UNDERCARRIAGE & TRACK INNOVATIONS FROM SENSORS TO COMPONENT WEAR POWER PROSPECTS

IN ADDITION TO EFFICIENT DIESEL, OTHER POWER OPTIONS FOR EXCAVATORS ARE GROWING IN POPULARITY

The Future of Skid Steers: Electricity, Automation & Efficiency Helping you optimize ROI on your construction equipment OCTOBER 2023 #1 Market Leaders

COVER STORY

Power Prospects

In addition to efficient diesel, other power options for excavators are growing in popularity

DEPARTMENTS

BREAKING GROUND

Today’s Alternative Power Trends Are the Equipment of the Future

Efficient diesel, electric and alternative fuels all must be considered as the industry strives to lower emissions.

EQUIPMENT INTRODUCTIONS

Check Out the Latest Equipment

The latest machines from major manufacturers.

PROFIT MATTERS

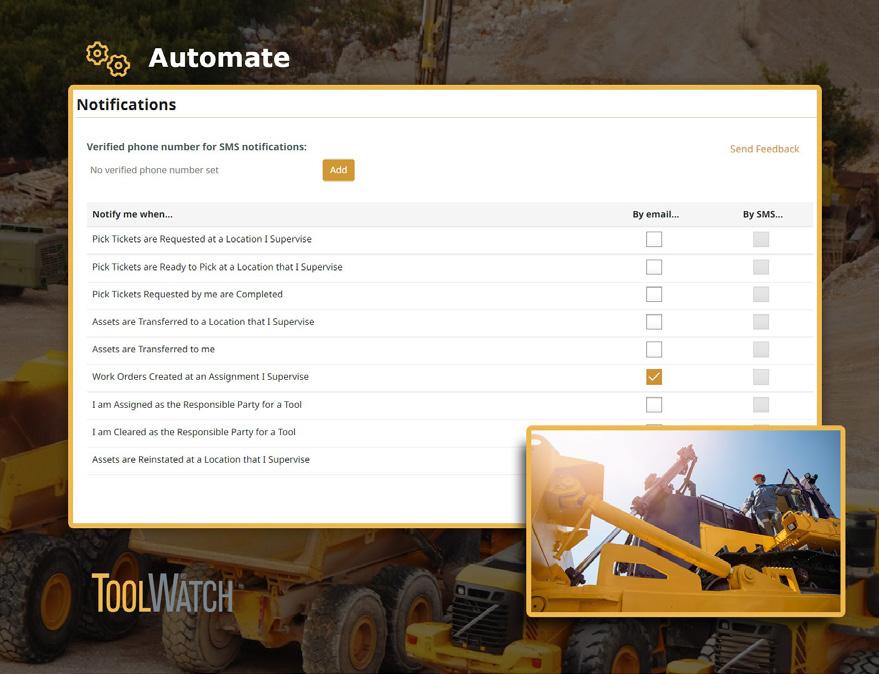

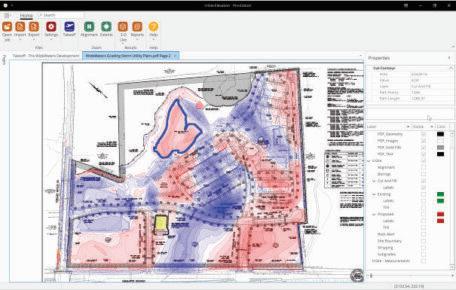

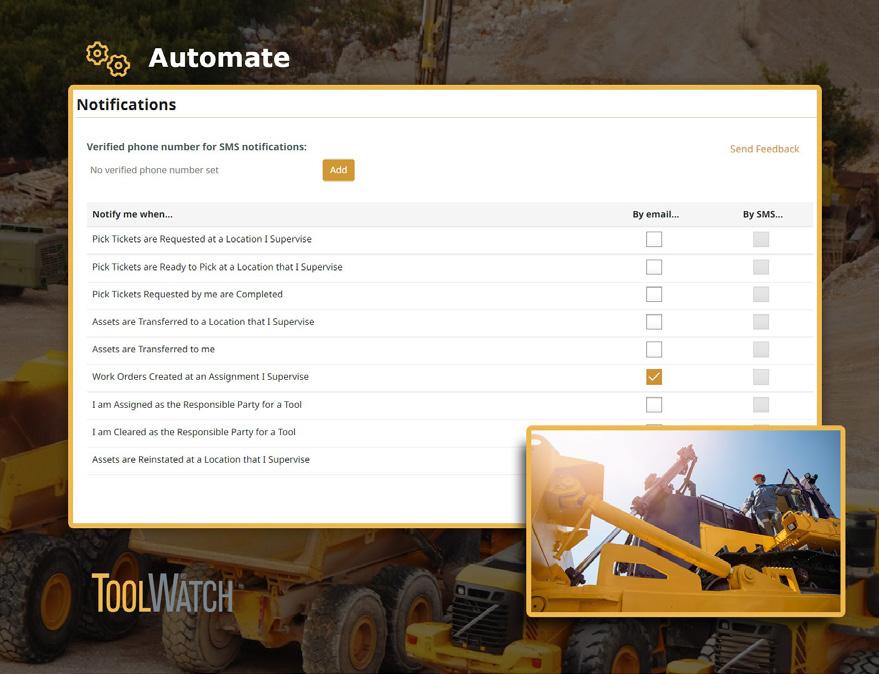

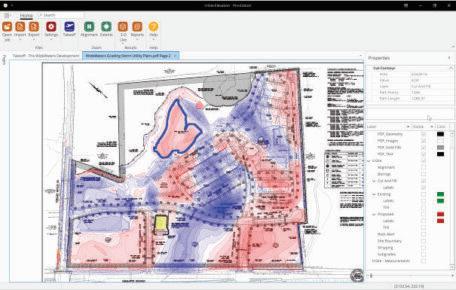

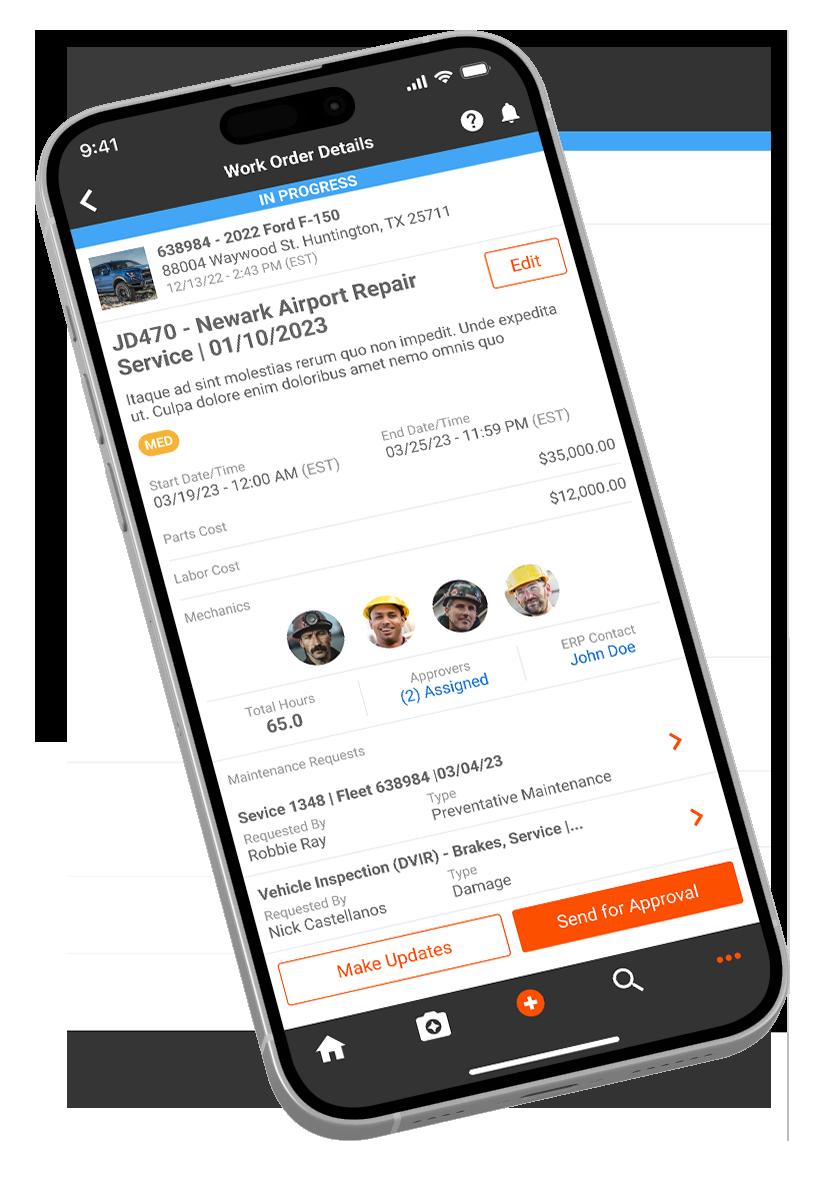

Revolutionary Mobile Devices & Interfaces

Construction software continues its evolution to harness the power of mobile apps to increase productivity and safety.

RUNNING THE BUSINESS

Construction Economy: What Does the Future Hold?

Business owners should continue to expect high prices and need to keep a close eye on their balance sheets in upcoming quarters.

BRIDGING THE GAP

Confront Labor Shortage With Refocused Training Effort

The best ways to deal with the industry’s labor shortage is by dialing in on training and investing in employees.

14

EARTHMOVING TRENDS

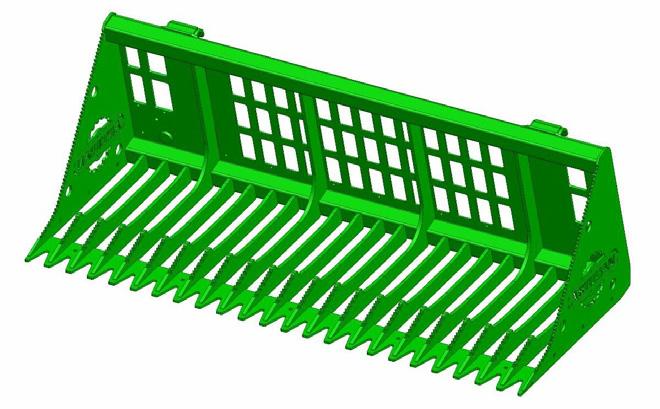

Skid Steer Tech Trends: Increased Use in New Applications

There will be a need for both diesel and electric equipment for years to come, and a variety of factors are pushing the use of skid steers into new applications.

EARTHMOVING TRENDS

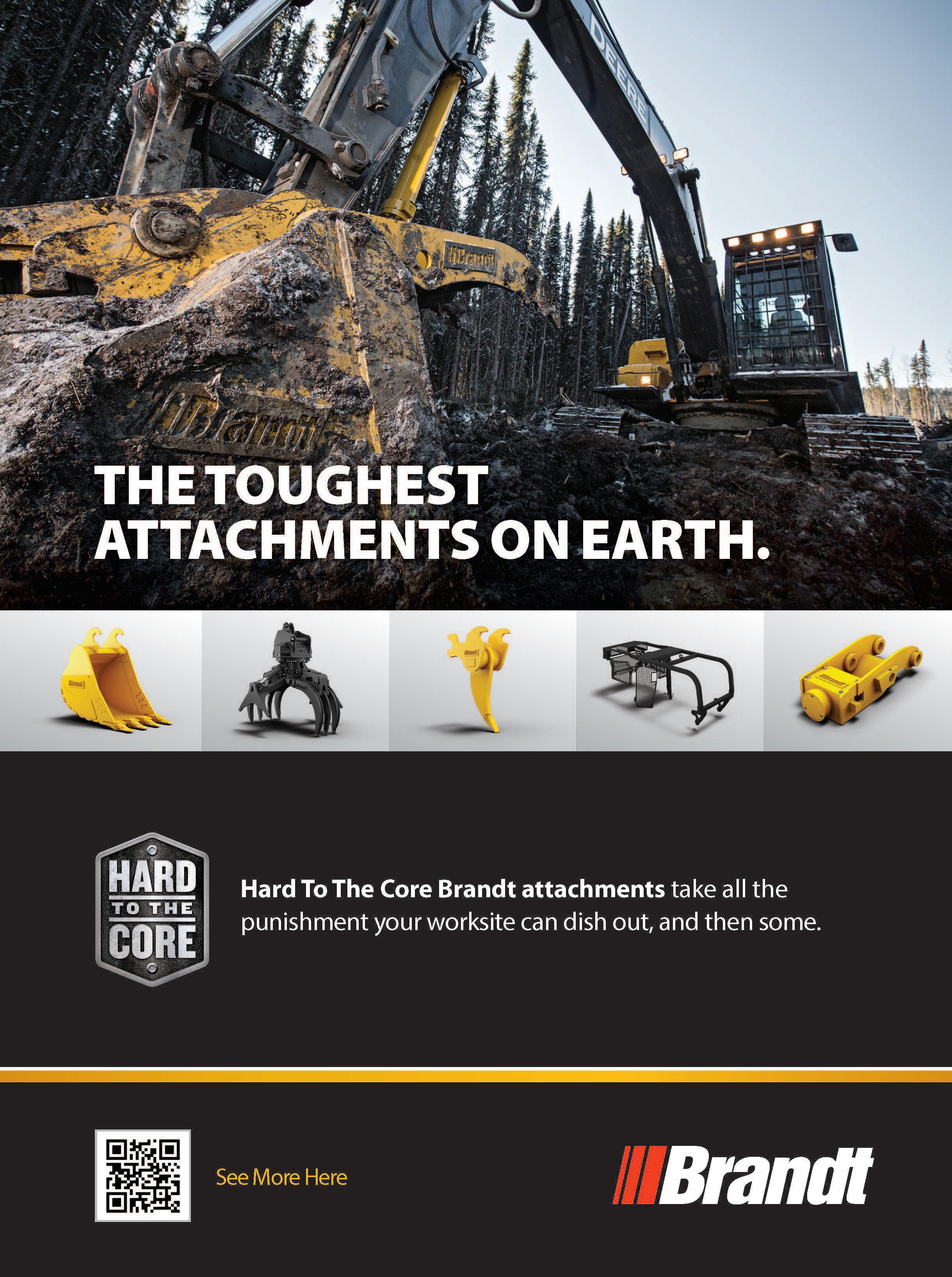

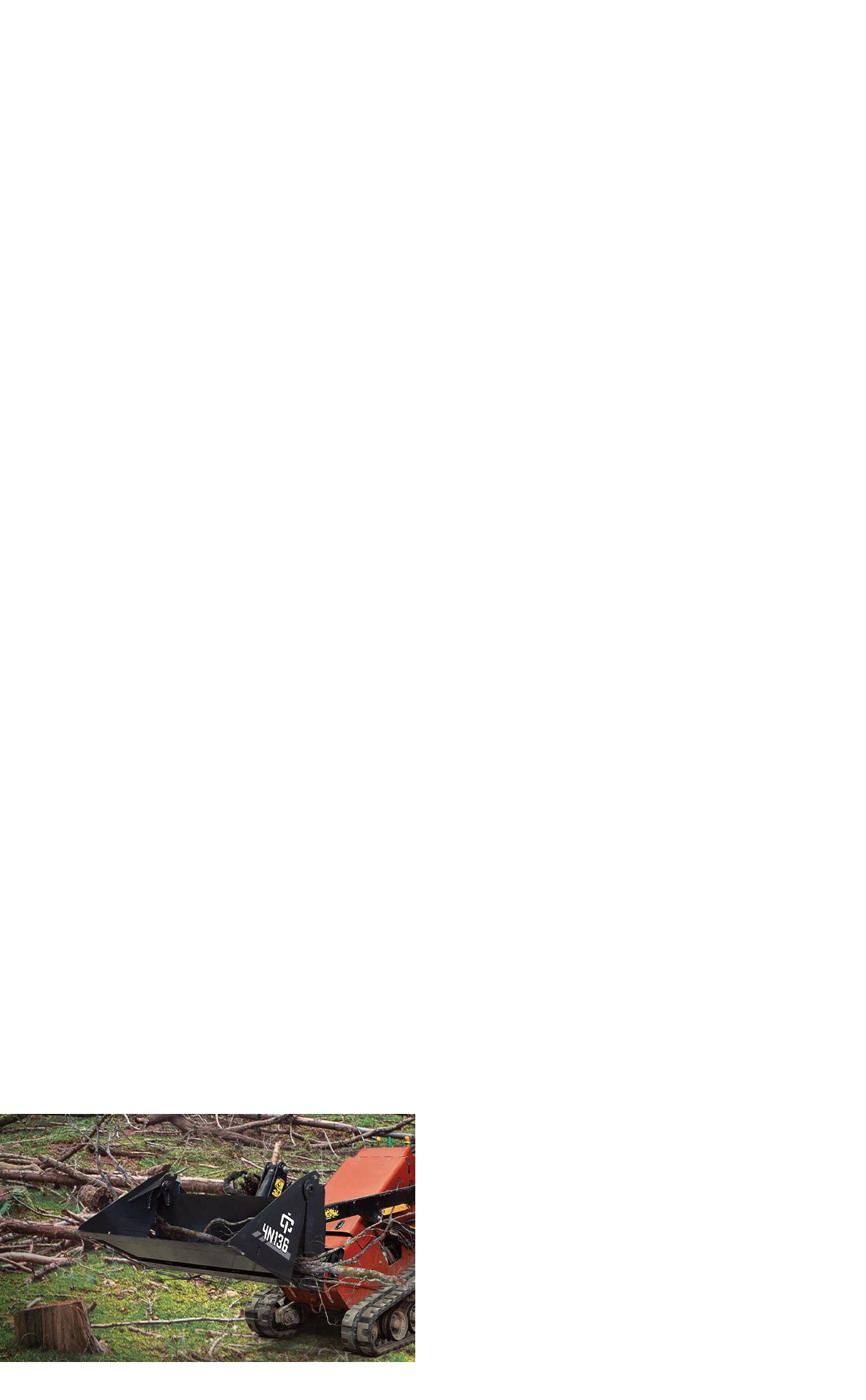

Attachment Safety 101

A big factor in attachment safety is ensuring that attachments are well taken care of and maintained.

