FROM 1.8 TO 95 TONNES THE ALL NEW F-SERIES BREAKS THE MOULD.

It goes without saying that a majority of our readers, contributors and advertisers will have been at a Buxton quarry for a varying amount of time last week.

Naturally we were there in force and perhaps surprisingly my time was not spent entirely in The Omnia Arms, because it feels like I met most of you.

Never has my camera roll been so overloaded with kit and characters both aplenty at the splendid Hillhead 2024, the UK’s largest quarrying, construction and recycling event. Timings worked out in our favour and we are able to bring you a hot off the press review.

By the time this issue is printed we will almost certainly have a new government and with the bookies laying odds of 1/100 on anything but a Labour majority, Keir Starmer has pledged to construct 1.5 million homes within the next five years. It will be interesting to see what difference these plans could make in fostering the construction industry’s growth.

Debuting columnist in this issue is Jacqui Miller-Charlton MBE, shareholder of Miller Groundbreaking Ltd and Chair of OSA Distribution Ltd. With a successful career in construction under her wing, Jacqui will offer her invaluable knowledge on a variety of topics, she has even managed to pen a few words for this edition. I am delighted to have such a respected industry leader, a powerhouse and friend onboard.

I’m not much of a gamer. I enjoy the odd game of Mario Kart but these new generation consoles have bypassed me. Having said that I have always said that when the next Grand Theft Auto came out I would buy whatever corresponding console it could be played upon. I mention this as Ben Hinchcliffe, one of the designers of that game while at Rockstar Games and now lead designer at Just Add Water has got in touch with us.

Via publishers Wired Productions, Just Add Water is launching DIG VR, and yes it really does do what it says on the tin – a virtual reality game for experienced or budding excavator operators.

Looking past the obvious fun a game with a VR headset can be, especially when paired with the responsibilities of running an excavator as Ben explains in our interview, for me the bigger picture of this technology is how it could encourage the next generation of men and women at the levers.

Dig VR will be demonstrated at this year’s British Demolition Awards in September.

Continuing the interviews within issue #24 we have Jeff Haines, owner and Director of Dragon Equipment Ltd. In six years Dragon Equipment has grown to be one of the leading UK manufacturers of micro crushers and has also developed a range of other complementary machines. Please read more in the EQUIPMENT ENGAGEMENT. For our regular BUSINESS INSIDER interview, Alex Holmes, Head of Commercial at Hill Engineering lets us in on his responsibilities with global sales, aftersales and customer service at the attachment giant.

This issue includes all the latest news and industry updates. Additionally, we have features on Telehandlers and Finance.

With me nearly over that seemingly endless Hillhead hill, I hope you enjoy this issue. As always, please stay in touch with us as we approach our fifth anniversary. You know where we are, enjoy the football.

Ben Chambers, Publisher

CEA Manifesto for the next five years CPA calls for government to consider priorities for plant sector

With Jeff Haines, Director of Dragon Equipment Limited

• Diggers LIVE! Hillhead review

• Bobcat busy at Hillhead 2024

• DEVELON quarry and construction range excels at Hillhead ‘24

• HD Hyundai goes big

• LiuGong changes the game

• Terex MP showcases strength and sustainable innovation

• Thwaites adopts CESAR to protect and detect

• Wacker Neuson innovations for safety and efficiency

• Louise Carney speaks to Flannery Plant Hire

With Alex Holmes, Head of Commercial at

Diggers LIVE!’s Ben Chambers meets with Ben Hinchliffe Lead Games Designer at Just Add Water to discuss its upcoming release, DigVR

Clifton

Close

Paragon

• AUSA

• Bobcat

• Faresin

• JCB

• Warwick Ward (machinery) Limited supplies Faresin

• Liebherr

• Magni Telescopic Handlers

• Mecalac

• Merlo

• SANY

• Sennebogen

• Wacker Neuson

Diggers LIVE! and Kicking – Ben and the team out promoting the industry between issues

Building a better brighter future for all by Jacqui Miller Charlton MBE

inspHire introduces innovative secure payment system

Cat Grading Beams deliver high productivity material grading

New Bobcat S630 and S650 skid-steer loaders for Europe

New DX10Z-7 Mini-Excavator from DEVELON

First Goldhofer STEPSTAR Z in UK

UK contractor celebrates a decade of Hitachi construction machinery

JCB breaks ground at $500m North American factory

K-Plant goes backhoe to the future with Platinum JCB

Mecalac launches the Revotruck: the safest and most ergonomic dumper on the market

Mecalac deploys electric machines on power supply site

construction, engineering, manufacturing and education sectors. To support this, we have focused on four key areas that are critical for sustainable growth and innovation in the construction equipment industry.

The construction equipment sector is working hard to achieve decarbonisation targets. Leading manufacturers are developing a range of innovative solutions to support climate objectives, increase efficiency, and reduce emissions. The CEA maintains a technology-neutral position and believes legislation should do the same.

• Adopt technology-neutral regulation to encourage investment in lower carbon intensity technologies.

• Adopt regulation that supports outcomes that are technologically feasible and cost-effective rather than technology-specific.

With an incoming government this month, it is paramount the CEA continues to be the voice of the industry to national, local and devolved governments and Europe. The CEA Policy Group was

• Coherent planning for a national fuel infrastructure.

established in Spring 2024 to prepare a Manifesto, setting out our position for a clear and transparent approach to tackle the challenges facing the construction equipment sector, as well as the wider

• Further investment to bolster research and development of alternative fuel technologies.

• Support companies wishing to invest

in low-emission products, which often attract a higher capital investment and a different talent acquisition profile.

• Joined-up action on regulatory alignment to deliver regulatory stability and provide the sector with sufficient lead time from regulation enactment to implementation.

• The development of hydrogen combustion engines aligns with the UK’s Net Zero ambitions and presents a significant opportunity for the country. However, UK legislation needs to be aligned to that in the EU which considers hydrogen ICEs as a zero-emission technology.

The success of UK construction equipment manufacturing and engineering is critical to the country’s overall economic growth.

The 2022 GVA of the sector was £2.5 billion, employing over 44,000 people. The skills agenda within manufacturing and engineering has suffered from a fragmented and disjointed approach.

the UK as a centre of excellence for technology and to sustain highvalue engineering jobs, develop apprenticeships and increase productivity.

• Funding for new technologies that aid the development of digital solutions for the sector.

• Provide the skills ecosystem necessary to further enhance the UK’s position as a centre of excellence for construction equipment manufacturing and technology.

make the UK an unattractive market for international OEMs.

• Achieve final settlement with the USA on the Steel and Aluminium tariffs currently due for review in March 2025. The same with the Boeing/ Airbus WTO dispute scheduled a year later.

• Harmonise UK digital legislation and cyber security in line with the EU Data Act, EU Cyber Resilience Act and EU AI Act.

• Avoid unnecessary changes to the education system and apprenticeship programmes allowing business to fully understand and build on the current programme.

• Tackle the digital skills gap with a coordinated approach to attracting and developing talent in the construction equipment manufacturing sector.

• Stabilisation and simplification of the import and export process documentation, which is currently leaving the UK at a competitive disadvantage to global competitors.

• Increase supply chain resilience, supporting inward investment and reshoring or nearshoring.

• Continue to develop a joined-up strategy to drive the STEM agenda in UK schools.

• Support further education institutions and technical colleges to attract and retain the quantity and quality of teaching staff required to train future talent.

Manufacturing requires the regulatory environment to be consistent. Unnecessary changes or U-turns should be avoided.

• Increase full expensing allowance for short-term rented plant in construction. Simplifying the rules between plant rented with or without an operator will support housebuilding and infrastructure projects while generating revenue for the Exchequer.

Digitalisation is key to improving sustainability, efficiency and safety, and the CEA views digitalisation as a positive benefit for the wider construction industry. The rise of digitalisation poses challenges over synchronisation of legislation. Harmonisation of standards and consistent implementation across borders is key to remaining competitive.

• Support to maintain and promote

Long-term stability in major infrastructure projects is needed alongside a streamlining of the planning process. Geopolitical events such as the war in Ukraine and tensions in Gaza and the Middle East, as well as the pandemic, have financially impacted the global supply chain, calling for greater resilience.

• Increase and enforce anti-dumping regulations and Country of Origin surveillance on non-compliant imported equipment and parts that are unfairly subsidised.

