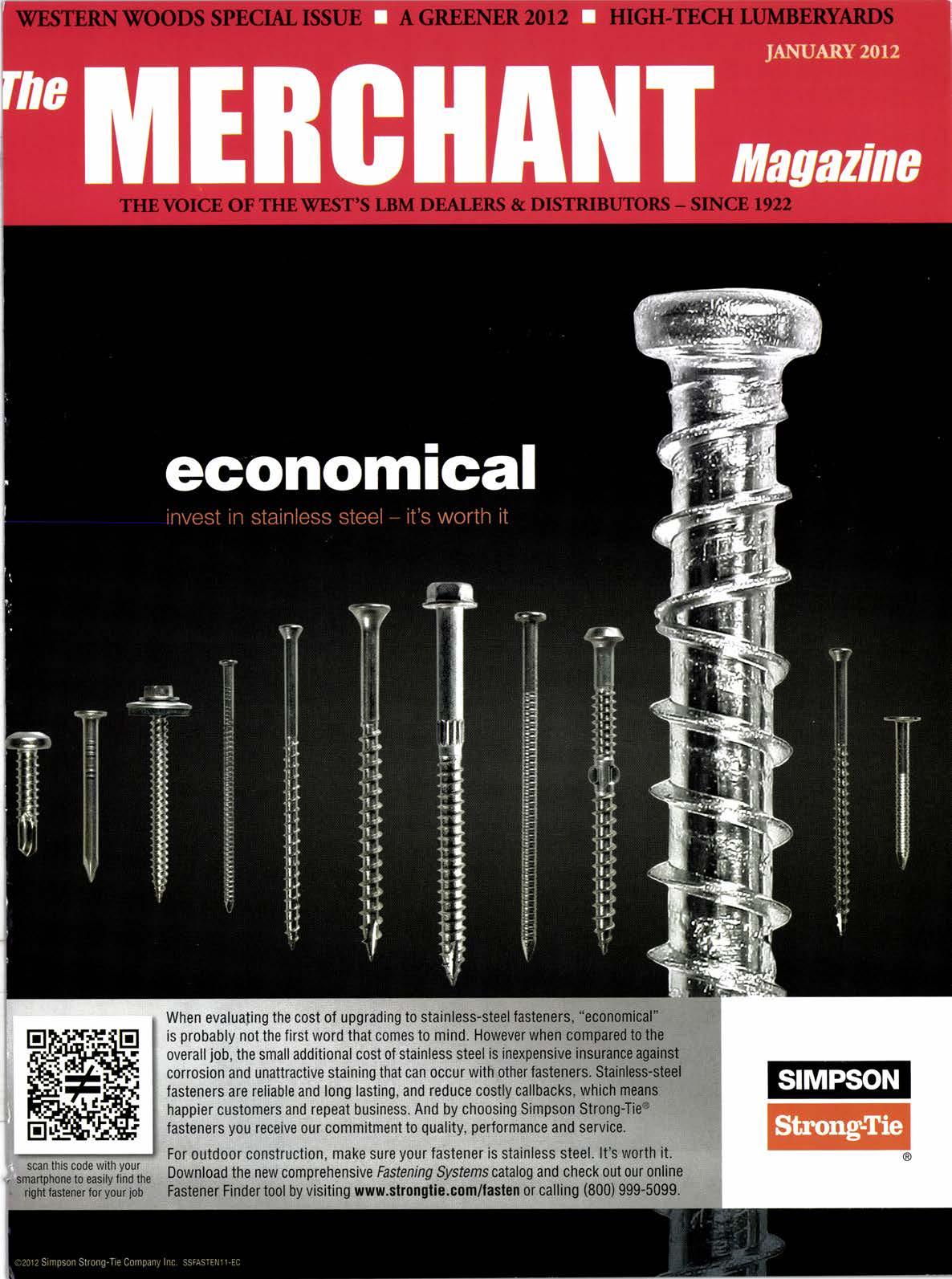

When evaluating the cost of upgrading t0 stainless-steel fasteners, "eCOnomiiaf " is probably not the first word that comes t0 mind. However when compared to the overall job, the small additional cost of stainless steel is inexpensive ins*iancsagainsl corrosion and unattractive staining that can occur with other fasteners. Stainless-steel fasteners are reliable and long lasting, and reduce costly callbacks, which means happier customers and repeat business. And by choosing Simpson Strong-Tie@ fasteners you receive our commitment to quality, performance and service., For outdoor construction, make sure your fastener is stainless steel. lt's worth it. Download the new comprehensive Fastening Systems catalog and check out our online Fastener Finder tool by visiting www.slrongtie.com/faslen or calling (800) S99-5099.

f,i::

scan this code with your smartphone to easily find the right-{astener for yout iob

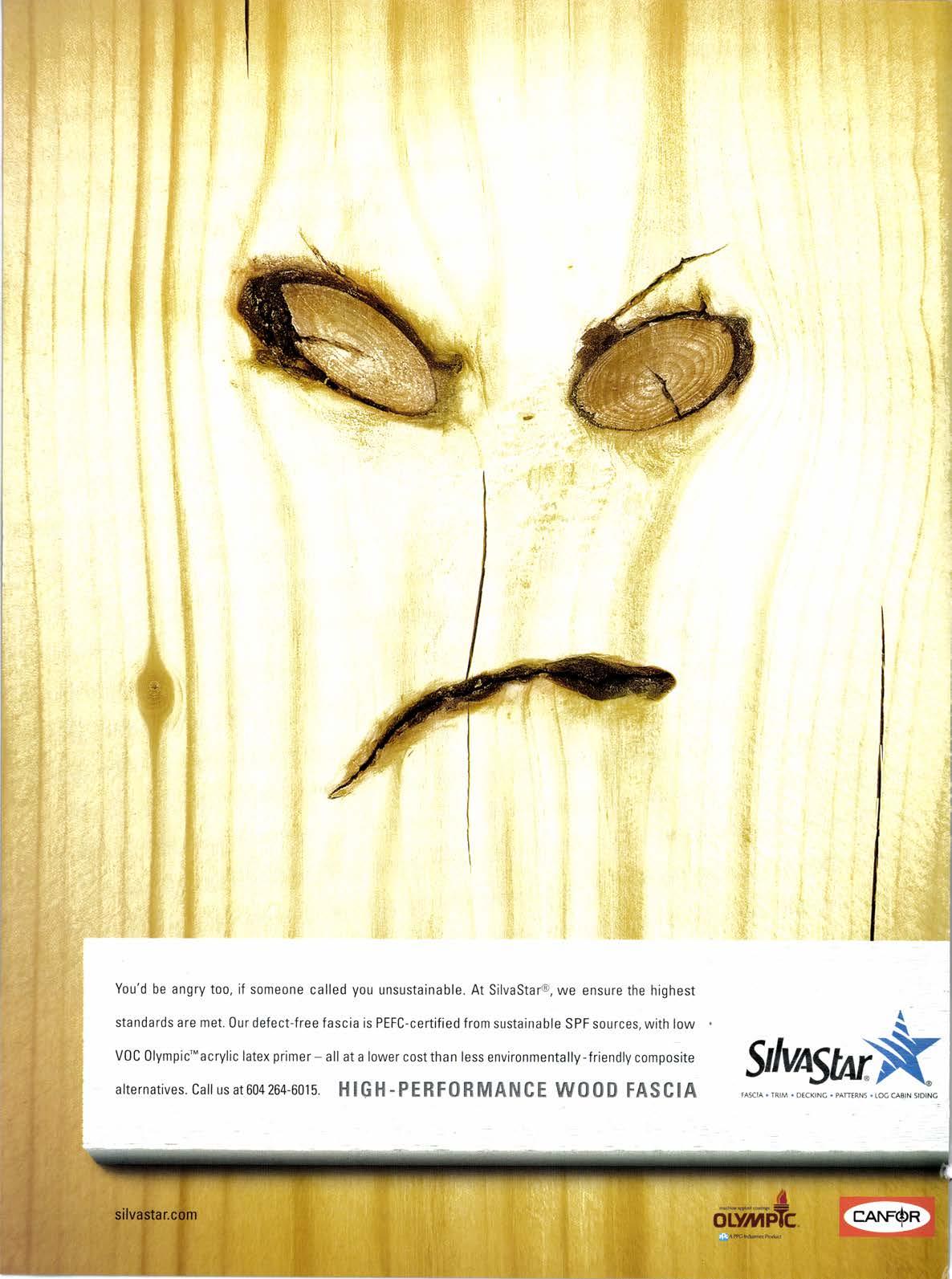

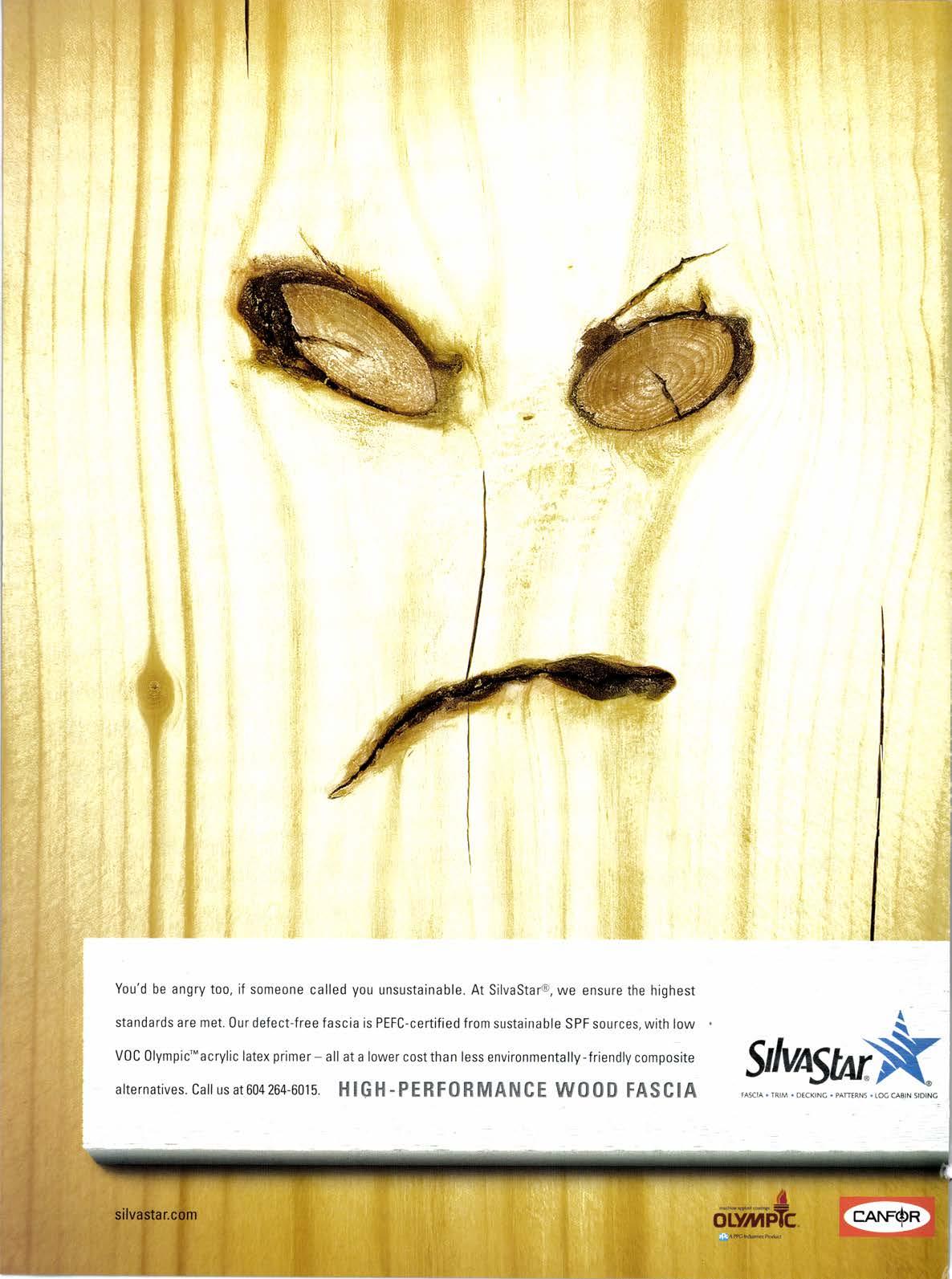

You'd be angry too, if someone called you unsustainable. At SilvaStaro, we ensure the highest standards are met. 0ur defect-free fascia is PEFC-certified from sustainable SPF sources, with low V0C 0lympic"acrylic latex primer - all at a lower cost than less environmentally-friendly composite alternatives. call usat6042G4-6015. HIGH -PERF0RMANCE W00B FASCIA

r

lilffif..: ,i:: lil: " j. l !,., I fi i r .) g + e t

Stins[nr.fi'

