The expanding lineup of -7 Series mini excavators delivers more standard premium features, technologies and maneuverability to help you dig, lift and travel where other machines can’t.

-DEVELON Fleet Management

- Superior Air Conditioning System

-Hydraulic Quick-Coupler-Ready

-More Auxiliary Hydraulic Flow

- Zero and Reduced Tail Swing Models Available

Doosan construction equipment is now DEVELON.

We have a bold new name and vision to develop onwards and help build a better world.

Awarded to DX27Z-7, DX35Z-7 and DX50Z-7

Awarded to DX27Z-7, DX35Z-7 and DX50Z-7

PARDON OUR REACH: THE FUTURE OF EXCAVATION IS HERE

SURPRISING WAYS TO USE TECH TO AVOID THEFT

Outsmart tough steering with a driver-assist technology that monitors road variations at 2,000 times per second. Mack Granite ® with Command Steer can reduce your driver’s effort up to 85%, making less strain at the wheel and more productivity on the job.

EARTHMOVING TRENDS

Pardon Our Reach: The Future of Excavation Is Here

Four excavator manufacturers are preparing for tomorrow— today—by releasing several new models.

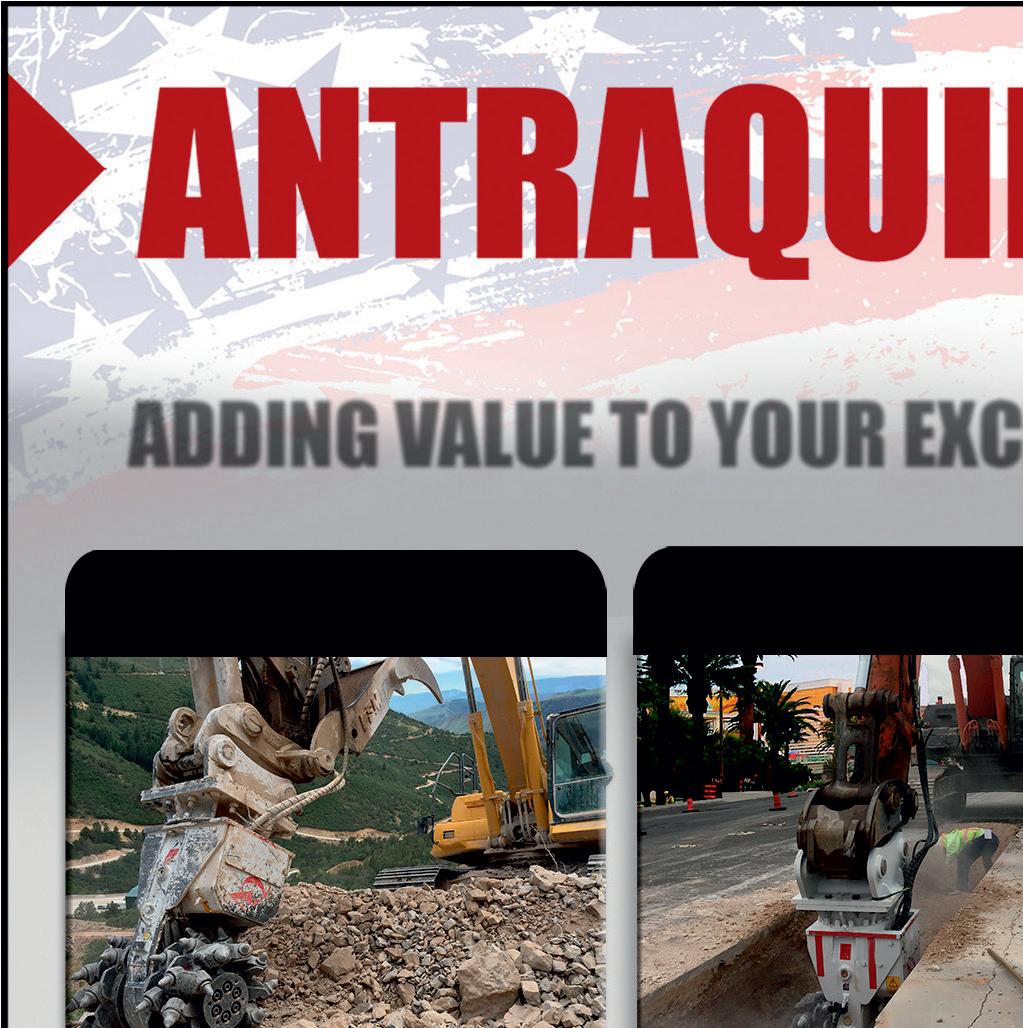

ATTACHMENTS

How Attachments Turn Machines Into Multipurpose Tools

The use of attachments transforms one piece of equipment into a multipurpose tool for a variety of construction functions.

ROAD BUILDING EQUIPMENT

Roadbuilding: What’s New from CONEXPO & Beyond

THE story in 2023 is new equipment and technology, especially when it comes to roadbuilding equipment.

TECHNOLOGY

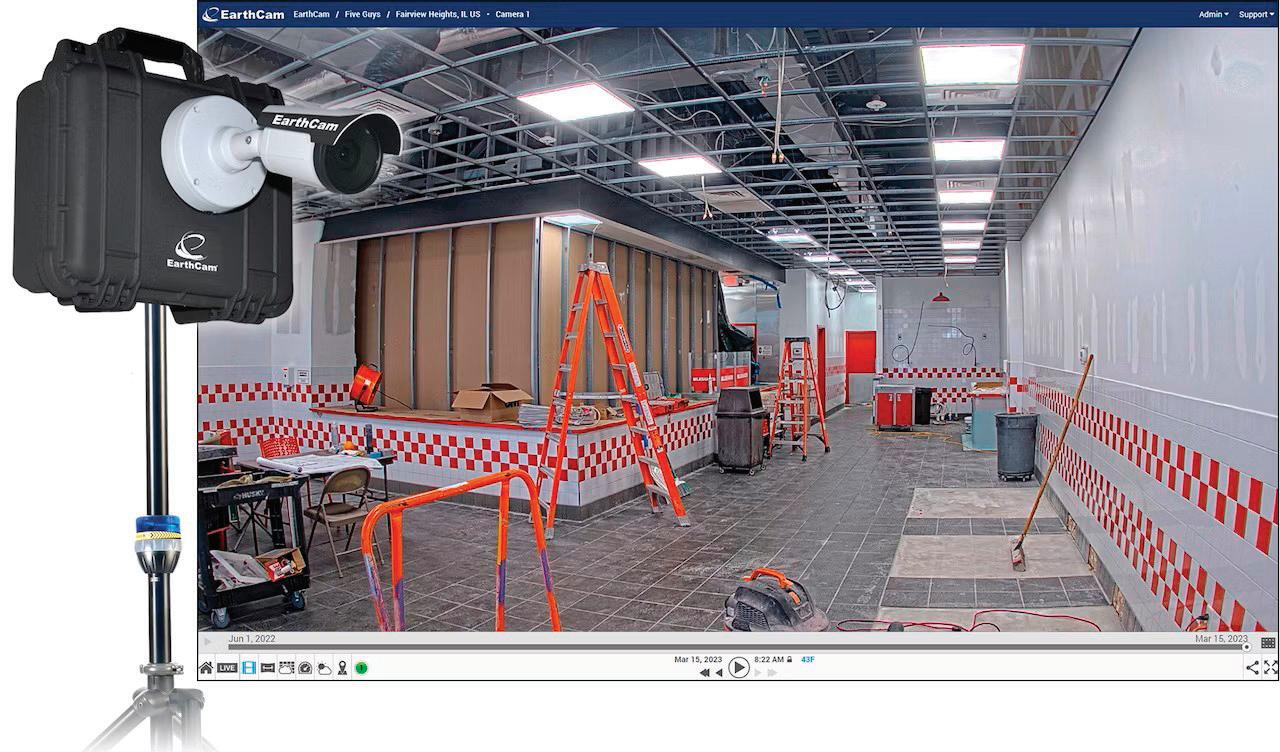

Surprising Ways to Avoid Theft

From GPS tracking and cameras to back office tech for white collar theft, criminals may soon find contractors a harder target.

BRIDGING THE GAP

Inexperienced Worker Conundrum

How green are your workers? Protect your construction business from business issues related to injuries and accidents.

®

Lori Ditoro Editor-in-ChiefEquipment Today

In our offices, we cannot seem to stop talking about CONEXPO-CON/ AGG (CONEXPO) 2023. The story from the show has been so much new equipment and technology … enough to fill several issues of Equipment Today and our sister publications.

The June issue is no exception. You’ll find many new excavators featured in the Excavator Spec Guide (page 10) and in “Pardon Our Reach: The Future of Excavation Is Here” from Chris Lewis, (page 18).

Even after CONEXPO, the NEW just keeps coming with the Caterpillar RM600 and RM800 reclaimers/stabilizers. These new machines and new technology from Astec Industries, BOMAG, LeeBoy and Wirtgen are covered in my article “Roadbuilding: What’s New from CONEXPO & Beyond” on page 38.

Curious about attachments? New technology has been released in this area, as well. You can learn more from “How Attachments Turn Machines into Multipurpose Tools” by Carol Brzozowski on page 30.

New was what I saw on a recent beautiful, warm day in Denver, Colorado, with the Mecalac team. During their media event, we saw a demo of several machines, including the new MCL Wheel Loader series. During the presentation, Patrick Brehmer, head of design and product management for Mecalac, explained that the MCL Series

combines worksite functions for a skid steer and mini excavator into one machine. It provides the work of a skid steer loader with space management and versatility.

