Dennie Ortiz Publisher

Dennie Ortiz Publisher

Dennie Ortiz Publisher

Dennie Ortiz Publisher

Welcome to our jam-packed December is sue, allow me to walk you around to help you unpack it!

Keeping your operators safe and your ve hicles on the road are the perennial challeng es faced by our industry. In order to keep your operators safe, you need to have them to begin with. Current labor shortages not withstanding,

finding, hiring and retaining operators has always been a hurdle that tow business owners have had to deal with. Contributing writ er, Chase Clough, offers an angle that’s worth considering when it comes to hiring and keeping good employees for this specialized industry. Once you have hired, Brian Riker recommends methods to conduct safety meetings that will have your team engaged and get ting the most from their time dedicated to this important endeavor.

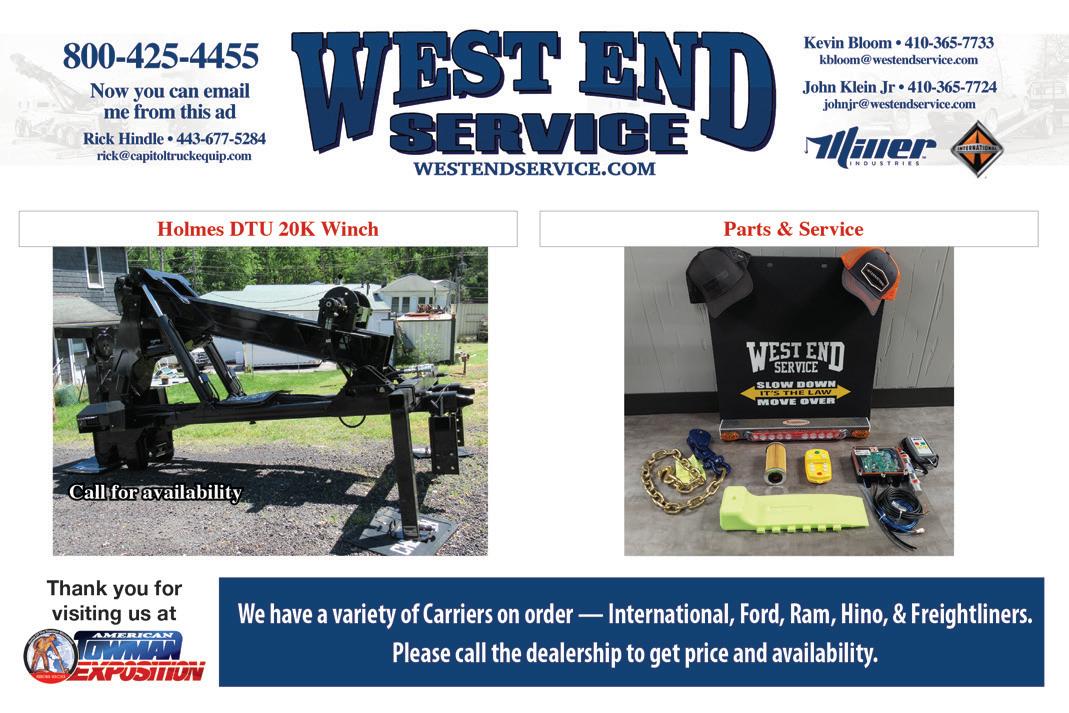

In order to keep your trucks on the road, they have to pass a DOT inspection. John Borowski offers sound suggestions, along with strong visuals, for specific areas on your vehicle to focus on and prepare to ensure your truck will pass.

Knowing the proper procedures to do any tow or recovery is crit ical. Randy Resch tackles the ins-and-outs of off-road recoveries while offering specific guidelines to avoid bodily injury.

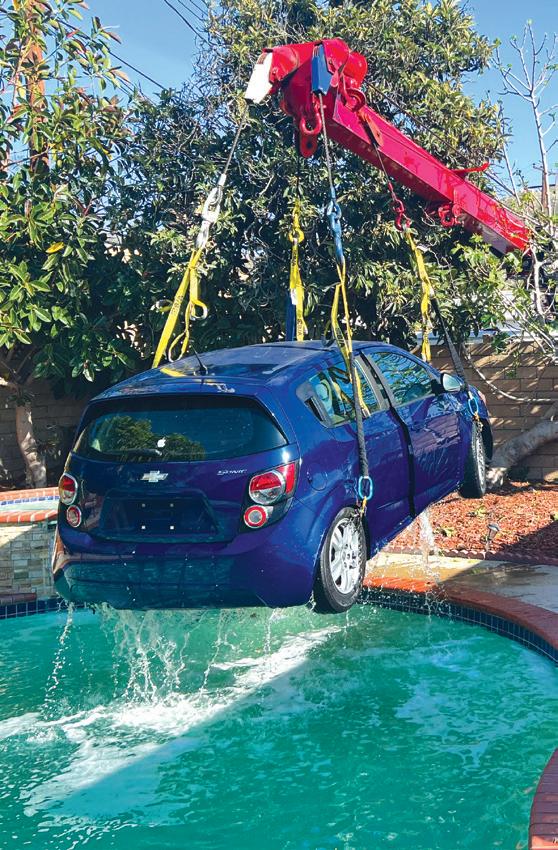

Moving towards an eye-widening scenario faced by a solo op erator, a unique poolside recovery awaits you that challenged Chris Navarro from Pepe’s Towing & Recovery out of California.

With more treats for your senses, fasten your eyes to some souped-up glamour that packs a punch, in this month’s My Baby featuring Chima’s Tow’s 50-ton rotator, Century 1150.

Our annual Product Showcase featured in this issue will give you an at-a-glance view of what suppliers are offering this coming year that can keep your vehicle and your business healthy.

Hope everyone has a happy and healthy holiday! As always stay safe out there!

As Dennie notes above, we cover safety topics in every issue, because we all know that towing can be really dangerous. So often just keeping certain simple tips in mind can avoid roadside injuries or even death. In addition to our articles on engaging safety meetings, offroad recoveries and DOT inspection trouble spots, all of which can help you avoid accidents, even our feature on Chima’s rotator includes some practical points. It notes ways to set up a wrecker that minimize time in the “kill zone” and hopefully keep them out of harm’s way.

On November 15, 2022, the Towing and Recovery Association of America, Inc. (TRAA) celebrated passage of the Move Over Law Resolution (H.Res. 1463) in the U.S. House of Representatives. The resolution, introduced by Congressman Jim McGovern (D-MA 2), urges both Federal and State agencies, plus nongovernmental organizations involved in traffic incident management response, to support and promote Move Over laws.

“Roadside emergency responders…know all too well the dangers of roadside response,” said Congressman McGovern. “They keep us safe every day, and we have a responsibility to do our part to keep them safe in return,”

The passage of H.Res. 1463 will undoubtably increase public awareness of Move Over laws and the need for drivers to slow down and move over when they see any incident responder on the side of the road. Every state has a “Move Over” law, but according to the Emergency Responder Safety Institute, there were still 65 traffic incident management responders who were killed due to roadside collisions in 2021, and studies show that a tow operator dies every six days in the United States.

“TRAA is incredibly proud to have worked with Congressman McGovern and his staff on this over the past year and especially since its introduction in April,” says Cynthia Martineau, TRAA’s Executive Director. “We strongly believe that this resolution will bring much needed attention to each state’s existing Move Over Law and increase roadside safety for every responder.”

The TRAA looks forward to the anticipated passage of the Senate companion, S.Res. 734, introduced by Senators Blumenthal (D-CT) and Braun (RIN), in August 2022.

Source: traaonline.com

Tammy Duckworth, an Illinois Senator (D-IL), who is a co-sponsor of the bipartisan resolution to raise awareness of “Slow Down, Move Over,” recently highlighted the advocacy of TRAA in promoting roadside safety.

Senator Duckworth said, “The increase in roadside incidents and fatalities in Illinois and across the country is both troubling and heartbreaking. I am pleased to have partnered with the Towing and Recovery Association of America (TRAA) over the years, as they advocate on a number of issues such as enacting the Protecting Roadside First Responders Act. I look forward to continuing to work with TRAA on these and other issues as a voice of the towing industry in Washington.”

TRAA’s advocacy takes center stage on Capitol Hill in March, when TRAA members are encouraged to meet with congressional members to work on promoting positive legislation and opposing potentially negative legislation. At this year’s event, key relationships were forged that lead to representatives Alex Mooney, Marcy Kaptur and Teras Leger Fernandez becoming bipartisan co-

State Senator Tammy Duckworth has worked together with TRAA to promote roadside safety initiatives.

sponsors of a National Move Over Day Resolution.

TRAA’s efforts are also on display next week during Crash Responder Safety Week (CRSW), November 1418. This weeklong initiative involving Emergency Responders across the country is sponsored by the U.S. Department of Transportation’s Federal Highway Administration, where TRAA sits on FHWA’s Executive Leadership Group. Week long events are designed to raise public awareness to help keep roadway responders and the public safe around traffic incidents.

