Crafco Supply Centers have everything you’ll need for your project, from Crafco materials and equipment, to blowers and safety apparel from exclusive brands. Our friendly and knowlkedgable staff will work with you and help you find the right prioduct solution for your pavement issue. Experience the Crafco difference. Get started at crafco.com/sales

16 NPE

The good news is the industry is thriving, and people are as passionate about the work as ever. Pavement Maintenance and Reconstruction Magazine was on the show floor, sitting in on sessions, and reports back to readers on what went down in Chartlotte, N.C. this year.

Learn seven tips for building successful business relationships. 30 NAPSA

New Year, New Goals!

31 WSA

Let’s talk about sweeping and pavement surface preservation. 32

Think through

A family owned paving company in South Dakota showcases the benefits to accurate fleet tracking, digital e-ticketing and up-to-minute data.

For more informationvisit

https://pavemg.com/nyhguf

Technologies are available to help contractors better manage their processes which can improve efficiencies and profitability.

For more informationvisit

lhttps://pavemg.com/rxptzq

The new X10 diesel will emit 75 percent less NOx emissions than required at launch in 2026.

For more informationvisit

https://pavemg.com/4xgu7y

Vol. 36, No. 3 March/April 2023

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

Subscription policy: Individual subscriptions are available without charge in the U.S. only to pavement maintenance contractors, producers and government employees involved in paving or pavement maintenance; dealers, and distributors of pavement maintenance equipment or materials; and others with similar business activities. Complete the subscription form at www.forconstructionpros. com or use your company letterhead giving all the information requested. Publisher reserves the right to reject nonqualified subscribers. One year subscriptions for nonqualified individuals: $35.00 U.S.A., $60.00 Canada and Mexico, and $85.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). Pavement Maintenance & Reconstruction (ISSN 1098-5875), is published eight times per year: January, February, March/April, May, June/ July, August/September, October/November, December by AC Business Media, 201 N. Main St. Ste 350, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI and additional entry offices.

POSTMASTER: Please send change of address to Pavement, PO Box 3605, Northbrook, IL 60065-3605. Printed in the USA.

PAVEMENT MAINTENANCE & RECONSTRUCTION is proudly supported by these associations:

ADVISORY BOARD

Agua Trucks Inc .................................................................... Wickenburg, AZ, Scott Duscher

Asphalt Contractors Inc., Union Grove, WI ............................................... Robert Kordus

Asphalt Restoration Technology Systems, Orlando, FL Connie Lorenz

Brahney Paving, Hillsborough, NJ Steven Brahney

Eosso Brothers Paving; Hazlet, NJ Tom Eosso

Maul Paving/Concrete/Sealcoating, PLainfield, IL Chris Maul

Parking Lot Maintenance, Lake St. Louis, MO Todd Bruening

Petra Paving, Hampstead, NH Chris Tammany

Pioneer Paving, Albuquerque, NM Don Rooney

Roberts Traffic, Hollywood, FL Lisa Birchfield

Show Striping Inc. (SSI), Wisconsin Dells, WI ...................................... Amber Showalter

T&N Asphalt Services, Salt Lake City, UT ........................................................ Nick Howell

Young Sealcoating Inc, Lynchburg, VA Steve Young

The Paving Lady Mauro Comuzzi

JMP Excelsior Services Jim Panzenhagen

Sweeping Industry Veteran Gabe Vitale

Flat Nickel Management Michael Nawa

Wis-Coat Asphalt Maintenance Marvin Joles

Clear Choice Sealing Warren Johnson

Jacketta Sweeping Services Debbie Jacketta

Royal Pavement Solutions ............................................................................. Kenneth Roy III

ASSOCIATION REPRESENTATIVES:

Pavement Coatings Technology Council Brian Riggs, Executive Director

Even though NPE came to a close at the end of January, now is the perfect time to reflect on the show, and start looking ahead. In this month's issue, we have two separate features breaking down NPE from different perspectives. As a first-time NPE attendee, the show was definitely a great learning experience.

I witnessed an enthusiasm and passionate energy from so many people who've been attending for years, and in some cases, decades. The educational sessions I attended were some of the best examples of this. Every speaker engaged with their audience in a unique way, often indicative of their own personal and professional experience. Having at one time been in the shoes of the session goers, it was clear the speakers knew how to communicate in effective ways.

Brandon Noel, Editor bNoel@ACBusinessMedia.com 234-600-8983

From another point of view, I couldn't help but hear from many of those same passionate NPE faithful, when I would tell them it was my first show, that this particular iteration wasn't exactly the most representative of what the show has been in previous years. They described the NPE of years past, when there were more, and more varied, vendors.

What almost everyone universally agreed upon was a unifying excitement for the show's new home of Tampa, Fla., for 2024. It wasn't terribly cold in Charlotte, N.C., but attendees unanimously praised the decision to take the NPE talents further south.

Sealcoating is the name of the game this month. In addition to our post-NPE coverage, we highlight the work of sealcoaters and some of the adjacent technology. For instance, be sure to check out a returning legend to the pages of Pavement Maintenance and Reconstruction Magazine. Girish Dubey takes us through a detailed analysis of sealcoating additives, what types there are and how those additives effect your mix, as well as the end results.

Following that, there is an article looking at chipsealing as an alternative to sealcoating. However, we show a lot of love to our sealcoating friends with this month's contractor snapshot. ARM Pavement Services is a newer outfit based in Detroit, Mich., and their story of generational entrepreneurship is not the usual. It's definitely inspirational, and shouldn't be missed.

For business owners, we have two great features. One highlights the process for hiring seasonal migrant workers, both efficiently and within the proper bounds of the legal process. There can be lots of questions regarding the special work visas, and we've got some of the important details you'll want to know ahead of the busy season. Seasonal workers can be a valuable way to supplement some of your staffing shortages.

Technology remains another area of running the business that is growing increasingly important. Our "Your Business Matters" feature shines a bright light on ways to utilize tech platforms to streamline the sales process for pavement professionals. If you've been putting off incorporating some new technology solutions, there's never been a better time to find a platform that works for you.

EDITORIAL

Editor Brandon Noel bnoel@acbusinessmedia.com

Contributing Editor Jessica Lombardo jlombardo@acbusinessmedia.com

Digital Content Director, IRONPROS Wayne Grayson wgrayson@acbusinessmedia.com

Managing Editor ............................................................... Gigi Wood gwood@acbusinessmedia.com

Technology Editor .............................................. Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

ADVERTISING/SALES

Brand Director Amy Schwandt aschwandt@acbusinessmedia.com

Sales Representative Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer....................................................Ron Spink

Chief Financial Officer .......................................... JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education ............. Jim Bagan

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

In slightly less than a year, Felling Trailers, Inc. has moved buildings, built buildings, acquired new technologies and moved existing equipment to streamline the production process and increase manufacturing efficiencies. All of this has transpired with the result of a state-of-the-art Fabrication Center.

In the fall of 2016, Felling Trailers worked with Thein Moving Co. Structural Movers to relocate existing Building 51 to make way for an expansion of the Main Warehouse to incorporate space for a new Fabrication Center. During the 40-plus years of Felling Trailers’ existence, equipment and manufacturing space has been added, as the company grew to meet demands of the market. The addition of the Fabrication Center is step one of many in Felling Trailers’ goal to streamline the production flow from parts to production to finishing. Construction of the new Fabrication Center started in early 2017, providing 15,000 square feet of space for new and existing technologies in the main warehouse. With the two buildings connected, it allows for an efficient flow of production parts from the fabrication area, to the warehouse, to the production floor.

The Fabrication Center now houses all three of Felling Trailers’ press brakes. The Accupress Edge 250 ton press brake and Cincinnati CB-II 350 ton press brake were moved from the front production bays in mid-June with the help of Quick-Way Rigging of Minneapolis. This fall, Felling Trailers’ Marvel 2150 Vertical Band Saw and Hyd-Mech S23A horizontal band saw were moved into their places in the new Fabrication Center.

Mark Ishee is the new president of FP2 Inc., succeeding Tim Harrawood.