• A formalised UK Industrial Strategy.

• Careful consideration of all current major infrastructure projects with the UK to maintain the forecast growth in the construction equipment sector.

• Maintain UK/EU regulatory alignment wherever possible. Avoid unnecessary UK legislation that differs from Europe, which could inadvertently

Ahead of the general election, the Construction Plant-hire Association (CPA) urged the next government to consider key priorities to ensure that the UK plant-hire sector remains a key part of the wider construction eco-system.

Without the plant-hire industry, the UK’s construction sector cannot function. Contractors and subcontractors hire most construction equipment. Very few own their own plant. CPA members operate and represent all the different types of construction equipment available. From small diggers and handheld tools, to tower cranes and large-scale construction equipment. Without their expertise, knowledge and investment in such equipment, the construction sector would be vastly inefficient and ineffective in its delivery and ability to deliver for clients –both public and private.

The plant-hire industry also invests heavily in the workforce of the future. The sector is responsible for a vast array

and we look forward to working with the next government on building on these foundations in the coming years.”

The CPA document, Priorities for the Next Government, details a number of key issues that the association urges the next government to consider.

• Establish a credible timetable for the extension of the Full Expensing Allowance to every aspect of the construction plant-hire industry. “When fiscal conditions allow” is too vague and undermines confidence in business investment decisions.

• Reforms to the planning system must be realistic and proportionate. Learning from past failures at both central and local levels are important if we are to build the future homes we need.

• Have one single government department responsible for decarbonisation of construction plant. Current policies and roles are split between at least three government departments.

by the police on abnormal loads and embargo times are having an adverse effect on the efficient movement of construction plant, especially mobile cranes. Some companies are facing an existential threat. The next government must get the Home Office and Department for Transport to work with the industry and police chief constables to outline concerns and ensure the current lack of flexibility amongst police forces, is addressed.

• Build on current work with the construction industry to grow the domestic skills base, improving both apprenticeship funding and retention rates among apprentices, while also making the industry an attractive career option for people already in the workforce. Realism is needed in recruiting from overseas, with the Migration Advisory Committee working with the construction sector in addressing current skills gaps.

of apprenticeships within the industry and is a leader in the recruitment of young people and those looking for a major career change. Offering long-term roles with the ability to train, progress and build a sustainable career, the plant-hire industry is playing its role in making construction a more attractive industry to have a career in.

• Temporarily reintroduce the rebate for Hydrogenated Vegetable Oil (HVO) to the construction industry for at least the next two years.

• Develop a trial scrappage scheme for NRMM (Non-Road Mobile Machinery) businesses operating in Freeport zones, with a view to widening the scheme on a national basis.

CPA Policy Manager Chris Cassley said: “The next government must recognise the role of construction in a growing and sustainable economy. These priorities are an essential part of ensuring plant hire continues to grow and develop as the modern, innovative sector it is, with a highly motivated workforce and ambitious companies that are at the heart of UK construction.

• Publish the Low Carbon Fuels Strategy as soon as possible and develop a road map for the decarbonisation of NRMM.

• The legislative impasse on the creation of Great British Railways (GBR) must be resolved as soon as possible and should be a key legislative part of the King’s Speech, helping provide certainty for planning and business investment in the rail plant sector. A growing rail plant and rail maintenance industry is at the heart of a successful rail sector and the current delays have undermined progress, with the supply of future work bank visibility fragile.

“Issues such as skills, boosting the workforce, net zero and business investment are all key areas impacting on our members and their day to day operations. The industry has made tremendous progress since the pandemic

• The position of construction minister must be solely dedicated to the sector and not split amongst a range of different ministerial responsibilities across different industrial sectors.

• The current approach

QTell us about the history, development and design principles of Dragon Equipment

Dragon Equipment’s inception was rooted in practical necessity and innovative engineering. I needed a concrete crusher for a home building project and none of the available machines could access my back garden. So I used my engineering expertise to design and build a crusher box, that was PTO driven from my garden tractor. This would become the CR300 Tracked Crusher we know today. It was born out of necessity, but quickly demonstrated its potential beyond my immediate needs.

Interviewee: Jeff Haines

Role: Director

Company: Dragon Equipment Limited

With over 37 years’ experience working as a director, technical director and partner for leading engineering firms, including 22 years at one of Europe’s leading woodchipper manufacturers, Jeff is now the owner and director of Dragon Equipment. Since starting in 2018, Dragon Equipment has grown to be one of the leading UK manufacturers of micro crushers and has also developed a range of other complementary machines, include power barrows, lifters and dust suppression units. Jeff is a keen motorcyclist and world record holder for the fastest sub one-litre motorcycle over one mile. To achieve this Jeff used his engineering experience and expertise to achieve something no one had ever done before.

The turning point came when my son Zac recognised the market potential of the machine. He said, “I think you’ve got something here Dad, you could sell this machine,” sparking the entrepreneurial journey of Dragon Equipment. I refined the design and built a more polished prototype, leading to the creation of the first CR300 Tracked Crusher.

My extensive industry network played a crucial role in the development process. I sourced or fabricated the necessary parts, prioritising local suppliers whenever possible. In the early stages, the engine manufacturer Briggs & Stratton provided

significant support. They supplied the essential engine for the prototype and offered a platform to launch the CR300 Crusher and the Dragon brand at the 2019 Saltex Show. This event marked Dragon Equipment’s introduction to the world, with Briggs & Stratton hosting our team on their stand.

The design principles of Dragon Equipment focus on two key aspects: product quality and usability. We dedicate substantial effort to ensuring that every product is built to last, employing rigorous testing and high standards for materials and construction. At the same time, they

emphasise making the machines as userfriendly as possible. This often involves complex and intricate work behind the scenes to simplify the end user’s experience, ensuring products are easy to operate without compromising on performance.

QTell us about your team and working culture

Our team is at the heart of our success. We operate under a simple yet powerful philosophy: “Go with it.” This means we encourage quick decision making and foster an environment where any problems can be addressed and resolved collaboratively later. This approach ensures agility and responsiveness, crucial in our fast-paced industry.

Brainstorming sessions at Dragon Equipment are particularly unique. We firmly believe that there are no stupid questions. Every idea, no matter how unconventional, is valued. This openminded approach has been the birthplace of some of our best innovations. By

creating a space where everyone feels comfortable sharing their thoughts, we harness the creativity of our team, leading to ground-breaking solutions.

Listening to customers is fundamental to our operations. Our customers are hands-on with our machines daily, making their feedback invaluable. This customercentric approach drives our development and has led to some of our best features, including the new remote control for the CR400 and CR450 Crushers. By integrating feedback into our design process, we ensure that our products meet the real-world needs of those who use them.

We are a close-knit group where everyone mucks in, gets involved and makes it work. Each team member is dedicated to the mission, bringing their unique skills and enthusiasm to the table. This shared passion and collaborative spirit are what drive our success and innovation.

Dragon Equipment stands out due to our unwavering commitment to both innovative design and exceptional customer service. When customers choose Dragon Equipment, they can expect a combination of cutting-edge technology and dedicated support that sets us apart from the competition.

We are proud that our great design is backed up by outstanding service. We recognise that many of our customers rely on our machines to make a living and when a machine is out of action, it directly impacts their ability to earn. We respect this reality and always go the extra mile to resolve any issues as quickly as possible.

The relationship we have with our customers is more than transactional; it

is a partnership. We see our customers as collaborators in our journey towards continuous improvement and innovation. This partnership approach ensures that when customers buy from Dragon Equipment, they are not just purchasing a machine but investing in a relationship with a company that genuinely cares about their success.

QHow do you go about keeping employees’ skills up to date?

We may be a small and relatively young company, but we place a high value on investing in and supporting our employees’ growth. To ensure each team member can develop their role and maximise their potential, we work closely with a consultant who regularly meets with our employees. These sessions are tailored to address individual needs and aspirations, providing personalised guidance and support. This approach helps our team members identify their strengths, areas for improvement and opportunities for career growth.

QHow do you see the outlook for Dragon Equipment?

The future looks promising for both the plant industry and Dragon Equipment. As a new company, we have already made a significant impact by developing highly sought-after machines and the interest in our products and Dragon Equipment in general is very high.

