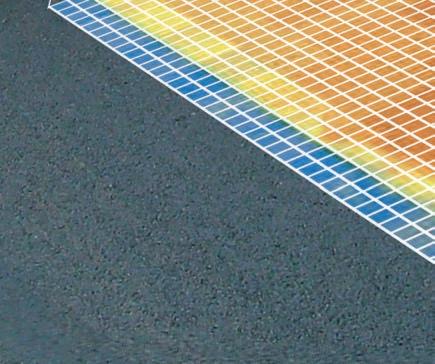

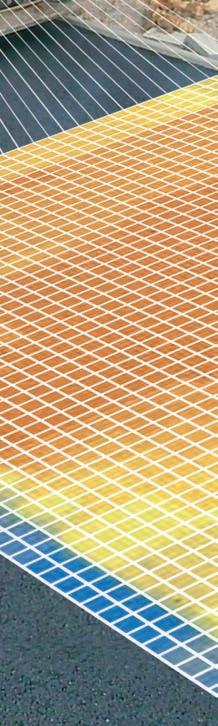

Introducing Cargill’s Anova® Warm Mix Additive. A non-toxic, bio-based solution that reliably achieves density and improves workability at lower temperatures. This game-changing innovation leads to a safer work environment for crews. Plus, the unique chemistry of our Warm Mix Additive helps reduce moisture susceptibility, causes less emissions and aids compaction while eliminating the need for anti-stripping agents. Ultimately, our industry leading warm mix additive provides a safer, lower cost solution without sacri cing performance. Paving better, more sustainable roads across the globe.

Come see us at ConExpo! Our Global Technical Lead Hassan Tabatabaee will discuss “Balanced Mix Design and Recycling: Advancing Technology and Economics” on March 14, 2023 at 10:45 AM, 2nd floor of West Hall (exact room tba).

Scan

how Anova’s Warm Mix Additive can work for you.

We have an early look at many of the awesome new hardware you’ll see at this year’s show in Las Vegas! As well as highlights from the prime educational sessions to take advantage of. | 22

10 Preparing for a Highly Sustainable Future

Whether they’re loved or hated by the industry, electric excavator offerings continue to progress rapidly as manufacturers strive to drastically decrease emissions.

16 Work Smarter, Not Harder: How Advanced Grade Control Tech Brings Efficiencies

Automated grade control technologies are becoming an integral part of compact machines and attachments, as they create a noticeable reduction in downtime.

38 Evolving Asphalt: What You Should Know About EPDs

An overview of the CONEXPO educational session from NAPA’s Director of Sustainable Pavements Joseph Shacat covering all things Environmental Product Declarations.

44 How the Sanibel Causeway Reopened Less Than a Month After Hurricane Ian

An updated look at the achievements and progress since the 2022 disaster.

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Asphalt Contractor (ISSN 1055-9205, USPS 0020-688): is published 10 times per year: January, February, March/April, May, June/July, August, September, October, November, December, with an additional Buyer’s Guide issue published in August by AC Business Media, 201 N. Main St. Ste 350, Fort Atkinson, Wisconsin 53538. Periodicals postage paid at Fort Atkinson, Wisconsin and additional entry offices.

POSTMASTER: Please send change of address to ASPHALT CONTRACTOR, PO Box 3605, Northbrook, Illinois 600653605. Printed in the U.S.A.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge only in the USA. The Publisher reserves the right to reject nonqualifying subscribers. One-year subscription to nonqualifying individuals: U.S. $45.00, Canada & Mexico $65.00, and $95.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International).

World of Concrete 2023 offered a taste of the equipment trends contractors and dealers should look out for at CONEXPO.

On this episode of Digging Deeper, ForConstructionPros’ Wayne Grayson is joined by Jason Hurdis of Caterpillar and a special guest: Jaus Neigum, the winner of the very first Global Operator Challenge.

Read more at: https://asph.link/ye1gtp

Ajax Paving Industries relies on 3D control from Trimble to meet demanding requirements on mission critical asphalt and concrete paving projects.

Read more at: https://asph.link/x5pymk

Read more at: https:// asph.link/5st6y3

The software-based technology gives Trimble end users and equipment manufacturers the ability to optimize and automate the trajectory, speed and overall path design of industrial equipment to increase efficiency of work.

Read more at: https://asph.link/ows1gp

The report cautions that inflation, a possible economic downturn and China’s stance on COVID protocols will keep prices high throughout the year. In 2023, the construction industry is expected to shrink by 7%.

Read more at: https://asph.link/afpmva

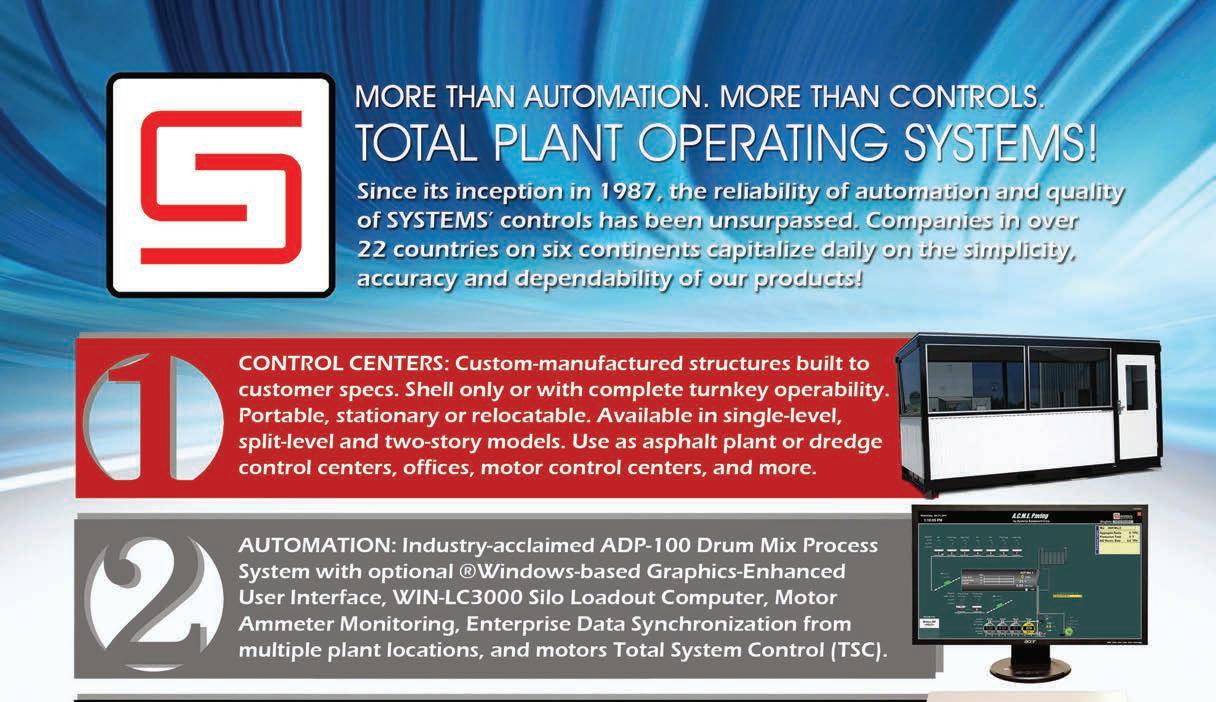

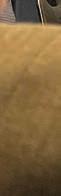

As a decades-long leader in asphalt plant innovation, Astec has introduced numerous products contributing to sustainability. From the Double Barrel® dryer/mixer introduced in 1988 to the debut of the high RAP Double Barrel XHR in 2016. In addition to these industry-changing products, Astec also leads in sustainability with our warm mix system, the V-PAC stack temperature control system, low emission burners, and blue smoke systems.

Astec is well-equipped to carry our culture of innovation into the future. Our dedication to sustainability includes new product development teams and an on-staff product manager for sustainability.

MARCH 14-18, 2023 •

Reach out to learn more about how we can help you meet your asphalt plant sustainability goals.

