MAY/JUNE 2024 HIGH-RISE PROJECT MANAGEMENT HOW PRE-CONCRETE POUR SCANNING TECH SAVED TIME & MONEY A MILESTONE OF SUSTAINABILITY PROFILING MILESTONE CONTRACTORS AND THE REPAVING OF RUNWAY 5R-23L THE LEADING TRADE MAGAZINE IN THE CONCRETE INDUSTRY

WWW.FORCONSTRUCTIONPROS.COM/CONCRETE

Never settle. Leave your mark. LEAVEYOURMARKWITHJLG.COM

No matter how hard the job gets, JLG® is built to help you stand tough through it all. High-capacity telehandlers are engineered to weather the worst while delivering state-of-the-art tech including Smart Load technology that keeps focus up and downtime down.

WORK STANDS THE TEST OF TIME. YOUR EQUIPMENT SHOULD TOO.

YOUR

www.ForConstructionPros.com/Concrete MAY/JUNE 2024 CONCRETE CONTRACTOR 3 MAY/JUNE 2024 Issue 3, Volume 26 18 With Concrete Paving, the Word is Stringless How the changing technologies of concrete pavement equipment have adapted to the industry. 28 The 2024 Top Products Award Winners The year's best tools and equipment for concrete contractors. 36 Mock it Up: Repairing Cracked Polished Concrete Key steps to take when the inevitable happens. 38 Unleash the Power, Respect the Battery The best-care practices for optimal performance and longevity of light equipment. DEPARTMENTS 4 Editor’s Letter 6 New Products 20 Product Focus Concrete Placement 42 Product Focus Battery-Powered Tools & Equipment 50 The Last Placement SPECIAL REPORT 44 Quality, Safety, Productivity & Sustainability Saunders Construction's progressive approach to project management. 48 The Savings With Tire Monitoring Tech How Ernst Concrete found savings and increased services. This and cover photo courtesy of Milestone Contractors 8 A Milestone of Sustainability Profiling Milestone Contractors and the repaving of runway 5R-23L. Published by: IRONMARKETS 201 N. Main Street Ste 350 Fort Atkinson, WI 53538 (800) 538-5544 • WWW.IRON.MARKETS COVER STORY Published and copyrighted 2024 by IRONMARKETS All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Concrete Contractor (USPS 021-799, ISSN 1935-1887 (print); ISSN 2471-2302 (online) is published six times a year:January/February, March/April, May/June, July/August, September/October and November/December by IRONMARKETS, 201 N. Main Street, Ste 350, Fort Atkinson, WI 53538. Printed in the U.S.A. Periodicals postage paid at Fort Atkinson, WI, and additional entry offices. POSTMASTER: Send address changes to Concrete Contractor, PO Box 3605 Northbrook, IL 60065-3605 May/June 2024, Issue 3, Volume 26 One year subscription to non-qualified individuals: U.S. 1 year: $35, 2 years: $70. Canada & Mexico 1 year: $60, 2 years: $105. All other countries 1 year: $85, 2 years: $160 (payable in U.S. funds drawn on U.S. banks). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International) Printed in the U.S.A. 22 Crowdsourcing Safety Forming the Alliance for Naloxone Safety in the Workplace.

FEATURES

JUST A FEW NOTABLES

For many of you out there, I’m hoping “construction season” has already begun. Here’s to being safe. Here’s to being successful. Here’s to being busy.

Among the metric ton of content found within this issue, I’d like to draw attention to three pieces:

Inside is a short piece on concrete paving equipment and slipformers (page 18). When I started asking about how the concrete paver and slipfomer has changed over the years, my original plan was an article about the equipment. The assumption was I would be writing about industry-breaking innovations or improved spreaders and screeds for higher-quality placement. While the machines likely having improved slightly over the years, I learned instead that any discussion about concrete paver equipment also includes the machines and technologies in support. How stringless technologies have improved precision. How the equipment width capabilities have increased—and the need for a source (concrete plant) capable of keeping the concrete supply going.

Since we’re on the subject of “improvements” within construction and concrete contractors, Concrete Contractor is overjoyed to announce this year’s Top Products winners (page 28). Concrete Contractor’s Top Products award recognizes the innovative products, tools, machines, solutions, and equipment designed for the concrete contractor. Winners of the Concrete Contractor Top Product Award are designed to not only help overcome the challenges contractors face daily but do so with innovative ideas and ingenuity setting contractors up for success in the years to come. Join us as we recognize all these great products, tools, and equipment.

Another special addition to this article is a piece by Cal Beyer and Scott Kubiszewski of DPR Construction (page 22). The story is about how Scott and drove the support to have Naloxone available on construction jobsites, later forming with Alliance for Naloxone Safety in the Workplace with 23 founding members. In some exciting news—since co-authoring the article, Cal has been hired on the SAFE Workplaces team as senior director for the national nonprofit SAFE Project (Stop the Addiction Fatality Epidemic). SAFE Workplaces is an organization that supports businesses like yourselves with programs on substance misuse/disorder and mental health.

There’s a lot more so I hope you enjoy this issue. Stay safe out there.

EDITOR’S LETTER

4 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete WWW.FORCONSTRUCTIONPROS.COM/CONCRETE Published by IRONMARKETS 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 • www.iron.markets ADVISORY BOARD Kim Basham KB Engineering Cheyenne, Wyo. James Baty II Concrete Foundations Association Mt. Vernon, Iowa Dennis Purinton Purinton Builders, Inc. East Granby, Conn. Jim Cuviello Cuviello Concrete Polished | Stained | Crafted Stevensville, Md. Chris Klemaske T.B. Penick & Sons, Inc. San Diego, Calif. Published and copyrighted 2024 by IronMarkets.All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher. JONATHAN KOZLOWSKI, EDITOR JKOZLOWSKI@IRON.MARKETS EDITORIAL Editor Jonathan Kozlowski jkozlowski@iron.markets Managing Editor Gigi Wood gwood@iron.markets Junior Editor Merina Shriver mshriver@iron.markets AUDIENCE Audience Development Manager Angela Franks PRODUCTION Senior Production Manager Cindy Rusch crusch@iron.markets Art Director Marcy Murphy ADVERTISING/SALES Brand Manager, OEM & Construction Nikki Lawson nlawson@iron.markets Sales Representative Patty Maroder pmaroder@iron.markets IRONMARKETS Chief Executive Officer ............................................ Ron Spink Chief Revenue Officer Amy Schwandt VP, Finance Greta Teter VP, Audience Development Ronda Hughes VP, Operations & IT Nick Raether VP, Demand Generation & Education Jim Bagan Corporate Director of Sales Jason DeSarle Brand Director, Construction, OEM & IronPros Sean Dunphy Content Director .................................................Marina Mayer Director, Online & Marketing Services Bethany Chambers Director, Event Content & Programming Jess Lombardo CIRCULATION & SUBSCRIPTIONS P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.ConcreteContractor@omeda.com LIST RENTAL Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com REPRINT SERVICES Brand Manager, OEM & Construction Nikki Lawson nlawson@iron.markets

FAE RPL/EX FIXED TOOTH ROAD PLANER

FAE has expanded its construction line with the RPL/EX road planer for excavators with specially designed teeth specifically for use on asphalt and concrete road surfaces. The new road planer for excavators is based on “cold planer” technology. With cold planer technology, the road’s surface is scraped and cut by the impact of special teeth attached to the rotor. The RPL/EX has a specially designed layout to reduce vibration. With these features, the RPL/EX can be used to prepare roads for resurfacing or to support excavation operations. The RPL/EX is compatible with excavators from 8 to 14 tons, can mill up to 5.3 in. deep and has a working width of 18 in. The head comes standard with technological and structural features. These include an adjustable hydraulic base that allows you to manage the machine’s working depth, a wide-stroke self-leveling system that allows you to keep the head properly aligned while in operation and an adjustable right skid that allows the operator to keep the head aligned in overlaps.

https://CONC.me/i6utrzkd

HUSQVARNA DXR 95 DEMOLITION ROBOT

Husqvarna has introduced the new DXR95 demolition robot for construction projects. The launch adds a fifth model to the company’s demolition robots for use in confined spaces. The DXR95 features a powertrain delivering 13 hp and 3,626 psi to the end-of-arm tool. Weighing around half a ton, it’s small enough to transport in a standard van and steer through narrow passageways, as well as sturdy enough to manage steep inclines at an angle of 30 degrees. Operating the DXR95 is straightforward with remote controls. Features include joysticks and knobs that make it possible to select and change settings, written messages for machine feedback and the ability for operators to choose their preferred language on the LCD screen.

https://CONC.me/whipd42y

COAST FUEL CARDS

Built for rapidly growing trades and transportation businesses, Coast is an ultra-secure fuel and fleet card that helps you control, monitor, and manage your fleet and business expenses. Spend less at every fill-up by eliminating card misuse, and optimizing your fuel spend to fight the small wasteful expenses that can quickly creep up. Coast runs on the Visa network, so you can focus on finding the cheapest, most convenient station. Coast cards and software are easy to use, so you can order cards or update your spending rules with just a few clicks. Should you run into any issues, the Coast US-based customer service is committed to finding a solution by the time you hang up. Coast integrates with top telematics and fleet management providers so you can supercharge your fleet operations. By integrating with other fleet tools, Coast empowers you to make the right decisions for your fleet with accurate data and increased fraud protection.

https://CONC.me/91ancffo

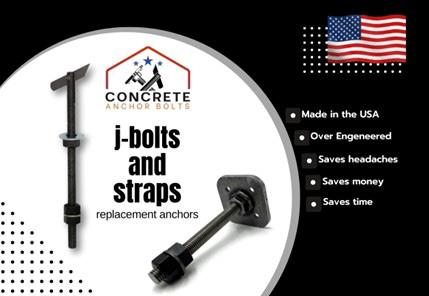

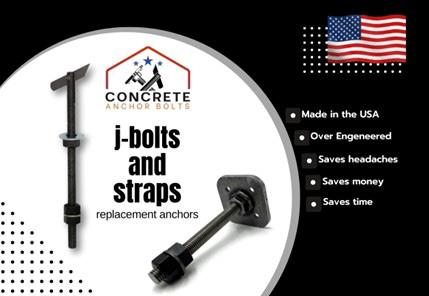

CONCRETE ANCHOR BOLTS FOUNDATION REPAIR SOLUTION

Concrete Anchor Bolts has showcased its new solutions, a suite of foundation repair bolts. The products repair foundation cracks, corroded anchor bolts and Simpson Straps. Each bolt is made from corrosion-resistant, 5/8-in. B7 rods that exceed ACI and ICRI standards worldwide for wood structure foundation repair. The bolts are all made in the U.S. and are currently permit-ready in every city and municipality in America.

https://CONC.me/d9xonlq6

PECORA’S PECORA-DECK HB1100-SA COATING

Pecora Corp. has announced an addition to its Traffic Coatings and Sealants line with Pecora-Deck HB1100-SA. The product is an aggregate, single-coat application, polyurethane waterproofing and traffic bearing coating. Pecora-Deck HB1100-SA is a two-competent, self-leveling, fast curing, UV and weather resistant, low VOC, polyurethane traffic coating system designed for use in both exterior and interior applications exposed to pedestrian and vehicular traffic. This coating is applied as a one-step traffic coating system that includes an integral aggregate and functions as both a waterproofing and traffic bearing deck coating system.

https://CONC.me/6xmnz7qr

6 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete

PRODUCTS

NEW

As a small business owner, you can’t escape your to-do list. That’s why Progressive makes it easy to save with a commercial auto quote, so you can take on all your other to-dos. Get a quote in as little as 7 minutes at ProgressiveCommercial.com

Progressive Casualty Ins. Co. Coverage provided and serviced by affi liated and third-party insurers.

Progressive Casualty Ins. Co. Coverage provided and serviced by affi liated and third-party insurers.

