HIGH QUALITY NEW GEARBOX DESIGNS

Mining Applications for Mine or Plant

Standard Machine designs and manufactures high quality gearboxes for all mining applications. From design concept to manufacture, whatever your critical equipment needs are we have the engineering experience and know how to get your equipment up and running.

The Timken Power Systems team applies their know-how to improve the reliability and performance of machinery in diverse markets worldwide. The company designs, makes and markets mechanical components, including bearings, gears and related mechanical power transmission products and services.

Serving Western Canada since 1968

Saskatoon, Saskatchewan

306.931.2820

Specializing in Industrial Coatings and Linings

We’re ready to meet any of your protective coating and lining needs. We can work on your site or in our facilities, with large shops (53,000 sq ft),30 acres of yard space, and cranes and forklifts on site.

• Protective Coatings

• Plant Maintenance

• Shop and Field Service

• Tank Lining

• Environmental Containment

• Industrial Fiberglass

• Concrete Protection

• Structural Steel

• Spray Polyurethane Foam Insulation

• Fire Proof Coatings

• Stainless Steel Pickling and Passivation

• NACE Certified Inspectors on Staff

• Industrial Standard Quality Program

in this issUE

Message from the editor, Shayna Wiwierski – 6

Message from the Minister of Energy and Resources, the Honourable Jim Reiter – 8

Potash industry update: Most recent available data – 10

Supporting Wanuskewin Heritage Park in its bid to be Saskatchewan’s first UNESCO World Heritage Site – 14

PADCOM: Sprinting for the finish line – 16

Mosaic’s Esterhazy operation: One of the largest, most competitive potash mines in the world – 20

How Gensource is working to reduce global food insecurity – 24

Government of Canada invests in BHP project to develop a worldleading low-emissions potash mine – 26

Millennial Lithium Corp. executives transition to next success – Potash – 28

Canada’s powerhouse of the future – 30

State of the union: An update on Unifor negotiations in the potash sector in Saskatchewan – 32

K+S Potash Canada Short Line 101 at the Western Development Museum – 34 Salt cavern storage potential across Saskatchewan – 36 New legislative changes for Saskatchewan’s potash sector – 38 Using immigration to your advantage – 40

The need for good science in the design of selective solution mining of potash – 42

Cleaning conveyor belts and maintenance – 44

PDAC 2023 Convention welcomes 23,819 attendees to world’s premier mineral exploration and mining event in Toronto – 46

DEL CommuniCations inC www.delcommunications.com

president & cEo DaviD Langstaff

managing Editor shayna WiWiErski shayna@delcommunications.com

Director of online marketing & sales miC PatErson mic@delcommunications.com

advertising manager Dayna ouLion

contributing writers: kEELy CamEron, BrEtt J. Cavanaugh, CorinnE DaELiCk, Laura gLovEr, stEvE haLaBura, harvEy haugEn, martin ignasiak, JEssiCa kEnnEDy, yohaLy mWamBa, Lana PaynE

© 2023 DEl communications inc.

all rights reserved. contents may not be reproduced by any means, in whole or in part, without the prior written permission of the publisher

While every effort has been made to ensure the accuracy of the information contained in and the reliability of the source, the publisher in no way guarantees nor warrants the information and is not responsible for errors, omissions or statements made by advertisers. opinions and recommendations made by contributors or advertisers are not necessarily those of the publisher, its directors, officers or employees.

from thE EDitor Shayna Wiwierski

s we delve into the latest edition of The Potash Producer e-newsletter, it is clear that the potash industry continues to be a vital component of the global agricultural landscape. The importance of potash as a key nutrient for crop production cannot be overstated, and the industry plays a critical role in meeting the growing demand for food in a sustainable and responsible manner.

In this issue, we bring you a diverse range of articles that delve into the latest developments in the world of potash. Our contributors have explored topics such as the evolving market dynamics, advances in potash mining and production, innovative applications of potash, and the potential impact of new technologies on the industry.

On page 16, we hear from the Potash and Agri-Development Corporation of Manitoba (PADCOM), who are working to create Manitoba’s first potash mining operation. The mine is set to begin production this spring at the Russell Harrowby Deposit and the operation will use a more environmentally friendly mining process.

On page 26, the Government of Canada shares the news that they are investing in BHP’s Jansen Potash Project to create a more green and sustainable mining industry. This will bring strong economic benefits to the province of Saskatchewan, including creating well-paying jobs that will support global demand for Canada’s critical minerals.

As always, our goal with this magazine is to provide you, dear reader, with the most informative and up-to-date content on the potash industry. We hope you find Issue 1, 2023 of The Potash Producer e-newsletter informative and insightful, and we welcome your feedback and comments.

We also welcome you to help spread the message about our publication. We also publish a handful of other mining-related e-newsletters. You can find out more and subscribe at www.delcommunications.ca/mining.

Finally, we wish to thank all the companies who have contributed a story for this issue of The Potash Producer. Special thanks go out to the following contributors:

• Steve Halabura Potash Consulting Ltd.

• The Minister of Energy and Resources for Saskatchewan, Jim Reiter

• Beechy Potash Products

• Bennett Jones

• Gensource Potash

• The Mosaic Company

• Innovation, Science and Economic Development Canada

• McKercher LLP

• Millennial Potash Corp.

• Nutrien

• PADCOM

• The PDAC

• The Saskatchewan Chamber of Commerce

• Unifor

• Western Development Museum

• Bit Service

• RESPEC

We invite all interested companies to share their news and editorial ideas with us. If you would like to contribute a story for future issues of The Potash Producer e-newsletter, please contact myself at shayna@delcommunications.com.

Enjoy this issue! l

Message froM the Minister of energy and resources thE honouraBLE JiM ReiTeR

on behalf of Premier Scott Moe and the Government of Saskatchewan, I am pleased to provide an update on potash in the province.

For many years Saskatchewan’s economy has benefited from the mining and production of potash. In 2023 potash remains firmly fixed as Saskatchewan’s largest critical mineral export. I’m pleased to share that in 2022 the value of potash sales was $18 billion – a new record and doubling the $9 billion target established in Saskatchewan’s Growth Plan. Production also reached a new record high of 14.35 million tonnes K2O.

AMI SUPPLY

• MATO Belt Fasteners

• Belt Cutters and Clamps

• Belt Trackers • Belt Cleaners

• Safety Nets/Guards

The industry is thriving and playing a key role in providing jobs and economic opportunity for Saskatchewan.

Internationally, the ongoing situation in Ukraine has impacted major producers Russia and Belarus. Historically they accounted for one-third of global supply. Since the invasion, together, they account for only 21 per cent of global production. Due to sanctions and customers looking elsewhere for ethically produced potash from stable jurisdictions, Saskatchewan is uniquely positioned to fill the gap. As the only producer of potash in Canada, the future opportunities in this sector are immense. Our

JAMIE YAGANISKI

Main: 306-652-9878

Cell: 306-227-7414

Email: jyaganiski@amisupply.ca

major producers have already signaled that they will be increasing production in the near term and we’re seeing increased investment in operating capabilities to help increase those production numbers in the long term.

Nutrien Ltd. has announced their plans to accelerate their increased production capabilities. By 2026 they will be producing 40 per cent more than 2020 production numbers. Also, the Mosaic Company announced that it is planning to resume operations at the Colonsay mine in the first half of 2023 and overall increase its production levels by 1.5 million tonnes KCl. K+S Potash Canada plans to nearly double production at its Bethune mine by 2040 and has commenced hiring to carry out these operations. BHP is looking to accelerate its $12 billion Jansen project and is conducting studies for Stage 2 that would add an additional four-million tonnes KCl of capacity.

Saskatchewan’s world-leading resource companies play a crucial role in supporting food and energy security around the globe. It is both a tradition we are proud of and a future full of possibilities. Whether you are a potash company, a supplier, or an industry professional, thank you for supporting Saskatchewan. l

Disaster recovery. Hosting. Colocation.

Cloud Services

When you’re ready for the next level of power and cooling, bandwidth usage, and 24/7 security, you’re ready for SaskTel. Whether you choose Hosting, Colocation, or Disaster Recovery, your SaskTel Data Centre will provide the secure environment you need to protect your data and applications as well as access to technical experts to assist you with running these deployments.

sasktel.com/

cloud

MoST receNT AVAILABLE DATA POTASH INDUSTRY UPDATE

PoTaSH

THe RoDney DanGeRfieLD of CanaDian CRiTiCaL MineRaLS?

