NWT & NUNAVUT CHAMBER OF MINES Diamond Standard Mining PEI ROAD BUILDERS Building a Successful Network Inspired by YOUR SUCCESS UK £4.95 CAN $7.95 USA $7.95 EUR €5.95 SA ZAR 69.00 CANADA www.littlegatepublishing.com

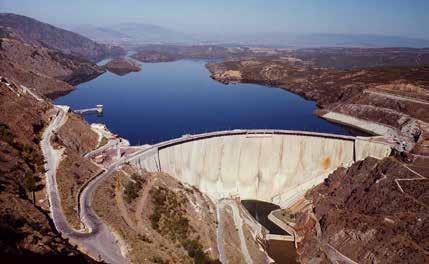

A CCIONA, a trusted partner .

We continue to successfully complete highly complex and acclaimed infrastructure projects. The challenges are tough and demanding, and we face them with confidence thanks to our leadership, experience and capacity for innovation. acciona.ca partner . row's top and acclaimed infrastructure projects. e face them

A CCIONA, a trusted partner .

A CCIONA, a trusted partner .

Delivering tomorrow's top infrastructures.

Delivering tomorrow's top infrastructures.

Delivering tomorrow's top infrastructures.

We continue to successfully complete highly complex and acclaimed infrastructure projects. The challenges are tough and demanding, and we face them with confidence thanks to our leadership, experience and capacity for innovation.

We continue to successfully complete highly complex and acclaimed infrastructure projects.

We continue to successfully complete highly complex and acclaimed infrastructure projects.

The challenges are tough and demanding, and we face them with confidence thanks to our leadership, experience and capacity for innovation.

The challenges are tough and demanding, and we face them with confidence thanks to our leadership, experience and capacity for innovation.

ACCIONA.CA

ACCIONA.CA

INNOVATION • DEDICATION • EXCELLENCE

INNOVATION • DEDICATION • EXCELLENCE

INNOVATION • DEDICATION • EXCELLENCE

ACCIONA.CA

confidence capacity for

DEDICATION • EXCELLENCE a trusted partner row's infrastructures.

continue to successfully

highly

to

INNOVATION • DEDICATION ACCIONA.CA A trusted partner. Delivering tomorrow’s top infrastructures. A CCIONA, a trusted partner . Delivering tomorrow's top infrastructures.

continue to successfully complete highly complex and acclaimed infrastructure projects.

challenges are tough and demanding,

we

thanks to our leadership, experience and capacity for innovation. INNOVATION • DEDICATION • EXCELLENCE ACCIONA.CA A CCIONA, a trusted partner . Delivering tomorrow's top infrastructures.

continue to successfully complete highly complex and acclaimed infrastructure projects.

challenges are tough and demanding,

face

thanks to our leadership,

capacity for innovation. INNOVATION • DEDICATION • EXCELLENCE ACCIONA.CA

with

innovation.

We

complete

complex The challenges are tough and demanding, and thanks

our leadership, experience and

We

The

and

face them with confidence

We

The

and we

them with confidence

experience and

Heads of Departments

Editor-in-Chief Carley Fallows editor@littlegatepublishing.com

Space Management Emlyn Freeman emlynfreeman@littlegatepublishing.com

Media Coordinator Andrew Williams andrew@littlegatepublishing.com

Lead Designer Alina Sandu Research Kristina Palmer-Folt Editorial Research Amber Winterburn

Corporate Director Anthony Letchumaman anthonyl@littlegatepublishing.com

Founder and CEO Stephen Warman stevewarman@littlegatepublishing.com

For enquiries or subscriptions contact info@littlegatepublishing.com +44 1603 296 100

ENDEAVOUR MAGAZINE is published by Littlegate Publishing LTD which is a Registered Company in the United Kingdom.

Company Registration: 07657236

VAT registration number: 116 776007

343 City Road 60 Thorpe Road London 79 Norwich EC1 V1LR NR1 1RY

Littlegate Publishing Ltd does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

Copyright© Littlegate Publishing Ltd 2023

Editor’s Note

When you think of Canada, you maybe think of an exhilarating game of hockey, or vast woodland with spectacular lakes. However, an aspect that Canada is also greatly known for is its variety of sustainable and successful industries.

As an integral part of North America, Canada can boast great advancements in natural resources and mining, with an abundance of resources at its disposal. As such, within this specifically dedicated Canadian issue we can see how Canada expertly excels in industries such as gold, SSR and Orford mining, as well as great lithium advancement to power the cars of the future.

Mining, as Canada’s most integral industry, has for decades faced many challenges, alongside many successes. As we shall see in this issue, mining has greatly adapted to cope with growing pressures, demonstrated through the tenacity of IOS Mining. Furthermore, it can also be admired how the mining industry in Canada has adapted to the pressures of climate change, evidenced in a push for sustainability. Amongst others, Energold has adapted over the last ten years to be more resourceful and diversify into minerals, metals and energy sectors, whilst maintaining its commitment to the environment.

Therefore, it is easy to see how Canada needed its own publication, to efficiently demonstrate its diverse and exciting range of businesses.

Endeavour Magazine | 3

6 Kamloops Exploration Group Teaching the Future of Mining 12 NWT & Nunavut Chamber of Mines Diamond Standard Mining 18 Canadian Freight Forwarder Association 75 Years of Uniting the Industry 24 Procon Mining & Tunnelling Majestic Mining 30 PEI Road Builders & Heavy Construction Association Building a Successful Network 36 Piedmont Lithium Limited The Lithium Lifeline 42 SSR Mining A Sharper Eye 48 Orford Mining Mining Its Own Business 54 CALGARY INTERNATIONAL AIRPORT Capacity and Communications Are Crucial 60 MANITOBA HYDRO A unique utility, with some powerful projects 66 IOS Can you work through decline? 72 ENERGOLD A sensitive approach to drilling 78 UBC A Wooden Way Forwards CFFA Features 4 | Endeavour Magazine

Procon Mining

Tunnelling

&

SSR Mining Endeavour Magazine | 5

Piedmont Lithium Limited

TEACHING THE FUTURE OF MINING Kamloops Exploration Group chevron-square-right https://www.keg.bc.ca/ phone-square 250 320 2411 envelope-square kamloopsexplorationgroup@gmail.com

Situated as Canada’s most western district, British Columbia has an array of active industries, including agriculture, forestry, and construction. The mining industry, however, is a vital part of British Columbia’s output. This is predominantly due to the fact that for nearly 200 years, mining and mineral exploration has thrived as a generator of economic growth. This is exemplified by the sheer amount of mineral production that has taken place over recent years. Evidently, in 2021 British Columbia’s estimated profit was approximately $10 billion dollars from mining alone.

As the mining sector is such a dominant force of economic growth in the region, it is imperative that there is awareness of the mining industry’s place in a sustainable world. Thankfully, Kamloops Exploration Group (KEG) is a proactive registered society that promotes the interests of sustainable mining services for minerals, metals, and petroleum. This is particularly prudent as there is an ever-increasing demand for mineral mining as the industry continues to transform from the more traditional attainment of fossil fuels to a future of advanced and sustainable practices.

KEG is a fantastic business entity that is unique in its status as a non-profit organisation, which encourages real compassion in each project. Such dedication is accomplished by a board of nine volunteers. The board’s selfless commitment means that they are a strong pillar of the company and community, acting as a testament to the importance of sustainable mining.

Kamloops Exploration Group 8 | Endeavour Magazine

Teaching the Future of Mining

Being a part of the KEG means that companies can acquire key knowledge on the challenges and adversities of the mining industry, as well as learn how to overcome such difficulties. This service is provided routinely at KEG’s conferences and trade shows, which are not only informative but also act as an excellent networking platform.

As the industry continues to develop, particularly in the British Columbian region, the notion of business expansion through networking becomes increasingly pertinent. Despite the fact that the pandemic caused a two-year break, last year’s conference was attended by 354 registered delegates, 78 exhibitors, and many prospective students. Accordingly, KEG greatly focuses on the education of younger generations so that sustainable mining practices are continued.

This is further demonstrated by the numerous educational outreach programs that take place across the year, highlighting the importance of sustainable mining, as well as the endless opportunities that a career in mining has to offer. Furthermore, KEG is a key contributor to local

museums and schools and thus establishing its place in the local community.

The educational outreach programmes, as well as additional scholarships, are an important element of the company. This is prevalent in the $35,000 per year that is funnelled into educational activities, which are made possible by comprehensive conferences and programmes that KEG has to offer. The educational activities in question include highly advanced technology in the world of education, such as KEG’s Virtual Lecture Series, which is widely regarded by students as highly effective in the transferring of knowledge of sustainable mining practices. Many speakers from across the mining industry are invited to be a speaker at the Virtual Lecture Series, which brings together nationwide practice and the local mining sector.

Moreover, speakers can adapt their information depending on the age group, ranging from talks for preschool children to university students. Due to its virtual nature, any others that are interested in the ideas of sustainable mining have access to the website or can even learn via KEG’s Public Lecture

AKF MINING SERVICES INC. Adding Value to your Mineral Resource Geological Modeling • Grade Estimation Mine Design and Planning • Pit Optimizations Ore Resource/Reserve Evaluations High Level Reviews • Scoping Studies PEA, 43-101, S-K 1300, JORC info@akfmining.com • Vancouver, BC, Canada www.akfmining.com

Endeavour Magazine | 9

Kamloops Exploration Group

Series, in which anyone is welcome. Consequently, KEG’s important lesson in sustainable mining can reach an even broader horizon.

KEG’s Public Virtual Lecture Series is for anyone that wishes to delve deeper into the realm of British Columbian mining, free of charge! Alongside mining, the dynamic lecture series touches upon topics such as the earth and natural sciences, as well as mineral exploration. Each enlightening talk is conducted by leading lecturers, spreading vital knowledge across a range of ages.

