It helps to have a team working in unison toward an effective and efficient solution. That’s why we created ProjectWorks™ – a complimentary design and pre-construction service that streamlines the process into one convenient work package. From countless panel shapes, sizes, and colors to flawlessly integrated lighting and diffusers, our ceiling design team collaborates with you to achieve your vision. See how teamwork makes the dream work at armstrongceilings.com/projectworks

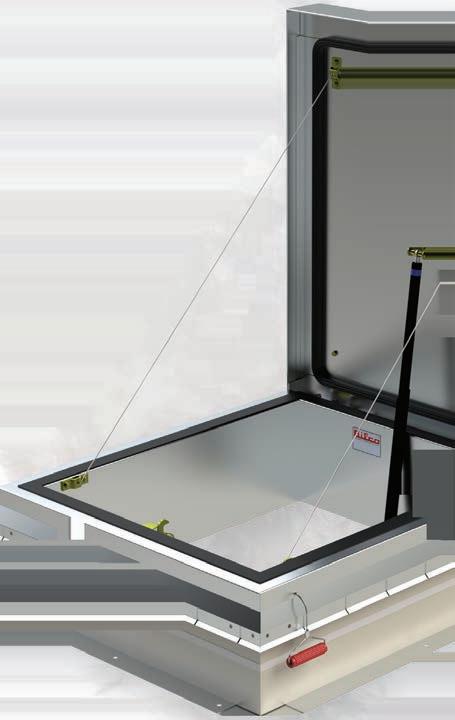

Drawing from four decades of innovation, NanaWall once again

the most advanced family of folding glass walls.

Increased Transparency: Clean aesthetics with the slimmest profiles available and minimal exposed hardware.

Flexible Stacking: Unique floating panel sets can stack either to the left or right.

Uninterrupted Transitions: Only ADA-compliant sill with a water rating and a high heel resistant feature.

Proven Durability: Air, water, structural, and forced entry tested. Swing door tested to 500,000 and bi-fold panels to 20,000 open/close cycles.

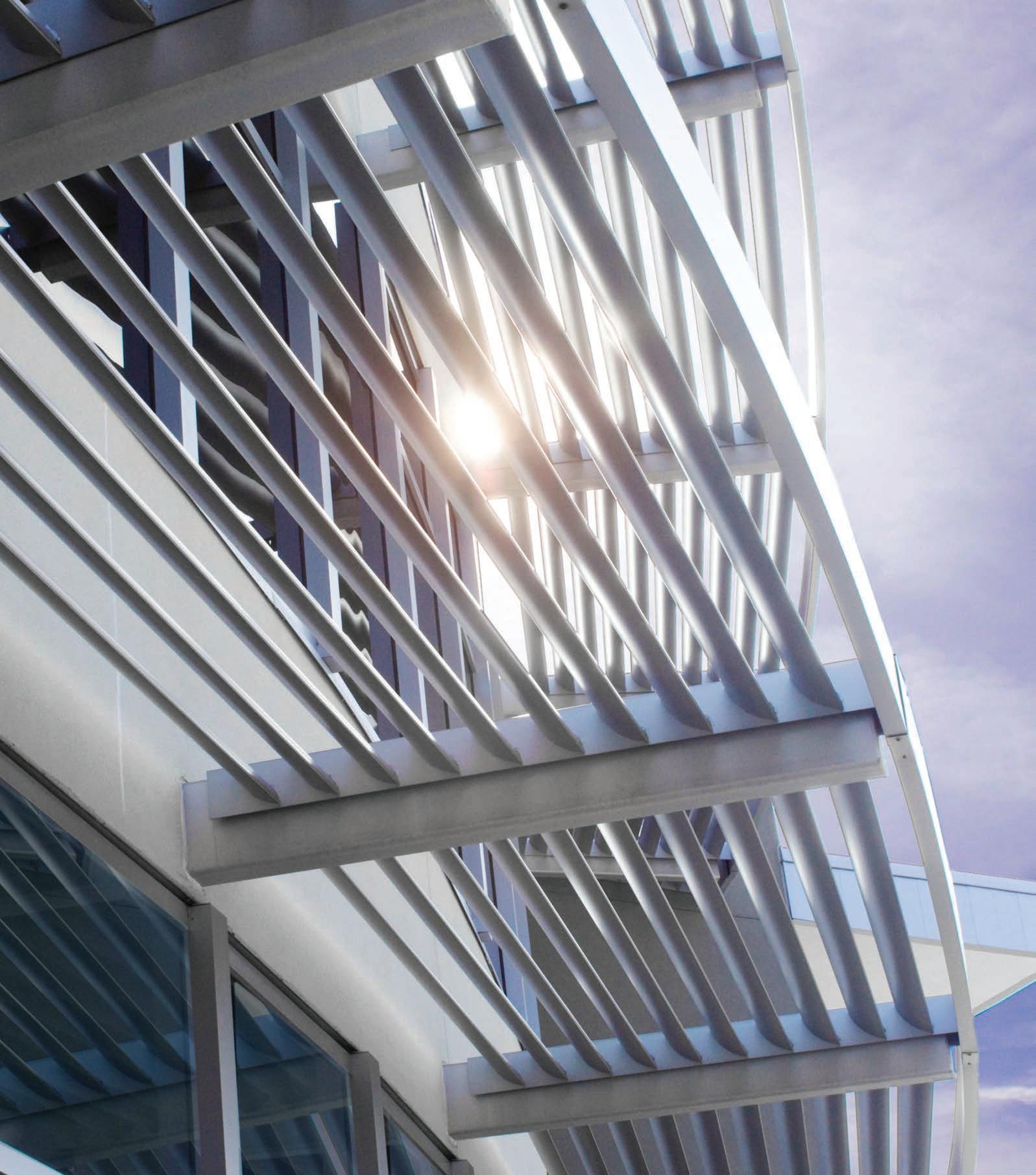

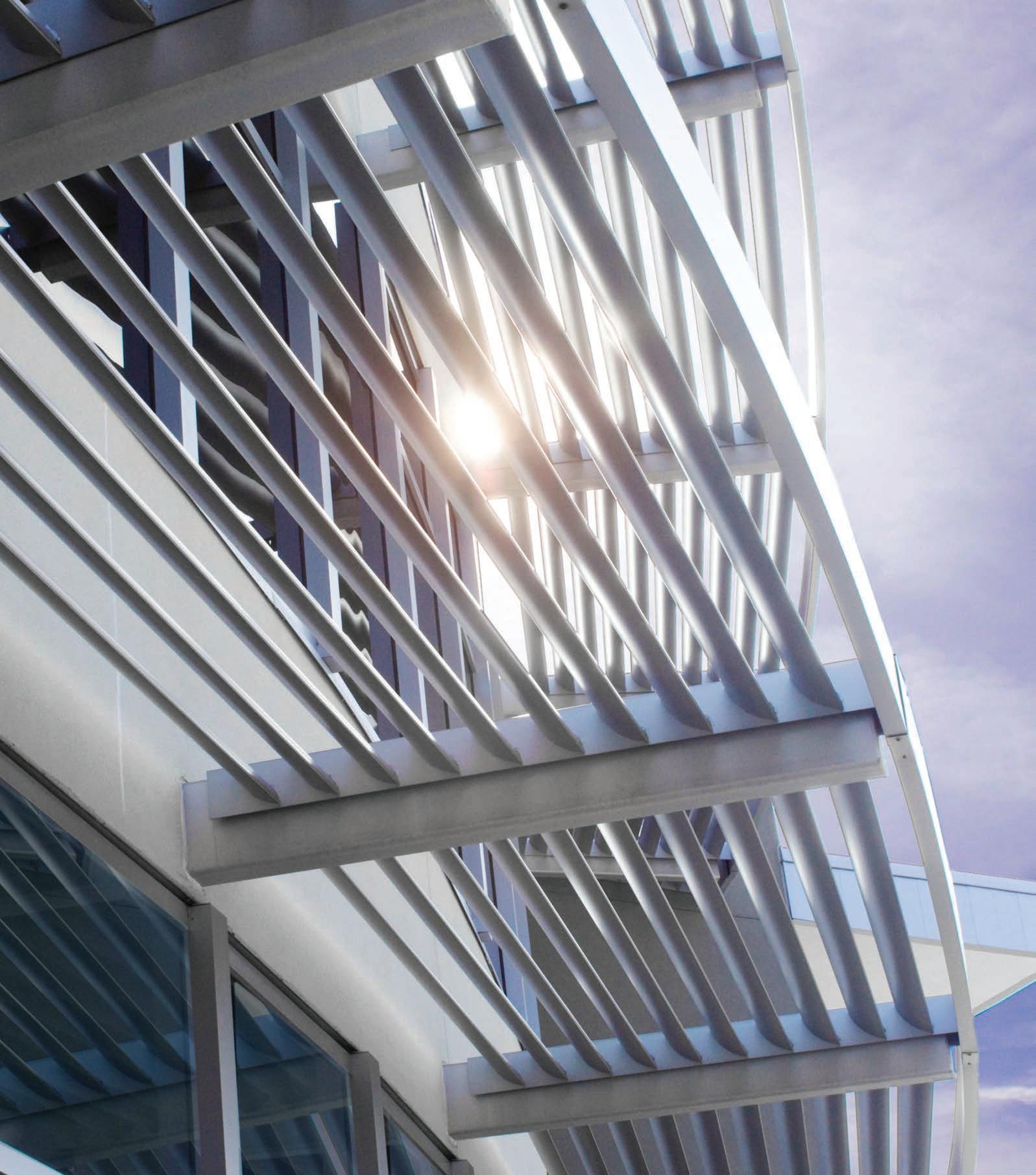

Series aluminum panels created a very affordable

a

that would weather well and gave

that architectural

we

trying to

THE COVER:

LEED Gold, Less Water

residential tower in San Francisco reaches great heights in water conservation.

