t tr Highest Quality Beautiful Color Excellent Durability premium quality, import fencing # 1 & Btr,2 face no downfall r elegant, gold, yellow hr . kiln-dried . no holes, no wane .lightweight & easy to work with r dog-eared, square top, f rench goth ic A Redwood /JEmpllg_ I Divisiorr of lhcific Statcs lndushres. lilc. Distribution Sales 2 W Santa Clara St. PO Box 1438 2nd Floor San Jose, CA San Jose, CA 95109 95113 408.779.7354 So. California 800.800.5609 800.743.6991 www. red woodem p. com Dag*Eared jr-'t;ri ' Square Top I t w;& :ir

ffiffi:1;s:ljflli{

I are backed by limited warranty.

lly penetrates to the core of the board. , cut surfaces, ends and drilled holes not require retreatment at the jobsite. This is ensured by a quality protection program that includes Independent Auditor verification,

The TruCore@protection system is user friendly and does not include volatile organic solvents, heavy metals, arsenic, chromium or similar metals and has no offensive odor and thus can be used for interior applications.

nted Radiata Pine Trim.

The TruCore@ protection system components have been used for over 50 years with an excellent performance history.

The TruOore@ protection system components are recognized by the Window and Door Manulacturers Association (WDMA) and the American Wood Preservers Association (AWPA), Active ingredients are registered with the U.S. Environmental Protection Agency (EPA).

A new generation acrylic primer system: The prime coat has been formulaled with excellent adhesion, minimum tannin bleed, and maximum filling properties. The undercoat has been formulated via use of modified acrylic technology delivering maximum toughness while not compromising the exterior durability of the product.

Sleep Soundly at Night Knowing You are ffiering Customers a Trim Product that is Unrivaled by Any Other on the Market Today.

Distributed By Manufactured By

fr*ffi

8OO-37f -0637 goz) 4ss-ssrs .Faxzoz-4}r-2er3 www. nuforestproducts. com *!*:Lg*" 877-287-44()6 www.clar.rmark.com

Special Features ln Every Issue

rN

rHE

PnoDUCrs.coM

92660.1872 by Cutler Publishing, Inc. Periodicals Postage paid at Nervport Beach, Ca., and additional post offices. It is an independently-owned publication for the relail, wholesale and distribution levels of the lumber and building products markets in 13 westem states. Copyright@2o11 by Cufler Publishing, Inc. Cover and entire contents are fully pmtected and must not be reproduced in any manner without written permission. All Rights ReseNed. lt reserves the right to accept or reject any editorial or adverlising matter, and assumes no liability for materials turnished to it.

M I n G il A il I nasazini''""x1'rt' 3r"'

The

Online 9 lNousrnv TnrHos Hvenro Srrrs Aoo Socrnr Meorn

BusrNrss

26 Sprcrnr- SrcloN: WrsrrnN Wooos

PRooucrroN, Exponrs & OpponruNrrrrs 48 PHoro Rrcnp: 2No Gnowrn 4 r lhe tvlerdrant lhgazine r hnuary 2011

Tornllv RnNoou 'l6 Omnr ON Snlrs 'l B GnrrN Rrrnrr-rNc 24 Movrns & Snnrrns 38 ovrn rnr CouNrrn 42 Knnu On Snlrs 44 Nrw Pnooucrs 49 lN Mrmonrnm 50 Assocrnnor Uponrr 50 BusrNrss Cnno Aos 52 Cmssrnrro Manxrrpucr 53 Dnrr Boox 54 lom Frlr 54 Aovrnrsrns lNorx

lNousrnv Nrws, lNousrnv

& TnE MrncnnNr:

u

lorNc-

1 0 Frnrunr Sronv Grr DrnrEo

To

BusrNEss AovRNrnces or S,rannrpHoNES 'l2 Pnooucr Sporucnr NnruRar Bnnr SrorNc 'l 4 Co,r.rprrrrvr lnrrurGENCE Lu,rasrn & Mrrrwonr Denlrn Gors GneeN ro Gnow 22 tnuw

UstNc MoorRN Co,v,vuNrcATtoNS

Upo,qre oN WESruRN

6

BnrnruNc

Pnoro Dowruloeos,

Drcrrll Vrnsrou B

r

OF ADDRESS Send address label ftom recent issue if possible, new address and 9{igit zip to address below. POSTMASTER Send address chanoes to The Merchant Magazine, 4500 Campus Dr., Ste. 480-, Newport Beach, Ca. 92660-1872.

Merchant Magazine (ISSN 7399723) (USPS 796-560) is published monthly at 4500 Campus 0r., Ste. 480, Newport Beach, Ca.

A California Timberlineo Inc. -t Sugor ond Ponderoso Pine t sa Douglos Fir, Redwood, Western Red qnd Colifornio Incense Cedo ( rh,Mo,oo,T,?,?,,,o,"oounnHordwood Lumber & Plywood Chino, cA 91 71o . (909) 591-481 I . FAX (909) 591-48r 8 &ildiqtftodudsom

Tnr MrncHnNT oN Fncrsoox STRnCH ,,THE MERCHANT MACAZT NE" oN F,tce goor.co,ra CHANGE

The

A LOOK INSIDE:

. Premium Tight Cell Structure * No Volds

. '100oo Cellulcr fl/CNo Fibers or Fillers No Moisture Penetrotion; No Delcminotion

Celtr.rlsr Core Cool to tlre Touch, Even sn Hottest Dcys

Proprietory Copstock

o* All Four Sides

I do love a good whine!

[nsr. I sope vou Hno a Meny Christmas and a happy holiday, and I wish you I' a healthy and successful New Year. Let's hope that at some point in 201I will be the kick-off to the turnaround we are all waiting for. As I wrote last month,I am seeing more optimism, but remain cautious.

I have never been one to make resolutions, since I know there is a fat chance of keeping to them, especially any involving weight loss. I have put on about 2 lbs. a year since joining the industry 10 years ago. Like everyone, as I get older, it is harder and harder to take it or keep it off. So my big first resolution is that I am not going to put those 2 lbs. on this year! Big deal, you may say, but now my second: I shall try to not eat that candy at my desk three or four times a day, I will not eat those cakes at lunchtime, and I will moderate all the free drinks I am offered during the year. Okay, on second thought, as I said, fat chance.

But it was reading an article out of the U.K. that has really made me think twice for 20tl .h turns out in a recent survey that Britain is a nation of moaners (as I was born there, I guess I qualify). Research showed that the average adult complains four times a day and spends about nine minutes a day doing it. So by extrapolation, the average Brit has 1,400 gripes a year and spends 53 hours a year complaining and whining.

Government annoys 50Vo of the population,52To complain about money worries, and 58Vo complain about household tasks. TV and the cost of goods get 65Vo grumbling at least once a week. Monday is the worst day (which is why I have always found Mondays to be the worst sales day).

Now, if they are a nation of moaners, what about the U.S.? Frankly, after the last few years, it is probably just as well that the survey was not taken here, as I suspect the percentages would be even higher. Wouldn't, for example, government and money concerns be in the 9O-percentage range?

I find myself complaining more than I have ever done in my life. I just cannot stand some of the so-called advances today. All those companies who state their customer service is the best should be on the other end of a call one day. Like the call centers where you are hold for an hour and can never get a straight answer, or the health insurance companies (I have been fighting one for four months now for a measly $200, which has cost them about eight hours of labor so far), or the myriad places that give you misleading information.

You know what I mean. Everything seems a hassle today. You have to fight for everything. And, I have found the only way to get things resolved is moan, moan some more, and moan again, and maybe, just maybe, you might get some attention. Indeed I think I am becoming a professional moaner, which confirms I still have my British genes-not jeans, as they do not fit any more!

But I am going to change! I am going to become calmer, take everything in stride, and let it all flow over my head. I am going to become kinder, gentler and more tolerant. But on second thought, why should I? I have decided there is nothing better to get it out of your system than having a good moan. But, perhaps 201I will give us a little less to moan about.

Alan Oakes, Publisher ajoakes@aol.com

*illIRGH[]lr*,*

www. building-products.com

A publication of Cutler Publishing 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

Publisher Alan 0akes ajoakes@aol.com

Publisher Emeritus David Cutler

Dhector of Editorial & Production David Koenig

dkoenig@building-products,com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Dwight Cunan, Cada Waldemar, James Olsen, Jay Tompt, Mike Dandridge

Advertising Sales Manager

Chuck Casey ccasey@building-products.com

Administration Director/Secretary Marie Oakes mfpoakes@aol.com

Circulation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www. building-products.com

Phone (949) 852-1990 Fax 949-852{231 ajoakes@aol.mm

CLASSIFIED

David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather Kelly

Phone (949) 852-1990 Fax 949-852-0231 hkelly@building-products.com or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A.: One year (12 issues), $22 Two years, $36

Three years, $50

FOREIGN leer year, paid in advance in US tunds):

Surface-Canada or Mexico, $48 Other countries, $60 Air rates also available.

