IS IN

s r Innov at i or

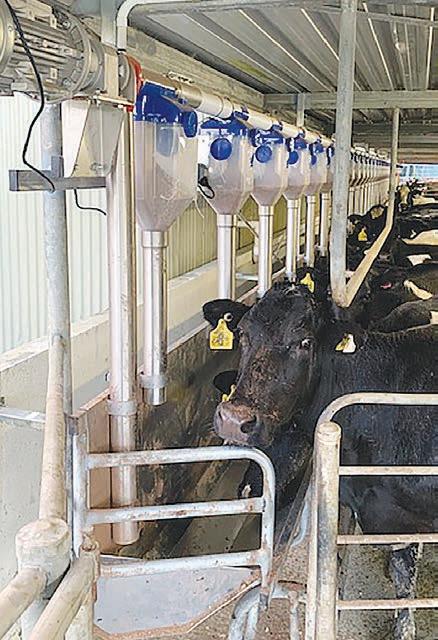

we believe a successful farmer is a prepared farmer. Monitor every cow on your dairy farm 24/7 with real-time insights into fertility, health, and nutrition. With CowManager, you can focus on the right cow at the right time.

“We nearly paid it o completely in the first 12 months because it saved cows’ lives.

Because of CowManager, I identified that the cows needed more fibre in their diet, so we added dry silage to their diet and their rumination climbed instantly.

When you get to the sixth or seventh week of mating, you’re starting to get a little over it. My concentration starts to wain a little bit, which I’m sure contributes to the empty rate. CowManager doesn’t allow you to do that. It just keeps telling you the cows.”

JODY ANDERSON 027 474 6094 Waikato/BOP jody.anderson@agrihq.co.nz

DONNA HIRST 027 474 6095 Lower North Island donna.hirst@agrihq.co.nz

www.farmersweekly.co.nz ISSN 2624-0939 (Print) ISSN 2624-0947 (Online)

ANDY WHITSON 027 626 2269 South Island andy.whitson@agrihq.co.nz

GRANT MARSHALL 027 887 5568 Real Estate realestate@agrihq.co.nz

ANDREA MANSFIELD 027 602 4925 National Livestock Manager Salesforce Director livestock@agrihq.co.nz

DEBBIE BROWN – Directory classifieds@agrihq.co.nz 06 323 0765

LANA KIESELBACH 027 739 4295 Production Manager lana.kieselbach@agrihq.co.nz

Advertising material: adcopy@agrihq.co.nz

By Phil Duncan

By Phil Duncan

The team at Weather Watch crunch the data to see what farmers may have in store for the summer growing and harvesting season.

Our third La Niña in a row is still with us – but 2023 looks to be different with neutral conditions returning, and even some chatter about El Niño. So what is the set-up for summer and beyond?

Firstly, our third consecutive La Niña remains but isn’t very powerful. It peaked in November (not that you may have noticed) and is expected to gradually fade away over summer. La Niña means sea surface conditions north of New Zealand are warmer than average (they are warmer than average around most of NZ too, but that isn’t due to La Niña).

This encourages more low pressure to our north and that simple formula or low pressure north of NZ and more high pressure over southern NZ creates an “easterly flow” in the north. This is why some popular camping grounds and holiday spots in the east aren’t always super flash in a La Niña summer (this is coming from experience of tents being ripped during our family summer holidays in Hahei, Coromandel Peninsula).

“At other times NZ acts like pins in a bowling alley and that cyclone just rolls straight in for a strike. It’s really luck of the draw – or by that measure, luck of the high-pressure zones that actually guide cyclones.”

The tropical cyclone risk in NZ is usually the same each year – we generally have the risk of being impacted by two or three ex-tropical cyclones. Sometimes they head to NZ but track just off to our

east so we entirely miss them (and all their rain).

At other times NZ acts like pins in a bowling alley and that cyclone just rolls straight in for a strike. It’s really luck of the draw – or by that measure, luck of the high-pressure zones that actually guide cyclones.

Cyclones behave like rivers on land –they go for the path of least resistance. Cyclones avoid high pressure zones (the hills in the atmosphere) and track around them and between them. If they run into one the cyclone usually falls apart, or, as New Zealanders say, becomes “a fizzer”.

With La Niña fading over summer, it still actually adds a little more oomph to that tropical cyclone risk – but doesn’t necessarily make that path to NZ any easier. It will still be down to the large high pressure zones in our part of the world.

So what happens in 2023? Keep in mind that during peak La Niña in spring, NZ was still frequently being dominated by weather patterns out of Australia, the Tasman Sea and the Southern Ocean (very much NOT La Niña!). So the often chaotic weather pattern driven by the Southern Ocean may still impact us.

Neutral (that is, no La Niña or El Niño) is generally good for NZ as it creates

more variety and chaos – that’s usually good in the world of animals and pasture as you get a healthier mix of rain, warmth and sun rather than just one of those, which can fast lead to flooding or drought. Chaos and variety are good.

Firstly, it should be noted that no one is locking in El Niño. But the “model of all models” (which places the most reliable climate and weather global models side by side) shows our Pacific climate strongly heading back to neutral in 2023 – and perhaps even continuing on to El Niño, the opposite of La Niña.

El Niño is when warm sea surface waters at the equator get blown more towards South America – which cools the sea north of NZ and encourages more high-pressure zones in the Tasman Sea.

The result for NZ? Drier, windier west to southwest winds, more cloud in the west and a higher chance of drought and heat in the east and north of both islands.

The last El Niño was in 2018/19 but it was mild. The last major El Niño was 2014/16 and prior to that 1997-98. So be prepared for dry conditions in 2023 – but remain optimistic that NZ’s location on Earth means no long range forecast is ever set in concrete.

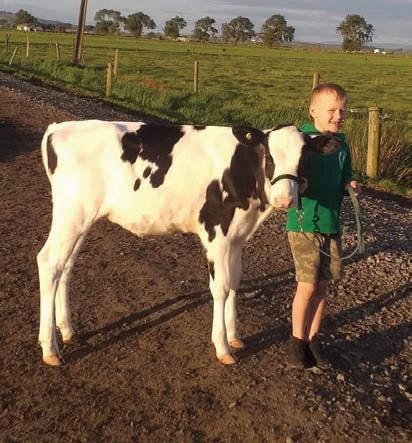

Taranaki farmers Stefan Buhler and partner Amanda Linders’ high-achieving herd are award winners.

ASouth Taranaki farmer believes that to have high producing cows, they must have been fully-fed and wellgrown as young stock,.

Stefan Buhler has once again topped the Nutritech Performance Awards run by Holstein Friesian NZ, making it three in a row.

He and partner Amanda Linders milk 260 cows on their 80 hectare, System 5, Manaia farm, Buelin Holsteins. They also have two (25ha and 30ha) runoffs.

Buhler believes that what happens in a calf’s early life carries through to its milking performance.

The herd has a reputation for recordbreaking production.

The farm’s 2400-2500kg MS per hectare average is also a personal record.

They aim to produce 750kg milk solids per cow as a minimum, and usually average around 760-770kg. According to DairyNZ the 2020-21 national average is 398kg MS. Some cows regularly produce more than 1000kg MS.

Achieving such high milk production hasn’t happened overnight. Buhler has been on a quest throughout his farming life to discover the amount of production that can be achieved from the New Zealand dairy cow.

His love of farming began at an early age. One of six children, every day he and his three brothers would divide up the lounge floor into four little farms.

“The first person to set up the farms got the best one. The worst farm was the

one in front of the television because you were always getting told to get out of the way. But that’s when my love of farming began,” he says.

“We brothers would always squabble over who would help dad feed the calves. Often dad just gave up and told us all to come. It was a real privilege to go through the ranks and get to the age where you could hold the lids of the old cream cans that dad used to feed the calves.

“The ultimate farm job was to be allowed to drive the tractor.”

He left school to work on his parents’ main farm for two years, then began 39% sharemilking on one of their small farms.

When he was 21 he was approached to be a 50:50 sharemilker on a 40ha Otakeho farm, milking 160 Jersey cows. They were beautiful cows and he ended up buying the herd and remained on that farm for six years.