By steve halabura, P.geo., halabura Potash consulting Ltd.

Let’s clear one thing up right from the start: for those of you not of a certain age, Rodney Dangerfield was a standup comic during late-night talk shows during the ‘70s and ‘80s whose stock opener was “Let me tell yah, I get no respect, no respect at all! Why just the other day…”.

At this moment of writing, the Prospectors and Developers Association of Canada (PDAC) Convention, the annual “high holidays” of Canada’s (some might say, the world’s) mining business, is going on (editor’s note: the PDAC Convention happened in Toronto from March 5-8, 2023). I did not attend, but I have closely followed the program of events, happenings, and gatherings. My impression is this: the general theme of the mining industry, especially the junior mining sector, is that earth resources, and the ways and means of extracting those resources for the betterment of humankind, rests upon one mission: Energy transition, which may be translated to “Lithium!”, “Copper!”, and “Nickel!”.

But what about the mission of mining

to combat food insecurity? It would seem to me that a family would like to ensure that it will be fed before it thinks about buying a new Tesla, no?

In speaking to junior mining people, mining a resource means extracting lithium, or copper, or nickel. When the theme of mining a resource to ensure safe, secure, and sustainable global food production, there is often a pregnant pause, followed by a somewhat embarrassed admission that “hey, you must be talking about that other stuff, whatacallit, ‘putt-ASH’?”

nrCan Website (2022)

NRCAN Website (2022)

Why is potash on this list? Because it is vital to global required by farmers worldwide, and since it cannot be occurring deposits. The Province of Saskatchewan hosts supplies some 40 per cent of the world’s potash requirement.

Like I said, potash gets no respect amongst the junior resource sector, not to mention the critical mineral crowd… However, potash is not a joke! Critical mineral refers to a material that is needed by the global community to allow achievement of strategic aims, such as decreasing carbon emissions, increasing alternate forms of energy generation, supporting the transition to new energy storage systems, or supplying global communities with essential materials such as nutrients.

Guess what this means?

Given that 40 per cent of the world potash trade comes the war is strongly driving the re ordering of supply long term, safe, secure, and sustainable supply of what

Furthermore, since 100 per cent of Canada’s potash Scott Moe is a very popular fellow when he walks into Saskatchewan’s potash resource of more than 100 billion replace 100 per cent of the current global Russian and provides major incentive to rapidly produce an additional and in the long term , the opportunity for Saskatchewan

In March 2022, Canada declared 31 commodities to be critical minerals. One of these is potash. At the time, the government stated its intention is to capitalize on the rising global demand for these minerals, driven in large part by their role in the transition to a low-carbon and digitized economy. In addition to providing the materials essential for energy transition, they are also required inputs for advanced manufacturing supply chains, including defence and security technologies, consumer electronics, agriculture, and critical infrastructure.

Why is potash on this list? Because it is

Where else do you find such an opportunity available flocking into potash by droves? Well, here is the problem:

There are two elements to cost, the first being

DEEPLY INVESTED IN MINING.

vital to global food security. Potash is a mineral fertilizer required by farmers worldwide, and since it cannot be synthesized, it must be mined from naturally occurring deposits. The Province of Saskatchewan hosts the world’s largest deposit of potash and supplies some 40 per cent of the world’s potash requirement.

Guess what this means?

Given that 40 per cent of the world potash trade comes from Russia and Belarus, it is no surprise that the war is strongly driving the re-ordering of supply chains such that potash end-users can establish a long-term, safe, secure, and sustainable supply of what I call “ethical” potash.

Furthermore, since 100 per cent of Canada’s potash comes from Saskatchewan, I can see why Premier Scott Moe is a very popular fellow when he walks into the “Potash End-Users Club”.

Saskatchewan’s potash resource of more than 100 billion tonnes means it has the raw material to replace 100 per

Where else do you find such an opportunity available for the taking? Why aren’t the junior miners flocking into potash by droves? Well, here is the problem: cost.

cent of the current global Russian and Belarusian potash supply. In the shortterm, this provides major incentive to rapidly produce an additional two-tofour million tonnes of potash per year, and in the long-term, the opportunity for Saskatchewan to double its current potash sales.

Where else do you find such an opportunity available for the taking? Why aren’t the junior miners flocking into potash by droves? Well, here is the problem: cost.

There are two elements to cost, the first being exploration cost. While the size of the Saskatchewan in-situ potash resource in Saskatchewan is enormous, its sheer size means that to define the NI43-101 compliant “Mineral Reserve” needed for financing a new mine, it requires significant exploration and con-

firmatory drilling and seismic beyond the one or two pre-existing historical drill holes needed to define a mining “sweet spot”. Potash wells on the prairies are deep, complex to drill, and expensive.

The second is the capital cost of the mine itself. Traditional “shaft and tunnel” and vertical solution cavern mines are very expensive. For example, BHP Billiton’s Jansen potash mine, which is currently under construction, will produce 4.35 million tonnes per year (TPY) in its first phase. This will require an investment of USD$5.7 billion, in addition to an existing expenditure of USD$4.5 billion for a total expenditure of USD$10.2 billion, or USD$2,345 per tonne of nameplate capacity. Of this amount, the largest single item is the shafts and infrastructure, which cost USD$2.97 billion.

The above two factors represent significant barriers to entry into the potash business for majors, let alone the juniors. So, it is no surprise the junior resource sector steers away from exploiting potash, preferring to focus on the incentivized and cheaper-to-develop battery metals.

The result of this is that the gap between conflict and ethical potash supply widens, and food insecurity only gets worse. How can we deploy Canada’s bountiful potash resource to combat global hunger now? The world needs Canadian potash today, not in five to 10 years.

Here is an idea: incentivize the search

and development of Canadian potash so that the junior mining sector (AKA the “PDAC crowd”) is attracted back to the potash fields of Saskatchewan and Manitoba. This is the sector that has traditionally driven the development of Canada’s resource economy, and they need to be given a reason to pay more attention to developing new potash supplies for hungry global markets.

How do we get them back? Its obvious: we need to overcome the cost barrier to entry into the potash business, and I see two ways to do this.

First, stimulate innovation in mining methods so that there are cost-effective alternatives to traditional, and costly mining technologies like shafts and tunnels. The federal and provincial governments can incentivize investments into new and innovative mining technologies that overcome these barriers, for instance, what I have been calling “small modular potash” technology. Tied to this effort is making sure that existing mining innovation funding programs specifically include potash within their scope of approved commodities.

Second, the easiest and most effective way to get the attention of the junior miners is to offer financial incentives, the easiest and most obvious being for the federal government making potash eligible for the Critical Mineral Exploration Tax Credit (CMETC). Yes, we know Saskatchewan has potash, but that’s like saying “the supermarket has cheese”. Further field work (i.e., drilling and seismic) is required to convert the broadly defined “resource” into a tightly constrained “reserve”. Increasing the CMETC to include potash work would be extremely beneficial to attracting the juniors back into building new mines.

Potash is no joke (no offense intended to Mr. Dangerfield). What was once a quiet, backwater type of industrial activity is now on the front lines of war and global food and economic security. Potash should be uttered at venues like the PDAC as much as is the words “Lithium” or “Copper”.

Do not forget this: every tonne of pot-

ash that Canada puts into the global marketplace is one tonne of potash taken out of the hands of an autocrat. Therefore, we as a nation must rapidly advance our potash advantage, if we are any bit serious about fighting global food insecurity.

‘Nuff said… l

Positioning you for success.

Construction Surveys

+ Construction layout

+ As-built

+ Earthworks modeling

+ Inspection surveys

+ Deformation surveys

+ QA/QC reporting

caltechgroup.com

SuPPoRTinG WanuSKeWin HeRiTaGe PaRK in iTS biD To be SaSKaTCHeWan’S fiRST uneSCo WoRLD HeRiTaGe SiTe

on a beautiful fall day, under a clear blue sky with a light wind, a buzz of excited energy could be felt among the crowd gathered at Wanuskewin Heritage Park, just outside of Saskatoon, Saskatchewan.

