We showed off a lot in Vegas this year. New features, new cabs, electrification, but across all of it, one thing stands out. For us, finished is never finished. Once something is done, we look to how we can do it better. That’s why when we decided to make our new excavators 100% ourselves, we told R&D to use our current production benchmarks as the numbers to beat. Because the work deserves it, you deserve it, and because we didn’t get into this business to settle for anything less.

12

EARTHMOVING TRENDS

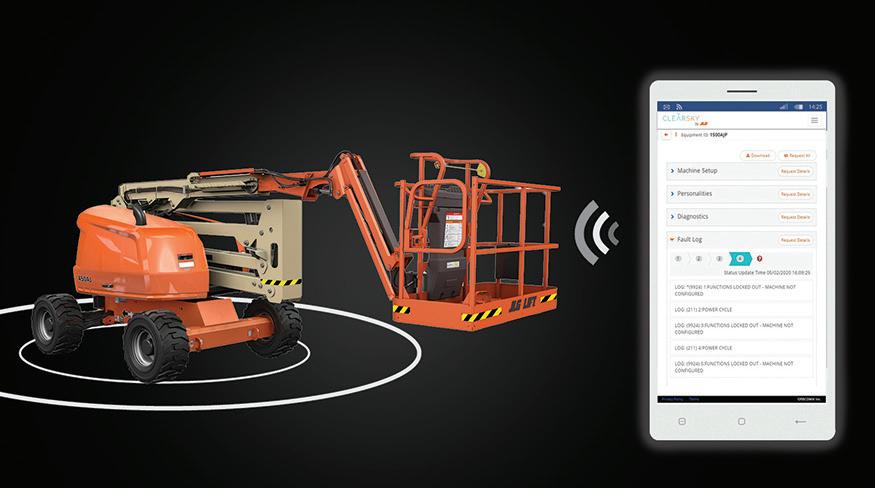

Data Upgrades to Fleet Maintenance

Data points are like puzzle pieces that when connected properly, can change the way you operate your business.

FLEET MANAGEMENT

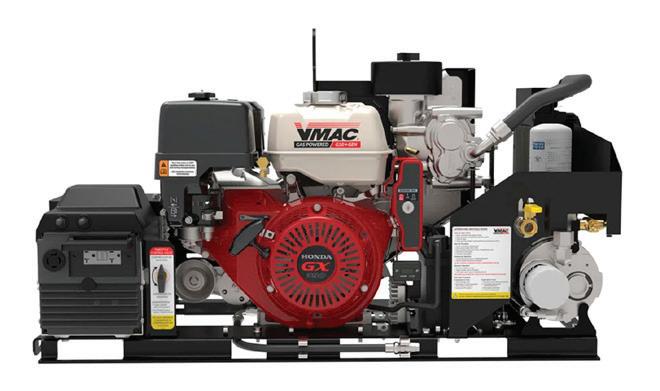

Smart Compressors Adding Advanced Monitoring to Jobsites

Compressors are able to adapt operations to best suit the needs of a jobsite, especially with increased “smart” features.

FLEET MANAGEMENT

What to Consider Before Renting Generators & Compressors for Construction

Generator and compressor manufacturers lay out the trends rental companies should keep top of mind.

FLEET MANAGEMENT

Unlock Hidden Data to Improve Construction Fleet Efficiency With Telematics

The construction fleet industry has advanced in ways we previously would not have imagined.

Next Generation CTLs From CONEXPO Equipment manufacturers respond to high demand for land-clearing power and technology in easy-to-use compact track loaders.

BREAKING GROUND

New Editor-in-Chief Joins the Equipment Today Team Lori Ditoro becomes editor-in-chief after more than a year with OEM Off-Highway magazine.

EQUIPMENT INTRODUCTIONS

Check out the Latest Equipment Compact track loaders and other earthmoving equipment.

PROFIT MATTERS

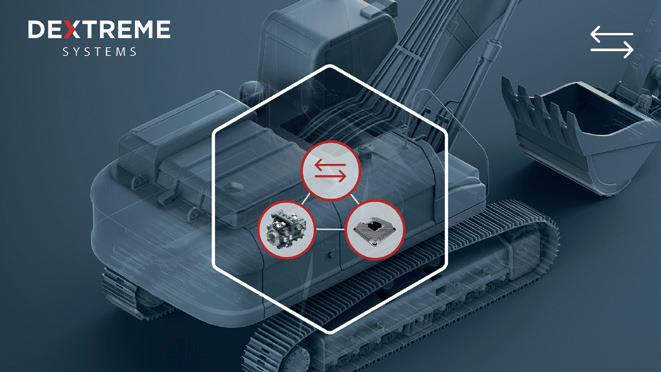

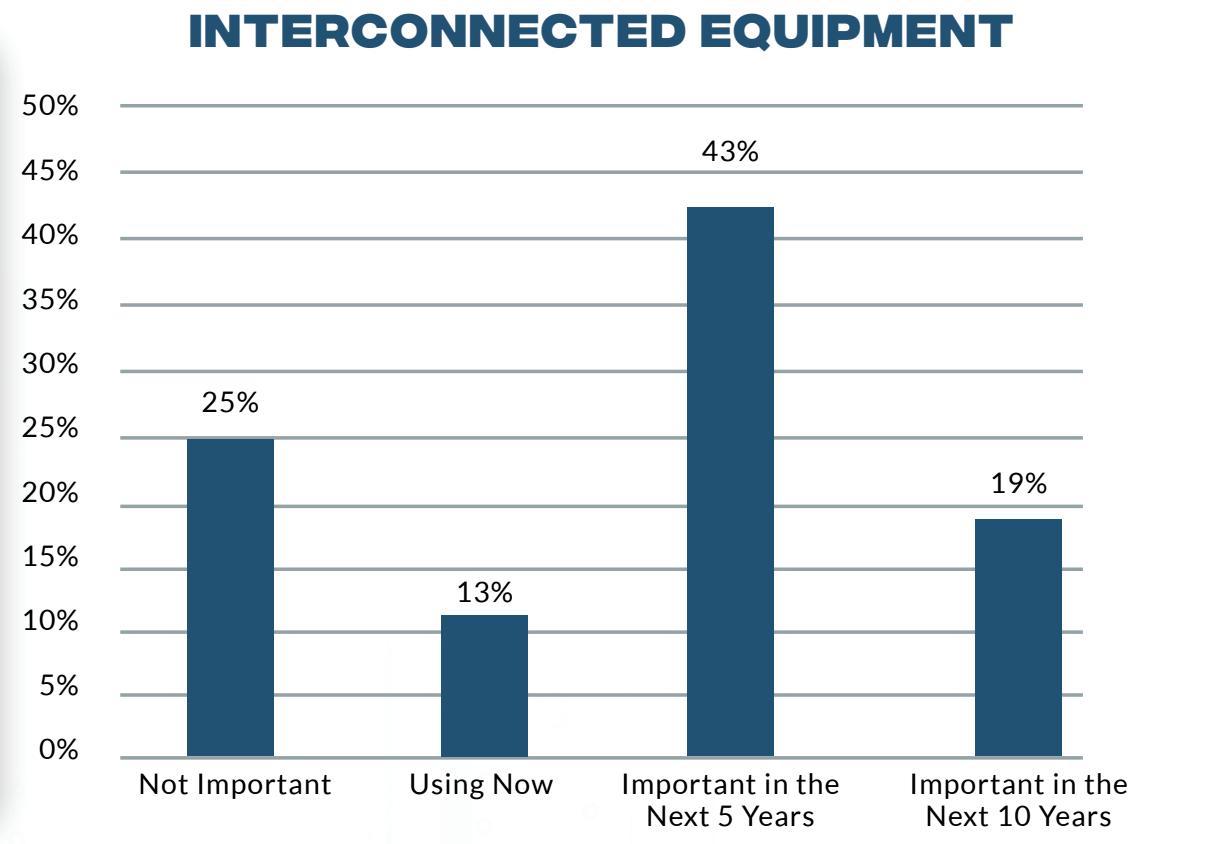

Why Connected Construction Equipment is Hot in 2023 Machine control is being thrust to the forefront of construction technology.

RUNNING THE BUSINESS

The Agony of Idle Equipment on a Construction Jobsite Poor controls cost you money two ways; loss of work and increase in costs.

