Bakersfield 9150 Golden State Hwy. Bakersfield, CA 93308

661.387.6090

Corona 22099 Knabe Rd.

Corona, CA 92883

951.277.7620

Fresno 4501 E. Volvo Ave. Fresno, CA 93725

559.834.4420

Lakeside 12345 Mapleview St.

Lakeside, CA 92040

619.441.3690

Redding

4963 Mountain Lakes Blvd. Redding, CA 96003

279.201.4869

Sacramento

8594 Fruitridge Rd. Sacramento, CA 95826

916.504.2300

San Leandro 1944 Marina Blvd. San Leandro, CA 94577

510.357.9131

Turlock

1275 Venture Ln. Turlock, CA 95380

209.410.6710

vcesvolvo.com

You work hard every day and need to get the job done right the first time.

At VCES, we know that your work is important. When it comes to machines that are rugged, reliable and productive, Volvo is the market leader. Our equipment lineup will give you the capability to tackle every job — and unmatched performance that allows you to focus on building tomorrow.

Contact your nearest VCES location today.

Mortenson/ McCarthy Joint Venture in Early Stages of Construction on Gaylord Pacific Resort Hotel and Convention Center on Chula Vista Bayfront for RIDA Development Corporation

The construction team of Mortenson Construction and McCarthy Building Companies, Inc. (Mortenson/McCarthy Joint Venture) broke ground on the Gaylord Pacific Hotel and Convention Center project on July 27, 2022. The Mortenson/McCarthy Joint Venture is working directly with RIDA Development Corporation (RIDA) out of Houston, Texas who is partnering with owner, Marriott

By Brian Hoover,International and real estate fund manager, Ares Management. The total estimated cost of the 1.8 million square foot, 22-story resort hotel, convention center, parking structure and associated public infrastructure and parks is estimated to be $1.23 billion. This amazing new hotel and convention center, designed by HKS Architects, will anchor future development of Chula Vista’s prime bayfront area.

The Gaylord Pacific Resort Hotel and Convention Center will open in summer 2025 and include 1,600 rooms operated by Gaylord Hotels (a Marriott company), multiple restaurants, an amazing sports bar, a resort style pool with a lazy river, a spa and numerous other recreational facilities. Additionally, there will be a 275,000 square foot state-of-the-art convention center with an open-floor exhibit hall space,

meeting rooms, elevated ball rooms and other support areas to host future large events and conventions. The hotel and convention center will be the centerpiece of the entire Chula Vista Bayfront Master Plan, a decade-long joint planning effort by the Port, the City of Chula Vista and a broad coalition of stakeholders.

“After a multi-year preconstruction process, the Mortenson/McCarthy Joint Venture team is pleased to officially break ground on Gaylord Pacific alongside owner RIDA, designer HKS and Chula Vista Bayfront Facilities Financing Authority,” said Maja Rosenquist, senior vice president at Mortenson. “Mortenson and McCarthy have a long history of building landmark projects together, and we know Gaylord Pacific is a project with the power to transform the community. It’s not just a resort. It’s an opportunity for new jobs and future economic development to take place and ultimately for Chula Vista to be on the forefront of growth in the region.”

“It’s an absolute pleasure to join together with Mortenson to build the Gaylord Pacific Resort and Convention Center,” said Robert Betz, executive vice president at McCarthy. “As a local Southern California builder, McCarthy understands this project is incredibly important for Chula Vista and the broader community. The Mortenson/McCarthy team has experience working together to set new standards for quality, innovation and safety and we’re wholly committed to delivering a world-class resort we can all be proud of for generations to come.”

The Mortenson/McCarthy Joint Venture is constructing the Gaylord Pacific Resort Hotel and Convention Center west of Marina Parkway between H and G Streets. RIDA performed early underground utility construction in 2021 with Mortenson/ McCarthy Joint Venture starting construction activity in May 2022. The daily operations on the Gaylord Pacific Resort Hotel and Convention Center project is being overseen by Andrew Corson, Project Executive for the Mortenson/McCarthy Joint Venture (MMJV) and Eric Halverson, Senior Project Manager for MMJV. “One of the first things we did when mobilizing onsite was some site clearing and demolition work, which took around a month to complete,” says Andrew Corson (Corson), MMJV Project Executive. “We then moved into the rough grading and preparing the pads for vertical construction, followed by underground utilities, auger cast pile and foundation work. We are

performing many of these trades simultaneously, and there are a lot of moving parts. This includes three active tower cranes and whole lot of yellow iron moving at once within the 36-acre jobsite.”

MMJV Senior Project Manager, Eric Halverson (Halverson), explains that Mortenson/McCarthy is self-performing all of the structural concrete work on the Gaylord Pacific Resort Hotel and Convention Center project. “We are working within a relatively empty 36-acre site with another adjacent 24-acres to be used for parking and laydown prep work. That’s 60 acres of earth being moved around, and utilities being installed to feed the hotel, convention center and parking garage. That is where we are at right now,” says Halverson. “The slab on grade work has just begun and we will soon go vertical with concrete decks. Once we get to the fifth level, the structural steel will begin to be erected in the

Above & Left: Mortenson/McCarthy Joint Venture pouring foundations and walls for the Gaylord Pacific Resort Hotel in Chula Vista.

Photo credit: Brian Hoover / CMS,LLC

Above & Left: Mortenson/McCarthy Joint Venture pouring foundations and walls for the Gaylord Pacific Resort Hotel in Chula Vista.

Photo credit: Brian Hoover / CMS,LLC

convention center. From there, we will go into enclosure work and start the pool deck construction.”

According to Halverson, after the utilities are in place, the large resort style pool and lazy river will be constructed, along with several outbuildings. From there, the interior work will commence with an army of craft personnel to perform everything from electrical and plumbing to drywall, down to the most detailed finish work. “We placed the first slab on grade on Saturday, January 14. Weather permitting, we will start going vertical with decks by the end of January,” continues Halverson. “The entire project, including the parking structure, will utilize approximately 110,000 cubic yards of concrete and 8,000 tons of steel. The convention center is a structural steel building with a standard slab on metal deck, while the 240-foothigh hotel is a post tension cable concrete structure.”

