OCTOBER / NOVEMBER 2022SAWMILLING • LOGGING • BIOMASS SAWLINES Harvester Heads Prime Movers & Mulchers Tyres & Tracks

Horizontal Grinders • Whole Tree Drum & Disc Chippers • Flails • Forestry Mulchers • Mulching Attachments

MORBARK WOOD HOG HORIZONTAL GRINDERS

MORBARK DRUM CHIPPERS

MORBARK

CHIPARVESTOR®

DENIS CIMAF MULCHING ATTACHMENT

You begin each day before dawn with a drive and determination to do more than the day before. When you move at this pace, you know to do more you need equipment that is made for more. That’s why our forestry, biomass, and recycling equipment is built from the ground up to meet your needs, delivering: More Power and Production Consistent, Quality End Product Lower Operating Costs Ease of Maintenance Greater Longevity and Resale Value Find your local Morbark, Denis Cimaf, and Rayco Dealer at www.morbark.com/b/international-dealer-network

Cover - Ponsse launches new technology: an electric forest machine

Ponsse and Epec introduced 17th of August 2022 the PONSSE EV1, an electric forest machine technology concept. While the forest machine will be commercially available later, Epec’s technology can already be used in electric or hybrid-electric commercial vehicles and nonroad mobile machines. Ponsse’s technological concept is a peek into the future, paving the way for technological development and sustainable harvesting solutions.

Ponsse provides sustainable harvesting solutions by listening closely to customer needs, and it also

aims to lead the way in the development of forest machine technologies. Ponsse is part of sustainable forestry and seeks carbon neutrality in its operations and solutions. This launch of a new technology concept is part of the company’s strategy and a tangible step towards the goal of carbon neutrality. Sustainable development guides all the company’s operations.

www.ponsse.com

International Forest Industries | OCTOBER / NOVEMBER 2022 1 47

TYRES & CHAINS

New

launches of Tyres, Tracks & Wheels for Forestry Tractors, Skidders, Harvesters and Forwarders

42

PRIME MOVERS & MULCHERS Industrial tractors and Mulcher heads from around the world

29

HARVESTER HEADS

Including

Ponsse, Komatsu, John Deere, SP Maskiner, Logmax, Keto-Ketonen, Waratah, Tigercat

42 29 HARVESTER HEADS LOGGING • BIOMASS CONTENTS OCTOBER / NOVEMBER 2022 REGULAR FEATURES 6 Logging News 48 Advertising Index LUMBER PROCESSING CONTENTS

OCTOBER / NOVEMBER 2022 SAWMILLING • LOGGING • BIOMASS SAWLINES Harvester Heads Prime Movers& Mulchers Tyres & Tracks 47

22 MOELVEN

Moelven it is investing in five continuous kilns and the Valmatics 4.0 control system to three of its sawmills

20 KOSKISEN

Koskisen’s future

line represents world-class

future

that also

22 USNR

USNR is to supply a new Shape Chipper Canter with profiling, Bandmill Monitoring Systems for 10 bandmills and a Multitrack Fence for the trim line at the Balcas Timber Mill

24 KOSKISEN

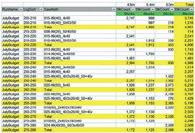

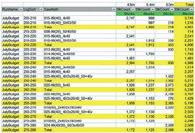

Image System’s business area RemaSawco receives order of just over SEK 2 million from Moelven Timber

This is the last order linked to the existing framework agreement signed between RemaSawco and Moelven Timber in June this year.

This framework agreement, which has a term of up to and including September 2022, can result in a business volume of a maximum of SEK 27.4 million.

The framework agreement covers the upgrade of measuring stations, sawlines, green sorting, and adjustment works at seven sawmills with RemaSawco’s system RS-715, RS-LogScanner3D, RS-FlexCon, RS-Opt optimization system, RS-ProSort, TopRot measuring system and RS-Con measuring system.

This order has been placed by

the sawmill Löten and includes upgrading of several existing systems.

In total, Moelven Timber has now ordered projects for a total of approximately SEK 28 million within the framework agreement (102%).

“With these orders, we are now modernizing our sawmills to a higher and uniform standard, which ensures improved production and supportability of our existing systems” says Peter Rockedahl, Technical Director of the Timber Division within the Moelven Group.

“It is very satisfying that we now have managed to close all the planned orders within the framework agreement, a real

milestone. Now we look forward to delivering and commissioning our systems” says Emilien Saindon, CEO of RemaSawco

2 International Forest Industries | OCTOBER / NOVEMBER 2022 LUMBER PROCESSING

sawing

product development

takes into account

needs 21 UAB “JUODELIAI” Installs a tomograph for use in the evaluation process of raw wood 21 20

16 SENSOLLIGENT

Progress thanks to IoT: Sensolligent’s innovative software solutions get the most out of your machine data

Stick-stacking

plant ready to serve new sawmill

22 16 SAWLINES 24

22

Emilien Saindon, CEO of RemaSawco

Peter Rockedahl, Technical Director of the Timber Division within the Moelven Group.

Millwide. Worldwide. +1.360.225.8267 usnr.com

SUBSCRIPTIONS

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Annual Subscription UK and Europe £160, €230 Rest of the world US$270

EDITORIAL

T: +44 (0)1442 877 583 F: +44 (0)1442 870 617 www.internationalforestindustries.com

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

Editor

Chris Cann chris@internationalforestindustries.com

Editorial Board

Dr Patrick Moore – Chairman and Chief Professor Piotr Paschalis-Jakubowicz –Warsaw Agricultural University (Poland)

Mr Kim Carstensen

Director General Forest Stewardship Council

Eduardo Morales

South American Forestry Consultant

EDITOR’S COMMENT

Look after yourselves

As we put the finishing touches on our October-November edition, the Autumn, or Fall, has well and truly closed in around our Northern Hemisphere readers. That means a few things.

The poets will draw inspiration from morning frosts and golden leaves. For those of us lucky enough to work in the forests of the world, we’ll also enjoy the change of season, but it is too easy to push aside some of the challenges this Autumn may bring.

This is no ordinary shift into winter. The trauma for many wrought by the COVID -19 pandemic has changed the landscape. Perhaps not the physical landscape – the stands are still there, and the sawmills continue to hum – but the mood is likely to have changed. The world, including those who rely on the forests, has been scarred.

Those already suffering from depression, and the increased proportion of society now vulnerable to more severe mental health conditions need support. And they need to know they can ask for that help.

Waking up to the dark and watching the nights close in early is already a tough time to manage your mood. My worry is the nature of forestry work combined with post-COVID challenges has made this Autumn a particularly dangerous period in our industry.

The forestry sector, though increasingly diverse, is still dominated by men. Though in many places the percentage of women in forestry is as high as 40%, this includes administrative and ownership positions. Though statistics range, we would speculate the percentage of women actually working in the forests is around 20%.

ADVERTISING AND PROMOTIONS

International Forest Industries Ltd Advertising Manager

Phil Playle phil@internationalforestindustries.com +44 (0)1442 87 77 77

Associate Editor

Robin Peach robin@internationalforestindustries.com

Advertising Production Enquiries

Emma Smith emma@internationalforestindustries.com

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTER: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831 © International Forest Industries Ltd 2007 – 2019 IFI uses, as preference, SI units throughout. All dollars are US unless otherwise stated.

As we deferred to advice almost solely from tropical disease experts, and politicians counted their success by the most confronting of immediate metrics – deaths – communities locked down for months on end. Some asked about the health challenges we were deferring by implementing this policy and the price we would be asked to pay in the future. They were reminded of the more pressing priority.

The fallout from neglecting treatment of other medical conditions could play out over the next couple of decades, but one immediate consequence from both the pandemic and our means of fighting it has been the impact on mental health.

Research published in The Lancet Psychiatry in 2021 was already showing up mental health problems for a third of those infected by COVID. This is before we consider the effects from lockdowns, loss of livelihoods and loss of loved ones.

More recent research from mental health charity Mind found another third of people were reporting their mental health was “much worse” post-pandemic.

As we welcome the opportunity to put COVID behind us, we mustn’t ignore its legacy.

The reason this is important is because research shows women are far better at managing mental health and seeking assistance when needed.

