NAHB RESEARCH CENTER GREEN APPROUED

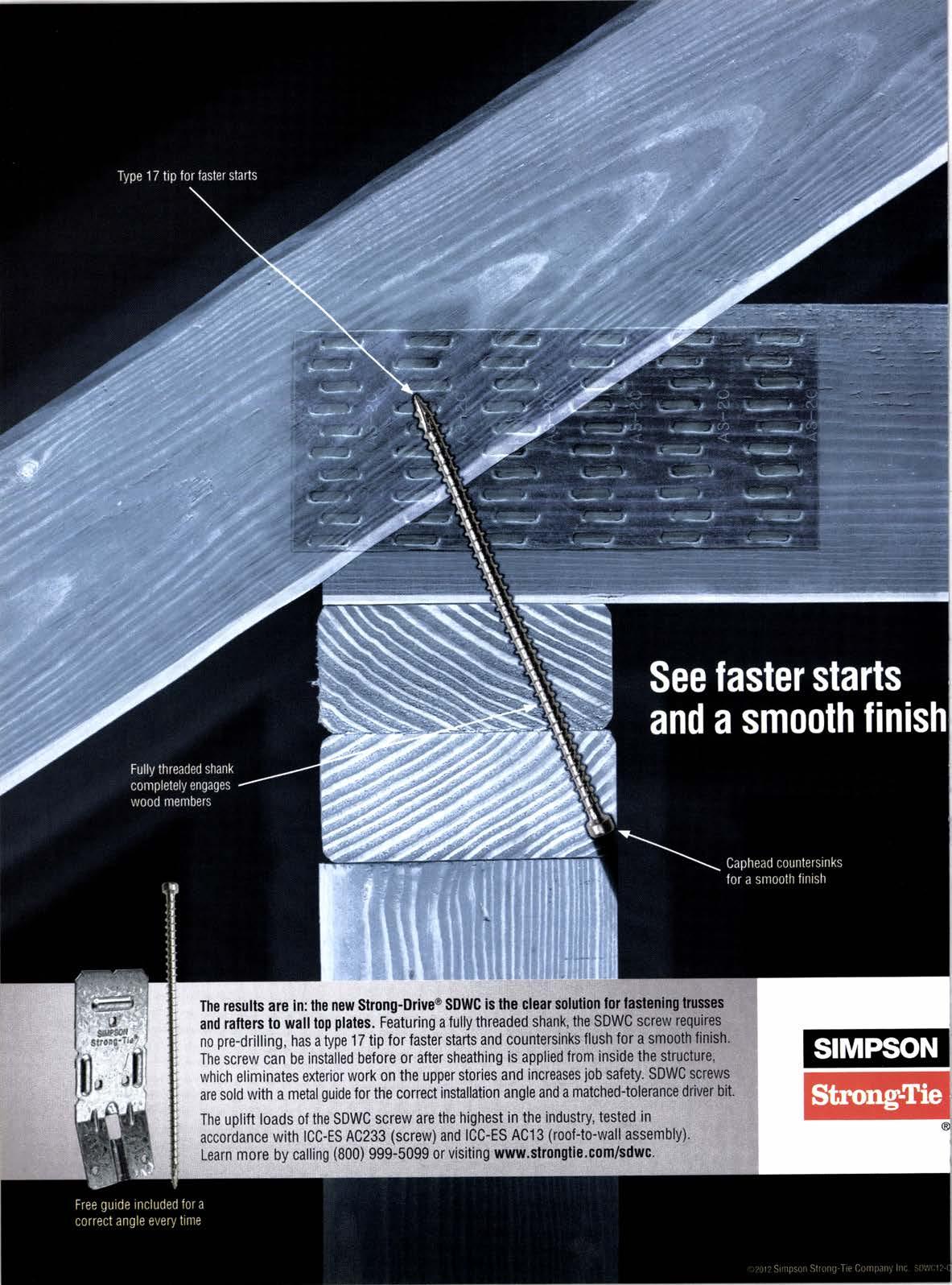

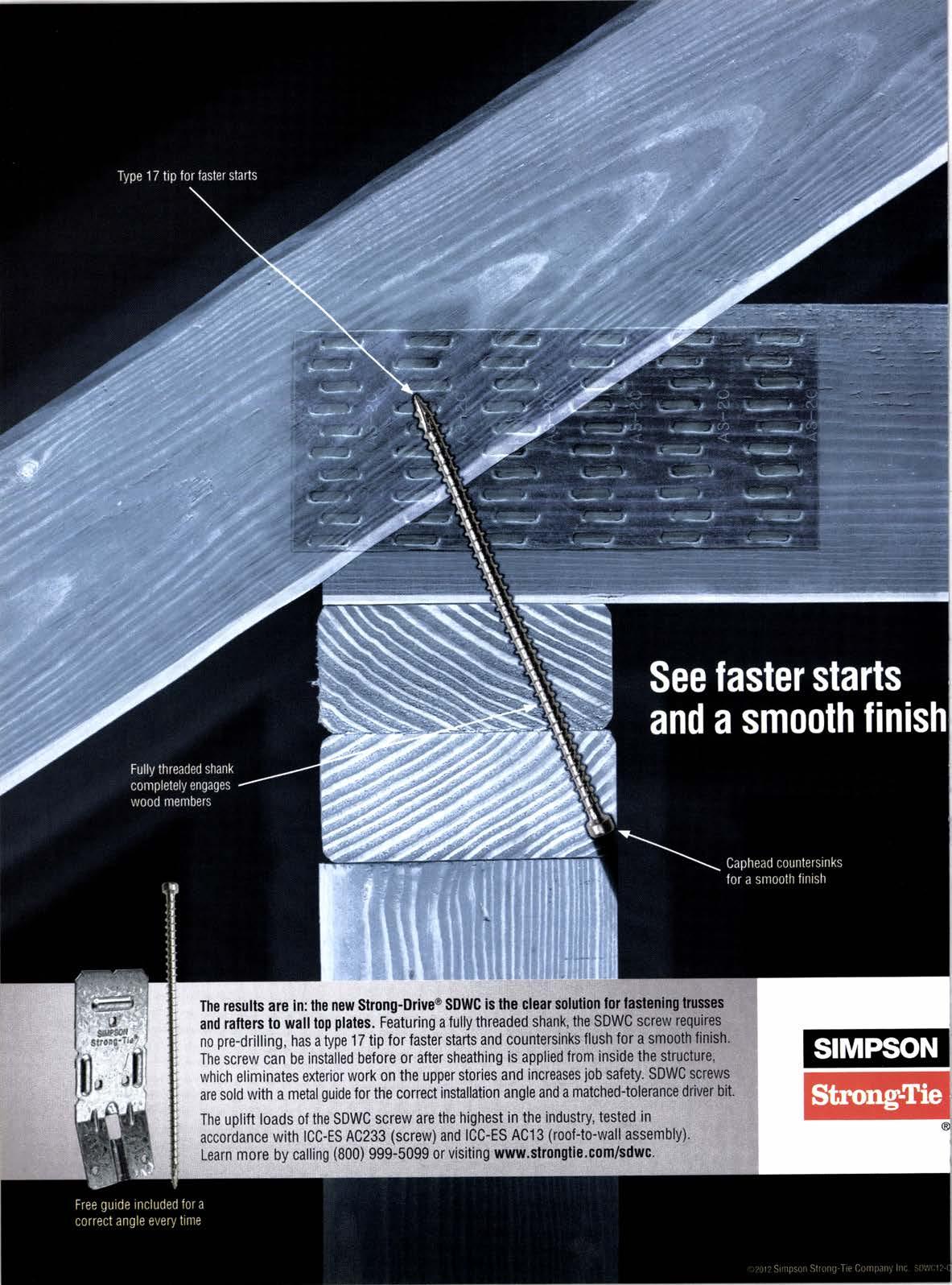

The resufis are in: the new Srrong-Driveo SOWC is ihe,cleu solutlon lt and rafters t0 walllop plates. Featuring a tully threaded shank, the Snt no pre-drilling, has a type 17 lip tor faster starts and countersinks llush The screw can be installed before or after sheathing is.applied lrom which eliminates exterior work 0n ihe uppef stories and incrcams,ioh

? ,g c 6 a $i$ .$ri; 15.; ii .t's gi *.; {"4 *' ii -n E{ ihs

;l,k', { r't .,f t &.' N'T r f" :i,, ,t {/ {{ YYoUWOULD,

Special Features

9 Rrrnosprcrvr Tut Mmcu,qNr nr 90

1 0 Frrrunr Sronv ls NnNorrcHNoLoGY rur NExr FnoNr rN Wooo PRrsrnvtNc?

1 4 tvtnNncrurNr Ttps Crvr Youn Rncrs Recurnn CHrcr-Ups

17 MnsrunrNc Lrnornsnrp CHrcxlrsr ro ENsunr You'nE RrcsvrNc Gnr,qr ConcutNc

28 SprcrnL Focus APA oN E,rtclrvrrRrp WooD1 3-Pncr SprctRr SecrtoN, lNcruorNc EWP Fonrcnsr, APA Upo,crI, AovnNcto Fnn,ratNc TrcHNrqurs, Cunvro CLuLRvs, S,crrrv Lrnorns

Online

Bnmxrrc lruousrnv NEws, lNousrnv PHoro DowNronos, & Tnr MrncHnNr: Drcrrnr VrnsroN

B urr-orNc- PnoDUCTS.coM

CHANGE 0F ADDRESS Send address label from recent issue if possible, new address and 9{igit zip to addfess below.

POSTMASTER Send address changes to The Merchant Magazine,4500 Campus Dr., Ste.480, Newport Beach, Ca.92660-1872.

The Merchant Magazine (ISSN 7399723) (USPS 796560) is published monthly at 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-,|872 by Cutler Publishing, Inc. Periodicals Postage paid at Newport Beach, Ca., and additional post offices. lt is an independentlyowned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 westem states. Copyright@2012 by Cutler Publishing, Inc. Cover and entire conlents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. lt reserves the right to accept or reiect any editorial or advertising matter, and assumes no liability for materials fumished to it.

