PLUS GETTING STARTED THE SECRET BEHIND XCMG’S SAUDI SUCCESS

RANGE REVIEW

PLUS GETTING STARTED THE SECRET BEHIND XCMG’S SAUDI SUCCESS

RANGE REVIEW

MANITOU

ON HIGH

Cummins Engine

217 hp @ 2200 rpm

Operating Weight

16,500 kg

Moldboard Length/ Cutting

4,270 mm / 736 mm Cutting

8,150

The LIUGONG 4215D and 4260D AWD Motor Graders are your ideal partners for heavy-duty construction and mining tasks, offering power, precision, comfort, and safety. With versatile features, superior performance, and high durability, these graders will keep your projects running smoothly.

08_NEWS

The major news stories and company moves this month.

14_MANITOU’S MARVELS

CMME explores Manitous rotating portfolio telehandlers.

18_XCMG EXCELS IN THE KINGDOM

Looking at the Chinese giant’s succcess in Saudi Arabia.

24_TAKES IT TO THE LIMIT

Trenching and mechanical laying goes seamless in KSA.

30_QUARRYING TECHNOLOGY

DEVELON takes a transparent approach.

36_NEW RELEASES

The latest releases from the world of construction machinery.

40_TOP TEN TIPS: PRESTART CHECKLIST

The essential way to run your inspection processes.

42_GOLD STANDARD

Goldhofer speakes to CMME about how it will use bauma 2025 to set new benchmarks in heavy transport.

44_THE LAST WORD

The Middle East should avoid global disruption.

12 SPOTTED!

Johnson Arabia opts for Superlift to get the job done.

The construction industry in the Middle East is no stranger to harsh environmental conditions, from extreme heat to unpredictable storms. But in recent years, an unusual challenge has emerged: the rising risk of flooding. Following last year’s heavy rainfall in the UAE, I know some workshop owners and contractors have been reassessing their flood preparedness, with some even considering sandbagging their operations to prevent water damage.

While it may seem like a simple and effective solution, relying solely on sandbags is a short-term fix. As climate patterns shift and instances of extreme weather become more frequent, the industry should probably take a more strategic and long-term approach to flood mitigation.

First and foremost, proper site planning is crucial. Many construction sites and workshops are in low-lying areas, making them more vulnerable to flooding. Investing in proper drainage infrastructure, including stormwater management systems, can significantly reduce the risk of water accumulation. Contractors should also consider elevating machinery, materials, and electrical systems where possible to minimise damage in case of unexpected floods.

Preventative maintenance is another critical aspect of weatherproofing operations. Regular inspections of equipment storage areas, drainage systems, and waterproofing measures can help identify vulnerabilities before they lead to costly repairs. Additionally, keeping critical assets on elevated platforms or within waterproof storage units can make a significant difference in reducing waterrelated damage.

Technological advancements also offer viable solutions. Smart monitoring systems

can provide early flood warnings, allowing workshop owners to take precautionary measures in advance. Mobile pumps and temporary flood barriers can also serve as rapid-response tools to manage water accumulation effectively.

Beyond infrastructure, contractors must implement comprehensive emergency response plans. Training teams to respond swiftly in extreme weather scenarios can help minimise downtime and financial losses. Developing clear protocols, including evacuation plans, equipment relocation procedures, and contact lists for emergency support services, should be a priority.

While sandbags may offer an immediate buffer against flooding, they are not a sustainable solution. The industry must think beyond temporary fixes and embrace proactive flood mitigation strategies. Climate change is not a distant threat—it is a present reality affecting business operations today. By investing in resilient infrastructure, leveraging technology, and fostering a culture of preparedness, the construction sector can better withstand future storms and ensure business continuity in an era of uncertainty. The time to act is now. Waiting for the next storm to arrive before taking precautions will only lead to greater disruptions. Let’s build smarter, prepare better, and weather the storms ahead with resilience and foresight.

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

GROUP

MANAGING DIRECTOR

RAZ ISLAM

raz.islam@cpitrademedia.com

+971 4 375 5471

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM

shiyas.kareem@cpitrademedia.com

+971 4 375 5474

PUBLISHING DIRECTOR

ANDY PITOIS

andy.pitois@cpitrademedia.com

+971 4 375 5473

EDITORIAL

HEAD OF CONTENT

STEPHEN WHITE

stephen.white@cpitrademedia.com

+971 58 584 5818

ASSOCIATE EDITOR

PRIYANKA RAINA priyanka.raina@cpitrademedia.com

ADVERTISING

SALES MANAGER

BRIAN FERNANDES

brian.fernandes@cpitrademedia.com

+971 4 375 5479

STUDIO

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

MARKETING

MARKETING & EVENTS EXECUTIVE

LAKSHMY MANOJ lakshmy.manoj@cpitrademedia.com

SOCIAL MEDIA EXECUTIVE FRANZIL DIAS franzil.dias@cpitrademedia.com

CIRCULATION & PRODUCTION

DIRECTOR OF MARKETING & MEDIA OPERATIONS

PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com

PRODUCTION & IT SPECIALIST

JARRIS PEDROSO jarris.pedroso@cpitrademedia.com

DIGITAL

SENIOR DIGITAL MANAGER

ABDUL BAEIS abdul.baeis@cpitrademedia.com

WEB DEVELOPER

UMAIR KHAN umair.khan@cpitrademedia.com

FOUNDER

DOMINIC DE SOUSA (1959-2015)

PUBLISHED BY

Prestige One Developments to launch 11 new real estate projects in 2025

CONSTRUCTION

Hidden Marina works underway as Phase I of THE LINE

DIVERSITY

Acciona launches operational skills development program for women

PROPERTY

Azizi announces launch and sales plans for Burj Azizi

CONSTRUCTION

Diriyah’s ‘City of Earth’ announces major milestones

INTERVIEW: Raising the bar

INTERVIEW: Building the Kingdom’s Future

EXPERTS: Achieving Net Zero is a Middle Eastern imperative

CONSTRUCTION

Khansaheb appointed as main contractor for Dubai Exhibition Centre expansion

The entire development is expected to be completed in 2031. Phase One is set for completion by 2026, expanding DEC’s capacity to 140,000sqm, nearly 2.5 times its current size of 58,000sqm.

FINANCE

Financing for Wynn Al Marjan Island Completed

In the low-rise portion of the building, the concrete and steel structures is combined 70% complete. Exterior facades and interior fit out have commenced

CONSTRUCTION

Project awards in Kuwait saw 44% increase in 2024

Of the total project awards, the majority (around 50%) went to the construction sector, with the Public Authority of Housing Welfare making progress on various housing projects

PROPERTY

Red Sea Global introduces Red Sea Residences

The residential brand aims to set new benchmarks by offering elevated residences designed by renowned architects and interior designers

CONSTRUCTION

Dubai Holding Asset Management unveils Nad Al Sheba Mall

The mall is set to offer a curated selection of over 100 stores spanning fitness, retail, entertainment, F&B, healthcare, and supermarkets

SUSTAINABILITY

RAK launches new sustainability initiatives

CONSTRUCTION

SR150B packs a lot of performance into one small package. With a small compact footprint, it is the perfect machine to navigate tight and restrictive worksites. The new larger cab and interior layout ensures a comfortable and safe operator workspace. With our single piece frame design and our long wheelbase, we maximize stability and lift capacity. With an easy forward tilting cab access to all major components makes servicing a breeze.

Radial for digging and pushing, vertical for loading and carrying.

marketing.ase@alshirawi.ae

RAIMONDI CRANES

JLG MAKES LITHIUMION MOVE ACROSS ITS RANGES

Yanmar Compact Equipment (Yanmar CE) has announced a strategic shift in focus for 2025, prioritizing direct support for its global dealer network and customers. As part of this decision, the company will forgo participation in the 34th edition of the prestigious bauma exhibition in Munich, Germany, the world’s leading construction machinery event.

While Yanmar CE acknowledges bauma’s significance in fostering industry collaboration and innovation, the company has chosen to channel its resources into localized initiatives aimed at enhancing customer experience and strengthening dealer relationships.

“This strategic decision reflects our commitment to close engagement and focus on what matters most — our customers and dealer network,” said Jon Lopez, President of Yanmar CE’s Europe, Middle East, and Africa

(EMEA) region. “While bauma remains a fantastic platform for the global construction equipment community, we believe this approach allows us to provide even greater value during a period of dynamic industry change.”