The new series includes two small machines with 25-horsepower engines and two larger machines with 49-horsepower engines. The larger machines can reach speeds of 12 miles per hour to 18 miles per hour. The new models also simplify machine entry, human-machine interface and operator comfort.

Geoffrey Andrews, product specialist and regional sales manager for Mecalac, and Lori Ditoro, before Geoffrey showed Lori how to drive the MCL2 wheel loader.

Mecalac

If you’d like to see me drive a compact wheel loader for the first time, use the QR code below. Let me know how I did.

Watch the video: https://eqtoday.co/mecalacdrive

EDITORIAL

Editor-in-Chief Lori Ditoro lditoro@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction

Technology, IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Kristin Pride kpride@acbusinessmedia.com

Sales Representative Megan Perleberg mperleberg@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Marketing, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: (877) 201-3915 Fax: (847)-291-4816 circ.EquipmentToday@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 bart.piccirillo@data-axle.com

REPRINTS & LICENSING

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

lditoro@ACBusinessmedia.com E @EquipmentToday D @EquipmentToday C @equipment-today-magazine-official Q @equipmenttoday

Published by AC Business Media 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 www.ACBusinessMedia.com www.ForConstructionPros.com/equipment www.IronPros.com

A different view of the infamous drive.Peter Bigwood, Mecalac

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

New products include the Middle Buster implements, which have a wing cutting blade used primarily for breaking topsoil and more. Its laser-cut, heattreated steel allows for reliable operation while the corrosion-resistant finish provides durability in harsh elements. The Light Duty Pallet Fork attachments are durable and lightweight, featuring an adjustable fork width and low profile for visibility while transporting and maneuvering loads. These can be used on small skid steers and tractors.

Read More at https://eqtoday.co/fe6ovc

The S7X is all electric, powered by a 60.5-kWh, lithium-ion battery. It features electric drive motors and utilizes ball screw actuators for lift and tilt functions. Together, the battery and electrical powertrain generate performance characteristics, with instantaneous torque that is as much as three times greater than traditional loaders. The loader balances sustainability and performance with zero emissions and is equipped to outperform its diesel-powered equivalent. This skid-steer loader offers operators a smooth and comfortable experience with minimal vibration and nearly silent operation. The S7X can operate for up to eight hours on a single charge depending on the application, giving most operators more than a full day’s work when breaks and downtime are considered. A full charge takes approximately 10 hours. At this time, the S7X skid-steer loader is being debuted as a prototype with plans to move to commercialization.

Read More at https://eqtoday.co/10k5nv

The Morooka MST110C dump carrier offers heavy hauling, material handling and cargo transportation on construction sites. Built in Japan, this model replaces the MST-2200VD and features several upgrades. Equipped with a Cummins B6.7 Tier 4 Final engine, the Morooka MST110C delivers 250 hp during use. This allows the carrier to haul over 24,000 lbs. The new Morooka E-Hydro Control, or M-EHC, system is an upgraded hydraulic control system from previous models. The M-EHC system electronically monitors multiple systems and can stop the machine safely if any faults are detected. The dump carrier features joystick control, as well as accessible inspection and maintenance points. This machine has a HARDOX steel dump bed, which is resistant to impacts and wear.

Read More at https://eqtoday.co/10k5nv

The Movex Track-O MINIDOZER AL-48 is designed for aluminum smelters’ potline basements cleaning and recovery operations on construction sites. The electric machine is resistant to external conditions in aluminum smelters such as heat, dust and electromagnetic fields. It can also be used in confined spaces. Equipped with an external charger, the mini dozer has a runtime of nearly 10 hours. The batteries on the Track-O MINIDOZER AL-48 are interchangeable, which enables it to work continuously. The Track-O MINIDOZER AL-48 is controlled by a long-range wireless controller. This mini dozer features a steel frame with an aluminum cabinet. During use, it offers up to 1,170 lbs. of lifting capacity.

Read More at https://eqtoday.co/bfuhlu

This addition to the CASE excavator lineup features a short radius design for working in metro areas and on roadside projects. The wheeled excavator features powerful hydraulic performance, attachment flexibility for versatility in a maneuverable asset and a large cab with automotive styling. As a wheeled machine, the WX175E SR self-transports from site-to-site with maximum travel speeds up to 22 miles per hour. The WX175E SR on display at CONEXPO weighs in at just over 44,000-lbs. and operates at a rated 173-hp at 2,200 rpm. The short radius design allows it to work up against structures, existing infrastructure and along roadsides while taking up a minimal amount of space.

Read More at https://eqtoday.co/10k5nv

The DR 500 features a Sullair rotary screw air end and comes with a remote separator tank for flexible mounting and maintenance. During use, the machine offers 500 cfm and up to 200 psi. Accessible instruments include temperature and pressure gauges, as well as an oil level sight glass. Dual two-stage air filters with dust evacuators promotes clean air. These drill modules are protected by a galvanneal sheet metal enclosure with a powder coated finish for durability in rugged conditions. Integral forklift pockets facilitate transportation around the jobsite. Mounting provisions are also available at the bottom of the frame for permanent installations.

Read More at https://eqtoday.co/43wcfx

GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/spreaders, texture/cure machines and bridge/canal finishing equipment. GOMACO equipment features our exclusive and proprietary G+® control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.

Several new excavator models are being ushered into the market in 2023 by manufacturers, many of whom launched their new machines at CONEXPO-CON/AGG (CONEXPO) in March in Las Vegas. This new league of excavators features more power and torque with improved fuel efficiency and attachment performance, better cab comfort and longer maintenance intervals. There are new technological bells and whistles, too, such as improved grade control and obstacle detection.

We sat down with some of the manufacturers to take a closer look at what these new models offer.

At CONEXPO, Volvo Construction Equipment (Volvo CE) unveiled its most recent crawler excavator, the EC500. A 50-ton crawler excavator and a successor to the EC480E, the EC500 will be produced later this year.

Built for tough applications, including aggregates, demolition and quarrying, the excavator, when compared to the EC480E, offers construction professionals an upgraded cabin design. The cabin features:

• A high-definition Co-Pilot screen

• Keyless engine start

• Tiltable console box

• Wired and wireless smartphone charging

• New work mode switch

Alongside the EC500, professionals will be able to use Volvo Smart View with Obstacle Detection, too. Delivering a 360-degree view as a result of its enhanced camera system, the radar detection offering provides operators automatic alerts whenever the EC500 approaches obstacles. While doing so, it will identify and classify each obstacle either as an object or a human, enabling operators to adjust accordingly. Aside from these alerts, the excavator has two other significant safety features: a top handrail, which is foldable for transportation, and three-point access guard rails.

“The EC500 is also set up with a range of machine options to help

JCB North America increased its lineup with two new offerings last year: the 50Z-1 Compact Excavator and the 245XR.

operators complete their tasks faster, easier and more safely, while boosting their performance and productivity, too,” said Sejong Ko, product manager, large-size excavators, Volvo CE.

“These include the Operator Coaching app and the Dig Assist and Lift Assist machine control systems. Volvo Active Control, a semi-automated grading system and part of the Dig Assist suite of tools, will be available for the first time on an excavator of this size, as well.”

Built for tough applications, including aggregates, demolition and quarrying, Volvo CE’s EC500, when compared to its EC480E, offers construction professionals an upgraded cabin design.

This February, Volvo CE launched its 30-ton EC300E Straight Boom demolition excavator at Demolition Phoenix.

Unlike digging-biased excavators with a traditional boom-and-stick approach, the EC300E features a 23-foot-long straight boom, along with a purpose-built arm.

Because of the excavator’s extra-long, straight boom, it offers operators height and reach advantages that standard machines, on which it’s based, don’t.

And since it features a demolition-specific cab and a frame-mounted falling object guard, the excavator protects operators from falling debris— without obstructing operators’ views out of the top and front side. Operators can clearly observe their worksites.

The excavator’s roof window, and its front side one-piece glass, are comprised of P5A, which resists high impact. In addition, its main structure has a reinforced frame that features heavy-duty plate steel, along with head protection for its bolts.

“To further increase its robustness, the excavator also has heavy-duty undercover protection, a belly guard and a full track guard,” said Tony den Hoed, director, key accounts, demolition equipment, Volvo CE. “Meanwhile, a slew ring cover and heavy-duty side doors, which have screens and shutters, offer additional protection, too.”

For demolition applications, the EC300E has features like:

• X1 and X3 auxiliary piping

• A quick-fit piping and oil drain line

• Water lines, which are connected to a dust suppression system that can be used in auto or manual mode

“A comprehensive range of Volvo services are available with it as well, including Genuine Volvo Parts from Volvo’s dealer network and service plans like oil analysis and routine wear inspections,” den Hoed added.

In addition, the EC500 will offer on-board weighing, an option that will provide operators real-time insights, concerning their bucket’s loads. To ensure that they have optimal loads, operators can establish limits for each hauler and truck type. From there, the on-board weighing system will count every bucket that’s unloaded in a predefined truck loading zone. The total tonnage moved is also recorded for each shift or day.

Featuring new electric joysticks, which offer operators a higher amount of control over its hydraulic system than other excavators did, the EC500

has hydraulic pumps that can either operate together or disconnect virtually. As a result, operators can control the excavator’s boom without negatively impacting its track speed, leading to smooth rides and further safety. At the same time, fuel efficiency will improve, cycle times will decline and controllability will increase.

