January is the time of year when people take stock of their lives and resolve to do better. But New Year’s resolutions are often not kept. In any case, the idea that making a decision to be better in some way can make you a better person overall is, to be frank, fatuous. So this year I will not becoming vegan, I will not be having a Dry January, and I will not be shaving my beard.

But perhaps HCB can offer a resolution or two that would improve the industry. Here’s one: transport companies could remind their drivers to do a walkaround of their vehicles before leaving the yard. There are a whole lot of enforcement issues that could be avoided, simply by checking the load, fire extinguishers, personal protective equipment and the Instructions in Writing. Drivers used to do it – have they forgotten?

And there’s something else. As I was writing up my report from the European Chemical Transport Association’s (ECTA) Annual Meeting, which took place in Düsseldorf, Germany last November, I noticed something I had scribbled in the margin: we were still talking about the same old issues.

Don’t get me wrong: the ECTA Annual Meeting is always a fascinating and instructive day, as our report that starts on page 20 demonstrates. But some of the same topics came up again, notably driver shortages, the need to take advantage of advances in IT, and the need to build trust across the supply chain and for all participants to be more open with the information they have.

These three points have something in common. They are all to do with identifying and removing inefficiencies in the chemical supply chain, particularly in the transport of goods by road. And the ECTA meeting did address them in some ways. For instance, shortening gate-to-gate times at loading

and unloading points can make drivers more productive, helping to reduce the pressure to hire more drivers. ECTA itself has also been at the forefront of the development of the new electronic European Cleaning Document, the eECD, which leverages the power of digitisation to reduce paperwork and inefficiencies in the transmission of crucial information on tank cleaning between the various participants in the chain.

Those are, though, only two illustrations of what can happen if the chemical industry and its logistics partners approach the well known blockages in the system with an open mind. And there was still no sign that the need for more openness between supply chain partners (and, if the problem is to be addressed to the fullest extent possible, supply chain competitors) has any solution.

The need for trust and greater openness in the chemical supply chain is nothing new; we have been writing about it for more than ten years, and there are examples of how neutral platforms can give participants more confidence that the information they need to share will not be used by others to gain an unfair advantage. And yet, after all this time, both shippers and logistics providers display a reluctance to share that information.

HCB is now entering its 40th year of continuous publication. Looking back, I can see how attitudes have changed over those four decades. The current attitude to trust in the supply chain also needs to change. Perhaps I could persuade you to resolve to be more open with each other.

Peter Mackay

Peter Mackay

Letter from the editor

Years Ago

by Training

Go west!

encourages hub for the Med

Going for gas

tweaks growth strategy

bulletin – storage terminals

Sign of quality ITCO continues @tco depot audits

in the Gulf

GPCA recognises need for change

A grand day out

chemical transport with ECTA

Editor–in–Chief

Plastic fantastic

Eurotainer gets into composite tanks

The acid test

Vale protects against corrosion

on Benelux Broekman buys VLS sites

bulletin – tanks and logistics

Training courses

diary

Incident Log

It’s not going to work CBA attacks Brexit REACH plans

by wireless DGOffice updates XML standards

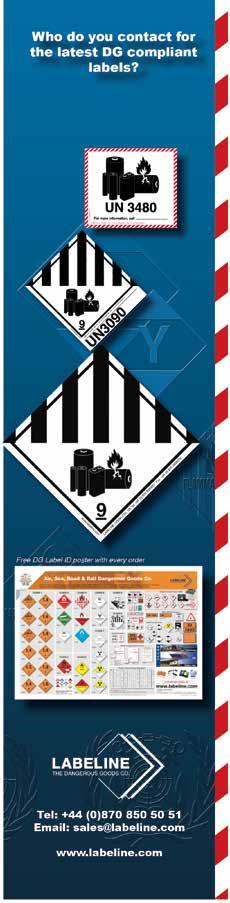

On the road again

All the talks from the Labeline roadshow

The late show

readies harmonisation rule

Long train coming

experts line up next changes

Calendar of meetings

Not otherwise specified

Chemical tankers – markets

Dangerous goods by air European chemical logistics Digitisation in the supply chain

Deputy

Cargo

Commercial Manager

Media

Campaigns

Flicking back through the pages of HCB’s January 1989 issue provides a fine example of just how far industry has come in the past three decades. A major survey on drums for the transport of dangerous goods looked in particular at fibre drums – actually ‘fiber drums’, as the piece concentrated on the US market.

However, the writing was already on the wall – the US DOT’s now-famous HM-181 rulemaking proposed severe limitations on the products that would be authorised for transport in fibre drums, especially corrosive and/or flammable liquids. Larry Bierlein, then general counsel to the Fibre Drum Technical Council, provided a thorough examination of the DOT proposals and the action that the Council was to take to protect its market. As an indication of the level of success that was achieved, it is sobering to look at the list of manufacturers that accompanied the article and realise that only two of the 13 companies are still in business.

Packagings were also high on the agenda at the IMO’s Carriage of Dangerous Goods Sub-committee, which had just finalised Amendment 25 to the IMDG Code. Our report highlighted the range of substances that IMO deemed unsuitable for transport in the various types of IBC, provisions for the use of which had only recently arrived in the UN Orange Book. In those days, the IMDG Code followed its own journey and today’s Code is much better aligned with the Orange Book, but in 1989 shippers needed to be very careful when consigning all manner of goods in IBCs.

That amendment to the IMDG Code also included substantial revisions to the provisions for marine pollutants, to align with Annex III

of Marpol, due to enter into force shortly. An article in the January 1989 issue by Hans Hermansson of Intertanko looked at the impact of the arrival of Annex II of Marpol, which applies to tankers carrying chemicals in bulk and which entered into force in April 1987. As expected, there had been a significant impact on the design, construction and equipment of chemical tankers but there had been some more unexpected impacts, in areas such as the wording of charterparties and the issue of waste treatment.

There was a sign of things to come with the launch of a standardised, computer-based dangerous goods checking and tracking system by the International Air Transport Association, SITA and Exis. The system promised to offer airlines, shippers and freight forwarders “both improved safety margins and considerable commercial benefits” by increasing the speed and accuracy in the transmission of crucial documentation. It is only now that IATA is getting to the point where electronic documentation is as commonplace for dangerous goods freight as it is for passengers and, as DGOffice reports elsewhere in this issue, there are still problems to be addressed in terms of the use of standardised forms and language.

There was plenty of interesting imagery in the January 1989 issue, most of it in black and white (colour printing still being comparatively expensive). But picture of the month was definitely a shot of Colum Boyle, chairman of CPV, handling over Stolt Tank Containers’ 2,000th tank to the then president of STC, Reg Lee, now president of ITCO. Thirty years on, only the hairstyle and the cut of the suit are different.

Recently, I was invited to pitch my innovative research and ideas on management of complex systems (marine storage terminals) at the OpslagTanks conference in Spijkenisse, Holland. I was allowed 10 minutes in which to explain 9 years of research findings and to corroborate the conclusion that complex systems cannot be regulated from the outside with for example the PGS 29.

The results of my research by using systems science and cybernetics are that complexity is simply too large to be contained and described by regulatory standards, laws or compliance rules. After about 7 minutes, I started noticing the audience of about 100 people working in this industry looked lost, perhaps overwhelmed by the too technical explanations and abbreviations such as non-linearity, causality or my own definition of the limits of reality, coined Realimiteit.

Despite that I saw that few had understood, I was not approached by them to perhaps ask for an explanation, but was mostly met with silence. “What happened?” I asked myself. Did I explain this too fast, did I use too many difficult new expressions or definitions? Did I meet indifference, misunderstanding or did I discover that a reductionistic educated and trained audience was not yet able to understand a holistic vision? Were people in the audience suffering from psychological biases such as cognitive dissonance or confirmation bias?

I could not tell and the 10 minutes were just not enough time to show them the value of maximally controlled complexity. Back to the drawing board?

