From the NZ Stud Merino Breeders Society

From the NZ Stud Merino Breeders Society

Oral

Treat

Armidale

Awapiri Eric and Sally Smith Awatere Valley 03 575 7990

Balmoral Sam Simpson Lake Tekapo 021 336 806

Benmore Bill and Kate Sutherland Omarama 03 438 9474

Blairich Tom and Ron Small

Valley 03 575 7257

Cleardale Ben Todhunter Rakaia Gorge 03 302 8233

Earnscleugh Duncan Campbell Alexandra 027 489 2820

Eskland Helen Hedell Darfield 027 436 1389

Glenmore Will and Emily Murray Lake Tekapo 03 680 6752

Glentanner Mark Ivey Lake Pukaki 03 426 9638

Gray’s Hills Mark and Sherie Urquhart Lake Tekapo 03 680 6640

Hawksburn Phillip McElroy Cromwell 03 445 0874

Isolation Rob and Sally Peter Ward 03 575 6866

Kaiwara Geoff Millar Swannanoa 03 312 6635

Knowsley Park

Little

PGG Wrightson is 100% committed to the New Zealand wool industry. Providing strong, competitive, and reliabale sales platforms ranging from auction right through to long term contracts directly with international brands.

To discover how we can add value to your farming business scan the QR code or visit www.pggwrightsonwool.co.nz

FOR MANY OF US, the last 12 months is one to forget. Much of the country experienced a summer and autumn drought with feed reserves put under severe pressure, if not breaking.

To top it off, winter decided to come late, impacting lambing on many properties. Prices for livestock early in the year were well below what we need to remain viable, and costs of running a business are continuing to climb.

However, we are starting to see an improvement in lamb and mutton prices with beef currently really strong. Wool contracts year on year are our shining light and always the envy of our Australian neighbours.

These contracts give us the assurances that we need to keep operating and as growers we really appreciate the work our brokers do in securing them. The increasing awareness around sustainable fibres, I believe, puts us in a really good place and we need to keep telling our story.

A highlight for me this year was attending the Devold conference in Christchurch with two real take home points. The first being market growth

will come from turning people away from synthetic fibres and not trying to compete with other Merino products.

The other was the performance of the Devold clothing since sourcing the majority of their wool from New Zealand properties. The return rate of products went from 15% down to 0.5%.

To me, this re-emphasises how good the New Zealand Merino clip is, and why wool quality needs to remain near the top of our breeding selection decisions.

It’s easy to destroy wool quality in one cross, but it can take multiple generations to get it back. Luckily, we have some very progressive studs here in New Zealand that realise this, and are also building in animal welfare and carcase traits, along with maternal efficiency.

The NZ Stud Merino Breeders Society

PUBLISHER

Merino Review is published by CountryWide Media Limited on behalf of the NZ Stud Merino Breeders Society.

CONTRIBUTORS

Sarah Perriam-Lampp (Editor)

Joanna Grigg

Anna Munro

Ben Doubleday

Rina Sjardin-Thompson

ADVERTISING

David Paterson

david@countrywidemedia.co.nz

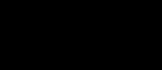

ON THE FRONT COVER

Lake Heron Station - Anna Munro

n Ideal for trimming cows tails, shearing sheep, alpacas and goats

n Variable speed from 2600-3500 rpm

n Latest brushless motor technology means minimal heat build up

n 1400gms means 100-200gms lighter than standard handpiece

n At 2800 rpm the 12-volt lithium battery will trim up to 400-500 cows tails or crutch 300-400 sheep

n Auto reset fuse for overload or lock up

Ultrafine down to 10.2 Micron

Superfines suitable for the Italian Market

Mediums suitable for Icebreaker with fast growth and higher fertility Merinos with fertility genes

Quaterbreds suitable suitable for Smartwool contracts and high resistance to footrot

Stud

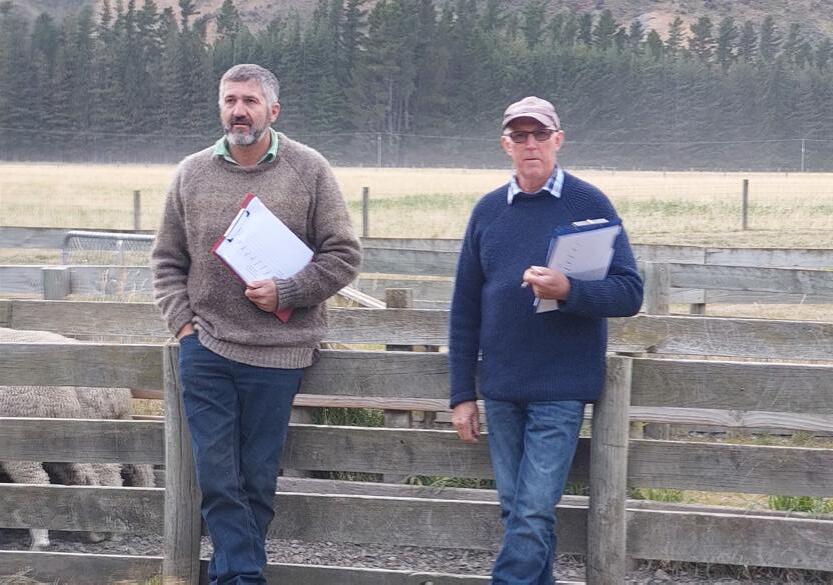

Results from the NZWTA/Otago Merino Association Two-tooth Competition held on the 18th and 19th April 2024 across various properties.

• 1st Patearoa Station – Charlie Hore and Belinda Colling

• 2nd Matarae – Willie and Emily Jones

• 3rd Merino Ridges – Bevan and Tiffany McKnight

• 4th Armidale – Simon and Sarah Paterson

• 5th Geordie Hill – Matt and Jo McCaughan

• People’s Choice – Geordie Hill (voted on at the Dinner)

Judges - Ian Stevenson, The Gums Polled Merino Stud and Bill Sutherland, Benmore.

Otago Merino Association Two-Tooth Competition Chair - Will Gibson, Foulden Hills.

Results from the Canterbury Merino Association Two-tooth Competition held on the 21st and 22nd of March 2024 across various properties.

• 1st Glenaan – Owner: Paul and Prue Ensor.

• 2nd Grampians – Owner: Jono and Sarah Reed, Manager: Graham Reed

• 3rd Glenthorne – Owner: John Shrimpton, Manager: Chris and Jo Johns, Mark Ferguson

• 4th Lake Heron – Owner: Philip and Anne Todhunter,

• 5th Lake Coleridge – Owner: Bruce Miles, Manager: Mark and Rebecca Rose, Chris Bowman

• Gordie McMaster Trophy for Most Improved/Encouragement award: Grampians - Jono and Sarah Reed

• Wool Trophy: Glenaan Station – Paul and Prue Ensor

• Canterbury Merino Association Conformation Award: Glenthorne Station –John Shrimpton

Judges - Bill Sutherland, Benmore Station and Guy Martin, Martin Suftex and Livestock Confirmation Ltd

Canterbury Merino Association Two-Tooth Competition Chair - Paul Ensor, Glenaan Station.

Merino sheep and stud fleece results from the 2024 Wanaka A & P Show held on the 8th and 9th March 2024.

SHEEP

Superfine Merino

• Champion Superfine Ram - Matarae

• Champion Superfine EweMatangi Station

Polled Merino - Superfine/fine

• Champion Polled Superfine/Fine Ram - Malvern Downs

• Champion Polled Superfine/Fine Ram Ewe - Malvern Downs

Fine Merino

• Champion Fine Ram - Armidale

• Champion Fine Ewe - Armidale

Medium Merino

• Champion Medium Ram - Armidale

• Champion Medium Ewe - Armidale

Polled Medium / Strong

• Champion Polled Medium/Strong Ram - Armidale

• Champion Polled Medium/Strong Ewe - Malvern Downs

National Pairs

• 1st Armidale

• 2nd Malvern Downs

• 3rd Blairich Merinos

Woodchester Cup

• Malvern Downs

Grand Champion Merinos

• Grand Champion Merino RamArmidale

• Grand Champion Merino EweArmidale

• Supreme Champion Merino - Armidale

LEFT: Armidale’s Supreme Champion Merino with Hugo Paterson (Armidale), Kate Campbell (Associate Judge), David Zouch (Australian Judge), John Bensley (Australian Judge), Craig Smith (Devold).

BELOW: Armidale’s Supreme Champion Fleece.

