Our new electric lineup made a lot of noise in Vegas. Which is impressive, since they cut noise in half while keeping the same power. That means you can work overnight or indoors. And we also built them to fast charge at a station, or recharge directly on the jobsite, because even small machines should deliver big results.

2023 CONEXPO, Work Truck Week Showcase Equipment. Highlights of both shows included rebranding, brand personalities, new compact electric machinery and green truck initiatives.

BREAKING GROUND

2023 CONEXPO and Work Truck Week Usher in Spring with Refreshed and New Equipment

The first CONEXPO after the simultaneous pandemic shutdowns of March 2020 did not disappoint.

EQUIPMENT INTRODUCTIONS

Big Iron

Check out the newest construction equipment and products, many of which are from CONEXPO.

PROFIT MATTERS

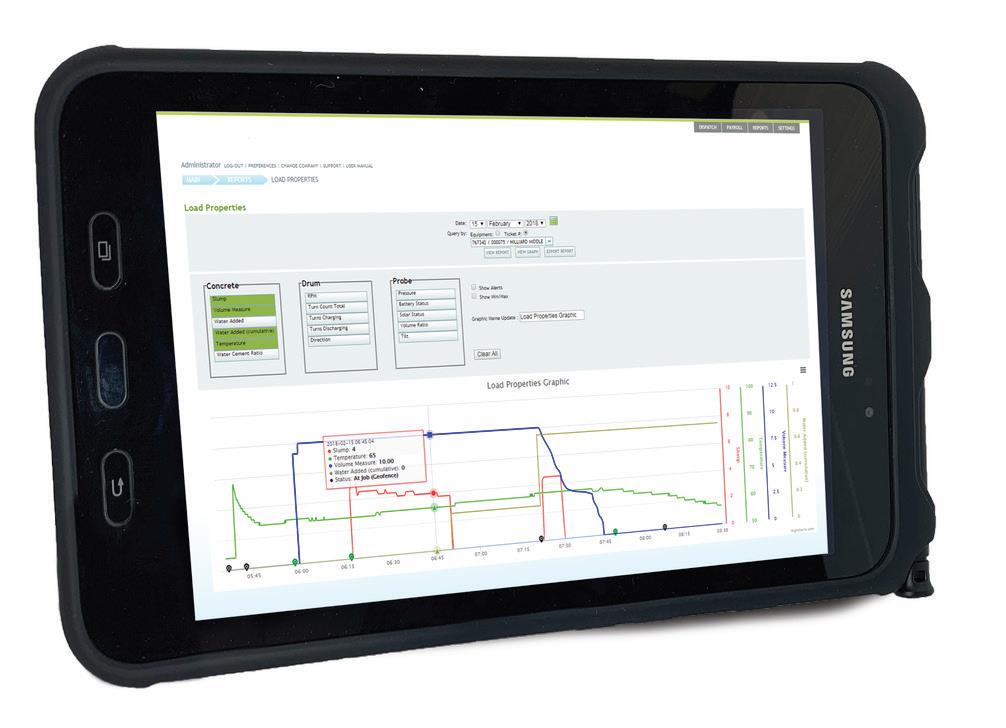

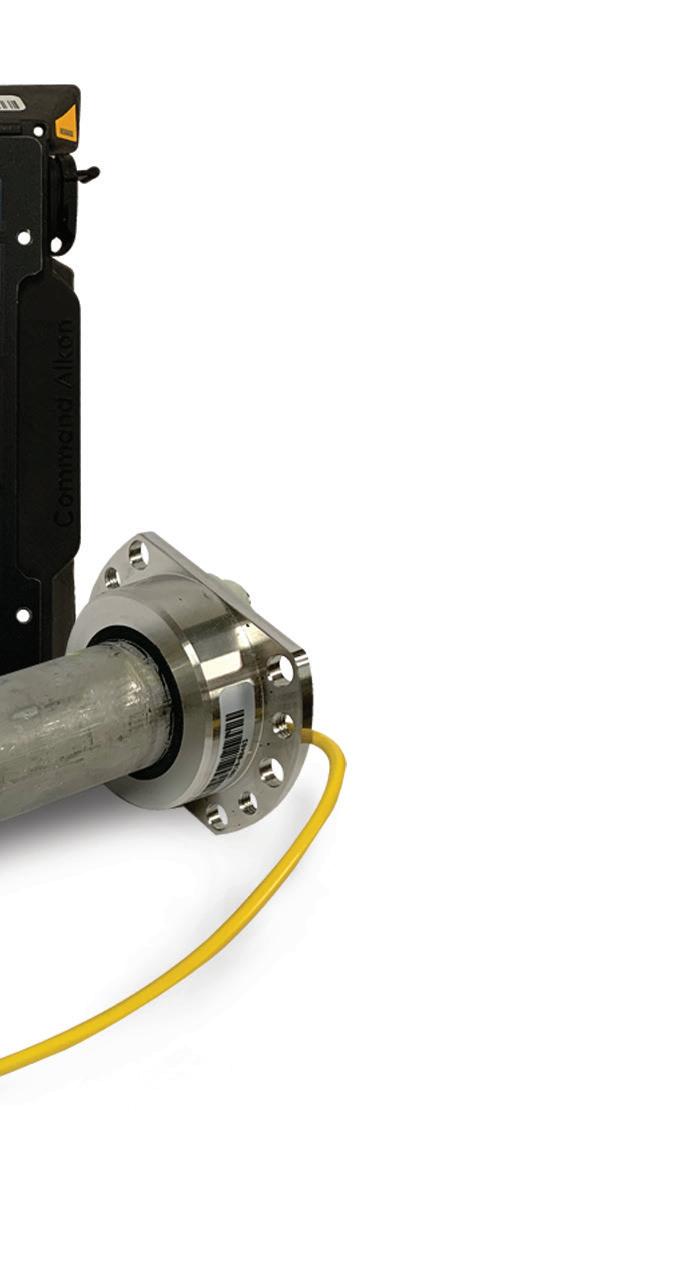

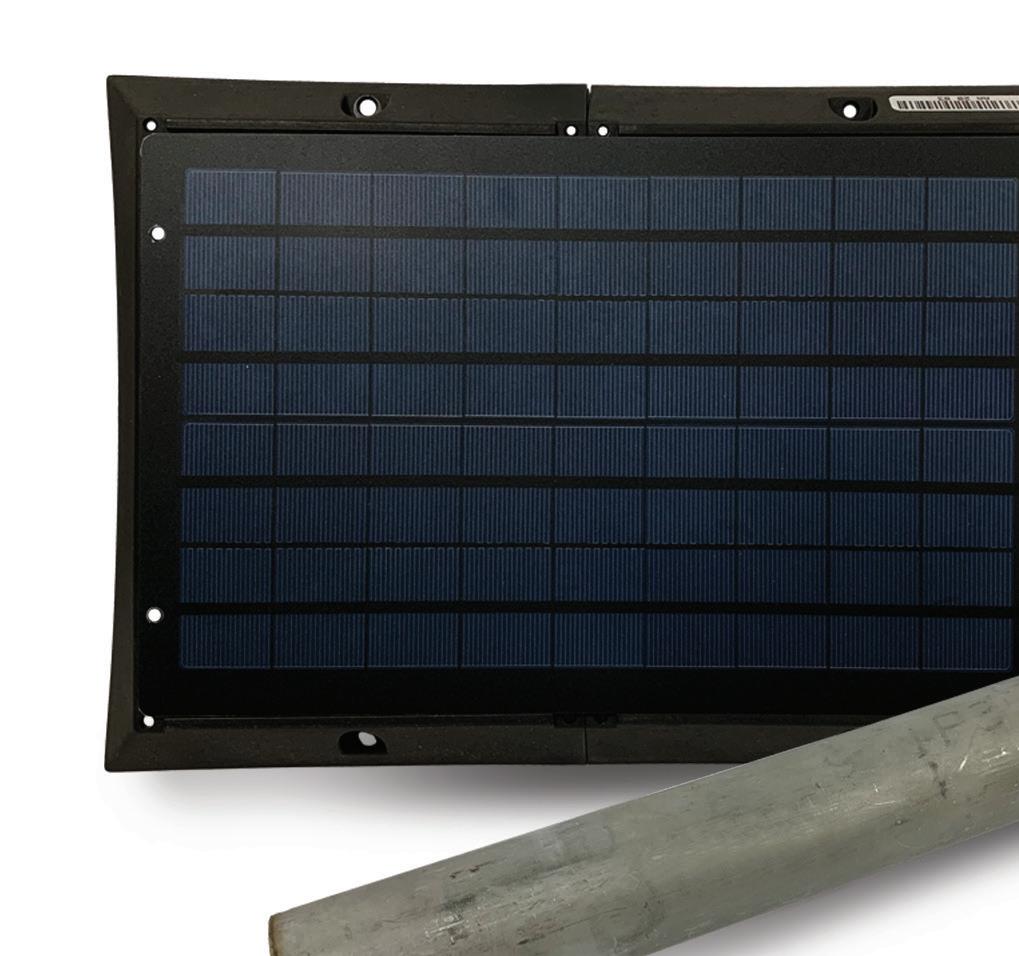

Heidelberg Materials Rolling Out IoT In-Drum Monitoring in Southeast

In-drum sensors and supporting software from Command Alkon already reducing waste and saving dollars by enabling concrete re-use and improving quality.

BRIDGING THE GAP

Inexperienced Worker Conundrum: Help Protect Your Employees and Your Bottom Line

How green are your workers? Protect your construction business from business issues related to injuries and accidents.

RUNNING THE BUSINESS

How to Handle Construction Equipment Spending in 2023 Business owners need to be careful with their spending and managing their balance sheets during 2023, to avoid the pitfalls of inflation and overspending.

FLEET MANAGEMENT

Mobile fueling, generators, chargers and more to maintain a sound fleet.

