UV-PROTECTION OIL

Clear UV protection for vertical

xterior surfaces

Dela

to untreated wood

Improves and maintains the appearance of wood

Highly water and dirt resistant

Available with (420) or without (410) active ingredient for mould and algae protection

No sanding necessary when topping up coating

515288

FUTURE CONSTRUCTOR & ARCHITECT MAGAZINE

EDITOR IAL

Rebecca Kemp rebecca@redhutmedia.com

PRINT & DIGITAL ADVERTISING

Sam Ball sam@redhutmedia.com

Jim Moore jim@redhutmedia.com

PRINT DESIGN MANAGER

Jack Witcomb jack@redhutmedia.com

DIGITAL DESIGN MANAGER

Matt Morse matt@redhutmedia.com

ACCOUNTS/ CREDIT CONTROL

Rachel Pike accounts@redhutmedia.com

PUBLISHER

Sam Ball sam@redhutmedia.com

As we bid farewell to last month's April showers, we're reminded of the impact that water has on our daily lives. From navigating through flooded streets to disrupted travel plans and logistical challenges, substantial amounts of water can profoundly influence our routines.

The recent floods in Dubai are a stark reminder of the havoc that extreme weather events can wreak on infrastructure. With a year's worth of rainfall inundating the city in just 12 hours, the aftermath left runways submerged and even luxury cars floating down streets. While cloud seeding was initially blamed for the deluge, attention has shifted towards the broader implications of climate change.

Here in the UK, we've experienced our share of flash floods, too, prompting architects, housebuilders and specifiers to reassess their approach to urban planning. On page 2 8 , Richard Eddy, Category Manager of Underground and Utilities at Polypipe Building Products, sheds light on the importance of sustainable drainage systems (SuDS) in mitigating flood risks and safeguarding our communities for the future.

In the realm of building design, advancements in glass technology are also playing a crucial role in adapting to the challenges posed by climate change. On page 08 , Phil Brown, Technical Advisory Service Manager at Pilkington UK, explores the innovative glazing solutions that are enhancing the resilience of buildings against extreme weather events, from flood-resistant glazing to energy-efficient alternatives.

I hope you enjoy this issue. Don’t forget, you can also access the magazine’s features, product news and supplier information on FC&A’s user-friendly and engaging website. Fully responsive, the website allows you to read all the latest stories on-the-go either on your phone or tablet. Simply search www.fca-magazine.com.

ON THE COVER:

The world's first green hydrogen refuelling network for recreational boating will be brought to life by Zaha Hadid Architects in partnership with NatPower H. SEE PAGE 32.

NonCom Beak Weeps

High-rising structures demanding non-combustible cavity trays, now have a compatible NonCom weep. The NonCom Beak Weep is different.

• The taller a building rises, the more sensitive it is to wind pressure.

• The outlet protects against direct wind restrictive interference.

• The outlet also has radiused sides allowing mortar wash debris to spread and drop at the critical evacuation point.

Non-Combustible Beak Weeps, from the longest-established cavity tray company

The Cavity Trays Helpdesk – your route to compliancy and consistency in construction

LEGAL & BUSINESS:

Is Georgian-style development the best means of delivering 'gentle density'? Grant Leggett, Executive Director at Boyer (part of Leaders Romans Group), investigates.

VOICE OF THE INDUSTRY:

Richard Eddy from Polypipe Building Products illuminates the crucial role SuDS plays in combating urban flooding and enhancing environmental sustainability.

FEATURES

GLASS & GLAZING:

From solar control to flood resistance and low-carbon options, Phil Brown, Technical Advisory Service Manager at Pilkington UK, talks about how innovative glass technologies protect buildings and occupants against extreme weather events.

CIRCULAR ECONOMY & CONSTRUCTION WASTE REDUCTION:

Explore the power of retrofitting and reusing materials with Lime Green and the Alliance for Sustainable Building Products (ASBP) to slash carbon emissions and minimise waste in the built environment.

AI, ROBOTICS & 3D PRINTING:

Simon Herod, International Lead at EstimateOne, explores the transformative potential of AI-driven tools for boosting accuracy, optimising supply chains and minimising delays.

ACOUSTICS & SOUNDPROOFING:

Sophie Weston, Head of Marketing at Geberit, reveals the challenges and solutions of acoustics in residential buildings and explores the path to a more peaceful living environment.

ACCESS:

From compliance with stringent regulations to providing robust protection in case of fire, discover why architects are prioritising third-party-tested access panels to ensure building integrity and safety.

BUILD FOCUS: F loating A rchitecture, W ater- B ased C ities & M arina D esign:

The world's first green hydrogen refuelling network for recreational boating will be brought to life by Zaha Hadid Architects in partnership with NatPower H.

TECH INSIGHT: RCI :

Ardit Strica, Technical Manager at Onduline Building Products, provides a comprehensive overview of low-pitched roofs, their challenges and the transformative benefits of sub-roof systems.

PORTFOLIOS

20 26

Snøhetta's latest masterpiece is the world's largest climatised reading space. From its innovative design to its sustainable technology, this architectural marvel redefines the role of libraries. 28 24 10 14 32 34 16

THE AQUATICS CENTRE, PARIS, VENHOEVENCS AND ATELIERS 2/3/4/:

Designed by VenhoevenCS and Ateliers 2/3/4/, the award-winning Aquatics Centre in Paris is the only permanent new building for the 2024 games.

BEIJING CITY LIBRARY, SNØHETTA:

NonCom Beak Weeps

High-rising structures demanding non-combustible cavity trays, now have a compatible NonCom weep. The NonCom Beak Weep is different.

• The taller a building rises, the more sensitive it is to wind pressure.

• The outlet protects against direct wind restrictive interference.

• The outlet also has radiused sides allowing mortar wash debris to spread and drop at the critical evacuation point.

Non-Combustible Beak Weeps, from the longest-established cavity tray company

The Cavity Trays Helpdesk – your route to compliancy and consistency in construction

01935 474769 enquiries@cavitytrays.co.uk www.cavitytrays.co.uk Yeovil

A contemporary addition to our concrete paving portfolio.

Developed with UK designers, our unique granite-inspired blends are brought to life through a patented colour application - creating a multihued, subtle and elegant aesthetic.

Manufactured using MaxiMix® Technologyfor looks that last and stay true to your design.

IN BRIEF:

MCLAREN CONSTRUCTION’S MIDLANDS AND NORTH DIVISION CELEBRATES RECORD TURNOVER

The Midlands and North division of international contractor, McLaren Construction, has announced a record turnover of £271m for the latest financial year. Following a year of expansion for the division and McLaren Construction group as a whole, the milestone follows news that the contractor generated overall revenues up 22% to £964m in 2022/2023 and is on course to break the £1bn annual turnover barrier in 2023/2024. The contractor has experienced growth over the past 12 months, with new appointments across its leadership, project and sustainability teams and six projects handed over for 2022/2023.

ARCHITECTURE FIRM COMMITS TO A MORE SUSTAINABLE FUTURE

Holmes Miller has outlined its commitment to a carbon-neutral built environment with the publication of a refreshed sustainability charter. The practice has updated its 2020 charter, to reinforce the integration of sustainability principles into every project and service it offers. Ambitious targets set out for the coming year include: Integrating Passivhaus principles into design approaches – regardless of whether a project is targeting Passivhaus certification – using a new embodied carbon assessment across all projects, monitoring in-use energy across all projects and by promoting both post-occupancy evaluation and monitoring office energy use to improve performance.

INDUSTRY UPDATES

FC&A ROUNDS UP THE LATEST INDUSTRY NEWS AND UPDATES.

HEATHERWICK STUDIO TO DESIGN NEW SCHOOL FOR LEADING UNIVERSITY IN BOGOTÁ, COLOMBIA

Heatherwick Studio has unveiled its latest project, a design school and makers’ space for Universidad Ean in Colombia. The studio has been appointed to create a new home for the university’s School of Sustainable Design, located on the existing campus in central Bogotá.

Th e seven-storey building sits on Calle 72, one of the city’s main arteries, with the front facade made up of colourful, crafted columns and open terraces. The design pays homage to the local craft traditions, including Werregue basketry, a form of weaving unique to Colombia’s Wounaan indigenous community.

