April 2024 Issue 140 Public Sector Build Journal Leisure Housing Education Healthcare psbjmagazine.com

FASHIONING FUTURES AT LONDON COLLEGE OF FASHION Step into the future of fashion education as Allies and Morrison redefines creativity’s home

The Future Homes Standard and sustainable construction

Tech shift: NBS report decodes construction’s digital transformation

Europe’s pioneering solar car park arrives at Salisbury health centre

Specialising in modular construction for 90 years CONTACT US TODAY 0800 18 18 22 | www.wernick.co.uk buildings@wernick.co.uk Find out more Scan the QR code 50+YEARS DESIGN LIFE SUSTAINABLE CONSTRUCTION FULL PROJECT MANAGEMENT MINIMUM ON-SITE TIME FLEXIBLE RELOCATABLE WERNICK MODULAR BUILDINGS DELIVER...

jim@redhutmedia.com

jack@redhutmedia.com

Welcome to the April issue of PSBJ...

sam@redhutmedia.com

In today’s construction landscape, leveraging technology isn’t just an option – it’s a necessity. By embracing tech, both the public and private sectors stand to gain significantly. Not only does it streamline operations, enhance safety measures and reduce expenses, but it also fosters a culture of collaboration, a key focus across the industry. Moreover, technology empowers decision makers with valuable data insights, facilitating informed choices at every stage. And let’s not forget its role in promoting sustainability practices and aligning construction efforts with environmental goals.

Traditionally labelled as a latecomer to embracing high-tech innovations, the construction industry has faced criticism for its perceived reluctance to adopt modern technology. However, there are clear signs that this mindset is shifting, indicating a promising transition towards technological integration within the sector.

In this month’s issue, we delve into the findings of the NBS’ 2023 Digital Construction Report, showcasing a significant change in the industry. Positive statistics abound, including a notable 50% surge in the adoption of digital twins since 2021, a marked uptick in interest in AI and machine learning and an impressive eight out of 10 professionals now integrating cloud computing into their daily workflows. For further insights, turn to page 30.

Elsewhere, we look at the recent installation of the first large-scale solar car park (SCP) in Europe, constructed from sustainable glulam timber beams and Glass-Glass solar panels. Opening to the public this month, the SCP at Wiltshire Council’s Five Rivers Health & Wellbeing Centre is a significant leap in maximising the lifetime sustainability of solar installations. Learn more on page 20.

I hope you enjoy this issue. Don’t forget, you can also access the magazine’s features, product news and supplier information on PSBJ’s user-friendly and engaging website. Fully responsive, the website allows you to read all the latest stories on the go either on your smartphone or tablet. Simply visit www.psbjmagazine.com.

03

Rebecca Kemp • Editor • rebecca@redhutmedia.com Find us on Social Media: Contributions are invited and when not accepted will be returned only if accompanied by a fully stamped and return addressed envelope. No responsibility will be taken for drawings, photographs or literary contributions during transmission or in the editor's hands. In the absence of an agreement the copyright of all contributions, literary, photographics or artistic belongs to Red Hut Media Ltd. The Publisher accepts no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the view of the publisher. The Publisher does not accept any liability of any loss arising from the late appearance or non publication of any advertisement. Editor Rebecca Kemp rebecca@redhutmedia.com Print & Digital Advertising

Allies and Morrison has unveiled the stunning new home for the London College of Fashion at Queen Elizabeth Olympic Park. See page 08.

Sam Ball sam@redhutmedia.com Jim Moore

Print Design Manager

Sam Ball

Published by Red Hut Media Ltd. 2, The Old Stable Block, Crescent Road, Faversham, Kent, ME13 7GU psbjmagazine.com 01795 515288 redhutmedia.com PSBJ is a proud supporter of the Chartered Institute of Architectural Technologists. WELCOME NOTE @psbjmagazine

Jack Witcomb

Digital Design Manager Matt Morse matt@redhutmedia.com Accounts Rachel Pike accounts@redhutmedia.com Publisher

Rebecca

Image: ©Simon Menges

06 News

A round up of the latest industry news, including charity events, awarded contracts, completed projects and much more.

08 Upfront

Allies and Morrison has unveiled the stunning new home for the London College of Fashion at Queen Elizabeth Olympic Park.

12 Education

ADP Architecture has completed Shireland CBSO Academy, the first free, non-selective state school in Britain to be established in partnership with a professional orchestra.

14 Legal & Business

The updated National Planning Policy Framework (NPPF) is here, bringing significant changes to housing delivery, energy efficiency and more. Dive into the key updates with the planning and compulsory purchase team at Burges Salmon.

16 Healthcare

Phil Pavey, Managing Director at Algeco Offsite, looks at how the latest platform design solutions are improving access to crucial diagnostic services by rolling out Community Diagnostic Centres (CDCs) faster than other construction techniques.

Latest

26

18 RCI

Lisa Stephens, Product Manager for the Building Envelope at ROCKWOOL UK, explains the requirements to ensure fire safety for roofs with solar installations.

20 Leisure

Europe’s first solar car park with carbonfriendly construction is coming to Wiltshire Council’s Five Rivers Health & Wellbeing Centre this month.

22 Street Furniture

Discover a vibrant heart in London at Gascoigne Park, where innovative design meets community spirit, thanks to the collaboration between Turkington Martin, Barking Council and All Urban.

24 Interiors

National fit-out and refurbishment specialist contractor, Willmott Dixon Interiors, has handed over the newly-upgraded Larches Ward at St. Michael’s Hospital.

No need to compromise on performance, quality or service.

Schöck products meet full compliance with relevant UK building regulations, are approved by the BBA, NHBC accepted and classi ed as re resistance class REI 120. www.schoeck.com

04 CONTENTS

Thermal break technology you can trust.

240175_Anz_IK_PSBJ Magazine_185x131_GB_rz.indd 1 22.03.24 12:20

Schöck BBA Certi cation raises the bar.

26 Housing

Barny Evans, Director of Sustainability and ESG at Turley, asks what the Future Homes Standard means for the future of sustainable construction.

28 KBB

Learn from Sophie Weston at Geberit about the importance of addressing acoustics in residential buildings and how thoughtful design choices can enhance wellbeing.

30 Digital & Software

Is construction’s digital revolution underway? NBS’ 2023 Digital Construction Report sheds light on the industry’s evolving tech landscape.

32 Talking Point

With a looming general election and potential administrative changes in the public sector, securing green lights for projects becomes crucial. Here, Rebecca Hartshorn, National Framework Director

at Sisk, delves into the pivotal role contractors play in navigating uncertainties and driving project viability.

34 Technical Focus

Ardit Strica, Technical Manager at Onduline Building Products, provides a comprehensive overview of low-pitched roofs, their challenges and the transformative benefits of sub-roof systems.

36 The Fire Safety Event

The Fire Safety Event will open its doors at the NEC, Birmingham, from 30th April to 2nd May and will play host to leading manufacturers and suppliers to showcase their latest approved products and solutions.

38 Product Guide

A dedicated focus of industry news, products and case studies to help specifiers and local authorities make informed decisions.

05 CONTENTS 08 18

Manufactured, Tested, Specified, Certified For more details, call our specialised team on: 01233 639039 sales@sunraytimberdoordivision.co.uk | www.sunraytimberdoordivision.co.uk Sunray is the specifiers choice for Timber Fire Doors and passive Fire Protection. Our comprehensive Timber Door Range provides Fire Integrity from FD30 to FD120 and Security Rating of SR1 & SR2 with Fire Secure.

Doors are bespoke enabling specialist hardware, vision panels, overpanels and of course colours and finishes. We operate in numerous sectors and provide performance specifications to meet project requirement.

All

INDUSTRY UPDATES

Each month, PSBJ rounds up the latest public sector construction updates, from new contracts to industry awards.