The picture all this paints is a worker sitting alone in the cab of a forestry rig for long periods in an environment growing increasingly dark. That worker is likely to be more vulnerable to mental illness than prepandemic and in most cases will be reluctant to ask for help if struggling.

We’re lucky in the sense our industry generally inspires comradery. There are also more mental health support networks than ever before, and contractors and employers are more aware and supportive than was once the case.

But it feels like this is a very real challenge of which we should all be aware. We should be encouraged to ask for help when needed, and be on the look out for signs a colleague may be battling.

Let’s look after each other.

Enjoy Chris Cann

4 International Forest Industries | OCTOBER / NOVEMBER 2022

ISSUE 89 October / November 2022

Tackle demanding forestry processing environments with the Komatsu PC230F-11

Your forestry crews need equipment that can deliver exceptional performance in difficult environments. Control downtime and drive productivity with the robust, dependable and fuel-efficient Komatsu PC230F-11 processor. Delimb and cut and stack timber with this powerful and maneuverable processor, designed specifically to meet the demands of forestry work.

Large trees can be moved more easily thanks to a powerful swing system and a large swing circle. With exceptional reach of up to 29 feet (8,951 mm), the excellent maneuverability of the PC230F-11 helps drive productivity.

Designed with a high and wide undercarriage, powerful swing motor and ability to withstand high-debris conditions, the PC230F-11 is backed by excellent service, easy access to parts and an industry-leading warranty. Built to tackle demanding forestry processing environments, the PC230F-11 has exceptional reach, a high and wide rugged undercarriage and a powerful swing system.

Quick specs for the PC230F-11

• Net horsepower: 197 HP (147kW) @ 2,050 rpm

• Operating weight: 67,516 lbs. (30,625 kg)

• Swing torque: 8,065 kgm (58,334 ft lbs.)

Engineered for high-debris environments

When operators are working in high-debris conditions, the robust wide-fin radiator is protected by heavy-duty forestry screens and a variable pitch reversing fan helps improve airflow.

Offering excellent ground clearance, the PC230F-11, provides reliable maneuverability in tough forestry environments thanks to a high and wide undercarriage designed with larger class-size components.

Operators can adjust quickly to a sudden change in load weight without losing productivity with the Auto Power Max feature. It automatically senses the difference and reacts with a seven-second burst of additional horsepower to help pull the trees through, during the delimbing process.

Operator comfort supports productivity

To reduce operator fatigue, the PC230F-11 provides a quiet, comfortable work environment. Cabs are climate-controlled and equipped with Bluetooth

Powerful and maneuverable processor can delimb, cut and stack felled timber

technology. The cushioned airsuspension seat can be heated or cooled.

An extra-rugged exterior protects against falling limbs with a 1.26 inch-thick (32 mm) polycarbonate front window and metal designed to withstand demanding environments. The PC230F-11 features heavy-duty service undercover guards and rear compartment doors, and a right corner guard with a standard tree deflector.

Less refueling

The Komatsu SAA6D107E-3 Tier 4 Final engine is more fuel efficient than the prior Tier 4 interim engines. Thanks to proprietary Komatsu engine technology, the larger size-class (PC290LL-11) factory-installed engine also powers performance.

Your operators can spend more

time on the job and less time refueling with the additional fuel storage on the PC230F-11. The tank is in the rear of the carrier and built into the counterweight, delivering double the fuel capacity. Because the fuel tank was moved to the rear, there is a large tool storage area on the side for the operator to store an extra five-gallon bucket of oil, extra chains and other tools.

New managing director for Ponsse’s subsidiary in Russia

A new managing director has been appointed for OOO Ponsse, Ponsse’s subsidiary in Russia. Jaakko Laurila, the company’s current managing director, will transfer to another position in Ponsse Group, and Mihail Menshikov will start as the new managing director.

In its release issued on 28 June 2022, Ponsse announced that it has signed a deed of sale

regarding the sale of all shares in OOO Ponsse to the Russian company OOO Bison. While the process to complete the transaction is continuing, it has not yet been approved by the Russian authorities. The delay is caused by a regulation entered into force in Russia on 8 September 2022, relating to the approval of sales of companies owned by foreign parties.

Ponsse aims to complete the sale as soon as possible, depending on the approval process of the Russian authorities, The company has previously announced that it will complete the sale of its Russian subsidiary by the end of the third quarter of this financial period. Ponsse’s export and service operations in Russia have been suspended since 2 March 2022.

Mihail Menshikov, OOO

Ponsse’s new managing director, has previously worked as the deputy managing director of OOO Ponsse and been a member of OOO Ponsse’s management team.

6 International Forest Industries | OCTOBER / NOVEMBER 2022 LOGGING & BIOMASS NEWS

A SMALL, FAST AND RELIABLE THINNING HEAD

The unit is small, just over a meter high and weighs about 420kg, but can cut down trees with a diameter of up to 41 cm. It feeds about 4 m/s and has the very best performance to withstand a tough everyday life in the forest.

Log Max 2000T complements our thinning units in the T-Series.

Contact your local dealer for more information or visit logmax.com www.logmax.com

Timber to make full time return to Welshpool railway

timber, on the 100-mile (160km) trip to Chirk. The success of those trials has led to a permanent contract being agreed between Colas and the timber processing company.

The railway through Welshpool is set to become a lot busier following confirmation that the timber trains will become a permanent addition reports My Welshpool.

Following the successful April trial runs, Colas Rail has agreed a permanent contract to move raw timber logs from Aberystwyth to the Kronospan processing plant at Chirk, south of Wrexham, via Welshpool.

The company described the addition of a new service as “environmentally friendly” and has been made possible with support from Network Rail. It is the first regular locomotive-hauled freight service to utilise the scenic Cambrian rail route in over 25 years.

A series of trials – hauled by Network Rail locomotives – took 800 tonnes of round logs, the industry term for freshly felled

“The service removes 16 heavy goods vehicles from the road, saving a quarter of a tonne in carbon,” says a Colas statement. “After a successful trial in late April, with Network Rail’s Class 97 fleet operated by our Freight team along with support from our Class 37s, the service was rolled out a to haul of timber from Aberystwyth through to the Kronospan manufacturing plant in Chirk, North Wales on a weekly basis.”

There are calls from all over Britain to relieve rural roads of timber trucks, and replace them with rail freight transportation. Other successful trials have been made.

“This is a great opportunity to expand our freight business”,

Simon Ball Freight Director Colas Rail UK

said Simon Ball, Colas Rail UK freight director said during the April trials. “We lead the field in the transportation of timber by rail. We provide a sustainable alternative by operating on rail, reducing the number of HGVs on the road, especially during the shortage of drivers. Working with the client and Network Rail, I’m convinced that we can move forward and build on the success of the trial.”

New west coast contract promotes timber transport by sea

A new £2.6 million contract to move thousands of tonnes of timber by sea, instead of by road, aims to continue the Scottish Government’s commitment to help decarbonise the forestry sector.

Scottish Forestry has signed a three year deal with Associated British Ports (ABP), the UK’s leading ports group, for the TimberLINK service to move the timber from a number of ports in Argyll.

Over the course of the next three years, around 225,000 tonnes of timber will be shipped across the Firth of Clyde from Argyll’s forests to wood processors based in Ayrshire, instead of using timber lorries. This will save around 2.2 million lorry miles, and nearly 4,000 tonnes of harmful CO2 emissions.

The move will also result in 9,750 fewer lorry trips via the A83 trunk road. This will be of benefit to communities and visitors using this busy route, which passes the Rest & Be Thankful and Loch Lomond and the Trossachs National Park area.

Welcoming the funding, Environment Minister Mairi McAllan said:

“Scotland’s forestry sector is a success story, providing a great range of benefits. It generates over £1 billion to Scotland’s economy every year and supports around 25,000 jobs.

“We want to help grow this prosperity ensuring that we have a sustainable timber transport resource to help achieve this.

“Where practical, I am keen to see a modal shift to coastal shipping and away from using rural roads, helping to decarbonise the forestry sector and contributing towards Scotland reaching Net Zero.

“I’m also pleased that this project substantially reduces the number of timber lorries having to use the A82, which is a key route used by rural communities.”