T he building will serve as a new centre for the campus, complementing the existing heritage structures on the site and providing a rare new public space in the city. The design team is also working on innovative facade materials to deal with the high levels of sunlight at this altitude and ensure the longevity of the building.

C olombia is the world’s second-most biodiverse country, and Bogotá is considered one of the leading cities in terms of sustainable development. Universidad EAN’s ambition is to celebrate this by bringing the cloud forest, which surrounds the country’s capital, to the building. The studio’s biophilic design will incorporate local plant species on the open terraces and usher in nature to the metropolis as part of the pledges made by the city as a signatory to the C40 Urban Nature Declaration. This will be the studio’s first project to go to construction in South America, with works expected to start in 2025.

E liot Postma, Group Leader and Partner at Heatherwick Studio, says: “Creativity is intrinsic to the city of Bogotá. You see it everywhere. We want students to feel proud of their campus before they even enter the building, arriving through a public square that offers passers-by a welcoming, communal oasis amidst the hard urban surroundings.”

www.heatherwick.com

PERSONNEL

The latest appointments from the construction and architectural industries.

DUDLEYS MAINTAINS GROWTH WITH TWO NEW APPOINTMENTS

Structural and civil engineering consultancy Dudleys has recruited two professionals to its team in Leeds following the sustained growth of the business. Dudleys has also relocated its North West office to central Manchester. David Cardani has joined as a Principal Engineer. With more than 34 years’ industry experience, David is a highly-skilled engineer and will provide senior support to clients across the board in all sectors.

Frances Wallbank has also joined Dudleys as a Graduate Engineer. Having graduated last year with a first-class honours degree in BSc civil engineering, Frances took on a five-year apprenticeship before joining Dudleys, where she will shadow the senior team on projects spanning residential, commercial and care sectors.

RELOCATION FOR EXPANDING PROPERTY CONSULTANCY FIRM

One of the construction sector’s fastest-growing consultancies, EDGE, has solidified its presence in Leeds with new office space for its expanding team of project managers, cost managers, building surveyors and advisory services professionals. The move comes as a result of major business growth across the region just two years after EDGE opened its first Leeds office in January 2022, and coincides with a raft of senior staff appointments.

The latest additions to the team include Mathew Ingall-Tombs as Associate Director, Andrew Hope-Robertson as Clerk of Works, as well as Laura Grainger and Gordon Parkinson as Senior Project Managers.

This further expansion of services in Leeds represents the latest step in EDGE’s growth strategy.

NEWS IN BRIEF:

MACE COMPLETES STAGE 1 OF BUILDING A SAFER FUTURE’S CHAMPION ASSESSMENT

One of the UK’s biggest tier-one contractors, Mace Group, has completed Stage 1 (Leadership and Culture) of Building a Safer Future’s Champion assessment scheme. The champion assessment requires organisations to commit to putting building users first in an ongoing building safety journey and provides organisations with actionable data and practical tools to help review and upgrade processes and regain public trust following the Grenfell Tower disaster. Mace has been awarded the ‘Certificate of Commitment and Progress – Building Safety Stage One’ in recognition of its successful completion of the first of the two champion assessment modules. Steve Elliott, Non-Executive Chair of Building a Safer Future, commented: “It’s fantastic to see Mace coming through this first stage of the BSF Champion assessment. Their leadership is critical in bringing about change in the UK built environment industry. I congratulate them on their achievement of the Stage 1 certificate.”

MILLER HOMES NORTH EAST MAKES NEW APPOINTMENT

One of the North East’s most experienced sales figures has joined the team at Miller Homes North East. Lauren Angus, whose career in the housebuilding industry spans more than 18 years, has been appointed Sales Director at Miller. Among her key strengths is her knowledge of the newbuild market, which began when she joined the industry in 2006. Lauren, from Sunderland, joined Miller – which currently has 10 live developments and a further four due to launch this year –from Taylor Wimpey North Yorkshire, where she held the position of Sales and Marketing Director. Miller, one of the North East’s leading housing developers, has announced plans to construct more than 500 homes this year as far afield as Bedlington, Durham and Seaham.

Systems starting from £17.90 per metre

BUILDING FOR THE FUTURE: RESILIENT GLAZING SOLUTIONS FOR EXTREME WEATHER

Phil Brown, Technical Advisory Service Manager at Pilkington UK, part of the NSG Group, highlights the innovative glazing solutions that are helping to protect buildings and occupants as climate change increases the risk of extreme weather events.

PILKINGTON UKIn an era marked by the escalating impact of climate change and an increasing frequency of extreme weather events, architects and specifiers face a dilemma: meet the challenges head on or carry on as before.

T he choice here, of course, is obvious. With higher temperatures, more intense storms and flooding, the need for resilient building materials has never been more urgent.

C limate change demands innovative solutions to mitigate its impact on the built environment. From heatwaves and heavy rain to hurricanes and wildfires, building materials are increasingly at the mercy of nature. Conventional building materials and design practices are often ill-equipped to withstand extreme weather conditions, resulting in costly damage and risks to public health and safety.

M odern, advanced glazing is a critical line of defence in buildings to help protect against the elements.

Mitigating the impact of heatwaves

A mong the challenges architects and specifiers must face is the rising threat of heatwaves, which can have a dramatic impact on public health when buildings run the risk of overheating. Architects are turning to innovative glazing solutions to meet this problem.

E ncouragingly, architects and specifiers are taking the right steps to make sure that our homes remain comfortable and safe even when extreme heat threatens. In a recent survey by Pilkington UK, nine in 10 architects said they were already going above and beyond the minimum requirements to tackle overheating in homes to protect residents.

Solar control glazing has emerged in the UK as a critical solution for addressing overheating in homes, in part driven by the introduction of

Part O of the Building Regulations in England in 2022. These products, like Pilkington Suncool, limit solar gain in buildings to keep heat out. This also reduces the reliance on mechanical cooling systems like air conditioning, helping make our buildings greener.

B eyond homes, organisations have been working hard to retrofit buildings, from offices to schools, with heatwave-beating solar control glass. For example, two West Midlands primary schools, Ridge Primary School and Gig Mill School, replaced 380m 2 of glazing with Pilkington Suncool 70/35 solar control glass. The glass helps to keep the buildings at a comfortable temperature without compromising on natural light, creating a suitable learning environment. In educational buildings, access to daylight has been shown to result in a demonstrable improvement in student academic achievement, behaviour, calmness and focus, so ensuring such environments do not overheat is crucial.

W ith schools contributing to 36% of public sector emissions, solar control glass helps reduce their carbon footprint while also reducing the cost of expensive air conditioning.

Flood-resistant glazing

A dvanced glass also has a more direct role to play in the critical infrastructure designed to protect against the impact of climate change. A new glass flood barrier in Kendal, for example, epitomises the strength and resilience provided by modern glazing. The glass flood barrier safeguards thousands of homes and businesses without protruding on the town’s historic beauty and riverside view.

A t the heart of this strategy lies a sophisticated glazing solution. Engineered with alternating layers of glass and interlayer, the creation forms a robust 35mm laminated glass,

fortified by Pilkington Activ selfcleaning technology, which is designed to withstand the intense pressure that flooding poses. Projects like these demonstrate the versatility of glass in protecting our communities from the impact of climate change.

Before any glass can go to market, it must be assessed. This is particularly important for resilient glazing, where durability is critical to help protect against the damaging effects of climate change. Manufacturers of laminated glass and coated glass ensure their products are extensively tested for durability, adhesion, resistance to abrasion and condensation – with much of this testing being undertaken independently by recognised laboratories. In the case of Pilkington Activ, its long-term, selfcleaning performance is also evaluated. Furthermore, glass specifically intended for use in flood barriers is subject to detailed load-resistance calculations and modelling to make sure that it can safely hold back the threat of rising water levels.

Low-carbon glass

I t’s important that glass reduces its contribution to climate change, while also helping buildings and residents to be protected from the impact of extreme weather events.

I n the quest for resilient glazing solutions, architects and specifiers are turning to Environmental Product

Declarations (EPDs) as a valuable tool for assessing the environmental impact of building materials, signalling a manufacturer’s commitment to measuring and reducing the environmental impact of its products and services.

