Discover the MaxRap® 25 Portable on display at World of Asphalt. Eagle Crusher’s latest new-product innovation for the asphalt industry. Featuring Eagle’s UltraMax® 25 impactor with its high reduction ratio and North America lifetime rotor warranty, the MaxRap 25 Portable provides the same precision crushing of the stationary MaxRap, allowing operators to crush RAP at multiple locations with ease.

Experience the benefits of multi-feature deck selection, blending, and bypass; sampling to verify the mix-design spec requirement is correct, and ability to use the system for screening, direct-to-stockpile only. Discover even more RAP benefits. Plus, this versatile plant may be used as a secondary unit for recycled concrete and aggregate by removing the diverter chutework to become two plants in one.

At Gencor, we’ve led the industry with the most fuel-efficient, environmentally clean and lowest-maintenance design available to the hot mix industry. Gencor Industries remains focused on proactively serving and satisfying its customers from all aspects. Through improved cost-effectiveness, and quality of its products and services, Gencor’s personnel are dedicated to the principle of providing the highest quality to the industry to maintain a sustainable competitive advantage for Gencor.

Call 407-290-6000 or visit www.gencor.com

10 Alternative Power, AI & Remote Control in Roadbuilding

The demand for quicker delivery and increased sustainability on projects has placed a heightened focus on the need for largescale digital transformation in road building.

SPECIAL REPORT

20 EXCLUSIVE:

2024 World of Asphalt Preview

The biggest product showcase and event for asphalt producers, paver, and everything in-between.

42 Why States Should Prioritize Pavement Preservation

Many states don’t prioritize preserving their existing paved infrastructure.

46 The Opportunity of a Lifetime

A first-generation immigrant’s story of how the industry provided the chance to follow his dreams.

50 A Runway Revamp

Strategic planning and teamwork create a smooth landing pad for $10.4 million job.

www.ForConstructionPros.com/Asphalt

From electric equipment to technology innovations that make things easier on the jobsite, Wirtgen Group brought their line of equipment to contractors in the paving and pavement maintenance space at the first-ever PAVE/X event in San Antonio.

Came from Humble Beginnings, Casts Big Vision at NAPA Annual 2024

The National Asphalt Pavement Association (NAPA) held its annual meeting, a new chairman took the reigns, and, in the shadow of an election year, political influence was a hot topic.

Read more at: https://asph.link/ jjk76dtb

The new features include Tire Management, Warranty Management, Sensor Data Snapshots and Enhanced Service Tasks.

Read more at: https://asph. link/mw4z3w2o

Three leaders within the construction industry share their stories of how they recognized and responded to the growing opioid crisis. Read more at: https://asph.link/ vzppb1e6

Watch the video at: https://asph.link/r6i1fzn3 Get social with us! Share pictures of what you’re working with over 29,000 other asphalt contractors on our Facebook page:

So far in the United States, transportation electrification has largely focused on the needs of light-duty passenger vehicles, a far different market segment that does not require the same unique considerations as M/HDs.

Read more at:

https://asph. link/9s5kkwde

Astec’s commitment to its customers extends beyond making the sale.

From the beginning, our service team has provided construction services for the equipment we build. Astec construction and relocation services for asphalt plants include plant and equipment installs, plant tear-downs and moves, silo repairs, and industrial piping and tank farm installs.

Efficient planning minimizes downtime, local regulations and permits also play a key role. Astec has an extensive history and experience with permitting and regulations. Safety, efficiency, and compliance are paramount throughout the process.

Brandon Noel, Editor bNoel@iron.markets

Brandon Noel, Editor bNoel@iron.markets

About a year ago, I worked on a story focused on how asphalt plants could improve their energy efficiency, and, as a result, positively impact their EPD scores, as well as, their bottom-line. After talking to three different experts, and two major manufacturers, I learned a lot about the complexities that go into a plant’s energy needs. However, the most interesting, recurring detail was related to proper aggregate and supply storage on-site.

Last fall, I visited a plant on the East Coast and I talked to them about why they don’t have their aggregates in piles situated with underneath drainage or with overhead protection from rain or other elements. When I asked about it out of curiosity, the plant manager told me that, “In a perfect world, yes, we would have that kind of set-up.”

I won’t name the plant, obviously, because I don’t want to put them on blast, or anyone else for that matter. The storage solutions I’ve seen are an added cost to install, and, beyond money, the time and space to relocate aggregates could pose some serious headaches. However, the benefits of improving shelter, drainage, and ventilation can all greatly reduce the moisture content in your aggregates before they go into production.

Once there, all the excess moisture is going to have to be dried up, and reducing aggregate moisture by even 1 percent before drying can reduce energy use upward of 11 percent, or more, and can increase plant production by up to 15 percent. There’s big payoffs for making these low-tech changes.

If you’re looking for low-tech solutions to increase your plant’s overall efficiency, this is a great place to start.

This is the BIGGEST ISSUE of AC since I started as editor. It’s jam packed with more than 60 new, redesigned, or refreshed products that will be featured at the upcoming trade show in Nashville, Tenn. This is a fantastic place to start planning out your booth visit strategy ahead of time.

It takes a lot to launch into a new career in a field that you don’t have a lot of experience in. Now, imagine you are leaving your home country, family, and moving to the other side of the world on top of that. This month’s Face of the Industry is our first contributor who works for a major manufacturer. Vijay Palanisamy is the product marketing and business line manager for Dynapac North America. He’s also a first generation immigrant from his home in India. His story and passion for the industry are second to none.

The March issue sees the first outside contribution to this feature, exploring the dynamic between government investment in pavement repair or maintenance of the highways and roads we already have, versus spending more money on never-ending expansions. It definitely builds on some of the themes that we’ve been exploring this year. If you haven’t been reading this section, I recommend going back and doing so. There are some really interesting topics being talked about.

See you on the road!

EDITORIAL Editor

Brandon Noel bnoel@iron.markets

Contributing Editor Jessica Lombardo jlombardo@iron.markets

Managing Editor Gigi Wood gwood@iron.markets

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@iron.markets

Junior Editor Merina Shriver mshriver@iron.markets

AUDIENCE

Audience Development Manager ........................ Angela Franks

PRODUCTION

Senior Production Manager Cindy Rusch crusch@iron.markets

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@iron.markets

Brand Manager Megan Perleberg mperleberg@iron.markets

Sales Representative Sean Dunphy sdunphy@iron.markets

Sales Representative Kris Flitcroft kflitcroft@iron.markets

IRONMARKETS

Chief Executive Officer....................................................Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Corporate Director of Sales ................................... Jason DeSarle

Brand Director, Construction, OEM & IRONPROS Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director ....................................................... Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Director, Demand Generation & Education Jim Bagan

Content Director, Marketing Services ...............Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605

(877) 201-3915 | Fax: (847)-291-4816

circ.asphaltcontractor@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Brand Manager Megan Perleberg mperleberg@iron.markets | (800) 538-5544

Published and copyrighted 2024 by IRONMARKETS. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

