INSIDE

Customer Centricity

The Focal Agenda of CSCOs

Interview

with Rodrigo de Moraes Rodrigues, Vice President –Logistics, Budweiser APAC

Customer Centricity

The Focal Agenda of CSCOs

Interview

with Rodrigo de Moraes Rodrigues, Vice President –Logistics, Budweiser APAC

Those miniscule chips called Semiconductors, an essential component for anything digital – from cars to mobile phones and more – is now driving geopolitics. India aims to create a new global supply chain of semiconductors that is currently dominated by Taiwan, whose sovereignty is questioned by China. Global semiconductor majors Foxconn, Micron Technology, Applied Materials, SEMI and Cadence and AMD bullish on India as a manufacturing base and a key global market driver.

India also joined the 14 member Minerals Security Partnership, led by the U.S. that will help emerging sectors like electric vehicles and new age electronics. India is also signing the Artemis Accords and promoting stronger ISRO-NASA collaboration. It is visible also in the creation of a joint Indo-US Quantum Coordination Mechanism.

With ambitions to be firmly entrenched in critical global value chains, Indian Government has been pushing the manufacturing sector, with initiatives like Make in India, Aatmanirbhar Bharat, Skill India, and Digital India, as well as the Production-Linked Incentive (PLI) schemes in 14 critical sectors. India does have all the necessary will and global support to be a big player in the supply chain shift from China.

While the global stage calls, our CSCOs delve into the intricacies and best-case scenarios for developing a resilient and customer-centric supply chain.

Our article under Focus section looks at circularity in tire supply chains and the second one deep dives into how Environmental, Social, and Governance (ESG) initiatives can ensure long-term business sustainability and success.

There is a lot in this issue, so read on.

Charulata Bansal Publisher

Charulata.bansal@celerityin.com

www.supplychaintribe.com

Over the past few years, there have been more and more disruptions, from natural catastrophes to trade conflicts to pandemics around the world. Due to these interruptions, supply chains are now more vulnerable than ever, emphasizing the need for proactive actions to increase resilience. To cope with complexity and uncertainty, resilient planning is the need of the hour. This was the basic tenet of our panel discussion on the sidelines of our recently held Supply Chain Tribe Conference & Awards 2023 where the industry leaders deep dived into smart & sustainable ways to make their supply chains resilient and explored the enabling role of technology in achieving the same.

07 | Tire Retreading – A True Case to Promote

Dr. Sourabh Bhattacharya, Professor of Operations and Supply Chain Management and Vinay K. Kalakabandi, Associate Professor of Operations and Supply Chain Management, Institute of Management Technology, Hyderabad consider the case of the unorganized tire retreading industry in India and examine the barriers it faces in contributing to a circular tire supply chain in India.

Sandeep Chatterjee, Supply Chain and Sustainability Leader, IBM Consulting, presents his take on ESG as the key driver of long-term business sustainability and success.

|

Rodrigo de Moraes Rodrigues, Vice President –Logistics, Budweiser APAC, decodes the changing supply chain paradigms in APAC.

|

Aashish Rathore, Supply Chain Lead, UMA Consumer Products Pvt Ltd., highlights the ever-evolving food supply chain.

26 | SPECIAL REPORT

Our recently held panel discussion deciphered on the parameters that supply chain managers need to re-invent for improving customer experience and discussed the dos and don’ts towards achieving a truly customer centric supply chain…

Editor: Prerna Lodaya

DISCLAIMER: This magazine is being published on the condition and understanding that the information, comments and views it contains are merely for guidance and reference and must not be taken as having the authority of, or being binding in any way on, the author, editors, publishers who do not take any responsibility whatsoever for any loss, damage or distress to any person on account of any action taken or not taken on the basis of this publication. Despite all the care taken, errors or omissions may have crept inadvertently into this publication. The publisher shall be obliged if any such error or omission is brought to her notice for possible correction in the next edition.

The views expressed here are solely those of the author in his private/professional capacity and do not in any way represent the views of the publisher. All trademarks, products, pictures, copyrights, registered marks, patents, logos, holograms and names belong to the respective owners. The publication will entertain no claims on the above. No part of this publication can be reproduced or transmitted in any form or by any means, without prior permission of the publisher. All disputes are subject to the exclusive jurisdiction of competent courts and forums in Mumbai only.

“I am very excited about our journey towards end-to-end synchronization of our supply chain – connecting our suppliers, their suppliers, our manufacturing and distribution operations with our customers’ operations and understanding the consumers’ needs. All this connected through data and analytics, can one day, lead us to higher levels of prediction and therefore faster and efficient reactions to customer and consumer needs. It is a big dream, but we are starting to see it happening, perhaps this is going to be the most relevant legacy my generation of supply chain leaders will leave,” highlights Rodrigo de Moraes Rodrigues, Vice President – Logistics, Budweiser APAC, during an exclusive interview…

You have a vast experience in managing supply chains of dynamic yet complex territories such as India & China. Which APAC territory do you find the most exciting to work with and the most challenging to work with?

Each country is different, with a combination of challenges and excitement and I cannot single out just one. All countries I have worked in my life provided me an amazing time and rich experience from both personal and professional aspects. It is a true privilege living in APAC for most of the past 15 years and I am very grateful for having this opportunity.

How has the Business and Supply Chain changed over the course of your career? What are the most transformative changes you have witnessed in this domain?

Before talking about what has changed, I would like to tell what hasn’t changed and I believe will never change – the basics of supply chain management remains the priority and by focusing on improving it will continue to drive most of the value in supply chain – in other words, having the best people in your team, making sure the processes are managed at excellence level, always opening gaps with 100%

mindset that we shall be able to perform at the best regardless which metric we are looking at is the key for a successful supply chain. However, indeed dramatic changes have happened in the last years. In APAC, I would say that the most remarkable ones are the quality of young talents – high level of education and rich personal experience are bringing broader possibilities for us to keep improving.

Another change that has to do with the quality of the people is what I call the democratization of the analytics – more and more data are becoming available, and tools are becoming more user-friendly. This, combined with better quality of talents, creates the perfect environment for what some people call digitization, which is a buzzword that, in my view, means empowering large percentage of your teams, especially frontline with more information readily available to make better decisions.

What’s the secret sauce of managing complex supply chains?

There is no secret, it is a lot of hard work, focusing on the basics of supply chain management and keep opening the gaps to further improve. But if we need to pick one priority, I will say focus on your planning – the success of your supply chain depends on the quality of the

plan you put together – better accuracy, multiple scenarios, understanding of your constraints, triggers and early alerts to make sure we predict disruptions are all part of it.

What are some of the lessons you learned in your career that you would like to share for others to learn from?

Several mistakes or failures over the years I wish I could make sure other people don’t repeat but it is hard to put here, maybe I need to write a book someday. But I will try to summarize on what I call the top 5 priorities of supply chain :

People – Make sure you have the best team and take very good care of them; nothing can be achieved without highly motivated and top performing talents.

Customers/Consumers – A supply chain exists to serve a customer or a consumer in the case of beer and we must make sure that we are delivering happiness to our consumers, and you can describe it in many metrics such as cost, quality, availability, etc., but in the end, they need to be happy and we need to know when they are not and fix it.

Excellence – Focus on the basics, spend as much time as needed to get the

processes right and inspire your team to keep opening the gaps to make it even better.

– As the name says, supply chain is a “chain”, meaning that moving one piece of it will affect multiple other parts in different forms, therefore we need to look for efficiencies that make sense for the chain, not just for a part of it, there is no room for siloed thinking in modern supply chains. Communication, collaboration, transparency and trust are key to achieve that.