The high seismic loads that exist within the San Diego area called for a relatively innovative approach to constructing the hotel with castin-place concrete. Mortenson/ McCarthy will build the structure utilizing concrete shear wall cores with coupled walls. The width of the main tower section is 70-feet, while the length is over 700 feet

long. The tower also includes several 45-degree turns, which coupled with the overall length, pose a significant challenge to Mortenson/McCarthy. “We will use a combination of shear wall blades and closure pours in order to provide an efficient slab thickness. This will actually lower construction cost and is just one of the innovative means and methods that we are implementing on this project,” says Corson. “We used another means and methods technique for the excavation of footings. We cement treated the soil to provide solid foundation walls instead of having to bench it all back to form it. This has worked out well and is the first time we have used this method for digging foundation and footings.” Corson continues by pointing out that the conference center and exhibit hall will both be steel structures utilizing buckling restraint brace frames for seismic resistance. These steel core braced frames are wrapped in concrete and then covered by another layer of steel to provide safety and

performance for the highest potential seismic events.

Both Corson and Halverson point to the seemingly constant rain and storm conditions as one of the current most challenging aspects of the massive bayfront development project. “The rain remains a challenge, and with the added factor of being located so close to the bay, extensive dewatering efforts have been necessary and ongoing to mitigate the high-water table. We cannot discharge the water to the utilities, so it all has to go to the bay,” says Corson. “This is an arduous and expensive process where permits are required, and regulatory agencies and control boards set the parameters and conditions. Keller North America is performing the dewatering operations and they are required to pump the water through a treatment system before discharging it into the bay. Everything must be done right from an environmental standpoint.” Cc

Above Left: Mortenson/ McCarthy Joint Venture poured 1,800 auger cast piles on the resort and convention center project. Left & Above: Mortenson/ McCarthy Joint Venture will pour approximately 110,000 cubic yards of concrete before completing construction of the Gaylord Pacific Resort Hotel and Convention Center.

The Port of San Diego initially contracted Sierra Pacific West, Inc. to import around 350,000 cubic yards of fill dirt deemed necessary to complete the Gaylord Pacific Resort Hotel and Convention Center on the Chula Vista Bayfront. Tom Brown is the President of Sierra Pacific West, Inc. out of Vista. “After being awarded the contract for the import and preliminary rough grade work from the Port of San Diego, we were fortunate to also receive the final site grading contract from the Mortenson/McCarthy Joint Venture,” says Brown. “We began our work for Mortenson/ McCarthy on June 7, 2022, and most of the mass excavation has been completed. This is an ongoing operation as we are now moving to finish grade, backfill and other remedial excavating operations and will remain on the job for the next 10 to 12 months.”

According to Brown, there was a previously operational RV park onsite that needed to be completely demolished and removed. “Our crews removed approximately 21,000 cubic yards of existing asphalt and concrete. The asphalt was milled out by Pavement Recycling Systems and transported to a local recycling center. We had our own crushing operation onsite and processed around 25,000 cubic yards of concrete from the curb and gutter on the RV park site which was used as fill material,” says Brown. “There was also a clubhouse, a pool, and some other auxiliary buildings that needed to be removed. Additionally, our crews excavated and removed around seven miles of existing underground utilities, including water, sewer, gas, electric and all of the communication lines.”

From this point, Sierra Pacific West crews moved on

to the onsite excavation where they moved almost 400,000 cubic yards of dirt. Sierra Pacific West operators utilized Cat 627 twin engine push/pull scrapers, Cat 336 excavators with buckets, breakers and processors, Cat articulated rock trucks, Cat 980- and 972-wheel loaders, Cat D8 and D9 dozers, Cat 14 motor graders, Cat skid steers and backhoes and other smaller compaction and support equipment. “We excavated down a foot or two above the water table, removed the material and replaced and recompacted the dirt. We imported 6-inch minus rock for use in a few areas where the water table was a bit more troublesome within the recompaction zone,” continues Brown. “Mass excavation is mostly complete and we are now moving over to the parking structure and have already been working with Mortenson/

McCarthy on the foundation and pile work. Soon, our crews will be providing around 135,000 yards of backfill throughout the convention center and hotel work area. This will be an ongoing operation up to when we finish backfilling the new curbs and gutters. We still have a lot of work to do, and we are all honored to be a part of such an important, high-profile project.” Cc

Advantage Backhoes, out of Crestline, was contracted by the Mortenson/McCarthy Joint Venture to perform the footing excavation for the Gaylord Pacific Resort Hotel and Convention Center, along with some backfill, fine grade and other footing excavation. Travis Snyder is the owner of Advantage Backhoes, and his company has been onsite since early November 2022.

“Our first task when we mobilized onsite was to excavate the footings for the three tower cranes that will remain onsite from start to finish. Our operators excavated three pads at 12-foot in width and length and around 14-feet in depth for these structural tower crane pads,” says Snyder.

“We then left the jobsite for around three to four weeks while Sierra Pacific West finished the building pad grading and excavating work. This was followed by

Mortenson/McCarthy pouring the structural footings for the tower cranes so they could start swinging.”

Snyder explains that his crews returned to the jobsite to begin excavating the footings for the convention center.

“We had four operators and a couple of mid-size excavators, a compact excavator and a couple of backhoes to start digging footings. This is a turnkey footing operation where we went through and dug all the spread footings, grade beams, and thickened mats and edges around the convention center. One of the biggest challenges was digging around the auger cast pile caps that were drilled down to the bedrock. There is rebar flaring out in every direction, so the excavation was both intricate and tedious, but our operators did a fantastic job,” says Snyder. “We eventually moved over to the hotel site to begin digging

more footings with around 11 operators and multiple excavators, both mid-size and large. We just completed the hotel footings and are wrapping up the convention center work over the next few weeks. We are also contracted to perform the footing backfill work as well as backfilling the ramps inside the buildings. There is some fine grade work left to finish as well, so we have left a couple of our operators on the footing operation and transferred the others to the backfill and fine grade operations.”

