Helping

A bold vision for tomorrow.

Now as DEVELON we will continue to develop onwards — expanding our equipment lineup, delivering outstanding value and developing new technologies to address future challenges. Our vision is to help build your success.

Discover

Premium features come standard.

To ensure a high return on your investment, we include more premium features as standard — features that often come with an additional cost from other manufacturers.

We’ve also expanded our lineup of innovative equipment and continue to deliver the dedicated customer service you expect from a local dealer.

SEPTEMBER 2023

AVOIDING THE HAZARDS OF DEMOLITION

JOBSITE SAFETY INVOLVES OEMS, OPERATORS, CONTRACTORS AND EVERYONE ON THE SITE.

CONTRACTORS’ TOP 50 NEW PRODUCTS #1 Market

Leaders

All it takes for the challenges you face.

Moving, lifting, digging or loading, Wacker Neuson vertical lift skid steers and compact track loaders are designed to handle tough applications. In addition to high hinge pin heights, these versatile machines also feature the best service accessibility in the industry and comfortable cabs with simple, intuitive operation. For lighter-duty work, as well as commercial or residential landscape projects, Wacker Neuson’s stand-on utility track loaders are the perfect fit in confined spaces.

Put your job site challenges to the test. Contact your local Wacker Neuson dealer or visit us online today.

www.wackerneuson.com

COVER STORY

Contractors’ Top 50 New Products

Many winners were launched or featured during construction events.

DEPARTMENTS

BREAKING GROUND

The Joy of Driving Big Equipment & Our Top New Products

An August event at Volvo CE gave me the chance to drive my largest vehicle yet.

EQUIPMENT INTRODUCTIONS

New & Noteworthy

Some of the latest equipment available.

PROFIT MATTERS

Tilson CTO Offers Software Tips for Utility Contractors

With utility contractors bracing for explosive growth, we asked Tilson CTO Jason Burns what his company was using and what steers their advisory group gives utility contractors.

BRIDGING THE GAP

8 Ways to Run a Better Construction Business

Everything I have learned in my decades-long masonry career is reflected in these eight lessons: Put your culture first, learn from your mistakes, share your knowledge, be confident, believe in the old and new, and always be a neighbor.

FEATURES

16 20 22 28 30 36

EARTHMOVING TRENDS

Avoiding Demolition Hazards

Jobsite safety involves the OEMs, operators, contractors and everyone on the site.

EARTHMOVING TRENDS

Downsizing for the Win

Compact excavators’ benefits and advantages.

EARTHMOVING TRENDS

How to Get the Best ROI on Equipment: Renting vs. Buying

Just as it’s important to examine factors such as market conditions when determining whether to rent or buy a mini excavator, it’s also helpful to have a good understanding of inventory.

EARTHMOVING TRENDS

8 Elements of ADCM & the Future of Technology on the Jobsite Site prep best practices: what works today, what contractors need to let go of and where the industry should be headed.

EARTHMOVING TRENDS

Winch Optimization on New Fire Dozer Packages

Feedback from agencies helped inform the engineering of new fire dozer packages for the Caterpillar D5 and its predecessor, the D6N.

UNDERGROUND UTILITY EQUPMENT

Equipment for Underground Utility Construction

Numerous equipment and technology offerings are enhancing underground utility construction employees’ productivity and safety long term.

34 40

PRODUCT ROUNDUPS

EARTHMOVING TRENDS

The latest equipment for moving dirt.

UTILITY EQUIPMENT

WEB EXCLUSIVES

PREMIUM

Lori Ditoro Editor-in-Chief Equipment Today lditoro@ACBusinessmedia.comThe JOY of Driving BIG Equipment & Our Top New Products

®

EDITORIAL

Editor-in-Chief Lori Ditoro lditoro@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction

Technology, IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Kimberly Fleming kfleming@acbusinessmedia.com

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Patty Maroder pmaroder@acbusinessmedia.com

Sales Representative Megan Perleberg mperleberg@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Marketing, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: (877) 201-3915 Fax: (847)-291-4816 circ.EquipmentToday@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

On Friday, Aug. 18, 2023, I attended a presentation and ribbon-cutting ceremony at the Volvo Construction Equipment (Volvo CE) campus in Shippensburg, Penn. During the presentation, Volvo CE marked the production of the DD25 Electric Compactor, a battery-electric machine that touts 30% more power than diesel, with first models expected to deliver later this year.

I also had the opportunity to talk with Ray Gallant, vice president — sustainability and productivity solutions, North America, Volvo CE, and rode in and drove an A45FS articulated haul truck.

Volvo CE expects to receive a $1.1 million grant from the U.S. Environmental Protection Agency (EPA) to conduct a pilot project of its new DD25 Electric asphalt compactor in California. The company will put another $758,000 toward the project, bringing the total to nearly $1.9 million.

The ribbon-cutting ceremony was for the new technical training center on the campus. Taking two years to build, it is for Volvo CE dealer service technicians who work on diesel and electric heavy equipment, machine control

technology, connectivity and productivity services, and more. The new center doubles the number of students that can be trained in a year, compared to its former off-site location. It will also provide hands-on and virtual training to Volvo employees globally.

After the formal events, I had the chance to interview Gallant and climb into the A45FS. The ride was amazing and then getting to drive it was so much fun. I even took it up and down a hill, which admittedly was intimidating. However, it was easy to drive, almost like driving my car.

CONTRACTORS’ TOP 50 NEW PRODUCTS

We are excited to announce the Contractors’ Top 50 New Products on page 6. From telematics to excavators, every area of construction equipment and technology is represented with these products. Make sure you check out all the winners and use the QR codes to get more information. Congratulations to all our winners!

REPRINTS & LICENSING

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

E @EquipmentToday

D @EquipmentToday

C @equipment-today-magazine-official

Q @equipmenttoday

The Winners: Contractors’ Top 50 New Products

With the return of bauma in 2022 and CONEXPO-CON/AGG (CONEXPO) in March 2023, new and exciting products for the construction industry have been a hot topic during the past year. As a result, several of the top product winners this year were launched or featured during CONEXPO or bauma.

The Contractors’ Top New Products Awards showcase new equipment, technology and products that the construction industry and the Equipment Today team have identified as the most intriguing and innovative of the year.

Award recipients are based on nominations and page view data on new products featured in Equipment Today and on ForConstructionPros.com during a one-year period from April 2022 through April 2023.

We are thrilled for all the winners and excited to share them with you!

AUSA D151AEG ELECTRIC DUMPER

AUSA’s new electric dumper has a 3,300lb. payload on its swing skip, allowing you to offload earth, rubble, or other materials at any angle with a simple movement of the joystick. Due to its compact size, this machine is designed for earthworks in reduced spaces, e.g. municipal works, property renovations, small demolitions and landscaping.

It is the first 3,300-lb. dumper on the market that is equipped with a lithiumion battery power unit, batteries that are known for their reliability and durability. In the case of this dumper, it features a pack with a 9.3-kWh capacity, enough for at least one full day of work with this type of equipment.

Read More at https://eqtoday.co/ujr93y

BOBCAT S7X ALL-ELECTRIC SKID-STEER LOADER

The Bobcat S7X is an all-electric skidsteer loader. Powered by a 60.5 kW, lithium-ion battery, the loader emits zero emissions, allowing it to tackle tough jobs on environmentally sensitive worksites or indoors where exhaust is restricted. The loader promotes sustainability without sacrificing performance.

The S7X is built to be more productive from the ground up. Its drive system consists of electric motors and ball-screw actuators that deliver more power than its diesel-hydraulic.

This skid-steer loader offers operators a smooth and comfortable experience with minimal vibration and nearly silent operation. Even with these differences, the S7X provides a familiar environment for equipment operators thanks to the dieselconsistent controls and instrumentation.

Read More at https://eqtoday.co/torbv7

BRANDT C550 HEAVY HAUL TRAILER

Brandt launched its lineup of new heavy haul trailers at CONEXPO 2023. On display were the C550 55-ton construction trailer and the H850 85-ton square-tail trailer. These trailers are reliable, designed with long-lasting components that eliminate costly repairs and reduce the total cost of ownership.

They are also backed by customer service and support. Through its collaborative product design process, Brandt has consulted extensively with customers to create heavy haul trailers that set the standard for the industry, providing versatility and reliability in a premium product offering.