He 50:50 sharemilked on a 65ha Auroa farm for a further five years before buying an 80ha Awatuna farm at the foot of Mount Taranaki. He put managers on that property and stayed milking on the Auroa farm.

“After five years sharemilking I knew it was time to move to the new farm. The land was harder up there and it was far wetter and colder. The Awatuna farm was the same size as my current one, but could only milk 220 cows whereas I can milk 280 here.

“I worked that farm for seven years and one day I said to myself ‘I don’t enjoy

• Farm owners: Stefan Buhler and Amanda Linders

• Location: Manaia, Taranaki

• Farm size: 80 hectare, two runoffs of 25ha and 30ha each

• Cows: 260 Holstein Friesian

• Production: 2400-2500kg MS per hectare average, aim for 750kg/cow

this anymore. I’m either going to give up farming, or instead of buying a bigger farm, I’ll buy a better one’.”

His parents owned two adjoining 40.5ha farms, with dairy heifers on one and 50:50 sharemilkers on the other. They wanted to move to town and asked him to make them an offer for both farms. He bought them at market value to run as a single dairy farm.

That summer he employed a worker to help milk on the Awatuna farm and

with converting the two farms. This allowed him to continue working on the conversion and was a major factor in getting that farm converted on time. He was fortunate to be able to begin

the conversion during autumn and pulled out every fence, hedge except the boundaries, race and water pipe.

He could put the fences in during summer, but had to wait until the May

1 to start the remainder of the work. Halfway through he began to wonder why he was doing all the work and maybe should’ve just run heifers instead.

“I continually doubted myself. I’d already converted one farm so knew how hard it was, and here I was doing it again. But I always knew that when finished, everything would be exactly how I wanted it to be.

“It’s amazing what can be achieved when your contractors have the same vision as you and step up and go the extra mile.”

Neither of the farm’s two 14 a side herringbone sheds were suitable for the 280 cow herd on the combined farms,

We have a long-term solution.

Struggling with your holiday roster?

“It was a real privilege to go through the ranks and get to the age where you could hold the lids of the old cream cans that Dad used to feed the calves.”

so a 44-bail rotary cowshed with ACR, in-shed feeding and a Protrack system was built, but delays meant that it wasn’t operational until December. He’s been tempted to use collars and understands their benefits, but is holding off at this stage.

“It was a headache milking through one small shed. I’d employed a worker and we milked a herd of 140 cows each. Each milking took three-and-a-half hours, which tired the cows and they often sat down in the yard. It was a very stressful time.”

The new farm was producing around 420kg MS per cow, which was similar to

his previous Awatuna farm. Even with a new cowshed and in-shed feeding he could reach 460kg MS, but not the 500kg MS per cow he was aiming for. He couldn’t understand why he couldn’t achieve higher production, even though he was sure his cows were capable of doing it. A chance encounter changed his way of thinking.

“I bumped into an old boss who said that I wasn’t setting my sights high enough, and that if I aimed for 600kg MS, I would easily reach 500kg. He told me that any horse can run a race, but if you want it to win, you must give it the best feed.

“It got me thinking how I could achieve that. I decided to build a feed pad and haven’t looked back since. We have quite tough summers and I needed to learn how to farm them too.”

His cows must be fully fed to achieve their high production, and the feed pad is an important component for that. It’s used every day to some degree, except to a lesser extent during summer when silage is fed out in the paddock.

He never goes above a 25 day round, even in late autumn because he uses the feed pad to manipulate feed quantities. It’s only increased when the cows are being dried off in small groups, or at the start of calving. When the spring grass is growing strongly the round drops to 1820 days. Any surplus grass is harvested as baleage in front of the cows.

Topping plays a big part in his pasture management to ensure high quality pasture. He tops the paddocks in front of the cows from early September to the January 1. The main reason he tops is to make it easier for the cows to hoover up the grass.

If he sees a paddock with a surplus of grass he’ll mow it, often mowing up to four paddocks ahead of the cows, and gets the contractor in to bale three of those paddocks.

“A cow can eat far more grass if she doesn’t have to rip it up, and by topping I can get a lot more food into them. The analogy I use is; that two people have a wheelbarrow each, and one has to rip the grass up to fill it up and the other simply

picks up the pre-mown grass. The person picking up the cut grass would do it much faster and be far less tired.

“It’s a really simple concept. A cow can only do a certain number of bites. So I can get more food into a cow, in a far shorter period of time, because she does fewer bites and doesn’t get tired. She also has more time for rumination.”

The runoffs play a major part in achieving his high MS production per hectare. Anything harvested from them is food that doesn’t have to be bought, and makes the farm more self-contained.

About 11ha of maize and 22-24ha of grass silage are harvested from the runoffs and approximately 9ha in front of the cows on the day the runoffs are harvested. A further 3ha of maize is harvested from the dairy farm.

“Silage is my summer milking feed for the dry period. Cows don’t milk well on just maize, they need protein. So we make good quality silage for them. We’re a System 5 farm but strive to grow as much as possible from the farm and runoff and are self-sufficient in grass and maize silage.”

Maize silage mixed with DDG, PKE and molasses is fed on the feed pad. Currently the in-shed feed is made up of 3.5kg per day of a 50/50 blend of DDG and soya meal.

Every farmer has a different way of doing things and Buhler always stresses that his method is what works for him, for his particular situation.

He emphasises the need to consistently feed high quality food to your cows every day, including summer, because if you inadvertently drop the ball you never recover that production. And having cows capable of achieving high production helps along with knowledge and good management.

Effluent is spread over all 26 paddocks,

After Janneke van Wagtendonk, Managing Director for AHV NZ, explained how the AHV udder support solutions work, I bought a bucket of Quick, Extra and Aspi boluses each and used them on cows with deviating milk values. AHV also analyzed my herd test data and we looked at the history of each cow and prioritized what cows to support first.’

The AHV Udder Health Program supports your animal’s natural resistance for production, longevity and development of the herd. I am very happy with the results and that cows can remain in the milking

herd after the boluses, which means less hassle and no risk of mistakes to be made by me or my staff.

‘‘A

“Silage is my summer milking feed for the dry period. Cows don’t milk well on just maize, they need protein. So we make good quality silage for them.”

which reduces fertiliser use.

“In the years that we’ve been using the feed pad and bringing silage and maize home from the runoffs, we’ve put so much food through the cows that it’s given the farm a great deal of fertility.”

He prefers his cows to be 600kg. If he milked a smaller cow he would need to milk more cows, regardless of the breed, to achieve the same production. This would only increase his workload.

“The amount of milksolids a Friesian cow can produce is pretty incredible. I’m yet to see the limit of what breeding can give me, and I’m sure I haven’t reached the limit.”

The 25ha runoff is used to run the yearlings until November when the calves go there. The 30ha runoff is used for the yearlings from the November 1 before returning as in-calf heifers in midMay, before 135 winter cows are moved on.

Calving begins on July 1 for the main herd and the heifers traditionally began calving on June 22 but the date has been brought back to the middle of July due to the last two springs being so wet. It’s

been too tough calving that early, and he would rather milk longer towards the end of the season.

The farm has a 12-13 week calving season and the last cows calve around the first week of October. The last cows still come in and milk well and often come in early the following year. Last year one of his late cows calved in October and this year calved in August.

“I don’t get tired of calving. Late cows aren’t a problem because we have runoffs and don’t have late cows eating our precious spring grass at home. The late cows stay on the runoff until 10 days before calving, before coming back to the farm. The early cows come home three weeks before they’re due to calve.”

They need 65 replacement calves but more are raised if they’re from imported genetics or bought in animals, to assess

the quality of those calves.

The calves are collected daily and fed colostrum for as long as it’s available. Milk powder is then fed through an automatic feeder. The feeder recognises each calf’s ear tag and only allows it to consume its correct daily milk allowance.

“I prefer to feed fewer litres to the calves but make higher concentrated milk. I’ve tried feeding whole milk through the feeder but had too many blockages.”

