www.kirby-smith.com

Oklahoma

OK

800-375-3339

Tulsa, OK

918-438-1700

McAlester, OK

918-310-1550

Kansas City, KS

913-850-6300

St. Louis, MO

314-729-0125

Dallas, TX 214-371-7777

Fort Worth, TX

817-378-0600

Abilene, TX

325-692-6334

Waco, TX 254-261-1370

Amarillo, TX

806-373-2826

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000

www.mgxequipment.com

Baltimore, MD 443-399-7100

Baton Rouge, LA

225-251-7500

Belle Chasse, LA 504-394-7400

Billings, MT 406-698-6768

Birmingham, AL

205-661-1323

Dallas, TX

972-986-0910

Houston, TX

713-433-6411

Norfolk, VA

757-935-4300

Phoenix, AZ

602-232-0660

Salt Lake City, UT 801-297-8500

Winston-Salem, NC 336-582-7400

2 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com manit Benefit from th reliability of a N has driven adva options you ne owoc.com/national-crane e limitless configurations, first-class ser v National Crane boom truck. For over 75 ye ances in truck-mounted hydraulic cranes, ed to get more done. ice, and exceptional ars, National Crane giving you the Contact your local dealer www.stephensonequipment.com www.hoffmanequip.com Corporate Headquarters Piscataway, NJ 732-752-3600 South Jersey Deptford, NJ 856-227-6400 Long Island Medford, NY 631-207-2900 Mid-Hudson Valley Marlboro, NY 845-236-3000 New York City Bronx, NY 718-822-1180 Corporate Headquarters Harrisburg, PA Harrisburg, PA 800-325-6455 Pittsburgh, PA McDonald, PA 800-692-7600 Philadelphia, PA Prospect, PA 800-220-4033 Wilkes-Barre, PA Pittston, PA 866-667-6756 ALT Sales Corp. Richfield, OH 330-659-2100 Dawes Rigging & Crane Rental Elk Mound, WI 800-943-2277 Kaukauna, WI 800-236-8630

City,

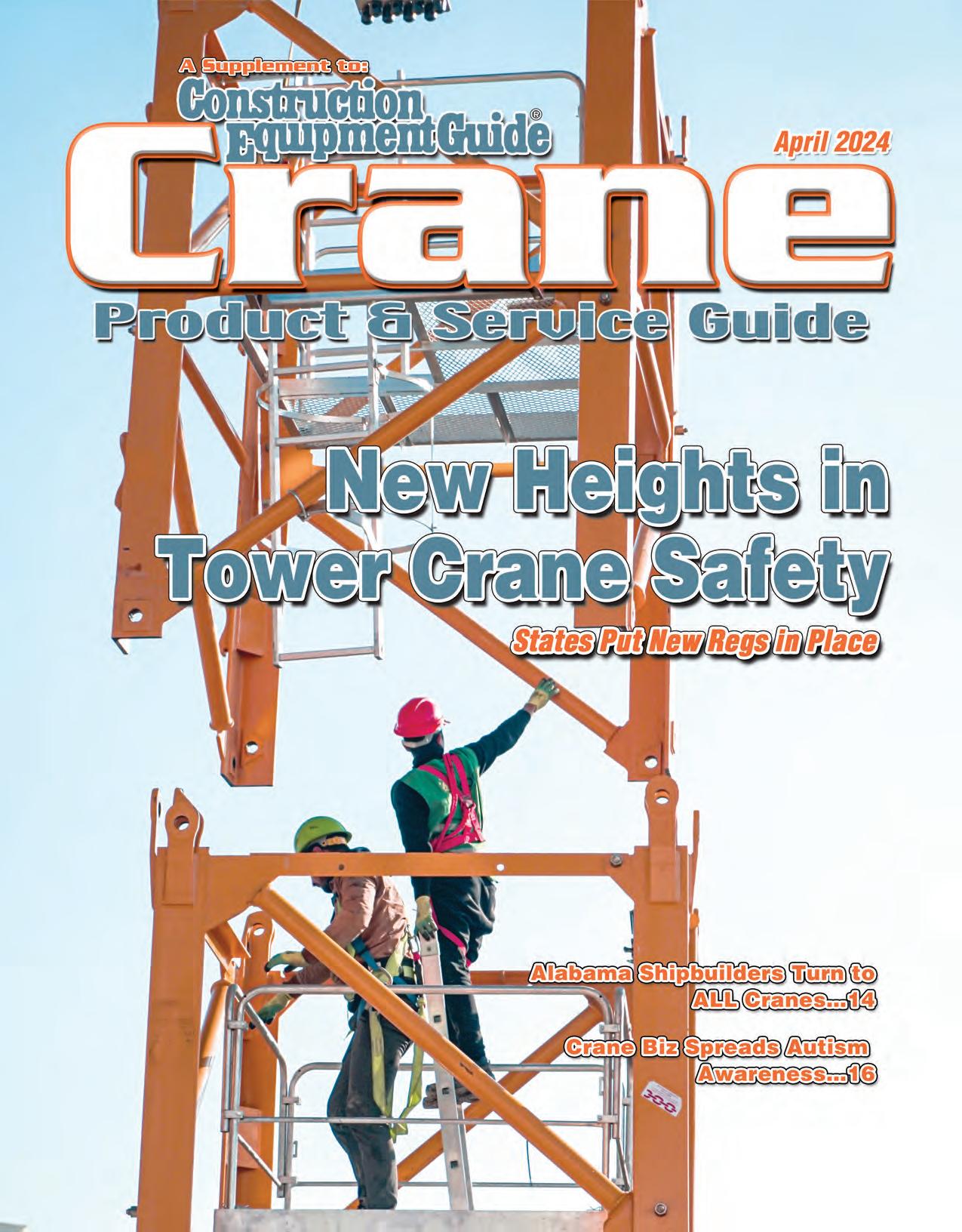

NEW HEIGHTS IN TOWER CRANE SAFETY

By Lucy Perry CEG CORRESPONDENT

By Lucy Perry CEG CORRESPONDENT

Washington State was poised to join other states regulating safety surrounding tower cranes. The state passed legislation in response to a deadly 2019 tower crane accident in Seattle, joining other major cities and states with tower crane regulations in place.

