Ily

Desire

$ids pfMidt Etddw Prudrcbt@s6n€sfre Eesl)

F$BLISHER Alan Oakes (aioakes@a0l.com)

PUBLISHER EIIER|TUS David Cutler

EDIIOR David Koenig (dkoenig@buiHing-products.com

ASSOCIATE EDFOR Karen Debatc (kdebats@building-producls.com)

CONTRIBI.'TING EDTTORS

Owight Curran, Carla WaBemar

AD SALES ITANAGER Chuck Casey (ccasey@building-producls.com)

CIRCULATPN HeatherKelly (hkelly@building-products.com)

ADI'II{ISTFATION I'IRECTOff$ECRETARY Marie Oakes (mfpoakes@aol.com)

Conlact our adyerfuing otllcos lor r8tos: WESI, lllDWEST, SOUIIIEASI: Chuck Casey, Newport Beach, Ca.; (949) 852-1990; Fax 949852-0231 ; Email ceasey@building-products.@m

NORTHEAST: Paul Mummolo, Brick, N.J.; (732) 899-8102; Fu 732-899-2758; Email pmummolo @aol.com

How to Subscribe

conhct lbathel at (9{9) et2-1s0

U.S.: 1 year (12 issues), $15; 2 years, $24; 3 years, $30

FOREIGN (Per year paid in advance in US funds): $39 for Canada and Mexico, $50 lor all other counries; Air rales also available.

S|I'IGLE COPIES: $3 + shipping; Back issues (when availabb), $4.50+shipping www,bul ldlng-products.com

ALAN OAKES publisher ajoakes@aol.com

ALAN OAKES publisher ajoakes@aol.com

As you travel around the U.S.A., you cannot help but notice how our national infrastructure is simply eroding away. I am sure every one of us can look at our own neighborhood, town and city and see how bad it is getting. What our local, city, regional and federal govemments spend is simply not enough to keep up with the crumbling bricks and mortar of our living environment.

Whatever youlook atour schools, roads, bridges, sewers, power grids, transit systems, parks, drinking water-is not getting the investment required to bring it up to our current needs. The long-term impact is that our quality of life is eroding, and the cost of catching up and replacing the patch mentality mindset we have today is only getting higher. At some point the piper has to be paid.

A recent survey by the American Society of Civil Engineers concluded the United States is falling apart, and gave a D grade-worse than the last report in 2001 which gave a D+ rating. Some of the findings included: for every $1 needed to be spent on our drinking water, only 10 cents is being spent; the number of unsafe dams has risen to 33Vo; fwding has been cut for waste water despite many of the older systems discharging untreated sewage; railroad capacity is increasingly limited, at a time when demand is increasing (as our industry is well aware); probably a quarter of our bridges are either obsolete or close to.

Yet it seems no one is talking about it. The whole issue is not only about the engineering issues or the money needed, it is about the social issues as our way of life and our health and safety are on the line. One of the issues most of us can identify with is how much time we spend in our cars getting to or from work or getting to

visit or deliver to customers. We are not only spending more time driving and less time with our families, but we are also using more fuel, creating other issues. A recent study suggested that here in Los Angeles, commuters are wasting $1,668 annually in excess fuel costs and lost time. My son does a minimum 2.5 hours each way to work that should barely take an hour. It does not matter what time of day or night, the freeways always seem choked up. In this report,TIVo of roads were seen to be in a poor or mediocre condition.

Our children are not only paying now with the increasing enrollment demands for our schools with lower quality education, but they will be the ones who will have to pay down the road, not unlike the social security issues they will also have to face in the future.

Now maybe we are not talking about it because we may understand what it will cost us to put these issues right. In fact, the cost for needed repairs and improvements over the next five years is estimated to be for every citizen (adult and children) about $1,000 annually until 2010. It really did not come up as an issue in the last election, probably because not one of us thinks we do not pay too much in taxes already. However, first of all one wonders how much of the current taxes we pay is wasted in ridiculous pork barrel schemes that could be put to better use. While I cynically believe that politicians are not likely to make the right choices, I am equally concerned about what happens if these issues are not taken care of and, from a selfish point of view, what would be the value to this industry if all the repairs and rebuilding that are needed actually took place. Maybe this is where our industry lobbyists should spend some of their time.

As the leading producer of glulam products in the U.S., Rosboro has once again responded to customer demand and is now offering a 24F 1.8E Treated Glulam.

Rosboro Treated Glulam is a24F glulam beam made from Southern Pine and treated to resist rot and decay. Installation is easy because the beam is straight, has no top or bottom, and is manufactured to match standard framing widths.

Treated with Permapost K-8

K-8 is an industrial wood preservative and water-repellent treatment containing solubized copper-8-quinolinolate, which provides chemical resistance to insects, decay, mold, mildew and bacterial growths. It is a clean, non-swelling, non-leaching, and non-corrosive treatment.

Treated Glulam not only resists rot and decay, but with simple precautions, it is easy to work with. In fact K-8 is low in toxicity to humans and is the only wood preservative approved by the U.S.

Food and Drug Administration as registered by the EPA for treatment of wood products that come in contact with foodstuffs.

Recommended Applications

Rosboro Treated Glulam is recommended for applications such as decks, porches, trellises, and balconies where the member may be directly exposed to the elements but will not reach the equilibrium moisture content level of 16%o (the threshold for wet-use). To learn more about dry vs. wet-use and specific restricted uses, visit the Rosboro website.

Available in Common Sizes

Lengths: 48 feet

Widths: 3 ll2" and 5 7116'

Depths: 9 ll2', ll 7 18', 14', 16" and 18"

Call

Llincreasingly are finding ways to make technology a larger-and more profitable-part of their business, from sales to merchandising.

Making shopping more convenient was the goal at Lowe's Web site, where more than 2,000 wood products are now available for purchase. Customers shop online from inventory at their local Lowe's, which then arranges delivery.

This means contractors can spend more time building, and sales reps can spend more time selling.

"Lumber in particular is one item that can be difficult for people to transport to their homes," said Bob Gfeller, senior v. p. of marketing and advertising. "Now, customers can order the wood they need and have the assurance those products can be delivered to their door."

Lumber was added as part of a continuing effort to make Lowe's Web site more user-friendly and to offer inspirational solutions for do-ityourself projects. In addition to the new lumber offerings, Lowes.com offers more than 20,000 products and 1,000 how-to projects online.

In its search for more effective merchandising, Home Depot partnered with SAS, a software provider in Cary, N.C., to develop revenue

optimization software that keeps track of pricing, promotion, and clearance decisions throughout the entire merchandise life cycle.

Currently, Home Depot collects merchandising information from various sources. According to SAS, the new software will streamline this operation and "retailers will no longer have to rely solely on gut instinct or historical analysis."

"We believe the SAS software platform will enable our merchanding operation to perform more efficiently and effectively," said Mark Healy, senior director of merchandising at the chain. He added that the software represents a single, comprehensive solution to making the right pricing decisions, while consolidating multiple applications with one software vendor.

At White Cap Construction

Supply, BuildSite LLC was chosen to consolidate product and technical information from more than 200 manufacturers on a single Web site. Both companies are based in Oakland, Ca. White Cap has tested the site successfully at its sales support center in Ontario, Ca. "Now, salespeople throughout our network will be able to quickly access information that is current and accurate, and easily provide it to customers," said Peter Wragg, major projects manager.

BuildSite is designed to reduce information overload and time-consuming research for contractors and the suppliers who serve them. The company's mission is to deliver products that help its customers "do what they signed up to do." This means contractors can spend more time building, and sales reps can spend more time selline.

II/HAT IF you built a deck and no one came? After all, Y Y a deck is a place to hang out, to have fun, and to sit and enjoy the company of ydur friends and family. The way it looks and feels is everything. Like your living room, family room, or kitchen, the ambiance can be the difference between a destination and a passageway to someplace else.

Move the place outdoors and now the question of durability and maintenance plays a large role in your choices of materials. What shall it be, composite? Which one? Wood? What kind of wood? It turns out that there are advances in coatings out there that make wood competitive with the maintenance of a composite. This is handy new information. What's the most important factor in choosing a deck? Is it aesthetics, is it uniqueness, is it architectural fit, or is it maintenance? For most. it is a combination of these and other factors.

Mahogany, in its various incarnations including red meranti and others along with tropical hardwoods such as cambara, ip6, etc., are strongly considered when choosing a decking option. They are also more available than ever which means the pricing is more advantageous than ever to the buver who. after all. reallv wants wood. The beautiful hardwoods are, in fact, less expensive than the composite imitations.

While composite decks have a place, they are presented as a virtual replica of that which they are essentially not, which is made of solid wood. Up close, there is no mistaking this fact. Composites cannot compare to the beauty of real wood. It is also worth examining how well these substrates compare with respect to maintenance. The answer might surprise.

