GRADE CONTROL'S INCREASING POWER DRIVES ADOPTION

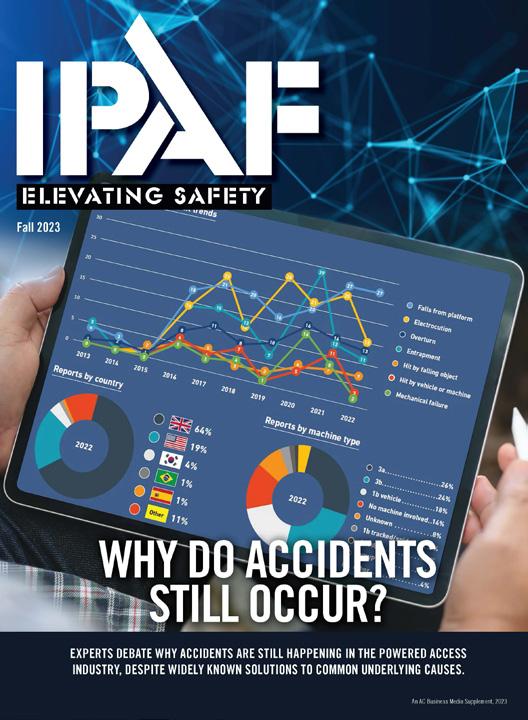

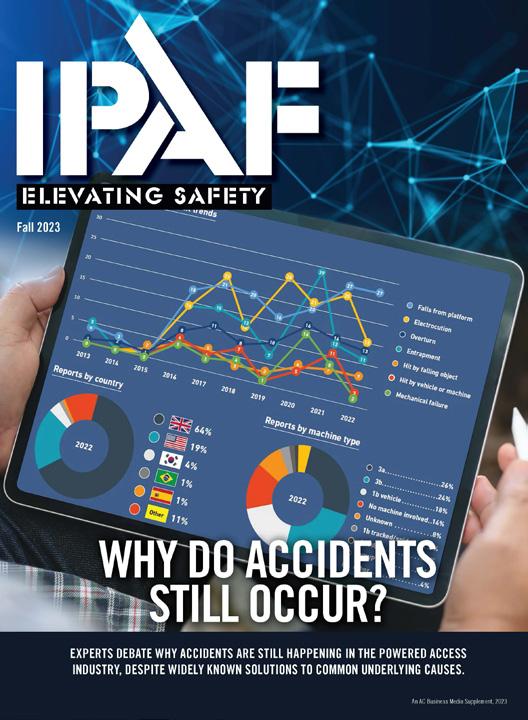

AERIAL LIFTS: ELEVATING SAFELY WITH STABILITY

BIG DOZERS

COMPACT EQUIPMENT IS POPULAR, BUT SOMETIMES, YOU NEED A LARGER MACHINE.

Leaders

READ BONUS ISSUE OF IPAF ELEVATING SAFETY HERE

Helping you optimize ROI on your construction equipment AUGUST 2023

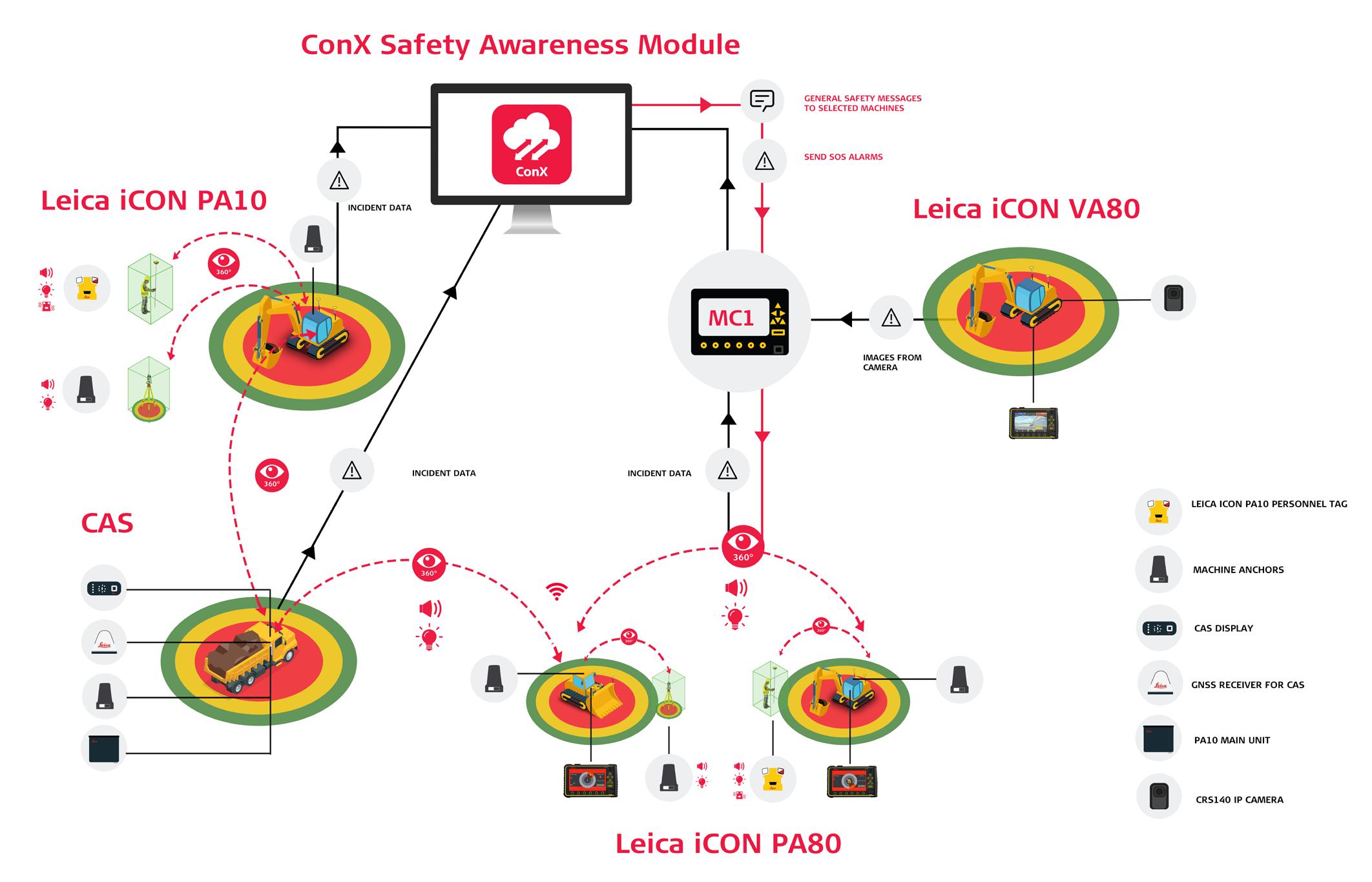

How Tech Boosts Safety: Risk detection improved with new systems

#1 Market

COVER STORY

Big Dozers

Compact equipment is popular, but sometimes, you need a larger machine.

DEPARTMENTS

BREAKING GROUND

Construction Technology Becomes a Focus of Federal Infrastructure Funding Biden-Harris administration to fund digital tech that saves time and money.

EQUIPMENT INTRODUCTIONS

Check Out the Latest Equipment

The latest machines from major manufacturers.

PROFIT MATTERS

Grade Control’s Increasing Power Drives Adoption by Diverse Contractors

A quick overview of how grade control, already indispensable to heavy and civil contractors, is evolving for additional use cases and construction disciplines.

RUNNING THE BUSINESS

Valuing & Selling for Larger Contractors

How companies with more than 25 employees should plan for the future.

BRIDGING THE GAP

Alternative Employee Incentives

For smaller corporations and LLCs, those with relatively fewer employees, incentives like employee ownership can improve retention and engagement.

PRODUCT ROUNDUPS

COMPACT EQUIPMENT

Mini excavators, CTLs, skid steers and more.

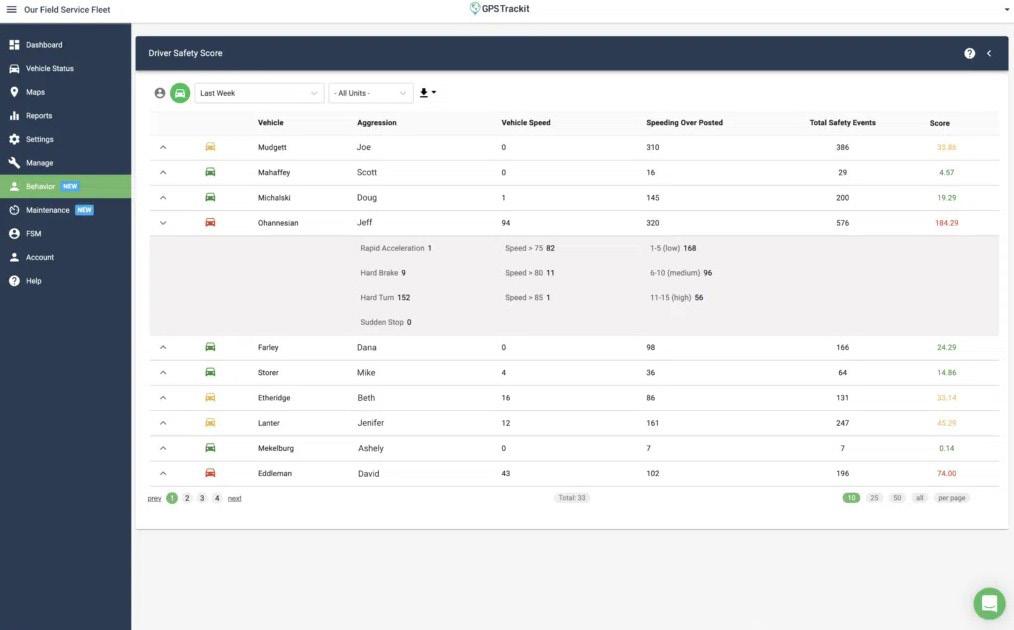

FLEET MANAGEMENT

The latest tech for asset management.

LIFT EQUIPMENT

Telehandlers, boom lifts and forklifts.

CONCRETE EQUIPMENT

Screeds, pavers, breakers and more.

