SINGAPORE THE ENGINEER

The RTS Link project reaches another milestone

The RTS Link project reaches another milestone

12 The RTS Link project reaches another milestone

The commemoration of the pile caps installation in the Straits of Johor, on the Singapore side, also marked the next phase of works.

14 Signs of improvement but concerns remain The Ministry of Manpower (MOM) has released the Workplace Safety and Health Report 2022.

17 Exit from Heightened Safety Period and new measures for sustainable WSH outcomes These are part of efforts to reach the Workplace Safety and Health (WSH) 2028 goal.

18 Enhancing workforce development in the built environment sector BCA Academy (BCAA) takes on the role as the dedicated Continuing Education and Training (CET) Centre for the sector.

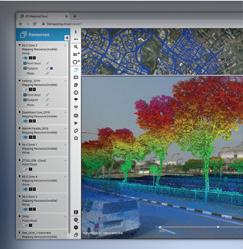

20 Singapore Land Authority develops digital twin of all public roads in the country Rapid modelling with Orbit 3DM saved SGD 26 million and one year of data capturing.

President Mr Dalson Chung

Chief Editor

T Bhaskaran

t_b_n8@yahoo.com

Publications Manager Desmond Teo desmond@iesnet.org.sg

Publications Executive Nuraini Ahmad nuraini@iesnet.org.sg

Editorial Panel

Dr Chandra Segaran

Dr Ang Keng Been

Mr Syafiq Shahul

Mr Jaime Vega Bautista Jr

Dr Victor Sim

Mr Soon Ren Jun

Dr Alexander Wiegand

Media Representative

Multimedia Communications (2000) Pte Ltd sales@multimediacomms.sg

www.ies.org.sg

22 Running powerlines underground

The first-of-its-kind project in France involves boring out tunnels in a highly built-up area with road, rail and river infrastructures.

24 New lease of life for industrial landmark in Berlin

The formwork and scaffolding systems help to ensure that the refurbishment and shell construction work is implemented quickly and professionally.

26 Setting marine tie rods with telescopic crawler cranes

For the dredging work at Straubing port in Germany, the sheet pile wall of the port quay will have to be reinforced by additional tiebacks.

28 Why electric mini excavators are a better choice than diesel-powered machines

Three important reasons are provided.

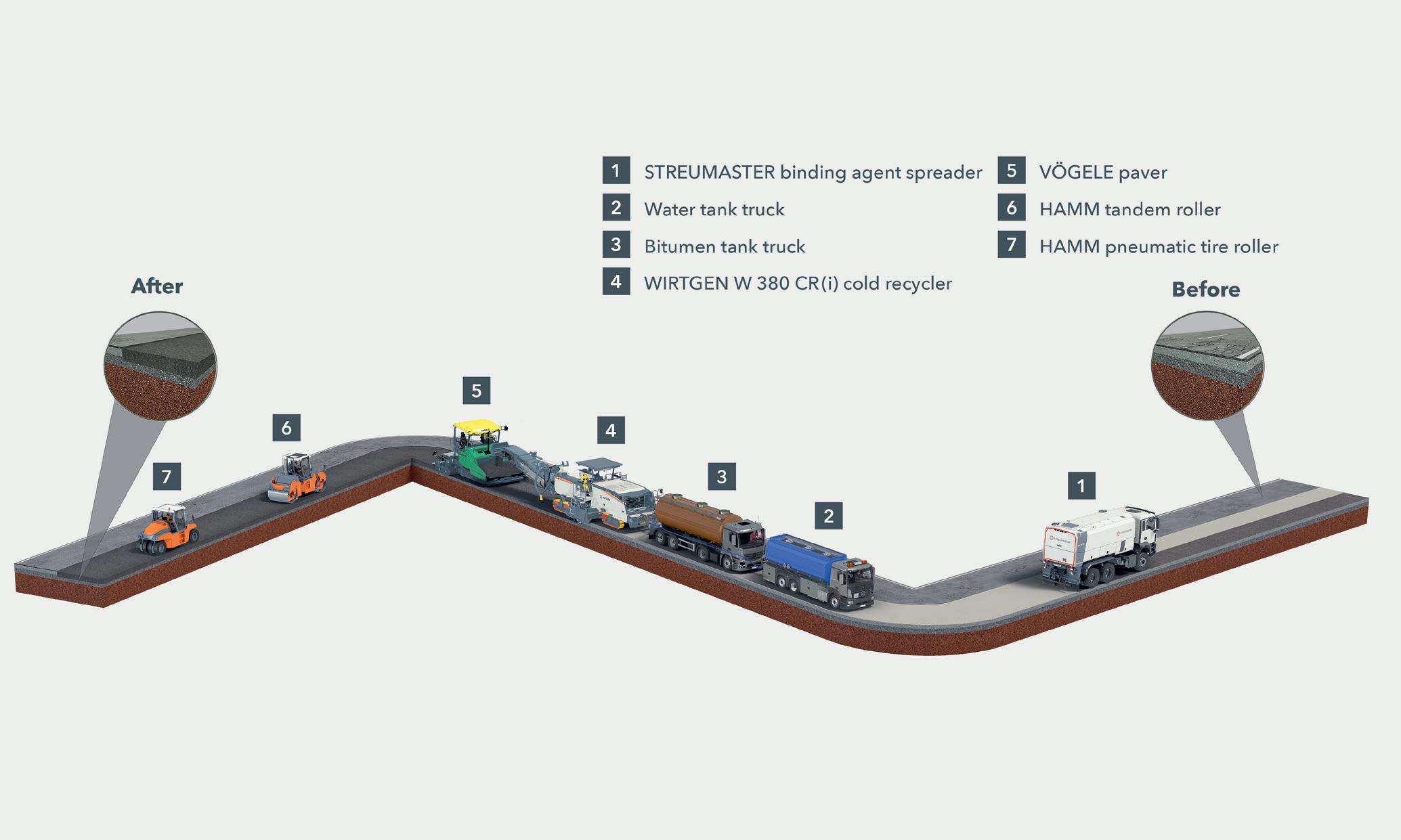

30 The path to climate-neutral road construction

This will require improvements in the production of machines and materials, and in the work processes.

The Singapore Engineer is published monthly by The Institution of Engineers, Singapore (IES). The publication is distributed free-of-charge to IES members and affiliates. Views expressed in this publication do not necessarily reflect those of the Editor or IES. All rights reserved. No part of this magazine shall be reproduced, mechanically or electronically, without the prior consent of IES. Whilst every care is taken to ensure accuracy of the content at press time, IES will not be liable for any discrepancies. Unsolicited contributions are welcome but their inclusion in the magazine is at the discretion of the Editor.

Developed by the Land Transport Authority (LTA), in close collaboration with industry and union partners, the Land Transport Industry Transformation Map (ITM) 2025, launched recently by the Minister for Transport, Mr S Iswaran, aims to build a sustainable and resilient land transport sector, a future-ready workforce and a vibrant ecosystem.

The Land Transport ITM 2025 will help the sector navigate through the immediate challenges of manpower constraints and decarbonisation. It aims to achieve three strategic outcomes:

• A future-ready workforce

• A sustainable and resilient land transport sector

• A reliable and cost-effective transport system through Innovation & Technology

“Talent development and skills upgrading for workers remain key to the land transport sector’s transformati on and resilience. LTA is partnering the public transport operators and unions to equip workers with the skills to meet new challenges, so that our workforce remains producti ve and future-ready,” said Mr Chee Hong Tat, Senior Minister of State, Ministry of Transport and Co-Chair of the Future Economy Council (FEC) Connecti vity Cluster.

“Co-innovati on between the public and private sector can accelerate the development of a safer, more effi cient and future-ready land transport network. We encourage industry players to collaborate with LTA on platforms like the Land Transport Innovati on Portal, and ideate and test-bed soluti ons for Singapore’s land transport challenges,” said Mr Alex Hungate, Chief Operati ng Offi cer, Grab and Co-Chair of the Future Economy Council (FEC) Connecti vity Cluster.

The land transport industry, a key pillar in enabling connectivity that supports the economy, is able to achieve this only through the efforts of its workers. The more than 100,000 workers undertake various roles including that of bus captains, bus mechanics, customer service officers, railway engineers, station managers, as well as point-to-point (P2P) drivers. In particular, public transport is a growth segment in the industry. Since 2018, about 1,000 new jobs have been created in the rail sector.

Another approximately 800 more new jobs will be created as the rail network expands, and even more with the development of the Jurong Region Line and Cross Island Line. Overall, the workforce in the public transport sector is expected to grow by around 4% by 2025, from 22,000 workers currently.

The nature of work will also change with advancement in technology and digitalisation. Under the refreshed ITM, LTA will work with National Transport Workers’ Union (NTWU) and public transport operators to upskill rail workers to use new and emerging technologies such as data and statistical analytics, as well as condition monitoring, to increase efficiency and productivity. So far, more than 2,900 workers have enhanced their skills since 2020, under the Rail Manpower Development Incentive.

For example, through the use of video monitoring and image analysis, faults can be detected and physical checks reduced. Bus captains and technicians are also being upskilled progressively to handle electric buses. In this regard, the Singapore Bus Academy (SGBA) has been working with the relevant stakeholders including bus suppliers, Institutes of Higher Learning, NTWU and bus operators to curate relevant training programmes on cleaner energy buses for the bus workforce.

Towards a sustainable and resilient land transport sector

In the area of private transport, LTA will also continue to work closely with partners such as tertiary institutions to help gear the workforce to support Singapore’s push for vehicle electrification.

Besides vehicle electrification, Walk Cycle Ride is the other key thrust in the efforts to reduce land transport emissions.

Under Walk Cycle Ride, LTA will continue to encourage commuters to take public transport or active mobility options.

LTA is also supporting the increased adoption of electric vehicles by building up the EV charging infrastructure and strengthening the EV regulatory framework. By 2030, half of the public bus and taxi fleets will be electric. Electrification will provide exciting new growth opportunities for industry and workers.

In a fast-changing world, LTA is keenly aware of the importance of collaborating with the private sector to find new solutions to build a reliable and cost-effective transport system.

An open innovation approach with industry and academia partners will help tap on external ideas to enhance the efficiency of the land transport system.

This includes democratising data and co-creating innovative solutions to enhance operational processes and well as environmental sustainability.

In September 2022, LTA launched the Land Transport Innovation Portal as a one-stop platform for all innovation matters, to streamline outreach to industry partners.

A sustainable land transport sector with a future-ready workforce and a vibrant ecosystem.