Wanuskewin is known as the “Gathering Place”. And on this day, the day before Canada’s National Day for Truth and Reconciliation, people gathered to hear Nutrien President & CEO Ken Seitz announce that Nutrien is making a $3 million investment to the UNESCO

Ready Campaign, as the premier partner. This $12 million fundraising campaign is to support Wanuskewin’s application to become Saskatchewan’s first UNESCO World Heritage site by 2025.

“I know that it’s not a small undertaking to gain UNESCO World Heritage Site status, and it takes significant resources,” Seitz said during the event. “It’s for that reason that Nutrien is proud to partner and support this endeavour.”

Wanuskewin has a 6,000-year history in Saskatchewan, and Nutrien is a com-

“i know that it’s not a small undertaking to gain unEsCo World Heritage Site status, and it takes significant resources. it’s for that reason that nutrien is proud to partner and support this endeavour.”

mitted supporter of the organization and its goal to showcase Saskatchewan’s history on a global scale.

“Nutrien has been a constant supporter, not only in our day-to-day capacity, but as allies in our efforts to address Truth and Reconciliation,” says Darlene Brander, CEO Wanuskewin Heritage Park. “As in the past, Nutrien’s support will play a fundamental role in our newest endeavour: to achieve Saskatchewan’s first UNESCO World Heritage designation.”

To achieve this goal, Wanuskewin must meet rigorous UNESCO criteria while simultaneously expanding its already extensive and multi-faceted programming and resource management activity.

Wanuskewin gives the opportunity to delve into the past and discover what life was like for nomadic hunter-gatherer peoples and to be a living reminder of the peoples’ sacred relationship with the land. The theme of Wanuskewin Heritage Park is one of interpretation –exploring and explaining the meaning of Plains cultures to gain a better understanding of ourselves, Saskatchewan’s Indigenous peoples, and our common heritage.

Nutrien’s support for this project is in alignment with its sustainability strategy and is a part of its Diversity and Inclusion community investment focus area. Driven by those commitments, the company strives to leverage its influence to build meaningful relationships and deepen conversations around reconciliation.

“As a company that has a large operating base in Canada, Nutrien acknowledges the colonial history and trauma that has led to the contemporary context we live in today,” says Pam Beaudin, senior Indigenous relations manager at Nutrien. “We work in partnership with

Indigenous leaders and communities to close the gaps colonial policy has created, and we collaborate with Indigenous organizations and institutions to

offer community programs, training and employment programming, and stand in solidarity advocating with our partners.” l

Grow with us

Now hiring at all Potash sites across Saskatchewan:

- Industrial and Heavy Duty Mechanics

- Engineers and Technologists

- Mill and Mine Operators

- Electricians and other Trades

www.HDengineeringDesign.com

We provide high-quality, fit-for-purpose solutions. safety . people . integrity . experience . quality . innovation

PaDCoM SPRinTinG foR

THe finiSH Line

Manitoba’s first potash mine is set to start production this spring

As the company gets closer to its goals, there are intensifying operations around PADCOM’s Manitoba potash mine that have the company working on multiple fronts, including final construction at the mine site itself, ongoing technical and administrative work in Russell, and an effort to boost its profile in the community as it settles in for decades to come.

“Manitoba, historically, has never had a potash mine, so that alone is quite important in the province’s development and locally, even more so, a project of that size,” says Guillas.

The company was formed to advance rural development opportunities in Western Manitoba, specifically to develop a potash mine at the Russell Harrowby deposit.

as the eastern neighbour to Saskatchewan, the world’s leading potash producer, Manitoba has officially entered the potash mining business. For those who do not know of the Potash and Agri-Development Corporation of Manitoba (PADCOM), the company has taken a big step in putting Manitoba on the map for potash.

The PADCOM mine is set to begin production this spring at the Russell Harrowby Deposit. It will have taken PADCOM 15 years to become a potash

producer by spring 2023. The project’s success has resulted from the strong support of investors, key stakeholders, a diligent operations & management team, and the Government of Manitoba.

“Our operations manager and engineers have worked very strenuously to get the mine up and running toward our production goals. I’m extremely happy with the progress being made,” says Daymon Guillas, president of PADCOM.

“As a member of the neighbouring community, I realized years back that there needs to be more money put into the local economy and better rural community development. This is where PADCOM comes in. I think it’ll be a great local advantage.”

Emphasis on diversity and community ties into the company’s ambitious plans in its overall operations. PADCOM has developed a partnership with the Gambler First Nation, which have a 20 per cent equity stake in the project. Ad-

Poorly designed transfer chutes reduce productivity along your conveyor system — often increasing the chances of costly downtime.

The transfer chute is a critical piece of equipment in mining, quarrying, and other material handling operations. Considering all factors up-front will result in a transfer chute design that aids, rather than restricts, production.

West River Conveyors pays careful attention to the properties of the material being conveyed — with an expert understanding of how it moves through the transfer chute. From the design stage forward, we can find a solution that fits your needs.

ditionally, PADCOM will present community benefits agreements to several Indigenous communities in the area, Gambler First Nation, Birdtail Sioux First Nation, Waywayseecappo First Nation, Treat 2 Territory, the Manitoba Métis Federation, and the Municipality of Russell-Binscarth.

In addition to its partnerships, PAD-

COM also pushes for a more environmentally efficient forefront.

“This operation will use a more environmentally friendly mining process,” said Guillas. “The physical footprint is small, and the process will use green energy.”

Using a sustainable process, the production capacity of the potash mine is

Pumping and mixing specialist for the fertilizer industry

estimated to be 250,000 tonnes per year. The potash would be processed right on-site at the potash processing facility.

Guillas and the rest of the PADCOM team look forward to completing the assembly and operating the mine for many years to come.

To find out more about PADCOM and its mine, please visit manitobapotash.ca. l

Pumps are at the heart of fertilizer production, and correct equipment selection that takes into consideration hydraulic design, materials, application knowledge, duty point and maintenance regime are critical to achieving reliable long-term pumping operation and maximum plant production. As an expert in solutions for corrosive and abrasive liquids, or those with high gas content, Sulzer offers a complete range of pumps, agitators, mixers and compressors for the fertilizer industry. Our innovative products are suitable for the production of potash, phosphate and NPK compound fertilizers as well as acids and industrial chemicals.

Sulzer’s global presence provides local support and expertise through a network of manufacturing facilities and service centers. Our solutions combine energy efficiency, low lifecycle costs, reduced environmental footprints and excellent reliability.

Contact us today to learn more.

Sulzer Pumps (Canada) Inc. Phone (514) 836-3796, salah.attie@sulzer.com

www.sulzer.com

We offer outstanding personal service and quality in the areas of:

MoSaiC’S eSTeRHazy oPeRaTion:

one of THe LaRGeST, MoST CoMPeTiTive PoTaSH MineS in THe WoRLD

Design and development are underway for a third compaction circuit that will be added at Esterhazy’s k1 mill to increase blend-grade production capacity. When operational by the end of 2023, this third circuit will provide additional production flexibility to meet varying market demand for Mosaic’s different potash products.

now running on all cylinders, Mosaic’s Esterhazy operation is one of the largest, most competitive potash mines in the world. Both shafts at K3 have been in operation for more than a year, and production continues to ramp up towards full hoisting capacity of more than 72,500 tonnes per day. A new daily hoisting record of 63,180 tonnes was reached in September 2022. Having both shafts in production removes historical ore handling constraints at Esterhazy and ensures capacity for additional ore supply as more mining machines are assembled

underground and put into production. Commissioning of a twelfth four-rotor mining machine began in January, and a thirteenth is expected to be completed later this year.

All machines in K3’s fleet can operate autonomously in fully developed production areas – which reduces risk for our employees and eliminates downtime, as they can be safely operated 24/7.

integrated operations: operational visibility and real-time information

K3 is built on technology and innovation. It is designed to provide annual production of six-million tonnes, which is about 60,000 rail cars full of potash. This means moving 17 to 19 million tonnes of ore per year.

Much of those operations are now being monitored and run from a technology-enabled pilot Integrated Operations Centre, or IOC, on the surface at K2. Cameras and sensors monitor allow employees in the IOC to view the entire 12-kilometre conveyance system that transports ore from where it is mined 3,350 feet underground, up through the shafts, and across the surface to the K1 and K2 mills for processing.