Read More at https://eqtoday.co/34fex5

BRIGGS & STRATTON VANGUARD LITHIUMION 48V 1.5KWH COMMERCIAL BATTERY (SI1.5)

Selected for its cutting-edge design and ground-breaking approach to technology, the Vanguard Lithium-Ion 48V 1.5kWh* Commercial Battery (Si1.5) is the latest in battery power from Briggs & Stratton.

The Si1.5 Battery features an innovative, self-contained package with a handle on top for easy swapping between equipment—or equipment and charger—on the jobsite. Designed, engineered and assembled in the U.S., this globally distributed product is backed by the robust Briggs & Stratton dealer network.

Learn more about this game-changing battery.

*Total energy measured using a 0.2C discharge per IEC 61960-3:2017

Read More at https://eqtoday.co/pc4zjq

CASE CONSTRUCTION EQUIPMENT MINOTAUR DL550 COMPACT DOZER LOADER

Half-dozer, half compact track loader? That does a pretty good job of describing the CASE Minotaur DL550 compact dozer loader. But the design, the engineering, the years of development and the nearly 12,000 hours of in-the-field testing behind it go much deeper than six words.

At the heart of this beast is a 114-hp engine. The Minotaur DL550 weighs in at 18,000 lbs., which makes it heavier than the 16,000-lb. CASE 650M and one ton lighter than the 750M dozer.

CASE offers steel and rubber tracks for the Minotaur. A 17.7-in. rubber track configuration is available. The steel tracks can be 14-in. single-grouser or 18-in. triplegrouser configurations.

Read More at https://eqtoday.co/rpmz3n

Many 2023 winning equipment and products were launched or featured during construction tradeshows.

CATERPILLAR INDUSTRIAL POWER/PERKINS LITHIUM-ION BATTERIES

As part of the company’s strategy to support customers during the energy transition to a lower-carbon future, Caterpillar has announced the development of 48V, 300V and 600V batteries for the off-highway industry. The program focuses initially on battery solutions for equipment used predominantly in industrial applications.

The battery range uses lithiumion technology and features a modular design for performance and packaging. Furthermore, they have been engineered with sustainability in mind with the potential to reuse and recycle at the end of life.

Read More at https://eqtoday.co/ix0css

CATERPILLAR 350 HYDRAULIC EXCAVATOR

The Cat 350 Excavator delivers classleading productivity, redefining efficiency and performance on demanding jobsites. Featuring a powerful digging force and strong swing torque, the 350 effortlessly maneuvers large buckets to get the work done with ease.

Three power mode options match the excavator to the job to reduce fuel consumption. Standard technologies increase efficiency, including Cat 2D Grade and 2D E-Fence. Assist technologies help operators stay on grade and use less fuel. Cat Payload gives real-time weight estimates, allowing operators to achieve precise load targets consistently.

Read More at https://eqtoday.co/9rqwny

CHEVRON ANTIFREEZE COOLANT

Delo ELC Antifreeze/Coolant products are single-phase, ethylene-glycol-based, nitrited organic additive technology products available in different dilutions that are based on patented aliphatic carboxylate corrosion inhibitor technology specifically formulated for heavy-duty cooling system applications that require nitrite.

Delo ELC is free of nitrates, borates, silicates, phosphates and amines. It is recommended for use in a variety of cooling system applications including on-road, off-road and stationary engine applications. These products are also recommended for mixed fleet applications where heavy-duty and light-duty trucks are present.

Read More at https://eqtoday.co/z6p2jf

COJALI USA INC. JALTEST OFFHIGHWAY DIAGNOSTICS

Cojali released Jaltest 22.2, the second version of the company’s diagnostics software. Jaltest renews itself every four months and every update aims to expand the software’s features.

This software evolution comes as a response to both the changes within the industrial vehicle industry and the current demands of users. These updates allow Jaltest to be a solution that serves the day-to-day needs of repair shops and fleets.

Read More at https://eqtoday.co/g9bkdb

DEVELON DD100 DOZER

DEVELON introduced its first dozer— the DD100—in North America in 2022, competing in the 140 hp and under category. Standard premium features for the DD100 dozer include DEVELON fleet management telematics for remote monitoring; ECO mode for reduced fuel consumption; a rearview camera for enhanced visibility; a blade shake feature for removing material stuck to the blade; and an easy-to-read, user-friendly touchscreen display for access to the dozer’s functions and machine settings.

EARTHWAVE FLEETWATCHER ESCALATING IDLE ALERT FEATURE

FleetWatcher’s Escalating Idle Alert proactively informs managers when equipment has been idling for too long, allowing immediate corrective action to be taken. This can help slash idle time, and extend equipment life span, or dramatically impact its value at trade-in.

• FleetWatcher monitors the rpm over time and actively alerts managers with a text or email when a preset threshold has been reached.

• Users set an excessive idle time threshold and then enter that into the third-party telematics platform.

Read More at https://eqtoday.co/r3eucs

Read More at https://eqtoday.co/kq87np

• The parameters and alerting structure are completely customizable by the user.

• Data can be integrated with other business systems.

EPIROC SMARTROC T25 R

The SmartROC T25 R radio remote construction rig features exceptional coverage area with versatile boom options, excellent terrainability for safety and productivity, and a Smart Rig Control System (RCS) reducing fuel consumption and environmental impact. Its Smart RCS enables precise drilling process tuning, quick setup, and future updates. Automatic adjustments to engine rpm and compressor load optimize efficiency.

The rig’s advanced boom geometry minimizes drill movements, maximizing productivity. With a 180-degree boom swing angle, 360-degree feed swing, and varied feed lengths, it offers valuable application versatility in drilling. This innovative rig stands out with its technology, efficiency, and sustainable practices.

FECON FMX BULLHOG MULCHER

Fecon, a global manufacturer of heavy-duty site preparation attachments and forestry accessories, debuted the FMX28 Bull Hog compact excavator mulcher attachment at CONEXPO 2023.

Read More at https://eqtoday.co/5jksgc

Capable of mulching overgrowth, underbrush and small trees, the FMX28 offers a versatile solution for clearing property lines, pasture land, real estate lots, ditches, trails, fence rows and invasive species, and more. Paired with 3.5-ton to 8-ton excavators, the compact package makes it easy to access traditionally difficult-toreach places with precision—making it a perfect fit for owner-operators, rental centers and right-of-way maintenance.

Read More at https://eqtoday.co/h90655

GENIE GTH-1256 TELEHANDLER

The Genie GTH-1256 high-capacity telehandler was designed and tested for the realities of heavy-duty jobs. A strong load chart throughout the lifting range—not just max capacity—is important for productivity and provides flexibility to do more with one machine.

Proprietary, long-life Enduro A/T tires deliver performance in a variety of terrain and one-third longer wear before replacement is needed. Shared parts across the GTH product line further reduce owner costs and simplify fleet maintenance.

Read More at https://eqtoday.co/s4rfh7

GOMACO GP460 PLACER/SPREADER SLIPFORM PAVER

With its debut at CONEXPO 2023, the GOMACO GP460 is the industry’s first combination concrete slipform paver and placer/spreader on two tracks. Designed for wider-width operations, as a placer/spreader with a 60-in. (1,524-mm) belt, the GP460 will accommodate widths up to 50 ft. (15.2 m) wide. As a concrete slipform paver, the GP460 will pave widths up to 40 ft. (12.2 m) wide.

It’s built on the framework of the GOMACO two-track GP4 slipform paver with the ability to convert the prime mover into a concrete placer/spreader. The prime mover is equipped with vibrator circuits.

Read More at https://eqtoday.co/ycbb84

HITACHI CONSTRUCTION MACHINERY ZX50U5N COMPACT EXCAVATOR

With its reduced tail-swing design, the compact 10,560-lb (4,790-kg) Hitachi ZX50U-5N is designed for working in congested areas. An independent swing boom lets you set up and work almost anywhere. Unobstructed visibility and control make it a great tool for excavating around existing utilities.

The ZX50U-5N offers height and reach to get up and over truck sideboards with a maximum reach of 19 ft. 7 in. (5.96 m). It also provides a maximum dig depth of 11 ft., 7 in. (3.53 m). Engine speed can be matched to the job with power/economy work modes, which are usually only available on larger excavators.

