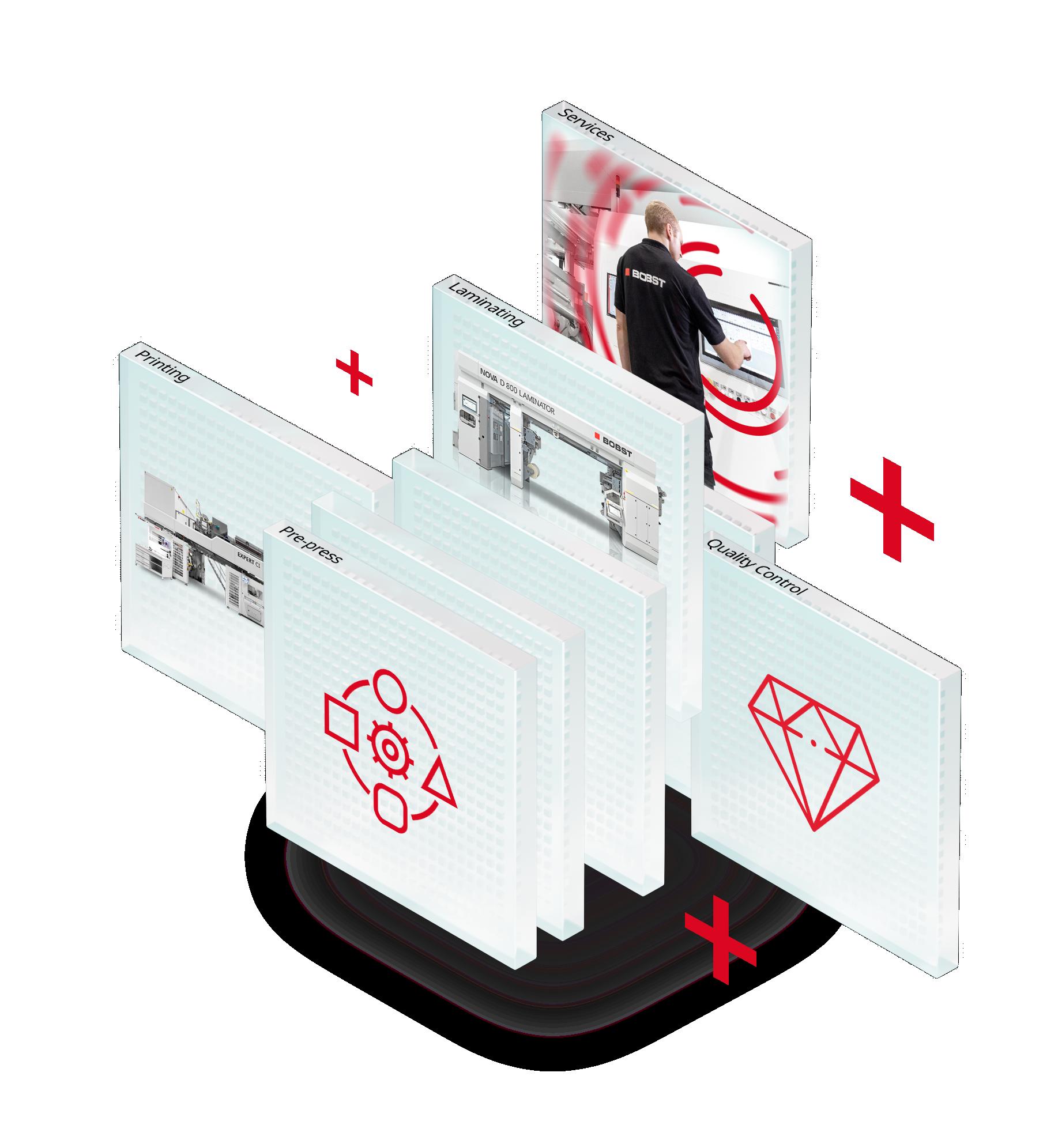

One complete solution from BOBST connects, integrates and orchestrates your flexible packaging workflow. With the help of BOBST Connect, it enables you to manage pre-press, printing, converting and quality control seamlessly while maximizing sustainability and empowering continuous optimization. Interested? Find your local BOBST representative at www.bobst.com/contact

AWARDS: 2023

Issue 4 - 23

Print - Packaging INNOVATION

Asia Magazine

Published by Asian Print Awards Management Pte Ltd 65 Chulia Street #46-23 OCBC Centre 049513 Singapore

Print Innovation Asia

Labels and Packaging Innovation Asia Asian Print Awards Packageing Excellence Awards Label and Packaging Conferences

Publisher Paul Callaghan paul@printinnovationasia.com

Editorial Elizabeth Liew elizabeth@printinnovationasia.com

Packaging Sales Elizabeth Liew elizabeth@printinnovationasia.com

FUJIFILM Business Innovation Asia Pacific launches three new production colour press models -- Revoria Press™ EC1100 and Revoria Press™ SC180 / SC170. The new digital presses provide professional printing solutions for the printing industry and in-house printing delivering superior productivity with high image quality*1. They are now available in the Asia Pacific*2 region.

The Revoria Press™ EC1100, mainly targeting both commercial printing and quick printing, prints at 100 pages per minute*3, whereas the Revoria Press™ SC180 / SC170, which caters to quick printing and in-house printing, prints at 80 pages and 70 pages per minute*4. The three new models are highly versatile and can handle a broad range of paper weight, from 52g/m2 to 400g/m2*5, and various paper sizes from small sized paper of 98x148mm to banner sheet of 330x1200mm*6

The Air Suction Feeder*6 improves feed performance of all media, including paper carrying a lot of paper dust, pre-printed paper using powder, paper with uneven texture, and coated paper that is prone to poor feeding. Stable and high-speed feeding is achieved for various paper types, from lightweight to heavyweight, small sizes to long banner sheets.

The new models also have new colour management features to produce accurate colour consistently with less operator involvements.

• “Colour Profile Maker for Display” reproduces printed colours accurately on the monitor The Revoria Press™ EC1100 and Revoria Press™ SC180 / SC170 offer a newly developed colour management feature “Color Profile Maker for Display,” which can match colours accurately by adjusting the colours on the monitor to match the printed output.

• Colour match your reprint job by scanning previous output

The Revoria Press™ SC180 / SC170 have a new feature that can scan previously printed materials from the same or other presses to reproduce consistent colour when reprinting.

Colours are matched easily and effectively when reprinting while reducing errors and wastage by allowing colour matching of reprints by scanning an existing printed material regardless of previous print technology; thereby further providing a simple yet powerful experience to the user.

• AI-based photo quality optimisation AI (Artificial Intelligence) automatically reviews the scene for each photograph on the page and corrects it. Each photograph will be automatically enhanced based on its existing lackluster conditions such as image being too dark/too bright, backlight exposure, correction of skin tones, and bringing out the hues in blue skies.

[Other features of the new products] Features available in all three models

•The print server, Revoria Flow™, performs RIP processing at 1,200 dpi and

Revoria Press™ SC180 / SC170

10-bit colour, generating high-quality image data.

• Along with Revoria Flow™, Fiery servers will also be available for the new presses at a later date. With Revoria Flow™ and Fiery print servers, two choices of print servers will be offered to fit the print workflow for every customer.

•A versatile lineup of in-line postprocessing options caters to creasing, saddle stitching, three-way trimming, and square-back finish for saddle stitch binding, thus contributing to diverse printing production.

Other features available in Revoria Press™ EC1100

• The in-line sensor automates colour

calibration and front and back registration alignment*7.

Other features available in Revoria Press™ SC180 / SC170

•The presses are equipped with copy and scan functions for office.

• Featuring the SIQA*8 function, which involves scanning a calibration chart to automatically correct image quality, to streamline processes such as registration mark alignment and uneven colour correction.

To allow customers to enjoy business continuity, Production Remote Services delivers responsive assistance and implements preemptive measures via remote connection to customer’s support systems and tools. The cus-

tomer’s production environment is further enhanced with improved machine dependability, uptime and productivity, and auto updates of firmware.

With the introduction of the Revoria Press™ EC1100 and Revoria Press™ SC180 / SC170, FUJIFILM Business Innovation now offers a comprehensive portfolio of the Revoria Press ™ series targeting various segments and needs, spanning mono printers, entry-level production colour printers to high-end production colour press with specialty colours.