A new low-carbon glass, Pilkington Mirai, recently acquired an EPD, which verified it as the lowest-carbon glass of its kind, with 52% less embodied carbon than standard float glass. Importantly, while this glass offers the additional benefit of reducing the carbon footprint of a building, it does not oblige the architect or developer to compromise on performance, quality or aesthetic appearance.

Building for the future

A s climate change continues to exert its influence on the built environment, the importance of resilient building solutions cannot be overstated. By embracing this according to the building’s specific needs, architects and specifiers can play a pivotal role in developing buildings that are better equipped to withstand the challenges of a changing climate.

As we confront the realities of climate change on our weather and landscape, it is critical we prioritise resilience in our designs to ensure that the safety, sustainability and longevity of our buildings is maintained for generations to come.

www.nsg.com

Sections starting from £1.00 per metre

DRIVING SUSTAINABLE CHANGE: RETROFIT AND REUSE TO REDUCE CARBON EMISSIONS AND CONSTRUCTION WASTE

Decarbonising the UK’s built environment is a key goal for Government with several ambitious targets set for local authorities, industry and business between now and 2050.

LIME GREEN AND THE ALLIANCE FOR SUSTAINABLE BUILDING PRODUCTS (ASBP)

So is the construction sector doing enough? Should we be prioritising retrofit over demolition and new build? And, how can we minimise construction waste and embrace a more circular economy? Here, we speak to two expert organisations in the field to find out.

Retrofit

R etrofit – it’s a big buzzword at the moment amongst professionals, and for good reason. It’s estimated that 80% of the buildings we’ll still be occupying in 2050 already exist; decarbonising them is going to be essential.

W hile it’s not always the cheapest option, it’s by far the greenest. Embodied carbon associated with a new building is, on average, twice that of a deep retrofit*.

S imon Ayres from Lime Green in Shropshire knows a thing or two about retrofit, having created lime-based products over the last 20 years that greatly enhance the longevity and thermal efficiency of solid wall buildings. Latest figures show there are still some 7.7 million solid wall homes in the UK –many in need of retrofit measures – and that’s before you consider commercial spaces.

S imon says: “Circular principles mean long-lasting design, maintenance, repair, reuse, remanufacturing, retrofit, recycling and upcycling, and you need to adopt these if you want new or existing buildings to function well for future generations.

“ Retrofit can seem like the boring option but it shouldn’t be, it should be the first consideration. For architects, it can be really exciting to take something and completely reimagine it for the future.

“ So much can be done now in terms of thermal efficiency with proven products, such as wood fibre insulation (made from the waste products of the timber industry), allowing older buildings to be fit for the future.

“ Of course, it’s not always possible or desirable to retain absolutely everything and, here, the next consideration has to be how to reclaim some of the building’s components. For example, we have so many beautiful brick buildings in this country because lime mortar – traditionally used and unlike modern counterparts – erodes before the brick, so you would be able to reuse the brick in this or another project. We really need to think disassembly rather than demolition.”

S imon’s advice to architects and specifiers would be to be bold in your thinking; it is not just new builds where you can make your mark.

We know Government is looking deeper into the whole area of retrofit and whoever is going to take this forward over the next five years needs to commit some serious funding to achieve their targets. We also need to upskill the industry quickly and ensure retrofit and a circular state of mind are at the heart of architecture degrees.

Reuse

T he Alliance for Sustainable Building Products (ASBP) has been calling for greater reuse of building materials within the construction industry for over a decade.

T he construction industry accounts for over a third of global carbon emissions and produces around 60 million tonnes of construction and demolition waste annually in the UK. Whilst

much of this is recovered and recycled (though downcycled – which loses its value), only a small percentage is reused.

E stimates suggest** that 22.3 MtCO 2 e of GHG emissions could be saved over nine years by increasing our reuse of construction products. This is a significant opportunity to reduce the industry’s carbon footprint, minimise waste and deliver cost efficiencies.

T he ASBP’s ‘Reuse Now’ campaign, launched in August 2023, aims to become the ‘go-to’ place for practical guidance and information on the reuse of products in construction. Outputs to date include in-person events, webinars (for example, on material passports – information to identify materials and aid reuse); a directory of physical and digital reuse platforms and hubs; reuse case studies and blog posts.

T he campaign builds upon the ASBPled DISRUPT research projects, which explore the innovative reuse of structural steel in construction and encourage the adoption of new circular economy business models. A free-to-download toolkit has also been published, providing major supply chain stakeholders involved in steel reuse with guidance, business considerations, case studies and more, to facilitate new market entrants and, ultimately, achieve a greater supply of reused steel in the construction industry.

S teel is one of the most widely-used and resource-intensive materials used in construction. Although commonly recycled at end of life, the reuse of steel is minimal despite the apparent environmental, carbon and circular economy benefits, though there are an increasing number of case studies. The high value of steel at end of life can be realised by being reused in a wide range of construction applications.

Scenario mapping conducted as part of the research shows that reclaimed steel has the potential to make significant contributions to our net-zero targets, saving

up to 250,000+ tonnes of CO2 per year by 2050, in addition to substantial cost savings on construction projects of £40m a year.

O ne of the main barriers identified, which is preventing the significant uptake of steel reuse, is the lack of available material generated during refurbishment and demolition projects. Through the DISRUPT II project, ASBP is engaging with the demolition sector to create new sector guidance and incentivise demolition contractors to favour reuse over sending scrap for recycling.

S imon adds: “Reusing materials isn’t a new phenomenon. Brick, stone, timber and metals have been recycled for hundreds of years. Roman masonry from Wroxeter can be seen reused around the local village, including the church. Ships timbers were used for oak framing, and lime plaster was normally crushed and reworked into new lime plaster, especially in cities far from sand quarries. We need to value materials and be less of a throwaway economy.”

T here’s a long way to go to meet our decarbonisation targets, but the work of ASBP to raise the profile of construction product reuse and a will to reimagine what already exists means there are strides in the right direction. We need to run, not walk, though, if we want to meet the targets already set.

W hen you have to build new, those buildings need to be designed in layers that are flexible, adaptable and easily maintained, which can be deconstructed for reuse. At its most basic, it’s about LEGO-inspired design, with components and systems creating buildings that can be taken apart and put back together in the same way or completely differently, adding in elements or taking them away to be reused in a different project; longlasting, robust elements that can be replaced when damaged but not to the detriment of the other pieces around it.

U ltimately, consideration of the material choice is essential, with priority given to

lower-carbon options, including natural materials from renewable sources and those that can be deconstructed and reused at the end of life, because today’s new build is tomorrow’s retrofit.

www.asbp.org.uk/workstream/reuse-now www.lime-green.co.uk

SOURCES:

*Net Zero Carbon Guide **https://green-alliance.org.uk/wp-content/ uploads/2021/11/Less_in_more_out.pdf

MASTERING ESTIMATION WITH THE USE OF AI

Artificial intelligence (AI) is everywhere, weaving its way into every corner of our lives and industries. For the construction landscape, it’s not just a trend – it’s become the new normal. So get ready, because we’re about to embark on a journey where AI reigns supreme, transforming how we estimate costs and manage projects like never before. As someone who works alongside estimators daily, I know the pain points all too well, says Simon Herod, International Lead at EstimateOne.

ESTIMATEONE

By harnessing the power of AI, construction firms are not only slashing preconstruction costs but also gaining a competitive edge in the market. With AI-enabled tools at their disposal, estimators can turbocharge their productivity, minimise errors and generate estimates with unparalleled precision and speed. This translates into more competitive proposals, paving the way for increased profitability and business growth.

T he rate of AI adoption is staggering. According to McKinsey’s 2023 AI report, one third of all respondents say their organisations are already regularly using generative AI in at least one function 1 . With AI scepticism still prevalent in the industry, what are the transformative potentials of AI in construction and how it will benefit your estimating team?

Sharper

accuracy

I n the world of construction estimation, accuracy is king and could be the driving factor to win you the project. With AI algorithms at our fingertips, we’re taking accuracy to a whole new level.