Read More at https://eqtoday.co/q9g03w

HYUNDAI CONSTRUCTION EQUIPMENT HS

120V SKID STEER

Hyundai announced the HS120V skid steer, designed for many construction jobs including debris removal, demolition, loading, clearing, lifting and excavation. It is equipped with a Tier-4-Final diesel engine. With a maximum lifting height of 13 ft., 4 in., the skid steer’s boom has a vertical lift path when raising the bucket. An auto-leveling system keeps the bucket stable without manual adjustments. With an enclosed cab design, operators can access a 12-V electrical outlet and USB outlet for powering or charging.

Read More at https://eqtoday.co/rmwcuq

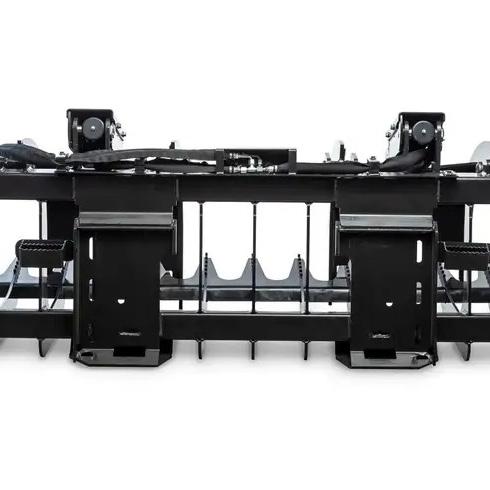

IGNITE ATTACHMENTS GRAPPLE FAMILY

Ignite Attachments launched a new line of grapple attachments for construction and landscaping applications. The root grapple headlined the grapple line launch in late April, with the bucket grapple following the first week of May, the rock grapple the second week of May and a rake grapple to come later this year. It aims to improve operations in industries that use mini excavators, compact wheel loaders, multiterrain loaders, compact track loaders and skid steer loaders.

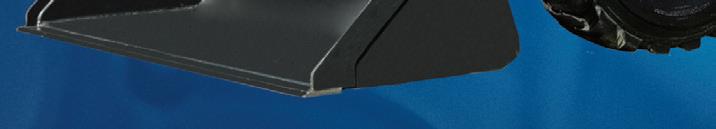

IRONCRAFT 4-N-1 POWER RAKE ATTACHMENT

The 4-N-1 Power Rake Attachment was designed because there was a need in the industry to be able to combine the functions of these attachments. It makes landscaping jobs involving a power rake quicker and more efficient, while also cutting out the number of attachments needed for a job. After power raking, you can scoop or clamp the accumulated material. The 4-N-1 Power Rake Attachment is also efficient and effective for leveling/planing/ backfilling.

JCB ELECTRIC EQUIPMENT

JCB has a corporate saying that “innovation is our lifeblood.” The need for new thinking never diminishes and JCB is focused on developing the machines that will support construction and agriculture in a zerocarbon future.

Read More at https://eqtoday.co/v9o3t3

Read More at https://eqtoday.co/zkxc49

To meet its sustainability initiatives, JCB offers a range of 100% electric machines with zero emissions, zero compromise on performance and a lot less noise. JCB’s electric range currently includes: the 505-20E Telehandler, 19C-1E Mini Excavator, 1TE Site Dumper, 66-40E Teletruk, HTD-5E Dumpster, and a range of electric scissors.

Read More at https://eqtoday.co/wdatph

JLG E18MCL VERTICAL MAST LIFT

The JLG E18MCL vertical mast lift is well suited for applications that require outdoor- and indoor-capable machines for up-and-over work as an alternative to using ladders and scaffolding. The “E” in this model’s nomenclature stands for “Electric,” and it has scissor-style steering. The E18MCL’s platform height is 18 ft. indoors and 13 ft. outdoors. It can go on most freight elevators, work on sensitive flooring and fit through doorways.

JOHN DEERE 335 P-TIER

John Deere introduced a new generation of large-frame 335 P-tier compact track loaders for hauling, surface grading, material loading and equipment transportation on construction sites. The construction vehicles in the P-tier series feature redesigned cabs, heated and vented seats, touchscreen displays, hands-free Bluetooth technology and JDLink telematics.

Read More at https://eqtoday.co/q4m18k

Read More at https://eqtoday.co/2veo3m

KATO-CES 9V5 MINI EXCAVATOR

The all-new, redesigned KATO 9V5 ultra-mini zero tail swing excavator is a much faster and easier alternative to any shovel or wheelbarrow for working in tight spaces. With its ultra small size and roll down ROPS the 9V5 can even fit through doorways, standard yard gate, and even the tightest spaces making it ideal for any project. The 9V5 features high operator comfort thanks to low vibration and noise, improved interface with digital hour counter, and improved machine stability with improved weight distribution and a larger front blade.

Read More at https://eqtoday.co/49ogp8

KOBELCO SK350LC11 EXCAVATOR

KOBELCO Construction Machinery

launched the new SK350LC-11 excavator. The new SK350LC-11 features a 265-hp Isuzu Tier 4 Final engine. With the press of a switch, the machine dedicates one hydraulic pump to the travel system and one to all the other functions. This allows the 11-series Kobelco machines to travel while lifting and swinging heavy loads.

Read More at https://eqtoday.co/e741yb

KOMATSU PC900LC-11

Built for tough jobs, the Komatsu PC900LC-11 excavator is designed for heavy construction, demolition, material handling, deep sewer, water, large mass excavation, and mining or quarry. It offers 25% more arm crowd force and 12% more swing torque. The new counterweight removal system helps with moving and the boom configuration reduces transport height.

Read More at https://eqtoday.co/xca4ph

KUBOTA TRACTOR SVL75-3 COMPACT TRACK LOADER

Kubota Tractor Corp. announced the newest addition to its popular compact track loader lineup with the introduction of the SVL75-3. Powered by a 74.3-hp Kubota engine with higher maximum torque, and features that include an innovative advanced multifunction valve for smooth simultaneous operation of all hydraulic functions, a new 7-in. color LCD panel with jog dial that puts a wide range of functions and information at the operator’s fingertips and a new one-piece sealed cab. The SVL75-3 is available now at Kubota dealerships.

Read More at https://eqtoday.co/r2sd7d

LEICA GEOSYSTEMS BLK360

The new BLK360 creates accurate digital image data within 20 seconds. Its sensor is designed for any application requiring up-to-date scanning, such as digital construction and building lifecycle monitoring. It enables users to move without interruption, viewing and sharing the data during capture to provide real-time access to updated digital twins.

Read More at https://eqtoday.co/0yyl5w

LIEBHERR MID-SIZE WHEEL LOADERS

Liebherr redeveloped and revised its range of mid-sized wheel loaders. The three models, L 526, L 538 and L 546, in the latest Generation 8 have bucket sizes between 2.2 m3 and 3.0 m3; in the standard version and are characterized by an increase in performance compared to the previous generation. The new L 526, for example, has around 20% more engine power and more than 20% higher breakout forces than its predecessor.

The newly designed lift arm ensures maximum breakout, holding and lowering forces. It has optimized z-bar kinematics and improved working hydraulics.

Read More at https://eqtoday.co/pbss7c

LINCOLN ELECTRIC POWER MIG 215 MPI MULTI-PROCESS WELDER

The POWER MIG 215 MPi multi-process welder is a reliable, easy-to-use machine for the general fabricator, small contractor or repair personnel. The sleek and solid ergonomic design with multiple lift points maximizes mobility around the shop. The user-friendly technology makes the setup process and selection of weld settings incredibly simple. Take on any job with the versatile POWER MIG 215 MPi welder.

Read More at https://eqtoday.co/82u90b

LINK-BELT EXCAVATORS X4S SERIES

The new X4S line from Link-Belt focuses on performance and innovative features, offering power and high productivity to provide operators with lower daily operating costs. The line is equipped with forwardthinking technologies, including custom flow balance and four new work modes, which help to improve cycle times by up to 5% and fuel efficiency by up to 19%.

Cab comfort and safety are at the forefront of the line, with a 10-in. portrait monitor and WAVES 270°, giving remarkable site awareness. Dual LED cab lights are standard on all models, and the all-new hydraulic oil sampling port is hassle-free, requiring no tools.

Read More at https://eqtoday.co/nyydqh

LOFTNESS SPECIALIZED EQUIPMENT, INC.

