800-422-3120

www.superiorwoodtreating.com

800-422-3120

www.superiorwoodtreating.com

PRODUCT FEATURES

r UL@ Classified with FR'S Rating

r Code Compliant under ESR'2645

I Very Lovv Smoke Rating

r AfllPA Standardized

r Cfty of los Angeles nB'?r';502

r S0-Yerr limited lfarranty

r No V0Cl or Formaldehyde

r BlM,Obiects at www.ARCAT.com

800-826-8709

www.thunderboltwoodtreating.com

BRI'ISH COLUMBIA SUPERIOR WOOD TREATING Sumner, WA THUNDERBOLT WOOD TREATING CO. I}IC Riverbank, CA coLoRADo

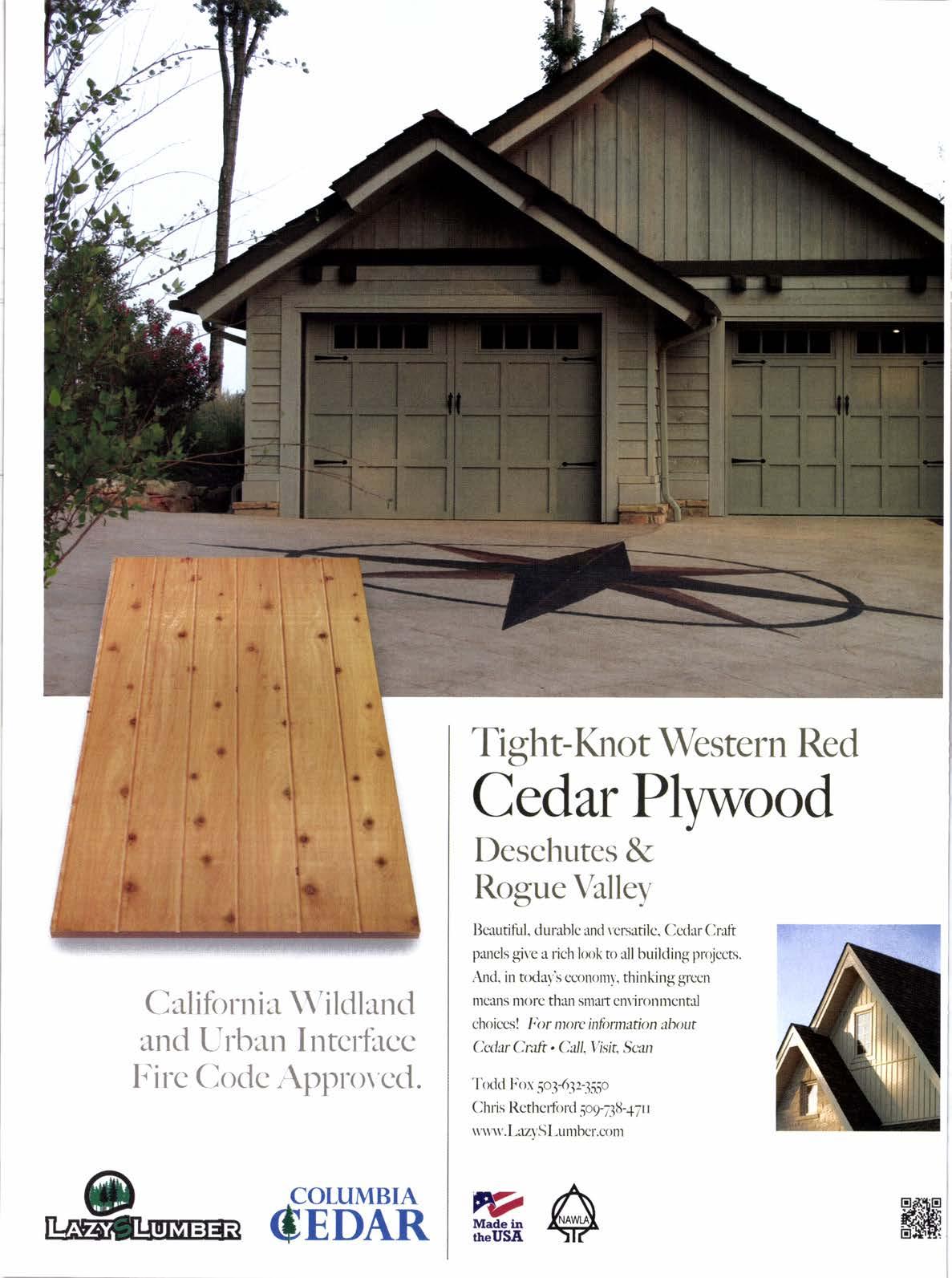

From the heart of redwood country comes this product line of certifred sustainable redwood garden products. Gardening, entertaining or relaxing, we guarantee your customers wiil love these handcrafted, premium redwood products. Our product line ineludes the following redwood accessories with additional designs in development.

Adirondaek chair & footrest

Adirondack table

6'picnic table with attached benches

43" louvered bench

Elevated planters (available in several sizes)

Round planter tubs (available in several sizes)

Garden door 42"W x72" H radius top

48" premium heavy-duty arbor kit (half round)

AII products are unsto.ined

Stack them, slide them, trell.is them, garden with them

All heart redwood (green, rough and full dimension) for years of service

Quality fasteners

Corner posts profiled for convenient PVC or redwood stake trellising

Stack and position for perfect look and frt Convenient kit format for outside display/storage

Assembly hardware and instructions included

Beautiful, premium redwood

. Quality, craftsman construction & fasteners

Built to iast

Designed to maximize plant heaith

Easy to use and maintain

All products come fully assembled a include a removable GeoPot" planter bag

9 Pnooucr Sporlrcnr Trps ro Srlr Monr Drcr SrntNs

1 0 Frnrunr Sronv Wunr ro Srocr tN DrcrtNc & R,qtrttc

12 MnncrN Bunorns Brrren Urrrrzr Youn Drcr Sorrwnnr

1 4 lr.rousrnv Tnenos

How GnreN ls Hnnowooo DecrtNc?

1 6 Pnooucr Sporucur Posr Wnnps CnrRtr Nrw CoruttNs

33 Sprcrnr Focus: NAWLA

o LuveEn lNousrRv RecnutrvrNt

. STLLTNC to Nrwrv Acqutneo Ftnvs

. CoNrLrcrs wtrH SRres AccouNrs

. MntRcr Mulrt-Ce NenRrtoN,qr TeRt',ts

. FuNotNc WonxtNc CnptrRl

Bnrnxrrc lruousrnv Nrws, lnousrnv PHoro Dowrloeos, & THr Mrncnnrut: Drcrrnl VtnsroH

BurrorNc-PnoDUCTS.coM

CHANGE OF ADDRESS Send address label from recent issue if possible, new address and g-digit zip to addfess below.

P0STMASTER Send address changes to The Merchant Magazine,4500 Campus Dr., Ste.480, Newport Beach, Ca.92660-1872.

The Merchant Magazine (ISSN 7399723) (USPS 796560) is published monthly at 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-,|872 by Cutler Publishing, Inc. Periodicals Postage paid at Newport Beach, Ca., and additional post oftices. lt is an independently{wned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 western states.

Copyright@2012 by Cutler Publishing, lnc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. lt reseryes the right to accept ot reject any editorial or advertising matter, and assumes no liability for materials furnished to it.

fllHer wAS wHAr My pARENTS taught me from a very early age. But I feel-and I perhaps chalk it up to the natural aging process-life at times seems to be moving too fast. Consequently, patience and tolerance levels are declining just as quickly. I cannot believe how much screaming and shouting goes on around me-especially on television and on line. In a world of Twitter (and it is time that went away, IMHO) this got-to-know-now, got-to-do-now world we live in makes me worry about the future.

Times have changed, and not all for the good. In the good old days, there were the weekends when that project around the home could take three months. Now it has to be finished the same weekend! At work, the project that would have taken weeks now has to be done by tomorrow. Dinner that used to be slaved over for hours now is out of a bag, oven to table, in 20 minutes. Kids eat dinner, play video games, and do their homework all at the same time, while rushing to the next outof-school activity. Everything has to be done now and instantaneously!

Much of the troubles our economy has gone through these past years can be blamed on the need for instant gratification, that regardless of whether it could be afforded or not, there was the need to have it now, rather than save for it.

We are living in a time that gets faster by the day, hour and minute. It's a world where a newsperson gets fired if another network gets on air with a breaking story a few minutes earlier. Sometimes even seconds are too long. I must admit my wife is always saying, "Hold on! I'll get to it in a few seconds when I finish the last thing you barked your orders for." Yes, it seems I have succumbed, too.