The calves are weaned at 100-120kg. Buhler says weaning is a critical period in an animal’s life. His philosophy is that the calf has to be ready for weaning, the weather has to be right, and the grass must be growing. If the calves are weaned too early and there’s not enough grass, the calves quickly go backwards.

He loves seeing new stock coming into the herd and attending sales.

“Amanda is supportive of that because she knows it’s what makes me tick.” he says.

“I’m the handbrake,” Amanda jokes.

“But I know that buying cows is Stefan’s passion. He calls it his very expensive hobby.”

He has a passion for breeding and calf rearing and enjoys being in control of each animal from birth until the day it leaves the farm.

He isn’t averse to buying cows if it has the right look and production.

“You don’t get it right every time, but I’ve bought some really good cows. I’ve paid good money for some, but I don’t mind paying for something good. But the cow that comes must be better than the one that’s going out.”

They started their stud, Buelin Holsteins, about six years ago and they

have bulls with LIC and CRV. But he is not driven by that, he’s driven by production and type.

“I prefer a cow that comes in to be milked and my first thought be ‘Wow; what a cow’ so that puts a lot of emphasis on breeding the right cow.

“I like my cows to come in as mature animals because I want them milking from day one, rather than them spending the next few years trying to grow. To achieve that you need the right genetics, because you can’t grow a strong cow from frail genetics.”

This year AI started on October 10 using nominated bulls and ran for five weeks before short gestation bulls (AI) are used. Jersey bulls were put over the heifers. The in-calf rate is 89-90%.

He’s now finding it difficult to find New Zealand cows with his preferred udder type. Consequently he’s been using some overseas genetics and has been wowed by their udders. Their udders tend to hold together far better when doing big production.

“I’m demanding more from the NZ cow. She’s a strong cow except for udder support, so I’m using some genetics from Holland and USA.”

When selecting a bull, he first looks at their protein breeding value (BV) and fat BV to ascertain what they’re capable of producing before he looks at their BW.

He believes the incoming emission regulations are going to force farmers into milking fewer cows, but do more production.

“Udder conformation will then be even more important.

He favours a capacious cow and one

factor he loves about the NZ cow is that she is capacious. But she is now being bred to be too small for his needs. He believes a 500kg cow doing such high production doesn’t last long in the herd.

They have two staff, one of who has worked on the farm for 15 years and the other is his young nephew. Buhler believes his youthfulness has brought a new lease of life to the property. Amanda has been a fulltime kindergarten teacher with Kindergarten Taranaki since 2007 but helps out when needed.

“Stefan loves going to the cows, but loves going to his yearlings even more. There are plenty of pets among them that rush up to us and nearly bowl me

over. The calves aren’t his pets of course, but he never regards any of his animals as ‘just commodities’ either,” Amanda says.

‘Farming is an awesome life. I love the cows and enjoy occasionally cupping the cows and doing the farm jobs. Hosing down the yard is my favourite job though. If I sense Stefan needs some moral support I might say ‘Do you want some help?’ as he goes to the runoff.”

“I often don’t need the help, but the company is important. Sometimes that’s all that’s needed,” Buhler says.

Looking ahead, his greatest concern is government emission tax regulations and he’s still trying to determine how to remain a profitable farmer. He’s surmised that the solution will probably be to milk less cows.

“My future over the next few years will probably be to drop cow numbers, buy in less dry food and work with what I can grow. I think all farmers are unsure of how the regulations are going to affect them.”

But the challenges are why they are farming. No two days are the same and as challenging as it can be, it’s a job they have a passion for.

It’s been an interesting life and he

“I think that in the short term things may be tough for farming, but long term it will be very rewarding because farmers will be doing less work.”

wouldn’t change anything about it. He always tells younger farmers that farming is still a good life.

Buhler has been milking cows for 41 years and is now wondering how much longer he can continue. He knows that he can’t sustain his current workload

and will need to alleviate some of the pressure.

“It’s the cows that keep me farming. The thought of not milking my cows is strange. It’s a difficult decision, but I think that in the next few years the time will come to sell my herd.

“I think that in the short-term things may be tough for farming, but long term it will be very rewarding because farmers will be doing less work. There’ll be fewer cows, and farmers will be getting paid more for milk solids. The farmers who hang in will be well-rewarded.” n

Anew fundraising campaign by Breast Cancer Foundation NZ (BCFNZ) has been launched to protect more rural women from breast cancer through its early detection education programme.

The campaign aims to raise $600,000 – although a generous donor has agreed to match donations up to $300,000 – and BCFNZ is asking Kiwis to help.

The money raised will be used to build a new, state-of-the-art Pink Campervan that will allow its team of specialist breast nurses to reach more women in New Zealand’s most isolated rural communities.

Latest figures show the regions that have the lowest participation rates in the national breast screening programme: Waikato (56.3%), Tairāwhiti (58.7%), Northland (63%) and Bay of Plenty (63.3%). These rates fall well short of BreastScreen Aotearoa’s 70% target.

With one third of breast cancers being diagnosed outside of New Zealand’s main centres, BCFNZ is endeavouring to reach more women in these regions with its education programme to encourage more women to undergo regular breast screening.

“Getting more women into screening and educating them about early detection is key to our vision of reaching zero deaths from breast cancer –especially in the wake of covid-19, which set screening levels back by 10 years,” Ah-Leen Rayner, chief executive of Breast Cancer Foundation NZ, says.

“If we don’t act now, we’ll lose one of the best tools we have to deliver our life-

saving messages, as our old Pink Caravan faces too many limitations.”

The charity’s old Pink Caravan, affectionately known as Pinkie, has travelled around the motu since 2014 with breast nurses on board, educating women about the signs and symptoms of breast cancer, family risk, and the importance of mammograms and selfchecking.

After thousands of kilometres travelled, the iconic retro caravan has become increasingly unfit for purpose. It relies on volunteers to tow it around, which restricts the timing and location of visits. The charity is building a new custommade campervan that nurses will be able to drive themselves, giving them better access to hard-to-reach communities.

“We’re asking New Zealanders to help us to raise the funds to build a new Pink Campervan, so we can take these messages to every corner of the country, no matter how remote or isolated, where women need us the most. And the impact of your donations will be doubled, as a generous donor has already committed to matching every dollar raised up to $300,000,” Rayner says.

Breast Cancer Foundation

NZ has launched a fundraising campaign to raise money to build a new Pink Campervan to travel around rural areas to help women through its early detection education programme.

BreastScreen Aotearoa provides free mammograms to women aged 45-69 every two years, with the aim of detecting breast cancer early, at a stage when it is easier to treat and more survivable.

The programme has achieved a 34% reduction in overall breast cancer mortality in NZ women. But after breast screening was paused during covid lockdowns, participation in the programme has fallen dramatically and much work is needed to restore it to precovid levels.

During 2020 and 2021 BCFNZ’s Pink Caravan visited more than 160 towns and sites across New Zealand. BCFNZ nurses addressed the questions and concerns of over 6,000 people, enrolled 10 women each week on average with their local BreastScreen Aotearoa provider, and engaged with women who otherwise wouldn’t be able to speak to a healthcare professional. n

MORE: Donations towards the new Pink Campervan can be made at www.breastcancerfoundation.org.nz

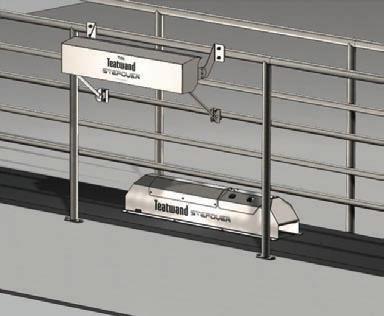

Easy Draft has been designed and refined over many years to be reliable, easy to use, gentle on animals and has seamless integration with CowManager.

Get in contact and request a free quote today

Each month the Milk Monitor delves into the dairy industry and gives us the low-down on the good, the bad, the ugly and everything in between.

The so-called spring flush is appearing more like a trickle across some North Island farms as the wet spring weather continues to affect pasture growth.

It’s reflected in production numbers, with Fonterra’s NI milk collection down 6.3% for September and 5.9% for the season to date.