“The goal of this IOC is to improve production capabilities and increase reliability by integrating our operations from when the ore is mined to when product is loaded on railcars to ship out to our customers,” said Dustin Maksymchuk, general manager – Esterhazy. “This provides our employees with the operational visibility and information they need, and they are empowered to act on that data in realtime.”

Integrating operations has also allowed us to build management systems and governance processes that help us op -

helping support, manage, and implement change is a focus across mosaic. t he Esterhazy team recently held training for Change management Project Leads and are ingraining Change management in their culture through dedicated resources, documented processes, ongoing training and continuous improvement feedback.

During the week of January 8, Esterhazy employees joined with others across mosaic to launch Employee inclusion networks – voluntary, employee-led and leader-sponsored groups that help foster a diverse and inclusive workforce through advocacy and allyship.

funds and gifts from the Esterhazy team’s holiday celebrations were donated to three local food banks in Esterhazy, Langenburg, and Churchbridge. Pictured: raelene andres, senior administrative assistant – Esterhazy, presenting a check to Lynette Griffith with Esterhazy and area hampers.

erate efficiently, effectively, repeatably and sustainably. It also provides new opportunities for employees.

“Employees helped us design the IOC, and their input will continue to be crucial as we move forward,” said Maksymchuk.

New roles were created to support integrated operations, including IOC coordinators responsible for managing the daily operations plan. There are also training and developmental opportunities available for employees to learn about and help refine automated mining controls and systems.

everaging the full capacity of K1 & K2 mills

With both shafts at K3 up and running, operations at Esterhazy are no longer shaft-limited and can leverage the full capability of the mills. In addition to the IOC and implementation of new processes like Short-Interval Control, which helps employees maximize production by improving coordination and optimizing runtime, there is other work underway to improve operational reliability of the mills and ensure they are utilized to the fullest capacity.

At the K1 mill, a third compaction circuit is being added that will improve our ability to convert standard tons to

over 100 risk reduction projects were completed in 2022, each one an employee idea that helps reduce safety or environmental risks.

granular tons. This means more blendgrade product, which gives us additional production flexibility to meet market demand for specific products. This project is underway and expected to be completed by the end of 2023. At the K2 mill, a project was recently approved to add a hydrofloat circuit that will increase K2’s overall production capability by 400,000 tonnes – 80 per cent of which will be natural crystal granular and the remaining standard product.

s taying focused on delivering on our commitments

Throughout the K3 ramp-up and as we look ahead, the Esterhazy team has remained focused on delivering on our commitments and providing the products our customers need to feed the world.

Over 100 risk reduction projects were completed in 2022, each one an employee idea that helps reduce safety or environmental risks. The K1 and K2 mills operated without a recordable injury for the entire year. We are also making considerable progress improving the safety culture across the site by focusing on employee awareness of ground conditions at K3 and heightened daily inspections in all immediate work areas to identify and address potential hazards.

“Our talented workforce is looking to the future and finding new ways to increase safety, efficiency, and connection across our immense operating footprint – building a ‘digital mine’ to power us into the future,” said Maksymchuk. “Employees are leading innovative, technology-enabled improvements that will help ensure we have the operational capacity, reliability, and flexibility we need to meet

the changing needs of our customers. We’re also remaining focused on safe, responsible operations and investing in our team and local communities.”

This includes our commitment to partnering with local Indigenous communities and building a diverse, inclusive workforce and culture.

“The sustainability of our business and our communities are indelibly linked, and we’re proud of the progress we’re making in these areas,” said Maksymchuk. “We’re taking action to strengthen local communities and ensure Mosaic is a place where all people feel welcome, safe, valued, and respected.” l

HoW GenSouRCe iS WoRKinG To ReDuCe GLobaL fooD inSeCuRiTy

climate change, conflict, and inequity have more people than ever going hungry. With food security challenging 10 per cent of the population, it equals approximately a billion people around the world being affected, and the problem is growing. The urgent need for sustainable agricultural technology to help reduce the global food crisis has never been greater.

Gensource recognizes the responsibility of delivering a strategic and critical nutrient (potash) to support global food production needs. With bridge engineering at its flagship Tugaske project already underway (further advancing its front-end engineering and design work completed in October 2021), the company is using this unique opportunity to simplify certain aspects of its operations, uncovering significant potential to improve both overall performance and profitability.

In particular, process and technology improvements within the surface process plant and optimization of its underground cavern design and layout are expected to yield significant simplifications. The outcomes of the bridge engineering efforts are anticipated to be shorter construction schedules, capital cost savings, and operating cost reductions.

As one of the safest jurisdictions to do business in the world, Saskatchewan lays claim to 50 per cent of the known global potash resource. Included on the critical minerals list by the Canadian federal government, potash produced in Saskatchewan is essential to world food production, land management, and sustainable development. Agri-food exports also help drive the provincial and federal economies. The province makes up 21 per cent of Canada’s agri-food exports and 40 per cent of Canada’s total farm area.

Like many other industries, the potash industry has been hit by wide-ranging cost escalations stoked by inflation, supply chain disruptions, global security issues, and more that have resulted in escalating CAPEX and operating costs for most capital projects, Gensource Potash included.

Gensource conceived the modular and scalable approach to potash production that is now being widely considered. Its modular technology will produce potash with near-zero environmental impact, and its diminutive production footprint is designed to integrate into smaller rural Saskatchewan communities. With no salt tailings or brine ponds, both synonymous with traditional potash production, and 75 per cent less water used, it presents a new and sustainable way of extracting a critical mineral that is essential to both the Canadian and global food production industries.

Against a backdrop of a tenuous global economy and tumultuous financial markets, a prudent business strategy called for a close look at every facet of the development of the company’s flagship Tugaske project for both synergies and cost savings.

Now, with the recent close of a non-brokered private placement, the company is poised to advance, with plans to implement its design and process changes, and start drilling its first cavern as early as summer 2023.

The company is proud of its recently announced strategic business partnership with the Nekaneet First Nation, a relationship that encompasses equity ownership that will bring both multi-generational benefits to its shareholders and the local community, as well as an opportunity to help shape the future of the company through board representation. The deal reflects Gensource’s commitment to truth and reconciliation.

“Part of truth and reconciliation means working together as a community and as leaders in local development opportunities,” said Mike Ferguson, Gensource’s chief executive officer. “In this case, the opportunity is to participate together in the ownership and development of resource projects in Saskatchewan and we couldn’t be more excited to work together.” l

GoveRnMenT of CanaDa inveSTS in bHP PRoJeCT To DeveLoP a WoRLDLeaDinG LoW-eMiSSionS PoTaSH Mine

Investment will help create a greener, more sustainable mining industry and bring strong economic benefits to Saskatchewan

greening Canada’s mining sector is a crucial part of the transition toward a low-carbon economy. That is why the Government of Canada is making investments that will help build a greener future by supporting advancements in sustainable mining practices, while creating well-paying jobs that will support global demand for Canada’s critical minerals.

On January 30, 2023, the Honourable François-Philippe Champagne, Minister of Innovation, Science and Industry, announced an investment of $100 million through the Strategic Innovation Fund to support BHP’s $7.5 billion project to develop its world-leading low-emissions potash mine. This mine, located in Jansen, Saskatchewan, is expected to generate the lowest di-

rect emissions of any potash mine in the world. Through this project, BHP will significantly minimize the carbon footprint of the mine, improve worker safety and implement technology to further reduce emissions from mine operations.

“This investment shows that our government is committed to the hard-working people of Saskatchewan,

as well as to Canada’s mining and agricultural sectors. Potash is a critical and strategic resource in the global agricultural industry, and we are pleased to partner with BHP on this project to bring strong economic benefits to Saskatchewan,” said the Honourable François-Philippe Champagne, Minister of Innovation, Science and Industry. “This project will lead to the creation of hundreds of well-paying jobs for Canadians, while also encouraging green initiatives in the mining industry.”

We know how critical potash is for our country when it comes to food security. By investing in critical minerals today, we’re building a stable industry for future generations in Canada. This support will lead to the production of critical minerals that will support transformation and growth across the Canadian economy, while enabling BHP to transform its own operations, reduce greenhouse gas emissions, and prepare for a net-zero future.