Ishee is vice president, Pavement Preservation & Specialty Products, Ergon Asphalt & Emulsions, Inc., of Flowood, Miss. Harrawood is Southern Regional general manager for Vance Brothers, Conway, Ark. The position is a two-year term.

Ishee brings a strong background in asphalt emulsions to FP2 leadership. He's been employed with Ergon for the past 42 years, the last 39 of which have been with the Asphalt & Emulsions division. He has experience in many aspects of the emulsion industry, including plant operations and management, laboratory testing, research and development, field applications, troubleshooting, specification development and product marketing.

With Ergon’s support, Ishee also has worked with the asphalt emulsion industry at-large. From 2002 to 2006, he served on the board of the International Slurry Surfacing Association, including two years as ISSA’s technical director. He's been a member of the Asphalt Emulsion Manufacturers Association’s board since 2008, and served as AEMA president in 2017-2019. He wrapped up his extended term as immediate past president in February. His work with FP2 began around 2004, as a contributor of content, and serving on diverse committees and task forces. In 2011, his commitment increased as he worked with FP2 and was officially seated on the board in 2014. Mark was elected for terms as secretary/treasurer in 2018 and as vice president in 2020.

For more information visit https://pavemg.com/mz1q1r

Yanmar Compact Equipment North America (YCENA), encompassing the Yanmar Compact Equipment and ASV brands, finalized its status as a single legal entity. The major milestone comes three years after the Yanmar Group acquired ASV Holdings, Inc. Now, the Yanmar Compact Equipment division in North America and ASV officially join to become YCENA.

“This is a huge step for us, our dealers and our customers,” said Tate Johnson, president of YCENA. “The alignment of the two brands allows us to focus on expansion, new products, and overall strategic growth in North America while finding new ways to serve our customers.”

Yanmar CE and ASV have operated as YCENA from a commercial standpoint since July 2020. The alignment as a single, legal entity allows for a better, more capable, and dedicated compact equipment entity focused on leadership in the North American compact equipment market. It will also allow a wider range of compact equipment offerings long-term, offer a single way for compact equipment dealers to do business with YCENA and strengthen the global Yanmar Compact Equipment team, the company said.

The Yanmar CE and ASV brands will remain distinct under YCENA with each brand retaining its product lines and dealer networks. Currently, Yanmar Compact Equipment offers mini excavators, compact wheel loaders and tracked carriers with a focus on commercial construction, residential construction, utility and rental applications. ASV offers compact track loaders and skid steers in the landscaping and forestry markets.

A round-up of recent news, moves and events impacting the pavement maintenance industry

General Equipment Company

General Equipment’s SG24EM M-Series surface grinder features the convenient, versatile MAGNETACH magnetic tooling system and is easy to use for anyone from homeowners to professional contractors. The grinder is powered by a 2-hp electric motor that operates from a 115 VAC, 60Hz, single-phase power source and can also be field wired for 230 VAC operation. Compatible attachments include a PCD Coatings Removal System, Tungsten Carbide Coatings Removal System and Diamond Segment Diamond Grinding System.

SealMaster

Liquid Road is a high performance mineral and fiber reinforced asphalt emulsion blended with polymers and special surfactants for superior adhesion, flexibility, and durability.

• Extends the service life of pavement

• Replaces the pavement binder lost through oxidation

• Provides a rich black color that helps to melt snow and ice

• Protects pavement from oxidation, UV rays, and moisture intrusion

Neyra Industries

Neyra PolyPro is a quality, readyto-use pavement coating composed of refined coal tar that is fortified with rubber prior to emulsification. In addition, Neyra PolyPro contains a unique surfactant formulation which allows greater compatibility with asphalt surfaces.

• The high solids, polymer modified formula provides increased resistance to oil, gasoline and chemicals

• You can expect up to three times the wear of other pavement coatings

• Neyra PolyPro comes in a ready-to-use formula

• Tough, tight, waterproof pavement coating

2 4 6

Black Diamond XL is a premium heavy-duty, superior performance, polymer-modified petroleum-based emulsion pavement sealer, containing a high molecular weight polymer that has been crosslinked with the base to enhance durability, adhesion, elastic, and wear resistance.

• The base binder has been cross-linked with a high molecular weight polymer compound prior to emulsification, resulting in superior performance not achievable by other processes

• Protects all asphalt surfaces including commercial and residential parking areas and driveways

• Resists gasoline and oil penetration

• Alternative to both coal tar and asphalt base sealers

• Weatherproofs and seals porous asphalt surfaces, preventing damaging effects of water penetration

In 250/300 Gallon Capacities

• Diesel engine and heating system

No propane required.

• Oil-jacketed kettle with fast heat-up time (Approximately 2.5 hours from a cold start)

• Plow-point agitation for faster heat-up, with forced material discharge

• Agitation system provides unmatched power / torque with safety interlocks to protect the operator and prevent damage to the machine

• Hydraulic system is highly efficient and designed to run cool (lowering maintenance costs), providing power to the torquemounted, planetary agitation drive system

• The waterproof steel control cabinet houses the Crack Pro brand’s proven control system.Burner temperature controllers with improved material temperature accuracy

1 3 5 10 PAVEMENT MAINTENANCE & RECONSTRUCTION | March/April 2023 | www.ForConstructionPros.com/Pavemen t

A specialty coating, designed for road surfaces that have deteriorated over years of use. STAR ROAD-GUARD is an asphalt emulsion-based pavement coating. STAR ROAD-GUARD delivers cost savings compared to commonly used surface treatments like slurry sealing or micro surfacing. STAR ROAD-GUARD is formulated with tough rubber polymers, specialty chemicals and select mineral fillers which impart flexibility and durability to the coated pavement surfaces.

• Outstanding flexibility, toughness and longevity. Apply to parking lots and roadways where traffic has damaged the asphalt surface prematurely

Engineered and built to exceed the demands of commercial paving, Weiler pavers, compactors and tack distributors incorporate proven designs with new innovations to provide performance, reliability and outstanding results in a wide range of applications. Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America, providing unmatched support with factory trained technicians and readily available parts to keep your operation up and running.

weilerproducts.com

There are many different sealcoating additives on the market, and knowing what they can do is a valuable resource on the jobsite and for your business.

thus improving the overall performance properties of the cured film to produce a uniform dry color. The choice of polymers in the additives is crucial. If the polymer has any inherent deficiencies, e.g. water sensitivity, it will drive down the sealer performance, by introducing weak links in the cured sealer film.

Simply defined, additives are specialty chemicals that are used to enhance the performance of sealcoatings. They’re akin to turbocharging engine performance. They’re specifically designed by material suppliers to boost the performance of sealcoatings based on refined tar-, asphalt- and petroleum-based resin. Nowadays, sealcoating professionals have become quite familiar with these additives and use of these products have enabled them to sealcoat even in unfavorable application conditions and not only accomplish the optimum performance, but also greatly enhance it.

Sealcoating additives have been used since the 1960s. Additives based on specialty latex/rubber polymers have been a part of the Federal Aviation Administration (FAA) specification since early 1970s. The technology of these additives has come a long way since then.

As to how additives work, the polymer particles fuse with the resin particles in the sealcoatings (as it dries) and the network tightens within the film,

Additives can be distinguished into following categories, depending upon the type of additives, one can accomplish different objectives.

1. Fast Drying : Even under not-soideal drying/ weather conditions, these additives speed up drying time, thereby reducing labor cost and allowing traffic to open sooner.

2. Uniform Dry Color: These additives help in uniform drying of sealcoating, even under sun or shade, resulting in a uniform dry color.

3. Sand/aggregate suspension: Large amounts of sand/aggregate are used in the sealcoating mix to improve skid resistance, produce uniform texture, and fill minor surface defects. Additives keep sand/ aggregate uniformly suspended in the mix, thus eliminating settling at the bottom of the tank. Additionally, additives help distribute sand evenly throughout the sealcoat and produce a uniform, streak free appearance.

4. Performance Boosting : Sealcoatings modified with properly selected additives improve:

• Resistance to chemicals, deicing salts, oil, jet fuel etc.