In the process, we have lost patience and tolerance. Patience is the ability to tolerate delay, and it seems that most of us are guilty of a lack of it. Our shortage of patience suggests our time and needs are more important than anyone else's. I'd like to think that I am better at it than in the past when someone jumped the line at the supermarket or cinema line. I let it go now, but maybe because people seem a lot meaner than they used to and you never know what they will pull from their pocket. When I get cut off on the highway, I just take a breath (or two, or three).

Maybe it is maturity, but today I am better at gauging how important something really is. So many times, I see people lose their tempers when, once out of that moment, minimal analysis would show that it really did not matter. Things that would have gotten my cheeks boiling not so long ago now do not. I find my stomach is no longer in the knots it used to be in.

Instead, look around you and marvel at our universe. Understand what is really important and learn to accept other's failings. Once you have serious illnesses around you, for instance, you renumber your priorities.

Lastly, looking at my own field, I am astounded at the decline of real journalism. It should alarm anyone of any intelligence. It's all brought about by the needto-know crowd. On television. news has been dumbed down to the lowest common denominator. Real thought and insight have been thrown out of the window for the sake of expediency. Editorial standards evaporate when "news" has to be published in seconds. And, yes, the biggest danger is that real editorial costs money and cannot be given away free. Because of that, our journalism has evolved into covering what some celebrity was wearing, instead of creating intelligent debates on the issues that face us. Serious journalism is in real decline. and we all should unreservedly lament this loss. How can you have an opinion when you have had no serious news to base your opinion on? Are we going to base our worldly opinions on the Huffington Post?

www. build ng-products.com

A publication of Cutler Publishing 4500 Campus Dr., Sle. 480, Newport Beach, CA 92660

Publisher Alan Oakes ajoakes@aol.com

Publisher Emeritus David Cutler Director of Editorial & Production David Koenig dkoenig@building-products.com

Ediior Karen Debats kdebats@building-products.com

Gontributing Editors

Dwight Cunan, Carla Waldemar, James Olsen, Jay Tompt, Mike Dandridge

Adverlising Sales Manager

Chuck Casey ccasey@bu ilding-products.com

Administration Director/Secretary Marie 0akes mfpoakes@aol.com

Circulation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 ccasey@building-products.com

Alan Oakes www.building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com

CLASSIFIED

David Koenig

Phone (949) 852-1990 Fax 949-852-0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather Kelly

Phone (949) 852-1990 Fax 949-852-0231 hkelly@buildin g-products.com

or send a check to 4500 Campus Dr., Ste.480, Newport Beach, CA 92660

U,S.A.: One yeat (12 issues), $22 Two years, $36

Three years, $50

FOREIGN per year, paid in advance in US funds): Surface-Canada or Mexico, $48 Other counhies, $60 Air rates also available.

SINGLE COPIES $4 + shipping

BACK TSSUES $5 + shipping

Alan Oakes, Publisher ajoakes@aol.com

C1 Er-r-rNc HrcH-END stains can be challenging with current \)economic conditions, but recession or no recession, there is something to be said for the value of a quality wood coating.

You need less product, there's less labour involved, and the end result looks and performs better. The key is educating staff so they have the tools and knowledge to help customers make the right choice for their homes. To help with that, wood stain manufacturer Sansin questioned three of its most successful dealers in Nonh America. Their strategies can boost your sales, which will not only help your customers, but also help your bottom line.

L. Ur" the stain yourself. This gives you first-hand experience when talking to customers and telling them

why they should use a premier brand.

2. Knorn the product inside & out. When customers are going to spend big money on stain or finish, they need a dealer who knows more about the product than just the literature. That's why Doug Janzen of Janzen's Paint & Decorating, Brandon, Mb., makes sure his sales reps know wood stains like the backs of their hands.

3. Set out samples. Every stain and finish product claims to last a certain amount of time. But when you see how well they work in action, it really makes an impression.

4.t"t them try it. Hands-on experience can often make or break a sale. So why not let your customers try the product in the store? That's what Janzen does. He has samples of the stains that he lets customers brush onto wood right in the store, so they can get a sense of how it works and how it looks. "This gives people a first-hand sense of the rich, warm tone of the finish," he says.

5. Co to your best contractors. Many customers won't be working first-hand with the stains themselves, but their contractors will. That's why Bjorn Hanson, Burnell's Decor, Rice Lake, Wi., let his best contractors try it out first. "They were so impressed with the product that I now make most of my sales to my regular contractors," he says.

6. Foc,rs on custom colors. Some higher-end stains and finishes allow you to custom-tint the product. "Not only can we do the 80 colors in Sansin's catalog, but the custom-tinting process allows us to make any color our customers want," says James Housser, owner of Housser's Paint & Wallpaper, Orillia, Ont. "That's a major selling point."

7 go green. Another key selling point, says Housser, can be a water-borne formula that makes the staiin a more environmentally friendly choice. Or, perhaps it dries faster, has less odor, or is easier to apply.

8. Off"" tips & tricks. When you have strong knowledge of the product, you can provide pointers about using it that will make customers more willing to try it. According to Hanson, "I try to offer my customers as much information as possible so that they'll have success with the product."

tTt"t INCREASTNGLy DtvERSE product I- off,erings in decking and railing are a good thing for the typical LBM dealer-that is, unless he wants to stock something. "We don't know what color to stock and as soon as we make a choice, it will be the wrong color" is a very common statement in the industry.

It used to be that you had treated, some gray composite, and if you were savvy, a vinyl rail that came in any color a prospect wanted as long as it was white. The only salesmanship that was needed was to point out the maintenance differences and you were done.

Today, the decking selection area

in a lumberyard is typically a shelf with so many choices that a prospect may not know where to start. The sales staff at the store very likely does not have enough time to learn about all of the brands and lines that they have access to. Finally, what happens if the prospect decides on a color that has been discontinued or the distributor stopped carrying?

The crux of the matter is that if you don't stock anything. you may not be a player. The contractors rely on dealers to stock products and normally will try to sell what they can get, today. Homeowners may wait for special delivery, but the option of an in-stock product will always weigh

heavily on their buying decision. It's no one's fault, we are just instant gratification people. We like service now, our way, right away, and there is no need to plan ahead in today's world.

Principia Partners's report from 20 I I shows that the pro contractor buying from the pro dealer is the top channel for decking and railing by a vast margin. Freedonia reports that the entire category is due to increase over the next few years by a significant measure. From these sources of information, dealers may want to revive their focus on the category, but how?

Here are some ideas on how dealers can be involved in this saturated market and, perhaps, make a few bucks in the process:

In addition to treated, stock an alternative decking in three lengths and a fascia board. Stock the fasteners and clips, and consider stocking a complementary railing. It's good to have everything in your yard that is needed for the typical 16x20 deck.

Choosing the color is crucial, but most manufacturing reps can help you decide which one is best for your location and market.

If the brand you go with has a hidden fastening system, go with that. Get the tools to install the products and sell them or rent them out. Stock the brackets and bolts needed for decks to meet code.

Once you decide on the color and brand, run a special on it and make sure it is priced more competitively than your special orders. It's okay to have all of the other samples and have them there if someone asks for them, but you must clearly show your choice as the frontrunner and have a really good sales pitch as to why you made that choice. Keep the materials

onsite in your inventory, and make sure your yard guys ship it perfect and clean with an emphasis on clean.

Leverage your suppliers and sales staff. Manufacturers reps and distribution reps are always huppy to make calls to contractors to help you grow your business.

Choose a member or two of your sales staff who will be responsible for decking and railing sales. By not diluting it, you will create a specialist who closes more deals then if you spread the responsibility out amongst the entire store. Make that person the doctor, the person everyone trusts because he knows so much about it that they will let him do surgery.

Homeowners and contractors trust validated knowledge in a decking salesperson-a person who affirms factual information found online or in publications read by the public. The salesperson should possess the ability to capture the prospect, determine the objections and needs the prospect values, and apply those to the product you want to sell.

Salesmanship requires more work but is also more profitable.

. Market your store as a resource. People go on the Intemet to research what they want to buy, but in today's world they look for validation from the salesperson they deal with, whether it is on the phone or in person. Decking rarely sells in an electronic transaction. Market online aggressively with a website, search engines, and social media. Link to your supplier websites and ask for help from them with content to put on yours.

Advertise that you stock decking materials and that you can provide product knowledge. Participate in the industry associations, such as NADRA, and host events at your store.

Learn the codes and interact with the codes officials that inspect your customer's projects.

By stocking products and proving to your market that you are committed to the decking industry and are a stocking resource for the materials, you will begin to gain marketshare and see growth in decking and railing.

