BALIHT

Raising the temperature of redox flow batteries

Organic redox flow batteries show a lot of promise as a means of storing energy generated from renewable sources, yet further work is required before they can be widely applied.

We spoke to Marta Pérez and Thomas Hoole about the work of the BALIHT project in developing and testing a redox flow battery capable of working at high temperatures.

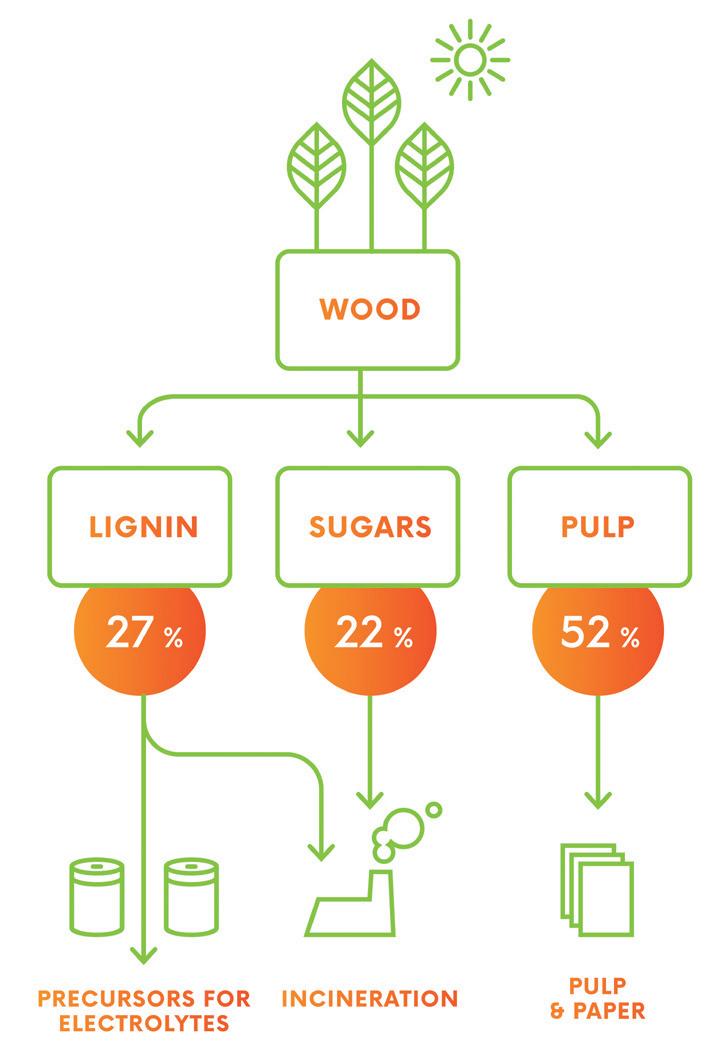

An increasing proportion of Europe’s overall energy demand is being met by renewable sources such as solar and wind, as countries across the continent seek to reduce their dependence on fossil fuels. Organic redox flow batteries could play an important role in storing renewable energy and in encouraging the shift towards a more sustainable economy, yet there is more work to do before the technology is ready for wider application. “There are not many redox flow batteries at a high Technology Readiness Level (TRL),” acknowledges Thomas Hoole, a Technology and Innovation Engineer at Grupo Cobra. This is an issue central to the BALIHT project, an EU-backed initiative bringing together 12 partners from across Europe to develop a redox flow battery capable of working at temperatures right up to 80ºC. “We are developing a new type of redox flow battery and aim to bring it to a higher TRL,” outlines Hoole. “We’re using a material called lignin in the electrolytes, which is a by-product of the wood industry.”

BALIHT project

This material is abundantly available in Europe, in contrast to some of the materials used in other redox flow batteries such as vanadium, which has attracted a lot of attention in research.

and renewable energies group at BALIHT partner Aimplas. The German company CMBlu is responsible for the work on the electrolytes in the project, with researchers aiming to identify the most promising candidates. “They investigated a few different combinations of molecules for the electrolytes. The main characteristics they were looking for were temperature tolerance, and they also wanted to make sure the electrolytes didn’t decompose over several cycles. The more resistant it is to decomposition, the better,” says Hoole. The performance of the electrolytes will decay over time, but as they are kept externally in the BALIHT battery there is the possibility to refresh the electrolytes and recover their performance to a certain degree. This is not possible in lithium-ion batteries, which are commonly used in electric cars. “With the BALIHT battery, the electrolyte is kept externally, separate from the cells, whereas lithium-ion batteries have a standard rate of decay, because everything is internal,” explains Hoole.