Anecdotally, some farms are definitely down in production in both single- and double-digit numbers.

It’s also starting to flow through in mating with submission rates back on last year because the tough autumn and winter have meant farmers have simply not been able to put on the right amount of condition on their herd.

The GDT has fared no better, lumbering on in October with three consecutive falls before surprising everybody by lifting 2.4% on November 15. NZX in its analyst opinion cautioned that is potentially a technical bounce before prices keep easing.

Buyers saw the auction as an opportunity to secure product at a bargain price, potentially allowing them to step away again for a few auctions, it said.

Aided by a softer exchange rate, it did give enough optimism for both ASB and Westpac at $9.40/kg milk solids and $8.75/kg MS respectively.

The tough spring and subsequent production decline look more and more likely as a possible industry trend. At an industry level, Fonterra’s acceptance that supply is declining has obviously had a major influence in the proposed amendments to the DIRA Act.

When a shareholder told Fonterra chair Peter McBride that the declining milk supply was concerning him at the co-operative’s recent annual meeting in Rotorua, McBride replied that he sympathised, and that the co-operative was losing 1% of dairy land to land-use change per year.

Looking further out, it’s not going

to get any easier. In the South Island, according to a new Land and Water report, convergence of water-use consent renewals and dairy shed renewals could be a catalyst for land-use change in mid-Canterbury around the early 2040s.

It found that about 40% of all dairy milking sheds in the district were built between 2007 and 2015, according to resource consents.

Using the IRD calculation of a 33.3year economic life for a dairy shed, those 230 sheds will reach the end of their economic life between 2040 and 2048. This means nearly half of all dairy sheds are likely to need replacing during that period.

Replacing an aging dairy shed requires a significant amount of capital and any farmer making that decision is going to look at climate suitability, regulations and the prevailing economics of dairying compared to other land uses of the day – there’s no guarantees that dairying will still stack up like it did when those sheds were built.

The researchers also found that between 2030 and 2040, 78% of all wateruse consents in the district will expire.

The area of land involved in this process will, however, be even greater, as the water consents of all three irrigation companies in the district also fall due in this period.

You don’t need to be an Einstein to work out there are no guarantees that dairying will continue to dominate land usage in that part of New Zealand given what we know now about the environmental impact irrigated dairying has had on the region.

This will all mean a further shrinking milk collection pool for Fonterra and the other dairy companies in that region.

Whatever climate change legislation is decided on will also be well in place by then. It is to be hoped it will have provided a way forward for the industry to remain viable and profitable, but this could also affect the future of these consents.

The report noted that over the past 20 years, irrigation has transformed Ashburton District in the central South Island away from sheep and grain growing. Irrigated farming now covers 65% or 220,000ha of the Ashburton District Plains. Dairy farming now accounts for 63% of net farm income for the district.

So what, some might say: That’s 20 years away and by that stage – to paraphrase Matt Damon’s stranded astronaut character from the movie The Martian – we may well have scienced the sh*t out of the dairy industry to find solutions to these issues.

But in any case, the clock is definitely ticking.

A Canterbury couple started in dairying later than most but are still reaping the rewards.

ACanterbury farming family are finding ways to achieve high production at the same time as enhancing their environment.

Their efforts have seen them named supreme winners of the 2022 Canterbury Ballance Farm Environment Awards.

Phill and Jos Everest, along with their son Paul and his partner Sarah Hayman, milk 730 cows on the 248ha effective farm at Willowby that Phill and Jos converted in 2010.

It’s been a several decades-long journey since Phill and Jos sold their home in Christchurch in the mid-80s to buy a 130ha farm at Willowby, borrowing $300,000 at 28% to complete the deal.

they leased the land to a cropping farmer, working in with his programme to rear 100 bulls annually as well. Phill finally retired from consulting in sheep and beef, deer and cropping but not dairy four years ago. But it has only been in the past 11 years he began to seriously transition to dairy farming full-time.

“Jos gave me a lecture and said, ‘If you don’t get started soon, you’re never going to start farming’,” Phill laughs.

Born in Methven, his parents were both school teachers and he’s the only one of his family to have gone farming. He studied at Lincoln, graduated with a Bachelor of Agricultural Science, and went on to become a respected consultant.

Jos is from a farming family and on the road she grew up on, in Pukeatua near Te Awamutu, her father and four brothers all had farms. Like Phill, she’s always wanted to go farming but feared they may be leaving it too late.

• Farm owners: Flemington Farm - Phillip and Jocelyn Everest, Paul Everest and Sarah Hayman

• Location: Flemington, Canterbury

• Farm size: 248ha

• Cows: 730 Kiwicross

• Production: 2021-2022: 360,630/kg MS

• Production target: 2022 –2023: 360,000/kg MS

“It was a lot so we really had to keep our eye on the ball,” Phill recalls

He carried on with his full-time occupation as a farm consultant and

“It is a physical job. My family are all farmers and my brother Andrew said when he got to 50 he wondered if he was getting too old for it after 30 years,” Jos says.

“Every year we goal set and it’s, ‘In 5 years’ time I’m going to’, and then, ‘In 5 years’ time I’m going to’, and we got

to 50 and I said to Phill, ‘You can’t keep pushing this out, you’ve got to retire and if you’re going to farm, you’ve got to do it now, otherwise you never will.”

When a neighbouring farm came up for sale, they roughly doubled the farm size when they and a neighbour bought the property and split it equally.

Their conversion goal was to have a one-man shed where two staff could each do one milking a day and they travelled around both islands looking at sheds and infrastructure to find the best way of achieving that.

Their new shed came with leading edge labour-saving technology of the time, automatic drafting and automatic cup removers and later heat cameras were added. The shed’s also set up for feeding grain the Everest’s grow but that’s limited to the shoulders of the season.

“We tried to be as water-efficient as we possibly could and put in all the watersaving technologies we could and to save energy we insulated our silos and had a heat recovery unit on the chiller,” Phill says.

“The key things were we wanted to be grass based, with one man milking a day

A Canterbury farming family is on the top of their game when it comes to the environment.

“Jos gave me a lecture and said, ‘If you don’t get started soon, you’re never going to start farming’.”

Phill Everest

and we set out to have an aesthetically pleasing environment for the guys to work in.”

Since they bought the first half of the farm in the mid-80s they have planted thousands of trees and shrubs, close to 20km of shelter and riparian planting.

But when they bought and converted the second part and put on centre pivot irrigation, they had to make some tough choices about some of the trees they’d planted.

“When we came here there was about 150 metres of trees and we’ve done everything since then. We’ve already sheltered the farm once but when the pivots came we had to pull a lot of those out and start again so I now know what it feels like for the my clients I used to advise.

“What we’ve tried to do is have some internal shelter to provide stock shelter from mainly the southerlies in the spring so we’ve developed different things as we’ve gone along. Toi toi’s been really good, pampas was excellent but we’re not allowed to use that now because it’s a noxious weed.”

Seven years ago their son Paul came home from three years working on cropping farms in Australia, keen to go dairying.

“He started at the bottom which he has, to his credit, and he’s worked up and done his Ag ITO to level 4 and he’s going really well,” Phill says.

Today Paul’s in charge day-to-day and while his parents are still actively involved, Phill has a variety of projects onfarm that keep him busy. Paul’s partner Sarah Hayman works off-farm as an

environmental manager for Ashburton Lyndhurst Irrigation.

Before Paul and Sarah met, she’d actually been on the farm, doing research as part of her university studies. She completed a science degree at Canterbury University, along with a post graduate qualification in water resource management.

“I looked at quantifying the amount of nitrogen that’s in groundwater to how that could be used to minimise fertiliser use,” Sarah says.

She later met Paul through his sister Anna who was in the same hockey team.

The farm gets its irrigation water from bores, not the scheme Sarah works for,

but Phill says her expertise is valuable on-farm and she helps with “watermonitoring stuff”.

Sarah says she’s noticed farmers’ attitudes to water management are slowly changing and while putting in soil moisture probes was once something of box-ticking exercise to satisfy regulators, now most farmers are using the data to make better decisions.