Yanmar CE plans to launch a series of initiatives designed to bolster its partnerships and support sustainable growth across its markets. These targeted efforts aim to deliver innovative solutions and provide exceptional service to its stakeholders, reinforcing the company’s dedication to customer success.

Yanmar CE extended its gratitude to bauma’s organiaers for “their continued contributions to the construction equipment industry. While the company will not participate in the 2025 event, it looks forward to exploring future opportunities to engage with this esteemed platform”.

TARGETS SAUDI MARKET WITH SHOW DEBUT Raimondi Cranes (Raimondi), a leading Italian manufacturer of lifting solutions, is making its inaugural appearance at the 13th edition of Big 5 Construct Saudi, the largest construction event in the Kingdom of Saudi Arabia. Under the leadership of HRH Prince Khaled bin Alwaleed bin Talal Al Saud, Group Chairman, Raimondi will use the platform to unveil its newest crane model featuring advanced lifting capacities. The new model showcases Raimondi’s commitment to innovation and its ability to address the demands of complex construction projects in Saudi Arabia.

JLG Industries, Inc., a leading manufacturer of mobile elevating work platforms and telehandlers, has unveiled significant updates to its electric equipment range to address industry demand for zeroemission and noise-controlled job sites. The enhancements include the introduction of standard AC drive motors and lithium-ion battery options across several product lines, including the ES electric slab scissor lifts, E18 driveable vertical mast lifts, and the E18MSP stock picker. AC drive motors will now come as standard on the ES1932, ES2632, ES2646, and ES3246 scissor lifts, as well as the DaVinci™ all-electric AE1932 model. This development builds on the capabilities of the recently introduced ES4046, which already features an AC drive motor in Europe. The motors are virtually maintenance-free, reduce battery draw, and improve energy efficiency, offering lower operating costs and enhanced reliability.

The addition of lithium-ion batteries provides customers with greater flexibility and performance options. Customers can choose between Lithium, with one battery on most models, or Lithium+, which includes an additional battery for extended duty cycles. These options ensure fast charging, longer lifespans, and zero performance degradation, addressing the growing need for efficient, sustainable equipment. The upgraded battery options will be available from Q1 2025.

From high-rise installations to restricted-access sites, we have the right tools for the job!

We are Leaders in providing Solutions that

are safe and that save you money. Who we

Spider Plus is your trusted partner in advanced lifting equipment, delivering cutting-edge solutions for handling glass cladding, steel, façade installations, material

handling and access equipment.

• PICK AND CARRY CRANES

• TRACKED PLATFORMS

• Glass Lifters ( at or curved) VACUUM

Joly Location, one of France’s leading aerial work platform (AWP) and lifting equipment rental companies, has taken delivery of a customised Palazzani XTJ 52+ Spider Lift. This latest addition enhances the company’s capability to serve diverse industries with innovative and efficient solutions.

Founded in 1973 by Marcel Joly, Joly Location has over five decades of experience in the rental sector. The company is renowned across Europe for providing safe and efficient lifting solutions. Since the 2000s, it has focused on expanding its AWP offerings, catering to industries such as wind energy,

Bobcat has secured significant contracts to supply the Dutch Armed Forces with 53 telehandlers, 63 PA12.7v portable air compressors, and 127 compactors. The deals were facilitated by Apeldoorn-based InterTechno, the authorised dealer for Bobcat in the Netherlands. Most of the 53 Bobcat telehandlers were delivered in 2024, with the final units scheduled for early 2025. These include TL25.60 and TL35.105L models customised in army green for military logistics. The Dutch Armed Forces have also taken delivery of 127 Bobcat light compaction machines.

nuclear power, petrochemicals, and the preservation of cultural landmarks like Notre Dame de Paris. With a fleet currently supporting working heights of up to 90 meters and plans to reach 100 meters by 2025, Joly Location continues to lead the way in meeting demanding project requirements.

Lionel Joly, Managing Director of Joly Location, explained the rationale behind the addition: “The Palazzani platform’s working height complements our existing fleet while its ease of use and positioning speed, even in complex environments, set it apart.”

Laura Gasparini, Export Sales Manager at Palazzani Industrie, shared her excitement: “The XTJ 52+ is designed for challenging environments, offering topnotch performance and versatility. We are confident it will significantly contribute to Joly Location’s success.”

MERED, the award-winning international real estate developer, has officially commenced the main construction phase of its flagship project, ICONIC Residences Design by Pininfarina. The milestone was celebrated with a special ceremony marking the first concrete pour. Strategically located in Dubai Internet City, the project will be the tallest building in the area, standing as a landmark on Dubai’s iconic skyline. The development comprises 310 luxury apartments offering direct access to Sheikh Zayed Road and proximity to premier destinations such as Burj Al Arab, Palm Jumeirah, Dubai Marina, Dubai Harbour, and Emirates Hills. Michael Belton, CEO of MERED, remarked: “The ICONIC Residences are more than just a development, they are a statement of innovation where cutting-edge design meets unparalleled luxury.“

In its annual press conference, UD Trucks highlighted its performance and vision for the Middle East and Africa markets. With a focus on customer needs, sustainability, and market adaptation, executives shared key insights into the industry’s challenges and opportunities. The company has also expanded into Kenya and Egypt, engaging over 300 customers in Nairobi and Mombasa and strengthening its partnerships in Cairo. “Egypt is a large and complex market, and we’re confident in our long-term prospects here,”

Scania Middle East has entered into a new partnership with Abu Khader Group to represent the Scania brand in Jordan. With over 80 years of experience in the automotive industry and a strong reputation in Jordan and the wider region, Abu Khader Group marks the return of Scania’s presence in the Kingdom.

Nicola Abu Khader, CEO of Abu Khader Group, expressed pride in the collaboration, stating, “We are honoured to add Scania, one of the world’s most respected and valuable commercial vehicle brands, to our portfolio.”

Customers can now access Scania’s offerings at the newly inaugurated Commercial Vehicles

said Mourad Hedna, President of UD Trucks MEENA.

Mourad Hedna began by painting a picture of the global economic landscape, describing 2025 as a “challenging year” with uncertainty in major economies such as Europe, the US, and China. “We expect big economies to face tough years due to limited GDP growth forecasts. Truck demand, which surged during the pandemic, is now seeing a correction. Many players may feel the pressure,” Hedna explained.

Despite this global slowdown, the Middle East remains a beacon

of opportunity. “The GCC is maintaining strong momentum, particularly in Saudi Arabia and the UAE,” he added. “Sectors like construction, real estate, and last-mile delivery are thriving, supported by mega-projects and regional diversification efforts.”

UD Trucks has continued to outpace market growth, reporting a 100% increase in wholesale volumes between 2021 and 2024, with a 30% year-on-year growth for 2024. “For three consecutive years, we’ve achieved doubledigit growth,” said Hedna. “As we enter 2025, we’re proud to start with a healthy order book and strong market confidence.”

Nothing typifies the company’s determination to expand regionally than its successful re-entry into Kenya and launch into Egypt in 2024. These markets, we were told, are pivotal to UD Trucks’ Africa strategy, and highlight the importance of strategic local partnerships. “Kenya was a key focus for us,” Hedna noted. “After launching operations in Nairobi and Mombasa, we engaged over 300 customers.

a fully equipped service centre, a dedicated body workshop, and a training centre ensuring

The Access and Handling Confex will return on 26th May, 2025 in Dubai, the organisers CPI Trade Media have announced.

The Access and Handling Confex 2025, formerly known as the Access and Handling Summit, will bring together the region’s leading industry professionals, manufacturers, and technology providers for a comprehensive exploration of the latest advancements in access and material handling solutions. The event features a unique demonstration and exhibition programme, alongside the annual conference.

Scania’s global standards.

Juan Carlos Ocampo, Managing Director of Scania Middle East, highlighted the importance of selecting the right partner for Jordan. “Abu Khader Group’s proven track record, professional management, and dedication to customer service make it a valued addition to our network.” Scania remains at the forefront of sustainable and efficient transportation, leveraging advanced technologies to boost fuel efficiency and lower operational costs. The brand’s innovative approach was recently recognised with the prestigious ”Green Truck” award for 2024.