Other educational programmes and events include delegate programmes for both junior and senior students. These special events are all about education and fun. In the juniors’ event, students learn a wide range of mining tasks, including learning how to gold pan, as well as learning how to cut and polish different minerals, whilst playing interactive games and partaking in treasure hunts. On the other hand, the Senior Delegates Programme encourages students to share their thoughts on sustainable mining in a round table discussion.

Their eyes are further opened by a trade show where they can chat with different representatives of leading companies in the industry and explore the possibility of a mining career.

In a world where more traditional forms of mining are beginning to be transformed, KEG’s work in informing the public (both young and old) comes at the perfect time. Not only do they teach a large majority of sustainable mining practices, but they are also an established part of the community. Such committed and significant work can act as an exemplar to other mining communities across the world, as it harnesses a younger generation that can pave the way in an eco-friendly world.

10 | Endeavour Magazine

DIAMOND STANDARD MINING NWT & Nunavut Chamber of Mines chevron-square-right https://www.miningnorth.com/ phone-square +1 867 873 5281

Canada is well known for its natural beauty, including mountains, lakes, bears, and even hockey. However, a key sector that is also integral to the country is the mining industry. So much so, that mining has been a vital economic source in the country for nearly a century. The northern regions in particular are populated with an abundance of geometric minerals. Consequently, NWT & Nunavut Chamber of Mines harness this mineral potential, championing the northern mining sector since its founding in 1967.

Ever since its initiation, NWT & Nunavut has been a clear voice for the northern mining sector, which helps to promote the mining industry domestically in the country, as well as Canadian mining more globally. This is even more pertinent when we consider the vast amounts of economic, employment, and community developments that NWT & Nunavut has facilitated. The company also advises governments, regulatory agencies, investors, as well as other large institutions like universities, schools and the media. Evidently, the Chamber is not only a mining company but a key pillar of the northern region. Within the company, their knowledge of the sector is expanded by their significant training programmes, and employment and business opportunities that contribute greatly to the infrastructure of the territory.

As of 2019, there are seven mines operating in the NWT and Nunavut region. These mines primarily garner the mineral potential of diamond mines, gold mines, and iron mines. As a collective, they generate the largest private sector contributors to each territory’s economy. And yet despite the vast operations of the Chamber, the northern region still remains one of the largest untouched mining areas in the world.

For the Chamber, this is viewed as a positive, as it opens the opportunity for the exploration of advanced projects. According to them, an advanced project can be defined as a “project with known deposits that are measured, indicated or inferred, and/or have completed our environmental approvals process.” This means that they are constantly seeking to expand their repertoire and advance the territory’s natural resources.

The history of the company is entangled with the wider chronology of the local area. In the early 1960’s there was increased attention towards government affairs in the Northwest territory. Consequently, the government felt that they should come to a negotiation with the region’s mining sector, helping them represent their views in a more official and influential way. Consequently, a group of passionate individuals applied for a charter that consequently formed the Northwest Territories Chamber of Mines. However, the company went through another change in the period soon after the division of the Northwest Territories, which consequently created the new territory of Nunavut in April 1999.

NWT & Nunavut Chamber of Mines

14 | Endeavour Magazine

Diamond Standard Mining

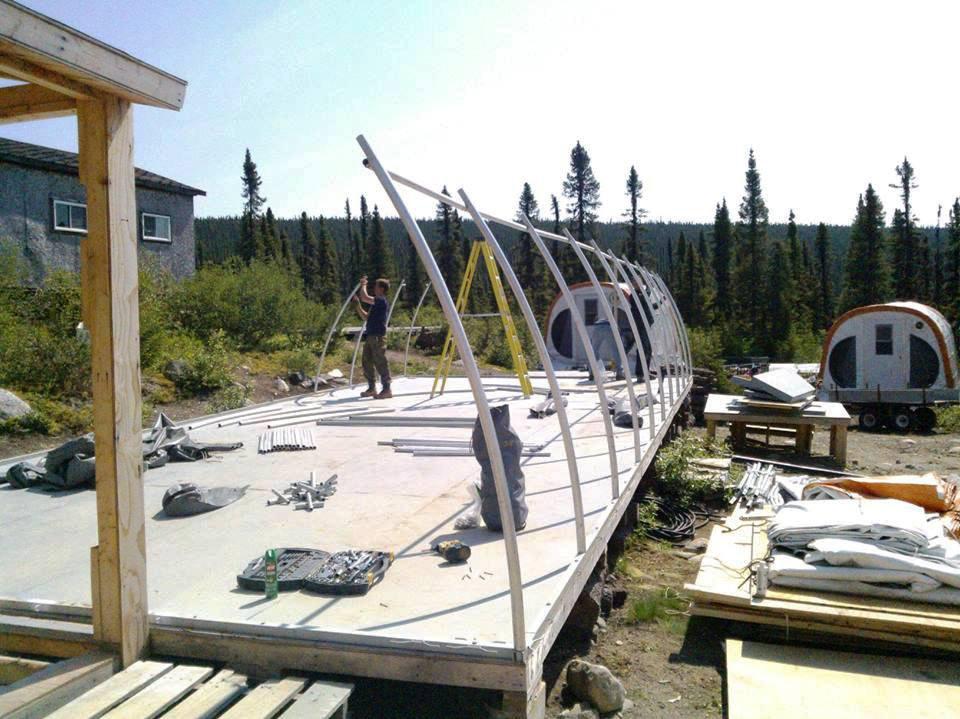

With over 40 years of remote support services experience in North America, ESS is the market leader in total support service solutions for clients in the mining, construction, oil & gas, and defence sectors.

Our range of services include catering, housekeeping, janitorial, complete camp management and more. Wherever the location, we are there to provide our premier guest experience for clients and their employees.

Endeavour Magazine | 15

NWT & Nunavut Chamber of Mines

The organisation’s Board of Directors subsequently changed the name to ‘The NWT & Nunavut Chamber of Mines’ to further emphasise its representation of the mineral industry in both territories.

More recently, between the period 2016 - 2020, the Chamber of Mines was greatly focused on the ‘Chamber Strategic Plan’. This programme guided its work through 6 main pillars:

• Public and Community Engagement

• Government / Landowner Relations

• Development of infrastructure

• Regulatory Matters/ Lands Access

• Membership support

• Sound Governance and Financial Responsibility

In accordance with the plan, the chamber endeavours to be a “strong mineral industry that benefits the Peoples of the North”. This is achieved by a range of commitments to the local community and government that create a meaningful benefit for each territory. This is measured through the socioeconomic effect on each region, based on employment and business spending. Consequently, the Chamber has accumulated some tremendous statistics. Just to name a few, between 1996 and 2019, the mines have been responsible for 40% of the northern territory’s employment and 60% of the southern region.

Furthermore, in between the mentioned time period, they have generated $32.7 billion in business, as well as contributing several hundred million dollars to communities through IBA Payments, scholarships, donations, and community wellness projects. In particular, the NWT Diamond Mines is one of the biggest benefactors, providing significant socio-economic benefits to the NWT community and business, whilst generating substantial revenues for the territorial government. For example, it has generated $6.7 billion in spending with northern indigenous territories.

To this end, the company has totalled 30, 616 person-years of northern employment (48%) from 1996 to 2019, of which 15, 383 person-years are

indigenous. Through just some of the Chamber’s impressive statistics, we can see how they have greatly given back to the communities in which they operate, particularly in the wealth of employment and the improvements in indigenous living.

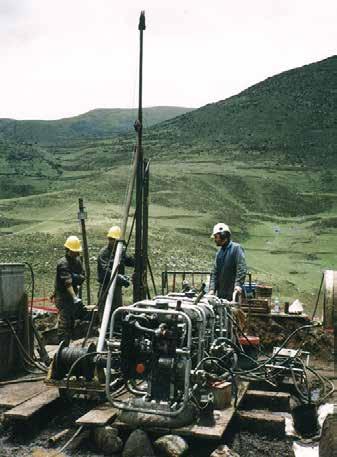

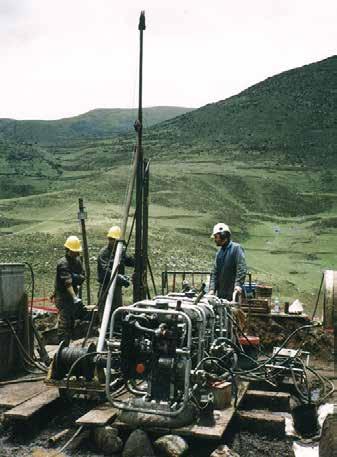

Alongside its social commitments, the Chamber Mines also has a clear set of practices that promote a greener initiative and protective forms of drilling in specialised areas. Although the aim of the Chamber’s resource exploration process is to complete diamond drilling programs as quickly and cost-effectively as possible, it does so in a way that is efficient and safe, and significantly, protects the environment.

Although there are huge investments and costs involved with diamond drilling, there is little known about the actual technical aspects of the process. This creates a major need for technological innovation and examination of the effects that diamond drilling has on the environment. In order to combat the lack of knowledge, the Chamber created the ‘Alternative Diamond Drilling in Permafrost/Artic

16 | Endeavour Magazine

Conditions’ workshop hosted by the NWT & Nunavut Chamber Mines in Toronto. This encompassed a focus on issues and challenges that arise from drilling for resources in the Arctic. Thus, the workshop brought experts and experienced miners together to discuss the latest innovations around the Arctic conditions, as well as piloting ideas for existing technology.

Another aspect that is a great concern for NWT & Nunavut Chamber is energy conservation, exampled by the fact that their northern mines are leaders in energy conservation. An important element to note is that many of their mines are so remote and thus far off the power grid and must create their own electricity. There are clear steps that have subsequently been taken to improve the efficiency of diesel power generation and the use of alternative energy sources.

