Supply a versatile connector that works as a tension tie or holdown.

New from Simpson Strong-Tie, the code-listed LTTP2 light tension tie securely attaches wood joists, studs, or posts to concrete or masonry walls and foundations. With allowable loads 25% higher than previous models, it enables greater design flexibility. This connector has two distinct nailing patterns for horizontal installation as a tension tie with I-joist purlins or 2x solid sawn purlins, plus an extruded anchor bolt hole that accommodates multiple bolt diameters. The LTTP2 also is suitable for vertical installation as a holdown, and can be fastened with nails or Strong-Drive ® SD Connector screws. Add the LTTP2 to inventory as a single SKU, along with Simpson Strong-Tie ® fasteners. Call your representative to order, or learn more at go.strongtie.com/lttp2

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Claudia St. John, Dave Kahle

CONTRIBUTORS

Rich Brooks, Simon Cameron, Kim Drew, Jeff Easterling, Jessica Hewitt, Brad Kirkbride, Susan Palé, Donna Willis

ADVERTISING SALES

(714) 486-2735

Chuck Casey • ccasey@526mediagroup.com

John Haugh • jhaugh@526mediagroup.com

Nick Kosan • nkosan@526mediagroup.com

DIGITAL SUPPORT

Alek Olson • aolson@526mediagroup.com

Stephen Ornelas • sornelas@526mediagroup.com

info@526mediagroup.com

151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 Phone (714) 486-2735

CHANGE OF ADDRESS Send address label from recent issue, new address, and 9-digit zip to address below.

POSTMASTER Send address changes to The Merchant Magazine, 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626. The Merchant Magazine (ISSN 7399723) (USPS 796-560) is published monthly at 151 Kalmus Dr., Ste. E200, Costa Mesa, CA 92626 by 526 Media Group, Inc. Periodicals Postage paid at Newport Beach, CA, and additional post offices. It is an independently-owned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 western states.

Copyright®2023 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. We reserve the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles are intended for informational purposes only and should not be construed as legal, financial or business management advice.

Volume 102 • Number 9

“GET COMFORTABLE working without a safety net,” he said. I was in my 20’s and the way he said it, I knew it wasn’t a joke, but more of a warning. Growing up, there wasn’t really a “routine” or things I felt were predictable. Instead, chaos is what felt like normal and predictable. As I’ve moved into my later years, I’ve learned how unhealthy this is and that embracing routine and a predictable life is a blessing.

It seems though that life is becoming less predictable. What was normal is no longer normal. All around us is more noise, more chaos, more change, and yet, it seems like as a result, we’re getting more numb to it all. Maybe this is our own defense mechanism because thinking and processing it all is too stressful and depressing? Or perhaps pointless because who really knows what will happen next? I really struggle with this in my life and what is the right balance? I know putting my head in the sand is not the answer (at least for me), but trying to grab all this data and assemble it like a puzzle that will reveal a picture is equally ridiculous.

They say inflation is bad, so we will raise interest rates so that businesses have a harder time growing, investing and hiring. This will increase unemployment, which will reduce demand for products and services and therefore, force companies to reduce prices. Did everyone hear that correctly? The government’s plan to curb inflation is to put more people out of work so that prices come down due to reduced demand. They say this out loud… and we say, “OK, great, prices come down.”

The median price of housing has increased to $416,000— a 26% increase since just three years ago. In places like California, it is over $838,000. To afford a $416,000 home, you need a household income of about $150,000 per year to even consider qualifying. Why are home prices still going up? Why is there such a shortage of homes? Have you considered that corporate institutional investors have quietly purchased around 15-20% of all residential properties sold in the past five years and that by one forecast, will hold more than 40% of all single family rentals on the market by 2030?

I won’t even dive into how much pressure this places on young people wanting to get married, start a family,

and pursue their “American Dream.” Or about things like politics, elections, the age of our government representatives, global conflicts, or even our own national patriotism. We are in uncharted waters. While economists attempt to use data to predict where we are going, they have about as much credibility as weather newsmen predicting next year’s winter forecast.

What is the answer? Do we civilized, educated citizens stay quiet and polite and wait for logic and normalcy to return? Is all of this just the daily news carnage report to get ratings and in reality just under the surface, the current is actually calm? What do I tell my kids and how do I raise them to be prepared for their future??? This is the only real question, isn’t it?

While I’m comfortable operating without a safety net and living in a world of “improvise, adapt, overcome,” how do I raise my kids? My daughter is getting to the age where she actually thinks, and observes, and listens, and now is asking thoughtful questions. Do I simply answer, “Don’t worry, it will all be OK,” or do I stress how important it is to be prepared for everything and always be aware?

I rest peacefully because I know this is not our first time in uncharted waters. Yes, things are a little crazy, but also remember there have been World Wars, depressions and even Civil War. Yes, it’s easy to say, “But this is different,” which is true because everything is different until it becomes the norm. Instead, I force myself to be a presence of calm, and respect, and optimism in these uncharted waters. They can either been seen as scary, or as an adventure. We can choose to long for the “old days,” or be excited about what we can learn from what’s ahead. I choose to look for the good and to celebrate it when I find it because at the end of the day, who wants to sail the exact same course everyday of their life.

I hope you’ve explored some uncharted waters this summer with those who mean the most to you. As always, thank you for the privilege of serving you and this great industry.

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.comOur incredible buying power and logistical strengths have transformed RAKS Building Supply into New Mexico’s best and largest independent building materials dealer.

Join the company with a team of industry experts who are committed to take your business beyond your vision.

Read Kenny and Richie’s success story at doitbestonline.com/RAKS.

With

it Best, we can expand our vision without limits.

Do it Best gives Kenny Trujillo and Richie Tabet the power to quickly and efficiently deliver building materials to customers across a vast 122,000-square-mile service area.

LUMBERYARD or lumber palace?

Ganahl Lumber Co.’s newest flagship location—so impressive onlookers have commented on it being

“the next iteration of design and architecture for a pro lumberyard”— officially opened for business on Aug. 7 in San Juan Capistrano, Ca.

As CEO Peter Ganahl explains: “What Bass Pro Shop is to outdoor enthusiasts, this Ganahl location is to contractors and home remodelers.”

Ganahl’s Becky Acosta added, “It’s not just a store—it’s a destination.”

“This was a big investment, and we did not skimp out on design or materials,” CFO Dan Delaney elaborated. “We put a lot of effort into making sure we had the right adjacencies and traffic flow to save our customers time. The site includes a dedicated traffic signal for easy access to the facility, and we have wide drive aisles to help our customers navigate the yard without having to wait for vendors or other customers to load or unload. Additionally, we purposefully used high quality materials to save on maintenance costs over the long run.”

An official grand opening will be held Sept. 11-15, which will include vendor exhibits, food trucks, games, raffles, prizes, and product knowledge opportunities.

The new facility will allow Ganahl to expand its scope of operations to better serve South Orange and north San Diego counties.

The total property is roughly 16 acres, 10 of which will be used as a lumberyard. The main store is approximately 50,000 sq. ft., plus an additional 100,000 sq. ft. of drivethru materials storage, sheds and operations buildings.

One visitor during a preview and ribbon cutting event on July 27—an architect for 40+ years— wandered around, mouth agape at the showplace’s expansiveness and attention to detail. “This is unlike any lumberyard or home center I’ve ever seen,” he enthused.

It replaces Ganahl’s leased facility in nearby Capistrano Beach, which permanently closed Aug. 4. Much of the crew, including manager John Lopez, made the move to San Juan Capistrano, supplemented by new hires needed to staff the significantly larger quarters. (So much larger, Acosta said, that “you could practically fit the old location in the lobby.”)

Several team members have transferred in from other locations, including order-pulling manager Ryan Barnett from Costa Mesa and finish lumber sales manager Gavin Morris from Los Alamitos, who oversees both finish lumber and counter sales at the new location.

Ganahl purchased the Capo Beach operation from Capistrano Beach Lumber in 1995. But, noted Peter Ganahl, “even at that time our site was tired so we started looking for a different one. We spent many years looking and finally settled on this one after we were the successful bidder to the city of San Juan Capistrano in 2016. Over the past seven years, we have been working on all the processes from entitling, designing and constructing. It takes a lot of time and patience to bring a project like this to a successful conclusion.”

Brad Satterfield, COO, added, “Our Capistrano Beach facility has always been a beehive of activity, but due to the space constraints, we were unable to stock the depth and breadth of inventory that our customers required. This required us

to ship millions of feet of lumber and other building materials to our local customers from our other locations which cost our customers time and effort. In addition to a substantial increase in products and stocking volumes, our new San Juan Capistrano facility features a greatly expand-

ed delivery fleet to increase number of same and next-day deliveries into the South Orange County and San Diego markets.”

