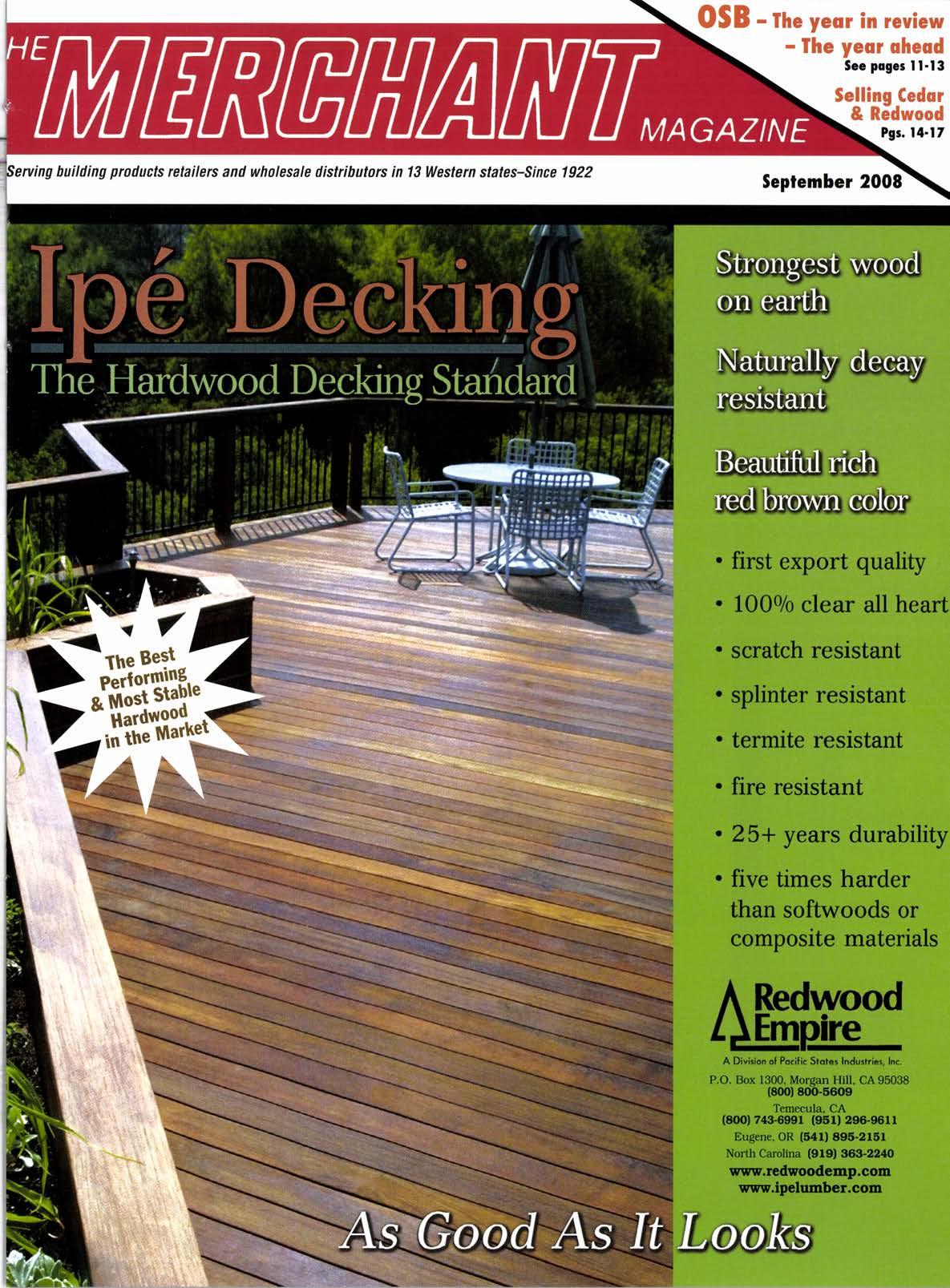

OSB - The yeor in review - Ihe yeor oheod Scc pcger ll-13 Sellinq Cedor & Ridwood Pgr. lt[-|7 Septenber 2008

building products retailers and wholesale distributors in 13 Western states-Since 1922

/ ROSE 10599 Old Hwy 99 South tel 800-347-7260 | web www.Roseburg.com I BURG I Dillord Oregon 97432 fox 541-679-2612 emoil ewpsoles@rfpco.com

