.

The Process

It’s a two-step process: First, the learner needs to become aware of some practice, process, idea or skill. Then, they need to intentionally work to put it into practice.

The first step is the easiest. It only takes a small amount of effort to identify practices, processes and skills

which have been proven to be effective in your job or profession.

For trainers, the real challenge lies in helping the learner to actually use those practices. For someone intent on helping people develop, tap into their potential, and become more successful, it is the primary hurdle. I call it the “gap between idea and action.” It is relatively easy to transmit ideas; it is incredibly difficult to help the individual put them into action.

It is a complex problem, with lots of reasons that dissuade people at different times and places. For example, they can be as simple and superficial as not having the time: “I was so busy with other things that I just didn’t have time to give it the thought necessary to make the change.”

Fear of the discomfort that comes with any change in behavior is one of the most common. “I’m not comfortable doing that new thing. I’m not an expert at it, and I’ll feel foolish for a while. I’d rather not pay that price to gain a new skill.”

The Most Potent Obstacles

That list of reasons why the gap between idea and action is a difficult one to traverse can go on for pages. For now, I’d like to focus on a class of obstacles to changed, and better, behavior: our pre-existing beliefs.

As an educated and experienced practitioner in the profession of helping people change their behavior, I’ve come to the conclusion that our set of pre-existing beliefs supplies the largest and most potent set of

obstacles to self-improvement, and is the most difficult hurdle preventing greater success and fulfillment.

Human beings naturally make observations and conclusions about our experiences as we grow up and experience life. Eventually, some of these become hardened into beliefs. These beliefs that form our base set of assumptions about the world, and we make choices and live our lives based on those beliefs.

For example, a child can have a difficult relationship with one of his parents and begins to think that all people of that sex are arbitrary, aggressive and can’t be trusted. He forms a “confirmation bias,” which leads him to look for those things in others of that sex. After a couple of experiences that seem to confirm his bias, that thought coalesces into a belief, and then begins to influence all his behavior.

This belief becomes buried into the deeper layers of his heart. And it burrows into the subconscious level. He doesn’t even know that he believes it, he just operates on the basis of it. So, when he is dating, for example, he sees his potential life mates through the lens of this pre-existing belief. And that hinders his relationships with the opposite sex.

He may go to an excellently presented workshop on “Communicating with the Opposite Sex,” for example, and learn some of the best practices of communication, but is unable

(Continued on page 30)

28 • the merchant magazine • may 2023 building-products.com

------------| SELLING WITH KAHLE

FlamePRO ® is a registered trademark of Koppers Performance Chemicals Inc. FlamePRO treated wood products are produced by independently owned and operated wood treating facilities. © 5/2023 253-863-8191 • 800-472-7714 • westernwoodpreserving.com DO YOU HAVE QUESTIONS About Fire Retardant Treated Wood? WE HAVE ANSWERS! Give Us a Call! Are FlamePRO ® products backed by a warranty? FlamePRO ® offers a 50 year limited warranty. Other products may only offer 20 year warranty coverage. What is the advantage of pressure treatment? With FlamePRO, fire retardant protection is pressure impregnated into the wood fibers. It is not just surface applied. If FlamePRO fire retardant treated plywood is damaged on the job site can it still be used? The performance of FlamePRO is not impacted from normal shipping, handling or incidental job site damage. Is FlamePRO expensive? FlamePRO offers one of the most cost competitive options for fire retardant protected wood products.

to put them into practice because the gap between idea and action harbors his belief, and that belief prevents him from turning the good idea into action. With the best of intentions to implement his newly found practices, his belief trumps his intellectual ascent, and prevents him from following through. His potential for a loving, life-long relationship is hindered because of the unconscious belief he developed along the way.

This process is such a part of human life that every human struggles with it. The Bible, for example, calls these unconscious beliefs “strongholds” and indicates that they are destroyed through the spiritual power inherent in Christians.

Cultural Beliefs

Limiting beliefs are not just an individual issue. They can be distributed among affinity groups of people and become part of the culture of that group. Families have limiting beliefs that they share, as do larger communities.