Planning approved for £9m regeneration project in Gloucestershire

A state-of-the-art leisure, enterprise and education centre being developed by leading multi-disciplinary consultancy Pick Everard is one step closer to realisation, following council approval. The Five Acres site in Berry Hill, Coleford, is set to undergo transformation via Pick Everard and contractor BAM Construction, after unilateral agreement on plans submitted by Forest of Dean District Council. The work will be completed in phases. The first of these will focus on repurposing classrooms at an existing educational building – Speedwell House – to create new office and community spaces, alongside a cafe and outreach space for Hartpury University’s Aspiration Centre. The new building will connect Speedwell through a glazed atrium and include the construction of a new multipurpose four-court sports hall, small performance space, party rooms/ dressing rooms and internal changing rooms. Outside, there will be a separate external changing block, a secure cycle hub and a new carparking layout, which will introduce 12 electric vehicle charging spaces on the site for the first time. The project, accelerated through the SCAPE Consultancy direct award framework, designed to drive collaboration, efficiency, time and cost savings on construction projects, will be delivered by Pick Everard, operating through Perfect Circle to provide a wide range of services, including project management, cost management, health and safety and sustainability consultancy.

Boutique Modern expands in Newhaven with new factory

Construction company Boutique Modern will start building a new factory in Newhaven this year, which will create more than 35 further jobs at the business and double its capacity. The B Corp modular housing company was given the green light by Lewes District Council to build the factory in Avis Way and plans to move in at the end of this year. The business specialises in delivering sustainable homes for affordable and social housing schemes in the South East, helping the most vulnerable people in society to find a place they can call home. Dick Shone, Managing Director at Boutique Modern, said: “This is an exciting new chapter for Boutique Modern, which will mean more homes and jobs for local people. This will prepare us for the next exciting phase when we open satellite factories in other areas with housing demand. Each new factory will create upwards of 100 new jobs and generate more than £20m for the local economy per year, per facility. It’s our belief that social and affordable housing should be beautifully designed and sustainable and it’s a privilege for us to be able to make a difference.” The factory has been designed by award-winning Brighton architect firm Morgan Carn and will feature a two-storey industrial building to be used to manufacture offsite modular housing units.

Pupils cut ribbon as Conlon hands over Springfield School SEND provision

Conlon Construction has handed over the newly-expanded Springfield School site in Wilmslow, creating up to 80 much-needed local school spaces for children and young people with special educational needs and disabilities (SEND). Cheshire East Council awarded Conlon Construction the contract as part of its commitment to increase the number of specialist school spaces within the borough and support young people with a range of needs, including autistic spectrum condition, severe learning difficulties and profound multiple learning difficulties. The satellite site has been designed and built with special consideration for the access, safeguarding and sensory requirements of pupils aged four to 18. A handover ceremony was held on Friday 16th February with pupils given the honour of formally opening their new school. Students, alongside other dignitaries, cut the ribbon to officially kickstart a new era of learning, focused on being healthy, safe, both enjoying and achieving, making a contribution and entering the adult world with multiple life and education skills. Darren Lee, Commercial Director at Conlon Construction, said: “Springfield School is a fitting showcase for our extensive education credentials. From early years to university, we have delivered modern, appealing and sustainable education facilities across the region.”

£18.5m contract awarded for new Whitecraig Primary School

Work on a new Whitecraig Primary School is due to begin this spring following the award of an £18.5m contract to Morrison Construction. East Lothian Council appointed Morrison Construction following a competitive tender process. The firm has worked on a number of council projects including Wallyford and Letham Mains primary schools and, most recently, Wallyford Learning Campus. A replacement primary school is needed in Whitecraig in response to a growing school population from ongoing and planned housebuilding in the area. The project will see the current 1959 building replaced to increase capacity by a new building suited to modern learning. Built on land adjacent to the current school, the new building combines eight classrooms with an integrated early learning facility behind a facade of charcoal grey brick and copper cladding panels and accents, including on some window surrounds, designed by the council’s in-house architect. Landscaped spaces have been designed to improve pedestrian and cyclist safety with a dedicated community entrance provided to the northeast. Upgrades will also take place to Whitecraig Road. Cabinet member for Education and Children’s and Family Services Councillor, Fiona Dugdale, said: “Our vision is for a modern school that is energy efficient and supports excellent teaching and learning. We also believe that it can support the wider community and, together with the Whitecraig Village Hub, provide spaces and opportunities for residents.”

06

NEWS

Milton Keynes City Council selects GRAHAM for £70m Lakes Estate Renewal Project

Milton Keynes City Council has selected GRAHAM as the principal contractor for Phase A of the Lakes Estate Renewal Project in Bletchley through Pagabo’s Major Works Framework. This two-stage design and build contract represents a landmark moment in the rejuvenation of the Lakes Estate, marking one of the first regeneration projects of its kind for Milton Keynes. Originally built in the 1960s, the Lakes Estate has played a crucial role in Bletchley’s history but now needs renewal. With planning approval granted in 2022, the Lakes Estate Renewal Project aims to breathe new life into the area, addressing the need for new homes, improved amenities and healthier living conditions. This phase of the project focuses on the construction of 183 new homes. New community facilities will be also created, including a nursery, a community hub and two retail units, envisioned as a pharmacy and food takeaway, catering to the needs of residents living on the estate. Rob Joyce, Development Director at GRAHAM, said: “We are proud to have been selected by Milton Keynes City Council to deliver this crucial phase of the Lakes Estate. This renewal project signifies not only a substantial investment in community regeneration but also a commitment to enhancing the wellbeing and vitality of the residents who live there. We are committed to working closely with the council to transform the Lakes Estate into a thriving and sustainable living space for the community.”

Manchester Metropolitan’s state-of-the-art library given planning green light

Planning permission has been granted for the new state-of-theart library at Manchester Metropolitan University. Manchester City Council approved the project in February, which will see the current library at All Saints on Oxford Road replaced with a modern and dynamic learning environment. Architecture practice Hawkins\Brown and Schmidt Hammer Lassen were commissioned to design the new iconic building and demolition works are expected to begin on site in the autumn of 2024. Construction is due to complete in spring 2028, with the library ready for the start of the 2028/29 academic year. Plans were announced for the new library in November 2023, ahead of Manchester Metropolitan’s 200th birthday. The university is currently celebrating two centuries of driving innovation and progress through excellence in education and research. The eye-catching new building will feature digitallyenabled teaching and research facilities to enhance students’ data science and analytical skills and flexible breakout spaces to support collaboration and nurture ideas. It will also house the university’s Special Collection Museum and the Manchester Poetry Library – the North West’s first public poetry library, plus a new gallery and event spaces that public audiences will be invited to engage with.

Work commences on new pioneering education campus in Cardiff

A special groundbreaking ceremony has marked the start of construction of a new pioneering joint education campus, to be located in the Fairwater area of Cardiff. The £110m project is the largest in scale and investment, of Cardiff’s education developments delivered under Cardiff Council and Welsh Governments Band B Sustainable Communities for Learning Programme. The development will include the construction of three new-build schools for Cantonian High School, Riverbank School and Woodlands High School, all situated on a single site. The development will be net-zero carbon, in line with Welsh Government standards, and will set the standard for future Cardiff school projects. Each of the three schools will be highly energy-efficient buildings that are powered from renewable energy sources, enabling Cardiff to deliver on its One Planet Strategy, which outlines the city’s ambition to mitigate climate change. First Minister, Mark Drakeford, said: “It’s great to see the construction of the new campus get underway, which will provide young people from Cantonian, Woodlands High and Riverbank with an inspirational and modern learning environment. As well as being net-zero carbon, the campus will provide facilities that will benefit the community in this part of Cardiff for years to come.”

Morgan Sindall set to deliver Innovation Centre to Crawley

Morgan Sindall Construction’s Southern Home Counties business has been appointed by Crawley Borough Council (CBC) to complete a significant building conversion, which includes the major upgrade to MEP works to deliver a state-of-the-art Innovation Centre to the town. Procured through the SCAPE framework, the development will take over the former TUI Travel House on the Manor Royal Business District and is expected to bring an economic boost to Crawley as it continues to bounce back from the COVID pandemic. Morgan Sindall marked the start of work on site with a Golden Hammer ceremony that took place in January, with Leader of CBC Cllr Michael Jones, Cllr Atif Nawaz, CBC Chief Executive Ian Duke, all in attendance. Crawley Innovation Centre was a key part of the town’s 2022-2037 recovery plan and was agreed by the CBC Planning Committee. It will benefit from £8.4m in funding from the Coast to Capital Local Enterprise Partnership. Finished work at the 2500m2 Innovation Centre will include five workshop rooms, two offices, flexible working space and a cafe. In line with Morgan Sindall’s Intelligent Solutions approach, the project team has engaged with innovative recycling and reusing management company Encore, which ensures that all waste from the preexisting site and throughout construction will be 100% reused or recycled.