• Resistance to water and elements of weather (UV etc.)

• Toughness, flexibility and elongation

• Change the thermal susceptibility, where sealcoatings stay flexible at cooler temperature while reducing stickiness at higher temperatures

5. Thickening : These are commonly used to suspend large amounts of sand, and/or where the sealer has been excessively diluted with water. Besides thickening the sealer, they do not contribute much to sealer performance. Generally, thickeners introduce permanent water sensitivity, and therefore should be used with caution. The problem is that sometimes they are used to thicken a “watered down” sealer, thus putting down an inferior product, which can wear prematurely. Sealer performance is driven by what stays on the pavement (dry film thickness), after the full cure.

Most of the additives are made with polymers and specialty chemicals. They are commonly formulated as water dispersible products. Performance enhancement depends on the type of polymer used to make it. So, it’s important to understand the benefits of choosing the right additive for the job. Based on the building blocks, additives can be distinguished into following categories:

1. Acrylonitrile Butadiene Rubber Based additives are most frequently used for rubberizing refined tar-, asphalt- and petroleum-based resin sealcoatings, thus enhancing their

flexibility and toughness. They also have excellent resistance to most chemicals, oils, fat, greases, hydraulic fluids, kerosene, etc. These additives enhance the properties of the sealcoatings in the real sense.

2. Acrylic Polymers and Copolymer Based additives are frequently used for thickening, sand/aggregate suspension and faster drying. Acrylics are generally resistant to ultraviolet radiation, oils, fats, lubricants and hydrocarbon solvents. These additives are capable of delivering all the abovementioned performance properties into the sealcoatings.

3. Styrene Butadiene, Natural Rubber, Butyl Rubber Based additives have been used over the years in sealcoatings for thickening, sand/aggregate suspension, faster drying and improved chemical resistance. These polymers have excellent resistance to water, moderate chemicals, alcohols, organic acids, etc. Their use is limited to the areas that have minimal contact with hydraulic oils, fats, etc. due to their poor resistance towards such products.

4. Polyvinyl Acetate/Acrylic Copolymer Based additives are frequently used for thickening, sand/aggregate suspension and faster drying. These types of polymers generally have poor resistance to water, therefore, they are likely to introduce permanent water sensitivity in the cured sealer film, which may lead to premature wear. These polymers have poor resistance to ultraviolet radiation, salts, fuels, oils, fats, etc. limiting their use as an overall performance enhancer.

5. Alcohol Based additives are specially developed to enhance the drying properties of the sealcoating, so that they can cure optimally even under cooler ambient and surface temperatures. Thus, improving overall color, performance and durability of sealcoatings. They do not contribute towards viscosity of the sealer.

Most of the additives are specific to sealer types and must be selected and used according to manufacturers' recommendations. The common misconception about the additives is that they can be used in

all types of sealcoatings, that’s not true. Most additives are specifically chemically designed to enhance the performance of a certain type of sealer, and they may not be compatible with other sealer types, which, in turn, may degrade their properties. It’s always best to ask the manufacturer for detailed information on their compatibilities and how to use them.

Also, the use of additives will not compensate for poor mix designs, such as excessive water and aggregate addition. Seek the help of the supplier and follow manufacturer's recommendations.

Though the end use is the same, additives made by different manufacturers may have been formulated with different complex chemical compounds. Don’t crossmix additives from different suppliers in the same mix design of sealcoatings. This will likely void the manufacturer warranty and may degrade the performance properties of sealcoatings.

The optimum level of addition should be according to manufacturer’s recommendations. The level of addition is different for different additives. Too little will not improve the performance properties as expected. Too much is a waste of money and in some situations, it may degrade the properties of sealer. For example, too much of thickening additive will make the sealer too thick to even mix or apply. So always follow manufacturer's guidelines and instructions.

Even though the usage amounts are small, additives are the key to success in achieving the superior properties of a sealer, which could be the difference between a good job and a great job in the sealcoating business. For contractors, this can attract a lot of customers, thus increasing business and, for property owners, you can reduce the time between redoing a pavement/parking lot, which will save a lot of money. It is a win-win for everyone.

by Girish C. Dubey, president of STAR Inc. and Nihal Pandrapragada,research and development chemist for STAR, Inc.

To read the full article: https://pavemg.com/gdxf5q

Rodney Hilton, of Xpress Asphalt Solutions, in Lorraine, Ohio, agreed, remarking that, “the best part about NPE is the chance to network and bounce ideas off of people. You always learn something new at NPE.”

Paving, sealcoating, striping, sweeping, crack repair, and snow removal all add up to hard work performed by dedicated people. There are a lot of projects to go around, but owners and managers can be competitive, and even protective, of their trade secrets. At NPE, however, much of that goes away in a spirit of cooperation.

“We meet people at NPE who are in the trenches, just like us, and we can freely talk about our successes and failures,” said Alex Sarandinaki, from Eosso Brothers, of Farmingdale, N.J. “People are here from all over the country, so you’re usually not speaking with direct competitors.”

Educational sessions and networking events such as the NASCAR Hall of Fame Party on Jan. 26 amounted to a fun time for attendees, and in the coming months, these events may foster connections that directly lead to business expansion. Todd Eichholz, owner and CEO of A&A Paving, in Roselle, Ill., is one of those repeat attendees who credits NPE networking with greatly expanding his business and its overall financial success.

“One of the coolest things about this industry is that everyone is open and honest,” said Eichholz, who also serves on the educational advisory board for NPE. “At NPE, you could have a guy who has two employees and a striping machine sitting next to a $50 million contractor at a round table and everyone is sharing and helping each other.”

Trade shows are three-pronged operations with networking, education and products on display. Some attendees look for all three, while others hone in on one aspect. For Alaska-based McLean of Alaska Road Striping, the education/equipment mission was eventually accomplished.

“In addition to the education, we’re here to look at machinery, particularly Graco,” Mclean said. “We want to see what’s new and exciting, and the show is delivering.”

“The classes and all the information here at NPE is valuable,” added attendee Troy Wilkes, of Tustins Asphalt Sealing, in Plainwell, Mich. “Neal Glatt and Brad Humphrey both had excellent educational sessions and we are learning different sales tactics for sealcoating and crack filling. We brought four people this year from our company, and I told the owner that we must come back.”

Eichholz believes that seeing equipment in-person on the tradeshow floor also has real value, particularly when pondering the considerable cost of relevant units. “With the equipment, everyone needs to see it, touch it, feel it,” Eichholz explained. “In our industry, nothing is inexpensive. To be able to see it and its competitive counterparts is super important.”

For exhibitors, NPE is a chance to see of lot of existing clients under

one roof, with the added benefit of cultivating new relationships. On Day One, attendees got a two-hour window to check out the show floor during Preview Night.

“Preview Night was awesome,” said exhibitors Don Wincek and Kevin Coleman of Titan Tool, Plymouth, Minn. “The camaraderie in talking with contractors and helping them with their business is rewarding. I don’t know what it was about that opening night, but we were slammed. ”

Exhibitors appreciated the serious nature of NPE attendees, frequently commenting that the show attracted the right audience.

“We’ve had serious inquiries, a lot of great conversations, and strong interest,” enthused Josh Bond, of Curb Roller Manufacturing, in Fairview, Kan. “Overall, it’s been a really good show for us and we’re looking forward to next year in Tampa.”

“NPE has been awesome and it feels like we’ve recovered from COVID,” added Brett Fairbourg, from Crew Tracks, in Layton, Utah. “If we don’t close a handful of sales, I’ll be shocked. We got a ton of leads.”

“NPE delivers more than 50 conference sessions over a 3.5-day span,” said Morgan Wilson, show director. “Whether attendees want to increase industry knowledge, sharpen skills, improve efficiency or learn about the latest and greatest products, they can do it at NPE.

by Porscha Brooks, marketing manager, National Pavement Expo

by Porscha Brooks, marketing manager, National Pavement Expo

Read the full article: https://pavemg.com/

NPE2023There’s plenty of opportunity to strengthen or create new connections.