Source: TRAA Newsletter

Wintry weather and black ice in Denver, Colorado caused a 100+ vehicle pileup. The pile-up brought dozens of tow trucks to recover wrecked vehicles, where they were brought to Mile High Stadium, used as a makeshift tow yard. Later vehicles were towed to auto body shops or impound lots.

Although multiple people were taken to the hospital, most walked away with minor injuries. One driver noted that he saw cars piled up as he was coming down the highway and when he braked, slid into a dump truck and then got hit four more times from this chain reaction. His truck was totaled but he was not injured.

“It was a scene out of Mad Max,” another driver involved said. “All you could see was debris on the highway. There were car parts under my car.

Dozens of tow trucks were on scene in Den ver, Colorado after a 100+ vehicles collided.

There were people who lost the wheels on their car. You could see radiators and fenders. It ran the gamut.”

According to DOTI’s public information officer, Vanessa Lacayo: “In Colorado, road conditions can change quickly, which is what happened, creating slick conditions.”

Source: nbcnews.com abc7.com

Tommy and Tess Anderson were presented with the 2022 Dave Jones Leadership Award at a ceremony during the International Towing and Recovery Hall of Fame annual induction weekend. The award, presented by Mike McGovern, president of TT Publications, acknowledges the work of an exemplary tow operator or company owner, named for the visionary towing pioneer Dave Jones.

Tommy and Tess head the Southwest Tow Operator Association (STO) in Plano, Texas, respectively serving as Executive Director and Accounting Executive. Speaking about his wife Tess, Tommy said, “She takes care of everything.” With 45 years in the tow industry, 30 years as tow owners and 15 years with the STO, together they oversee licensing and training of tow operators and promote tow legislation beneficial to the industry.

Jerr-Dan sponsored the auction night that kicked off the International Towing and Recovery Hall of Fame annual induction weekend. Jerr-Dan’s vice-president and general manager Bob Nelson also presented the Survivor Fund with a $20,000 donation on behalf of the company.

Since 2007, the International Towing and Recovery Hall of Fame and Museum’s Survivor Fund has provided immediate financial support to families of towing operators who lose their lives in the line of service. Auction Night, held this year at the Chattanooga, Tennessee Westin on Friday, October 7, opened the annual Hall of Fame event. Proceeds from the auction benefit the Survivor’s Fund. When the total was finalized, donations from the 2022 silent and live auctions set a record— more than $335,000, far above the previous record.

“Of course, we all enjoyed the evening and the auction itself, but we can’t lose sight of this event’s

purpose,” said Nelson “As individuals and corporations, we came together to financially assist the families of our industry’s heroes. We all need to maintain that commitment to grow and strengthen the Fund the other 364 days of the year as well. As a company, we appreciate our opportunity to sponsor the auction and make a special donation tonight, but we also want to urge all who can to participate in the Museum’s continuing supporter program.”

Survivor Fund www.jerrdan.com

Pennsylvania Governor Tom Wolff signed legislation enacting the “Blue Lights Law.”

“Countless lives will be saved thanks to this legislation and it was my honor to get it across the finish line,” said Senator Doug Mastriano, who sponsored the legislation. “It’s a simple fix that will make the roads safer for everyone.”

Under previous law, tow truck operators could only use flashing orange or yellow lights. Studies from the Texas Department of Transportation and the University of Michigan demonstrate that drivers routinely ignore the sight of these lights on the road, often resulting in fatal accidents.

“The flashing blue lights will no doubt give drivers more time to react, protecting both tow truck operators and the people waiting in disabled vehicles on the side of the road,” Mastriano said. “I appreciate the administration’s support of this commonsense legislation and the urgency of the General Assembly to get it to his desk.”

Source: pasenategop.com

In November, roadside safety initiatives took center stage with the Federal Highway Administration’s (FHWA) National Crash Responder Safety Week (CRSW). This initiative took place from November 14 – 18 with the purpose of engaging the Traffic Incident Management (TIM) community to make a difference individually and jointly for roadway safety during traffic incidents.

During the week, Emergency Responders and TIM initiated a variety of campaigns within their respective communities to engage each other and motorists, with a focus on safe and quick roadway clearance. The program increased awareness of the Move Over laws; promoted “Steer it, Clear It” with motorists; spread awareness of traffic incident management; and encouraged responder participation in the National TIM Responder Training.

Source: fhwa.dot.gov

Donations to the Survivor Fund exceeded $335,000.If you have been looking for an easy way to add a boom to your Zacklift, check out the company’s all new D-BOOM 25T. This sturdy unit attaches to your Zacklift Fifthwheeler system with two pins and a few hydraulic connections. The D-BOOM 25T has a lifting capacity of 50,000 lbs in the retracted position, and the ability to extend eight feet hydraulically.

Zacklift has always focused on ways to get the most out of the equipment you own. The D-BOOM can easily upgrade your existing setup, eliminating the need to replace good working equipment. Called “Cost Effective Versatility,” the D-BOOM comes with everything you should need to convert your detachable Zacklift into an even more capable wrecker. Standard equipment includes a 20K Warn winch with 200 feet of 5/8-inch cable. Single- and two-line configurations are available. Hydraulic valve sections and hoses connect to existing Zacklift standard equipment.

Brian J. Riker is a third-gen eration towman, with 26 years of experience in the ditch as a tow operator, and president of Fleet Compli ance Solutions. He special izes in helping navigate the complex world of federal and state transportation regula tory compliance. He can be reached at brian.riker@fleet compliancesolutions.net

Nobody ever said that safety is an exciting topic. When not presented properly, it can be as dull as watching paint dry. But it doesn’t have to be. How can you make safety fun and engaging? You could start by checking out the “safety third” YouTube video by Mike Rowe of “Dirty Jobs.” Dating back to 2009, his lively approach is an ingenious way of explaining occupational safety.

Basically, he was drawing attention to the reality of “risk compensation”; that is, adjusting behavior in response changes in our surrounding environment. As examples, the most dangerous traffic intersections are actually the ones with more safety signs. And motorcycle riders wearing helmets tend to drive faster and take more chances than those who don’t. We assume more risk when we “feel” safer, and become complacent.

“Bottom line: Guidelines are great, but are no substitute for common sense,” Rowe pointed out. “Your safety is your responsibility.” In other words, being in compliance doesn’t necessarily mean you’re out of danger.

So what does this have to do with conducting an effective safety meeting? It all begins with a positive attitude towards safety. Towmen—yes, we are singling out men— have a mindset that causes them to take extra risks and tackle the job no matter the cost. Our valued female counterparts tend to have a better risk filter built in, and often complete the same task with a much lower risk factor.

According to the US Bureau of Labor Statistics in 2020, the most recent data available, there were 4,377 fatal workplace injuries among male workers. But only 387 deaths among females!

Hey guys, we could learn a thing or two from the ladies. A study conducted by Mara

Mather and Nichole R. Lighthall concluded that men are more likely to take risks when under stress than women. Women tend to be more conservative during stressful situations. Perhaps this accounts for the differences in driving behaviors and other workplace activity.

Safety is not just a department or job title, it needs to be a way of being for your entire organization. From the equipment you purchase and the jobs you accept to the support and autonomy you allow among your team. Everything should be framed through the lens of, “Is it a necessary risk or can it be done safer?” But how do you get to that point?

Employee engagement is key. Listen, truly listen, to what your team is saying about their concerns. Understanding what they see daily will help you present the critical points in a way they will grasp and make their own.

On the other hand, don’t continually relive the past. We all have those moments where something horrible has happened, equipment was damaged and people were hurt. While it is important to study these events and learn from them, do not focus an entire safety meeting on just one bad event. This approach will shut everyone down and they will tune out, even when great solutions have been offered. Instead, touch upon the key points, while also pointing out what has been done correctly.

Reward positive behavior. No one likes to

be criticized or yelled at, so actively try to catch your team doing things right and make a big deal out of it. Gift cards or other positive recognition will go a long way to support a safety culture. Extend this behavior to your training and safety meetings. Maybe include a gameshow-style quiz or other form of funny, lighthearted and entertaining engagement.

No one wants to sit through a boring one-sided lecture on safety and compliance. Keep your training and safety meetings engaging and upbeat. Ask questions and do not demean somebody for a wrong answer. It takes a lot of courage to speak up and answer a question in front of peers. Most people are not comfortable being put on the spot. Have compassion and be gentle when explaining why their answer or response was incorrect. As one veteran incident commander observed, “It’s not easy to tell a grown man what to do.” And especially what not to do.

Funny videos—the internet is full of them—can be an instructive tool. A little bit of humor can help valuable information really sink in. Mind you, funny is something light and entertaining, not gross and showing serious injury. Get the group to talk about what could have happened in the clip to make it a very serious mistake and how to prevent it.

For instance, there was an old Caterpillar training video series called “Shake Hands With Danger” that really showcased this type of humor as an education model. Take

a moment and watch some clips on YouTube, as they are not only entertaining but also still mostly relevant today.

