FUTURE CONSTRUCTOR & ARCHITECT NOVEMBER 2022 ISSUE 153

After the shortest tenure of any British prime minister, Liz Truss resigned last month after just a fleeting 44 days in office. She made the decision following a chaotic chain of events, such as sky-high mortgages, a slump in the pound and the loss of our longestreigning monarch – which resulted in 10 days of Government activity being paused, making her days in power even briefer. As the pound begins to rise again (at the time of writing) and the public compares Truss' time as PM to that of a wilting, 60p Tesco iceberg lettuce, the nation was, once again, left in a momentary period of uncertainty prior to the succession of Rishi Sunak.

While Truss will be remembered for her impact on housing, specifically for firsttime buyers and private renters, many from the construction industry have already stressed that Sunak must act urgently to increase supplies of housing and stabilise interest rates.

Whilst this resignation has resulted in a last-minute change in content plans in this month's edition of FC&A, we continue to bring you the latest news from other areas of the industry. Once again, sustainability runs through the pages of this issue, with a focus on roofing systems. On page 26 , Sarah Peake, Sustainability Manager at Sika UK, talks about sustainability regulations and initiatives affecting architects and specifiers and the roofing systems that can meet their requirements.

Elsewhere, turn the page to page 28 to learn more from Ross Finnie, Sales Director at SIG Design & Technology (SIG D&T), about a new type of roof that combines the powergenerating benefits of a solar roof with the biodiversity gains of a green roof.

I hope you enjoy this issue. Don’t forget, you can also access all of the magazine’s

information on FC&A’s user-friendly and engaging

allows you to read all the latest stories on-the-

tablet. Simply search www.fca-magazine.com.

REBECCA KEMP

Editor, Future Constructor & Architect

ON THE COVER:

Announced in the Engineering Prize Shortlist for this year’s World Architecture Festival (WAF), the largest built area of Expo 2020 was masterplanned, designed and delivered by Hopkins Architects.

SEE PAGE 16.

FC&A – NOVEMBER – 20223

WELCOME TO EDITOR’S NOTE

features, product news and supplier

website. Fully responsive, the website

go either on your phone or

Red Hut Media Ltd 5 Mansion Row, Brompton, Kent, ME7 5SE Tel: 01622 946150 Rebecca FUTURE CONSTRUCTOR & ARCHITECT MAGAZINE EDITOR IAL Rebecca Kemp rebecca@redhutmedia.com Hannah Woodger hannah@redhutmedia.com PRINT & DIGITAL ADVERTISING Sam Ball sam@redhutmedia.com Jim Moore jim@redhutmedia.com PRINT DESIGN MANAGER Jack Witcomb jack@redhutmedia.com DIGITAL DESIGN MANAGER Matt Morse matt@redhutmedia.com ACCOUNTS/CREDIT CONTROL Rachel Pike accounts@redhutmedia.com SALES SUPPORT & STATISTICS Klare Ball klare@redhutmedia.com PUBLISHER Sam Ball sam@redhutmedia.com Terms and Conditions: Contributions are invited and when not accepted will be returned only if accompanied by a fully stamped and return addressed envelope. No responsibility will be taken for drawings, photographs or literary contributions during transmission or in the editor’s hands. In the absence of an agreement the copyright of all contributions, literary, photographics or artistic belongs to Red Hut Media Ltd. The publisher accepts no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the view of the publisher. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. NOVEMBER 2022 RED HUT MEDIA fcamagazine fcamagazine fcamagazine FC&A Magazine CAVITY TRAYS specialism • experience • service01935 474769 enquiries@cavitytrays.co.uk www.cavitytrays.co.uk Yeovil Flat and Monopitch Roof Intersections Combined Cavitray and Flashing ● Bed and build using the preformed Type G Cavitray. ● Ready to use lengths and angles link together to form long runs. ● Cavitray compatibility - Adjusts to suit the ‘as-found’ cavity width. ● With or without attached flashing. ● Approved ETA solution with accompanying warranty from the longest-established specialists Email enquiries@cavitytrays.co.uk and request our guide delivered to your door The B&B Solution

GLASS BALUSTRADE

as

only

T +44 0161 804 9500 | F +44 0161 804 9505 sales@onlevel-uk.com | www.onlevel.com TL 6020 1.5 kN TOP MOUNT | Fully adjustable from one side. | Only system in the UK which will meet 1.5 kN with 21.52 mm PVB Glass | Tested to 0.74 kN with fixings at 600 mm centres (all competitors are generally 200/250 mm) meaning you only need a third of the fixings saving you a lot of time and money | Tested to 1.5kN with fixings at 400mm centres (all competitors are generally 200/250 mm) so again you need half

many fixings saving you time and money | Tested to 1800 mm high with 21.52 mm Sentry and

deflects 18 mm at the top making it an ideal solution for privacy screens when you want the channel detail to remain the same CHESHIRE PLAINS, ENGLAND TRANS LEVEL FRAMELESS

VOICE OF THE INDUSTRY

CPMG Architects’ Director,

LEGAL & BUSINESS:

involved with building back the

industry and

Ananya Banerjee, Director and Head of Design at Boyer, explains how the ‘third space revolution’ has considerable potential to

LONDON BUILD PREVIEW:

One of the

to Olympia London’s Grand Hall from 16 to 17th November

DOORS, WINDOWS & BALUSTRADES:

Peter Ashworth, Specification

OFFSITE CONSTRUCTION:

at ASSA ABLOY Door Hardware Group, argues that the built environment

of leadership when it comes to building safety.

James Mead, Projects Director at Saint-Gobain Weber, and Mike Doolan, Sales and Partnerships Manager at LoCal Homes, share their experience of

traditional building products with offsite manufacturing to deliver the housing the UK

RCI:

FC&A speaks to Sarah Peake, Sustainability Manager at Sika UK, about sustainability regulations and initiatives

architects and specifiers and the roofing systems that can meet their requirements.

GREEN ROOFS & LIVING WALLS:

Ross Finnie, Sales Director at SIG Design & Technology (SIG D&T), explains the benefits of bio-solar roofing and how to approach its design and specification.

BUILD FOCUS : U rban Developments:

James Brett, Managing Director of Edgeley Construction, discusses the construction of a unique mews-style development at Rectory Gardens in the heart of Clapham Old Town.

TECHNICAL FOCUS:

What

Steve Warne, National Sales Manager at Ideal Heat Solutions, investigates.

H2-OFFICE-TOWER, 3DELUXE:

EXPO 20 20, HOPKINS ARCHITECTS

FC&A – NOVEMBER – 20225 18 20 34 NEWS

:

Chris White, discusses the unique set of factors

airport

securing its future.

create genuinely sustainable environments.

UK’s leading construction and design shows will return

with more content, networking and entertainment than ever before. 12 16 PORTFOLIOS

The H2-Office-Tower is part of a redevelopment site located on Wiesbaden's Rhine riverfront that serves as a model for sustainable, smart and future-oriented urban development.

: Announced in the Engineering Prize Shortlist for this year’s World Architecture Festival (WAF), the largest built area of Expo 2020 was masterplanned, designed and delivered by Hopkins Architects. 22 24 26 28 30 32 FEATURES

Sales Director

industry needs to move from a place of compliance to one

combining more

so desperately needs.

affecting

are the key considerations and challenges when it comes to plant rooms, and how can they be overcome?

NOVEMBER CONTENTS CAVITY TRAYS specialism • experience • service01935 474769 enquiries@cavitytrays.co.uk www.cavitytrays.co.uk Yeovil • Somerset • England • UK Sloping Abutments in Brick, Block or Stone Combined ready-moulded DPC cavity wall protection with attached roof flashing ● Adjustable Type X Cavitray to suit all cavity widths ● Ready to use – eliminate cutting, fabrication and variances on site ● Control cost and stock + packaged per dwelling ● Look for the name and logo to secure approved ETA solution with accompanying warranty from the longest-established specialist Email enquiries@cavitytrays.co.uk and request our guide delivered to your door Cavitray Compliancy & Consistency

INDUSTRY UPDATES

IN BRIEF:

WARRINGTONFIRE COMMITS TO FUTURE OF FIRE SAFETY FOLLOWING INAUGURAL GRADUATE INTAKE

Warringtonfire has welcomed four new engineers as part of its inaugural graduate recruitment scheme. The company launched the scheme to help futureproof the fire-safety industry, which coincides with the 50th anniversary of the first commercial fire test at its fire testing laboratory. The extensive history and experience of Warringtonfire’s multiple laboratories enable the company to provide graduates with the support and knowledge needed to make valuable contributions to the fire-safety industry. Amman Ahmed, Evandro Valente, Shannon Muir and Susie Hall joined Warringtonfire as Graduate Engineers in September.