SINGLE COPIES $4 + shipping

BACK ISSUES $5 + shipping

TOTATLY Random

6 r Thelvledantltihgaane r hnuary20ll &rildin4iProdu<lson

t The California Redwood Company we've made it easy to tailor the look and feel of your project to mateh individual taste. Simply select the board profrle you prefer below and match it to one of our 3 distinct dwood styies; Classic Heart, Premium Blend or Alpine.

The Classic Look

' Time tested & simply beautiful 'Redwood shrinks & swelis less than other woods so its warm and rich beauty is long lasting too.

The California Redwood Company carefully air-seasons or kiln dries the wood before shipping to ensure less twisting warping or cupping like other woods do.

Elegant &Modern

Engineered shape designed to ensure your deck is as long lasting as it is beautiful.

All four sides of the Meridian board feature a subtle radius, designed to increase water runoff and airflow.

. Each board is hand selected and placed through our planers at a reduced speed, giving you a premium board with a finish that looks oreat on both sides.

The Classic Re-Shaped

Each Summit board features an elegant crowned surface on one side, beveled edges and drip lines on the bottom, meaning water and debris simply have no place to hide.

Each Summit board has been hand picked at the mill and placed through the planer at a slower speed for a more ref:.ned frnish.

lour favorite board profile can be purehased in any of the following unique redwood styles:

PremiumBlend

A rich contrast of wood tones with a refined finish.

Each board is hand selected to minimize knots, providing a deck look that is warm, rich and elegant.

With its mix of warm yellows and deep reds, your prcrject is guaranteed to be one of stunning beauty.

Claeeic Heart

The color and look that made redwood famous. Hand selected, heartwood only. Features a deep red, uniform appearance.

The iook and feel others trv and matchto no avail.

AJpine

A full rich and dynamic color range of redwood, inciuding the character and texture of knots.

. No board is the same, each comes with its own unique history to tell. Great for decks and other outdoor projects Unlike the eomposites, redwood is the real deal. No faking it here.

THE CAI.IFORNIA SERTES'' THE HERITAGE COLLECTION*

or a full list of products offered by the California Redwood Company please visit our website, www.californiaredwoodco.com lr contact one of our redwood specialists, 707-2688AA0 or 800-637-7A77.

A long history behind us. A longer one in front of us.

The California Redwood Company and our parent company, Green Diamond Resource Company, trace our roots back to r8go. Our shared history is one of environmentai stewardship with an earned reputation for progressive and innovative voluntary forest and wildlife protection. Green Diamond's dedication to practicing responsible and sustainable forestry brings together experts in wildlife biology, herpetology geology, botany and frsheries to work in tandem to nurture and protect our vibrant. workinq forests.

These forests are certified by independent auditors to comply with the rigorous forestry and environmental standards of the Sustainable Forestry Initiative (SFI) program as well as the California Department of Forestry standards. Because of this shared commitment, you can be assured that the quality iumber products produced by The California Redwood Company are not only beautiful, they also come from sustainable and renewable resources so that we can all enjoy the beauty of redwood today, and forever forward.

Green Diamond Resource Company is a famiiy-owned company that owns and manages timberland in California and Washington. The California Redwood Company, produces high-quality wood products in California. Green Diamond is headquartered in Seattle, Washington.

rfVTcnenru DTAMoND

".""@,." -c^rrl?i*nrt RE DWOOD coMPANY_Build history General Sales Office: 707-268-3000 or toll free 800-637-7077. www.californiaredwoodco.com The Cali{ornia Redwood Company,5r5r Highway rot North/P,O. Box to89, Arcata, CA gSSrS-to8g

RESOURCE COMPANY

Hybrid sites use social media to hook builders

rflftEEniR G!!

ffi g

SITES SUCH AS Builderlink provide tools to help businesses thrive, while also providing space for interaction and networking.

[r,+ceeoor FoUNDER Mark Zuckerberg once remarked L' about his own sprawling creation: "It's not done, and we don't know what we're doing yet." Faced with the task of figuring out how to make social media work for our businesses, we in the construction industry might be thinking: If he doesn't know, how are we supposed to?

Sites like Facebook, Twitter and YouTube are fueling a social-media revolution. Ninety million tweets and two billion YouTube videos watched per day... more than half a billion Facebook users around the globe... the numbers are staggering. The conversation is big and loud. But is there any value for the building community?

Second-hand promotion is one tactic. Many companies use social media as an inexpensive marketing tool to reach large audiences with minimal investment. This can be as simple as setting up a profile and attracting a following of friends, clients and colleagues. Yet, passive promotional strategies rarely offer the clearly measured deliverables craved by the hammer-in-hand, old-school audience.

"There is a generation gap," explains Leah Thayer, publisher and editor of daily5Remodel, an online publication for remodeling professionals. "Social media is a fast, interactive communication channel that many business owners in our industry aren't inclined to keep pace with."

Undaunted, Thayer, formerly an editor at Remodeling, created daily5 as a one-stop digital resource for her core professional audience. It's an online destination for news and updates that matter to the remodeling crowd, from young, tech-savvy newcomers to veteran tradespeople.

So, it saves time. Now we're talking about tangible ben-

efits that transcend generation gaps. Other industry-related sites are getting in on the action, combining Web 2.0 functionality with back-to-basics builder sensibility.

Builderlink is an online community of builders, lumberyards and manufacturers who aren't necessarily posting pictures of their pets, but they are taking care of business. On the site, more than lg00 builders are gathering technical data and getting real-time estimates on lumber and building materials, lumberyards are creating new channels of access to their customers. and manufacturers are reaching a whole new focused, web-based audience. And they're all gathering in one place. So is that social media?

"With a twist," explains Builderlink president Steve Killgore. "There's a social media function, but Builderlink is really based on tools that offer time- and money-saving value. Within the context of an online community, we're supporting lumberyards with the estimating tool, offering a technical library with product specifications and tech guides, and giving a platform for webinars on relevant industry topics."

About this hybrid form of social and business mediums, Killgore lauds "the possibility of increased efficiency," which, tech wiz or not, is something for which everyone in the building industry is still striving.

The social-media universe will no doubt continue its rapid evolution, as the early adopters break away from the Facebook and Twitter masses to offer industry-focused content and tools. If these new hybrid players can offer the promised efficiencies of information and transactions, the benefits of the union between social media and the buildine sector just got a whole lot easier to measure.

Network with Builders

A sampling of construction+elated web destinations with social-media fu nction ality :

Builderlink (www.builderlink.com) Online tools connecting lumberyards, builders, engineers and manufacturers, Cadreas (cadreas.com) Web-based platform to unite consumers and home design professionals.

Daily5Remodel (daily5remodel.com) Online info hub for remodeling industry professionals.

Hard Hat City (hardhatcity.com) Professional networking site for construction industry members.

My Online Toolbox (myonlinetoolbox.com) Platform to help contractors manage theirjobs and businesses.

Remodel Crary (remodelcrazy.mm) Ongoing dialogue of blogs, news and chatter from the remodeling world.

l-lgkbfr ) g x a tiq*"ii.iiiliBuilder Community Websites ryry

sil. et[ h@

BuilderLink In@a$on + ommunltl .milrry.rn trne6. nnhFr. 8ub{d ts. 9tury d6.ommudry oreieR, [mb.ry.6. & bw ebno@i .d :.e.!on.l

ftc spccd of Thdght qtitu@Dr - - yos oarm b6es nr.6ry r .v.3r r'^{b.5N. s$ nbr.ry

Thc lulldlng Indssty unld m . Slngl. Oollnc Plsttm

Use smartphones to energize your business

into a texting, tweeting, multi-tasking productivity, and entertainment gadget that offers a wide range of possibilities for you and your business.

The lightning-speed advancement of the smartphone has left many companies scrambling to keep up with the technology and new opportunities. According to ComScore, 45 million smartphones are now active just in the U.S. Like social media, they are the new wave of communication and the only place they are going is into the hands of more and more consumers.

So, how can you capitalize on the growing popularity of this new technology? Here are four things you can start doing today to increase brand awareness, build relationships and grow your business:

1. Use text message advertising

2.Create a smartphone app

fn sonaeoirrE HAD rolo Alexander

IGraham Bell that one day his invention would evolve into a device that could turn your lights on and off, he would have taken your temperature with a mercury thermometer, which incidentally, in 1876, hadn't changed much in over 100 years.

Remember when cell phones first emerged? Chances are, you were just as cynical as Mr. Bell. You probably made that first call with a furrowed brow, skeptical to the possibility it promised. You were certain that your call wouldn't connect, or at the very least your voice would be overridden by static. Like the rest of us, your bulky cordless phone had conditioned you to only walk within a certain range to avoid disconnect. Then you made that first call... from an oversized bag-type cell phone and-shazam-how cool was it to have the umbilical cord of your landline cut and the freedom to connect anywhere in cell-phone range?