* 1: High image quality at the output resolution of 2400×2400 dpi

* 2: Please check with your local FUJIFILM Business Innovation office on the availability of the presses

* 3 When using uncoated A4 sheets weighing 52-300 g/m2

* 4: When using uncoated A4 sheets weighing 52-220 g/m2

* 5: When using the Air Suction Feeder

* 6: Banner sheet support and the Air Suction Feeder are optional.

* 7: Correcting the misalignment of printed images on both sides of paper

* 8: Simple Image Quality Adjustment

Ahmedabad based Letra Graphix, India’s leading label solution provider gets the country’s first Gallus Labelfire 340 – Hybrid Press

The Gallus Labelfire is a system with an end-to-end logical operating concept that integrates digital printing with conventional printing and further processing. Labels are produced inline in a single production operation from the unprinted roll to the matrixstripped end product.

Letra Graphix aims at adding value to client’s brand by making it more appealing across the market.

The Gallus Labelfire 340 with state-ofthe-art technology at its best, presenting the unboxing of Gallus Labelfire 340. A true hybrid press with flexibility and versatility of digital printing, reliability, and precision of conventional printing. Gallus Labelfire 340 is equipped with power of hybrid, digital flexibility and maximum integration for ultimate productivity. The Gallus Labelfire 340 is in process of installation, and soon production will start.

Q. Why did you decide to go Hybrid and why with Gallus:

Nirav Shah. It is now the period of Transformation. As a company, we made the decision to advance and implement innovative sustainable

printing techniques. Hybrid technology, which combines conventional flexographic printing with digital printing, is a solution to that challenge.

For 26 years, Gallus- Heidelberg has been a part of Letra's journey and has been one of our most trusted partners. Therefore, if not them, then who else?

Q. What has been the reaction for your customers - and for those who are not aware what Hybrid is, how you will educate them on this.

Nirav Shah. Prior to the machine arriving at our location, our marketing efforts had already begun, and the machine did generate some talk within the industry. Customers who were already familiar with this technology through their contacts in Europe or

other nations where this machine is present expressed great excitement that it will soon be available in India.

The others, on the other hand, were excited to learn more about this press and how it might aid in improving their product labels and provide sustainable solutions.

The briefings on the technology to our customers have already begun by our Marketing Team.

Q. Why are you convinced that the Hybrid technology is the future when it comes to your business?

Nirav Shah. As indicated previously, we wanted to focus on more sustainable printing techniques rather than only digital printing. We also wanted to remain true to our Flexo roots.

As demand for packaging continues to grow, more packaging businesses are now looking at leveraging digital printing technologies to help generate more capacity and improve time-to-market and profitability, as well as capitalise on new opportunities in e-commerce packaging. This is a trend which is particularly relevant to retailers, brands, the manufacturers of corrugated boards, boxes and, of course, printing equipment.

One of these companies is EFI, a market leader in the digital direct-tocorrugated printing segment, which is seeing increasing demand from packaging businesses globally.

These packaging businesses are interested in leveraging the innovative EFI Nozomi single-pass technology as an enabler for their businesses, to help meet the requirements for high graphic printing and applications for their point-of-sale (POS), retail marketing and e-commerce customers. EFI has been in this business for almost seven years now since they launched their first Nozomi digital single-pass printer at Drupa 2016.

Since then, the EFI Nozomi has been a very successful technology, and EFI was proud to announce its 50 install at the company DS Smith in March. DS Smith is a leading provider of sustainable packaging solutions, paper products and recycling services worldwide. It is an example of an innovative customer that has leveraged Nozomi’s capabilities to move their business forward. The

second Nozomi printer the company has acquired with the first installed in Portugal in early 2021.

In APAC, there has been significant growth in demand for high-value consumer product manufacturing, which is driving the demand for higher quality short-run packaging and accelerating the adoption of digital printing in the region. Through EFI’s interactions with packaging businesses, from corrugated sheet plants to paper manufacturers, the company has observed an increasing need for the capacity, time-to-market, and variable data printing with minimal set-up costs offered by Nozomi printers.

Q: What is the overall opportunity for corrugated providers in the e-commerce segment?

Kerry Sanders - According to the Smithers report, “The Future of E-commerce Packaging to 2027”, the global market for e-commerce packaging in 2022 was estimated to be worth $63.60 billion, having increased

2017. Corrugated boxes represent a large proportion (80%) of the value of the e-commerce packaging market and is expected to grow to 83% of world e-commerce packaging value by 2027.

Total global sales of corrugated board for boxes (referred to as corrugated

Q: What are the biggest e-commerce packaging trends for brands/retailers?

Kerry Sanders - An ever-increasing portion of retail transactions are e-commerce. For these retail journeys, the unboxing experience represents the

brand awareness is their top goal , the box has now become an important brand activation platform. Amanda Mull, in her article, “The Package Is the Message ,” sums it up well when she states, “The experience of opening and handling a purchase can be more important than the thing itself.”

Sophisticated brands have also realised there is a social media amplification opportunity through publication of popular unboxing videos, essentially free advertising. In fact, a recent survey states that 42% of marketers solicit unboxing videos from the creators and influencers they work with to help promote their brands.

Paul Sanelli - Another emerging trend is Livestream shopping which is especially big in Asian markets. Since this e-commerce journey usually includes influencers and heavily curated shopping experiences, the consumer’s expectation about the quality of the experience, including unboxing, is higher than in a normal purchase. Plus, the influencers’ branding requirements are accommodated as well, helping them to continue to grow their following.

EFI’s innovations in digital print for corrugated allow brands and retailers to efficiently and cost effectively improve their packaging so they can deliver better brand engagement and the associated business outcomes. Our value proposition allows for better design, unlimited colours, image variation during the same print job, and faster turn-around-times. EFI digital print solutions for corrugated are perfectly aligned to deliver against these robust emerging requirements.

Q In EFI’s view, what is on-box advertising or turning boxes into billboards?

Kerry Sanders - All large retailers are creating Retail Media Networks (RMNs) with the purpose of

monetising their physical and digital ecosystems through third party ad placements. For the past several years, this has mostly been about placing ads on digital channels; however, the return on ad spend for digital ads is declining due to consumers being bombarded by as many as 10,000 ads a day.

Because of this, RMNs are creating alternative ad channels to enable brands to cut through the noise and achieve better conversion and loyalty rates. An emerging category is onbox advertising (OBA), whereby the retailer allows third parties to place ads on their e-commerce shipper boxes. A recent AdAge article describes how Amazon is offering this to brands with impressive results.

According to the article, the engagement rate for OBA is 4.1x better than traditional digital ads. Interestingly, this result is achieved because OBA is not only a novel ad channel but also because OBA ad life is measured in hours/days instead of milliseconds. Since no printing plates are required in EFI’s digital printing solutions, better ad targeting can be offered to brands through regional or seasonal variation, A/B testing or variable data printing.

Paul Sanelli - In addition to brand activation and OBA already discussed, there are a few more trends to be considered. The first is Ships-In-OwnContainer (SIOC). This is a program being driven by large etailers like Amazon. Essentially, a brand can avoid additional handling fees from the etailer if their product package doesn’t have to be re-boxed for e-commerce delivery.

This is also a more sustainable solution since less packing material and shipping weight is required. EFI digital printing solutions are well aligned to the application requirements for SIOC because less rigid materials are being replaced by corrugated and lines are blurred between primary and secondary packaging (and associated decoration).

Q Has EFI conducted any research to identify the most compelling benefits of and biggest barriers to adopting digitally printed corrugated packaging?

Paul Sanelli - Yes, in late 2022 we completed both qualitative and quantitative research projects to help us understand benefits and barriers. For the qualitative research, we spoke to over 70 brands and retailers.

For the quantitative research, we conducted a survey with 800 respondents from brands, retailers, 3PLs and ad agencies. In summary, the research identified the biggest benefits: better branding, better speed to market to keep up with the demands of retail, and a more sustainable

Make the move to digital – and unbox your business with the flexibility to accommodate fast turns, versioning requests, last minute edits, and changing buying decisions. With the new EFITM Nozomi 14000 LED digital press for corrugated packaging and POS, you can reduce process steps from weeks and days to hours and minutes. And personalise runs from one to infinity at higher margins and with lower costs – all in a single pass.