I did feel like Cassandra whose story I told to the audience as an introduction so they’d understand that someone who was able

to predict the future would never be believed. And, dear reader, that is exactly what happened. My story about an overlooked science called cybernetics was not yet really believed.

Steering with information, knowledge and through conversation would change mechanistic terminals into self-regulating, autodidact and autopoietic, but complex living and social systems of communication. But no one asked if I could explain these statements, so I felt quite alone as someone shouting in an empty desert.

But it is true; we can predict sustainability, longevity and prosperity of organisations because we have the sciences to do so. We can design viable systems which will be flexible learning systems, always open for change and not ignoring negative, corrective feedback. I mentioned that a badly designed system cannot be regulated into a well designed system. No, it needs to be redesigned.

Thousands of years of creating laws to prevent invasive behaviour have not led to the erasure of crime. Thousands of rules about Health, Safety and Environment have not yet led to a total erasure of accidents. More is needed. So when I tried to explain the Law of Requisite Variety, I felt I lost my audience all together. I regretted that despite my creative and concerned intentions, I was not able to warn them for an unavoidable entropy that lies ahead in the not too far future. They could not believe me.

This is the latest in a series of articles by Arend van Campen, founder of TankTerminalTraining. More information on the company’s activities can be found at www.tankterminaltraining.com. Those interested in responding personally can contact him directly at arendvc@tankterminaltraining.com.

THE BULK LIQUIDS storage terminal network in the Mediterranean is far less concentrated than its counterpart in northern Europe. Lacking a focal point, as is provided by the major ports of the Hamburg-Le Havre range (and, in particular, the Amsterdam-RotterdamAntwerp (ARA) region), the diversity and lack of coordination among the numerous ports and terminals results in inefficiencies and a weak focus for terminal customers.

In order to address this, the Port of Tarragona has for some years now been promoting itself as a hub for the chemical industry in the western Mediterranean,

highlighting its benefits in terms of a comparatively large chemical node, deepwater jetty facilities and connections both within the Iberian peninsula and more widely into the rest of Europe. As part of those efforts, the Port of Tarragona organised a second Hub Day workshop this past November to provide a forum for the discussion of a creation of a logistics hub for petrochemical products and to stress its aim of becoming a sustainable alternative to the ARA region.

The two-day event focused on the benefits that Mediterranean ports can offer in contrast to other well-developed logistics platforms in Europe. The port of Tarragona itself has 11 roro ramps and is equipped with four twin-gauge intermodal rail tracks for trains of up to 750 m. The port’s rail lines connect to the ZaragozaMadrid service and to Valencia and Barcelona.

The port of Tarragona is also recognised as the largest petrochemical cluster in southern Europe, with enormous potential for more rail transport links in the future.

Tarragona’s Hub Day aimed to raise debate about the steps that must be undertaken if Mediterranean ports are to become a serious competitor of the ARA region. The port of Tarragona acts as an excellent launchpad for innovation in this sense, due to its geography and infrastructure.

The event kicked off with a boat tour around the port followed by a site visit to the TEPSA terminal, The tour, which was led by Genoveva Climent, commercial director at the Port of Tarragona, gave delegates to see first-hand the different areas that are dedicated to petrochemicals. According to Climent, petrochemicals represent more than 60 per cent of the port’s total traffic. The site visit gave an excellent overview of the growth happening within the port’s bulk liquids terminals while giving some idea of the potential of the port of Tarragona to act as a hub for the petrochemicals sector.

According to TEPSA, the port’s flexibility and commitment to the quality of its services

has led to the company becoming a strategic ally in its clients’ logistics chain, and its latest investment in tank storage at the Port of Tarragona has facilitated that journey. Other liquid bulk and container terminals at the port, such as DP World, mirror this sentiment, proving the potential for growth and development in the west Mediterranean region and specifically within the Port of Tarragona itself. Day one of Hub Day 2018 closed with a networking event and drinks reception, allowing everyone to come together and discuss the experience so far.

The second day started with a welcome address from Josep Andreu iI Figueras, president of the Port of Tarragona Authority. Andreu welcomed everyone with a brief insight into the port as well as an introduction to the day, which primarily focused on presentations from the event’s speakers on topics such as market trends, competitiveness and sustainability.

The keynote presentation came from Olivier Maronneaud, associate director chemicals at IHS Markit. Maronneaud spoke about the current state of the European petrochemicals market and trends over the past three decades. In his opening statements, Maronneaud discussed the different drivers that propel the petrochemical market, in the form of feedstocks, intermediates and end products. “When we talk about industry globally, we track the different markets,” said Maronneaud. “We track capacities and demand, as well as prices, and analyse production costs and margins.”

“When looking at trends over the last 40 years, we can see a clear cycle in average earnings on base chemicals and plastics,” continued Maronneaud. “From what we can see, these cycles repeat every five to seven years, with another down cycle expected soon.” Maronneaud also gave an insight into surplus capacity and annual demand growth trends over the last 30 years. There have been several spikes in both capacity and demand at various points throughout recent history. Notably, there was a large spike in surplus capacity, increasing to 12 per cent in 2008 during the global financial crisis, as a result of demand falling by an all-time record of 4 per cent.

“Any time that there has been a big decline in demand, it has impacted the capacity surplus and that has put more pressure on the market,” said Maronneaud. “The impact that we see in the early 2000s was actually relatively short-term. The investment cycle –or at least the consumption cycle – has picked up globally through the support of the central banks, which has helped to lift demand leading to a relatively positive environment for quite some time now.”

According to Maronneaud, the petrochemicals sector is currently in a period of stability. HIS Markit runs analysis reports every six months, with current results showing a relatively good view with regard to capacities coming onstream in the next five years.

According to Maronneaud, most of the global demand is being driven by China. It is expected that the market will remain stable over the coming five years.

Discussing the European market, Maronneaud said: “Europe is the third largest market in the petrochemicals industry. Looking forward, the relative share of west Europe is declining in both capacity and demand. This is mainly due to increases in consumption in Asia and production in China.” That means that Europe is becoming

significant as a key import region for chemicals. European domestic demand is slowly picking up after a wave of closures and rationalisations during the recession. Additionally, new investments have been announced throughout the value chain, which aim to drive growth in the European chemicals market.

Focusing specifically on the Spanish market, Maronneaud explained that imports into Spain equate to 2.3m tonnes in 2016, rising to 2.5m tonnes in 2017. Spain accounts for 9 per cent of the western European market for methanol, most of which is sourced from the Americas and Africa, with west Europe and the Middle East holding smaller shares. Maronneaud concluded by pointing out that the industry remains positive about the dynamic for petrochemicals in Europe, especially given that chemicals imports are rising.

Patrick Kulsen, managing director at PJK International, spoke about storage market trends and competitiveness between the ARA region and the Mediterranean. “The ARA region benefits most from the River Rhine,” said Kulsen. “The infrastructure of the region allows it to serve intercontinental trade flows. »

The ARA is concentrated in the Benelux, while the west Mediterranean ports are stretched out along the coastline. According to market share analysis, throughput through the ARA – in terms of liquid bulk – is four times greater when compared with the west Mediterranean.”

In terms of overall bulk liquids storage capacity, the Port of Tarragona is the smallest with 911,000 m3 while the Port of Rotterdam boasts more than 20m m3 of total storage capacity. However, when it comes to logistics capabilities, there are fewer observable differences. “Logistics capabilities determine the accessibility and attractiveness of the port,” said Kulsen. “From my point of view, inland shipping is the major difference

between the north of Europe and the west Mediterranean. A lot of canals and rivers that enable transport of liquid bulk via barges prove to be a very efficient mode of transport. Additionally, a lot of pipeline connections in the ARA region boost its attractiveness.”

Kulsen provided two case studies as examples to support the adoption of the western Mediterranean as a logistics platform: jet fuel imports via Marseille and chemicals imports via Lavéra, both in southern France, versus Antwerp. The former is a matter of competitiveness in the southern part of the Central Europe Pipeline System (CEPS) pipeline. Due to increasing demand for jet fuel at European airports, there is more demand for pipeline capacity.