Embrace Technology – The world is evolving, and supply chain managers must embrace and lead this evolution. Make sure we go to the end and empower our teams with technology. If our frontline is not using technology fluently on a regular basis and not embracing it as part of their life, we are not doing our job and we don’t deserve the best people, that is how it all connects.

I once read a book called Grit and it somehow simplifies a lot about what is the life in supply chain – in summary, it says that everybody has a set of talents and when you put effort to develop those talents, it becomes your skills, when you put effort on your work, performing your skills, it will turn into achievements, ultimately a set of achievements will turn into success. Those are not my words but summarizes a lot my principles of hard work and resilience, doing what you love and are good at is what will make the difference at the end. I don’t believe in stereotypes, for me, regardless of the country, gender or cultural background, there are always great people out there that fit in a high-performance supply chain team. If you ask me specifically to comment on young India SCM professionals, I can say that over the years, I met many very ambitious, highly educated and hard working young talents in India, as I mentioned, there are always great people, no matter where you are in the world, you just need to connect with them.

What has been one of the most challenging tasks managed by you in your professional journey so far?

No doubt safety, the most important and still the most challenging because there is no end to it, there is no guarantee that 100% of our people are safe 100% of the time and it really keeps me awake at night. If one accident happens, no matter how small it is, is my fault, I take it personally.

We would like to know from you the technological innovations happening in this industry. What are the tech developments that you are the most excited about embracing?

I am very excited about our journey towards end-to-end synchronization of our supply chain – connecting our suppliers, their suppliers, our manufacturing and distribution operations with our customers’ operations and understanding the consumers’ needs. All this connected through data and analytics, can one day,

lead us to higher levels of prediction and therefore faster and efficient reactions to customer and consumer needs. It is a big dream, but we are starting to see it happening, perhaps this is going to be the most relevant legacy my generation of supply chain leaders will leave.

What would be your advice to young logisticians to excel in their respective roles? Have you witnessed any peculiar traits of supply chain professionals across the geographies you have managed supply chains?

What’s your take on the young Indian SCM professionals?

I once read a book called Grit and it somehow simplifies a lot about what is the life in supply chain – in summary, it says that everybody has a set of talents and when you put effort to develop those talents, it becomes your skills, when you put effort on your work, performing your skills, it will turn into achievements, ultimately a set of achievements will turn into success. Those are not my words but

I believe the basics of supply chain management remain the priority and by focusing on improving it will continue to drive most of the value in supply chain – in other words, having the best people in your team, making sure the processes are managed at excellence level, always opening gaps with 100% mindset that we shall be able to perform at the best regardless which metric we are looking at is the key for a successful supply chain. However, indeed changes happened in the last years. In APAC, I would say that the most remarkable are the quality of young talents – high level of education and rich personal experience are bringing broader possibilities for us to keep improving.

summarizes a lot my principles of hard work and resilience, doing what you love and are good at is what will make the difference at the end. I don’t believe in stereotypes, for me, regardless of the country, gender or cultural background, there are always great people out there that fit in a high-performance supply chain team. If you ask me specifically to comment on young India SCM professionals, I can say that over the years, I met many very ambitious, highly educated and hard working young talents in India, as I mentioned, there are always great people, no matter where you are in the world, you just need to connect with them.

What are the parameters on the basis of which companies should select their supply chain partners? How can they you keep them updated with changing market dynamics?

If by partners you are talking about suppliers and vendors, I think the most important factor is transparency. Without transparency, there is no trust and without trust, there is no business. After that it becomes a business case where you will evaluate several factors such as cost, quality, location, technology, etc., and balance the best fit.

What’s your take on sustainability? How can companies embrace green measures in supply chain be it transportation or packaging?

Great supply chain leaders shall lead sustainability. No one will do it for you, and you don’t do it just for your company,

it is your social duty you owe due to the privilege you have in life to lead a supply chain business. We need to influence and make an impact through our supply chain on our planet, our society and it is really important. It is part of the basics of our supply chain management I always talk about. It shall start by small actions such as proper maintenance, proper recycling, etc. Small actions, at the end, will become habits from our team and those habits will become who we are. On top of the basics, when I say we shall lead, I mean, we shall invest and expand the use of green technology, such as EV trucks or solar energy in manufacturing and promote circular packaging in our business such as recycle content packs or returnable containers. We shall be proactive in partnering with companies that have same principles in sustainability and drive the development of green technologies that meet the needs of our business, customers, consumers.

What are the critical aspects that will help improve supply chain in India and across China?

Talking more about external factors, supply chain in both countries at the end will benefit from the same aspects but due to the different stages of economic development, I would say that in India probably the most relevant would be infrastructure development – roads, ports, railways and waterways. In China, the standard of infrastructure is already quite high and the challenge now is becoming labour cost, therefore advances in technology, more obviously automation will bring the next lead on

the supply chain efficiency in the country.

What gets you up in the morning?

What keeps you going after a hard day at work?

The energy of the people around me, helping to inspire people, being at work or at home to continue to do their best and achieve their dreams and my dreams are a great reason to be awake and working hard.

What’s the one best advice you have ever received?

It was from a former boss – “Make sure you surround yourself by great people”. Great people can achieve amazing things and if you are among them, you can also achieve your dreams.

Rodrigo de Moraes Rodrigues holds over two decades of rich experience in Supply Chain in both aerospace and FMCG industry. With an exceptional acumen in both logistics and manufacturing, he has worked for over 12 years in Asia, serving in multiple countries, including China, Vietnam, India, South Korea, etc. A 2010 China Europe International Business School (CEIBS) MBA Graduate, he is currently leading logistics for Budweiser APAC, a HK listed subsidiary of ABInbev.

The retreaded tire represents the symbol of the circular economy, avoids the consumption of raw materials, and drastically reduces the energy requirement compared to the production cycle of a new tire, and current technology ensures similar performance and durability. To understand the role of the unorganized sector in the push toward a circular economy (CE), Dr. Sourabh Bhattacharya, Professor of Operations and Supply Chain Management and Vinay K. Kalakabandi, Associate Professor of Operations and Supply Chain Management, Institute of Management Technology, Hyderabad consider the case of the unorganized tire retreading industry in India and examine the barriers it faces in contributing to a circular tire supply chain in India. There are more opportunities than ever for disruption in the tire recycling space, where all players in the ecosystem— manufacturers, tire recyclers, retailers, and consumers—can win. Here’s a take on this…

CORPORATIONS and Governments worldwide are pursuing scalable and sustainable strategies to promote the growth of a Circular Economy (CE). However, the recent circularity report published by the Ellen McArthur Foundation suggests that circularity in the global economy has plummeted from 8.6% in 2020 to 7.2% in 2023. Further, despite a high potential, India has been experiencing a deficit of investment in the CE space. Consequently, more effective measures are necessary to prevent further planetary resource depletion.

One industry that holds significant potential for increasing circularity is the tire industry. By nature, a tire is a product well suited for remanufacturing. Apart from the tread (the outer rubber layer that meets the road surface), all the other components of the tire (body plies, belts, liner, sidewall, and beads) are generally well-preserved even after extensive use. So, a used tire could be brought back to

life using what is known as a Retreading process, where a new tread is installed over a used tire. When done skillfully, a retreaded tire could fully match a new tire in quality and safety. Given the widespread use of tires, keeping them in circulation and maximizing retreading is crucial for promoting a circular economy while realizing significant cost savings for commercial vehicle operators.