Let’s build your brilliant future. Together. Scan to learn how corrugated converters and packaging printers are opening up new ways to say, “Yes!”

approach to decorating corrugated packaging through less waste and less consumption of water and energy.

Kerry Sanders - The biggest barriers generally fell in two categories. First, brands and retailers pointed to the lack of education of corrugated providers on the capabilities of digital print for corrugated and, more importantly, how digital can help deliver better brand and business outcomes. Second, traditional relationships between brand/retailers and corrugated providers are managed exclusively through purchasing departments so the commercial engagements are focused only on price per piece.

Our research shows that the marketing organisation in brands/retailers is keenly interested in the digital print value proposition, but corrugated providers do not typically engage this group. If they were more involved in the decision process, we believe the use of digitally printed corrugated packaging would be accelerated significantly.

Q Is the EFI Nozomi printer a sustainable solution?

Paul Sanelli - The topic of sustainability often forms a big part of our customer discussions as manufacturers work to reduce their environmental impact.

The EFI Nozomi is a sustainable printing solution for corrugated. This efficient digital alternative to analogue corrugated production delivers energyefficient productivity, with virtually no volatile organic compound (VOC) emissions and up to 35 percent lower energy consumption than flexo printing.

The Nozomi presses also significantly reduce ink and board waste compared with flexo and litho-lamination. Nozomi inks are a key part of Nozomi’s contributions to a true circular economy, meeting recyclability and repulpability OCC certifications. Plus, unlike analogue printing methods, Nozomi does not require water for cleaning, and uses minimal

ink and boards during set-up, which reduces converters’ costs and their environmental footprint.”

Nozomi is truly the industry’s best single-pass inkjet corrugated technology in terms of power consumption efficiency, according to testing by the Fogra Research Institute for Media Technologies against the ISO 20690 energy standard.

Plus, EFI Nozomi is the only singlepass inkjet offering in the industry to have its output certified for OCC recyclability and repulpability by the Western Michigan University Recycling, Paper and Coating Pilot Plant – a leading certification organisation for corrugated recycling.

Q How does EFI partner with its customers and go the extra mile?

Paul Sanelli – At EFI, we work with our customers to identify pain points to configure the Nozomi to best suit their needs. We find a consultative approach helps drive a better customer relationship, as well as better profitability as we work together to maximise the technology. EFI’s expertise, our broad installed base, and our long history of innovation make us the ideal consultative technology provider for converters making the move to digital corrugated packaging production.

Beyond equipment installation, EFI closely collaborates with customers through the necessary technology adoption curve, offering a 12-week ramp-up and training programme, a one-year warranty, and 24/7 remote and in-person service maintenance packages. Nozomi users can also take advantage of additional professional services that help them get the very most out of their digital investments, including advanced training in prepress, colour management, sales and more.

https://techjury.net/blog/branding-statistics/#gref https://www.theatlantic.com/magazine archive/2021/12/unboxing-packaging-shoppingdelight/620523/

https://www.marketingcharts.com/cross-mediaand-traditional/sponsorships-traditional-and-crosschannel-226499

https://siteefy.com/how-many-ads-do-we-see-a-day/ https://adage.com/article/marketing-news-strategy/ amazon-ads-box-advertising-4x-more-effectivetraditional-media/2440636

Connect to Grow. That is your key to stay ahead in a demanding market. By connecting with MPSConnect, you ensure the best in reliability and productivity from your printing press. You will increase competitive advantages and maximize profits.

To improve productivity and profi tability, it’s critical to increase the understanding of your overall label print operation. With MPSConnect, you get real-time insights in the operator activities. You dive into the printing press and see exactly what’s happening.

With MPSConnect we see recurring annual cost savings of €50,000 - €100,000 and even more thanks to a more efficient workflow, time management and waste reduction.

mps-printing.com/connect-to-grow

Bobst Indonesia has hosted an Open House in collaboration with its customer PT. Samheung Indonesia, where it showcased the latest BOBST equipment with a live printing and converting run

Attendees to the event on 14 March 2023 enjoyed a first-hand experience of BOBST One - a complete solution for flexible packaging which builds on the company’s industry-leading printing, metallizing, coating, and laminating technologies. Helping converters worldwide provide exceptional quality and sustainable manufacturing, One is a portfolio of end-to-end workflows that optimizes production by connecting each step - from initial production file and pre-press operations through printing and converting to the final finished reels of flexible packagingwhether the substrate is fiber-based or a high-barrier functional film.

The one-day event started at Nuanza Hotel with a program of informative presentations in which

expert speakers took a deep dive into BOBST technologies, such as oneECG for digitalized extended color gamut printing, Digital Inspection Tables (DIT) for quality control, and smartGPS for automated register settings, along with its 24/7 service and support offering. There were also talks from customers and technology partners. After lunch, the event continued at the Samheung factory in Cilangkara, in the Serang Baku district, Bekasi, West Java.

“The flexible packaging industry is under enormous pressure to deliver faster, with less waste, and consistently high quality at a low cost despite the incredibly challenging market conditions,” said Bill Duckham,

Technology Sales Director Flexo, at BOBST. “The One complete solution combines all the process steps into one smooth workflow to optimize production and eliminate waste. We have shown this innovative concept in action during the BOBST Open House in Indonesia and explained in detail how it can support converters to be competitive and profitable in this segment.”

Visitors experienced BOBST’s CI flexo capabilities, demonstrating highquality printing with solvent-based inks combined with advanced finishing and converting solutions. BOBST technology experts were on hand throughout to provide extensive insight into the machines and associated tools.

This is the second time Samheung has opened its doors to show visitors its capabilities following a successful BOBST Open House held in 2018. Its modern factory specializes in producing products for national and international brands in the hygiene

segment, including Unicharm Indonesia, Kimberly Clark, and Proctor & Gamble. Its systems can efficiently manage the whole manufacturing process from printing and laminating to slitting and bag making.

Hengki, Sales Manager of Bobst Indonesia added, “BOBST has the knowledge and solutions to offer complete end-to-end solutions for flexible packaging, allowing converters to deliver the ultimate in productivity and quality for their customers. The Open House event was the perfect opportunity for discussing and analyzing the many demands converters are facing in today’s market, and explaining the many benefits of BOBST’s holistic approach. We are very grateful to Samheung for partnering with us to host the event.”

ALFT is one of the most innovative packaging companies with over 25 years in the industry. Their focus is to serve their clients with almost all the jobs' sizes which is why they have equipped themselves with MIRAFLEX ll, the most advanced CI Flexo press by W&H.

ALFT is a high-tech, internationally standardized, high-quality, nextgeneration packaging enterprise and now BRC AA certified. Being a 100 percent locally owned company, ALFT is confident in its ability to grow further, help more local companies, and eventually break into worldwide markets.

Their focus is to serve their clients with almost all the jobs' sizes which is why they have equipped themselves with

MIRAFLEX ll, the most advanced CI Flexo press by W&H, along with the best-in-class in-house plate making system from Kodak. Their passion for technology has helped them to choose the best.

During the Covid period in 2021, ALFT packing installed the CI Flexo press MIRAFLEX ll. The local staff from the W&H Indian office completed the installation, commissioning, and startup. Within a short period, the

press was operating at 500 m/min, its maximum speed. The press has a ton of specific features that cut down on startup and changeover waste and changeover time. It is the most sophisticated and feature-rich printing press delivered to the nation.

The Easy Set HD and Reg D enable them to complete impression setting and registration of the most challenging and time-consuming jobs in 2 minutes 15 seconds without relying on the

operator's expertise. The print results obtained with integrated line scan cameras that optimize the print results in a closed loop are often the results that hardly need any additional manual optimization.

The space frame technology, satellite color deck arrangement, and powerful drying mechanism provide high-speed printing on all their assignments. With the least amount of solvent, the innovative turbo clean system (inking and washup system) produces the greatest cleaning results. The doctor blade chambers' large opening and revolutionary pressure-free chamber design provide the best inking outcomes needed for high-speed printing.