All of the active mines now use heat recovery systems to extract what would otherwise be waste heat from diesel engines and diesel exhausts, which are subsequently used to heat minining buildings.

Diamond Standard Mining

Many of their mines also utilise alternative methods such as large wind generators, winning ‘Best Use of Wind in Mining’ by the Energy and Mines World Congress in 2016. This means that the remote northern mines are able to double the efficiency of their diesel power plants. As a result, the mines have had a great reduction in fuel consumption and overall cost. In further attempts to improve the local community, the Chamber marked the 60th anniversary of the Northwest Territories and Nunavut Mine Rescue Competition. Significantly, it is one of the few mine rescue initiatives that was developed proactively rather than in reaction to a crisis.

As a pillar of strength for the Canadian mining sector, NWT & Nunavut Chambers of Mines has amassed a thriving history of innovation, but also conservation that has worked to greatly progress the mining industry and benefit the communities in which they operate.

Endeavour Magazine | 17

75 YEARS OF UNITING the INDUSTRY Canadian Freight Forwarder Association chevron-square-right https://www.ciffa.com/ phone-square (416) 234-5100

Canadian Freight Forwarder Association

Last year, the Canadian freight forwarding and logistics sector brought a sizeable $2.2 billion to the country. It is, therefore, no surprise that thousands of international companies utilise Canadian ports and freights as part of their global trade. In order to meet this demand, there is an increasing necessity for the Canadian International Freight Forwarders Association, who are on hand to teach, support and represent hundreds of member companies that are a valued part of the international Canadian freight forwarding industry.

Canadian International Freight Forwarders Association (CIFFA) understand the need for flexibility and endurance when it comes to supporting its excess of 250 member companies. Accordingly, CIFFA values every single member, regardless of how big or small their role may be in the overall industry. Throughout their 75-year history, CIFFA has held on to this promise, having been founded in Montreal in September 1948. Since its initiation, they have demonstrated a caring and genuine attitude toward its members, as was encouraged by the small group of freight forwarders who identified a need to create an association that met the demands of the fluctuating industry. Consequently, CIFFA grew from a strong set of core principles that are still important today. Firstly, and arguably most importantly, CIFFA’s main focus is to strengthen the freight forwarding industry by supporting its most important element: its members, as the association was founded on an established set of rules that led to a proper arbitration between members and professionals. Moreover, CIFFA was created so that a professional body could stand firmly in the international parliament to represent the industry to the best of its ability. The company has evolved since these founding principles, but the same message still resides.

From a member’s point of view, there are countless reasons why being part of the team is advantageous to your company and the overall industry. Firstly, nowhere else will you find such a strong international presence, as they have developed an expert reputation for their world-class relations and noteworthy connections to governing bodies. This means that as a member, CIFFA will always be on your side with a promise to represent your business with conviction and fairness. Furthermore, you can feel protected due to a commitment to numerous international standards, such as Freight Forwarders Liability Insurance and load brokers that commit to the FMSCA Surety bond requirement. Therefore, member companies can rest assured knowing that the association is always held accountable and acts responsibly according to its member’s needs.

As part of representing the industry, CIFFA firmly believes in its members’ education and facilitates an open forum for training and learning. Consequently,

20 | Endeavour Magazine

they provide state-of-the-art education programs and resources seldom seen elsewhere.

Some of their education programs include international freight forwarding courses, that have standardised exams created by industry experts. For members who are looking for something a bit less intense, CIFFA also offers non-exclusive workshops that are more practical, cost-effective, and ideal for those wanting to stay informed of the undulations of the industry. Furthermore, the significance of safety and protection is not lost on the educational aspect of the company, as they provide vital dangerous goods training. The courses in question meet many Canadian and international transport standards, allowing members to acquire specialised certification which is a globally recognised qualification.

As the association’s main focus is to promote the success of the Canadian freight forwarding industry, they place great effort in instilling the importance

of the sector in younger generations. Hence why they are partnered with numerous schools and colleges to help train future generations of freight professionals. A noteworthy example of this would be the CIFFA Internship Program: a fantastic program that puts college students in contact with member firms, so that they can gain valuable work experience for a month as part of the college diploma requirements. In a similar vein, member companies can obtain promising college graduates that hold a CIFFA certificate, which can be achieved through a course with the Schulich School of Business. Such dedication to future freighters is an example of how strongly CIFFA fights for the industry, as they endeavour to leave a strong legacy.

CIFFA hold regular webinars which bolster the educational aspect of the company. An exciting recent event includes the M2M Webinar, ‘Ensuring Compliance and Quality of Pharmaceutical Transport.’ This is a conference held for members who want to gain knowledge on the latest advancements in risk assessment and tracking in the shipment of pharmaceutical products. This is a

75 Years of Uniting the Industry Endeavour Magazine | 21

Canadian Freight Forwarder Association

good example of how specialised the association will go to meet specific needs. Particularly for such a vital sector, since many pharmaceutical products can contain incredibly sensitive material that can become dangerous when not kept in the right conditions. The audience will also learn about the notorious relationship between GDP regulations and the pharma supply chain, as well as have the opportunity to discuss questions or developments in a live Q&A session, demonstrating the association as a space for an informative dialogue.

As part of the requirements of CIFFA membership, each company must pledge to follow a professional code of ethics. A common theme throughout the code of ethics is honesty, integrity, and diligence, as they simply ask that each member respects their clients and delivers on their duty. As a prerequisite, this means that all members are held accountable for their business practices, which in turn maintains a safe open forum for united voices, and mains the outstanding reputation of the association.

CIFFA work tirelessly to accurately represent its members and actively promote their best interests, and the interests of the industry. Thus, the association works hard to champion its member’s rights in an industry that is in a constant state of fluctuation, through the demonstration of a united front for both freight forwarders, load brokers, and carter/drayage companies. On the other hand, CIFFA also proactively liaises with governments, conventions, carriers, and authority standards, both domestically and internationally. Examples of such admirable work include providing insights to the Canada Border Services Agency to aid in the drafting of regulations, as well as collaborating with carriers and governments when drafting key procedures. Most visibly, they provide a united voice for their members and make the Canadian freight industry visible in significant government initiatives and on an international plain.

22 | Endeavour Magazine

MAJESTIC MINING Procon Mining & Tunnelling chevron-square-right https://procongroup.com/ phone-square +1 604 291 8292

Procon Mining & Tunnelling

Procon Mining & Tunnelling has established itself as a leading mining company since 1992. Primarily headquartered in Vancouver, Canada, it is situated at the heart of one of the biggest mining countries in the world, providing tantalising mining opportunities both at home and internationally. The company’s expertise in underground mining, as well as tunnelling and construction, means that they take on some of the most challenging projects in a way that is sustainable and inclusive. And yet, such a position in the mining industry did not just happen by chance. Here at Endeavour, we looked at Procon Mining and Tunnelling to see how they reached such a strong position in the mining industry.

Procon Mining prides itself on its capability to deliver ample mining and infrastructure solutions to the most complex of problems. Significantly, Procon can offer all their clients comprehensive in-house mining development. This means that each client can be sure to receive quality products and production systems that are cost-effective and work best for the client. Procon is therefore a diamond in the rough, whether it be materials, equipment, or the mobilisation of people, they are always willing to deliver to the best of their ability. In the past, this has led to obtaining projects that need barges, helicopters, or even light aircraft. Thus, whatever the operation, Procon is more than willing to use a diverse range of infrastructure to get the job done.

The same hands-on approach is also applicable to the location of their projects. Although they are primarily based in Canada, they have also developed hundreds of operations internationally, this means that they have faced the toughest environments, whether it be Greenland, The Kyrgyz Republic or even the Arctic. And yet, due to such an assorted range of locations and projects, Procon are well equipped with the appropriate infrastructure and strategy to overcome any challenges that may arise. This transpires in tasks such as primary and secondary ventilation, heating, process water, dewatering systems, mine power and much more, all completed inhouse and strategised by the Procon team.

Another vital sector of Procon that is worthy of recognition is their tunnelling and construction efforts, which is a natural and necessary progression of their developments in underground mining. The channelling and tunnelling expertise can be divided into hydroelectric and civil projects. Within these two bisectors, they focus on site establishment, drill and blast tunnelling, mass excavation, as well as soft rock drift cutting. Firstly, site establishment is an important but delicate part of the procedure. Many of their construction projects take place in environmentally sensitive areas, therefore much forethought goes into how they design and build projects so that the end product meets the client’s needs whilst still respecting their surrounding environment.

Secondly, clients can also bear witness to expansive drilling and blast tunnelling. So far,

26 | Endeavour Magazine

Procon Mining & Tunnelling

Procon has completed an impressive 8,000m of drill and blast civil tunnelling construction, mainly taking place on hydroelectric projects in British Columbia, Canada. To deliver on clients’ needs, tunnel sizes range from 3.0 mW by 3.0 mH to 9.6mW by 9.8 mH. Key projects of this scale include the Forest Kerr Hydro Project, McLymont Hydro Project and Tyson Creek Hydro Project.

As well as focusing on construction, they also concentrate on deconstruction too, as mass excavation and soft rock drift cutting are also a noteworthy part of the business. The team are highly proficient in bulk excavation techniques used on underground ore handling and conveyance systems. Such projects include mass excavation of crushing chambers, conveyor accesses, powerhouses and civil infrastructure. Such mammoth undertakings encouraged the company to even greater heights, as the completed projects can structurally affect the landscape, which demonstrates how Procon remain mindful of the area around them.

