Dare to be different

Canterbury farmer game to try new things

PLUS:

Always improving

➜ Waikato farmers strive to be better

➜ Award email was no prank

➜ Dealing with FE APRIL 2023 | $14.55

April 2023 | $14.55 AgriHQ

ROSS NOLLY 027 332 6867 ross_nolly@yahoo.co.nz GERALD PIDDOCK 027 486 8346 gerald.piddock@agrihq.co.nz

SAMANTHA TENNENT 021 217 3590 sommer.limited@gmail.com

CHEYENNE NICHOLSON 021 044 1335 offthehoofmedia@gmail.com

TONY BENNY 021 383 156 troutstream@farmside.co.nz

ANNE BOSWELL 027 394 3904 anne@anneboswell.co.nz

Sales

ANDY WHITSON 027 626 2269 Sales & Marketing Manager. andy.whitson@agrihq.co.nz

STEVE McLAREN – Auckland 027 205 1456 steve.mclaren@agrihq.co.nz

is a farming family owned business that donates 1% of all advertising revenue in

Weekly and Dairy Farmer to farmer health and wellbeing initiatives.

you for

prompt payment. 18 CONTENTS NEWS ON FARM STORY FARMING CHAMPIONS FEATURES REGULAR FEATURES 16 Milk Monitor Dairy demand from China still soft 17 Dairy Women’s Network Brighter. Braver. Bolder. Conference 2023 8 A different outlook Canterbury farmer game to try new things 18 Many hands make farm work Waikato farmers know the value of their team 7 Guest column – Phil Duncan 38 Primary Pathways We profile the vast array of opportunities on offer in the dairy industry and the pathways, training and educational opportunities designed to help people get there. 26 Research 30 Industry good – DairyNZ 32 Road to dairying 34 Animal health Editor SONITA CHANDAR 06 374 5544 sonita.chandar@agrihq.co.nz 027 446 6221 Publisher DEAN WILLIAMSON 027 323 9407 dean.williamson@agrihq.co.nz

CLAIRE

claire.robertson@agrihq.co.nz 06 323 0769

Farmers

Thank

your

Sub-editor

ROBERTSON

Contributors

JODY ANDERSON 027 474 6094 Waikato/BOP jody.anderson@agrihq.co.nz ANDY WHITSON 027 626 2269 Lower North Island andy.whitson@agrihq.co.nz OMID RAFYEE 027 474 6091 South Island omid.rafyee@agrihq.co.nz GRANT MARSHALL 027 887 5568 Real Estate realestate@agrihq.co.nz ANDREA MANSFIELD 027 602 4925 National Livestock Manager livestock@agrihq.co.nz DEBBIE BROWN – Directory classifieds@agrihq.co.nz 06 323 0765 Production LANA KIESELBACH 027 739 4295 Production Manager lana.kieselbach@agrihq.co.nz Advertising material: adcopy@agrihq.co.nz Subscriptions subs@agrihq.co.nz Printed by Crucial Colour Ltd Delivered by Reach Media Ltd www.farmersweekly.co.nz ISSN 2624-0939 (Print) ISSN 2624-0947 (Online)

Discover how rumen function affects health and productivity Alltech IFM Laboratory can help you 0800 ALLTECH, alltech.com/newzealand, newzealand@alltech.com 8 Canterbury farmer game to try new things COVER STORY 7 38

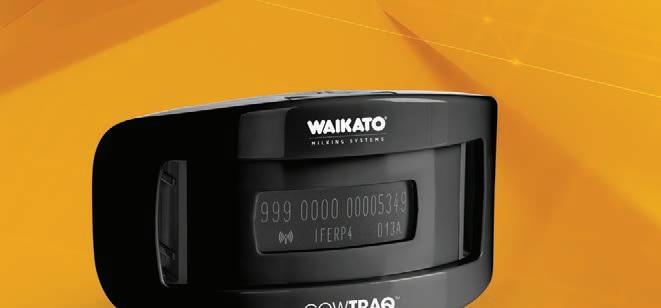

GET MORE FROM YOUR WEARABLES

ROAD SHOW Wearables

We invite all farmers and agri-professionals, whether your are currently using or considering a monitoring system, or you would like to learn more.

HEAR FROM COWMANAGER REPRESENTATIVES

Events: Palmerston North: 5th April

Taranaki: 6th April

Southland:

RSVP OR GET MORE INFORMATION

Awamutu:

TBC

Matamata: 13th April Te

14th April Canterbury: TBC Otago:

TBC YOU’RE INVITED PROUDLY PRESENTED BY 07 280 5798 www.senztag.co.nz Automation

Climate driver changes gears

By Phil Duncan

By Phil Duncan

The team at WeatherWatch takes a look at the weather patterns to see what farmers may have in store for autumn.

As La Niña conditions continue to clear away, many are asking whether that means El Niño is next. We talked about this in the December edition of Dairy Farmer, but between La Niña and El Niño we need to go to neutral. If La Niña is first gear, El Niño is reverse.

The neutral phase can be a very positive one for farmers and growers –though maybe not for all – but generally speaking this neutral phase offers one key word: “variety”.

Neutral patterns have no big climate driver – we don’t have La Niña creating more rain to the north, we don’t have El Niño parking more high pressure zones in the Tasman Sea. Instead, New Zealand has what can be described as a “typical” weather pattern set-up.

Variety also means chaos. We can have a tropical low one week, a southerly blast the next week, then maybe two weeks of calming high pressure in between.

As we left February and slipped over to March the weather pattern changed with it. Easterlies, which had been dominating many parts of NZ for the past couple of months, have now switched to the typical windy westerlies of autumn. This weather pattern has already set in across southeastern Australia, with Victoria and Tasmania particularly exposed to gales and colder, wetter changes in the past couple of weeks.

In true autumn style places like Melbourne are swinging from highs in the teens to highs in the 30s from week to week.

The South Island of NZ is similar to Victoria, also getting hot nor’westers one day and colder southerlies the next. Likewise, Christchurch is also having daytime highs in the teens some days, other days in the mid to late 20s.

Normally in autumn the eastern North Island doesn’t want a surge of dry, windy westerlies. This year it is just what the doctor ordered. This set-up is

ideal for helping the saturated eastern North Island (Hawke’s Bay in particular) start to dry out and return to normal. Rivers remain muddy (or murky), so the longer dry spells will also help clear up waterways further. It will also help solidify slips that may still be unstable.

But neutral patterns also mean we need to keep an eye on the tropics. March is the peak of the cyclone season and so even as La Niña goes the risk for tropical storms is still there. The tropical cyclone risk carries on through April, too. Our long-range IBM data at RuralWeather.co.nz suggests an increased risk of rain still for the upper

and eastern North Island in April – this may be due mostly to the risk of tropical lows. So while the risk is heightened for more rain, there is still a good chance any tropical lows/storms that form will entirely miss NZ.

Sometimes it feels like NZ is a few bowling pins and a tropical cyclone is the bowling ball – the cyclones often go into the “gutter” east of NZ and get pulled away to the southeast due to the Coriolis effect (Earth’s spin and the effect that has on the tracking of air pressure systems).

In a nutshell, the neutral weather setup brings variety and chaos – and less of an obvious pattern. Autumn’s westerlies tend to always pick up around now though.

This is caused by high-pressure systems tracking further north and this placement creates westerlies.

It’s also likely to be warmer in NZ over the next three months compared to what has historically been recorded. This continues a trend we’ve had in NZ for the past several years now. As you can see from the map, it’s not the case across Australia due to more rain/cloud in some areas.

DAIRY FARMER April 2023 7

GUEST COLUMN

n

The weather pattern is changing and it could be a bit warmer than normal, though nothing is guaranteed.

Sometimes it feels like NZ is a few bowling pins and a tropical cyclone is the bowling ball – the cyclones often go into the ‘gutter’ east of NZ and get pulled away to the southeast due to the Coriolis effect.

A different outlook

A Canterbury farmer likes to try new ways of doing things so he can get the best from his farm and herd while still caring for the environment.

ON FARM

Canterbury farmer Phil Garrett owns Rushbrook Farm at Leeston, which is 440ha and milks 1000 cows. The property is managed by his son Andrew. Photos: Tony Benny

By Tony Benny

Aveteran Canterbury farmer has always been happy to do things a bit differently, whether it be his affection for Milking Shorthorns, his hybrid barn and pasture system, or replacing conventional fertilisers with effluent, but he’s succeeded in his goal of high production as well as leaving his land in a much better state than when he started out.