Grindlazer ® Standard-Series

Graco GrindLazer Standard Series scarifiers are great for removing trip hazards and smaller traffic markings. These highly-portable scarifiers pack a ton of capability into a light, compact package that’s easy to load into the back of a truck. This makes them ideal for tackling multiple smaller jobs quickly or working in urban areas with limited parking.

PRODUCT FEATURES:

• Highly-portable design for increased mobility

• Cut a path up to 8 in wide

• Wide variety of cutters and accessories for job flexibility

• Depth control lever and dial for fine-tuning your removal

• Adjustable handlebars and vibration-reducing grips for operator comfort

• Reliable 6.5 HP and 9 HP Honda® gasoline engines

•

On the evening before the official beginning of the expo, Marvin Joles and the team behind Blacktop Banter hosted a multisponsor event at The Public House, within walking distance of where the convention was held. The free event was highly attended by contractors and fans of the popular pavement-themed podcast.

The mood was energetic as Joles pulled a raffle giveaway for a sealcoating equipment package worth an estimated $15,000. As the winner was selected, those who gathered shouted, clapped, and cheered. It was a good omen, a vibrant sign of life ahead of the week of NPE.

One of the people in the raucous crowd, Marco Menna, co-owner and founder of All Out Parking Lots, said, “This is the future of the industry right here—this group of people.” He gestured around the room. “Connecting with the next generation is the most important thing.”

His sentiment was echoed throughout the expo: things have changed.

At every booth, in every session, people were talking about it. When the expo floor opened up to the public, there were a number of groups walking about

with what have become some of the standard symbols of social media content creation. Steady-cam type rigs, with shotgun mics and boom arms, lighting setps, all following around one group or another, generating content for Instagram, Snapchat, or, more likely, Tik-Tok. The latter has seen an explosion in views, engagement, and popularity for various hashtags and online communities that surround the "asphalt life" and brands like Matt Stanley's hugely popular "Raised on Blacktop".

Despite NPE 2023 being this editor's first such trade show, there was definitely an air of ascendency. This group was really staking a lot of ground, and showing that the industry, these days, looks and sounds a lot like what they're doing. More and more, businesses are seeing that to survive or grow, at least a semblance of these new methods need be applied and taken seriously.

The education sessions kicked off with a broad array of classes and workshops that varied from the basic, to advanced operations and technologies, and business-related seminars focused on growth and profitability. One in particular was hosted by Pavement Advisory Board member Nick Howell, where he diagnosed and diagrammed common pavement failures with photo examples.

In the standing-room-only session, well over 150 contractors were shown how to examine sites for clues and evidence to determine, as well as how to treat, the causes of pavement failures as if they were asphalt doctors.

Steve Young, of Young Sealcoating Inc., hosted a three-hour workshop on “Becoming a Sealcoating Pro: Sealcoating A to Z,” giving a full class detailed instructions on sealcoating types, application methods and additives, as well as strategies for successful business techniques and sales methodology.

“Be friendly, be engaged and interested, but most importantly, listen to

The good news is the industry is thriving, and people are as passionate about the work as ever.Photo taken of GRACO's official NPE booth.

Stay ahead of the game with Dynapac’s decades of experience in the world of compaction and paving. The compact line of equipment gets the job done in confined spaces, small parking lots or landscaping projects. From sand to soil, rock to asphalt, Dynapac’s plate compactors, mix spreader and walk-behind rollers are the preferred choice for contractors

what the customer has to say,” Young said. “Build the value of your service with each step.”

There were more stellar sessions than a single person could attend, like, “Women in the Workforce,” and “The Impacts of Job Costing,” and many others. The largest observation was just how full the foundational knowledge seminars were. It revealed an underlying thirst for the vital, basic knowledge that undergirds the entire industry.

Over and over again, the importance and value of these classes was reinforced by, not just the instructors, but everyone. This is what makes NPE, and other shows like it, so important.

The NPE show floor opened to what one attendee describe as an “intimate” environment. But there was a fair amount of foot traffic and energy from the crowds making their way up and down the show aisles.

One of the most exciting and different products on the floor was a fully-electric sweeper, made by the AebiSchmidt Group. The cabin is deceivingly spacious, despite what it appears like from the outside. It’s a cool design top-to-bottom. It boasts a 10-hour work

cycle. The company representatives said the current lead time on new orders is around 12 months.

Some features of the E-Sweeper:

• Recharges in just four hours

• Low noise emission

• High performance and driving performance even on demanding sweeping jobs

• Battery service and diagnosis are carried out by Aebi Schmidt, as well as free take-back and recycling.

• Two or three-broom systems available with a pulled suction shaft.

Another that garnered a lot of attention was the Blacktop Banter specially branded sealcoat rig, which featured a unique sneaker-headlike colorway different from KM International's usual designs. KM International, who produced the rig, also had their own separate booth, as well.

In a situation that did strike some attendees as odd, voiced in a few overheard comments, the only “paver” on the floor was a skid steer attachment produced by Road Widener LLC, used for shoulder applications and asphalt patching. Amidst the various other sweeping companies like Tymco, Schwarze, and Nitehawk; there was a really good turnout of striping manufacturers and sealcoat producers. The maintenance side was well represented.

NPE’s official party took place at the NASCAR Hall of Fame, and sported a big room filled with refreshments and race cars. It was a great addendum for expo attendees, and all that was required was your badge to get in.

At another party, simultaneously hosted by SealMaster across town at the Charlotte Beer Garden, partygoers were treated to a wall of over 400 different varieties of beer, and a nice spread of food.

These types of gatherings serve an important purpose for the industry. So much of what makes NPE what it is, comes from the relationships that people get to make.

Getting this kind of face time with customers, clients, and OEMs can be an invaluable thing when discussing

where people are going to put their preciously tight budgets.

“Whenever you can get people together in person like this, it’s a good thing,” said Nancy Terry, the executive director of NAPSA.

“This is my 30th show,” said Michael Nawa, a veteran of the sweeping industry. “No matter how many years you’ve been in, there’s always something to learn.”

That sentiment rang true from almost every man or woman at the expo. Even in Nancy Terry's article in this month's issue, she describes the power of networking, so be sure to read her feature.

Next year's National Pavement Expo is moving to Tampa, Fla. For

As with other industries, asphalt and pavement companies are not immune from challenges that compete for time and resources. Between supply chain shortages, the industry-wide push to go green, and the existing demands on the business, many are feeling the pressure to compete.

One of the often-discussed outcomes of the COVID-19 pandemic was the impact to workforce that many industries still face today. The U.S. Chamber of Commerce reported in late 2021 that “Almost all (92%) contractors report some level of difficulty finding skilled workers, but this quarter, 55% indicate high levels of difficulty… This lack of workers is having an impact on contractors’ bottom lines.”

In the same report, those contractors that reported struggling to find skilled labor had to turn down work, and experienced difficulty meeting project deadline requirements. And, because of the impact this is having on their bottom line, more than half have increased their bids for projects.

We often tell clients who face these kinds of challenges that there are things they can do to keep their current workforce and bolster loyalty, and many employers are often doing these things already. This can include healthcare and retirement benefits, training and educational opportunities, and professional development, including performance review structures.

And while this may help keep the employees you do have, it is only part of a solution for filling your labor gaps.

An often forgotten or seemingly overwhelming fix to this workforce problem is immigration.

In fact, there are various avenues for solutions based on business needs, especially if you have specialized needs that require education, and some solutions can lead to a more permanent results.

The H-2B Visa is the most commonly utilized visa for companies in the asphalt and pavement industry. This is a nonagricultural, non-immigrant visa so there is a limit on how long these individuals can stay in the country. The length of stay in the United States varies based on the seasonal justification for the work.

Like other visa types for businessbased immigration, there are various requirements for the employers, which is why it is valuable for employers to hire skilled immigration attorneys to ensure compliance.

And, there are other things to consider with the H-2B Visa, such as the annual cap of 66,000 and the amount of time necessary to go through the application process. But for many, this can prove to be a great solution for companies who face seasonally fluctuating labor demands.