But first, a brief history. Not many years ago, when asked what could be used to protect a hardwood deck, the answer was "not much." While products were available, there was not a good solution for the wood seller to apply a factory coat to ensure great protection prior to the sale of the material. Further elaboration to the customer always included comments about how decks are, by nature, maintenance items. They need attention every year. For those who like to let things go a bit, every two years is

sometimes okay if the deck is in the shade.

This answer didn't work well so the industry set about searching for products to prestain the decks. Companies such as Cabot. Penofin, Messmers and Duckback, to name a few, have produced successful penetrating oil-based stains for hardwood decks, often used to pre-finish the decking boards prior to installation. This represented the beginning of a solution. The advantage to the approach of pre-staining with these products is three-fold: (l) It protects the deck on day one of the install which is critical to the long-term quality of the material. (2) It coats the underside and sides of the decking which can be difficult or virtually impossible after the install. It's important to coat the underside to ensure stability and prevent cupping. And (3) It demonstrates to the builder and homeowner that coating the board is necessary and, in effect, explains how to do it. Today, Cabot has a new product called S.P.F., which is water-based and forms a film. Not long ago, we would have said, "You're asking for trouble using a film-forming finish on a deck." But this is a new technology that is advanced enough to allow use on damp wood and it won't peel like the old decking enamels. We can now dispense with the phrase, "What do you mean the painters are here, it rained yesterday." For the factory coating applicator, this coating, and I suspect there will be others, is used to create decking products that can last for several years without recoating.

Back to the question of comparing maintenance costs: A coating that simply wears away on a wooden deck in several years can be recoated on a Saturday morning. The same deck in composite form is often pressure-washed every spring, similarly using up a Saturday morning. Take a closer look at wood decking as a less expensive alternative to composite decking. Then, surprisingly, take a closer look at wood decking as a lower maintenance alter native. Hmmm. What's more, with the beautiful look of a prestained tropical hardwood deck, the fear of "if I build it, will they come" will go away. Unless of course, the beer's warm and the jokes are old, in which case, sadly, I can't help you

NORTHEAST dealers can acquire prestained hardwood decking from Boston Cedar.o The right product at the right place at the right time.

To learn more, contact us at 800-676-7777, or visit primesourcebp.com. PrimeSourceglobal reach, hometown service.

By Carla Waldemar

By Carla Waldemar

LTAMPA is the fastest-growing I \ community in Idaho, says Roger Kotter, who grew up there. He's seen the before and hastened the after.

Following graduation from college with honors and a two-year stint in South America, Roger opted to return. He already knew why hordes of Californians were following their MapQuest printouts in that direction, searching for a slower, saner pace of life.

The migration wasn't lost on Lowe's and Home Depot, either. A year ago they both invaded Nampa, a mile down the road from Stone Lumber Co., where Roger serves as president.

Sure, Stone lost some business to the boxes-the d-i-yers who dropped in for a paintbrush or a couple of bolts. But Roger's not worried. "They can squash the best yard in the beginning, but over time, they need to show a profit and can't sell below cost," he knows.

And he's more than happy with the strong pro business (75Vo and growing) that's always been Stone's mainstay. Maybe they might cherry-pick Lowe's for hardware, but they retum to Stone's for lumber and building materials, the backbone of any contractor's budget, where prices on those items are 25Vo lower than the boxes'.

Yet Stone doesn't depend on price as its ace in the hole. Armed with 32 expert employees, for whom "turnover" means stock, not people, Stone trumps the boxes big time. "Our customers need the knowledge we can offer vs. the box mentality, where you ask a question and the guy's eyes fog over as you distract him from thoughts of his next paid holiday."

In contrast, Stone's troopers walk the talk. "They've all built the stuff. And they're truly involved in every facet of a builder's business. They'll visit the jobsite and if they see something that isn't going to work, they'll tell him, 'You might think of trying this....' This is where we shine: We know what we're talking about and we partner with our pros," because that's where the bread is buttered: "The contractor is the salvation of our business," Roger knows full welland cares.

can squash the best yard in the beginning, but over time, they need to show a profit and can't sell below cost."

Word gets out. Builders come knocking, saying, "Company X didn't work out." Roger rises to the challenge: "Okay, we'll do a take-off at no charge and see if we can help you better."

The personal interest he takes in folks pays off, too. Roger likes to tell the story of a stranger who ambled in. "Just browsing," he said when Roger offered help. But Roger kept the conversation going. Three weeks later he was back with a blueprint and an order for the whole house. "Let me tell you something, Roger," the man explained. "I shopped every major yard in Idaho, and you're the only one who took an interest in me."

This practice drives as much busi-

ness Stone's way as it can handle, so the outfit doesn't go trolling: "We don't want to overbook the plane," Roger notes. "We want return clients, so it's not 'Hey, they're new, so we can take advantage of them.' Our philosophy's simple: Treat people honestly and fairly, as if you were them."

Ask Roger how he gets his staff to buy into his credo and he comes back with the usual sidebar stats: medical insurance, 401-k plan, profit-sharing bonuses, commissions.

Nice, very nice, but not the whole picture. "My greatest fault," he says, "is that I'm not strict enough; this isn't Camp Pendleton Induction Center. I'm a little more flexible than the average owner. If there's a marital problem, we'll work through it, not fire 'em on the spot. If they want to go to college, we'll work around their schedules. I always want people to better themselves," he documents, "the way I was able [to]."

A quick dip into Roger's work history, which has burnished his management style and capabilities. Remember the kid with the young wife, new baby and college degree? They'd seen the bright lights of the big city but preferred the stars above their home town. So Roger asked his father-in-law, Stone's owner-for whom he'd driven trucks in high school-about a job.

Salesman's clipboard, car allowance, nameplate on an office? Sorry. He was welcome to begin at the bottom (again) as a driver at$425 a month. Mulling over his prospects, Roger figured. "He's giving me a chance; I'll take it."

The older man must have seen a future in the kid, for that first Christmas he gave him a $2,000 bonus (right: four times his monthly

pay) and started advancing him through the ranks-inside sales, commodities buyer, on up the ropes.

Boot camp paid off. "Now if a truck driver phones in having trouble with the hydraulics, there's a good chance I can solve it because I'd been there," Roger states. "I'm a hands-on type guy: never ask somebody to do something-deliver sheetrock, whatever-that I'm not willing to do."

By the '80s, when the boss was ready to retire, his son, Monte Schlerf, and Roger bought the business. Today Monte oversees the administrative side and hardware department, while Roger manages the outside sales staff and lumber operations. "We work really well together," Roger declares, which is particularly fortunate because they're now related. Each man married the other's sister. "The kids are double cousins," the fellows laugh.

They've weathered the bad times along with the good. In 1994, arson struck-"the second-worst fire in the history of the city"-destroying the better part of the square block that Stone occupied. The next morning Roger met with employees, voicing his determination not to let anyone go ("The payroll," he admits, "presented a little bit of a challenge.") He called his wholesalers, arranging to buy units-not caseloads-of replacement lumber, and they helped out. Thanks to the SBA ("our lifeblood"), he secured a bank loan and started rebuilding, using employees' labor to keep them occupied.

The glass, it turns out, was half full. Stone had the opportunity to scout a new location. "After looking at eight sites, we came back to the most expensive," Roger has to laugh. "We put our homes on the block."

The risk paid off. "We're now on the most prominent street in Nampa. With 14,400 sq. ft., we've expanded our choices of material, added paint, power tools. We doubled our outside sales staff and bought more trucks (we now have 22 vehicles). The store is bright and clean and wide open, with a finished ceiling rather than exposed trusses like a Home Depotthe kind of a store that makes women customers feel comfortable. "

And Home Depot maybe not so comfy. "People have to drive past us to get to the boxes," Roger can smirk. Since those chains have come to town, Stone has remodeled its exterior, updated the landscaping, installed

an electronic sign in front and updated its Web site with an "Ask the Experts" page and links to brandname manufacturers. Presently the company is building another storage facility across the street.

Stone also has opened new avenues for partnering with its pros. "If they're featured in the Parade of Homes, we give them $1,000," Roger reports. "We also do TV ads for them, filming the insides of their homes. We just bought a Reader Board and use it for digital photos of their homes to honor a Builder of the Week: free advertising for them. And if a retail customer walks in and comes to realize he's in over his depth, we refer them directly to a builder. (This pays big dividends.) We work together. When you get too big to do that, you forget what got you there, and you're in trouble.

"We have no mid-management here-Monte and I run the show. There are no doors on our offices. We're doing $12 million a year and could get a whole lot bigger, but we're not after making multi-million dollars if it means that you have to look down at the ground when people walk toward you. We're fair and honest, and if something's wrong, we'll fix it.