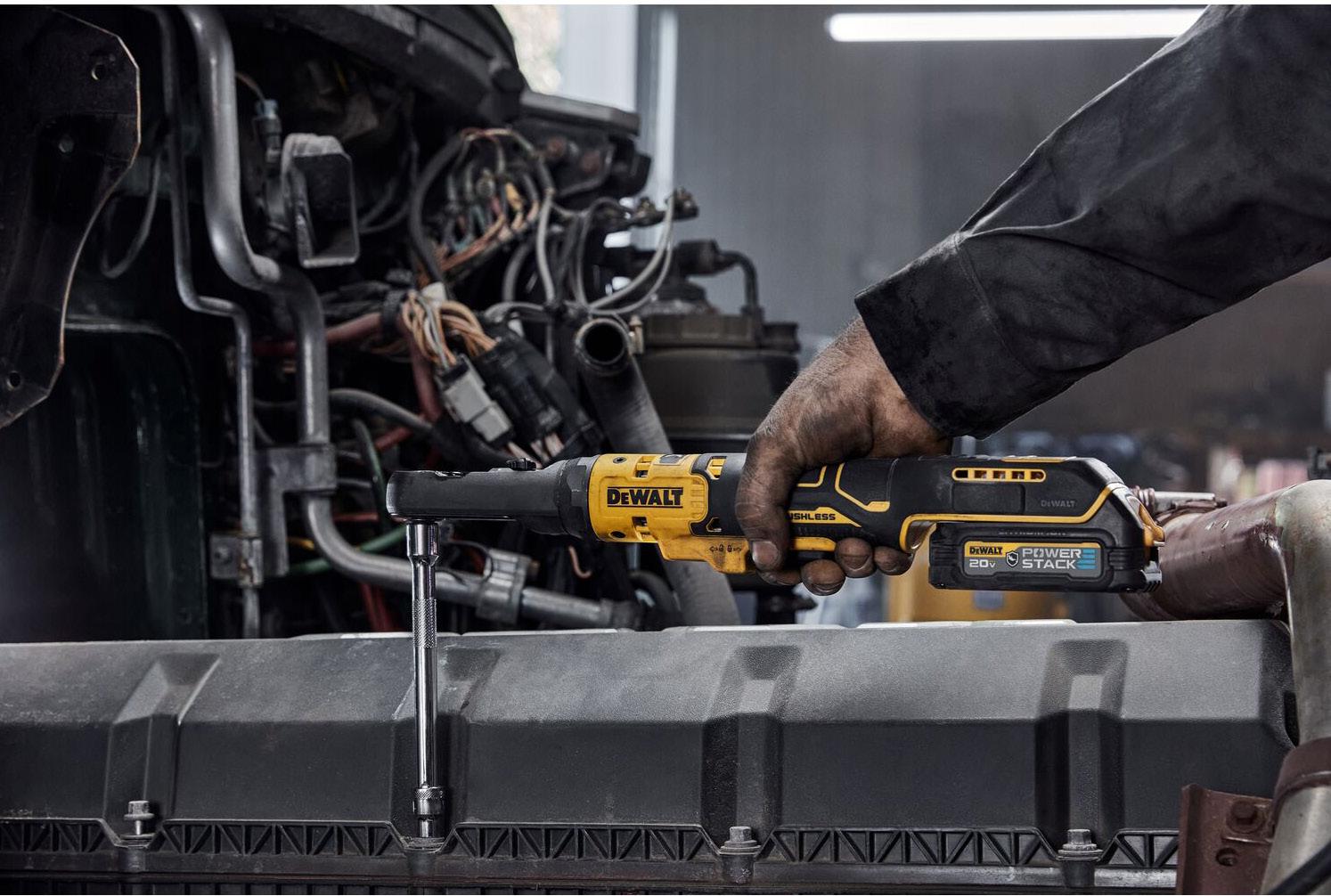

TECHNOLOGY PRODUCTS

Technology advancements for the industry.

FEATURES

COMPACT EQUIPMENT

Compact Excavators for Tight, Urban Construction Sites

By using these machines, operators can enhance their productivity as sites’ sizes continue to decrease.

FLEET MANAGEMENT

Non-CDL Lube Trucks Address Labor & Jobsite Maneuverability Challenges

Finding drivers and navigating tight urban jobsites require an innovative approach.

LIFT EQUIPMENT

Aerial Lifts: Elevating Safely With Stability

New ANSI regulations and technology make scissor lifts and boom lifts even safer.

LIFT EQUIPMENT

IPAF Talks Lift Equipment Safety & Certifications

Learn some scissor lift and boom lift safety basics from this Q&A.

CONCRETE EQUIPMENT

Surface Prepping Blades: Which Tool Is Best?

How the right blade tool choice impacts floor removal rates.

CONCRETE EQUIPMENT

Exploring Concrete Screed Options

For concrete contractors, there are few purchases more essential than a screed.