CHAS TEAMS UP WITH NORMCYBER TO HELP CONTRACTORS CONTROL CYBER RISK

CHAS, the trusted expert in supply chain compliance, has teamed up with NormCyber, the award-winning managed security service provider, to offer CHAS members an easy and affordable way of managing cyber risk. The agreement provides CHAS’ members – which include more than 32,000 contractors and more than 2000 client organisations across sectors including construction, facilities management and manufacturing, to name a few – with access to Norm.’s range of award-winning, managed cyber security services at a preferential rate. Norm.’s services are designed to meet the cyber security needs of mid-sized organisations that may not have the in-house expertise or resources to protect their operations from ever-more sophisticated threats.

ACPV ARCHITECTS UNVEILS INTERIOR DESIGN OF THE RESIDENCES AT 1428 BRICKELL, MIAMI

ACPV ARCHITECTS has revealed the interiors of Miami’s luxury residential tower, The Residences at 1428 Brickell. Standing at one of the city’s most soughtafter locations undergoing profound development, the 70-storey building is characterised by high-quality, contemporary finishes and pieces of furniture by Antonio Citterio.

ARCHITECTS

Developed by Ytech – 1428 Brickell, LLC, a subsidiary of Miami-based real estate development firm Ytech – the tower comprises 189 residential units: a mix of apartments from 170 to 370m2 and penthouses from 370 to 930m2. The design of the interiors, conceived as sculptural and flexible spaces, stands out for meticulous attention to detail, a particular care for the materiality of the elements, and the warm tones of the furniture and the finishes that create a natural and welcoming atmosphere.

“For the tower’s interiors, we selected furniture, materials, textures and colours that create an ambience of informal luxury,” Architect Patricia Viel, CEO of ACPV ARCHITECTS, says.

“Throughout the property’s amenity spaces, we integrated pieces of furniture from a selection of world-renowned Italian and international designers, focusing primarily on earth tones to bring nature inside the building while simultaneously celebrating the joyful feeling of spending time outdoors in the company of your loved ones.”

The interiors integrate the private residences with 7500m2 of shared spaces that spread over the entire height of the tower, concentrating amenities at the top of the tower that opens to breathtaking views. The amenities include a swimming pool and spa with a relaxation area on the 70th floor, while the 67th floor features a double-height wine

lounge with a refined selection of wines and works of art, office suites with private offices and lounge and a bookable private dining room with a Vaselli kitchen in travertine. The 66th floor houses an expansive 930m2 gym with a weight room, HIIT room and an indoor/ outdoor yoga room.

FC&A – NOVEMBER – 2022 6 INDUSTRY UPDATES NEWS

www.citterio-viel.com

ACPV

FC&A ROUNDS UP THE LATEST INDUSTRY NEWS AND UPDATES. 1428

Brickell, Miami

1428

Brickell, Miami

PERSONNEL

The latest appointments from the construction and architectural industries.

DUO APPOINTED TO CONSTRUCTION ALLIANCE NE BOARD

Regional lobbying organisation Construction Alliance North East (CAN) has appointed new board members for 2022 as the alliance’s first Chairman, Jeff Alexander, and longtime board member, Jack Redfern, step down from their positions. Peter Fowle, Managing Director of Able Construction (Northern) and Regional President of the NFB, and Matthew McCarrick, Managing Director of McCarrick Construction and NCBF board member, join the board, bringing more than 60 years of experience to their roles. CAN was formed in 2015 to better represent regional SME contractors in the North East and has grown to represent more than 500 businesses since. It consists of construction and civil engineering contractor bodies with a combined turnover of £3bn.

DUO OF PROMOTIONS AT RACE COTTAM ASSOCIATES (RCA)

Healthcare architectural practice, Race Cottam Associates (RCA), has announced the promotion of two team members following a farewell to the firm’s health sector lead. After an 18-year career at RCA spanning the delivery of more than 60 healthcare schemes, Tim Robinson retires. Paul Foster, Associate Director, becomes RCA’s new Health Sector Lead and will oversee the healthcare team, including the newly-promoted Architect, Jacob Peplow. With almost two decades of combined experience at RCA, Paul and Jacob are well known to the practice’s client base. Paul is a designer, who is confident in devising refurbishments, retrofits and reconfigurations as well as new projects.

Jacob shares this passion for delivering futureproof and energy-efficient buildings as BREEAM Lead.

NEW CHAIR AND VICE CHAIR FOR BUILDING HARDWARE GROUP

Door & Hardware Federation (DHF) has announced the Chairman of the Building Hardware Group as Richard Bromley; he will be supported by Vice Chairman, Neil Rule. Richard has many years of experience in the lock and hardware industry. In 2021, he was appointed Business Development Director and Chief Technology Officer for ASSA ABLOY UK & Ireland. Neil started working in the industry in 1998. After leaving school, he served an electrical apprenticeship at Gateshead Metropolitan Borough Council. For more than 20 years, Neil has held sales and commercial roles of increasing responsibility within the area of mechanical cylinder locking and electronic access control systems. He is the ARGE Work Group Convenor for Masterkey Systems Data Security, sits as a UK expert on CEN/TC33/WG4 and is a BSI committee member. He is also a member of DHF.

NEWS IN BRIEF:

PERKINS&WILL LONDON STRENGTHENS COMMITMENT TO DE&I WITH HIVE LEARNING PARTNERSHIP

The London studio of Perkins&Will is the first architectural firm to partner with digital peer learning platform, Hive Learning, to pilot its award-winning ‘Inclusion Works’ programme – designed to help people embed inclusive behaviours as a daily routine. This comes as part of Perkins&Will’s longterm commitment to creating a fully-inclusive culture by driving long-lasting behaviour change. Using a combination of network science and nudge theory, Hive Learning delivers large-scale, strategic behaviour change programmes. People learn in groups or ‘cohorts’ to create a shared understanding of what ‘good’ looks like and how to make people accountable to one another.

BRAND-NEW AWARDS CELEBRATE HISTORIC BUILDINGS AND CRAFTSPEOPLE IN UK AND IRELAND

The SPAB is proud to announce a shortlist of 28 of the best-built heritage projects and craftspeople from across the UK and Ireland. The winners of the first SPAB Heritage Awards received their award from Designer, Writer and TV Presenter Kevin McCloud on 3rd November at an event at Conway Hall in London. The SPAB’s (Society for the Protection of Ancient Buildings) expert judges have shortlisted a range of wonderful buildings, cherished by their communities and owners. Building repair projects on the shortlist include a Glasgow tenement, a country house in Yorkshire, an ancient church in Holyhead and a historic town centre in County Donegal.

FC&A – NOVEMBER – 20227

INDUSTRY UPDATES

1428 Brickell, Miami

ARCHITECT IN PROFILE

Richard Parker is a Chartered Architect and currently leading design and engineering company BakerHicks’ architectural team in the UK, focusing on delivering positive and impactful spaces for its clients. Here, he talks to FC&A about how a childhood interest in constructing and deconstructing objects led him to follow architecture as a career path.

RICHARD PARKER

Please tell us a bit about your career background.

During my 25 years in the industry, I have led and managed multi-disciplinary teams on a variety of complex, large-scale projects within highly-regulated environments.

Delivering a myriad of schemes through all project stages and across a range of sectors, including commercial, education, healthcare, life sciences, leisure, transport, industrial and Government.

Have you always wanted to pursue a career in architecture?

From an early age, I had a love of art and a passion for constructing and deconstructing everyday objects. I think this combination ultimately led me to want to pursue a career in architecture. Although the deconstruction part probably infuriated my parents along the way!

Who has been your greatest influence and source of inspiration?

From an architectural perspective, I’ve always admired Alvar Aalto for his humanistic use of form and materials to make both rational and intuitive buildings that also respond to the landscape.

Outside of architecture, I would say Pixar for their sheer creativity and ability to show us the power of pure imagination. They demonstrate that collaboration between groups of talented individuals within the right environment can produce magical outcomes.

What has been your most notable project to date?