In the medium term, we foresee a continuous increase in demand for our innovative machines. To meet this growing demand, we will need to expand our factory facilities. This expansion will not only allow us to increase production capacity but also to enhance our

production methods. By adapting and developing new manufacturing processes we can ensure that we keep pace with market needs while maintaining the high levels of quality that are essential to our brand.

We currently have four dealers spread across the UK who help us to expand the reach of our machines. We have also seen considerable and rapidly growing interest from other European countries, and we have importers currently selling Dragon Equipment machines in France, BeNeLux, Portugal and Ireland.

QAnd how do you see Dragon’s product development?

Full on! Our product development efforts are in full swing, with a growing list of machines and features on the drawing board. There is no intention of slowing down; if anything, we are ramping up our efforts.

A significant focus will remain on listening to our customers and integrating feedback into our development process. The insights from those who use our machines daily are invaluable, guiding us in designing features that enhance usability, efficiency and overall performance.

Embracing the latest technological advances will be a cornerstone of our product development strategy. This includes integrating smart technologies, remote operation capabilities and advanced automation features. By staying at the forefront of technology we can offer products that are not only more efficient and productive but also easier to operate and maintain.

QTell us about some of Dragon’s technological developments

One of the most ground-breaking developments we have introduced is the ‘no stress’ feature on our crushers. This innovation addresses a common issue in crushers: the propensity to jam, block and ultimately break down. We have focused on creating a solution rather than just addressing the symptoms.

Our crushers may look sleek and simple – a deliberate choice to ensure ease of service and maintenance – but they incorporate sophisticated programming to eliminate jamming, blocking and breaking issues. The ‘no stress’ and ‘anti-stall’ technology programmed into the machine’s Electronic Control Unit (ECU) detects when the load is too high. It then switches

the jaw movement into an alternate mode, reducing the load on the engine until the difficult material is processed. If this isn’t sufficient, the ECU will stop the feed entirely to prevent the engine from stalling. With the engine still running, the operator can manually toggle between forward and reverse to clear the jam. While the robust jaws of the Crusher Range make these features rarely needed, having them available is crucial for preventing downtime.

QWhat is Dragon doing with regard to sustainability?

At Dragon Equipment sustainability is at the core of our philosophy. Our range, including our crushers, lifters and power barrows, is designed to promote recycling, efficiency and a reduced carbon footprint.

By their very nature our crushers are instrumental in promoting recycling within the construction industry. Reusing materials on site reduces the need for buying and transporting new aggregate, thereby decreasing emissions from heavy machinery and vehicles and reducing costs in the process.

Producing new concrete requires significant energy and natural resources like sand, cement and aggregates. Our crushers enable the recycling of concrete waste, which saves energy, reduces the need for mining new materials and cuts transport costs associated with hauling materials to and from construction sites. By crushing and reusing concrete on site, we contribute to more sustainable construction practices and resource conservation.

Our other products such as lifters and power barrows also support sustainability by promoting time efficiency and making the use of recycled materials easier. These products contribute to reducing overall project times, further reducing the environmental impact of construction.

All Dragon Equipment machines are designed and made in Suffolk. Keeping fabrication local allows the team to retain control not only over quality, but also the supply chain. Dragon Equipment is proud that 90% of components are supplied from within 50 miles of the factory. This focus on local suppliers helps to reduce emissions and ensures the business is contributing to the economic growth of the local area. The machines are built to last and are all built by a highly skilled local workforce. Higher quality fabrications lead to lower machine maintenance.

QTell us about one of Dragon’s key products

The new CR450 Diesel Crusher is taking things to the next level. It is our first diesel-only crusher and is designed and built at our head office and production facility in Suffolk.

QOutline the key benefits of the product

The 460 mm x 205 mm Hardox jaw aperture is the largest in our range to date. Its funnel is perfectly designed to be loaded by a mini excavator, helping operators to handle larger jobs quickly and efficiently and the large 33-litre fuel tank can keep the machine crushing for in excess of 12 hours.

The CR450 is powered by the Kubota D722 three cylinder water-cooled 19 HP diesel engine. This is highly regarded within the hire industry and complies with EPA/CARB Tier 4 emissions regulations. The higher torque provided enables the CR450 to power through even the hardest of materials at a higher speed for a sustained period, dramatically increasing the output.

With a total weight of under 1,450 kg the CR450 Crusher can be easily loaded onto a trailer with an excavator to minimise transportation cost. It features all-terrain tracks and an increased width

of 970 mm, significantly improving stability for the increased workload while remaining compact enough to give the machine a real advantage on more demanding sites.

The machine includes instant jaw adjustment for crush size from 3 to 55 mm, anti-stall, auto reverse and the Dragon-designed fold up conveyor for ease of storage and transportation. The CR450 also has a remote control option, enabling excavator drivers to operate the machine from the comfort and safety of the cab.

“The new CR450 Diesel Crusher is taking things to the next level. It is our first dieselonly crusher and is designed and built at our head office and production facility in Suffolk”

QWhat do you find most rewarding in work? Which parts of work are most challenging?

QHow long have you been in the industry and how did you start out? What attracted you to the industry?

I have been in the engineering industry since I was 16 years old and have always had a passion for designing things, fixing things, finding out how things work and making them work better. It was when I had moved on from another major plant manufacturer six years ago that I had my eureka moment with the first crusher prototype, which I developed for a project at home.

QHave you been involved with any interesting projects in your career?

The most notable was the design of the revolutionary Maltese Film Industry pump house. This has attracted movies such as Pirates of the Caribbean, which was partially filmed there. I still laugh at the fact that the grand opening was attended by the President of Malta with a big song and dance, but it was designed by a scruffy bloke in his Suffolk shed.

QTell us about the different aspects of your work. What range of tasks do you undertake?

My primary focus is on sales and product design and development, however in reality I wear many hats and have an active role in every part of the business.

Rewarding: when you push the button for the first time on a new machine. That’s what it’s all about.

Challenging: striking the right balance between home life and work life.

QWhat kind of projects would you most like to be involved with before retirement?

Full hybridisation across the range. We have developed a hybrid CR300 Crusher, however there is still much development needed to make this technology span the entire range.

Who is your favourite artist? AC/DC

What do you do for fun? Design machines

What’s your bucket list activity? To visit Monaco and watch the Monaco Grand Prix