Fully integrated 100% defect detection technology improves dependability even further and aids in online printing problem identification. Finding the source of the print defects is made easier with the help of the online

root cause detection capability. This makes it easier for the operators to diagnose problems and operate the printing press confidently. All the fault detection data can be kept for a longer period for study in the future. It is possible to study the printed job data and identify the causes of errors to implement corrective measures in subsequent production.

As the icing on the cake, Ruby Check incorporates "AI" and assists in determining the reason of printing issues in addition to providing the fundamental capabilities of data recording, alarm creation, and remote access available in Ruby Go.

Rubycheck@slitter helps in filtering out and removing the print defects online in the slitting/inspection machine. The slitter stops automatically once it reads the defect which was detected during printing and confirmed by the quality department as a defect. The operator can cut out print defect regions. It

helps in making sure that printed rolls with defects are not dispatched to the end customer or brand owners. Which is in line with their goal of “ZERO Defects”.

“MIRAFLEX ll installed at our plant is a very good machine. It performs up to the mark and to our expectations. We have been quite successful in converting many of the conventional rotogravure designs to Flexo with the help of our good team and the technology offered by MIRAFLEX ll W&H.

We are the first company in the whole Sri Lanka to implement ECG for printing the short jobs. Another highlight of the project is that we have an in-house plate making system from Kodak. Which helps us to be faster in the market from processing design to the final print.’’ says Mr. Lakshman De Fonseka, Chairman of ALFT Packaging Company

“The conventional four-color process (CMYK) can only produce a limited range of colors. Spot colors have traditionally been used to achieve colors outside the CMYK gamut. However, printing with spot colors is not costeffective. With ECG we can add extra colors to CMYK, expanding the gamut and reducing the need for custom spot colors.

This results in higher cost effectiveness with reduced downtime and wastage. ALFT has been able to effectively utilize and master the strengths of the MIRAFLEX ll and the ECG process to cater to the short run and high-quality job demand. It gives us immense pleasure in being part of ALFT’s journey and future endeavors.” Says Mr. Sunil Kumar, Technical sales Manager Printing.

Following the huge success of Fujifilm’s ‘New Blueprint for Wide Format’ appearance at FESPA 2022 in Berlin, Fujifilm will use FESPA 2023 (Munich, 23rd -26th May) to present developments to its existing Acuity models, as well as unveiling an entirely new machine in the line-up.

Additionally, Fujifilm will present more details on its partnership with industrial manufacturer Barberan, to bring singlepass inkjet to the sign and display market.

Fujifilm’s 500m2 stand, will consist of six display bays. Four of these bays will showcase printers first displayed at FESPA 2022, allowing Fujifilm to highlight technological developments and enhancements made since then, as well as early market success. One of the remaining bays will highlight Fujifilm’s partnership with Barberan, while the sixth will be used to unveil a brand-new machine in the Acuity line-up for the very first time.

The Acuity Prime was first revealed to the world at FESPA 2022. This stylishly designed new flatbed – which is a larger version of the Acuity Prime 20 and 30 models – has a 3200mm x 2000mm flatbed, prints at speeds of 202m2/ hr, is easy to operate and produces high quality results at high speed. It features six vacuum zones and 16 media location pins, and allows tandem printing – printing on one side of the bed whilst setting up on the other.

Now with installations in the European market, the Acuity Prime L is commercially available and market proven.

The Acuity Ultra Hybrid LED, also first unveiled at FESPA last year, will be showcased again at this year’s event. The 3.3m high-end printer offers exceptional print quality and performance on both rigid and flexible substrates. It prints at speeds of up to 218 m²/hr (RTR) and delivers a print resolution of up to 1200 x 1200 dpi. The printer is unique in combining ultra-high quality and a competitive return on investment for both rigid and flexible applications, all in one platform.

With a beta model now in place with a customer in the UK, and a number of technical developments since last year, this machine is a must-see.

Acuity Ultra R2 (5m and 3.2m configurations)

Announced in mid-2021, the awardwinning Acuity Ultra R2 is available in 5m or 3.2m versions.

On-stand, Fujifilm will exhibit its 5m, four-channel conventional UV curing High Speed model, which was developed in the last year and prints up to 65% faster than the standard 5m machine.

Fujifilm will also highlight the substantial speed increase – of up to

39% – that it has achieved for the 3.2m High Speed model.

The Acuity Ultra R2 is now being shipped as a modular system and existing models can be upgraded onsite to add light colours, white or High Speed modes, depending on the requirements of the print business.

Big reveal

Fujifilm will also display a brand-new addition to the Acuity range – which will be announced ahead of the show – while its historic partnership with Barberan will be demonstrated with an intricate scale model and video demonstration.

“FESPA 2023 offers the perfect platform to highlight both the sales success and the technical improvements we’ve made to the existing range over the last 12 months, while also looking ahead at what is to come, with the unveiling of an all-new machine on the stand and a lot more detail about our exciting partnership with Barberan.

“To all those attending FESPA this year, we look forward to welcoming you to our stand.”

One of the great things about print is that it can come in all shapes, sizes, and colours. It demands to be touched and interacted with. It grabs and holds our attention.

Print is supremely flexible, able to transform a book or magazine, a mailer or brochure, in look, feel and style. Design and shape can be altered while different substrates can be chosen to convey a wide range of aesthetics from a luxury look, to energetically colourful or a more natural sustainable feel.

That is exactly what Tyler Brule, editorial director of global affairs and lifestyle magazine Monocle, did. He used the creativity of print to deliver new formats and push margins, both editorially and profitably.

He wanted to move away from digital formats such as laptops or mobile devices which he described as constraining, as the framing boxes content in. So, he took the opportunity to explore the ‘quite endless’ possibilities of what can be created on the page in a magazine or in a newspaper format.

In Print Power’s Print Media Predictions 2023 he explained how last year he helped create the hugely successful Monocle Companion. The thick, pocketbook sized volume of essays required a special approach to display in a retail environment and raised some distribution challenges. However, the fresh approach for Monocle helped drive profitability and deliver its most successful year in print – ever. The sales it achieved far outstripped revenues from digital media such as podcasts.

Another area where print transforms the potential impact made is in magazine covers.

For Jaap Biemans, designer and art director for weekly Dutch magazine Volkskrant, is it an essential medium for his passion. Online the covers don’t hold the same appeal. It is too easy to scroll quickly past them and miss some of the tone, wording and imagery chosen to communicate a theme or message.

Using the power of print he is sharing his love for the topic further and compiling a book of the favourite covers of around 250 creatives.

The next few years will be defined by how we can recast print into something more relevant and useful to new audiences according to Sonoo Singh, founder of Creative Salon, a platform that champions excellence in commercial creativity.

She points to a Reuters survey that says more newspapers will stop daily production while highlighting significant advertising campaigns by General Electric (it took over The New York Times print advertising for a day which amounted to 22 full page adverts) and ad agency TBWA in America (it placed a ‘Last Ad from the Last Big Ad Agency on Madison Avenue’ full page advert in The New York Times

announcing its move to a different location), and last year’s Confused. com comic strip style print ads in Great Britain. There is also the use of print catalogues by fashion brands. One such supporter of the medium is the ME + EM brand which sends out a monthly Lookbook.

Physical print is the main conversation for Steve Lister, Director of Sustainability at HH Global, a leader in tech-enabled creative production and procurement. He says there is a big knowledge gap around sustainability and moving to digital communications is not always the more sustainable choice. He says physical print will remain an influential factor and as such he focuses on blended marketing campaigns when talking to clients.

The creativity that can deliver effective campaigns, drive transformation, and help define a successful future for print, is made possible with digital printing technology.

Short runs produced quickly and cost effectively with vibrantly colourful results on a wide range of substrates start conversations, inspire action, and continue to be memorable long after the first viewing. The addition of personalisation can make a dramatic difference to memorability and engagement. This is something Graffica found when Ricoh technology helped it produce 4,000 unique magazine covers. That is why physical print is so powerful.

• Technology Days at the new manufacturing location in Gavà (Barcelona)

• Live presentation of the CutPRO Q 106 – the benchmark in flat-bed diecutting from Koenig & Bauer

• Folding carton gluing on the Omega Allpro 110

In March, Koenig & Bauer Iberica opened the doors of its new manufacturing location in Gavà (Barcelona) to existing and prospective customers from the folding carton industry. More than 90 branch professionals from 15 countries accepted the invitation to attend a series of Technology Days under the motto: “Transforming Your Post-Press with Koenig & Bauer”. They were, at the same time, among the first people to be given first-hand insights into the new premises occupied by the Koenig & Bauer die-cutting specialists since they relocated last year. They were able to experience both the modernised facilities and the new production processes in flat-bed die-cutter manufacture for themselves.