EARTHMOVING TRENDS

20

Efficiency Extraordinaires: Streamlining Snow Operations

Snow removal professionals describe how they best prepare in season and out of season for whatever snow events come roaring their way.

EQUIPMENT MANAGEMENT

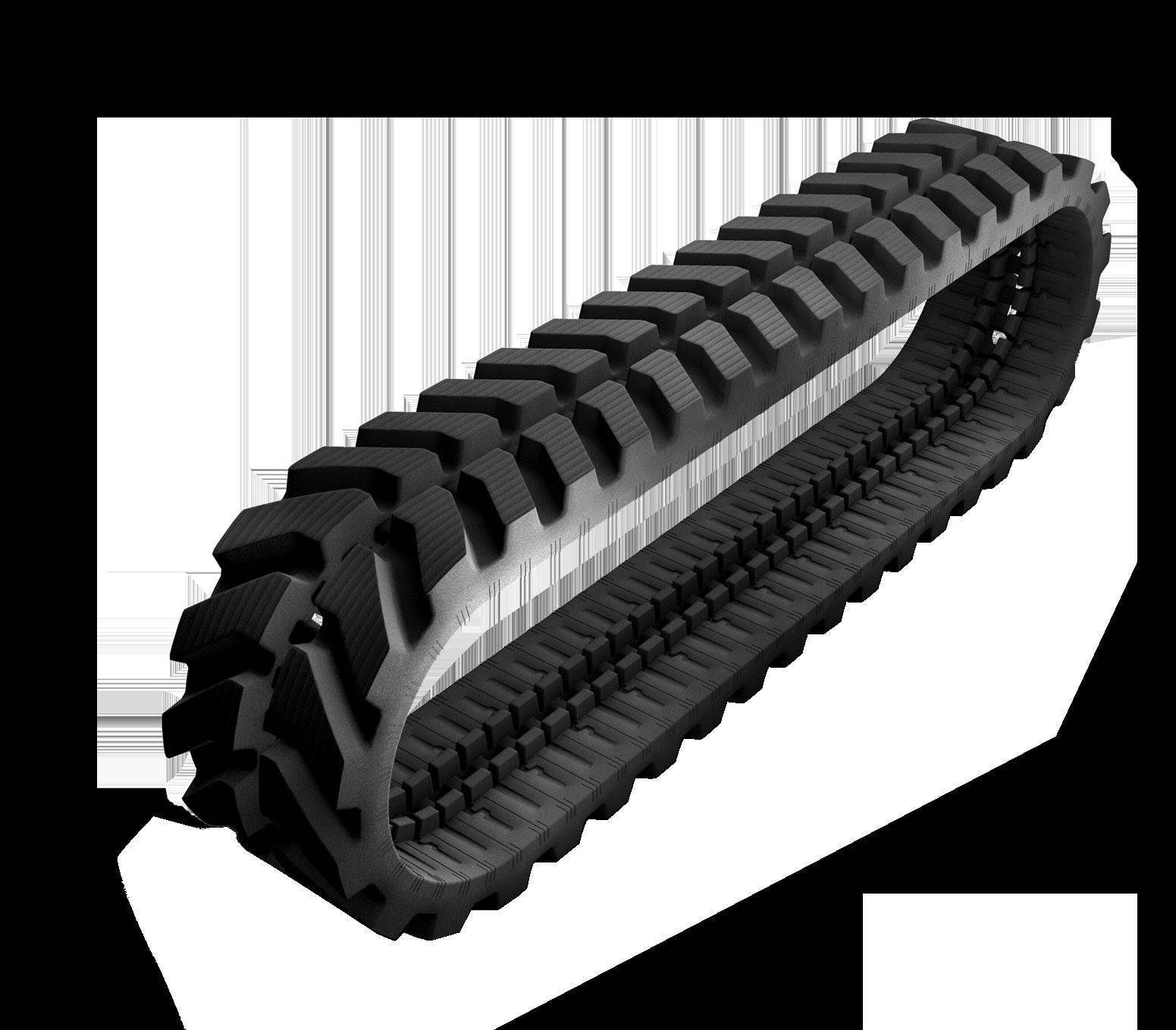

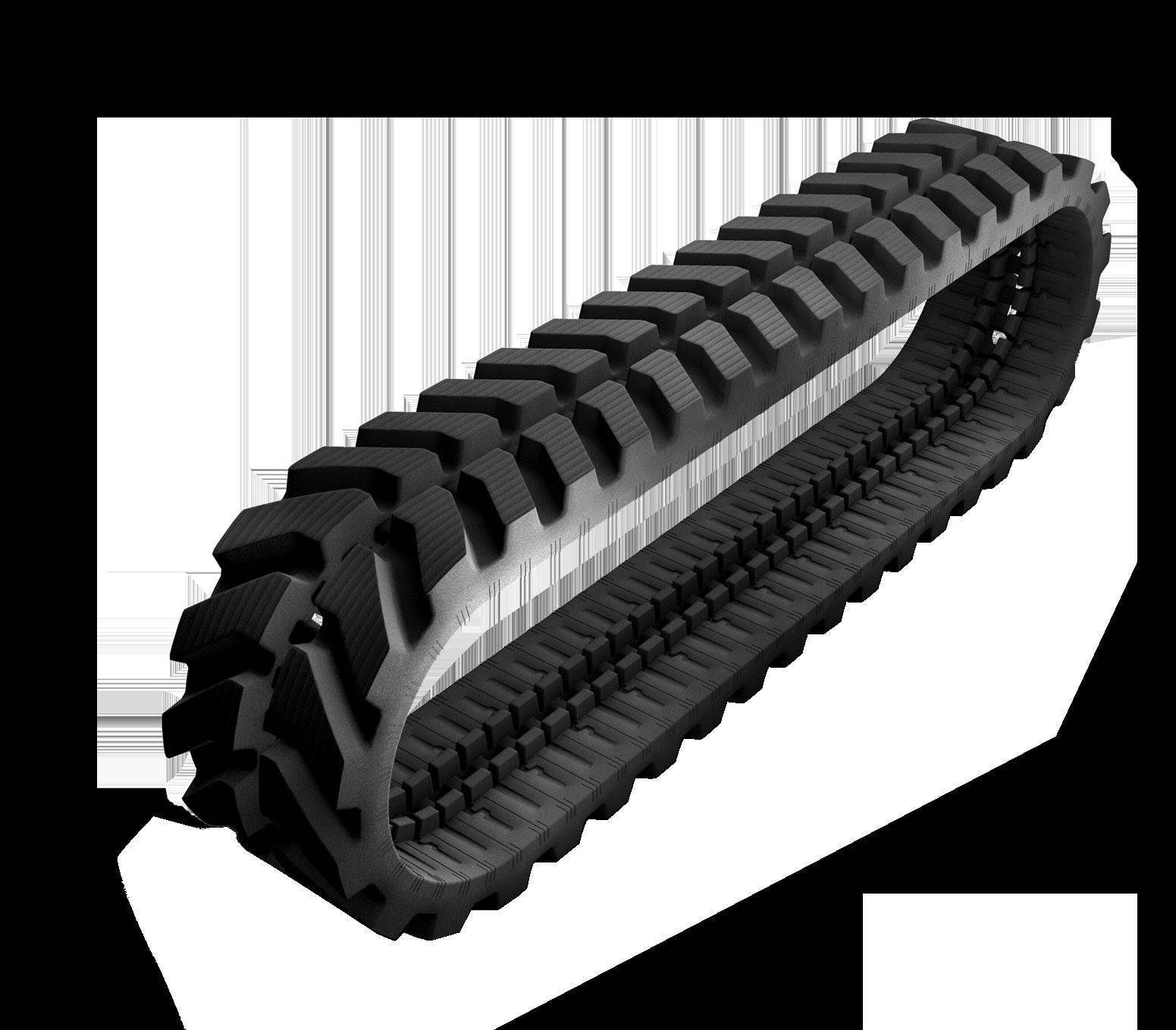

Heavy Equipment Undercarriage & Track Advancements

Tread designs and rubber compounding define recent trends, leading to longer-lasting, smoother running tracks.

EQUIPMENT MANAGEMENT

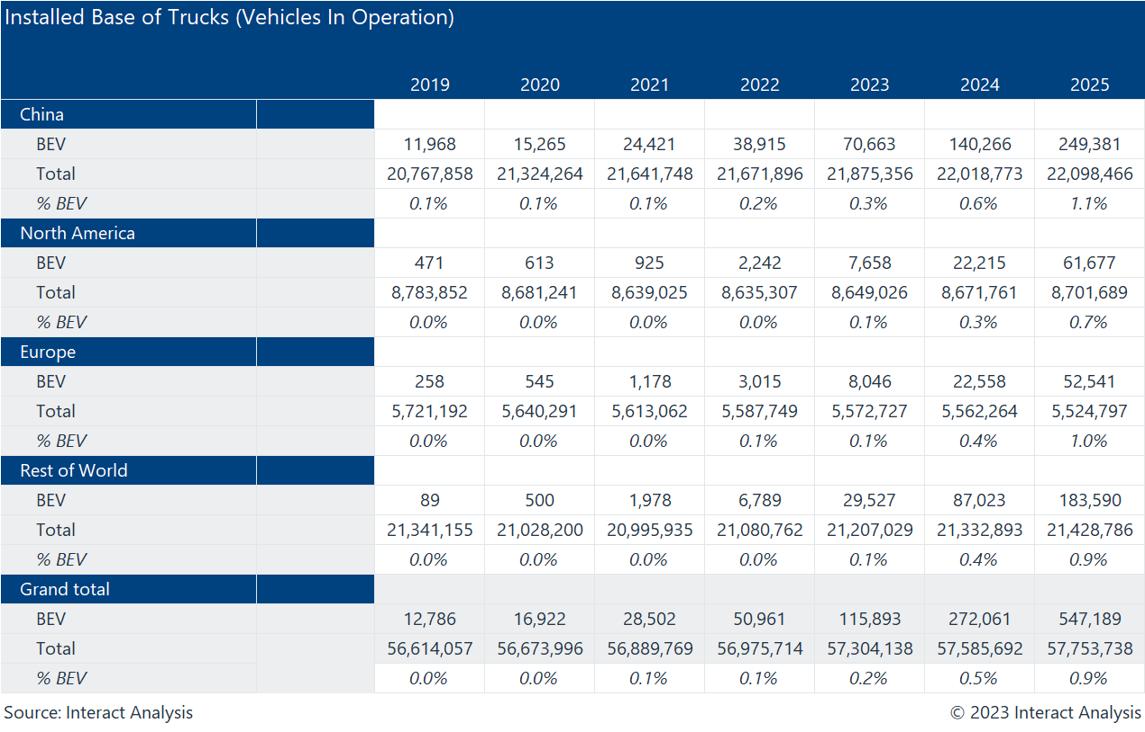

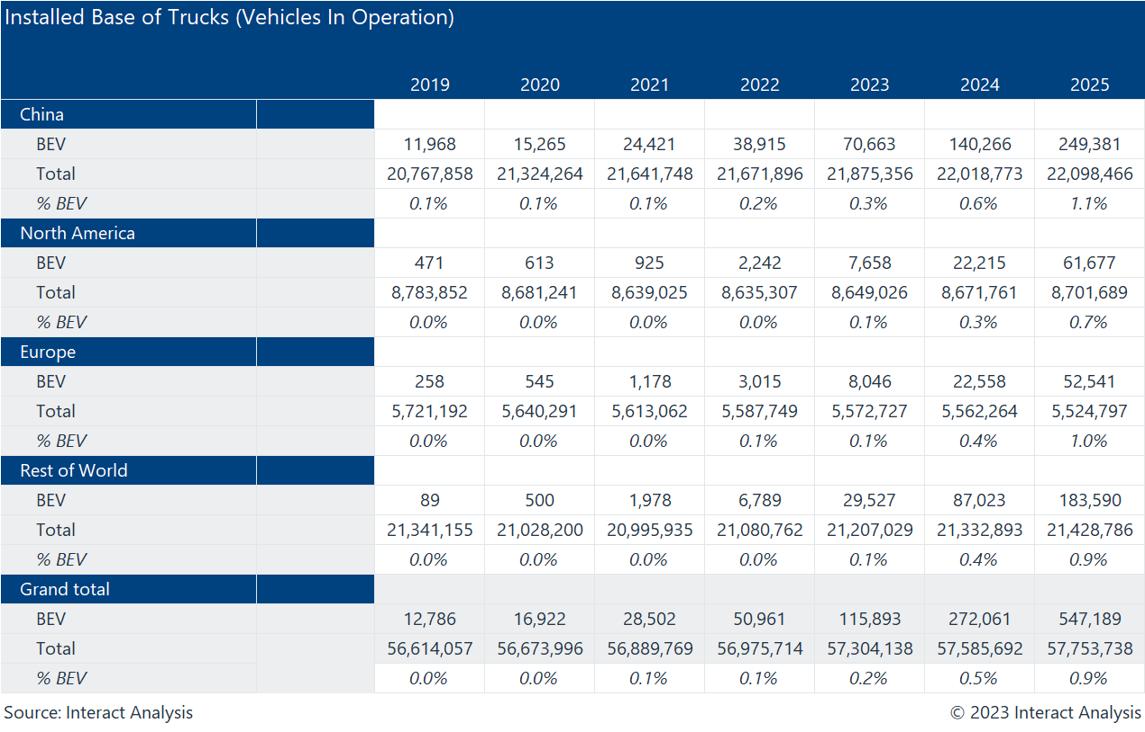

Zero Emission Machines to Shake Up Oil & Lubricant Industry

Change is underway in the vehicles oil and lubricant industry as a result of the inexorable move toward zero emission vehicles, in particular battery-electric machines.