This will ensure Canada remains a global leader in both potash production and sustainable mining. It will also provide critical environmental benefits and long-term benefits for the people of Saskatchewan by creating and maintaining 600 highly skilled jobs and over 100 co-op terms for students, supporting Indigenous communities through employment and economic opportunities, and cementing Canada’s leadership position in potash production. BHP has signed opportunities agreements with six First Nations.

“The demand for potash will continue to grow due to a need to increase crop yields to feed a growing population. Canada has some of the best potash deposits in the world, along with a great skill base and strength in resource de-

velopment. We know that being successful is not just about what you mine, but also about how you mine, and we take this responsibility seriously,” said Ragnar Udd, president, Minerals Americas for BHP. “Jansen Stage 1 is setting a new standard for potash—not just for Canada, but around the globe. BHP is honoured to partner with the

Investing in Saskatchewan’s future. It’s happening now.

The BHP Jansen Potash Project is one of the world’s largest potash mines and the largest economic investment in Saskatchewan’s history, creating local employment and procurement opportunities, whilst providing the potash essential to help increase global food production.

The future is clear. It’s happening now.

To discover how, visit bhp.com/betterfuture

government, Indigenous peoples, and the people of Saskatchewan to create a mine that will use the latest technology to deliver a productive, efficient, and sustainable operation that will bring widespread benefits to the region, the people of Saskatchewan, and BHP shareholders for decades to come.” l

MiLLenniaL LiTHiuM CoRP. exeCuTiveS TRanSiTion To nexT SuCCeSS – PoTaSH

financial markets rarely offer a do-over, and it’s certainly not often that ground-floor opportunities present themselves in such a promising package. After the development of Millennial Lithium Corp. (Millennial Lithium) (OTCQX: MLNLF, TSXV: ML) into a desirable, advanced-stage lithium company, which resulted in an overwhelming success, Millennial Lithium was acquired for more than $400 million USD, generating a return of over +1,300 per cent for early investors. As a result, two key members of the company’s board of directors have transitioned from lithium to potash to create Millennial Potash.

Graham Harris and Farhad Abasov— two names very familiar to Millennial Lithium investors – will now bring their expertise to the ever-promising potash industry.

millennial p otash – leadership

Three members of Millennial Potash’s board of directors and its chief financial officer (CFO) come directly from Millennial Lithium. Graham Harris, who was the founder and chairman of the board at Millennial Lithium. Farhad Abasov, who was Millennial Lithium’s president and CEO. Dr. Peter J. MacLean, Ph.D., P.Geo. was the senior vice-president technical services at Millennial Lithium; and Max Missiouk, CPA, CMA, who served as CFO for Millennial Lithium.

If past is prologue, then Millennial Potash’s investors are in for quite a journey. It’s a trip that could resemble the path Millennial Lithium’s shareholders wandered down that recently landed them squarely in the middle of an attractive buyout deal with the NYSE’s Lithium Americas Corp. (NYSE: LAC) that was completed on January 25, 2022.

Leadership at Millennial Potash has kept the vision simple—identify and acquire a significant asset that is amenable to known/proven extraction techniques that fits in the lowest quartile of extraction costs.

Millennial Potash’s stated mission to execute that vision is a familiar one, “Build a strong team that has done it before and that can execute the strategy”. That strategy is locating a lowcost project, fast-tracking exploration, and fully developing the project to drive shareholder value.

Millennial Potash’s dream team is no stranger to developing companies and then positioning those projects for successful exit strategies. Abasov and MacLean, as well as their team, have been involved in potash projects before. The most recent, Allana Potash Corp., was taken from a very early stage (even earlier than Banio) through feasibility and sold to Israel Chemical Ltd. for $170 million. Abasov was also the cofounder of Potash One, sold to German producer K+S for $430 million. Making the transition to the potash industry

even easier, the group chose a project with a history and with some key development assets already in place.

millennial p otash – company & project

Currently trading in both the U.S. and Canadian markets, Millennial Potash Corp. (Millennial Potash) (TSX-V: MLP) is an advanced startup mining company that is anything but an upstart. Its seasoned board of directors and executives, combined with a meticulously chosen property located in the potash-bearing basin of Southwest Gabon, makes Millennial Potash a real player in the potash sector. The Banio Project’s owner, Meridian Drilling (Meridian), have been sitting on the project for a couple of years. Meridian approached Millennial Potash earlier in the summer of 2022. After some research, Millennial Potash decided to move ahead with the Banio Potash Project because it has a combination of three key components: right location, strong resource, and right jurisdiction.

The Banio Project covers 1,238 square kilometres and is in the southwest corner of Gabon along the Atlantic coast of Africa. Banio is located 50 kilometres south of a port city of Mayumba. Access to the Banio site can be made via several accessible roads from Mayumba and waterways provide alternative access to the project. The Banio project sits on the border with the Republic

“Leaders don’t force people to follow. They invite them on a journey.”

of Congo and is located 70 kilometres north of significant potash deposits and the historical mines of the Kola and Dougou potash deposits, all of which are located within the same sedimentary horizons of the past-producing Congo Basin. The potassium-bearing salt layers of the Republic of Congo extend into Gabon, at similar depths and thicknesses. The Banio project has a proximity to Brazil, which is a large importer of potash. The project also represents reduced shipping times to the India and China market compared to other potash projects.

The Banio project was drilled in 2017 and 2018. A three-hole drill program including BA-001, BA-002, and BA-003 was completed on the Alpha Section in order to test the previously reported exploration target. Drill holes BA-002 and BA-003, drilled 2.2 kilometres apart, were successful in intersecting multiple wide potash seams. Drill hole BA-01 was stopped at 364 metres after intersecting steeply dipping evaporites.

Millennial Potash doesn’t just plan on completing a 43-101 compliant resource. Millennial Potash will look to complete a feasibility study setting up the potential to become a target for acquisition. The production and processing method is critical. Millennial Potash envisions using solution mining to extract the sylvinite and carnallite. The reasoning for solution mining is because it has been done before by similar projects in the region and has been quite successful. Solution mining also has a lower CapEx compared to traditional underground mining. After the extraction of the resource there will also be a processing plant of crystallizers, drying, and compaction to produce Muriate of Potash (MOP) product. The MOP product will be delivered on 7,000-tonne barges to a Mayumba off-

shore loading facility and loaded onto bulk carriers. Millennial Potash had money in the bank for the initial Phase 2 exploration program to be expedited and to start drilling in Q2 2022. Drilling was to be followed by an updated mineral resource estimate and continued permitting. Phase 3 exploration will follow and include a resource update and a preliminary economic assessment (PEA) by end of Q4 2023.

Gabon is a stable country with low sovereign risk and a recently revised mining code. It has the third-highest per capita GDP in Africa and recently joined the British Commonwealth in June 2022. Transparent mining industry laws have allowed Gabon to diversify from their mainstay oil and gas export. Major global foreign firms such as Fortescue, Eramet, Total, and Shell all have developing projects in the country.

t he p otash marK et

Currently there is a lot of expressed interest in potash. Potash prices surge on disrupted production from Russia

and Belarus due to sanctions caused by the war in Ukraine. Potash prices are expected to remain strong as elimination of approximate sanctions against Russia and Belarus decreased the global annual MOP capacity to approximately 55 million tonnes, while demand is approximately 73 million tonnes. Demand is expected to increase to approximately 90 million tonnes by 2030 due to population growth where the increase in affluence in developing nations will lead to higher-quality food products.

Even if the potash price dips, this will be a very strong project with solid margins.

Millennial Potash Corporate Office: Suite 300, 1455 Bellevue Avenue West Vancouver, BC, Canada V7T 1C3

Email: info@millennialpotash.com www.millennialpotash.com

Farhad Abasov – Chairman: Farhad@millennialpotash.com

Graham Harris – SVP, Capital Markets, Director: Graham@millennialpotash.com l

• Custom machining and milling on small to large work pieces, in shop or on-site.

• Extensive industrial mechanic services, includes refurbish, maintenance, and installations.

CanaDa’S PoWeRHouSe of THe fuTuRe

western Canada is positioned to become a global powerhouse as the world struggles to address the growing food and fuel insecurity challenges of the future. Businesses, small and large, in the resource-rich prairie provinces are making significant gains in innovations that increase food and fuel production, while also focusing on decarbonization and transitioning to a low carbon economy. Much of the innovation underway is also focused on establishing value-added and supply chain services in the prairie provinces, creating jobs and supporting economic growth in Canada.