@ASPHALTCONTRACTOR

@ASPHALTCONTRACTOR

@ASPHALT-CONTRACTOR-MAGAZINE

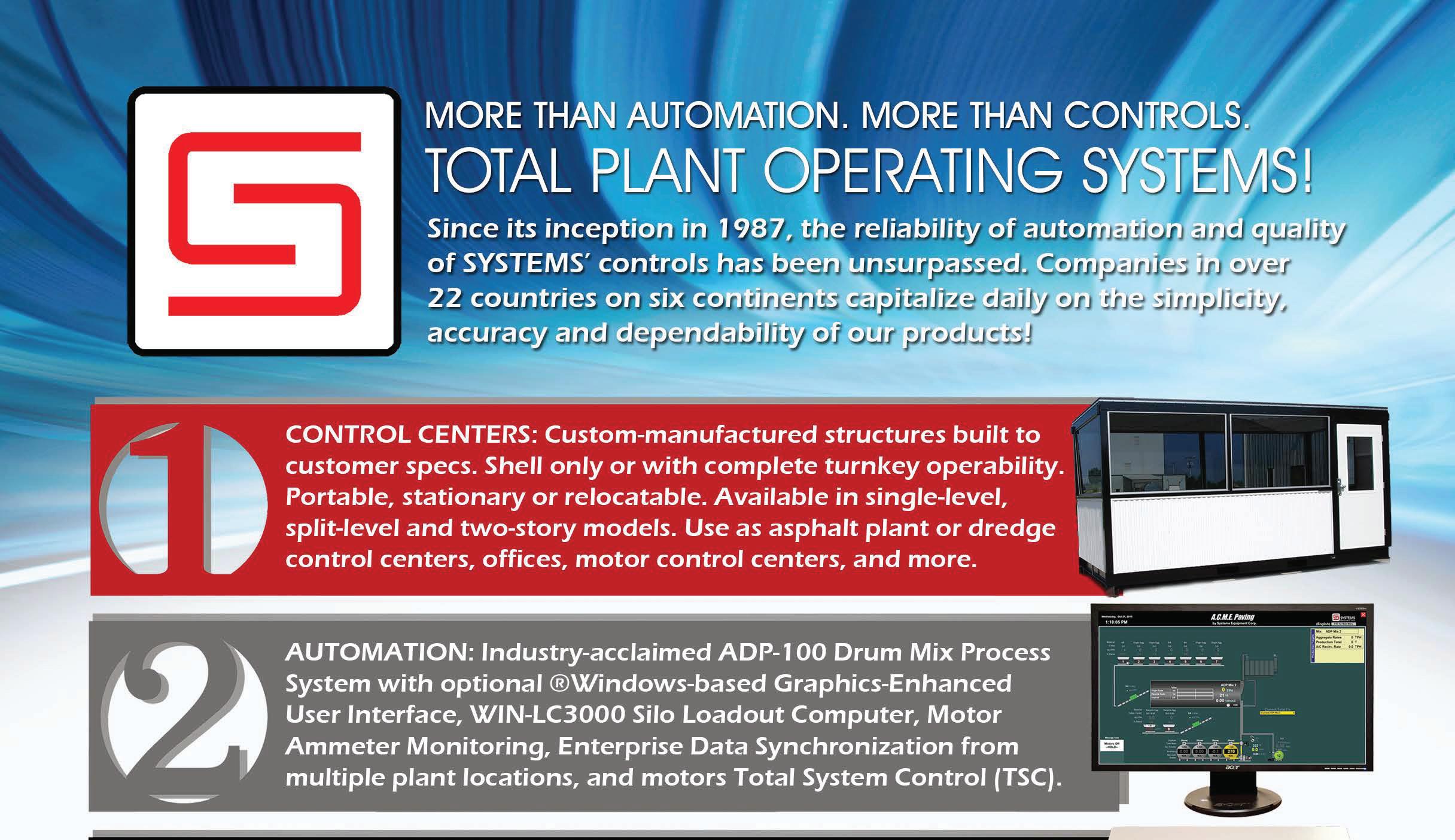

We’ve built our business and reputation through our unparalleled focus on equipment durability, attention to detail, and the ability to customize our products for each customer. We apply these foundations to our complete range of asphalt mixing plants and asphalt plant equipment designed for producers of all sizes.

Road Widener offers the Offset Vibratory Roller, designed for easy operation without the need for extensive training.

Road Widener

and increased sustainability has upped the focus on digital transformation in road building.

he nature of building a road has not changed much throughout the years, in terms of the earthworks, constructing a foundation, creating an embankment, and paving the sub-base, base, and top layer according to traffic load and weather conditions.

What has changed is that the technology being used to execute the tasks has become more sophisticated and now includes alternative power sources, artificial intelligence, and remote control.

Experts at Topcon, which develops technology for the construction industry, noted that demand for quicker delivery and increased sustainability puts heightened focus on the need for

large-scale digital transformation.

U.S., and especially in industries like construction. It is taking a toll on our customer’s ability to complete work,” noted Jeremy Dehnel, director of sales at Road Widener, which produces road construction equipment attachments.

always sought to design solutions to

The experts pointed out that technology helps mitigate the challenge of finding skilled machine operators. Also, material costs call for more efficient approaches to jobs, to avoid waste.

The experts listed five reasons why now is the time to integrate the latest technology into a company’s operations. Today’s technology:

• Maximizes efficiency, a plus in projects where short timeframes to complete paving work are common in projects requiring full closures.

• Improves accuracy and consistency.

• Saves money and materials by speeding up the process.

• Increases jobsite safety, reduces human error, and requires fewer people on the jobsite.

• Enhances a connected workflow. Additionally, today’s technologies help to extend the lifespan of equipment and assist in mitigating the labor shortage.

“We are also all very aware of the tremendous labor shortage across the

“This has driven interest in a need for machinery that has the technology and features to complete more work with a smaller crew,” he said. “We have always sought to design solutions to limit labor and increase safety.”

Dehnel noted that among the number of trends influencing the equipment that contractors look to for paving technology and other road construction, is machinery that is compact enough to keep one lane open in the work zone to reduce traffic congestion.

To that end, Road Widener offers the FH-R material placement attachment and Offset Vibratory Roller, designed for easy operation without the need for extensive training.

“They connect to equipment commonly found in contractors’ fleets, including skid steers, compact track loaders, front loaders and graders,” Dehnel said.

Dehnel pointed out that with the U.S. Department of Transportation Road to Zero safety initiative and an overall focus on safety in the construction industry, “we recognize the importance of OEMs and contractors working together to ensure that crew members get home safely each night.

•

•

•

“One area that Road Widener noticed a gap in construction safety is in compaction, which is why we developed the Offset Vibratory Roller,” he added. “This attachment is designed to allow the host machine to drive safely on level ground while compacting sloped shoulders, ditches, trenches, and other hard-to-reach areas alongside the road. These tasks have typically put road crews in danger of rollover accidents, and increased workers’ comp costs and poor safety ratings.”

Road Widener

The FH-R material placement attachment can run a wide variety of materials including asphalt, aggregate and gravel, so contractors can use it for different utility and road construction jobs, said Dehnel.

The FH-R requires only one operator to run, which can be done remotely from the host machine, increasing the crew’s safety by keeping them off the road and out of harm’s way, Dehnel added.

“Its accurate material placement prevents material from scattering onto the roadway, eliminating the need for an operator to follow with a street sweeper to clean up,” said Dehnel.

The Offset Vibratory Roller is designed to offer the same benefits of the FH-R, in terms of operation from

the host machine cab, as well as the additional safety benefit of eliminating rollover risk when compacting material.

Additionally, the compact design of both the FH-R and Offset Vibratory Roller allows the attachments to be transported with a standard trailer and pickup truck rather than a lowboy trailer and semi required by a large, self-propelled shouldering machine, Dehnel said.

Road Widener also offers the Curb Backfiller accessory for the FH-R material placement attachment.

“This really comes down to efficiency and how the Curb Backfiller accessory accelerates project timelines, increases safety and cuts out unnecessary steps in the backfilling process,” Dehnel said of its use on construction projects.

The Curb Backfiller accessory is designed to easily attach to the FH-R and can fill on the righthand side by default, or the left, with dual configuration and dispense material over the curb to backfill with dirt or aggregate.

“It includes pass and temperature mapping like Compact Assist Start, but also provides greater accuracy and reporting opportunities through the addition of a high-accuracy GPS antenna, recorded and saved job data, automatic job report creation with USB and over-the-air downloads,” said Eckert.

Compact Assist with Density Direct is Volvo’s most comprehensive package that combines all features of Compact Assist with density mapping functions “for those serious about increasing productivity and delivering a faster bonus,” Eckert added.

The Trimble Roadworks Paving Control Platform is Trimble’s next generation machine control paving technology, said Kevin Garcia, Trimble’s general manager of civil specialty solutions.

It provides a cleaner, more accurate process by backfilling curbs and keeping debris off the road, while boosting efficiency, accuracy, and safety by replacing a backfilling method typically done manually, said Dehnel.

Intelligent compaction is not necessarily new, but has made major advancements recently, Mark Eckert, product manager, Compactor, Compact Assist, Volvo Construction Equipment (CE) noted.

Volvo now offers three different packages of its Compact Assist software, providing access to the core functions of pass mapping, temperature mapping and density/stiffness mapping.

Compact Assist Start is the company’s entry-level package, “that’s perfect for customers who haven’t used intelligent compaction before,” Eckert said. “It provides real-time information on pass and temperature mapping in a system that’s as easy to use as a smartphone.”

Compact Assist is the middle level that is ideal for those looking to record and track data across a jobsite, he added.

“The latest version of Trimble Roadworks includes horizontal steering control and automatic screed width functionality specifically for Vogele Navitronic asphalt pavers,” he added. “This functionality automatically steers properly equipped asphalt pavers and controls the screed width according to a 3D design, making it Trimble’s most advanced 3D paving system to date.

“The auto steering and screed control functionality provides higher quality and more accurate paving faster and with substantially less operator fatigue than traditional asphalt paving methods. The system also helps reduce waste and improve jobsite sustainability, making it easier to accurately estimate material quantities and use less asphalt during the paving process.”

BOMAG’s remote-controlled single drum roller (SDR) is designed “with the goal to prevent major safety issues for construction companies by taking the driver out of the dangerous areas at the construction sites,” said Ruben Garcia, BOMAG product marketing manager, soil compaction.

“The operator can fully control the equipment from a distance up to 100 meters from the machine for a safe operation even in challenging conditions along edges, in trenches, or in the risk of a landslide,” he added.

Asphalt paving solutions from Topcon deliver smooth pavement on highways, parking lots and runways around the world. We provide road planning and design software, as well as machine control systems for pavers, milling machines and compactors. The time is now!

Learn more about Topcon Products at World of Asphalt in Nashville, March 25-27, 2024 — Booth #2331

Scan the QR code to get in touch. We’ll take care of the rest.

One of the several trends in today’s roadbuilding technology is the rollout of more battery electric vehicles. More intelligent vibration control and autonomy options are emerging. Machine data and performance is augmented by technology offering comfort, ease of use and a more comfortable environment for the operator in the cab.

Volvo’s new battery-electric compactor, the DD25 Electric, brings the advantages of lower noise and zero-emissions equipment to road building, noted Justin Zupanc, head of electromobility and autonomous solutions, road products, Volvo Construction Equipment.

“This double-drum compactor offers 24 kW of available power, which is 30 percent more than its diesel counterpart,” he added. “The result is a more responsive machine in terms of speed and vibrations. The 360-degree visibility and high-frequency compaction allow operators to achieve a smooth finish with speed.

“It can do all the jobs a similarly sized diesel machine can do, including street repairs and patching, parking lots and driveways, and its emissions-free operation allows the DD25 Electric asphalt compactor to help organizations meet emission regulations.”

The DD25 Electric can run for a full shift on a single charge, Zupanc said.