Champion Stud Fleece

• Champion Stud Merino Ram Fleece - Glentanner

• Champion Stud Merino Ewe Fleece - Armidale

• Champion Stud Merino Hogget Fleece - Glenmore

• Grand Champion Stud FleeceArmidale

• Supreme Champion Fleece - Armidale

Champion Flock Fleece

• Champion Flock Merino Ewe or Wether Fleece - Glenbrook Station

• Champion Flock Merino Hogget Fleece - Meg Taylor - Riverun

• Grand Champion Flock FleeceGlenbrook Station.

Ben’ Satterthwaite's win of the 2024 National Merino Junior Judging comes on the back of another success for Muller Station, winning the Westpac Osgrow Seed Marlborough Farmer of the Year for 2023.

HEAD SHEPHERD AT HIS family

Marlborough property, Muller Station, since June 2023, Ben Satterthwaite and his sister Alice are now involved with the property, alongside parents Steve and Mary, and are kicking their own goals.

Ben has been back since June 2023 after completing his Diploma in Agriculture and Farm Management at Lincoln University, spending a year and

“When judging you need to relate it to commercial reality and justify your order, even if it may be in a different order to others. ”

Ben Satterthwaite, 2024 National Merino Junior Judging winner, Muller Station

a half shearing in Gisborne, working on a cattle station in Australia for a season and a summer working at Otematata Station.

He’s also been through one of the driest periods for the upper Awatere Valley, making for a challenging home-coming.

Ben says that most of his understanding of Merinos has come from his parents, Steve and Mary, but getting alongside visiting Australian sheep classers was also helpful in going on to win the 2024 National Merino Junior Judging title at the Wanaka A&P Show.

Ben says he enjoyed the Junior Judging competition and recommends anyone to have a crack.

“When it comes to tips to help score points, it helps if you look over all areas of the fleece. While the mid-side is the best indication of wool, it’s good to talk about the overall coverage, belly and points,” advises Ben.

Ben says you have to be able to verbalise what you see and can't be shy

ABOVE: (Left to Right) Sophie

judge

Paterson and the winner for the 2024 Merino Junior Judging title, Ben Satterthwaite.

Sponsored by the NZ Merino Company and The NZ Merino Stud Breeders Association. Prize money $1,000 plus a trip to Australia.

• 2024 National Title (hosted by the Wanaka A & P Show Show): 1st Ben Satterthwaite, 2nd Sophie Wright, 3rd Archie Calder, 4th Alexis Faulkner, 5th Louise Stevenson.

• Marlborough (hosted by Blairich): Lou Stevenson, Ben Satterthwaite, Will Brown

• Otago (hosted by Earnscleugh): Archie Calder, Sophie Wright

• Canterbury: Samantha Harmer, Emma Ashworth

• Mackenzie: Alexis Faulkner, Jacob Rollo

The 2025 competition is open to those under 28-years as of 31 May 2024.

about talking out loud as it’s important to explain clearly to the judges why you have put the sheep in a particular order.

There were at least 50 people watching the judging process, with D’Arcy Palmer the 2024 judge.

“Relate it to commercial reality and justify your order, even if it may be in a different order to others. Correct handling of the sheep and the wool is important too,” says Ben.

As well as receiving $1,000, Ben says part of the prize he really values is being a guest judge for the following year.

“In 2025, I’ll be able to go around all the sheep sections with the judges and follow along.”

Ben’s win comes on the back of another success for the family business, winning the Westpac Osgrow Seed Marlborough Farmer of the Year for 2023. Since being home, Ben has been

working on achieving his private pilot licence (PPL) aircraft rating, out of Kaikoura. Other interests are horse breeding with Ben and Alice both

travelling to Australia this year to choose an Australian Stock Horse/ Quarter Horse stallion to cover the station mares.

• Breeding true dual purpose 18-20 micron Merinos, focusing predominantly on polled genetics.

• Incrementally increasing muscle and fat whilst staying focused on wool quantity and quality.

• High fertility stud scanning 190% M/A ewes and 150% 2ths.

• ASBV’s and full recording information including muscle and fat scan available.

• Using industry-leading genomics to improve foot-rot resilience.

• Ideal for adding value to your sheeps’ performance.

• View Muller Station on Facebook.

Having farmed at Castle Ridge for more than 30 years, Paul and Kerry Harmer have learned to farm to the conditions — whether it’s climatic, economic or regulations.

WORDS SARAH PERRIAM-LAMPP

PHOTOS BEN DOUBLEDAY AND RURAL CO

A CONTINUOUS FOCUS TO find the balance of farming profitably within the constraints of their environment is what motivates Paul and Kerry Harmer to run Castle Ridge Station for the next generation by working with the environment.

The Harmers have learned over 30 years that farming in the Ashburton Gorge at high altitude (the homestead is at 650 metres above sea level) has extreme weather, from hot, dry summers to harsh winters and short growing seasons, so have adapted their stock policy to best fit.

They purchased the station in 1992 from Paul’s parents, Peter and Mary Harmer, to then buy part of neighbouring Clent Hills in 2004 and part of Barrosa went through Tenure Review in 2011.

All of the Harmer’s childrenBen (24), Sam (22) and Annabel (19) are showing an interest in farming. Ben is currently working for the Ensors at Glenaan in the Rakaia Gorge after working at Armidale with partner

Kate Campbell, who is woolclassing. Sam has recently completed the New Zealand Merino Company’s Wool Classer Scholarship programme and Annabel is planning to start vet school at Massey University after returning from a gap year in the UK.

“It’s incredible to have two passionate female woolclassers in the family with Kate and Sam. It was extra special to have Kate, Ben and Sam the top three in the National Merino Judging last year too,” Kerry says.

Sam is passionate about her flock of 50 ultra-fine ewes (13 micron) ewes she is building up. “Growing up here, I have always been fascinated by the whole process, from the sheep right through to the garment. If you know where a product is going and what it’s going to be used for, you have that in the back of your mind when you’re classing, when you’re taking fleeces out,” Sam says.

Sheep are the backbone of the farming operation with a dual focus between terminal store lambs and their merino contract with Icebreaker (18.5 micron).

Castle Ridge Station, Ashburton Gorge 5,900 hectares (22,000 stock units), Ashburton Gorge

16,000 Merino, 600 Angus cows and 250 red deer

TOP LEFT: The Harmers worry about the lost skill of blade shearing with only three gangs left in New Zealand

TOP RIGHT: Castle Ridge have very little animal health worries other than footrot.

All merino wool that meets specifications goes to supply their 10-year Icebreaker contract as a longtime supplier to The New Zealand Merino Company (and a part of Icebreaker’s Growers Club).

With the property prone to snow at any time, Castle Ridge continues to employ the age-old art of blade shearing for their main shear in July.

“Blade shearing leaves more wool on the sheep, which is crucial for our climate and altitude so we really worry about the fact there’s not many new blade shearers taking on the skill,” Kerry says.

The station's main animal health pressure comes from footrot. With their lamb cheque in February they go on to purchase Merino ewe hoggets from two other properties that have similar conditions. The Harmers started a few years back on a long-term plan to build

Mixed-aged ewes go to the Poll Dorset while the two-tooths with better-woolled ewes go back to Merino rams for replacements

"Growing up here, I have always been fascinated by the whole process, from the sheep right through to the garment. If you know where a product is going and what it’s going to be used for, you have that in the back of your mind when you're classing.”

Sam Harmer, Woolclasser

up naturally tolerant animals. They are working together with son Ben with an elite ewe mob so that the station can have its own footrot tolerant rams to select from.

Despite Castle Ridge’s extensive nature, the Harmers put much effort into lambing time. Starting around September 20, most tend to lamb in early October. While the two-tooths lamb a month later on the hill, the rest are split into mobs and shedded off daily with any obvious spares bought in.

“While Merinos are not renowned for their mothering abilities, Armidale genetics do have good maternal traits, which has improved our ‘survival to sale’ percentage.” Kerry explains.

The onfarm team has reared up to 800 lambs with automatic lamb feeders. “We absolutely hated seeing lambs dying. Not only because it’s a loss of profit, but it’s an animal welfare and caring thing.”

The 2024 drought meant a lot more reared due to ewes being lighter and them dropping off one lamb to go travel further to forage, Kerry explains.

The lamb cheque has sometimes made up more than half the farm income from the February on-farm lamb sale by PGG Wrightson and Hazlett. It’s become one of the biggest on the annual calendar since 2005, with close to 8,500 Poll Dorset-Merino cross lambs sold with

up to 80% going prime. Any leftover lambs are taken through winter and sold after they’re shorn in July for their half-bred wool.