Upskill rail workers to use new and emerging technologies such as data and statistical analytics

Upskill bus captains and technicians progressively to handle electric buses

Expanding the rail system and improving rail reliability, supported by an extensive public bus network and active mobility options

Land transport emissions peaked in 2016 and we are striving towards further reduction in emissions through encouraging commuters to Walk Cycle Ride and vehicular electrification

A Reliable and Cost-effective Transport System through Innovation & Technology

Drive innovation across the land transport system through democratising data Co-create innovative solutions to enhance operational processes as well as for environmental sustainability

PUB has launched the country’s first research programme dedicated to strengthening coastal protection and inland flood management capabilities. The SGD 125 million Coastal Protection and Flood Management Research Programme (CFRP) will advance knowledge in coastal and flood resilience, as well as spur the growth of a vibrant research and development ecosystem for coastal and flood resilience in Singapore. It will be funded under the Research, Innovation and Enterprise 2025 Plan.

With climate change, sea levels around Singapore are projected to rise by up to 1 m by 2100. Compounded by transient effects such as high tides and storm surges, sea levels could rise to 4 m or 5 m.

More extreme storms with higher rainfall intensities could become more frequent, resulting in increased flood risks. As a low-lying island surrounded by the sea, enhancing the nation’s overall coastal and flood resilience is a critical long-term endeavour that will require new capabilities and technologies.

As Singapore’s coastal protection agency, PUB seeks to develop effective climate adaptation measures to protect the country’s coastline against sea level rise, supported by robust climate science and deep understanding of climate change impact. The CFRP consists of four research verticals to develop innovative, sustainable and smart solutions tailored for Singapore’s urban and land-squeezed environment – a challenge which many other coastal cities also face.

The four research verticals are Innovative Engineering Solutions for Coastal Protection and Flood Management, Integrated Nature-based

Solutions for Coastal Protection, Sustainable Infrastructure Solutions for Coastal Protection and Flood Management, and Smart Management Solutions for Coastal Protection and Flood Management.

The verticals will be supported by three cross-cutting research horizontals:

• Advance coastal science research to deepen understanding of extremities and changes in coastal processes affected by climate change.

• Enhance capabilities in monitoring, prediction and digitalisation of Singapore’s coastal environment.

• Develop an effective framework to support integrated and adaptive planning, to strengthen risk management and decision-making processes when prioritising investments made in coastal and flood protection infrastructure.

Ms Hazel Khoo, Director of PUB’s Coastal Protection Department, said, “Coastal protection is a long-term challenge. The CFRP will catalyse coastal science and technological advancement that will support Singapore’s multi-decadal agenda to enhance flood resilience in the face of climate change. The CFRP will form a key platform for expert knowledge development and exchange, through driving multi-disciplinary research and forging strong partnerships.”

A new multi-institutional Centre of Excellence (CoE) will be set up to conduct research in the above areas. The CoE will be hosted at the National University of Singapore, with Nanyang Technological University (NTU Singapore), Singapore University of Technology and Design (SUTD), Singapore Institute of Technology (SIT), and Agency for Science, Technology and Research (A*STAR) as partner institutes. With collaboration at the core of the CoE, the research community will

grow to include international institutions as well as industry partners.

The CoE will anchor in-house research, with the aim of growing the local talent base of research scientists and engineers. Institutes of Higher Learning can capitalise on the synergies with research work to enrich education and professional training in coastal engineering and flood management. These are in line with PUB’s objective to develop long-term capability in coastal protection and flood management, and groom a sustained pipeline of local professionals for coastal protection and flood management work.

The translation and commercialisation of coastal protection and flood management solutions will be achieved via two of the CFRP’s components – Applied Research and a Living Lab.

Applied Research projects can be executed through Request for Proposals (RFP) or direct award (administered by PUB), while the Living Lab will provide a platform for promising research projects that have a higher technology readiness level to be proven and to accelerate their adoption.

Developed solutions that are successfully test-bedded will be implemented locally and could be exported overseas.

The CFRP will build on the existing research on coastal protection and flood management knowledge and expertise. In the longer term, PUB will consolidate and coordinate all future research initiatives related to coastal protection and flood management under the CFRP, to support the national agenda.

The CFRP will also support PUB’s ongoing coastal protection and flood management efforts.

CONEXPO-CON/AGG & IFPE 2023

was held from 14 to 18 March 2023 at the Las Vegas Convention Center, Las Vegas, Nevada, USA. The event, which featured innovative product launches, major company announcements, education sessions and networking opportunities, featured the displays of more than 2,400 exhibitors from 36 countries, spread over 3 million ft2 of exhibit space. The expected attendance numbers were exceeded as CONEXPO-CON/ AGG & IFPE 2023 attracted more than 139,000 construction and fluid power professionals from 133 countries.

This year’s show emphasised how the construction industry is evolving in many ways, to adapt to sustainable technologies, products and practices. Show attendees were able to learn about sustainability in action, through the adoption of electric and hydrogen-powered construction equipment to more recyclable materials and waste reduction methods.

The next CONEXPO-CON/AGG & IFPE will be held from 3 to 7 March 2026, at the Las Vegas Convention Center in Las Vegas, Nevada, USA.

Holcim’s ECOPact low-carbon concrete was selected as the CONEXPO-CON/AGG Next Level Awards Contractors’ Choice, at the inaugural awards programme at CONEXPO-CON/AGG and IFPE 2023.

The Next Level Awards are awarded to exhibiting companies that are pushing the boundaries of technology and developing next-level products, technologies and services, that will advance the construction industry.

“We are proud to announce Holcim as the winner of the inaugural Next Level Awards – Contractors’

Held every three years, CONEXPO-CON/AGG features the latest equipment, products, services and technologies for the construction industry, as well as industry-leading education. CONEXPO-CON/AGG is owned in partnership with National Ready Mixed Concrete Association (NRMCA), National Stone, Sand & Gravel Association (NSSGA) and AEM (Association of Equipment Manufacturers), and managed by AEM.

International Fluid Power Exposition

The International Fluid Power Expo-

sition (IFPE) targets the fluid power/ power transmission/motion control and construction and construction materials industries.

The Association of Equipment Manufacturers (AEM) is the North America-based international trade group representing off-road equipment manufacturers and suppliers. AEM represents more than 1,000 companies with more than 200 product lines in the agriculture and construction-related industry sectors around the world.

Choice. Their commitment to excellence and innovation in the construction industry is truly impressive, and it is evident that they are highly regarded by the industry,” said Dana Wuesthoff, Show Director of CONEXPO-CON/AGG.

ECOPact provides the global construction industry with a versatile solution to the carbon challenge. It offers up to 90% lower CO2 emissions compared with standard concrete mix designs.

Projects using ECOPact low-carbon concrete are expected to increase

in the future, and Holcim has been able to partner with leading businesses and companies to design innovative mixes that meet their needs and help build a sustainable future.

Attendees at CONEXPO-CON/ AGG and IFPE 2023 voted for their choice of winner, from among 10 finalists, to determine the Contractors’ Choice Award.

The finalists for the Contractors Choice Award were selected by a diverse panel comprising members of the Associated General Contractors of America (AGC).

Jointly organised by the Institution of Engineers, Singapore (IES), Singapore Polytechnic (SP) and the World Federation of Engineering Organizations (WFEO), the Charles Rudd Distinguished Public Lectures 2023 were held at the SP Convention Centre, on 25 May 2023. The event attracted more than 1,200 in-person attendees and 3,000 virtual attendees from around the world. Themed ‘Transitioning to a Net-Zero World’, the event spotlighted key strategies, challenges and trends accompanying Singapore’s endeavour to move to a circular economy, with the aim to better place engineers, businesses, students and the public to embrace a net-zero future.

Minister for National Development & Minister-in-charge of Social Services Integration, Mr Desmond Lee, graced the event as the Guestof-Honour, while Government Chief Sustainability Officer, Mr Lim Tuang Liang was the distinguished speaker at the event.

Mr Lim spoke about the current progress made in the five pillars of the Singapore Green Plan 2030, the impetus for societal change towards sustainable development and how engineers can contribute to these shifts in design, systems thinking and value.

The event, in celebration of World Engineering Day, explored four topics – Green Plan; Circular Economy; Environmental, Social, and Governance (ESG); and Green Finance. Leading sustainability practitioners and experts delivered insights via two panel discussions, on ‘Empowering Net-Zero Transition through Green Plan and Circular Economy’ and ‘ESG and Green Finance: Latest Strategies, Trends and Future

Outlook’. From the environmental impact of the linear to circular economy shift on our waste management system to the latest ESG strategies, the event focused on the hottest issues related to Singapore’s transformation towards a sustainable future.

The event concluded with a series of green-centric learning journeys. Participants had the opportunity to explore the first Grundfos APAC Industry Demo Truck that features a range of world-class sustainable water technologies, as well as to visit various SP Centres of Excellence, including Advanced Materials Technology Centre (AMTC), Consumer Chemicals Technology Centre (CCTC), Data Science & Analytics Centre (DSAC), and 5G & AIoT Centre. SP industry guests and partners were invited to host sessions, facilitated by the School of Architecture & The Built Environment (ABE) and School of Business and UOB.

IES organises the lectures annually, in honour of the late Charles Rudd, an IES Member and a distinguished engineer, who had bequeathed

more than SGD 1 million to IES.

“IES has chosen to focus on net-zero for this year’s lecture as it is a national imperative that requires collective efforts across government, businesses and the public to be successful. Building on the momentum from launch of the IES Green Plan 2030 in January 2023, we hope to elevate understanding of key topics associated with our net-zero transition, inspire engineers to contribute to the nation’s green goals and create interest amongst students to be part of our sustainable development journey,” said Mr Dalson Chung, President of IES.

“As an educational institution, responsible for shaping the minds of more than 10% of each birth cohort, SP is committed to go beyond the various sustainability measures required under the GreenGov.SG initiative. We have embarked on a consultancy study to assess how we can meet our net-zero target ahead of 2045, the target set for all government bodies. At the same time, having infused sustainability into our curriculum, all our staff are strongly encouraged to walk the talk, set examples for our students and take steps towards a more sustainable lifestyle. Our collaboration with valued partners like IES on the Charles Rudd Distinguished Public Lectures and UOB on joint projects to raise awareness of sustainability, are also part of our role to educate the community at large on the challenge of sustainability,” said Mr Soh Wai Wah, Principal and Chief Executive Officer of SP.

“We hope this event will ignite inspiration and provide attendees with the knowledge and tools required to proactively drive the transition towards a net-zero world. We firmly believe that through collaboration, idea sharing, and leveraging our collective experiences across industry sectors, we can engineer a more sustainable and equitable future,” said Mr Danny Lee, Chairman of The Charles

At the event, IES presented a cheque of SGD 300,000 to the National University of Singapore (NUS) for the establishment of the YC Wong-IES Research in Construction Project Management Fund. Minister Desmond Lee witnessed the presentation of the gift, made possible by the donation of SGD 1 million from Engineer Wong Yui Cheong, also known as Er. YC Wong.