July 2012 I Number 1

ln Every lssue 6 Tornllv RnNootvt 1 2 Corr,rprnnvr lNrnLrcENCE 16 oLsrN oN Snlrs 20 cnrrr Rrrnll.rNc 36 Movens & Snnrrns 38 Fn,r,rrLv BustNrss 41 lr.r Memonrrm 42 Nrw Pnooucrs 47 AssocrrnoN Uponrr 4B Cr-nssrrrro Mnnxrrpucr 49 oxr Boor 50 lom Frlr 50 Aovrnnsrns lNorx {j 7. 1t ' '- ACO acoPneserve . Borates D-Blazet Intenior Fire Betardant Heat Treating ISPM 15 Compliant . Custom Drying Flail Senved aNsr TPI tniro Party Inspected FSC Certified scs-coGoozs1 3 909-35tI1214 155OO Valencia Ave. [Box 1O7O\ Fontana, CA S2335 Fax 909-35G9623 email - sales@fontanawholesalelumben.com www. fontanawholesalelumber, com 4 r Ihe lvledEnt llagazine r lu$2012 &tiHing'Rodudsom

The ill [n G H[ilI n,o,,io)'umee

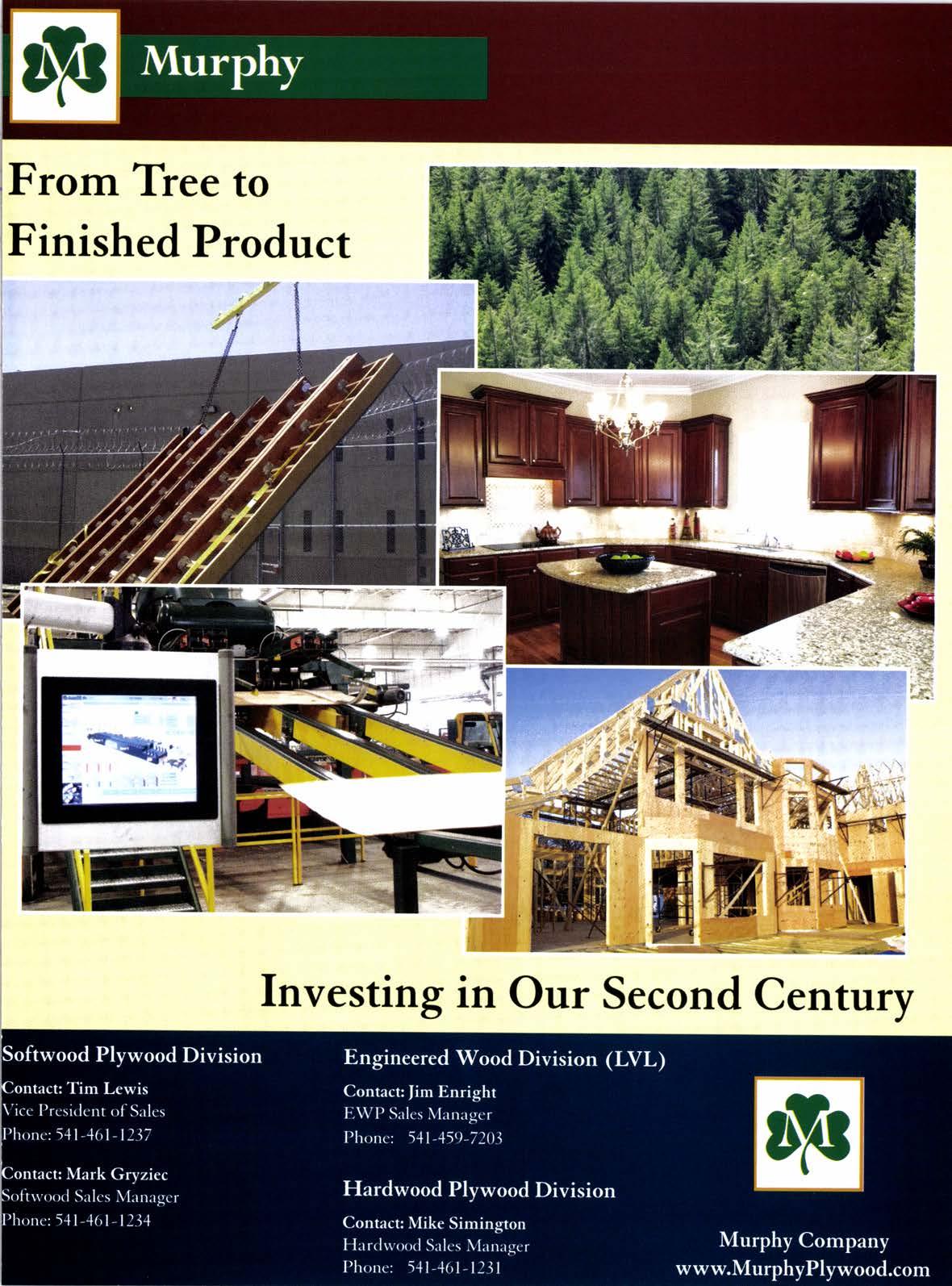

From Tree to Finished Product

-n'--?-

By Alan Oakes

The (guilty) pleasures of traveling

s I weS JUST ABOUT to leave for vacation, I read an ad we have running in our classified section about a "Road Warrior" and realized just how much I, too, enjoy traveling, and how much I could not do without it as part of my life. Whether for business or pleasure,I love to travel. I love the stimulation, the new sites and sounds, hotel rooms (sans cockroaches), different food, and seeing how other people live. I love meeting customers and hearing what they think and how they think.

The thought of landing in a far-off place where I do not understand a word, where there are no signs in English, roads with no lanes, and general chaos doesn't scare me, it stimulates me. The excitement of packing my bag and the expectation as I leave the house is still there after all these years. The one rule I created for myself many years ago was that if you have to do it, you better enjoy it!

In my prior business life, I would spend 407o to 5O7o of my days traveling, and it became a way of life. A different day, a different city is an opportunity to learn something new. It may be in the U.S. or Canada, India, Hong Kong, or... This lifestyle is not for everyone, but it has helped to define me. Yes, we've seen willy Loman in Death of a Salesman and, more recently, George Clooney inUp in the Air, both sad in many ways (although I would not mind being more like George...). When I share my upcoming travel plans, many tell me that they don't know how I do it, or that they would not want to do it. But I enjoy nothing more than heading off with my suitcase, even when it is a 4 a.m. start.

From my first international travel as part of a school trip at the age of 12 to France and Switzerland, I became fascinated with local life domestic and international. When I left school, I went into sales because I knew it would get me traveling, enjoying new experiences, and unchaining me from a desk. In those days, I thought nothing of driving 300 miles a day, day after day. Since 1968, my life has been constantly on the road both for business and pleasure. Those off-site sales meetings and management meetings were my guilty pleasure-having fun and enjoying the camaraderie. I even count much of my business travel as personal travel as I enjoy one as much as the other. I may have worked hard all day, but I love to walk and enjoy a new city at night by visiting galleries, cafes, and finding ways to blend in with locals.

Sure, I've had catastrophes (my business trip to India in the 1990s is worth a movie in its own right), but I love to land somewhere and try to find my way and start a new adventure. I have been sick, landed in a hospital, had my money stolen, lost my luggage, and at times have been desperate to retum to my own bed, but I still have the travel bug. Whether here in the U.S. or abroad, I have gathered experiences I would not tlade for anything: watching the sun rise and set in distant cities, eating in a cafe overlooking an illuminated monumint, turning the corner and seeing a piece of history thousands of years old and wondering how they could possibly build those small hilltop villages or giant pyramids. I have met the most fascinating people at all ends of the spectrum, from business celebrities to film stars to politicians (okay, that part I'm stretching) to simple folk on their pilgrimage or trying to eke out a living. I have stayed in some crummy hotels and in some of the best. I have eaten poorly and have eaten well. My planes has been hit by lightning and wind shear, and I have had one or two scary moments, but still give me a ticket and I am off.

And, yes, I love those frequent flier miles and the perks that go with them. I find great pleasure in trying to find ways to buck the system, finding the best deals, getting an upgrade or a free breakfast. And, yes, I don't enjoy being scrunched up on a commuter jet. or being stranded for hours or days in an airport, but these types of stories give me memories to talk about for years.

In business I learn far more getting out of the office than I ever could sitting in the office. While I like hearing how good our publications are, I also appreciate learning from disappointed customers and field reps what we could do better. Face to face gives no one a place to hide. I use my travels to probably meet 50Vo of my future customers and to save a few customers. too!

So as I head out-only to return by the time you read this-I hope you will get a chance to travel over the summer with your families and enjoy travel the way my family does. I have learned that travel lets me escape from the normal crazy. And nothing can be better. Bon voyage!

Alan Oakes, Publisher aioakes@aol.com

www. building-products.com

A publication of Cutler Publishing 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

Publisher Alan Oakes ajoakes@aol.com

Publisher Emeritus David Cutler

Director of Editorial & Production

David Koenig

dkoenig@building-products.com

Editor Karen Debats kdebats@building-products.com

Contributing Editors

Dwight Cunan, Carla Waldemar, James Olsen, Jay Tompt, Mike Dandridge

Advertising Sales Manager Chuck Casey ccasey@buildin g-Products.com

Administration Director/Secretary Marie 0akes mfpoakes@ad.com

Circulation Manager Heather Kelly hkelly@building-products.com

How to Advertise

Chuck Casey

Phone (949) 852-1990 Fax 949-852-0231 cmsey@building-prod ucts,com

Alan Oakes www. building-products.com

Phone (949) 852-1990 Fax 949-852-0231 ajoakes@aol.com

CLASSIFIED David Koenig

Phone (949) 852-1 990 Fax 949-852'0231 dkoenig@building-products.com

How to Subscribe

SUBSCRIPTIONS Heather KellY Phone (949) 852-1990 Fax 949-852-0231 hkelly@building-products.com or send a check to 4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

U.S.A,:One yeat (12 issues), $22 Two years, $36 Three years, $50

FOREIGN (Per year, paid in advance in US funds):

Surface-Canada or Mexico, $48 Other countries, $60 Air rates also available.

SINGLE CoPIES $4 + shipping

BACK ISSUES $5 + shipping

TOTATLY Random

6 r The Med|am ltbsatne r July 2012 ""lllIRGHAIIT',,-.

&rildingiRodudscom

PERIOR TO PAINT OR COATINGS

ONGEST FRTW WARRANTY MPETITIVE PRICING AT

FOR AI.I YOU R INEAfED TUTBER IEEDS coilTAgT us r -800-339-6480 ffi'T#:'$ry- urvvw.californiacascade.com ; Browntone

Treatcd -floorur

X Trcated -llooyerPlttGuard lnterlor Flrc Treated --- --t-----(1, FIRE RETARDANT LUMBER AND PLYWOODFIRE.X* FIRE RETARDANT TREATED LUMBER AND PLYilAOD