Through the TimberLINK service, timber will be shipped from Argyll using ports at Ardrishaig, Campbeltown and Sandbank to ABP’s Troon and Ayr harbours, to be forwarded by lorry to wood processing plants in Troon,

Auchinleck, Girvan and Irvine. Stuart Cresswell, ABP’s port manager of Ayr and Troon, said: “The TimberLINK operation out of the Ports of Ayr and Troon is a real success story and I am delighted that this forward-thinking service will continue. The sea route not only reduces lorry traffic on rural roads but also uses less fuel and produces fewer greenhouse gases.

“This project has created many growth opportunities for local businesses, both in Argyll and Ayrshire, and I feel confident that they will only strengthen and multiply with this continued operation.”

ABP has operated the service on behalf of Scottish Forestry since

2000. The funding is made through the Strategic Timber Transport Fund, which is run by Scottish Forestry and jointly financed by Transport Scotland.

In the last five years, around £33 million has been invested through the Fund into over 180 timber transport projects, helping over 47 million tonnes of timber get to market.

8 International Forest Industries | OCTOBER / NOVEMBER 2022

CAN YOU AFFORD NOT TO DRIVE ROTTNE?

A recent survey shows that Rottne has the lowest total costs for labour and spare parts. The survey, carried out by TSG (Swedish Forest Agency’s Technical Collaboration Group), compared the repair costs incurred on machines made by Rottne and our competitors.

With Rottne Xparts, the company’s unique replacement system for spare parts, the aver age cost for spare parts as reduced to a mere 60 percent of the price as new, meaning that repair costs are sunk even more for Rottne machines. We also provide twice as long warranty on Rottne Xparts compared to new spare parts.

Can you afford not to drive Rottne?

Rottne forwarders and harvesters meet every need, from light thinning to heavy final felling. We offer Swedish-made products of the highest quality and the latest technology, an extensive service network and a competent and friendly atmosphere.

ROTTNE.COM

– THE LOWEST REPAIR COSTS IN THE INDUSTRY

Ponsse launches new technology: an electric forest machine

Juho Nummela, President & CEO Ponsse Plc

Juho Nummela, President & CEO Ponsse Plc

Ponsse and Epec are introducing the PONSSE EV1, an electric forest machine technology concept. While the forest machine will be commercially available later, Epec’s technology can already be used in electric or hybrid-electric commercial vehicles and nonroad mobile machines. Ponsse’s technological concept is a peek into the future, paving the way for technological development and sustainable harvesting solutions.

Ponsse provides sustainable harvesting solutions by listening closely to customer needs, and it also aims to lead the way in the development of forest machine technologies. Ponsse is part of sustainable forestry and seeks carbon neutrality in its operations and solutions. This launch of a new technology concept is part of the company’s strategy and a tangible step towards the goal of carbon neutrality. Sustainable development guides all the company’s operations.

“Technological development is fast and offers us excellent opportunities to develop our solutions further, even in unexpected directions. We have worked hard with our technology company Epec to enable this concept. At the same time, both companies have developed their capabilities, and we have gained significant new knowledge during this project. This launch of a new technology concept is a peek into

the future and one of the solutions offered by electric powertrains. Sustainable development is a significant future success factor for Ponsse. We want to strongly develop our solutions with Epec. Our strategy reform has been successful at Epec, and we’re very happy with Epec’s excellent development,” says Juho Nummela, President and CEO, Ponsse Plc.

PONSSE EV1 technological concept

The PONSSE EV1 concept has been developed for forwarders with a 15-tonne load-carrying capacity, the most popular Ponsse forwarder size category. The concept machine features a fully electric powertrain, as well as Epec’s power distribution unit and hybrid control unit. The machine’s powertrain operates fully with battery energy. Batteries are charged using a Range Extender, which is a combustion engine at this stage of development. Testing and development are advancing

continuously. This technology provides significant improvements in fuel economy in this size category.

Ponsse has been studying and developing new technological solutions for several years now. The PONSSE EV1 concept took its first steps in 2019 when Ponsse and Epec started to investigate responsible power source solutions in line with sustainable development.

Epec Flow: a comprehensive electromobility system solution

The PONSSE EV1 features Epec Flow, Epec’s electromobility system solution. The solution is based on the Epec Flow Power Distribution Unit (PDU), to which electric motors, batteries and various devices can be connected. The PDU’s integrated safety solutions enable effective manufacturing and maintenance of the machines, as well as their operations in

Jyri Kylä-Kaila Managing Director Epec

demanding conditions. The Epec Flow Hybrid Control Unit (HCU) controls the electric powertrain and includes software developed through simulations, enabling optimal energy consumption, productivity and usability.

“The Epec Flow solution is at the heart of everything. It has been developed for the electrification of various commercial vehicles and non-road mobile machines. The software can be developed using simulation models, and the solution can be agilely developed for the needs of different machinery. The different systems, including the transmission and control system, work seamlessly together, enabling the manufacture of safe and efficient zero-emission machines in the future,” says Jyri Kylä-Kaila, Managing Director of Epec.

10 International Forest Industries | OCTOBER / NOVEMBER 2022

John Deere enhances Knuckleboom Loader visibility with cab upgrades

Knuckleboom Loader models, we are significantly improving visibility for the operator, making for a safer and more comfortable work environment.”

The 2022 model-year upgrades also feature a new hood profile in the left-rear corner of the machine, which opens up the view behind the machine. The new design partners with the window updates to make for a safer, easier-tooperate machine. By offering enhanced visibility, these models enable the operator to be more precise, maximizing uptime.

John Deere introduces the latest updates to its Knuckleboom Loader lineup, including visibility enhancements. Aiming to increase operator safety and accuracy, the 2022 models of 437E and 337E Knuckleboom Loaders feature a newly designed front window by removing the external mesh guard and replacing it with a clear, polycarbonate window for

uninterrupted view.

“We are always looking for ways to increase operator comfort on the job while keeping a focus on machine safety and design,” said Jarvis de Groot, product marketing manager, Forestry Swing Machines and Knuckleboom Loaders at John Deere. “By removing the external window guard and redesigning the front window on the 437E and 337E

In addition to visibility enhancements, the latest models will offer optional satellite-ready radio, improving the operator experience in the cab. A new optional hydraulic vacuum pump can also be added to 2022 modelyear machines, minimizing oil loss and spillage during times of hydraulic maintenance and repair.

Jarvis de Groot, product marketing manager, Forestry Swing Machines and Knuckleboom Loaders

From waste to money. Use JENZ Shredders.

www.jenz.de

John Deere has updated its Knuckleboom Loader lineup with enhancements that improve visibility, precision and overall operator experience

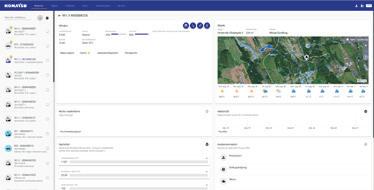

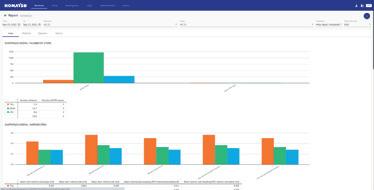

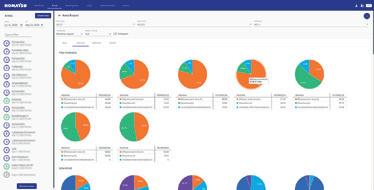

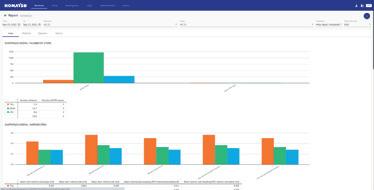

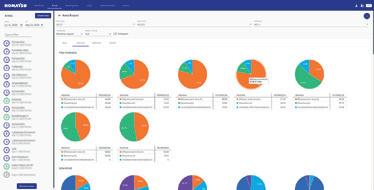

New design for Komatsu MaxiFleet

MaxiFleet

MaxiFleet digital service is a comprehensive tool that simplifies your working day - regardless of whether your fleet is comprised of one or one hundred forest machines. MaxiFleet helps you to keep track of your machines, collaborate with colleagues and make informed decisions based on facts.