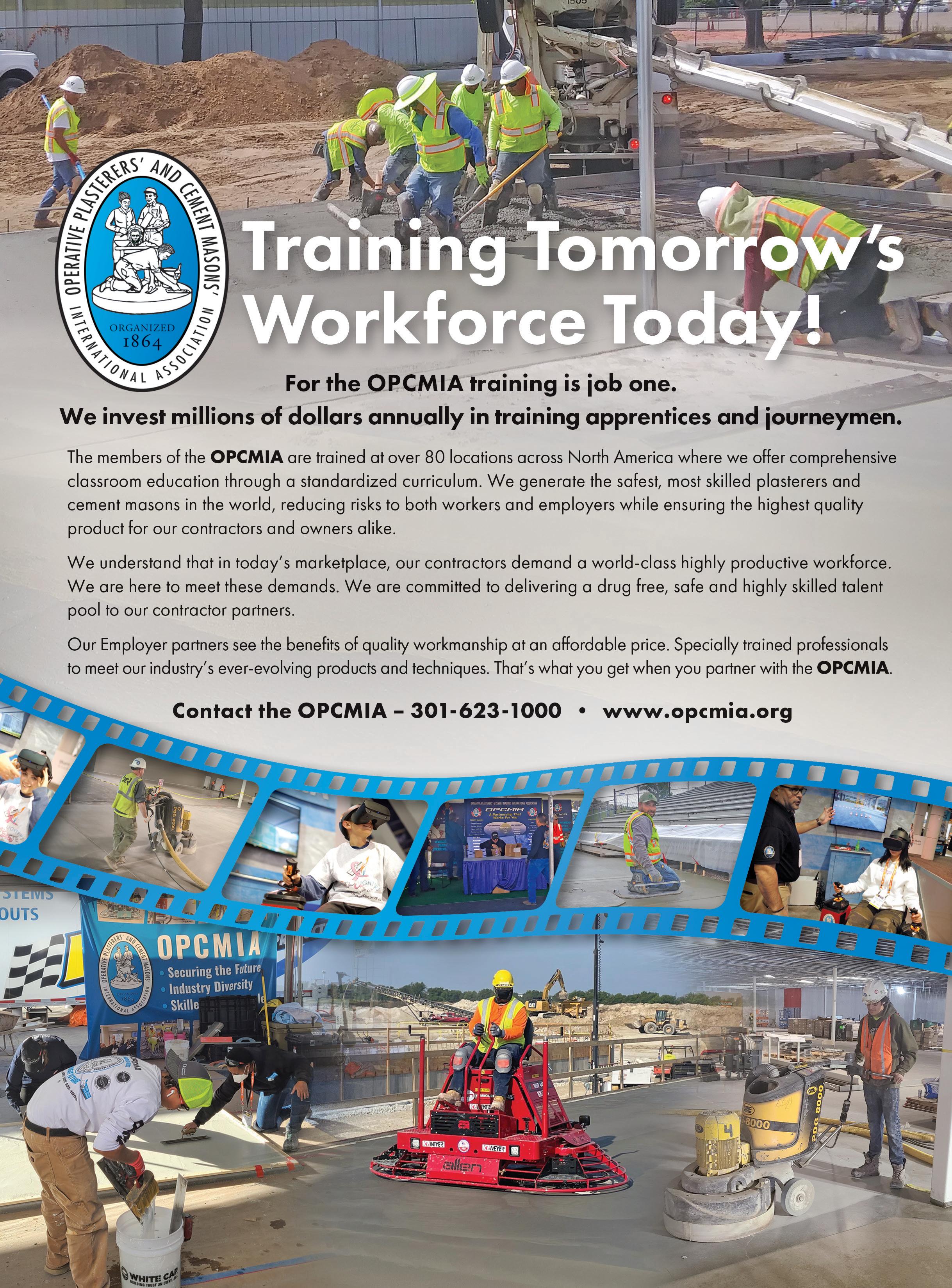

A MILESTONE OF SUSTAINABILITY

MILESTONE CONTRACTORS USED RECYCLED MATERIALS, RECLAIMED WATER, AND CAPTURED CO2 FOR THE CONSTRUCTION OF RUNWAY 5R-23L AT THE INDIANAPOLIS INTERNATIONAL AIRPORT.

COVER STORY » BY JONATHAN KOZLOWSKI, EDITOR

The Indianapolis Airport Authority received an Envision award by the Institute for Sustainable Infrastructure for the innovative and environmentally sustainable approach to a reconstruction project for the Indianapolis International Airport (IND). When it came time for the concrete pavement replacement of runway 5R-23L and taxiway D, they turned to local concrete paving company Milestone Contractors to earn a second.

The work done earned an Envision: Plutonium award in 2023.

Based in Indiana and one of the larger contractors in the state, Milestone is a multifaceted company, providing services for concrete and asphalt construction. Not one to shy away from a too large or too small of a job, they work on everything from bridges, curbs, sidewalks, driveways, work for the Department of Defense work, as well as airports. As Steve Friess puts it, “We pretty much cover the whole gamut.”

Friess is the vice president of concrete operations at Milestone. He’s been with the company for 11 years and has an extensive background in concrete paving. For those in the Indiana concrete pavement world, if the name sounds familiar, it should. He was named Chairman of the Board of the American Concrete Pavement Association (ACPA) in December 2022. In his nearly 40 years of experience in the pavement industry, Friess has enhanced Milestone’s concrete offerings by developing Heritage Construction + Materials and seeing the company earn accreditation in ASHTO R-18 and ASTM C1077. Ernie Peterson from Ash Grove Cement Company is the current ACPA chairman.

While Milestone does put down a greater amount of asphalt, its concrete work is still nothing to scoff at. Friess expects Milestone to place 3 million tons of asphalt and about 700,000 yards of concrete this year. The company has a ready-mix division and owns seven portable plants they move around for airport and freeway jobs.

Milestone is owed by The Heritage Group, a fourth-generation family-owned business out of Indianapolis led by Amy Schumacher, chief executive officer. “Even as big as we are,” says Friess, “they are still very family-oriented. Milestone has a motto that says ‘We make lives better one road and bridge at a time.’”

The Heritage Group celebrated 90 years in business in November 2020. In the 1930s, John Fehesenfeld opened a residential home heating oil delivery service which evolved into a brand of convenience stores and eventually sold to Speedway. In the 1950s, the company moves into the paving industry with Fehesenfeld’s sons at the helm. Milestone originally began as Columbus Paving Company in 1954 by the Meshberger family and Herman Newen, after several mergers and purchases, it eventually became Contractors United Incorporated (CUI) in the 1970s and made of a unification of a handful of local companies—making it the largest construction firm in the area in 1971. CUI, Fauber Construction Company, and Astro Paving joined to become Milestone Contractors LC in 1994. They added Speedway Co. in 2022 to supply ready-mix concrete.

www.ForConstructionPros.com/Concrete MAY/JUNE 2024 CONCRETE CONTRACTOR 9

Photos courtesy of Milestone Contractors

“With this new paver and the QC team that I have, they were spectacular from day one. In fact, the first day I kind of looked at it and said, ‘If this goes this good the rest of the time, we’re going to be golden.’ It even went better. We had a great team out there. I can’t say enough about the team we had, they were spectacular.

We had to have a plant that would do 500 yards an hour. It would do 600 yards an hour if there was the area for it – that’s almost a load a minute for 10-yard loads. It will produce more concrete than you know what to do with sometimes.”

—Steve Friess, Vice President of Concrete Operations, Milestone Contractors

INDIANAPOLIS CONCRETE PAVEMENT

The Indianapolis Airport Authority was aiming for another Envision

up for the challenge. He saw what needed to be done and went to work.

three is scheduled for this year April to October.

PHASE ONE

Phase one was the center point of the runway and taxiway 23, the middle

5,000-6,000 ft. of an 11,000-ft. long runway (plus a little).

This also included the adjoining taxiway in front of the FedEx location – a major hub for the airport (the second largest in the country for FedEx).

10 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete COVER STORY CONTINUED

Photo by Circle City

award–something extremely difficult to earn. Friess and his team were

Milestone was hired for the second and third phases of the project. Phase

PHASE TWO

PHASE TWO

Milestone was hired for phases two and three. At about $88 million, according to the request for bids document, major work items for phase two included:

• 79,000 square yards of concrete pavement removal

• 104,000 square yards of P-501 concrete pavement at 37.5 ft. wide, 22 in. thick

• 104,000 square yards of asphalt pavement removal

• 52,000 TN

• 54,000 cubic yards of unclassified excavation

• 75,000 cubic yards onsite borrow

• along with work in storm sewer, watermain, airfield electrical, signage, lighting, NAVAIDs, and pavement marking

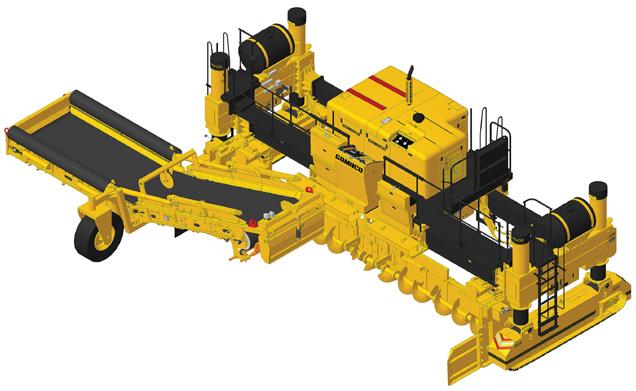

Aside from the men and women of the Milestone crew, carrying the load of the major paving work was GOMACO equipment. The paving line included two spreaders (a second with a conveyor to increase production), a GP4 slipform paver, and dump trucks to transport the concrete mix from an Erie Strayer concrete plant. They used a portland limestone cement from Buzzi Unicem USA and injected captured carbon into the mix. Milestone purchased the GP4 about four years ago, paving up to 30-32 ft. for different interstates. When they were finally awarded the job, they also purchased a PS460 placer/spreader—capable of paving to 40 ft. wide.

Having paved for the Atlanta Hartsfield and Cleveland Hopkins airports previously, he’s had experience paving to 37.5 ft. before. Friess’ advice: “it all comes down to good mix and good setup on your equipment.” Needing to pave 22 in. of concrete, the challenge in Indianapolis was the depth. While they had worked on 18 in. before for “fill-in” work. Indianapolis required them to pour without forms reinforcing the need for a good mix. The concrete was specified to be 625 psi in accordance to FAA flexural strength tests with a 0.25 to 0.5 slump. Their test lab was able to keep on target to avoided any panel removals due to strength. The pavement was finished with transverse grooves.

Ultimately, they recycled the existing runway and asphalt shoulders for base material.

RECYCLED MATERIALS

• 135,000 cubic yards of the existing runway into base material

• 65,000 tons of asphalt from shoulders for under the pavement and shoulders

• Reused more than 4 million gallons of water

Friess explains that most of the construction was kept to a centralized location onsite to minimize the carbon footprint of the project. Crushed concrete pavement was pulverized into multiple sizes for the reuse of base materials, pipe backfill, and a special fill for lighting. “In the words of sustainability, this is what it was all about… because these quantities are just unbelievable,” he notes.

COVER STORY CONTINUED 12 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete

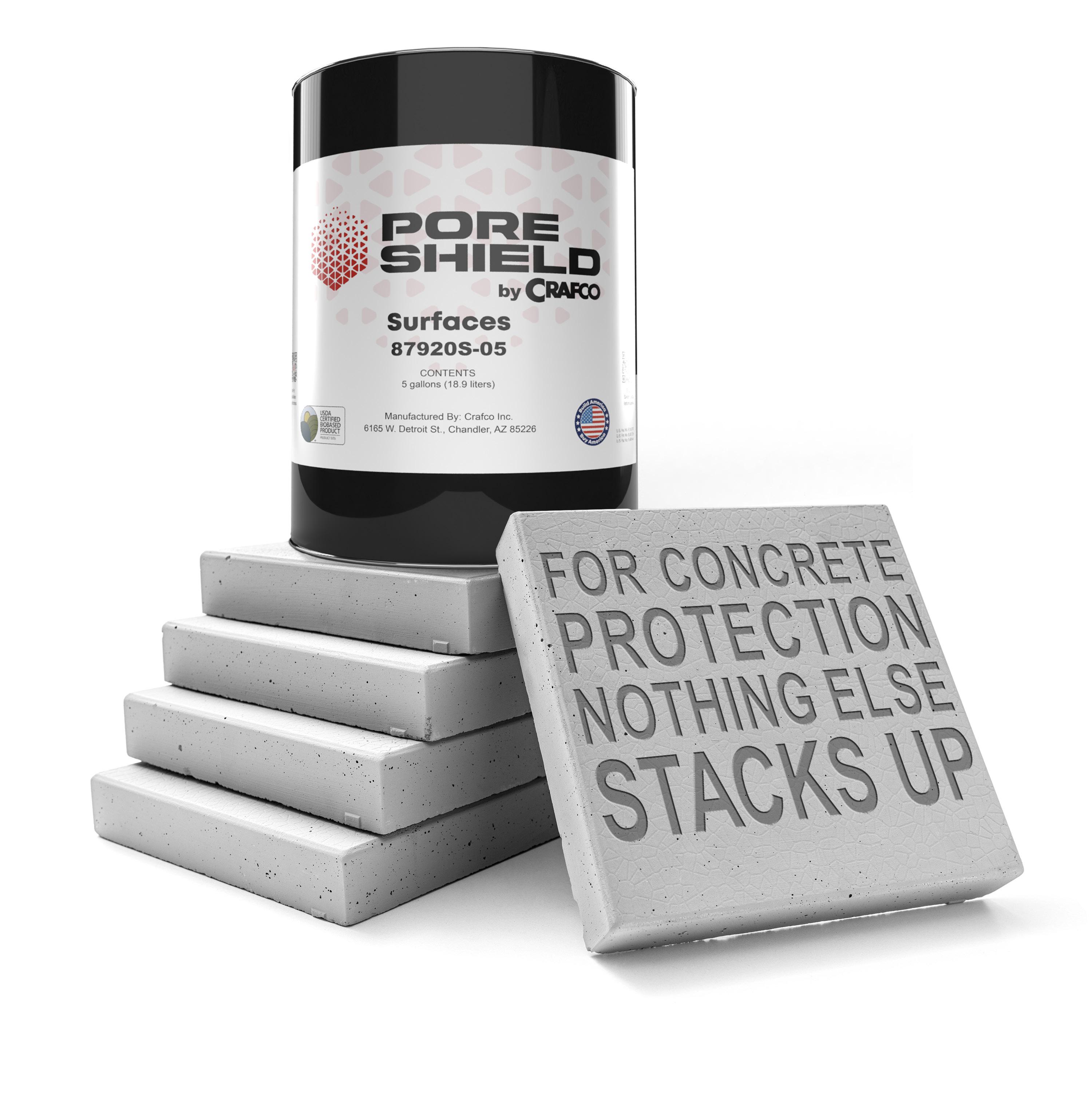

Conventional concrete sealers don’t last. PoreShield™ does.