Galifurnla Gascade lndustrles

Trtabd -Adyanco Guard Bontc

Erterlor Flrc

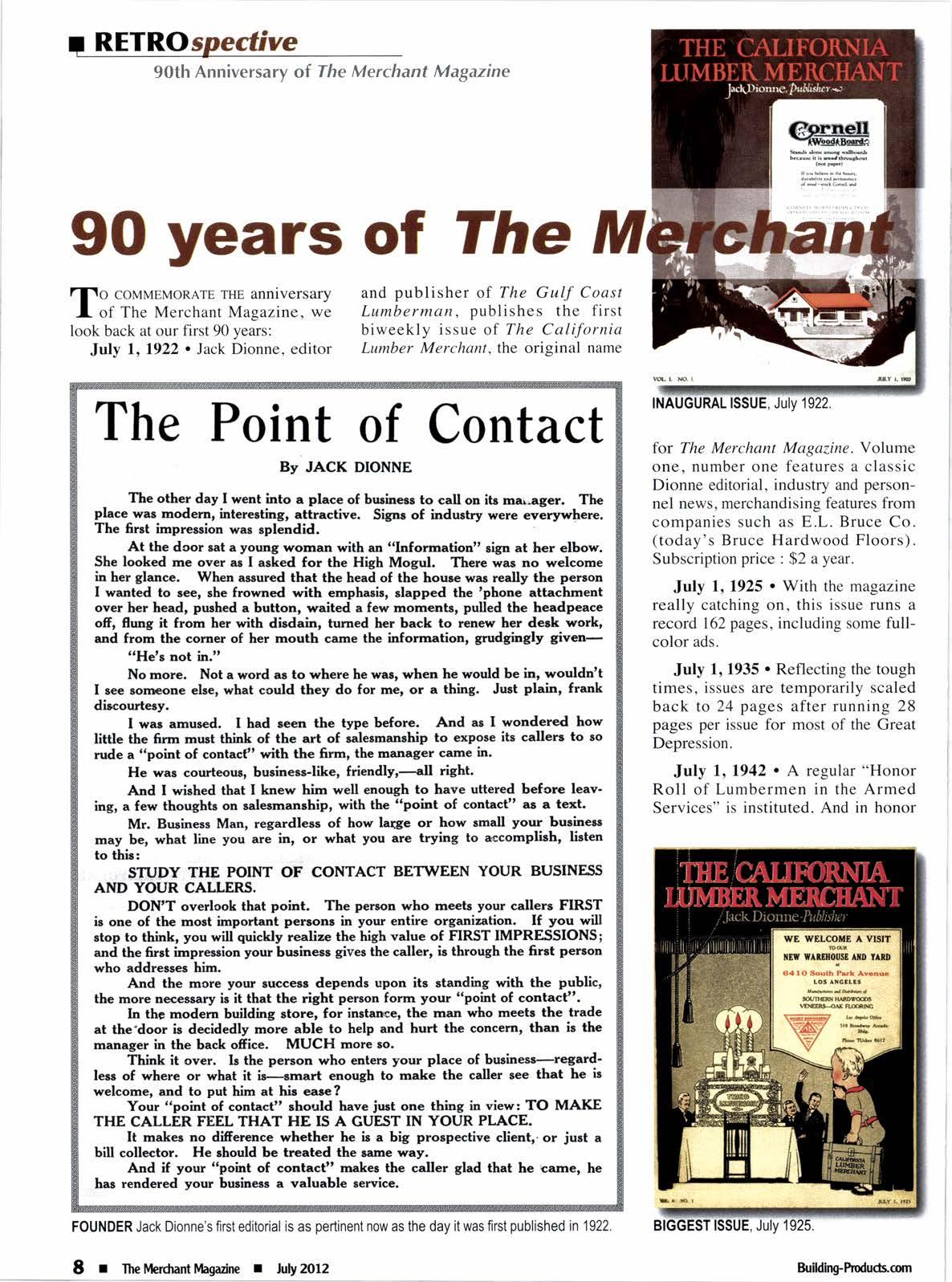

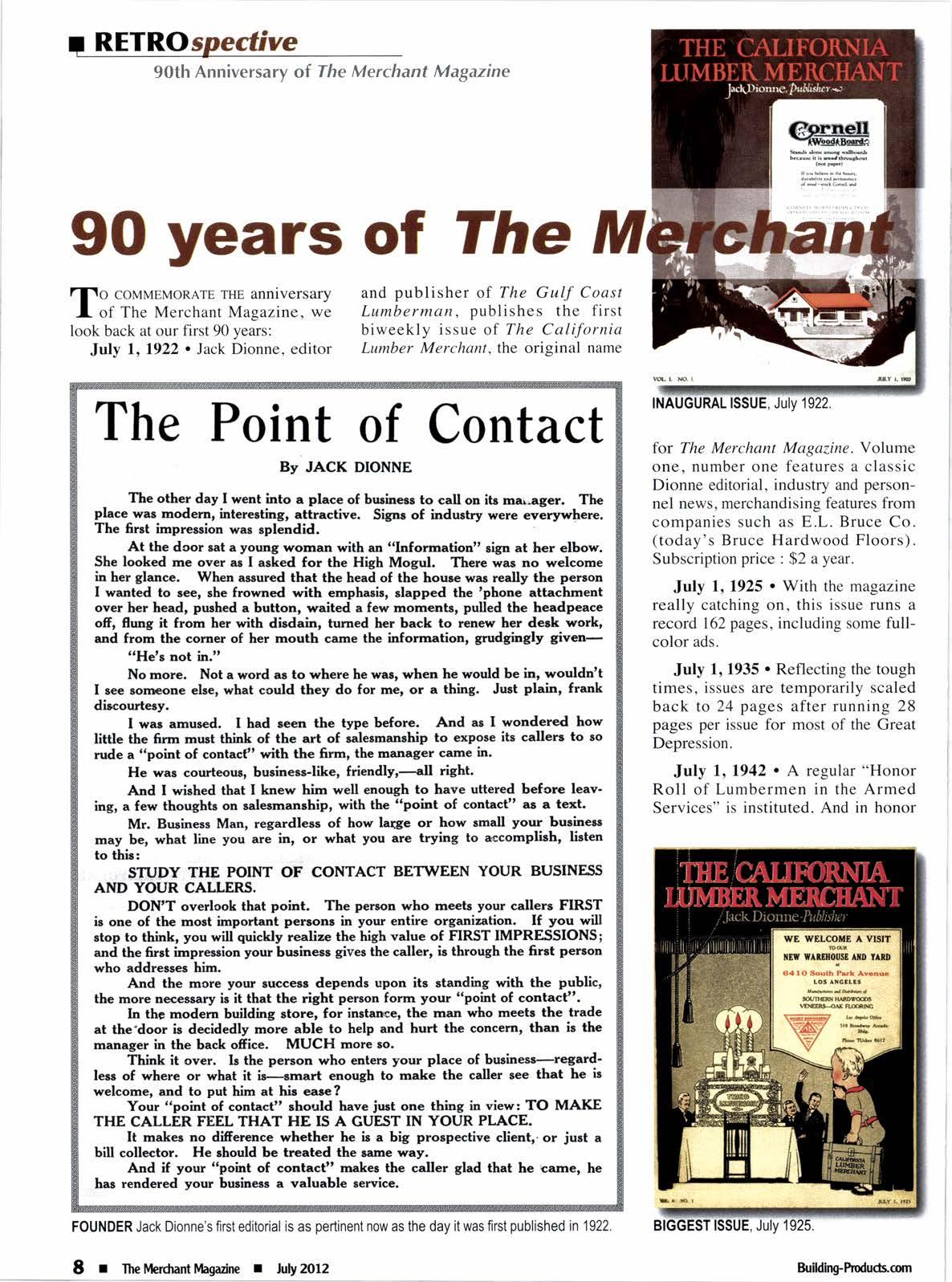

90 years of The

o COMMEMORATE TFIE anniversary of The Merchant Masazine. we look back at our first 90 years: July 1, 1922 . Jack Dionne, editor

and publisher of The Gulf Coast Lumberman, publishes the first biweekly issue of The California Lumber Merchant, the original name

The Point of Contact

Bv JACK DIONNE

The other day I rvent into a place of burincr to call on itr mar.agei Tbe place war modern, intcrerting, attractive. Sig1rr of indurtry were ev-r;rw.he.e. The frrrt imprerion war rplendid

At the door rat a young wonan with an "Information" tign at her elbow. She looked me ov€r ar I arked for the High Mogul. Tbere war no welcome in her glance. Wbea arured that the head of the houre war really the percon I wanted to ree, rhe frewned with empharir, rlapped the tphone attaclunent over her head, puhed a buRon, waited a few norncntr, pulled t'he herdpcace o4 frmg it frorn her with dirdain, turned ber back to tuew ber deek work' and frorn thc corner of her mouth canre the information, Sruddmsly given* ttHett not in.tt

. No nore. Not a word aa to where hq rva$ when hc would be in, wouldn't I ree rormone ebe, wbat could tiey do for me, or a thing. Jurt plainr frank di*ourtery.

I war amued. I htd reqr tte type before. And ar I wondered how little the fitra mut th'nt< of the art of ralermanrhip to orpore its cdlerr to ro rude a ttpoint of contacft with the firm, thc manrger carne in. He war courteour, burine*like, friendlyr-a[ risht.

And I wiehed that I lnew him wetl enough to have uttered before leav' ing, a few thoughtr on ralermanrbip, with the t'point of contacttt ar a tcxt.

Mr. Burinerc Man, regardleu of how lalge or how rmall your bulinerr may be, what line you are in, or what you ane trying to accomplirb, lirten to ttb:

],:sTX-IpY THE POINT OT CONTACT BETWEEN YOUR BIJSINESS AND YOI'R C.A,IIERIi.

DOtiatT overlool that point. The perrcn who ureetr your callen flRST ir one of the moct importent perlonr in your entire organization. If you will rtop to think, you wil quickly rqlize the high value of FIRST IMPRESSIONS; and the 6rt imprerion your businer giver the caller, ir ttrough the f,rrt person who addrerrer him.

.And the more your rucces! dependr upon itr rtanding with the public, the more nsees$ary i! it that the right penon form your ttpoint of contact't.

In the modern building store, for inrtame, the rnan who meetr the trade at the'door ir decidedly more able to help and hurt thc concern, than i! the manager in the back ofice. MUCH mone.o.

Think it over. Ir the perron who enterr your place of budnecr-regard' Ieu of wherc or what it ir-<mart enougb to make the caller cee that bc ir welcome, and to put him at hir earc?

Your ttpoint of contact" rhould have iurt one thing in view: TO MAKE THE CALLER FEEL TH.AT HE IS A GUEST IN YOUR PLACE.

It nahec no differcnce whetbcr he b a big prorpectivc client.or jurt a bill collector. He rbould be treatcd the rane way.

And if your'rpobt of contect't rnaker the crllq' g1"4 that he barne, he har rendered your burbeg a valuable rerwice.

fot The Merchant Magazine. Volume one. number one features a classic Dionne editorial, industry and personnel news, merchandising features from companies such as E.L. Bruce Co. (today's Bruce Hardwood Floors). Subscription price : $2 a year.

July 1, 1925 . With the magazine really catching on. this issue runs a record 162 pages, including some fullcolor ads.

July 1,1935 . Reflecting the tough times, issues are temporarily scaled back to 24 pages after running 28 pages per issue for most of the Great Depression.

July 1, 1942 . A regular "Honor Roll of Lumbermen in the Armed Services" is instituted. And in honor

RETRO 90th Anniversary of The Merchant Magazine

FOUNDER Jack Dionne's first editorial is as pertinent now as the day it was flrst published in 1922 8 I fte Medlant l4agadne r tuly2ill2 &rlHit4ihodu<lsom

of the magazine's 20th anniversary, the "Ten Years Ago Today" column is renamed "20 Years Ago."

January 1, 1951 The subscription price skyrockets to $3 for 24 biweekly issues.

October l, 1954. The first New Products section profiles a number of interesting products, literature and sales aids, including an amazing new floor wax.

January 1963 After 40 years as a biweekly, the magazine goes monthly.

August 1963 . Well known California lumberman A.D. Bell Jr. succeeds Dionne as publisher.

October 1966. The becomes The Western California Lumber Merchant Lumber & Building Materials Merchant, reflecting its expanded coverage of other products and reach to all 13 states.