“The machine comes with an integrated on-board charger that enables charging from zero to 100 percent in as little as three hours,” he said. “With an optional off-board DC fast charger, this can be achieved in just over an hour.”

The DD25 Electric compactor requires much less time and money in terms of maintenance because it does not have an engine, said Zupanc.

“Charging a battery is more costeffective than buying diesel fuel, and there’s no need for engine-related maintenance products like engine oil, oil filters, diesel particulate filters or diesel exhaust fluid,” he added.

The DD25 Electric is the newest addition to Volvo’s electric lineup, which includes electric compact excavators and electric compact wheel loaders.

The machines are designed to offer the same performance as their diesel counterparts, “so any task a roadbuilder uses a compact excavator or wheel loader for could also be done by these batteryelectric machines,” Zupanc noted.

As road construction usually involves medium or large class sizes, Volvo is launching its midsize EC230 Electric excavator in North America in 2024.

In early 2023, Volvo introduced remote control technology called Short Range Remote Control as an option on the company’s EC250E, EC300E and EC350E excavators.

The remote control works at a 100-meter distance, and the operator can communicate with the machine via a radio transmitter and receiver.

“Ideal applications include ones where visibility, falling debris or machine rollover may be an issue, as well as when the operator needs to keep a closer eye on the tool. If a road construction project includes steep grades or needs enhanced operator visibility, Short Range Remote Control could be a solution,” Zupanc pointed out.

has a number of AI projects in the pipe, Garcia said.

The company’s remote controlled single drum rollers is just the beginning of a number of technologies the company will be rolling out, followed

by lane assist/field assist technology, teleoperation electronic coupling, highly automated SDR, and full autonomy compaction, he adds.

There are numerous opportunities for constructing new roads and repairing existing ones, with alternative power, AI and remote control giving contractors the ability to do so efficiently and safely.

In early November, the U.S. government announced it will allocate $2 billion through the Inflation Reduction Act to fund 150 low-embodied carbon materials projects, including repaving.

The announcement is designed to further the Buy Clean Initiative, which prioritizes the purchase of asphalt, concrete, glass, and steel that have lower levels of greenhouse gas emissions. It is viewed as another step toward President Joe Biden’s federal sustainability goals, including a net zero emissions federal building portfolio by 2045 and net zero emissions procurement by 2050.

For more information visit

By Brandon Noel, Editor & Jessica Lombardo, Contributing Editor

By Brandon Noel, Editor & Jessica Lombardo, Contributing Editor

Opening a new asphalt plant is not a decision to take lightly. Not only is it a large capital investment in equipment, but companies need to invest in training, resources, permits, construction and more. Even under normal circumstances, all those things can be incredibly difficult to have on-hand or readily accessible. As everyone in our industry is well aware, the last few years have been anything but normal circumstances.

No one could have predicted what would happen in the world when Principio Asphalt started having

conversations about buying and building a new asphalt plant in early 2020. The team quickly visited with the people at Astec in Chattanooga, TN, to finalize details, and while those were locked in-place, everything else in the world suddenly flipped on its head. Understandably, for lots of contractors, this might have made them second guess their choices or their plans, but that wasn’t the case here.

In fact, for Principio Asphalt, their decision to purchase a new plant was one they knew they were ready for, no matter what. They trusted in their team, their experience, and their plan even as they faced several challenges along the way.

“Principio Asphalt is a new company backed by decades of experience,” Paul

Lester, Executive Vice President at Diamond Materials, LLC said. “This new venture is backed by a joint venture between York Building Products, P.Flanigan & Sons, and Diamond Materials. Each of these companies has the knowledge and expertise in their fields to ensure this new plant would be successful.”

Once the three companies decided to form Principio Asphalt, their location for the plant was easy - the York Belvedere Sand & Gravel in North East, MD.The area is in the midst of huge growth with an interchange to I-95 that will allow the plant to provide service regionally to the Cecil County, MD,

greater Newark, DE, and southeastern PA markets.

“We were sending a lot of our mix from the Wilmington Diamond Materials plant out to the Maryland market and knew it was an underserved area,” Lester said. “With the new plant, P. Flanigan and Diamond Materials as a laydown contractor would be a great customer for the plant and the partnership with York and P. Flanigan allowed for it to happen.”

The York Belvedere quarry provides a variety of hard rock products in many sizes, making them an ideal partner and location for asphalt production.

“The experience and materials at the York quarry gives us the ability to control the quality of the mixes we produce,” Lester said. “Being able to design the mixes and then deploy them

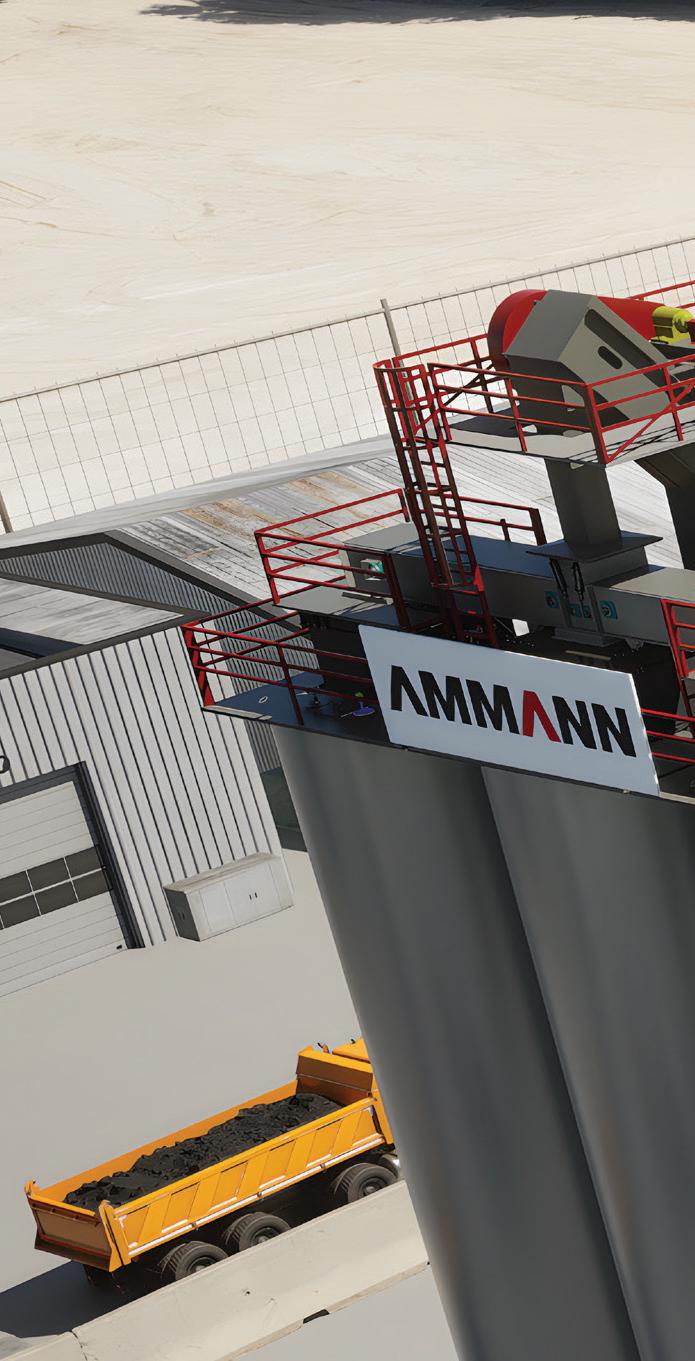

Principio Asphalt’s new asphalt plant, 400-tph

Double Barrel drum mixer plant from Astec, York

Belvedere Sand & Gravel in North East, MD.

Provided by Astec Industries

for our customers was a huge advantage of this install and location instead of transporting mix into the area.”

When Principio Asphalt was in the market to purchase the new plant, they knew they were going to need a unit that could reach high capacities, while also being able to utilize a high amount of recycled materials.

“Right now we’re producing mixes with at least 15% of recycled asphalt material in it and most of our normal everyday mixes are up to 40% recycled material,” Lester said. “We’re definitely seeing a demand for it in Delaware, and we think Maryland and Pennsylvania are coming right behind. Eventually in our industry, producers will need to supply environmental product declarations (EPDs) for their materials and so recycled mixes are the way to go.”

While demand for these types of mixes has grown, Lester reinforced that the key for customers is still quality, even if they’re looking for a good deal at the same time. “They want a good product that’s inexpensive. So, that’s what

you have to make,” he said. “That’s why we went with the double barrel mixer. We believe it’s best at achieving a high recycle rate, getting the moisture out, and rejuvenating the asphalt.”

The Double Barrel sequence also passes the material through a series of veiling flights that transfer the heat from the burner to the aggregate. The aggregate then exits the inner drum, dropping down into the outer drum shell, where paddles sequentially mix in RAP, liquid AC, and dust/filler in a flame-free environment. In this zone, the constituents are mixed for the remainder of the drum length before exiting to the drag.

Since Diamond Materials has experience with asphalt production, Lester and his team knew they also wanted to have a plant they were familiar with at the first Principio location.

“We wanted a plant we knew we could handle and Diamond Materials has a plant in Dover, DE that we really like,” Lester said. “That location is an Astec Double RAP plant so we have a good background with that plant and knowing what to do and wanted something similar in this location.”