"For instance," Roger demonstrates, "we did a duplex for a builder within $500 of the estimate. 'Can you do it again?' he asked us. This time he came back, saying we were $1,867 over. I wrote him a check on the spot, saying, 'You and I agreed on a price.' (Turned out his neighbor had 'bor-

rowed' some lumber and built a garage at our expense, but we kept our word. That's how we operate.)"

Roger's no softie; don't get him wrong. He's grown the business by keeping an astute eye on the bottom line. "I myself buy the larger items, the dimensional lumber, and I watch things closely," he indicates. "We have bid sheets for our outside salespeople, but I also give them latitude with a new customer, to be more aggressive and get the horse headed in our direction. Then, on his next house, once you've developed that trust, you can start a little higher. Now, many builders come to us and don't even ask for a quote; they know from the experience between us that we're honest." For such qualities and achievements, Roger was named Businessmen of the Year for the State of Idaho in 2000, resulting in a trip to Washington, D.C.

Roger reflects on his history. "Above all else, it's permitted my wife to stay home with our five children." None will carry the torch. "I chose not to transfer the business down the line; there's so much pressure on small businesses today. They're the endangered species, not the spotted owl," he exclaims. "Very few people can do startups anymore." Yet, Roger cannot imagine doing anything else. "It's been a great ride."

mon description of the field salesperson's modus operandi. In a misguided attempt to stay busy and see as many people as possible, too many salespeople subscribe to the theory that any activity is good activity.

There was a time when this was true. Customers had more time, sales was a simpler job, and any conversation with a prospect or customer was a good thing. But times have changed, and the job of the salesperson has become much more complex. The pressure on the salesperson to make good decisions about the effective use of his time has never been greater. Salespeople now must confront an overwhelming number of potential "things to do," and that requires them to make decisions about which customers in which to invest their time, to prioritize their activities every day, and to continually choose from a menu of possible activities. In other words, salespeople must now engage in strategic planning.

Not that this is new. There have always been salespeople who have regularly planned strategically for the effective use of their time. It's been a characteristic of superstar salespeople and highly effective sales forces. For that small percentage that do it instinctively, or are encouraged to do so by their management, it's as much a part of their routine as brushing their teeth in the morning.

Unfortunately, that describes the minority of salespeople and sales forces in the world. What was a practice of only the best has now become a requirement for everyone. Most salespeople have never been trained in the best practices, processes and disciplines that will set them apart from the pack. In this case, that means that most salespeople have never been exposed to the principles, processes

and disciplines of effective strategic planning.

Let's define our terms. A strategic plan is composed of a set of measurable goals, coupled with a list of the most important, most effective things you (or your company) can do to reach those goals. A strategic plan is not a detailed action plan. That comes later. The plan itself is often limited to two or three pages. The idea is to identify the highest and most effective priority; too much detail defeats the purpose.

Strategic planning is the process of thinking about yourjob (or your company) in such a way so as to develop your strategic plan.

Creating a strategic plan for your company always involves a dedicated chunk of time devoted to the process. So too for a strategic plan for a salesperson. Creating a strategic plan for your company always involves preparation and gathering the best minds in the company. So too for a salesperson's strategic plan-prepare and meld the ideas of the salesperson and his/her manager. Strategic planning for your company always involves the discipline to adhere to a formalized process. So too for a salesperson.

With your company, the creation of a strategic plan is often an energizing. inspiring event, from which everyone leaves optimistic and full of confidence, assured that they have identified the goals, plans and tasks that will bring them the best results. And that is exactly the benefit for a salesperson creating a strategic plan. Salespeople spring up out of the strategic planning process confident that they have identified the most effective focus for their action, that they have identified the highest priority activities. They emerge confident, focused and optimistic, ready to take on the world (or at least their customers) with renewed vigor.

How to so about it?

1. Set aside once ayear a significant amount of time dedicated to the task. I'd suggest at least a full day or two. The date of the planning session should reflect the salesperson's selling situation. Salespeople vary in their seasonal "busyness" depending on the industry to which they sell. For some, a time towards their end of their fiscal year might be in order, for others, a time at the end of their busy season. For most, a time around the Christmas holidays works best.

One of my clients brings all his salespeople into the office for a planning retreat once a year. In another, salespeople come together for an annual goal setting and strategy developing retreat. At this three-day event, they meet with their sales manager and create specific goals for the year. Then, together with the manager, they jointly develop the overall strategy for achieving those goals. If your company organizes such an event, good for you. If not, then you need to do it yourself.

2. r'lno a space where you can work virtually unintemrpted. This may take some creativity. I doubt if it's your company office. It may be your home if you have a room in which you can seal yourself. One year, I was one of two people responsible for leading an organization. The two of us drove to a state park, climbed in the back of my old conversion van, and worked in the back ofthe van all day long.

3. Gather the materials you'll need: all your account folders, account profiles, your company's goals for the year, information about key products, services, or categories, computer print-outs of last year's sales, maps of your geographical territory, and anything else you may want to review.

4. I--"rt" yourself in the process. For the duration of the planning, don't

do anything else other than emergency tasks. You want to focus your thinking on the strategic decisions you'll be making. Any intemrption will disrupt your thinking.

5. Fo"ur on what you are going to produce in this planning event-the output or result of your efforts. You are going to create these things:

A set of sales goals for your territory.

A well-defined ABC analysis of your customers and prospects.

. Individual goals and strategic plans for each of your key (A) accounts.

A basic territory plan.

Sounds arduous, and it is. But when you spend disciplined, focused time thinking about these things in detail, you'll find it to be much easier than it looks. You will prepare the best, most effective plans that you are capable of, freeing you to implement effectively when you are in the field.

Later in the year, you won't be tempted to head out on Monday morning without a clear plan in mind, because you have spent this time formulating the plan. And when the press of customer problems and inquiries threatens to overwhelm you and force you into becoming too reactive, you'11 be held on track by the goals and plans created in your planning discipline.

Consider each of these four outcomes of your planning retreat:

l. A set of sales goals for your territory.

Your work should lead you to a series of sales goals for your territory. In order to get there, you must first determine the categories of goals that you are going to create. It may be that you work for a company that has already determined this, like my clients described above. If so, good for you. If not, then it will be up to you to determine your own set of categories. Depending on your unique set of products and services and your company's emphasis, you may create goals for the most frequently used categories:

. Total sales

Total gross margin

Number of units

Total sales per product category (dollars, gross margin, or units) for each of several categories of product or service that you sell.

Goals for new accounts.

This is just a list of the most common sales goals. You can have a virtually unlimited variety of goals. The categories of goals are up to you, your company, and your manager.

I advise no more than five categories. Remember, one reason you create goals is to help focus your energies on the most important issues, thus becoming more effective. More than five goals defeat that purpose. Too many goals cause you to diffuse your energies, not focus them.

Let's illustrate. Assume that I sell sophisticated cleaning equipment and supplies to three different market segments: manufacturers, school systems, and shopping malls. My product line consists of a series of heavy-duty floor cleaning machines and the associated supplies used by those machines. I select the following categories to create goals:

Total sales.

. Total number of cleaning machines

Total number of Superscrubbers, our new, high{ech machines.

Number of new accounts.

Total sales of supplies (as opposed to equipment).

After determining which categories to focus on, you next need to create specific numbers for each. This is where the art comes in. You consider your company's goals, you consider your understanding of what the market is doing, you factor in your best understanding of what your competitors are doing, and you consider your customers' situations and yours. Out of this comes your best attempt to predict a result that will cause you to stretch, but not be unreasonable.

I prefer to look at each account individually, think about it, and derermine its likely contribution to each of the categories. Examine each account, analyze the potential, consider your situation, and set a realistic goal. Go on to the next account and do the same. Then compile each of the numbers from the specific accounts, and presto! You have an annual number. Back to the example. Say we've come up with a set of annual goals like this:

r Total sales = $1,765,000

Total number of cleaning machines = 7l

Total number of Superscrubbers

=16

Number of new accounts = l0

Total sales = $1 million

2. A well-defined ABC analysis of your customers and prospects.

One of the most important exercises is determining in which accounts you want to invest the bulk of your sales time. Too many salespeople become very reactive in their decisions, responding to whoever happens to be on the other end of the phone. Others find themselves in a route-type rut, mindlessly traversing their sales territory out of habit.

The cure to both of these is to strategize about each account's potential and rank each by its potential. Grade each prospect and customer as "A" (highest potential), "B" (medium potential), or "C" (low potential).

3. Indiuiduul goals and strategic plans for each key (A) account.

If you are in the kind of selling position where you are attempting to sell more to certain key accounts, then you need to create specific, monthly strategic plans for each of those key accounts. For now, let's assume that you have prioritized your accounts.

In the typical sales territory,5OVo to 80Vo of your business is going to come from A accounts. That means these accounts warrant special attention, special preparation, and special thought. Apply the disciplines we have already discussed to your A accounts (i.e., create annual sales goals for each A account, and think about how you are going to do that, one account at a time).