“Furthermore, the EC500’s Comfort Drive Control allows operators to move forward and backward, while also steering with two proportional switches on the joysticks,” Ko added. “And each operator can set up their own hydraulic settings, based on their

preferences and the application, and save them in the monitor so that they can be easily and quickly accessed for future sessions.”

Offering a rise in cooling capacity, when compared to other previously released excavators, the EC500 can handle extreme weather conditions, along with long service intervals—as high as 2,000 to 3,000 hours—for its hydraulic oil and filter. As a result, operators will save money long term, because the excavator will have higher uptime and fewer maintenance requirements.

In the past, CASE Construction Equipment excavators have been known for their responsiveness, power and speed—three assets that have been taken “to the next level with the new E Series excavators,” according to Diego Butzke, product manager.

“We’re really focused on the operator with these new units, building out a massive new operator interface and an ergonomic workstation, which provides each operator more precise control as they operate their excavator,” Butzke emphasized. “Offering

Each E Series excavator, provided by CASE Construction Equipment, has a SiteConnect Module that increases its connectivity abilities, enables collaborative fleet management and decreases downtime risks.

excellent fuel efficiency, each excavator has a low, predictable total cost of ownership for the first 3 years in which it’s owned, too, due to the CASE ProCare heavy machine support program.”

Because of the excavators’ large operator interfaces, which are highly intuitive and easy to navigate, operators will be able to simplify their operations and increase their confidence, even as they use their excavators in challenging areas. And they’ll have more awareness whenever they operate their excavators in these types of areas, due to the excavators’

massive side, rear and Max View camera angles.

Available in options, ranging from the 130 to the 470, John Deere Construction and Forestry's P-Tier models have standard LED work lights, along with an optional right, rear and left camera system.

concerning different boom and stick flows, leading to the exact type of machine responsiveness they need.

“We’ve also enhanced the ability to dial in attachment performance, enabling the E Series excavators to become extremely versatile platforms for all kinds of attachments, from breakers, to claws, to compactors,” Butzke said. “And

we’ve really doubled down on the excavators’

excavators’

collaborative fleet management capabilities, resulting in further peace of mind for equipment owners.”

As an example, each E Series excavator has a SiteConnect Module that increases its connectivity abilities, enables collaborative fleet management and decreases downtime risks. It also has a SiteManager App, which allows operators to provide CASE Construction Equipment dealer service technicians remote access for diagnostics and software updates so that they can become fully operational in a

Construction Equipment dealer service technicians remote access for diagnostics and software updates so that timely manner.

Furthermore, each E Series excavator can be monitored by the manufacturer’s CASE Uptime Center, leading to high visibility into operating conditions so that operators can identify issues before they become more

manufacturer’s CASE Uptime Center, conditions so that operators can idensignificant.

“E Series excavators have new FPT Industrial engine technology that delivers improved power, response, torque and emissions simplicity, in

“E Series excavators have new FPT delivers improved power, response, simplicity,

past,

When compared to the manufacturer’s previously released D Series of excavators, the E Series provides faster cycle times, more responsive hydraulics and new working modes, which enable operators to determine exactly how they want their excavators to perform, particularly with regards to how powerful they need them to be. Additionally, unlike in the past, operators can specify their hydraulic priorities,

excavator and successor to the this year.

EC480E, Volvo CE's EC500 will be produced later

So far, operators of the 50Z-1 Compact Excavator and 245XR from JCB have noticed savings regarding fuel consumption. Just as importantly, they’ve diminished their downtime and increased their short- and long-term productivity.

“Additionally, due to JCB’s wide range of excavator sizes, aside from the 50Z-1 Compact Excavator and the 245XR, operators now have the confidence they need to ensure they’ll have the correct excavator for whichever job they have to complete,” Marin stated.

On the market since July 2022, CASE Construction Equipment’s E Series excavators’s comfortability, ease of operation and performance have made them increasingly popular.

“The level of calmness that’s often associated with the support of CASE ProCare must not be overlooked either,” Butzke stressed.

Similarly, operators have shared feedback about Deere’s P-Tier excavators. In particular, they’ve been pleased with the excavators’ monitors, which are effortless to navigate, and heated and cooled seats, each of which weren’t provided with the manufacturer’s G-Series excavators.

“By adding grade control technology to more models, John Deere is also enabling operators to experience the value and efficiency of getting to grade faster and more accurately, while eliminating costly rework, as well,” Steger said.

The impact of Volvo CE’s EC500, meanwhile, has yet to be fully seen. The manufacturer anticipates that many operators will utilize it as a tool carrier, in addition to usual excavator functions. And since its platform uses the latest technology, which can be set up depending on each operator’s jobs and particular needs, the excavator offers users higher productivity and fuel efficiency than previously released excavators, too.

“Our goal with all excavators is to ensure owners’ and operators’ jobs become easier, safer and more productive,” Ko concluded. “With the EC500, we’ll continue to achieve this goal well into the future.”

Link-Belt Excavators X4S line of excavators offers new features on all models, such as customizable joystick function buttons and new work modes, allowing the operator to prioritize hydraulic functions based on the application. The Wide-Angle Visual Enhancement System (WAVES) with 270-degree, bird's-eye view, is now standard. X4S excavators feature up to 5% improved cycle times, increasing fuel efficiency without sacrificing productivity.

“The new X4S line, with a focus on performance and innovative features, delivers up to 17% increase in engine horsepower and 19% improved fuel economy over its predecessor,” said Adam Woods, general manager of innovation and product portfolio strategies at Link-Belt Excavators. “With this performance and efficiency improvement, many OEM’s would stop there, but LinkBelt Excavators didn’t. Now the customer will get WAVES, therefore improving site awareness. Other features within the newly designed cab are customizable switch layouts for the joysticks, four new work modes enabling increased efficiency and productivity, and technologies such as Custom Flow Balance, allowing the operator to prioritize hydraulic functions based on the application. All of this, coupled with a standard Precision Grade ready spec, are examples of the focus Link-Belt Excavators put into X4S to make this machine the performer our customer base has come to expect.”

Greater digging power and increased lift capacities are the result of the spool stroke control system, which reduces pressure loss and distributes hydraulic oil more smoothly. Pilot pressure sensors detect the type of work, such as digging or leveling, and then relays that data to proportional solenoid valves that quickly determine where optimal hydraulic pressures should be directed for that operation.

Two electronically-controlled Kawasaki variable-displacement axial-piston pumps and one Kawasaki gear pump assure that hydraulic power is delivered precisely when and where it’s needed. At the same time, hydraulic flows in noncritical areas of the system are reduced. The result is better breakout force, more lifting strength and faster machine response.

comparison to the D Series excavators’ engines,” Butzke said. “These benefits are noticed throughout the E Series product lineup, but they’re really evident in a workhorse machine like the CX300E, in which we’ve noticed a 25% increase in power and an 18% increase in torque.”

Offering longer service intervals than the D Series, leading to less downtime, which is generally associated with maintenance, the E Series

excavators are also more fuel efficient because of operating mode enhancements along with other efficiencies.

“If an operator is familiar with the D Series, they’ll notice that the E Series provides a very similar experience because it has extremely fast responsiveness, smooth operation and, again, excellent fuel efficiency,” Butzke added. “In addition, the E Series offers a low total cost of

ownership, along with reliable, straightforward service.”

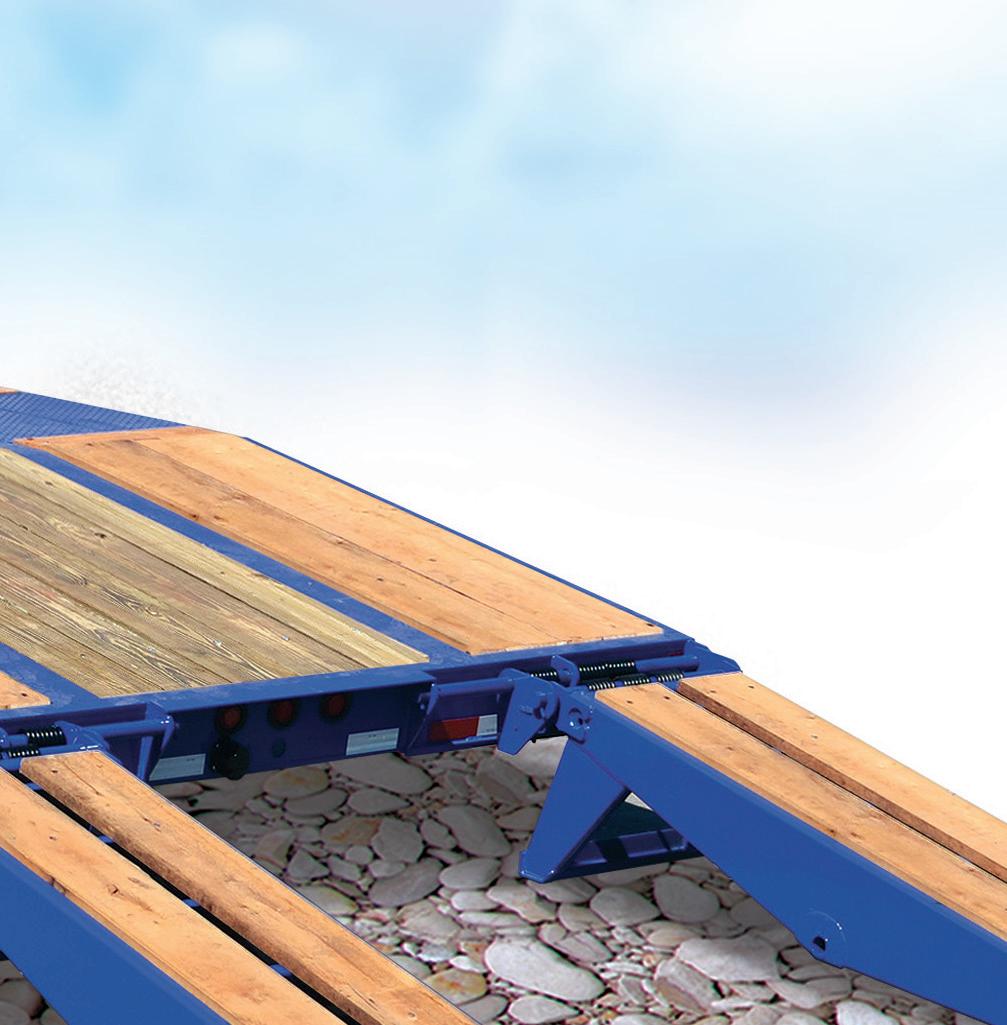

Providing a wide range of standard, full-sized excavators, as well as compact or mini excavators, JCB North America increased its lineup with two new offerings last year: the 50Z-1 Compact Excavator and the 245XR. Developed to offer longer dig end