In terms of fully-realised and completed projects, it would have to be the newlyupgraded Whitechapel Crossrail Station for its sheer scale and complexity.

I’m extremely proud of the part we played in this much-publicised and historic project. I was part of the multi-disciplinary BakerHicks team who delivered the design concept from RIBA Stage 3 to completion, including the repair and overhaul of the original Victorian facade and the construction of a modern ticket hall and concourse.

Architecturally, it is quite an interesting building, with the refurbished Victorian facade, then behind that the sweeping roof that forms the concourse. This features a green roof, offsetting some of the carbon emissions produced or embedded in the construction process, as well as helping to improve air quality and reduce noise. Glass above the concourse allows daylight into the station and down to the platforms, making it a light space with a very open, calm and modern feel. The culture and history of the area are also embedded into the building, both in the urban realm and in the details; for example, the area was known for producing bells, so one of the bell soundwave patterns is replicated in the detailing.

It has helped regenerate the area maintaining its cultural integrity whilst also delivering this fantastic modern transport interchange that will deliver improved transport infrastructure for generations to come.

FC&A – NOVEMBER – 2022 8

INDUSTRY UPDATES www.bakerhicks.com

BAKERHICKS

IS AN ARCHITECTURE DIRECTOR AT BAKERHICKS

Whitechapel Crossrail station

How do you approach your projects?

Listening and having a collaborative, open approach that creates a positive impact through design for our clients, the building’s end users and the wider communities they serve. Having clear processes and constant communication with and between disciplines to achieve the delivery goals and design vision is also hugely important.

What do you think is the greatest challenge for designing in sustainability?

Designing sustainably challenges us to deliver efficiencies within

What is your favourite building?

My ultimate favourite is the Barcelona Pavilion by Mies van der Rohe, which, on the face of it, is a very simple building. Yet, on closer inspection, it’s apparent that everything has its place and has been wonderfully considered. It is an education in drawing a visitor through a space by framing views and carefully-positioned walls, all based around a formulaic grid. Coupled with a limited but luxurious palette of materials, the overall effect is extremely tranquil and relaxing.

I also have real admiration for the 2010 UK Expo Pavilion Shanghai by Heatherwick Studio, as it just makes you smile.

The Seed Cathedral is a brilliant example of how an architect has taken a brief and thought beyond the norm to create a joyful space.

What do you think is the greatest challenge for architects today?

The built environment has a key role to play in meeting Government net-zero targets; therefore, it is an exciting time for architecture. The challenge is to holistically embed low- and carbon-neutral solutions into designs and dispel the common preconception that sustainable solutions cost more. Working with the supply chain and manufacturers to ensure that products are available to meet regulatory and statutory compliances, whilst still maintaining the desired spatial aesthetic, is key. Keeping up with technological advancements in the digital environment is also another key challenge for the industry. For example, BIM should be used as a tool to aid the design process and help the client manage their building once handed over. However, its use needs to be appropriate. Just because you can, does not always mean you should.

What do you think is the greatest challenge for architecture students?

Ensuring they have the key digital skills required by the marketplace but also stand out from the crowd. Being able to express and present your ideas and creativity through sketches without losing perspective on reality and the ability to transform the dream into buildable solutions is also key. Equally important is to understand that architecture is fundamentally a business, and it is not always glamorous.

What advice would you give to newly-qualified architects?

our designs, consideration of transforming existing buildings over new-build solutions, and capitalising on minimising embodied and operational carbon. This has to be achieved without compromising the functionality and aesthetics of a building. These requirements have pushed, and are still pushing, architects, and other disciplines, to rethink conventional design and explore innovative solutions.

The main challenge, however, in designing sustainable buildings is to remove preconceived ideas that sustainable solutions can be ‘bolted on’ subject to budget allowances.

I encourage all architects to be observant and curious, to look closely and take influence from everything they see. Whether it is manufactured or natural, modern or historical, functional or beautiful. Remember the Mies Van der Rohe quote, “God is in the detail”, and take a keen interest in how good design is put together. Good detailing is key to great architecture. Planning your delivery is also key. Rushing headlong into a project without a plan will all too often result in failure.

What can we expect to see from you over the next year?

I will continue to deliver impactful and exciting spaces and buildings for our clients, highlighting the profile and work of our hugely talented architectural team within BakerHicks.

FC&A – NOVEMBER – 20229 INDUSTRY UPDATES

Whitechapel Crossrail station

Whitechapel Crossrail station

Whitechapel Crossrail station

PLASLOC GOES BIG – THE AUSSIE WAY

Hoarding solutions specialist Plasloc has completed three retail projects in Melbourne, Australia – with its unique external and internal sustainable hoarding systems set to be a mainstay in the country from now on.

Th e Newton Abbot-based company’s product has been an essential component in more than 6000 projects and is the go-to hoarding solution amongst the UK’s major building

PLASLOC

contractors, and has made a successful move over to the other side of the world.

A delighted Leigh Matthews, Plasloc’s Director, explained: “18 months ago, we were approached by an enthusiastic team

of like-minded entrepreneurs who work within the construction industry that wanted to make a change by looking for sustainable hoarding solutions and had a keen interest in our product.

“ We offered them the Plasloc business model and assistance in creating the brand in Australia. The first few projects have been successfully delivered through the hard work and commitment of the team in Melbourne, Australia.

“ It has been a long process, but we are delighted to have patents pending to cover the product in Australia and have trademarked Plasloc in the country. Plasloc Australia PTY LTD is gaining momentum over there, and we now have a positive pipeline. For a familyrun business, it’s fantastic to be taking Plasloc global.”

T he projects were on a number of different sites for three clients – COLES, Westfield and Woolworths. COLES required internal hoarding and a demo wall, while Westfield required external hoarding and Woolworths internal. All the temporary and permanent hoarding systems were professionally and efficiently installed for use in live retail environments.

P lasloc is a lightweight, safe and secure interlocking freestanding hoarding system that removes the need for ground penetration. Clean in appearance and hygienic, it has been developed as an environmentally-friendly alternative to standard building materials and, at the end of its life, it is removed and granulated, ready to be closed-loop recycled to produce more Plasloc in a process that creates zero waste.

T he product’s sustainability is the reason for all the interest, with COLES producing artwork to be printed on the hoarding in store to promote the plastic that is being diverted from landfill.

Plasloc also donates all funds received from the recycling of its products to Just One Ocean, a charity committed to preserving the ocean for future generations and Plasloc Australia PTY LTD, which is currently looking at local recycling centres for the product at the end of its use, is in discussions with a similar charity to make the same agreement.

Leigh added: “Long term, we are looking to get tools produced in Australia. However, at present, to reduce the emissions from shipping from the UK, we are having tools produced in China, and we will offset the emissions produced on containers shipped with carbon credits to ensure we maintain a carbon-neutral status.”

For a cost-effective, sustainable, innovative and unique hoardings solution, or for more information on how Plasloc can help you with your next construction project, visit the below website.

FC&A – NOVEMBER – 2022 10 www.plasloc.com 01626 356995 info@plasloc.com

HOARDING SOLUTIONS

FC&A – NOVEMBER – 202211 Counter-balanced operation for ease of use Telescopic handrail & large treads for comfor t and safety The Elite loft ladder offers strength & ease of use w w w.premierlof tladders.co.uk/elite 0345 9000 195 | sales@premierloftladders.co.uk Heavy duty ladder for strength & durability (load rating of 200 kg/tread)

FLAGSHIP PROJECT FOR SUSTAINABLE URBAN DEVELOPMENT IN WIESBADEN

The H2-Office-Tower is part of a redevelopment site located on Wiesbaden’s Rhine riverfront that serves as a model for sustainable, smart and future-oriented urban development. The project involves converting a former industrial wasteland into a campus-like site that considers all the requirements of a modern office and work culture in a densely-populated urban environment. The CO2-reduced and resource-saving redevelopment and green densification create urban biotopes and encourage micro-mobility.

3DELUXE

Th e architectural studio 3deluxe was commissioned by the Wiesbaden urban development company SEG to identify various utilisations and design options and to investigate how the site between the industrial park and the Rhine meadows can be developed with a promising future. The site’s innovation driver will be the construction of an appealing timber hybrid high-rise building that, along with a listed classic high-rise from the 1960s, forms the site’s core.