It absorbs deep below the surface to block salt and moisture damage for 10+ years.

Plus, it’s non-toxic, easy to apply, cost-effective and sustainable.

Learn more about this game-changing concrete protectant at PoreShield.com.

As the breaker shattered the pavement, off-road trucks hauled material a short distance—less than 1,500 ft.—into a pile. While Milestone were able to recycle themselves, they subcontracted it out to a crushing company from Chicago. “This was such a mammoth project, we figured we’d let them do it,” says Friess. “Since then, they have crushed almost everything that they had onsite at the airport above and beyond our current job. We had them crush at least another 150,000 tons of this material that they’ve used on other projects at the airport.”

The concrete runway included 2 in. dowels in both directions on every joint cut into 6 ft. sections to help with the weight. “If you pick six 18.5 lbs. dowels, plus the weight of the basket unit itself, you’re like 120 lbs. for a six footer. We were pouring 30-37.5 ft. across, so there’s no way to pick up 36 ft. of dowels.” A Minnich drill made quick work of drilling the 2 1/8 in. holes.

No one said concrete work was easy. “Just the fact of putting in 500 bars a day at just under 20 lbs. a piece, you know, that’s a lot of weight,” says Friess. “The whole crew worked very hard.”

PHASE THREE

PHASE THREE

Phase three is on the far west end of the airport which includes the construction of a 5-acre $15 million solar panel field. “With the solar, we’ll actually be able to do one of the complete runways at the airport. Going back to sustainability and all that, the Indy airport is really probably ahead of the times in that kind of work,” comments Friess.

According to an announcement from IND in July 2023, phase three is being funded by the nation’s largest allotment of funding via the Airport Improvement Program of the FAA: $22.58 million. The funding is part of $92 million to help airports reach the net-zero emissions by 2050.

14 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete COVER STORY CONTINUED

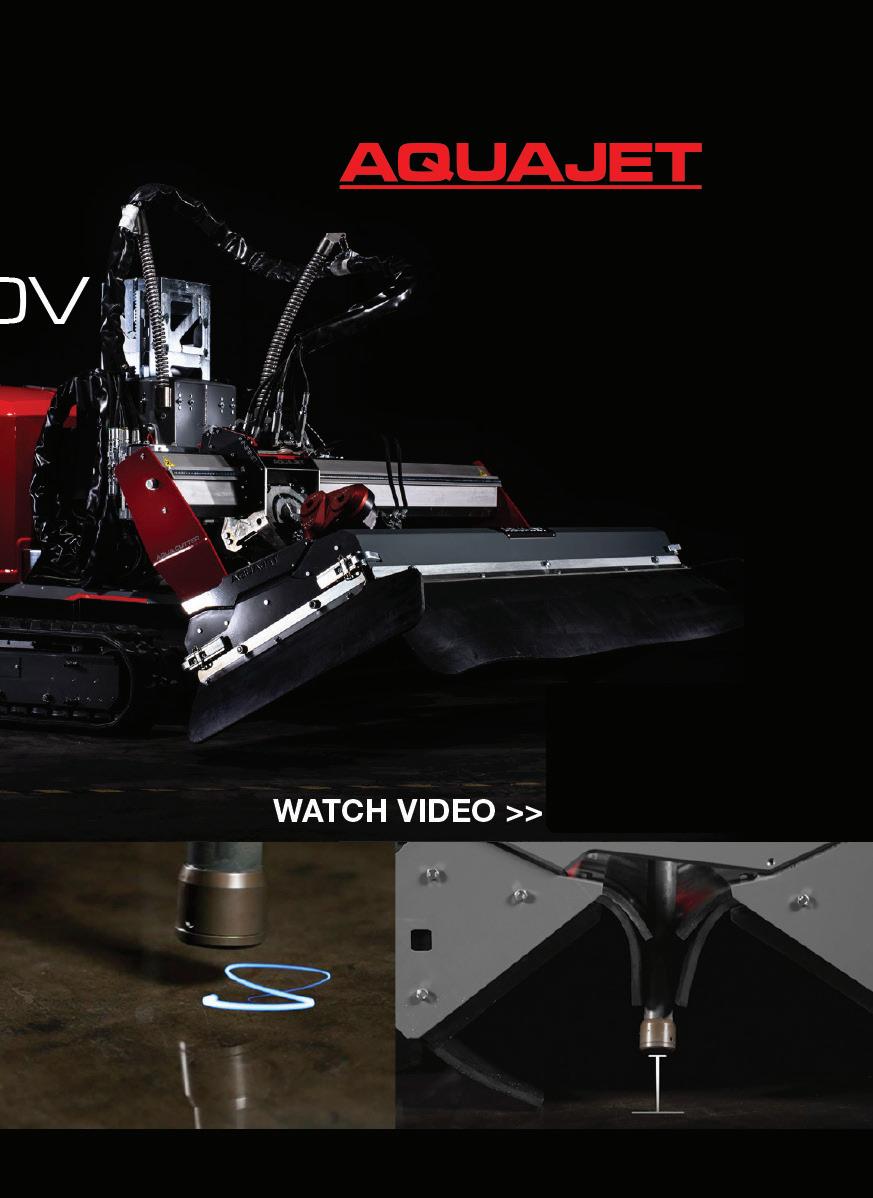

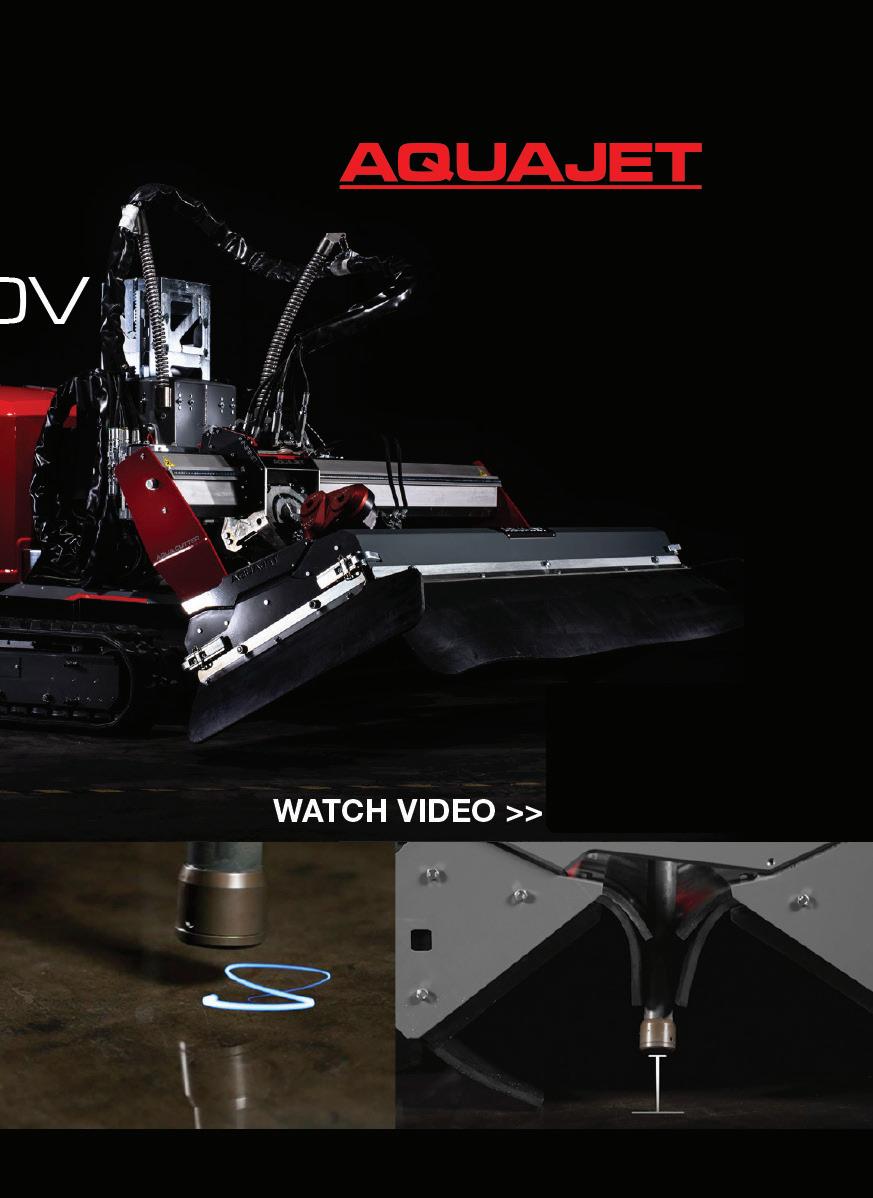

YOUR BEST 1-2 PUNCH FOR HYDRODEMOLITION.

Conjet Robots and NLB Pumps make a Powerful Combo.

Power, reach and stability are crucial for Automated Concrete Removal™ on bridges and parking decks. Combining an NLB 605 Series water jet pump unit with a Conjet robot gives you all that and more.

The NLB 605 is a 600 hp diesel unit known for performance, reliability, and low maintenance. It’s easily convertible to pressures up to 40,000 psi. The Conjet ACR™ Robot 557 MPA XL features a multi-position arm that cuts more than 20 feet high, and shifts its center of gravity to maintain stability and maximize safety.

Learn about this highly productive tandem by visiting our website at www.nlbcorp.com, or giving us a call today!

NLBCORP.COM (800)441-5059 © Copyright 2024 NLB Corp. | PSaleHydro_24_001_v2

™

605 Series Diesel Unit

Conjet ACR™ Robot 557 MPA XL

Sustainability efforts also included injecting CO2 with technology from CarbonCure into the concrete mix to encapsulate the captured carbon. Unfortunately, the carbon injection plans didn’t go exactly as intended. While injection was successful, Milestone wasn’t able to get captured carbon close enough to the plant to make it a viable option and had to purchase carbon from within a 60-mile radius.

With carbon injection, Friess says that they might have been able to conduct tests to potentially reduce cement content after some time. However, the pouring ended before they were able to do so.

Signage and constant reminders urged everyone to keep trucks off to keep emissions down.

Waste and water sources were another issue. Milestone set up three settling ponds to capture water and used an ozonator to oxygenate and help clean the water. They used this as well as any collected rain water to spray the grade for dust control and compaction efforts. They kept track of every tanker load, how many times they filled the truck up, and where it was filled (pond or hydrant). “After a big rain, there were four ponds around the airport that would fill up and we’d go

COVER STORY CONTINUED 16 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete

Photo by Circle City

suck it up out of there—there was a lot of effort made to recycling everything.”

This project exemplified the value of organization and communication. “We learned sustainability isn’t a bad word…with good organization and good communication, you can run one of these jobs and you don’t have to work day and night, seven days a week.

When we got down to the end, when we were paving, we were working 10-hour days, and still getting our 200-300 yards a day. We found out we don’t have to work 24 hours a day, 365, seven

days a week. You just don’t have to. You just have to be organized and have a plan.” Beyond that, he strongly suggests any concrete paving contractors to join the national ACPA and attend the airport workshops.

www.ForConstructionPros.com/Concrete MAY/JUNE 2024 CONCRETE CONTRACTOR 17 Distributed by: Brokk Inc. | Monroe, WA | 1-360-794-1277 | info@brokkinc.com | www.brokk.com

WITH CONCRETE PAVING, THE WORD IS

STRINGLESS

A

AT HOW THE CHANGING TECHNOLOGIES OF CONCRETE PAVEMENT EQUIPMENT HAVE ADAPTED TO THE INDUSTRY.

Any investigation about how pavers and slipfomers have changed starts with a simple question. But instead of discussing the machinery involved, it became a conversation on the supporting technology for the machine and the concrete paving crew.

“The buzzword is stringless,” says Stephen Bullock, president of Power Curbers Companies. “It’s been batted around for 15 years, 10 years ago we started seeing some real interest. Over the last 5 years, it’s moving toward becoming the norm.”

Like many, Hi-Way Paving Inc. paves stringless. They started back in 2008 as one of the early adopters using radio communication but often found interference on the signal troublesome. While the radio and antennas improved, around 2020 they opted to use a long-range Bluetooth system. It provided a similar range but allowed more precision in the work. As Matt Landers, machine control and survey manager for Hi-Way, explains it, Bluetooth helps them to keep adjustments tight within their tolerance. Reportedly, they say that the Bluetooth system can reach out to 1,000 ft. but 500-600 ft. pushes the limits. They keep it between 300-350 ft.

“It’s been a game changer for us,” says Landers. “It’s less wiring. Before, you had four radios on the paver that had to be wired to the computer. Then the computer was wired to the paver—we’re talking masses of wires you’re hooking up every morning. It takes you about 20 minutes to pick up all these wires onto the paver. Now it’s as simple as go up, clip the computer and we’re ready to go.” Hi-Way uses GOMACO pavers with Leica total stations. They’re upgrading their mainline spread with a new GP4 set for delivery in Spring 2024 and having a two-track model from 2008 sent out for refurbishing.