“We are very pleased to take another big step forward for the YC Wong-IES Research in Construction Project Management Fund, with our second gifting to an institute of higher learning to support postgraduate research in construction project management in Singapore. With its well-established, reputable project management programmes, NUS is an exceptional partner for IES to advance towards Er. YC Wong’s vision for the scholarship. This collaboration will boost standards of project management to accelerate the transformation of our built environment towards greater safety, quality and sustainability,” said Er. Chong Kee Sen, IES Emeritus President and Chairman of the YC Wong-IES Research in Construction Project Management Fund.

“The NUS College of Design and

Engineering is honoured to receive this gift from IES for the YC Wong - IES Research in Construction Proj ect Management Fund. In a global environment which has become increasingly more complex, there is a clear need for professionals who can apply interdisciplinary knowhow and skill sets. CDE’s Depart ment of Civil and Environmental Engineering will work closely with engineering professionals, project managers in the built environment, and forward-thinking partners such as IES to help catalyse the sector’s continued growth to meet future challenges,” said Professor Richard Liew, Head, Department of Civil and Environmental Engineering, NUS.

SP and United Overseas Bank (UOB) signed a Memorandum of Understanding (MoU) to support local enterprises in their adoption of sustainability solutions and to support students on their entrepreneurship journey in the sustainability space. SP and UOB will also work together on joint projects to raise awareness of sustainability and to invest in activities that are environmentally positive. This MoU also aims to support local enterprises in their adoption of sustainability solutions. SP and UOB’s innovation accelera-

tor, The FinLab, will jointly organise workshops for start-ups within the SP ecosystem via workshops and sharing sessions on sustainability, digitalisation or other emerging areas, to help these enterprises keep up with current market trends and better strategise their business models. The MoU’s signatories were Ms Janet Young, MD & Head, Group Channels & Digitalisation of UOB and Ms Georgina Phua, Deputy Principal (Development)

The IES 57th Annual General Meeting (AGM) was held on 27 May 2023, at Suntec Singapore Exhibition and Convention Centre.

The AGM began at 1.00 pm, with IES President, Mr Dalson Chung and Honorary Treasurer, Er. Simon Lee updating members on IES’ activities and financial performance for 2022, as well as the election of Honorary Auditors of IES for 2023/2024.

The Honorary Secretary, Er. David Ng, revealed the election results for vacancies in the Council for the May 2023 to May 2025 Sessions.

The meeting also paid tribute to the late Er. Au Kow Liong, Deputy Chair of the M&E Engineering Technical Committee, who served in the Council since 2021. The late Er. Au passed away on 17 April 2023.

The new Council (Session 2023/2024) looks forward to

serving all members and the wider engineering community in the upcoming term.

The President thanked all outgoing

Council Members for their distinguished service to the Institution, and to members for attending the AGM.

Er. Au was Deputy Chair of the Mechanical & Electrical Engineering Technical Committee and served in the IES Council since 2021. He was also a SCDF Registered Inspector who conducted fire safety inspections in buildings for issuance of the Fire Safety Certificate.

A member of the Professional Engineers Board, who served his second term in 2021, Er. Au had significant expertise in the fire safety of

IES Annual Dinner and IES Annual General Meetings. Apart from these initiatives, he was actively involved in the various committees in which he held leadership positions.

These include the SCDF Fire Code Review Committee, FSE Selection Panel Interview, NEA/PUB quarterly Dialogue Session and the iNPQS Platform.

His contributions to the engineering

community will forever be remembered and his loss is keenly felt.

The President, Council and Secretariat are deeply saddened by this news and express their sincere condolences to his family.

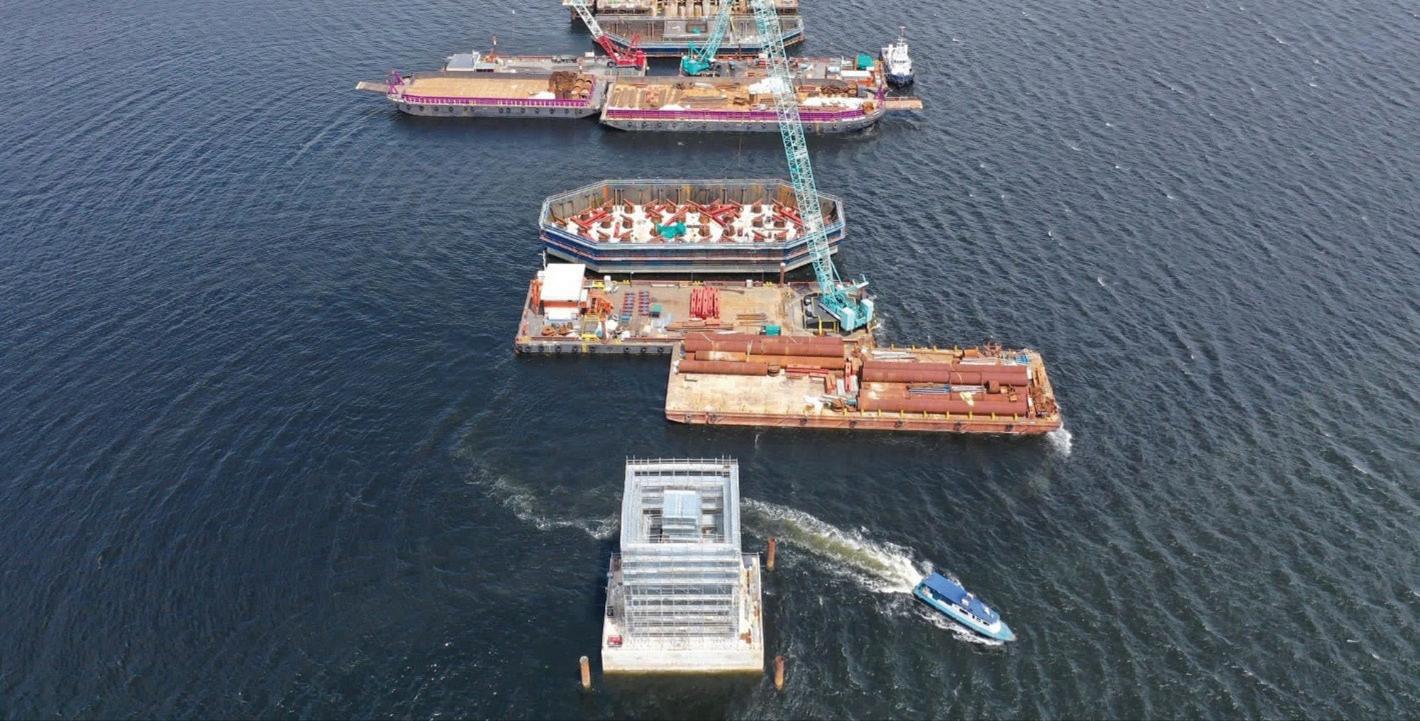

The commemoration of the pile caps installation in the Straits of Johor, on the Singapore side, also marked the next phase of works.

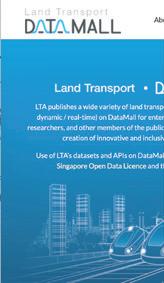

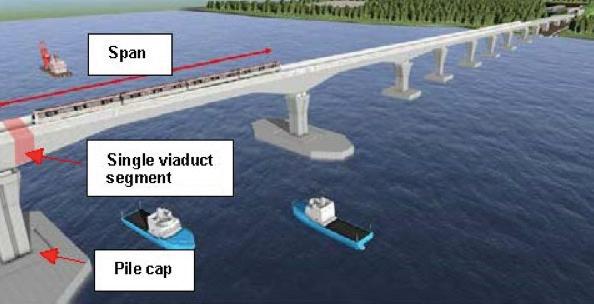

The Land Transport Authority recently commemorated the pile caps installation works in the Straits of Johor on the Singapore side, for the Johor Bahru – Singapore Rapid Transit System (RTS) Link project. The event, officiated by Minister for Transport S Iswaran, marks another milestone in the project and the next phase of works for the installation of the rail viaduct structure of the RTS Link.

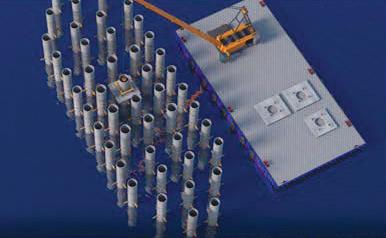

The pile caps, including 161 bored piles, serve as the foundation of the RTS Link viaduct in the Straits of Johor, on the Singapore side. The diameter of each pile is typically 2 m and is installed at an average depth of 30 m. Once at the required depth, each pile is filled with concrete before the pile cap is cast over the piles.

A total of 12 pile caps will be installed on the Singapore side, to form the foundation for piers which support the rail viaduct structure on

land and on sea/over water. Once all the piers are completed, the launching of the viaduct segments will commence. The 730 m viaduct (on the Singapore side) will be made up of 207 segments, with each span length ranging from 50 m up to a maximum of 110 m.

The RTS Link viaduct stands at a

height of 25 m above the water level, in the middle of the Straits of Johor. On the Singapore side, it transitions gradually to underground tunnels connecting to the RTS Link Woodlands North station.

The RTS Link Woodlands North station will be constructed underground at a maximum depth of

28 m. There will be three storeys, with two basement levels and an underground B3 linkway to the Customs, Immigration, and Quarantine (CIQ) building. The RTS Link Woodlands North station and CIQ building are approximately 10 times the size of a typical MRT station. These facilities will be adjacent to the Thomson-East Coast Line (TEL) Woodlands North MRT station and will be seamlessly connected via an underground concourse. Construction works for the CIQ building, tunnels and viaduct started in 2021. Works are progressing well and on target to achieve timely completion.

The RTS Link is a 4 km rail shuttle service between the Singapore terminus at Woodlands North station and the Malaysia terminus at Bukit Chagar station in Johor Bahru, with a capacity of up to 10,000 passengers per hour in each direction. Passengers will enjoy a fast and seamless experience travelling between Singapore and Johor Bahru on the RTS Link, and a train journey time of about five minutes between the two stations.

The CIQ facilities of Singapore and Malaysia will be co-located at the Woodlands North and Bukit Chagar stations, which means that passengers only need to clear the

immigration authorities once, i.e. at their point of departure. When the RTS Link opens for service at the end of 2026, it will be a game changer that will greatly improve connectivity between Singapore

The Ministry of Manpower (MOM) has released the Workplace Safety and Health Report 2022.

There was an increase in workplace fatalities last year, compared to 2021. In 2022, the workplace fatality rate per 100,000 workers was 1.3, as compared to 1.1 in 2021. To mitigate the spate of workplace fatalities in 2022, the Ministry of Manpower (MOM) implemented the Heightened Safety Period (HSP) in September. The encouraging development is that during the HSP, the monthly average for fatalities dropped from 4.5 per month to 2.5 per month, translating to an annualised fatality rate of less than 1.0 per 100,000 workers.

