. The Osmose' MicroPro. Technology is the first treoted wood process to be certified under Scientific Certificotion Systems Environmeniolly Preferoble Producl (EPP) progrom bosed on Life-Cycle Assessment.

. [oh9 Term Field Testing shows thot MicroPro treoted wood provides effective protection ogoinst fungol decoy ond termite ottock.

. Building Code Complionl. ICC - ES Reporls, ESR - 1980 & ESR - 2240

. Lighter, more Noturol Wood Appeoronce.

. tmproved Pointing ond Stoining quolilies.

. Better Corrosion Profection for code-opproved fosteners ond hordwore, ond Approved for Aluminum Conlocl.**

. End Uses include interior ond exterior Above Ground, Ground Contoct, ond Fresh Woter lmmersion.

Since 1934, Osmose has produced quality, tested, reliable wood preservatives such as MicroPro. We fully stand behind our products and back them with industry leading warranties.*

For more informolion visif www.osmosewood.com

t0 t4 t9 ,7

Itlicrcnired prc$urc fieo|ed wood ftnolly onives on the Wect CooC

Treoter begins offering 0smose's MicroPro{reoted wood to the Pocific Northwest.

Solec oids: Colifomio redwood prcdutts ond plont eodel lo find

Eurekol Dlscover prcfitr wilh hidden deck fogtenen

Itlew grcen misrion: Iexos-bosed distributor rclb out ceilllled prcdud

Slowdorm llnolly catcheg up to wertem edor

Soruing 13 Wostem Slates, IncludlngAL.k .nd lLw.li

(SbEt publication Suilding Products Digest sefles ne East)

PUBLISHER Alan 0akes (aloakes@aol.com)

PUBLISHEB EXIERITUS David Cutler

EI)|T()R David Koenig (dkoenig@building-products.com)

ASS0CIATE EDIT0F Karen Debats (kdebats@buildin0-products.com)

CO}ITRIBUTIIIG EDIT(IRS

Dwight Curran, James 0lsen, Carla Wddemar, Jay Tompt

A0 SALES ilAl{AGER Chuck Casev (ccasey@building-prodticts.com)

ClRCUl.ATl0ll Heather Kellv (hkelly@building:products.com)

ADtrllllISTRAT|0ll DIRECTORAECRETARY Marie 0akes (mtpoakes@aol.com)

How to Advertise

Conhcl our adycdisino oflices l0r ralos: llrEST, MIDWEST, S0UTHEASI: Chuck Casey, Newport Beach, Ca.; (949) 852-1990; Fu 949-8520231; Email ccasey@building-products.com

II0BTHEIST: Paul Mummolo (N.J.); (732) 8998102; Fax 732-899-2758; Email mummolop@ comcast.net

How to Subscribe

Gonlacl Heatior al (949) 852.1990

U.S.: 1 year (12 issues), $22; 2 years, 936; 3 yean, $50

t0RElGll (Per year paid in advance in US funds): $48 for Canada and Mexico, $60 for all other countries: Air rates also available.

$lt{GtE C0PIES: $4 + shipping; Back issues (when available), $5 + shipping wwrY. building-prodmh.com

MicroProi fft€€ts the demond for green building producls. The Csmose MicroPrc technclcgy is the flrsi treote d wood process 1c be certifled under SCS's Fnvircnrnentolly Preferoble Product (EPP) prcgrcm bosed cn Life Cycle Assessment.

Bef ter ccrrcsicn resistonce f or code Cpprove| fosteners cnd hordwcre, ond cpproved for clut-t-rinunr ccntcci.'o*.

End uses lnclude interior ond exfertor obove grcund, ground ccnloct, onC fresh woier immersion.

TreoteC wocd wcrronty Progrcms."

Building code conrpliont.

ICC-ES Repcrt, FSR l9B0

MicroPro treotecJ wooC products ore cvciloble in decking cnd occessories, ond ground contoc'l dimension lumber.

wEB srrs: www,TUFboard. net

E-MArL: tufboard6inteplast. com

rat:800-452-2lU Exr2

That headline used to be the start of a song we sang in kindergarten in England long, long ago. Certainly, it could have been a valid headline for any of the past many months. As I travel, a number of readers have thanked me for trying to be positive through these tough times, but I have to say that over the last several months it has become a stretch, as we've seen the economy go from bad to worse.

There are very few of us who have not been impacted either at work or home with current realities. It simplv defies logic that so many super-inteiligent economists and people in our government cannot understand that. with all of us in retrenchment, whatever is done must change the national psyche from "don't spend" to a confidence that "it's okay to spend." Until that changes, we are in for trouble. Some of you may remember my first columns after September 11,2001, when I indicated we needed to go out and spend. And spend we did, leading to three to four years of a very healthy economy. Unfortun ately, everything got overblown, leading to the current debacle. But, frankly, we need a similar uturn today. Yet we have all been squeezed of our net worth, so we do not have access to funds to go out and do the same thing today.

As I write this column, the stimulus package has not yet been passed, and there is a one-sided debate of what it should include or not include. But iust about everyone I know has zero to little confidence that it will work in its current format. For me, I cannot see anything that will make me feel better, because too much of it will take too long to implement and fails to deal with the problems of this industry, which I believe is the key to changing our national psyche. In England we used to say an Englishman's castle is his home, and I believe that to be true here, too. However, one home is going into foreclosure every 13 seconds.

Enough saidl

I understand that 64,000 U.S. companies filed for bankruptcy in 2008, and that is expected to rise to almost 100,000 this year. The issue we all face is that this is a downturn very different from the normal economic downturn we have seen before, in that it is a credit crisis and it is impacting just about everybody-corporate and private, in every industry and every country. This is the time when that apparently healthy competitor can go out of business next month. When customers no longer return calls. Inventories are cut or are non-existent. Getting paid is a problem. And the banks that told you how important you were are pulling the plug and cutting credit lines.

It is in these times when all the flaws in your business model are exposed. If you do not take steps to correct the flaws, the problems will eventually put you out of business. No business, even wildly profitable ones, are absolved from understanding that everything is now off the table. As I have said many times in the past, no one gets business by right; it has to be earned each and every month. As the tide turns. and it will. many companies will look nothing like they did going into the recession. Indeed. this is the time when new market leaders will evolve. Customers will have a different set of expectations. You will need to be different, too. And therein lies an opportunity for each of us.

The deep and fast changes that many of us have had to take actually bode well for the future as a rebound takes effect. It doesn't make us feel any better right now and will be painful even for those that survive, but you will be well positioned for fast growth hopefully later this year or early 2010.

And to all our readers and advertisers, I'd like to say we here at Cutler Publishing will do everything we can to help you. Please call me personally with your ideas and thoughts. We serve with thanks and we serve with humility in your support of our magazines.

ITIHREE vears after its launch in the .1 gurt"- U.S.. "micronized" treated wood has finally arrived on the West Coast.

Western Wood Preserving Co., Sumner, Wa., has begun using Osmose's MicroPro technology, which reduces the copper content to solid, "sub-micron" sized particles. The process creates a treatment that is corrosion-resistant for code-approved fasteners and hardware, enabling MicroPro treated wood to be used in direct contact with aluminum.

MicroPro has become so popular so quickly that it is now sold in over 4900 home centers and lumberyards, and competitors have since rolled out similarly altered preservatives, such as PhibroWood's Sustainwood micronized copper azole and Arch's Wolmanized dispersed copper azole.

Yet while more than 75 treating plants are currently offering MicroPro products, the only western sites are Universal Forest Products' facility in Windsor. Co.. and Simmons Wood

Treating in Albuquerque, N.M. Both plants use southern yellow pine.

"For our company to use the MicroPro technology, it had to be formulated to treat western species such as hem-fir," said Western Wood Preserving Co.'s Mike Reimer.

WWPC received third-party approval to treat hem-fir wood products with MicroPro, which it will use primarily on kiln dried dimension lumber to distribute thoughout the Pacific Northwest. It will continue treating green timbers with ACQ, as well as offer borates, fire retardants,

and CCA.

MicroPro treated wood applications include interior and exterior above ground, ground contact, and fresh water immersion.

Reimer noted, "Another important benefit of this new technology is that it is the only treated wood process that is Environmentally Preferable Product certified based on life-cycle assessments. This certification is not only important to us, but also to our customers,"

Environmental benefits include:

. Reduced energy use and greenhouse gas emissions.

. Wood products treated with the

MicroPro process result in the release of 9OVo to 997o less copper into aquatic and terrestrial environments when compared to standard treated wood products, thus effectively eliminating eco-toxic impacts.

. Reduced air emissions (since it is four times more concentrated than standard industry formulas).

"We love that it's a green product," said Reimer.

Osmose continues to develoP its MicroPro technology to treat other West Coast species, such as Douglas fir. "Our goal is to make MicroPro available for all our West Coast markets," said Osmose's Gary Converse.

MICRQNIZED treated southern pine burst onto the scene in 2006. Now the technology has been refined to treat hem{ir, allowing it to be used by West Coast treaters.

IatALIFORNIA Redwood Associ\-zation has expanded its efiforts to make it easier foi contractors and doit-yourselfers to locate-and be successful with-redwood.

CRA recently revised its website (www.calredwood.org), a central source for information on redwood

products and forests, to update its "online locator." Now a single-click service with current information, consumers need only to enter a zip code to find lumber retailers in their area that carry redwood products. Retailers carrying redwood are listed by proximity, nearest retailer first.

CRA encourages retailers to try the locator (www.calredwood.org/ref/ locate/locate.php) to ensure the association is providing a comprehensive listing for consumers. "We have made every effort to be all-inclusive," says Bob Mion, CRA marketing director, "but we recognize the possibility that

we have inadvertently missed a few retailers along the way. lf we have, we want to know about it."

Retailers wishing to be added to the locator service should email contact information to info@calredwood. org.

The locator update is Part of CRA's continuing effort to reach out to lumber retailers. "We launched a very successful pilot effort last year," says Mion. "We have some Programs in place that we are readY to grow to include more retailers. Certainly, updating our website to make it easier for consumers to find the redwood products they want is consistent with our retailer services efforts."

Mion also notes that CRA's "Build a Deck, Win a Deck" Promotion, which engages redwood retailers and debuted last summer in select northern California markets, is poised to expand this year.

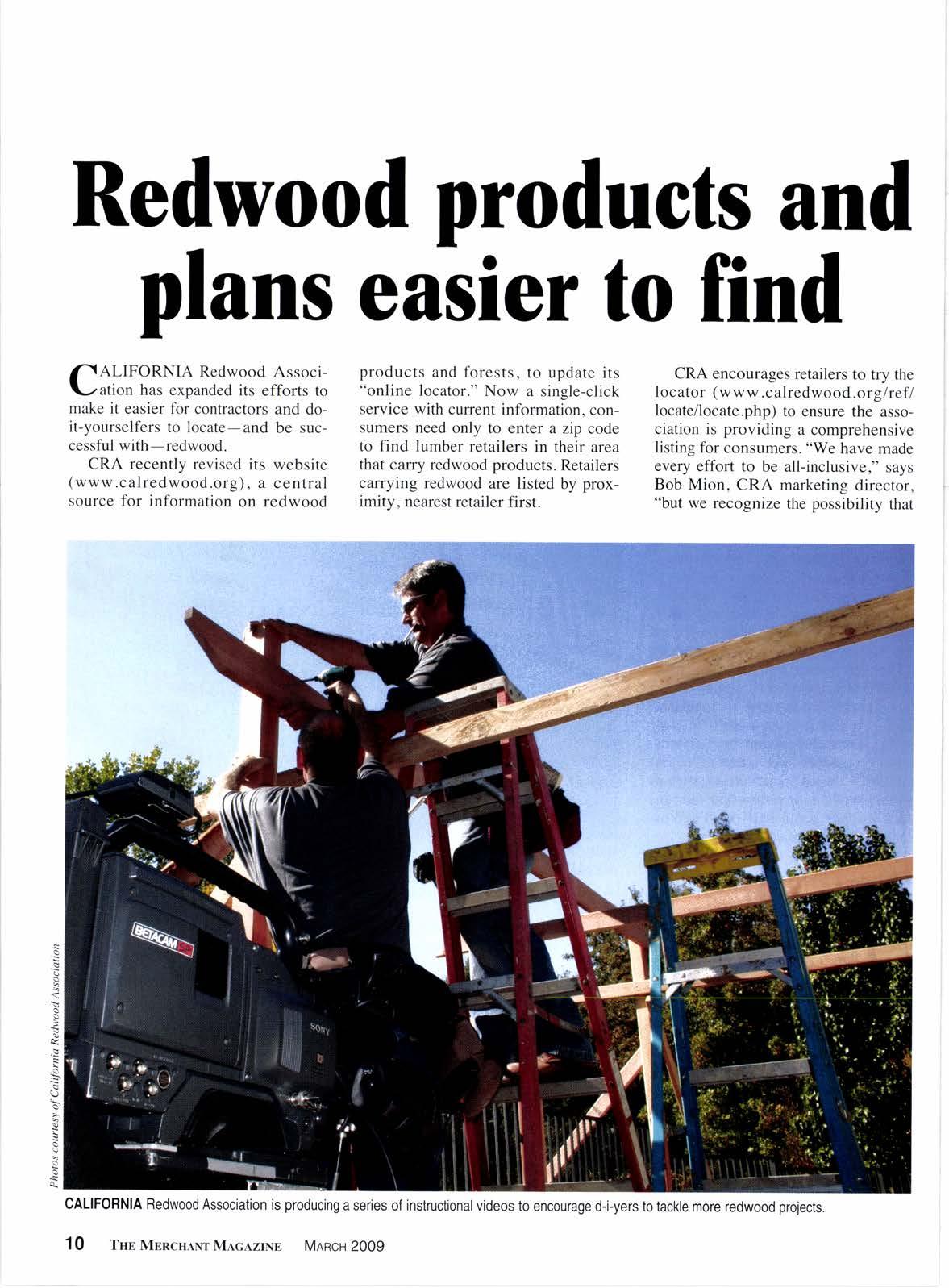

CRA is also introducing the first of its d-i-y "how to" videos to encourage current redwood customers to take on more projects. "Our website already has a number of project Plans, from picnic tables to gazebos, that d-i-yers and contractors can download," Mion shares. "The plans are already there and generate a remarkable amount of web traffic. The next step is to provide instructional videos to accompany those plans, and help redwood enthusiasts be successful in creating projects that enhance their outdoor living."