What started as a must-have device that didn't tie you down has morphed

3. Make your website smartphonecompatible

4. Engage mobile customers via social networks

Text Message Advertising

More people now use their mobile phones for texting, rather than making a phone call. Plus, most users have it attached to their hip, figuratively speaking. Imagine the impact of advertising to your target market via SMS (Short Message Service) text message: you have the opportunity to get their attention, anytime, anywhere. Smart marketers get creative with these campaigns and often include a chance for the recipient to win something by responding to the text. Other ideas include mobile coupons, event invitations, mobile alerts, and special promotions.

SMS text marketing works for virtually any industry, is relatively inexpensive, and allows creation of highly targeted campaigns. The first step in launching a text-messaging campaign is to find a company that provides sub-

scriber lists and can distribute your ads. Search your favorite search engine for "mobile marketing," "SMS text marketing," or "SMS advertising," and you'll get plenty of options.

Create a Smartphone App

Like most things, smartphone apps have been created to solve a problem, increase productivity, offer an intrinsic benefit, or for pure entertainment. Apple's iPhone store alone has more than 150900 apps available for download and users have downloaded more than 3 billion apps. The HTC and Motorola Droid (a.k.a, Android phones) also have millions of users and offer thousands of apps.

You don't need to be a member of the geek squad to capitalize on this trend; all you need is an idea for an app. There are plenty of companies who can help you develop an app to sell or to offer for free. A word of caution: do your due diligence and check the developer's references to ensure your intellectual property and ideas are protected.

If your app can solve a problem (i.e., the Jott app records voice messages and converts them to text messages), then you're on the right track. If you own a smartphone, think about your favorite apps and how you heard about them. Most likely you heard about them from a friend. Viral wordof-mouth marketing is why popular apps can grow in use so fast with virtually little marketing expense.

Make Your Website Smartphone Compatible

The Internet is going mobile. Have you visited your website using a smartphone? What type of user experience did you get? If you want to gain a competitive advantage over your competition, your brand needs to be as mobile as your customer. Your customers and prospects don't have the

By

Ford Saeks

10 r lheltrkrdrantltrhgadne I hnuary201l ---r-r r-- ]- T

&rlHirg-hodudsom

patience to view websites on their phone that aren't user-friendly.

Start by viewing your current website on a smartphone or iPad. If you haven't designed a mobile-specific site, it probably won't look the same. Text is smaller, graphics may not show up, and you have to scroll up, down, left or right to view content. You'll get much more targeted traffic and improved conversions if you create a mobile-enabled version of your site's main content to meet the demands of today's multifaceted Internet mobile user.

Creating the mobile version of your

Smartphone Brands

Apple iei'one

BlackBerry Bob, curve, storm, Tour

D€ll Aero, venue Pro

HTC oesire, oroid, Evo, Fuze, Hero, Pure, Snap, Sunound, Tilt

LG nrena, Dare, expo, Incite, Neon, optimus, Prime, Rumor. Vu Plus. Xenon

HP/Palm iPAo, Pixi, Pre, Treo

Huawei nscena

MOtofOla charm, cliq, DEFY, Evoke, Flipside, i1, Milestone

Nokia surse

SamSUng Acclaim, Behold, Blackjack, Caliber, Captivate, Code, Crafl, Delve, Epic, Etemity, Exec, Fascinate, Flight, Focus, Gravity, Highlight, lmpression, Instinct, Intercept, Inhepid, Jack, Mesmerize, Mythic, Omni, Popel, Reality, Seek, Solstice, Transform, Vibrant

Pantech Ease. Laser. Pursuit

S?]ltO tncognito, Innuendo, Zro

Sharp rx

Sony Ericsson xpedo

T-Mobile comet, MyTouch

website's content from a layman's point of view requires reformatting the navigation, text and graphics to fit the smaller screen size of smartphones. The files are then published on your web server, and special code is added to your regular website to identify the type of device accessing your website. When a user visits, the appropriate version of your site is displayed. It's a good idea to provide links from your mobile version to your full site.

those users commenting on social networking sites and 43Va contacting with friends through the sites.

Imagine the impact you can have when your customers can view your YouTube videos anytime they want using their smartphones. Just think of the effect a viral video could have on your business success. This can only happen if you create and upload the videos to content sharing websites like YouTube or Vimeo. There are hundreds of video-sharing websites, but start with YouTube since it's the second largest search engine.

If you're not friending and following, tweeting and YouTubing, you're missing out on a lucrative opportunity to connect and engage with your target market. Social networking has leveled the playing field; it's no longer just the companies with an over-inflated ad budget who can make waves. If you learn to add value and create a presence on websites like Linkedln, Facebook and Twitter, you can expand your reach, increase awareness ofyour brand, and create a loyal following of customers who will help promote you. Research shows that more people access social media via smartphones than with their desktop computers. People who access the Internet with their smartphones are more likely to socialize online than their desktop counterparts, according to a Ruder Finn study. The study found 9l7o of mobile Web users socialize online, while just 79Vo of desktop users can say the same. The average American spends 2.7 hours a day on the mobile Web, the study found, with 45Vo of

Keep your videos short, authentic and to the point. If you have a larger message, you may want to break it down to shorter segments as user's attention spans have shortened.

Don't Wait... Make Your Brand Mobile

Not only is mobile marketing a great way to gain and connect with new customers, it also enables you to add value for your current customers. By making your brand mobile, you will increase awareness about your company. products and services.

The future of your business is in the palm of your hands, and in the handheld devices of your customers and prospects around the world. If you aren't on board already, make sure you jump on-or you and your business will surely get left behind.

- Ford Saeks, a business growth expert specializing in integrated marketing and social media campaigns, is a speaker, author and c.e.o. of Prime Concepts G roup (www.prime c onc epts.com ).

Roshoro $ facitic Wood Laminates,lnc. --;//F TFtr Distributed By NIOR.ilTAN P.O. Box 1802, Medford, OR 97t01 ' Fax 541-535-3288 (541) 535-3465 . www.normandist.com pomtrlAt DURAsTRANDFtooHT BniHingrRodudsom hnuaryZ)ll r Thettlerdantl{agadne r 11

Bark hopes to take bite out of siding market

For a tree, bark acts like a suit of armor, protecting it against extreme weather and insect attack. Consequently, a small but growing market has surfaced for siding made of bark, to provide similar protection to homes.

The Merchant Magazine asked Patrick Parton, bark siding specialist at hardwood manufacturer Parton Lumber Co., Rutherford, N.C., for a rundown on the bark siding market:

The Merchant Is this a new trend, or has bark siding been around for a while?

Parton Actually, bark siding has been around for more than 500 years, dating back to the North American Indians. Modern use of bark, however, began in the mid-1800s. The original tree of choice for bark siding was the chestnut. So, with the decline of the chestnut tree went the decline of chestnut bark siding. Later, in the 20th Century, another suitable species was identified-yellow tulip poplar. Found throughout the eastern U.S., yellow poplar has many of the same-and some would say bettercladding qualities as chestnut. With the switch to poplar, bark siding is making a comeback.

How is it used?

Typically bark siding is used as full siding on the building or as an accent on various areas such as dormers or

gables. This gives the structure a durable, tough and visually appealing exterior cladding, as well as a unique rustic appearance. It is generally installed over housewrap and roofing underlayment, with only a few simple tools. Bark siding can also be used inside the home, as paneling. Bark shingle thickness ranges from ll4" to 9116" for interior application, and 5/8" to l-3l8" for exterior. Bark outside this range is rejected. A minimum thickness of 5/8" makes it better able to withstand harsh weather conditions. Shingles come 18" and24" long. The width of the shingles varies randomly between 4" to 18", but can be recut.

Weatherability then must be its strongest selling point?

Poplar bark siding is extremely rugged and durable. Houses 75 years old exist that still have the original bark siding intact. Remember, bark is a non-living, protective covering for trees, comparable to a human fingernail. Its weather surface lasts the lifetime of the tree.

In addition, bark siding is kiln-dried to reduce moisture content, further increasing its strength and long-term integrity and reducing the chance of shrinking, cracking, staining and decaying.

Does bark siding needed to be treated with preservatives or sealant?

No, it's naturally weather resistant. Bark siding doesn't require sealants, chemicals or preservatives, meaning there are no additives to potentially seep into the ground.

Is bark siding resistant to insects?

Yes. The kiln drying process ensures that insects and

PRODUCT Poplar Bark Siding

I n_-l_t \ v) s 12 r fheMedantltrhgadne l,lanuary2Oll

Bnlldlngrhoducts.on

NATURAL BARK provides a rustic, weather-resistant sidinq material.

their eggs are killed when the wood is heated above 130 degrees, especially at high humidity. Also, bark does not attract carpenter bees or termites.

How' muc'h does it <:ost, relcttive to othe r s iding mat e r i al s ?

The bark is expensive to ucquire and process, so bark siding will cost more than, say, vinyl or hardboard. But when you take into consideration that it is maintenance free. will last the lifetime of the home, and provides that distinctive look, the cost becomes quite reasonable.

What are the prospects Jor grow'th in the bark siding market? Can its popularity grow beyond Appalachia?