Snyder points to another interesting aspect of the footing excavation process. “The Mortenson/McCarthy Joint Venture elected to use a cement stabilization process to strengthen the footing sidewalls. This made the excavation process a little more challenging as it was now more like digging into concrete,” continues Snyder. “They went ahead of us and cement treated the areas where the sidewalls for the major footings would be located and we followed after a 72-hour cure time.”

According to Snyder, his operators and crew members, led by General Foreman, Chad Nichols, performed

more than 30,000 cubic yards of footing excavation. “We developed an efficient method or technique enabling us to move a lot of cubic yards each day. The spoils were loaded into dump trucks right off the footing line and moved to designated stockpile locations onsite. We placed a couple of our

operators with John Deere 544 wheel loaders at the stockpile site for continuous consolidating and condensing of the material,” says Snyder. “In all we had around (16) dump trucks running at the height of the footing excavation. Five of these trucks were our own 7-yard bobtail dump trucks. We also had

(2) 135 JD excavators, (4) JD 80 excavators, (3) JD compact excavators, (2) Ford F750 2,000gallon water trucks and a JD 245 excavator. We are ahead of schedule on both sites and are also doing some footing work on the new parking structure under a separate contract through RIDA.” Cc

Castle Contracting, LLC began working on the underground utilities in July of 2022 on the Phase 1A Improvements for the Gaylord Pacific Resort Hotel and Convention Center. Jason Mrozek serves as the Vice President for Castle Contracting (Castle) and is providing oversight and support to the Castle team working on the Mortenson/McCarthy Joint Venture project. “Phase 1A encompasses a significant underground utility package for this massive project. This phase alone consists of more than 14,000 linear feet of various underground utilities (over 2.5-miles) being installed throughout the perimeter of the 28-acre site. Part of our Phase 1A work involves bringing services from the utility mains located out on the street to connections located all over the construction site,” says Mrozek. “We are performing both wet and dry utility work consisting of water, sanitary, sewer, storm

drain, power, telephone and gas. We are around 40 percent complete on this package and are looking forward to starting Phase 2 work soon.”

According to Mrozek, Phase 2 of their underground utility package work involves installing the utilities for the hotel, convention center and parking structure portion of the project. This phase of the work includes an even greater amount of underground utilities to be installed, nearly 24,000 linear feet (over 4.5 miles). So, when all their work is completed, Castle will have installed over 7-miles of utilities on this project. “When our Phase 2 work begins in the next three to four weeks, our craft personnel will reach its peak for the project at around 40 craft personnel on the job, operating in 8-person crews,” continues Mrozek. “We also have a sizable amount of equipment on the project to support the work effort, with nine large excavators, including two Cat 336, two Cat 345, and

two Cat 349 excavators, along with two John Deere 544 wheel loaders, several dump trucks and lots of utility service trucks. With this many crews spread out over such a large site, it takes a lot of coordination amongst not only our team members, but all the other trades as well.”

Mrozek points out that even the best of plans can be challenged by Mother Nature at any time of the day or night. “We are situated very close to the San Diego Bay, so we have to pay close attention to every detail, including the cycle of the moon and the timing of the tides,” says Mrozek. “Ultra-low tide is currently at 1 pm, so we try to plan for our deepest excavations at that time of day. Also, at times we will also work split-shifts to coincide with low-tide cycles. We also have to pay attention to moon phases because when the moon is full, the tides reverse. There is definitely a higher level of complexity than typical to

GAYLORD PACIFIC RESORT HOTEL AND CONVENTION CENTER, A JOINT VENTURE

Left: Castle’s Vac Master 4000 removing debris from a sanitary sewer manhole. Middle: Setting a trench shield and manhole box in preparation for 12” sewer. Right: Backfilling around recently installed sanitary sewer manhole.

GAYLORD PACIFIC RESORT HOTEL AND CONVENTION CENTER, A JOINT VENTURE

Left: Castle’s Vac Master 4000 removing debris from a sanitary sewer manhole. Middle: Setting a trench shield and manhole box in preparation for 12” sewer. Right: Backfilling around recently installed sanitary sewer manhole.

our work on this project, especially when you consider the fact that the water table is at a mean sea level (msl) depth of 6 msl, while a number of our utility installations are at a depth of negative 2 msl.”

Castle crews are digging as deep as 18 feet and that has required the implementation of an extensive dewatering plan. “Keller North America (Keller) is handling all dewatering onsite, and have drilled over 50 wells for our work package at predetermined locations throughout the site to drawdown the water table so that we can excavate and install our utilities,” says Mrozek. “The project permit limits the dewatering process to 4,000-gallons per minute of discharge and it takes approximately 3-weeks to sufficiently drawdown an area before excavation can begin, so a lot of coordination has gone into planning for dewatering on the project.”

Castle turned to Trebor Shoring Rentals (TSR) of San Diego for all their shoring needs. “We are using a mix of standard open-end trench boxes, aluminum hydraulic shoring and engineered slide rail systems, depending on the location, configuration, or complexity of the work. For the majority of deep sewer excavations on the project we’re using open-ended trench boxes, while on the power and communication work, we’re using aluminum hydraulic shoring,” says Mrozek. “For unique and offset installations, like large vaults, we’ve utilized slide rail systems. TSR takes care of all our shoring needs, and are a trusted partner to help ensure we’re creating safe excavations for our crews, no matter the application or challenge.”

Mrozek says that the Gaylord Pacific Resort Hotel and Convention Center project is one of Castle’s largest projects in company history

working in Southern California. “This has been a challenging project, due the sheer magnitude of our work package and complexity created by its proximity to the San Diego Bay. However, with the joint venture Mortenson/ McCarthy team always putting safety-first, and being extremely organized it has helped the project progress successfully. In reality, we are working for two well established and highly regarded general contractors, but they work so well together that it is very difficult to tell which company a person works for outside the Joint Venture,” concludes Mrozek. “We are on target to be substantially complete with our Phase 1A work around the end of July 2023, while our Phase 2 work will continue through the remainder of 2023, with set-finish and miscellaneous items completing in early 2024.”