Notwithstanding the above, some areas of concern remain. The impact of HSP varied across industries. For example, the top contributing sector to both fatal and major injuries – Construction – showed the most improvement, with the monthly average number of fatal and major injuries decreasing during HSP. However, other industries such as Manufacturing saw their monthly average worsen during HSP.

To address this, MOM extended the HSP till 31 May 2023, and convened the Multi-Agency Workplace Safety Taskforce (MAST) to identify and implement sectoral strategies to strengthen workplace safety. Overall, there was some improvement in the workplace safety landscape, with the introduction of HSP, but continued vigilance is needed. Safety measures announced earlier in February are being implemented.

Senior Minister of State for Manpower, Mr Zaqy Mohamad, said, “The HSP measures have worked well to arrest the spate of workplace fatalities in 2022 and the construction sector has seen improvements in reducing workplace accidents. However, the incidence of major injuries did not improve in some sectors, such as manufacturing. I call on all employers and

workers to remain vigilant. Only with our collective resolve can we get back on track to achieving our WSH 2028 goal of keeping our fatality rate at below 1.0 per 100,000 workers.”

Fatalities

The top cause continues to be Vehicular Incidents. There were 15 fatal vehicular incidents in 2022, of which seven were work-related traffic accidents (WRTAs). Incidents with higher fatality risk (Type A) formed 80% of all fatalities in 2022.

Major and Minor injuries

There was an overall decline in major and minor injury rates. Slips, Trips and Falls remain the leading cause of non-fatal injuries. Taking into account the growing workforce and HSP measures, the major injury rate per 100,000 workers trended down only slightly, from 18.5 in 2021 to 17.3 in 2022. The reported minor injury rate also trended down from 653 per 100,000 workers in 2021 to 596 per 100,000 workers in 2022.

Major injuries were analysed by incident types, to better prioritise the key areas of concern for more targeted interventions and enforcement. They have been categorised into Type A and Type B incidents.

Major injuries caused by Type A incidents (i.e., those with a higher risk of fatality, such as falls from height and vehicular incidents) accounted for 35% of all major injuries in 2022 and has hovered around this figure in the last five years. Type A incidents are stronger precursors to workplace fatalities. The common root causes of these injuries included inadequate fall prevention measures, unsafe worker behaviours, inadequate traffic management plans, inadequate WSH management systems leading

to incompatible works and inadequate lifting plans.

Major injuries caused by Type B incidents (i.e. those with a lower risk of fatality, such as slips, trips and falls, and machinery incidents) accounted for 65% of major injuries. The common root causes included lack of control measures, including machine guarding, non-compliance with safety measures such as bypass of safety interlocks, lack of safety measures to manage flow of goods, lack of provision of suitable tools, or failure to provide anti-slip footwear.

Slips, Trips and Falls (STFs) remained the top cause of non-fatal injuries, accounting for 33% of all major and 28% of all minor injuries. In 2022, there were 200 STF-related major injuries, slightly lower than the 208 in 2021. Falls from height (FFH) incidents were the second common cause for major injuries, accounting for 14% of all major injuries in 2022. There were 86 FFH-related major injuries in 2022, an increase from 63 in 2021. However, FFH incidents are not a common cause for minor injuries. There were 589 falls from height-related minor injuries in 2022 (close to 3%), a decrease from 621 in 2021.

Injuries by Industry Construction, Transportation & Storage, and Manufacturing continue to be top industry contributors. They accounted for the highest numbers of fatalities in 2022, at 14, 9 and 7 workplace fatalities, respectively, in 2022. Collectively, they accounted for about 65% of all workplace fatalities in 2022.

The workplace fatality rate per 100,000 workers for the Transportation & Storage industry decreased to 3.4 in 2022, from 3.6 in 2021. Similarly, in the Construction industry, the workplace fatality rate per 100,000 workers decreased to

Rate for workplace fatal injuries in 2022 was higher compared to 2021, while rate for total workplace injuries declined. More dangerous occurrences and occupational diseases in 2022 compared to 2021.

Slips, Trips & Falls remained the top cause of major injuries in 2022.

2.9 in 2022, from 3.3 in 2021. In contrast, for Manufacturing, the rate per 100,000 workers rose from 1.0 in 2021 to 1.7 in 2022.

These three industries were also the leading industries for major injuries and accounted for 55% of all major injuries in 2022. Within these industries, SMEs had poorer WSH performance as compared to larger firms.

Dangerous Occurrences

There was an increase in Dangerous Occurrences (DOs), with collapse/ failure of structures and equipment continuing to be the main cause. The number of DOs increased from 13 in 2021 to 27 in 2022. Amongst the 2022 DO cases, 20 involved Collapse/Failure of Structures & Equipment and 7 involved Fires & Explosion. The increase in 2022 was due to a rise in crane-related incidents. To mitigate this, MOM announced a new SGD 4 million grant in January 2023 to co-fund the installation of stability control systems (SCS) on lorry cranes. Further, MOM is reviewing additional measures that would enhance crane operators’ competency and increase deterrence of unsafe crane-related operations.

The Occupational Diseases (ODs) incidence rate per 100,000 workers increased from 20.0 cases in 2021, to 29.7 in 2022. This increase was driven by the rise in reported Noise-Induced Deafness (NID) cases due to ongoing Enhanced Workplace Health Surveillance (WHS+) efforts, which heightened awareness of reporting amongst doctors and employers, and expanded the surveillance footprint.

Under WHS+, companies with workers found to have higher exposures to toxic substances or noise are required to adopt upstream risk controls and put in place programmes (e.g. Hearing Conservation Programmes, Management of Hazardous Substances Programmes) that effectively reduce health risks. Companies also need to undergo third party audits to ensure their workplace health programmes are effective and submit an audit report to MOM.

MOM will continue to increase the number of workplaces under WHS+, as well as collaborate with the WSH Council to increase awareness and implementation of workplace health programmes.

IOSH’s influence and work to raise safety standards around the globe has been recognised with an award.

The Mukaidono Distinguished Achievement Award was presented to IOSH’s Head of Strategic Engagement, Alan Stevens, at the Well-being Tech International 2023 conference in Osaka, Japan, held recently.

The award is promoted and managed by event organisers, The Institute of Global Safety Promotion (IGSAP), to recognise organisations and individuals who have helped to advance global safety standards, particularly in industrial settings.

It is named in honour of the achievements and spirit of Professor Dr Masao Mukaidono who worked to improve the safety of the world’s manufacturing industries.

In a video message played at the event, IOSH Chief Executive Vanessa Harwood-Whitcher thanked the organisers for this honour and said, “IOSH has an understanding that when work is safe and healthy, it is productive and can be of the greatest benefit to our societies and to us as individuals. And we will continue to work together with the global OSH community to move towards our vision of a safe and healthy world of work.”

The International Powered Access Federation (IPAF) will be holding its annual Asia Conference & Showcase in Bangkok, Thailand, on 3 and 4 August 2023.

This year will see the second in-person Asia Conference since the pandemic, following a successful return in Singapore last July.

The two-day event will consist of a full-day conference followed by a half-day site visit to a rental company in Thailand, and there will also be an equipment showcase and networking activities.

At last year’s Asia Conference, emerging markets in Vietnam, Cambodia, Laos and Thailand were among the hot topics under discussion, prompting organisers to decide to host the event in Thailand for the first time.

The Osaka event is the second of four to be held by the Global Coalition for Safety and Health, in the lead up to the Global Initiative for Safety and Wellbeing at Expo 2025, at which IOSH will join partner organisations.

This is part of IOSH’s work with organisations around the world to represent the views and considerations of OSH professionals alongside partners who will bring perspectives from the occupational health community, social security associations, employers and more.

The Institution of Occupational Safety and Health (IOSH) is the world’s chartered body for safety and health professionals.

These are part of efforts to reach the Workplace Safety and Health (WSH) 2028 goal.

At the launch of the National Workplace Safety and Health (WSH) Campaign 2023, the Ministry of Manpower (MOM) announced that the Heightened Safety Period (HSP) implemented on 1 September 2022 will end on 31 May 2023, without further extension. The HSP has served its purpose as an urgent call on employers to prioritise safety and bring down workplace fatalities. Workplace fatality rate per 100,000 workers declined from 1.5 for January 2022 to August 2022 (before the HSP) to 0.8 for September 2022 to May 2023 (during the HSP), but the major injuries rate has not improved.

Efforts will continue towards achieving the WSH 2028 goal of keeping the fatality rate at below 1.0 per 100,000 workers, and the major injury rate at below 12.0 per 100,000 workers. The Multi-Agency Workplace Safety Taskforce (MAST) will retain some HSP measures and implement new measures to strengthen WSH ownership on a sustained basis and build a strong safety culture amongst all stakeholders.

Since the HSP, the workplace fatality rate per 100,000 workers decreased from 1.5 for the period January 2022 to August 2022 (before the HSP) to 0.8 for September 2022 to May 2023 (during the HSP). This outperformed MOM’s WSH 2028 target of 1.0. The major injury rate per 100,000 workers, however, worsened, from 16.8 before the HSP to 19.2 during the HSP.

Among the initiatives announced during the HSP was the setting up of MAST, comprising key sector lead agencies, which set out to identify measures to address the leading

causes of workplace incidents, particularly in higher-risk industries. MAST will implement a set of SAFE (Safety Accountability, Focus and Empowerment) measures to further improve WSH outcomes. These measures include the following:

Strengthening ownership at the sectoral level

• Requiring more stringent safety requirements in Government Procurement Entities’ (GPEs) construction tenders, as well as introducing new measures such as a WSH Bonus Scheme, to align the interests of businesses to WSH. MAST member, Senior Minister of State Tan Kiat How, will be consulting the industry before the Ministry of National Development (MND) and MOM announce the finalised measures.

• Requiring Video Surveillance Systems at worksite locations where high-risk work activities are ongoing, for Construction sites with project value ≥ SGD 5 million, to help companies better manage safety.

• Expanding the Demerit Point System for the Construction sector to Manufacturing, to deter WSH breaches and uplift standards. MAST member, Minister of State Alvin Tan, will share more details.

• Imposing legal duties on manufacturers and suppliers to ensure safe usage of more types of industrial machines, equipment and hazardous substances; labelling of organic combustible dusts and notifying MOM and building owners / landlords of the use of combustible dusts, in prescribed amounts, by the users.

Strengthening ownership at the company level

• Retaining selected HSP measures

such as requiring Chief Executives (CEs) to be personally accountable to MOM for serious WSH lapses and take responsibility for WSH rectifications, in order to strengthen corporate leaders’ WSH accountability.

• Requiring CEs and Board Directors of all companies in higher-risk industries to attend the new Top Executive WSH Programme, to focus their attention on how to meet their WSH responsibilities.