- David Elenbaum is owner of a deck construction firm in South Carolina and has worked in the contracting, manufacturing and distribution channels during his 12 years in the deck and rail industry. Reach him at davidelenbaum@ gmail.com. &rlldingrhoduds"om

Lyle Lee hos been building custom homes for over 20 yeors. Here is whot he hos to soy obout Roseburg's Engineered Wood Products.

"When building o quolity home, il's importont for oll the froming moferio/s to motch. ln other words come logelher os specified in fhe design plons. lf the froming is off by even o l/a of on inch, it con cosf me lhousonds of dollors in time ond moferiols.

I find Roseburg's RFPI@-Joist ond Rigidlom@ LVL to be very consislenf in width ond depth. When I use Roseburg's RFPI@-Joisf, my floors ore more level, stiffer and truer, moking my job much easier.

fhis home is 6,000 sguore feelso I used lJoisf ond LVI from severol different unils ond the monufocluring consislency wos exoctly fhe some. lf you wont to moximize your profit, I would recommend using Roseburg's Engineered Wood Products".

Lyle Lee Lee Building Compony

Parr recently partnered with two of its loyal contractors on two deck projects. "They knew we had the software, and being able to see a picture of the finished product was huge. It also was a big selling point," Roe said.

\-/have invested in software to help their pro desks design and sell decks. All too many of these dealers, however, have found their deck design software is underutilized by associates.

That said, you might be surprised to leam that a number of lumberyards and pro dealers are finding new ways to grow their business organically by partnering with their existing contractor customers and capturing more share of wallet from their d-i-y customer base. Three lumberyards provide examples of how using deck software is generating growth.

Headquartered in Hillsboro, Or., Parr Lumber is a family-owned business that opened its first lumberyard in

1930. Today, there are 19 stores in Oregon and Washington, primarily in the Bend-Tacoma-Seattle area.

For Parr, deck building is seasonal. "Currently deck building is about 507o of our business in the spring," said Traci Roe, counter sales at Parr Lumber. "It's about 50/50 contractors vs. homeowners."

The chain recently invested in deck software, but it's currently underutilized. "I'm the only one trained on it, but ideally, I would like to have a center where anyone can take their customer and build their deck," said Roe. "The software is easy to play with and pretty forgiving. so having everyone trained shouldn't be too difficult. I'm not the most computer savvy, so it's nice that I can go back and change anything."

Although Parr would like to expand the use of its software, they have noticed that it has increased the efficiency of their deck design process and their ability to upsell. "With the click of a button, I can change materials and give customers more options," said Roe. "I had three d-i-y customers and all three chose us for their deck. They knew what they wanted, and having that visual piece added a lot. The ability to show materials other than wood made it easier for us to sell them on it. Oregonians tend to want real wood and organic, natural materials, but when we tell them about the upkeep and how rain affects mold and overgrowth, they're more willing to look at other options. We moved to composite, and now we're moving more toward PVC."

Parr believes that once they get a deck station set up in their store in Hillsboro, they'll have everyone trained on the software. Roe added. "I want to give it to our outside salespeople for use with their customers too. With full integration into our business, it's a phenomenal tool for us. We can crank out a deck design in 15 minutes. I love it."

About 15 miles north of Atlanta, Ga., PMC Building Materials opened its doors in September 2008. As a fullservice lumberyard focused mainly on remodelers, they also serve deck builders, contractors and homeowners/ d-i-yers. PMC often uses focus groups

OFFERING DECK design services, such as with Simpson Skong-Tie's DeckTools software, helps boost dealers' decking sales.to gain valuable feedback from their remodeler customers. With their input, PMC decided to build a deck center two years ago. Today, it's the biggest deck display in the Southeast. About lOVo to l57o of their business is now deck building, and 9OVo of that comes from contractors and remodelers.

PMC's goal is to become a onestop shop for all of their customers' decking needs. "We needed software that could handle multiple (product) libraries as well as build a library quickly, because we have more than l7 deck brands and 2l railing systems," explained Thomas Matula, IT/web/marketing manager for PMC. "The software had to be easy to understand and work with. We're still gearing up and have one outside sales guy working specifically on the software, and one front desk person designated to teach our front counter staff."

PMC's plan is to get the design stage out of the hands of their customers in order to free up their time so they can focus more on leads and generating more income for their business. "We're just starting with the software, but the belief is that by utilizing it in the real-world stage, we'll ultimately be able to improve it as we grow across multiple markets," Matula said.

To date, the software has helped provide more professional-looking quotes and more opportunities to upsell projects. "As we continue to brand ourselves as the one-stop shop for all decking needs, the software is truly the icing on the cake. We have the knowledge to help a builder make a sale, which means they keep coming back," said Matula.

With over 50 years in the business, J&W Lumber has 45 employees across six stores-five in San Diego County and one in Riverside County, Ca. Their main focus is decking and patio covers.

Decking is 4O7o of J&W's total business, with707o coming from contractors and 3OVo from d-i-yers. Providing deck design has been a part of J&W's business for much of its history. "We used to spend hours with a pencil and a ruler drawing a design," explained J&W's Scott Walter. "But we didn't give customers a visual of what their deck could look like. Today, we use software that provides customers with a 3D digital presentation of their deck."

The software also reduces design time. "It used to take us a day to design a deck. Now it takes a fraction of the time, so we can have it done while the customer is in the store," added Walter.

For contractors, J&W can provide plans and estimates for their customers. "Even when they come in with a difficult design drawn on a napkin, we'll review it on the software to figure out if it can be done. As we've become more proficient with the software, we're using its railing design and customized features a lot more, and now are beginning to design patio covers," said Walter.

The software also has made J&W's deck design process more efficient. "It's more visual and we can provide quicker quotes to our contractor customers, who can then provide quicker turnarounds to their customers," he said.

It has made an impact with homeowners as well, influencing upgrades. According to Walter, "D-i-yers are absolutely amazed. They see the finished product within a few minutes, and we can change options on the fly. Often, they have three to four ideas in mind, and we can switch those around and show them in color. Even thoueh

they think something might be more expensive, once they see it, they like it. And we can show them that it might not affect price as much as they thought so they tend to buy upgrades."

J&W currently has 20 employees trained on the software. Walter added, "We want to continue to improve our skills and use the advanced features, so we can do things like tweak designs even more, design better railings, and price out patio covers. It really helps you expand beyond the deck."

While deck design software is not new, the technology continues to evolve and improve. The latest software on the market can produce 3D photo-quality deck designs with sophisticated railings and customizable product libraries as well as estimates, take-offs and plans. As showcased by these dealers, deck software is helping expand business with contractors and d-i-yers and contributing to the bottom line-not only with how fast it can generate a deck design, but with the visual presentation in showing upgrades that ultimately lead to increased sales.

and treated softwoods have a significantly lower environmental impact than composite or plastic decking productsx. Given this information, we can infer a number of conclusions about hardwoods by focusing on four environmental factors: responsible sourcing, durability and lifespan, environmental impact, and end-of-life disposal.

Hardwood decking is made of tropical tree species, harvested from tropical forest areas around the world. Contrary to popular belief, however, logging is not the root cause of tropical deforestation. The conversion of tropical forestland to ranches and farmland is far more destructive, a trend that's exacerbated by energy companies seeking to produce more agro-fuel crops. In fact, most countries in the tropics have initiated strict logging regulations that are growing in scope and enforcement.

f, s rN Mosr PARrs o[ the building la.industry. the demand for green decking continues to surge. Savvy marketers are taking advantage, promoting the green qualities of their manmade or natural wood materials. But the greenest option might be the one consumers know the least about and comprises less than 57o of the decking market.

So just how green are tropical hardwoods?

Most people think of green products as having minimal long-term impact on the environment, from raw

material sourcing to manufacturing, selling, and end-of-life disposal. The challenge for hardwood advocates is that most cradle-to-grave life cycle studies focus on other decking materials, specifically natural softwoods, treated softwoods, and wood-plastic composites. We can still learn from these studies. however. as hardwoods share many of the same life cycle traits as softwoods.

Let's start with the studies' basic findings: Solid wood products with natural resistance to insects, rot, and decay (such as redwood and cedar)

When properly regulated, sustainable logging can actually slow or reverse deforestation by adding value to forestland and providing a viable alternative to farming and ranching. Plus, tropical countries are eligible for carbon sequestration projects, providing incentives to plant new forests, replace old ones, or grow plantation forests consisting of fast-growing decking-appropriate species. Replenishing depleted forests or planting new

* Studies include Life Cycle Assessment of ACQ Lumber vs. WPC b7 Christopher A. Bolin & Stephen Smith, Journal of Cleaner Production, June 30,2010, and WPC vs. Wood Decking by Dr. Jim Bowyer, Dovetail Partnerships, July 28, 20 1 0.

forests has the potential to provide income to developing countries, offset companies' fossil fuel emissions, boost the supply ofeco-friendly wood products, and increase tropical forest area (this has already started in some countries).