62

© Tom Harris, Courtesy Studio Gang

Feature // by Barbara Horwitz-Bennett

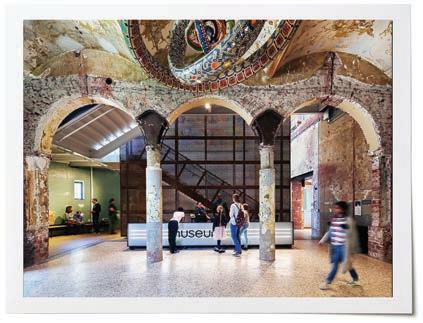

The renovation of the century-old Carnegie Free Library, into MuseumLab by Children’s Museum of Pittsburgh, leans into the structure’s dilapidated state.

Form // by Jeff Pitts

lights and a big curve at Harim Tower in Seoul, South Korea.

Function // by Jana J. Madsen

MIRA achieved 12 of 10 LEED points in Water Efficiency combining a greywater recycling system with low-flow fixtures and a vegetated roof.

WOODExtraordinary design, engineering, and construction efforts allow mass timber projects to be built taller, larger, and with a creative

by Barbara Horwitz-Bennett, Contributing Writer

by Barbara Horwitz-Bennett, Contributing Writer

Explore the unexpected surprises of design with a twist. by Jeanette Fitzgerald Pitts, Managing Editor

Resources, Events & Letters

On Spec

Innovative Solutions for Commercial Washrooms by Jeff Pitts

A new barometer for measuring sustainability with +Vantage Vinyl verification by Jay Thomas, Vinyl Sustainability Council

Product Developments

Elevators and Smart Mobility

Fire Protection Solutions for Modern Mega Warehouses by Jeff Pitts

New and Improved 42

The latest product, material and system advances by Architectural Products staff

Specifiers’ Solutions 70

Arcana’s mirrored cabins blend seamlessly with the forest while offering protection for wildlife. by Vilma Barr

Ceiling clouds provide effective sound management in an office exterior.

Stone veneers add rugged beauty that weathers well in Pacific Northwest.

Exterior panels are a homerun for a new office building adjoining Greensboro, N.C. ballpark.

Last Detail 80

Jessica Mann-Amato, iida, Principal Heading up Mancini Duffy’s Interiors division in NYC, MannAmato sees opportunities for young designers in VR. by Barbara Horwitz-Bennett

The unexpected. It’s exciting. While most people appreciate a good plot twist in a story, seeing some thing unexpected achieved in architecture can be unforgettable. What’s more intriguing is when the stunning, new-age design successfully solves a problem, a need. The need could be unique to that specific time and place and client or more universal. Sometimes, it is both. Take MIRA, for example.

MIRA is the high-rise housing complex, designed by Studio Gang, that appears to rise like a drill bit into the San Francisco skyline. Aesthetically, this brilliant take on the bay window is striking, but dig ging a little deeper into the story, there’s a twist. Not only is it beautiful, but this residential development accomplished something quite extraordinary.

Through a combination of design and advocacy, the design team was able to achieve LEED Gold certification for the project and offer 40% of the units as below market housing, meeting both the sustainability and affordability needs so prevalent in the city. To read more about the twists of MIRA, turn to page 62.

There are a myriad of reasons that mass tim ber construction is growing in popularity—beauty, sustainability benefits, biophilic properties, and faster construction times, but, until recently there were a lot of limits on the type of project that could be con ceived as mass timber. Now, those limits are being pushed by design and engineering teams, allowing structures previously thought to be “impossible to build” to be realized. Today, the tallest mass timber structure in the world is in Wisconsin, the Ascent residential tower rises 25-stories and proves to many that it is possible to build taller and larger mass tim ber projects. To read more about the real-world feats of mass timber design, check out page 22.

Sometimes the need is unknown to many. The growing demand for larger warehouses has been making lots of news as of late, but a little-known fact is emerging about the heightened need for greater fire protection in these spaces. The use of Automated Storage Retrieval Systems (AS/RS) combined with the practice of packing these spots to the gills has left these merchandise-filled mega warehouses vulnerable to fire. One interesting—and unusual—response is to reduce the oxygen level in

the area to below what fire needs to propagate, stop ping fires before they start. Learn more about this fire-protection solution and others on page 18.

Prepare for the unexpected as you dive into this issue of Architectural Products. The projects we profiled offer a stellar showcase of the various ways that architects are addressing need with design. The results are quite incredible.

Happy reading.

Chris Ferrell CEO

June Griffin President

Mark Zadell CFO

Patrick Rains COO

Tracy Kane Chief Administrative & Legal Officer

Tim Shea Group Publisher

Gary Redmond Managing Partner gredmond@endeavorb2b.com

Tim Shea Managing Partner tshea@endeavorb2b.com

Jeanette Fitzgerald Pitts Managing Editor jfitzgerald@endeavorb2b.com

Jim Crockett Editor at Large

Vilma Barr Barbara Horwitz-Bennett

Jana Madsen John Mesenbrink

Jeff Pitts Heather Ronaldson

Katy Tomasulo

Lauren Lenkowski Associate Art Director llenkowski@endeavorb2b.com

Jim Wessel 847-504-8180 arp@omeda.com

Gary Redmond Tim Shea 847-359-6493 847-359-6493 gredmond@endeavorb2b.com tshea@endeavorb2b.com

Bob Fox Jim Führer 917-273-8062 503-679-5409 bfox@endeavorb2b.com jfuhrer@endeavorb2b.com

David G. Haggett 847-917-0287 dhaggett@endeavorb2b.com

For editorial submissions, email Jeanette Fitzgerald Pitts: jfitzgerald@endeavorb2b.com or call: 847-359-6493

“Recognizing the need is the primary condition for design.”

—Charles Eames

Whoever said the washroom (the most frequented room in any building) shouldn’t be as nice as the showroom? ASI just gave the washroom a makeover—you can too. Visit americanspecialties.com/showroom to explore the new standard for basis of design in washrooms. Featured in this ad are our exclusive Velare™ and Piatto™ collection of washroom accessories, ASI Alpaco™ partitions, and ASI lockers.

IT’S YOUR

“Achieving a Balance of Life Safety and Well ness” is an AIA-approved CEU course that awards 1 HSW, 1 LU credit. It is sponsored by Acoustical Surfaces, Altro, Aluflam, CR Laurence. This course focuses on solutions helping architects to address some of the com mon design issues they face today. Explore fire-rated curtainwall assemblies that look like their non-fire-rated counterparts, glass partitions that help to manage sound, and the potential pitfalls in specifying products with anti-microbial additives. www.thecontinuingarchitect.edu/course/ achieving-a-balance-of-life-safety-and-wellness

“Bird Friendly Glass Solution: Understanding the Fundamentals of Safe Design” has credits: 1 HSW, 1 LU. It is an AIA-approved continuing education course, sponsored by Guardian Glass. Glass and glazing are used to blur the lines between inside and out, helping elevate performance and the experiences of people. While humans can use environmental cues to identify glass as a barrier, birds cannot. The solution is bird-friendly glass that delivers on performance, energy efficiency, and the needs of people. This course is intended to provide the basis for a better understanding of how to recognize issues affecting the bird population while learning about best practices and design fundamentals for smarter, safer buildings. www.thecontinuingarchitect.edu/course/ bird-friendly-glass-solution

Came for the education, left with a Subaru.

For 15 years Architectural Products magazine has given away a car at the AIA Conference and Expo. This year’s winner is Eric Pros, aia, ncarb, mba, cpted, Director of Design with DS Architecture out of Cleveland, Ohio. Eric’s winning enthusiasm was delightful. He said this to our seven sweepstakes sponsors, “thank you again for your generosity and creating this amazing opportunity.” Eric did admit that despite the magnitude of this sweepstake victory it takes a back seat to his most important event this year, his marriage in just a matter of weeks! The car he chose to walk away with is a 2022 Subaru Outback Wilderness Edition. Congratulations to the luckiest attendee at the show.

HCD Healthcare Design Expo & Conference

Oct. 8-11

Henry B. Gonzalez Convention Center San Antonio, Texas www.hcdexpo.com

MetalCon

Oct. 12-14 Indiana Convention Center Indianapolis, Ind. www.metalconstruction.org

Greenbuild Nov. 1-3 Moscone Center San Francisco, Calif. informaconnect.com/ greenbuild/

ASLA

Conference on Landscape Architecture Nov. 11-14 Moscone Center, San Francisco www.aslaconference.com

World of Concrete Education: Jan. 16-19 Exhibits: Jan. 17-19 Las Vegas Convention Center www.worldofconcrete.com

In a typical high-traffic public restroom, there might be a dozen hand-washing stations, but most people will still opt to use the same one or two faucets. As a result, the corresponding one or two soap dispens ers will more frequently be found depleted and, over time, an abundance of annoyed handwashers can be produced. As mild frustration sets in, these frazzled folks generally feel their blood pressure elevate as they hover from sink to sink seeking to score a hit of Softsoap. People in this state are thought to be at an elevated risk of lashing out at other bathroom appa ratuses or even harboring a lasting grudge against the host establishment.

While the scenario described above might sound petty, this sort of situation can lead to increased costs for maintenance, cleaning and repairs—plus a tarnished image for the building and the archi tect. The little things can make a big difference. By investing properly in the design phase of pub lic bathrooms, some of these little issues can be avoided, according to Cyrus Boatwalla, Director of Marketing for ASI Group, an industry leader in designing, engineering, and manufacturing fully integrated washroom accessories, partitions, lockers and visual display products. Well-informed product choices alleviate problems from the outset.

