FUTURE CONSTRUCTOR & ARCHITECT MAY 2023 ISSUE 159

Discuss your project with us today and visit origin-global.com/commercial The future is... Carbon Neutral

Aerogel delivers an incredible A++ Energy Rating

ISO 14001 accredited, so you can specify with confidence

Origin OB-49 Single Doors and OW-80 Windows with Aerogel were a perfect match for these newly built Carbon Neutral houses. The inclusion of Aerogel, known as the worlds best insulator, meant that the buildings were able to achieve the best possible U-Values in the industry.

The Black Grey finish was chosen to complement this stylish new development, and the completely bespoke doors and windows were delivered within 48-hours to meet the clients schedule.

This project was completed by long standing Origin trade partner, The Glass Centre, so they knew the addition of revolutionary Aerogel would be a perfect match for the newly built Carbon Neutral houses. Origin are a first choice for developers requiring the most thermally e cient aluminium windows.

150 RAL COLOURS

Colour options to suit every property style

Manufactured and delivered in as little as 24-hours if required

o ering is geared towards helping you design with style and confidence

In addition to a full product suite that boasts a beautiful and elegant design with exceptional performance, we pride ourselves on o ering a 360° service. Whether your requirement is supply only or a complete turnkey service, we are a one-stop-shop and can o er the right solution for you.

Call

EHT RMALPERFORMA ECN

Products meet and exceed building regulations us on

0808 192 0019

Specify our products in your projects today

Origin’s

Opens doors, invisibly

More features, more functionality, more choice

The versatile, efficient UFO NT automatic swing door operator is completely hidden from view – perfect for glass facades, historical or listed buildings, or where maximum transparency at an entrance is demanded.

Yet it still ensures access for all and complies with the Equality Act and Building regulations.

Suitable for internal and external doors, and for retro-fitting, the UFO NT can even be used manually thanks to the Smart swing function – all-in-all an innovative operator, just a shame you can’t see it.

More information: info.uk@geze.com www.geze.co.uk

FC&A – MAY – 2023 4

EDITOR IAL

Rebecca Kemp rebecca@redhutmedia.com

Hannah Woodger hannah@redhutmedia.com

PRINT & DIGITAL ADVERTISING

Sam Ball sam@redhutmedia.com

Jim Moore jim@redhutmedia.com

PRINT DESIGN MANAGER

Jack Witcomb jack@redhutmedia.com

DIGITAL DESIGN MANAGER

Matt Morse matt@redhutmedia.com

ACCOUNTS/ CREDIT CONTROL

In last month's welcome note, I highlighted the issue of greenwashing, which was a dominant topic at March's Futurebuild event. In this issue of FC&A, we have decided to delve deeper into this vital discussion. As part of this coverage, we invited Mark Clark of Cemfree to contribute an insightful article on the issue of greenwashing in the housing development sector. In his piece, Mark explains how misleading claims about sustainability are becoming increasingly common and hinder genuine efforts to find carbon savings. He provides examples of how developers may use green credentials to sell their homes without implementing genuinely sustainable practices and suggests potential solutions for a more sustainable future, such as developing new materials and engaging with the supply chain to encourage sustainable practices. You can read the full article by turning to page 34.

Greenwashing and a circular supply chain are closely linked in the construction industry. Greenwashing undermines the credibility of sustainability claims, leading to the adoption of unsustainable practices that do not address the environmental impacts of construction. Conversely, a circular supply chain can promote transparency and accountability in the industry by encouraging the reuse, refurbishment and recycling of materials and products. This can help reduce waste, carbon emissions and other negative environmental impacts while promoting innovation and economic growth. By adopting a circular supply chain approach and avoiding greenwashing, construction companies can position themselves as leaders in sustainability and create value for their stakeholders. In this issue, Andrew Cooper from Senior Architectural Systems discusses the theory behind supply chain circularity and how specifiers and manufacturers can implement it. Turn to page 24 to learn more.

Elsewhere in this issue, we highlight two inspiring architectural ventures: Heatherwick Studio's inaugural public library design in Maryland, USA, and SOUR's victorious design for the Geomdan Museum Library Cultural Complex in South Korea. Additionally, Kelly Westwood from Knauf Insulation offers valuable insights into ensuring the accuracy of your rainscreen insulation specification.

Klare

Sam

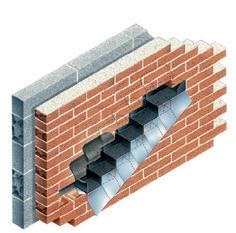

Compatible Compliant Protection

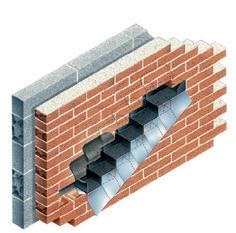

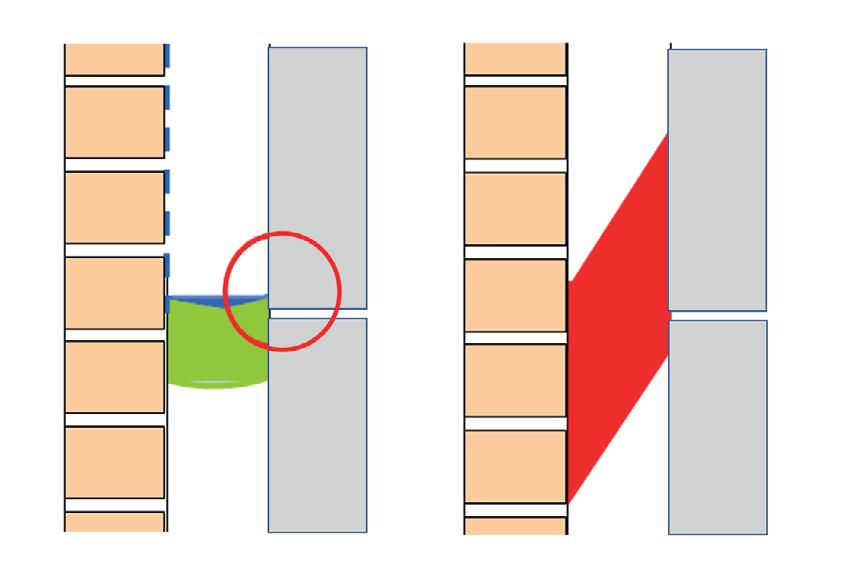

Lintel types and styles over cavity wall openings vary in size and shape. Using a preformed Cavitray instead of conventional DPC removes the variances of onsite cutting and forming.

and request our guide delivered to your door

FC&A – MAY – 2023 5 WELCOME NOTE ON THE COVER:

Geomdan

in Incheon, South Korea. SEE PAGE 18. REBECCA KEMP Editor, Future Constructor & Architect WELCOME TO Red Hut Media Ltd 5 Mansion Row, Brompton, Kent, ME7 5SE Tel: 01622 946150 Rebecca

MAGAZINE

SOUR, in collaboration with Seoinn Design Group, has been named one of the winners of the international architectural competition for the new

Museum Library Cultural Complex (GMLCC)

FUTURE CONSTRUCTOR & ARCHITECT

Rachel Pike accounts@redhutmedia.com SALES SUPPORT & STATISTICS

Ball klare@redhutmedia.com PUBLISHER

Terms and Conditions: Contributions are invited and when not accepted will be returned only if accompanied by a fully stamped and return addressed envelope. No responsibility will be taken for drawings, photographs or literary contributions during transmission or in the editor’s hands. In the absence of an agreement the copyright of all contributions, literary, photographics or artistic belongs to Red Hut Media Ltd. The publisher accepts no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the view of the publisher. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. MAY 2023 RED HUT MEDIA fcamagazine fcamagazine fcamagazine FC&A Magazine CAVITY TRAYS specialism • experience • service 01935 474769 enquiries@cavitytrays.co.uk www.cavitytrays.co.uk Yeovil • Somerset • England • UK

Ball sam@redhutmedia.com

Email enquiries@cavitytrays.co.uk

The compliant protection is scheduled, cost-controlled and stock-controlled. Type C Cavitrays – cavity width biased – self-supporting or inner leaf integration option – ready-shaped solution.

30 CONTENTS

Hollywood Monster's CEO, Simon McKenzie, is urging the industry to commit to trying new materials to reduce their carbon footprint and prevent plastic waste from ending up in landfills.

LEGAL & BUSINESS:

FEATURES

24 26 28 32 36 34

SUPPLY CHAIN CIRCULARITY:

Here, Andrew Cooper from Senior Architectural Systems discusses the theory behind supply chain circularity and how specifiers and manufacturers can put it into practice.

WATER MANAGEMENT & PROTECTION:

Wavin explains how innovative sustainable drainage systems (SuDS) are helping urban developers futureproof their projects and ensure our towns and cities remain resilient long into the future.

FACADES, RAINSCREEN & LOUVRES:

Kelly Westwood, Head of Construction Projects at Knauf Insulation, shares her expert insights on what makes a good specification, from fire safety to buildability.