Oftentimes attendees in these meetings are there against their will, or feel the material being presented is not relevant to their “real world” job duties. As a safety educator, your job is to read your audience and find ways to both get and keep them engaged. Even those who love

to learn can find themselves falling asleep in some of these presentations, especially when the instructor is just droning on or speaking very monotone without any audience participation.

Don’t want to have a formal safety or training meeting? That’s fine too. A key principle of adult learning is active participation. How about having your team create their own safety video clips? These can be as simple as shooting video of real safety issues they find around

Positive recognition will go a long way to support a safety culture

their workplace, or maybe creating “unsafe” scenario just for the purpose of the video clip.

Note, though, that no one should ever deliberately put themselves or another person in harm’s way just to film a video clip. “Unsafe acts” can be staged for the camera with no risk to the participants. This method is sure to get your team involved with thinking and talking about safety.

Whatever way you provide training, it must be relevant to the actual tasks at hand. Nobody likes to feel like their time is being wasted, so keep the material focused on task without a lot of general awareness information. Don’t try to cram everything into one session or meeting. Just a few strong points are remembered better, and in particular the ones you highlight or summarize

at the end.

Your tow truck operators only have limited overlap with your shop mechanics or dispatchers, so they should each have specific presentations, if not completely separate meetings. Yes, under the general-duty clause of the OSH Act, all employees require a basic understanding of workplace safety. But nothing says that can’t be customized for each department.

Bottom line, no one cares about your own personal safety more than you should, except perhaps your momma and spouse. So at the end of the day, it really is up to each of us individually to do our part for safety. Remember, mere compliance with the regulations and best practices does not always mean safety is guaranteed. Stay alert, so you and your fellow towmen don’t get hurt!

California

Randall C. Resch is a

and veteran tow business owner, manager, consultant and trainer. He writes for TowIndustryWeek. com and American Towman, is a member of the Interna tional Towing & Recovery Hall of Fame and recipient of the Dave Jones Leadership Award. Email Randy at rre schran@gmail.com.

Somewhere beyond a ridge of granite and scrub-oak, a sheriff’s deputy points to a far off location where a deserted Jeep is abandoned. Access to recovery is “sketchy at best” as the tower looks for a solid location to access the casualty. Because it’s not possible to get a heavy wrecker to the location, the tower’s wits and experience are important factors in making this recovery successful. Meanwhile, the deputy retreats to his truck and laughingly offers the tower, “Good luck!”

For towers yearning to work as off-road recovery specialists, it’s important to fully understand the dangers and complexities of working in an off-road environment. If ever called to some rural outback to recover a burned, stolen and stripped vehicle, loadand-go techniques take a backseat to the hazards and complexities off-road recovery represents.

Off-road recovery is often a far more complicated process, so creative techniques are best practiced in real-world settings. While watching off-road recovery online is great for entertainment purposes, but nothing can meet or beat the value of handson training.

Too many towers choose internet videos as their best training source, and not knowing firsthand the dangers and complexities is flirting with fate. The internet is famous for displaying “Hollywood techniques” which are not a proper basis of training and can turn into a deadly proposition.

Fact: Working a recovery off-road can result in great bodily injury or death. While towers recognize there’s great profit to be made in off-road recoveries, they sometimes fall short in learning the proper procedures before heading into an unforgiving outback. Off-road recovery is dangerous business and one that can’t be taken lightly. That’s because an off-road environment fights back with three known resistances: grade, surface and rolling resistance. Let’s break down each of them:

• Grade—Angle, hillside, or incline are the working areas where a vehicle is being recovered, otherwise known as an overan-embankment, up-slope, or “dead-lift.”

• Surface—The material that the recovery is situated in, such as mud, sand, rocks, shale, trees, ice and snow. Each type of surface creates unique complications.

• Rolling—What is the casualty vehicle’s “roll-ability” during extraction? For instance, a small Honda with no E-brake and the gear in neutral, roll-ability is likely no problem. But with the E-brake 50-percent “On”, not so easy. And no tires, wheels or upside down, the roll-ability

simply “Ain’t gonna happen.” In a far away rural location, a casualty on dollies probably won’t stay together, so would dragging on its roof be a better alternative?

Resistances also occur when driving to and from off-road recovery scenes. In order to successfully extract the casualty vehicle from getting stuck or sliding-off the beaten path, an off-road vehicle’s driver/operator must assess other factors as well, such as both up and down slopes that impact climb-ability, along with braking and tip-over potential when side-angles become too steep. Just how stable is the surface, and can you navigate your wrecker up or down a rutted goat path? You’ll like need to rely on your skills with brake/throttle modulation, and/or rock crawling in the lowest gears.

Having arrived at the extrication site, careful rigging, approach and recovery truck placement are necessary to achieve the best mechanical advantage possible. Not recognizing potential hazards before winching starts is a mistake towers and off-road group alike often fail to determine.

An off-road recovery might be completed with minimal effort, but can turn into that proverbial “cluster” due to failing to follow a simple offroad recovery rules. What starts out as an easy, straight-line pull can end in a near-death experience for the operator and his customer! If you think off-road recovery is an easy no-brainer activity, consider four examples that ended horrifically bad:

• A light-duty wrecker worked to extract several 4x4 pickups stuck in the sand at San Diego’s Fiesta Island. The typical scenario included other 4x4 trucks that came to the first stuck guy’s rescue. They too got stuck due to factors common with beach recoveries

(wet sand, the suction it creates and ignorance on the part of other inebriated buddies).

• The light-duty wrecker was in newer condition, had twinwinches and two operators, both there to assist a dozen more “experts” working to get these trucks unstuck. The recovery was going well until an outstretched winch-cable separated. When heavy pull commenced, a separating cable suddenly recoiled without warning. Luckily, nobody

was injured or killed.

• A solo vehicle skidded across an icy roadway, winding up in a ditch upside-down. In what should have been a simple rollover recovery, the wrecker’s winch cable separated, whiplashed back toward the tower and striking him in the face. He was transported to an area hospital with serious injuries.

• A fire truck was leaving the incident’s location when it became stuck in a muddy field. To ◀

Work the non-traffic side - Stay Safe!

extract the mired fire truck, firefighters used a tractor and a lengthy tow rope to pull it as a firefighter was seated behind the wheel to steer it. A screw-pin shackle detached from the tractor’s end and rocketed back toward the firetruck. The shackle smashed through the firetruck’s front windshield, striking the driver in the forehead and exited through the truck’s back window. He died instantly.

Because there are many ways to extract vehicles from off-road environments, consider the following components as the basis of every off-road recovery.

Point of Origin—When under critical load, cable separation and an unintended recoil never announce themselves. Because stretched cable, ropes, shackles and straps tend to recoil toward their “Point of Origin” (POI), they may snap back in either direction. Recoiling cable or attachment accessories become instant ballistic missiles capable of great bodily injury or death

Straight Line Winching—For best mechanical advantage, winch lines and recovery (kinetic) straps should be straight to the casualty vehicle. Protect from cut-points and sharp edges. Winching in a straight line is important to prevent bending a wrecker’s outstretched boom or tipping a wrecker on its side.

One Boss Only—Recovery activities should include only one individual directing recovery activities when critical winching commences. “The Boss” is that person best versed in off-road recovery, noting that may not be the tow operator

Identify the Work Zone—Work zones are easily identified by employing cones, red flags, and even yellow caution tape to keep “Lookie Lou’s” out of potential whiplash zones. For back country and rural environments, avoid using road flares for obvious reasons.

Double-Distance Rule—When critical winching commences, remove all persons from the winch/ whiplash zone double the amount of cable employed. For example, with 50 feet of cable out, remove all persons beyond 100 feet for safety

Cable Brake—Something heavy (tossed over stretched cable) helps to deflect the cable’s whiplash and kinetic energy in any direction away from the recovery team. While naysayer’s suggest a cable brake has no effect in arresting separating cable, it could be that additional level of safety to deflect whiplashing cable.

Chain, Straps, Nylon Rope for Pulling—Experts suggest nylon rope has no memory, claiming it “shouldn’t whiplash” in the same manner metal cable does. Don’t bet your life on that rumor!

Trailer Ball Recovery—Never attach looped kinetic

ropes, straps, or hank of chain around a trailer ball’s shaft. During a hard pull, should the ball’s shaft snap, the ball becomes that projectile back towards the operator or through the windshield of the casualty vehicle

Plywood Window Protection— Critical winching should have available a thick, plywood board that’s more horizontal than tall, to be placed across the driver’s windshield. Or, at the very least, open the vehicle’s hood (if so equipped). Do not have anyone seated in a casualty vehicle that’s being winched.

These safety recommendations might seem a bit excessive to some towers, and some will say, “Nah, I’ve done this a million times and nothin’s happened to me.” That might be a true statement, up until such time an unintended accident or detaching tow

accessory injures or kills the operator or someone inside the recovery location.

Keep in mind that recovery vehicles also “talk to you,” making snap, ping and singing noises as the winch or truck comes under a heavy pull. Listen for the truck’s rpm slowing, and pay attention to any movement. When loud noises or banging happens, stop to evaluate what is the best response?