Johnson Arabia has successfully completed the lifting and installation of a steel bridge in Jaddaf, a crucial infrastructure component designed to connect directly to a Metro station. The project, carried out for UNEC, required the deployment of the Terex Demag AC700 crane, a 700t capacity machine renowned for its stability and efficiency. The operation also incorporated the Superlift attachment to enhance safety margins, making it the optimal choice for this high-stakes lift.

Given the scale and technical challenges of the project, meticulous planning was essential. One of the primary considerations was the presence of underground services, which necessitated precise calculations to maintain a low outrigger load. Furthermore, strict regulations required the

lift to be executed outside Metro operating hours, demanding careful coordination with the Roads and Transport Authority (RTA) to secure the necessary permits.

The steel bridge segment being lifted weighed 65 tons and measured 29m x 8m x 6.5m. The site presented significant spatial constraints due to underground utilities, requiring adjustments to the lift plan to ensure both safety and efficiency.

A highly skilled team carried out the lift, consisting of four riggers responsible for rigging and slinging, and a supervisor overseeing the lift and signaling operations. The crane operated at 73% of its chart capacity, maintaining an 89-ton lifting capacity, ensuring a significant safety margin throughout the process.

A key challenge arose when the load, which had been connected and rested using welding, needed to

be held in position for an extended period — ranging between four to eight hours—to achieve proper alignment and installation. Despite this complexity, the experienced crew relied on proven lifting techniques to complete the job safely and efficiently.

“The experienced crew relied on traditional but effective lifting techniques to complete the job safely and efficiently,” said Sreethu Thulaseedharan, Engineering Manager at Johnson Arabia.

Safety was the paramount concern throughout the operation, particularly due to the bridge’s direct connection to the Metro station. The narrow connection area required extreme precision in signaling, which was meticulously managed by the lifting team. To mitigate risks, the team conducted a plate load test to determine ground-bearing pressure, adhered to strict safety margins in

the lifting plan, and implemented precise signaling and communication strategies to navigate the restricted workspace. Working within the constraints of an active Metro station added further complexity. The lift had to be precisely timed to align with Metro engineering hours, necessitating close collaboration with authorities. Additionally, securing the required permits posed logistical challenges, but the team’s extensive experience in regulatory compliance facilitated a smooth process.

“Despite the complexities involved, the lift was executed on schedule and with complete success. The project showcased Johnson Arabia’s capability to handle highly technical and regulated lifts while adhering to the highest safety and precision standards,” said Mohammad Fareed Naser, Executive Manager for Cranes – UAE & KSA.

As the construction and oil & gas industries continue to be pillars of growth in the UAE, the demand for high-performance lifting solutions is becoming increasingly important. With major infrastructure, industrial, and energy projects underway, the need for reliable, versatile, and high-capacity lifting equipment is at an all-time high. Fredrick Victor, Deputy Director of Al Shirawi Enterprises, the brand’s official dealer in the UAE, shares insights into the demand for telehandlers and how the Manitou MTX 1840 is addressing the evolving needs of these critical industries in the region.

“The demand for telehandlers and lifting equipment in the UAE is strong and expected to increase this year,” says Fredrick. “The country’s ongoing investments in mega building projects, especially residential villa projects, play a vital role in driving this demand. Additionally, the oil and gas sector continues to expand, requiring specialised equipment for both offshore and onshore operations. This is where highly specialised rough-terrain machines, such as those offered by Manitou, come into play.”

Fredrick tells CMME that there is an increased demand for multi-functional machines, as projects become more complex and industries require versatile machines capable of performing multiple tasks on a single job site. Given the UAE’s desert landscape, rough-terrain capabilities are essential for construction and oil field operations. Safety and efficiency are also a

priority for customers, and the Manitou MTX 1840 features best-in-class safety options, including a frame-levelling system that allows for material lifting on uneven surfaces while meeting the highest international safety standards: “The Manitou MTX 1840 addresses these trends by offering high lift capacity at maximum reach, strong performance in rough terrain, and a variety of attachment options to ensure versatility across multiple sectors like construction and oil & gas,” Fredrick explains.

The Manitou MTX 1840 is well-suited to the UAE’s evolving demands for high-performance lifting solutions. “Its combination of an 18-metre reach and high capacity at maximum extension makes it ideal for construction and heavy industry projects,” says Fredrick. “The machine’s design ensures it performs well in rough terrain while its compact size allows it to operate in tight spaces.”

Fredrick notes that the MTX 1840 stands out for several reasons. Its versatility, for instance, allows it to function as a telehandler, rough-terrain crane, and lifting solution in one easy-to-operate machine. It also, importantly, delivers high performance in tough environments, with advanced boom technology that provides superior speed and high load capacities at maximum reach. The advanced control systems ensure simple and intuitive operation, allowing for easier lifting and placement of materials, which increases efficiency and safety, he explains.

“The perception of telehandlers has shifted from being secondary equipment to becoming essential across various industries,” Fredrick says. “Today’s telehandlers, like the MTX 1840, are recognised for their durability,

Several features make the MTX 1840 ideal for UAE-based projects. It boasts strong roughterrain capabilities, allowing it to handle the region’s harsh, sandy, and uneven conditions.

“The demand for telehandlers and lifting equipment in the UAE is strong and expected to increase this year” –

Fredrick Victor, Deputy Director, Al Shirawi Enterprises

productivity, and strong service support in the UAE market. The ability to lift heavy loads, navigate rough terrain, and reach challenging heights enables businesses to streamline operations and reduce the need for multiple types of equipment.

Fredrick also highlights the growing interest in Manitou’s rotating telehandlers, such as the MRT Series, which offers lift heights ranging from 16 to 35 metres, making them suitable for increasingly dense urban environments: “The city is shrinking with less open spaces, and we can see a growing interest for our MANITOU Rotating Telehandlers with the MRT Series.”

Several features make the MTX 1840 ideal for UAE-based projects. It boasts strong rough-terrain capabilities, allowing it to handle the region’s harsh, sandy, and uneven conditions. Its 18-metre lift height makes it ideal for construction and heavy-lifting applications in oil & gas. Advanced safety systems ensure secure operation in both urban and industrial environments, while its durability and ease of operation are enhanced with onboard diagnostics, making it simple to monitor and maintain.

With sustainability becoming a greater focus for end-users, Manitou continues to integrate energy-efficient and environmentally friendly technologies. “The MTX 1840 is known for its durability and high performance,” says Fredrick. “Our R&D team is consistently working on improving environmentally friendly technologies to meet international standards.” Manitou also provides strong support through Al Shirawi Enterprises, offering training, maintenance contracts, and a comprehensive spare parts network across the UAE. As Fredrick explains: “Ensuring maximum uptime is crucial for our construction and oil & gas clients.”

With the UAE’s large-scale infrastructure and industrial projects, the Manitou MTX 1840 is positioned as a key lifting and handling

solution. “The machine’s ability to operate across various terrains, combined with its lifting capacity and manoeuvrability, makes it an ideal choice for construction and oil & gas projects in the region,” says Fredrick.

Al Shirawi Enterprises ensures fast and efficient access to the MTX 1840, spare parts, and maintenance services. “With service centres across the UAE, we provide customers with timely support, ensuring optimal machine performance and uptime,” says Fredrick. “With its strong adaptability, innovative features, and comprehensive after-sales support, the Manitou MTX 1840 is well-positioned to meet the UAE’s growing demand for highperformance lifting solutions in construction

and oil & gas. With ongoing urban development and industrial expansion in the region, we expect the market for telehandlers like the MTX 1840 to grow. Additionally, we see strong potential for the MRT Series, which functions as a mini crane in tight urban spaces, making it a valuable addition to a city growing at a pace which we are all amazed to be a part of.”

2024 saw Al Shirawi Enterprises once again recognised as a dealer partner by Manitou Group. Fredrick predicts that Manitou’s lineup will boost the firm’s continuing growth in the UAE. He tells CMME that Al Shirawi Enterprises will be a key partner as Manitou strengthens its distribution networks while providing tailored solutions for key industries.

Benoit Renard, Managing Director, Manitou Middle East adds that by working alongside Al Shirawi Enterprises they will set new benchmarks in the UAE market – and beyond.