They credit part of their successful lamb operation to the introduction of Poll Dorset rams to their mixed-aged ewes to get around the challenging climate and terrain. The Harmers have been buying their Poll Dorset rams from George Lowe’s Windermere Stud, near Ashburton, for more than 20 years.

Not only do the Poll Dorset-cross lambs seem to thrive in the environment and are up and running as soon as they hit the ground, but there is also a short turnaround, as they are only on the ground for four months before being sold. It gives us the best of both worlds: fine wool and good finishing lambs.

This season has been one of one of the toughest, with Castle Ridge getting just half its annual rainfall.

“We had a really dry summer, and it’s basically carried on. We’ve had less than half our annual rainfall to date. Usually, we make around 1,000 bales of lucerne baleage, and this year, we only got 380 and had to buy in bales and 100 tonnes of barley.”

Their last significant rainfall was snowfall in October 2023 and it went from a cold spring to a dry summer, with their autumn window for growth shut

Sam

has recently completed her woolclassing certificate and classers at the family station.

MIDDLE: Woolshed at Castle Ridge Station.

BOTTOM: The Harmers have been a longtime supplier on contract to Icebreaker.

down with the first frosts arriving in the middle of March 2024. There was no good winter rain until late July 2024.

“We normally grow 300 hectares of turnips and swedes (winter feed) but after getting the swedes in and spraying off the next paddocks for turnips to feed young stock we made the call against putting the drill in the ground because of the rain shortage. We’ve had seasons like this before. But it’s a bit different this time. Usually, we can rely on rain in the autumn, but we didn’t get any, and we didn’t get as much snow either.”

The most efficient and cost-effective option was to concentrate on feeding barley to ewes with the poorest condition scores. The main ewes got some barley at tupping on top of diminished winter crops and baleage brought in.

"Our cost of production will be significantly higher, but we have to look after our capital stock and grazing off farm isn’t such an easy option for Merino ewes. We could get rid of cattle as far as the heifers go, but that’s about the only class of stock we could send away grazing realistically. The cows will just work around hill country blocks and

“We are just stewards for a short space of time. Our job is to leave an environment in a better place for everyone who has a relationship with it, not just us as owners. Our children grew up with that understanding more than our generation that has had so much imposed upon us.”

Kerry Harmer, Castle Ridge Station

use some of the fat off their backs that we’ve been building up the past couple of years."

Kerry says farmers this year have had to accept they would not get every last dollar and the stock would not look as good as they wanted, but nobody could be perfect all the time.

As part of being a grower for Icebreaker, the Harmers are part of the ZQRX programme, a pioneer quality assurance programme committed to strict animal welfare codes and having strategies to protect and enhance the natural environment.

The swedes and turnips are drilled with an Italian ryegrass using a cross-slot drill,something they have done for the past 20 years. The focus is on preserving and growing soil in a high wind erosion area. The Harmers have been relocating some of their winter grazing to reduce the nutrient load near Environment Canterbury (ECan) “sensitive” lakes red zone, as they’ve required consent to farm for a number of years.

Castle Ridge is in the Ashburton Lakes Catchment,which encompasses some 58,000 hectares that includes 13 Lakes, the Te Araroa Walkway, numerous recreational hunting, fishing, water, tramping, and snow opportunities, and is enjoyed by many in the extended community.

In 2019, the four farmers within the catchment joined the Ōtūwharekai Working Group, which includes members from the local iwi, Department of Conservation (DOC), LINZ, Ashburton District Council (ADC), ECan, Central South Island Fish & Game, the Ministry for the Environment, and the Ministry for Primary Industries (MPI) to look to collaboratively halt and reverse the degradation of ecology and values in the region.

On the back of that, in early 2023, the farmers officially launched the Ashburton Lakes Catchment Group, which falls under the Mid Canterbury Catchment Collective, to actively monitor impacts on water quality in a planned way and work on mitigation strategies to lessen their environmental footprint on their own farms.

“All the heat is on us as the landowners, but actually, we are only part of this, only part of the problem, and only part of the solution. So, we want to build the science knowledge with everybody collaboratively. Up until now, the finger has been pointed at us as the sole cause of it all, based on computer modelling and assumptions,” Kerry says.

Since September 2023, farmers have been measuring water quality where the water enters their properties, at a midpoint, and as the water departs. These nitrate tests range from less than

0.002ppm to 1.05ppm, which is extremely low, Kerry says. Some are less than 10% of the nitrate levels in the drinking water of the Ashburton town water supply.

“It would cost over $1 million to do all the fencing that previous regulations have suggested. We need to have ways to water stock that enables them to use it but with minimal impact. Long term, we are committed,but nothing happens overnight; this is a long-term challenge.” She says in up to 60% of areas measured,

the water quality does not change or improves as it travels through the properties. In June 2024, they received a grant from MPI over the next four years from the Catchment Extension Services Fund, which will allow them to further their research and work to develop practices that will improve their environmental footprint in the basin and then share their findings with others.

The catchment group has been a part of a Plant & Food trial ‘Pushing the boundaries of catch crops’, which is enabling them to trial sowing oats, ryegrass and ryecorn in July. These crops both grow in a cold time of year and soak up nitrogen behind the winter grazed crops.

The Harmers will continue to work collaboratively towards an environmental outcome and hope they will be able to reach a sensible, sustainable solution for their children to continue farming.

“We are just stewards for a short space of time. Our job is to leave an environment in a better place for everyone who has a relationship with it, not just us as landowners. Our hope is that our children will be able to continue to improve and enhance the environment while continuing to farm into the future,” Kerry says.

This year the finest wool ever sold through a PGG Wrightson Wool auction of 'The Bend' from Ranfurly’s 12.5 micron achieved an impressive $155 per kilogram greasy destined for Italian mills.

WORDS SARAH PERRIAM-LAMPP PHOTOS PGG WRIGHTSON WOOL

THE SCHNEIDER GROUP, AN internationally renowned company specialising in the sourcing, processing and supply of high-quality fibres for their mill in Italy, regularly purchase merino wool from ‘The Bend’ in Ranfurly, but this year was a milestone.

On October 24 2024, driven by solid competition for the ultra-fine clip, PGG Wrightson Wool’s South Island C17 Auction broke a world record for the finest merino wool sold through auction at 12.5-micron, which was grown on the Central Otago property of John and Sam McAtamney.

PGG Wrightson Wool South Island Wool Sales Manager, Dave Burridge, says he is incredibly proud to have been part of the selling process that day, achieving an impressive price of $155 per kilogram greasy. This set a new benchmark for New Zealand fine-wool, the highest price that the team at PGW Wool has seen for ultra-fine merino wool.

“John and Sam have dedicated years to producing some of the finest wool in New Zealand, if not globally. Their dedication to quality and meticulous preparation have earned them a well-deserved reputation for excellence in the wool industry. Their latest achievement is a testament to this hard work,” Dave says.

He explains that the wool is exceptionally well-grown and well-prepared as key qualities that truly set The Bend’s wool apart on the global stage.

“Kevin Waldron (PGG Wrighton’s Wool Representative) is a huge part of our achievements having been our wool classer for over 20 years with an exceptional eye for ultra-fine wool. He's been selecting rams with us at Forest Range every year. They just do really well here with no special treatment,”

John McAtamney says.

He explains that The Bend’s breeding selection has moved beyond chasing

“Kevin Waldron is a huge part of our achievements having been our wool classer for over 20 years, as he has an exceptional eye for ultra-fine wool. He's been selecting rams with us at Forest Range every year. They just do really well here with no special treatment.”

John McAtamney,

The Bend, Ranfurly

ABOVE: (Left to Right) Doug McKay, South Island auctioneer and procurement manager for PGG Wrightson Wool, Helen Cameron, fine wool procurement specialist for the Schneider Group and Dave Burridge, South Island wool sales manager.

BELOW: 12.5-micron merino wool from ‘The Bend’ in Ranfurly.

micron over the years to getting wool weights up and improving the style of the wool.

Representing The Schneider Group at the auction was fine wool procurement specialist Helen Cameron, who expressed her excitement about acquiring such a rare fibre.

“It’s always thrilling to see wool of this calibre coming out of New Zealand. While we do see some ultra-fine wool like this from Australia, it’s rare to get it down to these microns, making it a truly special find for us.”

The drought brought double trouble for Devold growers; extra feed costs plus fleece tenderness due to issues with feed

transitions.