All of this is made possible by the MaxiXT control system, which processes vast amounts of data about your machine and its production. These data are then analysed in MaxiFleet, and the result is a number of help functions to simplify your working day and help you to make profitable and sustainable choices.

Machine information view, banner and Icons changed to new color scheme.

Area Management: Change of color scheme for area status and area reports for a clearer display and separation of data.

12 International Forest Industries | OCTOBER / NOVEMBER 2022

From 1 September 2022, MaxiFleet has a new look with brighter colours and more user-friendly graphics.

Creating value together

Forestry provides the valuable essentials we all benefit from – material for housing and fencing, packaging for goods and consumables, energy to heat our houses, or printing paper for our children’s books. It is your hard work that makes it possible. Thank you. We want to be the partner to rely on when creating those values.

komatsuforest.com

John Deere introduces new FR27 Disc Saw Felling Head

• The new FR27 Disc Saw Felling Head offers increased cut and accumulation capacity compared to previous models.

• The FR27 is now standard on the 953M and 959M models and is available as an optional enhancement on the 853M, 859M, and 903M with special boom and track option configurations.

John Deere has announced its newest forestry attachment offering with the FR27 Disc Saw Felling Head. Now standard on the John Deere 953M and 959M feller buncher models, and available as an upgrade on the on the 853M, 859M and 903M feller bunchers,

this felling head attachment has a larger cut capacity compared to previous felling head models.

Building upon the success of the FR24B, John Deere has successfully designed the durable FR27 as a solution aimed to increase productivity on the job.

“We are always looking for ways to enhance operator efficiency and machine capacity. By introducing a larger felling head solution to our line-up with the FR27, we are providing our customers with a larger, more durable attachment to help increase their bottom-line,” said Jim O’Halloran, global product marketing manager, tracked feller bunchers and harvesters & disc saw felling heads, John Deere.

“The newly designed FR27 enables loggers of all experience levels to tackle even the most ambitious jobs with confidence knowing their machines are built to endure larger timber and excel in a variety of forestry applications.”

The FR27 Disc Saw Felling Head is designed to take on a variety of timber applications, from large single stem cutting to mid-sized accumulation, and boasts an all-new design and overall rebranding from previous John Deere felling head models. In addition, this robust, high rotation felling head features excellent cut and accumulation capacity, offering top-of-the-line productivity compared to previous models. The FR27 features an impressive cutting capacity of up to 27.2 in. and an accumulation capacity of up to 7.5 ft, improving capability in the woods.

Building upon the success of the field proven FR24B, the FR27 features an updated frame and wrist design, which includes a tall horn, long harvesting arms and continuous hose routings that promote easy machine clean-out. The hardened saw housing wear plates are now standard and offer improved saw housing wear resistance.

Additionally, the FR27 offers bolt-on saw housing for improved serviceability, with three separate saw housing sections with integrated skis getting you back on the job sooner. The incorporated large side chip exhaust chute minimizes build up and plugging, keeping your machine up and running. The side chip exhaust chute also includes a cover that can be added or removed depending on application.

Starting now, the FR27 are available for purchase on the 800 and 900 M-Series Feller Bunchers models. To learn more about the FR27 Disc Saw Felling Head or the full line-up of John Deere forestry solutions, contact an authorized John Deere dealer or visit www. JohnDeere.com/.

14 International Forest Industries | OCTOBER / NOVEMBER 2022 LOGGING & BIOMASS NEWS

we are always looking for ways to enhance operator efficiency and machine capacity. By introducing a larger felling head solution to our line-up with the FR27, we are providing our customers with a larger, more durable attachment to help increase their bottomline

Jim O’Halloran, global product marketing manager

Ponsse is one of Finland’s most reputable listed companies

According to the survey conducted by the Finnish Shareholders’ Association, the Finnish Foundation for Share Promotion and T-Media, the most reputable listed companies in 2022 are Kone, Ponsse and Vaisala. The survey evaluated the reputation of 81 listed companies in the eyes of Finnish private investors.

The reputation of listed companies was studied in May and June 2022, with a total of 16,847 Finnish private investors

responding to the survey. Based on the Reputation&Trust model, the reputation of each company was rated on a scale from 1 to 5. In the top three, Kone’s reputation was 4.13, Ponsse’s 4.09 and Vaisala’s 4.04, each being an excellent score.

Responsibility and effective management influence investment decisions

The survey shows that the best parts of reputation are considered

Torgerson’s takes Montana

Early in 2022, Tigercat dealer

Titan Machinery sold its Montana branches to Torgerson’s LLC, a Case IH and New Holland dealer in Montana. One of the affected branches in Missoula is an active Tigercat dealer location with full parts supply and service capability for Tigercat machinery.

Torgerson’s is a privately owned family dealership that has been in business for 110 years. In regard to the Missoula location, fourth generation CEO, Brion Torgerson comments, “Torgerson’s has kept the forestry sales team and the parts and service support teams intact. We will maintain continuity of service in all aftermarket functions to the customer base.

Torgerson’s has committed to the forestry industry and the Tigercat brand by expanding parts and

Besuchen Sie uns!

service. We have substantially increased our on-hand Tigercat parts inventory to support our area’s fast-growing customer base.”

“We have hired additional experienced service technicians and added field service vehicles to assist us in fast and efficient responses to our customers’ needs,” Brion continues. “Tigercat factory training is ongoing and a very important part of supplying top-rate service and support. Tigercat is a core part of our business, and we look forward to growing with Tigercat and our Tigercat customers.”

According to Tigercat district manager James Farquhar, “I have been very excited to work with the Torgerson’s group. The family business has a long, successful

to consist of listed companies’ products and services, finances and management. Responsibility was also found to have a significant impact on investment decisions. The reputation was measured using the Reputation&Trust survey model, in which the evaluation is based on eight dimensions: governance, financial performance, leadership, innovation, dialogue, products and services, workplace, and responsibility.

Considering all listed

companies included in the survey as a whole, their reputation is at a high level on average, while it decreased overall from the previous year. More information about the survey is available on T-Media’s website.

history. Brion and his team have been very proactive in entering the forestry market. The Tigercat family and I look forward to helping Torgerson’s support existing and new Tigercat customers.”

38017 Mezzocorona (TN)

SeppiMulcher

International Forest Industries | OCTOBER / NOVEMBER 2022 15

Contact us! sales@seppi.com www.seppi.com Italy,

■ FORESTRY MULCHERS ■ S TUMP GRINDERS ■ S TONE CRUSHERS for pto-tractors, excavators or prime movers

Brion Torgerson, CEO, Torgerson’s LLC, ,

Torgerson’s LLC, takes over Missoula, Montana branch and doubles down on forestry

Optimise production processes without disrupting running machinery and detect problems before they occur! Sensolligent’s two flagship solutions, IoT Roots and IoT Trees, allow customers to monitor their complete installation at all times and everywhere – regardless of from a desktop or mobile device. The Austrian company provides an all-encompassing IoT solution in an individual modular system and supports its customers throughout the entire digitisation process.

Progress thanks to IoT: Sensolligent’s innovative software solutions get the most out of your machine data

Sensolligent transports industrial installations into the digital world, regardless of whether new or old. Michael Gruber founded the start-up in 2018 and its shareholders include the globally operating SPRINGER. The business idea stemmed from his bachelor’s thesis at the University of Klagenfurt in Austria. Sensolligent has its head office in the Lakeside Science & Technology Park in Klagenfurt am Wörthersee. Alongside the University of Klagenfurt and non-university research bodies, Lakeside Park is a highly specialised centre of research and development for information and communication technologies.