Brandon Noel, Editor

Brandon Noel, Editor

bNoel@ACBusinessMedia.com

It seems like CONEXPO is this largerthan-life event that I've been hearing about ever since I took on the role of editor here at Asphalt Contractor. From day one, it loomed over every meeting, and even now that it is here, it almost doesn't seem possible. For those who were in attendance during the last CONEXPO, things couldn't be more different. There's definitely been an excitement flowing through the industry during the first few months of the year. As I've travelled and talked with producers, CEOs, contractors, experts and, yes, even the people who put down the asphalt on the road, everyone has been looking forward to this.

In this month's issue, we have a great deal of pre-show coverage from many of the leading manufacturers who are looking to bring wholly new, refreshed and/or redesigned versions of their most in-demand products. In our special report, you'll find some great examples that you'll want to put on your "must see" list, and you can use the "Asphalt Pavement Guide to CONEXPO" insert map, included with this issue, to plan that list effectively. If this is your first CONEXPO, like it is for me, you'll certainly want to have a good plan of action to get the most out of your time. Seasoned veterans will tell you that just getting from one end of the show to the other is an ordeal, so take advantage of the tools we've put together here for you. You'll be glad you did!

EDITORIAL Editor Brandon Noel bnoel@acbusinessmedia.com

Contributing Editor Jessica Lombardo jlombardo@acbusinessmedia.com

Digital Content Director, IRONPROS Wayne Grayson wgrayson@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@acbusinessmedia.com

of the guidelines and information surrounding EPDs is still under development. Check out our interview with him, especially if you aren't able to make his session at the show, and make sure you're aware of all thats is changing within the industry regarding sustainability and the environment.

And speaking of NAPA, in this month's Last Exit, I cover some of the big takeaways from the annual meeting that took place last month in Miami. There's a lot to be excited about within our industry, because there's a lot of change happening, and all toward a netpositive outcome. However, that doesn't mean there aren't or won't be growing pains that come along with it.

The editor for Equipment Today, Erica Floyd, provided an excellent feature that fits nicely within this theme of sustainability, in an article that covers trends in the broader construction industry that can help prepare contractors for this more sustainable future that NAPA and the government are currently guiding us toward.

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction ..................................Sean Dunphy

VP, Audience Development ................................... Ronda Hughes

VP, Operations & IT ..................................................... Nick Raether

Content Director ....................................................... Marina Mayer

Director, Online & Marketing Services ...... Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

234-600-8983 @ASPHALTCONTRACTOR

Additionally, I was able to speak with Joseph Shacat, the head of sustainability for NAPA, about his CONEXPO educational session that is set to cover all the ins-and-outs about Environmental Product Declarations or (EPDs). There is a lot to know, and some

To round things out, I spoke with the team behind the repair work done on the Sanibel Causeway, destroyed in the wake of last autumn's Hurricane Ian. As a native Floridian, and someone who loves Sanibel personally, it is a story I felt compelled to cover. The crews’ work, the speed at which they built, and their coordinated efforts are worthy of examination. Be sure to check it out. See you on the road.

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALT-CONTRACTOR-MAGAZINE

The industry is evolving, and what has been "behind the scenes" will soon become the general norm.

One of the hottest construction topics lately is whether electric excavators are worth the time, money and commitment. Battery charging times may slow down a day's work, some argue. Others proclaim that a small electric excavator would not run for eight continuous hours on a jobsite. As operators run dozers or wheel loaders, their small electric excavator battery packs could charge. Despite wide-ranging opinions, more manufacturers are focused on achieving two primary goals as they release new electric excavators: sustainability and fuel efficiency. Whether they're loved or hated by the industry, excavator engineering and product development is progressing rapidly on the road toward drastically lowered emissions.

Although JCB produces roughly 400 diesel engines every day for its agricultural and construction machinery, the company is considering alternative ways to power its machines.

After all, governments around the world are striving to end the use of diesel and gas in passenger cars, along with light goods vehicles. However, JCB has encountered one significant issue: batteries aren’t usually a viable power

option for the agricultural and construction industries, as heavy machinery typically requires massive batteries. Not to mention, batteries are not always easily charged in remote areas.

With zero-emission technology as its ultimate goal, JCB doesn’t provide hybrid-diesel electric technology as a solution, either. In July 2020, JCB engineers began to design an engine for a backhoe that runs completely on hydrogen. Six months later, the first working prototype was tested, as the engineers successfully developed a zero-carbon dioxide hydrogen fuel engine from the ground up.

“Hydrogen engines solve all of the problems that are associated with battery charging on busy, remote sites, as OEMs work on the internal combustion principle,” said Chris Giorgianni, vice president of government and defense, product and marketing, JCB. “They’ll feel familiar to anyone who is used to diesel or gas engines.”

Of equal importance, the costs of using hydrogen-powered excavators are roughly the same as utilizing excavators powered by traditional engines. Furthermore, unlike batteries, hydrogen engines aren’t inflationary. And, above all else, hydrogen engines don’t release any carbon dioxide into the atmosphere,

as they’re completely carbon neutral.

“Now that hydrogen-powered excavators are here and proven, global governments need to be encouraged to adopt hydrogen engines and incentivize investment in hydrogen energy infrastructure,” Giorgianni emphasized. “While the benefits of hydrogen power are hopefully clear for everyone to see, it is still a relatively new technology. So, it is crucial that we start to take the lead in getting the message out.”

To help ensure that hydrogen power is viewed as a genuinely viable alternative to electric and battery-powered machinery within the construction industry, JCB is investing $130 million to create super-efficient hydrogen engines for a wide array of machines.

In addition, the company is working to offer its first hydrogen-powered excavators to customers as soon as possible.

“This commitment reinforces our conviction, as a company, that hydrogen power will be a key part of the solution, in response to climate change’s ongoing threat,” he said.

On the other hand, KATO-CES has two models of battery-electric miniexcavators: the 9VXB, which has a 5-foot, 2-inch digging depth, along with a bucket force of 2,360 pounds, and the 17VXB, which has a 7-foot digging depth, as well as a bucket force of 3,687 pounds. Since they each utilize a standard hydraulic system, users can run the same attachments with them as the diesel versions.

“There is definitely a growing demand and a market for these miniexcavators,” said Bart DeHaven, director of sales, North America, KATO-CES. “The electric units are a little heavier than the diesel units, but they still have the same dig depth. The only drawback is run times, as the diesel mini-excavators can be filled at any time, yet the battery-electric miniexcavators need to be charged for eight to 12 hours to ensure they’ll run for eight hours.”

Additionally, the battery-electric mini-excavators release fewer emissions, are less noisy and have fewer vibrations than diesel mini-excavators, thereby improving operators’ comfort and reducing their fatigue. Maintenancefree, the mini-excavators’ lithium-ion batteries and electric motors have lifespans that are just as long as a diesel engine’s lifetime, if not longer.

“Battery-electric mini-excavators do have higher purchase prices than their diesel equivalents, but the total cost of ownership should be considered when

evaluating them,” he added.

“This total cost of ownership includes the fuel savings and extended component life of not having an engine.”

Focused on minimizing its environmental impacts, while also helping customers achieve the same goals, Bobcat Company is leveraging technology to become more productive and utilize resources more efficiently. As an example, the company is now using alternative-energy products that aren’t only environmentally conscious, but also ensure customers can continue their business operations as government mandates are steadily established, regarding zero emissions and clean energy.

The company has advanced its commitment to environmental sustainability through the launch of the T7X, which is the first-ever all-electric compact track loader. It’s also producing batteryelectric excavators, as well as a variety of electric products that offer alternatives to diesel-powered equipment.

“While significantly reducing their carbon footprints and producing much less noise than diesel-powered offerings, the battery-electric excavators will also expand users’ jobsite versatility,” said Joel Honeyman, vice president of global innovation, Bobcat. “Producing no emissions, the battery-electric excavators can tackle tough jobs—outdoors and indoors—as they also require less maintenance than their diesel counterparts.”

During bauma 2022, Bobcat revealed its latest electric excavator, the E19e compact excavator, which joins the E10e and the E32e. Each of the battery-electric excavators have compact footprints, quiet operations and zero emissions. Their electrical motors deliver full torque, regardless of rpm, leading to higher productivity, on-demand, multifunctioning performance (without any noticeable decline in power) and smooth hydraulic control.

Providing users a run time of roughly four hours of continuous operation on its lithium-ion battery pack, each of the battery-electric excavators can be fully recharged overnight. The E10e and the E19e have standard 120-volt outlets, whereas the E32e has a 240-volt.