Ke ller North America (Keller) has also contributed greatly to the Mortenson/ McCarthy Joint Venture Gaylord Pacific Resort Hotel and Convention Center project. Keller was contracted by the Mortenson/McCarthy Joint Venture to perform mass soil mixing, auger cast pile installation, and site dewatering. Matt Redfern is the Area Manager for Keller in the San Diego area, and he explains the details of his company’s contributions. “We started performing mass soil cement mixing for the Gaylord Pacific Resort Hotel and Convention Center in July 2022 and completed the work by the middle of August 2022. This was a value engineered approach to optimize the excavation of the pile caps and mat slabs. This mass mixing approach created soil cement treated walls within the hotel and convention center areas, making excavation safer, less expensive, and more efficient,” says Redfern. “This innovative process allowed the contractor to excavate without installing traditional shoring that is expensive and nonconducive to strict schedules and time constraints. After treating the soil, the excavating process becomes more like digging against a concrete wall.”

In addition to mass mixing, Keller also installed approximately 1,800 auger cast piles to support the hotel and

convention center structures. “The auger cast piles were necessary to transfer the heavy loads of the proposed structures to competent formational material to mitigate any future settlement or movement of the building,” says Redfern. “We started drilling the auger cast piles in August 2022 and were finished by the first week of December. We had three crews using three large rotary style drill rigs equipped with continuous flight augers up to 100 feet in length. The average pile length was approximately 75 feet, however locations with larger loads required piles be drilled up to 100 feet. The geological makeup of the site required Keller to utilize modified techniques for placement of grout.”

Redfern explains that auger cast piles are constructed by rotating a continuous flight auger (CFA) containing a hollow stem into the soil to a specified depth. Grout is then pumped through the hollow stem to fill the cylindrical cavity created as the auger its slowly being extracted. “As our crews are pumping the grout into the hole, they are simultaneously withdrawing the auger which removes the soil from the hole at the same time. The operator then swings the rig away, and a pre-tied rebar cage is inserted into the pile at full depth. Keller was responsible for all the necessary dewatering onsite. “We were contracted for two scopes on the project. The first dewatering process was designed to provide dewatering

wells along the utility corridors for Castle Construction, the wet and dry utilities contractor. “We install the wells ahead of the excavation and dewater these areas. They begin excavating once the water is drawn down to appropriate levels. Once one section is complete, we turn those wells off and progress forward to the next section.”

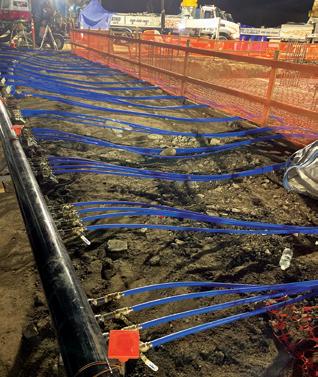

According to Redfern, the dewatering process began in June 2022 and will continue for various construction phases through mid-2023. “The other dewatering scope of work was for the deep slab excavations throughout the hotel construction area. After we completed mass soil mixing and auger cast pile installation, MMJV began digging out for mat slab installation. Since the bottom of these excavations were below the static groundwater table, it was necessary to install

a dewatering system so the construction of the mat slab could be done in the dry. We strategically drilled several dewatering wells and set up a system of pipes and pumps to provide a continuous dry work area, allowing crews to also place rebar and pour concrete,” says Redfern. “In all,

we drilled around 25 wells for the hotel excavations and 110 wells for the underground utility installations.”

Redfern concludes his comments by recognizing the Mortenson/McCarthy Joint Venture. “It has been a pleasure to work with the Mortenson/ McCarthy Joint Venture on the project from the early stages of the bidding process all the way through the completion of our scope of work.” They’re two very professional contractors with a standout group of individuals working on the project,” concludes Redfern. “The Joint Ventures focus on quality and safety did not go unnoticed. They consistently made the effort to support our operations as if it were their own self-performed crews. I expect this project to be a overwhelming success for the Mortenson/ McCarthy Join Venture.” Cc

Murray Company was awarded the plumbing contract for the Mortenson/McCarthy Joint Venture on the Gaylord Pacific Resort Hotel and Convention Center project in January 2023. Harley Hall is the VP of Operations in San Diego for Murray Company, and he has been directly involved with this project since June 2018. “We collaborated with RIDA Development and the Mortenson/McCarthy Joint Venture several years ago on preconstruction to help develop their design.

I supervised the oversight of preconstruction, working hand in hand with engineers, subcontractors and other MEP (mechanical, electrical, plumbing) trade partners,” says Hall. “We transferred the plans into the 3D model and coordinated with the other trades. Murray Company is performing all the plumbing for the hotel tower, the associated site buildings, including a restaurant and wave pool, and the convention center. There are 42 food service areas, including multiple restaurants, bars and pantries in the hotel, and the convention center cafeteria is said to contain the largest kitchen in all of San Diego. We are working within the concrete podium and all around the convention center.”

After completing all of the preliminary planning and scheduling, Hall brought on

Jacob Pessa, Murray Company Project Executive, San Diego, to manage the project going forward, with field supervision by James Adamson and Ryan Sperry. “We broke ground in October 2022 and are currently involved with the underground construction, which is around 75% complete at this time. We expect to start going vertical in around four weeks,” says Pessa. “We have partnered with Bali Construction and Karcher to assist with the underground excavating work. The deep excavations of the interceptors have been critical points for us, concerning

the underground part of this project. When we approached that sequence of the job, we hit all three grease interceptors in the same month and got them completed. That was a huge month for us in December. January had a lot of rain, but we got all of our deep excavations in on time in December.”

According to Pessa, the grease interceptors are located in several areas within the hotel footprint. “The building itself is 600 to 700 feet in length and that is too long for just one grease interceptor, so you need multiple locations. There

are five different areas where the sewer and grease exit the building to different laterals at the site utilities. The deepest pipe excavations are at nine feet below finish floor, but the grease interceptors are five feet deeper at 14 feet,” says Pessa. “After 8 feet of excavation, we start hitting water from the bay, making it necessary to navigate water intrusion or have dewatering wells. When you are operating this close to the water, it is always important to pay attention to the weather and tides, and know when to open trenches and when to wait.”