EQUIPMENT MANAGEMENT

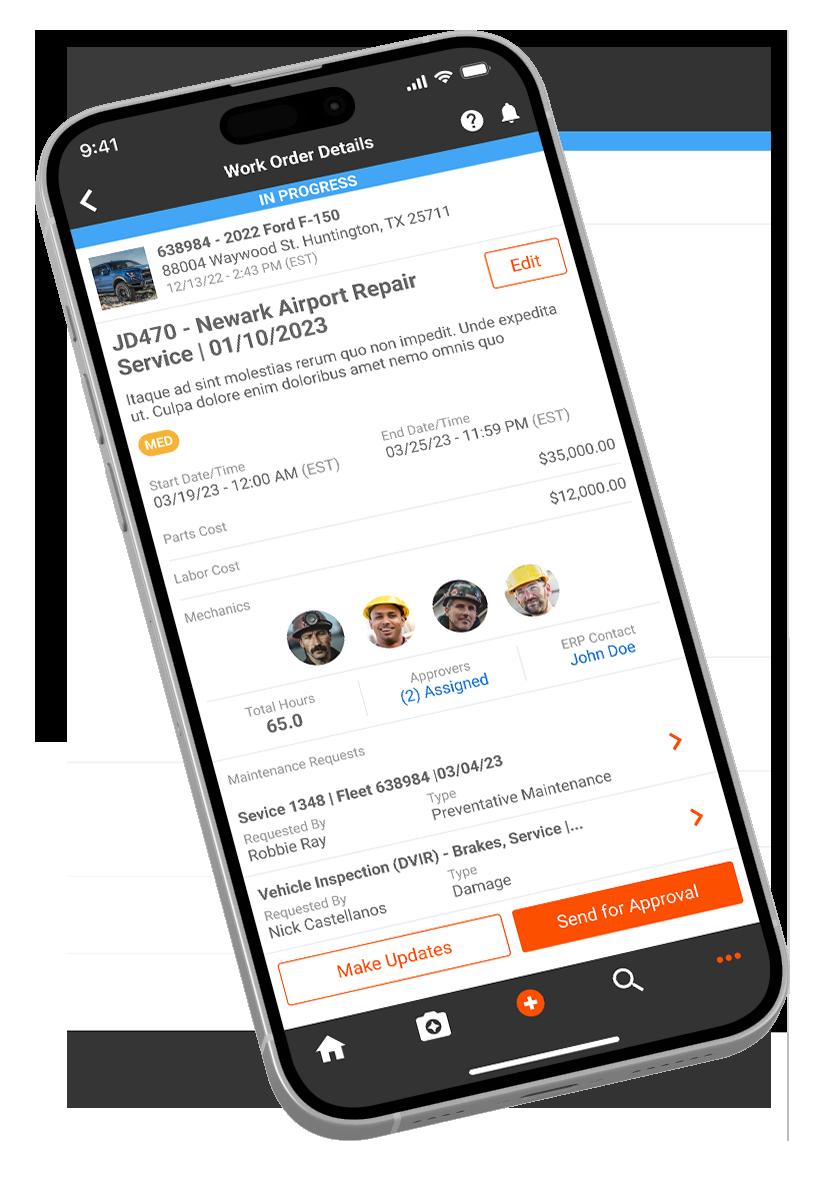

The Value of Proactively Planned Fleet Maintenance

Planned maintenance is very valuable—maximizing fleet performance and equipment longevity while reducing downtime and operation costs.