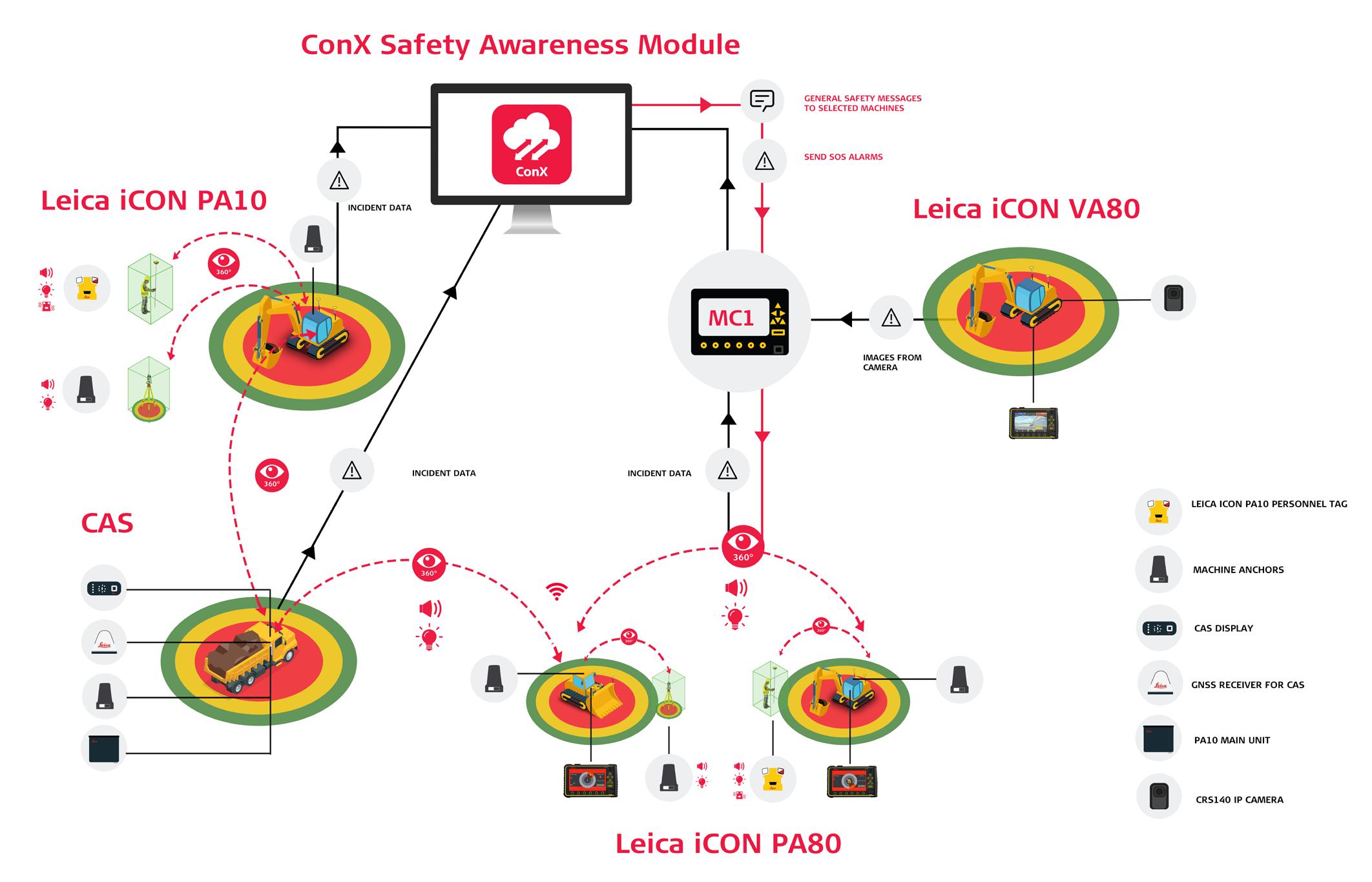

TECHNOLOGY

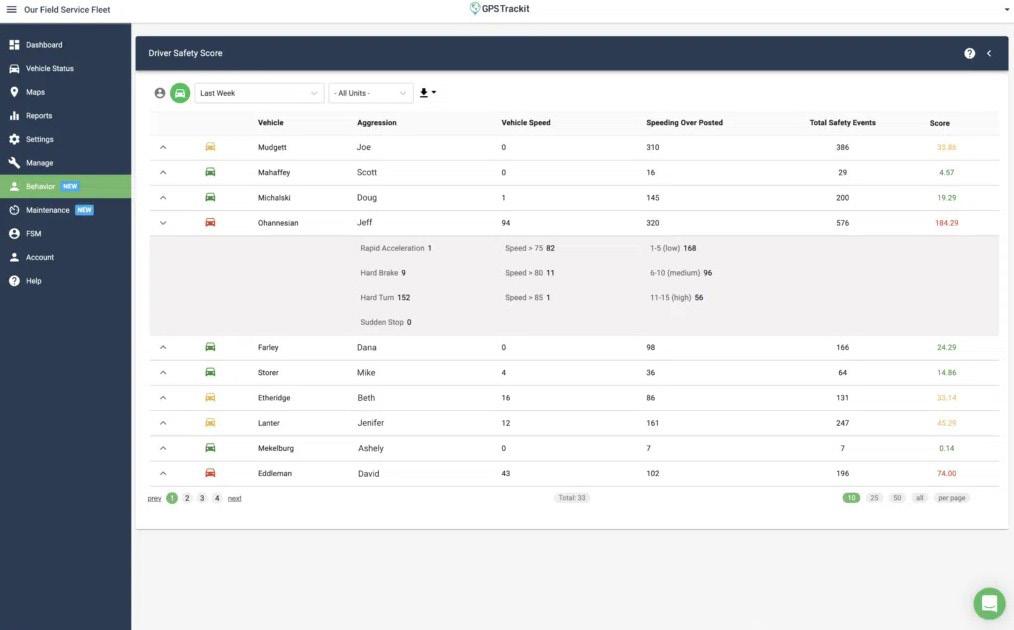

How Tech Elevates Safety

Technology transformations improve safe operations on construction sites

WEB EXCLUSIVES

VIDEO NETWORK https://eqtoday.co/k2p285

DIGGING DEEPER PODCAST https://eqtoday.co/s7sfkm

CONTENT https://eqtoday.co/9pd73s

July 2023 | EQUIPMENT TODAY 3 www.ForConstructionPros.com/Equipment Contents www.forconstructionpros.com/equipment August 2023 | Vol. 59 No. 8 Published and copyrighted 2023 by AC Business Media Equipment Today makes every effort to report manufacturers’ product news accurately, but is not responsible for validity of news claims. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. and Canada to management, engineering, supervisory, equipment maintenance and other personnel who have buying influence in the construction equipment industry. Subscribe online at www.ForConstructionPros. com. Publisher reserves the right to reject non-qualified subscribers. One year subscription to non-qualified individuals: U.S. $50; Canada/Mexico $70; all other countries $100 (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). For change of address or subscription information call (847) 559-7598 or fax (847) 291-4816. Equipment Today (USPS 369-290, ISSN 0891141X) is published is published 12x with issues of January, February, March, April, May, June, July, August, September, October, November and December by AC Business Media, 201 N. Main St., Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional entry offices. POSTMASTER: Please send change of address to Equipment Today, PO Box 3605, Northbrook, IL 60065-3605. Printed in the USA. Canada Post PM40612608. Return Undeliverable Canadian Addresses to: Equipment Today, PO Box 25542, London, ON N6C 6B2. PREMIUM

4 6

48 50

18 22 32 37 42

10

12

20 24 30 33 34 40

44

®

Lori Ditoro Editor-in-Chief

Equipment Today

lditoro@ACBusinessmedia.com

ungvar, Adobe Stock

For decades, experts have encouraged construction contractors to embrace technology to improve equipment operation, fleet management and business operations. While adoption has progressed, that progress has been slow. Now, the federal government is giving contractors financial incentives to speed adoption.

In a June 27, 2023, press release, the U.S. Department of Transportation’s Federal Highway Administration (FHWA) announced that the application period is open for the first year of a new, $85-million grant program under President Biden’s Bipartisan Infrastructure Law.

The Advanced Digital Construction Management Systems (ADCMS) grant program will focus on digital construction, such as computer modeling and 3D design, to encourage modern best practices in project delivery. It complements Biden’s Investing in America agenda that is rebuilding U.S. infrastructure.

“Technology has transformed many facets of life in the modern era, and we want the transportation construction industry to take advantage of these advancements to deliver projects on time and on budget,” said Federal Highway Administrator Shailen Bhatt.

“These technologies, along with funding from President Biden’s Bipartisan Infrastructure Law, will help us more quickly deliver the transportation system of the 21st century.”

At the one-year mark (November 2022), key highlights of the Bipartisan Infrastructure Law include:

˜ Launched 2,800 bridge repair and replacement projects across the country

˜ Awarded funds for over 5,000 new clean transit and school buses

˜ Approved state plans for water funding, electric vehicle charging networks and high-speed internet deployment

ADCMS Program Goals

The $85 million competitive grant program will help accelerate project delivery. The ADCMS program is one aspect of FHWA’s multifaceted Technology and Innovation Deployment Program and provides funding as an incentive for state departments of transportation. It promotes access to more meaningful, accurate and easy-to-use data by construction professionals with enhanced software modeling tools and features. Better and more consistent modeling allows the seamless sharing of design and construction plans. The program goals include:

˜ Accelerated adoption of advanced digital construction management systems to boost productivity and manage complex projects

˜ More timely and productive information-sharing

˜ The development and deployment of best practices

˜ Increased transparency from real-time data sharing

Grant Award Schedule

The ADCMS grant program will award up to $34 million for combined Fiscal Years 2022 and 2023 and up to $17 million each fiscal year thereafter through Fiscal Year 2026. The funding will focus on projects that promote information-sharing, reduce reliance on paper, improve productivity and savings during project delivery, and serve as models for the adoption and deployment of digital construction technologies. While state departments of transportation, the District of Columbia and Puerto Rico are eligible to apply, they are encouraged to partner with local governments, tribes and private industry when designing their proposed projects.

Is your company taking advantage of the money from the Bipartisan Infrastructure Law? If so, email me and tell us what you’re doing.

EDITORIAL

Editor-in-Chief Lori Ditoro lditoro@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction Technology, IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Kristin Pride kpride@acbusinessmedia.com

Sales Representative Megan Perleberg mperleberg@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Marketing, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: (877) 201-3915 Fax: (847)-291-4816 circ.EquipmentToday@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS & LICENSING

E@EquipmentToday

D@EquipmentToday

C @equipment-today-magazine-official

Q @equipmenttoday

4 EQUIPMENT TODAY | August 2023 www.ForConstructionPros.com/Equipment BREAKING GROUND

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com Published by AC Business Media 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 www.ACBusinessMedia.com www.ForConstructionPros.com/equipment www.IronPros.com

Construction Technology Becomes a Focus of Federal Infrastructure Funding

SAY HELLO TO MY LITTLE FRIEND.

THE NEW CASE MINI EXCAVATORS

We’re so all in on helping you make more money with mini excavators; we’re going big on expanding our line. We’re rolling out new diesel models and new electric models, starting at CONEXPO. Like our big machines, our mini excavators are well-appointed and operator friendly. Get big things done in tight spaces with CASE. Learn more at CaseCE.com or talk to your dealer.

©2023 CNH Industrial America LLC. All rights reserved. CASE is a trademark registered in the United States and many other countries, owned by or licensed to CNH Industrial N.V., its subsidiaries or affiliates.

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

Kobelco SK45SRX-7 Compact Excavator

Movex Mini Crawler Crane

The Movex Mini Crawler Crane is a remote-controlled solution for utilities and electrical installations on construction sites. This work vehicle can be used to transport pad-mounted and underground transformers in the field. Designed for maneuverability in tight spaces, the crane is capable of taking on different types of terrain, including up to 15 degrees uphill or downhill. This machine is capable of handling up to 1,100 lbs. at a height of 16 ft., 5 in. or 2,090 lbs. at a height of 8 ft., 5 in. For transporting equipment or materials, operators can remove the crane interface. The crane is fully electric and offers zero emissions, allowing use in public locations and at night without disturbing neighborhoods.

The next-generation SK45SRX-7 weighs in at 10,030 lbs. with canopy and 10,300 lbs. with cab and has a 37-hp Yanmar Tier 4 Final diesel engine. Maximum digging height with the standard arm is 18 ft. 10 in., maximum reach at ground level is 18 ft. 8 in. and maximum digging depth is 11 ft. 3 in. The unit includes an energy conservation mode as well as a standard auto-deceleration switch to reduce fuel use. A new hydraulic system shortens the digging cycle time by up to 7% over the previous model, while redesigned travel motors increase travel speed by up to 5%. A twoway dozer blade with float comes standard or a four-way (power angle) dozer blade with float is an available option.

Read More at https://eqtoday.co/SK45SRX-7

Morooka MST80CR Crawler Carrier

Read More at https://eqtoday.co/stjsqx

Cat MH3050 Material Handler

The new Cat MH3050 material handler electrohydraulic system supports cycle times to handle materials. This machine is powered by the Cat C9.3B engine, capable of operating on up to B20 biodiesel. Meeting EU Stage V and U.S. EPA Tier 4 Final emissions standards, the engine’s maintenance-free aftertreatment system maximizes machine uptime. Operators can fine-tune power requirements to the task at hand with the choice between Power, Smart and Economy modes. Boom and stick offerings combine to provide up to 59 ft., 3 in. of reach, allowing operators to move material without repositioning the machine. The MH3050 also offers high swing torque when moving material. Allowing the boom to freely travel up and down without using pump flow, standard SmartBoom enables the operator to focus on stick and grapple control. Several attachments are available for flexibility. An optional 25-kW generator is available ex-factory for magnet applications.

Read More at https://eqtoday.co/hu054a

FISHER XRS Snow Plows for Skid Steers

The Morooka MST80CR, made in Japan, offers capabilities for hauling, material handling and dumping in various working environments. The MST80CR is another entry into Morooka’s rotator lineup. All Morooka rotators feature an upper structure that can rotate 360 degrees independently from the undercarriage. This allows them to maneuver around jobsites while reducing damage to the ground. With a payload capacity of nearly 18,000 lbs., the Morooka MST80CR can handle heavy loads. The machine is powered by a Kubota V5009 Tier 4 Final engine producing 210 hp. This carrier also features a heated and air-conditioned ROPS certified cab. A joystick control and rear and side view cameras support operation and visibility. The HARDOX dump bed is durable and resistant to wear and impacts.

Read More at https://eqtoday.co/5urc8z

The XRS Skid Steer Plow by Douglas Dynamics offers versatile snow removal in winter conditions. Designed specifically for skid steer applications, this rugged plow automatically retracts the inside wing when fully angled and then automatically returns to the scoop position once straight. The XRS plow leverages the onboard hydraulic system of the skid steer to lift and lower the blade, supporting operator performance. The oscillating skid steer mount comes standard and provides six degrees of side-to-side oscillation for scraping while reducing damage to the terrain. Available accessories include a 10-in. rubber deflector, shoe kit and quick coupler set.

Read More at https://eqtoday.co/FISHERXRS

www.ForConstructionPros.com/Equipment

EQUIPMENT INTRODUCTIONS 6 EQUIPMENT TODAY | August 2023

Engineered to do more www.liebherr.com Earthmoving machines Liebherr USA Co. • Construction Equipment Division • 4800 Chestnut Avenue • Newport News, VA 23607 • Phone +1 757 240 4250 Construction.USA@liebherr.com www.facebook.com/LiebherrConstruction www.liebherr.us/dealers-emt www.liebherr.com

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

Loftness Stump Grinder Attachment

Bobcat AT450 Articulating Tractor

Bobcat expanded its grounds maintenance equipment lineup with the debut of the Bobcat AT450 articulating tractor. The AT450 powers a variety of front-mounted, belt-driven attachments. Because of the machine’s four-wheel drive, low center of gravity and its ability to both articulate and oscillate, operators get stability across various types of terrain and conditions. The AT450 features a 32-hp, liquid-cooled gasoline engine that produces power for front PTO attachments. With the articulating tractor’s attachment system, operators have added versatility to put a host of attachments to work.