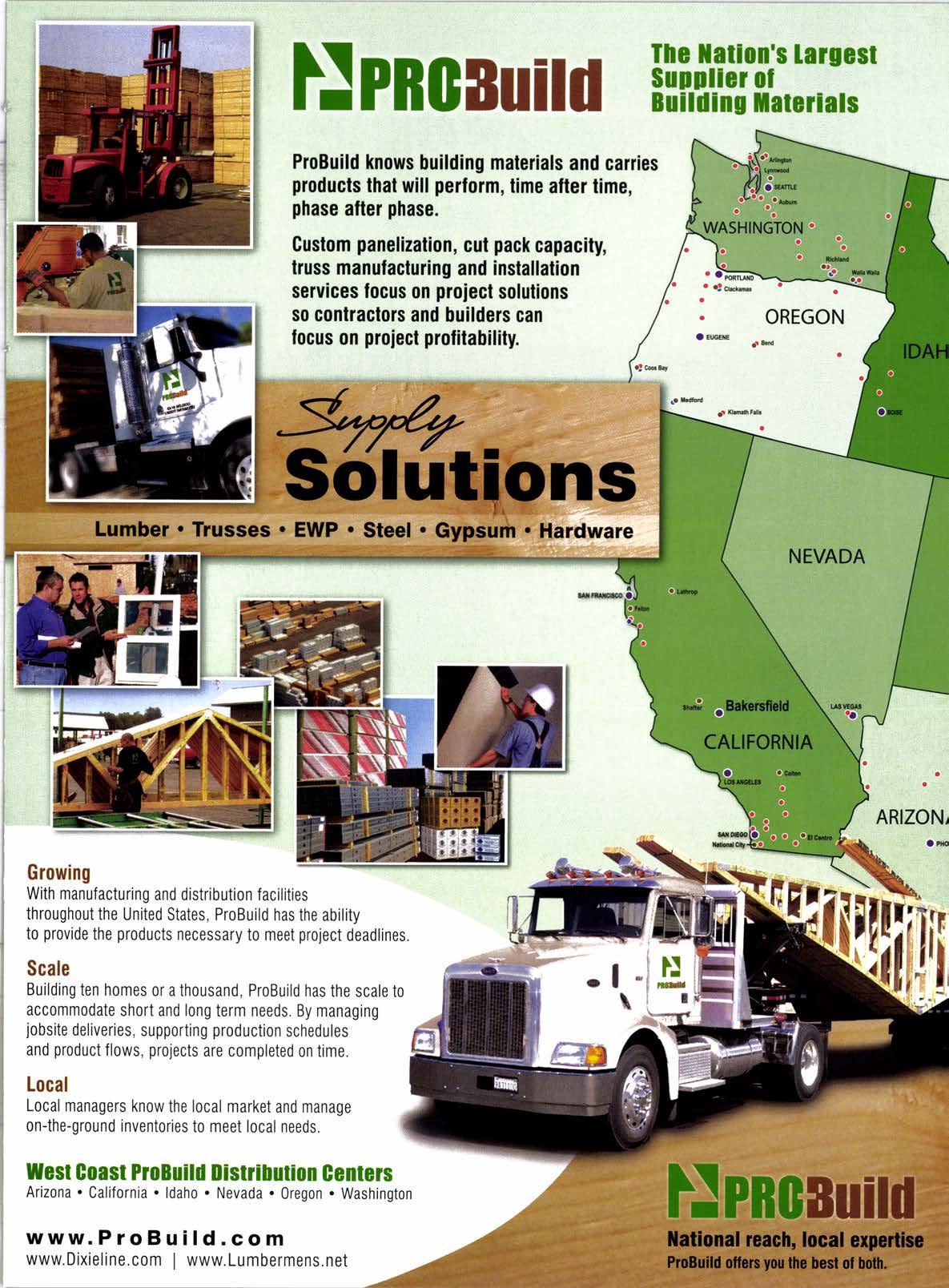

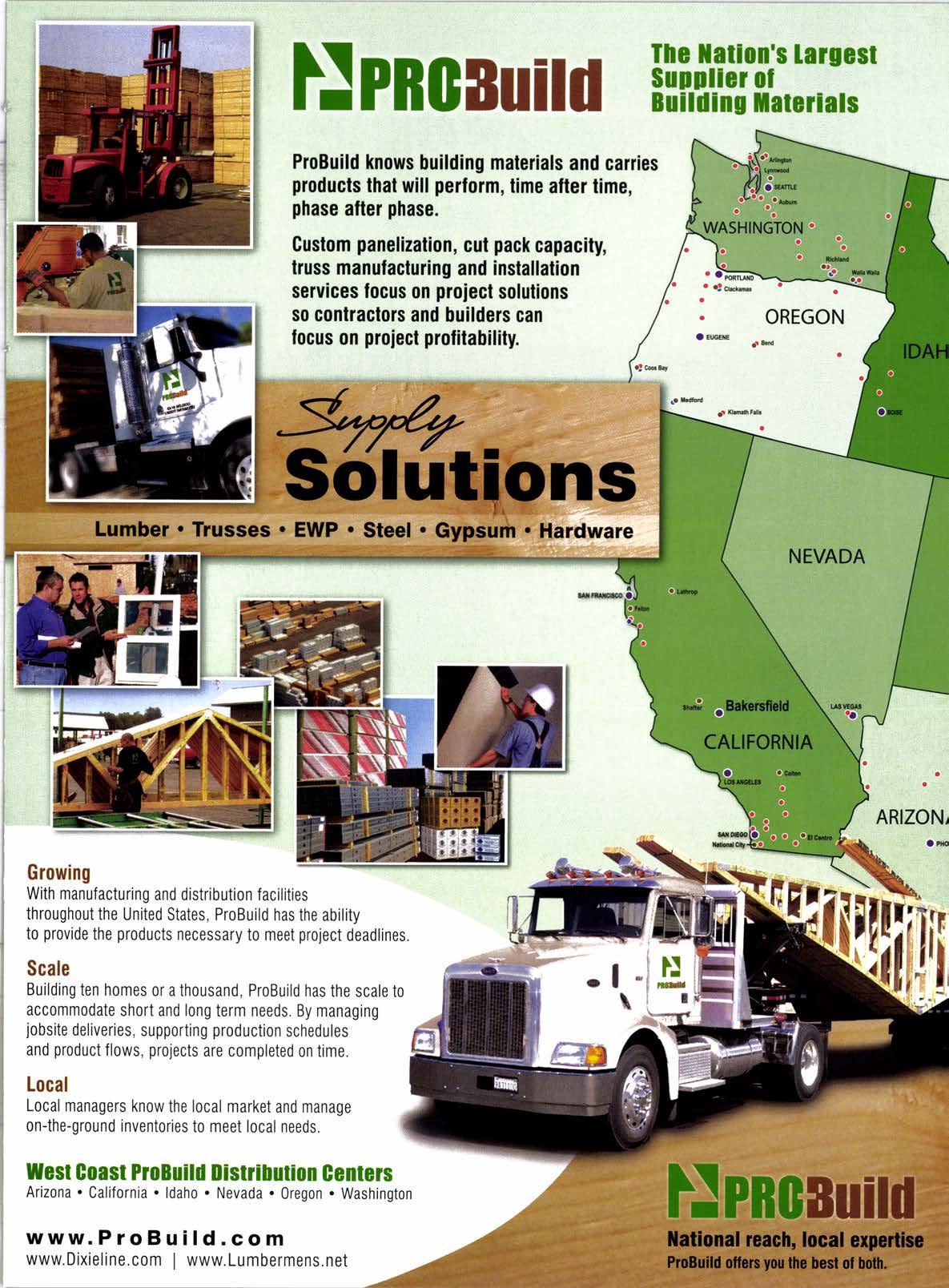

ProBuild knows building malerials and carries products that will perlorm, time alter time, phase after phase.

Custom panelization, cut pack capacity, truss manufacturing and installation services focus on project solutions so contractors and builders can focus on project profitability,

Wtth manufacturing and drstribution fac lrt es throughout the United States ProBurd has the abrlrty to provrde the products necessary to meet project deadlrnes

t,..i

Building ten homes or a thousand ProBu ld has the scale to accommodate shortand longlternt needs By managing lobsrte delrveries supportinq production schedu es and product f ows prolects are completed on time

Local managers knolv the ioca marketand manage on-the-ground inventories to meet local needs

'&.1|*,:,r, t, '&X!j.:t

(...,,, Lumber . Trusses . EWP . Steel . Gypsum . Hardware --{ ..t ry56lutions ldaho . Nevada 0regon . Washington $w I -r , ]f I , ,' , $f rrj t; fit -rd itrl lr uild.com www. LU m 0e rmen s. n et Iv ,ou r*^rc srr *.) Lilhrop l;,,"" * Bakersfield CALIFORNIA & , Co[.n LOSANGELES IDAH ARIZONT * Pro

ltl; ll:aar.:'il

:.i I :'

'js$,',li 'tl s t w re:: l, Arizona . Cal forn a www.ProB www D xiel ne com ffiw&&ffi l{ational reach, local expertise ProBuild olfers you the best of both. & r: WASHINGTON NEVADA

A FBL

Innovation and dependabiLity make up the fibers ofour company and the products we create.

We understand that your customers count on you to seek out the most distinctive and retiable new products. That's why we've ted the industry in devetoping innovative timber products, [ike Accuruff"i our rough-sawn product with a uniformty apptied rustic finish, and Tru-Dry', the most consistentty and evenly dried Douglas f ir product avaitabte. We are committed to providing you with outstanding forest products that remain strong and beautifuI for generations.

,,.:::..'.::. ,.:li::::: ta,l,l:'

**ffiPtffiYffitY NruGffiAANMM.

FOREST GROVE LUIIBER. Accuruff, the Accurutf logo, Tru-Dir lre Tr:.1ry Lcgo and the FGL loqo ..c re! sle.ed i.ad€rmnrks of Frr.:t Srove I umber C!rrp3ir, .n.. a a.pr.'!ft 2408

Quolity this good or-rly oor-nes fror-n r-r tother notu[e, l\ow rneet sor-ne of l'ler ossoototes WRCLA MEN/BERS Downie Timber/SelkirL Speciolty Enyeorl Cedor Producls Gilbert Smilh Foresi Products Ltd. Hoidq Forest Products Ltd. lnterfor Norlhwest Foresl Products Norih Enderby Timber L1d. OrePoc Building Products Premier Foresi Proclucls, Inc. Power Wood Corp. Quodro Wood Producfs Soworne Lumber Compony Lld Shokertown Skono Forest Products Ltd, Twin Rivers Cedqr Tyee Timber Products Ltd. Welco USA Western Forest Products, lnc. AFFILIATE MANUFACTURERS BW Creotive Wood Industries Cedorshed lnclustries Ouidoor Living Todoy Roinbow Pl<ry Systems WWW EOICEdOT,CTO 1.866.77B.9096 u6w

Selvlng l3 Weaterrr strte., Ineludlng Alask!.nd H.w.ii

(Sistet publication Building h1ducts Digcst seiles the East)

PUBLISHER Alan Oakes (ajoakes@aol.com)

PUBIISHER EIIERIIUS David Cutler

EDIT0B David Koenig (dkoenig@building-products.com)

ASS0GIATE EDIT0R Karen Debats (kdebats@building-products.c0m)

COIITRIBUTII{G EDITORS Dwight Curran, Carla Waldemar, Roy Burleson

A0 SALES MAIIAGEB Chuck Casev (ccasey@building-proddcts.com)

CIRCULATI0I{ Heather Kellv (hkelly@building:products.com)

ADMIIIISTRATIOII DIRECT(IB/SECREIAEY Marie 0akes (mfpoakes@aol.com)

How to Advertise

Conlael our advedising olflccs l0r ratss:

WEST, ttllDwEST, S0UTHEAST: Chuck Casey, Newport Beach, Ca.; (9a9) 852-1990; Fax 949-8520231 ; Email ccasey@building-products.com

I{0BTHEAST: Paul Mummolo (N.J.); (732) 8998102; Fax 732-899-2758; Email mummolop@ c0mcast.0et

How to Subscribe

Gontacl Healher at (949) 852-1990

U.S.: 1 year (12 issues), $22; 2 years, $36; 3 years, $50

F0RElGll (Per year paid in advance in US funds): $48 for Canada and Mexico, $60 for all other c0untries: Air rates also available.

$lllGLE C0PIES: $4 + shipping; Back issues (when available), $5 + shipping www. building-prodIots.Gom

The Merchant Magazine

{ € c a | | $rucurd poneh 2fi18 ond hyond: whot's oheod lor 0SB ond plywood I I OSf - the yeol in rcview: monufodurcn Intensify prcdudion cutbocks lf nefnooa pitots rcloiler outrcoch plogrum to sell morc decks 16 ruot the rlump: Sellwesiern red cedor for remodels of otl hnds j[ moilgoge boilods hit cloee io home for LBfrl indufi 8 tditoriol 20 Gonpetitive tnfelligenee 22 ilews Briefs 24 colendor 26 Arsoriotion llews 28 on soteg 30 Gteen Retoiling 34 Personols 36 ronily Business 48 le* Produrts 53 ilew lileroture 58 Gtossilied llcrketptore 59 obiruories 60 Buycrr'Ouide 62 tdvertiscrr Index CHAI{GE 0F ADDRESS Send address label from recent issue il possible, new address and 9-digit zip to address below. P0STMASTER Send address changes to The Merchant Maoazine, 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-1872. The Merchant Magazine (USPS 796-560) js published m0nthly at 4500 Campus 01., Sle. 480, New9ort Beach, Ca. 92660-1872 by Cutler Plblishing, Inc. Periodicals Postage paid at Newport Beach, Ca., and additional post offices. lt is an independentlyowned publication for the retail, wh0lesale and distribution levels 0f the lumber and building products markets in 13 western states. Copyright@2008 by Cutler Publishing, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without wfltten permission. All Rights Reserved. lt reserves the right to accept 0r reject any editorial 0r advertising matter. and assumes no liabilitv for materials furnished to i1. A California Timberline, Inc. --lSugor ond Ponderoso Pine, Douglos Fir, Redwood, Wesfern Red ond Colifornio Incense Cedor Dimension - Commons - Cleors Serving the Western lJnited Sfofes ond Mexico Since 1976 4650 Edison Ave., Chino, CA 9l 710 . (909) 591 -481 I . FAX (909) 591-4818 6 Tnn MBncHaNr Ml<;azrNB SEprE[,leen 2008

D.BLAZE' Fire Retardant Treated Wood TimberSaver PT Vteseryd Wood For Today'c Enwlronmpnc

It's all about who you know

Over the last couple of months, I've had a few people call to let me know they had left their companyunfortunately not of their own volition. No doubt times are hard and there are many in similar situations.

It got me thinking about when I had been in similar straits in my career. What seems a brave new world to conquer can quickly turn quite dark and foreboding, especially iffinding a new job is not something you have done in a long time. You quickly learn that experience isn't everything, and there is a lot of competition for that same new job. Equally, if it is about wanting to find a better job when ready to move on, or simply getting new clients to build business, this can also be daunting to all of us. I have long since learned that it's important to find someone who can guide you successfully through the minefield.

Networking is key to understanding what is going on around you and can provide a sounding board when you need help. I know that two of my c.e.o. positions came about from prior networking. One job I left because I just wanted to, was the hardest to rebound from because I had been in an isolated position and had not networked. This suggests that the best time to network is when you are in a job, not out of one. Then you also quickly learn [ho your friends are and who were just using you.

But networkins doesn't come natu-

rally to many of us. It makes some of us uneasy. Whether you are in a job or out of one, you have to learn to effectively use the knowledge and power of the many people you come into contact with. Networking is not only important with your business contacts but also with contacts you have through your community and social circles. This industry offers many, many ways to network at the myriad association events held throughout the country each year. Utilizing that base of knowledge at the right time can help you through difficult situations.