What’s your favourite cuisine? Italian

What’s your tipple of choice? Belgian beer

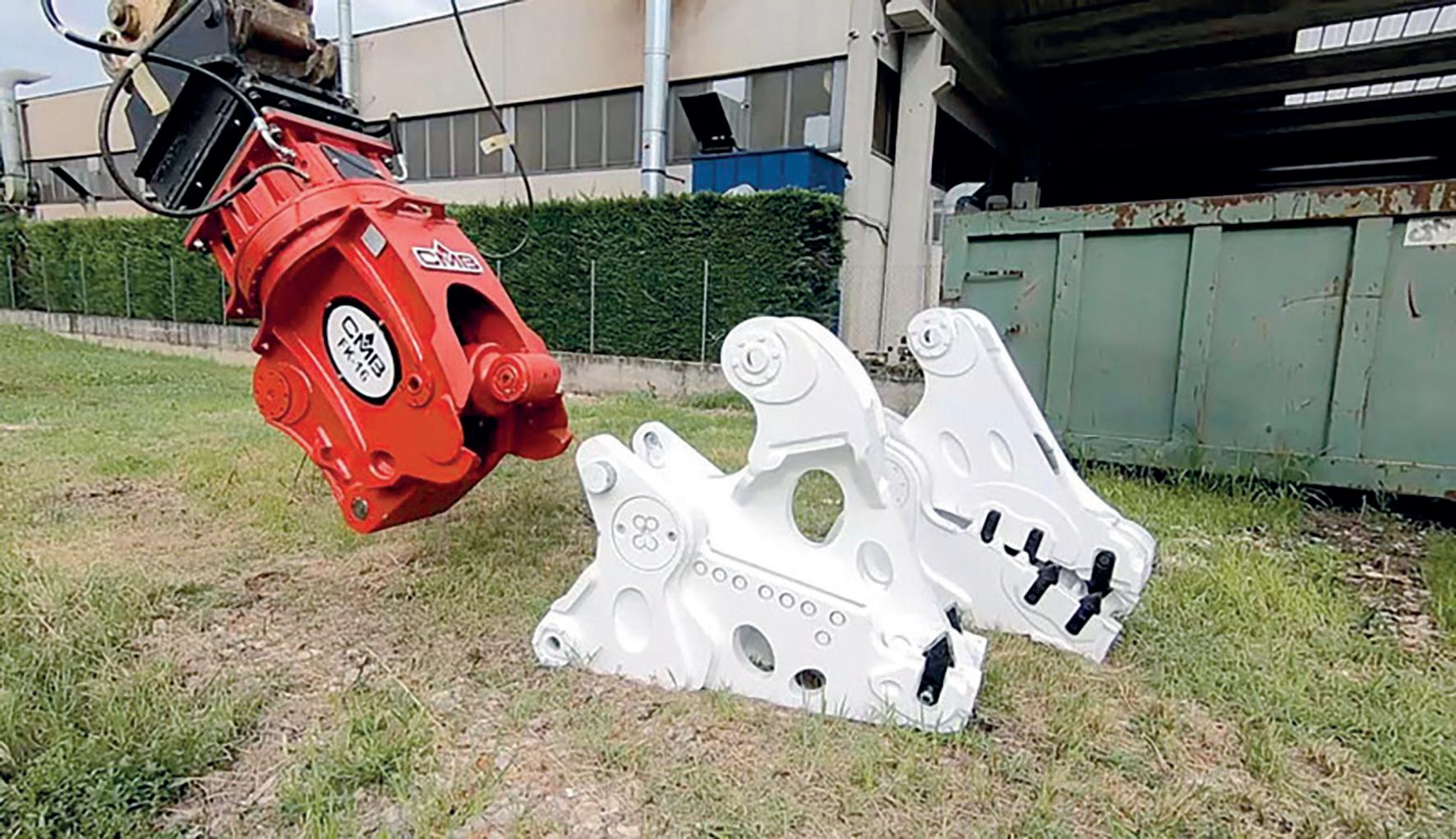

Interviewee: Alex Holmes

Role and company: Head of Commercial, Hill Engineering

Sector: Excavator attachments manufacturing

Turnover: £20,000,000

Employees: 50-100

Current brands: TEFRA, TITAN

Geographic reach: Global

Established: 1994

After 11 years in the automotive industry with luxury and volume brands I wanted to move into other areas of manufacturing. The opportunity at Hill came up and I made the move in March 2024. My most recent role before then was at McLaren Automotive where I oversaw the growth of their retailer network in new and existing markets, along with retailer standards and retailer of the year programme.

QHow do you fit in to Hill Engineering?

As part of the senior leadership team, as Head of Commercial, I’m responsible for the global sales, aftersales and customer service teams. I’m also looking at new markets for the company to expand into in the coming years.

QWhat is it about your role that attracts you?

The ability to make a difference – we are able to drive innovation with quick thinking and decision making.

QTell us about Hill Engineering, its history and development Hill Engineering specialises in designing and manufacturing high quality excavator attachments and has been doing so since 1994 from our base in Newry, Northern Ireland. In that time we’ve become renowned for our innovative thinking, exceptional quality and superior safety standards.

Our philosophy is to always look for ways not only to improve our products but also to work smarter and safer. We’re continually developing new products, meeting stringent safety standards

and delivering exceptional quality and we are now regarded as the foremost manufacturer in our industry – leading the way for others to follow.

We’ve set new standards with our products through relentless focus on quality, innovation, reliability and safety. We consider customers’ safety above all else, build value for money into every product and see every customer as a long-term commitment, with our team available to them for as long as they need that support.

Q

Tell us about its growth path up until now – and perhaps the future

Hill has a very strong presence in the domestic UK and Ireland markets but we also have a strategy to grow the business in other markets globally.

Qthe TEFRA hitch, is that it is simple. We developed our market-leading product to have the least working parts of any of our competitors. We call these relatively few moving parts the Hill Active Protection System.

Q customers?

With fewer moving parts there is less that can fail on our product. And with fewer moving parts, those parts are more easily replaced in the field.

QQuality is at the forefront of everything we aim for at Hill. We demand perfection at every stage to maintain and build our reputation for excellence. Innovation is also at the heart of Hill Engineering as we constantly look for new ideas and ways to improve.

Q

What can we do to attract young people into manufacturing industry, particularly plant and related attachments? Is there a good pool of potential recruits?

We do not see many young people looking for manufacturing roles early in their careers so this needs to be a key focus for the industry. Most people appearing in our recruitment talent pool have multiple years in roles.

Q

How do you see the company in five or ten years?

Hill Engineering will be continuing to innovate and push the boundaries of attachment safety and expertise. We will be developing new products that have the same impact on the industry as TEFRA has done, and seeing the business growth plans come to fruition.

When and where were you happiest?

Family is everything to me, so the day my son was born, seeing his little face and hearing him cry for the first time.

What’s the most expensive nonessential you’ve ever bought?

Does anyone remember those kangaroo jumping stilts? With them attached to your feet you could jump up to around two metres high, with two-and-a-halfmetre strides and run at 20 miles per hour. I bought a pair at university, wore them once, fell over – never worn since. They are still in a box in the loft.

What would your ideal company excursion be?

It would have to be go to Las Vegas – the perfect place for team building.

The premium wheel loader and the essential crawler excavator are ready for any challenge.

QTell me about the project and how it came to fruition

I’m the Lead Designer from Just Add Water, we’re the developers of the game and we’re working with Wired Productions, who are the publisher. It’s a joint effort between us. Their high level idea originated from Leo, who is the director of Wired. He was over in Italy during lockdown and while he was there on his family farm, he was a bit bored and decided, I’ll just hire an excavator and potter around the farm and do a couple of jobs. He’d never done it before so just jumped in the excavator and as he was at the controls he thought, this is perfect for VR, why hasn’t this been done? So he got in touch with us, Just Add Water, and pitched the high level idea.

QWhy did he come to you? What brought his attention to Just Add Water?

We’ve had contact with them before, they know us, and we did Sniper Elite VR. That went down really well, everyone loves Sniper Elite. So we’ve got a bit of a rep for good VR games. So Leo came to us to talk about it. In our first sit down meeting, the pitch from them was: “Hey, can you guys do a digging game?” And that was it, “diggers in VR,” and we were like: “Cool. Okay, anything else?” And they said no, just diggers in VR.

So this is when we thought, how do we make a game out of diggers? We didn’t want to do a hardcore simulation game. We wanted it to be fun. We wanted to get people who don’t love diggers excited

about them and maybe want to try them.

So we evolved the idea of having a digger with some crazy attachments, ones that would not exist in the real world. We’ve got four different diggers in the game, ranging from a mini digger up to a 50 tonne machine. Each one comes with three different bucket attachments – the thin trenching bucket, a very wide bucket and a deep bucket. You’ve then got the breaker, a compactor, a circular saw, a trimmer for doing hedges, a grabber and a hook We’ve even got a bowling game and hook a duck. We’ve got so many crazy things.

We thought, let’s do the ones that actually exist and then let’s take it a bit further. Let’s take the tools that do exist and use those for crazy things. People

who know these tools and know diggers will get it, people who don’t will find something in it too. There’ll be something in it for everyone really.

QHave you had skilled operators have a go on it yet?

Not yet. However, the few public tests we’ve done, we’ve had a couple of people play it, who have operated them, and gone: “You’ve nailed it, this feels exactly like a digger.” And when we first started making the prototype for the game, we wanted to make sure those controls were one-to-one, with a joystick to control the boom, the stick, the bucket and the cab accurately. Getting authentic control was key.

And then we went to Diggerland.

All we had tried in the dev team was the prototype. We jumped in the diggers and I was on it – straight away I could do it.

QYou had learned the levers off your own VR?

Yeah, and they were like, “Have you driven a digger before?” And I was like, “No, first time. We’ve just done it on our prototype.” He said that was crazy. I was doing the full bucket, boom, stick operation at the same time, digging it. I couldn’t believe that I’d picked it up.

QHow you’d taken to the levers on an actual digger from your experience on the game interests me. This could be a real learning tool, possibly bigger than the game itself. We think that too. The game is our primary focus, but we’re slowly seeing that there are more opportunities. Maybe we will make one that’s more realistic, without the bowling or the hook a duck, more like a training aid. There’s huge opportunity there.