A I can analyse large amounts of data and identify patterns that would be difficult for humans to detect. This can lead to more accurate cost estimates, better project scheduling and an improved level of safety on construction sites.

B ut AI’s impact transcends mere number crunching. Take the E1 platform, for instance. With AI integration, it automates

the process of document superseding, intelligently suggesting updates based on document names.

E mphasising this point is vital: AI isn’t here to replace the estimators’ role. In fact, according to the House of Lords’ Communications and Digital Committee, jobs in construction are deemed unlikely to be fully replaced by AI, with less than 30% of workloads being completed with AI support 2 . Instead, AI serves to enhance efficiency and eradicate human errors, bidding farewell to manual guesswork and welcoming a new era of unparalleled precision and decision making.

Supply chain optimisation

W ho has time for endless Excel spreadsheets and mindnumbing calculations? Not us, thanks to AI-powered project planning tools. It’s like having a virtual assistant that sifts through mountains of data in seconds, churning out detailed reports and forecasts at the snap of your fingers.

E stimators hold the key to making crucial cost-versusquality decisions and balancing labour, equipment and materials. Accurate cost forecasting and budget management empower contractors to make informed choices and maintain financial stability.

D igital software has revolutionised the cost estimation process, preventing bids that are either too high or too low and eradicating the frustration of inconsistent quotes. Three out of five professionals in the built environment

expressed either agreement or strong agreement that digitalisation has enhanced their organisation’s capabilities in cost estimation, prediction, planning and control 3

A I is the next step in this process, streamlining reporting, tracking and communication with other stakeholders in the project with real-time data sharing. This is where AI truly leaves its mark on the industry. Amidst ongoing labour shortages plaguing the sector, AI steps in by creating a reliable subcontractor database for present and future collaborations

Fewer delays

E fficiency is the name of the game when it comes to estimating. With AI in our corner, we’re optimising resource allocation like never before.

W ith its dynamic scheduling capabilities, AI ensures resources are always allocated efficiently, maximising productivity and minimising downtime.

T he team at E1 are well aware of the impact any delay in delivering estimates can have on a project, not only incurring costs but also affecting a construction firm’s competitiveness.

I t may make estimators appear less qualified compared to other bidders, cause tardiness in proposal submissions and limit the number of proposals that can be submitted annually.

The future of AI for estimators

A s AI continues to revolutionise the construction industry, there has never been a better time to embrace its transformative potential in estimation processes. By harnessing the power of AI, construction firms can gain a competitive edge, drive profitability and navigate the complexities of modern construction projects with confidence.

A s AI continues to evolve and become more accessible, the seamless integration with Building Information Modeling (BIM) and other cutting-edge technologies makes the possibilities for its application in construction estimation endless. Let’s empower construction firms to deliver projects with unparalleled accuracy, clarity and efficiency to innovate the construction landscape further.

www.estimateone.co.uk

FOOTNOTES:

1 https://www.mckinsey.com/capabilities/ quantumblack/our-insights/the-state-of-ai-in2023-generative-ais-breakout-year

2 https://publications.parliament.uk/pa/ld5804/ ldselect/ldcomm/54/5402.htm

3 https://www.rics.org/content/dam/ricsglobal/ documents/research/Digitalisation%20in%20 construction%202023_final.pdf

A SOUND SOLUTION –ADDRESSING ACOUSTICS IN RESIDENTIAL BUILDINGS

Unwanted noise in the home continues to have a direct impact on the wellbeing of homeowners, particularly in the bathroom, with research showing that the issue is far bigger than many of us might think. Here, Sophie Weston, Head of Marketing at Geberit, explores the challenges of designing out noise inside the home.

GEBERIT

Ar chitects and specifiers are increasingly aware of the need to mitigate the impact of external noise, such as road, rail and air traffic, for building occupiers.

N oise impact assessments are commonplace in planning applications and are required to show that any new development is not adversely impacting residential or commercial properties located nearby. And, the World Health Organisation, which has been tracking noise levels for over a decade, describes noise pollution as an “underestimated threat” that contributes to everything from stress to high blood pressure, cardiovascular disease, dementia, diabetes and, of course, hearing loss.

H owever, the issue of noise is not restricted to the outside world. Rapidlyincreasing numbers of connected devices, poor end-user awareness and

lack of clarification in UK standards and Building Regulations can leave many people unable to shake off the effects of noise in the home, too.

T here is even an argument that increased external sound insulation has actually amplified noise within the home, highlighting internal noises more than ever before.

Identifying the issue

T he issue is bigger than some might think. Geberit research published in a previous white paper 1 shows that 38% of people say noises inside the home, such as electrical appliances, bathroom noise or central heating systems, affect them more than traffic from outside.

I n the bathroom, one in four of us (28%) are regularly disturbed by bathroom sounds at night or when trying to relax, and one in five (19%) homeowners are

regularly disturbed by flushing toilets, running taps or pipe and drains.

C ritically, more than half of respondents (51%) cited unwanted noises as having a negative impact on their wellbeing.

P art of the challenge is that there is very little clarification within the relevant UK regulations on what products should be used to achieve specific sound pressures, particularly when it comes to water and bathroom noise.

For example, BSI’s British Standard 8233:2014 Guidance for Sound Insulation and Noise Reduction in Buildings simply states that water systems, including hot and cold water services and waste pipes, “are not to cause disturbance in normal use”. This rather vague guideline is the standard’s only reference to reducing sanitary noise in buildings.

T he UK Building Regulations are no more specific. Building Regulations (2010) Approved Document E ‘Resistance to the passage of sound’ largely focuses on measures to control external sound. It does stipulate that any wall or floor should reduce the noise transmitted to the next room by 45 dB or more, but then fails to set a maximum noise level. Importantly, nor does it mention the use of any acoustically-optimised products.

Presenting solutions

T he onus, it seems, is on designers and architects to make well-informed choices to reduce the impact of noise inside the home and, in turn, increase wellbeing.

T here are products available in the UK market to mitigate the impact of noise in the bathroom. Sound-optimised drainage piping can reduce noise transfer from flushing water, washbasins or showers. Likewise, wall-hung toilets with concealed cisterns can prevent noise from travelling down the wall and through the floor.

H owever, without specific UK standards on the noise pressure from water systems inside new buildings, there is no requirement for a building to meet a baseline figure.

This is in contrast to Germany, where the DIN 410 acoustic standard outlines maximum acoustic levels in a building. It also outlines buildings’ sound insulation with requirements and verifications, as well

as clear requirements on internal noise. It sets maximum requirements for sanitary noise at 30dV(A) in terms of LAFmax, n.

T here is also no defined approach to testing and, therefore, no incentive for different specifiers across a single project to work together and undertake collaborative testing to ensure that they are achieving the best acoustic rating –as is the case for heating or energy loss.

S ome leading manufacturers, including Geberit, are working to the best practice German standards for products sold in the UK market. Still, until UK standards are revisited and maximum figures outlined (not to mention a defined approach to testing acousticallyoptimised products), it will remain a challenge to specify a well-informed, collaboratively-tested solution across an entire building. And, as our research shows, noise in the home is affecting the majority of homeowners.

I t’s time for the UK to revisit standards and outline maximum sound pressure figures and fair testing – thus enabling the industry work together to achieve better results for our end users.

www.geberit.co.uk

SOURCE: 1Geberit - ‘A Sound Solution – Embedding Acoustics into Building Design’

Starting from £1.10 per sq. foot

THE ESSENTIAL ROLE OF CERTIFIRE-RATED ACCESS PANELS WITHIN FIRE SAFETY

The need for proper fire safety measures in commercial buildings is now more critical than ever, meaning the design process poses new and unique challenges, while architects are required to stringently adhere to fire safety regulations and standards.

PROFAB ACCESS

Here, Profab Access, a leading manufacturer of access panels, highlights the vital role that third-party fire-tested access panels can

play in fire safety and how, by specifying products that have undergone such testing, architects can ensure the integrity of their buildings.

Following the Grenfell Tower fire in 2017, the Golden Thread concept was introduced as part of the Building Safety Act, which highlights the need for better documentation, transparency and accountability in the context of building safety.