“Although applications vary, each of the excavators’ charges can support common, daily work operations and a full day of operation during intermittent use or a typical contractor workday,” said Mike Wetzel, director of product management, excavators, Bobcat.

Furthermore, the battery-electric excavators support environmentallysensitive worksites, while also enabling users to operate indoors—areas in which diesel exhaust is always restricted. And, at the same time, they provide significantly lower noise levels and vibrations than diesel-powered excavators, leading to an improvement in jobsite communication, as they can also be used in sound-sensitive areas.

Earlier this year, Takeuchi announced that the first 100 units of its TB20e, an electric compact excavator, will be available at various United Rentals locations. Built by Takeuchi itself, the batterypowered excavator is the first product to be released in the company’s anticipated full lineup of electric products, which will be created to meet its ESG goals.

Offering the same performance that Takeuchi’s diesel-powered TB216 compact excavator does, the TB20e is 100% battery powered, enabling it to provide lower noise and vibration levels than the diesel-powered compact excavator, while also emitting no

There’s always something new at Eagle Crusher. Eagle Crusher consistently leads the industry in new product innovations and 2023 will be no exception. Join us at CONEXPO-CON/AGG, and see our newest equipment and technologies on display, including the UltraMax®1600X-OC Portable Impactor Plant and the 8x20 Screen Plant with Integrated Feed Conveyor and Blending Gates.

Learn about the many plant options for asphalt producers from our expert personnel in the booth. Outstanding plant options include onsite RAP systems for crushing and precise screening, allowing product consistency with a minimum of white rock and a minimum of fines. Also available are highly portable plant options for larger-sized jobs with high volumes of material at- or near-spec, allowing most to be removed before crushing to increase overall production and reduce wear.

exhaust emissions. When it’s completely charged, the TB20e provides a continuous working time, which ranges from four to eight hours, dependent on the application and environment.

In addition to offering an operating weight of 4,255 pounds, the electric compact excavator has a bucket capacity of 1.34 cubic feet, along with a primary auxiliary flow of 9.0 gpm. Furthermore, it has a reach of up to 13 feet and 4 inches, as well as a digging depth of 7 feet and 10 inches, at most. To ensure its operators remain as comfortable as possible, the TB20e also has a spacious station that features a high-definition, multi-informational color display.

“United Rentals and Takeuchi have a long history together, [so] we’re pleased to be the first to offer the environmentally-friendly TB20e excavator,” said TJ Mahoney, vice president, supply chain, United Rentals. “Not only does [the excavator] provide our customers a more sustainable equipment option, it’s also more cost efficient to operate.”

stood out: the Cat 301.9 electric miniexcavator. Providing users a Cat 48V, 32kWh battery, the excavator has a run time of up to eight hours on one charge; this run time declines to five hours during continuous trenching, though.

Additionally, the company has created the Cat 320 electric excavator, which also has a run time of up to eight hours on one charge. It utilizes a different battery than the Cat 301.9 electric miniexcavator does, as it features a Cat 600V, 320kWh battery instead.

“Each machine will also include an onboard AC charger, which will enable it to be charged overnight,” said Corne Timmermans, vice president, sales and marketing, Europe, Africa and the Middle East, Caterpillar. “We’re also planning on providing DC fast-charging options that customers can utilize during their break times.”

Both excavators are anticipated to be available in Europe and North America within the coming years, as the Cat 301.9 electric mini-excavator is expected to be the first commercially available electric excavator offering.

its compact excavators. The battery pack can store enough energy for the excavators to conduct their daily work tasks on a general duty cycle basis. In order to recharge them, the company offers an assortment of charging solutions.

“The product and market development for the TB20e took place in North America, so it made sense to debut the machine here as well,” added Clay Eubanks, director of global sales, Takeuchi.

Meanwhile, Caterpillar, which has been working on electrification for the past 30 years, is focused on increasing the power of some of its high-volume loader and excavator product lines. In October, the company showcased a variety of fully electric prototype machines at bauma 2022. From a sustainability standpoint, one excavator especially

As Ray Gallant, vice president of product management and productivity at Volvo Construction Equipment looks ahead to the evolution of zero-emission heavy construction equipment, he believes manufacturers need to realize a crucial fact. The key response to electrification or sustainable power isn’t just a single technical solution, but a variety of solutions that manufacturers will need to develop and then “bring into play.”

“Volvo Construction Equipment is working with technologies such as battery-electric, hybrid, hydrogen fuel cells and alternate fuels, like hydrogen combustion, as a result,” Gallant said. “Simply stated, we’re interested in any energy source that can provide the energy we need in a sustainable process.”

For instance, small excavators are great fits for battery-electric drives. So, Volvo Construction Equipment has placed a 48-volt battery pack in each of

“Even heavier machines that use up to 120 kilowatts can be powered with a battery pack,” he added. “The difference is that the battery pack goes up to a much higher voltage (600 volts for our excavators, in fact), so that we not only have faster recharge times, but also acquire the power we need, all with a reasonable weight and power balance.”

Once manufacturers’ customers require 120 to 150 kilowatts of power, along with longer duty cycles, they’ll need to consider other types of technologies, as well. The primary reasons? For these types of requirements, excavators’ batteries are too heavy to supply the power that such customers need, especially if they have applications in which their excavators are utilized continuously for 24 hours. And very large battery packs tend to have very long recharge times.

“Therefore, we’re looking at different technologies like hybrids and alternative fuels that can power these systems in the future,” he said. “And we’re considering cable electric excavators that can connect directly to the grid and draw power while they’re being used, which are especially excellent options if customers have stationary excavators or applications.”

Chris Lewis is a freelance writer.

For more information visit https://asph.link/9ywso6

Volvo Construction Equipment

Caterpillar offers operators the Cat GB121/GB124 Smart Grader Blade attachments, which come with an Operator Assist feature.

Caterpillar

tear of operators’ equipment, but it’s also delivering enhanced efficiency and quality in fine grading applications.”

Created for applications where operators need a motor grader’s precision, but are unable to justify it based on its access, cost and size, the grader blade allows them to convert their large-frame CTLs into precision grading solutions. Aside from its power, the grader blade can be used on jobsites where larger machines aren’t feasible.

There's no doubt that compact track loaders (CTL) and skid steers are becoming more integral on construction jobsites. Not only are the machines easier to learn than their larger counterparts, but also offer unmatched flexibility in a variety of applications. With this trend, contractors are relying more heavily on interchangeable attachments, which can be digitally linked to the machines. Automatic grade control technologies have also advanced, transforming compact equipment into powerful precision grading solutions.

Several equipment manufacturers offer advanced grading options, through attachments and technology, to help

contractors complete jobs faster, even if they’re short staffed. For instance, CASE Construction Equipment’s Precision Grader Blade is designed to give operators the performance of a motor grader in an agile, compact footprint. Compatible with 2D and 3D machine control systems, such as the CASE SiteControl grader solutions powered by Leica Geosystems, the grader blade is providing operators machine control, along with large-scale enhancements.

“The grader blade is enabling operators to finish their work in fewer passes, while offering them greater quality assurance, too,” said Jeff Jacobsmeyer, product manager at CASE. “In addition, it’s not only reducing the wear and

The grader blade is also compatible with GNSS/GPS (single or dual), laser receivers (single or dual), sonic tracers (again, single or dual) and total stations. As a plug-and-play” offering, it also has auxiliary hydraulics and a 14-pin electrical connection for large-frame CTLs.

“And it has a 108-inch moldboard that’s capable of jointly changing elevation and slope through dual lift cylinders, while achieving 60 degrees of combined blade rotation and 26 inches of combined blade side shift, too,” Jacobsmeyer added. “All motion and action for the grader blade are controlled through a CTL’s existing joysticks, as no additional controls are required.”

In addition to the grader blade, CASE has created yet another automatic grade control technology offering: the CASE

Precision Laser Grading Box. Used with CTLs and skid steers, the grading box is designed for fine-grading applications, ranging from concrete subgrade, to driveways and parking lots.

Featuring a reversible cutting edge on each of its sides, the grading box can also create very accurate finish grades—to within 0.1 inches. The grading box has distinct push-pull design grades, which can either move forward or in reverse, enabling operators to capitalize on the maneuverability of CTLs and skid steers.