The first digital video accompanies the "Windsor Shade Structure" plan, one of the plans most frequentlY downloaded from the CRA website.

The video is broken into six sections, following the project plan and demonstrating how to set the footings, install the posts, beams, braces, rafters and finally louvers. Host Jeff Imwale, a licensed Northern California contractor, explains each steP being taken and provides "contractor's tips" throughout.

CRA also has posted a video to

help consumers finish and maintain their redwood decks. "Redwood is a low-maintenance decking material," says Mion. "You can leave it alone and let it weather naturally, or take a few simple steps to keep redwood's distinctive warm red tones fresh. The video shows the proper techniques for cleaning a redwood deck and applying a finish to keep the like-new look

California Redwood Association is making available to lumber retailers that carry redwood products three publications designed to inspire consumers to build with redwood. The publications, once available for a fee, are now free while supplies last.

While redwood is often the natural product of choice for a range of outdoor living projects, decking and fencing applications account for the vast majority of redwood used. CRA is therefore making copies of All Decked Out'.. Redwood Decks: Ideas and Plans for Contemporary Outdoor Living (Skinner, Tina; Schiffer Publishing 1998) available free. The 160-page high-end book features dozens of pictures of redwood decks to sPark the imagination. All Decked Out.. Redwood Decks also features redwood pavilions and shade structures, and ideas for using redwood around spas and pools.

In addition to the attractive Pictures. the book also includes architectural diagrams and tiPs for

designing the perfect deck.

CRA is also offering FancY Fences and Gates (Skinner, Tina; Schiffer Publishing 1998), which features the next most popular uses for redwood products. FancY Fences and Gates showcases elegant architecture and innovative designs perfect for any number of settings on 80 pages.

To demonstrate redwood's allaround versatility, CRA is also offering its Redwood Design Gallery free of charge. This 8-page, full-color tabloid publication helps homeowners visualize the manY ways redwood can enhance their outdoor living areas with pictures of a range of redwood projects.

All Decked Out...Redwood Decks (regularly a $30 value) and Fancy Fences and Gates (regularlY a $21 value) are available free to retailers while supplies last, limit 20 per retailer. Redwood Design Gallery is also free while suPPlies last, limit 200 per retailer. To order, email shipping information and quantities desired to info@calredwood.org.

VIDEO host Jeff lmwale helps fellow contractors build with redwood.for years. It also shows how to restore weathered redwood decks and remove stains like barbecue grease. Restoring a deck doesn't take a whole lot of effort, and the results can be quite impressive. It's a great way for consumers to protect their investment

in redwood."

While contractors and d-i-yers can download plan files from the CRA website, CRA is also making colorprinted versions of the project plans available free to retailers who want to stock them. CRA offers plans that

show how to build an Adirondack chair, Adirondack swing, garden tool shed, Lake Tahoe gazebo, Mendocino bench, Santa Cruz sandbox, free standing deck and other projects. View them all at www.calredwood. org/refllit.htm.

recyclable and biodegradable. Plus, Jourdain points out, "Trees are essentially carbon eaters. Lumber stores the carbon that trees absorb from the air when they grow, and keeps it safely out of the atmosphere for the long haul. That reduces emissions and a consumer's carbon footprint."

Trees remove carbon dioxide from the air through photosynthesis. They absorb carbon and release oxygen, converting the carbon to wood fiber in roots. trunks and branches. The faster a tree grows, the more carbon it removes from the atmosphere.

redwood forests are managed sustainably by law," says Jourdain. "They are all subject to the state of California's Forest Practice Rules. which an independent study found to be as strict as, or stricter. than the FSC and SF[ programs."

The push to be green often ends up with customers turning to retailers for answers to questions about green building and how different building materials measure up. Consumers increasingly rely on third-party certification and rating systems for guidance, but seldom delve very far into how various rating programs are structured or what makes one material greener than another.

"The green movement is all about sustainability," says Chadie Jourdain, president of the California Redwood Association, "Its ultimate goal is to make consumers more aware of the impact of their consumption choices and encourage wise decisions about resource use. There's a lot offocus on the 'carbon footprint' because of the concerns around global warming and greenhouses gases, and certainly energy efficiency and renewability are a big part of the equation. Those are areas where wood in general, and redwood in particular, excel."

Wood is the only major building material that is entirelv renewable.

"Managed redwood forests are perhaps the most efficient scrubbers of greenhouse gases on the planet," says Jourdain. "Because redwood is such a fast-growing species, it pulls more carbon out of the air than most species. Using redwood lumber then stores that carbon and replanting continues the cycle. The typical redwood deck stores more than a halfton of carbon, and it looks great doing it."

Jourdain also notes that redwood is grown, harvested and brought to market in a sustainable manner. Some of the most advanced forestry science and technology in the world is found in redwood country. "Commercial redwood forests are subject to some of the most restrictive regulations anywhere and managed to highest environmental standards in the wodd."

In fact, nearly 90Vo of lumberproducing redwood forests are certified to be well-managed and sustainable under the two largest independent certification programs in the world, the Forest Stewardship Council and Sustainable Forestry Initiative. Those certification programs examine air and water quality, harvesting and regeneration practices, wildlife protections, and other forest management issues.

"Really, all lumber-producing

In addition to its renewability, sustainability and carbon sequestration advantages, Jourdain points to energy efficiency as one of redwood's significant green attributes. "Redwood has a great story to tell when it comes to energy efficiency," he says. "Not only is redwood essentially a product of solar energy, converting sunlight to wood through natural growth processes, but many redwood sawmills are powered by clean energy produced from wood chips, bark and sawdust. Mills even make electricity available to California's power grid to lower the need to produce energy from carbon-emitting fossil-fuel sources."

"About the only thing that's not green about redwood," says Jourdain, "is the color that makes it so distinctive. Customers looking for green options should choose redwood with confi dence."

By Don Martel Tiger Claw

By Don Martel Tiger Claw

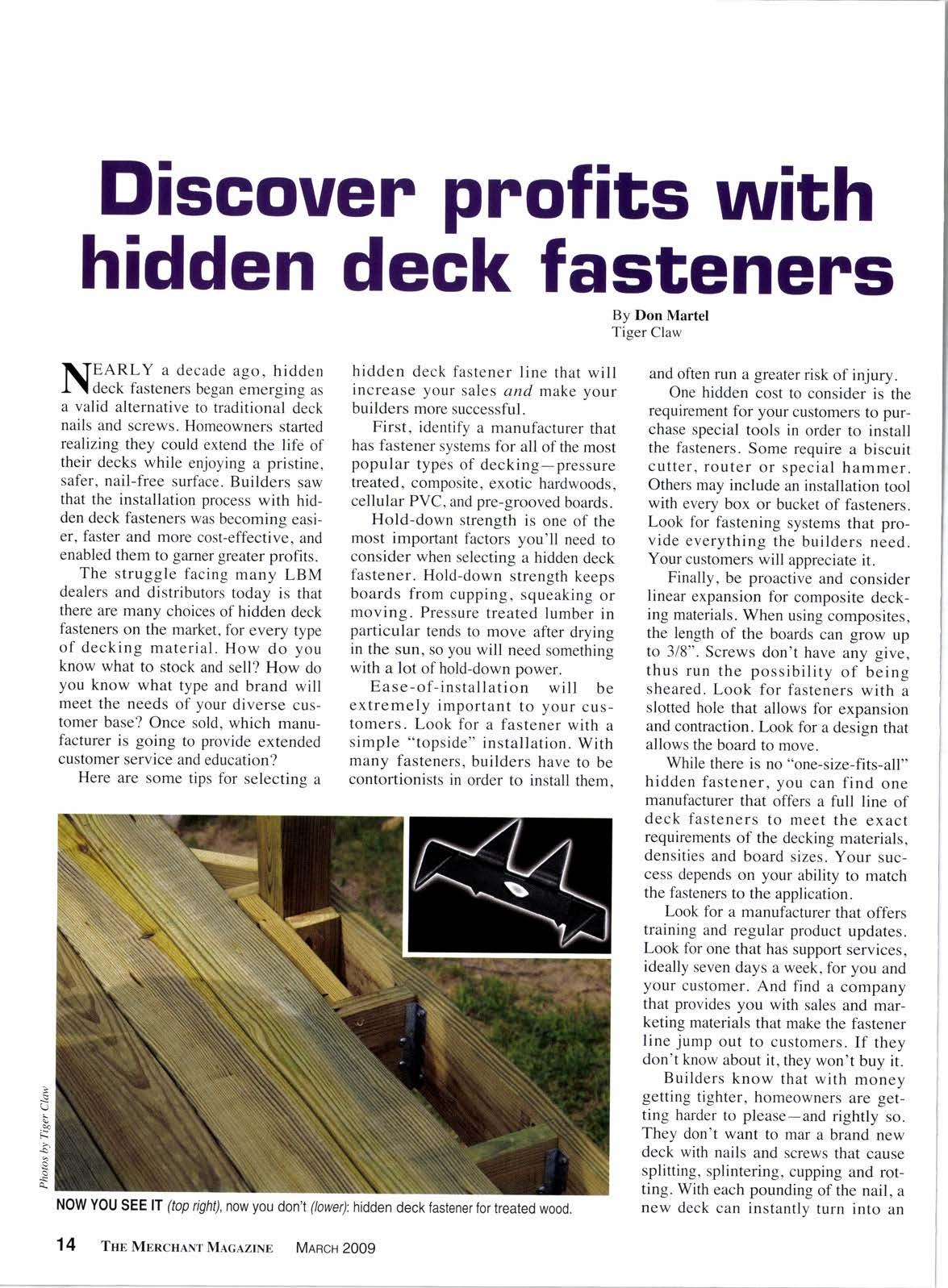

NEARLY a decade a-eo. hidden I \ deck fasteners began emerging as a valid alternative to traditional deck nails and screws. Homeowners started realizing they could extend the life of their decks while enjoying a pristine, safer, nail-free surface. Builders saw that the installation process with hidden deck fasteners was becoming easier, faster and more cost-effective, and enabled them to gamer greater profits.

The struggle facing many LBM dealers and distributors today is that there are many choices of hidden deck fasteners on the market, for every type of decking material. How do you know what to stock and sell? How do you know what type and brand will meet the needs of your diverse customer base? Once sold, which manufacturer is going to provide extended customer service and education?

Here are some tips for selecting a

hidden deck fastener line that will increase your sales and make your builders more successful.

First, identify a manufacturer that has fastener systems for all of the most popular types of decking-pressure treated, composite, exotic hardwoods, cellular PVC, and pre-grooved boards.

Hold-down strength is one of the most important factors you'll need to consider when selecting a hidden deck fastener. Hold-down strength keeps boards from cupping, squeaking or moving. Pressure treated lumber in particular tends to move after drying in the sun, so you will need something with a lot of hold-down power.

Ease-of-installation will be extremely important to your customers. Look for a fastener with a simple "topside" installation. With many fasteners, builders have to be contortionists in order to install them,

and often run a greater risk of injury.

One hidden cost to consider is the requirement for your customers to purchase special tools in order to install the fasteners. Some require a biscuit cutter, router or special hammer. Others may include an installation tool with every box or bucket of fasteners. Look for fastening systems that provide everything the builders need. Your customers will appreciate it.

Finally, be proactive and consider linear expansion for composite decking materials. When using composites. the length of the boards can grow up to 3/8". Screws don't have any give, thus run the possibility of being sheared. Look for fasteners with a slotted hole that allows for expansion and contraction. Look for a design that allows the board to move.

While there is no "one-size-fits-all" hidden fastener, you can find one manufacturer that offers a full line of deck fasteners to meet the exact requirements of the decking materials, densities and board sizes. Your success depends on your ability to match the fasteners to the application.

Look for a manufacturer that offers training and regular product updates. Look for one that has support services, ideally seven days a week, for you and your customer. And find a company that provides you with sales and marketing materials that make the fastener line jump out to customers. If they don't know about it, they won't buy it.

Builders know that with money getting tighter, homeowners are getting harder to please-and rightly so. They don't want to mar a brand new deck with nails and screws that cause splitting, splintering, cupping and rotting. With each pounding of the nail, a new deck can instantly turn into an

ugly deck. Money spent on beautiful wood or higher-priced comPosite decking is wasted because of the immediate and unavoidable damage to the surface boards.

Providing a line of high-qualitY, easy-to-use, and affordable hidden deck fasteners can make a difference in your bottom line and in Your customers' satisfaction.

- Don Martel is co-inventor of Tiger Claw. He can be reached at (800) 92844 3 7 o r ti ger c law @ de c kfastener.c om.