EARTHMOVING TRENDS

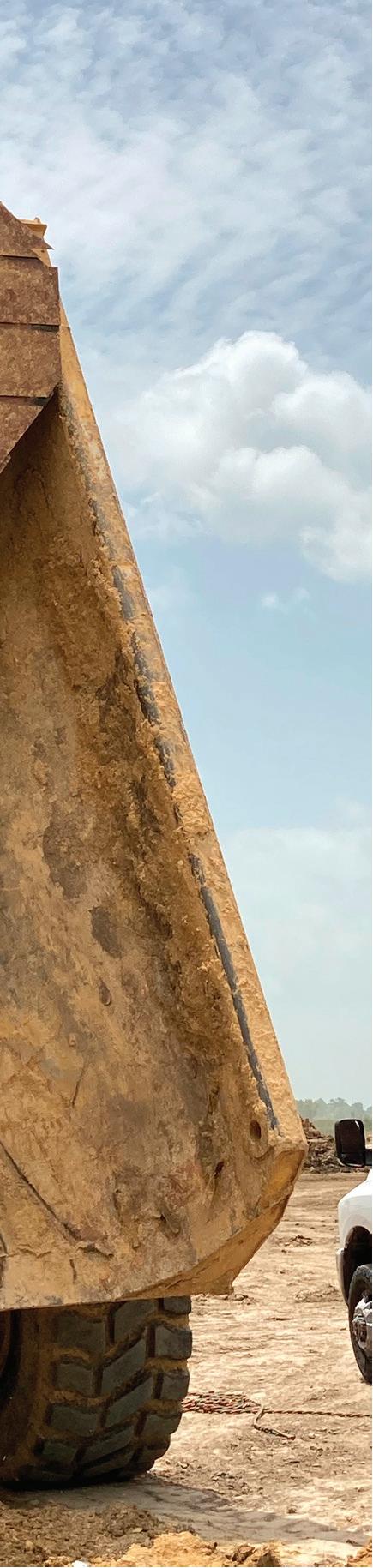

Moving dirt with heavy equipment.

FLEET MANAGEMENT

Products to manage your fleets.

TECHNOLOGY

Mobile apps and machine control to optimize equipment and the jobsite.

VIDEO NETWORK https://eqtoday.co/k2p285

FLEET MANAGEMENT

Construction Fleet Sustainability Targets Find an Efficient Solution in Mobile Fueling

The hunt for solutions to decarbonize construction fleets is on.

FLEET MANAGEMENT

Reducing Equipment Carryback & Improving Hauling Efficiency

Carryback works against efficiency by reducing payload in the haul truck.

TECHNOLOGY

Construction Software X Factors

Moves by HCSS, Trackunit, Trimble, Procore and others are showing that when it comes to construction software, life is better with friends.

TECHNOLOGY

3 Ways to Add Technologies to Your Construction Site

The construction business has an enormous amount to gain from digitalization.

TECHNOLOGY

Is Technology the Key to Stronger Supplier Relationships? Strong supplier relationships are the lifeline of a successful construction business.

DIGGING DEEPER PODCAST https://eqtoday.co/s7sfkm

PREMIUM CONTENT https://eqtoday.co/9pd73s

®

Lori Ditoro Editor-in-Chief Equipment TodayIam thrilled to be the new editor-in-chief of Equipment Today!

During my time as editor of OEM Off-Highway, I enjoyed learning more about the construction industry and the trends affecting it. I also gained knowledge about components and technology, and I expect that knowledge will help me share ideas about aftermarket additions to your fleets to improve efficiency, decrease emissions and help operators with their jobs. I look forward to sharing this knowledge with you, the readers of Equipment Today, and learn more about what these trends and tech mean for contractors with boots on the ground.

Before joining OEM Off-Highway, I worked as the marketing manager for SEPCO, a fluid sealing manufacturer focused on the industrial and municipal sectors. I was a content marketing strategist for Fluke Reliability, where I spent a lot of time learning about the reliability and maintenance world of industrial plants and facilities.

Prior to my content marketing roles, I was in editorial roles including editorial director of the Process

Flow Network, publishers of Water Technology, Processing, and Flow Control; editor of Pumps & Systems; and editor of Upstream Pumping.

Some of the trends affecting original equipment manufacturers (OEMs) are impacting contractors, too. A few examples are:

Decreasing carbon and particulate emissions

An aging workforce and workforce shortages

An unstable oil and gas industry

Supply chain slowdowns and disruptions

However, challenges bring disruption, and disruption often results in innovation. Innovations that the industry is embracing are alternative fuels for powering equipment, digital technologies to improve operations and efficiencies, and onboard telematics to maximize maintenance intervals and monitor equipment operations and operator activity.

Of course, we have been talking a lot about CONEEXPO-CON/AGG (CONEXPO), and the trends mentioned above were front and center during the construction industry’s main event. In the April issue, we included a comprehensive look at CONEXPO and Work Truck Week. If you missed it, you can check it out here: https://eqtoday.co/2p6a7h.

I look forward to learning and building upon my base industrial knowledge as our team continues to share valuable information with you, while we, likewise, receive information from you to inform us. I look forward to seeing where we are headed and sharing it all with our print and digital readers. If you have topics you would like covered, or questions for me, please reach out. I would love to hear from you and get to know you. Email me at lditoro@acbusinessmedia.com, or message me on Twitter using @LoriDitoro.

EDITORIAL

Editor-in-Chief Lori Ditoro lditoro@acbusinessmedia.com

Digital Content Director, IRONPROS Wayne Grayson wgrayson@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

Editor, Construction Equipment & Product Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Kristin Pride kpride@acbusinessmedia.com

Sales Representative Megan Perleberg mperleberg@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Marketing, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: (877) 201-3915 Fax: (847)-291-4816 circ.EquipmentToday@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS &

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

lditoro@ACBusinessmedia.com E @EquipmentToday D @EquipmentToday C @equipment-today-magazine-official Q @equipmenttoday

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

Kubota Tractor Corp.'s SVL753 compact track loader is powered by a 74.3 hp Kubota engine with higher maximum torque, and features that include an Advanced Multifunction Valve (AMV) for simultaneous operation of all hydraulic functions, a new 7-in. color LCD panel with jog dial that puts a wide range of functions and information at the operator’s fingertips, and a new one-piece sealed cab, the SVL75-3 will be available at authorized Kubota dealers beginning in May 2023.

Read More at https://eqtoday.co/56qtfv

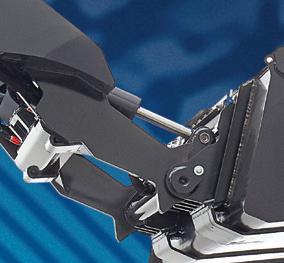

Caterpillar announced a range of new attachments available for backhoe loaders and mini excavators, increasing application versatility for these machines. The new models span the range of demolition and sorting grapples, multipurpose grapples for Cat tiltrotators, vibratory compactor plates and cold planers. Expanding the Cat Demolition and Sorting Grapple line, the new G306 and G308 models are specifically designed for 5- to 6-ton and 7- to 10-ton mini hydraulic excavators, respectively. With open and close functions controlled by the machine’s first auxiliary function and rotation head handled by the second, these grapples deliver fast and productive material handling with 360 degrees of bidirectional rotation. A slim design makes it easier to get into tight spaces, and material capacities range from 160 l (0.21 yd3) with the G306 to 240 l (0.31 yd3) for the G308. Vertical perforated shelves offer high wear resistance, positive penetration, good load visibility and easy positioning, while the oversized heavy-duty cylinder with load holding valve delivers constant clamping force, even when maneuvering the grapple or machine. Providing low maintenance intervals, the swing bearing features a single-ball heavy-duty, internally driven design.

Read More at https://eqtoday.co/fe3r1w

The new Kobelco SK350LC-11 features a 265-hp Isuzu Tier 4 Final engine to support lifting heavy loads and operating large tools. With redesigned boom cylinders, the SK350-11 can handle trench boxes. With the press of a switch, the machine dedicates one hydraulic pump to the travel system and one to all the other functions on a continuous basis. This allows the 11-series Kobelco machines to travel while having the ability lift and swing heavy loads. The SK350LC-11 has three working modes: Eco, S and H mode for balancing between high performance, economy and fuel consumption. The in-cab hydraulic pressure release function allows customers to change work tools or hoses safely. The machine’s 84,200-lb. operating weight provides stability in reach and lift situations. The machine’s side panels are thick, while the increased diameter of the bucket cylinder pin contributes to durability for using various work tools.

Read More at https://eqtoday.co/dk7ur7

Offering front-joint durability, the P-Tier mid-size models, including the 135, 210, 245, 250, 300 and 345, promote operator stability. With grease points at the arm-tip for accessible greasing, extended uptime and torque retention at the clamp, which reduces the likelihood of the front hydraulic pipes moving, the new P-Tier models were designed to provide performance and serviceability. The redesigned boomfoot bushings offer durability for an extended machine lifespan. The latest addition to the John Deere lineup of mid-size excavators is the 200 G-Tier. The PowerTech 4.5-l engine on the 200 G-Tier delivers performance for operators.

Read More at https://eqtoday.co/nksn2d

Tackle trench work and other compaction jobs with the remote-controlled Bobcat TR75 Trench Roller. Outsmart operator fatigue and get compaction results with the remote-controlled Bobcat TR75. The TR75 achieves compaction on a wide range of materials, including dense soils. The powerful TR75 is designed for a variety of compaction applications, including pipeline trench construction, commercial, industrial and residential development, structure backfill work, as well as electric and cable installation. With a tight turning radius, low center of gravity and an oscillating articulated joint, the TR75 is highly maneuverable and maintains more complete contact on uneven ground.

Read More at https://eqtoday.co/ztwemg

Available in late 2023, the TL100 has a rated operating capacity of 1,000 lbs. (35% of tipping load). The 25-hp CASE TL100 features hydraulic pilot controls (ISO pattern) and a standard auxiliary hydraulic setup of 13 gpm and 2,700 psi. Attachments connect through a common industry interface (CII) compatible with most major manufacturers of MTL attachments. Optional equipment will be a 14-pin front electric connector that includes a hydraulic case drain circuit, multiple track widths, additional counterweights, hydraulic oil and multiple bucket options. The CASE TL100 MTL will become available in late 2023.