Regardless as to size or complexity of any extrication, always err to the side of safety. Be aware that the tow truck or recovery vehicle will move as it fights against resistances. Tire chocks and teethed-spades help keep recovery vehicles firmly planted. When winching with tow trucks, operators should rest one foot atop the rear rim so to feel the truck’s movements. If something were to break loose, the operator simply pushes away allowing the truck to settle.

Old school techniques were originally created by farmers, ranch hands and mechanics. This applies to Ernest Holmes’ first tow truck, invented out of need to recover a ditched Model-T. The path then to recovering vehicles was a process of trial and error, where techniques were learned and deployed. One example is the Stiff-Leg Technique, used to pull tree-stumps. Archaic at best, the StiffLeg Technique is one that’s still used in recovery situations today.

No matter what level of off-road experience a tower has, take time to practice tried-and-true techniques that end in success, not in unfortunate catastrophe. When recovery scenarios are miles from emergency resources, taking a chance is never one’s best option, and can become a deadly proposition.

Now that Tom Brennan is semi-retired from T&T Towing after 37 years in Cohoes, New York, he has plenty of time to spoil his grandkids with ice cream runs in a couple of cool rides. The older one, a ’49 Ford, infatuates Jackson. While Brennan (the younger one with the mop of blonde hair), enjoys climbing on the bed as well, he yells out, “Vroom, vroom!” every time grandpa pulls up in his 360-powered ’74 Dodge Challenger.

Tom had never owned a classic truck before, but his brother had an old GMC pickup that he used for delivering ice cream, so that partly explains his reason to get one (and ice cream too). Anyway, he came across the Ford on eBay, but initially lost out to a higher bidder. But that deal fell through, and Tom got it for his lower price. Good thing, since the aging Ford required a significant investment to restore, since the bed of the truck was thrashed and the fenders rotting.

“I guess I had more money than brains,” Tom admits with a chuckle. After raising the Holmes 515 Split Boom off the bed into the rafters of his garage, he found that fortunately the truck frame underneath was still solid. But his shop

workers had to buy an English wheel to form those big fat fenders. The front bumper was custom-fabricated out of steel in his shop. The only item not handled in-house was the two-tone paint job, done in his green-and-white company colors to match his fleet of 25 assorted wreckers, flatbeds, trailers and service trucks.

The Flathead Six is in good running condition, with about 46,000 miles showing on the odometer. The engine only needed work on accessories such as the carb, ignition, and clutch. As for the cab, the headliner and bench seat needed new upholstery, which turned out to be readily available from the aftermarket for a fair price. The dash cluster is all original, and gives the interior that nostalgic old-time feel. ◀

Tom came across his Dodge Challenger muscle car through a neighbor who had stored it in his garage and never got around to working on it. He kept telling his neighbor, “Don’t sell that car without asking me!” Finally he decided to let it go to a better home, and Tom was pleased to find it didn’t have a lick of rust on it. But he does take it out with wife Terri to get some licks of ice cream for his grandkids, while the Ford also does parade duty and wins show trophies in Jackson’s name.

By the way, besides his fascination with wreckers, Jackson also loves reading American Towman magazine, Tom notes. This grandpa tower is sure a good influence!

John Borowski is VP of Tow Industry Programs for Au toReturn. John has over 45 years experience as a tow business owner, wrecker manufacturer specialist, trainer and writer. He was awarded the first “Towman of the Year” by American Towman magazine and two Towman Medals for hero ism. He was inducted in the Towing and Recovery Hall of Fame in 2001.

Even a small infraction can keep your wrecker from staying on the road and bringing in revenue from a recovery. A tow truck that doesn’t “pass muster” can not provide any tow services for the city until the failing items are corrected. More important, there’s an added concern about driver safety. That’s why Federal DOT Level 2 inspections are done, for your own protection—and your customers as well.

To help you avoid any issues, listed below are the most common problems and omissions that disqualify a truck from service. Check these out before you head to a DOT inspection, and you’ll likely pass with flying colors so you can get back to doing your job, both safely and efficiently.

Here’s a typical form used to inspect a tow truck, with all the areas that will be evaluated—tires, wheels, rims, suspension, lighting, fuel system, frame, exhaust, steering, etc.

Time to retire? Working crash scenes can damage tires when they pick up sharp or jagged materials which can cause punctures and tread chunking. Tow company owners can be reluctant to change tires if they hold air because the very next crash scene could cost you another tire or two. But the amount of tire tread depth helps with the handling of your truck in wet or slippery conditions. That’s cheap insurance as well as the law. During an inspection, many tow operators are happy to get those bad tires to fail so they can now get them changed.

Can you see clearly? In hotter, southern locations, windshields can become extremely brittle, and are more prone to crack when rocks kick up from the roadway. Or when your wrecker hits a hard bump, it can cause a crack to spread. If you notice a pit in the windshield early, a spot repair will likely pass inspection. But if it expands into a crack, you’ll need new glass. ◀

Work the non-traffic side - Stay Safe!

During inspections, it often seems that when items are missing the usual excuse is, “Well, it was there yesterday.” Or the missing oil-drying agent is absent because the operator just used it on the last call. (And probably left the broom and shovel there, too!) Daily checks for equipment and understanding where the tools and supplies that you need are located help reduce scene time and efficiency. Also, keep in mind that if you have a spill and can’t handle it, now another driver has to respond and tie up another truck, which doubles down on exposure—all to make up for your shortcomings. When towing a wreck, the operator is required to remove the debris from the crash and stop fluids from traveling, then collect and properly dispose of them.

Besides cleaning up oil spills, the very truck that you are operating shouldn’t be leaking oil either. If it does, get it repaired before you cause a crash. Check for leaks dripping down from the

oil pan and front axle, also the suspension and the hydraulic rams for the rear wheel lift. Don’t ignore any oil spots on the pavement, as those are telltale signs of a potentially serious problem. ◀

Whole lotta shakin’ going on here! This closeup of the bed lock on a car carrier indicates repeated and serious damage that has been sloppily repaired with “booger welds” (poor penetration). When not locked down tight on pivot points, the bed can rip apart, causing a dangerous load shift. This carrier clearly couldn’t pass inspection, and required a much better repair job for safety’s sake.

Every time a driver starts his or her shift, a daily circle check should be done. Verify that all of your rigging equipment is onboard, where it is supposed to be stowed, and usable condition. When a driver is exposed to roadside moving traffic and heavy weather conditions, that’s certainly not the time to be digging through tool cabinets to locate needed equipment. Also, the straps and ratchets for your 4-point tie-down need to be taken care of properly. After every use, a quick visual for dirt or damage should be done while rolling up the straps for stowage. The ratchet should be inspected, cleaned, and lubricated as well. Another item that needs serious attention is the flatbed of a carrier. If not clean, it can be very dangerous and is where most Workers Comp claims happen.

During a circle check on a tow vehicle, make sure all your lights are functional, and nothing is hanging down like wires, chains or straps. The normal inventory on your tow truck should be neat and well organized. Think of your daily tow and service calls as a NASCAR pit stop, and plan accordingly. Without question, the less time spent outside of the cab equates to a much lower chance of being involved in a strike or a direct hit.