Founded in 1884 and based in Anaheim, Ca., Ganahl operates 11 locations in Southern California. MM

INTERNATIONAL RECESSIONS? Mills pinched by rising material costs and falling OSB prices? No worries. Apparently, nothing can seem to stem the demand for oriented strand board.

1 West Fraser Headquarters: Vancouver, B.C.

OSB Mills (13): Huguley, Al.; Cordele, Ga.; Guntown, Ms.; Bemidji, Mn.; Allendale and Joanna, S.C.; Jefferson and Nacogdoches, Tx.; Grand Prairie and High Level, Alb.; Barwick, Ont.; Chambord and La Sarre, P.Q. [Plus Scotland, Belgium]

West Fraser’s North American sales of OSB fell 12.9% in 2022 to $3.004 billion, despite production increasing 8% to 6.006 billion sq. ft. 3/8” basis. Consequently, the company expected to hold production fairly steady in 2023 (5.9-6.2 billion sq. ft.), yet an encouraging second quarter convinced West Fraser to revise expectations to 6.1-6.4 billion sq. ft.

The company has ample capacity, which will increase even more—to an industry-leading 8+ billion sq. ft. a year of OSB—thanks to its newly modernized mill near Allendale, S.C. Although modernization of the facility (purchased in late 2021 from GP) is largely complete, it will continue to be optimized and ramped up gradually over the next three years.

Estimates on the size of the global market for OSB vary wildly. Global Industry Analysts, Inc. pegs it at $19.5 billion in 2022, and expects it to increase 12.6% yearly to 2030. The Business Research Co. views it at $23.94

2 Louisiana-Pacific

Headquarters: Nashville, Tn.

OSB Mills (7): Clarke County and Hanceville, Al.; Watkins, Mn.; Roxboro, N.C.; Carthage and Jasper, Tx.; Fort St. John (Peace Valley), B.C.; Maniwaki, P.Q. [Plus Brazil, two in Chile]

As other manufacturers add OSB capacity, LP has been strategically subtracting. Reduced capacity—exacerbated by plummeting OSB prices—contributed to a 14% drop in sales last year. LP’s OSB sales dropped 75% in the first quarter of 2023 and 66% in the second quarter.

This spring, LP closed on the $80-million acquisition of Forex’s Wawa OSB plant in Ontario, Canada. But, like its OSB mill in Houlton, Me., last year and its facility in Sagola, Mi., this year, Wawa will be converted into an LP SmartSide Trim & Siding mill. Once converted, the mill will add approximately 400 million sq. ft. of capacity, making it LP’s largest singleline siding mill. This will bring LP’s total siding capacity to 2.7 billion sq. ft. annually. The changes at Houlton and Sagola mill together added 720 million sq. ft. of Siding Solutions capacity while removing 670 million sq. ft. of OSB capacity.

Within LP’s OSB product mix, its value-added products for the first time began outselling commodity panels during the second quarter of this year (354 million sq. ft. commodity OSB sold vs. 412 million sq. ft. Structural Solutions).

billion in 2023 and growing at an annual rate of 14.79%. IndexBox describes it closer to $12.5 billion and rising 5% annually to 2030.

What they all see in common is steady, sizable growth. They attribute their rosy forecasts to increasing construction activity across the world and a growing focus on sustainable building practices. Domestically, OSB prices have begun to tick back up in recent months, accelerating over the last few weeks.

However, the industry does face several challenges, including fluctuations in the prices of raw materials and intense competition from alternative materials. Additionally, environmental regulations and concerns around deforestation can impact the growth of the industry.

The U.S. remains the world’s largest consumer of OSB, followed by China (the world’s second largest economy). Hearty growth is also anticipated for Japan, Canada, Germany, and Asia-Pacific (led by Australia, India and South Korea). MM

Headquarters: Seattle, Wa.

OSB Mills (6): Arcadia, La.; Grayling, Mi.; Elkin, N.C.; Sutton, W.V.; Edson, Alb.; Hudson Bay, Sask.

Weyerhaeuser’s six OSB mills increased production by 3% last year to 2.96 billion sq. ft., while sales fell about 1.5% due to lower prices. Most recently, during the second quarter of 2023, sales and production volumes were moderately lower and unit manufacturing costs moderately higher due to planned downtime for annual maintenance as well as a temporary period of unplanned downtime resulting from wildfire activity near the company’s facility in Alberta.

Weyerhaeuser anticipates comparable sales volumes and fiber costs, along with slightly higher unit manufacturing costs for OSB in the third quarter.

Headquarters: Atlanta, Ga.

OSB Mills (5): Fordyce, Ar.; Hosford, Fl.; Clarendon, S.C.; Brookneal, Va.; Englehart, Ont.

This spring, GP completed installation of a third strander at its Clarendon, S.C., mill. The $40-million expansion adds 150 million sq. ft. of capacity, bringing the five GP mills’ overall capabilities to 2.8 billion sq. ft.

5 Huber Engineered Woods

Headquarters: Charlotte, N.C.

OSB Mills (5): Commerce, Ga.; Easton, Me.; Broken Bow, Ok.; Spring City, Tn.; Crystal Hill, Va.

After two years of working to build its sixth OSB plant in Cohasset, Mn., Huber has decided to instead settle in Shuqualak, Ms. Located on 550 acres, the facility “will feature some of the most advanced processes and technologies available for manufacturing operations.”

The plant could increase Huber’s overall OSB capacity by 30%. Its five mills currently have the ability to produce up to 2.556 billion sq. ft. a year.

6 Tolko Industries

Headquarters: Vernon, B.C.

OSB Mills (3): High Prairie and Slave Lake, Alb.; Meadow Lake, Sask.

Tolko continues to work toward reopening its High Prairie OSB mill, after the building and equipment were consumed by a fire in May 2022. High Prairie is responsible for about a third of Tolko’s overall OSB capacity of 2.26 million sq. ft.

“Work on assembling the new continuous press is progressing well, and the mill is aiming to be up and running by the end of the year,” said Tolko’s Chris Downey. “The construction at the site has included new concrete foundations and expanding the building size to accommodate the longer press. Along with the repairs, other projects and maintenance work include updates to the mill’s painting and wrapping area (which will use innovative robotic systems), and the installation of equipment that was repurposed from Tolko’s decommissioned Kelowna mill.”

7 Arbec Forest Products Headquarters: St. Leonard, P.Q.

OSB Mills (3) Miramichi, N.B.; Amos and Shawinigan, P.Q.

This spring, Arbec increased its total OSB production capacity by 64% to 1.15 billion sq. ft. annual by acquiring Forex’s OSB mill in Amos, P.Q.

8 RoyOMartin Headquarters: Alexandria, La.

OSB Mills (2): Oakdale, La.; Corrigan, Tx.

To meet rising demand beyond its two mills’ combined 1.7 billion sq. ft. capacity, RoyOMartin is currently building a second OSB plant in Corrigan, anticipating to be in production “closer to the end of the year.”

9 Langboard Headquarters: Quitman, Ga.

OSB Mill (1): Quitman, Ga.

Langboard OSB has a 440-million sq. ft. annual capacity.

10 One Sky Forest Products Headquarters: Prince Albert, Sask.

One Sky plans to break ground this year on a new $250-million OSB mill adjacent to the Prince Albert Pulp Mill.

NO LONGER A COMMODITY: LP, the industry’s second-largest producer of OSB, in an effort to add value to its products, has been converting production at several of its OSB mills to SmartSide siding and trim.INNOVATION IN SAFETY

Tolko Armstrong, BC (EquipmentBased Innovation)

Boise Cascade Lena, LA (ProcessBased Innovation)

SAFEST COMPANY AWARDS

Structurlam (3 or fewer mills)

LP (4 or more mills)

SAFETY/HEALTH HONOR ROLL

Division I (Plywood)

RoyOMartin Chopin, LA (1st)

Tolko Armstrong, BC (2nd)

Division II (OSB)

LP Ponta Grossa, Brazil (1st)

West Fraser Nacogdoches, TX (2nd)

APA – THE Engineered Wood Association announced the winners of its 2022 Safety & Health Awards—the premier safety award program for North America’s engineered wood products industry. The program’s goal is to promote and recognize operational excellence and reduce injury and illness rates.

Structurlam Mass Timber Corp. and LP won Safest Company Awards, while the coveted Innovation in Safety Award went to two winners: Tolko Industries’ Plywood Division in Armstrong, B.C., as recipient of the Equipment-Based Innovation Award for its Veneer Loading Marking Robot, and Boise Cascade Wood Products, Lena, La., as recipient of the Jeff Wagner Process-Based Innovation Award for its New Hire Mentorship Program.