The fact that poplar bark is a beautiful, resilient and renewable siding material makes it appealing to individuals in all parts of the country. Since it is such a versatile material. it can be used in both residential and commercial appl ications.

With the growing consumer demand for sustainably harvested wood products and eco-friendly building materials, the market for bark siding shows a lot of potential for growth. ln addition. an increuse in demand for bark siding would help make it a more affordable optionmeaning buyers would get 'more bang for their bark.'

At PLM, we understand that you need an insurance company with property and casualty insurance products and services that you can trust today and tomorrow.

For over 'l OO years, our experts have been providing quality claims and risk management services to the lumber, woodworking and building material industries. Remember, "you get what you pay for." We understand wood. We know your business... because it's our business too. Wood is all we do.

lf you're looking for quality and value from your insurance provider, please contact us at 800.752.1895 or log onto www. plm ins.com/ad/M M.

CPCU President ond Chief Executive Officer

ffi ;r rk .$ r *:$ i rt 61 f#im n * 1l;l nf ri.* i:.; Barkclad Natural Products Canton, N.C. www. poplarbarksid ing.com (distributed in West by Bridger Forest Products, Belgrade, Mt.) Everhart Lumber Go. Tellico Plains, Tn. everhart-lumber.com Furniss Enterprises Lake Toxaway, N.C. www. naturalbarksidi ng. com Hardin Creek Boone, N.C. wvwv. ha rd ncree km lwo rk. co m Highland Craftsmen Spruce Pine, N.C. barkhouse.com

Lumber Rutherford, N.C. www. pa rton barks id n g.

Building-Producb.<om PeruNsvlvnNrA LUMBERMENS Murua.l . \ '! l: . r I ,r "i :' I 'r i SERVINC CONTINENTAL , @ jporii. neiitieni. Enduring.

Parton

com

Grow knowing you're covered. Jilo Snit/t fohn K. Smith,

Pennsylvania Lumbermens Mutual Insurance Company { )rrt' { .onrrrrclr"t \rllrart:, J{X}5 \llt'lirt Stri'r'1. \uiic I l(X} lllril.rrk'lnlriu, l'\ l'.;it!.{ I lcl: S{}{}.7i1.!$*i UNITED STATES tanuary 20ll r lhe lvterdrant tihgazine r 13

By Carla Waldemar

Virginiats Better Living gets better yet

Derrsn LrvINc INc., CharlottesIlville, Va., was saluted last year with a Governor's Environmental Excellence award for its new, eco-forward millwork shop.

Most often, in outfits that have been going since 1893-the year the original lumber company was founded-it's tradition that's trumpeted. So why lead the vanguard-*hy take the pains-to become the first LEED-certified building in central Virginia, instead of simply glorying in the good old days?

"It just made sense," says president John Nunley, the fourth generation of his family to lead the company, in his gentle, no-big-deal Virginia accent. Well, "sense" is what Better Living (formerly Charlottesville Lumber) has employed all along. So, it seems, we're looking at tradition after all.

John's father, Richard, demonstrated his own brand of forward-thinking by purchasing (gasp!) a forklift way back in 1958, then presenting his

unwitting boss (and father-in-law) with the bill. In 1960 he went on to open a furniture store as a sideline. It's still going strong. Richard also guided the company, his son, John recounts, in opening a second building center in2OOT,located 30 minutes distant, to capture further market share.

Today that vanguard forklift has grown to a versatile delivery fleet of 40 vehicles, all painted the same distinctive green-and-yellow colors and sporting the company's logos on both doors as free advertising as the company keeps on trucking forward.

To justify the new "green" millwork shop was a no-brainer, according to John's mode of thinking: "We've been in business since 1893 and plan to be around a whole lot longer." Thus, a solar-assisted heating system that will pay back after five years. An 80,000-gallon water storage tank under the parking lot that collects rainwater ("With so much sawdust,

we've got to think of fire retardation"). In addition, low, or no, VOC materials were employed in its construction, and over 92Vo of building debris was recycled.

Do Better Living's customers, 857o of whom are pros, give a rip? Maybe they ought to. "It's the trend of the future," John declares.

Looking ahead is a huge part of what's helped Better Living grow from its three original employees to a current staff of 110. "We watch trends through a very good group of managers heading our four departments: building supplies, cabinets, the door/mill shop and furniture. Each department is run as its own profit center by those managers, who foresee and meet market demands-by reading, attending shows, and seeking out customer feedback," says their boss.

Keeping abreast of technological innovations as well, five years ago Better Living adopted a deliveryldispatch software model with GPS that allows the sales department to track trucks; each driver is equipped with a mobile communications device as well. A recent decision to update its electronic network now assures that everyone is on the same page (well, screen).

Managers, schooled to sell addons, take advantage of those weekly meetings to report on jobs they're quoting as a nudge to other departments to get in on the bid and snare the whole package-the stairs man passing on leads to the lumber guy, and so on. In an even more robust marketing strategy, if a contractor is known to shop at Rival X for a certain item, he's likely to be visited by a Better Living salesperson who can demonstrate why his company's simi-

t4 r Thelilednntllagazine r hnuary2011

_I Bulldltrgrhodudsom

FOLLOW THE FLEET: Virginia dealer has built its delivery service up to 40 multi-purpose vehicles.

lar product is more efficient, cheaper, a better cholce.

These folks check building and remodeling permits on a weekly basis, then set out to woo those builders with insights on superior customer service (the company had developed and built many homes and commercial buildings on its own for years, so they demonstrate they can walk the talk.) As well as guaranteeing adept delivery, they set forth how they can deliver on their promise of easy, one-stop shopping-for Better Living not only has added millwork to its dance card, but the Nunleys also own Better Living Components, maker of wall panels and trusses.

And for its customers' customers-the home owners themselves-its design department gladly hand-holds prospective buyers through 3-D computerized demos of their options, from trusses down to cabinets. Add in the furniture line in a third, adjacent location, and folks are ready to move right in. "Furniture sells better in the opposite cycles, when home construction doesn't," notes John, who keeps eggs in several baskets. ("Except this time," he groans.)

Better Living recruits d-i-y devotees through "advertising that explains our products and promotes confidence in shopping here," says marketing manager Pat Mete, who

nity made us successful, so we want to give back," John explains.

Contractors are reached, and rewarded, with programs of their own, beginning with imprinted give-aways like carpenter pencils, sweatshirts and hats, chosen not only for quality but to convey a specific message. For instance, says Pat Mete, "Our mill shop wanted to bring attention to its onsite measuring service for stair systems, so 'Better Living...We Measure' was imprinted on the pencils."

The company regularly hosts appreciation events such as barbecues, in-store trade shows, golf tournaments, and outings that range from football games to concerts. But Mete doesn't simply toss tickets at anyone who wields a hammer. "Each social event is well-planned," Mete insists. "We would never just throw something together because the quality of the experience should reflect the quality of our business and the respect we have for those who trust us with their business," she emphasizes.

In hiring employees, John places prime importance on a strong work ethic, unearthed by "putting a lot of time into our interviewing process." Once on board, they receive cross-training to insure a backup for every position, as well as ongoing education in new products, including emphasis on the growing 'green' movement to which Better Living is committed.

And why do these staffers stick around? "Because we care about them!" John responds. "We're very conscious of putting the shoe on the other foot in the way we handle things. And my door," he likes to stress, "is always open."

Facing up to today's Slim-Fast economy, John has eliminated slow-moving SKUs from the company's diet. He's also curtailed overtime and bundled deliveries by geographical route. Prices are kept in line by shopping the competitors ("unfortunately, they are many"), and utility bills are pared by dimming lights and lowering thermostats in off-hours.

Every little bit helps the bottom line. But the big switch-focusing on remodelers-is what's keeping Better Living alive and kicking in these troubled times. Fortunately, there's a little gravy at the high end, too. "If people have the money, now is a great time to build, while labor costs are low and materials can be had at very competitive prices," John underscores.

also heads the furniture store. Traditionally, she has chosen a mix of radio, print and TV to convey the company's message, but when faced with budget cutbacks imposed by the recession, she decided to focus solely on print, explaining, "By shifting dollars to a single media source, we were able to increase buying power and exposure while lowering our overall advertising expensesand it's working effectively. Because of our longstanding support of public television, however, we continue to underwrite Home Time, a targeted home-renovation program."

The company also actively updates its website, www.betterlivingvirginia.com, as a customer resource for product and service info as well as to spur the more warmand-fuzzy hometown connections fostered by sharing the history of a committed, fourth-generation family business. It also adds modestly stated insight into the huge impact on local quality of life its charitable giving program has effected. The Better Living Foundation,launched in 1988, focuses on education and feeding the hungry, John reports. But beyond donations ($313,000 in 2008 was typical), he and employees volunteer their time as well. "The commu-

Looking ahead, 2011 will be no picnic: "Rough," he intones: "Pretty flat. But things should get better by 2012, when we get out from under the blanket." In the meantime, calling on both his MBA and OTJ training (He's clocked time in the family yard since he turned 13), John, by his own admission, is "always looking for ways to improve the processes and the equipment-finding efficiencies and passing those savings on to the customer"-which means moving forward with everything from new software to greening his corner of the world. because he's in it for the long run. "Never a dull moment, and that's what I love about the business: our employees, our customers, visiting the jobsites-it's all about the people!"