The grading box has a hydraulic valve system, which can be modified whenever operators require adjustments. As a result of each of these attributes, it can provide accurate performance even when it’s used in severe environments.

“The CASE Precision Grader Blade and the CASE Precision Laser Grad-

are able to enter areas that larger machines, which also have precision technologies, simply can’t. Due to the CTLs’ and skid steers’ smaller sizes, they’ll be easier to transport from one job to the next, as well.”

For several years, Caterpillar has provided operators a variety of automatic control technologies, including Cat Grade solutions, which are attachmentmounted, aftermarket offerings for CTLs and skid steer loaders. Meanwhile, the company has also added Cat Grade/Earthworks products—with sensor types like Global Navigation Satellite System (GNSS), laser and sonic, along with Universal Tilt Sensors (UTS)—on its box blade and grader blade attachments. The company also has a laser-based grade system for box blades and grader blades, with Trimble’s Earthworks GO!

“In cooperation with Trimble, we have recently introduced the Earthworks GO! 2.0 2D system too, which is an update that’s providing operators Bluetooth-based communication, along with more robust components and improved user interfaces, when compared to the first version that was released,” said Jason Knowles, engineering specialist at Caterpillar.

The company is offering operators Cat GB121/GB124 Smart Grader Blade attachments, which come directly from its factories with an Operator Assist feature. The feature automatically controls cross slope as operators are grading.

and near obstacles, as operators can also spread truck dumps and cut out hard material.”

Kubota Tractor Corp. has also collaborated with Trimble, providing its dealers the Trimble Earthworks GO! 2.0 2D system, enabling them to offer their customers a complete system, through Kubota as a single source.

“The system is incredibly simple to set up and operate, as it can be installed or disassembled in just a few minutes,” said Jerry Corder, product manager, construction equipment at Kubota. “Not to mention, its calibration is simple and intuitive, too.”

Operators’ smart phones can be used as control pads, as they’re connected to the system wirelessly, via a free app. As a result, operators can easily add updates and troubleshoot onsite, leading to a considerable decline in downtime.

“All controls and instructions are clearly laid out and shown on the app with animations and simple phrases, ensuring that nearly anyone can operate the system,” Corder explained. “This, in turn, will help operators fill positions on their jobsites.”

Aside from offering dealers and operators the Trimble Earthworks GO! 2.0 2D system, Kubota is also providing an open platform, bi-directional box blade, the BB3084/96. Compatible with third-party automated grade controls, the box blade is able to grade slopes and flat surfaces.

ing Box are also easy to use and learn, and they offer operators precision construction capabilities on equipment that’s highly accessible to a wide range of companies,” Jacobsmeyer said. “To experience these capabilities, companies won’t need to own any larger dozers or graders either.”

He continued, “And, by utilizing CTLs and skid steers, alongside the grader blade and grading box, operators

The company also has blade slope sensors that are used with Operator Assist. Included with the Trimble Earthworks GO! 2.0 2D system, the sensor allows operators to upgrade to a grade control system in a more affordable and effortless manner, in comparison to other attachments, especially when it’s combined with a standard grade system wiring harness.

“This system fills a different niche than the grader blade and box blade,” Knowles said. “Since it doesn’t guide wheels out front, the Smart Dozer is more suited to grading in small spaces

“And it will not only accept 2D and 3D grade controls systems, but a majority of the control systems that are on the market today, as it’s set up as an open platform,” Corder added.

Trimble’s technology is also used on Doosan Bobcat machines, which is a partnership dating back to 2015. Due to the collaboration, the company has offered the Trimble GCS900 3D grade control solution as an option for its CTLs and skid-steer loaders.

Paired primarily with Bobcat grader attachments, the system allows operators, particularly smaller contractors, to quickly and effectively

> Comprehensive measurement of asphalt temperature across entire pave width up to 10 m

> Simple operation and real-time display via the paver operator’s ErgoPlus 3 console

> Simple installation, no adjustments (plug & play)

> High-precision, permanently-integrated GPS receiver for recording exact position data

> Option of recording sub-base temperature before paving

> Can be combined with weather station to record external parameters affecting the project

work on complicated projects that require 3D machine control and digital designs. On the other hand, large contractors can use the system’s 3D machine control to finish the final phases of their projects more cost effectively and accurately.

“Operators can choose between a GPS-based option for outdoor applications, and a universal total station (UTS) for indoor and outdoor applications,” said Mike Fitzgerald, marketing manager, Doosan Bobcat North America. “After the computergenerated model is loaded to the 3D system, it will automatically grade the ground with an accuracy of roughly 0.12 to 0.2 inches.”

He continued, “The UTS is able to measure angles and distances; by measuring known points of a jobsite, a total station can calculate its position, relative to known points and coordinates. In robotic mode, the total station will measure the position of the UTS target and report the position information, via radio link, to the UTS controller.”

CASE’s automatic grade control technologies, according to Jacobsmeyer, will help operators conduct their work tasks more efficiently in a variety of ways, including the following:

• Enhanced performance: Due to the technologies, operators will get up to speed, so to speak, quicker than they previously did, enabling them to enhance their productivity.

• Quality: Not only will grading quality improve, but so will operators’ overall performances.

• Productivity: By reaching their grades or the contours of their plans faster, operators will also be able to focus on the next phases of their jobs.

• Reduced equipment wear and tear: Since they’ll complete their work in fewer passes, operators will also decrease the wear and tear of their equipment.

Meanwhile, by using Caterpillar’s grade control for CTL and SSL attachments, operators will arrive to

their grades faster, more precisely and more effortlessly than they otherwise would have been able to, especially if they had previously used manual operations, Knowles said.

“In the real world, this means higher quality, with less experienced operators, as operators are also able to achieve cost savings through more efficient material usage and move on to their next jobs sooner,” he said.

• Materials: Due to the rise in accuracy that’s associated with the Trimble Earthworks GO! 2.0 2D system, operators’ material requirements are identified up front, enabling them to know exactly how much they need.

• Timeliness: “With no measurements needed throughout the job to guarantee grade and level, operators’ jobs are completed much quicker so that they can take on more projects,” Corder added.

Fitzgerald added that fleet owners are buying grading systems for one primary reason: to save on materials.

“While conducting significant grading work for applications like asphalt, concrete (commercial or residential) and site prep, a highly precise grading system —such as Bobcat’s Trimble package, the Trimble GCS900 3D grade control solution—will ensure that there is no wasted fill material, along with more even spreading,” he said.

One operator can set grade and move materials accurately and efficiently without requiring any assistance whatsoever, while using the Trimble Earthworks GO! 2.0 2D system with the BB3084/96, Kubota’s Corder said.

The system, for example, will eliminate the need for extra workers on site, as operators no longer need assistance while acquiring measurements or using a grade stick. The system will completely remove the need for a second machine on site to pull from a spoil pile and add materials for an operator’s leveling machine, as one machine can conduct all of these tasks.

Corder said that, by adding the Trimble Earthworks GO! 2.0 2D system, along with the BB3084/96, to their toolboxes, operators will notice immediate increases in profitability and productivity, concerning the following areas:

• Labor: “A single operator with a single machine can do the work, so fewer workers are needed to perform the job,” Corder said.

Operators will notice an increase in efficiency, when using the Trimble technology, Corder said. For instance, according to Fitzgerald, a Bobcat customer was able to complete a job in three weeks, rather than three months, as the customer had originally projected.

Along with the Trimble GCS900 3D grade control solution, operators are implementing the Bobcat Automatic Grade Control Laser attachment. Able to be moved from one machine to another, the attachment is allowing operators to use industry standard Controller Area Network (CAN) harnesses for effortless transferring. While looking ahead to the future, Jacobsmeyer has predicted that precision construction technologies, particularly those that have been built for use on compact equipment, will continue to be adopted on a more frequent basis. This increase will especially occur as business owners and operators realize the practical benefits they provide, he said.

Provide

Easy to change timing belt — only 2 working hours needed

Drum shell is made of highly wear resistant Hardox® steel, ensuring many hours of trouble free running

Record number of passes, potion, temperature and compaction value in real time with Dyn@Lyzer

Eco Mode and automatic idling saves up to 15% fuel while lowering noise level

high-quality compaction in areas where vibration needs to be reduced with oscillation technology; bridge decks and joints, near foundations and concrete structures and better performance on thin asphalt layers.