ACOUSTICS:

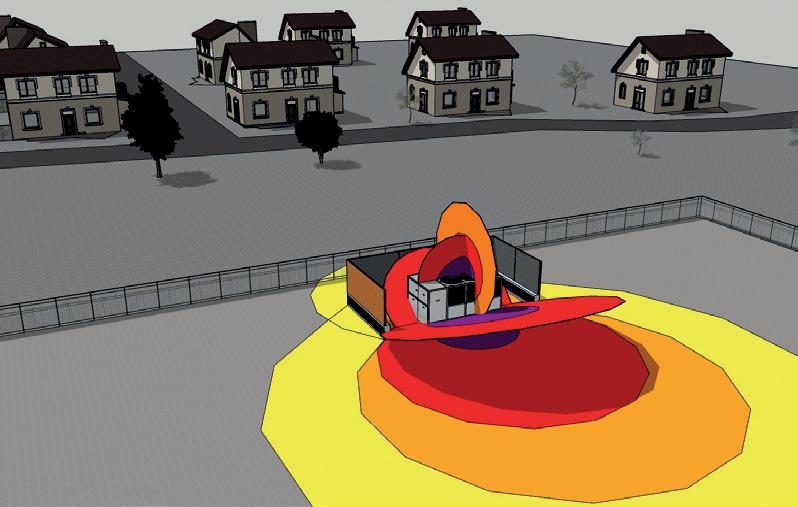

While air-source heat pumps offer a greener alternative to traditional methods, their acoustic challenges cannot be ignored. In CPW's latest article, Jamie Large, Senior Acoustic Consultant, explores how to deal with these challenges and provides tips for a robust acoustics strategy.

SECURITY & BUILDING ACCESS:

Ensuring the safety of building occupants in an emergency is crucial. Learn about the key considerations for specifying and installing panic and emergency exit hardware with expert advice from HOPPE brand ARRONE's Technical Manager, Rob Adams.

BUILD FOCUS: Housing Developments :

Mark Clark of Cemfree explains how greenwashing is deterring housebuilders from finding genuine carbon savings. In this article, learn more about the impact of misleading claims and potential solutions for a more sustainable future.

TECH NICAL INSIGHT: RCI :

PORTFOLIOS

MARYLAND, USA, PUBLIC LIBRARY, HEATHERWICK STUDIO:

Heatherwick Studio has unveiled its first public library design, which will act as a centre for events, learning and lending of objects of use. Set on Columbia's main promenade and with panoramic views of Lake Kittamaqundi, the library will serve all county residents and visitors from across the US.

GEOMDAN MUSEUM LIBRARY CULTURAL COMPLEX (GMLCC), SOUR:

James Pecz, Global Marketing & Business Development Manager at Ramtech, explains how connected technologies can provide a preemptive, proactive approach to managing risks and improving safety. 14 18

SOUR, in collaboration with Seoinn Design Group, has been named one of the winners of the international architectural competition for the new Geomdan Museum Library Cultural Complex (GMLCC) in Incheon, South Korea.

Sloping Abutments in Brick, Block or Stone

Combined ready-moulded DPC cavity wall protection with attached roof flashing

● Adjustable Type X Cavitray to suit all cavity widths

● Ready to use – eliminate cutting, fabrication and variances on site

● Control cost and stock + packaged per dwelling

● Look for the name and logo to secure approved ETA solution with accompanying warranty from the longest-established specialist

Cavitray

Compliancy

FC&A – MAY – 2023 6 CAVITY TRAYS specialism • experience • service 01935 474769 enquiries@cavitytrays.co.uk www.cavitytrays.co.uk Yeovil • Somerset • England • UK

& Consistency

Email enquiries@cavitytrays.co.uk and request our guide delivered to your door NEWS

20 22

VOICE OF THE INDUSTRY:

Discover how BMI Redland's Rosemary Clay Classic tiles were used in the complete roofing replacement for the Miller Court apartment complex in Romford, Essex, as part of a vital regeneration project.

COMPLETE CREATIVE FREEDOM

AWARD-WINNING WINDOW COLLECTION

The Origin Window Collection consists of two di erent systems –the OW-70 Slimline Window and the OW-80 Premium Window. Available in a wide range of configurations, colours and bespoke personalisation options, its versatile nature means it can o er e ortless elegance to any property.

Discuss your project with us today and visit origin-global.com/commercial or call 0808 192 0019 Product displayed: OW-70 Casement and Fixed Windows, Colour shown: Anthracite Grey7016M MADE IN BRITAIN ULTRA SECURE

Casement Bay

Gable

the rest of the

at

View

range

origin-global.com

PENDOCK CASING SOLUTIONS – THE ART OF CONCEALMENT

Since Pendock was formed in 1987, its name has become something of a byword for highquality, decorative casing and enclosure solutions for concealing structural elements and building services to improve a project’s aesthetics and, in many cases, provide protection.

PENDOCK

Wh ile all Pendock products are relevant to architects, specifiers and contractors, the most commonly specified are those within its Linea building lining and Radius column casing ranges.

L inea building linings

T he extensive Pendock Linea building linings range comprises nine different architectural finishing products. In addition to wall linings, ceiling rafts and lift reveals and soffit linings, the range also encompasses bulkheads and fascias, as well as parapet capping and pilasters and perimeter casings. Specialised rooflight linings and atrium beam casings complete the range.

Each provides a practical and aesthetic solution for specific applications while also retaining a high degree of versatility, as every Linea product is bespoke manufactured to the dimensions and specifications of individual projects.

T he Linea range allows architects to specify several lining elements within a project from a single source, as opposed to these items being unlisted or ‘floating’ within various sections of a specification document.

B y using this approach, a high degree of consistency can be achieved across different aspects of a project, as the elements can be manufactured, supplied and installed, if required, from a single specialist manufacturer. This helps reduce risk, mitigate potential coordination issues on site and allows a uniform, high-quality finish to be achieved.

Radius column casings

C olumn casings are a widely-used and highly-versatile method of concealing interior and exterior structural steelwork. Pendock’s Radius brand unites the company’s six individual column casing types to make specification simpler while also identifying the key differences between each option.

The pre-formed plywood range is purely for interior use and is available as circular or square profile casings, as well as extended circles or rectangular shapes. Although they are available unfinished for onsite painting, most are specified pre-finished with high-pressure laminates (HPL), which provides increased durability and a very wide choice of finishes.

G lass-reinforced gypsum (GRG) casings are also for interior use only and are regularly specified as circles. However, as they are produced from moulds, GRG casings can also be manufactured to bespoke shapes and dimensions to meet the needs of specific projects.

Pendock’s GRP casings are also produced from moulds, which enables them to be bespoke manufactured to meet individual project specifications. However, they can be specified for use on both interior and exterior applications. Their durability and weather resistance also make them well suited for high-traffic areas, such as public buildings and retail.

T he versatile metal column casing range is also designed for interior and exterior projects. As they are manufactured from aluminium or stainless steel, they are weather resistant, highly durable and can be specified in a wide range of standard and bespoke shapes with finish options including RAL, BS colour PPC finishes as well as anodised, brushed, polished and textured.

www.pendock.co.uk

01952

FC&A – MAY – 2023 8

580590 sales@pendock.co.uk

CASINGS

Ceiling rafts from the Pendock Linea range

Bespoke metal column casings – West Cheshire College

Square section column casings – Pendock Radius range

FC&A – MAY – 2023 9 Now you see it Now you don’t! Take control with SwitchableTM www.esg.glass t: 01376 520 061 e: sales@esg.glass

INDUSTRY UPDATES

IN BRIEF: HKR ARCHITECTS CONFIRMS ITS STEADY GROWTH WITH MOVE TO BRAND-NEW LONDON OFFICES

HKR Architects, a leading architecture and design practice, has recently moved to new premises in Southwark, London, and agreed to open a new office in Dublin 2, the Southside Quarter of the capital. Managing Director, Jerry Ryan, states that the expansion is in response to client needs, with highprofile projects in these core locations. HKR has recently collaborated with Atkins to gain planning for an affordable housing development in Hounslow West, which will include 348 homes, a retail store, public square and community spaces. HKR has also worked with Niche Living to deliver a co-living facility at Eblana Avenue, Dun Laoghaire.

LOW-CARBON CONCRETE TO BECOME STANDARD ON ALL LAING O’ROURKE UK PROJECTS

Laing O’Rourke has mandated the exclusive use of low-carbon concrete on all its new UK projects starting 1st April. The move follows a longterm research programme co-funded by the company and Innovate UK, and in collaboration with the University of Cambridge and Sheffield University’s Advanced Manufacturing Research Centre. The programme has proven that low-carbon concrete options can be used as a like-for-like substitute for traditional concrete. The switch to low-carbon concrete will reduce the company’s Scope 3 carbon emissions by 28% compared to its 2022 concrete usage, resulting in a saving of 14.4 million kgCO 2 e.