Access Tools 57

Akins Body & Carrier Sales 35

All American Jerr-Dan .................... N,S,M 59

American Towman Expo. N,S,M,W 64

AmeriDeck 27

Atlanta Wrecker Sales ...............................32

Austin Insurance N60

AutoReturn 51

Chevron Commercial ................................28

CrashFilm by Boxes 4 U 16

Crouch’s Wrecker & Equipment Sales 17

Custer Products ........................................38

Driverlocate.com N63

Dual-Tech Wreckers & Carriers 47

Dynamic Towing Equipment & Mfg. 49

EdgeTech/Hooks W61

Elizabeth Truck Center 50

G. Stone Commercial N63

GM Consultants 55

Hale Trailer Brake & Wheel N61

Hino Trucks Back Cover

ICW Group Insurance 32

Intek Truck & Equipment Leasing/Financing 27 ITI 20

Kalyn Siebert 34 Len Zermenos 4-5

Lodar USA .................................................28

Lynch Truck Group 33

Matjack 47

McMahon Truck Center .......................... M61

Metrocom 50

MIller Industries 3

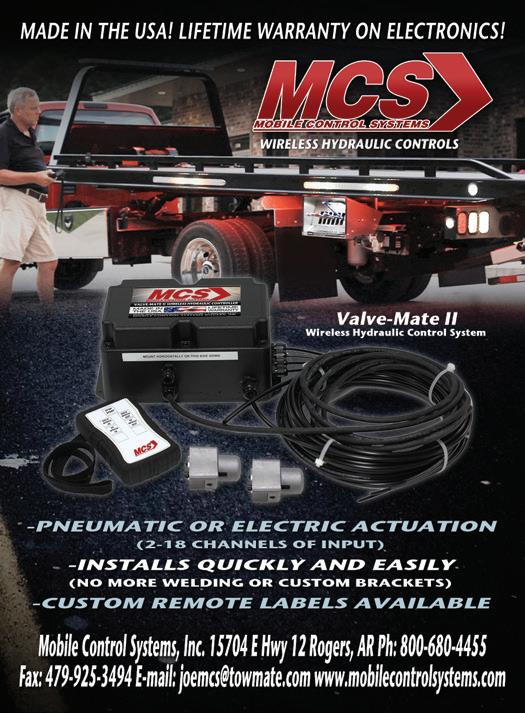

Mobile Control Systems .............................55

North American Bancard 13

Nottingham Insurance N62

OMG Tow Marketing ..................................29

Online Impound Auctions 23

Pacific General Insurance Agency M62

Peak Wrecker Sales W63

PeakPTT 56

Performance Adv. Comp. Inside Back Cover

Progressive Commercial Insurance 21

Recovery Billing Unlimited 24

RimSling 24

SafeAll Products 15

Sea Crest Insurance Agency W59

Select Truck & Equipment M62

ServiCase 31

Smyrna Truck & Cargo 25

Speak Easy Communication 28

Steck Mfg. Co. ..........................................39

Talbert Manufacturing N62

TDI Repair Facility 48

Texas Towing & Storage Assoc. (TTSA) ......30

Tow Industries W62

Towbook Mgmt. Soft. Inside Front Cover

TowMate ...................................................16

Trail King Industries 31

Traxero North America 56

Ultra Built Mfg. ..........................................30

Urgently 52

Utility Trailer Sales Southeast Texas W61

Warn Industries 7

West End Service 25

Will-Burt Company 20

Winches Inc. W59

Wrecker Warehouse W62

XINSURANCE M63

Zacklift International 48

Zip’s AW Direct 9, 19

By George L. Nitti

By George L. Nitti

George L. Nitti has written for American Towman since 2009. He started out as a news writer and now writes a weekly feature on TowIndus tryWeek.com, Tow Illustrat ed, which spotlights the tow truck graphics.

What are the odds that your parked car lands in your swimming pool? You’d probably have a bet ter shot at winning the Powerball!

When the call came in early morning of March 17, manager/rotator operator Chris Navarro of Pepe’s Tow ing & Recovery in Socal made sure to grab a pair of swim trunks and orange Crocs on his way out the door to begin a day’s work. What led to this unusual aquatic recovery?

“The homeowner parks his car in the back yard,” Chris explained. “When he woke up to warm it up, he didn’t realize that it was in gear and dropped the clutch. The car took off on him, landing inside the pool.”

Chris, who has been a rotator operator for a little more than a year, felt that he could handle the job solo.

“I grew up in the business, watching my father Lorenzo Navarro and Uncle Joe Acosta, who is the president of Pepe’s,” he related. “Lucky for me I’m blessed to be around skilled and experienced people who have been able to give me pointers.”

Later in the afternoon, when Chris showed up in his 2017 Peterbuilt with a 1140 Century Rotator, he was outfitted in swimming attire, ready to determine what needed to be done. But it

my rotator on his driveway—which was already damaged—so I wasn’t worried about cracking concrete,” he pointed out. “I was able to park right along the wall and had just enough reach to get above the pool so that I could lift without any of the car

hitting the pool walls.”

Good thing, because without the driveway there, “The job would have been a little more expensive,” Chris observed. (And also way more difficult.) Next up was to ensure the outrigger legs were placed securely.

“If you don’t have your outriggers in place, your truck is going to go with it,” he explained. “I set a strong platform to lift off the side.”

After figuring out the points to tie up on the Chevy Sonic that had gone for a dip, Chris prepared to get wet to make those connections between the car and rotator. Using B/A Products rigging straps with smaller chains on them, he was able to get inside the car’s small rims and wheels.

“I used my main lines to connect to the back of the vehicle, and ran my auxiliaries to the end of the boom, and used them to hook up to the front of the vehicle,” he said. “I had to get in the water.”

Chris then used the front auxiliary lines to bring the car to the front center of the pool to avoid hitting any walls, since the homeowner wanted me to make sure to avoid any damage to the pool.

Although the car didn’t weigh all that much, it was filled with water when Chris brought it up with his wireless remote, which was powered by the Miller Raptor control maneuvering the boom.

“I knew that there was going to be a big resistance factor in terms of weight,” he noted. “So I had the idea that before I lifted it out of the water,

I would open up the doors to let the water drain back into the pool, thus making the car lighter.”

The Raptor control system on the 1140 Century Rotator has load sensing on it, and was able to tell how much weight was on the boom and provided a readout of the maximum load capacity. Chris noted that once the water was drained from the vehicle, it shed about 4,000 pounds—a much better weight to lift a car with a boom at or near a 0-degree angle.

“I was completely extended,” he said. “So my lifting capacity was significantly decreased until I drained the water.”

Not worried, Chris then checked the outrigger legs to ensure that they were not starting to float. He said, “As I was lifting, I kept my eye on the platform to see how it was handling. It had no issues.”

He also needed to be mindful that the rigging was holding up under the duress of the load angle. “As you start getting into crazy angles, you are almost doubling the load on your lines,” he explained. “Somebody once told me to ‘Fear the veer.’ As the angles reduce, you are putting a lot more tension on your rigging.”

Chris made sure to set straight lines to the vehicle. He said, “If I had used two lines to the vehicle, I would have had to use a different angle.”

Once up in the air, the dripping Chevy was rotated in mid-air and placed back down on the driveway, for the owner’s insurance company to inspect and haul away, a total loss casualty.

“It was one of those things,” Chris said. “Accidents happen and the owner was grateful that he wasn’t injured and no one else was injured. You live and you learn.” And don’t forget to bring your swim trunks, too!

Editor’s note: Have a recovery story you’d like to share? Please email sample photos and a short description to: Stemple@towman.com

Work the non-traffic side - Stay Safe!

low profile, towing and See Page 47 See Page 49

of See Page 27 See Page 20

equipment.

Dual-Tech See Page 50 See Page N63 See Page N61 See Page 34

Financing new and used tow trucks and equipment since 1986. Home of the original 10Year Lease Financing program for rotators and heavy wreckers.

zine Senior Editor Charles Duke has written and served as editor for trade, music and nonprofit publications. He also serves as the editor for AT’s online sister publica tions Tow Industry Week and Tow Industry Today.

One of the most positive people in the towing industry is Joe Coram, president and owner of Canton Towing in Canton, Ohio. It’s been quite a success story for the young man from humble beginnings who is always giving back to the community and to the industry. His company has grown in the 14 years since he purchased it from Canton Auto Repair and Towing in 2008, serving over 47,000 customers in 2021. Coram projects that growth will continue with his purchase of Oscar’s Towing, also in Canton, this past March.

They do heavy-, medium- and light-duty towing, using 90 pieces of equipment, with 68 of those units consisting of tow trucks and service vehicles, and the rest trailers for transport work. They maintain a staff of 67 employees. What’s the most lucrative part of his business?

As alluded to at the outset, Joe Coram came from humble beginnings, and it is from those beginnings he entered the towing industry.

“The first ten years of my life I spent in low-income housing. Between the ages of 10 and 15 years old, I went through about five different foster homes.”

Lenny Lemmon (founder of of Can ton Auto Repair and Towing) was his fifth home, and he adopted Coram on August 28, 1997.

“I was 16 years old, and that’s how I got in the industry,” he shared. “I happened to be in the explorer post of Canton PD, a youth core pro gram. Don Diamond (since retired police officer) was in charge of the youth core program, and he knew my story. He also knew Lenny. He told Lenny, ‘Hey, you gotta meet this kid. He does American Red Cross charity work, he’s been very successful in the Big Brother/Big Sister program, he gets extensive counseling, he goes to school reg ularly.’” His earnest efforts led to bigger and better things.

“Lenny gave me a shot and took me under his wing and said, ‘This is the deal: You’re going to work for me for the next 15 years. Then, we’re going to put a percentage of your paycheck in an Alger Fund. In 15 years, we’re going to cash it in and you’re going to help me retire.’” While that’s pretty much how things went, there was a significant set back along the way.

“Unfortunately, he ended up hav ing a stroke about a year after his retirement, and he passed away five years later in February of 2020, Coram shared. “We spent 25 years together. That’s what hardened me for the marketplace, to not only understand competition, not in an aggressive manner, but also to be the better man at all times.”

“I would say it’s in the heavy towing and recovery,” Coram replied, “and then the transportation side. We do all state, sheriff, and local police departments. We hold seven municipal contracts.”

This past year, Joe also served as the chairman of the Association of Professional Towers – Ohio (APTO). He feels that legislation is the key to creating structure and standards within the industry. In order to be a

part of that dynamic of change, he decided to involve myself in that process.

“I’m a ‘social-fly’,” Coram commented, “so I really network with a lot of other Ohio towers to get an idea of what are their concerns and challenges. I found out we all share the same wants and concerns.” Even so, he’s had to overcome some challenges.