Every three years, the industry convenes in Las Vegas to showcase the latest and greatest construction equipment and technology from all of the biggest names in manufacturing. Of course, it is hard to think of this year's CONEXPO-CON/AGG without considering what took place three years ago. The world literally changed in the middle of the show. Now, the industry stands poised to bounce back, bigger and better than ever! The event will be held March 14-18 at the Las Vegas Convention Center. There's so much to do and see in just a few days time, here are some of the highlights to help you plan you booth stops. Be sure to refer to our Asphalt Pavement Guide to CONEXPO included as an insert with this issue, which maps all the most essential locations for asphalt pavement professionals visiting the show.

Tuesday, March 14 - Saturday, March 18, 2023

Hours: Tues - Fri: 9 AM - 5 PM · Sat: 9 AM - 3 PM

Tack Coats

(Tuesday, March 14 9:30 AM - 10:15 AM) -

Location: West Hall 208-210

The proper application of tack coat is an integral part of good pavement performance. A wide variety of tack coats are available to the asphalt industry. This session will provide information regarding material characteristics, construction practices, and their effect on the asphalt pavement performance.

Key Takeaways:

• Understand importance of tack coat

• What is the proper application rate for tack coat

• What is the best quality control for tack coat applications

Like the SUPER 1703-3i 8 ft paver, the SUPER 2000-3i tracked paver is specially tailored to the demands of the North American market, and comes with the same features. Achieving a maximum laydown rate of 1,540 tons per hour and featuring a powerful 6-cylinder diesel engine, it is particularly suitable for paving highways and large commercial areas. In combination with the AB 600 extending screed, the paver achieves a maximum pave width of 27 ft., 11 in., or even 25 ft., 5 in. when fitted with bolt-on extensions.

At CONEXPO, the SUPER 2000-3i is equipped with the AB 600 extending screed. In addition to vibrators, this screed features a tamper bar, meaning it achieves particularly high precompaction values. Two other screed types are also available for the 10 ft. paver, specially adapted to its needs: the VF 600 front-mounted screed and the VR 600 rearmounted screed. The screeds in the 10 ft. class feature only vibrators, and effectively meet the demand of being able to pave at high speed and widely varying pave widths.

Balanced Mix Design and Recycling: Advancing Technology and Economics

(Tuesday, March 14 10:45 AM - 11:45 AM)Location: West Hall 226 This session will explore how concepts of balanced mix design are being applied in practice towards implementing higher recycled asphalt content in a responsible and economic manner. The session will provide an overview of Recycling Agents and provide a step by step explanation of the process of implementing into a mix design and an asphalt plant. This will be followed by practical examples and case studies, used to further illustrate best practices that can be employed by producers today.

(Wednesday, March 15

9:30 AM - 10:15 AM) -

Location: West Hall 226

Porous asphalt pavements are being used by many owners to construct asphalt pavements that become part of the stormwater solution, reducing runoff, improving infiltration, and saving land. The performance of these pavements depends on proper design, materials, construction methods, and quality control. In this session you will get an understanding of

porous pavement design and understand the details of proper construction practices, material selection, and how to market porous pavements.

Learning Objectives:

• Understand the basics of porous pavement design and applicability.

• Learn the best practices for construction and preparation techniques, rules of thumb, quality assurance, and maintenance.

• Understand how to protect your product and investment.

(Wednesday, March 15

1 PM - 2 PM) -

Location: West Hall 213-215

Today's paving sites look very different than they did just a few short years ago. First was the introduction of 2D/3D grade control, then intelligent compaction. Now we have thermal profiling, automatic screed width control and steering. Couple all that with the data that can be collected while performing the operation and things can be overwhelming. In this session, we will navigate through technologies that are benefiting the paving industry today and what is likely to come in the near future. We'll also cover what you'll need to know to be prepared for these modern job sites and future forward visions for the industry.

Take an early look at some of the things you’ll see at this year’s show in Las Vegas!Booth #S5020

Learning Objectives:

• Intelligent asphalt paving technology overview

• Lessons learned from projects and their challenges.

• Technology's role in material management and increasing pavement life

7 Habits of Highly Effective Asphalt Producers

(Thursday, March 16

10:45 AM - 11:45 AM)Location: West Hall 208-210

With so many variables involved during asphalt production, it seems plant personnel need to be good at juggling! Field experience shows if we break down the complex process of asphalt production into seven best practices, and repeat these best practices consistently, they become habits, drastically improving consistency and success throughout the entire operation. While it is unclear how long it takes a person to develop a ''habit,'' by implementing the following procedures every day at the plant, asphalt producers are sure to see more consistent production successes.

Achieving Optimal RAP Gradation in Milling and Processing

(Thursday, March 16

2:30 PM - 3:15 PM)Location: West Hall 226

Learning Objectives:

• Understand milling operations impact on RAP properties

• Learn processing strategies that efficiently achieve RAP properties

• Enhance RAP properties to allow for optimal use in asphalt mixtures

Getting A Smooth Take-off

Every Time!

(Friday, March 17

9:30 AM - 10:15 AM) -

Location: West Hall 208-210

A common challenge for paving crews is to get a smooth take off at the start of paving. The purpose of this session is to review the steps every paving crew should follow each time they get ready to pull off the joint and start paving. This session will also cover how to manage the mix moving through the paver to ensure a smooth mat. In this session you will learn:

• How to set up the paver to get a smooth take-off

• How to Manage Head of Material

• How to Transfer Mix to the Paver

Compaction 101: Doing the Right Things, the Right Way

(Friday, March 17

10:45 AM - 11:45 AM) -

Location: West Hall 208-210

Roller compaction is the last opportunity during the paving process to produce a long-lasting and high-quality pavement.

The E2850C features 25 tons of onboard storage, enhanced elevator motors and triple-pitch remix augers to provide 600-tph discharge capacity for non-stop, non-contact paving with reduced particulate and thermal segregation. The frontmounted control station layout includes a 10-in. color touchscreen display with integrated camera and a proportional conveyor swing joystick control. The crab and coordinated rear steer with auto-center is standard for a 15-ft. inside turning radius. The storage hopper management system, paver hopper management system with distance to paver control and auto-center options allow the operator to focus on truck exchanges while maintaining proper material feed to the paver.

Booth #C32301

This session will cover the compaction basics that will help prepare attendees for challenges faced during construction operations. The common objectives include uniform target density and a pavement surface smoothness that earns rideability awards and bonuses. Using compaction best practices will consistently produce highest quality pavements with lowest production cost.

Learning Objective:

• Understand the four elements of compaction

• How to balance production, laydown, and compaction operations in order to match paving speed with rolling speed.

• Understanding which factors can affect compaction, and practices to mitigate negative impacts

For more information visit https://asph.link/vw0w7r

From innovative designs to Caterpillar dealer service and support, Weiler is paving the way to success for contractors across North America. Weiler material transfer vehicles, commercial pavers, road wideners, windrow elevators, compactors, soil stabilizer, rock drills, grader, screeds and tack distributors are engineered with proven features to increase productivity while reducing operating costs. Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America, providing unmatched support with factory trained technicians and readily available parts to keep your operation up and running.

weilerproducts.com

With ADM’s standard components, the choice is yours. We can customize any plant we make to your specific production needs.

“ADM helped with everything we needed to get the right plant for our business. From zoning ordinance restrictions to environmental testing, ADM was with us every step of the way.”

EX Series plants produce up to 425 TPH and can handle up to 50% RAP. Using counterflow technology, these plants provide the longest aggregates drying and mixing times in the industry to ensure consistent, quality asphalt that meets all federal and state specifications. Also on display at the show will be a 12' x 28' ADM Control Room.

Booth #S5467

Hyundai Construction Equipment

Americas will be showcasing a range of new, current and future machine models, plus demos of machine safety and remote management systems. The company’s 31,000 sq. ft. (2,900-m2) exhibit will be located in the West Hall of the Las Vegas Convention Center, Booth W42501. The triennial construction equipment exposition –the biggest in North America – runs March 14-18.