Pessa explains that the plumbing contract consists of roughly 20,000 linear feet of underground pipe, 100,000 linear feet of cast iron pipe, 200,000 linear feet of domestic water pipe, and 150,000 linear of PEX going into the units. That is nearly 100 miles of pipe when you do the math. This includes 8, 10 and 12-inch sewer mains that tie into the building. Additionally, there is 12-inch sanitary sewer pipe and 6 and 8-inch grease lines from the kitchens. “We are installing large 14-inch and 16-inch PVC conduit, instead of cast iron due to the water table and the presence Brackish salt water. We are using a lab waste, CPVC, system for the grease, which eliminates the metal contact with the salt water,” continues Pessa. “This is a massive hospitality project, our crews are projected to peak at around 50 to 60 team members by August 2023 and that will continue for around 8 to 10 months as we proceed through the tower. We estimate that we will be in the third and fourth level by June 2023 and topping out at the 22nd story by summer 2024. As the plumbing contractor, we are always one of the first to arrive and the last to leave a jobsite.”

In addition to all of the underground and vertical plumbing work, Murray Company will also be installing 9,000 to 10,000 fixtures.

“There are approximately 100 units per floor on the 16 levels of guest rooms. We have pretty much wrapped up the underground construction on the hotel and are now moving toward the convention center cafeteria at this time. All of the underground work should be complete by March 2023,” says Pessa. “We have a long history with McCarthy and a very good relationship. When Mortenson joined McCarthy on this Joint Venture, we could not tell who was working for McCarthy and who was with Mortenson. They blend and work well together, and have branded themselves as one unit, with a mutual goal of providing an outstanding finished product, on time and most importantly, keeping everyone healthy and safe. MMJV has just done an outstanding job and we are honored to be a part of this incredible project.”

Harley also has great praise for the Mortenson/McCarthy Joint Venture and RIDA, whom he has worked with since the planning stages. “I have worked with Dave Bray (Senior Vice President of Construction) from RIDA Development for several years on this project. Dave brought everyone together early on and successfully created a family type atmosphere with everyone embracing the same combined goal of pride and success. He has incredible leadership skills and has been great to work with as the owner’s representative on this fast-paced, high-profile project,” concludes Harley. “Our General Superintendent, Trevor Delong, also deserves a lot of credit for being such a great leader. He holds a Stretch-and-Flex meeting every morning to review daily goals and safety protocols while keeping his hand on the pulse on all the constantly moving parts of this massive project.” Cc

Top: Sanitary sewer in deep excavation locations where groundwater was present. Middle: Deepest excavation for the grease interceptor install.www.coastlinecd.com

No matter the job site, Sunbelt Rentals is ready to cover your equipment rental and service needs. With more than 100 Sunbelt Rentals locations across California and the industry’s most extensive fleet, we’re here to support your project from start to finish. From small tool rentals to specialized turn-key solutions, let’s work together to make it happen.

We offer a diverse product mix that can accommodate any project SERVICE

We’re able to assist with all your needs, from regular maintenance to unplanned situations.

SAFETY

We offer safety training for your crew to keep work running smoothly

Ready to get started on your next project?

Visit sunbeltrentals.com or give us a call at 1-800-667-9328

Construction crews are mobilizing on hundreds of emergency cleanup sites across California to mitigate damage from floods and mudslides that have caused road and property damage from recent rainstorms. Many roadways have completely washed away while others remained fully or partially closed. Additionally, thousands of homes have been damaged, but worst of all, at least 20 human beings have lost their lives. The vast damage has affected 41 of California’s 58 counties, with more than 500 landslides being reported across California since December 30, 2022. Several rainfall records from the 1978 El Nino event fell with cities like Los Angeles receiving 1.82 inches, beating the previous 1.56-inch number. Long Beach went from

1.48 to 1.72 inches, Paso Robles’ from 1.1 inches to 1.13 inches and Camarillo going from 1.03 to 1.43 inches, which was set in 1990. Further north, San Francisco has received around 22 inches of rain since October, making it the sixth wettest year on record. Additionally, water from the Sierra Nevada snowpack and other mountain ranges is more than 250% of normal to date.

Key roadway sections like State Route 154 were hit hard with mud and rockslides. Numerous atmospheric rivers have caused power outages, flooding, levee breaks, washouts, and landslides throughout the state. Residents have been evacuated in areas like the remote community of Matilija in the Los Padres National Forest near Ojai with estimates of repairs that could take up to six months to

be complete. The cost of removals and repairs is not yet known but is expected to be over $1 billion statewide. Fortunately, there are emergency contractors standing ready to immediately arrive onsite to mitigate damage and potential traffic nightmares. Graniterock and C.A. Rasmussen are just two such contractors who are working tirelessly to help keep us all safe and productive through these heavy rains.

A 250-foot-long mudslide recently closed two lanes of the northbound I-5 freeway near Templin Highway in Castaic. Recent rainstorms contributed to loose soils that allowed a large section of the hillside to slide right

Photo provided by C.A. Rasmussen, Inc.

Photo provided by C.A. Rasmussen, Inc.

onto the number 3 and 4 lanes of the I-5 freeway. Caltrans immediately contacted one of their emergency contractors, C.A. Rasmussen to help evaluate the situation and begin cleanup operations. Tom Charon is the Operations Manager for C. A. Rasmussen, and he explains the situation. “We arrived onsite on Friday, January 13 at 7:00 a.m. to assess the situation and do a preliminary cleanup. After further evaluation by Caltrans officials and geologists, the decision was made to not go forward with any work until further evaluation was made of the stability of the earthen slope adjacent to the freeway,” says Charon. “The northbound I-5 number 3 and 4 lanes remain closed due to mud flows that continue to flow

onto the freeway. We have, however, installed K-rail and craft cushions along with temporary striping to protect lane 1 and 2 from additional mud flow.”