ASI’s multi-feed, top-fill soap dispensing system allows up to 12 soap dispensers to be replenished with a single pour into a unified soap reservoir via a counter-mounted port. The EZ Fill system utilizes a peristaltic pump—electrically operated, using bat teries or alternating current—that pumps soap as needed to the dispensers, so the most in-demand dispensers won’t run out at a higher rate than the others. When the time for refills does eventually arrive, instead of maintenance personnel duck ing beneath 12 separate wash stations to top off a dozen different canisters, the same tedious task is accomplished with a single, top-of-the-counter pour—no kneeling necessary. The product makes maintenance easier, less expensive and more man ageable—especially in a multi-story high-rise with dozens of hand washing stations.

Another trending product that aims to solve a public restroom problem is ASI’s Integrated Privacy Parti tion. Equipped with built-in privacy strips, no retrofit ting is necessary. They are integrated into the prod uct from the beginning. The strips remove sight lines into bathroom stalls and other partitioned spaces to prevent accidental peep shows and obstruct inquiring eyes—bathroom breaks are not a spectator sport.

The modern era’s explosion of technological advancements has delivered the aforementioned solutions and a plethora of other new-and-improved products. But combing through this ocean of options to find every perfect solution can be overly oner

In a school, for example, some locker materials will perform better than others depending on the surroundings. “You may want metal lockers for a school’s hallways,” informs Boatwalla. “But plastic lockers make more sense for the athletic facilities. High-traffic areas should generally offer easy-toclean surfaces that won’t easily rust or dent.”

ous for architects. Boatwalla suggests a shortcut to avoid getting bogged down: Collaborate with a wellinformed representative of a global manufacturer that boasts a wide range of competing materials, colors and product types.

“If you work with a partition manufacturer who only makes solid plastic partitions then the answer to every question you have is going to be, ‘Solid plas tic partitions,’” he cautions. In contrast, ASI reps can offer information on all product types, not just a single kind.

“Architects are typically busy people,” he says, and while busy people naturally work to minimize distractions, ASI reps offer reliable expertise to help design teams focus. “They’re an asset and not an interruption,” he adds.

A well-informed rep should act as an advisor, offering a wealth of product information to pinpoint the ideal materials for various spaces within a proj ect’s entirety. With access to a variety of product material types, reps can help determine the precise option that is ideal for each specific space.

Marker boards and visual display products likewise operate best while being utilized in specialized set tings. ASI offers a multitude of differing options, including different framing systems and surface options to suit a myriad of needs and cost structures— porcelain and glass writing surfaces, for instance, as well as cork, fabric, vinyl and Forbo tackboards.

“Materials and products are the most important choices an architect can make in any building,” reminds Boatwalla. “If you put a powder-coated steel partition in an aquatic facility, that’s going to end up in the landfill a lot quicker than if you put a plastic one or a phenolic one.” So even though the project might pile up LEED points, in actuality it’s a bad outcome for the client and less than ideal for the environment, too.

“Some architects, designers and building owners tend to think more about the initial cost than the life cycle cost, and that can create problems.”Stainless Steel

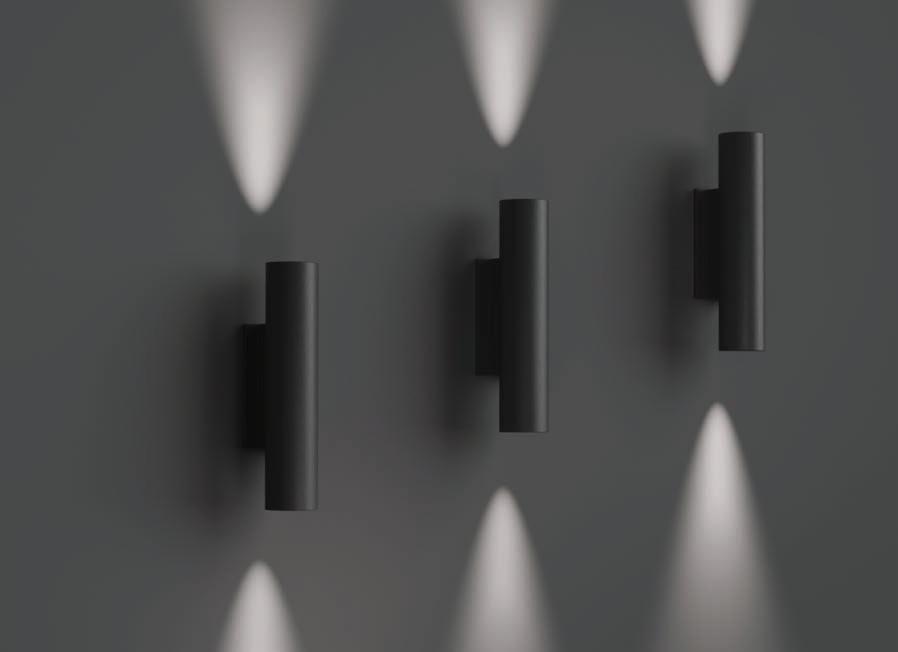

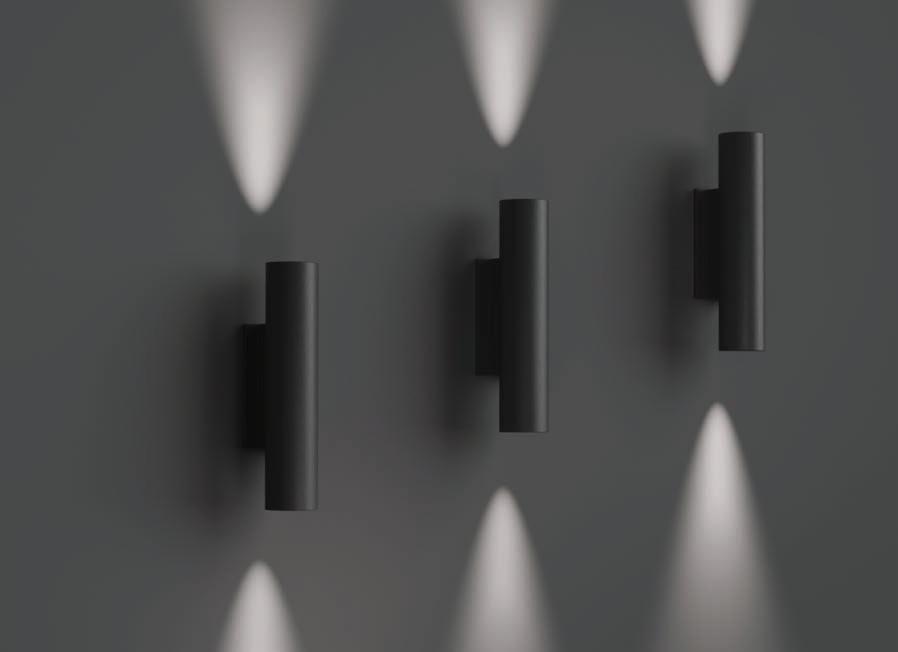

An elegant, high-performance 3” diameter cylinder, offered as a pendant, surface, and wall sconce, with direct and indirect lighting capabilities.

Designed to illuminate both interior and exterior applications. Scope Medium offers up to 20 watts of illumination, delivering up to 100 lumens per watt with 4 optical distributions.

Scope Medium is the perfect choice to illuminate commercial interiors, hospitality spaces, and highlight the features of a building facade.

e Vinyl Sustainability Council has set a new barometer for measuring sustainability through environmental, social, and governance markers with +Vantage Vinyl verification. e program is leading the industry with a framework to track, verify, and advance a company’s operations and efforts. Companies that undergo the verification process Earn the Mark, and they can then demonstrate to the world that their company meets specific criteria for sustainability.

e vinyl manufacturing process includes several important players. Resin suppliers make vinyl polymer. Additive suppliers make chemicals

Unlike other sustainability initiatives, +Vantage Vinyl is holistic, addressing the entire industry value chain.

that are added to those vinyl polymers to improve processing and performance. Material compounders combine vinyl polymers with additives to create specific vinyl formulations. End-product manufacturers make building products and consumer goods from vinyl formulations. Recyclers process production scrap and end-of-life vinyl products for reintroduction into product production. en, the process returns recycled vinyl material to compounders that combine it with additional additives for use in new products.

Across the entire industry value chain, sustainability initiatives are implemented to improve performance and lifespan of products. Transparency across the value chain helps meet the changing needs of vinyl companies and provides additional insights into the material. Increasing transparency and collaboration in sustainability efforts reduces risk and keeps the industry moving forward.

+Vantage Vinyl verification is open to any company in the vinyl value chain—resin suppliers, raw material and additive suppliers, material compounders, converters and formulators, endproduct manufacturers, recyclers, and distributors. To Earn the Mark, company commitments must be aligned with the voluntary industry sustainability targets in resource efficiency, health and safety, and emissions. Companies must report on sustainability performance every year and be reverified every three years to maintain the mark. An independent verification through the GreenCircle Certified process provides assurance of achievement.

Companies that make vinyl polymer

Companies that make chemicals that are added to vinyl polymer to improve processing or performance

Companies that combine vinyl polymer with additives to create specific vinyl formulations

by Jay Thomas, Executive Director, Vinyl Sustainability Council

by Jay Thomas, Executive Director, Vinyl Sustainability Council

Companies that make products from vinyl formulations

Companies that process production scrap and end-of-life vinyl for reintroduction into product production

e +Vantage Vinyl program facilitates industrywide collaboration by working with domestic manufacturers and international counterparts to develop standards and initiatives across all steps of the value chain. All the companies involved in the processing of vinyl products from resin producers to additive suppliers, material compounders, endproduct manufacturers recyclers and retailers can verify to +Vantage Vinyl. is provides the consumer with assurance that the product is being produced and handled cradle-to-grave in an environmentally responsible way.

Optimal Environmental Performance Research shows that the construction marketplace rewards companies that address environmental, social, and economic aspects of sustainability. It is good for the Earth, and for business.