Cooperating successfully: Sensolligent and SPRINGER

“Renting parts of the Lakeside Park infrastructure was the right decision and an important one for Sensolligent. Moreover, a joint power unit was implemented at Lakeside with SPRINGER in 2021. Software engineers and mechanical

engineering technicians not only share workstations there, but also the meeting and common rooms. This has made it possible to accelerate our dynamic and successful cooperation further,” reports Michael Gruber. SPRINGER is a family-owned business that plans, develops and produces machinery and state-of-the-art digital solutions for the timber processing industry. From transporting, sorting and qualifying wood through to automation, all processes implemented are at the cutting edge of technology. “Sensolligent is the digital partner of SPRINGER, which means that SPRINGER looks after the mechanical engineering and Sensolligent the digital products for our largely joint customers,” adds Gruber. Three co-founders supported Michael Gruber during the foundation process: Stefano Probst, Ferdinand Köppen and Martin Hrast. “Scaling the team for the realisation of large software solutions with SPRINGER was Sensolligent’s main goal at that

time. We focused on the timber processing industry with a wide range of software products,” says Gruber. A strategic realignment then took place in 2021 due to the economic slump and the effects of the coronavirus pandemic, amongst other things. Our product range was reduced and we focused on the development of our two software solutions, IoT Roots and IoT Trees. Since then, the company has been growing again and the number of employees has also increased. Sensolligent now has 19 employees. “The life of a start-up is shaped by many ups and downs. Having said that, our order position is more than good currently and in the foreseeable future, which means that we have been able to concentrate especially on the ups and downs of our IoT platform diagrams for some time now,” adds co-founder Martin Hrast.

IoT data – recognising and harnessing the value

Sensolligent’s innovative software solutions get the most out of your machine data, delivering live data analyses and visualisations, reports and alerts which are specifically tailored to the installation and needs of the respective customer. The Sensolligent team works with the customer to establish which data the respective installation provides and what added value that data can deliver.

To begin with, it must be decided which data should serve as a basis. The most important data for the Sensolligent IoT platform are direct signals from the respective PLC control circuits of the customer’s installation. The possibility of data contamination is excluded. These signals are tapped via an OPC UA server and converted into intelligible metrics using edge computing. This defines

16 International Forest Industries | OCTOBER / NOVEMBER 2022

SAWLINES SENSOLLIGENT

the interface between Sensolligent and mechanical engineering, making the close cooperation clearly visible in the case of SPRINGER installations at the same time. SPRINGER specialists can retrofit additional sensors to the installation, while Sensolligent can deliver any data required (e.g. for optimisation). A perfect environment for cooperation between SPRINGER, Sensolligent and the respective end customer is thus created.

The entire installation monitored at all times and everywhere

Sensolligent IoT platforms make it possible to gain an overall impression of the customer’s entire installation and a comparison of several installations, even at different locations. This overall impression is presented to the customer on two levels:

• real-time visualisation of the installation with one or more characteristics

The metrics collected are visualised in real time for the customer on a smart dashboard.

The difference to many other IoT solutions is the flat display, i.e. only two levels to the last level of detail and the intuitive operation. This means that product training or tutorials are not necessary.

“If the customer cannot operate our IoT platform without a lot of training, we have done something wrong. The end customer is closely involved in the project during development. We have contacts in machine operation, shift planning, supply chains, IT and management. Accordingly, we involve all areas of the customer from the very beginning of the project to the handover and the acceptance/subsequent use of our IoT solutions is given,” explains Michael Gruber.

• data storage, reporting, analysis, simulation and planning

All signals and data are stored and form the basis for the report system. The respective reports are developed with the customer and distributed cyclically (e.g. daily or order reports) or according to event, as required. Amongst other things, a separate push notification

system is available for distribution. Data from the IoT platform are also exported to the customer and/ or SPRINGER system. Interfaces are defined and implemented for this purpose. The data stored form the foundation for further IoT building blocks, such as the analysis of similar operations, the matching of microstops or the predictable planning of service and maintenance operations.

It is sometimes difficult for the customer to map a complete installation because many different manufacturers are usually involved in large lines or complete installations. By using the so-called Senso Pipes, components of the installation that do not originate from SPRINGER, for example, are also built into the IoT platform. When using the Senso Pipe, the PLC data connection to the OPC UA server is dealt with by the PLC technicians of the end customers. A wide variety of solutions are available to customers for the physical implementation of the IoT platform and the associated data processing and storage servers.

“Most of our key accounts do not want any data to go outside their

International Forest Industries | OCTOBER / NOVEMBER 2022 17 SAWLINES

Even though the development costs must be covered by us or through various funding agencies, this shortens the time to market for new modules for our end customers

Stefano Probst, Software Developer, co-founder of Sensolligent

JS-50 X6BNEW CARRIAGES & SHORT-INFEED EDGERS SIMPLY BETTER SAWMILL SCANNING

Usually, Sensolligent does not have permanent access to the customer’s IoT after the platform is handed over; rather, the end customer provides temporary access for service or update work

Ferdinand Köppen, Technical Director & cofounder of Sensolligent

customer’s IoT after the platform is handed over; rather, the end customer provides temporary access for service or update work,” says Technical Director Ferdinand Köppen, co-founder of Sensolligent.

company; the customer provides us with the complete hardware (whether physical or as a virtual machine). This means that internal login systems can be adapted and data are distributed directly from the customer’s IT department to authorised users, for example. Usually, Sensolligent does not have permanent access to the

IoT Roots and IoT Trees –perfectly tailored software solutions

Sensolligent’s two flagship solutions, IoT Roots and IoT Trees, allow customers to decide whether they want a standardised IoT platform designed for SPRINGER installation parts and geared to operation and maintenance or an

IoT solution that has been tailored specifically for their requirements.

The standardised solution is called IoT Roots and has been supplied with all new SPRINGER installations since 2022. IoT Roots forms the foundation of the IoT platforms. Data can also be managed, stored and distributed cost-effectively and securely via the AWS Cloud according to customer requirements. IoT Roots is optionally linked to SPRINGER’s customer app. “IoT Trees is the standardised IoT solution with a wide variety of features (such as availability and bottleneck visualisation/analysis,

material-related order evaluations, comparisons and reconciliations), which runs in the background and is tailored to the needs of the customer in the foreground,” explains Michael Gruber.

IoT Trees is an individual modular system that grows constantly. Any challenges are discussed with the customer.

As a result, further strategic partnerships – with Egger Sägewerk Brilon GmbH, for example – have already been or are in the process of being entered into, from which both parties (i.e. the end customer and

Predicted Order Sim – better and sparing use of resources through forward-looking planning

The new Sensolligent research and development department’s first project is the Predicted Order Sim module, which will augment Sensolligent’s modular IoT system. This is a simulator that in the first step makes use of historical data.

In a further step, these data –already sorted and labelled – are linked using artificial intelligence (AI).

By specifying pending order parameters, the AI simulates the best sequence according to

different viewpoints or rules and visualises it as a proposal for the end customer. Finally, the end user can rearrange individual sequences as required and receives the period needed for individual and total order processing in real time. The predictive simulation is intended to work up to three months in advance.

One of the external partners brought on board for the project was Fraunhofer Austria (with its KI4LIFE innovation centre in Klagenfurt and expertise in visual computing in Graz), with Fraunhofer providing the AI resources.

18 International Forest Industries | OCTOBER / NOVEMBER 2022

Sensolligent) benefit. Sensolligent has also had its own research and development department since April 2022 which addresses the challenges faced by customers and implements ensuing solutions as a standardised module alone or with the partner. “Even though the development costs must be covered by us or through various funding agencies, this shortens the

time to market for new modules for our end customers,” says Software Developer Stefano Probst, cofounder of Sensolligent.

Outlook

“Sensolligent’s engines are running at full speed and we are all looking forward to new and exciting challenges,” is the unanimous tenor of the Sensolligent team. A branch in Frankfurt with two employees was also recently established so as to provide customers in Germany with optimum support. “IoT platforms will continue to be the main area of business for Sensolligent, although the focus on the timber processing industry will remain dominant for some time to come due to the accumulated expertise in this area alone,” reports Gruber. Moreover, Sensolligent’s goal for the future is to acquire new customers from the textiles and paper industry, for example, as the processes for conveying and working with products are similar and the standardised modular IoT Trees system can also be used with other raw materials.

About Michael Gruber, CEO at Sensolligent

Michael Gruber, 43, founded Sensolligent in 2018. The qualified coachbuilder read information technology through second-chance education at the University of Klagenfurt in Austria and met the three co-founders during his studies. “We all struggled through our studies together and were a closeknit team even before Sensolligent was founded,” says Gruber. Thanks to the Carinthian Economic Promotion Fund’s promise of support, the four were able to focus on the development of a prototype. SPRINGER was brought on board during this period and the foundation of Sensolligent was no longer just a goal, but rather the beginning of the Sensolligent story in February 2018. Michael Gruber lives in Styria’s Murtal region in Austria and has been a proud father for two years.