Wood hybrid highrise building on the former area of concrete production 3 deluxe aims to create a clear, reduced office highrise building with a straight, urban and modern look that will set new architectural and urban development standards in an industrial neighbourhood characterised by concrete production.

P rimarily, climatic and energetic considerations determine the basic layout of the 15-storey high-rise building. The facades facing the sun are partially covered

with photovoltaic modules, which also serve as shading elements. The orientation of the Rhine facade has been twisted diagonally and thus optimised to the sun’s position to achieve maximum efficiency from the largescale integration of the photovoltaic modules.

T he regular rectangular grid of the visible wooden structure enables modularity and prefabrication of the facade and offers a formal affinity to the listed high-rise twin. Large floor-to-ceiling window areas and their black frame structure lend the building its modern warehouse appearance and create a reference to the industrial neighbourhood.

T he use of sustainable and renewable raw materials, the modular construction with a high degree of pre-fabrication as well as the recyclability of the planned building components are key features of the circular construction method. Energy generation is largely planned to be directly on the building: integrated large-scale PV systems, geothermal energy and use of the river water as a heat exchanger maximise lowemission operation.

FC&A – NOVEMBER – 2022 12

All images: ©3DELUXE H2-OFFICE-TOWER, 3DELUXE

FC&A – NOVEMBER – 202213 Design freedom without compromise Realise your project aspirations with leading product solutions in curtain wall. With bespoke and standardised product solutions from Reynaers Aluminium, you can rely on: Expertly engineered systems that perform to your thermal and acoustic requirements Uncompromising quality and craftsmanship Support that matches your project programme, timescale and budget World leading curtain wall solutions Achieves many test standards including CWCT (dependant on variants) Structural glazing, unitised glazing, roof glazing and fire rated solutions available Find out more... T 0121 421 1999 E reynaersltd@reynaers.com Together for better reynaers.co.uk

Designing the future of work

R egarding the neighbouring high-rise building from the 1960s, the H2-Tower is given the slender form that was characteristic of that time. The core is not positioned centrally but rather laterally in the facade. This provides generous room space to accommodate modern office formats for the post-corona age: office space that is open and participative, allowing for hierarchy-free, flexible working. The basement is an incubation space for young companies, and a light-flooded foyer is a communicative platform for the entire campus area.

G reen, communicative and recreational areas primarily dominate the outdoor area around the building right on the waterfront – a car-reduced, verdant site offering outdoor facilities in line with the shift in mobility, including bike parking, car and bike sharing, a bike repair shop and load bikes for transporting heavy goods. An outdoor gym, a recreation pavilion, a wildflower meadow, beehives and bird shelters condense the area into an urban oasis.

The highest veggie garden in the city

T he building concept intends to provide some space for nature. Integrated into the building are several green terraces, which enhance the quality of time spent in the building and contribute to improving the city’s climate. On the roof, a vegetable garden and greenhouse are integrated to supply the inhouse staff restaurant with fresh products. Bird and insect nesting areas are planned on the closed facade of the utility core. The building will be designed to be as animal friendly as possible to improve the coexistence of humans and nature in the built environment.

C ommenting on the project, Dieter Brell, Creative Director at 3deluxe, says: “Architecture today has to consider many more issues than just functionality or beautiful design. The massive global challenges we are currently facing are all reflected in architecture and urban planning, giving every building project a significant relevance to society as a whole. Exciting times!”

Background

T hroughout Germany, people are developing riverfront areas in urban locations and transforming these into highly-attractive living and working environments. Also, the 2.7-hectare site – acquired by SEG GmbH from the Dyckerhoff company –directly on the banks of the Rhine in Wiesbaden, with buildings that are partly protected as historical monuments, marks an extraordinary and extremely attractive section of the Rhine. Its proximity to water and thus to nature allows for a people- and environment-friendly redevelopment of the site –although an industrial park in the immediate vicinity permits only commercial use.

The site’s development offers a great opportunity for Wiesbaden to enhance its reputation further as a livable and future-oriented urban location. 3deluxe, in cooperation with the urban development company SEG, investigates options for modern and economically-sensible concepts for the utilisation and the design of the area. Additional building components for the development area, like the conversion of the historic power plant hall complex, are to be reported on in the near future.

FC&A – NOVEMBER – 2022 14 H2-OFFICE-TOWER, 3DELUXE

www.3deluxe.de

FC&A – NOVEMBER – 202215 w w w . f www fir manglass com In association with To find out more visit www.firmanglass.com Firman Glass,19 Bates Roa arold Wood, Romford, Essex RM3 OJH Tel: 01708 374534 Fax: 01708 340511 Email: sales@firmanglass com Structural Glazing Specialists w w www fir manglass com In association with To find out more visit www.firmanglass.com Firman Glass,19 Bates Road, Harold Wood, Romford, Essex RM3 OJH Tel: 01708 374534 Fax: 01708 340511 Email: sales@firmanglass com Structural Glazing Specialists www fir manglass com In association with o find out more visit www.firmanglass.com rman Glass,19 Bates Road, Harold Wood, Romford, Essex RM3 OJH l: 01708 374534 Fax: 01708 340511 Email: sales@firmanglass com Structural Glazing Specialists w w w . f i r m a n g l a s s . c o m w w w . f i r m a n g l a s s . c o m www fir manglass com In association with To find out more visit www.firmanglass.com Firman Glass,19 Bates Road, Harold Wood, Romford, Essex RM3 OJH Tel: 01708 374534 Fax: 01708 340511 Email: sales@firmanglass.com Structural Glazing Specialists Essex Life page ad_PRINT:Layout 1 17/3/14 14:54 Page 8 www.firmanglass.com

HOPKINS ARCHITECTS’ SUSTAINABLE MASTERPLAN FOR EXPO 2020

Announced in

this year’s

ARCHITECTS

Se nsitive to context, Hopkins focused on culture and climate to create something that was born of its location rather than imposed upon it. Three petal-shaped districts representing ‘Mobility, Opportunity and Sustainability’ sat at the heart of the expo masterplan, connecting to the central Al Wasl Plaza. Each district was anchored by a thematic pavilion and featured a number of individual national pavilions, designed by a range of participating international architecture and design firms. Geometry, colour and landscape have been used to give each of the three districts a distinct character.

Hopkins’ highly-contextual concept is a modern take on a traditional Arab city. A series of human-scaled, tree-lined streets efficiently deliver people to key events and pavilions but also create a pleasant landscape conducive to relaxed wandering and discovery. Streets are punctuated with courtyards, where people could sit and enjoy birdsong or the sound of water in an

environment that evokes the qualities and character of old Dubai.

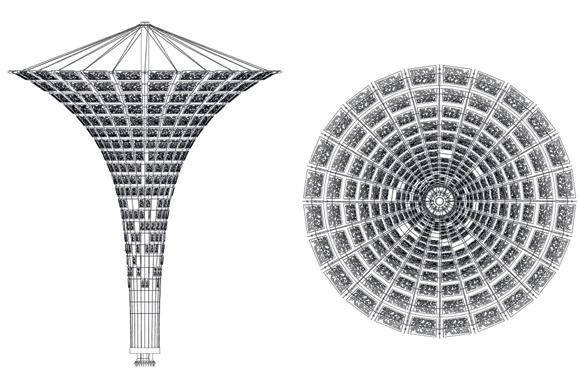

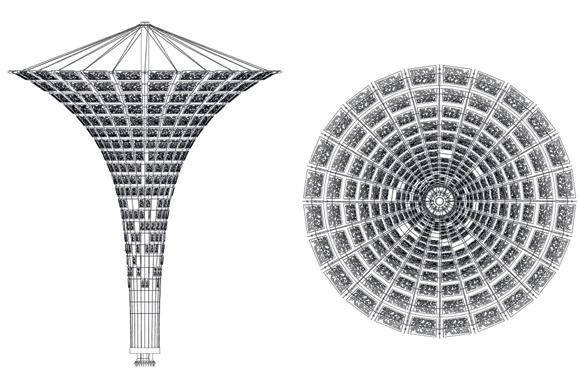

A central spine ran through each district connecting to the main plaza, with water features, event stages, activity areas and rest places; all clustered beneath elegant, funnel-shaped shade structures. These shading structures were one of the most striking elements of the expo site. Inspired by the shape of the date palm, they comprised 52 lightweight metal structures, slender at their base and rising to 16m in height and width to create an interconnected canopy. The individual metal panels of the shades feature the colour and patterns unique to the identity of each district and help with intuitive wayfinding. Dappled light and shade cast across the main pedestrian route to provide a comfortable visitor experience and protect the indigenous scented and flowering planting below.