Charon explains that lanes 1 and 2 remain open while C. A. Rasmussen will soon remove the mud and debris from I-5 lanes 3 and 4 and open them to traffic. “Caltrans will provide direction, but inevitably it will require removing the unstable material and importing appropriate backfill material to buttress and stabilize the existing slope,” says Charon. “This will require engineered fill material and perhaps some drainage to prevent future leaching.”

According to Charon, C. A. Rasmussen will utilize dump trucks,

excavators, wheel loader and motor graders to move earth from the 500-foot long affected area on the I-5 northbound Freeway. “The job was originally just an every day mud or debris cleanup, that quickly moved into a major mudslide situation,” concludes Charon. “We will probably end up removing about 100,000 cubic yards of earth before this job is complete. We will then bring in hundreds of cubic yards of engineered fill material that will be properly installed and compacted to sustain the hillside into the indefinite future,” concludes Charon. “We stand ready on the emergency list to respond to Caltrans and other agencies at a moment’s notice.”

Photo provided by C.A. Rasmussen, Inc.

Watsonville authorities put residents along the Pajaro River in Santa Cruz County on notice on January 10 of possible evacuations after major rains and flooding put the Pajaro River levee at risk of overflowing or even failing. The Santa Cruz Department of Public Works could see that the rainstorms had caused the approximately 200 foot-wide Pajaro River to rise to almost the top of the levee, and also noticed definite signs of seepage from the sides of the levee. Additionally, they could not ignore the already flooded agricultural land. As the water leaches through, it makes its way to the other side where it continues to flood the land. Santa Cruz County officials had already been inspecting the Pajaro River levee to locate the weak points and where the water was coming from, but after the heavy rains, they knew they had to call someone in to support the levee walls to prevent a possible catastrophe.

The Santa Cruz Department of Public Works contacted Graniterock, headquartered in Watsonville, to come out and support the outside of the levee with gabion rock.

Crews led by Graniterock Superintendent, Sergio Rubio, were immediately sent out on an emergency contract to mitigate the situation. “We arrived onsite early morning on January 11 and worked two 8-person crews in 12-hour shifts so as to work 24-hours, non-stop. By the end of day, January 13, we had placed 2,000 tons of gabion rock, or riprap, to successfully hold back the rising water and stop all seepage from the sidewalls,” says Rubio. “The riprap consists of a gabion rock size of between 4-inches and 10-inches in diameter. We had the material transported in super dumps that picked up and delivered rock from our Aromas quarry, located within minutes of downtown Watsonville, which also happens to be our company headquarters. The rock was delivered every 15 or 20 minutes, and each load carried around 20-tons of material.”

According to Rubio, before any of the riprap could be placed, a stabilization fabric had to first be positioned underneath. “We directed four of our laborers to don waders and walk into the water, which was about waist high. These brave Graniterock team members held the corners of the 40-feet-long by 25-feet-wide fabric down while

one of our excavator operators placed gabion rock on top of the material. Once a base layer was established to hold the fabric in place, our operators and laborers started stacking more gabion rock on top with the assistance of a John Deere 850 dozer, a Cat 320 excavator and a lot of light plants for working around the clock.”

Rubio says that the gabion rock was stacked to an elevation of around 5-feet high and 20-feet in width, at a slope of around 1.5 to 1, adding to the edge of the levee, and successfully supporting the weight of the water above.

“We had many safety measures in place and it was the laborers on the ground that concerned us most. They were walking around with self-inflated life vests. If the water touched the life vest, it would inflate, which actually happened a few times in pockets of deeper water,” continues Rubio. “Safety officers were also onsite for each shift, so 24-hours-a-day. A pickup truck was constantly monitoring the levee to make sure the super dumps would not create erosion or further compromise the roadway situation.”

The decision to bring in Graniterock to address the Pajaro

Graniterock operators and laborers place fabric and 2,000 tons of 4-inch to 10-inch gabion rock to hold back rising water on Pajaro River levee for Santa Cruz Public Works adjacent to the City of Watsonville.

River levee was definitely prudent, considering that the town of Watsonville was located adjacent to the levee structure. The homes and business in Watsonville had

sandbags in place anticipating some sort of flood scenario. All one had to do was look back to January 1995 when 125 residences located near the Pajaro River were flooded. The damage cost was around $2.5 million, in addition to an estimated $1 million in damage to public facilities and utilities in Monterey County. “We remain on the emergency call list for Caltrans and other agencies and stand ready to respond at a moment’s notice. We are doing another emergency job right now in Santa Cruz where we are placing 8-to10-ton rock. A portion of the road along Westcliff was washed out during the rainstorms and we were called on to place boulders the size of cars to hold back the water,” says Rubio. “We were also mobilized to Big Sur to help Caltrans with a slope mitigation project. We were first sent to clean up a mess from

SMALL BUT MIGHTY

The WORKMASTER™ 25S sub-compact tractor is the perfect “first step” tractor for homeowners and AG-lifestylers who need a hard-working, versatile small tractor to handle the chores a garden tractor just can’t. it’s ready to take on your yard, landscape, gardening and property maintenance jobs. Its compact size makes it easy to operate and maneuver around obstacles and in confined spaces

minor slide that later became a major slide that required greater repair and stabilization of the slope. I am always impressed with how our company, Graniterock, operates in emergency situations like these. From the quarry to the trucking and construction division, to dispatch. It always comes together professionally, and most importantly, safely. I am proud to be working for such a competent company.”

It is important to note that measures are in place to reduce the flood risk from the lower Pajaro River and Corralitos and Salsipuedes Creeks. The Pajaro River Flood Risk Management Project is a $400 million endeavor that is designed to provide 100year flood protection to the City of Watsonville and the town of Pajaro, along with the surrounding agricultural areas. Cc

COMPTON (CA) January, 2023. This year, Trench Shoring Company will celebrate 50 years of dedicated service to the construction industry in California and Nevada. The company that Tom Malloy created begins its fifth decade, successfully guided by the second and third generation of Malloys.