_ *\*.: l@d:--; /ffd I{ave Your Custorners Choose Any Color For Their Siding. Let LIs Do The Rest. Cabot Factory Finish'" ' Fade-Resistant, Nature Inspired Colors Saves Time and Eliminates Weather Delays ' Applied in Factory-Controlled Conditions Available with S-year, '1S-year or 25-year Warranty To Learn More, visit CabotFactoryFin ish.com orcall 1-8OO-US-STAIN Oun PERFoRMANcE Is LEGENDARY.*

Special Features In Every lssue

Bnrnrrruc lNousrnv Ntws, lNousrnv PHoro DowNlonos, & THr MrncHnnt Dtclrnl Vrnslott BurrorNc-PnoDUCrs.coM

CHANGE 0F ADDRESS Send address label from recent issue if possible, new address and 9-digit zip to address below.

POSTMASTER Send address changes to The Merchant Magazine, 4500 Campus Dr., Ste. 480, Newport Beach, Ca.92660-'1872.

UnenN lNrrnrncr Rulrs

. Loc PRtcrs UNsustntNnere o ExpoRt Ouloor

39 Pnooucr Sporucnr: SournrnN Ptnr

M,qnrrrrNc Atos ro ScLL Monr SYP

The Merchant Magazine (ISSN 7399723) (USPS 796' 560) is published monthly at 4500 Campus Dr., Ste. 480, Newport Beach, Ca.92660-1872 by Cutler Publishing, Inc. Periodicals Postage paid at Newport Beach, Ca., and additional post offices. lt is an independently-owned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 western states. Copyright@2Ol2 by Cutler Publishing, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. lt reserves the right to accept or reject any edi' torial or advertising matter, and assumes no liability for materials furnished to it,

ItI.[ IIATURAL MEEIS }II€H IECH

NATURIt W00D PR0DUCT UTlLlzlNG D0ltlESTICAIlY GROWN tASTtRt{ WHITE Pll{f cHEMICAL-tnff, rATuRAttY DURABTE WEATHER-sAtE W00D toR TRIM, SlDlNG, Ai{D PATIERl{5

SIIOWCASTS 'HT BTAUTY AND $ARAOER OT GENUII{E WOOI) WITH TXCEPTIOl{AI

RTSISTANG T() HARsH CONDITIONS Of EXTTRIOR UsT

coATtNG HAs THt PR0VEi{ tFFECTlVtiltSt 0F AN olt oNDlTl0l{ER, THE BARRIIR AllD

PRIP 0f A StAL[R, At{D THE PR0TECTI0il 0f A T0PC0AT

rne

Hl]il nasazini''""x**n' 3r, t: /_

M I n G

6 Tornuv RlNoot't 1 2 Cor.,rpnrnvt lNtrurcENcE 'l4 olsrN oN Snlrs 1B FnmrLv BusrNrss 20 Movrns & SnRrrns 38 lH Mrmonrnpr 42 Nrw Pnooucrs 49 AssocrnnoN Uponru 50 BusrNrss Cnno Aos 52 Cussrrtro Mnnrrrpucr 53 Dnrr Boox 54 lorn Frr-E 54 Aovrnnsrns lNorx 9 Frnrunr Sronv Tnerrr Covpurens RrRov ro Bne,qr rNTo rHE LututsrR BustNrss 'l 0 lruousrnv TnrNos Nrw Ytnn's Fonrcnsr Cnrrs ron Cr-ouos lNsruRo or PCs 16 GnrrN RrmttNc CurorNc LtcHrs ro GnErN IN 2012 24 Sprcrnr Focus: WrsrrnN Wooos . CoNstoentNc Nrw DrstcN Va'rurs o Wooo Dusr WnnNtNc UPonru . Tgr TnutH ABour Cronn SHnrrs WtLoL,qNo