Passed by both the Washington house and senate, the bill addresses safety by “establishing permits for tower crane operation.”

The rules regulate assembly and disassembly, establish a work zone during these phases and set criminal penalties for safety law violators.

“We think this creates a structure that is going to protect people,” said Rep. Julia Reed who supported two tower crane safety bills along with Sen. Noel Frame.

Supporters believe the laws will help protect both workers and the public by requiring stricter safety protocols, reported Axios.com.

Those protocols include the work zone rule, which would

require closing nearby streets when cranes are being assembled or disassembled.

An investigation of the Seattle accident that killed four people determined the contractors didn’t follow manufacturer’s dismantling instructions. It was found that the companies “prematurely” removed nearly all of the pins and sleeves that helped hold the crane together, reported Axois.

The new laws would require contractors to acquire a state permit before assembling, disassembling or reconfiguring a tower crane.

According to Axois, the measure would require a qualified supervisor to oversee assembly and disassembly. The law also mandates that local governments coordinate street closures in either phase of the tower crane’s operation.

“Employers could be found guilty of a criminal misdemeanor if they let someone take apart or assemble a crane without qualified supervision,” according to the bill’s language.

continued on page 6

4 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Adobe Stock photo

The Washington state legislature passed new safety regulations governing the assembly and disassembly of tower cranes.

States

in

Put New Regs

Place

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 5 “We Have What You Need – Call Today” 562.273.7013 Headquartered: Long Beach, CA sales@coastlinecd.com Rental Purchase & Leasing Options Available - Call for Details SALES RENTAL PARTS & SERVICE www.coastlinecd.com CRANE FILTERS CRANE SEAL KITS WORLD WIDE CRANE PARTS IN STOCK PROVIDING PARTS FOR: 2019 TADANO MANTIS GTC 1200 130 Ton Crawler #86798 $795,000 SALE - RENT - Rental Purchase bl97dt 2017 TADANO MANTIS GTC 600 66 Ton Tele Crawler - Ready To Work #74369 $355,000 Sale Rent RPO ar13iq 2023 TADANO GR 800XL 80 TON #110023 $755,000 Sale Rent RPO New Units Available - Call Today bv41qx 2022 TADANO GR 1300XL 130 Ton #97746 $945,000 New Units Avail SALE - RENT - Rental Purchase bm35mr 2021 MANITEX 30100C 30 TON #95596 $275,000 New Units Avail SALE - RENT - Rental Purchase bj14it 2023 MANITEX 26101C 26 TON #100736 $295,000 New Units Avail SALE - Rent - Rental Purchase bq68hs 2024 MANITEX 2281T 22 TON #113257 New Unit - Avail April 24 SALE - RENT - Rental Purchase by55yo 2023 MANITEX 22101S 22 TON #109945 - IN STOCK - Call For Price CRANE IS PRICED TO SELL - CALL bt91zk 2023 TADANO GR 1200XL 120 TON #110203 In Stock - New Units Avail SALE - RENT - Rental Purchase bv41qu 2019 SKYJACK ZB2044 20K #86016 $195,000 Sale Rent RPO New Units In Stock - Call Today az32ji 2024 MANITEX 2892C 28 TON #113287 New Unit In Stock - Call SALE - RENT - Rental Purchase by55yp 2023 MANITEX A62 STK #107419 62 FT Work Platform - IN STOCK Ford F550 - AUTO TRANS - CALL bv68sp 2019 TADANO GR 550XL 55 TON #83632 $345,000 New Units Avail SALE - RENT - Rental Purchase bx79js 2023 MANITEX 35124C 35 TON #106087 - Call For Price - Pete 567 Basket&Remotes - Sale Rent RPO bs75ge 2020 TADANO GR 350XL 35 TON #90595 $325,000 New Units In Stock SALE - RENT - Rental Purchase bu43vz 2024 MANITEX 1970C 19 TON #114070 - UNIT IN STOCK - CALL SALE - RENT - Rental Purchase by10gq 2023 MANITEX 3051T 30 TON #106069 New Units In Stock SALE RENT - RENTAL PURCHASE bw03ud 2023 MANITEX 2250T 22 TON #109942 - New Unt - In Stock - CALL SALE - RENT - Rental Purchase bt76tt 2020 BRODERSON IC200-3J 15 TON #93545 $195,000 Unit In Stock SALE - RENT - Rental Purchase bh82cq 2021 SHUTTLELIFT SCD20 20 TON #97707 $255,000 Unit In Stock SALE - RENT - Rental Purchase by10gp 2018 MANITEX M150 15 TON #80192 - $205,000 Unit In Stock Call SALE - RENT - Rental Purchase ay67dt

from page 4

Employers also would be liable for failing to follow a tower crane manufacturer’s disassembly instructions.

Breaking Down the Bill

According to wacities.org, the new amendment is intended to give local governments more flexibility in their roles in tower crane operation. The language allows the city “to coordinate permitting schedules with applicants, while still retaining the city’s ability to establish its own timeline.”

An amendment to the bill also allows cities to develop a process for notifying neighbors of the assembly, disassembly or reconfiguration. This takes the burden off the city itself for going door to door in order to notify work site neighbors.

The legislation defines assembly/disassembly work zones as the total area the crane, components and attachments could reach if a collapse were to occur.

Work zones can change over the course of a project, noted wacities.org. Tower heights, boom length, attachments and crane loads all factor in.