TECHNOLOGY

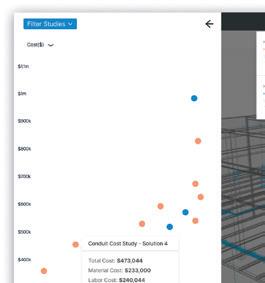

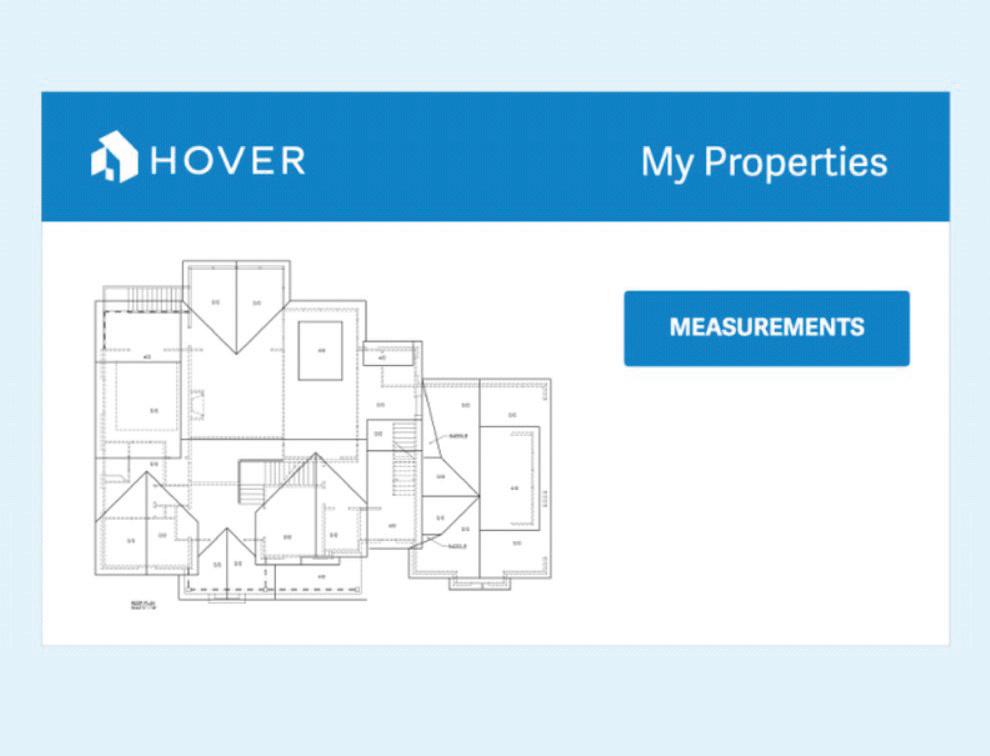

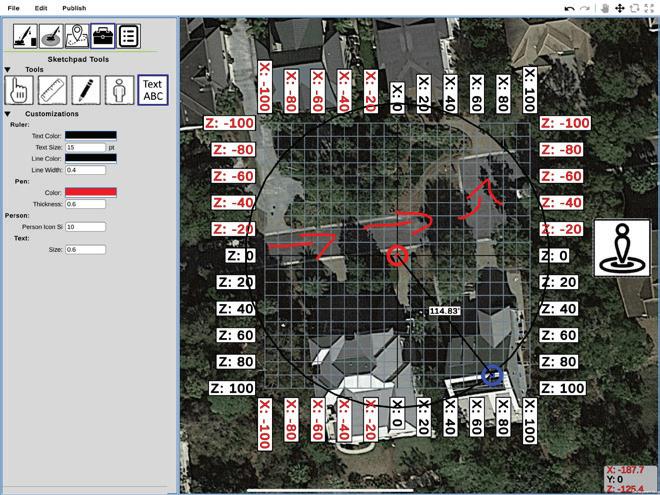

Surveying and layout software to plan the perfect worksite.

18 24

EARTHMOVING TRENDS

Alternatively Powered Wheel Loaders Perform Heavy Lifting on Jobsites

Wheel loaders with traditional combustion engines are practical, well-established and familiar to fleet managers and operators alike, and yet the new, electric versions don’t have engine maintenance costs, have fewer emissions and can be used indoors.

FLEET MANAGEMENT

Maintaining Equipment, Following Best Grading Practices Earn Contractors High Marks

Not only is proper grading on construction jobsites crucial to a job’s long-term success, but improper grading can have significant ramifications on a job’s timelines and costs.

FLEET MANAGEMENT

28

Electrification is Coming for Mid-Size Fleets

With the electric medium-duty vehicle market booming and sustainability deadlines looming, companies must keep a pulse on these four key industry trends throughout 2023.

31

FLEET MANAGEMENT

Increase Site Responsiveness With Mobile Fuel Tanks

Transportable fuel tanks can help control costs and allow contractors to respond to the quickly changing market conditions that impact their bottom line.

TECHNOLOGY

36 39

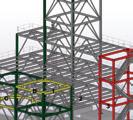

How Technology Revamped a Historic Racetrack

The Walbec Group worked with Road America to repave the historic track.

TECHNOLOGY Using Autonomous Reality Capture on Jobsites and Why it Matters

As reality capture technology is more commonly used on construction jobsites, decision makers are constantly evaluating the upside of the investment.

VIDEO NETWORK https://eqtoday.co/k2p285

DIGGING DEEPER PODCAST https://eqtoday.co/s7sfkm

PREMIUM CONTENT

https://eqtoday.co/9pd73s

Spring is a time of new life and renewal, so it is fitting that the April issue of Equipment Today should publish shortly after the biggest construction equipment show in North America, the once-everythree-years extravaganza of CONEXPO-CON/AGG.

Spring is a time of new life and renewal, so it is fitting that the April issue of Equipment Today should publish shortly after the biggest construction equipment show in North America, the once-everythree-years extravaganza of CONEXPO-CON/AGG. Fresh new branding (DEVELON), a decisively customer-centric attitude (CASE), a commitment to going green (Volvo) and electric innovation (Bobcat Co.) were all highlights of this year’s CONEXPO. Alternative power – hybrid and electric fuels in particular – continues to proliferate throughout the industry, a forward-thinking attitude reflected both by the machines at CONEXPO and the stories in these pages.

Similarly exciting, electrified products and solutions-oriented equipment shone at Work Truck Week earlier in March, though it occurs every year. Ford Pro, Ram, Mack Trucks and Mercedes-Benz all demonstrated commitment to solving customers’ challenges, one feature or engine at a time, or with entirely new models. Keep an eye out for our Work Truck Week coverage both in this issue and on ForConstructionPros.com.

The impressive construction heavy equipment product launches of the past six months will set the tone in the construction equipment industry for the next decade, at least. A bold statement? Perhaps. But by the time you read this editor’s letter, 2023 CONEXPO-CON/AGG, IFPE and Work Truck Week will be over, with many new products, machines and technologies launched at the shows. Many of the products, equipment and tech touted and displayed at CONEXPO had their big launch on the global scene at bauma 2022, which took place in Munich in October 2022, a mere six months ago.

While the time between those massive outdoor displays in Germany and the splashiness of 2023 CONEXPO’s many equipment demos might seem short, the quick-turnover

and fanfare of the high-power tradeshow season are a celebration of years of hard work, behind-the-scenes innovations, and long-view engineering. CONEXPO 2023 may very well have been the most all encompassing, innovative lineup of construction heavy equipment in the show’s history. Creative brainstorming, constant thought, meticulous design, intense collaboration and dedicated cross-departmental product management and marketing efforts brought us these new and exciting machines. There were so many new machines presented at CONEXPO 2023, we decided to create a special product section in this issue of Equipment Today, to feature a smattering of the thousands of machines at the show. While only a small sampling, we hope you find the entries useful as you look to update your fleets. The technologies have really been fine tuned and improved in recent years, making an alternative-fueled construction vehicle fleet one step closer to becoming a reality. Let’s not forget, however, our traditionally-fueled equipment, which continues to power our jobsites. There were many Tier 4 engines on display, featuring tech improvements to reduce fuel use and maintenance downtime.

We want to thank the countless heavy equipment manufacturers who hosted us at their exhibit booths, gave us demonstrations and walked us through their newest technologies. We are grateful for the time you took to share your knowledge with us so we can pass it on to our readers. Look for CONEXPO coverage in the pages of this and future issues of Equipment Today, on our website, ForConstructionPros.com, and in our social media videos and our podcasts.

EDITORIAL

Editor-in-Chief Erica Floyd efloyd@acbusinessmedia.com

Digital Content Director, IRONPROS Wayne Grayson wgrayson@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Kristin Pride kpride@acbusinessmedia.com

Sales Representative Megan Perleberg mperleberg@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Marketing, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: (877) 201-3915 Fax: (847)-291-4816 circ.EquipmentToday@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS & LICENSING

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

E @EquipmentToday D @EquipmentToday

C @equipment-today-magazine-official Q @equipmenttoday

Tsurumi America has a new line of electric submersible pumps, engine pumps and generators. The pump manufacturer displayed a range of newer products at the ARA show, including its TM, HSE and UT series. Tsurumi also showed the LSC and LSR drainage pumps and will highlight the recent introduction of Vanguard Series engine pumps, as well as its new line of Honda-powered heavyduty contractor-grade generators with carbon monoxide detectors.

The product lineup on display at this year’s event includes:

• HS Series (HS, HSD, HSE and HSZ) submersible pumps

• LSC and LSR series low-level, highvolume drainage pumps

• LB Series slimline dewatering pumps

• NK Series high-volume contractor pumps

The SW405K has an operating weight of 40,786 lbs., a full turn tipping load of 28,881 lbs. and is powered by a 252-net-hp Deutz TCD 7.8, four-cycle, turbocharged, electroniccontrolled diesel engine.

• Z-bar linkage design delivers nearly 40,000 lbs. of breakout force

• Comes with a 4.2-cu.-yd. bucket capacity and has a 123-in. maximum dump height

The NANO10-XD has a compact design and eliminates the potential risk of an oil leak for environmentally-sensitive applications due to zero hydraulic oil with all-electric lift, steer and drive.

The NANO10XD delivers extended battery duty cycle with standard lithiumion batteries while requiring less charge time and delivering more up time. With a platform height of 10 ft., the new scissor can be used in data centers, hospitality, food service-related operations and pharmaceutical applications. Along with being lightweight at 1,235 lbs. and low ground pressure, the machine can be used on a wide range of floor types. At 63 ft. tall and with no folding rails, the machine can pass through standard door frames.

ELGi has launched its portable compressed air solutions for the construction industry, the D185T4F and GP75 compressors. Powered by a Kohler KDI diesel engine, this portable air compressor provides a compressed air source with a capacity of 185 cfm at 100 psi or 150 cfm at 150 psi. The Kohler engine design enables the portable air compressor to achieve Tier 4 Final EPA requirements without the need for a Diesel Particulate Filter (DPF) or a Diesel Exhaust Fluid (DEF) system. In addition, the D185T4F is equipped with a new DeepSea controller and Intelligent Start-Stop System that prevents coldstarting and blowback.

The all-new AS750, AS850 and AS1000 swing loaders feature a rigid chassis and three steering modes. At just over 11,000 lbs. (5,000 kgs) and with a bucket capacity of 0.98 yd3 (750 liters), the AS750 is the second smallest swing loader model. The mid-size AS850 has an operating weight of 13,184 lbs. (5,980 kgs) and a bucket capacity of 1.1 yd3 (850 liters). This model encapsulates the capabilities of the AS series swing loaders with optional increased travel speed up to 25 mph (40 km/h). A step up in power from the AS850, the AS1000 is also a mid-size model at 14,639 lbs. (6,640 kgs) with a bucket capacity of approximately 1.3 yd3 (1,000 liters). It is powered by a 4-cylinder 75 hp (55.4 kW) high-torque engine.