As the powerhouse of the future, with the resource wealth and the growing decarbonization opportunities it of-

fers Canada today and into the future, thought leaders in the key food, fuel, and fertilizer industries believe western Canada must play a significant role in shaping the country’s approach to food and fuel security of the future.

Over the summer of 2022, the Saskatchewan Chamber of Commerce initiated discussions with other chambers, and leaders of western Canadian businesses about a western Canadian Food, Fuel and Fertilizer Summit. The summit was intended to bring awareness to the significant work being done in the prairie provinces to address global food and fuel insecurity, and to take a leadership role in advocating for a strategy to take critical western Canadian food and fuel resources to the world.

Western Canadian businesses were

overwhelmingly supportive of a summit that would showcase the leading low carbon innovations underway, and that would assist the Government of Canada in taking greater action to address the looming food and fuel challenges of the future. In February 2023, this vision became a reality, and the Food, Fuel, and Fertilizer Business Summit (FFFBS) was held over a twoday period in Saskatoon, Sask. The event was a monumental success.

The FFFBS included a world-class lineup of presenters, including president and CEO, Nutrien, Ken Seitz; president and country chair, Shell Canada, Susannah Pierce; president and CEO, Cameco Corporation, Tim Gitzel; president and CEO, AGT Food and Ingredients Inc., Murad Al-Katib; president and CEO, Canadian Chamber

of Commerce, the Honourable Perrin Beatty; and president and CEO, Vancouver Port Authority, Robin Silvester. Event attendees also heard from Federated Cooperatives, KPMG Advisory Services, FHQ Development, and several SMEs in Saskatchewan.

What did we hear during the two-day event? Canada’s role as a food-producing nation has never been more important than it is today, and western Canada’s role, as the source of that food, is critical. Western Canada has abundant access to all that is needed to produce food. We have vast amounts of land. We are home to the world’s largest producers of crop nutrients, we have access to the fuel needed in food production, and we have a large resource pool with a strong work ethic and commitment to western Canada.

With so much at our fingertips, Canada has created a powerful brand in the world today. We are a democracy, we are seen as ethical, we respect the rights of minorities, we are seen as responsible in our treatment of the environment, and we are respectful in our interactions. This is critical for us in so many ways and will play an important role in helping us market our food, fuel, and fertilizer to the world.

With all great opportunities, challenges do exist, and successfully producing and exporting the food and low carbon fuels the world needs will require government cooperation. We must work together to position western Canada as the powerhouse it is. This will take vision and commitment from all levels of government, and the voices of small, medium, and large enterprises to capitalize on the food, fuel, and fertilizer boom in western Canada. l

Electrical Cable Supply Ltd. Understands the demanding nature of the Industrial sector and with our extensive product knowledge and broad selection of products, we can provide the value you need to successfully complete projects in potash extraction, production, and manufacturing.

• Blasting Wire

• Extra Flexible Reeling & De-Reeling Cable

• Leaky Feeder Cable

• Mine Power Feeder

• Portable Power (SOOW, SJOOW)

• Power Cables (5KV, 15KV)

• SHDGC (2kV-25kV)

Winnipeg

• Teck90 (600V, 1kV, 5kV, 15kV)

• Type G, GGC, P, & W

• Vertical Riser Cable

Servicing Saskatchewan, Manitoba, Northwest Ontario

ECS Senior Account Manager: Eddy Lussier

Web: ecswire.com

Tel: 431.998.3232 Cell: 204.805.4747

STaTe of THe union: an uPDaTe on unifoR neGoTiaTionS in THe PoTaSH SeCToR in SaSKaTCHeWan

By Lana Payne, national President of uniforUnifor is Canada’s largest union representing workers in the private sector, and one of the largest unions in Saskatchewan’s potash sector. It represents workers at both the Mosaic mine in Esterhazy and the Nutrien mine in Lanigan.

The province’s potash sector accounts for approximately 11 per cent of Saskatchewan’s GDP, supporting thousands of direct and indirect jobs.

According to the Saskatchewan government, potash production and the value of sales both set new records last

year, reaching 14.4 million tonnes and $18 billion respectively.

The collective agreements signed between Unifor and potash companies in Saskatchewan are a key tool for sharing the tremendous wealth generated by extraction. Unifor wages and benefits drive local economies, especially in rural regions, and help form the template for mining agreements across the province.

One of those agreements was ratified on February 14, 2023 by Unifor Local 892, which represents more than 750 Mosaic workers.

Despite strong profits that more than doubled to $3.6 billion in 2022, Mosaic did not make it easy to reach a new agreement. A provincial mediator was called in (without much success) and the local conducted a strike vote in January. But with a few late-night sessions, the parties found enough common ground to sign a four-year contract. The new agreement contains 11.5 per cent wage increases over the term. It includes an eight-week maternity leave top-up, increases to the employer’s contribution to pension plans, and paid domestic violence leave. Going forward, the unit will have three employer-sponsored Women’s Advocate positions.

The next contract coming due in the potash sector is for the 430 workers at the Lanigan mine. Like their fellow members in Esterhazy, Local 922 members at the Nutrien mine worked throughout the pandemic to keep the domestic industry afloat.

On the heels of the COVID-19 crisis, the war in Ukraine has reshaped the potash sector by imperilling potash production in Eastern Europe and driving prices to their highest levels ever. In 2023, the work done by Saskatchewan’s potash miners is arguably more important now than ever.

With their product in demand unlike ever before, Canadian potash companies are making record profits. But it is not automatically a windfall to working people in Saskatchewan. While some royalties and taxes will flow into provincial government coffers, it is critical that these record profits be reflected in the industry’s wages and benefits.

Collective bargaining is workers’ democratic framework for leveling the playing field with their employer. Later this year Unifor members at Nutrien will demand their fair share of the profits that they’ve had a key role in generating. If they’re successful, it’s a win for miners, the Lanigan community, and Saskatchewan workers. l

Find

Regina:

Saskatoon:

Edmonton:

Sudbury:

K+S PoTaSH CanaDa SHoRT Line 101

aT THe WeSTeRn DeveLoPMenT MuSeuM

By Corinne Daelick,WDM Content Specialist

the K+S Potash Canada Short Line 101 is the only place in Saskatchewan where you can experience the sounds, smells, and feeling of a steam train. The little train – as the Vulcan locomotive is affectionately known – started chugging along the tracks at the Western Development Museum (WDM) in Moose Jaw in 1978.

Early History of the Vulcan Locomotive (Artifact: WDM-1973-S-3146.6.A-F)

The story of the Vulcan locomotive (Vulcan, for short) begins in 1914 when the Vulcan Iron Works in Wilkes-Barre, Pennsylvania shipped the shiny new narrow-gauge locomotive to Hillcrest, Alta. For the next few years, the Vulcan

worked in the coal mines at Hillcrest Collieries in the Crowsnest Pass. It is believed that the Vulcan was onsite on June 19, 1914 for Canada’s worst mining disaster when an underground explosion killed 189 miners at the Hillcrest coal mine.

From Hillcrest, the Vulcan moved to Alsask, Sask. on the Saskatchewan-Alberta border where it hauled hopper cars loaded with sodium sulphate from a salt lake bed to the Saskatchewan Minerals dehydration plant. The Vulcan moved again to another sodium sulphate mine at Bishopric, Sask., southwest of Moose Jaw. The locomotive ended its working life as a steam heating unit for the Bishopric plant.

the vulcan comes to the Wdm

Fortunately, the Vulcan did not fall victim to the cutting torch, a fate that befell thousands of steam locomotives in the 1950s and 1960s. Instead, the engine was acquired by the WDM in 1958. From the mid-1960s to 1971, the Vulcan was used to transport people at the WDM Saskatoon during their major summer event, Pion-Era. The little train ran back and forth on a straight track carrying WDM visitors.

It was in 1977 that the Vulcan made its move to the WDM Moose Jaw. Staff and volunteers began a restoration project to rebuild the engine and build a 550-metre (1,800-feet) loop track. Rebuilt as

engine 101 on the Short Line 101, the Vulcan made it’s inaugural trip on September 4, 1978.