We’re not shying away from the OEMs at all. We’d love them to partner with us and have their brands in the game – we’ve had to make the diggers in the game from scratch without looking like any of the real diggers to avoid any IP infringement. The diggers look like real diggers, but you couldn’t tie them to any one company, it’s a bit of a mashup to get them looking real.

We’ve got all the other realistic aspects

– you have to push the safety lever down, you have to start the engine, you can listen to the radio or loads of different music options while you’re digging. We’ve also got a tablet so you can look at emails from clients.

QThese cabs are better than hotel rooms these days.

Exactly. So we’ve tried to get all the key things in, but we haven’t got all of the buttons because we didn’t want to overwhelm people. We want to get people doing the basics on the joysticks and learning the controls.

QYou’re coming to the British Demolition Awards. What will attendees be able to see?

Loosely, the release date is this year, so I’ll be able to give more details later, but we’d love to be able to show this off and get it in as many hands as possible.

We think we’ve done something really special. It’s the first ever digging game in VR and it’s the first game on Meta Quest to use dynamic terrain. The dirt has to work like real dirt or what would be the point?

When the ground’s really flat you get that satisfaction from the first scoop with a bucket like when you take the first scoop of ice cream and it does that nice roll. When you’re digging, the terrain actually digs and you dump it out. That’s huge. No one’s ever done that in VR.

QLearning a bit more about diggers would appeal to a lot of people that aren’t necessarily in the industry. I can see a lot of people being interested in this. What has been your personal role within this project?

I lead design, creating and directing the project as a whole, coming up with the intricacies of the design and the different tool heads and the level designs. We’ve got a team of designers and we give them briefs on how to design the levels. Wired gave us the high level brief “Digging game in VR” and at Just Add Water we’ve filled in all the gaps, added all the bits and come up with the mechanics, how it feels and how it works. We think it’s going to appeal to a lot of people, they’re going to have a lot of fun with it.

We’ve tried to make the controls as authentic as possible but we’ve added things for people who are more casual. We found a lot of people were struggling with moving the boom and digging with the bucket, it’s like patting your head and rubbing your tummy at the same time.

So we’ve put in a function called Dig Assist to alleviate that. If you’re pulling the boom back and it connects with the

dirt, the bucket will start to auto curl to collect the dirt – you don’t have to curl the bucket, you can just get the teeth into the ground, pull it back and it will curl for you. But that’s just an option. You can turn that off if you want the full authentic digger experience.

QTell us about the plot.

You start the game as a lazy teenager on your family farm. You’ve not really been doing much with your life and your dad’s saying, “You need to sort yourself out, we’ll put you in the family digger, teach you how to use it and go from there.” After that your dad says, “You’ve got a bit of a flair for this, maybe you should do more with it.” You’re given your own warehouse, the mini digger and set loose in the town of Diglington in the county of Digshire where the game is set.

Jobs come to you from different people in the town. They’ll ask for different things; someone will say they need a pond digging out, some will need the foundations of their house digging out, there might be a rockslide on the road into Diglington blocking off the town, with the mayor saying, “Oh my God, these rocks, we need you to break them, clean it all up and let people come through again.”

So we’ve got loads of missions set in this town and this world. It’s about you taking the business from really small business to a booming business with all these different diggers.

We’ve got loads of customisation options. You can really personalise your digger, applying different paints, skins and stickers to it. You’ve got mini-games in your warehouse, you have access to a ball pit, hook a duck and bowling. But the main element of the game is the campaign

to grow your business by doing all these different jobs using all eight tool heads.

QIs there anything you particularly want us to convey to our audience of professionals?

I think if they see the game or watch the DigVR YouTube trailer, they’ll see that it’s one of those games that will appeal to professionals and people who love diggers because of the authenticity of the controls. But there’s also something there for people who aren’t experienced or aren’t into excavators or diggers. I think both camps will find something to enjoy and even those who really love the diggers and want that authentic experience will love the bowling or playing hook a duck because it’s different from what they do in their job every day.

We’ve also got levels where you can just smash everything up, which I’m sure people can’t do on a real site.

QWe are very into encouraging the next generation coming into the industries we represent so I would also apply the spin of appealing to the professionals, but also to their children and the next generation of operators. Is that on your radar as well?

We would love to get this to as many different people as possible and in many different hands. Because actually, I think there’s a great opportunity there, as a training aid and a training tool. There’s a great opportunity to make people realise they actually want to do it as a job. And then there’s the casual gamers who just want to experience driving a digger.

We’re super excited. We think there’s a lot of different people who will enjoy this game.

Incredibly I have now attended Hillhead since 2016. I am well versed in the laborious five-hour journey, the route, the likely brands on display and where they are likely to be as well as excavators in action. But with that learned experience, Hillhead is never a box-tick event that you feel you should attend, and it is the polar opposite of a chore.

When you hit that Derbyshire countryside, you cannot help but get those butterflies akin to at the triannual CONEXPO, the excitement of a plethora of likeminded people in one place, watching big equipment move about, talking shop and laughing with friends old

and new with a beer in the sunshine makes Hillhead something very special indeed and this particular show had a bit of magic to it.

I joked in my leader about meeting everybody, but blimey, days later the team of four that were there representing Diggers LIVE! are still coming out with new anecdotes, names and retrieved business cards from deep inside last week’s pockets.

I saw a post the day after the event from someone on LinkedIn with a countdown clock stating 730 days to go, and it made me smile. I really cannot wait for the next event in 2026.

Bobcat was showing off new products at Hillhead 2024, including the Super Compact TL25.60 telehandler, the T86 compact track loader and the S650 skidsteer loader. The display also included the top-of-the-range T40.180SLP 18-m telehandler, the L85 compact wheel loader, the E10z, E27z and E60 miniexcavators, T590 and S76 compact loaders and models from the Bobcat portable power, compaction and material handling ranges.

John Christofides, Regional Sales Director for Bobcat EMEA, said: “We are very pleased to show visitors the very latest from Bobcat at the 2024 Hillhead exhibition. As our stand at Hillhead shows, Bobcat offers solutions for all types of job sites both big and small,

for customers in construction, rental, quarrying and many other industries.”

As the smallest machine in the range, the new TL25.60 brings the number of rigid frame telehandlers from Bobcat for construction, rental and general handling to 13 models. The new TL25.60 telehandler has been designed for simplicity of use, excellent stability, optimum comfort and safe operation in any type of application and is powered by a 56 kW Bobcat Stage V engine. The machine has a lift capacity of 2,500 kg, offers a maximum lift height of 5.9 m and a maximum reach of 3.3 m. The Bob-Tach carriage (manual or hydraulic)

increases versatility by allowing the TL25.60 to utilise attachments designed for the Bobcat loader range.

John Christofides said: “Because job sites are becoming ever tighter on space, telehandlers must also become more compact and agile. We have designed the TL25.60 to not only meet this demand but to be the best compact machine on the market, with the same cab that is used in larger models in the range.”

Top-of-the-range T86 compact track loader

Delivering a higher engine and hydraulic output, the Bobcat T86 is the most powerful compact loader the company has ever built. The T86 uses a wellproven Stage V-compliant 3.4-L Bobcat engine producing 78 kW at 2,600 RPM. Just like all R-Series loaders, the engine is mounted in line with direct drive, which improves the cooling capacity of the engine and hydraulic components. This change increases reliability in high-intensity applications such as road

construction and forestry work.

John Christofides said: “The T86 has set new industry standards in every area, from in-cab comfort and safety to available power and attachment versatility. The T86 takes what is possible with compact loaders to a whole new level.”

New version of S650 skid-steer loader Hillhead provided the first sight in the UK of the new S650 Stage V skidsteer loader, which has been developed for use in European markets. Its D24 engine, which features a Bosch fuelinjection system, delivers 55.3 kW, providing superior performance while adhering to strict emission regulations.

The S650 loader has a vertical lift path, combining a lift height of 3.1 m with a rated operating capacity of 1,227 kg and a tipping load of 2,455 kg for truck loading and pallet handling. Its wide attachments range also opens up many new applications where very high lift capacity in a compact-sized loader, are important.

The L85 on the Hillhead stand and the L75 model were launched in 2021 and 2022, respectively, marking Bobcat’s entry into the compact wheel loader market and the company’s portfolio has recently been extended with the introduction of the new top-of-therange L95 model.