Read More at https://eqtoday.co/xqrpal

The excavator is designed for heavy construction, demolition, material handling, deep sewer, water, large mass excavation and mining or quarry. The 842-hp PC900LC-11 was featured in Komatsu's booth at CONEXPO-CON/AGG 2023. The PC900LC-11 offers major design enhancements compared to the earlier model. The new counterweight removal system helps with moving and the boom configuration reduces transport height. A new service pass through area allows access to filters, oil level checks and sample ports. The major structures, booms and arms, with a redesigned revolving frame, were engineered for longevity. To help operators with situational awareness, tools such as the KomVision camera system come standard on the PC900LC-11. KomVision is a 360-degree monitoring system that uses six cameras for a real-time view of the surroundings. Smart Construction 3D guidance and payload monitoring are other available options.

Read More at https://eqtoday.co/99se5w

This 43,652-lb. (19,800-kg) excavator offers a 23-ft., 2-in. (7.07-m) maximum digging depth and 28,551-lb. (127-kN) bucket breakout force. The HIOS IV hydraulic system minimizes hydraulic loss. The HIOS IV hydraulic system features a responsive boom, arm and bucket with intuitive control. On the ZX190LC-7, the system produces a maximum flow rating of 100 gpm (380 lpm). Attachment, arm and swing priority can be adjusted on the monitor to match the attachment or the operator’s preference. A Yanmar engine’s output is 132 hp (98.6 kW). The Yanmar power system features economy, power and high-power modes to match available power to the working conditions. An auto idle system with auto shutdown control prevents wasted fuel.

Read More at https://eqtoday.co/itaxl8

This 1.7-ton machine is a zero-emission solution for indoor applications and in areas where noise and exhaust are a concern. The EZ17e mini excavator offers zero emissions and reduced maintenance. With its minimal-tail swing design, it has a maximum digging depth of 97.7 in., a breakout force of 4,608 lbs. and the ability to run auxiliary attachments such as hydraulic breakers. The lithium ion battery offers all-day run time and can be recharged using a common 240-V, single-phase outlet. Charge time is between five and six hours.

Read More at https://eqtoday.co/6p7v2a

The new DX89R-7 mini excavator replaces the DX85R-3 and features greater lifting capacity and more horsepower. The mini excavator has a reduced-tail-swing feature, permitting more power in cramped, congested worksites. Powered by a Tier 4-compliant D24 diesel engine offering more horsepower, the DX89R-7 provides increased productivity from its predecessor. Auxiliary hydraulic flow remains readily available. An increased machine operating weight and the excavator’s new counterweight design provide better stability for increased lifting capacity:

• Horsepower: 65 hp at 2,100 rpm (48.5 kW)

• Operating weight: 21,005 lbs.

• Maximum digging depth: 13

ft. 6 in.

• Maximum digging reach (ground): 22 ft. 6 in.

• Maximum loading height: 15

ft. 5 in.

• Travel speed: 1.8-3 mph

Read More at https://eqtoday.co/k9tik4

The new HT Series model features a Tier 4 Final compliant Hyundai engine that provides power while meeting emissions standards. The new compact track loader is powered by a Hyundai HTI4 four-cycle, turbocharged, electronically controlled diesel engine. The new engine, designed and manufactured by Hyundai, meets Tier 4 Final and E.U. Stage V emissions standards and deliver 70 net hp (52 kW) at 2,200 rpm. The Hyundai HT100V has a rated operating capacity of 2,300 lbs. (1,220 kg) and its heaped bucket capacity is 0.58-yd3. Standard features include a multifunction joystick enabling operators to control all machine functions with their hands only; a vertical lift path that allows the boom to raise the bucket straight up to full height for stability, less spillage and lift height and two-speed travel enabling movement around the jobsite.

Read More at https://eqtoday.co/0zx91z

InSite Software's InSite Elevation Pro features a slope to daylight tool for construction designs, including excavation projects. The slope to daylight tool allows estimators to turn incomplete data into a manageable surface and create intermediate surfaces for foundation excavation, vaults, road construction, phasing and trenching. Configurable settings available in the slope to daylight tool include the following: Slope Up, Slope Down, Direction, Side, Miter Corners and Maximum Run. This tool adds surfaces to rough designs lacking data. The design can be exported to GPS machine control devices found on construction vehicles.

Read More at https://eqtoday.co/aje1nq

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

The new VT-100 compact track loader (CTL) is a vertical-lift machine for loading and grading applications in landscaping and construction. The VT-100 Forestry is designed for mulching, right-of-way clearance, site prep and more. The models include visibility and performance features. ASV’s VT-100 and VT-100 Forestry come equipped with a 103.5-hp Tier 4 Final Yanmar diesel engine and standard 40-gpm high flow. The CTLs’ large line sizes, hydraulic coolers and direct-drive pumps transfer flow and pressure directly to the attachment and reduce power loss. The VT-100 features a 3,500lb. rated operating capacity and 10,286-lb. tipping load while the VT-100 Forestry includes a 3,700-lb. rated operating capacity and a 10,571-lb. tipping load. The models feature ASV’s patented PosiTrack rubber track suspension. The dual-level suspension of the VT-100 and VT-100 Forestry features both suspended wheels and axles, allowing it to manage various terrain.

Read More at https://eqtoday.co/j2xcsr

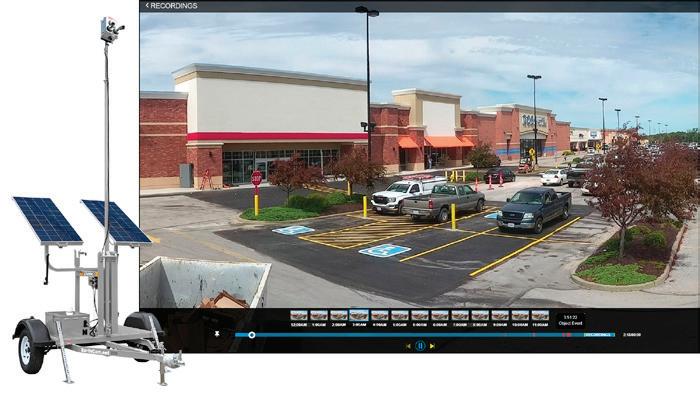

This multi-camera perimeter detection system features AI object and audio recognition, livestreaming video and continuous security recordings. The self-contained, solar powered unit is designed for safety and security in locations ranging from single store exteriors to parking lots in malls. The AI Safety Trailer generates essential alerts for security, vandalism and theft detection based on visual or auditory triggers. AI audio analysis recognizes specific sounds. AI object detection recognizes specific vehicle types or unauthorized interactions with equipment or vehicles. A user-controllable pan-tilt-zoom camera can be used to investigate specific areas of the site in real-time. The perimeter detection system uses twoway audio “talk down” capabilities, LED strobes and sirens to act as deterrents. Alerts may be sent to EarthCam’s Central Station Monitoring (UL Listed, Five Diamond CSM) where trained professionals review the incident, assess the risk and dispatch law enforcement as necessary.

Read More at https://eqtoday.co/erusyg

Ignite Attachments offers the General Purpose Bucket attachment for construction work vehicles, including skid steers and track loaders. This 50-in. bucket can be used for light-duty grading and leveling applications, as well as material handling. During use, the bucket combines reliable breakout force and a longer bottom for increased capacity and visibility to the cutting edge. It features a round back design for loading and cleanout, as well as a low heel to support cutting to grade and back dragging. The attachment has thick walls with weld-on side cutters that promote bucket strength. Operator guidance is facilitated by dual level indicators. Operating weight is 223 lbs., length is 30 in., width is 50 in., height is 19.9 in.; ISO heaped capacity is 8.5 cu. ft.

Read More at https://eqtoday.co/zfshbv

RIDGID introduced the SeeSnake Mini Pro Inspection Camera with TruSense Technology for pipe inspections and assessment. The compact, rugged Mini Pro is designed to inspect up to 200-ft. of 1.5- to 8-in. pipe with its mid-flex push cable that can navigate hard 90-degree bends. Its innovative 25-mm digital self-leveling camera always keeps the in-pipe image upright and is shorter than the traditional 25-mm camera head. TruSense establishes a two-way datalink between the camera head and a TruSense enabled monitor. With TruSense, advanced sensors on the camera head convey information about the in-pipe environment, including the high-dynamic range (HDR) image sensor that offers bright, clear in-pipe imaging in difficult lighting conditions.

Read More at https://eqtoday.co/gvazdb

Yanmar Compact Equipment has introduced the TL100VS, the first machine in its new compact track loader line. The TL100VS comes equipped with a 103.5-hp Tier 4 Final Yanmar diesel engine and standard 40-gpm high flow for performance capacity on the jobsite. Paired with a 3,600-lb. standard operating capacity and 10,286-lb. tipping load, the TL100VS is available in Yanmar Premium Red color. Travel speeds up to 8 mph round out the performance features, while 4.5-psi ground pressure allows performance on sensitive, unstable surfaces. The TL100VS improves operator experience with premium 360-degree visibility and a 7-in. color display. Operators can access a standard suspended seat and a removable roof hatch escape inside the cab.