• Providing an additional avenue for Small and Medium-sized Enterprises (SMEs) to consult and access resources for improving their WSH capabilities through SME Centres and Business Advisors.

Strengthening ownership at the worker level

• Empowering workers to take greater ownership of their own safety, by equipping them with updated WSH know-how through a new online micro-learning component in the Safety Orientation re-certification assessment.

– Launch a National WSH campaign to encourage workers to report unsafe practices.

The SAFE measures will be implemented progressively over the next six to 12 months, to allow for industry consultation and lead times for companies where required. Fuller details will be announced when ready.

To instil stronger tripartite ownership and accountability for both workplace safety and health risks, MAST will be retained as a standing committee after HSP, with additional members incorporated.

MAST will continue to study and implement further measures to foster a stronger WSH culture.

Mr Desmond Lee, Minister for National Development & Minister-in-charge of Social Services Integration, urged Built Environment (BE) leaders to strengthen the transformation of their firms and workforce, even as normal activity resumes in the sector. He emphasised the pivotal role of leaders in guiding, inspiring and motivating their teams, and also announced the publication of a study on the BE workforce. Additionally, BCA Academy will take on the role as the Continuing Education and Training (CET) Centre. Mr Lee was speaking to more than 300 sector leaders at the opening of the BuildSG LEAD Summit 2023 held recently at Sands Expo & Convention Centre.

Nurturing a future-ready and resilient workforce, led by a competent Singapore core, is one of the key enablers under the refreshed Built Environment Industry Transformation Map (BE ITM) [1]. This will allow the sector to be better prepared to respond to rapid advancements in technologies and drive industry transformation towards greater sustainability and productivity.

Supported by Workplace Singapore (WSG), BCA together with Ernst & Young Advisory Pte Ltd (EY) had conducted a study on the BE workforce. Building on the BE Skills Framework [2], the study evaluated the impact of key trends on the BE workforce to identify necessary evolution by the BE workforce to drive industry transformation.

The Study on the Built Environment Workforce in Singapore serves as the Jobs Transformation Map (JTM) for the sector to sup-

port employers in their transformation efforts [3], [4].

The study engaged close to 130 organisations across the BE sector, to outline jobs and skills trends, as well as the impact to workforce due to industry transformation efforts for the Design and Construction (D&C) and the Facilities Management (FM) clusters.

The study also includes a global benchmarking exercise involving 10 other cities, namely, Copenhagen, Frankfurt, Helsinki, Hong Kong, London, New York, Riyadh, San Francisco, Shanghai and Tokyo, on their workforce challenges, and highlights best practices and plausible solutions to help employers succeed in their transformation efforts.

The study reaffirmed BCA’s approach for multi-stakeholder collaboration towards workforce development and made five key recommendations:

The study makes the following five recommendations:

• Recommendation 1: Accelerate the adoption of technology enabling greater efficiency and productivity, to develop a skilled local workforce to drive talent attraction.

While there was general industry awareness of the need to accelerate adoption of technology, actual adoption remains slow across the sector. The recommendation provides guidance for firms to develop technology roadmaps and adoption strategy, with consideration of downstream impact to employees and the business. With that, companies are enabled to make informed decisions and commit to technology adoption in support of the business.

• Recommendation 2: Industry forerunners to lead the way for the entire value chain to drive upskilling and to adopt and implement ITM skills.

The workforce skills gap remains a critical area of concern for firms. The industry forerunners must lead the value chain in driving workforce transformation. The firms need to invest in upskilling employees, attracting and recruiting new talents with the right skillsets to drive industry transformation. This recommendation aims to better align skills needed by the sector and available training programmes. It also strives to introduce more conducive learning environments for employees to have sufficient and effective learning opportunities.

• Recommendation 3: Jobs to be redesigned to drive workforce transformation, in response to technology adoption and process changes.

Jobs must undergo change to address the challenge of technology adoption and experience improvement in work processes in the BE sector. Companies can redesign jobs to support employees in impacted job roles. This recommendation guides companies to understand the job transformation process and its impact, precautions to take and ways to overcome challenges to ensure success in job redesigning. Companies will be able to make decisions and commit to job redesigning efforts to add value to job roles and complement transformation efforts.

• Recommendation 4: Enhance sector attractiveness by changing people culture and practices.

The BE sector is expected to face greater difficulties in attracting

new talent and/or retaining existing talent if employee preferences and the sector’s offerings continue to diverge. This recommendation highlights the critical roles of companies, Government, and Trade Associations and Chambers (TACs)/Unions to work together in enhancing human resources (HR) practices and employee value proposition (EVP), and eventually increase the overall attractiveness of the BE sector.

• Recommendation 5: Increase focus on designing, curating, and implementing programmes that provide exposure and experience for current and future workforce.

Given the local context of an ageing workforce and declining talent joining the sector, establishing a robust talent pipeline is a challenge. This recommendation suggests ways for industry to attract and retain potential talent through the intentional design, curation and implementation of programmes that provide greater exposure and experience, with long-term recognition of valuable work experience desired by the sector.

BCA will continue to work closely with industry and Institute of Higher Learning (IHL) partners to nurture a future-ready BE workforce.

The study is published on BCA and WSG’s websites. Firms and individuals can reference the study to take charge of their career development journey and seize the opportunities that emerge alongside transformation of the BE sector. For instance, firms can identify emerging roles, such as Environmental Sustainability Engineer and Facility Management Data Analyst, and start to prepare their workforce to meet these demands. Workers can utilise the various self-help dashboards to identify new skillsets they need to develop as they progress in their career or transition between different job roles in the sector.

Given the rapid pace of change, there is a need to embrace contin-

uous learning so that the workforce continually updates and refreshes their skillsets. When new jobs are created, the workforce will then be well equipped to take them on. To support these efforts, SkillsFuture Singapore (SSG) will be appointing BCA Academy (BCAA) as the CET Centre for the BE sector.

This will augment BCAA’s existing efforts to nurture a future ready workforce.

• New courses, like robotics and automation, net zero carbon, smart and integrated facilities management, and collaborative contracting, will be launched to equip BE stakeholders with in-demand competencies. This will prioritise the training needs to enable the key transformation areas articulated in the BE ITM. To capture opportunities amidst rapid development of technology, the CET Centre will prioritise training in the areas of advanced adoption of digitalisation and data for improved information management across the value chain, as well as integration of technology for a more automated production of prefabricated components. In addition, the CET Centre will also curate programmes to support leadership development.

CET Centres deliver quality adult training. The CET Centres are public training providers that offer a comprehensive array of courses and training in areas which now includes the Built Environment sector. Additional services offered include employment advisory and placement.

The CET Centres undergo a rigorous accreditation and Continuous Improvement Review process to ensure that the standards and quality of training are maintained. They are also required to monitor their trainees’ training and placement activities, in accordance to SSG’s reporting

• New Train-and-Place programmes, as well as courses under the SkillsFuture Career Transition Programme (SCTP), will also be introduced to help mid-careerists transit and pivot into the BE sector and help firms build up their talent pipeline. This will complement existing Career Conversion Programmes (CCPs) that support mid-careerists already in the BE sector.

• Beyond supporting training at the individual level, BCAA will also provide support for enterprise development and transformation to maximise the gains from such efforts. As a CET Centre, BCAA will also be able to channel more resources to support BE firms to upskill their staff in emerging areas, including defraying training costs.

References

[1] https://www1.bca.gov.sg/buildsg/ built-environment-industry-transformation-map

[2] https://www1.bca.gov.sg/buildsg/ manpower/skills-framework-for-builtenvironment-be

[3] https://www.wsg.gov.sg/for-employers/jobs-transformation-maps.html

[4] https://www1.bca.gov.sg/buildsg/ manpower and https://www.wsg.gov. sg/for-employers/jobs-transformation-maps.html

requirements.

The role of CET Centres include:

• Providing comprehensive services such as advisory and placements, and reach out to partners to support enterprises.

• Achieving strategic industrycentric outcomes including placements, improved career prospects, and positive impact on workplace performance.

• Providing comprehensive array of training and mentorship, including bite-sized courses and enterprise transformation projects.