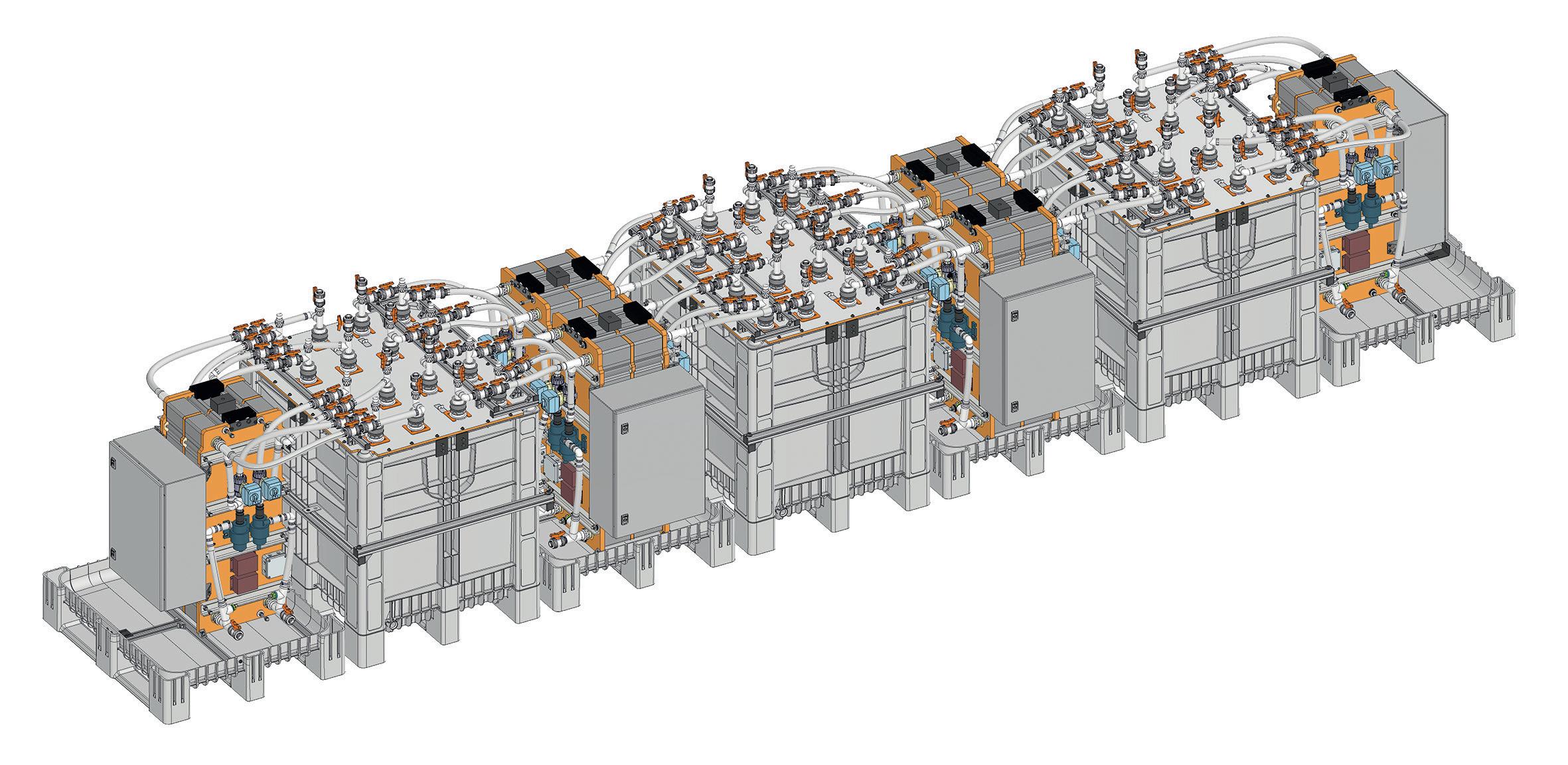

We’ve also looked at the tanks and their connection to the system,” she outlines. “We have tested the different parts, to be sure that each works effectively within the battery overall. These tests were designed to validate the efficiency of the battery.” Researchers are working to achieve an energy efficiency level 20 percent higher than other organic batteries. A key point here is that the BALIHT battery doesn’t include a cooling system, which consumes a lot of energy, while Pérez says it also offers some other important advantages over comparable systems. “It’s high-power and it requires less pump energy,” she says. However, redox flow batteries remain relatively costly in comparison to more mature technologies, which is a limiting factor in terms of wider adoption, an issue

“We want to check that the electronics control the battery as expected and that the battery functions inside the factory,” outlines Hoole. The next step will be to test the battery on photovoltaic panels currently under construction at a port on the island of Ibiza. “The idea is to optimise the amount of renewable energy and integrate it with the battery,” explains Hoole. “We will have a SAT (Site Acceptance Test) test in Ibiza, which basically builds on top of the FAT. We will do some standard tests to assess the capacity and power of the battery, along with some additional tests. Then hopefully we will run the battery for a few months, depending on whether we have enough time before the deadline. In that case, we would have a final test in the last week, where we would compare the original and final results.”

We are developing a new type of redox flow battery and aim to bring it to a higher Technology Readiness Level. We’re using a material called lignin in the electrolytes, which is a by-product of the wood industry.

being addressed in the project. “We’re looking at how to bring the overall cost down,” says Hoole. “The main sticking point when it comes to cost is around creating the electrolyte from the lignin. If it was done on an industrial scale, then the cost would come down. That’s not being done at the moment, so the price remains high. Over the next few years, we hope these batteries will be shown to be a very good alternative to lithium and vanadium-based batteries.”

Testing stage

This work is already in progress, with preparations to test a prototype of the battery ongoing, both in a factory and on site. The first step is to conduct a FAT (Factory