Online

4 r The tvledtant Magazine r lanuary 2012 BuildingiProdudscom

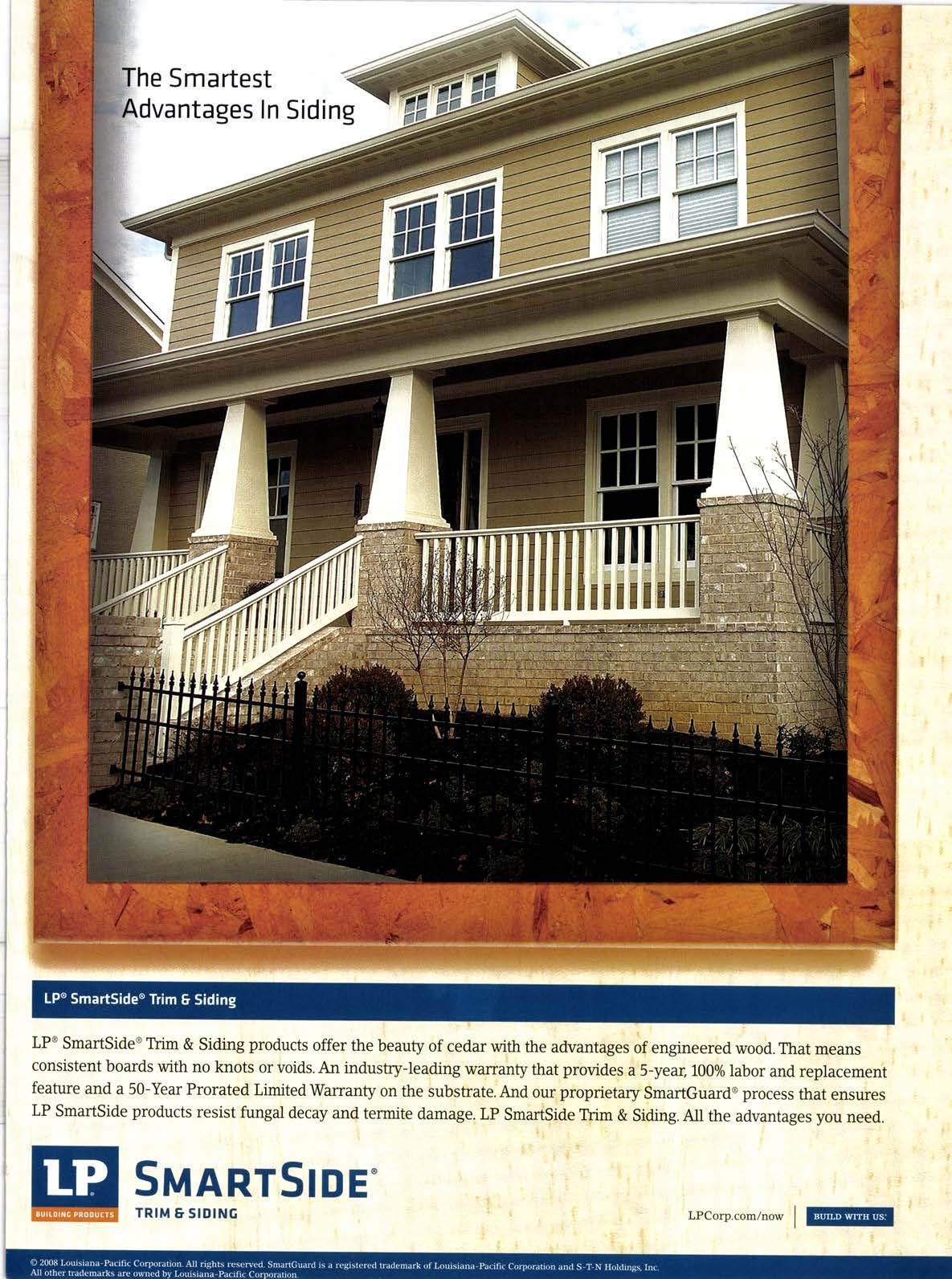

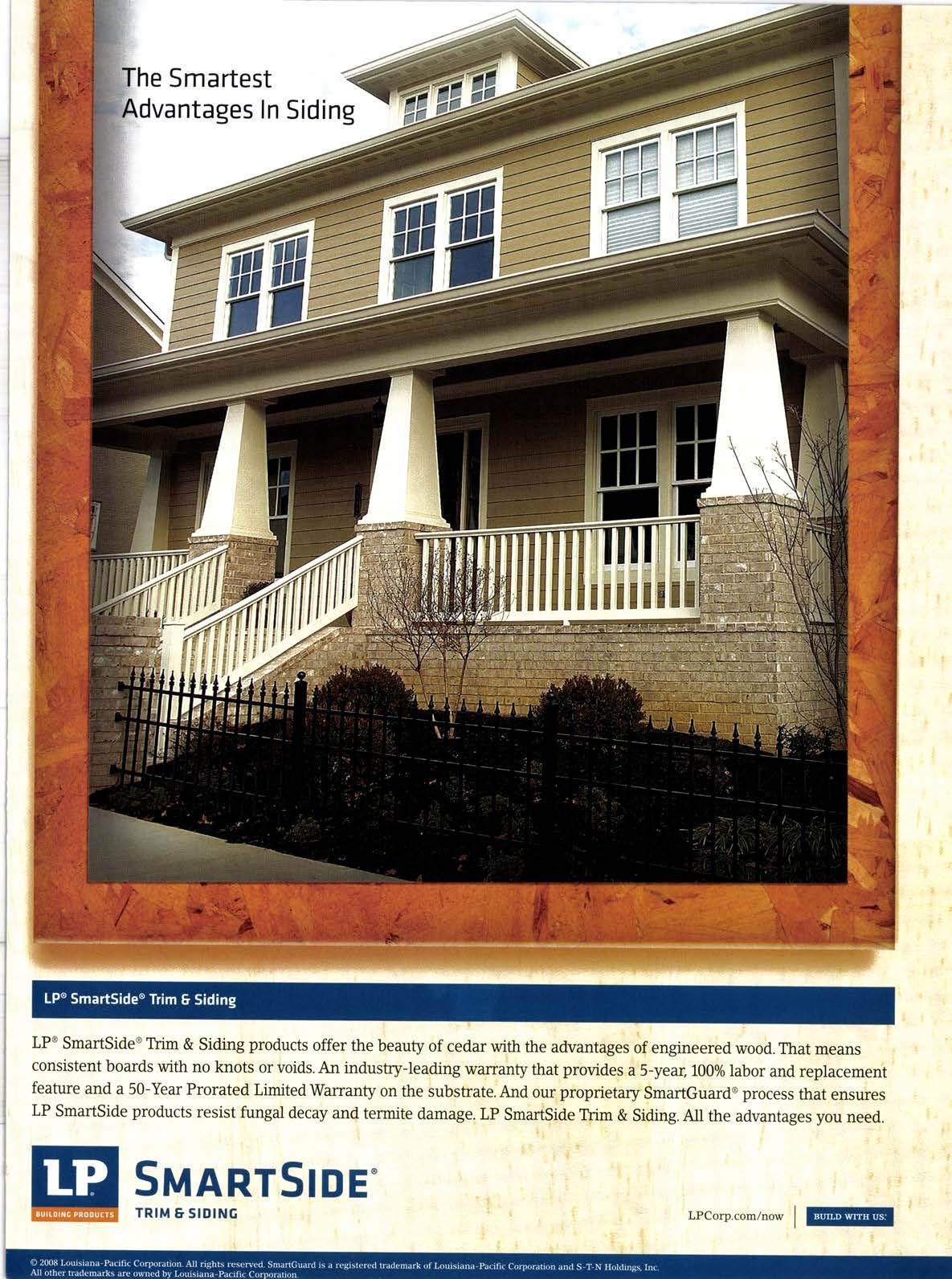

Smartest ntages In Siding

LP@ SmartSide'TYim & Siding products offer the beauty of cedar with the advantages of engineered wood. That means consistent boards with no knots or voids. An industry-leading warranty that provides a 5-yea4, 100% labor and replacement feature and a 50-Year Prorated Limited Warranty on the substrate. And our proprietary SmartGuard@ process that ensures LP SmartSide products resist fungal decay and termite d.amage. LP SmartSide T?im & Siding. All the advantages you need.

1 j I

SptARTSIDE" TRIM E SIDING LpCorp.com/now | @@

By Alan Oakes

Herets hoping!

f,"lrnsr, A HAppY belated New Year and I hope that you had time with family and -[ friends and have been able to recharge your batteries for the year to come. As we enter our fifth or even sixth year of recession (for those of you who do not believe it is over), let's hope that we start to see a turn round sometime in2012. As I wrote last month, I am seeing and hearing some guarded optimism for a better year. Certainly 20l l was very disappointing and I know difficult for many. Let's hope for calmer waters and sunnier skies and especially better Spring weather that we so badly missed this year!

As I write this column midway between Thanksgiving and Christmas, and I think back to all the things that happen throughout a year and especially when it is a not so good one, it is easy to feel down or question your judgment as to whether you made the right decisions or business moves. I think though that we can be often too hard on ourseiner and while I believe in introspection, let's look at the bright side of life if only for a few minutes. Much of what we have dealt with has been outside of our control and we have had to invent new ways to do business or stay in business, unlike perhaps never before in our business lifetime.

First, if you are reading this column, for 99+Vo of you, you are still in business. No mean feat let me say when you consider how this industry has been decimated. The business you own or work for has gone through the most traumatic time in the recent eras. Your company is still providing jobs and income for everyone seated around you and also for many of your customers and their customers. With all the businessesmany decades old-that have shut shop, you should be thankful that you have survived. Yes, it has not been easy, but you have achieved what many could not.

Second, be thankful for those customers who have stayed with you through thick and thin. Customer loyalty is what we all strive for and it was certainly easier a few years back. But we should be thankful for those that have stuck with us. If it was not for them, then your company might also be one of the casualties.

Third, thank your staff. No business owner can do it on their own (although many think they can). Employees have had to buy into a whole new agenda, accept swirling change and a lot of uncertainty. Yes, it's true some might have wanted to leave but couldn't because there were not many jobs out there. But think about how much fun it has been coming into work each and every day in this environment. With often stagnant wages, lost commissions and bonuses, cut benefits, covering what two people did. Yes, you get the picture. The pressure has been no fun and yet everyday most go overboard without an awful lot of praise or reward to help keep the lights on and serve customers to the best of their ability.

Fourth, thank the people who supply or support your business. Like you, they have wrestled with many of the same problems. Sometimes they have had to support you or take a chance on you in some way. When you read how badly banks have acted to this industry, what about thanking those that really stood by their promise of being with you in the good and the bad times (hopefully there are some). To those that gave you some extended terms when you needed it, to those who got you that shipment ahead of the queue. We often take them for granted.

Last of all, many of us have people at home who support us through thick and thin. Those who have to live with our insecurities and worries, have to put up without travels and craziness at times, but love us anyway. None of us can do what we do without the family behind us in every way.

Even in the dark days we have still much to be thankful for. We are still lucky to live in this countrv. even with all its frailties at this time. It is still the country where everyone wants to come and live and work.

Again, my best wishes to all our readers for 2012. Let's get going!

Alan Oakes. Publisher aioakes@aol.com

www. building-products.com

A publication of Cutler Publishing 4500 Campus Dr., Ste.480, Newport Beach, CA 92660

Publisher Alan Oakes ajoakes@aol.com

Publisher Emeritus David Cutler Director of Editorial & Production David Koenig dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Dwight Curran, Carla Waldemar, James Olsen, Jay Tompt, Mike Dandridge

Advertising Sales Manager

Chuck Casey ccasey@building-Products.com

Administration Director/Secretary Marie 0akes mfpoakes@aol.com

Circulation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www.building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com

CLASSIFIED

David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather KellY

Phone (949) 852-1990 Fax 949-852-0231 hkelly@building-products.com or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A.: One year (12 issues), $22 Two years, $36 Three years, $50

FOREIGN (Per year, paid in advance in US funds): Surface-Canada or Mexico, $48 Other countries, $60 Air rates also available.

SINGLE CoPIES $4 + shipping

BACK ISSUES $5 + shipping

6 r lhe Nlerdrant fi'lagazine r hnrnry Z)12 *]TIERGHAIIT.,,,,,

I Highest Quality Beautiful Color Excellent Durabllity \ )ilision oi ltrifir S1r!r._- lniirrsh il:. lrl Distribution Sales 2 W. Santa Clara Sr. PO Box 1438 premium quality, import fencing "#1&Btr,2tace I no downfall . elegant, gold, yellow hue . kiln-dried o no holes, no wane lig htweig ht & easy to work with dog -eared, square top, french gothic Redwood Em@2nd Floor Sarr Jose. CA 951 13 448.779 7354 800.800.560s Sarr Jose. CA 95.109 So. California 800.71r3.699 1 ,Square Top I , t,''"i lg.. ll!* # www. redwoodemD.com

Look Who's Back in Town!

TIIBA.FOR CONS"rE.T WTSTERN RED CENRN FENCING Manufactured exclusively for the Pro's PO BOX 1328, MORTON, WASHINGTOTV 9S:16 Phone (36O) 496-6777 E r Ihe lrhrdnnt ftbsatne I lanrnry 2012 BuiHing-hodudscom

Tablet computers make a run at the lumber business

7fteer-er coMpurERS such as the t iPad have taken the consumer world by storm and now have their sights on the business world, including the lumber and building materials industry.

According to Gartner Inc., tablet sales worldwide rose from 17.6 million in 2010 to 63.6 million unirs in 20ll -a 26l.4Vo jump. Tabler sales are forecast to reach 326.3 million by the end of 20 I 5.

Tablets offer most of the best business advantages of both a smarlphone (touchscreen functionality, electronic communications, social media marketing) and a laptop (larger online viewing screen, business process and

intelligence software).

Yet, as a hybrid between the two devices, tablets do something more. They can basically act as a mobile point of sale. Tablets conceivably can bring all facets of the sales process directly to the customers-whether they're working in their office, walking a trade-show hall or a construction site, or even waiting, parked, in your drive-thru lumberyard.

Equipped with a tablet, salespeople can...

. ...help customers quickly search for and select products using vendor websites, interactive catalogues, and inventory lists (with instant access to specs and prices). Never again need

your sales force say, "I'll need to get back to you on that...."

...deliver elaborate sales presentations and product demonstrations, all on the go.

. ...input and retrieve customer account data. Tablets can remotely and securely access a business's primary account information.

...arrange delivery, financing and payment. A receipt can be emailed to the customer or printed out via wireless signal.

. ...review or track past orders.

Although there have been no reports thus far of LBM businesses incorporating tablet computers into their POS processes, Epicor (formerly Activant) is among the industry software vendors that recently introduced a tablet-compatible POS app.

"We've experienced an incredible amount of interest from more than 30 retailers who are anxious to mobilize their Epicor Retail deployments-in particular to iPad and iPod devices," said Ian Rawlins, v.p.-retail product marketing. "We're having conversations with a great number of retailers who are anxious to leverage the power and performance of these new devices to drive transaction efficiencies, improve operational visibility, and customer engagement."

In the meantime, LBM businesses will discover that serving customers in other ways with a tablet computer should give at least their image a high-tech upgrade.

FEATURE Technology Trends

hnuary 2012 r The tyledunt ftbgazine I 9

Building-hodudrcom

TOMORROW'S lumberyard may use a tablet computer to bring the pointof-sale to the customer.

By fohn Barco Sr., NCornputing

New yearts forecast calls for clouds, no PGs

LTow DAys tNTo the New Year, businesses are taking l\ stocl of their IT assets and wondering, is it time to upgrade those computers that still use an obsolete version of Windows? Is it time to replace all those nasty keyboards filled with dust and coffee stains and monitors that are way too big for the desk?

Setting up or even updating an office often means expensive computing equipment and hardware. However, while the right IT can make a difference in a business' bottom line, replacing aging PCs is often enough to put you in perpetual sticker shock. For instance, if you run a business that requircs 20 PCs, that can easily run you over $20,000. And that doesn't even include the software license upgrades or the keyboards and monitors.

But that is the price of doing business, right? Well, not necessarily. What if you could set up or upgrade your office by replacing all of your PCs, keyboards, monitors and servers, as well as install new software and operating systems, at half the cost? What if you only had to purchase one or two PCs and servers, but could still outfit your entire staff with their own desktops? What if you could save on energy, train new employees quickly, and basically run

your IT for a fraction of the cost?

No, we are not talking about buying refurbished PCs. There is actually a technology called Desktop Virtualization Infrastructure, or VDI, and it is changing the PC industry as we know it.

Today, IT administrators are working hard to do more with less as they become overwhelmed by the number of desktop PCs they must maintain. While there might be 50 to 100 desktop PCs in an office, IT administrators recognize that their employees typically utilize only 57o of the capacity of a typical computer. Nowadays, there are opportunities to better address a business owner's needs and to deliver inexpensive PC computing power to more employees than ever, while simultaneously driving down typical operational expenses such as desktop PC hardware, maintenance, and support costs.

The solution lies in transitioning a desktop PC environment from a physical machine into a "client/server computing experience." That is, a user's desktop is hosted remotely by a server or another PC and accessed via a small device that sits on an employee's desk. In other words, an office worker no longer has a physical PC, but instead has

r INDUSTRY Trends

@ffi@ mtf@ 10 r The tvlednil lvtasazine r January Dl2 Building-Productscom

lN A DESKTOP virtualization system, all software and flles are held in one master serverlike a cloud-and can be accessed by 100 or more workers, using their own access device, monitor and kevboard.

an access device that is connected to one server, plus virtual desktop management software, a monitor, and a keyboard. The good news is that their computing experience would be similar to the PC experience they know-minus a lot of expensive hardware.

The new VDI system literally disrupts the economics by changing the typical structure from one operating system, one user, to one virtual or physical host, one operating system, and 100 users.