TECHNOLOGY

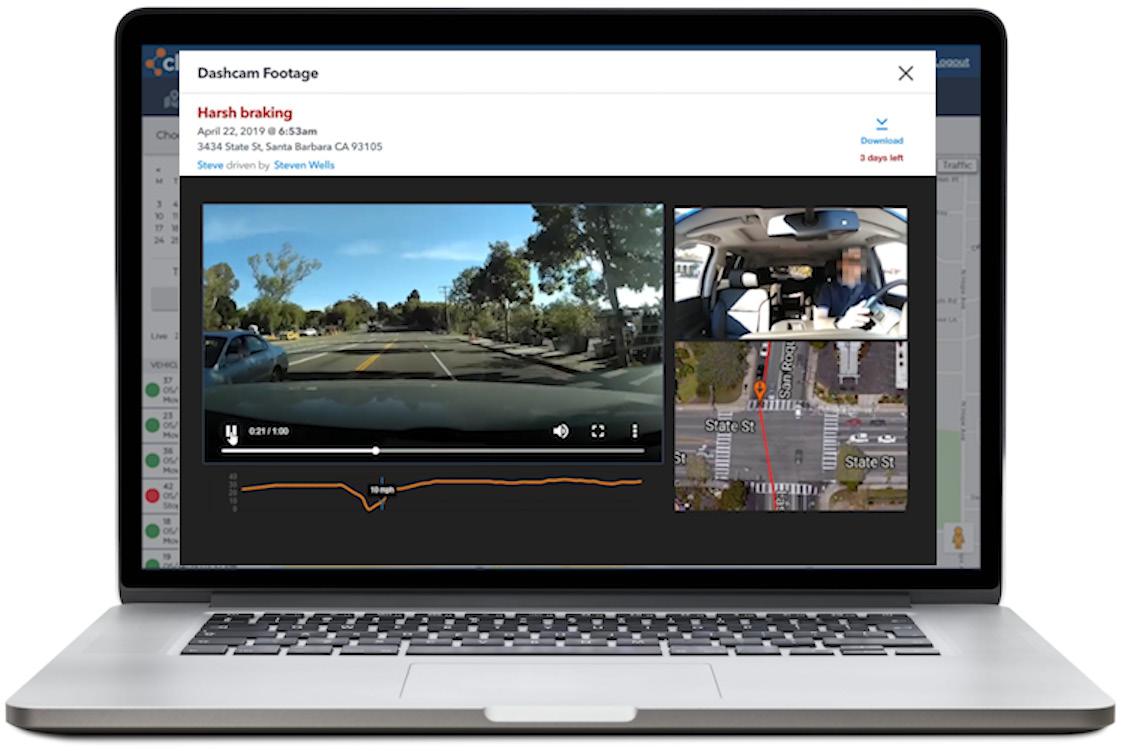

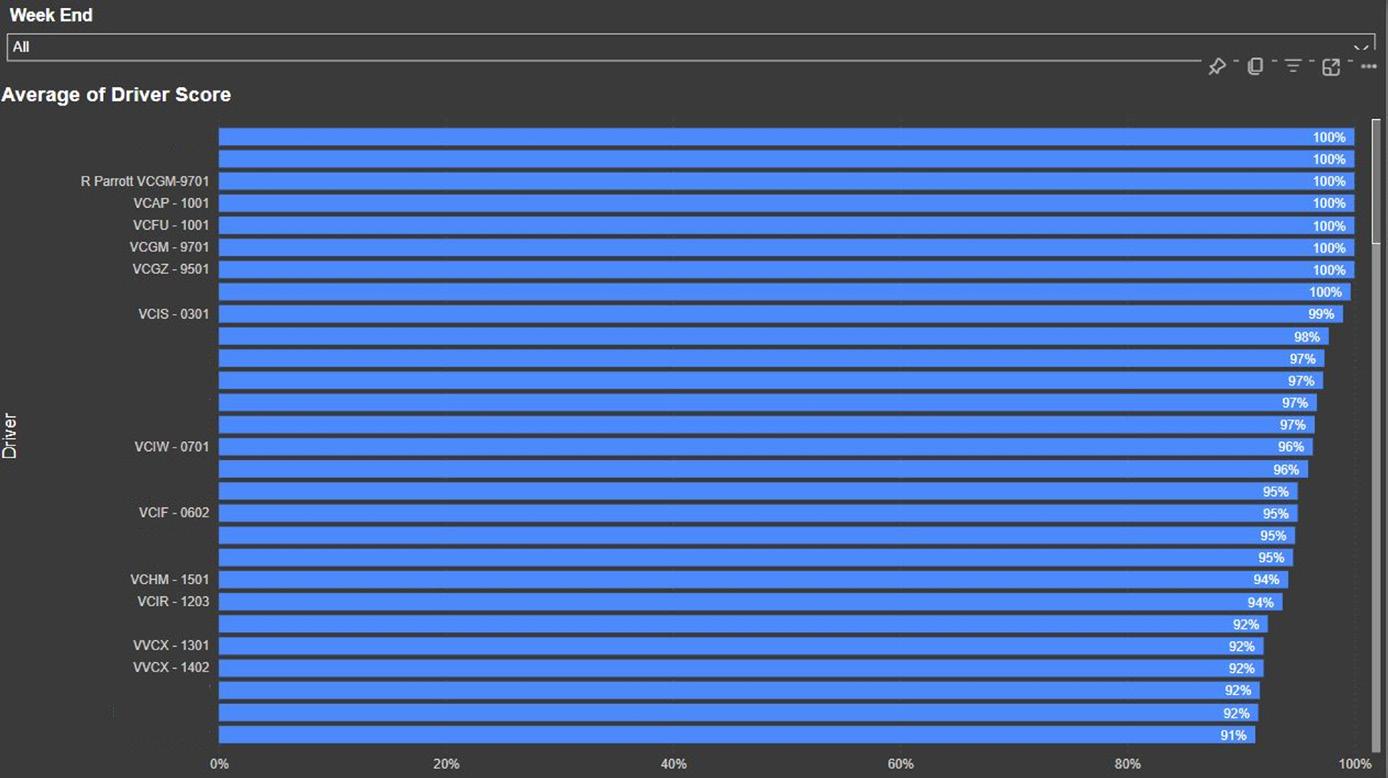

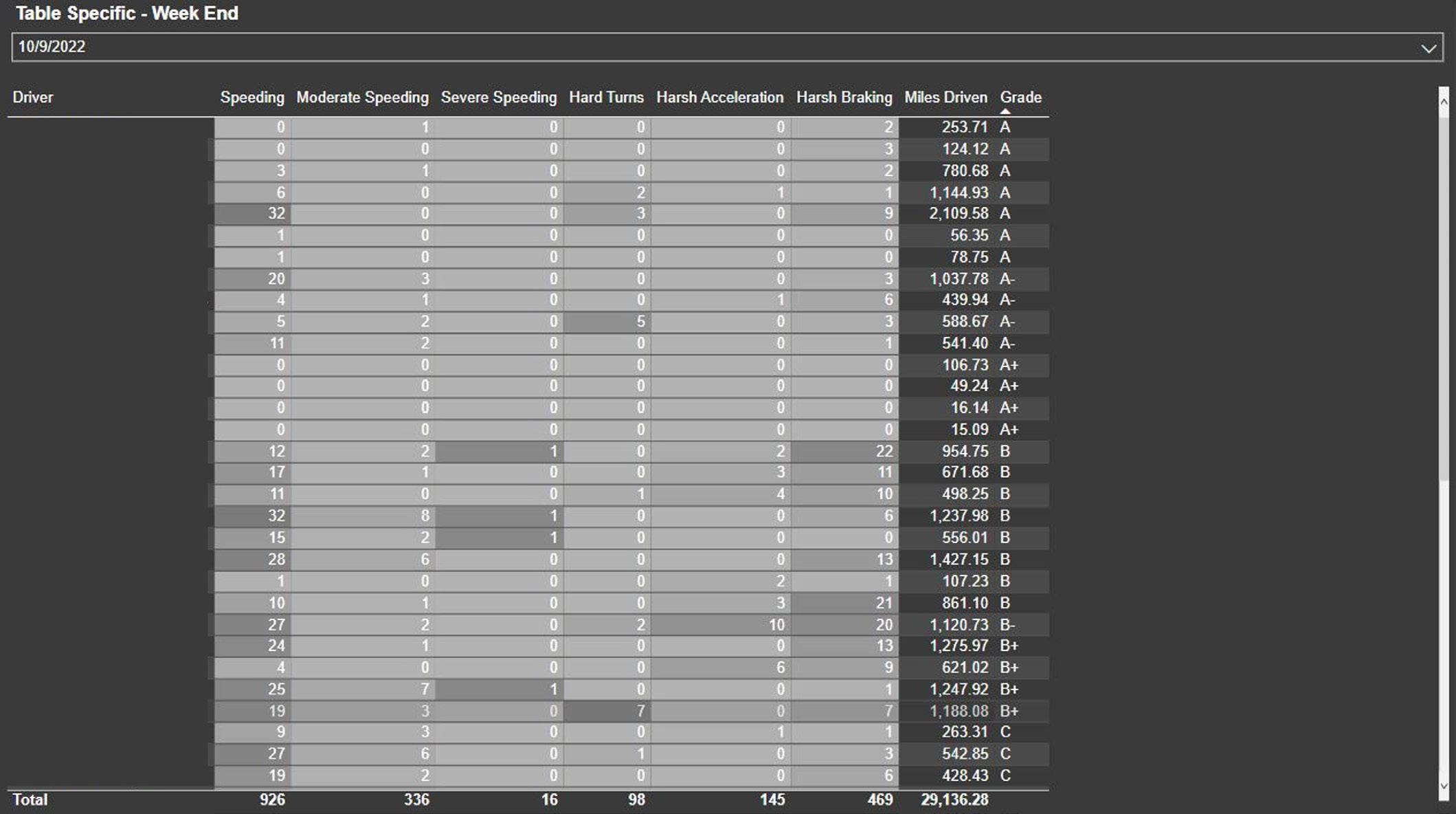

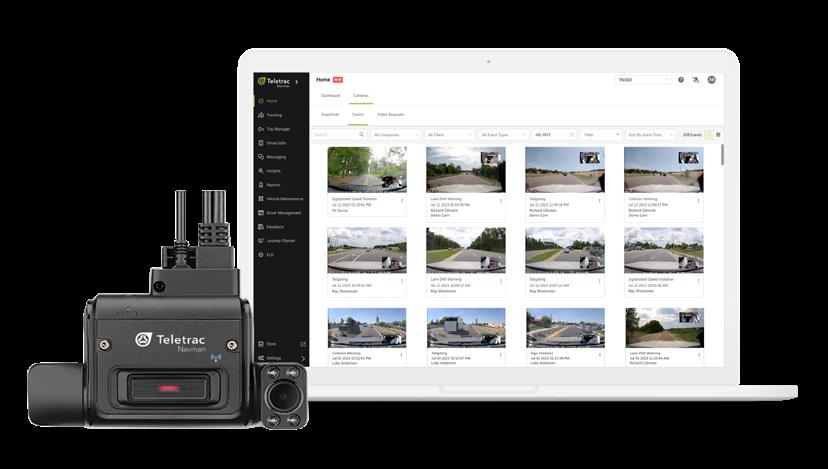

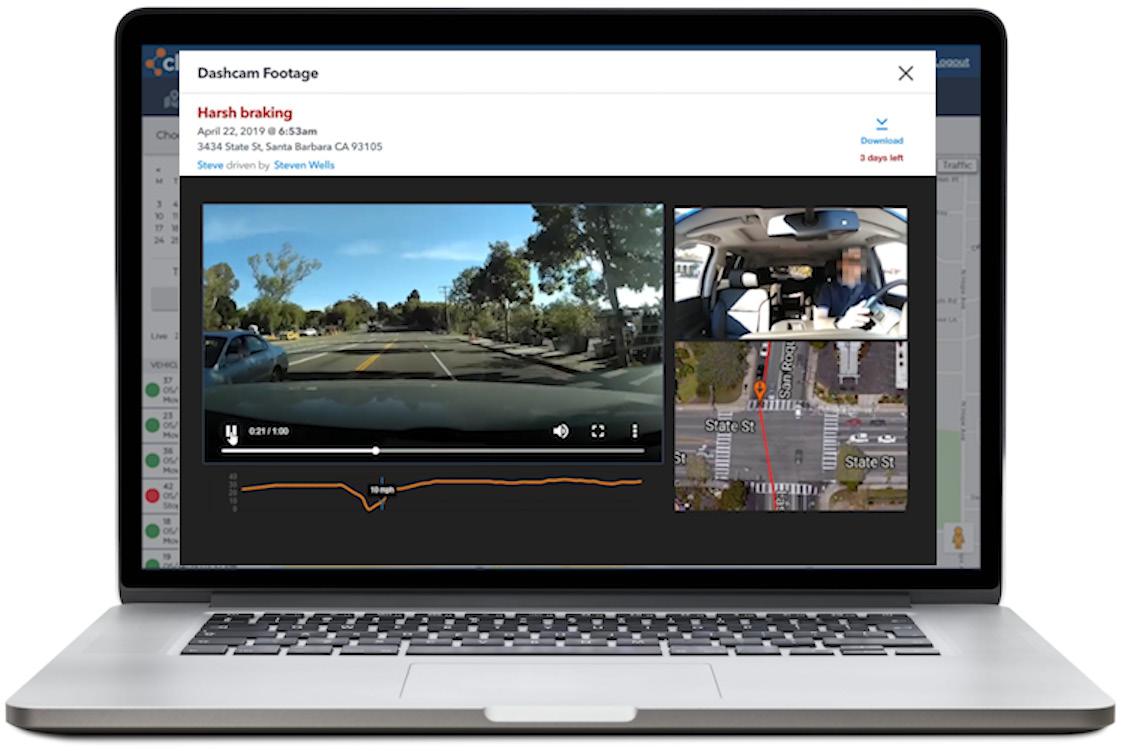

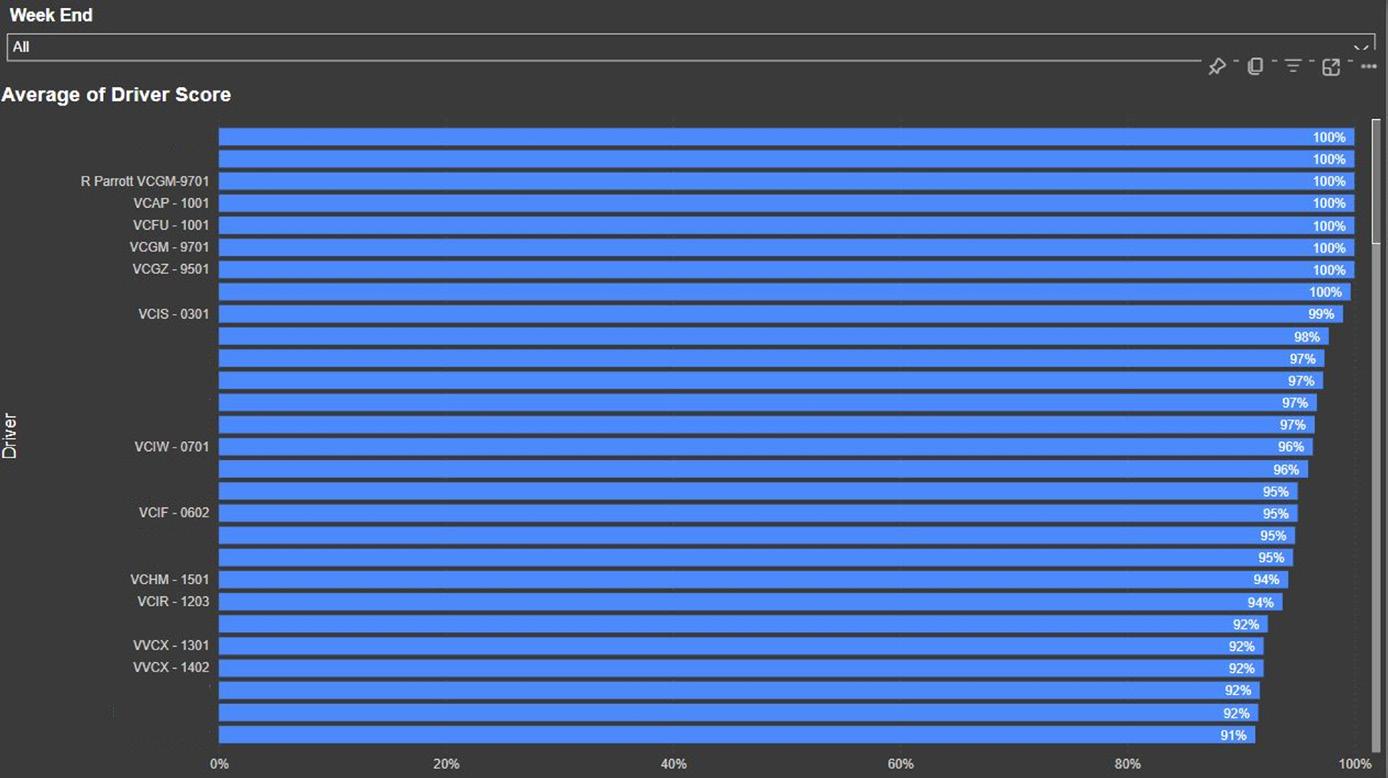

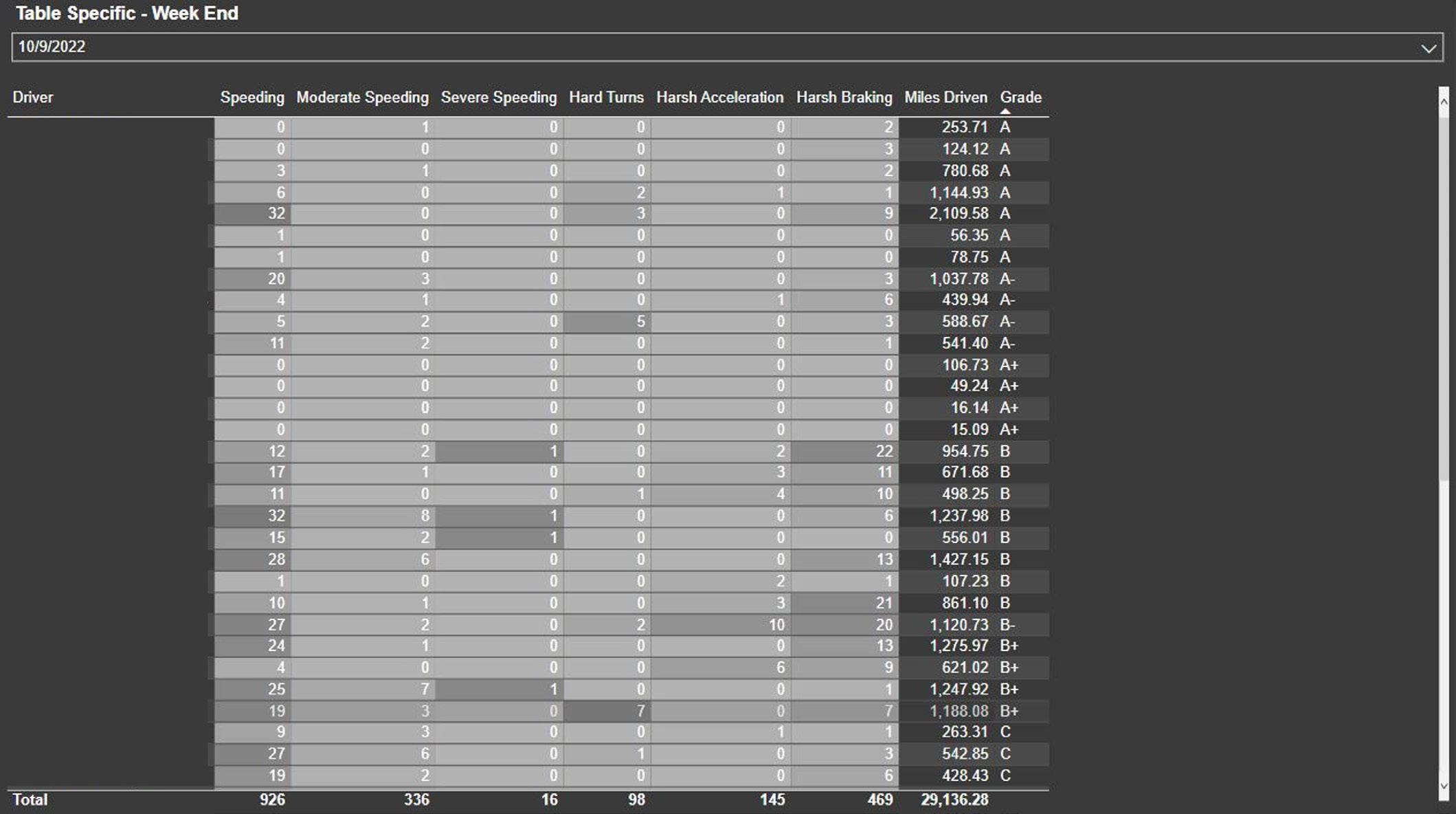

Georgia Contractor Reins in Driver Behavior With Telematics

Decreases in speeding and hard braking events and improved truck spacing were just some of the wins for this company.

TECHNOLOGY

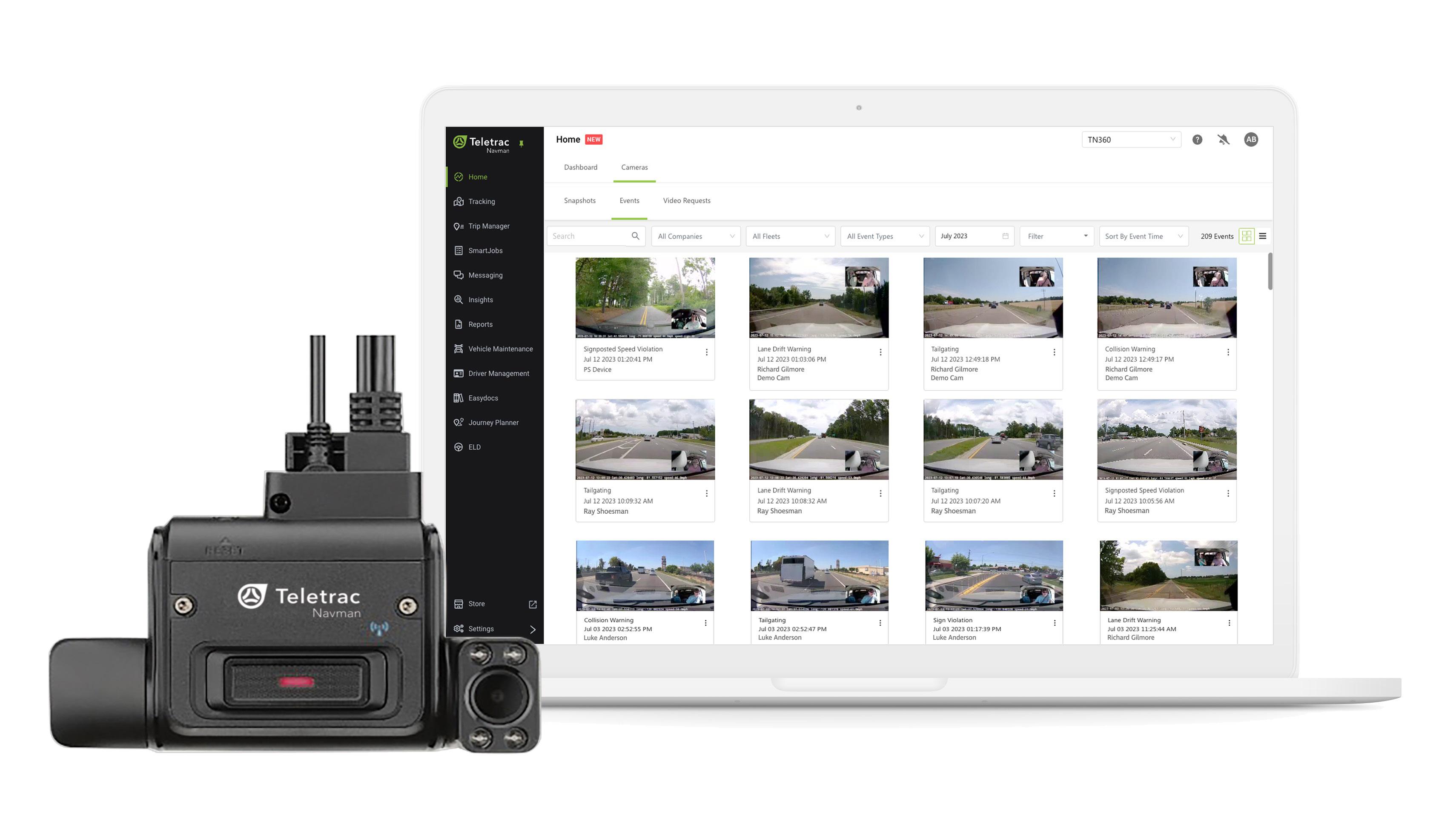

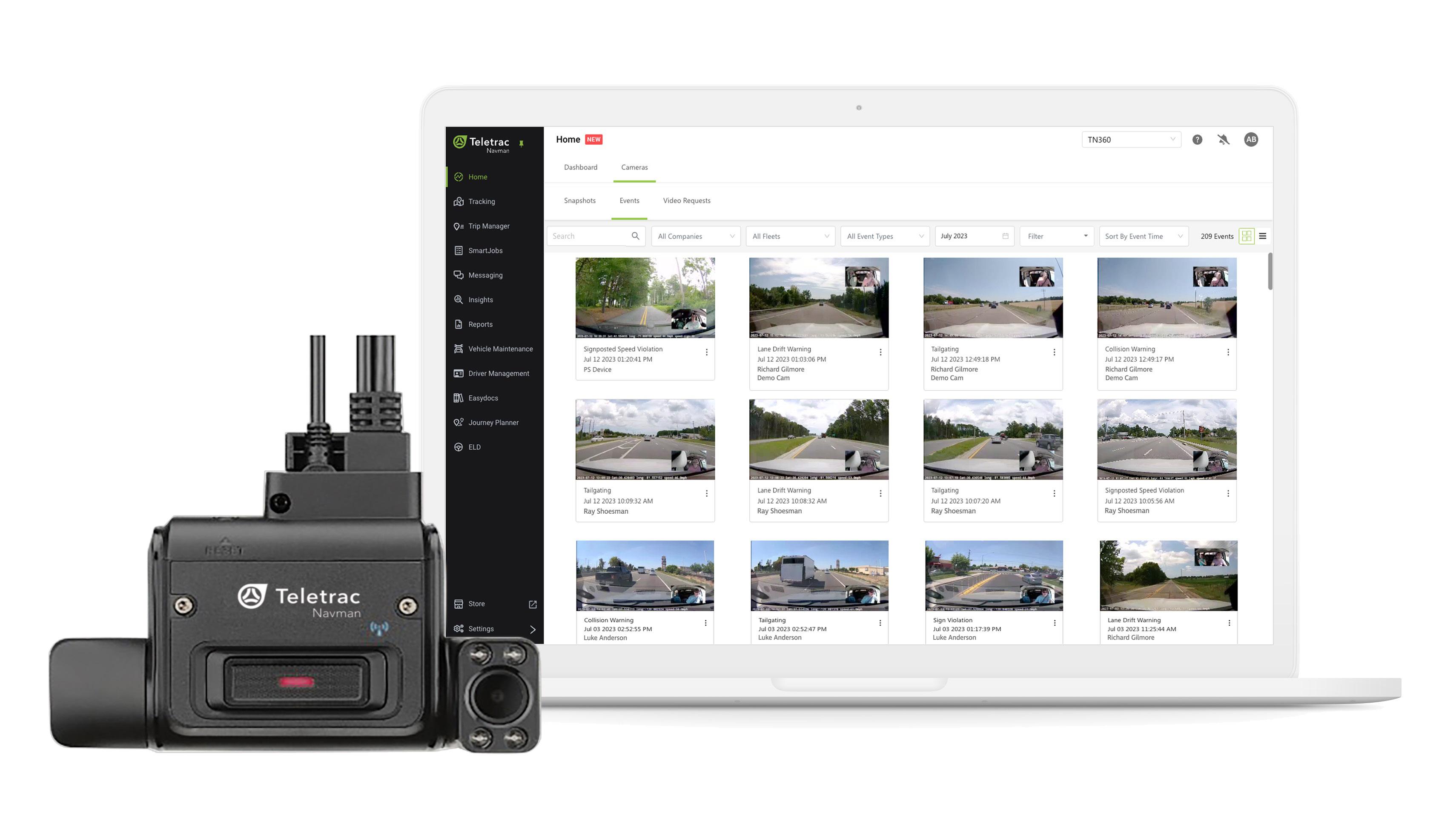

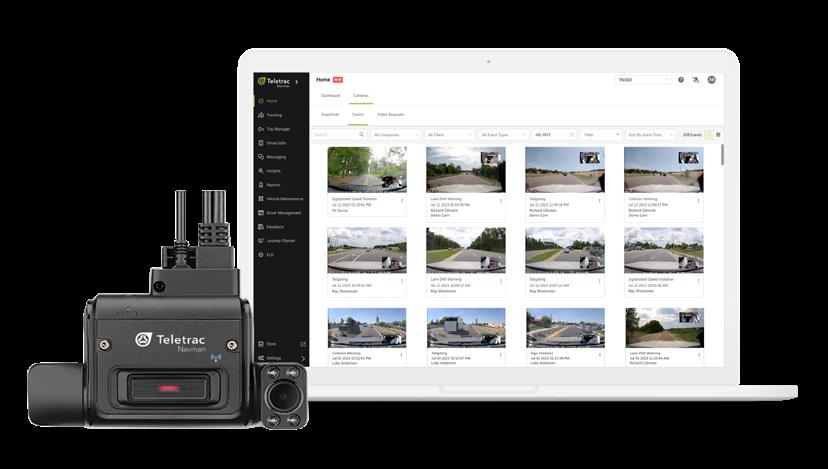

Beyond Dash Cams for Construction Equipment Fleet Management Software

How Teletrac Navman sits as the market for GPS-enabled fleet management and telematics splinters into subcategories

TECHNOLOGY

Antifragility Explained: 5 Ways to Build Agile Construction Companies

PRODUCT ROUNDUPS

EARTHMOVING TRENDS

The latest in skid steers and attachments.