Read More at https://eqtoday.co/hcp69m

The 80-V max (40-V max X2) XGT Brushless 28-lb. Demolition Hammer (GMH02Z, tool only) is a cordless concrete solution designed for heavy-load applications. It delivers the power, speed and run-time for corded demands, without the cord. The demolition hammer delivers up to 15% faster breaking than the equivalent HM1213C corded hammer. Designed to accept SDS-MAX bits, the tool features Anti-Vibration Technology (AVT) for reduced vibration. AVT is an internal counterbalance that uses air pressure to move counterweight pistons in the opposite direction of the drive piston to actively reduce vibration. For added durability in harsh jobsite conditions, Extreme Protection Technology (XPT) is engineered for dust and water resistance.

Read More at https://eqtoday.co/rt3c0e

Manufacturers spent years honing technology

to allow contractors to do more with less, to more quickly train new workers and to find ways for construction companies to complete projects more effectively and with fewer emissions.

Of all the new construction heavy equipment product launches at CONEXPO-CON/ AGG, one of the hottest product categories was the compact track loader (CTL). Equipment makers have revamped and upgraded the design and technology of their existing models, and many showcased entirely new machines. The clamor to create the latest generation of CTLs was sparked by an industry need for equipment that is easy-to-use for new

operators and powerful enough for land-clearing construction jobsites.

“We’re seeing more and more customers, big and small, looking to push the limit when it comes to what a CTL can do on a jobsite,” said Luke Gribble, solutions marketing manager for John Deere. “They’re asking for a solution that can push more dirt, can grade more accurately, can run hydraulic attachments a lot more efficiently and effectively, and are utilizing bigger and

more complex attachments, too, with that.”

The entire industry is seeing an increase in CTL use and buying. Market research firms predict CTL market demand to increase 5% to 10% throughout the next decade. Equipment makers are creating many improvements to CTLs, which are known for their low ground pressure and task versatility, to increase sales at a compound annual growth rate (CAGR) of 5.2% by 2031 globally,

according to Transparency Market Research. While the market reached about $3.2 billion in sales in 2022, it’s expected to grow to $4.8 billion by 2032, a CAGR growth rate of 3.8%, according to market research firm Fact.MR. Meanwhile, TechSci Research predicts the CTL and skid steer segment will grow at a CAGR of 10% by 2026 due to demand, stating that CTLs

dominate the market and the trend is likely to continue due to broad uses of the equipment.

Most construction heavy equipment producers told Equipment Today that they are seeing increased demand for larger CTLs. Contractors are turning to CTLs more often because they are easy for new operators to learn, during a time when the industry is short 546,000 workers, according to Associated Builders and Contractors. Versatile compact equipment also allows contractors to do more with less.

Deere introduced its largest-ever CTL at CONEXPO, the 118-gross-hp 335 P-tier with load-sensing hydraulics. The 335 will be available in early 2024.

“Traditionally, what we see is that skid steers and CTLs are easier to operate. They're more comfortable in the field for new operators,” he said. “They're not as intimidating to operate as some other ... equipment. I think that's attracting a lot of customers into utilizing a CTL more on their bigger jobs, instead of more of a secondary

piece of equipment. And you can utilize more attachments on the machine, instead of having multiple machines. That's another shift that we're seeing in that space, which is why we're putting such a focus on attachment performance.”

CASE, which introduced the world’s largest CTL, the 16,000-lb. TV620B, in 2021, displayed different CTL sizes at CONEXPO this year, debuting the TL100 mini track loader with an operating capacity of 1,000 lbs. The medium and larger frame CTLs are getting a lot of attention at CASE. Part of the reason behind the popularity of the larger CTLs is the “cool” factor, said Jeff Jacobsmeyer, product manager at CASE Construction Equipment.

“I think we all like to think we have a sense of self control, but like many other things in life, you see the biggest and baddest tool, and you want it,” he said. “So you may not need more horsepower, and you may not need a CTL that weighs more than 16,000 lbs., and you may not need all that auxiliary hydraulic power, but you definitely want it. That is certainly part of the phenomenon that has contractors looking at larger, more powerful equipment.”

There are several reasons for bringing a larger machine into the fleet, such as growing a business, he said.

“A machine like the TV620B may be more machine than you need today, but as you

grow your business, it has the ability to load larger trucks, lift heavier loads, run more demanding attachments –you’re essentially specifying that added performance into your business growth and development,” Jacobsmeyer said. “Having said that, medium frame CTLs offer the best of both worlds: machines with strong hp and operating capacities, as well as machines with lower hp ratings that deliver even more simplified maintenance, while still delivering great performance and capacities. Between size classes, lift geometries, rated operating capacities and attachment strength, there are many great options in that medium-frame size class.”

Larger CTLs also perform well for grading and material-handling, said Kevin Coleman, product specialist at Caterpillar.

“Many customers are also looking to the larger, high-hp CTLs to deliver high performance and productivity when paired with high performance hydro-mechanical attachments,” he said. “The larger models have grown in popularity due to customers finding new ways and applications in which to use the larger machines with the higher load handling and hydraulic horsepower capabilities. The larger, more powerful CTLs deliver a machine and attachment combination designed to bring unparalleled speed and quality when paired with tools such as mulching heads or cold planers/ milling heads.”

At Doosan Bobcat, mid-frame CTLs are the long-term market driver, but there is also demand for large-frame models, said Julie Portillo, loader marketing manager.

“A variety of CTL sizes will continue to be in demand because they are among the most versatile tool-carrying, multipurpose machines available on today’s jobsites,” she said. “The increased floatation provided by their track systems makes them ideal on a wide range of jobsites with soft ground surfaces such as sand, mud and clay. With their weight distributed throughout the track and ground contact area, CTLs can travel across uneven ground more efficiently and are better at maneuvering through softer ground conditions.”

Specific jobsite needs also drive the larger CTL trend, said Ryan Anderson, product marketing manager for New Holland Construction North America.

“As subdivisions get smaller with tighter property lines, the need and demand, for medium-frame CTLs grows,” he said. “Overall trailer weight is also something that is constantly on customers’ minds. If they can get the same job done with a lighter, medium-frame machine, customers will do

A machine like the TV620B may be more machine than you need today, but as you grow your business, it has the ability to load larger trucks, lift heavier loads, run more demanding attachments," said Jeff Jacobsmeyer, product manager at CASE.

requirements,” she said. “This allows them to maximize the attachment performance and gives them precise control of the loader’s movements.”

when you’re running some of those really high- low, high-pressure attachments, the machines were able to more capably run them.”

One of the most popular aspects of any CTL is its ability to work in compact spaces and switch out attachments quickly. Equipment makers are rapidly growing their attachment portfolios to meet growing demand from owners and operators. Land clearing, grading and excavation are primary jobsite applications when it comes to the development of advanced attachments, and with it, comes improved hydraulics.

“Using any of the many attachments on a CTL is the definition of versatility,” Caterpillar’s Coleman said. “Not only can you finish grade with the machine, but you can do an innumerable amount of other tasks by simply changing the attachment connected to the machine. Other, more dedicated grading pieces of equipment do not provide that versatility for maximum asset utilization. Speed is also an advantage over other pieces of equipment.”

CTLs tend to be nimbler than dozers and Cat CTLs come with the company’s Smart Technology, which is designed to offer easy integration with grading Smart Attachments, the Smart Dozer with Assist and Smart Grader Blade with Assist, as well as the Smart Backhoe attachment, he said.

“The standard Smart Technology can be paired with the Smart Attachments to deliver an unmatched level of integration and attachment control with the new grading and excavating attachments, such as our Smart Grader Blade, Smart Dozer Blade, Smart Backhoe, he said. “The new Smart Creep feature senses the load on a cold planer or wheel saw attachment and automatically adjusts the drive command to keep the attachment running at the most productive speed. This helps reduce the likelihood

of stalling the attachment. If the attachment does stall, the Auto Reverse portion of Smart Creep can reverse the machine travel to clear the stall, then move the machine forward to continue cutting.”

Cat also offers its Dual SelfLeveling system, Return-to-Dig feature and Work Tool Positioner for automatic leveling, to fully lower the arms and select the working angle of attachments.

“This advanced machine technology allows the machine to recognize when a Smart Attachment is connected and tailor the controls and operator information to match the tool and the task,” Coleman said. “This integration allows for better machine utilization and a better-finished product by delivering easy, intuitive operation of these advanced grading and excavating smart attachments.”

The machine also comes standard with auxiliary hydraulics controlled with a multifunction joystick, as well as a 14-pin auxiliary hydraulic control connector.

Using the correct attachment can make all the difference on the jobsite, Bobcat’s Portillo said.

“That’s one of the reasons why we have such a huge variety of attachment types that can be matched to our CTLs,” she said.

TheT86 can use many attachments, including those specifically designed for super- low hydraulics such as super- low snowblowers, planers and forestry drum mulchers.

“Several attachments require control of more than one function, and our small, seven-pin attachment harness activates power and fingertip control functions, while eliminating the need for the mechanical relays used on other loaders,” Portillo said. “The T86 delivers more usable engine and hydraulic power than ever before with 105 hp and an ROC of 3,800 lbs.”