07

NEWS

CATWALK TO CLASSROOM: LONDON COLLEGE OF FASHION’S STYLISH NEW HOME

Allies and Morrison has completed the new home for the London College of Fashion at Queen Elizabeth Olympic Park. Through robust and flexible architecture, it aims to suit the long-term needs and ambitions of one of the UK’s most important arts universities.

The new college provides over 40,000m2 of space for 5000 students over 17 storeys. It is rich in creativity and production with classrooms, workshops, offices, a lecture theatre, canteen, an archive, digital studios and social spaces.

Previously dispersed across six sites, this is the first time in the college’s history that all its departments colocate under one roof. Catering for courses from journalism to jewellery, fashion illustration to footwear, menswear to marketing, the building has been conceived as a 21st-century factory atelier. Outwardly straightforward, internally, it can accommodate multiple strands of production with process-driven internal arrangements that are continuously adaptable to future change. It is the UK’s largest centre for fashion excellence in all its diversity.

The building operates like a vertical campus, bringing together a diverse range of functions and typologies. Needing to accommodate, and be appropriately scaled, for both individual and group work and fully exploit the benefits of bringing all departments together, the circulation and shared spaces at the heart of the building actively encourage planned and incidental interaction, exploration and a sense of shared identity.

Square in plan, the college’s structural stability derives from a simple rectilinear column grid that delineates a central circulation route. At this ‘heart’ are the fixed elements: vertical circulation, lifts and WCs. In cross section, through the layering of different configurations, the heart becomes a singular, yet ever-

changing, interconnected atrium that links the generous entrance hall and public functions at its lower levels – the auditorium, gallery, cafe and library – to the workshop and teaching floors at its middle and the refectory, drawings studios, roof terraces and support functions at its upper levels.

Through this heart travel the stairs. The publicly-accessible lower levels are generous, expansive and sculptural, unfurling like an orange peel to create a dramatic vertical catwalk to see and be seen. The upper floors are simpler and made of steel but have openings that provide visual and physical connectivity between faculties as well as natural light and ventilation to the centre of the plan. At every level, they allow people to understand where they are in the building.

UPFRONT 08

All images: ©Simon Menges

Flexible and adaptable workspaces are located around the perimeter. They vary in depth of plan, and because their partitions are lightweight and non-load bearing, they are capable of future reconfiguration without impacting the building’s organisational code. Their tall, repeating, factory-warehouse-like windows give the building its distinctive and robust character.

The material palette is simple and muted – concrete, timber and black metal – with a consistency of detailing to all elements that, while complex and rigorous, enables the informal character of students and their activities and creative outputs to take centre stage. As the college’s ‘forever home’, these have been specified with long-term robustness in mind.

Each of the three materials performs a distinct function: concrete is the robust structural skeleton, timber a warm maple, provides the tactile elements of the building – the components that users touch (doors, screens, balustrades, fixed furniture and handrails) and dark metal accommodates services.

High levels of cement replacement (up to 50% GGBS) reduce the building’s operational and embodied carbon footprint. The building relies on the self-finished nature of the surfaces used in construction to minimise the need to apply further internal finishes. A significant portion of the aluminium used in the curtain walling and windows has been sourced from recycled sources.

The origins of the college lie in the trade schools founded at the beginning of the 20th century to meet the increasing needs and new technologies of the textile and clothing industries. These include, for one, the internationally-renowned Cordwainers College, specialising in footwear. Courses representative of the fashion industry today have progressively been added to these craft-based skills, expanding to include fashion journalism, management and marketing.

As well as a broadening scope in terms of what it teaches, like other higher education institutions, the college has seen a shifting emphasis in ways of learning and teaching practice.

09 UPFRONT

While non-specialised space with flexibility and capacity for change was fundamental to the brief, the college’s creative, practicebased making courses require specialist spaces equipped with machinery and tools. Complementing these internal requirements was a need for spaces where the college’s disciplines might come together and interact.

Before embarking on the design, the architecture team visited the various sites across London that were hosting the college: Curtain Road, Golden Lane, Mare Street, John Prince’s Street, Lime Grove and High Holborn. Several of the workshop spaces discovered had a particular impact, each with a distinct atmosphere that arises from spaces where things are made. They were inspired by both the spaces – their functionality and adaptability – as well as the ordered productivity they encouraged. Certain qualities found in these places now find themselves in the architectural detailing of today’s college.

Housing such a variety and diverse character of departments in one place represents a step change in the functional organisation of the college. The new building has also been an opportunity to build a new tangible identity for the college and its students. So, of equal importance has been the need for a building of character. In response, Allies and Morrison looked at the 19th-century factory and warehouse buildings common to many industrial cities –spaces capable of use and re-use, with long histories of creativity and production. The key attributes of these buildings – lofty, solid, well-lit, simple and adaptable spaces – define a large part of the new building. The new London College of Fashion feels at home in this part of East London, once characterised by factories and industry.

London College of Fashion is the largest of the four cultural and education buildings that, along with 600 homes and over a hectare of new public realm, make up Stratford Waterfront, a central component of London Legacy Development Corporation’s (LLDC) Eastbank project. The overall vision is to create a place that is welcoming and usable by all; that is comfortable, safe, accessible and fun; that is able to accommodate large numbers of people throughout the day and evening; and that is free of social hierarchies and boundaries.

Allies and Morrison led the multidisciplinary team that won the commission for Stratford Waterfront in an international design competition in 2015. The team secured planning consent for the masterplan of Stratford Waterfront in 2018 and subsequently developed detailed designs for the cultural and education buildings. Having opened in late 2023, the college is the first to complete. The remaining venues that will become operational through 2024 and 2025 are the Victoria and Albert Museum (V&A East), Sadler’s Wells East and BBC Music. Allies and Morrison is also the design architect of BBC Music; O’Donnell & Toumey is the design architect of the V&A and Sadler’s Wells buildings.

www.alliesandmorrison.com

10

UPFRONT

11 Fire

To find out more about these products visit www.firmanglass.com Firman Glass,19 Bates Road, Harold Wood, Romford, Essex RM3 OJH Tel: 01708 374534 Fax: 01708 340511 Email: sales@firmanglass.com Each system is designed specifically to suit the requirements of the particular application. Sections can be provided in mild steel, finished to any standard RAL colour, aluminium clad as well as our new range of stainless steel sections available in either a satin or bright polished finished. Firman offer a full selection of fireglass, on either a supply only or a supply and install basis, providing fire protection from a basic 30 minute integrity only rating through to the highest levels of integrity and insulation. www.firmanglass.com To further compliment our range of fireglass, Firman now offer complete steel framed fire doors and screens. Built to the most demanding specifications for commercial buildings, shop fronts, entrances, interior fire screen walls and virtually any other application.

rated glass Steel Framed Fire doors and screens

ADP ARCHITECTURE RETROFITS OFFICE BUILDING INTO A WORLD-CLASS MUSIC SCHOOL

ADP Architecture has completed Shireland CBSO Academy, the first free, non-selective state school in Britain to be established in partnership with a professional orchestra.

The collaboration between Shireland Collegiate Academy Trust and City of Birmingham Symphony Orchestra (CBSO) marks a radical new approach to music education, innovatively addressing the much-publicised decline in the position of the creative arts in many schools.

The academy’s design is a complete internal remodelling of an existing five-storey office building, providing high-quality facilities to support a worldclass music education for 870 students in the West Midlands. The academy accommodates teaching areas for the new secondary school and sixth form, alongside a new sports building on an adjacent road. The retrofit involved leaving the main structure of the building untouched, including the existing fabric, external cladding, the full-height atrium at the core of the building and the internal stairwells. The open-plan office space surrounding the atrium has been refitted

and repurposed, while the car park has been converted into an outdoor social space for students.

Visitors and students enter the academy through a double-height entrance lobby, linked to adjacent open spaces including a box office area. The triple-height performance hall, built within the original atrium space, serves as a centrepiece for the academy, accommodating fixed seating for 300 people. The hall is directly adjacent to the drama studio, which can act as a green room during performances.