“I’ll talk to farmers and at first they weren’t into it and they just did it just to tick a box but now they can see they’re saving water and with expensive pumping costs and water charges on irrigation schemes, that can be a good saving,” she says.

The family are committed to using water wisely and reducing the environmental impact of their farming operation but Phill warns that can come with significant costs. He cites the 190kg/ ha limit on nitrogen application as an example.

“We were sitting at about 240 - 270kg of N, depending on the year, and we went down to 190kg a year early and that decision that year cost us $40,000; we grew less grass, put more supplement in and produced less milk,” he says.

“So there is sometimes a cost and I think we need a balanced approach on this thing. There’s always efficiencies you can extract but sometimes there’s a cost to those efficiencies.”

Phill’s also running his own water quality trial on the farm, testing water in a stream at the top of the farm and again once it’s made its way to the other end. Surprisingly, despite high nitrate levels in

the stream, in theory at levels where fish can’t survive, both native and introduced species are thriving, he says. Phill believes that could be down to efforts to improve the stream by adding pools and riffles and riparian planting.

“Nitrate levels are too high and we need to get them down. That’s easy to say but hard to do but what else can we

do to improve the stream characteristics? We’ve put in the pools and riffles, we’ve planted carex so it’s sheltered on the north side and it’s all those things. It’s not one just one factor.”

Last season, the 730-cow herd produced 360,630/kg MS and they are

targeting 360,000/kg MS for this season.

The farm is relatively lightly stocked, around 3.2 cows/ha, but per cow production is high, hovering around 500kg, more than their live weight. The herd has been fully A2 since year four after conversion.

“There’s a premium for it and it was something we were pretty keen to follow through and Synlait were keen for us to do it,” Phill says.

“We screened all our cows and brought some A2 screened heifers in so we got the numbers and then just worked away. It meant you kept everything that was A2 whether she was great or not and it was sad to see some of the others go but that’s progress and we’ve been selecting intensively since then.”

In another effort to add facts and data to environmental debates Phill is working with Synlait, AgResearch and multi-

national food corporation Danone to trial a mixed species pasture, as promoted by regenerative farming advocates. He has two side-by-side paddocks, one planted in a conventional, mainly ryegrass and clover mix and the other in species including ryegrass, plantain, Timothy, fescue, meadow fescue, vetch, lucerne, five different clovers and an annual clover.

Cores have been taken already and more will be taken at the end of the study to assess soil carbon, one of the main focuses of the research.

So far the conventional paddock is producing more dry matter, Phill says, but during summer intensive testing will be undertaken, including putting milk produced on the two paddocks in separate vats to see if there are any differences in their characteristics.

As well as looking for new opportunities to improve production and profitability at the same time as minimising environmental impact, the existing operation is set up with the same aims in mind.

To reduce the amount of nitrogen in the cows’ urine, one of the main sources of nitrate leaching, plantain is used in all pasture mixes on the farm and extra seed is sown with fertiliser applications to help the plantain persist in the sward.

Another way N loss is minimised is using Ravensdown’s N-Protect coated urea product that slows down the conversion of nitrogen in urea to ammonia gas (ammonia volatilisation)

Feeding fodder beet rather than kale as winter feed also reduces nitrate losses from the farm. Fodder beet is much lower protein which equates to lower nitrate.

“Less protein means less nitrogen going in in the autumn which is critical, that’s your leaching period, and it flows through in terms of our winter feed as well which is predominantly fodder beet with some silage and a little bit of kale at the end.”

The Everests grow some fodder beet on the milking platform and use it as part of their pre-conditioning for winter.

“It’s an easy step during lactation to get cows on to fodder beet, though it’s got its challenges. We start with 10 minutes and then go up five minutes every second day,” Phill says.

“We split the herd in half and there’s usually three or four of us out there for the first few days so that if something goes wrong you can get them out of the paddock in a hurry. If you get it wrong, they get a guts ache and you’ve ruined them for life.

“We’ve got a regime we’re happy with, it works well for us and is good for the

“We’ve pushed the envelope as far as we can with the Herefords in terms of selling those and to reduce our bobbies and this might be another opportunity.”

Phill Everest

environment as well. They’ve got to be on 5kg (dm/day) when they leave here to go to the support block.”

Calving for the heifers begins on July 25 and the main herd on August 1. This year they have reared 340 calves, comprising 160 replacements and 140 white-faced beefies. About 40 of the Hereford-cross calves are part of milk-

fed veal trial and they’re being kept well away from the other calves.

“They get milk out of the vat and grass so we keep them at end of the farm in case we have a breakout and they get into the meal or anything up here so it’ll be interesting to see how well they grow.”

The aim is to grow the trial calves to

300kg live weight, feeding only grass and milk with no meal.

“We’ve pushed the envelope as far as we can with the Herefords in terms of selling those and to reduce our bobbies and this might be another opportunity.”

It costs more to feed milk from the vat than it does to use powder, along with meal, to rear these calves so the trial’s success depends getting the calves up to weight quickly enough and for there to be premium for milk-fed veal over standard beef. Hereford cross calves are being used in the trial but Phill says he’s open to using other breeds, depending on results.

Mating started on October 23 and ran for nine-and-a-half weeks, all AI with no bulls. Short gestation semen is used in the final two-and-a-half weeks to shorten calving by 10 days in an effort to give cows longer after calving to get in calf again.

“I’m less focused about the milk, it’s actually more about getting them in calf because one of the challenges we’ve got as an industry is our empty rate,” Phill says.

“We want to try to bring the number of replacements back down because they contribute greenhouse gases and no

They use sexed semen from A2 bulls over the top 30% of the herd for replacements and then gene test the progeny to make sure they are A2. Hereford semen is used over the remainder of the herd to generate another source of income and to minimise the number of bobby calves.

There are two staff on the farm, Filipino Dennis Dacquel and Kaji Sherpa from Nepal. Dennis, 54, has worked for them for nine years, supporting his family back home.

“His wife has since died, his kids have all had covid and he says, ‘Five more years and then I’m going home’. His youngest has just finished design school over there so they’re all out and working now which has been his goal.”

Phill and Jos met Kaji Sherpa in Nepal when they took the opportunity to go there when some tickets became available after friends had to pull out of the trip. They went to base camp where Kaji – who has climbed Mt Everest six times – was their guide.

“We said, ‘If you’re ever in New Zealand, look us up, come and see us’,” Jos says.

“That was in April 2015, the year of the Nepal earthquake and he turned up in September, ‘I have come to see you’. We thought he may stay for a week, well that was seven years ago.”

As a consultant, Phill didn’t have much to do with dairy farming but nevertheless he’s been able to use his wide knowledge, along with talking to a neighbour who happens to be a dairy farming consultant, to achieve high production and meet ever stricter environmental constraints, including a requirement to reduce N-loss by 36% by 2035.

He and Jos are now relaxing their hold on the reins. Last year Paul and Sarah bought the original block from them and this year bought into the farm’s operating company. The other half of the farm is in a family trust, providing for daughter Anna and son Mark who is a consultant with Macfarlane Rural Business in Ashburton.

Kaji has since brought his wife Gelmu Sherpa and their children to New Zealand, and, like Dennis, they now have the security of NZ residency.

“We’ve been lucky with those guys and Paul and the two boys get on really well. They are like family. We know each other pretty well.”

“In terms of cows, Phill’s experience in consulting is not dairy, it was everything else, deer, crop, sheep and beef so I feel like Paul and Phill have grown up with the cows together,” says Jos.

And Phill is enjoying seeing Paul blossom on the farm. “It’s great, it’s really good. There are challenges with fathers and sons but we work together and he’s running the cutter now.” n

“We’ve been lucky with those guys and Paul and the two boys get on really well. They are like family. We know each other pretty well.”

Jos Everest

It’s been a long journey from Brazil to New Zealand, but a South American veterinarian has overcome the language barrier to find a home here.

When an opportunity to work in New Zealand arose, a South American veterinarian jumped at the chance even though he barely knew it existed.

And, having grown up in Brazil speaking Spanish and Portuguese, Jair Mandriaza spoke no English.