HOLLAWAY STUDIO TRANSFORMS RESTAURANT OF NEWLY-OPENED GRADE II-LISTED BOYS HALL, KENT

Hollaway Studio, the award-winning London- and Kent-based practice, has used sympathetic and considered design to transform the restaurant of the newlyopened Grade II-Listed Boys Hall in Ashford, Kent.

Boys Hall is a design-led hotel situated in Kent, England, just minutes from Ashford International Station. The Jacobean Manor building, originally built in 1616 and previously a wedding venue, has been transformed into a restaurant with rooms. The new restaurant seats 70 and is steeped in traditional methods and local heritage, including the use of 17thcentury building skills and materials with modern technology. The restaurant features glass walls, a large oak fireplace and natural light from a double rooflight that delivers views of the courtyard garden to the walled garden behind. The next phase of the project will be the design of a garden bar in the walled garden and lodges around the lake, using heritage building methods.

The hotel comprises seven en-suite bedrooms, two reception rooms, private dining rooms and the 70seat restaurant. The owners

of the hotel, Bradley and Kristie Lomas, restored the 400-year-old house with the help of family, friends and local specialists, transforming it into a beautiful restaurant with rooms set within three acres of grounds on the southern edge of the North Downs. Boys Hall was listed due to its historic significance, and the owners were granted permission to knock down an unsightly plastic conservatory with a swimming pool and replace it with the new

Restaurant at Boys Hall

restaurant. Hollaway Studio, the architect behind the restaurant’s design, worked closely with the owners to ensure that the new addition did not detract from the building’s history and listed status.

The second phase of the project is in planning, which will include the garden bar and lodges around the lake, with Hollaway Studio again using heritage building methods.

www.hollawaystudio.co.uk

FC&A – MAY – 2023 10 INDUSTRY UPDATES NEWS

HOLLAWAY STUDIO

FC&A ROUNDS UP THE LATEST INDUSTRY NEWS AND UPDATES.

Restaurant at Boys Hall

PERSONNEL

The latest appointments from the construction and architectural industries.

DHF ANNOUNCES NEW COMMERCIAL DIRECTOR

Door & Hardware Federation (DHF) has announced that the current Head of Commercial Operations, Patricia Sowsbery-Stevens, has been promoted to Commercial Director. The announcement was made by CEO Bob Perry in a statement that praised Patricia’s “significant development and improvement of our commercial offering involving membership, marketing and training”.

Patricia joined DHF in 2015, and over a seven-and-a-halfyear period, has transformed the Tamworth-based trade association into a modern, progressive, forwardlooking organisation that is committed to maintaining and raising quality standards and very much remains the industry’s ‘go-to expert’ on training and technical advice in the industries it serves.

WATSON BATTY ANNOUNCES BOARD DIRECTOR TRANSITION

Andrew Grindrod, a Board Director at Watson Batty Architects, is stepping down from his senior role after dedicating 22 years to the award-winning practice. Grindrod’s contribution to architectural design has had a significant impact on the Yorkshire landscape, particularly in the care and supported living sectors. Watson Batty has grown to become a UK-leading practice with 35 employees nationwide working for many leading brands. Grindrod has been a popular and proactive ambassador for the business and the industry, and his leadership and commitment will be missed. The practice continues to thrive, with a robust and incentivised team in place, focusing on sustainability, fire safety, modern methods of construction and inclusive design.

MATTHEW ROBINSON JOINS DESIGN TEAM AT BOYER

Matthew, a Senior Architect at Boyer, has over seven years of experience in residential design. He joins from Morse Webb where he led the design of bespoke residential developments, which ranged from domestic extensions to larger housing developments. Prior to that, Matthew worked for Ayre Chamberlain Gaunt, where he qualified as an architect and gained considerable experience on larger housing schemes. Matthew studied for his BA in Portsmouth and Masters in Architecture at the University of Kent before obtaining his qualification as an architect from the University of Bath. Nigel Booen, Director of Architecture at Boyer Design, said: “We are delighted to welcome Matthew to Boyer. This comes at a time when commitment to placemaking and design excellence is essential.”

MARCHINI CURRAN ASSOCIATES APPOINTED TO LANDMARK CLARENDON CENTRE REDEVELOPMENT

Marchini Curran Associates has been appointed as the architect and interior designer for the redevelopment scheme of the Clarendon Centre in Oxford. The scheme will transform the shopping arcade into a mixed-use scheme, including a highspecification research and development facility in partnership with Oxford Science Enterprises. The development will also feature student and Grade A office accommodation, retail and leisure units, and a new public square. The first phase of the project is set to begin in Q1 2023, with completion expected in Q2 2025. Marchini Curran Associates has designed a diverse portfolio of projects across various sectors since its formation in 2002.

GRAHAM UPSKILLS EMPLOYEES WITH BESPOKE FIRE AWARENESS TRAINING

Contractor GRAHAM has partnered with firestopping solutions manufacturer Nullifire to provide fire awareness training to more than 100 of its employees. The in-depth training, developed by Colin Green, Area Sales Manager for fire protection at CPG UK, was designed to upskill the team in fire prevention and protection information for day-to-day activities. The training was facilitated both in office and on site, and employees from all levels of the business, including directors, quantity surveyors, site managers and planners, have participated in the sessions, improving everyone’s awareness of fire risks across different disciplines and onsite environments.

FC&A – MAY – 2023 11 NEWS

IN BRIEF:

INDUSTRY UPDATES

Restaurant at Boys Hall

UPDATES

ARCHITECT IN PROFILE

Meet Jerry Ryan, Director of HKR Architects, who shares insights on his career, inspiration and approach to sustainable design. Read on to discover his notable projects and thoughts on the greatest challenges for architects today.

www.hkrarchitects.com

Please tell us a bit about your career background.

In the 1980s, I worked in several practices in Dublin, eventually leaving to establish HKR Architects in 1992. I chose not to work for any of the ‘great gods’ of architecture, focusing instead on developing the skillsets necessary to design and deliver large-scale commercial projects. In the early days, these included Microsoft’s first HQ in Ireland (which signalled the beginning of foreign direct investment in Ireland) and the David Lloyd Tennis Centre in Dublin (formerly Riverview Tennis Centre).

Have you always wanted to pursue a career in architecture?

I was greatly interested in Greek and Roman cultures and their imposing public edifices. The Romans invented the basilica, the amphitheatre, the aqueduct and the first residential housing blocks. The Temple of Knossos, built 4000 years ago, was a very sophisticated structure with all the infrastructure of a modern city; hot running water and drainage. It intrigued me that they had the skillsets all those years ago. Architecture is not only a representation of a society or culture but also holds out the potential to positively impact society. It affords the opportunity to create buildings and public spaces that can improve the quality of life of those who inhabit them. When I joined Horan Cotter, I developed a keen interest in residential design, in many ways the most challenging sector for any architect.

HKR was founded in 1992 with some colleagues from Horan Cotter, and over time, we grew the business by empowering our key people who became stakeholders in the business. We followed clients into London and Central Europe opening offices in seven different jurisdictions. Our largest project executed to date is Abu Dhabi Plaza in Astana. It was the subject of an intergovernmental agreement, a $2bn project that included the tallest tower in Central Asia. HKR not only designed the building but followed through and delivered it on site.

What has been your greatest influence and source of inspiration?

I don’t have one single source of inspiration. There are many notable buildings we can point to, but I am energised when I get the opportunity to visit cities seeking out buildings and structures of interest. London has a rich history and a correspondingly rich tapestry of buildings ranging from the Georgian and Victorian eras through to the Post-War Modernism of the Barbican estate to the Postmodern Gherkin.

What has been your most notable project to date?

Abu Dhabi Plaza, Astana, ranks as our most notable in terms of sheer scale.

Another is Moor Place in London, a 12-storey BREEAM-rated ‘Excellent’ office building with a series of stepped-back, green-landscaped roof terraces to the upper levels, providing spectacular city views. We had to respond creatively to the constraints imposed by the proximity of the Barbican estate, St Paul’s and the subterranean Crossrail tunnel, which resulted in creating a wedge-like form design with the building floating on iconic, splayed columns and large open-plan floor plates that cantilever over the tunnel beneath.

FC&A – MAY – 2023 12

INDUSTRY

HKR ARCHITECTS

JERRY RYAN IS THE DIRECTOR AT HKR ARCHITECTS

Smithfield Square in Dublin

Lastly, Smithfield Square in Dublin, a large mixed-use development on a four-acre plot that forms the western side of the historic square, is notable as it creates a significant new public realm, including a new square and curved street. It was built 20 years ago and still looks fresh.

How do you approach your projects?

All projects are delivered through effective teamwork, where all disciplines work harmoniously to optimise the design. Where possible, we will select team members whose skillsets are aligned with the design challenge. Every project has different challenges. At the early design stages, we are not prescriptive and maintain a degree of loose fit in the evolution of the design so that we can embrace the aspirations

of other stakeholders, such as local councils or, on occasion, the interests of adjoining property owners/occupiers. As a commercial practice, we understand the importance to clients of delivering projects on time and budget. We ensure there are always two directors involved in each project, specifically the design lead and a construction lead providing the design principles are developed into rational constructible and affordable outcomes.

