System solutions for maximum productivity

Tailored to your needs, well thought out, innovative

Tailored to your needs, well thought out, innovative

We assist you with customized and modular solutions for workpiece clamping, presetting and measuring as well as automatic loading and data transfer to make economical and sustainable investments in your production systems.

Machine tools from all manufacturers and different generations can be integrated, regardless of the various manufacturing processes.

EROWA‘s headquarters are based in Büron in Central Switzerland. With our subsidiaries and worldwide customer service, we can provide you with comprehensive and competent advice and support.

The suitable EROWA components will enable you to make optimal use of your machines.

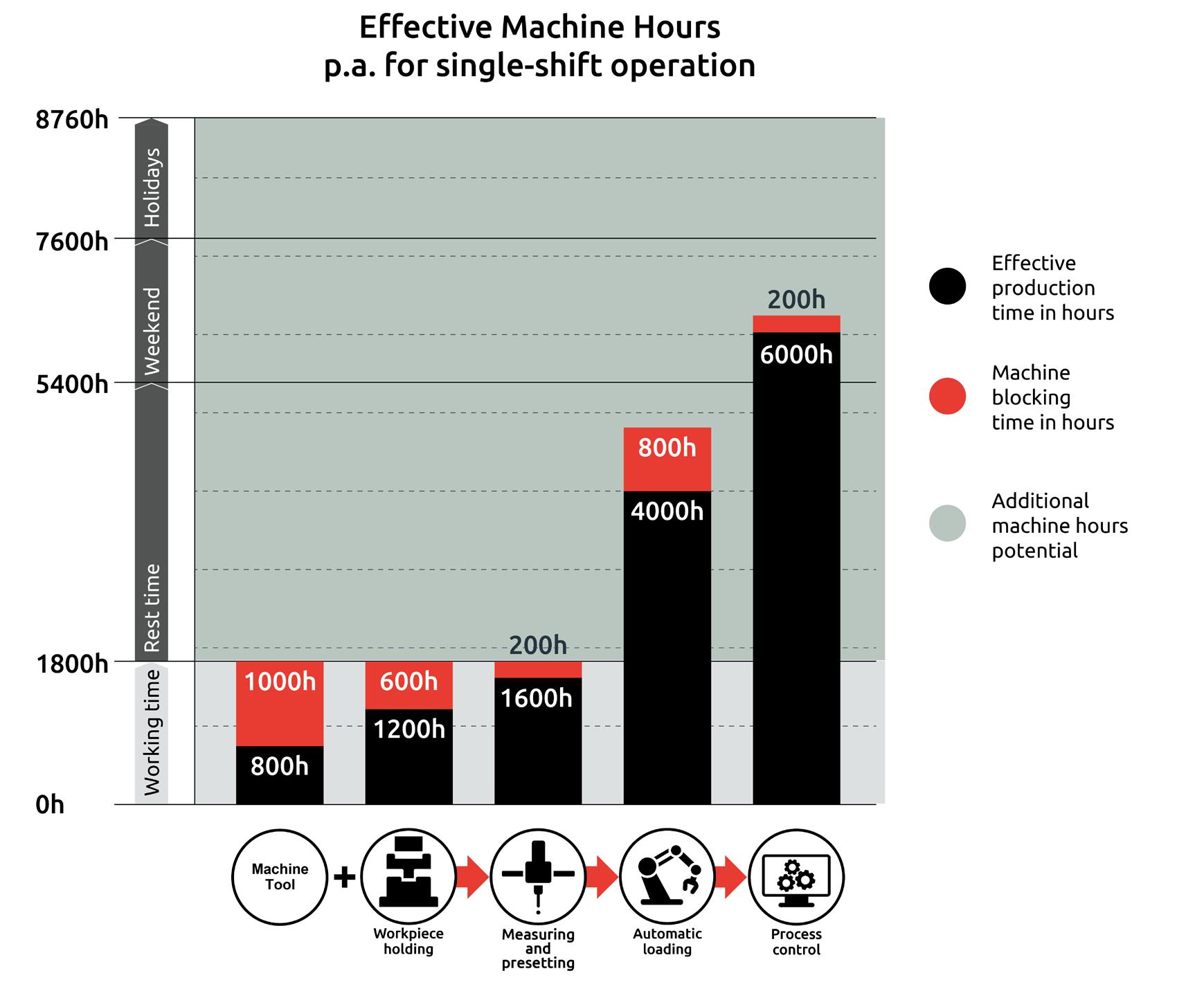

In order to manufacture efficiently and productively, it is important to reduce set-up times as much as possible. Building on this, automated loading, even from batch size 1, can generate more machine running time through the night or over the weekend. The EROWA process control system manages all processes safely and clearly.