The company chose the 400-tph Double Barrel drum mixer plant from Astec. This plant is capable of capacities up to 400-tph and can make mixes with up to 50% RAP. The sequential mixing that happens in this plant ensures ingredients are added to the hot mixture in an order that allows better temperature equalization and even distribution of all particles throughout the mix - something important to production at Principio.

In order to meet the ambitious timeline that Principio had planned, it required a lot of back-and-forth communication with Astec’s team.

“We had an aggressive timeline to get this all done and Astec was ready to meet our demands,” Lester added. “We were having conversations in April of 2020 to order the plant and the plan was to put it up over the winter going into the spring of 2021. COVID, however, pushed us back quite a bit and we were finally able to get permitting done later in 2021.”

With the delay, the Principio group was busy gearing up for the paving season, so the team at Astec stepped in to help with construction. The plant was installed and ready for production in late 2022.

“Almost every person that runs a plant for me started out on the ground straight out of high school, in a loader, doing mechanic work, or maybe welding,” said Lester, who also started out originally as an entry-level laborer. “I started out there and here we are now, I’m the Executive Vice President of the entire company. So, it’s kind of bred into us, to bring guys up and bring guys along with you. That’s the only way to build a strong company.”

Provided

“With our materials, we don’t look at it as what percentage is recycled materials, we’re using terminology that indicates the percentage of virgin binder we’re replacing instead,” Lester said. “We have mixes that are 25%, recycled asphalt pavement (RAP) and 5% shingles that we use and we’re also large believers in using a rejuvenator in most of our high recycled operations to ensure quality with these materials.”

Since Principio is a new venture, they also wanted to know they would have reliable support behind the location during design, construction, and beyond.

“We knew what Astec brings to the table as far as customer support,” Lester said. “Anytime you picked up the phone, when we were designing the plant, or if we had an idea for something we wanted to change, we never got an answer of, ‘We can’t do that.’ It was always, ‘Let’s get into it, let’s talk about it.’ We never asked them a question that they haven’t been able to answer. From their sales team to their parts guys, everybody from top to bottom answers when we call.”

“We are very familiar with Astec plants and so our team was able to assist with installing the electrical and complete some initial training for this location, but the Astec team was on hand to help with anything we did need,” Lester said. “Our team at Diamond Materials has attended the Customer School events put on by Astec and we were lucky to have some of those people available to get this plant up and running and ensure its success long term.”

What is impressive about Principio’s achievement here isn’t necessarily obvious on the surface, but those anyone owning or operating a plant right now will tell you that staffing a single asphalt plant is a challenge in today’s labor market.

While many would be content to have enough skilled and trained employees for their existing plants, Principio has forged ahead in one of the most difficult times in history to expand their operations by building this new plant. They achieved this through a grassroots, farm-team approach to recruitment. Each person who joins their team can look at every employee that works above them and know that they once were where they are now. Being able to see the potential for your own growth, combined with management that has spent years getting their hands dirty, breeds a positive job environment.

In such a competitive labor environment, Principio takes a twoheaded approach to identifying those employees with the potential to grow their knowledge and skill to rise to great positions within the company. Some people they recognize have a specific drive to do more which they express through their work-ethic or by how they conduct themselves. Others might not see that potential within themselves, and the leadership helps foster it over time. Overall, it’s a mentality that looks at employee investment as a net-gain for the company in the long run.

“We push everybody to grow,” said Lester. “Some guys want to be operators, because they like it. Ohers want to be estimators, but there are some that are always asking if they can learn a new thing or try out something else, to see if it’s a good fit, and we want to give them that chance.”

Principio also planned ahead at this location, anticipating the future needs of the market.

“We believe that there’s going to be a large future here,” Lester added. “We planned for four silos upfront and we planned enough room that we can add four more silos at any time.”

And when they are ready to upgrade their facility, Lester believes they will likely return to those who helped them make this plant a reality in the first place, despite all the outside challenges they faced.

For more information visit https://asph.link/wmjikv

Whether expanding operations, replacing existing equipment or looking for more flexibility, look no further than Cat® Cold Planers. Cat Cold Planers give you the options you need to choose what is right for your operation, regardless of size or project type. With the power you need, they deliver performance and productivity you have to have. And now select models feature VisionLink® Productivity to help improve productivity and efficiency and reduce costs.

Combine that with excellent service access and outstanding operator visibility and comfort, and Cat Cold Planers deliver. So whether you’re milling project is large or small, turn to Cat Cold Planers for you next milling machine.

For more information, go to cat.com/coldplaners

The biggest product showcase and event for asphalt producers, pavers, and everything in-between.

The entire asphalt pavement world will descend upon Nashville, Tenn., March 25 -27, 2024, and it’s shaping up to be one of the best yet. In the following guide, we’ve compiled more than 60 of the brand new, upgraded, redesigned, and refreshed products from the most in-demand manufacturers in the industry. Are you heading to the show? Browse these top selections and make notes on which booths to stop by and see in-person. Not going to make it? You can see some of the key items right here.

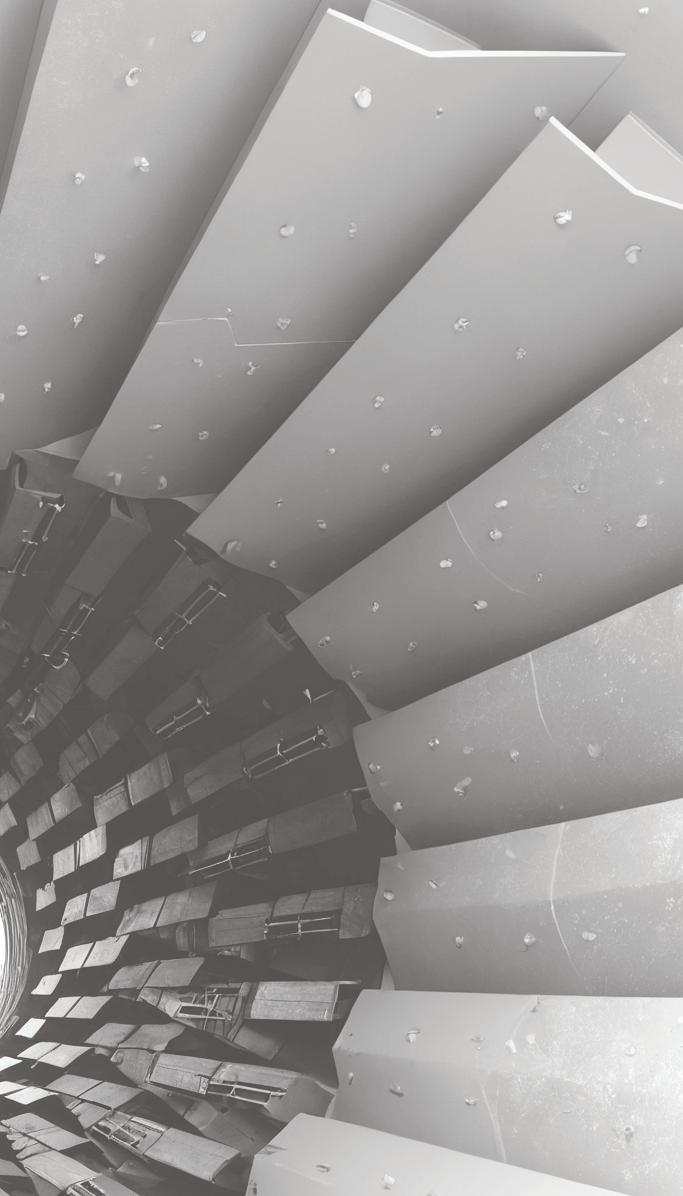

BROCK Industries will now be one of only two companies building this style of dryer/ mixer drum. Booth square footage doubled in size versus World of Asphalt 2022. The exhibit will feature the company’s people, products, and services. Booth #1043

• BROCK noffers the market a viable option for drum replacement and/or refurbishment in this style drum

• BROCK also offers in field construction services for hot mix asphalt plants including repairs, maintenance and plant relocation services

BROCK engineers, sells, manufacturers, and services several different types of dryer/ drum mixers. One of them, featured at the show, is an inner drum of a multi-zone continuous mix dryer/drum mixer. This is among the most popular dryer drum mixer types in the United States, and BROCK is one of the most qualified suppliers of this type drum in the world.

BROCK engineers, sells, manufactures, and services a complete line of vertical liquid asphalt storage tanks ranging from 5,000 to 40,000-ga. capacity along with multiple sizes of thermal hot oil heaters and related piping systems.

BROCK on-site services include equipment installation, tear-down, relocation, and maintenance of asphalt plant equipment in the field. The company has multiple in-field construction service crews, and they are among the most experienced in the industry.

CMI’s new and improved Cedarapids Magnum “Bullet” series is available from 150 to 600 tons per hour and has been redesigned with an emphasis on substantially reduced installation time to provide a market leading set up time within two days when combined with a CMI portable self-erecting hot mix storage system. Find CMI Roadbuilding at World of Asphalt booth #2747

Cedarapids Magnum “Bullet” 150

The Cedarapids Magnum “Bullet” 150 Super-Portable counterflow drum-mix is the latest development in the series with a capacity of 150tph and capable of up to 35% RAP recycling in the mix.

SAKAI America specializes in asphalt rollers, soil compactors, and light compaction equipment for the road paving and construction site work markets. World of Asphalt 2024 show attendees will be able to see the latest prototype in the SAKAI America booth #1301

(New) HV620E Prototype Electric Walk-Behind Roller powered by Honda’s Removable Battery System

SAKAI partnered with Honda in Japan to implement their new Mobile Power Pack removable lithium-ion battery system in a familiar double drum walk-behind roller format. This resulting electric roller will render charge anxiety a moot point by allowing battery swaps on the jobsite and the ability to easily charge in off hours without transporting the whole machine.