Sensolligent’s latest offering is the distribution of the Microsoft HoloLens with a software bundle including Remote Assist, where the hardware is certified for industry. “Our main goal is to pool the resources of Sensolligent and the SPRINGER Group further so as to be able to offer our customers an

all-encompassing traffic solution, both mechanically and digitally. Sensolligent is not me, but rather all Sensolligent players as well as the outstanding cooperation in our extended family,” Michael Gruber concludes.

International Forest Industries | OCTOBER / NOVEMBER 2022 19 SAWLINES

Sensolligent is the digital partner of SPRINGER, which means that SPRINGER looks after the mechanical engineering and Sensolligent the digital products for our largely joint customers

Michael Alexander Gruber CEO at Sensolligent GmbH

Koskisen has an investment in Kärkölä worth EUR 48 million, with production scheduled to start up in summer 2023. The new unit’s annual production will initially be 400,000 cubic metres of softwood sawn timber. The investment is a continuation of the further processing capacity expansion carried out in 2020 and the power plant investment in which heat production was converted entirely to biofuel.

Construction of Koskisen’s new sawmill in Kärkölä moving at pace

The starting point for Koskisen’s integrated mechanical wood processing operations in Järvelä is high ecoefficiency and the highest possible utilisation of the wood material.

The investment project will involve moving the sawmilling operations from the centre of Järvelä to the sawn timber finishing and further processing operations, 4 kilometres away from the current

Tommi Sneck, Director Koskisen Sawn Timber Industry

location. This will create synergies in production and significantly reduce the emissions from the sawmill’s internal logistics.

“The new production line will increase sawmilling productivity by up to 40% and enable the utilisation of a broader range of log diameters. This will allow us to offer our customers new products, and the wood raw material can be used even more effectively for end products that store carbon for a long time,” explains Koskisen Sawn Timber Industry Director Tommi Sneck.

A sawing line that looks to the future

Koskisen’s future sawing line represents world-class product development that also takes into account future needs. Tuomo Kauppinen, sales manager with HewSaw, the company that delivers the line, is nothing less than shocked at how good Koskisen’s new sawmill will be.

Discussions concerning Koskisen’s and HewSaw’s joint project started back in 2015, when boosting the sawing line’s yield was set as a main goal of the future investment. The plans were to build a sawmill with a movable saw assembly, and North American sawmills were the place to start looking for an example.

“The intention was to check out references in other places too, but those plans were cancelled due to Covid,” recounts Kauppinen.

Although six years have already

passed since the first drafts were drawn up and the investment is running full steam ahead, the final plans are still not locked down. Kauppinen speaks of the company’s continuous product development and about the upgrades that are to be introduced in the machinery currently in production and which will be applied to the line to be delivered to Koskisen.

“I believe that the line, equipped with the latest bells and whistles, will be perfect for Koskisen. Looking at all the drawings, I’m almost afraid at how good it will be,” says Kauppinen with a laugh.

All the bells and whistles

At the heart of the plan is the large-log SL250 sawing line, which

includes three machines: a chipper canter, cantsaw and ripsaw. The sawing line is 85.6 metres long in total, and so far no other sawmill has a setup that compares.

Kauppinen lists all of the line’s productivity-enhancing features, such as Prologic’s sorting and optimization scanners, log spacing control, log rotators, curve sawing, optimized edging, high feed speeds, movable saw assembly and fast setting changes.

“The chipper canter’s chipper heads has also been made from special steel for some time now. The blades used to be made of the steel used in aircraft landing gear, but nowadays a better material

20 International Forest Industries | OCTOBER / NOVEMBER 2022 SAWLINES

is used,” says Kauppinen with a chuckle.

The sawing line also comes with the DX option, which makes it possible to ramp up the line’s speed and use thinner kerf saws.

“More efficiency can also be achieved by adding circular saw blades to both the cantsaw and the ripsaw. Thinner kerf saws result in either a higher yield or a longer interval between blade changes. In Koskisen’s case, this would mean a production increase of as much as

200,000 cubic metres.

The line’s maximum speed is 180 metres per minute, but with DX sawing, the speed could even reach 230 metres per minute. However, faster speeds are not the goal, since Koskisen’s line is meant for sawing larger logs.

Pioneering projects that use the latest technology, like this investment, are important not only for the sawmill, but also for the machinery supplier.

“It’s great to be able to make a

sawing line for a Finnish sawmill. It is a combination of Finnish work and expertise, and the product development will be easy to continue even after the line is delivered, since we’re working on home ground. This finely tuned sawing line is also an important reference for us globally,” Kauppinen sums up.

TUOMO KAUPPINEN Hewsaw Sales Manager

UAB “Juodeliai” installs a tomograph for use in the evaluation process of raw wood

In the Marijampolė production unit of the wood processing company UAB “Juodeliai”, and at the same time, for the first time in the Baltic States, a tomograph has been installed, which will allow raw wood to be used even more efficiently - each log will be assessed not only by its exterior, but also by its internal structure, using X-rays. This investment of >3 million euros is implemented

together with a long-term partner from Italy, Microtec.

The technology, called CT Log, will help shorten the production process. Due to its unique function of determining the geometric parameters of wood under the bark, the technology will significantly contribute to the improvement of the quality of wood products.

It is also interesting that “CT Log” can distinguish the type of wood without human intervention in order to meet very specific needs of customers.

International Forest Industries | OCTOBER / NOVEMBER 2022 21 SAWLINES

Microtec CT Log

“We have been using the screw solutions from SPRINGER since 2018. We are thankful to have chosen SPRINGER equipment because maintenance is more manageable. With that, we can focus on our business, namely veneer production.”

Shawn Eby, Coastland Wood Industries Ltd

Log merchandiser – Coastland

Springer USA Inc | office@springer-usa com | www.springer-usa.com | 550 Brookshire Rd Ste A | Greer SC 29651 | T +1 (864) 908.3822

Moelven’s record order to Valutec – invests in five continuous kilns to three sawmills

Moelven

it is investing in five continuous kilns and the Valmatics 4.0 control system to three of its sawmills. It’s the most extensive single order the Moelven Group has ever placed with Valutec.

“It’s an honor to be entrusted with this delivery now that Moelven is shifting its lumber drying operation up a gear,” says Jon Lindberg, sales manager at Valutec.

Moelven sees opportunities for major synergies by using Valutec’s technology.

“Everyone using the same system in the future will bring many advantages. It will mean we can offer each other great support,” says project leader Ylva Kleiven at Moelven.

The new continuous kilns will allow Moelven to raise both quality and capacity in the drying process, and the latter is something Moelven needs at its Våler and Mjösbruket sawmills in Norway and Notnäs in Sweden.

“We have reached the very limit of our drying capacity. Because lumber drying has become a bottleneck, finding a solution is essential if we are to continue developing. So we decided to make a joint effort, partly to safeguard our ability to continue production

at the current level, and also to take the next step towards an increased production,” says Ylva.

Valutec will deliver two FB model continuous kilns each to the Våler and Notnäs sawmills and one to Mjösbruket. Våler already uses Valutec batch kilns as well as the Valmatics control system. As project engineer, Ylva also managed the project when the sawmills analyzed their requirements and how they would proceed.

“Our experience of Valutec is excellent, and they’re a fabulous team to work with. They also put in a lot of effort when it comes to further the development of lumber drying, so it’s natural that we purchased more Valutec kilns,” says Ylva.

The FB model continuous kilns have two separate zones with individual climate control in each.

“We evaluated our requirements and those presented by Moelven, and the FB model continuous kilns proved to be the best solution. We look forward to starting work on this project,” says Jon Lindberg.

Moelven also sees opportunities for synergies during project planning, construction and operation.

“This will be new for the sawmills have not used Valutec, so I think it’s a great idea to make this investment together and procure the same sort of kilns and control systems. Because it always takes time to learn something new, I’ve started a group where we bring the kiln operators together so that we

Jon Lindberg Sales Manager Valutec

can support each other and get to grips with any issues that come up,” says Ylva Kleiven.