Carla Waldemar cwaldemar@ comcast.net

EACH of four departments-door/mill shop, cabinets, building supplies, and furniture-is run as its own oroflt center.

BnlldingRodu<lscom

lanuary 20ll r lhe ttlednnt ihgazine r 15

By fames Olsen

Tough is not enough

Our customers don't know how we are selling. They do know and feel how we act. If we act proud of what we do, they will buy more.

Underachieving sellers are ashamed. They talk and carry themselves in a way that screams second-class citizen. Life is a mirror, so these salespeople are treated poorly and blame it on the customer.

Rule 3: Prospect. The top 2OVo prospect for new business a// the time. The bottom 807o prospect when times are tough. Too late! Master sellers make prospecting an ongoing part of their business. Minimum 107o, that's one full day every two weeks. We do it and our business grows-guaranteed.

fN rue MovrE Pretty Baby,Clint Eastwood plays a wizIened boxine trainer who has seen it all and more than he'd like. He ias a sign over his office door: "Tough Is Not Enough." Later in the movie, Clint explains, "Show me a kid with nothin' but heart, and I'll show you a kid who's ready to take a beating."

Many struggling sellers are hard working and honest, stand behind their products l$OVo, and offer a good product mix, great service, and competitive pricing. Many think this is enough. It's just the sit-down money.

There are high stakes poker games where all you need is the money it takes to sit down. The less you know, the better. There are "different" and "secret" rules that the professional player of any activity knows that the amateur does not.

Rule 1: Pareto's Cruel Truth: If there are 10 salespeople in any territory, two of them are getting 807o of the business.

What are the top two doing differently than the other eight? The bottom 80%o are:

Information dispensers: They give the customer anything they ask for, but don't ask for anything in return.

. Product presenters: They are knowledgeable about product and are glad to talk to potential customers about specifications, about anything-except purchasing.

. Service agents: Service is a sub-set of sales. The bottom 8O7o think they can service their way to the top of a sales business. Master sellers sell and service their accounts.

Rule 2: Be Proud to Be a Salesperson. The difference between the top and the bottom is pride. The top 207o arc proud to be salespeople. The bottom 80Vo are ashamed. They don't like salespeople. How can you compete against someone who loves themselves and what they do, when you hate yourself and what you do?

Rule 4: Promote, Don't Quote. If we are asking customers what they need after the needs analysis step in the sales process-master sellers are thorough and meticulous in this step-then we are in the bottom 807o.

The top 207o offer products and solutions. They ask lots of questions, listen for pain, and then prescribe a solution(s). We cannot have a good life as sellers if we chase customer inquiry/RFQ. Customer desires are too diverse and frivolous to chase. We must uncover customer need and sell to that need.

Rule 5: Ask More Often. The bottom 80Vo are waiting for the magic phrase that will change their sales lives. Working with a group of new sellers, I had Donnie, a master seller, come into class to show them how it was done. Donnie is self proclaimed "Mr. Wonderful." (Another characteristic of many master sellers-they live in their own dream world.)

Donnie is not smooth. He is not artful. He does not have the magic turn-of-phrase that makes customers buy. He is positive and he is persistent. Donnie asks for the order-a lot.

The biggest "technical" sales difference between the master producer and the rest: The top 20Vo ask for the order and ask more often. I repeat, they ask more often.

The underlying psychology: Master sellers understand that the basics are just that-basics. Tough is not enough. Master sellers add the element that makes all the difference: salesmanship.

r OLSEN On Sales

16 r lhelvlerdantlhgadne r JanrnryA)ll

James

Reality Sales Training (s03) 544-3572 j ames @ realitysalestraining.com &rlldhqrPndudsom

Olsen

Backed by 20 years of proven performance, and a lifetime limited warranty.

Choose Preserve' ACO pressure-treated wood, an environmentally advanced preservative svstem that provides proven, long-term protection f rom decay and termites.

. Standardized by the American Wood Protection Association

. NAHB Research Center National Green Building

Certified as a "Green Approved Product"

. Winner, 2002 US EPA Presidential Green Chemistry Award

ICC Evaluation Service Report (NER 643)

Above Ground and Ground Contact applications

Approved for fresh water immersion and salt water splash zone

For decking, fencing, playgrounds, walkways, benches, sheds and gazebos.

Wood For Today s '*-' a a

lir"&&.

[or more nformation on these and the full line of Viance keated wood proCucts, cali 800-421-8661 or visil W$mms* -,,,,_ .n 73PN, Thi5NAHBResearchcenter W &Br ffiW ii{$'?,,*1;;1qHlHi"ii:t" P,oud spon5of \(d!Pz' lppnOvro Buitdinq certification.

Taking the long view

to less toxic and more eco-efficient products from socially responsible producers. Competition between "big box" chains and independent dealers will continue, with increasing activism from localization groups. The green d-i-y and urban agriculture movements will continue to take root across the country. And a host of global and domestic macroeconomic factors will attenuate or amplify these opportunities and threats.

65fN rHE LoNG nur.r, we'll all be dead." That unfortunate lutterance from a now-dead economist has provided a handy excuse for shortsighted business planners focused only on extracting the maximum profit from the here and now. That kind of thinking is responsible for many business failures, yes, but also many environmental problems more daunting even than the federal deficit. Failure to consider the future implications of decisions made today virtually guarantees a legacy of difficulty and hardship for the next generation.

Taking the long view, on the other hand, is at the heart of green thinking. Therefore, this January, I encourage you to forget about 20ll's top trends for a moment and invest some quality time considering the next decade, and the opportunities and threats it will present to your business and community.

The best place to start is at the end-what will your business look like in 20202 Has it been passed down to your children? Acquired, shut down or thriving with you securely at the helm? Is it connected to the same old supply chain? Is the local economy vibrant and strong, or struggling along? Most importantly, what do you want your business to look like and what sort of realistic scenarios will lead you there? To answer these questions, one must first consider the long-term forces reshaping our industry.

The next decade will see plenty of change and probably as many surprises as the last. Obviously, green building is on its way to becoming the new normal. Whether it's LEED or another approach, it creates new opportunities for growth. Transport fuel prices are trending higher with the very real possibility that periodic episodes of price volatility will devastate marginal businesses. Households, businesses, and governments will continue to shift purchasing

But underlying whatever scenario one wants to envision for the next l0 years, there is the inescapable reality that the global climate system is changing, most likely due to human activity. The last decade was the warmest on record, but more important to consider are the local and regional impacts. Extreme weather is becoming more common. NASA has published a slideshow depicting the number of temperature anomalies each decade going back to 1880 (earthobservatory.nasa.gov/features/worldofchange/). The trend is unmistakable, which should be cause for concern, especially in the context of the massively destructive heat wave that hit Russia last summer.

Regional climate patterns are changing in ways that dealers and distributors should understand and anticipate. The U.S . Global Change Research Program (www.globalchange.gov) provides useful analysis for each region of the country. Depending on your location, expect more drought, more fires, more floods, more heat waves and cold snaps, and more precipitation when it comes. And when these "anomalies" occur, they will probably be at the wrong time, disrupting water supplies, agricultural harvests, supply chain logistics, and more.

These broad trends suggest that merchandising and business model innovations will be required to sustain a successful business. Households, businesses and governments will be forced to invest in mitigation and adaptation strategies. Dealers will, too. But the long-term planners among them will be prepared to weather whatever the decade has rn store, with solutions that will help their customers and communities, too.

JaY TomPt Managing Partner William Verde & Associates (415) 321-0848

GREEN By fay Tompt

18 r lhe llerdrant Magadne r hnuary 2011

info

&riHing-hodndsom

@ williamverde.com

Hutchison Lumber has closed its store in Fairplay, Co., and Bryan Hutchison has stepped down as president. Matt Morrow will oversee the remaining yards, in Pine Junction and Florissant, Co., as general mgr.

Former Fairplay yard mgr. Bill Kelz may expand his new business, South Park Stove & Solar, to sell windows, doors and some lumber.

ProBuild's TimberROOTS, Butte, Mt., is now distributing Lite. Steel beams throughout Montana.

Channel lslands Do lt Best Hardware, Port Hueneme, Ca., has added a new store in Carpinteria, Ca. (Don Johnson, assistant mgr.), and a kitchen design centelshowroom in Ventura, Ca,

Ace Hardw?ro, Everett, Wa., was opened Dec. 7 by Judith Moratti (Sonia Mills, assistant mgr.).

Home Depot is negotiating with city officials to build a new store in San Juan Capistrano, Ca.

The chain expects to open 10 new stores in 2011.

Lowe's opened new 94,000-sq. ft. home centers Dec. 27 in Covina. Ca. (Jim Phillip, store mgr.), and Sonora, Ca. (Heather Farris, mgr.).