Bobcat’s T86 has selectable joystick controls that allow operators a range of options and low-effort hand control of all machine workgroup functions, with ISO or H patterns.

“Operators can dial in their travel speed in small increments to match their attachment operation

The T86 also comes with a telematics option, the Bobcat IQ, which allows owners and operators to track, monitor and manage equipment. Bobcat MaxControl offers geofencing capabilities.

Bobcat’s T86 has a larger, higher capacity radiator and a reversible cooling fan to offset the heat created when using high-powered attachments.

“The fan achieves more cooling at a slower rotation, which is more energy efficient,” Portillo said. “The T86 also features larger auxiliary hydraulic tube lines for less restriction and greater low.”

The base machine comes with an enclosed cab, dual-direction bucket positioning, the Power Bob-Tach system, automatic ride control, a reversible fan, two-speed travel, a rearview camera and selectable joystick controls.

Deere has found success in the vegetation management segment and is creating attachments to fit that niche.

“That’s a that’s a key area that continues to grow,” Gribble said. “There are a lot of customers who are running mulching heads, different kinds of rotary cutters and things like that on the front of the machine, so that they can clear property before there’s some kind of housing or growth or business development there.”

At CONEXPO, Deere announced plans to launch two new mulching heads, the MK76 and MH72D.

“With the 335, one of the things we showcase, too, is we’re going to be offering a new mulching head to help customers in that space,” he said. “We also equipped that machine with what we call a severe-duty package that provides additional guarding around the machine to again, let customers know that not only is the machine more capable, we’re giving you an attachment that’s more capable, and also protecting the machine.”

Gribble said Deere has improved the hydraulic system on the larger machines.

“Previously, our 333 had 41 gpm of low capability, and the 335 will now have 44 gpm. So, almost a 10% increase,” he said. “When it comes to the auxiliary, when you’re running an auxiliary hydraulic function, we’re also increasing this auxiliary pressure system from 3,500 psi to 4,000 psi so that

Those hydraulic system improvements will make life easier for the operator, he said.

“When I think about how that actually improves operator experience, it’s going to be much easier to multitask,” Gribble said. “If you’re, let’s say, raising an attachment, wanting to keep low to the attachment, move in different directions, that’s a lot easier to do. It’s going to be quicker to do compared to an open center system. And we do know that a pressure compensated system actually improves fuel efficiency, as well, because it’s better able to manage how much power you need for the attachment versus an open center system that’s basically running at a constant low all the time.”

The CASE TV620B was designed to run big, tough attachments, Jacobsmeyer said.

“We’re talking about cold planers and mulchers,” he said. “We’re talking about big-bodied attachments, like the CASE precision grader blade. The long tracks, strong frame and auxiliary hydraulics available with the TV620B make this an extremely powerful attachment platform.”

CASE incorporated high- low hydraulics into the CTL.

“It features ‘Hydraulics on Demand,’ a feature that sets the percentage of hydraulic low to the attachment,” he said. “This allows the operator to dial in hydraulic low specifically to the demands of the attachment, their preference, or the job. And it really helps ensure that the attachment is working within the optimal parameters that the attachment is designed for.”

CASE also created the TV620B with the capability to handle its precision grader blade.

“It’s a machine control attachment that is compatible with a full range of 2D and 3D machine control solutions that ultimately turn a large-frame or extra-large-frame CTL into a compact motor grader,” Jacobsmeyer said. “There are other attachments, as well, that make these very practical finalgrade machines, and ultimately dispel any myths about the performance of compact equipment with machine control technology. Construction is rapidly expanding the attachment offering to include more precision-

controlled attachments every year.”

DEVELON’s DTL35 comes standard with 23 gpm of standard auxiliary hydraulic low and 40 gpm of high- low capacity, Lee said.

“The reason for this is because owners of this size class regularly operate attachments that require significant hydraulic low, such as forestry cutters and brush cutters,” he said. “The high hp, combined with the high- low hydraulics, provides exceptional attachment performance for CTL operators. DTL CTL operators will be able to change nonhydraulic attachments without leaving the loader cab. The machine’s quick coupling system will also allow for faster and easier connections for hydraulic-powered attachments.”

Kubota’s CTLs use hydraulic pilot control with control levers directly connected to the machine’s hydraulics, Corder said.

“This allows for sensitive, proportional control of the machine, as a slight movement of the stick initiates a corresponding response to the hydraulics in the machine,” he said. “We have borrowed the Advanced Multifunction Valve from the SVL65-2, which allows for enhanced, simultaneous machine and attachment operation. The auto-downshi t feature from Kubota compact excavators has been incorporated, as well. This function automatically shi ts from high to low range when executing a turn, for a smoother ride and maximum available torque when exiting the turn.”

Kubota CTLs also accept any “skid steer coupler design” attachment, regardless of brand.

Yanmar is like the Swiss Army knife of attachments, Storlie said. Multiple brands of attachments can fit on the TL100VS, and it comes equipped with a 14-pin connector. Adjustable high low is available. Operators can preset the attachment angle and loader arm position to keep measurements precise during repetitive tasks.

“Even in a 118°F day it can do full loads all day with its air-cooling system,” he said.

The standard auxiliary hydraulic low on Takeuchi’s TL8R2 is 19.1 gpm, Padgett said.

“The TL8R2 is designed with versatility in mind to handle a wide variety of attachments and applications,” he said. “A high- low option is available that delivers 33.8 gpm at 3,045 psi. If you opt for the high- low configuration,

you also get Creep Mode. For example, if you have an attachment like a trencher, tiller, mower, cold planer—or any other tool that requires a consistent and repeatable travel speed—you can throw the TL8R2 into this new Creep Mode, and that will allow you to match the speed of the machine exactly to your attachment without having to meter the travel lever.”

The Hyundai HT100V’s quick coupler allows for changing attachments without leaving the cab and bucket self-leveling.

“The auto, self-leveling system keeps the bucket or fork level without the need to manually adjust the angle on the way up during li ting,” Ford said.

Wacker Neuson carries a number of various width and profile buckets, toothed and lat, as well as several wood and rock removal attachments, trenchers, pallet forks and augers, Clark said.

“But Wacker Neuson’s CTLs are also compatible with any Common Industry Interface tools, for maximum lexibility on the jobsite,” he said.

The JCB 300T has a quick hitch for quick coupling to all JCB attachments and other brands’ attachments. The standard hydraulic circuit is 18 gpm and a high low option up to 30 gpm (114 lpm) is available for maximum attachment versatility.

New Holland expects an entire suite of attachments to be available for the C330, from pallet forks and buckets to grapples and more.

“We do offer lasers, receivers and laser grader boxes and blades,” Anderson said. “We have a partnership with Leica to supply our customers with the best precision tools.”

Hyundai’s HT100V comes standard with a hydraulic quick attach coupler.

“The hydraulic quick coupler allows the operator to quickly and safely change attachments without leaving the cab,” Ford said.

Manitou’s VT CTL series can be used with many different attachments. With typical machine weight ranging from 8,865 lbs. to 10,051 lbs., they are lexible when it comes to hauling and transportation, Ryan said.

“We also offer the new and optional high low boost, which increases auxiliary low performance for attachments like mulchers and planers,” he said. “It uses the same lines and connectors as the standard auxiliary hydraulics and is controlled easily by the display in the cab.”

so in order to avoid costly overweight expenses.”

DEVELON launched its first CTL, the DTL35, at CONEXPO. The 12,604 lb. machine has 116 hp and an operating capacity of 3,657 lbs.

“The combination of the hp and the rated operating capacity make this vertical-lift-path compact track loader an ideal choice for earthmoving contractors,” said Thomas Lee, director of product management for DEVELON. “Both the hp and auxiliary hydraulic flow make this size class a popular choice for heavy-duty construction and site prep projects. Our first compact track loader will be available for use with land-clearing attachments.”

Hyundai Construction Equipment Americas brought with it to CONEXPO its re-entry into the CTL market, the HT100V, designed to provide increased vertical lift.

“This lift path was chosen because the geometry of the arm allows the boom to raise the bucket straight up to full height,” said Adam C. Ford, product manager, Hyundai. “Our HT100V provides the best of both worlds: powerful engine, robust structural construction, superior lifting capacity of a large frame machine and low ground pressure and maneuverability of a smaller frame machine.”

Meanwhile, Yanmar Compact Equipment North America entered the CTL market for the first time at CONEXPO, with its TL65RS, TL75VS, TL80VS and TL100VS models, ranging from 67 hp to 103.5 hp and Tier 4 Final diesel engines. Yanmar, too, is seeing a pivot to larger CTLs.

“We’ve seen a shift from the smaller frames to the mid-frame to larger frame sizes, said Buck Storlie, product manager for Yanmar. “They’re looking for the machines to do more, more, more. CTLs continue to replace skid steers as their transportability and uses are increasing.”

Also at CONEXPO, ASV unveiled its VT-100 and VT-100 Forestry CTLs. Designed for mulching, right-of-way clearance and construction site prep, Storlie said they are ideal for owners who need a mid-range machine.