• High-pressure, load-sensitive hydraulics offer a 10% to 15% reduction in energy usage

• Features a boom suspension system, bucket self-leveling, return-to-dig and automatic transmission kickdown

Cannon

BossTek has introduced the DustBoss DB-10 atomized mist cannon, which can be used to suppress indoor particulate emissions during demolition and raw material handling.

Engineered for enclosed working environments, the maneuverable unit provides suppression in a compact, portable design. The outcome is airborne particle control with minimized emissions and less standing water. The compact mist cannon is mounted on two wheels with a tall handle. A ¾-hp fan delivers 3,335 cfm of airflow, powered by 120-volt current. Mounted on the front of the cannon is a circular manifold with 12 atomizing nozzles that fracture pressurized water into a fine mist. About as loud as a hand-held hair dryer, the fan forces air through the barrel then pushes millions of tiny droplets in a cone-shaped pattern up to 30-ft. (10 meters).

The 3-ton WL28 has a compact design with minimized tailswing and optimized steering angle that allow navigation in tight spaces.

• 45- or 54-hp Yanmar Stage V engine offers an efficient regeneration system, optimal power-to-weight ratio and lower fuel consumption

• Electronic regulated drive system provides improved pushing power, speeds up to 18.6 mph and an electronic parking brake with hill-hold function

• Standard auto/eco mode and optional attachment mode

• Cab offers increased operator space, improved ergonomics with intuitive controls, air conditioning and increased visibility on all sides

Compatible with Genie S-45 XC, S-65 XC and S-85 XC boom lifts, the 13-ft. platform is for tasks that involve an extensive working area, as well as jobsites with limited space to maneuver on the ground. The extra space in the platform also provides access to twice as much work area with the same number of boom movements, compared with a standard sized 8-ft. (2.44 m) platform. After following instructions to install the 13-ft. platform and calibrating the machine, the S-45 XC, S-65 XC and S-85 XC can take up to two workers to height and deliver a 600-lb. lift capacity. Additionally, operators can utilize other features on Genie’s XC machines, including automatic envelope control, working curve and active load sense.

ASV's lineup includes four Posi-Track loaders for landscaping, construction and forestry. The repowered RT-40 compact track loader includes a more powerful, new 38.2-hp Tier 4, three-cylinder Yanmar engine. The small-frame machine is for landscaping applications, rental and more. Its operating weight is 4,005 lbs, with a rated operating capacity of 931 lbs. Ground pressure is 3.3 psi. ASV’s MAXSeries RT-135F and RT-75 loaders include a next-generation cab featuring 360-degree visibility, an operator area, a fully adjustable seat, a new touchscreen display and more. The RT-135 Forestry Posi-Track loader features 10% more horsepower than the previous titleholder it replaces, the RT-120.

The PC210LCE was created for construction businesses that need a high-performance machine. The excavator has 451 kWh of battery capacity and is designed for up to eight hours of operating time. The lithium-ion battery technology was developed by Proterra. Designed to reduce operator fatigue with less noise, exhaust emissions and zero engine vibration, the PC210LCE is for use in urban areas and indoor environments. The low operating noise levels of the PC210LCE allow for nighttime construction work both indoors and out. Coming soon to North America, the PC210LCE supports Komatsu’s global sustainability targets of 50% reduction in CO2 emissions by 2030 and complete carbon neutrality by 2050.

Komatsu displayed the PC210LCE at CONEXPO-CON/AGG with Smart Construction Retrofit, a guidance kit that gives operators in the field and managers in the office access to 2D and 3D design and payload data. Installed by a local Komatsu distributor, this technology upgrade is designed to support grading performance and drive operations.

Subsite Electronics has introduced the Marksman for shallow bore projects. The Marksman is the second product introduced in the Marksman series of HDD guidance systems, following the release of the Marksman+ in 2021. The Marksman features single-button calibration, minimizing the risk of human error and supporting the preparation process. Six frequency options and simplified features are designed for completing shallow bores for service installation. The Marksman is compatible with Subsite’s TD Recon and Commander 7, as well as the Subsite Field Scout.

Pettibone has showcased the Cary-Lift 204i wheel loader for material handling jobs on construction sites. The Cary-Lift 204i is part of the company's line of pole and pipe handlers. The machine is built to deliver safety and performance on the jobsite.

Features:

• Overhead lift arm design gives operator full front visibility when transporting loads

• Lifting forks capable of tilting down 90° for specialized lifting tasks

• Powered by a 200 hp Cummins QSB6.7 Tier 4 diesel engine

• Maximum load capacity of 20,000 lbs. and max lift height of 16 ft.

Ditch Witch has introduced the W12 truck vacuum, for potholing applications or cleaning up spills and debris. The W12 features 1,200 gallons of fresh water and a 12-cubic-yard debris tank. With 5,000 cubic feet per minute (CFM) and 27 feet Hg of vacuum power, the truck vac comes with a remote-control system for managing the water system and boom, as well as for lifting and lowering the tank. The design and layout of the debris tank, positioned between dual 600-gallon saddle tanks of fresh water, supports operation. Operators can stay on the job with the 2,400-gallon tank capacity and powerful vacuum.

Volvo Construction Equipment has developed a solution to convert the L120 wheel loader to electric. Developed in conjunction with partners – Parker Hannifin and converted by Volvo Group’s own CE Engineering Solutions – the 20-ton L120H Electric Conversion will be commercially available for select customers in Europe in 2023. The electric conversion model will deliver the same performance with zero emissions. Powered by 240 kWh batteries, it provides a runtime of five hours in most mediumduty applications. It is estimated to charge from 0-100% in just 1.5 to two hours.

The Merlo eWorker has a maximum load capacity of 5,511 lbs. It features a maximum lift of 15 ft., 7 in. and a load capacity of 3,307-lbs. at maximum lift. The no-flex boom has a maximum reach of 8 ft., 5 in., handling a maximum load of 1,984 lbs. The eWorker can put in a full day’s (eight hours) work without recharging. It is a compact machine with dimensions similar to those of an industrial forklift. Equipped with a telescopic boom, the machine has a low center of gravity. Stability is gained by positioning the battery in the middle of the vehicle. The telescopic boom operates from its own electric motor that is connected to a load sensing hydraulic pump. A dedicated electronic control unit manages the rpm of the electric motor and the oil flow of the hydraulic distributor. In addition, the telescopic boom descends by gravity via a valve controlled by the same control unit.

The three models, L 526, L 538 and L 546, in the latest Generation 8 have bucket sizes between 2.2 and 3.0 m3 in the standard version and are characterized by an increase in performance compared to the previous generation. The new L 526, for example, has around 20% more engine power and over 20% higher breakout forces than its predecessor. The newlydesigned lift arm ensures maximum breakout, holding and lowering forces. It has optimized z-bar kinematics and improved working hydraulics. Increases in engine power and tipping loads prepare the wheel loaders for demanding operations in various sectors, such as excavation, recycling or log handling. Available in Europe, the L 538 and L 546 models also have performance increases in various areas: for example, with the optimized travel drive, providing increased traction to ensure that the new wheel loaders accelerate dynamically in everyday work, and can penetrate powerfully into all materials.

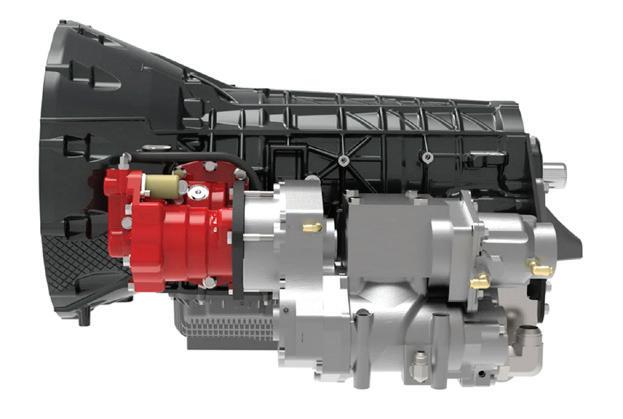

The updated L350H wheel loader has a more responsive hydraulics system featuring new lift and tilt cylinders, and an increased hydraulic working pressure for 10% faster work cycles and higher productivity. The upgraded driveline features new Volvo axles and an all-new Volvo transmission, which enables the third-generation OptiShift to be equipped as standard. This technology integrates the Reverse By Braking function and the lock-up function in transmission to improve fuel efficiency by up to 15%. An optimized gear shifting ratio and a new converter that delivers outputs of up to 22% more tractive force depending on the selected gear and machine speed. The machine also has a tougher form with a more robust upper center hinge bearing and updated frames to accommodate the new axles and transmission. The L350H

comes with a Z-bar lifting arm with double sealing on each of the pins, and strong frame structure, which is joined by a reinforced upper center hinge and new Volvo axles. Updates also include extended service intervals that increase uptime and reduce maintenance costs. The engine service interval has doubled to 1,000 hours, and axle oil change intervals have been extended to 4,000 hours thanks to an axle oil cooler with filtration fitted as standard.

John Deere is launching E-Power machines with battery solutions from Kreisel Electric. Offering a hybrid solution, E-Drive machines feature an electrified drivetrain with an engine as the primary power source. In addition, E-Drive machines support powertrain component life and provide pushing power. The 644 X-Tier Wheel Loader offers performance with its combined E-Drive and Power Shift transmission system. In addition, the 944 X-Tier wheel loader is newly rebranded from the 944K Hybrid to align with the John Deere performance tiering strategy. With over 3 million collective customer hours since entering the market, John Deere E-Drive machines are built on customer experience and electric technology. Other new E-Drive machines include the 850 X-Tier dozer, which has been recently upgraded from the 850L model, providing customers with multiple operating models to tailor performance and fuel consumption to their specific jobsite needs. The less complex drivetrain powers each track with an electric motor to maintain the maneuverability and control of a traditional hydrostatic John Deere dozer. Lastly, the 744 X-Tier E-Drive wheel loader, featuring an electric variable transmission, provides performance in worksites.

The new 950 and 962 Next Generation Wheel Loaders have a Cat C7.1 engine with high-power density with a combination of electronics, fuel and air systems. Equipped with the automatic Cat regeneration system, the engine meets U.S. EPA Tier 4 Final, EU Stage V, Korea Tier 5 and Japan 2014 emission standards without interrupting operation. Electric fuel priming pump, fuel-water separator and secondary fuel filter combine with component design and machine validation to offer reliability and uptime. A range of standard technologies on the 950 and 962 wheel loaders monitor, manage and support jobsite operations. Providing accurate weighing of material, Cat Payload with Assist displays data in real time. The operator can now fully automate bucket loading using new Autodig to boost fill factors and loading times. Working in combination with Autodig, new Auto Set Tires facilitate proper loading technique to reduce tire slip and wear.

DEVELON, formerly known as Doosan construction equipment, has introduced its next-generation tool carrier models — the DL200TC-7 and DL250TC-7 — in the United States and Canada. These new models round out the 7 Series wheel loaders for the company.