geometry, leading to an increase in dig depth, reach and dump height, the 50Z-1, a mini, tracked excavator, continues the manufacturer’s 50-yearlong tradition of creating tracked excavators. Cost effective, easy-to-use and highly efficient, the excavator can be used on highly challenging jobsites and it’s comprised of 100% steel. Using a 48.3 horsepower (hp) engine, the excavator, which has an 11,089-pound operating weight, provides 500hour greasing intervals, along with sectioned hydraulic hoses that have bulkheads, which are easy to access.

“Highly comfortable, due to its spacious interior, the 50Z-1 has a dig depth of up to 11 feet and 11 inches,” said Javier Marin, product manager, heavy excavators and wheel loaders, JCB North America. “It also offers a dump height of up to 13 feet and 5 inches, along with zero tail swing.’

Meanwhile, the 245XR, a 28-ton, reduced-tail-swing excavator, provides operators considerable space, high power and comfort— all within a compact unit. Created over 4 years because extensive electrical, electronic and hydraulic development were required, the 245XR underwent hot and cold climate tests, ranging from -22°F to 131°F, along with machine shaker

When compared to CASE Construction Equipment's previously released D Series of excavators, the manufacturer's E Series provides operators faster cycle times, more responsive hydraulics and new working modes.

rig testing, which duplicated 15,000 hours of tracking and vibrations.

Featuring the manufacturer’s DIESELMAX 173 hp engine, which has been used in 70 different machines thus far, the 245XR has an operating weight of 61,749 pounds, a bucket capacity of 1.63 cubic yards and a dig depth of 21 feet and 9 inches, at most. Additionally, it has different hydraulic

components that deliver efficient, accurate control for any task that users need to conduct.

“Furthermore, it offers customizable, electro-proportional controls, which enable operators to establish their own preference, regarding their attachments’ control and speed,” Marin said. “And for further efficiency, the 245XR also has

the latest generation valve block that's available.”

Because of its reduced tail swing—a radius of 5 feet and 9 inches, a decline of 40%, when compared to the previously released 220X—the excavator can be safely used in tight, high-traffic areas and against buildings and road barriers.

“Our excavators provide

Starting with the highest quality o f equipment, KATO’s CL35 is builtto handle the toughest projects andthe most rugged terrain. KATO’s versatile CL35 Compact Track Loader, meets the needs of any job-site. The CL35features an operating weight of 7,800 lbs. and is easily trailered to your next jobsite. The CL35 alsofeatures a comfortable cabin and responsive pilot controls for a superior operator experience. Additionally, KATO’s US-based distributor, Compact ExcavatorSales, is a family-owned business that puts customers first. Knowledgeable product experts are always standing by to assistwith anyservice ormaintenance issuesthat arise and our streamlined parts distribution minimizes downtime, keeping projects o n schedule. Call today to find out how KATO’s superiorservice can helpyou achieve your goals.

cutting-edge technology that’s backed by years of research and development to ensure operators receive the best products possible,” Marin stated. “In fact, thousands of hours are spent on testing to make sure our excavators hold up to the demands put on them.”

Moreover, JCB North America has an ever-increasing dealer network that enables operators to properly service their excavators if any issues arise.

“Each of our excavators may have their own unique characteristics, yet they all have one similarity: the same amount of attention, concerning details, are given to each of them, ensuring their long-term efficiency,” Marin stressed. “As a matter of fact, operators will notice many similarities across our entire excavator portfolio since JCB’s technologies benefit each of its excavators, no matter how small or large they are.”

Over the past year, John Deere Construction & Forestry has been transitioning its excavators, model by model, to performance tiering.

For instance, it’s offering P-Tier models, which are highly comfortable, efficient and technologically driven.

Providing a wide range of standard, full-sized excavators, as well as compact or mini excavators, JCB North America increased its lineup with two new offerings last year: the 50Z-1 Compact Excavator and the 245XR. JCB

Cost effective, easy-to-use and highly efficient, JCB North America's 50Z-1, a mini, tracked excavator, can be used on challenging jobsites.

Available in various options, ranging from the 130 to the 470, P-Tier models have standard LED work lights, along with an optional right, rear and left camera system. Providing additional LED surround lighting, the system, in turn, offers operators 270-degree visibility, which is integrated into each camera’s main monitor.

In the meantime, the 210 to 380 models utilize electronic cooling fans, leading to 7 percent higher fuel economy, when compared to the manufacturer’s rugged G-Series excavators. They also have central lubrication at their arm tips, along with enhanced pin and bushing designs, which simplify their greasing maintenance requirements, resulting in front joint life improvements, as well.

And, finally, four of the P-Tier models—the 210, 350, 380 and 470—have optional SmartGrade precision technology, too, enabling operators to run them without any limitations whatsoever, as well as within any position. Consequently, they can lean their excavators’ front wheels, control their articulation and pitch their blades effortlessly, all while maintaining a high amount of accuracy.

“Our prior G-Series excavators built a foundation of performance and reliability, backed by our dealership network for sales, service and support,” said Justin Steger, solutions marketing manager, John Deere. “We took that foundation and built upon it, as the P-Tier has various features that meet operators’ needs and offer value to their businesses.”

Preventing Thefts, Via GPS And Telematics Available with the 50Z-1 Compact Excavator and the 245XR, JCB LiveLink enables operators to effortlessly monitor their excavators and the amount of hours in which they’re used, while also providing them alerts for routine maintenance or critical issues that need to be addressed as soon as possible.

Using GPS to know exactly where each of their excavators are operating, JCB LiveLink allows operators to establish operating areas so that they’re alerted whenever their excavators leave their work areas. And they can receive immediate notifications if their excavators are ever turned on outside of the working hours they’ve determined.

Choose

“Every JCB excavator is also stamped with numerous serial numbers to assist law enforcement with recovery if they’re ever lost or stolen,” Marin said.

On the other hand, CASE Construction Equipment’s excavators enable operators to lock and store codes to prevent unauthorized usage, while CASE SiteWatch telematics can be used to enhance the security of operators’ excavators, as well. To do so, the telematics set alerts for engine starts during off hours, and they can track excavators’ locations if operators believe they’re being used at unauthorized times or by unauthorized individuals.

Likewise, John Deere Construction & Forestry excavator users have JD telematics to connect their excavators to an operations center account,

resulting in a convenient, remote view of their excavators’ locations.

“Operators will also receive utilization data, along with alerts, which help them maximize each of their excavator’s efficiency and productivity,” Steger explained.

Similarly, Volvo CE requires its operators to enter a code through a keypad that’s available on each excavator. By entering this code, operators can start their excavators; ensure that they can’t be moved; and, in turn, reduce the risk of theft.

Every code can be changed whenever operators need a new one, too, via the manufacturer’s machine management system.

In addition, the manufacturer offers an integrated engine lock, which further reduces theft risks through several

Hitachi’s 49,833- pound ZX210LC-7 excavator has a maximum dig depth of 21 feet, 11 inches (6.67 meters) and a bucket breakout force of 35,520 pounds (158 kilonewton).

“The ZX210LC-7 builds on the success of the award-winning ZX210LC-6 HP introduced last year. We have focused on fine-tuning and enhancing the core capabilities of the ZAXIS-7 excavators to maximize efficiency, so you get more for less,” said Patrick Baker, product manager, medium and large excavators, Hitachi Construction Machinery Americas Inc.

The machine’s next generation TRIAS III hydraulic system reduces fuel consumption while improving performance. The three-pump system quickly responds to control inputs while reducing hydraulic losses. An arm roll-in metering control valve allows hydraulic pump power to be reduced when the arm is operated with a low load. When digging, the roll-in metering control valve reduces hydraulic pressure loss to the tank. This decreases the pump power needed for digging operations, improving fuel efficiency.

Attachment/arm priority can be adjusted on the monitor to match the attachment or the operator’s preference. When the attachment and arm are operated at the same time, the operator can adjust whether the speed of the attachment or the arm should be prioritized.

An Isuzu engine pumps out 164 horsepower (122 kilowatts). It uses a durable diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR) aftertreatment solution to protect the environment while preventing downtime. An auto idle system with auto shutdown control prevents wasted fuel.

triggers, including machine movement and tamper detection, along with time and geofencing functionalities. As a result, operators can immobilize and track their excavators remotely.