Depending on the size and scale, a desktop virtualization deployment can pay for itself from day one. Initial acquisition costs are often 50+o/o lower than traditional PCs; the cost of ongoing maintenance and support are J57o lower, and energy costs are typically 90Vo lower.

There are additional strategic benefits in the form of business agility and productivity. For example, if you have a new employee come on board and you need to provision a new desktop, it can take minutes rather than hours to get them up and running.

In addition, implementing VDI automatically turns your business green. Get this: over 850 million PCs are turned on every day. According to a recent study, if virtualized desktop systems were used at a ratio of six virtual desktop devices to each PC:

. Energy use would decline by over 120 billion kilowatt hours per year

. CO2 emissions would decrease by 96 million metric tons (like planting 460 million trees)

. E-waste would be reduced by 6.7 million metric tons

What this comes down to is that desktop virtualization allows organizations to reduce the amount of hardware they purchase (which in turn reduces e-waste), minimize energy consumption, diminish costs, improve data integrity, simplify desktop maintenance, increase security, and extend PC refresh cycles. Many technology companies are continuing to innovate on VDI technology to ensure the experience is user-friendly and can perform the same functions as a traditional PC. Small and mid-sized businesses are srarring to adopt VDI in serious numbers, and many vendors will work with your IT administrator to design an infrastructure that is right for your organization.

- John Barco Sr. is vice president of product marketing Jbr NComputing. Reach him via w,ww.ncomputittg.com.

lanuary 2012 r lhe lvlerdnnt lUagazine I 11 'm /--.."...T. l ---------\. Building-hodudscom

By Carla Waldemar

Gompetitors ioi n forces

f oorrNc FoR rHE silver bullet to l'success? Heck, to survival? Here's a key: right-sizing.

For several operations I've brought to your attention lately, that's meant seizing a golden opportunity to expand in order to outwit a queasy economy. For the outfit we'11 talk about this month, the opposite direction was the savvy one. Consolidation-right-sizing-proved the right decision.

It's working perfectly for Ken Grause, of Bellevue, Ky., who took over Pilot Lumber in the late '70s from his dad. And it's working out equally well for Bruce Moore, owner of Moore's Home Improvement in

nearby Fort Thomas. The once archrivals are now business partners in the blended operation renamed Pilot Lumber and Moore! (Yes, that exclamation point is part of the new logomore on that later.)

Right-sizing seems to be the takeaway lesson throughout the Grauses' business run. In 1971, Fred Grause, Ken's dad, who owned a tile comPanY here in Bellevue, took over Peters Coal-built as a railroad depot in 1919, later slammed by first, a devastating flood, and then, a series of fires that knocked the wind from its aging owners. Fred planned it as depository for distributing the sand, cement and

what-all needed for his tile business, but soon a fellow walked in from the town's recently shuttered hardware store, suggesting Fred add that line of merchandise-and, ahem, him. Which he did.

Fred loved the business-but lumber, not so much. So it became his young son Ken's domain (never mind that the kid was still in high school.) He worked full-time while devoting his evenings to earning the college degree that would be his passport to another. better life. (For back then, Ken, too, professed "no interest" in the lumberyard.)

But that was in the scary finale to the '70s, a recession called "the big one"-until now. "I was worriedl times were really tough," recalls Ken, who not only remained on the job, but bought his dad out before the end of that dismal decade. By 1982, Ken's new addition doubled retail space. Not long after, he completely overhauled the lumberyard. adding a new main shed, cantilevered outside racking, and concrete pavement. Fast forward to 1998, when Ken bought a second store-the former Hess & Racke in Alexandria, Ky.-as a second location.

Sounds slick and painless. But that's the Hollywood version, not the real-life story. Ken is the first to admit he had his share of learning bumPs, starting back in 1974,"a terrible time for the construction industry," as he remembers all too clearly. An oldtimer in the yard, convinced of his moral duty, lectured the young man: "If you haven't money in the bank, you can't buy anything."

But Ken saw bigger reasons to worry by standing still. "When your A line gets cleaned out and you're left with only the Cs and Ds, who wants to shop there? So, we had a difficult discussion, which ended with (the old-

I COMPETITIVE fnfelligence

FORMER CQMPETITQRS Ken Grause (left) and Bruce Moore have merged their operations.

12 I The tyledrant lvlagazine r lanuary Z)12 BuildingrPtodu<frcom

(Photo by Michael E. Keating. Published coulesy of The Cincinnati Enquier.)

timer) saying, 'Okay, smart college kid: YOU do itl"'

And Ken did. But still, there was the occasional stumble. "I was hard-nosed, made everybody pay-didn't extend credit, just when banks were pushing builders out of business. So I lost a lot of contractors' business. Instead of thinking, 'What can I do to help?' I was thinking, 'I can't believe they cannot pay their debts!"' Welcome to reality, and a kinder, gentler way of doing business.

"Then, the whole d-i-y thing was just getting started." And this time, Ken was in the vanguard. "I doubled the square footage of the store and moved product from the back room, where sales staff had pulled contractors' orders, and set up shelves, supermarket-style, so customers could wander, pick things off the shelves themselves. It was very consumer-friendly, and business grew steadily." In fact, "It was a blast! We had fun."

But he overlooked one thing: Those d-i-yers generally were away at work each weekday. "So, Saturdays, we got slammed. We learned to adjust our hours," he says with a laugh.

Buying the Alexandria store was a boon, but also presented another learning curve. "The stores were only 20 miles apart, but the customers were completely different," Ken quickly discovered. "Unbelievable! Retail and remodel-oriented vs. new construction. And serving farmers, who provide steady business, good times or bad."

Pilot's Design Center, launched in 2OO4 to overcome the perception that it was solely a lumber operation (although it already carried the usual K&B inventory), also presented unforeseen obstacles. It had been planned as a boon for Pilot's many pros, who could now have card-key access 2417 in order to assist their own customers-which, turns out, was not what these contractors wanted, after all. "They never used it! Instead, they wanted us to be there."

The builders made it clear they expected Pilot's own people to be front-and-center at all times, to do the comparisons and explaining to homeowners. And that took staff Pilot couldn't supply. The project ended up with a part-time staffer arranged on demand, called away from other duties. Not ideal. For the past five years, its business was up and down.

So was business as a whole, as it's been for every one of us. Looking for a solution, Ken cast his eye way outside the box, gritted his teeth, and picked up the phone. He telephoned his longtime arch rival, Bruce Moore in Fort Thomas, saying, "There's not room for both of us. Let's talk."

Bruce Moore, his "fierce competitor," agreed that their combined three locations now represented one too many. The wisest solution was to shutter Moore's, in the middle, and join forces in Bellevue and Alexandria as Pilot Lumber and Moore's! That exclamation point deliberately signified the excitement of growing stronger, better, by the move, which incorporated all five of Bruce's staff, as well as his unique product lines and discrete customer base, where the two discovered very little duplication.

"Only two builders overlapped," says Ken. "And one of them, for 25 years, had been shopping both of us for price. He bought his lumber from Moore, then the fill-in from us. That way, the builder was the real winner. It used to drive us crazy! And Bruce's outside salesman loves the new arrangement-no more competing with us. Now, it's scary, it's so good. This merger is the most exciting thing we've done in five years," Ken declares.

Pilot, with hardware, electrical, and plumbing, had more

retail business, while Moore had concentrated on selline decks and rails to pro builders, developing an enviable loyl alty-"and this business is strongly based on loyalty," Ken reminds us. "Bruce is definitely a 'people person' and enjoys chatting, giving help, while I'm more of an IT guy. He's just the opposite-has trouble getting his email up," his new partner laughs.

While both operations were strong on composite decking, incorporating Moore's line with the three that pilot carries, creating an even stronger showing. Result: "Business has been so good, it's absolutely crazy! It's really a help in this economy: a good problem to have," Ken agrees, noting that builders who wouldn't deign to touch a deck addition in the past are now more than eager to take on that bit of business. "We've added two phone lines," Ken notes.

And brought in-house such facets as HVAC, insurance, and property maintenance. Other savings: "Our two yards are doing as much business as the three used to, and we can operate with the same trucks, no additional racking, etc. We made sure we have all the products our customers expected to see at Moore, adding 'their' brand of caulking or whatever. And because we have more room, there's the Wowl factor."

The potentially problematical aspect of merging employees was not difficult at all, thanks to careful advance planning. "We were very sensitive and did a nice job integrating, by announcing the merger to both at the very same time," Ken stresses. "My people were pumped up-a chance to expand." And adding that exclamation point to the logo-Pilot Lumber and Moore!-shows the folks from Fort Thomas how much they're valued, too.

Now, back to that flagging, on again, off again, design center. "We opened it up full-steam again when we merged with Moore and brought in their displays, and we're very pleased. Sales are up, even with no advertising nor a grand opening yet. It's such a positive change, and our customers really love it."

In other words, call the merger a win-win. Best of both.

The biggest obstacle was integrating two computer systems. "We worked hard on that," Ken acknowledges. "Also, to blend customers, we made the credit application much easier," he adds.

"It's working out perfectly," Ken declares once again. In fact, the outfit is growing even stronger in serving outlying areas such as Dayton, Louisville, Lexington, even Cincinnati. "Our builders are branching out there now. We have the products, the knowledge, and super selection of composite decks. We can explain the various differences and features between the lines, and we've added displays, not only little color patches, so folks can see the real deal, not just a sample. "

What's next? "Our advisors are telling us, 'You really need to duplicate this move. How can you do it again?' But," Ken insists, "after the last five years, being together since August has been really enjoyable, but I don't wish to grow. I'd really enjoyed working with a staff of 18, not 45. But," he ponders, "now we're 23. And that's okay, too! It's been a very interesting challenge."

Carla Waldemar cwaldemar@ comcast.net

&rilding-hodu<tsom

lanuary2012 r Th€tYledantMagazin€ I 13

lru,s,l.B.F.u.?

IIfe cANNor eeRr the computer at information dispensV Y ing. We do have an advantage-if we choose to use it -in the inspiration business. We must first accept that we are in the inspiration business, and then we will have to commit to more inspirational speech.

If a young man is being paid to make pizza and he spends his whole shift cleaning up the parking lot, he may be working hard, but he is working hard on the wrong thing.

Many sellers are working hard at information dispensing while ignoring the persuasive and inspirational arts.

I'm happy with my current supplier

Goals: (l) Get the customer to relax.

(2) Keep the conversation going. Uh, uh, well, uh won't get it done. (3) Get permission to continue calling.

The secondary supplier strategy. We don't challenge the customer. Any kind of i "I-can-do- it-better-or-cheaper-than-whoyou-are-buying-from-now" direct challenge will raise our potential customer's defenses and will make it difficult to get permission to continue calling.

"John,I don't want to get in the way of the business you are already doing. What I would like is to find out more about you and your business and become a secondary supplier to you. That way, you can get to know the quality of my service and products and, if anything does happen with your current supply, we will already have a working relationship and we will continue to supply you without interrupting the smooth running of your business."

The challenge strategy. To get some customers out of their curent habits (buying from others), we will have to challenge their view of the world. This is delicate; it can backfire and blow up, so use with care.

Customer: "I've been buying from Susie Smithers for 20 years. She has been with me through thick and thin, so I owe her. In our current market, I can barely keep her happy, much less take on a new supplier."

Bold Seller: "It's great that you are loyal. But changing times call for changing strategies. In shifting times, only the crafty, flexible and open-minded survive. I bring new and different ideas to my customers that help them make money in these dynamic times. Why don't we open a dialogue?"

W.SJ.BJ'.U.?