Among new Hyundai models at the show are three compact excavators – the HX35AZ, HX40A and HX48AZ – that collectively earned an international Red Dot Design Award, honoring the best product and industrial designs. The company will also showcase skid steer loaders and compact track loaders, wheel loaders and more. Booth #W42501

Western Global will display fuel storage and tanks at indoor and outdoor booths at CONEXPO. The company will introduce a new product line and highlight current products in booths S61138 and D2138 at CONEXPO-CON/AGG 2023 March 14-18 in Las Vegas.

Both booth locations will feature a new product line that will further maximize jobsite efficiency for equipment fuel and fluids.

Booth S61138 in the South Hall will focus on the company’s fuel storage solutions for extending generator runtime and refueling jobsite equipment. The booth will feature both a 251-gallon (10TCG) and 1,204-gallon (50TCG)

TransCube Global transportable fuel tank, as well as the TransCube Mobile Refueler trailer-mounted tank. Western Global will also highlight its full range of tanks.

Booth #S61138

Durex offers numerous urethane, rubber, and wire screen media options, which allow customers to fine-tune production and increase tons per hour. Wear liners for aggregate and concrete equipment, wear parts and screen accessories round out the company’s offerings. Products include:

• Modular Urethane and Rubber Screens.

• Livewire Screens.

• Armor Screens.

• Accuslot Screens: A self-cleaning-type screen that helps eliminate plugging and/or blinding.

• Vibraspan Screens: A self-cleaning-type screen.

• Vibraclean Screens: A self-cleaning-type screen.

• Woven and Slotted Wire Screens.

• Wear Liners.

• Concrete Wear Liners.

• Wear Parts: Including urethane and rubber.

• Screen Accessories: Including, but not limited to, side-tension rails, J-bolts, U-bolts, donuts, stringers and ferrules.

Booth #C32567

JCB will feature its new hydrogen combustion engine—the company’s solution for zero carbon emissions for construction and agricultural equipment—at CONEXPO. It will debut in North America.The hydrogen combustion engine from JCB revealed this week during a media event in EnglandJCB NA

The company will reveal the new hydrogen combustion engine during CONEXPO at its both, South Hall3, Booth S83751. “While our team is excited to see it at the show, we are thrilled with the preview we received this week during a media event with JCB North America,” company officials said.

Booth #S83751

BE SURE TO VISIT ASPHALT CONTRACTOR MAGAZINE AT OUR BOOTH ON THE EXPO FLOOR # N12839

Felling Trailers will debut design modifications to the X-Force hydraulic detachable’s gooseneck at CONEXPO-CON/AGG 2023. The X-Force product line offers over a dozen models with load capacities ranging from 35 to 60 tons with a selection of available options to ensure the trailer is built to the user’s spec.

The redesign's driving factors focus on operator usability and reducing production time and materials. More often than not, an operator must offload and load equipment on complex terrain that is soft or uneven. Considering this scenario, the gooseneck stirrups were designed to provide an additional 1-¾ -in. ground clearance for hookup and disconnect. Auto-ratcheting load blocks have also been factored into the neck design. As the deck is raised into position, setting the trailer's ride height, the load blocks auto-ratchet into position.

Booth #D1021

Boasting of a small footprint yet retaining a 15 foot-wide screed, the LeeBoy 8500E allows for wider and longer pulls than competitive pavers. The new and improved 8500E series paver is equipped for the next generation, with a 71 hp Kubota turbocharged diesel engine: DOC only. No regen required. This machine is enhanced with 12” augers, heavy duty radius hopper wings, and more robust hydraulics for cooling and efficiency. The larger fuel tank increases the daily run time. These enhancements make the 8500E more productive than ever, along with less hand work, means the end user minimizes the number of stops which increases productivity and profitability. The 8500E features upgraded controls which lessens any learning curve and allows for immediate use.

Booth #C31731

The technology is designed to monitor the health of vibrating screens using modern algorithms and artificial intelligence. It provides accurate measurements and forecasts complemented by information that is easy to understand. Pulse CM is a wireless diagnostics tool that helps mineral processing operations be proactive, rather than reactive, when it comes to maintenance efforts. This leads to increased efficiency, decreased downtime and improved reliability.

To collect all data from the body and drive components, Pulse CM is equipped with a gateway that can connect with up to 20 wireless sensors, within a radius of up to 246 feet (75 meters). Using a cellular signal or Wi-Fi from the plant, it will send all data to the Haver & Boecker Niagara cloud, available through the company’s web app. The sensor configurations are customizable and placed on both the body and bearings of the vibrating screen.

Booth #S5948

From rural roads and parking lots to highways and city streets, Crafco hotapplied asphalt crack sealants have been the trusted choice of agencies and contractors for sealing cracks in the US and abroad. Crafco’s high-quality sealants will work in all climates and provide long-lasting protection, durability, and reliability. When tested, Crafco’s sealants demonstrated the longest service life in the industry.

Booth #C20549

Weiler’s P385C paver continues to raise the standard for commercial class pavers with improvements to provide performance, reliability and outstanding mat quality in a wide range of applications.

The P385C features a Cat® C3.6 Tier 4F/Stage V engine with an increase to 120 hp (90 kw) for unmatched power and performance. The best-in-class undercarriage features 90” (2286 mm) track length, 68” (1727 mm) of ground contact and 140 mm track chain pitch provides smooth ride and excellent flotation with automatic track tensioning.

The improved conveyor drive system features a sealed chain case, hydraulic motor with heavy duty bearings and splined shaft for increased reliability. An updated hydraulic system with proportional valving provides variable speed and reversible conveyors and augers.

Booth #C32301

MAJOR has reinvented FLEX-MAT Modular to bring you an even stronger, longer-lasting product. This media offers all the benefits of FLEX-MAT — high open area, efficient stratification, no blinding or pegging — combined with a new and improved wear life comparable to polyurethane screen media. FLEXMAT Modular Plus can withstand harsh screening conditions with the most abrasive materials, such as granite and basalt.

• Increased wear life, giving longer productive use

• Heightened Resistance to Blinding and Pegging

Booth #C32267

Colorbiotics® asphalt solutions are ready to change the asphalt industry as much as they change the molecules inside asphalt. That’s because our solutions attack the effects of aging at the molecular level and transform recycled material from the inside out.

Equipped with exciting new features that were truly designed with the paving professional in mind, the LeeBoy 8520C is a 125hp workhorse. Standard machine assets include the 3,450 lbs Legend HD Screed with, heavy-duty conveyor chains, dual seating and sliding main controls, a LeeBoy 2-year product warranty as well as many other enhancements. As always, LeeBoy’s wide slow-moving conveyor system moves material from the truck to the screed without segregation which ensures a flawless mat.

Booth #C31731

Low bid? Best value? Win contracts either way with the first technology that truly reacts and restores asphalt. You can take RAP content beyond the 50% threshold and make pavement that’s good for the planet — but even better for your bottom line.

Give us a call to use more of your RAP than ever before.

888-663-6980

asphalt@colorbiotics.com www.colorbiotics.com

Volvo CE’s entry-level intelligent compaction system, Compact Assist Start , provides operators with real-time information on pass and temperature mapping. Pass mapping gives a clear view of the roller’s coverage of the asphalt, highlighting stop points and overlaps so adjustments can be made quickly and efficiently without missing a spot. Temperature mapping ensures that compaction is completed at the optimum pavement temperature. Adding a productivity service like Compact Assist Start to a proven machine provides a comprehensive solution teams can rely on.

Booth #F8926

The SUPER 1300-3i is a highly compact paver yet features a maximum laydown rate of 385 tons per hour and a pave width of up to 16 ft 5 in. Whether for a combined footpath and cycle path, a farm track or a minor road or square, thanks to the AB 340 extending screed the Compact Class paver has the pave width range to match. With cut-off shoes, a pave width of just 2 ft 6 in is possible. The maximum pave width with the right bolton extensions is 16 ft 5 in. This makes the SUPER 1300-3i ideal for compact paving. The intuitive ErgoPlus operating system, featuring a wide array of convenience and automation functions, assures process reliability and quality when paving.

Booth #S5020

Designed for contractors demanding high mobility, rapid installation with minimal foundations and quality assurance of the final mix, the RoadStar range is renowned for being a true contractors plant and is considered to be the most portable range of batch production asphalt plants on the market today.

The 120tph RoadStar 1500 will be erected in its working position along with the portable dryer, burner and integrated Booth #S5183

National Flooring Equipment offers the Viking ride-on scraper for roadways, bridge decks, airport runways, parking structures, sport flooring and more. This product is powered by a 49.5 hp turbo diesel Kubota engine and features an 18-gallon fuel tank.