SW884G - Asphalt Roller with Guardman Automatic Emergency Braking

SAKAI’s latest Guardman-equipped asphalt roller is the 79-in. SW884G. Like other Guardman-equipped machines, this roller detects personnel, objects, and other equipment in the path of the roller and automatically stops if a collision is imminent. The SW884G features both rear and front detection/braking with a total of four sensors. This safety technology has the potential to reduce injuries, prevent deaths, and minimize equipment damage on paving jobsites. Guardman is factory-installed as a distinct model variant due to many critical components that are changed over a standard roller.

SW354 3-ton 47-in. Double Drum Asphalt Roller with No Aftertreatment Required

The SW354 features 47-in. double drums and makes for quick but accurate work with 10 impacts-per-foot at 4,000 vpm. The Kubota diesel engine is completely mechanical: NO DPF and NO DEF, saving maintenance cost and time. Operators prefer the combination of quiet operation, rubber isolated deck and drum vibration, easy visibility to drum edges, and a comfortable waterproof wide bench seat.

Dynapac has new and upgraded machines including the D14/D17 pavers, but their biggest launch is SEISMIC technology on asphalt. Come by World of Asphalt booth #2549 to see this and all Dynapac has on display.

SEISMIC technology for asphalt offers a whole host of benefits for both optimal compaction and operator comfort. SEISMIC automatically determines the optimal frequency for any compacted material, constantly monitors the variations, and automatically adjusts to changing

conditions. The SESIMIC system is active on both drums to help reduce the required vibration power and energy consumption. The resulting lower noise levels and vibrations within the cabin provides the operator with greater comfort, while a general reduction of the number of passes which saves time, fuel, and money.

TransTech Systems is an instrument company that develops innovative and nondestructive evaluation products for the construction industry, all of which are based on our core technology. The patented Pavement Quality Indicator (PQI 380), developed and manufactured in New York, is the leading non-nuclear asphalt pavement quality control device in the world. The groundbreaking PQI set the standard for non-nuclear gauges when it was introduced over 25 years ago. Find them at World of Asphalt booth #2528

Our flagship product, the PQI, is what put TransTech Systems on the map. The PQI is our NONNUCLEAR asphalt density gauge. Precise density measurement is nearly instant (3 seconds). The PQI is more accurate than the nuclear gauge but without the hassle of regulatory training and certification. Easy for your crew to use. The PQI 380 complies with ASTM D7113 and AASHTO T343.

Fast, reliable, accurate and repeatable readings by a NON-NUCLEAR soil density gauge; the SDG 200. This gauge is user friendly, and a cost-effective tool for your crew. No badges, no licenses and no storage and transportation concerns! The SDG 200 complies with ASTM D7830.

Innovative and reliable operator friendly features such as paver hopper management system with distance to paver, storage hopper management and auto chain tensioning.

shell doors and full width drop down floors provide unmatched access for cleanout and maintenance.

Variable speed elevator and conveyors meet production requirements while minimizing wear.

The multiple, incremental improvements to the 4th generation of chains, sprockets and augers are retrofittable to all machines and provide increased wear life.

Road Widener puts more than 30 years of road construction experience to work manufacturing innovative shoulder maintenance equipment. They will highlight the FH-R, along with other innovative solutions and technologies, at booth #2755

The FH-R is a versatile solution for material placement, precisely dispensing topsoil, gravel, asphalt, limestone and more — all with an attachment compatible with common machines that contractors already own. The remote-controlled attachment easily connects to most skid steers, compact track loaders, road graders and wheel loaders, operating off the host machine’s engine and hydraulics. It is available in left, right or dual dispensing configurations to take on any roadway around the world. The attachment streamlines a variety of tasks including backfilling, road widening, road shoulder repairs, remediation and aggregate placement. The material is poured into the hopper at the top of the FH-R and then precisely dispensed via remote control in adjustable lay down widths from 1 to 6 ft. (.3 to 1.8 m). The attachment dispenses up to 20 tons of material in under 10 minutes.

The attachment’s offset, patented design allows the host machine to drive safely on flat ground while compacting sloping shoulders, ditches, trenches and other hard-to-reach areas alongside the road, a task that has traditionally put road crews in danger of rollover accidents, increased workers’ comp costs and led to poor safety ratings. The Offset Vibratory Roller attaches to most loaders, graders, compact track loaders and skid steers, operating off the host machine’s engine and hydraulics. Utilizing the host machine for power reduces maintenance by 90% over self-propelled rollers while also offering the versatility of three interchangeable drums sizes and up to 30-degree pivot angles.

The accessory extends to the left or right of the FH-R and precisely dispenses material over the curb to backfill with dirt or aggregate. Paired with the FH-R, the Curb Backfiller boosts efficiency, accuracy and safety by replacing a backfilling method typically done manually by workers with shovels. Crew members can operate it with the original FH-R remote, improving convenience and reducing the number of needed laborers to just one.

FleetWatcher to Feature “Connected Site” Technology in World of Asphalt booth #1656 with Seamless integration allows users to manage all apps from one platform. Their telematics platforms seamlessly integrate with other applications and software programs, aggregating data and allowing users to manage site functionality with the FleetWatcher platform. In addition to establishing geo-zones, tracking equipment productivity-versusidle time, tracking driver behavior, determining yield dynamically, thwarting theft, and reporting whether personnel are qualified to operate particular equipment, the company will introduce functionalities like buckets and attachments tracking, fuel burn management, equipment inspection, and more.

• FleetWatcher continues to innovate and their popular telematics platform steadily evolves to include new functionalities. They will feature “the connected site,” which integrates with other popular software programs and allows users to run their entire site from a single platform–FleetWatcher. Among the new functionalities that will be featured at World of Asphalt are Unauthorized/untrained user and attachment tracking.

• Unauthorized/Untrained user monitors who is signing on to equipment and then notifies them and their supervisor if they are not authorized or trained n that equipment. Attachment tracking is just that–tracking of buckets and attachments.

Booth #2731

Booth #2731

Meeker is now building certified UL142 Asphalt Tanks. Specifically designed and registered with Underwriters Laboratories, their asphalt tank allows customers to have the assurance the tanks are built to the best standards. Booth #2063

Meeker is a licensed manufacturer for the Steel Tank Institute, and are the recipient of STI’s Quality Award 16 consecutive years and inspected two time annually.

Environmentally Conscious Electric Hot Oil Heaters

• No emissions. Since the heater is powered by electricity, there are no gaseous emissions coming from the heater.

• SCR Control of electric heat allows heat generated to match the load on the system. This means the heater only provides enough heat to the demand it is seeing. It is not overheating the system.

• PLC Controls allow the heater to operate the way you want it to. Optional phone app allows you to change settings remotely plus operators get notified of heater status.

• Removable Expansion Tank provides way for customers to mount the expansion tank remotely if they so desire.

• Low Expansion Tank Limit, high oil temperature limit and no flow limits provide safety to the heater and to the heat transfer oil.

Broom Box By Etnyre

Introducing the Broom Box by Etnyre, a piece of equipment designed to streamline road maintenance operations. This self-contained unit mounts effortlessly to any distributor with minimal modifications, offering unparalleled convenience and efficiency. Booth #2931

With hydraulically adjustable width ranging from 8 to 14 ft. via a wireless remote control, the Broom Box ensures precise coverage tailored to your needs. Its quick-release broom heads facilitate easy replacement, while the high-lift attachment enables self-loading onto trailers, minimizing downtime.

Equipped with a box that contains emulsion, the Broom Box eliminates run-off against curbs or road edges, reducing mess and ensuring environmental compliance. Its hinged design automatically flexes on crowned roads, while the firm attachment to the distributor prevents drifting on sloped surfaces.

The Broom Box features a self-contained electric over hydraulic control system, eliminating the need for external power sources. Its cordless controller offers freedom of movement and ease of operation. Additionally, three variable broom types cater to different surface conditions, ensuring optimal performance in various environments.

Iincludes a storage stand to extend the life of brooms between production days and during transportation, preventing brooms from matting when not in use. With its positive height adjustment and poly head brooms for extended life, the Broom Box is engineered for durability and efficiency, making it the ultimate solution for road maintenance professionals.

Find Weiler at booth #2349

P385C Paver

The P385C features a Cat C3.6 Tier 4F/Stage V engine with an increase to 120 hp for unmatched power and performance. The best-in-class undercarriage features 90 in. track length, 68 in. of ground contact and 140 mm track chain pitch provides smooth ride and flotation with automatic track tensioning.

The Weiler designed 3,700 lb screed features a paving range of 8 ft. to 15 ft., 8 in. The redesigned heating system eliminates GFCI breakers and utilizes insulation monitoring for increased reliability and performance.

D560 Top Hammer Rock Drill

Powered by a Cat C9.3 Tier 4F/Stage V engine with 375 hp and a 550 ft³/ min compressor for 3.5 in. to 6 in. hole diameter at a max depth of 102 ft. Multiple drifter options are available and provide low cost of ownership through at simple design and high strength materials. The six rod carousel holds multiple diameter rods with a precise position function that indexes and locks, eliminating switches and sensors for increased reliability. The mast accepts a start rod of up to 20 ft. for a max pass depth of 18 ft., 6 in.