Solid wood has a long track record of performance. Softwood decks (not old growth) may last l0 to 15 years on average, depending on care.

By comparison, tropical hardwood decking can last two to three times as long as softwood decking. For example, the Coney Island boardwalk was renovated with ip6 (he first proven hardwood decking species, along with Tigerwood and cumaru) in the 1960s and sections of the Atlantic City boardwalk in New Jersey were replaced with ip6 in 1989. In both of these heavy commercial applications, the hardwood decking is still performing well.

All solid wood decking products require UV protection for color preservation, but as you move from treated to cedar/redwood to hardwoods, the required maintenance declines. Because hardwoods are much denser, they're also far more resistant to scratching, denting, and other surface degradation.

Wood-plastic composites have a significantly higher impact than solid woods in every environmental measure, including embodied energy, global warming acidification, aquatic eutrophication, ozone depletion, smog formation, and human respiratory effects. Although the referenced studies focus only on North American softwoods, the practices used in tropical forestry are extremely similar up to the point of shipping from source to market.

Because decks made of tropical hardwoods can last up to three times longer than softwood decks (and equal to or more than composites), it's reasonable to assume this longer lifespan offsets additional embodied energy used during transportation in overall environmental impact. Even if the wood composites last three times as long as softwood-no one really knows their life expectancy-the studies still believe that solid wood products will have a smaller environmental impact.

What happens when the product wears out? Natural solid wood products are recyclable and biodegradable, eventually reverting to soil over time. Hardwoods generally take longer to biodegrade than softwoods, but the slow degradation is offset by hardwoods' longevity.

Wood-plastic composites are not recyclable and end up in a landfill. Some manufacturers claim to make plastic decking from l00vo recycled materials, but the plastic can't be recycled indefinitely; eventually it ends up in a landfill as well and will not biodegrade in any reasonable time frame.

Tropical hardwood decking offers a number of environmental advantages over other materials. It lasts longer, requires less energy from cradle to grave, is available through selective and sustainable logging practices, and is biodegradable. Those looking for a green decking option should consider tropical hardwoods as a viable option.

The wraps are available in a full range of sizes to cover posts measuring 4"x4" to 8"x8", up to l0' tall. Kits with complementary base moulding and post caps in both 5" and 7" sizes are also available.

Kleer also offers a wide variety of product solutions to help contractors create custom columns. Trimboard with TruEdge fully sealed edges and a wide variety of extruded moulding profiles can be used to create the exact look their customers desire. The company also offers an assortment of color-matched adhesives. cement, sealant and fasteners for a complete solution and the best results.

f lroerrNc ExTERIoR wood columns lL,/ with cellular PVC post wraps and trimboard is a cost- and time-saving alternative to repainting or total replacement-which makes these products attractive to cost-conscious homeowners.

Over time, wood posts and columns on porches and patios can weather and require repainting-while still being structurally sound. Or, perhaps a homeowner just wants to add more curb appeal. On new projects, PVC wraps can be added at the end-reducing the chance of accidental damage.

KleerSnap post wraps from Kleer Lumber, Westfield, Ma., look and work like natural wood but are virtual-

ly impervious to moisture and insects. They provide an easy, cost-effective way to improve the appearance and durability of exterior posts. Although the product doesn't require painting, it can be painted to match existing exterior details and is guaranteed to never rot, warp or delaminate.

"Exterior posts represent one of the more visual elements of an outdoor structure," says Jack Delaney, senior vice president of sales and marketing at Kleer Lumber. "KleerSnap post wrap is a simple and cost-effective way to enhance the aesthetic appeal of the posts while lowering the amount of maintenance required to preserve their beauty."

Fypon, Maumce, Oh., are available in l l styles. to quickly transl-ornt an ordinlrr') strLr( tural post inlo sonrething distinctive. Clhoices incluclc tapered and non-taperecl column styles. plus a variety of cap and basc styles.

An unirs:enthlcd eolumn u rrrp irr lr plainer. box style is also available. in widths liorn 6" to 12" and a variety o1' standard heights that can be trirnmed on the jobsite. Each kit includes all needed components. includin-g adhesive. scrcws. ancl cleats necdcd for installation

PVC products manLll'acturcd by AZEK Building Products. Scrarrton, Prr rtllow buildcrs to srt erci.rli\e whcn wrappir.rg colurrns tirr porchcs. pergolas. and outdoor roolns.

"Easy workability allows the contractor to be creativc. while pro."idin-u low-maintenance," says Michacl Gori, director ot' product mana-gement nI AZEK. "For widcr coluntns on porches and entryways, contractors typically opt fbr AZEK Trim either in board profiles or cut l'rom AZE,K Sheet."

Steve Gray. who owlts and operations a rcnovation firnt in Inclianapolis, In.. uses AZE,K trim fbr bcarns and large columns. "Wc intertr,'",ine hall- of the end grain so it's interlockcd and won't comc apart." he says. "We f ind a continuous neecl fbr this t1pe ol' lou-lrrlrintcnirncc lrim. whicl.r needs no upkccp."

It's elegant. It's affordable. And it's energy smart, It's also an easy-install post cap that transforms into a mood light with the flip of a switch. All around, it's a great addition to Terratec's solar post cap line.The Zapper comes with a solar rechargeable battery, two blue LED bug bulbs and one white LED mood bulb. For a brochure featuring our full line of post caps, including our new solar stair and fence lights, visit us at mcfarlandcascade.comlpostcap.htm.

KLEERSNAP post wraps by Kleer Lumber make short work of column upgrades on a front porch/entry.

KLEERSNAP post wraps by Kleer Lumber make short work of column upgrades on a front porch/entry.

Clo, rsts BUILDER walks into a bar, L)meets a man... and the punch line is, they decide to open a home center-a sustainably focused one, no less. But this is no joke-especially the fact that they pulled it off in this difficult economy.

TreeHouse opened late last year in Austin, Tx. Now, usually I wait well beyond a few months before portraying a success story. But success it certainly is-business has multiplied five-fold in that short span. And, more to the point, the project had been on the drawing board ever since that meeting back in 2006.

That's when Jason Ballard. the builder from Boulder, Co., who's now v.p. of sustainability (a biologist by training and environmentalist by passion) met up with an old college chum-groomsmen for each other and both originally from Texas-to collab-

orate in launching a green operation. They did their market research, then came up with a business plan and seed funding. While the two were visiting D.C. on business, Jason recalled another Texas buddy now working there and connected once again. When asked to sign on, his answer was "Absolutely!" He left his Wall Street job to become v.p. of marketing.

They next approached a contact with a legal background, working for a high-priced San Francisco firm, who was looking for more satisfying employment. "He came with a fantastic reputation and dove in head-first," says Jason. "That's the way we grew, through friendships - people excited about the possibility, not just a business motive."

Why Austin? More market research revealed that it was the state's birthplace of-green building. Plus, the boys

OUT FRONT visitors to Treehouse are greeted by a massive rainwater collection system

from Boulder, D.C., and San Francisco were more than eager to return to good ol' Texas turf. So, says Jason, "The decision made itself."

Okay, how about the site within the city? As you can guess by now, that, too, was not left to chance. "It was not,'If you build it...,"'Jason avers. "'Location. location. location' is not an adage for no reason. We looked for a part of the community that offered a demographic of thoughtful, educated people. We also looked for a major thoroughfare with high traffic. And a place with good neighbors, like Central Market, where we ended up taking over a former Borders bookstore site and remodeling it to LEED standards. Then, on October 22,we opened."

How did you spread the word?

"Man! We're still working on that! But mostly, through guerilla marketing: as guest speakers, at conferences, at the farmers' market. We've used print mailers, groupons [Web couponsl, radio, even billboards" to reach a customer base that caters equally to pros and weekend warriors.

"We're geared to serve both; The layout is d-i-y-friendly. But I had been a builder, so I also knew their needs as a pro. We offer delivery and installation, calling on our list of approved subs, plus a dedicated professional team" that includes everyone from certified interior designers to a solar engineer and a staff member with a master's degree in architecture, among TreeHouse's close to 30 employees.

Jason adds, "We hired folks with a high level of education. not necessarily in this field, then trained them in green building-the salesmanship, the products-with one of the most thorough front-end programs I know of."