I recently read that about 807o of all jobs are garnered from direct or indirect connections (yes, the old rule applies here, too). Speaking with industry acquaintances at industry events, being on industry committees, targeting contacts in different parts of the industry, all become valuable networking opportunities when done right. Keeping in contact with your old company or past colleagues builds up that circle of life that one day might be able to help you.

The best time to introduce yourselves to headhunters is before you need them, not when you need them. Many companies don't advertise or even post jobs. so having connections to people inside those companies who can act as a conduit is vital. A referral from an employee who takes your resume to HR and lifts your resume to the top of the stack gives you a 70Vo

greater chance of being interviewed. Believe me, picking out whom to interview can be so arbitary. My experience tells me that most resumes get discounted within 20 seconds, especially if you have a desk of 500 resumes for one job (and I have had that many times).

And what about building your sales funnel? I know personally how tough in can be to break into certain industries or companies. I try to find contacts who can help me through the front door-or often the back door. How much easier it is when I can say "I was speaking with John Brown at XYZ, who says you are a good friend of his and suggested I give you a call to see if I can help you do ..." Or how much better if John Brown called his friend to say " I have asked Alan Oakes to call you next week to introduce himself, as he gave me great service, and I think you might want to hear him out." You get the point. Sometimes you need help to build your network, and it is never ending.

Now let me say that it is a two-way street. When someone approaches you for advice and help-give itl Do unto others as you would have done unto you. Go out of your way if you have to, because the time may well come when you need the same help.

Similarly, do not expect that if you were a jerk throughout your career that anyone will help you, because they won't. It is always interesting to me that the people who never return your calls make you the first one on their list when they need help.

Last year I helped an ex-manager of mine in a different industry land a job after he was unemployed for many months. I called twice to the president of a company to be grilled about my former colleague's performance at my company, and he got the job. My reward, not that I wanted one, was not even a call acknowledging he got the job or thanking me for helping him. Go figure. What comes around goes around.

6tp-eCtip Vf ;* "''.''.. - t;. r : i { r\ EeEf,rrE:E eoaoo r Anileble in brom, black ot grcy olor, t I 00o/o malntqoceftc Gsteoing syrtm. * Achloc flawls bauty wlth no vlsiblc fartencn. t No worrying about oail PoIE on th€ dcking

r Compatible wlth hardwood & composite dccking. r Availeblc with a stalnls steel imn moldcd inrldc br addcd stmgth. phone (864)-902-8818 toll free L -866- 427 -2547 TsB MnncHlNr Maclzlxn SepreMarn 2008 www.IpeClip.com

surfae.

CnrtroRNIA PnrrtntuM* REowooD DtcKrNG

California Premium redwood decking is the top-of-the-line dimension lumber product in the Cnlrronmrn Rgowooo CorupnNv Redwood Collection. lt is graded visually to limit knots and other characteristics that detract from its quality appearance. This makes it perfect for outdoor projects where high-quality appearance is demanded.

Redwood naturally resists shrinking and swelling. California Premium is air seasoned to reduce moisture content, making it even more dimensionally stable. This means that California Premium redwood decking goes down flat and stays flat.

Available in dimensions SfS EE: 2x6, pulled to lengths 8' - 20'

2x4, 2x8, 2x10, 2x12, 4x4 available in group lengths of g" 10'/14" 16,/20,

Calf 1-8OO- 637 -7 O77 for dastributor details and product specifications.

/A l()f

for this mark

5Fl \lt crRffr[o I nAmoPANILook

when purchasrng lhese products.

O2008 California Redwood Company. Use of the SFl6 label indicates ihat Califomia Redwood Company is a participant in the SFI program and that our operations and facilities have been certified by an independent auditor to be in comOliance, in all material respects, with the SFI Standard and SFI label guidelines. For more informstion on the SFI program, visit

www.aboutsfi.org.

trA\F6R L WORLD'S Nol MSR For retiable information. catt 604-26 4-6204 or visit www.canfor.com/msr

L.TORTH American structural wood

I \ panel production is expected to roral 31.66 billion sq. fr. (3/8" basis) this year, down l SVo from last year

plywood

By Jack Merry APA-The Engineered Wood Association

and 26Vo from the record 43.1 billion sq. ft. of plywood and OSB produced in 2005, according to the annual fall forecast of APA-The Ensineered

Wood Association.

Production next year may be even slightly less, according to the forecast, (Continued on next page)

OSB 2OO7 r Producers Begin Paring Back

The highs ol2NO took a turn for the worse in 2(N7, as most OSB manufacturers, faced with waning demand and prices, began reining in productlor*a trend that has continued to heat up in recent monhts,

Louisiana-kcific Corp., Nashville, Tn., has been the longtime leader in OSB production with

One method for coping was converting its millin Houlton, Me., to LSL production. A more efficient, state-of-the-art OSB mill in Clarke County, Al., was recently completed and is "ramping up operations."

but necessary economic deei$ion," said Jeff Wagner, v.p.-OSB. "Unfortunately, current conditions require these types of action."

BUILDING PRODUCTS

13 OSB plants in North America. Last year, the mills produced 5.5 billion sq. ft. of OSB, 8.57o below 2006 levels, but still enough to account tor 23o/o of all OSB sold in the U.S. and Canada.

However,last year LP was forced to permanently close its OSB mill in St. Michel, P.Q. Last month, the millin Silsbee, Tx., was also shut down, for an indefinite period. "Ongoing turmoil in the market pushed demand for most of our products significantly lower than the same quarter last year,' said c.e.o. Rick Frost in late July.

At the SmartSide mill in Hayward, Wi., production has been curtailed until at least October 31, 2008. 'The curtailment is a difficult

Norbord, Toronto, has gone against the trend to cut back by actually increasing production at its nine OSB millsto rnore than 5 bil,

lion sq. ft. in 2007. ltalso attempt' ed to weather the downturn by shipping more OSB to Europe.

*Our management team worked hard to educate European homebuilders on the benefits of using

(Continued on next page)

Nruarbord

LP

SepreMaen 2008 TnB MBncnlrvr Mlclznn 11

'OB OSB & Plywood

(Continued from previous page) with output falling another 37o to 30.87 billion ft.

That outlook is based on the expectation that U.S. single-family and multi-family housing starts will total just 880,000, down from about 910,000 this year. Housing starts are down by more than half since the peak of the housing market boom in 2005. Single-family starts have experienced the most severe declines, falling from 1.716 million in 2005 to an anticipated 610,000 this year.

Softwood plywood production is forecast to total 12.57 billion sq. ft. this year, down nearly l4%o from last year, while OSB output is expected to reach 19.1 billion ft.,a20Vo drop. The larger drop of OSB production is a

osB 20a7

(Continued from previous page)

OSB," said c.e.o. Barrie Shineton. 'We believe that the continuing acceptance of OSB will supPort future growth, especially in Eastern Europe."

Shineton is less optimistic about OSB sales in Nofth America.

'There are several market adjustments that must occur before we see a meaningfulimProvement in housing starts and strong OSB prices," he said.'We believe all these things will happen, but not before 2010."

Weyerhaeusot, Federal Way, Wa., which had enjoyed record, near-capacity OSB Production in 2006, cut back by 18% in 2007, to 3.4 billion sq. ft.

A rreyerhaeuser

Then, during this past summer, Weyco permanently closed three of its nine OSB mills. In July, the company shuttered mills in Drayton Valley, Alb., and Hudson Bay, Sask. Both facilities are being maintained for possible reopening once the market picks up or the company decides to sell them.

"Continued challenges in the

reflection of that product's greater reliance on the residential construction market. Approximately 807o of the 12.59 billion sq. ft. of structural wood panels expected to be used in residential construction this year is OSB.

Production of both plywood and OSB next year is forecast to decline an additional 2-3Vo.

Declines are also forecast this year and next for engineered wood framing products, such as glulam timber, wood I-joists, and laminated veneer lumber. Glulam production is expected this year to fall by 22Vo to 300 million bd. ft., I-joist production by 3OVo to 675 million linear ft., and LVL production by 27Vo to 55 million cu. ft.

The still unknown housing market low point remains a forecast wild card. Residential construction remains the single largest market for structural

North American housing market require us to bring supply into balance with demand,'said Phil Dennet, v.p,-strand lechnologies. 'lt is the result of today's challenging business environment.'

In June 2008, unable to find a buyer, Weyco permanently closed its mill in Miramichi, New Brunswick-which has not operated since January 2007.

'We worked hard to sellthe facility for more than one year," said Craig Nesser, president of Canadian operations. "A lack of buyer interest, the continuing poor state of the U.S. housing market, and the high cost of maintaining this idled site led to the company's decision."

Ai nsworth, Vancouver, 8.C., is operating only four of its seven OSB mills. OverallOSB production slipped 16% in 2007 to 2.3 billion sq. ft., and should lallfurther in'08.

Its mill in Grand Rapids, Mi., has been idle since September 2006. The plant in High Level, Alb., which

Atnsworth

is jointly owned with Grant Forest Products, has been down since late last year. lts Cook, Mn., mill went dark this past January.

wood panels, and the percentage of North American production going to residential construction is expected to fall to 40Vo, compared with 48Vo last year and 6l%o in2OO5.

The outlook for next year could be somewhat better if the Housing Recovery Act of 2008 has the desired effect of stemming 400,000 foreclosures, perking up the credit system, and getting more buyers into the market, the forecast suggests. In that case, there might be 100000 additional single-family and multi-family housing starts, resulting in almost one billion square feet of additional structural wood panel demand.

Under that scenario, glulam, wood I-joist, and LVL production also would be expected to rise by 15 million bd. ft., 35 million linear ft., and 5 million cu. ft., respectively.

The company recently emerged from restructuring after three bondholders gained 96% control of the company, usurping Allen, Brian, and Catherine Ainsworth-who were president, chairman, and c.e.o. of the business founded bY their parents in 1950.

Georgia Pacific, Atlanta, Ga., continues to operate seven OSB mills under its own name, as part of Koch Forest Products. Its OSB millin Fordyce, Ar., was down briefly last month, following an early morning fire. Although the facility suffered "significanf damage, production was resumed after machinery was tested.

Grant Forest Products, Earlton, Ont., is adjusting the prod' uct mix at three of its five OSB facilities.