by Aude Camus, Senior Product Marketing Manager, Bentley Systems

by Aude Camus, Senior Product Marketing Manager, Bentley Systems

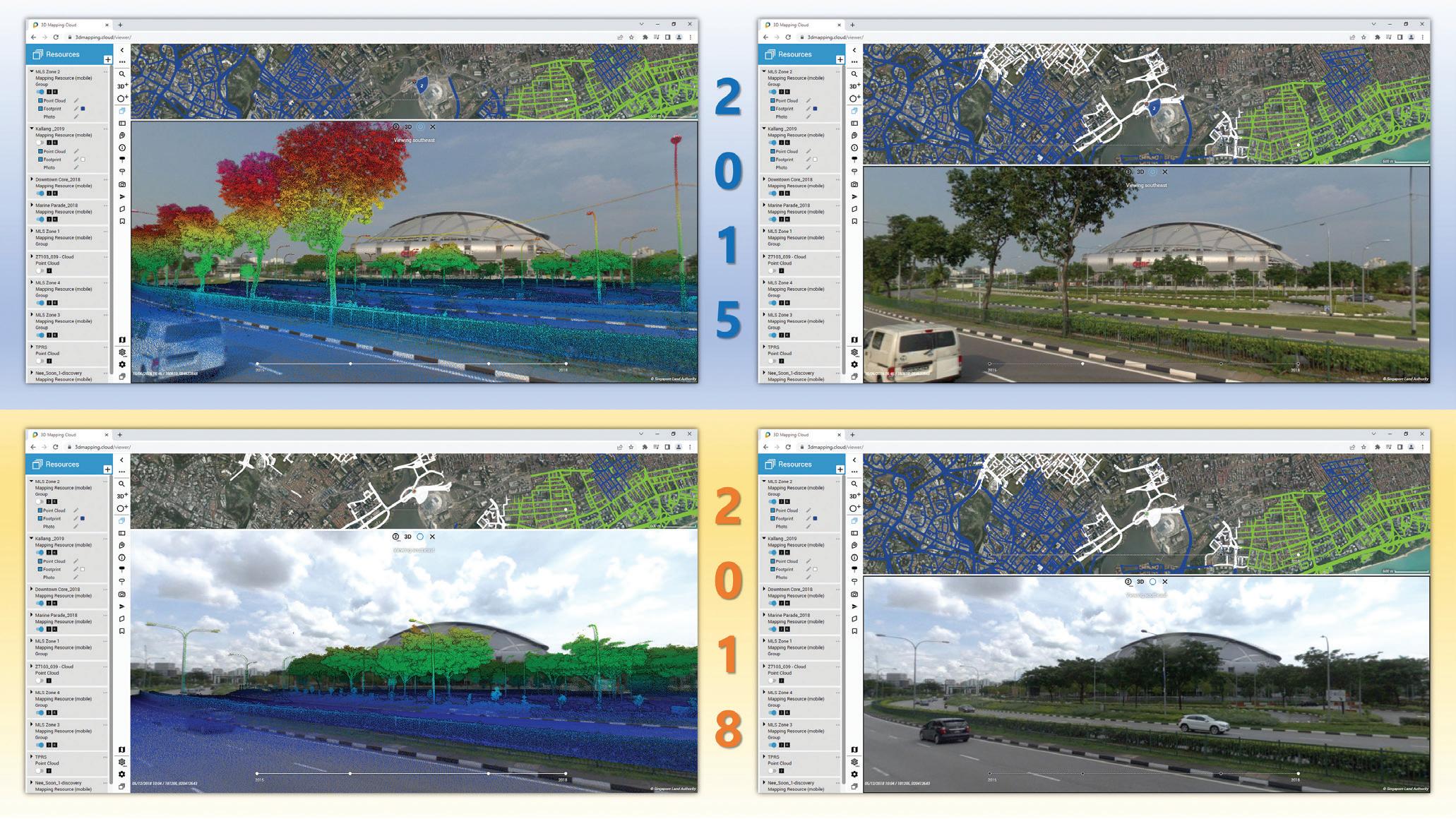

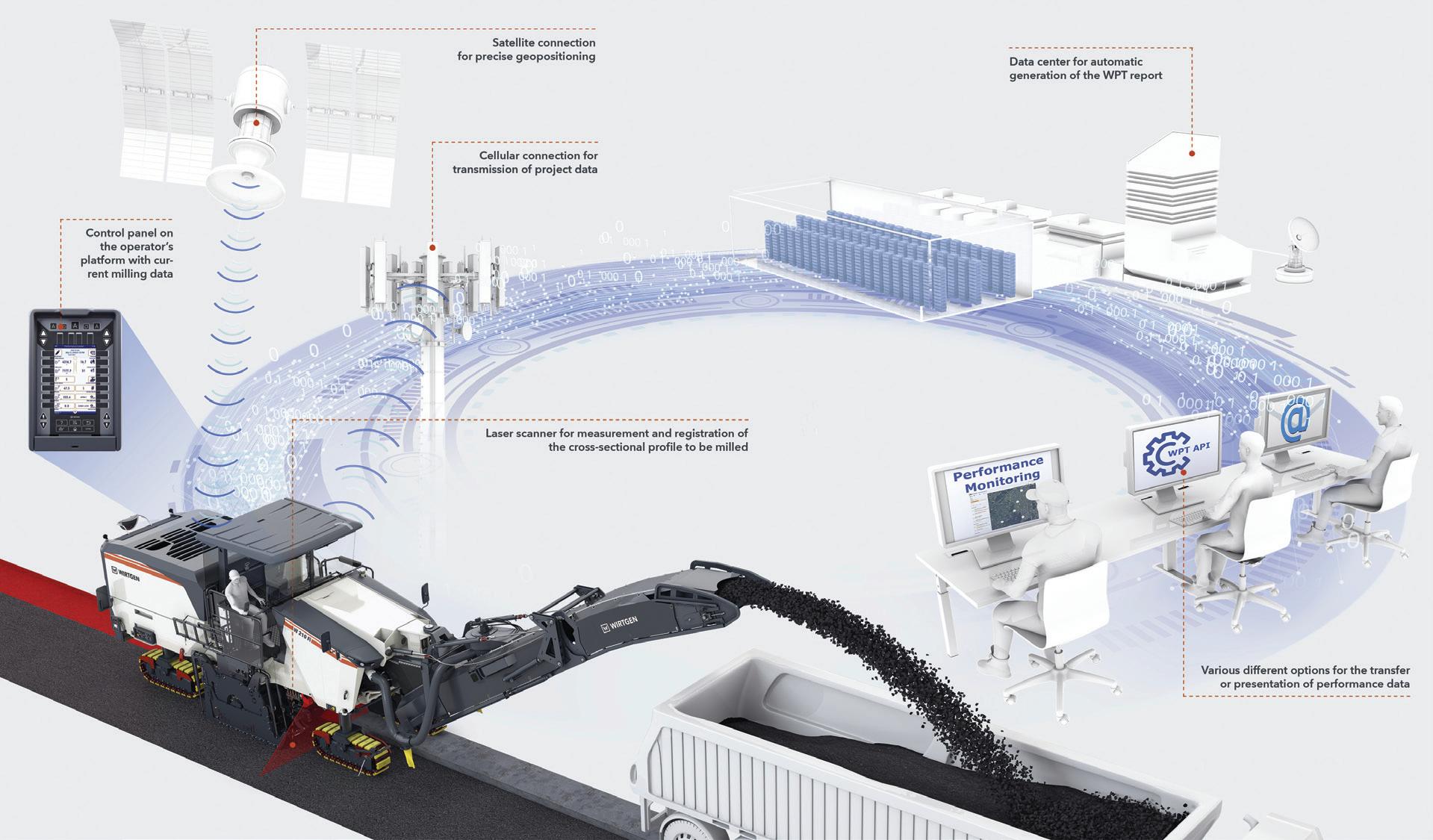

Rapid modelling with Orbit 3DM saved SGD 26 million and one year of data capturing.

As it grows and develops, the island nation of Singapore wants to ensure that it effectively uses its land and space resources. Therefore, the government agency, Singapore Land Authority (SLA), initiated a national 3D mapping of Singapore, via aerial and street mobile mapping, with a ‘capture once, use by many’ objective, to create a smart, resilient and sustainable nation. Over two phases, the project sought to map the entire nation with rapid reality data capturing technologies, creating an accurate, reliable, and

consistent national 3D map that supports government agencies in their policy formulation, planning, operation and risk management.

“Singapore is a garden city and 47% of land is vegetated. With the national 3D mapping, we were working with research institutes to take stock of our natural capital, as well as carbon stocks,” said Ms Teo Hui Ying, Senior Principal Surveyor, Singapore Land Authority.

For aerial mapping, the team would need to conduct 3D mapping over the entire land mass within 40 days, at the highest level of detail. Mobile

mapping meant providing point density of 40 points per square metre and 360° panoramic images at 20 metre intervals. However, the team also needed to remove people or cars from all images and ensure that it captured the reality data hidden behind these objects.

SLA knew that conventional methods for handling the data would not be effective on this project. The mobile mapping data collected for all of the island nation’s public streets amounted to about 25 terabytes. Sharing that reality data

with government agencies would mean duplicating the data sets. This method would mean that agencies could potentially be using old or inaccurate data to make decisions, leading to longer decision-making workflows.

Additionally, the team needed to refine about 600 billion point clouds. They sought to integrate the aerial mapping data and street mobile mapping data – such as point clouds and 360° panoramic images – to ensure that there were no overlapping data points. SLA realised that the best method was to create a digital twin with reliable 3D data. Therefore, they needed a comprehensive, web-based application to manage the massive amount of reality data and develop a digital twin.

Already familiar with Bentley applications, SLA selected Orbit 3DM, one of the key technologies powering iTwin Capture along with ContextCapture, to create a web portal, allowing the team to manage and integrate the large volume

of point clouds and images. They then generated a digital twin, called SG Digital Twin, to bridge reality data sharing with multiple users, via cloud-based resources.

“Bentley’s Orbit 3DM solution enabled us to deliver a digital twin to our government agencies through just a web portal, without these agencies investing in IT infrastructure to host and store the datasets at their end. Users with passwords can access the datasets from their web browser, streaming terabytes of datasets effortlessly from their offices or homes,” said Ms Teo.

This capability was especially important during the COVID-19 pandemic, as it allowed users from different agencies to discuss a specific site without having to meet in person. Instead, they could annotate and collaborate within the virtual environment, while knowing that everyone was looking at the same – and the latest – data. When other users required access to the data, the team could create a localised publication that allowed these individuals to view the site

and provide their own feedback. Data owners could manage, assign and control access to users, ensuring that everyone had the right information and the right time to make the best decisions.

and cost

SLA’s SG Digital Twin increases data availability by 50%, enables accurate information extraction and delivers a sustainable, collaborative digital twin that can be used for multiple planning purposes.

“With these data capture methods, the annual potential savings by the government is at least SGD 5 million with a refresh cycle of once every two years,” said Ms Teo.

By using rapid national street mobile mapping, SLA is seeing significant savings when compared to traditional means of topographic or terrestrial surveys. With topographic surveys to map out public streets across the nation estimated at SGD 30 million, SLA and the Singapore government saved SDG 26 million. Additionally, rapid street mobile mapping saved about a year in mapping the nation, allowing planning to take place within a shorter period of time. In addition, the point cloud and imagery have provided more ground information than what conventional surveying can achieve.

“We are excited to see the plans that Bentley has in the pipeline to elevate the Orbit solution, [and] perhaps even talk about metaverse in the near future,” said Ms Teo.

Cupix recently announced the addition of its leading product, CupixWorks, to Bentley Systems’ ‘Powered by iTwin Program’.

Cupix is a partner of choice for delivering global, spatial digital twin platforms that provide visualisation and analytics for owners and builders across the

entire built-world lifecycle. CupixWorks is a 3D digital twin platform that enables decisionmaking and collaboration through all stages of a building’s life cycle.

Project Managers, General Contractors, Architects, and Owners can remotely view, track and manage on-site

progress via 3D spatial contexts and life-like 3D navigation.

By leveraging the Bentley iTwin Platform, CupixWorks can synchronise and visualise 3D, 360° capture data – along with BIM models plus customised data – and use georeferencing to place the capture in the site’s physical location.

The mobile mapping datasets will help with estimates for roadside trees, which would reflect a more accurate carbon capture for the nation.

Ms Teo Hui Ying, Senior Principal Surveyor, Singapore Land Authority

The first-of-its-kind project in France involves boring out tunnels in a highly built-up area with road, rail and river infrastructures.

In preparation for the 2024 Paris Olympic Games, and construction of the Olympic and Paralympic Village, in particular, work is ongoing in Paris and its outskirts, to run powerlines underground and freeup more than 80 hectares of land. In fact, by 2024, the local provider RTE (Réseau Transport Electricité) is planning to run four 225 kilovolt (kV) powerlines underground, which are going to substitute 15 km of cables running on 27 pylons, and pass through the towns of Saint-Denis, Villeneuve-la-Garenne and l’Île-Saint-Denis, close to the French capital. This intervention is part of the Mesil (Mise en Souterrain d'Initiative Locale) project.

The sheer size of the project is awe-inspiring – and the first of its kind in France – and will involve boring out deep tunnels in a highly

built-up area where numerous road, rail and river infrastructures are located. Work is carried out on extremely important powerlines that feed the Gare du Nord railway station, Line 13 of the Paris Metro and the entire area to the northwest of the city (with a population of more than 800,000). There are other sites currently where work is ongoing in the same area, which means work needs to be very carefully coordinated, by also taking into account the future reorganisation of the urban layout, with 2 km of tunnels at a depth of 50 m.