Safety features include a rear-view camera, emergency shut-off button, emergency brake control and four LED lights (two front and two rear). The noise-dampening cab has a 2-speed fan for airflow. Operators can adjust heat settings and air conditioning via a climate control knob.

Booth

The Cedarapids® Magnum Bullet 150 Super-Portable 150tph counterflow drum-mix, with 35% RAP capability, will be on display with a Roto-Aire® RA3-14 baghouse.

The Magnum Bullet series has been designed with many upgrades including high efficiency drying & mixing zone, railroad bearing trunnion roller assemblies, direct drive gear motors, and drum insulation & cladding as standard. Designed with an emphasis on substantially reduced installation time to provide a market leading set up time within 2 days when combined with a portable self-erecting hot mix storage system.

• Field proven counterflow technology

• 30% + RAP with low maintenance costs and a single shell design

• Tuneable performance provided by indexing slingers

• Longest mixing zone in the industry produces high quality material

• Super-Portable, Portable, Relocatable and Stationary configurations

• Magnum "Bullet" Super-Portable series have hydraulic erect systems which provide unrivaled set up times

Booth #S5183

The UF Series of counter-flow asphalt plants has been designed for producers who appreciate the importance of the details at their hot mix asphalt production facility. The portable 92UF drum mixer is designed with features that allow portable operators to set up, produce efficiently, and move to another location quickly and cost-effectively without sacrificing heavy-duty drum and component construction.

Booth #S6816

Vögele will be presenting not only the optimal technical equipment for large-scale job sites, but also for narrow paving jobs such as on pedestrian and cycle paths. In combination with the AB 220 extending screed, the SUPER 700i small paver can pave at widths between 3 ft 11 in and 7 ft 3 in. Fitted with cut-off shoes, the Mini Class paver even achieves a minimum pave width of just 1 ft 8 in, and with bolt-on extensions a maximum width of 10 ft 6 in. That makes it the ideal paver for any smaller construction job demanding maneuverability and small dimensions.

The Mini Class paver comes with the ErgoBasic operating system, an intuitive and well organized concept incorporating all the basic functions for high-quality paving. They include clearly structured function and status indicators, different operating modes, glarefree backlighting for night-time jobs, and simple steering by a rotary controller. The ErgoBasic and ErgoPlus 3 operating systems are based on the same design concept and symbols, enabling users to switch easily between the different Vögele paver classes.

Booth #S5020

Yanmar Compact Equipment will launch a new product line, expanding its offering of compact equipment at CONEXPO-CON/AGG 2023 in Las Vegas. The company will display its new products as well as its mini excavators, wheel loaders and tracked carriers.

“This will be Yanmar Compact Equipment’s first CONEXPO appearance since 2014 and we are thrilled to be returning to the show after an almost 10-year absence,” said Tate Johnson, president of Yanmar Compact Equipment. “We’ve grown immensely since our last visit to CONEXPO and the new products we will introduce will prove our focus on compact equipment growth in North America.”

Yanmar will feature 12 machines and attachments, showcasing the company’s full line of compact equipment offerings for worksites. The event will also feature several vignettes marking Yanmar’s presence in the construction industry: heavy civil, commercial and residential. Engines will also be showcased at the event.

Yanmar will exhibit new equipment at the show.

Booth #S84014

A zero-emissions solution for small-scale compaction projects. The battery electric double-drum machine has more available power than its diesel counterpart, providing improved on-grade performance and operation at high altitudes where naturally aspirated diesel engines lose power. The DD25 Electric battery charges from zero to full in as little as three hours depending on the AC power level, and an off-board DC fast charger can do the job in about an hour.

Operating weight: 6,195 lbs.

Drum widths: 39.4 in. and 47.2 in.

Battery: 48-volt, 20 kWh

Electric drivetrain rating (net): 24 kW

Vibration frequency: 3,300 vpm/55 Hz to 4,000 vpm/67 Hz

Amplitude: 0.021 in.

Overall length: 8 ft. 4 in.

Booth #F8926

The ALmix Portable, Split-Level Control House provides a safe, refined, and controlled environment for your asphalt plant operators and automation. The splitlevel control house is designed to house both a UL-Approved Motor Control Center (MCC) as well as a separate Operators room in a single, portable unit.

Booth #S6816

A reliable multi-purpose machine that road crews will appreciate. With a rear swing of 5 ft., 1 in. and a front swing of 5 ft., 11 in., the EWR130E has the shortest swing radius in the 12-ton to 13-ton range. When coupled with four-wheel steering and in-line outrigger options, the result is a machine that is stable and easy to control. Plus, its wheels make travel a breeze and cause significantly less ground disturbance

Booth #F8926

The SUPER 1703-3i 8 ft paver meets the demands placed on asphalt pavers in the North American road construction industry, especially when combined with the VF 500 front-mounted screed.With its compact dimensions and Pivot Steer brake, the wheeled paver features excellent maneuverability, and enables pave speeds of up to 250 ft per minute. Achieving a maximum laydown rate of 770 tons per hour and pave widths ranging from 8 ft to 15 ft 6 in, and fitted with bolt-on extensions up to 19 ft 6 in, the Universal Class paver is ideal for large commercial applications.

The paver and screed are equipped with the user-friendly ErgoPlus 3 operating system. It makes controlling the machine, including the Niveltronic Plus system for automated grade and slope control, very easy and convenient. The Vögele EcoPlus low-emissions package cuts fuel consumption by up to 25%, depending on the application and workload, and significantly reduces noise. When equipped with Vögele RoadScan, the non-contacting temperature measurement system, checking and documenting the paving temperature is very easy. Temperature monitoring across the entire surface makes quality measurable.

Booth #S5020

A mammoth in the industry, the new 1600X-OC plant features the UltraMax 69X Impactor with a 69-in.-x-51-in. feed opening to allow larger material into the impactor to increase throughput, up to 1,000 tph. The plant’s massive, solid-steel rotor weighs in excess of 13 tons and crushes even the largest feed material in a single pass.

Booth #C30949

The SUPER 1300-3i is a highly compact paver yet features a maximum laydown rate of 385 tons per hour and a pave width of up to 16 ft., 5 in. Whether for a combined footpath and cycle path, a farm track or a minor road or square, thanks to the AB 340 extending screed the Compact Class paver has the pave width range to match. With cut-off shoes, a pave width of just 2 ft., 6 in. is possible. The maximum pave width with the right bolt-on extensions is 16 ft., 5 in. This makes the SUPER 1300-3i ideal for compact paving. Booth #S5020

The satellite-based AutoTrac steering system for Wirtgen WR-series recyclers enables precise and efficient completion of each successive project task. It steers the machine with a precision measured in centimeters on the basis of a previously determined reference strip and a specified overlap of adjacent strips and enables consistent utilization of the machine’s ideal working width. This results in greater process efficiency and the minimization of environmental impact.

The WR-series machines are also available with the Wirtgen Performance Tracker. The system registers all relevant location-specific working parameters to provide a comprehensive database for construction site analysis and documentation. In the case of soil stabilizers, these include the working width and depth, the area and distance worked, the fuel consumption, and numerous other parameters.

Booth #S5020

The new 8x20 Screen Plant with Integrated Feed Conveyor can produce up to four products simultaneously, three with absolute sizing, or return the oversized product for further reduction.

The integrated 60-in. feed conveyor remains on for transport and eliminates the need for a separate conveyor, while each screen deck features four blending gates to allow for a wide range of custom product mixes to meet specific product needs.

Booth #C30949

Wacker Neuson plans to showcase its battery-powered equipment at CONEXPO, including a new 1.7 ton excavator, which will soon be sold in North America. The company will be at booth W43501 at the show, which takes place in March in Las Vegas. The booth’s theme, “All it takes for the challenges you face,” reflects the company’s dedication to helping contractors meet their daily challenges of the on the jobsite.

Wacker Neuson will be exhibiting its 1.7-ton battery-powered excavator, the EZ17e .

“This zero-emission excavator has been a success in the European market and will launch in North America in late 2023 or early 2024,” explained Gert Reichetseder, president and CEO of Wacker Neuson America Corp.