Deck Clip

Screw Pnoducts www. screw-pnod ucts. com

DeckEase

Titan Metal Werks www.splitstop.com

Deckmaster Gnabber Construction Products www.deckmaster.com

Eb-TY www.ebty.com

Equator Univensal Forest Pnoducts www. latitudesdeck. com

Hidden Link

Ty-Lan Entenpnises \ /WW.shadoetnack.com

Hidden GRK Fastener www. gnkfastenens. com

lnvisi-Fast www.invisifast.com

lpe Clip www.ipeclip.com

lGl Hidden Fastener System FastenMaster www.fastenmaster.com

Lumber Loc KK Mfg. www.lumberloc.com

Shadoe Track

Ty-Lan EntenPnises www.shadoetrack.com

Tebo Fastener www.spotnails.com

Tiger Glaw unruw. deckfastenen. com

0ur two-coat process starts with an alkyd sealer to btock tannin migration, fotl.owed by a high-performance acrytic primer The result: RESERVE quatity, inside and out'

Superior Wood

Made of quatity, ctear, finger-jointed Western Red Cedar or Redwood, these products are naturatty designed for exterior use-both species are ideaI for enduring extreme weather.

RESERVE products come in a wide range of sizes, [engths and finishes. Whether the project calts for 51S2E or S4S, we offer [engths ranging from 16'to 20'. Pattern stock is atso available.

1,x4 - 1xI2

s/ax4s/axl2

2x4 - 2x12

Our Siskiyou Forest Products RESERVE line is specially manufactured and treated to create the highest quality product available. Using state-of-the-art application and curing equipment, our premium Western Red Cedar and Redwood stock is made to last for many generations. We are proud to offer a beautiful, durable product that is ready for installation and final painting the moment it reaches the craftsmen.

S

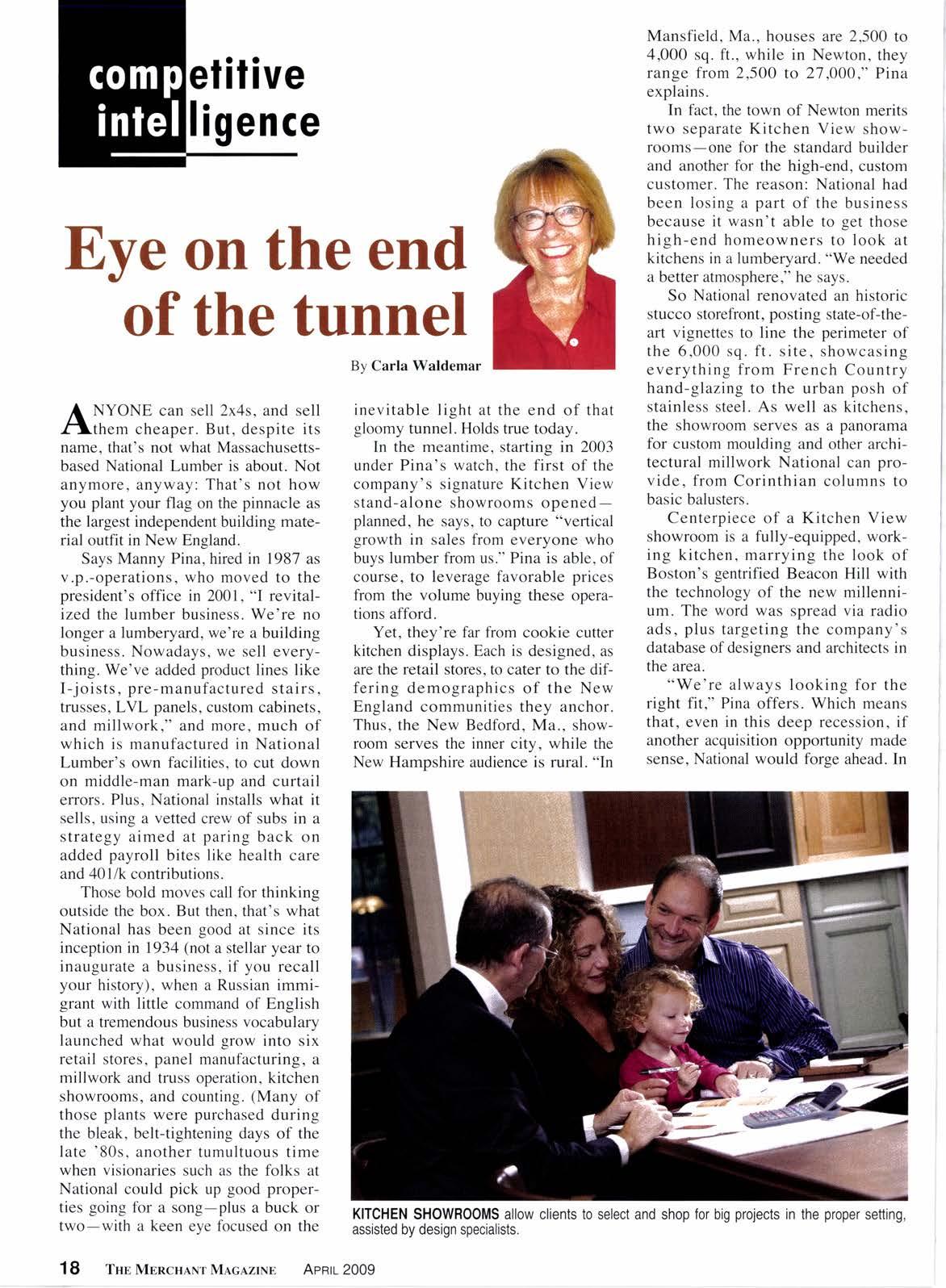

A S A reporter, I'm the journalistic .fa,equivalent of a coupon clipper. No, I'm not looking for discountsI'm after leads.

So when I read a 3-inch announcement in this magazine a year ago about the expansion of a company launched in January 2006 called Green Depot, I tucked it away, like a wine that needs aging, to uncork later and see how time had treated the venture. Did it-as they say about a good Merlot-have "legs"? Had it developed (another wine-geek term) "character"? In other words, was there something behind the pretty label thar was worth cellaring long-term?

The short answer. as I discovered

East, along with a proactive solution: Open a green retail outlet to serye residential and commercial contractors and concerned homeowners, like her. "The idea," recounts Holiber, "was to get the message out to the trade and become a retail dealer for contractors: bring green products to them."

Marjam's existing set-up eased the start-up pains. Rather than reinventing the wheel, Green Depot was implanted as a retail store within the organization's existing buildings, "so we could use the same trucks, same warehouse, and keep the same hours," Holiber explains.

in an in-depth phone interview with Green Depot's general manager, Jim Holiber, is yes. Here's how and here's why.

Blame it on the kids. When a young East Coast businesswoman, Sarah Beatty, became a new mother, like many in that demographic, she wanted to renovate their living quarters to achieve a cleaner. greener-in a word, healthier-place to raise her family. But, as she soon discovered, finding green products on the East Coast to meet those parameters was difficult, to say the least.

She canied her frustrations to her husband, the owner of a large distribution company-Marjam-in the

Plus, these locations had been established in major East Coast cities, where the green market is ripe. Headquartered in Brooklyn, N.Y., the first expansion site became Newark, N.J. In 2008 the number of Green Depot locations rose to six, with two more set to launch in March 2009. "Because these sites are in industrial areas, they're not pretty," Holiber demurs. "But the homeowners find us; they're glad to make the trip," he's found. Next on the drawing board is a reach into the Midwest via Chicago.

The initial task, of course, was to select and assemble green products, and in breadth, depth and quantity to allow consumers one-stop shopping. "At first, they were hard to locate," Holiber notes, "but we've come a long way and added many product lines," including FSC-certified lumber, zero-VOC paint, carpet, energy and water conservation items, kitchen and bath cabinets, wood flooring, windows, caulking, filters, and the list goes on.

All had to pass the company's stringent, proprietary Green Depot

Filter, he says. Here's how that works. Holiber, a 2}-year veteran of building distribution, heads a committee that includes an on-staff chemist evaluator and recycling specialist. Together, they analyze each product. "First off, does the product work?" Holiber asks. (Otherwise, who cares how green it is?) "Then we look at its sustainability and life cycle, its recyclability and energy efficiency, and make an evaluation. FinallY, we attach our icon, which carries different shades of green color, from light to dark for degree of greenness, so consumers can make their own informed decisions."

"Sure, sometimes the greenest may cost a bit more, but often over its life span it more than pays for itself. Yet," he emphasizes, "the decisions are up to them. And of course we have to make sure that the vendors can handle the volume we need-no start-uP in some guy's garage. We need fulfillment."

Education is a big deal at Green Depot, and that starts with its sixlocation staff of 60. "They're really excited, true believers-very smart, college-educated, and have a high interest," he says. "At the outset, we others do product knowledge training for a few days, then give them a breather out on the floor. Then back in the trenches for more Product knowledge. After that, we reinforce it with monthly training sessions."

Gettine the word out has not

proved difficult. "We visit contractor firms and do presentations, do speaking engagements, and it's catching on," Holiber notes. "In todaY's tougher business environment, contractors have the time and want to make changes to help their business.

"At the beginning, it was homeowners who found us through their research and sent their contractors, telling them, 'You must go to Green Depot.' Now, the idea has taken hold. Especially when the economy is bad, they look toward trends of the future, and we're here to educate them. Also, we do cold calls and visits and are involved in trade shows and local events. We even visited a high school! Okay, we didn't draw 10,000 people, but the hundred who showed up were interested.

"In fact, we're opening a consumer store in New York City, in the uPand-coming Lower East Side, with a showroom"-all Green Depots offer extensive showrooms-"and plan to offer educational seminars for homeowners. But this store will be a bit different: We're expanding our product line to include fumiture and baby products-cribs, mattresses, carpets. We find this is a huge market for the families re-doing their houses. For them, their kids' health-especially indoor air quality-is a big deal."

"With the buzz we've created, we're able to pick up more regional products, and thus not have to pay the

SIGNAGE reminds customers how products help the environment, such as how caulking cari seal air leaks to reduce heating and cooling costs.

huge freight costs coming from California," he adds-a value-formoney feature he can pass on to the end-user.

Another unique service is Green Depot's Flip It Green program. People are invited to bring in their blueprints, and Depot's staff will recommend CSF products in all areas"provide alternatives, such as adhesives, flooring, plywood without formaldahyde, whatever. It's a good selling point," Holiber attests.

Bottom line: Is this a green dream, or is it working? "We're in a growth mode," he declares. "We're managing our growth and investing our profits back into the company. Contractors like our services-boom trucks, forklifts for delivery-and we've Put together a strong education staff to inform the customers, hold the contractor/s hand to help them transition from the conventional waYs. We're very aggressive," he doesn't hesitate to add.

And that stance has paid off, all right. From 2007 to 2008, Green Depot experienced revenue growth of 2507o. Not bad, even in the best of times....

- A former award-winning LBM trade magafine editor, Carla Waldemar writes frequently on the industry. Contact her at cwaldemar@ comca st.net.fN A previous life I worked for INike. I remember one of the marketing people saying, "These shoes sell themselves!" Yet working with salespeople in the field, it didn't seem to me that the Nikes were selling themselves!

While some products may sell themselves, most products are in competitive markets that need salespeople to sell them.

Why do I bring this up? Because it is important for us as salespeople to understand our part in the process. We go into the world and qualify customers for our product or service. We ask the tough questions early. When we find out that this person or company qualifies for our product or service, we persuade them to buy from zs.

Salespeople who feel guilty about persuading customers should redirect those feelings and feel guilty about not doing a good enough job in discovery, i.e. qualification. A mistake that honest sellers make is not being clear, direct, assertive or aggressive (pick the word that works for you) enough in discovery. Failing to qualify the customer leads many honest sellers down the path of trying to sell a customer something they aren't really looking for. Non-qualification of customers is one of the biggest time/money robbers for salespeople.

The negative myth about sales is that we are talking people into things they don't need or want. Does this happen? Yes, but not often. First, the majority of professional sellers are honest, hard-working people. Second, professional sellers know we can't build a career on lies. Third, in most business-to-business sales we are selling to a professional buyer, not an

unsuspecting neophyte. Ultimately, as professional sellers we want customers, partners and orders while the lying non-pro is just looking for orders.

Struggling sellers believe customers only want a number. Because these salespeople agree, that is all they give the customer-the number. Since all these sellers give them is the number, they don't get much business. Think about it-when was the last time you bought something solely on the number?

Human beings are intellectual and emotional animals. Thus. in addition to using our minds to make buying decisions, we also use our emotions. Think about your favorite coffee shop, barber, clothing store, or bar. In most cases, thepeling the place gives us is more important than the prices they charge. Is price a factor? Yes, but more in a general sense of being competitive. We don't want to get rippedoff, but as long as the price is competitive, we will spend our money where we are most comfortable.

Human beings like to be persuaded. This is where master sellers and strusgling sellers differ. Struggling selleis are intimidated by objections while

master sellers hunt for them. Master sellers understand that obiections are a cryfor help.

Be pleasant. Our attitude during the selling process is pleasant, up-beat and positive. I am shocked at salespeople who talk and act as if they are going to their own funeral. Nobody is going to jump off a bridge with us, but many will follow a pleasant sales person.

Promote positives. We must know c// the positive factors about our product or service. Too many sellers will mention only the obvious (if that!) factors of their product without getting into the other factors. I have a customer, for example, who provides Saturday delivery. This is a valuable asset to their customers, yet many of the salespeople in the organization fail to bring up this service when prospecting. The service itself is a benefit yes, but it also sends a powerful message: we go the extra mile. Here is a valuable service that is left un-promoted and thus cannot be used to persuade customers to buy.

Listen. If we listen to our customers they will tell us what will persuade them. That is why discovery is so important. We must be thorough in discovery so we can be thorough in our persuasion. Our product may be the same as our competitors in every way but one and that could be the one thing that makes the difference in the customer's buying decision.

Our challenge as master sellers is to embrace and master the art of persuasion. Happy persuasion!

- James Olsen, Reality Sales Training, specializes in sales taining for the lumber industry. Reach him at james@realitysalestraining.com or ( 503 ) 544-3 572.