Email or text alerts are also submitted to operators of Volvo CE equipment whenever preset triggers have been activated. Upon receiving these alerts, excavators can be shut off, leading to their immobilization.

“Each excavator can be easily immobilized or remobilized through the CareTrack web portal or by using the excavator itself,” Ko said. “A back-up battery is integrated in our anti-theft

Unlike digging-biased excavators, which have a traditional boom-andstick approach, Volvo CE's EC300E features a 23-foot-long straight boom, along with a purpose-built arm.

hardware too, which ensures active tracking is possible even if the main power is cut or the ignition is off.”

Read more at: https://eqtoday.co/reach

Chris Lewis is a freelance writer for Equipment Today.

245XR,a 28-ton reduced tail swing excavator, provides operators considerable space, high power and comfort—all within a compact unit.

The 210 X4 HD, 250 X4 HD and 300 X4 HD come factory equipped with a high-wide and heavyduty undercarriage with larger components for added durability, strength and performance.

• Feature an 11% to 17% wider stance and 40% to 50% higher ground clearance for enhanced stability and increased lift capacities

• Traveling performance improved with up to a 30% increase in drawbar pull

The intelligent Machine Control 2.0 (iMC 2.0) is now available on the mid- to large-size PC290LCi-11, PC360LCi-11 and PC390LCi-11 excavators.

• Updated, factory-integrated systems help to minimize over-excavation and empower operators to dig straight to grade quickly and accurately

• Auto tilt bucket control assists operators by aligning bucket parallel with the slope so finish grading can be accomplished without needing to align the machine with the target surface.

The new Cat 352 Straight Boom Excavator is designed for low-level demolition work up to five stories high, bridges and industrial infrastructure. Its stick-boom configuration delivers a higher vertical reach up to 12.85 m (42-ft., 2-in.) with 36% more stick pin height compared to the standard 352’s reach. Working with up to a 6,000-kg (13,228-lb.) attachment weight, the new 352 Straight Boom now features standard Cat technologies for versatility in both demolition and excavating applications. The excavator’s new optional 11.35-ton (25,022-lb.) removable counterweight design supports transportation. The mechanical variable gauge undercarriage has a 2,990 mm (9-ft.,10-in.) transportation width.

The new Kobelco SK350LC-11 features a 265-hp Isuzu Tier 4 Final engine to support lifting heavy loads and operating large tools. With redesigned boom cylinders, the SK350-11 has the power to handle trench boxes. With the press of a switch, the machine dedicates one hydraulic pump to the travel system and one to all the other functions on a continuous basis. This allows the 11-series Kobelco machines to travel while having the ability lift and swing heavy loads. The SK350LC-11 has three working modes (Eco, S and H) for balancing between high performance, economy and fuel consumption. Heavy Lift and Power Boost add power needed to get through tough conditions. The in-cab hydraulic pressure release function allows users to change work tools safely.

• Bucket angle hold control automatically

The new DX89R-7 mini excavator replaces the DX85R-3 and features greater lifting capacity and more horsepower. The mini excavator boasts a reduced-tailswing feature, permitting more power in cramped, congested worksites. Powered by a Tier 4-compliant D24 diesel engine offering more horsepower, the DX89R7 provides higher productivity than its predecessor. Auxiliary hydraulic flow remains readily available for operators to use hydraulic-powered attachments with the mini excavator. An increased machine operating weight and the excavator’s new counterweight design provide better stability for increased lifting capacity.

This 1.7-ton machine is a zero-emission solution for indoor applications and in areas where noise and exhaust are a concern, such as construction sites in urban areas and those operating around the clock. The EZ17e mini excavator offers the same performance as the company’s conventional diesel model, but with zero emissions and reduced maintenance. With its minimal-tail swing design, it has a maximum digging depth of 97.7-inches, a breakout force of 4,608 pounds and the ability to run auxiliary attachments such as hydraulic breakers. The lithium ion battery in the Wacker Neuson EZ17e offers all-day run time and can be recharged using a common 240-volt, single-phase outlet. Charge time is between 5 and 6 hours. In addition, the machine can be operated in a stationary position while connected to a power source, if necessary. The maintenance-free battery reduces the overall service and spare parts costs of the machine.

Compared to the 85 G-Tier model, the new 85 P-Tier offers an 18% engine horsepower increase and the addition of turbo for highaltitude performance. Hydraulic performance improvements include increased pump torque and improved dig forces. The redesigned cab is equipped with an 8-in. monitor with Bluetooth and a 270-degree camera system integrated into the main monitor. Improved service access and optional features, such as angle blade with float and continuous flow auxiliary hydraulics, round out the updates. Coming in at 51-metric tons, the 510 P-Tier is a replacement for the current 470 P-Tier model. Including a variable undercarriage and the ability to handle buckets 5 yards and above, this new model will continue to deliver performance and capability in its class. This machine is designed to deliver performance to customers in mass excavation or deep underground applications.

Takeuchi has expanded its TB300 Series excavator product line with the new TB350R short tail swing compact excavator, the first short tail swing model in the manufacturer’s 5-ton class. The TB350R has a rear swing overhang of just 2.95 in., helping minimize rear-swing impacts. The TB350R weighs 10,980 lbs. in canopy configuration and 11,235 lbs. when equipped with a cab. It is powered by a Kubota V2607-CR-E5B diesel engine that is U.S. EPA Tier 4 Final compliant and delivers 41.7 net hp (ISO 9249 and SAE1349) and more than 130.2-ft-lbs. of torque. A four-pump hydraulic system delivers smooth, harmonized control of the work equipment. The TB350R provides a bucket breakout force of 10,431 lbs., a traction force of 12,320 lbs. and a maximum dig depth of 11 ft., 8.8 in.

Powered by a 24.4-hp Yanmar 3TNV88F Tier 4F engine, the XE35U hydraulic excavator is compatible with a selection of tools for specific tasks on the jobsite. Applications for the XE35U include excavation, loading, leveling, trenching, crushing, drilling, clamping and more. This excavator features a tailless design, supporting compact requirements in outdoor worksites. A load-sending hydraulic system adjusts to the needs of the operator, adding versatility during use. Protected an X-track undercarriage frame to minimize buildup, the machine is equipped with a wide-entry door for visibility and accessibility. An LCD panel displays excavator stats, such as temperature, fuel, time and operating modes.

The PC210LCE was created for construction businesses that need a high-performance machine. The excavator has 451 kWh of battery capacity and is designed for up to 8 hours of operating time. The lithium-ion battery technology was developed by Proterra. Designed to reduce operator fatigue with less noise, exhaust emissions and zero engine vibration, the PC210LCE is for use in urban areas and indoor environments. The low operating noise levels of the PC210LCE allow for nighttime construction work both indoors and out. Coming soon to North America, the PC210LCE supports Komatsu's global sustainability targets of 50% reduction in carbon dioxide emissions by 2030 and complete carbon neutrality by 2050.

The all new redesigned KATO 9V5 mini excavator will debut summer of 2023. This ultra-mini zero tail swing excavator is a much faster and easier alternative to any shovel or wheelbarrow for working in tight spaces. With it’s ultra small size and roll down ROPS the 9V5 can even fit through doorways, standard yard gate, and even the tightest spaces making it perfect for any project. Need more stability?

Standard equipment includes expandable tracks to help you power through your job with stability and ease. All new 9V5 will be available summer 2023.

The 49,833-lb. Hitachi ZX210LC-7 excavator has a maximum dig depth of 21 ft, 11 in. (6.67 m) and a bucket breakout force of 35,520 lbs. (158 kN). This machine is designed for earthmoving, material handling, demolition, underground excavation and more. The TRIAS III hydraulic system provides response to all control inputs while minimizing hydraulic losses. A new arm roll-in metering control valve allows hydraulic pump power to be reduced when the arm is operated with a low load. When digging, the roll-in metering control valve reduces hydraulic pressure loss to the tank. An Isuzu engine pumps out 164 hp (122 kW). It uses a durable diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR) aftertreatment solution to protect the environment. The excavator features work modes to match available power to the jobsite conditions. An auto idle system with auto shutdown control prevents wasted fuel.

Built for tough jobs that require high performance, the Komatsu PC900LC-11 excavator is a versatile machine. The excavator is designed for heavy construction, demolition, material handling, deep sewer, water, large mass excavation and mining or quarry. The 842-hp PC900LC-11 was featured in Komatsu's booth at CONEXPO-CON/ AGG 2023. The PC900LC-11 offers major design enhancements compared to the earlier model. The new counterweight removal system helps with moving and the boom configuration reduces transport height. A new service pass through area allows access to filters, oil level checks and sample ports. The major structures,

booms and arms, with a redesigned revolving frame, were engineered for longevity. To help operators with situational awareness, tools such as the KomVision camera system come standard on the PC900LC-11. KomVision is a 360-degree monitoring system that uses six cameras for a real-time view of the surroundings. Smart Construction 3D guidance and payload monitoring are other available options.

Hitachi ZAXIS-5N compact excavators range from 1.7 metric tons to 6 metric tons (1.10 to 6.61 U.S. tons) that feature either a short-tail swing radius (U) or an ultra-short-tail swing radius with swing boom (USB). ZAXIS-5N compact excavators are commonly used as tool carriers with a wide range of attachments. Standard auxiliary hydraulic lines have been pre-plumbed to the end of the boom on the ZX17U-5N and to the middle of the arm on the ZX26U-5N to ZX60USB5N. A standard wedgelock quick coupler makes attachment hookup a snap. A factory-installed bracket for a thumb cylinder simplifies thumb installation. The operator can match the flow rate of the auxiliary hydraulic circuit to the requirements of the attachment being used with either a low or high setting.