A quick study-up on where NZ was in the world and a crash course in English did not prepare him for his first encounter in NZ.

Arriving at Auckland Airport in 2006, he had little idea of where to go and what to do and was looking rather lost when a kind security guard approached him and asked if needed to catch a connecting flight.

Mandriaza tried to communicate in his limited English but got himself flustered and started pulling out the letters he had explaining why he was in the country.

“It was the accent that threw me, I had been learning English with fellow Brazilians so I really wasn’t prepared,” Mandriaza says.

Luckily his English has advanced since that rocky start because his role as a

senior reproduction solutions advisor at LIC in Hamilton requires a lot of communicating.

“I was very passionate about learning English, I never saw it as an option not to learn it, and it’s a good thing because my role now involves a lot of talking to people,” he says.

team because of a growing need. They recognised that reproductive performance underpins so much in the dairy sector and he joined as the team was expanding.

“When the team started in 2011 we knew we wanted to support what was already established in the industry and that’s things like DairyNZ’s InCalf programme.

“And we’re always learning and helping farmers and the sector understand as new technologies emerge, like short gestation and sexed semen, and more recently wearable technology.”

His role involves a lot of education, supporting the LIC sales team to help farmers and interacting with many rural professionals.

He enjoys connecting across the sector because he knows how important it is to collaborate and keep messages simple for farmers.

“I do a lot of networking within LIC and across the sector, upskilling people and using data to provide insights.”

LIC established the reproduction

He also performs a lot of data analysis, looking at trends and what is happening across the regions and nationally. He alerts if risks emerge, or if there are any concerns for a particular area or farm he will dig deeper into the data to try

“It’s not usually one main thing that could be causing problems, usually it’s lots of little things that add up and a lot of what we do is about supporting the sector to understand that and try to improve to get better outcomes.”

to understand what might be causing problems.

“Reproductive performance has a huge impact on a farming business, but there are so many different elements that can have an impact,” he says.

“It’s not usually one main thing that could be causing problems, usually it’s lots of little things that add up and a lot of what we do is about supporting the sector to understand that and try to improve to get better outcomes.”

He was attracted to the role at LIC because he would be able to utilise advisory skills and have more of an impact on the sector.

“I’m really driven by being able to make an impact and help across the industry, that’s really valuable to me.

“In previous roles I’ve been able to support a specific set of farms and I’ve worked in a commercial sense but I really enjoy the opportunity to help further and wider here at LIC.”

Working with bovine animals is not quite what he had in mind as a youngster growing up in Brazil but he loves the role and the work he does with farmers and industry.

interesting option so he focused his practical placement in his final year around the equine embryo transfer world and really enjoyed it.

After graduating he attempted to gain a residency in equine reproduction but they did not think he had enough experience. As an alternative they offered him an opportunity to gain some further practical experience so he spent some time working unpaid in the clinic.

During that time, a chance conversation with another vet led to an opportunity with a business that specialised in beef cattle embryo transfers. He was quickly offered the role despite how much he had to learn and it was during his time in that role he worked with a sheep farm that had a connection to New Zealand.

Brazil and they needed a vet, so my boss offered my help and I worked with the New Zealand crew in Brazil for six weeks.”

During the project they mentioned if they had an opportunity to take him to NZ they would and four months later he got a call. They wanted to bring him here to learn more about embryo transfer in sheep and goats and go back to Brazil to run a new branch of their company.

“Until then I didn’t really know

anything about New Zealand, I knew it was close to Australia but other than that I barely knew it existed.”

But off he went, heading over for three months of training.

“Within a week I had fallen in love with the country, although I couldn’t speak English I really liked the place.”

“And as luck would have it the joint venture between ABS and the Brazilian crew didn’t go ahead so I was given the option to go back to Brazil and wait to see if it would work out or they offered for me to stay in New Zealand and work for them in dairy embryo transfer.”

There was no hesitation to accept the offer to stay, he had not experienced dairy cows before but he was able to use the skills he had learned in Brazil and enjoyed learning about dairying. And when the joint venture attempts were halted he was offered a permanent role to stay.

Although he loved what he was doing he did find it challenging learning how to communicate. He had grown up speaking Spanish at home and Portuguese at school but English was a whole different kettle of fish.

“I had taken a course in English back in Brazil once I knew I was coming over, but it was completely different to what I experienced when I arrived.

“I found it exhausting in the first few months, sometimes we would be travelling for three, four, five hours to where we were working and I’d be in a car with a bunch of English speaking people.

“I was with my boss and he got a phone call from some people in New Zealand from Animal Breeding Services (ABS) that were going to do a project on embryo transfer with some sheep in

“Within a week I had fallen in love with the country. Although I couldn’t speak English I really liked the place.”

“By the end of the day I would just crash out as I was exhausted from long days trying to understand.”

After three months he started to understand what people were telling him and he could speak around 30 words combined with drawing and gestures to get the message across. After six months his English was slightly better but still limited. After nine months he felt like he did not know any English again.

“I worked out I had only been hearing about 30% of what people were saying and I was making up the rest.

“But around that time I started dating a kiwi lady and being able to communicate regularly with her helped a lot.

“By twelve months I finally felt like I was making headway and I realised I was able to communicate in a high level of detail.”

Whenever anyone comments on his lack of accent now he takes it as a huge compliment and he appreciates how lucky he was being forced to communicate in English so often.

“I see it a lot with friends and others around me, they can speak English in

a very technical way but because they go home and speak in their native language they don’t master the casual conversational skills as easily.”

with dairy cows until he came to NZ.

“I had been working alongside vets while I was going through the recognition process and seeing the lifestyle of a dairy vet, the long hours and on-call work, I wasn’t sure if that lifestyle was actually for me.

“So when I didn’t make the cut I wasn’t too worried, I was disappointed I failed but it hasn’t held me back because it was around the same time the opportunity at LIC came up.”

After improving his communication skills extensively spending two and a half years with ABS he was offered a role as a technician for a vet clinic in Te Awamutu. His veterinary degree was not recognised in NZ but there was a process he could go through to validate his qualification and allow him to work as a vet and the clinic was willing to support him through it.

He was warned it was common to fail on the first attempt and he missed out by 3% in the exam but by then he was starting to doubt whether he wanted to become a dairy vet. He had not dealt

He is very grateful to be living in NZ and now calls it home, although he tries to get home every second or third year.

“Back in Brazil you are constantly aware of violence around you, worried about being robbed and the risks anywhere you go.

“But in New Zealand I have a strong sense of freedom and I feel like I can be the person I’m meant to be.

“Something as simple as offering help to a stranger, I can do that here but if you tried to help a stranger back in Brazil you’d be mistaken for trying to rob them or something.

“Here people take you for face value, it’s refreshing.” n

Designed and manufactured in our Christchurch factory for over 60 years, the Skellerup range of rubberware offers a national footprint and can supply parts and accessories for the vast majority of New Zealand milking sheds.

Our products are made specifically for New Zealand conditions and deliver consistent performance and durability that farmers need to maximise their returns.

Is your shed compatible? Scan here to find out more, or book a free dairy shed rubberware review.

skellerup.co.nz skellerup.co.nz/dairy

“In New Zealand I have a strong sense of freedom and I feel like I can be the person I’m meant to be.”

A Taieri Plains farmer is enjoying the sweet smell of success with her small-scale flower growing business on the side.

Farmer and grower

Keryn Luke jokes that as a practical-minded person, she doesn’t see much sense in flowers –but there’s something she loves about them, and she’s been able to turn that love into a growing little business. Riverbend Flora is a smallscale flower farm producing a range of unique flowers purposely grown for cutting.

“Flowers bring so much happiness,” Luke says.

“I feel much more connected to and appreciative of the land since starting this business. I think it’s something I get from my grandmother, who also had a love for the land and growing.”

She grew up on a dairy farm on the Taieri Plains, right next door to their current farm, Riverbend. Her grandparents owned Riverbend before they passed, and she recalls many happy hours spent in her grandmother’s company tending the garden and enjoying everything the outdoors has to offer.