The Indian tire market, the fourth largest in the world, is similar to any other large market. A handful of original tire manufacturers (OTMs) corner a significant market share. While OEMs in the automotive sector form the primary end-user segment of these tires, the replacement market consisting of end consumers (those using passenger and commercial vehicles) forms the bulk of the demand.

The Indian tire retreading industry

Dr. Sourabh Bhattacharya studies the challenges of implementing Circular Economy and close-loop supply chains in emerging economies, especially focusing on the unorganized sectors. He also researches on the societal issues of Sustainable Innovation focusing on ethics and moral paradoxes Sustainable Innovation organizations face and navigate through. Dr Bhattacharya holds a Ph.D. in Supply Chain Management from ICFAI University, Dehradun and been part of the prestigious Executive Education Program of Harvard Business School, USA.

Vinay K. Kalakabandi’s research mainly revolves around studying human behavior in Operations and Supply Chain context. Dr. Kalakabandi holds a Ph.D. in Supply Chain Management from Indian Institute of Management (IIM) Bangalore.

Dr. Sourabh Bhattacharya studies the challenges of implementing Circular Economy and close-loop supply chains in emerging economies, especially focusing on the unorganized sectors. He also researches on the societal issues of Sustainable Innovation focusing on ethics and moral paradoxes Sustainable Innovation organizations face and navigate through. Dr Bhattacharya holds a Ph.D. in Supply Chain Management from ICFAI University, Dehradun and been part of the prestigious Executive Education Program of Harvard Business School, USA.

Vinay K. Kalakabandi’s research mainly revolves around studying human behavior in Operations and Supply Chain context. Dr. Kalakabandi holds a Ph.D. in Supply Chain Management from Indian Institute of Management (IIM) Bangalore.

is characterized by a small proportion of Original Tire Manufacturer (OTM)owned and franchised tire retreading facilities and a large proportion of fragmented small and mediumsized unorganized players. However, anecdotal evidence points to a crucial role that unorganized players could play in the push towards CE. For instance, India has the highest polyethylene terephthalate (PET) waste recovery rate, mainly achieved by a network of unorganized scrap dealers. Additionally, the unorganized sector powered the sale of 17 million refurbished/second-hand smartphones in India in 2020, compared to 3 million by the organized sector. Similarly, unorganized tire retreaders, characterized by ubiquitous pre-existing capacity, widespread physical footprint, and unparalleled reach, are well poised to play a crucial role in the journey towards CE. They hold the potential to extend the usable life of products made using

natural resources (natural rubber, carbon black and steel), reducing greenhouse gas emissions and resource waste while creating employment opportunities, and providing economic benefits to the customers by reducing their total cost of ownership (TCO) of tires.

Academic research on the barriers to circular economy suggests that CE stakeholders face technological, regulatory, market (economic) and cultural (behavioral) barriers. As can be seen, these barriers are generic in nature. To make the understanding of these barriers more nuanced and actionable policy makers and OTMs, there is a need to add context specificity to these barriers. To this end, we conducted a comprehensive study involving 23 tire retreaders from 15 cities across 8 Indian states. Our analysis identified many critical and interconnected barriers to the retreader's business growth, classified under four main categories: policy-

related, retreader-related, customerrelated, and supply chain-related. Here are some key findings on each of these barriers are as follows:

7 Policy Related barriers: The Bureau of Indian Standards defines process specifications for tire retreading and certifies the retreaded tires for their safety, quality, and reliability. Retreaders are mandated by law to follow these standards. However, the unorganized retreaders we interacted with were unaware of these standards, pointing towards a poor implementation of standards. Moreover, there is also no specific government policy or incentive for the tire retreading industry.

7 Supply chain related barriers: Retreaders reported huge variation in the monthly demand for retreading leading to erratic capacity utilization. Further, increased raw material prices are reducing the gap of prices between retreaded and new tires.

7 Retreader-related barriers: Retreaders reported a lack of skilled labor in the industry with a high number of sub-par players. Absence of effective promotional tools impacted their business development capabilities. While there were no specific government incentives and support schemes specifically for the tire retreading industry, there are some government schemes for SMEs in general. Retreaders, we interviewed lacked awareness of these schemes.

7 Customer related barriers: Customer’s choose least price

India has the highest polyethylene terephthalate (PET) waste recovery rate, mainly achieved by a network of unorganized scrap dealers. Additionally, the unorganized sector powered the sale of 17 million refurbished/second-hand smartphones in India in 2020, compared to 3 million by the organized sector. Similarly, unorganized tire retreaders, characterized by ubiquitous pre-existing capacity, widespread physical footprint, and unparalleled reach, are well poised to play a crucial role in the journey towards CE.

According to BlueWeave Consulting research, India retread tire market size to grow at a significant CAGR of 3.21% by 2029. The demand for retread tires is expected to continue to increase during the forecast period. The India Retread Tire market for retread tires is seeing new growth due to the continuously developing vehicle sector. Consumer preference for sustainable alternatives is also more likely. Leading retread tire producers are employing cutting-edge production techniques and strategies to get rid of operational problems and provide customers with high-quality retread tires. Retreaded tire sales are also flourishing due to the growth of the logistics sector and increased freight demand. Tire wear and tear is causing a tremendous rise in the need for tire retreading.

option for retreading which usually means using a sub-par retreader which results in poor quality and consequently bad perception about retreading itself. A customer’s lack of awareness plays an important role in shaping the perception about retreading.

We found that the two major barriers that most retreaders in our study reported were lack of effective promotional tools and poor implementation of standards. As can be discerned, these barriers are interconnected and often reinforce each other resulting in subdued profitability of retreaders, thereby going against the cause of CE. To overcome these barriers, our study suggests the following implications for the Government and the Original Tire Manufacturers (OTMs).

Development of retreaders' awareness and skills: One of the critical obstacles our study identified is the ineffective promotional methods employed by unorganized retreaders. The Ministry of

MSMEs has established schemes to offer marketing and business development assistance to retreaders. However, the awareness of such programs and schemes among retreaders is alarmingly low. Hence, the government must conduct campaigns across multiple platforms to educate retreaders about these programs and schemes.

Retreader certification: OTMs should implement regular training programs for developing retreaders' technical skills and encourage them to obtain industry-standard certifications. These certifications would serve as promotional tools for retreaders, fostering overall improvements in the quality of retreaded tires. By endorsing certified retreaders to customers, OTMs can strengthen trust in the retreading process and establish themselves as effective sales channels for the retreaders. Moreover, OTMs are in a favorable position to raise awareness about the government's incentive and support schemes.

Customer Education: Due to the lack

of adequate knowledge, customers generally prioritize short-term economic advantages when choosing a retreader and overlook the long-term perspective of total ownership costs of tires, leading to skepticism surrounding tire retreading. Since many customers are fleet owners of trucks, buses, and off-the-road (OTR) vehicles located in various states, it is recommended that local road transport authorities implement awareness campaigns using print and electronic media in the vernacular languages. OTMs, on the other hand, must leverage their position as the primary point of contact with customers to educate them about the retreading process.

Recognizing the importance of retreading, governments worldwide have begun implementing rules and regulations related to tire retreading processes, such as those seen in EU countries (UN-ECE Regulation No 108 for car tires and No 109 for truck tires) (European Commission, 2014). However, in India, these regulations are still in their early stages. Currently, OTMs lack the incentive to expand their retreading capacities due to high upfront

investment costs and concerns about the potential cannibalization of their new tire businesses. However, the introduction of extended producer responsibility (EPR) regulations mandates that Indian OTMs be responsible for recycling 100% of the tires they produce by 2024/25. Complying with the EPR regulations would necessitate significant collaborative efforts between the government, OTMs, and the existing retreaders and recyclers.