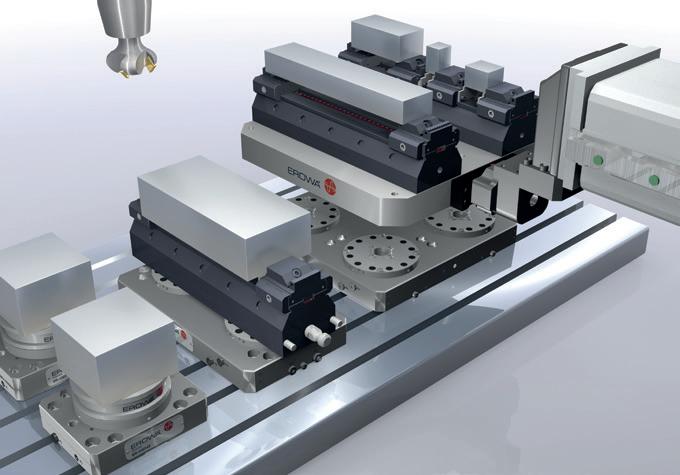

A standardized interface between machine, workpiece or clamping device enables fast and precise retooling. By using a continuous EROWA workpiece clamping system on all processing and measuring machines, downtimes are reduced to a minimum.

Gain valuable production time I

With the use of EROWA tooling systems, set-up takes place parallel to production. While the machine is pro- ducing, new workpieces are clamped on EROWA workpiece carriers or clamping fixtures and prepared for machining.

Standardized interface for all machines I

EROWA tooling systems and palletizing of workpieces are crucial for ensuring flexibility in automation. The standardized interface with a defined zero point is the basis for fast and precise pallet changes on the machine table.

Stay flexible I

Depending on size and weight, workpieces and clamping devices are attached to the appropriate EROWA system size. By using adapter pallets, the different workpiece carriers are integrated flexibly and consistently into the system.

High precision and repeating accuracy I

EROWA tooling systems meet the highest manufacturing. They guarantee maximum precision, stability and flexibility when machining complex workpieces.

Clamping solutions according to your requirements I

EROWA develops ideas and solutions together with the customer. The result is ready-to-use clamping fixtures tailored to your individual requirements.

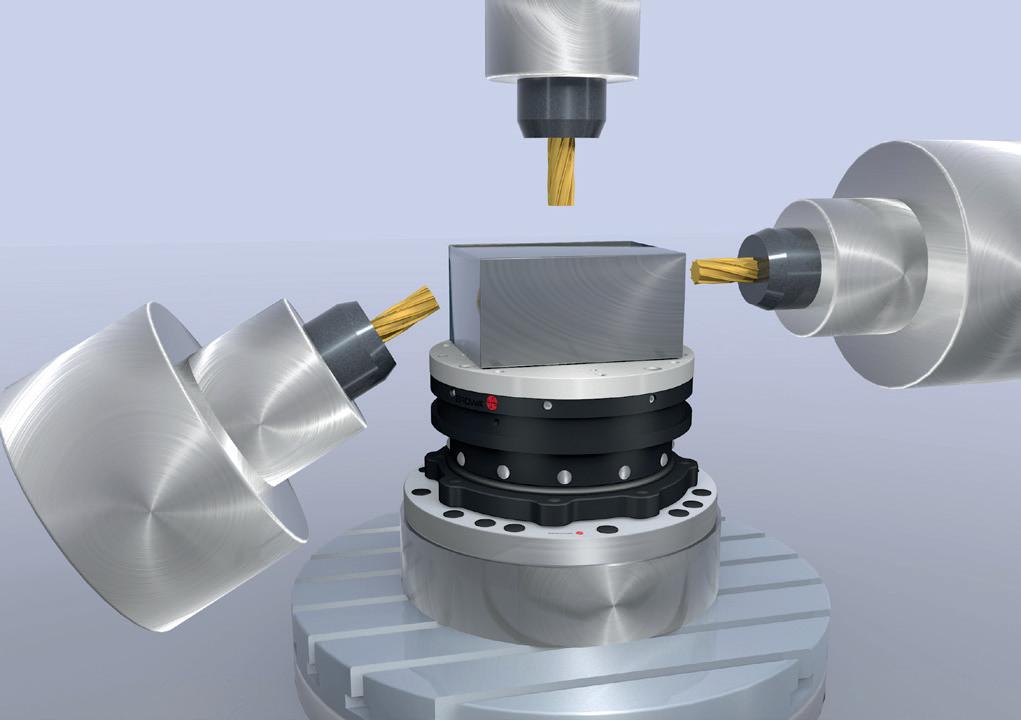

The complexity of the part plays a key role in the search for an optimum production process. This is especially true for workpieces with long machining times, many tool changes and complex shapes. Each additional set-up takes time and means a possible loss of accuracy. EROWA tooling systems can be operated manually or automatically. We will be happy to provide you with comprehensive advice and find the right EROWA workpiece clamping solution for your needs.