WORDS

JOANNA GRIGG PHOTOS BELLA BLACK & CRAIG SMITH

DEVOLD GROWERS’ WOOL HAS largely ended up half a micron finer than last year and the wool weight is also lower.

“Reflecting on the growing and selling season, everyone knew it was going to be tough to avoid tender wool given the drought conditions rolling out across the South Island. Unfortunately, the result has hit some farmers’ pockets hard, with tender wool being excluded from the more lucratively priced contracts for the best fleece wool,” says Craig Smith, aka “Smithy”, general manager, New Zealand for Devold.

To meet the Devold contract, wool strength must be at least 38 NKT (Newtons per kilotex). Around 20% of signed-up wool has not met this strength parameter this year, explains Craig.

“The phone calls have been tough at times. There can be thousands of dollars riding on it. But Devold won’t compromise on quality as the best consumer experience is only found when using quality ingredients and this starts with the quality greasy wool we buy.”

Craig says it is very disappointing to hear and see other contracts with lower NKT specifications.

He suggests that more diligence at classing time may have helped the wool clip make the grade and urges that classers need to check three or four areas right across the fleece for tenderness, not just one spot.

“Some areas of the fleece were fine but other areas were tender, and it only takes a sample of the tender wool to downgrade the whole bale.”

This lack of uniformity is puzzling and he says he and growers are scratching their heads about why, and what could have been done to avoid it.

The break has occurred at the base of the staple, suggesting an autumn feed change, he says. The transition from poor-quality, hill feed to higher-protein, autumn crops may have been the moment.

There are definitive answers on the effects of sudden feeding changes, he says.

“What’s less clear is why there is variation over the fleece.”

From a supply perspective, Craig says Devold is extremely happy with the wool that did meet the contract.

“We won’t be topping up from auction and accept that one year is okay to be a bit short of supply and we hope for a better season next year.”

Strength and length are critical to how wool will perform during carding, gilling and combing. Wool that is tested as being tender can still make relatively good prices at auction.

Growers got to see wool samples being collected firsthand, at the tour of the PGG Wrightson Wool Store in Christchurch, in June.

As part of the Devold Growers Summit, growers were taken through the wool handling process.

This included from truck drop-off to viewing grab-sampling of the bales, to presentation of the samples in viewing boxes for auction.

Growers saw the grab-sampler machine in action. This has mechanical jaws that extract wool from various positions and depths within each bale. The number of grabs per bale depends on the number of bales within a lot. More grabs are taken per bale from smaller lots, to ensure a representative sample. A second MTS machine took random tuft samples from the grab samples as they passed through the machine. A minimum of 63 tufts per grab sample are taken. These were rolled up into a gauze, ready to be transported to the laboratory.

The final piece in the chain is for a single staple from each tuft to be removed and measured using an ATLAS machine. Each end of the staple

is clamped by jaws and pulled until the staple ruptures. The force needed to break it is measured in newtons. The weight of each piece of broken staple is used to determine where the break is. Craig Smith, Devold, says fewer than 25% of Devold growers had been through the Christchurch store so it was a great opportunity to take people through.

The Summit was attended by 105 growers. They heard from the Devold chief executive officer (via video link) and Tor Jonsson, the factory manager in Lithuania, attended in person. Craig says Devold has been weathering challenging economic times quite well. Sales are 20% above budget and pre-orders are tracking well.

“We just need a good cold winter in Europe to push sales.”

The Devold Global retail sales team have been learning about NZ wool and for some, this included showing them wool in its greasy form.

“Some had never seen wool in its raw form or had really understood about the way quality can vary from sheep to sheep.”

The Devold sheep to shop principal means the company works to control and manage the whole pipeline. The company aims to double sales across

the world by 2028, but only if we get the right wool to do it, Craig says.

George and Sarah Murray, Aschworth Station, Marlborough, attended the Growers Summit and said it was their first Devold event and visit to the wool store.

“It was really nice to be involved and understand the full journey of where the wool goes. We got to understand that length is really important to a quality garment and tenderness and monitoring is really important during classing,” Sarah says.

The Murrays say that all the statistics from the farms, including average wool staple length and strength, were shared.

Sarah classes the Aschworth clip and this year she says she “pulled the fleece often more than once” to check tenderness.

“We shore late so we were very aware of tenderness issues emerging this season, so we really worked to keep all tender fleeces out of the main line.” All of the Aschworth main line made ‘contract’.

“Tender wool can still sell okay but it’s not worth the risk of contaminating your main line and missing contracts.”

These drought events are just the nature of farming, Sarah says.

Chris Nicolson recalls the days before signing with Devold, when their wool was a traditional style, and the entire clip went to auction. The original merino had its challenges in the North Canterbury climate and the decision was made to move away from that style of sheep and into an easier care, higher micron sheep with a bit more grunt.

AND PHOTOS PGG WRIGHTSON WOOL

in North Canterbury is Barcaldine Farm (2,600 hectares) located between Waiau and Hanmer running a 70 percent sheep to 30 percent cattle ratio (7,500 stock units). Barcaldine has been part of the Roxburgh family since 1945 run by by Hamish Roxburgh, shepherd Deegan Devree and Chris Nicolson.

“Emily and I are the third generation to take the reins at Barcaldine along with our children Archer (5), Elsie (4), and Sylvie (6 months). We’re grateful to Hamish and Grace for the opportunity to be part of this incredible place,” expresses Chris. Most of the farm is hard hill well suited to merinos and a switch to a type of merino that was a

slightly higher micron they were seeking more security with our clip.

Thanks to PGW Wool, Barcaldine has locked in a sought-after partnership with Devold, which offers fixed-price contracts for their wool, providing price certainty in an often uncertain market. PGW Wool rep, Peter McCusker suggested Devold and arranged for Craig “Smithy” Smith from Devold NZ to explain the benefits to the Barcaldine team. They ended up signing most of their fleece to the merino clothing brand, and as the saying goes, the rest is history.

“The farm has worked with PGW for generations, and the relationship has been great. Peter does a fantastic job.

He’s a great all-around sheep man, and his knowledge is invaluable,” says Chris.

Chris says it was a sound financial move, but we’ve also been very impressed by Devold’s business model. It’s exciting to be part of the frequent gatherings, where growers can meet each other, hear from the Norway team, and learn about markets and innovations they’re working on.

“The feedback we get is great, and the lines of communication are always open, which we really appreciate. Going through the wool store and hearing what others are doing also helps us see what we could accomplish. The whole system is so aligned and in-house; we feel very fortunate to be part of it. We’re excited to see what the future holds!”

Founded 173 years ago by Ole Andreas Devold, who made beanies, scarves, and gloves for Norwegian fishermen, Devold is now a global brand specialising in outdoor active merino clothing. They differ from other manufacturers by being fully vertical — they buy wool on a forward contract basis, directly from growers.

With typical wool commodities, there are usually intermediaries between the

LEFT:

and Sylvie (6 months).

farmer and the brand. But because Devold aims for the highest wool quality, they offer fixed prices to growers, so farmers know what they’ll be paid, and Devold knows what they’re buying and their values align with topquality merino wool from New Zealand.

Devold NZ’s General Manager, Smithy, says the reason is that the wool in New Zealand is really consistent.

“Devold’s ethos is to strive for quality in everything we do and make, so we have to buy the best wool we can. Wool is a bit like wine in that it’s affected by climate and feed. While New Zealand wool can fluctuate, it’s not as dramatic as Australia, where the weather swings from one extreme to the other,” says Smithy.

“We do this because quality is central to everything we do. If we don’t know the wool’s quality, we can’t make good garments. We also pay a premium above the commodity price to meet our specifications,” says Smithy.

This practice has had clear benefits. When Devold was buying processed wool, the rejection rate was about 15 percent out of every 100 garments, either by consumers or in production. Now that they buy directly from growers, the rejection rate is under 0.5 percent.

Smithy believes that the wool industry is often too disconnected from growers.

“When it comes to merino, 80 to 85 percent is sold through auctions, leaving the grower with no idea where it goes, and the brand not knowing where their wool came from,” he explains. “With our partnership with PGW Wool and our growers, we know exactly where our wool is shorn and can trace it from

In partnership with PGG Wrightson Wool

“The feedback we get is great, and the lines of communication are always open, which we really appreciate. Going through the wool store and hearing what others are doing also helps us see what we could accomplish. The whole system is so aligned and in-house; we feel very fortunate to be part of it. We’re excited to see what the future holds!.”

Chris Nicolson, Barcaldine, North Canterbury

the farm to the wool store, all the way to Lithuania, where the clothing is made.”