4. A basic plan for your territory.

You have, at this point, decided what you want to do (your goals), with whom you want to do it (ABC categories), and how (key account plans).

Now, it's time to put it all together in an implementation plan-how you will use your sales time. Where are you going to be on Monday? How will you manage that trip to the outer reaches of your territory? When will you schedule office time? Lay out your basic schedule of how you will travel your territory. Make sure you focus your time and attention on A accounts, and that you work in time for the achievement of all your goals.

This annual exercise will guide you to the most effective use of your time and keep you focused on activities that bring the greatest result.

- Dave Kahle, "The Growth Coach," is a sales consultant, trainer and author of six books, including Ten Secrets of Time Management for Salespeople. Reach him at (800) 33 1 - 1 287 : www.davekahle.com.

Montana Ace Hardware opened its 5th location April 1, a 25,000sq. ft. store in Kalispell, Mt.; Stu and Meg Weis, owners; Don Pearce, general mgr. ...

Frontier Building Supply, Friday Harbor, Wa., has closed its retail operations and laid off 8 workers, but will continue as a point of distribution for deliveries from its store in Anacortes, Wa.

Canby Ace Hardware, Canby, Or., will open this summer in a 15,000-sq. ft. building that previously housed an Ace Hardware until three years ago

True Value, Glenwood Springs, Co., is losing its lease and, unable to find a suitable new location, will likely close its 26,000-sq. ft. store by Jan. I

84 Lumber Co. this summer anticipates opening a 34,550-sq. ft. store and 19,200-sq. ft. components manufacturing plant on 20 acres in Chandler, Az.; a 12,000sq. ft. store and 16,800-sq. ft. component plant on 20.13 acres in Post Falls, Id.; a 48,000-sq. ft. store on 9.71 acres in Tucson. Az.. and an 11.36-acre, 105,600-sq. ft. truss plant on the 23.96-acre site of its store in Sacramento, Ca. ...

F ergus on Ent erpri s e s, Stockton, Ca., received a lO-year lease for a 120,000-sq. ft. building and 30 acres from the Port of Stockton ..

Home Depot opened a new store March 31 in Payson, Az.; made a bid to buy land in Tooele, Ut.; received approval to build stores in Phoenix, Az., and Ceres, Ca.; applied to add another store in Salem, Or.; withdrew plans to build in La Mirada, Ca., due to local opposition, and had workers evacuated at a store in San Diego, Ca., after a forklift driven by an employee broke a natural gas line leading to an overhead heater

Lawe's Cos. has broken ground on a 116,000-sq. ft. store in Apple Valley, Ca.; received approval to

build new stores in Torrance, Ca., and Kent, Wa.; expects a 4th quarter 2005 opening in Longmont, Co., and is scouting sites in Turlock. Ca. ...

Building Materials Holding Corp., San Francisco, Ca., has acquired a majority interest in Tucson and Phoenix, Az., atea installer Riggs Plumbing, LLC through its wholly owned subsidiary BMC Construction,Inc.

Cooley Industries subsidiary Cooley Reload, Phoenix, Az, has opened a 9-acre, Union Pacificserved reload facility serving the Southwest with rail capacity handling up to twelve 81' cars; Dean Cooley, president; Jeff Pappe, yard mgr....

Orgill has opened a 500,000-sq. ft. Southwest regional DC in Hurricane, Ut. -its first warehouse west of the Mississippi River; the facility could be expanded as large as 800,000 sq. ft.

Cascade Capital, Tacoma, Wa., has leased 3 acres across the street from its current location for expansion, particularly of EWP

Jeld-Wen, Klamath Falls, Or., has temporarily laid off 43 employees to retool its Everett, Wa., door plant from producing softwood doors to higher end custom hardwood products ...

Lester Shingle, Sweet Home, Or., rebuilt and reopened its mill that was damaged by arson fire last September ...

Louisiana-Pacific Corp. is permanently shuttering its OSB plant in Malakwa, B.C., and its longidled facility in Woodland, Me,, and agreed to sell its pine mill in Gwinn, Mi., to Potlatch Corp., Spokane, Wa. ...

P ennsylvania Lumbermens Mutual Insurance Co. is now doing business in Arizona, Colorado, Nevada. New Mexico and Utah

Gorman Bros. Ltd., Westbank, 8.C., added three new dry kilns for a total of 2l

Canfor Corp., Vancouver, 8.C., completed the sale of its Fort St. James sawmill and related tenures to Pope & Talbot Inc., Portland, 0r.. and the sale of its sawmill in Slocan, B.C., to Springer Creek Forest Products Ltd. ...

Sierra- P acific Industries sold two tracts of forestland along the American River and near Barker Pass totalling over 1,000 acres to the Tahoe National Forest ...

PIum Creek Timber Co., Seattle, Wa., agreed to buy roughly 56,000 acres of timberland in Florida from Greif, Inc. subsidiary Soterra LLC for $90 million

Advantage Busine s s Computer Systems acquired the distribution systems business of Versyss Com' mercial Systems; Advantage has taken over the employees, client portfolio and contracts through a wholly owned subsidiary, Versyss Data Systems ...

Progressive Solutions Inc. has sold its 50th bisTrack system, reportedly making bisTrack the fastest growing business software solution for building materials dealers and distributors ...

National Association of Home Builders is pulling its 2007 and 2008 conventions out of Atlanta, Ga., explaining that its show has outgrown the city

BMD, Galt, Ca., is now exclusive Ca. distributor for Jager IJoist and is carrying Ainsworth's Durastrand flooring and Therma' strand radiant barrier ... BMD was recognized for sales performance in2A04by GRK Fasteners ,..

New site: Morgan Creek Forest Products, Healdsburg, Ca., www. morgancreekforestproducts.com

Anniversaries: Goodman Build' ing Supply, Mill Valley, Ca., 50th ... Redhill Forest Products,HaYden Lake, Id., 10th ...

Housing starts in March (latest figures) declined lSVo to an annual rate of 1.837 million single family starts fell I4Vo,with multifamily down 3l%o ... permits slipped 4Vo ... starts were off I2.7Vo in the West.

innovative railing system allows you to simply place the 6'wide panel into the pre-engineered rail slots. rail slots, seven glass panels. lt's that easy.

Listings are often submitted months in advance. Always verifu dntes and locations with sponsor before making plans to attend.

North Cascade Hoo.Hoo Club - May 13, golf tournament, Eaglemont Golf Course, Mount Vernon, Wa.; (425) 259-3836.

National Hoo-Hoo-Ette Convention - May 13-15, Kings Inn Hotel, San Diego, Ca.; (714) 256-5830.

Woodworking Show - May 13-15, Neal S. Blaisdell Center, Honolulu, Hi.; (800) 826-8257.

Do It Best Corp. - May 14-17, spring market, Indianapolis, (2r9)'748-5300.

American Wood Preservers' Association - May 15-17, annual meeting, New Orleans, La.; (800) 356-1974.

North American Building Material Distribution AssociationMay 15-17, convention, Portsmouth, Va.; (888) 747-7862.

Lumber Association of California & Nevada - May 16-18, mill & forest tour, Arcata, Ca.; (800) 266-4344.

National Hardware Show - May 17-19, Las Vegas Convention Center, Las Vegas, Nv.; (847) 605-1025.