The money savings for the setup time was a boon by itself. “That’s money saved there,” says Ed Wessel, president and CEO of Hi-Way Paving Inc. “Going back to when we first started stringless in 2008…the labor savings from setting stringlines and pans…that was transformative for us.”

Paver and slipform equipment manufacturers like GOMACO and Power Curbers work directly with the big three providers like Leica, Topcon, and Trimble, adapting so that the machines are nearly plug-and-play. Many modern slipformers have now integrated electronic sensors in lue of hydraulics.

Stringline was the standard in the industry 20 years ago when Power Curbers launched into the industry (2002).

“When the 3D technology started improving and getting to a point where it met our specifications, it was a big step to be able to eliminate having to set up that stringline and start using 3D or GPS signals,” says Bullock.

“It’s definitely come up with the times. It’s a lot better than it used to be,” says Landers, referring to concrete paving. His team used to have a number of steps when changing total stations including stopping the paver completely. Instead, they keep rolling with the communications system able to jump to the next station.

EMISSIONS

Like many in the concrete construction industry, concrete paver and slipform equipment manufacturers are doing their part in reducing CO2 emissions. GOMACO, for example, announced its GT-3600 Hybrid machine utilizing lithium-ion batteries to provide supplemental power to the diesel engine.

As the describe it, the exclusive G+ control system switches the

18 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete EQUIPMENT BY

Photo courtesy of GOMACO Corporation

LOOK

JONATHAN KOZLOWSKI, EDITOR

48-volt generator from recharging the battery to providing extra horsepower to the 74 hp engine. Reportedly, it should provide an estimated 10-15% fuel savings and “eliminates the inconvenience and extra expense of DEF.”

Bullock sees the potential in fully electric equipment, but jobsites aren’t quite ready yet. “There are real issues with the size of the batteries required and what that would do to the size and the cost of the machine…and then how long that charge would last. There’s still definitely some hurdles, but we are exploring everything including hydrogen,” he says. He likens the change to a football field, placing a fully automatic/ fully electric situation at the end zone. Today, he says we’re at our own 20/30yard line.

With remote operation technologies and sensors, the potential of a fully-electronic and automated machien may be there but it’s a long way away. If we ever reach that end-zone, there will always need to be someone involved.

“I can see someone in our office, running that machine from the office and paving without a lot of big crew around it… we’ll always have guys around the paver checking the concrete and all that but the machine’s got to do all the work, the heavy lifting. I can see that going more in autonomous operation for the paver,” says Wessel. Wessel also recognizes the potential for artificial intelligence to step in the direction of creating project drawings and CAD files—provided a person checks the work, of course. “Time-saving. That’s the big thing,” says Landers.

According to Jason Hogue, vice president of Flores Automation & Machine Control LLC, an authorized national distributor of Leica Geosystems paving products. It’s estimated that 95% of members of the American Concrete Pavement Association use 3D stringless paving.

“From the time we get the project until the time we start the project, it’s usually a 2-3-month lull in there. It takes me a good bit of that time just to get

everything built and ready to go in the field. With progressing technology…I can do it half that time.”

“The focus of manufacturers is on anything using technology to help in reducing labor,” says Bullock. “Making sure we’re keeping up with the trends, sustainability, and making sure we provide contractors what they need when their state or federal government requires it.”

www.ForConstructionPros.com/Concrete MAY/JUNE 2024 CONCRETE CONTRACTOR 19

Not All Trench Drains Are Created Equal When comparing PRO-PLUS® to polymer concrete its strength, weight and thermal expansion are unmatched. STRENGTH - 1.5 times Stronger | 35% greater Compressive, 80% greater Flexural, and 78% greater Tensile Strength WEIGHT - 70% Lighter THERMAL EXPANSION - 1.7 times less Josam.com Easy-to-Install Labor-Saving Solutions ® Trench Drain System See Brochure

CONCRETE PLACEMENT

MULTIQUIP’S MAYCO LS300GK SMALL CONCRETE PUMP

The Multiquip Mayco LS300GK compact, trailermounted concrete pump combines levels of performance with the build quality you would expect on larger pumps. Multiquip designed the LS300GK to be unique and distinct from other pumps with a 30-yard/hour output, handling up to 1 1/2-in. aggregate. The LS300GK pumps a variety of concrete mix designs and is ideal for slab work, block fill, shotcrete and more. The pump features a 10 cu. ft.

AUSA D151AEG ELECTRIC DUMPER

capacity hopper that is easily removed for maintenance and accessibility to wear components. Operators will appreciate the easy to read, solid-state digital control panel and optional wireless remote control.

https://CONC.me/z4qhwz

MAKITA 18V LXT CORDLESS WHEELBARROW KIT

Makita offers the 18V X2 LXT Cordless Wheelbarrow Kit (XUC01PTX1) for material handling and transport in construction sites. This kit includes a steel bucket secured to a frame with motor and tires, batteries and dual port charger. The heavy-duty bucket has a load capacity of 290 lbs., allowing professionals to move large and bulky loads around the work area. Two forward speed options and one speed setting in reverse mode are available on the wheelbarrow. The motor is powered by one 18V LXT battery and features the option to install an additional battery for extended applications. One 18V LXT battery provides up to 100 minutes of runtime per full charge.

https://CONC.me/bn2z63tp

AUSA has launched the D151AEG electric dumper, which can be paired with a mini-excavator. The D151AEG, which has a 3,300-lb. and 1.18-cu.-yd. payload on its swing skip, allows operators to offload earth, rubble or other materials at an angle using a joystick. Due to its compact size, this machine is designed for work in tight spaces. The D151AEG dumper is equipped with a li-ion battery power unit. In the case of this dumper, it features a pack with a 9.3 kWh capacity, enough for at least one full day of work. Its 7.6 kW-power batteries and peaks of up to 17.3 kW are managed electronically to offer power and all-terrain capabilities.

https://CONC.me/ni1pikqt

PROBST PIPE LIFTER

Mechanical pipe clamp designed to unload, transport, and install concrete pipe 16 in. to 48 in. ID (400 –1200mm) and a max weight of 9,900 lbs. (4,500 kg). Slings, chains, and various other lifting devices are eliminated. Mechanical clamping (no hydraulics) holds the pipe securely, without any damage to the bell end, and allows accurate placement and joining of pipes without damage to the spigot. Labor is saved by eliminating at least one laborer top-side for rigging and guiding pipe. However, the increased safety is why this device will prove to be an invaluable asset to you.

https://CONC.me/yk0di1cl

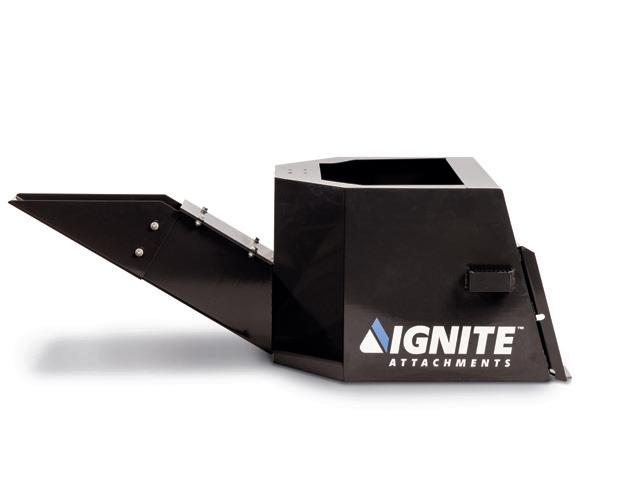

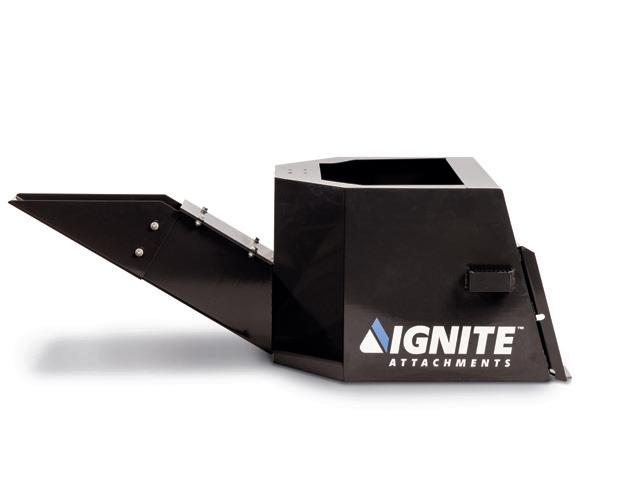

IGNITE ATTACHMENTS BREAKER AND CONCRETE CHUTE BUCKET

Ignite Attachments offers a heavy-duty line of breakers, designed for use on construction sites. The threemodel series features a straightforward design. With a dual mounting option and a powerful strike, Ignite breakers can be used with mini track loaders and skid steer loader adaptors, supporting fleet flexibility for demanding demolition jobs. The company also offers a new concrete chute bucket. The new bucket features a removable spout, for maneuverability in tight spaces. It also employs laser-cut steel and robot welding. The new concrete chute bucket is available in one size and has a capacity of up to 0.75 yd.

https://CONC.me/5bmpqloz

20 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete

Minnich Flex Shaft Vibrators: The Experts Choice for Solid Results

Minnich Flex Shaft Vibrators

Built to exceed your expectations and outperform the competition. With results in mind, our vibrators are engineered for control and durability, ensuring a smooth and flawless pour every time. With more control over your results and a longer lifespan than other options on the market, our flex shaft concrete vibrators are the perfect choice for the professional looking to take their work to the next level.

CROWDSOURCING

SAFETY

FORMING THE ALLIANCE FOR NALOXONE SAFETY IN THE WORKPLACE.