“The challenge was to design a district that could meet the individual needs of countries exhibiting during the expo, whilst

being flexible enough to convert to almost any building type for a long-lasting legacy. We wanted to create a series of streets and courtyards that people could meander through on their way to the next big event, which evokes the character of old Dubai and a traditional Arab city, but in a modern way,” recalls Simon Fraser, Principal and Lead Designer at Hopkins.

Hopkins Architects used a modular system for speed and efficiency of construction that was easily adaptable for a variety of building scales and types.

Following the closure of Expo 2020 in March this year, the project is set to be repurposed to provide a creative, vibrant district for start-ups and innovative tech companies with a lively campus of mixed-use buildings interconnecting via bridge links that overlook landscaped spaces. Transforming into Expo City, the site is planned to follow a human-centric, mixed-use smart city format.

www.hopkins.co.uk

FC&A – NOVEMBER – 2022 16 EXPO 2020, HOPKINS ARCHITECTS

the Engineering Prize Shortlist for

World Architecture Festival (WAF), the largest built area of Expo 2020 was masterplanned, designed and delivered by Hopkins Architects. The ‘Thematic Districts’ created a new piece of city, which housed over 87 new permanent buildings and hosted the work of more than 136 participating countries in last year’s COVID-delayed exhibition. HOPKINS

©Hopkins

Architects

FC&A – NOVEMBER – 202217 EXPO 2020, HOPKINS ARCHITECTS

©Hopkins Architects

©Hopkins Architects

©Hopkins Architects

©Mohamed Ashour

©Mohamed Ashour

©Marc Goodwin

©Simon Fraser

ON THE RADAR: WHAT DOES THE FUTURE HOLD FOR AIRPORT DESIGN?

Airports have experienced unprecedented challenges in recent times, with the impact of major changes like Brexit and the COVID-19 pandemic on top of the growing demand for international travel. With no sign of slowing down, it is important to consider how the design of airports can be futureproofed for growth, success and sustainability.

CP MG Architects’ award-winning experience in the transport sector includes designing and completing eight air traffic control towers – more than any other architectural practice in the UK – along with baggage handling facilities, major terminals, departure lounges, multi-modal interchanges and jet hangars. Director, Chris White, discusses the unique set of factors involved with building back the airport industry and securing its future.

A irports were hit hard during the pandemic, and it is safe to assume many capital expenditure projects have had to take a back seat. As a result, more refurbishment and upgrade projects are likely to take place. The current phase is now all about rebooting the industry, with a specific focus on improving how airports can promote sustainability. Other key focuses that have transcended the pandemic include improving passenger experiences, enhancing security – without detriment to that experience – and ensuring that travel by flight remains competitive, affordable and enjoyable.

B y adopting informed, problem-solving solutions and recognising that cost-effective design is essential to promote development and improvements, this forms a starting point and framework for the aviation industry getting back on its feet.

The challenges

T he current economic situation is also having a detrimental effect on the airport industry. The energy crisis has caused fuel prices to soar, with increasing taxation often passed onto passengers – both of which have a direct impact on how airlines and airports operate and, therefore, the experience they can offer. In addition, the pressure to meet net-zero targets has been heightened, coupled with environmental campaigners’ activity. This is a major concern for the reputation of each airport and the wider industry.

A nd not forgetting the overall challenges of successfully expanding airport capacity. Although the current narrative is around the pressure on airlines to fulfil the flights planned, at some point, the question around UK capacity will follow – such as the creation of extra runways. A further challenge is ensuring the relationship between airports and airlines remains positive, along with the Levelling Up agenda that will also apply to, what has often been seen as, a disparity between regional airports and international airports.

T he challenges are not insurmountable ones, but acknowledging these challenges is important to inform design decisions that can ultimately help in providing long-term solutions.

FC&A – NOVEMBER – 2022 18

CPMG ARCHITECTS

CHRIS WHITE

HAS BEEN WITH CPMG ARCHITECTS FOR THE PAST 18 YEARS AND BECAME AN OWNER AND BOARD DIRECTOR IN 2016. AS THE LEAD FOR CPMG’S LONDON STUDIO, HE IS DELIVERING THE STRATEGIC VISION FOR GROWTH IN THAT MARKET, WITH A KEY FOCUS ON RESIDENTIAL, COMMERCIAL AND AVIATION PROJECTS.

VOICE OF THE INDUSTRY

The critical question is how the aviation industry can truly reconcile net-zero carbon when it is responsible for such high carbon emissions – and it’s one that does not have an easy answer. From an architectural perspective, we can inform sustainable design solutions both as part of a wider site strategy or individual buildings, both in new build and refurbishment. As for the wider industry, it needs to look at innovative ways of addressing the environmental agenda; offsetting, research and investment in environmentally-friendly fuel solutions, the operation of the plane movement when taxiing and generally just joined-up industry behaviours.

Design opportunities

A irports are effectively small cities. In the book Aerotropolis by Dr. Kasada, he promotes the idea that airports are central to commercial and economic growth due to their critical mass of people and their ability to connect countries. China has adapted this approach in its airport design, and there are many other examples, but when you think about it, an airport touches on so many sectors; retail, hospitality (hotels), masterplanning, industrial, blue light services and the commercial sectors; so, a fair bit to consider and probably why airports have so many design opportunities.

I t is also worth remembering that many airports have ageing buildings, therefore, reappropriating building stock and refurbishment is arguably as important as the design of shiny new terminals. For architects, the ability to get under the skin of existing buildings is an important design skill to have in your arsenal.

From my personal perspective, I find the air traffic control tower design to be iconic. If that sounds too self-indulgent, at the very least, they can be seen as a landmark. As the most vertical element of any airport, they represent a key aspect of its identity and are a strong symbol for the aviation industry. CPMG was fortunate to work on the air traffic control tower (ATCT) for Birmingham Airport, which has transpired to be a firm favourite within my experience with a truly collaborative effort from all involved.

D esigning facilities, such as ATCTs, to enhance the professional experience is also deeply rewarding. The air traffic controller is a well-trained and very focused individual, so the buildings we design must ensure that they have the environment within which to do the job to the best of their ability. This includes considerations such as good viewing angles, clear visibility, ergonomically-driven furniture, hardware solutions and optimum environmental conditions.

In practice

I t is important that new design projects offer a comprehensive understanding of the technical and compliance requirements – something CPMG has become accustomed to working on across multiple projects. Delivery constraints in a 24/7 facility mean architectural input beyond the design stage is critical. Delivery is even more complicated working, as well as the safety and security associated with potential airside working.

O n a positive note, there is an opportunity for real innovation and the chance for exciting architectural influence that will shape a new era for the airport industry.

I n addition, communication and lobbying across the various bodies representing the industry are important. The Airport Operators Association (AOA) and the British Aviation Group (BAG) are examples of leading industry groups that need to continue dialogue with the Government to put in place objectives that align with both the economic growth and environmental agenda of the country. The industry needs to be agile but focused on what our infrastructure platform looks like over the next 10, 20 or 30 years and be clear on that industry-wide vision.

FC&A – NOVEMBER – 202219

www.cpmg-architects.com VOICE OF THE INDUSTRY

THIRD SPACE REVOLUTION IN COMMUNITY PLANNING

The traditional housing estate – the standard product of most developers’ output for the past half century – is nearly over. Development has evolved from being solely residential to a more integrated product, more community-oriented and more befitting of local areas’ specific needs, says Ananya Banerjee – Director and Head of Design at Boyer (part of Leaders Romans Group).

Although the trend towards genuinely sustainable communities has been emerging for some time, it was undoubtedly hastened by the pandemic as ‘community’ took on a new meaning, and the ban on unnecessary travel created a need for easy access to daily facilities. This was further exacerbated by flexible working and spending more time at home. Therein lies the emergence of the 15-minute neighbourhood. But there’s more to it than being within easy walking distance of a shop – although, as Department of Transport research shows, this alone has substantial potential to make developments safer, cleaner and more sustainable.