The partners are also working on an agreement to keep the battery in Ibiza for a full year of testing, beyond the conclusion of the project. This would provide an opportunity to test the battery throughout the year and build a deeper picture of its performance.

“It can then be tested at varying levels of energy demand and in different seasons,” points out Pérez. The results of this testing could then inform the ongoing development of the battery and guide further research, with researchers aiming to bring it closer to practical application by the end of the project. “There is interest in scaling up the technology, but we will have to see the test results first,” says Hoole.

Development of full lignin based organic redox flow battery suitable to work in warm environments and heavy multicycle uses.

Project Objectives

BALIHT develops a new organic redox flow battery suitable for use at higher temperatures, without the need for a cooling system. This innovation allows the battery to be up to 20% more energy efficient than existing organic redox flow batteries.

Project Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement No 875637, under the topic LC-BAT-4-2019 - Advanced Redox Flow Batteries for stationary energy storage.

Project Partners https://baliht.eu/projectpartners/

Contact Details

Project Coordinator, Itziar Carracedo Fernandez AIMPLAS València Parc Tecnològic Calle Gustave Eiffel, 4 46980 Paterna Valencia, SPAIN E: icarracedo@aimplas.es W: https://baliht.eu/

https://doi.org/10.1111/jiec.13347 https://doi.org/10.1016/j.isci.2023.106060

Thomas Hoole is a Technology and Innovation Engineer at Grupo Cobra in Madrid. He has experience working on the cradle to grave of several different battery technologies and holds a Masters degree in nanostructured materials for nanotechnology applications.

Marta Pérez Argilés is a researcher in the construction and renewable energies group at AIMPLAS. She holds a Master’s degree in Polymer and Composite Technology and has collaborated in several research lines and projects related to thermoplastics.

Lignin has some interesting electroactive redox properties as well as other attributes which make it an attractive option for redox flow batteries. “Lignin is relatively easy to recycle, it’s pretty safe, and it also tends to be inexpensive,” explains Marta Pérez, a researcher in the construction

The project’s agenda also includes research into the other components of the battery, including the battery management system and the tanks, and Pérez says the different parts have been rigorously tested. “We have tested the materials with respect to certain mechanical and chemical parameters.