And it's paid off: The feedback online, via Yelp and Facebook, has been oositive. with raves like

"extremely helpful, knowledgeable staff." Plus, that kind of word-of-mouth marketing not only is the most effective kind, it's also free.

Contractors, however, notoriously drag their heels when confronted with something new and different, like this emphasis on building green. Jason finds he's attracting two kinds of pros: those who are committed to green construction, and those pushed in that direction by their own, maybe more savvy, clients.

For one and all, TreeHouse provides lots of educationnot in a traditional showroom, but in a format Jason calls a hybrid, far from the endless aisles of products a la Depot. In each department there's an Education Pod, where customers can interactively learn about choices in, say, countertops or flooring and keep up with new technical innovations. "But we also give the drawbacks of any particular product, so customers can make their own informed decisions," Jason says, adding, "Kids love to use it, too."

The store also features an Idea Center, another key source of information. Here, classes are held for pros-in everything from financing to courses supplying AIA and Green Building Board professional development-and two

three or four years. Spend lOVo more on something that lasts 20 to 30 years," he'll counsel.

Plus, "We do a good job of qualifying our customers," he notes. (That's just a fancy marketing term for finding their sweet spot.) A pregnant woman is concerned about her family's health. An environmental fanatic is already convinced it's the way to go. And both of them are willing to pay a premium for their choices. On the other hand, the average homeowner migh come in because his energy bill is killing him. "We'll help him save money, and live healthier as a by-product. He's moving in the green direction, whether that's his intention or not."

Best-selling single item? Windows, without a doubt. But the best-selling category is floorcoverings. "We offer amazing prices, plus full installation. We have the best flooring selection in all Austin," he can brag, adding, "Take off the blindfold... and it's green!"

TreeHouse is fast becoming known as the go-to place for anything solar, from a little-bitty product like a solar charger for your iPhone to a garden fountain, a generator, or even a whole-house system.

By the way, even the coffee is on the green list, bearing fair-trade credentials. It's there for architects and builders sitting down with clients to go over specs and blueprints and for contractors, who stop in for an early-morning jolt of java before hitting the jobsite.

Ask TreeHouse if it faces any local competition and the answer is, not really. There's a little mom-and-pop greenfriendly outfit selling everything from dinnerware to baby clothes, and another showroom taking orders, where folks cannot walk off the floor with their purchase. "We're all in thig together," in Jason's view.

And how often, we just had to ask, were Jason and his team snickered at as beyond stupid for opening in this sluggish downward turn? Yeah, he laughs, they were. "But the part of the building industry that's growing is the sustainable slice of the pie," he defends their choice. "A McGraw Hill study indicates that by 2016, green building will be five times bigger."

And today, folks are remodeling to save energy costs. "We educate them about the available rebates, too-local, state, and federal. We'll print them out, help them fill in the form, even pop them in the mail. For instance, you can get l5%o off a composter, or reduce your solar system bill by $10,000. And the staff are all very, very happy to work here. They believe in what they're doing.'

or three per week for the home consumer-on gardening, kids' health, home cleaning, or energy-saving solutions.

Products carried will always be a moving target. Jason, in charge of product stewardship, notes that his choices are based on four criteria: health, sustainability, performance, and core responsibility. "Curating the products is like curating art," he says. "I've been at it for five years, and it's always evolving. I'm still adding 50 products a month. We strictly limit them to products we ourselves would use in our homes."

And what about price? You dealers out there are well aware of the fable that green costs more. "And that's just what it is: a fable, exactly!" Jason contends, and backs up his belief with a price-matching policy. "But we also teach customers the relative value of things. For instance, a linoleum floor is cheap, but you'll need to replace it in

And the feedback's terrific. "Everybody loves the store. Eventually, as a business we'll be profitable, but we're not here for all the money we'll make. We're here as a vote for sustainability. And sales are up, so people also are voting with their wallets. Putting your money where your mouth is, is the most powerful tool-and we're not yet done with putting the message out.

"We've made a unique commitment to what matters-first to ideals, and then to making money. We're not just another aesthetic," Jason declares. "We've a different soul." And that's the kind of soul food folks clearly are hungry for.

Carla Waldemar IN-STORE IDEA CENTER is a ready source of green product info and site of frequent seminars.

f'\ven rHE LASr 20 years. 1007o of \-fthe groups I have worked with have grown their year-over-year sales.

What does it take to double business in 12 months? The sales groups and individuals who grow the fastest:

Commit to Change.

Change can be difficult, especially iT.

This goes for organizations as well as individual sellers. Many organizations have leadership logjams based on seniority, for example. Changing long-term leadership or lack of leadership can hurt. Magic words don't grow sales; we must have systemic change. If we plan on selling the same way and just tweaking a couple things, we will not double our business.

If we are waiting for our current account base to get busier, we are looking at 5Vo max growth! It just won't happen. If we want to double our business in 12 months we are going to have to get "new business."

Let's define prospecting: Prospecting is looking for brand new, never-sold-by-your-company-before business. Many salespeople and organizations are just moving accounts around or bringing old business back from the dead. This is not prospecting and will not bring the kind of change needed to double business.

How much? If you are an experienced salesperson, two hours a week is a minimum. This is two hours of calling a pre-printed list or hitting a pre-organized list of businesses if you are in the field. This is not two hours with an hour and a half of looking things up on the Internet or driving around "checking for leads." This is a focused two hours a week. If you are a journeyman or rookie, much more prospecting time will be needed.

To sell volume, we must talk to all of our customers in terms of quarterly, six-month, and year-long programs. This is essential with existing and new customers alike. Especially when we are the preferred supplier in a competitive situation (we are getting over 50Vo of the business), we absolutely need to propose programs to our customers for all the business.

Once we have sold one program, it is time to copy and

paste. Program selling becomes easier and easier the more we do it.

Comfort is the enemy of growth. Hanging onto C+ accounts while trying to construct an A+ sales career is lunacy, but many do it.

We start by doing an 8Ol2O analysis of our accounts. Typically, 807o of our business is coming from 2OVo of the accounts we are working. When we understand where our business is coming from (and not coming from), we can begin to put our energy where we get the biggest return.

Once the bottom 20Vo is split out, do another 80/20 analysis on that group. Anyone in the bottom 807o (who we have been working for over six months) after this split should be taken out of our rotation.

We should do this individually. Sales managers should do this for their group if they are not doing for themselves (they are not). Although account management can be a contentious challenge for sales management, it is the best thing management can do for a sales organization. (Note to sales managers: Get the group to do this on their own and it will be a lot less painful.)

The best place to get business is where we are already getting business. Our best accounts are doing business because we are doing something, or many things, right. We must push them for more. Many sellers are afraid of upsetting their best accounts. Our accounts are expecting us to come to them with new and better solutions. When we bring them these solutions, we

need to ask for more commitment from them.

Dream.

Think about it. Dream about it. Eat it and sleep it. Execute the steps and believe it, and you will double your business in l2 months.

James Olsen Reality Sales Training (so3) s44-35'72 james @ realitysalestraining.com

tTt"t wEATHER LATELY has been weird and wild, but get I used to it. It's the new normal. Climate scientists tell us that weather extremes will be more common and that long-term patterns are shifting.

This doesn't just make the weather report on the evening news more interesting. Consider, for example, that shifting rainfall patterns can affect water supplies, livelihoods, and lifestyles. Some communities are facing drought-or worse-for the first time in living memory. Some places are seeing much more rain, and some are getting their rain or snow sooner or later in the season. Any of these changes can cause big problems for communities who fail to adapt.

This is where dealers can come to the rescue. Changing weather patterns, whether drought or deluge, create opportunities to do good for your community and your business.

For starters, educate yourself about water issues in your areas of operation. If you're in a community already affected, you may already be aware of local and regional rainfall patterns and water supplies. If not, there are good resources online, such as www.noaa.com.

Second, build your expertise in those mitigation and adaptation strategies your community needs. In a drought? Look into rainwater harvesting, greywater recycling systems, high-efficiency toilets, even composting toilets. (Believe it or not, collecting the rain that falls on your roof is illegal in some places, and residential greywater systems are not approved in all communities.) Read Rainwater Harvesting for Drylands & Beyond by Brad Lancaster, one of the nation's leading experts, then share it with your staff.

If your community faces periodic deluge and flooding, there are short-term mitigation and longer term adaptations to evaluate, too. For example, in West Coast urban areas facing huge El Nifro storms, rain barrels can help reduce the runoff that overwhelms storm sewer systems. Softening urban hard surfaces and hardscaping to allow for "slowing, spreading, and sinking" of rainfall, also reduces runoff and recharges aquifers. Permeable pavers, anyone?