THE FAIIILIAR block logo of lhe Merchant flrst appeared in '1966, during a 10-year phase with a longer name.

JulY 1975 '

The magazine realizes its name is too long after readers keep calling it everything from The Western Lumber Machine and Lumber & Druggist to The Western Lover Merchant.It's shortened to its lonstime nickname, The Merchant Magazine.

October 1975 Editor David Cutler, who joined the company in 1962, succeeds Bell as publisher.

July 1978 . The first personnel change-Beau Dayshus -is made at Mungus-Fungus Forest Products, Climax, Nv., and The Merchant Magazine is there to report it.

March 1982. The Merchanl comes full circle by inspiring a sister publication, Building Products Digest, which initially concentrated on the same 13 southern state territory as the o\d Gulf Coast Lumberman.

December 1993 . First pull-out, wall-hanging Deluxe Industry Calendar of Events.

October 1998 First Traders Preview for NAWLA Traders Market.

April 2001 New publisher Alan Oakes replaces retiring David Cutler.

June 2004 . First "Competitive Intelligence" dealer profile by columnist Carla Waldemar. She's currently at 98 and counting.

May 2006 Relaunch of The Merchant's website, Buildins-Products.com

February 2007 First "Olsen on Sales" column by James Olsen. He's recently compiled the 55 best into a new book-An Unfair Fight: How Winners Sell & Sellers Win.

THE FOREST

TO THE FRONT

dM quality dmdcds cnd Bed Biver's €rtqblished policy ol iorest con. 'quANTtTY WTIr{OIIT OF QUAIITY" ig the rule {foshrcod '?ol 3uyat" CALIFONNIA PINES Solt Poadcrq 6d Sugq Pite r*o noffT:dplYwooD VENRNAN SLIND SLATS

It ge! up @ily atd Inst. All oI tle advdiagos ol buildiagr witL wood ue re taiaed whea Wolmmi:ed Luber is enployed. Ii stayr up, beaw Wolmanized Lumber addg the at'tut to witL*nd d@ay and termits attack. Wood colsttuctior is being eoployed rlere tle eositid ol wd do d6udiag apeedy *etio ol &uctlra lor houinq wu itrdustdes. Wolmanired Lumler eues loog poatvlr liit ol lh@ bdldilgs od trow upl*p c*ts, De riges oI th€s rb!ctu!* ae lokiry to th6 futue. Adrertiroments lile lhat !how! boF e lelliBg this 8b!y to rd{oatructiot oq bulaemo ard iadusirlelirt!, WCre outidg oa you lo supply &e 1*twu deaad lor Woldeizod Lubsr wiicL thid 6dEfiiring is L6tpit q io @l€, Amdic& Lmb* & Tralag Cmpaul I448 McCornict< Buit'*iag, Cldcagq trlimis, lo AryLr: 16l SS Biod'.t Pf,aFt 1363 $n!r@r 116 Xd tditonq SL suhr 1026

llEa sm ft e@tfloi @hw6DtdffitK. €..r*n *,,.r*,

RTD RIYER LUIISER (0.

THE WAR EFFORT was a huoe consumer of lumber durino WWll.

H. W. KOLL MILL & LUMAER COMPANY E'5i6 rcare KUX E ry M IN W ''flreF WG|.f NR Uru LOt AiCErS 6a c&aFoilr^ PFoE&rffia-tAZ

&rs. 6. 1950

Od1lorala Lb?. Idcb.Dt IOt t-t 6tb gtlcd tro. lo8cld. CautoEt! CGtIE!

I haE at la.t pt Er.!.t h a I'c.Ltto to IEJt ysq b tuu. for tht eEt I or€al tm rlo I ba ry fl'Ecnrl rrrttr.. baol f! 19P.

Pt.G.r tlail .qclo.cal ry ct.cL +L1r. rhfcb 1r lryrd b nrll. yltfr@t 1atc..t. scalallnc to ry tacdd.ToFr vcjr trclgr.

&rildir4rhodudsom AS A TESTAMENT to the integrity of the lumber industry, Koll Lumber Los Angeles, Ca., sent in this letter and a check for $493.05 as backpayment for ads he placed in The Merchant 30 years prior.

'li[ood lor the Wq Mccbbe utiliti:es Red River lccility to copacity. od shipping rcor& cs broke& but lbere is ao let

**@***

luty?f,l2 r lhellhrdrantlrhazine t 9

ls nanotechnologythe next front in wood preserving?

L.TorrNc rHE PoPULARtTv of wood I \ oressure treated with micronized *ood p."r".vatives, researchers are experimenting with even smaller "nanotech" particles, to further prevent leaching.

A team of Michigan Technological University scientists is preparing to reveal their findings, following a fiveyear study of nanotechnology in wood preservation.

"It's a new method that uses nanoparticles to deliver preservatives

into the lumber," said chemistry professor Patricia Heiden. "In our experiments, it reduced the leaching of biocidesby 9O7o;'

The nanoparticles are tiny spheres of gelatin or chitosan (a material found in the shells of shrimp and other shellfish) chemically modified to surround the fungicide tebuconazole. The little spheres require no special handling.

"You just pressure-treat the wood in the usual wav." Heiden said. "We

used tebuconazole as an organic preservative-donated by Lanxess Corp., Pittsburgh, Pa.-and copper oxide nanoparticles we made ourselves as an inorganic preservative. Our main goal was to study how we could reduce the leaching."

The initial tests show that nanoparticle-treated wood is just as resistant to rot and insects as conventionally treated lumber. The researchers have now moved their tests from the confines of MTU to the warm, wet weather of Hawaii. "Most of the work is already done. but we are testing a few other things out of curiosity," Heiden said.

The research is funded by the U.S. Environmental Protection Agency, under the program name "Environmentally Benign Manufacturing & Processing 2005GO-A1." The preliminary study was completed last year and one group of findings has been published so far, with several more in the offing.

The researchers had completed similar studies before, using petroleum-based components and dilute conditions. "We used gelatin and chitosan (biopolymers) and methyl methacrylate (MMA, which is petroleum based and is used to make plexiglass),"

Heiden explained. "We made the nanoparticle in water by a simple combination of gelatin or chitosan with methyl methacrylate, an initiator,

Pressure Treated Wood

10 r Ttlelylerdrantlilagazne r Ju!2012

SCANNING electron microscope shows the interior section of a nanoparticle{reated field stake. The small white spheres are the numerous chitosan/methyl methacrylate nanoparticles inside the wood.

BuildiqrRodudsom

and the tebuconazole biocide and heated for a few hours. We then isolated the nanoparticles or diluted to the appropriate volume to treat the wood. We found that these nanoparticles reduced the leaching by 9OVo or so, and were effective in soil jar studies. We have treated field stakes to make sure we could penetrate wood completely, but did not do field studies."

MTU scientists initially tried to use some commercial copper-based preservative systems, according to Heiden, "but they were highly formulated and we did not always know with what, so we made a simple 'inhouse' ACQ system and also a simple copper oxide nanoparticle, made in a solution method rather than by any sort of a mechanical reduction system of copper carbonate." She found the results "rather surprising," saying that the nature of the copper oxide surfaces influenced how much the nanoparticles leached and promising to share further information in the coming months.

Here's what she can divulge: "The organic nanoparticles definitely reduce leaching of organic biocide, and the reduction is substantial compared to a straight solution or emulsion treatment of organic biocide, even without the use of a surfactant. In our work, we found that the use of a chitosan shell did not reduce the leaching of copper oxide nanoparticles."

John Lounsbury, managing editor and co-founder of Global Economic Intersection, speculates that the new technology could result in preservatives that are both more effective and more affordable. Current preservatives for residential use, says Lounsbury, "are much more expensive than the older most common compound used before 2004 (CCA), so manufacturers try to use less of it. That leads to at least 12 different grades of treated wood product today and makes choosing the correct wood for each application a process that requires greater care."

So while he optimistically has his "fingers crossed" about the viability of nanotechnology, questions remain: "How expensive is the nanotech process?" he asks. "Does the reduced leaching mean that much less of the expensive treatment chemicals can be used? And, can nanotech processing mean that more toxic chemicals that have been phased out-or never

Two Coat Exterior Prime

0ur two-coat process starts with an alkyd sealer to btock tannin migration, fottowed by a high-performance acrylic primer. The result: RESERVE quality, inside and out.

Superior Wood

Made of quatity, clear, finger-jointed Western Red Cedar or Redwood, these products are natural.l.y designed for exterior use-both species are ideaI for endurinq extreme weather.

Surfacing + Sizes + Lengths

RESERVE products come in a wide range of sizes, lengths and finishes. Whether the project catts for 51S2E or S4S, we offer tengths ranging from 16' to 20'. Pattern stock is atso availabte.

1,x4 - txt2 s/a1aA, - s/axl)

2x4 - 2x],2

The Finest Stock, The Best Coating

Our Siskiyou Forest Products RESERVE line is specially manufactured and treated to create the highest quality product available. Using state-of-the-art application and curing equipment, our premium Western Red Cedar and Redwood stock is made to last for many generations. We are proud to offer a beautiful, durable product that is ready for installation and final painting the moment it reaches the craftsmen.

hrildinghodudsom

S I S I<IyOU. FoRE ST. P RoDUCTS www.siskiyouforestproducts.com 400.427.8253 . 6275 Hwy 273 Anderson, CA 96007 JuU 20f2 r lhe lvledunt ltlagadne I 11

By Carla Waldemar

Downsize? HeGk, llo. Expand!

fnv Suonr is making lemonade.

j When the economy turned sour a few years back, the president/c.e.o. of Tifton, Ga.-based Short & Paulk Supply Co. didn't waste time in wringing hands.

"Sure, it's bad," he acknowledged, then moved on. "Focus on things you can control. Find something that works. We're aggressively trying to grow, looking for opportunities."

He professes: "When things slow down, you've got two choices. You can considerably downsize your business or you can find sales to keep it going. Study the numbers, the demographics..."

And then, open a new store. May 4 was the grand opening of the new Dawson, Ga., location, after S&P purchased and remodeled a former hardware store as its fourth location. It joins Albany (where Jay picked up a closed yard in 2010), Sylvester (launched by his father in 1985), and headquarters in Tifton, as well as a truss plant and door manufacturing plant.

Now well into its third generation-Jay joined his dad and grandfather in 1989 after graduating from the U. of Georgia and bought his dad out in 2008-the operation originated in 1941 with three employees. Back then,

its phone number was 97. Today Jay Short V signs paychecks for 55 coworkers and the phone line (10 digits) takes a back seat to the Internet.

But what hasn't changed is the philosophy instilled by Jay's grandfather, which Jay recites: "Sell good products, unite with good, accountable suppliers, and treat folks right. If you do that, they'll come back. We focus on imparting that to our employeesto do what we say we'll do, at a competitive price and with top-notch staff. If there's a problem, it's an opportunity for us to solve it."

Each location serves a slightly different market. Dawson, set amid farmers' fields, is unique in carrying feed and seed. Albany's larger footprint of rental units sends S&P a hunk of commercial repair business. Sylvester, a small, rural town, carries 'tust about everything, including coffeemakers," laughs Jay, while Tipton focuses on the new home and remodeling slice of the pie.