“We are proud of our members’ commitment to establishing processes that improve workers’ safety,” APA president Mark Tibbetts said. “It is important that we as an industry continue to implement best practices so we can continue to make our workplaces as safe as possible.”

Other competition categories include the Annual Safety & Health Honor Roll, Safety Improvement Award, and Three-Year Safety

Award. The annual award, safety improvement and three-year average categories are divided into three divisions based on the type of product manufactured at the mill (plywood; OSB; and glulam, CLT, I-joist, LVL and SCL).

Seventy-two APA-member structural wood panel and engineered wood product facilities participated in the 2022 program. A total of 11 facilities representing seven companies earned awards in various competition categories. Some mills won multiple awards.

While the awards are limited to APA members, data is collected from member and non-member mills to provide a broad-based industry performance benchmark. This is the 15th year of the program and led by a revitalized safety effort spearheaded by the APA Safety & Health Advisory Committee comprised of several APA member company safety professionals. Under the committee’s guidance, three main goals were established: make the APA program the premier safety awards program in the industry, encourage the sharing of best practices to improve the industry’s safety culture and programs, and, most importantly, improve the industry’s overall safety performance. MM

Division III (Glulam, CLT, I-Joist, LVL and SCL)

Structurlam Penticton, BC (1st)

Boise Cascade St. Jacques, NB (2nd)

THREE-YEAR SAFETY AWARD (2020-2022)

Division I (Plywood)

RoyOMartin Chopin, LA

Division II (OSB)

LP Ponta Grossa, Brazil

Division III (Glulam, CLT, I-joist, LVL and SCL)

Resolute Engineered Wood Larouche, PQ

SAFETY IMPROVEMENT

AWARD (2020-2022)

Division I (Plywood)

Boise Cascade Florien, LA

Division II (OSB)

West Fraser Jefferson, TX

Division III (Glulam, CLT, I-joist, LVL and SCL)

Boise Cascade White City, OR

INCIDENT-FREE HONOR SOCIETY

Anthony Forest Products El Dorado, AR (Glulam)

Anthony Forest Products

Washington, GA (Glulam)

Boise Cascade St. Jacques, NB (IJ)

LP Dawson Creek, BC (OSB)

LP Ponta Grossa, Brazil (OSB)

LP Tomahawk, WI (OSB)

Resolute Engineered Wood Larouche, PQ (IJ)

Resolute Engineered Wood St. Prime, PQ (IJ)

Structurlam Penticton, BC (Glulam)

West Fraser Bemidji, MN (OSB)

West Fraser Jefferson, TX (OSB)

West Fraser Nacogdoches, TX (OSB)

------------ BY JESSICA HEWITT

------------ BY JESSICA HEWITT

IN PARTNERSHIP with the U.S. Forest Service and WoodWorks, the Mendocino Companies hosted a tour of its Ukiah, Ca., timberlands and sawmill facilities on May 12. The 30 tour participants included architects, engineers and other specifiers and most were Bay Areabased with a few traveling from further afield to attend the day-long tour.

Commencing at the Ukiah Forestry Office, marketing director Jessica Hewitt and business development manager Charlie Jourdain provided an overview of the Mendocino Companies’ business, product lines, and environmental credentials, including Forest Stewardship Council (FSC C031337, C013133) certification, Life Cycle Assessment (LCA) results, and Environmental Product Declaration (EPD) documentation.

The tour continued with lunch and two stops on the timberland property to highlight how long-term management aims to restore the lands to a natural, conifer-dominant landscape, and to create a wildfireresilient forest. Led by John Andersen, Mendocino Companies’ director, forest policy, the first stop

highlighted a section of old-growth forest that is permanently protected from logging. Andersen further described how variable retention is utilized to create opportunities for replanting and regenerating redwood and Douglas fir trees where other, non-conifer tree species may be dominant.

The next tour stop focused on forest management activities that reduce fuels to prevent catastrophic wildfire events. The stop was located at Miller Ridge, a major north-south trending ridge west of the city of Ukiah. Ladder fuels, brush and small to medium-sized trees, which allow fire to reach the crowns of conifers, were removed through mastication activities. Wildfires that have burned through areas treated in this manner have shown these treatments are effective in retaining forest canopies post-fire.

Lastly, participants were guided through the Ukiah Sawmill where redwood and Douglas fir logs are processed into solid-sawn lumber. Led by John Crosswhite, director, operations, participants learned that the facility is unique in that it can cut multiple

wood species while most mills cut only one. Crosswhite described the technology in the mill that maximizes lumber production while minimizing waste, ensuring maximum value extraction from each log that is milled.

“Choosing wood as a building material can help support sustainable management and restoration of forest ecosystems on federal, state and private forest lands throughout California and the United States,” said Helena Murray, regional wood and biomass utilization program manager at the U.S. Forest Service.

“Our program has the unique role of working directly with design and construction professionals to encourage and support the use of wood in commercial and multifamily buildings,” said Chelsea Drenick, WoodWorks’ regional director for Northern California, Nevada and Utah. “People are interested in sustainability topics like biogenic carbon and LCA, and an important part of our message is that the use of wood in buildings helps to incentivize landowners to invest in practices aimed at long-term forest health. The ability to demonstrate sustainability at work on the Mendocino Companies’ lands, and the process of making lumber, was an invaluable education opportunity.”

Mendocino Companies’ John Andersen added, “I thank the U.S. Forest Service, WoodWorks, and everyone who attended to see firsthand the sustainable forest management policies we employ. There is no better source of lumber than in California where regulations ensure protection of all the forest resources we value.” MM

– Jessica Hewitt is marketing director for the Mendocino Companies (www.mendoco.com).

Hi-bor® brand treated wood is a borate treated wood product designed for interior house framing in Hawaii. Hi-bor treated wood resists attack by Formosan and subterranean termites and numerous household insects and pests, as well as fungal decay. Hi-bor borate treated wood is also backed by a 20 year limited warranty*.

FirePro® brand re retardant treated wood is treated with a patented formulation that contains no phosphates and has been shown to exhibit exceptional re performance properties without compromising other critical engineering properties such as strength, durability, corrosivity, and hygroscopicity. FirePro treated wood is also backed by a 50 year limited warranty*.

Advance Guard® borate pressure treated lumber is recommended for sill plate, furring strips, joists, studs, roof trusses, blocking, rafters, beams, and other framing applications. Advance Guard is also recommended for fascia, trim, wall sheathing, roof sheathing, and sub- oors. Advance Guard borate pressure treated lumber is also backed by a lifetime limited warranty*.

AT THE WESTERN Red Cedar Lumber Association, we have a mandate to enhance demand for western red cedar and drive sales and value. To do so, we follow market trends and consumer behavior to capitalize on opportunities that will increase usage and grow market share.

Over the past several years, we’ve generated strong results from our advertising and outreach program to architects and designers, both of which are highly influential groups when it comes to specifying materials for their projects. To continue to build awareness of and a preference for WRC in the market and leverage the efficiencies and successes we’ve had with our targeted audiences, the association is now expanding its outreach to include custom home and multi-unit dwelling builders and contractors.

There’s one ultimate goal for all our initiatives: sales. We aim to grow sales by removing the barriers to considering WRC; facilitating the specifying process and leading the customer to a retailer to complete the sale. The first step in getting WRC on the consideration list is knowing what will motivate a builder to use a particular material.

A study by Ducker Attitudinal Research found that about 90% of builders are familiar or very familiar with WRC, and most (about 80%) are interested in knowing more about the benefits of using WRC.

Likely due to its high awareness, WRC rates well on the attributes and benefits that builders deem most important: beauty; durability, and the character it adds to projects.

Factors such as installation and maintenance are also key, as of course is cost. It is interesting to note, however, that while the majority of builders researched stated that cost was important in influencing the buying decision, it wasn’t critical, and “if the material wasn’t seen as providing value, it wasn’t valuable to [them] as a homebuilder.”

What is valuable to a builder is meeting their clients’ needs, and increasingly those needs include sustainable and natural materials like western red cedar. “Basically all my clients are eco-minded and going with wood framing and wood siding is an effective way to build when sustainability is the goal,” said California-based architect and builder Brett Farrow. “Western red cedar has been my preferred building material for over a decade. It’s versatile, can be used in a variety of applications and is long lasting. Using western red cedar is a mark of quality all on its own.”

Awareness of building with sustainable materials is on the rise, as is the emerging trend of biophilic design, in which studies have shown that using natural materials like wood can reduce stress and stress-related illnesses.