DL200TC-7 (replaces the DL200TC-5)

• 142-hp (104 kW)

• Operating weight: 26,868-lbs. (12,187 kg)

• Bucket capacity: 2.6-cu.-yd. (2 m3)

• Dump height: 8-ft.,10-in. (2.7 m)

Breakout force: 20,682-lbs. (9,381 kg) with 2.6 cu. yd. bucket

DL250TC-7 (replaces the DL250TC-5)

• 172-hp (127 kW)

• Operating weight: 31,350-lbs. (14,220 kg)

Bucket capacity: 3.1-cu.-yd. (2.4 m3)

• Dump height: 8-ft., 9-in. (2.7 m)

• Breakout force: 20,231-lbs. (9,177 kg) with 3.1 cu. yd. bucket

Compared to the 85 G-Tier model, the new 85 P-Tier offers an 18% engine horsepower increase and the addition of turbo for high altitude performance. Hydraulic performance improvements include increased pump torque and improved dig forces. The redesigned cab is equipped with an 8-in. monitor with Bluetooth and a 270-degree camera system integrated into the main monitor. Improved service access and optional features, such as angle blade with float and continuous flow auxiliary hydraulics, round out the updates. Coming in at 51-metric tons, the 510 P-Tier is a replacement of the current 470 P-Tier model. Including a variable undercarriage and the ability to handle buckets five yards and above, this new model will continue to deliver performance and capability in its class. This machine is designed to deliver performance to customers in mass excavation or deep underground applications.

Mack Anthem 6x4 Day Cab and 6x4 70-in. Stand-Up Sleeper

The Mack Anthem day cab is outfitted with a Cummins Compressed Natural Gas (CNG) engine with 400-hp, 1,450-lb.-ft of torque and a 12-speed automated manual transmission (AMT). The Mack Anthem 70-in. stand-up sleeper is powered by the Mack MP 8HE engine with 445-hp and 1,860-lb.-ft. of torque. Transferring that power to the wheels is a Mack mDRIVE 12-speed automated manual transmission. Both Mack Anthem models are equipped with Mack GuardDog Connect, Mack’s integrated telematics solution.

Mack Anthem 6x4 Day Cab

• Engine: Cummins ISX12N-G 400-hp ,1450-lb.-ft. torque

• Transmission: Eaton Endurant 12-speed Overdrive AMT

Features: Mack GuardDog Connect; Mack Road Stability Advantage; Bendix Wingman Fusion 2.0 front and side collision avoidance system and Mack aero+ day cab roof fairing

Mack Anthem 6x4 70-in. Stand-Up

Sleeper

• Engine: Mack MP8-445HE engine, 445hp, 1,860-lb.-ft. torque

SEPPI has launched its latest mulching equipment: the MAX 50 le, a mulcher than can be operated by remote control, the MICROFORST cl compact mulcher for skid steers or compact track loaders and the MINISOIL cl that crushes stones and mulches wood. The MAX 50 le can be operated from a safe distance by using a remote control that displays key machine data like fuel, rpm and speed. The MICROFORST cl is a compact mulcher that can attach to any compact track loader or skid steer loader that delivers between 13 gpm and 27 gpm of hydraulic flow. The MINISOIL cl takes the power of a PTO stone crusher and mulcher and brings it down to size for skid steers, compact track loaders and hydraulic tractors that deliver at least 28 gpm to 66 gpm of hydraulic flow.

Makinex has announced it will launch a 32 kW Power Generator. The new model contains advanced alternator technology bringing control, flexibility and reliability to construction sites. The 32 kW Power Generator is the smallest generator in its class. The 32 kW generator allows for seamless running of both three-phase and single-phase equipment, is light enough to transport in the bed of a pickup truck or trailer and small enough to fit through standard doorways. With less than 3 percent harmonic distortion, no transients or voltage spikes on load rejection, the 32 kW Power Generator offers brushless three-phase power. Equipped with a permanent magnet alternator, the generator does not use electronics to regulate the voltage.

New Holland Construction added the C330 vertical lift compact track loader: a medium frame, powerful machine with the ability to maneuver in tight spaces. Notable items include:

The AT120 features 15,500 ft.-lbs. of rotational torque and 3,000 ft.-lbs. of inner rotational torque, a 50 percent increase over the AT100. With 120,000 lbs. of thrust and pullback, the AT120 allows operators to take on a wide variety of projects, as well as move through longer bores and larger diameter installations more efficiently. The drill is powered by a 280-hp Cummins Stage V diesel engine that meets European emissions standards for cleaner jobsites. Built to boost jobsite uptime, the AT120 offers a 20-ft. end-to-end drill pipe on board, helping operators put more pipe in the ground. New technology enhancements include a patent-pending Virtually Assisted Makeup and Breakout (VAM) solution, which ensures the drill pipe and tooling are at the correct levels observed by the torque gauge during a bore.

• The C330 vertical lift compact track loader, with 68-in. working width and 67-hp engine, features the super boom design, New Holland Construction’s Super Boom lift, with low shoulder positioning and small towers to enhance operator visibility and worker safety on the jobsite.

The track loader allows operators to switch between ISO and H-Pattern controls, providing control over drive function and attachments.

• The power management function enables RPM speed management to deliver power to the drives, while the loader valve is under load. This allows the operator to move heavy loads without interruption.

• The C330 vertical lift compact track loader offers more height and reach to load materials into high-sided trucks.

• Engine Brake: Mack PowerLeash

• Transmission: Mack mDRIVE 12-speed overdrive AMT Manual

• Features: Mack Command Steer; Mack MP8HE+ full aerodynamic package; FlowBelow rear chassis fairing; Bendix Wingman Fusion 2.0 front and side collision avoidance system and Mack GuardDog Connect

The S7X is all electric, as it is powered by a 60.5-kWh, lithium-ion battery, features electric drive motors and utilizes ball screw actuators for lift and tilt functions. Together, the battery and electrical powertrain generate performance characteristics, with instantaneous torque that is as much as three times greater than traditional loaders. The loader balances sustainability and performance with zero emissions and is equipped to outperform its diesel-powered equivalent. This skid-steer loader offers operators a smooth and comfortable experience with minimal vibration and nearly silent operation. The S7X can operate for up to eight hours on a single charge depending on the application, giving most operators more than a full day’s work when breaks and downtime are considered. A full charge takes approximately 10 hours. At this time, the S7X skid-steer loader is being debuted as a prototype with plans to move to commercialization.

The LiuGong 856H-E MAX Wheel Loader is part of the company’s range of electric construction vehicles worldwide. The 856H-E MAX is reinforced by an IP67 rated wiring harness and waterproof integrated battery package. This machine is designed for worksites where traditional combustion engines aren’t allowed, or in fixed site operations where investments in charging infrastructure make sense. During use, the 856H-E MAX consumes zero fuel, produces zero emissions and creates lower noise and vibrations. The 856H-E MAX features intelligent controls and a human-centric design to support the operator experience. This includes load-sensing hydraulics, an EAT700 transmission with electro-proportional valve for shifting and independent control of the dual-motor drive for hydraulic lift.

Greater digging power and increased lift capacities are the result of the Spool Stroke Control (SSC) system, which reduces pressure loss and distributes hydraulic oil more smoothly. Pilot pressure sensors detect the type of work being done, such as digging or leveling, and then relays that data to proportional solenoid valves that quickly determine where optimal hydraulic pressures should be directed for that operation. Two electronically-controlled Kawasaki variable-displacement axial-piston pumps and one Kawasaki gear pump assure that hydraulic power is delivered precisely when and where it’s needed. At the same time, hydraulic flows in noncritical areas of the system are reduced. The result is better breakout force, more lifting strength and faster machine response. The X4 Series features innovative EPAcertified Final Tier 4 engines from Isuzu that strike a balance between power, productivity and fuel efficiency.

To meet the challenges of waste management, Komatsu’s WA475-10 WH is a heavy-duty wheel loader with customizable waste guarding packages and tire options that can be configured for specific waste or scrap handling applications. Displayed at CONEXPO/CON/AGG 2023, the WA475-10 WH was developed based on customer feedback and incorporates a pressurized cab, machine visibility and operational features like independent work equipment control. In addition to the customizable waste guarding package, optional joystick steering for maneuverability and visibility is also available. The model includes the next-gen Komatsu hydraulic mechanical transmission (K-HMT).

The Bobcat RogueX combines technologically advanced features to make it a one-of-a-kind conceptual machine. While most closely resembling a track loader, the machine is in a category all its own. As a research and development project, the machine was built as a proving ground to advance the Bobcat innovation roadmap, evaluate customer perceptions and test the limits of machine functionality. As jobsites change and operators turn to remote operation, Bobcat took its concept further by fully eliminating an operator station. The machine explores the idea of operating where humans cannot go to tackle more work in more places than ever from a remote position. RogueX is in the early research and development stage at Bobcat. No additional details on future commercialization are available at this time.

The PC210LCE was created for construction businesses that need a highperformance machine. The excavator has 451 kWh of battery capacity and is designed for up to eight hours of operating time. The lithium-ion battery technology was developed by Proterra. Designed to reduce operator fatigue with less noise, exhaust emissions and zero engine vibration, the PC210LCE is for use in urban areas and indoor environments. The low operating noise levels of the PC210LCE allow for nighttime construction work both indoors and out. Coming soon to North America, the PC210LCE supports Komatsu's global sustainability targets of 50% reduction in CO2 emissions by 2030 and complete carbon neutrality by 2050.

The CL36EV compact wheel loader is designed to deliver all the benefits of electrification in a machine with a small footprint that will excel in applications such as supply yards, large-scale building renovations and construction where indoor operation may be required, and any other operation that may require less noise and no emissions. The CL36EV is a 3.6 metric ton machine with a hinge pin height of over 10 ft. Additional product information and commercial availability at CASE dealers in North America for the CL36EV will be announced at a later date. The updates also include all-new collaborative fleet management capabilities with the introduction of the CASE SiteConnect Module. It improves telematics data transfer, and allows for remote access and software uploads.

In 2024, New Holland Construction will be launching the C314 mini track loader, its first mini track loader to accommodate general contractors.

A lightweight stand-on mini track loader, it's built to maneuver on a variety of jobsites and handle a range of task including loading, dumping and drilling. Additional features include:

• 25 hp

• Paired with an extensive list of loader attachments that can be used with the machine, the new C314 mini track loader has the versatility to dig, load, drill and more.

• The new machine is compatible with New Holland Construction’s 29 attachments and is enabled to operate this wide range of attachments due to its auxiliary flow rate of 15 gallons per minute.

• Thanks to its approximately 1,000-lbs. rated operating capacity (at 35 percent of tipping load) and 35 in. of working space, operators are able to power through mild structural projects, like laying footings for a small building, fence line work and irrigation or drainage tasks.