Meanwhile, the truss plant, established in the early '70s in Tifton, supplies all four stores, plus other independent dealers beyond a radius that deflects competition. The door operation, relaunched with new equipment in 2008, "is mainly for our customers," Jay explains-"a low-volume shop that gives us control over the quality of the work and a quicker turnaround time. Before, when we dealt with special orders, a six-panel door, with one available hardware style and one style of moulding, took two to five days to reach us. Now, it's a dayand-a-half turnaround, with six different frames, four or five different hardware options, and l0 to 15 door panels. There are some cost savings, too. And, with the trusses, we can offer one-stop shopping.

"We've always concentrated on new construction, and, l0 years ago, it was going at a really good clip. Now, we're going after other avenues: institutions - schools, hospitals; commercial, like the apartment market; the remodeler, and the d-i-y folks. And each of our locations has something a little different to offer."

Add it all up, and you arrive at S&P's potential customer base, which Jay defines as "anyone alive and breathing with a good credit record."

To go after the remodeler, S&P has reset its inventories and showrooms. (They've recently changed to affiliate with Orgill.) "To keep moving positively. we market to new homeowners,

COMPETITIVE

12 r Ihe lvledEnt Wazine r tuly 2012

SHORT & PAULK Supply cut an l-joist May 4 to celebrate the opening of its newest location in Dawson, Ga.

BulHlry-Rodudsom

not only builders," Jay says. "We want to get our name out to young couples, to have them think of our store firsthave an opportunity to show them new products and prove we have quality people. If we get the opportunity to take on a little project, do that little repair-if we take care of that now, do the job right, then we'll build a customer. And five years down the road, when things have turned around and they build a house, they'll think of us."

And how to reach these 20-somethings? Social media, duhl Sure, TV and print ads, but more to the point, YouTube videos, Facebook and Twitter messages, blogs, web offers and instruction. "I do a lot of the marketing myself," says Jay, who appears on talk shows and You Tube features, "but I've got a l4-year-old marketing manager who's very good with computers." Happens to be his son, Jackson.

"Our philosophy hasn't changed, but technology helps us do it better-for instance, inventory control and dispatching," Jay continues. "It makes us more efficient, but still in tune with my grandfather's ideals: Make sure you greet people, stay on top of them. We have a crew in the front of the store for the retail trade, and salesmen in the back office to assist builders. We sell the same commodities as everybody else, but the difference is, we do what we say we'll do. We really, really focus on service. Plus, we just joined LMC, whose buying power allows us to offer better pricing."

What about the touted green market? Jay Short prefers to take a practical approach. Rather than jumping on the bandwagon of hype, he opts to offer selected services S&P

calls Living Smart. "I find so much conflicting information, so much uncertainty and 'greenwashing."'Thus, he's chosen the middle road, aka "helping the customer live better"-light bulbs, air filters. "You might not replace all your windows, but there's weatherstripping, insulation" and the 40-gallon challenge he spotlights on talk shows.

The new Dawson store fits the conservation mode. "The existing store had a lot of opportunity to it. It's in a growing area we already serve, 20 miles from Albany. It could be the feeder store down the road-location, size, everything. What we did is, open it as a pick-up yard, with a pick-up truck. If it sells a roofing job, they'll get a delivery from Albany. But it can also save builders from running 20 miles for a couple of 2x4s. At our grand opening," he chuckles, "we didn't cut a ribbon. That's for jewelry stores. We cut through a I l-7l8-in. joist with a chainsaw!"

In these trying times, efficiencies have kicked in all across the board. "We're working at 110, l20vo,and we all change hats every 30 minutes," he laughs (sort ol;. "You learn how to do with a lot less."

The results from the new marketing push are in: "One-third of last year's business came from clients we didn't even have three years ago. You try to grow, but very carefully. And," he underscores," we're growing!"

Carla Waldemar cwaldemar@ comcast.net

PST is lacoted in Weed, CA, the historicol heort of the West's timber cauntry, ideolly situoted on Interstote 5 to seNice 0ll of California and the Westem U,S,

PRESgRVED WOOD PROOUCTS

I GREEll| IF?f,ITUEII

. NolureWood. Uond ACO trcofed prcducts

.fi,!ffiitril1=1J}tffi;

Producls lmpeclion Agenq (IP) ! trrtxrl#l;1f*l$H"6 trm"

THIRD.GENERATION owner Jay Short V is flanked by sons J.P.Vt (eft), a high school senior, and Jacksoh (right),his 14-year-old marketing jurJ.'

&riHlrphoduclsom

@

SHEATHING rolls out of S&P's headquarters yard in Tifton, Ga.

I NAHB r I nESEARCH I I cENTER

luly ?{|.lZ r lhe lylerdant tllaSadne I 13

Give your lumber racks regular check-ups

support some loads, but possibly not the maximum design Ioad.

. Make sure the racks are being used as intended. Are loads properly positioned? Are loads exceeding the designed weight? Is the rack designed to accommodate that type of product?

In a lumberyard or warehouse, information as to how much a load weighs is not always immediately available. One way to detect overloading is by measuring the amount of beam deflection present. All load beams will and are allowed to deflect, or sag, a certain amount. According to the Rack Manufacturers Institute, a roll-formed beam has an allowable deflection of the length of the beam divided by 180 (i.e., a 10-ft. beam would have an allowable deflection of two-thirds of an inch). If the deflection is greater, the beam has been overloaded.

REGULARLY review all racking for signs of damage and deterioration or for improper loads.

p ecr SAFETY should be a primary concern at all luml\bervards and home center warehouses.

FBS b.oup, Chicago, Il., which provides rack protection products and conducts rack safety inspections, suggests regularly reviewing your racking for signs of damage or deterioration.

Inspections should include:

. Look for signs that the rack's structural integrity has been compromised. Lumber racks, like any other structures, depend on their form for their structural integrity. Once their form is compromised, their load-carrying capacity decreases. And once a rack member deteriorates, it may no longer carry its rated load.

Most rack damage occurs gradually. It's easy to spot and recognize the need to repair, say, a frame leg that has been struck so forcefully that it's now bent to the point it's no longer touching the ground.

Less obvious, but perhaps equally in need of repair, is the frame or beam that has been banged into repeatedly for months or years and appears "merely" dented. It may still

Identify any loose, missing or damaged fasteners. Forklift impact can shear off anchor bolts or disengage load locks, snap locks, and other locking devices designed to prevent beam end plates from being lifted up and separating from the slots in the column.

. Ensure accessories are not missing or damaged. Accessories such as wall ties, cross bars, wire mesh decks, pallet stops, corner guards, and other impact protectors are usually installed to protect the rack structure or enhance safety.

. Pay special attention to any modifications to the original rack structure. The primary areas of concern are non-engineered additions that introduce loads to or change the original structural design of the rack system. In particular, welding anything to a rack, even if the addition seems to be of inconsequential weight, can drastically affect the member it is welded to. And, the weld itself can also be a problem.

If columns have been repaired, make sure the kits were installed properly. FBS inspectors have observed column repair kits installed without a splice cuff, with all or parts of the backer column removed, and lacking the specified weld per the manufacturers specifications.

MANAGEMENT Rack Safety

14 r lhe Mednnt Magafie r July 2012

&lldlng.Rodudscom

: Kiln-dried upper-grade siding

I Lurury interior moldings, fascia and trim

t B, Heart B, Clear and Clear Atl Heart grrades

I Vefiical grrain available in all upper grad,es

I lxZ thru lxlZ; 2x2 tluu 2xl2

I Green and air seasoned decking up to 20'lengths

lr fimbers up to 12" xl?" x24'

I Rail-car service and fleet trucking available

we can match vtrtuatly any pattern elver made - call ls today!

$armill Sales 31401McCrayRmd POBor 158 Clwerdale. CA 95425 ?0?49it-43itl wrr.buyzeduood.corn Redwood A {t?. of D|/crlc trAIES tNttusttts, ${

Proper care and feeding of your sales force

t o w il

:""$JS lYi,i:f ::""xl."xJi: f

?:','iK

ffi

i sell." I've heard a version of this statement from many managers. These same managers are disappointed in their team's results. There's an Egyptian saying: "Giving friendship to a man who is looking for love is like giving a loaf of bread to a man who is dying of thirst." Giving merely "tools" to your team is the same thing.

Salespeople need tools, yes, but what they need more than tools is attention. Your sales team cannot pay attention to itself. That's your job. Telling them what to do and walking away is not management and will not deliver the kind of results you want.

If you want extraordinary results from your team, you will have to give them extraordinary attention (and caring).

Respect or Cogs?

Some managers have the attitude (sometimes even voiced aloud): "You're lucky to have a job." If you say this to any good salesperson, you are saying *#*@Vo you" in their head and they will start to look somewhere else immediately, if not sooner. They definitely will underperform and passively or actively resist all company (and specifically your) initiatives.

"They want us to be smart enough to find new business, negotiate with crafty customers, solve claims without giving away the farm or losing the customer, and make a profit, but they don't want us to be smart enough to know when they are trying to slip one by us." This is a quote from a disgruntled salesperson who was getting jerked around on her commissions.

Salespeople are not factory workers. They are profitmaking partners in your business. If you treat them like

cogs in your wheel, you will self-select for low-performing cogs in the wheel because all self-loving salespeople (who are always the best) will leave your organization.

Treat your sales team the way you want them to treat their customers. If you want them to give their customers their all, you will have to give them your all.

Spouses & Children. Do you know anything about your team members' families? What kind of support do they get at home? Show a genuine interest. If you have a good relationship with your team member's family, you will have more (positive) influence on that salesperson.

Making your team's families feel like "part of it" will also create more loyalty. Company bowling nights, picnics, holiday parties are all easy and effective ways to bring your team together-but you must be present and active at these events. You are not an "event planner." You are a leader who makes individuals feel your presence.

Lunch. There are approximately 22 wotking days in each month. That's 22 lunches you can have with individual salespeople. These are not "business" lunches. This is not a review of their progress at work. Talk about everything but work-make a point of it. And talk about what your salesperson wants to talk about-just like we would with a customer. Weird, huh?

Contests. Salespeople love to compete. Go as heavy on contests as you can. Salesman of the morning, day, month, year, department. Top new salesman. Make sales teams for contests. Make teams matching your top guy with your bottom guy and on down the line to create camaraderie.

Love & Favoritism. UCLA's John Wooden struggled for years with the fact that he liked some players more than others. He didn't want to play favorites, but knew in his heart how he felt. His initial philosophy was, "I may not like them all the same, but I treat them all the same." He was still uneasy. Years later, he hit on a better philosophy: "I don't r like them all the same, but I love them all the same."

Great managers have this attitude. Who they like has nothing to do with it. They give attention, caring and love to all team members and get world-class results in return.

James Olsen Reality Sales Training (s03) 544-35'72 james@realitysalestraining.com

By fames Olsen

" "dd;{dFftt-

By Cregg Thompson

Are you receiving great leadership coaching?

\Zo, KNow you ARE getting great leadership coaching I when...