What do you think is the greatest challenge for designing in sustainability?

As sustainable designers, we must reduce negative impacts on the environment and the health and wellbeing of building occupants, thereby improving building performance. Buildings

are massive raw materials and energy users. We need to reduce/eliminate the use of virgin or nonrenewable materials and develop a new material mindset. We also need to embrace the use of fewer materials in buildings. Prefabricated construction offers a pathway to efficient material usage and eliminates waste.

What is your favourite building and why?

There is no one building that comes to mind. In Dublin, I admire Busaras, a building inspired by some of Le Corbusier’s pre-war work, such as Maison Suisse, with the use of elements like pilotis, glazed facades and a pavilioned top storey.

In London, I regularly defer to the urban housing projects designed by Neave Brown and Peter Tabori in Camden in the 1960s, where the architects turned away from the cult of tower blocks and returned to the concept of streets with front doors. Like the majority of my peers, I would love to live in the Barbican estate developed from designs by Chamberlin, Powell and Bon. It is one of London’s best examples of Brutalist architecture. I particularly acclaim the stunning outdoor spaces by the water and the private residents’ garden.

What do you think is the greatest challenge for architects today?

There are several challenges. The architect must strive to remain the design team lead. In recent years, the architect’s role has been undermined by the many consultants involved in projects – much driven by over-regulation, which, in turn, leads to an inevitable increase in construction costs.

By way of example, apartments now cost circa £3000 per square metre to build in the UK, while in the US, that figure is half! We must find ways to build affordable homes for people. Every European city is struggling to house its burgeoning population. It is a huge political challenge.

Architects can be part of the solution by promoting new materials, such as timber frames and offsite construction methodologies.

What do you think is the greatest challenge for architecture students now?

As with qualified architects, maintaining an upto-date knowledge of the technologies that will drive sustainability in the industry. Additionally, the advent of artificial intelligence in design is the great known unknown.

What advice would you give to newly-qualified architects?

The world has moved eastwards. Travel. Gain international experience in your first years of practice. Bring the knowledge home and challenge the conventions of our existing construction sector.

What can we expect to see from you over the next year?

As a medium-sized practice, we enjoy working on both large- and small-scale projects. Everything from masterplans in the MENA region to boutique hotels to the occasional one-off houses in the UK/IRE.

In the case of large-scale projects, we can act as lead design consultant managing, on many occasions, the inputs of up to 15/20 sub consultants. As stated, we see the architect’s traditional role as that of the leader of the design team.

Closer to home, we will be delivering several new hotels and residential projects. The practice will continue to grow organically and steadily.

FC&A – MAY – 2023 13 INDUSTRY UPDATES

Abu Dhabi Plaza in Astana

Abu Dhabi Plaza in Astana

Abu Dhabi Plaza in Astana

A NEW CHAPTER: HEATHERWICK STUDIO’S REVOLUTIONARY LIBRARY DESIGN

Heatherwick Studio has unveiled its first public library design. Conceived for Howard County Libraries in Maryland, USA, the building will reflect the changed role of the library and serve a community with a rich heritage of fostering diversity and promoting wellbeing in the city.

HEATHERWICK STUDIO

Th e new library will sit at the heart of Columbia, a planned community consistently voted as one of the best places to live in the USA. Working with Howard Hughes Company and the Howard County Library team, the studio has designed the building to reflect the changed role libraries play in our lives. Going beyond a simple repository of knowledge and book-lending services, the new space will act as a centre for the community and will become Columbia’s hub for events, learning and lending of objects of use, such as art or tools.

Stuart Wood, Partner and Group Leader at the studio, says: “Columbia has always been driven by a socially radical vision. This legacy inspired us to evolve the traditional library beyond books and into a new type of community centre for broader learning and social exchange. A walkable, planted building that emerges from the lakeside landscape will house an amphitheatre for events, play areas and light-filled rooms designed for working and learning anything from cooking to IT. This will be the community centre everyone in Howard County deserves.”

FC&A – MAY – 2023 14 MARYLAND, USA, PUBLIC LIBRARY, HEATHERWICK STUDIO

All images: ©Devisual for Heatherwick Studio

I nspired by the vision of James Rouse, the founder of the community who saw “cities as gardens for the growing of people”, the building will be tightly integrated into the neighbourhood both through its facilities and its location. Set on the city’s main promenade and with panoramic views of Lake Kittamaqundi, the library is designed to host educational and cultural programmes. Its five storeys will accommodate working spaces and play areas as well as a makers’ lab, teaching kitchen and a cafe.

T he building itself appears as if lifting from the surrounding landscape, with cascading planted staircases weaving across the facade to reveal the open, double-storey atrium where the

county plans to host a programme of public events. Honouring the Rousian vision of respect for nature for the enjoyment and recreation of the city’s residents, the building’s many terraces will be richly planted with native plant species. The facade will seamlessly join with the surrounding public park and lakefront, thus becoming an integral part of the community’s natural gathering and relaxation place.

T he library will serve all county residents and as well as visitors from across the US. Construction is expected to start in late 2024, with the library opening to the public in 2027.

www.heatherwick.com

FC&A – MAY – 2023 16

MARYLAND, USA, PUBLIC LIBRARY, HEATHERWICK STUDIO

FC&A – MAY – 2023 17 Heavy duty folding ladder for strength & durability (load rating of 250 kg/tread) Highly insulated hatch to keep in the warmth (U value from 0.34 W/m K ) Counter-balanced operation for ease of use w w w.premierlof tladders.co.uk/k limatec 0345 9000 195 | sales@premierloftladders.co.uk 30 minutes

GEOMDAN MUSEUM LIBRARY CULTURAL COMPLEX: WHERE THE PAST MEETS THE FUTURE

SOUR is excited to be among the winners of the international architectural competition for the new Geomdan Museum Library Cultural Complex (GMLCC) in Incheon, South Korea.

Th e metropolitan city of Incheon, together with the Housing and City Development Corporation, organised an international competition for the new Geomdan Museum Library Cultural Complex. Of the 75 entries from around the world that responded to the open call, SOUR, in collaboration with Seoinn Design Group, was selected among the final five to present for the second stage of evaluations in front of an international jury. The jury decision was announced by the metropolitan city of Incheon, together with its Housing and City Development Corporation, during the ceremony at the Center for Architecture and Metropolitan Planning in Incheon, South Korea. The design team, led by SOUR, was awarded the fourth prize.

T he proposal’s ambition was to urge architects to a necessary paradigm shift in the making of landmark architecture, where the design criteria and form

making should be driven by energy endurance and climate resiliency.

T he proposal envisages a cultural, eco-friendly community landmark housing a futuristic library and indooroutdoor museum, working together to become Geomdan’s new archaeology park: a place for nature and people to thrive and explore and where form follows sustainability measures and environmentally-responsible design.

“Climate and energy crises, the global economic downturn and the COVID-19 pandemic urge us architects to re-evaluate our priorities and methods in the generation of signature architecture,” explains Inanc Eray, Partner and Creative Director at SOUR. “Any and all proposals for the built environment need to present purposefully-viable solutions that address issues around energy usage, material waste, supply chain inefficiencies and carbon footprint. We, therefore, had two main questions with the design of

this building: ‘How might we use lowtech strategies for the (re)discovery of sustainable landmark architecture?’ And ‘how might we evolve beyond energyintensive technologies and high-cost construction methods to generate scalable solutions in the built environment?’

“ We believe that a landmark project, such as a new library and museum complex, represents a great opportunity to reform landmark aesthetics to be informed by climate resilience and to rediscover low-tech strategies to generate truly sustainable architecture, and I hope we have a glimpse of what this shift can look like here.”

T he new Geomdan Museum Library Culture complex will help kick start the transformation of one of Incheon’s most important brownfield sites, which will eventually become home to 180,000 residents. www.sour.studio

FC&A – MAY – 2023 18 GEOMDAN MUSEUM LIBRARY CULTURAL COMPLEX (GMLCC), SOUR

SOUR

FACT FILE:

Project: Geomdan’s Museum Library

Cultural Complex

Typology: Cultural venue, museum, library and park

Location: Incheon, South Korea

Date: 2023

Area: 27,768m2

Client: Incheon Housing and City

Development Corporation, Incheon

Metropolitan City

Credits:

Architects: SOUR Studio + Seoinn

Design Group

Design: Inanc Eray with Dong Kyu Choi

Design team: Pinar Guvenc, Alex Yoocheol Choi, Marianne de Zeeuw, Mariana Evangelista, Merve Guven, Pinar Gursoy, Merve Akbay, Irem Gocmenoglu, Derin Sahin, Nicholas Doghlass and Gamze Gurgenc

FC&A – MAY – 2023 19 GEOMDAN MUSEUM LIBRARY CULTURAL COMPLEX (GMLCC), SOUR

All images: ©SOUR

FOOTNOTES:

1Department for Environment, Food & Rural Affairs (DEFRA)

2Department for Environment, Food & Rural Affairs (DEFRA)

CALLS FOR THE CONSTRUCTION

INDUSTRY

TO STOP THE USE OF HARMFUL PVC SIGNAGE

Hollywood Monster, one of the UK’s leading printing and signage contractors, is calling on the construction industry to do more when it comes to reducing the use of harmful plastic signage.