As indicated by over 200 projects across the world, the last thirty years have witnessed Procon consistently adapt and build on each success. Since the early 1990s, they have demonstrated a

fantastic track record of reliable and safe delivery of projects that have accelerated the company to the unbeatable position that they are in today. The obtaining of Quebec-based Promec Minier Ltd. in 2018 was a particular stand-out moment, as it increased their capabilities and subsequently facilitated a greater capacity of people and operations, helping them serve their clients in the best way possible.

Despite their recent successes, Procon still consistently strives for developments in the mining process. As an industry leader, they feel it is only right that they pave the way for innovative solutions in the resource and construction sector, setting an example for Canada and the rest of the world. Currently, Procon’s focus is placed on developing valuable connections with its clients, as well as continuing to implement safe and sustainable mines across the world. This is also supported by a clear set of values and accountability that drive the business forward in the best way possible.

The values that underpin the company are greatly represented by Procon’s efforts in reducing any adverse effects on the environment that mining has, alongside social and cultural aspects. It is widely

11031-166 A Street N.W, Edmonton Phone: (780) 484-2324 Fax: (780) 484-0128 www.controlflow.ca Hydraulics & Pneumatics Sales, Service & System Design Piston, Gear & Vane Pumps Piston, Gear, Vane & Orbit Motors Filters,Valves Accumulators & Accessories Component Repairs & Testing Cylinder Repair & Manufacturing Machine Shop Services (Including CNC) Truck Service Bay Custom Hydraulic Power Units

28 | Endeavour Magazine

recognised that historically the mining industry has had a detrimental effect on the environment. Therefore, Procon has a responsibility in ensuring that their projects and services protect the environment and meet established requirements to protect the planet.

This is enabled via strict policies that are integrated to minimise the overall consequences of their actions. Another vital branch of their values can be found in the great ways that they give back to their local community. Evidently, Procon is a benefactor of community investment, through numerous scholarships, donations and sponsorships. Thus, you cannot argue against the integrity and accountability they hold as a mining corporation, demonstrated by their ecoconscious practices and their commitments to the local community.

Refreshingly, Procon also holds the Indigenous community in high regard. The company places effort in areas of employment, procurement, and community relations that garner a symbiotic

relationship between the company and their Indigenous partnerships. This takes shape through economic benefits and capacity building that moves beyond compliance and creates respect. The inclusion of Indigenous cultures is measured through the Progressive Aboriginal Relations (PAR) program, which places a priority on Indigenous relations, as well as paving a way for reflection on how mining operations impact those around the company.

Overall, Procon are a shining example of how mining, and tunnelling, can be diversified and expanded to meet any need. This is also prevalent in the CSR of the company, as they place their surrounding area in high regard and make the best effort to preserve Canada’s natural beauty whilst also achieving great mining innovation. Thus, as we have seen, they are certainly not a one-trick pony, as they supply a range of operations in-house and reliably, maintaining their position as a trustworthy and leading mining entity.

Majestic Mining

Endeavour Magazine | 29

BUILDING A SUCCESSFUL NETWORK PEI Road Builders & Heavy Construction Association chevron-square-right http://www.peirb.ca/ phone-square (902) 894 9514 envelope-square info@peirb.ca

PEI Road Builders & Heavy Construction Association

Located just east of Canada, Prince of Edward Island is Canada’s smallest province. However, it is also one of the nation’s major maritime provinces with major commerce in lobster and mussels, which gives way to the fantastic trade of seafood. From a tourism perspective, it also boasts idyllic sandy beaches and green pastures, which tempt millions of visitors every year. And yet, the bustling maritime, agriculture, and tourism sectors could not survive without the dedicated efforts of the Prince of Edward Island Road Builders & Heavy Construction Association. They work tirelessly to provide a tenacious voice for the many contractors and suppliers, amongst other industries, across the island, as well as guaranteeing the smooth running of vital operations like road building and infrastructure.

The Association’s predominant strength can be found in the power it has in uniting companies under a common goal. As a collective, the Association totals a staggering 90 companies. This spans many industries, including construction equipment, insurance, and hospitality. Even though there is such a broad variety of companies, every business comes together with one common vision, to create a strong and impactful voice for the heavy construction industry.

As with many construction associations, teamwork is necessary to tackle challenges that occur both in political grievances and construction projects. Consequently, each associate is given equal priority and purpose, and no stone is left unturned in relation to helping others.

Exciting events taking place this month include the 61st Annual General Meeting. This is a fantastic event that allows for many of the Associates to congregate and not only share ideas but celebrate the previous year’s achievements. The Association also provides handy advice for residents by communicating traffic alerts on their website and providing guidance regarding the roads and infrastructure, amongst much more.

As can be imagined, there is a lot of management and expert strategy involved in keeping the well-oiled machine running. Accordingly, the PEI Road Builders & Heavy Association possesses a dynamic Board of Directors, which contains eight representatives from the Regular Member category and two representatives from the Associate Member category. The Board holds monthly meetings to discuss the progress of the Association, as well as briefing the manager who ensures that the dayto-day running of the Association is kept to a high standard. Overall, they work to maintain a strong network of discussion and encourage an open forum that facilitates continuous improvement and innovation within the field.

The Association was first formed in 1962, birthed from a need to have a united voice that could proficiently negotiate with governments to overcome any concerns or grievances. First incorporated by local contractors and their suppliers, the Association has always had the voice of the people at the top of its priorities, allowing for any adversities to be quickly and professionally handled. Case in point, the Association has in

32 | Endeavour Magazine

PEI Road Builders & Heavy Construction Association

the past negotiated with the PEI Department of Transportation, Infrastructure & Energy in developing numerous successful policy changes that have had a meaningful impact in the region. Furthermore, the Association is a necessary force to allow for the continued success of the sector, which is particularly significant when we consider how many industries and livelihoods it incorporates, including contractors and highway officials.

As commonly known, for any region to reach optimum efficiency, it had to possess an effective network of roads. It is for this reason that the Island’s highway system is of great significance to the Association. So much so, that the highway system is the beating heart of Prince Edward Island’s economy. Evidently, the efficiency of the roads affects every source of financial input.

On the business front, the Association’s work can have great ramifications on many businesses, namely agriculture, fishing, maritime business, and tourism. Perhaps of even greater importance is the safe and quick transportation of the Island’s

residents. These two subsectors come together through the employment of contractors and suppliers, who as a necessity to business, are reliant on an effective network of roads.

The Association has a tight network of channels to drive the local economy forward. Accordingly, they stress that “the number of people who are employed by the contractors, the suppliers and services that the contractors require, the involvement of the private truckers hauling and bringing material to and from the marketplace, and the general amount of money that is left in the various communities by the employees of the member contractors etc., are ways in which this industry affects our economy.”

Some of PEI’s Road Builders most recent projects include vital improvements made to Route 2, a major highway that runs across the entirety of the Island. This particular project needed a range of expert capabilities, such as Earth excavation, the installation of storm sewers, landscaping, hydroseeding, and much more. Consequently, creating a noticeable difference to Route 2 in the Kensington area, last September. Further proficiency is demonstrated the Asphalt Resurfacing as the relaying of the top surfaces of the road is vital for safe passage.

34 | Endeavour Magazine

Such projects are a positive impact on a renewed appreciation for the construction industry on PEI. This is most clearly reflected by the approval of $37.7m in special warrants for the Island’s transportation and infrastructure department. This was due to the significant work of the Association, consequently enabling them to effectively utilise the money to overcome previous adversities and rise from the ashes! The funds were primarily funnelled into the expenditure needed to maintain the safety of roads and bridges, and allow the Association to take the lead.

Evidently, the Association oversees and implements essential work for the Island, acting as a key pillar of the community. By supplying an indispensable voice for the construction industry on PEI, many contractors and suppliers can work effectively to build and operationalise an Island that works best for everyone, whilst simultaneously generating significant money for the economy. Thus, the impacts that PEI Road Builders & Heavy Construction Association have are unmeasurable and restore an appreciation for the work of construction workers across the Island and beyond.

As the largest supplier of asphalt in Eastern Canada, Irving Oil can offer various asphalt products, including performance grade, polymer-modified, viscosity grades, cutbacks and so much more.

In addition to building trusting relationships, the company offers a safe and reliable supply network that allows them to respond to their customer’s needs promptly and efficiently.

Paving the way forward Proud to supply the PEI Road Builders & Heavy Construction Association and help develop a highway system that enables the province’s economic growth. To learn more about how we can help you to get the job done, call us at 1.866.865.8800 or email IOCCustomerSupport@irvingoil.com

Network

Building a Successful

Endeavour Magazine | 35

PIEDMONT LITHIUM LIMITED WWW.PIEDMONTLITHIUM.COM // 61 8 9322 6322

THE LITHIUM LIFELINE

If you’re not au fait with lithium and why it’s such a valuable resource, read on and discover exactly why Piedmont Lithium is so vital to the continued development of new and exciting future technologies.

WRITTEN BY AMY BUXTON

PIEDMONT LITHIUM LIMITED

Piedmont

Lithium (Piedmont), located in North Carolina, is taking a different approach to mining and exploration projects. Having identified a clear need for lithium supplies to be significantly increased, Piedmont has a defined goal in mind of “becoming

a strategic domestic supplier of lithium to the increasing electric vehicle and battery storage markets in the US.”

It’s no secret that the electric vehicle market is increasing at an incredible rate, thanks to a number of initiatives being brought in to encourage drivers to make the switch to greener energy. With this in mind, of course more lithium is going to be needed, but sourcing it from ethical companies and minimising its footprint has to be a priority, which is where Piedmont comes in.

The Piedmont Lithium Project is concentrated on North Carolina, which happens to be “one of the premier regions in the world for lithium exploration, given its favorable geology and ideal location with easy access to infrastructure, power, R&D centres for lithium and battery storage and major high-tech population centres.”