• The right system size for every work piece size.

• Standardized and consistent interface.

• For all machining processes.

• Modularly expandable.

• System precision < 0.002 mm.

• Manual operation or can be automated with EROWA loading device

• Expert advice and customized solutions to meet your needs.

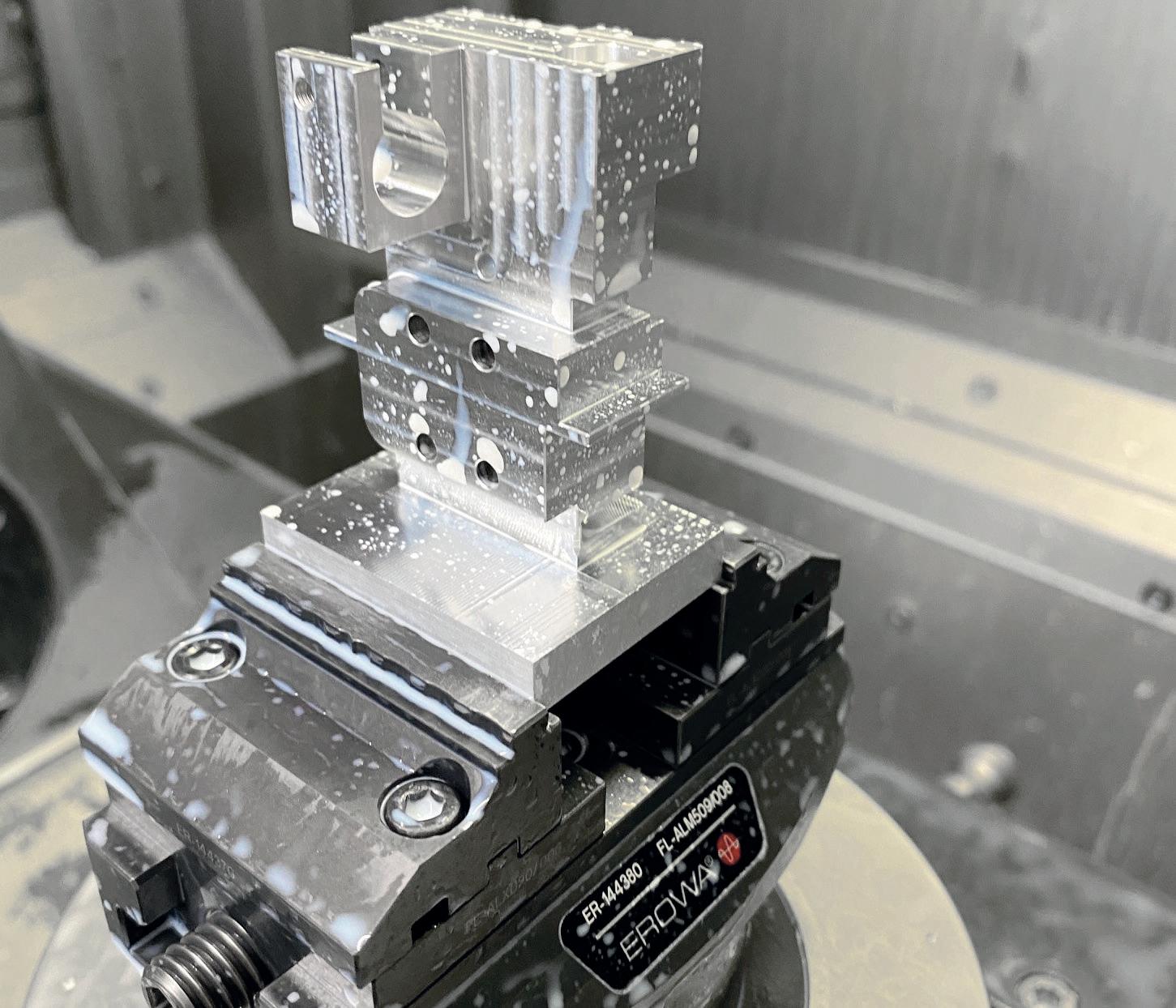

Workpiece carriers can be clamped into the chuck with a repeatability of 0.002 mm within a few seconds.

5-axis HSC milling - UPC 2.0 chuck with adapter pallet VPC clamping system and centric clamp.