Coram said that competing

towing companies must find a way to look past losing out on money, and instead should focus on how to provide the customer with good, fast, quality service.

“The only way to do that is if we can trust one another; because

at the end of the day it should only be about our customer,” he pointed out. “Let’s face it: 90 percent of our customer base is our community. Only ten percent are people who just happen to be traveling through. So, if we could ever look at that I think we could get over the hump of the competitive ideology and look at it more as a unified approach of taking care of our customer and just helping each other.” How does he put that into practice?

“I don’t let my customer wait an hour or an hour-and-a-half,” Coram continued. “It’s not the $30 profit that I’m concerned with as much as it is getting them serviced. When you’re busy we tend to just want to give longer ETAs; and really that could be an inconvenience to the (customer). Why not punt it to the next so-called competitor and let them? I think that’s our struggle as to why we’re not getting to where we should be as

fast.”

One thing that Coram has been investing his time in recently is his ambitious American Towing and Recovery Apprentice Program. He feels that the program will ultimately create a pool of what he calls “journeymen” who will be able to relocate freely from state to state, with the ability to prove their towing experience. Coram feels this approach would allow towmen to go to another area without having to take a pay cut, as they’ll be able to prove that they have the necessary experience to do the job.

He registered the program with the Ohio secretary of state in 2020 and has been building different curriculums for the past seven years based on his 25 years of service. The curriculums, Coram said, are based on the classifications of tow trucks that towmen operate.

“To me, an apprentice ◀

program is much more than a certification or a participation completion certificate,” Coram observed. “This is something that you do for 2,080 hours that you have to put in; and you’re doing it daily. Not only are you learning, but you’re earning.” What would be the longterm benefits?

“If we could ever get to an apprentice program, an accredited course, then a lot more owners would invest and have a facilitator [for] the curriculum within their organization. They would be more interested because that facilitator is funded by federal dollars. These are grant dollars that the association would get, because in essence if I could ever get there, and that’s my goal, I’m going to sign it over to the state associations. I believe every state towing association should own the rights to the Apprentice Program, because that’s where your federal

funding is going to come from.”

Another benefit of the Apprentice Program deals with working incidents that have fatalities.

“I basically tried to, from the psychology standpoint, prep an operator for what he or she might come up against when it comes to (a fatality),” he said. “Let’s face it: we’re asking these people to go out to these scenes with dead bodies, where just last week they were bagging groceries. So they’ve never come across such a thing, and we don’t offer anything for that…So I have a segment and a curriculum that talks about how they can overcome that.”

Under Coram’s leadership Canton Towing has been the recipient of much recognition in his area. The company has garnered Cross Country’s Agero Number One Provider of the Year for three years, AAA’s Number One Provider of the Year for three years

and also AAA Silver Service Award from 2008-2015. This year, Canton Towing received the 2022 Canton Regional Chamber of Commerce Business Excellence Award.

In keeping with these significant industry recognitions, Coram feels that building a brand is of most importance in gaining a good business reputation. Putting it simply, he sums up his goal this way: “If we could…look at each other not as competitors but as peers, we’re going to have great brands.”

Find us on Facebook

Read more towing news at towman.com

Work the non-traffic side - Stay Safe!

How can a rotator deliver more power than what it’s rated for? Well, just ask Iran Chima about that. His company, named simply Chima’s Tow, is based in Sacramento, California, where there are state weight restrictions for wreckers. They are limited to 80,000 pounds max in order to prevent damage to the roadways and bridges. So how could he put more punch in his 77,000-pound Century 1150?

To start with, the injectors and programming on the Cummins X-15 diesel in his Kenworth W990 were modified to deliver much higher torque. It was upped by Jeremy Ervin of MHC Kenworth in Chattanooga, Tennessee from a typical output of 1600 to 1850 lb/ft to a hard-hitting 2050 pounds of twist.

Of course, this upgrade also required beefing up the 18-speed transmission, and adding a separate oil pump and filter. In addition, the truck was equipped with the biggest driveline allowed for on-road use, running through a lower rear-end ratio of 4.30:1 for more mechanical advantage when hauling up a steep grade. (Chima’s wreckers need extra pulling capability for making monthly runs through Donner Pass in the High Sierras to deliver EV trucks near there.)

Another “counterpunching maneuver” involved the dual H-beam for the rear outriggers. Iran went with a wider footprint (260 inches instead of 220 inches), providing more

lifting power and better stability. Also, the Century 1150 normally comes with five winches, but Iran asked Miller Industries to outfit the rotator with six winches in all—four in the boom, and two in the bottom of the deck.

“There’s an extra drag winch on the opposite side to stabilize the truck,” Iran explains. “The more winches you have, the more you can tie onto.”

He didn’t stop there, as he sent all his tools and rigging equipment back to Zip’s for a quick-deployment setup with custom-made brackets.

Truck: 2022 Kenworth W990

Engine: Cummins X-15, upgraded to 2050 lb/ft of torque

Transmission: 18-speed manual with heavy-duty driveline and 4.30:1 differential ratio

Body: Century 1150

Custom features: Wider setup for rear outriggers; six winches; extra toolbox,

“For a quick grab,” he points out. “If you keep your operators more efficient, it makes them safer. They spend less time in the ‘kill zone’.”

Since his service area can get really congested with heavy traffic, he says nearly all 30 of the trucks in his fleet are set up in a similar way, for operators’ cross-over. In other words, they all know where everything is right off if they have to jump in another truck for a quick recovery.

“Their eyes are used to looking at a certain area for checking temps,” he adds. They need to monitor readouts for the trans, crankcase oil, rear axle, pusher gauges, torque, and air-filter restriction. So the “muscle memory” of a trained prizefighter kicks in, with no steep learning curve required when an operator climbs in the cab and fires up the engine.

This approach includes the switch

layouts in the cab, too, helping an operator be familiar with controls for the lights, diff lock, suspension dump, and so forth. Chima’s consistency of dash layout is based on decades of experience since the company was established in the Sacramento area back in 1987 by Iran’s father Ted.

There’s another custom feature on this rotator that allows for easier service as well. The DEF tank was relocated lower down on the chassis, since it’s difficult and time-consuming to maintain when mounted higher up. With this modification, it takes only 30 minutes to service the DEF filter. Plus the truck now has two more feet of space for an extra custom toolbox, a useful addition.

As for the rotator’s body graphics, Iran appreciates eye-catching visuals, and hired Danny Hill to apply custom lettering. But all told, he’s really more concerned about function.

“It’s gotta work,” he notes.

Safety is a high priority for Iran in another way. He works with ERSCA as a trainer (both virtual and hands-on classes), teaching the essentials of light-duty towing. In addition, he works separately with both fire departments and searchand-rescue teams from all over the country to integrate a wrecker into their programs. Since a rotator is so much more efficient than using a crane or excavator at an accident scene (and now a FEMA requirement as well), he’s providing a valuable and necessary orientation for first responders working with towmen.

All told, Chima’s rotator is one heavy-hitting rig. Rocky would give him a thumbs up!

Editor’s note: Have a special truck that would make a good My Baby feature? Please send us an email with some sample shots and a few words about what makes your wrecker really stand out to: stemple@towman.com

Icommend Cyndi Marteneau and the TRAA for getting the Move Over Law Resolution 1463 passed in the U.S. House of Representatives. I too thank Congressman Jim McGovern for working on this resolution. Anything that will help move this ball down the field is positive.

protected by a state trooper present at the scene.

2) Funds allocated to states for use of technology that “catches” truckers and motorists failing to move over one lane when passing a tow truck or other service vehicle stopped on the roadside flashing its emergency lights.

Steve Calitri Editor-in-Chief scalitri@towman.com

In reading over this resolution, the predominant word used in it was “urge.” It urges government agencies, state and federal, to get behind ways to promote awareness of the Move-Over law that’s on the books in each state.

Resolution 1463 offers up a concise, yet comprehensive, understanding of the MoveOver law and why it exists. It lays out the dangers of working the roadways and the number of first responders killed each year.

In effect, the resolution is an acknowledgement by the Federal government that towmen and other first responders are being killed on America’s dangerous roadways while trying to do their jobs; that the Move-Over laws can help prevent these tragedies if enforced, and the motoring public is aware of it.

Okay. All positive.

The resolution however puts nothing into law regarding the whole issue, nor does it allocate funds to any government agency towards raising awareness or enforcing the law.

I am hoping this resolution will be a boost to the writing and passage of a law that sinks teeth into the problem. Here is what I urge to be proposed into Federal law:

1) An emergency service vehicle working on the roadside of a Federal Highway must be

There are several things you or I could propose that turns this resolution into meaningful action. But I would like to change tact on the remainder of this message.

The most immediate action that can be taken is by tow bosses and tow operators. In recognizing the risks of working the white lines, they must do whatever they can to lessen the risk. One split second of distraction at the wrong moment can mean death. The owner of the tow company must set the tone of vigilance among the operators; and instructing to work the non-traffic side whenever possible, where to position the tow truck, where to set out cones, etc.