BATTLE AX S SERIES

Loftness updated its Battle Ax S Series mulching head with new features for durability and serviceability. Designed for skid steers and compact track loaders with 28-gpm to 62.9-gpm hydraulic flow and 50 hydraulic hp to 150 hydraulic hp, the S Series now includes a reversible secondary shear bar in the two-stage cutting chamber to allow a fresh cutting edge.

After all four edges of the shear bar have been exhausted, the component can be replaced via a bolt-on mechanism. Previously, the secondary shear bar was welded on the front bumper, and only the primary shear bar was replaceable.

Read More at https://eqtoday.co/15asd2

MACK TRUCKS GRANITE WITH IMPROVED VISIBILITY

Mack Trucks launched an updated Mack Granite model at World of Concrete 2023. The refreshed vocational truck features a new, more modern fascia with an updated chrome grille and self-heating LED headlamps with brighter illumination, improving forward visibility by up to 29% and peripheral visibility by up to 50%.

The new grille and air intakes modernize the look of the Granite, and the choice of two grille treatments offers customers another way to customize their vehicles.

Read More at https://eqtoday.co/otrnpf

MANITOU NORTH AMERICA 2750VT COMPACT LOADER

Manitou launched three all new “V Series” compact skid steer loaders and three “VT Series” compact track loaders to the North American market: 2100V, 2300V, 2750V, 2100VT, 2300VT and the 2750VT. These new models have a capacity of 2,100 lbs. to 2,750 lbs. The new loaders feature keyless start requiring only code activation, LED lighting, and a patented Pilot joystick system as standard, adjacent to the operator’s seat.

MILWAUKEE TOOL MX FUEL CONCRETE VIBRATOR

Dedicated to the concrete contractor, the MX FUEL Equipment System was developed to deliver the performance and durability demanded by the trades. Safer, more reliable, and more productive than running extension cords and generators, the MX FUEL Concrete Vibrator eliminates exposure to emissions and tripping hazards.

MINNICH MANUFACTURING A-1CL SINGLE GANG MINNI DOWEL PIN DRILL

Read More at https://eqtoday.co/f68x8u

ROOSTER ASSET TRACKING SYSTEM

The Rooster Asset Tracking System is an equipment management tool that tracks activity and automates reporting. It provides visibility, accountability and efficiency for any asset in inventory using a patented pairing protocol based on the LoRa longrange standard with a ½-mile range.

Rugged Activity Trackers capture every minute of activity for up to five years and transmit that data to Rooster Hubs up to a ½ mile away and through most concrete and metal Hubs nearby.

SANY SMG200AWD

Designed to be highly functional, easy to operate, and easy to maintain, the SMG200AWD grader is intuitive to operate—even for new operators. Some SMG200AWD standard features are:

8.9L Cummins engine, 14-ft. blades, front auxiliary hydraulics, transmission and rear brake line guards, wet disc brakes for improved handling with all-wheel drive, low -maintenance circle bearing, adjustable independent control positions for operators, AM/FM radio with bluetooth capabilities, multifunctional LCD FOPS- and ROPS-certified cab.

STELLAR SINGLE-REEL UTILITY & TELECOM TRAILERS

Read More at https://eqtoday.co/ji8pju

The Minnich A-1CL dowel pin drill is a lightweight, on-slab, high-production drill that offers horizontal, vertical and 35-degree stitch and skewed drilling positions. The drill is maneuverable but without a formal steering system. The A-1CL reaches a maximum drill depth of 18 in. with an under-collar drill steel length of 24 in. The drill requires 92.2 scfm and 120 psig of pneumatic power.

Read More at https://eqtoday.co/ww974s

MOROOKA MST80C CRAWLER CARRIER

The Morooka MST80C is designed for construction projects and material handling tasks. It features a range of improvements compared to the previous model.

Equipped with a 228-hp Cummins B6.7 Tier 4 Final engine, the Morooka MST80C features auto deceleration when not in operation. This machine has a payload capacity of nearly 18,000-lb. The carrier serves as a mid-sized addition for fleets.

Read More at https://eqtoday.co/2dkqt5

Read More at https://eqtoday.co/gpfanj

Self-Loading Single-Reel Utility and Telecom Trailers from Stellar Industries are designed to help boost the efficiency and effectiveness of cable removal and cablelaying processes. With just one reel and a lower setup, these trailers have a low center of gravity and are perfect for more basic operations and improved safety. They also feature a convenient way to keep cables neatly contained and organized on the jobsite to prevent tangles or damages.

Read More at https://eqtoday.co/n1ztv2

Read More at https://eqtoday.co/2i7ojr

Stellar Trailers are built to withstand challenging industrial conditions and are well known for their strength, simplicity and safety. They feature easy loading and unloading, helping to keep productivity moving.

TAKEUCHI TB350R SHORT TAIL SWING COMPACT EXCAVATOR

Takeuchi developed the TB350R short tail swing compact excavator to deliver a unique combination of performance, durability, operator comfort and serviceability. A rear swing overhang of just 2.95 in. allows operators to focus on their work and worry less about rear-swing impacts. To improve the operator’s experience and enhance their productivity, Takeuchi completely redesigned the TB350R’s interior for greater comfort.

Maintenance is simple with a wide-opening rear engine service door and a right-side cover that opens overhead for quick access to key daily inspection points. Takeuchi’s Fleet Management telematics system comes standard, providing valuable information, remote diagnostics and scheduled maintenance reminders. Read More at https://eqtoday.co/9z3k2t

TENNA TENNACAM 2.0 DASH CAMERA WITH AI TECHNOLOGY

Safety is the No. 1 priority when traveling on the road. TennaCAM 2.0, with exterior and optional interior video capabilities, helps contractors find the truth behind safety incidents and protects businesses and drivers from liability. Different settings choices allow users to customize their cameras to best suit their organization’s needs for safety, privacy, and liability management.

THUNDER CREEK MULTI-TANK OIL TRAILER

Read More at https://eqtoday.co/thpam6

Thunder Creek Equipment launched the all new MTO service, fuel and lube trailer, which handles up to five different fluid types, including fresh oil, grease, reclaim, diesel exhaust fluid and diesel fuel.

The MTO is engineered to be a scalable solution for contractors of all sizes. The engineering of the MTO is modular, giving customers control over the type and amounts of fluids they need to keep their operation running.

Read More at https://eqtoday.co/9gfr4u

TOPCON POSITIONING SYSTEMS 2D-MC

Topcon Positioning Systems announced the 2D-MC, an automatic grade control solution for compact track loaders.

Designed for slope work, sidewalk grading, road base and drain rock replacement, parking lots, sports fields, landscaping, flat pads, indoor work and concrete site prep, 2D-MC is an automatic grade control solution capable of adapting to different grading attachments for compact equipment.

TORO EDINGO 500

Toro engineers built the eDingo 500 to allow contractors and construction professionals to reap all the benefits and power of a standard CUL with zero exhaust emissions and a significantly lower cost of operation. The new design is now capable of fitting through even the tightest of doorways with a narrow width of 30 in., yet still boasts a rated operating capacity of 515 lbs. and 6.5-gpm hydraulic flow. The HyperCell Power System allows for all-day run times.

TRIMBLE SITEWORKS MACHINE GUIDANCE MODULE

Trimble introduced the Trimble Siteworks Machine Guidance Module, extending the capabilities of Trimble Siteworks Software. With the addition of the new module, contractors can use the same site positioning systems hardware and software to perform tasks on the jobsite, including surveying, machine guidance, in-field design and reporting.

Read More at https://eqtoday.co/3px68e

VOLVO CONSTRUCTION EQUIPMENT L350H WHEEL LOADER

The L350H is built upon the success of the L350F, first introduced in 2007. Upgraded with the latest technology, the L350H is ready to tackle a range of applications, from mining and quarrying to heavy infrastructure.

Customers can take advantage of specialized packages with features for log loading, rock loading, rehandling, block handling or slag handling.

WACKER NEUSON ST27 TRACK LOADER

Read More at https://eqtoday.co/309l85

The Wacker Neuson ST27 offers the best power-to-weight ratio in its class, with an ideal operating weight of 7,310 lbs. The 74.3-hp engine gives high performance, a flat torque curve and superior tractive effort. In addition, the vertical lift provides a hinge pin height of 120 in., with a dump height of 94.3 in. The design also maximizes the rated operating capacity of 1,890 lbs. (at 35% of tip), with extra reach at max height making it easier to dump material into the center of a dump box. and keeps the loader farther away from the vehicle or trailer being loaded.