The bill means “that cities will need to pay closer attention to active construction projects using tower cranes within their jurisdictions,” said wacities.com.

This monitoring is required for issuing the right permits and avoiding potential liability for accidents.

What Happens in Other States

Other states and major cities have addressed the tower crane operation process through rules and regulations. Here is a sampling:

In August 2023, New York City’s department of buildings updated its required protocol for third-party tower crane erection certifications. Erecting a tower crane is only permitted after the engineer of record (EOR) submits, and the city’s cranes and derricks unit reviews, required documentation.

The cranes & derricks unit then grants crane notice approval to the equipment’s applicant.

“To be granted a crane notice, the EOR must submit third-party certifications, which include certification letters, reports and documentation.”

The rule states that provided third-party certifications must include certification letters from the EOR, inspector and owner. They must contain equipment and project references, such as the CN approval number, crane device number, serial number and model number.

The letters also must include project location as well as all other relevant documentation outlined in the protocol.

After a 1989 accident killed five in San Francisco, the state enacted some of the toughest tower crane laws in the nation, according to TorkLaw. Since then, the state has been looked to as a model for tower crane safety regulation.

“Since the size of an assembly/disassembly work zone can change over the course of a project, cities will need to keep an eye out for these changes and adjust permit issuances accordingly.”

And cities will need “to play an active role” in giving notice to nearby residents within the ever-changing work zone of the tower crane activity.

“Cities will also need to ensure they are able to process permits in a ‘timely manner,’” according to the law, though that particular term is undefined.

Multiple permits over the life of the construction project may be a reality because of the ever-changing size of the tower crane operation work zone.

“The contractor will need to apply for new permits before they can assemble, disassemble or reconfigure their crane and change the size of the work zone,” according to the bill.

The cranes must be inspected three times before the first load is lifted, notes TorkLaw.

“State-certified inspectors perform the first two inspections,” and Cal/OSHA completes the third assessment. Once the crane is in operation, it must undergo intensive inspections every six months.

In between formal inspections, crane operators are required to conduct daily checks of the tower crane. Operators also must perform more rigorous inspections for every 750 hours of tower crane operation.

Inspectors must be on the scene when the tower crane is being jumped or dismantled.

Before the crane lifts its first load, a CalOSHA inspector must look for loose bolts, cracked welds, rust, fail-safe device problems or frayed cables.

“OSHA requires that the tower crane be inspected only once a year,” reported TorkLaw. “After the 1989 catastrophe, California passed legislation requiring inspections every six months.”

That legislation also mandated that operators submit drawings of the crane’s placement before receiving a permit.

“California law also requires that inspectors of the tower crane be independent,” said the law firm.

Inspectors cannot be considered employees of the owner or contractor and can have no financial interest in the development.

TorkLaw noted that, “despite California’s stringent laws and regulations of tower cranes, Cal-OSHA inspectors routinely find safety violations.”

In most inspections, detected defects can run from a minor problem to a major condition and some safety breaches result in formal citations or fines.

“Some are so serious that the crane owner must make immediate repairs or shut down the operation on the spot, costing the developer potentially hundreds of thousands of dollars.”

In 2008, the Associated Press analyzed “wildly varying rules governing construction cranes.” Some, noted the news service, rely on federal guidelines.

6 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Adobe Stock photo Contractors would have to have a qualified supervisor to oversee assembly and disassembly of a tower crane on a job site.

The

The burden of our profession and our industry is to learn from things that go wrong, develop corrective means and strategies and apply them.

Beyond operator certification, in Nevada state law calls for clear zones during assembly and disassembly, or hazardous lifts.

“They also demand annual certification of cranes’ mechanical lifting parts, plus certification each time a tower crane is erected,” according to the AP.

Fifteen days before a builder puts up or dismantles a tower crane, the company must notify Nevada OSHA, bring in building plans and meet with OSHA officials.

Canada’s New Approach

The government of Ontario, Canada, opened this year with an overhaul of its crane regulations, which include tower cranes.

The updates reflect a commitment from stakeholders with a goal to keep operators and the public safe. The new provisions under the Occupational Health and Safety Act (OHSA) include new installation, inspection and record-keeping regulations.

Some “significant” changes came after efforts by safety advocates, Mike Gallagher, business manager, IUOE Local 793, told Daily Commercial News.

“It’s a fairly good overhaul of the regulations. I mean, the real deep dive was done by industry, including employers and the union and engineers.”

Considered key amendments by the local ministry are the clarification and addition of design, installation, inspection, maintenance and record-keeping rules.

The new language requires more comprehensive tower crane inspections and introduces new references to national standards in tower crane design and operation.

Gallagher also considers a key change the decision to incorpo-

rate more external materials into the OHSA Green Book, to reduce redundancy.

“A lot of the changes in terms of inspection of crane components and whatnot were already referred to in manuals that the operators had to put in place.”

Gallagher said now that it’s all been transferred into the OHSA, the regs are easier to locate.

Widespread consultation among the crane industry went into developing the reform package, he said.

Input included the formwork sector, engineers, the Ontario Crane Rental Association and individual general contractors.

He believes the cooperation among stakeholders will continue as parties work towards education and implementation goals.

At the End of the Day

Historically, crane accidents were treated as economic losses, said Lawrence Shapiro, crane consulting engineer.

And while the economic impact has not diminished, today the social cost has increased. “Society is … more inclined to assign blame,” he said.

“Crane accidents will always occur, as humans, materials and machines are imperfect, hazards are sometimes hidden and nature is fickle.”

The burden of our profession and our industry is to learn from things that go wrong, develop corrective means and strategies and apply them, said Shapiro.