“In terms of clients making environmental and biophilic requests, it goes in waves,” noted Kurt Vernon, CEO of Vernon Construction, Halfmoon Bay, B.C., “but we are seeing a growing trend towards sustainable materials like Real Cedar, particularly among European clients. As well, the younger generation is far more knowledgeable about biophilia and the environment.”

As a younger demographic moves into the housing market, WRC’s benefits like sustainability and its role in biophilic design will play a greater role in the purchase decision, underscoring the importance of creating WRC advocates in the building community. Natural products like wood meet environmental needs, but are more susceptible to availability and price fluctuations than non-wood substitutes, as was evidenced in the spring of 2021 and early 2022.

Fortunately, new engineered WRC products are gaining popularity and helping mitigate such issues, which are concerns for builders. Engineered products provide ready availability, even when fiber is hard to source. They’re incredibly attractive and an excellent value product. They’re available in three main product categories: engineered clear solid western red cedar, engineered T&G WRC with a clear veneer overlay, and engineered knotty western red cedar—all of which are creating opportunities for architects, builders and designers, as well as competitive advantages over non-wood and off-shore market products.

With almost 90% of the builders surveyed saying they are involved in choosing the materials used in their projects, the building community is a highly influential group that will have a significant impact on cedar sales. Opportunities including online searches, social media marketing, trade shows, interaction with WRCLA technical reps, educational tools and events, and influencers can all be utilized to reach builders and keep WRC top of mind and promote the Real Cedar value proposition. MM

ARTIFICIAL INTELLIGENCE (AI) seems to be a wildfire topic these days, as industries plow new ground and determine what—if any—part of this technological disruption works for them. Where does the retail lumber industry stand? And how does AI fit into the future? Read on for one expert’s opinion.

Rich Brooks founded flyte new media, based in Maine, in 1997 primarily as a web development company. Soon after, he found himself expanding his services to include search engine optimization (SEO), social media, digital ads, content marketing, and content advertising. His company has now grown to a staff of 10 people who are, in his words, “better than he is at anything they do.” He considers himself a generalist, but he is clearly stepping into the limelight as an artificial intelligence thought leader.

The Northeastern Lumber Manufacturers Association sat down with Rich to talk about how AI relates to the lumber selling industry—it does—in advance of his presentation at the group’s upcoming annual meeting.

Q. Give us a quick overview of what AI is.

A. AI—artificial intelligence—is the umbrella term for machine-learning as opposed to human-learning. The way business people should think of it: AI is like a very talented assistant with very little real-life experience. AI comes in lots of different flavors, one of them being LLM (large learning models). An example of this that many people might have heard of is ChatGPT, which falls into the category of generative AI, or basically AI that can create content based on patterns.

A quick overview of how ChatGPT works: when you ask it a question/give it a prompt, it pulls from data that it’s scraped from the web and other sources to create a sentence that makes sense. It’s content that’s literally created on the fly to provide answers to questions that feel real— and this is why it’s magical and limiting at the same time.

Another popular use of AI is through programs such as Midjourney, which is an image creator that works the

same way: you feed into it what you want—Bigfoot grading lumber in a lumber mill—and it will use art, photos, and imagery to create a solution based on your prompt.

Q. What are your general thoughts on AI?

A. I am passionate about AI and believe it will change everything. Period. AI is a bigger deal than the internet in how it will affect our lives in the future; some say it’s even bigger than fire! Just like the internet, when something like AI starts, there is lots of attention and lots of giant promises with everything overblown. Then we traditionally see a settling down as users begin to understand the capabilities and how they can best use the technology. What people don’t realize and what they will soon discover is that AI is already in everything that we do, and that we’re using it even when we don’t realize it. Anything where a technology tool is doing a job for us, that’s a form of AI. As AI progressed into our culture, ChatGPT became the tipping point and suddenly the future with AI is clear.

Q. How can AI best be used by the retail lumber industry?

A. Honestly, the possibilities are limitless. AI can be used for marketing, for content creation, for ad copy and graphics, for SEO copy, email marketing copy, social media content and posts, images to accompany all of the above—these are the most obvious answers. It’s in the additional uses of AI for selling lumber that it gets interesting: AI can be used for summarization, to record meetings and summarize them for attendees and those unable to attend. It can also be used real-time during meetings to help summarize thoughts (with the permission of everyone in the room, of course).

Spotting and acting on trends is an important part of selling, and AI can help there, too. You can ask an AI tool to find patterns within a sales cycle—or within the industry in general. Once the patterns are located, this information could be used to stay ahead of competitors, perhaps even influence what kinds of wood you sell.

The opportunities are endless. What about invoicing? AI can be used for that. Repetitive drudgery work is the first place lumber retailers should look for AI use opportunities.

Q. How can lumber retailers get started with AI?

A. The best thing lumber retailers can do for the near future is to focus on small, repetitive tasks and start running pilots for one, two or three months. Not everything will work, not everything can be outsourced to AI, but it’s time to get started to see what works for them.

Technology advances lead to new jobs. Think about the log drivers of the past, the people who moved logs from a forest for the sawmill and pulp mills downstream by maximizing the current of a nearby river. For the early logging industry in the U.S., this was the primary method of transportation. But when was the last time you saw someone do this? It’s no longer necessary, because better and faster ways of doing the same job were invented and put to use.

Every technological advance is a disruptor. It’s been said that marketers won’t lose their jobs to AI, but marketers who don’t understand AI will lose their jobs to those that do. Using AI is the latest technological advance that every business can use. How can you take your current employee base and train them to stay ahead of the competition? AI works across the board from finance to human resources, to strategy. The pace of growth we’re seeing with AI is exhilarating.

And for those who say they don’t want to use it or are reticent to adapt: you’re already using it. If your cell phone uses facial recognition, that’s AI. If your text messages fill in sentences or words for you, that’s AI. We’re all already using it in so many places—it’s going to become invisible in a lot of ways.

Q. What challenges do you see with AI?

A. Biases and hallucinations. Let me explain. AI is only as unbiased as we are as humans—and we are not an unbiased species. AI content is created by humans with intrinsic biases, and this has to be part of the conversation as we can never assume these AI tools are perfect. They are far from it.

Concern about AI is a significant part of the Hollywood writers and actors strike that’s caused so many movies and shows to shut down. The issue: actors are worried that their images can be AI-generated on camera, rendering the human potentially unneeded. Which is a valid concern!

We’ve all seen The Terminator and what happens when the machines take over; there are real challenges regarding AI becoming too strong and taking over too much, especially around the use of private data. We’re seeing growing concerns around privacy issues, data issues, and who’s in control of the data.

Another huge challenge: hallucinations. There’s a story out there about a lawyer who used ChatGPT to build an argument for him. The content came back, and it looked great: the arguments were strong and multiple cases were referenced as precedent. The only problem? Each and every case included by the AI tool was fake. Made up. That’s what a hallucination is: an AI-made-up fact.

FORMS of AI, such as ChatGPT, can be an asset to the lumber industry, particularly if used for small, repetitive tasks.

With generative AI, we need to always be aware of the need to fact check with a real human being. Disinformation is becoming real.

Q. Last thoughts on using AI in the lumber retail arena?

A. Forward-thinking lumber retailers would be doing a disservice to themselves if they—or someone on their team—isn’t spending time figuring out how to leverage AI tools. They can provide a potentially huge competitive advantage! MM

THE TITLE of my second book is Leadership Sales. I named it that because the Master Sellers I know lead their customers. Do they give great service? Yes, but they are not servants. They have an equal partnership relationship with their customers.

Many sellers are in a master/ servant relationship with their customers. Their main goal is to not irritate the customer, so they are too cautious in their sales approach. We cannot service our way to the top of a sales business.

Call

Master Sellers know exactly how they want their calls to go. They have several items to promote and know why what they are promoting is a good deal. As simple as it seems, many sellers go into calls with only a vague idea of how they want the call to go and of what kind of value they bring to the call.

Many sellers use this or a veiled option of this approach. This is lazy “selling.” What it says is, “I am too lazy to do my job, so can you tell me what you want to pay and what you want to pay for it?” This brings no value to the customer and deserved poor treatment to the “salesperson.”

Master Sellers control their calls. This may sound adversarial to some. It is not. Master Sellers know they bring value and don’t want to waste their customers’ time or their own.

Master Sellers are in the “Yes/No” vs. “I’ll Let You Know” business. Many sellers are so afraid of the “no” they

beat around the bush, which is frustrating to the customer.

We need to tell our customers what we have, why it’s a good deal, and ask for the order. Seems simple but many sellers don’t do it, forcing the customer to control the call.