One of our travel experiences that made a life-long impact on me occurred in the ‘90s when Coleen and

I were visiting Soweto, a township on the outskirts of Johannesburg, South Africa. On the day that we were there, the children were on strike, refusing to go to school. Even stranger than that was the reason they were on strike: they objected to being graded as individuals. Their tribal belief system promoted the idea that they

not to be respected. As a result, family members are regularly in trouble with employers and the courts.

In my Soweto example, the belief holds people down, and prevents individual achievement that would lift up the entire community. As a result, the community lives at the level of subsistence generation after generation.

While these two examples illuminate some life-changing and societyimpacting beliefs, not all limiting beliefs are so potent. We all have a host of them that impact our on-thejob performance. They can impact professional salespeople and hold them back. “Salespeople are good talkers” is one. “I have great relationships with my customers” is another.

were a closely connected group, and that any attempt to recognize that one person did better than another was an attack on that belief. Either the whole class passed, or the whole class failed. The individual had value, not as an individual, but only as a part of the larger group.

As with all such cultural components, these beliefs have consequences. A family can share a belief that all authority figures are arbitrary and

Overcoming Limiting Beliefs

Beliefs can be both positive and negative. Martin Seligman’s great book, Learned Optimism, describes the impact that positive beliefs can have in bringing success to one’s life.

Not everyone is hindered by the gap between idea and action, for example. Some—typically about 20-30% of a training class—go on to incorporate the new practices into

30 • the merchant magazine • may 2023 building-products.com

tptrucking.com The Logical Solution TP Tucking & Logistics have provided quality transportation and logistics services with award-winning safety for over 50 years. Whether you need your goods moved, stored in a warehouse facility or trucks serviced for maintenance or body paint, we are here to get the job done right! TP Tucking & Logistics service highlights: • Van, Flatbed, Residual & Maxi Dedicated Options • 3PL - Rail, Marine, Truck & Intermodal - Brokerage Services • Warehouse/Storage/Transload Services • 24-Hour Customer Service • Shipment Tracking Contact us today to learn more! Tami Chesnut 3PL Manager (541) 799-5012 tchesnut@tptrucking.com Sheri Tarr Sales Manager (623) 225-5191 starr@tptrucking.com

their routines and enjoy the positive outcomes as a result. My focus here is not on developing positive beliefs, but rather on overcoming negative ones. It’s not the minority who seamlessly incorporate the training that is my focus; it is the majority who don’t.

In many ways, our development as humans is dependent on our ability to eliminate or overcome our limiting beliefs. Since limiting beliefs are subconscious, and influence our behavior, the way to identify them is to study our behavior. Patterns of behavior that seem to be unreasonable, that often lead to negative outcomes, are often indicators of a limiting belief that prompted that behavior.

Back to our example of the man raised with a limited belief about the opposite sex. If he sees himself acting unreasonably in multiple situations, then that behavior indicates a pattern, and that pattern of unreasonable negative behavior indicates a limiting belief. For example, he may get overly angry at the slightest perceived insult, when none was intended, and other reasonable people would not have acted that way.

A little introspection indicates that this is a pattern of behavior. That it has become habitual. Those are indications that there is a limiting belief prompting that behavior.

So, the first step is to identify patterns of unreasonable, negative behavior. Friends, family members, and colleagues can provide some insight into this.

The next step is to identify the belief that prompted that behavior. This is where a professional consult can help. If you’re working by yourself, ask the question, “Why” and as objectively as possible, search for the belief. See if you uncover and label it. Give it words and describe it.

This is difficult work. Multiple books have been written on various aspects of it. It is much more complex than my few words indicate.

Once you identified the negative behavior and the underlying belief, you can attack it at both levels. You can become aware of the behavior, and whenever you find yourself in that situation, follow one of Seligman’s techniques: Simply tell yourself to “Stop” and then “Switch” to some

other behavior. Do that enough, repeat it enough times, and you will have built a more positive habit.

Or you can attack it at the level of the belief. Now that you have uncovered and labeled it, argue with yourself. Think through all the reasons why the belief is false. Convince yourself that the belief is unfounded and leads to negative behavior, Defeat the belief itself. You may find it helpful to formulate a positive rule and substitute that every time the old belief expresses itself.

If you can successfully bridge the gap between idea and action, you’ll have gained a self-improvement tool that will serve you well for the rest of your life.

TRUE GENUINE MAHOGANY

The most sought-after wood for generations is Back!