Its flaghip mill in Englehart is producing two new flooring products: Rainblock and Flooring Plus.

ln South Carolina, the

12 TnB Mnncruxr MlclzrNB SepreMaen 2008

The industry's production to capacity ratio is expected to drop this year to just 737o, down from 86Vo last year and a high of 97Vo during the peak of the housing boom in 2004-2005. The substantially lower demand resulting from collapse of the housing market has made structural wood panels an extremely good bargain over the past several months compared with other building materials. According to the Bureau of Labor Statistics, the cost of steel and concrete products has increased l00%o and 3570, respectively, over the last four years, while the cost of wood products over the same period has fallen 6Vo.

Excluding trans-border shipments between the U.S. and Canada, structural plywood and OSB imports by the two countries are forecast this vear to

total 530 million sq. ft., down 37Vo from last year and 807o from 2005. The drop continues a trend that began in 2006 and is most pronounced in the U.S. as a result of the housing market collapse and low valuation of the U.S. dollar, which drives up import costs.

The escalation of transportation costs also is a factor. That trend is expected to reverse direction next year, however, with imports continuing to rise in ensuing years in response to improving U.S. housing market conditions and a strengthening U.S. dollar.

U.S. and Canadian panel exports, again excluding trade between the two countries, are expected this year to total 1.25 billion ft., up just slightly from last year but an increase of 1387o from 2005. That trend, too, is expected

to moderate with improving domestic market conditions and a halt in the decline of the value of the U.S dollar.

The longer term forecast is for the U.S. housing market to begin a recovery in 2010, with housing starts rising to 1.55 million in 2011 and 1.9 million two years later. That would help boost North American structural wood panel production to a record 45.4 billion sq. ft. in 2013.

Founded in 1933 and based in Tacoma, Wa., APA represents approximately 160 plywood, OSB, glulam timber, wood I-joist, rim board, and LVL mills throughout the U.S. and Canada. APA's primary functions are quality auditing and testing, applied research, and market support and development.

Allendale County mill is producing 8'x24' jumbo OSB panels for export worldwide. At its new millin Clarendon County, S.C., equipment is being installed to make two new OSB products-Thermoblock and Windblock-once the market picks up.

Its millin Timmons, Ont., remains closed, due to both market conditions and an ongoing strike. The High Level milljointly owned with Ainsworth is also shut down indefinitely.

Huber Engineered Woods, Charlotte, N.C., announced that its five OSB mills

Erucrne:Reo WooDs

will undergo the yearly inspection required for renewal of Sustainable Forestry Initiative certification.

Tolko Industries, Vernon, 8.C., which operates three OSB mills in Canada, indefinitely mothballed its millin High Prairie, Alb., in February.

"Restart will be considered when there are meaningful and sustain-

able improvements in the business conditions that prompted this announcement,' said Brad Thorlakson, president of marketing and sales. 'These include improved customer demand in key markets, transportation and energy costs, and competitively priced wood supply."

In early July, employees moved into the company's new building in downtown Vernon. According to Jim Baskerville, regional operations manager, work on the building was begun two years agHefore the industry was hit with .uncertain market conditions."

Canfor, Vancouver, B.C., planned to indefinitely close one of iis two O$B mills, the PolarBoard OSB mill in Fort Nelson, this summer, once existing log inventories were depleted and finished products were shipped.

state-of-the-art OSB mill in Oakdale, La., and is now exporting OSB panels to Europe.

Langboard, Quitman, Ga., reports that extra-long lenglhs and other specialty products are selling

l:IIl found diflf lll iaranr mor-

and are better diversified, which will serve us well when the outlook gets better," said sales manager Chuck Rigoni. "Commercial and multi-family construction is also picking up again."

"As the market

LAr\FiORslump continues without evidence of a tumaround, Canfor must continue to adjust iis production to address reduced market demands," said president and c.e.o. Jim Shephard.

Roy O. Martin, Abxandria, La., sought new markets for its

Arbec Forest Products, St. Leonard, P.Q., reported lhat its

single millin St. Georges de Champlin, P.Q., was closed from Aprilto June. Limited production was resumed in July.

o*i;=

LANGBOARD H"'I,I:I: rNc'llll=

,arErttsTBtEs LTarSEpTEMBER 2008 Tnn Mnncnlxr Mlcazrxn 13

Redwo relqiler pro

rnHE California Redwood

|. Association has launched a pilot program to reach out to independent lumber retailers and drive redwood sales. The goal is two-fold: to thank retailers for carrying redwood, and to encourage contractors to purchase more redwood from participating retailers.

"We've done deck contests in the past," says Bob Mion, marketing director for CRA, "but not like this. This is more than a contest. This should become the cornerstone of a partner program and an increased presence in the supply chain."

The "Build a Deck, Win a Deck" contest has been promoted primarily online and through in-store efforts. There has been a radio advertising component as well.

"We recognize that independent lumber retailers will be an important part of our future and that contractors are one of our most critical audiences." Mion says. "This program is designed to encourage repeat business, increase product loyalty, and solidify relationships to help retailers be successful with redwood."

The deck contest is at the heart of the program. Entries can be submitted online through a graphic link on each participating retailer's website. Decks

built after January 2OO7 are eligible to be entered. Decks must be clean and able to be photographed well. The deadline for entries is September 30, 2008. A panel of experts will judge the entries. and one winner will be selected from each participating retail location.

Retailers receive a payment from the CRA for participating in the program, and contractors submitting a winning entry will receive a $3,000 store credit toward the future purchase of redwood products. Pictures of the winning decks will likely be used in future CRA promotions.

"In our past deck contests," Mion says, "we've had national-level partners sponsoring our events. This time the focus is squarely on the independent retailer. The initial response has been overwhelmingly favorable. We're reaching out to retailers and helping retailers reach out to some of their most important customers."

Redwood continues to be a popular choice for outdoor projects. Its resistance to rot and decay plus its distinctive look make redwood a preferred product for decking, fencing, gazebos and architectural accent features.

"Our redwood decking sales have been relatively strong," says Steve Stevenson, Truckee Tahoe Lumber,

Truckee, Ca. "Redwood is a very good performer for us. Especially in mountain and foothill communities, people like the natural look and feel of redwood. Contractors like redwood because it provides good value, it's durable, and leads to high customer satisfaction. We move a lot of redwood, and programs like the one the California Redwood Association has put together help create that much more enthusiasm for the product."

Mion notes that the CRA partner program is in its infancy and that the "Build a Deck. Win a Deck" contest is a pilot program. The contest features eight participating retailers in Northern Californra markets.

"We want to be more active with our partners throughout the supply chain," he says. "We hope to use what we learn from this experience to build the program and expand the campaign going forward. We started in our own back yard, and we plan to grow from there."

- Details on the " Build a Deck. Win a Deck" promotion and entry forms can be found at www.deckcontest.com. For more information about redwctod or the CRA redwood sales training program, visit www.cqlredwctod.org or contact Bob Mion at rmion@ cal redwood.or p.

14 Tnn MrncuaNr MlcazrNn SrpreMeen 2008

"Frorn desiglrJ f z* e:)- -? -:rur'@ . --. t' i *r,,4' 'F'ti fi;,ti,r' .f,r;l:' €.j' ''-'" Sunbeft is the LBNFh construction of metal and we oould nd fu leader in the design and and storage systems. Doug La}ouhe, Yard Foreman McCray Lumben Edwardsville, KS :,,. _ ,. lncrease storage capacity. Minimift | ------t-t- - - - | | l ::. , : :;,'. Lower labor overhead lncreasd . Streamline overall operations :" 'ii 'r,. ;-, r'".+

Sunbelt

What can

bu r you?

ITHE

construction of new homes

I reached a 17-vear low this summer, according to ihe U.S. Commerce Department, yet renovations and remodels are increasingly popular.

To capitalize on this burgeoning opportunity, lumber and building material dealers should understand the two primary reasons why homeowners are remodeling, renovating and adding on to their homes: to improve quality of life or improve resale value, or both.

In a soft real estate market, homeowners can significantly improve their sales price by sprucing up the curb appeal to entice prospective buyers. Instead of moving, some homeowners are also planning upgrades with the intent to stay in their home

$ell rn red Gedar s of all kinds

Projects can be as simple as sprucing up the landscaping with a western red cedar arbor, trellises, or adding a wood fence to increase privacy. Or they can take the form of a pergola or even a gazebo or deck to expand the outdoor living space. From the smallest project to the grandest, western red cedar's versatility can add beauty to the outside of a home.

Western red cedar offers endless choices to fit the style of any house. It is free from pitch and resin, making it ideal for a wide range of stains and finishes. Stains can bring a new, enhanced hue to the wood. Clear finishes can also be applied to add an extra level of protection without altering the wood's natural beauty. Or, the wood can be left alone with its natural resistance to decay, allowing the wood to develop an elegant weathered appearance.

for a long time. Either way, retail sales success hinges on providing highest quality, versatile and environmentally friendly materials, such as western red cedar.

0utdoor improvements

Homeowners seeking to improve their living spaces are not making the traditionally popular-yet costlyupgrades to kitchens and baths. Instead, they are adding to the curb appeal with outdoor structures, or landscaping, if they are planning to sell. Or, if they are planning to stay, they are investing in do-it-yourself type projects and projects to enhance and expand living spaces. Projects can vary depending on a homeowner's level of commitment.

Ouality materials

High-quality and long-lasting materials are important to people making home improvements. Curb appeal improvements-such as landscaping, new paint, or outdoor structures like trellises and pergolas-grab the prospective customer's attention. However, homeowners need to make the whole package appealing, which means it has to be long-lasting, lowmaintenance, and visually attractive.