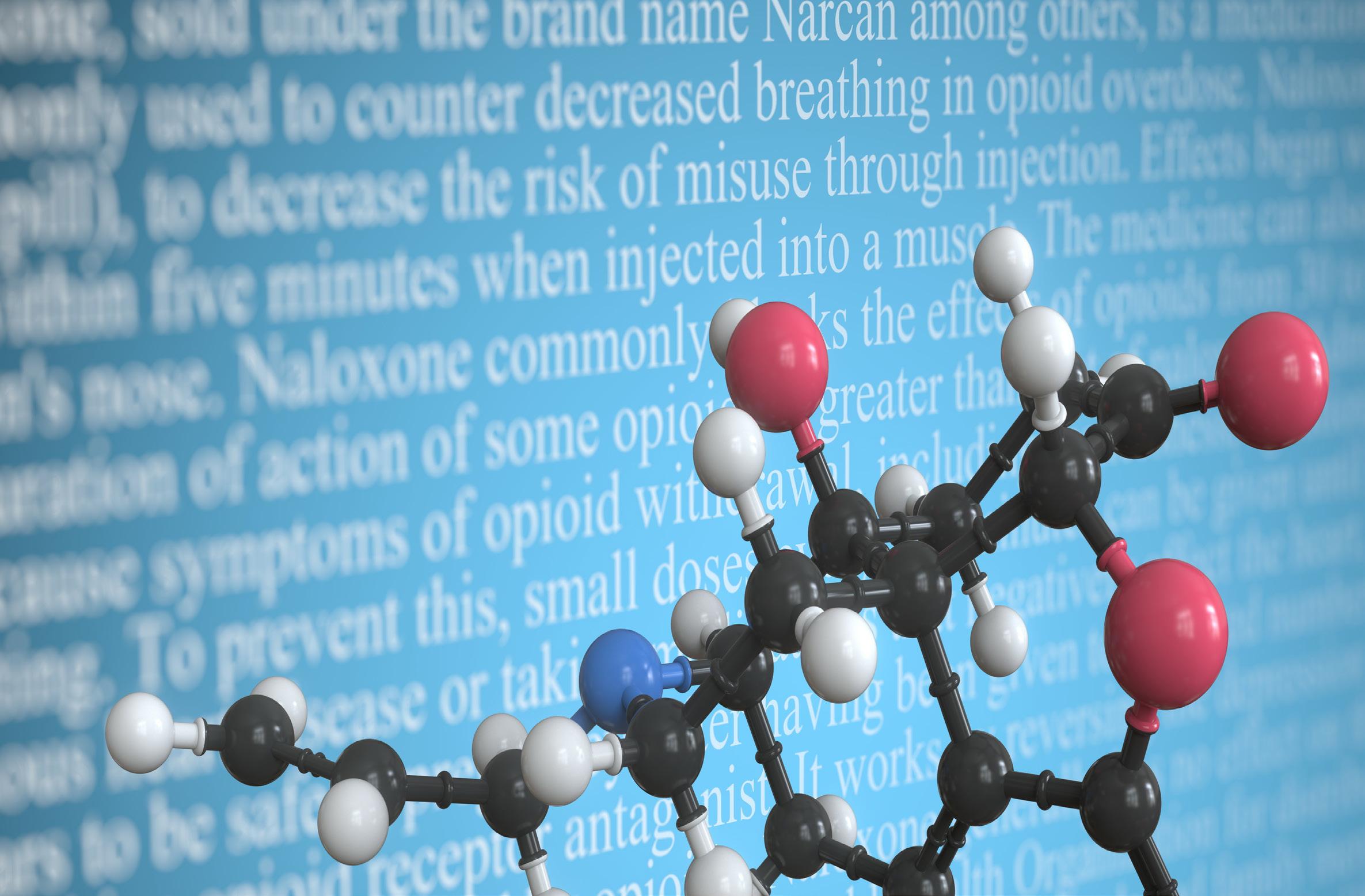

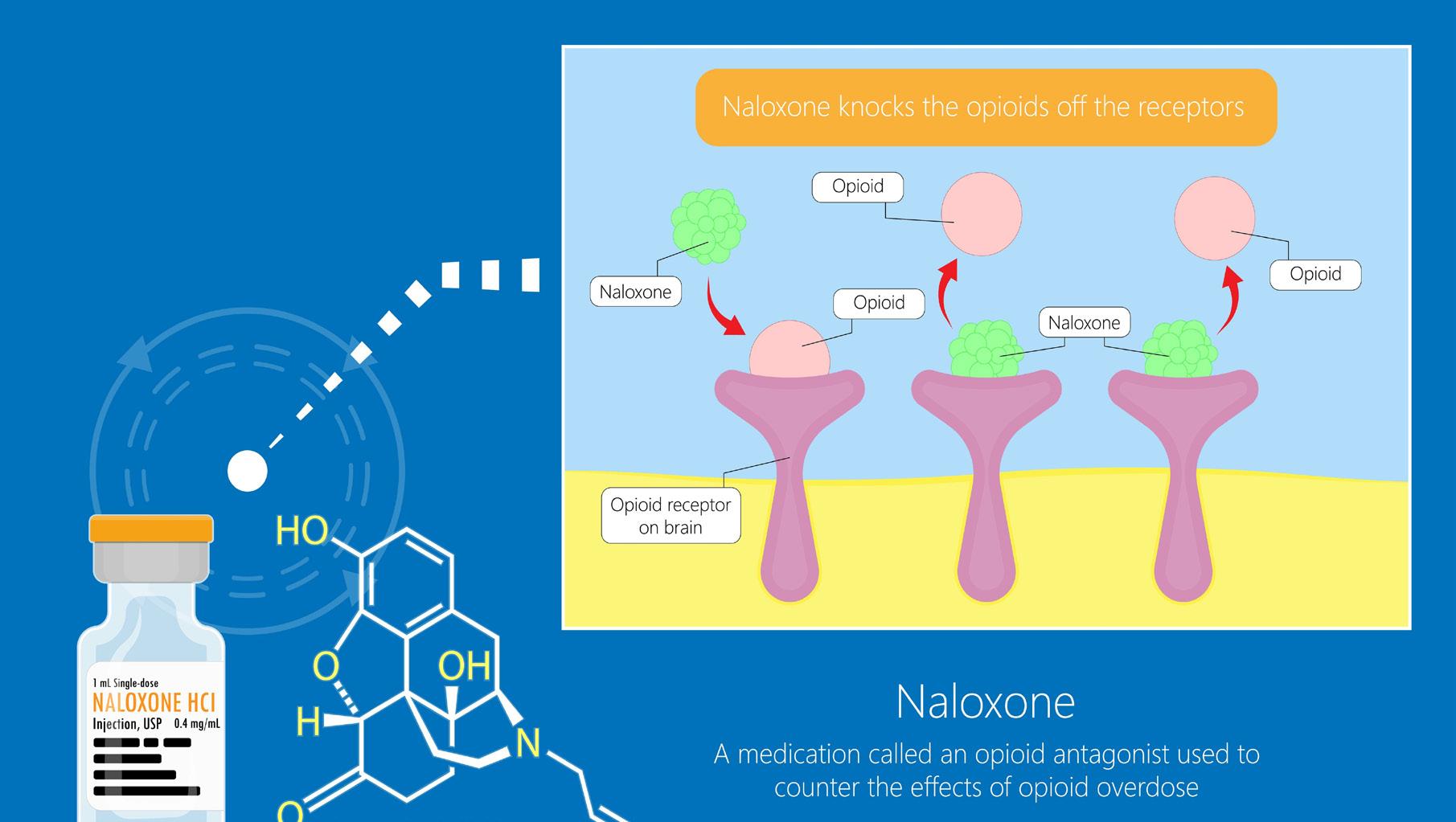

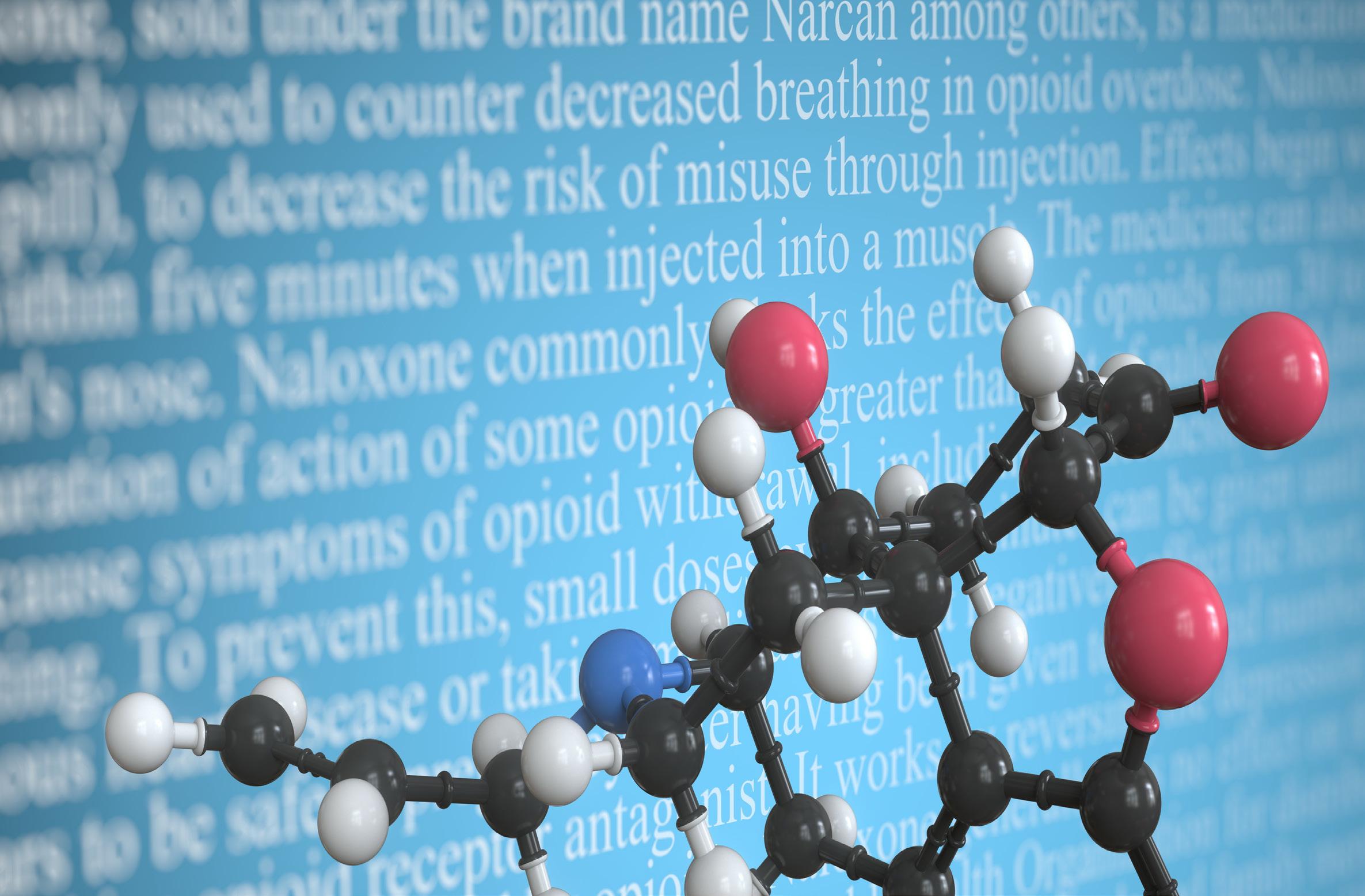

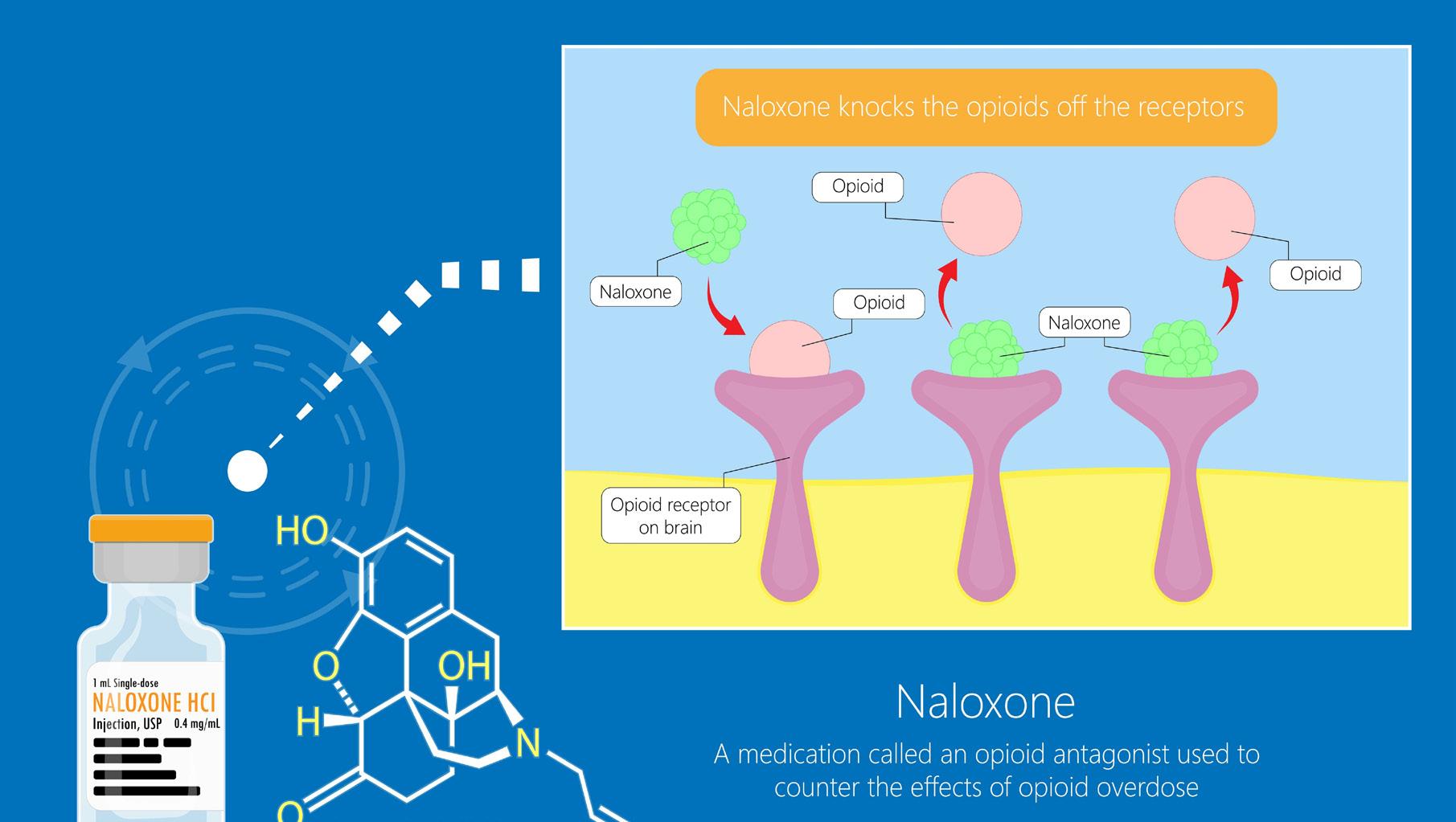

In the summer of 2022, while working for DPR Construction Scott Kubiszewski was spearheading an initiative to consider stocking naloxone on all the company’s jobsites in the Pacific Northwest. Kubiszewski was growing increasingly aware of the rising rate of both fatal and non-fatal overdoses attributable to opioids. Kubiszewski was knowledgeable about the benefits of stocking naloxone in the workplace to help reduce the risk of overdose for opioids. Naloxone (also known as Narcan) is a medication that reverses the effects of opioids and is used to help save lives by administering it to persons experiencing signs and symptoms of overdose.

Unfortunately, Kubiszewski and other safety/health practitioners were receiving pushback and resistance from other industry professionals about potential legal and risk management concerns about stocking naloxone in the workplace. He reached out for guidance; we previously collaborated on workplace suicide prevention initiatives. I provided resources to Kubiszewski regarding state-by-state

laws for both naloxone access and Good Samaritan provisions. I also advised that the US Food and Drug Administration (FDA) was considering approving naloxone for over-thecounter use, but that approval was not expected until 2023.

NALOXONE AS THE NEW AED FOR WORKPLACES

Kubiszewski secured support from DPR Construction to move forward with stocking naloxone on the company’s jobsites in the Pacific Northwest. He often cites how early adopters were quickly viewing naloxone as the new AED on jobsites. AEDs are automated external defibrillators used to revive persons in cardiac arrest. Kubiszewski recounted the rapid adoption of AEDs in workplaces and on jobsites once the initial resistance was overcome. “A dozen years ago, AEDs were rare on jobsites and today they are commonplace,” exclaimed Kubiszewski. He imagined “how many lives might be saved if naloxone were available in first aid kits throughout the construction industry.”