Read More at https://eqtoday.co/lq6cut

This attachment is compatible with skid steers, compact track loaders and excavators. Equipped with a rigid mount, the Stump Ax features a repositioned power unit. The attachment does not swing the cutting wheel during use. It has an angled hitch and forward-reaching boom to give the operator visibility and control on the job. The Stump Ax includes the Phantom Wheel with Tomahawk teeth from Leonardi, which offers cutting performance. The Phantom Wheel also has cut-outs to create a see-through effect for visibility. A 200-cc, high-torque radial piston motor on the Stump Ax is compatible with power units that have 30-gpm to 60-gpm hydraulic flow ratings. A reversible design allows the motor to be mounted either forward- or rear-facing.

Read More at https://eqtoday.co/LoftnessAttachment

Komatsu Upgraded PC130LC-11 Mid-Size Excavator

Komatsu has released the upgraded PC130LC-11 excavator with a longer undercarriage design. The excavator also features increased lifting capacity by up to 20% compared to the previous model. This 97.2-hp tail swing excavator offers a combination of lightweight power and agility on construction sites. Operating weight is 28,440-29,101 lbs and bucket capacity is 0.34 yd3 to 0.78 yd3. The PC130LC-11 uses up to 12% less fuel than the previous model (PC130-8). The Komatsu diesel oxidation catalyst (KDOC) helps reduce particulate matter by using passive regeneration over 98% of the time.

Read More at https://eqtoday.co/nfm51g

Metabo HPT 18-V MultiVolt LED Handheld Spotlight and LED Tripod Light

Metabo HPT announced the newest additions to its cordless lineup featuring water and dust resistant lighting with the launch of the 18-V MultiVolt 1,050-lumen LED Handheld Spotlight (model UB18DHQ4) and 18-V MultiVolt 4,000-lumen LED Tripod Site Light (model UB18DGQ4). Both are sold as tool body only and accept 18-V batteries or 18-V/36-V MultiVolt battery (sold separately) for flexibility. The portable lights can be used on the jobsite for a wide range of tasks and projects in indoor or outdoor areas. As 18-V, the user can decide to GO lighter by using an 18-V battery or choose to GO longer with the flexible 18-V/36-V MultiVolt battery to double the runtime per charge.

Read More at https://eqtoday.co/evzloj

Western Global FuelCube Type-S Fuel Tank

The FuelCube Type-S is a compact fuel tank that fits in the back of a truck. Available in the U.S., the FuelCube Type-S is a reliable, flexible and transportable fuel tank for fleets on jobsites. Designed to safely transport and dispense diesel fuel without hazardous material placard requirements, it serves as an alternative to slip tanks. This new solution offers 110% containment, security features and versatility for fleet operators. The dual-purpose adaptability of the tank allows businesses to use it as a truck bed tank or an on-site tank. The FuelCube Type-S features a 119-gallon capacity and is for 3/4-ton pickups or larger because of the tank’s weight when filled with fuel.

Read More at https://eqtoday.co/7qvefm

EQUIPMENT INTRODUCTIONS 8 EQUIPMENT TODAY | August 2023 www.ForConstructionPros.com/Equipment

The Worldwide Leader in Concrete Paving Technology

GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/spreaders, texture/cure machines and bridge/canal finishing equipment. GOMACO equipment features our exclusive and proprietary G+® control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.

CONCRETE STREETS AND HIGHWAYS x AIRPORT RUNWAYS x CURB AND GUTTER x SIDEWALKS RECREATIONAL TRAILS x SAFETY BARRIER x BRIDGE PARAPET x BRIDGE DECKS x IRRIGATION CANALS GOMACO CORPORATION IN IDA GROVE, IOWA, USA x 712-364-3347

x info@gomaco.com

www.gomaco.com

BIG DOZERS

many of the popular features found in its smaller counterpart. The DD130 dozer delivers more horsepower, better tractive effort and superior pushing power to help operators move more material and get more work done efficiently,” said Jacob Sherman, dealer and product marketing manager at DEVELON. “The DD100 is a 10-metric-ton dozer, while the larger DD130 weighs approximately 13 metric tons.”

says that all Komatsu dozers in the D65/85/155 family offer contractors outstanding power, economy and reliability.

Attachments

Compact construction equipment is having a moment right now and with good reason. These machines are beneficial on small sites because of their size and maneuverability. During CONEXPO-CON/AGG 2023 (CONEXPO), manufacturers launched or previewed new machines of many kinds.

Among them were compact models including skid steers, track loaders and wheel loaders. However, some larger models were also announced, including large dozers. So, what are the new details around some of these larger machines, and how can they benefit contractors and operators?

Larger Models

More power, more push and more traction are some benefits of larger dozer models.

“The DD130 [previewed during CONEXPO], the latest addition to the DEVELON dozer lineup, builds on the success of the DD100 by incorporating

They also “improve jobsite productivity and lower operating costs on the industry’s toughest and most challenging jobsites,” according to Matt Goedert, solutions marketing manager, roadbuilding, for John Deere. John Deere’s dozer lineup includes two large dozer models, the 950K and the 1050K. The 1050K has a 13.5-liter engine producing 350-horsepower (hp) (261-kW) and weighs 95,400 pounds. (43,270 kilograms).

“The 950K dozer is available in both outside dozer and power angle tilt (PAT) blade configurations, making it the industry’s largest sixway blade. The 950K PAT weighs 73,700 pounds. (33,431 kilograms) and is capable of doing largescale dozing work while also being versatile enough to complete fine grading tasks over large areas,” Goedert said.

Casey Zbinden, product marketing manager for Komatsu,

In addition to their size, the attachments available for dozers are expanding. From shake buttons to remove material to increased blade capacity and simplified coupling, manufacturers are listening to their customers to improve the productivity and efficiency of their dozers.

“The 1050K [blade was] redesigned … to better match the capabilities

of the machine. We made the blade over 6 inches wider and reshaped the radius of the blade to roll and carry more material. Both changes increase blade capacity and make the machine more productive, pushing more material every pass than the previous design,” Goedert said.

He continued discussing a preview of the 1050 P-Tier. “We continue to listen and react to our customers’ feedback. [The 1050 P-Tier] shows that. The machine will feature a redesigned blade linkage and a shorter mainframe, both allow the blade to be moved back over 17 inches reducing

10 EQUIPMENT TODAY | August 2023 www.ForConstructionPros.com/Equipment COVER STORY | By Lori Ditoro, Editor-in-Chief, Equipment Today

Compact equipment is popular, but sometimes, you need a larger machine.

The 1050K has a 13.5-liter engine producing 350 horsepower and weighs 95,400 pounds.

The 950K dozer is available in both outside dozer and PAT blade configurations.

John Deere

John Deere

the overall length of the machine. This also will improve the machines’ balance and make it easier for operators to grade smoother.”

The DEVELON DD130 dozer offers two blade sizes: a standard 4.6 cubic yard blade or an optional 5.5 cubic yard capacity blade.

“The dozer blade moves freely to lift, tilt and angle, and 2-way mechanical adjustments can change the blade pitch to control how steeply the blade will dig into the ground,” Sherman said. “Operators can adjust the dozer blade pitch from 52 degrees to 58 degrees. To further enhance the operator’s experience, the DD130 is available with a blade shake button ...[that] enables operators to quickly remove materials that may become stuck to the blade, thereby maximizing productivity.”

Zbinden explained that the Komatsu D155AX-8 has semi-U and full-U blade options and blade capacity up to 15.6 cubic yards. The D155AX-8 has variable multi-shank and variable giant ripper options.

Safety & Operator Comfort

With the need to maximize safety and to retain experienced operators, the cab environment and safety capabilities matter now more than ever. Camera systems, improved seating for comfort and minimized cab vibration are a few of the improvements that manufacturers have made.

According to Zbinden, LED lights and a light for the ripper (when equipped) are new safety enhancements for Komatsu large dozers. In addition, a rearview camera

monitoring system is standard and displays the view behind the dozer on a large, color monitor in the cab.

Visibility is another safety improvement important to operators.

“One of the biggest differences between the DD130 dozer and other brands is the visibility to the machine’s blade,” Sherman said. “The front engine compartment of the DEVELON dozer offers a narrower design to make it easier for operators to see their work and perform tasks with increased precision.”

The John Deere 1050 P-Tier also prioritized visibility and seatbelt safety.

“A notable change on the next generation 1050 P-Tier shown at CONEXPO was the lowered hood. This increases the glass area of the front window, [improving] visibility to the front of the machine,” Goedert said.

“The 1050 P-Tier will also incorporate an operator presence system that will not allow the parking brake to be disengaged unless an operator is in the seat with the seatbelt fastened.

A surge in designs to improve operator comfort is occurring. “The most notable change on the [1051K] was the addition of the suspended double bogie undercarriage to provide exceptional operator comfort. This undercarriage update provides dampening of vibrations when working in rough terrain and rock,” Goedert said of the John Deere 1050K dozer.

New Tech

Automation, grade control, emission minimization, telematics and fleet management are all priorities for

contractors to improve efficiency, productivity, uptime and return on investments. For helping less experienced operators, grade control is a game changer.

The DD130 dozer delivers more horsepower, better tractive effort and superior pushing power when compared to the DD100.

“The DEVELON DD100 and DD130 dozers are available with a 2D grading system option to make precision grading easier, even for novice operators. The 2D grading system is accessible on the Smart Touch display in the DEVELON dozer cab,” Sherman said. Goedert agrees that grade control is an integral part of today’s dozers. “SmartGrade reduces operating costs by fully optimizing machine performance and production throughout the entire job cycle. Advanced features like Auto SmartGrade integrate the grade control system with the machine’s power management system and control the blade based on engine load, making this system easy for operators of all skill levels.”

For fleet management and data to improve productivity and uptime, equipment telematics are requirements now instead of options. All the manufacturers discussed the importance of this technology.

“John Deere’s JDLink is included on all large dozers and enables machine

information to be visible in a digital environment called John Deere Operations Center. In the operations center, [operators’ teams] can monitor machine health, maintenance plans, fuel usage and operating parameters. Using data gives customers insight to make decisions,” Goedert said.