The next step – one which my clients are already embracing enthusiastically – is the inclusion of a hub or community incubator space on a new scheme. With the potential to provide a community service, a workplace, energy efficiency and much more, all under one roof, this innovation is driving genuinely sustainable communities today and is being positively received by local authorities. Even in our local communities and town centres, this model is picking up pace in all forms, providing a multi-functional community hub which has the potential to house workspace for SMEs and start-ups, nano breweries, bike hire facilities, rapid electric charging points and much more.

A key player in this market is the Plunkett Foundation, which is showing how community facilities can be maintained and managed. Plunkett has been inspiring and empowering rural communities for over a century, demonstrating that the aspiration to “create a sustainable initiative that will make your community a better place to live” is an enduring value rather than a knee-jerk reaction to COVID. Specifically, Plunkett has spent the last decade developing and delivering major programmes that provide business support to

help start-ups and runs a range of community businesses. Another initiative is the creation of the Community Business Team, which aimed to provide a one-stop shop for all forms of community business at all stages of their journey. Similar case studies could also include Cassia and Incuhive. With hubs across the country, they are leading the way in offering everything under one roof and creating connected spaces to work, socialise and be healthy.

As masterplanners, this is having a direct impact in relation to how we think, plan and make our future communities resilient. In one of our projects, we have been fortunate to collaborate with SNRG in the early stages. A by-product of British Gas owner Centrica, SNRG is leading the way with the emerging concept of EMC (Energy Mobility and Community) Hubs with sustainable energy generation and use, lowcarbon travel and community cohesion at their core. We are increasingly looking at new sites that will prioritise the 15-minute neighbourhood model and are exploring possibilities for a community incubator space integrated within the landscape-led design principles. For larger communities, we are ensuring that each hub is placed within a 10-minute walking distance of all homes, therefore, creating a community of neighbourhoods, each with its own distinct identity whilst being integrated as part of a bigger whole. This physically ushers in the third space revolution with new masterplans.

With participation from enlightened landowners, community-spirited masterplanners, developers and local investors, this ‘third space revolution’ has considerable potential to create genuinely sustainable environments, which will prove crucial to community ownership and a holistic ESG (environmental and social governance) model for new settlements.

FC&A – NOVEMBER – 2022 20

BOYER

ANANYA BANERJEE

IS A DIRECTOR AND HEAD OF DESIGN AT BOYER

LEGAL & BUSINESS

www.boyerplanning.co.uk

FC&A – NOVEMBER – 202221 ZERO SEAL SYSTEMS LTD: 01785 282910 FIND OUT MORE AT: WWW.ZEROPLUS.CO.UK FIRE DOOR HARDWARE As important as the door A fire door is an essential part of a building’s passive fire protection system. A critical component of every fire door is the hardware on it. At ZEROplus we have been independently fire testing door hardware for over 20 years, to be able today to offer an extensive range of tested products. Seals Hinges Locks Euro Cylinders Lever Handles Door Closers Letter Plates Door Stays Vision Frames Louvres Door Viewers Flush Bolts Panic & Emergency Exit Hardware 01634 835290 www.marmox.co.uk Look out for the Honeycomb Finish! It means... Genuine Marmox and an ultra-str ong surface for adhesion! Pipe Boxing Niches Curved Boards Showerlays Bath Paneling Floors Walls Vanity Units Waterproofing Insulating Walls & Floors Tiles or Plaster Shower Bases Pipe Boxing & Niches Bath Surrounds Vanity Units Giving wetrooms the backing they need! Marmox Feb 2022 (FC&A).indd 1 15/12/2021 14:41:12

THE NEED TO MOVE FROM COMPLIANCE TO LEADERSHIP IN BUILDING SAFETY

Peter Ashworth, Specification Sales Director at ASSA ABLOY Door Hardware Group, argues that the built environment industry needs to move from a place of compliance to one of leadership when it comes to building safety.

ASSA ABLOY DOOR HARDWARE GROUP

ASSA ABLOY DOOR HARDWARE GROUP

In light of the recent series of reports on building safety from Dame Judith Hackitt and the Industry Safety Steering Group (ISSG), it is clear that more needs to be done to accelerate culture change in the built environment industry so we can move from a position of compliance to one of leadership.

T he reports have set into motion a number of new acts and frameworks based on the ISSG’s recommendations. However, for the prescribed changes to have any impact, there must also be a change in mindset when it comes to building safety. Here’s a breakdown of four ways in which this needs to happen.

1 . Whole-life costs

O ne fundamental change is to move away from the culture of purely cost-based decision making. While it is tempting for decision-makers to try and save money wherever possible, this change in mindset will play a crucial role in driving culture change throughout the built environment industry. By taking a long-term view of decision making – which prioritises the quality, performance and longevity of a solution – we will all be moving closer to the industry culture that the ISSG is advocating for.

I ndeed, this is not only preferable from a safety point of view, but often turns out to be the most cost effective in the long term. While alternative solutions might look better on this year’s budget sheet and the bottom line right now, any savings can be quickly lost if the costs throughout the entire lifetime of a product are not considered by doing a lifecycle cost analysis.

2 . Levelling-up competency

I n most industries, the need for training and development cannot be underestimated. The Open University’s annual business report, which monitors the skills landscape of the UK, recently reinforced the fact that skills shortages are a long-term strategic challenge

FC&A – NOVEMBER – 2022 22 DOORS, WINDOWS & BALUSTRADES

for organisations: almost two-thirds of leaders admit they have struggled to find individuals with the right skills and experience when recruiting 1

It’s encouraging, then, that the results of a Confederation of British Industry and Birbeck survey found that 41% of employers are planning on increasing investment in training over the next 12 months2. Set against the ISSG’s agenda for greater competence and standards, it is clear that this investment will be needed to help foster culture change throughout the built environment industry.

3 . Identifying insights with BIM

O ne tool that will help deliver greater compliance and capacity building is Building Information Modelling (BIM). First of all, it’s important that BIM is seen as a process rather than a piece of software: the process of assembling all of a building’s parts and combining them to enable you to visualise how a building will look. However, it’s more than simply a 3D rendering of a building. BIM enables decision makers to assess which products and solutions are best for a project while providing valuable information and insights about a building during its lifetime.

The information provided by BIM can offer greater insights into what’s the best solution throughout a building’s lifespan. And, as previously mentioned, a specification process that places the total cost of ownership at its heart can help deliver buildings that are built more effectively, last longer and better meet the needs of users.

4 . Meeting the standards

F inally, to ensure products operate as expected, they must meet certified standards and undergo stringent testing. This provides an official seal of approval that products meet the requirements expected for security, robustness, longevity, compliance and fire safety.

For instance, it’s vital that the right accreditations are in place for those installing fire safety doors and their associated hardware. Key ones to look out for include:

Warringtonfire’s FIRAS Installer Certification Scheme

BM TRADA’s Q-Mark Fire Door Installation

The GAI Diploma from the Guild of Architectural Ironmongers.

A nd then, systems must be certified and have undergone independent third-party testing. Fire doors should be tested to EN 1634-1 or BS 476 22, accredited by a UKAS independent organisation, which completes any testing and certification.

Accelerating culture change in the built environment industry should be an ambition for everyone involved. While legislation is an important measure to drive change, this will often set safety standards at the minimum acceptable level of what should be undertaken. Instead, we, as an industry, should be advocating that the solutions we deliver exceed these requirements, taking pride in how these measures will create safer, futureproof developments that better meet the needs of their users.

To download the new white paper from ASSA ABLOY Door Hardware Group, titled ‘Accelerating Culture Change’, please visit www.assaabloy.com/uk/en/stories/whitepapers.

www.assaabloy.com

FOOTNOTES:

1Open University, ‘Business Barometer 2021’, https://www.open.ac.uk/ business/news/open-university-business-barometer

2Confederation of British Industry, ‘Skills for an inclusive economy: CBI/ Birbeck Education and Skills Survey 2021’, https://www.cbi.org.uk/articles/ skills-for-an-inclusive-economy-cbibirkbeck-education-and-skillssurvey-2021/

FC&A – NOVEMBER – 202223 DOORS, WINDOWS & BALUSTRADES

MARRYING TRADITIONAL AND OFFSITE MANUFACTURING

James Mead, Projects Director at Saint-Gobain Weber, and Mike Doolan, Sales and Partnerships Manager at LoCal Homes, share their experience of combining more traditional building products with offsite manufacturing to deliver the housing the UK so desperately needs.