22 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete SPECIAL REPORT

Editor’s Note: This is the second entry of a series relating to lived experience with opioid addiction treatment and recovery, providing naloxone in the workplace and on jobsites, as well as resources for grief and bereavement.

@Alexey Novikov - stock.adobe.com

HUSQVARNA POWER TROWELS

ONE BRAND FROM POUR TO FLOOR

No matter the type, size or ambition level of your project, we can support you in finishing your concrete slabs and floors. With our complete range of vibration equipment, screeds, ride-on and walk-behind trowels, and our Hipertrowel™ system solution, we can support you all the way from the pour of concrete to a finished floor. Visit husqvarnaconstruction.com to find your solution.

www.husqvarnaconstruction.com

FORMING THE ALLIANCE FOR NALOXONE SAFETY IN THE WORKPLACE

By the fall of 2022, Kubiszewski expressed a desire to form an industry workgroup to further collaborate on developing starter resources for companies interested in stocking naloxone in company workplaces and jobsites. He asked Beyer for guidance since his efforts years earlier led to the formation of the Construction Industry Alliance for Suicide Prevention. Beyer offered to help Kubiszewski identify a group of likeminded national safety/health and wellbeing leaders from various disciplines to brainstorm the needs of the industry to help expand the adoption of naloxone on jobsites. Twentythree founding members of the Alliance for Naloxone Safety in the Workplace (ANSW) agreed to collaborate. A list of all founding member organizations is prominently posted on the ANSW website.

Kubiszewski says, “The group quickly morphed to an active team comprised of various construction industry stakeholders, including contractors/employers, labor unions, trade associations, mental health advocates, population health and employee benefit service providers, and other industry professionals.” The group instituted working subcommittees with assigned chairpersons and accountability standards for updating the group on action steps taken since the most recent prior biweekly meeting. Kubiszewski shared how alliance leaders “worked diligently and with urgency.” He states that the group was “aware of the desperate need to reduce potentially preventable overdoses by educating and equipping all industry stakeholders on the benefits of providing naloxone in the workplace and on jobsites.”

The much-anticipated FDA approval of naloxone in March 2023 for over-the-counter sales helped “grease the skids” for the ANSW. Demand for informational resources, policy

guidance, and training support relating to naloxone across all industries has grown exponentially. Various nonprofit organizations have been ramping up resources to support employers seeking to become trained on using naloxone in the workplace. According to Jeff Horwitz, CEO of the national nonprofit SAFE Project, “This is great news because it not only provides us with an opportunity to help employers protect their workforce today from overdoses, but it also allows us to discuss little-known alternatives to opioids as well as first dose prevention techniques to manage pain to better protect their employees and family members in the future.”

STIGMA AS THE MAJOR BARRIER

A guiding principle of the ANSW leaders was to help employers in all industries overcome common obstacles in considering stocking naloxone in workplaces and jobsites. The group wanted to expand awareness of the risks posed by opioids and increase the adoption by employers of naloxone in workplaces. The group identified the biggest obstacle to overcome is the stigma and judgement associated with substance misuse and overdose prevention. Stigma creates a barrier that limits workers and their family members from seeking access to treatment and recovery programs. Stigma also commonly restricts some employers and labor organizations from discussing addiction and taking measures to educate employees and families about treatment options.

LAUNCHING THE ANSW WEBSITE

The founding members of ANSW focused on the development of shared resources that would be freely shared online. The website launched in November 2023 with a detailed set of frequently asked questions. The website provides access to a downloadable sample policy with standard

24 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete SPECIAL REPORT: CROWDSOURCING SAFETY

@Pepermpronstock.adobe.com

OTHER BARRIERS TO OVERCOME IN SUCCESSFULLY DEPLOYING NALOXONE IN WORKPLACES

Beyond stigma, the Alliance for Naloxone Safety in the Workplace recognized that other barriers needed to be overcome. The major barriers challenging employers and labor unions seeking to stock naloxone in the workplace and on jobsites include the following factors:

• Understanding state-specific Good Samaritan and Naloxone access laws

• Instructing employees and posting signage highlighting the availability of naloxone

• Educating employees on the common causes of opioid overdose

• Recognizing the signs and symptoms of an opioid overdose

• Developing a written policy with operating procedures to ensure clear understanding of where to stock naloxone, when to administer doses, and the need for prompt medical attention for a person after the administration of naloxone

• Ensuring adequate training of staff responsible for the administration of naloxone

• Obtaining multiple doses of naloxone and being prepared to quickly replenish supplies of naloxone after doses were administered procedures. Founding member MindForge produced a standardized training video that can be downloaded for free as well.

The ANSW is quickly spreading across the industry to reduce the risk of opioids and prevent overdose deaths. This expanding social movement has the potential to save lives by educating millions of construction stakeholders on opioid risk reduction.

Cal Beyer, CWP is the Sr. Director of SAFE Workplaces for national nonprofit SAFE Project (Stop the Addiction Fatality Epidemic).

Scott Kubiszewski, CSP, CHST, LEED AP supports safety across the Pacific Northwest region. He has 20 years of experience in construction and construction safety.

Kubiszewski says he is both “happy and humbled to have taken part in such an impactful industry initiative.” He expresses “respect and admiration for the fellow founding members of the ANSW for their commitment of passion, time, and energy to this volunteer project.” Kubiszewski is pleased that ANSW.org is “receiving positive feedback throughout the industry both in the US and internationally.” Adding that he “is excited by the number of postings being shared about the ANSW website on LinkedIn and other social media channels.”

www.ForConstructionPros.com/Concrete

MX FUEL™ - FROM POUR TO FINISH SOLUTION FOR EVERY STAGE | FORGE BATTERIES + SUPERCHARGER

From pour to finish, the MX FUEL™ Equipment System by Milwaukee Tool provides an innovative battery-powered solution for every stage of the concrete process.

With the most consistent starts and most reliable pours, MX FUEL™ eliminates the emission and noise headaches associated with traditional gas-driven tools.

A worldleader in cordless technology, Milwaukee® is committed to disrupting the gas-powered equipment space with battery-powered alternatives that are integrated with cutting edge electronics, REDLINK™ intelligence, and POWERSTATE™ Brushless motors.

From pour…

Streamline site-prep with solutions like the MX FUEL™ Plate Compactor. With gas-engine like power, this plate compactor delivers the fastest travel speed without sacrificing compaction. As the only plate compactor in its class with the ability to go in both forward and reverse directions, professionals are provided greater control during application. The handle can also easily fold down, creating a smaller footprint for storage and safer transportation around the jobsite.

…to finish

The cordless MX FUEL™ 14” Cut Off Saw w/ RAPIDSTOP™ also provides the power and performance of a gas-powered unit, cutting through reinforced concrete and rebar with ease. A push button start allows users to start the cut off saw in seconds, eliminating the strenuous, repetitive motions of priming, choking, and pulling the engine to start. Meanwhile, the RAPIDSTOP™ Brake offers enhanced safety, stopping the blade within three seconds. The tool also features advanced safety features like Milwaukee’s revolutionary AUTOSTOP™ Kickback Control, which senses severe kickback and automatically shuts off the saw to reduce strain or injury to the user.

Each product within the MX FUEL™ system can be powered by the cutting-edge MX FUEL™ REDLITHIUM™ FORGE™ line of batteries— Milwaukee’s most powerful, fastest charging, and longest life batteries. Pairing these batteries with the MX FUEL™ Super Charger, professionals can maximize their productivity, being provided up to 2X faster charging. The Super Charger is also COOL-CYCLE™ Capable, providing high-speed battery cooling and increased duty cycle for less downtime.

Advertorial

https://www.milwaukeetool.com/Innovations/MX-FUEL

™ TM MOST POWER FASTEST CHARGING LONGEST LIFE MXFSC SUPERCHARGER UP TO CHARGING 2X FASTER HD12.0 MXFHD812 XC8.0 MXFXC608 RUN-TIME UP TO VS REDLITHIUM™ XC406 2X MORE MX FUEL™ CORE RIG w/ STAND MX FUEL™ 14" CUT- OFF SAW w/ RAPIDSTOP ™ MX FUEL™ 20" PLATE COMPACTOR MXF315-2XC MXF220-2HD MXF302-2HD NEW TM EQUIPMENT REDEFINED TRADE FOCUSED SYSTEM WIDE MX FUEL™ ROCKET ™ TOWER LIGHT/CHARGER MXF041-1XC MXF336-3HD MX FUEL™ 24" WALK-BEHIND EDGING TROWEL MXF324-2HD MX FUEL™ 36" WALK-BEHIND TROWEL

TOP PRODUCTS AWARDS

THE 2024 TOP PRODUCTS AWARD WINNERS

LIGCHINE SCREEDSAVER PRO PLUS

The Ligchine SCREEDSAVER PRO PLUS is the culmination of 15 years of experience building laser guided screeds. Taking advantage of frame leveling technology that makes achieving FF/FL specifications not only possible but repeatable on a daily basis. The PRO PLUS has SCREEDSHIFT technology that was first developed on the MAX PLUS allowing the operator to move the screed head around obstacles and penetrations without rotating the head. The PRO PLUS also utilizes a rotating undercarriage for versatility and speed when operating in smaller or congested areas. With an increased auger size, longer boom reach and wider head, the PRO PLUS is highly productive in all applications from warehouse floors to exterior multiple slope pavements. All these features are achieved while keeping the size and weight of the machine compact, providing the ability to transport the machine with a 3/4-ton truck and trailer.

TORO NEXT-GEN EDINGO 500 COMPACT UTILITY LOADER

Toro engineers built the next generation eDingo to allow contractors and construction professionals to reap all the benefits and power of a standard CUL with zero exhaust emissions and a significantly lower cost of operation. The eDingo is the ideal choice for indoor construction jobs that require heavy or continuous operation, fast completion times and reduced overall costs. The new design is now capable of fitting through even the tightest of doorways with a narrow width of 30 in., yet still boasts a rated operating capacity of 515 lbs., and 6.5 GPM hydraulic flow. It also boasts a hinge pin height of 81 in., which allows for clearing into most standard dumpsters. The HyperCell Power System allows for all-day run times. Toro redesigned its eDingo 500 with a new lithium-ion battery power system. The improved unit lets concrete contractors expand their work options, with a compact utility loader that can work as hard outside as it can indoors. The high operating capacity allows for the effective use of many Toro attachments, including new 30-in. options for tight indoor spaces

MINNICH SINGLE GANG BARRIER WALL DRILL

Minnich Manufacturing is preparing to launch a new Single Gang Barrier Wall Drill. The Single Gang Barrier Wall Drill is a self-propelled, pneumatic drill that has been designed to optimize safety during the process of securing concrete barrier walls. The Single Gang Barrier Wall Drill eliminates the time of making manual adjustments to align multiple drill hole measurements. There is no need to line up drill holes. Simply align the drill steel through the pre-molded opening in the barrier wall, penetrate the sub-base, drop in the steel pin anchor and move to the next securing point. This solution is designed for roadway construction and patching projects requiring concrete barrier wall protection.

SMARTSENSE WAFFLEMAT

Wafflemat is the leading foundation system for single and multi-family residential and light commercial structures built on expansive, rocky, compressible, or liquefiable soils. Wafflemat has been used in over 30,000,000 sf in foundations across the USA, since its introduction in 1993. Wafflemat not only delivers significant cost savings by reducing soil prep, concrete, reinforcing steel, and building cycle time.

A highlight that the Wafflemat Foundation System offers is its recovery time after rain. A Wafflemat foundation is set on a level building pad, eliminating the need for trenching interior beams.

28 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete FEATURED

Find more details at https://CONC.me/2024TopProducts

DEWALT POWERSHIFT ELECTRIC TOOLS

DEWALT’s POWERSHIFT electrified equipment system for concrete jobsites was designed to meet the needs of concrete professionals, the line will allow users to transition away from gas-powered equipment. The system, made up of six concrete tools, uses the same DEWALT POWERSHIFT 554 WH battery and high-speed charger across all tools. It is backed by DEWALT’s portfolio of complimentary tools, accessories and technology.

• Battery and Charger: High Power Density battery with 554WH of capacity weighing 11.5 lbs. High-rate charger can charge the battery in less than one hour.

• Plate Compactor: Provides 3,370ft lbs. of force through its 15.7-in. plate with controls that are mounted on a folding handle for user control.

• Rammer: Features 2,660 ft. lbs. of impact force with antivibration insulators and mounted controls on the two-position handle.

• Backpack Vibrator: Lightweight at 25 lbs. with the DEWALT POWERSHIFT battery installed and features a durable roll cage with adjustable hi-vis harness.

• Powerpack Vibrator: Can be activated remotely through DEWALT Wireless Tool Control and carried with an over-body hi-vis harness for transport.

• Power Screed: Features adjustable handles for customizable height and width in addition to ambidextrous controls that can be mounted on either handle.

• Core Drill and Stand: Designed with close wall or ceiling clearance. As a part of the DEWALT PERFORM and PROTECT line of tools, the drill features anti-rotation technology to prevent over rotation in a bind up situation.

• Adaptor: DEWALT FLEXVOLT to DEWALT POWERSHIFT adaptor allowing use of DEWALT FLEXVOLT batteries for additional runtime when using DEWALT POWERSHIFT equipment.