When growers join the Devold family, they know exactly where their wool goes. Most have even seen the end result with their own eyes. “We’ve taken two tours to Europe so our farmers can follow their wool through the pipeline, so to speak. They saw production at the factory and visited Devold’s head office in Norway, meeting our entire team. Seeing the finished garments with their label on it was an emotional experience, and many shed tears of pride,” says Smithy.

"Traditionally, once you shear a sheep, the wool goes on a truck, and you never know where it ends up. But not with us. Our 'sheep to shop' program is 100% traceable, and we love sharing our growers’ stories with those who buy our merino garments."

With such a strong bond between grower and brand, Devold is selective about who joins their partnership. As Smithy explains, they carefully vet new growers, consulting everyone involved.

3

Working alongside PGW Wool has also contributed to this successful venture. “We trust Peter McCusker, Dave Burridge, and the growers they represent. Their knowledge not only adds value to farmers like Chris but ultimately extends our brand,” says Smithy. “The quality wool we seek drives them to deliver.”

1. The Nicolson family from left to right: Archer, Emily, Sylvie, Chris and Elise.

2.

3. Devold strives for absolute superiority in their wool.

4.

1

2

3

4

Canterbury.

Meet the Aussie bush kid who’s bringing The New Zealand Merino Company back to its roots.

ANGUS STREET MADE AN exciting decision when he accepted the top job at The New Zealand Merino Company (NZM). Not only was he signing on to succeed the company’s inaugural chief executive officer (CEO) in the midst of one of the worst wool markets seen in decades, he and his wife Elly were committing to uprooting their family for a move across the ditch.

Angus, Elly, Sullivan and Sibella, along with Potts the Dalmatian, left Sydney - and their easy access Green Creek, the livestock property Angus grew up on near Murrurundi - to take up residence in Christchurch.

“Anytime you can enforce change, uncomfortable as it may feel in the

moment, it is a way of slowing down time and adding chapters to your life. Elly and I had both lived overseas and talked about giving the kids that experience while they’re young.”

Angus says that joining NZM just felt right, here was this company with a deep legacy, strong values and so much potential in a world where consumers are rapidly turning towards natural fibre. But it was also somewhere where he knew he could make a difference.

The NZM board of directors clearly had their sights set on growth when they selected Angus as the company’s second ever leader. Prior to accepting the role he was CEO of AuctionsPlus, one of

“From the start I was set a clear challenge to examine every facet of this business. Yes, the wool market has been going through tough times but I don’t think there is a single soul working at The New Zealand Merino Company who would be happy to simply wait for recovery.”

Angus Street, NZ Merino chief executive

Australia’s oldest Agtech businesses, and in his four-year tenure he transformed the platform into the country’s largest agriculture marketplace.

Since Angus took the reins, he has guided NZM through a wide-ranging strategic review, fronted up to report a year-end loss and announced the company’s EpicFibre strategy which he believes will provide the roadmap for long-term stability and growth.

“From the start I was set a clear challenge to examine every facet of this business. Yes, the wool market has been going through tough times but I don’t think there is a single soul working at NZM who would be happy to simply wait for recovery.

“This company was founded to protect growers from commodity fluctuations. For many, the consistent wool cheque has been crucial over the last few years –how can we make that a reality for all?” says Angus.

NZM’s EpicFibre strategy includes forming a dedicated Integrity Services team tasked with shoring up its data and systems, increased investment in its marketing and sales functions and a profitability improvement plan to take care of the bottom line. However, Angus says it's much simpler than it sounds.

“The main goal of our strategy is simple, to be the world’s number one preferred supplier of ethical and sustainable wool. We know our growers’ wool is the best – it's our job to make sure everyone else knows it too,” says Angus.

BLAIRI CH MERI NO & POLL MERI NOS

POLL MERINOS • 650 STUD EWES • 18.5 MICRON

127% lambing (10 year average)

Heavy cutting, superior, white waterproof wools Conformation, Constitution, Profitable

Global success hasn’t swayed Kiwi brand, Rodd & Gunn with their continued commitment to home-grown excellence from their knitted ZQRX merino wool.

WORDS DEBS SIM PHOTOS NZ MERINO

RODD & GUNN’S ICONIC English

Pointer logo is a familiar sight to New Zealanders. It was first stitched on a boutique range of men’s shirts back in 1946 and was reignited in the brand’s current form in 1987.

Debuting as a standalone store on Auckland’s Queen Street, the adored Kiwi brand’s little dog has found admirers now in 11 countries from Australia, across Asia, North America, Europe and the UK. The brand shows no signs of stopping, with 10 store openings in the works set to bring its standalone retail offering to 74 – not to mention concessions within retail royalty hubs including Nordstrom, Bloomingdales, and Macy’s.

Despite its enviable success in the tough American retail market and beyond, Rodd & Gunn remains committed to its roots in Aotearoa. This year, it partnered with The New Zealand Merino Company (NZM) for a 100% New Zealand-grown ZQRX Merino Wool collection.

“Clothes have the power to connect when you can create a garment that is literally made from the land on which the brand was born. I think it carries a huge amount of impact that goes both upstream and downstream.

Through Rodd & Gunn, the consumer has a direct connection to New Zealand’s community and growers should be proud of what their efforts have created,” explains Rodd & Gunn creative director John Prikryl.

Origin is one thing, but Rodd & Gunn won its following by producing quality, timeless pieces. The brand stands by its garments offering a two-year guarantee on all products and John explains that this sort of promise can only be delivered if you start with the best fibre available.

“It comes down to two very simple factors - performance and quality. No matter what the marketing brochures may say, there is no man-made filament or pseudo-fibre that can match the multi-faceted performance of greatquality wool garments. There is an inherent quality to the touch of natural products that you can’t go past either and it's something that our customers value immensely,” says John.

NZM’s ZQRX programme is the company’s answer to escalating demand worldwide for regeneratively farmed products. Launched in 2021, it is designed to recognise and reward the great work growers do onfarm, over and above the requirements of standards and certifications.

Rather than prescribing practices, growers must implement (or avoid), ZQRX works by measuring outcomes for 15 key indicators across animals, the environment and people. NZM’s chief customer officer Dave Maslen explains why this is crucial for growers – as well as brands like Rodd & Gunn.

“Standards are simple to understand – if the product has a tick, consumers know it’s ethical and they feel good about buying it. But you can’t standardise regeneration when every farm, every grower, faces unique challenges.

“Many of our growers were already doing what international groups are calling for. Striving to have a positive impact and leave the land better than they found it. ZQRX is our way of measuring their efforts, connecting them to expert help when needed and crucially, communicating positive outcomes to appeal to brands and consumers,” says Dave.

NZM has seen great success with the introduction of ZQRX. The programme represents 508 growers and has been adopted by more than 30 global brands, with Rodd & Gunn’s collection being the latest in a line of successful range launches. Dave puts its success down to its focus on progress, over perfection.

“No matter what the marketing brochures may say, there is no man-made filament or pseudo-fibre that can match the multi-faceted performance of great-quality wool garments. There is an inherent quality to the touch of natural products that you can’t go past and it's something that our customers value immensely.”

John Prikryl, Rodd & Gunn, Creative Director

“The brands who have embraced ZQRX are the ones who are committed to making a positive difference. They want to collaborate with our growers to do good for the planet and they understand that while no one has all the answers right now, there is value in moving in the right direction,” says Dave.

So exactly what was it about the work of ZQRX that caught the attention of Rodd & Gunn over other New Zealandgrown fibre?

“The respect for the land, animals and community is one of the first things that stands out. The quality of the fibre is obviously incredibly important, and we can’t take that for granted, but when you combine it with the RX elements (regenerative index) of the program it really shows the innovation and forethought that is being put into the industry.

“New Zealand is such an immensely special place for so many reasons, and to see the land and communities being taken care of by the growers is quite inspirational and not an easy task,” says John.

With its success around the globe, the Rodd & Gunn team is well-placed to ascertain consumer sentiment, both now and in years to come. When asked about the future of sustainability and regeneration for the business, John had plenty to say.

“For Rodd & Gunn, quality natural fibres have always been the foundation of our designs and to source them to the highest quality possible. It is intrinsic to our design process and our decision-making. As we’ve been able to refine the provenance of our raw materials it has become a natural part of our brand philosophy –so I would say the role it plays is extremely important - both to our brand and our customers.

“We strive in every aspect to do better and I’m not sure when or if that journey ever ends, but continual steps forward is our ethos and ZQRX is a perfect example of our commitment in this area,” says John.