Further, effective regulatory enforcement and monitoring by the government are crucial in implementing tire retreading standards. Adherence to the standards is necessary to ensure retreaded tires' safety and high quality, instilling customer confidence in the unorganized players and ultimately fostering their business growth. Moreover, rigorous enforcement of standards will effectively eliminate unskilled and ill-equipped retreaders, resulting in improved capacity utilization among the remaining players and reduced demand uncertainty. However, the government must carefully consider the societal implications of strictly implementing these standards, as it may potentially lead to the loss of employment and financial distress for numerous retreaders.

Green tax incentives: To encourage environmentally friendly transportation, the Government of India has incentivized the purchase of electric vehicles (EVs) by reducing the Goods and Services Tax (GST) on EVs from 12% to 5% in 2019. However, there is a notable absence of similar green tax incentives for retreaded tires. This disparity in tax implications within the same circular supply chain discourages collaboration and undermines the objectives of the circular supply chain. The government should introduce green tax incentives like reducing the current GST on retreaded tires and procured rubber treads, ultimately reducing the costs of raw materials for retreaders.

Sustainability is top of mind for tire manufacturers, retailers, recyclers, and consumers alike. In fact, many major manufacturers have already announced far-reaching sustainability goals. For example, Michelin has committed to making its tires 100% sustainable by

2050, Goodyear aims to replace all petroleum-based oils in its tires by 2040, and Bridgestone intends to slash its CO2 emissions by 50% from 2011 levels by 2030 and become carbon neutral by 2050. Indian OTMs, including JK Tyre and Apollo Tyres, have committed to achieve carbon neutrality by 2030, while India as a whole aims for netzero emissions by 2070. With both the

government and OTMs dedicated to their carbon-neutral goals, they hold significant responsibilities in tackling the challenges confronted by tire retreaders. The collaboration between these three key stakeholders—the government, OTMs, and retreaders—will be crucial in establishing strategic partnerships that can bring about genuine circularity in India’s tire industry.

Environmental, Social, and Governance (ESG) factors are increasingly recognized as key drivers of long-term business sustainability and success. Companies that prioritize ESG practices are better positioned to address risks, capitalize on opportunities, and create value for all stakeholders. Between shifting governance and regulation, ongoing health crises and political conflict, ESG challenges are sure to take centerstage in the near term. Companies must fundamentally rethink how they capture data, report their carbon emissions to meet regulatory standards, and act to reduce emissions by reshaping strategies, tactics, and operations. Sandeep Chatterjee, Supply Chain and Sustainability Leader, IBM Consulting, presents his take on the matter…

Harlem Brundtland was once quoted as saying, “Sustainable development is the development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” Sustainability and ESG initiatives face heavy headwinds—namely from inflation, geopolitical upheaval, profitability, lack of uniform standards. Will good intentions wither in the face of a looming global recession? And to add to the misery is the constant reports on greenwashing. According to a survey done by IBM Institute of Business Value (IBV), consumer trust in corporate sustainability statements has nosedived.

Like any other wave, there is initially a mistrust followed by slow acceptance. According to the ‘ESG Conundrum’ report authored by IBM Institute of Business Value (IBV), roughly three in four (76%) out of the CEOs now view ESG as central to their business strategy and more than 7 in 10 (72%) approach it as a revenue enabler rather than cost centre. And while most ESG efforts focus on

Sandeep Chatterjee is responsible for engagements in supply chain, sustainability leveraging technology at IBM Consulting. Prior to this, he has worked with Deloitte, KPMG, Tata Motors, Lafarge, Infosys and Oracle Consulting and his key strengths lie in the areas of supply chain management, business process reengineering, emerging countries enablement, network optimization, sustainability, ERP advisory across multiple industries and geographies. He holds an MBA from Indian Institute of Management, Kozhikode and a Bachelor of Engineering (Mechanical), Bengal Engineering and Science University, Shibpur (formerly Bengal Engineering College).

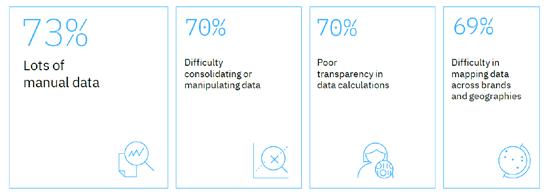

Source: IBM Institute of Business Value (IBV)

compliance and risk management, many now expect to see improved profitability (45%) and improved innovation (35%).

Though there is a lack of consumer trust, the same report iterates that roughly two-thirds of consumers say environmental sustainability (68%) and social responsibility (65%) are very or extremely important to them. And more than 7 in 10 agree that they would be more willing to apply for a job with a company they consider environmentally sustainable or socially responsible. More than 40% even say they would be willing to accept a lower salary to work for an employer that is environmentally sustainable or socially responsible—and nearly one in four of those who changed jobs in the last 12 months say they did just that. Overall, the salary cut people say they would be willing to accept is close to 20%.

According to an IBM study, across all organizations, the integration of ESG metrics into core functions is limited, mostly focused on risk management (44%), brand strategy (40%), and customer service/engagement (39%). Only 20% are integrating ESG metrics into supply chain operations; 26% into procurement and sourcing; and just 11% into real estate and facilities management.

GHG emissions are categorized into three groups or 'Scopes' by the Greenhouse Gas Protocol (GHGP) —the most widelyused carbon accounting tool. Scopes 1, 2 and 3 are a way of categorizing the different kinds of carbon emissions a company creates in its operations, and its wider value chain. These scopes cover the six greenhouse gases as covered by the Kyoto Protocol namely Carbon dioxide

(CO₂), Methane (CH₄), Nitrous oxide (N₂O), Hydrofluorocarbons (HFCs), Perfluorocarbons (PFCs), Sulphur Hexafluoride (SF₆).

To reiterate, Scope 1 includes all direct emissions from an organization, such as company vehicles, emissions from manufacturing processes, and fuel combustion on site, such as burning gas to produce heat. Scope 2 encompasses indirect emissions from the consumption of purchased electricity, heat, or steam. Scope 3 includes all other indirect emissions that occur in a company’s value chain and include instances of carbon emissions outside of their direct physical footprint. Scope 3 emissions for one organization are often the Scope 1 and 2 emissions of other companies in its value chain.

While companies are comfortable with Scope 1 and 2 emissions, it is the Scope 3 emissions which is itchy. Scope 3 emissions are comparatively more difficult to measure and control because they are generated by third parties (e.g., a supply chain partner or investment holding) for which the reporting company has limited visibility or control.

When it comes to Supply chains, they have the greatest room for improvement

to meet sustainability goals. According to McKinsey, the typical consumer company’s supply chain creates much greater social and environmental costs than its own operations. Supply chain impacts account for more than 80% of greenhouse gas emissions and more than 90% of the impact on air, land, water, biodiversity, and geological resources.

While all this looks positive, there is a mismatch between what consumers want to see vis-à-vis what corporates are actually doing. With stricter regulations coming in and a renewed focus on sustainability, lot of companies are serious about sustainability, but it seems to be channelised in a different direction though.

With plethora of consulting firms jumping into the bandwagon, there are structural challenges in the ESG Journey. Some corporates assume it to be a reporting need while some view it as an overnight fix. The important point here is that it is a long-term journey and needs fundamental corrections in the structure and mindset.