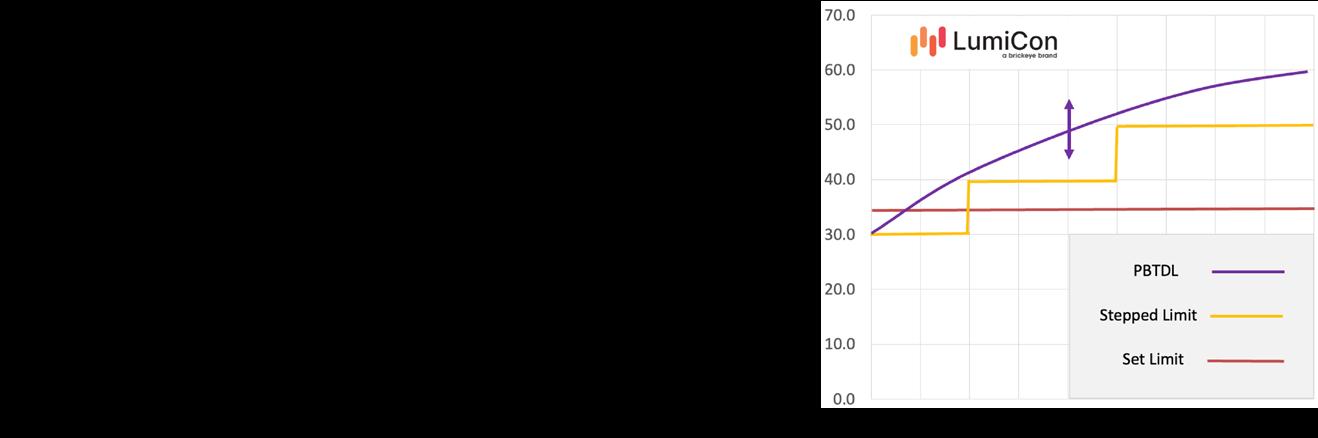

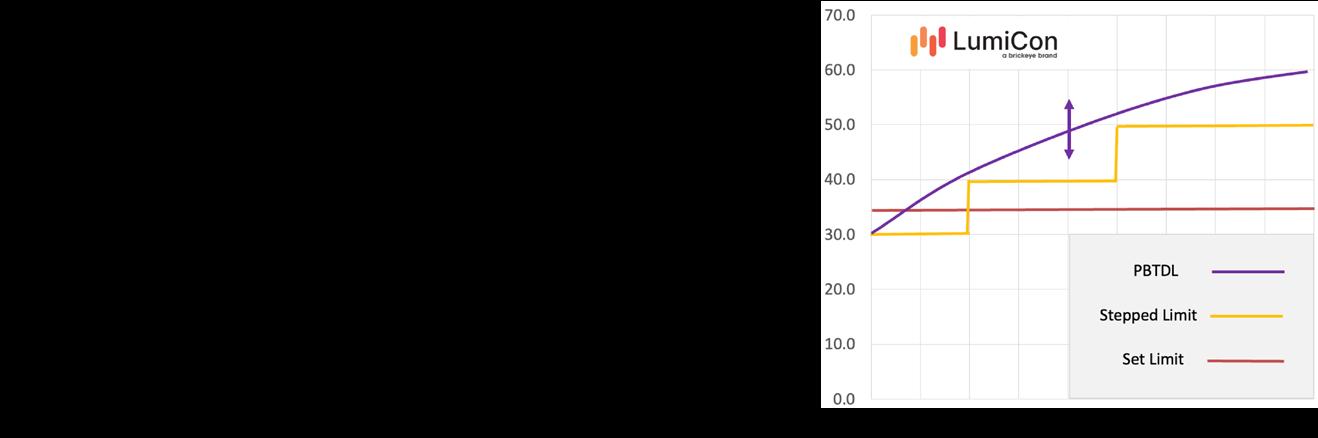

BRICKEYE PERFORMANCEBASED TEMPERATURE DIFFERENTIAL LIMIT

Brickeye’s Performance-Based Temperature Differential Limit (PBTDL) feature was one the newest additions to the company’s LumiCon Concrete Monitoring solution. Through real-time data and analytics on mass concrete projects, the PBTDL method provides contractors, engineers and project owners with a temperature differential limit directly tied to the concrete’s strength. This approach enables an increased allowed temperature differential, while still maintaining a safe threshold, through monitoring of the maximum temperature and temperature differentials. Thanks to ruggedized IoT-enabled sensors and devices, project stakeholders can remotely and continuously access data in real-time, transmitted directly from the jobsite to the cloud, without needing to be onsite to assess temperature or strength data.

MAKINEX 6KW PORTABLE POWER BOX

In a bold move geared specifically towards the unique challenges faced by concrete contractors, Makinex’s Portable Power Box (PPB) is as a transformative solution that goes beyond powering tools—it powers progress. Experience noise-free, fuel-free, emissions-free power, extremely suitable for indoor sand confined spaces. This versatile device offers up to 15kWh of battery capacity, tailored to the energy-intensive demands of concrete projects. It ensures that contractors have a reliable power source for concrete mixers, drills, and other essential tools, promoting seamless project execution. It charges via 240V mains or connected solar photovoltaic (PV) and is equipped with 3x15A outlets, 2x5V USB-A outlets, RCD protection, and a battery management display. With thermal overload protection, a spring-actuated brake, and a durable frame, manoeuvring and storage is effortless. This IP44-rated unit provides weather resistance, ensuring reliability and durability for a long operational experience. Charge overnight and enjoy an 6kW output wherever, or whenever you need quiet emission-free power.

• Concrete projects often operate on tight schedules, and the PPB’s rapid 7-hour charging time is a game-changer. It minimizes downtime, allowing contractors to maintain on-site productivity and meet project milestones efficiently.

• The PPB’s sturdy frame is designed with the challenges of concrete jobsites in mind. Its portability and easy storage accommodate the spatial constraints of these environments, enabling contractors to navigate and position the power source with ease.

www.ForConstructionPros.com/Concrete MAY/JUNE 2024 CONCRETE CONTRACTOR 29 FEATURED

CEMEN TECH CD2 VOLUMETRIC CONCRETE MIXER

Cemen Tech’s CD2 volumetric concrete mixer allows contractors to produce a more durable and sustainable concrete while exceeding expectations for accuracy, durability and efficiency. Fully automated, the CD2 features a unique split bin with individual compartments to transport and blend up to 115 cu.ft. of cement and 80 cu.ft. of supplemental cementing materials—doubling the amount of mix the unit can produce compared to other volumetric concrete mixers. Pushing the boundaries of what is possible in volumetric concrete solutions, Cemen Tech’s CD2 comes equipped to handle fly ash, including requirements from the Department of Transportation and municipalities across the U.S. The second bin can also be used for rapid setting powder or other dry additives that can be used in concrete. The CD2 ensures precision measuring, mixing and dispensing concrete from a single unit. Each ingredient—sand, stone, cement powder, fly ash, water and additives—is stored in separate compartments and mixed precisely in real-time, on-site. The unit can be programmed to save multiple mix designs, which can then be selected and started with the touch of a button by a single operator for fresh concrete every time.

• Diversifying and building the contractor’s book of business by being able to produce their own concrete and take on more projects.

• Cost savings by mixing only what is needed when needed, improving productivity, and reducing material and fuel waste due to time spent waiting for concrete, overages and hot loads.

• Environmental responsibility with significantly lower emissions and CO2 production compared to a traditional drum mixer.

GLAZE N’ SEAL EZ STAIN PREMIUM

EZ Stain Premium is a line of easy-to-use pigment-based concrete stain from Glaze ‘N Seal. For indoor or outdoor use, EZ Stain Premium uses advanced nano-bonding technology and rich pigments to deliver a beautiful, natural look that will not peel or flake and outperform commonly used dye-based stains. EZ Stain Premium is now available for professional contractors and homeowners. Building on the success of the company’s lacquer product, “The Wet Look,” Glaze ‘N Seal’s new EZ Stain Premium will easily deliver the professional results contractors are seeking. Straight out of the bottle, this new stain can be used for a natural look, diluted using water for a modern, washed look, and applied in coats for deeper opacity. It can also be combined with over a dozen EZ Stain colors to create a custom look—all with zero VOC.

BLASTCRETE X-40D SWING TUBE PISTON PUMP

Blastcrete Equipment has introduced the X-40D trailer-mounted concrete pump system. This compact pump provides highvolume pumping in a compact design for a variety of applications and rounds out the Blastcrete product line with a lowmaintenance, versatile pump capable of handling a range of rock sizes. Capable of handling aggregate mixes up to 1.5 in., the X-40D incorporates a PULSAR piston pump from Mecbo to deliver high volume in a compact design. The 6-in. x 39-in. (150 mm x 1,000 mm) swing tube piston pump is supported by a rugged receiving agitator to keep the concrete mixed and ready for pumping. The X-40D pump features 1,000 psi of piston face pressure, with a 5-in. discharge and the ability to put out 40 cu. yd. of concrete per hour. The 7,080-lb. pump and integrated trailer can be hauled to jobs that range from creating piers for overpasses to backyard projects such as installing in-ground swimming pools.

HUSQVARNA K 540I POWER CUTTER AND LF 60I LAT PLATE COMPACTOR

Husqvarna has expanded its range of batterypowered machines with the launch of a compact power cutter, the K 540i, and a plate compactor, the LF 60i LAT. Both machines are part of the company’s BLi-X 36V battery offering for hardscaping and construction applications. The K 540i is a new 10-in. battery power cutter with an adjustable blade guard and cutting depth up to 4 in. (100 mm). For performance, the K 540i power cutter is supplied with Husqvarna diamond blades. The LF 60i LAT is the newest product to run on the BLi-X battery system. In addition to the new power cutter and plate compactor, the BLi-X battery system also features the DM 540i core drill, the DE 110i dust extractor, the BV 30i screed for concrete placement, the WT 15i water tank and the WL 8i work light.

30 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete TOP PRODUCTS

CONTINUED

AWARDS:

FEATURED

FullForce(XP)ECO

FullForce(XP)ECO

20% mass

slab FULLFORCE(XP)ECO SYSTEM=02 FIBERREINFORCED SLAB = 045 CONTROLSLAB = 1

FRC Pavement Traditional Concrete Pavement

loss of the control

TOP PRODUCTS AWARDS: CONTINUED

COMMAND ALKON CUSTOMER PORTAL

Command Alkon’s Customer Portal is a mobile application that provides visibility in the materials delivery cycle. Customer Portal allows materials buyers to self-serve through data sharing and create, manage and track orders 24 hours a day. Customer Portal is fully integrated with COMMANDbatch, TrackIt and Command Alkon Dispatch systems (COMMANDseries, Integra and the new Dispatch solution) and can integrate with other third-party systems through open APIs. “If materials are late, it creates a ripple effect that affects every single jobsite activity and significantly adds to project costs; the value of Customer Portal is that it answers the question ‘where’s my truck,’” says Ranjeev Teelock, chief product officer at Command Alkon. “Ticket data shared through Customer Portal informs buyers of when the driver picks up the materials and the exact quantities that are on the way to the job. Sharing order information with customers gives them the insight that they need to improve planning and utilization and can dramatically cut down on unnecessary phone calls – by as much as 30%.”

Sharing truck locations and ETAs provides visibility from dispatch to delivery. Construction crew managers rely on actual order data without having to pick up the phone or depend on jobsite crew. Everyone gets mobile access from anywhere—at the jobsite or on the road. “Field personnel can monitor inbound movement of supplies so that they don’t stack up at the gate and instead can flow easily in and out of the jobsite,” says Deepa Vangimalla, senior product owner at Command Alkon.

BOBCAT SUPER-FLOW PLANER ATTACHMENT

Bobcat super-flow planers are high-powered attachments capable of milling concrete and asphalt up to 7 in. thick. The super-flow planers are available in 24-in. and 48-in. cutting widths. These versatile attachments utilize the extra hydraulic power available in the Bobcat T86 compact track loader and S86 skid-steer loader equipped with super flow generating up to 42 gpm and 4,061 psi. Bobcat also offers a 40-in. planer compatible with both super-flow and highflow hydraulics. In all, Bobcat offers six planer attachments that accommodate standard, high-flow and super-flow hydraulics. To cater to different cut angles, the attachment is capable of oscillating up to +/- 15 degrees.

SOMERO S-940E ELECTRIC LASER SCREED

Somero offers the S-940E electric laser screed. The self-propelled screed serves as a solution for projects requiring reduced noise pollution or zero emissions. An 11-ft. wide screed head covers large areas during use. Weighing 1,950 lbs., the S-940E features four-wheel drive with hydraulic motors for performance on worksites. This machine is powered by three, 7 kwh lithium-ion batteries at 48V. The S-940E provides eight hours of runtime and can cover up to 35,000 sq. ft. per full charge. A full charge takes approximately four hours using a 240V outlet or 10 hours using a 120V outlet. Optional features include a rotating head dolly, high float tires, spare hose kit, hydraulic fittings kit, tripod kit, column clamp, spare tire or wheel assembly and spare auger kit.