The person asking the questions is the one controlling the call. The purpose of the prospect call is to qualify the customer, but many sellers lose control early because they let the customer take over and (try to) qualify them. For example:

Customer: “OK, what’s your price on 2x4 16’s?”

Quotron: “We can get those into you at $650/MBF.”

Customer: “We are paying $625/ MBF from our current supplier, so I don’t think we need you.” Click.

Customer: “OK, what’s your price on 2x4 16’s?”

Master Seller: “I’d love to sell you something today, but that really isn’t the purpose of this call. Let me find out a little bit more about you, your company, and the products you bring in and see if we are a good fit. After we cover all that, if you would like to give me an inquiry on something, I would love to work up a professional quote for you and we can start doing business. So, let me ask you this. What are the main items you are bringing in on a regular basis?”

So...

So… is a great transition word to help us take control of many situations. We answer the customer’s

question and then say, “So,” and ask our question. Again, the person asking the questions is the person controlling the call. Most customers are not going to buy from us on the first call, so we don’t want to waste time quoting something they aren’t going to buy. Distribution sellers can sometimes get orders on the first call because there is less risk on smaller volumes, but truckload sellers almost never get an order on the first call.

Customers will often start with negative talk about the market, their business, or the economy. Many sellers will let them go on and on or will even commiserate with them. After five minutes of negativity, they then try to sell them something. Too late. They are digging out of a “negativity well” that is so deep it is almost impossible to get back on a positive theme.

Master Sellers listen to one negative sentence, commiserate a little, and then say, “Yes, there are some bad things happening, but I have found a ray of light in a stormy sea. I have found a great deal for you on…” and promote something of value to their customer—yes/no but not complain, complain, complain.

Koppers Performance Chemicals is a leading, global developer of innovative, patented wood enhancement technologies used in residential and industrial applications. Our products preserve, enhance and protect the beauty and performance of wood used in essential industries around the globe.

Koppers cares for the communities in which we live and work, and we take our responsibility to be a good neighbor seriously. At Koppers, we know that how we treat people matters because everything we do starts and ends with people.

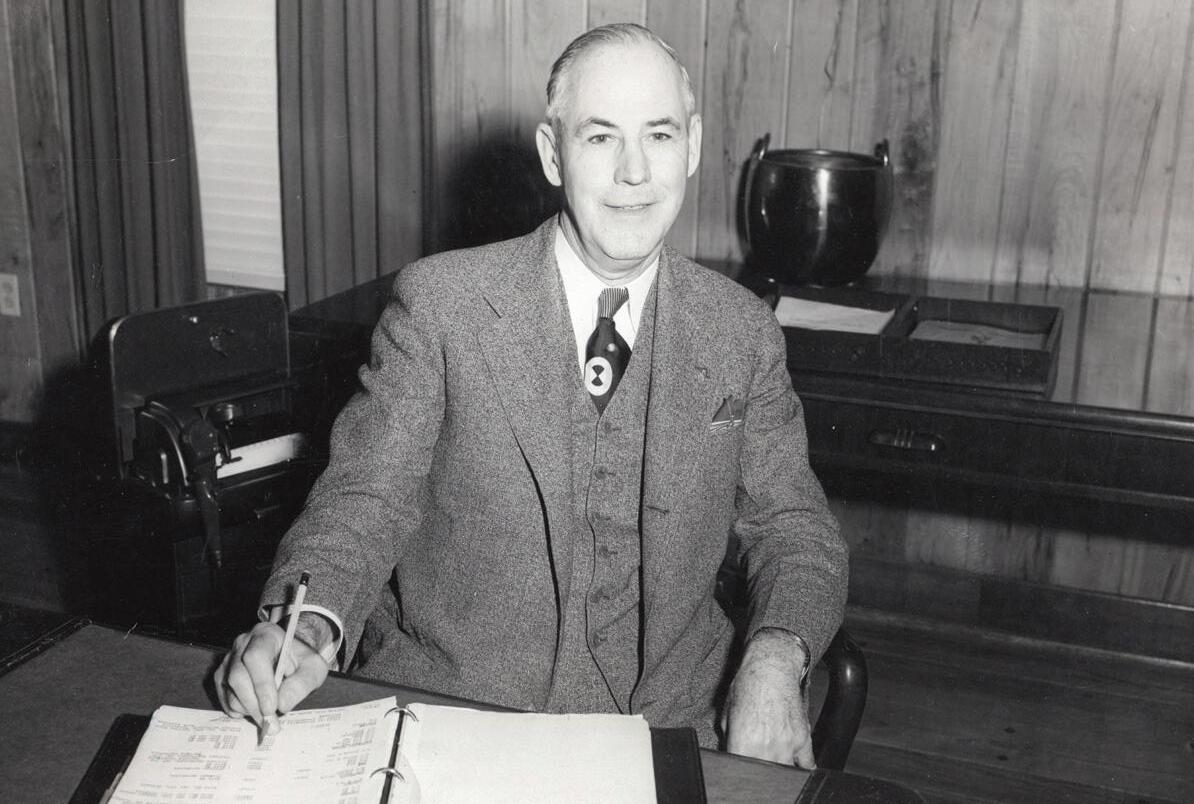

1923

1929

This was Roy’s mantra as he began building the business buying 6,500 acres of the Black Lake timber block. Through his vision, Martin Timberlands L.L.C. practices sustainable forestry on its nearly 600,000 acres of timberland today.

1933

After rebuilding after the first fire in 1933, the sawmill in Castor, Louisiana, opens again and thrives, but burns down six years later.

1948

RoyOMartin used the last mule team to haul logs in Louisiana, moving on permanently to modern trucks and vehicles.

1950

The Martin family presents The Martin Public Library to the citizens of Pineville, LA.

The Martin family presents The Martin Public Library to the citizens of Pineville, LA.

“Buy land and hold land because they don’t make any more land.”Roy Otis Martin of Elkhart, Indiana, purchases Creston Lumber Mill in Alexandria, Louisiana, for $32,000. He names it Roy O. Martin Lumber Company.

WHERE HAS 2023 gone? It’s a question I keep asking myself, and I’m guessing many of you are asking the same thing. It seems we were just ushering in a new year. But a lot has happened—inflation rates are going down, fuel prices are $1 less than this time last year in many places, and grocery prices dipped in March for the first time since 2020. That’s all good news, right? At the same time, tech, media, finance and, most recently, retail organizations have announced layoffs of thousands of workers. That’s bad news, right? And the economy has added an average of 341,000 jobs every month during the last 12-month period.

The 2023 labor market has economists, business leaders, and a lot of others scratching their heads. As always, it’s difficult to pick a few “hot topics” when there are so many right now. So here are some of the 2023 mid-year items to keep you awake at night.

I reviewed several articles by economists and business leaders before writing this in an attempt to get some clarity around current labor market issues. The result: I’m more confused than ever but not feeling so bad because everyone else seems pretty confused too.

This economic roller coaster is best illustrated by egg prices. Egg prices increased over 70% during 2022. Prices here in Arizona were $5+ a dozen in December—if you could find them. The last ones I bought were $1.39. USA Today reports that wholesale egg prices are down more than 80% since December, with no single, simple explanation of why.

There’s quite a bit of good news out there for employers.

• The debt ceiling deal reached in early June removed a lot of economic uncertainty for markets and decisionmakers—at least in the short-term.

• The debt ceiling deal is expected to have minimal impact on the overall economy. Goldman Sachs and JP Morgan estimate only a decrease of .1%-.2% in GDP over the next year.

• The June Federal Reserve decision to not raise interest rates—at least for now—will make borrowing money a bit more affordable for both businesses and consumers.

• The U.S. unemployment rate remains at historic lows. As of June, the number is 3.6%.

• The economy continues to add jobs at a brisk pace—339,000 new jobs were added in May, 209,000 in June.

• Despite headlines describing massive layoffs, many of these job cuts are open positions, reductions through attrition, and the need to recalibrate after “bulking up” hiring

during the last three years.

But there are also some areas of potential concern.

• Despite the Federal Reserve decision to hold interest rates at current levels, rates remain high. These high interest rates may be a deterrent to businesses desiring to expand and hire.

• The Federal Reserve has left the door open to additional interest rate hikes later in the year.

• The U.S. inflation rate was 3.0% in June, down from last year’s high of 9.1%. That’s still a high number, and disproportionately impacts lowincome workers.

• Student loan payments, deferred since the COVID-19 pandemic, are scheduled to resume in September. These payments are often substantial, and incomes in many households will be negatively impacted.

I’ve written about both pay transparency and pay equity in the past, but increasingly we’re seeing the two terms used interchangeably. They aren’t really the same.