“The proven quality of our products, our expertise in handling materials and people on all types of terrain, and our DNA, which reflects in adapting our products to the needs of our customers and their diverse applications, are all factors that set our offering well above the rest,” he says. “All this combined experience is further enhanced by our excellent relationship with the Al Shirawi Teams, once again recognized in 2024 as a dealer partner by Manitou Group. Not to mention that Al Shirawi Enterprises sets the benchmark for our global network of dealers when it comes to the after-sales and customer service.”

“Al Shirawi Enterprises sets the benchmark for our global network when it comes to aftersales and customer service” – Benoit Renard, Managing Director, Manitou Middle East

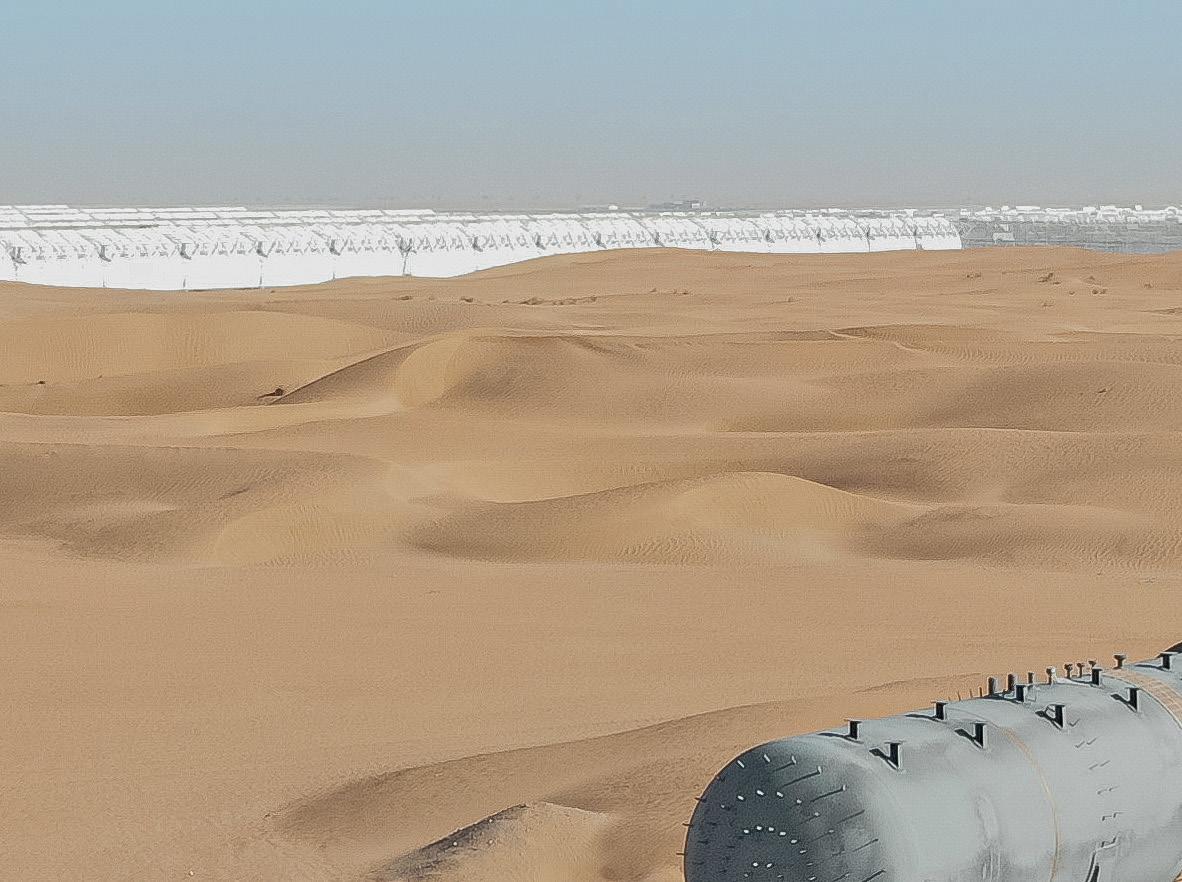

XCMG’s rising success in Saudi Arabia is no accident. The company has strategically positioned itself as a reliable and innovative partner for Middle Eastern contractors by focusing on three key areas: localisation, innovation, and sustainability.

XCMG has invested heavily in understanding the unique needs of the Middle East. From offering machines tailored to the region’s harsh climatic conditions to setting up local service centres, the company has prioritised proximity and responsiveness.

The Chinese firm continues to invest in cutting-edge technology to meet the evolving demands of the construction industry. At the HEAT Show, the company showcased several flagship machines equipped with advanced telematics and automation features. This focus on innovation has made XCMG equipment increasingly attractive to contractors seeking efficiency and performance.

The HEAT Show in Dammam, Saudi Arabia, was therefore the perfect stage for XCMG, the Chinese construction machinery giant, to demonstrate its growing dominance in the Middle East. Amid the bustling activity of one of the most significant equipment shows in

the region, XCMG announced a series of landmark deals and partnerships that underscored its commitment to supporting Saudi Arabia’s ambitious infrastructure goals under Vision 2030. Hosted on stage by CMME Editor Stephen White, the company celebrated these achievements while providing valuable insights into its strategy for success in one of the world’s fastest-growing markets.

The highlight of XCMG’s HEAT Show presence was the announcement of a partnership with eXpertise, a rapidly expanding equipment rental firm in the Middle East. The deal, which involved the supply of 120 cranes, was part of eXpertise’s ambitious $700 million plan to expand its fleet and cater to the burgeoning demand driven by the Kingdom’s megaprojects, including NEOM and The Red Sea Project.

Speaking about the deal, eXpertise’s spokesperson Mohammad Ayaz said, “Saudi Vision 2030 means the demand is there. With the giga-projects in the market, we are focused on meeting this demand. And the demand is so great that there is enough for everyone.” The agreement, signed on the HEAT Show’s main stage by K.S. Sheik, COO of eXpertise, and Kang Jian, General Manager of XCMG’s MENA Region, marked a significant milestone in XCMG’s efforts to solidify its role as a key machinery supplier for Saudi Arabia’s transformative infrastructure plans.

Beyond eXpertise, XCMG also secured a deal with Makhavi Machinery & Equipment Rental for 100 Euro-V Concrete Transit Mixers, a testament to the growing confidence in the company’s ability to deliver high-performance, sustainable solutions. This transaction underscored Makhavi’s commitment to providing reliable equipment for time-sensitive concrete operations in the Kingdom. A spokesperson for the company noted, “The rising demand for premium

construction equipment, especially for concrete delivery, requires technology that is not only robust but also environmentally compliant. XCMG’s mixers are an ideal fit for these needs.” Earlier in the week, XCMG also announced an order from Al Kifah Readymix and Block for an additional 100 Euro-V Concrete Transit Mixers. Chairman Salman Al Afaleq expressed his confidence in XCMG’s products, stating, “The Euro-V Transit Mixer is a game-changer for us. It’s built to handle the harsh conditions of

Saudi roads while ensuring that we meet the Kingdom’s sustainability goals.”

XCMG’s ability to secure such highvalue deals is no accident. The company’s strategy of localisation, innovation, and a focus on sustainability has been central to its success. Muhammad Sami, XCMG’s Regional Sales Manager for the Eastern Region, explained that the company’s deep understanding of the Saudi market has given it a competitive edge.

“Our team has been working here for the last seven years, building strong relationships with local partners and understanding the market’s unique challenges. This local expertise is invaluable and helps us anticipate and meet the needs of our clients,” he said. Sami also highlighted XCMG’s after-sales service as a critical differentiator in the region, adding, “When eXpertise initially ordered 124 pieces of equipment, they were concerned about the service. But the way we delivered — from top management to service teams— exceeded their expectations. This trust is why they’ve now ordered 500 additional machines from us.”

A cornerstone of XCMG’s success is its commitment to innovation. The company’s manufacturing facilities in Xuzhou, China, are equipped with state-of-the-art technology and produce some of the most advanced construction equipment globally.