The floorspace surrounding the atrium has been converted into teaching spaces and music rooms, and above the performance space is a double-height open-plan library with large overhead rooflights to bring natural light into the space. ADP has also included audiovisual experience rooms that double as immersive spaces for SEN pupils.

The external design of the new sports block is influenced by the existing main building, with red and grey cladding creating a visual connection between the two sites. The building includes a multi-purpose activity studio and a large sports hall with three badminton courts, alongside changing rooms, WC and shower facilities.

ADP Architecture’s design challenges the Department for Education’s baseline model, creating spaces that meet the needs of both a secondary and a music school. Alongside standard secondary school teaching areas, the design incorporates a highly-considered approach to acoustics, wider corridors and the need for larger-than-typical storage facilities to house instruments. In the performance hall, acoustic properties are optimised to match a traditional orchestral space, embracing its use for public musical performances.

12

EDUCATION

Image: ©Paul Karalius

Claire Mantle, Schools Sector Director at ADP Architecture, comments: “We are honoured to be part of such a truly inspirational project. The project was driven by a vision for equal opportunities for every child, no matter where they are from and, as a team, we were all excited to be behind delivering this amazing school.

“Our design concept reflected the school’s vision, with performance and learning at the centre of the new school. We located the theatre in the existing central atrium, which unlocked the ground level as the performance floor, housing all the music and drama classrooms.”

David Green, Principal at Shireland CBSO Academy, comments: “We are proud to be providing our students with an education that not only offers academic and musical excellence but also nurtures their creative and personal growth, instilling a lifelong love of learning and the arts.”

Emma Stenning, Chief Executive at CBSO, comments: “With state-provided music education in the UK at a crisis point, and our orchestras acknowledging that something must be done to make our musical forces more representative of the communities they serve, what better way to respond than opening a school that will immerse its pupils in music. We’re delighted that CBSO musicians have a tailored space to provide pupils with masterclasses, mentorship and performances, as well as supporting each young person’s ongoing musical endeavours.”

13 EDUCATION

www.adp-architecture.com

Image: ©Paul Karalius

Image: ©Paul Karalius

Image: ©Shireland CBSO Academy

THE UPDATED NATIONAL PLANNING POLICY FRAMEWORK

Gary Soloman, Partner, Matthew Tucker, Senior Associate, and Sofiya Yerokhina, Solicitor, in the planning and compulsory purchase team at independent UK law firm, Burges Salmon, outline key planning and housing changes to the framework.

Shortly before Christmas, on 19th December 2023, the Government published its long-awaited revisions to the National Planning Policy Framework (NPPF), following a yearlong process of consultation. The revised NPPF sets out the Government’s planning policies and how these will be applied.

The biggest change is that the revised NPPF introduces various reforms to housing delivery. The revised NPPF also includes new drafting on protection from “out-of-character” residential development, green belt alterations, energyefficient building improvements and allocation of agricultural land for development.

The key changes are set out below:

1. Reforms to housing delivery

The Government’s intention with these changes is to increase the delivery of new housing by giving local planning authorities a strong incentive to update their local plans amidst a supply shortage in many areas of the country.

Changes to the five-year housing land supply and delivery requirements

Under the previous version of the NPPF, all local planning authorities in England were required to continually demonstrate a deliverable five-year housing land supply.

The updated NPPF states that local planning authorities will not need to meet this requirement as long as their adopted plan is less than five years old, and that it identified “at least a five-year supply of specific, deliverable sites at the time that its examination concluded”.

There is also a reduced requirement for some local authorities with an ‘in-progress’ local plan, i.e. where a local plan has been consulted on (under regulation 18 or 19) or submitted for examination.

If the draft local plan includes a policies map and proposed housing allocations towards meeting housing needs, those authorities will only have to demonstrate a four-year housing land supply. This particular change only applies for two years from the publication date, until 19th December 2025.

As a result of these changes, it is estimated that 40% of local planning authorities will no longer be required to demonstrate a five-year housing land supply.

Changes to the assessment of housing supply

Under the previous version of the NPPF, all local planning authorities were required to build a buffer of 5% (by default), 10% or 20% into their calculations on five-year housing land supply. In the updated NPPF, the 5 and 10% buffers have been removed, but the 20% buffer has been retained where delivery falls below 85% of the requirement over the previous three years.

In addition, historic oversupply can be accounted for in the five-year housing land supply calculation, and further guidance will follow. The expectation is that the removal of 5 and 10% will simplify the five-year land supply calculations for local authorities. There is a concern, however, that their removal will reduce a key incentive for local authorities to keep delivering housing supply and maintain accountability where delivery exceeds the 85% threshold.

Greater flexibility for local authorities in assessing local housing need

New text has been added to the NPPF in paragraph 60, clarifying that the overall aim of local authorities, in the context of delivering homes, should be to “meet as much of an area’s identified housing need as possible”.

Under paragraph 61, the revised NPPF also states that the standard method for calculating housing need, to establish the number of homes required, is now considered as an “an advisory starting point”. Under the previous NPPF, the standard method was not classified in this way and there was no similar explanatory text.

As a result of these changes, local authorities have greater flexibility to plan for fewer or higher numbers of homes than the standard method indicates, and where there are specific local circumstances that justify an alternative approach to assessing housing need, that is now explicitly supported.

14

LEGAL & BUSINESS

Photo by Bobby Allen on Unsplash

Photo by Joe Smith on Unsplash

Alteration of green belt boundaries

New paragraph 145 of the revised NPPF provides that local authorities may choose to (but are not required to) review and alter green belt boundaries (in the event that they consider that they cannot meet housing needs) during the plan-making process where exceptional circumstances are fully evidenced and justified.

The changes do not explicitly describe how green belt boundaries are expected to interface with housing supply and do not represent a substantive change to the policy position.

Protection against out-of-character residential developments

New paragraph 130 of the revised NPPF provides that a significant increase in the average density of residential development in an existing urban area may be inappropriate if it will result in developments which are “wholly out of character with the existing area”.

The effect of this change is to enable authorities to describe “out-of-character” circumstances in the process of preparing design codes and plan making.

Support for mansard extensions

The NPPF provides that authorities should “allow mansard roof extensions on suitable properties” where their external appearance “harmonises with the original building”. This reform will offer the ability to enable new housing by extending upwards as long as these extensions are in keeping with the local character and context, particularly in conservation areas.

2. Energy efficiency of buildings

New paragraph 164 in the NPPF requires local authorities, in determining planning applications, to give “significant weight” to the need to support “energy-efficiency and low-carbon heating improvements” through the adaptation of buildings. This represents strong in-principle policy support for energy efficiency.

When assessing applications for energyefficiency improvements, it is important that heritage protection is considered. Paragraph 164 in the revised NPPF provides for this by stating that where the proposals would affect conservation areas, listed buildings or other relevant designated heritage assets, local planning authorities should also apply the relevant policies set out in detail in chapter 16 of the NPPF.

3. Allocation of agricultural land for development

In paragraph 181, the revised NPPF requires local authorities to consider the availability of agricultural land used for food production when allocating sites for development. Where significant development of agricultural land is demonstrated to be necessary, areas of poorer quality land should be preferred to those of a higher quality.

It is important that developers take an evidence-based approach towards determining the condition of agricultural land before a development scheme is proposed. This amendment means that the availability of land used for food production is now explicitly a part of that exercise.

4. Other general changes

Planning conditions on design and materials – new paragraph 140 of the NPPF encourages planning authorities to use planning conditions to require clear and accurate drawings/details of a scheme’s design and materials. This is intended to provide greater certainty for those implementing planning permission on how to comply with the permission.

Integration of “beauty” – the latest NPPF revisions mean that “beauty” now features heavily as a consideration across policy. However, the NPPF itself does not include substantial details on how to assess beauty; this exercise will primarily be the role of design codes.

Gary

Burges

is

planning and compulsory purchase team. He specialises in major planning applications, infrastructure agreements (including section 106 agreements), compulsory purchase and compensation (including advocacy) and highway aspects of development.

Matthew Tucker is a Senior Associate in the planning and compulsory purchase team at Burges Salmon. He advises clients on a broad range of planning and compulsory purchase issues, including planning agreements and infrastructure provision in order to unlock delivery of large-scale, comprehensive schemes of development.