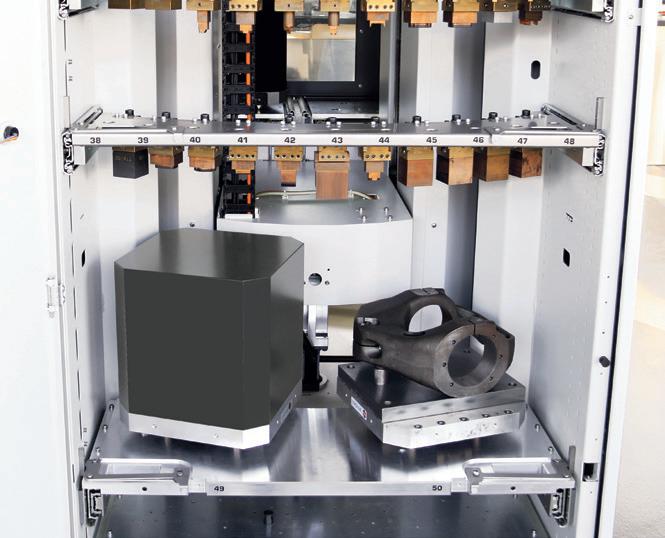

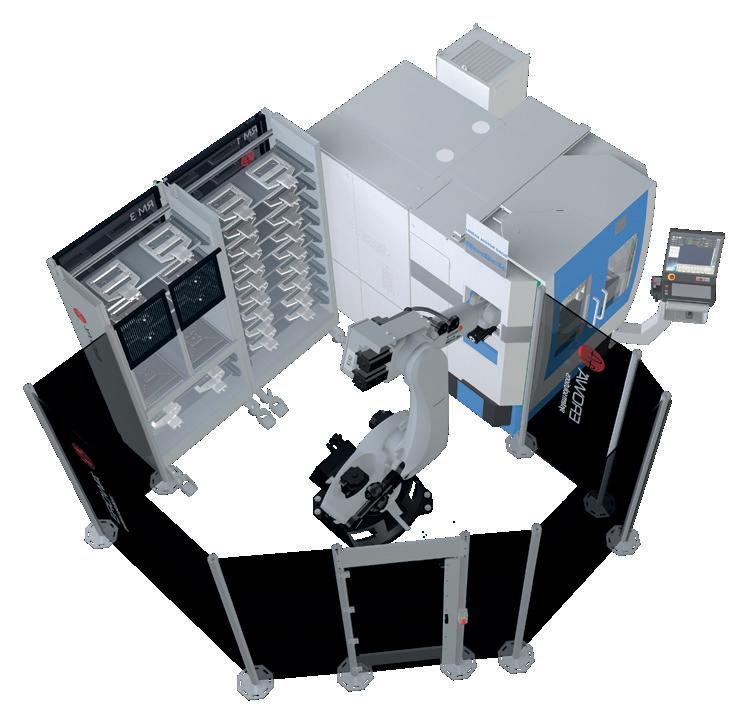

The operator removes the machined workpieces from the robot magazine and loads them with new parts to be machined.

Powerful and reliable hold during workpiece machining. PowerChuck P chucks are the precise basis for workpiece carriers.