To overcome the challenges of this part of the project, RTE opted for the construction of an underground tunnel through which the new powerlines will pass – an appropriate solution for a particularly congested and densely populated area. The tunnel, around 2.5 km long, is 3 m in diameter and runs at a depth of 50 m. For the tunnelling work, carried out by a 120 m long Tunnel Boring Machine (TBM), called Ambra, with a diameter of 3.9 m, 120,000 liner segments had to be installed.

While tunnelling, a TBM leaves an annular void between the ground and the extrados of the segments, when they are placed in position, and this void has to be filled as the TBM advances. Depending on particular site constraints and decisions taken by the main contractor, the voids may be filled with grouts

or a two-component grout, in which component A is made from water, bentonite, cement and a set retardant, and component B is a set accelerator.

The two-component system proposed by Mapei, thought to be the most suitable for this site, by the main contractor, Spie batignolles, had already been used on other sites, such as Lots T2A and T2B of the 15 Line South of the Gran Paris Express project, the extension of the safety tunnel for the RER C in Meudon and site SMP4 for the Tunnel Euroalpin Lyon Turin (TELT). Because of the constraints imposed by the mechanical properties required, along with the high pressures due to the sheer depth of the tunnel, a preliminary study had to be carried out in the Mapei laboratories. The products proposed were the following:

• MAPEBENT API 2 – a natural sodium bentonite suitable for all types of civil engineering applications. It conforms to the international API specifications on materials to be used for drilling fluids and bentonitebased slurries and can be used especially where quick activation of bentonite in water is required and where the mix should have easy pumpability and high volumetric stability.

• MAPEQUICK CBS SYSTEM 1

– a liquid retarding agent with plasticising effect which inhibits the setting times of cementitious mixes for long periods. It is specifically designed for

cementitious mixes that need long workability times, for example, because of long transportation times or long pumping distances.

• MAPEQUICK CBS SYSTEM 3 – a liquid product used as accelerator of cement-based mixes for injection, which is particularly suitable for extremely fluid mixes with a very high water content.

PROJECT DATA

Project Mesil RTE, Seine Saint-Denis (France)

Owner

RTE (Réseau Transport Electricité)

Project Manager’s Assistant

Arcadis

Contractors

Spiebatignolles génie civil Spie batignolles fondations

Spac and Setec TPI

Works direction

Setec

Period of construction

2021-2024

INTERVENTION BY MAPEI

Period of the intervention

2021-2022

Contribution by Mapei

Supply of products for injection and TBM works

Application of Mapei products

Bentonite – MAPEBENT API 2, MAPEDISP FLS

Backfill grout admixtures –MAPEQUICK CBS SYSTEM 1, MAPEQUICK CBS SYSTEM 3

Website for further information

www.mapei.fr

www.mapei.com/sg

utt.mapei.com

This editorial feature is based on an article from Realtà MAPEI INTERNATIONAL ISSUE 95.

Images by Mapei.

The formwork and scaffolding systems help to ensure that the refurbishment and shell construction work is implemented quickly and professionally.

The historic gasometer in Berlin’s Schöneberg district is being transformed into an office tower which will become the new landmark of the EUREF (European Energy Forum) Campus district. This is a construction project that symbolises the energy revolution. As part of the conversion work, the listed building will be gutted within its steel frame, and rebuilt.

Since 2008, a commercial and science campus with 150 resident companies has been built in the area around the decommissioned low-pressure gasometer, on the site of the former municipal gas works. This pilot district for the climateneutral city of the future is being developed by EUREF AG. Numerous listed clinker and brick buildings have already been refurbished in an energy-efficient manner and complemented by architecturally outstanding, energy-efficient new buildings. This future-oriented site in Berlin is where more than 5,000 people are now researching, learning about and working on energy management, the mobility transition and climate protection.

Gasometer becomes the new landmark of the EUREF Campus

The gasometer is the last building to be refurbished. The 78 m high steel structure of the industrial landmark was being used as an imposing location for TV presenter Günther Jauch’s talk shows. It is now being converted into an office and conference centre. Maintaining a respectful clearance of 1 m, the grey steel structure provides the framework for the new circular building inside. This way, the historical landmark is preserved, while having new life breathed into it, at the same time. The new design is reminiscent of the former

telescopic vessel that moved up and down within the steel skeleton. Around 28,000 m2 of office space is being constructed across 15 floors, with a sky lounge and a publicly accessible roof terrace at a height of 66 m, as the finishing touches. Large glazed areas in the facade allow for a lot of transparency and natural light in the building. In future, around 2,000 Deutsche Bahn employees will press ahead with the digitalisation of German railways from this setting.

The turnkey conversion project is

being carried out by the contractor, WOLFF & MÜLLER, as has been the case with numerous other buildings on the EUREF campus. As part of the well-coordinated team, engineers from the PERI branch office in Berlin were brought in again to work on the Gasometer project, taking care of the challenges relating to formwork and scaffolding. After all, the shell of the high-rise building was to be constructed at the same time as refurbishment work was being carried out on the historic steel structure that surrounds it – in

the tightest of spaces and, to the greatest extent possible, without interfering with the surrounding area.

After a short planning period of only three months, the shell construction work began in August 2021. At the same time, the construction team started the refurbishment work for the historic steel structure. The distance between the edge of the building shell and the surrounding steel structure was just 1.50 m –but the experts from PERI found a solution that was as practical as it was elegant. With the PERI UP Scaffolding Kit, they designed a scaffolding solution that closely followed the shape of the circular steel structure across the entire height. Completely enclosed inside and out to protect the surrounding area, the scaffold was moved around the gasometer in sections, in a clockwise direction, during the refurbishment phase. This made it possible to decoat one steel segment after the other, using the sandblasting technique, and then apply new corrosion prevention technology, at the same time as the shell construction work was taking place. As a result, the surrounding area was largely spared from excessive construction noise and dirt until the refurbishment work was completed.

Almost imperceptibly, because it was concealed within the lower steel ring and partly behind the PERI UP Working and Safety Scaffold, the new building sprouted upwards simultaneously, one floor at a time. An entire standard floor was completed every two weeks. With the MAXIMO Wall Formwork System and SKYDECK Slab Formwork, it was also possible to realise the numerous architectural concrete surfaces on the walls and slabs quickly and professionally. To cover the additional demand for formwork elements, the contractor took the opportunity to combine PERI purchase and rental elements.

Protected by the surrounding RCS Climbing Protection Panel, it

was possible to work quickly and safely on the building shell at any height, sheltered from the weather. The single-sided tie system of the MAXIMO Wall Formwork and the easy-to-handle SKYDECK Slab Formwork System were instrumental in keeping the project on schedule, without any difficulty.

The building shell was completed in November 2022, two months earlier than planned. This has resulted in several advantages. The shell construction and finishing work phases have now been staggered, which simplifies logistics on the cramped construction site considerably. And completing this stage ahead of schedule also shortened the rental period for the formwork elements, meaning that the budget for the building shell was adhered to without any difficulty. Therefore, formwork and scaffolding systems that make work safer and simpler prove their worth, especially on challenging projects such as the Gasometer Schöneberg. This is complemented by efficient project planning with coordinated solutions from a single source, as offered by PERI. The formwork and scaffolding manufacturer also contributed its expertise to this construction project as a digital construction partner, from virtual planning for the formwork and scaffolding to implementation on the construction site with a wide range of tools, and right through to assistance

with the use of BIM processes and technologies.

Contractor

WOLFF & MÜLLER Hochund Industriebau GmbH & Co KG, Berlin branch office, Germany

Project planning

EUREF-Consulting, Berlin, Germany

Field service

PERI Berlin branch office, Germany

For the dredging work at Straubing port in Germany, the sheet pile wall of the port quay will have to be reinforced by additional tiebacks.

In order to promote navigation and flood protection on the Lower Bavarian Danube, the depth of the river channel between Straubing and Deggendorf is currently being increased. Since the port of Straubing-Sand is a so-called ‘shelter port’ which is intended to provide ships with protected anchorage in emergency situations, such as low water, the depth of the port basin must also be adjusted and dredged to a depth of approximately 65 cm. To ensure that the stability of the basin continues to be guaranteed after this extensive modification, the long-established German foundation engineering company, Stump-Franki, was commissioned to reinforce the

port quay sheet pile wall by means of additional tiebacks.

Within three quarters of a year, therefore, exactly 1076 marine tie rods are to be installed on all three sides of the basin. For this purpose, the company used a 33 t telescopic crawler crane from SENNEBOGEN and supplemented it, especially for the port project, with a 50 tonner, the 653E, rented from SENNEBOGEN Vertriebsgesellschaft and specially equipped for use in the port.

Teamwork in handling the tie rods and debris troughs

As port operations are to continue unhindered during the work, the

hydraulic engineering project requires a considerable amount of coordination between the specialist civil engineering company, the port operator, the operating ships and hauliers. In addition, this also means that the cranes, which work hand in hand when handling the marine tie rods and debris troughs, have to be particularly reliable and flexible at the same time. Telescopic crawler cranes, which are known for their high flexibility in operation, prove to be ideal here.

The SENNEBOGEN 653E, a 50 t

telescopic crawler crane, which was rented specially for the project, works on the quay and is therefore equipped with rubber pads on the crawler floor plates, that are gentle on the ground. On the one hand, it takes care of loading and unloading the lowloaders which regularly deliver new tie rods and collect the debris troughs filled with the washed-out rock material.

On the other hand, it also loads the supply pontoon that travels

back and forth between the quay and the work pontoon. For this purpose, it moves in continuous pick-and-carry operation with the debris troughs weighing up to 11 t, or with the up to 29.5 m long marine tie rods, on a 20° sloping ramp down to the port basin.

The SENNEBOGEN 633E

The compact, SENNEBOGEN 33 t telescopic crawler crane is used directly on the working platform. In this particularly confined space,

it acts as the central lifting device. This means it picks up the tie rods from the supply pontoon, threads them into the drill rig, and also handles the debris troughs. They must meticulously hold all the soil material that is flushed out so that the increased environmental protection conditions that apply to the construction site, which is located directly on the water, are properly met. A total weight of up to 11 t is therefore not uncommon for the skips.

Three important reasons are provided.

Like many industries, the construction vehicle and machine industry is on the path to electrification. It has been one of the late-comers to the electrification game, with little happening from OEMs until after 2020. But this is changing, with more electric product announcements covering a wider selection of vehicle types under the construction banner.

The new IDTechEx report ‘Electric Vehicles in Construction 20232043’, finds that the EV construction vehicle market is about to take off and grow rapidly, with a 10-year CAGR of 37%.