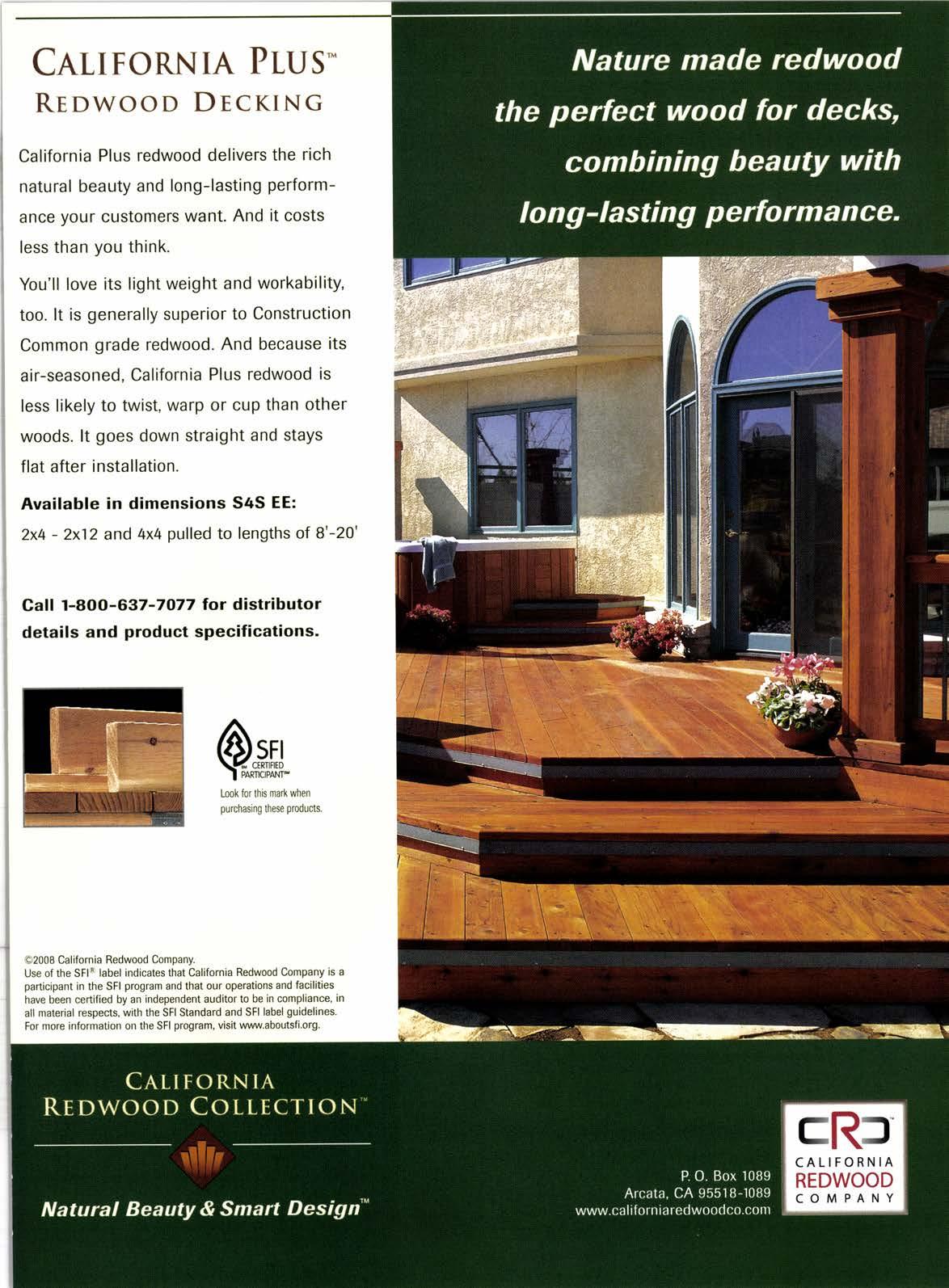

California Plus redwood delivers the rich natural beauty and long-lasting performance your customers want. And it costs less than you think. You'll love its light weight and workability, too. lt is generally superior to Construction Common grade redwood. And because its air-seasoned, California Plus redwood is less likely to twist, warp or cup than other woods. lt goes down straight and stays flat after installation.

Available in dimensions S4S EE: 2x4 - 2x12 and 4x4 pulled to lengths of 8'-20'

Gall

Piedmont Lumber & Truss, Tracy, Ca., has closed after 18 years...

Bronson Lumber, Island City, Or., reopened Jan. 12 after a ffue last September destroyed its main building

F oxw orth-Galbraith Lumber agreed to sell its shuttered yard in Cottonwood, Az., to the city and has mothballed its truss plant in Prescott Valley, Az.; the Prescott lumberyard remains open ...

OB Lumber, Fresno, Ca., has closed its lumberyard to concentrate on its truss operation

Helms True Value Hardware moved into a new, larger location in Selah. Wa. ...

Tabet Lumber Co., Belen, N.M., lost a lumber warehouse in a Jan. 28 fire

Lafayette Ace Hardware, Lafayette, Co., is liquidating after five years

Home Depot opened a new 99,500-sq. ft. store with 24,000-sq. ft. garden center Feb. 18 in N. Auburn, Ca. (Garrett Churchill, store mgr.; Leonard Schaefer, asst. store mgr.; Adam Lauder, operations mgr.), and has purchased 15.5 acres in Grants Pass, Or., from Timber Products, Springfield, Or., to build a 102,513-sq. ft. store with 28,086-sq. ft. garden center ...

Big Horn Lumber Co.,Laramie, Wy., is shutting down this summer after 49 years

Timb e r S I Lw o o d D i s trib ut i on California has been launched in Placentia, Ca., headed by Gary Chopic, to supply TimberSIL glass

wood products to Southern California (www.woodwontburn.com),..

Sunset Moulding, Live Oak, Ca., relocated its pine solid lineal moulding production line from Cottonwood, Ca., to Chico, Ca. ...

SierraPine's MDF mill in Rocklin, Ca., has ceased thick board production until market conditions improve; the thin board line continues operating

Idaho Veneer Co., Post Falls, Id., has temporarily idled its two sawmills and planer mill until the market rebounds

Humboldt Redwood Co., Scotia, Ca., laid off 30 employees in Feb. and will also reduce staff at sister company Mendocino Redwood Co.,ForI Bragg, Ca. ...

Weyerhaeus er Co., Federal Way, Wa., indefinitely eliminated the 67-man second shift at its sawmill in Dallas, Or., and indefinitely idled its veneer and lumber mills iil Pine Hill, Al., laying off 300

Contact Industries, Clackamas, Or.,laid off 45 employees from its facility in Prineville, Or. ...

Boise Cascade, Boise, Id., temporarily ceased plywood production Feb. 2 at its facility in Oakdale. La. ...

Harwood Industries' shuttered lumber mill in Branscomb, Ca., suffered a Jan. 28 fire: the 58-vearold facility was closed in2AQi and had been partially dismantled ...

L.J. Sntith, Inc., has opened a new stairway components manufacturing plant in Anaheim, Ca., specializing in styles popular in the western U.S. ...

Pap6 Group, Eugene, Or., has acquired Bobcat dealerships in Reno, Nv.; Portland, Or., and

Hubbard, Or., for its Bobcat West chain; the Reno facility has been relocated within its local Papd Material Handling location

Hacker Industries has relocated to larger offices in Newport Beach, Ca....

Pacffic Western Wood Works Ltd., Delta, B.C., has been FSC and PEFC certified

Las Plumas Lumber & Truss. Riverside, Ca., has completed F,SC chain-of-custody certification

Capital Lumber, Phoenix, Az., is now distributing TruWood products from Collins Cos. throughout Northern California ...

B lueLinx Holdings, Atlanta, Ga., has signed a three-year deal to be the exclusive two-step distributor of Georgia-Pacific's GP LAM LVL, Wood I Beam joists, and FiberStrong rim board in the U.S. and Canada

Setzer Forest Products, Sacramento, Ca., has enlisted Coastal Forest Products, Bedford, N.H., to distribute its ponderosa pine mouldings in the East ...

Huttig Building Products' Phoenix, Az., DC this month begins distributing ZP SmartSide sidings and trim; it already carries LP SolidStart EWP, LP TechShield, and LP TopNotch ...

Anniversaries: Burnett & Sons Planing Mill & Lumber, Sacramento, Ca., 140th ... Bennett Lumber Products,Princeton, Id., 70th ...

Housing starts in January plunged 16.8%o to a record low annual rate of 466,000 ... singlefamily housing starts fell l2.2%o in to a 347,000 annual rate nationwide, while creeping up 2.5Va in the West permits dropped 4.8Vo to a 521,000 pace.

Listings are often submitted months in advance. Always verifi dates and locations with sponsor before making plans to attend.

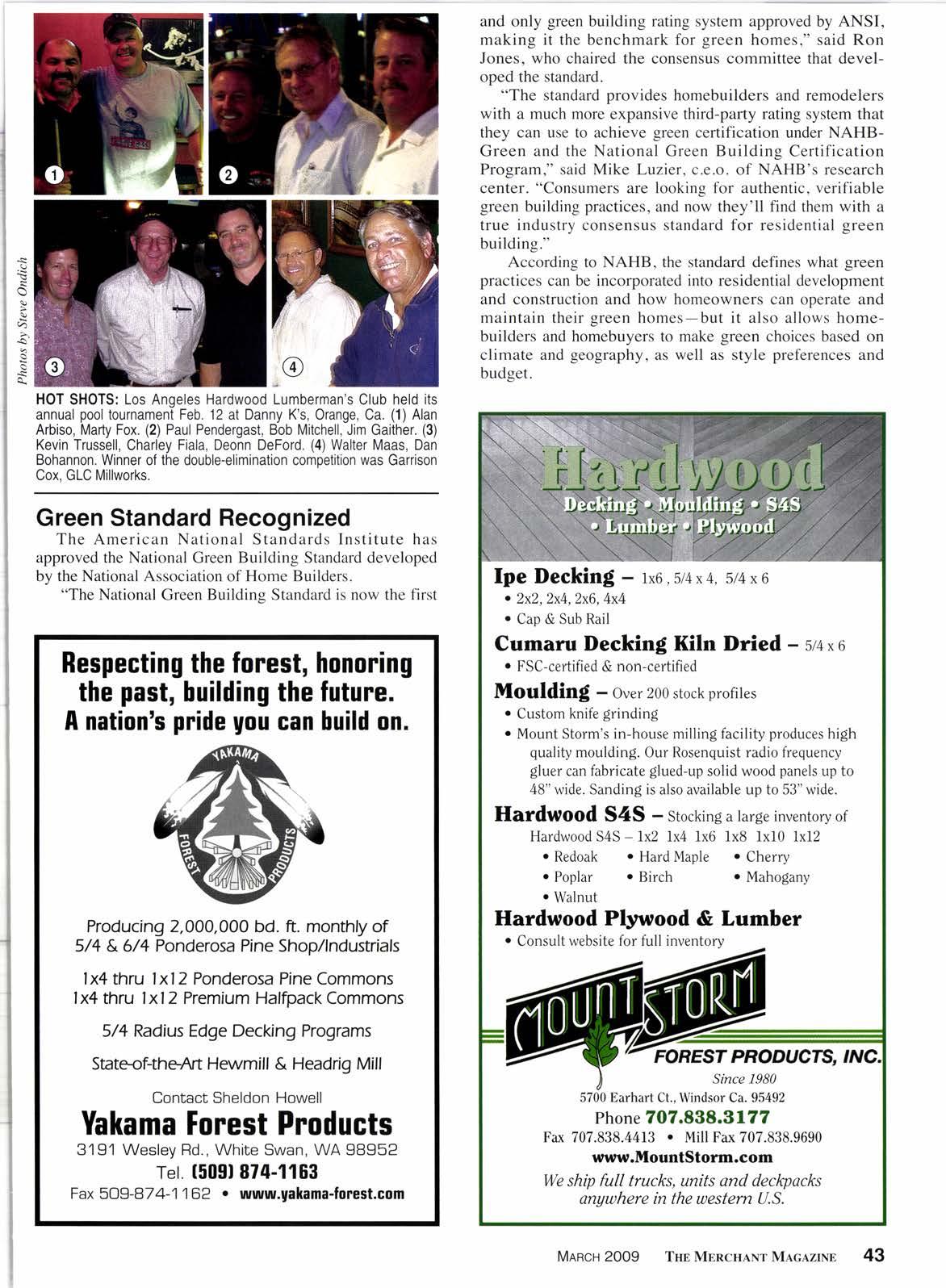

Los Angeles Hardwood Lumberman's Club - March 12, golf, Black Gold Golf Course, Yorba Linda, Ca.; (714) 611-3079.

Tacoma Remodeling Expo - March 13-15, Greater Tacoma Convention & Trade Center, Tacoma, Wa.; (800) 374-6463.

National Lumber & Building Material Dealers AssociationMarch 16-18, legislative conference & green building forum, Marriott, Washington, D.C.; (800) 634-8645.

Moulding & Millwork Producers Assn. - March 17-20, winter business meeting, Lake Las Vegas, Nv.; (800) 550-7889.

Mountain States Lumber & Building Material Dealers Assn.March 19-20, expo, Denver Merchandise Mart, Denver, Co.; (800) 36s-0919.

Redwood Region Logging Conference - March 19-21 , Fairgrounds, Eureka, Ca.; (707) 443-4091

International Home & Housewares Show - March 22-24. McCormick Place, Chicago, Il.; (847) 292-4200.

American Architectural Manufacturers Assn. - March 24-26, westem region spring meeting, Oakland, Ca.; (847) 303-5664.

Greenprints - March 25-26, Atlanta, Ga.; (404) 872-3549.

International Wood Products Association - March 25-27, annual convention,Indian Wells, Ca.; (703) 820-6696.

Arizona Home & Garden Show - March 27-29, Phoenix Convention Center, Phoenix, Az.; (877) 663-6186.