E1650A Remixing Transfer Vehicle

Features 18 tons of onboard storage, enhanced elevator motors and triplepitch remix augers to provide 600 tons per hour discharge capacity for nonstop, non-contact paving with reduced particulate and thermal segregation. The new, front-mounted control station layout features increased visibility with a 10 in. color, touch screen display with integrated camera along with proportional conveyor swing joystick control. The crab and coordinated rear steer with auto-center is standard for a 17 ft. inside turning radius.

It’s time to unleash your team’s productivity because…

Astec Digital is the leader in plant automation, telematics, and data management from Rock to Road and beyond. We are creating a platform to connect every piece of your operation and tear down the silos so that you can have the visibility and insights to improve efficiencies and reduce costs. Real-time data, increased control, and higher profits start here.

The future is connected: AstecDigital.com

Indicator

Cimline continues to offer cutting edge technology through its worldwide network of distributors. Come visit Cimline at booth #2517

The ME2 is a mid-sized mastic melter applicator by Cimline, designed for smaller municipalities and contractors. With a 250-gal. capacity, the ME2 offers faster melt times, increased maneuverability, and efficient pavement maintenance for roadways and parking lots. The unit boasts Cimline reliability, featuring sturdy controls, a proven Isuzu Tier IV diesel engine, and a robust 7-gauge steel tank. Renowned for high quality and supported by an extensive dealer network, the ME Series stands out as a customer-preferred choice for prepackaged mastic applications. Choosing Cimline means opting for a Buy American-made solution that prioritizes safety and ease of use.

The M2 stands out as the workhorse of pavement maintenance, equipped with a 230-gallon capacity, dual loading doors, and tandem axles to tackle the demands of the job efficiently. Whether your focus is on parking lots or road and municipal projects, the M2 is designed to meet your specific requirements. Ideal for operations with lane miles totaling less than 100, this versatile vehicle ensures optimal performance. Its capabilities shine particularly in scenarios where the average daily production ranges from 5 to 7 lane miles or even more. With the M2, you can count on a reliable and high-performing asset to get the job done effectively in the realm of pavement maintenance.

MA4 Longitudinal Joint Sealer

The Cimline MA4 stands out as an innovative solution for VRAM applications, longitudinal joint sealing, bridge deck application, and other HOT applied jobs that require computer rate application. Whether you are looking to complete an entire project or need a supporting piece of equipment other than a full distributor truck, the MA4 is designed with a simple operations platform of intuitive controls to ensure consistent expert application after minimal training. No CDL is needed to operate the MA4 and it can be towed by a 1-ton work truck providing flexibility in scheduling jobs for mainline application or support application to increase profit margins. 230

410

Find more information about these products and more at Volvo CE’s World of Asphalt booth #1231

DD25 Electric Compactor

Building on the success of Volvo’s electric compact excavators and wheel loaders, the company recently introduced the DD25 Electric asphalt compactor. The DD25 Electric brings zero-emissions equipment to the road and landscaping segments. This doubledrum compactor offers 24 kW of available power, which is 30% more than its diesel equivalent. It’s ideal for jobsites with emission regulations or for organizations looking to meet their own sustainability goals. Zero tailpipe emissions also mean a cleaner, more enjoyable work environment for operators, site teams and passers-by. The DD25 Electric can operate for a full shift on a single charge, depending on the intensity of the work cycle. It comes with an integrated on-board charger that enables charging from zero to 100% in as little as three hours.

L180 3-Pass Rehandler

Volvo took their tried-and-true L180H wheel loader, swapped in larger tires and a long boom, added a rehandling counterweight, and created a new truck-loading dream machine called the L180 3-Pass Rehandler. Larger tires give the loader a wider footprint, providing extra floatation, durability and stability with an additional 675 lbf in breakout force and two more feet of dump clearance. The longer boom enables more efficient pile penetration, additional room between the loader and the truck, and better reach for dumping material into the center of the truck.

The machine’s configuration also decreases the risk of wheel spin and better protects the tires because operators can stay farther from the pile where the ground is less stable and rocks can damage the tires. The rehandling counterweight allows for a bucket that is approximately 0.25 yd³ larger than what a standard L180H can accommodate. Customers can choose between four different buckets to match the material density. Cycle times are improved by the higher reach because the operator won’t have to roll the bucket back to move away from the truck. Better cycle times mean better fuel efficiency, and a smaller class size saves buyers on the purchase price, as well.

T.J.

With over 47 years of industry expertise, Command Alkon’s services and products empower heavy building materials suppliers to improve production and quality control, dispatch and trucking, and office efficiency and performance. The company is thrilled to showcase its next-generation platform, Command Cloud at the 2024 World of Asphalt. The company will host live product demonstrations in booth #1941 throughout the week. Stop by to see any of their solutions in action, including:

Command Cloud

Find these and more at booth #2301

8680 Paver

• 210 hp (157 kW) Kubota Tier 4 Final diesel engine

• Legend HD PRO Screed

Command Cloud serves as the latest evolution of the company’s CONNEX platform, boasting consumer-grade technological capabilities with 99.9% uptime reliability, scalability, and NIST certified security. Engineered as a comprehensive technology ecosystem to supercharge heavy building materials operations, Command Cloud delivers all the inherent value of cloud systems, including cost-efficiency, easy integrations through an API-first approach, and modern user interface design. The platform will harness the latest advances in machine learning, generative AI, predictive analytics and IoT-enabled technologies.

Apex

Apex improves site productivity for bulk materials suppliers by offering advanced scale ticketing software for impressive improvements in the speed and efficiency of operations and digitizing and streamlining manual processes.

Apex Automation

Apex scale ticketing works with site-automation technologies to ensure seamless truck throughput with automatic truck recognition, driver kiosks and display, remote print enclosures, video verification of scale loading, antitheft modules, wireless loader systems, and more.

As a worldwide presence in the asphalt industry, Cargill delivers results for hot mix plants, DOT agencies, refineries, and asphalt mix plants. They have successfully contributed to millions of tons of asphalt, amplifying profits, and performance across customers and applications. Visit Cargill at booth #2851

Anova Warm Mix Additive

With Cargill’s Anova warm mix additive, crews can reliably achieve density and improve workability at lower temperatures while reducing costs, emissions, and odor. The unique performance of our liquid is backed by more than 60 years of technical expertise in bio-based chemistry.

• Promotes adhesion as a proven anti-strip

• Compaction aid at lower temperatures

• Reduce emissions and mix global warming potential (GWP) by lowering production temperatures

Anova Rejuvenator

Anova rejuvenator is a bio-based recycling agent that reverses the impact of aging on pavement. Cargill’s proprietary technology goes further than simply softening the aged bitumen in RAP. By rejuvenating the aged bitumen, your high RAP mixes will deliver performance that equals or exceeds that of your typical asphalt mix.

• Enables reduction in mix costs and mix global warming potential (GWP) through the use of higher recycled content

• Create high performing mixtures with up to 100% RAP

• Functions as a compaction aid

• Enhances low temperature cracking resistance

• Paving widths variable up to 15 ft., 6 in. with PRO screed

• 12-½ ton capacity material hopper

• Dual electronic steering and adjustable operator platforms

• Two 18-in. feeding conveyors

• Hydraulic extending power tunnels

• Automatic Temperature Control (ATC) standard

• Smooth rubber tracks with oscillating bogeys

• Actuator driven hood lift to aid in maintenance

• 48 kWh battery pack

• J1772 / CCS Combo 1 charging receptacle, North American EV standard.

• Level 1 (120 VAC) and Level 2 (240 VAC) charging with onboard charger

• Level 3 DC fast charging enabled and compatible with North American EV charging stations, battery trailers.

• 10 ft. inside and 18 ft., 9 in. outside turning radius

HB4T Hotbox

• Trailer-mounted 4 ton hopper

• Thermostatically controlled diesel burner

• 110 VAC overnight heater

• Single material unloading door

• Full-width shoveling platform with integrated material shutes.

• Hydraulic dump hopper

• Curbside operation

• Cantilever side-to-side material loading doors

• Integrated compactor storage compartment

See BOMAG at World of Asphalt booth #2731

CR 1030 T

The modernized BOMAG CR 1030 T retains many of the legacy Cedarapids designs while incorporating an Independent Auger/Conveyor system with Outboard driven Augers, a new HMI Interface and a brand-new Front Mount screed.

The operator console is now more organized as related functions for the machine are sectioned together. With a new seven-inch touchscreen and similar functions being close together, the operator can quickly locate relevant information.

The CR 1030 T features a new Front Mount screed, the VERSA 20. The VERSA 20 provides infinitely variable paving widths from 10 ft. to 19 ft., with a maximum paving width of 23 ft. with bolt-on extensions. New hose routing designs improve screed system reliability in the field. The VERSA 20 will have the option for integrated BERM capability. Coming along with the new VERSA 20 is new screed controls with Integrated Moba Automation Displays as well. An updated control panel on the main screed and remotes on the extensions help the screed operator achieve the desired mat.

The new, compact BOMAG BW 120 AD e-5 electric tandem roller introduces sustainable, low-noise and zero-emissions operation to the 2.5-ton class commercial roller market. With its 39.4-in (1,000 mm) rolling width, this powerful and versatile machine makes short work of parking lot, driveway, and asphalt repair.

Featuring a low-voltage, 48V system with long-lasting 25 kWh Li-Ion batteries, the system requires no special safety precautions for maintenance, and the batteries offer plenty of capacity for a typical day’s work before recharging.