1. ... you are in the pit of despair. Many of your basic beliefs and assumptions about your role as a leader have been challenged, and you feel like you are losing your footing. You are seriously questioning your career to date and your personal aspirations.

2. ... yo, are really excited about the future. You don't know what the next chapter of your leadership career is going to look like, but you do know that there is no going back now. Something new and fresh awaits you.

3.... you are angry, frustrated and ready to fire your coach. None of your expectations for great pieces of advice and insights have been met. All you get are annoying ques-

between the leader you are and the leader you can be. You've taken stock of your talents and strengths, and realized that you can have an enorrnous, lasting impact on your organization and the people in it. Very cool

6. ... you are shaken by some sharp, gut-wrenching feedback. It's getting tougher to dismiss this feedback as the product of people who simply don't understand you or who have ulterior motives. What if this is actually true? What if I am wrong?

7. you are feeling energized and powerful. No longer a victim of organizational circumstances, you now have options and alternatives. You are committed to making your own choices and crafting your own leadership story. Wow!

8. your personal life has become brighter. You now show up to your friends and family as a kind, caring and patient person who sees the very best in them and continually seeks out ways to serve them. You have realized that you can only be the best possible leader at work by being the best possible person at home.

9. you have stopped wasting your precious time and energy. You have embraced your emotions and become their master, not their slave. You have ceased to bum emotional energy reacting to organizational issues that you cannot influence and people you cannot control. You have developed an inner muscle that gives you the strength to choose your own best leadership actions and reactions.

tions like, "What will happen if your performance as a leader does not change?" and even more annoying statements such as, "I think you are much better than this."

4. you are feeling a little sheepish. Your coach has called you on the many ways you sell yourself short or get in your own way, and you havejust realized you have been blaming others in the organization for holding you back when, in reality, most of your limitations have been selfimposed.

5. you have a renewed excitement about yourself as a leader. You have just realized that there is a huge gap

Development

le ers, sloths and misfits that used to be ever-present are now gone and have been replaced with wonderfully creative and highlyengaged teammates. Interesting! &\,t Building-Productsorn luty?|.lz r lhet{edantwlagazine r 17

tp

Gregg Thompson Bluepoint Leadership

10.... remarkably, the peop around you have changed for the better. Somehow, the under-perform(513) 683-4702 greggthompson@bluepointleadership.com

75-Year-Old Northern California Dealer Closes

DeCou Lumber Co., Atascadero, Ca., filed for bankruptcy June 5 and will close after a liquidation sale is complete. The company owed about $1 million to Mission Community Bank and an additional $300.000 in merchandise was not paid for.

"Some people have been shopping here for 40 and 50 years, and they're devastated," said president Jay DeCou, whose family purchased the business in 1937

DeCou said that the market doesn't carry the demand it once did, and competition with national retailers and online suppliers has been tough. "I've lost hundreds of thousands of dollars in lumber sales to the Internet," he added, noting that online outlets can offer cheaper prices because there is no sales tax.

BMD Buys Fastener Firms

Building Material Distributors, Galt, Ca., has acquired Master Fasteners International, Long Beach, Ca., and sister company Fastener Source, importer/wholesalers of fine wire and pneumatic fasteners with a DC in Memphis, Tn.

BMD will be merging Fastener Source under the Master Fasteners International name, and will operate the company as a wholly owned subsidiary of BMD.

"We believe that Master Fasteners' proven capabilities in the fastener market align very well with BMD's strategy and enhance our ability to drive value in the channel by making our customers and suppliers more successful," said BMD president/c.e.o.

Jeffrey Gore. "Master Fasteners adds to our already significant capabilities in this product line, with a depth of technical expertise and strong channel partnerships that clearly open up new markets and opportunities."

BMD operates DCs in Stockton, Riverside, Eureka and Visalia, Ca.; Colorado Springs, Co., and Santa Fe/ Albuquerque, N.M.

Historic Yard For Sale

The family that owns Mill Valley Lumber, Mill Valley, Ca., has put the 120-year-old business up for sale for $1.8 million.

"As a family, we've decided that it's time to have closure and end on a high note instead of putting more money into this business and never

seeing it back," said general manager Dan Cerri, who has owned and operated the business for 14 years with his father, Tom, and his brother, Tony. "We're trying to find someone who can buy it and maintain it as a lumberyard, to continue its history."

As the sixth owners, the Cerris had anticipated passing the family business on to the next generation, but the recession erased that hope.

Colonial Lumber, san Mateo. Ca., is closing with the retirement of owner Jim Baly. His grandfather, Hal Baly, co-founded the company in 1953.

Builder's Surplus NorthwOSt has opened in Chehalis, Wa. (Larry Ledl, mgr.).

Hoyt Lumber closed its Upland, Ca., yard June 1, but continues in Rancho Cucamonga, Ca.

The Upland yard, opened in 1929 by Rugg Lumber, was acquired by Hoyt in 1996.

Old West Lumber, choteau, Mt., held a grand re-opening June B to show off its extensive remodel.

The renovation doubled the size of its showroom to more than 2,400 sq. ft. and expanded inventory, courtesy of OrgillHardware.

Scarborough Home Center, Scotts Vallev, Ca.. late this summer will open two +2OO-sq. tt. Carmel Ace Hardware stores in the same Carmel, Ca., shopping center-one focusing on hardware, the second on home & garden, outdoor living, outdoor power equipment, and patio furniture.

DOMESTIC SALES: Jerry Long, Michael Parrella, Janet Pimentel, Pete Ulloa, George Parden, Vince Galloway, Chris Hexberg, Matt Wright, Bert McKee, Joe McCarron.

INTERNATIONAL SALES: Nestor Pimentel.

Orchard Supply Hardware, San Jose, Ca., plans to expand beyond California to the Pacific Northwest in 2013.

ProBuild Holdings cut 127 positions at its Denver, Co., headquarters, primarily in the finance, marketing and human resources departments.

Anniversaries: Dunn Lumber, Seattle, Wa., 105th Mead Glark Lumber, Santa Rosa, Ca., 100th Wholesale Builders Supply, Las Veoas. Nv., 40th Escondido Buildinq Materials, Escondido, Ca., 35th l. Barrelhead Building Supply, South Beach, Or.,35th...

TUMBERCOMPAI{Y

lt r The Dledtant l4agazine r luly 2012 Buildit4rhoduclsom

14023 Ramona ) P.O. Box 989 l Chino, Ca.977L0

Unlilre Falre Shaftes, Cedar $hakes & $hingles are Gsnuine!

Real lfaGk RgCOfd used, tested, and proven for centuries!

Bgal Pf0tgGli0n Higt"test wind resistance, highest insulation value, available with Class 4 Hail Resistance and warrantied Class A Fire Treatment

Real LOW MaintenanGe Avaitabte with 50 year warrantied factory pressure preservative treatment, virtually eliminates upkeep.

Bgal BgaUly Natural Endurins charm, often lmitated, but never Duplicated.

Bgal ECOl0giG0l n truly renewable resource, lowest in energy use and pollution in production.

Real UalUg Check with your distributor for cedar prices compared to fakes, or contact us for supply assistance.

) \ \ n 'A

t EIi &+ forcstry luovatiorr lrrwctionl F

Gompliance or leadershi p?

Cl t,q,ntrxc FRoM A cleau slate confers all sorts of beneL)fits. For new merchants, those just starting up (a rare breed, I know), it's relatively easy to develop a green business model and brand, stock only greenest-in-class products, and forge winning customer relationships with green bui lders and remodelers.

For those saddled with the baggage of history, existing customer and supplier relationships, and predictable revenue streams, it's a different story. How do you green your product lines and bring your existing customers with you, while appealing to a new breed with rising green expectations?

We've been dealing with these questions in this column for the last several years. Based on personal experience, as well as observations of what has worked for others, we've drawn the conclusion that any merchant can become a green merchant and, inevitably, every merchant must. But it is a difficult journey fraught with many compromises. The recent kerfuffle over a new credit category proposed for the latest incarnation of LEED 4 highlights one of the trickiest.

First, the kerfuffle. Without getting too bogged down in technical detail, the main issue is the proposed "Avoidance of Chemicals of Concern" credit, which aims to raise the bar on indoor air quality by eliminating certain chemicals in emitting products and that certain products include disclosure of chemicals used. In one part of the proposal it references REACH, an European Union program that monitors chemicals.

The American Coatings Association took exception in widely publicized comments it submitted to U.S. Green Building Council, arguing that compliance would hurt the market. They suggested an alternative, compliance with 2007 California Air Resources Board Suggested Control Measure. Even 61 members of Congress got involved.

There are two points to be made here. First, let's recall some recent compliance history. There were a few industry leaders who saw new CARB regulations coming in 2007, did nothing, and were forced to take back their non-compliant product from retailers' shelves and distributors' warehouses. Second, LEED does not require compliance. On the contrary, it aims to identify leadership-that's what the "L" in LEED stands for-and more to the point, it is voluntary. No manufacturer is required to make, test, or certify

products that meet LEED credits. This is an all important difference that separates compliers from leaders.

For merchants trying to create a winning, green formula, being able to identify the difference between products and manufacturers aiming for compliance, and those focused on leadership, is crucially important. Who would hire a builder or an employee whose main selling point is compliance with minimum regulated standards? Don't we all want to work with leaders who go beyond the minimum and set their own standard? Don't we want to be leaders? But the unfortunate reality is that because of longstanding channel marketing practices, with manufacturer spiffs, promotional deals, brand or industry dominance, and so on. this is also an area where compromises are inevitable. And probably, there are long-term relationships involved, too, which can make it tricky.

So, what to do? First, develop an understanding of current vendor relationships and identify the manufacturers with a commitment to continuous product improvement, innovation, and leadership. Second, start strengthening relationships with the leaders and collaborate on new programs wherever possible. Third, identify gaps and seek new greenest-in-class alternatives in every category. Fourth, engage those manufacturers in the compliance camp and encourage a change in their product development philosophy. You never know, they just might listen. Finally, develop a Iong term trend toward greenest-inclass products. It may be tricky to manage existing relationships and the short-term benefits they confer, but in the end, working with leaders delivers its own rewards.

Jay Tompt Managing Partner William Verde & Associates (415) 321-0848 info @ williamverde.com

By f ay Tompt

20 r The lvledrant t*hgadne r July 2012

Bnilditrg-hodndsom

www.williamverde.com

W customer wants a deck mrfdo br peaceful rdatation srd frlendly gref.rsingg. Phstic lurnber? | don't thlnk so. I want to make sum this deck ts strung and durable wlth natr.nalwamth, beauty, and lastlng charactsr. And I earg about the environmqrt and so does rny customor. That's why this deckis gohg q be bulft wfth F$Ca certlfied sustalnabls Humboldt Redwood.

Ard trtpn lt omes to stuctural support, I choose FSC chain*of-uustody certiffed Allweather Wood pressure-treated tumberfo,r long-lastlng rasistance to tennites, rot and decay. Humboldt Redwood and Allweatfrer Wood, fo'r me and my customers it's an unbeatable combination,

Oon't your

contractors deserve thE best of both wds?