Greater digging power and increased lift capacities are the result of the Spool Stroke Control system, which reduces pressure loss and distributes hydraulic oil more smoothly. Pilot pressure sensors detect the type of work being done, such as digging or leveling, and then relays that data to proportional solenoid valves that quickly determine where optimal hydraulic pressures should be directed for that operation. Two electronicallycontrolled Kawasaki variabledisplacement axial-piston pumps and one Kawasaki gear pump assure that hydraulic power is delivered precisely when and where it’s needed. At the same time, hydraulic flows in noncritical areas of the system are reduced. The result is better breakout force, more lifting strength and faster machine response. The X4 Series features innovative EPA-certified Final Tier 4 engines from Isuzu.

HEVI offers the GEL-1800 all-electric wheel loader for material handling and land clearing on construction sites. Its operating weight is 11,464 lbs., with a rated load of 3,968 lbs. Its bucket capacity is 1.3 cubic yards and dumping height is 8 ft. 6 in., and its speed is 16 mph. Built with flexibility, the GEL1800 comes with a JRB 416 quick attach coupler, compatible with a variety of attachments. Compatible attachments include bale spears, forks, log grapples and more. The wheel loader includes a 141-kWh battery, a base charger (220 V, with an optional 480-V upgrade) and a 1.3-cu.-yd. bucket. This machine is compatible with a range of Electric Vehicle Supply Equipment (EVSE) brands such as Blink Charging and Siemen’s.

The CX42D delivers a high level of feature standardization with excellent options to further improve performance. A standard twoway blade with float improves backfilling and grading operations, while an optional six-way blade seriously beefs up those capabilities. While the zero-tailswing design provides excellent access to tight sites, additional counterweights can be added for further balance and confidence. Standard two-speed travel with automatic shift down improves performance when tracking/carrying up hill. Standard multifunction (1-way/2-way) hydraulics and standard second auxiliary (2-way) circuit make these new D Series machines attachment beasts, while an optional third auxiliary circuit delivers even more versatility. Each machine comes standard with a thumb bracket and can be ordered from the factory with an optional thumb.

With a powerful Cummins engine and wellconstructed componentry throughout, the XE155UCR 16-tonne excavator is designed and manufactured for a wide range of worksites: excavation, mining, loading, leveling, trenching, crushing, drilling, clamping, lifting, etc. With structural components, performance, comfortable operation and safety, the XCMG XE155UCR excavator is designed for any and every operator seeking a value machine in the 15- / 16- / 17-tonne size class.

• Overall width: 2490 mm

• Flow range: 2x113.4 lpm

• Operational weight: 16670 kg

• Engine: Cummins B4.5

• Power: 90 kW/121 hp

https://eqtoday.co/digging-deeper-podcast to listen to the latest podcast interviews with contractors and equipment manufacturers about the newest technology, tools and equipment.

The 245XR fits in the 22- to 26-ton reduced swing size class and features a 173-hp JCB Ecomax 448 Tier 4 Final-compliant diesel engine with no DPF required. The hydraulic system uses the latest generation Kawasaki pumps and a Kayaba main control valve for precise control. The unit is equipped with a 9-ft. 10-in. dipper arm, for increased breakout or maximum reach. With the monoboom, it offers a maximum digging reach of 3 ft. 1-in. and a maximum digging depth of 21 ft. 9 in. An optional dozer blade is available. The 3-ft.wide cab offers updated CommandPlus control switch packs, a large 7-in. multifunction display, standard adjustable air suspended seat with mechanical lumbar support, climate control, Bluetooth radio, enhanced storage and more.

SANY expands its 10-ton or smaller compact excavator line with four models powered by Yanmar Tier 4 Final engines ranging from 19.6 to 72.1 gross hp.

• Feature 5,908-lb. to 20,238-lb. weights, maximum digging depths from 9 ft. 3 in. to 14 ft. 2 in. and digging force from 3,192 lbs. to 14,298 lbs.

• SY26U and SY50 include a pivoting boom and zero tailswing

• SY95 includes a SANY-developed control system with load-sensing hydraulics

• All models offer auxiliary hydraulics down the arm, easily accessible service points

Bobcat’s E19e compact excavator offers a compact footprint, quiet operation and zero emissions. The electrical motors deliver full torque regardless of rpm, hydraulic control and multifunctioning performance with minimal power drop. Like the E10e and the E32e, the E19e offers a run time of four hours of continuous operation on its lithium-ion battery pack. It charges with a standard 120-volt outlet, requiring 8 hours to fully charge. While applications vary, each charge can support common daily work operations and the use of work modes for up to 4 hours of continuous operation time and a full day of operation during intermittent use or a typical contractor workday. Producing zero emissions, the battery-electric excavators support environmentally sensitive worksites. They allow users to operate inside structures.

The R 940 Demolition is powered by a 268hp Liebherr engine that complies with Tier 4 Final/Stage V exhaust emissions. The Liebherr Demolition Control System provides real-time information on the tilt angle of the machine and the tool position. If a critical value is exceeded, the excavator automatically triggers electronic range information. The unit features a 30-degree tiltable cab to ensure an optimal view of the working area. The hydraulically adjustable undercarriage with variable track gauge facilitates transport and the counterweight is removable. Options include a cab air filtration system, a spray system for reducing dust in the work area and an air compressor for cleaning the radiator and cab.

The 19,180-lb. 909ECR limited tailswing midi-excavator with wide undercarriage provides a maximum digging depth of 14 ft. 11 in. and a lifting capacity at ground level of over 11,500 lbs.

• 62-gross-hp Yanmar Tier 4 Final engine

• Boom slew allows digging parallel to blade with the swing post and cylinder staying within tracks while working in an offset position

• Improved cab design comes with rear cameras, proportional joystick controls, air suspension seat and enhanced monitor

• Features two-speed travel with auto downshift, dozer blade with float and dual auxiliary hydraulic circuits

Hyundai Construction Equipment Americas revealed three new models in its HX-A series of compact hydraulic excavators: the HX35AZ, HX40A and HX48AZ. All three new models feature low-emission engines that are Tier 4 Final compliant. The Hyundai HX35AZ excavator is powered by a Kubota D1703 diesel engine with a net power rating of 24.8 hp (18.2 kW), while the HX40A and HX48AZ feature Yanmar 4TNV88C engines, rated at 37.4 hp (27.5 kW). The HX35AZ has an operating weight of 8,300 lbs. (3,765 kg), dig depth of 9 ft., 8 in. (2.95 m) and bucket breakout force of 7,081 lbs. (3,212 kg). The HX40A has an operating weight of 9,479 lbs. (4,300 kg), dig depth of 11 ft., 2 in. (3.4 m) and bucket breakout force of 9,846 lbs. (4,466 kg). The HX48AZ has an operating weight of 10,912 lbs. (4,950 kg), dig depth of 11 ft., 5 in. (3.5 m) and bucket breakout force of 8,223 lbs.

Lightweight, rugged thumb attachment maintains a tight hold on material with limited reduction in lifting capacity. Controlled movement with precise hydraulics allows you to easily grab delicate material or clamp tightly on debris. Installs quickly due to thumb-ready arm and standard auxiliary hydraulics on the excavator.”

VERSATILE PROFESSIONAL CONTRACTING TIRE FOR YEAR-ROUND USE

Nokian Tyres TRI 2 excels in a wide variety of tasks from job sites to highways, from snowy winters to hot tarmac. Its durability, economy and comfortable driving response make it a reliable choice for versatile contracting work.

nokiantyres.com/heavy

The use of attachments transforms one piece of equipment into a multipurpose tool for a variety of construction functions, enabling contractors to complete their jobs more efficiently, bid on more and larger projects, create a more diversified portfolio and work in numerous weather and ground conditions.

Solving Challenging Jobsite Tasks

Attachments are the means to conquering some of the most difficult tasks on construction jobsites, said Jacob Sherman, product and dealer marketing manager for DEVELON. To that end, the company has a range of attachments and accessories to enable added flexibility and efficiency on the jobsite. Excavators can be configured with a hydraulic quick coupler, resulting in ease of changing attachments.

DEVELON offers a variety of buckets to best suit the most specialized applications, Sherman said. The DEVELON wheel loaders have an available quick coupler and buckets to allow the optimal configuration for the job, he added.

Attachments are a key part of the jobsite, as they help increase the versatility of a machine, Kristin Stout, Caterpillar senior sales support specialist, pointed out.

“Using multiple attachments allows more tasks and jobs to be completed with a single machine,” she added.

“An excavator cannot dig a trench without a bucket just as a vehicle cannot drive without tires,” noted Alex Andrews, product manager at Werk-Brau, of the criticality of using attachments on the jobsite.

Taking on a Variety of Tasks DEVELON attachments are designed to create optimal performance with the associated machine, with some

examples including excavator and wheel loader buckets, excavator thumbs and quick couplers.

“This allows all aspects of the machine to perform at its maximum ability, resulting in added efficiency and productivity for the operator,” Sherman said. “For example, if an application requires a high volume of low-density material to be transported with a wheel loader, a light-material bucket may be the best attachment for the task.”

DEVELON has partnerships with several attachment manufacturers to provide an assortment of models and types. Most recently, DEVELON provided machines during CONEXPOCON/AGG 2023 (CONEXPO) for the Steelwrist and GRYB booth, manufacturers of heavy equipment attachments. Also in the DEVELON booth, a crawler excavator and a mini excavator were paired with Steelwrist attachments to showcase the partnership between the two companies.