A foundational element in ensuring the quality, safety and longevity of a building, it signifies the link between the initial design intent, through to the construction and maintenance stages of a building’s lifecycle.

N aturally, architects are among those who uphold a great responsibility in ensuring that the Golden Thread is adhered to during a building’s initial design stages.

C ommercial buildings house numerous complex systems, including fire suppression systems, electrical installations and HVAC infrastructure. One critical component that houses these components is access panels.

I n the world of modern architecture, functionality and compliance must meet,

and this can be achieved through an architect’s choice of access panels. Beyond their functional purpose of providing access to these systems for maintenance personnel, they stand as vital yet overlooked components within the broader framework of fire safety within buildings.

D uring a building’s initial construction, it is essential that architects seek to install fire-rated access panels where third-party certification can be supplied. An example of this third-party certification is the Certifire scheme.

T he significance of Certifire-rated products extends beyond adherence to regulations, and represents a commitment to safeguarding lives and property. With this in mind, architects should always prioritise the specification of Certifire-rated access panels for several reasons.

F irstly, Certifire certification provides a mark of quality and reliability. This guarantees that the products have undergone rigorous testing and are proven to withstand the spread of fire for a specific

period of time and that they comply with relevant European fire test standards. This certification provides architects with the confidence that the access panels they specify meet the highest standards for fire safety in their buildings.

B y specifying Certifire-rated access panels, architects can ensure that the building’s fire safety systems are robust and reliable in the event of a fire. These panels provide the highest standard of protection against the spread of flames and smoke through containment, acting as a barrier to control the fire, which gives occupants more time to evacuate safely. This, in turn, can minimise the risk of both structural damage and loss of life.

C ommercial buildings are environments where the safety of hundreds or even thousands of occupants is at stake and where the rapid spread of fire can be catastrophic. The need for this swift and effective containment of flames and smoke is all the more crucial in these buildings. Here, the Grenfell Tower fire serves as a stark example of the potential consequences of specifying building materials and products that fail to provide this effective containment.

W ith regards to the responsibility of architects to uphold the Golden Thread, the installation of Certifire-rated access panels provide a transparent link between design intent and real-world performance. By specifying panels with a proven track

record of fire resistance, architects can weave a clear thread of accountability, and thus always remain compliant with the requirements of the Golden Thread.

T he importance of fire safety cannot be overstated, and every design decision during a building’s construction must reflect this priority. As architects navigate the complexities of evolving safety standards, they must prioritise solutions that uphold the highest standards of fire safety integrity.

B y working with reputable manufacturers who offer Certifire-rated products, architects can be confident that they are choosing products that have been rigorously tested and proven to perform in the event of a fire, and demonstrate a dedication to public safety.

A s a leading supplier of Certifireapproved products, Profab Access is now offering customers ‘Certifire as Standard’ after investing in extensive third-party fire testing across its product portfolio, in order to provide customers with the ultimate peace of mind.

T he presence of Profab Access’ panels within a building’s structure can ensure architects are able to fortify the building’s fire safety resilience, help to safeguard the lives of occupants, whilst ensuring that building safety regulations are always met with confidence www.profabaccess.com

Slotted Channels from £5.60 each

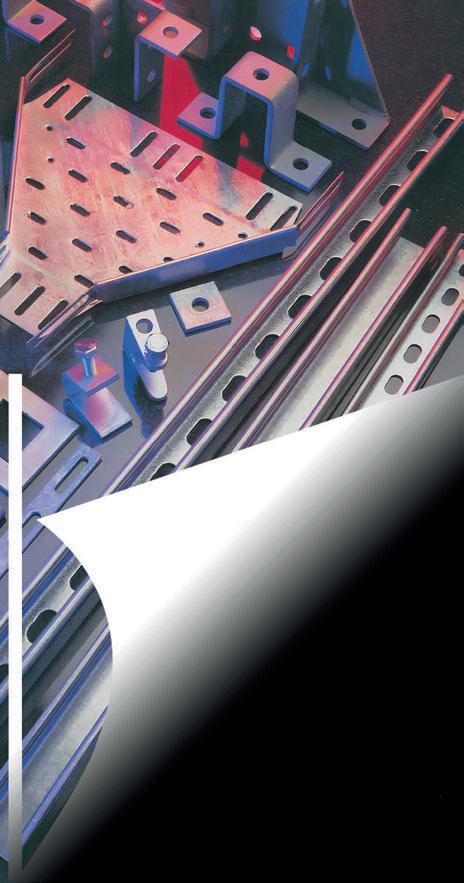

CREATE WITHOUT COMPROMISE –GREAT PRODUCTS, HUGE CHOICE AND FAST DELIVERIES FROM

F.H.BRUNDLE

As architects, you know better than anyone that structural components are vital – no structure, no building. But you also know that it’s the non-structural elements – the balustrades, handrails, fencing, decking and more – that make the space stylish, comfortable and somewhere people want to be, says F.H.Brundle.

F.H.BRUNDLE

At F.H.Brundle, we’ve been supplying quality products and exceptional service for over 135 years. We understand the challenges you face in sourcing reliable, high-quality, nonstructural systems for your commercial projects.

T hat’s why we offer a comprehensive range of products that don’t compromise on style, function or add weeks to your project times –regardless of size and volume.

Vast choice of balustrades and handrailing

B alustrades have boomed in popularity in recent years. At F.H.Brundle, we’ve responded by offering the UK’s biggest selection of metal and glass balustrade systems, letting us cater to virtually any vision.

P roducts like our sleek and minimalistic Pro-Railing range, available in stainless-steel and marine-grade Duplex 2205, offer a wide variety of components for quick and easy installation.

Architects can choose from glass panels, round tubes, perforated metal or wire mesh infill solutions to create balustrades that are both functional and aesthetically pleasing.

W hat’s more, we’re one of the UK’s biggest distributors of handrail solutions, meaning that no matter the setting, we’ll have a product that will excel on your next project.

S ecurity with style

P erimeter security is a crucial aspect of many commercial projects. We provide robust, highly-secure products that don’t make you compromise on aesthetics.

O ur stylish made-to-measure steel gates come with a rapid turnaround, meaning no frustrating hold ups, helping your project finish on schedule.

Versatile decking

For gardens, walkways, balconies or rooftop terraces, our aluminium decking systems are the perfect choice. Exceeding the highest European safety standards (EN 13823, EN 13501 and EN ISO 1716), they deliver exceptional strength and durability.

Additionally, the Synergised system achieves Euroclass classifications of A1 and A2fl-s1, making them ideal for hightraffic areas and compliant for installation in high-rise buildings.

E xpert support

H owever, products are only the start of what makes F.H.Brundle an outstanding supplier. What truly sets us apart is our unwavering commitment to expert support. Our team of specialists is here to assist you throughout the entire process, from product selection to technical guidance, and even providing readily-available CAD files for all our systems. This eliminates the need for timeconsuming technical drawings and ensures our products fit in seamlessly with your plans.

Next-day delivery

I n construction, time is money – and that’s why our products have been meticulously selected for low maintenance and quick, simple installation.

W hat’s more, we offer free delivery across the UK, eliminating logistical headaches and further streamlining the process.

O ver the years, we’ve built up a network of depots, which means we can quickly dispatch products and have them with you in no time. We have branches in East London, Ilkeston, Southampton, Newton, Birmingham, Glasgow and Cardiff – plus, in Burton, our state-of-the-art 270,000ft 2 distribution centre. Our huge stockholding means we can get you the products you need when you need them.

A n extension of your team

A t F.H.Brundle, we see ourselves as an extension of your team. We provide the tools and expertise you need to bring your architectural vision to life.

W ith our extensive product range, dedicated customer support and focus on time-saving solutions, we give you what you need to create outstanding commercial and domestic spaces.