The real objection behind all objections is, "Why Should I Buy from You?" About 95Vo of the sellers you compete

against every day cannot answer this question in an inspirational way. That957o wing it so they all sound the same. Here's how to write a great WSIBFU?:

No more than four sentences.

. What's in it for the customer? Saying you are the biggest and baddest and that you have been in business for 1,000 years means nothing to the customer. They do not care. Telling them you are currently helping people just like them to make money and buy better products will resonate.

. Something about ourselves. If we go to the psychologist and she says, "Tell me about your family," and we spend the hour talking about everyone but our father, the psychologist surmises issues with our father, by omission.

Sellers who only talk about how great their company is without mentioning something about themselves-the thing they most want to communicate-"I am a man you can trust," "I make a great partner," "I treat your needs as mine," "I am passionate about creating profit for my customers," "I'm fun to do business with"-sends the message that they don't believe in themselves, by omission.

Our customers want to buY from people who are confident. Say something good about yourself; don't go overboard, but we must saY something about the value we bring. . Tailored to personality. Everyone is different. Communicate with customers in their language. We approach the aggressive buyer differently than the laid back buyer, for example.

The most important thing is to have a well-planned, inspirational answer you believe in.

"You should buv from me because I will bring you value.There are all kinds of suppliers in this market. Direct suppliers, wholesale suppliers, distribution suppli' ers. I am a customer needs supplier. What my customers need, I supply them. I am a profit-making partner. That's why m\ customers buy from me and that's why you, too, will love doing business with me." WSIBFU?

James Olsen Reality Sales Training (503) s44-3s72

james @ realitysalestrain

ing.com

By fanres Olsen

14 r lhe lvlerdrant llhgazine r lanuary 2012

BniHing-Ptodudsom

Parr Lumber ooened a 4.4-acre lumberyard with 20,200-sq. ft. warehouse and 1,500-sq. ft. retail showroom in Marysville, Wa., Dec. 14, to replace its yard in Everett, Wa.

Doug Nelson, general mgr. in Everett, transferred to Marysville.

Meek's Lumber & Hardware closed its Grass Valley, Ca., yard Nov. zJ.

The chain continues serving the community from its Rocklin and Yuba City, Ca., locations.

Barr Lumbof is down to four yards after closing the lumberyard at its headquarters in San Bernadino, Ca.

Mead Lumber Co. aoreed to buy Truss Claf!, Cheyenie, Wy., from Dakota Craft, napiO City, S.D.

The deal is set to close by Jan. 31.

Marin Ace, San Rafaet, Ca., has been opened by Michelle and Jeff Leopold, owners of Standard 5&10 Ace, San Francisco, Ca.

Lowe's will open a 65,000-sq. ft. customer support center in Albuquerque, N.M., by March, to complement its CSC in Wilkesboro, N.C.

The facility will provide such support functions as customer care, store support, Internet sales support, and repair services for customers.

Ace Hardware Express, Shasta Lake, Ca., reopened at a new, slightly larger location Dec. 28-exacf ly three months after a fire destroyed its previous facility.

All nine employees were retained during the interim, working at the Hardware Express stores in Redding and Anderson, Ca.

Bill's Ace Hardware is ctosing its S-year-old store in N. Concord, Ca., March 31, reducing the chain to three locations.

Sammamish Ace Hardware, Sammamish, Wa., is scouting for a new home following a rent dispute with its landlord.

Seventeen-unit Crown Ace Hardware, Huntington Beach, Ca., received a 2011 Familv 0wned Business of the Year Award from the Orange County Business Journal.

Two Family-Operated Dealers Join Forces in Hawaii

HPM Building Supply, Keaau, Hi., acquired Kauai Lumber, Lawai, Hi., on Dec. l.

"We saw this as being a merger of resources and being good for the community, and also for our associates at both companies," said c.e.o. and president Mike Fujimoto.

Founded 90 years ago as a small, family-owned mill in Hilo, Hi., HPM is now 1007c employee-owned, with three full-service building supply centers and four lumberyards on the Big Island, one building supply center and lumberyard on Oahu, and one on Kauai. The company manufactures pre-engincered trusses, wall panels, metal roofing, and prc-hung doors, and treats its own lumber.

Jcle McEvoy. Kauai Lumber's former owner, will stay on as -general manager and all nine employees will continue to work for the business. which will retain its name.

McEvoy's grandfather owned and operated McEvcly Lumber, Kirkland, Wa., and his father worked for and then owned Matheus Lumber. Woodinville. Wa. After working for his dad, McEvoy came to Hawaii to

work at his brother's company, Maui Lumber. He opened Kauai Lumber in t992.

"I really belicve that the two o1'us together, HPM and Kauai Lumber. make a great team," said McEvoy. "HPM has all the experience and buying power, and I bring along years und yelrs of experiencc running u successful lumberyard on Kauai."

Treater Completes Energy Test

Fontana Wholesale Lumber. Fontana, Ca., has completed a six-rnonth field trial with Southern California Gas using ultra low-emission control technology for natural gas-powereil engrnes.

Fontana Wholesale produces ncarly l00a/c of its electricity on site. using waste heat from a natural gas engrne to operate kilns used to treat lumber. The system that was tested is a retrofit conversion kit for rich-burn engines.

"This breakthrough low-emission control lechnology has stratcgic impor-tance in a region where the lafest emissions requirements have been lowered to unprecedented levels," said Hal D. Snyder, v.p.-customer solutions at Southern Calitbrnia Gas.

Building-Productrom

lanuary 2012 r lhe lhrdrant Magazine r 15

Two guiding lights to green in 2012

fr's JnNuanv. a time when we're all starling into the headlights of an oncoming new year bearing down and wondering how it's all going to turn out. Perhaps you've had the same premonitions I've had about 2012. Clearly, there are going to be some rough patches. It's an election year and the electorate seems in a bad mood. The economy seems in a bad mood, too, with high unemployment, rising foreclosures, and little building activity.

Some dealers will do well and some won't-it's going to be a mixed bag. So what can you do to put yourself in the former category? It all depends, of course. Do you serve mostly pros or consumers? Are you are a chain or a locally-owned independent? There is no one size fits all strategy.

I've said it before and I'll say it again, green dealers seem more buoyant, more resilient. But I think this year's going to take a little more effort. What's my advice for taking your green strategy to the next level? Two things: energy efficiency and community.

First and foremost, make energy efficiency job one. If you're a dealer in this channel, this needs to be top of mind for everything you do. I'm talking about the whole picture - operations, products, merchandising. If you can find a way to pay for it, do a lighting retrofit, install solar panels, and insulate every building you're heating. This is going to reduce your operating expenses and demonstrate your leadershiP.

Stock products that will save money for your customers: insulation products that meet LEED or other green building program criteria, triple-glazed windows, insulated doors, LED lighting. Finally, do your homework on rebates and other incentives and plaster the information everywhere. Label products that are energy efficient and can reduce bills. Stocking the right products and merchandising them effectively will help maximize your sales. (Besides, if you don't, who will, Best Buy? Yes, apparently. They're piloting a new home energy retail concept.)

Secondly, do everything you can to get closer to your community-customers and other stakeholders, too. Whether you're primarily serving pros or consumers, be

energetic in learning about your customers' needs and finding ways to serve them. Who is building houses? Who is remodeling? What are homeowners doing on their own? Host events in your store that bring your buyers and customers together and get them talking. Walk the aisles and the yard with your customers and listen carefully to their feedback. If you're getting this information from manufacturer reps, you are listening to the wrong people.

Don't be afraid to leave the comfy confines or your store, either. Attend local USGBC meetings. If your community has a "shop local" campaign or a business alliance, such as a chapter of Business Alliance for Local Living Economies, for example, join it.

And don't forget other groups that are active in your community. Forging these links may make all the difference this year. It will keep you from stocking useless inventory and will identify the products and materials your customers need.

Energy and community. It's simple and clear. It provides a solid mission for your staff that's imbued with optimism. It can provide the basis for a marketing campaign. And if you follow through, if these are truly priorities for your organization, you will be doing all the right things to appeal to green builders and remodelers, homeowners and d-iyers. Certainly, you'll learn about other needs, products and oPPortunities along the way, too.

And whatever turmoil the year may have in store, I believe you'll find that energy and community will see you through.

JaY TomPt Managing Partner William Verde & Associates (415) 321-0848

ay f ay Tompt

16 r ftett4eduntlihgazine I hnuary2Ol2

Building-Productscom

info@williamverde.com

A.C. Houston Gives Up Las Vegas

A.C. Houston Lumber is down to two locations-Indio, Ca., and Ketchum, Id.-after selling the assets of its Las Vegas, Nv., operation to Desert Lumber, N. Las Vegas.

Although A.C. Houston retained the lease on its Vegas lumberyard/truss/wall panel complex, it signed a non-compete clause for southern Nevada. President Ron Mason will expand instead in California. Its corporate office, however, will remain in Las Vegas for the short term.

Desert Lumber will continue operating out of its own N. Las Vegas lumberyard, Las Vegas truss plant, and Las Vegas fastener and supply center.

Western International, AIFP Merge

Forest City Trading Group consolidated operations of Western International Forest Products, Portland, Or., with American International Forest Products, Portland, effective Dec.12.

"The combination of the commodity, industrial and specialty products from WIFP added to the strong sales and diversification of AIFP provides a unique opportunity for near- and longer-term growth for traders, suppliers and customers," according to FCTG.

Hambro ldles Particleboard Plants

Hambro Forest Products, Cresent City, Ca., has closed its particleboard facilities in Crescent City, Arcata, Ca., and Lenoir, N.C.

The plants in Arcata and Lenoir are up for sale, while the Crescent City operation will be mothballed, in hopes of restarting should market conditions improve.

Hambro had produced particleboard since 1964.

Accidental Death at Hampton Mill

Hampton Affiliates' mill in Morton, Wa., was shut down Dec. l3 after a 20-year-old employee was fatally injured on a conveyer.

According to the Lewis County coroner, Dillan Davis died after his clothing snagged on rhe machinery, pulled against his neck, and cut offoxygen to his brain. The state Department of Labor and Industries is investigating the death, which has been labeled as an accident.

Big Sky Lumber Sales, Hamitton, Mt., has been formed by Steve Roberts, Marty Wilson, Jim Murray, and David Bourne, allex-lndustrial Lumber Sales. Hamitton.

Simpson Lumber Co. taic off 19 workers at its Commencement Bay sawmill in Tacoma, Wa., due to sluggish lumber demand, but continues operating three shifts.

Timber Products Co., Springfietd, Or., has acquired sole ownership of the company's 114,000 acres of timberlands in Northern California from a long{ime partner group.

Butfelen Woodworking, Tacoma, Wa., is now the primary fir door supptier to DW Distribution, DeSoto, Tx.

Boral Roofing Co., trvine, Ca., is now selling its BoralPure concrete roof tiles nationwide.

BW Greative Wood- Industries, Mapte Ridge, 8.C., has a-cquirei. tfre Probuilt d-i-y atuminum iailing Susiness from Alco Ventures, Langley, B.C.

Kitwanga Lumber Co., Smithers, B.C., has fited for bankruptcy protection.

Skana Forest Products Ltd., Richmond, B.C., has taken over the lumber division of Evergreen Empire Mills Inc., Burnaby, B.C., which now oierates undei the Skana name.

AltruWood Inc., Portland, 0r., has rolled out a new ecommerce website (www.dougfirflooring.com) to sell FSC-certified Douglas fir flooring.

Simpson Strong-Tie, pbasanton, Ca., has inhoduced an online Fastener Finder tool, making it easy for customers to find the fastener products they need to compare, specify or ourchase.