For more specialized and skilled labor, the TN Visa is an additional solution. Created through NAFTA, the TN Visa is a non-immigrant visa for certain qualified Canadian and Mexican citizens for professional roles. Both the job title and responsibilities, as well as the candidate, must fit within certain qualifications for specifically identified professions.

One of the benefits of the TN Visa is that it allows for candidates to remain in the United States for up to three years with additional extensions available. This is critical for providing long-term employment for companies in need of specialized labor, ensuring your business can focus on business rather than spending time on hiring for positions that require professional qualifications.

And, there are other options for more permanent solutions, such as the PERM (or EB-3). A candidates’ eligibility for the EB-3 is determined based on education, specialized skills, and relevant experience. There are three types of EB-3 Visas, all of which may be relevant for the asphalt and construction industry: Skilled, Professional, and Unskilled.

Each year, roughly 40,000 EB-3 green cards are issued. But similar to the H-2B Visa, there is an annual cap on the number of EB-3 green cards (140,000 per year).

The process to apply for and be approved for this type of visa varies on a number of things, including visa availability, if the application is audited, among other reasons. PERMs can be a great solution for companies who do not have a seasonally fluctuating demand for labor, but face a perpetual labor shortage.

The process for any of these visas are often perceived as time consuming and costly, especially at first glance. But there are resources to help you determine the right course for your business and understand all the available options.

If you keep trying the same recruitment tactics, you’ll likely end up with the same results. This labor shortage is expected to continue, and many have gone as far as to argue that the worker shortage in the U.S. may be an immigration shortage.

The solution to your workforce problem may not be as simple as it once was, and the answer to growing your business could be via immigration.

by Vas Sakamur, chief revenue officer, Farmer Law PC

For more information visit http://asphalt.com/kk3fi1

The competition for workers is steep.

No matter the initial quality of asphalt pavement, it will need preventative maintenance over its service life to continue to provide safe, viable and beautiful roads. Pavement preservation can help maximize road budgets. Experts estimate that, depending on road conditions, every $2 spent on pavement

preservation can save $4-$18 on future costs. Sealing cured asphalt can help the pavement resist oxidation from the sun, revitalize its surface and provide a protective layer against water, oil and salt. As such, sealing is a worthwhile investment for asphalt surfaces that are still structurally viable but are showing signs of age. When it comes to sealing, contractors generally have two options: sealcoating or using an asphalt chip seal. While sealcoating seems to be an initially less expensive option, it cannot repair cracks and other forms of distress because it is a surface treatment that only mitigates water and other chemical penetration. It has no structural strength of its own and will need to be reapplied every few years or so. On the other hand, asphalt chip seal not only provides similar protection, but it also can reconstruct more distressed pavements (including those with minor alligator cracking). It can also last up to five times longer than sealcoating.

Chip seal made with lightweight aggregate, such as expanded shale, clay or slate (ESCS) can provide a

cost-effective surface treatment that both repairs roads and improves their safety and durability. Because ESCS has a network of unconnected voids, it provides an increased surface area to bond to the emulsion. As such, it can withstand high-speed traffic and normal wear-and-tear that pavements undergo—resulting in a surface treatment that can last up to 10 years.

The voids increase the retention rate of aggregates, which can lead to a significant reduction of application and maintenance costs. For example, in 2017, the Carbon County Road Department reported that the increased retention rate of lightweight aggregate, as well as reduced fuel costs due to the material’s lower density, resulted in more than $300,000 in savings annually.

In addition, these voids lower the aggregate density, which means if a patch of pavement were kicked up, the force it would inflict on windshields and headlights is much lower than conventional aggregates. In fact, after switching to lightweight aggregate asphalt chip seal to repair Interstate-84, representatives from the Utah Department of Transportation (UDOT) stated they had zero complaints about damage. They continued, “This is unheard of for a chip seal.”

The voids also help asphalt chip seal resist polishing for long-term skid resistance. This contributes to safer roads in both wet and dry conditions. And despite the long-term skid resistance, the aggregate creates a more uniform road surface, ideal for vehicles and bicycles alike. Using lightweight aggregate chip seal can be an efficient

How chip seal made with lightweight aggregates can be an economical means of preventative maintenance.Crews place aggregate over oil emulsion Courtesy of the Expanded Shale, Clay and Slate Institute

W 240 CR(i) / W 380 CR(i): Cold in-place recycling offers ideal solutions for the sustainable maintenance and repair of existing road infrastructure. The W 240 CR(i) and W 380 CR(i) machines recycle the old road surface and add new binding agents to the material on the spot. This enables the creation of an enduring, hard-wearing and sustainable base layer as the basis for a good road infrastructure that can stand up to a future with ever-increasing traffic volumes. Take advantage of the innovative solutions from the technology leader in the road construction segment.

www.wirtgen.com

means of preventative maintenance, if project managers observe the following steps as a best practice guide.

Before starting a chip seal project, it is important to survey the site to ensure it is in good enough condition for preventative maintenance. While chip sealing can repair some damage, it is not recommended for unsealed cracks greater than a quarter of an inch, rutting deeper than 1 inch and medium- to high-severity alligator cracking. If a site has these damages, sealing and repair will need to take place prior to the placement of asphalt chip seal.

In addition to surveying the site, it is recommended to have a pre-construction meeting, so all parties have clear and defined expectations. This includes detailing any pre-application maintenance that needs to occur, confirming timelines, determining application rates and whether a site needs a single or double layer. Taking these steps before starting a project increases both the effectiveness of asphalt chip seal and the overall satisfaction with the finished project.

The next step is to prepare the site for chip sealing. For highly-distressed sections of pavement, contractors should have crews seal any large cracks, fill ruts and repair other damages roughly three to six months prior to the application of asphalt chip seal. This timeline allows these repairs to cure fully, creating a suitable foundation for the asphalt chip to adhere to.

On the day the chip seal is to be placed, the road should be thoroughly cleaned. This includes washing off mud and sweeping away any dirt and debris from the pavement surface. If washing is required, the surface should be allowed to dry completely. This step helps the emulsion stick directly to the old surface— reducing the risk of misapplication.

It should also be noted that ambient temperature should sit between 55

degrees and 90 degrees Fahrenheit (F), and the pavement temperature should be 70 degrees F and rising.

Once the preparations have taken place, contractors can place the chip seal. First, contractors should dial in the proper shot rate of emulsion based on site conditions—generally between 0.33 and 0.38 for type A, or 3/8 inch, chip sand 0.42 and 0.48 for type C, or 1/2 inch, chips. It should be noted that the rate should be increased for new asphalt or roads with more distress. For these projects, the spreader should stay very close to the distributor truck. For high traffic areas or ones with less distress, the shot rate can be decreased slightly.

the road. Perform at least three passes with the rubber tire rollers.

During these processes, contractors will need to pay attention to all equipment to sustain the quality of chip seal placement throughout the project. This includes maintaining the proper spray bar height and watching for plugged nozzles. Staying vigilant on these aspects of the job will keep the emulsion uniform and smooth, which will not only help the chip seal bond to the pavement better, but will also ensure the most cost-efficient use of materials.

After the chips have been placed and rolled, contractors should lightly broom or sweep the loose chips from the tip of the chip seal. Waiting longer, especially if the chips have been placed too heavily, will result in crushing. For non-curbed streets, the brooms can sweep the aggregates off the side. ESCS lightweight aggregates are chemically inert and free draining, so they will not cause harm to neighboring ecosystems. For guttered streets and residential areas, the brooms should be able to vacuum or pick up the chips into a box rather than side casting them into the gutter.

After applying the emulsion, the spreader should distribute chips in a uniform, single layer. Doing so helps ensure the chips will not grind against each other, crushing and breaking. It is also important that the chips are not spread too thin; this will allow oil to bleed through the spaces between the ESCS aggregate. Then rubber tire rollers should follow the spreader to embed the chips firmly into the emulsion, so the chips will not peel off

Following these steps can help contractors utilize asphalt chip seal as a preventative maintenance material. When the chip seal is made with lightweight aggregates like ESCS, it can provide a smooth and longlasting surface to highway and municipal roads—extending the service life of most asphalts by five to 10 years, depending on traffic and environmental conditions. As such, asphalt chip seal presents a costeffective alternative to sealcoating for pavements that are still structurally sound but are showing signs of aging.

by Steve Hoard, committee chairperson Expanded Shale, Clay and Slate Institute.

by Steve Hoard, committee chairperson Expanded Shale, Clay and Slate Institute.