SAINT-GOBAIN WEBER

In 2019, the Government set a target of 300,000 new homes a year by the mid-2020s. This figure was originally unveiled in 2017 by then Chancellor Philip Hammond as the number of new homes needed to make “inroads on the affordability of housing”.

T he closest we have been to achieving this target was in 2019-20, with 243,770 net additional dwellings. With housing output continuing to fall short, it has been debated over recent years whether increasing the use of modern methods of construction (MMC) is the quickest way to reduce the deficit.

T he Government seems to be supportive of this approach and is encouraging the use of MMC via initiatives like the Affordable Homes Programme (AHP) from Homes England, which requires strategic partners to deliver 25% of homes using MMC if they’d like to access funding. Under the AHP, homes will only be considered as “being delivered using MMC” if they have a Pre-Manufactured Value (PMV) score of 55% or more.

Increasing demand for offsite construction

In 2020, real estate advisor Savills predicted that the proportion of homes built using MMC over the next 10 years would rise from around 8% to closer to 20%.

“Awareness of the possibilities that offsite construction offers is definitely increasing,” says Mike. “The drive from Government, as well as the need for housing associations to deliver new homes that meet the new Part L (conservation of fuel and power), Part F (ventilation) and Part O (overheating) requirements of the Building Regulations in England, are providing a good platform to showcase the benefits of using MMC.

“ We’ve also found that there is a growing appetite for offsite timber frames with factory-pre-fitted external finishes. An offsite, panelised timber frame is a viable alternative to full modular or volumetric systems due to its lean and flexible production processes.”

Traditional facades, modern construction

A lthough clients are more open to building this way, many still want new-build homes to have a traditional appearance. Around 70% of the UK’s new homes are built with a brick facade, and, therefore, James argues, more traditional products still have a large role to play.

“ Category 6 of the MMC definition framework includes traditional single building products that are manufactured in large-format, pre-cut configurations or

with easy jointing features to reduce the extent of site labour required to install,” explains James.

“As we transition from traditional building methods to offsite manufacturing, products within this category are set to play a huge part in bridging the gap. Builds will become quicker thanks to the ease and speed of installation, and there will be, on the whole, no requirement to retrain, as existing labour is sufficient – it simply needs redeploying.”

Weber developed its weberwall brick – a fast-fix, lightweight brick system – as a solution for offsite manufacturers who wanted to give their homes a brick finish without having to manually apply brick slips.

“When we were looking for a brick slip system to use on our closed-panel timber frame system, we found lots of them required additional labour and works on site to achieve a similar appearance,” says Mike. “This impacts both the assured quality of the build and speed of the programme."

Introducing site application also reduces your build’s percentage of PMV, which goes against the whole principle of offsite construction. We also needed something that wouldn’t add lots of additional weight to the panels. Using a brick-effect finish like this can also help us meet the requirements for colour and brick texture as required by planners.

FC&A – NOVEMBER – 2022 24 OFFSITE CONSTRUCTION

“ weberwall brick suited LoCal Homes’ system because it can be fixed more than three times faster than traditional brick slips, and one sheet, which contains 20 bricks, weighs the same as one brick, so only adds 13kg per metre squared to the timber frame panel,” adds James.

A lighter overall wall structure means that the build can become more efficient in other ways, such as foundation design. Smaller foundations mean that less concrete is required.

Benefits of factory application of final facades

Weber worked with LoCal Homes to develop an efficient application process with minimal waste.

“ We’ve designed a precise setting out method, which enables projects to be priced accurately with very little wastage,” says James. “Lasers are used in LoCal Home’s factory to ensure accuracy when making any cuts, and we’ve also optimised the adhesive application to make it even faster."

For LoCal Homes, another benefit of keeping all elements of the build within the factory include being able to buy product in bulk and store it in secure, weathertight facilities, which helps to maintain a steady flow of products.

“ There are two huge benefits of working this way – noticeable time improvements on project delivery and the ability to design and build more sustainable homes in line with the latest standards,” says Mike.

“ There is no ‘downtime’ as the works aren’t weather dependent. And that’s not just bad weather – during this summer’s heatwave, lots of building sites had to pause works, further highlighting the advantages of manufacturing off site.

“ We are currently producing around 1000 units a year and are expecting an increase in social housing orders because closedpanel timber building is extremely efficient, helping all stakeholders towards net-zero targets and will also help to ensure adherence to the uplift in Part L that came into place on 15th June, as they can be constructed with this in mind.”

LoCal Homes is currently using weberwall brick at a development in Daventry, where it is building two three-storey blocks to create 22 apartments, and in Kirton, Lincolnshire, where it has been used o n two bungalows and four houses

FC&A – NOVEMBER – 202225 OFFSITE CONSTRUCTION

www.uk.weber

ROOFING SYSTEMS FOR SUSTAINABLE SPECIFICATIONS

FC&A speaks to Sarah Peake, Sustainability Manager at Sika UK, about sustainability regulations and initiatives affecting architects and specifiers and the roofing systems that can meet their requirements.

Ba lancing the need for a functional, forward-thinking design with an increasing demand to reach net zero is the unenviable task faced by architects and specifiers today.

With sustainability, every part of a building needs to be considered, and every stage of the building’s lifespan. Operational carbon, the emissions of a building in use and embodied carbon – the emissions produced during manufacture, demolition and end of life – are equally important considerations for architects.

R oofing systems are only one part of a wider plan for a project, but as 25% of the heat from a building escapes through the roof, the roof build-up has a huge influence on the energy efficiency and sustainability of the whole building. A sustainable roofing system is one that is able to effectively insulate and waterproof the building: an important consideration during specification. A roof has the potential to make or break a project’s sustainability credentials and greatly affect the sustainability assessments of a BREEAM or LEED rating.

O n the legislative side, there are few concrete rules in place, but with net-zero targets set for 2050, and the drive towards UN Sustainable Development Goals, this is likely to change. At present, two of the most pertinent are Procurement Policy Note (PPN) 06/21, which decrees Government contracts over £5m will only go to businesses with a carbon reduction plan, and PPN 06/20 – taking account of social value in the award of central Government contracts. As Government policy typically sets the standard for others working in the industry, it is likely

that others will follow suit in making more stringent, legally-enforced sustainability demands; many local authorities have surpassed this already and are demanding more from a social value perspective than the Government.

A t this stage, however, the majority of sustainability efforts work to reduce emissions and essentially futureproof a building, ensuring it is compatible with legislation that doesn’t yet exist and aligns with net-zero targets.

Sustainable roofing systems

For sustainability in the construction industry, physical performance is as important as any other factor. In some ways, there is no sense in declaring a certain system as the most sustainable: if a roofing technology doesn’t suit the roof and quickly fails, it is ultimately no longer sustainable.

T hat being said, there are roofing systems with more sustainable potential than others that combine sustainability and physical performance exceptionally well. Provided they are carefully chosen to work well with any given project, any of these roofing systems could help you meet Environmental, Social and Governance (ESG) targets, adhere to potential sustainability legislation and futureproof a building.

Green roofs

I n a discussion of sustainable roofing systems, green roofs usually sit top of the list. With their eco-credentials the focus of any discourse, green roofs have become almost synonymous with sustainability in the roofing industry.

Available in three types, biodiverse, extensive and intensive, these roofs have a vegetative layer that actively works to absorb carbon dioxide, insulates the building and controls stormwater levels. Green roofs are long lasting and work to reduce the urban heat island effect of cities; provided the roof is suitable, this roofing system is incredibly sustainable and could futureproof a building for decades to come.

S olar roofs

T his roof type is generally less about the roof build-up and more about what sits above it. Renewable energy as the single source of our energy needs is the ultimate aim of net-zero targets and many sustainability policies: a solar roof puts any business one step closer.

A business can generate its own green energy during the day, lowering its reliance on the national grid and potentially saving thousands of pounds in energy costs. Solar roofs are becoming increasingly efficient at generating energy and are becoming a more popular option as energy costs rise.

Hot melt

H ot melt roof build-ups are a little different from the other roofing systems mentioned here. Rather than any obvious feature, it is their durability that contributes to their sustainability. Construction is a notoriously carbonheavy industry, and a roof that needs regular maintenance or is replaced more frequently is going to amass all the additional carbon emissions associated with the work.