“The northern route is quite congested,” said Kulsen. “The southern route, however, is not, and a lot of that has to do with pricing.”

That pricing structure, which is based on the length of pipeline, led to Rotterdam and Antwerp were handling a lot more jet fuel than Marseille. However, changes introduced in 2018 mean that it is now cheaper to transport jet fuel through the French port, bolstering the potential of the Mediterranean. According to Kulsen, the total transport cost of jet fuel from the Middle East is now $27.02/tonne via Rotterdam and $22.91/tonne via Marseille.

The second case study looked at chemicals imports via Lavéra as compared to Antwerp. The northern region of Lombardy is the main centre of Italy’s chemical industry. Chemicals can be shipped in via the Mediterranean and the Adriatic Sea to Lombardy using rail and tank trucks; however, for imports from the US Gulf coast, the ARA is comparatively cheaper. Kulsen concluded by observing that it is difficult to gain an objective view and it is important to compare cost-effectiveness on a case-by-case basis.

In a brief presentation, Josep Forcadell (left), sales director at Vopak Terquimsa, presented the findings from a case study regarding Vopak and the potential in the Mediterranean. Vopak currently has 66 terminals in 25 countries, with a total storage capacity of 35.9 m3. Vopak has two terminals in Spain, one in Barcelona, which acts as a distribution terminal, and another in Tarragona, which is the company’s industrial and hub terminal in the western Mediterranean.

“What we can see when we look at Spanish port competitiveness is that there is growth for different products,” said Forcadell. “Of the different coasts in Spain, the eastern coast is the one that has the most potential. Obviously, it varies product by product, but in particular when we look at chemicals, we see a positive trend.”

Of the Spanish ports, Tarragona, Barcelona and Valencia are the ports with the largest volumes, especially in chemicals. Tarragona is also one of the largest import points for LPG. Forcadell explained that total traffic in the Mediterranean, while fluctuating the past,

has seen steady growth over the past few years, with hub activity beginning to pick up since 2013.

The main focus of Forcadell’s presentation fell on whether there is a case for business in Tarragona. His answer, simply, was: “We do not know yet.”

The case study that he presented showed two different options: traditional and alternative. “The traditional way is focusing on one particular type of chemical,” said Forcadell. “In this case, we are looking at methanol coming from the Middle East, going to the ARA region, then back to Tarragona via another ship. The alternative way looks at a ship going from Italy to Tarragona directly, dropping some cargo and then traveling to the ARA region where it leaves the remaining cargo.”

According to Forcadell, this door-todoor study not only covers the shipping and road legs but also the terminal costs, something Vopak had not looked at before. Forcadell concluded with the results that that alternative way, which travels through Tarragona directly, is cheaper, faster and cleaner. “It is approximately 8 per cent cheaper to go to Italy from Tarragona,” said Forcadell. In addition, that approach saves five days’ sailing time, which also has an impact on emissions. Vopak also found that Tarragona is less congested than the main ports in northern Europe and, with more capacity coming to the port in the future, Forcadell concluded: “I believe that we will start to see a diversion from the more traditional way to the alternative way.”

The last to speak was Charles Misseghers, an analyst at Union Maritime et Fluvial Marseille Fos (UMF), who discussed the potential benefits of moving the shipping industry into

a new digital era. According to Misseghers, there is a local problem and a global problem.

The local problem is that the discrepancy between the liquid bulk flows in the north and south is too large, with 70 per cent of flows in the north range and only 30 per cent in the south. “Even if Marseille is a big player in the south, they are nothing when you look at the global market,” he said. When compared with the ARA region, the western Mediterranean has more than 30 sites that are scattered over several thousand kilometres, and as such the west Mediterranean has weaknesses that the ARA region does not.

“We are extremely split,” said Misseghers

“The downsides of this mean that we attract lower volumes per site. It is also more difficult to massify flows as there are fewer vessels of differing capacities. It is a shipping industry problem that we are facing, whether you are a ship owner, a cargo owner or a ship broker. The ship broker is receiving money from the ship owner, not the cargo owner. This means that the broker is looking for a ship for every »

type of cargo and not thinking about the global market. Currently, you have one vessel and one type of cargo, so the only player that is receiving money is the ship broker, with a small percentage going to the ship owner.

“However, the situation should be that there is one vessel that is split into several capacities, and those capacities should then be sold as such. The main problem is that players do not talk to one another. Hub Day brings everyone together once a year and people talk at conventions, but other than that, players do not collaborate. It is time to boost and optimise the supply chain and unlock the potential of commercial and operational efficiency. When talking about digitalisation, the question is not when are we going to be disrupted by digitalisation, but how are we going to be disrupted?”

Misseghers spoke further about the necessity for partnerships within the shipping industry and about the importance of moving towards a collaborative community marketplace: “The aim is for everyone to work together. We need an online marketplace with full transparency where every player can utilise digital tools that will promote collaboration.” Misseghers introduced Shipping4all, a collaborative marketplace aimed at helping ship owners and operators to significantly improve the performance of their fleet, as well as to reduce costs and increase revenue margins across the board. The aim of the Shipping4all platform is to bring together businesses that want to buy or sell spare capacities and gives ship owners the opportunity to have an open discussion with

one another, facilitating transactions and contributing to market and supply chain efficiency.

The second Tarragona Hub Day closed with an interactive Q&A session moderated by Arnaud Waché, president of AWBP Solution. The session provided an excellent opportunity for an open discussion with the event’s speakers and opened the floor for debate.

The event’s aim is to shed light on the potential for the Mediterranean to improve the current logistic routes, reduce costs, improve delivery times and reduce CO2 consumption, all of which it is working hard to accomplish. Through collaboration and open discussion, Hub Day is – and will continue to be – a great player in the move towards innovation and change within the Mediterranean region. HCB www.porttarragona.cat/ca/

VOPAK HAS REPORTED a 4 per cent drop in revenues and operating profit for the first nine months of 2018 compared to the year-earlier figures, with group EBITDA excluding exceptional items off by 3 per cent at €553.6m. For the third quarter, there was some improvement in profitability, despite a very slight decline in revenues compared to 2017.

Unusually, the company has not commented directly on the third quarter’s results. That is perhaps a reflection of the fact that it is in the process of making changes to its network of bulk liquids and gases terminals around the world, and also the difficult market conditions that obtain at present. For example, overall tank occupancy fell from 90 per cent in the first three quarters of 2017 to 86 per cent this year; Vopak says that reflects market conditions at its oil hub terminals, not least those in Europe and south-east Asia. By contrast, occupancy – and EBITDA – was firmer in its China/North Asia and Americas divisions.

Furthermore, the third quarter saw some exceptional items, including an agreement on a new pension plan in the Netherlands, which resulted in a book gain of €19.1m, and the deconsolidation of its wholly owned terminal in Venezuela, where local financial problems make it impossible to reflect actual operating performance.

Indeed, financial performance overall in 2018 is expected to be influenced by

currency exchange movements (particularly the US and Singapore dollars), and changes in the structure of the oil market, which have impacted occupancy rates and price levels in hub locations.

On the other hand, Vopak says its efficiency programme, designed to support margin development and reduce its cost base on an ongoing basis, delivered the anticipated €25m saving by mid-2018; this programme is continuing, with a target of achieving €40m of annualised savings by the end of 2019.

During the quarter some 700,000 m³ of capacity was commissioned at the PT2SB

industrial terminal in Malaysia, in which Vopak has a 25 per cent interest. The remaining 1.5m m³ of capacity will be commissioned by the end of third quarter 2019, in line with the original plan. At the end of the third quarter 2018, Vopak’s global capacity stood at 36.7m m³, up from 35.9m m³ a year ago.

As part of its third quarter report, Vopak also announced a further expansion of activities in the LPG sector. A 15,000-m³ LPG import/distribution terminal is to be built in Richards Bay, South Africa, in partnership with its local partner Reatile, for commissioning in mid-2020, subject to final conditions. The site will, Vopak says, “facilitate further imports of a cleaner energy source into South Africa”.