For flooding, dry flood-proofing measures and elevation may be viable short-term strategies for dealing with periodic flood risks in some instances. However, flood mitigation is a complicated legal and technical domain-do your homework before diving in.

Once you and your key staff are prepared, start building stock and services around the solutions best suited for your community. Water conservation measures inside the home might be one category that works in every part of the country. And nearly all toilet manufacturers offer high efficiency toilets, but have a look at Niagara Conservation (www.niagaraconservation.com). They make it easy to source a range of water-saving devices, including their ultra high efficiency Stealth .08-gpf toilet.

I'm also a big fan of greywater recycling. It's still early days for residential systems, and most solutions are do it yourself or "green it yourself' projects, but this presents a wonderful merchandising opportunity. Pull all the right components into a robust display, along with the right tools, some books, and related products. Check out www.greywateraction.org for ideas.

And catching the rain-it's a no-brainer for many regions of the country. The key component is storage. The most innovative solution I've seen is RainTechnologies' RainSpace. It's flexible, capacious, and low cost.

These kinds of solutions may require some thinking outside the box and a little extra effort. But they can earn LEED credits for your green builders, conserve water, and improve quality of life in your community. You'll be doing wellby doing good.

Jay TomPt Managing Partner William Verde & Associates (415) 321-0848He's worried. And he should be. The SilvaStar@ guarantee means only the very best wood makes the grade - no exceptions. We're so confident in the high quality, performance and great look of our primed fascia that no matter what topcoat you choose, we'll extend our warranty to meetit. callusatoM264-6015. HIGH-PERF0RMANCE W00D FASCIA

Lumber Products, Tualatin, Or., has filed to reorganize under Chapter I 1 bankruptcy protection.

Founded in 1938, the wholesaler operates DCs in six western states, as well as importer Dansu International, Tualatin.

Barr Lumber, San Bernardino, Ca., held a liquidation sale and closed its 17-year-old store in Apple Valley, Ca., on April 13, blaming a poor

economy.

Barr was renting the 23000-sq. ft. space on 3.1 acres, which was purchased two years ago by a private investor. Barr continues to operate three stores.

Sterling Lumber & Investment, Westminster, Co., opened a new location March 26 in South Fork. Co.. at a site formerly occupied by ProBuild.

"Folks will see familiar faces when they come to buy goods here, because our employees were employed here

when it was ProBuild," said Jim Gudenkauf, v.p. of Sterling Lumber. "All of our employees live in Rio Grande County, primarily in South Fork."

Operating as South Fork Lumber, the new yard is Sterling's eleventh retail yard in Colorado.

"Usually the company buys out existing stores, so starting from scratch was a little more time-consuming for us, but we are right on track," said James Stephens, who serves as general manager.

New Mexico Stores Renamed Roswell Lumber Co. has given its two retail yards-Roswell Do it Center, Roswell, N.M., and Artesia Do it Center. Artesia. N.M.-a new name: Builders Do it Centers.

"Our history has always been one of change, innovation, and growth," said Bruce Ellis, president and c.e.o. of parent Roswell Lumber, founded in 1902. "We wanted our brand to reflect that bright past and help us be ready for a brighter future."

Both locations were extensively remodeled and re-merchandised. Two new websites were also launched: www.builderdoitcenter.com and www.buildersknowledge.com.

The company also operates Overhead Door of Southeast New Mexico and RLC Supply & Logistics.

U.S. demand for wood-plastic composite and plastic lumber is projected to rise 13.ZVo per year from $2.9 billion to $5.4 billion by 20L5, according to a new Freedonia Group study.

Percentage growth will be driven by a rebound in construction expenditures from a depressed 2010 base.

Composite lumber demand will grow l6Vo annually to $2.5 billion in 2015, while plastic will increase nearly ll%o annually to $2.8 billion.

Because composites incorporate recycled materials, they are often viewed as environmentally friendlier. Gains for plastics will be spurred by heightened consumer interest in its low maintenance properties, and manufacturers' efforts to create plastic lumber varieties with more realistic woodgrain textures and surfaces.

Many lumber dealers are seeing their annual d6ck DeckTools@ software. The program is simple to learn L dealers can design a deck in a few minutes, ket

ffi| is customizable and includes many'brand-ntme which makes it easy to show and sell upgrades that you takes care of all the paperwork with quotes, takeotfs and plam.

DeckTools makes it easy to deliver more deck sales. Leam how for a free demonstration at www.strongtie.com/decKools or (8r

By fames Olan Hutcheson

By fames Olan Hutcheson

(( L LL You NEeo is love." san-e the la.Beatles. But if the Fab Four had been family business owners, the lyric should rightly have been written, "All you need is trust." Family business members often profess their love for each other while withholding their trust. When they don't trust each other, they don't communicate and find it difficult to agree on a common direction. The result is a firm mired in toxic distrust, unable to discuss key issues, frozen in the face of crisis, and, all too often, sickly and short-lived.

A Tale of Mistrust. Brown-Wilbert Co. is an 8O-year-old Minnesota

company that builds burial vaults. It's mostly owned by chief operating officer Christopher Brown, but controlled through voting shares by his father, c.e.o. Jerry Brown, who has worked at the firm since 1960 after marrying the granddaughter of the founder. The company has $20 million in revenues. a solid market position, and a wellestablished brand name. It's also got a major problem with mistrust among the owners and top executives.

The father-and-son executives have sued one another for a combined total of several million dollars, each claiming that the other has misappropriated

company funds for personal use or for investment in other ventures. The two swap charges of self-serving behavior, incompetence, malfeasance, inattention to duty, and other failings in court as well as in the local media.

Will the company survive this battle? So far, Brown-Wilbert is bearing up. But similar struggles have destroyed countless other family firms. At the least, the mistrust has blocked communication, hindered cooperation, drained management attention, and consumed financial resources that would be better devoted to strengthening the company.

For my purposes, however, the Brown-Wilbert case is a good one. It neatly demonstrates the risks and costs of mistrust developing in a family business, as well as most of the available varieties of mistrust and their most common sources.

Kinds of Trust. Several varieties of trust are relevant to family business. First is trust in the competency of family business members. Other members have to be able to trust that their peers are trained, experienced and capable of discharging the responsibilities entrusted to them. That is a basic kind of trust, similar to the trust all business leaders must feel in the people who

work for and with them.

Ethical trust is another essential. It's vital that family business members can be counted on to behave ethically. This doesn't mean merely following the letter of the law. It means following the spirit of the law and the principles behind the corporate code of ethics. In a family business, ethical trust also means trusting family members to put the interests of the family and the firm ahead of their own.

When people have faith in one another's reliability, that's a different kind of trust. You can have the skills and ethics, but if you can't be counted on to show up, you won't win trust.

Communication is the heart of trust. You can't trust someone when you don't know what he or she is thinking. Family members must be able to trust that they can talk about their concerns and be heard, and that others will talk about theirs in a similar manner.

Trust in outsiders is uniquely relevant to family business. Family firms that can't absorb people, practices and ideas from the outside will not live long. It requires trust in foreign concepts and people for that to happen.

Building Trust. Building trust starts with communication. Family members must discuss candidly but

tactfully their thoughts, feelings and even dreams. Of course, communication is more than talking. It's also listening. It's hard to trust someone to look after your concerns when that someone doesn't appear to be listening to you when you express those concerns. So encouraging and institutionalizing talking and listening are key to building trust. Family meetings are the most visible tool for building communication, although there are others.

Talking the talk builds an element of trust, but walking it builds more. That's why trust-builders must welcome genuine, meaningful participation by those with whom they want to share trust. Family members should be asked and encouraged to join in making significant decisions, even if just by gathering information or injecting an opinion.

There are some things you should not do when trying to build trust. One is to trust blindly. It's a mistake to believe that someone should naturally be trusted because he or she is a member of the family, without any proof that the person is, indeed, trustworthy. Likewise, don't continue to trust someone who clearly, repeatedly fails to warrant it. In addition to setting the enterprise up for betrayal, bestowing

blind trust on the undeserving tells other family members that it's not necessary to work hard to develop trust based on competency, reliability, communication, ethical behavior, and openness to outsiders' efforts.

On the flip side, don't be too suspicious. When you monitor everything a family member does, you create an atmosphere of mistrust. Granting trust is a loose-tight proposition. Like holding a wet bar of soap, gripping too loosely allows it to fall, while gripping too tightly causes it to slip away.