EQUIPMENT MANAGEMENT

Engines, trailers and fleet management solutions.

TECHNOLOGY

Tech advancements for the industry.

WEB EXCLUSIVES

October 2023 | EQUIPMENT TODAY 3 www.ForConstructionPros.com/Equipment Contents www.forconstructionpros.com/equipment October 2023 | Vol. 59 No. 10 Published and copyrighted 2023 by AC Business Media Equipment Today makes every effort to report manufacturers’ product news accurately, but is not responsible for validity of news claims. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. and Canada to management, engineering, supervisory, equipment maintenance and other personnel who have buying influence in the construction equipment industry. Subscribe online at www.ForConstructionPros. com. Publisher reserves the right to reject non-qualified subscribers. One year subscription to non-qualified individuals: U.S. $50; Canada/Mexico $70; all other countries $100 (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10 each (U.S., Canada & Mexico), $15 each (International). For change of address or subscription information call (847) 559-7598 or fax (847) 291-4816. Equipment Today (USPS 369-290, ISSN 0891-141X) is published is published 12x with issues of January, February, March, April, May, June, October, August, September, October, November and December by AC Business Media, 201 N. Main St. Ste 350, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional entry offices. POSTMASTER: Please send change of address to Equipment Today, PO Box 3605, Northbrook, IL 60065-3605. Printed in the USA. Canada Post PM40612608. Return Undeliverable Canadian Addresses to: Equipment Today, PO Box 25542, London, ON N6C 6B2. PREMIUM CONTENT https://eqtoday.co/9pd73s

https://eqtoday.co/s7sfkm

NETWORK https://eqtoday.co/k2p285

DIGGING DEEPER PODCAST

VIDEO

4 6 12 46 48 49

22 34 44

10

18

26

Five actionable takeaways for how you can build an antifragile organization that wins more bids. 32

30

36 40 42

FEATURES

Lori Ditoro Editor-in-Chief Equipment Today

Iattended the collocated Battery Show and Electric & Hybrid Vehicle Exposition in Novi, Michigan, the second week of September. What a great gathering of experts, suppliers and attendees.

From humble beginnings, this year’s show had more than 15,000 attendees and 800 exhibitors. Because of the exponential growth, next year’s show will move from the Suburban Collection Showcase in Novi to the larger Huntingdon Place in Detroit.

One company that we spoke with, Zerotech, produces modular, customizable batteries for the construction industry and other off-highway applications. The battery packs can be combined to reach most required kilowatthour specifications. The company also has 12,000 customization options.

The Battery Show’s success ties directly to the topic of this month’s cover story, “Power Prospects” on page 8, which discusses the many power choices available today to

help decrease emissions. This includes battery power but also alternative fuels and hydrogen.

Another feature this month that connects with battery power is “Skid Steer Tech Trends: Increased Use Expected in New Applications” on page 14. It discusses electric and automation trends in these important machines.

Finally, “Heavy Equipment Undercarriages & Tracks Advancements” on page 26 covers crucial tracks and undercarriages in that keep equipment running optimally. Often underappreciated, this technology is increasing uptime and improving operator comfort and safety.

As we plan our editorial for 2024, email me at lditoro@ acbusinessmedia.com with any topics you would like us to include. We value your input.

EDITORIAL

Editor-in-Chief Lori Ditoro lditoro@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction

Technology, IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

Senior Editor, Equipment & Workwear, IRONPROS Michael Cheng mcheng@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Kimberly Fleming kfleming@acbusinessmedia.com

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Patty Maroder, pmaroder@acbusinessmedia.com

Sales Representative Megan Perleberg mperleberg@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Marketing, Marketing Services Jess Lombardo

Director, Demand

&

Jim Bagan

LIST RENTAL Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS & LICENSING

Assoc. Brand Director Nikki Lawson nlawson@acbusinessmedia.com

lditoro@ACBusinessmedia.com E @EquipmentToday D @EquipmentToday C @equipment-today-magazine-official Q @equipmenttoday

BREAKING GROUND

Generation

Education

CIRCULATION & SUBSCRIPTIONS PO Box 3605 Northbrook, IL 60065-3605, Phone: (877) 201-3915 Fax: (847)-291-4816 circ.EquipmentToday@omeda.com

® Published by AC Business Media 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 www.ACBusinessMedia.com www.ForConstructionPros.com/equipment www.IronPros.com Today’s Alternative Power Trends Are the EQUIPMENT OF THE FUTURE The floor’s growth and increased attendees moves The Battery Show and Electric & Hybrid Vehicle Exposition to a larger venue. Editor-in-Chief

Ditoro

Account Executive

Lori Ditoro Lori Ditoro

Lori

and

Greg Schulz talk with Xerotech’s Jesse Morris about the company’s battery packs.

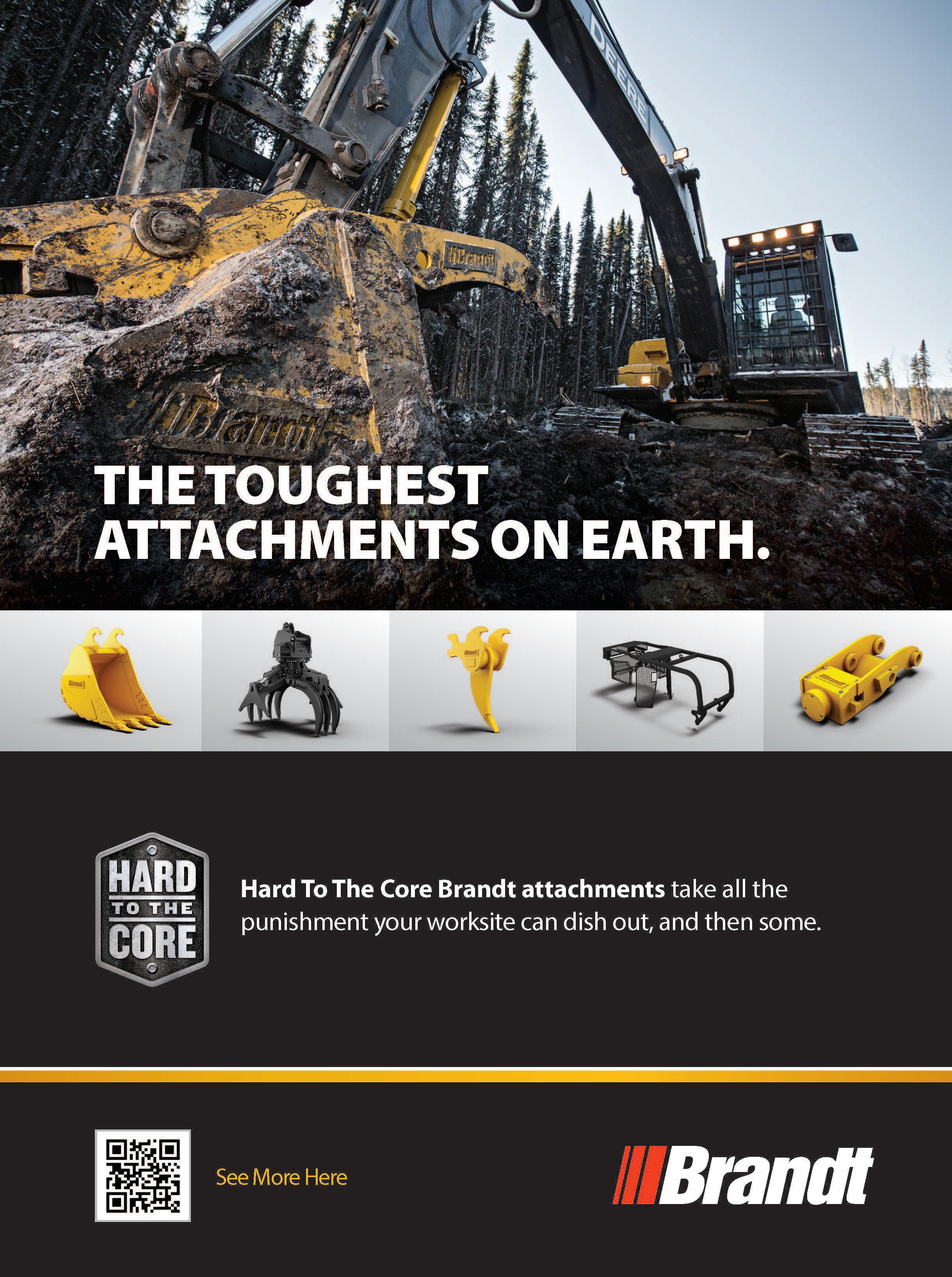

WE HAVE AN ATTACHMENT FOR THAT ® . ACCOMPLISH MORE WITH BOBCAT ATTACHMENTS.

® attachments bring you more capabilities, more productivity and more potential opportunities to expand your business. If you have the will to take on new challenges and major projects, Bobcat has the way. Bobcat Company is a member of the Doosan Group. Doosan is a global leader in construction, grounds maintenance and material handling equipment, power and water solutions, and engineering that has proudly served customers and communities for more than a century. Bobcat ®, the Bobcat logo and the colors of the Bobcat machine are registered trademarks of Bobcat Company in the United States and various other countries. ©2023 Bobcat Company. All rights reserved. BOBCAT.COM

Bobcat

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

Milwaukee Tool MX FUEL 36-in. Walk-Behind Trowel

With 5-hp performance, the 36-in. power trowel has a maximum blade speed of up to 130 rpm. The MX FUEL REDLITHIUM FORGE HD12.0 Battery Pack allows the 36-in. trowel to deliver up to 25 minutes of run-time, approximately panning

2,000 sq.-ft. or finishing 500 sq.-ft. over five passes. The new MX FUEL Super Charger provides 2x faster charging speeds, charging the REDLITHIUM FORGE HD12.0 battery pack in 65 minutes to 100% charge. The battery pack and new MX FUEL Super Charger are COOL-CYCLE capable, an Active Cooling System that provides cooling.

Read More at www.forconstructionpros.com/22738343

Western Global Top Tote

The Top Tote can be attached to the top of a TransCube Global fuel tank for a 2-in-1 diesel and diesel exhaust fluid (DEF) solution. This storage tank can help operations meet DEF requirements for Tier 4 Final engines. The Top Tote has a lowprofile design to keep the overall height below 6 ft. to eliminate using a ladder or harness to access the ports. This DEF storage solution has a capacity of 110 gal. and can attach to three models of TransCube Global fuel tanks — the 20TCG, 40TCG or 50TCG. This is an advancement for end users because it creates a 2-in-1 storage solution that holds both DEF and diesel at the same time.

Read More at www.forconstructionpros.com/22833625

Werk-Brau Tilt Bucket Attachment

Werk-Brau has introduced the Tilting Bucket attachment with increased tilt force and 45 degrees of tilt in both directions. The attachments are designed to minimize machine repositioning which reduces wear and tear on the tracks and undercarriage. An oversized cylinder design increases tilting force, allowing the unit to hold the desired angle. Integrated cylinder guards protect the cylinders and keep them functioning without damage or leaks. For compact excavators a single cylinder design is used, while full size excavators utilize dual cylinders. The heavy-duty excavator bucket is built with high quality T-1 steel utilized in critical or high wear components, with a rigid top section to eliminate flexing.

Read More at www.forconstructionpros.com/22864879

EDCO Two Person Post Hole Digger

EDCO offers the two-person post hole digger for a variety of construction projects. A compact design allows operators to drill in tight spaces or around obstructions. Heavy-duty composite resin handlebars provide stability. This machine is powered by a gasoline engine. During use, the auger generates 177 ft. lbs. of torque at 140 rpm. The auger measures 53 in. in length with a 29-in. width. Available accessories include 8- and 12-in. auger bits for meeting specific drilling requirements.

Read More at www.forconstructionpros.com/22869437

John Deere 510 P-Tier Excavator

Coming in at 51-metric tons, the 510 P-Tier is a replacement of the current 470 P-Tier model. Including a variable undercarriage and the ability to handle buckets 5 yards and above, this new model will continue to deliver exceptional performance and capability in its class, while specifically targeting customer enhancements in operating costs and reliability. By using a more efficient powertrain, including the integration of E-fans, this new model provides customers up to 25% lower maintenance costs, 15% lower repair costs and 20% lower fuel consumption. This machine is designed to deliver performance to customers in mass excavation or deep underground applications while providing significant improvement in the cost of ownership.

Read More at www.forconstructionpros.com/22869569

Perkins 2806J-E18TAG1 ElectropaK Generator

Perkins has announced the launch of the 2806J-E18TAG1 ElectropaK generator, a new addition to the range of EU Stage V power offerings. The generator features a new engine that delivers a powerful package and integration, to meet the requirements of the electric power sector. By achieving ISO 8528-5 G2 performance, the 2806J provides load acceptance in a wide range of electric power applications. The 2806J produces up to 610 kVA at 50 Hz and is switchable to 60 Hz, delivering up to 625 kVA. The ElectropaK features a single, on-engine electronic control module (ECM) that simplifies wiring harnesses and installation, supports future diagnostics and is capable of integration with customers’ telematics solution.

Read More at www.forconstructionpros.com/22870091

Kleemann MOBIREX MR 100(i) NEO/NEOe

Kleemann presents the first family member of the new NEO line with the launch of the MOBIREX MR 100(i) NEO/NEOe Mobile Impact Crusher. Two versions of the new impact crusher are available. Depending on the application area, it can be run all-electrically with the drive concept E-DRIVE, as well as locally, free of CO2 emissions [MR 100(i) NEOe]. Alternatively, the machine is available with the diesel-direct drive D-DRIVE. The MOBIREX MR 100(i) NEO/NEOe can be used in a wide variety of applications. Operation in tight spaces on worksites or in frequently changing places of work is possible.

Read More at www.forconstructionpros.com/22871103

6 EQUIPMENT TODAY | October 2023 EQUIPMENT INTRODUCTIONS www.ForConstructionPros.com/Equipment

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

JohnDow Low-profile Fuel Carrytanks

JohnDow Industries (JDI) has announced the launch of three low-profile fuel Carrytanks: 40-gal. Gasoline Carrytank (JDI-AGT40), 40-gal DEF Carrytank (JDI-DEF40) and 58-gal. Diesel Carrytank (JDI-AFT58LP). Designed to fit in the bed of a pickup truck below the height of truck bed sides, these Carrytanks offer a durable and portable refueling solution for a range of applications, including construction, automotive and fleet operations. Features include: Crafted from linear polyethylene, fuel level gauge indicates the amount of fuel available in the tank, 12V transfer pump capable of delivering fuel at a rate of 10 gal. per minute and more.

Read More at www.forconstructionpros.com/22868914

MB Crusher MB-R800 Drum Cutter

The MB-R800 Drum Cutter enables precision cutting, as well as grinding compact materials, on construction sites. The MB-R800 can be used for railway, airport, underwater work, tunnels, pipelines and road work. This attachment features a 40-in. cut width and a pick force of 25,003 ft.-lbs. Designed for heavy machinery equipment, the MB-R800 offers an output torque of 10,000 Nm. Available accessories include a spare parts kit, fixed coupling, low set drum kit, full set drum kit, dust suppression kit, high oil temperature reducing device, as well as rock and asphalt pick kits.

Read More at www.forconstructionpros.com/22866831

SafeGauge SafeTest Wireless Pressure Transducer Series

SafeGauge offers the SafeTest PT Series for technicians to monitor high-pressure hydraulic and pneumatic systems up to 164 ft. (50 m) away. This solution is wireless, enabling individuals to inspect systems at safe distances. Available in various sizes, these kits can also be configured with a variety of pressure ranges to meet the requirements of various applications. Individuals can pair the kit with a wide range of accessories, such as specialized fittings and adaptors, extension hoses and magnetic bases to facilitate hands-free pressure testing. Available pressure range options include: one to five bar, 25 bar, 100 bar, 300 bar and 600 bar.