As the rest of the UK reduces its plastic waste by 2.6%, the UK construction industry increased its plastic waste by 46% 1 over the same two years. Hollywood Monster thinks it has the answer; sustainable signage, including hoardings, banners and interior fit outs, to name a few.

N ewly-developed eco-friendly materials are available, but Simon McKenzie, CEO at Hollywood Monster, explains: “We have seen fantastic advancements in the development of eco-friendly alternatives to plastic materials over the last 10 years or so, and we have been working hard with our partners to offer sustainable alternatives to our customers. That being said, although companies are looking to reduce their carbon footprint and grow towards being more environmentally friendly, we have found many are hesitant to commit to trying new materials that they haven’t had experience with before.

“ What we want to do is to reassure the industry that these new eco-friendly materials are high quality, affordable and durable and

will stop some of the 98,284 tonnes of plastic the construction industry produces 2 ending up in landfill. Not only do we vigorously test every new material before adding it to our range, but its durability can be proven by many case studies.”

H ollywood Monster has been working with McDonald’s for over 20 years and has transformed over 1000 of its restaurants across the UK and Ireland, supporting it on its sustainability journey.

I n the last 18 months, Mcdonald’s has reduced carbon emissions by an impressive 132.3 tonnes just by swapping PVC print and signage for other environmentally-friendly options.

H ollywood Monster uses a material called Kavalan as an alternative to PVC. Changing one million square metres of PVC to Kavalan will not only prevent one million square metres of PVC from going into landfill, but it will also produce the following amount of clean energy and local heat:

1 .22 million hours of iPhone usage

5 8 days of heating for a typical UK threebedroom house.

FC&A – MAY – 2023 20

VOICE OF THE INDUSTRY

SIMON MCKENZIE IS THE CEO AT HOLLYWOOD MONSTER

HOLLYWOOD MONSTER

There is a wide range of alternatives to PVC banners; however, hoarding substrates are notoriously difficult to produce from eco-friendly materials without a substantial cost to the buyer.

Hollywood Monster has been working with its partners to offer the industry a 100% recyclable hoarding. It is so committed to sustainability that it is absorbing the 20% cost increase it takes to manufacture it. As a result, it is providing its customers with revolutionary eco-friendly materials at the same cost as non-sustainable alternatives.

Thanks to Hollywood Monster’s commitment and engagement with innovative suppliers, the amount of its signage ending up in landfill has been reduced by 80%, with a view to offering a 100% sustainable range by 2025.

S imon goes on to explain: “We’re pleased that we have been able to reduce our impact on landfill, however, we would like to see the entire process of making, displaying and disposing of signage eco friendly, from using plastic bottles to making pellets that then produce biodegradable materials, to working with our customers to recycle unwanted displays collectively.

“ It’s an exciting time for our industry as we continue to develop new formulas on our sustainable range to give the products more weldability and strength. We enjoy working closely with trusted partners to offer the industry new, revolutionary materials that help to limit our impact on the environment.

“Our vision is to collaborate with all those who work within the print industry and who use signage in their operations to achieve a 100% sustainable rage by 2025, negating the need for PVC altogether.” www.hollywoodmonster.co.uk

FC&A – MAY – 2023 21 VOICE OF THE INDUSTRY

JAMES PECZ

IS THE GLOBAL MARKETING AND BUSINESS

DEVELOPMENT MANAGER AT RAMTECH. A 20-YEAR VETERAN OF THE CONSTRUCTION MARKET WITH FIRE SAFETY TECHNOLOGY INDUSTRY EXPERIENCE, JAMES IS TASKED WITH LAUNCHING RAMTECH’S SYSTEMS INTO THE NORTH AMERICAN MARKET, WITH A STRATEGIC FOCUS ON IMPROVING ONSITE SAFETY AND PROJECT RISK MANAGEMENT SERVICES.

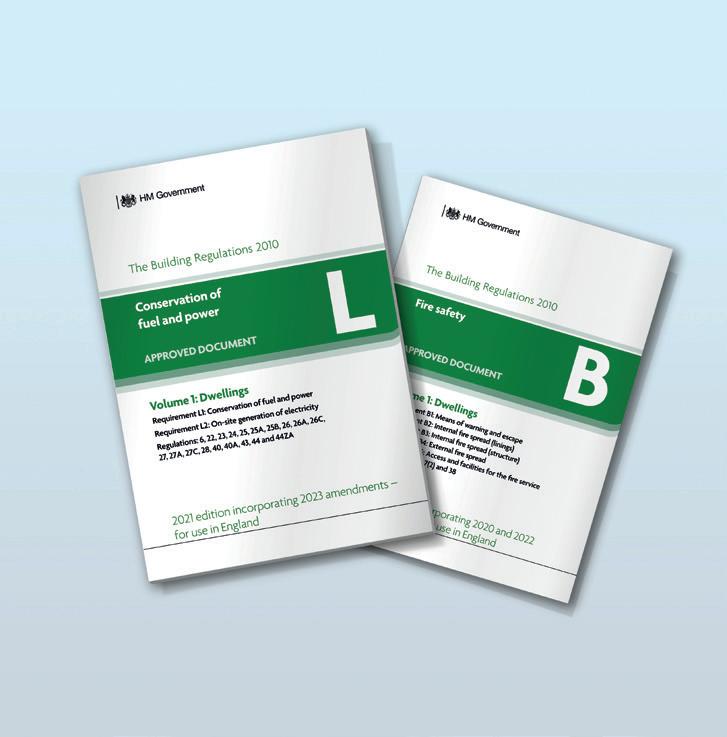

PREVENTION IS BETTER THAN CURE

Construction sites are dangerous places to work, with many tools and machinery needing constant supervision and the ever-present prospect of life-threatening consequences for small mistakes. To manage these risks, the industry must move away from detecting and responding to emergencies and instead look to connected technologies to provide a preemptive, proactive approach.

It is well documented that construction sites are dangerous places to work.

In fact, figures from the Home Office show that between April 2018 and March 2019, fire and rescue services attended 365 fires on building sites in England – increasing from 333 in 2014/15. And between April 2019 and March 2020, there were 4566 injuries to employees on UK construction sites.

E mergencies and hazards can be highly devastating, putting workers at risk and threatening the lives and property of the public in surrounding areas – not to mention how destructive they can be in terms of damage to materials and delays to the construction programme.

Using technology to improve site safety

A lthough a construction site full of primitive tools and raw materials may seem like an unlikely place to find the latest cloud-based innovations, advances in technology are helping to bring 24/7 safety to sites.

S mart equipment integrated with an IoT software platform creates a safer community where workers are connected with their environment, safety managers and their wider team.

W hile the construction industry has been moving forward with the adoption of technology in recent years, the COVID-19 pandemic has accelerated this trend to levels that were never anticipated.

T his innovation has given property owners, project supervisors and safety personnel the ability to receive alerts for a variety of events in real time – helping to prevent accidents, unauthorised access, vandalism and disasters.

A post-pandemic world

Even after the pandemic has ended, unsecured construction sites remain vulnerable to numerous threats, such as arson, vandalism, theft and trespassing accidents, to name a few. For example, the combination of waste and combustible material, wooden framing and a lack of fire-protection assets can turn one small ember into a full-scale blaze. Early detection of the threat of a fire can make a massive difference to the outcome, and this is happening right now with devices that monitor smoke or heat.

W ireless fire alarm systems have advanced greatly over the past few decades and contribute to solving these problems. Take our WES fire alarm system, for example; it can connect to our REACT platform, which is a real game changer for the industry as it has features that reduce risk and prevent incidents from occurring –avoiding potential loss of life entirely.

C urrently, innovative wireless technology is being used to alert all relevant personnel to emergencies as soon as they occur, enabling the situation to be stopped in its tracks before it becomes a full-blown disaster.

H owever, looking ahead, cloud-based data and integrating systems such as REACT with wearable devices, smart PPE and intelligent hard hats, for example, will take it one step further – raising the alarm to a potential risk so it does not even turn into a minor emergency.

Looking ahead

A ny security system works best when its individual components work together cohesively. Machine-to-machine technology through IoT now gives those components the ability to instantly and reliably stay connected and ‘speak’ to one another and key personnel.

Traditionally, the construction industry has been slower to adopt the digital technologies that have been radically changing other sectors. However, the growing need to avoid delays and improve safety has pushed the industry to embrace various technologies.