The high yields enjoyed by North Carolina have been well documented, with two large-scale mining operations being started in the region from the 1950s to 1990s. In addition to these, two enormous processing plants were also brought into being, both of which not only still exist but are also still supplying premium lithium products to consumers throughout America. It’s not merely a happy accident that Piedmont can be found within 20km of these tried and tested facilities; it’s calculated and considered management that can recognise a golden opportunity to lower production costs. Building on an already successful business model might sound simple, but steady and well thought out expansion is the key to sustained growth, as is integration. Piedmont knows this and has set the wheels in motion accordingly:

“With continued land expansion, sampling and drilling programs scheduled during 2018, our aim is to fast track the Piedmont Lithium Project towards production as a fully-integrated domestic source of lithium and capitalise on the widely anticipated shortfall of lithium in global markets over the next decade.”

While many companies look at finalising a five-year plan, Piedmont is defying the odds and thinking a full decade in advance. By maintaining such a steely gaze on the industry and more specifically, the material in question and the depleting nature of it, the team is setting a precedent for always staying one step ahead of the competition.

There’s little cause for wondering where the exceptional levels of inspired leadership and market awareness spring from, as the individuals that comprise the management team are known, respected and lauded for their previous successes within the mining industry:

“Our leadership team’s successful mining ventures include a multi-decade track record of creating wealth for shareholders in mining ventures, experience in building top-tier management teams in the US and the proven ability to fund exploration and development stage opportunities.”

Drawing on a range of industry experiences, from Wall Street strategic financing to banking, mining, geology, engineering and law, the senior management team is made up of a unique blend of talents that come together to create an unbeatable corporate force

38 | Endeavour Magazine

SPECIALISING IN DESIGN, CONSTRUCTION AND OPERATION OF GLOBAL RESOURCE PROJECTS. PRIMERO’S WORLD CLASS CREDENTIALS IN PROCESS ENGINEERING ARE NOW SERVICED FROM OUR NORTH AMERICAN LOCATION. NOW IN THE AMERICAS WWW.PRIMERO.CA 514-312-0264 Endeavour Magazine | 39

PIEDMONT LITHIUM LIMITED

that is spearheading the Piedmont Lithium Project. They have also launched a comprehensive press strategy to keep relevant people in the loop as to new developments and the profitability of the project.

The latest press release to come from Piedmont has revealed that the company has made inroads into continuing to consolidate its mineral holdings within North Carolina:

“Piedmont Lithium Limited (“Piedmont” or “Company”) is pleased to advise that the Company has increased its land position by 441 acres to 1,824 acres in the Carolina Tin-Spodumene Belt (“TSB”) located west of Charlotte in North Carolina. These additions were achieved via a combination of option agreements and deferred purchase contracts, making effective use of the Company’s funds to maximise exploration opportunities.”

What this means is that Piedmont is able to boast of the strongest lithium mineral position in the entire region. That’s no small brag, considering that the project has only been in operation since 2016, but thanks to the careful strategising of the management team, a dream has come into being “the Company has made steady progress towards establishing a large contiguous land package within the historic Carolina Tin-Spodumene Belt.”

Keith D. Phillips, President and CEO of Piedmont went on to reveal that, “The Carolina Tin-Spodumene Belt has been described as one of the world’s largest lithium districts. Piedmont has established a dominant position in the TSB and we hope to consolidate large contiguous land blocks to build a large, worldclass integrated lithium business. We have demonstrated the substantial cost advantages of operating in North Carolina and one of our 2019 objectives is to make clear the sheer scale of the business we intend to build.”

The scale of the company is set to be incredibly impressive, thanks to a wealth of exclusive option agreements and land purchase deals that are in place to allow for immediate purchase completions, should the right moment to expand arise. Totaling a large amount of acreage, few other operations have access to instantaneous expansion, but that’s the genius of Piedmont. Never a company to look back, it is always firmly facing forwards and attempting to preempt not only market conditions but also material demand.

Looking ahead to the rest of 2019, plenty of excitement is on the cards: “Piedmont will complete the Phase 4 drill programme and seek to extend Project life through an increase in the Project’s

40 | Endeavour Magazine

Mineral Resource, plus further metallurgical studies, including evaluating the potential for a Dense Medium Separation (“DMS”) before the flotation circuit, to further enhance operating costs in the concentrator. Permit applications will be completed and we will secure the necessary permits and approvals to commence mining and processing operations at the Project and continue expansion of the Company’s land position in the Carolina Tin-Spodumene Belt with a focus on areas of high mineral prospectivity.”

In short, more of the same that has seen Piedmont rise to such a prominent industry position in just two years. It will be interesting to see what the team can accomplish in the next two years, but one thing is certain; as long as there’s a demand for lithium, Piedmont will be ready to step up as a reliable supplier.

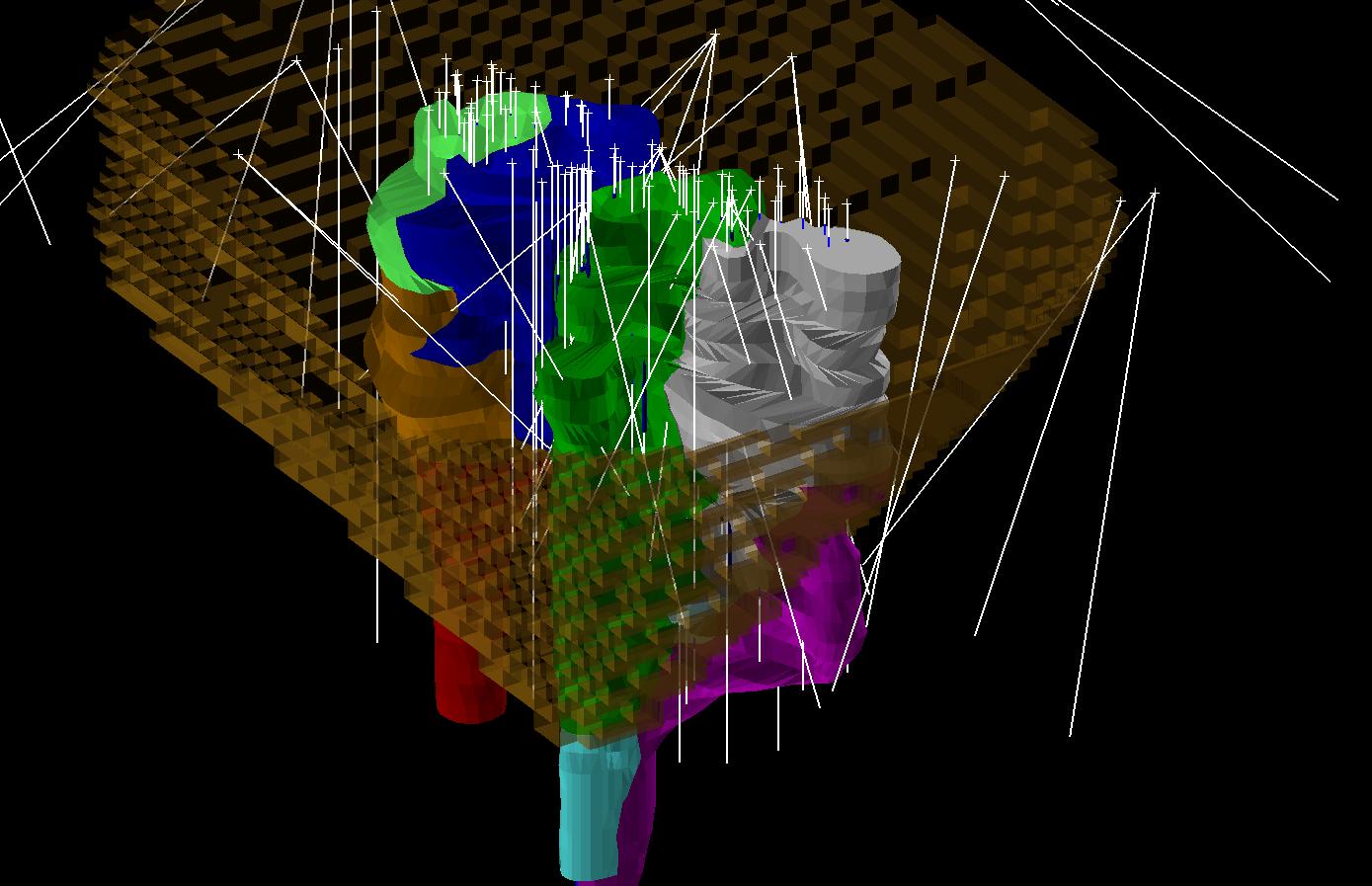

MARSHALL MILLER & ASSOCIATES, INC. (MM&A), an international consulting firm headquartered in Bluefield, Virginia, U.S.A, has provided geological and mining engineering services worldwide for 44 years. MM&A’s involvement in the Piedmont Lithium Project includes overall guidance based on local experience, mine planning and design, waste dump design, waste rock and tailings geochemical assessment, geotechnical assessment, geophysical logging, and mine permitting.

www.mma1.com

info@mma1.com

|

| +1 276.322.5467 | Bluefield, VA

Endeavour Magazine | 41

42 | Endeavour Magazine

A SHARPER EYE

SSR Mining

SSR Mining has been through a rapid expansion over the past five years, and now it’s undergoing changes again. Whereas its last burst of development was in the physical realm, its new changes are in the digital one, as the company seeks to streamline its operations with the latest IT solutions. We spoke with David Thomas, Director of Information Technology, about why it’s important for mining to digitise.