Portland Renovation & Remodellng Show - March 27-29, Portland Memorial Coliseum, Portland, Or.; (800) 374-&63.

True Value Co. - March 27-29, spring market, Ernest N. Morial Convention Center, New Orleans, La.; (773) 695-5000.

International Wood Composites Symposium & Technical Workshop - March 30-April l, Red Lion Hotel, Seattle, Wa.; (509) 335-2262.

Kitchen & Bath Industry Show - April 1-3, Georgia World Congress Center, Atlanta, Ga.; (800) 843-6522.

Remodeling & Decorating Show - April 3-5, Pasadena Conference Center, Pasadena, Ca.; (8 I 8) 557-2950.

Pacific Coast Wholesale Hardwood Distributors AssoclationApril 5-7, annual convention, Cordeville Resort, San Martin, Ca.; (925) 245-4320.

Fire: Flammability & Combustilbility in Building MaterialsApril 6-7, conference, Chicago, Il.; (703) 264-1690.

Lumber Assn. of California & Nevada - April 16, golf tourney, Black Gold Golf Course, Yorba Linda, Ca.; (800) 266-4344.

Structural Insulated Panel Association - April 17-20 annual meeting, Chicago, ll.; (253) 858-1472.

Los Angeles Hardwood Lumberman's Club - April 18, day at races, Santa Anita Racetrack, Arcadia, Ca.; (7 14) 67l-3079

American Institute of Timber Construction - April 19-21, annual meeting, Rancho Bernardo Inn, San Diego, Ca.; (303) 792-9559.

American Wood-Preservers' Association - April 19-21, annual meeting, San Antonio, Tx.; (800) 356-1974.

American Hardware Manufacturers Association - April 1922, technology forum, Philadelphia, Pa.; (847) 605-1025.

Transload Distribution Association - April 20-22, conference, Green Valley Ranch, Henderson, Nv.; (503) 656-4282.

Western Red Cedar Lumber Association - April 20-23, cedar school, Vancouver, B.C.; (604) 891-1231

California Forestry Association - April 21, legislative reception, Mason's Restaurant, Sacramento, Ca.; (916) 444-6592.

Inland Empire Hoo-Hoo Club - April 24, golf tournament, San Dimas Canyon Golf Club, San Dimas, Ca.; (760) 324-0842.

Mountain States Lumber & Building Materials Dealers Association has adopted the theme "Born to Be Wild" for its annual products expo March 19-20 at the Denver Merchandise Mart, Denver, Co.

Association installed Jason Sackmann, ProBuild, Meridian,Id., as president of its Young Westerners Club during the 36-and-under group's recent annual conference in Coeur d'Alene, Id.

New YWC v.p. is Kelly Fox, Dunn Lumber Co., Seattle, Wa.; secretarytreasurer Karnell Steele, OrePac Building Products, Tacoma, Wa., and immediate past president Aaron Newhouse, OrePac Building Products, Boise,Id.

Trustees are Karen Trulson, Western Materials, Pasco, Wa.; Blake Montgomery, Boise Building

Materials, Woodinville, Wa.; Melissa Page, McFarland Cascade, Tacoma; Jason Coleman, ProBuild, Sandpoint, Id.; Stuart Dutton, Sliters Ace, Somers, Mt., and Jameson Kersey, ProBuild, Moses Lake, Wa.

Lumber Association of California & Nevada has rescheduled its Government Affairs Day to March 25 at Sheraton Grand, Sacramento, Ca. Afterwards is the Annual Legislative Reception co-hosted with the California Forestry Association at Mason's Restaurant in Sacramento. April 1 is the date for "Money Matters h 2O09" at The Clubhouse, Rancho Solano Golf Course. Fairfield. Ca.

April 16 is the annual PAC Golf Tournament at the Black Gold Golf Club. Yorba Linda. Ca.

A "Train the Trainer" seminar on

forklift safety will be offered April 21 at the Holiday Inn, Rancho Cordova/Sacramento, and April 23 at the Courtyard by Marriott, Riverside.

Western Hardwood Association has scheduled its annual meeting for June 2O-23 at Sunriver Resort, Sunriver, Or.

North American Wholesale Lumber Association's annual executive conference is Aptil 26-28 at Loews Lake Las Vegas Resort, Henderson, Nv. The theme this year is "Stacking the Deck for Your Business Success."

Regional meetings are scheduled April 9 at the Portland City Grill, Portland, Or.; April 30 at the Vancouver Club, Vancouver, B.C., and May 13 at the DoubleTree Hotel, Monrovia, Ca.

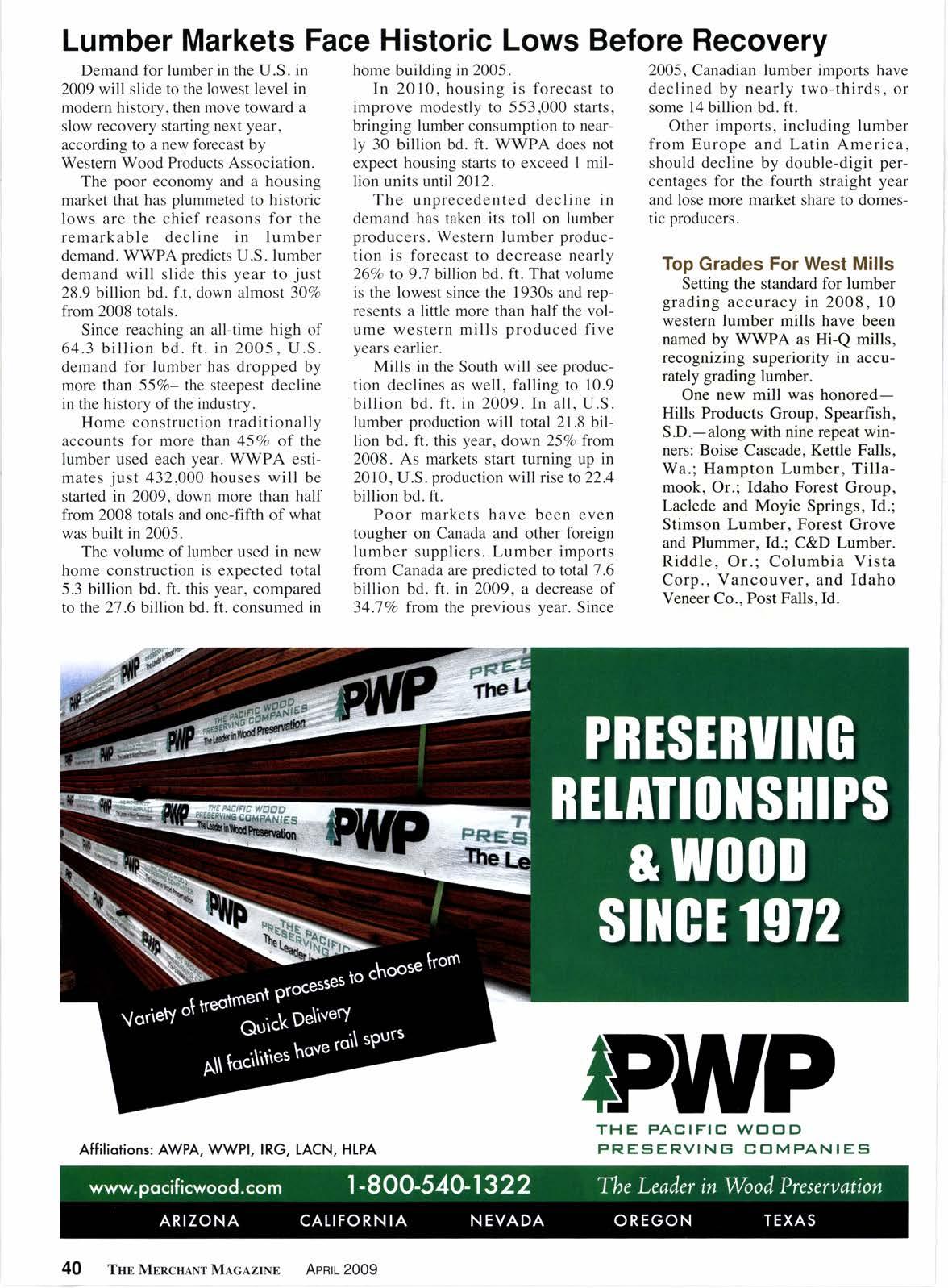

]-IHIS year may be remembered for I its gargantuan financial meltdown and economic crisis.

It may also be remembered as a foundational year for green home building for two big reasons.

First, energy and water conservation are even more important issues than ever before. With government incentives, such as rebates and weatherization financing, and water rationing looming in some regions of the country, energy and water efficiency are top of mind concerns for homeowners and new homebuyers.

Second, green homes are selling faster than non-green homes. The LEED for Homes program is barely a year old and already there's a ten-fold increase in new homes slated to be certified this year. With production home builders now taking notice. you can bet that a dramatically larger per, centage of new housing starts will be green.

If a rebound in new home construction will be led by green, how can retailers position themselves to benefit? To get a broader perspective on this question, I organized a virtual roundtable discussion with some green building professionals. It seemed everyone wanted to talk about LEED for Homes and rising consumer demand. Why? While it's not necessarily a good fit for every project, it's a national standard and a strong brand, which is especially good for production builders. New homebuyers are already looking for energy efficiency and healthy indoor air quality, so a credible national green certification for homes helps builders sell their green homes quicker.

To meet the growing demand for green homes, the new professional credential, LEED AP + Homes, is rolling out this year and will dramati-

cally increase the number of professionals working in the area. This is precisely where retailers should take notice.

"Retailers who are serious about serving their pro customers need to get themselves educated about the changes transforming the home building industry," says Michael Strong, president of GreenHaus Builders, Houston, Tx. He has been buildine green for years. was one of the first t6 build a LEED for Homes project, and was the 2008 NAHB Green Buildins Advocate oF the Year. He recoml mends that retailers have at least one staff member go through the LEED AP + Homes training and then bring the rest of the staff up to speed.

"Nothing's more frustrating than to spec a product, educate my supplier, and come back for a second ourchase to find they no longer stock the product because they didn't understand it," says Strong.

Education and trainins is also a main theme for Heather dadonniex. LEED AP, and president of Green It Group, a sustainability consultancy. "When I meet with maior retailers or distributors looking for frelp gerring into the green building market, I find there's enormous confusion about green building guidelines and product

certifications," she says.

Part of the blame must go to product manufacturers whose sales and marketing people often add to the confusion. But retailers must ultimately know about the products their pro customers want and develop the exper-tise to anticipate their needs as technologies, green building guidelines, and product certifications evolve.

"Retailers should look for products from manufacturers who provide back-up documentation to support the validity of their green product claims and, when necessary, obtain third party certification," she says.

While LEED for Homes is a national standard, it includes credit for locally produced materials and innovations appropriate for local conditions. Of course, there are also local and regional green building programs that very often offer a simpler alternative for local builders.

According to Clarke Snell, an author and principal of Think Green Building in North Carolina, thinking local is the right approach. "Building for local climate conditions with locally produced materials is what builders should be focused on. therefore it should be the focus for retailers. too." says Snell. "Selling FSC- certified lumber products from the other side of the planet just doesn't make sense."

While sourcing locally might be hard for big box chains, it could be a valuable differentiator for knowledseable independents.

- Jctl'Tompt is vice president ofgreen product development at Plan-lt Hardware, San Francisco, Ca., which distributes green products for hardware and home improvement stores throughout CaliJbrnia, und a leading expert in :;ustainable business and suppll'chain issues. He can be reached at info@plan-ithardware.com or (415) 359-9914.

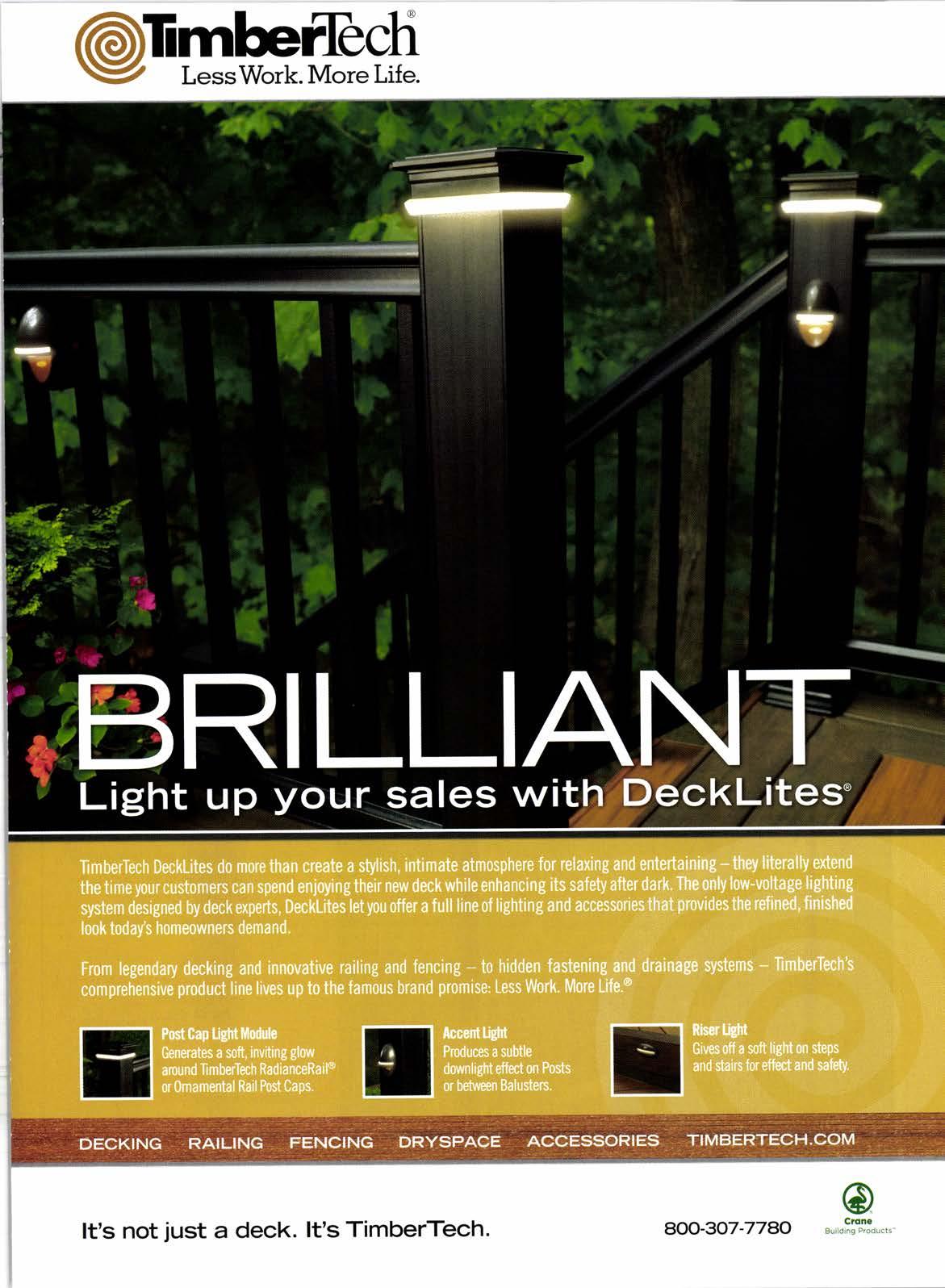

W LessWork. More Life.