Nrh !!c l-tNe ffiw*

,i4 -LU E, ,f ,t (1. \,r 1{ t,. |..i:,' \ (..aa,a ,. | -t

wrv,val@ant unrw.gstru*rood.com/melclent

Hurnboldt Redwood

State of Affairs lnterview

with APA president Dennis Hardman

A PA-THe ENcrruseReo Wood AAssociation president Dennis Hardman recently shared his views on the state of the industry and the association:

Q: It's been a tough few years for the structural wood panel and engineered wood products industry. What's your assessment of the challenges facing the industry at this point?

Hardman: Where do I start? Market demand, of course, is still the primary problem. North American structural wood panel production last year was 26.07 billion sq. ft. on a 3/8" basis. That was almost identical to 2010, and we're still way below the 43 billion ft. at the peak of the housing market in 2005. So we have a long road of recovery ahead of us.

There is also the ongoing challenge of safeguarding industry interests in codes and standards. Recently, for example, we've been working to gain fairer treatment of wood products in the International Energy Conservation Code. In addition, the industry faces numerous regulatory challenges, such as the Boiler MACT issue, ever more stringent formaldehyde emissions limits, growing green building requirements, among others.

And there is the continuing federal timber supply problem in much of the West. So there's no shortase of challenges.

Q: What's the industry production forecast for this year and beyond? Are things looking up?

Hardman: We're now forecasting U.S. and Canadian plywood and OSB production to rise this year by about 1.9 billion sq. ft., and to continue to increase next year and beyond. By

2016, we expect U.S. and Canadian structural wood panel production to be back at around 37 billion sq. ft., or about a 4OVo increase from 2011.

Q: What about the other engineered wood products that APA represents?

Hardman: Same thing. Glulam, wood I-joists, and laminated veneer lumber should all experience strengthening demand as the economy in general and the housing market in particular improve. Production of I-joists looks especially promising, almost doubling by 2016 from the 2011 volume.

Q: So, you're expecting some improvement now in the housing market?

Hardman: Yes, we believe we have hit or are very close to hitting the bottom of the market. We're forecasting a l5%o increase in U.S. housing starts this year compared with 2011. Looking farther ahead, we think U.S. single-family and multifamily starts could reach 1.4 million by 2016.

The problem right now is the continuing high inventory of unsold existing homes, including the millions that are in foreclosure. We also need to see stabilization and then increases in home values in order to renew consumer confidence and investment.

Q: What about exports? Those have been strong, correct?

Hardman: Yes. North American plywood and OSB exports, excluding shipments between the two countries, totaled 1.23 billion sq. ft. last year, the highest volume in l2 years. That's been fueled by the weak domestic markets, which have made manufacturers here more aggressive in selling

overseas.

As domestic demand improves, more of that product is likely to remain in North America, so exports are expected to slow. Conversely, imports have declined recently, but are likely to pick up again as the North American market improves and becomes more attractive to offshore producers.

Q: The industrial market is especially important to plywood manufacturers. How's that market looking?

Hardman: Solid. Demand in industrial markets declined by about 7Vo and 87o, respectively, in 2008 and 2009, but rose by 6Vo in 2010 and another 3Vo or so last year. We expect the rate of growth to remain at about 3Vo per year over the next several years.

Q: You cited regulatory matters as among other industry challenges, including energy codes. What's the issue there?

Hardman: That has to do with the International Energy Conservation Code. or IECC. which in late 2010 approved changes that in effect unfairly favor foam sheathing over structural wood panels. We did a study that indicated those changes could represent a potential U.S. market demand loss of approximately 905 million sq. ft. of structural wood panels. That's almost 2OVo of the structural wood panel wall sheathing market. So it's a big deal.

Q: How are you addressing that challenge?

Hardman: We helped last year to establish an independent coalition of wood products industry manufacturers and associations, called the Coalition

APA on Engineered Wood

A2 r The tvlednnt ttlag*re r luly 2Ol2

&rlldhgrhodndsom

for Fair Energy Codes. It has a twofold purpose: first, to ensure that identified priority states adopt energy codes that allow for the continued use of cost-effective building envelope design options that include oriented strand board, plywood and lumber framing, and, second, to influence development of future energy codes, including the 20 l5 IECC, to ensure structural wood products and systems are appropriately regulated and not disadvantaged in their acceptance and use in the marketplace.

Q: What does the coalition do exactly?

Hardman: It has several functions, including federal government-level education, monitoring and attempting to influence state energy codes and legislation, assembling technical data and information in support of credible energy code policy positions, establishing alliances with other industry partners and supports, and communicating key messages to stakeholder groups. I'm happy to report that our state efforts have been largely successful to date, but we still have a lot of work to do.

Q: What are APA's strategic priorities this year?

Hardman: Our priorities are based on a strategic plan that has four chief goals as established by our board of trustees. The first is maintaining an independent certification program that assures member compliance with product and performance standards, and that also performs a leading role in setting industry standards.

The second is protecting and growing wood product market share. The third is strengthening the voice of the industry through APA membershiP expansion and strategic partners. And finally, the fourth goal is exercising fiscal responsibility and maintaining organizational effectiveness.

Q: You mentioned membership expansion. Has APA's membershiP been affected by the recession?

Hardman: Actually, we've increased our membership quite substantially, with approximately 20 new member mills added to the ranks since 2009. Those are fairly evenly split between the U.S. and Canada, and represent most of the products for which APA provides services. During that same period, we have not lost a single

mill other than through closure. So we're quite proud of that record.

We consider it a remarkable statement of faith in the strategic direction and value proposition of APA during a period of extreme financial pressure on most wood product manufacturing companies. Our strong membership base positions APA very well for the eventual climb out of this down market.

Q: You also mentioned strategic partnerships. What are some of those and what are their purposes?

Hardman: One of the longest standing examples is our participation in the USDA Foreign Agricultural Service cooperator program, which each provides sizeable grants in support of our international market development efforts.

Another example is the Wood Products Council, of which APA is a charter member. The council administers a nonresidential construction market program, called WoodWorks, that is designed to increase wood product demand in that market.

Still another example is the Canada Wood Group, an alliance of mostly Canadian wood products industry associations that coordinates funding

&rildirtg,Produd.om luly20l2 r The lt{etdtant ltlagazine r 23

for inte rnational market development projects sponsored by the Canadian and British Columbian governments.

APA is a member of the Coalition for Advanced Wood Structures, a university, industry and government partnership whose mission is to identify and executc cooperative rcsearch and tcchnology lcading to improvement of wood structures.

Wc also have a close relationship with industry supplicrs through the E,ngincered Wood Technology Association. which is a related APA organization that serves as a networking ancl inforntation exchange vehicle fbr manuf-acturers and suppliers.

And also. as I mentioned, we participate in thc Coalition for Fair E,nergy Codes in partne rship with the American Wcxrd Council. In lact, the day-to-day opcrations of CFEC are managed by an APA staff member, and APA provides program budget accountin{r and financial reporting services fbr the group.

We also have longstanding rclationships with the U.S. Forest Products Laboratory, American Wood Council. Green Building Strategy Group, Institute for Business and Home Safety, National Association of Home Builders,

Canadian Wood Council, American Forest & Paper Association. and FPlnnovations in Canada, to name a f'ew.

Q: With regard to organizational effectiveness, how has APA adjusted or responded to the budget constraints that you must have faced when the economy collapsed?

Hardman: Well, like almost everyone elsc in this industry and throughout the country. we had to go through somc painful staff and budgct cuts, and then adjust our priorities in accordance with thc most important needs of our members. That gave rise to the fbur-point strategic plan that I mentioned earlier.

Obviously. quality certification is among the most important of those member needs, sct we'vc devoted a lot ol' resources to makin-g sure that we continue to opcrate thc best quality certification program in the industry.

I would add that the APA board continues ro revlew incrernental investment that would be necessary to restore APA functions and activities to some pre-recession baseline level, once conditions permit. That's important to our being as prepared as possible to capitalize on market development and other strategic opportunities as the economy and market improve.

Q: Speaking of the APA board of trustees, who serves on it?

Hardman: The board is comprised of l5 executivelevel members who reflect the broad product mix, geographic range, and diverse size of APA member companies. We also have an APA member advisory committee system that is actively involved in formulating recommendations and developing program plans related to market development, technical services, quality services, glulam and Ijoist/LVL. mill safety, etc.

Q: Given the very difficult business conditions over the past few years, what APA accomplishments are you most proud of?

Hardman: I'd have to say the strong member support that we've had during this period is certainly high on the list. That speaks, I think, to the dedication and expertise of the APA staff, and also to the excellent strategic guidance we'vc received from the APA board and advisory committees.

I'm also proud that despite budget constraints. we have continued to refine and improve our quality certification services, and have remained a globally recognized leader in the standards promulgation arena. I think we have done a good job of protecting market share through a variety of highly targeted promotional programs.

And I'm proud of the increased recognition within APA and among APA's members of the importance of safety, although I really need to give credit there to former ApA chairman and current APA trustee Jeff Wagner of LP, who is passionate on that subject. Jcff was the leading force in reorganizing the annual APA mill saf-ety awards competition and in forming a new APA mill safety advisory committee.

Q: Finally, what's the biggest lesson from the last few years of depressed markets?

Hardman: Clearly, within APA, we've learned a lot about efficiencies and essential member values. As market demand improves, we will definitely apply those lessons to rebuildins.

I{,-'16 i. :'i

&'f T t ti. {\;t l',*;'t ii 'ff; 24 I lhe l\4erdrant Magazine luly 2}tz Building-Productscom

Since 1951 we'vc use.l by distrihutors, bccn mrrking cltrality' forest prodr.rcts clealers, builclers, remoelelers, and do'it-yttr-rrsclf-ers.

For ovcr fiftv years we havc tt-rllowecl the same principles: take ciire of the land an.l it u'ill takc carc of vou; strivc ftrr excellence ilnel efficiency in mtrnuf:rcturing; and trenr all strppliers and customcrs the u/:l\,'\,()u wotrl.l like to be treate,-1.

For sales call: 1-800-331,0831

www. swansongroupinc. com

SxrrM

$, $il4.

.,'i ; f Ij I rl ;r I .f'. t,.,.....,.- ';- , I

$:'*ttt,'I^

SUSTAINABTE FORE5TRY INITIAIIVE APA fHt aNGtx,6zto wooo a350cr4t,oN M ift1BIR

Structural panel and EWP demand to grow

tTt"t sLow-BUr-sre,roy improveI ment in the housing market is expected to boost demand for engineered wood products throughout 2012, according to estimates by APAThe Engineered Wood Association.

U.S. housing starts are forecast to increase l1%o in 2012 to 700,000 units. As a result, and for the first time in several years, all of the major end-use markets for wood products are expected to move in concert and

increase this year. In addition to growth in housing, demand is expected to grow in repair and remodeling, nonresidential building construction and industrial uses, as well as exports to Asia, Mexico and the Caribbean.

"There is a little more life to engineered wood demand this year. Last year, we were just treading water," said Craig Adair, APA's market research director. "This year, we're expecting demand to pick up from 47o

to llVo,depending on the product."