Material science has made available new products that are durable and perform well. It is hard to imagine a return to purely natural materials when synthetic components support green design and construction with added durability. For vinyl manufacturers, the goal is therefore to choose materials that perform well in their intended applications with the lowest environmental impact.

Vinyl has a low relative CO2 footprint due to 57% of resin feedstock being derived from salt.

Vinyl insulated siding helps to make homes energy efficient while white vinyl roofs reflect solar radiation, reducing cooling energy consumption.

Vinyl is durable and noncorrosive, reducing product replacement frequency.

Vinyl is recyclable. Since 2014, the U.S. vinyl industry has increased recycling of post-consumer vinyl materials by 40%

As sustainability measures improve for building materials, it is increasingly important for manufacturers to develop environmentally sound products that optimize performance for sustainability.

Five pillars of +Vantage Vinyl verification guide the vinyl industry to continuous improvement of the entire supply chain. Vinyl companies dedicated to these five pillars—environmental stewardship, social diligence, economic soundness, collaboration, and open communication—showcase their commitment to advancing the industry once they complete the verification process.

Specifying products from +Vantage Vinylverified building product manufacturers signals a sustainable choice. Find out how you can Choose the Mark and what it means for your business at choosethemark.com.

Ding. There is an exciting buzz rising in the elevator industry—smart mobility.

Passengers calling elevators via smartphones. Hotels with cleaning-and-service robots moving autonomously or controlled from far-away stations. Mounds of relevant elevator usage data being quickly integrated and utilized to improve efficiency and prevent service

The latest advancements in eleva tors bring intelligence to these systems of conveyance.

disruption. It’s a brave new world in the “smart mobility” era of elevators, and information and efficiency are king. Thanks to the internet of things (IoT) and a host of cloud applications, new solutions for operating elevators are rapidly changing the way buildings move people up and down. Here are four such ways the industry leaders are making the elevator better.

Meet the Otis ONE, a connected solution armed with IoT sensors, big data, AI, and a cloud-native application. The product installs into existing Otis elevators or new models like the Gen3 and Gen360. Otis One offers realtime visibility to monitor an elevator’s health. Ditto for data insights, predictive maintenance, and options for remote troubleshooting.

Otis Elevator Otis One www.otis.com

MonoSpace DX saves space by removing the need for a machine room.

Powered by the compact and energy-efficient KONE EcoDisc hoisting motor, the MonoSpace DX saves space by removing the need for a machine room. These elevators are now enabled for connectivity making digital integration easy, simplifying upgrades, and providing energy-saving efficiency features that cut carbon footprints. KONE’s machine room-less elevators are for low-rise, mid-rise, and high-rise structures.

The use of smartphones to call or control elevators has arrived. TK Elevator announced in September its new brand of connected or “smart” elevators made possible by the company’s new Application Programming Interfaces that are built on the company’s cloud-based IoT solution MAX. MAX Link Voice and Multimedia digital emergency communication services (pictured) offer two-way voice, video and text messaging for emergencies.

Armed with an advanced algorithm that helps elevators be strategically assigned to riders, passengers select a destination floor while calling for the elevator and before getting on. Then PORT groups passengers by destination to provide the shortest possible trip more frequently and provide fewer chaotic elevator runs with multiple stops. Optimizing a building’s traffic flow for efficiency is the aim of Schindler’s PORT Technology.

Schindler Elevator

PORT Technology

A little organization goes a long way in moving people to their destinations more efficiently. PORT Technology enables people to group themselves so that they make it to their target floor with fewer stops.

The Automated Storage Retrieval Systems boom is on, or soon will be—architects need to consider these potential safety solutions.

Amazon, Walmart and the industry’s other retail shipping behemoths are all-in on the high-ceiling warehouses containing row after narrow row of densely packed shelving racks. Armed with mechanical robots stocking and picking merchandise to ship at the behest of automated storage retrieval systems (AS/RS), these modern marvels of efficiency can compact massive volumes of goods into evershrinking spaces—especially compared to old-school warehouses navigated by forklifts and foremen.

But until the recent global pandemic, the number of operations utilizing AS/RS was relatively low. The initial capital outlay combined with consumer hesitancy to submerge in online shopping presented just enough of a barrier to keep most merchants away. More than 80% of all warehouses have no automation of any kind, and 95% function without sophisticated automation—according to a report released in 2021, “Warehouse Automation—Robots, Technologies, and Solutions Market, 2021-2030.” Of course, then along came COVID-19 and pressed e-commerce’s proverbial fast-forward button. The boom is now in full bloom, or soon will be.

Grocery stores, major regional retail operations and others are exploring or gearing up to take the AS/ RS plunge, says Ralph Bless, a licensed professional engineer and VP at Telgian—he also boasts a resume with four decades of fire-protection expertise and an impressive slate of credentials too lengthy to list. Some entities will build from scratch. Others will

Larger, more densely packed warehouses with AS/RS need greater fire protection than is provided in the current design standards.

transition chunks of their no-longer necessary show room floor space or will look to repurpose vacated strip centers and other roomy ex-retail spaces.

“The challenge is putting these things into an area, into buildings that maybe weren’t designed for storage originally,” he says. “Or, even if they were, they don’t have the sufficient sprinkler systems to protect for the density that we’re now cramming into them.”

Automated storage retrieval systems have been allowed in some form or fashion for close to 40 years. But Bless says, the technology is ever-changing, and the way we are using them is vastly different than just a few years back. “The codes haven’t kept up,” he says.

In the past few years, a 1.2 million-sq.-ft. distribution center went to the ground in Indiana. Another major fire permanently shut down a similarly sized QVC home shopping network warehouse in North Carolina. Abroad, a warehouse near London ignited when three picking robots reportedly collided, and a robot also reportedly caused a facility in Andover to catch fire in February 2019—200 firefighters were called to extinguish the blaze.

The current guidance and protection metrics are based on conventional storage methods, or, at best, less compact, less dense AS/RS systems.

“Codes take three years to update,” explains Bless, “and the Codes reference the standards that the fire protection systems are designed and installed with, which are generally one to three years behind those referenced in the Codes. Then it is

Most common flammables won’t ignite if the air’s oxygen level is less than 16%. Meanwhile, humans can still easily breathe in those conditions—about the same as on most passenger airplanes. The SCU3x is a smaller system to protect rooms with volumes of up to 300 cubic feet, such as archives and server rooms, but FirePASS also offers both bigger oxygen-reduction, fire-prevention systems.

The super-high-volume robotic firefighter boasts a low center of gravity and a wide-chassis to navigate rugged terrain and push vehicles from its path or pull up to 8,000 pounds. It may not technically be an architectural product, but the rig could certainly help first responders save lives at a storage facility fire. By serving as an extension of the crew’s own senses and capabilities, the robot allows humans to remain at a greater standoff distance.

Thermite RS3; Howe & Howe

Sprinklers protect buildings from fires, but what protects the building from the accidental activation of those sprinklers? Engineered for performance and focused on prevention, SprinkGUARD is a “head guard,” as in sprinkler head guard, and protects the individual fire sprinkler.

Sprinkler

Protection

Integrated height

Vandal resistant changing surface that is cut resistant and easy to clean

Suitable for use by adolescents and adults, the KB3000-AHL is the first adjustable height changing station o ered by Koala Kare Products. Featuring contemporary aesthetics and intuitive design, the unit’s height adjustability from 12" to 41" allows the patron to be safely transferred to the changing surface without requiring the caregiver to assist with lifting.

Designed for public spaces, our adjustable height changing station incorporates exceptional safety features, unmatched durability and thoughtful features that will be appreciated by both the cared for and caregiver.

Easy

generally another three to six years for each state to adopt and start enforcement.”

So?

“Well, the most recently developed model International Building Code (IBC) is the 2021 edition. It references the 2019 edition of NFPA 13 (fire sprinkler design standard). Jurisdictions generally are using the 2018 edition of the IBC, so the 2016 edition of NFPA 13. The most recent edition of NFPA 13 is the 2023 edition.”

That’s a mouth full, but the bottom line is that most projects are building based on standards that are seven years old. “Do you want to use your cell phone from 2016?” quips Bless. “Probably not. The same concept goes for new developments in fire protection.”

Various cities and most jurisdictions don’t yet know how to handle compact AS/RS. They haven’t had to. Percentage wise, there is not that many. “Which is why there is a need for continuing full scale fire testing,” he adds.

Modern compact AS/RS systems allow products to be packed onto taller racks and into tighter spaces with narrower gaps in between. This limits traditional modes of fire suppression by hindering access to the products and/or fire. Stored items are more shielded from sprinkler systems.

Bless points out that if and when serious fires occur, the densely packed mega warehouse presents new challenges.

For one, the plastic containers in use function well for material handling, but they are also highly flam mable. “It’s basically gas in a solid form,” he explains, adding that the lids present additional problems, such as, “How am I going to get water inside that?” Further, AS/RS-equipped buildings typically have fewer peo ple on site. That’s helpful from a life safety standpoint, but not ideal from a fire protection standpoint.

Further still, repurposed spaces “may not have been originally designed to hold that high of a density of materials,” he says. “Or they don’t have the fire protection systems necessary.”

“Go find someone with a background in fire protection, engineering and analysis,” advises Bless, who happens to be one such person. “It may be fine to move forward, but you don’t want to get into a project and then find out that you’ve got a million dollars’ worth of improvements to be made.”

Sprinkler systems are the primary issue. Whether or not more sprinklers should be installed, or different or larger ones, architects might also consider smarter fire sprinklers. Bless points to Tyco’s line of smart sprinklers by Johnson Controls and sees what could be an important piece of extinguishing warehouse fire concerns.

“What Tyco and a couple of other manufacturers have done, they came up with these smart sprinklers tied to a gridiron system which can detect the fire much faster and activate enough sprinklers in the area to control the fire,” he says.