It's not just a deck. lt's TimberTech.

Kevin Paldino, ex-Pacific Lumber Co., has joined the Collins Cos., Portland, Or., as v.p.-sales & marketing.

Tom Comery, ex-Jager Building Systems, has joined Building Material Distributors, Inc., Galt, Ca., as senior v.p. of distribution.

Dennis D'Amato is new to inside sales at Taiga Building Products, Rocklin, Ca.

Dan Kepon, ex-Pacific Lumber Co., has joined the sales team at Zip-OLog Mills, Eugene, Or.

Steven Weisenberg has been named green & sustainable material consultant at Weber Plywood & Lumber Co., Tustin, Ca., heading its new green & sustainable products division.

Luis Montenegro has been promoted to mgr. of Meek's Lumber & Hardware, Chico, Ca.

Kevin Wellington has been promoted to sales mgr. for Sears Trostel Lumber & Millwork, Fort Collins, Co.

Sam Bacogiannis, ex-Falcon Lumber & Wholesale, is now in sales at Swanson Brothers Lumber Co., Noti, Or.

Marvin "Ray" Risco has been named v.p. of international operations for Weyerhaeuser Co., Federal Way, Wa.

Terry Simpson, Matt Dierdorf, Scott McPherson and Gary McPherson, ex-MFP, are now on the trading staff for Buckeye Pacific, Portland, Or.

Seth Beisner, ex-SelectBuild, is the new operations mgr. at Capital, Albuquerque, N.M, Casey Keller, ex-U.S. Timber, is now trading in Portland, Or., for Greenleaf Trading, Denver, Co.

Michelle Menkens, ex-Huttig Building Products, is new to sales at International Wood Products. Tumwater, Wa.

Andy Kirkendall is store mgr. of the new Lowe's Home Improvement Center in Eugene, Or.

Carl Schoenhofer, v.p., California Redwood Co., Arcata, Ca., has joined the board of directors for the California Redwood Association. Chris Brown. California Redwood Co.. will serve as an alternate.

Daniel Boss, ex-US Gypsum, has been named v.p. of engineering for Serious Materials, Sunnyvale, Ca.

Ken Swartz, ex-Cedartone Specialties, has joined the sales and marketing team at Mid Valley Lumber Specialties, Aldergrove, B.C.

Lori Bossmann has been named v.p.supply chain planning for Ace

Anfinson Lumber is the clear choice for Quality Redwood and Western Red Cedar Dimension, Boards, Patterns and Timbers

GAtt SAI.ES AT (800) 400-8383 o (951) 681-4707

Rick Anfinson

Ray MacDonald

Steve Lawrence

0utside Sales

Darin Curran (949) 412-1894

Eddie Howdershett (909) 993-2701

Hardware Corp., Oak Brook, Il. John Surane, ex-Robert Bosch Tool, succeeds her as v.p.-merchandi sing/advertising/marketing.

Agnes Flinn, ex-Pine Island Lumber; David Steinman, ex-Grant Forest Products, and Kelvin Johnston are new to the North American sales group of Weston Forest Products.

Charles Jourdain, president, Redwood Inspection Service, Pleasant Hill, Ca., has been appointed chair of the review task group of the Softwood Lumber Standard.

Will Rogers, president and c.e.o. of the nonprofit Trust for Public Land, has joined the board of directors of the Sustainable Forestry Initiative.

Michael O'Brien, National Lumber & Building Material Dealers Association president, was elected to the board of directors of the Small Business Legislative Council.

Eric Bechtle, outside sale rep, Stock Building Supply, Kalispell, Mt., was named Associate of the Year by Flathead Building Association.

Harrold "Jay' Black. environmental, health & safety mgr. for Trex's Fernley, Nv., manufacturing plant, recently was honored as the 2008 KellerOnline Safety Professional of the Year.

Bob Brown, salesman at Hills Flat Lumber, Colfax, Ca., has been named Supplier of the Year by the Contractors Association of Truckee-Tahoe.

Eric Ziedrich, president, Healdsburg Lumber Co., Healdsburg, Ca., was elected to a second term as mayor of Healdsburg.

Tripp Booker is handling travel arrangements for Mungus-Fungus Forest Products, Climax, Nv., according to co-owners Hugh Mungus and Freddy Fungus.

PARTNERS: Hadlock Building Supply recentlv honored Vandermeer Forest Products with iis Vendor Of The Year Award. On hand were (/-rl

In the past moment frames were the expensive option when designers wanted small wall sections and open floor plans. The Simpson Strong-Tie@ Strong Frame'u ordinary moment frame is changing that by offering engineered moment frame solutions complete with anchorage designs. Now designers can spend minutes choosing a pre-engineered moment frame rather than hours designing one. And since the Strong Frame moment frame installs with 100% bolted connections. it is easier for contractors to handle and install.

For more information, see our webinar at www.slrongtie.c0m/sfwebinar.

To view and request a copy of the Strong Frame )rdinary Moment Frame catalog, visit www.strongtie.com or call (800) 999-5099.

"We don't care about selling the guy a box of nails. We care about selling him every box of nails the guy has to buy for the rest of his life."

- Kevin Palotay, co-owner, Building Solutions LLC, Bend. Or.Hadlock general mgr. Bill Kraut,

Hardwood lumber and plywood distributor McKillican American has expanded into the Phoenix, Az., market with its acquistion of American Hardwoods from Patrick Industries.

The Phoenix branch, which Patrick had itself acquired just two years earlier, is adding a complete hardware line, additional decorative surfacing and high pressure laminate products, as well as a large assortment of certified wood products.

B ased in Edmonton. Alb.. McKillican operates 2l distribution centers in Canada and the U.S., from Hawaii to Texas.

After 60 years of business in Bellingham, Wa., BB Lumber & Hardware will close.

"All of a sudden to realize it's gonna disappear is a tough thing, and the hardest thing is of course letting people go," said Wayne Kirk, who has been owner for nearly three decades.

The store once had 18 employees, but lately it's been just him, his two sons, and a couple other workers. When the new housing market dried up, so did lumber sales. "Tapered off

to the point we couldn't afford to keep operating," he said.

Re-Cut Forest Products will open mid-March in Corvallis, Or., to provide material to the industrial pallet and packaging industry.

The company will produce stakes and pallet parts, including 2x4 doublenotched up to l0 ft. Nick Johnson will serve as president, with John Baskin as vice president. Both formerly worked for Willamette Industries, Sweet Home, Or.

Ted Fullmer, New Vision Forest Products, Albany, Or., will serve as exclusive sales agent.

Plum Creek Timber Co.. Seattle. Wa., has completed the second phase of its sale of western Montana forestland to The Nature Conservancy and The Trust for Public Land (see Jan. 2009, p.20).

Plum Creek received $250 million in cash for 112,000 acres. The third and final phase of the deal, covering 70,000 acres valued at $89 million, should be finalized durine the fourth quarter of 2010.

Your Green Home, which opened four years ago in Corvallis, Or., will have to close unless someone buys the business.

Owner David Graetz blamed the cost of moving the store to a new location and slow business. "We've gotten a lot of traffic in the store being downtown, but overall our sales are down," he said. "Over the years, the store has accumulated too much debt. and it's time to shut it down."

He also cites the challenges of selling new products to what he calls a "risk adverse" industry. "If they have one bad experience with a green product and it doesn't work, they'll write off the whole segment of green products," Graetz said. "Often, conventional products will go through many iterations of failure and people keep trying them."

TimberSIL glass wood products recently completed and passed Class A fire rating lO-year accelerated weathering "ignition resistance" testing. The approval enables TimberSIL to sell its products into wildfire areas in California.

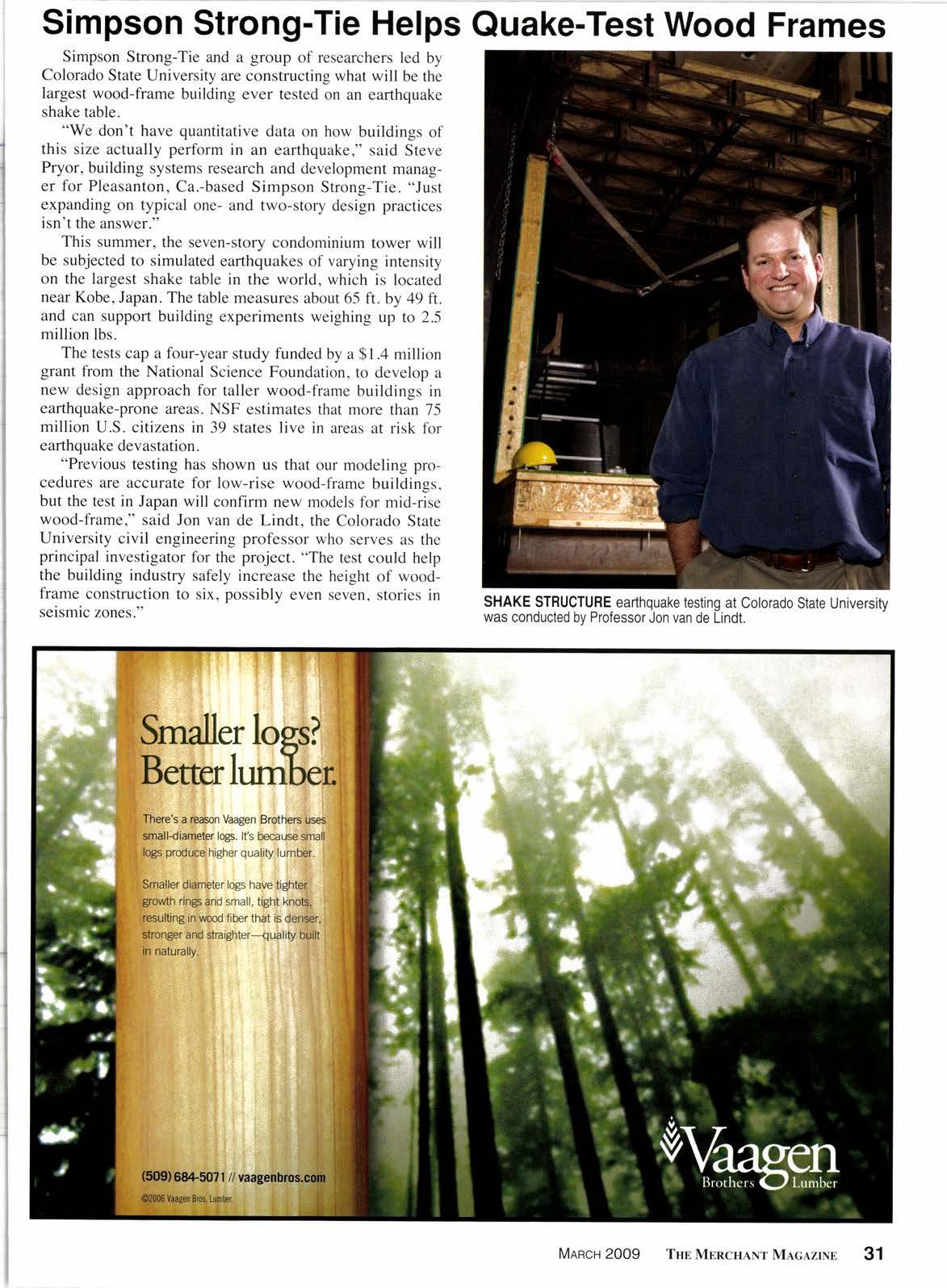

Simpson Strong-Tic and a -uroup of researchers lcd by Colorado State University are constructing what will be thc largest wood-frame building ever tested on an earthcluakc shake table.

"We don't have quantitative clata on h<tw buildings o1' this size actually perform in an earthquakc." said Stevc Pryor, buiiding systems rescarch and development manager for Pleasanton, Ca.-based Sirlpson Stron-e-Tie. "Just expanding on typical one- and two-story dcsign praetices isn't the answcr."

J'his sumnrer. thc seven-strtry condorniniurn tower will be subjected to simulated earthquakes of varf inS intensitl on the largcst shake tablc in the world, which is locatcd near Kobc,Japan. The tablc measures about 6-5 tt. by 49 lt. and can support building cxperiments wcighing up to 2.5 rnillion lbs.