Phil Garrett bought Rushbrook Farm at Leeston, south of Christchurch, near Lake Ellesmere/Te Waihora, in 1986 and has farmed it since then with his son Andrew. Originally 103ha, the property has now grown to 440ha and milks 1000 cows, but with young stock usually carries 1750 cattle.

Now nearly 84, Garrett has loved cows since he was a toddler and always wanted to be a farmer, a goal he achieved through hard work, not inheritance.

His parents had a farm in western Southland but when he was two, in 1941, his father died.

“There were five of us and then my younger sister was born six weeks after he died and we ended up coming to Christchurch because Mum’s father lived up here and had a tailoring business and he bought a little five acre [2ha] block in Heathcote [on the city’s outskirts].

HAT-TRICK.

We lived there from about 1942,” Garrett recalls.

The neighbours had a small dairy farm.

“When I was about four years old I used to hop through the neighbours’ fence and help milk the cows, put the cups on, and I’ve always been associated with cows ever since.”

When he left school at 15, Garrett took a job on the neighbour’s farm and stayed for seven years but he realised he’d never make enough money as a farm worker to get a farm of his own so he found a job with a malting company. That paid better but still not quite enough.

“For two years I also worked night shift at the Empire roller mill from 4pm till midnight and that got me the money for my little nest egg to get going, to buy the first piece of land.”

He went into partnership with a friend to buy the farm where he’d previously worked and they ran it together, though Garrett also traded sheep and cattle through the old Addington saleyards to boost his income.

“At one point we had the highest turnover of any client in Canterbury with Wrightson NMA [a predecessor of PGG Wrightson].”

In 1986, after 12 years, they split the farm partnership when his friend wanted to get married. They each took half the land and his friend built a house on his

FARM FACTS

• Farm owner: Phil Garrett

• Farm manager: Andrew Garrett

• Location: Leeston, Canterbury

• Farm size: 440 hectares

• Cows: 1000, Milking Shorthorns and crosses with Friesian, Jersey, Guernsey, Brown Swiss, Fleckvieh, Montbéliarde and Speckle Park.

• Production: 575,000kg MS

piece while Garrett sold his half and bought a 103ha sheep and cropping farm at Leeston, south of Christchurch, near Lake Ellesmere/Te Waihora.

It was among the first farms in the district to be converted to dairy farming.

“We had to build the dairy in a muddy paddock and it was raining and it was a

Continued page 10

1 5.99% P.A. INTEREST* IN STOCK NOW. FROM $13,999. WARRANTY T&Cs: This no deposit and 5.99% p.a. interest rate offer is fixed for the term of the loan and applies to new Suzuki KingQuad models financed from 20/01/2023 to 30/04/2023. A PPSR fee of $10.35, a monthly maintenance fee of $2, a UDC loan fee of [$105] and a dealer origination fee will apply (your dealer can tell you their applicable fee). This loan is provided by UDC Finance Limited. UDC’s lending criteria and standard terms and conditions apply. The three year warranty cover is subject to requirements laid out in the Suzuki owners’ maintenance and warranty policy manual. TALK TO YOUR PARTICIPATING SUZUKI DEALER TODAY OR VISIT SUZUKI.CO.NZ KINGQUAD THIS

TO PAY

SEASON’S OUTSTANDING

36 MONTHS

Getting the land to produce its best while leaving it better off is the aim of Phil Garrett of Rushbrook Farm at Leeston.

struggle to get it built.”

He took over on July 1 1986 and arrived there with one of his sons and a daughter (he was by now divorced) on July 5. On September 19, the shed was finished and ready for the first milking.

“The cows were still being milked in Heathcote until then but we had to get out of there because we’d sold it.”

The 119 mostly Milking Shorthorn cows had never seen a herringbone shed, having previously been milked in a walkthrough.

“The first milking in a strange shed was exciting. They had to learn to line up and they wondered what the hell we were doing to them. It was harder than

EPRINEX is not only the 1 and only drench to have worldwide NIL milk withholding when treating lactating cows - it is also the No.1 drench for return on investment by far. For example, based on an average herd size of 500 cows and a $9.00 payout, farmers can expect a return of $67.44 per cow. EPRINEX makes a lot of sense… and cents. For more info go to futureproducers.co.nz

BO1521 PROUDLY AVAILABLE FROM YOUR LOCAL PARTICIPATING VETERINARY CLINIC Boehringer Ingelheim Animal Health New Zealand Limited. Level 3, 2 Osterley Way, Manukau, Auckland, New Zealand. EPRINEX® is a registered trademark of Boehringer Ingelheim Vetmedica GmbH, used under licence. Registered pursuant to the ACVM Act 1997, No. A007191. © Copyright 2021 Boehringer Ingelheim Animal Health New Zealand Limited. All rights reserved. NZ-BOV-0012-2023. futureproducers.co.nz Ensure young stock become future high producers through improved health, growth and energy at: Together going forward. *Based on a 500 cow herd and $9.00 milk solid payout. $ 67.44 PER COW* Typical R.O.I. by using EPRINEX® on your dairy herd this season. Scan here to calculate the R.O.I. on your herd...

1 of a kind. makes a lot of cents.

The herd in the barn is well fed. Annually, they feed about 5000 Freeman bales of silage, chopped silage and maize silage, brewer’s grains vegetable waste from Watties.

“The first milking in a strange shed was exciting. They had to learn to line up and they wondered what the hell we were doing to them.”

Phil Garrett

training heifers because they were cows and more used to their ways. But we got there and after the first couple of days it wasn’t so bad.”

The herringbone had 30 bails and about 15 years ago another 25 bails were added alongside, to make a twin herringbone.

“It works well and we milk 1000 cows through it. It takes a while but we get there. Ideally we’d have a new shed but the only place to put it sensibly is where the existing one is and that creates difficulties – and a new shed is roughly $3 million so you think twice about doing it.”

For most of the year about 1000 cows are milked though that varies during the year – in early February it dropped to 800 in milk but with 400 cows due to calve that will increase. Approximately 25 animals are culled each month, a total of 250 annually.

Production is around 575,000kg MS, something Garrett is keen to build on, as he has year by year since he came to the farm.

“I know it could be better. Papers like yours have reported about other farmers doing 700kg; well, I reckon we’re capable of doing that if they’re looked after and fed, that’s all that has to happen, because we’re doing close to 600kg now.”

At the same time as the shed was being built in 1986, new fences had to go up, a task made challenging by the fact they didn’t have a tractor on the farm because it was still at the old place being used for feeding out.

“It was wet and we wheelbarrowed posts to the far end of the paddock and dug them in by hand. It was that wet we had a small hand driver we could use too. It was interesting,” Garrett says.

One of the things that attracted him to the farm was the availability of well water for irrigation, even though there was no irrigation in place when they arrived. In the second year they put in a gun and over the years have improved the irrigation on the now 400ha property, which now has six centre pivots plus some K-Line and a RotoRainer for the corners.

Being very close to Te Waihora, the farm has a high water table, especially when lake levels get high. That means it gets very muddy easily, and that used to make farming challenging, to say the least.

“We were just sick of it and my son Andrew said one day, ‘We need to build a pad or something,’” he says.

“He rang a Dutch fella who was

building a pad, and he told him ‘You don’t need a pad, you need a shed,’ so we got talking about it and I’d seen them overseas and I knew how they worked. I thought, ‘This is alright’.”

They talked about building a shed to house 500 cows but by then they were already milking 900, so Garrett said, “No, I’d rather house them all or we don’t do it.”

The big shed they built has 897 stalls and can safely hold 1000 cows, or up to 1200 for two or three days if there’s a snowstorm or similar weather event.

“We have had to do that at times and put dry stock in as well to keep them off the pasture.”

The shed has made a massive

Continued page 12

DAIRY FARMER April 2023 11

The farm is a hybrid barn and pasture system. The barn has 897 stalls and can safely hold 1000 cows, or up to 1200 for two or three days if there’s a snowstorm or similar weather event.

The extensive native planting on the farm and flax, other shrubs and carex along the waterways on Garrett’s farm have won various awards. Riparian planting along the stream that flows through the farm on the way to Te Waihora.

difference to the farm, Garrett says, and in the 10 years since it was built, production has virtually doubled. In that time the area the cows graze has been reduced from 280ha to 160ha and production is still improving.

“We have one herd in at night and they graze outside during the day and the other herd comes in during the day and grazes outside during the night,” he explains.

That changes for the six or seven weeks of mid-winter when the cows are only allowed out if the ground is dry enough and the sun is shining.