One of the market’s cornerstones of growth will be electric mini excavators. The market for mini exca-

vators is the third biggest construction vehicle market by volume and the biggest in Europe. Their small size and lighter workloads make mini excavators an ideal fit for electrification, and they are a common entry point for OEM electrification.

Equal or better performance

One of the main concerns that construction professionals might have when switching to electric is whether the new machines will have the power to get the job done.

IDTechEx’s ‘Electric Vehicles in Construction 2023-2043’ report finds that, in many cases, electric machines have equivalent or even superior power when compared with their diesel counterparts. Maybe

one of the best examples of this is the JCB 19C-1E, whose motor has a peak power of 20 kW, approximately 33% more than diesel examples in IDTechEx’s database, and nearly double the 11.7 kW engine found in JCB’s own 19C-1 diesel equivalent. There should be no doubt then that an electric vehicle is every bit as capable as a diesel-powered vehicle, but can the batteries provide endurance for a hard day’s work?

This is perhaps one of the biggest concerns for people wanting to transition to electric. IDTechEx’s research found many examples of electric mini excavators that offer six to eight hours of continuous operation – which is enough to get most operators through a normal work day.

It is well known that a major benefit of transitioning to electric is zero exhaust emissions. Even if a car is charged from a grid with high emissions, it still helps to remove emissions from city centres, improving air quality. The effect is even larger on construction vehicles. With open cabins and stationary vehicles, the air quality that an excavator operator and surrounding workers are exposed to can be very poor. This can lead to short- and long-term health effects, but zero-emission vehicles offer a significant ‘quality of life’ benefit to construction workers, improving the overall air quality around construction sites.

Finally, electric machines can offer a significant reduction in the total cost of ownership. While the batteries add a considerable premium to the cost of building and purchasing the vehicle, the cost of batteries in the construction industry has been coming down. This will be helped further by OEMs like John Deere, Caterpillar, XCMG and more, bringing electric products in-house and producing in larger volumes

(instead of electric vehicles being built in limited runs by retrofitting engineering firms).

Between maintenance and fuel savings, IDTechEx predicts an electric mini excavator owner can expect to see a return on investment in a short period of time.

Mini-excavators are just the start and other vehicle types are now following. When the benefits are proven, the construction industry will quickly switch to electric and

benefit from better working conditions for the operator and better job performance as well as savings for the owners.

IDTechEx Mobility Research

IDTechEx’s ‘Electric Vehicles in Construction 2023-2043’ report forms part of the broader mobility research portfolio. IDTechEx tracks the adoption of autonomy, electric vehicles, automotive semiconductors, battery trends, and demand across land, sea and air.

A market research report, produced by Industry Research, on the global ‘EV Construction Vehicles Market’, includes segmented information, based on geographical regions, countries, companies, types, and applications.

In the report, a comprehensive analysis of the major competitors in the market is provided, along with their strategies to tackle the competition.

In the EV Construction Vehicles market, several key players,

including Toyota, Kion, Jungheinrich, Mitsubishi Logisnext and Hyster-Yale, are leading the field, with various strategies to expand their market reach and enhance their position in the construction industry.

This report provides valuable insights for stakeholders and participants in the global market, enabling them to gain a competitive advantage and leverage the report as a powerful resource for their business requirements.

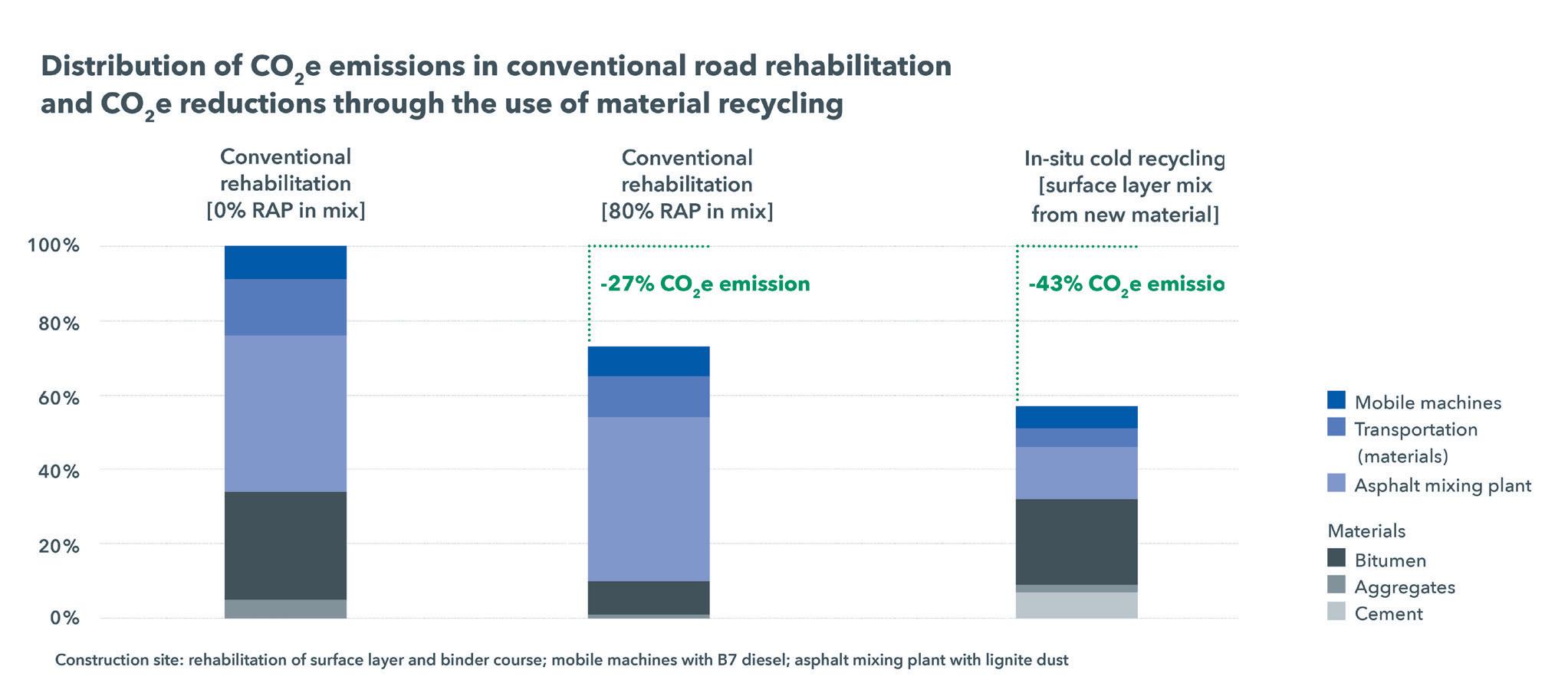

This will require improvements in the production of machines and materials, and in the work processes.

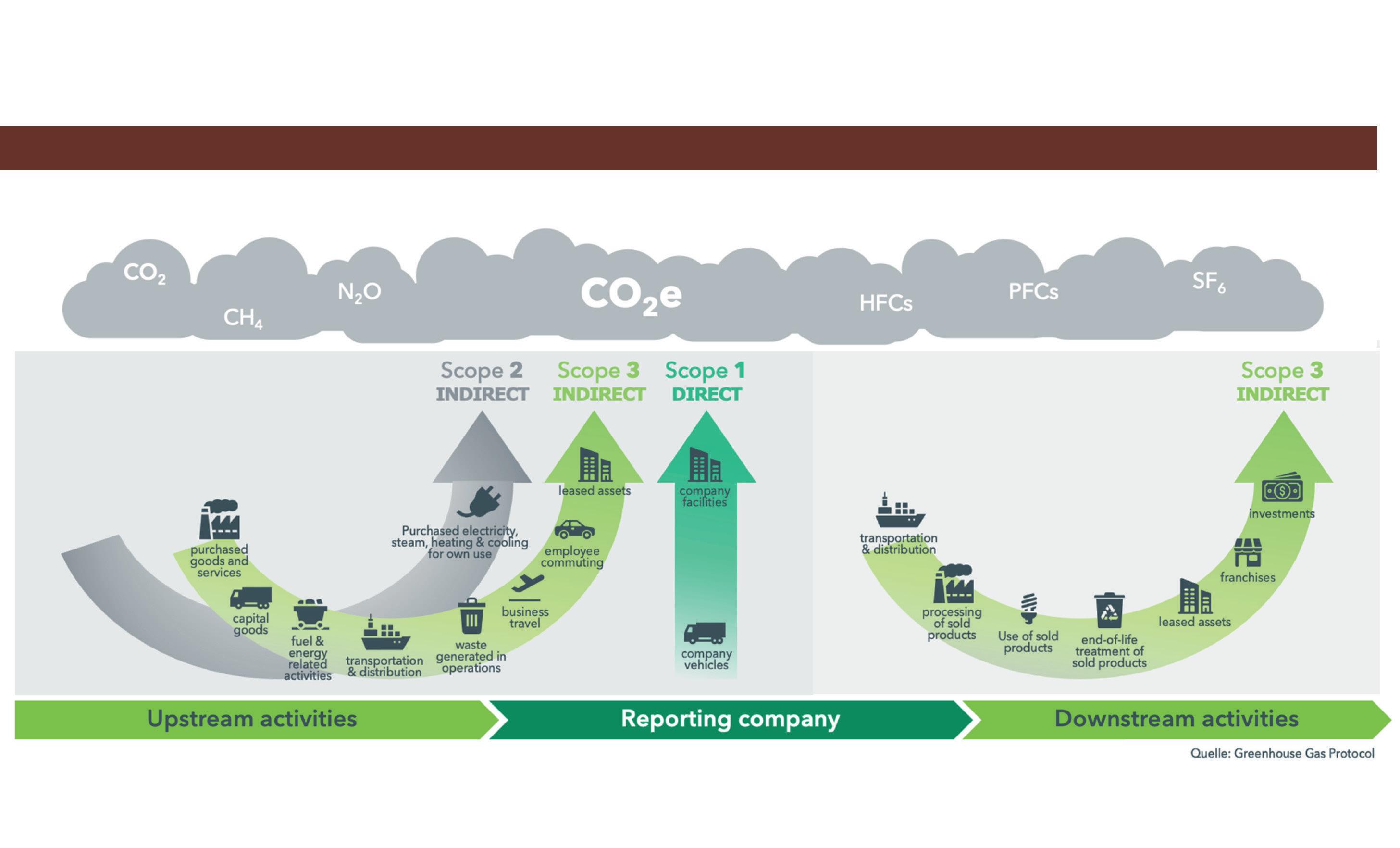

Machine manufacturers and construction companies around the globe are currently searching for ways to achieve the goal of climate-neutral construction. The challenge here is to successively reduce emissions of CO2 and other harmful gases around the world, to zero, over the coming decades. The other harmful gases are measured as CO2 equivalents (CO2e).