Sofiya Yerokhina is a Solicitor in the planning and compulsory purchase team at Burges Salmon. Sofiya is focused on expanding her practice on nationallysignificant infrastructure projects, compulsory purchase orders, planning appeals and judicial review.

15

www.burges-salmon.com

Soloman

Head of

Salmon’s

LEGAL & BUSINESS

Photo by James Feaver on Unsplash

THE ROLE OF MODULAR CONSTRUCTION IN DELIVERING CDCS

Phil Pavey, Managing Director at Algeco Offsite, looks at how the latest platform design solutions are improving access to crucial diagnostic services by rolling out Community Diagnostic Centres (CDCs) faster than other construction techniques.

The NHS is under significant pressure due to growing waiting lists, crumbling infrastructure and slashed budgets.

Discovering what is wrong with a patient is the vital first step in treating them as quickly as possible. CDCs provide essential tests and scans to patients, allowing for faster and more accurate diagnoses, while reducing the number of hospital visits and cutting waiting times. They are a crucial component of our modern healthcare system, providing patients with access to planned diagnostic care, closer to home.

13 new CDCs have already delivered 742,000 additional scans, tests and checks a year. Despite this progress, the demand for diagnostic tests continues to rise, with over 85% of NHS patients now requiring them. This waiting list has been expanding since 2008 and, as of April 2023, approximately 1.6 million people in England were awaiting diagnostic tests.

The national target is for 99% of patients to receive diagnostic testing within six weeks. However, the UK currently falls

short of the equipment availability of comparable nations. With 8.8 CT scanners per million population, we place 25th out of 28 OECD countries, and with belowaverage numbers of MRI units and PET scanners, it’s clear that the UK’s diagnostic infrastructure faces significant constraints.

Faster, more cost-effective way to deliver new NHS buildings

With waiting lists expanding faster than capacity, innovative and cost-effective ways to expand diagnostic infrastructure are required.

Traditional construction methods often lead to lengthy delays and project overruns, particularly due to skills shortages. Ultimately, this translates into longer wait times for patients seeking diagnostic services.

By harnessing the power of prefabrication, modular construction offers a faster, more cost-effective way to deliver high-quality, new NHS buildings, including CDCs, by maximising efficiencies at every level.

We’ve been supplying high-quality, modular buildings to customers across a variety of sectors, including healthcare, for over 60 years. We work under various NHS modular frameworks and our solutions are compliant with HTM, HBN, SHTM, WHTM and HAI-SCRIBE standards.

Lean manufacturing and Design for Manufacturing and Assembly (DfMA) are central to our approach, and we have invested heavily in both, along with an extensive R&D programme.

DfMA prioritises streamlining the manufacturing process by focusing on the ease of fabricating components and simplifying assembly procedures. This approach helps us reduce time to market and minimise overall production costs.

By taking a DfMA-led approach and adopting the principles of lean manufacturing, such as process optimisation and waste reduction, our offsite construction methods offer a faster way to deliver high-quality, new buildings.

16 HEALTHCARE

The methodology involves the design and fabrication of building components or ‘modules’ taking place off site in a factory setting, prior to them being transported to the construction site for assembly.

Offsite construction offers numerous benefits over traditional building methods, and there are many reasons why it represents the way forward for the NHS. Principally, offsite can deliver permanent healthcare buildings in up to half the time it takes for an onsite build, whilst the fact that most work is done away from the hospital minimises disruption to the care environment.

Accelerated delivery of high-quality buildings

To further streamline the design and manufacturing process, we have developed a standardised design platform for building modules, as part of an industry-wide consortium. This platform aligns with the UK Government’s Construction 2025 targets, and aims to enhance productivity, quality and carbon reduction across the construction industry.

The platform, now integrated into the Construction Platform Rulebook, facilitates the design, procurement, manufacture and assembly of buildings utilising standardised and interoperable components and assemblies. It uses a small number of repeatable base designs, which enable all modular manufacturers to work to the same specification when creating the basic building components. This approach

yields significant efficiencies and greater certainty for clients.

By fully embracing cutting-edge digital and manufacturing technologies, the platform enables the mass production and accelerated delivery of high-quality buildings that outperform traditional methods in terms of quality and performance.

In short, by utilising a platform-based design approach, CDCs can be delivered in a much shorter timeframe, providing essential diagnostic services to patients as quickly as possible.

The statistics are clear – the platform design approach can reduce construction costs by 33%, enable 50% faster project completion and reduce emissions by 50%, all without compromising on safety or quality.

The approach delivers significant sustainability benefits, too. Analysis shows that platform design comprises 581.3kg CO2e per m2, which is under the Construction 2025 target of 1300kg CO2e per m2. In addition, because the CDC modules we supply can be reused, either through relocation or by refurbishing individual components, a 234kg CO2e per m2 is added as clawback.

Case study: Modular CDCs

In collaboration with Hygieia, a consortium of leading modular healthcare specialists, Algeco has developed a range of standardised CDCs to meet the needs of NHS Trusts and the private sector. These standardised CDCs come in three sizes – small, medium and large – providing

flexible options to cater to different patient volumes and site conditions.

The CDCs are offered with a full design, delivery, construction and finishing service – a comprehensive approach that allows trusts to start using their CDCs from day one, eliminating the need for separate contractors. All necessary servicing is incorporated, including specialised electronics for sensitive imaging equipment.

Flexible financing is also available, to help with constrained capital budgets across the NHS. This highly-flexible operating lease option has low set-up costs, and is accounted for as revenue expenditure, spread over the life of the lease.

Our full turnkey solution is achieved through partnerships with leading brands in the sector, such as Tata Steel, P+HS Architects and CAD21, amongst others. The CDCs are fully compliant with HTM/ HBN requirements.

The introduction of standardised modular CDCs is revolutionising the delivery of essential diagnostic services, and addressing the growing demand for timely and accessible care, while contributing to a more sustainable and efficient healthcare system.

By embracing modular construction, trusts can expand diagnostic capacity, reduce patient waiting times, alleviate seasonal illness spikes and enhance overall quality of care.

17 HEALTHCARE

www.algeco.co.uk

MITIGATING THE FIRE RISK OF ROOFTOP SOLAR PV

Lisa Stephens, Product Manager for the Building Envelope at ROCKWOOL UK, explains the requirements to ensure fire safety for roofs with solar installations.

School buildings generally have large roofs, many of them flat. Rather than just providing shelter from the weather, an increasing number of flat roofs, especially in crowded, urban areas, are being utilised as extra space housing rooftop gardens, playgrounds or building services equipment including solar PV installations.

As the result of increased efforts to reduce carbon emissions, coupled with the rising cost for energy and general living expenses, the UK and Europe have seen a rapid growth of the market for solar energy. The European Commission reports that the cost of solar power has decreased by 82% over the last decade, making it the most competitive source of electricity in many parts of the EU1. As of the end of June 2023, there was a total of 15.2GW solar capacity in the UK across 1,353,261 installations2. This represents an increase of 6.7% (952MW) since June 2022. Solar Energy UK forecasts that the UK can achieve 40GW of solar capacity by 2030. This is a development that schools in the UK can capitalise on. In its policy paper ‘Sustainability and climate change: A strategy for the education and children’s services systems3’, the Government states: “All new school buildings delivered by

DfE […] will be net zero in operation.” Renewable energy from solar power will help to meet this goal.

Assessing the fire risk for every eventuality

As the use of flat roofs evolve and potential sources of ignition increase, consideration towards the way in which flat roof materials react to fire becomes increasingly more important.

While there is no legislative requirement for non-combustible materials (apart from where the roof passes over a compartment wall), specifiers should be conscious of escape requirements where the roof is occupied. Where a roof provides a ‘means of escape’ is one of two examples provided in Approved Document B (ADB) for where a roof should be considered to perform the function of a floor.

ADB provides guidance through minimum periods of fire resistance in Tables B3 and B4 for structural building elements, including floors. Fire resistance is measured in REI, a designation that identifies the performance of a building element in terms of its load-bearing Structure (R), Integrity (E) and Insulation (I).

This is significant for designers working around social spaces where escape routes must be considered, and they may find themselves needing to make a judgement on whether a roof requires a period of fire resistance.

While utilising a roof space for practical purposes is more of a well-established concept, complex considerations still apply. Statutory guidance for flat roof fire safety, including ADB, sets out key provisions for some of the practical applications, indicating routes to compliance for the Building Regulations. These include plant rooms, rooflights and junctions with compartment walls.