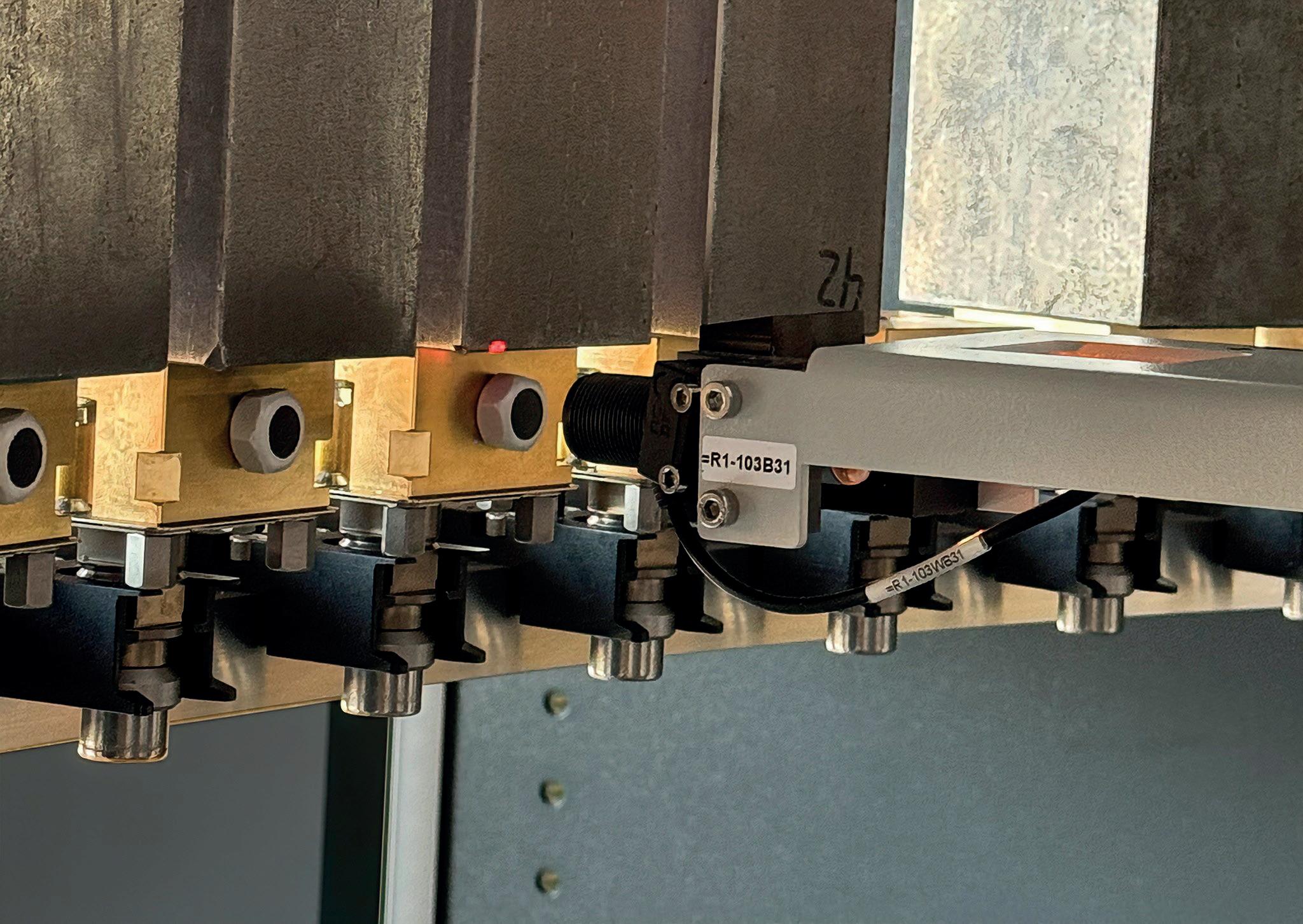

The EROWA MTS zero-point clamping system meets the highest demands. The new generation with wireless digital status monitoring makes Industry 4.0 a reality.

The ProductionChuck 210 tooling system is ideally suited for use on turning and cylindrical grinding machines.

EROWA tooling systems form the universal basis for all types of workpiece carriers like vises, workpiece clamps and clamping fixtures.

Palletize and precisely position large workpieces with the new and patented EROWA GTS-Giant Tooling System.

Automation according to your needsCustomized solutions for individual parts, small and large series

The automatic and reliable loading of production machines also significantly increases the number of productive hours. EROWA loading systems adapt flexibly to any production environment, whether as a simple standalone model or as a complex automation solution on rails for operating multiple machines.

• The right loading system for every need

• Variable robot types with continuous standard

• Standalone or linear solutions.

• Mixed pallet sizes in one robot

• Pallet monitoring in the magazine

• Depending on the robot model, max. transfer weight up to 5,000 kg.

• Process control system for reliable manufacturing

Significantly increase machine running times I

Flexible and mixed loading robots enable better utilization of the high-performance machines. This means that offpeak hours and weekends can be fully utilized productively and unmanned.

EROWA automation solutions optimize the material flow and increase production capacity. The linear EROWA Robot Dynamic model series is characterized by the possibility of integrating additional processing machines into the existing production cell over time and thus adapting to current requirements.