With the expanded compact wheel loader portfolio, Bobcat has the largest loader selection of any manufacturer in the world. Bobcat compact wheel loaders are ideal for construction, landscaping, rental, aggregates, industrial, waste, recycling, road work, snow removal, maintenance and many other applications, including agriculture.

In the L85, high performance is assured by the combination of the powerful Bobcat engine and the hydraulics. This is complemented by the high stability, breakout, push and pull forces and a comprehensive selection of Bobcat attachments. There

are multiple Bobcat loader attachments approved for use on the L85, including a general purpose bucket, light material buckets, a combination bucket, pallet forks and angle broom and snowblower attachments, making the L85 a truly multi-purpose machine.

With the addition of the S650, the Bobcat range offers 12 skid-steer loader models, complementing these wheeled machines with a selection of five compact track loaders, including the T86 top-of-the-range model. Bobcat also offers an extensive portfolio of

mini-excavators from 1.0 to 9 tonnes, including two electric models and a new range of rotary telehandlers, complementing the wide selection of rigid frame models.

Bobcat has recently introduced a full line of forklifts and warehouse equipment, alongside a complete portable power range of air compressors and electrical generators. Bobcat also offers a range of ground maintenance equipment, including compact tractors, mowers and turf equipment, alongside a comprehensive line-up of light compaction products, including rollers and vibratory plates.

Hillhead 2024 provided the perfect platform to both display and demonstrate for the first time at the show the latest products for the quarrying and construction industries from DEVELON. The static display on DEVELON’s stand included the DX530LC-7 53 tonne crawler excavator, the DL420-7 wheel loader and the DA45-7 articulated dump truck (ADT). In the demonstration area, further products for the quarry face showing their paces include the DX420LC-7 43.5 tonne crawler excavator, the DL550-7 wheel loader and the DA30-7 ADT. Among new products shown for the first time at Hillhead were the new DD130-7 dozer. Compact equipment was another strong aspect, with the DX27Z-7 and DX55R-7 mini-excavators on show. The stand

display was completed by DEVELON’s DX235LCR-7 24.3-tonne crawler excavator.

The DX420LC-7 and DX530LC-7 are part of the range of large crawler excavators that also includes the DX800LC-7 80 tonne and DX1000LC-7 100-tonne machines. Overall, all the models in the DX-7 range of crawler and wheeled excavators from 14 to 100 tonnes combine enhanced comfort with the latest features to boost fuel efficiency, uptime and return on investment, with a focus on increased power, robustness and agility.

The DL420-7 and DL550-7 are two

of the four biggest standard models in the DL-7 range of wheel loaders, which also includes the DL480-7 and DL5807 models. With redesigned buckets offering up to 7% more capacity, these DL-7 wheel loaders provide easier and faster loading with maximum bucket capacities from 4.5 to 6.4 m3

Altogether, the eleven DL-7 wheel loaders in the DEVELON range with bucket capacities starting at 2 m3 provide increased productivity for a very wide range of material-handling applications.

The market-leading DA30-7 and DA45-7 ADTs offer payloads of 28 tonnes and 41 tonnes, respectively. These models feature an articulation hinge positioned behind the turning ring to provide equal weight distribution to the front axle even during maximum steer articulation. This combined with a free-swinging rear tandem bogie ensures equal distribution of weight to each wheel and guarantees permanent six-wheel contact and drive for equal power distribution and excellent performance particularly on difficult terrains such as soft ground, uneven surfaces, very steep slopes, tight turns or a combination of all of these difficult conditions.

The DA30-7 and DA45-7 6x6 ADTs are now complemented by a new 4x4 version of the DA45-7 ADT intended to compete with rigid dump trucks (RDTs) in the 40-tonne class. In the new 4x4 ADT, the front truck and cab unit is the same as in the original 6x6 model, with modifications being made on the rear dumper unit only.

With the launch of the new DD130-7, DEVELON has entered the European dozer market. The wide range of features on the DD130-7 provides a productive fine-grading solution for residential and light commercial construction projects. One of the biggest differences between the DD130-7 and other brands is the visibility it provides of the machine’s

dozer blade. To facilitate this, the front engine compartment offers a narrower design and is combined with other features that make it easier for operators to see their work.

For further visibility and safety, a standard rear-view camera provides operators with an additional view of the dozer’s surroundings. The full-colour, 8-inch Smart Touch display shows the feed from the rear-view camera. Also standard are high-illumination LED lights and four premium wiper blades. The DD130-7 offers a high level of comfort with a premium high-quality seat. The seat and joysticks move together via the air suspension system, to absorb all vibrations.

The DX27Z-7 2.8-tonne and DX55R-7 5.7-tonne Stage V-compliant models are typical of the new DEVELON range of mini-excavators from 1 to 10 tonnes. The zero tail swing design of the DX27Z-7 and the reduced radius design of the DX55R-7 models make them ideal for confined space work.

The DX27Z-7 is powered by the D17 Stage V-compliant diesel engine providing 18.4 kW at 2,400 RPM. The DX55R-7 is powered by the D18

Stage V-compliant diesel engine providing 36.4 kW at 2,200 RPM. As a result, these models offer the highest power and torque in their respective classes and cover a wide range of applications including heavy duty work.

HD Hyundai Construction Equipment introduced two heavy crawler excavator models and its largest wheel loader at Hillhead. Customers and press gathered on the stand on the Tuesday to see the new HX1000A L and the HL985A in the metal.

• HX800A L and HX1000A L weigh in at 80 and 100 tonnes respectively

• 35-tonne HL985A designed to work with a 7 m3 bucket

• Superior cab environment delivers premium operator experience

• EU Stage V-compliant engines deliver class-leading power

Heavy excavation

HD Hyundai has announced its largest Stage V crawler excavators, with the arrival of the 80-tonne HX800A L and the 100-tonne HX1000A L. These heavy-duty machines have been designed to operate in mines and quarries, as well

in bulk earthmoving for construction and infrastructure project applications. They deliver maximum productivity with reduced total cost of ownership (TCO).

Both excavators are powered by Perkins diesel engines, delivering class-leading power and economy. The HX800A L uses the six-cylinder Perkins 2506J, providing 400 kW at 1,800 RPM and 2,468 Nm torque at 1,400 RPM. The larger HX1000A L is powered by the Perkins 2806J, offering 460 kW at 2,000 RPM and 2,952 Nm at 1,300 RPM.

An electronic hydraulic power control system minimises fuel consumption, while increasing digging efficiency. It utilises nine sensors across the machine to calculate the required flow and pump output, delivering maximum efficiency. The HX800A L has two variable displacement tandem axial piston pumps, each delivering 504 lpm

of flow, while the larger HX1000A L has three pumps producing 523 lpm each. A closed-centre main control valve ensures that there is minimal hydraulic flow in the stand-by position, reducing fuel use. In both machines, the pumps have a cross-sensing system to reduce fuel use and to ensure that dig-end hydraulics operate independently.

The excavators have four operating modes and four power modes, working in combination with Variable Speed Control and Pump Torque Control, allowing the operator to select specific engine and hydraulic system outputs to suit the task at hand. They come with a boom priority mode and a swing priority mode, that increase breakout power or slewing speed to suit the operation.

The HX800A L is suitable for 4.25-5.24-m3 buckets and the larger 100-tonne machine will be able to work with 5.4 to 6.8-m3 buckets. The two machines are offered with a choice of short mass excavation and longer monobooms, and with the option of two dipper arm lengths. To ease assembly on site, the counterweight is mounted horizontally and a hydraulicallyremovable counterweight is available as an option.

The HX800A L and HX1000A L have a state-of-the-art operator cab, offering level 2 FOPS protection when equipped with a FOPS guard. The cab is suspended on vibration damping mounts, to absorb more shocks than a simple block system. The operator has a high-quality heated seat with air suspension and the two machines come with HD Hyundai’s All-Around View Monitoring (AVM) camera system, providing the operator with a 360° view around the working area.

An eight-inch touchscreen monitor with rotary controller provides easy access to control menus within the screen, including power settings, mode operation and auxiliary hydraulic settings. The system also connects to Bluetooth to allow control of smartphones and other devices. The

excavators are equipped with low-effort joystick controls, providing fingertip operation and precise control over all functions. Proportional thumb switches can be mounted horizontally or vertically, to suit the operator’s preference.