The chain also purchased 11 acres in Fairfield, Ca., for a 139,000-sq. ft, store; received planning commission approval to build a 153,000-sq. ft. store in Thousand Oaks, Ca.; is waiting to move to a site in Poway, Ca., currently occupied by a car dealership; is wrangling for economic incentives from the city of Salinas, Ca., to build a store to anchor a proposed 200,000-sq. ft. shopping center, and is scouting sites in Union Gap, Wa., for a 120,000-sq. unit.

Habitat for Humanity relocated its ReStore discount LBM outlet in Durango, Co., to larger, 8,000-sq. ft. quarters and moved its HabiStore in Tucson, Az., Jan. 5 to a bigger, 18,000sq. ft. home.

Stone+Wood Outlet added its fourth retailstore in Portland. 0r.

Door to Door Store,

Wenatchee, Wa., has relocated after 23 years from a millwork shop to a 1,500sq. ft. showroom.

BMC Finds New Denver Home

BMC West is moving its two-acre distribution yard in Denver, Co., to a larger, l0-acre site.

"This property substantially expands our capacity for lumber and building materials in one facility that is strategically located," said c.e.o. Peter Alexander. "The size and location of the lumberyard was a critical factor in our decision as it is very scalable, and we can easily meet the demand for our customers on time and on budget."

The leased facility. set to open in first quarter 201 I, will be overseen by

Smartest ntages In Siding

Doug Whitin g, area operations manager for Colorado, and serve as a hub for distribution of all LBM in the state.

EcoBlu Unveils Own Formula

EcoBlu Products, Vista, Ca., has discontinued offering Bluwood mold treatment and instead has developed a proprietary line of non-toxic lumber treatments to protect against fire, mold and wood-ingesting insects.

Utilizing advanced polymer technology, the SubSurfaceFilm antimicrobial wood protection formula includes fire resistance as a standard feature.

Rocklin, Ca. r 800.348.1400 Sanger, Ca. o 559.876.3624

SunnrSrBE' Tf,ITAS|'If,G Lpcorp.sn/n* I M Distributed By L &riHlry-hodudsom lanuary X)ll r lhe lledrant lhgazne r 19

LP@ SmartSide@ Trim & Siding products offer the beauty ofcedarwith the aihantages of"engineered wood. That means consistent boards with no knots or voids. An indusfy-leading wananty that provides a 5-yex, l00o/o labor and replacement feature and a 50-Year Prorated Limited Varianty on the substrate. And our proprietary SmartGuard@ process that ensures LP Smar6ide products resist fungal decay and termite damage. LF SmartSide Trim & Siding. All the advantages pu need.

Redwood Empire, San Jose, Ca., purchased the former Piedmont Lumber facitity in Calpella, Ca.

No word on its plans for the 18-acre site, but it is expected to complement sister operations, including Pacific States Plvwood. Pacific States Treatino'. Redwood Emoire Sawmitb]'ano Redwood Enipire distribution operations.

Swanson Group has laid off about 100 workers-half the workforce-at its plywood plant in Springfield, 0r., with hopes to return to full production in the spring.

Premier Building Systems, Tacoma, Wa., has moved operations from its plant in Phoenix, Az., to a plant in Dixon, Ca., run by its parent company, Insulfoam. lts operations in Fife, Wa., will relocate later this year to Insulfoam's olant in Tacoma.

Ganfor. Vancouver. B.C.. will spend $120 million this year to upgrade its mills and another $5 million for maintenance.

ProBuild Closes 2O Facilities

ProBuild, Denver, Co., has shuttered 18 facilities-half of them in the West-with two more closures yet to be announced.

According to a company spokesperson, ProBuild is aligning its business with current market needs by closing facilities in markets where customer demand no longer requires multiple locations or where market demand does not exist.

Some facilities were consolidated with nearby locations, while others are being mothballed in hopes of quickly reopening once the construction market improves.

In the West, closures included

lumberyards in Newberg, Or.; Sequim, Wa.; Sacramento, Ca.; Cottonwood, Az., and Orem, Ut.; a home center in Poway, Ca.; framing plant in Auburn, Wa., and truss plants in Phoenix, Az., and National City, Ca.

Also closing were lumberyards in Jackson, Wi., and North Charlotte, N.C.; lumberyard with gypsum and millwork plants in Jacksonville, Fl.; framing/gypsum facility in Augusta, Ga.; millwork/window shop in Gainesville, Va.; components plant in Franklin, Tn.; gypsum facility in Easton, Md., and truss plants in Waldorf, Md., and Dry Ridge, Ky.

Trex Throws Contractors a Curve

Trex Co. has entered into a licensing agreement with Curvelt LLC, Castle Rock, Co., to market a device for heating and bending composite decking, railing and trim on the jobsite.

Trex CustomCurve bends all varieties of Trex products and features adjustable legs to simplify on-site lev-

eling. The lightweight unit can be transported easily between jobsites and no specialized crew is required for operation.

As the first on-site board-bending system made exclusively for contractors, it can achieve a lO-ft. radius and accommodates 8-ft. board lensths.

TSO & KDAT for Fire Retardants and Preservatives ' HOOVER 7 TRE TED WnD PRODI CTS, rrc. ' \nr\ n r.FRTW.com 20 r lhe lledrant llhgazine r January 20ll Call: 800-531-5558 : Ifr E-mail: sales@frtw.com Bullding.Roductsonr

An unidentified S0-vear-old worker at Lassen Forest Products, neo Bluff. Ca.. was killed Nov. 10 when he fell into a wood chipper.

Exterior Wood lnc., washougal, Wa., has entered the redwood market, with distribution out of its new warehouse in Newark, Ca.

All-Coast Forest Products will distribute Nova Batu decking products from Nova USA Wood Products, Portland, Or., from its facilities in Chino, Ca., and Englewood, Co.

Humboldt Redwood Co., Scotia, Ca., agreed to pay $330,000 to settle more than $4 million in fines from water quality violations by its bankrupt oredecessor. Pacific Lumber Co.

Ainsworth, Vancouver, 8.C., has earned Sustainable Forestry lnitiative certification at its three Canadian mills. All Ainsworth wood oroducts are now available chain-ofcustody certified under SFI and PEFC.

Ainsworth also agreed to acquire the remaining 50% interest in Footner Forest Products and its OSB mill in High Level, Alb., from joint venture partner Grant Forest Products.

Jefferson State Forest Products is relocating production from Hayfork, Ca., to Grants Pass, 0r.

AbitibiBowater emerqed from Chapter 1 1 bankruptcy.

GMI's CraftMaster doors have been certified for pre-consumer recycled wood content bV SCS.

MoistureShield's new Decklife online design tool is free from www, moistu resh ield. com/deck-desig n-tools.

Paper giant Domtar Corp., Montreal, P.Q., is completely out of the lumber business, after selling its 12% share in Elcotvt Timber Corp., Vancouver, 8.C.. for $24 million.

Columbia Forest Products was awarded the Healthy Home checkmark from Green Parents' List for its PureBond hardwood plywood.

Parr Lumbor, chino, ca., has launched a new website at www. parrlumberchino.com.

Colorado's Sears Trostel Consolidates

Next month, 82-year-old Sears Trostel Lumber & Millwork will consolidate its two Fort Collins. Co.. operations.

Sears Trostel is relocating its retail store and lun.rberyard to the site of its millwork facility. The plant's warehouse and manuf'acturing building are being remodeled to make room.

According to owner Curt Viehmeyer, "The construction industry is down 40 ro 60qc across the board from a few years ago. and our

business has declined enough that it makes sense to consolidate into one location so we can still serve our customers well and consolidate and reduce our expenses and just have a better operation for the future."

The move is expected to reduce overhead by 207o and eliminate the need for more layoffs, after cutting eight jobs last year. It will also allow thc retail store to showcase more mouldings and expedite the growth of its online store.

I* Tcday's 3)esigws

Tru-Dry Tirnbers

Geo. M. Huff Lumber Co. has teamed up with Forest Grove Lumber to become the exclusive Southern California stocking distributor of Tru-Dry Timbers.

All FGL Tru-Dry timbers are dried in "HeatWave USA's RFV' kilns, which use clean, renewable energy and have zero emissions.

Tru-Dry timbers are dried completely and evenly throughout so you won't experience the sticky problems often encountered with beams that are not dried to the core.

Combine our selection of Douglas fir timbers along with our skilled milling staff and you've got one ofthe best resources in Southern California.

Building-Productscom

Tru-Eln; HUTF LUMBTR COMPANY SANTA FE SPRINGS, CALIFORNIA 800-347-4833 tanuary 2011 r lhe Niledrant Magazine t 2l

By Stephanie Brun de Pontet

Modern lamily business communication

f, s rne PLATFoRM for modern la.communication has radically changed over the past decade, there have been countless articles and opinions offered on how to best reach your audience, in particular a younger audience. A whole new set of communication verbs and nouns have emerged in our vocabulary: "blogging," "social networking," "Web 2.0," and "tweeting," that testify to the changing landscape of information delivery.