Western red cedar is a commonly used material for these outdoor projects because the homeowner doesn't have to compromise beauty for durability. Compounds in the wood naturally resist insects and decay in all climates, and the wood is known for its

16 Tun MenculNt MlclzrNB SEprrl,teen 2008

Durastrand Flooring features an enhanced edge-seal and an engineered blend of waxes and resins that block moisture and reduce or eliminate swelling even in harsh conditions. Plus it comes with a go-day no sand and 5o-year guarantee against delamination and manufacturing defects. co for the new choice in flooring, and forget the usual hassles and call-backs.

stays firm and flat

Forget the sanding DurastrandFlooring

Durostrand Flooring-On the level' f,t* wARRANTY! "=;';"vno:i* #v""i t{o Delam --' E- *'-r--.-.F_--::lu;-- -'---*rd-. ** For morc infotmotion, please contoct: Ainsworth Group of Companiet 604 661 3260 O5B Sales 877 661 3200 Toll free 604 661 3275 tax sales@ainsworthengineered.com www.ainsworthengineered.com ,/finsworth Eng r neerra ffi /R1 AintwoilhlAintworthEngiheercda.Dwaetand:rhecolorPurpe:andE,g,,eeredPerhmancefotthewoddofwoodoaretestsretedrtadem.ill NA406lANs/REV206.08/2o2MpRTNTEDTNCANADAONFsCCERTTTEDToO,*/J*{i[?*.c.nno.swco(r160G,ee6x

rich color and variety of tones. The even grain and consistent density make western red cedar less likely to swell, warp, cup or twist than other woods.

"Homeowners may initially save money with cheaper materials," says Richard White, an Oregon-based architect who specializes in custom homes. "But in the long run, they are holding down the potential value of their home."

Just like the prospective customer who looks for quality materials, homeowners seeking to upgrade their current living space also want high-quality, long-lasting materials. While they are living in their homes, they are more willing to spend more to make the improvements that they want most on materials such as western red cedar that add natural beauty and will last for years.

Sticking with what works

Residential contractors and homeowners should avoid popular fads when upgrading homes. Whether homeowners are fixing to sell or are improving their place for the long

haul, traditionally popular materials maintain a home's appeal through years ofevolving fads.

"People trust building materials they know," White says. "If I grew up in a home with western red cedar siding, I know the qualities of the wood and what it will do for my home."

Long a traditional favorite, western red cedar has a number of qualities that make it a preferred, quality material for decking, siding, and the increasingly popular outdoor living spaces that can enhance a home's value, White says. Natural preservatives in the wood make it very durable for outdoor uses and curb appeal projects, even in more severe climates. Its texture and coloration give it a rich, natural beauty that enhances interiors as well, in features such as interior paneling, vaulted ceilings, trim and boxed-in beams.

The green movement

Retailers all across the country are experiencing the consumer-driven green movement. Contractors are increasingly concerned about energy efficiency. and homeowners give more

thought to the renewable supplies of their materials.

Homeowners seeking to improve their residence look at the steps a product takes to reach their home. Retailers are increasingly supplying them with products furnished in a sustainable manner.

Good examples of earth-friendly materials are woods such as western red cedar, pine and fir, which are renewable resources that are grown and harvested sustainably. The environmental costs of production are much less in wood products than in mineral or synthetic materials. The natural properties of western red cedar further lessen a structure's environmental footprint by eliminating the need for chemical pressure treatments.

Homeowners are making long-term investments with sustainable materials. It is an investment in the resale value and an investment in quality of life.

When homeowners are upgrading a home, either to sell or to stay, they should look for materials with a tradition of quality, durability and environmental responsibility.

SepreMeen 2008 Tnn MnncHlNr MlclzrNn 17

SPRUCING UP existing homes with quality materials, such as western red cedar garden structures and siding, is where the money is

Bailouts hit close to horne

By Gary Zauner Crow's Weekly Market Report

Opinion aside, studies show that "politically connected" firms are more likely to be bailed out than "non-politically connected" firms. One comprehensive study of 450 firms in 35 countries found that those firms linked more closely to political engines "exhibit significantly worse financial performance than their non-connected peers at the time of a bailout and over the following two years."

1f\NE of the great debates that \-f appear during difficult economic times, when institutions that steer economies experience fiscal difficulties, is whether government bailouts are appropriate or necessary.

This argument hits closer to home now that a string of bailouts and potential bailouts has sprouted from highly questionable mortgage lending practices and their influence on a vulnerable U.S. economy. While the government tries to save lending institutions from their own irresponsible behavior and demise, homeowners may also receive relief for agreeing to questionable mortgages that could very well be described as "too good to be true."

For many, the question of whether bailouts are appropriate or necessary revolves around whether a particular bailout is for the greater good of the economy and country. For others, bailouts do nothing but deteriorate the ethical fiber, will and strength of an economy. For yet others, bailouts, if utilized, should be fair and equitable for both institutions and individuals.

Bailouts are also usually considered when governments perceive that intervention is good for the overall economy. The Chrysler bailout in 1979 consisted of guaranteed loans of $1.5 billion and helped save thousands of jobs. The savings and loan bailout in 1989 came after hundreds of savings and loans failed, costing the U.S. government $124 billion. Two weeks after 9/l I and in response to a dramatic drop in airline passengers, a bailout of $15 billion was extended to already unprofitable airlines. Those same airlines today are still struggling to stay profitable. The perception at the time of each of these bailouts was that without extending a parachute, the country's economy would have suffered considerable harm.

The National Association of Homebuilders has been unabashedly backing a housing "stimulus" package in light of the dramatic decline in home construction over the past couple of years. The bill was recently passed by the House and is now awaiting a vote in the Senate, where aPProval is expected soon. According to NAHB, "The American Housing Rescue and Foreclosure Prevention Act contains

several provisions that would help put the economy back on track, save jobs, and restore confidence."

Provisions in the bill would make it easier for struggling homeowners to refinance their subprime loans to prevent foreclosures and to increase access to affordable mortgage credit. According to NAHB, the Congressional Budget Office estimates this could help as many as 400000 struggling homeowners stay in their homes. In other words, the bill would bail out homeowners, limit the amount of available homes in the market, and get builders back to building faster.

Meanwhile, opponents of the bailout raise a valid point: Why should the government bail out homebuilders when they helped create the mess in the first place? It is a viable question, particularly when thousands of homebuilders made more money in the latest housing boom than theY could have ever imagined. Now, the government is ready to provide them with aid when many either failed to see or react to the bubble bursting, some thinking the good times would last forever.

As a result of the current housing crunch, homebuilders are blaming lending institutions and lenders are blaming homebuilders for the cuffent MESS.

They are not the only two entities crying for government intervention. The National Association of Realtors and the Mortgage Bankers Association are also looking for help following a period in which their members compiled record profits.

In the words of one economist,

18 Tnn Mnncs.txr MlclzrNn SrprEMee n 2008

"We are at a crossroads in the history of American capitalism," regarding bailouts and how they are handled.

Perhaps the single most pressing concern regarding bailouts is the one often referred to as "moral hazard." It is the prospect that an element of risk makes people and institutions act differently than when little to no risk exists. Take the person who dog paddles to the deep end of the pool, knowing lifeguards are there to pluck him out if something goes wrong. When no consequences for one's actions exist, caution is thrown to the wind, leaving another party, in this case the lifeguard, to bear some responsibility for the consequences of those actions. It is theorized that when this continues to occur, lenders and homebuyers become less cautious, which in turn deteriorates the integrity of markets and the economy.

The theory of moral hazard is just that-theory-and not an acceptable explanation to many as to why governments should not bail out institutions. After all, they say, just because a person has dental insurance doesn't mean they will stop brushing their teeth. Some argue that bailouts, which are usually in the form of low interest loans backed by subsidies from taxpayers, are often less expensive than the alternative. One example would be keeping airlines operating, which provides more competition and less expensive airline tickets.

Complicating matters is the potential bailout of Freddie Mac and Fannie Mae, two government-sponsored lending institutions that are somewhat insulated from the same risks private or public companies must face. Together, they support nearly TOVo of all U.S. mortgages worth trillions of dollars. The reason for the potential bailout is that the two mortgage giants nearly collapsed after jittery investors sold off a large number of Fannie and Freddie stocks.

Treasury Secretary Henry Paulson announced that both the Treasury and the Federal Reserve will lend money and buy stock in both companies if needed to shore up the faltering firms.

It has been argued for years that Freddie Mac and Fannie Mae should have their ties to the federal government severed. Opponents of this arrangement between government and institution argue it is a breeding ground for moral hazard, in which the government plays lifeguard for institutions and industries in over their heads with debt.

If the sell-off of Freddie Mac and Fannie Mae stocks does not necessarily point to the degree of the housing crisis, it certainly speaks to the sentiment of investors regarding the current debacle mortgage lenders have created. Homebuyers who accepted those questionable mortgages, sometimes at llo%o of their home's worth, are not without responsibility, either.

Taking bailouts a step further, what about the forest products industry? If buyers, builders and bankers are considered for bailouts, why not lumber and panel producers? Do markets based on prices generated through the dynamics of supply and demand warrant a little boost when housing construction slows to a crawl?

Despite the importance of the LBM industry, bailouts would be unlikely. After all, it would appear that a significant amount of mismanagement, fraud, ignorance and "connection" is needed to warrant a bailout.

- Mr. Zauner is senior news editor for "Crow's Weekly Market Report," the longest-running source of prices in the North American lumber and panel industry. Free trial subscriptions are available at www.risiinfo.com/crows.

brand interior fire retardarfi is the consfuctom ftdusrv's newest and mosl adranced fte pmteoion s!,stsn for woti4 The unique fiftPro dremistrv ii a oat* xfidins formulniur fta corinins no ptnqphorcrbbosed mnipoundf

Proai,ding Customer Sati,sfaction in All We Do P.O. Box 75 . McMinnville, OR 97128 Phone 5oj-434-5450 . FA)ft 888-TSO-VOOD (888-8769663) Hl-btr, FldRO, rndrdvrc curd e ftthdcd @d@.rLr of $T-N Holdtq$ h Hlbtr, FtiePf,O, 6d AdyeE CEd Futs ft Fodtad by lodcpddcdt @rd aad opd.d wood |ffivlry frdlhle OM SEpTEMBER 2008 THn Mnncslxr MlclzrNB19

etitive ligence Mentored by one in amillion

By Carla Waldemar

LUMBER& IIARDWARE

p ACK in high school, Shawn Roehr drew up a proposal l)for a dreamed-up lumberyard-he called it Arrow-as a project for his business class. Today, he's working there.

That hypothetical classroom exercise was solid enough to carry his entry from small-town Buckley, Wa., to the state competition and then on to the nationals, passing the strict judgment of real-life business people, who vetted each entry to assure the hypothetical "new business" stood solid enough to secure a bank loan.