Limits of Trust. Trust isn't a cureall and does have its risks. Trusting others doesn't guarantee that they won't disappoint you. And trust won't overcome other management failings, weak markets, poor strategies, or just plain bad luck. But it does help. Without it, even superior management, markets, strategies and luck may come to nothing. From the perspective of family businesses, Elvis Presley may have come closer than the Beatles to the truth when he sang, "We can't build our future on suspicious minds."

- James Olan Hutcheson is managing partner and founder of ReGeneration Partners, a Dallas-based family business consulting firm. Reached him at (800) 406I I l2 or www.regeneration-partners.com.

For confi dence underfoot - and overheadbu i lders lr ust Ainsworth E n g i n ee red. For flooring systems that lay flat and true. For stairs that won't cup, sag or squeak. For cost-com petitive, susta i na bly sou rced products, reliably supplied, choose quality. Choose Ainsworth.

Elaina Jackson has been promoted to president and c.e.o. of Pacific Wood Preserving, Bakersfield, Ca., succeeding her late husband, Dick Jackson. Ken Laughlin was named executive v.p.

Bob Bretz, lumber sales, Yakama Forest Products, White Swan, Wa., retired April 30 after 38 years in the industry, the last three with Yakama.

Greg Moss, ex-Moss Lumber, has joined the sales team at The Mill Yard. Arcata. Ca.

Rick Ingram has retired after 40 years in the industry, the last six in sales at Mary's River Lumber, Corvallis, Or.

Kevin Dodds, Joe La Berge, and Grant Philtips, all ex-Buckeye Pacific, have joined Collins Cos., Portland, Or., focusing on green DF and panel sales.

Don Lampert, ex-North Pacific, is new to panel sales at Buckeye Pacific. Portland. Or.

Brett Bleichrodt, ex-Bluelinx, has joined Weyerhaeuser, Denver, Co., as a dealer sales rep.

Jeff Logue has been promoted to division mgr. for Capital Lumber, Healdsburg, Ca., succeeding Jeff Howard, who has retired after 19 years with the company. Asa Johnson was promoted to division mgr. in Denver, Co., succeeding Steve Myrick, who retired after 22 years with Capital.

Mark Jackson, ex-Bridgewell, is a new trader at Idaho Pacific Lumber Co.. Vancouver. Wa.

Jon Kimber, ex-Capital, is new to the sales and distribution division at Snavely Forest Products, Denver, Co.

Rob Robinette, ex-Lumber Products, has been named product mgr. for McKillican International, Sherwood. Or.

Kevin Pratt has been named sales mgr. of inland products for Konecny Brothers Lumber, Ogden, Ut., and will assist in exclusive sales for Goshen Forest Products, Eugene, Or.

Jim Shaffer has rejoined Franklin Building Supply, Boise,Id., as window mgr.

Dan Scherber, ex-BASF, has rejoined Orepac Building Products, Tacoma, Was., as senior certified Tyvek specialist.

Cherie Moorhead joined Nature's Composites, Torrington, Wy., as area sales mgr. for Northern California and northern Nevada.

Shawn Overholtzer, ex-California TrusFrame, is a new truss specialist for Simpson Strong-Tie, Stockton, Ca.

Jaeson Fikse is new to door & window sales at Ganahl Lumber, Buena Park, Ca.

David Bayles, c.e.o./president, Inland Builders Supply/Ace Hardware, Blythe, Ca., and Brennen Jeffers, general mgr., Sun Valley Do It Best Hardware, Deming, N.M., were honored as Young Retailers of the Year by the North American Retail Hardware Association.

T.J. Rosengarth, Northwest Hardwoods, Tacoma, Wa., was elected a director of the Hardwood Manufacturers Associatiorr.

Winsom Cash has resigned from Mungus-Fungus Forest Products, Climax, Nv., after striking it big in the state lottery, report Hugh Mungus and Freddy Fungus.

During our 63 years in the redwood business, Big Creek has developed a reputation fior being a reliable supplier of high quality lumber. We produce a wide range of grades and dimensions, custom cut timbers, pattern stock and fencing. Order full, mixed or paftial truckloads.

Big Creek Lumber Co. has a long

superior fonest stewaldship -

haruesting and milling high quality California redwood.

Mothballed since 2010, eight HeatWave Radio Frequency Vacuum Kilns are once again producing TruDry timbers.

Capital Lumber, Phoenix, Az., has entered into an agreement with Craftmark Inc., McMinnville, Or., to exclusively manage the inventory and act as sales agents for Tru-Dry timbers. The brand was previously manufactured by Forest Grove Lumber, McMinnville.

"We have been working for a while to obtain this technology," said Denny Elmer, president of Craftmark. "With the technical oversight of one of the original operators of the RFV kilns and the sales acumen of the original salespeople who are now with Capital, we will be well prepared to bring Tru-Dry back to market."

Jim McCluskey, manager of Capital's operations in Portland, Or., noted, "This is a great opportunity for Capital and a perfect pairing of resources. The Tru-Dry brand is well known, and there has been a noticeable void in the timber business without it."

Gene Secco and Ryan Williams, formerly with Forest Grove Lumber, have joined Capital in Portland to handle the inventory management and sales of Tru-Dry.

Orchard Supply Hardware, San Jose, Ca., held an April 14 grand opening for its new store in Fresno, Ca.-the chain's 88th store and its fourth in Fresno.

According to manager Mike Ellis, the 50,000-sq. ft. store has a 7,700-sq. ft. garden center and features a newly designed store format with an easy-to-navigate layout and a new customer service center called Workbench.

Distributors. Qualityr & Service you can trust!

Stock quality fasteners your customers will love!

o Quick Service - Same Day Shipping!

O Top Selling - Suggested Stocking Sections!

O Huge Variety! - 1-16" Lengths!

Decklok The Advanced LateralAnchor

@For Ledger, Rail PostsAnd Stair Stringers

@) ICC Code Compliant

@ Strengthens the Critical Deck Connections

NATIONWI DE STOCKI NG DISTRI BUTORS

SUPERIORTO PAINT OR COATINGS

STRONGEST FRTW WARRANTY

COMPETITIVE PRICING

TSO AND KDAT

,A'TER'OR FIRE RETARDANT LUMBER AND PLYWOOD

Parley '6Bill" Cherry, 86, retired founder of former Colorado Forest Industries, Denver, Co., died March l7 in Denver.

During World War II, he served with the Army Air Corp. as an air cadet. Afterwards, he attended the University of Idaho and graduated with a degree in forestry.

In 1983, he and his son Dan started CedarWest Corp., Lakewood, Co. Six years later, they moved to a new building in Denver and changed the

name of the company to Colorado Forest Industries.

Mr. Cherry retired in 1999, and the company was sold to J.M. Thomas Forest Products in 2009.

Harry Barth t'Barttt Palmer, 86, former general manager of Edward Hines Lumber, Lafayette, Co., died Dec. l6 in Broomfield, Co.

After serving with the Navy during World War II. he attended Colorado State University and graduated with degrees in industrial forestry and general education.

In 1975, he joined Edward Hines,

serving as general manager for the next l2 years.

George S. Yates, 86, former vice president of Denver Lumber, Denver, Co., died March 3 in Denver.

Mr. Yates joined the family business in 1952.In 1995, he was named Lumberman of the Year by Mountain States Lumber & Buildins Material Association.

Max C. Hittle, 83, longtime Colorado lumberman, died March 14 in Westminster, Co.

Mr. Hittle had a 30-year career in the lumber industry, working for such companies as Lumber Yard Supply, Gene Wright/Dependable Lumber Co., Rounds & Porter Co., Slaughter Brothers Lumber, and Reid & Wright.

Scarborough Home Centers, Scotts Valley, Ca., is opening a 4,200-sq. ft. Ace Hardware this summer in carmel, ca.

Orchard Supply Hardware has backed out of plans to open a store in Tamalpais Valley, Ca.

Mitchell Hardware is opening a third,7,000-sq. ft. Ace Hardware & Paint in Bend, Or. The chain also operates three stores in Washington.

Mayson Ace Hardw?ro has moved to a new location in Fresno, Ca.

Home Depot opened a new 106,000-sq. ft. store with 35,000-sq. ft. garden center April 26 in Lodi, Ca. (Jessica Larsen, store mgr.).

Depot will relocate its oldest Western region store-a 27 -year-old unit in Fullerton, Ca.-on Aug. 30.

Lowe's relocated its Sparks, Nv., home center to a new 103,000-sq. ft. facility in E. Sparks and opened new locations Feb. 2 in Fairfield (Suzanne Mooers, store mgr.) and Mid-City Los Angeles, Ca.

Habitat for Humanity neto a grand opening April 22 for its new ReStore discount home center in SimiValley, Ca., and by June will move its Roseville, Ca., store to a larger, 30,000-sq. ft. space.