While pouring water on a fire is the most triedand-true way to squelch an inferno, sucking the oxygen out of the area is another strategy to consider. Several oxygen-reduction systems populate the market. Various brands boast differing methodology, but they share the same basic idea: Fire needs sufficient oxygen to burn properly. If you reduce the indoor oxygen level from 21% to 15%, humans will remain relatively unaffected—that’s roughly the oxygen level within a commercial airplane—but it’s not enough for fire to thrive.

“They’re actually reducing the oxygen in the building so that people can still walk through and function,” says Bless, “but it’s still below the point for fire propagation.”

The FirePASS brand reduces oxygen levels by ventilating a given space with “hypoxic” air—air produced by filtering out some oxygen from the ambient atmospheric air. Nitrogen dilution systems, such as the OxyReduct Fire Prevention by Wagner Group, aim at the same outcome but do so by diluting the air with nitrogen.

“The challenge, of course, is creating the seal,” says Bless. For oxygen reduction to be success ful, “You’ve got to seal that building pretty tightly.” Otherwise, maintaining the right ratio will be overly difficult and/or cost prohibitive due to energy consumption.

Electronically activated and specifically engineered for challenging storage fire hazards, this system has heat sensors connected to an electronic control system that continuously analyzes temperature information. The system can then use less water because it locates the fire’s origin and responds with only the appropriate sprinklers.

Tyco (Johnson Controls)

EAS-1 Fire Sprinkler System www.tyco-fire.com

These innovative fire-protection products offer new solutions for this modern-day, mega-packed, warehouse issue.

For areas that need to be kept for-sure safe, but that sometimes aren’t easy to keep an eye on, meet the ASD Dual Channel Aspiration Detector by Honeywell. For fast and accurate detection, the ASD contains two built-in VIEW detectors plus two B524IEFT-1 isolator bases for high sensitivity detection.

ASD Dual Channel Aspiration Detector www.buildings.honeywell.com

Another hurdle, according to Bless, is that the still-new technology isn’t yet universally accepted. “Even if you get the jurisdiction to accept it,” he says, “even if it’s appropriate, even if the owner is going to maintain the systems and all of that, one of your issues is going to be ongoing maintenance. We don’t have enough technicians across the country that know what these things are, so it could be expensive. But it’s something that’s on the leading edge.”

Ralph Bless, VP at Telgian, is a licensed professional engi neer in six states and boasts a

filled with four decades of fire-protection expertise.

Fire needs sufficient oxygen or else it struggles to flourish. OxyReduct introduces natural nitrogen into the air to depress the available oxygen just low enough to provide fire protection yet still high enough to support human life.

Wagner Group OxyReduct Fire Prevention www.wagnergroup.com

Modernfold’s

Known for their warmth, beauty, bio philic properties, sus tainability and faster construction, mass tim ber buildings are gain ing mass appeal. After establishing a foothold in Europe—particularly Austria, Germany, and

Switzerland—by 2013, there were 26 mass tim ber buildings in North America. By 2021, that number had jumped to 576 and growing. “We’ve seen an increase not only in the number of projects, but also the type, scope, and scale of

project, including resi dential, office, mixeduse, library, education/ government, and even life science structures,” reports Jordan Komp, p.e., s.e., associate principal, Thornton Tomasetti, Milwaukee, Wis. As more mass

timber projects are undertaken, architects are pushing boundaries that require advanced engineering and new design solutions to real ize new levels of effi ciency, creativity, and beauty in mass timber development.

At 284-ft. tall, 25 stories high, Milwaukee’s Ascent residential tower recently became the tallest mass timber building in the world. Not only did Ascent recently surpass Norway’s Mjøstårnet tower by a few feet, but it significantly raised the bar for mass timber in the U.S. where the second tallest timber structure is just seven stories.

“The project is particularly meaningful to the U.S. where our code limitations and manufacturing capacities lag behind Europe and Canada. Ascent serves notice to other U.S. governing bodies and future code authorities that there is science/engi neering to support taller/larger mass timber struc tures,” reports Komp, whose firm did the structural design for the project.

Ascent utilizes a hybrid structural system. The bottom six floors, housing the parking garage, pool, and the building’s elevator shafts, are steel and con crete. The upper floors and its 259 multifamily units are made from mass timber beams, columns and boards. Half of the wood was left exposed, thereby requiring less labor to finish the interior, and creat ing the Scandinavian feeling of hygge sought by the Korb +Associates Architects.

Manufactured in Austrian Spruce and shipped

from Europe, from Europe, the residential tower was erected using 1,150 glulam columns, 1,320 glulam beams, and 1,273 cross-laminated timber (CLT) panels.

The glulam column sizes range from approxi mately 16 ft., 25 in., in width and 16 ft., 42 in. depth in cross-section. Typical beam cross sections ranging from 9-ft., 22-in. wide and 15-ft., 30 in. deep.

“From the start, the team never questioned the engineering/mechanics of designing a 25-story mass timber structure. The key was optimizing the system such that the project was financially viable for the owner,” explains Komp. “This involved many iterations, and in many cases, redesigning the entire structure, for various species, products, systems and manufacturers. There was an incredible amount of collaboration required between all the dedicated par ties (owner, architect, engineers, contractor, manu facturer), to come up with the most efficient solution.”

For example, the team at TimberLab reduced the typical CLT spans from 20 ft. to 16 ft. 8 in., eliminating the need for a composite timber slab and reducing the cost of the project.

According to Ascent Developer New Land Enterprises, the mass timber cost was $42 per sq. ft., as compared to an approximate $37 for concrete.

And as noted, much up-front design work was required. However, New Land estimates that Ascent required 90% less construction traffic, 75% fewer onsite workers and construction proceeded 25% faster.

The ground-breaking Ascent project required exten sive fire testing before the Milwaukee Department of Neighborhood Services the Authority Having Jurisdiction (AHJ), would agree to the proposed height. Fortunately, the AHJ acted as a partner in embracing the project while pushing the team to vali date the safety and performance of the structure.

The testing involved 16-in. × 16-in. cross sec tions, representing the smallest column size on Ascent. Three-hour column fire tests were per formed with Douglas Fir, Black Spruce and European (Austrian) Spruce.

Contrary to the popular belief that wood members are highly susceptible to fire, mass timber doesn’t burn like an average 2 × 4. Rather it chars, thereby creating a protective layer against the fire. This has been proven out by two-hour testing, but Ascent was the first to involve three-hour testing, as required by Type 1A construction for high-rise buildings.

“All soft surfaces have been chosen for their modern yet comfortable aesthetic and all have a textural feel with an earthy color palette. Throw pillows, hand-made rugs, fireplaces and wood accents further emphasize the natural wood structure.”

Jessica Dellenbach, asid, wrid, edac, Korb + Associates ArchitectsASCENT The 25-story residential tower in Milwaukee is currently the tallest mass timber building in the world. ASCENT LOBBY For the lobby of the Ascent multifamily high-rise, Korb + Associates specified Virginia Tile’s Etic faux-wood and a Maharam Lattice area rug from Hella Jongerius for the flooring. The guest chair is Capri from Hightower and the sofa is Luca from Bernhardt. The lighting is a Tech Lighting Brox custom pendant.Nairn

cork flooring, white oak

raw concrete

textured porcelain

Once completed, the honeycomb-façade of 2150 Keith Drive residential tower in Vancouver, Canada will be the tallest mass timber seismic force-resisting system in North America.

Self-centering

Soon to bear the distinction of the tallest mass timber seismic force-resisting system in North America, the 150,000-sq.-ft. 2150 Keith Drive residential building in Vancouver, Canada features a perimeter timber-braced frame system which creates a striking honeycomb façade, complements its composite metal panels, wood soffits and ample glazing, and eliminates the need for conventional cast-in-place concrete cores.

Designed by DIALOG, the hexagonal timberbraced frame also lends it itself to a balcony design, which wraps the building on three sides. “The honey comb balcony structure is made of CLT panels sup ported between steel members that are cantilevering off the building. The CLT shear wall panels in the center act in combination with the bracing. The floor systems feature CLT panels with flush steel transfer beams allowing the ceiling to remain a consistent height,” explains Maryse Campeau, M.Eng., P.Eng., project manager, Fast + Epp, Vancouver, Canada.

To meet the building’s seismic requirements, Tectonus devices were integrated in key locations. Functioning as a self-centering mechanism, the device snaps the building back to dead plumb fol lowing an earthquake. “Using resilient slip friction joints with a built-in, self-centering behavior, these devices can perform numerous loading cycles with out the need for replacement,” he explains.

In a TimberCon presentation, “Advanced Timber Structures: Breaking Out of the Box Paradigm,” last year, Campeau’s structural engineer colleague Robert Jackson stated, “We are really excited about this technology. We think it is necessary to make mass timber lateral systems work at height.”

To optimize the use of timber in fabrication, the team evaluated both general panel layouts and connection detailing to ensure the design did not require construction that is inefficient for production. “For example, machining CLT panels on both faces requires the supplier to flip large panels over on their CNC tables. This is a slow process suppliers want to avoid and our detailing was reviewed to ensure this was not required,” explains Campeau.

As the project proceeded, it turned out the win ning CLT subcontractor was able to offer larger panel sizes than assumed. This meant the team could opti mize the CLT wall layout by reducing the number of panels per section, thereby reducing the amount of splines and screws in the project, ultimately decreas ing the amount of crane time and overall cost.

Among the tests performed during the design, lateral drift testing of the form-fitted connections will allow for more widespread use of these connec tions in taller and more flexible buildings moving forward. “This testing proved that typical drift limits in structures will not cause premature failure in these types of connectors, which are becoming very popular due to the ease of assembly and fire rating,” reports Campeau.

Featuring a glass-enclosed, curved mass timber structure to fit its uniquely-shaped site, the Lakeview Office is the first mass timber office development on the Eastside of Greater Seattle. With great views of Lake Washington, the 46,000-sq.-ft. building acts as a new gateway to the city of Kirkland, Wash.