Most manufacturers also include technology to monitor and decrease emissions from diesel engines.

“Tier 4 machines use diesel particulate filters to burn off engine soot via regeneration. To help make sure it rarely impacts operations, all Komatsu D65/D85/D155 models use continuous passive regeneration and active regeneration that typically doesn’t require the dozer to stop,” Zbinden said.

Read more at: https://eqtoday.co/BigDozers

August 2023 | EQUIPMENT TODAY 11 www.ForConstructionPros.com/Equipment COVER STORY | By

Ditoro, Editor-in-Chief, Equipment Today

Lori

Komatsu D155AXi-8 dozer, part of the D65/85/155 family

Komatsu

DEVELON

Without question, excavator operators are encountering more challenges on urban construction sites than ever before. First, commercial and residential development is increasing at a steady pace, leading to larger buildings and homes on smaller lots. As these they are being developed, construction sites are becoming restricted, and operators cannot move their excavators as freely as they used to.

“Tight corners, narrow pathways and confined areas can limit excavators’ abilities to navigate easily, thereby requiring careful planning and skilled operation,” said David Caldwell, national product manager, Takeuchi-US.

Aside from restricting excavators’ movements, many present-day urban construction sites provide operators with another significant challenge—they typically don’t provide enough space to store their excavators. Therefore, they must use their equipment efficiently because they can generally only arrive at the construction sites, dig and then immediately leave, according to Brad Mace, product manager, CASE Construction Equipment.

To efficiently excavate on tight, urban construction sites, operators

Compact Excavators for Tight, Urban Construction Sites

must be precise and cautious. After all, according to Caldwell, excavators are often used near existing structures, like buildings, fences and walls. By being as precise and cautious as possible, operators can avoid collisions, along with any subsequent damage associated with them.

“Narrow gates or entrances can make it tough for some excavators to enter or exit construction sites,” Caldwell stressed. “In turn, delays can occur and additional efforts to create suitable access points may be required.”

At the same time, according to Drew Kolo, marketing manager, Doosan Bobcat, excavator operators must work near critical infrastructure that simply can’t be disturbed, including fiber optic cables, power lines and water and gas lines. And, of equal importance, they’ll have to overcome issues associated with noise. For example, while working in small, confined areas, the noise and vibrations produced by excavators will amplify, resulting in discomfort for operators, nearby coworkers, and occupants of businesses and homes that are nearby, according to Caldwell.

With the goal of protecting excavator operators and everyone near them, state and national governments have passed several noise restrictions

for construction sites. Additionally, to protect the environment, state and national governments have enacted carbon emission restrictions, too, which operators must bear in mind every time they use their excavators.

The bottom line? As a result of each of these issues, the smaller an excavator is, the better.

To determine which excavators are the most ideal for urban construction sites, Equipment Today recently spoke to four excavator manufacturers: CASE

Construction Equipment, Doosan Bobcat, Takeuchi-US and Yanmar Compact Equipment North America. The manufacturers discussed exactly how operators can overcome the challenges they’re encountering on construction sites. Furthermore, they shared which features excavators ought to have, as well as the technologies operators should consider implementing as they use excavators in tight, urban construction sites.

12 EQUIPMENT TODAY | August 2023 www.ForConstructionPros.com/Equipment COMPACT EQUIPMENT

Able to be towed with a conventional pickup truck—without any need for a CDL—compact excavators like the CASE CX26C are an easy addition to a majority of companies’ fleets.

CASE Construction Equipment

By using these machines, operators can enhance their productivity as many jobsites continue to shrink.

Takeuchi-US CASE Construction Equipment

Retractable undercarriages, available on compact units like the TB210R, minimize excavators’ footprints, allowing them to access constricted areas.

Increase Efficiency, Minimize Disruptions, Reduce Injuries

Spatial awareness, precise control and adaptability are key skills that operators should strive to enhance as they use excavators—particularly compact excavators—and face several issues on their urban construction sites. In addition, according to Caldwell, they must have effective communication with their coworkers and implement safety protocols to guarantee their excavation operations run as smoothly and safely as possible.

Training and practice, regarding compact excavators, are vital, too, as each will help operators become more efficient and precise whenever they use their machines. Aside from focusing on their excavators, operators should also verify whether any access or stability issues are present on their construction sites before they begin excavator operations.

“By finding ways to ensure clear access and impose additional safety measures, operators can prevent any potential of delayed projects once their compact excavators arrive on their construction sites,” Caldwell explained. “Because they won’t need to ask for additional time to dig or move materials, they can better meet and exceed customer expectations.”

Operators should also ask their clients which time of day is the most optimal for them to operate excavators at construction sites, based on any noise restrictions— whether they’re working for schools, hospitals, businesses or homeowners. In doing so, they’ll minimize any disruptions to neighboring properties, nearby residents and potential future customers.

Along with focusing on people near their construction sites, operators must direct their attention to their colleagues, particularly by maintaining awareness of their surroundings and ensuring that all team members

remain as far away from excavators as possible.

“Situational awareness also helps prevent impacts with structures or other obstacles,” said Wesley Foy, product manager, Yanmar Compact Equipment North America. “Aside from utilizing their own awareness, excavator operators can use certain equipment features too, which will help them minimize construction site injuries considerably.”

Consider Tail Swings

Above all else, contractors and operators should seek compact excavators that either have zero or short tail-swing designs, as well as swing booms that will effortlessly and safely dig next to walls and guard rails.

“If excavators don’t protrude over tracks, operators can get closer to structures or move around in tight areas more easily than if they had to use a conventional tail-swing excavator instead,” Foy added. “Yanmar offers excavators with zero and minimal tail swings.”

This capability to move effortlessly in tight areas is particularly because zero tail swings and minimal tail swings allow operators to have more unrestricted rotation and flexibility as they work near structures or against walls, according to Kolo.

“A zero-tail swing virtually eliminates any potential of a compact excavator’s tail inadvertently contacting surrounding objects and damaging them, along with the excavator itself,” he noted. “Meanwhile, a minimal tail swing significantly reduces the likelihood of inadvertent contact, thus minimizing the odds of damage to nearby objects and structures.”

Like Yanmar, Takeuchi-US provides excavators with short tail swings too, including its new TB335R and TB350R models, each of which enables operators to use their excavators in

“They’re also ideal for gaining additional lift capacity, yet they may limit operators’ abilities to efficiently work in tight spaces.”

Enhance Reach, Dig More Accurately

Doosan Bobcat’s excavators are always available with standard arm configurations too, offering operators maximum breakout force and lifting capabilities, leading to more enhanced digging performances. For further reach and dig depths though, Kolo advises operators to equip their compact excavators with a long-arm option instead. By having additional reaching abilities, along with higher dump heights, they’ll be able to conduct more work without ever having to reposition their excavators, ensuring that they can load trucks in a more effortless way. Since the long-arm option has an additional counterweight when compared to standard arm configurations, operators will be able to enhance their excavators’ (whichever ones have the long-arm option, that is) lifting capabilities.

To have even more reach, operators can also use Doosan Bobcat’s clampready extendable arm option—the only one currently on the market. Available on select compact excavators, the extendable arm option provides operators with high power and lifting performance, while enabling them to extend their excavators’ dig depth and reach whenever necessary.

small spaces in a less risky way than they did in the past, especially with regards to damage and disruptions to their surroundings.

“Ultra-compact designs, featuring retractable undercarriages, minimize excavators’ footprints, allowing them to access confined areas and work in them,” Caldwell said. “Those features are typically only available on Takeuchi-US’s compactors, from the TB210R to the TB225.”

As operators determine whether to use zero tail-swing excavators, minimal tail-swing excavators or conventional tail-swing excavators, the sizes of gates and property lines they must pass through may be a substantial factor. Zero and minimal tail-swing excavators are roughly 70 inches wide. In contrast, conventional tail-swing excavators, like 3-metric-ton to 4-metric-ton compact excavators, are approximately 60 inches wide.

“If operators anticipate routine work in which they must pass through narrow gates or property lines, conventional, tail-swing excavators may be the best fit,” Kolo stated.

“Additionally, Doosan Bobcat’s unique Pro Clamp system is optimized for a standard arm configuration, allowing operators to grab large, small or irregular objects with greater confidence,” Kolo emphasized. “This feature is ideal for snug working conditions, as it enables operators to perform demolition or tear-out work, create smooth trench bottoms, and install and repair utilities by removing the tool, as needed for optimum visibility.”

To further enhance digging capabilities, the manufacturer also offers an Excavator Depth Check System. Allowing operators to dig accurately, the system eliminates the need for coworkers to manually check trench depths. Therefore, contractors reduce their need for manpower and save time because operators can focus on other tasks, improving productivity.

“All Bobcat compact excavators feature an exclusive in-track swing frame as well, which allows operators to get closer to their work,” Kolo continued. “The manufacturer’s boom swing castings and cylinders also stay within their tracks whenever operators conduct offset digging tasks, enabling them to truly dig flush against an obstacle and work in tight areas.”

Speaking of offset operation, Takeuchi-US presently offers two compact excavators that have sideto-side boom designs: the TB257FR and the TB280FR. As a result of their designs, the excavators can be used

August 2023 | EQUIPMENT TODAY 13 www.ForConstructionPros.com/Equipment COMPACT EQUIPMENT

Operators should seek compact excavators that either have zero or short tail-swing designs, along with swing booms that will effortlessly and safely dig next to walls and guard rails.

Yanmar Compact Equipment North America

Earlier this year, Doosan Bobcat released the E10e and E32e battery-powered excavators. Releasing no emissions, the excavators can be used quietly for challenging job tasks on very tight construction sites.

Doosan Bobcat

offset, while requiring minimal rotation of their counterweights. Providing high stability and lifting capabilities, particularly over their right-side tracks, these excavators offer high visibility for operators as they work offset, too.

“Each of our FR series excavators can also rotate almost completely within the track frame’s width, allowing each one to perform a full rotation in very tight spaces with their booms fully retracted,” Caldwell said.

Commit to Sustainability

According to Mace, compact excavators are currently the second largest category in construction equipment, and their popularity continues to rise. Aside from using excavators with zero, short and standard tail-swing designs, operators can also use electric compact excavators, enabling them to comply with emission and noise regulations more easily than they have in the past.