"I knew since high school that I wanted to work in a lumberyard"-how crazy is that?-"because that's all I'd done," Shawn recounts a decade later. "I worked under Barney Wagner, who was also a friend and neighbor, at Lumbermen's. He helped me prepare the proposal because, while I knew the yard part, I had no idea about the financials."

So when Wagner left Lumbermen's in 1997 to pursue his own dream of launching a mini-empire of independent lumberyards on his own (see "Competitive Intelligence," Sept.2007), he nudged young (very young) Shawn (he's 32 at the moment) to come along: "Let's start something new."

Voila, as they say in cities a whole lot bigger than Buckley: Arrow Lumber (nice name!) was born, "using a lot of the same principles as we use today," says Shawn, now v.p. "I wanted to get in on the new venture, help it grow, give it our best. And work with Barney," he adds, an important factor-a mentor in a million.

Not only their best, they gave it their all. Coming from a behemoth corporation with what Shawn calls a "huge" staff, Arrow's fledgling crew of six (including Shawn and Barney) "had to do everything that had to be done. For instance, when a customer needed something we didn't have, we'd drive miles to Home Depot or Eagle every night and bring it back, so they would have it first thing in the morning.

"We didn't offer more types of services per se, we were just willing to do things faster. When the guys down the

road would take two weeks for a materials list, we'd have it in a day or two. As a small, new business, we'd do anything to set ourselves apart from the competition. If needed, we'd be outside, building loads or running deliveries. Barney'll still drive a truck-how many presidents do that?" poses Shawn, in admiration.

But then, how many presidents resist the temptation to micro-manage and instead encourage their promising people to rise as fast as they demonstrate they can? "If a competitor turned a job down, saying they were too busy, we'd get it done. Still do," Shawn professes.

Six months later, Shawn was promoted to store manager. "Things kind of progressed," he offers with an awshucks humility akin to that of his boss. In fact, Shawn was just named North American Retail Hardware Association's Young Retailer of the Year for multiple locationsbecause, in the 10 years Arrow has been up and running, the company has acquired four more stores, all also in small Washington towns, and a sixth is about to join the roster.

Arrow grew fast. "And the larger you get, the harder it is to keep the same attitude," Shawn acknowledges. The key, he feels, is "to hire like-minded people who want to keep customers happy. People tend to get stuck in their roles, but we'll push 'em outside their comfort zones. We look for attitude first, and experience second."

"In many businesses, it's the other way around," he's found. "For us, willingness in the most important thing."

Shawn became the go-to guy when it proved time for a new computer system, as, in 2006, Arrow acquired additional locations. "We eliminated the manual paperwork in favor of emailing invoices and using signature captures. No more filing and un-filing, which saves a lot of time and money. It wasn't cheap, but it was well worth it," he declares.

At the original Buckley store, Shawn designed the floor plan (drawing on that high school business project) and built the shelves-the only operation Arrow has built from the ground up.

At Eatonville, he tripled existing floor space by removing walls; which also allowed him to add new product lines based on listening to customers' feedback. Same for Port Orchard, "another old building to which we added on." By redesigning and remodeling one yard after another under Shawn's eye, Arrow multiplied sales. In fact, they're now nine times what they were initially-no small impact on the bottom line.

20 Tnr Mnncrunr MrcazrNr SeprrMeen 2008

"We took the good features from each store-what works for one will probably be good for all-and also implemented our own ideas, such as offering package sales. We started out small, with decks, and have expanded to other categories, like garages and pole buildings. We really have a good program for people who like to buy projects complete; they may not have the vision, ar architect, so we eliminate the work and stress and do it for them. Plus," he adds an important aside, "the margins are good."

But, cookie cutters? Never. "Each store retains its own business niche; different markets require different identities, he explains. "For instance, in communities where there's little retail competition, we focus on the builder, and vice-versa. Our ideal store would be 50/50, d-i-y and pro. We work toward that split," aiming to distribute the eggs into different market baskets.

Other services that help Anow hit the target: free material takeoffs and free delivery for pros. ("We'd love to charge for delivery"-Wouldn't we all these days?-"but none of the competition does. As soon as they start, we'll jump right on it!" Shawn insists.

And, yes, there's plenty of competition out there"some good operations we have a lot of respect for, and others where we think we can do better; they get big and bullish and start telling their customers what they can and cannot do. We, however, believe the customer is boss; they tell us what whey want and need."

And right now, what they seem to need is-a sixth store. Coming right up. Count on Shawn to be on hand to nurture its staffers, prodding them to tap what's within them, just as he's been guided, and given lots of rein. He's not going anywhere anytime soon, he says. And why

should he? He's fulfilling his high-school dream, rising from assistant manager to general manager to v.p. in the time it takes to say, "Stand out of his way."

And the key to that success story, Shawn is quick to remind us: "Barney." For independent dealers around the country looking at the future of their own operations, encouraging a young hire to achieve his best for the company isn't such a bad idea.

- Aformer award-winning LBM tade magazine editor, Carla Waldemar writes frequently on the industy. Contact her at cwaldemar@ comcast .net

WESTERN+RED CEDAR preferred by the fence ir@ tor ippearance, quality ind resistance to the elements ruCfff*VfrcOD stained or unstained rqrqh sawn S@ttemlocknrcrrawnoo ADVf,mAcE Stainedor unstained rough sawn Douglas Fir Fenctrg " llEIS tortbarlimibd Iffiy Seprrueen 20O8 Tnn MnncslNr MaclzrNn 21

YOUNG EXEC Shawn Roehr (far right, shown with his children and wife, Anne), proposed the idea for Washington State's Arrow Lumber while in high school.

Rrrln:rs

Lumber Plus True ry'alue, Kanab, Ut., celebrated the grand re-opening of its newly renovated store July 25-26 ...

Stringham Lumber, S. Salt Lake City, Ut., suffered a July 30 fire that caused $100,000 in damages; one employee was taken to the hospital for smoke inhalation

Anderson Hardware will hold a grand opening Sept. 12-14 for its new 229OO-sq. ft. Ace Hardware store in Wellington, Co.; Vicky and Doug Anderson, owners

General True Value Hardware, Denver, Co., is liquidating after 98 years, so the owners can sell the property...

Ace Hardware, Woodland, Wa., moved into larger, newly remodeled quarters next door ...

Home Depot opened new stores Aug. 21 in Warrenton, Or. (Lori Sarancik, store mgr.), and Aug. 14 in Pahrump, Nv. (Justin T. Keedy, mgr.)...

Home Depot signed a 35-year lease for a site in Ontario, Ca.. and hopes to break ground in Spokane, Wa., in the spring ...

Lowe's Cos. opened a new store Sept. 2 in S. Chino Hills, Ca.; has begun construction in Pacoima, Ca.; got the go-ahead to build in

Send us your news!

Have your recent expansion, promotions or other company changes published in the next issue o{ Ihe Merchant Magazine.

Just Fax your news to 949-852-0231 or send by email to kdebats@buildingoroducts.com.

(a trce seruice)

Rialto, Ca., and has abandoned plans to add a unit in Rocklin, Ca., due to planning commission restrictions...

Habitat for Humanity recently opened ReStore discount LBM stores in Temecula, Ca., and Portales, N.M.; is moving its Maui, Hi., ReStore from Happy Valley to a larger facility in Wailuku, and is adding a 4,000-sq. ft. second level to its 9,000-sq. ft. store in Carbondale, Co.

Wolseley plc. is reportedly considering selling off 302-unit Stock Building Supply ...

BMC West, Boise, Id., received a Partner of Choice Award from DavidWeekley Homes ...

Hines Horticulture, Irvine, Ca., has filed for Chapter 11 bankruptcy protection as it works to sell its assets to Black Diamond Capital Management, LLC ...

Wror:rlrrns/trrurrtrurrrs

Peery Brothers Lumber, City of Industry, Ca., installed a milling operation and expanded its FSC inventory to include timbers, fire treated, and preservative treated

Warm Springs Forest Products Industries, Madras, Or., has entered into an agreement with Vanport Internationnl, Boring, Or., to custom cut logs for the international market; roughly 80Vo of the production will be for export

Crown Building Materials, Portland, Or., has been acquired by Norandex Building Materials Distributio,n, Hudson, Oh., which hopes to move the operation to a larger facility

North Pacffic's Napa, Ca., distribution center is now stocking FSC-certified OSB from Roy O. Martin's new mill in Oakdale, La., including Tuff Strand, StrucWall,

StructWall XL. and The Grid brands, for next-day delivery throughout Northern California

Allied Building Products is now distributing ZP SmartSide trim and siding nationwide from its 140 branches...

Boise Cascade has eliminated one shift at its La Grande, Or., sawmill for an indefinite period

Jeld-Wen, Klamath Falls, Or., is closing its window and door manufacturing plant in Gainesville, Ga., and will use the facility as a sales and distribution office ...

Reid & Wright,lnc., Broomfield, Co., has earned triple chainof-custodv certification-from the Forest'stewardship Council, Sustainable Forestry Initiative, and Programme for the Endorsement of Forest Certification

Forest Products Marketing received FSC chain-of-custody certification for its offices in Oroville and Woodland. Ca. ...

Mary's River Lumber Co., Corvallis, Or., was presented the 2008 Best of Corvallis Award among lumber companies by the U .5. Incal Business Association

Anniversaries: Dixieline Lumber Co., San Diego, Ca., 95th ... Tirnber Products, Springfield, Or., 90th ... Nelson's Ace Hardware, whitefish, Mt., 60rh ... Reid & Wright, Inc., Broomfield, Co., 60th EarthSource Forest Products (formerly PALS), Oakland, Ca., 25th...

Housing starts in July fell IlVo to a seasonally adjusted annual rate of 965.000-the lowest level in more than 17 years single-family starts slipped 2.9Vo to 641,000 annual pace ... permits dropped I7.7Vo to a rate of 937.000.

- CORRECTION -

West Coast Juniper, Chiloquin, Or., does not export juniper logs to China for processing into flooring products (as reported on pg.40, Aug.2008), but does ship cants or larger blocks for remanufacture into flooring or furniture.

briefs

22 Tnn Mmcnlnr Mlclzrxr SEpTEMBER 2008

Listings are often submitted months in advance. Always vertfy dates aid locations with sponsor before making plans to attend.