With no warm-up necessary, the roller is quickly ready for work at the push of the ignition button. A digital 5-in. (127mm) color display gives operators a quick glance of critical operating parameters, including speed, energy output, asphalt temperature, compaction progress, operating hours, battery charging capacity, duration and power.

BVP 18/45 electric plate

The BP 18/45 e is the first battery-powered vibratory forward plate from BOMAG. This powerful machine is able to cope with any jobsite. Its compact size and low mass make it easy to maneuver and achieves a working speed of 25 m/min. The straightedged base plate, made of high-quality wear-resistant material, enables extremely precise compaction along curbs or walls.

From light earthworks to asphalt construction or paving work, the BP 18/45 e was developed as a high-performance machine with one clear objective: to be as efficient and environmentally friendly as possible. It produces no direct CO² emissions and no harmful exhaust fumes, so it can be used safely wherever strict pollution limits have to be met.

There’s even more to see at Crafco’s World of Asphalt booth #1501

Crafco Mastic One is a hot-applied repair material for fast, durable pavement repairs. It’s flexible to avoid breaking up the surrounding pavement but contains carefully selected aggregate to bear weight. Use Mastic One on wide distresses like raveling joints, depressions, fatigue cracks, utility cuts or even for leveling potholes.

The Crafco Patcher II is a 200-gallon mastic melter offering quick heating and simple application. The powerful 6:1 gear box offers consistent hydraulic agitation to evenly heat material and keep aggregate suspended. Standard safety features like an automatic agitator shutoff on the loading lid keep your crew safe, while options like a heated swivel chute make placing mastic outside the wheelpath easy.

See Crafco’s newest innovation, the EZ Patcher skid steer attachment for safer mastic application on roads. With integrated heating and agitation, in-cab controls and a wireless camera system, the EZ Patcher is designed to lay down mastic quickly while keeping workers out of traffic.

Our UL asphalt tanks have properly sized normal and emergency venting as standard.

All structural attachments are OSHA approved and are af xed to our tanks per code.

All tanks are tested to UL142 Section 42.2.1a 10th Edition.

All weld joints are per UL142 standards.

Your asphalt tanks will be properly labeled and registered with UL142.

Come visit Colorbiotics in booth #2658

Invigorate Plus Cold Mix

The re-binder offers a new way to pave with asphalt millings. The re-binder is a bio-based liquid topical that seals and binds loose millings to create parking lots, driveways and low-volume roadways. Its three-step process is so simple that property owners can complete projects themselves—and it also cures in less time than the competition.

Invigorate Plus Sealcoat

A polymer-modified surface treatment that both restores and preserves high-traffic pavements. This sealcoat penetrates four times deeper than the typical topical to reverse oxidation throughout the surface course, then its polymer component seals the entire top inch of pavement against moisture.

When using Invigorate at a 1% dosage rate, a 50° decrease in temperature at 40% RAP achieves similar or better results in both Hamburg and Ideal TC testing. In Ideal CT testing, Invigorate at 270° F received a test score of 174.9, besting test samples heated to 320° by more than 45 points. In Hamburg testing, Invigorate reached the -12.5 limit after more than 18,500 passes. These two scores together demonstrate an impressive relationship of resistance to cracking and pliability in the 270° test. Lower your mix temperature while also including up to 40% RAP; preferable to save costs. This warm mix solution is an all-natural additive, which contains 100% bio-based content and attacks aged binder at the molecular level to transform recycled material from the inside out.

Visit ADM at World of Asphalt, booth #2429, where expert personnel they will be on hand to personally consult with you and help you find just the right asphalt plant for your operation. Talk with ADM specialists about how ADM can customize your asphalt plant with any of the company’s wide-range of components, compatible with other manufacturers’ asphalt plants, as well as ADM plants, for maximum versatility.

The ADM EX 7636 with its 76-in. drum diameter and 36-ft. drum length. Like all ADM EX Series counterflow asphalt plants (120-425 TPH), the EX 7636 is designed for maximum asphalt production and can handle up to 50% RAP. Counterflow technology captures residual gases and reintroduces them back to the combustion zone, practically eliminating blue smoke and hydrocarbon emissions to meet strict environmental regulations.

With single-drum counterflow technology, EX Series plants also achieve maximum heat transfer and fuel efficiency through separate drying and mixing zones. This works to provide the longest aggregates drying and mixing times in the industry and ensures consistent, quality asphalt that meets all federal and state specifications.

ADM’s wide range of components include HMA storage and surge systems, control rooms and process controls, aggregate feed systems, emissions control equipment, filler and dust silo equipment, liquid asphalt storage, additive systems, and specialty tanks.

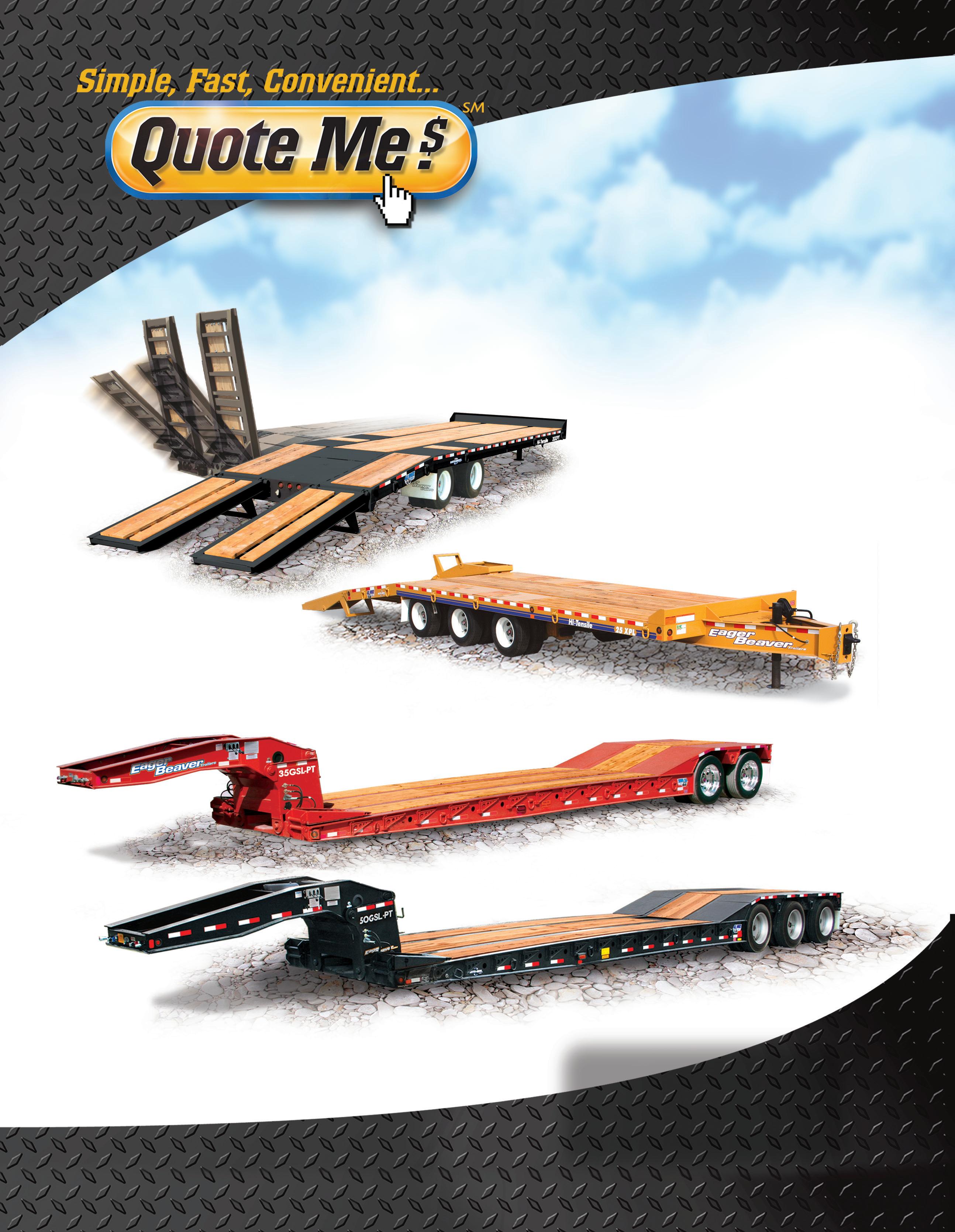

Eagle Crusher Co., a manufacturer in the crushing and screening industry, continues its tradition of new product innovation in 2024. The company will introduce two-newplants-in-one, on display in Eagle’s booth #1931 at World of Asphalt/AGG1, March 25-27, 2024 in Nashville, Tenn.

With just one capital investment, producers will get the benefits of an Eagle Crusher MaxRap 25 Portable, or the benefits of an UltraMax 1200-OCSS, open-circuit secondary system. Both plants feature Eagle’s UltraMax 25 impactor with its high reduction ratio and North America lifetime rotor warranty.

The MaxRap 25 Portable provides the same precision crushing of the stationary MaxRap, enabling operators to crush RAP at multiple locations with ease. Remove the actuated diverter chutework, and the plant becomes a 1200-OCSS. Recycled concrete and aggregate producers will benefit from the greater flexibility the newly-redesigned 1200-OCSS provides. Regardless of the primary crusher your operation is using, UltraMax impactors are a perfect fit as a secondary crusher.