Read More at https://eqtoday.co/es1bf2

WEILER P385C COMMERCIAL PAVER

The Weiler P385C’s improvements provide performance, reliability and outstanding mat quality. The P385C features a Cat C3.6 engine-120 hp (90 kW)-for better power. The undercarriage features a 90-in. (2286mm) track length, 68 in. (1727 mm) of ground contact and a 140-mm track chain pitch.

Read More at https://eqtoday.co/ycmv5v

WIRTGEN SP 20(I) OFFSET SLIPFORM PAVER

The production of concrete safety barriers with a height of up to 2 m and the paving of flat surfaces with widths of up to 2.5 m are typical applications for the SP 20(i) offset paver. With the machine, Wirtgen offers its customers the ideal combination of productivity and mobility. Despite the large paving widths and heights that it offers, the machine has a low transport weight and compact dimensions.

Read More at https://eqtoday.co/jryycs

Read More at https://eqtoday.co/zz5kz8

YANMAR MINI EXCAVATORS

Yanmar introduced several firsts, including the self-propelled mini excavator, the first swing boom excavator and the first zero tail swing excavator. Yanmar’s lineup includes zero tail swing and ultra-tightturning excavators, which feature either no protrusion beyond the track or minimal protrusion. The company backs its mini excavators with a four-year/4,000-hour bumper-to-bumper warranty. Additionally, Yanmar’s SmartAssist Remote telematics comes standard on all excavators, free for the first five years. The telematics’ range from error detection and work reports to integrated theft protection.

Read More at https://eqtoday.co/i53l9q

Read More at https://eqtoday.co/vllj4m

This page features some of the latest equipment available. For more information on these products, use the QR code shown.

IronCraft Snow Cannon

IronCraft Snow Cannon tractor snow blowers are designed to move heavy, wet snow. Offered in three models, the attachment is compatible with 12-hp to 50-hp tractors. Operators can use the Snow Cannon for site preparation, commercial snow clearing jobs (driveways, parking lots and pathways) and landscaping. Welded augers with high-tensile strength ribbon flighting, a heavy-duty gearbox and replaceable skid shoes provide durability and reliability. A manual pin-style deflector can be found on the attachment.

Read More at https://eqtoday.co/mtxyak

DEVELON DL320-7 Wheel Loader

The DEVELON DL3207 wheel loader is part of the next-generation -7 Series lineup, featuring upgrades such as increased bucket capacity, a redesigned cab with comfort features and fuel-saving technologies. The DL320-7 offers a 7% larger capacity bucket (4.5 yd3) and axle upgrades. The increased capacity has been designed to provide faster, easier loading in fewer cycles. Standard features include powershift 4-speed transmission, multiple power modes, Z-bar lift arm, return to dig and limited slip differentials. The machine comes with a 271 -hp engine, has an operating weight of 43,506 lbs., a bucket capacity of 4.5 yd3, and a static tipping load of 30,461 lbs.

Read More at https://eqtoday.co/rrb45i

FAE RCU-55

Equipped with a 56-hp KOHLER KDI 1903 turbocharged engine, the RCU-55 can work on steep slopes up to 55 degrees. This compact tracked carrier can mulch vegetation up to a 5-in. diameter with the BL1/RCU mulcher head and small shrubs and vegetation up to a 2-in. diameter with the PML/RCU mulcher head. The BL1/RCU mulcher head has a working width of 49 in., while the PML/RCU mulcher head features a 59-in. working width. The heavy-duty undercarriage of the RCU-55 features a hydraulic variable track system with independent undercarriage frames for stability on steep terrain.

Read More at https://eqtoday.co/qw33li

Makita 36V LXT Material Handlers

The three 36V (18V X2) LXT Brushless Material Handlers offer three forward speeds with one reverse and a maximum load capacity of over 650 lbs. Each material handling solution is powered by a 36V brushless motor and two 18V LXT batteries, the same batteries that are compatible with over 325 LXT tools and products.

˜ XUC04Z: The 36V (18V X2) LXT Brushless Material Handling with Dump Bucket features a large 200-L bucket, with a load capacity of 660 lbs.

˜ XUC05Z: The 36V (18V X2) LXT Brushless Material Handling, Dump/Pipe Frame features a pipe frame configuration with a load capacity of 650 lbs. for transporting a wide range of materials on the jobsite.

˜ XUC06Z: The 36V (18V X2) LXT Brushless Material Handling, Flat Bucket features a large 295-L bucket with a load capacity of 660 lbs.

Read More at https://eqtoday.co/kn41ic

Husqvarna LFe 60 LAT Battery-Powered Compactor

Husqvarna Construction introduced its first batterypowered compactor, the LFe60 LAT. This new, forward plate compactor delivers compaction of soil and asphalt and runs on the Honda eGX battery platform. The LFe60 LAT combines reliable handling, no CO2 direct exhaust emissions during operation and smart capabilities in a single machine. Operators can access several features on the machine such as a push-start button, transport wheels, lowvibrations and a handle that folds for compact transport. The electric motor of the LFe60 LAT compactor also helps minimize downtime.

Read More at https://eqtoday.co/r6t1sf

LiuGong 936F Crawler Excavator

The LiuGong 936F Crawler Excavator is designed for heavy digging and excavation. This 314-hp machine is powered by a six-cylinder, EPA Tier 4 Final L9 Cummins engine and features an operating weight of 85,538 lbs. Three accessible power modes, auto-idle and auto-shutdown help manage fuel consumption during use. Equipped with heavy-duty tracks, the 936F offers a maximum digging depth of 24 ft., 1 in. This combination allows the excavator to work near and above trenching areas, while maximizing reach. A large bucket capacity enables moving heavy loads.

Read More at https://eqtoday.co/au6ypm

AVOIDING DEMOLITION HAZARDS

Demolition work has its inherent hazards. Examples include the consequences of not using the appropriate safety equipment or not following proper safety procedures at work.

Occupational Safety and Health Administration (OSHA) safety training has outlined several demolition hazards.

Primary Demolition Hazards

OSHA notes that construction and demolition materials consist of the debris generated during the construction, renovation and

components such as doors, windows and plumbing fixtures. Trees, stumps, earth and rock from clearing sites may also be present. Primary hazards unique to demolition include:

˜ Changes from the structure’s design introduced during construction

˜ Modifications altering the original design

˜ Materials hidden within structural members such as lead, asbestos, silica and other chemicals

˜ Heavy metals requiring special material handling

˜ Unknown strengths or weaknesses of construction materials, such as post-tensioned concrete

˜ Personnel exposure to excessive dust, noise and vibration created by the demolition methods

of Scrap Recycling Industries. As such, he has a birds-eye view of demolition safety challenges.

“Hydraulically powered mobile shears and processors offer a controlled demolition process, making the process safer and more efficient,” he said of the prime way to mitigate the hazards to personnel.

Airborne Material Hazards

Marcus Barnes, senior product manager for Liebherr USA, noted that high exposure to airborne materials such as silica from the deconstruction of buildings is a common hazard. These materials can lead to illnesses such as lung cancer, he added.

“To help mitigate some of this risk for operators on equipment, you

Protecting Others on the Jobsite

For those outside the cab who are exposed, many excavators and highreach demolition equipment have water dust suppression systems at the end of the stick. They help minimize hazards in the air, Barnes noted.

He added, “This kind of equipment does the bulk of the deconstruction work on a jobsite. The water that is being sprayed through nozzles at the end of the stick helps in keeping the dust down.”

Equipment Design Promotes Safety

“Demolition is a rough and rugged application where hazards include falling debris, challenging visibility and pushing machines too far,”

everyone on the site.

noted Tony den Hoed, director, national accounts – demolition, Volvo Construction Equipment.

Safety is the highest priority on a demolition job, he pointed out. A design to address hazards is critical.

“A factory-fitted machine designed for demolition often means a safer machine,” den Hoed said. “A strong demolition-specific application package straight from the original equipment manufacturer (OEM) is a great way to mitigate some risk because it will incorporate heavy-duty guarding specific to the machine and features that help with visibility, like bigger, stronger window panels and cameras.”

OEMs Differ in Approach

Aftermarket options are available. However, aftermarket packages can be expensive, often involve a third party, and can void machine warranties, den Hoed added.