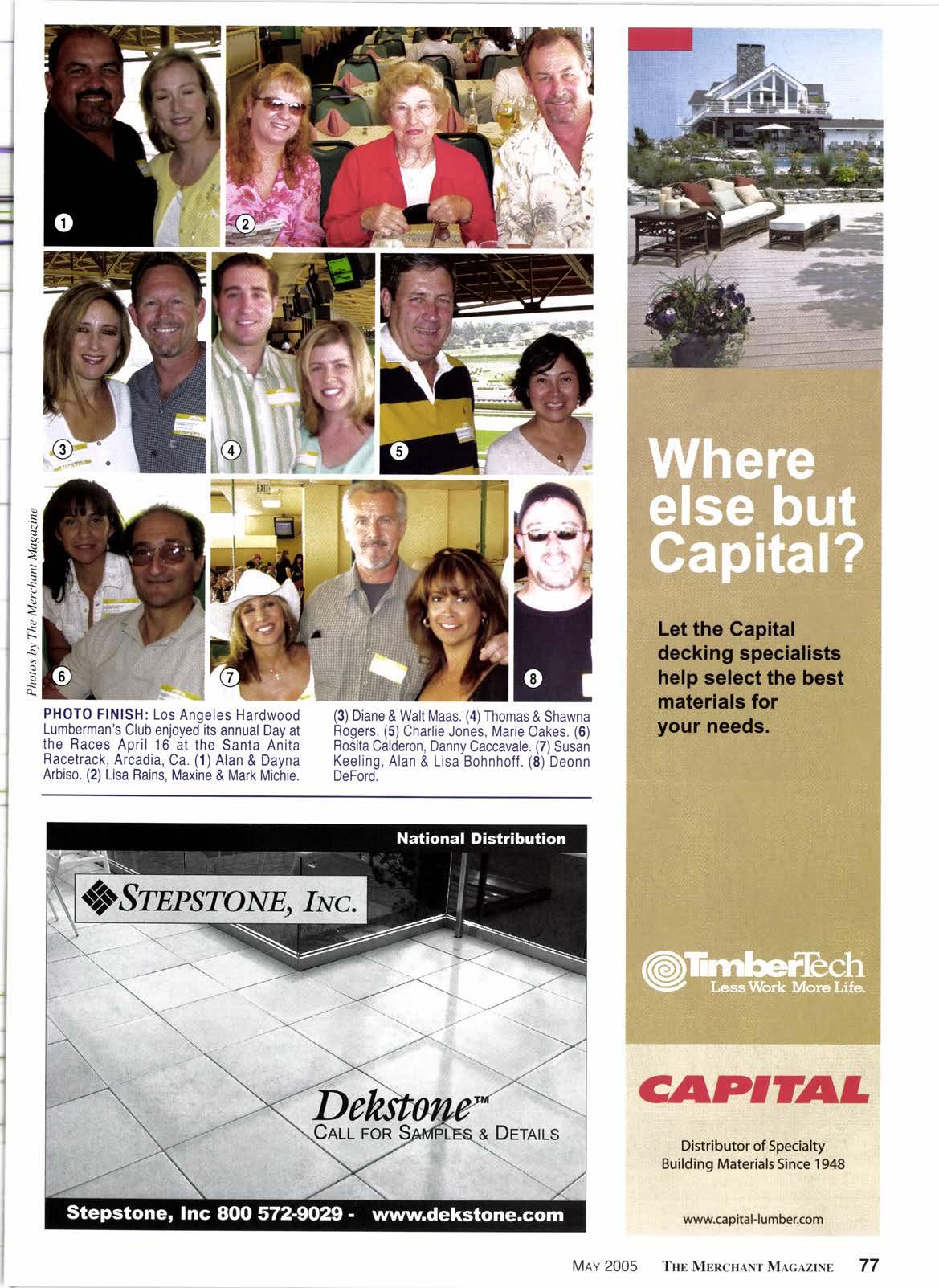

Los Angeles Hardwood Lumberman's Club - May 19, ladies night, Fullerton, Ca; (323)'l 23-9856.

Portland Hoo-Hoo Club - May 20-2l,regional mini-conference, Portland, Or.; (253) 796-7155.

Forest Products Society - May 23-25, international composites conference, Madison, Wi.; (608) 231-1361.

PCBC - May 3l-June 3, San Francisco, Ca.; (916) 443-7933.

Global Forest & Paper Summit - June 1-2, Westin Bayshore Resort & Marina, Vancouver, B.C.; (800) 274-6097.

Elmia Wood - June 1-4, Jonkoping, Sweden; (301) 838-9385.

Best Practices in Communications Forum: Wood Products & Forests - June 2-3, Westin Bayshore Resort & Marina, Vancouver, B.C.; (800) 274-6097.

Lumber Association of California & Nevada - June 2-3, strategic planning session, Resort at Squaw Creek, Olympic Valley, Ca.; (800) 266-4344.

Willamette Valley Hoo-Hoo Club - June 3, annual golf tourney, Springfield Country Club, Springfield, Or.; (541) 484-6144.

Kitchen Cabinet Manufacturers Association - June 5-8, annual convention, Colorado Springs, Co.; (703) 264-1690.

National Association of Wholesale.Distributors - June 5-10, management course, Columbus, Oh.; (202) 872-0885.

Oregon State University - June 6-7, plywood manufacturing course, Corvallis, Or.; (541) 73'7-2329.

Intertribal Timber Council - June 6-9, annual timber symposium, Radisson Hotel, Visalia, Ca.; (503) 282-4296.

Tacoma Olympia Hoo-Hoo Club - June 7, past presidents night & elections, Tacoma Elk Club, Tacoma, Wa.; (206) 399-0002.

National Lawn & Garden Show -June 7-9, Donald E. Stephens Convention Center, Chicago, Il.; (888) 316-0226.

Lumber Association of California & Nevada - June 9, golf tournament, Rancho Solano Golf Club, Fairfield, Ca.; (800) 266-4344.

Los Angeles Hardwood Lumberman's Club - June 9, election night, Maggie's Pub, Santa Fe Springs, Ca; (323) 723-9856.

National Oak Flooring Manufacturers Association - June 912, summer meeting, Paradise Point Resort, San Diego, Ca.; (901) 526-5016.

Seattle Hoo-Hoo Club - June 10, annual golf tournament, Snoqualmie, Wa.; (253) 796-7155.

Western Wood Preservers Institute - June 12-13, summer retreat, Jackson Hole, Wy.; (800)729-9663.

Mountain States Lumber & Building Material Dealers Association - June 14, golf tournament, Eagle Isleta Golf Course, Albuquerque, N.M.; (303) 793-0859.

Manufactured to provide high tensile, torque and shear strength with threads and points that bite instantly into the material (including hardwood), reducing splitting. Our round head with built-in washer head has no sharp edges while the added shoulder has the ability to center the screw in pre-drilled hardware like hinges and connector plates. No need to drill a pilot hole.

Lumber Association of California & Nevada hosted its annual Legislative Day March 30 in Sacramento.

The 30 members who attended visited legislators and listened to talks by Juli Broyles of the California Chamber of Commerce and Mike Prosio from the Labor & Workforce Development Agency. The day ended with a reception co-hosted by LACN, California Forestry Association, American Forest & Paper Association, and other allied groups.

LACN will host its annual Associates/Dealer Golf Tournament June 9 at Rancho Solano Golf Club. Fairfield, Ca.

Mountain States Lumber & Building Material Dealers is sponsoring a golf tournament June 14 at the Isleta Eagle Golf Course in Albuquerque, N.M.

Proceeds of the event will benefit local charities and fund educational programs.

Western Building Material Association honored Chinook Lumber, Snohomish, Wa., as its 2004 Distinguished Dealer of the Year. Lumber Products, Tualatin, Or., was honored as 2004 Supplier of the Year.

WBMA's headquarters in Olympia, Wa., will be the site of an insurance trustee meeting May 2O and an executive committee meeting May 21.

Western Hardwood Association will hold its 50th annual meeting June 25-2'7 at the Sunriver Resort. Sunriver. Or.

The itinerary includes business meetings and presentations on such topics as the Healthy Forest Initiative, the Hardwood Federation, alder refor-

estation, and East Coast hardwood issues.

A golf tournament is set for June 26. Other nearby attractions and activities include a marina, whitewater rafting, guided mountain biking, horseback riding, fishing, and guided outdoor tours.

Material Dealers & Suppliers is a newly formed association based in Brandon, Ms., to represent independent building material dealers and suppliers. Organizers include Bob Hellenthal and Lamar Buffington. A 36-member board of directors (12 each from the association, suppliers and dealers) will have equal votes and govern the organization. Two meetings will be held annually, and dues for all members are fixed at $4,500 a year.

APA Monufocaurer of Ptfwaod Speciolties

Sheathing

Siding

Marine Grade

BB Plyform

Sanded Panels

CCXPTS

MDO/HDO

Customer Specified 8', 9', l0' Press Capability

How can I be sure that the lumber I buy comes from a sustainably managed forest?

If you buy North American lumber, there are many reasons to feel confident that it comes from a sustainably managed forest-first and foremost, because North American forests cover about the same area of land as they did 100 years ago.

There's also the multitude of forestry and conservation laws designed to protect the long-term health of the resource. There's the fact that the United States and Canada work closely with the international community to advance ecosystem research and use the information to improve forest policy and practices.

For those who want added assurance, there's also the current trend toward sustainable forest certification. In the U.S. and Canada, about 225 million acres have been independently certified, which is equivalent to more than twice the size of Califomia.

To be certified, companies undergo independent audits. Among other things, they're required to demonstrate how they protect soil and water, conserve biodiversity, and maintain wildlife habitat. They also have to show that they're harvesting less wood than the forest can regenerate, which is, of course, critical.

It's interesting that forest certification becomes increasingly necessary the farther you get away from an actual forest. In forest communities such as the one I grew up in, people are

logically more aware of the efforts that go into forest management-the surveying, the planning, public consultation, regeneration, tendingmany of which are eclipsed by harvesting in the minds of people elsewhere. Those who live close by see for themselves that North America forests are vast and growing, that foresters are committed to sustainability, and that sustainability means more than simply planting trees.