The building uses dowel laminated timber (dlt), in place of the more common clt. This allowed for a larger 20-ft. span and a nicer aesthetic. The prefabricated panels are also connected with dowels instead of glue.

Because the city’s zoning requirements restricted the building’s height, LMN Architects sought to make

DLT, in place of the more common CLT, allowed the team design larger spans and a nicer aesthetic.

DLT connected to Glulam posts and beams.

the most of the floorplate, which also influenced the team’s decision to go with dlt

In addition, the mechanical piping systems are routed parallel to the one-way spanning beams to keep them high up in the ceiling as to not compro mise the floor heights. There is also a utility channel in between the panels to accommodate things like conduit. “To make everything fit, we worked closely with our structural engineer CPL Engineers and StructureCraft, performing constructability reviews to be judicious with the use of timber,” explains Jeremy Schoenfeld, associate, LMN Architects, Seattle.

Generally speaking, Schoenfeld sees much

potential for mass timber and is excited about the anticipated 2024 International Building Code allow ing for fully exposed mass timber ceilings in office and residential buildings up to 12 stories.

While the cost of lumber will continue to be an issue, he anticipates that ramping up supplies will help with this. And overall, the market is growing.

“There is a lot of interest in mass timber and fabricators have a long list of projects,” he says.

Meanwhile LMN Partner Pamela Trevithick identifies wood’s sustainable and biophilic properties as a key factor driving interest and growth.

The 4,000-seat Idaho Central Credit Union Arena at the University of Idaho in Moscow, Idaho is a welcome departure from the windowless, steel-framed boxes that typically house sporting events and musical performances. The striking mass timber arena features a curved roof design, umbrellaed canopy and stunning wood interiors that take its cues from the surrounding landscape.

As described by the project architects Opsis Architecture, “Beginning at the west-facing entry porch, the roof splits apart to create overlapping contoured forms over the north concourse. To the east, the roof wraps down around the practice court to connect with the ground. Infilled side walls are sheathed with charred cedar and a combination of clear and translucent glazing. A three-level CLT wood “bar” forms the west edge of the arena, containing the lower-level locker facilities, main-level athletic offices and team rooms. An upper-level special event room overlooks the main court.”

“The intent was not to mimic the surrounding topology, but to use the gentle flowing hills as a generator for architectural expression. The project’s formal and material expression creates a sense of place rooted in Idaho’s history while looking toward the future,” explains Chris Roberts, associate principal, Opsis Architecture, Portland, Ore.

In fact, the wood used for the arena was sourced from Idaho forests. This included 442 tons of glulam beams and 45,000 cubic ft. of wood products.

Working closely with StructureCraft, the project’s wood structure engineer and fabricator, the complex’s double-curved mass timber geometry was designed with advanced computer modeling.

“Utilizing their proprietary Grasshopper script allowed StructureCraft to maximize the efficiency of member sizing and find repetitive radius segments to reduce manufacturing timelines for the massive, curved beams,” explains Roberts.

This process also minimized the raw material amounts and fabrication set-up time required to

In this entry area, the fabricated glue laminated purlin and plywood wood panels can be seen on the foreground of the ceiling. e lower cord of the eyebrow truss is shown in the back of the ceiling and the portal frame is visible on the left side.

At the University of Idaho Central Credit Union Arena, the complex mass timber structure generously showcases the wood’s beauty on the exterior, through the entry lobbies and into the main arena.

e 133-ft. portal truss, with a load capacity of 400,000 lbs., provides the main structural support for the dowel laminated timber, cross laminated timber, glue laminated columns and beams.

create structural elements spanning distances up to 140 ft. “After the primary structure was set, 400 prefabricated glue-laminated/plywood roof panels were installed over the portal frame kingpost trusses,” he continues. “The individual roof panels were pliable, which allowed them to conform to the slopes and curvature of the roof’s geometry.”

One of the most complex engineering aspects of the mass timber structure was designing the portal frame, which carries much of the structural load. To transfer more than 400,000 lbs. of compression from the roof to the foundation, the thrust connection between the beams and columns had to be carefully engineered.

“The roof form sweeps over the gym as the glue-laminated beams transition from the horizontal

plane to curved columns carrying the vertical load of the structure gently down to the ground plane,” explains Roberts. “A horizontal fissure at the base of the wall was seen as an opportunity to provide natural light and framed views to the campus beyond while also showcasing the wood structure and lateral bracing for passersby.”

The design team worked to ensure that the exposed wood did not obstruct views of the court from the upper-level seating area. This involved the creation of an interstitial space to conceal the M/E components.

Overall, Roberts views this project as shining a light showcasing the possibilities of mass timber and inspiring the next iteration of mass timber development.

From the Outdoor Office to the Street Café.

We believe that for design to be truly great, it must stand the test of time, be sustainably crafted, and be proudly American made.

Backdrop : The one solution for every site.

Designed by Landscape Forms in collaboration with KEM STUDIO.

Altro Tegulis offers complete customization. Simply select any colored or patterned Altro wall product, choose a tile pattern or specify your own custom pattern. Each order is constructed to your exact specification. The robust PVC construction prevents water and bacteria from penetrating below the surface and allows for thorough cleaning and disinfecting.

look of tile with the hygienic performance of wall cladding

No matter what sustainability or design challenges you’re facing, the Armstrong® SUSTAIN® portfolio makes your decisions simpler – by offering the largest forwardthinking portfolio of healthy ceiling and wall solutions, with verified material transparency and low embodied carbon. Learn more at armstrongceilings.com/sustain

MuseumLab by Children’s Museum of Pittsburgh embraces the found condition of an abandoned 100+ year old library.

By Jana J. Madsen, contributing writer

With the addition of MuseumLab, the Children’s Museum of Pittsburgh has created the largest cultural campus for children in the country. The innovative exhibit and maker space for children 10 years and older provides the opportunity to experience art and technology hands-on in a facility that offers its own teachable moments.

MuseumLab is located in a building that was commissioned in 1886 by American industrialist Andrew Carnegie. The Carnegie Free Library of Allegheny opened its doors in 1890 in his adopted hometown of Pittsburgh.

“This was one of the first Carnegie libraries,” explains Julie Eizenberg, Founding Principal, Koning Eizenberg Architecture, Santa Monica, Calif. It was listed on the National Register of Historic Places in 1974, but by then had undergone so many interior renovations that only its exterior qualified. The public library operated out of this location for more than 100 years until, in 2006, lightning struck the clock tower and a three-ton chunk of granite fell through the roof. By the time the Children’s Museum of Pittsburgh brought Koning Eizenberg Architecture on board as the Design Architect and Perfido Weiskopf Wagstaff + Goettel (pwwg) as the local Architect of Record, the building had been abandoned.

The exterior of the historic Carnegie Free Library in Allegheny is constructed from granite block backed by four wythes of solid brick.

The Children’s Museum of Pittsburgh had a clear vision to expand its campus in the Allegheny Center neighborhood with a facility that would comprise a maker space and testing ground for teen learning, as well as a Title 1 charter middle school. The architectural design strategy necessary to transform the 52,000-sq.-ft. library into an environment suitable for exhibitions, formal and informal learning, and community events meant embracing a very different type of restoration.

“There had been a number of remodels that had happened over the

years; the most significant one was in the 1960s, which was done with the best intentions to modernize the building by covering up everything that was historic inside,” explains Eizenberg. The contractor began slowly peeling back years of renovations. What everyone expected to find—pristine ornamental details, colonnades, archways, and molding seen in historic photographs—was not there. Time, along with modernizations, had been more destructive than imagined. “The mortar had crumbled away so the plaster was falling off back to the brick,” recalls Eizenberg,

“and to simplify the architecture, parts of the ornamental column capitals had been cut.” The monumental interior from Carnegie’s days was now an architectural ruin.

Traditional restoration wasn’t in the budget. The design decision was made to embrace the building’s condition whenever practical. “What was truly poetic and beautiful and in line with the program of the museum, were the bones that held up the ornament of the building,” explains Eizenberg.

According to PWWG, “Every step

of the project revealed surprises—historic elements that could be mediated, transformed, highlighted, or covered, in context to how the client wishes to use the space.”

Leaving some of the ruin for children to observe provided the opportunity to see inside the building and understand its engineering. “It was a series of choices,” Eizenberg remembers. “We took the liberty of secretly fixing a number of things so we could get enough continuity. Plus, there is a level of rawness that people are comfortable with and a level of rawness that feels threatening—it’s a fine line.”

Not every aspect of the project was up to the mercy of what lay beneath the walls. “The core organization was pretty deliberate in advance—the placement of the elevator, the addition of the floor, the reorganization of the vertical circulation, that was all set,” notes Eizenberg. A big priority for the space was to improve accessibility and some major changes enabled the team to secure to secure Universal Design/Inclusive Design certification from the innovative solutions for Universal Design (isUD) program

pioneered by the University at Buffalo for the project. This was achieved, in large part, through the relocation of the elevator and by eliminating a light well. “We filled it in with a second floor gathering space, which leveraged the need to create access in a legal sense [and] to also create more opportunity for social interaction,” she adds.

Access to natural light was another priority. The second floor gathering area includes a skylight that created a wintergarden effect and, thanks to a glass floor on each side of the space, allows light to filter down to the first floor Grable Gallery below. White

metal mesh was used to form a new staircase and elevated walkway in the gathering space.

Openings in the building that had been closed off were opened once again and all the 1960s black tinted windows were removed and replaced for a lighter, brighter interior.

In order to meet aggressive sustainability goals, the project required both innovative materials and creative decision-making. The masonry building’s historic exterior could not be altered but the R-value of exterior walls had to be improved. “The team experimented with thermal plaster

The Children’s Museum of Pittsburgh’s MuseumLab occupies an abandoned Carnegie Library, providing a space for youth (10+) to experiment with art and technology, a charter middle school, and community events.