$ *ru,c Wosd Laminates,lnc.

VrFP Distrihuted By /VOB.]}TAN P.O. Box 1802, Medford, OR 97501 Fax 541-535-3288 (541)535-3465 . www.normandist.com BuiHingrhductsom hmnryZil2 r Thel{ednntltlagazine t t7

Boise Cascade EngineedWood Products

By fames Olan Hutcheson

share leadership When siblings

/iu,qNces ARE

GooD

lUrnat a lons-lived thmily business wlll eventually be led by a sibling team. But despite sharing common values, siblings face real obstacles when cast in the top leadership spot.

sure. perceptlons ol i. '* parental favoritism and l-f i longstanding rivalries can make cooperation difficult. But the biggest challenge? Almost all second-generation sibling teams must somehow adapt a decision-making process dominated by a single autocratic leader into one that works for two or more people. The key is preparation.

So how do you prepare sibling teams capable of this challenge? When your children are young, define your expectations in written form and formalize procedures that all employees, family and nonfamily, are expected to follow. If you wait until your kids are ready to assume leadership roles to do this, it may engender conflict rather than prevent it.

Do it before they enter the business and all involved will know what's expected and have a chance to grow into their roles.

Necessary Paperwork

Documents you'll need to include a buy-sell shareholder agreement, an employment policy, compensation guidelines, and job descriptions to help all understand who will be hired, under what circumstances, how they'll be paid' and what their responsibilities will be.

As children grow, they should be introduced to the business so they can get to know employees, hear stories about the business's positive and negative aspects, and learn why you started and continue to run the business. Older children should be invited to take summer jobs.

Before joining the company full time, siblings should be required to obtain the necessary education and training to execute their responsibilities. This may include college or

technical schools, and should include a period of time working at an outside company. where the family name carries no significance, before they join the family company.

'feam Concept from the Start

When siblings have joined the company but aren't yet in the toP leadership jobs, encourage them to work as a team by pairing them in jobs that require cooperation. Avoid putting them on tracks that have them following each other in the same job, or you risk encouraging unhealthy competition.

When siblings are sent out for training or seminars, have them attend together when possible. It will encourage a sense oftogetherness they can use to represent the family firm to outsiders.

You should also set up regular family meetings and organize a board of directors that includes outsiders. Prepare a process for breaking tie votes in the event the siblings can't agree on some future decision. Consider having an outsider or one of the siblings take a rotating role as the tiebreaker.

Once the siblings are in leadership roles, you as a parent should not act as a tiebreaker-it should be their responsibility.

The job of preparing siblings for sharing leadership of a family company is a challenging one. With luck, it will pay off during and after their successful run, when the next generation will be ready to take the reins.

- James Olan Hutcheson is managing partner and Jbunder oJ ReGeneration Partners, a Jamily business consulting headquartered in Dallas. Tx. He can be reached at (800) 406-l I l2 or wv)w .re 8e ne rat io n -pa rt ne r s.c o m.

Reprinted with permission of ReGeneration Partners. No portion oJ this article may be reproduced without its permission.

FAMIIY Business

lE r The Nkdrant ltrhgazine I January 2012

Building-Productrcom

New Owners Move into Stimson's Bonner Mill Site

The old Stimson Lumber Co. mill complex in Bonner, Mt., is slowly coming back to life.

Last month, Stimson sold the propertywhich has been quiet since 2008-to Western Montana Development, which plans to lease portions of the operation to various timber industry-related companies.

Logs began arriving at the facility in mid-December to feed a chipping operation being readied by Willis Enterprises. Willis has contracted to ship its output via the site's rail spur to Boise's paper mill in Wallula, Wa.

Willis is leasing 39 acres-about one-fifth of the property. For several years, Northwest Paint has been renting 90,000 sq. ft. of anorher building. Western Montana Development is

working with other possible tenants for the remaining 700,000 sq. ft. of building space.

Washington's Tri-County Truss Comes Back

Tri-County Truss, which until last August operated a facility on 8.5 acres at the Port of Skagit near Burlington, Wa., is back in business.

The business was acquired by The Truss Co., which operates two other facilities in Sumner, Wa., and Eugene, Or., in late October. Several members of the former management team, plus more than 30 of the 92 employees that were laid off, went back to work on Nov. I , under the Tri-County name.

"If we were back to where we were (in August) by next summer, I'd call that a success," said general manager Roger Helgeson.

PenPly Pulls the Plug on Former KPly Plywood Matl

Unable to meet a mid-December deadline to find new ownership, Peninsula Plywood has handed over the keys for its sawmill to landlord Port of Port Angeles, Wa., which expects to demolish the 70-year-old facility to make way for marine-related businesses.

The l9-acre mill site operated as KPly until November 20Oi and restarted in March 2010 as PenPlv. under Josh Renshaw. KPly's former sales manager.

Renshaw cited high operating and veneer costs, a May 2010 fire, and poor inventory control for the demise of the company that operated for 22 months, using the facility's original name from 1941.

Ysu deserue better.

You deserve top-notch software, service and technology from a fiercely independent, owner-operated, All-American partner. DMSi is the gold standard for customer satisfaction. Our software, Agility, will make you strong. Are you ready for better? lf so, call DMSi Software at 800.347.6720 or visit dmsi.com.

8o o.3q7.57a o dmsi.cam irmSfsonware flun better. Buildinghoducts.orn January 2012 r lhe lvlerdrant Magazine r 19

Don Hollinger has been promoted to general mgr. of ProBuild, Hermiston, Or., succeeding Earl Bellegante, who has transferred to Yakima, Wa., to take over for Brandon Huff. Huff is now general mgr. in Arlington, Wa.

Betsy Bendix, ex-Huttig Building Products, has joined Fiberon, as a deck specialist for the Southern California market. She is based in San Bernardino, Ca.

Jim Sitton has retired after eight years at Kruse EnterPrises, Albuquerque, N.M., and 39 years in the industry.

Mike McCollum, ex-WeYerhaeuser, has joined Roseburg, Dillard, Or., as national sales mgr. for engineered wood products. He succeeds Bob Berch, who is retiring at the end of January, after launching Roseburg's EWP division in 2001.

Chris Olsson and Stuart SimPson, both ex-American International Forest Products, have joined the lumber trading staff at Talon Forest Group-AFA/USA, Portland, Or.

Max Guetz has joined AlPine Lumber Co., Englewood, Co., as Front Range district mgr.

Don Schott has retired after 25 years with J&H Forest Products, Boise, Id., and 40 years in the industrY.

Rick Prinzo has joined Orchard Supply Hardware, San Jose, Ca., as regional v.p. for the Sacramento area.

Jitl Cheyne Roy, ex-All American Home Center, has been named store mgr. at Orchard SuPPIY Hardware, Burbank, Ca.

Rick Anderson, ex-ProBuild, is new to national sales at Idaho Pacific Lumber Co., Boise,Id.

Dennis Phitlips is retiring and dissolving Industrial Wood SuPPlY, Vancouver, Wa.

Steve Beckham, ex-Lifetime Doors, has been named chief oPerating officer and general mgr. at Heritage One Door & Building Solutions, Woodbridge, Ca.

Linda Walker is new to the inside sales team at Louws Truss, Burlington, Wa.

Cindi Hengstler, glulam account mgr. at Rosboro, Springfield, Or., has retired after 42 years in the industry, the last nine with Rosboro.

Chris Henderson, ex-Huttig Building Products, is new to outside sales for Keystone Windows & Doors, Seattle, Wa.

Julie Osborn-Moss, ex-Floform, is now an account mgr. at CaPital Lumber, Woodburn, Or. Joe Padilla and Jimmy Robbins, both ex-JM Thomas Forest Products, are new account mgrs. for CaPital in Albuquerque, N.M.

Ross Anker has been named v.p.-merchandising for White Cap Construction Supply, Costa Mesa, Ca.

Mark Ellsworth has been named coroorate director of research & development at TAMKo, JoPlin, Mo.

Rich Lynch has been named retail marketing director for Do it Best Corp., Fort Wayne, In. Scott Liggett has been promoted to application development mgr. in Do it Best's IT division. Steve Rose is new as safety director.

available in a variety of PS2-rated tliiclmesses and lergths, induding Struc-l. It's the panel to count on when every minute matters.

Available

LPo OSB panels, LPo trlarneBlock " Fire-Rated Sheathing is an ICC certjfierl GSR-1365), PSz-rated stuchfal sheathing with a Class A llame Spread Rating. It provides extended burn-thmugb resistance, delivering a 20-minute thermal banier (ASTME119). LP llameBlock Sheathirlg is Exposure{ nted durable on the job site and easy to rvork with. Backed by a 20-Year Transferable Limited Warranty, LP I'lameBlock Sheathhg is cost effective and

Created by applying a patented, non-combustible Pyrotiteu coating to

Now At Bear Fonest Products. For More Infonnatio4 Call (874 369-2327 or (95L1727-1767 m nh$,ll.EP*"gcK*"tr OSB I Smartside' I Techshield' O 2011 LouisiDi Pdcjlc ColF,ratun {l riqhrs los.ryed Pvdilc is n (Astered trade&nt of Bardct Tc<bDbtt ColP t.he UL urt $ a r€Ristered iradenafk ot !nderurles l,ahrarorier. ln. a) olh€r tadcm.ks are owned bv Louisrana Pacjhc Coryoralion LPCorp.com/Flamenr".t | @ 20 I The liledunt ttbgazine I lanuary 2012 BuiHiry-Bodudscon

Scott Jacobsen, ex-Lloyd Lumber, is new to sales at TJ Forest, Boise, Id.

Marie Eastlund has joined the sales team at Atlas Trading International, Beaverton, Or.

Dennis Conforto has been named v.p. for the retail di v i s i on of Solatube International, Vista, Ca.

John Venhuizen has been promoted to chief operating officer at Ace Hardware Corp., Oak Brook, Il.

Blake Fohl has been named v.p.-marketing and chief customer officer for True Value Co., Chicago, Il., replacing Carol Wentworth, who has left the company.

Carl Schoenhofer, v.p., The California Redwood Co., Eureka, Ca.. has been elected vice chairman of the California Redwood Association. Janet Webb, president, Big Creek Lumber Co., Davenport, Ca., is the new chair, succeeding John Russell, president, Mendocino Forest Products, Calpella, Ca.

Nate Bond, v.p.-sales, proB uild Holdings, Portland, Or., has been elected v.p./secretary of the Home Builders Association of Metropolitan Portland.

Jerry Guin, a retired salesman for James Redwood Sales and Bracut International, has been writins western fiction since 1995 and just released his latest novel, Drover's Vendena,available at Amazon.com.

Skip N. Wayne is a newly certified grader at Mungus-Fungus Forest Products, Climax, Nv., according to co-owners Hugh Mungus and Freddy Fungus.

Two Coat Exterior Prime

0ur two-coat process starts with an atkyd sealer to btock tannin migration, fottowed by a high-performance acryLic primer. The resutt: RESERVE quatity, inside and out.

Superior Wood

Made of quatity, ctear, finger-jointed Western Red Cedar or Redwood, these products are naturaLty designed for exterior use-both species are ideaI for enduring extreme weather"

Surfacing + Sizes + Lengths

RESERVE products come In a wide range of sizes, lengths and finishes. Whether the project catls for 51S2E or S4S, we offer tengths ranging from 16'to 20'. Pattern stock is atso avaitabte

1"x4 - 1x12 s/axy', - s/ax!)