“They are the perfect option for those looking for a little more power than the RT-75 without having to go

Manitou’s 2750VT loaders feature keyless start requiring only code activation, LED lighting, and a patented Pilot joystick system as standard, adjacent to the operator’s seat. Numerous innovations also facilitate maintenance with a lifting cab and centralized maintenance points.

to the heavy hitter of all CTLs; the RT-135,” he said.

Weighing in at 1,890 lbs., Wacker Neuson’s ST27 CTL was also released at CONEXPO. It’s the company’s smallest in its mid-range CTL lineup.

“In general, there is in fact a trend toward large frame loaders, while medium frame loaders, like the ST27 have remained fairly stable,” said Doug Clark, Wacker Neuson product manager for compact equipment. “The growth in the large frame loader segment seems to be coming from small frame loaders. It seems as if, across all customer segments, users are embracing a ‘bigger is better’ philosophy.”

At Manitou, customers are trending toward larger machines to achieve greater operating capacity, said Nathan Ryan, product line manager for skid steers and CTLs at the company.

“Even as you look at what is traditionally considered a ‘mediumframe’ compact track loader – that’s in the 1,800-lb. to 2,400-lb. capacity range – our new range beefs that up between 2,100 lbs. and 2,750 lbs. of rated operating capacity. People are looking to be able to do more but don’t always want the footprint that comes with large-frame or extra-large-frame CTLs,” he said.

Takeuchi-US also sees a shift toward higher-capacity CTLs.

“Both (medium- and large-frame) sizes are appropriate for traditional dirt work,” said Lee Padgett, product manager for Takeuchi. “For residential work or landscaping, medium-frame CTLs are easier to maneuver around the jobsite and to trailer from place to place. Applications like mulching often require higher hp and gpm for the auxiliaries.”

Kubota’s SVL75-3 also made its debut at CONEXPO. The 74.3-hp machine has a higher peak torque and many updates.

“The new Kubota SVL75-3 incorporates a number of new features, as

well as features taken from other products in the Kubota lineup,” said Jerry Corder, Kubota product manager, construction equipment.

The JCB 300T CTL has a 74-hp JCB EcoMAX engine that requires no DEF, DPF or engine aftertreatment. A rated operating capacity of 3,000 lbs. (1,360 kg) means the 300T is meant for lifting and loading, digging and to be used with multiple attachments, the company said.

Many of the equipment manufacturers have increased the power and lift available in their newest CTLs. Not only do these models feature more hp, but they also have improved hydraulics for better attachment control and breakout force and enhanced servicing accessibility. As the CTL market increases, manufacturers are adding more features and functionality, including improved lift. Many of the machines have further reach, greater lift capacity and better stability.

CASE’s TV620B with 114 hp has an operating capacity of 6,200 lbs. (50% of tipping load) and includes electrohydraulic controls and high-flow hydraulics.

“It also features some of the industry’s strongest breakout forces – 12,907 lbs. at the bucket, 12,084 lbs. at the lift cylinders – and it comes standard with High Flow hydraulics that offer 41.6 gpm for the demanding hydraulic-powered attachments,” Jacobsmeyer said. “AUX flow can be set by using the Hydraulics on Demand feature through the monitor to dial in the specific flow needed for efficient operation.”

When it comes to suspension, CASE recently announced the availability of the CASE EZ Trac suspension on its large-frame and extra-largeframe CTLs, including the TV620B.

“The bogie wheel system in the middle of the track frame absorbs the rough terrain as the machine goes over it, delivering a smoother ride. It delivers greater traction as the bogey wheels allow you to stay in contact with the surface at all times, so the track is always engaging the ground,” he said. “It also allows the operator to hold a more exact grade, as there’s no torsion movement between the frame and the undercarriage, and truck loading is improved, as you’ve got an even more solid base with no porpoising when dropping heaped buckets into the back of trucks, even at full height.”

All service points are accessible for maintenance and repairs at ground level, and the machine uses SiteConnect Module and CASE SiteWatch telematics for improved monitoring.

Last fall, Bobcat launched its most powerful CTL to date, the T86, which is

equipped with a 105-hp Tier 4 engine and has an 12,393-lb. operating weight.

“We’ve boosted the hp for the T86 while optimizing machine weight,” Portillo said. “The result is greater lifting capabilities, impressive breakout forces and leading maneuverability for fast cycle times.”

The T86’s vertical lift path provides higher lift capacity and more reach at full lift height than radius lift path, to keep the load closer to the machine while raising. The machine has three hydraulic flow options, including standard, which offers 23 gpm and 3,500 psi, up to super flow, which provides

components, we're going to continue to make that a focus with this next generation of machines.”

DEVELON’s DTL35 comes in at 12,604 lbs. and has a rated operating capacity of 3,657 lbs. The vertical-liftpath CTL comes with a choice of two track widths: 15.7 in. and 17.7 in.

42 gpm and 4,061 psi.

Bobcat’s R-Series CTLs, including the T86, are available with the 5-Link Torsion Suspension undercarriage.

“It dramatically reduces stress and vibration, making the ride more comfortable,” she said. “An additional pivot point improves ride quality, and a unique fifth link included in the rear axles provides a more comfortable ride. Other components like wider track rollers, dual flange front idlers and a longer track further improve the ride of the machine. The lengthened track of the undercarriage increases surface area and ground contact for better flotation.”

Meanwhile, Cat’s D3 Series CTLs come in multiple sizes, starting at the 239D3 and the 249D3, which weigh less than 8,000 lbs., omitting the need for a commercial driver’s license. The larger frame models, such as the 279D3 and the 289D3, offer more rated capacity and higher lifting heights, as well as increased hydraulic hp, Coleman said. Of the series, the 299D3 and the 299D3 XE have the largest load handling capacities and highest hp at 98 hp/110 hp.

The Cat CTL models are equipped with a torsion suspension system that attaches to the machine chassis with four torsion axles. Those axles require daily greasing, and the grease points are accessible at ground level.

“The suspension provides a more comfortable ride, along with greater load retention (even when using the standard two-speed travel)

when compared to competitive rigid undercarriage designs,” Coleman said. “More comfort means higher speeds on the job, which translates into higher productivity. The suspension also helps keep the tracks on the ground during digging/grading to provide maximum traction at all times.”

In recent years, Deere introduced its Anti-Vibration Undercarriage System, and it’s available on the new 333 and 335 models.

“That system is designed to increase operator comfort when you're going over rough terrain on a jobsite. We've actually isolated the undercarriage from the machine frame itself,” Gribble said. “There's also a bogie roller system incorporated into that undercarriage. If you're going over small rocks or small piles of dirt on the jobsite, you're able to keep the whole track ideally on the ground.”

One of Deere’s goals is to make equipment, especially CTLs, easy to service. These CTLs have a rear hood that opens for access and two side panels that can be taken off to view filters, access fluids and conduct daily checks.

“There's just a couple of bolts on the cab itself that you can take off with the cab up,” he said. “And if you do need to get into some more indepth repairs, you've got full access to some of the major systems underneath the machine. Between the ease of maintenance at the rear, and then the ability to raise the cab very easily and access some of the more complex

“The wider tracks will allow for less ground pressure in situations where operators are moving the machine across established surfaces for reduced disturbance,” Lee said. “The tracks will be available with either a block pattern or multi-bar pattern.”

When it comes to servicing the equipment, the DTL35 comes with a tilting cab for better access.

“When operators open the rear tailgate, they will have access to the key service components: diesel engine, battery, filters and fluid fills,” he said. “Above the rear tailgate area is the machine’s cooling system, which is also easy to access after lifting a top panel protecting the internal components. Operators working in extremely dusty and dirty conditions can easily access the cooling system to remove debris and minimize machine overheating issues. The radiator fan is also auto-reversible, which can be very beneficial in dusty environments.”

DEVELON’s CTLs are powered with D34 diesel engines and have a sloped undercarriage to reduce debris buildup.

One of the more popular CTLs at CONEXPO was New Holland’s C330. New Holland is known for creating the vertical lift skid steer loader in the 1980s and the first version of its SuperBoom. Today, the vertical lift C330 has a 67-hp engine and its SuperBoom.

“The patented SuperBoom vertical lift geometry is a huge factor for us,” Anderson said. “Some of the key advantages of the SuperBoom vertical lift are great hinge pin heights for dumping into higher containers and/or trailer, excellent bucket reach (essential for precision loading), and use of attachments.”

On large-frame models like the

C345 and C362, New Holland offers TerraGlide track suspension, bogiestyle design for working in harsh conditions. Fluid levels and grease points should be checked daily, and the oil change interval is at 500 hours.

“Checking track tension every day is important to ensure longer track life and safe performance of the machine,” he said.

Hyundai added an entirely new track system to its HT100V CTL.

“The suspension of this track system consists of a coil spring and shock damper, providing the operator with superior ride quality and load stabilization when traversing rough or uneven terrain,” Ford said.

The 69.7-hp model comes standard with two-speed travel is equipped with the Hyundai Escort system, which when the engine is turned off, the working lights on the front and rear remain on for 30 seconds to improve safety. Its preventive maintenance includes Hi Mate remote management with GPS satellite technology to access diagnostic information and verify equipment locations.

Yanmar’s TL100VS has a standard 40-gpm high flow with a 3,600-lb. standard operating capacity and 10,286-lb. tipping load.

“The hydraulic system improvements make it easier to multi-task,” Storlie said.