Vopak is also to expand its wholly owned Vlissingen LPG terminal in the Netherlands by 9,200 m³ to serve the local and regional market for LPG and chemical gases. Completion of this work is also due by mid-2020.

In August, Vopak announced it would conduct a strategic review and “test the market” for a potential sale of its terminals in Algeciras, Amsterdam, Hamburg and Tallinn; this review is progressing on schedule, Vopak says. HCB www.vopak.com

Inter Terminals has completed the acquisition of NuStar Energy’s European bulk liquids storage business, as announced at the end of October, for a cash consideration of $270m. The transaction increases Inter Terminals’ storage capacity by 33 per cent to some 37m bbl (5.9m m3). The acquisition was funded through a common share issuance and cash available through Inter Pipeline’s revolving credit facility.

Inter Pipeline, Canada-based parent of Inter Terminals, says it is to spend a further C$20m in 2019 on its European terminal operations, with enhancements to its facilities in the UK, Sweden and Germany and the Amsterdam site acquired from NuStar, (above) to meet increased demand for storage. www.interpipeline.com

Zenith Energy has acquired the Portland Terminal Facility in Oregon from CorEnergy Infrastucture Trust. Zenith had been leasing the site, which CorEnergy bought in 2014, and has

held an option to buy it since February 2017. It has 84 storage tanks with a total capacity of some 1.5m bbl and acts as a rail/marine transloading facility.

“Our tenant’s operating team developed the commercial potential for the Portland Terminal, while CorEnergy fulfilled our role of funding the initial acquisition and upgrades,” says CorEnergy CEO/president Dave Schulte. “The relationship has proven beneficial to both parties. We are pleased with the transaction, to have had Zenith as a tenant, and to have played a role in its continuing terminal acquisition success.”

CorEnergy acquired the Portland facility for $42m and has since invested $10m to improve the asset; Zenith is said to be paying $61m for the Portland terminal, as well as CorEnergy’s remaining interest in the Joliet terminal in Illinois, in which Zenith is the major shareholder. “With the funds we are receiving, CorEnergy expects to invest in another asset in 2019,” says Dave Schulte. www.corenergy.reit www.zenithterminals.com

Tallgrass Energy has secured a plot of land on the Mississippi River in Plaquemines, Louisiana, where it plans to build 20m bbl of tank storage for crude oil and refined products and export facilities capable of loading VLCC and Suezmax tankers.

As part of the $30m land deal, Tallgrassowned Plaquemines Liquid Terminal (PLT) has agreed to work collaboratively with the Plaquemines Port & Harbor Terminal District and to provide it with a 50-acre tract that will serve as a conservation easement adjacent to the historic community of Ironton.

“We are committed to being a good neighbour and we demonstrated that with this land transaction that represents a win for all parties,” says COO Bill Moler. “The community of Ironton benefits from a conservation easement that will provide a buffer between Ironton and any future development; and PLT procures the land needed for the proposed terminal and docking facility.” www.tallgrassenergylp.com

The Tanzania Port Authority is planning a new jetty at the Raskazone oil terminal in Tanga, local press report. The new jetty will be able to handle tankers of up to 120,000 dwt, a significant step up from the current limit of 45,000 dwt.

Tanga currently handles imports of refined products and LPG through two buoy moorings. Addition of the new jetty will provide capacity to handle imports for Uganda, which would be moved to consumers by rail. Tanga Port is currently engaged in a consultancy project following a successful geotechnical survey. www.ports.go.tz

Mobil Oil has commissioned a new diesel storage tank at the Idubada terminal in Port Moresby, Papua New Guinea, local press reports say. The new 5,600-m3 tank will “significantly improve” fuel supply reliability in the country, according to Mobil. Diesel will be sourced from the ExxonMobil refinery in Singapore. The Port Moresby facility now has five storage tanks. www.pngpartnership.exxonmobil.com

American Midstream Partners sold its refined products terminalling business to Sunoco LP for some $125m in cash, which will be put to reducing debt. The assets involved are located in Caddo Mills, Texas and North Little Rock, Arkansas and have a combined storage capacity of some 1.3m bbl.

American Midstream says the sale represents “continued progress towards [its] capital allocation strategy designed to reduce leverage and strengthen the Partnership”. Sunoco says the deal “builds on Sunoco’s strategy of adding fee-based refined product terminals into the overall portfolio”. Sunoco is part of Energy Transfer LP.

Partly as a result of the sale, ArcLight Energy Partners has revised the terms of its proposed acquisition of all of the common units of American Midstream Partners is does not already own. It is now offering $4.50 per common unit, rather than the $6.10 offered in September 2018. The proposed acquisition remains contingent on a number of approvals and agreements. www.americanmidstream.com

TransMontaigne Partners has approved the planned takeover by an affiliate of ArcLight Energy Partners, originally announced in June 2018, after negotiations resulted in an increase in the offer price from $38 per common unit to $41, valuing the company at $536m.

The transaction will be effected through a merger between TransMontaigne and an indirect subsidiary of ArcLight, TLP Finance Holdings. The merger is expected to close in the first quarter of 2019, subject to the usual conditions. www.transmontaignepartners.com

A new rail siding has been completed at Terquimsa’s terminal in Barcelona (above). The €1m facility can handle trains of up to 14 wagons along its energy wharf, in both Iberian and European track gauge.

“With this new infrastructure, Terquimsa allows Barcelona to connect with the Europe-wide railway, thus expanding our changes of being competitive as a port when it comes to putting products in Europe,” says Eduardo Sañudo, managing director of Vopak Terquimsa. www.vopakterquimsa.com

Buckeye Partners has completed the sale of a package of US pipeline and terminal assets, which includes a number of airport fuelling facilities and two refined petroleum products terminals in California, to InstarAGF Asset Management for $450m cash. Buckeye

Development & Logistics will continue to operate the assets for the buyer under a long-term agreement.

Buckeye further reports that the sale of its 50 per cent equity interest in VTTI is on track and is expected to close early in 2019. Both sales are designed to reduce leverage and allow Buckeye to reallocate capital to take advantage of higher returns elsewhere. www.buckeye.com

Martin Midstream Partners has completed the acquisition of Martin Transport from Martin Resource Management Corp, first announced in October 2018. Martin Transport operates a fleet of tank trucks that transport petroleum products, LPG, chemicals, sulphur and other products. It also has 23 terminals across the Gulf Coast and Midwest US and is “integral to Martin Midstream’s routine movements of sulphur and NGLs,” the company says.

Martin Midstream said in October that it was paying $135m plus up to $10m earn-out for Martin Transport, representing an EBITDA multiple of around 5.7 on Martin Transport’s estimated 2019 net income of $9.3m and EBITDA of $23.6m. www.martinmidstream.com

standards for repair, cleaning and waste management as well as for health and safety among depot employees. AICM had been concerned that many depots handled only dry box containers and had little experience with tank containers; moreover, surveyors sometimes had very close relationships with the depots for which they were working, something that tank operators felt was iniquitous to the need for independence.

WHEN THE ASIAN Tank Container Organisation (@tco) was first established, one of its main aims was to improve the provision of high-quality tank depot services in Asia. Working together with the Association of International Chemical Manufacturers (AICM), the body representing international chemical companies with activities in China, @tco developed an audit protocol and a network of properly trained and assessed surveyors.

Over the years, that system has been effective in lifting quality standards among tank depot operators, particularly in the independent sector. And the system is still in place, following @tco’s merger with the International Tank Container Organisation (ITCO) at the beginning of 2018. To show that nothing has changed, ITCO held an @tco Depot Forum meeting in Singapore on 22 November 2018, immediately after its Regional Meeting.

At the Depot Forum, ITCO president Reg Lee and technical director Graham Wood, both of whom were involved in developing the @tco depot audit scheme, stressed that it was designed to fill a gap, by setting recognised

There are, Wood said, many depots in China and other countries in the Asia-Pacific region that do not comply with local or government regulations. ITCO has no authority to get them closed down but it can report non-compliance and also make recommendations to chemical companies that they should only use @tcoapproved depots. ITCO does have the ability to withdraw accreditation from depots where standards are not being maintained.