“Andrew’s got it working pretty well, as well as the grazing management. You’ve got to manipulate their grass so you can feed them and you’ve got to manipulate the barn. You have to watch that the cows have cleaned up everything in the barn and if they haven’t cleaned it up, they’ve obviously got plenty of grass out in the paddock.”

The cows are very well fed in the shed.

“We’re very high input, no question about that and we buy a lot of feed in. We use about 5000 Freeman bales of silage a year and we have some chopped as well and we’ve got our own maize silage on top of that.

“Then we have brewers grains come in and we have about two truck and trailer loads a week from Watties from the vegetable waste – we’re their best friends because we take it all the time.”

The other key to making the system work is pasture management, only feeding grass that’s short and sweet and topping if it gets too tall or making silage it gets taller still.

“We’re on a 10-day grazing round, which will startle a lot of people,” Garrett says.

That’s made possible in part by using effluent from both the barn and cowshed as what Garrett prefers to call “organic fertiliser”. They use virtually no other fertiliser on the farm but every year spread about 32 million litres of effluent over the whole property, drawn from the 12 million litre storage pond next to the barn.

“The pastures have improved so much in the last 10 years without any fertiliser, just effluent, it’s absolutely astounding and we haven’t put any new grass in –they’re all old pastures with dandelions and God knows what – they grow like fury.”

The organic fertiliser is also used on the 85ha of maize grown on the farm every year, along with a small amount

of nitrogen added at sowing, the only additional fertiliser used.

“That will be chopped for silage at the end of March. We made about 17t a hectare last year, which is not bad for Canterbury. We’ve had it in one paddock for 10 years in a row and it’s getting better.”

Four to five tonnes of lime flour is used in the shed every week to keep the bugs at bay and that finds its way onto the pasture too, in the effluent.

“So that lime’s going out on the farm all the time, helping to balance things up – and even lime’s got a bit of phosphate in it.”

Ashburton contractor Matt Lovett spreads the effluent with a tanker that lays the slurry at the base of the plant and is on farm every 10 days to a fortnight. Before he arrives, two big stirrers go to work in the pond. The 28,000 litre tanker can spread up to a million litres a day.

“We’ve taught a lot of other people how to use their effluent,” Garrett says.

12 DAIRY FARMER April 2023

Around 85ha of maize is grown each year on Rushbrook, some of which has been sown in the same paddock for the past 10 years. Apart from a small amount of N at sowing, the only fertiliser the crop gets is effluent.

Son and manager Andrew Garrett gets the herd in for afternoon milking.

“We have one herd in at night and they graze outside during the day and the other herd comes in during the day and grazes outside during the night.”

Phil Garrett

“When they first started coming here, they were going to other places where they were told, ‘Dump it all in that paddock there’, but Matt told them we were spreading it over the whole farm and now he’s doing that on a hell of a lot of farms and they’re saving the fertiliser bill.”

In his nearly 37 years on Rushbrook Farm, Garrett has seen a huge improvement in its pasture and soils, something he puts down to the cows as well as the effective use of effluent. He tells the story of the second block he bought, which had previously been cropped for close to 50 years with nothing put back.

“It was in grass when we took it on and we just shut the gate and left it and thought there’d be enough feed there for winter for the cows but nothing grew for 12 months until we started to water it. It had rain but it just wouldn’t grow, it was just dead, completely robbed and now with cows being on it and the effluent going on, it’s one of the best blocks on the farm.”

Another unusual thing about the farm is the breed of cows, which is

quite different from the Friesians or Kiwi cross found on most New Zealand dairy farms. Garrett has liked Milking Shorthorns since he was a child and that breed still forms the basis of the herd but with other breeds too and many different crosses, including Friesian,

“It’s me who’s done it and as a business you wouldn’t do what we’ve done with the different breeds but to my way of

Continued page 14

DAIRY FARMER April 2023

Jersey, Guernsey, Brown Swiss, Fleckvieh, Montbéliarde and Speckle Park.

There are six centre pivots on Rushbrook that draw from the deep wells Garrett drilled to replace the original shallow wells to release the pressure on the aquifers beneath the farm.

Wheat straw is part of the diet in the cow barn, as well as barley straw.

thinking there’s not a lot of difference between any of the breeds. If you feed them properly, you’ll get similar results from all the breeds.”

While breeds like Friesians might produce higher volumes, other breeds make up for that with higher solids or protein, he argues.

“We’ve sort of focused on milksolids over the years and picked the bulls from cows that have over 4% protein. We still milk a few wishy-washy Friesians that are down in 3% of protein but they have a lot of milk so they help balance things up I suppose.”

A life member of the New Zealand Milking Shorthorn Association, Garrett is still winning most of its production awards, for highest milked and highest protein cows. He can recite the pedigree of the about 1750 animals on the farm, including young stock.

Sitting at the kitchen table, he spies a red-and-white bull calf grazing outside.

“His mother is one of the top breeding cows in the country with 760kg of milk solids. We have others that do that too.”

Garrett selects bulls from around the world, including Sweden and Norway, mainly red animals but also some Friesians, preferring Scandinavian semen to American because he believes breeders there adhere to higher standards.

“We’ve got some really good Friesians but they’re only as good as our good red ones, they’re not any better.

“When I was in Heathcote I thought wouldn’t it be great to have 200 cows to breed from. Well, now I have 1000 to breed from. It makes a big difference, the selection process is better. They’re all recorded and you can look them up on MINDA.”

in my mind’s eye now. It came from Winchester, and I’ve still got descendants of those animals. I’ve just carried on, that’s all.”

He’s following the worldwide movement to get rid of the horns by breeding, believing it’s just too much hassle removing them. About two thirds of the herd are polled and nearly all the calves born are polled too, thanks to the selection of solely poll bulls.

Breeding on Rushbrook is very different to most farms, to fit in with year-round milking, with 50-80 cows calved in February/ March from 42 days of AI, and another 100 calved in June to beef bulls.

During this time, they also calve spring-born heifers at 22 months.

The remainder of the herd calve in spring, the result of a 42-day mating period, and then over 28 days in November/December, the straggler heifers, which have been mated to beef bulls, are calved.

He’s moving all the breeds towards polled, something he picked up from the first farmer he worked for who put a polled beef shorthorn bull over his Milking Shorthorn cows.

“Some of the calves were awful beefy things. That was in 1946, and I was only a kid but I can still see the bull

“Over the last 18 months we’ve seen a dramatic increase in heifer weights as a result of my grandson Ethan becoming chief calf rearer and managing all young stock,” Garrett says proudly.

All calves born are reared and ready markets have been established for the beef breeds as well as the Friesian bull calves.

14 DAIRY FARMER April 2023

The 1000-cow herd on their way to afternoon milking. Each year they produce around 575,000kg MS – and Garrett believes they are capable of producing more.

“When I was in Heathcote I thought wouldn’t it be great to have 200 cows to breed from. Well, now I have 1000 to breed from. It makes a big difference, the selection process is better.”

Phil Garrett

But it’s not just production and breeding that drives Garrett. He’s a strong believer in looking after the land and has won various awards for riparian planting and looking after the stream that flows through the farm on the way to Te Waihora.

“We’ve got a lot of drains planted with carex, lots of flax. The farm’s different to other farms, we’ve got a different outlook. You should leave the land better than you found it and we’re certainly going to do that here.”

After 37 years on the farm, he is pleased with what he’s achieved but doesn’t pretend he’s done it himself, crediting his publicity-shy son Andrew and grandson Ethan for much of it.

“Andrew was the driving force behind the barn 11 years ago and has also overseen big changes to the irrigation system.”

Andrew is soon to retire from active farming for health and family reasons and Ethan plans to move on soon, too. Poor health has also forced Phil to take a step back and an operations manager has been appointed to continue the work he and his son have started. n

PUT THE ‘RE’ INTO PRODUCTION WITH MARKS-MIN ®

Optimising fertility and improving weight gains in their herd are the priorities for 50/50 sharemilkers Mel and Ben Lilley of Ashburton. MARKS-MIN ZMSC with B₁₂ delivers trace minerals and B₁₂ to support reproduction, growth and immunity in dairy cows and young livestock.

To watch the video go to futureproducers.co.nz/ dairy/MARKS-MIN-ZMSC

MARKS-MIN-ZMSC

“ The gains we’ve seen are better reproduction, better six week in-calf rate and less empties.”