Not only that: the event also provided an excellent opportunity to become familiar with the flat-bed die-cutters CutPRO Q 106 and Ipress 106 PRO, and to get to know the Iberica team in live demonstrations and individual discussions.

The CutPRO Q 106 SB (max. sheet format 760×1,060 mm, production speed up to 9,000 sheets/h) handled two jobs with cartons for food products and pharmaceuticals in different layouts and forms. The job changeover gave the guests a convincing impression of the fast makeready times and high level of automation (including Cut2Print register, Cut2Print PLUS register and the pneumatic quick-lock system).

Other outstanding features of the highend CutPRO Q 106 SB:

- Extremely compact design (10.9 × 6.17 m)

- Maximised output thanks to high diecutting speeds

- High flexibility to process a broad spectrum of substrates – from 90 g/ m² paper to solid board (1.5 mm) or corrugated materials (up to 3 mm)

- Outstanding quality and ultimate register accuracy thanks to the optical Cut2Print register system

- Comprehensive automation modules to guarantee the shortest possible makeready times at job changeover

- Ergonomic and convenient operation by means of touchscreens and an intuitive operating concept

Ipress 106 PRO: reliable and versatile The industry guests in attendance were then able to witness an Ipress 106 PRO in action processing identical jobs. This permitted a direct comparison of the two machine systems and their different scales of automation for 3b medium-format production.

The Ipress 106 PRO and the Ipress 106 K PRO (with integrated blanking) are aimed at folding carton producers who are interested in dependable, tried-andtested Iberica technology. Equipped with the innovative DriveTronic feeder from the Rapida family of sheetfed offset presses, the flat-bed die-cutters in the Ipress series process a wide range of folding cartons in practically all fields of application. The highlights of the Ipress 106 PRO include:

- Maximum production speeds of 9,000 sheets/h (or 8,500 sheets/h for

the Ipress 106 K PRO)

- High flexibility regarding the substrates that can be handled (identical to the CutPRO Q 106)

- Perfect complement to Rapida presses with a maximum sheet format of 750 × 1,060 mm

- Optical register control for stable sheet travel and perfect registration

- Comprehensive automation functions for uninterrupted production and fast makeready

- Modern control concept for maximum user convenience

Complete folding carton production chain

To complete the process chain and to demonstrate Koenig & Bauer’s credentials as a one-stop supplier of machines and equipment for folding

carton production, an Omega Allpro 110 folder-gluer could also be seen in action in Barcelona. Running at a speed of 400 m/min, it processed the freshly die-cut blanks into finished folding cartons.

Like the flat-bed die-cutters, the foldergluers manufactured by Koenig & Bauer Duran in Istanbul offer a multitude of benefits in daily production. These include:

- Extraordinary flexibility due to format widths from 96 to 1,100 mm, covering substrates from 200 to 550 g/m² and N-, F-, E-, C- and B-flute corrugated board

- Innovative solutions to adapt the machine to cater to individual requirements and product needs

- Fast job changeovers thanks to fully automatic processes and memory functions

- Intuitive operation

- Numerous automation modules to boost efficiency

- Flexible integration of peripherals before and after the gluing process

- Precise folding and gluing: economical use of resources, minimum waste

Alongside the presentations and practical demonstrations, the guests enjoyed ample opportunities to discuss all the interesting details with their colleagues, both during the event and at an evening get-together. Guided tours around the historical city centre of Barcelona rounded off the Technology Days.

The printing segment has always been coping with supply chain pressures. With energy prices now skyrocketing, the industry is facing a new challenge. The shortage of paper in Europe has caused mill shutdowns and curtailments and some businesses are even on the verge of closing. How is the sector grappling with the energy crisis and other industry challenges?

At the height of the pandemic, demand for production decreased. As a result, manufacturers laid off employees and reduced operations. As soon as the world awoke from the pandemic, the global supply chain couldn’t meet the high consumer demand.

With limited supply on one hand and skyrocketing demand on the other hand, manufacturers have increased their prices which has led to print companies having to raise their prices as well. In addition, interruptions have occurred in supply, especially

key materials like ink, paper, and printing supplies which are scarcer nowadays. Not to forget other socioeconomic factors, including inflation, transportation challenges and labour shortage, that pose a threat to the print and paper industries.

In light of the above, now with many businesses back on track, print marketing materials, especially catalogs, brochures and so on, are highly soughtafter. With reference to it, materials used during production including cartons, banding materials, pallets and

plastic wrap are in short supply, as the manufacturers are struggling to acquire the raw materials to produce these must-have supplies. Adding to the challenges, a shortage of transportation trucks and drivers is taking a toll on the reliability of deliveries since delays are inevitable.

During the current energy crisis, paper is definitely the leader in the supply chain challenges: the price of paper is rising due to its shortage and the increase in transportation costs, for example. Moreover, the pulp and paper industry is competing for raw materials with other wood product industries like construction, for instance. Nevertheless, demand for paper packaging will continue to grow since it can not only substitute plastics

but the expansion of e-commerce also accelerates its usage.

Jori Ringman, director general of the European association representing the paper industry (Cepi), confirms the significance of the paper material as well as the paper industry:

“[…] [T]he pulp and paper sector remains in the leading position for its recycling performance, use of renewable energy, energy efficiency and sustainable sourcing.”

As a result of the uncertainty of gas and oil supplies from Russia, Cepi appealed to the government for support for the paper and pulp industry earlier this year. The organization pleaded with the authorities for the paper sector to be acknowledged as an essential supplier for major European value chains,

such as the food, pharmaceuticals and essential hygiene industries. In addition, it is widely believed that interventions to supply might obstruct waste management operations as well as the EU-wide transport packaging value chain, which depends heavily on recycled material.

Best Practice: European Recycled Paper Leader Steinbeis Papier

As a pioneer, Steinbeis Papier launched its factory to recycle used telephone books in Germany back in the 1970s and to this day, Steinbeis Papier is a European market leader known for having blended economical sustainability in its manufacturing operations.

Ulrich Middelberg, head of IT at Steinbeis Papier, unveils the success behind the company’s circular production despite the gas crisis:

“We are producing recycled paper economically and sustainably. At our site in Glückstadt, our own power plant provides 100% of the thermal energy and 50% of electrical energy. Now with rising energy costs, it’s a real market differentiator for us.”

The sustainable paper manufacturer uses alternative fuel sources to produce energy for its plant that makes about 300,000 metric tons of printing and copying, offset, digital printing and label papers per year. On top of that, digitalization is equally crucial to lower raw material consumption for resources. Via digitalization and KPIs, Steinbeis Papier can track actual material usage which calls for action when data exceed certain thresholds. To sum up, recycling has become a primary element of the circular economy that will shape a sustainable future.

Sonipat-based Pinnacle Traxim, the label printing specialist grown its business by 40% since the installation of the Gallus Labelmaster 440 narrow-web flexo printing press in January 2022. The current setup of Pinnacle Traxim specializes in label and sleeves supply for FMCG, chemical, cosmetics, liquor, pharmaceutical, and Alcobev markets.

Lalit Kumar Gulati, Managing Director at Pinnacle Traxim, started the business with Surendra Kumar Juneja in 2008. Adding a comment on the investment, Lalit Kumar Gulati said, “Gallus Labelmaster is the first-in-class flexo press concerning quality , production capacity and capabilities.

The Labelmaster features include, operator-friendly platform, multiple converting options like rotary screen, dual cure drying systems, auto registration, and other customized options. Stable print registration at the speed of 150-m/min, with high-quality printing. However, the Labelmaster can print a maximum speed of up to 200 m/min.”

Ferdinand Rüesch Senior, Senior Vice President, Global Key Accounts Gallus Ferd. Rüesch AG, on his recent visit to India, spoke about his experience of visiting Pinnacle’s unit. He said, “I

am happy to see the enthusiasm of the press operators and their cheerfulness. It has been 11 months since Pinnacle has been operating the Labelmaster press. Congratulations to team Gallus and Heidelberg for a new family member. Gallus has put together a lot of ideas in the R&D segment of the press to make the life of the press operator easy with faster setup times and waste reduction.”