So what’s next for Rodd & Gunn, and its Kiwi growers?

“We all have to work with what we’ve got and do it in a sustainable way into the future as exemplified by ZQRX. I can’t see any way around that. As customer awareness of the provenance of our product increases and the incredible work that the farmers and growers at all levels put into it, it becomes essential,” says John.

The management of Lake Ohau Station hasn’t changed a lot through its history of leaseholders, and current managers Tom and Sally Moore continue to farm traditionally with the limitations of a hard high country station flanked against the Southern Alps.

WORDS SARAH PERRIAM-LAMPP

PHOTOS ANNA MUNRO

LAKE OHAU STATION HASN’T changed a lot in its management since three generations of the Weatherall family passed the baton of custodianship over in 2007. The private rich-lister New Zealand family have full faith in Tom and Sally Moore to run the station - as a traditional high country station.

“There’s a lot of similarities of how we run the station now as was when I was working around Omarama in the mid-80s - shorn off the hill on blades then back out onto the hill,” says Lake Ohau Station manager, Tom Moore.

Tom and wife Sally came to Lake Ohau in 2016 following a career managing stations such as Lindis Peaks and Bendigo Station.

“You learn something new in every place.”

With the leasehold’s topography stretching from the western shores of Lake Ohau to the 2220metre-high peak of Mt Peterson, over half the station comprises the dramatic mountain range in a glacier-carved valley.

Tom explains the juggling act of autumn musters bringing the ewes off their summer blocks and wethers down to the snow boundary to spell the South Temple in advance of the harsh snowfall they get mid-late July. The history books of Lake Oahu have documented the run holders that walked off the station in the 1880s under the pressure of the elements. Their farming

FARM FACTS

Lake Ohau Station, Mackenzie Basin

8,322 hectares leasehold

550 metres above sea level, through to 2,100 metres.

6,000 merinos (2,500 ewes, 2,000 wethers and 1,500 hoggets) and 140 cows

“We don’t have the country to do anything different - it’s

wool and store stock.

It’s not the easiest place to run - terribly windy and cold.”

Tom Moore, Manager, Lake Ohau Station

calendar annually remains similar to decades prior, which works with the unique environment that Tom describes as having to be in the top 10% of harder high country places in the country.

The couple only get in casuals over the busy period, with Sally shifting and feeding out to stock on the flats. Ewes are fed out to from June to October before shearing from the 10th - 20th

ABOVE: Lake Ohau Station on the shores of Lake Ohau in the Mackenzie Basin.

“Last year we couldn’t fill the Icebreaker contract with our wool strength and quality back. We weren't able to feed everything as good as we would have liked and then a dry summer. We are back filling the contracts this year but it was tough.”

Tom Moore, Manager, Lake Ohau Station

September and back out on the hill mid-October for lambing. Hoggets are shorn mid-October followed by wethers being brought in at the end of October for their haircut with the blades and back out. Once everything is back out on the hill, the low country is shut up to make as much silage as they can for the following season.

“We don’t have the country to do anything different - it’s wool and store stock. It’s not the easiest place to run, terribly windy and cold,” Tom explains.

With a dry season this year they worked hard to feed ewes better over the

June/July period and then get the wool off mid-September, as they didn't have any silage left and Tom believes this could impact next year's wool clip.

Two-thirds of Lake Ohau’s income comes from the 30,000kg wool clip that annually goes into their 75-bale Icebreaker contract with a further five bales to a Nike contract and 16 bales to Mons Royale. Tom says it’s challenging with costs rising and whole clip contracts being in decline every year since 2019.

“Last year we couldn’t fill the Icebreaker contract with our wool

strength and quality back. We weren't able to feed everything as good as we would have liked and then a dry summer. We are back filling the contracts this year but it was tough,” Tom says.

The Moores buy Glenmore Station rams every year as they like their big bodied sheep with above average fleece weight of ideal micron for their wool contracts (17.5 micron in the hoggets with 18 - 20 micron in the two-tooths to mixed aged ewes and wethers).

They like to run a meatier rear end for both body structure and to provide

consistent store lambs to Mark Ewiing every year. Mark’s late father Dick had been purchasing from the station since they arrived in 2016 to send to Canterbury for fattening.

“We have a limited selection for genetic gain with Glenmore being the only merino stud left farmed in the same condition as us, but also that our ewe replacements are limited each year as this is really wether country.”

Tom explains that his ram selection is balanced between wool and structure. While micron and wool weights are the priority, shoulder, feet and rear end are just as important to ensure they get a good-framed animal that requires minimal input in a harsh environment.

“I don’t look much into the EBVs as I believe if you feed a sheep property they will produce. I do look at the foot scores though with 1,000mm plus annual rainfall.”

The owners want the station to run traditionally and to ‘tick along’. Money for development needs to come from the station profits, which Tom describes as ‘very little fat in the system’ to meet the rules and regulations from their leasehold in the Ruataniwha Conservation Park area.

They have been fencing off Lake Ohau and surrounding rivers, such as the Dobson River, doing as much as they can each year as finances allow. The challenge of doing so has been the inability to even scrap a track for access for fencing without needing a consent.

“The expectations are high and we are trying our best to chip away at the environmental requirements whilst keeping up with general maintenance.”

Stafford Weatherall and Mary (nee Sutherland of Benmore Station) built the original shearer’s quarters in the early 1970s as they saw an opportunity for low-cost accommodation

for visitors to this isolated spot who came to tramp, duck shoot, ski at nearby Ohau ski field and fish the lake’s renowned salmon and trout.

The accommodation was closed on their departure in 2007, and demolished in 2012 when the new shearer’s quarters, a beautiful, modern lodge for groups of up to 24. The lodge is now managed by Karen and Geoff Friend.

The owners, along with the Moores, continue to look at diversification options, including trophy hunting, accommodation and/or land development to boost the revenue of the station.

“You do need to spend money to make money, but everything to diversify income is a huge capital outlay to the return on investment. So here’s hoping Merino prices improve.”

BELOW: Lake Ohau woolshed under the towering southern alps.

We combine EBVs with visual assessment to breed the best sheep we can.

The 12,000 commercial Merino ewes are weaning over 133% and clipping over 6kg of 17.7 micron wool.

Mating ewes as hoggets. Two-tooth ewes scanned 175% & clipped 6kg of 20.5 micron wool.

The 5,000 commercial Halfbred ewes are joined to terminal rams, wean 165% & clip 6kg of 24.5 micron wool.

Top percentile Foot Resistance, EBVS available on Sale Rams STRONG MOTHERING ABILITY

Merino, Poll Merino, Quarterbred and Halfbred rams sold by private selection January 2025.

Bill Sutherland: 027 451 0342 billsutherland.benmore@farmside.co.nz

Andrew Sutherland: 027 243 8577 deidre.andrew@farmside.co.nz

www.benmorestation.co.nz

Benmore Station has been the classroom for stock manager Luke Duncan to soak up knowledge in Merino breeding as the industry evolves to more dual-purpose animals.

WORDS SARAH PERRIAM-LAMPP

PHOTOS ANNA MUNRO

LUKE DUNCAN REFLECTS ON the past five years of his career at the Sutherland's Benmore Station with gratitude for being given a shot so soon after finishing at Lincoln University.

Growing up on a sheep and beef property between St. Bathan’s and Becks, Luke spent two summers with Bevan McKnight at Northburn Station at Cromwell which ignited his love for Merinos. Bevan stoked that fire by suggesting he head to Bill and Andrew Sutherland near Omarama where he is cutting his teeth on fine wool sheep breeding.

“I was really lucky to get the opportunity at 23 to become stock manager and be involved in learning at a stud that is already renowned for good fine wool as they gradually pivot towards more dual purpose,” says Luke Duncan currently 25 years old.

The future of the Merino industry, he says, is an animal that is shorn

and finished before the winter, as the cost of carrying them through and the animal health challenge is getting too high.

“It means we are moving the dial slowly on carcase traits over time to not lose the years of wool genetics that I find interesting.”

Luke has noticed over the past five years the new focus from farmers coming to buy rams privately from Benmore asking for figures such as the footrot EBV and worm traits with the rise in attention on drench resistance. He says the draft on conformation always comes first still, and then the data.

Feeding stock well is a key priority for Luke as he has noticed the rewards of condition scoring through the drought and preferential feeding of the lighter animals. The variety of work between the stud and commercial flocks provides a lot of learning for him from dag scoring and fleece testing to breeding selection.

“I would like to see more for those coming through the Merino industry with

more localised training days on

farm management focused topics. Once a year isn’t really enough to keep learning from each other.”