2x4 - 2\12

Gollins Gos., porfland, Or., earned FSC chain-of-custodv certification for its Gollins Hardwood mitt in Richwood, W.V.

Hycrete earned Cradle to Cradle Certified Gold status for its liquid admixture products.

Marvin Window & Doors now offers its Ultimate glider window in an all-wood version.

Deckorators wiil offer its ctassic baluster in copper and matte black.

TimberTech added two new cotors to its Radiance Rail Express line: classic black and haditional walnut.

The Finest Stock, The Best Coating

Our Siskiyou Forest Products RESERVE line is specially manufactured and treated to create the highest quality product available. Using state-of-the-art application and curing equipment, our premium Western Red Cedar and Redwood stock is made to last for many generations. We are proud to offer a beautiful, durable product that is ready for installation and final painting the moment it reaches the craftsmen.

1 !

Building-hoductrcom

S T S KIYOU. FORE ST" P RODUCTS www.siskiyouforestproducts.com 8OO.427.8253 , 6275 Hwy 273. Anderson, CA 96007 January 2012 I llre ltlednnt ltlagazine t 2l

Lowe's Buys Online Retailer

Lowe's, Mooresville, N.C., has acquired ATG Stores, which has two retail locations in Washington state and more than 500 websites selling lighting, tools, and home furnishings.

"The addition of ATG Stores is a strategic fit, providing more opportunities for Lowe's to be a relevant partner at every stage of the home improvement process and deliver better customer experiences from inspiration to planning to enjoyment," said c.e.o. Robert Niblock. "ATG Stores is

Stimson Invests in the Future

Stimson Lumber Co., Portland, Or., invested $5.5 million for computerized saw equipment at its stud mill in Tillamook, Or.

"This is just the first steP in becoming a state-of-the-art facility," said plant manager Chris Stirk, who explained that the recent upgrade will allow the mill to produce the same volume of lumber, using fewer logs, with no jobs lost. Future uPgrades will include a comPuterized resaw and optimized edgers.

The company has also invested in employee training, through its part-

an extension of Lowe's commitment to providing consumers with flexibility, simplicity and value, whenever and wherever they choose to shop."

ATG. which launched its first website in 1999, will operate as a whollyowned Lowe's unit and remain based in Kirkland, Wa. The sale represents the first in l2 years for Lowe's, which has invested record amounts in technology-including doubling the number of items on its own website to 260,000 and equipping emPloYees at its retail stores with iPhones.

nership with the Industrial & Manufacturing TechnologY Program at Tillamook Bay Community College. The program's goal is to train and apprentice local students to become technologically skilled workers.

"We don't have the qualified People with the technical skills we need," said Stirk. "With the IMT program, we can recruit kids from high school who want to live in Tillamook. It's a grow-our-own workforce approach." Stimson employees also benefit, bY teaching classes or by taking classes to update their own skills.

LBM Elves Deliver Gifts for Local School Children

Christmas was a little brighter for many students in the Inland EmPire, thanks to a program started by Maria Yazquez, human resource manager at All-Coast Forest Products, Chino, Ca.

Named Christmas in the Classroom, the program was founded in 2004 after Vazquez's daughter, an elementary school teacher, told her that many of her students' families could not afford to celebrate the holidays. With donations from familY, friends, and her employer, Yazquez was able to provide gifts for each child in the class.

As the program exPanded, she began to solicit donations from other LBM companies-such as CaPital Lumber. Chino Lumber, and Ganahl Lumber-as well as other local businesses. In December, the Program was able to provide gifts for everY student at four local schools.

"My goal is to somedaY be able to give a gift to all students attending Title I schools," said Vazquez, who explained that such schools have a majority of students who receive free or reduced-cost lunches. "It's a Christmas miracle."

INTERIOR FIRE RETARDANT LUMBER AND PLYWOOD

NATIONWT

DE STOCKING DISTRI BUTORS

SUPERIOR TO PAINT OR COATINGS

STRONGEST FRTW WARRANTY COMPETITIVE PRICING

TSO AND KDAT

22 r The Dledtant lvlagazine t hnuary 2012 Buildirq.hoductrom

Paint Color Trends

Wondering about the hot paint colrurs for next year'? Wonder no more. The 20 l2 paint palerre will draw hcavily upon natural colors fiom the American landscape, accctrding to Dcbbic Zimmer. color erpcrt ut thc Paint Quality Insrirute.

"Native plants and flowcrs. oceans and lakes, and rocks and mincrals arc thc sources of inspiration for the paint colurs that will bc'in'next year." Zirnmer says. "If you're thinking about rcpainting your home interior. look to the grcat American outdoors."

Here are some highlights:

Blue, the .Iewel of the Sea Blues gained popularity in 20 I I and continue to be red hot in 20 I2. "From sparkling sca--{lass blue tc'l colonial blue-gray, blues are suitablc fbr all livin-g spaces. beins a naturally s<lothing color that is loved-in one itcration or another-by almost cveryone," silys Zimmer.

Green, From Farm to Forest Greens. ranging from celery and asparagus to fir and f'ern. allow homeowners to bring the comforting l'celings of the world outside into the world within. According to Zimrner. dining rooms and kitchens are thc "natural" spots tbr in voguc greens. but the hue is also at home in farnily rooms ancl bedlooms.

Violet, Majestic Purple Mountains

"A harrnonious combination of patriotic blue and red hucs, violet can add 'punch' to any room when used as an accent color, or scrve as the dominant color in a bedroom." says Zimrner.

But natural hues aren't thc only ncws fbr 2012. Zimmer predicts that thrce paint and decorating trends will gain prominence next year:

Patterns

In 20 12. pattcrned paint will take center stage, with increased intercst in hound's-tooth finishes, lacy designs, and bold color blocking tcchniques. "ln somc cascs. pattern will be the muin dccoruting ll'ilture in a roorn: in others. it will provide a subtle, textured backdrop for fine furnishings and artwork," says Zimmer.

Black and White

Thc classic combination of blae^k and white isn't.just fbr Cape Cods any rnore. You'll see much more of it in all sorts of settings, fiom contemporary apartments to historic homes,

Draw on Outdoors

slys Zinrmer. "Thc pairing is a great way to freshen an intericlr with something smart and stylish." she says.

Exterior Paint Combinations

On thc home exterior. shutters colors will begin to shift away from rhe traditional look of h i-uh-contrast green, red. clr black to a rnore monochromatic palette. "You'll see morc shutters that are painted -just a shadc clarker than the siding," says Zimmer. "Owncrs of homes with stone cxteri-

ors can gct in on things by matching the shutter color to the dorninant color of the stone."

Dcspite al I the ncw colors and trends, Zimmer says sonte thin-es in the paint world will rcmain the samc in 2012: "Top quality 100% acrylic latcx paint will continue to providt: thc best perforntance ancl thc best value to budget-conscious homeowners." she says.

And, since paints are locally produced. consumers can easily support the growing "Made in Amcrica" dccorating trend.

Old World Crafumanship In

Today's Designs

Tru-Dry Timbers

Geo. M. Huff Lumber Co. has teamed up with Forest Grove Lumber to become the exclusive Southern California stocking distributor of Tru-Dry Timbers.

All FGL Tru-Dry timbers are dried in "HeatWave USA's RFV" kilns, which use clean, renewable energy and have zero emissions.

Tru-Dry timbers are dried completely and evenly throughout so you won't experience the sticky problems often encountered with beams that are not dried to the core.

Combine our selection of Douglas fir timbers along with our skilled milling staff and you've got one of the best resources in Southern California.

Building- Products.com

Tru-Elrtl HUFF LUMBER COMPANY SANTA FE SPRINGS, CALIFORNIA 800-347-4833 lanuary 2012 I Ihe fvbrdtant Magazine t 23

Cooperation marks monitoring of western lumber design values

for sample collection. This lumber sample represents the Douglas FirLarch lumber being produced for the marketplace. At the time of this writing, western lumber agencies are collecting samples (No. 2 grade Douglas Fir-Larch 2x4 lumber) for testing. The testing of Douglas Fir-Larch will be conducted according to applicable ASTM consensus standards and will be completed in the spring of 20 12. The test data analysis will be Performed by the cooperating western lumber agencies. The test results will then be reported to the ALSC board of review.

A cREAr neel of attention has la.been focused on the Southern Pine Inspection Bureau's recent American Lumber Standard Committee proposal to reduce southern pine lumber design values. Western lumber producers have taken notice and affirmed their responsibility to ensure the products they sell can be used with confidence.

For the past year, western lumber rules writing and grading agencies have pursued a consensus approach to monitoring western lumber design values. A coalition of western agencies (Western Wood Products Association, West Coast Lumber Inspection Bureau, Pacific Lumber Inspection B ureau, Redwood Inspection Services, and Timber Products Inspection) are working together on a monitoring program to

sample and test western lumber species. According to Dr. Kevin Cheung, WWPA's chief engineer, participating agencies are shouldering equal responsibilities to insure the successful outcome of the design value monitoring program.

A Western Lumber Sampling and Testing Plan for Monitoring Western Lumber Design Values prepared bY the coalition was reviewed by the USDA Forest Products LaboratorY and approved by the American Lumber Standard Committee's board of review on October 20,2011. The plan calls for destructive testing of lumber samples representative of production-360 lumber pieces in bending and 360 pieces in tension.

Working with statistical suPPort from Portland State University, a total of 36 mills were randomly selected

Western agencies will review preliminary test results and discuss appropriate actions, if required, with their respective companies. WWPA staff will review preliminary test results and discuss appropriate actions, if any are needed, with WWPA membership at their spring 20 12 meeting in Portland, Or. The monitoring program is designed to detect any significant population shift in structural lumber properties impacting the published design values. Should the test results indicate a need for an expanded testing program. the lumber agencies will cooperate for additional sampling and testing in a timely manner.

Following the evaluation of Douglas Fir-Larch, other western species such as Hem-Fir and SPFs will be sampled and tested. This monitoring program will provide for periodic testing of western lumber in the future. The goal of the lumber monitoring program is to maintain customer confidence in the performance of western lumber products.

Western Woods SPECIAL Focus

A r The l,ledant MaSazine r hnrary 2012

Buildinghodudsom

StimPro Inland Red Cedar

The Quality Choice

Contractors, architects, and designers, as well as homeowners are discovering the many advantages of StimPro Inland Red Cedar from Stimson Lumber Company.

StimPro cedar products are graded and sorted to assure that they conform to the highest standards of quality, with a wide range of patterns, tallys and packaging. Our boards are kiln-dried to assure dimensional stability.

Products Available:

o Decking

o Siding and patterns

o Boards and dimension

o Fence rails

Grading Beyond the Standard

StimPro provides you with the highest possible quality by limiting the WWPA allowable defects in all grades. Our V4F pattern stock is specially selected to assure a select tight-knot product.

Superior Surfacing

StimPro cedar products are surfaced using high-speed planers with the latest technology. We use a rougher-head planer process to provide a clean, uniform rough face to our S1 52E boards.

Special Packaging

StimPro cedar products are available in a variety of packaging options. Our Sl 52E boards are available in single length half-pack units. Our pattern stock is sub-bundled and end-capped for merchandising value.

^4N

A TRADtTt()N ()F QUAL.tTY 800-445-9758

strmson Lumtrer Company

New year, new Galifornia wood dust warnings

j-\altnonNtR PnoPoslrlol 65. the \-,Safe Drinking Water & Toxic Enforcement Act of 1986, now requires wood products Producers to inform their downstream customers about the potential hazards of wood dust and regulators to advise that each customer should acknowledge that the warning has been received.