The tests cap a four-ycar stucly funded by l $i 1.4 million grant Irom the National Sciencc Foundation. to dcvelop a new design approach for tallcr wood-frame buildines in earthquake-pronc arcas. NSF cstimatcs that tnore than 7-5 million U.S. citizens in 39 statcs livc in areas iit risk litr earthquake devastation.

"Previous testing has shown us that our moclelinl procedures are accurate ltrr low-rise wood-framc builclings. but the test in Japan will confirm new moclcls litr micl-risc wood-frame." said Jon van de l-indt. the Colorado Statc University civil enginccrinu prof'essor r"'ho serr,,es as the principal invcstigator 1br thc projcct. "Thc tcst coulcl help thc building industry saf'ely increase the hcight of woodfiame construction to six. possiblv evcn scvcn. storics in seismic zones."

By Dave Kahle

By Dave Kahle

detail the events of my most humiliating failure as a salesperson. It was early in my career, about three decades ago, and I had made the mistake of speaking badly about the competition to a customer. The customer was a personal friend of the competitive salesperson, and was personally affronted by my comment. The dressing down that I received at the hands of that customer remains painfully with me today. I don't believe that I have ever made that mistake since.

D EMEMBER John Delorean? He -[L*ur the suoerstar General lvlotors executive who started the Delorean Motor Co. When the company began to falter, he was anested and charged with complicity in a drug deal that some speculated was an attempt to raise money to prop up the comPanY.

All of this was big news in Detroit, where I was living at the time. One particularly insightful article in the Detroit News theorized that he had been supremely successful his whole life, and thus never learned to deal with failure. His development was stunted by a lack of failure in his life.

Faced with the pending failure of his auto company, he had nothing to lean upon and lost his moral compass. A long string of successes had not developed his character.

Perhaps. There is one thing for certain, regardless of the individual circumstances for Mr. Delorean. If we choose to, we learn more from our failures than we do from our successes. Within every failure there is the seed of a lesson well learned, of a solid character trait emerging. It is our failures that contribute most intensely to our development.

To this day, I can recall with vivid

Which is one of my points. Our failures are often far more intensely painful than the corresponding highs we get when we succeed. Since the pain is far more intense, the lessons stay with us. Or, they should, if we recognize the part that our behavior played in the failure.

That's a key part of learning from our failures: recognizing the role that we played in bringing them about. Of course, sometimes we are hapless and innocent victims of chance or someone else's misbehavior. But more often than not, we had 4 hand in the development of the sequence of events that resulted in a painful loss to us.

Remember Detective Sipowitz in the TV show NI'PD Blue? In one

episode, at the scene of a murder, he cynically remarked. "There are no victims." In other words. the victim was in some way partially responsible for his own demise. Of course that is not true for every event, but in a sober reflection of my life, which is the only thing I know well enough to make this kind of judgment, I find it to be true more often than not. Maybe, almost every time.

In other words, in almost every career and personal failure in my life, I was, at least in part, a contributor to the chaos that erupted. Once I realize that I am not a victim but a partial contributor, then the way is clear for me to assess my role and to determine never to make that mistake again.

As long as I refuse to acknowledge my role, then I remain a helpless victim, forever chained to the negative consequences of the failure and powerless to do anything about it.

Failure then. when our attitudc is right, provides fertile ground for the sowing of life lessons that often sprout into solid character traits. ln many ways, we become that which we learned from our failures. Show me a man of solid, substantial character, and I'll show you someone with a list of failures in his background.

Failure humbles us. That is one specific character trait that often sprouts from the fertile ground of multiple failures. It is hard to remain proud or arrogant when faced with the truth of several failures.

Maybe that's why the most common defense trait of proud people is denial. One of the most arrogant people I have ever dealt with spent most of his time denying his culpability in even the smallest busrness errors. Quick to point out errors in his customers, he never once said, "l'm sorry. It's our fault." His arrogance, untouched by the reality that he kept at arm's length, grew so insufferable that we could no longer stand to do business with him.

The opposite of denial is, of course, the acceptance of personal responsibility. And it is personal responsibility, coupled with the consequences of our less-than-perfect actions, that help build humility.

While no one should strive to fail, if we look at every instancc of our own failures as opportunities to learn and grow, and if we objectively search to identify our role in that failure. we'll come out of each better and stronger.

Herc's a step-by-step process to turn failure into growth:

1. Objectively analyze your role in bringing about the failure. What did you do?

2. No*, imagine what would have happened if you had done something differently. Is it possible that the sequence of evcnts that brought about that failure could havc been avoided if you had donc something differently?

3. Utrcon". what prompted you to do that. What was the precursor'? What prompted you to act the way that

you did'?

4. No*, decide that when that happens again, you will do something differently. Describe what it is you will do. as specifically and graphically as possible. Decide to change your behavior.

Using this simplc process you'll be able to turn even your most intense failures into stepping stoncs for your growth and developn.rent.

- Dave Kahla, "Thc Growth Coac'h," is a sulas consultont, troiner antl author ctl six books arttl a free rnonthlt' "Tltinkittg About Sttles" e?ine. Rcuch him ut (800) 3 3 1 - I 287 : v,wvt, tlavekahIc.t'om.

Bosed in Annopolis, MD, Fletcher Wood Solutionsn is the lorgest monufocturer o{ defect-free, oppeoronce grcde rodioto pine products in New Zeolond. Distributing our clecr boords, mouldings, LIFESPAN@ treoted wood, ond lumber to the North Americon morket through our proven ond completely integroted supply choin, Fletcher Wood Solutions@ mointoins direct occess to one of the lorgest FSC ceriified'-' pine plontotion forests in the world.

Kelseyville Lumber, Kelseyville, Ca., held a late January grand opening for its new 8l900-sq. ft. building.

"It's a big-box, but it's a little more homey," said general manager and part-owner Mark Borghesani.

The space dedicated to retail increased from 4,000 sq. ft. in its previous location in downtown Kelseyville to approximately 40,000 sq. ft. at its new location a few blocks west. Now there is room for an indoor/ outdoor garden center, an onsite restaurant and coffee cart, and everything from lumber to window glass and garden gloves to sleeping bags.

Employee Lisa Ridgeway said that a major difference is that customers can now walk in with an idea for a project and walk out with the materials they need. "We special-ordered a lot of things, but now we carry a lot of those things on our shelves," she said.

Borghesani said he knows hard times are ahead, but hopes the market will pick up again at the end of this year or the beginning of20l0.

"The demand was greater three years ago. The problem with a project like this is it takes so much energy and

work to get into it that you can't just stop it. We chose to be moving forward when the whole economy is moving backwards."

Borghesani said he is targeting the home improvement and rental markets, as well as providing recreational vehicle and marine supplies. "It's going to be tough because people aren't spending money," he said. "What we feel is that there are a lot of people who are going out of town for a lot of the stuff, who are really going to be supportive of being able to come in and get their cleaning supplies and storage units and chain saws and everything right in town now."

84 Lumber has closed nine more locations, including its yard in W. Jordan, Ut., leaving Spanish Fork as its sole presence in the state.

The Pennsylvania-based chain also began seeking state assistance for its debt financing, following the latest closings in W. Jordan, as well as Ocala, Fl.; Mount Hope, W.V.; Shelbyville, Ky.; Pocomoke City,

"The 84 Lumber people did have a meeting, as they are looking to readjust their financing and they were interested in seeing what DCED has to offer," confirmed Steve Weitzman, spokesman for Pennsylvania's Department of Community & Economic Development.

According to the company, 2008 sales had fallen about 32Vo. to 52.l billion from $3.1 billion in 2OO7.The 2007 safes total was down 20.5Vo from $3.9 billion in sales recorded in both 2OO6 and 2005. Since early 2007, the company has closed at least 87 stores nationwide, laid off 113 employees at its headquarters, and shuttered seven components plants. Last April, 84 Lumber signed new credit agreements totalling $590 million with SunTrust and Wachovia banks.

"People aren't looking for housing to correct before the end of this year or into next," said Dallas, Tx., investment banker Nick Beare. "Companies are having to come to grips with business offperhaps 507o, and their capital structure wasn't built on those kind of numbers."

Stock Building Supply's Home Selections Showroom in Salt Lake City. Ut.. hosted a Feb. l2 green solutlons open house. showing off thc facility's extensive green offerings and its consultant's expansive product knowledge.

"Our objective is to be the premier provider of green solutions," said Gail Kaufman, director of green business and customer programs for parent Wolseley. "Our u:sociales ure c()mrnitted to helping customers make small steps to help the environment."

The showroom, operatcd in tandem with sister company Ferguson, sells a broad range of green products, including doors, windows. fixturcs, czibinets, faucets. lighting and fireplaces.

National Association of Home Builders' NAHB Research Center has recognized structural frame products fiom ilevel by Weyerhaeuser with the first certificates under its new "Green Approved" seal.

The mark provides third-party evidence that LBM nteet the criteria for homes certified to NAHB's National Green Building Standard.

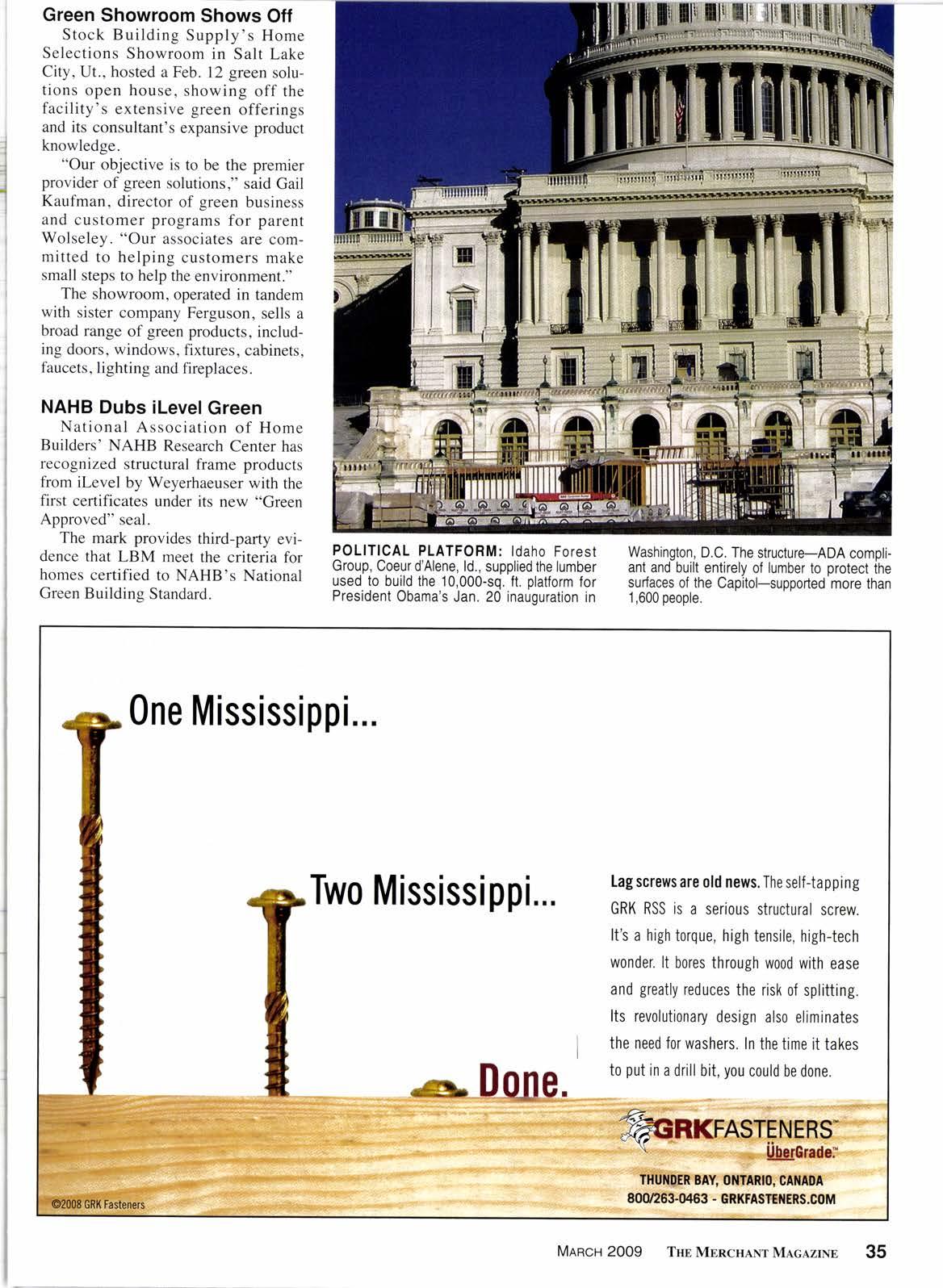

Washington, D.C. The structure-ADA compliant and built entirely ol lumber to protect the surfaces of the Capitol-supporled more than 1,600 people.

Lag screws are old news. Ihe self-tapping GRK RSS is a serious structural screw. It's a high torque, high tensile, high-tech wonder, lt bores through wood with ease and greatly reduces the risk of splitting. Its revolutionary design also eliminates the need for washers. In the time it takes to put in a drill bit, you could be done.

Green building continues to be a growing bright spot for the U.S. economy, according to recent surveYs of consumers, homeowners, and commercial real estate executives.

"The future of our built environment clearly centers on energy efficiency, water reduction, systems that encourage cleaner indoor air, the use of recycled and more sustainably developed materials, and communities that coexist with their environments," said Rick Fedrizzi, president, c.e.o. and founding chair of the U.S. Green Building Council. "The key to a prosperous future is sustainability, and the triple bottom line -environmental responsibility, economic prosperity, and social equity-is imperative as we move forward."