Although the Great Recession in the U.S. ended in mid-2009, the recovery has been uneven and only now is the U.S. economy showing signs of sustainable growth. Adair noted that single-family housing is still plagued with several obstacles, including banks that are reluctant to lend and more foreclosures on the way. Single-family construction is expected to improve in 2012, but it

APA on Engineered Wood

should have a more meaningful recovery in2013.

"It may not be a lack of consumer demand that's holding housing back; it's more likely a financial system that cunently doesn't freely accommodate residential mortgages, and it could take years to repair and reorganize the system," Adair said. Meanwhile, the demand for rental housing is so great that apartment construction has picked up, along with a wave of investment in existing single-family rental housing.

EWP, Panel Output Grows

Demand and production of North American structural panels and engineered wood products are expected to grow in 2012. Structural panels are forecast to increase 7Va in 2012 as all end-use markets demand more volume. Overall, structural panel production is forecast at 28.0 billion sq. ft. in 2012.

The outlook for glulam timber is better in 2012 than in 2Ol I because both residential and nonresidential construction are forecast to increase. North American production is forecast at 213 million bd. ft. in 2012, a 5Vo increase from 201 l.

l-ioist Production

Yesterday, Today & Tomorrow

I-joist market share is forecast to increase modestly in 2012 to 53Vo of raised floors. As the housing market improves, I-joist market share is expected to grow steadily. The forecast for 2Ol2 is an ll%o increase to 509 million linear ft.

In the structural composite lumber family, laminated veneer lumber production is expected to follow the

demand for beams and headers, rim boards and I-joist flanges. Production is forecast to increase 4Vo in 2012 to 43.4 million cu. ft.

Additional market details and historical data are contained in APA's 2012 Structural Panel & Engineered Wood Yearbook, avallable for $250 at www.apawood.org.

3'Go lor efficiency.t'

tosh Meschi, Meschi Construction

In Santa Cruz, California, Josh Meschi helps his framers and subs work more efficiently by putting color-coded information on the subfloor. (And not just any floor: pointSlX Durastrand Flooring with its innovative tapered edge.) See his system and learn more in "Three Things |tve learned: Tipr from Seasoned prosrt, one in a series of short high-value videos from pointslX and Ainsworth Engineered.

olntSIX' DURASTRANDFTOORING NOW WTH |-Y€AR t{O-SAtlD WAP;0ANTY

EIiiE ffi SCAN TO vtEwvtDEo

1.4 1.2 1.0 .8 .6 .4 .2 .0 (in billion linear ft.) hntl '98 '99 '00 '01 ',02 '03 ',04 '05 ,06 .07 ,0E '09 ,10'11 '12'13 '14 '15 '16 '17 www. p o in tsixexp e rt s. co m lj os h

Advanced Framing

New techniques boost efficienciest conserve resources

f, ovnuceo FRAMINc with 2x6 la.wood studs spaced 24 inches on center is one of the most cost-effective solutions for builders and installing dealers trying to balance energy and structural building code requirements. Installers who utilize advanced framing techniques optimize framing material usage, reduce wood waste and, with effective insulation detailing, boost the building's efficiency.

When properly designed and constructed, advanced framed walls that are fully sheathed with wood structur-

al panels, such as plywood or oriented strand board, provide the structural strength necessary to safely withstand the forces of nature.

What's Advanced Framing?

Advanced framing is a system of construction framing techniques designed to optimize material usage and increase energy efficiency.

Structures built with advanced framing techniques are more resource efficient and offer more space for cavity insulation than similar structures built with conventional framins.

Conventional framing, the industry standard for framing residential construction, typically consists of 2x4 or 2x6 wood framing spaced 16 inches on center, three-stud corners, multiple jack studs, double or triple headers, unnecessary cripple studs, and other redundant members.

Advanced framing reduces the unnecessary structural redundancies inherent in conventional framing by placing framing members only where they're needed. The most commonly adopted advanced framing technique is 2x6 wood framing spaced 24 inches on center.

Other commonly used techniques include insulated three-stud corners or two-stud corners with ladder blocking, multiple wall intersection options, single headers and insulated headers, minimal use of jack studs and cripples, and the elimination of redundant studs and unnecessary blocking and bridging.

Although some advanced framing techniques can be adopted independently, the greatest savings-in both cost of construction and energy-will be realized when the system is applied holistically.

Advanced framing-also known as optimum value engineering (OVE)was developed by NAHB Research Center in the 1970s for the purpose of optimizing material usage while maintaining structural integrity. Today, growing interest in energy conservation is leading more and more builders and installers to adopt advanced framing techniques.

APA recommends installers consult their local buildine official earlv

APA on Engineered Wood

ADVANCED.FRAMED R-20 code-compliant wall systems provide a greater whole-wall R-value than conventionally framed 2x6 walls or code-minimum 2x4 walls sheathed with foam. 2E I lhelilerdramMagazine r itlyml2

18

FIGURE I

WATI SYSTEMS THAT MEET R2O WAtt REQUIREMENTS1 (Whole Woll R-volue Comporisons)

2x6 froming 2x6 froming 24" o.c. with wood 24" o.c. with wood struciurol ponel structurol ponel sheothing ond sheothing ond double top plotes single top plotes

*Evoluolion bosed on uninsuloled heoders ond R2l covity insulolion in 2x6 wolls.

*'Represenls o typicol foom sheothed woll meeling R20 requiremenfs in occordonce wilh lhe 201 2 IECC, Toble R402. I .1 Assumes 4070 struclurol woll brocing covered wifh R2 foom sheothing.

2x4 froming 2x6 froming 'I 6" o.c. wiih R5 16" o.c. wiih foom sheothing wood struclurol + woll brocing** ponel sheothing &rildingrPndu<ls"om

froming

in the design phase to verify and obtain acceptance of 24-inch framing techniques in their jurisdiction.

Advantages of Advanced Framtng

The key advantages of advanced framing include:

1. Energy Efficiency

Advanced framing is a proven method for cost-effectively meeting energy code requirements. By maximizing space for cavity insulation and minimizing the potential for insulation voids, advanced framing delivers significant energy performance and cost savings for the builder.

Walls built with 2x6 wood framing spaced 24 inches on center have deeper, wider insulation cavities than conventional 2x4 framing spaced l6 inches on center. Increasing the amount of insulation inside the wall improves the whole wall R-value (see Figure I ).

In addition to maximizing space for cavity insulation, advanced framing simplifies the installation of insulation and air sealing. Conventional framing can leave voids and small cavities in the framing at wall intersections and corners that can be difficult to insulate and seal effectively. By installing fewer framing members, it is easier for the builder to apply complete insulation coverage and achieve a tighter building envelope.

As energy codes have become increasingly stringent, advanced framing has grown more popular in climate zones where high prescriptive wall Rvalues are mandated or desired. While framing with 2x6 studs spaced l6 inches on center is already common in many northern states with more restrictive energy demands, increasing stud spacing to 24 inches on center, insulating effectively and fully sheathing with wood structural panels, such as plywood or OSB, allows installers to cost-effectively balance energy and structural code requirements.

In addition, advanced framins can help builders meet the requirerients necessary to earn the Energy Star label for new homes.

2.Cost Effectiveness

Advanced framing is less expensive because it is more resource efficient than conventional framing. By framing with 2x6 wood studs spaced 24 inches on center, builders optimize framing material use and reduce framing installation labor.

Advanced framing can help to

Lyle Lee hos been building custom homes for over 20 yeors. Here is whot he hos to soy obout Roseburg's Engineered Wood Products.

"When building o quolity home, it's importont for oll the froming moferio/s to motch. ln other words come logelher os specified in fhe design p/ons. lf the froming is off by even o 1/z of on inch. it con cosf me lhousonds of dol/ors in time ond moferiols.

I find Roseburg's RFPI@-Joist ond Rigidlom@ lVl to be very consislenl in width ond depth. When I use Roseburg's RFPI@-Joisf my floors ore more level, stiffer ond lruer, moking my job much eosier.

fhis home is 6, 000 squore feet so I used I Jois t ond LVt from severol different unils ond the monufocturing consisfency wos exoctly fhe some. lf you wont to moximize your profit, I would recommend using Roseburg's Engineered Wood Products"

Lyle Lee

&rildit4rhodudsom

ROSEBURG

I ',l 5 /

m lFScl t_ rs6mJ -,Bgliq w Ju! 20f2 r The lyledrant lhgazine I 4)

L. Lee Building Compony

TF 800-245-',I

Engineered Wood Products I Reol Wood Siding I Softwood plywood I Lumber RFPI@, RigidLom@, RigidRim@ ond Quoliry Engineered Wood products for todoy,s builder@ ore regislered lrodemorks of Roseburg Forest products, Roseburg, Oregon

increase the efficiency of other trades as well. More space between framing members means fewer studs for plumbers and electricians to drill through and fewer cavities for insulators to fill. Additional savings may result from a reduction in construction waste and Dumpster costs.

3. Structural Integrity

The advanced framing method combined with continuous wood structural panel sheathing delivers an optimal solution: a cost-effective framing system that will produce more energy-efficient homes without compromising the strength or durability of the structure.

Where builders align the vertical framing members under the roof trusses or rafters, a direct load path is created in which compression and tension

loads are directly transferred through the vertical framing members. The result is a stronger structure with fewer framing members subject to stresses.

When properly constructed, advanced framed walls that are fully sheathed with wood structural panels provide the structure with the strength to safely withstand design loads. Of all the available wall sheathing products, wood structural panels are afforded the most flexibility within the building code for 24-inch on center wall framing, providing solutions to code limitations that restrict most other wall bracing materials and popular siding products.

4. Sustainability

Wood construction sYstems such as advanced framing techniques fit well

with green building strategies. Wood is a renewable resource that is manufactured in efficient processes that require less energy than is required for other building materials, such as steel and concrete. Wood-frame construction that utilizes advanced framing techniques delivers even greater environmental dividends by optimizing material usage and reducing construction waste. Many advanced framing construction techniques may be eligible for points under the leading green building standards and guidelines, such as the National Green Building Standard (ICC 700-2008) and the U.S. Green Building Council LEED for Homes Rating System.

Getting Started

To ease the transition to new methods, some advanced framing techniques can be adopted independently. "Builders can incorporate the techniques in stages rather than all at once," said Mark Halverson, field services manager for APA-The Engineered Wood Association. "For example, if meeting cold climate energy code requirements is the priority, adopting 2x6 framing at 24 inches on center while continuing to use double top plates will increase wall R-values without requiring roof, floor and wall framing to be aligned. The builder can add additional advanced framing techniques later to further reduce costs and increase energy efficiencY."

APA details several advanced framing techniques in the Advanced Framing Construction Guide, Form M400. The 24-page guide (shown at right) is available for free download or print purchase at www.apawood.org.

Single iop ploles (v3.

Singlc hoodcrs (vs. double

lnsuloicd lhrcc-stud cor nlrs or lwo-stud corn6r wilh lodder blcking. 2x6 wood studs spoced 24 inches on c€ni6r (vs. 2x4 w@d studs spoced '16 inches on cenl6r). Wolls continuously

Ml rui Mi 30 I The ltlerdunt tlagafie I July 2012 &rlldhrgFhodudscqn