In other countries and even some U.S. cities, people have little idea of the laws that exist to ensure forest sustainability-or they don't believe the laws are being followed. It's up to forest companies to prove themselves; certification allows them to do that.

As a sensible environmentalist, I find the abundance of forests in this country gives me confidence in the laws that govern forest sustainability. I support certification, however, as a way to encourage continuous improvement and show people around the world that North Americans take seriously their role as responsible forest stewards.

- Dr. Moore has been a leader of the environmental movement for more than 30 years. Send questions to patrick@sensib le e nv iro nme nta I i st.c om.

Armed with state-of-the-art technology, Kelleher has invested in a wide array of new marketing tools and strategies to help our partners succeed. Come see what keeps Kelleher the benchmark in the industry.

To make sure that we always have the product you need when you need it.

With "palmOne's Treo smartphones with 3G Touch Solutions we're updating and improving our order processing and fulf illment system.

Each and every truck in the Kelleher fleet is equipped with a state-of-the art GPS tracking device.

See our new marketing tools such as a website based product catalog, online installation PDF's, collateral materials and look for our new catalog launching in Summer 2005.

Desert Lumber, Las Vegas, Nv., has acquired an RV park in Pahrump, Nv., to convert into a full-service, contractor-oriented lumberyard.

The company gave trailer park residents until May l5-more than two months-to find a new home. Trailers remaining after the deadline will be moved off the property, allowing construction to begin soon after.

Co-owner Dale Eggers hopes construction will be complete by the third quarter of 2005, but admitted a fourth quarter opening was more realistic.

Terry Ono founded the company in 1989 and l0 years later sold it to Crown Pacific, which renamed it Alliance Lumber. Eggers and Ono bought the firm last year and restored the Desert Lumber name.

Looking for opportunities to further expand into the Northwest after buying three mills from Crown Pacific last year, Interfor Pacific has agreed to acquire Floragon Forest Products by May 31.

The subsidiary of International Forest Products, Vancouver, B.C., will pay $50 million for the Molalla,

Or., stud mill-plus a bonus if the facility hits certain profit levels in the next year. In 2004, Floragon had $91.5 million in sales and production of 220 million bd. ft.

Floragon has invested over $8 million to upgrade the plant and turn it into one of the nation's highest producing stud mills.

With the addition of Floragon, Interfor will become the world's 12th largest lumber producer with 35Vo of its output from the U.S.

Floragon's principals-Ben Beddingfield, v.p. Rick Schaefer, and sales manager Howard "Lefty" Page -are expected to continue managing the Molalla mill. Three silent partners will not stay on. Interfor also agreed to hire all215 Floragon employees.

Residents in Ketchikan. Ak.. are frantically try to raise funds to purchase part of a 4,800-acre old growth forest before it can be logged.

The landowner. the Alaska Mental Health Trust Authority, has been selectively harvesting old growth timber behind the former pulp mill town and next wants to clear-cut most of the Leask Lakes parcel. The trust is

in a hurry to log the old growth timber since sawmills increasingly are retooling to handle smaller, second growth logs. "The industry is moving to the next generation," said acting executive director Wendy Woolf.

A consultant retained by the trust predicted that the market for old growth timber from Southeast Alaska would probably evaporate in three to five years.

"That market is coming to an end," said Doug Campbell. senior resource manager for the trust. "Knowing that, we moved forward to do asset management planning, and we're moving forward with that."

The coalition of homeowners had hoped to raise $1.5 million to purchase several hundred acres that abutted two lakes and a salmon stream. Then, in March, trust officials informed the group that, because of its fiduciary duty to maximize revenue for its beneficiaries, it would only sell all 4,800 acres together and only after it was logged.

Campbell estimated the property to be worth $10 million to $13 million as is or $3 million after logging.

It s the business software you've been waitlng for. bisTrack is loaded with features and flexibility to expertly manage all buying, selling and inventory tracking foryour lumber and building materials supply business.

Best of all, bisTrack works the way you do. We designed bisTrack to simplify the tasksyour staff does every day-creating q uotes and orders, checking inventory, finding prices, negotiating discounts, invoicing and payment matching, and much more. Searching for products or documents is remarkably easy.

Since it uses Microsoft@ technologies, bisTrack is easyto use, support and scale to your needs. Plus, it's interoperable with any Windows@-based software including the Officeo suite, reporting packages such as Crystal Reports@, and financial packages such as Creat Plains@.

Our customers will tellyou that bisTrack is powerful, yet incredibly easy to use. You really must see it to believe it.

Call 1877 146-4174 or email info@progressive-solutions.com today to a rrange for a free on-line demonstration.

Stock Building Supply is partnering with sister company Ferguson in Anchorage, Ak., to open a new lumberyard-the first of many steps to introduce and expand Stock into the Anchorage market.

Stock will offer lumber and building materials, with Ferguson providing plumbing and HVAC supplies.

"The Anchorage location is an excellent opportunity for both Stock and Ferguson to offer our products

North Pacific Group, Inc., Portland, Or., has integrated nearly all of its businesses-including Landmark Building Products, Rancho Cucamonga, Ca.-under one name, North Pacific.

Other subsidiaries now known as North Pacific include Saxonville USA, Delta Forest Products, Allen Timber, and Schultz, Snyder & Steele.

Staff, locations and product lines have not changed. All Web sites were merged into www.northpacif-

together in a 'whole house' solution where we have already established a presence," said Stock executive v.p. Gary Robinette. "And we also are excited to have a 'local' introduce Stock to the Anchorage community and look forward to the relationships and business that will be developed."

The "local" connection is location manager Brandon Ray, an Anchorage native who has worked at Stock yards in Utah since 1996.

Raleigh, N.C.-based Stock now

ic.com and email addresses now end with @northpacific.com.

"Uniting all businesses under one name leverages the ownership of North Pacific and strengthens our position in the markets we serve," said NorPac c.e.o. Jay Ross. "What will not change is our ability to respond quickly and make deci sions locally to the benefit of our customers and suppliers."

Founded in 1948, NorPac is one of the largest distributors in the U.S., reaching $1.5 billion in sales annuallv.

operates more than 238 locations in 27 states, with sales of $3.6 billion in fisca|2004.

The tree farms subsidiary of Port Blakely Co., Seattle, Wa., has acquired Pacific Lumber & Shipping, Seatttle, to assist with lumber sales in the Pacific Rim.

Port Blakely Tree Farms owns and manages forestland in Oregon and Washington. The company was founded in 1864 and has 100 employees, according to c.e.o. and president Jim Warjone.

Pacific Lumber & Shipping is a log export and forest products company with operations in Longview and Olympia, Wa., and Vancouver, B.C. The company has more than 30 years of marketing experience in Pacific Rim countries.

Pacific will operate as an independent company and retain its l2 employees, including c.e.o. and president Jerry Weed.

"This acquisition will help ensure an increasingly competitive market for high-quality timber exports throughout the Pacific Rim," said Warjone.

LP's Gang-Lam laminated veneer lumber is a vast improvement over solid wood beams. Problems that naturally occur as solid sawn lumber dries - twisting, splitting, checking, crowning and warping - are greatly reduced. And pound for pound, Gang-Lam LVL has more loadcarrying capacity than solid sawn lumber. The result: a building material that is more reliable, more useable and higher-performing than traditional lumber. Plus, unlike anything available with traditional lumber, Gang-Lam LVL is backed by LP's limited lifetime warranty. For more information on LP Gang-Lam LVL, including component design review services for your designs using LP Engineered Wood Products, contact 1.800.999.9105 or visit the LP web site at www.lpcorp.com.

Days after receiving additional delays in its attempts to harvest its timberlands (at right), Pacific Lumber Co. announced plans to permanently shutter its sawmill in Fortuna, Ca., citing the unpredictable log supply.

The mill will close June 30-60 days after l0l employees were handed notice of the action. Some of those laid off could be offered jobs this summer once an expansion is complete at PRt-co's Scotia, Ca., mill. Eighteen to 20 new positions should be created-or more, if Palco can ensure a more stable log supply.

Earlier this year, Palco agreed to sell the 7S-acre site to a shopping center developer, but had intended to continue running the mill for several more years, until the retail mall project received all necessary approvals.

Last spring, Pnlco's Carlotta mill closed and Fortuna laid off 38 workers and reassigned I I others.

An early morning fire destroyed the retail contents of Lumbermens, Sedona, Az., but firemen were able to save the store's lumberyard.

Also spared were delivery trucks

The California state water resources board ordered Pllco to halt logging in the Freshwater Creek and Elk River watersheds.

Recently, the board agreed to let Pnt-co cut up to 50Vo of the annual 1,100-acre harvest limit (see April, p. 34).However, complaints were received o'about flooding damage to proper-ty and significant impacts on water quality and fisheries resulting from runoff of dirt and debris from Pelco sites." Environmentalists then petitioned to stop the logging.