He believes, “laws and standards are merely one set of means to mitigate” the potential for loss. CQ

Washington state law would establish and regulate the tower crane work zone during assembly and disassembly. Adobe Stock photo

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 7

Bay Crane Companies Makes Strategic Entry Into Baltimore, D.C. MAKING ITS WAY TO MID-ATLANTIC

The Bay Crane Companies Inc., one of the 10 largest providers of crane services in the North America, announced the acquisition of two leading crane service companies in the Mid Atlantic region from ML Holdings: United Crane & Rigging and Crane Rental Company Inc.

This acquisition adds to Bay Crane two full-service locations — Baltimore, Md., and Capital Heights, Md. — along with a fleet of 88 cranes and hoists and almost 200 trucks, trailers and other support equipment.

“Both these companies have over 50 years of proud history serving the Mid Atlantic market. We are pleased that they will be joining the Bay Crane Companies and welcome everyone on the team,” said Kenneth Bernardo, president and CEO of the Bay Crane Companies.

“The Mid Atlantic market is very strategic to Bay Crane, being located just south of our New Jersey operations. These platform businesses will help to expand Bay Crane as a premier crane service provider in the northeast corridor from New Hampshire to Virginia.

“The team at United Crane and Crane Rental will now have access to one of the largest and most comprehensive crane fleets

on the east coast along with all the specialty rigging and trucking equipment. This will uniquely position Bay Crane to substantially increase the scope of services provided to customers in the MidAtlantic region.”

“We are already seeing immediate benefits from this combination,” said Joe Mirabile Jr., regional vice president of the Mid Atlantic region. “We are moving larger crawler cranes and other high-capacity and specialized equipment into the market and are very confident our loyal customers will see a significant benefit from this combination in the years ahead.”

“When ML decided to focus its crane business exclusively in the Mid/Southwest markets we knew we needed to find the right buyer for United Crane and Rigging and Crane Rental Company. While we’re sad to part ways with all the great people at these companies, we can’t think of a better partnership for them than The Bay Crane Companies,” said David Matz, president of ML Crane and ML Holdings Company.

“We look forward to the continued success of the expanded Bay Crane and redeploying capital in our core businesses.”

For more information, visit www.baycrane.com.

Longtime Manitowoc customer

W.O. Grubb Crane Rental received a new Grove GMK6400-1 in December of 2023 and immediately put the crane to work in high-profile jobs throughout Virginia.

The 450-ton all-terrain crane has already played a crucial role in tasks such as removing lock gates at the Deep Creek Locks on the Intercoastal Waterway in Chesapeake.

“We were keen on embracing the newest technology and improved roadability without compromising on lifting performance,” said Bill Grubb, owner of W.O. Grubb. “This prompted us to upgrade from our reliable GMK6300L model to the GMK6400-1. With MegaWingLift and luffing capabilities, this marks our first investment in a brand new, large all-terrain crane tailored for the Portsmouth-Newport News market.”

Grove dealer MGX Equipment Services guided W.O. Grubb through its GMK64001 purchase.

“MGX and W. O. Grubb have had a successful partnership for several years,” said Bruce Austin, director of sales at MGX. “We

are very excited that Grubb is adding the GMK6400-1 to their already impressive fleet. With the capabilities of this crane, I am confident that it will perform exceptionally well for them in the Mid-Atlantic region.”

The GMK6400-1 is currently scheduled for a significant project, involving the precise setting of two precast panelized builds at the James River Water Treatment Plant in Newport News. Additionally, W.O. Grubb’s Newport News branch anticipates a furnace relocation project at the Howmet Casting Facility in March. This project will require the GMK6400-1 with the main boom and MegaWingLift to lift an impressive 68,000 lbs. through the facility’s roof.

The GMK6400-1 self-erecting MegaWingLift eliminates the need for an assist crane, streamlining operations and significantly influencing W.O. Grubb’s buying decision. The crane’s 450-ton capacity, powered by a single engine, enables efficient transport with the boom in the boom rack as well.

The Grove GMK6400-1’s self-rigging capabilities ensure rigging time remains

under 20 minutes. Its versatility allows it to handle tasks that traditionally require a seven- or eight-axle model. The hydraulic system, designed for faster flow, guarantees quick operating speeds and seamless movements on the job site, according to the manufacturer.

W.O. Grubb is a family-owned company with an extensive fleet. It has been a cornerstone in the Mid-Atlantic region’s crane rental industry since its establishment in 1962.

For more information, visit www.manitowoc.com.

8 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Manitowoc photo (L-R) are Bill Grubb, owner of W.O. Grubb Crane Rental; Dean Spruill, regional operations manager; Doug Adkins, director of fleet operations; and Kris Becker, crane operator.

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 9 CONTACT LINK-BELT MID-ATLANTIC TODAY! Ashland, VA • 800-552-3837 Chesapeake, VA • 800-342-3248 Frederick, MD • 833-546-5235 SERVING VIRGINIA, MARYLAND, DISTRICT OF COLUMBIA, DELAWARE www.link-beltmidatlantic.com Find us on: Link-Belt Cranes Lexington, Kentucky, USA | www.linkbelt.com The Link-Belt TCC is the future of how tough jobs get done! Low overhead clearance Unprecedented pick and carry capacities Link-Belt's vision package Cummins Tier 4F diesel engine Fast set up & move

4160 CEG Mid Atlantic TCC family ad 2.10.22.indd 1 2/17/2022 1:15:49 PM

55-ton |50 mt Telescopic Crawler Crane

STEPHENSON EQUIPMENT, INC.

www.stephensonequipment.com

Philadelphia, PA 800/220-4033

Harrisburg, PA 800/325-6455

Wilkes-Barre, PA 866/667-6756

Pittsburgh, PA 800/692-7600

Syracuse, NY 800/368-6455

Albany, NY 518/357-2200

KIRBY-SMITH MACHINERY INC.

www.kirby-smith.com

Oklahoma City, OK 405/495-7820

Tulsa, OK 918/438-1700

McAlester, OK 918/310-1550

Kansas City, KS 913/850-6300

St. Louis, MO 314/729-0125

RING POWER CRANE

www.ringpowercrane.com

St. Augustine, FL 904/494-1219

Pompano Beach, FL 954/977-5010

Orlando, FL

407/855-6195

Tampa, FL

813/671-3700

Union City, GA

770/774-7300

Concord, NC 704/795-3636

Aiken, SC 843/818-1954

SHAWMUT EQUIPMENT COMPANY, INC.

www.shawmutequipment.com

20 Tolland Turnpike

Manchester, CT 06042

800/829-4161

136 Eastman St.

South Easton, MA 02375 877/526-9213

SHAWMUT EQUIPMENT OF CANADA, INC.