Caterpillar has an extensive portfolio of attachments for any job, ranging from general construction to forestry, landscaping, demolition and agriculture, among others, noted Stout.

During CONEXPO, Caterpillar displayed a new PC35 cold planer, CVP55 vibratory plate compactors, mini hydraulic excavator grapples G206 and G208, and 3D grade control for Cat Smart Dozer Blades.

“The new PC35 and PC45 cold planers are now compatible for backhoe loader and mini excavators, and come standard with the Max Pro Gauge, helping operators run more productively,” said Stout.

The new CVP lineup has added two additional models for backhoe loader and mini excavators, she added.

“This allows operators to be better matched to their machine and trench width,” she said. “These new sizes range from a width of 12 inches on the CVP16 up to 26 inches on the CVP55. The G306 and G308 are demolition and sorting grapples designed for fast, productive material handling with 360 degrees of bidirectional rotation. The G206 and G208 multipurpose grapples are specifically designed for use with Cat TRS systems.”

Caterpillar’s recent rollout of new

Cat attachments available for backhoe loaders and mini excavators aims to increase the machines’ application versatility. The new models are designed to be rugged and reliable and span the range of demolition and sorting grapples, multipurpose grapples for Cat Tiltrotaters, vibratory compactor plates and cold planers.

The new G306 and G308 Grapples are specifically designed for 5- to 6-ton and 7- to 10-ton mini hydraulic excavators, respectively. The new models are designed to excel in waste, recycling and heavy-duty material handling applications, where precise material placement is required. With open and close functions controlled by the machine’s first auxiliary function and rotation head handled by the second, the grapples are designed to deliver fast and productive material handling with 360 degrees of bidirectional rotation. A slim design makes it easier to get into tight spaces. Material capacities range from 160 liters (0.21 cubic yards) with the G306 to 240 liters (0.31 cubic yards) for the G308.

Vertical perforated shelves are designed to offer high wear resistance, positive penetration, good load visibility and easy positioning, while the oversized, heavy-duty cylinder with load holding valve was created to deliver constant clamping force, even when maneuvering the grapple or machine.

The swing bearing features a single-ball, heavy-duty, internally driven design for reliable operation with low maintenance intervals. The weld-on base edge design is made of HB500

Brinell equivalent material and bolt-on cutting edge from high-strength, abrasion-resistant steel.

As the first hydraulic attachment expansion for the Cat Tiltrotator (TRS) product family, the new Cat G206 and G208 multipurpose grapples expand the grapple technology in combination with the TRS6 and TRS8 models for 5to 10-ton mini hydraulic excavators. The models are designed to allow maximum maneuverability with TRS attachments. An integrated bracket is designed to provide minimal offset to optimize grapple functionality performance.

With the G206 sized for 5- to 6-ton excavators and the G208 for 7- to 10-ton models, these multipurpose grapples provide 14.5-kilonewtons (3,260-pound-feet) and 18.4-kilonewtons (4,136--pound-feet) of maximum closing force respectively.

An integrated cylinder load holding valve maintains grapple closing pressure with no leakage, while the hard-mounted piston accumulator maintains grapple arm closing forces with shifting loads. Optimal routing of the integrated jumper lines and hoses is designed to protect against damage and dirt infiltration.

The grapple design is matched to the tilt rotate system. The TRS rotation enables quick and easy material engagement. A welded box structure helps avoid any bending torques in radial direction.

The grapple arms and arm edges’ AR450 steel construction is designed for high abrasion resistance that provide longer wear in extreme conditions.

The new CVP28 and CVP55 Cat Vibratory Plate Compactor models relaunches the CVP16 and CVP40 compactors with new design enhancements and expands the Cat Vibratory Plate Compactor line. They are designed for the compaction of soil, sand, gravel and asphalt and for lower investment and maintenance cost for contractors working industrial, commercial and residential jobsites.

The Cat CVP range is performance-matched to Cat machines, covering all backhoe loaders and excavators

At CONEXPO, Caterpillar displayed a new PC35 cold planer, CVP55 vibratory plate compactors, mini hydraulic excavator grapples G206 and G208, and 3D grade control for Cat Smart Dozer Blades.

ranging from the Cat 302.7 to the 313, offering compaction widths from 304.8 millimeters (12 inches) to 660.4 millimeters (26 inches) and compact areas ranging from 0.19 square meter (2 square feet) to 0.53 square meter (5.7 square feet) at vibration frequencies from 33.3 hertz to 40 hertz (2,000 vpm to 2,400 vpm).

The optimized compaction frequency is designed to combine with

force to drive material particles close together for solid, stable compaction. A heavy-duty steel frame is designed to deliver maximum power to the ground. Rubber mounts isolate compactor attachment vibrations from the compactor attachment, minimizing feedback to the rest of the machine. The high efficiency gear-type hydro-motor is vibration driven for consistent, reliable power.

The design’s access cutouts are laser cut for ease of access to hardware when mounting the top bracket. The compactor is designed to be simplified with standard auxiliary hydraulics. Post and plate driver attachments bolt to the bottom of the CVP28 for specialized applications.

All models can be equipped with a backfill blade to help spread material in the ditch before compaction.

A swivel mount rotates 90 degrees in each direction to minimize machine movements.

The new Cat cold planers are designed for small paving jobs in residential and commercial applications for use on asphalt and concrete surfaces. They also efficiently mill imperfections prior to resurfacing and remove deteriorated pavement and traffic lane stripes.

The new PC35 offers a working width of 350 millimeters (13.8 inches) and a 120-millimeter (5-inch) maximum milling depth. It is designed for operation with side-shift backhoe loaders and 5- to 6-ton mini hydraulic excavators.

The new Cat PC45 replaces the PC404 with its 450-millimeter (17.7inch) cutting width and 150-millimeter (6-inch) cutting depth. It is ideal for use with backhoe loaders and extends the planer’s compatibility to 7- to 10-ton mini hydraulic excavators.

The cold planers come standard with a cut depth indicator to offer the operator a quick view of set depth. Milling depth is manually adjusted and locked in for consistent depth control. Their heavy-duty gear motor is designed for high torque and efficiency across the speed range.

A hydraulic relief valve limits pressure to the motor to extend longevity. A standard pressure gauge provides feedback to the operator, allowing for ground speed adjustments and enhanced productivity. The PC35 and PC45 reuse existing hammer lines and are equipped with drum center and width indicators.

Caterpillar recently announced

new options for the Cat Smart Grader Blade and Smart Dozer Blade. The new external control kit for GB120 and GB124 smart grader blades is designed to expand the use of these blades to Cat D and D2 series SSL and CTL machines, enabling customers with previous models to run smart blades.

Automatic blade control can easily be added to the Cat Smart Dozer Blade with the new 3D grade control kit, using existing connections.

Previously, the smart blades were made available for customers with Cat D3 series SSL and CTL machines. The new external control kit enables end users to run smart grader blades on all D-series and select older machines.

The GB120 and GB124 blades automatically detect whether they are being operated on a D3 series or machine equipped with the external controller.

The new external control kit includes a third joystick for operating blade raise/lower, tilt, angle and wing functions such as smart control for D3 series machines.

It also includes the wiring harnesses, a RAM mount, brackets and all necessary hardware required for smart grader blade control. Compatible with Cat Grade and Earthworks GO! systems, the new external control features selectable modes for left, right and tandem control.

Standard cross-slope assist and full proportional control of all functions are designed to improve operating efficiency.

The new 3D GPS/GNSS grade control for smart dozer blades on Cat CTL machines guides the operator to accurately grade planes, slopes, contours and complex curves.

It provides blade vertical height and horizontal positioning guidance, or, alternatively, the system controls the blade relative to a design loaded into the grade control system.

Automated blade control is designed to take the guesswork out of what the grade should be, allowing operators to achieve design plans faster. The 3D grade control system is designed to reduce rework, labor and materials used on the job.

The base Cat Smart Dozer Blade comes standard with all the required connections to install 3D grade control

An excavator cannot dig a trench without a bucket just as a vehicle cannot drive without tires.

— Alex Andrews, Werk-Brau

components. Software updates and the hardware are available for existing machines and smart dozer blades to operate grade control.

With all of the attachment choices available on the market, several factors should be kept in mind for choosing the right attachment for the piece of equipment being used on a particular job.

The first consideration when adding attachments to a machine is the attachment’s spec requirements, Sherman pointed out.

The second consideration is the likely operating environment.

“Considering these two variables will generally ensure you have an attachment with complementary capabilities enabling an operator to take full advantage of a machine’s potential,” he added.

Stout pointed out that the most important factor to keep in mind is “to ensure you are buying the right attachment for the job, as well as the

right attachment for your machine. Caterpillar has variety of attachments that are optimized for the customer’s specific machine and working needs to help get the job done more efficiently.”

Keep it simple, Andrews advises of attachment choices.

“What application is intended for the attachment? Are you performing everyday general construction? Are you into a more severe-extreme-rocky environment calling for upgraded attachments?” he added.