MARSHALLTOWN SPEED STRIKER 2.0 POWER SCREED

Save time and effort with the MARSHALLTOWN Speed Striker 2.0. This power screed vibrates over concrete resulting in a stronger slab. It features a dependable 4-stroke Honda GX35 engine, a direct drive shaft, and excellent vibration dampening so little vibration is passed to the operator. The power trowel-style throttle lever provides control while reducing operator fatigue, and the ergonomic design includes an adjustable handlebar complete with grips for a customized working position and easy transport. The kickstand conveniently keeps this screed upright when not in use. New to the design is the forward mounting 9-in. hole spacing, compatible with most competitor power screed blades. MARSHALLTOWN’s Speed Striker 2.0 is proudly manufactured in the USA.

PLATE 2000 BIG FOOT SYSTEM PAN SAVER

Plate 2000’s Big Foot System is a game changer. It’s perfect for leveling floors and making float pans last longer, thus making the job easier than ever before. The Big Foot System was created with the goal of prolonging the lifespan of float pans while simultaneously enhancing the flatness of concrete finishing. The company’s innovative patented design achieves this by effectively distributing the weight of the power trowel. This results in faster finishing times and increases the durability of the float pan. With the Big Foot System, you can expect concrete that is flatter, stronger and finished faster. It is specifically designed to fit under the largest machines, and it can be easily adapted to accommodate various sizes and arms. The product is available in 59- and 62-in. machine diameter configurations.

32 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete

FEATURED

Helping You, to Help Your Customers.

Customer PortalTM enables you and your customers to gain real-time visibility into their orders and deliveries through a cloud-based mobile application.

Part of our cloud-native portfolio, Customer PortalTM empowers your customers to self-serve and efficiently create, manage, and track orders round the clock. Current system users report a 30% reduction in customer calls to their dispatch teams. Let us help you to elevate your customer experience. www.commandalkon.com

TOP PRODUCTS AWARDS: CONTINUED

FULLFORCE(XP)ECO SYSTEM

FullForce offers the FullForce(XP)eco exterior pavement system for concrete projects involving exterior pavements. This solution uses GeoForce, FiberForce 750, DuraForce(i) and DuraForce(t) to stabilize soft subgrade soils as well as ncreases the concrete’s durability, impact and abrasion resistance, fatigue strength and ductility. The system also improves sustainability by densifying the concrete, increasing the life of its wearing surface and contributing to a decrease of embodied carbon.

• Performance tested

• Stamped designs and third-party consulting

• Optimized joint layout

• Abrasion and wear resistant

• Increased reflectivity/luminance

• Reduced heat island effect

The FullForce(XP)eco system is designed for exterior pavements in industrial warehouses, distribution centers, manufacturing plants and transfer stations. It provides soil stabilization, eliminating the need for soil cement or lime and allowing the use of lesser-quality in-fill materials. The system comes with Environmental Product Declarations for most products. By increasing the flexural strength of the concrete and thinning the pavement section, the system supports service life and contributes to a decrease in embodied carbon.

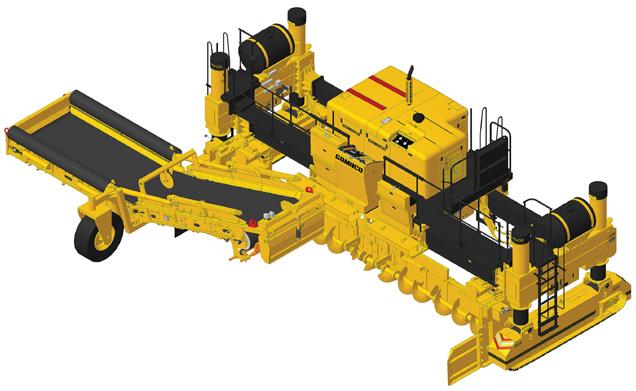

GOMACO GP460 PLACER/SPREADER & SLIPFORM PAVER

With its debut at CONEXPO-CON/AGG 2023, the GOMACO GP460 is the industry’s first combination concrete slipform paver and placer/spreader on two tracks. Designed for wider-width operations, as a placer/spreader with a 60-in. (1524 mm) belt, the GP460 will accommodate widths up to 50 ft. (15.2 m) wide. As a concrete slipform paver, the GP460 will pave widths up to 40 ft. (12.2 m) wide. It’s built on the framework of the GOMACO two-track GP4 slipform paver with the ability to convert the prime mover into a concrete placer/spreader. The prime mover is equipped with vibrator circuits for paving and auger drive circuits for placing. Controlling the new technology is made possible with the GOMACO-exclusive G+ digital control system. G+ seamlessly handles the controls conversion needed for each application while also bringing onboard Machine to Machine communication, sonic sensors, 3D machine guidance, and more. The GOMACO GP460 is powered by a Caterpillar C7.1 turbocharged diesel engine to efficiently drive the conveyor belt and distribute concrete across the grade. The high-volume, 60-in. (1524 mm) conveyor belt can be mounted on either the left or right side, depending on job-site conditions and the location of the haul road. It has a discharge speed of up to 492.5 ft. per minute (150 mpm) for fast and efficient concrete placement. A controllable material deflector directs the flow of concrete at the discharge end of the conveyor for placement accuracy. A dual-drive auger system moves the material to the center or outer areas and across the strike-off. The GP460 is available with an optional sonic sensor system to monitor the concrete depth as it is placed. Information from the sonic sensors is utilized by the G+ control system on the paver using M2M communication to provide an optimum and consistent head of concrete in front of the paver.

MILWAUKEE TOOL ROLL-ON 2.5 KWH POWER SUPPLY

Milwaukee Tool introduced the ROLL-ON 7,200W/3,600W 2.5 kWh Power Supply.

With the capability to charge to 100% in three hours and 25% in 35 minutes, the ROLL-ON can charge and discharge simultaneously. Delivering 7,200W of starting power, users experience instantaneous peak power and 3,600W of continuous running power to support between two and four operators per unit. ROLL-ON is equipped with a non-removable, REDLITHIUM integrated 2.5 kWh battery, two 20A GFCI duplex outlets with circuit breakers, one USB-C and one USB-A to provide power for two 20A corded tools or a piece of capital equipment while charging batteries and personal electronics. The ROLL-ON weighs 104 lbs. and features 9.5-in. all-terrain wheels and an IP54 rating.

DIABLO TOOLS AMPED REBAR DEMON HAMMER DRILL BIT SYSTEM

Diablo Tools offers the AMPED Rebar Demon 4-Cutter Full Carbide Head Dust Extraction Hammer Drill Bit System for concrete applications. Diablo-made Dura-Carbide withstands up to 1,800° F of intense heat to combat rebar hits. A compact snap-lock adapter connects the AMPED Rebar Demon bit to vacuums for dust and debris extraction. This component also allows users to exchange different drill bit sizes. The snap-lock adapter fits most common vacuum cleaner attachments. The impact resistant 4-cutter tungsten full carbide head extracts small bites of rebar for controlled consistent carbide wear and reduced vibration to deliver precise holes. The vacuum system and removable stainlesssteel dust sleeve captures dust particles and reduces airborne silica dust to create clean holes ready for epoxy and anchor placement all in one easy step. Find up to 3X faster chemical anchor preparation versus conventional drilling applications and up to 97% dust reduction versus conventional drilling applications

34 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete FEATURED

NEW FOR 2024

LIGCHINE® has over 15 years of experience building laser guided screeds right here in the USA. The PRO PLUS has SCREEDSHIFT™ technology that allows the operator to move the screed head around obstacles and penetrations without rotating the head. With an increased auger size, longer boom reach and wider head, the PRO PLUS is highly productive

in all applications from warehouse floors to exterior multiple slope pavements.

Achieving FF/FL specifications is not only possible but repeatable on a daily basis.

• 18 ft boom with an 11’ High Performance screed head

• Powered by a 36.9 hp Yanmar diesel engine

• SCREEDSHIFT™ Pivoting Frame up to 12˚

• Controlled by wireless remote

• 200 sq ft coverage per screed pass

• 20 gallon water tank/sprayer

• Transport with a ¾ ton truck and trailer

• Rotating undercarriage for versatility and speed in smaller or congested areas

LIGCHINE.COM 812-903-4500

MOCK IT UP: REPAIRING CRACKED POLISHED CONCRETE

KEY STEPS TO TAKE WHEN THE INEVITABLE HAPPENS.

Given time, concrete will inevitably crack. Concrete doesn’t care if it was placed for a warehouse, dining room area in a new restaurant, or an older concrete floor. Despite being a seemingly straightforward process, a crack repair can easily fail if not done properly. After assessing the damage, Nick Demonte, ITF cement mason coordinator for the Operative Plasterers’ & Cement Masons’ International Association (OPCMIA) suggests that the first step be plan and prepare a mock-up.

“Setting the customer’s expectations is the number one priority,” Demonte says. Whether you’re working with an owner of the building or the general contractor, having a meeting with them is going to be vital at the beginning of the job. Doing a mock-up will be instrumental in ensuring all parties involved understand the cost of your repair and the scope of the work.

Since everyone will want to see how their newly repaired floor may eventually look, making a mock-up will help manage expectations, but Demonte advises doing so in the

worst area of the floor: the space that’s beat-up the most. Size your mock-up based on how much work will need to be done. Among the many factors, consider if bolts are popping up, trenches installed, required saw cuts, staining, if you will need to match the size of an exposed aggregate, etc. Consider your time. Time is money and production is key; the mock area should be large enough to set expectations for quality and price.

Make sure joints get vacuumed out because if there’s any silica dust, any grindings, shavings—anything loose—will need to be completely cleaned. Any loose material will prevent any repair product from achieving the appropriate bond. Your preparation before installing any type of repair is going to be key, says Demonte.

PREPARATION

How much to cut into the slab will depend on the width and depth of the crack. Every situation will be unique. In OPCMIA training sessions, Demonte says they suggest cutting

36 CONCRETE CONTRACTOR MAY/JUNE 2024 www.ForConstructionPros.com/Concrete HOW TO » BY JONATHAN KOZLOWSKI, EDITOR

about 2-in. deep and then reassessing. Look at the edges of the saw cut. Will it need to be made wider? Are there imperfections?

“A lot of the times you’re turning an old warehouse into a polished floor area,” says Demonte. “They might have been running tow motors [or] pallet jacks, those wheels going over those joints tend to crack the edges even more.” The depth and width of the damage will help dictate what type of materials to use. Faster-setting concrete repair products and two-part epoxies tend to be more costly than regular joint fillers.

The size of the damage (or crack) relates to how you want to treat the area. For a hairline crack, Demonte explains that something roughly 1/8 of an inch wide or less, he suggests opening it up with tools like a nylon or soft wire wheel. For 1/8 of an inch or wider, his suggestion is to utilize an angle grinder with a U or V blade to open the crack up a bit; aim to go down about 1/2 to 3/4 of an inch.

The key here is to create a new surface for the repair product to bond while avoiding damaging any steel reinforcement within. Any bolts exposed should be trimmed to below the surface and chip the surrounding concrete away. Of course, treat any rebar corrosion.

Safety first, reminds Demonte. “Make sure that you’re wearing your proper PPE. Debris can be flying up. Make sure you have the safety glasses on. Make sure that you have gloves on. A lot of these wheels tend to explode and can do a lot of damage. Always make sure that you’re wearing the right protection,” he says. A mask or respirator may be needed.

• Utilize water to help with dust control

• Use a vacuum system with a HEPA filter to clean the crack and to help keep the air clean

• Make sure to have the right engineering controls

• Ensure grinders feature appropriate vacuum systems - whether your crack chasing or polishing

• Wear proper PPE

FILLER MATERIAL

Once cleaned, the crack will be ready for repair material. The OPCMIA offers a train-the-trainer class on concrete crack repair with experienced journeymen as instructors. While their repair training features Metzker

McGuire products, there are countless options for repair material on the market and some may behave differently than others based on concrete quality, even the freeze/ thaw cycle can be a major factor. Experience and time should lead you to “the sweet spot” when you find a product that works for you and your area. Be sure to read the label and manufacturer directions to use the right repair product for the situation at hand.

Be sure to know if you’re using a fastor slow-setting product. Noting “time is money,” Demonte prefers using a fastsetting repair material when possible. “If I’m waiting for those slower products to take place, I’m going to have to be really organized on how I’m attacking this floor area because I have to take that into consideration,” he says. Also, consider any necessary decorative requirements and if the repair product you’re using can be customizable to match the slab. Follow the manufacturer’s steps as needed. Color and stain matching any complex decorative elements may require additional time.

The application of the product depends on how large of an area is being treated. Many products can be applied using a cartridge gun. There are a variety of these tools available, some are designed for dual cartridges for convenient application of a two-part epoxy. Different repair product manufacturers may require purchasing their tool to install the product. A twocomponent joint filler pump may be needed for larger areas.

Demonte recommends filling the crack to the point to ensure adhesion; overflow it just a little bit. This may take a few applications. Once cured, return with a or grinder (handheld or walk-behind if the area is large enough to warrant) later and make it flush with the slab. “You don’t want a big mushroom cap over the width of the joint, you want it to be just enough so it covers the whole thing,” he advises.

The depth of the slab usually dictates how the depth of the crack. Since it’s likely safe to assume that the crack is going all the way through the slab come back once or twice with the repair material. If the crack does travel through the slab and depending on how fast the product sets, injected material can sometimes seep underneath the slab and fill any voids beneath.

www.ForConstructionPros.com/Concrete MAY/JUNE 2024 CONCRETE CONTRACTOR 37

Photos provided by the Operative Plasterers’ & Cement Masons’ International Association

UNLEASH THE POWER, RESPECT THE BATTERY