Tow business owners have every reason to offer protection to their tow operators on the scene. Some progressive owners are sending traffic control vehicles out to assist drivers by guarding their workspace. Some are seeing this as a new revenue stream for the business.

The tow boss that does all he or she can to protect their operators on the scene will be the most successful in recruiting quality people to do the dangerous work, and keeping them.

Again, hats off to Cyndi and the TRAA for putting a spotlight on this life-anddeath issue.

Chase Clough of DRIVE has a wide range of Marketing knowledge, including con tent creation across all social platforms, writing and ed iting. Her recent marketing positions include Florida State’s Career Center and she is now a master’s candidate at Florida State University. Chase uses these skills in her position at DRIVE based in Monrovia, CA.

Given that the towing industry is high stress and demanding work, it’s no secret that finding good operators can be tough. Adding to this challenge is the fact that there are many steps in the hiring process, and each one is just as important as the last. Which means everything from posting your open position online, to actually onboarding your new employee needs to be done right.

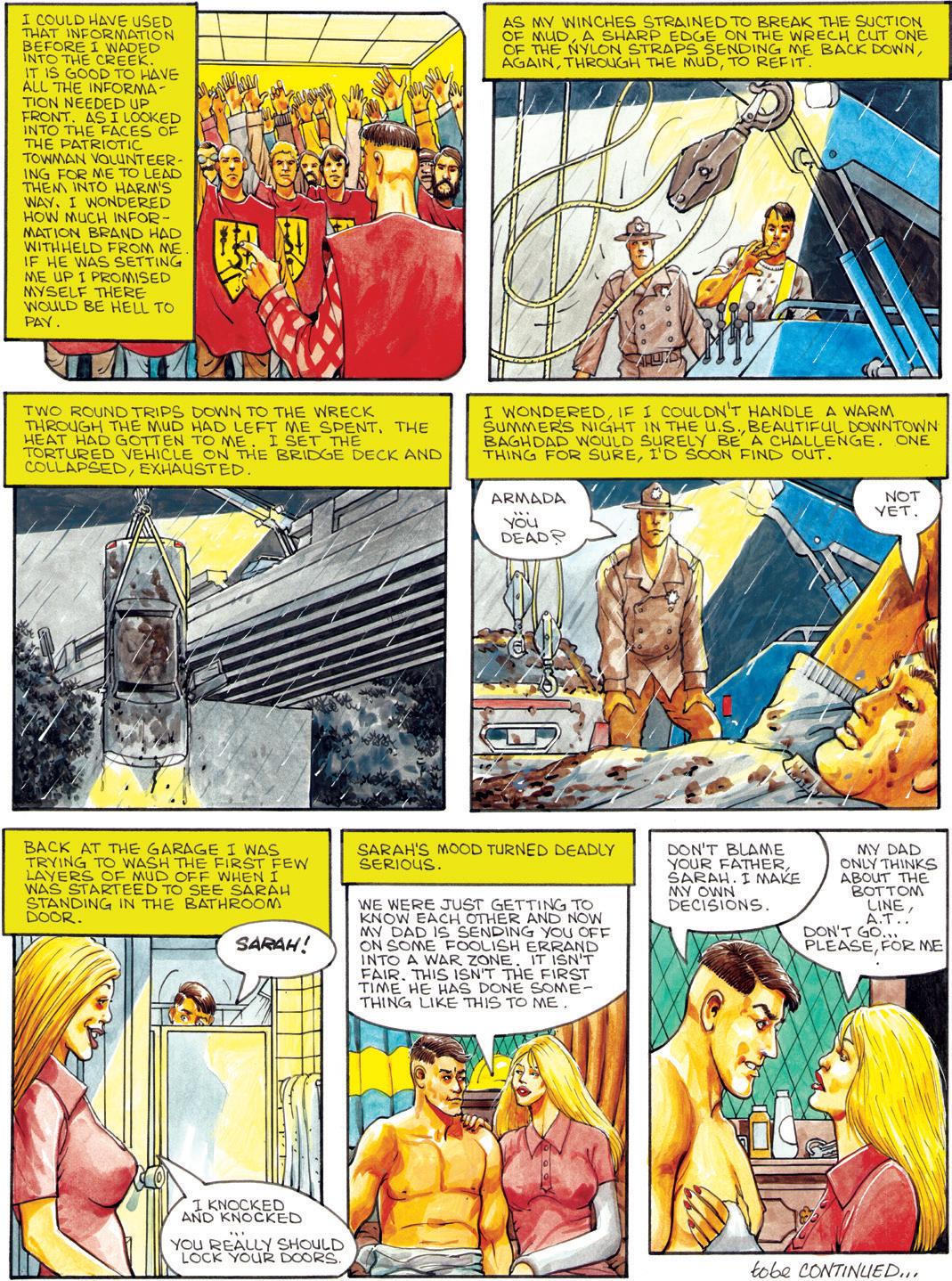

Let’s start by looking at a few stats that show the scope of the problem (as shown in the accompanying graphs). As of August 2022, there were 10.1 million open jobs and 5.8 million people looking for work in the United States. The towing industry has steadily grown over the past five years. The annual industry revenue has risen by 2.6 percent annually,

capping at $9.9 billion total. The industry is projected to continue growing at a similar rate, so as an owner of a towing business you should be prepared for the future. That means you will want to make sure a job at your business not only stands out from the others, but also has everything to entice top talent.

As an example, Davidson Wyatt, manager of Mobile Maintenance and Towing LLC, shared some tips on how to find and retain quality employees. He has been in business for 14 years and currently employs 26 people. Wyatt says the first step in the hiring process is obviously letting people know your shop has an open position. In today’s world, there are many avenues you can list your opening on. You can go the traditional route of listing the job in a local newspaper, but this may limit you to only talent in your surrounding area or only the people that even have access to it.

You could also post your job listing online. This way people looking to relocate to your area or those that are willing to commute can see the position as well as locals. Wyatt says he recruits on Indeed and Craigslist, but he also relies on word of mouth. By letting his loyal customers and members of the community know that he’s looking they can advertise the position for him. This way, he already has a level of trust based on the person who recommended them for hire.

Once you have selected which candidates are most promising, it’s time to start interviewing them. The towing industry is no joke, and you have to

be ready for anything. That’s why Wyatt tries to select someone that, “Has the drive and willingness to be able to handle the pressure, the ups and downs.” The best way to determine that? Face to face, Wyatt notes.

“I do all of my interviews in person,” he points out. To him, this is the best way to judge someone’s character and make sure they are right for his team. They should not only be competent and have the necessary skills, but also be a good fit in the company culture.

To make sure he is vetting people thoroughly, Wyatt has a list of questions he always asks them. These include “What methods do you use to diagnose problems with a vehicle that has broken down?” and “How do you deal with emotionally unstable clients?”

He also makes sure to always run a background check on the individuals he wants to hire. This process will reveal if the candidate lied about anything, such as educational attainment, work history, and even a criminal record. If something doesn’t match up with what the potential hire has said, he can either disregard the application altogether or mention it directly to them.

Before a new employee can start his or her first day on their own, Wyatt makes sure they complete strict training. This way, they are reasonably prepared for any troubles they might face. Training your staff is an important step in the hiring process, when a new employee feels supported and valued, they are more likely to want to stay on your team long term. Investing in your staff makes them want to invest in your business.

This approach also lets them know you expect to have them on your team long-term. Each employee should know exactly what they have been hired to do and how to do it. With these expectations in mind, your new employee will be focused on doing the best they can, and you can keep your towing business running smoothly and efficiently.

Chase Clough of DRIVE has a wide range of Marketing knowledge, including con tent creation across all social platforms, writing and ed iting. Her recent marketing positions include Florida State’s Career Center and she is now a master’s candidate at Florida State University. Chase uses these skills in her position at DRIVE based in Monrovia, CA.

Given that the towing industry is high stress and demanding work, it’s no secret that finding good operators can be tough. Adding to this challenge is the fact that there are many steps in the hiring process, and each one is just as important as the last. Which means everything from posting your open position online, to actually onboarding your new employee needs to be done right.

Let’s start by looking at a few stats that show the scope of the problem (as shown in the accompanying graphs). As of August 2022, there were 10.1 million open jobs and 5.8 million people looking for work in the United States. The towing industry has steadily grown over the past five years. The annual industry revenue has risen by 2.6 percent annually, capping at $9.9 billion total. The industry is projected to continue growing at a similar rate, so as an owner of a towing business you should be prepared for the future. That means you will want to make sure a job at your business not only stands out from the others, but also has everything to entice top talent.

As an example, Davidson Wyatt, manager of Mobile Maintenance and Towing LLC, shared some tips on how to find and retain quality employees. He has been in business for 14 years and currently employs 26 people.

Wyatt says the first step in the hiring process is obviously letting people know your shop has an open position. In today’s world, there are many avenues you can list your opening on. You can go the traditional route of listing the job in a local newspaper, but this may limit you to only talent in your surrounding area or only the people that even have access to it.