“This is just the beginning. XCMG is here to support Saudi Arabia’s growth with solutions that are reliable, innovative, and aligned with the Kingdom’s vision for a sustainable future”

Sami elaborated, “XCMG’s factories are among the best in the world. We manufacture everything in-house, from cranes to concrete pumps, and even the world’s largest all-terrain crane. This vertical integration ensures unparalleled quality and reliability.” Nigel Anthony, General Manager of Al Kifah Building Material Company, echoed these sentiments, saying, “We’ve visited XCMG’s facilities twice, and each time we’ve been amazed by the level of optimisation and production quality. It’s clear that this is a company focused on excellence.”

Anthony also praised the Euro-V Concrete Transit Mixers for meeting Saudi Arabia’s strict environmental standards while performing reliably under the Kingdom’s harsh conditions. “Readymix concrete is a unique business with stringent time constraints and technical specifications. XCMG’s mixers not only meet these requirements but also align with our sustainability goals. Having a reliable fleet is essential for us, and XCMG delivers that,” he added.

Another critical factor in XCMG’s success in Saudi Arabia is its alignment with Vision 2030, particularly in terms of sustainability. The introduction of the Euro-V Concrete Transit Mixers is a prime example of how XCMG is addressing the Kingdom’s demand for eco-friendly construction solutions. Sami highlighted the importance of sustainability in the company’s offerings, saying, “Our equipment is designed to meet both the technical challenges of projects and the environmental standards set by Vision 2030. We are proud to play a role in building a sustainable future for Saudi Arabia.” These efforts reflect XCMG’s broader strategy to position itself as a leader in sustainable construction equipment, a focus that is increasingly resonating with contractors and government agencies alike.

The HEAT Show also provided a platform for XCMG to strengthen its relationships with existing partners. A ribbon-cutting ceremony with Al Kifah Readymix and Block marked the handover of the first batch of Euro-V Concrete Transit Mixers, symbolising the trust and collaboration that underpin XCMG’s partnerships in the region. Anthony shared his optimism for the future, stating, “The market is extremely exciting right now. With partners like XCMG, we are confident in meeting the increasing demands of the industry and delivering on the ambitious projects shaping Saudi Arabia’s skyline.”

The HEAT Show not only showcased XCMG’s achievements but also highlighted

A highlight of XCMG’s HEAT Show presence was the announcement of a partnership with eXpertise, a rapidly expanding equipment rental firm in the Middle East.

its vision for the future. As the Kingdom accelerates its infrastructure development under Vision 2030, the demand for high-quality, sustainable construction equipment will continue to grow. XCMG’s focus on localisation, innovation, and sustainability positions it as a trusted partner for contractors tackling the region’s most ambitious projects.

The deals announced at the HEAT Show are not just transactions; they are milestones in XCMG’s journey to

becoming a leader in the Middle East construction market. As Sami succinctly put it, “This is just the beginning. XCMG is here to support Saudi Arabia’s growth with solutions that are reliable, innovative, and aligned with the Kingdom’s vision for a sustainable future.”

With a proven track record and an unwavering commitment to excellence, XCMG is not just participating in Saudi Arabia’s development story — it is helping to shape it.

In the heart of Saudi Arabia’s ambitious Vision 2030, which entails an eco-friendly, sustainable, and technologically advanced future, Tesmec Saudi stands as a leader in utility and renewable energy infrastructure.

The company’s cutting-edge technology and comprehensive approach cater to the kingdom’s unique geographical and environmental conditions, ensuring optimal outcomes for utility projects, especially in the ever-growing sectors of solar and wind energy.

Tesmec Saudi combines trenching and mechanical laying of underground utilities into one seamless operation, simplifying the cables installation process. This technology allows for faster, safer, and more cost-effective cable laying, ensuring that projects are completed with minimal disruption and maximum precision. Here’s how the company is redefining new standards within the industry and why its solution is quickly becoming the preferred choice for infrastructure projects worldwide.

One of the standout features of Tesmec Saudi’s approach is its efficiency. Traditional methods of trenching and laying cables or pipes typically involve

multiple pieces of machinery and a large workforce. These processes are done sequentially — trenching, laying, and backfilling each requiring separate teams and equipment. Tesmec Saudi’s solution, however, integrates these steps into one streamlined process.

At the heart of this system the company’s advanced trencher, which cuts the trench while the specialised laying box places cables directly into the trench. This setup also includes a reel carrier that unrolls the cable or duct and a wrapping machine that ensures multiple cables stay bundled together, eliminating the risk of twisting and reducing the need for joints.

Once the equipment is set up, Tesmec Saudi’s mechanical laying process significantly accelerates project timelines. Compared to traditional methods, which require longer timeframes and more machinery, this not only reduces labor costs but also shortens the duration of projects, allowing companies to complete infrastructure work faster and more efficiently.

In addition to its efficiency, Tesmec Saudi’s mechanical solution offers considerable cost savings. Traditional cable laying techniques demand significant resources in terms of machinery, crew size, and time. With the company’s technology, fewer

“From the protection of cables to reducing environmental impact and improving efficiency, Tesmec’s technologies are playing an instrumental role in shaping the future of Saudi Arabia’s utility and renewable energy sectors”

workers are required, and the need for multiple machines is eliminated. This directly translates to lower operational costs—by as much as 40% in some cases. By reducing the number of vehicles and machinery on-site, this solution minimises logistical challenges such as traffic management, worker safety, and equipment maintenance. Additionally, faster project completion reduces the amount of time spent on-site, lowering overall construction expenses. For large-

scale infrastructure projects, these savings can be significant, making Tesmec Saudi Arabia’s technological approach highly attractive for both small and large utility installations.

Safety is paramount on any site, and the mechanical laying process provided by the company offers a crucial safety advantage. Traditional trenching and cable laying often require workers to enter

trenches to position cables. This exposes them to the risk of trench collapses and other accidents. Tesmec Saudi’s solution eliminates this risk by placing the cable directly into the trench without any need for workers to enter the trench.

Tesmec Saudi’s laying boxes are designed with adjustable internal rollers and guides that position cables with precision, ensuring the correct depth and alignment as the trench is cut. By keeping workers out of the trench and automating the cable placement, the company’s technology significantly reduces the risk of injury and enhances overall worker safety on-site. This is especially important in hazardous environments, where worker protection is critical to the success of a project.

Tesmec Saudi’s mechanical laying process is built on precision. The company’s advanced machinery, such as the GPSenabled trenchers and the groundpenetrating radar used in its laying boxes, ensure that cables or ducts are laid at the exact depths and alignments required. This high level of accuracy minimises the chances of faults and reduces the need for costly rework.

The wrapping machine and specialised laying box also help maintain the integrity of cables during installation. By bundling cables in trefoil, the risk of twisting is eliminated, and longer lengths of cable can be laid without the need for additional

joints. This not only increases efficiency but also contributes to the longevity and reliability of the installation, ensuring that utility networks continue to operate smoothly for years to come.

As the world becomes more environmentally conscious, sustainability in construction is becoming increasingly important. Tesmec Saudi’s solution offers significant environmental benefits compared to traditional trenching methods. The use of a narrower trench reduces the amount of soil that must be removed, and less backfill material is required. This results in less waste and lower material costs.

Furthermore, the reduced number of vehicles and machinery on-site leads to lower fuel consumption, reducing the carbon footprint of each project. The shorter project timelines also mean that construction sites are less disruptive to

Tesmec Saudi’s advanced machinery, such as the GPS-enabled trenchers and its laying boxes ensure that cables or ducts are laid at the exact depths and alignments required.

local communities and the surrounding environment. For the company’s customers, these sustainability advantages are not only cost-effective but also align with increasingly stringent environmental regulations and the growing demand for eco-friendly infrastructure solutions.

Tesmec Saudi’s mechanical laying process is quickly becoming the go-to approach for underground cable installation due to its numerous advantages. The combination of speed, cost savings, enhanced safety, precision, and environmental sustainability makes it the ideal choice for projects of all sizes, from telecommunications to power networks.

As technology continues to advance, Tesmec Saudi remains at the forefront of innovation in this field. Its trenchers and laying boxes are constantly being refined and improved, incorporating the latest in GPS, radar, and automation technologies

to further enhance the efficiency and accuracy of the mechanical laying process. With the growing demand for more efficient and sustainable infrastructure solutions, the company is poised to become an even more integral part of the global infrastructure landscape.