In 1973 Tom Malloy reimagined his father’s general contracting company into a fledgling rental business. He envisioned the name “Trench Shoring Company” before he even had his own inventory. With the insightful vision that would guide his entire career and his company’s success, Malloy saw opportunity in Southern California’s explosive growth of new highways and building construction. He began purchasing land and shoring inventory and never looked back. Today, under the stewardship of current company President Kevin Malloy, this strategy has not wavered. The goal of Trench Shoring Company’s eleven locations is to continue to provide same day service to support projects near each of the facilities.

Over the years, the Company has made safety an integral component both for their employee workforce and also in the trenches for their clients and customers. To support their internal workforce, Kevin established a Safety Task Force with the dual goals of embedding a culture of safety throughout the company and correcting any unsafe practices.

These safety goals have evolved into a detailed training manual which today includes over 30 different safety policies and procedures.

To educate and help keep clients and contractors safe in the trenches, Trench Shoring University (TSU) instructors employ state-of-the-art training tools adapted for both online (remote learning) as well as classroom situations. Competent Person Training and Confined Space Training courses meet all OSHA requirements.

Tom Malloy’s early experiences as a contractor motivated him to ensure that he would never disappoint a customer by being unable to supply the required equipment on time. In the early days, carrying a large inventory was very costly but this ensured that customers got the needed equipment in rapid response.

Notes President Kevin Malloy, “From day one, each of our locations will not launch until it is equipped with a full inventory of

shoring equipment, including steel trench plates, trench shields, hydraulic shoring, slide rail and a wide range of safety equipment. Heavy and utility vehicles, crane, pickup and flatbed trucks and a well-trained staff at the ready to provide same-day service.”

There is a clear through line from Tom Malloy’s early vision for his company 50 years ago to the Malloy family management of Trench Shoring Company today: responsive service, comprehensive inventory, training, and safety. It’s a winning strategy that will continue to be foundational to the company’s future success.

For decades, the Southern California and Nevada construction industry has counted on Trench Shoring Company for their extensive construction knowledge, complete inventory and same-day service. They know time is money, so they produce same-day service from their 11 locations across Southern California, the San Joaquin Valley,

the San Francisco Bay Area and Las Vegas, Nevada. Whether it’s for a current project, or your next project, consider making Trench Shoring Company your choice for shoring equipment and service. Trench

Shoring Company has consistently handled their customers’ toughest jobs and the most challenging job requirements with safety, service and customer satisfaction since their inception in 1973.

Trench Shoring University (TSU) training courses meet all OSHA requirements and are an important element of the Company’s commitment to the industry. Cc

Left: Trench Shoring onsite class – Coachella Valley Water District (1980).

Middle: Preparing to load Trench Crossing Bridges for delivery (1979).

Left: Trench Shoring onsite class – Coachella Valley Water District (1980).

Middle: Preparing to load Trench Crossing Bridges for delivery (1979).

The total number of wage and salary jobs in California is almost back to where it was before the COVID recession hit in early 2021. It’s taken more than two years to do that, but a loss of 2.3 million jobs when COVID first hit is a big hole from which to recover.

The nature of the recovery, however, has been geographically uneven. For example, Riverside and San Bernardino counties have left all other counties in the dust.

The kinds of jobs being created have also been uneven. Jobs in leisure & hospitality, for example, are still under water. But jobs in Advanced Industries have recovered quickly. These highvalue-added jobs in a broad range of sectors – technology, software development, aerospace, scientific research, medical products, and pharmaceutical development – are tracked by the Chapman-UCI Innovation Index, an Index created by a Chapman research team that includes Professor Ken Murphy of UCI. We have found that these industries are strong job generators. In addition, the average wage paid

in Advanced Industries is roughly double that of all other jobs in the state.

Over the two-year COVID era between 2019:4 to 2021:4, Advanced Industry jobs increased by 2.5 percent in the five high-tech regions in California that we track. Although that outperformed job growth in almost all other California job sectors, it lagged the growth rate of Advanced Industry jobs in other states like Texas and Florida.

We believe a major reason for California’s slower growth in Advanced Industries relates to its higher rate of state and local taxation, where it ranks as the second highest of all 50 states. In an analysis of the 30 MSAs in the nation with more than 100,000 Advanced Industry jobs, the previous figure shows that job growth over the 2019:4 to 2021:4 period closely followed the rank in state and local taxes.

Except for San Francisco, none of the other 4 Advanced Industry MSAs in California, including Orange County, placed in the top 10 growth areas.

San Francisco is explained by sharp increases in remote work. Based on home price appreciation and commercial property vacancy rates, many of the Advanced Industry jobs generated by San Francisco MSA are remote workers living in the Peninsula and pockets of East Bay. Although the data does not currently show an exodus of remote workers in Advanced Industries to other states, the fact that workers have increased

Chapman University – A. Gary Anderson Center For Economic Research / Prepared and written by Dr. James Doti and Dr. Raymond Sfeiropportunities to leave areas where the cost of living is high has negative economic implications for states that rank high in taxation.

Recessionary forces at the national level will depress overall job growth in the state. On average, for 2023, our forecast calls for wage and salary employment in California to increase at a scant rate of 0.3 percent – the same as the U.S. That forecast of virtually no job growth for California in 2023 follows the post-COVID recovery years of 2021 and 2022 when California’s job growth hit 3.2 percent and 4.7 percent, respectively.

The weakest sector of the California economy will be its real estate sector. Mortgage rates exceeding 7 percent have already decimated home sales and building permit valuations.

As shown in the following figure, mortgage rates lagged one quarter have a significant inverse impact on annual percentage changes in total building permits. Note that after a mild upturn in mortgage rates from 3.9 percent in early 2018 to 4.8 percent one year later, permits dropped by 26 percent. Clearly, the sharp increase in mortgage rates from 2.9 in 2021:3

to our forecasted peak of 7.2 in 2023:1 will lead to a steep percentage decline in residential permits in 2023.

Our forecast for total residential permits calls for a sharp drop of 31 percent from 129,000 units in 2022 to 88,000 in 2023. Cc

The Economic & Business Review, published semiannually by the A. Gary Anderson Center for Economic Research, is owned and provided as an educational service by Chapman University. For more information on the https:// economicforecast.chapman.edu/

As Milton Friedman famously stated, “Inflation is always and everywhere a monetary phenomenon.” So too is disinflation. That is why we can be confident in forecasting that inflation has peaked and is now set to begin a slow, albeit fitful, drift downwards.