However, Wood said, all those depots that have been successfully audited according to the @tco standards have managed to maintain that accreditation; indeed, most of them have shown an improvement in standards in their second and third audit updates.

Since the merger of @tco and ITCO, accredited depots have been offered a preferential rate to become members of ITCO, while ITCO continues to promote the accredited depots to its global member companies. The benefits of ITCO membership include access to ITCO’s technical specialists, who can give direct advice on matters such as tank repairs, cleaning and the relevant regulations.

There was, though, a note of caution: ITCO membership does not necessarily mean that a depot has been audited or meets the @tco audit standards. Only those listed on the ITCO website are authorised to call themselves @tco-approved and use the depot plaque that marks their successful audit.

At the end of the Depot Forum, Lee and Wood presented an @tco plaque to the latest tank depot to be successfully audited – and the first in Taiwan: Union Tank Container Management of Xianxi, near Taichung. This is the 20th third-party depot to be accredited by the @tco scheme and the 29th in all. HCB www.international-tank-container.org

THE GULF PETROCHEMICAL and Chemicals Association (GPCA) held its 13th annual forum in November 2018, attracting some 2,100 delegates to the Madinat Jumeirah Hotel in Dubai, UAE.

The forum opened with a welcome address from Yousef Al-Benyan (above), vice-chairman and CEO of SABIC and chairman of GPCA.

“Global challenges to transformation are real,” he began. “In order to meet these, regional and global chemical industry players need to focus their efforts on portfolio enhancement, competitiveness and growth measures.

To remain relevant in this transforming value chain, we must collaborate through value-creating and win-win partnerships. Collaboration with international and national

oil companies in North America and Asia, research and development investment, customer intimacy, and digitalisation are key to the viability of your business so if you’re not there yet, the time is now.”

Delivering the inaugural address, HE Shaikh Mohammed bin Khalifa bin Ahmed Al Khalifa (opposite), minister of oil in the Kingdom of Bahrain, called on the chemical industry in the Gulf Cooperation Council (GCC) region to collaborate and innovate to meet today’s global challenges: “Trade wars, currency challenges and the commoditisation of products have led the chemical industry to the crossroads we are at today,” he said.

“We must acknowledge the key role the GCC plays in meeting global demand and utilise

our strong regional network, acknowledge best practices from across the globe and focus our efforts on capitalising on the numerous innovation opportunities that the move towards a circular economy will bring.”

According to Shaikh Mohammed, strong and visionary CEO leadership is essential for implementing the circular economy and reaching new levels of sustainable economic growth. By applying these principles, companies can design out waste, increase resource productivity and decouple growth from natural resource consumption. Citing the wave of innovation of ‘Industry 4.0’, the ‘fourth industrial revolution’ enabled by digital and physical technologies, Sheikh Mohammed urged industry leaders to embrace technology with cautious optimism, empower existing teams and future professionals keeping issues such as security and operation excellence at the forefront.

“To have the minister open the forum is a matter of great pride and underscores the significance of the GPCA Annual Forum in our sector and the region as a whole,” said Dr Abdulwahab Al Sadoun, secretary general of GPCA.

The minister’s speech set the scene for proceedings on day one, which included a glimpse into the future, and encouraged regional chemical industry professionals to leverage the full potential of data and circular economy, to increase efficiencies and foster further innovation.

Representing one of the world’s fastest growing markets for refining and chemical products, Raghavendra Rao, India’s secretary, chemicals and petrochemicals, was also among the dignitaries attending the forum and addressing its theme of ‘executing transformation and investing in growth’. From global industrial opportunities in India, regional growth prospects and fundamental shifts in customer preferences, he provided a global outlook and highlighted issues that the industry as a whole needs to address.

Keynote speakers on day two were Murat Sönmez, managing director and head of centre for the fourth industrial revolution, and Fernando Gómez, head of chemistry and advanced materials industry, both from the World Economic Forum. They highlighted the importance of Industry 4.0, while Dr Aabed AlSaadoun, Saudi Arabia’s deputy minister for company affairs, ministry of energy, industry and mineral resources, discussed Saudi Arabia’s national industrial development and logistics programme.

Citing strong growth figures, throughout the two-day event, speakers highlighted the need for evolution within the chemical industry, bearing in mind the emergence of new technologies, product slates and upgrades in capabilities. They also reiterated the importance of ensuring that the industry’s commitment towards a circular economy remains steadfast and integral to creating economic value, jobs and mitigating environmental impact.

Among the speakers at the forum were Amin Nasser, president/CEO of Saudi Aramco; Musabbeh Al-Kaabi, CEO petroleum and petrochemicals at Mudadala; Mutlaq H Al-Morished, CEO of Tasnee; Jim Fitterling, CEO of Dow Chemical Company; Mark Lashier, president/CEO of Chevron Phillips Chemical; and Daniele Ferrari, CEO of

Versalis. “These august speakers will address the challenges and opportunities of executing transformation and set out the key imperatives to invest in growth,” said Dr Al Sadoun.

Other exciting events on the forum agenda included a seminar on the circular economy and four masterclass sessions dedicated to the opportunities and challenges raised by digitalisation; cybersecurity; women in industry; and the global chemical industry in an era of protectionism. The forum focused heavily on the GPCA Sustainability Initiative, a new enterprise aimed at demonstrating the chemical industry’s commitment to achieving the global development goals and enabling a transition towards a circular economy.

In line with this year’s theme, GPCA, as the voice of the chemical industry in the GCC region, is placing greater emphasis on the need for increased plastics recycling in order to protect the environment and recover the utility of this valuable commodity. According to the association, GCC producers have a key role to play in positively transforming the industry. Governments and businesses in the region have been quick to grasp the importance of fostering sustainability, which must be supported and encouraged to help ensure a more sustainable and brighter future.

Indeed, the 2018 GPCA Annual Forum featured a Sustainability Zone, showcasing the technologies, techniques and initiatives responsible for transforming the industry by supporting a more sustainable future.

GPCA voices the common interests of more than 250 member companies from the chemical and allied industries, accounting for more than 95 per cent of chemical output in the GCC region. The industry makes up the second largest manufacturing sector in the region, producing over $108bn worth of products every year. GPCA supports the petrochemical and chemical industry in the Gulf region through advocacy, networking and thought leadership initiatives aimed at helping member companies to connect, share and advance knowledge, contribute to international dialogue, and become prime influencers in shaping the future of the global petrochemicals industry.

Committed to providing a regional platform for stakeholders from around the world, GPCA manages six working committees – plastics, supply chain, fertilisers, international trade, research and innovation, and Responsible Care – and organises six world-class events each year. The Association also publishes an annual report, regular newsletters and various other industry reports. HCB www.gpca.org.ae

THE EUROPEAN CHEMICAL Transport Association’s (ECTA) 2018 Annual Meeting took place as usual at the Hyatt Regency Düsseldorf this past 29 November, with a packed agenda for the one-day event. The meeting room was packed too, perhaps not surprisingly after what ECTA president Andreas Zink, director of LKW Walter, termed “quite a challenging year”. Companies involved in the transport of chemicals in Europe had faced continuing challenges from driver shortages and, after hot weather through the summer, low water levels on the Rhine. In addition, they were experiencing issues relating to the

interpretation by chemical shippers of the Safety & Quality Assessment for Sustainability (SQAS) audit scheme. On the upside, ECTA and its partner organisations had brought the electronic EFTCO Cleaning Document – eECD – to fruition.

Speakers throughout the sessions spoke at length about these and other issues facing the European chemical sector and its logistics service providers (LSPs), at the end of which they and the audience were rewarded with a fine dinner and yet more to chew over in the shape of a hard-hitting presentation on cyber-security.