“Even among factory-fitted demolition machines, there will be differences by brand,” he said. “For instance, almost every OEM that purpose-builds their high-reach excavators includes a modular joint boom concept, but the pins that hold the joint to the boom can differ.”

Some use a half hook for the top pin and short pins on the bottom. However, a well-designed demolition excavator uses full-length hydraulic pins, den Hoed said.

“Because they are hydraulic, an operator can pull them out without leaving the cab, which is always preferable,” he added.

Telematics can help prevent major downtime. They also spot instances of machine misuse. This supports safety and the total cost of ownership (TCO), den Hoed noted.

The Operator’s Role in Safety

Demolition safety depends in large part on the operator, as is noted in

“5

Tips to Maximize Jobsite Safety

With Remote-Controlled Demolition Machines,” on ForConstructionPros. com detailing five tips to maximize safety. Those tips include:

˜ Being vigilant

˜ Staying at arm’s length

˜ Conducting daily inspections

˜ Being mindful of overhead dangers

˜ Using personal protection

Safety First

To prevent and reduce hazards associated with the likely exposure to hazardous substances, OSHA has advised construction crews to conduct worksite inspections before beginning operations. Assess for the presence, contents and condition of tanks and equipment that might contain hazardous chemicals, gases or flammable materials. If the condition

of tanks or equipment is suspect, avoid disturbing them until after the assessment is completed.

Develop a plan of action to reduce exposure or eliminate hazardous substances. To eliminate hazardous substances that have been identified prior to and during demolition,

construction crews should purge lines, tanks and equipment containing hazardous chemicals, gases or flammable materials.

OSHA Guidance

OSHA also advises crews to use air monitoring equipment (a combustible

gas indicator, toxic gas monitor or oxygen monitor) to detect remaining hazards. When necessary, provide additional protection such as forced ventilation and respiratory protection.

Common accidents from demolition hazards are falls from elevated surfaces, exposure to

HERE FOR ANY JOB. ANYTIME.

Starting with the highest quality o f equipment, KATO’s CL35 is builtto handle the toughest projects andthe most rugged terrain. KATO’s versatile CL35 Compact Track Loader, meets the needs of any job-site. The CL35features an operating weight of 7,800 lbs. and is easily trailered to your next jobsite. The CL35 alsofeatures a comfortable cabin and responsive pilot controls for a superior operator experience. Additionally, KATO’s US-based distributor, Compact ExcavatorSales, is a family-owned business that puts customers first. Knowledgeable product experts are always standing by to assistwith anyservice ormaintenance issuesthat arise and our streamlined parts distribution minimizes downtime, keeping projects o n schedule. Call today to find out how KATO’s superiorservice can helpyou achieve your goals.

EARTHMOVING TRENDS

hazardous air contaminants, being struck by falling or collapsing structures and electrical shock.

Engineering Surveys Identify Hazards

OSHA points out that the engineering survey must identify framing, floors, walls of the structure and any adjacent structures that might be unstable. Key engineering and work practice controls for the hazards associated with structural instabilities during demolition include shoring and/or bracing walls and floors as needed to maintain safe work areas during demolition activities.

A competent person can recognize existing and predictable hazardous conditions and has the authority to take quick corrective measures to eliminate them, OSHA notes. That person should maintain an ongoing presence to inspect the work area to detect hazards.

Demolition crews are advised to not allow falling debris, stored materials or heavy equipment to exceed the safe carrying capacity of the floor. Demolition work should be conducted from the topmost floors down. Loadsupporting members should not be cut or removed until upper or supported loads have been removed. During demolition, unsecured objects such as glass and structural members may fall while workers are under them.

Hazard Control Strategies

Control strategies for issues associated with unsecured hazards in the work area during demolition include using debris netting, sidewalk sheds, canopies or catch platforms to reduce falling objects, OSHA notes. Ensure that employee entrances to multistory structures are protected by sidewalk sheds or canopies or both to provide protection from the face of the building for a minimum of 8 feet. OSHA advises that canopies should be at least 2 feet wider than the building entrances or openings capable of sustaining a load of 150 pounds per square foot.

Check Utilities for Potential Hazards

OSHA also notes the importance of reducing or eliminating hazards from utilities that are not properly located and secured. To do so, verify the location of all other utility lines; ensure that the lines have been shut off, capped, or otherwise controlled outside the building before beginning work. Notify utility companies before controlling their utility lines.

Walkways Provide Safety

To prevent slips, trips and falls, the site should be set up so that safe walkways are provided and used to reach any point without having to walk on exposed beams. Walkways should be at least 18 inches wide and formed by using 2-inch-thick wood with stringers installed as needed for support.

To ensure safe access to the structure, crews should use only inspected and designated stairways, passageways and ladders designated as access points to the structure of a building. Other access points must always be entirely closed.

In a multistory building when a stairwell is being used for access or egress, OSHA advises that it must be properly illuminated by either natural or artificial means. It should be completely and substantially covered over at a point not less than two floors below the floor on which work is being performed. Access to the floor where the work is in progress must be properly lit and protected and serve as a separate passageway.

Confined Space Challenges

One type of confined space demolition at industrial sites includes those with open tops and a depth that restricts the natural movement of air. Another is enclosed spaces with limited openings for entry, including storage tanks, vessels, degreasers, pits vaults, casings and silos.

OSHA notes that the hazards encountered when entering and working in confined spaces can cause bodily injury, illness and death. Accidents occur when workers fail to recognize a confined space is a potential hazard. It should be considered that the most unfavorable situation exists in every case and the danger of explosion, poisoning and asphyxiation will be present at the onset of entry, OSHA points out.

Current Technologies & Equipment for Greater Demolition Safety

Current equipment and technology are expanding the field of options. They include factors that help keep the equipment—and workers—safe.

Lewandowski noted that “today, you will see demolition contractors all over the world using large mining machines with purpose-built ultrahigh reach front ends equipped with very capable mobile shears, concrete processors, pulverizers, hammers, rippers and grapples.

“High-reach demolition machines equipped with capable hydraulic attachments allow the modernday demolition contractor to go after difficult projects in difficult locations—in some cases, having a 13-ton Fortress mobile shear working 30 meters in the air, cutting something very large down in a very safe and controlled manner,” he added.

Liebherr’s high-reach excavators are often used on deconstruction sites of large industrial plants and city buildings, Barnes said. He indicated that the demolition front on the machines can range from 75 feet to 180 feet with the demolition tool used varying depending on machine size, working height of the demolition front and the machine’s hydraulic

capacity. Liebherr offers the Liebherr Demolition Control system for its highreach excavator. It helps the operator keep the machine from tipping.

“On a separate screen, the operator can always see where the demolition attachment is to ensure it is in a safe working zone,” said Barnes.

“In the restricted mode, the demolition attachment automatically stops if the operator puts the demolition attachment in a compromised position. Experienced operators like the supervisor mode where they can still be monitored but not limited,” he added.

Operator Safety Is Critical

“To keep the operator safe, impactresistant glass is used. An integral protection guard surrounds the cab as a steel cage to further protect the operator,” Barnes said.

A slew of equipment protection is used to keep the equipment from being totally damaged from falling debris and rebar on the ground, Barnes noted.

“Protections are used on all the exposed cylinder rods,” Barnes said. “Upper carriage protection also is used to reinforce the lower sides of the upper carriage and along with reinforced protection plates underneath. We also use track chain cleaners–also known as scrappers–on the crawler excavators to help prevent loose rebar from damaging the machine while it is tramming on a jobsite.”

Industry ‘Workhorses’ Ensure Optimal Safety

High-reach excavators and straight boom excavators remain the workhorses of most demolition jobs, den Hoed pointed out. Volvo highreach excavators are designed and built to ensure maximum safety with a sturdy frame and a falling object guard, he added.

“The roof window and front onepiece glass are made from P5A, which is resistant to high impacts. Carefully placed cameras also help ensure that the operator always has a clear view of the jobsite,” said den Hoed.

“Nighttime visibility is aided by standard LED lights on both the boom and platform. Additional lighting for the cabin and counterweight are available as options,” he added.

Technology Extends Safety Features

To address demolition safety, Volvo recently launched the Lifting Mode for Multi Demolition Boom feature. It allows a high-reach demolition excavator to serve as a safe carrier for the lifting of machine components from a trailer to the ground.