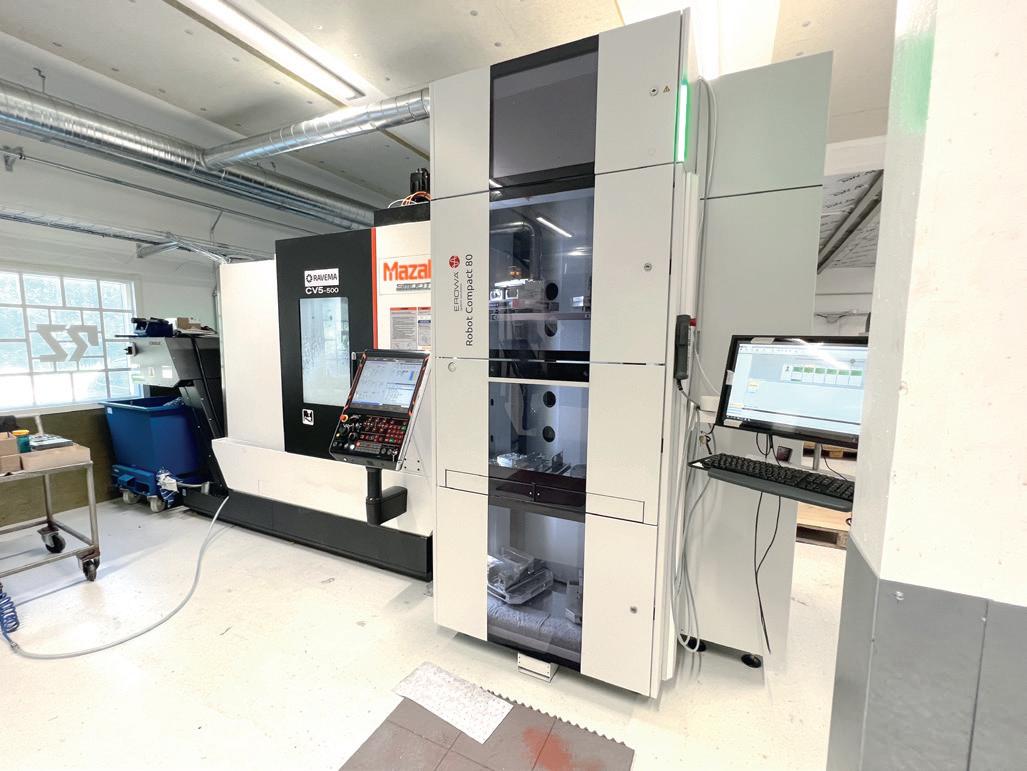

The highly productive production cell consists of an EROWA Robot Compact 80, which serves two vertical high-speed machining centers. The Robot Compact 80 takes up little space and yet offers a large number of magazine positions.

The machine and robot are a team, working quickly and precisely. This leads to shorter through-put times and lower error rates.

The EROWA process control system, JMS 4.0 monitors, and controls the entire production process. The accepted process data is transferred to the relevant production cells at the right time and in the right format. Feedback from machines, robots or the operator is recorded and made available centrally for evaluation.

With the large selection of EROWA loading systems, we meet your requirements in terms of transfer weight, magazine capacity and control interface. With the easy-to-use EROWA JMS 4.0 process control system, even orders from batch size 1 can be automated profitably.

Our core competence lies in the compatibility and expandability of our product range, which ensures seamless integration into your operation.

*Standard data (extended obstacle contours possible on request).

**Standard data (more machines possible on request).

EROWA loading devices are the perfect solution for the efficient and reliable operation of processing machines from a wide range of processing technologies and machine manufacturers. We will be happy to provide you with comprehensive advice and find the right EROWA automation solution for your needs.

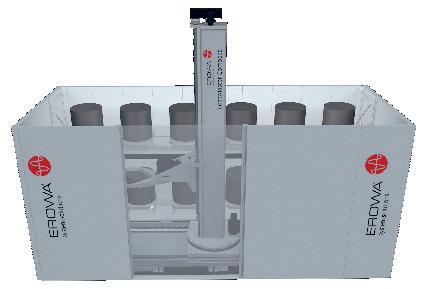

EROWA monoblock loading device for loading one processing machine.

EROWA monoblock loading device for loading two production machines and various production technologies.

Autonomous and highly efficient production cell for the flexible processing of different workpiece sizes.

The tall and slim design of the EROWA Robot Compact offers a large number of magazine places for different work-piece sizes.

EROWA 6-axis robot for pallet and blank handling. Single-machine loading or on rails for loading several processing machines.

Existing automation solutions are brought to a higher level of autonomy thanks to EROWA AGV technology.

Relieve your processing machines of unproductive set-up and presetting work. Determine offset data efficiently, carry out quick interim check measurements and increase process reliability.

The multifunctional EROWA measuring and presetting devices belong in every workshop and can be configured to customer specifications.

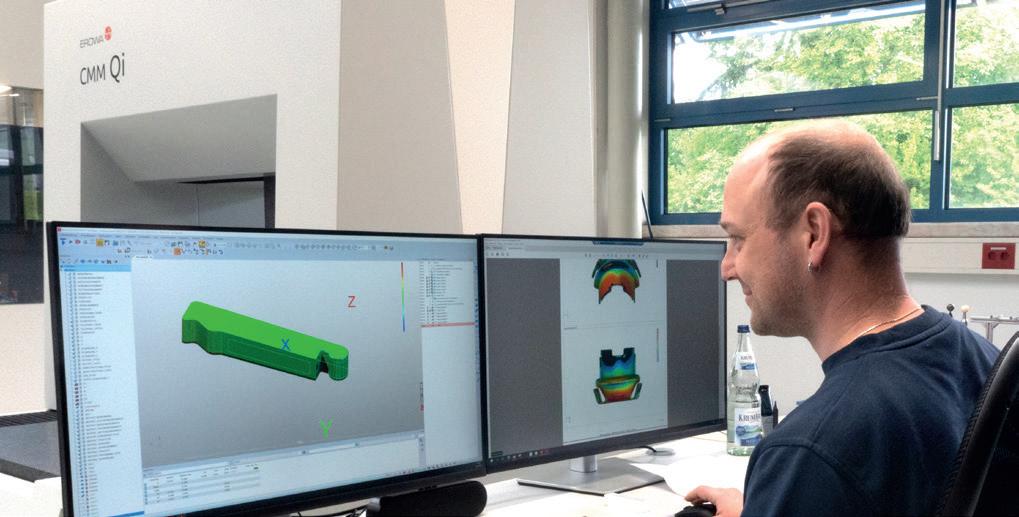

Everything is possible, from importing from various CAD systems and outputting graphically designed measurement reports to tactile scanning or the use of laser scanners. The system is perfectly configurable.