Glennon Brothers & Balcas Timber invest in equipment upgrades at the Enniskillen mill

USNR

is to supply a new Shape Chipper Canter with profiling, Bandmill

Monitoring Systems for 10 bandmills, and a Multitrack Fence for the trim line at the Balcas Timber mill in Enniskillen, Nothern

Ireland. This mill is now owned by Glennon Brothers and the new equipment will improve processing accuracy, produce more volume, and facilitate delivery of higher quality products to market.

Glennon Brothers has been

manufacturing high-quality timber products since 1913 in Ireland and the UK. The Glennon Brothers mills in Longford and Fermoy, and now the Balcas Timber mill in Enniskillen, along with Windymains Timber and Troon in Scotland, supply the Irish and UK markets with products for the construction, pallet wood, and fencing industries.

22 International Forest Industries | OCTOBER / NOVEMBER 2022 SAWLINES

Ylva Kleiven, Project Leader, Moelven

Red Stag purchases TimberLab to create one-stop-shop for mass timber structures

path by combining two very capable teams and leveraging off TimberLab’s long history and institutional knowledge in the mass timber space.

“This is an exciting merger for the New Zealand building design and construction community,” adds Verry.

Red Stag and TimberLab collaborated on the just-completed Clearwater Quays luxury apartment development – an exemplar for sustainable lowcarbon earthquake-resistant construction

“It means building designers and developers will be able to work with a single source for the entire building structure, and benefit from early supplier engagement to fully optimise the engineering of wooden structures to maximise advantages.

“This will make design and supply far simpler and more efficient than dealing with multiple suppliers.”

Surging

interest in sustainable construction has seen one of the country’s oldest mass timber businesses combine with one of the youngest. After 64 years in McIntosh family ownership TimberLab Solutions has joined the Red Stag group following a share sale completed last week.

TimberLab has been the company behind many of the iconic large-scale glulam and laminated veneer lumber projects in New Zealand’s history. The company also has a significant portfolio of impressive projects internationally.

Recognising the need from external investment to develop and grow TimberLab, discussions were initiated with Red Stag in late 2021.

“The purchase of TimberLab was a logical fit”, says Red Stag group CEO Marty Verry.

“In many ways, it brought the missing pieces of a puzzle that Red Stag has been building over the last two decades.”

Red Stag runs the country’s largest sawmill, Cross Laminated Timber (CLT) factory and a frame and truss operation, whilst TimberLab brings mass timber glulam, LVL and CLT capacity and expertise.

Whilst TimberLab has been operating in Auckland since 1958, Red Stag only opened its CLT factory in Rotorua last year.

“The merger allows Red Stag to get a jump start on its growth

Verry says the group is seeing strong uptake of mass timber, driven by the desire by government and private developers to address climate change and build sustainably.

“The property sector is starting to recognise the damage caused by high-emission building materials such as steel and concrete, and take a lead in doing something about it. For a developer, nothing says “I care for the planet” more than building in wood.”

There are other considerations driving uptake also, says Verry. He points to the imminent Building for Climate Change regulation which will require buildings to measure

and reduce their embodied carbon emissions. Embodied carbon from building materials makes up an estimated 10 percent of New Zealand’s emissions. He notes that steel prices having increased 58% in the last two years is also helping.

“One of the really exciting factors also driving the mass timber uptake is the data and recognition of the advantages of ‘biophilic design’ on people’s health, stress levels, and productivity rates.

“At Red Stag we aim to be at the forefront of these trends and be the first choice for mass timber solutions.”

The name of the company will become ‘Red Stag TimberLab’.

International Forest Industries | OCTOBER / NOVEMBER 2022 23 SAWLINES

Marty Verry CEO Red Stag group

P T Z & Bullet Cameras / Cámaras tipo bala y PT Z AL SO AVAIL ABLE / TAMBIÉN DISPONIBLE CC02 & CC04 Cameras / Cámaras Funciona con redes IP PoE , HDT VI y coaxial analógico Work s wi th IP PoE Ne t working, HDT VI and Coax Analog VIBR ATION RE SISTANT / HIGH IMPAC T RESISTENTE A VIBR ACIONES / ALTO IMPACTO

Stick-stacking plant ready to serve new sawmill

Sometimes even a solution that seems a bit unusual can prove to be effective. A case in point is the construction site of Koskisen’s new sawmill, where the old stickstacking machine made way for a new one in July.

Construction at Koskisen’s Tarhanmäki site has been brisk throughout the summer. Besides the yard area, the sawmill building itself, including the equipment foundations, is proceeding on schedule, and while there have been some delays, they have been resolved without a hitch by changing the order of the work.

“When the war started, suppliers warned of possible delays, but they have not materialised. Materials have been available as usual,” says the head of the project, Lassi Santala of Koskisen.

The work has also gone according to plan on a practical level. Despite the high number of machines on the construction site and the different operators from different work cultures, Santala says occupational safety has been top-notch. There has not been a single work accident leading to sick leave, only a few close calls causing nothing more than a startle.

“Ensuring occupational safety is a high priority in the project. Safety is monitored closely at the worksite and is part of every workday,” Santala stresses.

Out with the old, in with the new

The first new machine was installed during the summer shutdown period, when the Tarhanmäki stick-stacking plant that was built

in 1996 was updated with both new machinery and software. In order to ensure continuous production, the 45-metre-long stick-stacking line delivered by Renholm was initially built outside, next to the hall, and then moved indoors when the shutdown period started.

“The wall on one side of the hall was opened up, the old stickstacking line was dismantled and a new one was hauled in. It took over five days to dismantle and move the equipment, after which we could begin the electrical work and secure and equip the new facility. The line was ready to go when the shutdown ended,” recounts Santala.

The new line is 40 per cent

more efficient than the old one, which means it is also longer. This required foundation work also at the front end of the stick-stacking line before the line could be installed. The line is now in the ramp-up phase and is already running in three shifts. In addition to speed, the line was improved also in terms of disturbances, as, thanks to the machine vision system, broken or damaged drying sticks are automatically removed and thus do not cause problems in the stick-stacking process.

Until now, the stick-stacking line has been fed from outside, but once the line is integrated with the new sawmilling line, sawn timber will make its way from

ARAUCO Board approves construction of a new MDF line in Zitácuaro, Mexico

The project considers an estimated investment of US$235 million and incorporates leading edge operational, environmental and safety technology. The project is expected to begin operating during

the second quarter of 2025 reports Industry Intelligence inc.

ARAUCO is the primary producer of plywood in Mexico and this project is expected to add about 300,000 cubic meters of

MDF production per year, of which half would be melamine coated to meet the growing demand of the furniture, construction, and interior decorating industries in Mexico.

The plant will employ 220

dimension sorting to stick-stacking all under the same roof. Until the dimensioning plant’s access point is ready, however, the stickstacking line will continue to be fed from outside.

“The external feed option will also remain in use when the new sawmill is completed. This will allow us to feed batches that need to be dried again directly to the sticker-stacker if necessary,” explains Santala.

workers during its operation. In addition, its supply aims to promote a circular economy model, driving small local forestry producers and protecting the ecosystem values of its surroundings.

24 International Forest Industries | OCTOBER / NOVEMBER 2022

The external feed option will also remain in use when the new sawmill is completed. This will allow us to feed batches that need to be dried again directly to the sticker-stacker if necessary,

Lassi Santala, Head of the project, Koskisen

SAWLINES

EGGER boosts recycled content through investment

Wood-based material manufacturer, EGGER UK Limited, has invested over £15 million into recycling operations at its site in Hexham.

The investment reinforces the company’s commitment to make More From Wood, by improving the quality of recycled wood used to make EGGER’s chipboard panels.

Employing the latest technology, the new recycling plant will segregate, clean, and chip waste wood that would otherwise be burnt or sent to landfill. Recycled material maintains the carbon stored in the wood and benefits the environment.

Thanks to the new, state-ofthe-art processing facilities and the high quality recycled material processed, EGGER is able to increase the amount of recycled wood in each chipboard panel it produces. By improving its recycling processes to get a better quality raw material, EGGER can guarantee that the quality of the panel is not compromised.