“This mode can simplify transporting equipment to jobsites because it allows the excavator to safely lift components, such as cradles and digging or high-reach booms, from the trailer to the ground, at which point they can be safely installed on the machine,” said den Hoed.

The solution consists of machine software designed for the controlled lifting of equipment and visual indicators outside the cab to warn bystanders that lifting is underway. The software also controls hydraulic pressure and engine speed.

“This lifting mode includes a certified lifting accessory designed to fit the patented modular joint design from the multi-demolition boom, which can easily be connected to the lower pin of the boom,” said den Hoed. “When all components are safely unloaded, switching to the highreach or digging boom is easy, thanks to that modular hydraulic joint.”

The TCO is reduced by eliminating the need for a mobile crane or second excavator. Emissions are reduced because fewer vehicles are onsite, den Hoed pointed out. Another way Volvo CE is working to improve demolition site safety is with remote control.

“This technology is great for customers working on dangerous or difficult jobsites or in environments where operators need an up-close view of the task itself,” den Hoed said. “The function can operate over a 100-meter distance, more than sufficient to maintain a close eye on the machine.”

Two-way communication via a radio transmitter and radio receiver allows the operator to communicate with the machine, he added. The system can easily be turned on and off with a switch inside the cab. A light

beacon outside the machine alerts that remote operation mode is in use.

Alternative Fuel Sources

Addressing the impact of alternativepowered equipment, den Hoed noted that electric equipment provides an emission-free way to work indoors.

“For example, we have an indoor demolition customer whose team used

to only work overnight so as not to bother others working in the building,” he pointed out.

“He has told us that having a Volvo CE ECR25 Electric compact excavator allows for more daytime work hours, which often means more alert operators. An electric machine also boosts safety because it is so quiet that workers can easily communicate while

it is running, and no exhaust means no scrubber required to clean the indoor exhaust.”

Read more at: https://eqtoday.co/demolition0923

Carol Brzozowski is a freelance writer for Equipment Today

DOWNSIZING FOR THE WIN

There’s no denying that compact excavators are becoming more popular. Contractors are demanding more features out of a smaller package, and manufacturers are responding by launching several new models less than 8 tons. The compact excavator market in 2022 was $8.9 billion in North America and is projected to reach $14.6 billion by 2031, according to market analysis by Straits Research. CONEXPO/CONAGG 2023 saw a glut of new machines, many of which were in the compact category, and several that were in the compact excavator category.

Compact excavators offer countless benefits and advantages. As always, they can fit into tight spaces. These newer models, though, are much more built out with advanced features than their predecessors. An excellent choice for trenching and other earthmoving tasks, compact excavators now offer more hydraulic flow, improved cab comfort, better fuel efficiency, modern telematics features, machine control and more. There are other reasons for the popularity. Compact excavators, quite simply, offer a lot of value for a lower price. Many don’t require a commercial driver license to operate, and the smaller machines tend to have easier cab controls, making them simpler for new workers to learn.

CASE Construction Equipment is building out a lineup of mini excavators to fill a demand for earthmoving equipment in landscaping, underground utilities sectors and more. The launch included two electric mini excavators, a dieselpowered mini and other models that will be released in 2024. The CX15EV is a 3,186-pound mini excavator powered by a 21-hp/16-kW electric motor, and the CX25EV is a 4,828-pound mini excavator running with a 27-hp/20-kW electric motor. The lithium-ion battery featured in both machines is charged

by the 110V/220V on-board charger, or an external rapid charger that can have the machine charged typically within 90 minutes. Depending on the work, the two models will operate for eight hours per charge.

“Mini excavators are ideal for electrification because they go through varied work cycles throughout the day,” said Brad Mace, product manager, CASE Construction Equipment. “Between access to power and the fast-charging capabilities of the machine with both on-board and external technologies, these machines deliver excellent runtimes and are sure to be ready to take on any task.”

The cab includes a standard, color LCD monitor that shows battery information, machine settings and work modes.

It also features an electronic pattern changer (to switch between ISO and SAE patterns), customizable hydraulic proportional controls and auxiliary hydraulics to let the operator dial the machine to their preferences.

Both machines feature standard one-way/two-way hydraulics with an electronic detent hold to reduce operator fatigue, and an optional, second auxiliary circuit (two-way only) can be added for more hydraulic options. The new LCD monitor allows flow settings to be set and stored for up to five attachments for convenience and confidence when switching between attachments. An optional quick coupler simplifies switching attachments. CASE’s SiteWatch telematics is standard for visibility into machine performance and greater collaborative fleet management with the local CASE dealer.

Hitachi also launched new compact excavators earlier this year, including the ZX75US-7 and ZX85USB-7. An ultra-short-tail swing radius on the ZX75US-7 allows access to confined spaces while an ultra-short-tail swing radius with swing boom model ZX85USB-7 digs next to walls and guard rails. Power is provided by turbocharged Yanmar diesel engines. A power mode provides higher engine speeds when extra horsepower is needed. The economy mode reduces engine speed when performing normal work. This results in low noise and decreased fuel consumption.

Compact excavators are commonly used with a wide range of attachments. An optional attachment replacement support system simplifies swapping work tools. Attachment flow settings can be adjusted from the monitor and the operator can name and store up to 12 settings. An auxiliary function lever is available with an analog switch, trigger switch and horn for running attachments such as a breaker or an attachment with swing.

Cab space has been improved from past models. There is more head clearance when opening the front

window. A low cabin floor height facilitates access to the machine.

The Aerial Angle peripheral vision camera system provides a wide 270-degree bird’s-eye view of the machine’s immediate environment. The operator can select from five views on the monitor, and a camera allows the operator to see the area right below the counterweight.

Routine checks, such as engine oil level, are accomplished from ground level and all service points are within reach through the access panels. ConSite telematics remotely monitors operational status and alerts owners and operators to upcoming maintenance needs.

A new optional feature, ConSite OIL, monitors engine and

An ultra-short-tail swing radius on the ZX75US-7 allows access to confined spaces. An ultrashort-tail swing radius with swing boom model ZX85USB-7 digs next to walls and guard rails.

hydraulic oil conditions to detect issues before fault codes are triggered in the machine.

Yanmar recently launched its ViO17-1E and ViO25-6B mini excavators. The ViO17-1E is designed for residential work, landscaping and small general construction projects. The ViO25-6B can also be used in those applications but brings additional power and size for building maintenance projects, irrigation, plumbing pipeline and more.

“Operators will appreciate the upgraded features in these new generation models,” said Jeff Pate, director of sales at Yanmar Compact Equipment North America. “From improved operator comfort and lighting to enhanced attachment coupling, the improvements make long days in the cab a little easier.”

The ViO17-1E offers a 4,023-pound operating weight and 14.5-horsepower engine while the ViO25-6B features a 5,908-pound operating weight and 20.4-hp engine. These vehicles feature dig depths of 7 feet, 7 inches for the ViO17-1E and 10 feet for the ViO25-6B.

Yanmar builds the ViO17-1E and ViO25-6B with true zero tail swing technology for workplace performance. Zero tail swing models are designed so that no part of the cab or canopy extends beyond the track width.

The ViO25-6B includes SmartAssist Remote, Yanmar’s telematics system. Using the integrated theft protection, the mini excavator’s owner can set a range from a specific location or a starting time, triggering SmartAssist Remote to send a notification if that range is exceeded. SmartAssist Remote can also detect errors with electronic components and send notifications to service personnel and directly to Yanmar for diagnostics.

Additionally, the machine’s owner can view the operational status of the equipment in real time and see daily work reports that track use.

Finally, SmartAssist Remote can track maintenance intervals and inspection items, as well as notify the owner via email about upcoming maintenance requirements.

Read more at: https://eqtoday.co/00fmyw

The ViO17-1E offers a 4,023-lb operating weight and 14.5-hp engine while the ViO25-6B features a 5,908-lb operating weight and 20.4-hp engine.

How to Get the Best ROI on Equipment

Mini excavators’ compact size and versatility make them a popular choice for the construction industry. There are a large variety of attachments available allowing them to tackle almost any task on the jobsite. Although choosing from so many different models and configurations can be a challenge, one of the biggest decisions contractors may face is whether to rent or buy the mini excavator.