Our confidence is based on an analysis of price trends during previous periods of disinflation. An example of one of the five episodes since 1960 when inflation (CPI) retreated from a high of over 5 percent is shown below.

As M2 dropped sharply from a peak of 11.2 growth in June 1973, it wasn’t until 17 months later (November 1974) that the CPI peaked at 12.2 percent. Such a long lag before declining M2 growth led to disinflation is not unusual. In fact, the average lag for the five periods of disinflation since 1960 was 16 months.

Applying that average 16-month lag to the current period when M2 growth hit 26.7 percent in February 2021 leads to a projected inflationary peak in June 2022 of 9 percent.

Inflation trends appear to confirm that this did, indeed, represent a peak in the current inflationary cycle. Since then, inflation has slowly drifted downward to 7.8 percent as of October this year. While it may appear premature for us to believe that a disinflationary cycle has begun, the sharp deceleration in M2 growth that followed the 26.7 percent peak in early 2021 gives us a high level of confidence that the inflationary peak is behind us.

That doesn’t mean that inflation will drop sharply. History shows that the downward path of

disinflation is typically a long slog. Its pace will depend in large part on how quickly the economy slows in the face of a sharply contractionary Federal Reserve Board policy.

Since February 2020, aggressive Fed action has led to an increase in the Fed funds rate from practically zero to 4 percent. As a result, the spread between the Fed funds rate and the 10-year T-Bond rate has narrowed appreciably. By year-end 2022, we expect the spread to turn negative. This shift is significant since all seven recessions since 1969 occurred 6 to 18 months after the spread between the 10-year T-Bond and Fed funds rate turned negative.

The remarkably consistent pattern between a negative interest rate spread and recessions is not the stuff of sunspot theories. It occurs because the Fed’s actions

in increasing the Fed funds rate ultimately lead to a slowdown in the economy. That downturn, in turn, leads the growth rate in long-term interest rates like the 10-year T-Bond to stabilize before the Fed funds rate, a rate that is set by the Fed rather than by economic market forces. An example of the relationship between the spread and recessions can be seen in the following figure, which shows movements in the T-Bond and Fed funds before and during the 1973-74 recession.

If the spread turns negative by year-end, as we expect, that would be yet one more piece of evidence that a recession will occur by mid to late 2023. Our forecast calls for slower but continued increases in the Fed funds rate to 5.7 percent by mid-2023. At the same time, we are projecting that the 10-year

Chapman University – A. Gary Anderson Center For Economic Research / Prepared and written by Dr. James Doti and Dr. Raymond SfeirT-Bond in 2023 will decline to 3.5 percent towards year-end. These projections result in long-and short-term interest rate movements that result in a spread that looks uncannily like the 1973-75 recession shown in the above figure.

The normal trajectory of a recession begins with a sharp drop in construction spending. During the 1973-75 recession, for example, residential investments dropped sharply from a lofty high of almost 30 percent to an unsettling low of -25 percent. The resulting contagion led to lower consumer spending and eventually a recession.

Our forecast for residential investment spending looks eerily similar to what happened in 1974. Similar to that episode, current consumer spending seems unfazed by the initial drop in residential investment. We believe, however, that consumer spending will soon decline and pull total spending down, thereby leading to a recession by mid to late 2023. Cc

The Economic & Business Review, published semiannually by the A. Gary Anderson Center for Economic Research, is owned and provided as an educational service by Chapman University. For more information on the https://economicforecast. chapman.edu/

WATSONVILLE – Graniterock is pleased to announce Peter Lemon has been named the new president and chief executive officer effective Jan. 1, 2023.

Peter, an energetic and effective business leader, brings nearly 25 years of experience in heavy civil construction and aggregate mining to the CEO position of the familyowned company.

He succeeds Tom Squeri, who has served as CEO since 2012 and led Graniterock through some of its best performing years.

Tom will remain on Graniterock’s Board of Directors.

“I am honored to serve our team, customers and community as President and CEO to continue to build on our achievements of the past 123 years,” Peter said. “I am committed to leading this organization to deliver value to our customers and our community through our combined purpose of high-quality products and construction services.”

The Monterey native began his Graniterock career in 1998 as a summer intern while studying civil engineering at UC Davis, eventually earning his B.S. in civil engineering and certification as a professional engineer.

After three summer internships at Graniterock, Peter was hired in the company’s Construction Division, where he worked in estimating and project engineer/ manager roles.

In 2008, he was chosen for the Construction Division’s private works area manager, a position that requires developing strong

customer relationships in the San Francisco Bay Area’s commercial building market.

Peter took the next step in his Graniterock career in 2012 when company leaders asked him to run the A.R. Wilson Quarry, which is a hard rock quarry with more than 100 craft workers and a large fleet of heavy equipment.

During his 10 years managing the Wilson Quarry, Peter initiated several critical projects to improve operational efficiencies and reduce waste.

In all, Peter was instrumental in overseeing significant capital investment opportunities at the Wilson Quarry totaling roughly $104 million.

Key projects during his tenure as Wilson Quarry manager include standardizing the equipment fleet, construction and operation of a $10 million wastewater reduction plant and $15 million premium sand plant that produces highly specialized sand products for asphalt and concrete producers throughout the San Francisco and Monterey Bay Areas.

Most recently, Peter held the position of Vice President of Logistics.

Peter is active in the Boy Scouts of America and serves as leader of Troop 2 and Pack 126 in Monterey.

He reached the rank of Eagle Scout and attributes much of his business leadership to lessons learned from scouting, including how to lead and follow in challenging environments and help others conquer what may seem like an impossible task.

“Not only does Peter bring an incredible mix of engineering and business expertise to the CEO role, his passion for Graniterock and our people is unsurpassed,” said Marianne Woolpert, Board member and family owner. “The board is fully confident in Peter and his ability to continue building on Graniterock’s legacy in the construction industry and in the communities where we live and work.” CA

Sonsray has the machines you need to get it done!