A s we look towards the future of construction site safety, the real role and power of technology must be outcome driven. Using technology to improve the way things are currently done while achieving the same outcomes is not enough – the results really need to change. Luckily, the technology needed to do this is already out there; it just needs to be adopted by sites wanting to take a preemptive approach.

www.ramtechglobal.com

FC&A – MAY – 2023 22

LEGAL & BUSINESS

RAMTECH

FC&A – MAY – 2023 23 The e cient and e ective solution. Bene ts at a glance • Double-headed con guration can be installed before or after placing slab rebar • Quick and easy to install • Safety through BBA technical assessment • Supported by user friendly software for a simple design www.schoeck.com/en-gb/bole Schöck Bole®. From the experts in punching shear rail reinforcement. Energy Efficient Timber Windows and Doors 01344 868 668 www.sashwindow.com Traditional timber windows and doors, tailor made to your requirements. Conservation Area specialists. Supply only, supply and install, bespoke secondary glazing and draught proofing.

GOING ROUND IN CIRCLES?

MAKING SENSE OF A MORE SUSTAINABLE SUPPLY CHAIN

The road to net zero may be leading the construction industry in a new direction, but some processes, like the reliance on linear supply chains, can prove to be hard habits to break. Andrew Cooper, National Specification Manager from Senior Architectural Systems, one of the UK’s largest privately-owned aluminium fenestration solutions providers, discusses the theory behind supply chain circularity and how specifiers and manufacturers can put it into practice. SENIOR ARCHITECTURAL SYSTEMS

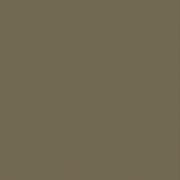

Su stainability is, as it should be, a key priority for the construction industry, and everyone has a role to play in reducing the environmental impact of the work we do. Last year’s uplift to the Building Regulations highlighted the importance of making and using more energy-efficient products, and the need to provide fully Part L-compliant systems has certainly encouraged significant innovation within the fenestration sector.

O ther important regulatory changes, such as the Building Safety Act and the planned Future Homes Standard, further support the ideology that the performance of building materials when in situ is only really as good as the quality of technical information, test results and third-party accreditations that support them. By only focusing on how well a window, door or other system performs when operational is to lose sight of the important issue of embodied carbon, which is often the more accurate indication of how sustainable a product

really is. Looking at whether a circular supply chain is in place is one of the best ways to get the whole view.

Working in the right circles

A circular supply chain is often based on three broad principles – reduce, reuse and recycle. This encourages the greater use of recycled materials in manufacturing to lessen the industry’s reliance on raw materials and natural resources. It also encourages the reuse of these materials at the end of a product or building’s life to reduce the amount of waste being produced and sent to landfill. Of course, this is a very simplistic overview as, in reality, there are many specific environmental, economic and logistical issues that need to be addressed and these vary greatly depending on the type of product in question. For example, some products may be able to be made from recycled materials but can not be as easily recycled at the end of life. Others may be able to be recycled in theory, but the

process could be so energy intensive that it becomes prohibitive. However, many manufacturers are increasingly being able to support the ‘cradle to cradle’ recyclability of their products and this closed loop is what gives a circular supply chain its shape. This has been widely adopted within the aluminium fenestration industry and has been a key focus for Senior as we look to reduce the environmental impact of our own manufacturing process. So, what does supply chain circularity look like in reality?

Sustainable supply chains in action

T he aluminium industry is a good example of a circular supply chain for many reasons, not least because aluminium is used to create numerous materials and products that are used extensively across the built environment. In fact, the development of thermally-efficient and low-U-value aluminium windows and doors have been essential in providing a Part L-compliant solution to reducing

FC&A – MAY – 2023 24 SUPPLY CHAIN CIRCULARITY

energy loss in new-build properties. Aluminium can also be endlessly recycled, without any detriment to its quality, and this plentiful supply can be reused to create new aluminium products, thereby reducing the reliance on the use of raw materials.

P artnering with an experienced and reputable product manufacturer that already has invested heavily in the sustainability of its products is one of the easiest ways that specifiers can tap into the benefits of a circular supply chain. Working with a UK supplier that also has a UK-based supply chain will also reduce risk and embodied carbon generated through transportation. Another benchmark is to choose a supplier that holds accreditation to BRE Global’s BES 6001 standard, which supports their commitment to the responsible and sustainable sourcing of construction materials.

A circular supply chain is only as successful as each of its component parts. For example, there must be enough investment in the development of suitable recycling plants so that the building products can be broken down and the aluminium elements recycled for future use. Ideally, these need to be located within the UK. Manufacturers must then commit to the responsible sourcing of recycled aluminium for use in the production of their own products. Architects, main contractors and end clients not only need to promote the use of sustainable materials but also need to ensure that they are disposed of correctly at the end of the building’s life.

Everyone has a role to play, and by taking a more holistic approach to the whole lifecycle of a product, collectively, we will fuel the collaboration and innovation needed to make supply chain circularity more widely accessible.

www.seniorarchitectural.co.uk

FC&A – MAY – 2023 25 SUPPLY CHAIN CIRCULARITY

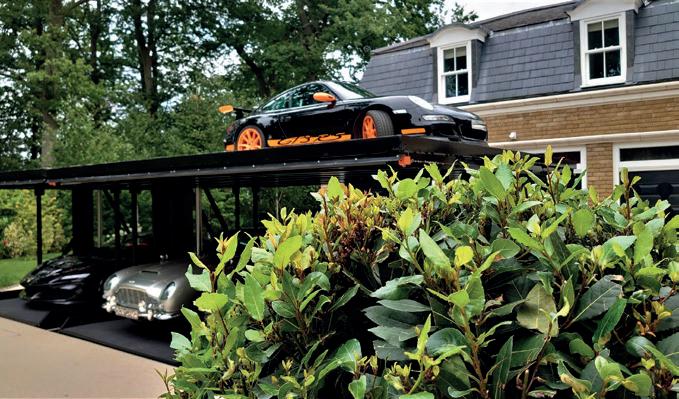

HELPING URBAN DEVELOPERS OUT OF A TIGHT SPOT

The latest report from the Intergovernmental Panel on Climate Change (IPCC) is a final warning on the climate crisis and an acknowledgement that weather patterns are progressing faster than expected. In UK cities, this means more frequent and intense rainfall events, resulting in more pressure on urban drainage systems. Here, Martin Lambley, Product Manager for Urban Climate Resilience, Northwest Europe, UK and Ireland at Wavin, explains how effective rainwater management requires an innovative approach in tight urban spaces.

In the UK, our urban communities have expanded at a faster rate than the supporting infrastructure – a problem that is particularly acute when it comes to water management. In fact, much of the water infrastructure in the UK dates back to the Victorian era and lacks the capacity and performance to handle the extreme weather of a changing climate and the growing population. Large-scale futureproofing of public infrastructure is likely to be a slow process, but there are measures that developers can put in place in their projects to ensure they remain resilient long into the future.

A new approach

P rotecting our cities from extreme weather requires a change in how we think about water in urban environments. Our current approach to rainwater is to get it out of town as quickly as possible with drainage systems that simply aren’t up to the job. Instead, developers and urban planners are increasingly looking to sustainable drainage systems (SuDS) as a water management solution that mirrors the natural water cycle.

SuDS are already widely used in new developments, but to deliver the necessary upgrades to our infrastructure, it is crucial to also incorporate them into urban retrofit

applications. The most effective SuDS combine natural elements, such as ponds, soakaways and swales, with artificial belowground systems like attenuation tanks. These are essentially large tanks that sit below the surface to prevent systems from becoming overwhelmed during extreme rainfall events and offer the more robust protection that we’re likely to need in years ahead.

H owever, attenuation tanks are often large and bulky, which poses a unique challenge in urban locations where space can be more restricted. Developers are under pressure to avoid delays to projects, which means opting for rainwater solutions that are straightforward to install while still

FC&A – MAY – 2023 26 WATER MANAGEMENT & PROTECTION

WAVIN

offering the necessary performance to perform long into the future.

C ity smart

T he latest attenuation tanks have been designed to address this issue. Minimising the space they take up on busy work sites was a priority for Wavin when designing its latest solution, the AquaCell NG, which has a nested design that allows it to be stored in a quarter of the space required for the previous generation.

This isn’t just about keeping sites tidy –cluttered working environments present a serious safety risk for people working throughout the site. City-centre builds also pose challenges when it comes to receiving deliveries, with tight site access arrangements meaning potential road closures that cause significant disruption to the surrounding community. Equally, a compact system requires fewer site visits to be delivered, freeing up slots for other deliveries and reducing the emissions burden of the project.

Intuitive installation

A s below-ground drainage systems are one of the first things to be installed on construction projects, delays or disruptions at the installation stage can have damaging knock-on effects for the rest of the build. With construction workflows looking further ahead than ever, the impact on schedules for deliveries and the work of other contractors goes beyond a couple of wasted days.

M any of the innovations that have transformed the latest generations of artificial SuDS are focused on making the installation process a faster and smoother one. Push-fit functionality is one such development, with integrated connectors allowing the system to be assembled without the need for tools, clips and pegs, dramatically speeding up the process. With this technology, AquaCell NG is three times faster to install than the previous generation, and the process can be completed by a smaller workforce.