On average, about 25% of contractors choose to rent their mini excavators, while 75% choose to

buy. Some businesses get the best of both worlds by purchasing the mini excavator size class they use most and renting additional machines during busy seasons to supplement their fleet. While there are benefits to both renting and buying, there are details to be aware of to determine which option will offer the greatest return on investment (ROI).

When Renting May be Best

An operator may choose to rent a mini excavator instead of buying it for several reasons. With a relatively low upfront cost and flexibility to return the equipment at any time, contractors can reap many of the benefits that come with owning a mini excavator. Whether to save money during a slow economic period or to increase productivity on a quick-turn project, certain conditions warrant a strong rental consideration.

It’s a Short-Term Task

Assess the usage needs before deciding to buy or rent a mini excavator. If this is a short-term task and the machine won’t have many uses afterward, renting can be a better choice.

To better understand what qualifies as a short-term task, estimate the machine’s annual hour usage and the amount of revenue that it would generate. Is that significantly less than the cost of the mini excavator? If so, renting may be the best option.

Money Is Tight

Buying any capital equipment requires a substantial financial investment, so opting to rent provides an economical alternative for those looking to save on upfront costs. Depending on the amount of time the equipment will be used, the cost of renting a mini excavator can be significantly less than the purchase cost, which can translate into thousands of dollars of savings. Renting a mini excavator also means there’s no need to worry about insurance costs, interest allocation or the sales tax that comes with purchasing a mini excavator.

You’re Looking for Less Commitment

The beauty of renting is that operators aren’t chained to one machine. No long-term commitment is involved. This way, contractors can change out machines based on the projects that arise or new configurations introduced to the market instead of finding attachments for their existing fleet or purchasing additional equipment.

Maintenance is a Pain Point

When renting a mini excavator, most if not all, maintenance and service requirements typically fall under the responsibility of the rental center. This means contractors can focus on the job without worrying about scheduled downtime for servicing.

Renting can also be a benefit if unforeseen challenges arise with the

machine where repairs are needed. Instead, contractors can simply return the unit and obtain a comparable replacement.

When Buying a Mini Excavator May be Best

Although renting a mini excavator involves less time, upfront costs and maintenance, purchasing a mini excavator as a long-term investment is sometimes the better option. With benefits such as having full control over when the machine is used and maximizing ROI with different attachments, buying a mini excavator can be an excellent strategic move for a business. This is especially true in market conditions with high economic growth. Here are some indicators buying a mini excavator is the best choice for you.

Future Utilization Opportunities

Similar to determining if renting is best, it’s important to look at the big picture when considering buying compact equipment. Buying often comes with financing payment cycles that can last several years so looking ahead at future utilization opportunities is critical to determining return on investment.

For example, if the monthly bill for the equipment is $1,200 and you’ll be working enough billable hours to cover that or more each month, buying is likely the best long-term choice.

Just as it’s important to examine factors such as market conditions when determining whether to rent or buy a mini excavator, it’s also helpful to have a good understanding of inventory. With the versatility that mini excavators provide when paired with different attachments, the equipment can easily be used in multiple applications, which means the benefits of owning one are even greater for businesses that do it all.

CLOCKS IN, NEVER OUT.

There’s only one member of your crew that will never quit, complain, ask for breaks or wish the day would end.

The TL8R2 track loader just wants to work. For those who value uptime above all, nothing else comes close. In fact, anything else is probably in the shop.

THE MARK OF TOUGHNESS

EARTHMOVING TRENDS

More Flexibility with Scheduling

Contractors that work in different industries, such as utility work, residential and commercial construction, roadwork, and municipality projects, should consider buying a mini excavator instead of renting. With the versatility mini excavators provide when paired with different attachments, the equipment can easily be used in multiple applications. This means the benefits of owning one are even greater for businesses that do it all. Purchasing also means the machine is available 24/7 whenever the contractor needs.

With renting, the rental company may not have the right machine available when it’s needed. However, those who own their equipment can have peace of mind knowing they are ready to go when the work comes in.

Consistently Renting the Same Size Machine

If renting a mini excavator originally seemed like the best solution but you now find yourself going back to the rental center to use the same machine time and time again, it may be time to buy.

Those who rent the same size machine multiple times each year fall into this category. Contractors who find themselves using their mini excavator rentals longer than expected instead of switching it out for different equipment with each new job may also be a candidate for purchasing.

Additionally, purchasing a mini excavator gives contractors the option to sell the machine and make money if they find they no longer need it.

The Dealer Offers Rental Purchase Options

For contractors who know buying a mini excavator is in their future but can’t get financing upfront or don’t know which model to buy, rent-to-buy programs can be an ideal solution. These programs allow contractors to start using the equipment right away and rent until they get approved for a loan or find the right model that they want to invest in.

The Equipment has Reputation for Quality

Investing in high-quality, new equipment often brings the added convenience of two to three years of minimal maintenance. Along those lines, if the new machine comes with a better-than-average warranty, that’s a sign that the manufacturer believes in the quality of their equipment and it’s likely worth the investment.

Some manufacturers offer warranties for new machines as long as four years/4,000 hours—double that of many other manufacturers.

Telematic Programs are Offered with Purchase

One of the newer benefits to buying a mini excavator are telematics

programs. Some manufacturers will offer the technology free for a limited time with purchase.

Telematics can help owners stay on top of service tasks by tracking maintenance intervals and inspection items. They also detect errors on the machine and send information directly to service personnel to streamline the diagnostic process.

Additionally, telematics systems can include integrated theft protection, real-time operational status of the machine and other helpful data that can improve jobsite productivity.

Just as examining factors such as market conditions when determining whether to rent or buy a mini excavator is important, having a good understanding of inventory is another critical piece of information.

Supply chain issues can have a negative impact on availability. This can influence the purchasing decision based on what is currently available from the manufacturer.

It’s worth reaching out to trusted dealers to discuss options or to learn about different rental and purchasing options. Contractors should also look into the manufacturer and learn about its reputation.

Are they known for reliable equipment and warranties that back their promises? That’s a sign that their equipment is worth the commitment— whether for rental opportunities or investing in ownership.

Read more at: https://eqtoday.co/kew2l5

Jeff Pate is director of sales for Yanmar Compact Equipment North America.

THE EBAY WAY

TRAINED PROS

End-to-end expertise, from the professionals who inspect your equipment to the support team who answers your every question.

DETAILED

REPORTS

Verified Condition you can rely easy-to-read grading all important features equipment.

START

Looking to buy heavy equipment now or in the future?

THE HARD WAY

“EXPERT” STRANGERS

You hop on a few national and local listing sites and find some equipment being sold by individuals or businesses you don’t know.

Do they respond to your call or email?

YES [CONTINUE]

NO [BACK TO START]

AMATEUR REPORTS

Your deal is dependent accuracy. As a buyer find yourself scouring reports.

Seems [CONTINUE]

Blurry photos?

Unbelievable glamor [BACK TO

Find the equipment you

DETAILED REPORTS

Condition Reports on with an report card the most features of your equipment.

PROTECTED PURCHASE

Your equipment is ensured to be authentic with Business Equipment Purchase Protection up to $200,000 on equipment that’s up to 20 years old. We’ve got your back.

AMATEUR REPORTS

dependent on buyer you could scouring unreliable reports. legit. [CONTINUE] photos? glamor shots? TO START]

TAKE YOUR CHANCES

You’ve set a safe meetup location for your equipment to change hands and found a way to make payment safely.

[CONTINUE]

Deal fell through or wasn’t what you expected [BACK TO START]

FINISH

Congratulations on your deal!

8 ELEMENTS OF ADCM & the Future of Technology on the Jobsite

contractors must develop a solid plan for the project to achieve success.

The latest data from The Civil Quarterly from Dodge Construction Network reveals uncertainty, including concerns over the unending labor shortages and increased regulations.

To conquer these impediments, contractors need unprecedented visibility into every aspect of their projects. They require real-time data to make informed decisions, ensure profitability and prevent costly overruns.

Data Is Vital to Accurate Estimates

Whether drones, reality capture or machine control, there’s little debate about technology’s role in the modern jobsite in enabling efficiencies in time, materials and resources. But it’s not just the fact that technology exists that is changing the jobsite. The revolution is how construction professionals use it to reimagine the jobsite and maintain their level of productivity amid an increasingly unstable climate.

As technology permeates the conversation, we need to make sure we are focused on technology’s larger role: Ensuring that a job is completed safely, on time and on budget.

Before beginning construction work,