You could also post your job listing online. This way people looking to relocate to your area or those that are willing to commute can see the position as well as locals. Wyatt says he recruits on Indeed and Craigslist, but he also relies on word of mouth. By letting his loyal customers and members of the community know that he’s looking they can advertise the position for him. This way, he already has a level of trust based on the person who recommended them for hire.

Once you have selected which candidates are most promising, it’s time to start interviewing them. The towing industry is no joke, and you have to be ready for anything. That’s why Wyatt tries to select someone that, “Has the drive and willingness to be able to handle the pressure, the ups and downs.” The best way to determine that? Face to face, Wyatt notes.

“I do all of my interviews in person,” he points out. To him, this is the best way to judge someone’s character and make sure they are right for his team. They should not only be competent and have the necessary skills, but also be a good fit in the company culture.

To make sure he is vetting people thoroughly, Wyatt has a list of questions he always asks them. These include “What methods do you use to diagnose problems with a vehicle that has broken down?” and “How do you deal with emotionally unstable clients?”

He also makes sure to always run a

background check on the individuals he wants to hire. This process will reveal if the candidate lied about anything, such as educational attainment, work history, and even a criminal record. If something doesn’t match up with what the potential hire has said, he can either disregard the application altogether or mention it directly to them.

Before a new employee can start his or her first day on their own, Wyatt makes sure they complete strict training. This way, they are reasonably prepared for any troubles they might face. Training your staff is an important step in the hiring process, when a new employee feels supported and valued, they are more likely to want to stay on your team long term. Investing in your staff makes them want to invest in your business.

This approach also lets them know you expect to have them on your team long-term. Each employee should know exactly what they have been hired to do and how to do it. With

these expectations in mind, your new employee will be focused on doing the best they can, and you can keep your towing business running smoothly and efficiently.

Illinois Governor JB Pritzker pro claimed October 15 as “Move Over Day.” The new law is designed to promote safe driving behavior and encourage motorists to move over for all vehicles, not just emergency vehicles, stopped on the side of the roadway, the Illinois State Police (ISP) said. They are committed to reducing traffic crash fatalities and limiting the risk of being hit while on the roadside.

“We cannot overstate the impor tance of the simple act of slowing down and moving over when there is a vehicle on the side of the road,” ISP Director Brendan Kelly said.

“We thank Governor Pritzker for this proclamation,” said AAA Auto Club Group Spokesperson Mol ly Hart. “It is important to have the public’s support to protect the first responders who come to the rescue of motorists, as well as drivers who are with their disabled vehicle.” State police say they have increased en forcement details to ticket and arrest drivers who fail to follow the law.

Source: lakemchenryscanner.com

In an effort to improve road side safety, Long Island County has passed a law requiring towers to properly remove glass, car pieces, road flares and other debris following crashes. The bill was signed into law

by Suffolk County Executive Steve Bellone.

County officials say keep ing the roads clear will pre vent other accidents from happening. “This legislation will take care of that, will provide the teeth necessary for enforcement and for law enforcement to do what they need to do and undoubtedly will enhance public safety out on our roadways,” Bellone noted.

Source: cbsnews.com

Stockpiles of diesel are at their lowest levels since 2008, with only enough fuel for a 25-day supply. De mand is also said to be at its highest point since 2007, which is causing higher prices. Even though invento ries of diesel and gasoline are lower than they historically have been, the U.S. is not going to run out, accord ing to energy experts.

“Inventories of diesel and gasoline are down below five-year averages, and if the entire world were to stop, we would have 25 days worth of die sel,” said Ed Hirs, a professor of en ergy economics at the University of Houston. “But the world doesn’t stop.

We’re not counting on it stopping,” According to U.S. Energy Informa tion Administration (EIA), the average price of diesel is at $5.34 per gallon. That’s an increase of $1.67 per gallon, compared to this time last year. The area getting hit the hardest is New England, where people burn diesel fuel for heat more than anywhere else in the country. The highest cost of diesel fuel is in California, where the average cost is almost $6.50 per gal lon, an increase of almost $2 per gal lon over this time last year. By com parison, the average price of gasoline in the U.S. is $3.87 per gallon, with the most expensive region also being California, at $5.84 per gallon.

Source: newsbreak.com msn.com

Chase Clough of DRIVE has a wide range of Marketing knowledge, including con tent creation across all social platforms, writing and ed iting. Her recent marketing positions include Florida State’s Career Center and she is now a master’s candidate at Florida State University. Chase uses these skills in her position at DRIVE based in Monrovia, CA.

Given that the towing industry is high stress and demanding work, it’s no secret that finding good operators can be tough. Adding to this challenge is the fact that there are many steps in the hiring process, and each one is just as important as the last. Which means everything from posting your open position online, to actually onboarding your new employee needs to be done right.

Let’s start by looking at a few stats that show the scope of the problem (as shown in the accompanying graphs). As of August 2022, there were 10.1 million open jobs and 5.8 million people looking for work in the United States.

The towing industry has steadily grown over the past five years. The annual industry revenue has risen by 2.6 percent annually, capping at $9.9 billion total. The industry is projected to continue growing at a similar rate, so as an owner of a towing business you should be prepared for the future. That means you will want to make sure a job at your business not only stands out from the others, but also has everything to entice top talent.

As an example, Davidson Wyatt, manager of Mobile Maintenance and Towing LLC, shared some tips on how to find and retain quality employees. He has been in business for 14 years and currently employs 26 people.

Wyatt says the first step in the hiring process is obviously letting people know your shop has an open position. In today’s world, there are many avenues you can list your opening on. You can go the traditional route of listing the job in a local newspaper, but this may limit you to only talent in your surrounding area or only the people that even have access to it.

You could also post your job listing online. This way people looking to relocate to your area or those that are willing to commute can see the position as well as locals. Wyatt says he recruits on Indeed and Craigslist, but he also relies on word of mouth. By letting ◀

his loyal customers and members of the community know that he’s looking they can advertise the position for him. This way, he already has a level of trust based on the person who recommended them for hire.

Once you have selected which candidates are most promising, it’s time to start interviewing them. The towing industry is no joke, and you have to be ready for anything. That’s why Wyatt tries to select someone that, “Has the drive and willingness to be able to handle the pressure, the ups and downs.” The best way to determine that? Face to face, Wyatt notes.

“I do all of my interviews in person,” he points out. To him, this is the best way to judge someone’s character and make sure they are right for his team. They should not only be competent and have the necessary skills, but also be a good fit in the company culture.

To make sure he is vetting people thoroughly, Wyatt has a list of questions he always asks them. These include “What methods do you use to diagnose problems with a vehicle that has broken down?” and “How do you deal with emotionally unstable clients?”

He also makes sure to always run a background check on the individuals he wants to hire. This process will reveal if the candidate lied about anything, such as educational attainment, work history, and even a criminal record. If something doesn’t match up with what the potential hire has said, he can either disregard the application altogether or mention it directly to them.

Before a new employee can start his or her first day on their own, Wyatt makes sure they complete strict training. This way, they are reasonably

prepared for any troubles they might face. Training your staff is an important step in the hiring process, when a new employee feels supported and valued, they are more likely to want to stay on your team long term. Investing in your staff makes them want to invest in your business.

This approach also lets them know you expect to have them on your team long-term. Each employee should know exactly what they have been hired to do and how to do it. With these expectations in mind, your new employee will be focused on doing the best they can, and you can keep your towing business running smoothly and efficiently. Read more towing news at towman.com

Find us on Facebook

Chase Clough of DRIVE has a wide range of Marketing knowledge, including con tent creation across all social platforms, writing and ed iting. Her recent marketing positions include Florida State’s Career Center and she is now a master’s candidate at Florida State University. Chase uses these skills in her position at DRIVE based in Monrovia, CA.

Given that the towing industry is high stress and demanding work, it’s no secret that finding good operators can be tough. Adding to this challenge is the fact that there are many steps in the hiring process, and each one is just as important as the last. Which means everything from posting your open position online, to actually onboarding your new employee needs to be done right.

Let’s start by looking at a few stats that show the scope of the problem (as shown in the accompanying graphs). As of August 2022, there were 10.1 million open jobs and 5.8 million people looking for work in the United States. The towing industry has steadily grown over the past five years. The annual industry revenue has risen by 2.6 percent annually, capping at $9.9 billion total. The industry is projected to continue growing at a similar rate, so as an owner of a towing business you should be prepared for the future. That means you will want to make sure a job at your business not only stands out from the others, but also has everything to entice top talent.

As an example, Davidson Wyatt, manager of Mobile Maintenance and Towing LLC, shared some tips on how to find and retain quality employees. He has been in business for 14 years and currently employs 26 people.

Wyatt says the first step in the hiring process is obviously letting people know your shop has an open position. In today’s world, there are many avenues you can list your opening on. You can go the traditional route of listing the job in a local newspaper, but this may limit you to only talent in your surrounding area or only the people that even have access to it.