Pay transparency is defined by World at Work as “the degree to which employers are open about what, why, how, and how much employees are compensated.” Pay transparency is often driven by legal

requirements. These may include requirements that employers list salary ranges for open positions (four states plus New York City), prohibit employers from asking salary history in interviews (currently 26 states), and provide protection for employees that discuss pay (all employees covered by the National Labor Relations Act are protected).

Compliance with legal requirements often means that current employees find out about pay ranges for their positions from job postings or external applicants. Employers that are proactive about communicating compensation information to all employees will have a competitive advantage not only in attracting new employees, but increasing employee engagement and satisfaction as well.

Pay equity is achieved by identifying pay gaps within an organization and taking steps to minimize/ eliminate them. This is most often accomplished by conducting internal pay audits and adjusting salaries to address gaps and inequities.

There is considerable pay equity legislation, much of which is designed to address gender pay gaps. The federal Equal Pay Act sets a minimum standard for pay equity, but most states have either passed, or are considering, some type of pay equity legislation. State laws vary significantly, so it’s important to be aware of the legislation that applies to you and your employees.

To summarize, an increase in pay transparency, whether legally required or not, can result in an increase in pay equity.

The first anniversary of the Supreme Court decision that overturned Roe v. Wade has just passed. And the number of questions and issues raised by the decision continues to grow.

The decision returned the power to regulate abortion to individual states. Abortion is now illegal in almost all circumstances in 15 states. That’s up from a total of seven states at the beginning of the year. An additional six states have proposed bans that are currently temporarily blocked by court rulings.

Nineteen states and the District of Columbia have passed legislation designed to protect abortion access. These laws are designed not only to protect residents of the state and doctors who practice in the state, but also provide some legal cover to women who cross state lines to terminate pregnancies.

Earlier in the year, 88 prosecutors— mostly district attorneys and state attorney generals—signed a statement vowing not to prosecute abortionrelated crimes. These prosecutors represent approximately 91.5 million people in 30 states. In response, lawmakers in Texas and Georgia have introduced bills that would ban district attorneys from having a policy of not enforcing prosecution of a particular offense.

We are starting to see other impacts as well. Medical residents typically get their residency assignments in May. There are declines in the numbers of students seeking residencies in OB/GYN specialties. And some residents are altering their plans of where to complete their training and where they will ultimately practice. What employers need to do.

• Understand the complexities of the current labor market (it’s not easy) and recognize that recruiting and retaining top talent will continue to present challenges.

• Educate leaders, managers and supervisors about compensation policies and procedures and hold them accountable for appropriate communication with employees.

• Conduct (at minimum) an annual review of current pay levels to ensure compliance with applicable laws regarding pay transparency and pay equity.

• Consider what short- and longterm actions you may need to take to attract and retain women in your workforce. MM

Q. We have received complaints about the hygiene of one of our employees. Can we address it with them?

A. Companies can usually require employees to follow basic personal hygiene while at work. This can include body odor, makeup, hair style, or facial hair. However, employers may not be able to require employees to “look” a certain way simply based on the personal preference of management, co-workers, or a client.

While certain standards may be set by a company, requirements that discriminate against an employee’s race, national origin, religion, ethnicity, etc., are prohibited. These may include prohibiting certain hair styles or restricting facial hair.

Certain factors may need to be considered when deciding on appropriate action.

• Job duties: An employee whose job duties require physical exertion or working in uncontrolled climate conditions should be given more latitude than those who work in an office, for example.

• Safety: Since it is a primary concern, any factor (including personal hygiene) which negatively impacts the safety of the employee or others can be required to be corrected or changed.

• Need vs. want: While some restrictions may be legitimate (i.e., “Beards must be short enough so a gas mask fits properly”), others based on preference (i.e., “All men must be clean-shaven”) may be prohibited.

• Reasonable Accommodation: Certain personal hygiene issues may need to be permitted as reasonable accommodation due to medical issues or religious or cultural beliefs.

When deciding whether to address an issue with an employee, assess all factors of the situation then, if needed, address the employee with sensitivity as there may be factors beyond their control, such as finances or a medical condition. Document the conversation and protect any information gathered. Be consistent in what is required of all employees in a similar situation, being sure to not target certain employees or groups.

in Salt Lake City, Uh.

Cameron Ashley Building Products has opened its first distribution center in Utah, located in Salt Lake City. Headed by distribution center manager Chad Stocking, the new location will stock drywall, acoustical ceilings, fiberglass insulation, residential and commercial spray foam, as well as all the associated accessories for fast delivery to customers’ jobsites and locations.

“Our Salt Lake City customers were previously being serviced by our Las Vegas distribution center,” said regional sales VP Rob Rutkowski. “This new location allows us to improve delivery efficiencies by providing same day and next day delivery in addition to having inventory available for will call.”

The expansion is a continuation of Cameron Ashley’s strategy to expand nationwide. In particular, the distributor is making a big push into the West, recently adding its first DC in California, in Sacramento (see Aug., p. 43).

Columbia Ace Hardware, Stevenson, Wa., held a grand reopening/retirement party Aug. 25-27 to welcome new owners Cora and Jared Sawyer and bid farewell to retiring former owners Greg and Brenda Wiebe.

Ace Hardware, West Linn, Or., permanently closed its doors on Aug. 7, saying it declined to renew its lease because it didn’t think the town was large enough to support two hardware stores.

Westlake Ace Hardware opened a 29,000-sq. ft. store in Porter Ranch, Ca., managed by Henok Aynalem.

Anawalt Lumber, Malibu, Ca., is a new stocking dealer of TruExterior poly-ash composite siding and trim, supplied by Capital’s Southern California branches.

Coeur d’Alene Window Co., Coeur d’Alene, Id., was presented the Gold Level Achievement from the Spokane Regional Clean Air Agency for implementing voluntary measures at our facility that go above and beyond clean air requirements, thereby providing additional benefits to local air quality.

84 Lumber was recognized for the fourth time on the Inc. 5000 List of America’s Fastest-Growing Companies.

Kruse Enterprises, Albuquerque, N.M., is celebrating its 25th anniversary with a dinner party on Oct. 2.

BMD (Building Material Distributors), Galt, Ca., is celebrating its 80th anniversary.

White Cap L.P. has signed a definitive agreement to acquire threeunit Reno Hardware & Supply, Inc., a distributor of construction supplies serving commercial, multi-family and residential contractors throughout Southern California.

Founded in 1966, Reno Hardware and Supply’s three locations in Riverside, Burbank and Signal Hill, Ca., will become part of the White Cap suite of brands in its Southwest region, upon completion of the deal.

“We look forward to adding more talented associates to our team in Southern California, where White Cap got its start nearly five decades ago,” said John Stegeman, CEO of White Cap. “The Reno Hardware & Supply team’s expertise and wide selection of products will allow us to serve our customers with even more exceptional service in both the residential and non-residential markets.”

Four-unit dealer West Coast Lumber, San Diego, Ca., has acquired San Diego-based Stone Truss, a 30-year-

old designer and manufacturer of roof and floor truss systems.

The acquisition marks WCL’s entry into the structural component manufacturing category and an evolution of its product offering. The transaction also comes within days of WCL’s announcement of Jason Walsh joining the company’s leadership team as vice president of component manufacturing.

Founded in 1986, Stone Truss specializes in the custom design, cutting and manufacturing of wood roof and floor trusses. The company will continue to operate from its North San Diego County manufacturing facility and has near-term plans to increase its production capacity.

Stone Truss owners Richard Thomas and Charlie Signorino will remain with the company.

Tim Brown, ex-Capital Lumber, has joined International Wood Products, Clackamas, Or., as business development mgr.

Jason Walsh, ex-California TrusFrame, has been named VP of component manufacturing for West Coast Lumber, San Diego, Ca.

Jason Swieso is new to construction materials sales for Ace Hardware/Mendo Mill & Lumber Co., Ukiah, Ca.

Manuel “Jason” Freitas, ex-New Century Door, is new to commercial door & window outside sales at Ganahl Lumber, Laguna Beach, Ca.

Kenneth Parsons, ex-Lakeside Lumber Products, is a new inside sales rep with Woodgrain, Tigard, Or.

David Grisham has been promoted to new hire trainer with Dunn Lumber, Shoreline, Wa.

Chad Stocking, ex-Rmax, is now distribution center mgr. for Cameron Ashley Building Products, Salt Lake City, Ut.

Peter Hampton has joined Hampton Lumber, Portland, Or., as a public affairs/resources, finance specialist. Jon Calhoun has been promoted to director of transportation.

Mike Farley, ex-Black Butte Forest Products, is new to wholesale lumber & hardware sales for Bridgewell Resources, Tigard, Or.