Staying afloat

T he artificial components of SuDS need to be designed in line with the reality of the challenges that developers encounter on urban sites. There is still time to avert the worst effects of the climate crisis, but change will be gradual, and we will have to weather the more frequent storms that it brings in the meantime.

For developers looking to futureproof their projects, it’s an opportunity to learn from our mistakes and pick an approach that looks beyond diverting water away as fast as possible. While this is easier said than done on tight sites and even tighter schedules, the latest generation of SuDS from Wavin are purpose built for these environments to ensure our towns and cities remain liveable and lovable.

www.wavin.co.uk/nextgen

FC&A – MAY – 2023 27 WATER MANAGEMENT & PROTECTION

A smaller installation team is also a safer one, as fewer people spend less time in the trench and in harm’s way.

WHAT MAKES A GOOD RAINSCREEN INSULATION SPECIFICATION?

The legislative landscape is changing at pace, not only bringing in stricter standards for how buildings must perform but also placing greater emphasis on accountability and product choice. So, to ensure your rainscreen projects perform in the real world, Kelly Westwood, Head of Construction Projects at Knauf Insulation, explains the factors that you need to consider to get your insulation specification right.

Failsafe fire safety

When specifying rainscreen facade insulation, always start with fire safety. In December 2022, the ban in England and Wales on using combustible materials in the external walls of relevant residential buildings was widened to cover all residential buildings between 11 and 18m high. The only exception for rainscreen facade systems is where a full-scale fire test to BS 8414-1 or BS 8414-2 has been conducted. Such tests are prohibitively expensive, and the system must be identical to that used for the test, so combustible materials have effectively been banned in external walls of residential buildings with rainscreen facades.

The changes also affect non-dwelling buildings. Materials used in the external walls of assembly and recreational buildings within 1m of a relevant boundary must have a reaction to fire classification of B-s3,d2 or better. For assembly and recreation buildings over 1m from boundary, classification B-s3,d2 or better is only required from 18m and above.

KNAUF INSULATION

While designed to improve fire safety, the changes add complexity. So, the best way to mitigate risk is to use noncombustible mineral wool insulation with A1 or A2-s1,d0 reaction to fire classification regardless of height or building type.

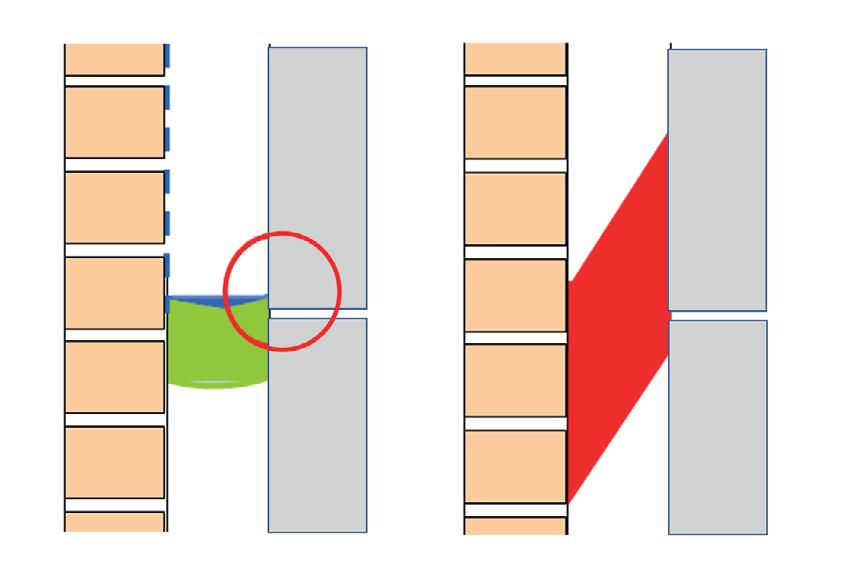

Accurate thermal modelling

Once you have fire safety covered, you can look at thermal performance. Approved Document L England and Wales was updated last year, bringing in much stricter thermal performance standards. The transition period ends on 15th June 2023.

Stricter standards are essential, but buildings will only deliver that performance in the real world if designs are underpinned by accurate thermal modelling.

Rainscreen facade systems feature numerous metal components that penetrate the insulation, compromising thermal performance. But the most common type of U-value calculation, the simplified methodology, cannot

accurately account for this, because a blanket correction factor is applied. This means insulation may not achieve the targeted U-value or may be overspecified, suggesting a thicker solution is required, increasing costs.

Instead, architects and designers should insist on the numerical method or 3D U-value calculations to BS EN ISO 10211. These calculations account for the precise bar and bracket configuration, so you can be certain your insulation and wall build up will perform as it is designed to.

Ensure compliance

In construction, there’s always the risk that one product can compromise the performance of another. Taking a system approach can help to mitigate this risk.

For example, specifying a throughwall system gives reassurance that the different elements of the wall build up have been designed to work together and have been tested both individually and as a system.

FC&A – MAY – 2023 28 FACADES, RAINSCREEN & LOUVRES

KELLY WESTWOOD IS THE HEAD OF CONSTRUCTION PROJECTS AT KNAUF INSULATION

A system approach should also be considered for fireresistance products such as cavity barriers behind masonry facades. Traditionally, these are installed by cutting into the insulation, which could introduce air gaps that reduce performance. Now it’s possible to get a system that includes cavity barriers that are installed against the face of the insulation, so no post-installation cutting is required.

Once you’ve identified suitable products or systems, it’s important to check third-party accreditations. British Board of Agrément (BBA) certification is a must as it confirms products have been tested and comply with the regulations. Also, check the manufacturer’s Environmental Product Declarations (EPDs), so you can keep track of the embodied carbon used in your project and ensure it’s truly sustainable.

Focus on buildability

The final factor that determines a good insulation specification is buildability – that is how easy a material is to install correctly. This may seem like it’s the installer’s domain, but it should be considered during specification.

Choose a material that’s harder to install correctly, such as rigid board insulation products, and you run the risk of air gaps being introduced during installation. Such gaps significantly reduce thermal, fire safety and acoustic performance, meaning that the building’s theoretical performance will not be achieved.

Instead, select materials that are easy to install correctly, such as mineral wool, which

means your insulation will deliver its intended performance for the lifetime of the building. Writing a specification can be complex. But by following these steps, you can be certain that your rainscreen insulation specification will stand up to scrutiny and deliver the real-world performance required of modern, safe and high-performance buildings.

www.knaufinsulation.co.uk

FC&A – MAY – 2023 29 FACADES, RAINSCREEN & LOUVRES

DIAL DOWN THE DISTURBANCE: DEALING WITH THE ACOUSTIC CHALLENGES OF AIR-SOURCE HEAT PUMPS

Air-source heat pumps (ASHPs) have become a key part of the decarbonisation toolkit in response to climate change. However, while their green credentials are second to none, Jamie Large, Senior Acoustic Consultant at CPW, says that without proper consideration for the acoustics, ASHPs can be a particularly noisy elephant in the room.

Bu sinesses and organisations are acutely aware of the climate challenge we are all facing and the ambitious targets set by the UK Government to reach net zero by 2050.

H eating infrastructure can be a significant contributor to a building’s overall emissions, so comprehensive, low-carbon energy strategies need to balance the heating network’s functionality with its carbon footprint.

G as boilers and diesel combined heat and power (CHP) installations have traditionally done a lot of the heavy lifting when heating buildings, particularly those of a larger scale. However, with energy centres that can reach the footprint of a small school, we often find there is a real drive from clients to move away from these incredibly carbonintensive heating methods and towards more sustainable approaches.

We were recently appointed to deliver an extensive MEP survey of a major university’s entire estate – which included a range of structures from new builds to centuries-old Grade I and II Listed properties that have wide-ranging thermal performances – and produce a decarbonisation plan.

Following our passive design approach, we highlighted the need to substantially reduce heating demand and incorporate lower carbon emission supply alternatives – with a significant drive toward ASHPs.

Making a noise

O n the surface, ASHPs seem like a simple solution to the carbon problem. They can operate from renewable energy sources or the increasingly green national grid supply and have a significantly lower carbon footprint than traditional methods.

H owever, while the positives outweigh the negatives for ASHPs in most circumstances, there needs to be careful consideration of one of their biggest perceived pitfalls – noise.

A SHPs primarily generate noise through two parts – aerodynamic noise across the fans and refrigerant pump noise. The reality is that any new noise source has the potential to cause disturbance to both internal and external receptors, so tackling this challenge with a robust acoustics strategy is critical.

N ot only do you risk falling foul of the local authority’s noise control teams, but also a plethora of other building design documents and standards, from

general certifications such as BREEAM, to industry-specific ones from the British Council for Offices Guidance or the Building Bulletin 93 Acoustic Performance Standards for Schools.

T his was particularly true for our client, given their local authority had a particularly stringent noise policy. Due to the proximity of residential dwellings, a detailed assessment was required to establish project viability and determine suitable noise control strategies.