Pacific Coast Supply, Rancho Cordova, Ca., has acquired six-unit Pioneer Builders Supply, Tacoma, Wa.

In business since 1960, Pioneer distributes roofing from locations in Tacoma, Bremerton. Tumwater. Kent. Seattle. and Bellevue, Wa.

One of several divisions of Pacific Coast Building Products, Pacific Coast Supply also operates yards under the banners Anderson Lumber, Diamond Pacific, P.C. Wholesale, and Weyrick Pacific.

A former worker at Stimson Lumber, Portland, Or., has pleaded guilty to aiding the transportation of stolen lumber.

According to court records, Trevor Mokry was responsible for loading and unloading trucks at Stimson's mill in Plummer, Id. He admitted entering into an unauthorized "mill direct" sales arrangement with Pallet Place, Spokane, Wa., which paid him $581,000 for the stolen lumber between June 2007 and June 201l. Mokry loaded Pallet's truck and received a check from the driver.

The charge is punishable by up to l0 years in prison, a maximum fine of $250,000, and up to three years of supervised release. Sentencing is set for July 16.

Meyer Moulding & Millwork, Modesto, Ca., has temporarily discontinued production, but continues selling from inventory.

Owner Jeff Meyer hopes to restart operations if new financing can be found.

Gompass Lumber Products, Cotati, Ca., is winding down operations after 34 years.

Bow Hill Mill, aunington, Wa., has resumed operations at its cedar mill.

Emerald Forest Products, Emmett, td., hopes to restart its sawmill May 15 and ramp up to full capacity within four months. The faciity has been idled since April 2011.

Sunset Moulding Co., Live Oak, Ca., has installed a new moulding and finishing line at its plant in ldabel, Ok.

CertainTeed's roofing plant in Portland, Or., has achieved lS0 14001 certification.

Amber Flooring, Emeryville, Ca., is now dishibutor of Coswick Hardwo6d's sotid and engineered flooiring in Northern California.

Dunn-Edwards' new 336,000-sq. ft. paint manufacturing plant in Phoenix, Az., received a real estate & development award as best industrial project from Arizona Commercial Real Esfafe.

National Nail Corp., Grand Rapids, Mi., launched a new website-stingerworld.com-to promote its Stinger cap systems.

Anniversaries: Straight Line Transport, Huntington Beach, Ca., 10th.

27'2547

An April 14 grand re-opening celebrated the transformation of Home Depot's store in Anaheim Hills, Ca., into a new 205,000-sq. ft. superstore.

The first of its kind in the WestDepot's only other superstore is located in Union, N.J.-the new facility was created by combining the original store and an adjacent Kmart that had been empty for years.

The store has a new layout with three main sections: home improvement supplies on one end and in the back, home design in the middle, and outdoor/garden on the other end. A large counter dedicated to returns has its own room and conidor, near one of the entrances. A large customer service area located in the center of the store features a central counter and a waiting area with armchairs.

Trade professionals such as interior designers can meet with clients in transparent but enclosed meeting rooms near the tile displays. Contractors have their own service counter near a door where they can pull up their trucks and load their purchases.

Other new features include free wifi, 50 additional employees, expanded

appliance and bath showrooms, a shower gallery, more kitchen cabinet displays, an outdoor living showroom, more rugs and other home accessories,

more hardware, and more space for tile, wood and laminate flooring. No other superstores are currently in the works for the West.

lne NAWLA Eottcsrror,t FoundaI tion, or "NEF," was started by the North American Wholesale Lumber Association in 2011 to educate, inspire, and plant a new generation of leaders throughout the forest products industry. NEF collaborates with universities to offer students engaging coursework, exciting field experiences, and practical internships in the lumber distributionfield.

The first NEF class was held at the University of Wisconsin-Stout in January. Twenty-one students spent one week learning about the complexities of the lumber supply chain and what the industry offers as a career option. The students ere now eligible for internships with NAWI,A members.

The article below is a firsthand account of the program from one of those students, Swaraj Pandey:

The construction department at my college, UW-Stout, paired with the NEF to offer a course that is a great fit for students in a broad range of majors. By enrolling in this course, students qualify for an intern opportunity with NAWLA members. In fact, to qualify for the internship, a student must complete this intensive, threecredit course focused on the lumber, building material, and supply chain.

The course consisted of lectures, field trips, and case studies. The first day of the course started with a brief introduction related to the course requirements and schedules. We learned about forest ecology, ecosystem services, forest succession, and forest regeneration under natural and managed scenarios. Additional lectures were given on forest management and harvesting, including forest

certification.

Later in the afternoon, we went for a field trip to the school forest in Bjornson Education-Recreation Center. The center has 443 acres of land. We were accompanied by a local forester who displayed extensive knowledge of forestry. We observed the principles of forest ecology, forest management, and harvesting. The property was a mix of northern hardwoods (maple, oak, ash, basswood, yellow and white birch) and coniferous plantations (red and white pine, spruce) with stands of poplar. The forest management plan included select hardwood cuts, pine plantation thinning, aspen cuts, oak regeneration, and timber stand improvement projects.

On the second day, we went for a two-hour virtual field trip to Andersen Windows in Bayport, Mn. We were able to look at step-by-step processes where several home projects were in progress by top builders. Andersen Windows uses 987o of their raw materials and develops long-lasting products that have a minimal adverse effect on the environment. Over 70Vo of their wood is sourced from forests certified by the Forest Stewardship Council and the Sustainable Forestry Initiative. It was an impressive tour packed with useful information.

The third day included a tour of Weekes Forest Products, a major stocking wholesaler. We toured their reload center and learned about a wide variety of lumber, panels, engineered wood, industrial products, and related specialty building products. Our next destination was Viking Forest Products, Eden Prairie, Mn., distributors of OSB, plywood and softwood lumber products. Viking's business

Kiln-dried upper-grade siding

turury interior moldings, fascia and trim

r B, Heart B, Clear and Clear All Heart grrades

r Vertical grrain available in all upper grades

I 1x2 thru 1x12; 2x2 ttuu 2xl2

I Green and air seasoned decking up to 20' lengths

l Timbers up to 12" * 12" x 24'

: Rail-car service and fleet trucking available

We can match virtually any pattern eves made - call us today!

CAREER PANEL allowed professionals to share with students how they chose the lumber industry.

model stresses a reliable supply of the right product, on time, at a fair price. They also gave us some hands-on work experience with the customer, which everyone thoroughly enjoyed.

Next stop was the Silverwood Park Visitor's Center in St. Anthony. The main purpose of the building is to showcase and promote sustainability, while reducing day-to-day operating costs. The building is a 2009 Woodworks Design Award winner for its innovative structural use of wood.

Next we went to Bethel University in Arden Hills and explored the George Brushaber Commons building, which has a 6,500 sq. ft. green roof that incorporates a water retention system. We learned about their use of glulam beams, purlins, and wood decks, which gives the place a warm appeal and timeless aesthetic.

We also learned about the challenges faced in constructing this space, necessitating the design of twoway cantilevered roof framing that extended outside of the building envelope. This building is also a 2OO9 Woodworks Design Award winner for innovative structural use of wood.

In the last two days of the course, we spent most of our time in the classroom learning about various aspects of the lumber business. The basics of logistic and supply chain management were taught in terms of wood and building materials. We had discussions based on the current issues that are prevalent in the corporate world and the importance of having industry associations.

Construction systems and wood use in non-residential construction area was our focus in a class comprise mostly of construction and engineering majors. We learned about evolving markets for wood-derived energy and bio-chemicals.

Discussion with the various members ofthe career panel was held at the end of the course. These professionals shared their life stories and their path towards the lumber industry. It was very inspiring because each of us could relate to what they were talking about. At the end. we had the chance to ask questions of each panelist.

Overall, this course provided students with a perfect platform that inspires us to get involved in the lumber industry in the long run. I have very positive impressions of the course and the industry. My major is business administration with an emphasis on supply chain management/quality management. I have always been curious to learn more about logistics in lumber: from logging to readiness for use as structural material for construction or wood pulp for paper production.

Many recent graduates are not familiar with the lumber business or the opportunities it offers, but this industry offers a wide range of professional opportunities in both private and public sectors. It is a multibillion dollar industry that is both high-tech and environmentally conscious. The wide focus of the professional training, with its emphasis on organization and management, offers extensive job opportunities inside the lumber industry. There are many possibilities for further professional development as graduates can progress to higher management positions within a few years of experience. Students like me have the opportunity to work at a variety of companies, contributing in such areas as accounting and finance, marketing and sales, management, engineering, and logistic operations.