CM Labs Wheeled Excavator, Walkaround Inspection and Instructor Operating Station

Comprised of proprietary and patented algorithms, the simulation training is based on real data and authentic machine behavior that interact with their environment and materials just as they do in the real world.

New introductions will include the following.

˜ Simulation training for Wheeled Excavator: Focuses on situational awareness and reduces safety risks within a dense urban environment.

Training Pack includes heavyduty bucket and narrow tiltrotator with live attachment change exercise.

˜ Sneak peek of Walkaround Inspection featuring Excavator: Train for this step that directly impacts jobsite safety. Includes training on identifying and spotting issues on equipment.

˜ Support training programs with Instructor Operator Station: Enables trainers to monitor, assess and engage trainees via tablet or single workstation, personalized learning paths, updated metrics reporting, as well as new administrator functionalities.

Read More at www.forconstructionpros.com/22870416

Read More at www.forconstructionpros.com/22866046

VOTLEQ SKY 1000 Electric Mini Skid Steer Loader

The VOTLEQ SKY 1000 Electric Mini Skid Steer Loader can be used for material handling, transfer or lifting on construction sites. Equipped with rubber tracks, the SKY 1000 is powered by a 14.34 kW lithium-ion battery. The mini skid steer loader features a breakout force of 1,798 lbs. and a lifting force of 2,473 lbs. It can travel at a continuous speed of 2.8 mph forward and 2.5 mph reverse. Made in the U.S., this machine is compatible with more than 15 attachments, including both hydraulic and electric solutions, for added versatility. Operators can access several telematics capabilities, including GSM, GPS, speedometer and inclinometer.

Read More at www.forconstructionpros.com/22872269

Screening Eagle Profometer PM8000 Lite

Screening Eagle offers the Profometer PM8000 Lite for locating rebar, allowing construction professionals to find safe and stable areas to drill. This product is the latest addition to the Profometer family and the successor to the Profoscope. Profometer PM8000 Lite is stand-alone with no wheeled cart or app connectivity. Operators can access a high-contrast OLED screen for viewing controls and rebar location information. Leveraging eddy-current technology, the tool features a 7.3-in. cover measuring depth and 2.5-in. rebar diameter measuring depth. The Profometer PM8000 Lite is powered by two, AA rechargeable or non-rechargeable batteries. This unit has a runtime of eight hours.

Read More at www.forconstructionpros.com/22871854

EQUIPMENT INTRODUCTIONS October 2023 | EQUIPMENT TODAY 7 www.ForConstructionPros.com/Equipment EQUIPMENT INTRODUCTIONS

These pages feature some of the latest equipment available. For more information on these products, use the QR code shown.

Legrand 11.5 kW Level 2 Commercial Electric Vehicle Charger

Legrand offers the Networked Level 2 Electrical Vehicle Charger for powering electric fleets and vehicles. Designed for commercial use, the 48-amp (11.5 kW) solution delivers a safe and reliable charging experience for users. A NEMA 3R rating enables the charger to be installed in outdoor locations and withstand exposure to water and debris. The Level 2 charging solution is compatible with 208-240V AC input power. This charger can be installed in parking garages, hospitality spaces, fleets, multi-unit dwellings, offices and more. The unit comes factory-configured with AmpUp, an EV charger operating system for drivers, fleets and station owners alike.

Read More at www.forconstructionpros.com/22872262

Elliott Equipment D47 Digger Derrick

The D47 features a 26,000lb. maximum lifting capacity, serving a range of lifting and material handling tasks. It also has a 17- to 26-ft. digging radius, making it capable of reaching difficult-toaccess areas. Standard features include 46 kV insulation, independent boom operation, transferable pole guide, line body and rear mounted hydraulic tool circuit. The D47 is also equipped with several features that facilitate operation and maintenance. These features include full pressure, open center hydraulic controls, hydraulic side load protection, a planetary swing drive and winch motor that are typically found on larger machines and a control console with high back air suspension seat.

Read More at www.forconstructionpros.com/22873045

DEVELON DD130 Dozer

Volvo CE Fluid Analysis Program

Volvo Construction Equipment is rolling out a new Fluid Analysis program. The service expands on its existing Oil Analysis program and now encompasses lubricants, diesel fuels, diesel exhaust fluid (DEF) and coolants. This new program will equip customers to take preventive action against contamination and wear. Fluid Analysis is Volvo CE’s first artificial intelligence (AI) platformdriven analysis to identify wear metals and contaminants or changes in fluid conditions. The new process uses data analysis to provide reports and insights to help customers make decisions. AI accelerates the testing process, allowing lab technicians to focus on more pressing issues such as analyzing abnormal or critical samples.

Read More at www.forconstructionpros.com/22872879

New Holland C330 Compact Track Loader

New Holland Construction has released the C330 Super Boom Vertical Lift Compact Track Loader in North America. Equipped with a 66-in. working width and a 67-hp engine, the C330 is designed with integrated elements such as low shoulder positioning and towers, supporting operator visibility and jobsite safety. The C330 vertical lift compact track loader features heavy load-carrying capacity to handle the transportation of substantial materials such as rocks, stone and timber. Leveraging electro-hydraulic control (E-H), the machine can navigate through tight residential spaces to pass through backyard gates and maneuver with ease between buildings. Featuring E-H controls, operators can transition between ISO and H-Pattern control, granting them full control over drive functions and attachments.

Read More at www.forconstructionpros.com/22872907

RIDGID K-4310 FXP Drum Machine

RIDGID has introduced the K-4310 FXP Drum Machine with a new cable counter that provides real-time, in-pipe cable distance for locating and diagnostics. Designed for residential and commercial plumbing and drain cleaning projects, its brushless DC motor spins at 230 rpm. Clearing 3- to 10-in. lines, the K-4310 FXP is powered by RIDGID’s new FXP Technology Platform that allows users to switch between battery and power adapters (in development). The Cable Counter feature helps professionals know where the cable is in the line as they are clearing blockages. The cable distance tracking feature allows professionals to always know where their equipment is located within the line.

Read More at www.forconstructionpros.com/22873096

The new mid-size 145.8-hp DD130 dozer is designed to do grading, leveling, site preparation and land clearing. Functionality is driven by the dozer’s six-way power-tilt angle blade. Operators can minimize the number of passes on each job by lifting, tilting and angling the six-way power-tilt angle blade to move dirt or other materials where they need to go. A two-way mechanical adjustment also allows operators to adjust the blade pitch from 52 to 58 degrees to control how steeply it bites into the ground. The DD130 comes standard with the oscillating serrated track system, which maintains consistent, stable ground contact for grading performance. The oscillating serrated track system follows the terrain and enables blade control. Also available is a blade float function for back grading. The dozer blade moves up and down following the contours of the ground. A blade shake button helps operators remove materials stuck to the blade without leaving the cab.

Read More at www.forconstructionpros.com/22872881

EQUIPMENT INTRODUCTIONS 8 EQUIPMENT TODAY | October 2023 www.ForConstructionPros.com/Equipment

POWER PROSPECTS

Diesel. Electric. Hybrid. Hydrogen. Deciding how to power heavy equipment no longer involves one choice, and many factors affect the method selected. The 2030 emission goals are seven years away, but the construction industry has already started to move toward them. Because the industry cannot flip a switch and change every piece of equipment in operation today, the process involves all fuel and power options. Original equipment manufacturers (OEMs) and contractors making improvements where they can today and planning for a cleaner industry tomorrow.

Optimized Diesel Engines

Diesel remains part of the solution for decreased emissions. While fossil fuels, in some cases, are slowly being phased out, millions of engines that operate on traditional fuels continue to be manufactured. During CONEXPOCON/AGG (CONEXPO) 2023, several manufacturers presented engines that

are optimized for fuel use efficiency and produce fewer emissions.

The Caterpillar C13D engine platform provides an opportunity for OEMs to downsize the engine and simplify the design, assembly and supply chain requirements. This consolidation can also reduce maintenance, parts and technical training complexity for end users, providing a lower total cost of ownership and operation. According to Dustin Childers, global marketing manager, Caterpillar Industrial Power Systems, the C13D also produces less noise and vibration.

The new engine platform offers up to a 20% increase in power and up to 25% more low-speed torque when compared to the previous generation of Cat engines in its power class. It is designed to perform at altitudes of up to 12,000 feet, twice as high as legacy Cat engines, and in extreme ambient temperatures as high as 140°F (60°C) and as low as -40°F (-40°C) with aids.

When sister publication OEM Off-Highway talked with Cummins

President and CEO Jennifer Rumsey, she discussed the zero goal. While she agrees that the move away from fossil fuels is the right direction, the industry is not there yet.

“Cummins built 1.2 million engines last year,” Rumsey said. “So, there’s a lot of engines going out into the field, ours and others, that will operate for many years.”

Electric Hesitancy often accompanies the conversation around construction equipment going electric. Among the concerns are:

˜ Having enough power and torque to do the work

˜ Keeping equipment charged

˜ Training operators and any changes in how the equipment is operated While these concerns are valid, OEMs are working to make sure all these problems are solved, particularly for larger machines.

During CONEXPO, Volvo Penta and Gradall shared a fully electric, highway-speed excavator that was

powered by a Volvo Penta electric driveline. The excavator will go through another year of testing before it is available.

The Volvo Penta team took a systems approach to this project and provided a complete system including batteries, motors and cabling. According to Darren Tasker, vice president, industrial sales, for Volvo Penta, the product will evolve over time. The Volvo Penta team is committed to science-based sustainability.

“At Volvo Penta we are firm believers that great projects begin with solid partnerships, and this collaboration with Gradall on the electric excavator is a prime example,” said Tasker. “Venturing into the realm of electromobility alongside Gradall marks a thrilling progression for both of us.”

“This nearly decade-long partnership, along with Volvo Penta’s full-system approach and expertise, made Volvo Penta the top choice for Gradall’s first step into

www.ForConstructionPros.com/Equipment COVER STORY | By Lori Ditoro, Editor-in-Chief, Equipment Today 10 EQUIPMENT TODAY | October 2023

The Gradall fully electric excavator with a Volvo Penta driveline.

PROSPECTS

electromobility. This was also Volvo Penta’s first electrification project in a construction application, and it paves the way for many more. Electrification will be one of the cornerstones in our transformation as we work toward meeting our goals of zero emissions by 2050.”

Here are the Gradall electric excavator electric driveline stats:

˜ The system will deliver 133 kilowatt-hours of energy

˜ Can reach full capacity in under 45 minutes from a 150-kilowatt charger.

˜ Powered by two Volvo Penta batteries matched to the duty cycle of the excavator, which fit into the engine bay

˜ Also includes the complete high voltage system (electric motors, gearboxes, inverters, junction boxes and cabling)

While much of Volvo Construction Equipment’s (CE) compact machines are electric, larger models are also moving in that direction. This includes the new Volvo EC230 excavator. Ray

Gallant, vice president — sustainability and productivity solutions, North America, Volvo CE, showed me the excavator and talked about the future of electrification in general and with Volvo CE.

With many companies focused on a goal of decreased emissions and fully electric inventory in some cases by 2030, we started with this aim.

“The goal is 2030, for a lot of this, but we spent 100 years building up the diesel infrastructure. Is that [goal] realistic?” Gallant asked.

Among the challenges of manufacturing electric equipment to perform in demanding construction applications is the fuel sources, including charging stations in remote locations. Gallant sees finding sources as the common challenge between all the power types.

“When we talk about alternative power, it’s a lot of different things. It could be electricity; it could be gridconnected; it could be alternate fuels; it could be renewable fuels; it could be hydrogen. So, the challenge unique or

in common with all of those is we need the fuel sources,” Gallant said.

Volvo has added a fully electric, medium-sized excavator, the EC230. The EC230 excavator is a 23-metric-ton excavator. It is one of Volvo’s heavier battery electric machines. It has an extendable battery pack and 264 kilowatt-hours of storage for 66-kilowatt-hour batteries.

Many other OEMs have electric machines, including Bobcat, CASE, Caterpillar, FIRSTGREEN Industries, HEVI, Hitachi, JCB, John Deere, KATO-CES, Komatsu and Wacker Neuson. If an OEM is not working on an electric machine today, it will be in the future.

Hydrogen & Other Alternative Fuels

According to Gallant and many others in the industry, electric power will not be the solution for all applications.

“Other technologies come into play … In my opinion, if we bring in multiple technologies in tandem or in

the applications where they fit, [that is ideal]. In our line are some heavier machines where a battery is just not practical. It would be too heavy, too expensive or too long to charge.

October 2023 | EQUIPMENT TODAY 11 www.ForConstructionPros.com/Equipment COVER STORY | By Lori Ditoro, Editor-in-Chief, Equipment Today

Lori Ditoro

The Caterpillar C13D

Caterpillar Industrial Power/Perkins

So, we go to other sources of power, alternate fuels, hybrids, gridconnected directly or even hydrogen to make that transition.”

To that end, many OEMs are manufacturing engines that can use multiple fuel types. This includes the

Cat C13D engine platform discussed earlier. It can operate using renewable liquid fuels, including:

˜ 100% hydrotreated vegetable oil (HVO)

˜ B100 distilled biodiesel

˜ Up to B100 standard biodiesel

Cummins displayed its fuelagnostic engine during CONEXPO. Cummins’ 15-liter diesel platform highlighted a practical route to emissions reduction and decarbonization for off-highway applications. It showed a common architecture optimized for low- and no-carbon fuels including biodiesel and HVO, renewable natural gas and hydrogen. All engines derive from the same base, providing parts commonality.

At CONEXPO, FPT displayed its range of engines, including the technology that operates on alternative fuels. The team is also working on a move to hydrogen and produced a 13-liter engine prototype last year.

Also at CONEXPO, DEUTZ CEO Sebastian Schulte discussed the need and desire to support and grow their classic diesel business, where the company produced 185,000 engines. The diesel engine range is 2.2 liters

to 18 liters. However, he knows that DEUTZ must look to the future. He said that a carbon-zero future includes a mix of power options: electric, alternative fuels, hydrogen fuel cells and hydrogen combustion. Schulte said he feels that hydrogen combustion is best for off-highway applications that require more power than battery electric energy can provide.

One OEM that is all-in on hydrogen for larger machines is JCB. During a media visit in January 2023, I learned about the company’s new hydrogen combustion engine. JCB has several compact electric equipment options. However, for larger machines, the company is opting for hydrogen combustion.

After experimenting with a hydrogen fuel cell excavator, the team decided that the fuel cell prototype was too complicated, not robust and too expensive. Then they moved to hydrogen combustion.

While the team faced some major challenges when working on the design, Tom Beamish, principal engineer, JCB, discussed that this engine is not a conversion. The engine was designed from the ground up to be

optimized for hydrogen combustion. While it’s not rocket science, it uses the same fuel and similar combustion principles as NASA.

Several engineering factors that had to be overcome:

˜ All materials that contacted hydrogen had to be carefully examined.

˜ A whole new control system for the engine was used.

˜ The spark system is new. This hydrogen-combustion engine made its North American debut during CONEXPO.

Reaching the 2030 goals

To begin or continue the move to zero emissions, all power prospects must be considered. This has been confirmed by virtually every OEM that the Equipment Today team has talked with. To learn what may work best for fleets, contractors should talk with their dealer or OEM to begin their transition.

Read more at: https://eqtoday.co/PowerProspects1023

12 EQUIPMENT TODAY | October 2023 www.ForConstructionPros.com/Equipment COVER STORY

Lori Ditoro

The Volvo EC230 fully electric excavator.

The JCB hydrogen combustion engine, officially launched in North America at CONEXPO.

Lori Ditoro

OurNameisOurPromise

For precision grading that any worker can do–and fits with existing equipment–there is only one best.

EVERY WORKER AN EXPERT OPERATOR

Level Best systems are so easy to learn that a worker who starts the day as a rookie will be precision grading with confidence by the end of the day if not sooner. Now you can have multiple crew qualified and not lose a day’s work when someone calls out.

UNIVERSAL COMPATIBILITY

No other grading attachment for CTLs and skid steers fits every combination of guidance system and compact power equipment already in your fleet.

CHOICE OF GRADING STYLE

The Level Best Precision Grading Blade works in windrows and cuts through tough soil. A Level Best Precision Grading Box works in both directions, shaving down high spots and filling low ones at the same time.

READY FOR ANYTHING

Every Level Best Precision Grader comes ready for both 2D and 3D precision grading.