FC&A – NOVEMBER – 2022 26 RCI

SIKA UK

Hot melt roofs are known to last for several decades and, in many cases, can have a lifespan as long as the building itself. Sika’s hot melt structural waterproofing, for example, is BBA certified to provide durable roof waterproofing for the design life of the roof in which it is incorporated. Hot melt is also compatible with green roofs, acting as the waterproofing membrane in the buildup, so it can be part of a wider sustainable roofing system.

S ingle ply

I n a similar manner to hot melt roofs, the durability and longevity of singleply roofs help make them sustainable. Single-ply membranes have proven their performance as a roof waterproofing product, lasting for decades on a roof, and when installed correctly, will require minimal maintenance and are straightforward to replace when required.

S ome single-ply membranes are more sustainable than others, however, as manufacturers strive to create a more sustainable roofing package. Leading roofing manufacturer Sika has created the Cradle to Cradle Silver-certified Sarnafil AT, a single-ply membrane with exceptional sustainability credentials.

Combining technologies

P erhaps the most sustainable roof of all is one that utilises multiple roofing technologies. If the project permits, combining multiple roofing technologies into one sustainable package can help you reap the benefits of all the systems. In a green roof system, the vegetative layer sits at the very top: in the buildup, the waterproofing membrane plays a vital role. Including a membrane with certified sustainability credentials like Sarnafil AT ensures the whole system is considered. Solar panels can also sit above a green roof, generating renewable energy for the building.

Third-party proof

To avoid greenwashing, you need a roofing system that has been assessed and certified by a third-party organisation.

An Environmental Product Declaration (EPD) has long been the standard for sustainability certification, but that is exactly what it has become: standard. An EPD is expected at this stage, and all it does is list the impacts; it doesn’t rank them or consider other aspects, such as social value. Therefore, companies must do more to prove the sustainability of their products and themselves.

For the highest level of sustainability ratings, you should look for a certification

from an independent, respected testing body with a rigorous assessment process. One such example is Cradle to Cradle, an organisation that evaluates a product’s ability to join the circular economy. To be certified, a product must excel in five separate sustainability categories: Material Health, Material Reutilisation, Renewable Energy Use, Water Stewardship and Social Fairness. Cradle to Cradle sets a high bar for manufacturers and is one of the most respected accreditations an architect or specifier can look for.

FC&A – NOVEMBER – 202227 RCI

gbr.sika.com

SARAH PEAKE

IS THE SUSTAINABILITY MANAGER AT SIKA UK

POWER TO THE PEOPLE

Bio-solar roofing is a new type of roof that combines the powergenerating benefits of a solar roof with the biodiversity gains of a green roof. Ross Finnie, Sales Director at SIG Design & Technology (SIG D&T), explains the benefits of this system and how to approach its design and specification.

The escalating cost of energy is leading more and more businesses and homeowners to look to the use of roof-mounted photovoltaic panels (PVs) as a means of converting the sun’s energy into electricity. The result is cheaper electricity and a reduction in the carbon emissions associated with the operation of the building.

F itting a green roof is also a positive environmental move. Increasing the amount of vegetation on the plot can help attenuate rainwater run-off reducing the potential for a building to contribute to flash flooding while simultaneously providing additional habitat for insects, increasing the biodiversity of urban environments. Combining both should compound the benefit.

P V panels are usually mounted close to the roof surface, where they shadow it from the sun and rain. In the past, architects and building owners have had to chose between fitting PVs or installing a green roof. Now, thanks to a partnership between SIG Design and Technology (SIG D&T) and Eco Green Roof (EGR), it is possible for a building to have both in a single bio-solar solution.

‘ SolarNature’ roofing solves the problem of a green roof’s access to sunlight and rainwater by holding the PV panels high above the roof’s surface with the front edge of the photovoltaic panel at a height of around 300mm above the roof substrate. Raising the panels up also helps ensure that they are mounted at the optimum angle to the sun to ensure they deliver maximum electrical output.

A bonus of combining PVs with a green roof is that the evaporation of rainwater from the green roof, combined with transpiration from the vegetation, helps to keep the temperature of the roof surface to a minimum. This, in turn, helps reduce the ambient temperature close to the PV panels, further increasing their electrical output.

M oisture is retained by the reservoir board at the base of the green roof. This is manufactured to incorporate a deeply-recessed profile to retain and distribute moisture, which ensures it is present beneath the raised PV panels. Excess rainwater is directed to the roof’s perimeter, where gullies and outlets enable the surfeit to drain away.

I n addition to storing water, the steel mounting rails supporting the solar panels are themselves supported by the reservoir board. This helps simplify the PV installation while eliminating the need to penetrate the roof’s waterproof membrane.

B allast, needed to keep the PV panels in place, is provided by the substrate into which the vegetation is planted. The amount of ballast required to prevent the panels from being affected by wind uplift will be dictated by both the area of the panels, the plan of the roof and its location. To ensure the sufficient substrate is specified, wind mapping is used. This is particularly important at the roof’s perimeter and corners where the wind vortex is generally at its strongest.

B allast weights are calculated based on the dry weight of the growing medium to ensure adequate loading in dry conditions. However, it is the figure for the increased weight of the growing medium and reservoir when saturated with rainwater that SIG D&T and EGR issue to the design team to enable them to develop the appropriate supporting structure

FC&A – NOVEMBER – 2022 28 GREEN ROOFS & LIVING WALLS

SIG DESIGN & TECHNOLOGY (SIG D&T)

www.sigdandt.co.uk

FC&A – NOVEMBER – 202229 www.firmanglass.com Further information is available from our sales and technical offices or visit www.firmanglass.com Firman Glass, 19 Bates Road, Harold Wood, Romford, Essex RM3 0JH Tel: 01708 374534 Email: sales@firmanglass.com GLASS EXCELLENCE With over 46 years’ experience and UK-wide coverage, Firman Glass aims to be your number one choice for commercial and industrial glass products. www.firmanglass.com • Toughened glass • Processing • CNC shaping • Laminated glass • Toughened and laminated constructions • EVA and Vanceva coloured interlays • Fabric and decorative interlays • Structural interlays • Specialist insulating glass units • Anti–slip glass • Fire rated glass • UV bonding • Electric switchable glass • Heated glass • Decorative glass • Sandblasting • ColorfirmTM back painted glass • Structural glazing • Glass floors • Partitions • Roof lights • Balustrades • Full height barriers • Canopies • Staircases • Treads and stringers • Shower screens • Shelving • Glass doors • Acoustic reduction • Fire rated • Decoration • Wall cladding • Splashbacks • Privacy • Technical Support • Nationwide Coverage Products Applications

BUILD FOCUS:

URBAN DEVELOPMENTS

SYMPATHETIC REFURBISHMENT BREATHES NEW LIFE INTO AN HISTORIC STREET

The stunning £7.2m residential scheme was delivered in multiple phases over the course of three years and involved both the refurbishment of 1870 to ‘80s terraced homes and the construction of three new townhouses, in keeping with the existing heritage buildings.

Re ctory Gardens was badly bombed during World War II, leaving the houses derelict and, from the 1960s onwards, inhabited by squatters. Previous plans were made, but abandoned, to transform the site, including a gated luxury residential scheme with the creation of 32 new-build homes and retail space. However, developers, Lexadon Property Group, were able to provide a more sympathetic solution that retained the existing terraces and matched the new-build homes to these. They called on us, their construction partner of 20 years, to deliver that vision. The result is a new community that both respects the area’s architectural past and answers homeowners’ current and future needs.

The original project involved the refurbishment of 26 houses at Rectory Gardens, a private close, with the addition of basement extensions to 16 of the properties, along with the refurbishment of three mixed-use houses, which contained apartments above shops over the basement

and ground. Three new-build townhouses were then added to the scope of works, establishing a development totalling 32 new and refurbished homes, plus three shops, all of which showcase traditional brickwork, features and materials authentic to the original Victorian construction.

We worked very closely with the developers from the pre-commencement stage onwards throughout the project, utilising in-house labour that was able to adapt responsively to challenges and unforeseen works. Two of the properties in Rectory Gardens were not included in the development scheme and remained occupied throughout the programme. This made it necessary to consider the impact of construction activities on residents and work with them to minimise disruption.

The excavation work required for the properties where basements were added to the existing structure was amongst the most demanding aspects of the project. Our team successfully created nine basements in just 10 months, which involved extensive

temporary works to enable major structural alterations. The temporary works were planned in house, and all construction works were 3D modelled to ensure viability and accurate sequencing.