A Spectacular Wood with an Authentic Green Story

FEATURES

• Clear, Beautiful, Stainable & Affordable

• CA WUI approved for decking & siding

• Plantation grown & sustainably harvested

• Class II Durability

BENEFITS

• Surprisingly cost effective

• An exotic hardwood NOT from the rainforest

• Stable and long lasting in any climate

Providing you with quality products and honest service since 1977.

JONESWHOLESALE.COM

building-products.com may 2023 • the merchant magazine • 31

DAVE KAHLE

Dave Kahle is a leading sales authority, having written 12 books and presented in 47 states and 11 countries. For more information, visit davekahle.com.

YOU ARE THE MOST IMPORTANT ELEMENT OF EVERY TRANSACTION.

HUTTIG FOLDED INTO WOODGRAIN

Woodgrain is combining its Huttig Building Products and Woodgrain Distribution Division into a single entity known as Woodgrain.

The formal consolidation comes 11 months after Woodgrain purchased Huttig and began to unite the two companies.

“Since the acquisition of Huttig, our combined teams have been hard at work building a stronger future,” said Todd Dame, president of Woodgrain’s Distribution Division. “We have been identifying the best of both companies, standardizing business processes, investing in facilities and equipment, and collaborating to deliver more value to our customers. We are excited to go to market as one company and continue Woodgrain’s growth. We also want to acknowledge and celebrate Huttig’s long history as a leading distributor of millwork and building materials.”

TAL HOLDINGS BUYS RENTAL SHOP

TAL Holdings, Vancouver, Wa., has agreed in principle to acquire Harbor Rental and Saw Shop,

Friday Harbor, Wa., complementing its Browne’s Home Center branch, which is also in Friday Harbor.

Harbor Rental has been a trusted name in the San Juan Island community since 1974, providing equipment and tool rental, small engine repair, and lawn mower sales.

“The acquisition of Harbor Rental is a key component of TAL’s growth strategy,” said TAL CEO Jason Blair. “This acquisition will allow us to diversify our business profile, expand our service offerings, and better support the San Juan Island community. By incorporating Harbor Rental and allocating millions of dollars towards the renovation of Browne’s Home Center, we demonstrate our dedication to helping build better communities for many years into the future.”

Owned by the Olshefsky family for 36 years, Harbor Rental has operated under a commitment to excellence and customer satisfaction. Darren Olshefsky, current manager and one of the owners, said, “We are excited for this partnership, as

it will provide our employees with additional resources and growth opportunities, benefiting all parties involved—employees, customers, and vendors.”

Effective May 1, Harbor Rental officially joined the TAL family of companies and continues to operate under the same name. With the acquisition, TAL now has a total of 30 locations in Idaho, Montana, Oregon and Washington.

ABC Supply has opened new branches in San Bernardino, Ca. (Kevin Banfield, branch mgr.), and Durango, Co. (Zachary Wynne, mgr.).

J.M. Thomas Forest Products is now distributing MoistureShield’s full composite decking portfolio from its branches in Ogden, Ut.; Denver, Co.; and Boise, Id.

Foundation Building Materials, Santa Ana, Ca., has completed the purchase of 32-unit Marjam Supply Co., Farmingdale, N.Y. Foundation has also signed on as the first “jersey patch partner” of the Los Angeles Angels for the 2023 Major League Baseball season.

McCoy’s Building Supply now offers customers Simpson Strong-Tie Deck Planner, Pergola Planner, and Fence Planner software on mccoys.com.

Westlake Royal Building Products is introducing PROS Perks, a contractor loyalty program for its 13 brands, including Zuri decking, Royal siding, Versetta Stone, Celect, TruExterior and Kleer.

ODL, Zeeland, Mi., has expanded into exterior doors by purchasing Tru Tech Doors of Ontario, Canada. It will roll out steel and fiberglass ODL Doors, built by Tru Tech, in the U.S. and Canada.

Fiberon issued an Environmental Product Declaration (EPD) for its Wildwood cladding.

Simpson Strong-Tie received the 2022 Specialties Vendor of the Year award from LBM Advantage.

32 • the merchant magazine • may 2023 building-products.com

------------| NEWS

BRIEFS

ROSEBURG EXPANDING BIG IN OREGON