Presetting is one of the decisive process steps for the automation of individual parts and small batches. Thanks to EROWA‘s presetting software and predefined macros, you can carry out measurements even without previous metrological knowledge.

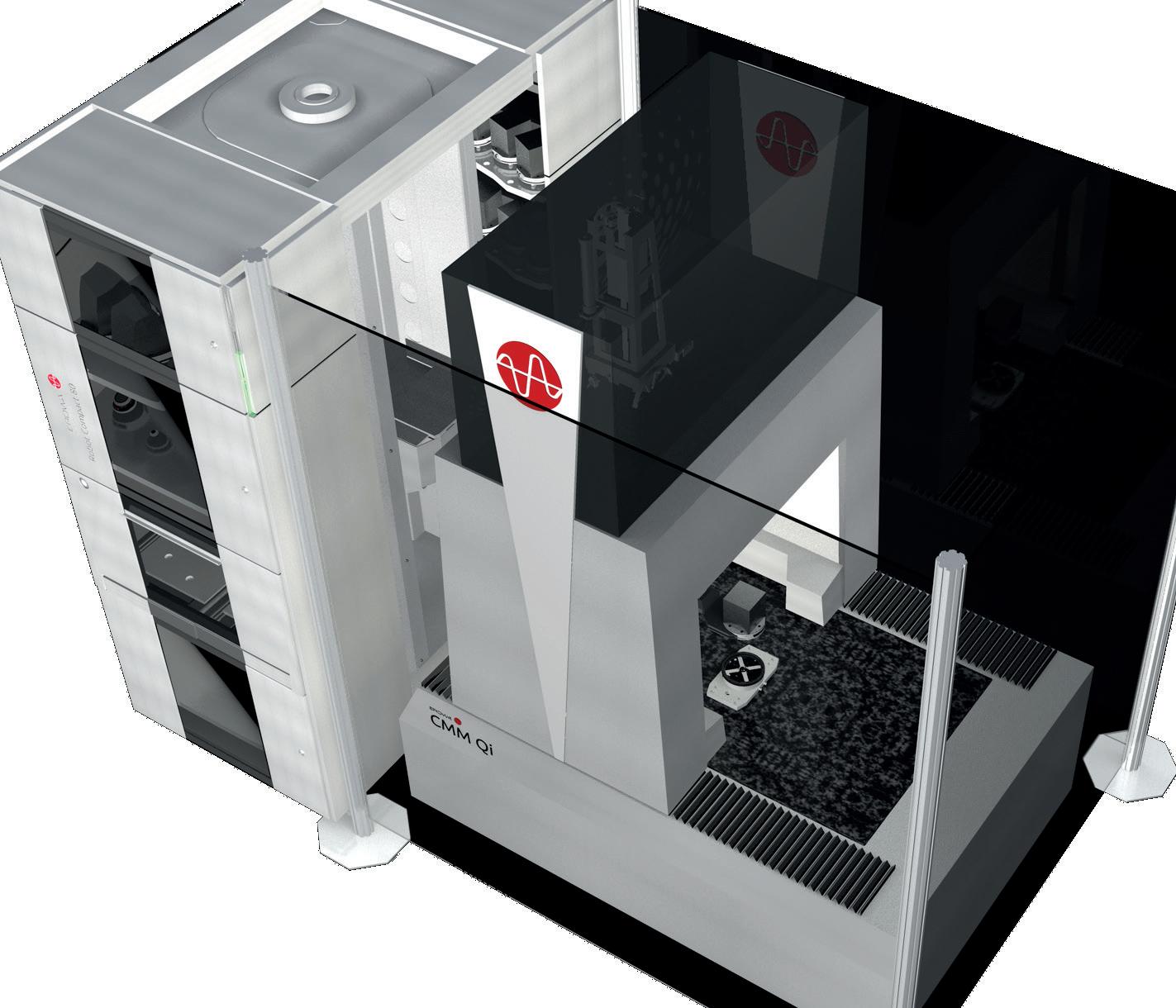

With the EROWA automation kit, the EROWA measuring machines can be easily integrated into the automated process chain. In this way, you can also carry out your inprocess measurements fully automatically in unmanned shifts.

Keep an eye on your process quality at all times. With EROWA measuring machines, you have the option of checking your components at any step in the process, even automatically.

EROWA measurement software solutions open up a wide range of possibilities in quality assurance and reverse engineering. From simple intermediate checks, presetting of tools and components and in-process measurements to sophisticated measurements on complex components or reverse engineering.

The EROWA process control system JMS 4.0 connects all data and controls the entire production process. It automates the data flow from the ERP and CAD/ CAM through to the production cells.