Of all the major European chemical manufacturers, BASF has been at the forefront of several logistics advances

in recent years, perhaps helped by the concentration of its activities at the massive Ludwigshafen plant in Germany and a few other large facilities. Indeed, BASF had alerted the ECTA audience to its initiatives at other annual meetings in recent years, and Andreas Backhaus, senior vice-president, European site logistics operations at BASF, brought the 2018 meeting up to date.

Backhaus’ presentation was couched in terms of the ways in which day-to-day operations at BASF will – indeed, must –change, giving a model to other chemical manufacturers. He said that there are some things that industry has to come together to fix but that a company such as BASF has plenty that it can do on its own.

High on BASF’s agenda was investigation of how it can reduce gate-to-gate times for vehicles loading and/or unloading at its plants. At Ludwigshafen, for instance, such times can be anything from two to five hours, which is not acceptable. It is, though, quite a challenge at such a large site, where it may take a vehicle up to an hour just to drive from the gate to the loading/unloading point and back again. And there is the sheer scale of operations: Ludwigshafen handles around 2,100 trucks every day, as well as 400 rail cars

and, in a normal year, 20 barges. It also has 106 km of roads within the site boundary –and drivers can get lost.

But inefficiency in the loading/unloading process blocks the production cycle. BASF saw the process of addressing gate-togate times as part of its overall digitisation process. Optimising gate-to-gate times requires good planning and this means involving transport companies and freight forwarders. “Truck drivers just turning up doesn’t work any more,” Backhaus said. It leads to congestion and inefficiency.

To address the issue, BASF developed its OPTIMiSM software, which allows it to plan all operations at all loading points for all modes. Customers or hauliers use the system to book time slots. This system is currently being rolled out and will be followed by a yard execution system that will collect all relevant data for loading/unloading. BASF will reach out to customers and hauliers for their input, so as to create a link to the gate and the loading point. It will also include a tool to all drivers to check themselves in at the gate.

In addition, BASF is piloting a pre-check system, through which vehicles are checked before they enter the site rather than at the loading point. This will lead to faster acceptance, fewer rejections and less wasted time. The use of the eECD, to which BASF has signed up, will contribute similar benefits.

On the hardware side, BASF is improving infrastructure at the main gate, extending the building and providing more parking space both inside and outside the gate. In the future, it may also be possible to move logistics operations to an external area, applying a ‘drop and swap’ system, which could cut turnaround times to a few minutes. In the nearer term, new automated loading stations are being installed – four were already complete, with another 22 due for installation in 2019 – that offer ‘smart filling’ by being linked directly to inventory management systems.

BASF has also set up a new team to draw up detailed schedules for loading points. This has also helped improve turnaround times. There is the potential for that process to be automated, Backhaus said.

BASF has also been extending the use of automated guided vehicles (AGVs) to move product around the Ludwigshafen site in 40foot ‘BASF-class’ tank containers. After a successful trial, three new AGVs have been added and are delivering in-plant efficiencies, Backhaus said – although it has been a bit of a challenge to get people used to the idea of self-driving trucks moving around the site.

Summing up, Backhaus said that the work that BASF is doing is an example of a change of mindset; it is no longer inwardly focused and holding on to its own data. The sort of predictive analytics that are needed to generate the efficiencies that it is looking for rely on the sharing of data. That concept offers a lot of benefits for the logistics sector as a whole.

There were plenty of familiar faces in the audience at the ECTA meeting but a few missing, among them Jos Verlinden, logistics director at the European Chemical Industry Council (Cefic), who was due to retire at the end of the year. In his place, Simon Goswell, supply chain director, EMEA at LyondellBasell and chair of the Cefic Supply Chain Issue Team, introduced delegates to “the new Cefic”. He described the new structure Cefic adopted in 2018 and its greater focus on advocacy, asking: “What does that mean for the supply chain group?”

In 2011, Cefic published its Chemical Logistics Vision 2020 document, which had three main elements: safety, sustainability and improving processes through collaboration. That vision is still the same, Goswell said, and Cefic has delivered on those objectives. It has not done that on its own, though – there has been a lot of collaborative work, not least in partnership with ECTA.

The backdrop to current discussions in terms of the chemical supply chain covers both legislative and operational issues. On the one hand there is the drive towards a modal shift away from road transport, the European Commission’s (EC) recent Mobility Package, and increasingly tough requirements for emissions reduction. In purely operational terms, there are issues such as road congestion, driver shortages, rail reliability and a lack of connectivity, water level problems, and port congestion.

Legislation and policy in the freight transport sector has the unfortunate habit of focusing on individual modes, Goswell said. That means that while there is a lot of investment and frequent initiatives, there is no cohesive approach. As such, the Cefic Supply Chain Issue Team has set some priorities, including a position paper on the EC Mobility Package, where it has some concerns, especially in respect of drivers. A position paper on rail and intermodal transport had »

recently been approved by the Cefic Board. And it is looking at the carbon dioxide emissions calculation methodology, which has been criticised.

Also during 2018, Cefic provided support and encouragement in the development of the eECD, undertook the 2019 revision of SQAS, and is participating in the development of a Risk Management Framework for dangerous goods alongside EC and the EU Agency for Railways (ERA). Goswell ended by reporting that Cefic was due to move to new offices in January 2019; it is now located at 40 Belliard, B-1040 Brussels.

After his presentation, Goswell joined a panel session, moderated by Andreas Zink, alongside Jan Arnet, CEO of the Bertschi Group, and Frédéric Derumeaux, CEO of the Vervaeke Group. Goswell began by noting that there are big problems in terms of the need

for more infrastructure investment, but it is hard to control that. “What we can control,” he said, “is the development of the end-to-end supply chain conversation”. Without that, “we will always be sub-optimal”.

Derumeaux said that LSPs are facing increasing demands from their customers for more digitisation. Referring back to Backhaus’s presentation, he also noted that plants and terminals are beginning to compete on their ability to turn vehicles around quickly. Arnet’s view of the current issues facing LSPs is that there is a need for more integration. And, while there is undoubtedly a shortage of drivers, there is also a shortage of qualified people in many positions. “The challenge is to attract people to the industry across the board,” he said. “It’s not that attractive.”

Derumeaux’s opinion was that drivers are leaving the sector because of long waiting times. “Things are easier in container

haulage,” he said. “We have to do something – if we don’t have drivers we have a big problem.” Arnet suggested going to areas of low employment and setting up schools for drivers, and also noted that one traditional source of truck drivers – the army – is not producing enough people any longer. “Truck driving is not seen as a good occupation,” Derumeaux added.

Goswell was of the opinion that asset utilisation – and that includes human assets – is ineffective in the sector. Detaching the load from the actual shipment is the way to go, he said. The use of ‘drop and swap’ operations is attractive but, Derumeaux said, there is a risk of disconnecting the driver from the vehicle.

Goswell summed up the panel session with the observation that “We have to understand where we are before we can change it.” And, while the audience digested that snippet of wisdom, lunch was served.

The extent of possibility offered by digitisation was ably illustrated by Erwin Verstraelen, chief digital innovation officer at the Port of Antwerp. Verstraelen took the position when it was created in 2017, with a remit to look at ways in which Industry 4.0 concepts could address the challenges being posed by increasing throughput in the port: notably growing pressure on space within the port and increasing congestion on roads and inland waterways. The solutions that the port is implementing require collaboration outside its boundaries, including with other ports.

“Creating a digital ecosystem is part of the port’s response to those challenges and it runs through most projects and initiatives,” Verstraelen explained. “Our role is to enable innovation in the port.” He described four initiatives that have been put in place within the previous 12 months:

• Portxl, which brings relevant start-ups into the port community and inspires new ideas

• NxtPort, a data platform that brings all stakeholders together

• Chainport, which brings together a group of 12 major ports around the world to exchange information and ideas

• Beacon, an Internet of Things (IoT) accelerator and ideas hub.

There are, Verstraelen said, several drivers for digitisation in the chemical supply chain. Maturing technologies bring new tools and opportunities at lower prices; some of those opportunities offer the chance to take a lot of inefficiency out of the system; and the process of globalisation during the 1980s and 1990s was built on the technology of the time and is due for an overhaul.