PROUDLY AVAILABLE FROM YOUR LOCAL PARTICIPATING VETERINARY CLINIC Boehringer Ingelheim Animal Health New Zealand Limited. Level 3, 2 Osterley Way, Manukau, Auckland, New Zealand. MARKS-MIN® is a registered trademark of the Boehringer Ingelheim Group. Registered pursuant to the ACVM Act 1997, No. A011687. See product label for full claim details and directions for use. © Copyright 2023 Boehringer Ingelheim Animal Health New Zealand Limited. All rights reserved. NZ-BOV-0003-2023. Ensure young stock become future high producers through improved health, growth and energy at: futureproducers.co.nz BOE1475

Mel Lilley, Mid Canterbury

At nearly 84 years old, Phil Garrett’s health is failing but he still keeps a close eye on the farm he and his son Andrew converted in 1986.

Market softens, margins shrink

By Gerald Piddock

The dairy commodity market has gone softer than a Camembert left out in the autumn sun, thanks to a slower-thanexpected return to the market for China.

It has resulted in two pretty sluggish auctions at the GDT, where prices remained flat at 1.5% on February 21 and 0.7% on March 7. Prior to that, prices lifted 3.7% of February 7, giving people hope that it was the start of China’s return to the market after it removed its covid restrictions.

That’s proven to be premature, with buyers in no hurry to push prices higher.

Fonterra finally bit the bullet and in late February it reduced and narrowed its 2022/23 season forecast with a new midpoint of $8.50/kg MS.

At the time, Fonterra chief executive Miles Hurrell said it reflected softening demand at a time of balanced supply.

A fortnight later, Synlait followed suit by dropping its base price forecast by 50 cents to $8.50/kg MS.

It cited subdued global economic activity and a slower-than-expected recovery of Chinese demand following covid-19 lockdowns. Global milk production also showed signs of recovery in late 2022, adding further downward pressure to dairy commodity prices, it said.

Westpac’s latest dairy update highlighted that it had expected signs of this behaviour. Instead what has happened is that prices are “treading water”, as senior agri-economist Nathan Penny described it.

Overall prices have fallen 2% since the start of the year, while WMP prices have increased by 0.7%. He expects global dairy prices to rise over coming months as the Chinese economic recovery gains further momentum.

“However, for now, dairy buyers appear in no rush to bid prices higher. This contrasts with meat prices, for example, which have seen a noticeable uptick in prices for products where China is a key market.”

He believes there may be an overhang of stocks.

“If this is the case, then prices should still pick up over time as the demand lift will eventually lead to a rundown in these stocks.”

Penny said the window for prices to lift is closing as the season fast approaches, bringing in downside risks to Westpac’s $8.75/kg MS forecast for this season.

However, he remains bullish for 20232024 with that forecast unchanged at $10/kg MS.

Equally pessimistic is ASB’s Nathan Keall, who is keeping a conservative outlook for dairy prices over the next 12 months. The bank has adopted Fonterra’s $8.50/kg MS midpoint forecast, down 15 cents from its previous forecast, and retains its pessimistic $7/kg MS new season’s forecast.

Economists aren’t as pessimistic about the outlook for the global economy as they were at the beginning of the year, but global growth is still projected to slow over the course of the year, with the recovery in China set to be offset by a deceleration elsewhere.

“And even in China, consumer spending remains sluggish, and Beijing’s

5% growth target for the year is fairly conservative. In aggregate, that should mean softer global dairy consumption,” he said in the bank’s Commodities Weekly publication.

Rabobank also lowered its forecast, from $9/kg MS to $8.50/kg MS, in its 2023 Dairy Quarterly report.

“But, with the re-opening of China, we do see the possibility of strengthening dairy demand flowing through to improved farmgate prices by the season’s end. And this does provide some upside risk to our new forecast,” the bank’s senior agricultural analyst, Emma Higgins, said.

Beyond China’s re-opening, the bank identifies developments in the South American dairy sector and ongoing geopolitical unrest as factors to keep an eye on.

Back on the farm, it all means the gap between income and production costs is now paper thin. While the weather has impacted milk production, on-farm inflation has remained a huge concern.

Rabobank’s Farm Expenses Price Index showed that dairy farm expenses were 17% higher in the fourth quarter of 2022 compared to the year before that.

“Interest rates are the key contributor, with the Reserve Bank of New Zealand recently hiking the Official Cash Rate to 4.75% – a far cry from the 1% OCR of early 2022.

“Fuel and fertiliser costs, followed by feed costs, are proving the nextbiggest headaches. However, the worm has turned downward for benchmark fertiliser costs, providing some optimism for input price relief over the coming months.”

16 DAIRY FARMER April 2023

Each month the Milk Monitor delves into the dairy industry and gives us the low-down on the good, the bad, the ugly and everything in between.

MILK MONITOR

n

China’s removal of its covid restrictions is not having the positive impact in the dairy market that was hoped for.

Brighter, braver, bolder and back

By Sonita Chandar

By Sonita Chandar

The Dairy Women’s Network conference, Brighter. Braver. Bolder, is back this year with what it promises will be another fantastic line-up of guest speakers and topics to explore.

The DWN conference description says the conference is about “learning from the wisdom of other women, making bold decisions and equipping yourselves with the resources to create a brighter future. Telling your stories with pride and celebrating the work of other women, and making new connections.

“It’s your farm, your business, your community and your sector. And we are with you every step of the way. Together, let’s continue to move towards a brighter, braver and bolder future.” Brighter. Braver. Bolder. recognises

the need for professional development, personal wellbeing, connection, celebration, learning and networking opportunities.

“As always, we have another incredible conference planned,” chief executive Jules Benton says.

“The conference is the Dairy Women’s Network’s biggest event on the annual dairy industry calendar.

“Our members are involved in DWN learning and social events throughout the year but our conference is a time when they can really connect with each other and be a part of something bigger.”

Guest speakers this year include Lucy Bloom, an accomplished leader with 30 years’ business building experience under a well-known pink mohawk. She ran an advertising agency for 20

years before she became the CEO of two international aid charities.

Other speakers are Dr Ellen Joan Nelson, an ex-army academic businesswoman with deep expertise and practical experience in leadership, gender, wellbeing and the future of work; and Abbas Nazari, who was one of more than 400 asylum seekers rescued by the Norwegian container ship the MV Tampa in the Indian Ocean.

Through interactive workshops, keynote speakers, breakfasts, dinners “and so much more”, DWN says it is making sure that attendees are equipped with the tools to face challenges, make bold decisions with confidence, support their farm businesses and – most of all – be proud to be farming during an undeniably challenging time. n

“Mastatest has taken the guess work out of mastitis for us. We’re getting higher and faster cure rates and our cell count is down 100,000 compared to last year” Paul Mahony, 650 cows, Waikato

AHMASTA-DEX2.22 Evidence based vet medicines 0800 821 421 www.agrihealth.co.nz On-farm rapid Mastitis test Bugged by High Cell Counts? Contact us on 0800 821 421 or talk to your local vet Test high SCC cows on-farm to identify the bug in 24 hours Reduce somatic cell count to achieve milk premiums AHMASTA-DF2.22 NEWS

farmer

Many hands make farm work

Industry experts and the on-farm team all bring something to the task at hand.

ON FARM

Craig and Kylee Mora run four farms at Ōtorohanga, milking 1700 cows on a total of 488ha. They employ contract milkers and have a large farm team across the group.

Photos: Jake van Vroonhoven

By Audrey Hayes

AWaikato farming couple believe no farm is ever complete, and improvements can always be made. Taking to new technology and enlisting the help of industry experts has turned their four farms into an astonishing success story.

But Craig and Kylee Mora say none of it would be possible without the supportive team they’ve built in the past 10 years since they first went into partnership with Craig’s parents.

Their team milk 1700 Friesian and Friesian Cross cows across the four farms at Ōtorohanga, covering 488ha for the dairy operation. Each farm is run independently, with contract milkers Ben Stewart and Deep Gill running their own teams. With their team’s help, they produce 1500-2000kg MS per hectare, at around 480-550kg per cow. The largest herd in the farm group is 580, and the smallest is 245.

They tackle their role of running the partnership with an understanding that

teamwork is at the heart of what they do, and there is always more to learn.

Craig came back to dairy farming full time after 14 years as a rural manager at ASB, which he says taught him the value of being part of a team.

“Within the industry at times people have referred to their team members as workers, and well, they’re not. They’re a team member, and we try to make them feel valued.”

Before that, he completed a Bachelor of Commerce in farm management at Lincoln University.

He says both his and Kylee’s parents really emphasised the importance of getting out and trying different things before coming back to farming.