COUNTDOWN

TO

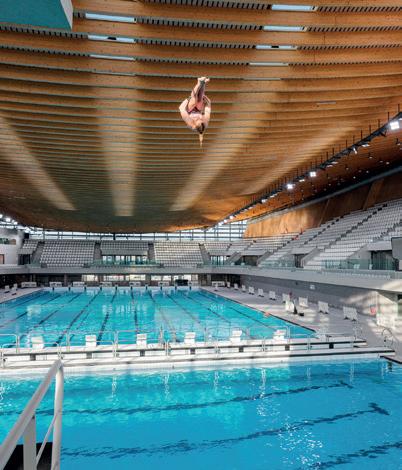

THE 2024 GAMES: THE AWARD-WINNING AQUATICS CENTRE

100 years after it last hosted the games, Paris is gearing up for 2024. Having created the design for the Aquatics Centre, architect firms VenhoevenCS and Ateliers 2/3/4/ are thrilled to witness its realisation.

VENHOEVENCS AND ATELIERS 2/3/4/

The only permanent new building for the 2024 games – together with the expanded green public space and the new bridge that connects the stadium with the Stade de France and the rest of Paris – the Aquatics Centre is an important investment in the future of Saint-Denis and the Paris metropolitan region. The innovative, award-winning project is set to create an unforgettable experience of the games and promises a lasting legacy for the neighbourhood and beyond. Winner of the Le Grand Prix du Grand Paris 2023 and Grand Prix BIM d’Or, the building is designed for multifunctional use. During the games, the competitions for diving, synchronised swimming and the qualifications for water polo will take place here. The building will function as a swim training facility during the Paralympics and, after the games, the building will remain as centre for various sports for the neighbourhood.

Eco-friendly design

Wood, one of the quintessential bio-based construction materials, has been used to create the main structure of the building. The design of the Aquatics Centre features a

wooden roof with a suspended shape and minimal construction height that strictly follows the required minimum space for tribunes, people and sightlines, thereby minimising the amount of air that needs to be conditioned over the coming 50 years. By using wood for this monumental structure, the design doubles the required minimum percentage of bio-sourced materials. The arena under the roof, with tribunes on three sides, can host 5000 spectators around an innovative, modular and multifunctional competition pool.

E nergy consumption is one of the big challenges for swimming pools due to water treatment and high-temperature demands. By reducing the energy demand and creating a smart energy system, 90% of the needed energy can be provided with renewable or recovered energy. The solar roof will be one of the biggest solar farms in France and will cover 20% of all required electricity production. 100% of the energy produced by the solar roof is utilised directly on site. All tribune chairs are newly designed and made of 100% recycled plastic collected from the neighbourhood.

©Architecture: VenhoevenCS & Ateliers 2/3/4/. Photo: Salem Mostefaoui.

©Architecture: VenhoevenCS & Ateliers 2/3/4/. Photo:

©Architecture: VenhoevenCS & Ateliers 2/3/4/. Photo: Salem Mostefaoui.

Improving the quality of life in our cities

T his design goes beyond environmental regulations and requirements. Sustainability and biodiversity are at its heart. It is a modern and innovative sports complex surrounded by abundant vegetation that will make a major contribution to creating a liveable and healthy city district for the people of Saint-Denis. The Aquatics Centre invites nature into the heart of the new city district in the making with a proposal that includes the addition of 100 trees and shrubs that will be planted to improve the quality of life and air, stimulate biodiversity and create new ecological connections. By gathering people around sports and leisure, the new Aquatics Centre creates a neighbourhood that builds bridges between cultures and districts whilst making use of the facilities and surrounding public spaces. There is also the literal connection, with a new pedestrian bridge that crosses the highway and connects the public spaces around Stade de France with the Aquatic Centre and the new heart of the future eco neighbourhood of La Plaine Saulnier.

www.venhoevencs.nl www.a234.fr/en

What’s in a Guarantee?

CA Group Complete Assurance Guarantee is the industry leading full system guarantee, with periods of 25, 30 or 40 years.

At CA Group we believe a Guarantee is more than just a number, it must also include for:

• Guarantee issued direct to client, and fully transferable

• No reduction in Guarantee period for inclusion of solar PV installations

• Meticulous system testing as a full assembly for durability, structural integrity, thermal performance, fire resistance, acoustics, weather & air tightness and Non-Fragility

• Independent Agrément certification, LPCB, LPS1181 and Secured by Design accreditation

• Stringent quality, environmental and Health & Safety control measures, ISO 9001, 14001 and 45001

• Installer support, training, design assistance and routine on-site quality inspections

• Aftersales care, periodic building inspections

• Environmental and social governance, independent system EPD’s and third party sustainability endorsement

Find out more

Visit

• Backed by Confidex® and Confidex Sustain® by Tata Steel for up to 40 years

IS GEORGIAN-STYLE DEVELOPMENT THE BEST MEANS OF DELIVERING ‘GENTLE DENSITY’?

Density is also a key theme of the National Planning Policy Framework (NPPF) – or more specifically, ‘gentle density’ – says Grant Leggett, Executive Director at Boyer (part of Leaders Romans Group).

BOYER

Pl anning policy also gives considerable weight to ‘beauty’, as determined by the work of the Building Better, Building Beautiful Commission and exemplified in its report ‘Building More, Building Beautiful: How design and style can unlock the housing crisis’. The report used extensive polling to show that, in the design of new homes, traditional building design was preferable to contemporary architecture. Across all demographics, a large majority agreed that newly-built properties should fit in with their surroundings. Support was used to substantiate the claim that NIMBYism can be overcome if design better reflects people’s desires for traditional architecture.

B ut what role should politicians have in prescribing specific styles of architecture? In advocating gentle density, the NPPF identifies mansard windows as "well designed" and states that considering them harmful to the character of neighbourhoods is "wrong". To my mind, making value judgements about specific architectural features a step too far for planning policy. After all, whether any architectural feature is ‘right’ or ‘beautiful’ depends upon the context.

M y view is that good design is closely linked to good land use. In most situations, especially in urban areas, density has many advantages. It helps create a mixed and balanced community, allows a range of facilities in close proximity, is economically advantageous and can facilitate a greater variety of uses, such as live/work and co-living. Denser schemes also have the potential to be more sustainable, not least in terms of sustainable transport, if located close to public transport or within reach of local services. Developable land, especially in cities, is a scarce resource, and it is essential that potential development capacity is not wasted.

W hile beauty and density are dependent on context, the similarities end there. In fact, context is one of the many features that demonstrates why the two cannot be synonymous. Poundbury, the Duchy of Cornwall’s experimental Georgian pastiche development in Dorchester exemplifies this. Georgian architecture may represent the very best in design to some; to others the repurposing of a centuries-old style is regarded defeatist, retrograde; even ‘Disneyesque’.

GRANT LEGGETT

IS THE EXECUTIVE DIRECTOR AND HEAD OF BOYER’S LONDON PLANNING TEAM. HE LEADS A TEAM OF 14 CONSULTANTS ON A WIDE SPECTRUM OF PROJECTS ACROSS LONDON AND THE SOUTH EAST, INCLUDING LARGE-SCALE REGENERATION PROJECTS, URBAN EXTENSIONS AND MORE BESPOKE, HIGH-VALUE RESIDENTIAL DEVELOPMENT.

And I would also question whether Georgian architecture allows greater density. In London, three-storey homes with generous gardens both front and back represent low density.

Perhaps the Poundbury approach will help encourage local communities to accept development; even higher-density development. But this only works in areas where the average density is lower than a typical neo-Georgian development. Take that approach in London, and the acceptable densities currently achieved will be lost, homes will become increasingly scarce, prices will sky rocket and local centres will become desolate and unviable.

To my mind, planning policy has no role in prescribing either a specific architectural style or a national baseline for density. Politicians should avoid tinkering with policy, especially when the motivation is politically motivated and the likely outcome is, at best, uncertain.

Functional aesthetics for facade and interior

Both aesthetic and functional values were prioritised when the water supply company Aarhus Vand planned a new domicile.

RMIG Solutions was contacted and a perforated metal facade with an aquatic theme was designed using RMIG ImagePerf, illustrating the company’s water-related activities.

Indoors, the creative workspaces were also clad in perforated metal to make them resemble free-floating water lilies, harmonising with the exterior design.