First and foremost is Data. What cannot be quantified cannot be improved upon. In fact, Data is the lifeblood of ESG. It provides visibility into an organization’s operations, letting leaders see where the business is reaching the bar—and where performance has fallen behind. ESG goals for the future lose their significance if they are not tied to current performance data. And without the right information, it is impossible for executives to assess the company’s impact, identify improvement opportunities, or showcase successes. And equally important is automated data

Fig 2: Mismatch of Expectations Source: IBM Institute of Business Value (IBV) Fig 3: Data Challengescollection and reliability of data.

And to add to the confusion is the plethora of frameworks, standards, consulting firms, ESG Assurance services and so on. From the International Sustainability Standards Board (ISSB) and the Global Reporting Initiative (GRI) to the Task Force on ClimateRelated Financial Disclosures (TFCD) and the EU’s Corporate Sustainability Reporting Directive (CSRD), companies find it difficult to keep up with the ever-expanding list of ESG disclosure standards, frameworks, and requirements. In fact, there are more than 600 reporting provisions globally, each offering its own interpretation of sustainability and social responsibility— and how companies can prove they are meeting the bar.

While all this looks a little gloomy, we do not have a choice but to march forward. If done with a long term strategic view, this can yield huge dividends for a company. In fact, a report

published by global accounting firm Moore Global argues that companies seeking to embrace ESG principles in recent years enjoyed higher revenues, stronger growth of profits and greater access to finance. Businesses publicly placing greater importance on ESG saw an average increase in profits of 9.1%. But this jumped to 11% in the US versus 8.1% in Europe and 7.4% in Australia.

While all this looks fine, it is time to get into an actional set of measures rather than discuss things theoretically. While there is no secret sauce, these are some of the potential ways in which an organization can traverse the ESG journey.

(a) Do Not Wait for the Right Time: It is important to align the Business Strategy with ESG strategy and not wait for the right opportunity. It is important to look at profitability

alignment as at the end of the day the goal of any organization is to make profits. We do not want companies burn cash just to be sustainable.

(b) Be Authentic: If there is one element which is critical to this journey is trust. Transparency becomes the key for long term benefits.

(c) Identify Needs: It is important to decide on the frameworks and the kind of data which needs to be collected. It is always advisable to break it into smaller projects rather than a big-bang approach. This gives an opportunity to relook at a totally new business process.

(d) Rationalize Technology: The panacea is not automation or sensors or a piece of software. While these definitely aid, it is important to relook at business processes first to explore avenues for improvement.

(e) Executive Compensation: Human beings thrive on incentives and a useful way is to link executive compensation to ESG goals. While this is imperative, it should not be an obsession to meet short-term quarter on quarter financial targets.

Times are difficult, ambiguous but these are interesting times. To quote Peter Drucker, “The best way to predict the future is to create it.”

India has emerged as a conscious aspirant and shown promise and capability to take great initiative in paving the way in combating climate change and meeting the Sustainable Development Goals (SDGs) of the United Nations in many of its regulatory schemes internally such as introduction of the Business Responsibility and Sustainability Reporting (BRSR) by SEBI in 2021 and the sustainability reporting format is based on the nine principles of National Guidelines for Responsible Business Conduct (NGRBC) introduced by SEBI. SEBI mandated the filing of Business Responsibility and Sustainability Report (BRSR) for the top 1000 listed companies (by market capitalization) replacing the existing BRR with effect from the financial year 2022-2023.

Fig 4: ESG=Profitability Source: Moore Global

Over the past few years, there have been more and more disruptions, from natural catastrophes to trade conflicts to pandemics around the world. Due to these interruptions, supply chains are now more vulnerable than ever, emphasizing the need for proactive actions to increase resilience. To cope with complexity and uncertainty, resilient planning is the need of the hour. Organizations need to take a comprehensive strategy if they want to detect potential hazards, diversify their sources of supply, and create backup plans. Adopting digital technologies like blockchain, predictive analytics, and real-time tracking systems can increase visibility and enable proactive risk management. This was the basic tenet of our panel discussion on the sidelines of our recently held Supply Chain Tribe Awards where the industry leaders deep dived into smart & sustainable ways to make their supply chains resilient and explored the enabling role of technology in achieving the same. Here’s presenting the stimulating strategies of supply chain leaders of leading organizations…

SUPPLY chain resilience, among other current buzzwords including economic diversification and de-risking, has become the key discussion agenda across global forums, be it World Economic Forum, G20 Summit, or any other bilateral event such as the G7 communique or the recent Indo-US joint statement. Global leaders have been echoing their voices on making their supply chains more resilient, efficient, and transparent.

In fact, at a recent press conference in Gandhinagar, US Treasury Secretary Janet Yellen praised India’s significance as an indispensable partner in the strategy of “friendshoring” to bolster supply chain resilience. “Friendshoring is an important foundation of our approach to increasing resilience of our supply chains, and we see India as an indispensable partner in that and I hope to use this trip to deepen what is already a significant relationship with respect to friendshoring that the US and India have,” said Yellen.

Such has been the testament of the country’s strong stance in achieving and enabling a resilient global supply chain. This statement also underscores the crucial importance of ensuing supply chain resilience in every industry vertical to sustain the growth momentum.

A recent Euromonitor report has

aptly emphasized on this very notion that the increased economic uncertainty, rising geopolitical tensions, the need to improve operational efficiency and still prevalent transportation bottlenecks drive the need to improve supply chain resilience to better withstand future shocks. “Unsurprisingly, building supply chain resilience has become one of the top priorities for companies. Over 56% of companies globally indicated that they plan to invest more in supply chain resilience,” according to the Euromonitor International Sustainability Survey 2023. Industries with long supply chains, such as packaging, as well as industries highly reliant on efficient transportation networks, such as apparel or retail, are driving this trend. Apple is one of the key examples, as it builds new production capacity in India to diversify supply risks.

“Companies in the services sector are also aiming to better shield their business activities from future disruptions. Approximately half of companies in the leisure, foodservice and travel sectors are planning to improve their own supply chain resilience. For example, hotel chain Hilton plans to utilize double sourcing from SME suppliers by 2030 as part of its sourcing and procurement strategy. More diverse supplier networks will also contribute to lower sourcing risks and add greater operational flexibility,” the report mentioned.

“Supply chain management has

become a crucial strategic component for organizations across industries in today's connected and globalized world. The COVID-19 pandemic has brought attention to the significance of effective and resilient supply chains, underlining the requirement for cutting-edge methods and sturdy frameworks,” states Naga Sundar Kumar P, Digital Business Consultant, Great Lakes Institute of Management.

To build resilience in future supply chains, companies are implementing strategies such as production globalization and regionalization of supply chains, while also aiming to create alternative transportation networks. Such actions are expected to help diversify supply chains, reduce production risks and improve operational flexibility. Besides these, in order to create resilient supply networks for a sustainable and prosperous future, Naga Sundar Kumar P identifies critical building blocks. These are:

Collaboration and Transparency: Encouraging trust and openness among all stakeholders is essential to the development of resilient supply chains. A cohesive environment where information and insights can be shared easily is made possible by collaboration with suppliers, partners, and customers. When disruptions occur, improved transparency ensures visibility throughout the whole

When we talk about managing complexity, the first thing that we need to deal with is resistance to change. We first need to accept that this complexity is here to stay. Secondly it is about enabling the processes and design of all the systems which can support complexity management. Next most important aspect in driving this change is through technology deployment. The supply chain today has become a source of competitive advantage for a forward-looking company and who is actually able to manage complexities far better than its counterparts. Finally, it is equally important for the supply chain teams to push back to business to quantify the impact out of creating complexity and whether it makes commercial sense to do so. Unless this entire loop is completed, we will not be able to fully manage the complexities well.

supply chain, enabling swift response and wise decision-making. Organizations should also actively engage in ethical and sustainable supply chain operations through responsible sourcing practices.