INDUSTRY-CHANGING INNOVATION

Once there were only three levels of grading accuracy. Rough, Finish and Final. But Level Best added Precision Grading to the mix. It grades with unrivaled accuracy.

IMMEDIATE PAYBACK

You can win more bids with Level Best in your fleet, because you don’t have to build in a 10% overage estimate for materials like gravel and concrete. With Level Best your bids come in with as little as a 2% overage. When you do the math you’ll see the bidding advantage.

THERE’S ONLY ONE BEST

Next time you’re thinking about grading equipment that adds to your bottom line and helps set you apart in the bidding wars, consider the best way to grade that construction site.

LEVEL IT BEST WITH LEVEL BEST.

The Level Best GB-108 works in windrows. Multi-axis adjustments.

The Level Best PD Series work in forward and reverse to level and fill uneven surfaces simultaneously.

Proudly made in the USA

LevelBestGrading.com

PRECISION GRADING BLADE

PRECISION GRADING BOX

Increased Use Expected in New Applications SKID STEER TECH TRENDS:

In early 2023, Bobcat Co. revealed the world’s first all-electric skid-steer loader, the Bobcat S7X. Operating on lithium-ion batteries like its compact track loader counterpart, the Bobcat T7X, the two machines promise high performance with electric power. Additionally, neither produce emissions.

“As a result, operators can tackle tough jobs on environmentally sensitive

worksites or indoors where exhaust is restricted,” said Joel Honeyman, vice president of global innovation, Doosan Bobcat.

Aside from emission control, both loaders offer high productivity and reduced noise levels when compared to other similar equipment on the market, despite being more powerful than their diesel-hydraulic equivalents. Of equal importance, they feature electric drive motors, ball screw actuators, and electric actuation and propulsion, instead of hydraulics.

“Since they’re both powerful and quiet, they can be operated at all hours of the day, too, including in dense, urban areas, in which noise often limits operators’ work hours,” Honeyman added. Because of their minimal vibration and quiet operations, the all-electric loaders enable operators, particularly construction contractors, to have

comfortable, smooth experiences with each use. They’ll also notice a considerable increase in power, in comparison to the traditional dieselpowered loaders they previously used. As an example of this boost in power, the S7X can be operated for up to six hours at a time, while the T7X can operate for up to four hours on one charge, depending on the application.

“It’s important to note that, unlike diesel machines, when the S7X and T7X are at idle, they’re not consuming energy,” Honeyman said. “Apart from routine recharge cycles, each lithiumion battery, which, again, is featured on every all-electric loader, doesn’t require any maintenance, either.”

With regard to maintenance, the compact, all-electric loaders’ straightforwardness is noticed well beyond their lithium-ion batteries, as they each include roughly half the parts that diesel-powered compact loaders do, along with nearly 20% fewer electrical connections. Since they are equipped with fewer parts and electrical connections, the compact loaders—created in partnership with Moog Construction, a motion control components and

systems developer—also have fewer components to maintain and repair.

“These all-electric loaders take about 2 gallons of eco-friendly coolant and a half-gallon of gear box oil, compared to the nearly 60 gallons of fluids that are required in dieselpowered loaders, leading to cost savings on a short- and long-term basis,” he emphasized.

Enhancing Construction Automation, Via Electric Skid Steers

Much like Bobcat’s S7X and T7X, VOLTEQ Equipment’s electric mini skid steer, the SKY 1000, offers a variety of benefits, including emission control. For example, the SKY 1000 is built with fewer components than diesel-powered skid steers, leading to less maintenance and, in turn, a lower total cost of ownership than dieselpowered offerings.

The SKY 1000 also provides operators lower operating costs, along with a reduced need for planned maintenance and the convenience of not having to warm up engines. Furthermore, the skid steers don’t consume any energy when idling.

“Unlike diesel engines that continue running, even when

14 EQUIPMENT TODAY | October 2023 www.ForConstructionPros.com/Equipment EARTHMOVING

Bobcat

machines are in idle, our electric mini skid steers will automatically switch off whenever operators stop them, thus minimizing unnecessary energy consumption,” said Mike Slattery, vice president of business development, VOLTEQ. “They offer significant advantages, in terms of both operating and maintenance costs.”

The mini skid steers also feature immediate slow speed control and provide instant torque, resulting in faster responsiveness and more precise, controlled movements. And, as is the case with the S7X and T7X, VOLTEQ’s SKY 1000 operates quietly, almost silently, in fact, enabling them to be utilized in cities, as well as indoors, according to Slattery.

“They excel in indoor environments especially, due to their zero emissions and quieter operation, making them suitable for automating tasks like cleaning, debris removal and material placement in confined spaces,” Slattery continued. “When they’re equipped with remote control technology, they can be automated for tasks in hazardous or hard-to-reach areas, thereby enhancing safety and reducing operators’ risks.”

As a result of their battery packs, electric skid steers offer low centers of gravity, too, leading to high stability, said Martin Havrda, chief marketing officer, FIRSTGREEN Industries.

“Due to the maintenance-free nature of electric skid steers’ lithium batteries, along with their simplified mechanical systems, they also reduce the risk of breakdowns and the costs of sourcing and fitting replacements,” VOLTEQ’s Slattery stated. “This translates to lower maintenance expenses and increased uptime for construction projects.”

By using electric skid steers, operators can also easily automate their bucket levelling, which is electronically controlled and, subsequently, capable of quickly reacting to acceleration, deceleration and gradient changes.

“Bucket loads are automatically estimated, as well, in order to prevent machine overloading,” Havrda said. “Data is then uploaded into a remote diagnostic tool, which simplifies troubleshooting.”

The Latest Construction Automation Trends

With regard to construction automation as a whole, Slattery has noticed a variety of trends:

˜ First, because of mobile electronics’ advancements, manufacturers can offer operators automated functionalities, such as self-leveling loader arms, which have float control, in an easier and more cost-effective manner than before.

˜ Second, as a result of return-todig, along with the ability to lock

in a desired speed, operators’ equipment can automatically travel at that preferred speeds as soon as they move their joystick.

˜ Finally, several tasks, including the movement of materials from one area to another in an effortlessly mapped environment,

can be automated, via GPS and light detection and ranging LiDAR technologies. Meanwhile, according to Havrda, another key trend is being noticed, concerning construction automation: electric skid steers that can react to outside conditions. For instance,

FIRSTGREEN Industries’ electric skid steers can drive with full loads, while their electric motors automatically adapt to prevent overheating, especially as outdoor temperatures rise.

“The automation of certain tasks is also a new development, when it

Not only is JCB the world’s biggest backhoe manufacturer, but we also sell as many backhoes around the globe as all other manufacturers combined. It’s not that big makes us better. Rather, we’re big because we’re better. Buy better at JCB.com

EARTHMOVING

Most TRUSTED in the world doesn’t happen by accident.

comes to activities that are repeated, including materials offloading into containers,” he said. “Electric skid steers, designed for automation, will have a higher number of sensors and cameras too, which will function as their ‘eyes and ears’.”

Meanwhile, according to Bobcat’s Honeyman, digitization is “changing the game,” regarding compact equipment, including skid steers.

“Automation, when applied intentionally and strategically, pushes productivity to new heights, resulting in more effective worksites,” he stressed. “For instance, technology features can reduce the number of operators that are needed on a jobsite, thus reducing costs and enhancing construction teams’ productivity.”

Bobcat provides digital offerings like Bobcat MaxControl and Bobcat Machine IQ, which enable operators to acquire as much from their investments as possible since they’re able to leverage smart, simple tools, in order to achieve more of their goals. As an example of its intelligence and ease of use, Bobcat MaxControl allows operators to control each of their Bobcat loaders and attachments from outside of their cabs, while using an iPhone, an iPad or other iOScompatible devices.

According to Honeyman, Bobcat MaxControl is especially useful when operators are shorthanded because two-person jobs can be handled by one person. In addition, by using Bobcat MaxControl, operators can avoid repetitive trips in and out of their cabs. While utilizing Bobcat Machine IQ, equipment owners can also monitor their Bobcat skid steers’ health, while remotely tracking information that enhances maintenance, security and performance.

“It’s also common for today’s skid steers to be equipped with displays and features, which streamline communication between operators and dealers as they discuss each of the equipment offerings,” Honeyman added. “This type of comprehensive detail and efficient communication will increase operators’ performance and uptime.”

Swarm Tech: Looking Ahead to the Future of Automation

As FIRSTGREEN Industries prepares for the coming months and years, Havrda anticipates the manufacturer will robotize its skid steers, enabling them to become fully autonomous in certain industries, such as agriculture and mining.

“We are aiming to reach a level of autonomy, in which the skid steers can operate without an operator, even a remote one,” he said.

At the same time, Slattery believes autonomous operation will likely emerge and follow the adoption of remote control that’s more near-term. He also thinks that, with autonomous

operation, swarm technology may very well be offered.

“Through swarm technology, groups of electric skid steers will be able to work together in concert, in order to accomplish the tasks that one skid steer might not be able to achieve alone or as quickly, at least,” he stated.

Additionally, Honeyman stressed that autonomous technology will offer operators new ways to complete their tasks more efficiently and precisely. According to Honeyman, autonomy can be associated with operatorassisted functionality, along with autonomous operation without any necessity for humans. In fact, Bobcat has implemented technologies that can do both—from its excavators that are equipped with depth check technology, which helps operators dig with increased precision, to self-operating mowers that can run without an operator onboard.

“Autonomous equipment, which can be used in agriculture, construction, forestry, landscaping and snow removal, will translate to smarter and more efficient jobsite performances,” he said. “And advanced technology will continue to play a significant role in the evolution of both electric and traditional compact equipment.”

As far as electric skid steers, as a whole, are concerned, Havrda believes that one trend will particularly be noticed in the future: they’ll be used in underground mining operations, as well as in enclosed areas without any ventilation, mostly in agriculture facilities, chemical plants, and other toxic and dangerous environments.

Moreover, according to Slattery, the construction industry’s continuous

shift to electric skid steers will lead to a conversion, in association with attachments—from those that are equipped with hydraulic motors, as is presently the case, to offerings that feature electric motors instead.

“This transition will not only demand less maintenance, but also extend battery life, due to electric drive’s heightened efficiency, in particular,” he said. “In addition, the adoption of electric skid steers could become a necessity, driven by local or federal regulations, especially in semiindoor or fully indoor work settings.”

Aside from this conversion, Honeyman adds that the ever-evolving construction industry will continue to demand alternative-power solutions that positively impact the communities in which they live and work, regardless of their environmental, social, and governance (ESG) goals. After all, many of Bobcat’s environmentally conscious customers have their own specific ESG goals, each of which can be supported by alternatively powered equipment to a degree. Yet, at the same time, they’ll also continue to acquire the power and performance that they’ve become accustomed to with their previous diesel-equivalent skid steers.

As a result of their steady focus on sustainability, operators and customers in general will notice more and more electric skid-steer loader offerings in the marketplace, according to Honeyman. Furthermore, much like every other innovation that was released to the public prior to electric compact loaders, enhancements to skid steers’ attachments, functionalities and tools will continue, leading to more

powerful, productive and versatile offerings.

“Instrumentation on Bobcat’s electric compact loader lineup is nearly identical to its traditional, diesel-hydraulic counterpart,” he said. “Since inventing the world’s first skidsteer loader, the manufacturer will continue to advance the construction industry’s skid steer options, as it strives to help its customers accomplish more.”

He continued, “We also think it’s important to recognize that there will be a need for both diesel-powered equipment and electric equipment for years to come. Therefore, we’re committed to offering variety, regarding our equipment selection, so that customers can choose what’s best for their jobsite needs.”

Popular Automated Tasks for Skid Steers Dedicated to providing operators diversity, with regards to their skid steers and other construction equipment, Bobcat’s machines, including its skid-steer loaders, have technology that will help operators become more productive and conduct their tasks more efficiently—even if some construction contractors may not be quite ready for fully autonomous loaders on their jobsites.

Again, Bobcat is currently providing enhanced, in-cab features and technology that enable two-person tasks to become jobs that one operator can easily accomplish. For example, since Bobcat MaxControl allows contractors to operate their Bobcat compact loaders from outside of their cabs, they can dig post holes more easily than in the past. And they’ll be able to maneuver their loaders

16 EQUIPMENT TODAY | October 2023 www.ForConstructionPros.com/Equipment EARTHMOVING

VOLTEQ Equipment

Since the SKY 1000 electric mini skid steers have fewer components than diesel-powered skid steers, they don’t require as much maintenance and they have a lower total cost of ownership when compared to diesel-powered offerings.

onto trailers and pass through gated entrances and exits more effortlessly than before, according to Honeyman.

Furthermore, Bobcat has introduced a radar collision warning and avoidance system in a concept format. Compatible on select Bobcat compact track loaders and skidsteer loaders, it’s designed to assist operators’ jobsite awareness, while operating in reverse.

“While using an active or passive setting, operators can either receive an audible alert or enable their machine to stop automatically, upon detecting an object in its path,” Honeyman said. “As evidenced by its offerings, Bobcat is focused on reinventing the way work gets done, a goal that will continue to evolve as its offerings continue to expand.”

Increasing “Workable” Hours With Electrification

In regard to trends concerning skid steer attachments, Havrda believes the construction industry will continue to shift toward the use of electrically powered attachments, rather than traditional hydraulic solutions. As this shift occurs, he stresses that FIRSTGREEN attachments won’t require any alternatives, based on automation or electrification.

“Not all traditional machines can run the new generation of electric attachments, but FIRSTGREEN Industries’ units are always equipped to handle both hydraulic and electric implements, in order to make them both usable with older equipment and future-proof as well,” Havrda said.

Along with utilizing electrically powered attachments more regularly, operators are also migrating toward cabs that will enhance visibility, particularly through features like improved lighting, enabling them to be utilized more easily in darker conditions. In addition, more and more cabs are becoming enclosed, thereby protecting operators from the elements and minimizing any downtime associated with bad weather conditions.

Automated functions, along with the ability to personalize different modes of operation that are the most ideal for them, particularly via time saving features, are becoming more popular, too. As a result, operators’ “workable” hours are increasing, resulting in a rise in productivity, according to Slattery.

“Versatility is another main advantage of skid-steer loaders, as they can use several different attachments for all types of work,” Slattery said. “By utilizing an automatic quick attach system, operators can easily switch their attachments without having to leave their cabs, leading to more efficiency between each of their tasks.”

As operators transition to electrical skid steers and attachments, Slattery

admits that minor adjustments, such as planning for charging, will be necessary. Nonetheless, due to time savings, along with the overall enhancements of their working conditions, he believes the shift is certainly worthwhile for operators and other contractors.

“Imagine working on a residential project without disturbing neighbors

with noisy equipment, or seamlessly operating in noise-sensitive areas like hospitals or schools,” he added. “Since electrical skid steers’ and attachments’ quieter operations enable operators to extend their work hours, they’ll be able to maximize their billable time and efficiency, leading to a potential rise in construction sites’ profits, possibly for years to come.”

Read

at:

EARTHMOVING

more

https://eqtoday.co/skidsteer Chris Lewis is a freelance writer for Equipment Today

Werk-Brau’s D-Lock Coupler design includes industry-leading safety features like automatic front lock, dual pin locking, and a patented slide lock design to ensure safety on the jobsite.

Werk-Brau

With construction work being a hands-on job, contractors need to be constantly aware of potential safety risks. This is especially true when using equipment attachments. When using attachments on heavy equipment, if not secured correctly, there is risk of serious injury to workers or damage to materials. Depending on the job, the work might have to be performed by hand or with smaller tools if not for a useful attachment. Having attachments makes your machines multifunctional and can greatly improve your crew’s productivity. Attachments are helpful in allowing workers to complete tasks more easily and efficiently, yet it’s important to be aware of potential hazards.

A big factor in attachment safety is ensuring that the implements are well taken care of and maintained. Forgetting to service or clean an attachment could result in the machine’s malfunction, possibly leaving your workers at risk. Maintenance isn’t the only thing to pay attention to, though. There are many different regulations and standards to monitor. Taking every precaution to keep you and your crew safe is extremely important.

What’s in Place Now

Knowing that there have been many construction workplace injuries and fatalities, the governing bodies in place to protect workers have standards and rules. One of the most well-known enforcers is the Occupational Safety and Health Administration (OSHA). OSHA provides regulations and requirements for attachments and their safety measures. The International Organization for Standardization (ISO) also has a specific standard (ISO 13031) for quick couplers on earthmoving machinery to keep users safe.