Alex West, Product Manager at EGGER UK, said, “Increasing our recycled content answers the demand from the interior design,

Not only does this investment strengthen our closed loop production cycle, but it also demonstrates the importance and commitment the company places on a sustainable supply of raw materials

Alex West, Product Manager, EGGER UK

furniture, and housebuilding industries for more environmentally conscious products. We are a major supplier to these industries,

so it’s important that we lead the way when it comes to sustainable product innovation.”

Alex continues, “Not only does this investment strengthen our closed loop production cycle, but it also demonstrates the importance and commitment the company places on a sustainable supply of raw materials.”

Plans for the project started in 2019, with breaking ground taking place in October 2020. Led by Andrew Shepherd with EGGER’s dedicated UK project team, installation was supported by the wider EGGER Group, Cubby Construction, Mibex Ltd, Garwen

Enterprises, and Parkgate. The team has collectively spent over 130,000 hours on this project and navigated many external challenges during the build, including COVID-19, skill shortages, and material availability. After commencing commissioning in August, chipboard production with increased recycled content is underway.

International Forest Industries | OCTOBER / NOVEMBER 2022 25

LUMBER PROCESSING NEWS Optimise your production plan... Optimise your operations www.halcosoftware.com Whatever your mill... Maximize profit by resolving trade-offs between recovery, production rate, and value HALCO Software Systems Vancouver, Canada• Tel: 1 604 731 9311 HALCO AD:Layout 3 3/8/10 17:22 Page 1 OVER 25 SYSTEMS SOLD

Drax Group - Acquisition of 90,000 tonnes Canadian pellet plant

Drax Group has signed an agreement with Princeton Standard Pellet Corporation (PSPC) to acquire its pellet plant in Princeton, British Columbia, Canada.

The plant, which has been operating since 1995, has the capacity to produce 90,000 tonnes of wood pellets a year, primarily from sawmill residues. Around half of the output from the plant is currently contracted to Drax.

The plant is located close to the Group’s Armstrong and Lavington

plants and the port of Vancouver, and has 32 employees, who are expected to join Drax.

Following completion of the acquisition the plant is expected to contribute to the Group’s strategy to increase pellet production to 8 million tonnes a year by 2030.

The acquisition is expected to complete in Q3 2022.

Will Gardiner, Drax Group CEO said:

“We look forward to welcoming the Princeton pellet plant team

to Drax Group as we continue to build our global pellet production and sales business, supporting UK security of supply and increasing pellet sales to third parties in Asia and Europe as they displace fossil fuels from energy systems. Drax’s strategy to become a world leader in sustainable biomass, supports international decarbonisation goals and puts Drax at the heart of the global, green energy transition.”

Hancock Lumber to acquire Madison Lumber Mill

Two of New England’s top performing eastern white pine manufacturing facilities will join forces reports LBM Journal, as Hancock Lumber has announced its plans to acquire Madison Lumber Mill. Hancock Lumber’s eastern white pine operations will expand to four mills with its first sawmill acquisition in over 20 years.

While Hancock Lumber will be purchasing Madison Lumber Mill following an expected Sept. 30 closing date, the Madison, New Hampshire based location will continue to operate under the Madison Lumber Mill name. The plan is to keep Madison Lumber’s employees, manufacturing systems, customer relations, and products unchanged.

“The addition of Madison Lumber is filled with synergy for both companies. The current

owners, Kim Moore and Jim Smith, have built an exceptional company. When you find caring owners that are looking for an exit strategy that can preserve and perpetuate their love for their business, employees, industry, and customers — well, it’s a win-win,” said Hancock Lumber CEO, Kevin Hancock. “Hancock and Madison combine to offer a dynamic set of capabilities within the eastern white pine industry for log suppliers, customers, and employees. This is a rare opportunity, and we are excited to maximize its full potential for the benefit of everyone associated with both companies. Our commitment to eastern white pine takes a long view and this partnership enhances that view.”

Located an hour west of Hancock Lumber’s headquarters in Casco, Maine, Madison Lumber Mill

is estimated to be the sixth largest manufacturer of eastern white pine. In addition to producing pine boards and products, the company operates a significant wholesale division. Current co-owners, Kim Moore and Jim Smith purchased the former International Paper mill in 2001. Hancock Lumber last acquired an eastern white pine operation when the company purchased the Chadbourne Sawmill in Bethel, Maine in 2000.

Adding this fourth mill to its portfolio will make Hancock Lumber the largest eastern white pine producer in the United States, the company says, expanding not only their manufacturing capacity, but also their talent with the addition of Madison Lumber Mill’s sales, operations, and log procurement teams. General Manager John Fuller, along with

all of Madison Lumber Mill’s employees, will remain part of the team while current owners Moore and Smith will remain during a transitional period.

Stella-Jones agrees to purchase wood pole business

Stella-Jones Inc. (TSX: SJ) has announced that it has entered into a definitive agreement to purchase substantially all the assets employed in the wood utility pole manufacturing business of Texas Electric Cooperatives, Inc. (“TEC”) for a total purchase price of US$28M plus inventories of approximately US$4M.

TEC produces southern yellow pine utility poles using Creosote and CCA preservatives at its wood treating facility in Jasper, Texas.

Wood pole sales for the year ended December 31, 2021, totaled US$28 million. “This acquisition, which adds a 43rd manufacturing facility to our network, will enhance Stella-Jones’ offerings and expand our capacity to supply the growing needs of North America’s utility pole industry, while optimizing the overall efficiency of our continental network”, said Eric Vachon, President and CEO of Stella-Jones. “We look forward to welcoming the Jasper facility employees to

our team of over 2,400 employees across North America.”

The transaction is scheduled to close prior to the end of 2022 and is subject to customary closing conditions. Stella-Jones intends to finance the transaction with its existing credit facilities.

26 International Forest Industries | OCTOBER / NOVEMBER 2022

Kevin Hancock, Hancock Lumber, CEO

Eric Vachon, President & CEO, Stella-Jones

Drax CEO, Will Gardiner

BID to deliver new state-of-the-art Turnkey Composite Pallet Block Facility for ArbaBlox Inc.

BID Group has announced a new partnership with ArbaBlox Inc. to build its first state-of-the-art turnkey composite pallet block plant in Winona, Mississippi. Through its industry-leading wood processing integrated solutions offering, BID will manage, design, build, install, and provide startup services for the $53 million project, the largest of its kind in the country.

The new operation will incorporate BID’s OPER8 platform, the only purpose-built, out-of-thebox industrial IoT solution in the wood processing industry. Wood panel expert, IMAL-PAL Group will provide the equipment and technology for the project.

“ArbaBlox is pleased to have BID Group as its turnkey partner for its new state-of-the-art composite pallet block manufacturing facility. We chose BID because of their excellent track record in delivering integrated projects within the wood processing industry and we are delighted to have them on the Winona project with us” said Ed Milburn, CEO at ArbaBlox.

Work on site will begin in the fourth quarter of 2022 and commissioning of the facility is scheduled for the first quarter of 2024. Fiber supply for the plant will come from Biewer Lumber’s Winona, MS facility which commenced operations in January 2022.

ArbaBlox and the BID Biomass team will begin the development phase of a second project late in 2022.

“We would like to thank ArbaBlox for their trust in our people and integrated solutions. We are humbled that they have chosen to partner with us for their significant capital investment strategy” said Travis McDonald, Executive Vice President, Integrated Solutions at BID. “The ArbaBlox projects will be the first of many for the BID Biomass Division which intends to deliver value-added solutions for sawmill residual products.”

Travis McDonald, Executive Vice President, Integrated Solutions at BID Group

USNR sells Dynastar™ maintenance management software to DrekiTek™ Software Solutions

WOODLAND, WA AND COURTENAY, BC September 6, 2022 – USNR announced they have sold the DynaStar™ Maintenance Management Software to DrekiTek™ Software Solutions Ltd.

USNR looks forward to a long-term relationship with DrekiTek™ Software Solutions Ltd as it continues the development and support of the DynaStar™ system. DynaStar™ customers will continue to receive the excellent support they expect along with ongoing development of the product. Existing Software Support

Agreement (SSA) customers will continue to receive product support through the DrekiTek™ organization.