318 Park Rd.

Elmsdale, NS B2S 0G2 902/883-7450

MGX EQUIPMENT SERVICES, LLC

www.mgxequipment.com

Baltimore, MD 443/399-7100

Baton Rouge, LA

225/251-7500

Belle Chasse, LA

504/394-7400

Billings, MT

406/698-6768

Birmingham, AL

205/661-1323

Dallas, TX

972/986-0910

Denver, CO

720/864-9842

Houston, TX

713/433-6411

Norfolk, VA 757/935-4300

Phoenix, AZ 602/232-0660

Salt Lake City, UT 801/297-8500

Winston-Salem, NC 336/582-7400

WESTERN PACIFIC CRANE & EQUIPMENT

www.wpcrane.com

8600 Calabash Ave.

Fontana, CA 92335

562/286-6618

1500 Madruga Road

Lathrop, CA 95330 855/927-2637

275 W. Larch Road

Tracy, CA 95304

209/597-3824

3521 Alken Street

Bakersfield, CA 93308

855/927-2637

19602 60th Avenue NE

Arlington, WA 98223

253/254-7950

91-210 Kalaeloa Blvd.

Kapolei, HI 96707

808/682-7263

10680 NW 289th Place Bldg A.

North Plains, OR 97133

971/202-4002

6720 Arctic Blvd.

Anchorage, AK 99518 855/342-7263

HAYDEN-MURPHY EQUIPMENT COMPANY

www.hayden-murphy.com

9301 E. Bloomington Freeway

Minneapolis, MN 55420 952/884-2301

800/352-2757

10 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 11 CLEVELAND CRANE & SHOVEL SALES INC. www.craneandshovel.net 26781 Cannon Road Cleveland, OH 44146 440/439-4749 Toll Free: 800/362-8494 aforepaugh@craneandshovel.net HOFFMAN EQUIPMENT CO. www.hoffmanequip.com New Jersey Corporate Headquarters 300 S. Randolphville Rd. Piscataway, NJ 08854 732/752-3600 South Jersey 1330 Hurffville Rd. Deptford, NJ 08096 856/227-6400 New York 1144 Zerega Ave. Bronx, NY 10462 718/822-1180 Mid-Hudson Valley 1440 Route 9W Marlboro, NY 12542 845/236-3000 Long Island 22 Peconic Ave. Medford, NY 11763 631/207-2900 Pennsylvania Philadelphia Metro Area 120 Gordon Dr. Lionville, PA 19341 610/363-9200

Versalift Midwest LLC

midwest.versalift.com

51761 Danview Technology Court

Shelby Twp., MI 48315

586-991-0054

L & M Truck Sales, Inc. www.lmtrucks.com

4001 E. Boone Ave. Spokane, WA 99202

509-535-4175

Stephenson Equipment

www.stephensonequipment.com

Harrisburg, PA

800-325-6455

Philadelphia, PA

800-220-4033

Pittsburgh, PA

800-692-7600

Wilkes-Barre, PA

866-667-6756

Albany, NY

518-357-2200

Syracuse, NY

800-368-6455

Nixon-Egli Equipment Co. www.nixonegli.com

2044 South Vineyard Avenue

Ontario, CA 91761 909-930-1822

800 East Grantline Road

Tracy, CA 95304 209-830-8600

Coastline Equipment

Crane Division

www.coastlinecd.com

325 N. 5th Street, Bldg. A Sacramento, CA 95811 916-440-8090

Santa Ana 714-265-6550

Long Beach, CA 562-273-7013

Bakersfield, CA 661-399-3600

Oxnard, CA 805-485-2106

Santa Maria, CA 805-922-8329

Las Vegas, NV 702-399-2700

Elko, NV 775-777-7070

Meridian, ID 208-888-3337

Jerome, ID 208-324-2900

JDC

teamjdc.com

777 Doheny Drive Northville, MI 48167 800-336-4369

Antioch, CA 925-434-0320

Bay Shore, NY 631-416-5070

Cincinnati, OH 513-250-3080

Corona, CA 951-281-2550

Gonzales, LA 225-647-3010

Joliet, IL 815-727-1000

Greenville, SC 864-315-2900

La Porte, TX 281-842-8700

Orlando, FL 407-654-3840

Sulphur, LA 337-607-3260

Westfield, MA 413-642-4000

Twinsburg, OH 330-486-0800

Wharton, NJ 973-206-4300

Whitestown, IN 317-768-2600

Aspen Equipment

aspenequipment.com

Minneapolis

9150 Pillsbury Ave. S Bloomington, MN 55420 952-888-2525

Quad Cities

1733 South Stark St.

Davenport, IA 52802 563-949-4045

Omaha

11475 S 153rd St.

Omaha, NE 68138 402-894-9300

Des Moines

1525 SE Cortina Dr.

Ankeny, IA 50021 515-965-1000

Kansas City

1150 SE Hamblen Rd. Ste 2

Lee’s Summit, MO 64081 816-451-1745

McCall, ID 208-634-3903

12 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 13

HULLS Turning

Alabama’s Shipbuilding Industry Turns to ALL’s Cranes

Bayou La Batre, Ala., sits right on the Gulf of Mexico, a fishing village so well-known that its four seasons are said to be shrimp, crab, oyster and fish.