Christian Yanes, SteelWrist’s vice president, region EMEA, explained that “there are many different quick coupler solutions on the market, as

well as local or regional regulations of what is allowed.”

This may complicate following regulations. But when these kinds of rulings and regulations aren’t taken into consideration, there can be major issues.

What Can Go Wrong?

A lot can go wrong if an attachment connection fails. Here are three possible consequences operators and crews could face because of a connection failure.

1. DANGER TO OPERATORS & WORKERS

If attachment connectors are not properly secured, the operator of the machine could be injured.

According to Mike Noward, WerkBrau’s regional account manager, operators experiencing a failed attachment “may be struck by or caught between the moving parts or be at risk of falling from an unstable machine.”

Workers or pedestrians nearby could also be hit by a detached tool or even by the machine itself.

2. PROPERTY & EQUIPMENT DAMAGE

When an attachment is not secured appropriately, the tool could fall and cause destruction to any property, buildings or machines in the area.

The sudden detachment may also result in damage to different components of the equipment.

The disruption caused by the disconnected attachment could lead to a breach of balance and would raise the likelihood of the machine tipping or rolling over. These possibilities could involve detrimental downtime as well as pricey repairs.

3. ENVIRONMENT & TIME CONSEQUENCES

If the machine is carrying toxic material when the attachment failure occurs, repercussions to the surrounding environment could occur.

Noward states that if the attachment “contains hazardous materials or fluids, [it] can pose environmental risks, including spills or contamination of soil, water, or air.”

The environment could suffer if attachment connectors are not properly secured. Delays could occur if you don’t practice safe attachment connections. An environmental spill may result in a delay in the work schedule. A slowdown could also be caused if a connection fails in general because of the time taken to pinpoint the reason for detachment, reattach the tool and make sure that the connector is placed back on correctly.

How to Prevent Detachments

Manufacturers in the industry try to minimize risk by adding things like visual and auditory indicators that machines are activated. There are also precautions that operators can take.

A new trend in attachment safety, according to Yanes, is “locking one of the attachment pins whether the attachment is well connected or not” because it helps prevent accidental detachment.

While much can be done to help prevent attachment failure, one of the best ways for contractors to protect their crew from injury is to make sure operators read and become familiar with the machine’s user manual.

Yanes said, “New technologies require education, and this education is handed over to the owner of the equipment in [the] form of user manuals that [manufacturers] expect the owners to read and understand.”

To prevent issues, OEMs are meeting safety regulatiosn during the design process. “Manufacturers are increasingly adhering to these standards during the design and production of excavator coupler attachments to enhance safety measures.”

But what can you do to prevent attachment issues?

Tips on Keeping the Crew Safe

˜ Read the machine’s user manual. User manuals are provided for a reason. They have all the important information about safety precautions and correct use.

˜ Conduct regular inspections. Your attachment connectors must be checked often to ensure that everything is running smoothly and is up to date. Operators should also complete daily walkarounds to ensure everything is in place and looks correct.

˜ Make sure that everyone is properly trained. Whether it’s the machine operator or ground workers, each crew member needs to be thoroughly trained on safe attachments and safety procedures. Operators, specifically, need to know how to care for the equipment and how to properly connect attachments and maintain attachment safety.

˜ Keep couplers clean and lubricated. The cleanliness of couplers is essential. Dirt and debris could cause damage to the coupler or cause it to not work correctly. If the team doesn’t maintain the lubrication of the coupler, smooth operation is less likely and might cause damage because of extreme wear and excess friction.

˜ Collect documents and avoid loose ends. File maintenance documents and keep them for a full record of the machine’s history. Tighten loose bolts, pins and other components.

˜ Keep things up to date. Checking the machines involves noticing when attachments need to be changed because of damage or regular wear and tear. When attachments become worn, the security and efficiency of the connection are at risk.

Attachment Safety Boils Down to the Contractors & Operators

Construction workers know what they are trained to know. This means that safety training must be taken seriously and safety precautions need to be taught. Proper handling and care of machines is a must, and the upkeep needs to be constant and consistent.

Becoming familiar with user manuals and attachment regulations and standards is critical. Being diligent with your crew’s training and being vigilant about the machines will allow crews to be in the safest environment possible.

Attachments can be useful on the jobsite and can make labor shortages more manageable. In this respect, attachments are important tools to have access to, but they can be dangerous if not taken care of and handled properly.

Read more at: https://eqtoday.co/attachsafe

October 2023 | EQUIPMENT TODAY 19 www.ForConstructionPros.com/Equipment

Steelwrist’s Quick Coupler features front axel locks for extra safety.

Steelwrist

Steelwrist’s SQ Coupler helps change attachments in a matter of seconds.

EARTHMOVING | By Merina Shriver, Junior Editor, ForConstructionPros.com and IRONPROS.com

Steelwrist

EFFICIENCY EXTRAORDINAIRES: Streamlining Snow Operations

By the time a snowstorm comes roaring onto the radar, snow and ice removal companies have already begun to run out of time to prepare for what’s to come.

That’s why it’s important that they streamline operations to become as efficient as possible during the busy winter months.

“Time is of the essence with snow, and you have to be able to adapt to the conditions at the drop of a hat,” said Elizabeth Bonadonna, president of Busy Beaver Lawn & Garden, in West Seneca, New York.

“You need a plan to make sure people are safe from the conditions but also that you are providing services you promised. Streamlining operations, reducing waste and increasing efficiency can all affect the bottom line of your business.”

Bonadonna and Joe Uran, president of Nordic Snow Management in

Hopkins, Minnesota, discussed how they keep their snow operations running smoothly and effectively.

For Busy Beaver Lawn & Garden, the recipe for a seamless snow season comes down to making the right hires, thorough training, and implementing technology to streamline processes and communication.

“We believe in hiring the right management team and teaching them the secret recipe for success, empowering our staff to make the right decisions and coaching them on how to adapt and overcome and providing feedback and reflecting on what worked and what didn’t,” Bonadonna said.

Hiring & Retention

At the beginning of a snow season, Busy Beaver holds a “winter kickoff”— part in-class training and part hands-on demonstrations. The class reviews standards and expectations,

while the hands-on portion includes familiarizing staff with equipment and reiterating safety features and functions.

“We have site maps and route lists that are all digitized, like a Service Autopilot application that has all the information they’d need, and then we also make sure they know how to operate the equipment properly— things like putting on a box and taking it off, what our standards are and what the industry standards are,” Bonadonna said.

The company, which staffs about 50 to 70 employees based on the snow event, also takes employees on site visits to show them what needs to be done and where to put the snow.

“We show them where the equipment’s staged, how to grease the equipment, make sure they know how to start it and ensure that they know specific details about it,” Bonadonna said. “We provide patterns for them,

but we also try to empower people to utilize their skill sets as best they can because they know what works. They know the wind patterns and what’s most efficient.”

The company has been providing such training since its inception.

“We believe it makes operations smooth and provides structure for our staff and our customers,” Bonadonna said.

To bring the hires in the front door in the first place, Busy Beaver relies on a hiring software and word of mouth.

“The software is constantly bringing in candidates, but it’s also our marketing and word of mouth,” Bonadonna said. “When people work with us and they like our company, they’re going to tell their friends that this is a great company with a great work culture. People see that we have structure and a good culture, and that’s attractive.”

www.ForConstructionPros.com/Equipment EARTHMOVING |

Green Industry Pros 20 EQUIPMENT TODAY | October 2023

By Sarah Webb, Editor,

coachwood - Adobe Stock

As snow removal companies add new contracts, they often need to seek out new equipment specific to those needs, routes and sites.

Systems & Processes

During the offseason, Busy Beaver’s staff is busy creating programs and a winter game plan using technology such as SiteMaps.

“This way, it’s all prepared with our contractual obligations and specifics to know hours, shift changes and maps,” Bonadonna said.

Additionally, the company’s equipment is all staged and ready when the winter season begins, thanks, in part, to its own fleet of mechanics staffed to service equipment.

“We have several hubs, but people will know where they’re dispatched to and what the expectations for service are at each site,” Bonadonna said.

During, the company implements checkoff sheets to know what sites were serviced and that processes were fully functioning and ensures that dispatch and office support are available 24/7 during snow events.

“It’s taking the time to know that you have X amount of time, X amount of equipment, X amount of people, and that you can use all of that efficiently,” Bonadonna said. “Taking all these things into consideration shows that the leadership continually wants to improve and rise above the rest. We believe that teams realize that when an organization is putting their best foot forward and making it better today for tomorrow.”

Equipment Focus

Communication through technology, preseason prep and ready-to-roll equipment are three big factors keeping Nordic Snow Management’s operations up and running.

“With snow, you basically have one chance and a 12-hour window to get it done,” Uran said. “You can’t call and say that you didn’t get there for this reason or the other, so we spend a lot of time preseason making sure everything is well planned and that there are backup plans. When

problems do arise, we can take care of them quickly and still have everything completed.”

For each site that it plows, Nordic Snow Management, which focuses purely on commercial sites, dedicates specific pieces of equipment and machines to that site.

“We match equipment to the site because you wouldn’t use a pickup truck to plow a big box store the same way you wouldn’t use a large wheel loader to plow a driveway at a house,” Uran said. “A big thing for us is equipment purchasing and planning, and then matching that equipment to specific sites.”

At its current capacity, all the equipment Nordic owns is committed to sites. As the company adds new contracts, it seeks new equipment specific to those routes or sites.

“So, if we were to pick up a shopping center, we would evaluate the contract length and value and potentially go purchase something for that site,” Uran said.

More so than helping with efficiency, Uran said this strategy helps with money.

“Equipment is typically more money upfront, but it’s cheaper to own and operate in the snow industry,” Uran said. “We started using the stuff we already own and put it to work. Then, as we grow, we purchase and seek out equipment specific to our needs for the upcoming season.”

To ensure its equipment is in tiptop shape, the company performs pre- and postseason inspections on all vehicles and performs maintenance and big repairs in the spring.

“Fall is very busy, so by then, everything is ready to go,” Uran said. “You never know when the snow will start, so by the preseason inspections, it’s quick once-overs to make sure nothing has changed and sending the machines out.”

Communication & Technology

Communicating with staff is another key to efficient operations, Uran said.

Before every snow event, the company communicates expectations and whether any changes are expected.

“Once we get started, we’re in constant communication with everybody to see how things are going, and we monitor in real time with GPS, so if we start to notice a crew or area is behind, we have flex position or management people that will help that crew catch up.”

Similarly, if a crew is behind or there are equipment issues, Nordic will be flexible and pull equipment from a different route to use on the route that crews are struggling to keep clear.

While the tracking is done through GPS and the snow management system, Yeti, communication and dispatching calls are made via phone.

“With Yeti, it’s already prebuilt, so crews only need to log in, and

the info they need for each site is already there,” Uran said. “There are site maps, site notes and other site information that anybody can go in and understand what we’re trying to accomplish. It lists where the snow goes, what to watch out for, complete with pictures and maps.”

Finally, Uran notes that having a backup plan is crucial.

“Don’t overcommit yourself. That’s a common problem,” Uran said.

“Undercommit your equipment and people because when a big storm comes and a problem arises, you’re stuck if you’re constantly scheduling at 100 percent capacity and there’s no room to adjust.”

Read more at: https://eqtoday.co/snow

October 2023 | EQUIPMENT TODAY 21 www.ForConstructionPros.com/Equipment

Elizabeth Bonadonna, president of Busy Beaver Lawn & Garden.

During winter, snow companies often implement checkoff sheets to know what sites were serviced and ensure that processes were fully functioning. Typically, dispatch and office support are available 24/7 during snow events.

Busy Beaver Lawn

Garden

Lane Erickson - Adobe Stock

&

EARTHMOVING | By Sarah Webb, Editor, Green Industry Pros

Boss Power-V XT Snowplow

The high-performance Power-V XT

“Extreme Duty” snowplow features a 37-in. flared blade wing to improve snow discharge.

• Available in two models (8 ft., 2 in. XT and 9 ft., 2 in. XT)

• Standard features include: X 6 highperformance cutting edges, heavyduty center section and pushframe, reinforced moldboard and snowplow sight system

SmartHitch2 Attachment System

• SmartTouch2 Hand-held Control

• High-performance hydraulic package

• Chainless hydraulic cylinder lifting system

Kubota SSV65 & SSV75 Skidsteer Loaders

The 64-gross-hp SSV65 boasts a 1,950lb. rated operating capacity (ROC) and 4,839-lb. bucket breakout force, and the 74-gross-hp SSV75 has a 2,690-lb. ROC and 5,884-lb. bucket breakout force.

• Vertical lift configuration can dump into a dump truck with 10-ft. sides

• Kubota Tier 4-certified 4-cyl. diesel engine

• Include a spacious, dust-resistant pressurized cabin with an optimized climate control system, slide-up, frontentry door and hand-foot controls

• Standard two-speed travel

• Optional high-flow hydraulics and multifunction lever for fingertip control of major machine and implement functions

ASV RS-75 & VS-75 Skid Steers

The large-frame radial-lift RS-75 and vertical-lift VS-75 feature an industrial 74-hp, naturally aspirated, 2.9-L diesel engine offering 192 ft.-lbs. of torque.

• VS-70 offers a 3,500-lb. rated operating capacity (ROC), 7,000-lb. tipping load and 10.8-ft. lift height, while the RS-75 has a 2,600-lb. ROC, 5,200-lb. tipping load and 10.4-ft. lift height

• Dedicated skid-steer frames enable a 10.5-in. ground clearance and a 24-degree departure angle

• Standard hydraulic joystick controls

• Travel speed up to 11 mph with optional two-speed drive

• Auxiliary hydraulic system with optional 30.9-gpm high-flow pump capacity

John Deere 320G & 324G Midframe Skid Steers

The 69-gross-hp 320G and 74-gross-hp 324G have 7,150-lb. and 7,700-lb. operating weights and rated operating capacities of 2,150 lbs. and 2,690 lbs.

• 324G features a height to hinge pin of 10 ft. 6 in.

• Pressurized cabs with reduced width and weight for contained jobsite areas

• Cab enhancements include heated seats, Bluetooth radio, a rearview camera and deluxe LED lighting package

• In-cab boom lock-out system makes maintenance safer and more secure

• Include Yanmar FT4 engine systems; flexible control choices; and performance package options for adjusting drive system response, boom and bucket speeds or setting creep mode on demand

Loftness Battle Ax Skid-steer Mulching Attachment

The heavy-duty Battle Ax horizontal drum mulcher is offered in 61- in. and 71-in. cutting widths for skid steers with 50 hydraulic hp to 120 hydraulic hp.

• 17-in.-diameter rotor features built-in depth gauges to prevent attachment from engaging too much material at one time

• Two-stage cutting chamber allows material to be cut twice by the rotor and helps produce smaller particle sizes

• Primary shear bar adjustable for customizing particle size

• Adjustable skid shoes (0.5 in. to 1.5 in.) enable below-grade mulching

Fixed-displacement gear or variabledisplacement piston motor

Caterpillar D3 Series Skid Steers & Compact Track Loaders

The D3 Series includes 16 skid-steer, compact track loader and multi-terrain loader models offering rated operating capacities (50% tipping load) from 2,185 to 6,200 lbs. and 67.1 gross hp to 110 gross hp.

• Wider opening cab door for easy entry and exit and an added 3 in. between joystick pods for extra space inside cab

• CTLs feature standard two-speed travel and changes to the undercarriage frame and torsion axles that reduce machine pitching and rocking

• Smart technology automatically recognizes and converts machine controls to align with Smart Attachments needs

• Advanced control features include Return-to-Dig and Work Tool Positioner

FISHER XRS Snow Plows for Skid Steers

The XRS Skid Steer Plow by Douglas Dynamics offers versatile snow removal in winter conditions. Designed specifically for skid steer applications, this rugged plow automatically retracts the inside wing when fully angled and then automatically returns to the scoop position once straight. The XRS plow leverages the onboard hydraulic system of the skid steer to lift and lower the blade, supporting operator performance. The oscillating skid steer mount comes standard and provides 6 degrees of sideto-side oscillation for scraping while reducing damage to the terrain. Available accessories include a 10-in. rubber deflector, shoe kit and quick coupler set.