Yet, while we clearly need to understand how to use these new vehicles of information delivery, there seems to be less thought or discussion around what we are actually saying to one another. What seems to have been lost in the discussion about medium is some renewed thought on the message.

Message is particularly important in a family business. "Who we are, and what we stand for" is often the key differentiator and competitive advantage of a family enterprise. As you think about the message you are crafting for your customers, ensure that no matter what platform you use to communicate-the essence of who you are-is not lost in translation. This is not to suggest that your business identity needs to stay stuck in the age of the dinosaur.

Family business brands and identities (like those of any company) do well to evolve and stay current with the times. However, if your clients perceive value in the personal touch of your company, you want to be sure that any new communication platform you embrace will not take that away

from your customer's experience. The point is not to get so distracted by the rush to jump onto the latest platform, or message system, that the communication you put out there is inauthentic to your business.

In addition to communicating with customers, families that are in business together need to communicate with one another on a regular basisand many are making use of more contemporary methods. Increasingly, we see families setting up Facebook pages or Yahoo groups to share information and encourage the involvement of the younger generation. Some families have set up blogs to journal a family member's or the company's activities.

While one could imagine how more channels of communication might facilitate the flow of information, it is also true that these additional channels can provide more opportunities for miscommunication-especially if they are used to deliver the wrong message.

Given the emotional load of both business and family issues. communication is a struggle for many family

\

22 r lhe lledrant llhgazine r January X)ll &riHingiRoductsom

enterprises. Even just on family matters. different communication norms (for example, notions of confidentiality) that might be found between the generations is a source of problems.

In fact, poor communication is the undoing of many otherwise strong family businesses-and has often also spelled the demise of family unity. Yet, the worst kind of communication is no communication, so this represents a challenge. We want to maximize the flow of information and communication, but we must be mindful of communicating in a productive and healthv manner. What to do?

Assume good intentions. Language is limited, not matter what the platform. When you are reading or listening to communication from a family member, assume they mean well and not harm. Not everyone is a skilled communicator and it is easy to be misunderstood, so it is important to actively seek the most positive spin you can put on a communication.

Be straightforward. No one likes to feel someone is trying to keep important information away from them-and the younger generation is particularly sensitive to this. If there is information you cannot share, or that should not be communicated through a particular medium, simply state this and explain why. It is reasonable to indicate that financial results should not be shared via email (who knows where that information can end up?), but you must then clarify how or when this information will be made available.

Understand

the protocol.

Different platforms of communication have different norms. For example, if you use CAPITAL letters in an email, the norm says you are yelling. Be sure that when you use a given communication tool you have good knowledge of how your message can be interpreted on this platform.

Be authentic. This comes back to the flavor of the message. When communicating with clients, ensure the personality of your business is shining through, no matter what platform you use.

Have tone fit the message. When communicating with family, the tone of the message should vary depending on the content you are communicating. There are some messages that should be delivered with a sense of BuildingrRoducts.com

professionalism: information about the company, minutes from a board meeting, etc. But when communicating about the annual family BBQ, the message should not be formal or it will be experienced as cold.

Clarify norms and expectations. It is important that everyone who will receive a communication understand what they are expected to do or not do with this information. If a reply or response is required, the family should establish norms around how fast responses are expected. Some people feel a three-day delay is fine, whereas others perceive anything longer than 24 hours as rude. Likewise, when information is sensitive, or should not be shared with others, it is important to explicitly clarify (especially to the younger generation) what this means.

Don't sacrifice the human touch. While modern technologies can allow us to feel more connected, and certainly can facilitate the frequency of communication, electronic platforms should never replace face-to-face interactions. If you work down the hallway from your sister, walk over there to chat rather than send an email every time. Do not get let electronic communication take the place of regular family meetings, shared vacations, or other opportunities to more deeply reconnect with your family.

The challenge of modern communication is another example of the tension between the old and the new. We want to be able to stay current and embrace new technologies in ways that will be to our advantage. But we need to be mindful of valued traditions and the older ways of doing things, which may continue to have some currency and should not be discarded lightly. The close connections of family are a vital ingredient in family business success. While you should embrace all the communication technologies that will help you in the business, don't let these technologies damage the positive family feeling for your clients or your family!

- Stephanie Brun de Pontet is a consultant at the Family Business Consulting Group, Marietta, Ga.; (800) 551-0633. She can be reached at brundepontetat@ efamilybusiness .com.

Reprinted with permission from The Family Business Advisor, a copyrighted publication of Family Enterprise Publishers. No portion of this article may be reproduced without permission of Family Enterorise Publishers.

Not

Buy your Western Red Cedar from these quality producers.

WRCLA MEMBERS

Downie Timber/Selkirk Specialty

Enyeart Cedar Products

Gilbert Smith Forest Products Ltd

Haida Forest Products Ltd.

ldahn Fnraqf Grnr rn

lnterfor

Mio Valley Lumber Specialties

North Enderby Timber Ltd.

OrePac Building Products

Power Wood Corp.

Ouadra Wood Products

Sawarne Lumber Company Ltd.

Shakertown

Skana Forest Products Ltd.

Western Forest Products, Inc.

AFFI LIATE MANUFACTU RERS

PLH/Health Mate

BW Creative Wood Industries

Cedarshed lndustries

Outdoor Living Today

Synergy Pacif ic/Ouattro Timber www,reolcedor,org 1.866.778.9096

AllSuppliers Are Creoied Equol

hnuary20ll r fheFledrantnbgazine t23

Steve Mitchell has been promoted to general mgr. of operations at Universal Forest Products. Riverside, Ca.

Jerry Hahn, ex-Diablo Timber, has been named director of sales & purchasing for Hardware Hawaii, based at the store in Mapunapuna (Oahu), Hi.

William Corbin, ex-Weyerhaeuser, and Manco Snapp, ex-International Paper, have been elected to the board of managers of Bridgewell Resources, Tigard, Or.

Rick Fortunaso is now general mgr. of Interfor's North American whitewood sales. He is based in Bellingham, Wa.

Dale Schenstrom is operations mgr. at the new Lowe's Home Improvement Center in Sonora, Ca.

Jay Umphrey has joined E.T. Horn Co., La Mirada, Ca., as senior account mgr. for the coatings & building materials group.

Tom Such now handles the equipment maintenance program at The Beck Group, Portland, Or.

Allen Ravas has been named chief administrative officer and a board member at Orchard Supply Hardware, San Jose, Ca. OSH has hired a national search firm to find a new president and c.e.o. to replace Robert M. Lynch, who resigned to become president and chief operating officer of Lumber Liquidators, Toano, Va.

Kevin Wentz is mgr. of the new Lowe's Home Improvement Center in Vallejo, Ca.

Mark Muus, ex-Arizona Tile, has joined Stone Source, as regional sales mgr. for the West Coast.

Jamie Kutzer has been promoted to president of exterior products for the western division of Allied Building Products Corp. Greg Bloom is now chief sales & marketing officer.

Chuck Dana has been named group president-building materials for Owens Corning, replacing Karel Czanderna, who has resigned. Arnaud Genis succeeds Dana as group president-composites.

Kevin Horsnell has been named chief operating officer for Conifex Timber. Vancouver. B.C.

Robert Young, ex-Briggs & Stratton Corp., has joined True Value Co., as divisional v.p. for the paint, hardware and tool departments.

Charles W. "Nicktt Canter, executive v.p.-merchandising, Lowe's Cos., retires March 4 after 36 years with the chain.

Doug Hoal is the new landscaping specialist at Mungus-Fungus Forest Products, Climax, Nv., report co-owners Hugh Mungus and Freddy Fungus.

Correction: Craig Evans did not leave Learned Lumber, El Segundo, Ca., as incorrectly reported last month.

Correction: In last month's photo coverage of NAWLA Traders Market, Denise Robinson, Sunset Moulding, Yuba City, Ca., was incorrectly referred to as Denise Morrison.

A I ]he tylerdrant llagiazne r hnuary 20ll Bnildingrhoductsom

Berkeley Dealer Expands

Ashby Lumber, Berkeley, Ca., plans to expand its location in Concord, Ca., onto a neighboring property and build two new buildings, totaling 13,000-sq. ft., to house its milling operation and door and window warehouse.

"When we put in the store in 20O2, we didn't really expect it to be quite the success it was," said Rick Kelley, who is manager of the location in Berkeley and will oversee the expansion in Concord. "We've been pretty steady all the way through the years."

Murphy Restarts Rogue River Plywood Mill

Murphy Co., Eugene, Or., reopened the former Panel Products plywood mill in Rogue River, Or., Dec. 13, after almost a year of renovations and repairs.

"We're excited about getting this facility back up and running and being a part again of the Jackson County economy," said John Murphy Jr., who oversees the company's interests in southern Oregon. "It's nice to see a few sprockets being turned over."

Most of the machinery in the mill had to be upgraded or replaced, and a new lunchroom has replaced an opensided, tin-roofed building formerly used. Duane Prazoo, who has worked at Murphy for more than 26 years, oversees plant operations.