With an economy initially dependent on the bounty of the local waters, the town also has emerged as one of the world’s leading locations for shipbuilding (at one point, it was even known as “the Detroit of shrimp trawlers”).

Trawlers are still a mainstay, although these days, the shipbuilding happening in Bayou La Batre has evolved to encompass everything from tugs, barges and oil supply vessels to cruise boats, yachts and ferries. Finished vessels are exported all over the world.

Finishing construction of some of these ships requires cranes supplied by ALL Crane Rental of Alabama, a member of the ALL Family of Companies. Particularly when it’s time to “turn” a hull — flipping it from upside down to right side up — that weighs hundreds of thousands of pounds.

A boat’s hull is a curved structure that sits mostly below the waterline. Many hulls are first built upside down, then turned over before construction is completed on the full vessel. Although shipbuilders often own their own cranes for this crucial step, some hulls are simply too heavy and large, and require the specialty cranes ALL is able to provide.

Scott Swearengin, sales representative of ALL Crane Rental of Alabama, said hull turns, also called boat rolls, have been a regular part of the annual workload at the branch for his entire 17-year tenure.

14 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Why build a hull upside down? It’s easier to make sure the top part (the “bottom” when it’s under construction) remains flat for joining to the rest of the boat. It’s also easier for welders to work in a down and across direction rather than over their heads. It’s actually faster and more efficient to build the hull upside down, then bring in cranes to turn it at the appropriate juncture.

Scott Swearengin, sales representative of ALL Crane Rental of Alabama, said hull turns, also called boat rolls, have been a regular part of the annual workload at the branch for his entire 17year tenure.

“I’ve helped with turns in which a 200,000 pound hull is flipped in the air,” said Swearengin. “On the opposite end of the spectrum, I’ve seen jobs involving hulls that weigh 900,000 pounds. When they’re that heavy, they literally are ‘rolled’ — using the earth to handle 50 percent of the load as the cranes guide it over.”

For one recent hull turning, Swearengin specified two 550-ton all-terrain cranes, a Grove GMK7550 and a Liebherr LTM 1450-5.1.

The hull weighed 520,000 lbs. and measured 76 ft. long, 35 ft. wide and 10 ft. deep. The Grove was configured with 84 ft. of main boom, 100 percent outriggers and 264,500 lbs. of counterweight at a 35-ft. lift radius. The Liebherr had 87 ft. of boom and 295,400 lbs. of counterweight, also with 100 percent outriggers, and a 35-ft. radius.

Maintaining an equal radius is critical to a successful outcome.

“During the initial setup of these jobs, it’s important that the hull is positioned exactly between the cranes,” said Swearengin. “We have to make sure that, as each crane is reaching to grab its lifting eye and maneuvering through the turnover, the hull remains dead center. It has to be a mirror image.”

Positioning of the lifting eyes, which are temporary welds applied to give the cranes something to rig to, are also dictated by the radius to help ensure equal load between the two cranes.

This type of roll, in which the hull never completely leaves the ground, can take approximately 45 minutes to execute. Turns that happen in the air can take significantly longer, usually around two hours.

Once the hulls are right side up, the shipyard completes construction, and ALL returns at a later date with more cranes to assist with placing the wheel houses on the hulls.

Given the location on the Gulf, storms happen frequently and can scuttle scheduled rolls. Ground conditions also can change rapidly based on recent rainfall. Swearengin and the ALL team in Alabama remain at the ready to accommodate their valued shipbuilding customers.

“We’ve worked on dozens upon dozens of boat rolls over the years,” said Swearengin. “The shipyards are vital to the local economy, and we’re happy to help.”

(All photos courtesy of ALL Crane.)

“We have to make sure that, as each crane is reaching to grab its lifting eye and maneuvering through the turnover, the hull remains dead center. It has to be a mirror image.”

- Scott Swearengin -

For one recent hull turning, two 550-ton all-terrain cranes, a Grove GMK7550 and a Liebherr LTM 1450-5.1, were used.

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 15

AwarenessSpreading

ANimble Crane to Shine Light On Autism Awareness Month

utism Awareness Month is in April and Nimble Crane has geared up to make a bold statement.

The company is preparing to launch a newly adorned Grove GMK5150L all-terrain crane with a vibrant wrap designed to draw attention to the cause. The initiative reflects Nimble Crane’s commitment to addressing important issues for both oilfield members and the broader Odessa, Texas, community.

Nimble Crane began advocating for autism awareness when VP of Business Josh Robbins, a close friend of a parent with an autistic child, took the lead. For many years now, Robbins has been a strong voice for the cause and uses his love for softball to raise awareness.

Nimble Crane’s workforce includes individuals with autistic children, underscoring the company’s commitment to the issue.

“We intend to use our platform to shine light on autism awareness while addressing other relevant social topics within our community, driving meaningful change,” said Ben Ellis, Nimble Crane’s president. “We are proud of this initiative, and it will mark the first time one of our cranes will serve as an ambassador for autism awareness to both the oilfield and community that supports us.”

While the company has promoted autism awareness in recent years, this is the first time one of its most active cranes will emblazon the colorful wrap.

In April, Nimble Crane plans to share photos of the crane on its website and social media platforms along with information on the company’s initiatives aimed at raising funds for autism awareness.

Nimble Crane routinely engages in flag-flying ceremonies to support various community charities; it currently owns a Grove GMK7550 crane equipped with a wrap that represents a tribute to veterans, launched on Veterans Day 2023.