Weighing in at only 7,350 pounds, this machine is easily towable and with a Rated Operating Capacity (ROC) of 1,890 pounds (@35% of tip), it can do more than many of its heavier competitors. The ST27 comes with a 74-horsepower Kohler KDI 2504 turbocharged engine. The compact design, measuring 60-inches wide and under 80-inches in height, makes it a good fit for working in tight spaces with low overhead clearance. The design also maximizes the ROC of 1,890 pounds, while offering best-in-class reach at dump height of 36.5 inches. This extra reach at max height means it is easier to dump

material into the center of a dump box and keeps the loader farther away from the vehicle or trailer being loaded. The vertical lift, ST27 offers a hinge pin height of 120 inches and dump height of 94.3 inches. Wacker Neuson’s ST27 features a 2-speed standard travel drive that offers an impressive 9.1 miles per hour resulting in faster cycle times. Enhancing the driving experience is a standard auto-shifting twospeed drive system which can be active or disabled based on the application. It automatically senses the operators need to shift. The auto feature engages in and out of the two speeds based on joystick input and eliminates the need for the operator to make manual shifts.

Yanmar Compact Equipment launched a new line of compact track loaders at CONEXPO 2023 in Las Vegas, Nevada. The TL65RS, TL75VS, TL80VS and TL100VS are constructiongrade machines featuring the company’s performance, technology and reliability standards. Ranging from 67-hp to 103.5-hp, the new compact track loaders cover a range of customer needs. They round out Yanmar’s compact equipment lineup made up of mini excavators, compact wheel loaders and tracked carriers. The new line is designed for construction work, rental applications and more. Tier 4 Final Yanmar diesel engines offer performance in outdoor jobsites. The machines have 360-degree visibility and a standard suspended seat. A removable roof hatch escape offers a safety feature for operators. The TL100VS will start production in the spring of 2023 while the other three machines will begin production in late 2023.

Weighing in at 270 lbs. (dry), the Boss BA870 utilizes a single-stage, hydraulic motor-driven, 8-cyl. engine that produces up to 70 cfm at 100 psi. Based on the piston air compressor BA 440, this new BA870 piston compressor is almost twice the performance but not twice the size. By putting two BOSS V4 piston compressors inline and utilizing the efficiencies of the hydraulic system, the BA870 is designed for the big jobs that require big power. At the heart of the system are two aluminum, single stage, V4, pressure and splash lubricated reciprocating air compressors. Fully assembled in the U.S., the aluminum compressor assembly offers lighter weight and higher thermal efficiency than cast iron compressor assemblies. The BA870 includes an internal oil pump for increased lubrication over that of splash lubrication only compressors. And to make life easier for you, all routine maintenance is accessible without removal of the canopy.

The Next Generation of Cat 926, 930 and 938 Wheel Loaders can be customized and equipped direct from the factory or through aftermarket upgrade kits. Target production date is Q4 2023. The models have four powertrain operating modes and Cat Payload for improved precision. Smaller cab pillars, increased window area, heated and electric rearview mirrors with lower parabolic, and standard rearview camera combine to improve operator visibility around the machine. The in-cab display delivers a view of operating parameters. Up to 50 different operating profiles can be set through the display, which the loader can recall when an operator starts the machine. Engine oil and filters and fuel filter service intervals increase to 1,000 hours.

The 3.5-cu.-yd. wheel loaders feature 33,047-lbs. (1,490 kg) of operating weight. The ZW180-7 offers either standard or high-lift front arms for bucket applications. The ZW180PL-7 features a parallel link arm configuration, and can be used in fork and tool carrier applications by keeping attachments parallel with the ground as the loader arms move up or down. Both models are powered by a 173-hp (129 kW) Cummins engine. Approach speed control and an auto power up function are available on the machine. With approach speed control, the travel speed can be adjusted with fewer pedal operations during loading. New for the ZW180-7, a payload weighing system uploads information reporting data to the ConSite telematic system. Operators can check the weight of the load in the bucket from the inside cab monitor and log the material loaded. It offers four modes — tip-off to truck, tip-off to pile, auto-add and manual-add. These modes allow the payload weighing system to manage loads according to their application. In addition, the unit is equipped with a warning function that reacts when the bucket is overloaded.

The addition of a zero-tailpipe emissions, battery-electric vehicle (BEV) to the Mack medium-duty lineup supports the company’s long-term sustainability goals. The Mack MD Electric will be available like its diesel counterpart in Class 6 and Class 7 ratings. The Class 6 model has a Gross Vehicle Weight Rating (GVWR) of 25,995-lbs., and the Class 7 model has a GVWR of 33,000-lbs. Both models are exempt from the 12 percent Federal Excise Tax (FET). The MD Electric’s three-phase Permanent Magnet Synchronous motor and all on-board accessories are powered by Nickel Manganese Cobalt (NMC) Oxide lithium-ion batteries, either in a 150 kWh or 240 kWH configuration. The MD Electric can be charged through AC or DC charging units.

The CX15EV is a 3,186-lb. mini excavator powered by a 21 hp/16 kW electric motor and the CX25EV is a 4,828-lb. mini excavator running with a 27 hp/20 kW electric motor. The lithium-ion battery featured in both machines is charged either by the 110V/220V on-board charger, or via an external rapid charger that can have the machine charged within 90 minutes, all while delivering the benefits of electrified construction equipment: no emissions, reduced noise, and less lifetime maintenance thanks to the elimination of the diesel engine. Both machines feature standard 1-way/2-way hydraulics with an electronic detent hold to reduce operator fatigue, and an optional 2nd auxiliary circuit (2-way only) can be added for more hydraulic options. The new LCD monitor allows flow settings to be set and stored for up to five attachments.

Available in 2024, the 116-hp compact track loader is the company’s first entry in this product category for the North American market. The DTL35 is on the large frame size of compact track loaders from a horsepower perspective. The compact track loader will come standard with a torsion suspension system, providing a smooth ride for operators and durability for use on jobsites. Additional stability with lifting and carrying loads is a benefit of the torsion suspension system.

• Horsepower: 116 hp (86.5 kW)

• Operating weight: 12,604

lb. (5,717 kg)

• Rated operating capacity: 3,657 lb. (1,662 kg)

Ground pressure: 5.7 psi (39.3 kPa)

• Auxiliary hydraulic flow, standard: 23 gpm (87.1 L/min.)

• Auxiliary hydraulic flow, high-flow: 40 gpm (151.4 l/min.)

Japanese-made and U.S. customized and distributed, the IC100-5 is versatile and powerful, designed for a wide range of construction applications. It features a 268-hp Cummins diesel engine to power through heavy-duty tasks, and a joystick for smooth operation and easy maneuverability in tight spaces. This 12-ton machine has a high-capacity payload of 22,000 and a low center of gravity. It is only 102 in. wide, which means it doesn’t require a wide-load permit. This crawler carrier also comes with an optional hydraulic winch. The IC100-5 is designed with both operator safety and comfort in mind. It features a spacious cab and ergonomic controls, which provides maximum visibility and ease-of-use for the operator. The carrier is also equipped with a number of safety features, including multiple camera angles and a ROPS-compliant cabin.

With a powerful Cummins engine and well-constructed componentry throughout, the XE155UCR 16 tonne excavator is designed and manufactured for a wide range of worksites: excavation, mining, loading, leveling, trenching, crushing, drilling, clamping, lifting, etc. With structural components, performance, comfortable operation and safety, the XCMG XE155UCR excavator is designed for any and every operator seeking a value machine in the 15 / 16 / 17 tonne size class.

Overall width: 2,490 mm

Flow range: 2x113.4 lpm

Operational weight: 16,670 kg

Engine: Cummins B4.5

Power: 90 kW/121 hp

As the largest model in Hyundai’s A series wheel loader product line, the new Hyundai HL985A wheel loader offers a standard bucket capacity of 9.1-yd3 (7.0-m3) for use in highproduction jobs such as quarrying, aggregates and other mass-volume material handling applications. The HL985A wheel loader is powered by a 430-hp (320-kW) Cummins X12 Performance Series engine, delivering power and torque, while meeting Tier 4 Final and Stage 5 emissions standards. Heavy-duty ZF axles with wet outboard brakes and with coolers are standard equipment on the HL985, which is powered by a ZF 5-speed transmission. The Hyundai HL985A offers a range of standard features. For example, Smart Power Mode adjusts the engine speed in heavy-duty applications. This can help with balancing traction and breakout forces. Hyundai’s Eco Gauge function enables the operator to monitor fuel consumption in real time or to review historical data. Displayed values include engine torque, fuel efficiency, as well as average and total fuel consumed. Hourly and daily fuel consumption are also viewable through the menu.

Manitou has launched a new line of electrified telehandlers to the North American market — two rotating telehandlers and a compact telehandler — all part of the manufacturer’s “Oxygen” line of low emissions equipment. The new electrified lineup includes the MRT 2260e and MRT 2660e VISION+ rotating telehandlers and the MT 625e compact electric fixed telehandler.

The MRT 2260e and the MRT 2660e are an extension of the manufacturer’s VISION+ line of rotating telehandlers — both delivering 13,200-lbs. of maximum capacity in a 100 percent electric machine. The 700V-65 kWh lithium-ion battery