Restoration and repair work has taken place regularly over the years. The late 1980s saw another overhaul of the engine, but by 2008, the locomotive needed a new boiler. In 2009, it was dismantled at the WDM Curatorial Centre (WDM corporate office) in Saskatoon and a new boiler was commissioned. This major restoration ensured that the Vulcan was safe and ready to operate. In 2017, the Short Line railway track underwent repairs with worn track and rail ties being replaced.

In August 2018, the Vulcan made the news when thieves broke into a locked storage compound and stole the bell off the locomotive. Despite the media attention, there were no leads on its whereabouts so a new bell was purchased and installed. As luck would have it, in March 2019 a good Samaritan found the original bell and it was returned to the WDM.

Important for the WDM is the support that the Short Line 101 receives. In 2018, the WDM was thrilled when K+S Potash Canada came on board to sponsor the little train. As a major attraction for the WDM, having the support of K+S Potash Canada means that the WDM can continue to share this piece of Saskatchewan history.

The K+S Short Line 101 has had a long and interesting life. From working in coalmines and salt beds to giving rides to excited museum visitors, the little train keeps chugging and is a beloved part of the Moose Jaw community. The Short Line 101 will be on the rails in summer 2023, continuing to offer a unique experience for visitors to the WDM Moose Jaw. Visit wdm.ca/ride-the-101/ or wdm.ca for more information. l

For over three decades Western Heritage has provided the potash industry with comprehensive solutions in Indigenous consultation and engagement, cultural heritage and environmental mapping and monitoring.

Our EFMP platform measures project’s key environmental indicators for your project over the complete lifecycle of the project. Benefits include:

• Reduced time, resources, and costs related to environmental monitoring

• Assist in monitoring and verifying reclamation and project environmental goals

• Reports on demand

For information on any of our services: 306-975-3860 | info@westernheritage.ca www.westernheritage.ca

SaLT CaveRn SToRaGe PoTenTiaL aCRoSS SaSKaTCHeWan

By Yohaly Mwambasaskatchewan’s wealth of natural resources has emerged as a significant hub for the mineral industry. The province’s abundant potash and halite deposits in the Prairie Evaporite formation have fostered the development of a thriving mining sector. However, the region’s natural riches are not the only area of growth—Saskatchewan is also becoming a leader in energy storage and carbon capture initiatives.

The province’s growing energy storage infrastructure is demonstrated through a map highlighting the locations of existing, planned, and future salt caverns. Salt caverns offer a cost-effective solution for natural gas storage and can also be used for carbon capture storage, thereby reducing greenhouse gas (GHG) emissions. Saskatchewan’s geology is particularly well suited for underground storage of compressed air, which can be used for dependable and flexible energy storage.

The integration of renewable energy sources into Saskatchewan’s electricity grid, with the help of salt caverns and compressed air energy storage (CAES), has the potential to lower GHG emissions while providing a reliable and

cost-effective energy storage solution. Strategic investment in advanced technologies and infrastructure can enable Saskatchewan to emerge as a leader in the transition to a more sustainable energy future while also promoting economic growth.

The potash industry in Saskatchewan can benefit greatly from using salt caverns. The formation of underground voids, resulting from solution mining techniques used to extract potash, can be repurposed for energy storage. These caverns can be used for storing hydrogen, natural gas, or compressed air, providing a cost-effective and secure storage solution for the industry.

The use of salt caverns for carbon capture and storage can also benefit the potash industry by mitigating its carbon footprint. Potash production involves energy-intensive processes that emit carbon dioxide, which is a GHG. By capturing and storing carbon dioxide in salt caverns, the potash industry

can reduce its environmental impact and fulfill its sustainability goals.

Additionally, the use of CAES can provide a flexible and dependable energy source to power potash mining operations. Saskatchewan’s abundant wind resources can be harnessed to generate excess energy that can be stored in salt caverns through the CAES process. This stored energy can then power potash mining operations during peak demand periods, thereby reducing the need for expensive backup power sources.

Using salt caverns for energy storage and carbon capture can offer numerous benefits to the potash industry, including cost savings, a reduced carbon footprint, and dependable energy storage solutions. By leveraging its natural resources and investing in innovative technologies and infrastructure, Saskatchewan can emerge as a frontrunner in the transition to a sustainable and resilient energy future. l

By capturing and storing carbon dioxide in salt caverns, the potash industry can reduce its environmental impact and fulfill its sustainability goals.

neW LeGiSLaTive CHanGeS foR SaSKaTCHeWan’S PoTaSH SeCToR

By Jessica Kennedy, partner; Keely Cameron, partner; Laura Glover, articling student; and Martin Ignasiak, partner and co-head of energy regulatory practice; Bennett Jones LLP

potash is a critical mineral used as a replenishing agricultural fertilizer. As a result, millions of farmers around the world depend on it. The Canadian province of Saskatchewan is the world’s largest potash producer, followed by Russia and Belarus. As the sole producer in Canada, Saskatche-

wan accounts for about 30 per cent of global production.

Potash sales in Saskatchewan hit an alltime high in 2022 at nearly $18 billion. This follows a (then) record-setting 2021, which saw 14.2 million tonnes of production and sales of $7.6 billion. Potash prices reached their highest level in over a decade during the first half of

2022 and the mineral has become “geopolitically essential” following Russia’s invasion of Ukraine, according to Canadian Finance Minister Chrystia Freeland.

In response to increasing global demand and growing concerns about food security, the Saskatchewan gov-

ernment has pledged to ramp up potash production to fill any market gaps left as a result of the sanctions placed on Russia and Belarus.

In light of this commitment, on September 15, 2022, the Saskatchewan legislature introduced The Subsurface Mineral Royalty Amendment Regulations, 2022, and The Potash Production Tax Amendment Regulations, 2022. These new amendments amend The Crown Minerals Act, The Subsurface Mineral Royalty Regulations, 2017 and The Mineral Taxation Act, 1983. Combined, these new amendments reduce the amount of royalties payable on potash production for eligible new mines.

In order to qualify as a new mine under the amendments, a potash mine must begin commercial production on or after January 1, 2023, and achieve an initial annual production capacity of over two million tonnes. Eligible new mines will receive reduced royalty payments for a period of 36 months, subject to prior written approval by the Minister of Energy and Resources.

The royalty reduction will be determined on an annual basis, with the specific amount calculated for individual potash producers according to (1) the overall quantity of potash they produced in the year (in K 2O tonnes), and (2) the average price of potash received by the producer in the year.

The amendments came into force on January 1, 2023.

Overall, these amendments represent the Saskatchewan government’s continued commitment to encouraging investment into the province’s robust potash-mining industry. The incoming royalty regime will have potash pro -

ducers enjoying a lighter royalty burden on new mining investments in the province.

One of the objectives identified in Saskatchewan’s Growth Plan, published in 2019, was to increase the annual value of potash sales to $9 billion by 2030. In

2022, sales exceeded $10 billion by July. While last year’s totals were driven by record prices, these newly announced legislative changes position Saskatchewan to continue to be a world leader in potash production and exportation well into the future. l

Where the World Comes to Explore

uSinG iMMiGRaTion

To youR aDvanTaGe

Intra-Company Transferee tips for resource companies

By Brett J. cavanaughour natural resources industry is crucial to Canada’s economy, contributing billions of dollars annually. However, the industry faces unique challenges in attracting and retaining talent, particularly overseas.

One of the best immigration solutions for global resource companies is the Intra-Company Transferee (ICT) immigration program, which allows Canadian companies with related entities in other countries to temporarily transfer key employees to Canada. The ICT program supports accompanying family members and facilitates a later permanent residence application.

intra-company transferee program overvieW

The ICT program allows for the transfer of employees between a company’s international offices. There are ICT programs under free trade agreements and generally under General Agreement on Trade in Services (GATS), but for the purposes of this article, they are effectively the same. To qualify, the employee must have been working for the foreign office continuously for at least one year, full-time, and be coming to Canada to work for a related company. The employee must transfer to an executive or senior managerial position or, most commonly, one that requires specialized knowledge or skills acquired through time, experience, and on-the-job training.

The mining industr y needed a better personnel carrier. CMI professionals came up with a tailored solution!

CMI designs, builds, and integrates mining and

solutions that can maximize the productivity and profitability of your company

Our expertise, years of experience and processes give us a unique perspective of our customers’ requirements.

Why use the ict program?