NxtPort, launched in early 2017, is fundamental to a lot of the work going on in this area, and not just within the Port of Antwerp – it is also the platform on which the eECD operates. NxtPort provides a link not only for the port and its immediate customers and users but also for the hinterland

community and overseas interests. It does not take a top-down approach, Verstraelen insisted: it was developed from a common realisation that something was needed.

“Stakeholders needed to trust each other and be willing to share data,” Verstraelen explained, and this took time. The first year of development was all about building the community and trust in the system. It was important that data owners can decide on who can see what information; NxtPort merely acts as a ‘data custodian’. Its core capability is to align and orchestrate data. This can speed up existing systems or prompt the redesign of systems for greater efficiency.

As an example of where NxtPort can go, Verstraelen explained the concept of ‘next mode of transport’. Every container arriving in the Port of Antwerp will move on. There is someone in the transport chain who knows where the container will move to next and by what mode, but that data is often not available to the terminal, which introduces an inefficiency. Sharing that information before the container arrives can have a big impact on the efficiency not only of the terminal operator but also on the container itself, which can move on to its next destination more rapidly.

“Current pressures mean this is the ideal time to be working on this,” Verstraelen said. “We either sit and talk to each other or we all fail.”

The availability of big data sets and the use of analytics can also help with the modal shift of freight traffic, Verstraelen added. Antwerp aims to reduce its reliance on road transport from 51 per cent of freight traffic in 2014 to 40 per cent in 2030, with much of that moving to rail. The port authority has always said that it has no power to force LSPs to make that shift but, through digitisation, it can now provide the information that can make it happen. There is the potential to take a similar approach to moving freight onto inland waterways but there are some specific problems that must be addressed first.

As with the case of BASF, Verstraelen believes that digitisation can help ease the driver shortage and reduce inefficiencies. A working group is looking at promoting night-time openings and driving, while another platform supported by the port, HAKKA, aims to reduce empty vehicle moves by matching cargoes with available space. The port is also looking at the possibility of allowing the use of AGVs on roads within the port area.

“I believe we are heading for a perfect storm,” Verstraelen concluded. Labour issues, mobility and sustainability all need to be addressed and digitisation provides the tools to do so. “This is the ideal time to change mindsets,” he said. “We need to take the next step together.” »

ECTA managing director Peter Devos brought the latest news of the eECD project, which had just gone live. “Subscribe now!” he said – BASF, Covestro and Evonik have all bought three-year licences, which Devos hoped would kick-start usage.

The story of the development of the eECD is a story of collaboration: ECTA worked alongside Cefic, the European Federation of Tank Cleaning Organisations (EFTCO) and the Belgian chemical industry association Essenscia; the same bodies have set up the European Chemical Logistics Information Council (Eclic), which was formed in March 2018, to administer the eECD system.

Application of eECD is now moving into a “learning by doing” phase, Devos said. Initially it will effectively be a manual system, until it can be integrated with other applications, such as Elemica. Other issues are emerging, notably how to run digital and paper versions in parallel.

Devos then led a panel session featuring Erwin Verstraelen, Michael Kubenz, CEO of Kube & Kubenz, and Simon Hardy, digital business network evangelist at Elemica. With the aim of discussing the standardisation of processes, Kubenz explained that his company is still investing a lot in its legacy systems. “We can’t operate without them any more,” he noted.

Verstraelen assured the audience that there is no need to give up on legacy systems; rather, find a way of giving everyone access to data networks. This is likely to be easier for larger companies; small operators may not have the knowledge.

There has been disagreement over the need for standardisation of systems but Hardy said that standards give breadth. Once they are out there – and here he mentioned eECD again – then companies will adopt them. And systems such as Elemica and NxtPort can help by translating difference data sources.

The final part of the day was left to Evert de Jong, Responsible Care director at ECTA, to give an update on developments with Responsible Care and SQAS. He began by summing up the 2017 results from the key performance indicator (KPI) reports from ECTA’s Responsible Care members. These showed continued increases in the number of movements and the total tonnage carried – now up to 101.6m tonnes – as well as more employees; on the other hand, there were also more incidents during transport and loading operations, which is worrying, even if there were fewer incidents at unloading points. Another concern is that 15 per cent of trucks used in the European chemical transport sector are Euro IV or earlier: there is a problem coming, de Jong said.

Cefic has been talking to its members after criticism has been expressed about the greenhouse gas (GHG) emission calculation methodology. ECTA and Cefic met in June 2018 to discuss the issue; it was decided to keep the subject in the KPI form but to make it voluntary. There was no agreement on revising the calculation guidelines. De Jong said that LSPs will probably be getting more questions from their customers on GHG emissions so they should keep making the calculation.

De Jong was also stern with some ECTA members who supply their KPI reports late; he wants the 2018 returns in February or March, not in October! Companies that consistently report late will have their

Responsible Care membership discontinued, he warned. On the other hand, he also reported that the Responsible Care workshop held by ECTA in October 2018 drew more than 50 participants, who provided a lot of input for ECTA’s 2019 programme. It was suggested that this level of interest indicates it may be worth holding two such events every year.

De Jong then turned to discussion of the revisions to the SQAS questionnaires for 2019. There are, he said, a lot of changes that will impact LSPs. Some of the questions that routinely get very high scores have been taken out: they provide no information. There have also been some textual changes for clarity.

But importantly – and this is something that LSPs will need to be alert to when they are being reassessed – several chapters have been

moved around and issues of sub-contracting, GHG emissions and plastics waste now have separate chapters. The pre-assessment document has been subjected to considerable amendment, the attestation is deleted, and the summary report has been amended.

De Jong highlighted the issue of subcontractors. Some Cefic members have been unhappy about the level of control that LSPs have over their sub-contractors, which has led to the introduction of more questions on the topic for transport service providers. LSPs will also have to report the number of subcontractors used and the tonnages involved.

ECTA is not happy with the extra work this will require and de Jong said he thought most LSPs will not have this data to hand.

It was a long day and delegates deserved the cocktails and dinner that were to follow, after a break to allow them to catch up on emails. Over dinner, Gerry Grant, who describes himself as ‘chief ethical hacking consultant’

working for the Scottish Business Resilience Centre, gave some tips to his audience on avoiding cyber-crime. “It takes a thief to catch a thief,” he began, but also noted that hackers are, by and large, lazy people. They go after easy targets, so there are some easy measures that can be taken to put them off.

Grant’s lively presentation ranged far and wide into areas that the audience may not even have thought about; it was also something of a scene-setter, as cybersecurity will become ever more significant as digitisation spreads through the supply chain. Look out for more on this topic during 2019. HCB

HCB will certainly look forward to ECTA’s activities this year; readers who want to know more should go to www.ecta.com; the website includes links to ECTA’s periodical newsletter, the October 2018 edition of which has more discussion of many of the topics on the agenda at the 2018 Annual Meeting.

COMPOSITE TANKS • TANK CONTAINER LESSOR EUROTAINER HAS TAKEN ADVANTAGE OF RECENT ADVANCES IN COMPOSITE TECHNOLOGIES TO EXPAND ITS TANK FLEET

EUROTAINER HAS JOINED the ranks of tank container leasing companies to offer tank containers manufactured from composite materials. After what Eurotainer calls a “thorough analysis of the available composite tank container manufacturers”, it placed an order with the Australian firm Omni Tanker and has begun taking delivery of new 20-foot tanks.

“Eurotainer chose Omni Tanker due to its years of expertise in composites, a superior composite technology and a willingness to work with Eurotainer to build tank containers that meet the needs of our global client base,” Eurotainer says. “In turn, Omni Tanker was looking for a tank container leasing company that could help them expand

globally. Omni and Eurotainer are now working together to provide a product that offers a lightweight alternative to lined/coated steel tank containers.”

Omni Tanker is one of the world’s leading composite technology and manufacturing companies, having its own proprietary composite materials technology that can be applied to the manufacture of hightechnology composite tanks with exceptional chemical resistance and low tare weight for the bulk transport of corrosive and highpurity chemicals.