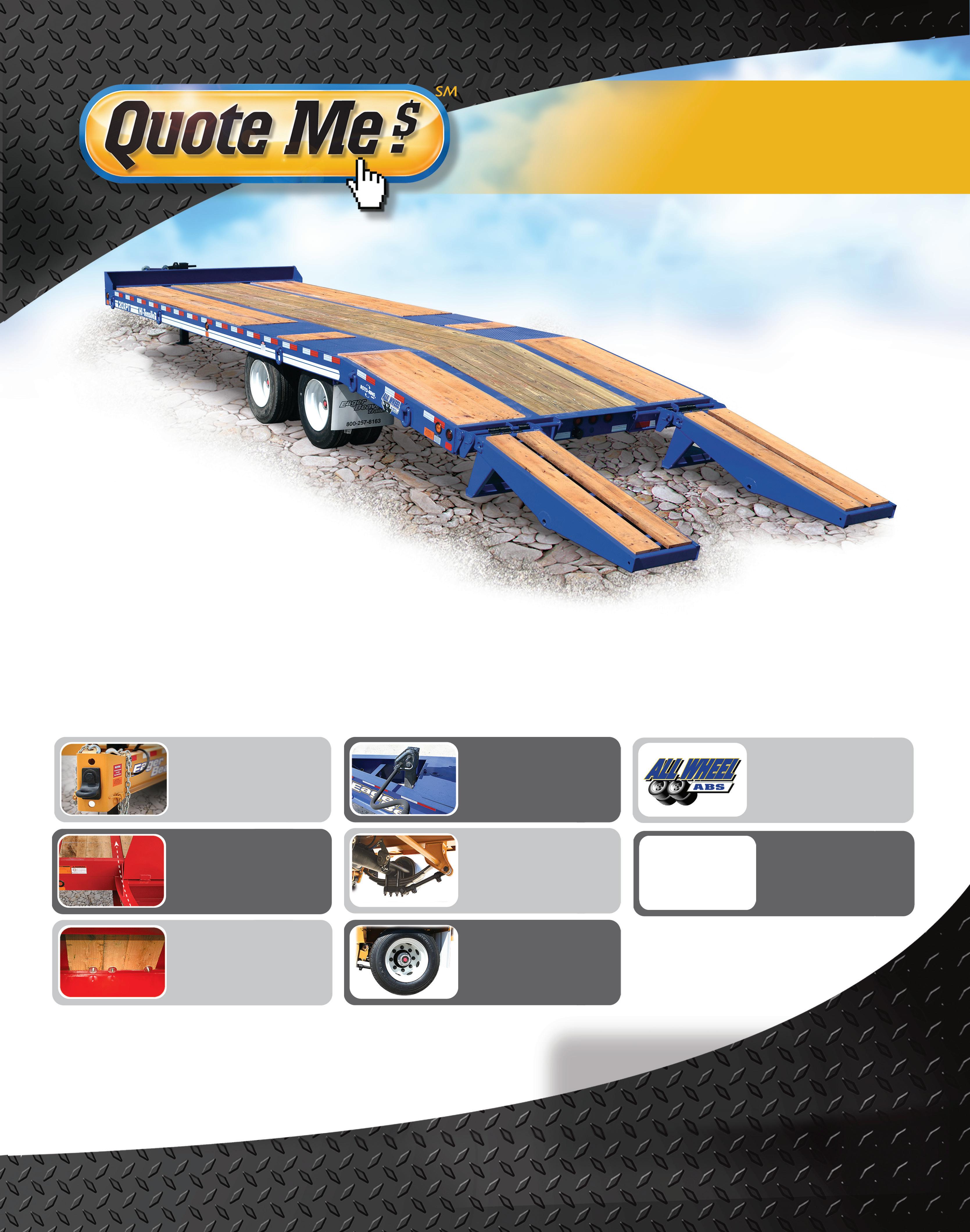

The C550 55-ton hydraulic removable gooseneck construction trailer delivers more load versatility and faster turnaround times to ensure you get more out of every minute on the road or on-site. Premium QT100 steel construction and the largest deck well in the industry enable you to haul a variety of equipment with ease. These trailers are reliable, designed with long-lasting components that eliminate costly repairs and reduce the total cost of ownership. They are also backed by unmatched customer service and support. Through its collaborative product design process, Brandt has consulted extensively with customers to create heavy haul trailers that set the standard for the industry, providing versatility and reliability in a premium product offering.

is built to sustain work in outdoor environments and an optional second battery doubles the battery capacity available for work. Charging times vary. An optional on-board fast charger can achieve charging times in less than an hour in the right conditions and an optional E-Xtra Generator delivers a hybrid experience that can be added to supplement the electric power. There is also a “plug-in” mode that allows the machine to operate while connected to the main energy supply when the stabilizers are extended.

The MT 625e is a 100 percent electric fixed compact telehandler with a maximum capacity of 5,500-lbs., max reach of 19-ft., 2-in., and a max outreach of 11-ft., 1-in. Outfit with either a 25 (standard) or 35 kWh (optional) lithiumion battery, the machine achieves a full charge in just over two hours when equipped with the optional 9 kW on-board charger (3 kW standard). Its compact size (6-ft., 4-in. tall; 5-ft., 11-in. wide; 10-ft., 10-in. turn radius) allows it to work indoors and in tight spaces while still delivering reach and capacity.

The Polaris Pro XD Mid-Size, the Pro XD Full-Size and the all-electric RANGER XP Kinetic are designed for material handling, transporting equipment and moving cargo on construction sites. Pro XD comes in full-size and mid-size versions. The Pro XD Full-Size is offered in both gas and diesel with two- and four-seat versions. It offers a payload of up to 2,075-lbs. and towing of up to 2,500lbs. The vehicle features maintenance intervals of up to 200 hours. RANGER XP Kinetic features an all-electric powertrain giving customers a sustainable option for off-road work needs while addressing the limitations of combustion fleet expansion. It has 110-hp, 140-lb.-ft. of torque and the ability to tow 2,500-lbs. and haul 1,250lbs. The RANGER XP Kinetic has a quiet electric powertrain, as well as a rigid one-piece chassis, full-body skid plate and large front bumper.

The Sullair E1035H features a number of proprietary and patent-pending features which focus on environmental responsibility and user-friendliness. The E1035H is the first to feature swing-out coolers, a patent-pending design which allows users complete access to the coolers – both front and back – enabling more thorough cleaning which helps keep the compressor running optimally. Additionally, the E1035H features unique condensate management technology which helps eliminate the need for additional equipment to dispose of condensate. Delivering equivalent power capacity and efficiency as similar-sized diesel-powered compressors, the E1035H produces 1035cfm at 150 psi, and the Sullair proprietary Electronic Spiral Valve (ESV) provides industry-leading efficiency. The E1035H also boasts added flexibility with its emissionless design allowing it to be used indoors and wherever a 60Hz power source is available. The E1035H runs exclusively on Sullube, a biodegradable, varnish-removing lubricant engineered by Sullair for performance and efficiency.

The all new redesigned KATO 9V5 mini excavator will debut summer of 2023. This ultra-mini zero tail swing excavator is a much faster and easier alternative to any shovel or wheelbarrow for working in tight spaces. With it’s ultra small size and roll down ROPS the 9V5 can even fit through doorways, standard yard gate, and even the tightest spaces making it perfect for any project. Need more stability? Standard equipment includes expandable tracks to help you power through your job with stability and ease. All new 9V5 will be available summer 2023.

Hyundai Construction Equipment Americas revealed three new models in its HX-A series of compact hydraulic excavators: the HX35AZ, HX40A and HX48AZ. All three new models feature low-emission engines that are Tier 4 Final compliant. The Hyundai HX35AZ excavator is powered by a Kubota D1703 diesel engine with a net power rating of 24.8-hp (18.2 kW), while the HX40A and HX48AZ feature Yanmar 4TNV88C engines, rated at 37.4-hp (27.5 kW). The HX35AZ has an operating weight of 8,300lbs. (3,765 kg), dig depth of 9-ft., 8-in. (2.95 m) and bucket breakout force of 7,081-lbs. (3,212 kg). The HX40A has an operating weight of 9,479-lbs. (4,300 kg), dig depth of 11-ft., 2-in. (3.4 m) and bucket breakout force of 9,846-lbs. (4,466 kg). The HX48AZ has an operating weight of 10,912-lbs. (4,950 kg), dig depth of 11-ft., 5-in. (3.5 m) and bucket breakout force of 8,223-lbs. (3,730 kg).

Capable of mulching overgrowth, underbrush and small trees, the FMX28 offers a solution for clearing land and more. Paired with 3.5- to 8-ton excavators, the compact package makes it easy to access traditionally difficult-to-reach places. The excavator-mounted FMX28 allows for precision in vegetation management, enabling the removal of a single tree in a group or even specific branches that need to be trimmed back, an ability traditional skid-steer mounted mulching heads can’t offer. Unlike competitive units which are simply shrunk down from a larger design, the FMX28 features a design purpose-built and optimized for standard flow excavators that are 3.5- to 5-tons and can operate with as little as 12 gpm, ensuring exceptional performance in demanding site clearing and mulching applications. With an overall width of 40 in. and a working width of 28 in., the attachment mounts on excavators up to 8 tons, allowing a narrow mulching cut for precision removal.

Compact and nimble, the TW60 Series 2 is well equipped to handle a wide range of jobs and attachments. A universal hydraulic skid steer coupler enables the TW60 Series 2 to utilize a wide range of skid steer attachments, and it is easily controlled from the operator’s station. The quiet and turbocharged engine is equipped with a DOC/DPF exhaust aftertreatment system and produces 61 horsepower (45.6 kW) for excellent power and performance around the job site. 100% locking differentials can be engaged at low speeds allowing the operator to work in varied terrain and extreme conditions. Daily maintenance and inspections are simple to perform on the TW60 Series 2 due to the engine hood that opens overhead providing access to key inspection points and grease points that are easily accessed on the loader and articulation points.

The Hitachi ZX130-7 and ZX160LC-7 excavators are fullsized hydraulic excavators engineered for a wide range of tasks on the jobsite. The 30,870-lb. (14,000-kg) ZX130-7 offers a maximum dig depth of 19-ft., 9-in. (6.03 m) and a bucket breakout force of 23,380-lbs. The ZX160LC-7 has an operating weight of 39,463-lbs. (17,900 kg), a maximum dig depth of 21-ft., 4-in. (6.49 m) and a bucket breakout force of 25,179-lbs. The HIOS IV hydraulic system helps minimize hydraulic loss during operation. It ensures a responsive boom, arm and bucket with intuitive control. The ZX130-7 and ZX160LC-7 feature adjustable attachment, arm and swing priority through the monitor to match machine performance with the attachment. The ZX130-7 uses a 100-net-hp (74.9 kW) Isuzu engine. A durable Yanmar engine powers the ZX160LC-7, producing 132-net-hp (98.6 kW). It features economy, power and high-power modes to match available power to the working conditions. An auto idle system with auto shut-down control prevents wasted fuel.

Apply today at BestContractorsToWorkFor.com

APPLICATION DEADLINE JULY 7, 2023

Wacker Neuson is expanding its utility track loader lineup with the launch of the SM60 and SM120, which complements the launch of the SM100 in late 2021. These stand-on utility track loaders are designed for operator comfort, ease of operation and to reduce maintenance costs and total cost of ownership. The smallest in the series is the new SM60. This unit is ideal for rental and homeowner applications. It is powered by a 26.5-horsepower Kohler Command Pro EFI gasoline engine, which is easy to start, fuel efficient and easy to service. The SM60 is designed for smaller, DIY jobs with 7.1-in. wide tracks and an overall machine width of 35.5 in. It has a rated operating capacity at 35 percent of 600 lbs., travel speed up to 3.9 mph and hinge pin height of 75.6 in. to reach into truck beds and dumpsters. Weighing in at only 2,760 lbs., this machine is easy tow. The SM60, with all its versatility is a great choice for the weekend warrior who needs to complete a to-do list. The largest in the series is the SM120, designed for the professional who needs to lift, move and place more during their landscape, tree service and site work. Powered by a 24.7 hp Yanmar diesel engine, the SM120 has a rated operating capacity at 35 percent of 1,226 lbs. and a travel speed up to 5.2 mph, providing fast cycle times. The 41-in. wide machine is equipped with 11-in. wide tracks providing ultra-low ground pressure to greatly reduce turf and soft ground disturbance, while also enhancing traction and stability for hill operation. The SM120 also features an optimized radial path design that provides vertical path performance with best-in-class hinge pin height of 85.6 in., which allows for dumping into high-sided trailers, truck beds and dumpers.