“Our veterans’ wrap hit home for numerous people in our company and community,” Ellis added. “Our goal is to launch a newly wrapped GMK on a social topic that is paramount to us and the community every time we purchase a new Grove. We have three more that we plan on launching in the future.”

For more information, visit www.manitowoc.com.

(Photos courtesy of Manitowoc)

16 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

Nimble Cranes unveiled a Grove GMK5150L crane with an autism awareness wrap in April as part of its support for the cause.

While the company has promoted autism awareness in recent years, this is the first time one of its most active cranes will emblazon the colorful wrap.

Five Potain Cranes Chosen for India’s Massive Airport TAKING ON

Terminals

Construction giant Tata Projects is leading construction on the impressive new Noida International Airport being built on the outskirts of New Delhi, India.

To manage lifting work on the huge infrastructure development, the company purchased two Potain MCT 565 A topless tower cranes and rented an additional three MCT 385 A tower cranes from Rental Partners.

Primed to become India’s largest and most important airport, the Noida International Airport is set to transform aviation infrastructure in the country.

The Potain cranes are heading the construction of the main terminal building, which is scheduled for completion at the end of 2024. The MCT 565 A M25 models have a maximum capacity of 27.5 tons and allow up to 262 ft. of jib. In collaboration with Manitowoc’s Lift Solutions, Tata extended this reach to an impressive 279 ft., allowing for greater jobsite coverage.

The capability of Manitowoc’s Lift Solutions team to engineer this extension was a leading factor in Tata Project’s decision to purchase the cranes.

“We’re proud to have a longstanding relationship with Potain India. Over the years, we’ve had remarkable performance from our older Potain cranes, some of which have been in operation for more than 25 years without a breakdown. That speaks volumes for the quality and durability of Potain cranes, and the MCT 565 A continues that proud tradition,” said Alok Banik, deputy general manager of plant & machinery at Tata Projects.

the end

2024.

The MCT 565 A cranes lift loads ranging from 1.1 to 4.4 tons and boast a freestanding height under hook of 200 ft. Alongside them are the three MCT 385 A L16 cranes which have a maximum capacity of 17.6 tons and have been configured with a 246 ft. jib length and at a height under hook of 201 ft.

Tata Projects is a long-time Potain customer and owns more than 50 of its cranes, using them on projects across the country. The company is one of the largest and most-respected contractors in India, with expertise in urban and industrial infrastructure projects. Previous landmark projects include the New Parliament Building, Delhi, and the Chennai Metro Rail. Tata Projects’ strategic investment in Potain cranes underscores the company’s commitment to delivering top-quality projects and contributing to India’s expanding infrastructure.

For more information, visit manitowoc.com.

The timeline for construction is very tight, so reliability and crane speed are crucial.

(All photos courtesy of Manitowoc.)

Primed to become India’s largest and most important airport, the Noida International Airport is set to transform aviation infrastructure in the country.

The Potain cranes are heading the construction of the main terminal building, which is scheduled for completion at

of

Looking Back: Cranes

Working to preserve the history of the construction equipment that shaped our world . . .

The Historical Construction Equipment Association (HCEA) is a 501(c)3 non-profit organization dedicated to preserving for public education the history of the construction, dredging and surface mining equipment industries.

18 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

An Osgood 18 ¾-yd. clamshell steam crane on wide-gauge traction wheels works a trenching project.

Courtesy of Historical Construction Equipment Association

Keith Haddock Papers, HCEA Archives

The Link-Belt LS98D was rated at 1½ cu. yds. as a dragline.

Contractor J. E. Drenneman Company is using a very rare Yale CM40 truck hydraulic crane on an unidentified highway project. The self-propelled version was rated at 25 tons capacity.

The Marion Type 5240 was one of a number of large draglines and shovels that could be mounted on wide-gauge railroad wheels for use on temporary trackage. This one is proudly lettered for McWilliams Dredging Company of Chicago and New Orleans.

Keith Haddock Papers, HCEA Archives

Keith Haddock Papers, HCEA Archives

The Osgood Company image, HCEA Archives

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 19 HAYDEN-MURPHY EQUIPMENT COMPANY | www.hayden-murphy.com | Minneapolis, MN QUALITY PRODUCTS | SUPERIOR SUPPORT | COMPETITIVE PRICES RT540E RT765E-2 RT880E RT890E GRT650 GRT650L GRT880 GRT8090 GRT8100 Looking To Sell Used Crane Inventory? Call Ken Boehm @ 612-720-4205 2020 GROVE GRT8100 Hours: 526, Stk# 1708, 154’ Boom, 56’ Jib, 2 Hoists, T4F Engine, Heavy Lift Counterweight $CALL 2003 GROVE GMK5120 Hours: 955, S/N: 51009287, 42’-167’ Boom, 39’-59’ Swingaway, Outrigger Pads, Single Hoist, Dolly, Block, Ball $CALL 2001 GROVE GMK5120B Hours: 21,000, S/N: 5100-9176, 42’-167’ Boom, 39’-59’

Swingaway, 2 Hoists, Outrigger Pads, 2 Inserts, Dolly, Block, Ball $CALL

2017 GROVE GRT655 Hours: 2,136, Stk# 1665, 164 HP, 4WD, 50 Ton Capacity, 35 Ton 4-Sheave QuickReeve Hook Block, 34’-114’ Four-Section Full-Power Boom, 26’-45’ Off-Settable Telescoping Swing-Away Jib, 2 Hoists $409,000

2006 MANITOWOC 10000 Hours: 7,436, Stock #: N001169, S/N: 10001032, Current Annual Inspection, 180’ Boom, 60’ Jib, Block, Ball $CALL

2019 GROVE GRT655 Hours: 1,363, Stk# 1680, 164 HP, 4WD, 50 Ton Capacity, 35 Ton 4-Sheave QuickReeve Hook Block, 34’-114’ Four-Section Full-Power Boom, 26’-45’ Off-Settable Telescoping Swing-Away Jib, 2 Hoists $CALL