The stay will remain in effect at least until the next hearing in June.

Robert E. Manne, P,lt-co presi-

that made their regular early morning deliveries. No injuries were reported.

The April 2l blaze was fueled by high winds and store contents such as fuels and paints, which made it unsafe for firefighters to enter the building. "The fire was so advanced when firefighters arrived that we had no choice but to go defensive," said fire captain Mike Rauton. "The potential for a roof collapse was very high."

dent and c,e.o., expressed disap' pointment that the board mads "a seemingly arbitrary decision that creates even more uncertainty for our company, our employees, and our future." He insisted the 140year-old company is an industry leader in environmentally sensitive forest management and science.

"These harvest plans had already been approved by the state and federal agencies who oversee our forest management plans," said Manne. "Now, their decision is invalidated by one individual from the state water board. We think this sends a terrible message t0 the newly appointed board."

Firefighters remained into the night, dealing with "multiple hot spots underneath the debris. The walls are steel and very heavy, causing us to peel them away to get at the fires," said fire inspector Gary Johnson.

The store had no sprinkler system. "The building was totally destroyed and probably will mean a multi-million-dollar loss." said Johnson. The fire's cause is under investisation.

is a borate-based wood oreservative applied to lumber and plywood using a pressu re-treatment process

to provide permanent protection against wood destroying insects and decay fungi in interior applications.

2

@qt

D.BLAIE From our pressure-treating cylinders to your warehouse, our new generation of treatments protects your wood right!

PO Box 1070 .15500 ValenciaAvenue . Fontana, CA 92335 909-350-1214 www.fontanawholesalelumber.com

When you need it treated right, bring it to Fontana Wholesale Lumber.

Owens & Hurst Lumber. Eureka. Mt., will permanently shutter its sawmill May 31, unless a sale to a hardwood importer and manufacturer based in the East goes through.

Planer operations are scheduled to halt at the end of August, when all mill equipment will be auctioned off (see Feb., p.22).

Jim Hurst, co-owner and mill manager, said the sale "would be good for the community." In discussions with the possible buyer, however, he has been "brutally honest about the nature of the wood products business in the state of Montana."

Even if a buyer is found, Hurst intends to close the plant so workers can qualify for federal training and relocation benefits. "I am going to terminate all employees so if indeed there is a buyout, some employees can go their own way with these programs. Most people I talk to want to stay here," he said. "I think some of them want to be retrained and start a business here."

Importing enough wood to keep the mill working would be crucial to the sale, said Hurst. "We're always

exporting something from this state," he said. "Here, you would be importing a raw material and doing something with it to export it out of state. That would be pretty novel for Montana."

Although competition from other countries has harmed business, he blames environmentalists and the "dysfunctional and leaderless" U.S. Forest Service for inadequate timber sales at the nearby Kootenai National Forest. "It used to be a good thing to be surrounded by national forest," said Hurst. "But not anymore."

When Hurst and a partner bought the mill 25 years ago, annual timber sales from Kootenai totaled close to 200 million bd. ft. The volume in recent years has fallen below 60 million bd. ft. and is mostly lower-quality dead wood. But the main problem, Hurst said, is how unpredictable the timber supply has become.

"They are entirely right," agreed Bob Castaneda, supervisor at Kootenai National Forest. "The ideal situation is for us to be able to provide a steady amount of timber. We can do our part on that, but if timber sales are held up

"The lumber market can literally change minute by minute. It's unimaginable for our customers."

- Rick Lierz, ownerlgeneral manager, Franklin Building Supply, Boise, Id.

by litigation, then it's out of our control and it's in the courts' hands."

Reducing timber sales is necessary to give timberland a rest from overzealous logging, maintains the Missoula, Mt.-based Ecology Center. "If we want to preserve old-growth forests and wildlife habitat, the slowdown in logging on federal lands is inevitable," said the center's JeffJuel.

With 90 employees and a $3.6 million gross payroll last year, Owens & Hurst was Eureka's largest employer. According to the Montana Wood Products Association, 22 mills or manufacturing plants have closed in Montana since 1990.

For more information call: l-866-372-9663

All-Coast Forest Products, Cloverdale, Ca., opened new remanufacturing mills in Cloverdale and Englewood, Co, that upgrade its existing operations in these areas.

"With all-new equipment and expanded capacity, the new plants dramatically increase the service value, product quality and responsiveness we're able to provide our customers," said president and c.e.o. Kent Bond.

The new 55,000-sq. ft. mill in Cloverdale replaces a plant that began operations in the 1950s. It produces finished mill products for decking,

siding, paneling, fascia and trim.

The expanded plant in Englewood will give the company additional capability for timber remanufacturing closer to its customers in the area. "Until now, most of our solid sawn timber has been shipped from the West Coast," said Bond. "Now, we can more efficiently meet the needs of our customers with this more centrally located facility."

Worker At Yard Electrocuted

A 39-year-old man was electrocuted while pouring concrete at Springdale Lumber, Springdale, Wa., on

April 6, according to Jack Le Bret, Stevens County deputy chief coroner.

Gary D. Martindale, who worked for Colville Valley Concrete Co., was standing on the ground and touching the back of a boom truck when the boom touched a high-voltage wire. He died at the scene. No one else was injured in the incident, said Le Bret.

Springdale Lumber is a speciality cutting sawmill north of Spokane. Facilities include a dry kiln, planer mill, and BNSF rail service. The company produces small to medium-sized timbers from Douglas and white fir.

Environmentalists are suing the U.S. Forest Service to block logging in 5,839 acres burned in July 2002 in Oregon's Malheur National Forest.

As stated in the lawsuit, the federal agency "has decided to log 'dying trees' in the Easy Fire Recovery Project that are, in fact, alive and well." The court action was initiated by Forest Service Employees for Environmental Ethics, Eugene, Or., which says that allowing logging in recovering forests is a violation of environmental laws.

According to many environmental groups, forest fires are part of the natural life cycle of forests and rejuvenate forests by recycling forest nutrients, creating food and habitat for wildlife, deterring unwanted weeds, and thinning stands of trees.

In contrast, the lumber industry believes that logging in burned areas actually helps the recovery of forests, wildlife habitats, and watersheds. It also help satisfy the increasing demand for wood products both in the U.S. and abroad.

When you choose AinsworthEngineered OSB with its distinctive Turquoise edge, you're getting more than just a color.

You're getting what's inside-the very best in engineered wood products from a company known for over half a century for exceptional quality and service.

With the Fall 2004 purchase of Potlatch's three 05B plants in Minnesota, the yellow-branded OXBoard you once saw now carries the Ainsworth name and the Turquoise edge plus a whole lot more. Customers throughout North America and abroad count on Ainsworth for industry-leading product standards and for timely service tailored to their needs.

Look for the Turquoise edge-the mark of quality in OS8.

Keith Brown Building Materials, Salem, Or., has been certified by the Forest Stewardship Council chain-ofcustody program.

The FSC maintains globally recognized standards for forest conservation and certifies companies whose lumber meets stringent environmental, social and economic provisions. By demonstating their commitment to these standards, Keith Brown can now offer chain-of-custody "green" building products.

"We want to educate our customers and offer the environmentally friendly option of FSC-certified lumber products," said Phil Cox, v.p.-operations.

ItErr*ef o ffiFno'.frry1-r${fr-ffffifflf,lUflr{ilrWffil'1iffiiiC'fi+-'ilisfir€r}Bhid{i'ffiir6'#*drlril{ffii*rl[S,# # l brond of trim, AZEK Trimboords siord oul becouse of fhe beoufy, workotility ond dumbiliV of our complele llno of lrim, beodboord. shoels, comerbcards ond milhrodr. Any wsy you look of if, AZEK Trimboord meons f

loyol cuslomere ond hugepro{ifs.Tobscomeon,{ZEKdeoler, coll 877-ASK-AZEKorvisitwwwazek.com.

Researchers from the College of Forestry at Oregon State University, Corvallis, have developed soy-based, formaldehyde-free adhesives they claim could revolutionize the wood products industry and have important environmental and economic benefits.

The research has already resulted in three pending patents. The first commercial application of the adhesive is at Columbia Forest Products, Eugene, Or., where it is being used to make decorative veneer-core and hardwood plywood panels.

"This new adhesive provides a cost-competitive solution to increasing moisture resistance without urea formaldehyde," said v.p. of sales and marketing Ed Woods. He said that Columbia currently produces formaldehyde-free panels in two of its facilities and plans a complete conversion in one year.

The research is based on the observations of Kaichang Li, an OSU assistant professor who noticed how mussels cling tenaciously to rocks despite being pounded by ocean waves.