The VMAC DTM185 air compressor is a directtransmission mounted PTO driven air compressor that delivers 185 CFM. The DTM185 was designed and engineered by VMAC to meet the demand for a powerful vehicle integrated air compressor for charging gas lines, fixing potholes, installing fiber optics, and breaking up concrete. This system has enough air to power two 90 lb. jackhammers at 100% duty cycle, or one jackhammer at PTO idle.

Apply for a chance to be acknowledged as an exceptional employer that demonstrates people are their most important asset.

Manufacturers have spent years honing technology to allow contractors to do more with less and find ways to complete projects more effectively and with fewer emissions.

Whether you attended Work Truck Week in Indianapolis or CONEXPO-CON/AGG & IFPE 2023 (CONEXPO) in Las Vegas in March, or stayed home and followed show updates from your smartphone, one thing was abundantly clear: this year’s construction industry tradeshow

season did not disappoint. Per usual, CONEXPO, North America’s largest construction heavy equipment exhibition was brimming with innovation throughout the 3 million square feet of show space.

The nearly 140,000 industry professionals who ventured to the record-attendance tradeshow were

able to network with peers, see new and updated heavy equipment, view demonstrations of the latest innovations and hear the latest business developments from their favorite manufacturers.

Specifically, industry-wide themes at CONEXPO included topics such as new product development, artificial

intelligence and automation, new power sources and technological advances in fuel efficiency, productivity and safety. Manufacturers have spent years honing technology to allow contractors to do more with less, to more quickly train new workers and to find ways for construction companies to complete projects more effectively and with fewer emissions.

Construction heavy equipment is our passion at Equipment Today, so naturally, we took our entire team with us to the show to cover it as thoroughly as possible. Throughout the pages of this issue (and upcoming magazines issues, as well), we’ve highlighted some of the trends and more than 100 products from CONEXPO. Many manufacturers gave booth tours and product walkarounds, which we filmed on video and recorded for podcasts and wrote several articles about – all of which can be found on our website, ForConstructionPros.com.

There is so much news and updates to share with you about CONEXPO, it’s challenging to summarize it all in one place. Here, we chose to focus on some of the world’s largest construction heavy equipment manufacturers and what they shared with us at the show. Many discussed new technologies they’ve integrated into their machines and ways to lower emissions. There were several announcements about continued business expansion throughout North America and improvements to the equipment supply chain. In this issue, we focus on wheel loaders, while in May, you’ll see more compact track loader coverage and in June: excavators.

The world’s largest construction heavy equipment manufacturer had one of the largest outdoor demonstration areas during the show, at 70,000 square feet, where attendees flocked to see more than 30 new machines, watch the Global Operator Challenge Finals and visit the company’s Services, Technology and Sustainability hubs. The company exhibited many new technologies designed to improve uptime and keep costs down. The Cat Command for Loading remote control system for its small wheel loader line was one of the many technologies demonstrated at the show. Cat also unveiled its 950 and 962 Next Generation Wheel Loaders that aim to increase productivity 10% while meeting U.S. Tier 4 Final emissions

standards. Meanwhile, Cat Payload is more widely available, as it now comes standard on the 926, 930 and 938 nextgen wheel loaders.

There are new options for the Cat Smart Grader Blade and Smart Dozer Blade. The new external control kit for GB120 and GB124 smart grader blades expands the use of these blades to Cat D and D2 series SSL and CTL machines, allowing customers with previous model fleets to run smart blades. The new 3D grade control kit uses existing connections to add automatic blade

control to the Cat Smart Dozer Blade. The new external control kit allows operators to run smart grader blades on all D-series and select older Cat machines and includes a third joystick for operating blade raise/lower, tilt, angle and wing functions like smart control for D3 series machines. Cat also showcased new mobile apps: Cat Central that can help locate replacement parts and manuals. The SIS2GO app helps users with maintaining, troubleshooting and repairing Cat equipment. The VisionLink app helps

simplify fleet management accounts for contractors, offering asset tracking and more.

At its Sustainability Hub, Cat exhibited four battery-electric machine prototypes: the Cat 301.9 mini excavator, 320 medium excavator, 950 GC medium wheel loader and 906 compact wheel loader, including AC and DC charging solutions. The Caterpillar-designed batteries are built on lithium-ion Cat technology with a modular design that offers

flexible configurations across multiple applications.

To showcase the capabilities of its Cat Remanufacturing services, the company exhibited a rebuilt dozer with a remanufactured engine at its CONEXPO exhibit.

“At Caterpillar, our machines are built to rebuild,” said Brian Edwards, a senior vice president of Caterpillar who oversees the Cat Remanufacturing Division. “So we design with the purpose of providing multiple lives (for equipment). Not only does that allow them to really maximize their investment, but we focus on the total cost of ownership. We’re constantly trying to provide valuable solutions that lead them to lower their cost of operating every day.”

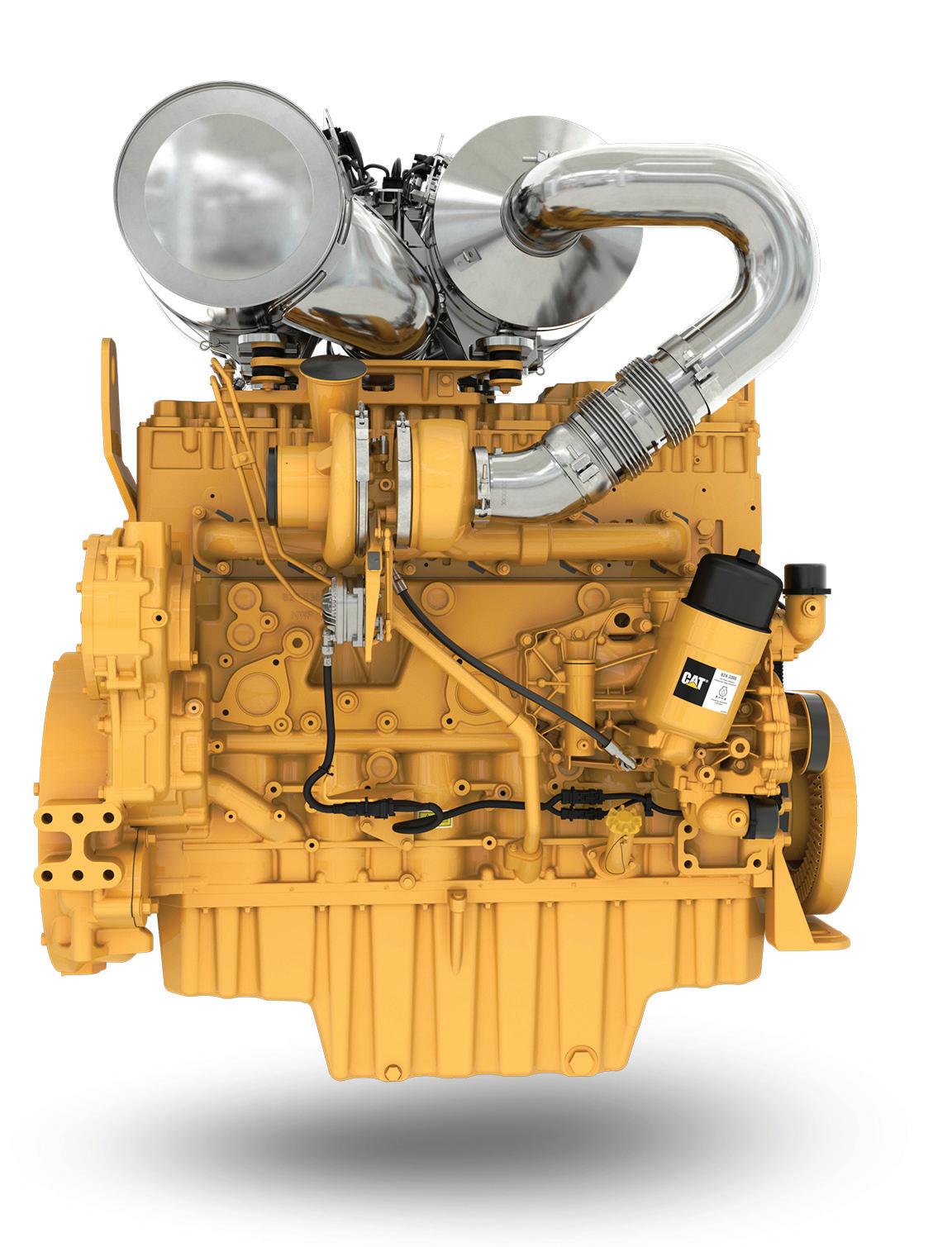

Another big hit at the Cat booth was the 6-cylinder Cat C13D engine platform, which will offer eight power ratings from 456 horsepower (hp) to 690 hp—340 kilowatts (kW) to 515 kW with up to 3,200 Newton meters of peak torque. Enginemounted aftertreatment and cooling packs will be available from the factory to reduce installation and validation costs. The C13D will meet the emissions standards of higher regulated markets, such as EU Stage V, U.S. EPA Tier 4 Final, China Non-road IV, Korea Stage V, and Japan 2014, with models available for lesser regulated markets, said Dustin Childers, global marketing manager, Caterpillar Industrial Power Systems Division.

CASE

CASE Construction Equipment also unveiled more than 30 new machines, including new attachments, technology and more. CASE spotlighted its backhoe loaders, which have been outfitted with new configurations and abilities. Among them, the industry’s first electric backhoe loader, the 580 EV. The machine promises to need less maintenance and emit less noise and emissions than its traditional counterparts.

The company also featured its TV620B compact track loader, one of the largest in the industry, with a 114-hp engine and a 6,200-lb. rated operating capacity. Its heavy-duty undercarriage and heavy-duty 17.7in. rubber tracks allow for 6.1-psi ground pressure and performance on improved surfaces.

The 3.6 metric ton electric CL36 EV compact wheel loader also made an appearance. Designed to include the benefits of electrification with a small footprint, the machine can be used indoors and outdoors.

67-hp engine, features the super boom design, New Holland Construction’s Super Boom lift, with low shoulder positioning and small towers to enhance operator visibility and worker safety on the jobsite.

“The C330 vertical lift compact track loader creates the perfect mix of job versatility and maneuverability on any residential construction and landscape jobsite,” said Ryan Anderson, product marketing manager for New Holland Construction North America. “We can’t wait to get this machine out into the field to showcase how our power management technology and enhanced visibility to get the job done more efficiently performs.”

New Holland also displayed its new D Series backhoe loader, economy-class B75D backhoe loader, C314 mini track loader and E15X electric power mini excavator.

Cummins

our customers and the important jobs they need to do every time.”

The company is pursuing development of engines that will use diesel, natural gas, gasoline and propane, as well as other sources.