For more information visit https://pavemg.com/ chipseal

There is an entire universe of challenges facing the asphalt paving and maintenance industry. When we interact with industry leaders and experts, there’s talk about inflation, the labor shortage, supply chain constraints and systemic inefficiencies. There is no doubt that the asphalt paving and maintenance industry is lacking in skilled workers.

The World Economic Forum predicts that the construction sector will be almost fully digital in 10 years, with potential worldwide savings of $1.2 trillion as a result of enhanced productivity and efficiency. The industry must, however, be prepared to absorb those changes. Is it ready?

While some businesses have struggled to cope with inflation and supply chain constraints, others have remained largely resilient. So what is the difference? Having worked with asphalt paving and maintenance industry leaders, we have developed a two-part theory to explain this.

Everything starts with your people. That is the absolute first. The best people bring the best results. We recently had the opportunity to speak with Brenda from Beary, Joshua from East Coast Facilities, and Michael from US Lawns. The common success mantra was: “It’s all about the people.” Finding and hiring skilled personnel will continue to be one of the biggest issues facing the asphalt paving and maintenance sector in 2023. Let's discuss how the biggest difficulties in paving maintenance and construction could also present our biggest opportunity in 2023.

The second part of our theory is–systems. Businesses that have solid systems and infrastructure to enable their teams to live up to their potential, win consistently. Systems that promote employee productivity lead to better

bottom- and top-line performance. And not just that, they also help employees realize their personal goals, keeping them happy in the organization.

So, let’s talk about some of the systemic problems that persist in the asphalt paving and maintenance industry and technology systems that can help solve them seamlessly?

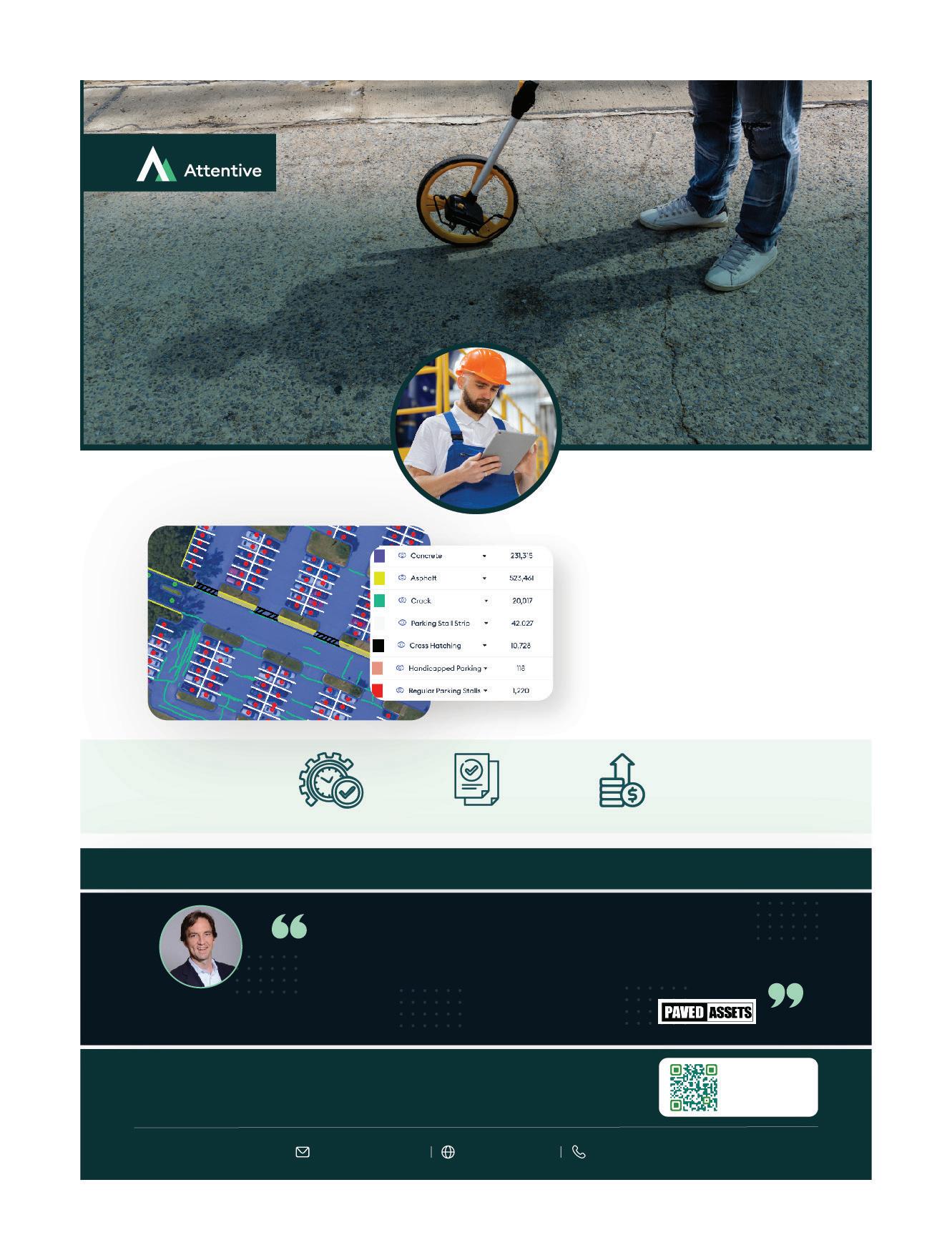

Imagine the entire asphalt paving and maintenance industry sales process. You receive a bid request. You then size up the property to measure asphalt and other materials, wheel off cracks and count the parking stalls. If you don’t have an estimating team, you manually measure it by visiting the site, which takes away time from core selling activities. While you do all this, you try to set time up with the property manager, to establish a rapport and understand the requirements better. Once you are done manually measuring the site, you work on the production rates to arrive at the estimate.

Then you write the proposal, sometimes very close to the submission deadline. Sometimes you are late or scramble to put a proposal together by guesstimating. Then there are the opportunities for additional work that are lost because you did not have time to work on the proposals.

The moral of the story is, there is just so much to do to put that proposal together. As a business developer, your job is to open doors. Build relationships. Win business. That’s what you want to do. But what ends up happening is hours spent away from doing all this, just because you had to measure, estimate and write the proposal. Let’s delve into these problems in detail:

Whether you are wheeling off the site or drawing polygons on Google Maps, it is a drag on your productivity and keeps you away from selling. In the peak season, you might be spending up to 10 hours per week just measuring. Think about what you can do with 10 extra hours every week in the peak season. Over time, these lost hours accumulate and multiply. It slows down your sales velocity heavily.

Building estimates manually is a task in itself. You need to devote time to building the off-the-site measurements and you need the right production factors in place. The cost of a mistake here is huge: if you bid too high, you risk losing business to your competitors; if you bid too low, you shave your margins thin. What often ends up happening is that paving maintenance professionals rely on guesstimates, resulting in lost bids.

Most contractors are passing up on project contracts worth thousands of dollars per month without even being aware of it. They are preoccupied, lack the time to estimate, and are leaving money on the table. The sales force in the asphalt paving and maintenance industry is stretched thin. This problem can especially be felt when instead of building customer relationships, salespeople are stacked with jobs that can be automated. No matter how skilled you are at your trade, you can’t win every job, especially if your team cannot get accurate proposals out the door.

The entire process requires you to use multiple tools for takeoffs, estimates, and proposals. Your manual takeoffs tool might not be so good when it comes to creating estimates or proposals. Therefore, you are stuck in the busy work of exporting outputs from one tool and importing them into another.