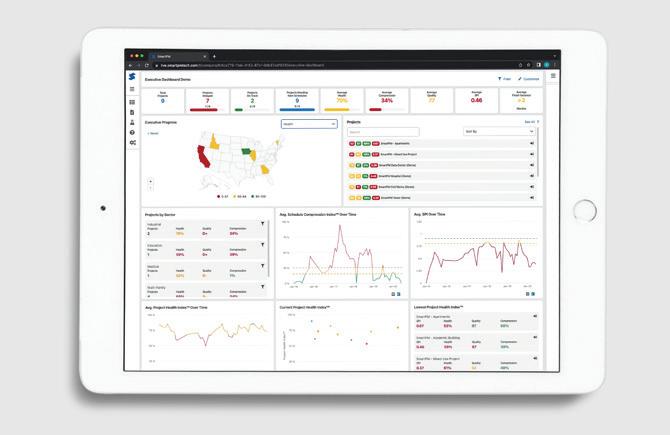

Sherman said the equipment industry continues to be driven by end users’ seeking enhanced management tools and more operating efficiency.

That is achievable not only with enhanced hardware but also with updated technology.

Sherman pointed out that technology incorporated into DEVELON machines is designed to enhance machine management, increase operating efficiency and improve operator safety.

“One example of DEVELON leveraging developed technology to improve

safety is the development and launch of wheel loaders with the industry-exclusive Transparent Bucket technology,” said Sherman. “The Transparent Bucket feature comes standard on all 2023 7 Series wheel loaders and allows operators to have greater environmental awareness and visibility.”

The Transparent Bucket option is designed to offer a supplemental view from a monitor inside the cab that allows operators to see objects or challenging terrain for greater work efficiency and productivity.

When added to a DEVELON 7 Series wheel loader, the Transparent Bucket allows operators to see large rocks, construction materials, obstacles and even people in front of the machine in contrast to an obstructed view using a traditional bucket.

This multiple-camera system helps minimize blind spots that occur when the wheel loader bucket is raised so operators can see what is ahead from the in-cab monitor.

Not only is that designed to contribute to safety, but the ability to

‘see through’ the wheel loader bucket allows operators to efficiently dig into and precisely place material where it needs to go.

The standard DEVELON Fleet Management telematics technology provides end user companies of all sizes the ability to monitor and manage equipment to optimize work uptime, said Sherman.

“Construction equipment owners can remotely monitor their machines and track usage by operators, fuel consumption, idle time, and more,” he said. “The telematics data is readily available to dealers, too.

“Dealers can often respond to an issue in less time because more information—such as the fault code and machine location—is available. A

service tech can be dispatched to the exact location with the right parts to correct the issue.”

Werk-Brau recently introduced the Tilting Bucket with increased tilt force and 45 degrees of tilt in both directions. It is designed for maximum control and articulation in ditching, grading and sloping applications. It eliminates machine repositioning to boost productivity while reducing wear and tear on the tracks and undercarriage.

An enhanced, oversized cylinder design increases tilting force, allowing the unit to better hold the desired angle.

Integrated cylinder guards protect the cylinders and keep them functioning without damage or leaks. A single cylinder design is used for compact excavators, while full size excavators use dual cylinders.

The Heavy-Duty Excavator Bucket is constructed of high quality T-1 steel used in all critical or high-wear

components with a rigid top section to eliminate flexing. Heavy-duty horizontal wear straps protect the bucket bottom.

Each bucket is engineered with tapered side plates and a dual taper radius to reduce wear and make dumping easier.

The Werk-Brau Tilting Buckets are designed for a wide range of ditch digging or cleaning applications, creating unique slopes, and grading projects.

At Werk-Brau, in-house design utilizing the latest in CAD and finite element analysis aids in testing the designs before any steel is formed, Andrews said.

Read more at: https://eqtoday.co/attach

With its V-shaped design, the latest drum cutter from Epiroc sets a new standard in trenching and quarrying. A seemingly simple solution with an extraordinary effectiveness, enabling energy savings of up to 40%. Thanks to the V-shaped design, that enables a cut with a flat base, no material is left untouched between the drums. Where a regular drum cutter must move side to side to create an even trench, an approach that causes extra wear on the carrier arm, the VC 2000 can reach the same result by just going straight. The distinguishing features of the classic Epiroc drum cutters, like the spur gears, adoptable high torque gear motor and the QuickSnap retaining system for fast and easy pick changing, are all to be found in the new VC 2000.

A pin grabber coupler was added to the Hard-To-The-Core John Deere optimized attachment lineup.

• Features a rear wedge to secure the rear pin to prevent a swinging attachment in the event of a hydraulic failure

• Spring-engaged/hydraulically released internal safety-lock

• Hydraulic interlock requires the coupler to be fully curled toward the cab to be disengaged

• Hydraulic check valve maintains pressure in cylinders if a hydraulic hose breaks

• Works with all Deere excavator models from the 80-Series to 400-Series

These L Series Battle Ax horizontal drum mulchers are designed for low-flow skid steers with 16- to 30-gpm hydraulic flow ratings.

• Feature a new rotor design with built-in gauges to provide optimum material flow into the drum.

• Includes a two-stage cutting chamber for producing optimal particle sizes

• Uses reversible Quadco blades

• Available with 51- and 61-in. cutting widths

IronCraft, formerly Titan Implement, introduced the 2512 Series Flex-Wing Cutter for large-scale landscaping projects. This cutter requires just 35 PTO-hp and one hydraulic outlet to cut grass, weeds and light brush up to 2 in. in diameter. Designed for compact tractors, the wings flex from 22 degrees down to 87 degrees up (22 degrees down and 45 degrees up wing free float), allowing it to tame slopes, gullies, ditches and other tough topography. It has a 75-hp outboard gearbox rating. The 2512 series has a cutting height range from 1½ in. to 12 in. for cutting grass, weeds and light brush on farms, in parks and recreational areas, on community green spaces and along roadsides.

Made for heavy-duty mulching applications, Diamond Mowers’ SK Drum Mulcher OD Pro X is a hybrid design that combines the versatility of an open drum with depth control precision. Ideal for users requiring both power and flexibility, this easy-to-operate attachment efficiently processes material up to 9 in. in diameter and is engineered to allow heavy ground engagement for maximum productivity. The shredding performed in the drum chamber reduces the need for back-dragging and produces a uniform mulch with a smaller particle size than conventional open drum models.

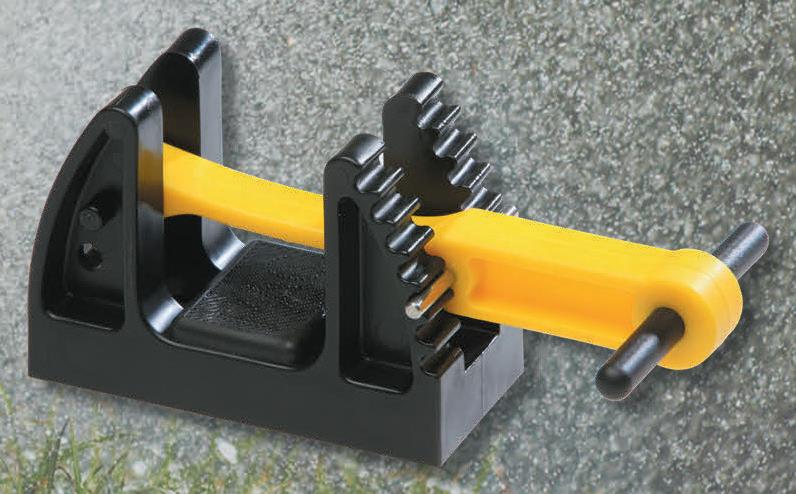

The configurable coupling system enables users to simultaneously connect and disconnect up to six hydraulic lines fitted with Danfoss flat-face, quick-disconnect couplings with a single movement, supporting assembly, maintenance and attachment changeout. When configured to connect under pressure, the multiplate system supports manual connection up to 350 bar.

Carbide rockwheels and diamond saw attachments are available for excavators of all sizes and various applications.

• Offer a cutting solution for soft to medium hard rock and concrete cutting applications with a minimum width of 2 in.

• Diamond saw rock wheels (AQD Series) cut the hardest rock including granite, basalt, etc., as well as reinforced concrete

Excavator Mulcher

Capable of mulching overgrowth, underbrush and small trees, the FMX28 offers a versatile solution for clearing land. Paired with 3.5-ton to 8-ton excavators, the compact package makes it easy to access difficult-to-reach places. The excavator-mounted FMX28 allows for surgical precision in vegetation management, enabling the removal of a single tree in a group or even specific branches that need to be trimmed. The FMX28 can operate with as little as 12 gpm.

The Werk-Brau D-Lock Coupler facilitates secure attachment connections on construction machines from 1.5 tons to 120 tons. This coupler is dual locking, meaning attachments remain securely engaged on both pins in the event of loss of engagement force. The product features a compact design of only seven moving parts, requiring only two hoses, no greasing and a simple operating sequence. For safety, the coupler is equipped with an automatic front lock. The unlock process is designed to release only when the operator intends and prevents accidental release.

MB Crusher has released three new padding buckets for material processing on construction sites: MB-HDS307, MB-HDS312 and MB-HDS412. Two of the buckets were designed for compact line equipment. The third is for heavy equipment. The models include:

• MB-HDS307

• MB-HDS312

• MB-HDS412

Caterpillar announced attachments for backhoe loaders and mini excavators. The new models include demolition and sorting grapples, multipurpose grapples for Cat Tiltrotators, vibratory compactor plates and cold planers. The new G306 and G308 models are specifically designed for 5- to 6-ton and 7- to 10-ton mini hydraulic excavators respectively. With open and close functions controlled by the machine’s first auxiliary function and rotation head by the second, these grapples deliver material handling with 360 degrees of bidirectional rotation.

Severe Duty & Sweeper Bucket Attachments