As Saudi Arabia accelerates its journey towards Vision 2030, Tesmec Saudi continues to provide cutting-edge solutions that support the kingdom’s ambitious energy and infrastructure goals. From the protection of cables to reducing environmental impact and improving efficiency, the company’s technologies are playing an instrumental role in shaping the future of Saudi Arabia’s utility and renewable energy sectors.

With a focus on sustainability, innovation, and safety, Tesmec Saudi is not just a provider of machines but a key partner in the kingdom’s transformation towards a greener, more technologically advanced future.

“The combination of speed, cost savings, enhanced safety, precision, and environmental sustainability makes it the ideal choice for projects of all sizes”

10 - 13 November 2025 / Dhahran Expo, KSA

z Make connections, expand your network and relationships, generate leads, elevate sales, grow your footprint with endless opportunities.

z Reach your target audience, engage with industry professionals, influencers, decision makers and highlight your products and services Explore the industry of construction equipment and commercial vehicles building the kingdom

THE ‘SEE-THROUGH BUCKET’ THAT IS SMOOTHING OUT AN ASPHALT QUARRY

Anew DL420CVT-7 wheel loader from Develon, formerly Doosan Construction Equipment, equipped with the company’s unique Transparent Bucket safety system, has proven to be the ideal solution to optimise the continuous flow of gravel and milled material in the asphalt production process at the picturesque quarry in Albaredo (TV) in Italy, owned by the Trentin Group.

The cutting-edge Develon machine is revolutionizing the efficiency and safety of the operations of handling extracted and recycled materials in a unique operating environment, characterized by two scenic artificial lakes.

The Trentin Group, dedicated for five generations to the extraction of gravel, the production of asphalt mixes and the transport of goods and road works, has found in the Develon DL420CVT-7 a reliable ally to optimize operations in its quarry. Over the years, the group has brought together several companies - Trentin Ghiaia, Trentin Asfalti, Trentin Trasporti, Padova Asfalti and Friulanasfalti - that work synergistically to ensure an efficient and high-quality production process.

In the Albaredo quarry, which covers a total area of 70 hectares, Trentin Ghiaia extracts the gravel material located under the aquifer, which

The DL420CVT-7 is equipped with a continuously variable transmission (CVT), the result of the permanent combination of hydraulic and mechanical transmission technology.

is then subjected to a washing, screening and crushing process to obtain different sizes. The gravel is then stored in piles divided according to their grain size. Trentin Asfalti, in turn, uses this treated gravel for the production of asphalt or to satisfy the requests of third parties.

The transport of gravel to an asphalt extraction and production plant of this calibre plays a fundamental role in ensuring a continuous and efficient flow of materials during the production process.

The Develon DL420CVT-7 wheel loader, recently purchased by Trentin Asfalti, has proven to be essential. The DL420CVT-7 works non-stop, collecting treated gravel from the piles located near the plant, and the milled asphalt, or recycled asphalt, stored at the opposite end of the Centre. With a bucket load capacity of 4.5 m³, exceptional power and smoothness of driving, and particular attention to fuel consumption, the DL420CVT-7 has exceeded Trentin Asfalti’s expectations.

Nicola Trentin, owner of Trentin Asfalti, comments: “We are completely satisfied with our first Develon purchase. The opportunity to test the vehicle for a week and receive in-depth training on the use of the vehicle from the DEVELON demonstrator and trainer, Giuseppe Santo, was decisive in our choice. This has allowed us to fully evaluate the significant advantages offered by the loader for our needs in the quarry and understand its driving style.

“In the first months of use, we were particularly convinced by the CVT transmission system, which guaranteed a reduction in fuel consumption of up to 25%. This not only represents a significant economic saving for us, but also contributes to our commitment to reducing environmental pollution. In line with this objective, we have recently installed a one-megawatt floating photovoltaic system in the quarry, capable of providing 20% of the energy needed,

and we are evaluating further extending its use.”

The DL420CVT-7 is equipped with a continuously variable transmission (CVT), the result of the permanent combination of hydraulic and mechanical transmission technology. This synergy offers continuous and uniform speed variation, adapting to traction needs, without impacting the engine, which can operate at a lower and constant rpm. This ensures high efficiency and a smooth, comfortable ride, keeping the engine in its optimal operating range, and therefore helping to reduce fuel consumption and emissions.

Frank Asiri, operator of the DL420CVT-7, says: “I have been using the DL420CVT-7 loader for several months now and I can confirm my full satisfaction with both the excellent performance and the smooth and progressive driving, with the bucket always loaded. I particularly appreciate the cab equipped with advanced command and control systems, including the new electric joystick, directly integrated into the armrest.

“The extremely wide view from the cab down to the ground is of vital importance, reducing blind spots to a minimum. This problem has been further solved thanks to the transparent bucket safety device, which even allows you to see beyond the bucket itself.”

the transparent bucket safety system into the DL420CVT-7 loader, a one-ofa-kind accessory developed exclusively by Develon, which offers operators a complete view, as if the bucket were not present on the machine.

The innovative system records images in front of the wheel loader through cameras mounted high and low on the front and displays the combined images in real time on the monitor in the cab.

In the quarry, characterised by the presence of numerous vehicles from different companies of the Trentin Group, the possibility for the operator to have a clear view is a fundamental solution to help prevent accidents and ensure safety at work.

In addition to improving safety, the system also increases operational efficiency as it offers a forward perspective view during loading/unloading operations or during the transport of gravel.

Nicola Trentin adds: “I am very grateful to the Develon Dealer, DMO, and in

“Trentin Asfalti is a new customer, who has chosen the DL420CVT-7 as its first Develon machine. In addition to the exceptional features of the loader, the scheduled maintenance plan, managed directly by Develon technicians trained by DMO, was particularly appreciated. Thanks to an extended warranty of up to 5 years/5000 hours, we ensure Trentin Asfalti the necessary technical support and complete and reliable aftersales assistance to maximize the performance and duration of their investment.”

The Trentin Group says the production of asphalt mixes and the transport of goods and road works, and has found in the Develon DL420CVT-7 a reliable ally.

particular to Maurizio Mantovani, whose contribution was decisive in our purchase decision. His decision to allow us to test the machine, combined with his expertise and passion for Develon and its products, guided us towards the ideal solution for our needs. We are so satisfied that we are evaluating the purchase of other wheel loaders also for our recently acquired Gradisca di Isonzo (GO) plant.”

Maurizio Mantovani, DMO Manager for Veneto for over 30 years, says:

Customer care is one of the fundamental principles of DMO, the exclusive Develon importer for Emilia Romagna, Veneto, Friuli Venezia Giulia and Lombardy, with a presence in the provinces of Milan, Cremona, Mantua, Lodi, Pavia, Varese, Monza and Brianza. To ensure a widespread service, in addition to the workshops inside the branches, DMO is supported by authorized workshops in each province, as well as mobile workshops capable of intervening directly on site.

“ In the first months of use, we were particularly convinced by the CVT transmission system, which guaranteed a reduction in fuel consumption of up to 25%”

WHY GET IT?

DESIGNED FOR LARGE-SCALE PROJECTS, THE WOLFF 8038 CLEAR DELIVERS A POWERFUL LIFTING CAPACITY WITH SIMPLIFIED TRANSPORT AND ASSEMBLY.

WOLFFKRAN has unveiled the WOLFF 8038 Clear, a groundbreaking addition to its flat top crane portfolio. Designed to meet the demands of large-scale projects such as airports, industrial facilities, and data centers, the WOLFF 8038 Clear combines exceptional lifting capacity with ease of assembly and transport.

Competing in the 560 mt class, the WOLFF 8038 Clear is the largest flat top crane in the WOLFFKRAN lineup. “Large cranes are in demand,” stated Mohamed Abouelezz, Head of Business Development and Product Management at WOLFFKRAN.

“Globally, we are witnessing a trend toward construction with prefabricated

parts and modules. At the same time, customers are increasingly focused on hassle-free assembly. The WOLFF 8038 Clear combines the performance of a hammerhead crane with the assembly advantages of a flat top design.”

Boasting an 80-meter jib length and a maximum lifting capacity of 20 tons, the WOLFF 8038 Clear rivals models with tower tops. Its point bearing capacity of 3.8 tons at an 80-meter jib radius is impressive even compared to the competition. An optional extension can increase the jib length to 85 meters, with a 2.1-ton lifting capacity at the tip.