After finishing school she trained to become a radiographer but ended up back on a farm after marrying her husband, Matt. The couple took on a lowerorder sharemilking job for her parents, running the home dairy farm while she worked full time at Dunedin Public Hospital as a radiographer

until the birth of their first child in 2011.

“I took a year off after that and went back to a few days a week. When my first was born, my grandmother, who lived on the small farm next door, passed away.

“After that Matt and I with my parents bought the farm and named it Riverbend. Because it had gone into estate when she passed, we didn’t move in right away as there were things to sort out, and we also had another baby in that time.”

Riverbend, aptly named for the bend in the river, is a fourth-generation dairy farm running 160 cows. It’s small, but that’s the way the couple like it.

“Matt still runs my parent’s farm next door as well, but we like having a small farm and being fairly self-contained. We now own Riverbend and feel blessed to have our own bit of land that we can put our mark on.”

She made it her mission to restore the gardens to their former glory. With three children under four years old at the time, she says getting her hands in the dirt also helped keep her sane. Her love of gardening started in her youth and gradually grew over the years, but she says it wasn’t until they settled into Riverbend that it really began to take root and eventually form into a business idea.

“I watched an episode of

Country Calendar on Nourish Gardens when my fourth child was a couple of months old. They grew cut flowers for sale and had a winery on Waiheke Island. I got thinking about how neat it would be to spend hours in my own garden and make a business out of it. I’m a fairly logical person and initially thought no, this isn’t a viable idea, but something about it interested me.”

After six months of researching the slow flower movement, finding other small flower farmers to talk to and figuring out what it would take to get a flower business off the ground, she was hooked.

“I trialled raising seeds myself as I hadn’t done a lot of that. I did it all in our little conservatory. I got hooked quickly and asked Matt if I could use the calf paddock out the back as a test paddock. It wasn’t a great paddock for calves, so he was quite happy to give it to me. Then we had the first lockdown, so we all got involved in setting it up.”

Her first official growing season was in 2020 and to start with she thought she’d grow and sell to florists and stay as a background person. She quickly realised that, at the scale of what she was doing, it wasn’t going to be financially viable to sell at a wholesale rate.

Almost by accident she discovered that selling direct to customers was the way to go. She started selling bouquets first to family and friends and then as interest grew to more customers.

“I could charge the same

“Because my field is small, I have to always think of ways to use my flowers.”

price for a retail bouquet as a full bucket of wholesale flowers for a florist, so going down the more consumer route made more sense for the scale of my field.

“When I started planning this business, covid didn’t exist, and the support was minimal. But when I first started selling it was at the height of people wanting to support local and seasonal products. It worked out really well.”

She also discovered growing interest from customers to learn about flowers and gardening, which encouraged her to start offering workshops. She holds them a few times a year, covering a range of topics from the art of cutting and arranging flowers to gardening and growing for beginners. Her workshops are well attended, and she enjoys having the chance to

pass on the knowledge she’s accumulated over the years from her family and fellow gardeners.

“The more I got into my business the more it took me to different places,” she says.

When a friend converted an old woolshed into a wedding venue, this took her

little business off on another course again. Doing wedding flowers was the perfect addition to her growing list of services. It added a level of stability while not sacrificing the flexibility she needs.

“Wedding flowers make a lot of sense for the stems I grow, and they don’t need

to last 10 days or be perfectly straight so I can be more creative, which suits what I grow.”

Flowers are grown in the house garden and the old calf paddock, which is about 20m x 31m. She cultivates

a huge variety of flowers, focusing on varieties that are not commonly commercially available. The growing season is typically from late September through to early April.

Being situated close to the river means the soils are sandy, providing a good natural soil base to work from. Regular mulching and use of seaweed products help keep

the soil thriving along with some strategic use of fertiliser when needed.

“We replant annuals every year, and I tend to have probably 10 main perennials that flower throughout the season starting with anemones, tulips, ranunculus, peonies, roses, lilies, dahlias, hydrangeas and chrysanthemums.

“Like farming, there are

times of the year when the garden is very intensive, like when we are planting, but the whole family pitches in and it’s quite a nice time of year.”

Now into her third growing season, Luke says there have been a lot of sharp learning curves along the way, from finding a niche that naturally worked for her to always thinking of ways to utilise what she grows.

“Because my field is small, I have to always think of ways to use my flowers. If I can’t sell them fresh I dry them, press them or photograph them. You have to think like that to make it financially viable.”

She’s also had to dip her toes into the realm of social media, which was an exercise in self-belief and stepping into the unknown. Not a regular user of social media in her personal life, she initially didn’t think she’d need it but quickly saw it as a free way to show people what she was doing.

“At the start I didn’t think what was I was doing was going to be interesting enough to share. Over the years I’ve met some wonderful people and I really enjoying sharing what I am up to here at Riverbend.”

While social media has certainly played a role in her business growth, word of mouth has been one of her biggest marketing successes.

“I love what I do, so I tend to talk to anyone who will listen about it, and you’ll be amazed what comes out of that.”

As her business has taken a shape of its own, she’s been well supported along the way by her family, in particular husband Matt.

“Over the years I’ve enjoyed listening to Matt speak about his highs and lows on the farm, his plans and all of that. This business of mine has given me to chance to do the same and for us all to do something together. Matt comes up with all these ideas and being a farmer he’s got great handyman skills, which has meant my little idea for a workshop turned into something quite amazing with the help of a builder friend.”

Flexibility was on her mind when she first started the business. Family time and time off farm is important to the family and by luck or design, that’s what she’s been able to achieve as she’s worked with the direction the business has taken her in.

“This business has multiple sides to it, which I love, so the future will just embrace that. I’m mindful that I only ever wanted this to be a parttime business and while it’s growing nicely on its own, I don’t have specific plans in place right for growth. I think I’m just enjoying the season of life that we are in right now.” n

Balanced

Genetically modified (GM) crops could provide considerable benefit for dairy farming and food production in New Zealand, but we need to get past ideologies and polarised views, a leading scientist says.

“There is no doubt that fact-based conversations are required, along with minds open to balancing risk and benefits,” says Dr John Caradus, an award-winning plant scientist and breeder who leads the AgResearch subsidiary, Grasslanz Technology Limited.

In a recently published review in the New Zealand Journal of Agricultural Research, entitled Intended and unintended consequences of genetically modified crops – myth, fact and/ or manageable outcomes? Caradus argues that there is some inconsistency and lack of logic in how regulation of genetic modification is applied in some countries, including New Zealand.

“GM technologies, like many non-GM technologies can bring risks, but these can and have been monitored and quantified, allowing decisions balancing commercial, societal and environmental benefits against measurable risks. While ‘checks’ and ‘balances’ are required, regulatory schemes must focus on balancing risks and benefits and not on ‘checks’ alone, which is the case for many countries.”

The review points to estimates of economic benefits globally from GM crops, between 1996 and 2016, being close to US$200 billion, and benefitting up to 17 million farmers. In 2018, the on-farm income benefit from the use of GM crops was estimated to be close to US$19b.

“GM crops are one successful means of improving on farm productivity and profitability, the environment, and consumer benefits. This does not exclude the use of other technology options for similar improvements.”

GM crops that provide food for people and feed for animals are already the most highly regulated biological technology in the world, the review says.

Traditional plant breeding has been a foundation of farming in NZ for decades, but genetically modified organisms

are classified as new organisms in NZ under the Hazardous Substances and New Organisms (HSNO) Act 1996. This includes crops that are gene edited, where targeted changes are made to the organism’s DNA rather than DNA from another organism being introduced.

Any genetically modified organism must be approved for release, and to date no GM crops have been approved for release in NZ.

Caradus points out that there is an “ever increasing list” of foods made from GM crops that can be sold in NZ, if appropriately labelled.

“But still the ability of farmers and growers to exploit the benefits of GM crops and forages is constrained. Adding to this inconsistency and lack of pragmatic logic is the fact that oil from nine GM events in canola, listed as approved on the Food Standards Australia and NZ website, can be consumed as food by humans but the by-product meal, left after the oil extraction process, cannot be consumed as feed by animals in NZ. So, the issue with foods from GM crops cannot be largely about safety to human health.”