We first undertook a detailed survey to establish the existing noise environment and an initial review of the proposed air-source heat pump plant and its location. This included the principles of assessing noise emissions from the proposed plant in the context of the highly-residential location and developing a range of control measures.

Lower the volume

O ur proposals for the client utilised a combination of acoustic screening and ‘off-the-shelf’ noise attenuation packages from the plant supplier.

T he acoustic screening includes an enhanced design, which wraps around ASHPs and comprises a solid, dense material, such as sheet metal or timber,

FC&A – MAY – 2023 30 ACOUSTICS

CPW

The UK’s first Passivhaus-accredited office building, which meets its tiny residual heat demand through air-source heat pumps

JAMIE LARGE IS THE SENIOR ACOUSTIC CONSULTANT AT CPW

backed with an absorbent material like polyethylene foam that is UV stable and water resistant. This solid portion of the screen provides protection from the loud fans, which are typically located on top of the ASHPs.

T he lower section of the screen would comprise an acoustic louvre – which avoids a ‘cold well’ within the acoustic enclosure – and is able to attenuate sound as air passes through it. This allows greater noise screening without compromising the airflow to the ASHPs.

Mind the pitfalls

W hen developing a noise strategy, collaboration is crucial between the project team, client, plant suppliers and local authority. It is important to balance the decarbonisation of energy sources with suitable noise control tactics that mitigate unwanted sound without watering down the scale of the proposals.

A s a result of the initial review work and collaborative feedback, we were able to advise on the viability of the proposed rooftop location and steer the plant selection toward a lower noise strategy, which comprises an increased number of ASHPs but with a reduction in output heating capacity and noise emission per unit.

M ore detailed assessments are currently being undertaken with the client to develop a range of potential noise control options for consideration, which will further limit noise emissions to achieve the local authority’s requirements and take the project to the next stage.

B y engaging with an acoustics team at an early stage, design teams can incorporate these valuable noise control measures from the start of a project, ensuring local authority requirements are met and avoiding the need to redesign for acoustics at a later stage, which can be costly as well as time consuming. By doing this in house and combining the skills and expertise of not just the acoustics team but also those on the engineering side, consultancies can develop solutions that work both on a practical level and a carbon emission one while aligning with environmental noise targets. www.cpwp.com

FC&A – MAY – 2023 31 ACOUSTICS

The UK’s first Passivhaus-accredited office building, which meets its tiny residual heat demand through air-source heat pumps

WHAT TO CONSIDER WHEN SPECIFYING AND INSTALLING PANIC AND EMERGENCY EXIT HARDWARE

In an emergency, the evacuation of a building needs to be as simple as possible. It is essential that building users can open doors easily so that everyone can leave safely.

Architectural ironmongery plays a key role in helping with this, so getting the specification right is key. Rob Adams, Technical Manager at ARRONE, a HOPPE brand, highlights some of the key considerations that must be made when it comes to panic and emergency exit hardware.

What is the difference between panic and emergency exit hardware?

T he building’s type, application, occupation levels and where it is in the building must all be considered as to whether it is panic or emergency exit hardware that is required.

The difference between the two is as follows: Emergency exit hardware is only used when building users are familiar with exit routes, such as private premises, including offices and warehouses, and the building is not accessible to the general public. Devices for emergency exits could be a simple push padtype device or a lever handle that operates a mortice escape lock or night latch.

Panic hardware is used in buildings where members of the public have access to the building but may not be familiar with the exit routes, for example, hotels, hospitals, stadia and cinemas. This also applies to any building that has more than 60 people in it.

A ny doors in areas that are accessible to the public must have a device fitted that is operable by a horizontal bar that covers at least 60% of the overall door width. As well as being easier to see and use from an accessibility point of view, it also adds another layer of safety functionality in the event of an emergency.

Performance standards

W hen it comes to panic or emergency exit hardware, there are two British and European standards that specify the requirements for the manufacture, performance and testing of these particular products:

Emergency exit hardware: BS EN 179:2008 applies to type A (lever handle-operated emergency device) and type B (pushpad-operated emergency device)

Panic hardware: BS EN 1125:2008 applies to type A (push bar panic bolts) and type B (touch bar panic bolts).

B oth standards require the following markings to be visible on the product when fitted: the manufacturer’s name or trademark or other means of positive identification; an identification number of the certification body and a CE mark with an additional UKCA mark from 30th June 2025 as things currently stand.

FC&A – MAY – 2023 32 SECURITY & BUILDING ACCESS

HOPPE

There are also markings that must be visible before fitting: the number and year of the European standard; the full classification code for the product and the month and year of final assembly by the manufacturer (which can be in a coded form).

Don’t forget security and accessibility

A ny additional functions, such as enhanced security and accessibility, also need to be considered at the specification stage, as this will dictate the type of device needed.

To deliver a basic level of functionality and a standard level of security, a door may only require a device with a panic latch passage function. However, if there is an additional security requirement, a panic bolt device would normally be recommended.

A panic bolt has a vertical rod to suit the door height and has locating bolts that go into the floor and the top of the door frame each time the door closes, providing two locking points in total instead of just one with a panic latch.

T here is an ongoing need for panic and emergency exit doors on commercial buildings to also be accessible from the outside. For this, an Outside Access Device (OAD) is used. It can be locked to

stop a manual attack on the device and prevent illegal entry to the building.

Follow installation guidance

N ot all panic and emergency exit hardware devices are the same, so it is crucial that anyone installing this type of hardware reads the fitting instructions for each product. The hardware must be fitted correctly to the manufacturer’s instructions and guidance as this is potentially lifesaving hardware.

Getting it wrong could result in expensive replacement work for the device and door, and it will invalidate all test evidence and certification for that product.

A pocket guide from ARRONE summarising everything you need to know about panic and emergency exit hardware is available to download from the HOPPE website. It includes a simple three-step product selector, a section on frequentlyasked questions and advice on positioning hardware on different types of doors. It also gives key advice on other aspects such as the correct signage being present, whether other ironmongery functions correctly and the checking of hinges and any other weather seals ensuring free operation of the door.

www.hoppe.co.uk

FC&A – MAY – 2023 33 SECURITY & BUILDING ACCESS

BUILD FOCUS:

DEVELOPMENTS

Greenwashing is a marketing tactic where companies promote their products or services as environmentally friendly, despite evidence to the contrary. This is practiced by many major manufacturers, who frequently use forest carbon offsets, which involves the planting of new trees, to claim that their products achieve zero carbon emissions, says Mark Clark of Cemfree.

IS GREENWASHING DETERRING HOUSEBUILDERS FROM FINDING GENUINE CARBON SAVINGS?

According to the UK Government’s ‘Building to net zero: costing carbon in construction’ report, the UK’s construction industry is responsible for 25% of the UK’s GHG emissions and is critical to the UK hitting its net-zero target.

Th e industry estimates it takes around 50 to 60 tonnes of carbon emissions to construct the average new home, and builders are under considerable pressure to bring that figure down, which means that they will be understandably attracted to manufacturers claiming to be carbon zero.

I t all adds up to the fact that the UK housing market is facing a major challenge in the coming years as the country seeks to reduce its carbon emissions and transition to a more sustainable future. An obvious way to achieve this is by looking at switching building materials.

W ith the 2050 deadline looming, an increasing number of products are purporting to be environmentally

friendly, but this is not always accurate. Some companies that are guilty of greenwashing are merely labelling their existing 50/50 mix as ‘green’, whilst others claim to be low carbon by means of carbon offsetting. Many companies employ a greenwashing tactic of planting new trees to offset carbon emissions. However, recent reports suggest that this approach may be less effective in combating climate change than it is promoted to be, such as the report by the Guardian Newspaper.

W hile planting trees can be a positive action for the environment, it can also be dangerous if, for example, companies use it as a cover for their unsustainable practices. It also means that there is no level playing field for users of construction products to be able to make comparisons.

A ccording to Sancroft, an ethical investment company, carbon offsetting also creates other issues. They argue that offsetting schemes are a largely unregulated space. This opens the door for schemes that don’t achieve the reduction or avoidance that is promised.

T hey add that avoidance or reduction amounts attributable to a particular project are hard to measure. This complicates the goal of balancing a company’s carbon emissions with the same tonnage of carbon offsets.

H ousebuilders who are genuinely committed to making a positive impact face challenges due to misleading claims of greenwashing. Such claims can create confusion and complexity in determining which material to use and provide a false sense of security.

FC&A – MAY – 2023 34

BUILD

FOCUS: HOUSING DEVELOPMENTS

CEMFREE

HOUSING

MARK CLARK IS A GENERAL MANAGER AT CEMFREE

Whilst tree planting is a positive step, it cannot replace real efforts to address the underlying causes of climate change, and this confusion ultimately affects end users. We should look at cutting carbon at the source.

T his is why it is important for companies to adopt Environmental Product Declarations (EPDs), a document that transparently communicates the environmental performance or impact of any product or material over its lifetime, according to software company oneclick.

W ithin the construction industry, EPDs make it possible to compare the impacts of different materials and products in order to select the most sustainable option for architects, engineers and designers.