Srprrilsrn

Lumber Association of California & Nevada - Sept. 10, 2nd Growth meeting, Red Lion, Redding, Ca.; (916) 369-7501

Sierra Pacific Industries - Sept. 11, open house, Anderson, Ca.; (530) 378-8000.

BC Wood - Sept. 11-13, global buyer's mission, Whistler Conference Center, Whistler, B.C.; (877) 422-9663

Mountain States Lumber & Building Material Dealers Association - Sept. 12, Western Slope golf tournament, Rifle Creek Golf Course, Rifle, Co.; (303) 292-9500.

Hoo-Hoo International - Sept' 12'17, annual convention, Murano Hotel, Tacoma, Wa.; (800) 979-9950.

Lumber Assn. of California & Nevada - Sept. 16, PAC baseball night, McAfee Coliseum, Oakland, Ca.; (916) 369-'15Ol

Willamette Valley Hoo-Hoo Club - Sept. 17' trap shoot, Sportsman's Club, Creswell, Or.; (541) 485-5979

Los Angeles Hardwood Lumberman's Club - Sept. 18' 8th annual golf tournament, Costa Mesa Country Club, Costa Mesa, Ca.; (626) 445-8556.

Jensen Distribution Services - Sept' 18-20, fall market, Spokane Convention Center, Spokane, Wa'; (509) 624-1321

Ace Hardware Corp. - Sept. 19'22,fall market, St. Louis, Mo.; (630) 990-'7662.

APA-The Engineered Wood Association - Sept. 20-23, annual meeting & expo, Ritz Carlton Lake Las Vegas, Henderson, Nv.; (253) 565-6600.

Lumber Quality Institute - Sept. 22-23,lumber quality & process control workshop; Sept. 24'25, leadetship workshop,

Corvallis, Or.; (541) 231-8628.

Setzer Forest Products - Sept. 26,25th annual golf tournament, Sacramento, Ca.; (916) 442-2555.

Lumber Association of California & Nevada - Sept. 30, safety/ risk management day, Marriott Sacramento, Rancho Cordova, Ca.; (916) 369-7501.

Ocrorrn

Building Component Manufacturers Conference - Oct. 1'3, Colorado Convention Center, Denver, Co'; (608) 310-6722.

California Forestry Challenge - Oct. 1'4, Sly Park Environmental Center, Pollock Pines, Ca.; (916) 369-7501.

Lumber Assn. of California & Nevada - Oct.2, safety/risk management day, Marriott, Riverside, Ca.; (916) 369-7501

Mountain States Lumber & Building Material Dealers Associ' ation - Oct.2-4, fall conference, Sonnenalp Resort, Vail' Co.; (303) 292-9sOO.

National Lumber & Building Material Dealers AssociationOct.2-4, industry summit, Westin La Palma Resort & Spa, Tucson, Az.; (800) 634-8645.

Lumber Association of California & Nevada - Oct. 8, LBM testing seminars, Marriott, Riverside, Ca.; Oct. 9, Marriott, San Diego, Ca.; (916) 369-7501.

National Hardwood Lumber Association - Oct. 8-11, annual convention. Marriott. San Francisco, Ca.; (800) 933-0318.

Remodeling & Decorating Show - Oct' 10-12, Los Angeles Convention Center, Los Angeles, Ca.; (818) 557-2950.

Do It Best Corp. - Oct. 11-14, fall market, Indiana Convention Center, Indianapolis, In.; (260) 748-5300.

Association of Millwork Distributors - Oct. 11-16, annual convention, Gaylord Palms, Kissimmee, Fl.; (727) 372-3665.

True Value Co. - Oct. 17-20,fall market, Atlanta, Ga'; (7'13) 695-5000.

Mountain States Lumber & Building Material Dealers Association - Oct.22, operations management seminar; Oct.23, outside sales seminar, Grand Junction, Co.; (303) 292-9500.

24 Tsn Mnnculrqr MAGAZINE SepreMeen 2008

Marine CC.PTS BB.O Sanded Siding We Do Specialty Plywood... ''i;l! & tl' , I 'gl: f, Spe.ciahty (spesh'al rc), n., adj. -n.1. a special line ol'work, skill, or the like on which one is dedicated, such as outstanding service in selling and delivering plywood. 2. an article or service particularly dealt in, rnanufactured, and rendered, such as manufacturing mariner plywood. -atlj. 3. producing or offering an unusual or specific product, such as concrete fbrrn panels. We Do It Right. Sffi,t:$$' A member of the Swanson Group, Inc. family of companies Grants Pass, Oregon . 541-956-4300 . 800-331-0831 . Fax 541-956-430'l . www.swansongroupinc.com

qlion news

Lumber Association of California & Nevada will present safety-risk management workshops Sept. 30 at the Maffiott Sacramento. Rancho Cordova, Ca., and Oct. 2 at the Maniott, Riverside. Ca.

Labor attorney Mary Farrell will discuss labor laws and compliance issues. Loss specialist Eric Taylor, Owen-Dunn Insurance Services. will speak on CaIOSHA inspections and forklift accidents. Distracted driving and hiring practices will be discussed by Federuted Insurance.

Seminars on testing lumber and building materials will be Oct. 8 at the Riverside Marriott, Riverside, Ca., and Oct. 9 at the Residence Inn by Marriott, San Diego. Both are presented by the California Department of Food & Agriculture's division of measurement standards.

On Nov. 6. members will meet at the Marriott Napa Valley Hotel & Spa

for two days of meetings and prescntations at LACN's annual convention.

A golf tournament at Chardonnay Golf Club. Napa, will start the event. That evening is an opening reception.

Day two will feature a government affairs update by LACN lobbyists and educational programs on such topics as proactive selling strategies for tough times, collecting money through mechanic's liens, and making your business more valuable during an economic downturn.

The last night will include a silent auction, the president's dinner, and entertainment by the Joe Stoddard Show.

Western Building Material Association is offering a trio of seminars next month at its Kincaid Learning Center, Olympia, Wa. A yard foreman class is set for Oct. 8. business management l0l Oct. 9, and estimating

workshops Oct. 14- 15.

WBMA's l05th annual convention will be Nov. l2-14 at the Red Lion. Seattle, Wa. Chris Rader, Rader Solutions, will speak on "Making a Profit in a Down Market," discussing how to increase margins and encourruge employee producti vity.

Mountain States Lumber & Building Material Dealers will converge on Sonnenalp Resort, Vail, Co., Oct.2-4 for its annual fall conference.

Keynote speaker is John D. Wagner. author of nine books on home building. Dena Cordova, regional sales manager fbr Foxworth-Galbraith, will share a 2008 economic overview and 2009 projections for the mountain region. Greg Shope, Alpine Lumber, will discuss "Green Building: Here and Now."

MSLBMDA is sponsoring a pair of seminars by Mike Butts, LBM Solutions-"Operations Management fbr Today's Lumberyard" Oct. 22 and "Business Management l0l for Outside Sales Reps" Oct. 23, both at Hampton Inn & Suites, Grand Junction. Co.

On Nov. I 3, B ill Lee, Lee Resources, will share "Action Steps to Boost Sales & Productivity" at Holiday Inn Central, Denver, Co.

26 THr. Mr:n<'Henr Mncnzlre SepreL/een 2008

Not only is Canfor SilvaStar@ fascia less expensive than composites or cedar, it can also be ordered in longer tengths. Why do we make our fascia in every key length up to 35 feet? Because supptying atl the lengths your customers need saves them installation time and expense. Every inch of SitvaStar is made from high-quatity KD SPF fiber with4o defects , so it's 1oo% usable. Then it's carefully factory primed with premium Olympic: latex primer. True, time is too short on any jobsite. Which is precisely why we make our fascia long.

For more information catl 6o4.264.6or5

9Y#3lC Stock SilvaStar" for your customers, and keep them satisfied.

't--'a -. !.: '-' \r*" j- l ,4-? --;- t:: t

*.*-*-

S,I*SN FASCIA. TRIM. DECKING. PATTERNS LOC CABIN SIDING I The silvStarnameand markaG rqtstered tademarkr ofCanadian Forcn ProdudsLtd I The Olvror name and mark are reoBrerd tademdrk! of PPG Indu{riFe trd www.sitvastarfascia.com

When to preclose the sale

By James Olsen

By James Olsen

t tD 8ffi 'fii" j,ll ":.T"TJ; ;i teacher told me 28 years ago as I walked into the teacher's lounge as an idealistic student teacher.

Teachers like that shouldn't be allowed around kids, but that's another article. But his point was well made. If you show weakness with a classroom full of 15-year-olds, you'll have a mutiny on your hands.

How does this apply to sales? Many salespeople think they are losing the order at closing, when actually they've lost the order well before the closing moments. How? They send the wrong messages early in the call and work uphill from there.

Struggling sellers send the message to the customer that they are there to serve them and nothing more. Along with the service message, master sellers also send the message to the customer that something will be expected from themthat they (the master seller) are there to help, but that they will also want the order once the help is given.

We should send the message from the very first call that we expect to get the business. Many sellers think ifthey send any kind of "I want the order" message too early, the customer will think they are pushy and will not buy from them. These concerns are unfounded. The buyer knows we are salespeople when they come to the phone or make the appointment. They expect us to ask for the busiNESS.

Here are four instances when we can pre-close with our customers:

At the end of a prospect call "Mr. Customer, I really appreciate your time. From what you've told me, I know we are a good match for each other. Do you think we can do some business together?"

Struggling sellers mistakenly think this will invite many no's. It will produce some no's, but more often the customer will respond in a positive way. If they do respond in a negative way with an objection-Hallelujah!we can overcome (discover) their prejudice against trying us and correct it on the first call and move forward in a positive sales relationship.

Buyers can't buy from everybody, so they have to test prospecting salespeople with objections. Salespeople who are ready and eager to overcome

these initial objections have a much better chance of becoming a supplier to the customer than the meek, timid seller whose only goal is not to offend!

After taking an inquirylRFQ

"John, thanks for a look at this one. I know we can cover it. Let me ask you a question: will you buy this from me?"