“I love farming because everyone is different, there’s no one right way to get things done. There are always different ways of doing things, and every system is different. You can go to one farmer, and he will have one way of doing things and reasons for why he does it. But another farmer in New Zealand will have a totally different system,” Craig says.

But for Craig, there really was no other option. He knew he wanted to be a farmer from a young age, and though he took his parent’s advice and worked in the corporate setting for a while, he was more than ready to get back to the farm. Even when he was working at ASB, he would always take a few weeks off to help with calving and would relief-milk whenever he could.

Kylee had always been drawn to going overseas and studied tourism. After

FARM FACTS

• Farm owners: BBC Farms

Holdings Limited

• Location: Ōtorohanga, Waikato

• Farm size: Four farms totalling 488ha for dairy operation

• Cows: 1700 Friesian, Friesian cross

• Production: 2021-2022: 805,000kg

MS/ha

• Production target: 20222023: 810,000kg

MS/ha

spending a little time overseas, she came back to New Zealand and worked on her parents’ farm. In 2008 she started working for LIC, spending around five years in that role before moving up to field and sales. She worked in that role for another five years before resigning to be on farm.

“My parents encouraged me to apply

Continued page 20

A Waikato farming family understand the value of having a great team working with them.

“Within the industry at times people have referred to their team members as workers, and well, they’re not. They’re a team member, and we try to make them feel valued.”

Craig Mora

for the role at LIC, they both actually met at LIC back in the day. I was unsure of what I wanted to do and it was in an industry that I love, and my career developed from there,” Kylee says.

Her parents farm nearby, so the Moras

have found themselves surrounded by plenty of support from their team and families.

“I suppose what we’ve learnt is that having farms in close proximity has been good. We’ve also found having family support close by has been positive for us,” Craig says.

This support has allowed them to work on expanding their farming operation. Craig’s parents owned their farm, and in 2013 the family started a partnership and expanded from the 220-cow dairy operation to purchase the neighbouring property. There’s a total of up to 16 staff at any time in the year, including Kylee, Craig and his parents, hitting a high around calving.

Steady growth allowed them to purchase what they call the bottom farm

in 2018, and then in 2020 they took on a lease farm close by. This was quickly followed with the purchase of another 210ha dairy farm in 2022, which they converted to a drystock farm.

“It’s all based off my parents originally,” Craig says.

“The original farm was next door. Whilst they leave a lot of the stuff to us, ultimately they’re still very much a part of it.”

Three of the farms are in the partnership, with 1450 cows in one entity and 250 still owned by Craig’s parents, but they choose to run them together.

Some team members have been around since the partnership was started.

“Deep worked for the previous owner, so he’s been with us since 2013, and he now has a family and is making his own way. Deep contract milks my parent’s farm, Burr and Waipa. So, he milks 1200 cows across three farms. Ben and his family joined us when we bought the bottom farm, so he’s been here since 2018 and he contract milks that with his team there. We’re real lucky to have those two guys as part of the team,” Craig says.

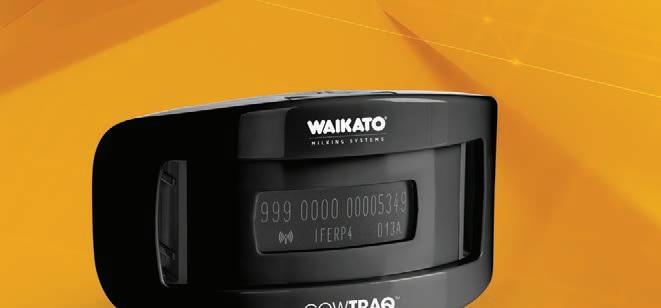

As the farms are run somewhat independently, they each have different equipment. Two of the farms are 42- and 44-bail internal rotaries, and two are 20and 36-bail herringbones. While they all have feed pads, only two currently have in-shed feeders. Every cow is fitted with a CowManager ear sensor, and as of this year, all of the sheds now have Protrack drafting gates.

Any changes in equipment or technology have been made to help with risk mitigation.

“The biggest risk for us is having a

20 DAIRY FARMER April 2023

Over the four farms, 1700 Friesian and Frisian cross cows are milked, producing around 480-550kg of milksolids per cow.

Craig Mora came back to dairy farming full time after 14 years as a rural manager at ASB, and he says it was that which taught him the value of being part of a team. Craig in the milking shed.

“I love farming because everyone is different, there’s no one right way to get things done. There are always different ways of doing things, and every system is different.”

Craig Mora

key person. We’ve got great people on the ground but relying on that key person for 10 weeks during mating was a real risk. And with the ever-changing environment, we potentially won’t be keeping these great people forever. So, we put a lot of thought into how we can minimise risk of change,” Craig says.

One thing Craig learnt from his parents was the value of measurements and accuracy, and that is something he has carried through into the running of the farms when it comes to making sure his cows are fed well.

“From a management point of view, we enjoy having well fed cows. I don’t

Nil withholding, for when she needs it.

enjoy having the stress of not feeding my cows very well,” he says.

“We don’t do random very well. I don’t like random.”

The wagons have scales, and everything is measured. Everyone in the

Continued page 22

To

out her best,

Pour–On provides flexibility when drenching. With nil withholding periods for milk, meat and bobby calves, you can treat your cows if and when they need it.

Pour–On is long lasting, with 35 days protection against Ostertagia ostertagi. It kills biting and sucking lice too.

CYDECTIN

So

CYDECTIN Pour–On — New Zealand

for healthy Kiwi cows. Zoetis New Zealand Limited. Tel: 0800 963 847; www.zoetis.co.nz. CYDECTIN is a registered trade mark of Zoetis. ACVM No. A6203. For more information visit cydectin.co.nz

bring

CYDECTIN®

keep your profits up and parasites down. Invest in

made

An aerial view of one of the milking sheds and herd coming at Mora farms at Ōtorohanga. Craig and Kylee Mora run three of the farms in partnership with his parents.

team knows the measurements and how much they’re feeding each day. To them consistency and simplicity are key.

“Our nutrition is very simple, in the past I’ve just done all the blends myself for the sheds, and we use maize, palm kernel and grass silage on farm. We do have a farm consultant who will visit every four to six weeks. Darren Sutton from FarmWise has been with us the whole time, and it’s an opportunity for everyone to check in and make sure we’re on track.”

Having the accountability of an external team member has helped them stay on track with their goals, and they both like that it gives an opportunity for everyone in the team to bring forward their opinions and challenge new ideas.

“You’ve got really good discipline to go out and condition-score your cows every month. It sets those disciplines for us and helps us to try and make things right.”

The farms are run as medium input with a stocking rate of 3.5 cows per hectare, and that’s just the way Craig likes it. He believes it’s easier to manage the farms this way, as “you’re always filling a deficit”. He says it’s easier for his team too, as back-calculating a deficit can be a lot simpler than managing grass alone.

“We look to hit residuals and fill feed gaps if necessary,” he says.

However, the weather over the last year has presented some challenges. Particularly with the maize grown on farm. This means they’ve had to contend with the weather changes and adapt to ensure their cows remain well fed.

“This season we’ve replanted our maize twice, losing it both times to flooding. In December we replanted again, thinking we’d be okay because it’s summer.”

The most recent weather events

caused 52ha of maize to be either flooded or lodged.

Nutrients and fertilisers are put into the soil on the farms based on recommendations from Ballance.

Craig says they try to run “pretty high nutrient levels”, but ultimately go off recommendations from experts within their network. They place high value on working with and trusting the opinions of industry experts.

Effluent is spread by travelling irrigator, and they try to use recycled green water wherever they can.

They know that ensuring their cows and calves are well nourished and taken care of goes hand in hand with reproduction and are hoping to use the data collected by the CowManager monitoring system to help them make informed decisions on farm.

They are constantly looking at what

changes can be made on farm to cause overall improvements.

“Our main goal is reproduction, which feeds back into nutrition. But we like to always consider what we can do within

‘MIX IT UP’ WITH PRECISION. Talk to us now about which

‘MIX IT UP’ WITH PRECISION. Talk to us now about which

ACCURATE MIXING IS IMPERATIVE TO ACHIEVE QUALITY RESULTS FROM YOUR FEED. QUALITY BUILT AND PACKED WITH FEATURES, THERE’S PLENTY OF REASONS WHY YOU’LL SEE AN ABBEY ON A FEED PAD NEAR YOU.

ACCURATE MIXING IS IMPERATIVE TO ACHIEVE QUALITY RESULTS FROM YOUR FEED. QUALITY BUILT AND PACKED WITH FEATURES, THERE’S PLENTY OF REASONS WHY YOU’LL SEE AN ABBEY ON A FEED PAD NEAR YOU.