The Labelmaster 440 helps for minimum substrate wastage, thanks to the short web path of 1.4 m between printing units. with a printing speed of up to 200 m/min, the Labelmaster can handle a wide choice of substrates ranging from 15-micron mono film to 450 microns of complex material such as tube laminates, and the credit goes to the integrated direct servo-driven printing cylinders and cool impression cylinder keeping perfect grip to the

material during print production.

The precise and stable print register accuracy across all printing speeds with a combination of printing possibilities and converting processes at any position makes the press of perfect choice and a key differentiator in the market.

Samir Patkar, President at Heidelberg India, commented, "It's important to scale up in the packaging industry and with the Labelmaster, Pinnacle will get the push. As the utilization of the Labelmaster press goes up with Higher OEE (overall equipment efficiency) , the cost of production gets reduced due to the technology behind the faster setup, lesser wastage, and minimal operator intervention. It was enthralling to see jobs printed on the Labelmaster from 12-micron films to shrink sleeves, tube laminates, and self-adhesive labels with the finest print quality”.

Patkar added, “The team at Pinnacle is trying flexo printing with a 250-lpi screen, and I haven’t come across it in India yet; while there are few converters completed 175 - 200-lpi. A Label converter aims for both production

scale and value embellishment as it is the recipe for success, we wish, ‘Pinnacle’ - a great journey with Gallus Labelmaster in fulfilling their dreams and many more Gallus presses to adorn the shopfloor”.

The Gallus Labelmaster is not just impressive with its flexibility in perfection but also beautifies with its performance in production. An optimized ink chamber ensures perfect ink transfer to anilox rollers with minimal splashing and reduced foaming.

Sandeep Juneja, Plant Head at Pinnacle Traxim, said, “Gallus Labelmaster is suitable for short and long runs, and we handle diverse clients from Food to Alcobev, Labels to flexible packaging, and the quality and sturdiness of the press is unmatched. We explored other presses, but the quality and productivity are exceptional with Gallus. We had been planning to purchase the Gallus press for a long time, and it is like a dream come true now"

In coming years, Pinnacle plan to setup a new plant at Baddi, Himachal Pradesh. Today the company is growing at a CAGR of 15%-20% and working for a better tomorrow.

Mangalore-based renowned printing firm Prakash Offset Printers has invested in a brand-new Heidelberg Supertaster A 106 CtP.

Heidelberg Suprasetter A 106 supports the firm for its upgradations and growth. It has boosted productivity and has given Prakash Offset Printers a more advanced pressroom. The modular design of the Suprasetter A 106 provides maximum flexibility for the medium-size print format. The patented laser system by Heidelberg offers an excellent imaging quality. The production reliability is ensured through the Intelligent Diode System (IDS), it means that if a diode fails, the operation can continue.

Prakash Offset Printers established in 1983 to cater to their in-house print requirements with complete prepress, press, and post-press setup. Today, Prakash Offset Printers has an immense reputation and standards in the print industry.

The Suprasetter A 106 CtP was installed at Baikampady unit at Mangalore in December 2022. The relationship between Heidelberg and Prakash Offset Printers is of more than three decades, like their experience in the industry. It's the fourth Heidelberg Suprasetter A 106 CtP at Prakash Offset Printers.

Prakash Offset Printers has an array of Heidelberg presses from Heidelberg M offset to Speedmaster XL 75 and Speedmaster SM 102. Also, Prakash Offset Printers had installed India's first Heidelberg SX 52 Anicolor press in 2014; and a complete range of Polar cutting and Stahlfolder folding machines at their shopfloor with three Suprasetter equipment.

Prakash Offset Printers has two units at Mangalore, the pre-press unit located at the heart of the city with a spread across 5,000 sq/ft area, and the production unit located at Baikampady industrial estate has a 35,000 sq/ft operational area, catering to commercial, book publishing, packaging, printing, and folding carton conversion.

P R Nayak, Director at Prakash Offset Printers, said, "We were certain about our investment right from day one. The Heidelberg Suprasetter A 106 is a rewarding equipment. We have been using Heidelberg Suprasetter CtP equipment for over a decade, and the performance and quality are exemplary."

"The Heidelberg Suprasetter A 106 is known for its proven record-breaking performances. We are very sure about the investment as it will enable us to grow and give amazing services to our valuable customers," added Nayak.

The Suprasetter offers a consistently high depth of focus to compensate for unevenness in the plates. The temperature of all the components relevant to imaging is maintained at constant levels. The imaging of the printing plates always take place under the same conditions – a performance feature particularly beneficial for plate remake. Any deviations caused by ambient temperature change is avoided, as this maintains the high register accuracy with the printing plates allowing a faster makeready on press and a minimum of waste.

The Suprasetter A 106 CtP has a dimension of 84.65 widths × 58.82 depth × 60.47 height (inches), with a minimum plate format of 370 height x 323 widths (mm); and a maximum plate format of 930 height × 1,060 widths (mm) and has a resolution of 2,400 dpi.

Heidelberg India is delighted to be part of this eminent journey of Prakash Offset Printers and will continue. "We believe in Heidelberg and are sure about the Suprasetter A 106 CtP as it will help us to reach new heights," concluded Nayak.

Hard photopolymer flexo plate with inherent flat top dots LED optimized plate formulation

Developed for the high end flexible packaging market Smooth plate surface is able to hold all customized surface screening patterns (e.g. Pixel+ and Woodpecker

+ Highest ink transfer and excellent highlights out of the box

+ Robust and consistent on press, simple to process, already includes flat top dots and a surface screening pattern

+ Optimal for short (quick to color) and long clean print runs (anti ink-filling)

+ Known in the market as THE digital plate for high quality Flexible Packaging Print

+ Excellent print results even under challenging printing conditions

+ Very good for long clean print jobs (anti-ink filling)

After extensive testing, the Scodix Polymer PolySense 850 (PS850) has been certified to be in compliance with Nestlé’s Guidance Note on Packaging Inks. Suitable for indirect food contact, PS850 is the latest Scodix polymer to be released, for exclusive use with the Scodix Ultra 6000 system. The polymer is suitable for embellishments including Scodix High Definition, Scodix Sense, Scodix Metallic, Scodix Foil, Scodix VDE and Scodix Cast&Cure, taking brands to new, heightened levels of impact for their food packaging.

As the largest publicly held food company in the world, Nestlé is committed to delivering its food products in safe packaging materials and, in turn, maintains strict and stringent testing of all vendor components in the supply chain. Achieving Nestlé compliance means

that Scodix Polymer PS850 has passed migration tests for secondary food contact at SQTS labs in Switzerland, according to Swiss Ordinance. The certification for PS850 certifies that Scodix embellished packaging excludes harmful chemical contaminants and is a safe method of product decoration for food packaging.

Ziki Kuly, Scodix VP Product Marketing, comments, “This is a great leap forward for customers needing the accreditation to win new types of work, or for brands that want to upscale the impact of their food packaging. This is now not only possible, but economical and sustainable, even for multi-SKU designs and jobs requiring a short timeto-market.”

Scodix PS850 is a new polymer that adds both Spot UV and Foil embellishments. It joins the PS550 to create a family of

indirect food contact products but the new PS850 enables the user to enjoy the benefits of Smart High Definition (SHD) from the Ultra 6000. PS850 supports embellishments that emulate traditional hot foiling but offers print converters the flexibility of digital technology. Scodix’ process achieves optimized value for economics, productivity, and sustainability.

“Scodix is leading the charge in adapting embellishment processes for today’s market demands,” adds Kuly, “The new Scodix PS850 enables brands to differentiate themselves and make greater impact on the shelf. Now that PS850 is certified by Nestlé as compliant with indirect food contact, brands can rest assured they can embellish food packaging items safely, and beautifully.”

As the world hurtles towards a future of 9.7 billion people with dwindling natural resources, one word on everyone's lips: sustainability. From fashion to food, energy to transport, sustainability is the buzzword that has become a pressing concern in all areas of life, including the manufacturing sector.