There is also guidance in BS 8579:2020 ‘Guide to the design of balconies and terraces’, which discusses the fire performance required by balconies and terraces, and references plant equipment and compartmentation.

However, across these documents, there is no specific guidance for the use of solar panels on flat roofs – a practical use that is increasingly common as specifiers incorporate the solution to address energy-efficiency and sustainability benefits.

Research and real-world evidence point to solar solutions introducing additional fire risk to flat roofs. There are known incidences of solar panel ‘arcing’ in which electrical energy passes through air gaps and can cause ignition of nearby materials or the solar panel itself, due to the high temperatures involved (described as “easily hot enough to melt glass, copper and aluminium, and to initiate the combustion of surrounding materials4”).

18 RCI

The Government guidance document, “Power to the pupils”: Solar PV for schools – The benefits5, gives recommendations on maximising the benefits of solar PV installations on schools. The list includes advice on maximising the educational benefits, choosing suppliers and site safety but stops short of including the potential impact on fire safety.

More recent guidance from the insurance industry, e.g. the Fire Protection Association (FPA) RISCAuthority Need to know Guide

RE3: Rooftop-mounted PV Solar Systems 6 , recommends that a suitable fire risk assessment should be carried out and, to ensure roofing materials are non-combustible or, if installation on a combustible/partlycombustible roof is unavoidable, a fireresistant covering be applied.

Simplifying flat roof specification

In England, ADB provides guidance on how designers can meet Building Regulation requirements for fire safety – but there are multiple routes to compliance, and different ways to demonstrate an appropriate level of fire protection.

Supplements, including BS 8579:2020, cover the requirements for specific applications – in this case, balconies and terraces. For schools, specialist guidance such as BB100 (Fire safety design for schools), can also influence decision making.

Against a complex legislative backdrop, one simple way to mitigate risk is to select noncombustible materials throughout the fifth facade. The trend towards increasingly multifunctional roofs only strengthens this case.

ROCKWOOL recently launched the new white paper, ‘Flat roofs: The functional fifth façade’, to help those involved in the design and installation of flat roofs to make responsible choices when selecting materials to enable a modern flat roof to be multifunctional, safe and long lasting. It offers practical advice to simplify specification whilst going above and beyond legislative requirements.

For more information and to download the white paper, go to https://rockwool.link/ fifthfacadepsbj.

www.rockwool.com/uk

Sources:

1European Commission (May 2022): Communication on EU solar energy strategy

2UK Government (August 2023): Solar Photovoltaics deployment in the UK – July 2023

3https://www.gov.uk/government/publications/ sustainability-and-climate-change-strategy/sustainabilityand-climate-change-a-strategy-for-the-education-andchildrens-services-systems#:~:text=All%20new%20 school%20buildings%20delivered,flooding%20and%20 higher%20indoor%20temperatures

4BRE (May 2018): Fire and Solar PV Systems – Investigations and Evidence

5https://www.gov.uk/government/publications/power-tothe-pupils-solar-pv-for-schools

6https://www.thefpa.co.uk/advice-and-guidance/freedocuments?q=RE3%20-%20ROOFTOP%20MOUNTED%20

19 RCI

PV%20SOLAR%20SYSTEMS

EUROPE’S FIRST SOLAR CAR PARK WITH CARBONFRIENDLY CONSTRUCTION TO OPEN FOR PUBLIC USE

3ti, a leading designer, installer, funder and operator of solar car parks (SCPs), is installing the first large-scale SCP in Europe to be constructed from sustainable glulam timber beams and Glass-Glass solar panels. Opening to the public this month, the new SCP at Wiltshire Council’s Five Rivers Health & Wellbeing Centre is a significant leap in maximising the lifetime sustainability of solar installations and showcases several advanced technologies that revolutionise the construction, efficiency and visual appeal of SCPs.

The new SCP structure is made from glulam, renewable, recyclable wood laminations bonded together to offer a natural alternative to steel or concrete. The engineered timber affords significant advantages over structural steel; it is three times stronger and a third lighter and uses only a tenth of the energy it would take to produce an equivalent steel beam, contributing to a more sustainable building process. The material has minimal environmental impact from its production, is highly repairable and is an excellent biofuel at the end of its life, further minimising waste.

As part of the construction, 3ti has used special Spirafix ground anchors to secure the SCP structure, without using conventional concrete bases or steel piles. This achieves significant carbon savings, speeds up the installation process, is more durable and can be recycled or properly disposed of once the anchors reach the end of their lifecycle.

The solar installation at Five Rivers comprises three gullwing solar canopies covering 70 car park spaces, with a combined total capacity of around 220kWp. The leisure centre will use 100% of the solar generation on site, which will contribute approximately 10% of the overall electricity demand at the site, saving around £50,000 a year on electricity bills. In its first year, the Five Rivers SCP is expected to generate 186MWh of electricity, enough to drive 679,856 miles in a modern EV, saving 36 tonnes of carbon emissions – the equivalent of planting nearly 600 trees and powering 50 homes.

20 LEISURE

The canopies are fitted with transparent Glass-Glass solar panels from German manufacturer, Solarwatt. The panels offer high efficiency and long-term yields thanks to their bifacial technology, which means solar energy is captured on both sides of the panel, increasing total energy generation. The solar cells are embedded in a highly-durable Glass-Glass composite, protecting them from challenging environmental and mechanical stress, including snow and hailstorms, and are ammonia and salt mist resistant.

In addition to its large-scale SCP, Five Rivers recently became the first leisure facility in the UK to install 3ti’s awardwinning Papilio3 pop-up solar car park and EV charging hub. Papilio3 is built around a recycled shipping container and can be installed in under eight hours. It can fast charge 12 EVs at 7, 11 or 22kW simultaneously, ideal for a range of destinations with longer dwell times, removing the reliance on carbon-intense and costly ultra-rapid charge points. Pre-fitted with a range of innovations and safety features, including motion lighting, CCTV, advertising screens and full accessibility for wheelchair users, Papilio3 can be rented on a monthly basis from 3ti.

Philip McMullan, Senior Technical Lead on Major Energy Projects at Wiltshire Council, said: “We have invested heavily in sustainability to achieve our 2030 carbonneutral goals. The new solar installations at Five Rivers will help reduce our carbon footprint and support the local community with the transition to zeroemission motoring by strengthening the county’s EV charging infrastructure.”

Tim Evans, Founder and CEO at 3ti, adds: “Our job is to champion workplace and destination EV charging to promote a ‘charge where you stop’ mentality across the UK while supporting customers to achieve their sustainability goals. Better EV charging infrastructure at destinations with long dwell times – offices, hospitals

and leisure facilities like Five Rivers – will encourage greater EV adoption rates; it’s refreshing to see Wiltshire Council adopting such a forward-thinking approach, and we are honoured to play a part in their sustainability vision.”

21 LEISURE www.3ti.co.uk

GASCOIGNE PARK: A BLUEPRINT FOR URBAN HARMONY AND SOCIAL CONNECTION

Gascoigne Park, a project completed in May 2023 through collaboration with All Urban and Barking Council in London, stands as a testament to the commitment to creating a multifaceted space.

Designed to be more than just a park, it serves as a canvas for social engagement, active recreation and moments of quiet contemplation. The park’s core objective is to foster a sense of community, ensuring it becomes a cherished space for everyone. A delightful blend of exploration, climbing, balancing and informal seating areas invites visitors to experience joyful moments in diverse ways.

The MoveArt structures add a layer of uniqueness to the park, encouraging users to explore and interact with it organically over an extended period. It inspires imagination and new ways of exploring.

Tim Spain of landscape architect firm Turkington Martin says: “The MoveArt furniture is integral to the park’s design and character, and the two have been developed hand in hand through an open dialogue and continual support from MoveArt and the All Urban team, enriching the user experience of the park, whether it be through play, social interaction, quiet contemplation or simply passing by.

“The way that users of the park are able to interact with the MoveArt furniture is key to the essence of exploration of a river/watercourse and each of the elements was selected with the MoveArt and All Urban team to provide different levels of energy across the park, from more passive, explorative experiences to more energetic opportunities.”