JMS 4.0 takes over the control of the robots and the data transfer and control of the connected machines.

more information: EROWA process sontrol system JMS 4.0

You determine the level of integration yourself. With or without automation, whether connection of a single machine or a fully integrated workshop solution. The EROWA EWIS handheld reader uses an identification chip to record all pallet/workpiece data and transmit it to the JMS® 4.0 process control system. Simple, safe, fast

JMS 4.0 provides a clear overview. All productionrelevant data is displayed in a user-friendly way. Current status and status messages support the operator.

Identification using RIFD chips can also be automated. When a magazine is loaded with workpieces or electrodes, the magazine is automatically identified by sensors and the information is transferred to the process control system. Automatic identification guarantees a high level of process reliability.

Dashboard and supervision applications show the efficiency key figures in real time and the current status of the production cells. These can also be viewed on the EROWA mobile app.

The EROWA process control system takes over the control and monitoring of production systems. The complete consistency of the data enables truly comprehensive control and process reliability.

Important things need to be planned. And your next step is certainly among the important things. It is your start into a new, efficient era. We are pleased to be with you on the way. As consultants, in practice. For you to know at all times what you’re engaging in. The next EROWA branch office is not far – take the step.

EROWA Technology, Inc. North American Headquarters 2535 South Clearbrook Drive Arlington Heights, IL 60005

USA

EROWA Group Business Network: a member of ORENDA Holding Ltd. Subject to technical changes. Registered trademark of EROWA AG, Copyright © EROWA AG, for a number of products of EROWA AG patents are existing or pending.

Tel. 847 290 0295 Fax 847 290 0298 e-mail: info.usa@erowa.com www.erowa.com

Singapore

EROWA South East Asia Pte. Ltd. 56 Kallang Pudding Road #06-02, HH@Kallang Singapore 349328

Singapore Tel. 65 6547 4339 Fax 65 6547 4249 sales.singapore@erowa.com www.erowa.com

Japan

EROWA Nippon Ltd. Sibadaimon Sasano Bldg. 2-6-4, Sibadaimon, Minato-ku 105-0012 Tokyo

Japan

Tel. 03 3437 0331 Fax 03 3437 0353 info@erowa.co.jp www.erowa.com

Italy

EROWA Tecnologie S.r.l. Sede Legale e Amministrativa: Via Alfieri Maserati 48 IT-10095 Grugliasco (TO)

Italy

Tel. 011 9664873 Fax 011 9664875 info@erowa.it www.erowa.com

Unità di Treviso: Via Leonardo Da Vinci 8 IT-31020 Villorba (TV)

Italy

EROWA AG Knutwilerstrasse 3 CH-6233 Büron

Switzerland

Tel. 041 935 11 11 Fax 041 935 12 13 info@erowa.com www.erowa.com

France

EROWA Distribution France Sarl PAE Les Glaisins 12, rue du Bulloz FR-74940 Annecy-le-Vieux

France

Tel. 04 50 64 03 96 Fax 04 50 64 03 49 erowa.france@erowa.com www.erowa.fr

Spain

EROWA Technology Ibérica S.L. c/Via Trajana 50-56, Nave 18 E-08020 Barcelona

Spain

Tel. 093 265 51 77 Fax 093 244 03 14 erowa.iberica.info@erowa.com www.erowa.com

China

EROWA Technology (Shanghai) Co., Ltd. G/F, No. 24 Factory Building House 69 Gui Qing Road (Caohejing Hi-tech Park) Shanghai 200233, PRC China

Tel. 021 6485 5028 Fax 021 6485 0119 info@erowa.cn www.erowa.com

Benelux

EROWA Benelux B.V. Segment 20A 6921 RH Duiven

Netherlands Tel. +31 85 800 1250 benelux@erowa.com www.erowa.com

Germany

EROWA System Technologien GmbH Gewerbegebiet Schwadermühle Roßendorfer Straße 1 DE-90556 Cadolzburg/Nbg

Germany

Tel. 09103 7900-0 Fax 09103 7900-10 info@erowa.de www.erowa.de

EROWA Nordic AB Fagerstagatan 18A 163 53 Spånga

Sweden

Tel. 08 36 42 10 info.scandinavia@erowa.com www.erowa.com

EROWA Technology Sp. z o.o. Eastern Europe ul. Spółdzielcza 37-39 55-080 Ką ty Wrocławskie

Poland

Tel. 71 363 5650 Fax 71 363 4970 info@erowa.com.pl www.erowa.com

India

EROWA Technology (India) Private Limited No: 6-3-1191/6, Brij Tarang Building Unit No-3F, 3rd Floor, Greenlands, Begumpet, Hyderabad 500016 (Telangana)

India

Tel. 040 4013 3639 Fax 040 4013 3630 sales.india@erowa.com www.erowa.com