The TL100VS has an optional load sensing system, work tool positioner, return-to-position technology, selfleveling, ride control and auto two-speed capabilities. The new construction-grade loader features a torsion axle suspended undercarriage with a pivot link system at the rear axle. This linkage technology uses a spring load to reduce oscillation and stabilize the machine, helping support material retention and ride quality. Additionally, the TL100VS includes large line sizes, hydraulic coolers and direct-drive pumps, transferring more flow and pressure directly to the attachment and reducing power loss.

“The undercarriage is a new design for the Yanmar model. It’s a steel embedded design with standard

Bobcat's S86 can power a variety of attachments including those specifically designed for superflow hydraulics such as super-flow snowblowers, cold planers and forestry drum mulchers.

Bobcat

suspension, best in class ride capabilities and traction,” Storlie said.

ASV’s VT-100 and VT-100 Forestry CTLs are equipped with a 103.5-hp Tier 4 Final Yanmar diesel engine and standard 40-gpm high flow. The VT-100 features a 3,500-lb. rated operating capacity and 10,286-lb. tipping load. The VT-100 Forestry includes a 3,700-lb. rated operating capacity and a 10,571lb. tipping load. The models include Posi-Track rubber track suspension with suspended wheels and axles, allowing it to manage diverse terrains. The models also have accessible daily checkpoints and removable skid plates for cleaning and include three-panel engine access.

“The ASV CTLs are for the premium performance buyer looking for more high-cooling capacity and luxury options like in the VT Forestry model,” Storlie said.

Wacker Neuson’s ST27 has a hinge pin height of 120 in., with a dump height of 94.3 in. The company states that the ST27 has the best power-to-weight ratio in its class with an operating weight of 7,310 lbs. and a 74.3-hp engine. The design also maximizes the rated operating capacity of 1,890 lbs. (at 35% of tip), while providing extra reach at max height making it easier to dump material into the center of a dump box and keeps the loader farther away from the vehicle being loaded.

When the loader arms are down, the cab tips forward, allowing access to the hydraulic system and the engine compartment openings.

“It’s purposefully designed to ensure the most frequently accessed components are also the easiest to access,” Clark said. “The easy-to-clean sloped undercarriage design sheds mud and debris while you work, reducing wear and cleanout time. The ST27 features lubricated and sealed forged steel rollers and idlers that require less maintenance, extend track life and are more durable than rubber coated rollers.”

Kubota’s SVL75-3 load arms have been redesigned for a taller hinge pin height – nearly 3 in. higher than the SVL75-2 – and improved rear visibility, Corder said.

“We have borrowed the Advanced Multifunction Valve from the SVL65-2, which allows for enhanced, simultaneous machine and attachment operation,” he said. “The auto-downshift feature from Kubota compact excavators has been incorporated, as well. This function

automatically shifts from high to low range when executing a turn for a smoother ride and maximum available torque when exiting the turn.”

Kubota has also adopted its skidsteer loader engine layout, putting the radiator on top and moving the fuel tank to the rear bonnet.

“This opens up the engine bay to provide unimpeded access to the battery, all filters and all fluid fill locations for easier routine maintenance,” Lee said. “The suspension design is a welded frame undercarriage to ensure durability and longevity, omitting wear part costs.”

Manitou has improved its breakout force by 12% compared to previous models and has increased fuel tank size by 14% for extended run times, Ryan said. The company introduced its entirely new lineup of CTLs at CONEXPO 2023, and that includes three new models ranging from 2,100 lbs. of rated operating capacity up to 2,750 lbs. in rated operating capacity (35% of tipping load). For contractors who reference the 50% tipping load metric for rated operating capacity, it ranges between 3,000 lbs. and just under 4,000 lbs., he said.

“We have focused on five very specific areas of improvement for these machines: safety, comfort, productivity, simplification and serviceability,” Ryan said. “All models are vertical lift and feature a new lift arm design, and the operator’s station has been improved.”

Each loader includes Manitou’s IdealTrax automatic track tensioning system, which keeps the proper tension. Instead of greasing to achieve proper tension every 50 hours, a hydraulic system keeps constant tension on the tracks.

“You’re also going to see improved idler and bogie bearing life. It eliminates tensioning with a grease gun,” Ryan said. “And the track immediately releases tension when not in operation, making cleanout super easy; and it also simplifies track removal and installation.”

Takeuchi’s newest CTL, the TL8R2, includes high-flow auxiliary hydraulics, creep control, auto twospeed travel and a new undercarriage.

Yanmar Compact Equipment North America entered the CTL market for the first time at CONEXPO, with its TL65RS, TL75VS, TL80VS and TL100VS models, ranging from 67 hp to 103.5 hp and Tier 4 Final diesel engines.

The undercarriage is welded directly to the frame for greater strength and rigidity, Padgett said. The TL8R2 has a ride control feature for traveling at higher speeds for longer distances to help retain the material in the CTL’s bucket. The 300T has boom suspension, which can be turned on or off for precise boom control.

“Its new undercarriage design features repositioned travel motors with internally routed drive lines and double and triple flange track rollers,” Padgett said. “This track loader comes standard with many new features.”

JCB’s CTL models include the single-arm JCB Powerboom and sidedoor entry. With a rated operating capacity of 3,000 lbs., the 300T is designed for lifting and loading, digging, and pushing while using a variety of attachments. These include blades, tilers and trenchers, grapple buckets, and rakes. Its welded chassis provides rigid structure for reduced weight, while the Powerboom protects the hydraulic hoses from impact, and greater breakout force is provided by the largest quick-hitch pivot pins in the industry, the company said.

Keeping up with the technological innovations taking place in the construction industry is no easy task. Owners and operators will likely see many of those improvements in the cab as controls, touchscreens and other dashboard electronics have improved. The improvements in joystick ergonomics and seating comfort also cannot go unnoticed. Most equipment manufacturers have made improvements to the cab in recent years and CTL cab upgrades are no exception.

For the past decade, an ongoing trend has been the one-piece cab. Kubota’s SVL75-3 has a new one-piece cab that is sealed to reduce dust, dirt, most noise and other elements. There is also a 7-in. touchscreen, keyless start, a wide-angle 176-degree backup camera and relaying of machine vitals, Corder said.

Deere redesigned its cab and offers a one-piece design in new CTLs.

“There are a lot of features that we're adding or making as optional to take operator comfort really to the next level,” Gribble said. “The cab itself, the structure, we moved to a one-piece design that's going to lower the noise inside the cab for operators, which is great for the jobsite, especially when running attachments. It's also going to help keep some of the elements out if you're in heavy rain or heavy snow, so that's going to be a big plus to keep our operators more comfortable.”

New technology will be incorporated into the cab, with asset location, improved maintenance monitoring and larger touchscreens, for example. A heated/cooling ventilated seat will be available, as well as Bluetooth connectivity and customizable joysticks.

“You can actually move them forward or backwards, depending where your arms rest on the machine, how long your arms are. That's going to be something new that you couldn't get previously,” Gribble said of the joysticks. “The features are suited for a machine that's going to be run all day long for both owner and operators or for larger companies, as well. I think that will help keep operators in the machine and again, that kind of helps with some of that retention of operators and attracting talent to the industry.”

When Caterpillar released its D3 series CTLs with a one-piece sealed and pressurized cab in 2019, the enclosed cab came standard. The cab door was wider than in the past and the distance between joystick pods had increased by 3 in.

At DEVELON, engineers spent considerable time designing the CTL cab for comfort and ease of use, Lee said.

“Our CTL cab offers a large interior space for operators that will come standard with electrohydraulic joystick controls for easy operation and less fatigue,” he said.

Among the standard equipment is a rearview camera to improve visibility, which is displayed on an 8-in. touchscreen, and Bluetooth connectivity for phone conversations and listening to music. Additional options include an air suspension, heated seat and 360-degree monitoring system.

Manitou’s new CTL lineup includes a cab that is 23% larger than older versions and has 23% more visibility.

“Each unit features a patent-pending sloped roof that provides better visibility, and uniquely shaped, patentpending vertical lift arms that reduce material buildup and increase visibility under the arm to the outer tracks,” Ryan said. “Ride Control is now standard, which delivers a smoother and more comfortable ride.”

Joysticks are now standard, and the seat and armrests are independently adjustable. A 7-in. color display shows operation data with telematics and the rearview camera footage.

“A foot throttle is now standard to increase and decrease engine speed without removing hands from the joysticks – and that also can act as a deceleration pedal when the hand throttle is set to high idle,” he said. “Each machine also features an optional creep mode, which is rare on machines with pilot controls.”

Meanwhile, Takeuchi’s TL8R2 cab includes an automotive-style cab that is becoming more popular in the industry with a high-back suspension seat, electronic throttle control, rocker switches, 12-V outlet and cup holder. The roll-up door pressurizes the cab, sealing in the air conditioning, heating and defrost capabilities. There is also an AM/FM radio with Bluetooth connectivity. The 5.7-in. color screen displays operation data and rearview camera footage. Additionally, its LCD display is 8 in.

New Holland’s C330 has customizable EH controls for operators of any skill level.