First, they can be used indoors without any risk of diesel or propane emissions being released into the air. And since they’re much quieter than the combustion-engine-driven excavators in the marketplace, operators can stand next to them as they’re running and have conversations with their colleagues at normal volumes.

“Electric excavators are being designed to deliver the same amount of power and performance as dieselpowered excavators too,” Mace said. “They also provide operators more adjustability, concerning their control panels—from adjusting performance modes, to setting flow rates for attachments, to customizing the machine parameters to their applications or preferences.”

Takeuchi-US also offers an electric compact excavator: the lithium-ion battery-powered TB20e. Because of its low-noise operation and zero emissions, the TB20e is ideal for

different applications, including in and around hospitals, municipalities, neighborhoods and schools.

“The TB20e provides excavator owners and operators a great opportunity to demonstrate their commitment to sustainability too, which many businesses, communities and organizations will look upon favorably,” Caldwell stressed.

In recent years, Doosan Bobcat advanced its electric offerings by releasing the E10e, E19e and E32e battery-powered excavators to the public. Each provides operators with diverse benefits. For starters, they don’t release any emissions. Very quiet, they’re also well-suited for environmentally sensitive sites or indoor applications, in which diesel exhaust is restricted. Finally, they can be used for challenging job tasks on tight construction sites.

“Because they release zero emissions, the excavators allow operators to work indoors, including when they need to conduct indoor demolition projects in which intensive manual labor is often the only other option that’s available,” Kolo stated. “They’re also quiet and can be operated at all hours of the day, even in dense urban areas where noise can, at times, limit operators’ work hours.”

Technology Offerings Increase Accuracy & Control

As operators use compact excavators in restrictive, urban construction sites, an array of technological offerings are available, some of which they may not even know they need.

According to Foy, boom swings can help them navigate around tight corners and dig around obstacles. In addition, by using a hydraulic quick coupler, operators can decrease their movements into and out of tight areas because they’re able to change attachments without ever having to move from their work areas.

According to Mace, operators

can also use CASE Construction Equipment’s intelligent and integrated displays, including touchscreen operator controls, which are highly visible and ergonomically accessible. Consequently, they can enhance operators’ safety and excavating efficiency, especially in spaceconstrained construction sites.

Additionally, retractable undercarriages are available on some of Takeuchi-US’s excavators, including the TB210R, TB216, TB216H, TB20e and TB225. For instance, the TB210 can retract down to 29.5 inches, enabling it to fit through a standard doorway. On the other hand, the other models have undercarriages that can retract, allowing them to fit through backyard gates. Once the excavators have entered the operators’ construction sites, their undercarriages can be expanded to ensure that they’re highly efficient and stable.

“Compact excavators are equipped with control systems that enable them to work with great precision and control,” said Caldwell. “Features like precise, low-effort pilot controls and proportional auxiliary hydraulic controls help reduce operator fatigue. Not to mention, they also provide operators greater precision, along with the ability to meter flow rates to the hydraulically driven attachments they may be using on confined construction sites.”

He continued, “With these offerings, operators can work on a wide range of projects, as they have the control and precision they need, resulting in improved performance, greater efficiency and higher profitability.”

Moreover, operators can adopt the latest telematics equipment management platforms, including the CASE SiteWatch. Able to generate real-time, remote information about compact excavator performance, the platform also creates service schedules, enabling them to set alarms

and receive notifications if excavators operate outside their normal parameters. In turn, operators can protect their excavators and prevent potential damage because they won’t be used when they’re not supposed to be. And they’ll be able to identify potential service needs before they evolve into issues requiring downtime.

To further enhance their efficiency and uptime, operators can add Doosan Bobcat’s 7-inch touch display, too. By using this wide, easy-to-use touch screen, operators can view detailed information regarding their excavators’ operating parameters and performance.

At the same time, they can also use Bobcat Machine IQ, a telematics system that helps them remain organized as they maintain their compact excavators. While using the system, contractors and operators can remotely track their compact excavators’ locations, maintenance and service issues, and operational statistics, thus minimizing maintenance costs and maximizing machine utilization.

“As construction booms in tight, urban spaces, by implementing these technological advancements, compact excavators will [allow] operators, managers and fleet owners to structure fleets that operate more easily and productively in these types of environments,” Mace concluded. “With ‘smarter’ excavators, operators can become more efficient and, in turn, reduce any of the issues that negatively impact productivity, profitability, safety and uptime.”

Read more at: https://eqtoday.co/MiniEx0823

Chris Lewis, a freelance writer for Equipment Today.

by

14 EQUIPMENT TODAY | August 2023 www.ForConstructionPros.com/Equipment COMPACT EQUIPMENT

Takeuchi-US provides excavators with short tail swings, such as its new TB335R model, enabling operators to utilize them in small spaces.

CASE Construction Equipment Takeuchi-US

The CASE CX60C comes with a standard adjustable boom that can be offset to either side, enabling them to operate in tight urban construction sites.

BETWEEN

A GIRDER AND A HARD

DO YOUR

Inspired by the challenges you face from foundation to finishing work, JLG is dedicated to developing the innovative solutions that deliver the productivity and safety you demand to leave your mark on the skyline of tomorrow today. LEAVEYOURMARKWITHJLG.COM

PLACE IS WHERE YOU

BEST WORK.

10 TIPS

Acompact excavator can be an important VIP on the jobsite and an investment that provides great returns. However, committing to a regular maintenance plan is key to reaping the benefits. Here are 10 tips for getting more hours out of a compact excavator.

1. Read the Compact Excavator’s Manual

An operator’s first task is to review the compact excavator’s operation and maintenance manual to become familiar with the machine’s safety features, instrumentation, controls, service schedules and maintenance points. The operator’s manual is delivered with the machine and contains service and maintenance recommendations. If you misplace your manual, you can buy replacements from your local dealer. Most compact excavators have an operator’s handbook in the cab. It’s a good resource for operators to review before using a machine.

2. Top Machine Fluids off Daily

An effective maintenance regimen starts with daily fluid checks, including coolant, hydraulic fluid and engine oil. If levels are low, refill with the manufacturer’s recommendation, paying attention to classifications and viscosities. When checking levels, avoid contamination by keeping areas dirt free and using clean rags.

Emission-compliant, diesel engine excavators have unique lubrication requirements. Manufacturers match oils to their engines to ensure proper operation of exhaust aftertreatment.

It’s also important to lubricate a compact excavator’s boom and arm cylinders at recommended intervals, considering the application and temperatures of the operating location. To increase uptime, manufacturers recommend quality, lithium-based, multipurpose grease for all key pivot points, including cylinders, booms, blades, buckets, arms and slew-bearing components.

3. Maintain Equipment Filters

A compact excavator has multiple filters—fuel, engine, air and

FOR BOOSTING COMPACT EXCAVATOR UPTIME

cooler and condenser by applying low pressure air or water. Be careful not to damage the radiator’s fins.

7. Maintain the Battery & Charging System

Battery cables should be tight and clean. Inspect for corrosion on the cable ends and the battery terminals. Fuses protect the electrical system. Always replace failed fuses with a fuse of the same amperage rating.

8. Examine Ground-Engaging Tools

Check attachment components, such as cutting edges, teeth and hoses, to determine if wear is developing or damage occurred in tough applications. Replace worn or damaged pins or teeth to maintain excavator uptime.

9. Pay Attention to the Instruments

hydraulic—and each may have different service intervals. When dirty or completely clogged, a filter can significantly reduce excavator uptime and component life. Most compact excavators have air filters with restriction indicators that alert operators to maintenance needs. To avoid system contamination, don’t remove the filter until it’s required.

4.

Use Clean, Quality Fuel

Most manufacturers specify the use of clean, high-quality No. 2 or No. 1 grade diesel fuel. Compact excavator operators working in colder climates may prefer specially formulated blends designed to prevent gelling. At a minimum, compact excavators need ultra-low-sulfur diesel fuel to reduce exhaust emissions.

5. Inspect & Maintain Tracks

The most obvious wear item on a compact excavator undercarriage is the rubber tracks. Jobsite conditions and operator behavior affect track life expectancy. Examine the tracks daily for cuts, tears and exposed steel embeds. Punctures and tears may allow moisture or contamination into the tracks, leading to a shortened life. One important undercarriage item to monitor is track tension. A loose

track may de-track, impacting its life and the machine’s uptime. Refer to your operation and maintenance manual for ideal track tension ranges and the correct way to make adjustments. While a daily inspection isn’t required, monitoring other undercarriage components like idlers, rollers and sprockets can help identify potential issues. Accelerated wear on the sprocket is not common, but you should still examine the teeth. A good sprocket tooth has a rounded end, while a worn tooth is more pointed. Always check the sprocket condition when installing new tracks.

Finally, careful and thoughtful driving is important. Operators should keep best practices in mind for curbs, object avoidance and inclines/declines. They should also avoid chemicals and debris. When not in use, the excavator should be stored in a cool, dry environment.

6. Inspect the Cooling System Daily

An effective cooling system relies on adequate airflow and coolant levels. When either is low, an excavator can lose power, and the engine can overheat and cause damage. Proper cooling system maintenance includes checking for proper airflow and hose leaks. Clean the excavator’s radiator, oil

Some compact excavators have onboard instrumentation with controllers that perform multiple maintenance functions. These systems display and log data while providing a warning if systems operate outside parameters. If an operator doesn’t heed the warnings, the system will shut down to prevent damage.

10. Safety Is Essential to Productivity

Compact excavators often operate in challenging terrain and different conditions. Before operation, operators should understand what each lever and control does and how to operate the machine safely. In addition to the handbook, the compactexcavator-specific Association of Equipment Manufacturers safety manual is valuable. Follow instructions for maintaining rollover and tipover protective structures and make sure that the mounting hardware is secure. Seat belts should be properly tensioned and in good condition. Control console lockout systems should be functioning. Safety decals should be intact and legible, and all lighting should be operational.

Read more at: https://eqtoday.co/10MaintTips

Drew Kolo is the excavators marketing manager for Doosan Bobcat.

16 EQUIPMENT TODAY | August 2023 www.ForConstructionPros.com/Equipment COMPACT EQUIPMENT

With proper maintenance, you can protect your uptime and rely on your compact excavator to do the heavy lifting day in and day out.

Doosan Bobcat

Big work in tight spaces.