20 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com LikBlt Y Rent tl fl ’ ditibt & Ro t h ll! in our eat capa fly system & gr ’s featuring lo -stock RT n ental flee ’s r distributor a o et has you Find Link- d us on: Belt Cranes Lexin linkb www | , USA entucky ngton, K belt com

Alta Equipment Company

www.altaequipment.com

Byron Center, MI (616) 878-7450

New Hudson, MI (248) 356-5200

Flint (Burton), MI (810) 744-4840

Traverse City, MI (231) 943-3700

Detroit, MI (313) 394-1811

General Equipment & Supplies

www.genequip.com

Shakopee, MN (952) 224-1500

Minot, ND (701) 852-0479

Fargo, ND (800) 437-2924

Bismarck, ND (701) 223-9700

Williston, ND (701) 572-0570

Atlantic & Southern Equipment

www.atlanticandsouthern.com

Birmingham, AL (205) 951-6656

Theodore, AL (251) 443-5229

Lake City, GA (404) 361-1100

NEW LOCATION

Midland, NC (704) 731-7272

Central/Eastern, TN (888) 951-6656

Kelly Tractor Co.

Crane & Foundation Equipment

www.kellytractor.com

Clewiston, FL (863) 983-8177

Davie, FL (954) 581-8181

Ft. Myers (239) 693-9233

Mulberry, FL (863) 205-2537

Miami, FL (305) 592-5360

Orlando, FL (407) 568-8055

West Palm Beach, FL (561) 683-1231

Rudd Equipment Company

www.ruddequipment.com

Louisville, KY (800) 283-7833

Corbin, KY (606) 528-9440

Prestonsburg, KY (606) 874-2104

Evansville, IN (812) 867-6661

Ft. Wayne, IN (260) 482-3681

Indianapolis, IN (317) 247-9125

St. Louis, MO (314) 487-8925

Clearfield, PA (814) 765-8500

Leetsdale, PA (412) 741-1731

Nitro, WV (304) 755-7788

Transport Equipment Sales

www.tes-inc.net

South Kearny, NJ (973) 589-4100

Columbus Equipment Company

www.columbusequipment.com

Columbus (614) 443-6541

Toledo (419) 872-7101

Cincinnati (513) 771-3922

Richfield (330) 659-6681

Cadiz (740) 942-8871

Dayton (937) 879-3154

Massillon (330) 833-2420

Zanesville (740) 455-4036

Piketon (740) 289-3757

Link-Belt Construction Equipment Mid-Atlantic

www.link-beltmidatlantic.com

Ashland, VA (800) 552-3837

Chesapeake, VA (800) 342-3248

Frederick, MD (833) 546-5235

Triad Machinery

www.triadmachinery.com

Portland, OR (503) 254-5100

Eugene, OR (541) 342-7700

Bend/Prineville, OR (541) 447-5293

Seattle/Tacoma, WA (253) 722-5560

Spokane, WA (509) 534-1900

Mt. Vernon, WA (360) 488-3948

Nixon-Egli Equipment Co.

www.nixonegli.com

Ontario, CA (909) 930-1822

Tracy, CA (209) 830-8600

Wood’s CRW Corp

www.woodscrw.com

Carlisle, PA (717) 795-0700

Central Square, NY (315) 676-2008

Williston, VT (802) 658-1700

North Oxford, MA (508) 499-1950

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 21

Altaequipment.com

18405 115th Avenue

Orland Park, IL 60467 877-399-6430

420 Nolen Drive

South Elgin, IL 60177 877-399-6430

613 E Stevenson Road

Ottawa, IL 61350 815-587-7610

1035 Wylie Drive

Bloomington, IL 61705 888-693-2271

480 Blaine Street

Gary, IN 46406 219-240-0268

exactcrane.com

Serving Ohio, Michigan, W. Pennsylvania, Kentucky

28985 Ambina Drive

Solon, OH 44139 440-349-1999

coastlinecd.com

325 N. 5th Street, Bldg. A Sacramento, CA 95811 916-440-8090

Santa Ana, CA 714-265-6550

Las Vegas, NV 702-399-2700

Meridian, ID 208-888-3337

Dallas, TX 214-391-4000

Corpus Christi, TX 361-289-2782

San Antonio, TX 210-629-0400

West Texas 432-517-4378

Oklahoma City, OK 405-639-8226

Tulsa, OK 918-224-2000

22 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com empirecrane.com 7021 Performance Drive N. Syracuse, NY 13212 800-342-7575

Industrial Blvd. Hanson, MA 02341 800-342-7575

Avenue,

7 Bridgewater,

68

9 Finderne

Ste

NJ 08807 908-203-0400 craneworks.com 2728 Reverend Abraham Woods Jr. Blvd Birmingham, AL 35203 205-278-5438

5215 Wills Road Mobile, AL 36582 251-679-0090

3090 State Hwy 20 Decatur, AL 35601 256-936-5438

smequipment.com 14925 South Main St. Houston, TX 77035 713-721-7070

TAC Distributor Ad 2021_CEG.indd 1 9/30/2021 11:06:04 AM 1 2 0 2 d t L s utortrib no ad a T © TAC Distributor Ad 2021_CEG.indd 1 9/30/2021 11:06:04 AM tadano w w w com ricasame aCcireomnAada Ts nee2r4WG,2n4oirtopr oa6P 607,X7nTotsu,odH R0 300-9)6188:+2eno h1(

For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com 23

24 For information about advertising in or submitting articles for Construction Equipment Guide’s Crane Product & Service Guide, call 800/523-2200 or e-mail: cmongeau@cegltd.com

By Lucy Perry CEG CORRESPONDENT

By Lucy Perry CEG CORRESPONDENT