USE

PRODUCT

Applying a coating of the Diathonite Evolution maximizes thermal inertia of walls, limiting thermal dispersion, rectifying thermal bridges, and protecting the façade from water absorption. It is three times lighter than traditional plasters and 10 times more elastic. It is an eco-friendly product.

Diasen www.diasen.com

“There had been a number of remodels that had happened over the years; the most significant one was in the 1960s, which was done with the best intentions to modernize the building by covering up everything that was historic inside.”

—Julie Eizenberg, Founding Principal, Koning Eizenberg Architecture

“We’ve been working hard, as have others, to stop thinking of accessibility as something you have to do and a band-aid, but to use it to facilitate ideas you wouldn’t have thought, or been able to do, otherwise.”

—Julie Eizenberg, Founding Principal, Koning Eizenberg Architecture

e art installation by FreelandBuck, “Over View,” is a three-dimensional drawing that depicts the leaded glass ceiling that once enclosed the room before it was removed during an earlier renovation of central lobby of the former Carnegie Free Library. Project Team: Alex Kim, Michael Raymundo. www.freelandbuck.com

Once home to a Tiffany glass ceiling, the gallery now displays a digitally cut fabric art installation by FreelandBuck that hides a maze of mechanical equipment and electrical runs.

e perimeter wall lighting in Grable Gallery

TRL WOODtures Spectrum’s Euro Series track fixtures, STT3XT (3 in.) and STT4XT (4 in.). Ideal for accent, display, and general illumination, the fixtures rotate 359 degrees and tilt/lock 90 degrees, while the rounded driver housing provides a clean design.

Spectrum Lighting www.speclightt.com

CIRCLE 259

A glass floor on either side of the second floor gathering space allows light to filter down to the Grable gallery below.

e Magis Spun Chair puts a new spin on sitting. is fun and functional chair is perfect for comfortable lounging, rocking back and forth, and even spinning around 360 degrees. e sculptural chair is made of rotationalmolded polyethylene and is suitable for indoor and outdoor use.

Herman Miller www.hermanmiller.com

258

Original Tiffany’s ceiling.

By eliminating a light well, a second floor gathering space was created. A skylight delivers natural lighting into the space and creates a wintergarden effect.

that hadn’t been used in the U.S. that was applied to the interior surface of the building,” says Eizenberg. Replacing the electrical and HVAC systems also reduced the building’s operational carbon and new windows further improved the efficiency of the project by reducing heat loss and solar heat gain. With the addition of insula tion to the roof and exterior walls, the building exceeded Pittsburgh’s 2030 district goal for energy use reduction. All these decisions, and the reuse of the Carnegie Library itself, resulted in recognition by the U.S. Green Building Council as a LEED Gold building.

With a tight budget, came the dilemma of how to deal with the new mechanical equipment, conduit, duc twork, and pipe runs. “The Children’s Museum likes to incorporate commis sioned art in their facilities,” explains Eizenberg. Above a digitally cut fabric art installation by FreelandBuck is a maze of mechanical equipment and electrical runs. When visitors look up, they only see an intricate sculpture that pays homage to the long-gone Tiffany glass ceiling that once illumi nated the space.

The challenges of the project pro vided ample opportunity for ingenuity,

which fueled the team and resulted in incredible spaces.

“Apart from the stress of making sure there was enough money (which the museum took the burden of), it was really a lot of fun to think through these issues. Subcontractors and contractors were really understand ing in terms of what the objectives of the project were,” reflects Eizenberg. It took tenacity, creativity, communi cation, and intention to recognize the potential of using the architectural ruin to teach how buildings are built and turn a beloved Carnegie library into a learning lab for children.

Pure Performance paint and primer in one interior latex is formulated to provide excellent hiding and application properties in addition to low odor and anti-microbial properties; a mold/mildew resisting component has been incorporated in this paint to make the dry paint film mildew resistant. The 100% acrylic latex formula provides overall durability and longlasting beauty.

PPG Architectural Coatings www.ppg.com

CIRCLE 257

The Gen2 elevator system has style, comfort, and speed and its technology eliminates machine room space and cost for greater architectural design freedom. Flexible coated steel belts allow a smaller machine sheave, reducing machine size by 80% and raising efficiency up to 50%.

Otis www.otis.com

CIRCLE 256

CURTAIN WALL

1600 Wall System 1 is a stick-fabricated, pressureglazed curtain wall for lowto mid-rise applications. Joinery with concealed fasteners creates unbroken lines and a monolithic appearance. Pressure equalization has been designed into the system, and all components are silicone compatible to provide superior longevity.

Kawneer Co. www.kawneer. com

CIRCLE 255

Hope’s 5000 Series doors are custom formed from heavy gauge steel. They are ideal for use in high-traffic areas and can accommodate various glass thicknesses and makeups. The doors provide narrow sightlines, welded construction, design flexibility, and are energy efficient.

Hope’s Windows www.hopeswindows.com

CIRCLE 254

For some of the classrooms, the design team selected a premium modular system of carpet tile products. Interface offers a modular system that combine flexibility, performance, and functionality. Made with superior fibers and yarns, the carpet tile is designed for the heavy foot traffic, ease of maintenance, and durability that today’s educational spaces require. Interface www.interface.com

CIRCLE 253

“Bringing back buildings brings back neighborhoods. It brings back a sense of community pride and value and also brings back eyes on the street, which in turn reduces the amount of crime.”

—Julie Eizenberg, Founding Principal, Koning Eizenberg Architecture

Designwall

The latest designs helping people take advantage of the great outdoors.

Outdoor spaces are being transformed by luxurious, high-impact designs that boast lowmaintenance materials. It’s no secret that out door furnishings should be highly customizable, weather resistant, easily cleaned and color sta bilized to withstand intense UV rays. But these pieces must also be durable, striking, and playful to elevate their respective environments.

This season, there are several burgeoning trends in the world of outdoor furnishings. Two of the hottest are backless seating and minimal design. The seating offers a light and airy aes thetic that is also stable and grounding.

Other designs emphasize casual luxury, including inflatable outdoor and pool seating as well as a stackable lounger, that is as comfortable as it is chic with its geometric steel frame.

The R-Blade bioclimatic pergola adjusts to fit any modern, contemporary, or classic housing style. Known for its motorized louvered roof (which can be automated with sensors), R-Blade optimizes a space’s climate management and protection, while improving natural ventilation. The roof is made with twin-wall aluminum louvers that are good for sealing and providing weather resistance. An invisible gutter system keeps the pergola dry by draining away the rainwater.

CIRCLE

R-Blade Bioclimatic Pergola with Louvered Roof www.azenco-outdoor.com

In downtown San Francisco, Handel Architects designed the rooftop of the new Serif and the Line hotel to provide a luxurious viewing deck where people can enjoy the city, the bay, and beyond.

Mitjorn is a stackable sun or garden lounger from iSimar. Suitable for either indoor or out door use, Mitjorn is distinguished for its steel structure, geometric armrests, and fabric padding. Made with a galvanized steel tube that is polyester powder-coated, the materials are weather-resistant, durable, 100% recycled and environmentally friendly. It was a 2021 Hospitality Design finalist.

Mitjorn iSimar www.isimar.es

Artur Leete showcases industrial and minimal design in the Eurema collection, an understated yet memorable bench for an outdoor or urban environment. Staying true to his Scandinavian roots, Leete’s Eurema is both simple and modern, while still able to “elevate its surroundings or stand out on its own merit.” The bench features a bridged or regular silhouette depending on the desired aesthetic and can be straight or curved.

Streetforms

The Air Collection includes five bold and iconic seating elements that are constructed from rotomolded high density polyethylene (HDPE) with hollow interiors. Extasi, Fortunato, Twig, Starfish and Stul make up the collection in a variety of backless, modular designs. The Air Collection is playful, casual, and light—which was long-time design partner Escofet’s primary inspiration—and is well-suited for a variety of indoor and outdoor spaces, including balconies, rooftops, decks, and transition spaces.

Collection

Backless seating and minimal design are two the this year’s hottest trends in site furnishings.

The Fillup Club’s inflatable luxury outdoor furniture has many advantages. The pieces, including the Lazy Chair XXL, float on water, are easily stored, and can adjust in comfort based on how hard or soft the chair is inflated.

portable and eco-friendly outdoor seat is made from an extreme temperature and abrasion-resistant material called TPU (thermoplastic polyurethane) and is upholstered with Sunbrella, an easy-to-clean outdoor fabric that is UV fade, mold, and mildew resistant.

Chair XXL

If the walls in commercial spaces could talk, they would probably say, “OUCH.” Specifically designed for hightraffic area walls likely to be scraped, bumped, or dented, Altro’s Fortis Titanium 15 complete wall covering system— with prefabricated corners, adhesives and color matched sealants—is made to shield vulnerable drywall. If scrapes do occur, the lightly textured surface and homogeneous

their

Slize is a sustainable, sound-absorbing light made of polyester and bi-component fiber. It was designed with “innovative functionality and expressive form” to create a better environment, “for both the eyes and ears,”—with character. The painted metal slices can be ordered in two, three or four layers, with a minimum of two slices in each position. They are also multi-colored in soft tones.

Bowery handcrafted wallcovering is made-to-order from Momentum Textiles and Wallcoverings. Momentum is the largest supplier of textiles and wallcoverings in commercial interiors and is leading the charge with sustainable materials to reduce its environmental impact. Momentum strives to use recycled content wherever possible, including PVC free, low-VOC, and Phthalate-free products that are GREENGUARD certified, and more.