“This machine will provide a solution for contractors and rental houses looking for a quiet, zero-emission excavator to expand their businesses into new applications, while meeting environmental regulations,” Reichetseder added.

Wacker Neuson will debut the industry’s first battery-powered reversible plate with direct drive, the APU3050e.

In addition to the EZ17e, Wacker Neuson will further highlight its zeroemission portfolio for battery-powered compaction and concrete consolidation equipment in the “Meet the Future” area of the booth. This includes the debut of the industry’s first battery-powered reversible plate with direct drive, the APU3050e. All of Wacker Neuson’s battery-powered plates and rammer, as well as its concrete vibrator are powered by the Battery One battery and charger system. This new vendor-agnostic brand is a single solution.

Booth #W43501

An

There are a lot of changes in store for the asphalt industry, and not just for producers. These changes will affect any contractor who deals in asphalt. Since the passage of the Infrastructure Investment and Jobs Act (IIJA) and then the Inflation Reduction Act (IRA), a lot of discussions have focused on the funding related to projects related to infrastructure. However, there's another facet to these laws, as well as more funding opportunities, that may be even more important in the long run.

Environmental product declarations, commonly referred to as EPDs, are

At center, Joseph Shacat, NAPA director of sustainable pavements, during the Sustainability Committee at NAPA Annual 2023

Brandon Noel

going to fundamentally alter the paradigm of the asphalt business. That potentially generates a lot of anxiety, and questions. Thankfully, to help you through it, NAPA Director of Sustainable Pavements Joseph Shacat is leading an educational session at CONEXPO-CON/AGG on Wednesday, March 15, 2:30pm in West Hall 226.

For those not able to attend CONEXPO this year, or unable to make it for Shacat's 45-minute session, you may still have lots of questions surrounding EPDs. Let's start with the basics. What is an EPD? To put it in the most understandable and relatable terms, it's a lot like the nutritional label on the food you buy at the grocery

What’s an EPD? What do I do when my customer asks for one? How do I develop an EPD, and how much will it cost? What do all the numbers and tables in an EPD actually mean? How can I use EPDs to benchmark my plant operations? Can I use EPDs to demonstrate the environmental benefits of RAP? Why should I publish the EPDs that I’ve developed? How can I use EPDs as a marketing tool? These questions and more will be answered in this informative session. Learn how operational changes such as burner fuel type, energy efficiency upgrades, aggregate moisture management, use of RAP, and more can affect EPD results. We’ll analyze real-world scenarios using NAPA’s new EPD Optimizer tool.

• Understand what an EPD is and how to develop EPDs for your asphalt plants using NAPA’s Emerald Eco-Label tool.

• Learn how changes to asphalt plant operations and mix designs can affect EPD results.

• Learn how to use EPDs as a marketing tool to provide value to your customers.

store. In our case, rather than dietary information about ingredients, calories, and vitamins, the EPD provides asphalt customers with the basic environmental impact information related to the production of a specific asphalt mixture at your plant.

"An EPD is a document, it's a report," said Shacat. "The scope of that is cradle to gate. Everything from

extracting raw materials to transporting your materials to your asphalt plant, to plant operations right up until it leaves your gate. This is so important because it provides the basis to measure or assess a product's potential sustainability benefits or drawbacks."

The EPD acts as a label for your product, quantifying the emissions and other environmental impacts associated with making it. This means wherever that asphalt goes, it will carry that documentation with it, which is important in newly emerging procurement policies. At every level of government, from the federal all the way down to local policy stakeholders, customers are beginning to require contractors to provide these EPDs for the mixes that they deliver.

"More and more, customers are going to ask for it," Shacat said. "In some markets already, like in Colorado, for example, if you want to do any work for either CDOT or any state

agency, you're going to be required to produce an EPD. If you're doing any federal contract work with the General Services Administration (GSA), for their projects, you're required to produce an EPD."

But the shift to EPD requirement isn't isolated to the public sector, because private corporations are shifting, as well. ”A large corporation that answers to the American public is going to require EPDs, too, because they want to get LEED credits or other benefits,” added Shacat. “Even if you don't own an asphalt plant, you should at least know something about EPDs, so you know what they're asking for and you know what to ask of your mix supplier."

Under the Federal Buy Clean policy, which for the first time prioritizes the use of American-made, lower-carbon construction materials in federal

procurement and federally-funded projects, asphalt is listed as one of the four materials as a major priority for federal procurement. Additionally, the Federal Highway Administration (FHWA) has, as part of its "Every Day Counts" initiative, EPDs for Sustainable Project Delivery. This puts the asphalt industry, and all the new technological advances squarely in the crosshairs of state DOTs.

"It's a pretty big deal to have any technology in 'Every Day Counts', because that means you have the attention of all the regional offices across the country," said Shacat. "It's a deployment effort, in the sense that it's going to provide as many resources as possible for agencies to adopt these new technologies. FHWA provides all the information about a product to persuade agencies to move forward."

Of course, the real driver is the money that is on the table now. Through the IRA and distributed

Since 1892, Homestead continues to be the most reliable manufacturer of asphalt valves. With cast iron and ductile iron material options, we offer a complete source of valves for any liquid asphalt application.

Our full line of hot-jacketed 2-way shutoff & 3-way diverter valves provide a ready solution to meet your flow requirements.

Homestead’s cutting-edge actuation design allows you to easily add actuators to your existing Homestead valves, in-line, without modification

Our fully stocked warehouse of valves and actuators offers you security in knowing that the valve you need is only a phone call away.

through the EPA, hundreds of millions of dollars will be used to exclusively help the industry develop EPDs, upgrade their technology and production processes, and offset the higher price tags associated with switching to raw and reused materials. With the industry operating as a system based on low-bid wins, the ability to offset the higher costs of doing low-emissions business means everything. All this to the tune of a hefty $2 billion.

Amount: $250 million to remain available until Sept. 30, 2031.

Agency: Environmental Protection Agency (EPA)

Purpose: To support the development, enhanced standardization and transparency, and reporting criteria for EPDs

Eligible Recipients: Businesses that manufacture construction materials and products, states, and nonprofit organizations.

When examining what an EPD is and what it is used for, there are really three main players at most companies that should stay apprised of how EPDs continue to impact the market. The first would be whomever is the lead person on your environmental team, because the EPDs will contain a lot of environmental data. However, that person might not know about the mix-design process.

So, the second group will be your quality control team. The EPD will reflect the mix ingredients and their relative percentages, and anything related to that is going to mean the QC needs to be educated and involved. Likewise, the QC team might not have a direct read on the hands-on operations at the plant. So, your plant operations lead, your manager, and/or superintendent are all going to benefit from a greater level of understanding.

General business managers, business development leads, or marketing should also be involved, because creating your company's EPD program can and will be a useful marketing tool when bidding for these projects. Having the EPD already in place, being out ahead of the wave of change, and being fully compliant will prove useful in many ways.

Amount: $100 million to remain available until Sept. 30, 2026.

Agency: EPA, in consultation with the Federal Highway Administration (transportation projects) and the General Service Administration (buildings).

Purpose: To identify and label construction materials and products that have a substantially lower levels of embodied greenhouse gas emissions associated with all relevant stages of production.

Eligibility: EPA for administrative costs

In addition to meeting the needs of the clientele, there will be further incentives in place for those who meet the highest standards.

"Where this is moving toward isn't just providing an EPD," Shacat said.

"It's moving toward providing the EPD and your carbon footprint as measured by a parameter called the global warming potential (GWP). If it is below a certain threshold, there are going to be incentives. In some cases, agencies will actually require products to be below a defined GWP limit."

Shacat said the NAPA team has traveled to just about every corner of the country in an effort to communicate the impact of EPDs and answer local questions. There isn't a region they've not been to: red states, blue states, west coast, east coast, mid-west, and west-west. They've seen it all and talked to people from all over, and companies of every size and

[March 14-18, Las Vegas, NV]

Sponsored by:

BROADCASTING: March 14-16, 2023

Las Vegas Convention Center Booth N-12839 | North Hall

Whether you attend CONEXPO-CON/AGG & IFPE in Las Vegas or can’t make the trip, the dedicated CONEXPO channel from AC Business Media Construction Network will keep you well informed.

Watch LIVE newcasts: at Booth N-12839 and meet the editors.