The park also includes traditional dedicated play areas to engage a spectrum of play senses – swinging, sliding, climbing, balancing and jumping. Beyond individual play, the design enhances social interactions between children and their caregivers, further enriching the communal spirit of Gascoigne Park.

“I am proud to see our vision come to life at Gascoigne Park. It exemplifies our commitment to innovative urban solutions and sustainable development, setting a high standard for excellence in our industry,” adds Paul Collings, Managing Director at All Urban.

22 STREET FURNITURE

www.allurban.co.uk

OSMO WOOD FINISHES. ENDLESS POSSIBILITIES OF COLOUR

Opaque interior and exterior wood finishes can be mixed on demand and available the same day using the Osmo Tinting System in-store.

Highly Repellent

High Coverage

Natural Ingredients Breathable FOR INTERIOR: FOR EXTERIOR: WOOD WAX FINISH COUNTRY SHADES

FIND YOUR LOCAL STORE:

www.osmouk.com

KEEPING PATIENTS SAFE FROM HARM

National fit-out and refurbishment specialist contractor, Willmott Dixon Interiors, has handed over the newly-upgraded Larches Ward at St. Michael’s Hospital, on behalf of Coventry and Warwickshire Partnership NHS Trust.

I t is the final phase of a project to upgrade 5853m2 across six inpatient wards at the hospital, which began in 2022 with the anti-ligature refurbishment of Rosewood Terrace.

The contractor has since upgraded facilities at the hospital’s Hazelwood, Rowan, Ferndale and Willowvale wards, which provide agedependent mental healthcare services.

All works were carried out in a live hospital environment and included the installation of new windows and internal doors, and adaptations to power, data and access control services.

Willmott Dixon Interiors has also made improvements to lighting, ventilation grilles, radiator covers and sanitaryware. Flooring has been repaired, and all six buildings have been decorated throughout.

The contract to refurbish St. Michael’s Hospital was awarded to Willmott Dixon Interiors via the Procurement Hub Major Project Framework and was delivered by a project team including Fulkers Bailey Russell and Design Buro.

It generated a social return on investment of almost £200,000 during the project lifecycle – equivalent to more than 19% of the total contract value – and met high sustainability standards with 99% of project waste diverted from landfill.

Nabeel Javed, Construction Manager at Willmott Dixon Interiors, said: “At the heart of this refurbishment is a commitment by Coventry and Warwickshire Partnership NHS Trust to improve patient experience and keep vulnerable people safe from harm.

“We’ve worked incredibly closely with the trust over the last two years to ensure the successful delivery of each phase of the project. Our understanding of mental health estates has enabled us to create a modern environment that will support patient recovery.”

Sonya Gardiner, Chief Operating Officer at Coventry and Warwickshire Partnership NHS Trust, said: “Safety and comfort of our patients is paramount, so we understand how important it is to invest in the refurbishment of our hospitals. St Michael’s Hospital is one of our main mental health facilities and these improvements ensure we will continue to provide safe and therapeutic environments to support the recovery of our patients now and into the future.”

Andrew Peck at Procurement Hub said: “This project demonstrates the improvement to quality of life for all involved with St Michael’s Hospital. This is a great example of how Procurement Hub, working with Willmott Dixon Interiors, provides great benefits for the public sector. It is also a clear indicator that social value is at the heart of what Procurement Hub and Willmott Dixon Interiors always strive to deliver through this framework.”

Willmott Dixon Interiors is currently working with Coventry and Warwickshire Partnership NHS Trust on the delivery of a separate refurbishment project at the Caludon Centre in Coventry. It includes remediation works, the replacement of fire doors and fire compartmentation line surveys.

24 INTERIORS

www.willmottdixoninteriors.co.uk

A POSITIVE FUTURE FOR THE UK’S HOUSING STOCK?

Barny Evans, Director of Sustainability and ESG at Turley, asks what the Future Homes Standard means for the future of sustainable construction.

Around 16% of the UK’s carbon emissions arise from our homes, and the UK has some of the oldest homes in the world, with relatively poor insulation compared to our European counterparts.

The consultation on the Future Homes Standard (FHS) was launched at the end of 2023. In it, the Government set out measures to improve energy efficiency and reduce the carbon emissions of new homes and non-domestic buildings.

The two options

The FHS offers two options. Both are similar in that they will ban fossil fuels, effectively mandating heat pumps.

However, option one includes slightly higher fabric standards, solar PV panels, mechanical ventilation and wastewater heat recovery. This would cost around £5000 more to implement per home than option two, which is effectively today’s regulations minus solar, but switching a gas boiler for a heat pump.

A challenge for the industry is that Government offers no preference between the two options and that makes it hard to plan.

Personally, I’d say option one is the better option, even acknowledging the extra cost. It is important that the public get a direct benefit from new homes, and the solar and energy-efficiency

improvements probably mean bills savings of more than £500 a year. Overall, option two could mean more expensive bills than current regulations.

Fabric standards and the management of energy

Many have been surprised and disappointed that the proposed fabric standards are either identical to those currently in force or, in the case of option one, a slight improvement. It is likely to be the main complaint by respondents to the consultation.

The consultation explains that higher fabric standards show only a very small reduction in energy use for a large cost in cash and embodied carbon. This finding is not new, but is taking its time to percolate through our industry, which can be observed in this Government analysis.

The standards proposed in option one are probably close to optimal in design terms, and the consultation discusses the need for improved quality control and some ideas around that.

What the consultation doesn’t sufficiently recognise is the need to incentivise and reward smart energy management techniques.

The biggest bill and GHG emission savings, after electrification, will be achieved by changing when we use energy, not how much. If we don’t recognise it as fundamental

to the future of our homes, then this update will not deliver the change we need.

This relatively-unchanged stance on fabric standards is interesting, particularly when we consider the future of the retrofit market. It indicates a shift away from the ‘fabric-first’ approach used in previous years, and more of a balanced approach to make homes lower carbon and cheaper to run.

Smart energy

The FHS consultation also includes proposals to replace the current Standard Assessment Procedure (SAP) with the Home Energy Model (HEM).

Unlike SAP’s monthly measurements, HEM analyses energy demand and supply every half hour, enabling it to calculate the advantages of actions like heating a hot water tank at specific times. This innovation promises lower bills and reduced carbon emissions down the line.

The implementation details of the new software remain unclear, however. If the Government implements the HEM with default static prices and emission factors, it could undermine the system’s benefits. To ensure success, accurate and dynamic pricing and emission factors must be integrated, enabling consumers to make informed decisions for cost savings and environmental sustainability.

26 HOUSING

Heat pumps

The most significant change proposed in the consultation is to ban gas boilers, effectively requiring heat pumps moving forward.

Despite sustained year-on-year growth in heat pump installations, reaching a 62% increase in 2023 compared to the previous year, the UK housebuilding sector is only installing tens of thousands of domestic systems a year. To put this into perspective, the UK currently sees 1.7 million domestic gas boilers installed each year.

As the UK adds around 200,000 new homes to the market annually and aims for more, we will need a step change in the rate of heat pump deployment and the whole supply chain is ramping up to meet this.

Heat networks

It looks as though heat networks will play a smaller role in the future of heating than has previously been suggested. Another Government consultation indicates that heat networks will be the cheapest option for less than 11% of heat in England, much lower than is usually quoted.

Most current heat networks operate using gas CHP engines and gas boilers. These emit high amounts of carbon and typically would not have complied with the current Building Regulations, however, the Government gave them a special allowance.

According to the new proposals, any heat network would have to be a heat pump system to comply, or be an existing network that has had equivalent heat pumps added.

This is a great improvement and will eliminate the situation where some planning policy is forcing new development to connect to high-carbon heat networks, rather than use individual low-carbon heat pumps.

Final thoughts

The consultation crosses the crucial line of banning fossil fuels in new builds – a step that ensures new homes can decarbonise to zero as the electrical grid does so. It has been a long time coming, but it should be welcomed.

It is encouraging to see the analysis that fabric standards only need to improve slightly, but the lack of clarity on how smart energy issues will be considered is concerning. From now on, exactly when you use energy is going to be as important as how much, and the proposals do not recognise that.

Furthermore, the fact that there are two options with no preference from Government does makes it difficult for the industry to plan around costs. Option

one seems to be the preferred choice –there is a substantial extra cost, but the reduction in bills will be large.