John Deere

Another one of the largest exhibitors at CONEXPO-CON/AGG, with 80,000 square feet of exhibit space, John Deere hosted a large outdoor area with a variety of equipment on hand. Of that space, 10,000 square feet was dedicated to Deere technologies, including SmartGrade and SmartDetect systems.

“Over the last couple of years, we’ve introduced a lot of new features, specifically with wheel loaders, when it relates to better visibility on the jobsite and better safety features,” said Luke Gribble, solutions marketing manager for John Deere.

“CASE is building on an enviable, 180-year heritage of making a difference in our industry and the world,” says Terry Dolan, vice president — North America, CASE Construction Equipment. “The past three years have led us to the next chapter in our evolution, focused on one goal: to help customers get more work done, easier and more profitably than ever before. We are committed to the promise that no one will outwork us in earning customers’ trust and helping their businesses thrive.”

CASE’s parent company, CNH Industrial, recently acquired Sampierana, to boost CASE’s miniexcavator lineup. CNH also signed an agreement with Tobroco-Giant for sales, distribution and support of CASE small articulated loaders.

CASE has also expanded its CASE SiteConnect Module and launch new programs like CASE TrackCare, an undercarriage monitoring program for the lifecycle care of steel undercarriages.

Also owned by CNH Industrial, New Holland Construction had several CONEXPO-CON/AGG product launches of its own. One of the more popular launches was the C330 Vertical Lift Compact Track Loader, with its compact, medium-sized frame. The C330 vertical lift compact track loader, with 68-inch working width and

Of note is recent announcements made by engine manufacturer Cummins. At Work Truck Week in March, the company announced the launch of its zero-emissions brand, Accelera. A business segment of Cummins, Accelera will serve as a components supplier and will focus on batteries, hydrogen fuel cells, e-axles, traction drive and electrolyzers. Accelera currently has operations in North America, across Europe and in China, with additional joint ventures that operate in the Netherlands and China.

Cummins also recently announced its X10 diesel engine that will be available in 2026, when it will be compliant with the U.S. Environmental Protection Agency’s 2027 emissions regulations.

SmartDetect uses a camera system with object detection technology, which can discern people from objects. The machine can even automatically slow down when objects enter its path.

Meanwhile, SmartWeigh, which is available on P- and X-Tier utility wheel loaders, is a payload weighing system that helps operators hit loading targets and minimize material loss.

Overall, Deere unveiled 36 products at the show. One of the highlights was the debut of its new P-tier construction machines, including dozers, skid steers, cold planers, excavators and more. The machines include upgradable technology and improved operator comfort and cab functionality. With EZ Grade in base models with EH controls, as well as optional slope control and 2D laser capabilities, the 450, 550 and 650 P-Tier machines have many technologies available.

“We are committed to advancing diesel technology while our markets and our customers need it to run their businesses. The new X10 has been designed drawing on our decades of experience as a leader in the medium and heavy-duty space,” said José Samperio, executive director, North America On-Highway at Cummins Inc. “We have applied those learnings to ensure the product will perform for

All models are compatible with laser receivers, helping control elevation and slope while using a rotating laser. The P-Tier small dozers with EH controls arrive from the factory with EZ Grade features, however, the owner can upgrade to Slope Control or SmartGrade technology in the future,. As an additional feature, the new 8-in. touchscreen cab display offers

navigation of slope control and machine settings on EH machines.

DEVELON

Formerly known as Doosan, DEVELON celebrated the launch of several new machines at CONEXPO with a ribbon cutting on the first day of the tradeshow. At that event, parent company Hyundai Doosan Infracore CEO Young-cheul Cho said it was DEVELON’s goal to become a top five heavy equipment manufacturer for the North American market by 2025. He said the company has plans to improve its performance in the compact equipment segment and grow its dealer network.

“This shows our commitment to North American customers,” Cho said.

The company has launched a mini excavator and a compact track loader in the North American market and has plans to add a small dozer to the lineup soon. Plans are also in the works to add electric versions of the machines.

The company announced several new products and upgrades to existing machines at the show. One of the product launches was the 116-horsepower DTL35 compact track loader, the company’s first entry in this product category for the North American construction market.

An existing machine, the DL3207 wheel loader, which is part of the next-generation 7 Series lineup, for example, received upgrades such as increased bucket capacity, redesigned cab with comfort improvements and fuel-saving technologies. The improved cooling system features wider radiator fin spacing and a reversible fan to clear debris and reduce clogging. The wider front fender also offers better windshield protection.

Bobcat

A member of the Doosan Group, Bobcat showcased two concept machines at CONEXPO.

The Bobcat T7X is the first allelectric compact track loader and the S7X electric skid steer loader. The S7X is powered by a 60.5-kWh, lithium-ion battery, features electric drive motors and utilizes ball screw actuators for lift and tilt functions. It can operate for eight hours and takes 10 hours for a full charge.

Bobcat launched its RogueX track loader at the show. The machine was

designed with remote operations and autonomous functionality in mind.

"We challenge what's possible, break new ground and empower people to do more," Doosan Bobcat North American President Mike Ballweber said.

Hitachi Construction Machinery Americas

Several new and improved machines were rolled out by Hitachi Construction Machinery Americas at the show, including excavators and wheel loaders.

The 33,047 pound, 3.5 cubic-yard Hitachi ZW180-7 and ZW180PL-7 wheel loaders offer standard or high-lift front arms. The ZW180PL-7 specifically has a parallel link arm configuration for fork and tool carrier applications.

“With the three front linkage options, these wheel loaders offer the versatility to handle any application, whether the loader is used to move pallets around the yard, load materials into trucks or manage stockpiles,” said Matt Koester, wheel loader product manager for Hitachi.

At its 31,000 square foot exhibit at CONEXPO, Hyundai Construction Equipment Americas displayed and demonstrated a variety of compact excavators, skid steers, compact track loaders and wheel loaders.

The three compact excavators at the show included the HX35AZ, HX40A and HX48AZ, which comply to Tier 4 Final emissions standards and have increased cab visibility and a number of operator comfort features.

The new Hyundai HL985A wheel loader, with a bucket capacity of 9.1-yd3 is designed for use in highproduction jobs such as quarrying, aggregates and other mass-volume material handling applications.

“We refer to the HL985A as a ‘true two-pass’ wheel loader because it can fill one of our HA30 articulated dump trucks with two bucket loads,” said Joe Turnage, Senior Product Manager, Hyundai Construction Equipment Americas. “With the addition of the HL985A, the Hyundai wheel loader line includes models that fulfill the needs of every important wheel loader application. At the same time, like every A Series wheel loader model, the new Hyundai HL985A provides the combination of power, performance, fuel efficiency, and operator safety and comfort that successful contractors expect from Hyundai.”

Jennifer Rumsey, president and chief executive officer of Cummins, gave the keynote address at the Green Truck Summit on Tuesday, March 7, highlighting her expansive industry knowledge and providing thoughtful analysis of what she deemed, “the messy middle,” or the time before complete decarbonization occurs in the on-highway trucking industry. Be sure to listen to OEM Off-Highway's exclusive interview with Rumsey here.

At the semi-annual work truck industry 2023 economic overview with NTEA director of market data and research Stephen Latin-Kasper, Kasper shared statistics on the United States’ and Canada’s current economic activity, including truck manufacturer production, orders, housing starts and inflation.

The NTEA research demonstrated that a small but likely quick recession may occur in the second half of 2023, but consumer spending is still well above typical recession time expenditures. And Kasper said, "we are expecting that [consumer expenditure] to continue growing."

"So, in '23, in all of these big segments of the industry, is expected to be a reasonably good year for sales," Kasper said of the commercial vehicle market. "The primary limiting factor is going to continue to be the availability."

Both Isuzu and Mack launched medium-duty electric trucks at Work Truck Week, on the heels of Navistar International's medium-duty electric truck launch in 2022. The Isuzu N-Series EV is the first electric truck from Isuzu to be introduced in the US market. It has a 19,500-lb. gross vehicle weight rating and will use 20 kWh lithium-ion battery packs in configuration options of three, five, seven or nine battery packs. Isuzu leadership predicts the truck will be available for purchase in early 2024. Its all new cab will be featured in the entire Isuzu lineup in 2024 and 2025.

"The charging infrastructure has grown considerably over the last several years. We have customers that are moving toward carbon neutrality and state and federal programs will reward early adopters," said Shaun Skinner, president and CEO of Isuzu Commercial Truck of America and Isuzu Commercial Truck of Canada. "We're ready for a future with multiple powertrain offerings. Gas, diesel and electric. And that means more power for our customer to choose the perfect truck for their needs."

The new Mack MD Electric will be available, like its diesel counterpart, in Class 6 and Class 7 ratings. The Class 6 model has a gross vehicle weight rating (GVWR) of 25,995 pounds, and the Class 7 model has a GVWR of 33,000 pounds. The MD Electric’s three-phase permanent magnet synchronous motor and all on-board accessories are powered by nickel manganese cobalt (NMC) oxide lithium-ion batteries, either in a 150 kWh or 240 kWH configuration. The MD Electric can be charged through AC or DC charging units.

Both Ford Pro and Ram launched new all-electric vehicles loaded with features. The new Ford Pro electric model is an all-electric school bus, an ideal EV because of its cyclical routes and ability to return to a home base for charging every day.

Ram estimates that its new electric pickup will be available by late 2023. However, this may be ambitious, given the persisting supply chain difficulties and tight labor market that Kasper referenced in his NTEA work truck industry economic overview, but we will see what happens later in the year.

Read more of this article at ForConstructionPros.com.

AC

Editors

Read more at: https://eqtoday.co/sf8h6q

There is no doubt about it. Reliability is critical for wheel loader owners. And, over the years, traditional wheel loaders have proven to be highly reliable, day after day, year after year.

It is no surprise then that manufacturers like John Deere continue to offer a variety of traditional wheel loaders in its lineup. In fact, a majority of its wheel loaders are considered traditional. And they provide operators several performance features that, simply put, enable them to be highly capable for practically any application.

Yet, despite some customers’ hesitancy to explore hybrid style wheel loaders, as they’re afraid of replacing their longstanding, reliable machines, John Deere is certainly not afraid to think outside of the box, as it’s looking ahead to the future. And the future — without question — is wheel loaders powered by alternative fuels.

Alternative fuel-powered wheel loaders are definitely not “new” or unproven in the field either, as several have been in the marketplace for years. One such example is John Deere’s E-drive loaders, particularly its 644 X-Tier and 944 X-Tier, each of which is hybrid powered.

“If customers are on the fence between purchasing a traditionally powered wheel loader and a hybrid-powered wheel loader, they should know that John Deere’s E-drive loaders have accumulated more than 3 million field hours between them,” said Luke Gribble,

solutions marketing manager, John Deere. “The 944 X-Tier is even backed by an eight-year, 20,000-hour electric drive component warranty that covers its electric drive components. An annual inspection, conducted by a certified dealer technician, is required though.”