Consider an end-to-end sales process automation solution that does everything for you, right from the moment you receive the request for a proposal to the moment you submit. You enter the address and select a preset proposal template. Then go back to spending time with your prospects, while the software does everything for you. Many are flexible enough to accommodate existing workflows. Just imagine what you could do with a sales process automation tool:

• Save time and spend it on what you love doing: selling.

• Accurately estimate costs to evaluate projects' profitability.

• Send out as many proposals as you want.

• Crush your quota with proposals that win. Remember everything starts with sales. So, once a job is won, you can always look back by performing project reviews to compare actuals to the budgeted costs. This gives you an idea of how accurate your bids have been and helps your ops team plan better.

Businesses of all sizes can adopt automated software, a testament to the value great systems bring to the table. Ryan, an asphalt sales manager at Elements Mountain Company said about their automated software, “It

gives me peace of mind that I am sending out accurate bids. Time saved on travel and manually measuring parking lots had been a huge savior. The HD sitemaps help plan crew movement on site efficiently, aid in better communication with clients about the scope of work, and the takeoff maps look very nice.”

With the right automated tool you can get site measurements for asphalt area, line striping length, crack length, and count parking stalls with zero manual effort and without having to visit the site in person. Additionally, you can find end-to-end sales automation, which can handle takeoffs and also create estimates and proposals based on pre-set templates.

by Shiva Dhawan, co-founder and CEO at Attentive.aiFor more information visit https://pavemg.com/sales

7 tips to a successful, lucrative relationship.

We have all heard of highmaintenance clients, and most of us have done work for them. First, let's break down exactly what a high-maintenance client is. I have found that most high-maintenance clients are homeowners. A close second place is the overachieving property manager, followed by the retired “expert” on an HOA board. The general theme with these folks is they want the best job without fail, and at the cheapest price.

In their minds, they do all they can to “help” you get to that point. Little do they know that their “help” ultimately just drives up prices, wastes time and really stresses out the crews. We are not afraid of people watching us work, but I have always said the best scenario is when the owner is not present during the job. It’s best when they can come and see the finished product.

Here are some clues to help identifying a high-maintenance client:

• Invite more than three people to bid.

• Have a scope of work that they created that is overly complex.

• Require pre-bid meetings.

• Many calls or emails prior to the bid.

So, if a potential client checks some those boxes, should you do work for them? I would emphatically say to give it a shot. We are in business to make money, so don't turn down a difficult client, just recognize what you are dealing with and plan (and price!) accordingly. If I am concerned a customer might be difficult, I might reach out to a friendly competitor or two to ask if

they have worked with them before. Usually, you can expect to spend more time communicating with them, you can expect to be questioned about everything, you can expect a day or two of touch-ups, and you can expect more paperwork. However, you can usually expect to be paid and, if bid right, paid more than a regular job.

If you know it’s a high-maintenance customer or suspect it will be, as you inspect the property, you can start putting things into action right from the get-go to make things go more smoothly, and to protect yourself. If you plan and prepare with these few tips, the return is often worth the risk:

• Only bid projects that you are comfortable doing. These are not the clients to try to spread your wings.

• Anticipate the extra time, extra trips, and aggravation that will be required, and charge for it. You must include this in your bid, otherwise it's easy to lose money on these projects. This is what makes these jobs worth it. Sometimes the additional effort required is significant, so don't be afraid to charge appropriately.

• Communicate clearly. I have found that extra communication with morethan-normal information is hugely important and extremely beneficial in the long run. Send “what to expect” sheets, progress emails, pictures and certainly an email and final pictures when the job is finished.

• Proactively schedule your own preconstruction meeting, even for a small job. Remember, it’s about making them feel comfortable.

• Be proactive and invite them to the

job one day. Pick a day that things will be easier. Walk with them and talk shop a bit, but keep it brief.

• Have an onsite meeting on the last day, while your equipment is still there. This is the time to address any issues. Get them to sign off on any fixes and sign off on the project.

• Schedule a follow-up in a week to have another walk-through.

I realize many of these items are what high-maintenance clients expect anyway, but by being proactive and by you scheduling them, you take charge of the situation. Some of my best clients now are ones that I was so close to walking away from. They now give us work (without going to bid!) are huge advocates for us with other customers.

High-maintenance customers can usually be won over, and through special handling will not only get you paid, but you might just find a client for life, and a higher-priced client, too. Working with this type of client is a challenge that most contractors don’t want to deal with, but if you can do it right, the benefits will pay off in the long run.

For more information visit https://pavemg.com/ highmain

Nick Howell, president of T & N Asphalt Services, Salt Lake City, UT, has been a regular presenter at National Pavement Expo since 2008 and a member of the Pavement Advisory Board since 2007. Let him know your thoughts on “From the Owner’s Desk,” and if you have a question or topic you’d like covered – let him know that too! You can reach Nick at nick@tnasphaltservices.com.

Held in conjunction with the National Pavement Expo, the new 2023 Board of Directors for the North American Power Sweeping Association met and set a direction for the association’s future. This volunteer group assesses the challenges that are faced in our industry and develops goals for solutions to those pain points.

This year’s list of needs included getting qualified and trained operators into driver seats. Finding and training qualified employees is probably the biggest pain point currently. The room of industry rockstars contemplated and strategized for two days on this topic.

NAPSA has a history of bringing education to talented people through the use of our SweeperSchool.com website. For 2023, NAPSA has slated a roll

out of a new Certified Sweeping Manager course in Emergency Preparedness, Certified Sweeping Operator Municipality and our Fleet Basics course in Spanish. These courses, coupled with some additional focused benefits, will fill the agenda and bring much added value to members and the industry. Let’s introduce the 2023 NAPSA

Board of Directors:

President: Cole Watts, More Clean of Texas, Texas

Vice President: Dustin Moist, Cantel Sweeping, Ore.

Past President and Treasurer: Chris Dick, Katsam Enterprises, Mo.

Secretary: Mark Carter, Peloton Sweeping Service, Calif.

Bill Smith, Smith Property Service, Massachusetts; Scott Duscher, Agua Trucks, Arizona; Joe Wise, Asphalt Enterprises, North Carolina; Jim Blackerby, Louisville Pavement Sweep, Kentucky; Becky Chamberlain, EcoSweeping, Colorado; Philip A. Alia, APR, Sweeping Corporation of America, Ohio; Logan Brasher, CP Maintenance, Tennessee; Joe Hendrickson, Schwarze Industries, Alabama; Jeff Old, Visual App, Texas; Jake Hoerman, Nite-Hawk Sweepers, Washington

The North American Power Sweeping Association (NAPSA) is a nonprofit association made up of 200+ contract sweepers, service providers and sweeping equipment dealers, manufacturers and suppliers. NAPSA is dedicated to providing beneficial support to the membership and enhancing services to the sweeping industry. NAPSA is committed to promoting and educating the power sweeping community while enhancing the environment. For more information on NAPSA membership,

by Ranger Kidwell-Ross

by Ranger Kidwell-Ross

Since this issue focuses on sealcoating, our WSA article this month addresses the critical importance of pavement sweeping, both prior to, and after, sealcoating the pavement’s surface.

First, before any sealcoating job, it takes at least a mid-level parking lot sweeper to get the surface cleared of all material, including any larger rocks/ gravel on which an entry-level sweeper will likely not do an effective job.

After sealcoating and re-striping, regular sweeping helps preserve and extend the life of both the asphalt and sealcoat due to its removal of dirt, debris and other harmful materials. This also helps to prevent damage from moisture and chemicals, which can cause cracks and other forms of wear and tear.

As a caution, though, be sure to discuss with your sweeping contractor the methods they will employ when sweeping fresh sealcoat, since the pickup head on most sweeper models is held off the ground by flat, carbide-surfaced skids similar, to skis. Extra care needs to be taken not to mark up fresh sealcoat with these via minimizing any downpressure of the head.

Regular sweeping is an important part of any maintenance program for asphalt surfaces, helping to keep them looking and performing their best. This helps to extend the life of both the sealcoat and striping, which maintains the appearance and performance of the pavement for longer.

The WSA provides a collection of over 250 articles and related information at WorldSweepingPros.org.