Since the launch of the WOLFF 6523 Clear, the WOLFF design team has continued to refine its jib design. The WOLFF 8038 Clear features a patented smart jib design with a plug connection for easy assembly. Its revised lower chord construction reduces material

costs by 10% and assembly weights by 20%, optimizing overall performance.

The WOLFF 8038 Clear is built for efficiency with ergonomic bolt depots, extra platforms for divided jib assembly, and a future-ready under-hook camera system for improved load positioning. Pre-equipped for global deployment, the crane fits into elevator shafts and can be transported on six trucks, making it a versatile solution for large-scale developments.

SPECIFICATIONS

WOLFF 8038

Max Lifting Capacity: 20t

Max Jib Length: 80m (extendable to 85m)

Tip Load Capacity: 3.8t @ 80m / 2.1t @ 85m

Hoist Winch Options: 75 kW or 110 kW

Max lifting speed: 190 m/min

WHY GET IT?

ATLAS COPCO’S X-AIR+ 750-25 IS A POWERFUL YET COMPACT DRILLING COMPRESSOR DESIGNED FOR RUGGED ENVIRONMENTS, DELIVERING IMPROVED PERFORMANCE AND ENERGY EFFICIENCY.

Atlas Copco has launched the X-Air+ 750-25, a next-generation portable air compressor designed to revolutionize mid-depth drilling applications. Offering 750 cubic feet per minute (CFM) flow and a maximum pressure of 25 bar, this model enhances efficiency and power in a lightweight design. At under 3,500 kg, the X-Air+ 750-25 eliminates the need for heavy-duty trailers, making it a cost-effective solution for industries such as water well drilling, geothermal projects, and foundation drilling.

According to Atlas Copco, the X-Air+ 750-25 features greater efficiency than its predecessor, ensuring low total cost of ownership for customers – and a notable reduction in carbon footprint across the DrillAir range.

The X-Air+ 750-25 heralds a new era in compact solutions for medium-depth drilling, by being fully flexible between 232-363 psi pressure and a flow between 701-678 cfm. Engineered with a highly efficient Cummins engine, it offers toughness and power with half the footprint and weight of the predecessor, (going from 14.400 lb to 7.716 lb) enhancing agility and versatility.

WHY GET IT?

DESIGNED FOR EXTREME VERSATILITY, THE XTJ 52+ FEATURES EXCEPTIONAL WORKING HEIGHT AND ADVANCED CONTROL SYSTEMS FOR PRECISE MOVEMENTS IN CHALLENGING ENVIRONMENTS.

Joly Location has expanded its fleet with the Palazzani XTJ 52+ Spider Lift, a high-performance aerial work platform tailored for complex applications such as telecommunications, electrical networks, and heritage site maintenance.

Equipped with Palazzani’s Plus series technology, the XTJ 52+ offers faster aerial operations with CAN-bus integration over previous models. The machine also offers the precision expected of spider-lifts with high-accuracy movement for delicate work. Operators also benefit from a machine designed for efficiency with the manufacturer claiming that the biggest machine in the Palazzani range still maintains smooth,

energy-saving functionality, as well as advanced drive controls for stability and reliability. Finally, the “Return to Home” function comes programmed into the machine for simplified stowage.

Super elastic rubber wheels, for driving easily and non-marking or wearing the most delicate floor. It can be used both outdoor, with the diesel engine, and indoor with zero emissions, thanks to the singlephase electric motor. The multi-telescopic arm and the articulated upper jib offer maximum aerial agility, with zero tailswing. The arm rotation is 660° with any set-up.

Thanks to the device for voice, the operator in the basket and the operator on the ground can communicate during the aerial work. The standard remote control allows maneuvering the platform from the ground with agility without the presence of the cable.

The model also features a unique artistic design by Pegaz, combining futuristic aesthetics with industrial-grade functionality.

SPECIFICATIONS

Maximum working height: 52m

Outreach: 19.5m

Capacity (basket): 400kg

Capacity (winch): 980kg

Check engine oil, coolant, and hydraulic fluid to prevent overheating and damage. 01

CHECK BEFORE YOU START, AVOID BREAKDOWNS LATER

A thorough pre-start inspection ensures safety and peak performance.

HYDRAULIC LINES CHECK

Look for leaks, cracks, or wear in hydraulic hoses that could lead to system failure.

LIGHTS ON

Ensure all safety lights, beacons, and indicators are functioning.

Test joysticks, pedals, and switches to confirm smooth and responsive movement.

ATTACHMENT SECURITY

Double-check pins, couplers, and bolts to keep attachments firmly in place.

10

Keep a fire extinguisher accessible and free from obstructions.

05 08 07 09 06

At BAUMA 2025, the world’s largest trade show for construction vehicles and machinery, Goldhofer Aktiengesellschaft will once again showcase its Self-Propelled Modular Transporter with Hydraulic Widening and E-PowerPack.

Goldhofer’s regular product demonstrations at BAUMA 2025 will feature a range of innovations, with a key highlight being the PST/SL-E split self-propelled modular transporter with hydraulic widening. With an axle load of 45 tonnes and a variable width ranging from 3,000 mm to 5,100 mm, this transporter provides a cutting-edge solution for handling bulky loads. Its impressive tractive power ensures unparalleled efficiency, while the hydraulic widening system offers enhanced stability and load security—reducing the number of axle lines required. This model is also highly compatible with the Goldhofer heavy-duty module family. The unit

at BAUMA will be powered by Goldhofer’s new E-PowerPack. Robert Steinhauser, Vice President of Sales and Service, explains: “For the development of our E-PowerPack, we leveraged synergies with our Airport Technology division. Our extensive experience with all-electric aircraft tow tractors— capable of moving over 300 tonnes — provided valuable insights. As a result, we will present a technically advanced product at BAUMA that meets our customers’ high expectations.”

Another key highlight at BAUMA will be the ARCUS P 5 featuring CARGOPLUS tyres. Designed for efficiency and flexibility, this model boasts the lowest loading height on the market. With a mere 735 mm loading height (thanks to CARGOPLUS tyres) and a suspension stroke of 500 mm, the ARCUS P 5 ensures safe and effortless loading. Its combination of forced- and friction-steered axles provides excellent manoeuvrability, reducing tyre wear at any ride height. The intuitive, centralised controls enable easy handling and maximum operational efficiency. Dennis Leschensky, Director of Sales Europe/North

Africa, describes it as a breakthrough in heavyduty logistics:

“With its low loading height and high manoeuvrability, the ARCUS P 5 sets new industry benchmarks. Customers benefit from its enormous payload capacity and minimal tyre wear, making it an indispensable transport solution.”

Additionally, the model offers multiple load securing options and incorporates innovative TRAFFIDECK GO flooring to ensure maximum safety.

Goldhofer will also showcase the RA 3-100 (4+7), an ideal solution for transporting wind tower sections. Designed for both safety and efficiency, it features a maximum payload of 100 tonnes and an impressive stroke of 2,000 mm. With a chassis width of 2,950 mm, it guarantees lateral stability, while air suspension axles ensure a load-friendly transport experience.

The RA 3-100 incorporates ergonomic operation and a maintenance-friendly design for ease of use. Its free-turning devices and adjustable rear

Goldhofer’s RA 3-100 (4+7) features a maximum payload of 100 tonnes and an impressive stroke of 2,000 mm

steering system enhance manoeuvrability, even with the largest tower sections. A four-point pickup system simplifies loading, allowing a single operator to handle the process without a crane.

Dennis Leschensky highlights its significance:

“With the RA 3-100, we are setting a new benchmark in tower transportation. Our customers benefit from its high manoeuvrability and straightforward system design, making tower section transport safer and more efficient.”

Since its launch at BAUMA 2022, the PST/SL-E split has proven to be a valuable addition to heavyduty fleets. It offers exceptional flexibility and performance, particularly in transporting loads with high centres of gravity or large wind turbine components. Jean-Philippe Martin, Director of Sales International Business, describes it as a “game changer”:

“The drive axle lines reduce the total number of axle lines needed while increasing transport efficiency, resulting in lower fuel consumption and enhanced performance.”

Its hydraulic widening system and support circuits improve rollover stability—crucial for transporting challenging loads.