SSR Mining Inc. is a Vancouver-based mining company producing precious metals – more specifically, gold and silver. For 70 years, the company operated under the name ‘Silver Standard’, but changed its name to SSR Mining Inc. in August 2017 as it evolved from a silver producer to a precious metals producer. In fact, a lot has advanced at the company recently: in 2014, it grew from being a one-mine operation to having three producing mines today, including the Marigold mine in Nevada, U.S.A., the Seabee Gold Operation in Saskatchewan, Canada, and Puna Operations in Jujuy Province, Argentina. SSR Mining also has two feasibility stage projects and a portfolio of exploration properties in North and South America.

The Marigold mine has operated consistently since 1989 and produced 205,161ounces of gold in 2018. The Seabee Gold Operation, in continuous production since 1991, produced a record 95,602 ounces of gold in 2018. SSR Mining’s Puna Operations, which consists of the Pirquitas property and the Chinchillas mine, declared commercial production in December 2018.

Written by Alice Instone-Brewer

Everyone knows that both silver and gold are used heavily in the production of jewellery and

chevron-square-right www.ssrmining.com phone-square 1-604-689-3846

Endeavour Magazine | 43

SSR MINING

other forms of decoration, but there are other, less immediately obvious industries that also use the precious metals. Electronics is one: gold is used in bonding wire production, and silver is used throughout everyday technology such as mobile phones and laptops, as well as more specialized applications such as satellites and even high-tech weaponry! As is well known, prices for both silver and gold fluctuate, as does investor interest, but the uses of the metals persist. The industry isn’t going anywhere, but due to factors such as world politics, competing stock interests and many more, the price of silver and gold is variable. We spoke to David about how SSR Mining responds to this, and his answer was so sensible, we wondered why we hadn’t thought of it. “While we can’t control the price of gold, we can impact our costs to drive margins, profit and cash generation.” This is a brilliant way for SSR Mining to take control and get as much benefit from its portfolio

as possible, but how is the company going about it?

By David’s own admission, mining is one of the last industries, along with agriculture, to fully embrace the benefits of digitisation, but, like agriculture, it is also one that can greatly benefit from the level of visibility and analysis this change supports. Mining is an industry with many factors at play, across multiple sites, with everything from exploration results to vehicle routes needing easy-to-read monitoring so that efficient, cost-effective actions and decisions can be made. This is exactly what SSR Mining is working towards. As Director of Information Technology, David was able to tell us more:

“For us, the key driver is to be more efficient, and also to improve on our operational processes. One example would be truck productivity; even just taking a different route on a pathway in the mine can have an impact on the cost per ounce, due to gas consumption. Multiply that by a thousand times a day, at multiple mines, and that’s a big impact.” And those are just the small details. Being able to monitor and manage everything from minor details to wider-scale planning allows for loose bolts to be identified and tightened. SSR Mining has been working on developing and implementing the software needed for this for the past two and a half years and is already seeing the impact, and there’s still a long way to go.

“I don’t think there is ever an endpoint. Mining is one of those industries with so many areas to apply Operational Excellence analytics to: from truck productivity all the way to exploration drillhole sampling, process mill productivity, and even safety and sustainability.” With so many areas to consider, this is a continuous process of improvement for SSR Mining.

Regarding this change, David described SSR Mining as fast followers rather than innovators. The desire to try new ideas is there, but to be on the front line of this development would be too costly an endeavour for the company’s size. However, whilst they don’t have the budgets of mining giants, they also don’t have the deeply entrenched legacy IT systems, which gives the

44 | Endeavour Magazine

SSR MINING

company a strong advantage. “We are able to quickly move into the Cloud any project we undertake, and we try to encourage our vendors to set up in such a way where they can be supported in the Cloud.”

Not reinventing existing research and development allows SSR Mining to leapfrog over steps of the process faced by larger companies. However, this, and being a fast follower, doesn’t mean there there’s no work at all. The company must carefully select which existing routes and approaches to take, and even though they aren’t process pioneers, they are devising the system in-house. “Quite honestly, there’s not really any off-the-shelf product. The software that is available was written by geologists in the 1980s and 90s.” Engaging with software developers, analytics, industry leaders and graduates alike, SSR Mining has been devising its system carefully for these past two and a half years. It is also working closely with vendors such as Komatsu

and Hitachi Wenco, whose trucks have inbuilt software that SSR Mining can upload and integrate into its own analytical processes.

One dramatic example of how gamechanging these capabilities could be relates to SSR Mining’s Seabee Gold Operation in Northern Saskatchewan. Access to the mine site is fly-in, fly out by small fixed wing aircraft to an airstrip located on the property. Equipment and large supplies are transported to the site via a 60-kilometer winter ice road, which is typically in use from January through March. Therefore, supply chain management and forward planning, down to the last detail, is essential for cost-saving, and simply making sure that the mine is ready to function for the year to come. “With ice road access between January and March only each year, we need to carefully plan, order and schedule shipments via the ice road in preparation for the year ahead. We need to transport fuel, equipment and all other items necessary to run a mine.”

We Manage, Solve, and Deliver I.T. Managed IT Services A comprehensive range of IT Support for Businesses, Organizations and Educational Sectors. Remote and Onsite IT Services We can provide our services remotely or onsite for customers requiring support within their environment. Proactive IT Services IT problems can be identified and rectified quickly by our proactive engineers. � � � � www.cystechs.com � helpdesk@cystechs.com � +1 (604) 219.3999

46 | Endeavour Magazine

By being able to dot all of the ‘I’s and cross the ‘T’s, and monitor its operations in new levels of analytical detail, SSR Mining can plan for this in a tighter and more cost-effective way than ever before. Whilst an extreme case, this same benefit is felt throughout SSR Mining’s operations – with so many factors at play, and at such a scale, every detail helps.

CHARTER 1-877-989-2677 RESERVATIONS 1-800-667-9356 /transwest air Follow us on Transwest Air and Northern Shield Helicopters are proud to support SSR with fixed wing and rotary services for their projects in Saskatchewan. transwest air. com | northernshield helicopters .ca

A SHARPER EYE

Endeavour Magazine | 47

48 | Endeavour Magazine

MINING ITS OWN BUSINESS

Orford Mining

A mineral explorer with a unique gift for sniffing out untapped potential in Northern Quebec, Orford Mining has two flagship projects currently underway, both of which are producing promising results.

Already known to be a viable mining location, Quebec plays host to a number of mining operations, but now, it can add Orford Mining to the list. Listed as the “8th most attractive mining jurisdiction” by the Fraser Institute, an independent research and educational company based in Canada, Quebec has long been an attractive prospect for ambitious mining operations and Orford Mining is producing the kind of results that demonstrate exactly why.

A diverse project portfolio

Far from being a one-trick pony, Orford Mining has interests in gold, as well as nickel and copper and is actively searching for them all at both the Qiqavik and West Raglan project sites,

“Qiqavik bears similarity to the Abitibi gold camp and has camp scale potential. West Raglan hosts outcropping nickel-copper-PGE sulphide mineralisation over more than 35 km of strike length.”

Written by Amy Buxton

With a 100% interest in the Qiqavik project, found in northern Quebec, Orford Mining is able to take full advantage of the high-grade gold, silver, copper and zinc deposits that are discovered throughout the 240 square km site.

chevron-square-right www.orfordmining.com phone-square 001 416 309 0609

Endeavour Magazine | 49

ORFORD MINING

With gold proving to be the most promising resource in the region, a thorough season of exploration in 2017 resulted in,

“…three new drill-supported high-grade gold discoveries and five new high-grade gold prospecting discoveries at surface that remain untested by drilling. Orford also identified a significant structural break, the Qiqavik break, across the 40 km property, a substantial portion of which is left to be explored.”

It’s quite something to not only find valuable deposits but also identify areas ripe for further exploration, as that directly contributes to a long lifespan for the mines and continuous shareholder value.