Many sellers think, "I can't ask that question, I haven't covered the spec yet." These sellers send the message: "I will give you great service and then let you decide." The seller who asks the "Will you buy this from me?" question before chasing the spec has sent a very powerful message: "I want the business!" Which message is better for the salesperson?

The point of asking the question is two-fold. One, the customer may say yes! Two, now the customer knows we aren't simply satisfied with covering specs-working for free. We want the order!

Right after losing an order

"Sarah, I've got us covered on that spec you gave me. You are going to love it. Let me ask you a question: will you buy this from me if I'm close?"

The fearful, timid seller thinks, "How can we ask for the order if we haven't given the price?" Let me flip this attitude around. How can the customer ask us to work for them without paying us?

Right before giving the price

"Darn it, John. I thought we had a great deal. When are you buying next? Can I have last look next time?" None of us likes to lose orders, but as pros we must keep our heads up and continue to sell. After a customer awards the order to someone else, they may feel a little guilty or beholden to us. That order is gone; let's start working on the next onel

Desire is difficult to say no to. Pre-closing sends the message that we want the business. Pre-closing makes us money and saves us time. Try it this week and see the difference!

Happy selling!

- James Olsen, Reality Sales Training, specialiles in sales training for the lumber industry. Reach him at j ame s @ re ality - sale s training.com or (503) 544-3572.

sq les

28 Tns Mrncuaxr MlclzrNn SepreueEn 2008

Greenhouse gases and retail

By Jay Tompt

By Jay Tompt

\tr/IIEN the topic of green buildY Y ing comes up in our industry, it usually starts up the debate about certified lumber. SFI or FSC? Which is better? Is chain-of-custody certification worth the trouble?

The questions are valid, but the debate is essentially over and has become a distraction from understanding the real issue driving the green building movement. Carbon. It may bring as much change to the hardware and building materials channel as the "big boxes" did decades ago.

Let me explain.

The green building movement continues to gain solid support from state and local governments. Solid? San Francisco recently passed mandatory green building guidelines that are the most stringent in the nation, but it's not another example of West Coast eccentricity. What's driving the green building movement on the West Coast and the rest of the country isn't some "tree hugger" ideology, but a sciencebased approach to curbing greenhouse gas (GHG) emissions, which includes carbon dioxide.

Buildings and the building industry account for nearly half of all greenhouse gas emissions, which includes both embodied energy-the energy required to produce the building materials and move it to where its needed-as well as the energy required for operations, such as lighting, heating and cooling. (See www. architecture2}3).com for more information on this, as well as really nice graphics that illustrate the depth of the issue.)

Cities and states are focusing on green building related policies as one strategy for limiting GHG emissions, because that's the sweet spot.

A major component of every green building program concerns energy usage. Adding renewable energy, like solar or wind, can earn a building project lots of green points. So, too, can adding a host of energy saving fea-

this a sign of some big changes headed for this retail channel? Could be. New products in the pipeline will make it easy for do-it-yourselfers to install small-scale solar and wind systems for room additions, out buildings, etc.

There are lots more new energy saving products coming our way, too. Because these products deliver big margins, they are attracting the attention of retailers like Ikea. And because "alternative energy" is becoming mainstream, established "alternative energy" retailers such as Northern California's Real Goods are seeing tremendous growth opportunities. It's a sure bet that in the years ahead there will be new retailers focused on meeting the demand for carbon-free energy and challenging traditional home improvement/hardware dealers in that category.

tures. While federal rebates for solar may end soon, most pundits predict a future that includes more rebates for renewable and energy-saving products, coupled with ever stricter building codes. In fact. there is a movement afoot to set the green building standard at carbon neutrality, or zeroenergy, well before 2030.

This increasing focus on energy and carbon reduction will create business opportunities and threats. Ikea recently announced their intention to sell solar panels and other home energy products in the next five years. Is

What will all this mean for traditional home centers and building materials retailers? For those that are energy savvy, the new wave of carbon-busting products will add growth to the bottom line. Retailers today that have a solid lineup of EnergyStar products and, perhaps, a relationship with a solar installation outfit, have a head start and will be well positioned to take advantage.

- Jay Tompt is vice president of green product development at Plan-lt Hardware, San Francisco, Ca., which distributes green products for hardware and home improvement stores throughout California, and a leading expert in sustainable business and supply chain issues. He can be reached at info@plan-ithardv)are.com or (415) 359-9914.

30 THn MnncHarvr MacazrNn SEprgvagn 2008

Mendocino Gives Former Palco Fresh Start

It's been a busy summer for Humboldt Redwood Co., Scotia, Ca., the new company formed when Mendocino Redwood took over Pacific Lumber Co.

After linal reorganization papers were signed July 30, transition teams from Mendocino Redwood's headquarters in Ukiah, Ca., quickly assessed the condition of Pnlco's timberlands, took inventory at its mill in Scotia, and extended employment offers to about 300 of PRt-co's more than 350 former employees.

Many of these former employees also received personal phone calls from Richard Higgenbottom, who serves as c.e.o. of both Humboldt Redwood and the Mendocino Companies, which celebrated its lOth anniversary last month.

"I think it was the appropriate thing to do," said Higgenbottom of the calls he made, since the 18-month bankruptcy proceedings had disrupted so many lives.

By August 4, Pnlco's former sales office had reopened for business. Two days later, the sawmill in Scotia was up and running, log deliveries were accepted, and lumber shipments for existing orders became available.

In a letter to customers, Higgenbottom stated that two important goals for the new company were to implement Mendocino's forestry practices and position the Scotia sawmill to be successful for the long term.

"For the mill," he said, "we will change the philosophy from a cost-driven approach to a market-driven approach. For customers, we hope this will have the practical result of allowing us to reliably provide the product you want, when you want it, with excellent and predictable service at a fair price."

Sandy Dean, c.e.o. of Mendocino Redwood and a major player in the reorganization, said that success will be linked to the health of the new company's 210,000 acres of timberlands in Humboldt County.

"This is a forest that's been managed aggressively," he said. "But it's a forest that has tremendous habitat value and a tremendous amount of standing timber." The new company has already applied for Forest Stewardship Council certification of these lands.

Under Pnlco, an average of 150 to 160 million bd. ft. was cut from 2000

Homboldt Redw.'od COMPANY. LLC

to 2005. That figure dropped to 99 million bd. ft. in 2006, and fell to 77 million bd. ft. last year. Under the new management, annual harvesting will

be limited to 55 million bd. ft. per year for the next decade and a no-cut policy for old growth will be observed.

"We chose a harvest rate that's based on careful assessment of the timber inventory," Dean said.

Although he expects the harvest rate to increase after l0 years, it will always follow Mendocino's principles of sustainable forestry-which include cutting less than what's grown.

These principles, which have

(Please turn to page 42)

Remanufacturing and Wholesale Distribution High Quality North American Softwoods of

Exclusive

NCalifornia Stocking Dealer Sales and Distribution of Wavey Edge Siding

McllAn"YAttIY ranlcrafted' JQajh, Pil4zk Exclusive Stocking Distributor of Cedar Valley

Shingle Products Superiora Br a:nd siding 7 o o %o us ea-b Ie STKSidings & Trim Exclusively Produced and Distributed by Lausmann Lumber WRC SPF Pine Ip6 Redwood WRC FI Specialty Sidings 3370 Rippey Rd., Loomis, California 95650 L-800-625-L233 www.lausmannlumber. com Seprei/een 2008 TUB MnncsaNr M.q.cA.zrNrn 31

Panelized

Sluitdns are going to find these frames much easier and less expensive to install. For example, if you look at a typical garagefront application and consider materials footing size and installation time, our moment frame is comparable in price t0 a portal built with factory-built shearwalls.l I

Tim Ellis, SE Product Manager, Strong Frame Team

Introducing the ualue-added moment-frame solution :

Strong Frame"

0rdinary Moment Frame

ow using moment frames doesnt have to a lot of extra design time for the designer additional work for the contractor. The Strong ordinary moment frame has been designed to reduce the time and cost associated with specifying and installing moment frames.

Complete engineered solutions save design time

Instead of spending hours designing their own frames, structural designers can now choose engineered Strong Frame moment-frame solutions from I 96 frames in sizes up to 16 feet wide and I 9 feet tall. Anchorage designs round out the package, for a complete oFthe-shelf solution.

Bolted connections slreamline installation

The Strong Frame ordinary moment frame is the only factory-built moment frame for wood construction that features 1000/o field-bolted connections. Instead ofa welder and special inspector, all you need are standard wrenches for installation.

Easy lo use anchorage assemblies save time for the concrele contractor

The Strong Frame anchor-bolt assemblies are designed to eliminate the need for larger footings. And with templates that mount on the forms and an optional telescoping layout tool, we make it easy to get the anchor bolts in the right place.

Convenienl to slore, ship and handle on the jobsite

Each frame is shipped disassembled to the job, meaning more frames can fit on one truck and there are no awlo,vard pre-welded frames to handle on the job.

Other features include:

' Wood nailers are pre-installed on the frame

Frames fit in a standa rd 2x6 wall, no thicker walls or furring required

. Field adjustable to account for anchor-placement issues

. Convenient ro srore and ship disassembled

. High-qualiry frames manufactured in a factory

@M trE@ Fp F1t lta +la it. _to. 10r 1tr 10o 13o

?7 ?7 Field-bolted connections allow for easier handling and installation

require and Frame

environment Strong Frame moment frames allow for larger windows and open floor plans

David Smith has been promoted to glulam sales mgr. at Rosboro, Springfield, Or.

Matt Chavez is the new director of marketing for Reid & Wright, Inc., Broomfield, Co.

Pete Martini, president of American Laminators, Drain, Or., has retired after 32 years with the company. Dave Anderson will move up from v.p. to fill the position.

John Helela, ex-PeLco, has joined Redwood Empire, Cloverdale, Ca.

Lee Alford, senior v.p.-residential wood products, and Craig Neeser, senior v.p.-industrial wood products & international, are retiring Oct. I from Weyerhaeuser Co, Fedeal Way, Wa. Thomas Gideon, executive v.p.-forest products, will assume leadership of residential wood products. James Branson, senior v.p.-timberlands, will take over industrial & international.