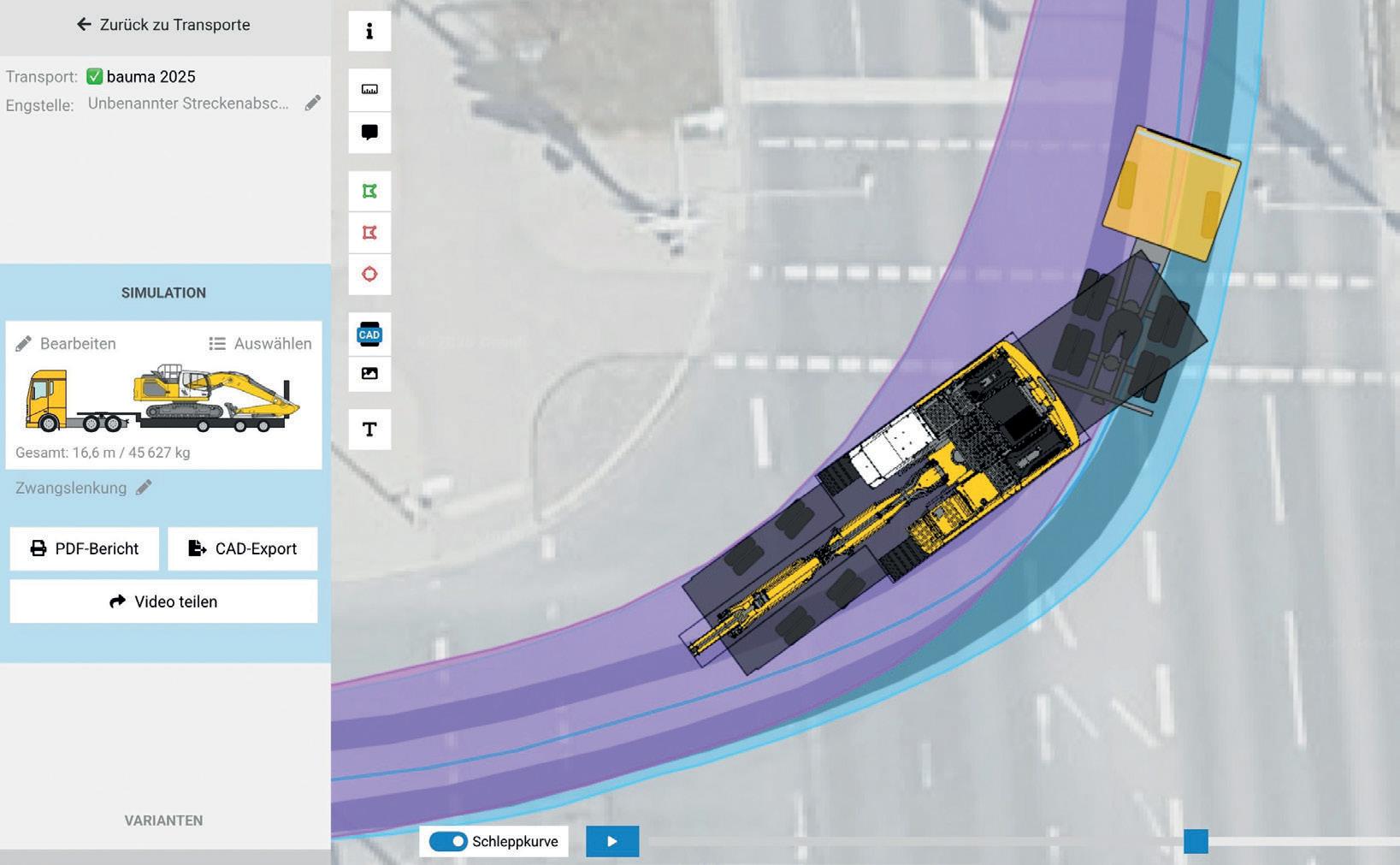

Goldhofer is also setting new standards in digital transport planning. In collaboration with the developers of HeavyGoods.net, the company is making heavy-duty transport planning more efficient and cost-effective.

From BAUMA 2025 onwards, Goldhofer’s easyLOAD software will be replaced by the highperformance HeavyGoods app. This web-based application uses advanced algorithms to calculate axle loads, bending moments, rollover stability, overload limits, and cargo lashing requirements. It can also integrate data from 3D drone images, streamlining the permit application process and often eliminating the need for route inspections.

Goldhofer remains focused on manufacturing premium vehicles, while the HeavyGoods.net collaboration ensures customers benefit from cutting-edge digital solutions. Visitors to BAUMA 2025 can explore the new software at the Goldhofer stand (FN.819).

Goldhofer’s STARLINE series, a long-standing benchmark in heavy-duty logistics, will also be on display. The STEPSTAR and TRAILSTAR models offer solutions tailored for various transport applications, featuring low ride heights and reduced deadweight for everyday efficiency.

The STEPSTAR Z 4 model stands out with CARGOPLUS tyres, two wheel recesses, and an excavator boom recess. Its forced-steered axles enhance manoeuvrability and stability. Robert Steinhauser notes: “With CARGOPLUS tyres providing a low ride height of 790 mm and an axle load of 10 tonnes, our customers benefit from faster mobilisation and reduced detour distances. Designed for durability and low maintenance, and built with quality components from BPW and Neumeister, the vehicle also holds a high resale value.”

Meanwhile, the TRAILSTAR 4 is optimised for transporting standard construction machinery, featuring a loading height of just 795 mm and an axle load of 10 tonnes. Its lightweight design maximises fuel savings while maintaining full operational flexibility.

Steinhauser concludes: “Our vehicles are designed to meet customer requirements while ensuring maximum efficiency and safety. With STARLINE, we provide solutions that combine high performance with reliability, all while remaining economical and environmentally friendly.”

in 2025, driven by geopolitical instability, economic uncertainty, and an ongoing shortage of skilled labour. According to a new report by Currie & Brown, Building a Resilient Future: Adapting to Uncertainty in 2025, the industry faces a dual challenge—strong demand for infrastructure, digital transformation, and renewable energy projects is being offset by rising costs and supply chain disruptions.

Construction costs are expected to rise at varying rates across different regions in 2025. In Saudi Arabia, costs are projected to increase between 5-7%, while the UAE is expected to see a rise of 2-5%. India is also forecasted to experience a 5-7% increase, while the United States anticipates a more moderate 4% rise. The United Kingdom is likely to see cost growth of 3-4%, with Europe following closely at 2-3%. In China, costs are expected to rise between 3-4%, whereas Hong Kong will see only a slight increase of 0-1%. Japan stands out as the only market where construction costs are predicted to decline slightly by 0.5%.

Saudi Arabia costs are projected to increase between 5-7% 5-7%

expansion comes with rising costs—construction prices in the UAE are expected to increase by 2-5%, while Saudi Arabia may see a steeper rise of 5-7%, surpassing many other global markets. Doug McGillivray, Managing Director Southern Gulf at Currie & Brown, cautioned that while the region presents significant opportunities, businesses must remain vigilant. He emphasised that uncertainties related to costs, delays, and project feasibility require companies to implement strong risk management strategies and maintain flexibility in project planning to build longterm resilience. While cost inflation remains an ongoing challenge, companies that prioritise strategic planning, risk mitigation, and technology adoption will be better positioned for long-term success. The report highlights that building resilience into operations will help firms navigate economic uncertainties and market fluctuations more effectively.

Despite global challenges, the Middle East remains a key growth market, with major government-led infrastructure projects continuing in Saudi Arabia and the UAE. However, this

Alan Manuel reaffirmed that cost inflation is now an expected aspect of the construction industry. However, he stressed that uncertainty remains the biggest challenge. Companies that take a proactive approach to adaptability and resilience will be best placed to thrive in an evolving global landscape.

7 th April 2025 @ 9:00am

KHIA9-19_20, Khalifa Economic Zone, Abu Dhabi, United Arab Emirates

Visit us in Munich Booth FS 1205

When it’s hard. When it’s painful. When it’s loud. TADANO Rough-terrain crane GR series has it covered. Demonstrating impressive robustness and high performance, our line-up from 13t to 145t rough-terrain cranes feature state-of-the-art technology to handle even the most demanding requirements. With efficient motors, the longest boom in its class (GR-1000EX-4), compact design and smart assistant systems, everything is on board for maximum success. The GR series: maximum flexibility for your success.