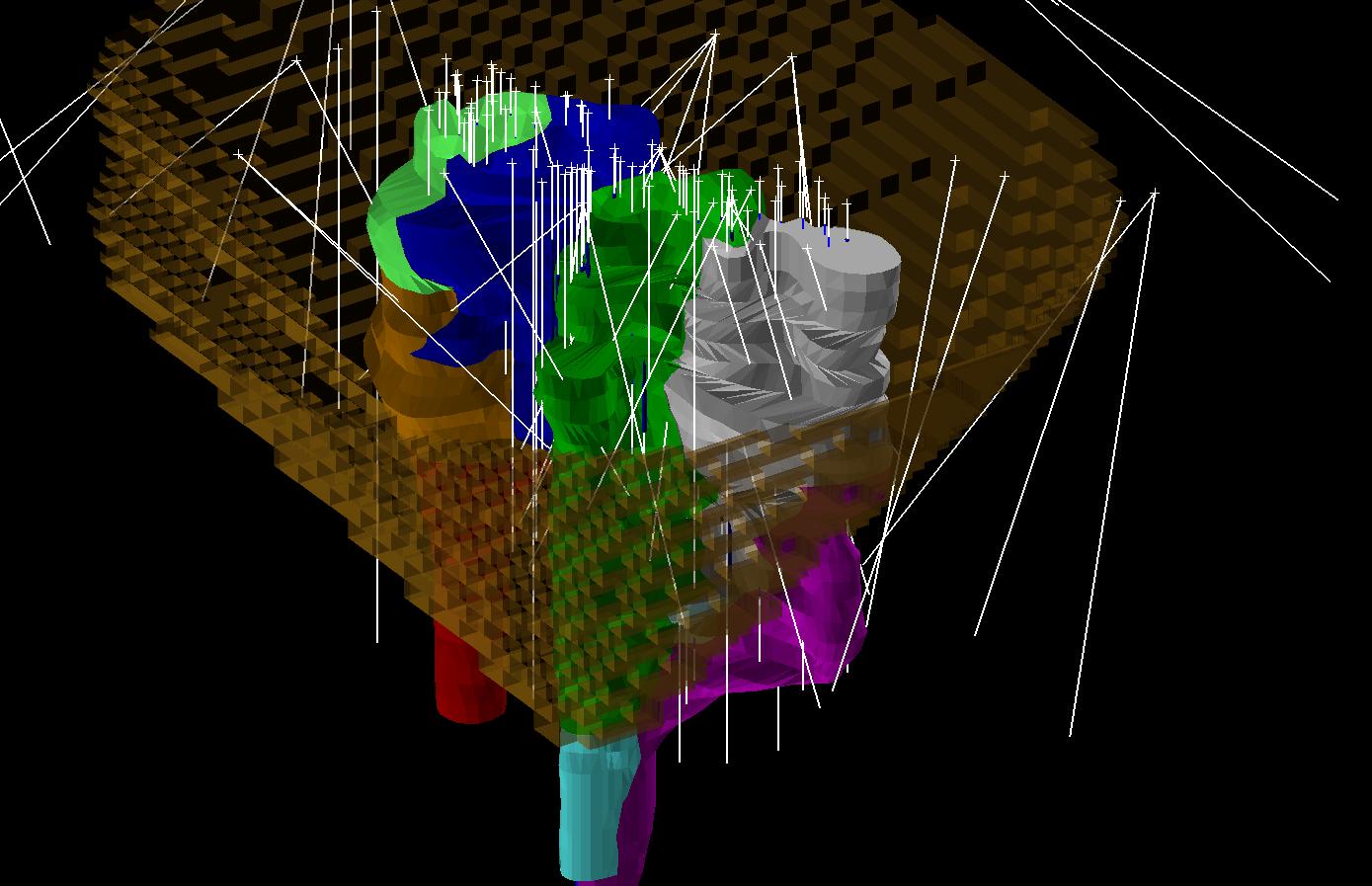

As with Qiqavik, the West Raglan project is a 100% Orford Mining-owned interest, but the comparisons end there. A fully established project, it is in a far more advanced state of progression, producing high-grade polymetallic nickel out of two mines, but explorations are giving rise to justified optimism of more,

“Exploration work to date at West Raglan has identified outcropping sulphide mineralisation over more than 35 km of strike length with very limited testing at many zones. Magnetic signatures, lithogeochemistry and geology are the same at West Raglan’s Frontier zone as Glencore’s Raglan Mine.”

Pooling resources

Mining is an expensive business, regardless of how much high-grade material is discovered, processed and sold. That’s why so many companies seek to attract outside investment and committed shareholders, with Orford Mining not being an exception to the rule.

Having opened itself up for private placement financing options in 2018, Orford Mining has now partnered with Alamos Gold with the latter snapping up “14,764,706 common shares of Orford, or 19.3% of its issued and outstanding common shares”. Discussing the transaction, Orford Mining CEO, David Christie, noted that,

“I look forward to working with Alamos as a partner and key Orford shareholder. We will benefit greatly from the expertise and experience of the Alamos representatives on our new exploration advisory committee as we advance the exploration program at Qiqavik –a greenfield gold discovery where high-grade gold surface showings have been discovered in multiple locations across 45 kilometres.”

It’s easy to see why Alamos Gold would be keen to hitch its wagon to Orford Mining, as it is a unique mineral exploration company that seeks to target sites that offer optimistic prospects but are, as yet, very much underexploited. It’s a formula that has demonstrably been working, given the lack of competition in certain locations, leading to easy acquisition and phenomenal yields. Of course, this sets in motion a self-sustaining cycle of success, with potential shareholders taking note of results and making a note to jump on the next opportunity to acquire shares and get a piece of the action for themselves.

50 | Endeavour Magazine

ORFORD MINING

Teeming with talent

Regardless of how promising a mining location looks to be, nothing ever gets started or reaps rewards for shareholders unless a spectacular management team and suitable board of directors is in place and Orford Mining has both.

Boasting a collective experience of many decades, within exceptionally specialist areas, both professionally and in terms of education, the Orford Mining management team is a force to be reckoned with. Led by professional geologist and resources expert, David Christie, the four-strong contingent of leaders clocks up an impressive 80+ years of mining industry knowledge and expertise. These years are further supported by the board of directors’ own experiences, which range from corporate finance through to legal and mineral exploration. It wouldn’t be a stretch of the imagination to suggest that when combined, there is nothing that the management team

and board of directors doesn’t know, when it comes to maximising the potential of any mining project.

A glittering future

Boasting a land package of more than 70,000 hectares in the northern Quebec Cape Smith Belt, Orford Mining is in a phenomenal position. Given that the region is largely underexplored, the potential for high-grade deposit discoveries is, essentially, limitless, which continuous exploration endeavours confirm. With a new phase of investigation having recently begun in the Qiqavik project, whereby increasingly technical equipment is being brought in to confirm and expand on the 2017 survey findings, David Christie revealed that the entire management team is feeling positive,

“We are very encouraged by the high-grade gold and high-grade gold-copper results yielded by the Qiqavik property to date, specifically in

52 | Endeavour Magazine

the Interlake area where large thicknesses of gold mineralisation were intersected during the 2018 drilling programme. We look forward to continuing to explore the potential of this new 40 km long camp-scale gold belt located in a previously unexplored region of Canada.”

Where some companies might shy away from seemingly uncharted areas, Orford Mining strides ahead, seizing every opportunity and looking to unleash previously undiscovered potential. It’s this entrepreneurial and adventurous spirit that continues to make it stand out from competitors and keep Canada firmly on the mining map.

MINING ITS OWN BUSINESS

La Fédération des coopératives du Nouveau-Québec is owned by it’s fourteen member co-ops in the Inuit communities of Nunavik, Canada. The purpose of the co-op movement is to get it’s members to achieve their own development through social and economical activities that are financially sustainable.

SUCCESSFUL

ACTIVITIES WITHIN THE LAST 50 YEARS

• Coop retail stores in each of the 14 communities of Nunavik with a wide selection of merchandise at competitive prices.

• Supply, storage and distribution of petroleum products (bulk or in drums).

• Construction of residential, institutional, industrial and commercial projects, as well as civil projects.

• Hotel and travel agency.

• Guided hunting and fishing experience, as well as tourism in Nunavik.

• Maritime cargo shipping.

• Specialized transport in mining industries.

• Logistical and provisional services for special projects.

SITE PHONE E-MAIL FCNQ.CA 1-800-363-7610 INFO@FCNQ.CA

Endeavour Magazine | 53

54 | Endeavour Magazine

CAPACITY AND COMMUNICATIONS ARE CRUCIAL

CALGARY INTERNATIONAL AIRPORT

Vibrant international airports are a vital resource and contributor to the economic climate of a country. Canada’s aviation sector is both competitive and efficient, and without it, the country’s business networks and social institutions would not function to their maximum potential.

International airports create essential links to trade by connecting to new and thriving markets such as China, as well as providing many jobs directly from the airports themselves. Calgary International Airport (YYC), a vital contributor to the economy of Alberta, is an example of this.

In February of this year, The Calgary Airport Authority, which manages and operates YYC, received recognition for the seventh time as one of the top employers in Alberta. The award recognizes workplaces that create a vibrant and rewarding working environment. This shows how the Authority employees are proud of the unique place in which they work and how they contribute to the Calgary and Alberta communities.

Written by Sarah Loiuse Brooks

This contribution is evident in the economic footprint of the airport, which is $8.3 billion a year in terms of GDP. Subsequently, this supports 48,000 jobs in the region. There are 24,000 people working directly on airport lands, as well as approximately 12,000 people employed inside the terminal building itself. Mr. Stephan Poirier, the Senior Vice President and Chief Commercial Officer of The Calgary Airport Authority, points out that airports are not simply nice things for a city to have, they are a

Endeavour Magazine | 55

CALGARY INTERNATIONAL AIRPORT

necessity: ‘If we do not build for future capacity, we are stifling the economic development prospect for the city and we want to make sure the region is set up for continued growth.’

skills is extremely valuable to the company in the long run and as it ensures that we have the best talent for our team.’

Economic prosperity has community benefits. YYC is not only beneficial to the local economy, but also rewarding to those it employs locally. ‘Nothing is completed without people; if you don’t have great people then you don’t have a company and being a top employer is a priority for us’, explains Poirier. The Authority offers various benefits in order to attract the best people. Examples of these incentives include ongoing opportunities for professional development, a one-year orientation program, as well as purposeful student work opportunities and peer-to-peer recognition programmes; demonstrating a clear commitment to its staff.

CALGARY INTERNATIONAL AIRPORT

As well as developing staff, the most significant new investment for Calgary International Airport is the construction of a new terminal. The new international terminal is due to be completed by fall of this year and according to Mr Poirier, ‘everything is running to schedule’. The new terminal will add approximately two million square ft. to YYC and will include 24 new aircraft gates for both U.S. and International destinations. With over 10.2 million hours worked by construction organizations on the new terminal, some of the most recent milestones reached include the completion of 20 out of the 25 of the passenger boarding bridges, as well as the new baggage handling system being completed and into the stage of testing the facility.

With the project nearing completion, Mr Stephan Poirier explains the difficulties with the final touches: ‘Many meetings are conducted in the final stages as the small details are of equal importance to us. Various activities are ongoing at the end of a project such as this one and coordination is essential to ensure we are managing well.’ The most significant economic impacts of the new terminal concern expansion, in regard to both connection and capacity. YYC is Alberta’s aviation hub of choice, doubling in both structural size and passenger volumes over the last 20 years.