The HSNO Act “needs review to allow a less adversarial path to the establishment of regulated field trials for research using containment to manage any risk,” Caradus argues.

“There is a considerable body of good science relating to GM technologies and their consequences, whether intended or unintended, and this must be the foundation for ensuring good and workable regulation.”

In NZ current research on GM crops includes modification of livestock feed such as ryegrass and white clover to achieve improvements in productivity, animal health and environmental outcomes such as reducing greenhouse gas emissions.

This work by AgResearch, funded by the government and industry, has been carried out in containment to meet the HSNO regulations, as well as in outdoor field trials overseas where regulations are less restrictive.

To date, this research shows some promise, but further work is required –including trials in Australia.

Kiwi farmers are urging progress in the development of tools that can help them reduce their on-farm emissions, as the government consults on an emission pricing system that would see farmers pay a levy based on their farm-level emissions from 2025. n

The review can be read in full at: https:// www.tandfonline.com/doi/full/10.1080/0028 8233.2022.2141273

An Australasian company is formulating ways to reduce methane emissions on farm.

The quest to reduce methane emissions on farm has become a focal point for most industry bodies – and research shows that a solution that works from the inside of the cow out may have substantial merit to address the problem.

Australasian company Terragen, which develops and markets biological products for agricultural applications, tested its liquid microbial feed supplement MYLO in a 40-day trial and found a difference in both the methane intensity and methane production in the cows.

Now, additional funding from the second round of the Australian Federal Government’s Methane Emissions Reduction in Livestock (MERiL) programme means Terragen will continue methane emissions reduction research in conjunction with Fonterra, with plans to find out if higher doses of MYLO will reduce methane emissions further.

“We are going back to refine the trial, increase the dose, and build on the robustness of the research,” Terragen general manager New Zealand Paul Grave says.

“With mounting pressure on farmers to address emissions and improve animal welfare, this is great news.”

The first round of research was undertaken at Australian dairy research facility Ellinbank SmartFarm, conducted by Agriculture Victoria Research in October and November 2021.

Forty lactating Holstein Friesian cows were used in the study and two separate treatments – a control treatment and a MYLO treatment – were allocated to cows at random (20 cows per treatment).

The cows in the treatment group received 10mL/day, the same formula and dosage rate as MYLO sold commercially throughout Australia and New Zealand.

Australian company Terragen has developed a probiotic to reduce methane emissions from cows. Terragen lab technicians test liquid microbial feed supplement Mylo.

The study ran for 40 days and the modified sulphur hexafluoride (SF6) tracer technique was used to estimate methane emissions from individual cows.

Milk production from individual cows was measured at each milking and liveweight of each individual cow was recorded twice daily.

The research found the cows not given the probiotic emitted 7.5% more methane per litre of milk, while methane production in the control group was 4.4% higher than in the treated group.

That translated to the reduction of methane emissions by the equivalent of 100 tonnes of CO2 for every 350-cow dairy farm per year – nearly a third of a tonne for each cow.

In June 2022, scientists from Ellinbank SmartFarm presented the findings to the 8th International Greenhouse Gas and Animal Agriculture Conference at Orlando, Florida.

In October it was announced that the

Albanese Government was granting an additional $615,000 to the Victorian Department of Jobs, Precincts and Regions, in partnership with Terragen and Fonterra Co-operative Group and Ellinbank SmartFarm, as part of the second round of the Federal Government’s Methane Emissions Reduction in Livestock (MERiL) programme. Terragen is committing a further $111,000 in support of the study.

The research will again use MYLO, but this time in higher doses as part of Terragen’s efforts to further increase the product’s methane reducing properties.

Grave says New Zealand dairy farmers tend to be cautious about research that has taken place overseas but believes Fonterra’s involvement will lend credibility to the results.

“Fonterra is part of the process to contribute their ideas and thinking,” he says.

Grave says it is exciting that the

product is already available to purchase in New Zealand, having been available in Australia since 2018. Currently 60,000 dairy cows and 80,000 calves in Australia are given MYLO each year.

There is also work underway to have it approved under the emissions pricing scheme, so farmers are able to get a financial incentive for using the product on farm.

Grave says a lot of the other products approved under the scheme will be chemical-based and will come at a cost and potentially a loss of milk production.

“In this case, farmers may simply choose to pay the methane tax as the easiest option,” he says.

“However, MYLO appears to be offering a dual solution for farmers: not only has it been shown to reduce methane emissions, but farmers are already using it to reduce somatic cell count (by up to 38%), increase milk production (by up to 3.3%), increase feed conversion efficiency, and increase weight gain in calves.”

Grave has been involved in farming for 20 years and says recently, there has been exponential growth of farmers wanting to try biological solutions.

“This solution is half science, half heart,” he says. “Most people are now open to trying something different – but it does take time for the message to get across.

“The science of soil biology is now more mainstream; it is now a common language, as opposed to being considered forward thinking, as we have

found with our other product, biological soil conditioner Great Land Plus.

“The sector has been challenged to change and adapt to the times – and MYLO is proving to help farmers become more sustainable and lift productivity.”

The second research trial is expected to get underway in early 2023. n

After a huge year of competition, we can announce the Calf Club NZ 2022 National Champions. The below champions have had an exceptional year and competed at the highest level.

If you are a champion listed below, keep an eye on your mailbox as you will soon recieve a "Champions Package" with a DeLaval calf coat, and a CRV brand pack.

NZ

Dairy Beef

1st 2nd 3rd 4th 5th James Kier Henry Scherer Anahera Schouten Summer Olding Alex Carter Emily Mogg Alexia Gordon Blake Bengston Matt Templeman Marley Williams

1st

Dairy Beef

With summer fast approaching, Farmstrong’s encouraging farmers to reconnect and schedule a decent catch-up with mates and neighbours.

Farmstrong ambassador Sam Whitelock has spent his sporting career managing pressure on the rugby field and helping others do the same.

He has helped Farmstrong create resources on how to have a listening conversation.

“I know myself, whenever there’s been

a challenging time, it’s nice to be able talk about it and share the load.

“Just listening can be a huge help to someone who is feeling ‘under the pump’.”

Sam’s take on what makes a good listener is:

• Choose a good time to talk.

• Begin with a simple question like

For tips and ideas, visit farmstrong.co.nz

‘how are you getting on?’

• Be comfortable with silence. Let the other person do the talking.

• Don’t jump in with your solution to the problem.

• Keep an open mind and be nonjudgemental.

Let’s hear what farmers have to say about the value of a regular catch-up.

“At

They also have two young kids, so life is plenty busy. Amber says regular catchups with her team and neighbours are an essential part of managing the ups and downs of farming.

Cambridge dairy farmer Marc Gascoigne has also helped roll out Farmstrong’s You Matter, Let’s Natter initiative.

“A big part of keeping well on farm is connecting with your mates and checking in on people. The thing is to get in touch while things are going well, don’t wait until things get on top of people. That just leaves them a bigger hole to climb out of,” Marc says.

“I reckon sharing listening skills with farmers is a good idea, because we all know people who don’t listen well and you can tell they’re not listening, they’re only trying to work out what they’re going to say next.

“One thing I’m guilty of myself is jumping in and solving people’s problems, but people aren’t looking for that, they just need to offload about something that’s happened to them. They want to talk to someone who

“Farming can be isolating anyway. There are times during the season when you just don’t leave the property and sometimes it can feel like the world is

closing in on you. That’s why you need to get off farm or get on the phone or Zoom and have those conversations. It’s mentally refreshing to talk to others and get things off your chest.”

If you’re only having that conversation with yourself or your partner, life can get tunnel-vision very quickly, she says.

When you catch up with others, you soon realise everyone’s experiencing the same thing, you’re not sailing the ship alone.

“That’s why I think You Matter, Let’s Natter is great because sometimes farmers are reluctant to talk. The thing I’ve learnt is that any interaction can help if you’re going through tough times. Just chatting with someone means you don’t have to think about your problems for a while. You get that mental break from the farm.