With the continued expansion of industries, the environmental impact of manufacturing processes has become more significant than ever before. Improving sustainability in manufacturing is crucial in reducing the environmental impact of industrial processes and safeguarding the planet for future generations. Businesses are in the fortunate position where automated solutions such as collaborative robots can contribute to sustainability efforts, and can constantly evaluate the evolving technologies that enable sustainable operations.

Themed “Invest in Our Planet”, Earth Day 2023 acts as the perfect opportunity for businesses to look

at key considerations in improve their sustainability efforts within the manufacturing sector, and how to combat this growing issue.

In Singapore, the amount of waste generated locally has increased sevenfold over the past four decades, with the nation’s only landfill – the Semakau Landfill, estimated to run out of space by 2035. For consumers, implementing waste reduction strategies such as recycling and reusing materials are crucial. In terms of businesses, optimising production processes can help reduce waste and improve sustainability. Manufacturing processes often generate a significant amount of waste, which has a negative impact on the environment. For example, producing more than demand required or products rejected due to unacceptable quality are some of the reasons for wastage in manufacturing.

Adopting flexible and adaptable manufacturing solutions which

allow manufacturers to shift towards made-to-order production without committing to large quantities, and automated solutions which delivers consistently high quality products are effective ways to reduce wastage. Some companies addressed these with UR cobots which key characteristic is the ability to reliably perform repetitive tasks with consistent deliverables, and the flexibility to reprogram to another task when product demand changes. Bajaj Auto Ltd, a leading manufacturer of motorcycles and three-wheelers in India, using cobots to carry out repetitive tasks with faultless precision. Using advanced tools is one of the key factors driving the company’s phenomenal growth globally. Preventing waste by optimising production processes can help reduce waste creation at the point of manufacturing and further improve sustainability. With the right equipment, tools, and automation in place, the deployment helps reduce waste, lower operating cost, enhance productivity, and most importantly – reduce waste.

Manufacturing processes are often energy-intensive, and reducing energy consumption can help improve sustainability. Implementing energyefficient practices such as using renewable energy sources, optimizing production processes, and investing in energy-efficient equipment can help reduce energy usage and improve sustainability.

Digitalisation of manufacturing processes supports sustainability by reducing travel costs, optimising energy consumption. It also provides tools that

As the world hurtles towards a future of 9.7 billion people with dwindling natural resources, one word on everyone's lips: sustainability. From fashion to food, energy to transport, sustainability is the buzzword that has become a pressing concern in all areas of life, including the manufacturing sector.

manufacturers can use to streamline their automation deployment, making it a win-win for both the environment and the business.

For instance, the constant evaluation of technology allows Universal Robots to apply renewable energy to their operations, with 715m2 of solar panels to be placed on the top of their building in Denmark for alternative sources of energy. Their collaborate robots (cobots) also support digitalisation through remote monitoring and access solutions, enable manufacturers to program their cobots remotely, providing a wealth of information on KPIs that can then be used to tweak the cobots’ performance, resulting in improved production efficiency and reduced electricity consumption.

Sustainability in manufacturing goes beyond the factory walls. Manufacturing firms may not have direct control over their entire supply chain, which can make it difficult to ensure that their products are sustainably sourced and produced.

However, firms have direct control in certain areas, such as how the manufacturing line operates. The adoption of cobots can help with improving the sustainability of the supply chain. Cobots not only helps with manufacturing as it allows

manufacturers to compete with lowerwage countries offering better rates, keeping production closer to home. In turn, this minimises the distances involved in supply chains by reducing transportation costs, which is better for the environment.

Even though it is difficult, ensuring that the entire supply chain is sustainable, from raw material sourcing to distribution and disposal, is essential for improving sustainability in manufacturing.

Creating a culture of sustainability within the organisation is essential for improving sustainability in manufacturing. Encouraging employees to adopt sustainable practices and providing training and education on sustainable manufacturing can help promote a sustainable culture within the organization.

Fostering a culture of sustainability is a collective effort by a business. This starts from the top down, and if businesses prioritise sustainability there will be a trickle-down effect throughout the organisation, which would lead to results.

As an example, Universal Robots promote alternative means of transportation and flexible work arrangements in their effort to

combating climate change. Flexible work arrangements allow employees to travel during off-peak hours and to work from home, further supporting efforts to mitigate activities that contribute to climate change.

At facilities in Universal Robots headquarters in Denmark, charging stations and electrical outlets in bicycle sheds have been installed which enables employees to charge their electrical vehicles. Many employees in Denmark also participated in a campaign (We are driving GREEN by Odense Municipality) encouraging green transportation, such as carpooling, biking, public transport and electrical cars.

Investing in businesses for bottom lines is important, but investing in the planet has never been more crucial. Choosing the more sustainable options have always come with the connotation that it costs more. However, improvements in technology mean that this is no longer the case, with options that help the environment also helping businesses and their bottom lines. Compared to our predecessors years ago, we have the information, resources, and ability to make the changes needed to go green.

by Adam Sobieski, Regional President APAC, Universal RobotsSIG, a leading packaging solutions provider for a more sustainable world, celebrates the 25th anniversary of its packaging plant for aseptic carton packs in Rayong, Thailand.

This year marks another key milestone – the fifth anniversary since installing the plant’s immense solar panels. This has reduced the plant’s carbon dioxide (CO2) emission by 12,871 tons since July 2018, equivalent to the offsetting of CO2 by 280 to 415 trees or a forest area of 10,000 sqm.

The SIG Rayong plant began operations in 1998 and spans across 109,600 sqm, supplying to customers in Asia Pacific and South Asia, specifically in Southeast Asia, Australia, Japan, and India. The plant has the capacity to produce around 11 billion aseptic carton sleeves per year for brands such as Thai Denmark, Nestlé, FrieslandCampina, Vinamilk, Indomilk, Ultrajaya, Parle Agro, Amul, and many others.

It was the first SIG production plant in the world to use an effective solar photovoltaic (PV) system to generate

solar power and has already reached Thailand’s 2036 goal of requiring 40% of electricity to come from renewable energy sources. Covering an area of 40,064 sqm (equivalent to five football pitches), the 12,350 solar panels produce up to 5,675 Megawatt hours of electricity per year, equivalent to powering up approximately 5,620 homes in a month.

“The SIG carton packaging plant in Rayong is of great importance in producing sustainable packaging solutions for our region. As one the largest solar-powered facilities in the region, it also demonstrates SIG’s commitment to reducing our carbon footprint and becoming a net-positive company,” said Miguel Gamito, Head of Operations and Supply Chain Management, SIG Rayong. “With our 25th Anniversary celebrations, we are also delighted to be contributing to the

community here in Rayong and doing our part to promote sustainability in the region.”

In 2019, the plant won the Thailand Energy Award Global-Warming Reduction Label for its rooftop solar array. The award from the Energy Ministry’s Department of Alternative Energy Development and Efficiency recognised SIG’s significant investment in off-grid alternative power at Rayong as part of the company’s commitment to put more into society and the environment than it takes out.

Besides the rooftop solar array, the plant also has a solar farm and a solar carport, making the plant the largest solar-powered factory in the packaging industry in Thailand. The plant currently produces packaging by using responsibly sourced materials: SIG is purchasing 100% of the paper board

used for its carton packs as Forest Stewardship CouncilTM (FSCTM) certified and 100% of the aluminium sourced is certified to the Aluminium Stewardship Initiative (ASI) standards.

“With the upcoming SIG packaging plant in Ahmedabad, India, expected to start commercial production at the end of 2024 and supply for our customers in South Asia, the Rayong plant will have the opportunity to produce more of sustainability driven packaging solutions such as the aluminium layerfree aseptic cartons for our APAC customers,” said Angela Lu, President and General Manager Asia Pacific South at SIG.

On top of employing the local community in Rayong, SIG’s solar panel supplier, Symbior Solar, also installed a 7kWp solar array on the roof of a local school as part of their contract with SIG. The free renewable energy generated is enough to power the Nikhom Sang Ton Eng Changwat Rayong 10 school and saves the school more than 4,000 baht (USD116) monthly in electricity costs. Installing solar power is also helping to raise awareness of energy efficiency and climate change among schoolchildren and their teachers.