In 2015 it welcomed 15.48 million passengers and in order to meet the increase in demand, this $2 billion expansion is the largest in the company’s history. The new terminal is not only significant in terms of investment size, but additionally, it includes innovative systems, designed to give the best customer experience possible to the passengers. These include a new Connections Corridor and connections processes, as well as a new gate system, which will mirror the modern process already in practice in airports such as Heathrow, London.

In regards to the logistics of passenger experience, the gate announcement will be made in the central departures hall, which is surrounded by retail outlets, allowing

56 | Endeavour Magazine

AIRPORT ELECTRICAL INSTALLATION NEW CONSTRUCTION TO REHABILITATION

AIRPORT ELECTRICAL INSTALLATION NEW CONSTRUCTION TO REHABILITATION

Tristar’s broad experience in helping to ensure the safety of some of Canada’s busiest airports has earned it a solid reputation for success across the entire airport lighting segment—from runways and taxiways, to aprons, high‐mast lighting and approach systems.

Regardless of project size, scope, or urgency, Tristar’s dedication to value, quality, efficiency and safety remain steadfast. Take a look at the porfolio of Tristar’s work—it speaks volumes about its experience, capabilities and commitment.

Tristar’s broad experience in helping to ensure the safety of some of Canada’s busiest airports has earned it a solid reputation for success across the entire airport lighting segment—from runways and taxiways, to aprons, high‐mast lighting and approach systems. Regardless of project size, scope, or urgency, Tristar’s dedication to value, quality, efficiency and safety remain steadfast. Take a look at the porfolio of Tristar’s work—it speaks volumes about its experience, capabilities and commitment.

THE CONVENIENCE OF A TRUSTED SINGLE-SOURCE PROVIDER - VALUE-DRIVEN SOLUTIONS

THE CONVENIENCE OF A TRUSTED SINGLE-SOURCE PROVIDER - VALUE-DRIVEN SOLUTIONS

The most complex construction and infrastructure development projects begin with one simple acton: listening. Tristar delivers measurable, bottom‐line value by first gaining a thorough understanding of clients’ needs and objectves; only then does work begin to start crafting a soluton designed to exceed expectations at every stage. To ensure high customer satsfaction, Tristar principals oversee each project, regardless of size. The systems and procedures used were developed for quality assurance and guarantee that clients receive end products of the highest standard. Aircraft have become so sophisticated that a pilot can Literally fly blind in the most appalling conditions. But even the most experienced pilot breathes a sigh of relief when he drops through the cloud cover and catches the welcoming sight of the airfield lights in the distance. And if that pilot is flying into Toronto –Pearson International Airport or any number of other major Canadian airports, there is a good chance that the lights he sees were installed by Tristar Electric.

The most complex construction and infrastructure development projects begin with one simple acton: listening. Tristar delivers measurable, bottom‐line value by first gaining a thorough understanding of clients’ needs and objectves; only then does work begin to start crafting a soluton designed to exceed expectations at every stage. To ensure high customer satsfaction, Tristar principals oversee each project, regardless of size. The systems and procedures used were developed for quality assurance and guarantee that clients receive end products of the highest standard. Aircraft have become so sophisticated that a pilot can Literally fly blind in the most appalling conditions. But even the most experienced pilot breathes a sigh of relief when he drops through the cloud cover and catches the welcoming sight of the airfield lights in the distance. And if that pilot is flying into Toronto –Pearson International Airport or any number of other major Canadian airports, there is a good chance that the lights he sees were installed by Tristar Electric.

TRISTAR ELECTRIC INC.

TRISTAR ELECTRIC INC.

6068 Netherhart Road, Unit #1, Mississauga, Ontario. L5T 1N3 tel: 905.670.1642 fax: 905.670.1932

6068 Netherhart Road, Unit #1, Mississauga, Ontario. L5T 1N3 tel: 905.670.1642 fax: 905.670.1932

E‐mail: info@tristarelectric.ca

E‐mail: info@tristarelectric.ca

CALGARY INTERNATIONAL AIRPORT

passengers to relax before moving to the gate to board their plane. Mr Poirier explains there are two important advantages from this systems implementation: ‘This process increases passenger satisfaction, as you are able to enjoy the offerings of the central departures area, with additional comfort and retail opportunities. Secondly, it will increase operational flexibility, as for example in busy periods, this process eliminates the changing of gates throughout the boarding process.’

In the central departure areas of the new terminal, the local community have an important involvement. The YYC expansion programme reached out to local concessions, the food and beverage operators, and upon the opening of the terminal, there will be a great mix of local operators as well as international players in terms of the food and beverage choice available to customers. Stephan Poirier noted: ‘There is a big footprint for local vendors inside the terminal to provide

a taste of who we are and what we do.’ Equally, the local community has also participated in the construction of the terminal itself in terms of the sourcing of raw materials. Wherever possible, the construction materials that went into the terminal’s construction were sourced regionally.

This evidences how financially beneficial the project has been to the surrounding communities. Finally, not only is the new International Terminal economically beneficial for the local communities, it also incorporates a range of sustainable features. The new terminal is a green building, with 660 km of in-floor radiant heating tubing, including co-generation power that will generate electricity and heat, saving 4,900 tons of CO2 each year. Stephan Poirier elaborates further on an additional environmentally friendly inclusion within the new terminal: rainwater for low-flow plumbing fixtures. He explains: ‘The new terminal will harvest 500,000 litres of rainwater, about a

CALGARY INTERNATIONAL

58 | Endeavour Magazine

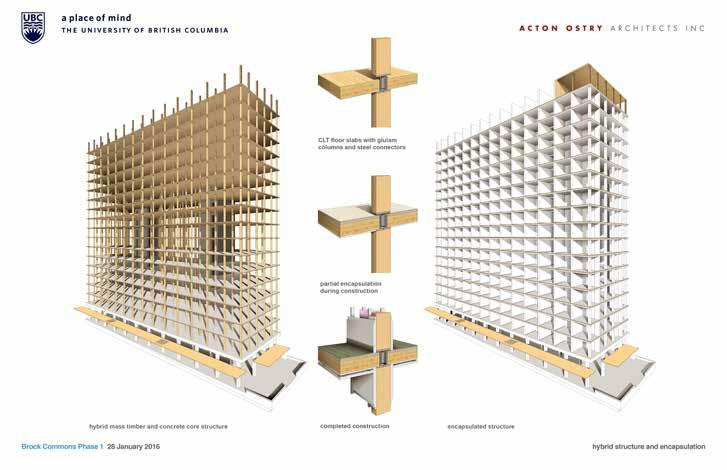

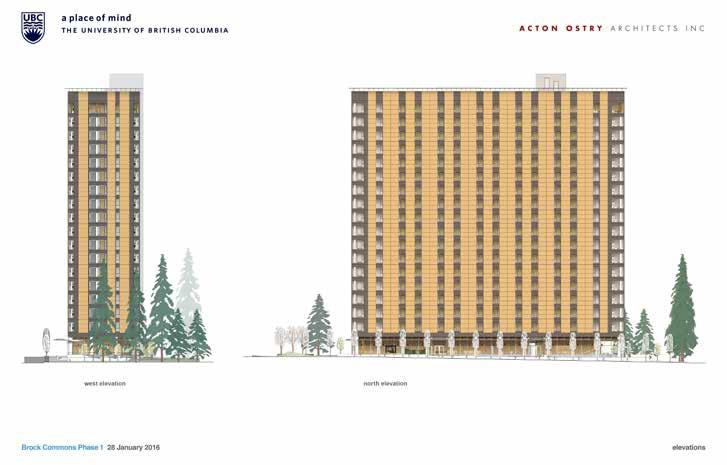

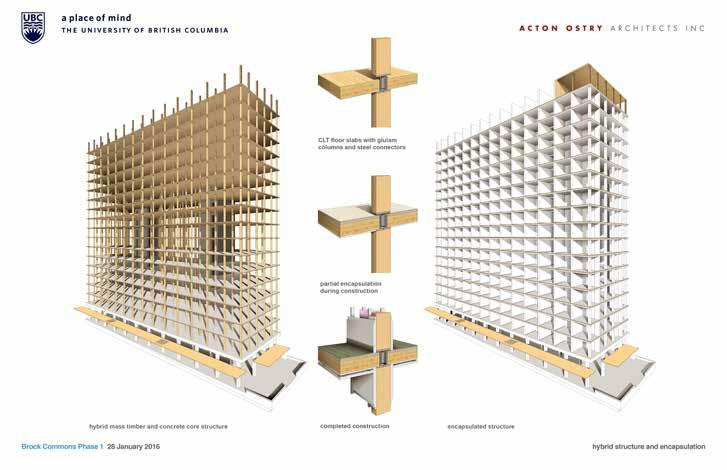

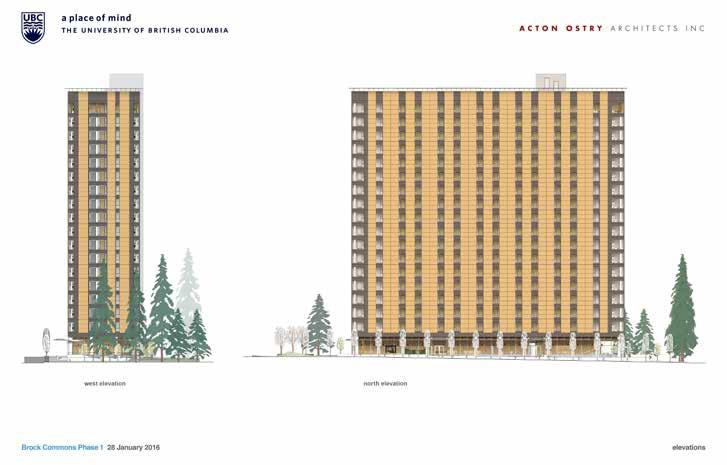

CAPACITY AND COMMUNICATIONS ARE CRUCIAL