William Mann, ex-D.R. Horton, is new to Encompass Building Materials, St. George, Ut., as district sales mgr. for Washington and Utah.

Ray Romero, ex-ORCO Block & Landscape, is now Southern California-based South Coast regional mgr. for RedBuilt.

Danika Hartley is new to Knight Wall Systems, Deer Park, Wa., as sales & marketing assistant.

James C. “Joc” O’Rourke, Mosaic Co., has been appointed to the board of Weyerhaeuser Co., Seattle, Wa.

Ray Ferris will retire Dec. 31 as president and CEO of West Fraser, Vancouver, B.C., after 26+ years with the company. He will be succeeded by Sean McLaren, current chief operating officer.

FOR MORE INFORMATION ON REGISTRATION AND SPONSORSHIPS AVAILABLE, PLEASE VISIT LUMBERASSOCIATION.ORG

Chi Lo has been named branch mgr. of L&W Supply, Santa Rosa, Ca. L&W has designated 44 branch mgrs. as managing partners, including Gary Barnson, North Las Vegas, Nv.; Ismael De La Cruz, Inglewood, Ca.; Landon Morgan, Logan, Ut.; Amy Harper, Benicia, Ca.; Don Nielsen, Idaho Falls, Id.; Nigel Smith, San Diego, Ca.; Manny Inostros, Modesto, Ca.; and Doug Weatherholt, Spokane, Wa.

Misty Williams is now traffic mgr. for Spenard Builders Supply, Lakewood, Wa.

Larry Oenning has been promoted to Western U.S. region mgr. for APA - The Engineered Wood Association’s Field Services Division. He is based in Vancouver, Wa.

Cesar Jimenez has been promoted to VP of regulatory affairs, product planning, & product assurance at Toyota Material Handling, Columbus, Oh.

Gabriel Farias has been named VP of OSB manufacturing and Landon Stephens director of OSB sales & marketing planning for LP Building Solutions, Nashville, Tn.

Chris Chmura is the new national sales mgr. for Strasser, Woodinville, Wa.

Brad Bemis, ex-Lowe’s, is now San Francisco, Ca., branch mgr. for Beacon. Gary Rider is new to outside sales in Grand Junction, Co.

Susan Soine, ex-LP, has joined Do it Best, Fort Wayne, In., as a LBM division mgr. Also new are associate merchandise mgrs. Katie Chrisman, Cody Croussore, and Mack Sengthongsavang, and lumber sales support coordinator Megan Robbins.

Andrea Nordaune was appointed senior VP, chief legal officer, and corporate secretary for Andersen, Bayport, Mn.

Michael F. Hilton was appointed to the board of directors of Jeld-Wen, Charlotte, N.C.

Scott McGill was promoted to president of Cornerstone Specialty Wood Products, Cincinnati, Oh. He succeeds retiring founder Greg Doppler, who will remain with the company through the end of the year as a senior advisor.

Dr. Reagan Flowers has joined the Sustainable Forestry Initiative as chief education officer, leading Project Learning Tree.

Anne Teak is heading the new reclaimed woods department at Mungus-Fungus Forest Products, Climax, Nv., report co-owners Hugh Mungus and Freddy Fungus.

Cornerstone Building Brands’ Ply Gem West Pro Series windows and doors have added an interior black laminate color option paired with a black exterior color option.

The products are specially designed to meet Western energy-efficiency requirements and come with glass packages customized to comply with stringent building codes, ensuring maximum comfort and protection against harsh weather conditions.

PLYGEM.COM

(888) 975-9436

Diablo Tools has added to its line of Amped carbide teeth reciprocating saw blades with two new blades: general purpose and medium metal blades.

The blades offer first-in-the-world technology, Titanium Cobalt (TiCo) Hi-Density Carbide and Black I.C.E. coating, to deliver extreme efficiency, cutting life, and versatility in wood and metal demolition and cutting applications.

They reportedly provide up to 100 times longer cutting life of standard bi-metal blades and up to double the performance of standard carbide blades.

DIABLO TOOLS.COM

(800) 263-7016

The most sought-after wood for generations is Back!

A Spectacular Wood with an Authentic Green Story

FEATURES

• Clear, Beautiful, Stainable & Affordable

• CA WUI approved for decking & siding

• Plant ation grown & sustainably harvested

• Class II Durability

BENEFITS

• Surprisingly cost effective

• An exotic hardwood NOT from the rainforest

• Stable and long lasting in any climate

Providing you with quality products and honest service since 1977.

JONESWHOLESALE.COM

YOU ARE THE MOST IMPORTANT ELEMENT OF EVERY TRANSACTION.

LP Building Solutions’ new Brushed Smooth texture for its SmartSide ExpertFinish siding and trim features a subtle linear brushed finish that gives exteriors a modern look. It is available in ExpertFinish’s 16 colors.

The line will roll out regionally, starting in the Northeast, Midwest and North Central

LPCORP.COM

(888) 820-0325

Protecto Wall VP is a primerfree self-adhering, self-sealing vapor permeable weather resistive barrier that can be applied in temperatures down to -20°F and up to 125°F.

The fully adhered membrane utilizes Super Stick Technology Adhesive, eliminating the need for mechanical fasteners, seam tape, or primer. It is compatible with and will adhere to most construction surfaces while maintaining a drainage efficiency of 98.5%.

It comes in full 40”x120’ rolls and 12”x120’ Detail Strip rolls for use along edges and corners. All sizes come with multiple split releases on the back for ease and speed of installation.

PROTECTOWRAP.COM

(800) 759-9727

DMSi has launched Frameworks, an LBM point-ofsale/ERP system that runs completely on the web. An end-to-end system, it handles retail POS, contractor sales, purchasing, inventory control, accounting and reporting. Accessed through a web browser, it has a mobile-friendly design so it can be used from a smartphone or tablet as easily as from a desktop computer.

The POS screen is easy to learn, making it ideal for seasonal or part-time staff. The project management dashboard lets service reps manage multi-job builds from one place, centralizing orders, tasks, pick tickets, deliveries and invoices. The eCommerce/service portal lets customers review products, pricing and account records. Pricing controls simplify challenges around rebates, special buys, and contract pricing.

DMSI.COM

(402) 330-6620

Outlive has expanded its Millboard product line with the debut of the Enhanced Grain Slim Board. The multi-use 126mm (4.96”) deck board can be used alongside the standard 176mm (6.92”) Enhanced Grain board for a unique design alternating every other board, in a random pattern, or the Slim Board can be used as picture frame edging or to define a certain area of a deck.

The only decking hand-molded from natural oak timbers for unmatched texture and variation, it has a strong polymer core that provides structure while also resisting the elements. Boards require minimal maintenance, are slip resistant, and won’t warp or rot from moisture decay, algae, or harbor insects.

OUTLIVE.INFO

(651) 207-4175

Milwaukee Tool introduces a versatile and powerful mid-sized routing solution with their new M18 FUEL 1/2” Router. With the ability to generate 2.25 peak horsepower, the cordless router provides elite control and comfort, and over 225 linear ft. of run-time per charge.

Generating up to 25,000 RPMs, the battery-powered tool delivers the fastest routing speeds with less bog down under load for clean, precise cuts, and more material removed per pass. It features a variable speed dial to optimize cuts across a range of bits and materials, micro-adjust knob and macro-adjust button with 2”+ of travel, dual-LED work light, and universal hose adapter and dust collection shroud.

MILWAUKEETOOL.COM

(800) 729-3878

Westlake Royal Building Products is expanding its Versetta Stone siding line with a new Large Light Box and new colors for stone accessories.

Featuring panelized installation, the siding provides the beauty and texture of authentic stone masonry without the added skill and time required for installation.

The new Large Light Boxes measure 9.5” by 15”, and come in Charcoal, Stone Grey, and Taupe.

Trim Stone, Starter Strips, and J-Channel are now also available in all three colors.

VERSETTASTONE.COM

(844) 521-8486

cally reject such an offer. As a result, the buyers face ‘adverse selection’—the only sellers who will accept $750 are those unloading lemons.

“Smart buyers foresee this problem. Knowing they could be buying a lemon, they offer only $500. Sellers of the lemons end up with the same price they would have received were there no ambiguity. But the peaches all stay in the garage. “Information asymmetry” kills the market for good cars.”

Structural wood panel buyers rely upon qualified inspection and testing agencies like the APA to routinely test and certify the quality of the products they buy. This creates an incentive for individual panel producers to “push” the standard. A passage from Ackerloff’s famous paper:

supplies of small-knot, dense, Douglas fir veneers). The “market for lemons” is likely having a major effect on the size of this market today.

and fall seasons with cold winters, which allow that growth to be gradual—hardwoods from the Appalachian region feature tight growth rings, strong fibers, and consistent colors and grain textures. This leads to strength, durability and beauty in the lumber, in addition to excellent width and long length characteristics.