©2023 HD Hyundai Infracore. All rights reserved. DEVELON is a brand of HD Hyundai Infracore; HD Hyundai Infracore is an affiliate of HD Hyundai. Awarded to DX27Z-7, DX35Z-7 and DX50Z-7

Bobcat MT85 Mini Track Loader

The 3,110-lb. MT85 mini track loader has an 850-lb. rated operating capacity (+35%), 80.9-in. lift height to hinge pin (+12%) and a 29% increase in lift arm breakout force over the previous model.

• Features a 25-hp Tier 4-compliant diesel engine and 12-gpm auxiliary hydraulic flow

• Dual ISO joystick controls include a left-hand joystick to control drive function and a right-hand joystick to control lift and tilt functions

• Higher forward travel speed of 4 mph (+23%) and 2.3 mph when operating in reverse

• Standard operator presence/safety pedal, ride-on platform, hip pads, larger grab handles, cup holder and storage compartment

• Measures 36 in. with narrow tracks or 44 in. with wide tracks

Takeuchi TB335R

Case SR240 & SV280 Tier 4 Final Skid Steers

The 7,400-lb. SR240 and 8,090-lb. SV280 Tier 4 Final large-frame skid steers feature a 74-hp Tier 4 Final engine with a maintenance-free particulate matter catalyst solution.

• Deliver 232 ft.-lbs. of torque, a bucket breakout force of up to 8,680 lbs. and standard (24.2 gpm) and highflow auxiliary (33.2 gpm) hydraulics

• Offer rated operating capacities of 2,400 (SR240) and 2,800 lbs. (SV280)

• 360-degree visibility with a cab-forward design, skylight and ultra-narrow wide side screens

• EZ-EH (electrohydraulic) setup menu

• Operator handles with detents improve controllability and feathering

Takeuchi has added the new generation TB335R short tail swing compact excavator to its TB300 Series. This excavator features a rugged interior and exterior design, as well as functions that provide performance on the jobsite. The TB335R’s short tail swing design results in a rear overhang of only 3.1 in. over the tracks for working in tight or confined spaces. The cab model TB335R has an operating weight of 8,310 lbs. (3,770 kg), a maximum bucket breakout force of 9,127 lbs. (40.6 kN) and a maximum arm digging force of 4,290 lbs. (19.1 kN). The excavator is powered by an EPA Tier 4, EU Stage V emissioncompliant engine delivering 24.4 hp (18.2 kW) and a maximum torque of 70.6-ft. lbs. (95.8 Nm). The TB335R offers two working modes—Standard and ECO—allowing operators to match the mode to the task at hand, choosing more power or fuel savings as desired.

Caterpillar D Series CTLs and MTLs

The D Series includes five compact track loaders (CTLs) and five multi terrain loaders (MTLs) ranging in rated operating capacity (50% of tipping load) from 2,800 to 4,650 lbs. The mid-size frame 257D MTL and 259D CTL and larger frame 277D and 287D MTLs and 279D and 289D CTLs feature the 74-hp Cat C3.3B electronically controlled, 3.3-liter, Tier 4 Final engine that provides 8% more torque and 6% improved fuel economy. The 297D, 299D, 297S XHP and 299D XHP CTL, feature the C3.8 electronically controlled, 3.8-liter, Tier 4 Interim engine. It produces 98 gross hp for the 299D and 297D and 110 net hp for the 299D XHP and 297D XHP. Other features include a torsion-axle suspension, “Cab-One” operator station and Intelligent Leveling System (ILEV).

John Deere 333G Compact Track Loader With Integrated SmartGrade

The SmartGrade 333G compact track loader helps automatically complete grading tasks faster with fewer passes and less rework.

Grade control system fully integrated into the machine’s structures and software, eliminating masts and cables

• DozerMode enables the EH joystick control system to function like a crawler dozer with the push of a button

• Machine-equipped six-way dozer blade attachment can both cut a grade and spread materials and enables accurate and automatic cutting or finishing of light materials in tight spaces

• Blade reduces the amount of operator input and does not require tools to change between attachments

Kubota SVL75-2 High Flow Compact Track Loader

The SVL75-2 with high flow offers 2,300 lbs. of operating capacity, a bucket breakout force of 6,204 lbs. and lift arm breakout of 4,766 lbs.

• Auxiliary hydraulic flow of 29.3 gpm

• 74.3-gross-hp Kubota four-cylinder, directinjection, turbocharged, Tier 4 Final diesel engine

• Electronic Travel Torque Management System constantly monitors the load to optimally control hydraulic pump output

• Standard two-speed travel and high-ground clearance ensure travel performance on difficult terrain

• Multifunction levers provide fingertip control of all major functions 24.6-gal. fuel tank

LiuGong 9027F Zero Tailswing Compact Excavator

The 2.7-metric-ton 9027F has a Yanmar 20.4-net-hp Tier 4 Final engine, inline hydraulic pumps and main control valve.

• Standard bucket capacity of 0.065 cu. yds. with a bucket/cutting width of 15.75 in. and bucket breakout force of 4,496 lbf.

• 9-ft. 4-in. maximum digging depth and 10-ft. 1-in. maximum dump height

• Improved load-sensitive hydraulic system with 23.8-gpm main pump displacement

• Hydraulic control for travel, boom swing, arm and bucket machine functions engaged via travel pedals and joysticks

• Available in a climate-controlled ROPS cab or open canopy design with tip-over protection system

• Standard hydraulic thumb

18 EQUIPMENT TODAY | August 2023 www.ForConstructionPros.com/Equipment COMPACT EQUIPMENT Products Read More at https://eqtoday.co/earthmoving

KATO 9V5 Mini Excavator

The all new redesigned KATO 9V5 mini excavator will debut summer 2023. This ultra-mini zero tail swing excavator is a much faster and easier alternative to any shovel or wheelbarrow for working in tight spaces. With it’s ultra small size and roll down ROPS the 9V5 can even fit through doorways, standard yard gate, and even the tightest spaces making it perfect for any project. Need more stability? Standard equipment includes expandable tracks to help you power through your job with stability and ease. All new 9V5 will be available summer 2023.

CASE CX15EV, CX25EV Mini Excavators

CASE Construction Equipment is developing its mini excavator line with the launch of two all-new electrified mini excavators and a new dieselpowered mini excavator, and more models scheduled to hit the North American market in 2024. Anchoring the new mini excavator launch for CASE is the introduction of two allnew electrified machines, the CX15EV and the CX25EV. The CX15EV is a 3,186-lb. mini excavator powered by a 21-hp/16-kW electric motor—and the CX25EV is a 4,828-lb. mini excavator running with a 27-hp/20-kW electric motor. The lithium-ion battery featured in both machines is charged either by the 110-V/220-V on-board charger, or via an external rapid charger. CASE is also launching a new diesel-powered, true zero tailswing mini excavator to the market: the CX42D. This is the first model of the new CASE D Series and complements the existing C Series product line, giving CASE a broader reach into core weight classes that are in high industry demand.

Hyundai HX-A Compact Excavators

Hyundai Construction

Equipment Americas

revealed three new models in its HX-A series of compact hydraulic excavators: the HX35AZ, HX40A and HX48AZ. All three new models feature low-emission engines that are Tier 4 Final compliant. The Hyundai HX35AZ excavator is powered by a Kubota D1703 diesel engine with a net power rating of 24.8 hp (18.2 kW), while the HX40A and HX48AZ feature Yanmar 4TNV88C engines, rated at 37.4 hp (27.5 kW). The HX35AZ has an operating weight of 8,300 lbs. (3,765 kg), dig depth of 9 ft., 8 in. (2.95 m) and bucket breakout force of 7,081 lbs. (3,212 kg). The HX40A has an operating weight of 9,479 lbs. (4,300 kg), dig depth of 11 ft., 2 in. (3.4 m) and bucket breakout force of 9,846 lbs. (4,466 kg). The HX48AZ has an operating weight of 10,912 lbs. (4,950 kg), dig depth of 11 ft., 5 in. (3.5 m) and bucket breakout force of 8,223 lbs. (3,730 kg).

DEVELON DX42-7 Mini Excavator

With 47 net hp and a conventional tail swing configuration, this 4-metric-ton model is designed for navigating tight, congested jobsites and urban areas. Part of the nextgeneration -7 Series mini excavator lineup, the DX42-7 offers fast cycle times, torquelimiting piston pumps that respond to load demands and a large counterweight for balance and durability. Its maximum digging depth is 11 ft., 5 in. and maximum digging reach (ground) is 18 ft., 3 in. Its maximum loading height is 2 ft., 6 in., and its travel speed is 2.1 mph to 3.1 mph. The DX42-7 comes with a standard thumb-ready arm, quick-coupler-ready design and lever pattern control.

Mecalac MWR Compact Wheel Excavators

The MWR Series of wheeled excavators enables maneuverability in tight working areas, offering the flexibility and versatility of a skid steer or compact track loader in one machine. Each of the three models in the MWR series offers speed in a compact footprint. The smallest of the three, the 7MWR, offers variable speed between 0 mph and 19 mph. Two of the larger models, the 9MWR and 11MWR, provide contractors standard travel speeds between 0 mph and 12 mph with an option for higher speed up to 22 mph on the 9MWR and up to 19 mph on the 11MWR. A 75-hp (55.4-kilowatt) engine is standard on each model. The smallest model is capable of lifting three metric tons at 10 feet (3 meters) through 360 degrees.

Wacker Neuson EZ17e Battery

Powered Mini Excavator

This 1.7-ton machine is a zero-emission solution for indoor applications and areas where noise and exhaust are a concern, such as construction sites in urban areas and those operating around the clock. The EZ17e mini excavator offers the same performance as the company’s conventional diesel model, but with zero emissions and reduced maintenance. With its minimal-tail swing design, it has a maximum digging depth of 97.7 in., a breakout force of 4,608 lbs. and the ability to run auxiliary attachments such as hydraulic breakers. The lithium-ion battery in the Wacker Neuson EZ17e offers all-day run time and can be recharged using a common 240-V, single-phase outlet. Charge time is between 5 and 6 hours. In addition, the machine can be operated in a stationary position while connected to a power source, if necessary. The maintenance-free battery reduces overall service and spare parts costs.