According to experts, two million new jobs would be created if a national economic recovery program focused on sustainability and invested $100 billion over 10 years in six infrastructure areas - including retrofitting existing buildings to improve energy efficiency, and investing in wind power, solar power, and nextgeneration biofuels.

Other key findings include:

The credit crunch will not discourage 75Vo of commercial developers from building green.

83Vo said they would be "extremely" or "very" likely to seek LEED certification for buildings they are planning to build within the next three years.

. TOVo of homebuyers are inclined to buy a green home instead of a conventional home.

567o of respondents who bought

The National Paint and Coatings Association is merging with the Federation of Societies for Coatings Technology, creating a single coatings industry association to serve corporate, science and technology professionals.

Since June, NPCA and FSCT have been operating as two seParate but aligned organizations. Now, due to the difficult economic climate and a substantial decrease in both short- and

green homes in 2008 earn less than $75,000 per year; 29Vo earn less than $s0,000.

. More than SOVo of commercial building owners have allocated funds to green initiatives this yeay 45Vo plan to increase sustainability investments in 2009.

. 60Vo of commercial building owners offer education programs to help tenants implement their own green programs in their space. uP 49.4Vo from last year.

. Spending on LEED-certified projects is expected to total more than $100 billion by 2O2O.

long-term FSCT revenues, a full merger is set to be finalized by March 31.

The groups' e-newsletters have been combined into a new semi-montly e-publicati on, C oatings Today.

NPCA's print newsletter, Coatlngs, has been discontinued, with its content moved to Coatings Today. A new industry publication is planned for 2010. Their websites will also be merged into a single site.

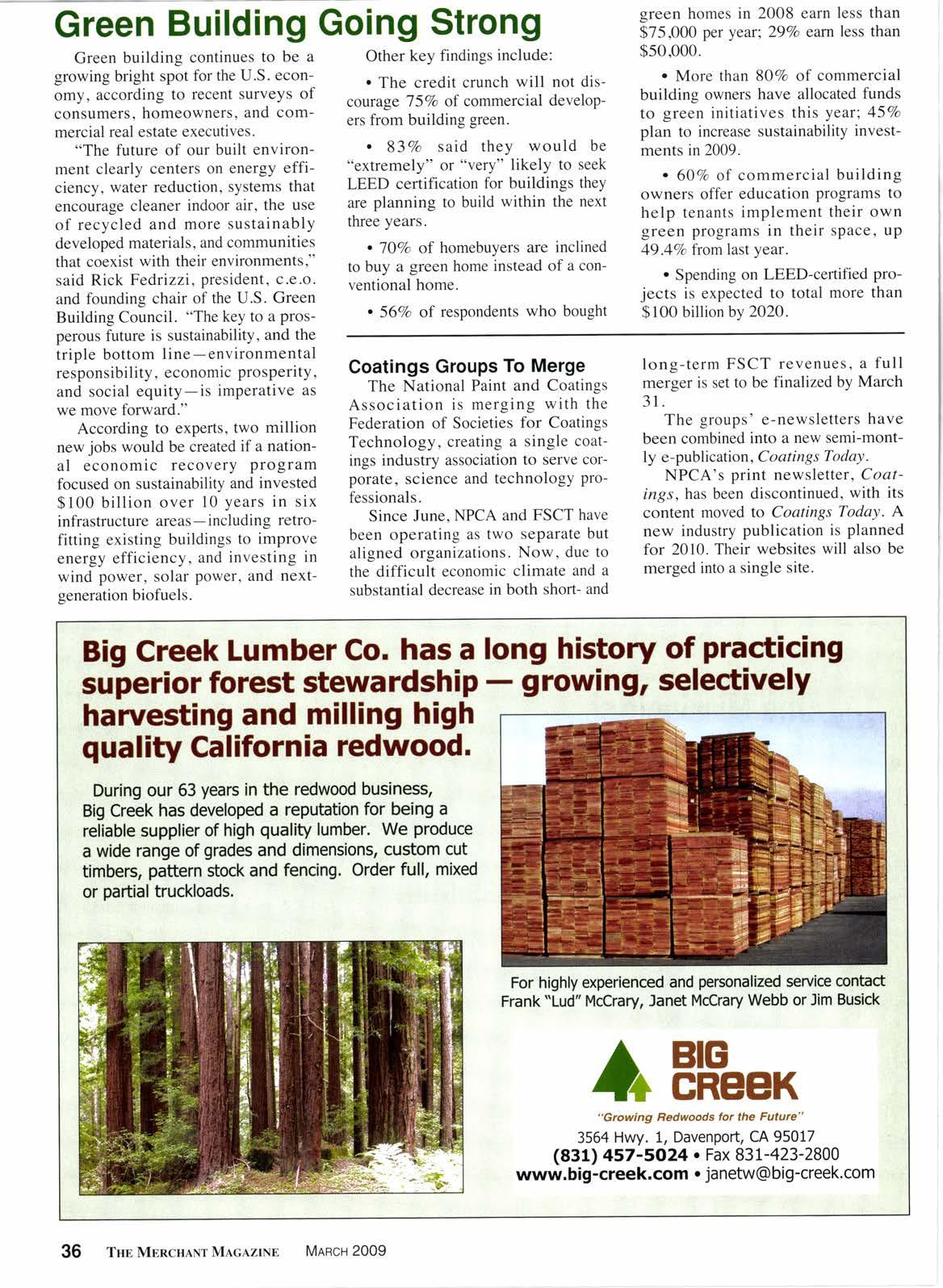

During our 63 years in the redwood business, Big Creek has developed a reputation for being a reliable supplier of high quality lumber. We produce a wide range of grades and dimensions, custom cut timbem, pattern,stock and fencing. Order full, mixed or paftjal truckloads. For highly experienced and personalized service ontact

Big Creek Lumber Co. has a long history of practicing superior forest stewardshiP : growin$, selectively haruesting and milling high guafiry California redwood.

Frank"Lud" McCrary, Janet McCrary Webb or Jim Busick

After holding strong through most of 2008, demand for western red cedar has fallen back in line with the rest of the dismal lumber market.

"We were about a year behind the curve, but now cedar is extremely slow," said Terry Baker, sales manager for Tri-Pro Cedar Products, Orofino, Id. "Cedar was strong while framing lumber prices were low, for about a year, then in the fourth quarter, it hit the wall."

Jim Vandegrift, sales manager for Bennett Lumber Products. Princeton. Id., agreed: "The market is a challenge. Cedar held on longer, until the last 60 days."

Baker lamented, "Wholesalers and retailers don't know what to do. There's no incentive to buy early with prices falling. Retailers are going to use their wholesalers, and wholesalers are going to use us (mills)."

He noted that numerous cedar mills have cut back on production, but that's not stimulating orders. "We're just going to have to wait it out," Baker noted. "It's strictly demand-driven."

According to Random Lengths, continued price cuts have most affected timbers and certain dimension items-a trend that can be used to the advantage of diversified manufacturers such as Tri-Pro. "We make a lot of different items," said Baker. "We can put five or six items on a truck. We can be nimble. Offer variety. Have it on the ground, ready to go."

Similarly, Vandegrift finds "the orders are highly specified. D&Better I can sell every day. Selects are no problem. 3&Better is extremely slow."

Most cedar mills hope the market will begin rebounding by the third quarter, although even more optimistic is Leslie Southwick, marketing and sales manager for C & D Lumber,

Lignum Forest Products, Vancouver, B.C., has engaged Tays Forest Products. Vancouver, to assist in developing its western red cedar and specialty products business.

Bruce Tays, principal of Tays Forest Products and formerly with Forest City Trading Group's Olympic Industries division, will act as sales manager. Chris Tays will assist in purchasing and sales.

Riddle, Or.

"The cedar market was quiet over the winter months; however, over the last few weeks inquiries have begun to pick up, especially for cedar timbers," Southwick said. "C&D continues to have a strong demand for our 514"x6" Port Orford cedar decking and decking accessories. We also continue to have

a strong demand for 2"x6" incense cedar Appearance Plus decking. Hopefully, this will continue to be the case into the summer months. Even though the housing market is down, current homeowners seem to still be investing in the remodeling of their homes, including adding on a deck or replacing an older deck." Remanufacturing

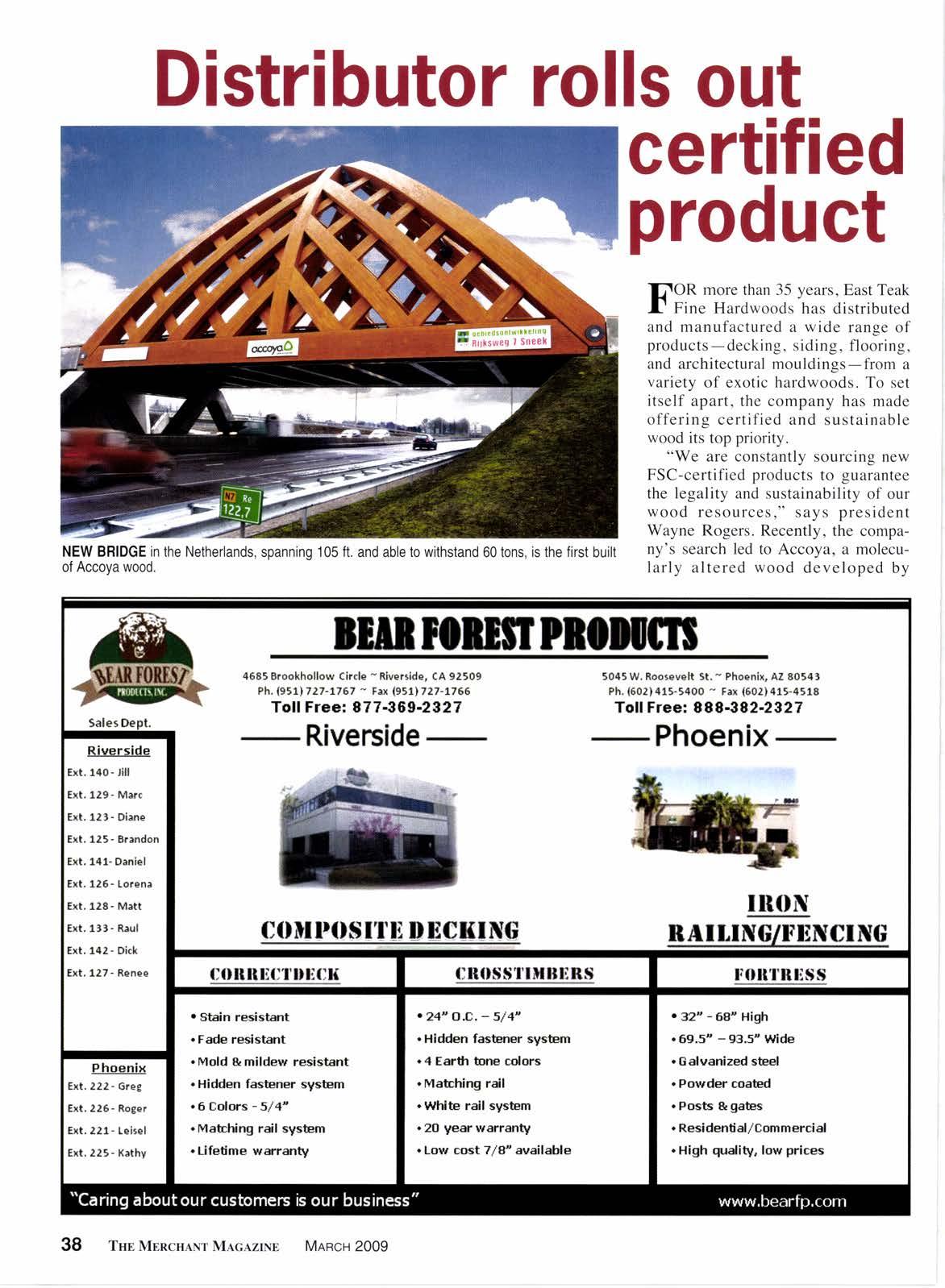

EIOR more than 35 years. East Teak l' Fine Hardwoods has distributed and manufactured a wide range of products -decking, siding, flooring, and architectural mouldings-from a variety of exotic hardwoods. To set itself apart, the company has made offering certified and sustainable wood its top priority.

"We are constantly sourcing new FSC-certified products to guarantee the legality and sustainability of our wood resources," says president Wayne Rogers. Recently, the company's search led to Accoya, a molecularly altered wood developed by

Toll Free: 877 -S6S-2t27

Toll Free: 888-582-2527

M:tt

Ext.1t3- R:ul

EIt. 142- Oick

Ert,127- i.nee cnO$$uilBnn$

Stain resistant

Fade resistant

Mold & mildew resistant

Phoenin Ext,222- Greg

Ert,226- Roger Ext,121- leiicl Ext,215- Xrthy

.Hidden fasbner sysbm

o6Colors-5/4'

.MabHng rdl sysbm

.Lifetime wtrranty

.24" OE. - S/4"

Hidden fastener svsbm

' 4 Earth bne cdors

Mabhing rdl

tAJhiE rail sysbm

.20 year rvarranty Lofl, cost 7/8" available

32o - 68" High

.69.5' - 93.5" Wide

Balvanized sEel

Fowder coabd

.Posts &gabs

Residentid/Commercial

High Srditv, low prices

NEW BRIDGE in the Netherlands, spanning 105 ft. and able to withstand 60 tons, is the first built of Accoya wood.Accsys Technologies and promoted by its wholly owned subsidiary. Titiin Wood.

"East Teak had been looking for a new product for some time that would be unique, FSC-certified as lcgal and sustainable. have the durable qualities of exotic hardwoods, and be moderately priced for all of those qualitics," said Matt Mladenka, East Teak's markctrng and sales director.