ARM

Services brings top-notch work to the Detroit metro area. For both asphalt and concrete jobs, they’re proving they can do it all.

Alot of times when you talk to people in the pavement maintenance industry who are third-generation entrepreneurs, the story is of a business being handed down, parent-to-child-to-grandchild. That story often follows with tales of being out on jobsites from an early age, either on weekends or summer breaks, at work on the blacktop. Those stories are something to be proud of, of course, but that particular type of story isn't the case with ARM Pavement Services. Their journey into the industry looks different.

"My dad said that he wanted us to be focused on school and in sports," said Ross Moore, part of the family that started ARM.

"They never had a job. Their job was to play sports," Ross's father and business partner Rod Moore said. "We've had great grace. For me to see their grades and other achievements is good, but, for me, what I really wanted to see was for them to just do their best." He went into detail about the varied and successful athletic careers all three of his children (two sons who both work with him at ARM, and one daughter) who brought home a combined four state championships, across three sports.

ARM formed in 2020, and in just three short years, has exploded in growth around the greater Detroit metropolitan service area, offering just about every kind of pavement maintenance or repair, including handling some concrete work. The three-man team of father and sons (and Mrs. Moore running the accounting side of things) has literally been beating the pavement, as they completed approximately 680 separate jobs in 2022.

"I gotta give my boys credit, it's a lot of wear and tear, and they go sun-up to sun-down," Rod said. "As a 60-yearold dad, I'm right there with them," he paused and looked at his elder son Ross and then continued, "but to make a long story short, this was his dream, his vision is how we got into it."

Rod's father JW Moore, of Macon, Ga., came to Detroit and eventually

started his own business that raised houses off their foundations, and dug out basements. For Rod, his entry into the asphalt side of the world came shortly after high school. After experimenting in a few different jobs he got his first asphalt paving job making $3.35 an hour.

"That was no money, but I always had an entrepreneurial mindset," said Rod. "For $3.35, I told myself that I'm gonna look at this like school. I'm gonna learn every position, and I'm going to perfect every position." With this motivating him, he quickly doubled his pay, and became one of the most experienced members of the crew. So much so, that his father called him about joining a different paving company, and by midway through that year, he had advanced from a general laborer to a foreman, and then to project manager.

However, the hours were long, and could be unpredictable, even if the money was a lot better. Rod left the paving world for a position with a local sweeping company, when he was made the type of offer he couldn't refuse. It was the type of offer that spoke to the most important thing to Moore, his family.

"My kids were little," Rod said, "and I told [the sweeping company] I had a great job, but they told me, 'One thing we'll guarantee you, you'll never have to miss anything that has to do with your

kids.’ I never missed a school conference. I've never missed a sporting event. I've never missed anything. My kids are my world."

But how did things get here? Where did ARM come from?

"My dad's always preached entrepreneurship," Ross said. "In my senior year, I was already thinking, yeah, this is what I want to do." During the first year of the COVID-19 pandemic, Ross had the opportunity to do a "Pro-Day" with the University of Toledo to play football, but the lockdowns cancelled that. He was disappointed, of course; he had worked hard his whole life to get to that point.

"I had to ask him," Rod said. "’What do you want to do now?’ And he literally said to me, 'I want to start a pavement maintenance company.'"

If the answer to his dad's question about his future plans seemed surprising, what happened next borderlines on fate.

When out on a sweeping job, Rod came across a local guy who happened to be sitting on a small fleet of nearly brand-new machines, going unused: a large sealcoat tank, a crack fill machine, an infrared patcher, and everything else Rod knew they needed to make his son's dream a reality. When he asked about the equipment, the owners explained they had plans to start up the work but, due to COVID, hadn't been able to get things going yet. So, point blank, Rod asked about acquiring the machines.

"The guy says, 'Well, let me run it through to my boss,’" Rod recounted the exchange. "I didn't hear back, but I'm persistent."

Eventually, Rod discovered the machines were to be sold out-of-state to a buyer in Arkansas. However, he wasn't going to let this opportunity slip away. After several calls back-and-forth, Moore was able to secure the equipment by negotiating against the other offer and the costs of transporting the machines. Someone in Arkansas had a really frustrating day, to be sure, but Moore delivered all that they needed to launch ARM.

Looking back now, from the show floor of NPE 2023 for the interview, Rod remarked on the way others in the industry embraced them, and how that has been just as important as landing the right equipment. "People like Marco [Menna], and the Raised on Blacktop

crew, I mean, those guys were awesome to us. They treated us just like family, Day One. They gave us a lot of good advice."

For more information visit https://pavemg.com/ ARMPave

Rarely do I write articles on a single point in history. But with the events of the past few years, my engagement with contractors around the world has led me to address more current issues.

No doubt the impact made from COVID-19 is global and it was, and is, devastating. This epidemic also “carpet bombed” leadership, production, safety and quality like we’ve never seen before, leaving some incredibly negative consequences in its wake. Between supply-chain inconsistencies, ongoing government overreach and financial concerns filling senior leaders’ discussions, it is important that we strengthen our focus as owners and leaders.

Financially, contractors must take an honest look at their cash situation. “Cash is king,” as the saying goes, may be more appropriate today than in the past. As interest rates are again moving northward, it is critical that contractors take a second, third and even fourth look at their cash situation, being careful to borrow money that will have greater rates.

Purchasing equipment may require more evaluation. Contractors

love their equipment and, like a proud collector of antique cars, it’s easy for many contractors to build a fleet of equipment. It is good for one’s pride to look out over a yard and enjoy the lineup of trucks, trailers and needed pieces of equipment.

Leasing equipment may need to be more the norm for contractors, and for more than only financial reasons. At the rate of updates now on equipment, it may make more sense to lease equipment where software upgrades are most likely covered.

Material costs have skyrocketed in many parts of the United States and the outlook doesn’t immediately look better, although any significant return to fossil fuel development would provide some relief. But again, at this time it doesn’t look promising. So, what’s a contractor to do?

• Don’t be shy about bringing increased material costs to the attention of your customers. They don’t like it either, but most are more understanding.

• Conduct a potential volume need and negotiate with your material supplier.

• Tighten up estimating procedures to ensure you are bidding for

the exact material use. This will require more accountable documentation. I still see contractors throwing a few extra yards of materials, tons of asphalt, etc. into a bid. Employee costs continue to be as high or higher than ever. With new employee loyalty at perhaps one of the lowest points in many years, contractors are working harder than ever to find and retain the right workers. I’ve written and spoke on this topic for years, but we are having more challenges in our industry than ever. Here’s a couple of thoughts for the next few years:

• Start preparing better when recruiting and interviewing. We’re still seeing too much hiring just because we’re very short on the bench.

• Pay competitive wages, but more importantly, start training on Day One.

• Start paying retention bonuses to the new worker, foreman and your crew. It’s the foreman or crew that often run off a new worker. Give them an incentive to work with, develop and retain the new worker.

• Personally make more trips to speak to new workers. My research

has shown that the top three reasons why new workers quit early, many after just 30-40 days, is because: No one is talking to me. No one is training me. No one is following up or coaching me.

Be more active and visible. Create a regular training program for workers that includes tool handling, required work processes, material knowledge and how to be a better team player, improve safety, etc.

No one has a crystal ball, but things look extremely challenging moving forward. Tread sure-footed by being honest and quick to address future indicators that might reflect bumps and hurdles ahead.

Being prepared for the worst may help you achieve the best!

For more information visit https://pavemg. com/retain

[March 14-18, Las Vegas, NV]

Sponsored by:

BROADCASTING: March 14-16, 2023

Las Vegas Convention Center Booth N-12839 | North Hall

Whether you attend CONEXPO-CON/AGG & IFPE in Las Vegas or can’t make the trip, the dedicated CONEXPO channel from AC Business Media Construction Network will keep you well informed.

Watch LIVE newcasts: at Booth N-12839 and meet the editors.

Watch ONLINE: ForConstructionPros.com/equipment Tune in for broadcasts and videos from the show, as well as continuous coverage before, during and after the show.

Brought to you by ForConstructionPros.com and AC Business Media.