Option two would mean that energy bills could even rise in new homes. In addition, going from a position today where solar is standard to a future where it isn’t would seem strange.

Overall, many are hoping that these changes will herald a future where new homes have a genuine cachet. They won’t need retrofitting and will benefit from variable energy tariffs and long-term electricity price reductions, meaning that the UK’s post-2025 housing stock could be more valuable than the current stock.

27 HOUSING www.turley.co.uk

A SOUND SOLUTION – ADDRESSING ACOUSTICS IN RESIDENTIAL BUILDINGS

Unwanted noise in the home continues to have a direct impact on the wellbeing of residents, particularly in the bathroom, with research showing that the issue is far bigger than many of us might think. Here, Sophie Weston, Head of Marketing at Geberit, explores the challenges of designing out noise inside the home.

Architects and specifiers are increasingly aware of the need to mitigate the impact of external noise such as road, rail and air traffic, for building occupiers.

Noise Impact Assessments are commonplace in planning applications, required to show that any new development is not adversely impacting on residential or commercial properties located nearby. And the World Health Organisation, which has been tracking noise levels for over a decade, describes noise pollution as an “underestimated threat” that contributes to everything from stress to high blood pressure, cardiovascular disease, dementia, diabetes and, of course, hearing loss. However, the issue of noise is not restricted to the outside world. Rapidlyincreasing numbers of connected devices, poor end-user awareness and lack of clarification in UK standards and Building

Regulations can leave many people unable to shake off the effects of noise inside, too.

There is even an argument that increased external sound insulation has actually amplified noise within properties, highlighting internal noises more than ever before.

Identifying the issue

The issue is bigger than some might think. Geberit research published in a previous white paper 1 shows that 38% of people say noises inside, such as electrical appliances, bathroom noise or central heating systems, affect them more than traffic from outside.

In the bathroom, one in four of us (28%) are regularly disturbed by bathroom sounds at night or when trying to relax, and one in five (19%) homeowners are regularly disturbed by flushing toilets, running taps or pipe and drains.

Critically, more than half of respondents (51%) cited unwanted noises as having a negative impact on their wellbeing.

Part of the challenge is that there is very little clarification within the relevant UK regulations on what products should be used to achieve specific sound pressures, particularly when it comes to water and bathroom noise.

For example, BSI’s British Standard 8233:2014 Guidance for Sound Insulation and Noise Reduction in Buildings simply states that water systems, including hot and cold water services and waste pipes, “are not to cause disturbance in normal use”. This rather vague guideline is the standard’s only reference to reducing sanitary noise in buildings.

The UK Building Regulations are no more specific. Building Regulations (2010) Approved Document E ‘Resistance to the passage of sound’ largely

28 KBB

focuses on measures to control external sound. It does stipulate that any wall or floor should reduce the noise transmitted to the next room by 45 dB or more, but then fails to set a maximum noise level. Importantly, nor does it mention the use of any acoustically-optimised products.

Presenting solutions

The onus, it seems, is on designers and architects to make well-informed choices to reduce the impact of noise inside and, in turn, increase wellbeing.

There are products available on the UK market to mitigate the impact of noise in the bathroom. Sound-optimised drainage piping can reduce noise transfer from flushing water, washbasins or showers. Likewise, wall-hung toilets with concealed cisterns can prevent noise from travelling down the wall and through the floor.

However, without specific UK standards on the noise pressure from water systems inside new buildings, there is no requirement for a building to meet a baseline figure.

This is in contrast to Germany, where the DIN 410 acoustic standard outlines maximum acoustic levels in a building. It also outlines buildings’ sound insulation with requirements and verifications, as well as clear requirements on internal noise. It sets maximum requirements for sanitary noise at 30dV(A) in terms of LAFmax, n.

There is also no defined approach to testing and, therefore, no incentive for different specifiers across a single project to work together and undertake collaborative testing to ensure that they are achieving the best acoustic rating – as is the case for heating or energy loss.

Some leading manufacturers, including Geberit, are working to the best-practice German standards for products sold on the UK market, but until UK standards are revisited and maximum figures outlined

(not to mention a defined approach to testing acoustically-optimised products), it will remain a challenge to specify a wellinformed, collaboratively-tested solution across an entire building.

It’s time for the UK to revisit standards and outline maximum sound pressure figures and fair testing – thus enabling the industry to work together to achieve better results for our end users.

www.geberit.co.uk/acoustics

29

KBB

SOURCE:

1Geberit - ‘A Sound Solution – Embedding Acoustics into Building Design’

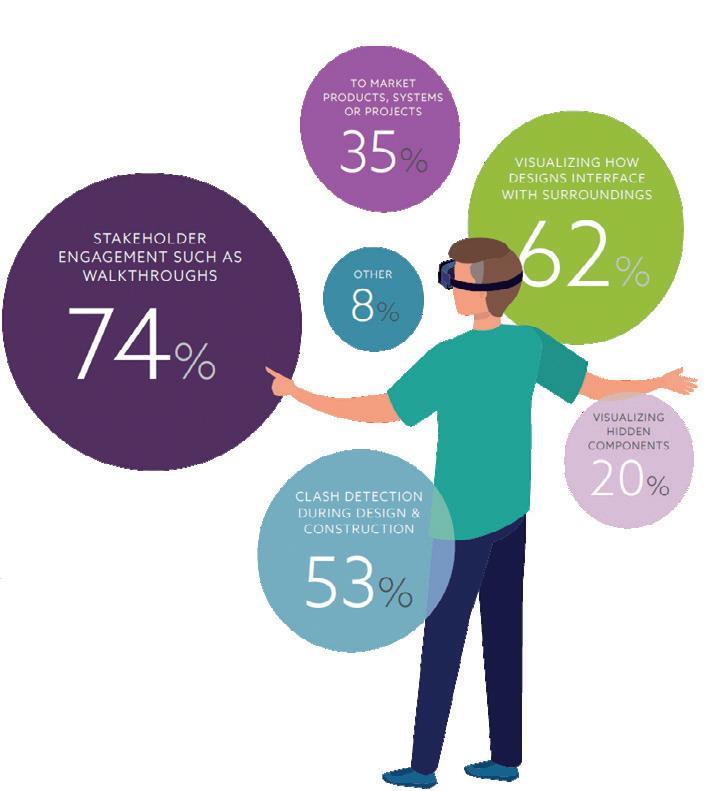

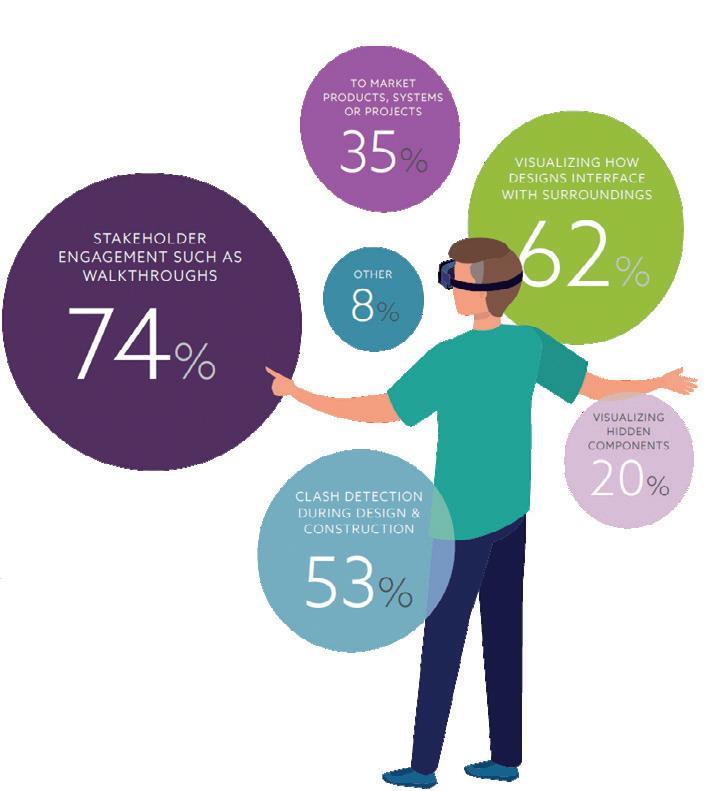

IS CONSTRUCTION’S DIGITAL REVOLUTION UNDERWAY?