Data is the lifeblood of supply chain management, and organizations must use advanced analytics to promote reasoned judgement. Organizations may learn a lot about customer preferences, inventory management, and demand patterns by gathering, analyzing, and interpreting data from numerous supply chain touch-points. Lead times are shortened, supply chain risks are reduced, and proactive planning is made possible by predictive analytics. Operations may be further optimized, disruptions can be predicted, and routine jobs can be automated using artificial intelligence and machine learning techniques.

For resilient supply chains, flexibility is a key characteristic. Organizations need to be ready to adjust to shifting consumer expectations, shifting market dynamics, and unforeseen disruptions. Organizations can react quickly to changes in demand and supply thanks to agile manufacturing techniques, just-in-time inventory management, and dynamic sourcing techniques. Rapid prototyping and customization

We have to look at all the parts of the supply chain in entirety, be it sourcing, manufacturing, inventory planning or distribution. All these steps have to factor in resiliency as the basic tenet, otherwise the overall supply chain will not be resilient. For us at Pepperfry, the last mile connectivity is the critical piece. If it’s broken, the supply chain will be impacted in a big way. Covid-19 pandemic has brought in a great shift in the way we take decisions. Earlier the asset-light model was the dominant model, but now Capex investment is also one of the pillars on which supply chain is based. We have, in fact, started taking initiatives towards that. Companies should identify critical parts of the supply chain and make them robust. Firefighting will always be there, but if your supply chain is robust, the time taken to rebound will be way less as compared otherwise.

are made possible by adopting flexible manufacturing technologies such as additive manufacturing (3D printing), which also reduces dependence.

Elaborating on these and many other critical pillars, our industry leaders share their insights on developing a resilient supply chain network of the future. Read on…

Complexity in the Supply Chain Planning Process. Is there a way to control it or manage it better?

Nitin Kathuria, EVP & Head Supply Chain, Marico: If I take you a decade back to understand shift in complexity, the end consumer used to purchase a product from the nearby kirana store primarily. Today, there are multiple channels for an FMCG company to reach his end consumer – e-commerce, modern trade, traditional kirana stores, supermarkets, just to name a few. The complexity accentuates when there are customized products curated for these channels and one has to ensure it is readily available on the shelf all the time. One can gauge the intensity of complexity that an FMCG company goes through now-a-days to serve the minutest needs of consumers every time wherever they are.

When we talk about managing complexity, the first thing that we need to deal with is resistance to change. We first need to accept that this complexity

is here to stay. Secondly it is about enabling the processes and design of all the systems which can support complexity management. Next most important aspect in driving this change is through technology deployment. The supply chain today has become a source of competitive advantage for a forwardlooking company and who is actually able to manage complexities far better than its counterparts. Finally, it is equally important for the supply chain teams to push back to business to quantify the impact of creating complexity and whether it makes commercial sense to do so. Unless this entire loop is completed, we will not be able to fully manage the complexities well.

Piyush Agarwal, Vice President - Supply Chain, Pepperfry: As an e-commerce company, we need to embrace variability. There are many techniques which can be used to handle the same. It includes having temporary spaces to store seasonal inventory, work with partners who provide us higher flexibility in terms of manpower and space availability, pre-planning the peak demand operations by hiring more people at the right time. It can also involve techniques like balancing out the dispatches much better so that even with

higher load you are able to manage with less manpower. In the end, it all boils down to planning it well, having a highly motivated team who is ready to execute the plan and if something fails then quickly shifting to the backup plan. Some of the advanced forecasting & demand sensing technologies do help us when it comes to planning it well.

What is a resilient supply chain?

Please share some examples

Nitin Kathuria: When we talk about resilience, people start talking about black swan events like what happened during COVID phase. In the context of FMCG supply chain, resilience also means being agile. Agility for FMCG plays out on a day-to-day basis. To be agile, there needs

The word ‘Resilient’ has become more pronounced post Covid-19 pandemic. But I believe, as supply chain professionals, we have always been resilient. Resilience is all about firefighting and being prepared to take immediate steps in times of adverse and unforeseen situations. We have been doing that all throughout our professional lives as supply chain leaders. I think post pandemic with the extensive and frequent disruptions that we are witnessing whether they are political or geopolitical disruptions, we need to have a long-drawn strategy around resilience in order to ensure business continuity.

to be end-to-end operations visibility. Agility also corresponds to the velocity to respond to the changing scenarios. At Marico, we are investing towards raising the digital quotient across the value chain to make the organizations future ready. This is also reflected in our talent strategy and how we are imbibing new ways of working, which we believe will enable us to transform into a digitally savvy organization and win amongst evolving consumer and marketplaces. We have also made significant progress in our journey to build strong digitalled analytical capabilities to enable real-time data-led decision making. We will continue to strengthen this further for prioritized use cases such as spend effectiveness, demand sensing and social

listening driven innovations, among others. We have also deployed a newly enabled forecasting system, which has increased the forecasting accuracy by over 10%. The new demand-sensing model improved the response to intra-month forecast changes, thereby lowering the possibility of stock-outs. We are pushing alerts for people to act on an immediate basis. This helps us respond to changes faster. We have also built a control tower to make our supply chain even more resilient and responsive.

Sandeep Baxla, Sr Vice President Supply Chain, Indofil Industries: The word ‘Resilient’ has become more pronounced post Covid-19 pandemic. But I believe, as supply chain professionals, we

Mohit Jauhari, Head (SCM), Shriram Pistons & Rings Ltd.

Collaboration will be the game changer for organizations to survive & thrive in the future. Companies can no longer win in isolation as data/information needs to be shared with the supply chain partners for the larger good of everyone in the chain. The concept of SME (Subject Matter Expert) will play a major role as companies try to cut down on time to market. Specialized tasks will be left to the SMEs so that the companies focus on other concurrent work to synchronize the tasks towards reducing the time to market. All this can be done seamlessly through Collaboration and the use of digital tools like AI/ML, etc. This collaborative approach, and taking timely & swift data-based decisions, will be the game changer and define the behemoths of the future.

have always been resilient. Resilience is all about firefighting and being prepared to take immediate steps in times of adverse and unforeseen situations. We have been doing that all throughout our professional lives as supply chain leaders. I think post pandemic with the extensive and frequent disruptions that we are witnessing whether they are political or geopolitical disruptions, we need to have a long-drawn strategy around resilience in order to ensure business continuity.

I have seen companies joining the digitalization bandwagon in order to be resilient. I disagree with that strategy to a certain extent. I firmly believe that organizations need to start their journey towards being a resilient one by adopting a People-First strategy. In order to fully leverage a sound digitalization strategy, companies need to have the requisite resources and that can only happen when we have buy-in of our employees and an open mindset to drive the shift. Employees need to be skilled enough to drive the change. Companies must own up their mistakes in order to drive a much-needed organizational strategy.

Mohit Jauhari, Head (SCM), Shriram Pistons & Rings Ltd.: Supply chain resiliency is the ability to respond quickly to operational disruptions through flexible contingency planning and forecasting – from material sourcing to logistics and the final delivery of products and services. A resilient supply chain is defined by its capacity for resistance and recovery. That means having the capability to mitigate most supply chain disruptions and greatly limit the impact of those that occur and also regain the

Transparency and accountability have become essential for a good SCM function. Having transparency in SCM means leaders can precisely know the status of each step in the supply chain pipeline. A transparent supply chain function also assumes that the data retrieved is quality tested and is of the gold standard. A transparent and well-governed SCM function can help business leaders understand the pain points at any given period and help them provide timely solutions. AI algorithms are very good at analyzing historical data to identify abnormal trends.

pre-disruption status at the earliest. Companies which countered the impact of Covid-19 and rebounded to near normalcy in the shortest possible time (Apple, Alphabet, Microsoft, Accenture, Thermo Fisher, etc.) are some of the recent examples of 'Resilient Companies'.