Luke Duncan, Benmore Station

The attempts at Merino judging have been good but he says at the end of the day you are being taught only one aspect - how to look at a sheep.

“I would like to see more for those coming through the Merino industry with more localised training days like neXtgen Agri’s muster on more farm management focused topics. Once a year isn’t really enough to keep learning from each other.” Benmore’s focus on the shepherd’s ability to have autonomy

over their own pivot blocks has been a good learning ground, Luke says.

Over the next five years, after he marries his fiance Bailey Smith, originally from Fairlie teaching at Omarama, he would like to progress to farm management with a focus on leasing land and eventually an equity partnership.

“I’d love to have skin in the game. Maybe not this past year (he laughs), but to own my own stock is the goal.”

Waihopai Downs’ Tom and Emma O’Sullivan share their passion for super-fine Merinos, kicking career goals together as they build towards their own stud at Emma’s family property, which they lease in the high country of west Marlborough.

TOM O’SULLIVAN WAS BROUGHT up on a half-bred property in the ‘wetter belt’ of north Marlborough. He went on to be 2IC on a composite sheep property in North Waikato, running 45,000 stock units. In between he got a taste for Merino wool and he’s now married to someone keen on Saxon Merinos. So, Merino it is.

Tom’s first job out of school was at The Hossock. He worked two seasons with Willie and Sue Macdonald at Middlehurst Station, which got him interested in Merino. He has since joined forces with wife Emma, to lease her family property Waihopai Downs, 3500 hectares of steep hill and high country in west Marlborough. Here they

run 1600 ewes, 700 two-tooths and 1100 mixed-age wethers. The flock is based on the MacKenzie family Saxon genetics and has an average micron of 15.8.

In July 2024, Tom was the recipient of the Marlborough Merino Association scholarship to travel to commercial and stud properties in Tasmania. A highlight for Tom was visiting one of the largest Saxon-influenced flocks in Tasmania, Miena.

The 12,000 head of stock had very similar wool to Tom and Emma’s flock. It was run by a young farmer that had just taken over from his grandfather, with the aim of creating a stud. It was part of the Australian Wool Excellence Group.

“I was a bit surprised to see that some Merino properties I visited were still mulesing and were happy to forgo wool

contracts to do it. Not a lot of growers sell on a contract, mainly on auction,” Tom shares. Other differences were that farm systems were based on less frequent shifts and had low staff to sheep ratios. “Camelfield had two full time staff for nine thousand head, including stud sheep.”

Emma was brought up at Waihopai Downs and, like Tom, is captivated by super-fine Merino wool.

She has only missed one shearing, being a shedhand or trainee classer since she was 10 years old. Emma has had her owner-classer ticket for 11 years. In 2022 she completed her Certificate in Wool Classing and Technology and in 2024 started a role as wool tutor with the Southern Institute of Technology. This fits really well with her Bachelor of Education.

LEFT: Tom has since joined forces with wife Emma, to lease her family property, Waihopai Downs.ABOVE: In 2022 Emma completed her Certificate in Wool Classing and Technology and in 2024 started a role as a wool tutor with the Southern Institute of Technology.

“I was a bit surprised to see that some Merino properties I visited were still mulesing and were happy to forgo wool contracts to do it. Not a lot of growers sell on a contract, mainly on auction.”

Tom O’Sullivan, following his Marlborough Merino Association scholarship to travel to Tasmania

“My two greatest passions in life are wool and teaching, so I combine them both.”

She credits wool buyer Bob Butt and her father for being great mentors. When she has time, between caring for three children, she also classes other clips. Tom and Emma have recently purchased 70 stud Saxon ewes from Angela Scott, Pendalla. The idea is to start selling stud rams themselves. Saxons are smaller frame sheep and are not put to the ram as two-tooths at

Waihopai Downs. They are grown out another year and run with the mixed-sex hoggets, Tom says.

“On Waihopai Downs they are slower maturing, but you should get another year at the other end,” Emma says.

Grazing sheep on 300ha of vineyards over winter has been a game changer. They also graze 500 wethers on a lease block in the Marlborough Sounds. All ewes are blade shorn in September and the wool is destined for a luxury brand.

• Heritage of Excellence: Decades of investment in genetic development.

• Resilient and Profitable: Sheep bred for productivity and profitability.

• Balanced Approach: Integration of EBVs and hands-on experience.

• Wool Quality and Performance: Targeting finer micron wool with enhanced growth rates, carcass traits, and fertility.

• Adapted to Thrive: Selection for key management traits, including footrot and worm resistance.

• Climate-Ready: Bred to handle higher rainfall and irrigated farming conditions.

• Future-Focused: Committed to innovative genetic selection and practices to future-proof the merino industry amidst a changing climate.

“Switching to Nine Mile Genetics transformed our flock into a high-performing, dual-purpose unit with enhanced carcass traits and overall performance.”

Shane MacMillan, Mt Pisa Station

Whether you’re a Merino breeder or looking to purchase rams for a commercial flock, the new MERINOSELECT indexes can hold the key to improving a flock's genetic merit.

WORDS SARAH PERRIAM-LAMPP

RATHER THAN OVERWHELMING yourself by inspecting every ram at the sale, you can use the Sheep Genetics MERINOSELECT indexes to do some presale homework and rule out the rams that don’t meet your requirements, leaving yourself with a shortlist of all the ones that do.

Meat & Livestock Australia’s Sheep Genetics manager, Peta Bradley, shares her tips and tools to help sheep producers target genetics that align with their production goals.

“I like to use the cereal aisle in your local grocery store as an analogy of how to use these indexes. If having a healthy breakfast is most important to you, you can look at the health star rating on each box to condense your shortlist,” she explains.

“The next most important factor may be having a tasty breakfast, so from the shortlist, you may then look at the individual ingredients to find something you know you will enjoy.

“Ultimately, you’re left with a drastically refined list of cereals you would buy, allowing you to make the final call based on value for money,” Peta says.

Step One: Set your flock production goals and breeding objectives:

• What is your flock’s current performance and where do you want it to improve?

• What is your target market i.e. fine wool, volume of wool, heavier lambs?

• What are your profit drivers to reach your goals?

• What is the operational environment you are working with?

For some indexes, wool traits are a main focus as for some sheep production systems a majority of the income is derived from wool production, whereas other Merino systems achieve more profit from lamb and surplus sheep sales.

Step Two: Choose the right index that best fits your goals. MERINOSELECT provides four standard indexes covering a broad range of production systems for producers:

• Fine Wool Index (FW) - Aiming to go finer while increasing wool production

• Wool Production (WP) - Greater emphasis on wool cut

• Sustainable Merino (SM) - Systems deriving more balanced income from wool and sheep sales with a focus on sustainability traits

• Merino Lamb (ML) - Prime lamb production from Merino ewes The following flowchart (right) helps producers determine the best index for their Merino production system.

Before the sale:

1. Rank animals in the sale on the value of your chosen index.

2. Consider the individual ASBVs that are important to you to create a shortlist of rams to look at on sale day. (ASBVs - Australian Sheep Breeding Value is a prediction of an animal’s genetic merit for a particular trait)

At the sale:

3. Look through your shortlist of rams to find the ones that meet your structural and type requirements.

“The indexes continue to drive genetic progress in the key production traits such as reproduction, growth and fleece traits.”

Peta Bradley, Meat & Livestock Australia’s Sheep Genetics manager

Following on from last year’s release of the new research indexes for Merinos, Sheep Genetics has refined the four indexes. Across all four indexes there is an emphasis on the health and welfare traits that are appropriate for the production system.

For example, the Sustainable Merino (SM) Index includes a focus on health traits such as:

• reducing breech wrinkle

• reducing worm egg count

• reducing dag score.

“The indexes also continue to drive genetic progress in the key production traits such as reproduction, growth and fleece traits,” Peta says.

“Indexes allow genetic improvement for a range of traits even if antagonistic relationships exist. For example, the new indexes yield favourable responses simultaneously for fleece weight and breech wrinkle.” Updated modelling that best captures the different types of Merino production system has been a focus during the development of the new indexes. Peta says feed intake is modelled and accounted for in the new indexes. The updated software also enables methane output to be incorporated in the future when there is an Australia Sheep Breeding Value (ASBV) available for that trait.

Which

SOURCE: Sheep Genetics Australia's MERINOSELECT indexes

If you would like further information on how these selection indexes are generated, please refer to MERINOSELECT Indexes (Breeder) at sheepgenetics.org.au/gettingstarted/ ASBVs-and-Indexes.