Product Manager Gert Peeters said: “These heavyweight excavators will build on HD Hyundai’s presence at the heavier end of the market across Europe, providing a highly productive digging and loading solution for mines, quarries, bulk earthmoving contractors and heavy civil engineering sites.”

The HL985A builds on the success of smaller A-Series machines, adopting the same robust, durable design, with proven driveline components and an exceptional operating environment. The machine is powered by the latest Cummins X12 diesel engine. This six-cylinder EU Stage V-compliant motor delivers 321 kW at 2,100 RPM and 2,300 Nm of torque, from just 1,400 RPM. That is 10% more power and 20% higher torque than previous non-Performance Series engines, despite lower fuel consumption and exhaust emissions.

The loader benefits from an Eco gauge within the cab that monitors fuel consumption in real time. This allows the operator to see fuel use, engine torque, average efficiency and total fuel consumed, enabling more efficient operation of the machine in varying conditions. A Smart Power mode further reduces fuel use, by adjusting the engine speed while loading the bucket. This reduces consumption while balancing traction, for improved productivity.

Driving through a five-speed transmission with lock-up clutch, the machine can achieve maximum travel speeds of up to 40 km/h, making it ideal for load and carry, or longer haul rehandling duties. The transmission is also equipped with Intelligent Clutch Cut Off (ICCO), which minimises power loss in the torque converter and prevents excessive power during braking. The loader has a hydraulically-locking

differential in the front axle to ensure maximum traction when digging and loading.

Built to work with a 6.5 or 7.0-m3 bucket, with or without teeth and cutting edges, the HL985A’s Z-bar linkage parallel lift arms provide a dump clearance at maximum height of up to 3,360 mm. Bucket breakout force is up to 28,400 kg and the machine has a full turn tipping load of up to 24,950 kg when equipped with the heavier counterweight. The HL985A has an operating weight of around 35,350 kg, depending on specification.

The HD Hyundai A-Series loader cab is around 10% larger than on previous models, providing the operator with a comfortable, quiet working environment. The ROPS/FOPS cab has a fully adjustable, air suspended, heated seat, with an adjustable armrest allowing the operator to find the perfect driving

position. A 7-inch colour touchscreen is easy to understand, providing all important information at a glance.

Operators benefit from a Bluetooth audio system with a hands-free function, allowing call answering and music choice to be made while working. In addition, the HL985A has a full colour, integrated rear view camera, visible through the main monitor. The machine is offered with HD Hyundai’s market-leading All Around Vision Monitor (AAVM) system, which employs multiple cameras to provide a 360° view around the working area.

Product Manager, Stefan Schwill said: “The HL985A sets a new performance and productivity standard for HD Hyundai in the heavy wheel loader sector.

“Suitable for a wide range of tasks, in quarrying, recycling and rehandling applications, the HL985A offers more power for less fuel used, delivering a total cost of ownership benefit for customers.”

LiuGong’s return visit to Hillhead was marked with the launch of seven brand new machines: the 975F and 856T, along with four new BEVs. These included two electric wheel loaders and two electric excavators, showcasing the company’s pioneering role in BEV technology.

Building on the success of its last Hillhead appearance, LiuGong presented another game-changing experience. Visitors to its stand had the opportunity to evaluate LiuGong’s impressive lineup of 10 static and demo machines designed to match the demands of the quarrying, construction, and recycling sectors.

“We’re thrilled to return to Hillhead this year,” said Dean Thornewell, Managing Director of LiuGong UK. “Continuing to listen to our customers, dealers, and operators has been key. It’s their insights that have shaped our development efforts, resulting in a range of machines perfectly suited to their needs. We see this as a game-changing event for LiuGong and the UK market.

“China leads the world in BEVs, and we are a leader in China. We are bringing all this BEV knowledge and expertise to the UK market in a tough range of electric machines that really put in a shift. We also have some game-changing new product launches on our stand including our new 975F, LiuGong’s new addition to our F-series excavator lineup and the largest machine in this series. With the 975F, we continue to change the game by creating the very best operator experience; combining design, toughness, intelligence and control.

“I believe the way we have listened to customers, learnt from them and used their insight has helped to establish our reputation and elevates the LiuGong brand in the UK and across Europe. Many customers now see us as a strong and highly credible alternative to mainstream brands.”

The New 975F made its debut at Hillhead and becomes the latest star

to join LiuGong’s formidable F-Series excavator team. Designed around the operator, this tough, powerful and intelligent excavator has a 510 HP Cummings engine at its heart and delivers a bucket starting force of 397 kN. Equipped with a double Kawasaki pump, it achieves a combined flow rate of 2 x 504 L/min. Standard features include a 5.0 m3 HD performance bucket and a 650 mm wide triple grouser chain, underlining its position as a powerhouse in the market.

LiuGong has really changed the game with the F-Series excavators and now, with the T-Series Wheel loaders, it plans to change it again. LiuGong wheel loaders have earned their global reputation for toughness and reliability. At Hillhead, LiuGong launched the New 856T, featuring an all new cab concept designed for maximum operator comfort, safety, visibility, and performance.

LiuGong’s green team

Taking the field were four BEV machines designed for the European market, two excavators – the 9027FE and 922FE, and two wheeled loaders – the 870HE and the 820TE. With their distinctive green livery, these machines share LiuGong’s Red Dot Award-winning design DNA and put the operator right at the heart of the machine.

Furthermore, as a leader in China’s booming BEV technology sector, LiuGong is at the forefront of driving a revolutionary wave in BEV R&D, with plans to launch over 40 BEV models by 2027, including new electric excavators, wheel loaders, telehandlers and access equipment.

Also taking the field was the new 9027FE. This compact model takes LiuGong’s popular short tail swing 9027F and changes the power pack to a 20kW LFP battery pack. The smallest of LiuGong’s new machines at Hillhead it has the power and performance you

would expect enabling three to four hours of constant work and a rapid charging time of 90 minutes when using a fast charger. Based on a 48V system, it is easy and safe to service and maintain without needing special high-voltage training.

The new 922FE

Powered by a 430 kW battery, this machine can work a full 8 to 10-hour shift. This is a high-performance machine with a motor delivering 140 kW, around 24 kW higher than a comparable diesel model and similar to a 26-T class machine.

The new 870HE

Equipped with a larger capacity loading shovel and supplied with a 4.7m3 bucket as standard, this high-performance wheeled loader is perfect for quarry and aggregate applications.

The new 820TE

LiuGong’s first compact wheeled loader product, this machine has a large spacious cabin, is capable of 40km/h travel speeds and is powered by

a 70 kWh battery. The 820TE delivers six hours between charges and can recharge within 80 minutes. At a maximum height of 2.5 m, and available with a fourth line auxiliary spool, this machine is excellent for agricultural and industrial applications.

Speaking before the show, LiuGong’s European Product Director Harry Mellor said: “At Hillhead, we are thrilled to showcase LiuGong’s latest innovations, and we know that visitors to our stand will be thoroughly impressed with the products we have on offer this year. These include the highly anticipated 975F excavator and the ground-breaking 856T wheeled loader.

constant pursuit of customer satisfaction. These machines demonstrate our commitment to delivering cutting-edge solutions to meet the evolving needs of our customers.

“This event marks a significant milestone for LiuGong, as the enhanced 856T now boasts an all-new cab, designed for unparalleled operator comfort, further exemplifying our

After their successful debut at Intermat, we are also thrilled to showcase our range of electric machines at Hillhead, with there being so many to see with two excavators, the 9027FE and 922FE, and two wheeled loaders, the 870HE and the 820TE.”

Terex® Materials Processing (MP) demonstrated its strength and commitment to sustainable innovation at Hillhead 2024 with a robust display of 19 products across six of its worldleading brands.

“Hillhead has always been a major event in the Terex MP trade show calendar and our presence this year underscores our position as a powerhouse in the aggregates industry,” said Pat Brian, Vice President, Terex

Aggregates. “Our impressive lineup, of which eight are new products, reinforces our strong portfolio of customer-focused products that are paving the way for a sustainable future.”