Shifting from Leaner sequence to Digital Supply Chain Planning can help supply chains become more resilient. Can you elaborate on this with a few examples?

Mohit Jauhari: Collaboration will be the game changer for organizations to survive & thrive in the future. Companies can no longer win in isolation as data/ information needs to be shared with the supply chain partners for the larger good of everyone in the chain. The concept of SME (Subject Matter Expert) will play a major role as companies try to cut down on time to market. Specialized tasks will be left to the SMEs so that the companies focus on other concurrent work to synchronize the tasks towards reducing the time to market. All this can be done seamlessly through Collaboration and the use of digital tools like AI/ML, etc. This collaborative approach, and taking timely & swift data-based decisions, will be the game changer and define the behemoths of the future. For example, companies which used to take three plus years in design/development/launch of cars are now launching new models within one year by using the abovementioned approach.

Aswini Thota, Analytics and AI leader, Bose Corporation: Adopting Digital Transformation – the shift from

a Lean Supply Chain to Digital Supply Chain Planning – can indeed bolster the resilience of supply chains. This process is akin to moving from a well-practiced manual sequence to a fully automated, data-driven operation. It offers a quantum leap in the ability to predict, adapt, and respond to changes.

Let's look at cold-start or new product introduction forecasting as an example. This is a critical process of estimating the sales demand for completely new products. Traditionally, this task was performed using heuristics or rudimentary approximation methods, somewhat similar to a hawker guessing the potential popularity of a new item based on his past experiences.

However, in our current data-rich environment, we can do much better. We can build on sophisticated technologies like Deep Learning to understand and predict the demand for a new product before it even hits the shelves. It's like getting a glimpse into the future market trends and customer preferences, based on patterns learned from extensive historical data.

For instance, we can merge our historical sales data with additional datasets such as media spending and product features. This approach can significantly reduce forecasting errors and enable a more proactive strategy towards manufacturing and distribution. Instead of reacting to market demand, we can anticipate it. For example, imagine we're launching a new smartphone. By analyzing the sales patterns of previous models, their features, and correlating with media spending and market trends, we can get a reliable estimate of the demand

for the new product. This insight allows organizations to adjust their production levels and distribution strategies, accordingly, preventing overproduction or stockouts, and ultimately, optimizing resource allocation.

Ashish Tripathi, GM & Head – Global Supply Chain, TORM A/S: Depending on the supply chain model whether it is a complex or agile, the concept of Connected Machinery can help shipping companies turn the tides in their favor. Supply chain intelligence can mitigate issues faced by the shipping industry. For instance, the Panama Canal is facing an exceptionally severe drought. Consequent restrictions have significantly reduced the volume of cargo that can be carried through the Canal. The shipping industry would be aided in dealing with such disruptions by using trusted data networks on the global supply chain – for instance, through the use of blockchain. Data points from sources such as customs authorities can be combined to chart the global supply chain. Supply chain parties can then respond to the updated information, mitigating the impact of any obstacles –such as the Panama Canal droughts.

AI can be used to optimize shipping routes, enabling shipping companies to reduce their fuel consumption and emissions, in addition to avoiding disruptions such as droughts. It may even also be possible to use AI to predict droughts, in much the same way as it is being used to predict water pollution in south-west England so as to minimize

Developing a resilient supply chain is crucial for companies to navigate uncertainties, disruptions, and challenges effectively. How can companies carry out risk assessment and mapping i.e., by identifying and assessing potential risks that could impact your supply chain, such as natural disasters, geopolitical issues, economic fluctuations, or supplier vulnerabilities. Create a risk map to understand the likelihood and potential impact of each risk. Also, relying on a single supplier or sourcing location can leave your supply chain vulnerable. Diversify your supplier base and consider sourcing from multiple regions to reduce the risk of disruption. This would ensure smooth operations of the supply chain.

impact.

A major disrupter to supply chains is port congestion. High volumes of cargo can cause shipping delays and increased costs. The impact of this can be exacerbated by the sudden increase in demand for different types of cargo. Ports can use AI, particularly machine learning algorithms, to optimize schedules for vessels. Port managers can use AI to produce accurate demand forecasts and plan for rapid increases in cargo volume, while avoiding congestion and consequent delays. Similarly, AI can help to optimize cargo routes. This can reduce the number of vessels that require access to a port, reducing the demands on the ports. AI technology could be used to reroute shipments away from congested ports. Therefore, the impact of AI usage in ports could reduce delays in the wider supply chain.

TORM has been a frontrunner in digitalizing surveys and improving performance through remote monitoring. We now prepare for our inspections digitally by uploading the data before an actual inspection. Most surveys – apart from annuals, intermediates, and specials – can now be undertaken remotely and more efficiently, saving time and travel costs.

The dashboards replace the initial and annual MPMS survey on board and provides a complete breakdown of any class related maintenance already completed and overdue. Torm can access data in real-time to create a maintenance plan and can compare sister vessels

to optimize performance. Recently we deployed PrimeServ Assist proactive service solution that constantly monitors and evaluates all parameters affecting engine performance. With the extensive data set and the history of the customer’s engine at hand, MAN PrimeServ service engineers sitting in Remote Operating Centres detect anomalies before potential breakdowns and advise on how to keep operations at peak efficiency. PrimeServ Assist acts in different ways to optimise machinery performance to avoid damages or downtime, including through ad-hoc notifications on engine performance (and auxiliary systems) and newly developed AI-based, advanced algorithms that predict the remaining lifetime of individual components and advise action accordingly.

Sandeep Baxla: Vulnerability into unscheduled and unexpected events equals to supply chain disruption. How do we actually capture the associated risks and have a mitigate plan drawn around it is critical while devising resilience strategy. Another important aspect to keep in mind is our vendors. We need to establish a transparent relationship with them and empower them with the end-to-end visibility into the value chain. Supplier relationship management needs to be made robust. We need to make efforts to make planning centralized. With digitalization drives going on at a fast speed, I believe

companies have already started taking this pillar seriously. We also must review our strategies on a frequent basis so that we can take corrective actions as per the changing market conditions.

What steps need to be taken so that the supply chain is able to become resilient so as to meet the ever-changing customer requirements?

Mohit Jauhari: Supply chain managers have to be good at predicting customer expectations. They should also be able to take action in advance so as to serve the customers as per their expectations. In order to do so, they need to have a seamless & real-time view of the entire chain from the customer's customer to the supplier's supplier. This can be done using the 3C Concept – Connect, Communicate & Collaborate. In essence, sharing data across the chain & using the same to collaborate & make decisions are the key to a successful Supply Chain. Companies which are willing to collaborate with their channel partners - and are also good at using data to build algorithms so as to predict/preempt customer behaviour will be the leaders in this day & age. Those who are secretive about their information and operate in siloes will find it tough to stay relevant in the ever-changing business landscape. As stated above, once the 3C State is achieved, companies will be able to leverage/mine the available endto-end data so as to predict customers’ behaviour. They will be able to optimally plan execution in sync with the projected customer behaviour. While doing so, they will also harness the benefits of optimal

use of resources. Companies need to be aware of the importance of data and should have teams to make use of the available data to make decisions towards ensuring customer delight.