“EH controls are our preferred method of operating CTLs and skid steers,” Anderson said. “Different from Pilot Control, EH controls send an electrical signal to the pumps, which allows them to be ‘tuned’ to the operator’s needs.”

an optional heated air-ride seat. The base machine also comes standard with dual-direction bucket positioning, the Power Bob-Tach system, automatic ride control, a reversible fan and twospeed travel.

“Operators sit high and closer to the front of the cab for an optimal view to the bucket’s cutting edge,” she said. “The optional clear side enclosure further enhances visibility to the sides of the cab. Rear cameras are available and offer a continuous rearview from the operator’s seat, helping to identify jobsite obstacles.”

CASE’s TV620B has 360-degree visibility in the cab and comes standard with EH controls.

“This allows operators to easily set total machine responsiveness to low, medium or high, or independently set tilt, lift and drive speed, as well as loader arm and drive control to best meet the demands of the job and the preference of the operator,” Jacobsmeyer said. “This is all achieved very easily through the massive LCD multifunction display in the cab, which also comes standard.”

Also offering 360-degree visibility is Wacker Neuson’s ST27.

“The track frame design allows a lower profile on the loader arm, improving side visibility, and the vertical arm linkage is aligned with cab posts to maximize rear visibility,” Clark said. “The roomy cab offers plenty of foot and head room, while all switches and controls are ergonomically placed for the operator’s line of sight, making the operation very comfortable on the ST27.”

Additionally, operators can toggle between ISO and H-controls depending on their preference.

Hyundai’s HT100V’s cab has a vertical sliding door, ergonomic multifunction joysticks, a mechanical suspension seat, five-vent HVAC, foot pedal, rotary-dial throttle and Bluetooth.

Bobcat’s T86 has selectable, ergonomic joystick controls.

“Three workgroup response settings allow operators to adjust the joystick sensitivity of lift and tilt functions to match operation preference with the demands of the job,” Portillo said. “Users can adjust between slower and smooth movements for precision operations, as well as faster lift and tilt functions for applications that require more speed.”

The CTL’s drive response can be adjusted to individual preferences, she said.

“It is possible to set the drive response for smooth movements and precise control or adjust to a faster response drive for a proficient operator or when applications require faster cycle times,” Portillo said.

The cab is pressurized with automatic heat and air conditioning and

“These machines can also sense the needs of the operator with standard auto-shifting, which will switch between gears automatically based on joystick input, removing the need for the operator to remove their hands from the controls,” he said. “These and many other control options are displayed in the large color LCD display in the cab.”

Yanmar’s TL100VS comes with a mechanical suspension seat, fixed pilot controls, 7-in. color display, roof panel, rear window, cupholder, and two-speed and standard flow. Electronic joysticks with ISO or H patterns and seven-vent air conditioning are available, among other features.

The JCB 300T has a wide-opening side door and 60% better visibility than previous models. The model’s myCHOICE control software allows operators to tailor the sensitivity of joystick movement, and ISO or H-pattern controls are available. A new touch-screen display mounted in the top right-hand side of the cab improves visibility, while the diagnostics, electronic throttle and ignition switch are within easy reach.

Read more at: https://eqtoday.co/NewCTLs

EARTHMOVING

| by Michael Cheng, Editor, Construction Equipment & ProductData points are like puzzle pieces that, when connected properly, form a fresh perspective that can change the way you operate your fleet and your business.

Telematics can help boost productivity on construction sites. According to Trimble, a company specializing in construction telematics, connected construction can help businesses increase productivity by 30%. So how exactly does a business use data to increase productivity in their operations?

The first step in leveraging data-driven insights is collecting information from connected machines and tools on the jobsite. This can range from large excavators and material handling equipment to cordless hand tools and wearables. There are many types of data available on construction sites, capable of providing the feedback and information you need to minimize risks when making operational decisions.

Vehicles: Engine Overspeed

Monitoring an engine’s overspeed rates through remote diagnostics can help equipment managers predict when construction vehicles are due for maintenance, as well as gain a thorough understanding of the challenges of the jobsite. Critical overspeed settings vary depending on the vehicle or motor type. Generally, engines hitting overspeed conditions are prone to reduced lifespan and engine failure, which influences maintenance, budget and rebuild strategies. Overspeed can also cause the engine to generate unwanted heat, resulting in higher operating temperatures associated with damage. Engine overspeed could serve as a warning for dangerous working conditions on the jobsite and should not be taken lightly.

“When we see engine overspeed, the first thing we take into account is the type of machine reporting out the data. Let’s use an articulated truck

as an example. Is it happening on one part of the job? Is it happening all over the job? It is critical to know not just the frequency of triggering engine overspeed, but also where it is happening on the jobsite,” said Jason Threewitts, performance services manager at Carter Machinery.

With more than 90 years of experience in the construction sector, Cater Machinery sells and supports Caterpillar equipment for construction projects. The company has an expansive network consisting of more than 30 locations across the United States.

“This information will tell you a couple of things. If it is happening across the worksite, then it is probably an operator thing. If it is happening on one specific part of the job, it is probably less of an operator issue. Instead, it could be an indication that this part of the job is dangerous. Maybe I need to go out there and check the area to prevent an unsafe situation,” said Threewitts.

Equipment managers monitor overspeed on construction sites using remote diagnostics. Remote diagnostics

refers to real-time monitoring of the vehicle’s status (in this case, overspeed). Upon detecting overspeed conditions, a fault code associated with the condition is triggered and a signal is transmitted to a management platform via a telematics device. These days, newer machines come with factory equipped telematics devices that can be used to capture engine overspeed data. A timestamp, vehicle identification and location data may come with the fault code during transmission.

Engine overspeed data can be combined with other types of information on construction sites for in-depth jobsite analysis.

“It is never just one thing. When analyzing the full situation, how can I continue connecting the dots all the way through? So then, I would start looking for related things. Am I getting an overheat reading at the same time while getting an engine overspeed condition? Am I getting filter plugging issues at the same time? Do I have engine or transmission oil samples coming out of the machine that is telling me something else? When you start adding

Monitoring fuel use is one of many ways data collection can be used on the jobsite.

@Kzenon - adobe.stock.com

all of that up together, if you have correlating data sets based on either other fault codes or sources, like an oil sample, then you have some powerful information to determine if you have a machine issue, how rebuild life is being affected or if you need to talk to the operator about how they are using the machine,” explained Threewitts.

Workers: Fall Detection Rates

When it comes to safety, fall detection is a critical piece of data to monitor in worksites. Falls, slips and trips are very common in the construction sector.

“The construction industry accounted for 46.1% of all fatal falls, slips and trips in 2020,” according to a report from the U.S. Bureau of Labor Statistics. Falls are tracked using gyroscope and accelerometer sensors on smart watches, tablets or safety devices. Some devices can detect both a normal fall and a hard fall. These wearable devices generate loud auditory alerts and issue emergency notifications to specified contacts or project management platforms in the event of fall without a response, increasing the possibility for workers to receive immediate medical attention.

stairways, can prompt managers to update work safety practices.

“Employers must set up the work place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls. The Occupational Safety and Health Administration (OSHA) requires that fall protection be provided at elevations of 4 ft. in general industry workplaces, 5 ft. in shipyards, 6 ft. in the construction industry and 8 ft. in longshoring operations. In addition, OSHA requires that fall protection be provided when working over dangerous equipment and machinery, regardless of the fall distance,” according to an OSHA overview about fall protection.

Fuel keeps construction vehicles and machines, such as generators and tools, operating, yet is a major cost in the budget of construction projects, usually second to labor. Monitoring fuel consumption is traditionally carried out at the fuel pump. Newer machines come with features that carefully monitor fuel consumption or

Threewitts highlighted a situation wherein an operator was light-loading a wheel loader vehicle on the jobsite. The operator was not fully loading the vehicle’s bucket during each pass. As a result, the operator needed to make two to three additional passes. The operator’s thought process was that he was able to work faster without fully loading the loader bucket. Threewitts utilized fuel consumption data to show the customer that not fully loading the bucket of the wheel loader and making additional passes burned 20% more fuel, compared to maximizing the load capacity of the machine and reducing the number of passes.

“Once you start correlating fuel savings or fuel efficiency and you’re also still able to get the production and payload out of the fleet that you need; that is solid gold for a production or equipment manager. Being able to correlate those two data points together or three data points is huge,” said Threewitts.

Monitoring the location and utilization of hand tools and equipment on jobsites is an effective way to streamline productivity, inventory, security and asset management for businesses. This information seems straightforward, though in application there are many ways to use this data to support operations on construction sites. From a hardware perspective, this involves installing small identification tags on equipment and using wireless Bluetooth technology to transmit the data.

Cloud-based management platforms allow managers to view the status of equipment, as well as historical usage data, where they can assess how tools are used on the worksite.

Tracking equipment uptime is also used in predictive analytics, enabling businesses to know when equipment is needing repair or replacement. Tools that do not meet expected uptime performance can prompt individuals to bring the equipment in for inspection or maintenance. This information can also help businesses stay ahead of costs related to replacing tools by anticipating the equipment’s end of life based on accrued uptime.

“Tracking small tools — whether in repair status, on location or with employees and the associated costs — is one of the most ineffective parts of accounting and internal controls in a construction company,” said Maria Lumke, CFO of Waterline Industries, a New Hampshire-based civil general contractor.