Wirtgen Group will present a collection of its sustainable technologies for the entire road construction process. In addition to the 13 exhibits, the special presentation of the Operations Center will be one of the highlights at the joint Wirtgen Group and John Deere booth #1555

W 150 Fi

Thanks to its milling width of up to a maximum of 1.80 m, the W 150 Fi is particularly suitable for large construction sites with limited space, such as in city centers. John Deere’s eco-friendly engine technology digital assistance and leveling systems deliver higher milling performance with lower fuel consumption.

Hamm HD+ 120i VIO-2 HF

The articulated tandem roller that has been specially designed for the American market. It is equipped with two completely maintenance-free VIO drums. Another highlight at the tradeshow will also be the battery-powered HD 12e VV electric tandem roller from the HD CompactLine series. It compacts locally emission-free, is also extremely quiet and is expected to be available in North America later this year. The solutions for asphalt paving on display will also include the SUPER 1703-3i wheeled paver and the SUPER 2000-3i tracked paver from Vögele , both well established in North America.

Kleemann MOBIREX MR 110i EVO2

This impact crusher is often seen in practical use together with the John Deere 744 P-Tier wheel loader, which will also be on display at the booth.In addition to machine efficiency and alternative application methods, digitalization and networked system solutions are important drivers in the further development of the overall process in road construction. In a special presentation, the Wirtgen Group will present the John Deere Operations Center for Construction Machinery, the central platform for all of the group’s current and future digital solutions for process, machine and service optimization.

Come and see all that Caterpillar has to offer at booth #2049

The Cat PM312 offers enhancements to operator comfort and machine performance. The PM312 is an efficient, highly maneuverable milling machine with a cutting width of 1225 mm (48.2 in) that performs controlled full-depth removal of asphalt and concrete pavements in a single pass. Integrated Cat GRADE and the latest System K rotors deliver performance, productivity and cutting precision. A comfortable operator environment puts intuitive controls at your fingertips, while long service intervals and easy maintenance access simplifies service. While designed for a single operator, the PM312 includes added features for supporting ground personnel. Many options are available to enhance machine versatility when optimum maneuverability or high production capabilities are required.

The new Cat CB10 asphalt compactor offers enhancements that simplify operation, provide versatility, and deliver excellent fuel economy. Rotary dials, oscillatory vibration, and 360-degree seating make this compactor a match for urban streets, highways, and other intermediate-type applications. In addition, new options for 2024 will include cab, edge management, touchscreen mapping display, and split drum options.

The Cat AP1055 Asphalt Paver is a rubber track paver that delivers a high-return on investment with its extremely versatile Mobiltrac undercarriage that delivers speed, traction, and flotation. This high-production paver offers easy to use technology options that include “Pave Start Assistant” that provides saves set-up profiles for repeatable set up on job sites. A hopper level sensor (option) with temperature indication keeps the operator informed of material height and delivery temperatures, indicators are in each tractor display. In addition, the Cat SDX Screed plates are now available for the SE60 V and SE60 V XW screeds. This unique screed plate design provides a kneading action that helps reduce air voids as mix passes under the screed. Furthermore, a modular fastening system enables quick screed plate changes after a one-time adapter plate installation.

Astec Inc. will be located in World of Asphalt booth # 1263

Astec ReMix Cold Central Plant Recycling (CCPR) System.

The Astec ReMix CCPR reliably churns out 300 tons per hour. It’s built on decades of Astec expertise, producing reliable performance through its field-proven technology, including the pugmill, foaming system, and controls. Easy access means less downtime, more uptime, ensuring an operation maintains production. Astec ReMix CCPR employs cold recycling technology, a sustainable approach to road construction that minimizes the environmental impact. By reusing RAP materials and mixing them at ambient temperatures, the system significantly reduces the need for both virgin aggregate and energy for heating the mix. This conserves natural resources and lowers carbon emissions.

The RP-195 features a fully oscillating track frame to provide a smooth ride and lay a smoother mat. Equipped with our exclusive anti-segregation design of the feed tunnel, discharge and rear augers. The heavy-duty frame, solid front axle and sturdy conveyors are engineered for durability. Seats on the dual operator stations can move hydraulically out beyond the sides of the machine to give the operator an excellent view down the sides of the paver. Visitors to World of Asphalt will be able to get a first look at the new SmartEdge screed automation system which utilizes advanced laser technology to precisely control joint matching automatically.

The versatile RX-405 milling machine is for contractors who need a smaller cold planer that offers versatility and flexibility in a variety of applications. Contractors of all sizes benefit from a powerful machine that can tackle size-restrictive job sites like trenches, utility work and parking lots. Visitors to World of Asphalt will get a first look at the new operator environmental awareness system. This industry leading camera system provide a full 360-degree view around the machine. No other machine in the industry has this level of onboard safety awareness.

There’s no denying that many U.S. states simply do not make a priority of preserving their existing paved infrastructure.

There’s no denying that many U.S. states simply do not make a priority of preserving their existing paved infrastructure. This is really a crime because pavement preservation is a cost-effective way to both extend the life of roads and improve their safety.

Let me be clear.

What we’re talking about here is actual preservation: preserving the integrity of the original surface. Adding an overlay to existing asphalt is not preservation…it’s repaving. So much material, labor, and money could be saved if we shifted our efforts to preservation first.

How did we get ourselves into this situation? Let’s look at a number of reasons why states may not spend more money on pavement preservation:

• Short-term thinking. Pavement preservation is a longer-term

investment, but many state legislatures are focused on short-term results. This can lead to a reluctance to spend money on pavement preservation, even if it is a costeffective way to extend the life of roads and improve safety.

• Limited funding. State transportation budgets are tight, and pavement preservation often competes with other priorities, such as new road construction and public transit (again, short-term thinking).

• Lack of awareness. Many people are not aware of the benefits of pavement

Dynapac’s CC900G/CC950, are modern small tandem rollers designed for small-scale compaction work such as patching, bicycle paths, parking lots, driveways, etc. These machines are equipped with reliable Honda gas or Kubota diesel engines and the largest drum diameter in the class (23 inches). The drive motors connected in series, together with the large drum diameter provide excellent gradeability and productivity.

Go the extra mile with a pressurized water system and spring loaded scrapers

Simple and easy operating controls

Service components are easily accessible

Reliable Honda gas (900G) or Kubota diesel (950) engine

Maintenance free heavy duty articulation hitch

Long lasting drum with the thickest drum shell in its class. (0.4 in)

Highest rated operator comfort with insulated front and rear drums

$

Now available with industry-leading finance options

Foldable ROPS for easy transport and working under low height jobs

Longer paving time between refills with large capacity water tank (50 gal)

Pave against walls with high curb clearance (18 in)

Better quality mat with the largest drum diameter in its class (23 in).

preservation, especially emerging biobased treatments, and this can make it difficult to advocate for increased funding.

• Political pressure. Some states may be under pressure from special interests to spend money on other projects— such as new road construction.

What happens all too often is this: transportation departments and municipalities just don’t budget for preservation, which results in throwing good money after bad.

aging of our infrastructure built in the 1960s, additions to our transportation system, and years of underfunding preservation has the state on a path to failure.”

“Washingtonians own a multimodal state transportation system that would cost nearly $200 billion to replace, but the state is not spending what is necessary to keep that system in good working order. This threatens not only the transportation system itself, but past investments by taxpayers.”

shouldn’t accept it as business as usual. There are many relatively simple things that can be done to prioritize pavement preservation, including:

• Increasing funding for pavement preservation by raising taxes, reallocating existing resources, or seeking federal grants.

• Educating the public about the benefits of pavement preservation through public awareness campaigns and outreach to stakeholders.

According to a Washington State Department of Transportation report, that state agency has requested, “$726 million towards a $10 billion need to preserve transportation infrastructure. This $10 billion includes approximately $8 billion to preserve the WSDOTmanaged portion of the transportation system in minimum acceptable condition at the lowest cost.”

As this document goes on to state, Washington’s, “transportation infrastructure is the backbone of our state’s economy and way of life, but the

Not good.

AdobeStock/artemstepanov

Why is this? It’s a systemic problem. Municipalities want the work to be noticeable, so what do they do? Overlays. But overlays are not preservation, they just make the old pavement darker. They’re a Band-Aid and, in the long run, an expensive one. Because darkening pavement just exacerbates the heat island effect, which contributes to higher temperatures and air pollution levels and, ultimately, climate change.

There’s little doubt that this situation exists in most U.S. states, but we

• Investing in biobased treatments and other technologies that show a commitment to not only pavement longevity but also environmental sustainability and fighting climate change.

• Streamlining the pavement preservation process by reducing bureaucracy and coordinating decision-making at the state and local levels— while holding agencies accountable for preservation budgets.

• Investing in training for state and local transportation officials on pavement preservation techniques. The Federal Highway Administration (FHWA) has a number of programs and initiatives to promote pavement preservation, and many states are beginning to develop their own pavement preservation programs. But none of these efforts is happening nearly soon enough. And states are still very slow to adopt new technologies that can lengthen the lifespan of pavement.

We as an industry can and must take an assertive—if not aggressive—stand on this issue. Or we will continue to squander state budgets on more-andmore paving projects where the money could be more effectively utilized elsewhere.

Ken VanDomelen is president and owner of Coast Pavement Services.

For more information visit https://asph.link/background

A first-generation immigrant’s story of how the road-building industry provided the chance to follow his dreams.