Piyush Agarwal: We have to look at all the parts of the supply chain in entirety, be it sourcing, manufacturing, inventory planning or distribution. All these steps have to factor in resiliency as the basic tenet, otherwise the overall supply chain will not be resilient. For us at Pepperfry, the last mile connectivity is the critical piece. If it’s broken, the supply chain will be impacted in a big way. Covid-19 pandemic has brought in a great shift in the way we take decisions. Earlier the asset-light model was the dominant model, but now Capex investment is also one of the pillars on which the supply chain is based. We have, in fact, started taking initiatives towards that. We own vehicles for transportation. We manage warehouses on our own. We need to have a fair balance on what parts of the supply chain we want to outsource and what parts we should manage on our own. When it comes to inventory, there are many models to adopt with lean being the most popular one, but it may not fit in every time. Companies should identify critical parts of the supply chain and make them robust. Firefighting will always be there, but if your supply chain is robust, the time taken to rebound will be way less as compared otherwise.

Ashish Tripathi: Developing a resilient supply chain is crucial for companies to navigate uncertainties, disruptions,

and challenges effectively. How can companies carry out risk assessment and mapping i.e., by identifying and assessing potential risks that could impact your supply chain, such as natural disasters, geopolitical issues, economic fluctuations, or supplier vulnerabilities. Create a risk map to understand the likelihood and potential impact of each risk. Also, relying on a single supplier or sourcing location can leave your supply chain vulnerable. Diversify your supplier base and consider sourcing from multiple regions to reduce the risk of disruption. This would ensure smooth operations of the supply chain.

One of the most neglected areas is supplier relationship, which if done thoroughly helps in building suppliers as strong allies. This includes regularly communicating with them, sharing forecasts and plans, and work collaboratively to address potential challenges proactively.

Another aspect is leveraging technology like supply chain management software and data analytics to gain real-time visibility into your supply chain. This will enable you to identify potential bottlenecks and risks early on, allowing for more informed decisionmaking. Another roadblock in seamless supply chain operation is Inventory management. Striking the right balance between lean inventory and safety stock is essential. While lean inventory reduces costs, having some safety stock can act as a buffer during unexpected supply chain disruptions. And above all the most important bit is the employee training and development, ensuring that your

For resilient supply chains, flexibility is a key characteristic. Organizations need to be ready to adjust to shifting consumer expectations, shifting market dynamics, and unforeseen disruptions. Organizations can react quickly to changes in demand and supply thanks to agile manufacturing techniques, just-in-time inventory management, and dynamic sourcing techniques. Rapid prototyping and customization are made possible by adopting flexible manufacturing technologies such as additive manufacturing (3D printing), which also reduces dependence.

employees are well-trained in supply chain management and understand the importance of resilience. Encourage a culture of proactive problem-solving and continuous improvement.

By following these steps, companies can build a resilient supply chain that can better withstand disruptions and thrive in challenging environments. Remember that supply chain resilience is an ongoing process that requires dedication and adaptability to stay effective in an everchanging world.

Aswini Thota: We live in a digital world. From ordering food, and buying groceries, to purchasing cars, we have digital options for everything. But what if I told you that the function responsible for shipping goods and delivering products is still largely paper-based? Yes, according to the Digital Container Shipping Association (DCSA), only 0.1% of bills of lading – just one of many paperbased trade documents – are issued electronically. There are several obvious reasons businesses should digitize their supply chain operations. Some of them are:

• Delays in supply chain processes because of document errors

• Maintenance overhead

• Vulnerable to security threats

• Wastage of valuable natural resources

But the most significant opportunity lost by not digitizing service is the ability to gather data and make data-driven decisions.

Most successful companies were always innovative. They constantly try to gauge what their customers want and develop solutions that strike the right chord with them. For a company to innovate using service, all the

components of its offering should work like a well-oiled machine, and the supply chain function is at the heart of this innovation.

Organizations realized a long while ago that innovation is key to success, and Covid-19 has created an environment where industry leaders must think on their feet and make fast decisions. The sudden shift in priorities caused by Covid-19 has exposed organizations that didn't have a foundational understanding of using modern technologies.

Perhaps a critical vulnerability that organizations realized after covid-19 was their lack of ability to make data-driven decisions. Enterprises that had a wellestablished data analytics practice were able to run what-if scenarios quickly and pivot to meet customer needs. Organizations that realized the value of timely information made data-driven decisions their top priority to correct these shortcomings. Data is turning out to be a key enabler for businesses, big and small. This is specifically true for supply chain functions.

Furthermore, data can significantly enhance supply chain transparency, which is critical for many reasons. For one, with increased transparency, businesses can better understand the path of goods from origin to destination, helping to ensure accountability and quality control. This level of detail can be instrumental in avoiding counterfeit items or mitigating the risks associated with unethical sourcing practices, factors that are becoming increasingly important to consumers. For instance, a luxury fashion brand could leverage data to trace the provenance of its raw materials, thus ensuring they are ethically sourced, and communicate this information to its customers. Moreover, in industries like pharmaceuticals, where the supply chain

must comply with stringent regulations and standards, data transparency can help to quickly identify and resolve any potential issues, maintaining product integrity and patient safety. Real-time data can also provide early warning signs of possible supply disruptions due to a multitude of factors, such as political unrest, weather conditions, or supplier insolvency. Thus, by utilizing data, companies can proactively manage their supply chain risks and operate in a more responsible, ethical, and sustainable manner.

AI/ML/Chat CPT,

What role do you see them playing in the near future towards transformation of Supply Chain Planning?

Piyush Agarwal: Pepperfry uses several AI and tech systems to streamline its operations and provide a better customer experience. Our recommendation engine suggests personalized products to customers based on their browsing and purchase history. The engine uses machine learning algorithms to analyze customer data and provide relevant recommendations. Chatbots provide instant customer support and assistance. The chatbots use natural language processing (NLP) to understand customer queries and provide accurate responses. Image recognition technology allows customers to search for products using images. The technology analyses the image and provides a list of products that are similar to the image. We introduced VR technology to allow customers to visualize how a product will look in their home. In addition to these systems, we intend to continue investing in AI and tech to further streamline its operations. The company plans to explore the use of predictive analytics to

Supply chain managers have to be good at predicting customer expectations. They should also be able to take action in advance so as to serve the customers as per their expectations. In order to do so, they need to have a seamless & real-time view of the entire chain from the customer’s customer to the supplier’s supplier. This can be done using the 3C Concept – Connect, Communicate & Collaborate. In essence, sharing data across the chain & using the same to collaborate & make decisions are the key to a successful Supply Chain.

forecast demand and optimize inventory management. Moreover, Pepperfry aims to use AI-powered chatbots to provide more personalized customer support and improve the overall shopping experience. The company is also looking at incorporating blockchain technology to enhance the security of its supply chain and improve transparency.

In supply chain, we have designed a complex algorithm that works on a selflearning model and consistently seeks areas for further improvement. It is an optimization engine that works on pin code level and takes into consideration multiple factors including current orders in process, vehicle utilization, product volume, kilometers run per vehicle, absenteeism of manpower and frequency and type of vehicle utilized, etc. The algorithm is evolving as we continue to improve the inflection point at which timeline and SLA are in right balance. The strength of this algorithm is in operating its own logistics network, as we control end to end network, we have access to data points in all phases through which furniture travels. This vast set of data ensures accuracy in statistical modeling. Further, handling our own infrastructure also helps us achieve the lowest distribution cost and damage rates in the industry.