Murphy said that the biggest challenge for the mill is getting enough raw materials. Oregon's 2009 timber harvest was the lowest since the Great Depression, and 2010 was probably about the same. "We're not getting enough trees," he said.

Murphy Co., which celebrated its l00th anniversary in 2009, also owns a hardwood plywood plant in Eugene, veneer mills in White City and Elma, Wa., and an engineered lumber facility in Sutherlin, Or.

Fortune Brands to Spin Off Home Products

Fortune Brands, Deerfield, Il., will spin off its home and security products division, to focus on its liquor unit.

Home and security brands include Moen faucets, Aristokraft, Omega, Diamond and Kitchen Craft cabinets, Therma-Tru doors, Simonton windows, Master Lock security products, and Waterloo storage products.

Two Coat Exterior Prime

0ur two-coat process starts with an aLkyd seater to btock tannin migration, fo[owed by a high-performance acrylic primer. The resutt: RESERVE quatity, inside and out.

Superior Wood

Made of quatity, clear, finger-jointed Western Red Cedar or Redwood, these products are naturatty designed for exterior use-both soecies are ideal for endurinq extreme weather.

Surfacing + Sizes + Lengths

RESERVE products come in a wide range of sizes, lengths and finishes. Whether the project ca[[s f or 51S2E or S4S. we of fer tengths ranging from 16'to 20'. Pattern stock is also avaitable.

1x4 - Lx12 s/ax{ - s/axll

2x4 - 2x72

The Finest Stock, TheBest Coating

Our Siskiyou Forest Products

RESERVE line is specially manufactured and treated to create the highest quality product available. Using state-of-the-art application and curing equipment, our premium Western Red Cedar and Redwood stock is made to last for many generations. We are proud to offer a beautiful, durable product that is ready for installation and final painting the moment it reaches the craftsmen.

S I s rcIyoU. FoREST. PRODUCTS

www.siskiyouforestproducts.com

8OO.427.A253 6275 Hwy 273 Anderson, CA 96007

Bnilding-hoduds.om

hnuary20ll r lheFledantltbsazine t 25

Western mills make difficult adiustments

tTt"t rwo-pl-us-yEen collapse in the residential construcI tion market has forced sawmills in the West to make difficult adjustments to stay strong. Most have cut shifts or mothballed facilities, hoping to ride out the storm.

The key to survival has been recognizing the coming challenges and adjusting quickly. "We're heavy to retail, so we identified where the market was heading early on and rightsized to fit," said Steve Schmitt, v.p.-marketing, Stimson Lumber, Portland, Or. "Eighteen months to two years ago, we reduced production by more than 507o. We've also worked with the crews in our mills to enhance productivity and remove obstacles and bottlenecks. We made our moves early on, because the we're the first product put in the home, not the last."

The reductions were implemented in such a way that if the log-to-lumber price ratio improves, Schmitt said Stimson "could add hours at any and all of our facilities."

Plum Creek Timber Co., Seattle, Wa., has closed two sawmills and idled its stud plant in Kalispell, Mt. Operational facilities have cut overhead dramatically, to the point where the same millwrights who operate the machinery also repair it if there's a breakdown.

A goal for Collins Cos., Portland, Or., has been to keep all facilities running, despite having to reduce the workforce. "It's a blessing for us that we are family owned," said Kevin Paldino, v.p.-sales & marketing. "We make decisions for the right reasons and we are very nimble, which isn't always the case with a large, publicly traded company. We are more long-term thinking."

With hard work and creativity, said Paldino, "our manufacturing facilities are producing more footage per man hour on a reduced-shift schedule than when they were running full tilt. Our hardboard plant in Klamath Falls, Or., can now produce almost as much on two shifts, five days a week, as it did when itran 2417 The mills are always looking for ways to cut costs and increase productivity."

Productivity is also up on the sales side, in part thanks to Collins' IT department. Orders can be written on the road from anywhere, even using a hotel's computer. In addition, Paldino said, "everyone carries an iPhone. And when we're out of the office, our business calls are forwarded to us. We can be reached virtually any time, anywhere, so that while the mills may not run 2417, the sales department does."

Other sawmills have adjusted product mixes. Sierra Pacific Industries, Anderson, Ca., is retooling its sawmill in Sonora, Ca., shuttered since 2009, to accept a broader

array of log sizes. SPI hopes to restart the mill in May with 130 workers.

Last May, SPI cut a shift at its large-log mill in Quincy, Ca., and restarted Quincy's small-log mill, which had been idle for a year The switch resulted in a net gain of 35 jobs.

"We are in it for the long run," said SPI's Mark Pawlicki. "We anticipate the market will come back."

Trinity River Lumber Co. is preparing to restart its sawmill in Weaverville, Ca., which was destroyed by fire 16 months ago. During the rebuild, Trinity River has been working out of the former Siller Brothers Sound Stud Mill in Anderson, Ca. Weaverville will reopen with up to 70 workers-50 fewer than it had before the fire, but considerably more than the 40 now in Anderson.

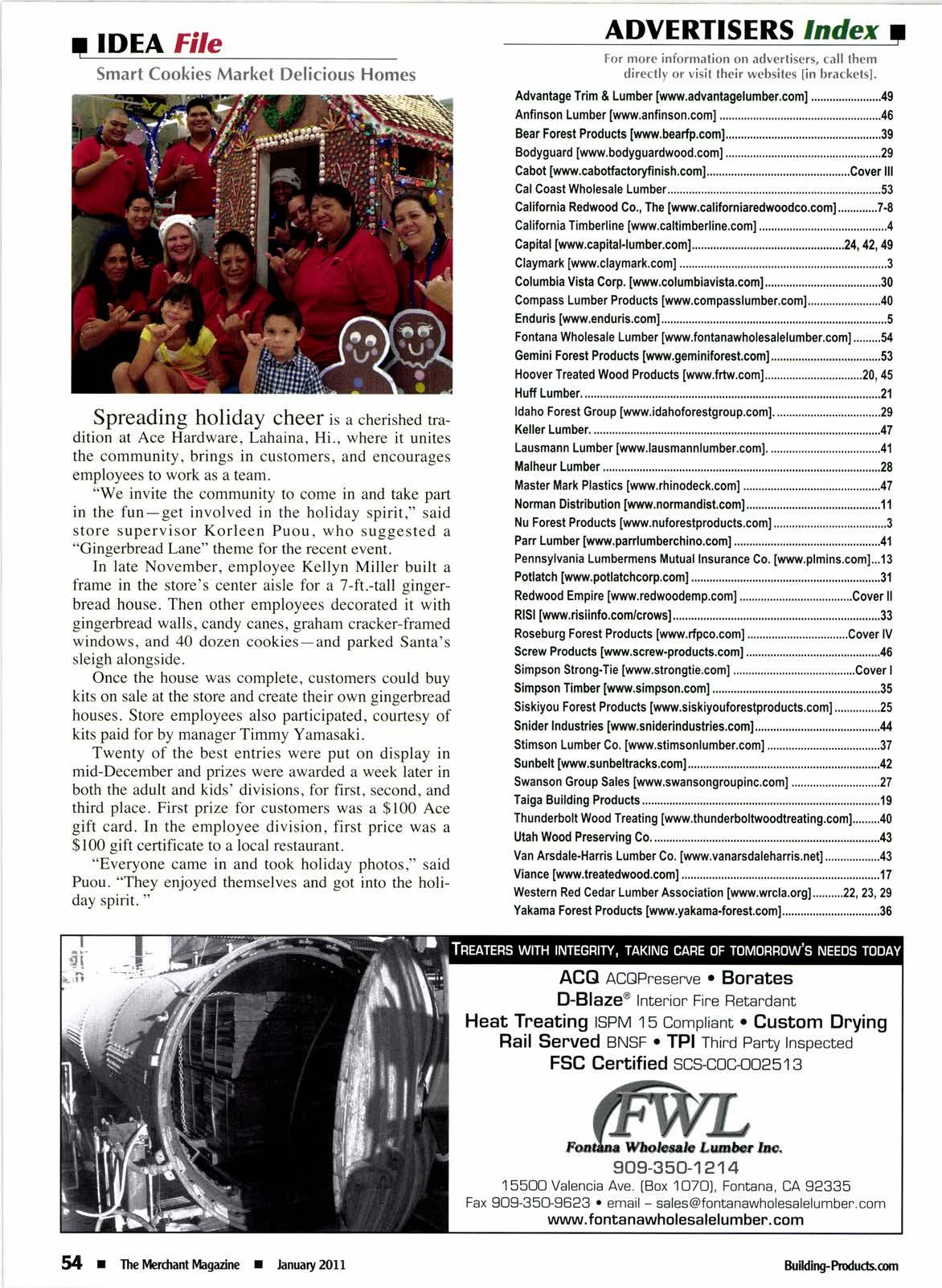

"It will take some time to get the bugs out of it totally, and we will not be jumping into two shifts immediately," said general manager Dee Sanders.