01925 839610 • info.uk@rmig.com • rmigsolutions.com

Technical characteristics

Raw material: Aluminium 55HQ / EN 1050

Pattern: RMIG ImagePerf

Thickness: 3.0 mm and 1.5 mm

Surface treatment:

Natural anodising N1 (exterior)

Finishing operation: Forming and bending

Tel: 01738 634 803 Email:

SNØHETTA UNVEILS THE WORLD’S LARGEST CLIMATISED READING SPACE

Snøhetta’s Beijing City Library has opened doors for visitors as the world’s largest climatised reading space. It is the firm’s latest innovation in the library typology, 35 years after it began work on Bibliotheca Alexandrina in Egypt. The project introduces a contemporary yet indelible place for learning, knowledge sharing and socialising to Beijing’s rich cultural and intellectual scene.

SNØHETTA

Th e new library is located in Tongzhou District, a designated sub centre of Beijing that is often considered the eastern gateway of the capital. As one of three new major cultural buildings in Tongzhou, the library further establishes the area as a vibrant district and an extension of Beijing’s urban fabric. It anchors the neighbourhood’s ambitious masterplan and will help to catalyse its transformation from a relatively undeveloped area into a lively arts and cultural destination. New transit links to Beijing’s centre are underway, promising to further integrate Tongzhou with the city and drive visitors to the sub centre.

S nøhetta was awarded the Beijing City Library in 2018 through an international competition, and the project was completed with local partner ECADI.

Reinstating relevance in the digital age

A decade or so ago, libraries were thought to be a disappearing typology as digitisation has increasingly made information accessible at any time and place. To reinstate the library’s relevance in the 21st century, Snøhetta set out to offer a new vision for how it looks, works and serves the community. The library draws focus on the physicality of a book as an object and the conscious exercise of turning the pages to take in the written word as the primary experience amidst the picturesque setting of hills, trees and the Tonghui River.

To reestablish the library’s role as an important pillar of public and intellectual life and become more than a mere repository of books, Snøhetta has positioned the building as a centre for

learning, culture and community. Drawing on the historical origins of libraries finding innovative responses to the needs of their time and place, Beijing City Library makes the open exchange of ideas and human dialogue its core purpose. Throughout, there are dedicated spaces for exhibitions, performances, conferences and the restoration of ancient books. The building firmly rejects the argument that the library is becoming a derelict typology with the numerous possibilities it creates by fostering an emotional connection between books, people and the natural landscape beyond.

S culpting the valley and the hills within

T he glass-lined building invites nature into the reading space and lends transparency to the enriched interior environment when

viewed from outside. At the heart of the library is a sweeping, nearly 16m-tall welcoming forum off of which rise stepped terraces along smooth, rhythmic curves. Carved through the centre is a meandering pathway called the ‘valley’, which serves as the main circulation artery of the building. The valley mirrors the course of the nearby Tonghui River, seamlessly continuing the experience of the landscape beyond and linking the north and south entrances to lead visitors to all other spaces inside.

T he terraced hills rising from the valley are designed to create a sculpted interior landform that serves as the ground, seating and shelving – an informal zone with opportunities to relax, talk or read quietly, all while staying connected to the larger space. Semi-private reading areas and conference rooms are embedded into the hills, while book stacks and table seating are set on long, flat areas atop. This central, open area is fully accessible and incorporates one of the largest book Automated Storage and Retrieval Systems (ASRS) in the world.

P unctuating the large space to transition between the scale of the valley and the books are tall, slender columns that mushroom into flat panels shaped like ginkgo leaves – referencing a 290-million-

year-old tree species native to China. The overlapping panels and the interstitial glass inserts create a canopy-like roof that floods the interiors with filtered daylight. Under this ginkgo canopy, one can reach the summit that overlooks the valley of books and the horizon of the vast landscape beyond. This experience of oneness with the immediate surroundings and the imagined world offered in books allows the reader to forge memories that are unique to the place.

At the northern and southern edges of the building, where real ginkgo trees are planted at the entry points, the hills focus their views outwards to enhance the connection with nature further. The library celebrates Beijing’s natural and cultural heritage by integrating reading, performance and landscape together.

S etting the green standard with sustainable technology

T he Beijing City Library rethinks how libraries today can address the pressing climate challenges while incorporating cutting-edge technology to improve visitor experience. The building achieved China’s GBEL Three Star, the highest attainable sustainability standard in the country, by minimising both embodied and operational carbon. The project is as

much a steward of its environment as of the communities it serves.

The use of modular components and a rationalised structural grid reduces the manufacturing waste for the building. For the ginkgo tree columns, a single module type is rotated on a 9 x 9m grid throughout the building to give the appearance of variety while being efficient to fabricate and install. These columns also house integrated technology to control interior climate, lighting and acoustics, as well as collect rainwater from the roof to be reused for irrigation by channelling it to a green infrastructure system.

G enerous roof overhangs reduce solar gain on the glass facades – currently the largest load-bearing glass system in China – achieving an important design element without compromising on sustainability. To further optimise the facade, the design reduces the height of the glass on the east and west wells and uses insulated low-E glass. The roof has integrated photovoltaic (BIPV) construction elements that replace the conventional roofing and facade materials, utilising the prime exposure of the rooftop to sunlight for renewable energy production.

www.snohetta.com

RICHARD EDDY

IS THE CATEGORY MANAGER OF UNDERGROUND AND UTILITIES AT POLYPIPE BUILDING PRODUCTS. HE BRINGS EXTENSIVE EXPERIENCE IN DEVELOPING INNOVATIVE DRAINAGE SOLUTIONS. WITH A FOCUS ON SUSTAINABILITY AND RESILIENCE IN URBAN INFRASTRUCTURE, RICHARD LEADS INITIATIVES TO INTEGRATE EFFECTIVE WATER MANAGEMENT PRACTICES INTO CONSTRUCTION, CHAMPIONING SUDS TO ENHANCE COMMUNITY WELLBEING AND ENVIRONMENTAL HEALTH.

UNLOCKING THE POTENTIAL OF SUSTAINABLE DRAINAGE SYSTEMS

Climate change and the increase in urban flooding pose a significant challenge to the UK’s ageing sewer infrastructure. Despite sustainable drainage systems (SuDS) being available for some time, adoption of these systems has been slow, even with the rollout of Ofwat’s Code for Adoption guidance in 2021, says Richard Eddy, Category Manager of Underground and Utilities at Polypipe Building Products.

If we are to work toward a more sustainable, flood-resilient future, architects and housebuilders need to understand the key considerations regarding the environmental impact of developments, the barriers preventing the adoption of SuDs and the legislative changes set to make these systems a mandatory part of new residential projects.

Reducing floods, enhancing environments

S ustainable drainage systems are designed to tackle the challenges of urban flooding and water management in a more environmentallyfriendly way. Unlike conventional drainage solutions that typically direct stormwater into sewers and watercourses, SuDS mimic natural processes to manage rainfall by storing water, allowing it to infiltrate into the ground or slowly releasing it. This approach not only lessens the impact of urban development on the natural water cycle but reduces the strain on our sewer systems.

T he benefits of SuDS include mitigating urban flooding by reducing the runoff entering sewer systems during heavy rainfall, which improves water quality by naturally filtering

out pollutants. Moreover, SuDS can enhance biodiversity and urban green spaces by being incorporated into the landscape in the form of green roofs, rain gardens and permeable pavements, all of which contribute to the cooling of urban environments by counteracting the urban heat island effect.

A rchitects and housebuilders, therefore, have both a challenge and an opportunity to innovate and integrate SuDS as standard practice in their projects. This will help them to align with broader environmental goals and legislative requirements while also meeting the needs and expectations of future residents.

C lear guidance and support

D espite the benefits and growing support for SuDS, their adoption across new developments faces several barriers. A key issue is the UK’s fragmented regulatory landscape, with varying local standards causing confusion and complex approval processes deterring developers.

A mbiguity in SuDS definitions and guidelines complicates their integration into projects, making it difficult for builders to comply with regulations and achieve environmental

benefits. There is a lack of technical expertise in hydrology and site-specific conditions also pose a challenge as designing the system often requires a bespoke approach. This has raised concerns about high upfront costs, particularly for retrofitting sites, which has historically deterred developers despite the potential long-term savings.

O vercoming these obstacles requires cohesive policies, clear guidance and more support for developers via technical resources, specialist support, training and even financial incentives. This means that, in order to promote sustainable drainage practices and address the challenges posed by climate change, cross-part collaboration is needed.