Wood dust warning materials must ultimately be Posted at any California retail location where a manufacturer's product maY be sold.

The first wood dust warning materials were sent out in late fall 2010 to California customers and regional distributors selling into the state. Because affixing labels to wood products presents unique challenges, the majority of manufacturers issue a warning letter and/or warning signage.

It should be noted that Proposition 65 does not require product warning labels. How manufacturers comply with Proposition 65 warning requirements may vary by manufacturer.

In 20 10, Western Wood Products Association established a Proposition 65 customer notification service for any manufacturer or distributor who wanted to take advan-

WARNING

Ddling, sandng, sending oe machinirg wood products generetes wood dust, a sub€tance known lo the Slal6 of Callfomia to causs cencar. Avold Inhallng wood dusl or use a dust mask or other safeguards for personal protec*9o.

Clliform l"lesllr ald Ssfety Codo Sodion 252/t.9'0

WARNING SIGNS are required at retail locations in California where lumber and wood products are sold. To obtain signage, email Lumber Association of California & Nevada at lacn@lumberassociation.org.

tage of a consolidated warning to customers. The WWPA service follows the Office of AttorneY General of California warning guidelines.

Signage and warning materials were developed, in consultation with the Lumber Association of California & Nevada, in meetings held with regulatory and enforcement officials. The 2012 wood dust warnings, issued through the WWPA notlfication service, are part of the required customer warnings, which are sent in JanuarY of each year.

This "Right to Know" regulation applies to the average retail consumer and is not related to occupational setting requirements enforced by OSHA and other government agencies. Each year, wood product distributors and others that sell to California customers will be informed of their duty, under Prop 65, to inform their downstream customer about the potential hazards of wood dust.

The warning requirement applies to any business employing ten or more employees that manufactures' produces, sells, distributes, or otherwise transfers a wood product into the stream of commerce in California.

Companies receiving 2012 warning materials may be initially surprised by their issuance since they may have received previous warnings in 2}l0l20ll According to California Health & Safety Code Section 25249.6, as of December 18, 2010, no person in the course of doing business shall knowingly and intentionally expose an individual to wood dust without first providing a clear and reasonable warning.

Representatives of the California Attorney General's Office have indicated that, in their view, annual downstream customer warnings satisfy the continuous warning requirements of the statute when coupled with appropriate consumer signage at the retail level.

Western Woods

26 r The llerdnnt lt4agazine I hnuary 2012

Buildinghoductsom

he Collins Jhe Co[in LOmn2nioc ompanies sii

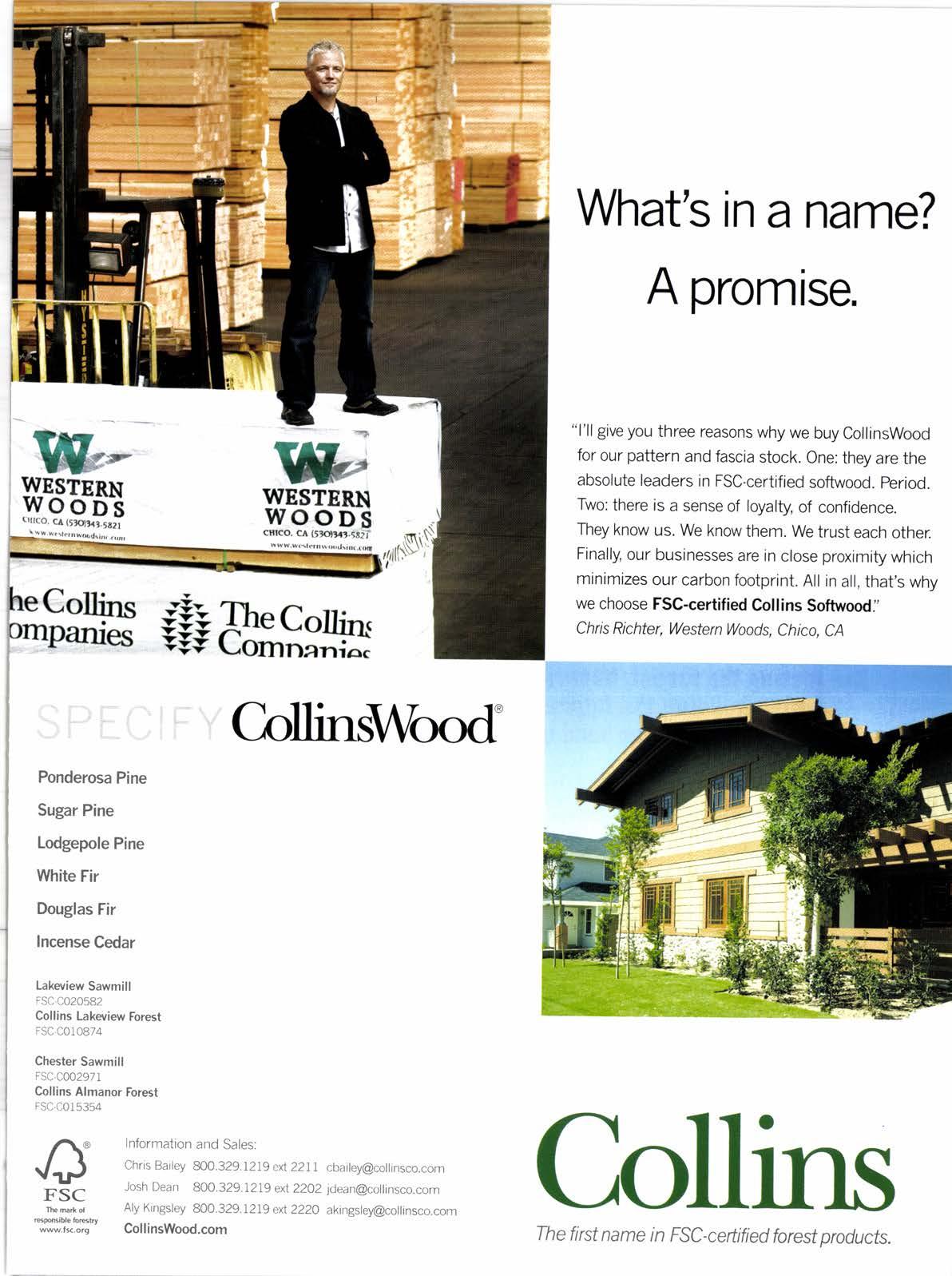

What's in a name? A promise.

"l'll grve you three reasons why we buy CollinsWood for our pattern and fascia stock. One: they are the absolute leaders in FSC certified softwood. period. Two: there is a sense of loyalty, of confidence. They know us. We know them. We trust each other. Frnally, our businesses are in close proximrty which minimizes our carbon footprrnt. All in all, that's why we choose FSC-certified Collins Softwoodl' Chris Richter, Western Woods, Chico. CA

rr!r-.-..-.-ii .l ' --:,rr '* ,iF:', .* "+

Collins vOni:1ci'{Ji..i I'f rtrl $ugar isine l-*cigepr:lc fline Whitc Fir {l}r:ug}ai; $:ir lnrunse fi:dar 1"..: rcv rcty; 5;oolil | t"'lll:rrr L;f.tlvirw l*regl Cl:i.,ll* !;rr,,nllll Callinl Alnr;nrir forest l:.r1 r.!a.L,, rt ttir.,..|,t rll l, ,, l-i:|i;rrii;l !f ir.::i-rt:l rr :r,1jr. iryittr;. r11 j: 1t::, ai).r CllIinsVYlLrd-cor.rr Ih, i; r.:; i I i.r i ] l l ; r: fSC r.l r-dlfiecl faresf prurJucfs.

By Craig Larsen, Softwood Lumber Export Council

lnternational outlook for western softwood lumber

tTtne NUMBERS: The international marketplace for U.S.|- produced softwood lumber is one of the few lumber markets that have continued to grow and provide added market demand over the past few years. In 2005 during the peak of the U.S. housing boom, international markets dropped to $449 million and 16,424900 bd. ft. By 2008' the market had climbed to $584 million ($372 million from westem species) and 86.8 million bd. ft. Exports for 2010 finished 5l7o ahead of 2009 at more than $843 million and 1.3 billion ft.

And then there was 2011. The numbers for the first l0 months indicate that this will be a $l billion export year'

with more than 1.5 billion bd. ft. shipped overseas. China entered the market in a big way, pushing to the number one spot with an estimated $225 million and 315 million bd. ft. Jipan continued to improve, with approximately $140 million and 165 million bd. ft. imported in 2011. Two other $100 million markets were Mexico and Canada, which include re-exports overseas.

In 2011, regional markets for U.S. softwoods included the Caribbean ($128 million), Southeast Asia ($38 million), and the European Union ($30 million). Southern Asia, including India and Pakistan, and the South Pacific' including Australia and the French Pacific Islands, combined for another $36 million in exports. Central and South America combined for over $5 million in shipments in 2011.

Western species have done well. Douglas fir has climbed from $58 million in 2005 to $256 million (297o of all $ftwood exports) in 201 l, and hemlock has risen from $l I'million to $145 million during the same period. Ponderosa pine has maintained a steady market, at about $26 million for the past two years. Southern pine shipments are at approximately $150 million in 2011-

Markets

In the global lumber market, U.S. softwood producers are still relatively small suppliers. Europe, Canada, Chile, New Zealand, and Russia are the major exporting regions or countries for softwood lumber products.

International market requirements and product uses vary widely by species, size, grade, and material end use. Traditional U.S. structural species, such as Douglas fir and hemlock, are found in many non-structural products. Lower grades of all species, which are of limited value in structural applications, find a home in crating, pallets, and packaging. Additionally, they are used in many remanufaciuring and gluing facilities in parts of the world with much lower labor rates for furniture and millwork components' Wood frame residential construction is mostly limited to North America, Japan, and parts of Oceania. Even in those markets, North American framing systems using 38mm x 89mm (2x4) structural members is limited. The U.S., Canada, and a small segment in Japan are the only countries that utilize 2x4 construction. Japan is the second largest wood frame building market in the world, but of the almost 500O00 wood frame units in Japan this year, only

t SPECIAL Focus Western Woods

Bespecting the forest, hononing the past, huilding the future. A nation's pride Uou can build on. Manufacturers of l0 million bd. ft. monthly of . 5/4 & 6/4 Ponderosa Pine Shop . 4/4 Premium Pine Board Programs Sate{fthetut Hewmill& Headrig Mill Contact Sheldon Howell Bob Bnetz (5091 874-1163 t8051 995-0700 Yakama Forest Products 3191 Wesley Rd., White Swan, WA 98952 Fax 5O9-874-1162 wurw.yakama-forest.Gom 2A r The ltlednnt l4agazine r hnuary 2012 &ildingrhodu&om

OUR PREMIUM IDAHO FOREST 6OLDT''1 I,trNE is in demand the wor-ld over inclircling Ccd;ri:, Idaho Whire Pine, ilcnderosa Pine arrrl lxpoi:t^

I RICK PALMITER

GARTH WrrttAMS

- ,t itli: ,i!,;i:.

tri:,\rt() *b i l.r i :

l'r )1.]i i i L "* /l \ t , t I LJ 208. 76:1. 6630 | i rlahoforrrsf grr)r"rp"corn

98,000 were 2x4 based. The vast majority were traditional Japanese metric post and beam timber construction using metric sizes. Structural framing sizes in Australia and New Zealand use 35mm and 45mm bY 90mm and l00mm sizes. U.S. softwood producers successful in these markets are providing metric-sized lumber to compete with other imported products, mainly from EuroPe and Canada.

lnternational Wood Uses