The breakthrough of low-cost DNA parentage data across commercial flocks is here thanks to some Kiwi No. 8 wire innovation, based on modified fencing pliers and designed by a geneticist who grew up with Merino.

WORDS SARAH PERRIAM-LAMPP PHOTO SHARRON BENNETT

TOTOGEN, A DUNEDIN-BASED business co-founded by Dr Tim Hore and Andy Ramsden in 2021, is set to provide low-cost analysis of sheep DNA as it launches the TotoPunch this season.

The TotoPunch is based on United Kingdom-designed fencing pliers, which were then modified as an ear punch, to simply and robustly collect a DNA ear tissue sample into a bar-coded collection tube fixed to the punch. The barcode can be scanned by a wand and added to the record of the animal. If not, a smartphone could be used to read the barcodes with the OrcaScan app and input the data, which is automatically uploaded to the cloud.

The aim is to bring the cost of collection down, meaning a lot more farmers will be able to receive the benefit of DNA parentage technology for improved genetic gain in commercial flocks.

“Where farming's heading we can no longer increase hoof numbers on farms. We've got to get more efficient with the animal that we've got, and the one thing we don't have is information on all our

individual ewes on commercial farms,” Totogen co-founder Andy Ramsden explains.

Ramsden has been a pioneer in sheep genetics, formerly with Focus Genetics and Headwaters, and says that to lift productivity, we need to get information on more individual sheep so that we can better select our higher-performing, more efficient breeding ewes. Dr Tim Hore’s academic research lies on the

intersection between epigenetics and development, an area in which he has established an international reputation, including his work on Covid-19 testing.

He grew up on a sheep and beef farm on the Maniototo in Otago and his brother and sister-in-law, Ben and Vanessa Hore, run Merino sheep on Blackstone Hill Station.

Tim and Ben realised how valuable it would be to have DNA data available across the commercial flock, but also knew that the cost from existing suppliers was prohibitive, even if just to provide parentage data. Tim, along with his wife Dr Donna Bond (also a molecular biologist), brought their research skills to bear and developed a genetic testing methodology that dramatically reduces cost. In summer 2022, Totogen happily processed the first samples from Blackstone Hill.

Tim says that while some were familiar with DNA technology, others were doing it for the first time, with farmers taking it up for various reasons - studs looking to create pedigrees and breeding values, others wanting to know more about how well their sheep were performing.

The last year has been about validating the technology — getting it out and working in the field in a diverse set of commercial circumstances with thousands of samples a day being taken in the yards, which Tim is proud as punch about.

Totogen processed four times the amount of samples that it did last year and is looking to double year-on-year, as the business continues to grow.

TOP: The bar-coded collection tube can be scanned with a smartphone to record against the animal.

LEFT: Modified fencing pliers make a robust collection of tissue from the animal’s ear.

RIGHT: Dr Tim Hore (right) who worked in their lab on their diagnostic test for COVID-19, which has had huge uptake internationally, is a co-founder of Totogen.

Country-Wide is more than a magazine. It’s exclusive online articles, weekly podcast episodes, Live Q+A’s and four seasonal journals dedicated to tangible, onfarm advice to ensure you’re equipped with the knowledge to succeed.

“I have really enjoyed the changes to Country-Wide in the past 12 months under new ownership of Sarah Perriam-Lampp and editor Rebecca Greaves. There’s alot of great advice and hope for the sheep and beef sector from inspiring case studies to technical experts - we have started to implement some of this into our business”

- George, Taihape

Drench resistance has been a ticking time bomb for a while. North Canterbury veterinarian Erin Riley first saw the signs of it in the UK before she moved to New Zealand, but was confident that the evolution of combination drenches would buy enough time - she was wrong.

WORDS SARAH PERRIAM-LAMPP

INITIALLY SHE THOUGHT IT was a North Island problem, but it became apparent to North Canterbury veterinarian Erin Riley that rapid acceleration of drench resistance was affecting her farming clients after years of drought, and that the dry had been masking a much bigger problem right under her nose.

“We are looking for it now, but I suspect we have had an issue for a while. When it was dry there wasn’t much drenching either, but the 2022 and 2023 wet season meant there were a lot more parasites about,” she explains.

North Canterbury Veterinary Clinic started running a drench resistance mitigation trial programme with local farmers in July 2021, combining regular faecal egg testing for parasites with knowledge of their drench use. After four years of collecting data to find trends across dry and wet seasons, Erin says there is still huge variability from farm to farm.

With the reduction in drench use, she fears farmers are unaware of the levels of trace minerals that are in some drenches, and are still required. For instance, with the removal of the bionic capsules that had 100 days of cobalt and selenium, the animal still

requires a source of these key minerals in replacement in the face of parasite pressure in the pasture.

“We are only starting to scratch the surface as most of the research was done in the 80s and 90s and we farm so differently now. We also have different sheep genetics, so what they knew back may no longer be relevant. It will take a lot of onfarm testing and a real focus on mineral solutions for the next 10-15 years to combat the situation we are in as a country.”

Why not apply the required minerals to the soil?

“Depending on the trace elements, as some can transition between the soil to the animal, you have to test the soil to know it’s there. It then has to be available to the plant to uptake and then eaten by the animal and then the animal has to utilise the minerals. Not all minerals operate that way,” Erin explains. An example is copper. A herbage test would indicate the plant has taken up the copper from the soil from fertiliser, but when it enters the sheep there are other trace elements, such as molybdenum (moly), sulphur and iron that affect the absorption of copper and the animal is therefore still deficient.

Selenium does transfer from the soil to the animal, but needs to be put on at the right time for when the animals need to absorb it, as it doesn’t last in the soil for 12 months. Cobalt is crucial for turning into B12 in sheep but she says grass doesn’t take up cobalt, so if it’s not growing at all from the dry, or growing fast, high-soil cobalt levels don’t transition to animal availability.

Erin works with Smartrace sheep boluses, which have been an integral tool in her mineral toolbox of solutions for her farmer clients. “You have your general oral drenches that have most goodies in them if you just want something you can drench and feel good. But if you want to target what you are deficient in, then you can target what the animal needs at certain times in the season,” she explains.

Sheep have high physiological demands for certain vitamins and minerals during critical periods of their reproductive cycle, pre-tup and late pregnancy, which may not be met by their normal feed intake. Vitamin E, for example, has been shown in trials to be a key trace element with lamb survivability. If you are in a hill country farm system where yarding-up ewes and lambs every few weeks is labour

intensive, considering boluses could be an advantage. Boluses ensure you are setting up your lambs for success with iodine, selenium and cobalt when ewes are in-lamb and will provide active cover for four months.

“Everything comes down to the right fit for the right system. For some, the cost of boluses may not make sense compared to an oral supplement, especially if you are on the flat and

“We found that even neighbours have different challenges and solutions that work. There is no one size fits all t o dealing with drench resistance.”

Erin Riley, North Canterbury Veterinary Clinic

yarding is relatively straightforward. But if you are on hill country and mustering every few weeks is harder, you will want the length of action and the ease of administration of a bolus. You just have to weigh up the cost versus the labour and what’s right for your system.”

Bolus application with a contractor on a conveyor may help ensure they are correctly administered if you and your team are not confident to do it yourselves.

Erin’s dedicated mineral focus group with North Canterbury sheep farmers has provided a peer-learning environment for the past four years.

They take data from lamb liver biopsy and blood tests pre-mating, pre-lamb and at lambing time to see what the trends are in trace elements, and they have a discussion three times a year about different products and approaches. The next step is to overlay production data and see what impact it is having.

“I present the data and they talk it over amongst themselves about different angles to try. I don’t mind what they want to try, I just want to track it as it might be useful for someone else to try. What we are finding is even neighbours have different challenges and solutions. There is no one size fits all,” Erin says.

At their wits' end after years of failed pour-on treatments and plunge dipping, the innovation of MSD Animal Health’s Flexolt is being praised as a game-changer by Marlborough farmers, Eric and Sally Smith, as they use the first ever oral lice treatment for sheep.

WORDS SARAH PERRIAM-LAMPP

MANAGING LICE

in sheep flocks is frustrating, disheartening and impacts the bottom line with the loss of quality fleece for Merino farmers.

Eric and Sally Smith know too well the challenges of dealing with lice at Awapiri Station where they have been farming 4,700 Merinos since 2012.

“We started with a pour-on but that wasn’t working so we went to a shower dip and you’d think we were spraying lice on them. It didn’t work at all. So we went back to pour-on and I did it myself