"I was amazed at the ability of these small mollusks to attach themselves so strongly to rocks," said Li,

who is an expert in wood chemistry and adhesives in the Department of Wood Science and Engineering. "I didn't know of any other type of adhesive that could work this well in water and withstand so much force."

The secret, Li discovered, was an unusual protein combination in the tenacles of mussels that allows them to attach themselves to rocks and other surfaces under water.

"Clearly, the mussels have evolved with the ability to make this protein so they can cling to rocks despite wave forces," Li said. The mussel protein is a superior adhesive, but is not readily available. Soy beans have a protein that can be adapted for this purpose and are widely grown in the U.S.

Soy protein is inexpensive and renewable, but it lacks the unique amino acid that provides adhesive properties. Li's research group was able to add these amino acids to soy protein and make it work like a mussel-protein adhesive. Then they began to develop other strong and waterresistant wood adhesives from renewable natural materials using mussel protein as a model.

The new wood adhesives are made

from natural resources such as soy flour and lignin. They could replace the formaldehyde-based wood adhesives used to make some composite products such as plywood, OSB, particleboard, and laminated veneer lumber products.

One of these patented adhesives is cost-competitive with commonly used urea-formaldehyde resin, researchers say, but does not use formaldehyde or other toxic chemicals. Formaldehyde fumes are associated with some health problems, including eye and throat irritation, and has been shown to be a human carcinogen.

The other key advantage of the new adhesives is their superior strength and water resistance. "The plywood we make with this adhesive can be boiled for several hours and the adhesive holds as strong as ever," Li said. "Plywood bonded with urea-formaldehyde resins could never do that."

More than $2 billion a year is spent on wood adhesives in the forest products industry in the U.S. and Canada.

"Based on the successful commercial application of our adhesives, the wood adhesive industry and wood products industry are going to see some major changes in the next few years," Li predicted.

Presenting the GeoDeck Composite Decking & Railing System

lf you specify, sell or install decking, you can recommend GeoDeck* with complete confidence. In fact, the leading consumer research publication rated GeoDeck a "Best Buy."

GeoDeck is a premium grade product offering Traditional, Tongue & Groove, and Heavy-Duty Commercial grade boards with matching railing.

Available in Cedar, Driftwood, and Mahogany, only GeoDeck is made with Biodac', a patented ingredient that makes CeoDeck virtually fade resistant.

GeoDeck is r0o/o lighter than solid composite boards. That makes for easier handling, transport and installation. No painting or sealing is ever required.

Best of all, GeoDeck is backed by a 20-year limited warranty. l ;,j,

j$lqj-

"Stiff. Strong. Stable. That's whv I specif,v Doug Fir. lt's proven pcrfirrnrance makcs e clualitv product. Swanson (iroup of-fcrs a varicty of panel n'pes that rvork in mtrltiple irpplications. Tliev'll delivel what you need on spcc, on nrrrrket encl on tinre."

Call to order clinrension, stucls or plvr.r,ood. All vour bLrilcling neecls rrt one place

rrrrrlrer: (541) 832.1241 (541) 832.1194 (541) 832.1222

Plvrvood: (541) 832.1t75 (541) 832.1254

Stucls: (541) 832.1 145

\\'.\\\ iln\( )ttqt'()u1ri 11. .66111

Mount Vernon Building Supply, Mount Vernon, Wa., is the prime building material supplier for a multimillion dollar resort hotel being built in North Korea.

Located in a free-trade zone in communist North Korea, the building site is leased to South Korean interests. "It's defintely an unusual situation," said Kevin Kok, co-owner of Mount Vernon. "They are developing this lavish destination resort, sort of like what you would find in Whistler."

Mount Vernon learned of the project through the Evergreen Building Products Association, which links U.S. manufacturers and product dealers with customers overseas-particularly in Asia.

As a test of their reliability, a Seattle architect of Korean descent asked Mount Vernon to pack and deliver all the components for 1,800sq. ft. house in Korea. When everything went well, Kok and his partners were asked to participate in the 100room hotel project.

"Asian customers work on trust and mainly by word-of-mouth from other developers," said co-owner Ed Gegen.

"With companies like ours, they get the attention to detail they demand. We hand-pack every container and triple check it. We rarely make even a small mistake."

So far, Mount Vernon has shipped l0 containers to get the project started. Future containers will be filled with "everything they need, front to back, on this project," said Kok. He then will fly to Korea to review the project.

Kok and his partners estimate that foreign customers, including ones in Japan and Guam, account for l5Vo of the store's business-and the market is steadily growing. "Once you've proven yourself, you have a customer for life," said Gegen.

A vandal who knows how to operate heavy machinery caused more than $200,000 in damage at a future Home Depot site in Anchorage, Ak.

A large front-end loader was used on April 5 to push other large equipment into a pile in the middle of the gutted structure, which used to house a Kmart. The vandal then crashed the loader through the wall of the build-

The Merchant welcomes your comments. Please write to Editor, 4500 Campus Dr., Suite 480, Newport Beach, Ca.92660; Fat 949-852023 l, or dkoenig@building-products.com.

In response to "Fighting Back" (Letters, April, p.36), I suggest a more appropriate caption would read, "Throwing in the Towel." I cannot imagine any local merchants want to be involved in a price war with the big boxes, much less initiate one.

Consumers will pay more for expertise, but when price is their only concern, they know where to go.

Stephen Ondich

Atlas Lumber Co. 13575 Benson Ave. Chino, Ca.9l7l0

ing, causing structural damage.

Anchorage police are investigating if the vandal had a grudge against the contractor, Alaska Frontier Services. Only equipment owned or leased by the contractor was damaged.

A beoutilul deck doesn't hqve to be o chore. If you build with TimberTech, you won't hqve to worry obout stoining, seoling, pointing, splintering or ony of the other heqdaches qssocioted with wood decks. So, iI you'd rqther be enjoying yoursell, qsk for the best. Ask for TimberTech.

For more inlormation, pleose visit wwwtimbertech.com.

It's hard not to realize the benefits of supplying Canfor MSR. For starters, it's manufactured with the latest technology and carefully kiln-dried for straightness and quality. Then it's stress-free. Because Canfor MSR is made from Western SPF, it's especially easy to work with. Easy to handle. Easy to cut. And overall, easy on your customer's machines. So supply a higher level of lumber-'and take some stress out of your customer's business. '",,,; W'lV. fl

DIVERSITY of tile roofing available led association to chanqe its name.

The Roof Tile Institute has changed its name to the Tile Roofing Institute to better reflect the association's new mission and industry objectives.

The 3O-year-old nonprofit association was established to support the advancement of the tile roofing industry. Until recently, membership was mainly comprised of tile roofing manufacturers and related producers. To extend its reach, the association now welcomes associate members such as importers, suppliers, distributors and contractors.

"Now that we've expanded our membership base, more industry professionals can take advantage of our technical support," said Rick Olson, technical director for the institute. "The Institute has published installation manuals for moderate climate, cold weather, and high wind. Our next step is to develop installation training programs that allow roofers throughout North America to take advantage of this expertise."

The association also updated its Web site and created a contractor database that matches prospective customers with contractors in their area. New educational programs focus on educating architects, builders, code officials, and consumers about the advantages of tile roofing.

"Many consumers relate a tile roof to Spanish architecture, but the colors and styles available now can reflect a wide variety of designs," said Charles McGrath, TRI's managing director. "Concrete and clay tile roof systems are durable, provide weather and fire resistance, and come in a range of colors and profiles that add beauty as well as long-term value."

Six employees and four customers were held at gunpoint during a robbery of Ace Hardware, Suisun City, Ca.

No shots were fired nor were any injuries reported, although the victims said they were roughed up.

Minutes after Ace opened at 8 a.m. April 7, two men wearing ski masks and armed with handguns stormed the store, took an undisclosed amount of money from the cash registers, and fled through the front doors.

Police are searching for the two suspects.

John Myer has been promoted to retail sales mgr. and Keri Thurston to corporate door & millwork sales mgr. at Lumber Products, Tualatin, Or. Trace Cunningham succeeds Thurston as branch mgr. in Salt Lake City, Ut. Welt Lowry is now assistant mgr. in Salt Lake, and Robert Cleland is now branch mgr. in Las Vegas, Nv.

Cameron Caudill was named general mgr. of Lane Stanton Vance Lumber Co., City of Industry, Ca.

Chris Liga has been promoted to mgr. of Farr's True Value Hardware, Coquille, Or.

Richard C. Wininger has been named v.p.-western timberlands for Weyerhaeuser, Federal Way, Wa. Janice Walston and Darlene Mclntyre will shift from plywood to lumber sales when Weyco relocates western plywood mill sales to Hot Springs, Ar., May 2.

Nick Elardo, Western Woods Inc., has relocated his sales office to Hollister, Ca.

Scott Whitmore has been promoted to v.p. of marketing for Jeld-Wen's window group, Klamath Falls, Or.