Is this the thinnest, high-powered, all-in-one, adjustable, recessed light fixture ever? That’s what USAI Lighting says about the BeveLED Mini Basic Pancake. The product also boasts a hard-to-believe 2.3-in. depth—enabled by a patented and compact design— with seamless and universal adjustability between downlight, adjustable and wall wash fixtures. BeveLED Mini Pancake is a Tier 2 Basic Family product.

Momentum Textiles and Walls Bowery www momentumtextilesandwalls.com

BeveLED Mini Basic Pancake www.usailighting com

All our architectural products serve a distinct, functional purpose. From louvers to wall coverings to every detail we perfect. But, at the same time, we never lose sight of the a ect a building has on people. The inspiration it provides. The satisfaction it brings to all who enter. For 70 years, we’ve based our success on the idea that putting people rst is the foundation for building better buildings. And, for 70 years, our partners have depended on us for architectural product solutions. Are you ready to think beyond the building with us? Visit c-sgroup.com.

Solutions for buildings. Designed for people.

Glide Square

become the lighting

make-it-your-own,

glide

suspension. The fixture is made from handfinished hardwood and emits 10 W/ft. MIYO Glide can be wired for direct and indirect light and offers individual dimming control. MIYO was designed by Gregory L. Kay, a champion of sleek, low-voltage technology and contemporary lighting.

As an organic oval-shaped bowl on a low-profile base, the minimalistic Alva soaker tub features graceful curves and an elegant silhouette. Made from MTI’s SculptureStone, which is a largely organic blend of natural minerals and high-performance resins, the bathtub offers the look and feel of molded stone. The tub is made with a semi-rolled rim and a large, continuously

comfortably-sloped backrests.

Now available in six colors, Ceilume EZ-On Drop Ceiling Grid Covers are a cost-effective way to renew suspended ceiling T-bar grids...fast. The snap-on vinyl strips cover stained, yellowed, or damaged grids with a durable, freshand-clean satin surface. New colors: Mist, Oat, Jasper, Garnet, Onyx—White, of course, is also available.

Ceilume

Drop Ceiling Grid Covers

Expanding its polycarbonate translucent wall system offerings, EXTECH’s new LIGHTWALL 3450 accom modates 50mm glazing panels and does not require framing members within the field of the glazing, pro ducing a clean, modern, architectural aesthetic. The wall system can extend up to 54 ft., thereby eliminat ing leak-prone horizontal joints. This product with stands high wind loads and has achieved impressive ratings in impact resistance, fire rating, air infiltration, water penetration and structural performance. This system has earned a U-Factor of 0.19.

Railing should enhance your design, not obstruct it. Maintain the unmistakable prowess of your work with the transparent elegance of Ultra-tec ® stainless steel cable railing.

Discover the design possibilities visit ultra-tec.com

Making strides in narrowing the weight and size of a triple pane insulating glass unit, PDS IG Equipment offers a way to produce a triple IGU with a single spacer. By fabricating the glass panes with two seals in place of four seals, and using a thinner middle lite of glass, as thin as 1.6 mm, this creates a thinner, lighter profile.

The Eucalyptus Leaf Linear Chandelier is emblematic of Palecek’s signature style: traditionalism with a modern twist. Palecek is known for using renewable materials with a lot of texture in design, and the Eucalyptus chandelier is no exception. This design brings the outdoors in with its satin brass stem and sweet leaves. The canopy measures 24-in. in diameter, making it a perfect statement piece in residential or commercial spaces.

Adorn is an artisanal wallcovering that comes in six shades.

Cassette-style metal cladding surfaces by PACCLAD offer multiple colors of panels that come in a variety of sizes and depths. Vertical and horizontal panels can be combined in the same layout and fin ished in any combination of 46 colors. Panels can be perforated to form patterns that spell words or form logos. Installation can be performed over plywood, insulation, purlins, or other surfaces.

PAC-CLAD / Carlisle Corporation

Modular AL - Metal Wall Panel Systems www.pac-clad.com

Adorn wallcovering is the winner of two prestigious design awards this year—the NeoCon Best of Year Awards and Hospitality Design magazine. Adorn is an artisanal wallcovering that comes in six striking shades, including deluxe white, grand greige, lavish charcoal, rich black and more. Each shade is accented with a vibrant gold or silver metallic leaf that is inspired by the ancient Japanese art form of Kintsugi. This wallcovering is ideal for luxe commercial interiors.

Phillip Jeffries

Adorn www.phillipjeffries.com

At Krieger, we’re excited to offer our newest radio frequency (RF) doors with 40 dB RF shielding in the electric, planewave, and microwave fields in the frequency range of 1 KHz to 18 GHz and an STC 51 acoustical rating—all in a 1 ¾" thick door panel. The thinner design of this game-changing product makes it the ideal choice for any new or existing construction where RF and acoustical ratings are required.

Our full range of custom finish options includes wood veneer, prime painted, stainless steel, plastic laminate, specialty finishes, and more—all perfectly matched to complement your project.

While a brick veneer offers a great aesthetic, building enclosure performance and details must be carefully considered. Assisting architects with designing an air and weathertight masonry façade is StoCorp’s new StoVen tec Render. The continuous air and moisture barrier also delivers excellent thermal performance and fire protec tion. The system comes in the form of a carrier board that combines light weight and high compressive strength, and allows for seamless walls and curved surfaces that can’t be achieved with other claddings.

StoCorp StoVentec Render www.stocorp.com

Eliminate the trials and tribulations of under-the-sink soap deck refills. That’s the aim of Sloan’s new ESD-360 Top-fill Soap Dispenser—“the only closed, top-fill soap dispenser on the market.” The patented refill bottle locks into place for handsfree refills without the risk of overflow.

Count on Siplast to safeguard your high-tech equipment, mission-critical processes or other valuables. Our SBS-modified bitumen roof and complementary liquid-applied PMMA systems are designed for years of unsurpassed performance. We make them strong and reliable because we want to protect your building – and what’s inside it – no matter what. siplast.com

A luxury, boutique hotel needed a hand sanitizing fixture to match its modern, upscale aesthetic.

hand sanitizing fixture

finishing touch

upscale hotel rebuild.

As the managing director of the newly rebuilt Hotel Versailles in Ohio, Jack Olshan was determined to infuse every part of the luxury, boutique hotel with modern, upscale elements.

But one detail eluded him.

Olshan was seeking a way to demonstrate the hotel’s commitment to the health and safety of its guests without detracting from the striking visuals of the property.

But he was frustrated that every hand sanitizer dispenser he encountered detracted from the carefully curated aesthetics of the hotel.

Olshan wanted a fixture that was not only visually appealing but highly functional as well. It needed to be depended upon to work reliably, withstand heavy use and be easy to maintain.

When he came across the Vaask hand sanitizing fixture at the 2021 HD Expo, the hospitality design trade show, Olshan finally found the answer. The fixture’s clean lines and all-metal construction fit right in with the ambiance of Hotel Versailles.

“Vaask is the only hand sanitizer company that has done something this beautiful,” Olshan said. “It looks like we designed around them.”

Jack Olshan wanted a hand sanitizing fixture that was not only visually appealing but highly functional as well.

Hotel Versailles’ architects and designers worked with Vaask to place the fixtures in high-touch, high-traffic areas. Architects learned that they could spec Vaask into projects because it is recessed into the wall, offering a permanent solution.

“Sustainability was important, and so were upkeep and aesthetics,” Olshan said.

Because each unit is hard-wired to AC power, there is no need for batteries. The high-capacity, easily refillable cartridge reduces maintenance and waste. The five-year warranty reassured Olshan that Vaask is built to last.

Located in the Gangnam District of Seoul, South Korea—serves as the HQ of Harim, a South Korean livestock and feed manufacturer. Highlights include a shell adorned with 10,000 LEDs, a spectacular S-shaped curve running up the face of the building, operable windows from top to bottom and a rooftop boardroom. At the base is a public, open-air plaza along with high-end restaurants, a café, retail spaces and a second-floor art gallery.

Located in Seoul, South Korea—the extraordinary exterior of the Harim Group headquarters dazzles onlookers with its signature “S” shaped curve. The recessed cavity billows up vertically through the building’s north face like steam rising from a cup of something hot and is accentuated by custom-made metal panels that are illuminated by 10,000 LEDs.

“I was just sitting in my backyard with a cup of coffee sketching,” remembers Rick del Monte, The Beck Group’s since-retired Chief Design Officer while describing his creative process.

The design team behind this 86,000-sq.ft. undertaking—del Monte and Jay Chung, the Director of Korea Operations at Beck Group—discussed what went into the building of this striking mid-rise office tower with 17 levels—three floors near street level for retail businesses, upscale eateries, open public spaces and other popular attractions, and then 14 stories that serve as the Harim Group’s headquarters.

The Curve Korea’s hot-and-cold climate brings four robust seasons including frigid winters and steamy summers. Due to the high cost of electricity— nearly twice that of the U.S.—natural ventilation is preferable to using the HVAC, explains Chung.

“What if we made a slot in the front?” del Monte remembers thinking. “The air typically moves from east to west during the summer. If we had a recessed slot, perhaps we could get negative pressure as the air sweeps across the surface and sort of draw air out of the building, creating a means for natural ventilation.”

With that function in mind, next came the fun part—figuring out how to best express its form. The facade lighting was an important piece of the puzzle. Korean lighting designer Jason Gil of Well Light was tasked with the lighting design. He proposed placing lights behind perforated, stainlesssteel panels, inside a recessed cavity.

“The goal being that it wasn’t just like an on and off,” says del Monte, “but that you would get these multiple reflections that sort of shimmered as you looked at it.”

Chairman Kim Hong-Guk, Harim’s owner, loved the idea, but he wanted to be sure the new structure dazzled during the day, too, not just at night.

Project: Harim Group Headquarters

Location: Gangnam District, Seoul, South Korea 86,000-sq.-ft. midrise tower

Completed: 2016

Architectural/Interior Designer: The Beck Group