ACCURATE MIXING IS IMPERATIVE TO ACHIEVE QUALITY RESULTS FROM YOUR FEED. QUALITY BUILT AND PACKED WITH FEATURES, THERE’S PLENTY OF REASONS WHY YOU’LL SEE AN ABBEY ON A FEED PAD NEAR YOU.

Built to mix efficiently an ABBEY mixer wagon reduces waste and ensures your stock get all the nutrients they need.

Built to mix efficiently an ABBEY mixer wagon reduces waste and ensures your stock get all the nutrients they need.

Built to mix efficiently an ABBEY mixer wagon reduces waste and ensures your stock get all the nutrients they need.

ABBEY

ABBEYs

action

website. FIND OUT MORE AT farmgard.co.nz CALL FARMGARD 24 HOURS 0800 FARMGARD Nationwide Dealer Service Network 35 years, Generations of Experience 35

mixer wagon is best for your operation. To see videos of

in

visit our

ABBEY

ABBEYs

website. FIND OUT MORE AT farmgard.co.nz CALL FARMGARD 24 HOURS 0800 FARMGARD Nationwide Dealer Service Network 35 years, Generations of Experience 35

mixer wagon is best for your operation. To see videos of

in action visit our

Talk

FIND OUT MORE AT farmgard.co.nz CALL FARMGARD 24 HOURS 0800 FARMGARD Nationwide Dealer Service Network 35 years, Generations of Experience 35

‘MIX IT UP’ WITH PRECISION.

to us now about which ABBEY mixer wagon is best for your operation. To see videos of ABBEYs in action visit our website.

Craig and Kylee Mora use the CowManager monitoring system to help them make informed decisions on farm. Craig, Jared Bekhuis, national manager of Senztag Automation, and Kylee get out among the herd.

“We’re just sort of reviewing potential around improving our calf-rearing and looking at that slightly differently as well. You know, are we feeding the calves to their potential, or are we feeding them to a system?”

Kylee Mora

our budget. Are there little things we can do to make changes to produce better or hold condition, or what are we missing?”

One thing they’ve decided to do to help inform these sorts of decisions is

enlist the help of Dr Krispin Kannan from Veterinary Enterprises. Kannan is a veterinarian whose business role focuses on technology solutions on farm and has spent the past 14 years as a dairy vet.

More recently he has been familiarising himself with new wearable technology and helping farmers turn data collected from their monitoring systems into meaningful, practical action.

He says “it’s about adding more value via insights and interpretation of the data this is already collected for the farmer by their systems”.

They didn’t originally seek out the system for the purpose of monitoring nutrition but have found the insights invaluable.

“The thing we are trying to find out by working with Krispin is, are we fully feeding them? We can think we are, but looking through the CowManager data, what are we feeding them, and what improvements can we make?” Craig says.

He hopes that adding someone like Kannan, who is experienced in turning data into action, will help the team make changes that will have a direct effect on their farming system.

“You’d think after 10 years of farming you could just flip back and look at each

Continued page 24

DAIRY FARMER April 2023

This season the Moras have replanted their maize twice, losing it both times to flooding. In December it was resown and the most recent weather events caused 52ha of maize to be either flooded or lodged.

Two of the farms have internal rotaries and the herd is fed with a blend of maize, palm kernel and grass silage through the in-shed feeding system.

month to work things out, but it is quite different,” he says.

With Kannan on board, they’re hoping to get back to the data. Soon they will have over two years of nutrition data on the herds and will be able to understand better what is happening during crucial times of the season.

Even though they’ve brought in experts to help sort through the data, they know any changes they make are going to be simple ones.

“Any changes and purchases still have to fit within a simple system and use the resources available to us to manipulate it to see if we can improve outcomes,”

Craig says.

Each of the farms has different topography, so this is something they consider within their mating goals. They’re currently aiming for a smaller cow for two of the farms, as one requires the cows to walk long distances and the other is flatter and wetter. Apart from that, Craig says, his goal is to breed the type of cows you don’t notice. Some of the herds are mated with Kiwi Cross, and he jokes that it doesn’t take long to see some colour coming through over the years of mating them to Friesian.

He reckons mating is like the Da Vinci Code, so they’ve tried to make processes as simple as possible for everyone in the team. Mating begins in October, and they start mating for all farms within the first week of the month.

“We only do spring calving and heifers start around July, so we send milk roughly in the first week of July, give or take.”

AI is around 10 weeks across the farms,

and they calve in about eight and a half weeks, and AI all their heifers.

“About four and a half weeks is getting replacements, and then we move on to short gestation after that, so everything is calving about 10 days earlier than it normally was,” Kylee says.

Each year, they aim to get replacement numbers of around 25% for each herd, and do well to hit that goal.

They have similar six-week in-calf rates across the four farms, ranging from 70 to 80%, and hope to continue improving those numbers each year. The average empty rate is 12% this season, which is something they’re proud of in what has been a challenging year.

Kylee rears the calves on one farm but oversees all the farms during calving.

They’ve started looking into how they can adapt and change their processes to give their cows everything they need from day one.

“We’re just sort of reviewing potential around improving our calf-rearing and looking at that slightly differently as well. You know, are we feeding the calves to their potential, or are we feeding them to a system? And I would question that we, like most New Zealand farmers are feeding to a system, rather than looking at ways to maximise growth.”

This year, they’ve started fortifying the milk with milk powder, so they’re getting the same number of litres but there’s an increase when it comes to the nutrients they’re getting.

They’re switching their thinking from what they call a milk litres-based system to a milk solids-based system, in the hopes that the extra care in accuracy will allow them to ensure their calves are well fed.

“If, for example, we feed them four litres, why do we feed them four litres?

24 DAIRY FARMER April 2023

Kylee Mora grew up on a dairy farm but had always wanted to travel overseas so she studied tourism. Returning from overseas she worked on her parent’s farm, which is nearby. She now rears the calves on one farm but oversees all the farms during calving.

Craig and Kylee are constantly looking at what changes can be made on farm to cause overall improvements and have engaged the services of Dr Krispin Kannan, VetEnt business development & integrated solutions manager, to help with this.

“If, for example, we feed them four litres, why do we feed them four litres? It’s just what we’ve always done. And if you ask someone else, everyone in New Zealand will have a different feeding system, but why?”

Kylee Mora

It’s just what we’ve always done. And if you ask someone else, everyone in New Zealand will have a different feeding system, but why?”

They aim to continue to make small changes while keeping things as simple as possible so they can retain the team they value highly.

“We just bumble along,” Craig laughs.

“There are probably too many things we’re focused on to be fair, we try get a

lot of stuff right and we try to do things right. I suppose like everyone, we’re just trying to improve everything all the time.”

Craig and Kylee are aware that their animal health cost per cow is higher than most, but they know that those costs are proactive, and they prefer that over reactive farming. Using technology and simple processes to their advantage, they’ve been able to stay ahead of

challenges brought forward from quick growth while remaining true to valuing the people who have helped them over the past 10 years.

“Our goal is to keep retaining people, obviously we’re going to go through some changes but we’re just trying to do all the little things right so we can hopefully get the benefits at the other end. We’re always running to try and keep up with what’s going on.” n

We were introduced to Animate at the beginning of the season and what a game changer it has been for us. We had a total of six down cows for the entire calving, something we can only put down to Animate.

It was easy to use, the cows loved it, was a massive time saver and there is nothing better than seeing your cows happy and healthy.

Sarah Woodley, 420 cows, Clandeboye, South Canterbury.

Talk to us today

0508 Animate (264 6283) | nzsupport@pahc.com | pahc.com Phibro Animal Health Corporation. Phibro, Phibro logo design are trademarks owned by or licensed to Phibro Animal Health Corporation or its affiliates. Phibro NZ Ltd. DAIRY 0508 Animate (264 6283) / nzsupport@pahc.com / pahc.com

I honestly couldn’t rate this product high enough, both dad and I would recommend it to anyone!

LK0114261© Talk to us today South Island Contact – Megan Hardy 027 488 2548 North Island Contact – Spencer Hickford 027 228 9277

Nutrition is kept fairly simple on the medium-input farms and Craig does all the blends himself for the sheds, using maize, palm kernel and grass silage on farm.

Surprise prize

By Greg Ford

An AgResearch scientist’s award-winning research has confirmed her rising-star status in the world of microbiology.

When an email landed in Tanushree Gupta’s inbox from an unknown overseas sender claiming she was a finalist for a prestigious award, she thought it was a scam.