How can individual panel producers overcome this “lemons market” problem, their industry’s “race to the bottom,” and depressed industry sales levels? They can offer company-specific product performance guarantees

Primary species include ash, cherry, hard maple, red oak, soft maple, white oak, basswood, beech, birch, walnut, poplar and hickory, which are great for high-end furniture, millwork, cabinetry, doors, flooring and paneling, and more.

No matter the region they come from, there are many North American hardwoods species to choose from. The decision as to which one to use comes down to the application and overall quality and look of the project.

“There are many markets in which buyers use some market statistic to judge the quality of prospective purchases. In this case there is an incentive for sellers to market poor quality merchandise, since the returns for good quality accrue mainly to the entire group whose statistic is affected rather than to the individual seller. As a result there tends to be a reduction in the average quality of goods and also the size of the market.”

Another approach is to more aggressively brand products. In either case, the mill’s products need to be clearly differentiated from their competitors’; as we discovered earlier, industry-wide, third-party quality certification is important but not sufficient. Like car buyers, panel buyers won’t chance paying peach prices when they may actually be buying a “dressed up” lemon.

Clopay is expanding its residential entry door line with a new Smooth Fiberglass collection featuring Shaker, Craftsman, Modern and Rustic styles.

The doors feature deep recessed panels with contemporary edge profiles; a brushed etched surface for better paint adhesion; and an internal construction that resists thermal bowing.

long, frigid winter climate, coupled with a short summer season, produces hardwoods with very tight growth rings. This creates lumber with outstanding color and fine texture, which is ideal for applications ranging from furniture, cabinetry and doors to flooring, paneling and more. This region supplies nine primary, widely used species, including: ash, basswood, cherry, hickory, hard maple, red oak, soft maple, white oak and walnut.

Vertical stiles made of laminated stranded lumber run the entire length of the door on both the hinge and lock sides for strength and rigidity against thermal bow. The visible edge of the door stile is made of hardwood, giving the appearance of a luxury door encased in a durable, sustainable package.

DeWalt’s new FlexTorq Impact Driver Bits are engineered for durability, with redesigned tip geometries that offer users optimal performance and fit.

For some structural panel producers, product differentiation requires a major change in company culture. For instance, it is very difficult to produce innovative, differentiated products for the end use market if the company doesn’t also adapt a different supplier-buyer mindset. Supplierpartners are often critical to the structural wood panel producer’s differentiation.

PH2 bits drive 100% more screws per bit, while the bits for use with T20 to T40 size fasteners deliver from two to five times superior fit.

As industry competition comes to focus more and more upon only one of the “4P’s of marketing”—price— “lemons” tend to proliferate and industry sales volume tends to decline.

They also feature a FlexTorq Zone that absorbs impact for up to 200 times longer life, as well as laser-etched, highly visible size markings for quick bit identification.

CLOPAYDOOR.COM

(800) 225-6729

When the industry is young, industry production technologies vary little and raw materials are relatively homogeneous (e.g., OSB), this isn’t a major problem. But it is a serious problem when the inspection and testing agencies find it difficult or impossible to keep up with a very rapidly changing industry. An example would be today’s overlaid Douglas fir plywood industry. There are rapid changes underway on both the demand side (e.g., much higher alkalinity concrete mixes are now essentially “pulping” conform panels) and on the supply side (e.g., much reduced

Spanning several states, including Ohio, Pennsylvania, North Carolina, Virginia and West Virginia, the Appalachian region produces a wide range of hardwoods species—all with one thing in common: superior quality. Thanks to the region’s climate conditions—warm summers that assist with tree growth, and cooler spring

DEWALT.COM

(800) 433-9258

–Roy Nott is president of Surfactor Americas LLC, Aberdeen, Wa., a German-owned producer of overlays, glue films, and press cleaning films for the global wood panel industry, with manufacturing operations in Finland, Germany and Malaysia. Reach him at roy.nott@surfactor.com.

Big Creek Lumber’s sawmill, in Davenport, CA, produces a wide variety of redwood lumber products to independent wholesalers, stocking distributors, and remanufacturing facilities. Big Creek is well known for producing high quality redwood products and providing an outstanding level of personalized service.

Wright now offers a revamped line of superior-quality, Americanmade screwdrivers designed for professional tradesmen.

Featuring rugged handles with a tri-lobe design for maximum strength and torque transfer, the drivers provide high-strength blades and precision machined tips for reliable fastener engagement. They are available in cabinet-tip design, Phillips head, round and square-shank styles.

WRIGHTTOOL.COM

(800) 321-2902

Milwaukee Tool’s redesigned M18 FUEL 16-Gauge Straight Finish Nailer delivers the power to sink nails in hardwoods while leaving clean, consistent nail holes. It is more compact and features a precision tip, allowing access to tight spaces and a clear line of sight for accurate nail placement.

Delivering zero ramp-up time, this finish nailer is ready to fire. With no delay between pulling the trigger and the nail firing, users get a pneumatic fire rate, without the hassles of an air hose.

MILWAUKEETOOL.COM

(800) 729-3878

Lift’n Buddy LNB-2 twowheel hand trucks from Presto ECOA combine the convenience, versatility and ease of use of a two-wheeler with the lifting and lowering capabilities of a compact powered stacker.

At the touch of a button, the platform raises loads up to 200 lbs. to over 3 ft. high, simplifying the transfer of items from floors to shelves, workbenches, etc.

PRESTOLIFTS.COM

(800) 343-9322

It’s summer. It’s hot. This brings back into focus the growing climate concerns that we face today. In response, our team has aggressively adopted a more sustainable approach to our operations here at Western Woods. We have upgraded our facilities to run entirely on solar power. And we didn’t stop there. We have also adopted other sustainable production practices, such as recycling all excess stains, coatings, and received packaging material. We have even found ways to reuse our lumber off-cuttings and sawdust. Just another example of how Western Woods is leading the industry forward.

Excellent products. Unrivaled service. It’s what we do.

» Le arn more at westernwoodsinc.com.

J&W LUMBER and sister company

CJ Wholesale Redwood held their Employee & Vendor Appreciation Event July 22 at its Escondido, Ca., yard, inside an old airplane hangar that had been converted into a lumber storage shed. Highlights were food ranging from wood-fired pizza to fresh Mexican, an open bar, live dance band, and casino tables.

[1] President Clyde Jennings singles out employees with 10 or more years of service. [2] Sean Maloney, Edson Ojeda, Moises Gonzales at the gaming tables.

[3] Lisa & Mike Vinum, Clyde Jennings, Doug Willis. [4] Eric Cashion, Charmaine Jennings, John Hineff. [5] Charmaine Jennings, Cara Jennings. [6] Candy Martinez, Tony Ayala.

[7] Mackenna Mitchell, Sean Murray, Bryce Johnson, Brandon Johnson. [8] Silas Morand, Caleb Morand, Tara & Mark Morand, Lynette Jennings. [9] Oscar Villalobos. [10] Jesse & Diane Grijalva. [11] Zenia Silvestri.

Progress Hardware, San Francisco, Ca., was forced to close following a devastating Aug. 7 fire—and the owners have turned to the local community to help get their 75-year-old business back on its feet. Insurance will help with rebuilding, but donations—through a GoFundMe campaign—are needed to help replace the destroyed merchandise and other property inside.

“The fire quickly engulfed the premises, causing extensive damage to the property, equipment, inven-

tory and infrastructure,” explained Randy Blair, who owns the store with his father, Joe Blair. “While the flames have been extinguished, the aftermath of this catastrophic event has left my business in ruins.”

The Blairs affixed posters to the store’s board-up entrance, directing customers to GoFundMe. “Luckily,” Randy told the San Francisco Standard, “there have been donations. It’s a great thing and shows that the community cares.”

Two weeks into the campaign, Progress Hardware had already raised $42,744 of its $50,000 goal.

Oregon’s Umpqua Valley Lumber Association held its annual Customer Appreciation Event Aug. 1-3, holding all of the usual activities—mill tours, golf tournament, Hellgate Jetboat excursion, networking social hour—but compressing the typical four days of fun into three.

Organizers said the tighter schedule allowed attendees to spend more time with their mill reps, adventure on their own, or get back to the office with a day to spare.

During the event, a fundraiser was held to help the family of UVLA stalwart Kris Lewis, C&D Lumber, who was battling cancer and would pass away three weeks later (see page 48). Her family extended their profound gratitude: “The outpouring of love and support for her is a testament to the impact and amount of joy Kris