Traipob Wongtrairat, Governor of Rayong Province, was the Guest of Honour at the 25th Anniversary celebrations, presided by Angela Lu, President and General Manager Asia

Pacific South at SIG. As part of the event, a plant tour was conducted for SIG’s customers, such as Thai Denmark, Lactasoy, Nutifood, ITC, Sambu, and many more from the region.

About SIG

SIG (FSCTM trademark licence code: FSCTM C020428) is a leading solutions provider of packaging for better – better for our customers, for consumers, and for the world. With our unique portfolio of aseptic carton, bagin-box, and spouted pouch, we work in partnership with our customers to bring food and beverage products to consumers around the world in a safe, sustainable, and affordable way. Our technology and outstanding innovation capabilities enable us to provide our customers with end-to-end solutions

for differentiated products, smarter factories, and connected packs, all to address the ever-changing needs of consumers. Sustainability is integral to our business and we strive to create a net positive food packaging system.

Founded in 1853, SIG is headquartered in Neuhausen, Switzerland, and listed at the SIX Swiss Exchange. The skills and experience of our approximately 9,000 employees worldwide enable us to respond quickly and effectively to the needs of our customers in over 100 countries. In 2022, SIG produced 49 billion packs and generated €3.1 billion in pro forma revenue (incl. Scholle IPN and Evergreen Asia unaudited revenue). SIG has an AA ESG rating by MSCI, a 13.4 (low risk) score by Sustainalytics and a Platinum CSR rating by EcoVadis

THE

BEST MACHINE FOR SHORT RUNS, EVER

Onyx Go continues the long-lasting success story of Uteco’s Onyx flexo presses.

Miraclon has received the prestigious FTA Technical Innovation Award for PureFlexo Printing.

Miraclon has received the prestigious FTA Technical Innovation Award for PureFlexo Printing. Accessed through KODAK FLEXCEL NX Print Suite, the technology addresses and controls unwanted ink spread to allow a wider operating window in printing – maximizing efficiency, repeatability and overall performance on press.

As one of only three Technical Innovation Award recipients, and the only recipient in the Prepress Graphics Category, it underscores the significant impact that PureFlexo Printing can make – and has already been making – in driving increased uptime for converters.

PureFlexo Printing utilizes Miraclon’s patented advanced plate surface patterning technology to resist the tendency of ink to spread during printing. Available only on the FLEXCEL NX System and focused primarily on printing with solvent inks on film, it brings a wider operational window regardless of line screen, with compound savings from fewer unscheduled press stops each day, reduced downtime and delays, and faster color setups.

Joe Tuccitto, Director of Education at FTA, said: “Recipients of the FTA

Technical Innovation Award are chosen by a panel of flexographic experts for having the potential to positively change the future of flexography. Once again this year, the judging process was extremely competitive with a wide variety of innovative technologies that utilize the flexographic process or have been designed specifically to enhance flexographic printing.

Miraclon should be very proud of this outstanding achievement; at a time where businesses are taking an extra hard look at maximizing efficiency and minimizing costs, PureFlexo Printing proves to be an innovation that can make a real impact across the whole production process.”

The award – the third FTA Innovation Award for technology from Miraclon – was presented this past weekend during the Annual Awards Banquet at FORUM 2023 in Columbus, Ohio, United States. In 2009, shortly after its commercial introduction, the FTA recognized the KODAK FLEXCEL NX System with a Technical Innovation Award which, as predicted by the judging panel, helped to change the capabilities of the modern flexo process over the last 15 years.

Miraclon received the second FTA Innovation Award for the KODAK FLEXCEL NX Ultra Solution featuring Ultra Clean Technology –another confirmation of Miraclon’s commitment to backwards-compatible, ongoing value-driven innovation for FLEXCEL NX customers – in 2020.

“We’re honored to receive this FTA Technical Innovation Award, which signifies the importance of innovations that can have a big impact across the flexo value chain,” comments Reid Chesterfield, Chief Technology & Innovation Officer at Miraclon. “PureFlexo Printing is being utilized to streamline efficiency and addresses the root cause of issues that result in unscheduled press stops and impact customers’ financial bottom line. The proven productivity benefits it brings to the print production process should be an important consideration for flexo trade shops and converters.”

The breakfast cereals firm aims for all of its packaging to be paperbased by 2024

Breakfast cereals manufacturer OneDayMore has successfully converted its packaging to a more sustainable solution, manufactured by Sonoco.

OneDayMore strives to help people take care of their health – and the planet – with its natural, nutritious, and easy-to-prepare breakfast products, including muesli, granola and porridge. The company said the next, obvious path for its development was a move towards more sustainable packaging – and Sonoco helped it to achieve this goal by converting its current packaging to EnviroCan™ with paper-bottom.

Hoping to increase the uptake in recycling by end users, Wojciech Mlodawski, Procurement Director, at OneDayMore said: “We wanted to design our packaging in a way that used the most environmentally friendly raw materials possible, while also ensuring consumers have no doubts about recycling the packaging at home, once the cereal inside was consumed..”

Previously, OneDayMore was using Sonoco’s metal-end cans, but it has since added paper-bottomed cans to its packaging lines in 13 European markets – and it hopes to expand into more. Its end goal is to have converted all of its packaging to paper by the end of 2024.

Mateusz Kurij, Business Development Manager at Sonoco said: “Sonoco

has a responsibility to adopt and maintain sustainable practices, allowing us to develop packaging solutions with minimal impact to the environment. We are proud to be part of OneDayMore’s journey to make its packaging easier to recycle and meet their sustainability goals.”

Mr Mlodawski recognises that consumers perceive the paper-bottom can as being a more eco-friendly packaging solution and the response to it having converted its packaging has been very positive.

Mr Mlodawski explains: “We had a great experience working with Sonoco during our packaging converting process. The company was very professional in terms of the product quality, delivery timings and customer service that it delivered. We also appreciated the flexible production timings and volumes, which allowed us to match our fluctuating production plans.”

Polish-based OneDayMore was founded in 2016 and has around 100 team members.

In February 2023, during an open house at the OMET Innovation Park in Molteno (Italy), a contract for the third OMET iFlex 370 printing machine was signed by Chagay Plus, Uzbekistan.

It happens rare that a printing house acquires a machine in such a short interval of time, 1 year, showing vividly the dynamic growth of the printing house, the high professionalism of the staff and of the company management. Thanks to the flexibility of the chosen

equipment, the OMET iFlex, the company’s growth is going beyond forecasts.

In the very near future, Chagay Plus plans to purchase another OMET machine, which is likely to be a big innovation in the Central Asian market.

The purchased iFlex is equipped with 8 flexographic printing units with chill drums, a die-cutting unit with quick change over system, movable cold foil unit and a relam /delam module to print on the adhesive side, UV/ HA systems which allows printing a label of any complexity and also film

products, including IML, shrink label. Chagay-Plus has been working in the flexographic printing market for more than 10 years, providing its customers with the highest level of quality in both printing and converting.

iFlex was created with as an alternative to expensive servo driven machines. This is one of the best-selling models in the world today, as the direct drive technology combined with iVision and the quick change-over of tools in the printing and die cutting units gives a tangible economic efficiency.

Patrick@printinnovationasia.com

FlexiLine 520 Compact Flex Line 520 Compact

Heidelberg Speedmaster CD 102-5+L

CP2000, Auto Plate, Diagonal Register, Preset, Auto Impression Cylinder Wash,Auto Blanket Wash,Auto Ink roller wash, I/R Dryer + Hot air, Extended delivery, Powder Spray, Technotrans refrigeration, InkTemperature Control, Dedicated Coater.

Type: Offset Printing

Year: 2004

Impressions: -

Colours: 5

Perfect: -

Sheet size H: 1020

Sheet size Y: 720

• 2-3 years practical experience (in printing industry )

• Singapore Citizen / PR

• Able to work independently

•Able to work overtime if needed

•Working Hours

Mon to Fri: 9am to 6pm, Sat : 9am to 1pm

•Responsible for setting up and operating high-end automated printing machine for quality output and timely delivery

•Ensure machine output is according to specifications required by the job run

•Examines printed results for ink density, accuracy of design and registration conforming to required artwork

•Perform first level analysis and optimize the set-up between the printed sheets

•Constantly monitors the output and take the necessary corrective actions to minimise rejects

•Perform quality control and troubleshoot during job run

•Prepares and updates all production documents required