The AgResearch microbiologist had only recently returned from a longoverdue catch-up with family in India and was recovering from jet lag and a travel bug.

“I was still sick and not really thinking straight. I read that email and I just closed it off thinking this must be a scam. Then, when I just got my mind sorted ... I did some investigating.”

The email was real and her work identifying natural bacterial metabolites that can be used as food preservatives or antimicrobials with commercial potential was in fact, award-winning research.

The email was followed by another a few days later saying not only was she a finalist, she’d won the Basil Jarvis Prize at the Applied Microbiology Awards.

“I couldn’t believe it and needed to look at [Applied Microbiology International’s] Facebook and Linked In pages and through a few people profiles before I’d let myself think maybe it was legitimate.”

She broke the news to her team leader, Gale Brightwell, and they discovered the award came with an all-expenses-paid trip to the ceremony in London. Within a few days of thinking she was being scammed, she was rubbing shoulders with the best microbiologists in the world at the Science Museum in swanky South Kensington.

She’d entered with no specific hope other than bringing her work to the attention of people who might be interested in funding it.

“We spend a lot of time in proposal writing and not getting anything. This time there were a lot of happy tears because people were noticing our work. The event was full of great scientists, and I had so many great conversations, which I have continued after the event over

LinkedIn. Most importantly, I was proud of representing AgResearch and New Zealand there.”

Gupta stresses the word “our”. The award, she says, reflects the work her team does.

“The method development for which I won the award took almost a year with constant work, including weekends. It was during the time that I found my niche in the team. My PhD students played an important part. The method was a core part of their research.

“Dr Amila Nawarathna helped find natural antimicrobials from anaerobic bacteria and Alexis Risson helped identify spoilage and pathogenic spore-forming bacteria in sheep milk. My team leader, Gale Brightwell, also encouraged me to pursue these crazy ideas.”

A few years ago, she and her team became aware of the shortcomings in some of the internationally accepted and published bacterial testing regimes they were using, particularly in a dairy environment, which provided an opportunity to come up with some

answers to a complex problem.

“We started to recognise that not all the recognised processing conditions for killing or stopping the growth of sporeforming bacteria were working as well as they might. When bacteria are in the form of spores, they are highly robust and resilient to environmental conditions, including processing technologies and heat. This was a problem in a New Zealand context because we wanted to look at what and where are higher numbers or a prevalence of these spore-

26 DAIRY FARMER April 2023 RESEARCH

AgResearch microbiologist Tanushree Gupta thought an email from an unknown overseas address saying she had won an award for her work was a scam, but it was real. Gupta at work in the lab.

“Because I know how to adapt, I’m also moving into new areas, such as animal health, which is a very important area to focus on, especially when we talk about facial eczema.”

Tanushree Gupta

forming bacteria on a dairy farm.

“We’d take samples from feed, soil, silage, maze, grass or whatever feed was fed to the animals, including swabs from milking cups and raw milk as well. From that I had that whole continuum, from one end to the other, with the aim to grow bacteria from those samples on a specific media, see the morphology of the bacteria, and then do the phenotypic analysis to find out what these bacteria are.

“We used the lab manual and methods used in papers.

“We used media with egg yolk to isolate Clostridium species and incubated bacteria using other specific media aerobically to kill off the Bacillus.

“But we couldn’t get a clear demarcation even when using the method to get the growth of anaerobic bacteria under anaerobic conditions.

“Some of the bacteria were actually able to change their metabolism and grow in the absence of oxygen as well. They were growing anaerobically. Some of them were proliferating so happily that they were all over the media and I could not identify or isolate species”.

Her background placed her in a unique position to help tackle the problem. Initially, she’d planned to be a food technologist.

“I did a Master’s thesis at Punjabi University looking into designing different vector systems which would produce antimicrobials in certain bacterial strains.

“I got a role as a research fellow in the National Dairy Research Institute in India, where I worked with enzyme technology for the dairy industry. And after that I thought that is what I am going to do.

“But then I got this really cool opportunity to study antibiotic resistance in nosocomial pathogens, which were circulating in hospitals.”

She did her PhD in antibiotic resistance and now at AgResearch has found her niche working with sporeforming bacteria in the food chain, whether it’s meat or dairy.

“And because I know how to adapt, I’m also moving into new areas, such as animal health, which is a very important area to focus on, especially when we talk about facial eczema.”

Her food and medical microbiology research, coupled with hands-on lab experience, inspired her to create a new method to differentiate bacteria.

The “textbook” method to distinguish anaerobes and aerobic bacteria wasn’t effective in a New Zealand farm context.

So they started isolating those anaerobic species and then whole genome sequencing them.

“We grew them individually or together. We tested the efficacy against different food pathogens and against different food spoilage microorganism, fungus as well. Through a lot of hard work we found the specific anaerobic bacteria that were untouched, that had the ability to produce antibacterial and antifungal metabolites thanks to our new method.”

She says publishing their findings helped change the understanding of how bacteria interact and has opened up research into new applications of antibacterial and antifungal metabolites. More work needs to be done, but there are several obvious applications in packaging and preventing food spoilage.

DAIRY FARMER April 2023 IS IT T I M E TO Upgrade Specialists Talk to the 0800 222 228 delaval.com REDUCE MASTITIS?

n

AgResearch scientist Tanushree Gupta won the Basil Jarvis Prize at the Applied Microbiology Awards and attended the awards ceremony at the Science Museum in South Kensington, London.

Doing the groundwork

The Southern Dairy Hub, the largest farm of its type in New Zealand, marks five years in operation.

With five years of operation now under its belt, the Southern Dairy Hub is reflecting on some significant progress to date, and opportunities to further establish its place as the go-to source for dairy research in the south.

“We’ve certainly come a long way in those five years,” says hub general manager Louise Cook.

“A lot of the research that the scientists do here at the hub does take time, but we put the work in because it is important to build the knowledge and support local farmers to address big challenges like winter grazing and environmental regulation.”

Located near Invercargill, the Southern Dairy Hub was established in 2017 in response to the needs of local farmers who were keen for science and local research to help them make informed decisions on their farms and for their farm systems.

The hub’s 349ha facility is jointly funded by southern dairy farmers, AgResearch and DairyNZ.

“It’s thanks to the generosity of the community, sponsors and funders that it’s able to deliver the ground-breaking research that it does,” Cook says.

The hub operates as a working dairy farm while also conducting research

trials, which makes it the largest farm of its type in New Zealand and one of the biggest internationally.

“The southern part of the country has unique climate and soil conditions and the research we do helps find solutions to address specific challenges within the context of long-term sustainable farm systems,” she says.

Hub research focuses on direct comparisons between four farmlet systems of about 200 cows each. The

research trials the performance of different crops, feeding approaches and systems, focusing on the impacts on productivity and profitability.

“Many of these research trials have been going for several years and the results are compelling.

“The projects are wide-ranging and focused on achieving practical and tangible information that farmers can use to help them make decisions on their own dairy farms. We share the key results on our Facebook page each week, and people are able to track the results back on our website”.

Cook believes that for the research to be meaningful it has to be shared with farmers in a way that works for them.

“We try to get as many people as possible engaged in the work that is being done and with field days, community events and educational get-togethers at the hub, the local community and our farmers are at the centre of everything the hub does,” she says.

MORE:

Find out more about the Southern Dairy Hub and its research by following it on Facebook or visiting southerndairyhub. co.nz

28 DAIRY FARMER April 2023 RESEARCH

n

Scientists work on a catch crop experiment at the Southern Dairy Hub.

Hub research focuses on direct comparisons between four farmlet systems of about 200 cows each. The research trials the performance of different crops, feeding approaches and systems.

This tool is highly reliable for predicting the potential BW of elite young sires.

Breeding The Pasture-Based Farmer's Dream Cow

Samen NZ's 2023 sire lineup has arrived. Stacked with sires selected to perform on pasture-based dairy systems, every New Zealand dairy farm can benefit from this leading catalogue.

Fast forward your herds genetic gain with the best in the world.

Moderate Frame Easy Calving Fertility Longevity Beef Value Efficient Production Tidy Udders Walking Ability Low SCC Less Mastitis No Dehorning Feed Efficiency

0800 220 232 | www.samen.co.nz Scan QR Code To Find Out More New Zealand Index gNZI

Meeting green targets with plantain

Kate Fransen

For around two decades DairyNZ has focused on developing farm systems that reduce environmental footprint, while maintaining profitable farm businesses. This is part of my passion, bringing farmers and scientists together to develop the information and tools required to run profitable businesses while improving environmental outcomes.