In the demo area, Terex MP featured the new Powerscreen® 1300X Maxtrak Cone Crusher, EvoQuip® Bison 220R Jaw Crusher, Finlay® Electric I-120RS Impact Crusher, Finlay Electric 883+ Scalping Screen – both of which were powered by the new Finlay TG500 Tracked Generator. On the stands, Terex launched new products including the Terex® Washing Systems STREAM software, Terex® MPS WG220E Portable

Cone Crusher, and the Finlay C- 1550+ Hybrid prototype. Other existing products featured on the stands included the Powerscreen Titan 600, Powerscreen Warrior 1400XE (hybrid), Finlay J-1170+, EvoQuip Caiman Shredder, MDS® M412 Recycling Trommel and a range of equipment from Terex Washing Systems’ Feeder to Filterpress Solutions.

Strength of the Terex materials processing portfolio

The collection of aggregates brands that sits within the Terex MP segment continues to grow from strength to strength, reinforced by Terex central sourcing platforms, advanced digital development tools, cross-portfolio technologies, and extensive engineering and manufacturing resources globally. The recent launch of MAGNA, a brand designed to meet the demands of customers requiring larger volume processing, demonstrates Terex MP’s strong track record of establishing and nurturing businesses by leveraging its industry leading technology, networks, and manufacturing expertise.

Driving towards a sustainable future

In line with the construction industry’s requirement for a greener tomorrow, Terex MP has focused on supporting customers in reducing carbon emissions in their crushing and screening operations. Electrification, designed to provide customers with alternative energy options, has been a significant focus. David Trimble, Group Engineering Director, Terex Materials Processing said: “Currently, almost 90% of our models are available with alternative power and we continue to launch new machines to bridge that gap. This is evidenced here at Hillhead with the new Finlay Electric I-120RS Impact Crusher and Finlay Electric 883+ Aggregates Environmental Concrete Handling Lifting Scalping Screen – both powered by the new Finlay TG500 Tracked Generator.”

Recognising that there is no onesize-fits-all solution, electrification is just

Terex Washing Systems introduced its new leader at the Hillhead 2024 exhibition, with Mark Fisher appointed as Business Line Director (above). With the urgent need in the marketplace for sustainable solutions that safeguard the Earth’s natural resources, Mark will lead Terex Washing Systems into its next chapter of growth and innovation.

Mark brings a wealth of experience and a proven track record in the industry, having previously served as Director at CDE Global

one part of Terex MP’s comprehensive alternative power strategy, which aims to develop flexible options that adapt to the customer’s preferred energy source. A pioneering £8.1m project with CATAGEN – a catalyst testing expert developing new technologies in green hydrogen and e-fuels – will deliver a decarbonised end-to-end demonstration of a Powerscreen Premiertrak 450E crusher and Chieftain 1700XE screener, powered by green hydrogen and e-diesel at a working quarry site in Northern Ireland in 2024. This project will showcase a solution for the decarbonisation of Terex MP crushing

and General Manager at Telestack Limited, a division of Astec Industries.

“We are excited to welcome Mark Fisher to Terex Washing Systems,” said Pat Brian, Vice President of Terex Aggregates.

“Mark’s extensive background and leadership experience will be instrumental in driving our next phase of growth. His initial tasks have been to meet with our team, distributors, and customers to ensure that Terex Washing Systems continues to lead the industry in supplying sustainable wet processing solutions.”

“I am honoured to lead the Terex Washing Systems team,” added Mark. “Born from the esteemed Powerscreen and Finlay lineage, Terex Washing Systems has evolved to become a global leader in wet processing. By collaborating closely with the team, I hope to build on this strong foundation and drive continued success in the global market.”

and screening equipment through driveline efficiency improvements and the displacement of fossil diesel with e-diesel and green hydrogen.

“Our presence at Hillhead celebrates our rich heritage, strong brands, and comprehensive portfolio,” concluded Pat Brian. “Thank you to our distributors, customers, and other industry partners who interacted with the team at Hillhead. The positive response to our new product offerings and ongoing efforts to support customers in this alternative fuel era marks a significant step towards sustainable success for generations to come.”

Thwaites confirmed from its stand at Hillhead that it had committed to the CESAR security and registration scheme powered by Datatag ID Ltd.

The scheme, which will protect Thwaites dumpers for life, adds further value to the proposition by deterring criminal activity. In addition in the case of theft, when any registered equipment is reported stolen, there is a much greater chance of recovery and likelihood of prosecution.

Owned by the Construction Equipment Association (CEA) and widely supported by the industry, the impactful, identifiable warning signs represent the only scheme recognised by the Metropolitan Police and Home Office. The scheme is monitored and responded to 24/7 and since its launch in 2007 has seen the likelihood of recovery increase to six times more than that of a machine not protected by multi-layered identification technologies.

Thwaites General Sales Manager Andrew Sabin said at the launch: “We are pleased to confirm our participation in the CESAR Scheme. Thwaites will always ensure we protect our brand, our distributors and our loyal owners and operators.

“Reducing the total cost of dumper ownership by lowering insurance premiums and further protecting market-leading residuals is something we fundamentally endorse and support.”

Viki Bell, Director of Operations at the CEA, said: “We are excited to see Thwaites join the CESAR scheme. Their decision highlights the industry’s growing recognition of the value and effectiveness of the CESAR scheme and its unique security measures in protecting valuable equipment and deterring theft. Thwaites’ commitment to this initiative emphasises their dedication to safeguarding their

machinery and supporting the broader efforts of the CEA to combat equipment theft across the industry.”

Kevin Howells, CEO of the CESAR scheme technology and delivery partner DatatagID, said: “We are delighted to welcome Thwaites to the CESAR Scheme after extensive discussions and a thorough evaluation process. Thwaites’ adoption of CESAR reinforces their commitment to security and the

critical importance of our multi-layered forensic identification technologies. This partnership marks another significant step forward in further improving security measures within the construction equipment industry.”

We have the largest central stockholding in the UK, which is supported by a finely tuned stock control program, a highly organised warehousing system and carefully selected logistics partners. This allows Astrak to have the undercarriage parts that you need available when you need them, minimising machine downtime.

Once it’s on the machine, our extended warranty is the most comprehensive in the market place. Each of our rubber tracks come with an extended 24 month warranty as standard.

All of our undercarriage and wear parts are manufactured in IS0 9001 and OEM approved production facilities with rigorous quality control procedures.

Place your order prior to 4.30pm and it will be despatched for delivery on the next working day.

Our wide range of heavy-duty components will keep your excavators, dozers and tracked machinery working harder, for longer. Every hour of machine downtime incurs avoidable costs! This is why you need a reliable partner you can rely on. Stocking the widest range from bucket teeth, cutting edges and OEM quality undercarriage components through to custom made wear parts. Astrak providing you complete undercarriage and wear part solutions. The right part, to the right place, at the right time!

Under the motto, “Meet the family”

Wacker Neuson presented its wide range of innovative Duel View dumpers, including the new DV45 and DV125 models, as well as selected excavators and other innovations. Visitors were invited to explore the new products and discover how Wacker Neuson is using innovation, efficiency and digitalisation to equip them for the future, with a focus on zero emission solutions.

Andy Williams, Managing Director of Wacker Neuson UK said: “We are very happy to be exhibiting again at the Hillhead show this year. It is an excellent platform to exchange thoughts and information with the professionals in our industry and the best way to show our extended family of Duel View dumpers with our solutions for improving safety and efficiency on the construction site.”

Meet the Wacker Neuson dumper family

Wacker Neuson offers its customers a wide range of wheeled dumpers, which set standards in terms of operator and construction site safety, flexibility and cost-effectiveness. The Dual View dumpers from 4.2 to 12.5-tonne payload allow the operator to conveniently and quickly change the seat position through a 180° rotation of the entire operating console. This always gives the operator a perfect view of the direction of work and travel – during transport, loading and unloading. At the Hillhead show Wacker Neuson displays the Dual View models DV45, DV60, DV90 and DV125.

With the new DV45 Dual View dumper, the electro-hydraulically rotatable cabin can be turned by 180° at the press of a button. In the so-called Multi-View mode, it is possible to work in a laterally (partially) rotated cabin. This gives the operator an ideal view of the lateral working area, and he can see precisely where he is offloading the material and where the machine is traveling along. The automatic skip return automatically returns the skip at the press of a button

to the initial position, while the operator can focus on driving. The installed hill-hold function, intelligent tilt monitoring, and seatbelt monitoring with optional start release provide additional safety.