There are several benefits to using the ICT program. It allows your company to transfer key employees to Canada quickly and easily compared to other immigration processes. No advertising or prior bona fide job search is required.

The ICT program allows you to bring in employees with specialized skill sets that may be difficult to find in Canada. This program can be especially valuable in the natural resource industry, where certain expertise is in high demand. There may be a need to upskill the Canadian workforce through knowledge transfer from experienced workers abroad.

Further, the ICT program can be used as a tool for employee retention. By offering the opportunity to work in Canada, which can lead to Canadian citizenship for the worker and their family, you can incentivize top employees to stay with your company long term.

ict tips for employers

1. Start early: The ICT program requires significant document gathering, especially for a first application. Our firm ICT checklist has 39 considerations that need to be ran to ground, but each subsequent application gets easier. If your worker is visa-required, they will be at the whim of lengthy and unpredictable processing queues abroad. A visa-exempt worker, by comparison, may be able to be onsite in Canada inside of a week by applying at the border. Your workers’ citizenship and residence can significantly impact timeframes.

DEL Communications Inc. –publishing and more...

Located in Winnipeg, Manitoba, Canada, DEL Communications Inc. is a publishing and web design company first incorporated in 2002. Over the past 20 years, DEL Communications has accumulated and is responsible for publishing hundreds of titles. DEL publishes print magazines, print directories, electronic magazines, e-newsletters, searchable online directories, websites, and more.

Specializing in association-based and proprietary publications, we have a highly trained experienced team who can make any publication for any industry possible.

DEL Communications Inc. creates national and international print magazines, as well as online magazines, and regional print and online publications for every industry imaginable. Examples include construction, potash mining, solar, dental, land reclamation, oil and gas, local chambers of commerce, airports

2. Keep detailed records: The ICT program requires extensive documentation, including proving employee qualifications and the corporate relationship between global entities. Everything is subject to a six-year audit review period. Be sure to keep detailed records of all information provided to immigration authorities.

3. Know your employer-side obligations: The ICT program can be complex. Employers are deemed to know of unauthorized work and are regularly reviewed for compliance issues. Playing within the rules is vital to using the immigration system to your advantage. Seek professional advice as needed and have appropriately high-level sign-off on applications.

4. Know the unique facts of the situation: Lack of international travel, poor finances, criminal history, previous immigration violations, and more can all derail an otherwise ideal application. For specialized knowledge applications, your employees’ unique skillsets and experience cannot be understated.

When planned well, the ICT program is a valuable tool for natural resource businesses looking to transfer key employees to Canada. Use the tips above to ensure the process goes smoothly and that your business benefits from the expertise of your international team members.

Brett J. Cavanaugh is a lawyer from McKercher LLP. Cavanaugh is a partner in the Saskatoon office where he focuses on corporate and commercial law, international business transactions, education law, and employer-side immigration. l

management, winery and vineyard management, association membership directories, and so many more.

• Magazines / Directories

• Advertising Sales

• Newsletters

• E-newsletters

• Web Design

• Editorial

If you would like your very own print publication, newsletter, or website design, please call Dayna Oulion at 1-866-424-6398 or email dayna@delcommunications.com.

If you would like to submit a story to The Potash Producer newsletter or to PotashWorks annual print publication, please contact shayna@delcommunications.com.

For more information about DEL Communications Inc., please visit us online at delcommunications.com. You can also visit our online library at issuu.com/DELCommInc.

THe neeD foR GooD SCienCe in THe DeSiGn of SeLeCTive SoLuTion MininG of PoTaSH

By harvey haugen, ceo, BPPcistarted working in potash in 1969, my son in 2000, and my granddaughter in 2020. A lot has been learned over the years since the early days. Unfortunately, sometimes as an industry matures, it starts to rely on established principles that need to be reconsidered. “That equipment has always been used”, “We tested that 20 years ago and it didn’t work”, “We need saturated NaCl brine”, and so on. Young process people come on site and are overwhelmed by the established body of knowledge. Even the highpriced consultants know how it is done.

This is particularly true of solution mining. Many of the designs for new selective solution mines are not working and will not work since they are designed from ideas out of old patents, and traditional ideas that cannot be supported by good science and engineering.

Carnallite was solution mined in Germany as far back as 1861. The first attempt at solution mining of potash in Saskatchewan was in 1951 by Western Potash at Unity. A number of companies tried solution mining through the ‘50s into the early ‘70s. Only one of these attempts produced an operating mine. The PP&G mine resorted to 400-year-old total dissolution mining techniques, but limiting vertical development with oil (German patent 182,042, 1907).

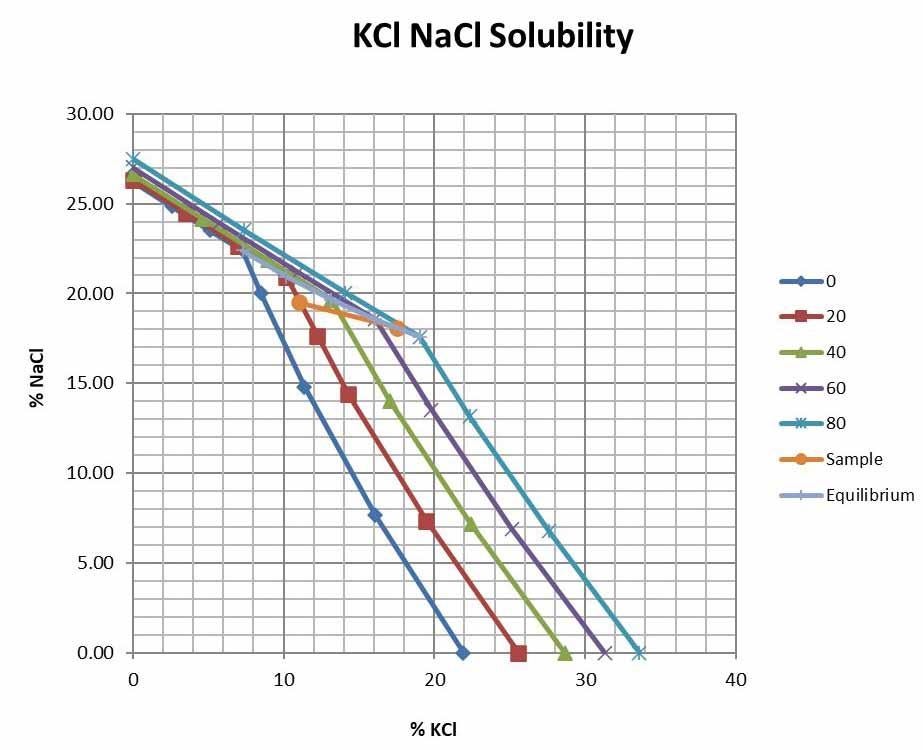

To go forward, we need to understand the phase chemistry. The simple phase diagram details solubility of mixes of KCl and NaCl at various temperatures. This is essential for design and modelling of a solution mining method. The mystery of the effect of carnallite is also readily explained by looking at the more complex phase diagram, including KCl, MgCl 2, and NaCl.

We need dissolution rate data. Starting in 1960, the Saskatchewan Research Council “undertook to investigate ways of eliminating the need for shafts” due to the difficulties being experienced in shaft sinking, and the lack of positive results in solution mining. The study was summarized by Selim Ozsahin and W.H.W. Husband in “An Investigation of the Potential of Solution Mining in Saskatchewan”. The report recognized the lack of any detailed study available in the public domain on dissolution rate versus temperature, flow velocity, degree of saturation, and ore grade, and provided valuable studies to correct that deficiency. This is a valuable resource.

The SRC studies were done on pressed salt-potash mixes. Over the past 20 years we have done hundreds of dissolution tests on real potash ore samples and have confirmed that these dissolution rate results apply to Saskatchewan ore. These dissolution studies are required to model the mining process.

The report does contemplate the possi-

bility of “selective dissolution” using a saturated NaCl solution and “replacement of NaCl with dissolved KCl”. The concern raised is the possibility of salt precipitation in the cavern coating the surface. This has been one of the real problems in current attempts.

The use of saturated NaCl solution and the plating of salt in the cavern are a couple of the problems limiting selective mine development. Use of saturated NaCl is simply an error. Plating is real but can easily be understood and managed by understanding phase chemistry. This is not complicated, but almost never appears in current design work.