I am pleased to lead the Sustainable Food and Fibre Futures’ Plantain Practice and Potency Programme, which is helping farmers achieve exactly that goal. The programme is a collaborative research initiative that aims to substantially reduce nitrogen lost to freshwater and greenhouse gases by using Ecotain plantain.

Lincoln University trial is showing similar trends after one year. The range in results is due to the amount of plantain in the pastures, and differences in annual rainfall.

Ecotain plantain is used in our research trials because it has proven environmental benefits. Through the programme, we are developing an evaluation system to assess the environmental effectiveness of other plantain cultivars.

Ecotain plantain reduces nitrate leaching by diluting urinary nitrogen and reducing the amount of nitrogen excreted as urine. The plant also changes the urine so that when it is returned to soil it is held in a less leachable form for longer.

with DairyNZ

farmers nationwide to develop regionally specific management practices and assess the cost and benefits for businesses.

Tools and information for farmers interested in plantain are available at dairynz.co.nz/plantain.

DairyNZ Farmers’ Forum will be showcasing the findings of the plantain programme at the upcoming DairyNZ Farmers’ Forum events, and farmers can hear about other DairyNZ research and solutions available.

The programme is funded by DairyNZ, the Ministry for Primary Industries, PGG Wrightson Seeds and Fonterra, working with six additional research and delivery partners. It builds on existing research and extension projects.

We’ve achieved some exciting results so far. Ecotain plantain pastures at our Massey University farm reduced nitrate leaching by 20 to 60% over two years, with no impact on milk production. Our

We know that farmers have tough nitrogen leaching targets to meet. Canterbury, Horizons and Bay of Plenty regional councils are currently recognising plantain as a mitigation option.

Plantain is fairly easy to integrate into farm systems, although there are some challenges, such as maintaining the levels of plantain needed to achieve significant nitrogen leaching reductions. We are working with more than 20

There are two in-person events in Waikato and Canterbury, which are free for levy-paying dairy farmers and their staff.

• Waikato

Don Rowlands Centre, Karāpiro

Thursday April 27

• Canterbury

Ashburton Events Centre, Ashburton

Tuesday May 9 n

MORE:

For more information visit dairynz.co.nz/ farmers-forum-2023

30 DAIRY FARMER April 2023

DairyNZ Plantain Potency and Practice Programme lead

Massey University farm trials have shown Ecotain plantain pastures reduced nitrate leaching by 20 to 60% over two years, with no impact on milk production.

INDUSTRY GOOD

“We are working with more than 20 farmers nationwide to develop regionally specific management practices and assess the cost and benefits for businesses.”

LAN 280 9 CALL YOUR LOCAL DEALERSHIP TO SEE HOW WE CAN HELP GROW YOUR BUSINESS

16 dealerships and 1 partner dealer holding up to half a million parts, 90 highly trained field technicians, a team of dedicated professionals and an extensive range of new and used CLAAS and other leading brands, you can be confident CLAAS Harvest Centre is here to keep you growing. claasharvestcentre.com HERE, THERE AND EVERYWHERE TO KEEP YOU GROWING NORTH ISLAND BAY OF PLENTY Rotorua 07 345 5599 CENTRAL DISTRICTS Feilding 06 323 0101 HAWKE’S BAY Hastings 06 872 1010 NORTHLAND Whangarei 09 430 3066 TARANAKI Hawera 06 278 0020 WAIKATO Rukuhia 07 843 9100 CLAAS HARVEST CENTRES SOUTH ISLAND CANTERBURY Ashburton 03 307 9400 Christchurch 03 341 6900 T imaru 03 688 6900 Waipara 03 314 6899 OTAGO Dunedin 03 489 8886 Ranfurly 03 489 8886 Wanaka 03 443 6781 SOUTHLAND Gore 03 263 1000 Invercargill 03 215 6114 WESTLAND Greymouth 03 755 8450 PUKEKOHE Roger Gill Agriculture 09 239 1035 PARTNER DEALER

With

By Samantha Tennent

A Southland farmer found the lure of the land and dairy farming stronger than any urge to sit behind a desk.

Getting more than he bargained for on his OE, a Southland farmer returned from a short stint in the United Kingdom with a lovely French lady and a newfound passion for farming.

Footy and farming had lured Hayden Diack overseas, where he played rugby in Edinburgh for six months then managed a beef farm in the south of England. He had intended to chase a dream job in meat marketing when he got back to New Zealand, but he found farming was too hard to give up.

“I was working on Dad’s sheep farm after I got back and realised how much I love being outside on the farm,” Diack says.

So he gave up the idea of the office job and landed himself a role managing a sheep and beef block. But when he started looking for growth opportunities he struggled to find anything viable.

“We were looking for equity growth opportunities but Dad’s farm was too small and it’s very difficult to get started in dry stock farming with nothing behind you,” he says.

“Our banker suggested dairy farming as it was a quick way to grow equity.”

Fast-forward three years and he and his now-wife, Alienor, are lower-order sharemilking 850 cows in Mokoreta,

too

Southland. And Diack says he is earning two and half times what he would have as a sheep farm manager.

“It’s been a whirlwind but I think it’s outstanding what we’ve been able to do in the dairy industry, there are just so many more opportunities.”

When he started exploring dairying he found an opening on a nearby farm

in Wyndham with Robin and Lois Greer while their manager was heading away for a season. He started some relief milking locally to get a bit of experience before he took the leap. Before that, he had rarely set foot on a dairy farm.

“I wanted to get some experience under my belt before I stepped straight into a manager’s role,” Diack says.

The right people grow everyone’s business. Become a licensee Find out about becoming a licensee in your area: Alister Shennan - 027 302 3713 | alister@agricademy.co.nz ROAD TO DAIRYING

Change accelerator

Southland farmer Hayden Diack had intended a career in meat marketing but loved working outside on the land

much to sit behind a desk, so he went dairying. Hayden with his son Ezekiel.

“And it was a big change starting dairying, but I really enjoyed those first 12 months. I love the technical aspect of dairy farming.”

They were milking 420 cows on a once-a-day system, which was nice and relaxed to give Diack a chance to find his feet. The following season he moved to a larger-scale farm near Woodlands as a manager for Blair and Brooke McKenzie, milking 1100 cows. He had a team to manage for the first time too.

“It was a great experience, I learnt a lot from the McKenzies, especially about managing people and larger scale farming.

“I quickly realised how passionate I am about working with people and being part of a team.”

He spent two seasons absorbing as much knowledge and experience as he could before shifting to the lower-order position.

On the current farm, they usually have a team of four but they have had difficulty recruiting recently so have had to juggle with three and utilise a range of casuals to plug the gaps.

They run a roster that works similar to five on and two off, where everyone has a three-day weekend every second weekend and a day off between weekends.

“I was given advice early that dairying jobs need to be attractive to compete with town jobs, where people have weekends off and we’ve found everyone loves having regular three-day weekends.

“It actually makes it hard to take annual leave because you’ve got so many opportunities to go away and you do feel recharged, it works well for the team.”

They are spring-calving crossbred cows on rolling hill country, milking twice a day until switching to 10 milkings in seven days in February. They operate a System

2 with grain being fed through in-shed feeding throughout the season, but the big focus is pasture with silage added as needed.

Outside of the farm, Diack is still heavily involved in footy, playing in the division one competition for Wyndham.

“It’s a tough competition, we train like professionals and it takes up a lot of time, but I love it.”

He and Alienor have a one-year-old son, Ezekiel, who they try to take to the beach whenever they can.

They have a property in Invercargill and, looking ahead, they will continue to build equity and pay down debt. They aspire to own a farm one day but that does not have to be outright ownership – they would happily look at some sort of equity arrangement.

Diack feels they have both gotten a lot out of entering the New Zealand Dairy Industry Awards, making the regional

finals in 2020 and placing third last year. It was meeting like-minded people and receiving feedback from the judges that made the most impact.

He is pretty proud of what he has achieved in only three years in the industry, knowing it is light years ahead of where he would have gotten in sheep and beef.

“I love the industry, I love how everyone is so keen to share knowledge and how you can see results pretty quickly.”

He encourages others to surround themselves with people who support personal growth and provide the best opportunities.

“There can be some pretty tough people to work for out there, but if you find a good system with good life balance there are some amazing opportunities.

“And there are plenty of people out there who are keen to see others succeed.”

for Get Milking.

Hayden operates a System 2 with grain being fed through in-shed feeding throughout the season, but the big focus is pasture with silage added as needed. Hayden and Ezekiel play around on the bales.