“It is these two primary attributes that separate Omni Tanker from the competition and makes their product the perfect choice for Eurotainer. The ability to offer our clients a safe, lightweight, durable, easy-to-clean and versatile composite tank container has been a goal of Eurotainer for some time,” Eurotainer adds.

“Omni Tanker has delivered with breakthrough technology that will transform

the tank container industry – a perfect fit for Eurotainer’s vision and commitment to provide innovative high-purity and corrosive chemical tank container equipment to its global customer base.”

Omni Tanker’s OmniTAINERTM tank container design is a 22,500-litre unit approved for the transport of dangerous goods by road and rail. It includes a specially developed fire protection system that has been tested in Germany by BAM and passed the full engulfment fire test requirements of ADR and RID. It can be supplied in both T7/L4BH (bottom outlet) and T10/L4DH (top discharge) formats, with a test pressure of 4 bar.

Omni Tanker says the new unit is suitable for the carriage of high-purity chemicals such as hydrogen peroxide and ammonium hydroxide without the risk of contamination. It is also suitable for use with aggressive corrosive products such as sodium hypochlorite, hydrochloric acid, hydrofluoric acid, ferric and ferrous chloride and other acids, without degradation of the liner.

The OmniTAINER is equipped with the OmniSHIELD polyethylene interior, which was specifically designed to provide high levels of chemical resistance while also creating a seamless and low-stress polymer interior that facilitates cleaning.

Eurotainer had the first of the new composite tanks on display at its Customer Technical Day, held in Houston on 10 October, where 150 clients from around the world were on hand to see the equipment that Eurotainer has on offer and learn about technical and regulatory issues that impact the sector.

In other developments, this past November Eurotainer opened an expanded office space at its Shanghai facility, welcoming customers and business partners to join its Chinese team at an opening ceremony. Eurotainer says the expansion was made necessary by continued business growth in China. HCB www.eurotainer.com www.omnitanker.com

The ability of stainless steels to withstand pitting corrosion is indicated by its Pitting Resistance Equivalent Number (PREN), calculated according to the proportions of chromium, molybdenum and nitrogen within the steel. For instance, 304L-grade stainless steel has a PREN of 18, and 316L-grade a PREN of around 25. Stainless steels that are constantly exposed to seawater require a PREN of at least 40 to be fully protected.

Fort Vale Engineering, one of the leading suppliers of footvalves, manlids, couplings and other fittings for tank containers, is taking the issue seriously. It has traditionally used 316-grade stainless steel but for the past two years has been looking at ways to improve corrosion protection for its equipment.

This has led to the development of a new welded coating for its Superseat tank container valves. Fort Vale had looked at using Hastelloy C276, a ‘super-alloy’ with high levels of nickel and the addition of tungsten, which achieves a PREN of 45, but this is very expensive.

Instead, Fort Vale has opted to apply a weld overlay of Inconel 625, a nickel-based super-alloy that has long been valued for its high strength, excellent performance in elevated temperature applications, and good corrosion resistance in highly acidic environments. It has a PREN of 41, offering protection against products such as hydrochloric acid and hydrofluoric acid that can attack the passive layer of more common grades of stainless steel.

TANK CONTAINERS ARE built to last; their shells are almost always made of stainless steel, as are their main appurtenances, including their valves. That makes them impervious to attack by almost all commonly carried chemicals, even those that are highly corrosive. But they are not totally immune to corrosion. The industry is becoming increasingly aware of issues of pitting corrosion, sometimes resulting from

improper classification or mis-declaration of the product being shipped.

During its members’ meeting in Antwerp in September 2018, the International Tank Container Organisation (ITCO) heard a presentation by specialists from Brookes Bell, a technical consultancy with experience in corrosion problems in stainless steel. They explained how the chromium that is added to steel to make it ‘stainless’ forms a passive layer on the steel, protecting it from attack. That passive layer can be damaged, notably by exposure to aggressive halide ions. Once the passive layer is damaged, the underlying steel can suffer pitting corrosion.

Graham Blanchard, recently appointed as European sales director at Fort Vale, explains that this Inconel overlay is being rolled out across the company’s range of tank container bottom discharge footvalves and Cleanflow valves and will be supplied as standard, without additional cost to users.

Fort Vale will be explaining the advantages of its new corrosion protection approach at a number of major trade shows during the course of 2019; these include Transport Logistic in Munich in June, Intermodal Europe in Hamburg in November, and the Tank-ex show in the UK at the end of May. HCB www.fortvale.com

ROTTERDAM-HEADQUARTERED BROEKMAN

Logistics has acquired the VLS-Group’s warehousing activities in Belgium and the Netherlands. The deal reinforces Broekman’s market leadership in the warehousing, distribution and value-adding logistics of packaged and speciality chemicals in the Benelux region.

“This acquisition, the largest in our nearly 60 years of existence, marks a major milestone for Broekman Logistics,” says Raymond Riemen, CEO of Broekman Logistics. “By adding 150,000 m² of storage space, our covered warehouse portfolio increases by over 40 per cent whilst we grow our employee base significantly. On behalf of us all at Broekman Logistics, I warmly welcome each of the new 230 colleagues to our company.”

The VLS-Group, owned by leading Israeli chemical distribution company Gadot Chemical Group, offers integrated logistics and a range of value-adding services, such as drumming, toll manufacturing, transport management and tank storage, to the European chemical industry. The transaction sees six warehouse locations in Rotterdam-Pernis and Antwerp move to Broekman; it does not include VLS’s tank storage activities and other assets in Ghent, nor the VLS activities at three locations in Germany. Both parties agreed not to disclose the terms of the transaction.

“The divestment of our Belgian and Dutch warehousing activities to Broekman Logistics allows us to focus on our core activities, while ensuring a long-term and sustainable future for the employees and clients of the VLSGroup,” says Alain Poublon, CEO of the VLS-Group.

Explaining the reasoning behind the deal, Willem Jan van Amersfoort, managing director of Broekman Logistics’ Warehousing & Distribution division, says: “There is a strong strategic fit between the two companies, as the client base, locations of the specialised warehousing facilities and the type of value-adding activities complement each other. This acquisition brings additional valueadded logistics activities to our company, such as filling, drumming and bagging, of which our clients and partners will surely benefit.”

Anton van Dongen, director of Benelux operations at VLS-Group, adds: “We are looking forward to become a part of Broekman Logistics. Our customers will be offered the benefits of Broekman Logistics’ global network and thought leadership for chemical supply

chain solutions. As a joint team, we are certain that this is a merger of benefits where the two companies will continuously strengthen each other, both now and in the future.”

The five VLS-Group locations in Antwerp and one in Pernis will now operate under the Broekman Logistics brand and be fully integrated into the Warehousing & Distribution division. “We now operate state-of-the-art warehouses in all the major logistics hubs and gateways into Europe: the Port of Rotterdam, the Port of Antwerp and the Limburg area, expanding our global reach, whilst maintaining our personal touch,” Riemen concludes.

Broekman Logistics now operates some 445,000 m² of covered warehousing facilities and employs more than 1,000 people at 43 locations worldwide. Outside its Benelux hub, Broekman has operations in Poland and the Czech Republic, representative offices in Shanghai and Singapore, and 14 offices in strategic locations in India. Coverage elsewhere in the world is managed through Broekman’s participation in a number of global freight networks.

Broekman Logistics offers supply chain solutions in three divisions: aside from Warehousing & Distribution, it has multimodal expertise in its Forwarding & Shipping division and niche expertise in Breakbulk Logistics. HCB www.broekmanlogistics.com

Davison, operations director at Hoyer Petrolog. “Scania have always offered an exceptionally reliable vehicle whilst also bringing the environmental benefits of returning excellent fuel economy and, importantly, this vehicle is always a popular choice with our driver workforce.” www.hoyer-group.com

Following the expansion of its rail wagon fleet through the acquisition of 4,400 units from Nacco, Wascosa has restructured its operations and management structure, trimming the organisation from seven divisions to five.