Impending mandate

T he adoption of sustainable drainage systems in the UK is significantly influenced by the

legislative framework that governs water management and urban development, notably the Flood and Water Management Act 2010. This legislation promotes SuDS use in new and redeveloped sites by mandating approval for drainage systems to manage surface water sustainably.

S chedule 3 of the act is yet to be fully implemented across England and is particularly important as it mandates the implementation of SuDS in all new residential developments larger than 100m 2 . Although Schedule 3 has been in force in Wales since 2019, its introduction in England marks a significant step towards standardising the use of SuDS and integrating them into the broader planning and development process.

T he necessity to comply with these regulations means that developers must integrate SuDS considerations from the earliest stages of planning and design.

This can involve navigating complex approval processes, adapting designs to meet specific site conditions and ensuring that SuDS features are maintained over the long term.

T he legislative environment fosters innovation and sustainability, encouraging creative water management solutions that add value to developments. So, while the industry’s understanding of SuDS and legislation is evolving, we should see this as an opportunity to enhance urban sustainability and resilience.

A more thoughtful and integrated plan

E ffective SuDS implementation depends on understanding a site’s unique characteristics, such as environmental conditions, soil types, topography and hydrology. These factors determine how water behaves, impacting the suitability and effectiveness of various SuDS components.

C ustomising SuDS solutions to fit the unique conditions of a site ensures that they will complement the natural water cycle. For instance, areas with permeable soil can use infiltration features, while urban areas might employ green roofs or permeable paving. Proximity to watercourses could also enable the creation of features like wetlands for additional drainage and environmental benefits.

T his approach not only maximises the performance of the drainage system but also can lead to cost savings over time. By aligning the drainage strategy closely with the site’s natural characteristics, it’s possible to reduce the need for extensive engineered solutions, which can be more expensive to install and maintain.

A site-specific approach to SuDS encourages a more thoughtful and integrated planning process, requiring collaboration among developers, planners and engineers to create solutions that respect and enhance the natural environment.

Investing in the future

W idespread SuDS adoption in the UK represents a vital step towards mitigating flood risks, enhancing urban resilience and promoting environmental sustainability. Certain areas, particularly those prone to flooding or undergoing rapid urbanisation, stand to benefit significantly from the integration of SuDS.

E ffective collaboration between the drainage sector, policymakers, housebuilders and developers is essential for promoting SuDS. The drainage sector can provide expertise and innovation, while policymakers provide clear guidelines and incentives, all of which will enable and support developers looking to integrate SuDS into their projects.

O f course, the successful and widespread adoption of SuDS will involve addressing misconceptions about costs, maintenance and feasibility. Instead, we must highlight successful case studies, provide clear cost-benefit analyses and offer technical support to help the industry gain and build confidence in both the benefits and implementation of SuDS.

A s climate change intensifies, the requirement for a sustainable, resilient future becomes more critical. By making SuDS a priority in our housing development projects, we are investing in the future health of our communities and ensuring they are equipped to handle environmental challenges.

www.polypipe.com

ARCHITECT IN PROFILE

Jon Ackroyd is this month’s exclusive Q&A profile. Jon is an Architect, retrofit champion, Carpenter and Founder of Ackroyd Lowrie, an award-winning, east London-based practice. Here, Jon discusses his inspiration, how he learnt to harness the power of dyslexic thinking to forge a successful career, his advice for aspiring architects and how Ackroyd Lowrie is supporting future generations.

Tell us about your career journey. How did you get started in the field of architecture?

As a child, school was difficult. I couldn’t articulate my thoughts in writing and would muddle up my words, but it wasn’t until I was nine that I was diagnosed as dyslexic. I found solace in drawing, so art GCSE was an obvious choice. Here, I learned about Richard Rodgers, a well-known visionary Architect who was also dyslexic. This inspired me so much that, when I turned 17, I walked into an open day at Rodgers’ firm, asked for an internship and got it. And so began my career in architecture.

At the Richard Rodgers Partnership (as it was known then), a colleague encouraged me to apply for my bachelor’s degree at Cardiff University, and this was the start of my formal qualification. These early interactions not only shaped my interest in sustainable design, but also showed me how thinking differently was an asset.

Were there any pivotal moments or experiences that solidified your decision to pursue a career in architecture and design?

A pivotal experience that shaped the direction of my career was my time at Architype. Architype is one of the UK’s leading sustainability practices, and the more projects I worked on with this emphasis, the quicker I realised this is what I wanted to specialise in.

While at Architype, I set up the research and innovation group with a colleague, Gareth Selby, to develop radical ideas around sustainability in buildings. Innovation was part of Architype’s ethos, and they later brought in Research Specialist Lisa Ann Pasquale to further develop knowledge. Together, we undertook Government-funded, post-occupancy research on the performance of schools in use, as part of the Technology Strategy Board.

This research really grounded architecture in reality for me. It taught me the importance of analysing data and real opinions to properly understand how buildings do and don’t work.

If you hadn’t followed your passion for being an architect, what other career path would you have pursued?

When I returned to London, I moved into a warehouse community in Vittoria Wharf on Fish Island, Hackney Wick. Here, makers and creators were working side by side, and this unity inspired me. As well as designing buildings, my research at Architype had taught me the importance of understanding how they are built, so I undertook a City & Guilds qualification in carpentry. My love of making things meant carpentry or construction could’ve been an alternative career.

I believe it’s really important for aspiring architects to understand the practical aspects of the profession, and gaining hands-on experience is the best way to achieve this. Ackroyd Lowrie has its own academy to bring students from different backgrounds into paid apprenticeships and onto BTEC qualifications, and part of this training includes hands-on learning, such as bricklaying and carpentry.

Who has been your greatest influence and source of inspiration?

Richard Rodgers was extremely influential on my career and my view of my dyslexia. From him, I learned that my dyslexia wasn’t the curse I thought it was. Rather, it’s the reason why I’m creative and can think around corners rather than in a straight line. Nature is another huge source of inspiration. The simple elements of light, sun and water show how structures can work and how sustainable cycles are created.

Then there’s also Jane Jacobs, Author of The Death and Life of Great American Cities, a remarkable book about urban planning, neighbourhoods and why cities do or do not function.

Ackroyd Lowrie’s design for a major, mixed-use retrofit scheme in Camberwell that will repurpose a civic building into new homes, community and commercial space

What’s been the most memorable project you’ve worked on, and for what reason?

Alva Coachworks in north London.

This was a really ambitious retrofit to transform a Victorian tram repair depot into pioneering film and photographic studios and an event space. We wanted to celebrate the building’s heritage and character while also achieving the client’s vision and reducing energy consumption. This involved overcoming many hurdles, including adjusting the building’s height, upgrading the 100-year-old sawtooth roof, designing custom roof trusses to support sliding acoustic partitions and installing a unique hydraulic ramp for access, to name a few.

It’s memorable because midway through the project, funding was put on hold, and it remained in danger of not being finished. Due to the imagination of the project team and the sheer resilience of the client, it succeeded and proved a real lesson in overcoming adversity. The result has been described as a ‘wowfactor’ space, and Alva Coachworks was highly commended by AJ Retrofit and an AJ Specification exemplar project for technical merit.

Can you share a personal anecdote or experience that taught you a valuable lesson about being an architect?

On one of my early projects, we ran into difficulties with the contractors on site. The roofing had failed, water was pouring through the building, and the construction team wasn’t accepting accountability. This taught me two things. One, I needed to know more about how buildings are built, and two, how to manage very complicated and difficult issues with people.

To resolve the situation, I created my own methodology, SOCIAL, which teaches how to communicate efficiently by combining professional and personal journeys. To begin, we need to ‘slow down’ and prioritise self care, which allows us time to ‘organise’ thoughts and do any necessary research. We can then ‘communicate’ clearly and effectively, ‘implement’ and ‘action’ accordingly and, ultimately, ‘learn’ from the situation to avoid future occurrences. So much in our industry demands a fast pace and immediate response, but this isn’t always the right approach. I teach our staff and academy students this method to help achieve a positive work-life balance.

Could you walk us through a typical workday in your current role?