Hitachi ZAXIS-5N Compact Excavators

Hitachi ZAXIS-5N compact excavators range from 1.7 to 6 metric tons (1.10 U.S. tons to 6.61 U.S. tons) that feature either a short-tail swing radius (U) or an ultrashort-tail swing radius with swing boom (USB). ZAXIS-5N compact excavators are commonly used as tool carriers with a wide range of attachments. Standard auxiliary hydraulic lines have been pre-plumbed to the end of the boom on the ZX17U-5N and to the middle of the arm on the ZX26U-5N to ZX60USB-5N. A standard wedgelock quick coupler makes attachment hookup a snap. A factory-installed bracket for a thumb cylinder simplifies thumb installation. The operator can match the flow rate of the auxiliary hydraulic circuit to the requirements of the attachment being used with either a low or high setting.

August 2023 | EQUIPMENT TODAY 19 www.ForConstructionPros.com/Equipment COMPACT EQUIPMENT Products

Non-CDL Lube Trucks Address LABOR & JOBSITE MANEUVERABILITY Challenges

The long-standing driver shortage continues to worsen while many contractors also face ever more crowded urban jobsites. These challenges place a squeeze on existing mobile lube activities.

Large Class 7 or Class 8 lube/fuel trucks have been the norm on jobsites around the U.S. for decades. These trucks help technicians maximize preventive maintenance efficiency by transporting large quantities of off-road diesel and oil. Technicians can service multiple machines in the field before returning to the shop for additional fluids.

The capacity of these trucks depends on the gross vehicle weight rating (GVWR), which defines the maximum legal weight of a vehicle including passengers and cargo. The GVWR helps determine how many gallons of fluid a lube truck can transport. It’s not uncommon for Class 7 or Class 8 lube/fuel trucks to haul up to 1,000 gallons of fuel and 400 gallons of maintenance fluids in one trip.

While the capacity provides a clear advantage for some applications, Class 7 and larger trucks exceeding 26,000 pounds GVWR require operators with a commercial driver’s license (CDL). With these drivers becoming harder to find, some lube truck owners are exploring smaller trucks that don’t require a CDL—those in Class 5 and Class 6—to help them care for equipment on the job. In the process, they’re discovering the cost and efficiency benefits of deploying these smaller non-CDL trucks that weren’t frequently seen on jobsites just a few years ago.

If the smaller truck has the capacity to tackle a full day of preventive maintenance without returning to the shop, it may provide a lower cost of operation.

When the maintenance staff must service more than 200 pieces of heavy equipment on 35 jobsites across the fourth largest U.S. city, efficiency is essential.

Larger tandem-axle trucks can be difficult to maneuver on jobsites, especially those with uneven terrain. A single-axle non-CDL service truck offers enhanced maneuverability on tight or crowded jobsites.

20 EQUIPMENT TODAY | August 2023 www.ForConstructionPros.com/Equipment FLEET MANAGEMENT

Finding drivers and navigating tight urban jobsites require an innovative approach.

Smaller, non-CDL trucks weren’t frequently seen on jobsites just a few years ago.

Sage Oil Vac

Sage Oil Vac

Sage

Oil Vac

Cope With the Driver Shortage

The first factor driving the transition to non-CDL trucks is the worsening driver shortage. Despite growing demand for all types of commercial transportation that requires a CDL— namely over-the-road trucking—the number of licensed commercial drivers in the U.S. has not increased. In short, the demand is growing but the qualified labor pool is not. There’s just a shortage of qualified, skilled drivers. It’s as simple as that.

This places lube truck owners in direct competition with over-theroad haulers and local businesses. A contractor or lube truck provider can invest more than a month sending an employee to a driver school to earn a CDL, but there is no guarantee that

they can retain that driver to recoup the investment.

Sprint Sand and Clay specializes in dirt work and selling construction materials to contractors and home builders in Greater Houston, Texas. When it comes to operating lube trucks for preventive maintenance, finding drivers with a CDL can demand higher compensation. It is also difficult to compete for available drivers because many don’t want to service equipment. They simply want to drive.

“Trying to find a CDL driver that wants to perform the service, not just take a load from Point A to Point B all day, is tough,” said Jacob Phillips, vice president of operations at Sprint Sand and Clay.

Lube truck owners can proactively address this challenge by eliminating the licensing requirement and creating new opportunities for existing employees. Without the requirement for special licensing, almost any technician in the shop can be assigned to run a non-CDL truck. This opens the door to more hiring opportunities for company owners and managers and more employment opportunities for operators.

Balance Capacity & Efficiency

The second factor in the transition to non-CDL trucks is the actual fluid capacity needed to service equipment. Contractors simply may not need the capacity or fuel-handling capability of a Class 7 or Class 8 lube truck. While not having enough capacity to service all the equipment on the jobsite leads to a loss of efficiency, hauling excess capacity decreases efficiency as well.

Sprint Sand and Clay knew they needed a solution that would balance capacity with efficiency. When the maintenance staff must service more than 200 pieces of heavy equipment on 35 jobsites across the fourth largest U.S. city, efficiency is essential. That’s the challenge this contractor faces each day. When its lube truck leaves the shop, it may travel two hours one way to a jobsite.

“It’s important that the truck has enough storage and fluid capacity to service many pieces of equipment on that side of town before going back and refilling the truck,” said Kyle Cain, president of Sprint Sand and Clay.

Sprint Sand and Clay’s service technician typically performs preventive maintenance on every piece of equipment while the truck is on a jobsite to maximize efficiency.

“In today’s world, you have to be as efficient as possible. We attribute our success a lot to equipment that we use and the innovation that’s provided with that equipment, from our dump trucks to our equipment to our lube trucks,” said Cain.

Sprint Sand and Clay turned to a

non-CDL open lube body truck. The non-CDL bodies are perfect for heavy equipment preventive maintenance, featuring a 180-gallon (681.37-liter) used oil tank and five fresh product tanks that can be configured for any fluids.

“We really believe in the small compact size of [this] lube truck. It’s very efficient and the cost of ownership compared to having a larger CDL truck with a CDL driver just makes sense,” said Cain.

Despite its compact size, the nonCDL open lube body is up to the task of servicing Sprint Sand and Clay’s 200-machine fleet. It offers the capacity to service all the equipment on up to two jobsites without having to return to refill.

Minimize Operating Costs

The third factor in the transition to a non-CDL lube truck is lower operating costs. It is easy to assume a bigger lube truck would drive efficiency, but that’s not always the case. Traditional Class 7 or Class 8 trucks have high fluid capacities, enabling them to service a lot of equipment. However, because of their size, they are also less fuel efficient when traveling long distances.

If the smaller truck has the capacity to tackle a full day of preventive maintenance without returning to the shop, it may provide a lower cost of operation. For instance, smaller displacement engines consume less fuel when driving long distances between jobsites.

Without wasted extra capacity, usage costs can decrease. Lower upfront costs paired with a smaller operating cost translate into a higher return on investment. Maintenance staff can calculate the total weight of the products that need to be carried to help assess truck size. It’s not always beneficial to automatically size up the next truck.

There are also regulatory costs to consider when operating larger trucks—which become an even bigger issue when traveling across state lines. Multiple non-CDL trucks will sometimes be more cost-effective and efficient than one Class 8 truck. Getting people to make a change like that is sometimes hard, but when pencil is put to paper, these changes can pay for themselves in months.

Access Tight Jobsites

A fourth factor to consider in the transition to a non-CDL lube truck would be jobsite access. Larger tandem-axle trucks can be difficult to maneuver on jobsites, especially those with uneven terrain. A single-axle non-CDL service truck offers enhanced maneuverability on tight or crowded jobsites. These lighter-weight trucks can also perform better than larger tandemaxle trucks in rough terrain. The lube

truck provider uses Chevrolet 6500, Ford F-600 and International 6500 fourwheel drive chassis. This adds mobility that a larger truck cannot perform because of its driven steer axle.

If personnel are working at a remote location that has a lot of challenging terrain, the smaller jobsite lube truck will be nimbler and will perform better than a larger, tandemaxle truck. This added maneuverability has been beneficial to Sprint Sand and Clay.

“It’s been very easy to maneuver in traffic, especially in Houston,” noted Cain.

Maneuverability coupled with quick connect fillings and the design of the lube truck provider’s system with sealed tanks reduces the chance of oil spills.

“A lot of our jobs are on government entity property—cities and counties—so being able to get in and out without having any spillage or environmental issues is very important to us,” said Cain.

Consider All Alternatives

There are several reasons for transitioning to a non-CDL lube truck. It opens the available labor force. It can reduce operating costs. It is more maneuverable, and there is a lower acquisition cost. The latter was particularly important for Sprint Sand and Clay.

The compact size and efficient operation of the non-CDL truck gives Sprint Sand and Clay a cost-effective heavy equipment service option. It provided a more cost-effective solution than relying on the local equipment dealer for preventive maintenance.

“I think when you compare what we would have to pay from the dealership versus doing it ourselves, it just really made sense for us,” said Cain.

But the non-CDL truck is not the best answer for every application. You need to look at all available options and determine if a larger lube/fuel truck, a trailer or a jobsite skid will work best in your specific application. Each solution has its own unique set of benefits.

Read more at: https://eqtoday.co/SmallNonCDL

Aaron Sage is CEO of Sage Oil Vac, Inc.

August 2023 | EQUIPMENT TODAY 21 www.ForConstructionPros.com/Equipment FLEET MANAGEMENT

The third factor in the transition to a nonCDL lube truck is lower operating costs.

Sage Oil Vac

Sage Oil Vac

Vanair DR 600XP Drill Module

The Vanair DR 600XP drill module provides a boost in pressure for demanding jobs, such as directional, down-the-hole, percussive hammer and rock drilling. During use, the drill module generates 600 cfm and 250 psi capable of supporting a 4-in. hammer drill. This machine comes with a vertical discharge tank, featuring a pressure relief valve, oil scavenge sight glass and coalescer restriction indicator. Dual two-stage air filters with dust evacuators promote clean air. Accessible instruments include temperature and pressure gauges. The DR 600XP has mounting provisions at the bottom of the frame for

Philippi-Hagenbuch Load Ejector System for Haul Trucks

DPL Telematics AssetView Mid Tracking System

AssetView is a solution for wireless monitoring and remote tracking of powered or unpowered assets to support logistics, manage inventory and curb theft. The small, portable GPS unit is self-contained and may be hidden on assets. AssetView

Mid allows managers to remotely monitor an asset from an internetbased software package and mobile app. Some features include no external wiring or antenna, unwired attachment to assets in a “hide and track” installation, long battery life and wireless communication.